Patents

Literature

570results about How to "Improve dredging efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

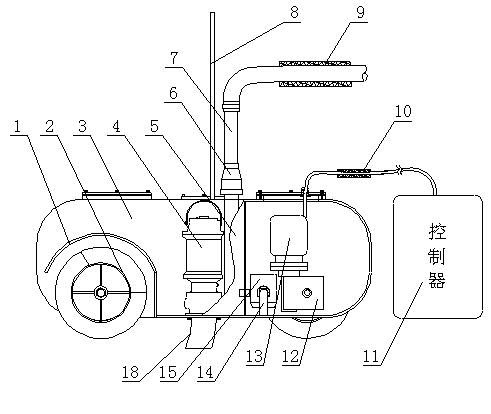

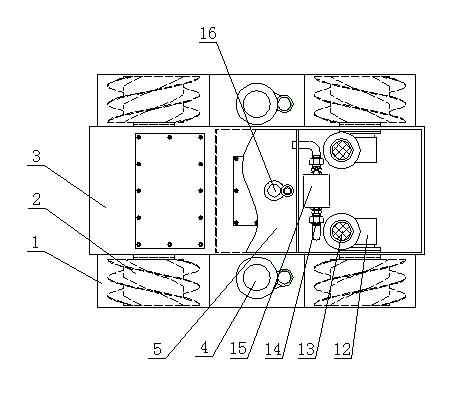

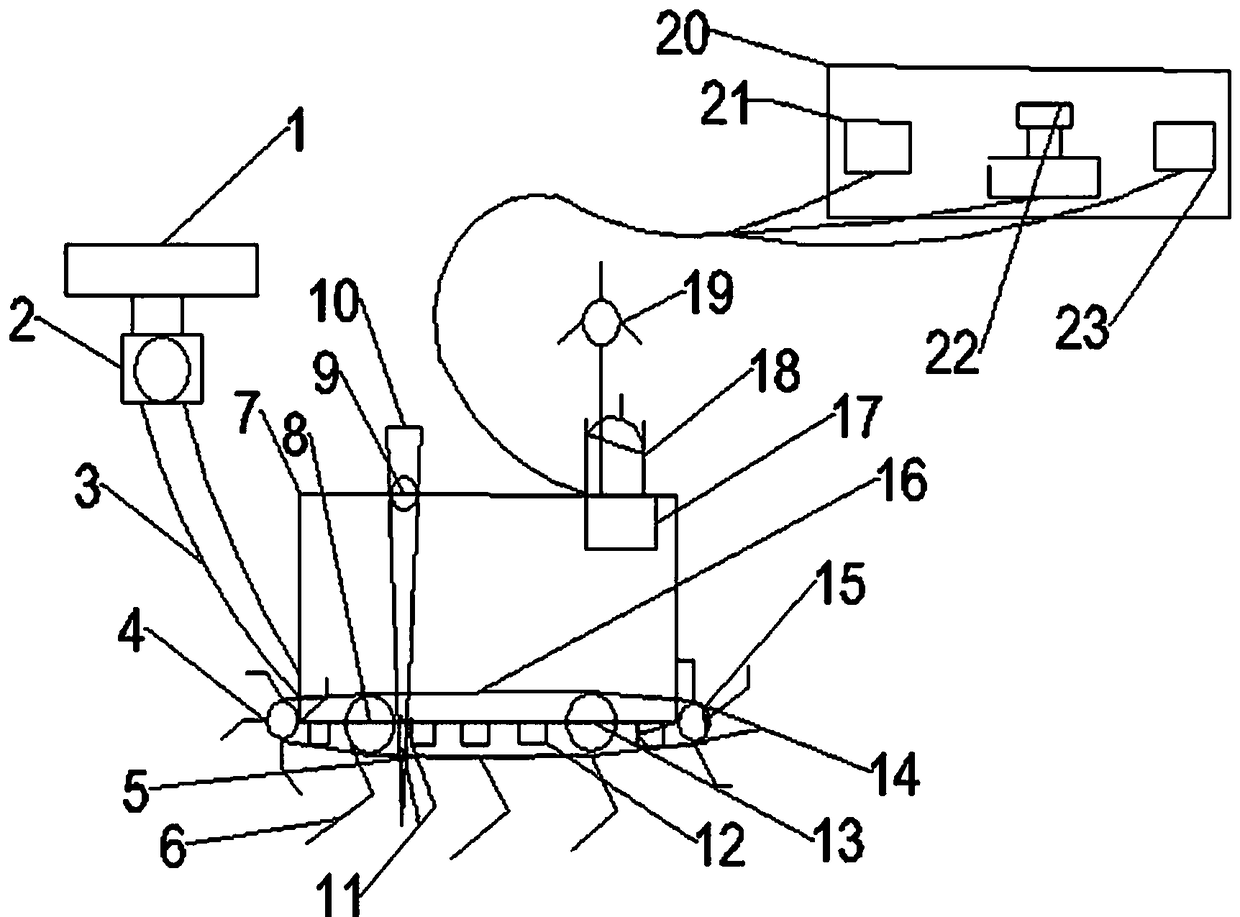

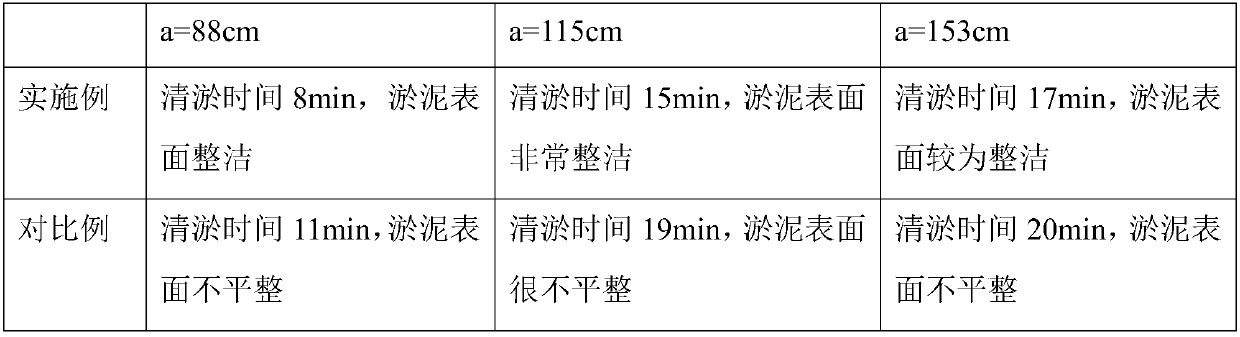

Polluted bottom sediment environment-friendly dredging system and dredging method thereof

ActiveCN104005441AImprove targetingHigh precisionMechanical machines/dredgersControl roomEngineering

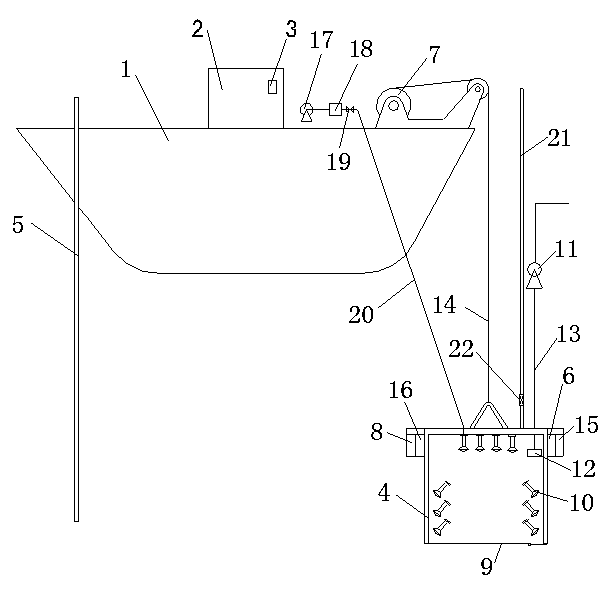

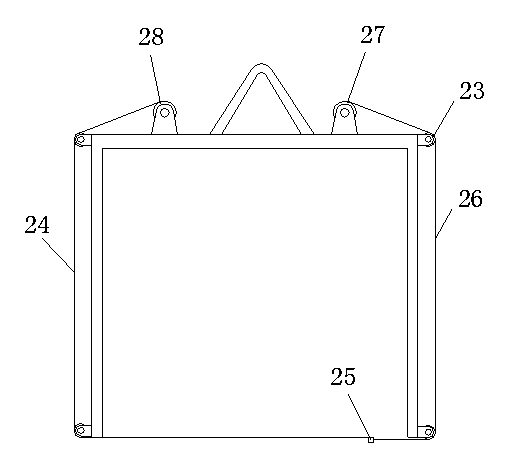

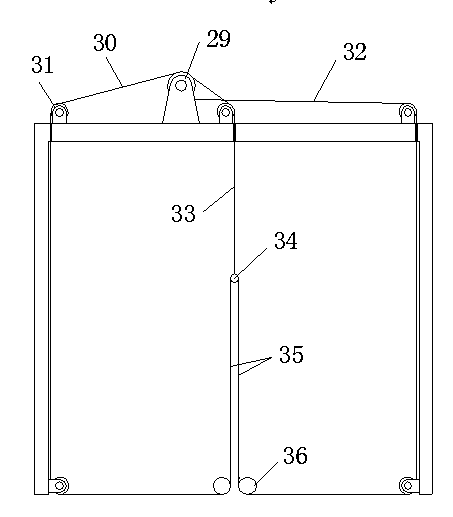

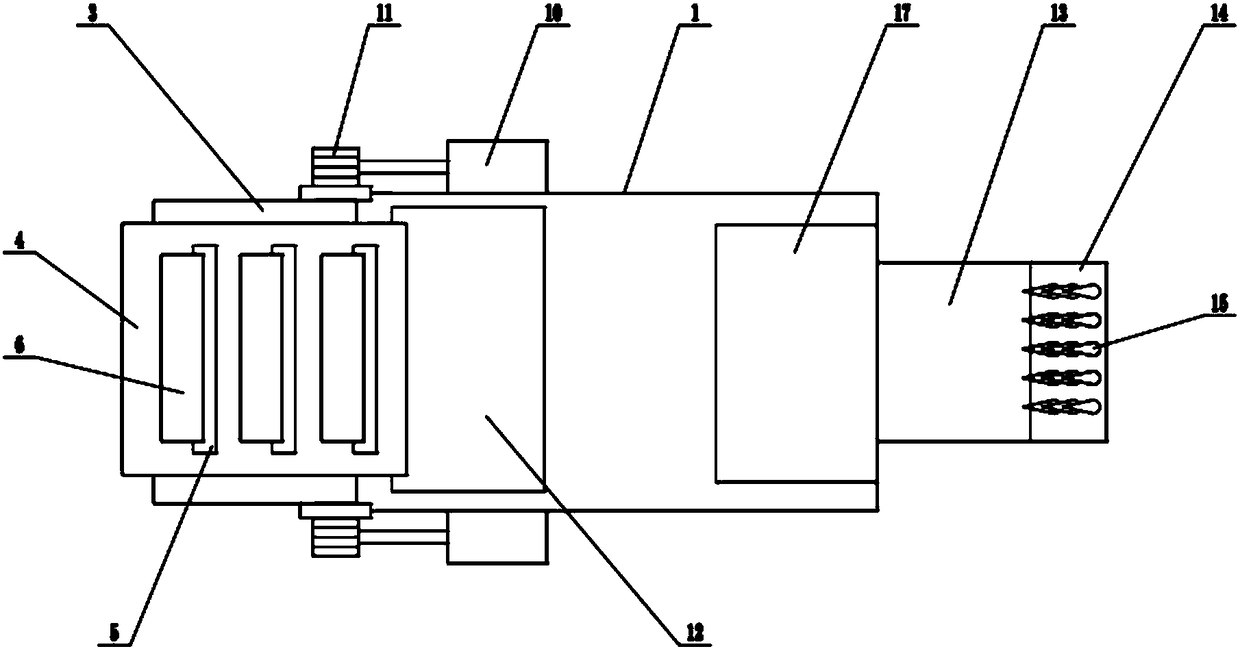

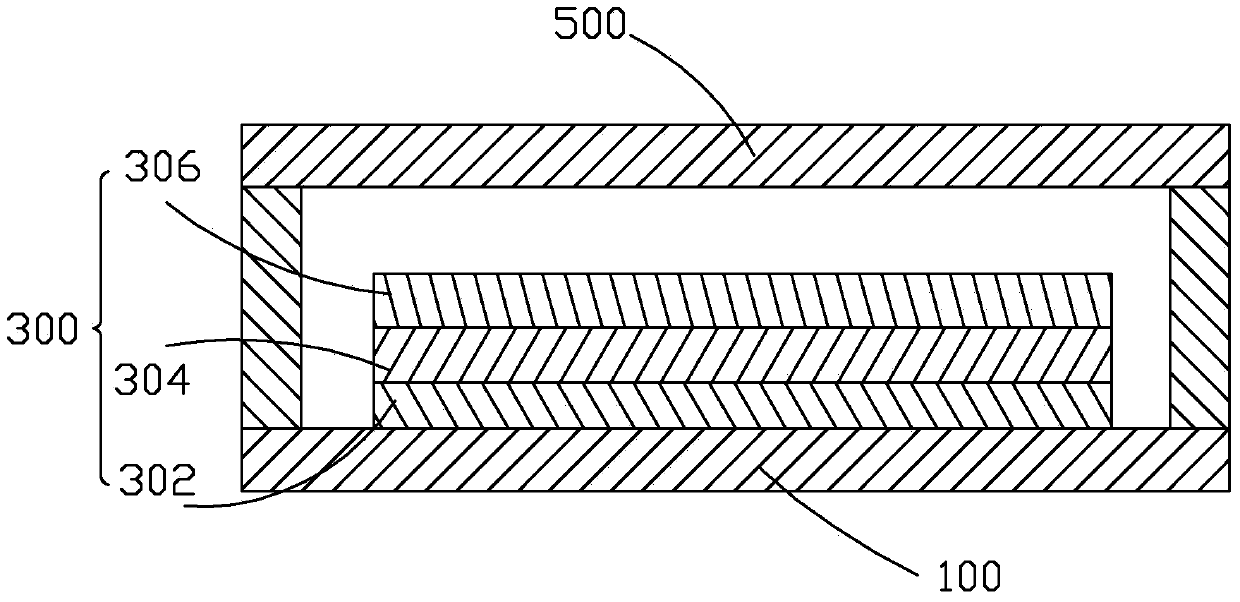

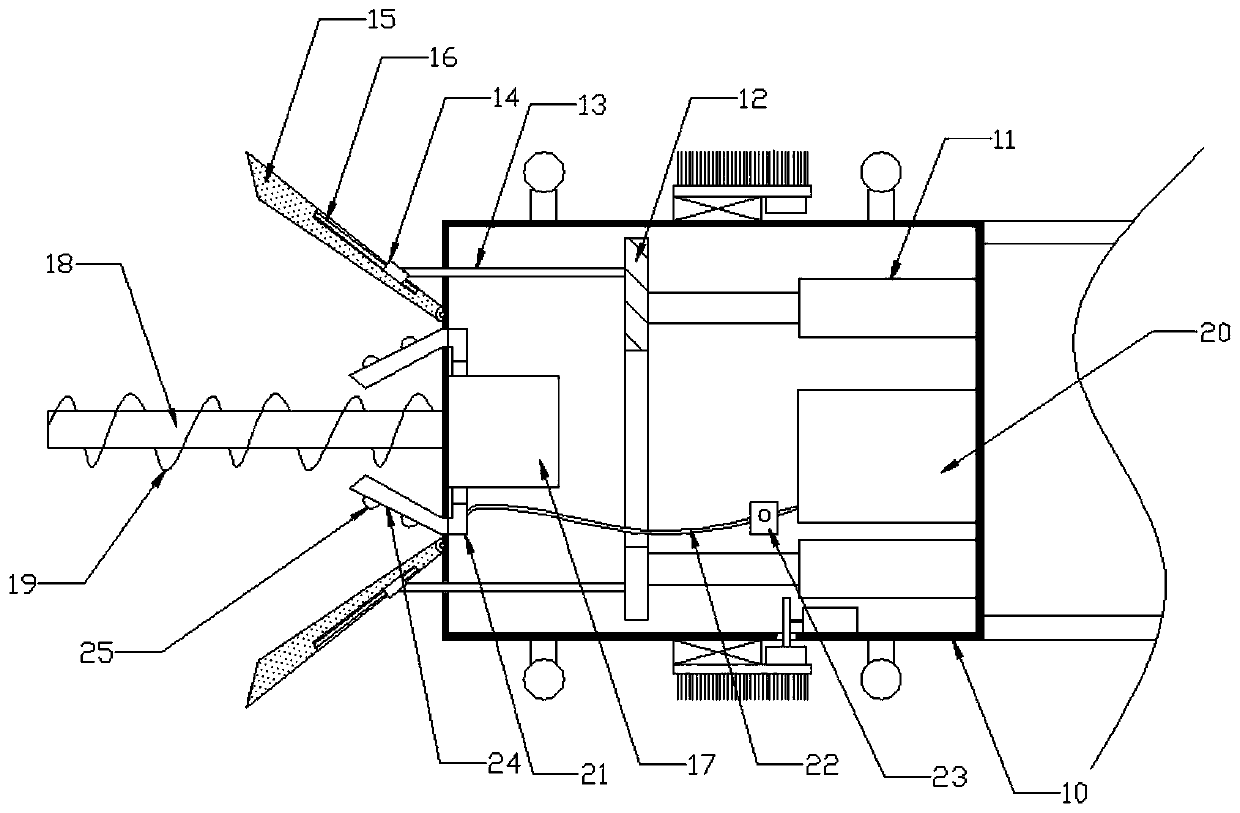

Disclosed are a polluted bottom sediment environment-friendly dredging system and a dredging method of the system. The system comprises a ship and a sediment suction square box, a comprehensive control room, a ship position GPS position indicator, a positioning pile and a winch are arranged on the ship, and the winch is connected with the sediment suction square box through a cable rope. The sediment suction square box is connected with a sediment suction pump through a sediment suction pipeline. A bottom sediment GPS position indicator and a fathometer are arranged on one side of the sediment suction square box, an underwater illumination lamp and an underwater camera are arranged on the other side of the suction square box, a fluidizing device is arranged in the sediment suction square box, a sealing device is arranged at the bottom of the suction square box, and an exhaust pipe is arranged at the top of the sediment suction square box. A controller is arranged in the comprehensive control room on the ship. The dredging method of the system comprises the steps that the ship is in place, sediment suction is prepared, environment-friendly sediment suction is carried out, leaving is prepared, and the ship leaves. High-precision positioning of a dredged position and precise control over the dredging process are achieved, secondary pollution caused by sediment diffusion in the sediment taking process is avoided, dredging cost is effectively lowered, and dredging efficiency is effectively improved.

Owner:SHANDONG ACAD OF ENVIRONMENTAL SCI CO LTD

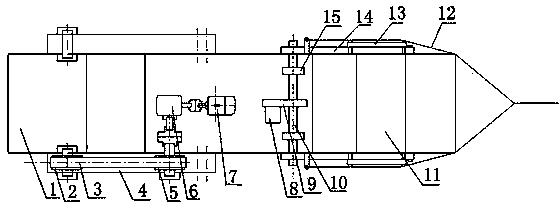

River dredger convenient for clearing weed

InactiveCN108082403AShorten the timeImprove dredging efficiencyWater cleaningWaterborne vesselsLitterEngineering

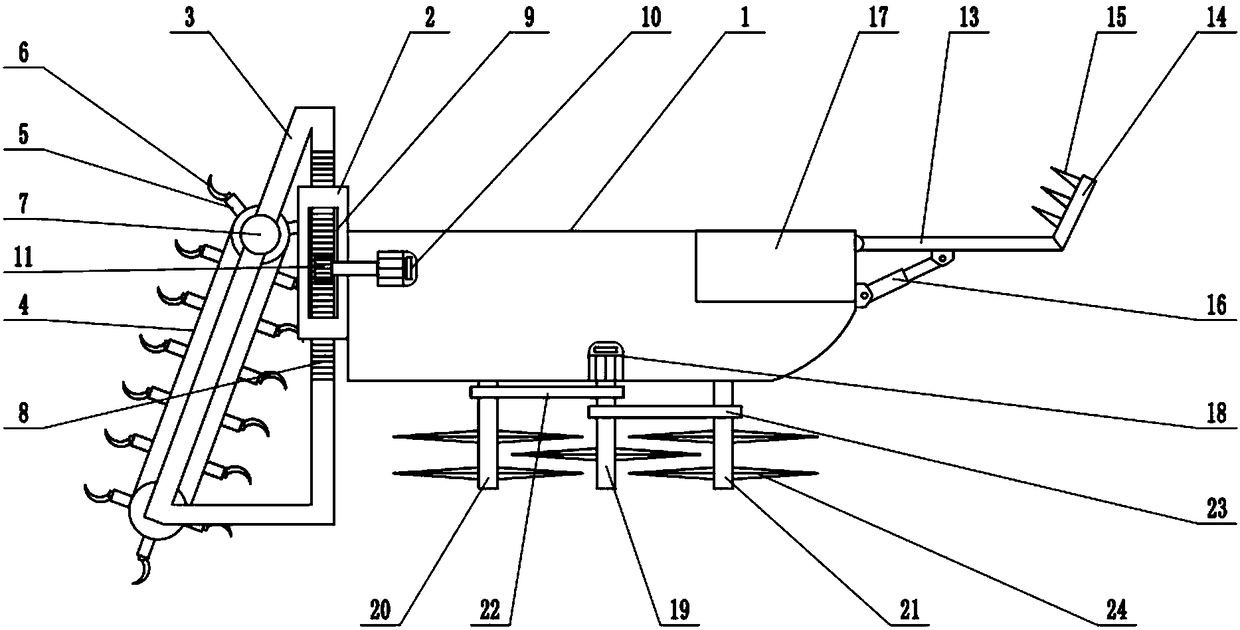

The invention discloses a river dredger convenient for clearing weed. The river dredger comprises a hull, sliding rails, a support frame, a silt groove, a collection groove and a cutter head, whereinthe sliding rails are fixedly connected to the rear part of the hull; the support frame is embedded between the sliding rails; a conveyor belt is mounted on the oblique side of the support frame; a plurality of fixing plates are distributed on the surface of the conveyor belt; curved plates are fixedly connected to the fixing plates; positive inversion motors are fixedly connected to the two sidesof the hull; gears are fixedly connected to the shaft-extension ends of the positive inversion motors; a guide plate is hinged to the bow section of the hull; a dredging plate is fixedly connected tothe right end of the guide plate; and a weeding motor is fixedly connected to the bottom of the hull. The curved plates are used for scraping silt from the bottom of a river and convey the silt to the silt groove for storage. The underwater depth of the left end of the conveyor belt can be adjusted according to the water depth so that the curved plates can be always in contact with the silt on the bottom of the water, so as to improve the dredging efficiency. The dredging plate and salvaging nails are used for hooking litter from the water surface and putting the litter in the collection groove. The cutter head is used for cutting off the weed in the water.

