Patents

Literature

194results about How to "Low process pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

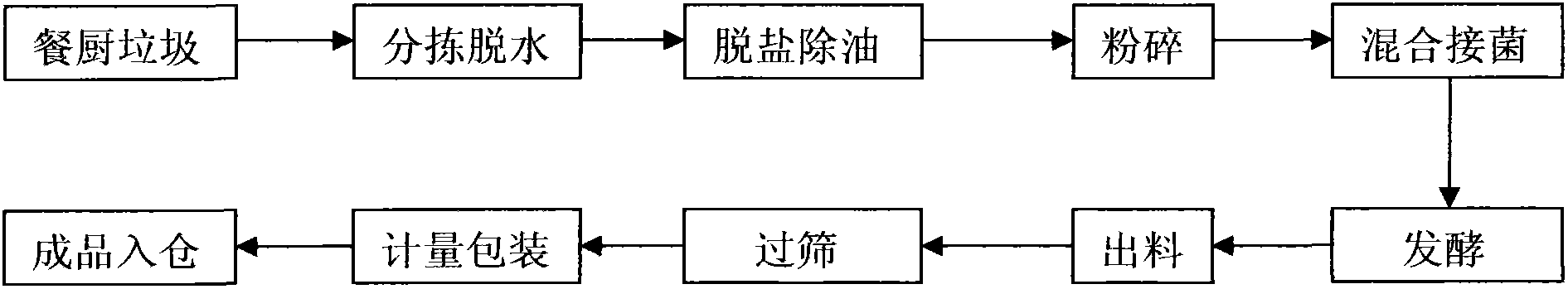

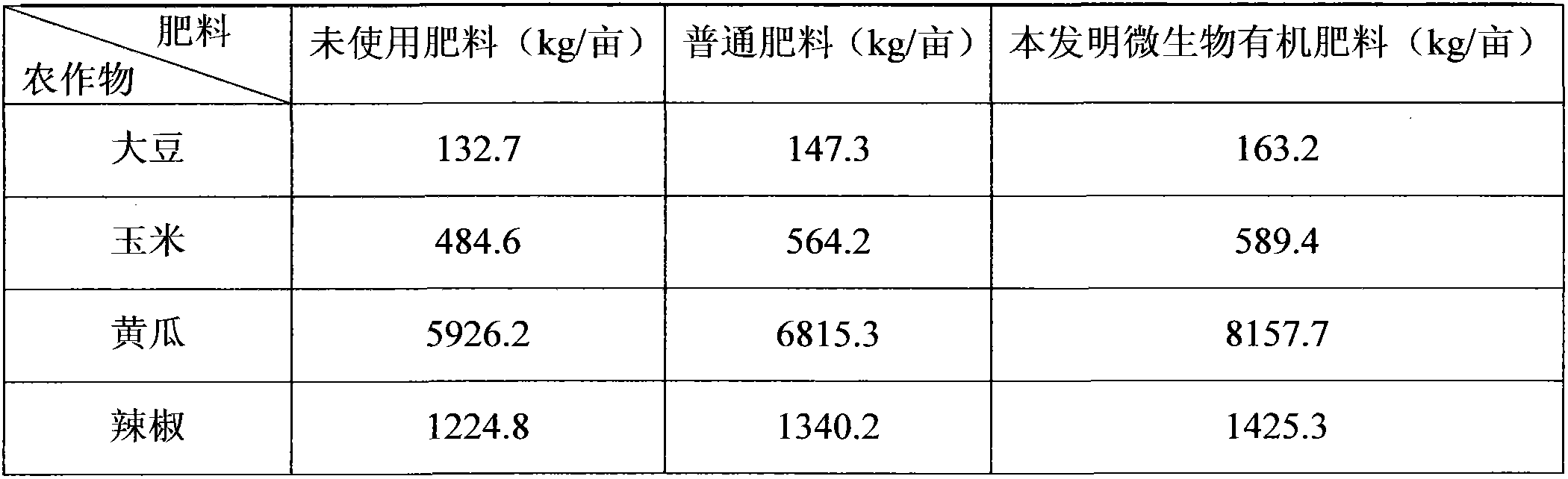

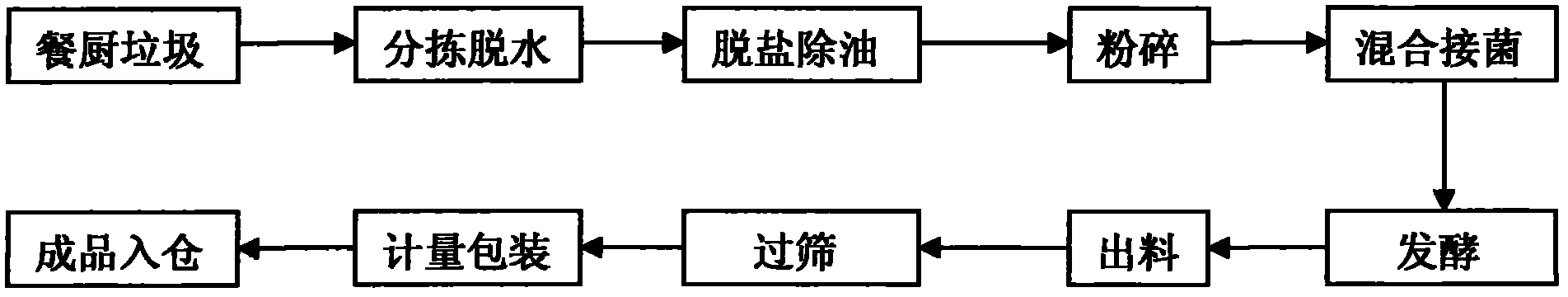

Microbial organic fertilizer prepared from restaurant-kitchen garbage and preparation method thereof

InactiveCN102320871ABig pollutionIncrease available nutrientsBio-organic fraction processingOrganic fertiliser preparationChemical structureOrganic manure

The invention relates to a microbial organic fertilizer prepared from restaurant-kitchen garbage, and relates to a soil improvement technique. The microbial organic fertilizer is prepared by taking the restaurant-kitchen garbage as the main raw material supplemented with additives, wherein the additives include subsidiary agricultural product waste, inorganic material and microbial composite bacteria groups, and the microbial organic fertilizer comprises the following components in percentage by weight: 60-75% of restaurant-kitchen garbage, 10-30% of subsidiary agricultural product waste, 1-10% of inorganic material and 1-5% of microbial composite bacteria groups. In the microbial organic fertilizer, the restaurant-kitchen garbage is adopted as the main raw material, so nutrition constituents in the restaurant-kitchen garbage can be effectively recycled, the problems of environment pollution and resource waste of the restaurant-kitchen garbage are solved, the physical and chemical structures of soil can be conditioned, the quality of agricultural products is improved, and the integrated fertility level of the soil is improved.

Owner:焦社杰

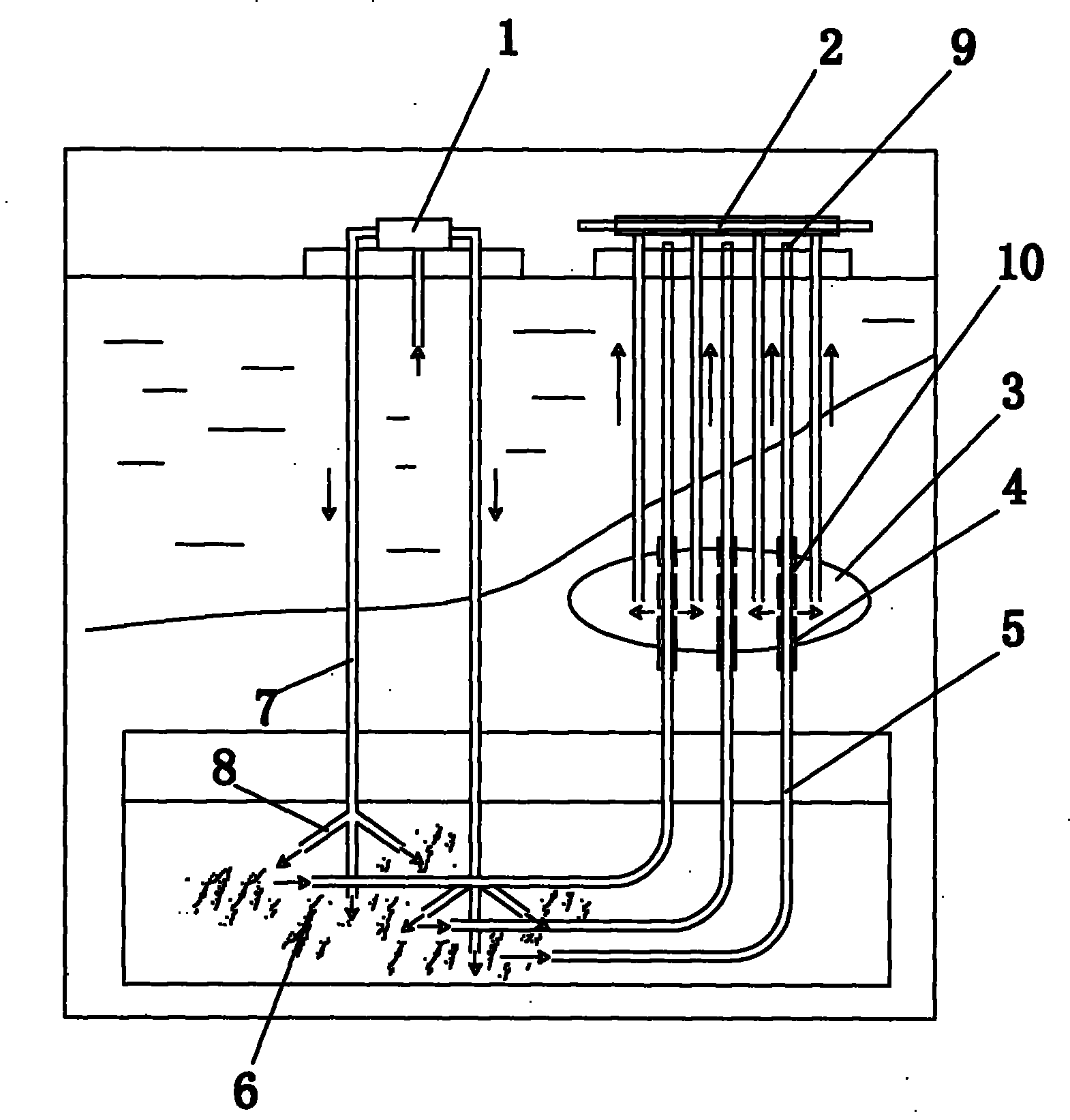

Process for exploiting ocean gas hydrate by utilizing terrestrial heat

The invention relates to a process for exploiting ocean gas hydrate by utilizing terrestrial heat, comprising the following steps: 1) digging a branch well on a target hot rock stratum; 2) utilizing a casing to penetrate through gas hydrate treasure, digging a directional well on the target hot rock stratum, perforating the casing penetrating through the gas hydrate treasure, and sealing the mouth of the well; 3) pressing seawater into the target hot rock stratum by utilizing a pump, pressing the seawater into the directional well after heat exchange heating, leading the seawater into the area of the gas hydrate treasure from the perforation of the casing, and obtaining decomposed gas hydrate and cooled seawater; and 4) transporting the gas hydrate and the cooled seawater to a sea surface by utilizing a gas-liquid recycling tube, separating the gas hydrate from the cooled seawater at an outlet, and collecting natural gas. The invention has the beneficial effect that the invention greatly reduces the heat injection cost in the exploration process, causes the exploration process to continuously develop and has less pollution and damage on environment, and each technical index in the exploration process can refer to the existing petroleum exploration process so as to lower difficulty for realizing the exploration process.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Plastic-aluminum separating agent and plastic-aluminum separating method

The present invention relates to aluminum-plastic separating agent and aluminum-plastic separating process, and belongs to the field of composite aluminum-plastic material recovering technology. The aluminum-plastic separating agent consists of formic acid and dichloromethane as the main components as non-ionic surfactant. The aluminum-plastic separating process with the aluminum-plastic separating agent includes the steps of crushing and washing composite aluminum-plastic material, compounding aluminum-plastic separating agent liquid, soaking, taking out, centrifugally separating, washing and drying. The present invention has high aluminum-plastic separating efficiency, less environmental pollution and low cost, and is suitable for industrial recovery of waste composite aluminum-plastic material.

Owner:曹光军

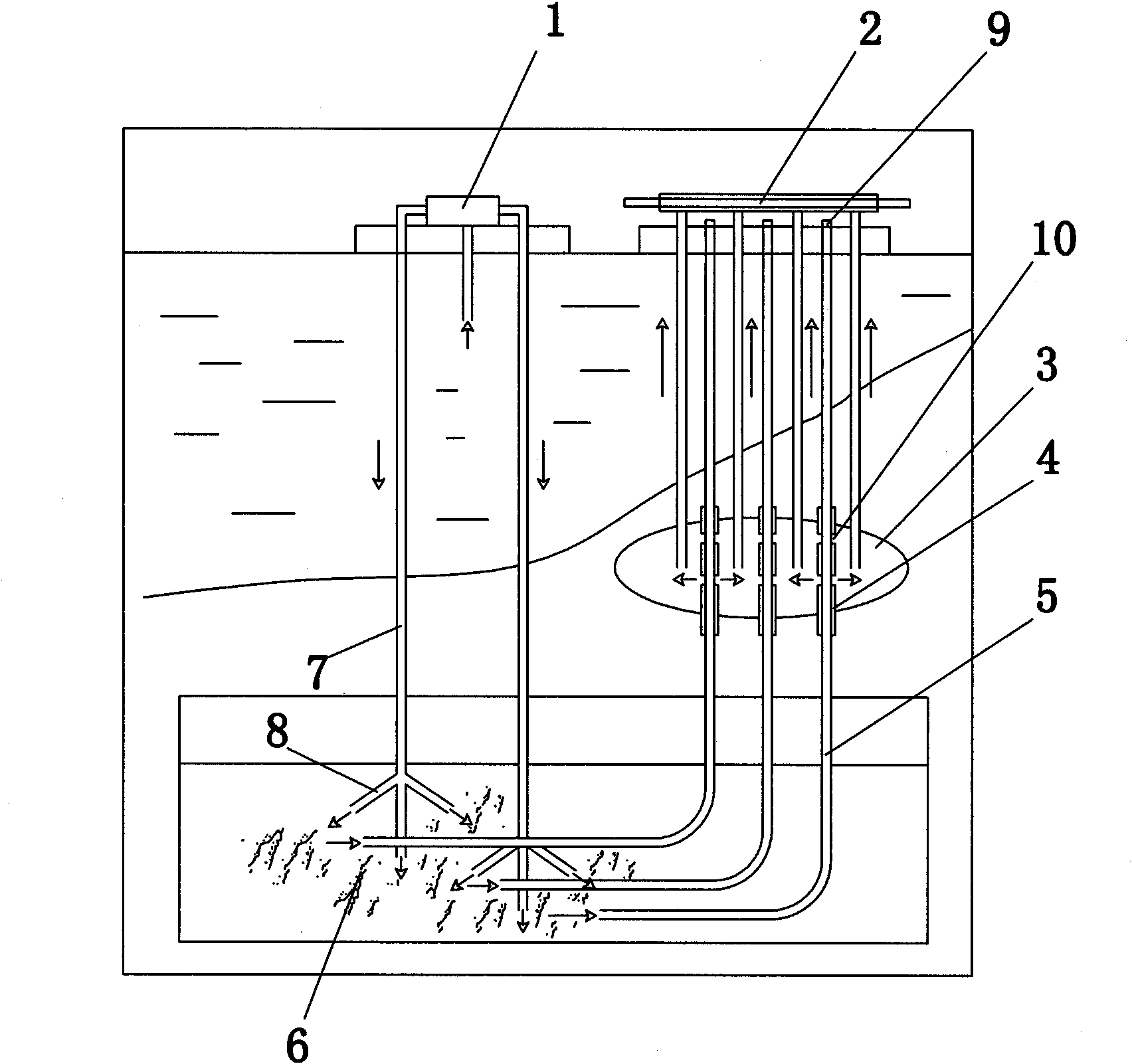

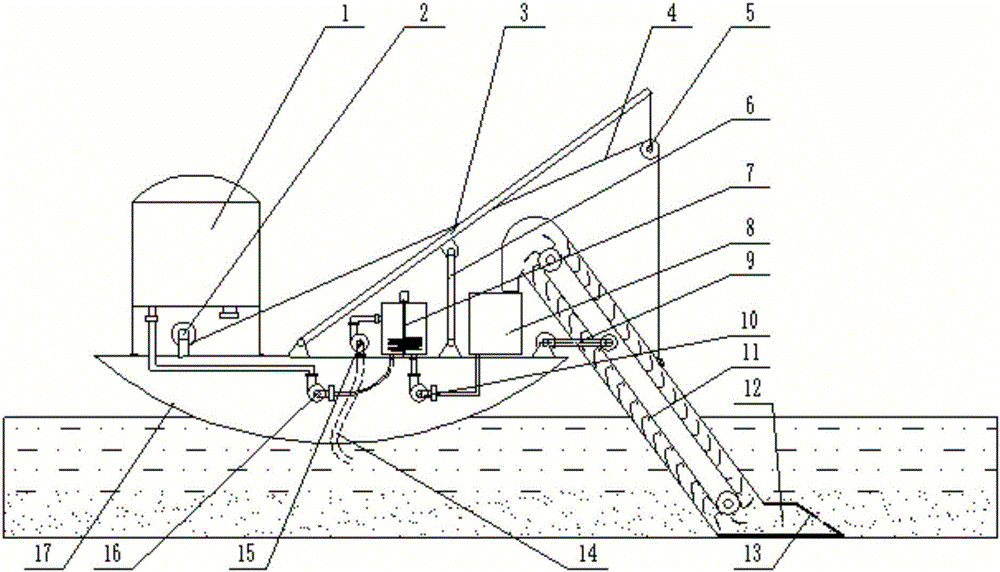

River silt cleaning system

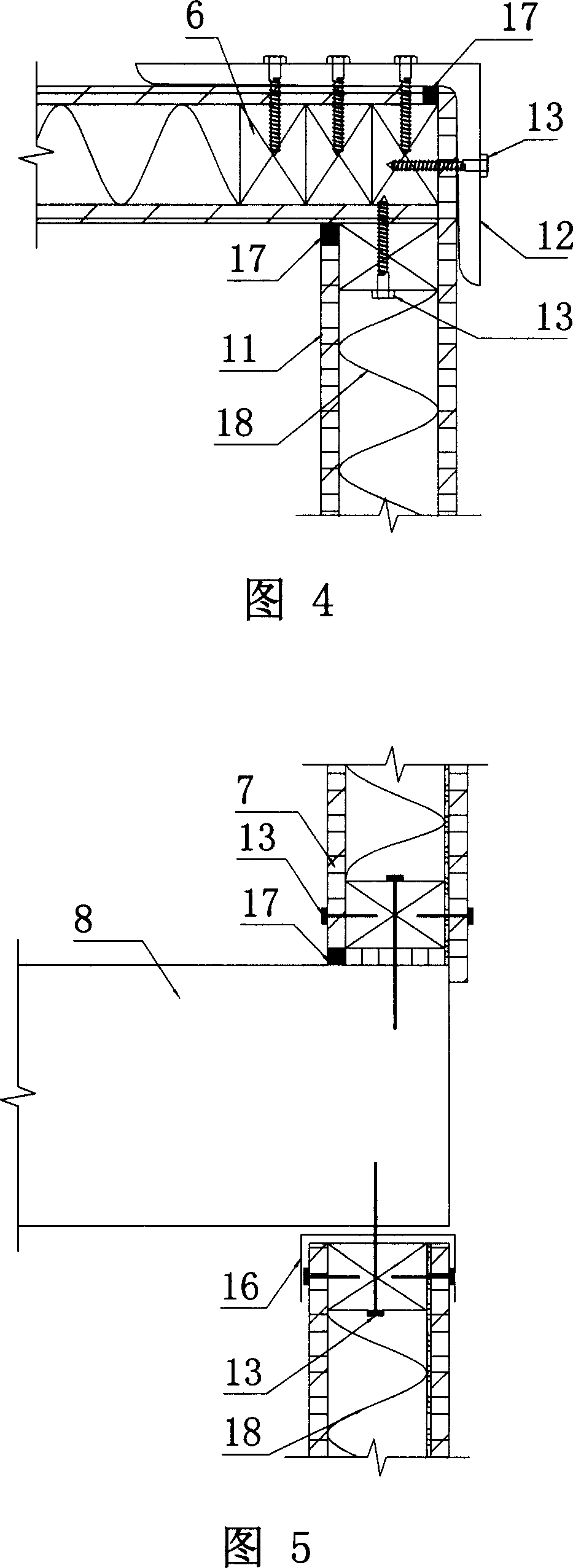

PendingCN106836357AImprove dredging efficiencyAvoid dehydrationSludge treatmentMechanical machines/dredgersGeotechnicsSilt

