Patents

Literature

32950results about How to "Reduce resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

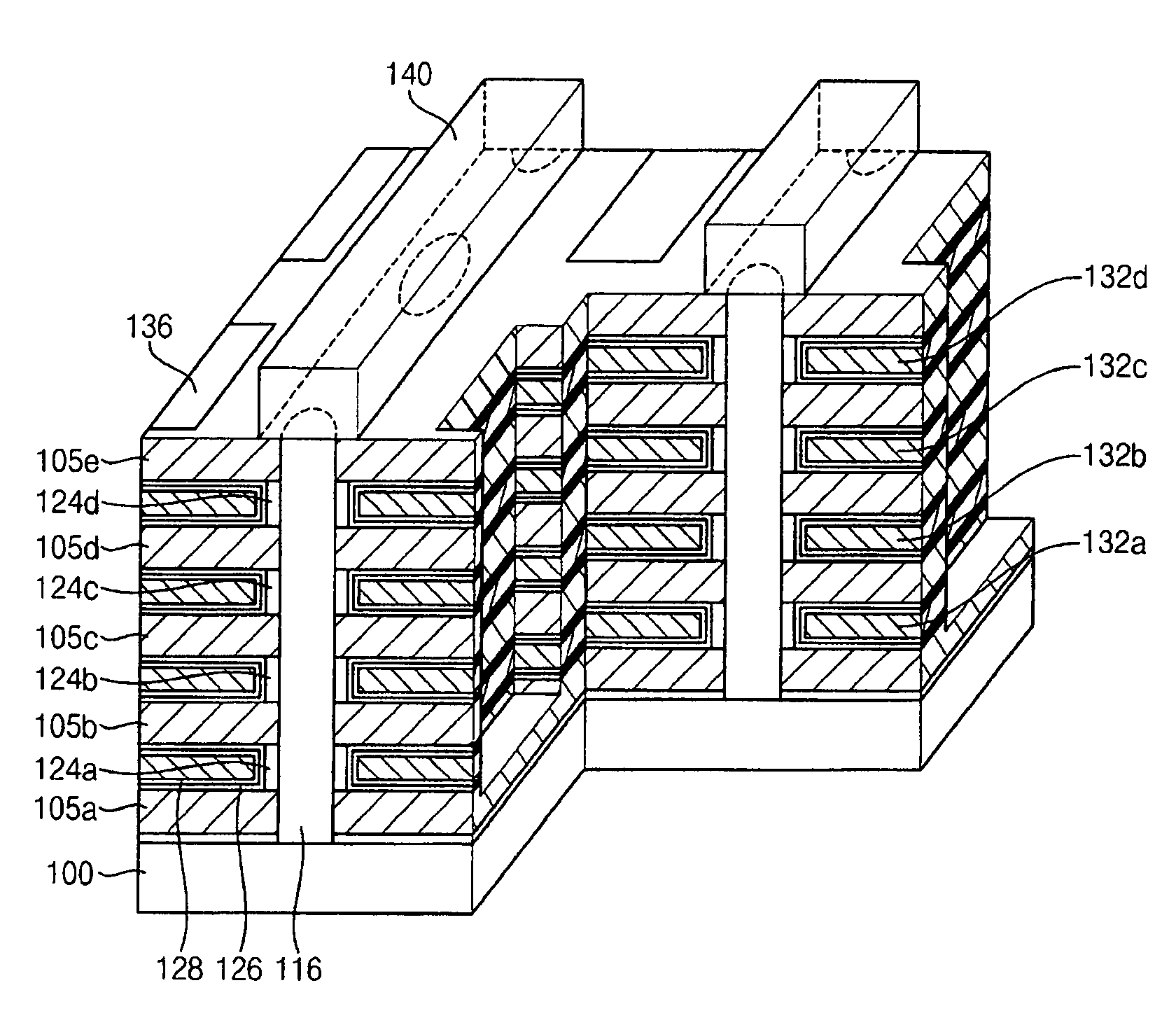

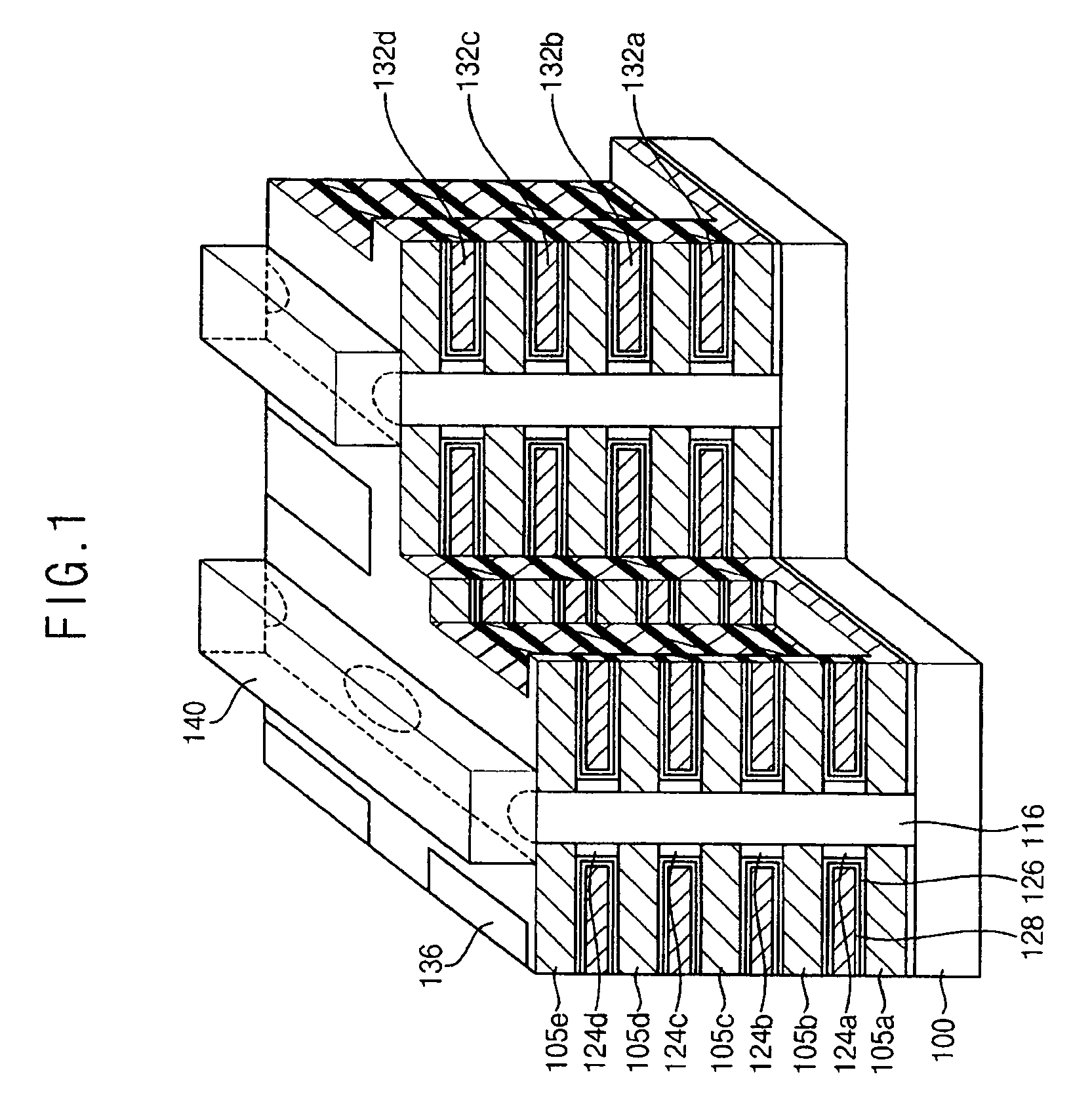

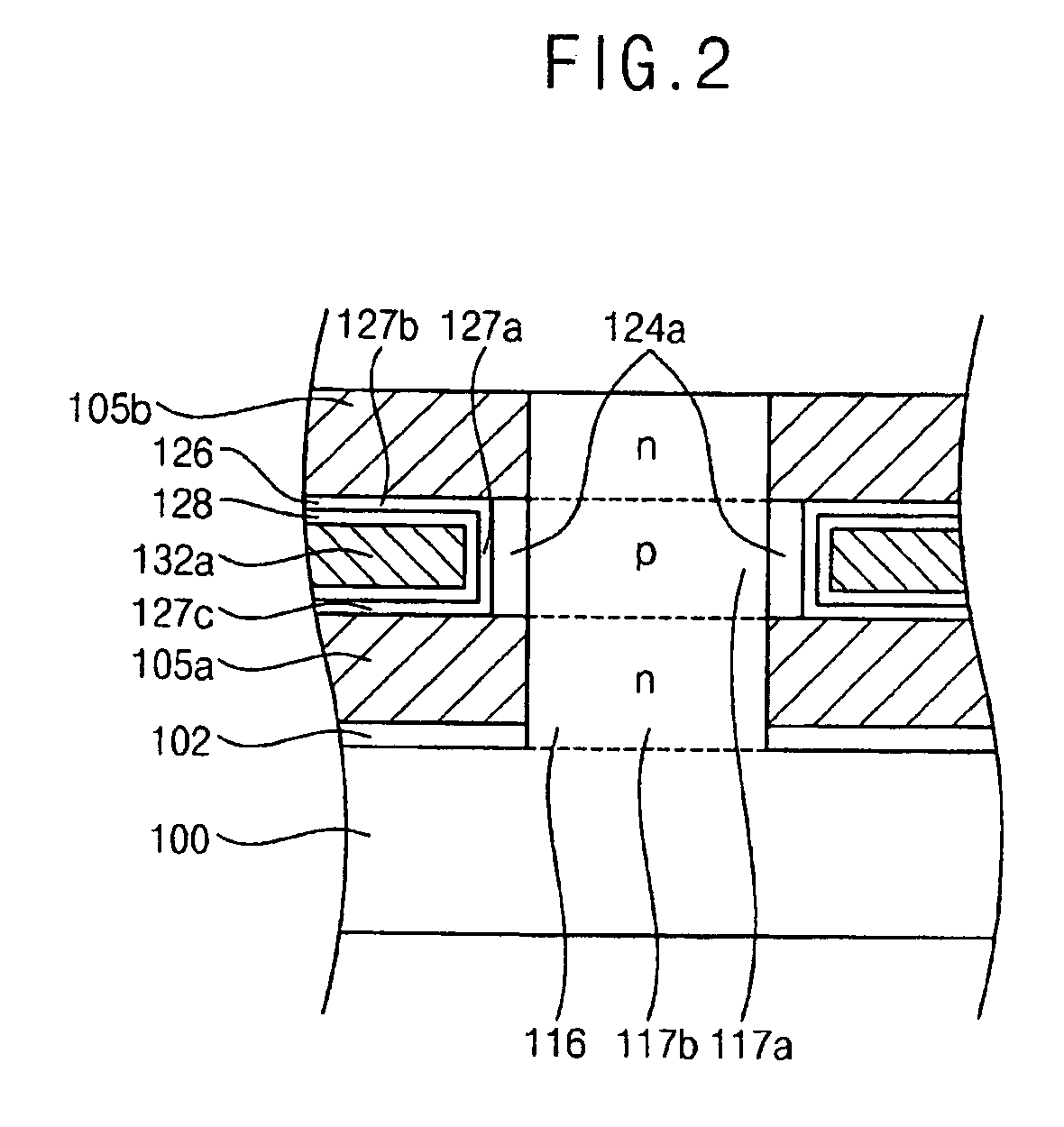

Three-Dimensional Semiconductor Memory Devices And Methods Of Fabricating The Same

ActiveUS20110233648A1Increasing the thicknessReduce resistanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