Owner:宁波市江北义盈工贸有限公司

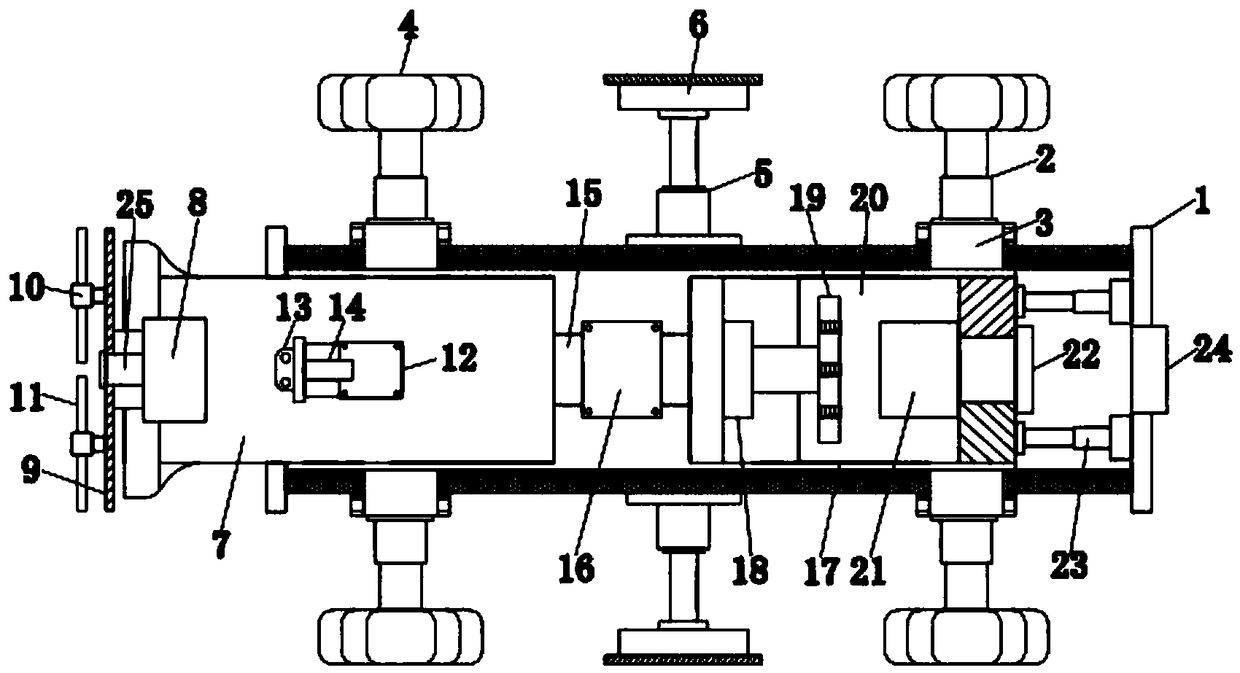

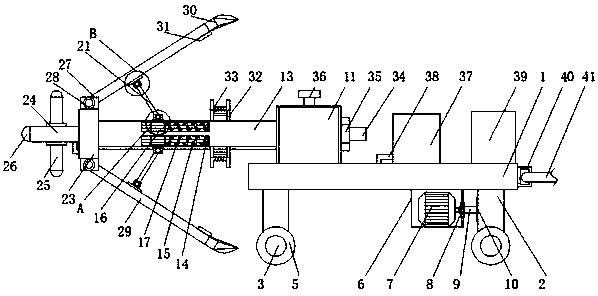

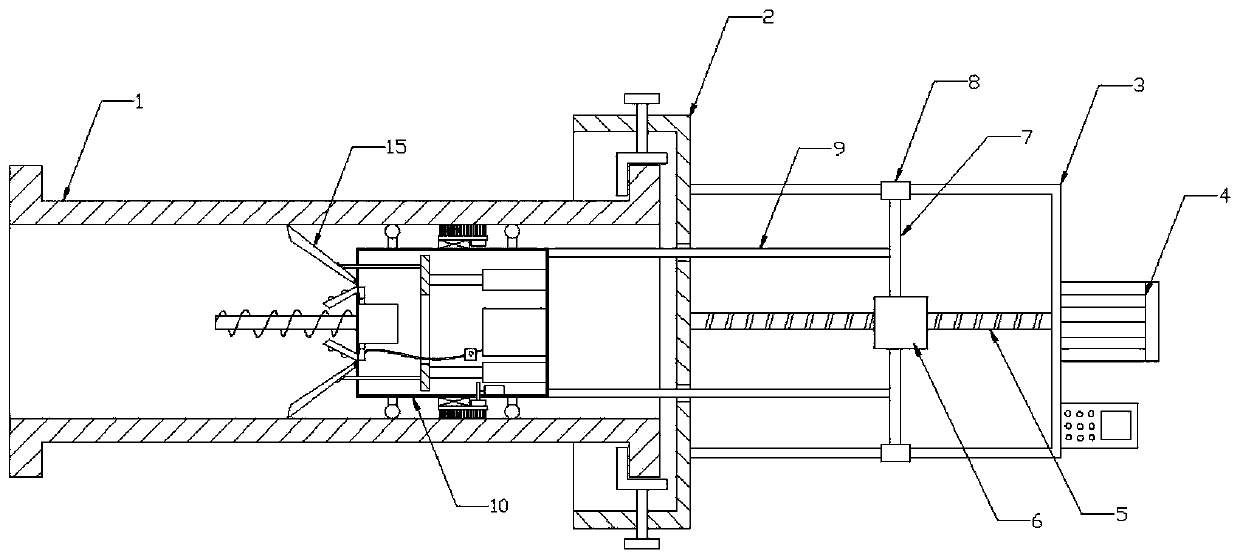

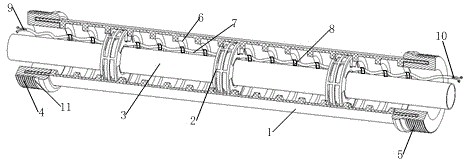

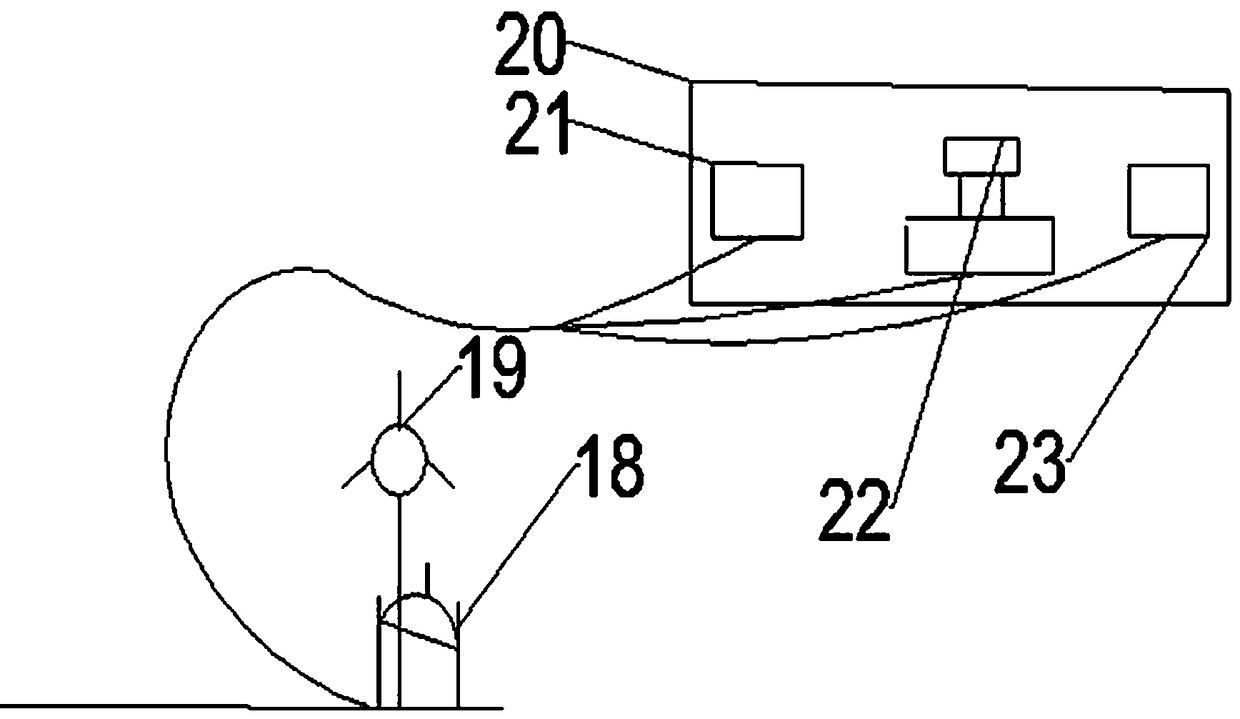

Method for pipeline sludge cleaning and pipeline sludge cleaning robot

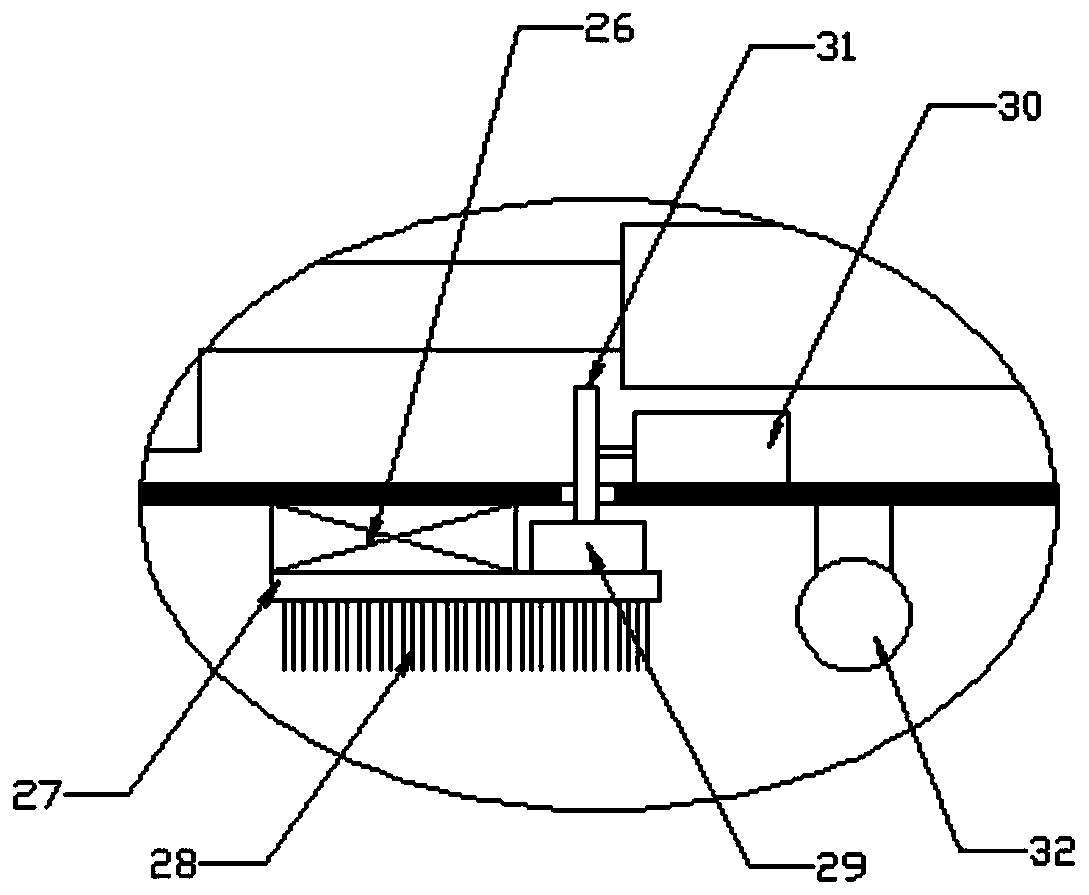

InactiveCN103981942AConvenient mobile dredging operationPrevent leakageSewer cleaningSludgeWire rope

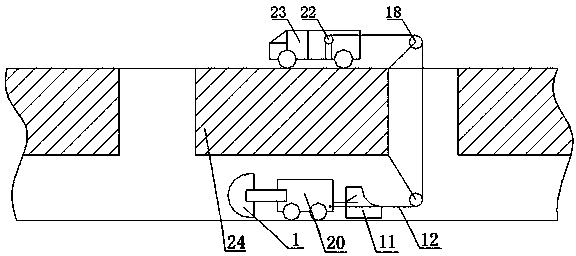

The invention relates to a method for pipeline sludge cleaning and a pipeline sludge cleaning robot and belongs to the technical field of water discharging pipeline cleaning. According to the technical scheme, the pipeline sludge cleaning robot comprises a sludge cleaning robot vehicle (20), a steel wire rope traction device, a front sludge cleaning hopper (11), a front sludge cleaning hopper lifting and overturning mechanism, a rear sludge cleaning hopper (1) and a synchronous belt drive device. In the reciprocating sludge cleaning process of the sludge cleaning robot, the sludge cleaning robot vehicle drives the front sludge cleaning hopper, the rear sludge cleaning hopper and the steel wire rope traction device to move to the position with sludge to be cleaned out towards the portion far away from an inspection well opening in an unloaded state. A traction steel wire rope drags the sludge cleaning robot vehicle to move towards the inspection well opening along with the front sludge cleaning hopper and the rear sludge cleaning hopper. In the movement process, the front sludge cleaning hopper and the rear sludge cleaning hopper are used for completing sludge cleaning. The front sludge cleaning hopper and the rear sludge cleaning hopper are matched for sludge cleaning, so that the one-time sludge cleaning amount of the sludge cleaning robot is increased. The method for pipeline sludge cleaning and the pipeline sludge cleaning robot have the advantages that the structure is simple and reliable, operation is stable, and the sludge cleaning efficiency is high.

Owner:TANGSHAN SHENGQUN TECH CO LTD

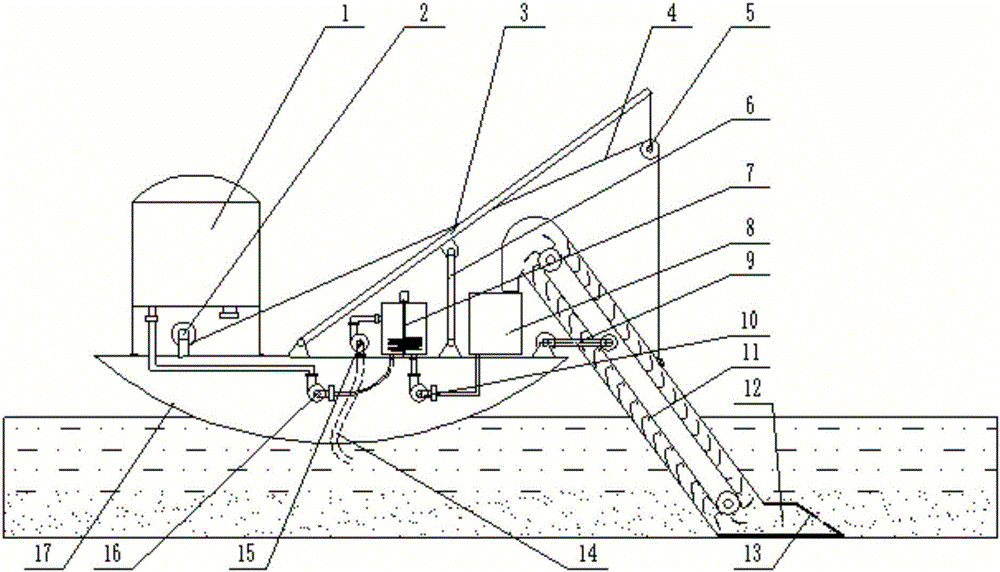

River silt cleaning system

PendingCN106836357AImprove dredging efficiencyAvoid dehydrationSludge treatmentMechanical machines/dredgersGeotechnicsSilt

The invention belongs to the technical field of environmental geotechnics and discloses a river silt cleaning system. The river silt cleaning system comprises a carrier, a silt cleaning device, a mud making device and a mud storage device, wherein the silt cleaning device is fixed on the carrier and goes deep into a river silt seam to clean river silt; the mud making device is connected with the silt cleaning device, smashes the river silt and makes the river silt into mud; the mud storage device is connected with the mud making device and stores the mud. The river silt cleaning system is efficient, convenient, anti-clogging and low in pollution.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI +1