The invention belongs to the technical field of environmental geotechnics and discloses a river silt cleaning system. The river silt cleaning system comprises a carrier, a silt cleaning device, a mud making device and a mud storage device, wherein the silt cleaning device is fixed on the carrier and goes deep into a river silt seam to clean river silt; the mud making device is connected with the silt cleaning device, smashes the river silt and makes the river silt into mud; the mud storage device is connected with the mud making device and stores the mud. The river silt cleaning system is efficient, convenient, anti-clogging and low in pollution.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI +1

Cold rolled coil strapping steel having tensile strength of 940MPa or more, and production method thereof

InactiveCN103352165ALow costReduce energy consumption and pollutionFlexible elementsProcess efficiency improvementAlloy elementStrapping

Cold rolled coil strapping steel having a tensile strength of 940MPa or more comprises 0.10-0.22wt% of C, 0.8-1.5wt% of Mn, 0.01-0.03wt% of Si, 0.020wt% or less of P, 0.020wt% or less of S, 0.020-0.070wt% of Als, and the balance Fe and residual elements. The cold rolled coil strapping steel has the advantages of no containment of alloy elements comprising Nb, Ti or V, low cost, small energy consumption and pollution, simple operation, and suitableness for the large-batch industrial production, and follows low carbon and environmental protection ideas. The strapping steel has a tensile strength of 940MPa or more, an elongation rate of 9% or more, and an alternating bending frequency of 4 or more (R=2.5mm), has no brittle fracture layering phenomenon, and has a flexibility of 25.4mm / 2.4m or less and a camber of 2.0mm / m or less.

Owner:武汉钢铁有限公司

Agricultural chemical composition containing fipronil and bacillus thuringiensis

InactiveCN101248800AOvercome the disadvantage of easy resistanceImprove efficacyBiocideAnimal repellantsFipronilAdditive ingredient

The invention belongs to the pesticide field and particularly relates to a synergic pesticidal composition with active ingredients to be the combinations of fipronil and a series of subspecies of Bacillus thuringiensis (Bt for short), wherein the Bacillus thuringiensis subspecies include six subspecies: Bacillus thuringiensis var.kurstaki, Bacillus thuringiensis var.aizawa, Bacillus thuringiensis var.tianmensis, B.thuringiensis var.israelensis, Bacillus thuringiensis subsp.aizawai and Bacillus thuringiensis subsp. kenyae. The main agent thereof includes the following active ingredients by the weight percentages as follows: fipronil 0.1%-80%, Bacillus thuringiensis 100-100000 IU (international unit) / mg, or 10-1000 billion spore / g, or 0.01-20% toxin protein, and the rest is an accessory ingredient. The pesticidal composition can be efficiently used for controlling agricultural pests such as rice leaf rollers, chilo suppressalis walkers, diamondback moths, prodenia lituras, corn borers, and so on, and has particular characteristics of high efficacy, long lasting period and safe usage, so that the pesticidal composition belongs to environment-friendly pesticides and can prolong the generation of resistance, reduce production cost and increase economic benefit.

Owner:JIANGMEN PLANT PROTECTION

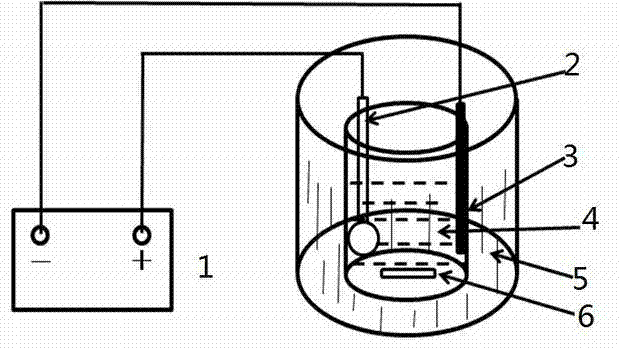

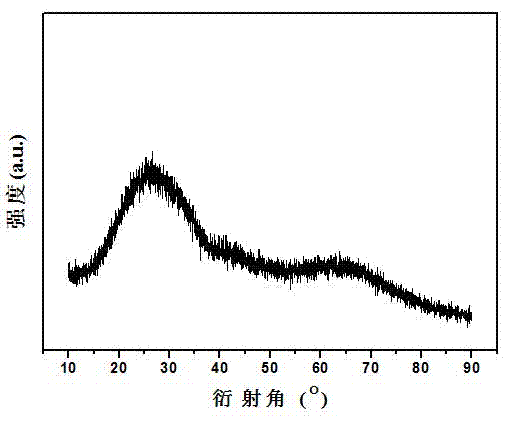

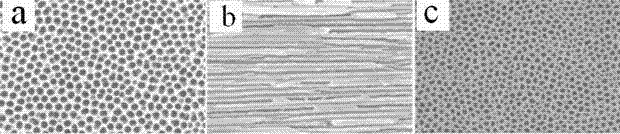

Preparation method of anodized aluminum film of through hole

InactiveCN102776542ALow process pollutionLow priceSurface reaction electrolytic coatingElectrolytic agentOXALIC ACID DIHYDRATE

The invention discloses a preparation method of an anodized aluminum film of a through hole. The preparation method mainly comprises the following steps: after a high-purity aluminum sheet is subjected to annealing, oxide layer removing, degreasing and electrochemical polishing treatment, placing into an anodizing electrolytic cell to carry out primary anode oxidation by taking oxalic acid, sulfuric acid or phosphoric acid solution as electrolyte, after an oxide layer is removed through treatment of mixed aqueous solution of chromic acid and phosphoric acid once, the secondary oxidation is carried out under the same conditions, the residual aluminum-based substrate is removed in acid solution, and reaming is carried in the phosphoric acid, so that the anodized aluminum film of the through hole with small aperture, and the controlled aperture and thickness is obtained. According to the invention, the relatively cheap device is used, through the simpler process, a large amount of anodized aluminum films of through holes can be simply and uniformly prepared in a lossless manner, and heavy metals are not introduced in a process of removing the residual aluminum substrate, so that environmental pollution is reduced. The prepared anodized aluminum film has the advantages of good uniformity and repeatability, highly ordered nanometer pore passage, uniform period, and controlled thickness and aperture.

Owner:SOUTH CHINA UNIV OF TECH

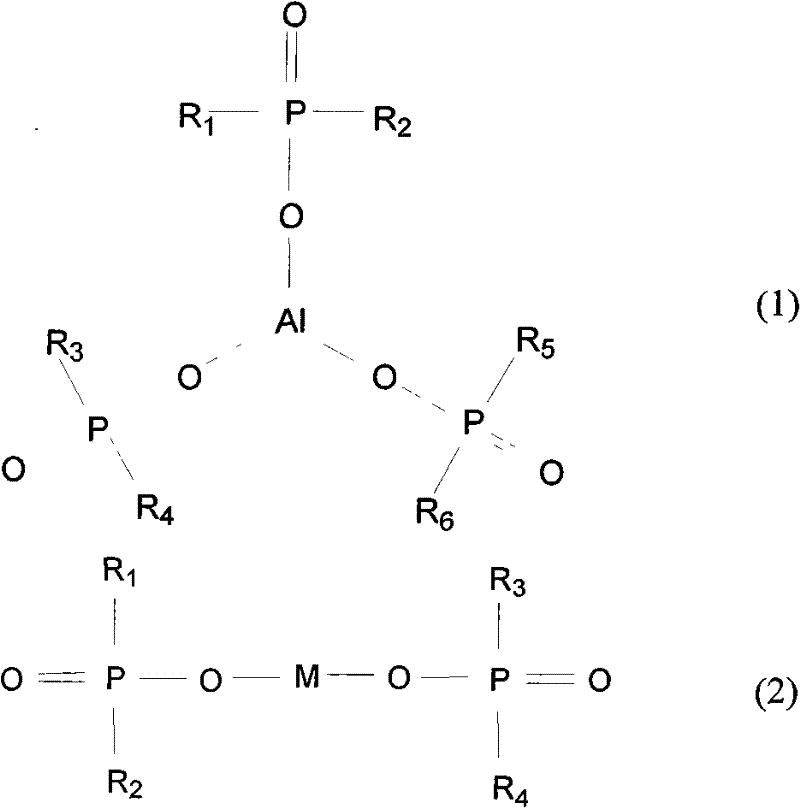

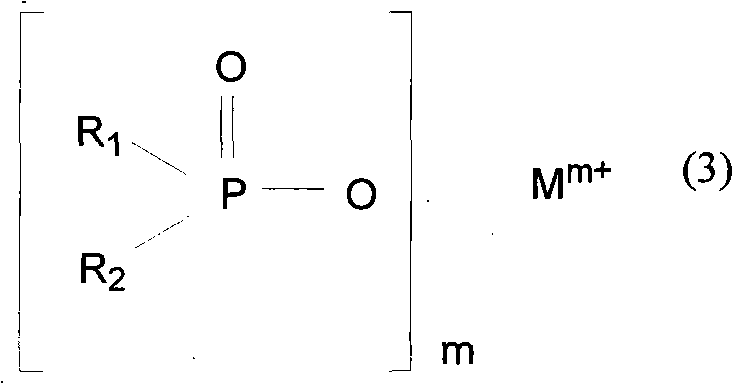

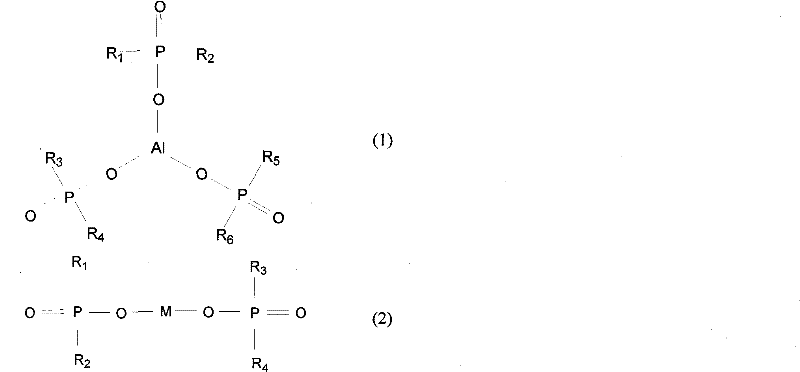

Partially alkylated phosphinic acid nonalkali metal salt and preparing method and application thereof

InactiveCN101747368AImprove flame retardant effectReduce pollutionGroup 5/15 element organic compoundsPhosphinic AcidsDouble bond

The invention provides a partially alkylated phosphinic acid nonalkali metal salt and a preparing method and application thereof. The preparing method comprises the following steps of: ensuring that radical addition occurs between a phosphinic acid nonalkali metal salt and compound containing double bonds in the presence of an initiator, and generating partially alkylated phosphinic acid nonalkali metal salt products. The application is as follows: a flame-retardant polymer comprises a thermoplastic polymer or thermosetting polymer, and more than one of the partially alkylated phosphinic acidnonalkali metal salt. The invention has the advantages of simple technical process, easy operation, less byproducts, low energy consumption and pollution and the like.

Owner:SOUTH CHINA UNIV OF TECH

Biomass fuel oil and preparation method thereof

InactiveCN101831326AImprove combustion efficiencyLess smokeBiofuelsLiquid carbonaceous fuelsSolventChemistry

The invention relates to biomass fuel oil. The biomass fuel oil comprises the following components in percentage by weight: 10 to 15 percent of vegetable oil, 10 to 40 percent of bio-alcohol, 5 to 15 percent of bio-diesel, 0 to 5 percent of fatty acid, 5 to 15 percent of mutual solvent, 0 to 10 percent of combustion accelerant, 0.1 to 1 percent of solid base catalyst, 0.1 to 1 percent of combustion improver, 0.1 to 0.5 percent of oxygenate and 0.1 to 0.5 percent of detergent. A preparation method of the biomass fuel oil comprises the following steps of: a, adding and uniformly stirring the vegetable oil, the bio-alcohol and the mutual solvent in a reaction kettle, adding the solid base catalyst into the mixture and stirring the mixture to form suspension; and b, heating the suspension to 50 to 70 DEG C, making the suspension flow back through a condenser, stirring the obtained product for 10 to 90 minutes, cooling the product to the room temperature, filtering off the solid base catalyst, then sequentially adding the bio-diesel, the fatty acid, the combustion accelerant, the combustion improver, the oxygenate and the detergent and stirring and reacting the mixture for 20 to 30 minutes to obtain the biomass fuel oil. The biomass fuel oil provided by the invention has the advantages of high combustion value, high lubricating property and high flash point.