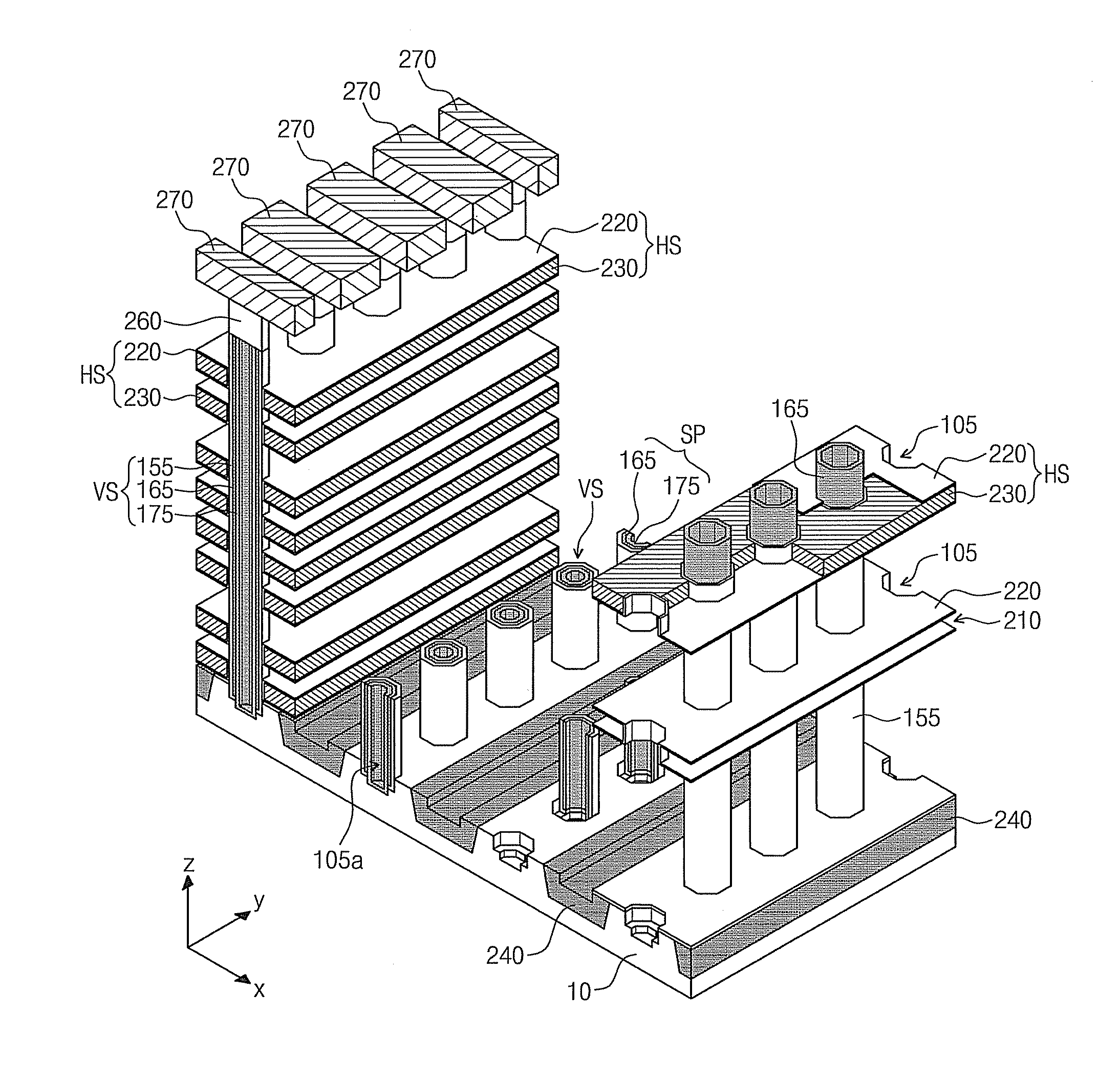

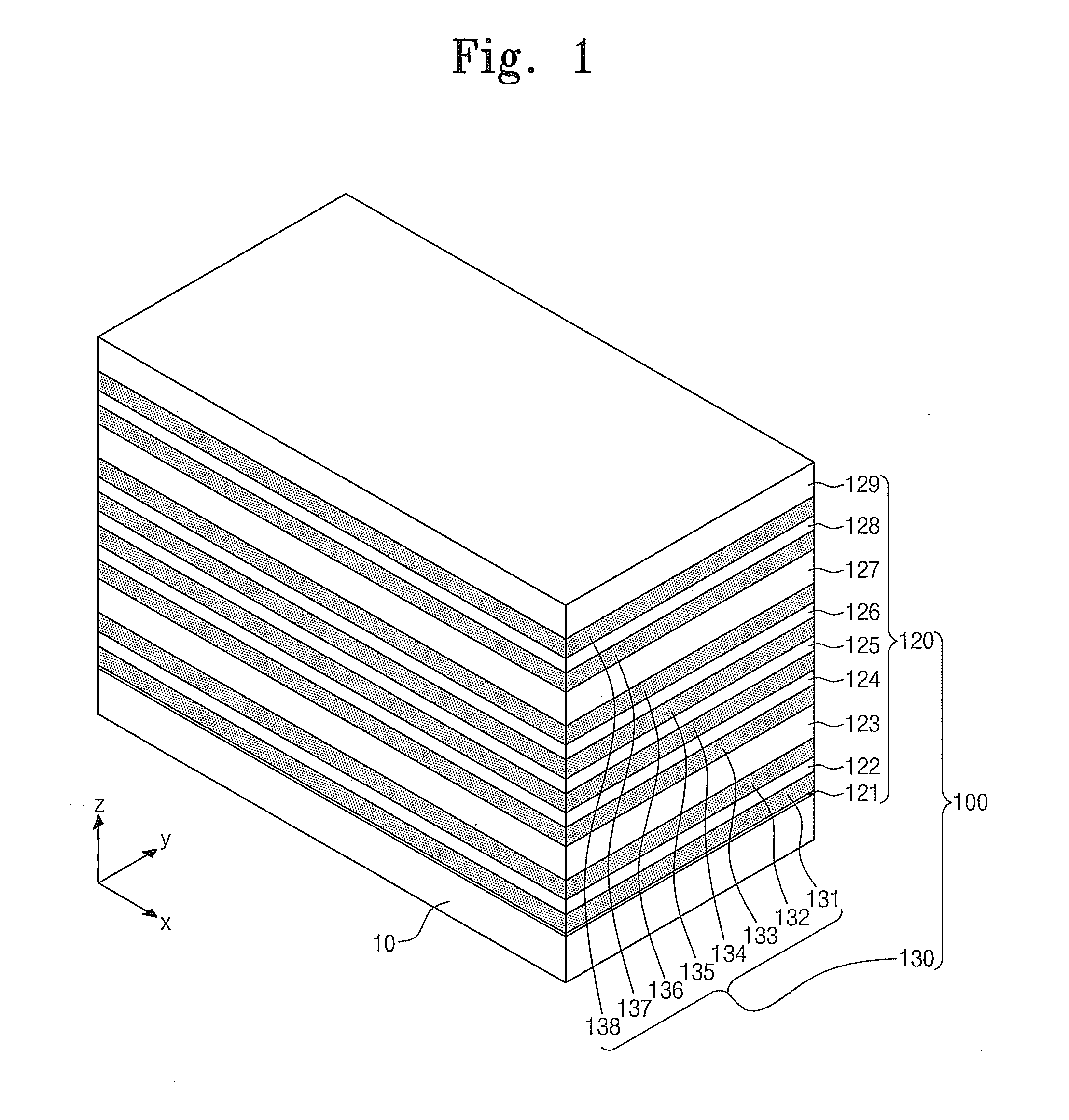

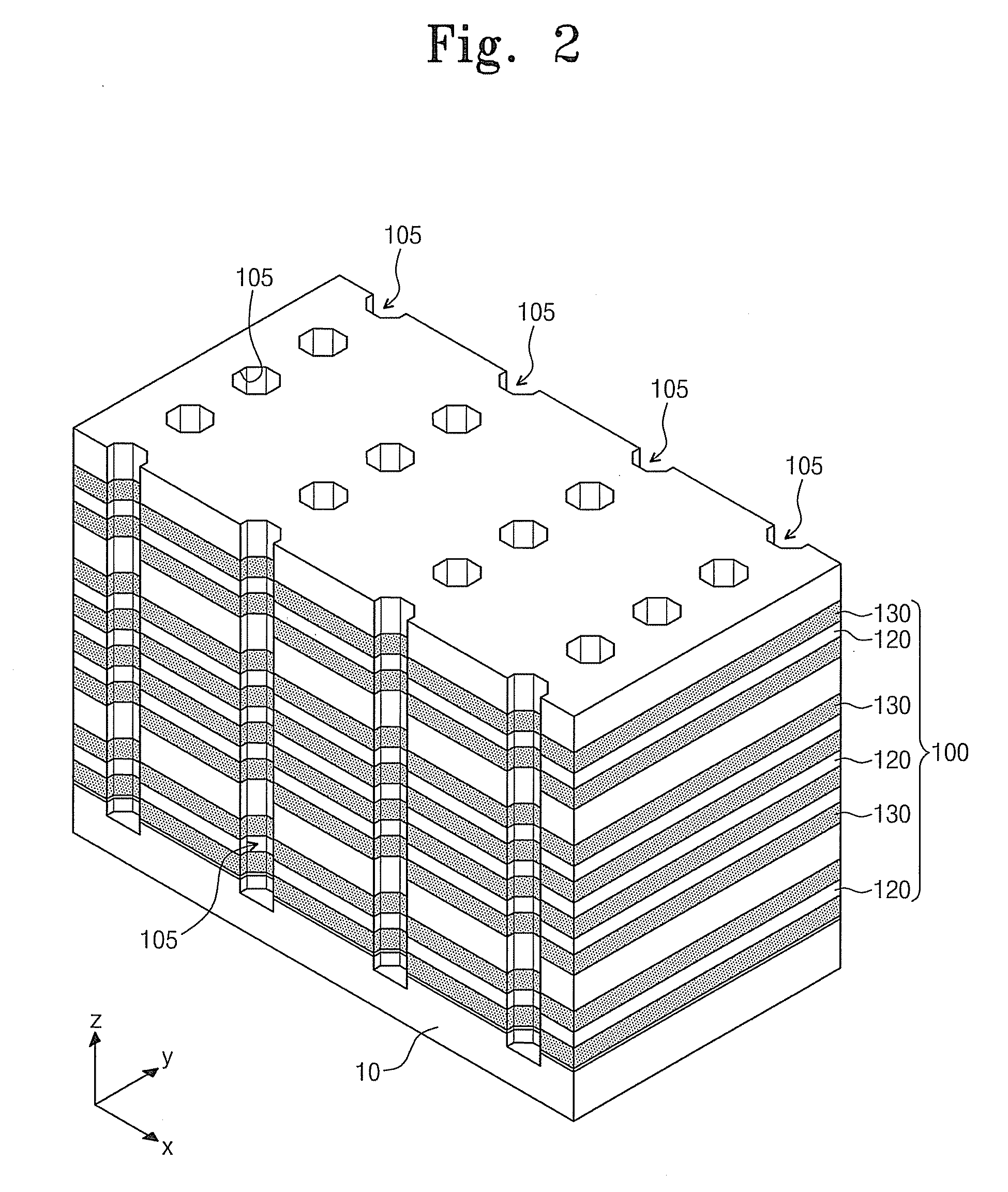

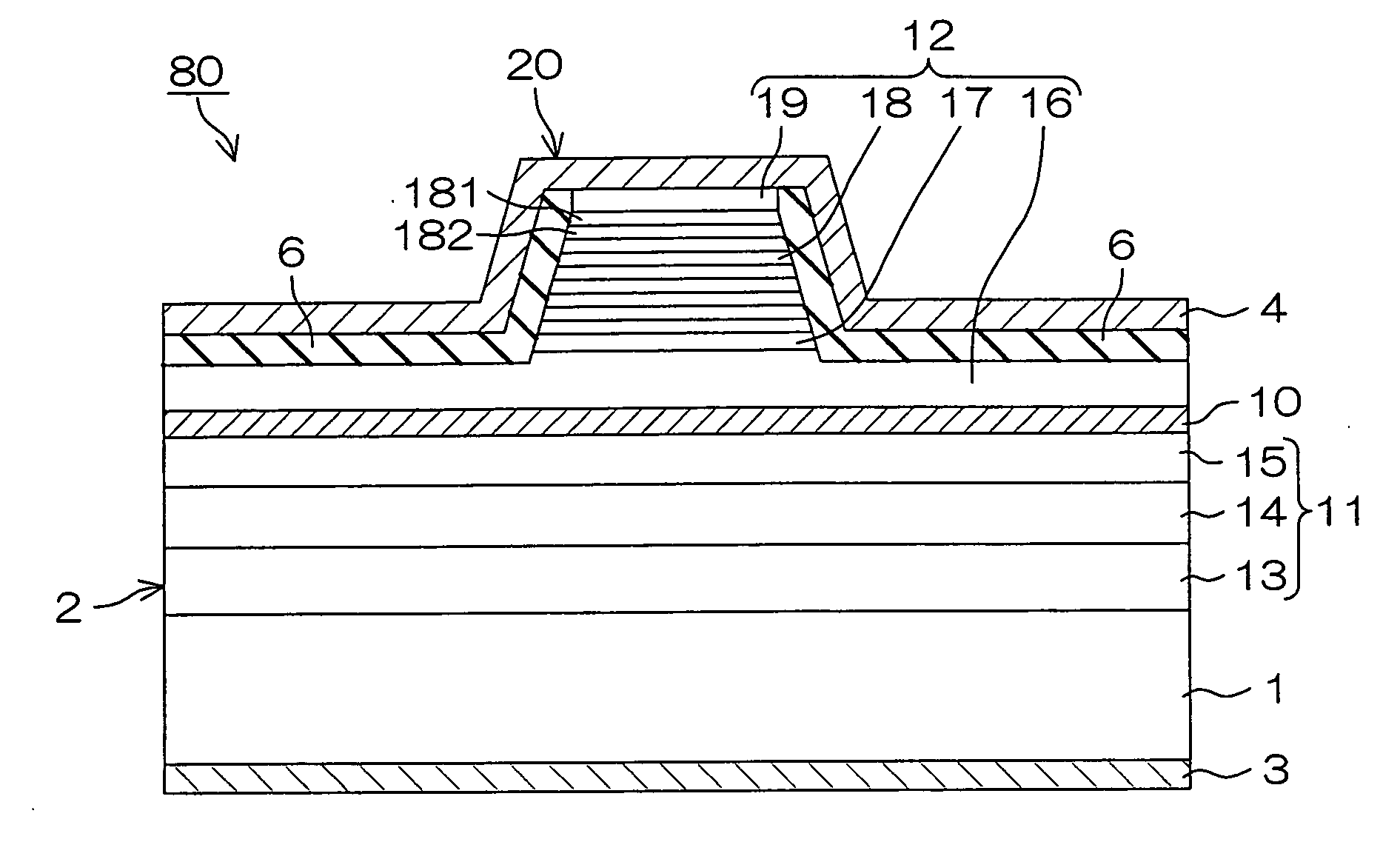

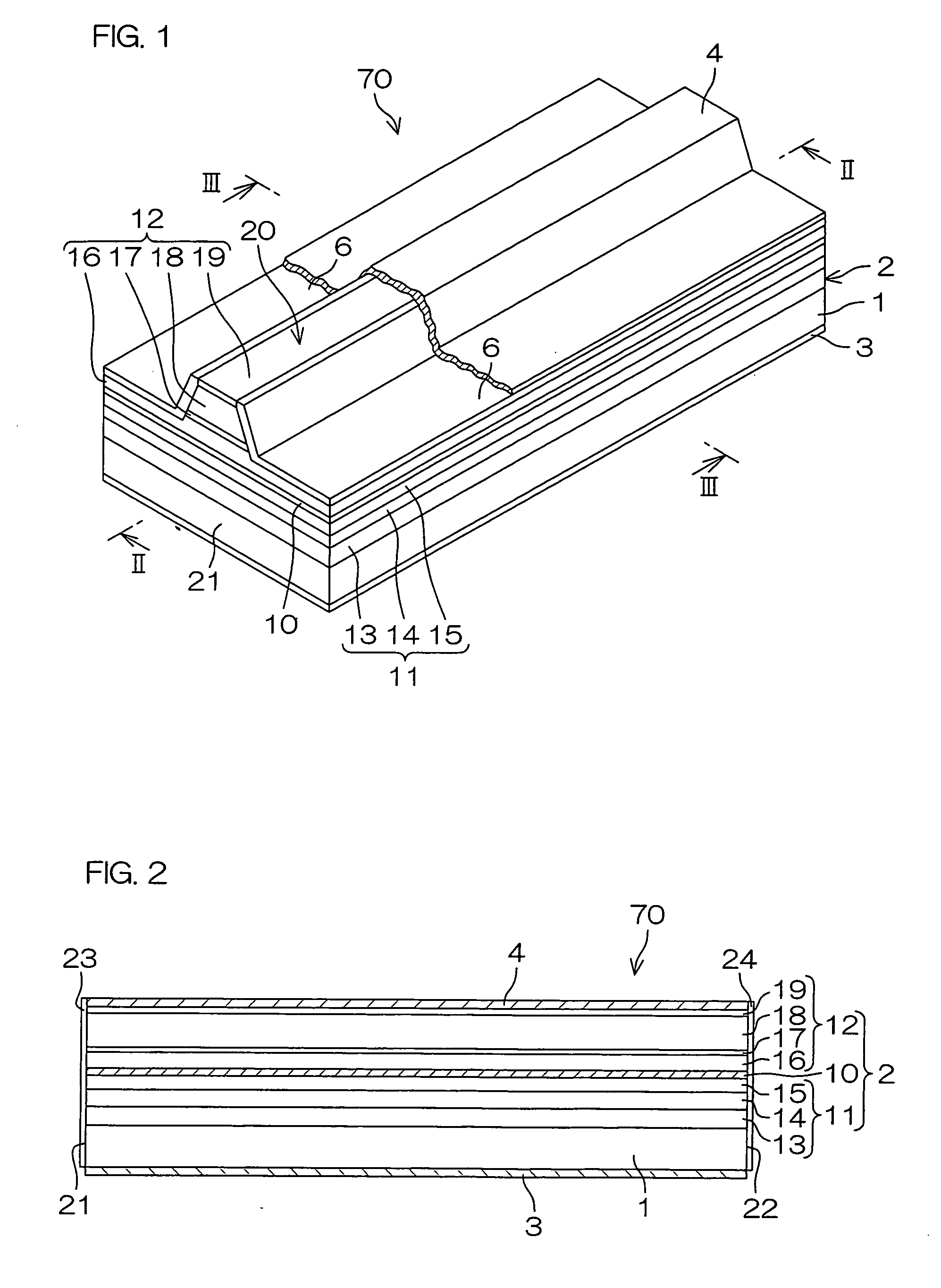

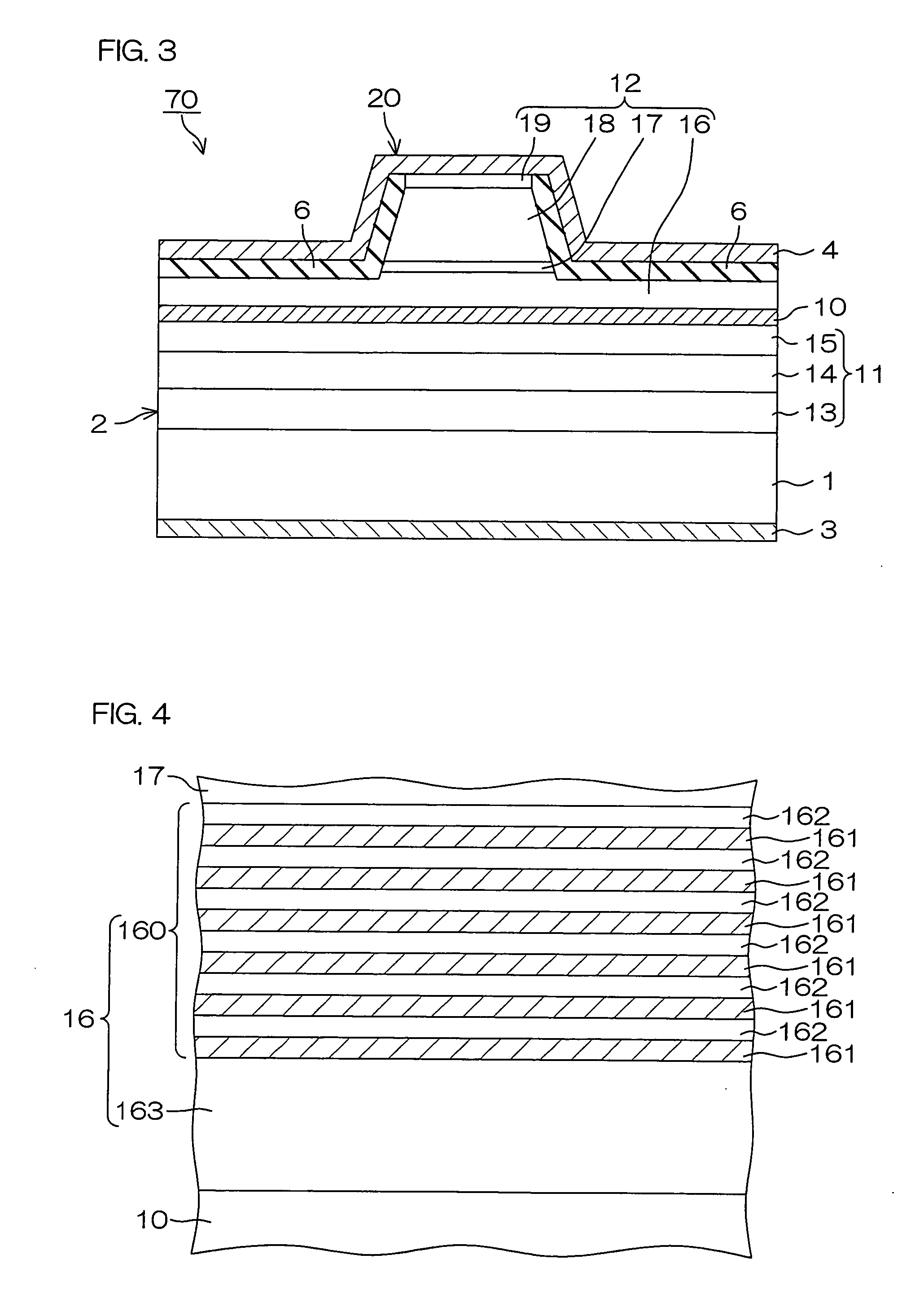

Three-dimensional semiconductor memory devices and methods of fabricating the same. The three-dimensional semiconductor devices include an electrode structure with sequentially-stacked electrodes disposed on a substrate, semiconductor patterns penetrating the electrode structure, and memory elements including a first pattern and a second pattern interposed between the semiconductor patterns and the electrode structure, the first pattern vertically extending to cross the electrodes and the second pattern horizontally extending to cross the semiconductor patterns.