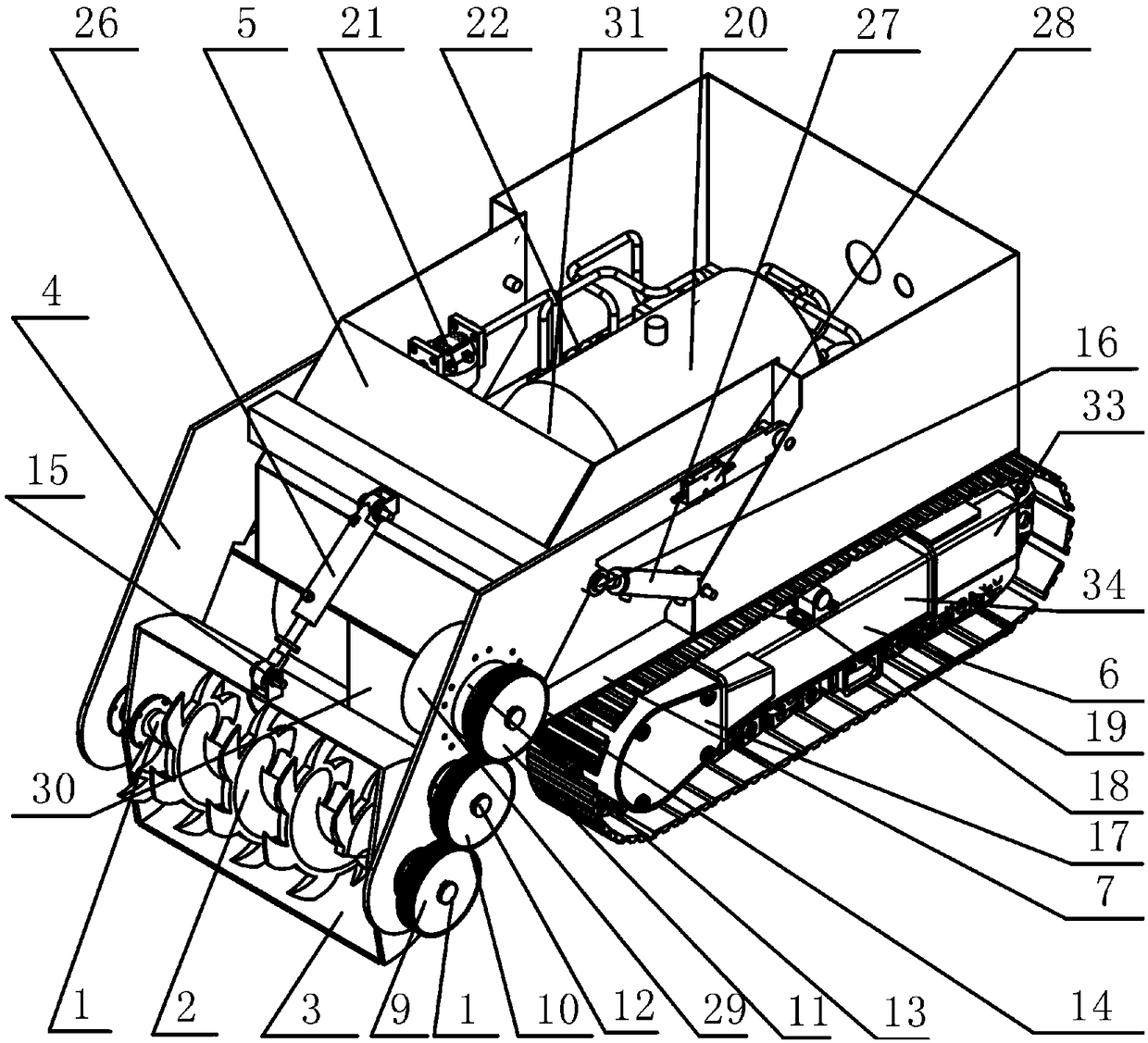

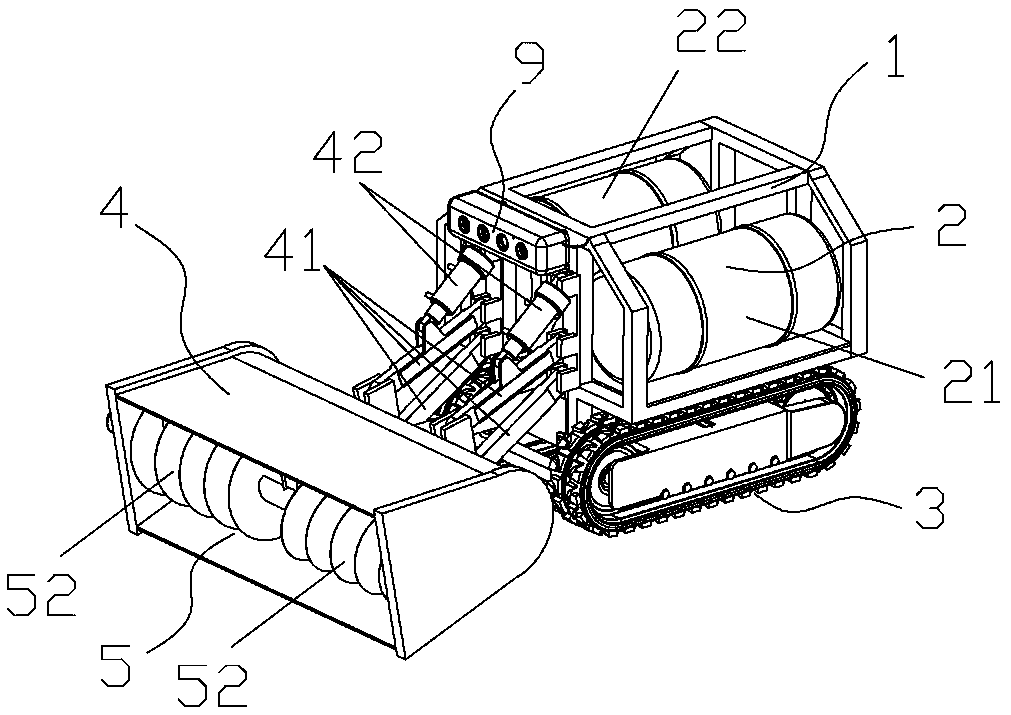

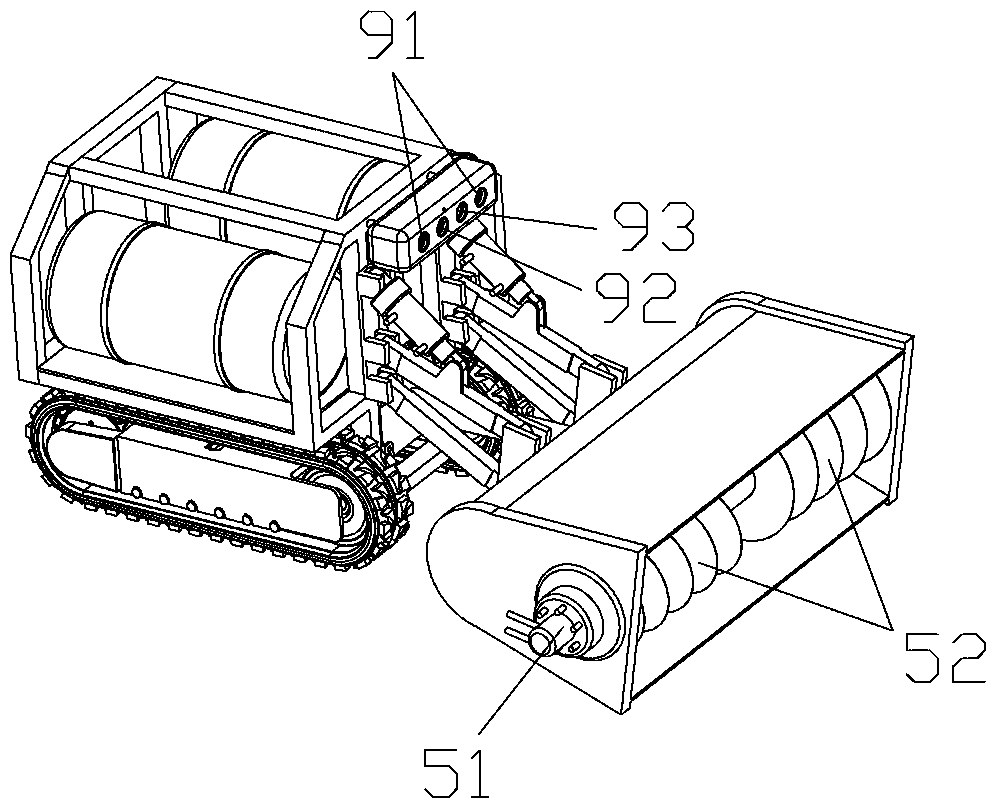

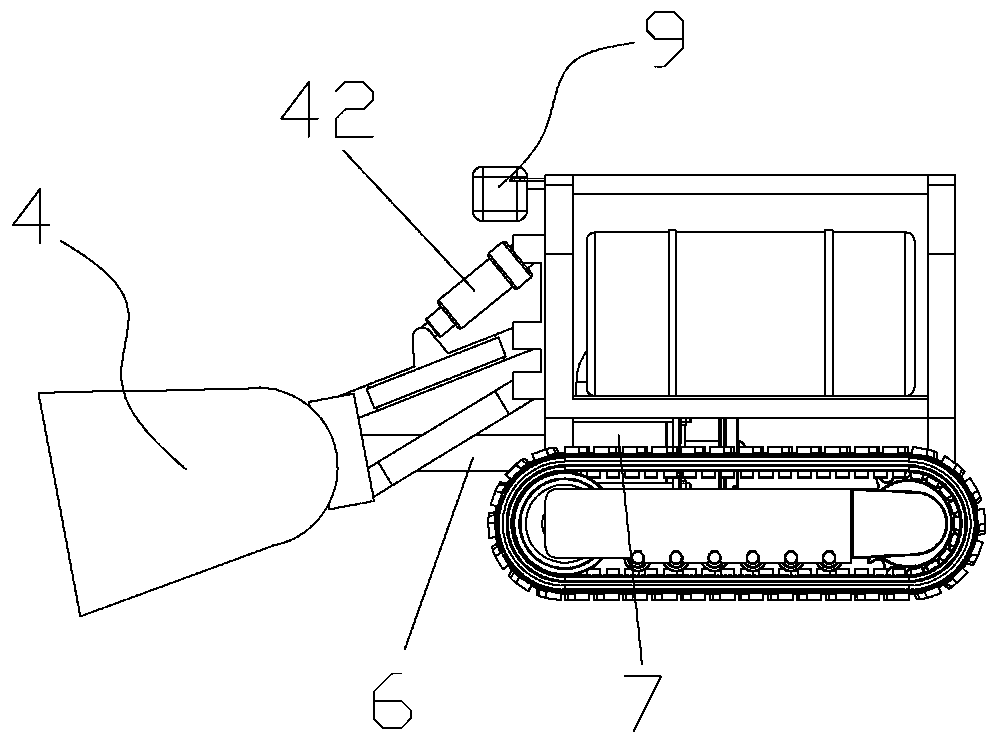

Crawler belt type dredging robot

InactiveCN108166606ASolve the current situation of difficult dredgingPowerfulSewer systemsHydraulic cylinderSynchronous motor

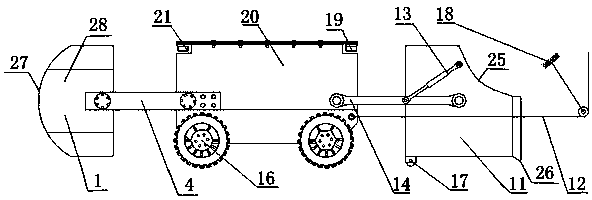

The invention discloses a crawler belt type dredging robot, and belongs to the technical field of environmental protection equipment. The crawler belt type dredging robot includes a dredging reamer device, a turnover mechanism, a double-arm pushing mechanism, a dredging robot body and a hydraulic system. An overturning hydraulic cylinder drives a bucket to turn over downward, the turn-over angle of the overturning hydraulic cylinder is set to be 35 degrees, and it is ensured that after dredging, residual sludge of the bucket can smoothly fall down. Big connection beams are connected with a left walking crawler belt and a right walking crawler belt respectively, at the same time, a base is provided for four supporting square steels, the speed of a walking motor is controlled by controllingthe displacement of a valve element of a load-sensitive proportional multi-way valve, a synchronous motor ensures synchronous advancing of the crawler belts, two-way electromagnetic throttles ensure left turning and right turning of the walking motor, and thus the walking crawler belts can stably walk. The robot is simple and reliable in structure, at the same time, sludge is conveyed efficiently,the dredging efficiency is largely improved, the robot can be suitable for dredging tasks of drainage pipelines large in pipe diameter and box culverts, and the problem that at present, the dredgingprocesses of existing drainage pipelines large in pipe diameter and existing box culverts are difficult is solved.

Owner:BEIJING UNIV OF TECH

Efficient pipeline dredging equipment for sewage treatment

ActiveCN112044887AGood dredging effectImprove dredging efficiencyHollow article cleaningSewage treatmentWater treatment

The invention relates to the technical field of pipeline sludge equipment, in particular to efficient pipeline dredging equipment for sewage treatment. The efficient pipeline dredging equipment comprises a housing, a traveling assembly, a crushing and dredging assembly, a reverse rotary mechanism and a steering drive mechanism, wherein the traveling assembly comprises a spacing regulating mechanism, a traveling drive mechanism and a front-end displacement mechanism, the spacing regulating mechanism is fixedly mounted at the tail end of the housing horizontally, and the traveling drive mechanism is fixedly mounted at the output end of the spacing regulating mechanism; the crushing and dredging assembly comprises a first crushing paddle for crushing sludge and a crushing mechanism for crushing sludge blocks, and the first crushing paddle is arranged at the front end of the housing. The efficient pipeline dredging equipment for sewage treatment disclosed by the invention can automaticallytravel in a pipeline, can quickly dredge sludge blocked in the pipeline, can flexibly turn in the pipeline, can clear sludge around the corner of the pipeline, can further perform crushing treatmenton large pieces of sludge, prevents secondary accumulation, and improves dredging effect.

Owner:安徽泽安智成科技有限公司

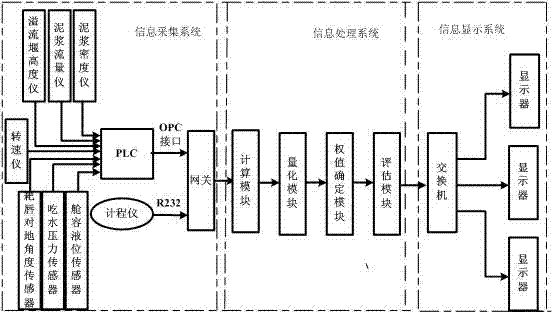

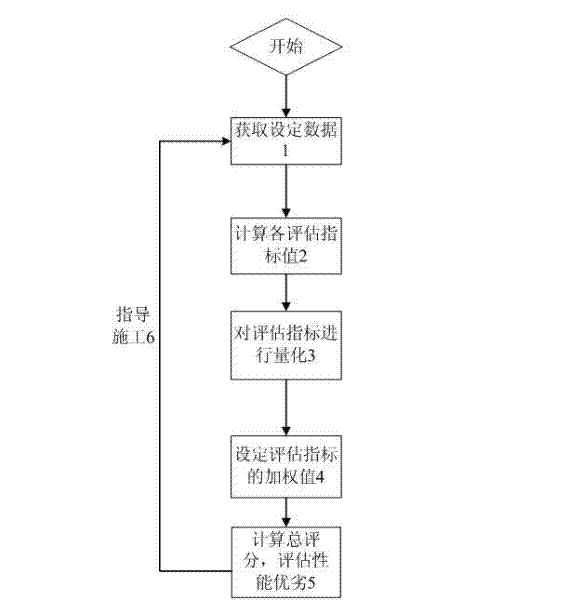

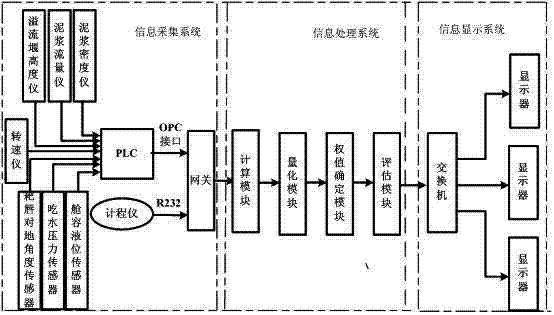

System and method for estimating dredging property of drag suction dredger

InactiveCN102175473ADirect and more intuitive understandingEffective assessmentStructural/machines measurementInformation processingInformation display systems

The invention discloses a system and a method for estimating dredging property of a drag suction dredger. The system comprises three parts: an information acquisition system, an information processing system, and an information display system. The method comprises the following steps: acquiring all the estimation index physical quantities for dredging state by using the information acquisition system of the drag suction dredger; using a calculating module to convert all the estimation index physical quantities for dredging state into three property estimation indexes capable of directly reflecting the dredging state; quantizing the three property estimation indexes capable of directly reflecting the dredging state; setting a weight of the dredging property estimating index of the drag suction dredger; according to each property estimation index and the weight of the dredging property estimating index of the drag suction dredger, estimating the real-time dredging state and periodic property quality of the drag suction dredger; using the information display system to feed back an estimation result and the construction parameters in the optimum period to an operator for guiding the construction. By utilizing the system for estimating property, the malpractice of totally depending on experience is eliminated and the high dredging efficiency is ensured.

Owner:JIANGSU UNIV OF SCI & TECH

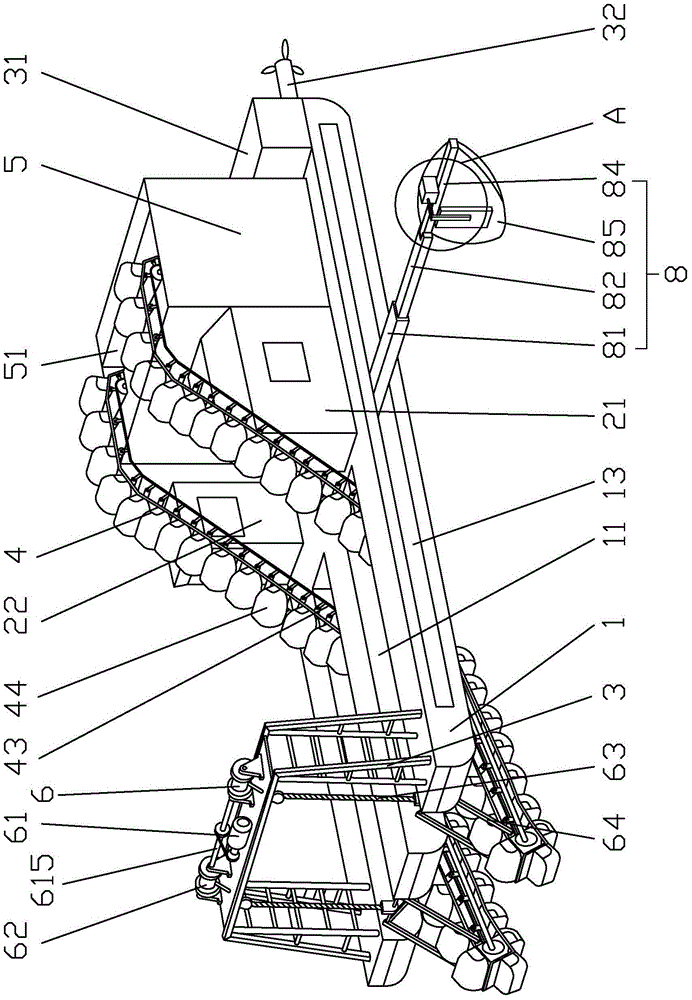

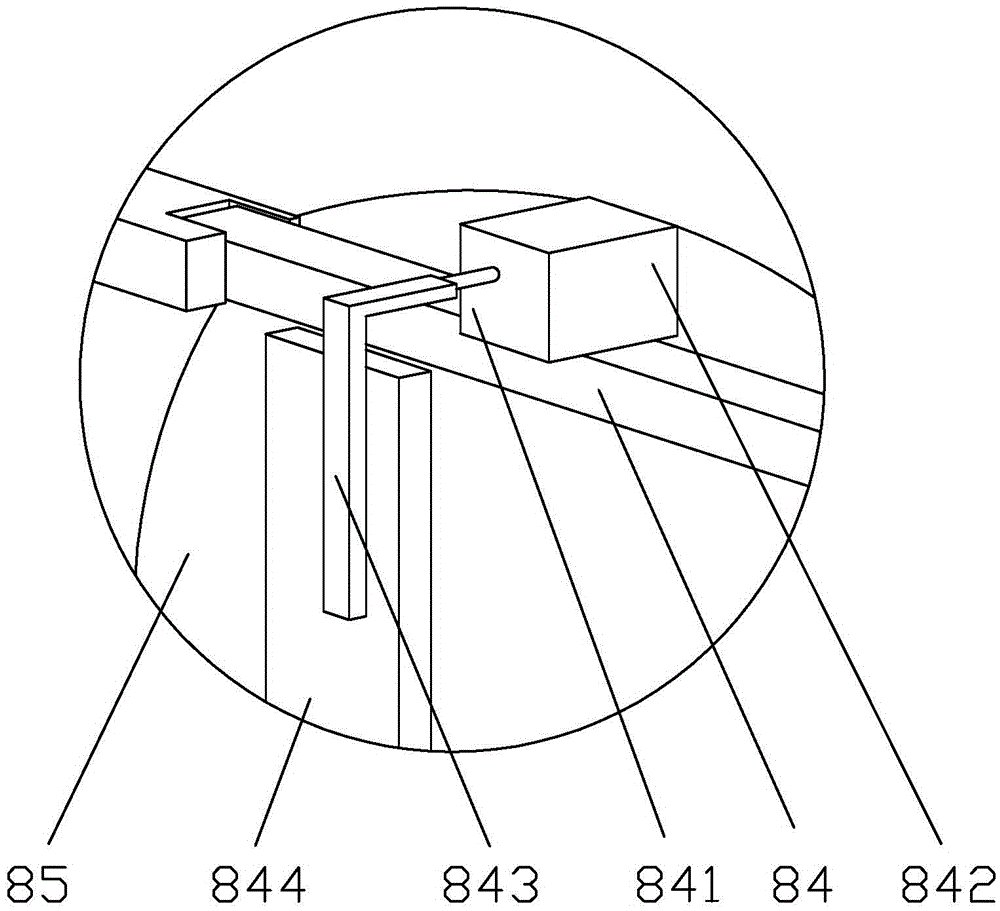

Riverway chain bucket type dredging ship and dredging construction method thereof

ActiveCN105672390AReduce resistanceAvoid damageWater cleaningMechanical machines/dredgersSludgeWater quality

The invention mainly discloses a riverway chain bucket type dredging ship and a dredging construction method thereof. According to the technical scheme, the riverway chain bucket type dredging ship comprises a ship body, a control chamber, a retiring room, a support, at least two chain bucket conveying mechanisms and a sludge collecting bin. A lifting mechanism is arranged between each chain bucket conveying mechanism and the support. Moving devices and salvage devices connected with the moving devices are arranged on the two sides of the ship body, and a salvage basket and a power paddle are arranged on the rear side of the ship body. The method comprises the first step of construction preparation, the second step of chain bucket type dredging ship position adjustment, the third step of chain bucket conveying mechanism descending position control, the fourth step of dredging work conduction, the fifth step of sludge treatment work and the sixth step of subsequent work. By means of the method, sludge at the river bottom can be efficiently removed, objects floating on the river surface can be removed as well, suspension pollutants brought from the sludge during salvage work are eliminated, and a riverway is dredged; and the flood discharge capacity of the riverway is improved, the water quality is improved, and water pollution is reduced.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

Dredging device for urban sewer

ActiveCN110439101AEnsure smooth circulationEasy to washSewer cleaningHollow article cleaningWater sourceSludge

The invention discloses a dredging device for an urban sewer. The dredging device for the urban sewer comprises a mounting block, wherein a rope is fixedly arranged on the upper end surface of the mounting block, the mounting block is internally provided with a telescopic fixing device, the telescopic fixing device internally includes left and right symmetrical arc-shaped butting blocks, a power supply device is arranged on the lower side of the telescopic fixing device, and the power supply device internally includes a power motor. The dredging device is small in size, can be directly placedin the sewer, and is suitable for the use of sewers with different inner diameter and depth ranges. In the process of dredging, clogged debris and adherent sludge in the sewer are crushed by a crushing device, the dredging speed is high, and water sources are saved. The solid debris after being crushed is filtered and collected by a filter screen, and the dredging device is highly automatic.

Owner:桐城市建设投资发展有限责任公司

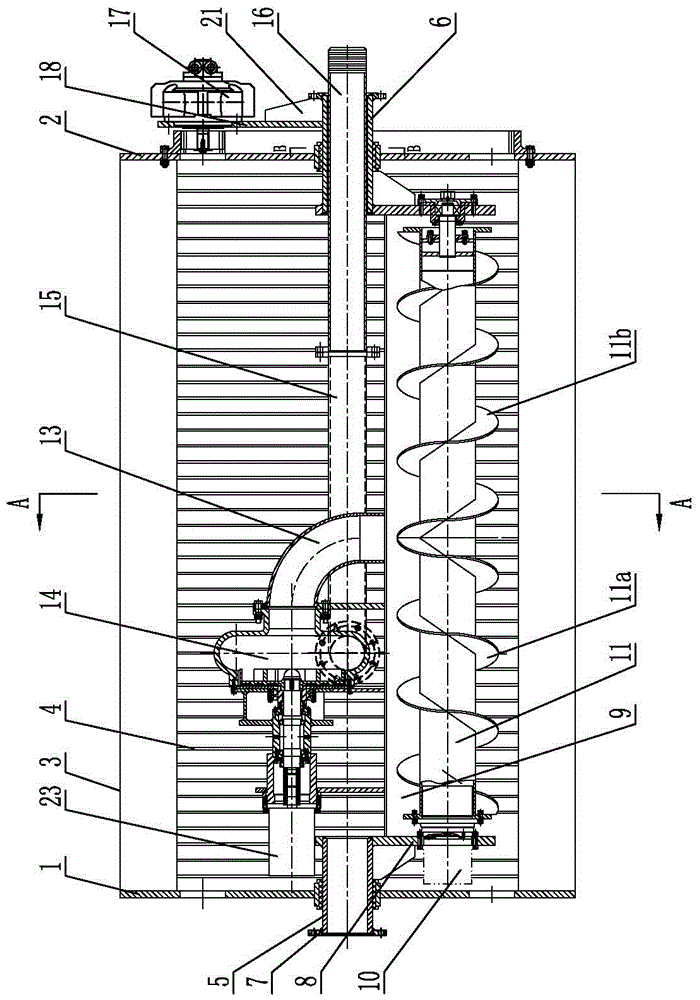

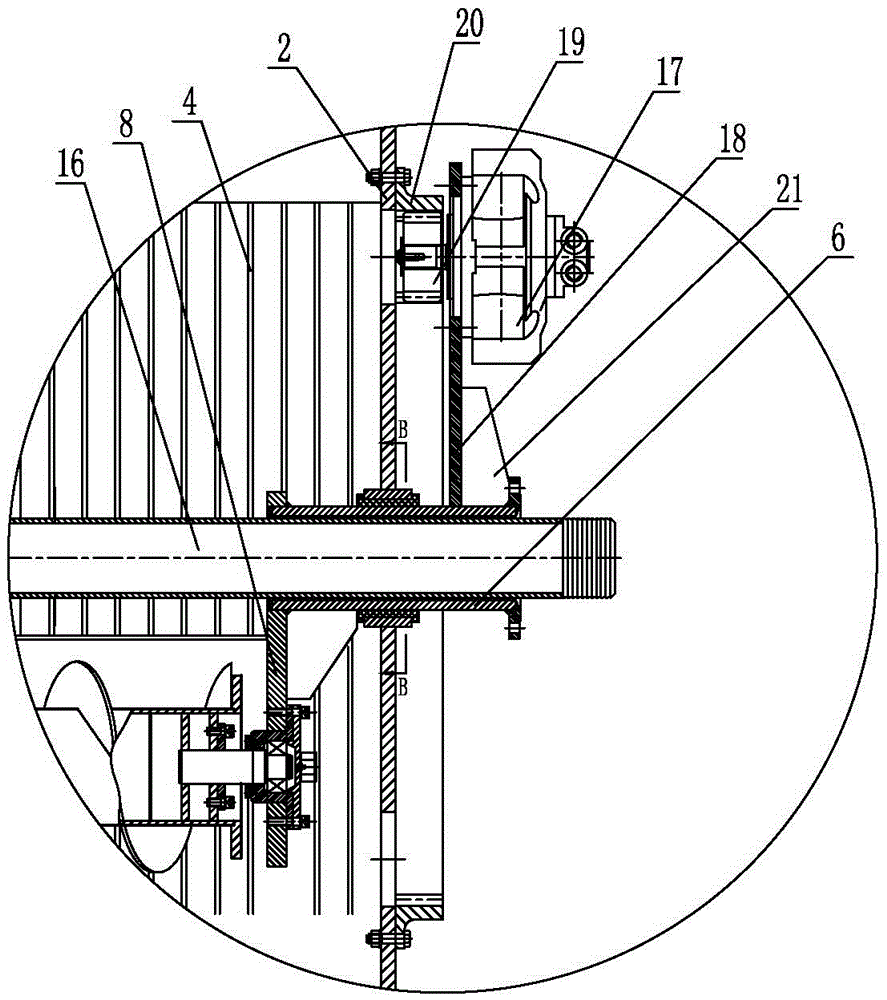

Efficient dredging device for water conservancy project

InactiveCN108560627AImprove dredging efficiencyIncreased efficiency of dredging operationsSoil-shifting machines/dredgersSpiral bladeSludge

The invention discloses an efficient dredging device for a water conservancy project. The device comprises a dredging cylinder, pushing pressing spiral blades, waling wheels, a dredging rolling brush,a dredging scrapping plate, a press filtering head and a dredging lifting cylinder, a driving shaft is installed in the dredging cylinder, a pushing pressing roller is arranged on the driving shaft,the pushing pressing spiral blades are arranged on the surface of the pushing pressing roller, the dredging scrapping plate is connected on the dredging cylinder at the bottom of the left side of thepushing pressing roller, a dredging rotary shaft is installed on the upper side of the dredging scrapping plate, and the dredging roller brush are arranged on the surface of the dredging rotary shaft;sludge on the dredging scrapping plate is removed by the dredging rolling brush, pushed to the dredging cylinder on the upper side and pushed rightwards by the pushing pressing spiral blades rotatedalong with the driving shaft, the sludge is intercepted by the press filtering net, moisture is filtered by filtering cottons and flows back to a river through press filtering grates, sludge which ispressed and filtered at the right end of the dredging cylinder is pushed and lifted to the dredging lifting cylinder by rotation of lifting spiral blades on a lifting shaft and lifted upwards to a dredging boat, the dredging operation efficiency is improved, the dredging efficiency is high, and the effect is good.