Owner:杭州绿洲能源科技有限公司

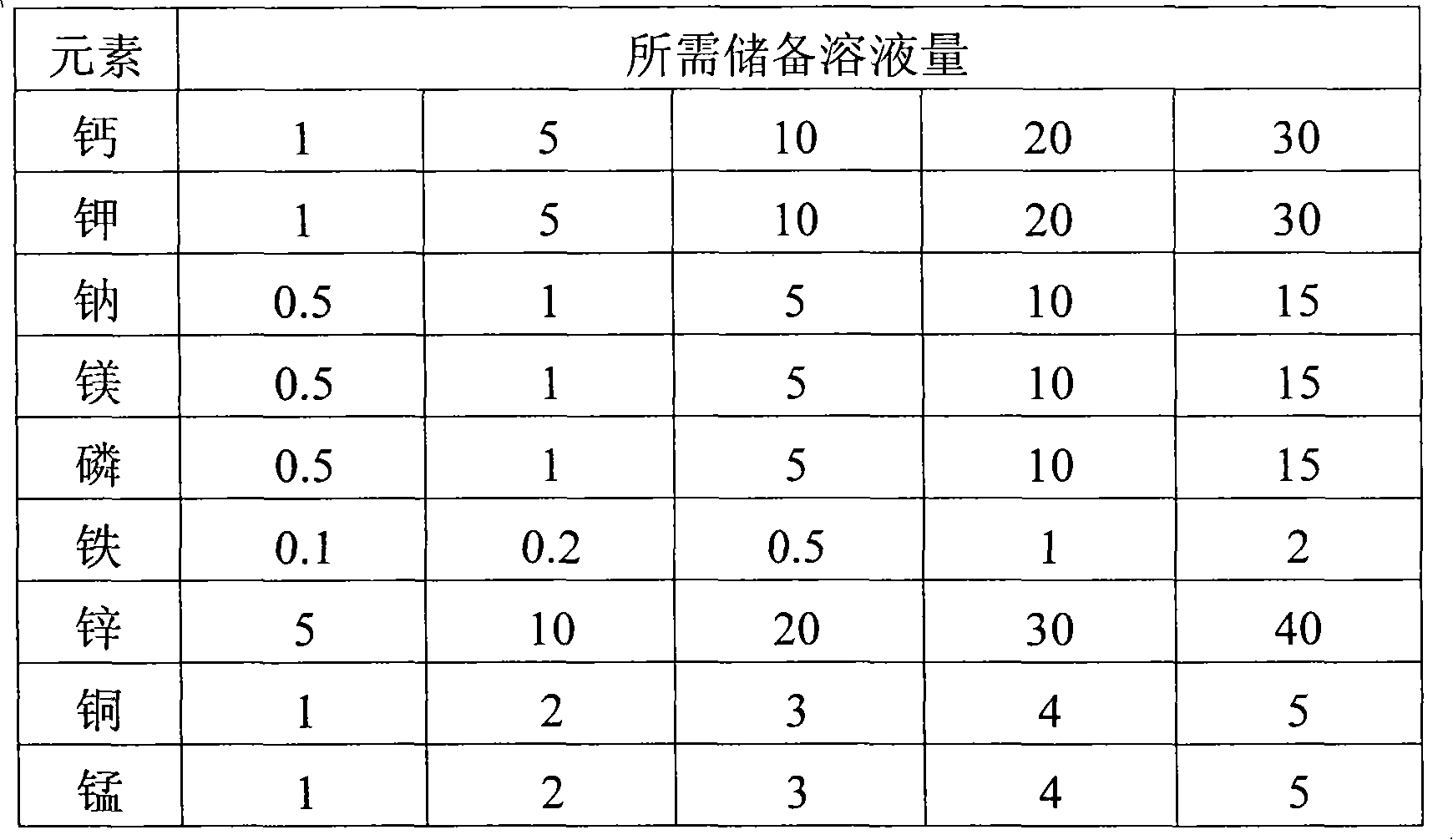

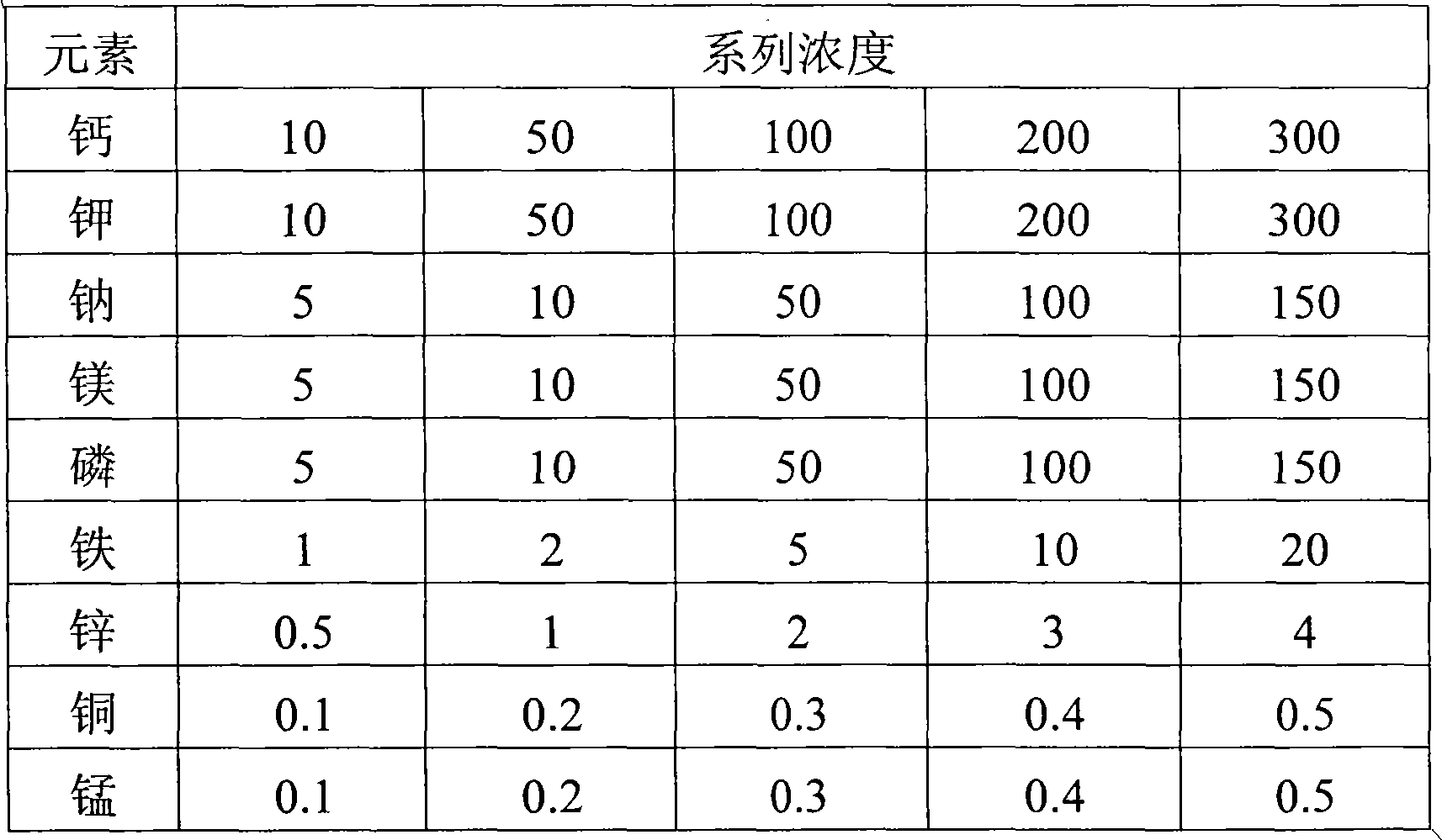

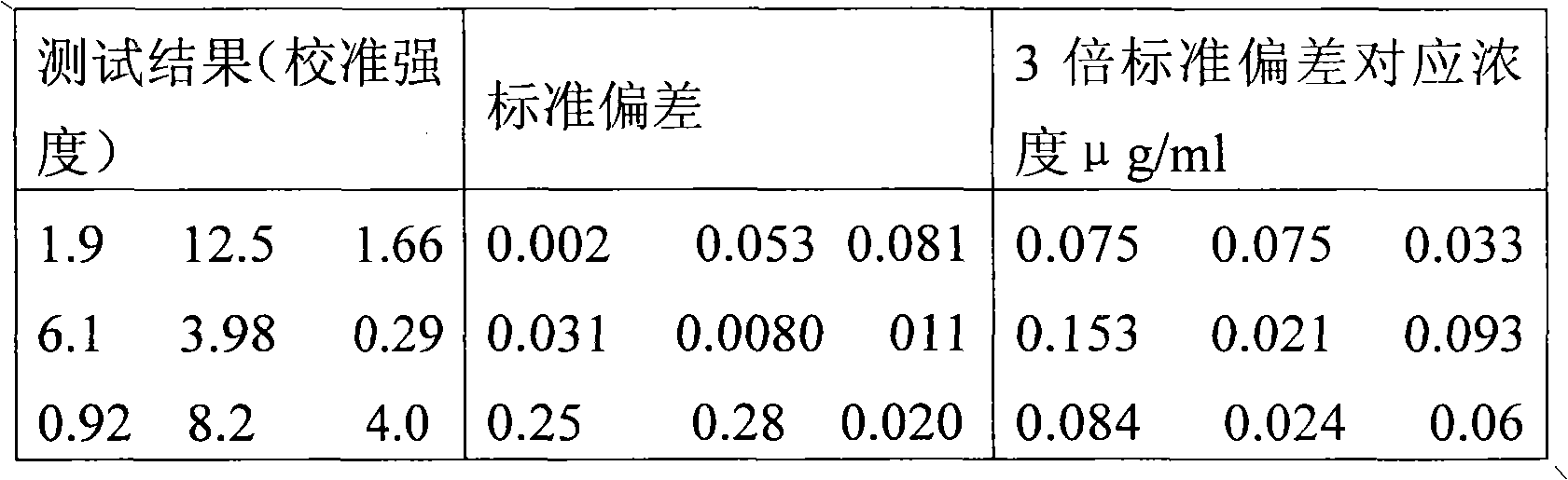

Method for detecting the content of trace elements in cheese

ActiveCN101539523AUniform injectionMaintain suspension stabilityWeighing by removing componentPreparing sample for investigationTrace elementSpectroscopy

The invention relates to a method for detecting the content of trace elements in cheese, which comprises the following steps of: 1) weighing a cheese sample and drying the sample for completely evaporating the water in the sample, then weighing the sample after drying and utilizing the weight difference of the sample before and after the drying to calculate the water content in the sample, and then taking the dried sample for being grinded and homogenized, adding acid for dissolving the dried sample, and adding suspension stabilizer for even mixing and stable dissolving, thereby obtaining solution to be detected; and 2) utilizing inductive coupling plasma emission spectroscopy or atomic absorption spectrometry for detecting the content of trace elements in the solution to be detected. By adding the suspension stabilizer, the solution is suspended stably, thereby achieving the purpose of leading the solution to be homogeneous. The detection method is simple, rapid and accurate, and has high-sensitivity.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Coupling refining method of high-purity L-lactide

The invention provides a method for refining high-purity L-lactide by way of liquid crystallization and melt crystallization. The method comprises the following steps of: based on 80% L-lactide crude product as a raw material, initially purifying the L-lactide crude product by way of liquid crystallization; and then secondarily purifying the L-lactide by way of melt crystallization. The method specifically comprises cooling and crystallizing, melt crystallization, sweating, and melting. L-lactide with purity over 99.5% can be prepared by applying the method.

Owner:TIANJIN UNIV OF SCI & TECH

A kind of nano aluminum paste and preparation method thereof

InactiveCN102258953AKeep the nano effectKeep aliveMixing methodsPolyethylene glycolAlicyclic Hydrocarbons

The invention discloses a nano-aluminum slurry. The nano-aluminum slurry is composed of the following components in parts by weight: 1-20 nano-aluminum powder, 0.05-3 dispersant, and 80-100 solvent; wherein the dispersant is selected from From polycarboxylates, polycarboxylates, polyethylene glycols, polysilanes, polyacrylic acid, silane coupling agents, titanates, aluminate coupling agents; wherein the solvent is selected from alcohols, Ketones, esters, aromatic hydrocarbons, cycloaliphatic hydrocarbons or water. The preparation method of the slurry comprises the following steps: (1) adding the dispersant into the solvent according to the proportion and stirring evenly; (2) putting the nano-aluminum powder into the above-mentioned mixed liquid, stirring it with a ladle to soak it Wet and preliminary dispersion; (3) Disperse by ball milling with a planetary ball mill for 0.3-1 hour to obtain a finished product. The method is to use a suitable dispersant to treat the nano-aluminum powder, coupled with the shearing and emulsification of the ball mill, the nano-aluminum powder can be highly dispersed in the medium to form a uniform and stable slurry, which can be widely used in explosives, fuels, Coatings, activated sintering additives, electronic device coatings and other fields.

Owner:BEIJING NACHEN TECH DEV

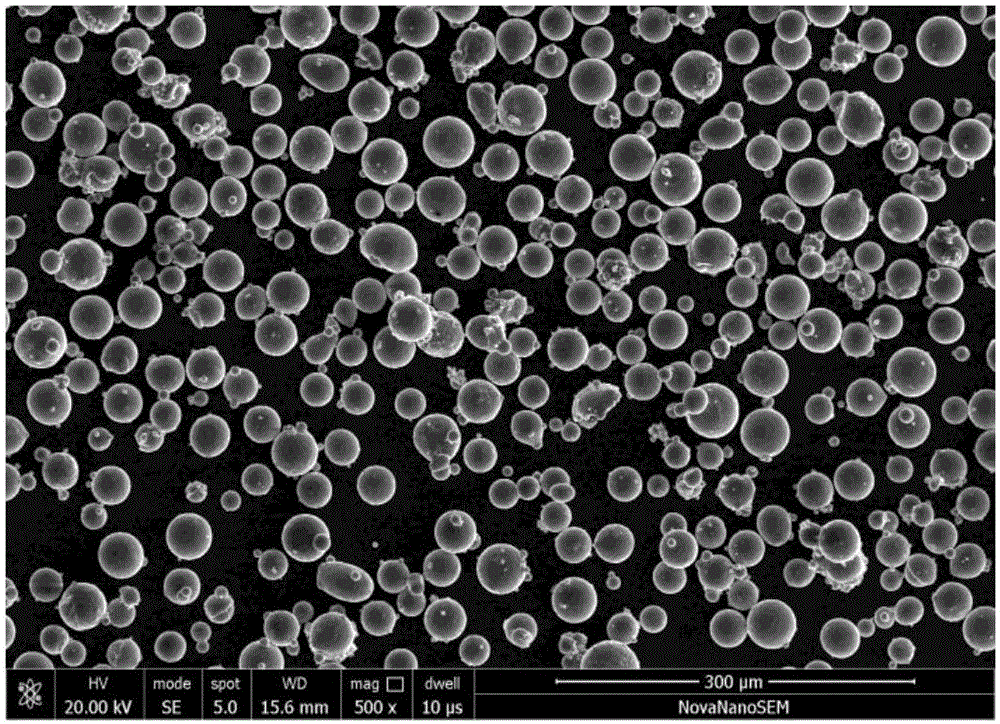

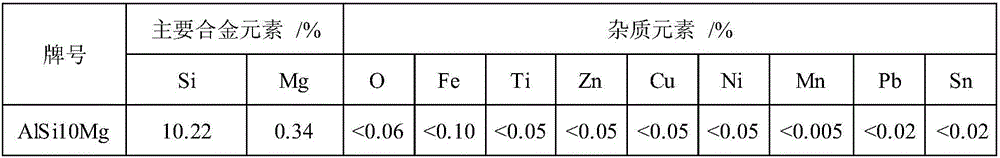

Preparation method for AlSi10Mg aluminum alloy superfine powder for 3D printing

The invention belongs to the technical field of metal and alloy powder preparation, and relates to a preparation method for AlSi10Mg aluminum alloy superfine powder for 3D printing. The preparation method is characterized by comprising the following preparation steps of: performing supersonic-speed gas atomization and ultrasonic-wave vibratory screening. By utilizing homemade equipment, the invention provides the preparation method for AlSi10Mg aluminum alloy superfine powder for 3D printing. Powder prepared by the method has the advantages such as small pollution in a process, high purity, low oxygen content, precise grain size control and low cost, can meet requirements of the 3D printing process, and also can realize replacing imported powder.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

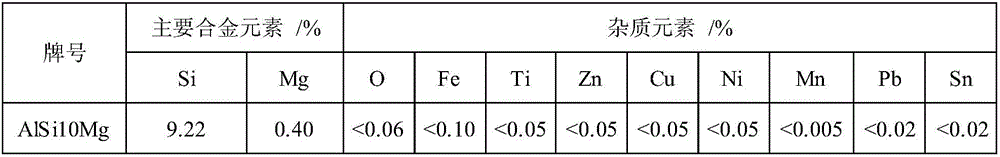

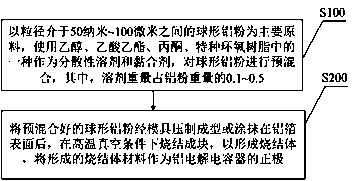

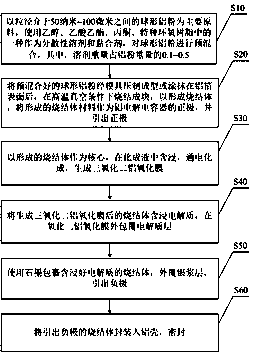

Novel powered aluminum positive electrode material and fabrication method of aluminum electrolytic capacitor

InactiveCN108172403ALarge specific surface areaReduce energy consumption and pollutionElectrolytic capacitor manufactureSolventMicrometer

The invention discloses a novel powdered aluminum positive electrode material and a fabrication method of an aluminum electrolytic capacitor. The preparation method comprises the steps of mixing spherical aluminum powder in advance by taking the spherical aluminum powder with a grain size being between 50 nanometers and 100 micrometers as a main raw material and taking one of ethyl alcohol, ethylacetate, acetone and special epoxy resin as a dispersion solvent and a binding agent, wherein the weight of the solvent accounts for 0.1-0.5 of the weight of the aluminum powder; pressing and formingthe pre-mixed spherical aluminum powder by a die or coating the spherical aluminum powder on a surface of an aluminum foil, sintering under a high-temperature vacuum condition to form a sintering body, and taking the formed sintering body material as a positive electrode of the aluminum electrolytic capacitor. The novel powdered aluminum positive electrode material and the fabrication method of the aluminum electrolytic capacitor, provided by the invention, have the advantages of small pollution, low energy consumption and low fabrication cost, and the fabricated aluminum electrolytic capacitor has high specific capacitance.

Owner:HUNAN AIHUA GRP

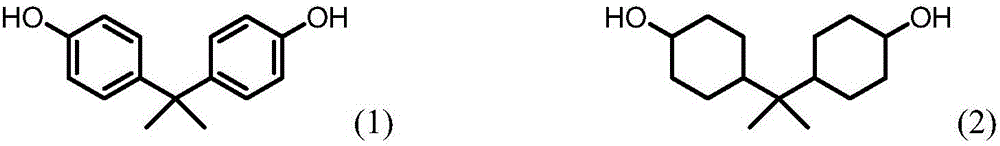

Preparation method for hydrogenated bisphenol A and catalyst for hydrogenation of bisphenol A

ActiveCN106083529ALow costResponse conditions are relaxedPreparation by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsHydrogen pressureSolvent

The invention provides a preparation method for hydrogenated bisphenol A and a catalyst for hydrogenation of bisphenol A. The preparation method comprises hydrogenating bisphenol A at a temperature of 50-100 DEG C, under a hydrogen pressure of 5-10 MPa and at presence of a solvent isopropanol and a ruthenium catalyst, so as to generate hydrogenated bisphenol A, wherein the ruthenium catalyst is a Ru-Zn-Ni / TiO2-CdO catalyst, that is, the ruthenium catalyst takes zinc and nickel as auxiliary active compositions and takes titanium dioxide and cadmium oxide as a composite carrier. The conversion rate of bisphenol A can reach 100%, meanwhile the selectivity of hydrogenated bisphenol A is larger than 97%, and the purity of hydrogenated bisphenol A is 99.5% or more.

Owner:JIANGSU QINGQUAN CHEM CO LTD

Viral suspension formulation pesticide with emamectin-benzoate

InactiveCN101204161ACompatibility is reasonableEasy to operateBiocideAnimal repellantsAvermectinSunscreen agents

The invention discloses a virus insecticidal suspension concentrate containing benzoate of dimethylamino avermectin. The main component of the suspension concentrate is the benzoate of the dimethylamino avermectin with a content of 0.1- 10wt percent; the virus is one or a plurality of viruses in karyotye and polyhedrosis virus NPV; the content of virus inclusion body in the suspension concentrate is 0.5-20 billion PIB / ml. The invention has no harm to human and animals as well as other higher animals and can effectively control occurrence and harm of agricultural and forestry pests with no environmental pollution and no pesticide residue. An antifreeze, a stabilizer, a sunscreen agent, a synergist, a dispersant, a defoamer and a pH value regulator are added in the preparation, which stabilizes the performance of the product and greatly accelerates the insecticidal speed, thus both the insecticidal speed and insecticidal effect of the virus pesticide are obviously improved.

Owner:海南利蒙特生物科技有限公司

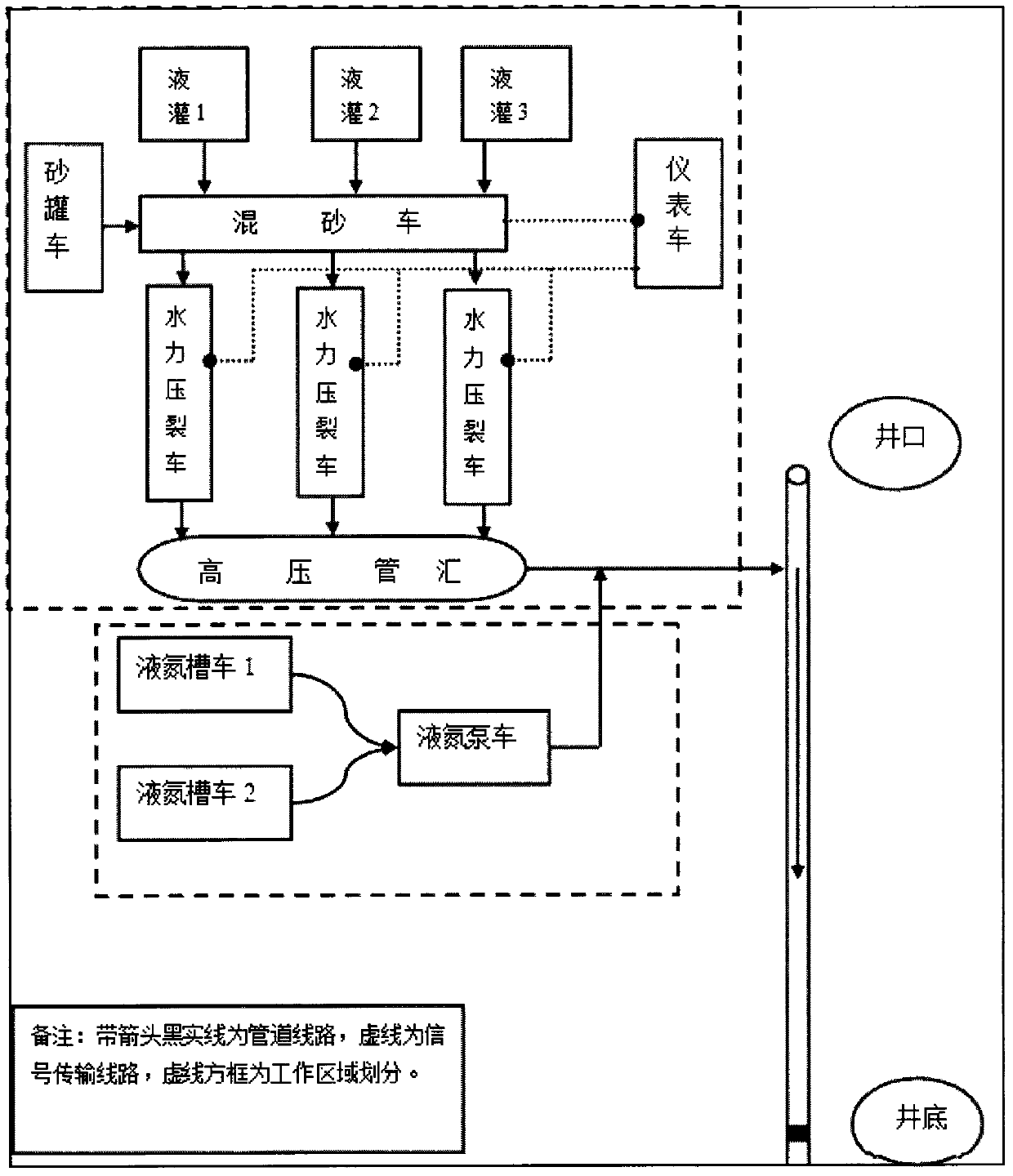

Method and equipment for reducing pollution through nitrogen foam fracturing of coal-bed gas well of low-pressure and low-permeability reservoir

InactiveCN104405359AAvoid damageLow process pollutionFluid removalCarrying capacityEnvironmental geology

The invention relates to a nitrogen foam fracturing technology of a coal-bed gas well of a low-pressure and low-permeability reservoir. In the fracturing process, the low-pressure and low-permeability reservoir is easier to damage. According to a method, high-quality and high-efficiency nitrogen foam of which the mass is 75 percent is adopted for sand-carrying fracturing, the liquid injection quantity of nitrogen foam fracturing is small, the sand-carrying capacity is high, and the de-filtration capacity is high, so that the damage to the low-pressure and low-permeability reservoir is reduced; after the fracturing is completed, an open-flow oil nozzle of which the size is 3-8mm is quickly mounted and is connected with an open-flow pipeline to perform quick pressure-control open flow, and fracturing liquid is returned and discharged to the greatest extent as quickly as possible. The conventional hydraulic fracturing liquid quantity is large, so that the low-pressure and low-permeability reservoir is polluted; the reservoir is heavily polluted by common guanidine gum fracturing; the high-quality nitrogen foam fracturing technology is small in liquid injection quantity, high in seam forming capacity, good in sand-carrying and sand-paving effect and high in after-fracturing return discharge rate, and the pollution of the reservoir is greatly reduced.