Owner:SAMSUNG ELECTRONICS CO LTD

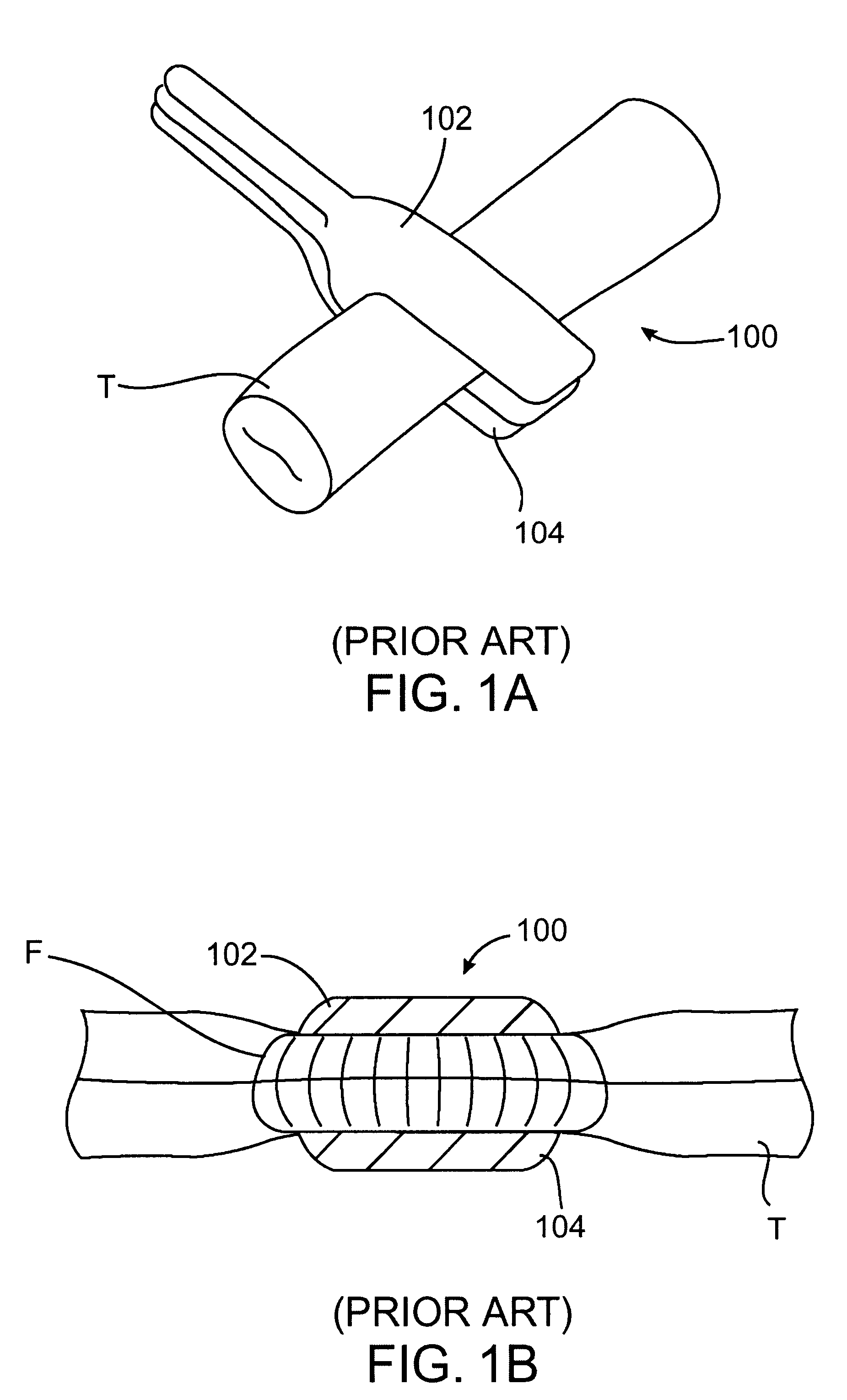

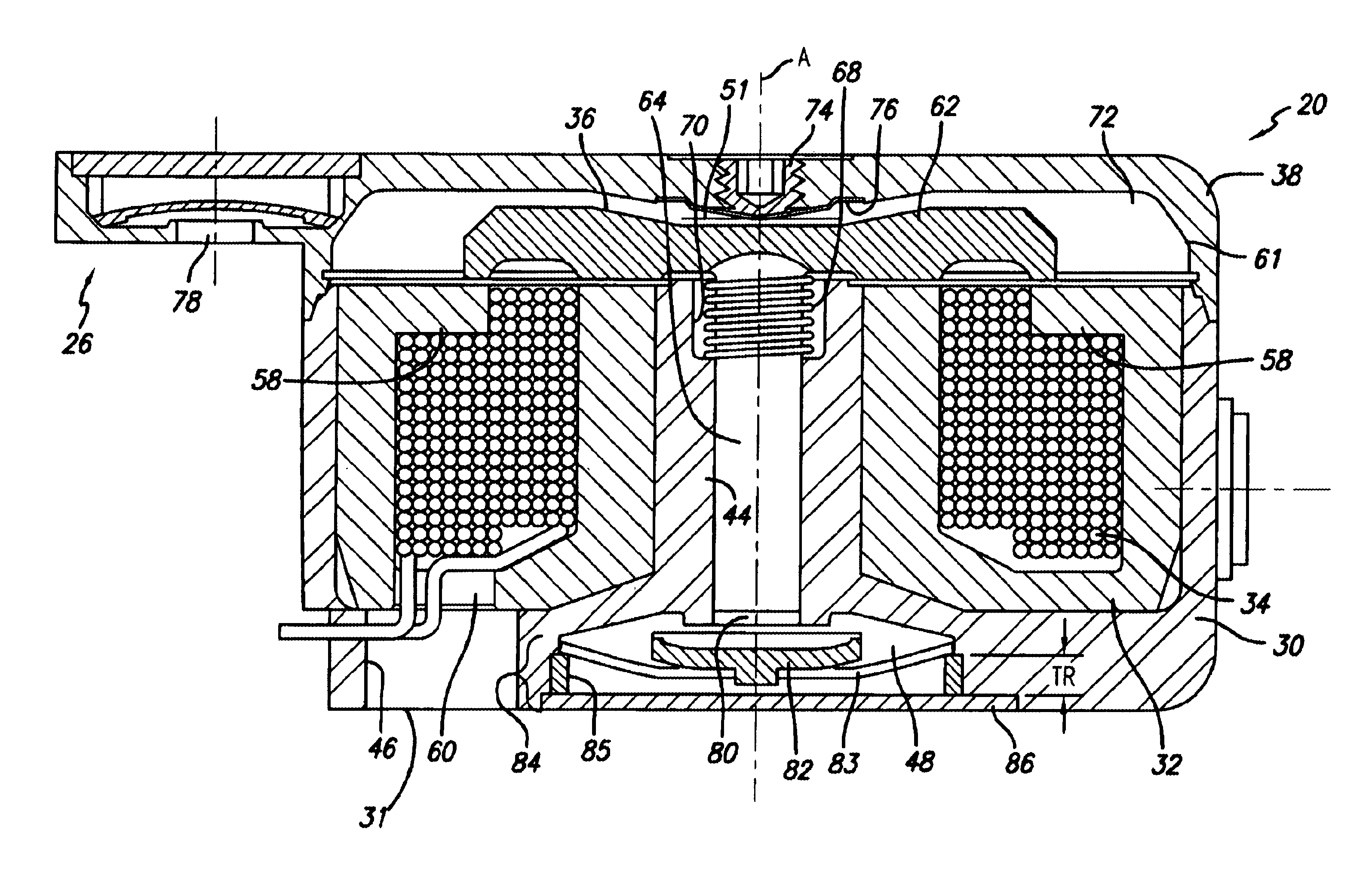

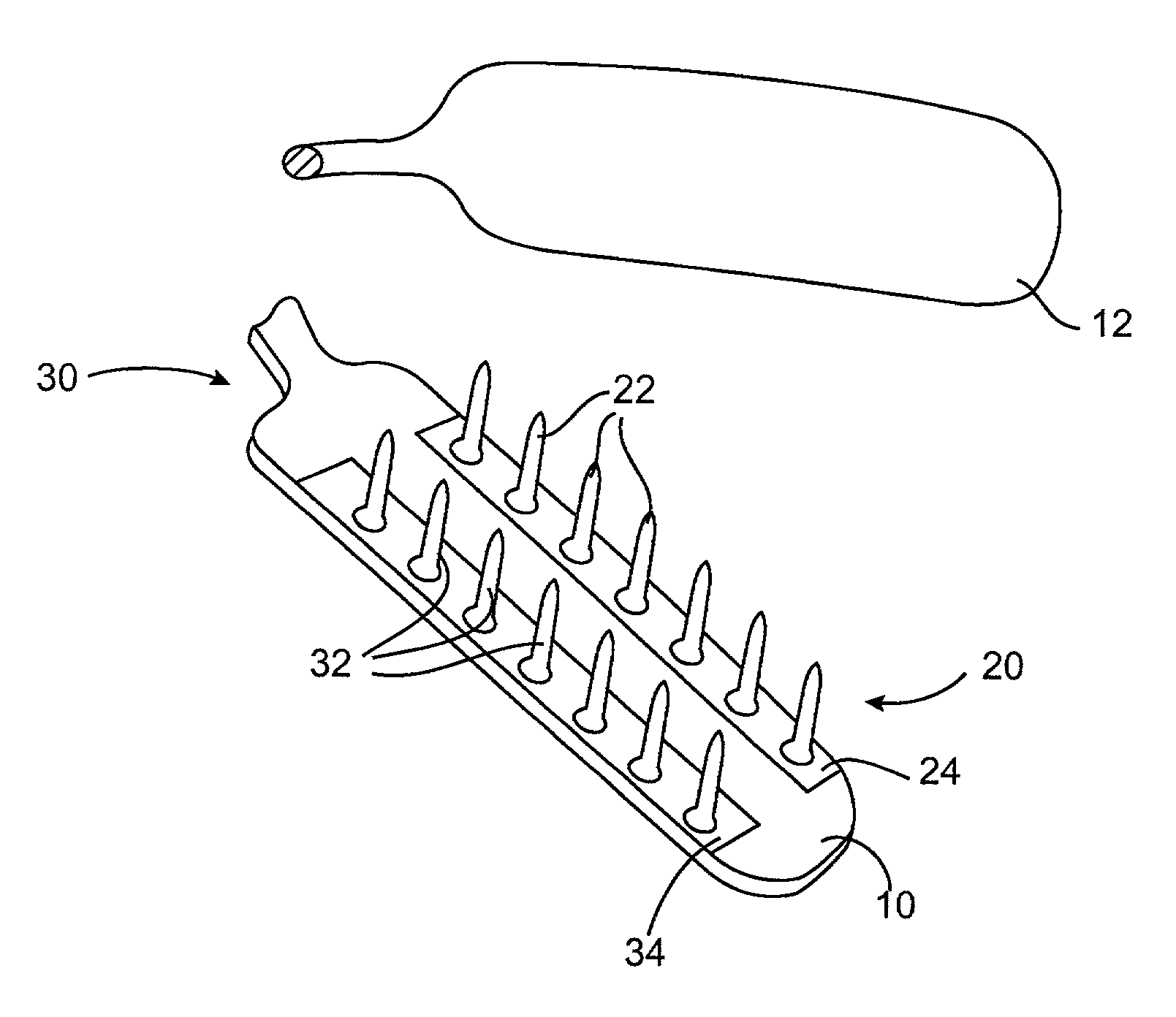

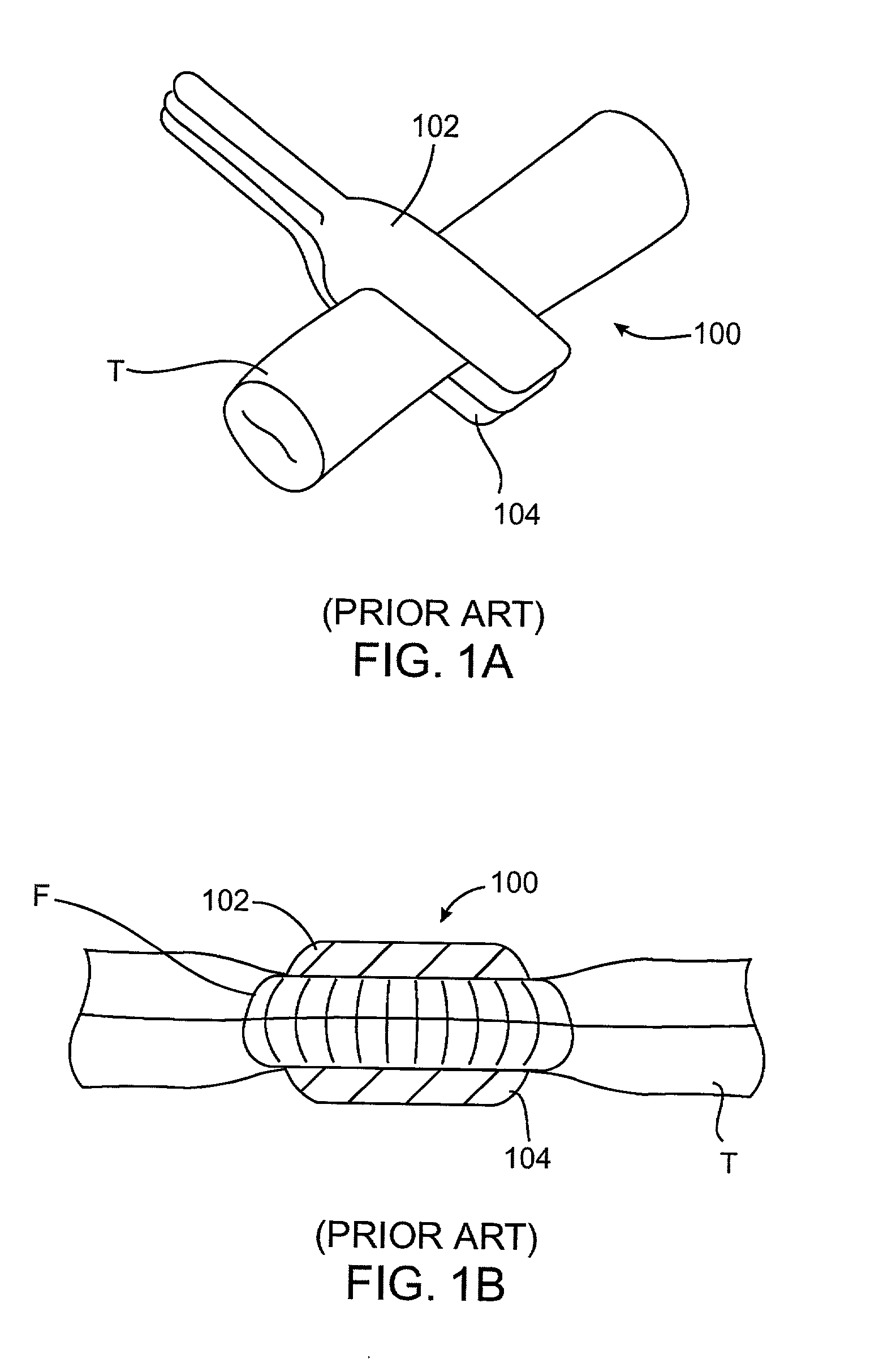

Bipolar surgical instruments having focused electrical fields

InactiveUS6514252B2Reduce capacityLower impedanceSurgical needlesSurgical instruments for heatingElectricitySurgical device

A bipolar surgical device comprises a pair of actuable jaws. A first electrode member which optionally includes a line of electrically coupled tissue-penetrating elements is formed on one of the jaws, and a second electrode member which optionally includes a line of electrically coupled tissue-penetrating elements is formed on the same or the other jaw. The electrode members are laterally spaced-apart and arranged in a parallel, usually linear manner so that the lateral distance therebetween remains generally constant. In operation, tissue may be grasped between the jaws so that the electrode members contact and / or the tissue-penetrating elements enter into the tissue. By energizing the electrode members at opposite polarities using a high frequency energy source, tissue between the jaws will be heated, coagulated, and / or necrosed, while heating of tissue outside of the lines will be minimized.