Owner:陈靖

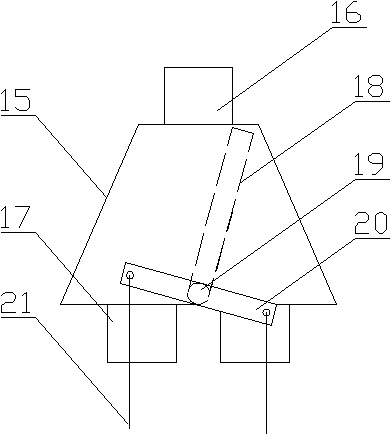

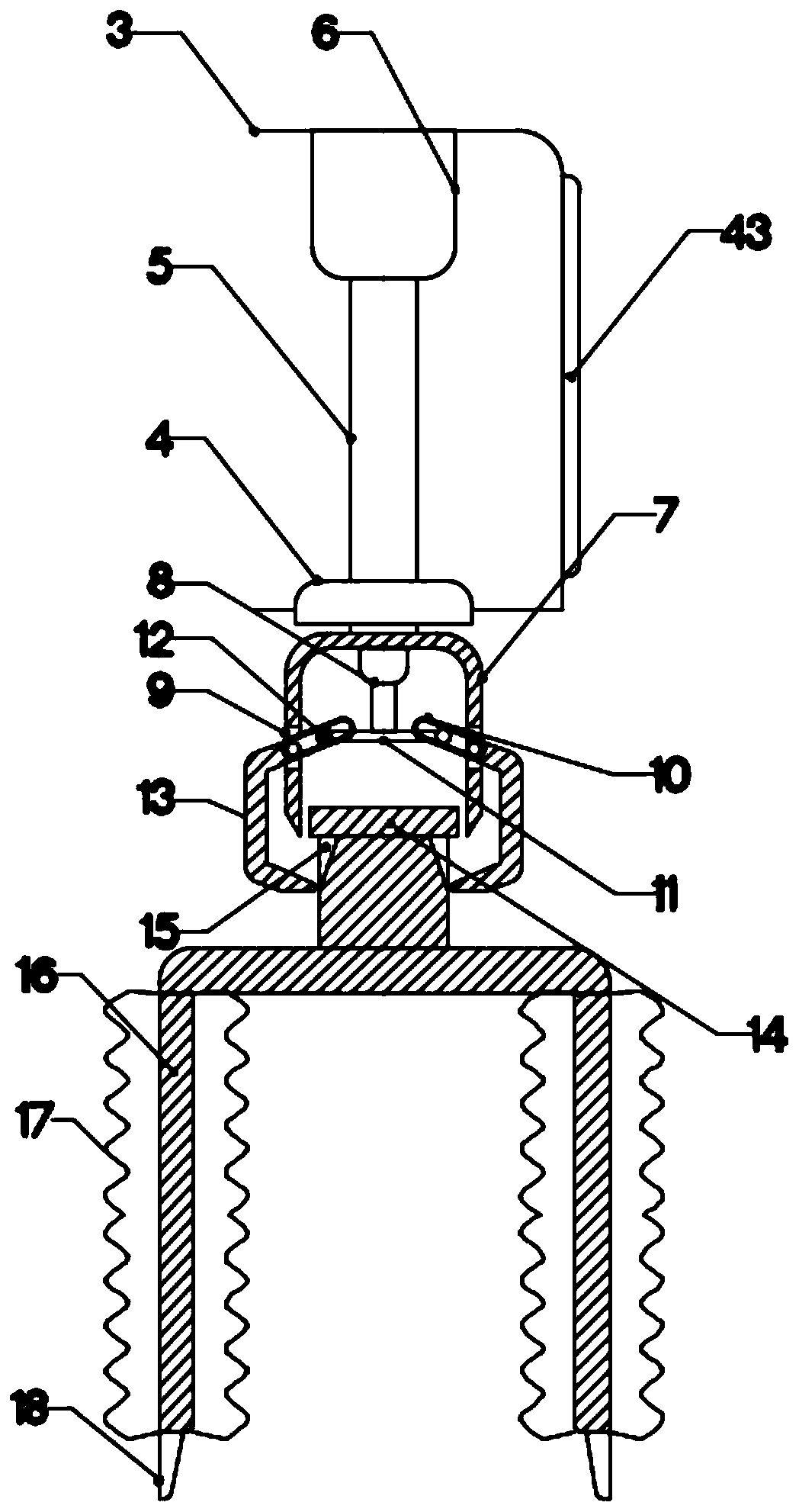

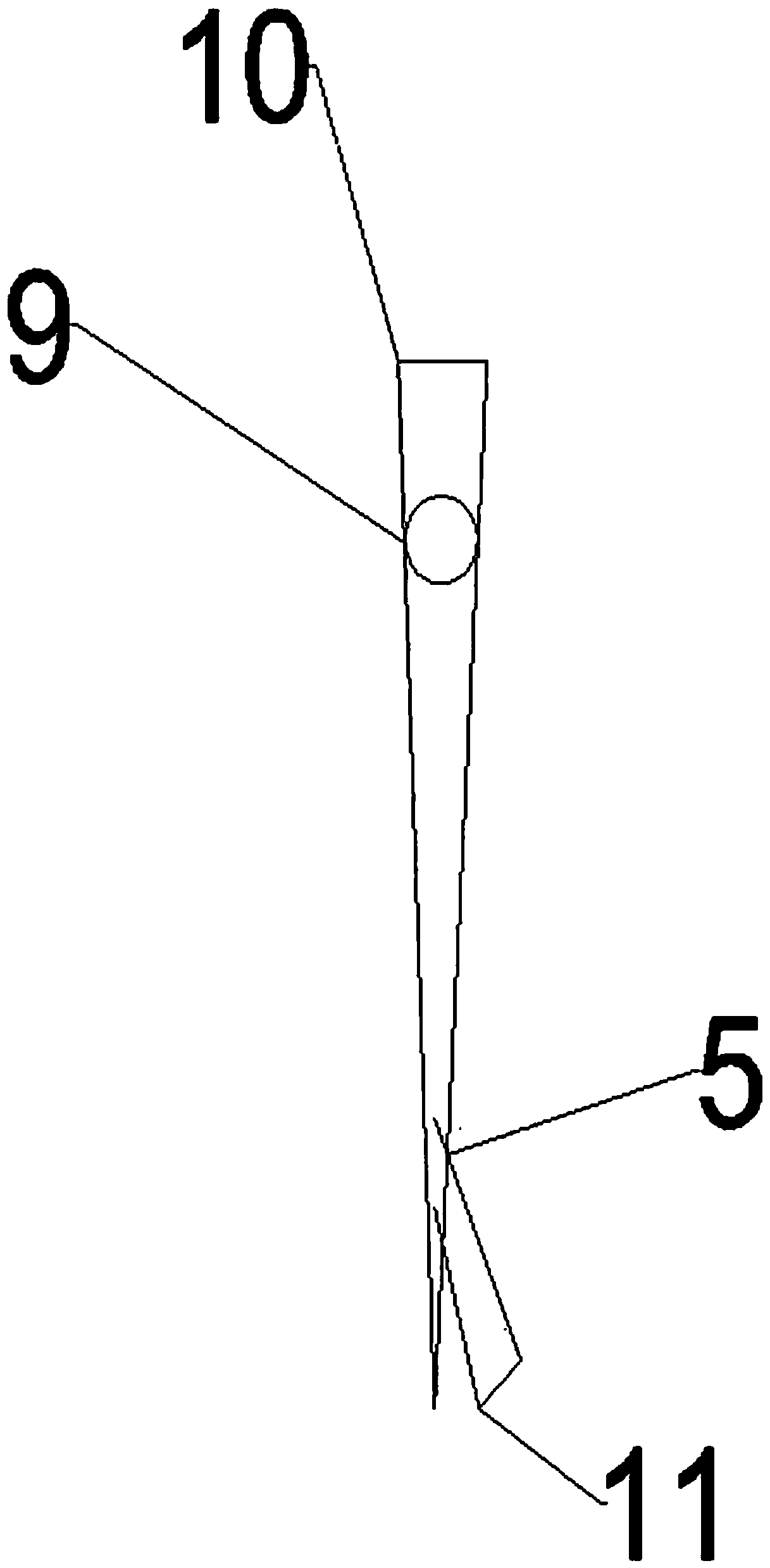

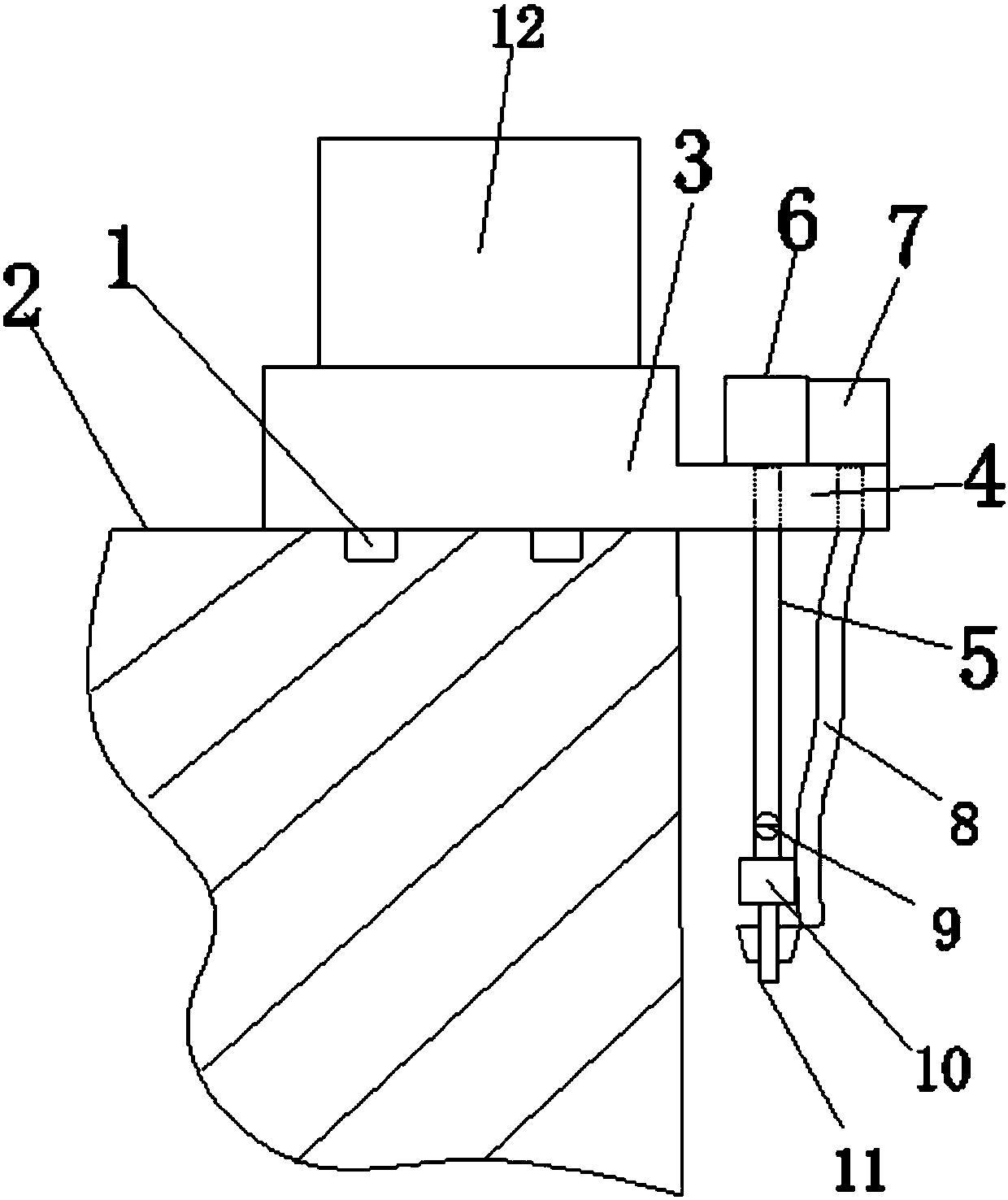

Dredging head in vibratin mode and application apparatus

The present invention discloses a vibration type dredging head and a deep-water dredging boat using said dredging head. Said vibration type adredging head includes rigid central sediment-discharging pipe, motor, delay contrifugal clutch, eccentric block exciting device and cutter disk rotating mechanism, and the dredging boat includes boat body, tower frame, hanging mechanism, sand stone pump, vibration type dredging head and control device.