Owner:HENAN POLYTECHNIC UNIV +1

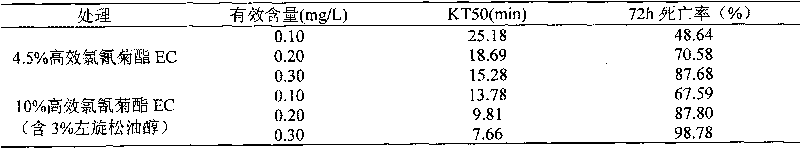

L-terpineol synergist-containing beta-cypermethrin pesticide composition

ActiveCN101731260AGood anti-mosquito effectNo side effectsBiocideAnimal repellantsCypermethrinEcological environment

The invention discloses an L-terpineol synergist-containing and beta-cypermethrin-containing synergistic pesticide composition, which is characterized in that: the pesticide composition consists of an active ingredient, a synergist and auxiliary materials, wherein the active ingredient is the beta-cypermethrin; and the synergist is the L-terpineol. The composition can overcome resistance of sanitary pests to the beta-cypermethrin, improves pesticide effect, reduces pesticide dosage, retards pesticide resistance of the pests and has less damage and pollution to ecological environment.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

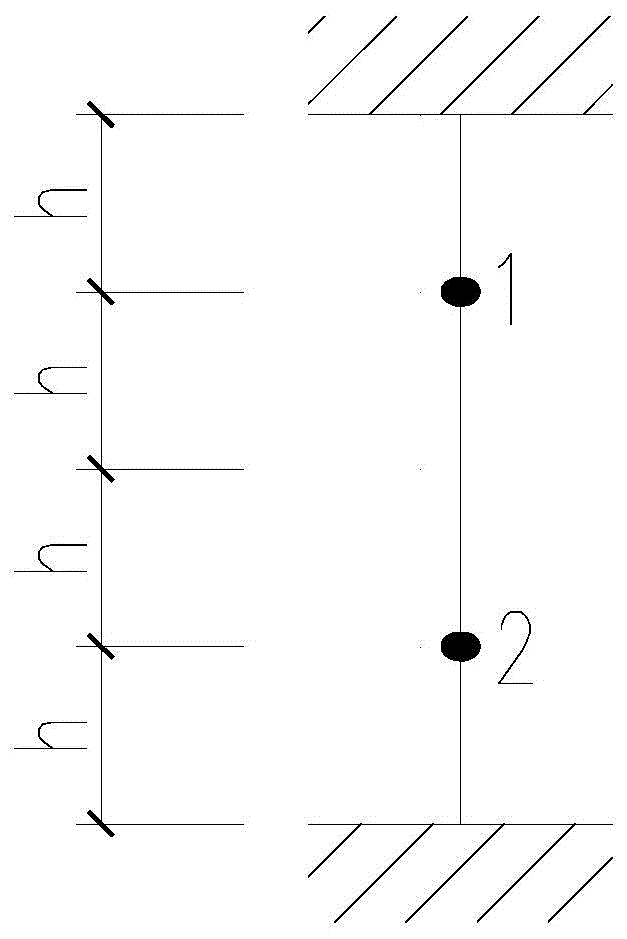

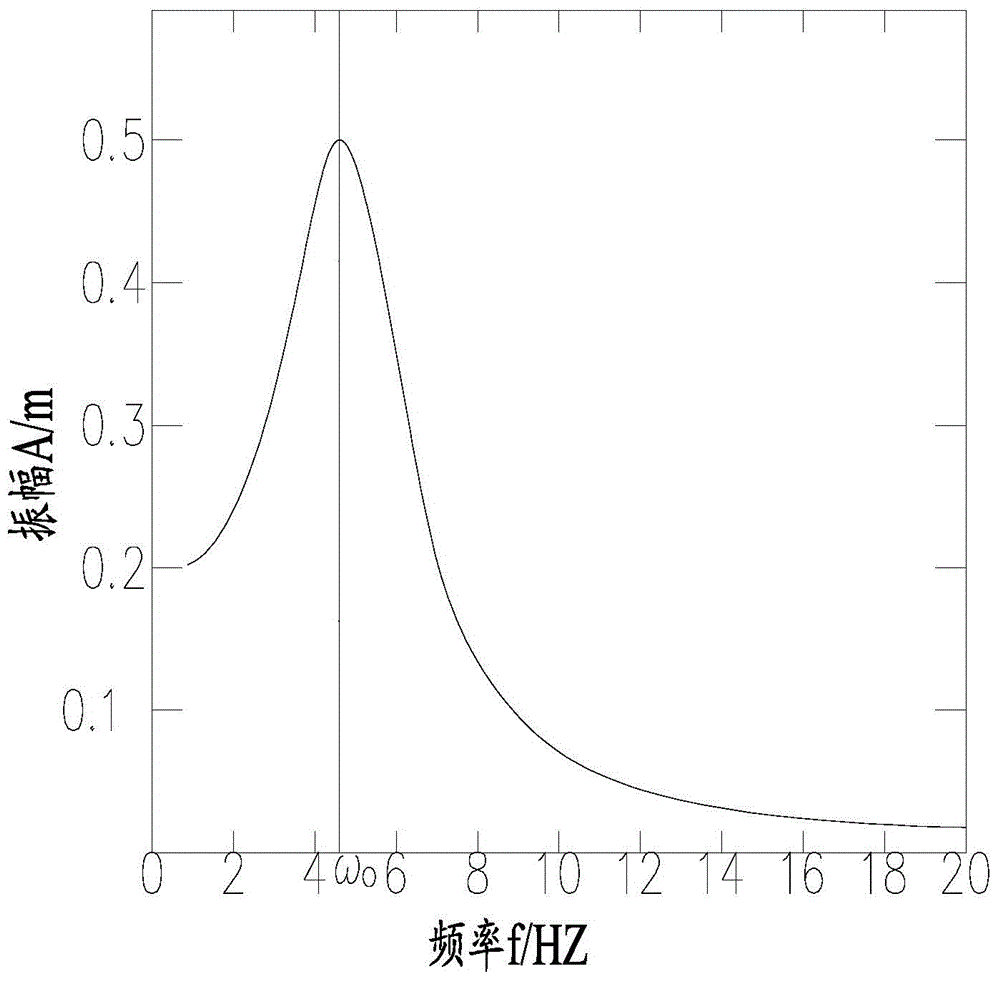

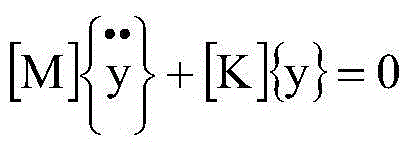

Method for demolishing building or building components based on resonance principle

InactiveCN104453275AImprove energy utilizationEasy to recycleBuilding repairsArchitectural engineeringMechanical resonance

The invention discloses a method for demolishing a building or building components based on the resonance principle. The method is characterized by comprising the technological steps that after the building or building component ancillary facilities are demolished, the distance between supporting facilities is measured, the natural vibration frequency of the building or building components is determined, a suitable vibration excitation device is selected according to the natural vibration frequency of the building or building components, the selected vibration excitation device is installed in the quality or rigidity center, the frequency of the vibration excitation device is adjusted to be equal to or approximate to the natural vibration frequency of the building or building components so that mechanical resonance of the building or building components can be achieved, and accordingly the building or building components can be demolished. The method for demolishing the building or building components is safe, economical and environmentally friendly, and the device can be recycled.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