Owner:PERFECT SURGICAL TECHN

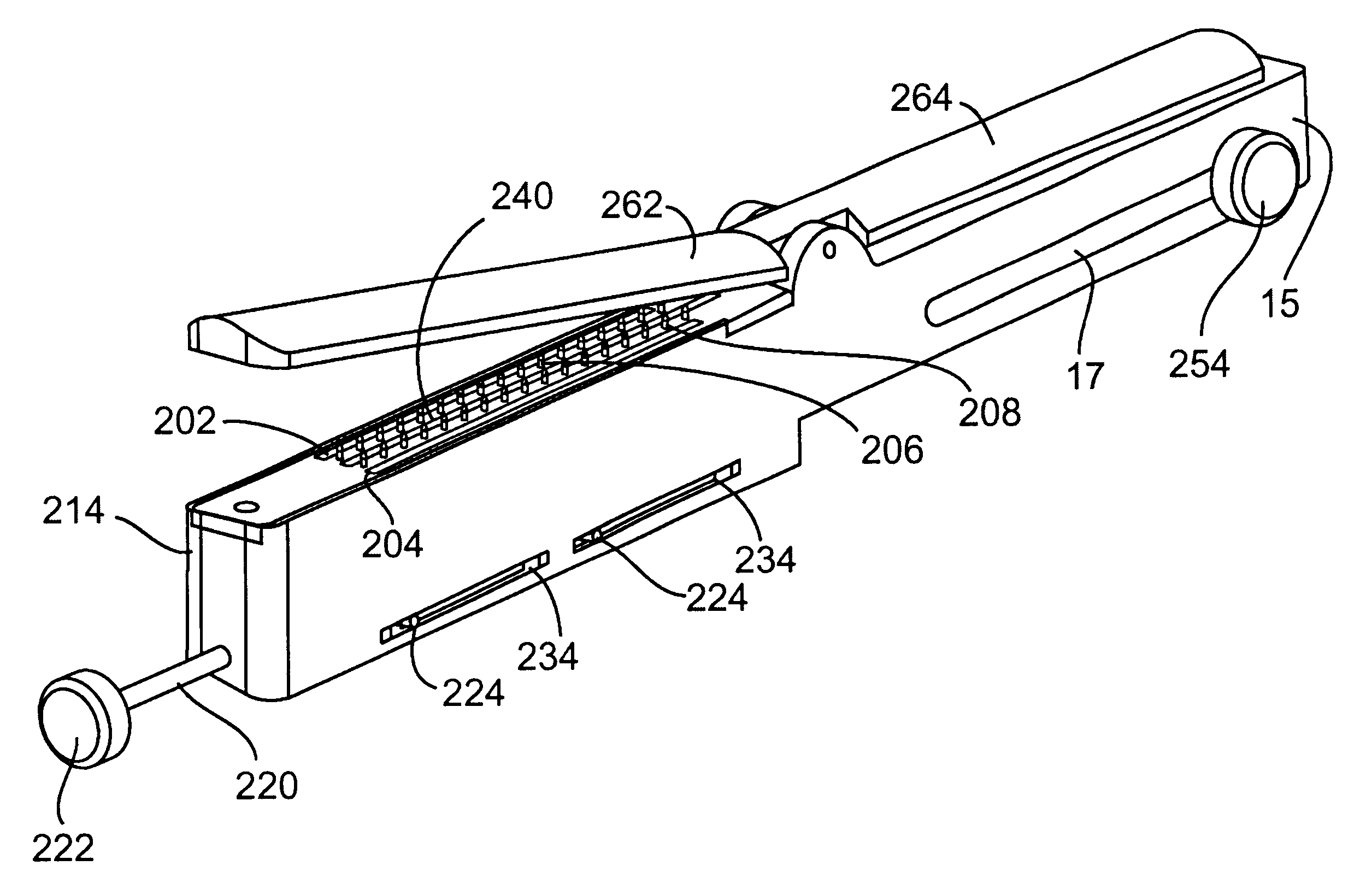

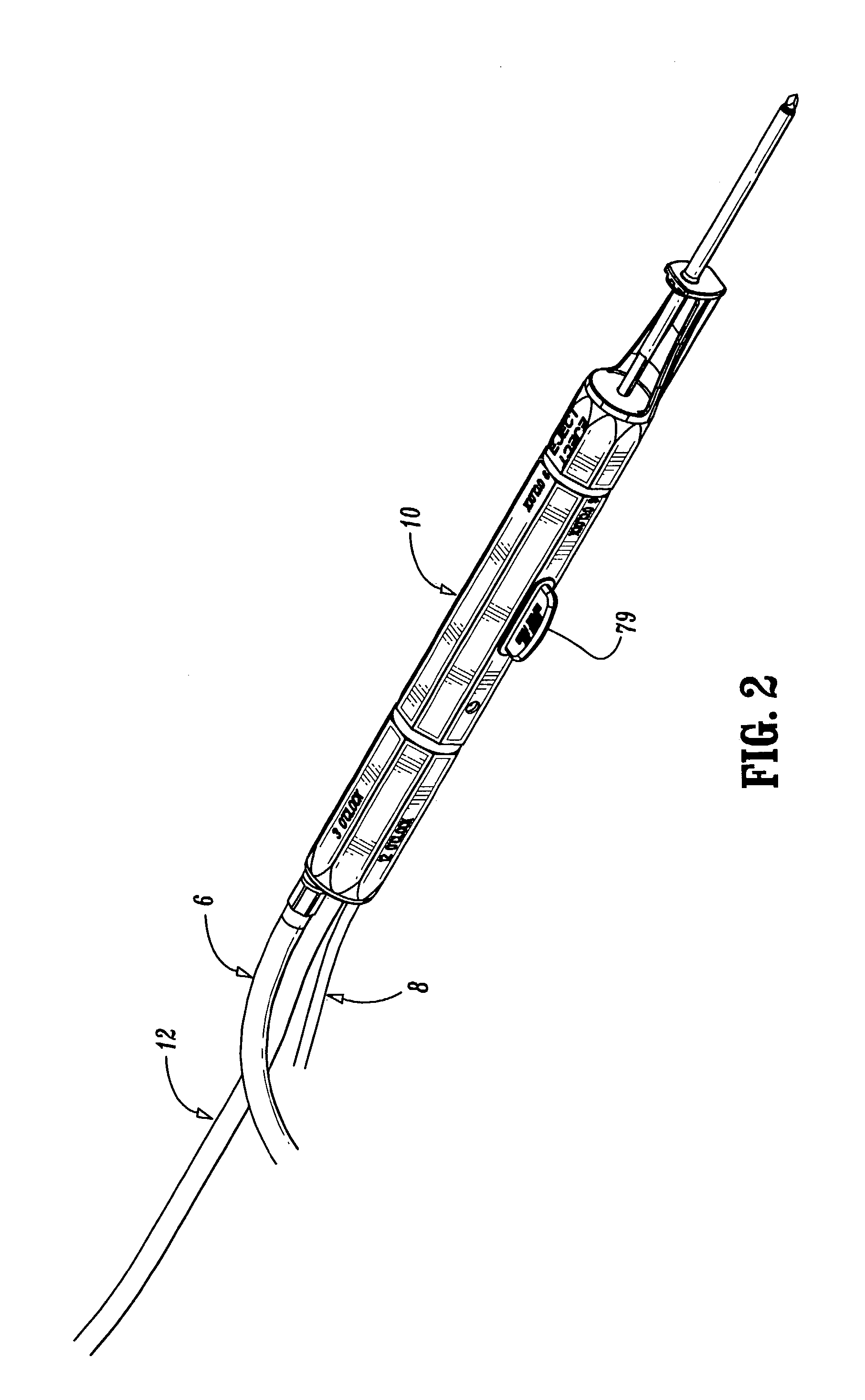

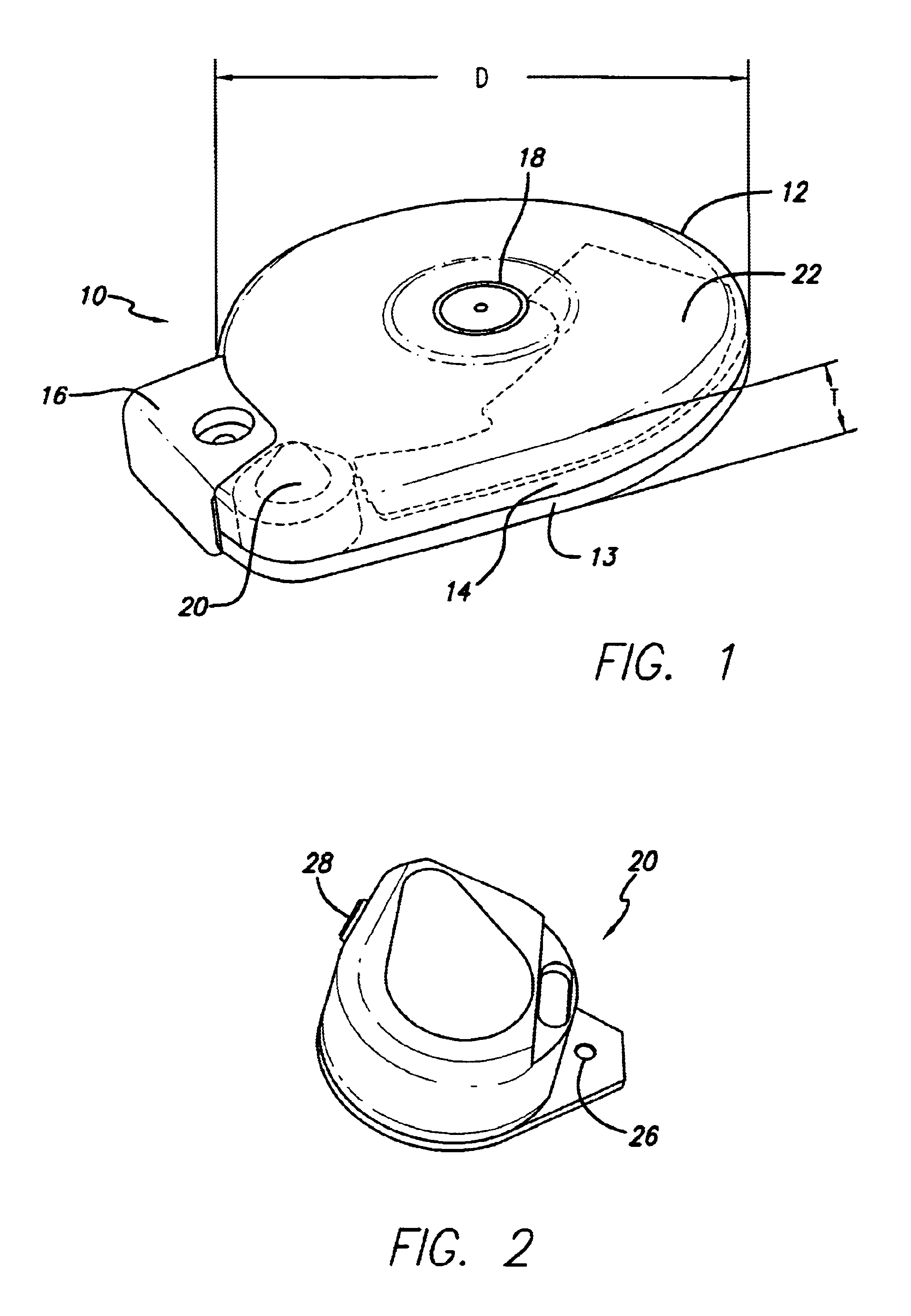

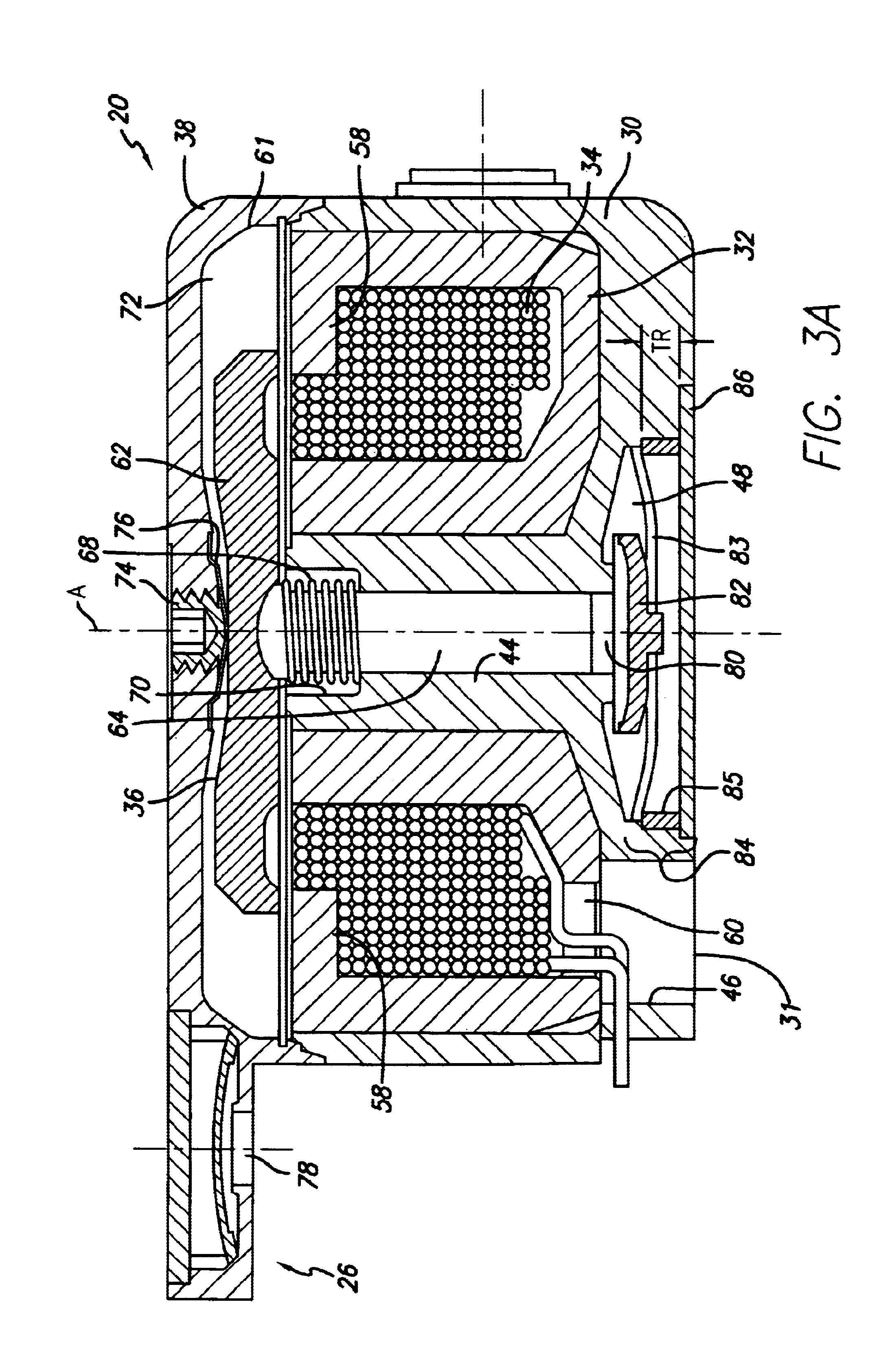

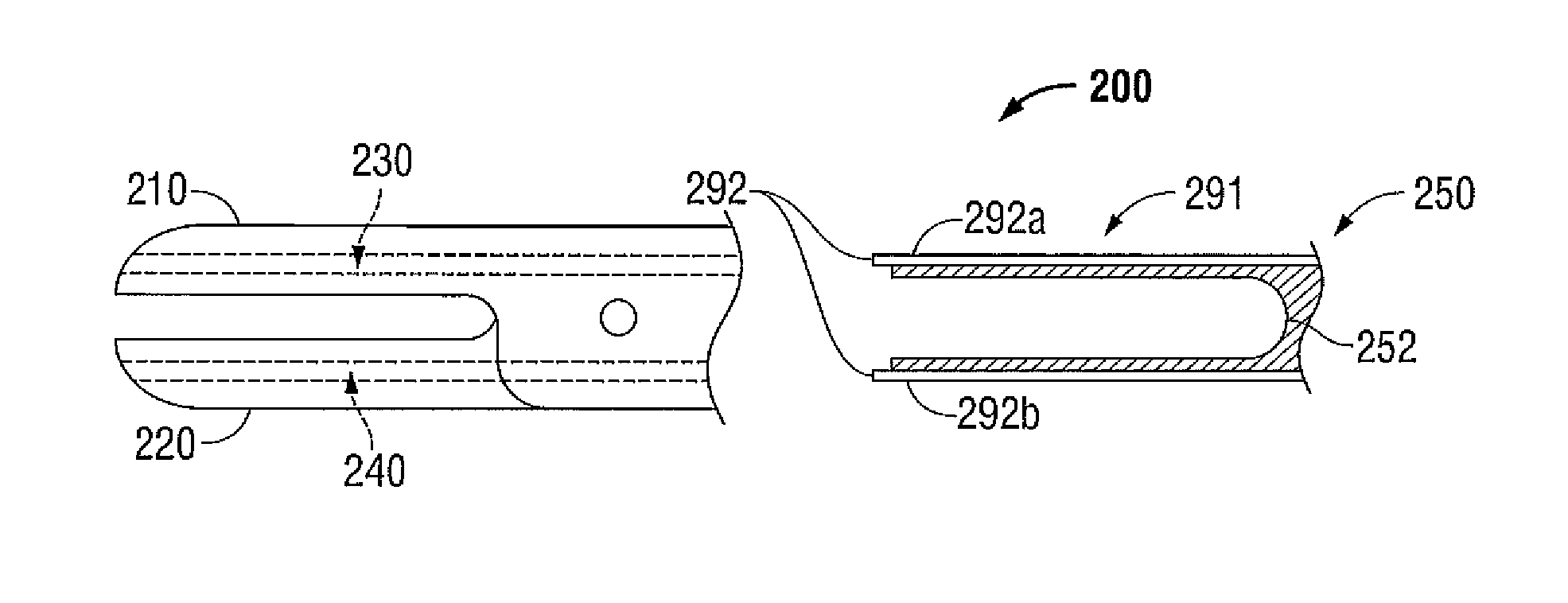

Biopsy system having a single use loading unit operable with a trocar driver, a knife driver and firing module

InactiveUS7189207B2Reduce resistanceIncrease speedSurgical needlesVaccination/ovulation diagnosticsTissue sampleEngineering

A biopsy system for retrieving biopsy tissue samples from different regions of the body is disclosed. The biopsy system includes a single use loading unit having a trocar assembly and a knife assembly. A trocar driver is operably connected to the trocar assembly and is actuable to move a trocar between retracted and advanced positions. The trocar driver is disengaged from the trocar assembly prior to firing the trocar into a target tissue mass to reduce drag on the trocar during firing. A knife driver is operably connected to the knife assembly such that when actuated, a knife is both rotatably and axially advanced about the trocar.

