Riverway chain bucket type dredging ship and dredging construction method thereof

A technology for dredging boats and chain buckets, which is applied in water conservancy projects, cleaning of open water surfaces, earth movers/shovels, etc. It can solve the problems of low dredging efficiency, inability to clean, and inconvenient movement, etc., to improve dredging Efficiency, improve work efficiency, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

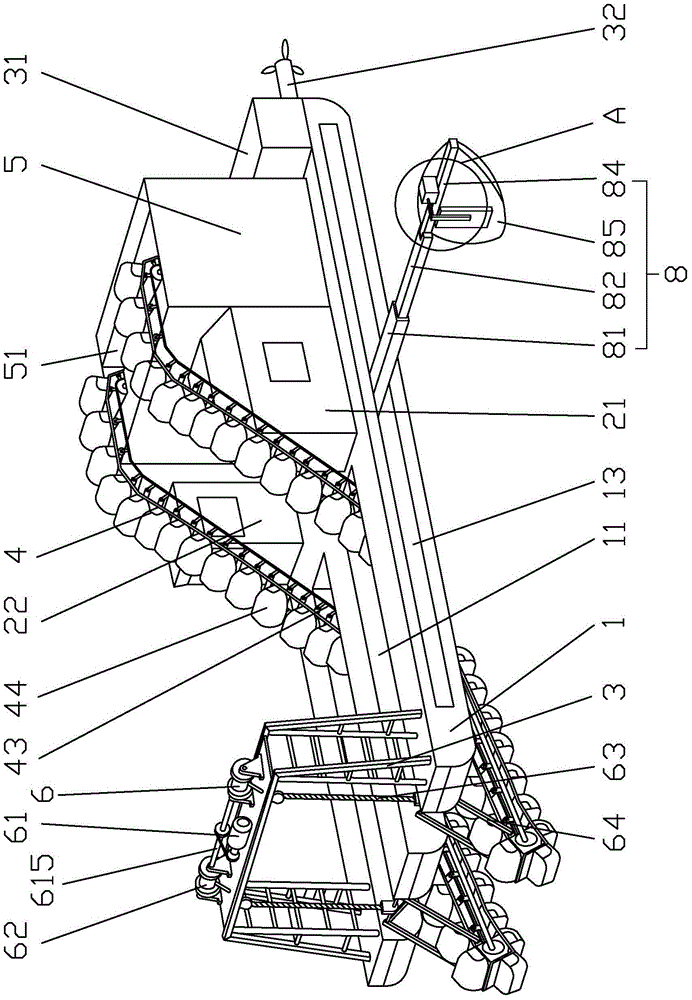

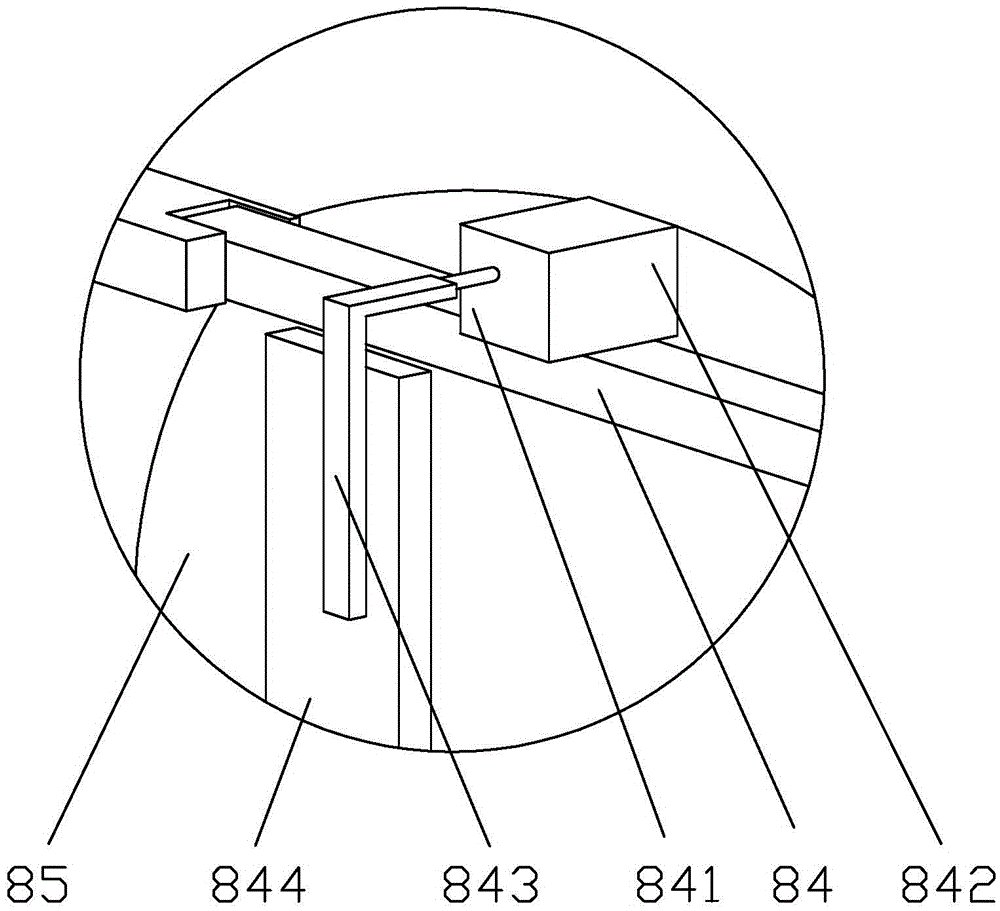

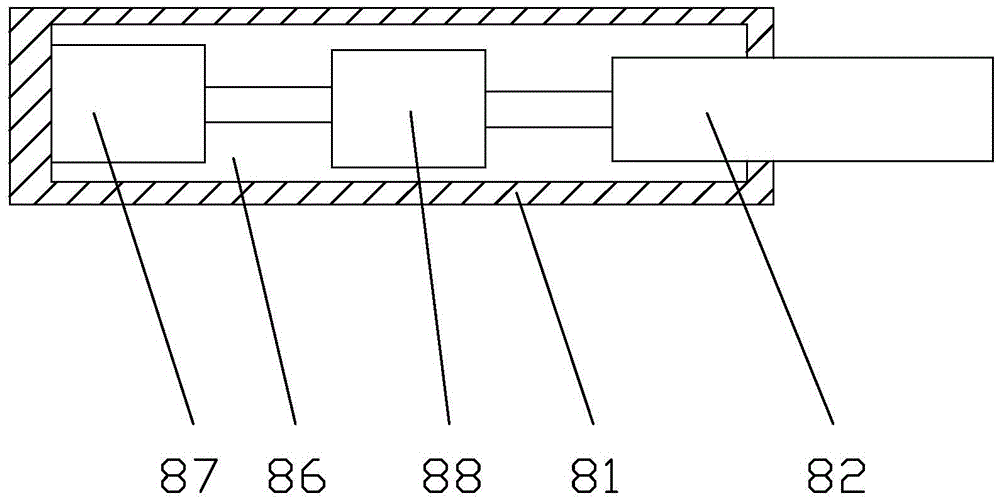

[0045] Such as Figure 1-8 As shown, it is a river chain bucket type dredging ship of the present invention, including a hull 1, a control room 21, a rest room 22 and a support 3, and also includes at least two chain bucket transmission mechanisms 4 and a silt collection bin 5, and the support 3 Located at the front end of the hull 1, the silt collection bin 5 is located at the rear end of the hull 1, the hull 1 is provided with at least two grooves 11, one end of the chain bucket transmission mechanism 4 is located in the sludge collection bin 5, and the other end of the chain bucket transmission mechanism 4 One end is connected to the bracket 3 through the corresponding groove 11 . By adopting at least two chain bucket conveying mechanisms 4, the scope of dredging can be increased in one dredging construction process, the dredging efficiency can be greatly improved, dredging time can be saved, and costs can be reduced. Chain bucket transmission mechanism 4 comprises drive m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com