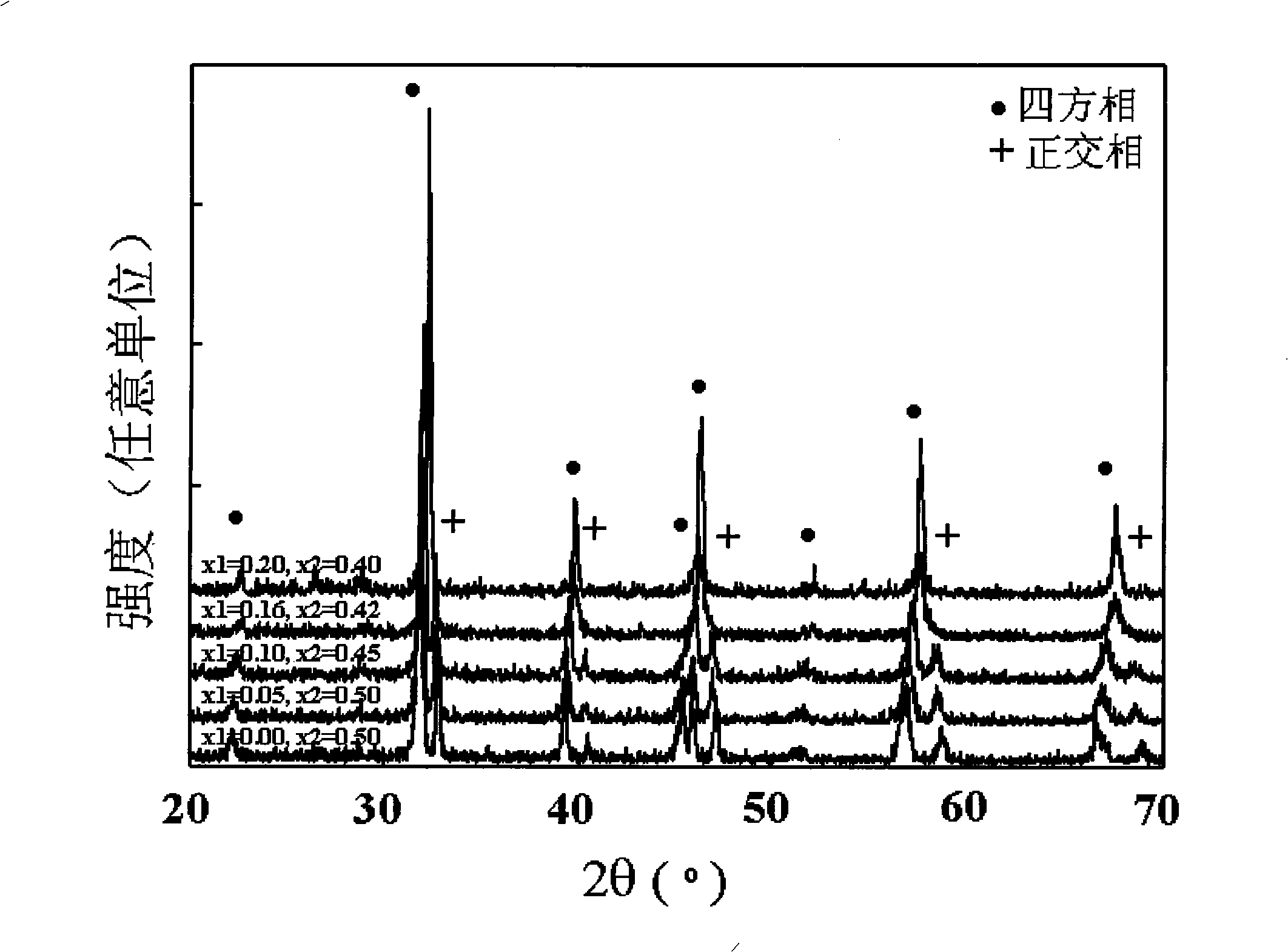

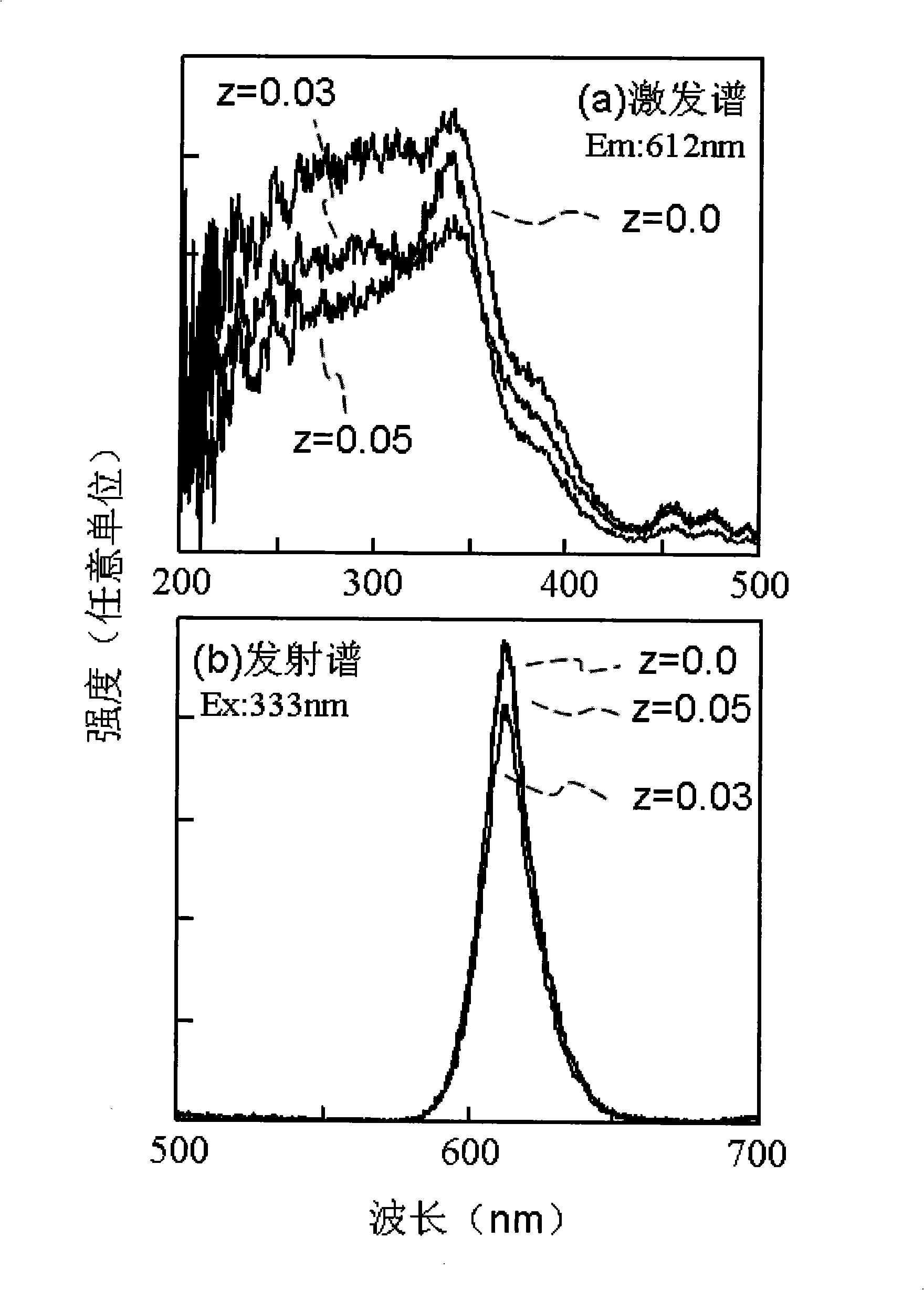

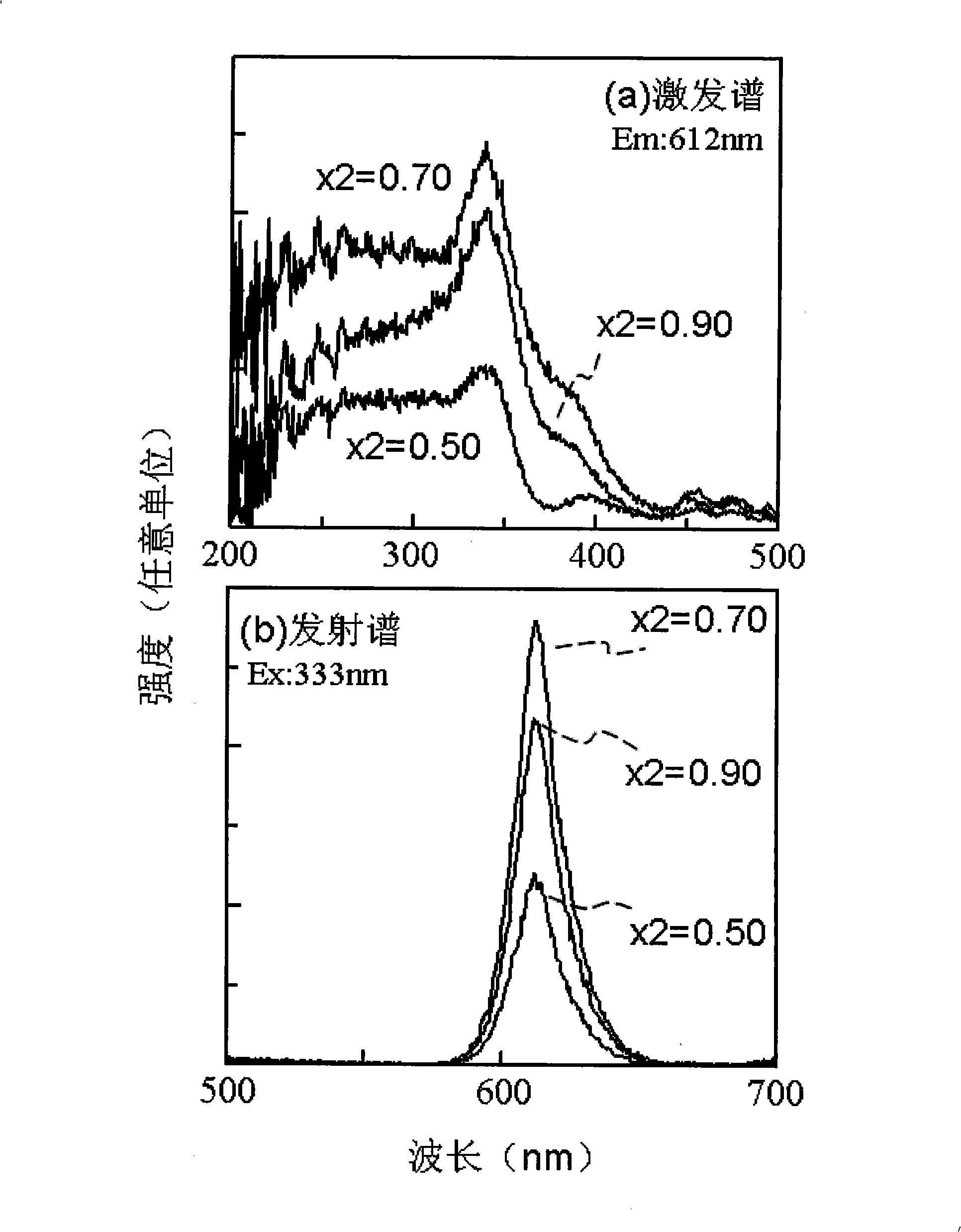

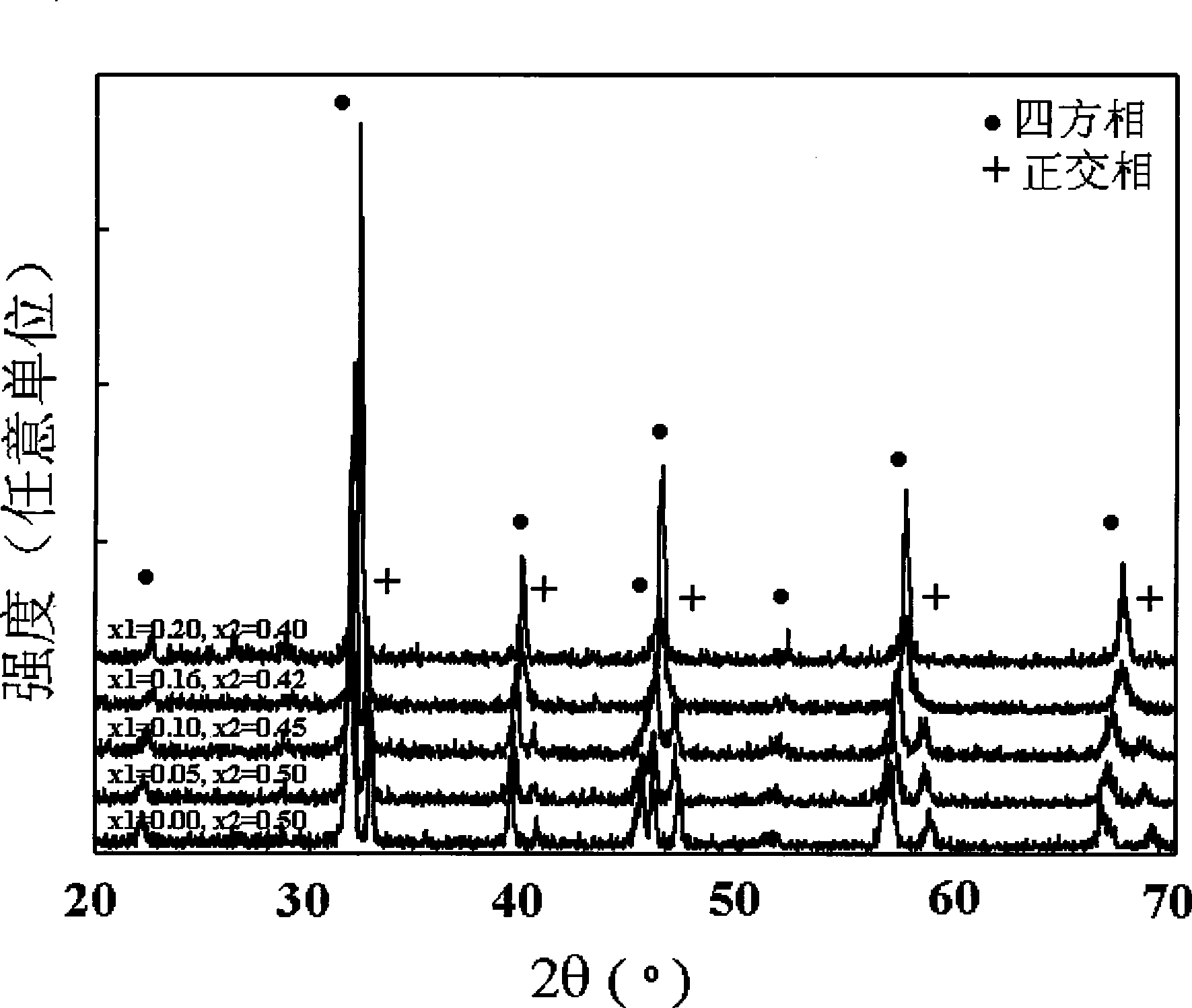

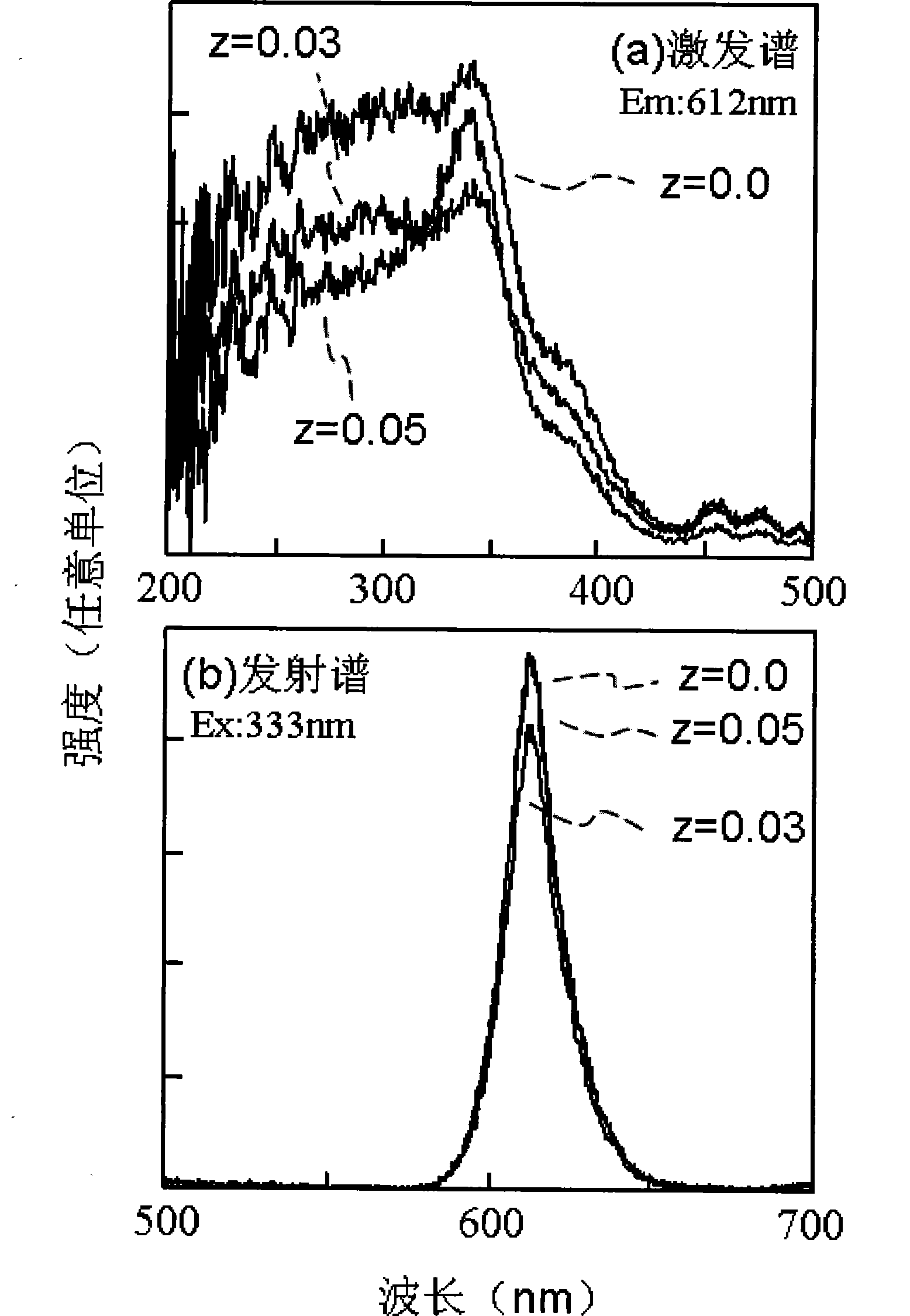

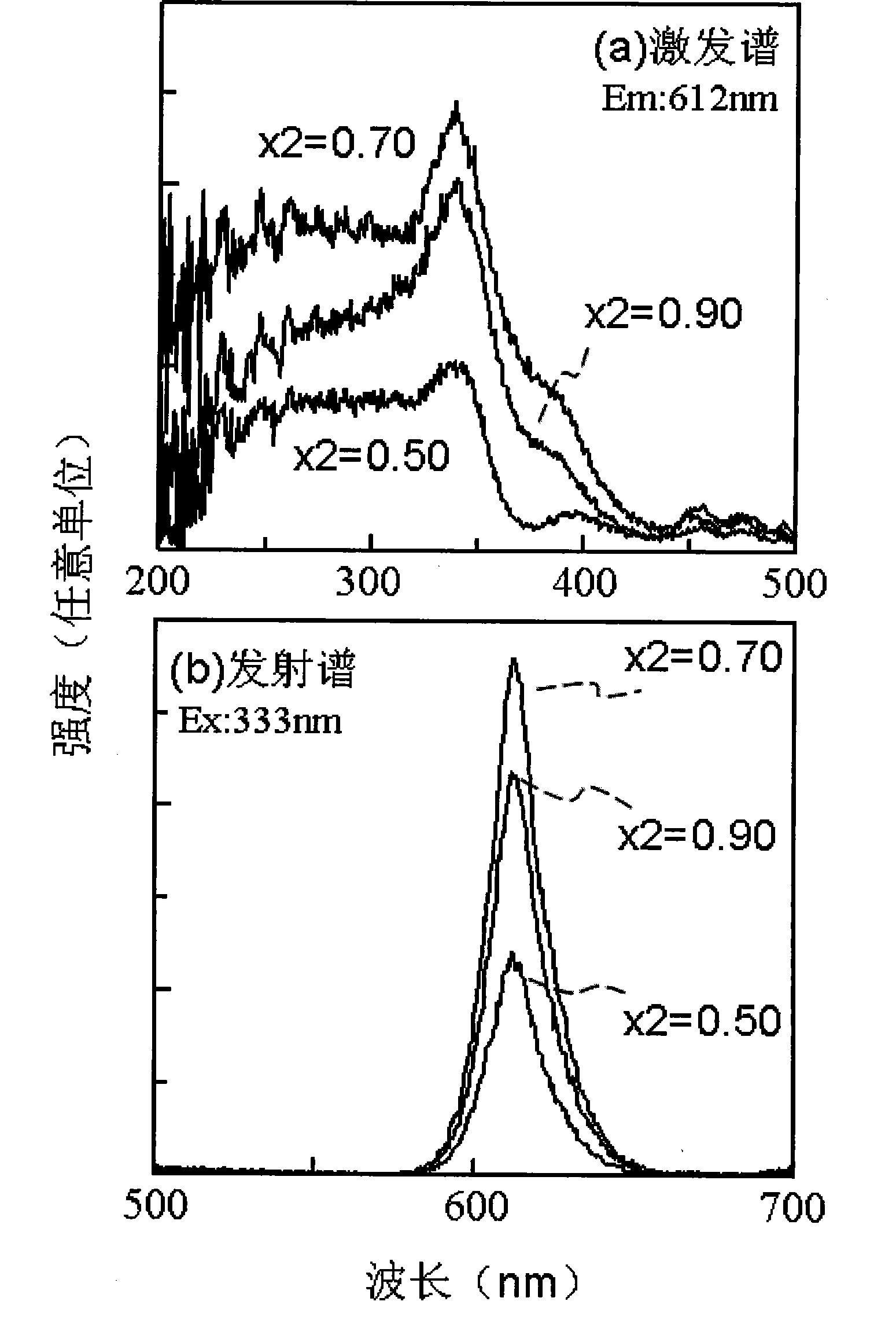

Complex-phase ceramic material with stress irradiance and electroluminescence characters and preparation thereof

InactiveCN101343180ASimple preparation processLow costTenebresent compositionsLuminescent compositionsIn planeStress distribution

The invention discloses a self-assembly bi-phase composite ceramic powder, which is characterized in that the powder has a molecular formula of Ba(1-x1-x2-x3-ySrx1Cax2Ax3Ry)Ti(1-zMz)O3, wherein, 0<=x1<=0.18, 0.21<=x2<=0.90, 0.0001<=x3<=0.13, 0.0001<=y<=0.05, 0<=z<=0.20; A is a bivalent element of Mg, Pb, Zn, Cu or Cr, R is La, Pr, Nd, Sm, Eu, Gd, Tb, Dy or Er, and M is a quadrivalent element of Zr, Ce, Cu or Sn. The composite ceramic includes two phases, the content of barium in the first phase is larger than the calcium content, and the calcium content in the second phase is larger than the barium content. The ceramic powder has the features of stress luminescence and electroluminescence, and can be used for the stress distribution measurement and adhesive strength measurement of various parts and members and in plane illumination devices. The parts can be luminous when being coated with ceramic powder on surfaces and applied with stress. The luminous intensity of stress luminescence is in direct ratio with the applied stress in the elastic limit.

Owner:TONGJI UNIV

Method for detecting magnetic substance content of lithium ion battery positive electrode material

InactiveCN106610352ALow process pollutionAccurate detection of contentPreparing sample for investigationAnalysis by thermal excitationLithium-ion batteryUltrasonic dispersion

The invention provides a method for detecting magnetic substance content of a lithium ion battery positive electrode material. The method comprises placing a positive electrode material and a polymer-coated magnet in a dispersion liquid, carrying out ultrasonic dispersion at frequency of 20 to 100kHz for 30 minutes, carrying out stirring at a rotation rate of 60r / min for 30min so that the polymer-coated magnet adsorbs the magnetic substance in the positive electrode material, tanking the polymer-coated magnet adsorbed with the magnetic substance out of the dispersion liquid, carrying out ultrasonic cleaning, putting the cleaned polymer-coated magnet adsorbed with the magnetic substance into hydrochloric acid having a mass concentration of 18% so that the magnetic substance is dissolved to form a solution, taking the polymer-coated magnet out of the solution, and detecting the content of the magnetic substance in the solution. The method can accurately detect magnetic substance content of a lithium ion battery positive electrode material.