Owner:TYCO HEALTHCARE GRP LP

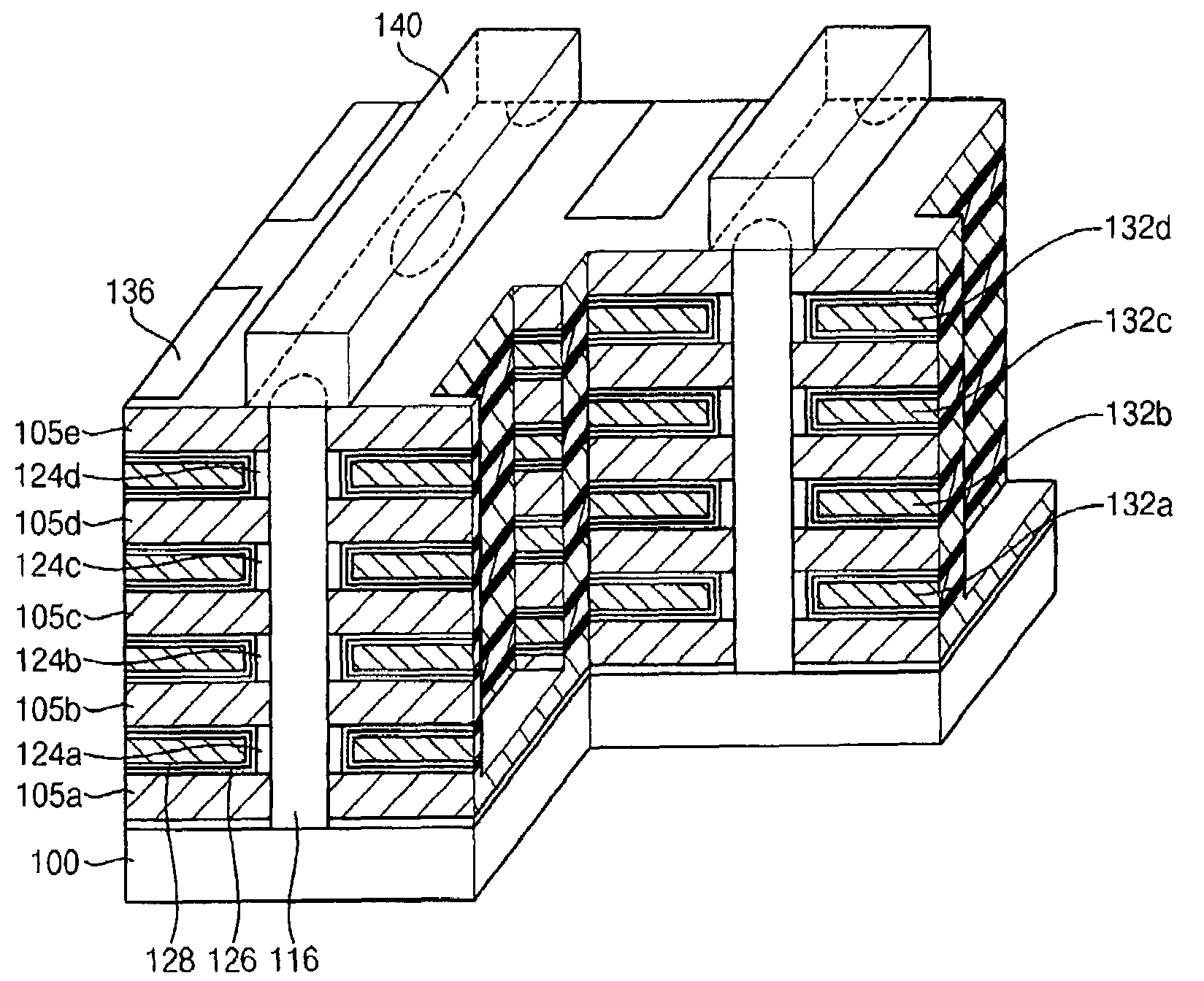

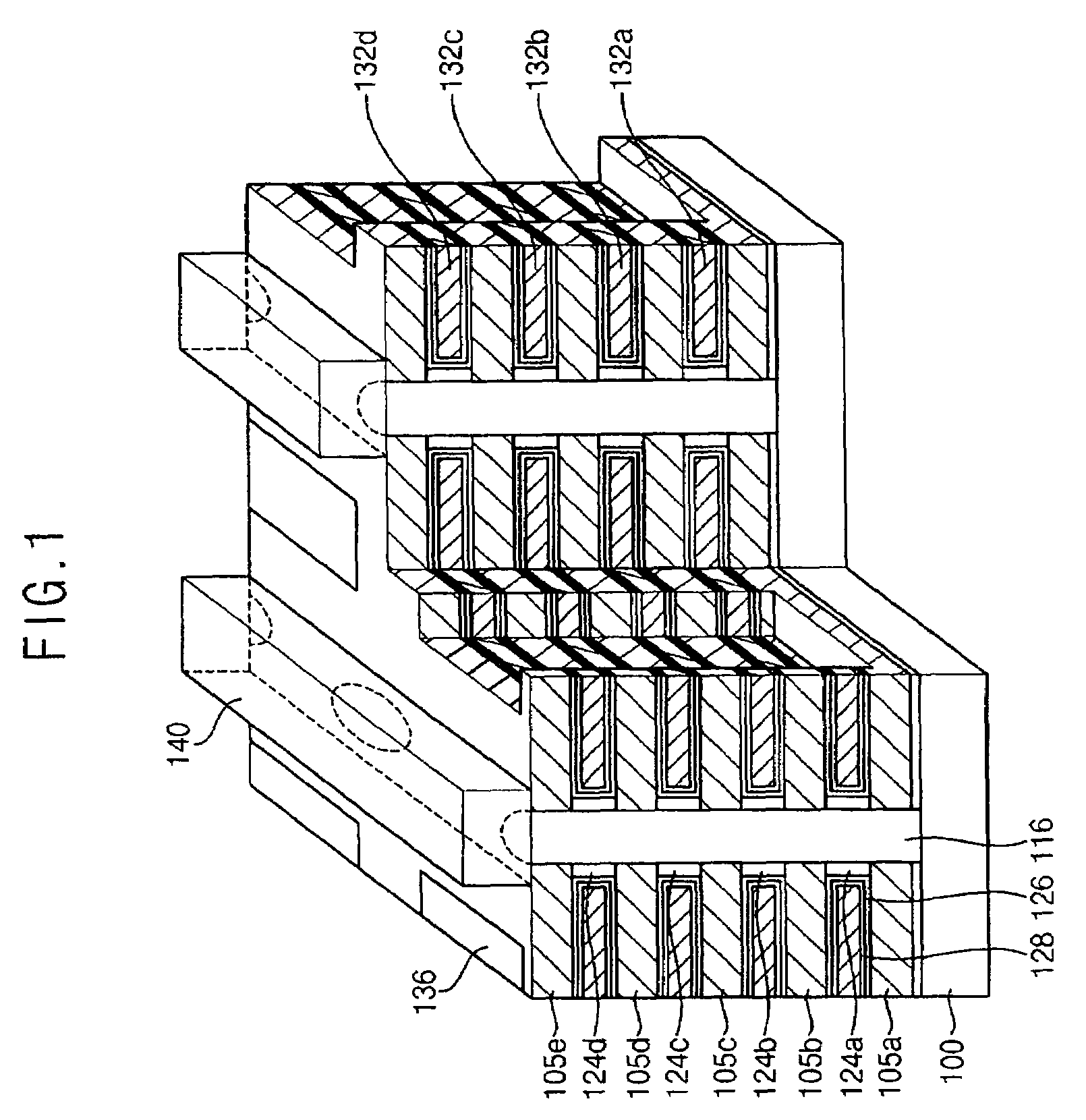

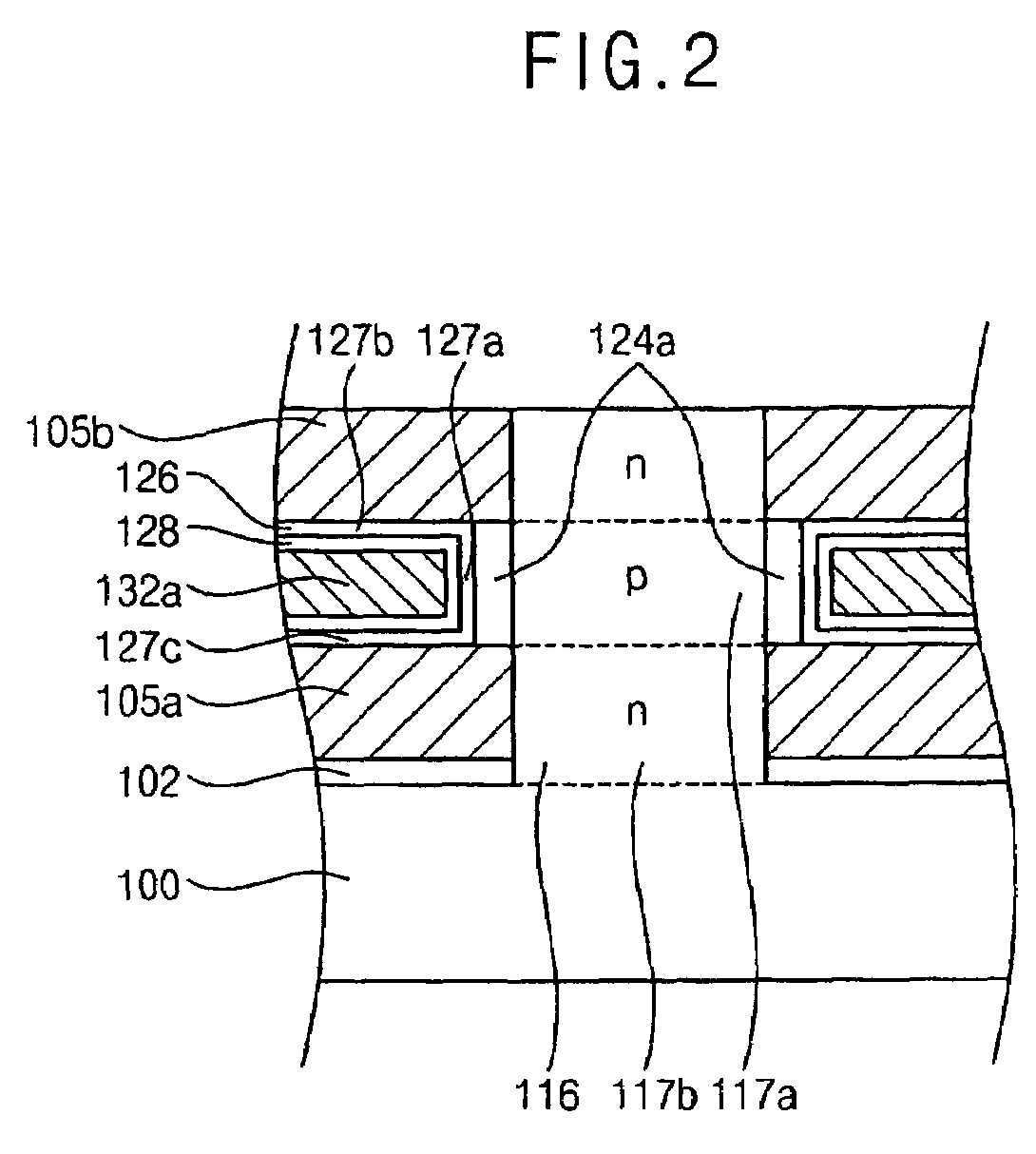

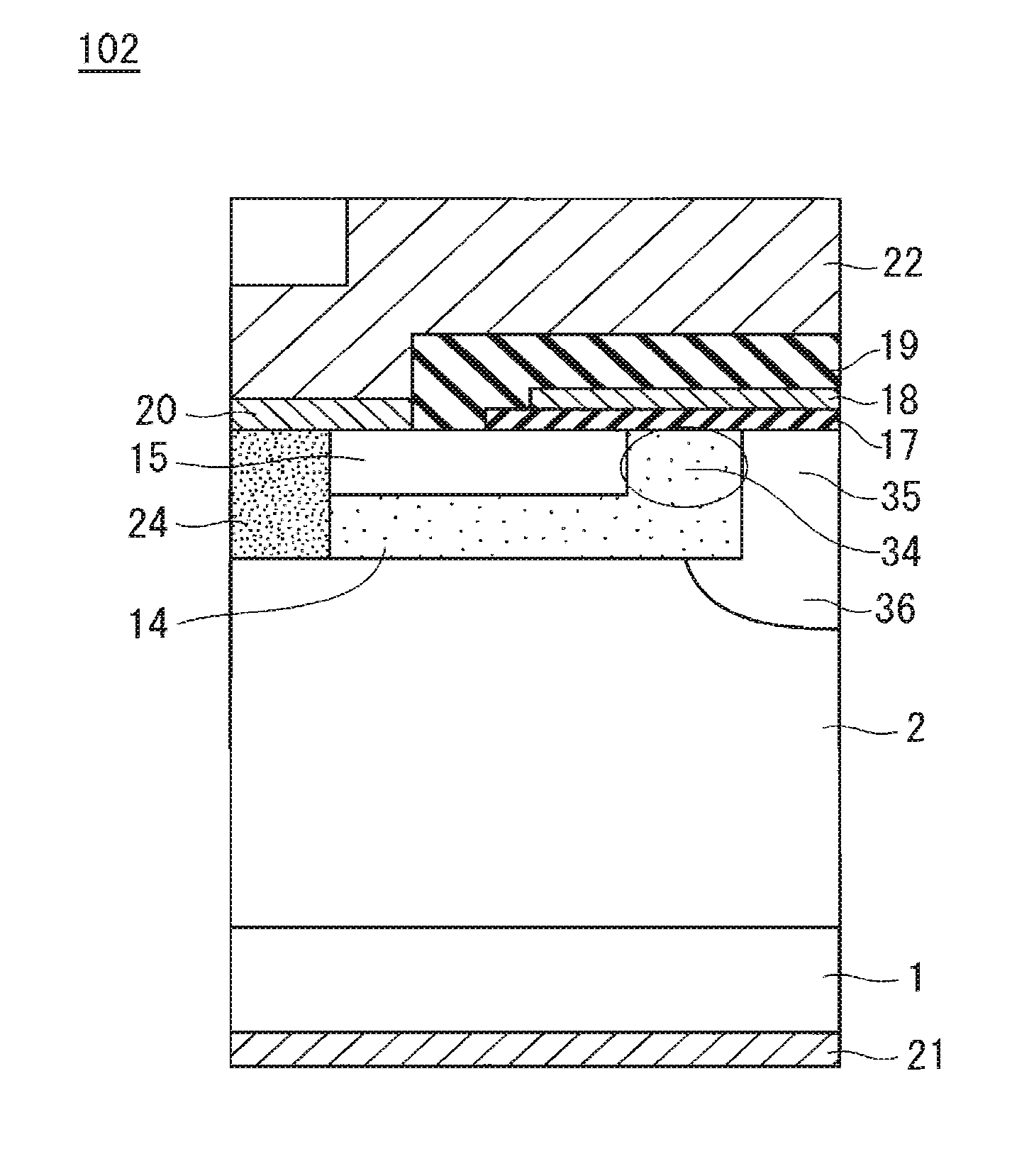

Vertical-type non-volatile memory devices

ActiveUS7679133B2Reduce the possibilityReduce in quantityTransistorSolid-state devicesSemiconductor materialsDevice material

In a semiconductor device, and a method of manufacturing thereof, the device includes a substrate of single-crystal semiconductor material extending in a horizontal direction and a plurality of interlayer dielectric layers on the substrate. A plurality of gate patterns are provided, each gate pattern being between a neighboring lower interlayer dielectric layer and a neighboring upper interlayer dielectric layer. A vertical channel of single-crystal semiconductor material extends in a vertical direction through the plurality of interlayer dielectric layers and the plurality of gate patterns, a gate insulating layer being between each gate pattern and the vertical channel that insulates the gate pattern from the vertical channel.

Owner:SAMSUNG ELECTRONICS CO LTD

Bipolar surgical instruments having focused electrical fields

InactiveUS6162220AReduce capacityLess of a tendency to cause bleedingSurgical needlesSurgical instruments for heatingElectricityEngineering

A bipolar surgical device includes a pair of actuable jaws. A first electrode member which optionally includes a line of electrically coupled tissue-penetrating elements is formed on one of the jaws, and a second electrode member which optionally includes a line of electrically coupled tissue-penetrating elements is formed on the same or the other jaw. The electrode members are laterally spaced-apart and arranged in a parallel, usually linear manner so that the lateral distance therebetween remains generally constant. In operation, tissue may be grasped between the jaws so that the electrode members contact and / or the tissue-penetrating elements enter into the tissue. By energizing the electrode members at opposite polarities using a high frequency energy source, tissue between the jaws will be heated, coagulated, and / or necrosed, while heating of tissue outside of the lines will be minimized.