Owner:孙孝庆

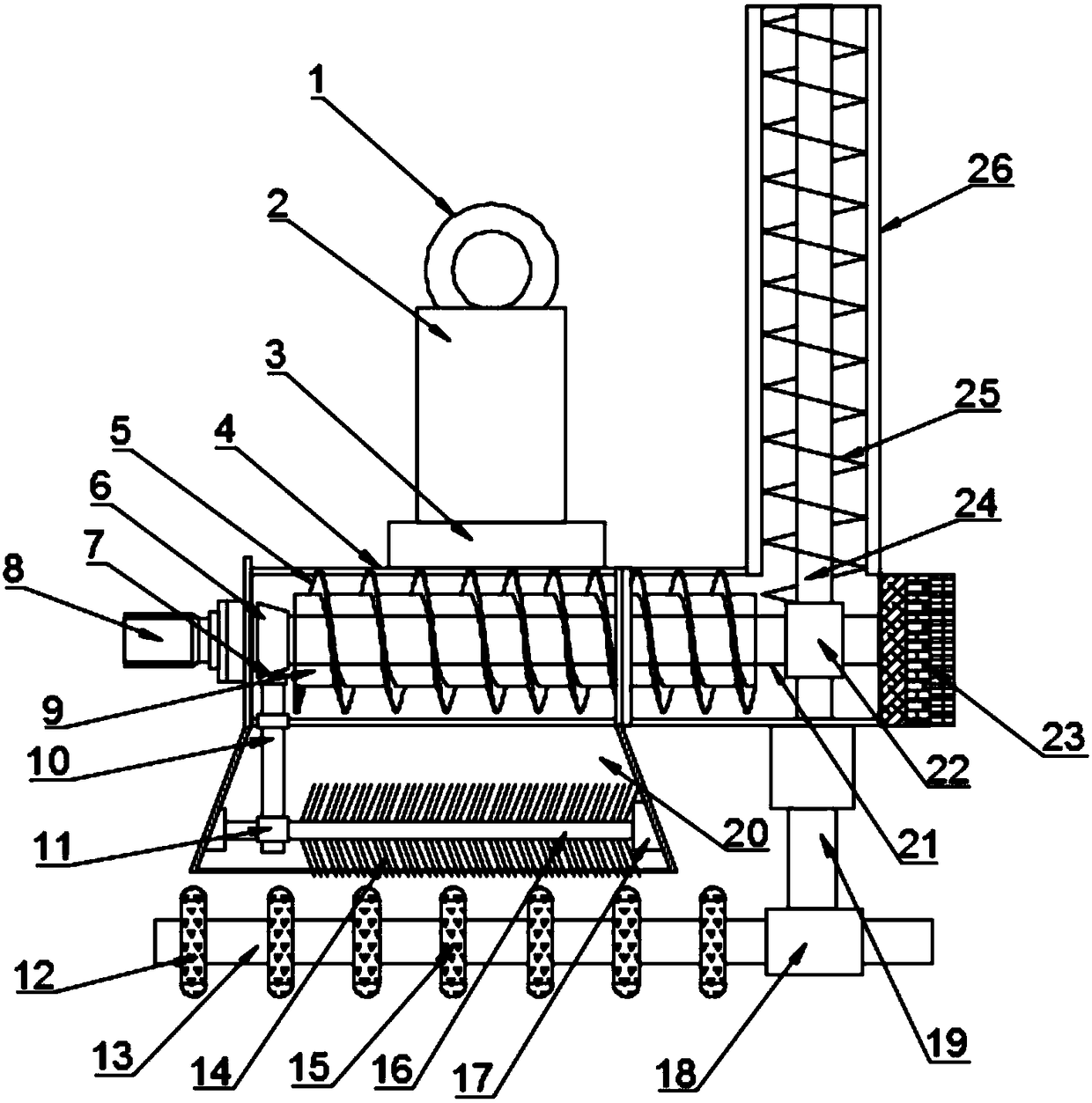

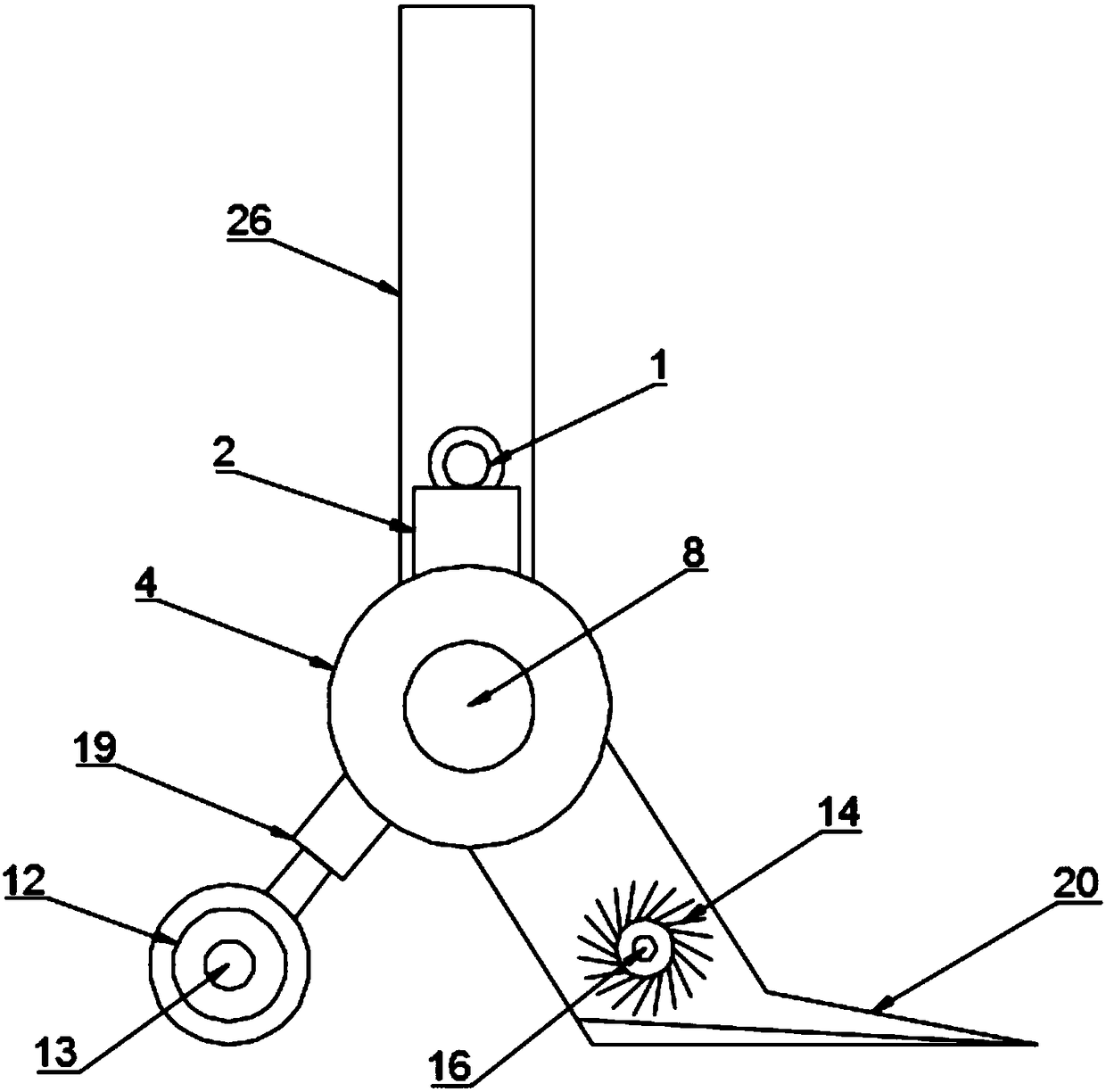

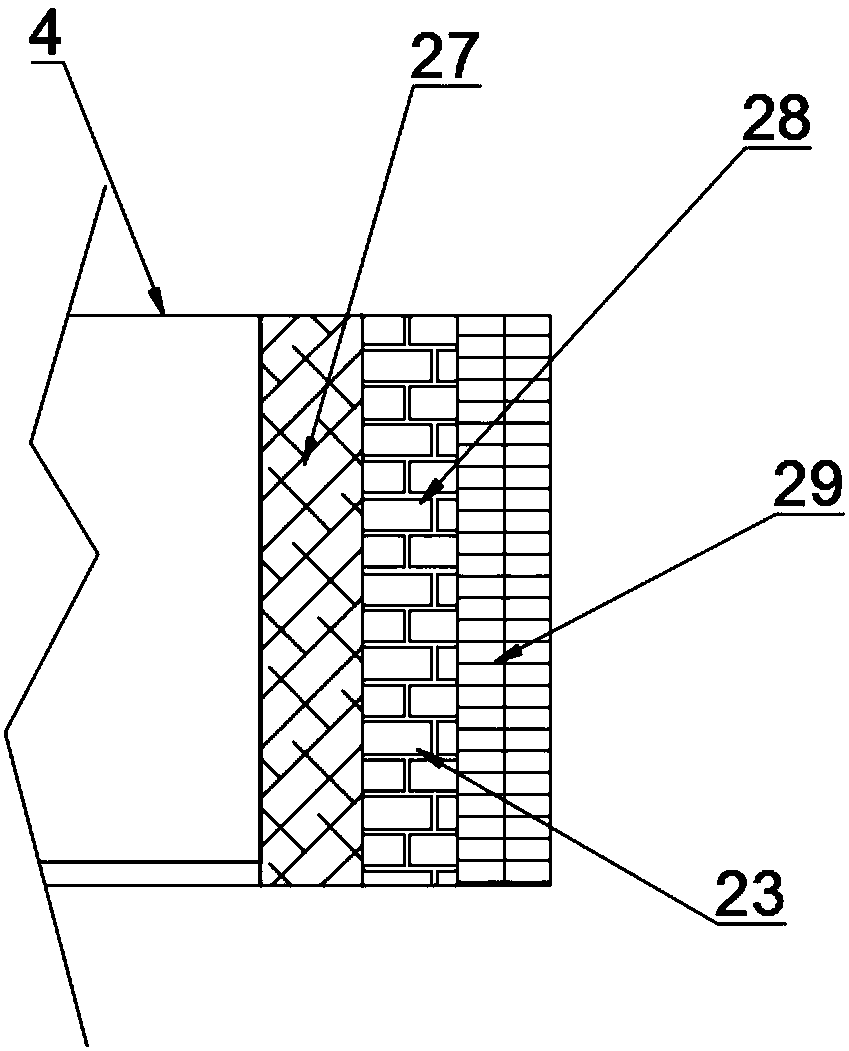

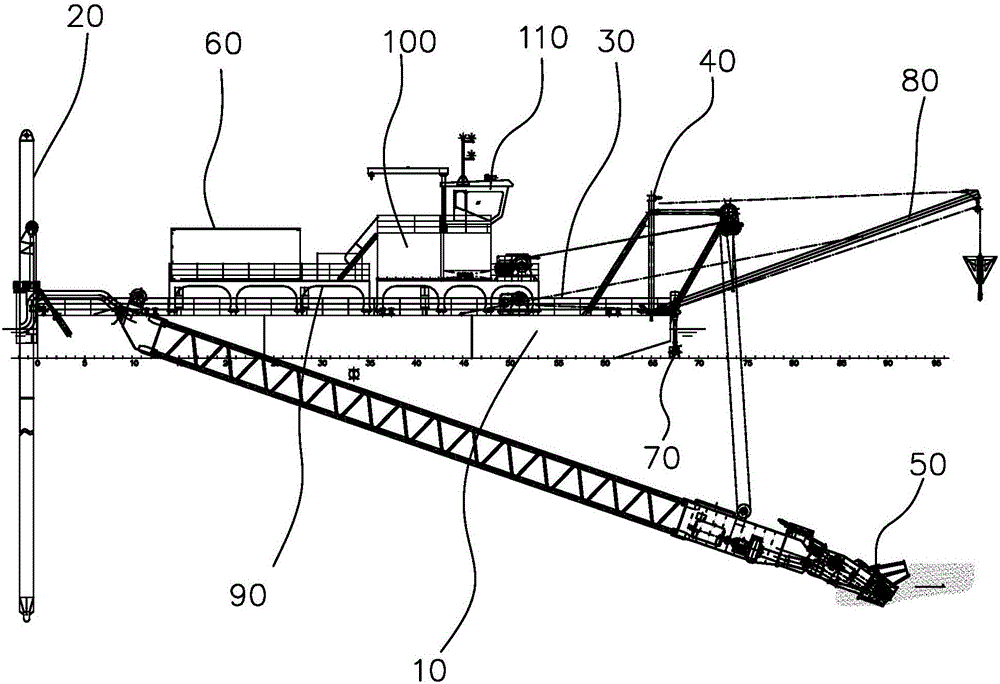

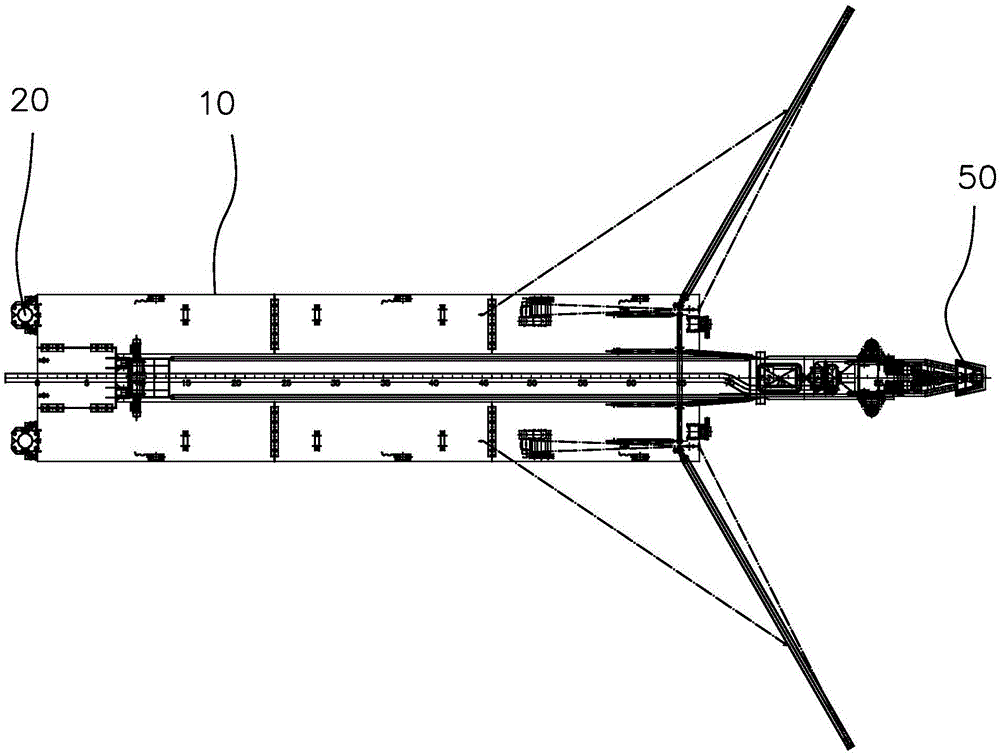

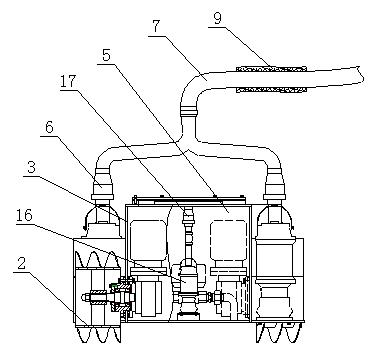

Environment-friendly modular dredger

PendingCN106088200AEasy to transportWide range of digging depthsMechanical machines/dredgersControl systemModularity

The invention discloses an environment-friendly modular dredger. The dredger comprises a buoyant box module, a positioning pile system module, a bridge system module, a digging device module, a portal module, a supporting platform module, a power system module, a propelling system module, a living and control system module and a manipulation module. The environment-friendly modular dredger is convenient to transport by land and assemble and disassemble with the adoption of the standard functional modules and can operate after being transported to a designated lake and reservoir areas and assembled, and the standard modules can be used for series of vessels as required.