Owner:SHENZHEN BAK POWER BATTERY CO LTD +1

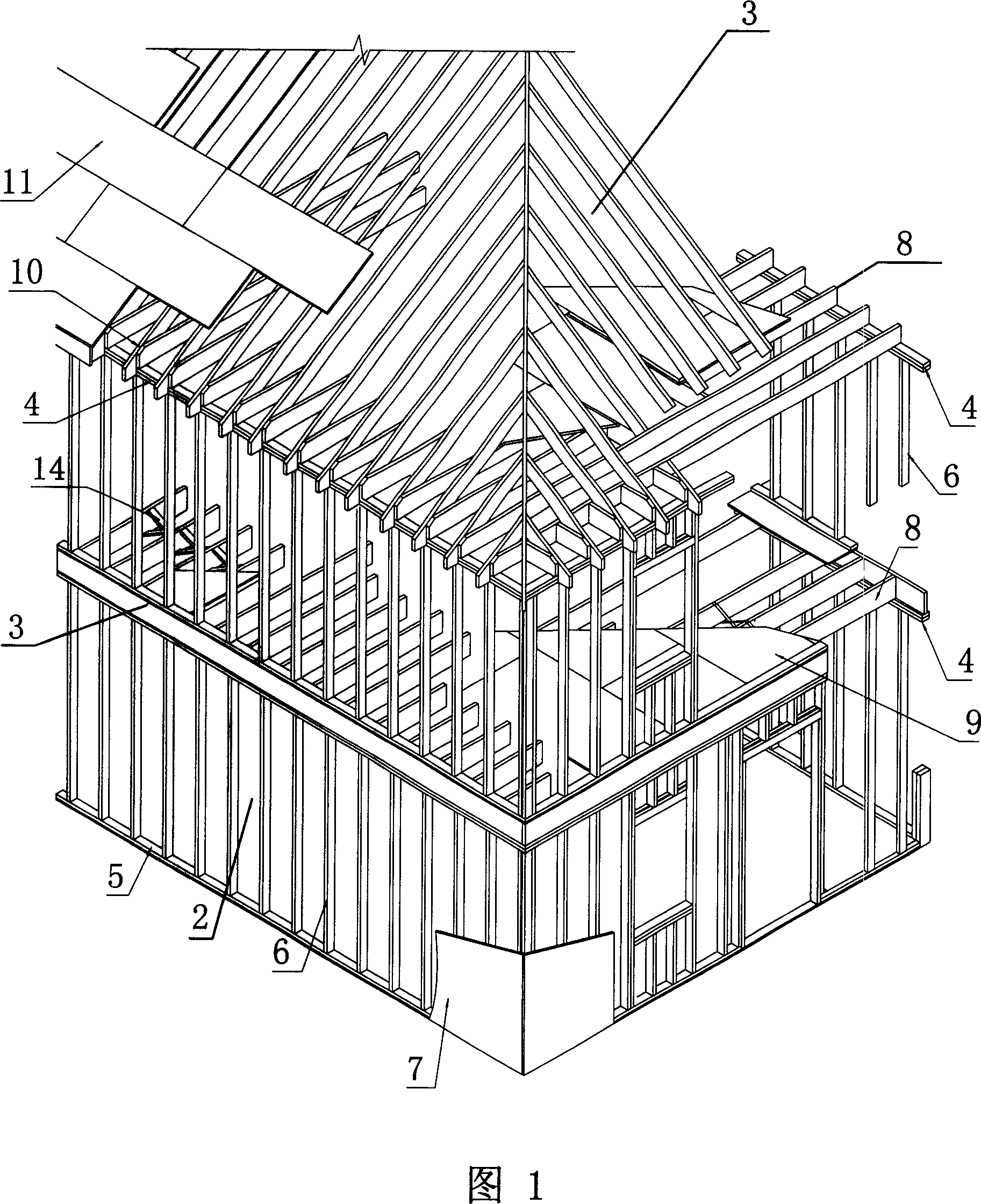

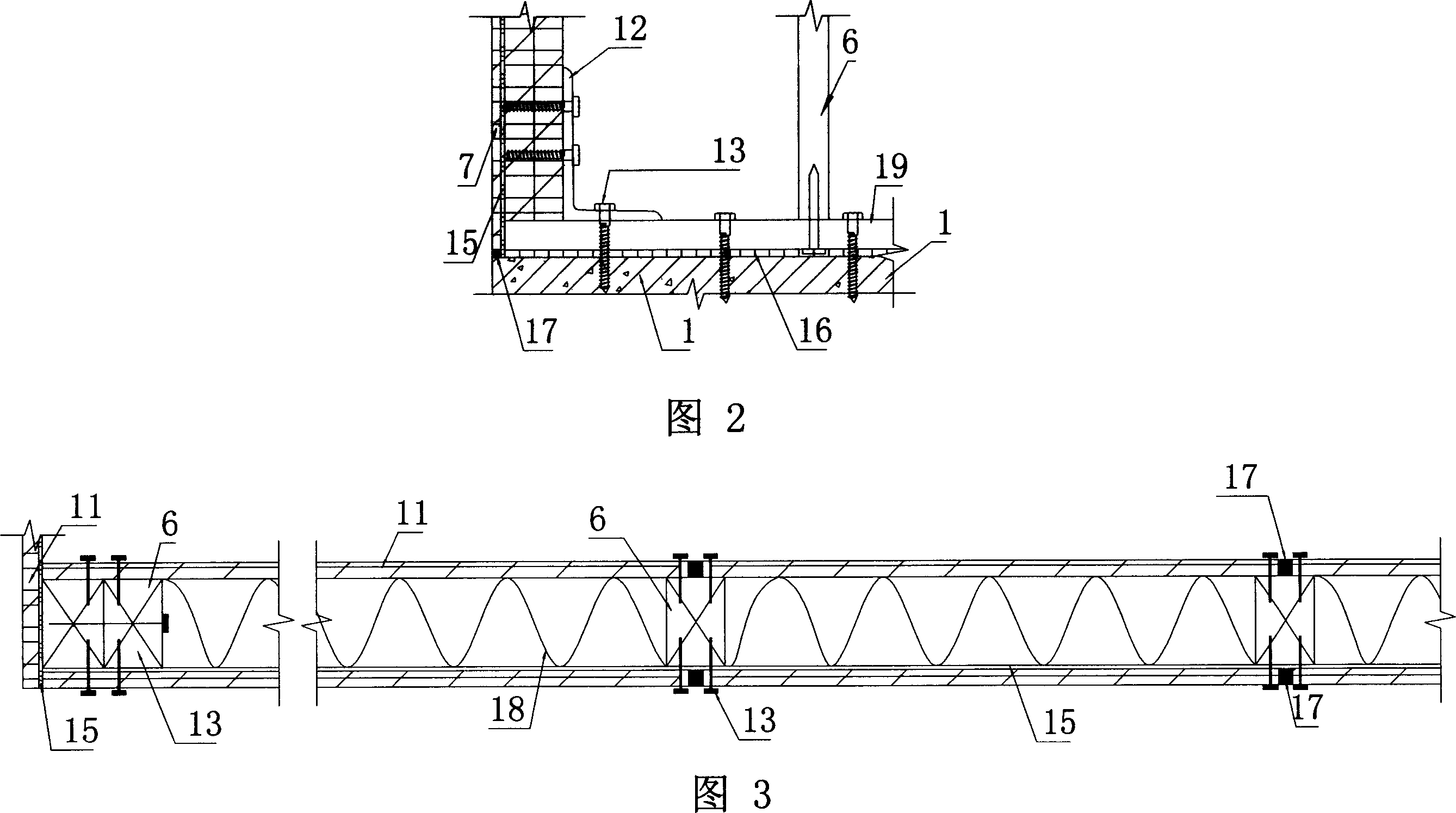

Bamboo residential building

InactiveCN1963056AShorten the growth cycleIncrease productionBuilding constructionsDwelling buildingReinforced concreteJoist

The invention discloses a bamboo domestic architecture; it includes foundation, walls, floor and roof one by one from the bottom to the top. Said foundation is bamboo concrete or armored concrete structure, the wall and the floor components use bamboo component or bamboo and wood assembly, the perimeter of floor is supported by the wall, the bamboo component of said walls comprises of beam, bottom beam, wall pillar installed between the beam and the bottom beam as well as the wall surface which covers the outside of wall pillar. The bamboo component of said floor comprises of many floor joists and floor surface using bamboo as base material, the floor joist is placed on the beam and the floor surface is placed on the floor joist. The invention is a simple, low cost, small construction difficulties, short construction period, better environmental protection and bamboo domestic architecture.

Owner:湖南博世安新技术有限公司

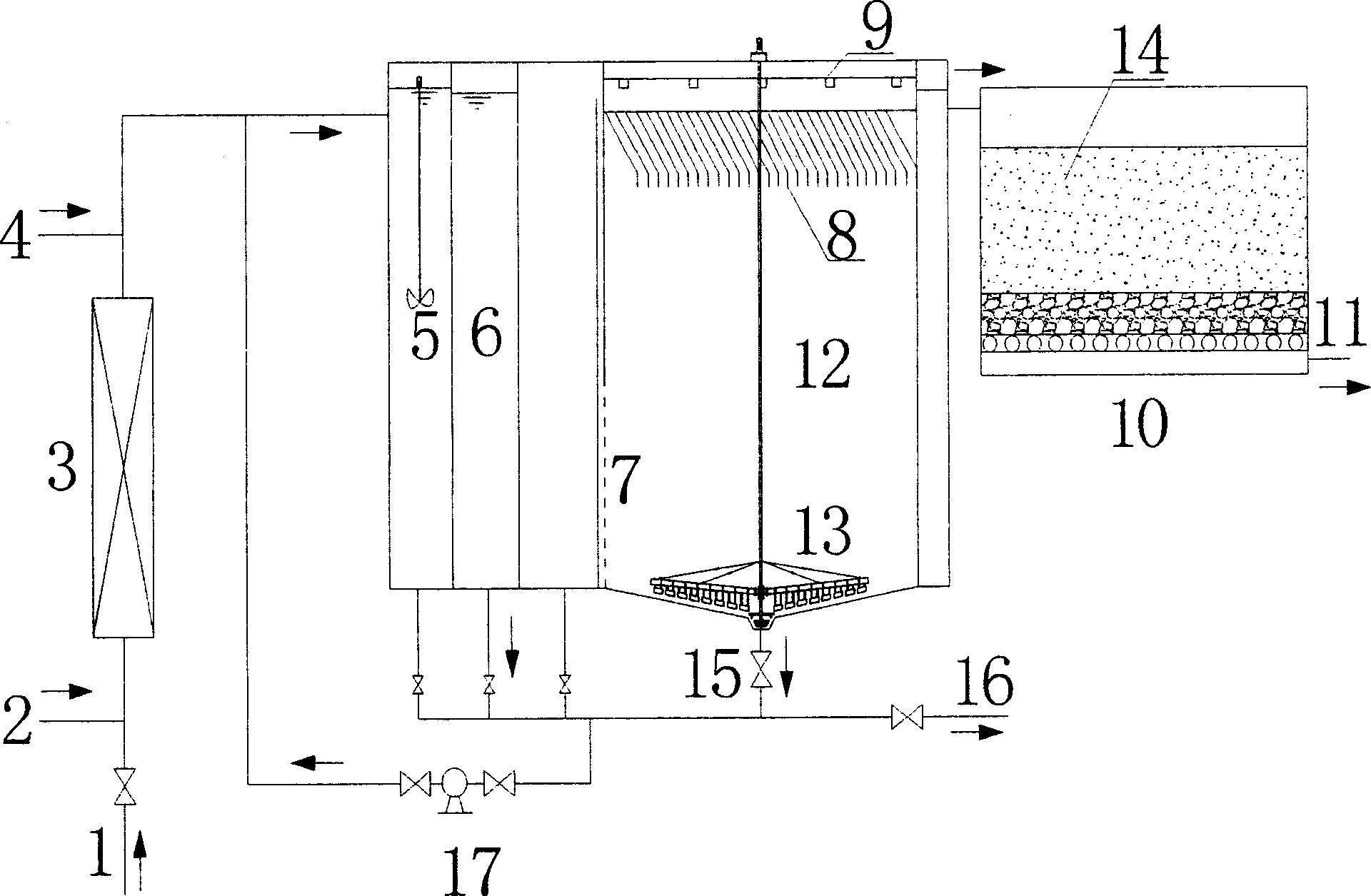

Method of treating low temperature low turbidity water by high density active mud sediment back flow

InactiveCN1948177AImprove water qualityLow water turbidityWater/sewage treatment by flocculation/precipitationHigh densitySludge

The present invention relates to a method for treating low-temperature low-cloudy water by utilizing high-density active sludge refluxing process, belonging to the field of water treatment technology. Said method includes the following steps: adopting external sludge refluxing system to make the chemical active sludge be lifted into feedwater pipe of reaction tank from sludge concentrated zone and mixed with primary water, then making them be passed through mechanical stirring mixing chamber and fed into reaction flocculating chamber, then adopting high-effective oblique plate precipitation process to produce complete, uniform and high-density alumen ustums from perforated wall to oblique plate precipitation zone and effectively implement sludge concentration so as to ensure stable water quality of discharged water.