Owner:PERFECT SURGICAL TECHN

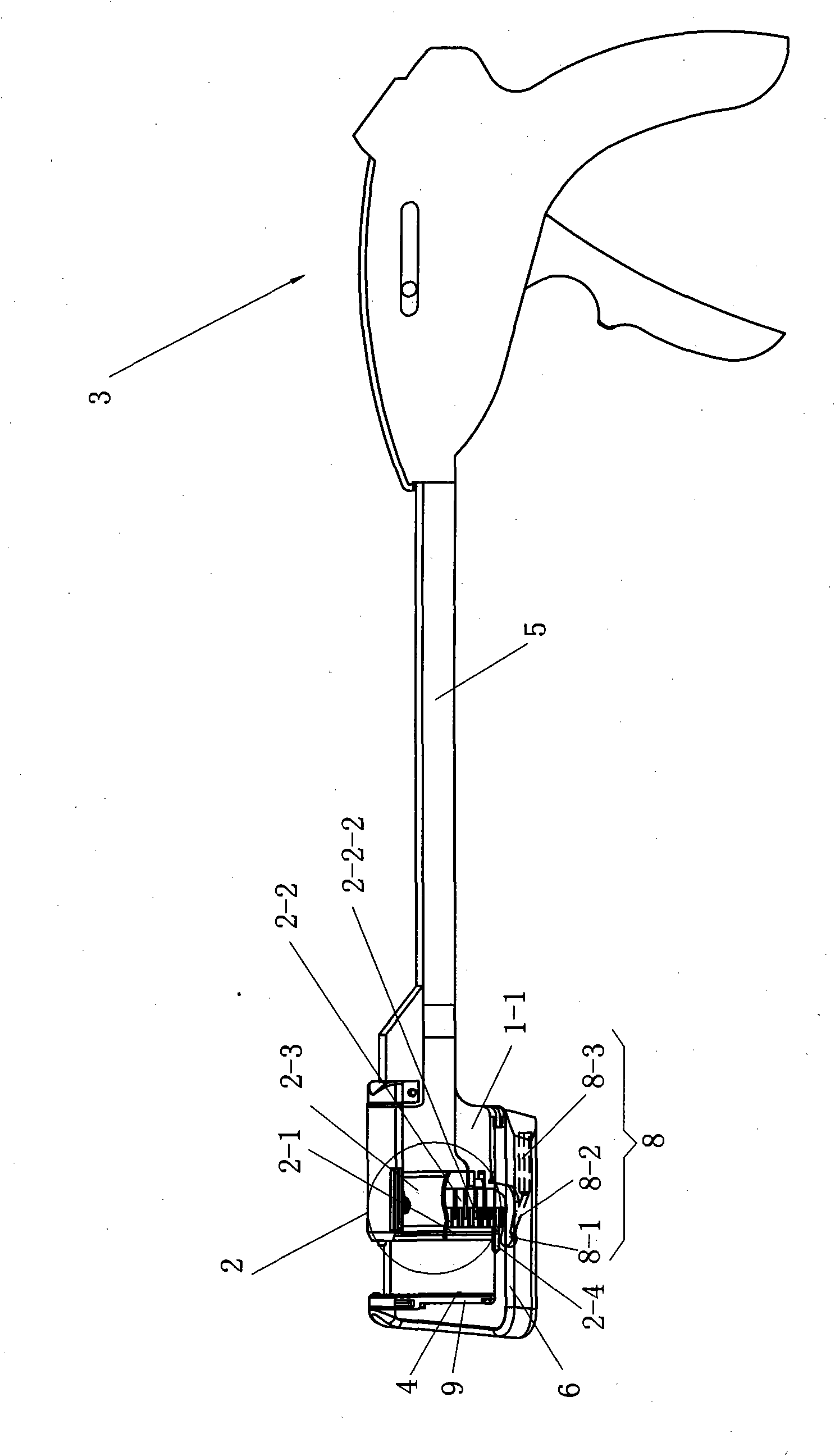

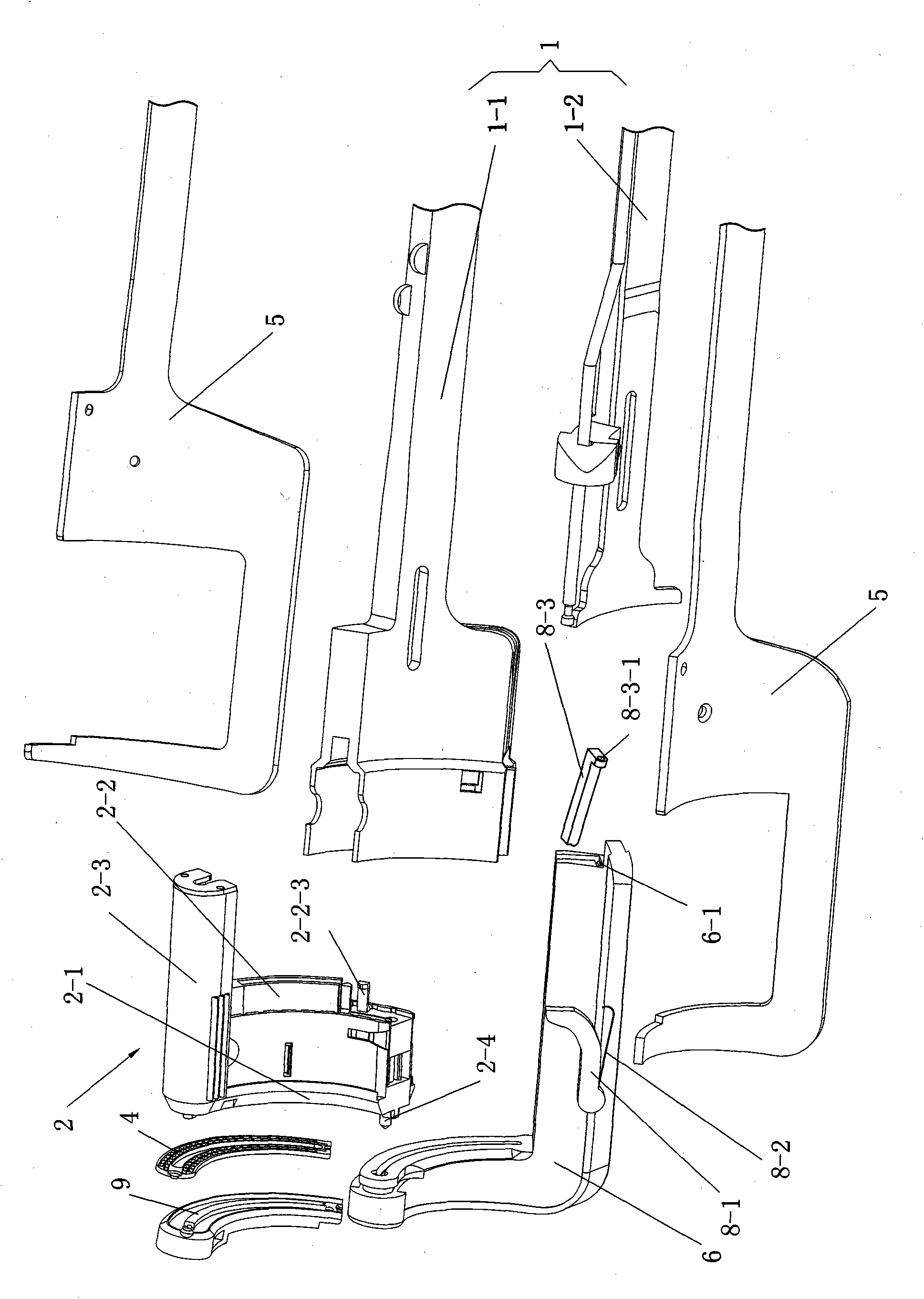

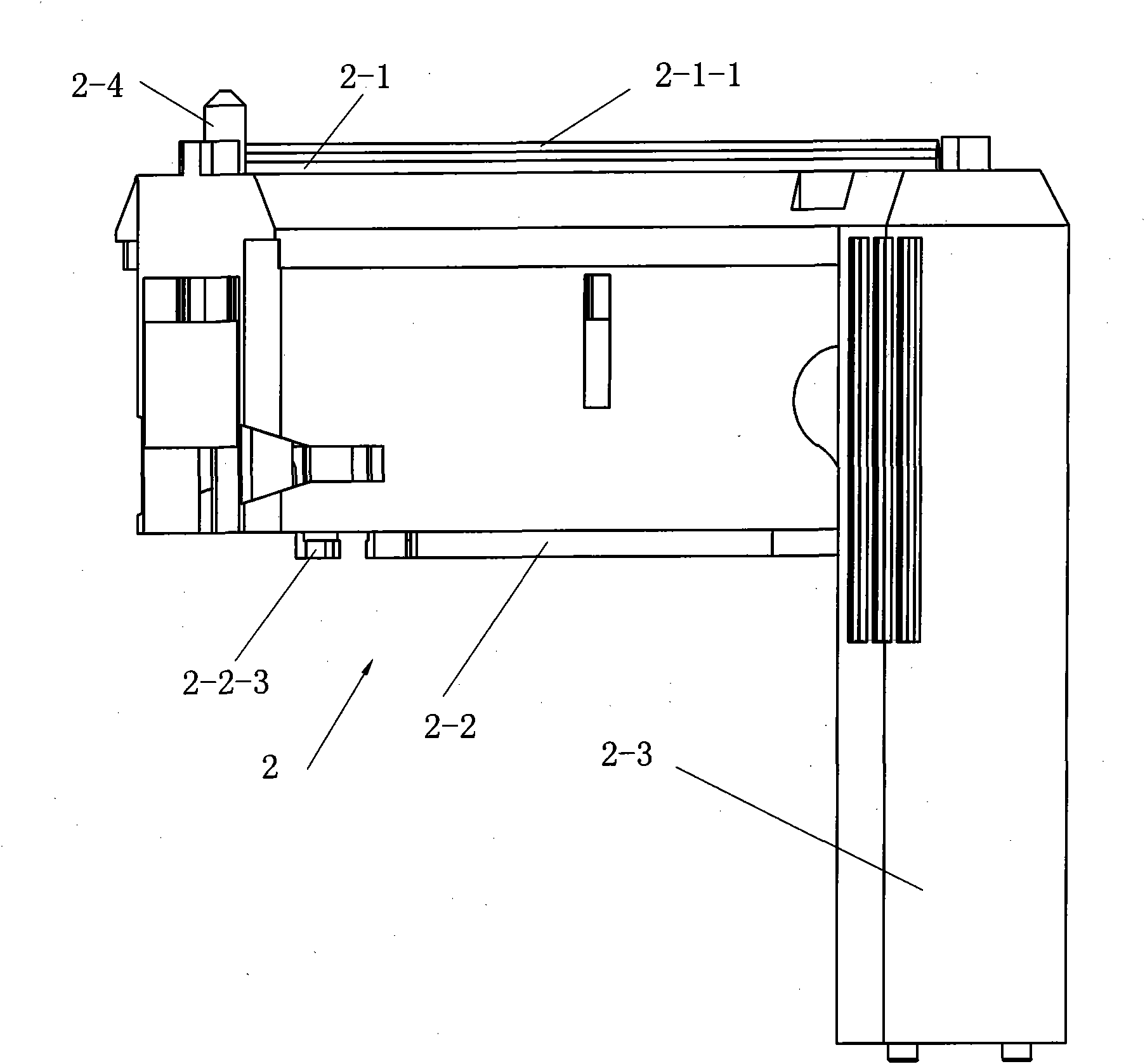

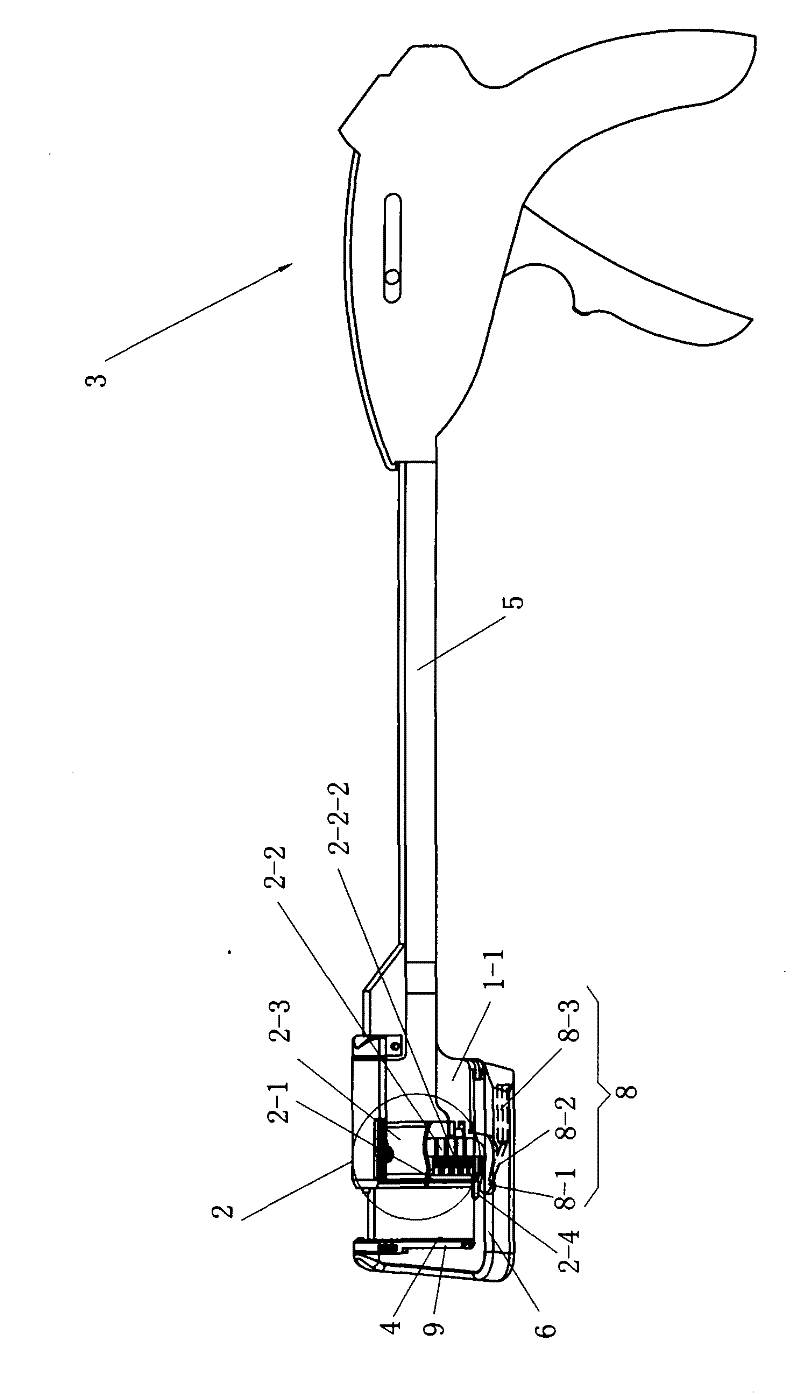

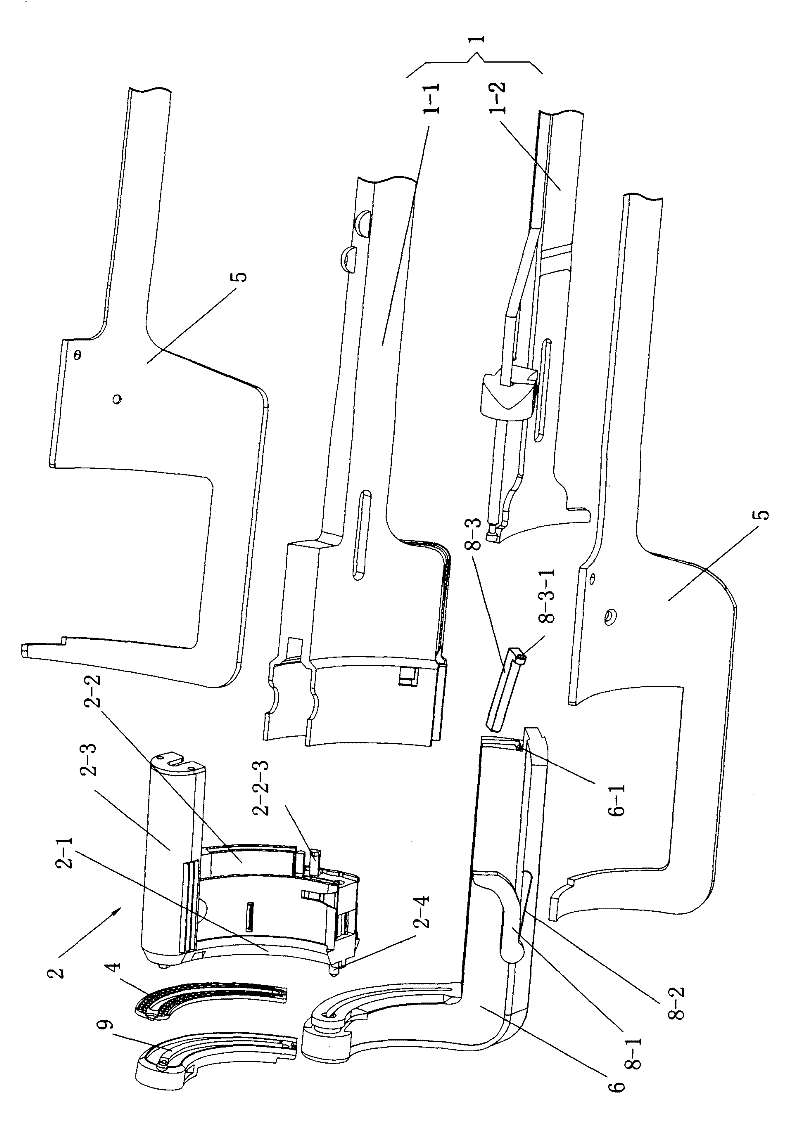

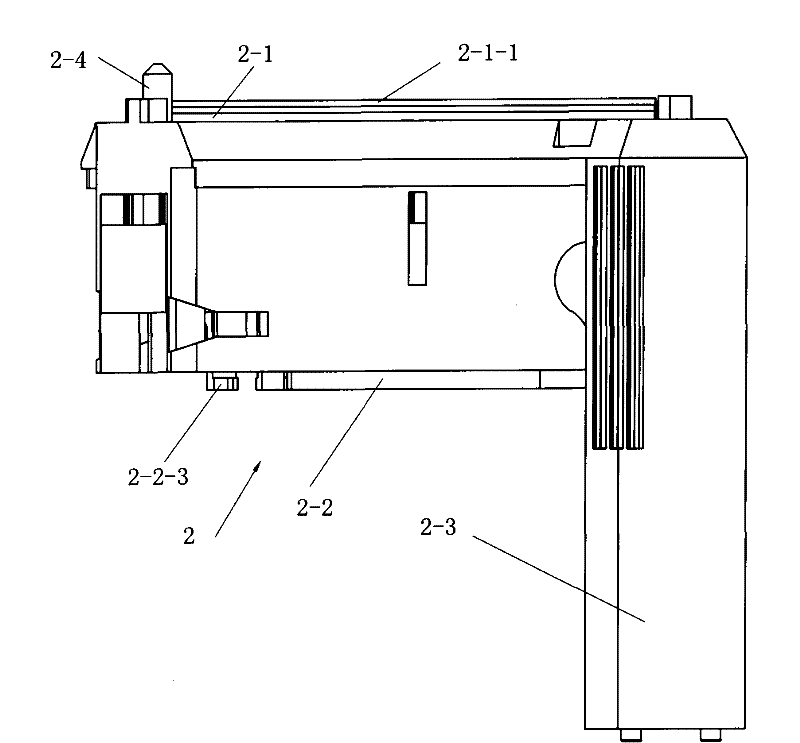

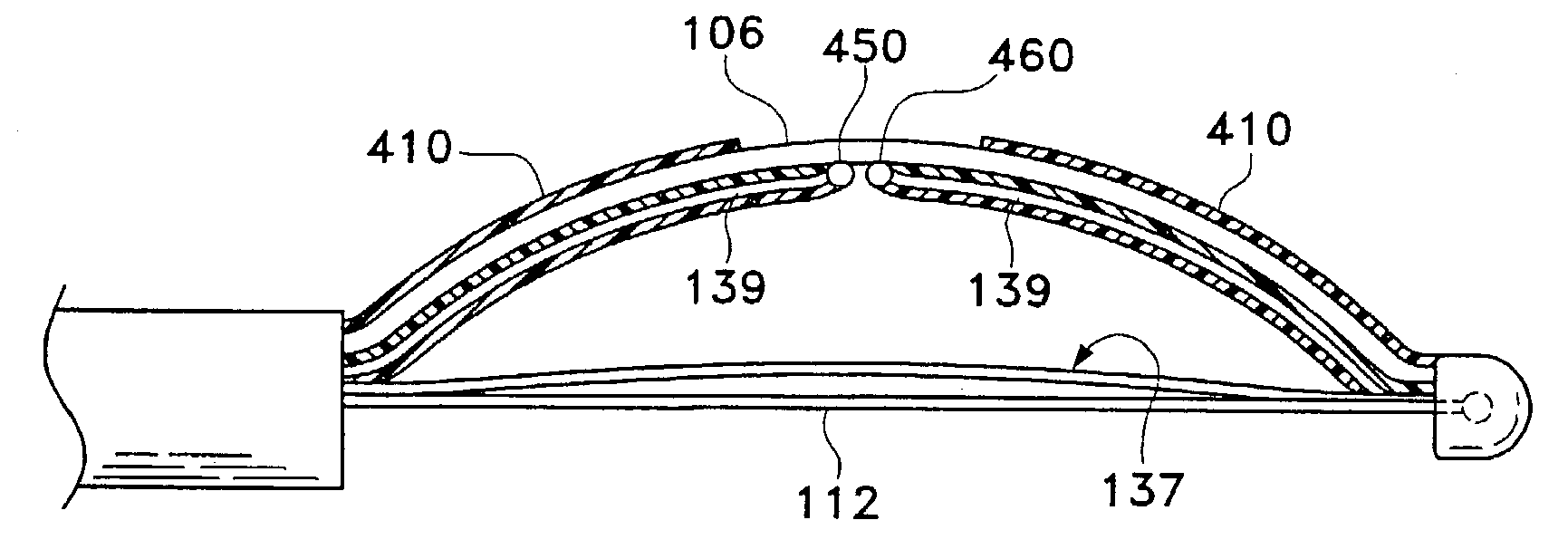

Arc-shaped cutting anastomat

ActiveCN101912284AGood assembly firmnessImprove reliabilitySurgical staplesDistal anastomosisEngineering

The invention relates to an arc-shaped cutting anastomat comprising an anastomosis nail shaping mechanism, a nail pushing assembly, a trigger handle, a nail supporting seat, a base of the nail supporting seat, a knife cushioning ring and two splints, wherein the nail pushing assembly comprises a cutting knife, a nail pushing sheet, a nail bin and a guide post; the end of the nail pushing sheet and both sides of the cutting knife are respectively provided with a plurality of inner nail pushing dental sheets which are near the cutting knife and a plurality of outer nail pushing dental sheets which are far away from the cutting knife; the cutting knife and the nail pushing sheet are injected and molded at a time to be fixed together; the outer side of the each outer nail pushing dental sheet on the nail pushing sheet is provided with a reinforcing rib; the inner side of each nail pushing dental sheet on the nail pushing sheet is provided with a reinforcing rib; both ends of the first guide surfaces of the nail pushing dental sheets are respectively connected with the first contact surfaces and the second contact surfaces of the nail pushing dental sheets through concave arc-shaped connecting surfaces, and both ends of the second guide surfaces thereof are respectively connected with the first contact surfaces and the second contact surfaces through the concave arc-shaped connecting surfaces; and the first contact surfaces and the second contact surfaces are respectively in contact with the inner walls of the nail pushing dental sheet holes of the nail bin. The invention has the advantages of good trigger anastomosis shaping effect and high safety.