Owner:SHANGHAI HANSAIL MARINE & OFFSHORE DESIGN

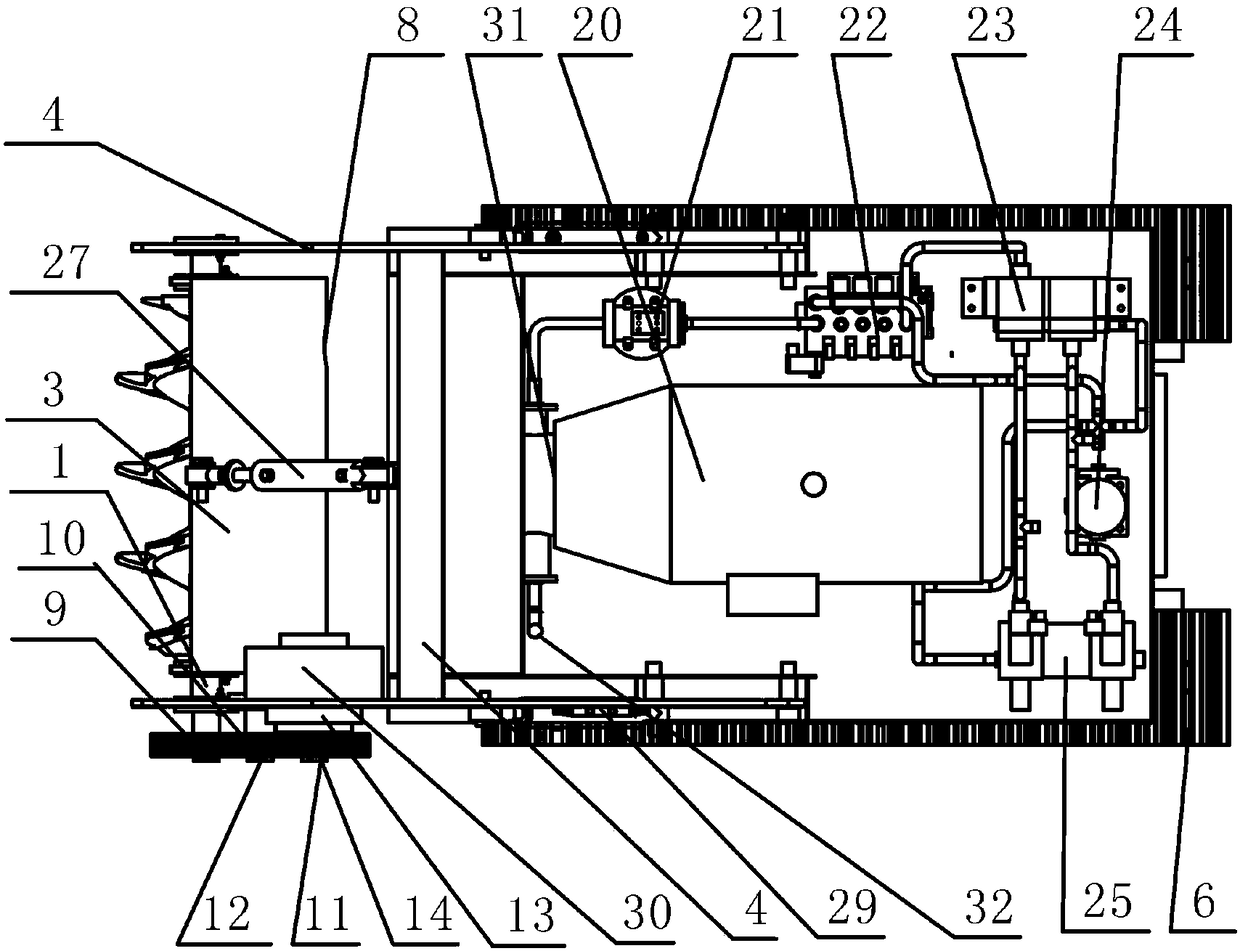

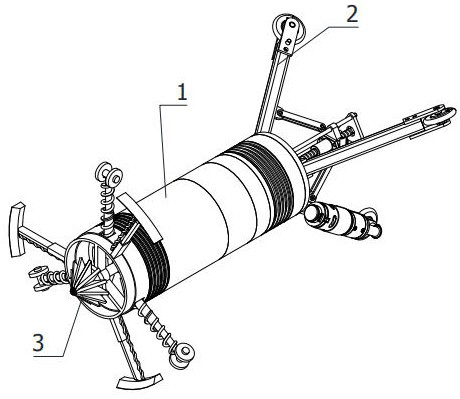

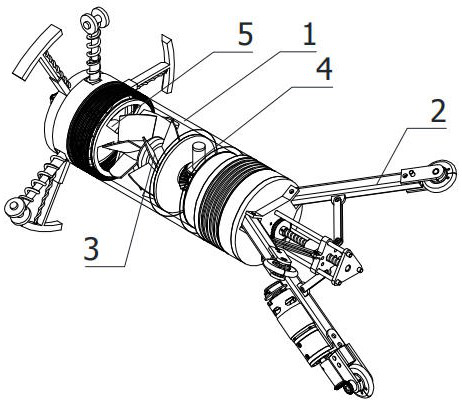

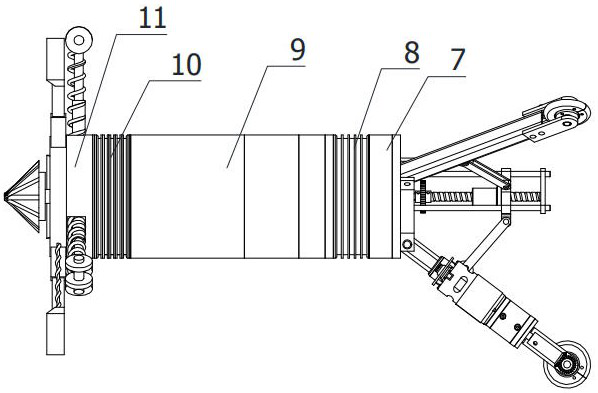

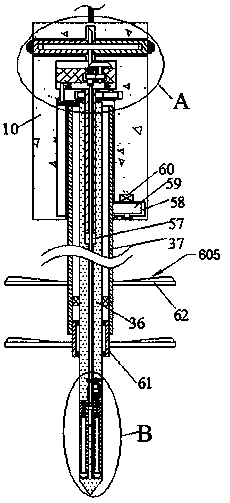

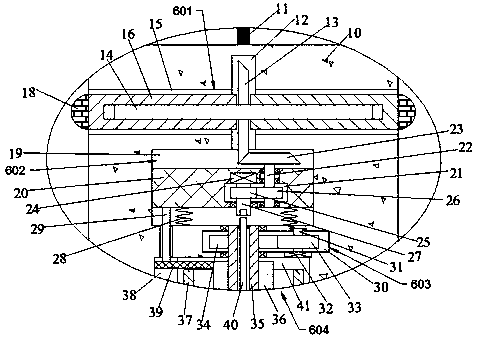

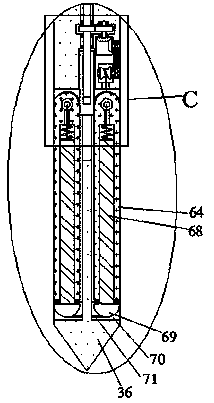

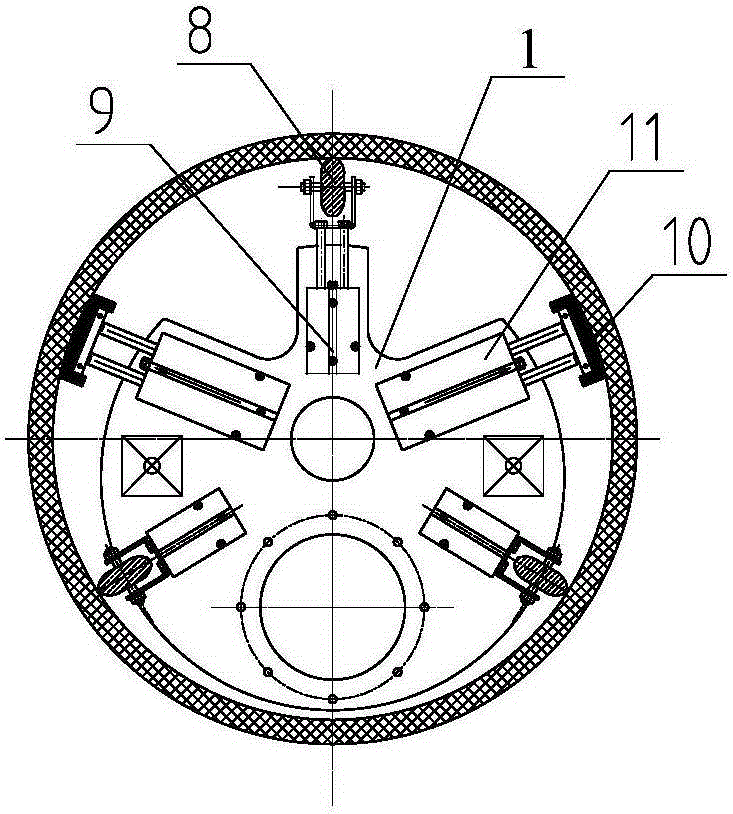

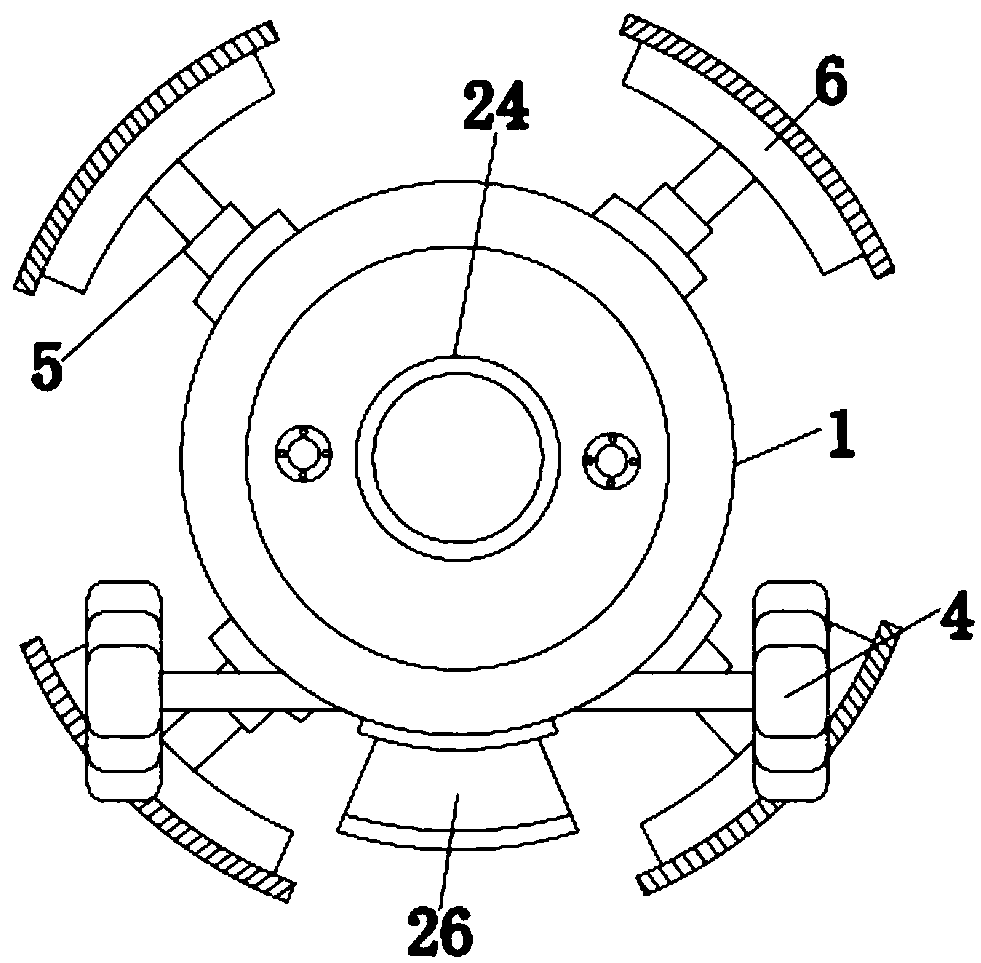

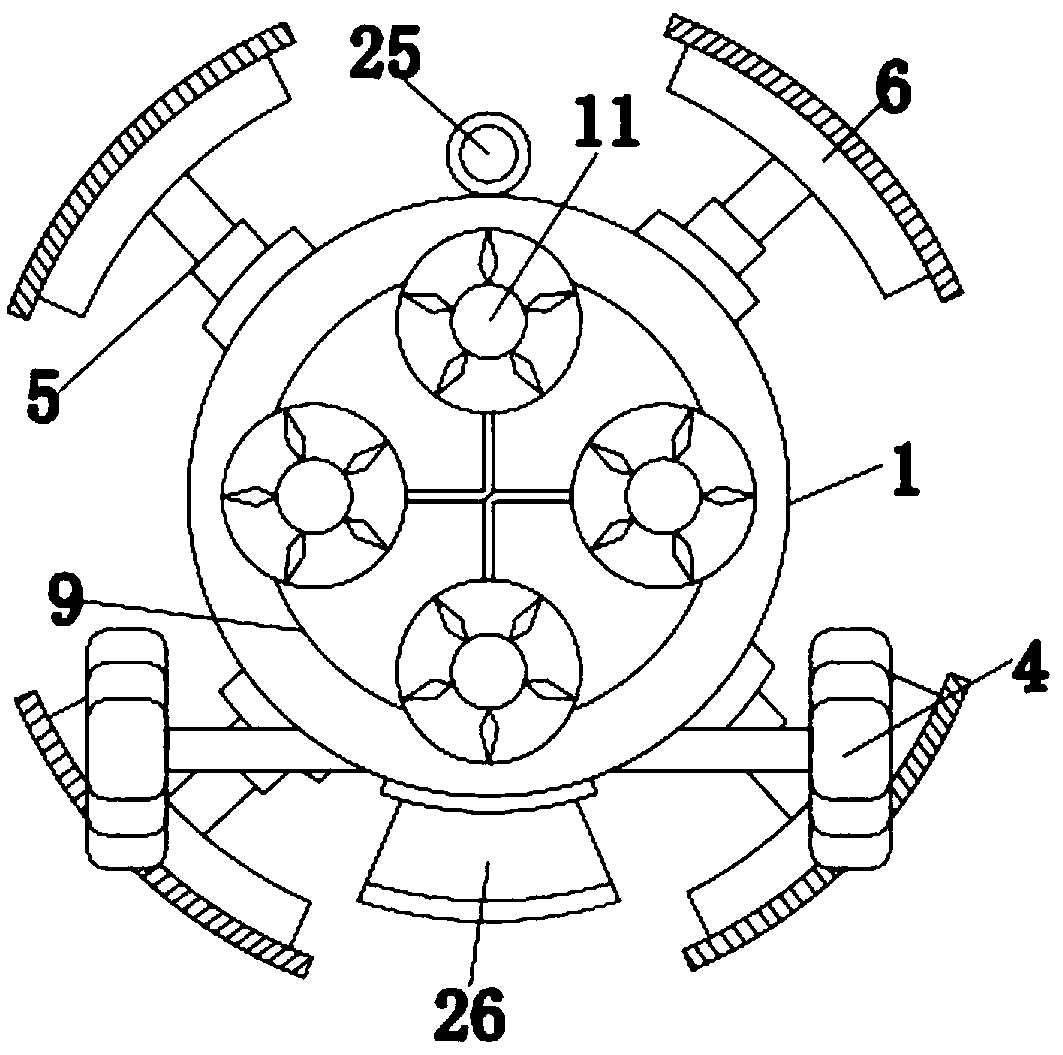

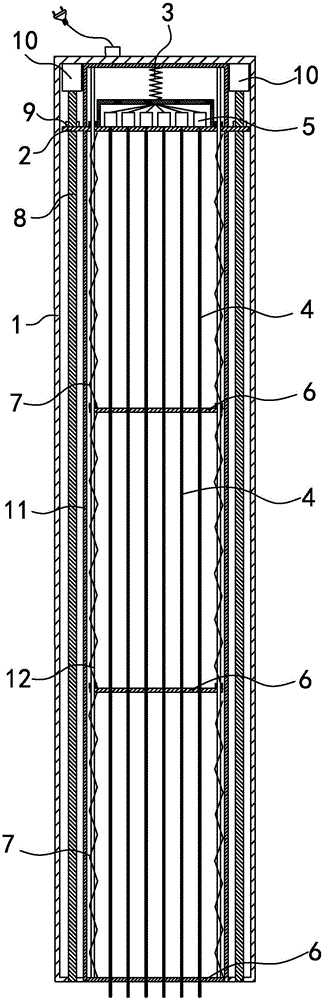

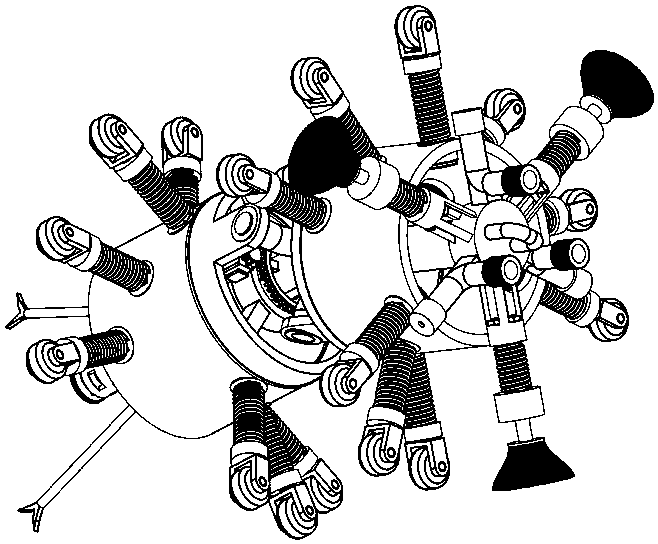

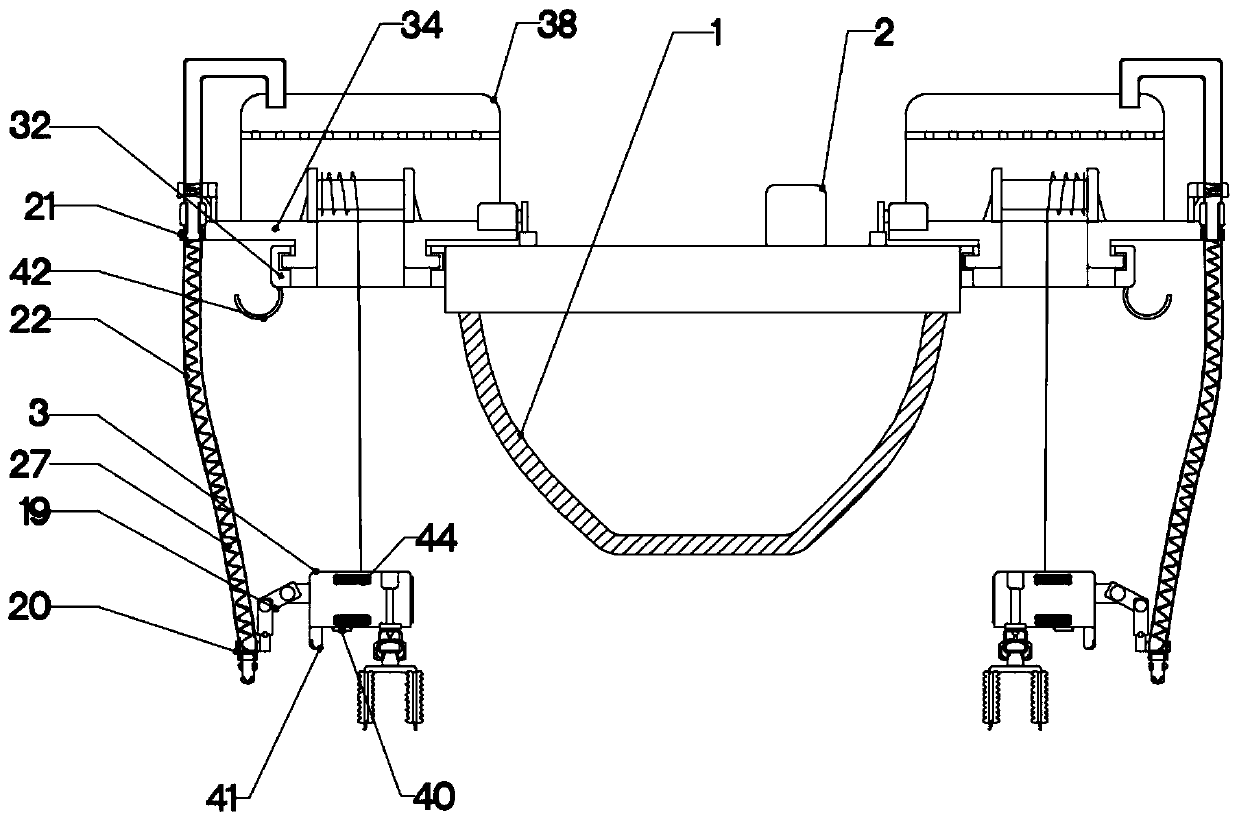

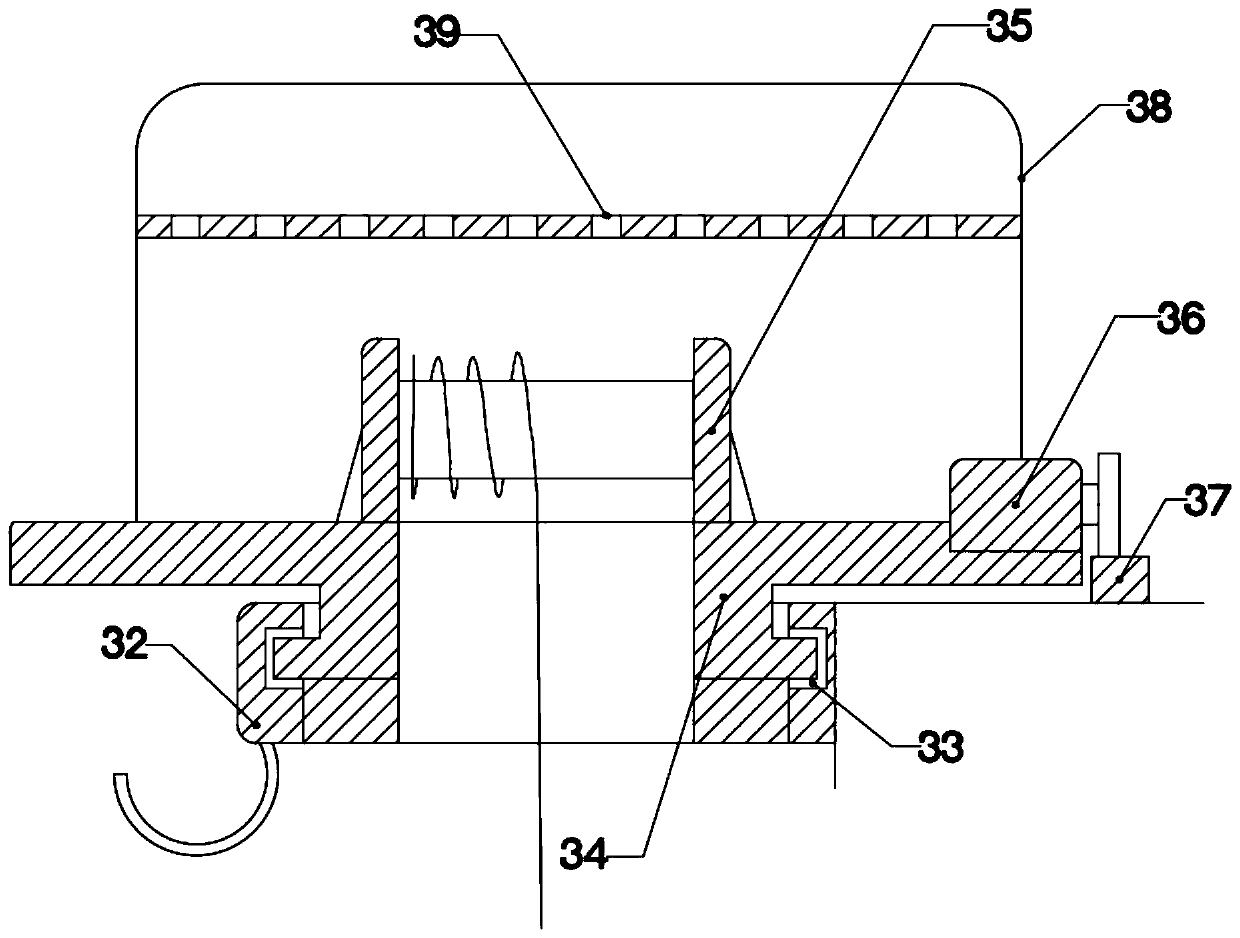

Submersible dredging robot and dredging method thereof

PendingCN110005009AGuarantee the safety of lifeImprove dredging efficiencyMechanical machines/dredgersSludgeSewage

The invention mainly relates to a submersible dredging robot and a dredging method thereof. The submersible dredging robot comprises a main bracket, a hydraulic station system is arranged in the mainbracket, traveling mechanisms are arranged on the two sides of the lower end of the main bracket, a tipping bucket is movably installed at the front end of the main bracket, the tipping bucket is usedfor gathering underwater sludge, the tipping bucket is internally provided with a scattering device, the rear side of the tipping bucket is connected to one end of a sludge suction pipe, the scattering device is used for scattering the sludge and sending the sludge into a sludge suction pipe opening, and the other end of the sludge suction pipe is connected to a sludge pump. The sludge pump is installed on the main support, the upper end of the sludge pump is connected with a sludge discharge pipe, the hydraulic station system provides power for the traveling mechanisms, the scattering deviceand the sludge pump, the upper end of the main bracket is equipped with a detecting device, and the detecting device is used for providing visual information for an operating worker on shore. The submersible dredging robot can replace manual dredging, sewage does not need to be drained, the robot can directly carry out dredging operation by entering the water bottom, the dredging efficiency is high, the worker only needs to conduct control on the shore, and the safety of the worker is ensured.

Owner:浙江君泰生态环保科技有限公司

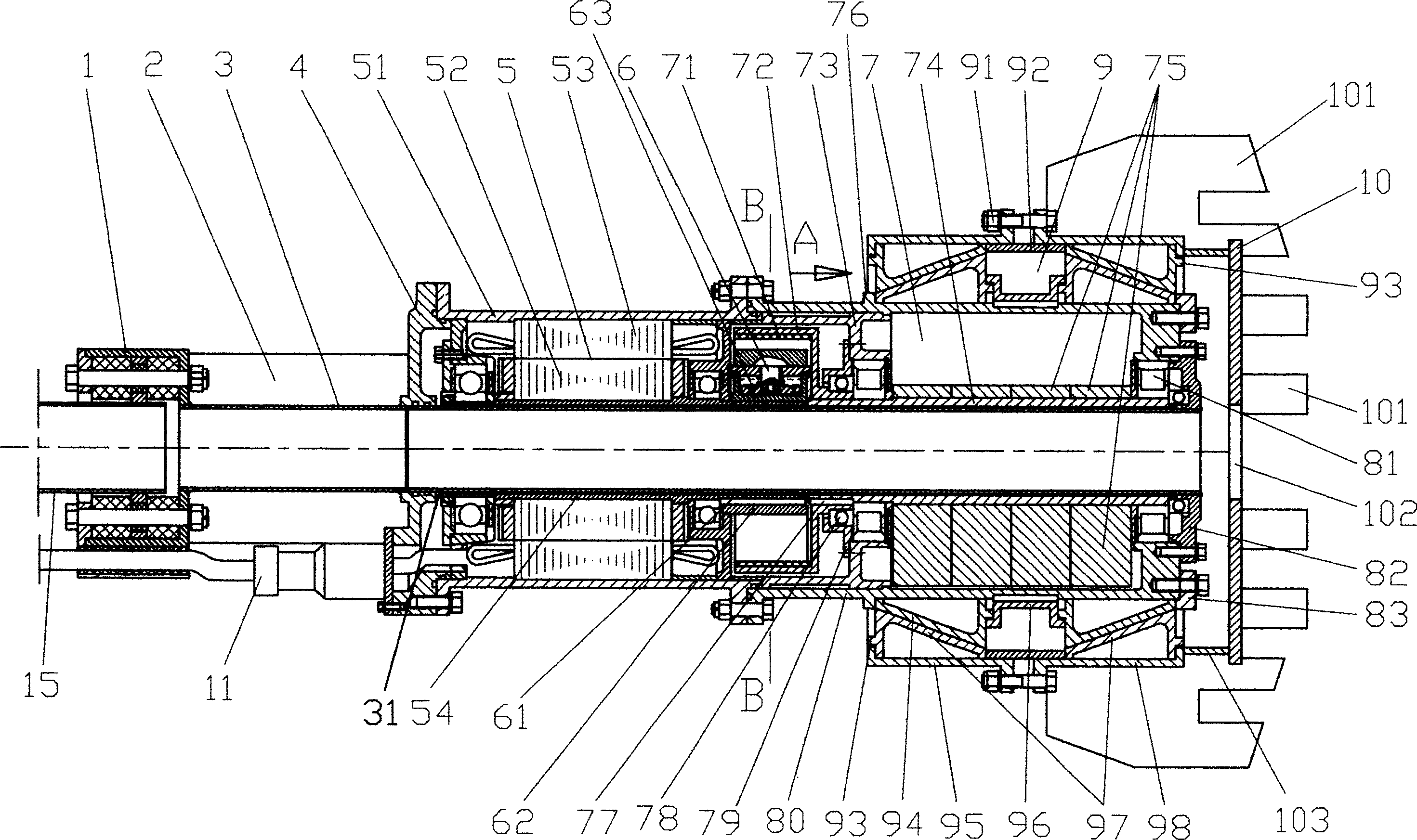

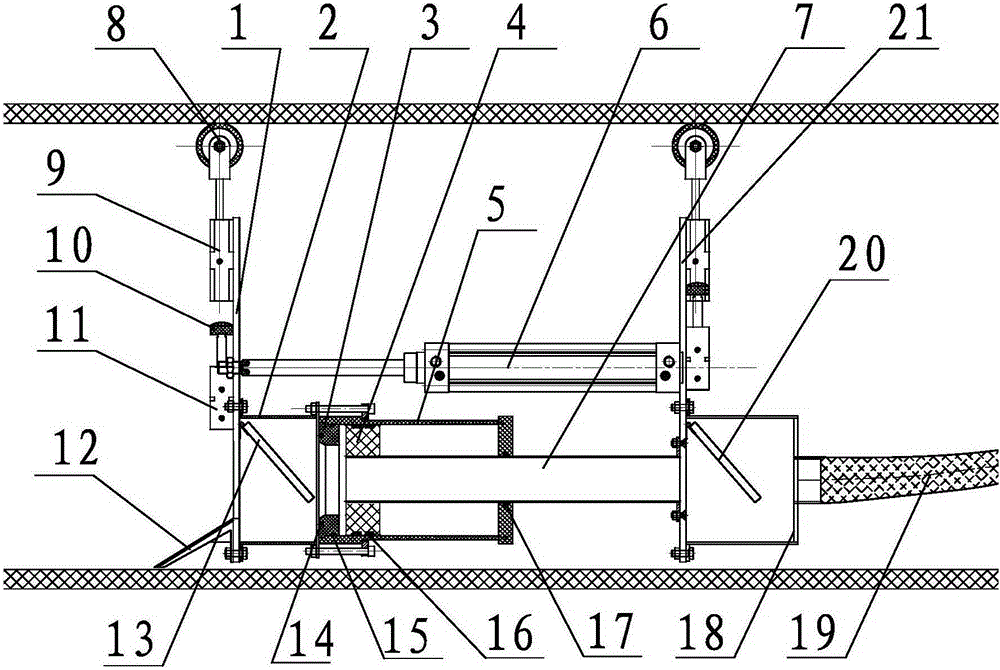

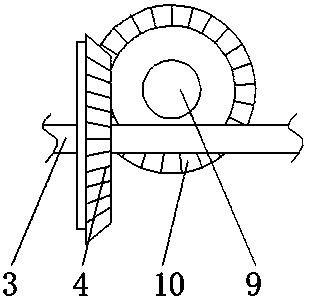

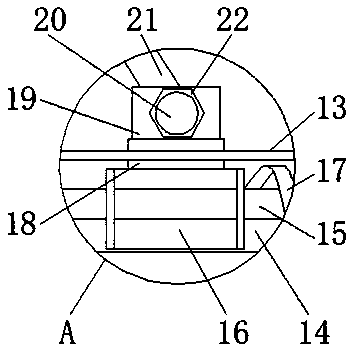

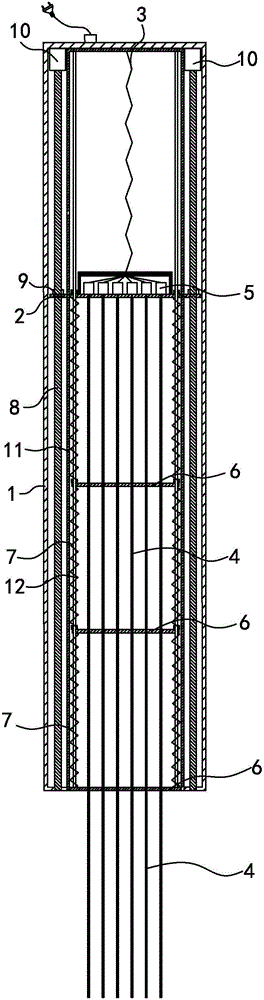

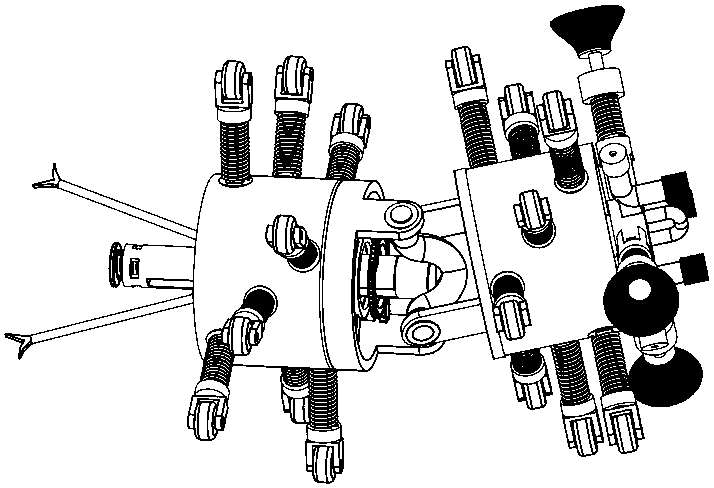

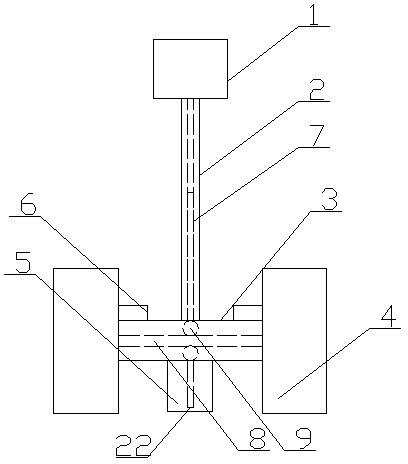

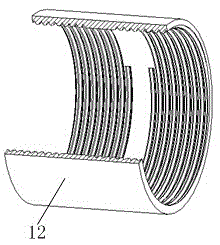

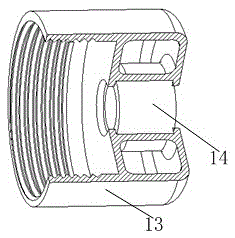

Desilting device used for underdrainage pipeline and stepped type moving method of desilting device

ActiveCN105220764ARealize stepping forwardReduce manufacturing costSewer cleaningDischarge efficiencyEngineering

The invention provides a desilting device used for an underdrainage pipeline and a stepped type moving method of the desilting device. The desilting device comprises a front installation disc and a rear installation disc which are arranged in the advancing direction of the desilting device; a propelling cylinder is arranged between the front installation disc and the rear installation disc and used for changing the relative distance between the front installation disc and the rear installation disc; the front installation disc and the rear installation disc are in contact with the inner wall of a drainage pipeline through support units; through the movement cooperation between the support units and the propelling cylinder, the desilting device is moved forward or backward; a silt discharging cylinder is arranged at the position, between the front installation disc and the rear installation disc, of the bottom side and used for delivering silt generated in the desilting process. By means of the desilting device, the silt is discharged thoroughly, the operation is simple and reliable, and the silt discharging efficiency is obviously improved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Submersible dredging vehicle

ActiveCN102561431APromote absorptionImprove crushing effectMechanical machines/dredgersDrive wheelPropeller

A submersible dredging vehicle relates to an underwater dredging technology. The submersible dredging vehicle is provided with a vehicle body, wherein a submersible sewage pump is arranged on the vehicle body, a drain pipe is arranged on a liquid outlet of the submersible sewage pump, four spiral propeller type driving wheels are arranged on the two sides of the vehicle body, spiral directions of the adjacent two driving wheels are opposite, a water retaining cover plate is arranged on the vehicle body, the vehicle body is provided with four driving motors connected with the four driving wheels and is further provided with a water storehouse and a draining pump, the draining pump is provided with a check pump, the water storehouse is provided with a water inlet pipe and a gas identification rod, an electric valve is arranged on the water inlet pipe, and the electric valve, the submersible sewage pump and the four driving motors are connected with a controller. The submersible dredging vehicle can move forwards and backwards, carry out translation, turn around by taking any one driving wheel as a circle center and by taking the center of the vehicle body as the circle center, move and the like through the turning matching of the four driving wheels. The submersible dredging vehicle disclosed by the invention has the advantages of high locomotive maneuverability, simplicity and convenience in position change, easy handling, no dead corner during working, more thorough cleaning, high dredging efficiency and strong subsidence and sliding capabilities.