Owner:SHENYANG JIANZHU UNIVERSITY

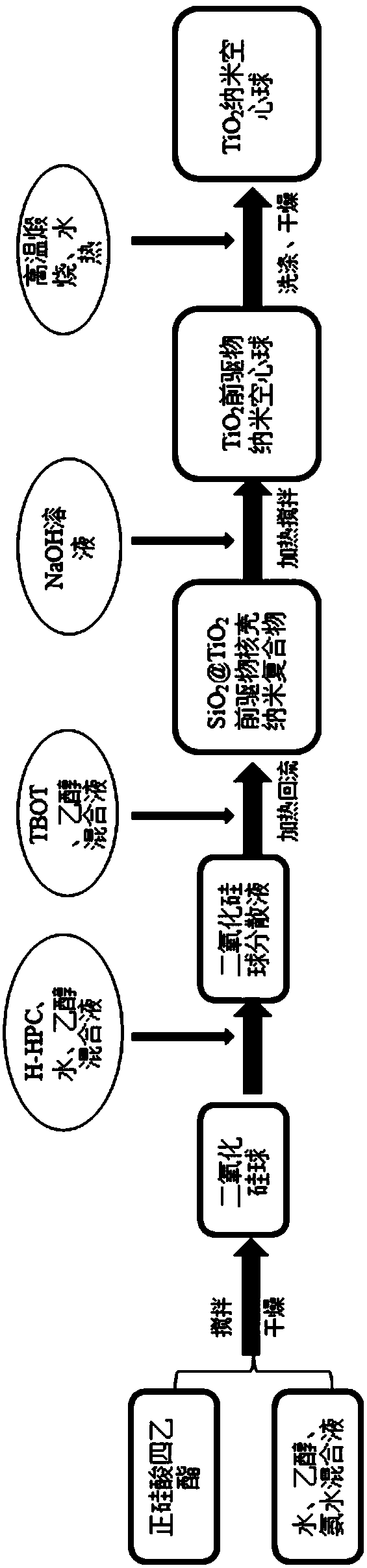

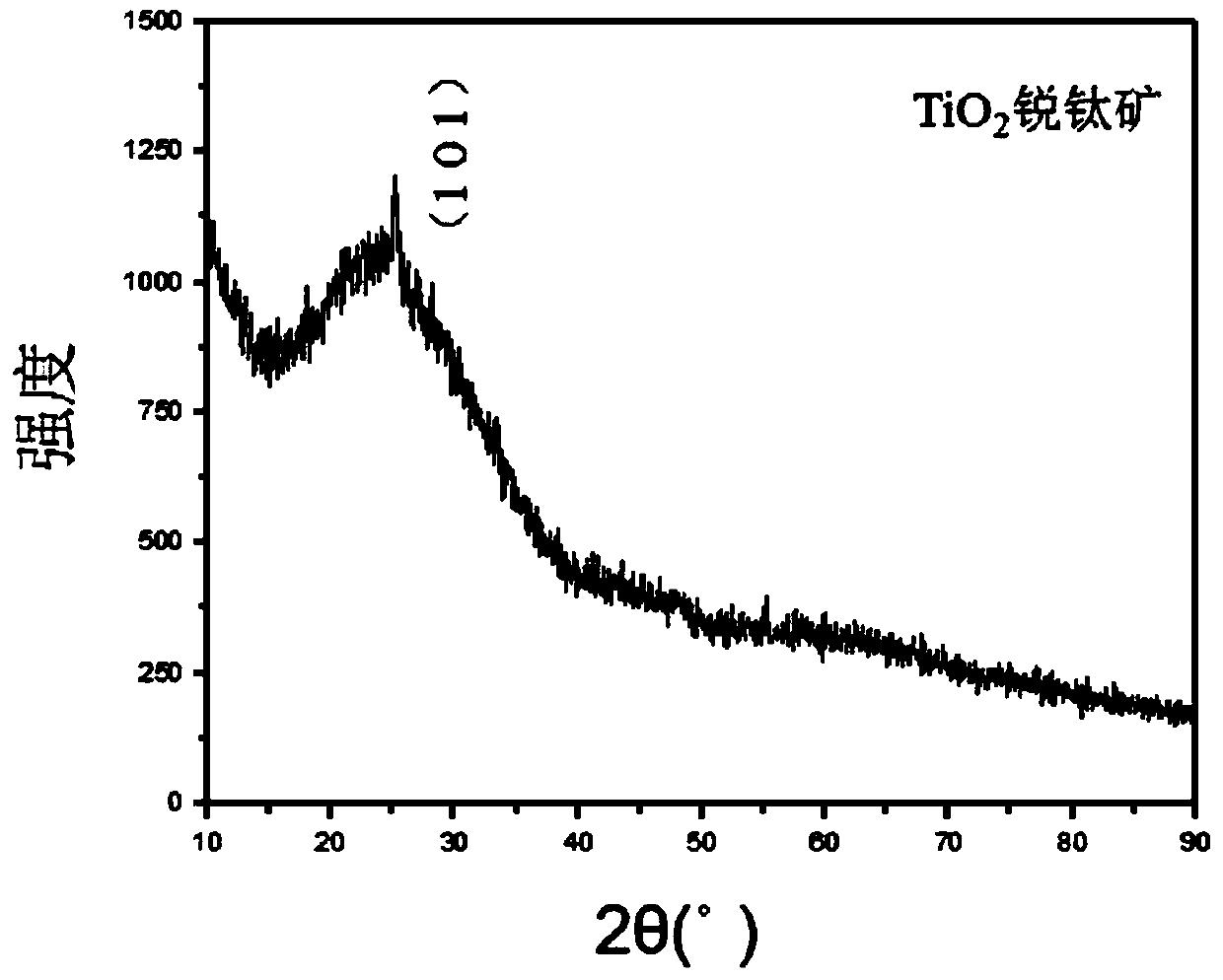

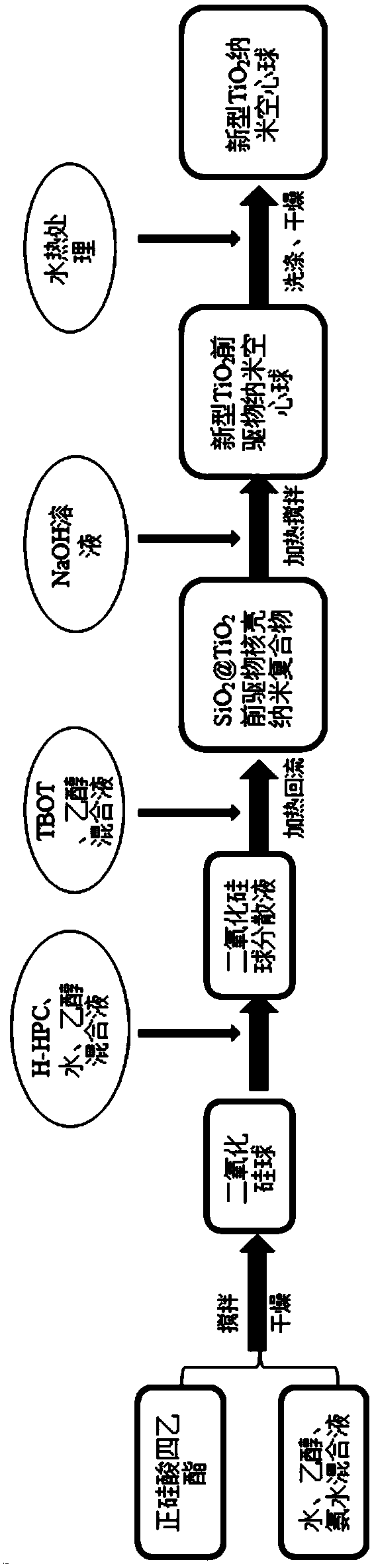

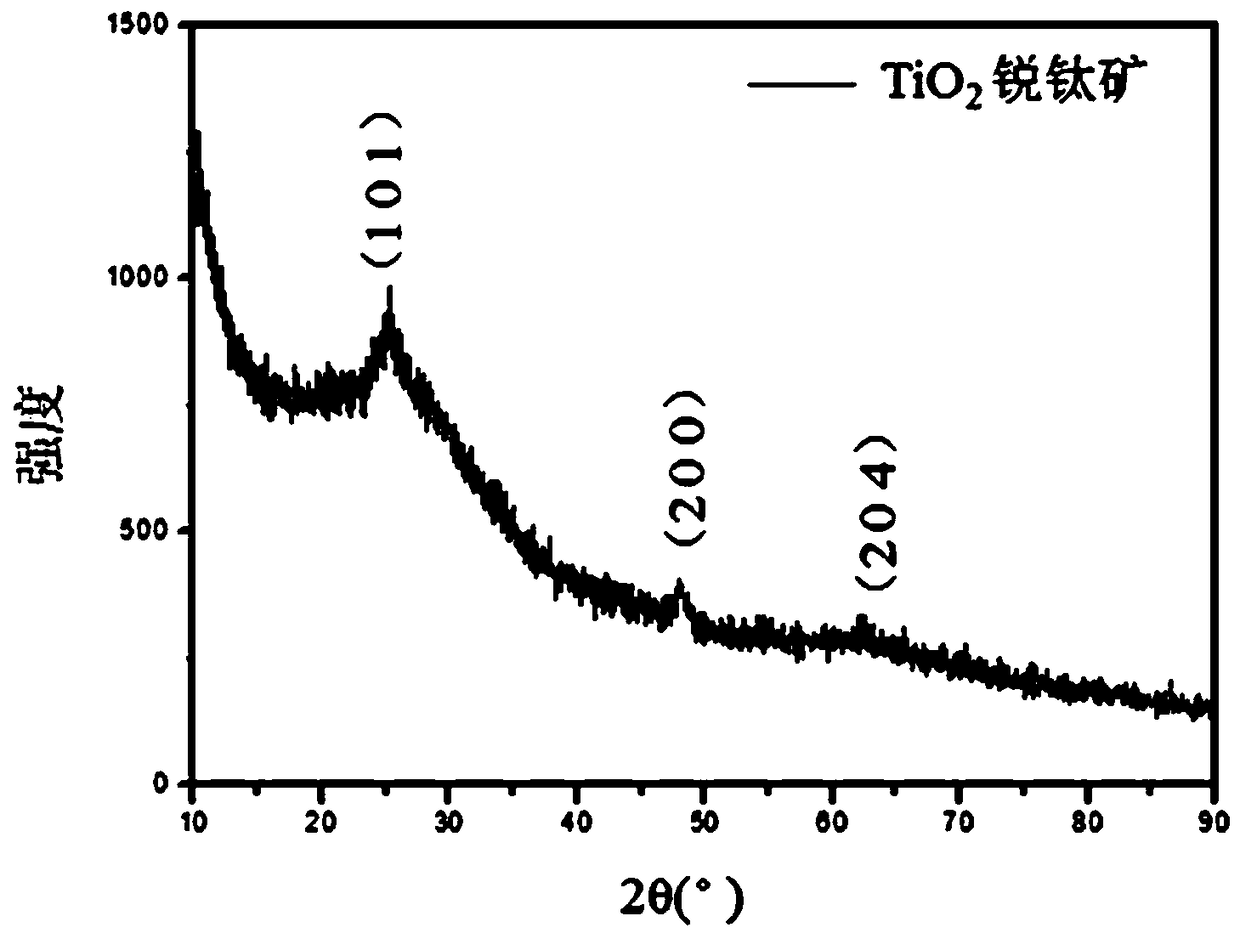

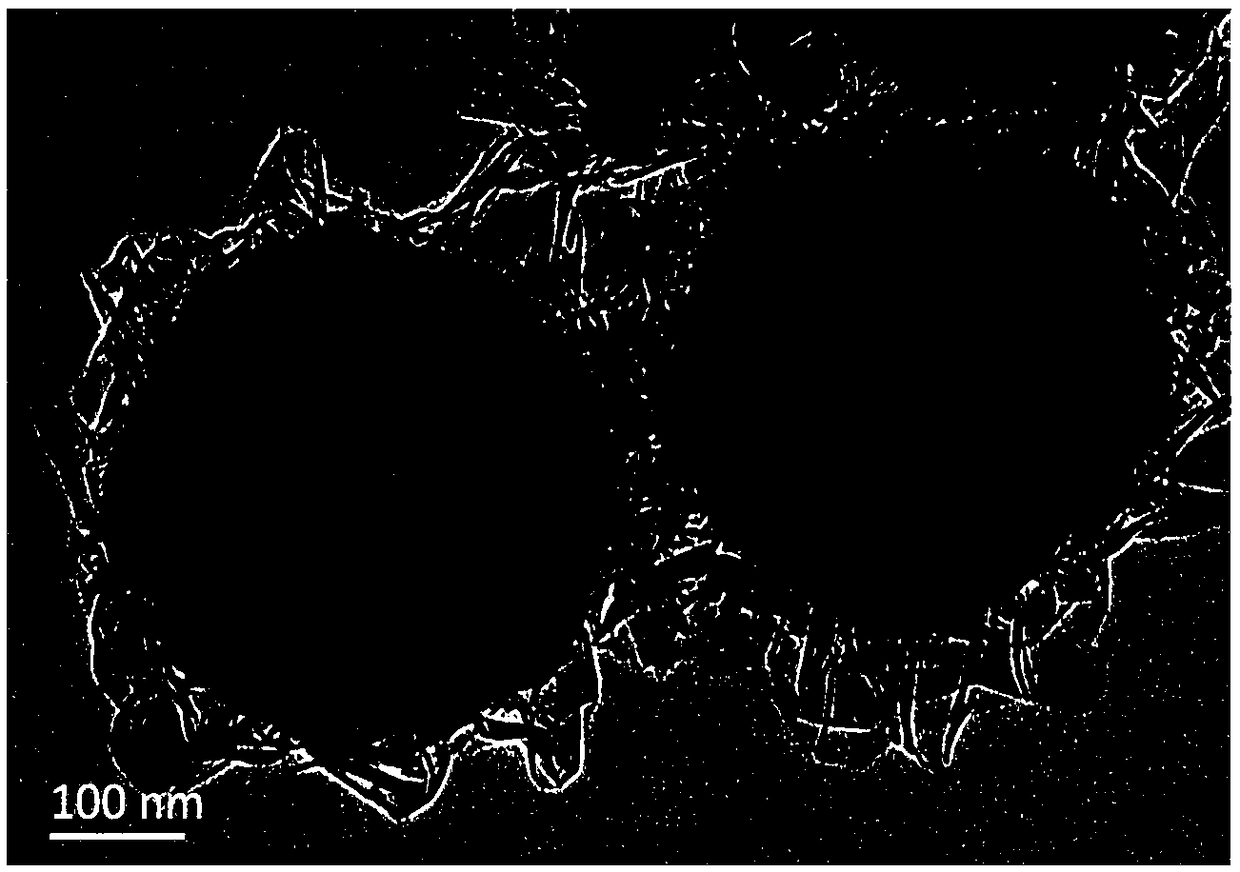

Titanium dioxide hollow nanospheres and preparation method thereof

InactiveCN108675345AGrowth inhibitionInhibition of coagulationSilicaPhysical/chemical process catalystsMicrosphereSilicon dioxide

The invention discloses a preparation method of titanium dioxide hollow nanospheres. The preparation method comprises the following steps: firstly, taking tetraethyl orthosilicate as a silicon sourceand preparing silicon dioxide microspheres by adopting a Stobe method; then cladding the surfaces of the silicon dioxide microspheres with a titanium dioxide precursor; then removing a silicon dioxideinner core by adopting strong alkali corrosion; finally, carrying out calcination and hydrothermal treatment to prepare anatase form titanium dioxide hollow nanospheres. The invention further discloses the titanium dioxide hollow nanospheres prepared by the preparation method provided by the invention. The method disclosed by the invention is simple to operate, low in production cost, small in process pollution, high in product yield, good in repeatability and suitable for large-scale production. A titanium dioxide nano-product prepared by the method has the advantages of high purity, good crystallization, controllable crystal form, fine particle granularity, uniform particles, good monodispersity, small particle size, large specific surface area and high photocatalytic activity.

Owner:NORTHEASTERN UNIV

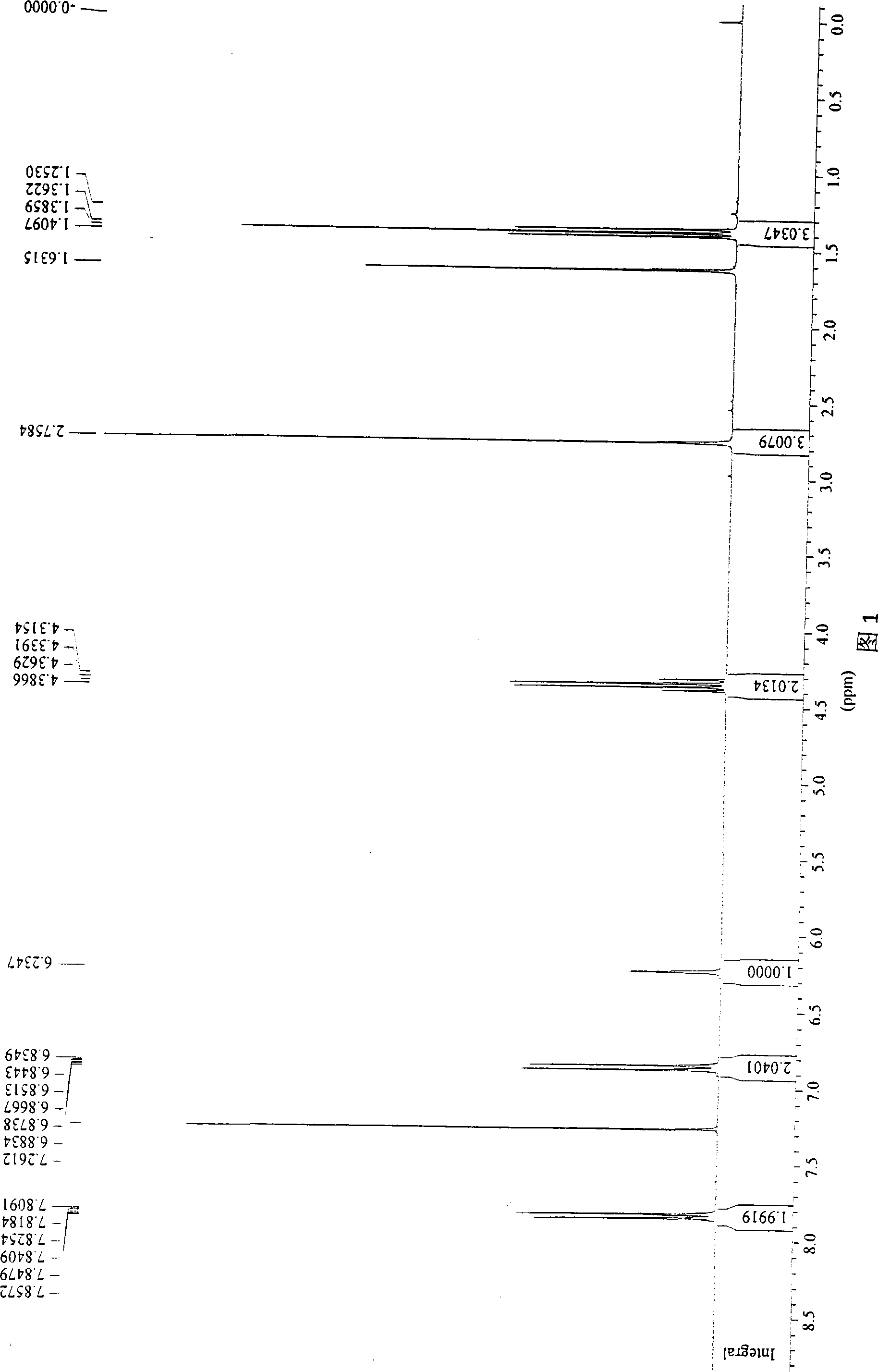

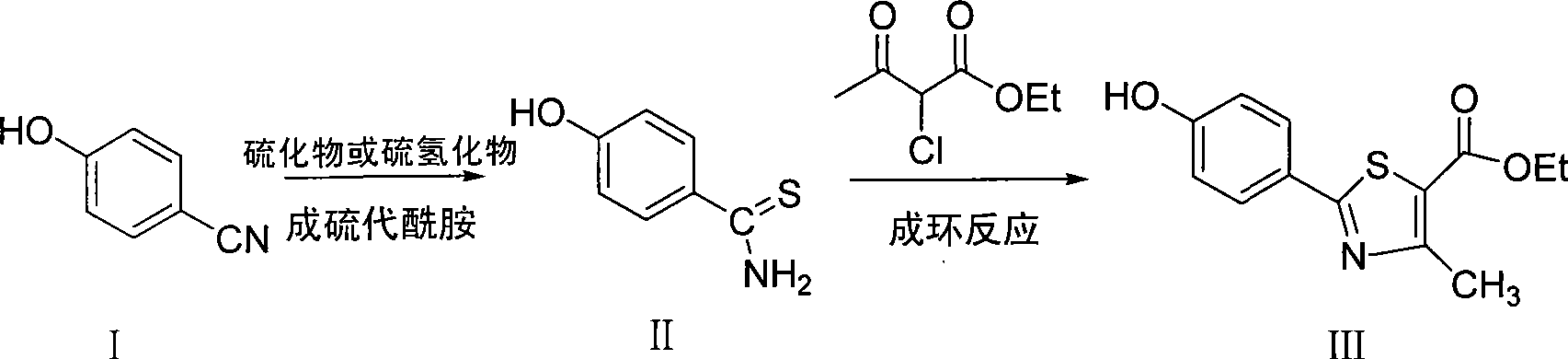

Method for preparing 2-(4-hydroxyl phenyl)-4-methyl-1,3-thiazole-5-carboxylic acid ethyl ester by one pot method

InactiveCN101391988ASimple reaction conditionsSimple and efficient operationOrganic chemistrySolventWater soluble

The invention relates to a method for preparing 2-(4-hydroxyphenyl)-4-methyl-1, 3-thiazole-5-carboxylic acid ethyl ester by using a one-pot method, which comprises the steps: p-hydroxybenzonitrile, sulphid or sulfohydrate and water-soluble metal chloride are dissolved in an organic solvent, the temperature is controlled, p-hydroxyl-thiobenzamide is generated by reaction; a refluxing solvent is added into a p-hydroxyl-thiobenzamide reaction system generated by the reaction, and 2-halogenated acetoacetate ethyl ester is dropped into the system, the temperature is raised and the reflux reaction is carried out, the reaction liquid is acidulated after the reaction is finished, then the target product, 2-(4-hydroxyphenyl)-4-methyl-1, 3-thiazole-5-carboxylic acid ethyl ester, is obtained by post treatment. The invention has the advantages of low-cost and easily-obtained raw materials, simple reaction conditions, simple and convenient operation, small toxicity and pollution, simple post treatment, high yield and purity and being suitable for industrial production.

Owner:NANJING UNIV OF TECH

Gas burner

InactiveCN1793724AIncrease burn rateImprove combustion effectGaseous fuel burnerMixed fuelAutomotive engineering

The invention relates to a fuel gas furnace end, especially a fuel gas furnace end for canteens and kitchens in hotel, wineshop, department, school, etc, comprising furnace end body and fuel gas pipe, and the jet end of the furnace end body is provided with a double-spherical gap flat-bottomed diffusion cavity whose middle is provided with a communicating truncated-cone jet cavity, the middle of the bottom of the jet cavity is provided with a communicating mixed cavity, and the gas outlet of the fuel gas pipe is arranged in the mixed cavity. It makes fuel gas firstly mix with the air in the mixed cavity, makes the fuel gas remix with the air in the jet cavity and diffusion cavity, and then jets the mixed fuel gas from flame hole to mix with the air again and burn, so as to make the fuel gas fully burn, improving combustion and effect of fuel gas.

Owner:YONGKANG HUAGANG KITCHENWARE

Titanium dioxide hollow nanospheres and preparation method thereof

ActiveCN108640149AHigh purityUniform particlesMaterial nanotechnologyPhysical/chemical process catalystsDispersityMicrosphere

The invention discloses a preparation method of titanium dioxide hollow nanospheres. The preparation method comprises the following steps: firstly, silicon dioxide microspheres are prepared from tetraethyl orthosilicate as a silicon source with a Stobe method, then, surfaces of the silicon dioxide microspheres are coated with a titanium dioxide precursor, silicon dioxide cores are removed by strong alkali corrosion, and finally, the crystalline titanium dioxide hollow nanospheres with flaky branch structures on the surface are prepared by hydrothermal treatment. The invention further disclosesthe titanium dioxide hollow nanosphere prepared with the preparation method. The method is simple to operate and good in repeatability, does not need high-temperature sintering, is suitable for large-scale production, avoids agglomeration of titanium dioxide powder, low in process pollution and achieves high product yield and low production cost; the obtained titanium dioxide hollow nanospheres have high purity, uniform particles, good crystallization, controllable crystal form, good dispersity, large specific surface area, high adsorption capacity and capture capacity for pollutants and highphotocatalytic efficiency, and a plurality of flaky branches are contained on the surface.