Owner:CHANGZHOU JIANRUIBAO MEDICAL DEVICES

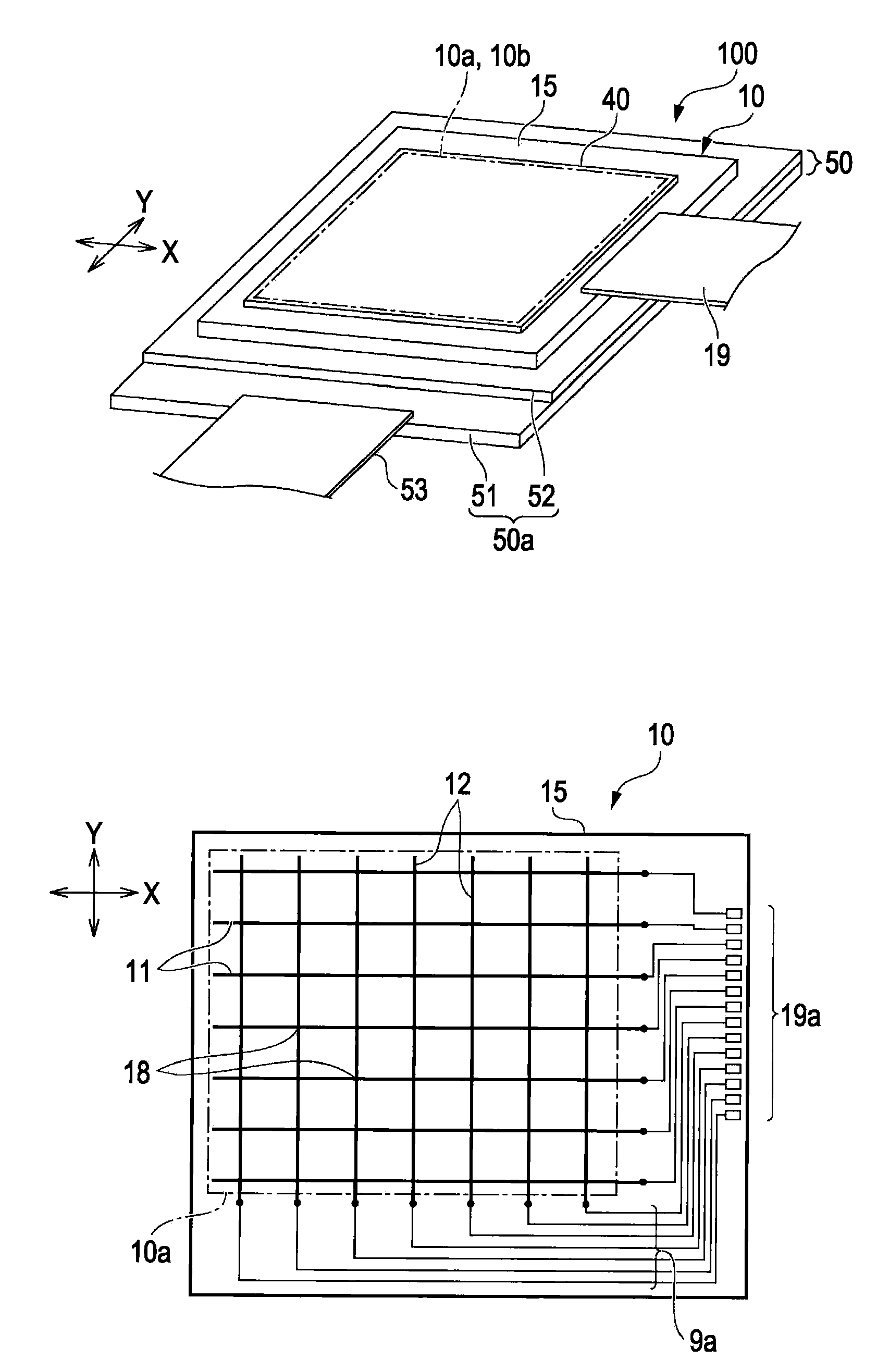

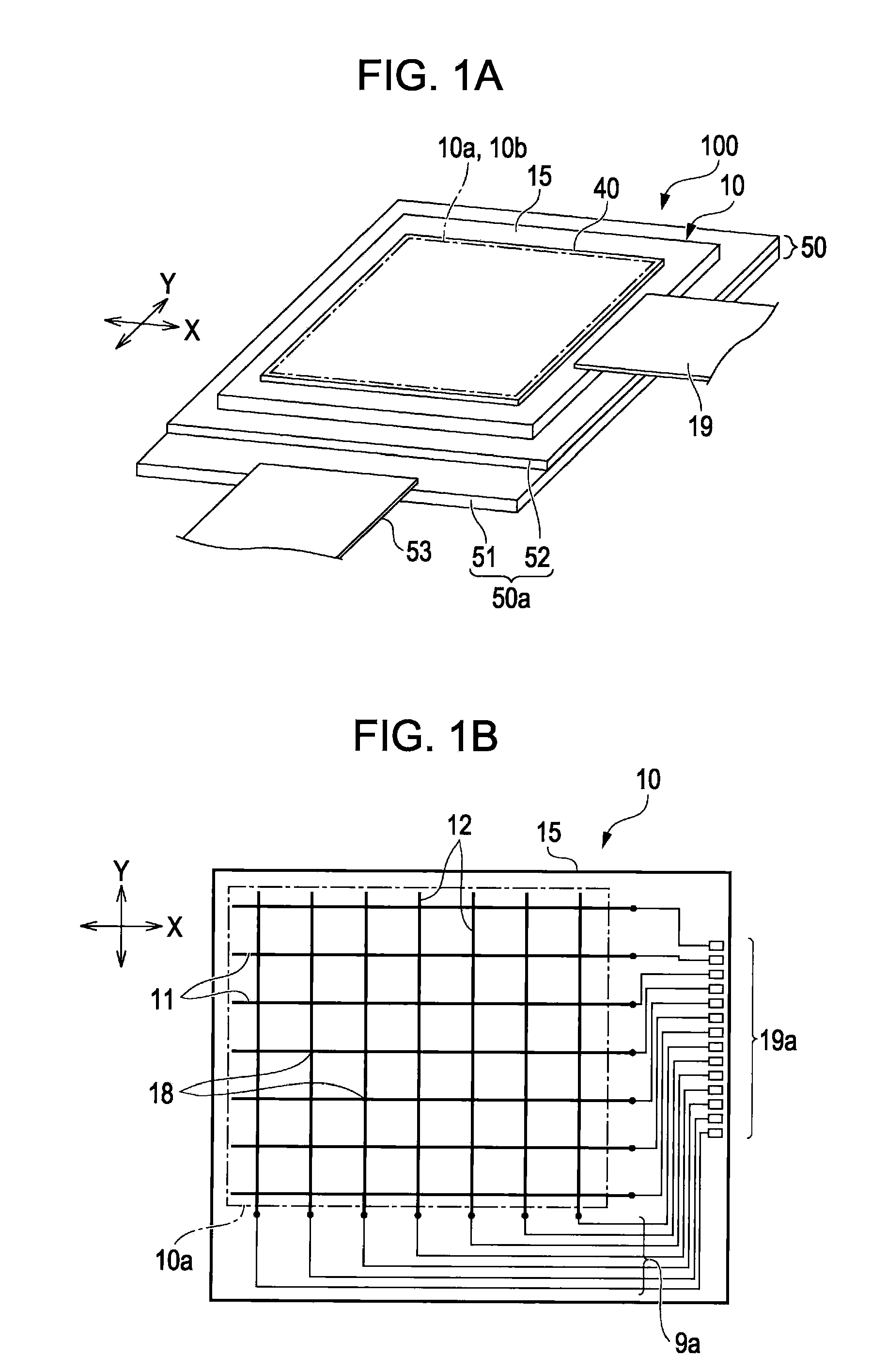

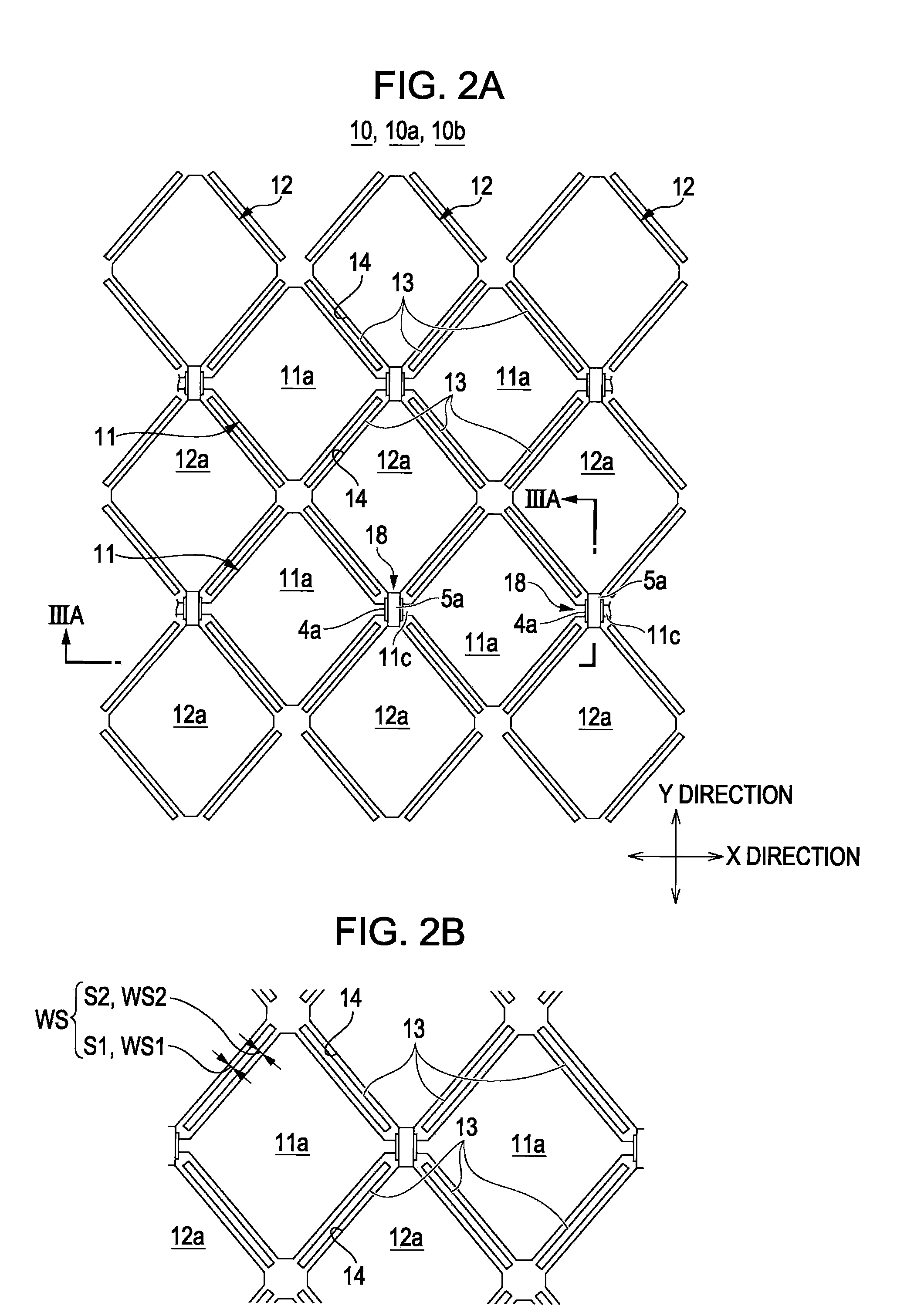

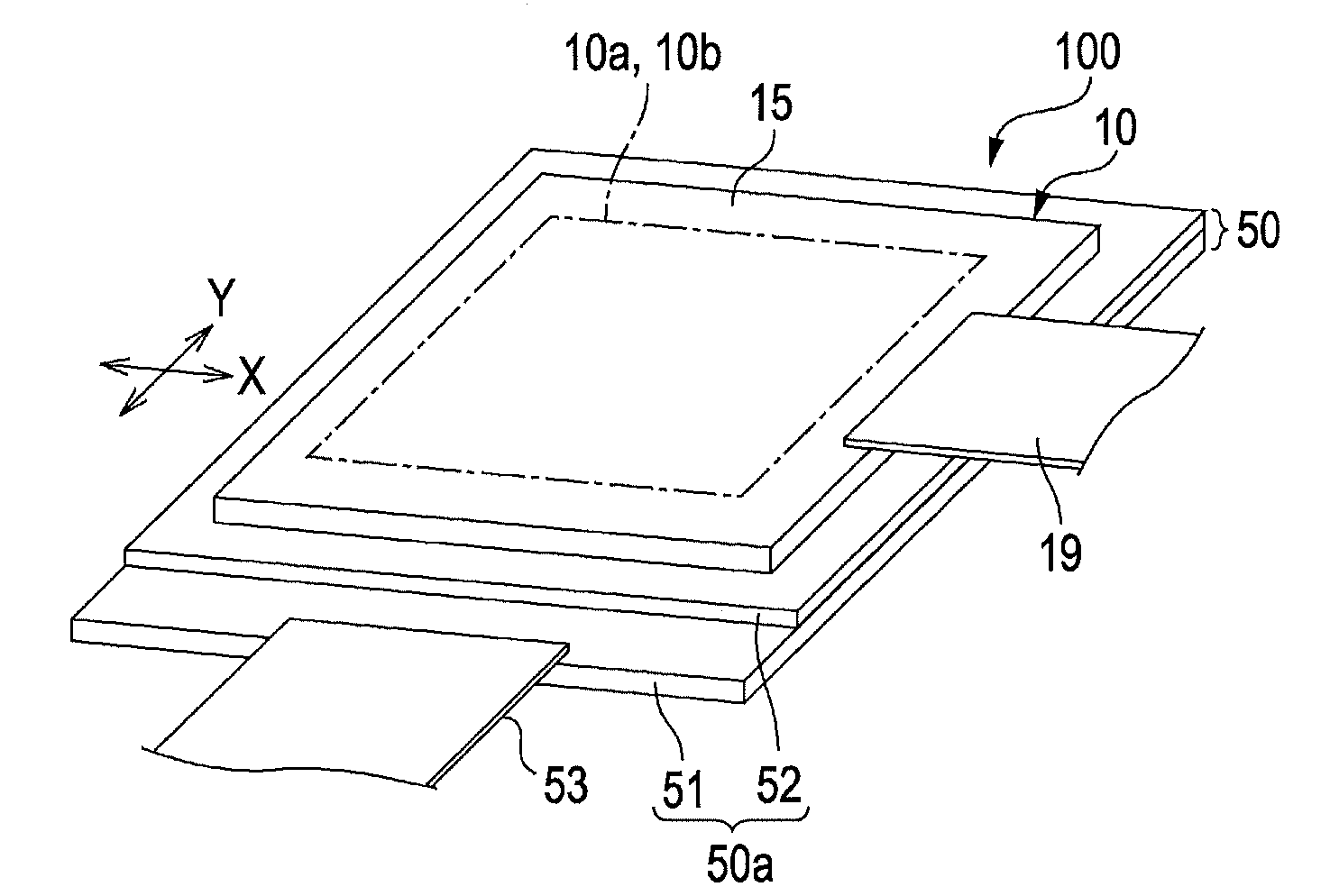

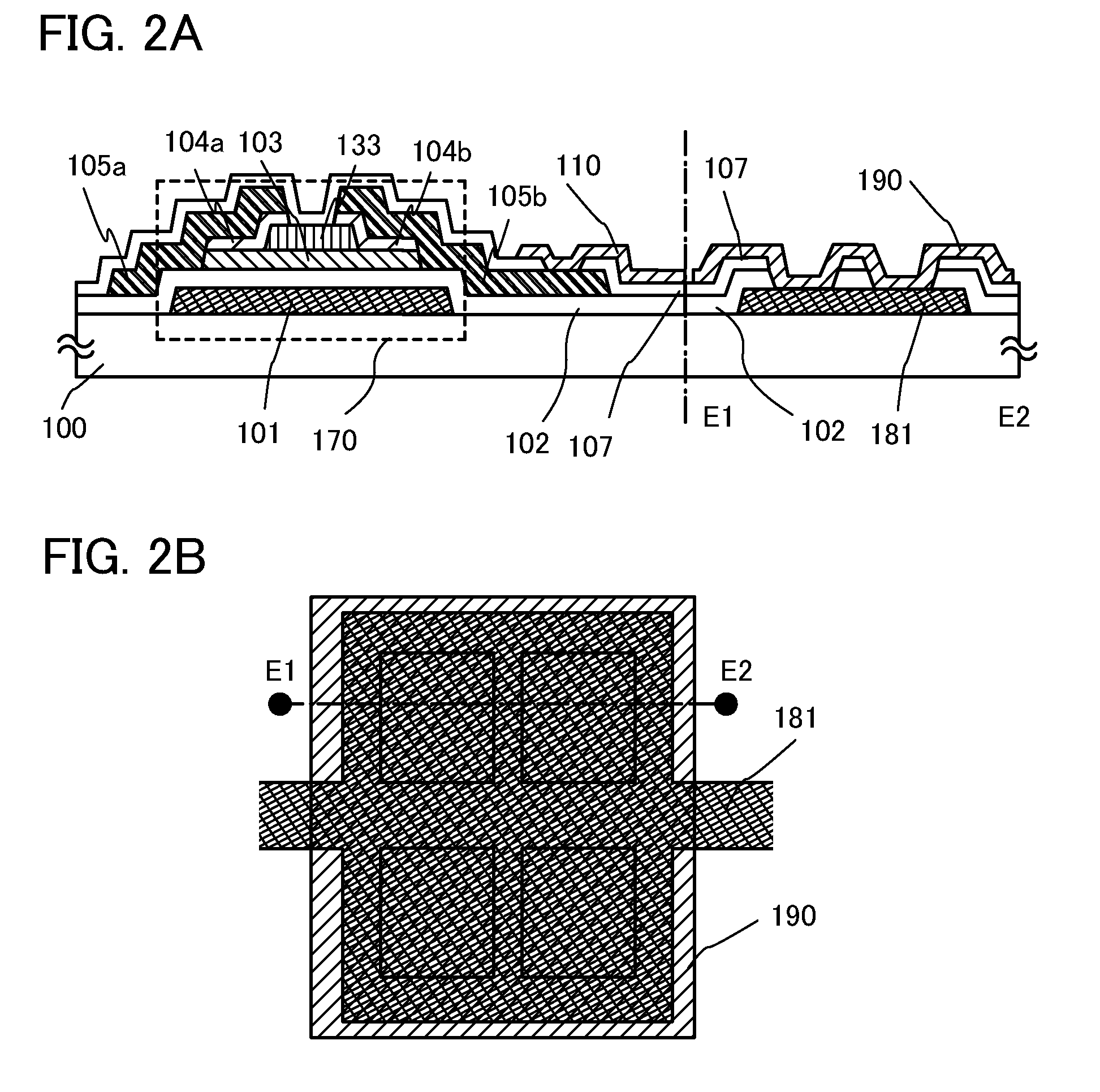

Capacitance type input device and display device with input function

ActiveUS20090315854A1Simple configurationResistance of light lightInput/output processes for data processingCapacitanceDisplay device

Provided is a capacitance type input device, in which a plurality of first light transmission electrodes extending in a first direction and a plurality of second light transmission electrodes extending in a second direction crossing the first direction are formed in an input region of a light transmission substrate, wherein, when the light transmission substrate is viewed from the top, dummy patterns formed of the same light transmission conductive film as the first light transmission electrodes and the second light transmission electrodes are formed in regions sandwiched between the first light transmission electrodes and the second light transmission electrodes.

Owner:JAPAN DISPLAY WEST

Arc-shaped cutting anastomat

The invention relates to an arc-shaped cutting anastomat comprising an anastomosis nail shaping mechanism, a nail pushing assembly, a trigger handle, a nail supporting seat, a base of the nail supporting seat, a knife cushioning ring and two splints, wherein the nail pushing assembly comprises a cutting knife, a nail pushing sheet, a nail bin and a guide post; the end of the nail pushing sheet and both sides of the cutting knife are respectively provided with a plurality of inner nail pushing dental sheets which are near the cutting knife and a plurality of outer nail pushing dental sheets which are far away from the cutting knife; the cutting knife and the nail pushing sheet are injected and molded at a time to be fixed together; the outer side of the each outer nail pushing dental sheeton the nail pushing sheet is provided with a reinforcing rib; the inner side of each nail pushing dental sheet on the nail pushing sheet is provided with a reinforcing rib; both ends of the first guide surfaces of the nail pushing dental sheets are respectively connected with the first contact surfaces and the second contact surfaces of the nail pushing dental sheets through concave arc-shaped connecting surfaces, and both ends of the second guide surfaces thereof are respectively connected with the first contact surfaces and the second contact surfaces through the concave arc-shaped connecting surfaces; and the first contact surfaces and the second contact surfaces are respectively in contact with the inner walls of the nail pushing dental sheet holes of the nail bin. The invention has the advantages of good trigger anastomosis shaping effect and high safety.