Owner:SHANDONG SHUANGLUN

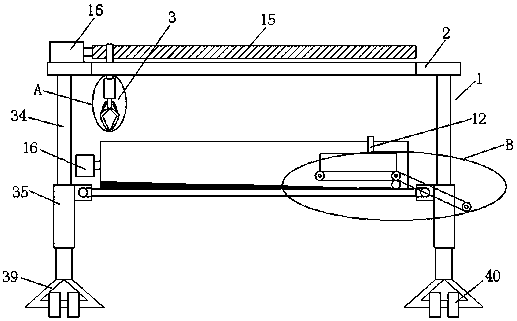

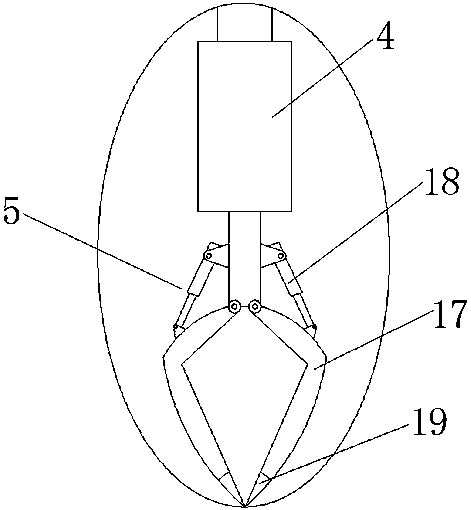

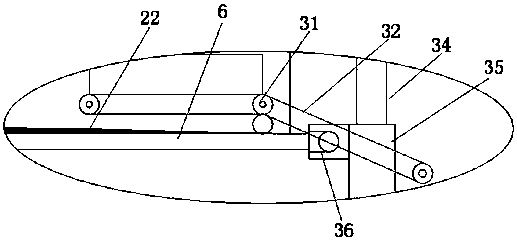

Simple integrated type river sludge treatment device

ActiveCN107587541ASimple structureVersatileSludge treatment by de-watering/drying/thickeningSoil-shifting machines/dredgersSludgeFishing

The invention discloses a simple integrated type river sludge treatment device. The device comprises a gantry-shaped support, a supporting plate, a crushing mechanism, a concentration mechanism and aconveying mechanism, wherein a fishing mechanism capable of moving left and right on a cross beam is hoisted on the gantry-shaped support, the fishing mechanism comprises a retractable rod and a sludge fishing claw arranged at the bottom of the retractable rod, the supporting plate is movably arranged in the middle of the gantry-shaped support, the crushing mechanism is arranged below the sludge fishing claw on the supporting plate, and a crushing cavity and a filtering cavity which is separated from the crushing cavity by a filter plate and arranged in the bottom of the crushing cavity are formed in the crushing mechanism; the concentration mechanism comprises a primary filter assembly and an extrusion assembly which are connected in sequence, the filtering cavity is communicated with theprimary filter assembly through a sludge discharge pipe, the front end of the conveying mechanism is connected with an extrusion mechanism, and the rear end of the conveying mechanism directly extends to the outer side of the supporting plate. The device is simple in structure, complete in function, good in motion flexibility, capable of improving the sludge removing efficiency, avoiding resourcewaste, and suitable for dredging of various river channels and ditches.

Owner:湖州优研知识产权服务有限公司

Pipeline dredging robot

The invention discloses a pipeline dredging robot in the technical field of pipeline cleaning. The robot is provided with a shell, rolling wheels, a driving shaft, a motor and a connecting flange; themotor is fixedly connected to the outer wall of the shell, the side wall of the shell is embedded into the connecting flange, an output end of the motor is connected with the driving shaft, the two ends of the driving shaft are connected with the rolling wheels, one end of a sleeve shell is fixedly connected with one end of a connecting column, a first stepping motor is installed at the other endof the sleeve shell, a lighting torch parallel to the sleeve shell is fixedly connected to a mounting base, a camera is installed on the lower portion of one end of the lighting torch, the other endof the connecting columns is fixedly connected with a dredging box, and a sewage pump is installed in an inner cavity of the dredging box. Accordingly, blockages are broken and discharged, secondary blocking of the blockages is prevented, and meanwhile the stability of a robot body can be kept in the dredging process; the dredging effect is good, and the practicability is high.

Owner:绍兴上虞复旦协创绿色照明研究院有限公司

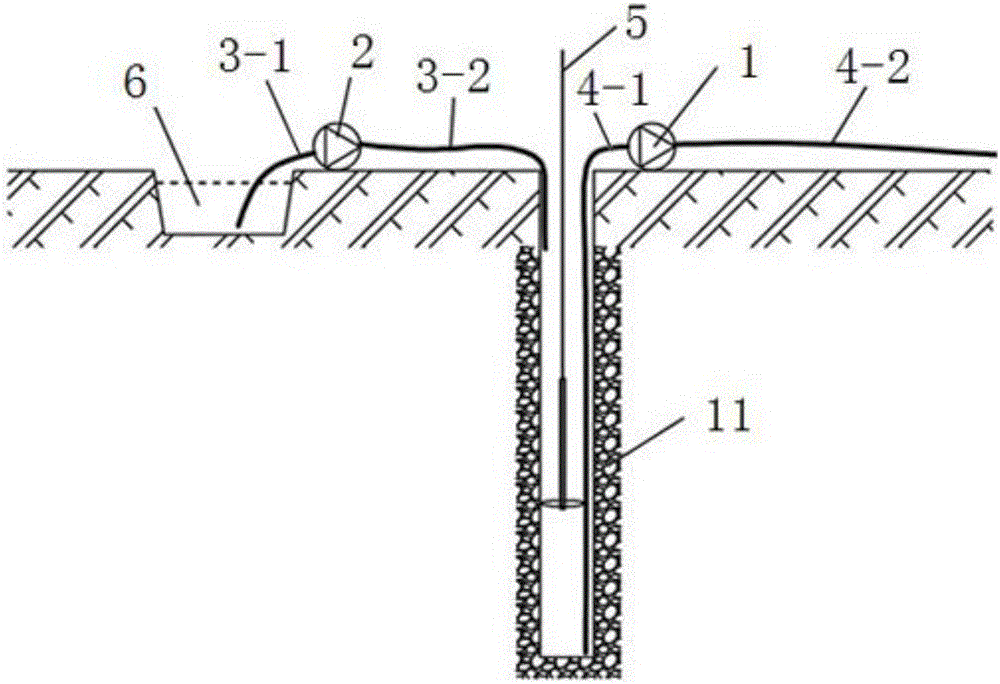

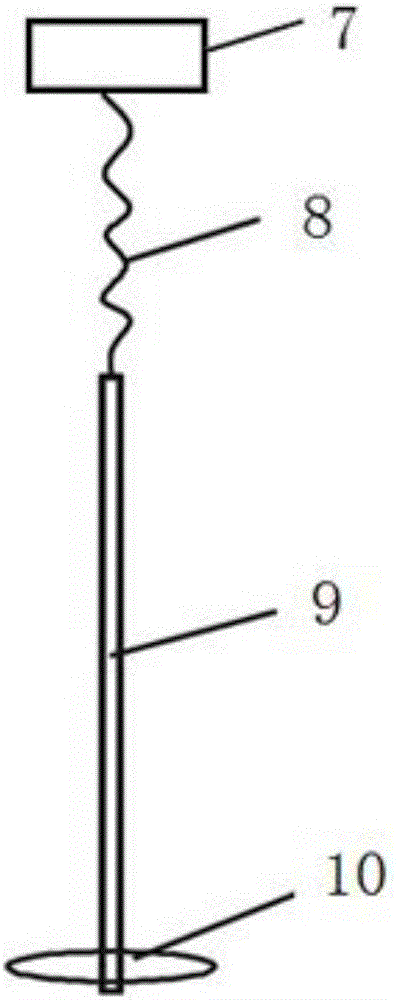

Simple hydrological-hole dredging device

InactiveCN105064312AImprove dredging efficiencyImprove dredging effectFlushingIn situ soil foundationEngineeringGroundwater

The invention discloses a simple hydrological-hole dredging device. The simple hydrological-hole dredging device comprises a first dieselized pumping machine, a second dieselized pumping machine and a stirrer. The first dieselized pumping machine is connected with hard plastic pipes and used for pumping out underground water at the bottom of a hydrological hole. The second dieselized pumping machine is connected with soft plastic pipes and used for injecting water into the hydrological hole. The stirrer comprises a thin rope and a metal rod. The thin rope is connected with one end of the metal rod. A cloth strip or a sponge is arranged at the other end of the metal rod and used for stirring the underground water in the hydrological hole. According to the simple hydrological-hole dredging device, circulating of the water in the hydrological hole is achieved through the two dieselized pumping machines; and as the underground water in the hydrological hole is stirred through the stirrer, the hole dredging efficiency is greatly improved, and the hole dredging time is shortened. The simple hydrological-hole dredging device is simple in structure and convenient to install, and can be repeatedly used.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Household intelligent pipeline dredging device

The invention relates to the technical field of pipeline dredging devices, and discloses a household intelligent pipeline dredging device. The household intelligent pipeline dredging device comprisesa base plate, four supporting legs are evenly distributed at the bottom of the base plate, the front faces and the back faces of the two supporting legs are movably sleeved through the two ends of a rotating rod, the rotating rod is fixedly sleeved with a driven bevel gear located between the two supporting legs, the two ends of the rotating rod are fixedly sleeved with universal wheels located atthe front faces and the back faces of the supporting legs, a protecting box is fixedly installed at the right side of the bottom of the base plate, a driving motor is fixedly installed inside the protecting box, and one side of the protecting box is fixedly sleeved with a bearing. According to the household intelligent pipeline dredging device, by cooperatively adopting the driven bevel gear, theuniversal wheels, the driving motor and a driving bevel gear, a cleaning device can enter a pipeline to be dredged, the device can enter a pipeline more conveniently, and the phenomena that when a pipeline to be cleaned is long, the cleaning device cannot enter the pipeline, and practicability of the device is affected are avoided.

Owner:方高健

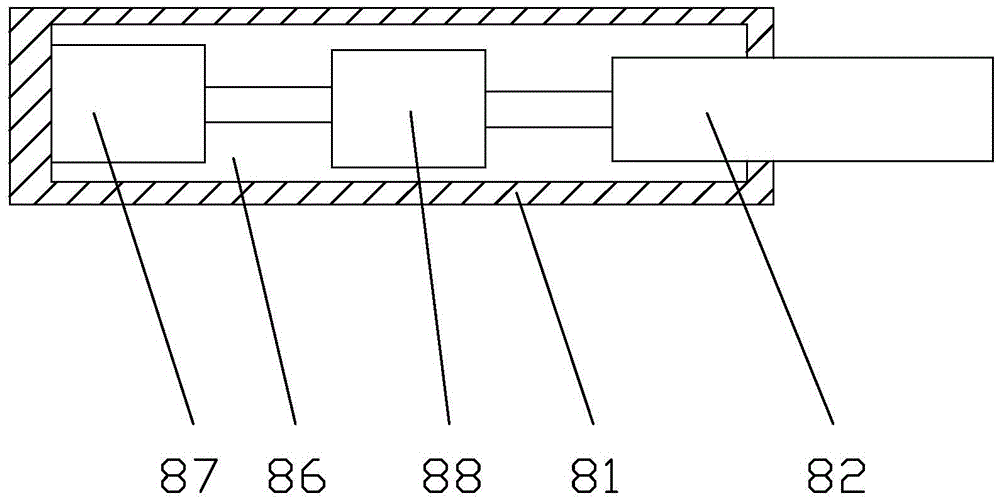

Portable denitration catalyst honeycomb hole dredge

ActiveCN105126615AImprove dredging efficiencySave human effortDispersed particle separationCatalyst regeneration/reactivationBiochemical engineeringHoneycomb

A portable denitration catalyst honeycomb hole dredge is characterized by comprising a housing, a mounting plate and dredging needles; the dredging needles are arranged corresponding to the position of honeycomb holes, the mounting plate is provided with mounting holes corresponding to the dredging needles, the dredging needles penetrate into the corresponding mounting holes, the tail end of each dredging needle is in transmission connection with a rotation output shaft of a motor, the motor is arranged and located in relative to the mounting plate, the mounting plate is slidably arranged in relative to a housing by a liner driving mechanism along the axial direction of the dredging needles, positioning plates are arranged in intervals along the axial direction of the dredging needles, the positioning plates are provided with guiding holes corresponding to the dredging needles, the dredging needles penetrate into the corresponding guiding holes, and springs are arranged between adjacent positioning plates. The portable denitration catalyst honeycomb hole dredge can simultaneously dredge multiple honeycomb holes, dredge efficiency is greatly improved, and manpower is saved.

Owner:苏州菲泰科过滤技术有限公司

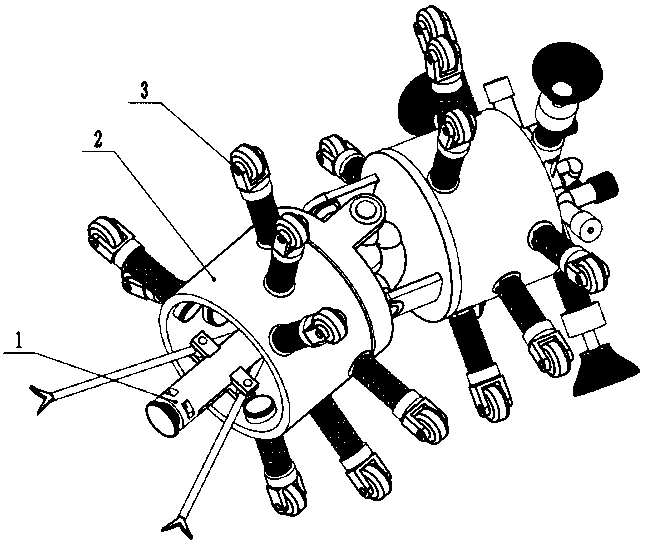

Domestic pipeline unchoking robot

ActiveCN107755372AFlexible moving processSolve the blockageHollow article cleaningUniversal jointEngineering

The invention provides a domestic pipeline unchoking robot comprising an unchoking module, two walking bases, eighteen walking modules, a first machine frame, a universal joint, a second machine frameand three cleaning modules. The domestic pipeline unchoking robot is characterized in that the unchoking module is rotationally installed in a guide rail of the first machine frame through a slidingblock, the first machine frame is rotationally installed at the two long shaft ends of the universal joint through two first rotating shaft seats, and the second machine frame is rotationally installed at the two short shaft ends of the universal joint through two second rotating shaft seats. The domestic pipeline unchoking robot is driven by the spirally arranged walking modules, connection in the middle is achieved through the universal joint, the domestic pipeline unchoking robot can flexibly move in a bent pipeline, the dredging module at the front end can clamp choking matter and smash the choking matter through a dredging rod and clamping jaws, hair, thin wires and other choking matter can be burned to break, the dredging efficiency is high, and common pipeline blockage problems canbe effectively solved.

Owner:安徽悦得自动化有限公司

Self-moving type bottom mud separating and collecting device

ActiveCN106120938AImprove collection efficiencyGood for cleaning mudMechanical machines/dredgersGratingSpiral blade

The invention discloses a self-moving type bottom mud separating and collecting device in the field of desilting and dredging devices. The self-moving type bottom mud separating and collecting device comprises a walking filtering mechanism. The walking filtering mechanism comprises a left end plate and a right end plate which are connected through a crawler tooth plate. A filtering grating is arranged between the left end plate and the right end plate. The left end plate is rotationally connected to a left supporting pipe, and the right end plate is rotationally connected to a right supporting pipe. Installing plates are arranged at the lower portions of the left supporting pipe and the right supporting pipe, and an arc protection cover is arranged between the two installing plates. A spiral blade shaft is arranged below the arc protection cover. A mud pump is arranged above the arc protection cover. A mud sucking opening is formed behind the arc protection cover and connected with an inlet of the mud pump through an inlet pipeline, and an outlet pipeline of the mud pump is connected with an outer mud discharging pipeline penetrating the right supporting pipe. The right supporting pipe is provided with a rotation driving mechanism through a seat plate, wherein the rotation driving mechanism drives the walking filtering mechanism to rotate. The self-moving type bottom mud separating and collecting device can efficiently collect riverway bottom mud and convey the riverway bottom mud out, energy saving and environment friendliness are achieved, and the desilting efficiency is higher.

Owner:THE JIANGSU GENERAL FACTORY OF WATER CONSERVANCY MACHINERY

Gravel bed desilting device and desilting method

PendingCN106948394AAvoid destructionComplete dredgingMechanical machines/dredgersMarine engineeringCrushed stone

The invention provides a gravel bed desilting device and desilting method. Silt on the surface of a gravel bed can be quickly and completely removed on the condition that the gravel bed is not disturbed. The device is installed on a desilting ship and comprises a desilting sucker and a moving unit used for moving the desilting sucker; the desilting sucker comprises a sucker body and a plurality of suction pipes made of a soft material, and the suction pipes are arranged at the bottom of the sucker body so as to make contact with the surface of the gravel bed; the moving unit is installed on the desilting ship and comprises a lowering part used for lowering the desilting sucker, and the lowering part is fixedly connected with the desilting sucker and can rise and fall relative to the desilting ship.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HARBOR ENG +1