Owner:NORTHEASTERN UNIV

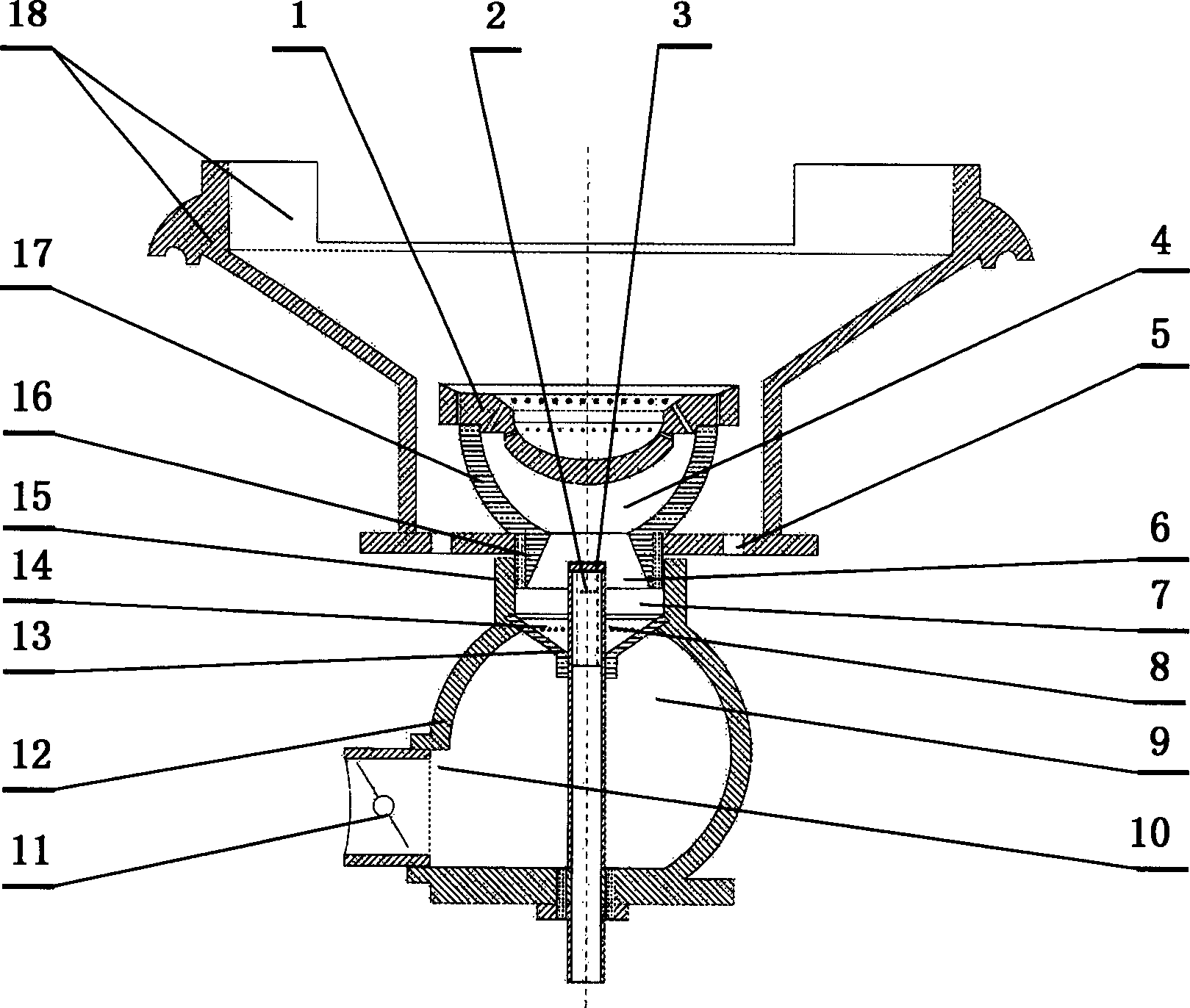

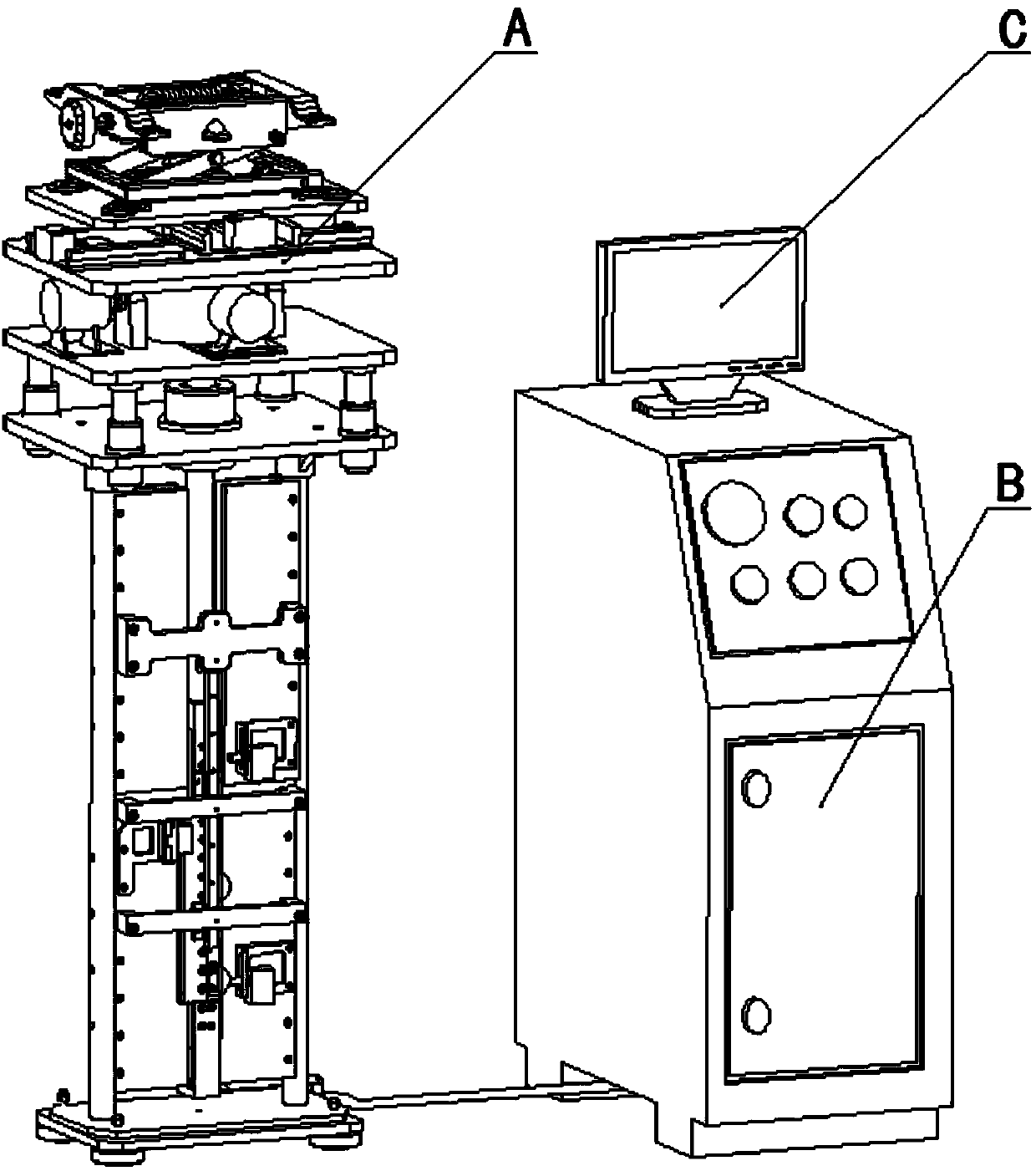

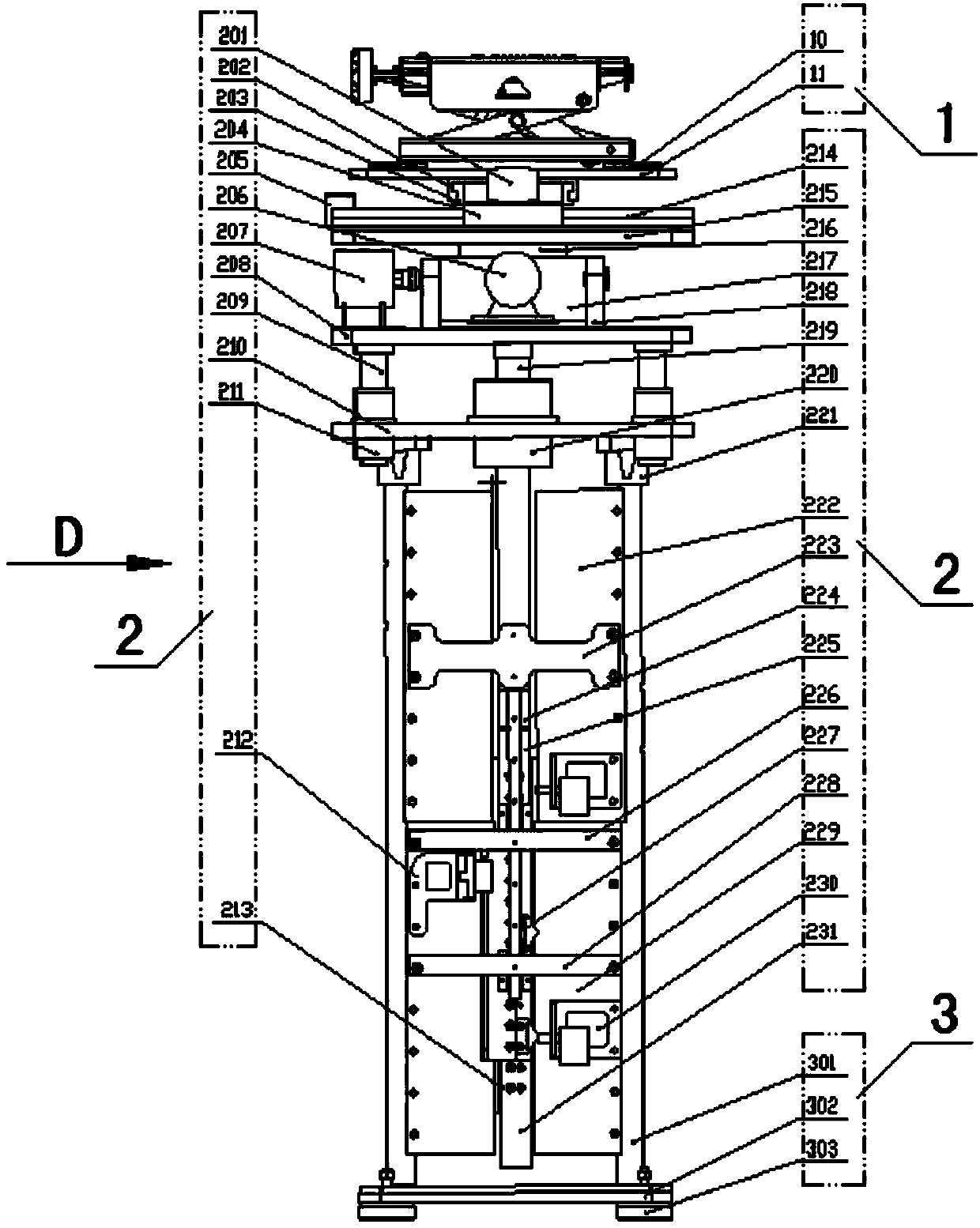

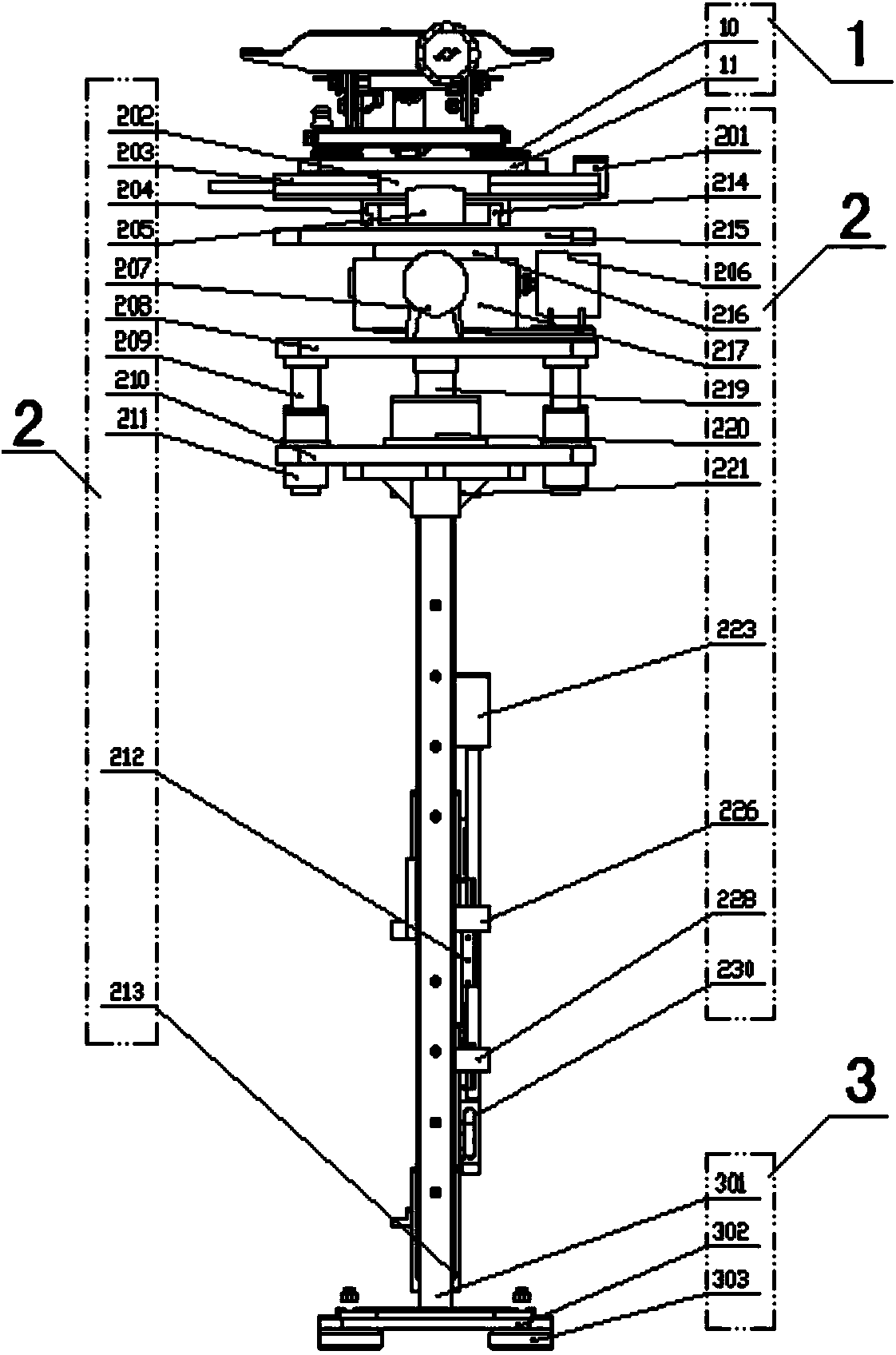

Five-freedom-degree automobile seat vibration test table

ActiveCN103698099AOvercome limitationsOvercome deficienciesVibration testingControl systemFive freedoms

The invention belongs to the technical field of automobile testing, and particularly relates to a five-freedom-degree automobile seat vibration test table capable of carrying out automobile seat smoothness tests and comfort subjective and objective evaluation tests. The test table comprises a machine body part A, a control system B and an upper computer C, wherein the control system B is connected with the machine body part A, the upper computer C is connected with the control system B, the machine body part A comprises a clamp module, a motive power module and a bottom support module, the motive power module is arranged under the clamp module, and the bottom support module is arranged under the motive power module. The five-freedom-degree automobile seat vibration test table provided by the invention is obviously superior to the existing single-freedom-degree seat test table in the aspects of precision, structure, installation, maintenance, environment pollution, noise and performance testing, the limitation of hydraulic motive power sources is overcome, in addition, the test table can be used for carrying out smoothness tests and comfort subjective and objective evaluation tests on an automobile seat, and the development time of the automobile seat is shortened.

Owner:浙江孔辉汽车科技有限公司

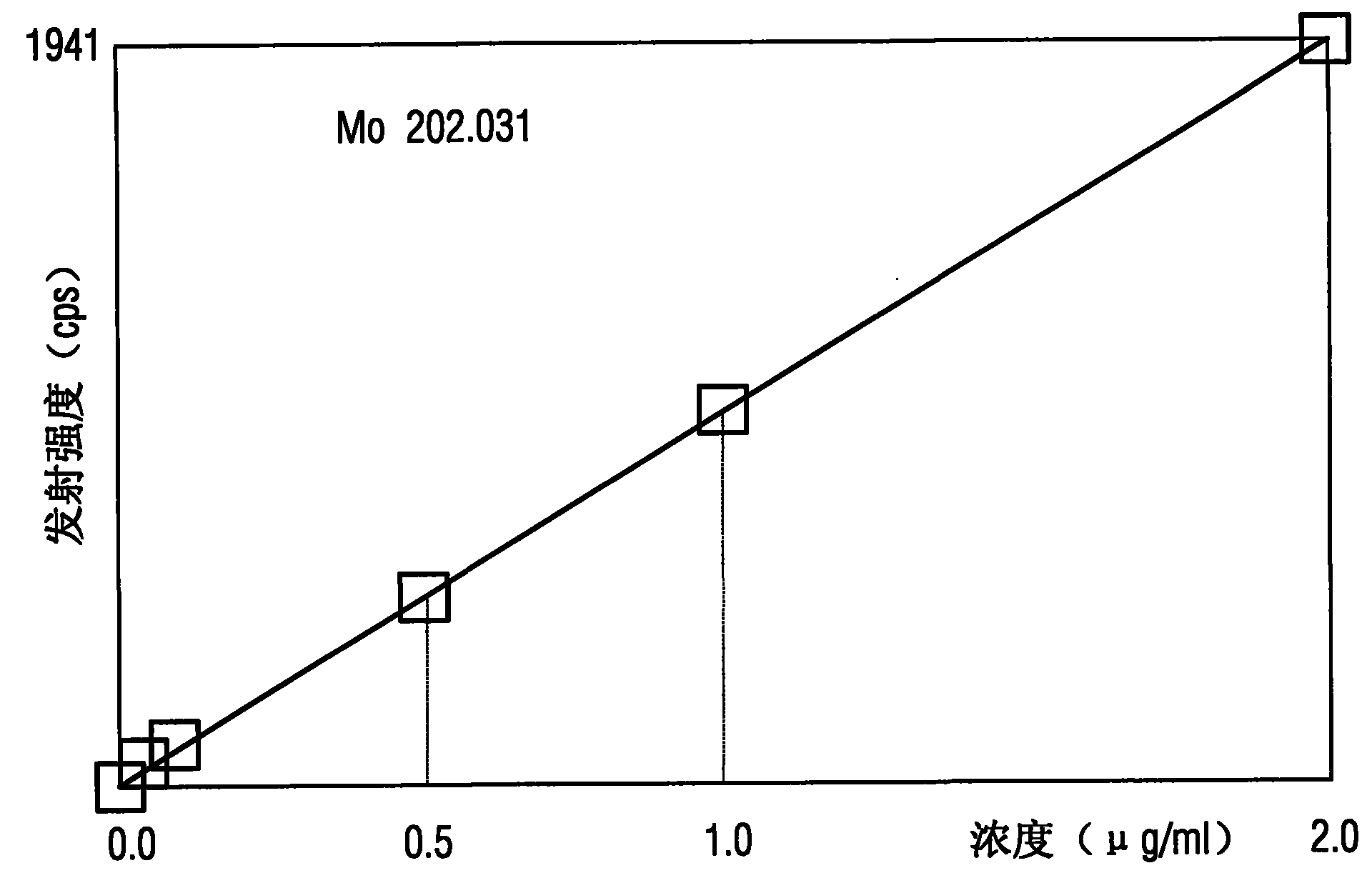

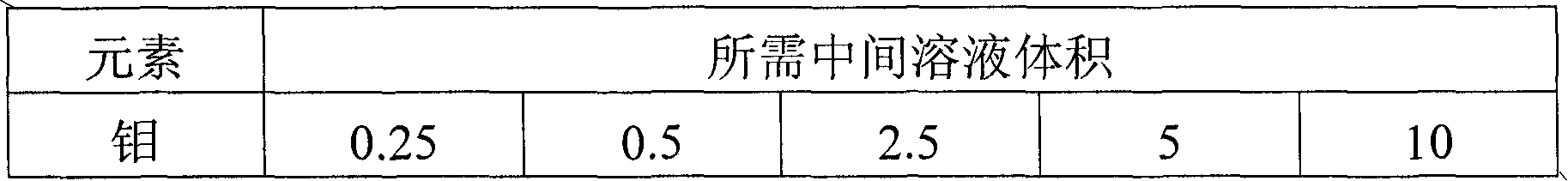

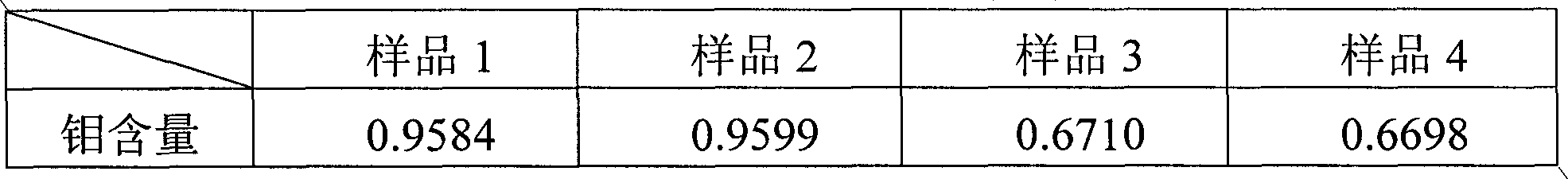

Method for detecting molybdenum element in milk powder

ActiveCN101813630AFast digestionThe result is accurate and reliablePreparing sample for investigationAnalysis by thermal excitationDevice parametersStandard curve

The invention relates to a method for detecting molybdenum element in milk powder. The used equipment is an inductively coupled plasma atomic emission spectrometer. The method has the following steps of: 1) preparing molybdenum element standard solution and making a standard curve according to the standard solution; 2) oxidizing a milk powder sample to be tested by using peroxide, performing acid treatment by using nitric acid, digesting in a microwave digestion system, and detecting by using equipment parameters same as the standard solution to obtain a detection result of the sample to be tested; and 3) comparing the detection result of the sample to be tested with the standard curve to determine the content of the molybdenum element in the sample to be tested. The instrument detection limit of the method is 0.0071 mu g / ml, and in an element linear range, the related coefficient r is over 0.999, and the recovery rate is 92.0 to 101.8 percent. The method can quickly and accurately detect the content of the molybdenum element in the milk powder, and has the advantages of low element loss and pollution probability in the sample preparing process, accurate and reliable result, good repeatability and high sensitivity.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Complex-phase ceramic material with stress irradiance and electroluminescence characters and preparation thereof

InactiveCN101343180BSimple preparation processLow costTenebresent compositionsLuminescent compositionsIn planeStress distribution

The invention discloses a self-assembly bi-phase composite ceramic powder, which is characterized in that the powder has a molecular formula of Ba1-x1-x2-x3-ySrx1Cax2Ax3Ry Ti1-zMzO3, wherein, 0<=x1<=0.18, 0.21<=x2<=0.90, 0.0001<=x3<=0.13, 0.0001<=y<=0.05, 0<=z<=0.20; A is a bivalent element of Mg, Pb, Zn, Cu or Cr, R is La, Pr, Nd, Sm, Eu, Gd, Tb, Dy or Er, and M is a quadrivalent element of Zr, Ce, Cu or Sn. The composite ceramic includes two phases, the content of barium in the first phase is larger than the calcium content, and the calcium content in the second phase is larger than the barium content. The ceramic powder has the features of stress luminescence and electroluminescence, and can be used for the stress distribution measurement and adhesive strength measurement of various parts and members and in plane illumination devices. The parts can be luminous when being coated with ceramic powder on surfaces and applied with stress. The luminous intensity of stress luminescence is in direct ratio with the applied stress in the elastic limit.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com