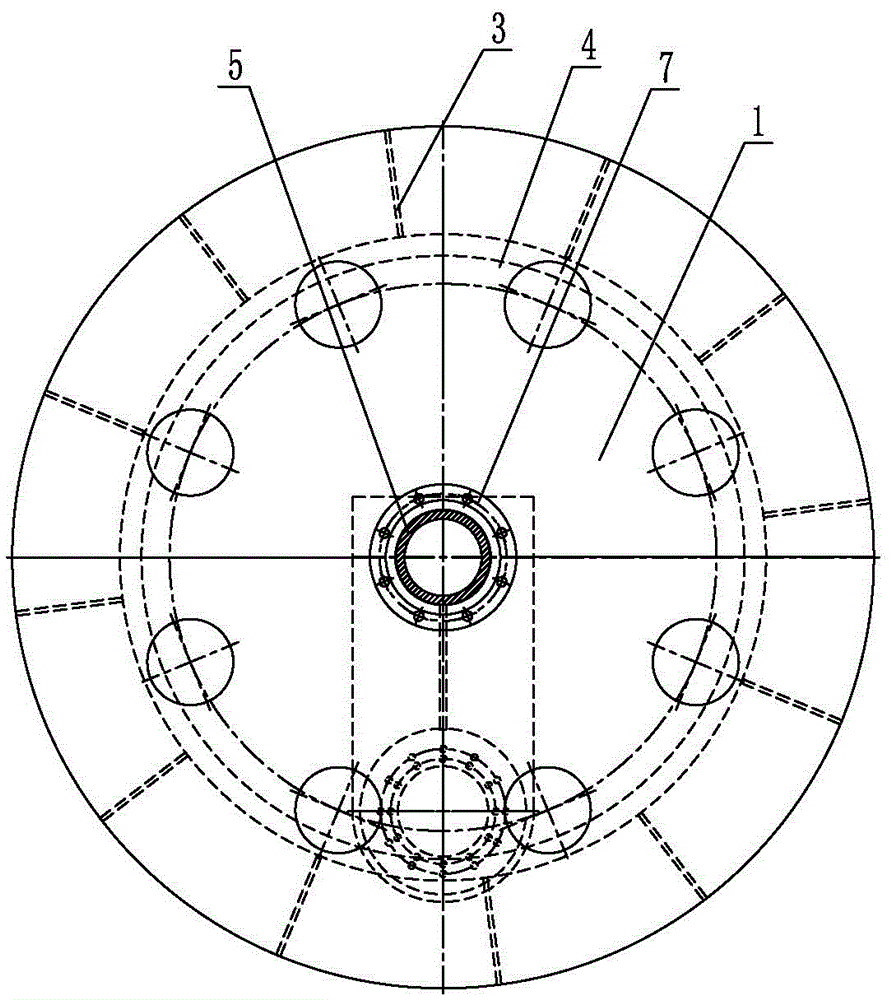

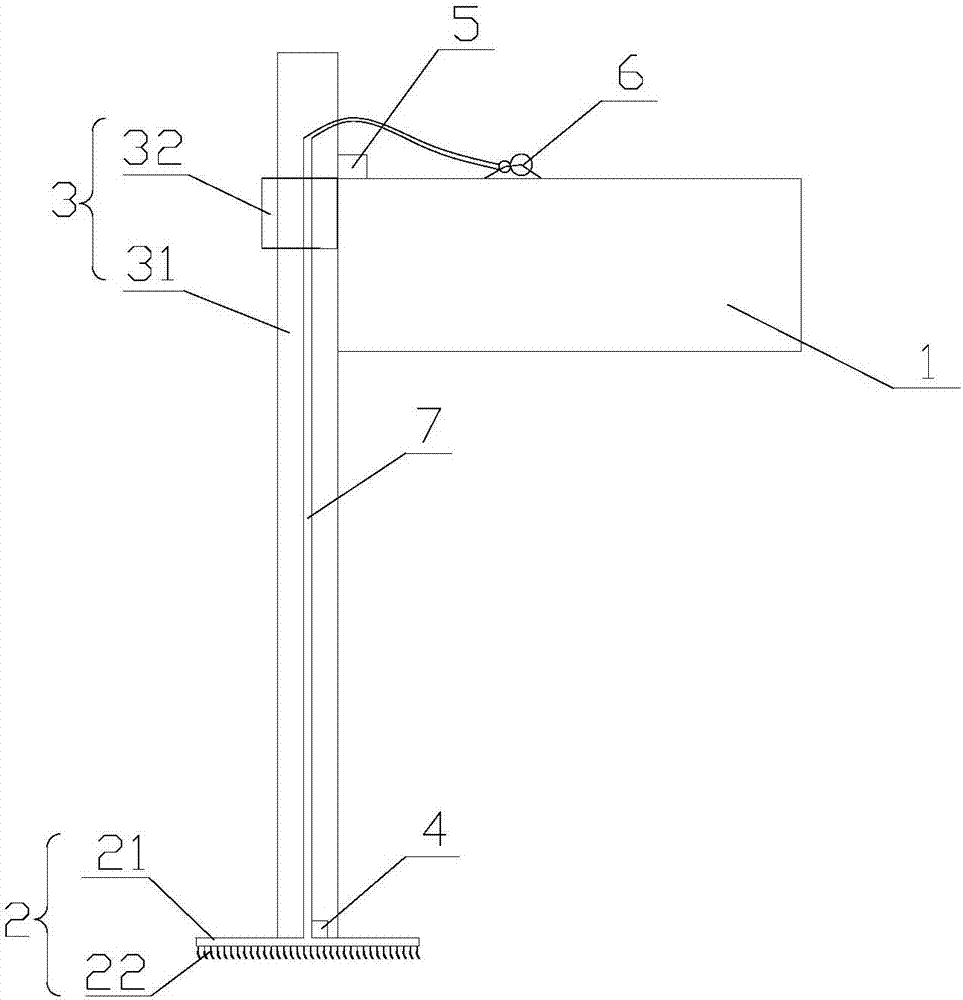

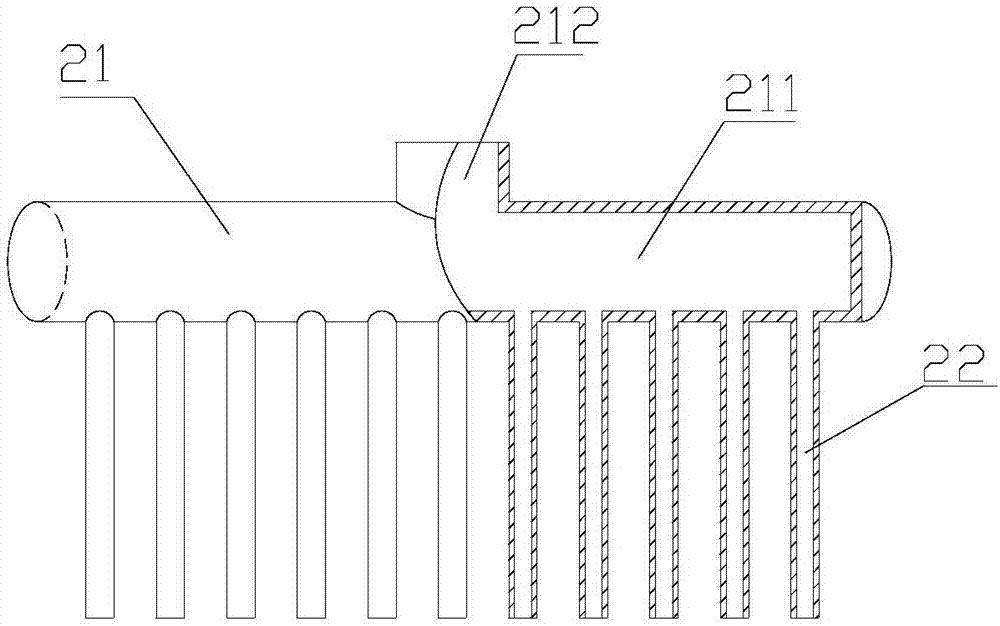

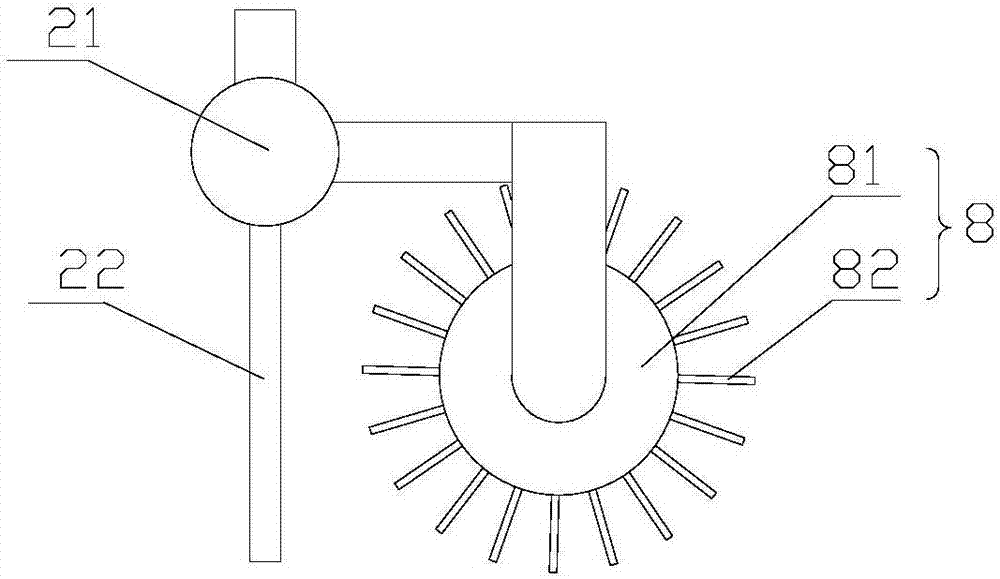

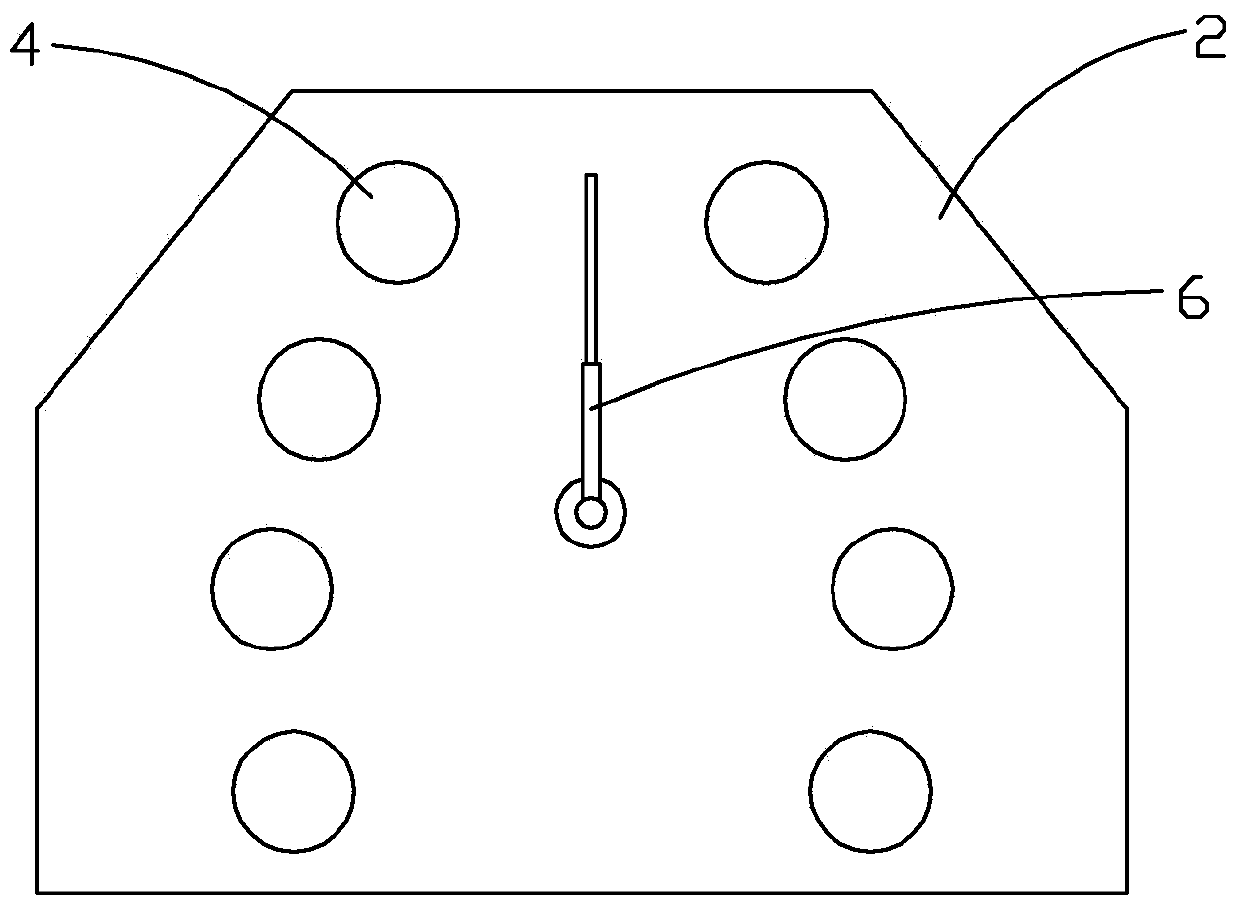

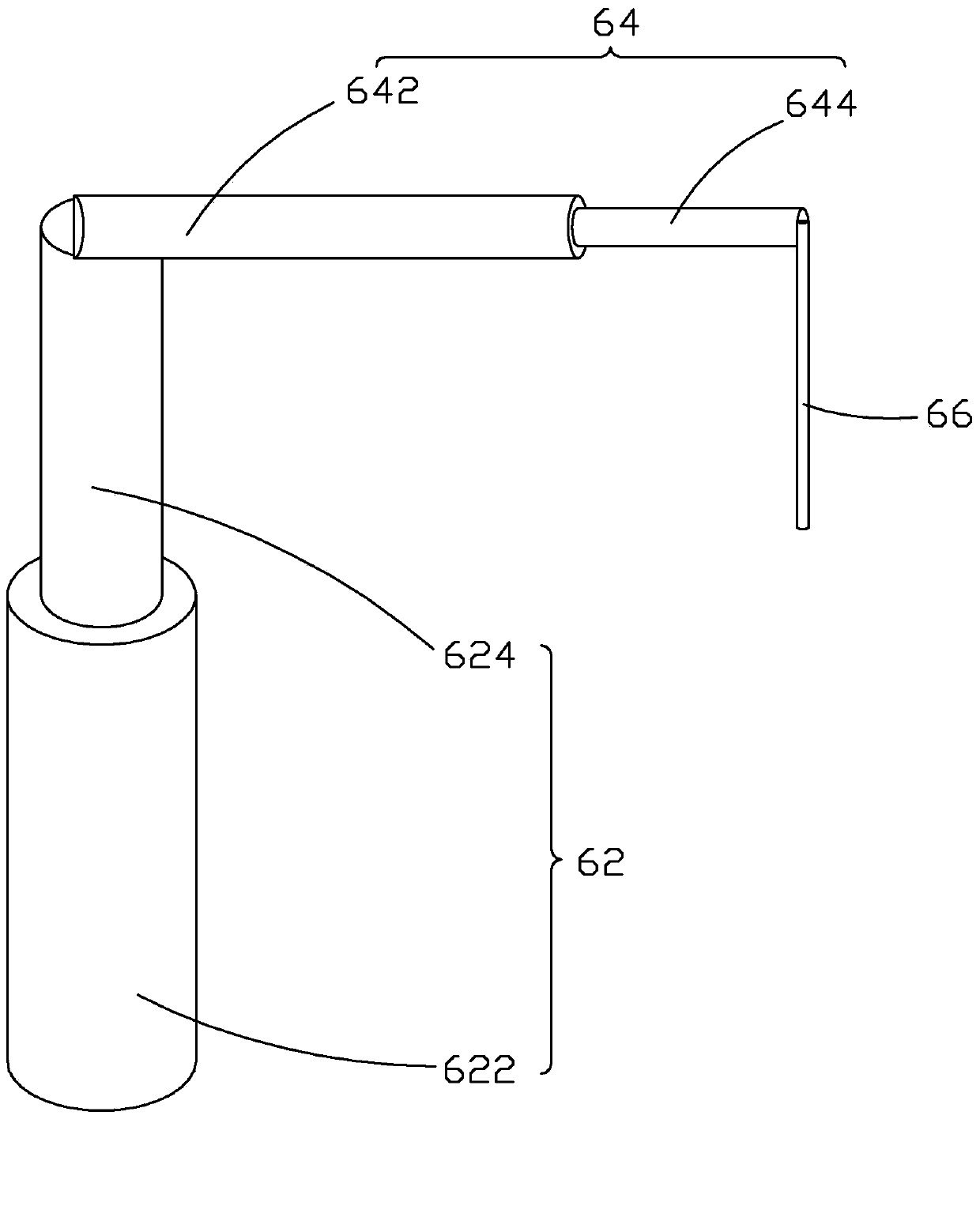

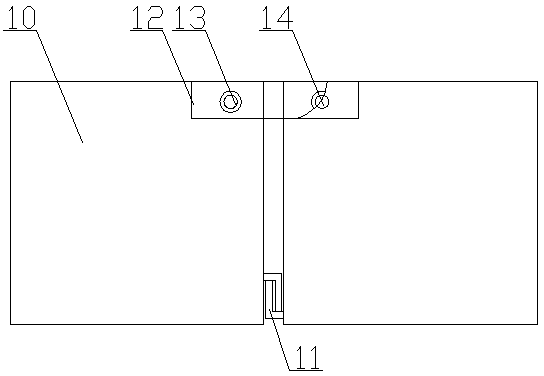

Evaporation source assembly of organic light-emitting diode (OLED) evaporator

ActiveCN103741096AIncrease profitShorten the timeVacuum evaporation coatingSputtering coatingCrucibleEvaporation

The invention provides an evaporation source assembly of an organic light-emitting diode (OLED) evaporator. The evaporation source assembly comprises a bearing platform (2), a plurality of evaporation crucibles (4) and a dredging mechanism (6), wherein the plurality of evaporation crucibles (4) are arranged on the bearing platform (2); the dredging mechanism (6) is arranged on the bearing platform (2), and comprises a vertical arm (62), a cross arm (64) and a probe (66); the cross arm (64) is vertically connected to one end of the vertical arm (62); the probe (66) is vertically connected with the free end of the cross arm (64); the vertical arm (62) is arranged on the bearing platform (2) in a scalable manner, and can rotate opposite to the bearing platform (2); the probe (66) is controlled to dredge gas outlets of the evaporation crucibles (4) through the cross arm (64) and the vertical arm (62). By adopting the evaporation source assembly of the OLED evaporator, disclosed by the invention, the gas outlets of the evaporation crucibles can be dredged under the condition of not opening a cavity of the evaporator by providing the dredging mechanism, the time is saved, the dredging efficiency is effectively improved, and the utilization rate of the evaporator is also increased.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Water conservancy project water supply and drainage pipeline internal wall dredging device

The invention discloses a water conservancy project water supply and drainage pipeline internal wall dredging device. The water conservancy project water supply and drainage pipeline internal wall dredging device comprises a pipeline and a mounting seat; a U-shaped frame is connected to the right side wall of the mounting seat; a first motor is connected to the right end of the U-shaped frame; a lead screw is connected to the left side output end of the first motor; a nut seat is screwed to the external wall of the lead screw; fixing rods are symmetrically connected to the upper and lower endsof the nut seat; guide sleeves are connected to the end parts of the fixing rods; the guide sleeves are movably arranged at the cross ends of the U-shaped frame in a sleeving manner; horizontal supporting rods are connected to the middle parts of the left ends of the fixing rods; the horizontal supporting rods run through the mounting seat; and a dredging shell is connected to one ends, extendinginto the cavity of the pipeline, of the horizontal supporting rods. The water conservancy project water supply and drainage pipeline internal wall dredging device has the advantages that the structural design is reasonable, the device is convenient for dredging works, the dredging efficiency is enhanced, the device is convenient for cleaning impurities out of the pipeline in a flowing manner, andthe dredging effect of the internal wall of the pipeline is further improved.

Owner:山东水利职业学院

Silt remover with three cutter heads

The invention relates to a silt remover with three cutter heads. The silt remover comprises a floating body, a silt removing device and a mud discharging device. The floating body comprises a plurality of floating body units and connecting plates; the silt removing device comprises a truss and a power device, a reamer rest which is perpendicular to the truss is arranged at the head of the truss, and bucket-wheel type reamers are respectively mounted at two ends of the reamer rest; the mud discharging device comprises two mud sucking openings, a reversing chamber and mud discharging pipes. The silt remover has the advantages that mud can be discharged by double pipelines, two mud sucking pipes are respectively arranged in bucket wheels of the double bucket-wheel type reamers, extend into the reamers and can suck mud which is just generated, the left reamer can remove silt when the truss of the silt remover removes the silt leftwards, the mud can be sucked by the left mud sucking opening, a right inlet is closed by a partition plate in the reversing chamber at the moment, the right mud sucking opening is closed, accordingly, influence of water suction actions of the right mud sucking opening on the efficiency of a mud pump and decrease of the content of the mud in mud water pumped by the mud pump can be effectively prevented, the silt removing efficiency can be improved, and the silt concentration can be increased.

Owner:卜建余

River and lake contaminated bottom sediment ecological desilting ship

PendingCN110439054AExpand the effective rangeProtection reachedMechanical machines/dredgersVegetationEngineering

The invention relates to the technical field of river and lake desilting, in particular to a river and lake contaminated bottom sediment ecological desilting ship comprising a ship body, conveying pipes, conical hoppers, suction pumps, rotation drive devices, connection devices and [-shaped rotation frames. Rectangular frames are fixed to the two sides of the ship body. A slide table is arranged on each rectangular frame in a sliding manner. A winch is fixed to each slide table. A vegetation protection device is hoisted on each winch through a steel wire rope. A mechanical arm is fixed to eachvegetation protection device. The upper ends of the conveying pipes are fixedly connected with the slide tables. The lower ends of the conveying pipes are fixedly connected with the movable ends of the mechanical arms. The drive ends of the rotation drive devices are fixedly connected with the connection devices. A clamping jaw used for grabbing or releasing the corresponding [-shaped rotation frame is installed on each connection device. Winding columns which extend downwards and are used for winding plant are arranged at the two ends of each [-shaped rotation frame. The ship body rotates todrive the [-shaped rotation frames to rotate, and therefore the strip-shaped plant can be curled, the coverage area of plant bodies can be minimized, and the aim of protecting the plant is achieved.Meanwhile, precise positioning can be achieved during desilting, and the river and lake contaminated bottom sediment ecological desilting ship can avoid river bottom vegetation.

Owner:HUBEI PROVINCIAL WATER RESOURCES & HYDROPOWER PLANNING SURVEY & DESIGN INST

Blockage preventing device for shotcrete pumping pipe

ActiveCN105605366AGuaranteed normal transmissionMeet spray mixing requirementsPipe elementsShotcretePolybutylene

The invention discloses a blockage preventing device for a shotcrete pumping pipe. The blockage preventing device comprises an inner pipe, an outer pipe and self-oscillating rings, wherein the outer pipe is formed by connecting at least two unit pipes by connecting components, and a splicing length is free and flexible; one self-oscillating ring is arranged inside each unit pipe, so that the dominant function of oscillating blockage prevention is realized; the self-oscillating rings are arranged on the outer wall of the inner pipe in a sleeving way and the number of the self-oscillating rings is at least two, so that the oscillating efficiency is guaranteed; a pipe body of the outer pipe is made of polyurethane rubber (PUR), so that various outside contact conditions and oscillating reduction requirements are met; the inner pipe and the connecting components are made of polybutylene (PB), so that concrete is efficiently conveyed; by using all the functions of three parts, the concrete is efficiently conveyed, the problem of pipe blockage in the shooting process is better solved, and the working efficiency of the shotcreting is improved; meanwhile, the occurrence of pipe explosion accidents is avoided, and the safety of working is guaranteed.

Owner:XIAN UNIV OF SCI & TECH

Intelligent stirring-smashing-type sewer dredging device

InactiveCN108193766AGreat suctionDesilting is widely applicableSewer systemsEngineeringHigh pressure water

The invention relates to an intelligent stirring-smashing-type sewer dredging device and belongs to the technical field of engineering machinery. According to the device, a combination dredging methodof high-pressure water jet, drill bits and monitoring is adopted, firstly, a drill bit device is used for stirring and smashing a blocking part of a sewer, a high-pressure water jet device is used for flushing the stirred and smashed blocking part and the pipe wall, and then a suction method is used for sucking loose debris; meanwhile, a camera shooting device and a detection illuminating lamp are arranged on a vehicle body, a row of cutting blades are arranged at each edge of the vehicle body, the stirring-smashing drill bits are arranged on a vehicle head, if the large-sized debris such asplastic bags, straw and stone blocks exist, stirring-smashing and cutting are facilitated, and the debris is quickly conveyed upwards by using the suction device and a conveying belt; a large quantityof human resources, physical resources and financial resources are saved, the device is widely suitable for sewer dredging, blocking unchoking and dredging of deep ditches and deep wells in small-sized and medium-sized cities, the cost is saved, the dredging efficiency is improved, and the device has wide application prospects.

Owner:唐林元

Wharf bottom desilting machine and method

ActiveCN107905281AImprove dredging efficiencyQuality improvementMechanical machines/dredgersWater pipeHigh pressure

The invention provides a wharf bottom desilting machine. The wharf bottom desilting machine comprises sliding grooves, a supporting table, a hydraulic air cylinder, a motor, a desilting component anda high-pressure water pump, wherein the sliding grooves are formed in the edge of the wharf ground; the lower surface of the supporting table is provided with sliding rails matched with the sliding grooves, the supporting table is provided with a connecting part which protrudes from the edge of the wharf ground, and a through hole used for allowing a telescopic rod to pass through is formed in theconnecting part; the output end of the hydraulic air cylinder is connected to the telescopic rod; the motor is arranged at the tail end of the telescopic rod; the desilting component is connected tothe output end of the motor, and comprises a rod part and at least two stirring fins arranged at the head end of the rod part; and the high-pressure water pump is arranged on the connecting part and connected to the desilting component through a water pipe. The wharf bottom desilting machine provided by the invention has the advantage of being high in desilting efficiency. The invention further provides a desilting method of the wharf bottom desilting machine, a full-mechanical mode is adopted, only assistance and observation functions are achieved by labor, the desilting efficiency is high, potential safety hazards are low, and the quality is high.

Owner:CHINA HARBOUR ENGINEERING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com