Owner:CHANGZHOU JIANRUIBAO MEDICAL DEVICES

Infusion device and driving mechanism and process for same with actuator for multiple infusion uses

InactiveUS6932584B2Small thickness dimensionMinimize traumaIntravenous devicesPiston pumpsEngineeringActuator

Owner:MEDTRONIC MIMIMED INC

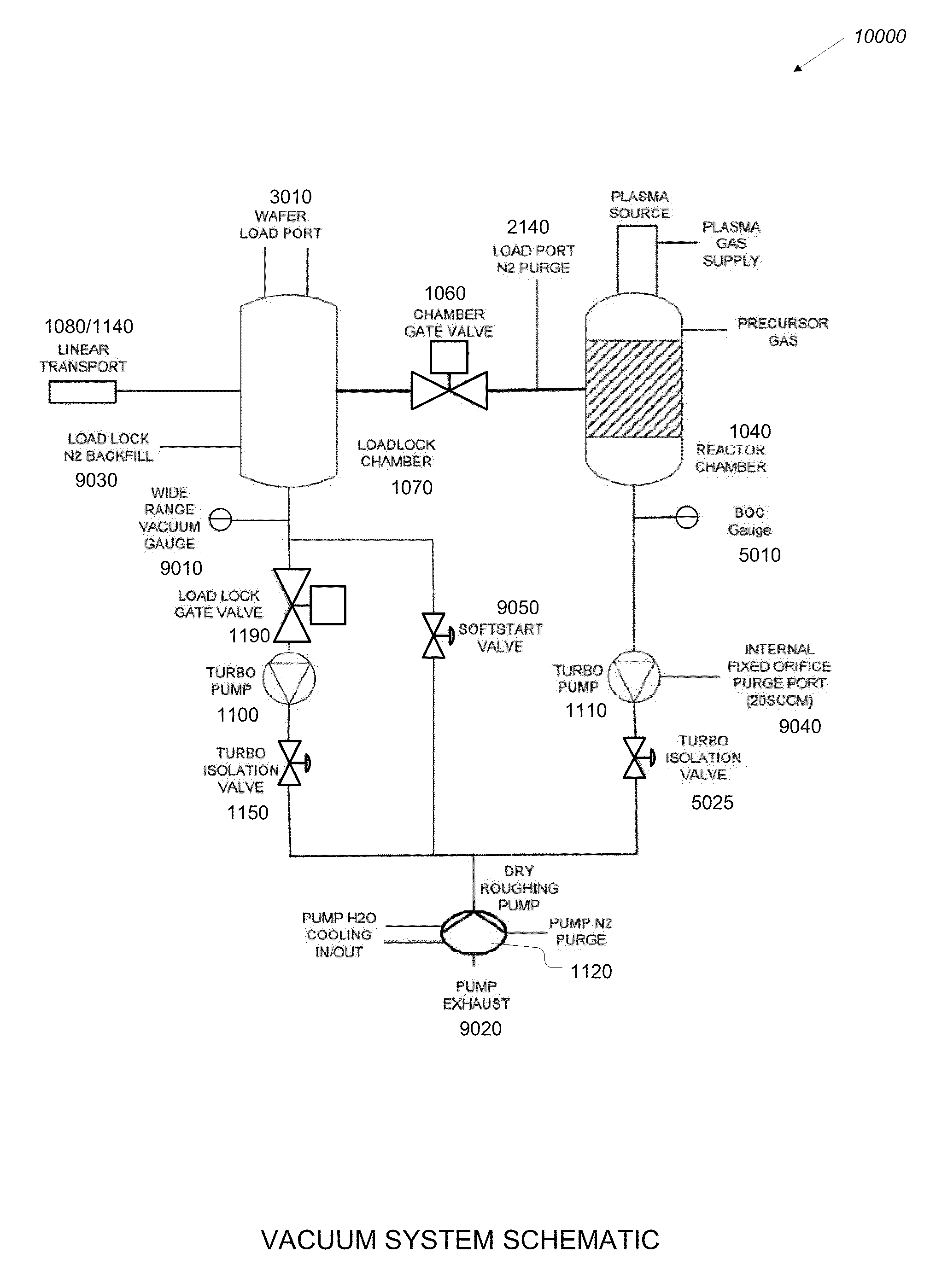

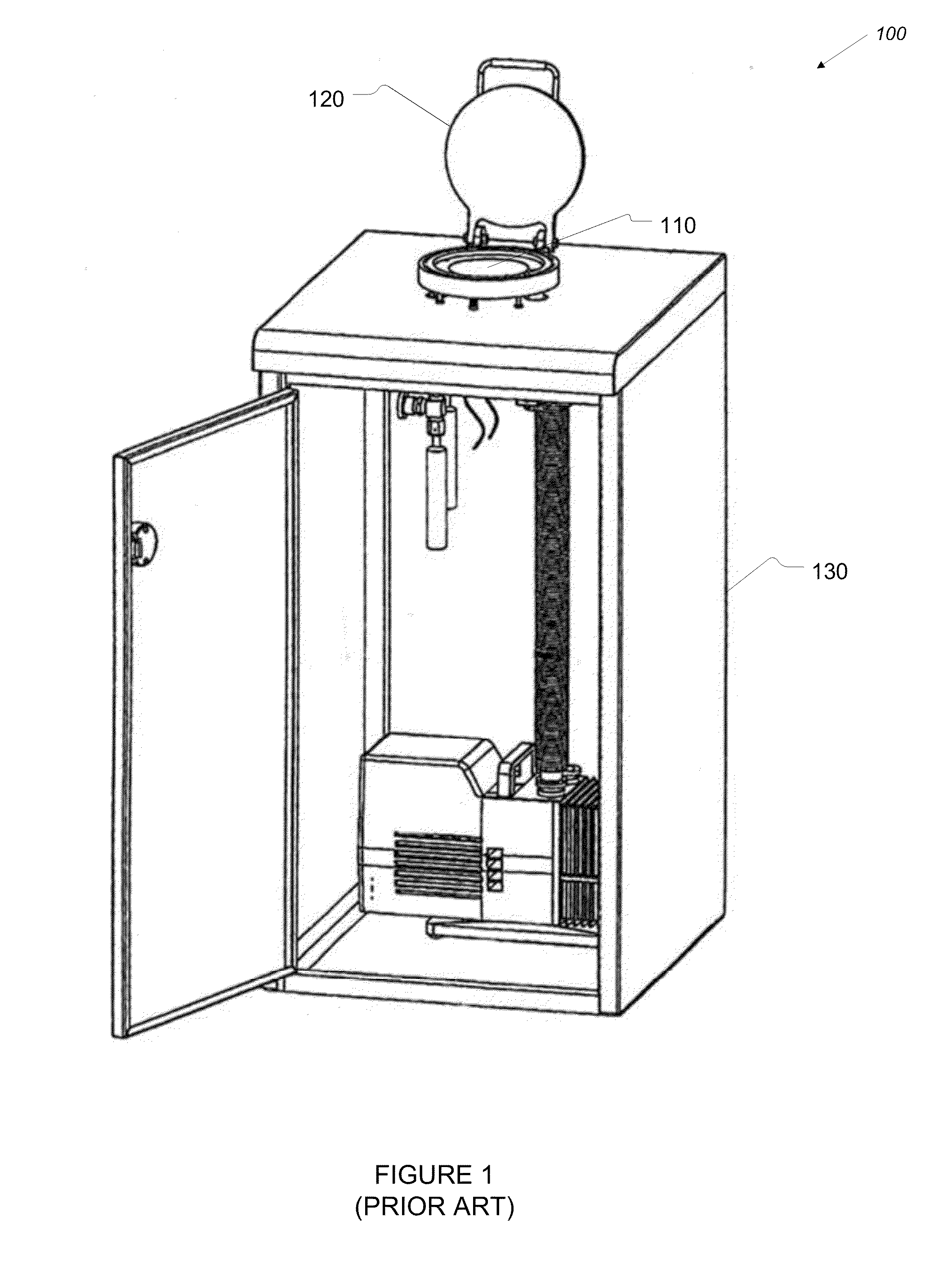

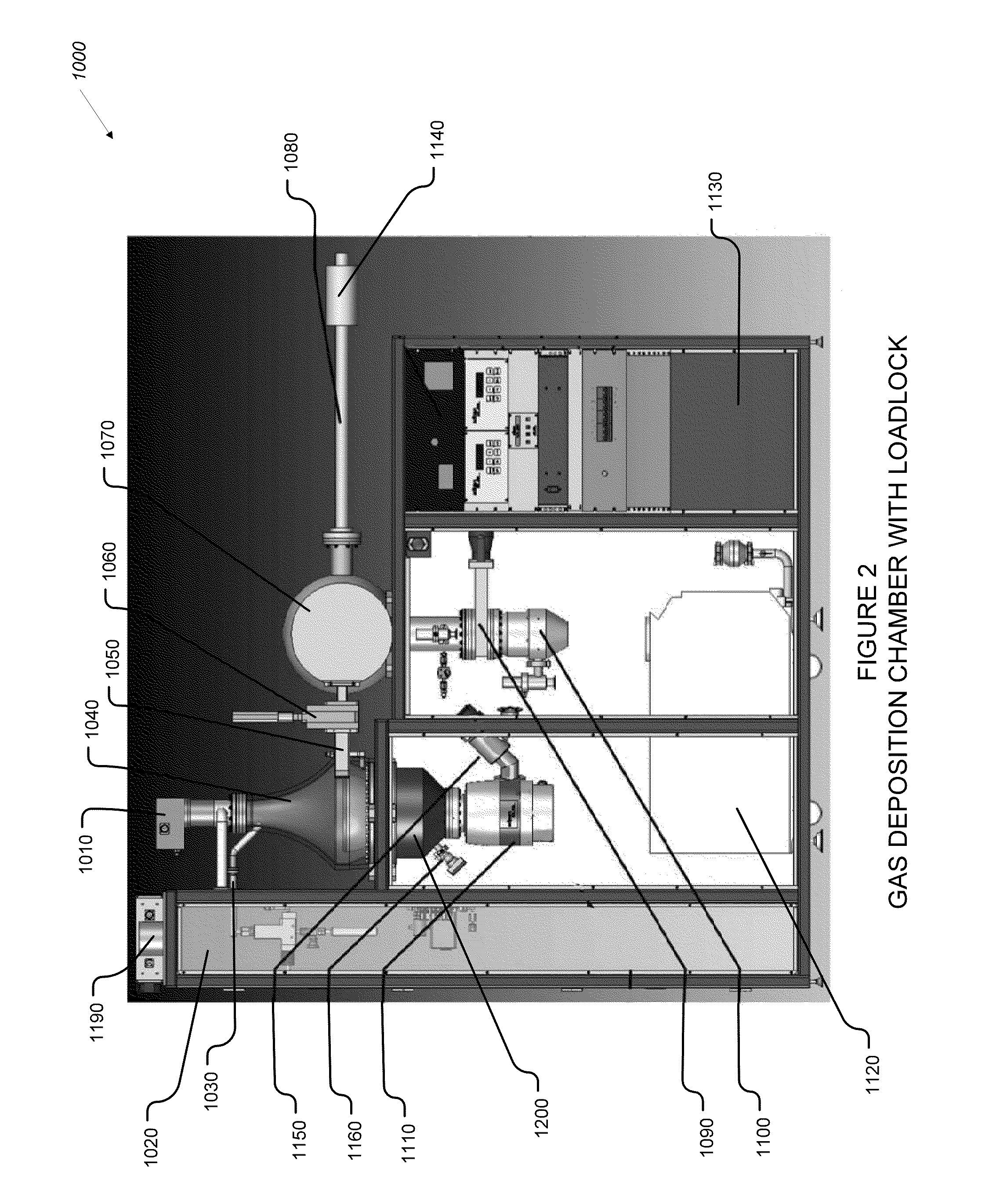

Plasma atomic layer deposition system and method

InactiveUS20100183825A1Lower the volumeShorten cycle timeChemical vapor deposition coatingPlasma techniqueEngineeringAtomic layer deposition

An improved gas deposition chamber includes a hollow gas deposition volume formed with a volume expanding top portion and a substantially constant volume cylindrical middle portion. The hollow gas deposition volume may include a volume reducing lower portion. An aerodynamically shaped substrate support chuck is disposed inside gas deposition chamber with a substrate support surface positioned in the constant volume cylindrical middle portion. The volume expanding top portion reduces gas flow velocity between gas input ports and the substrate support surface. The aerodynamic shape of the substrate support chuck reduces drag and helps to promote laminar flow over the substrate support surface. The volume reducing lower portion helps to increase gas flow velocity after the gas has past the substrate support surface. The improved gas deposition chamber is configurable to 200 mm diameter semiconductor wafers using ALD and or PALD coating cycles. An improved coating method includes expanding process gases inside the deposition chamber prior to the process gas reaching surfaces of a substrate being coated. The method further includes compressing the process gases inside the deposition chamber after the process gas has flowed past surfaces of the substrate being coated.

Owner:ULTRATECH INT INC

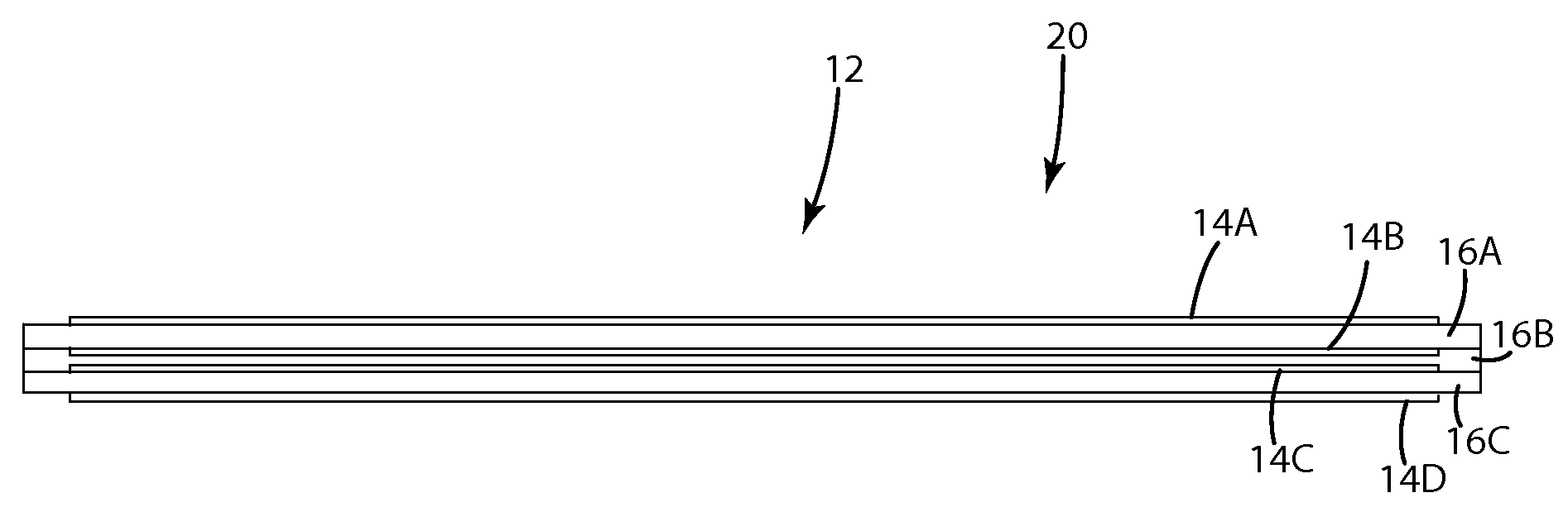

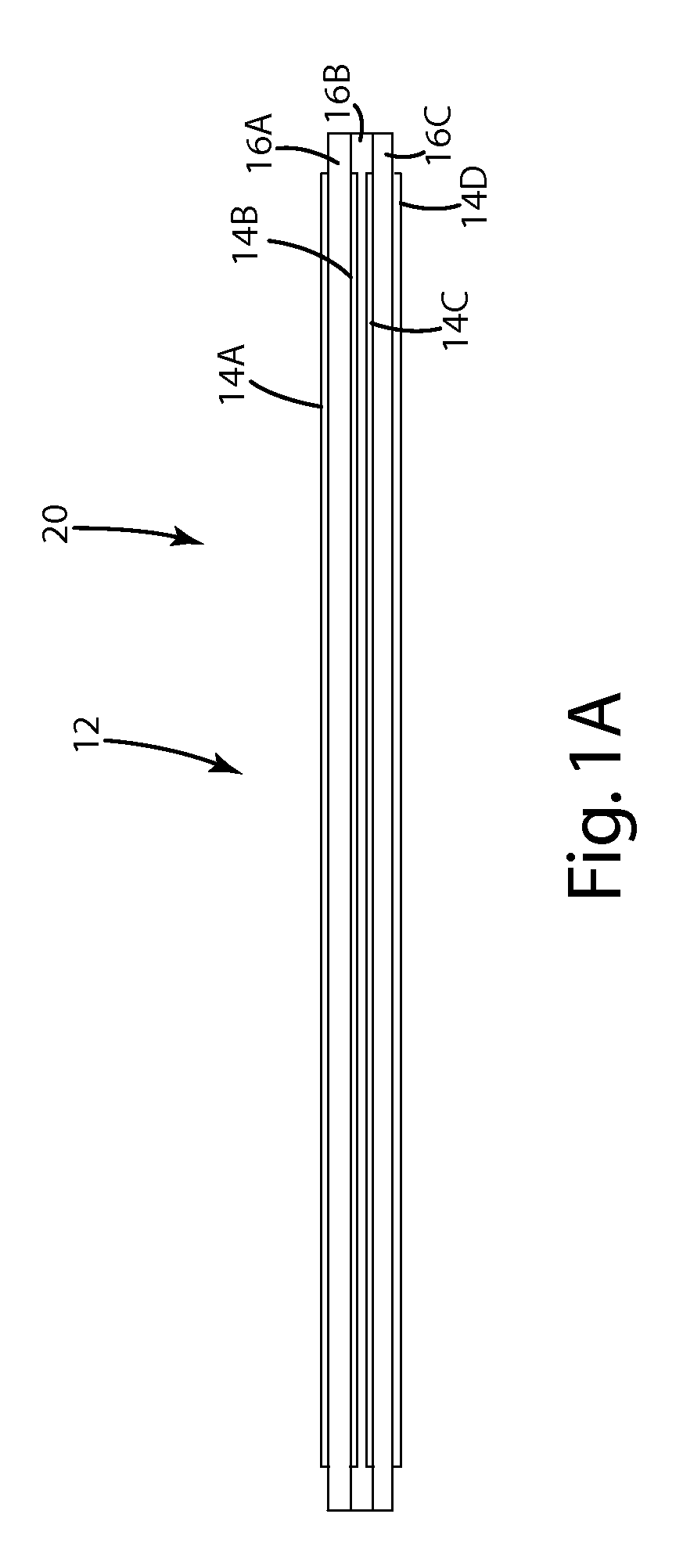

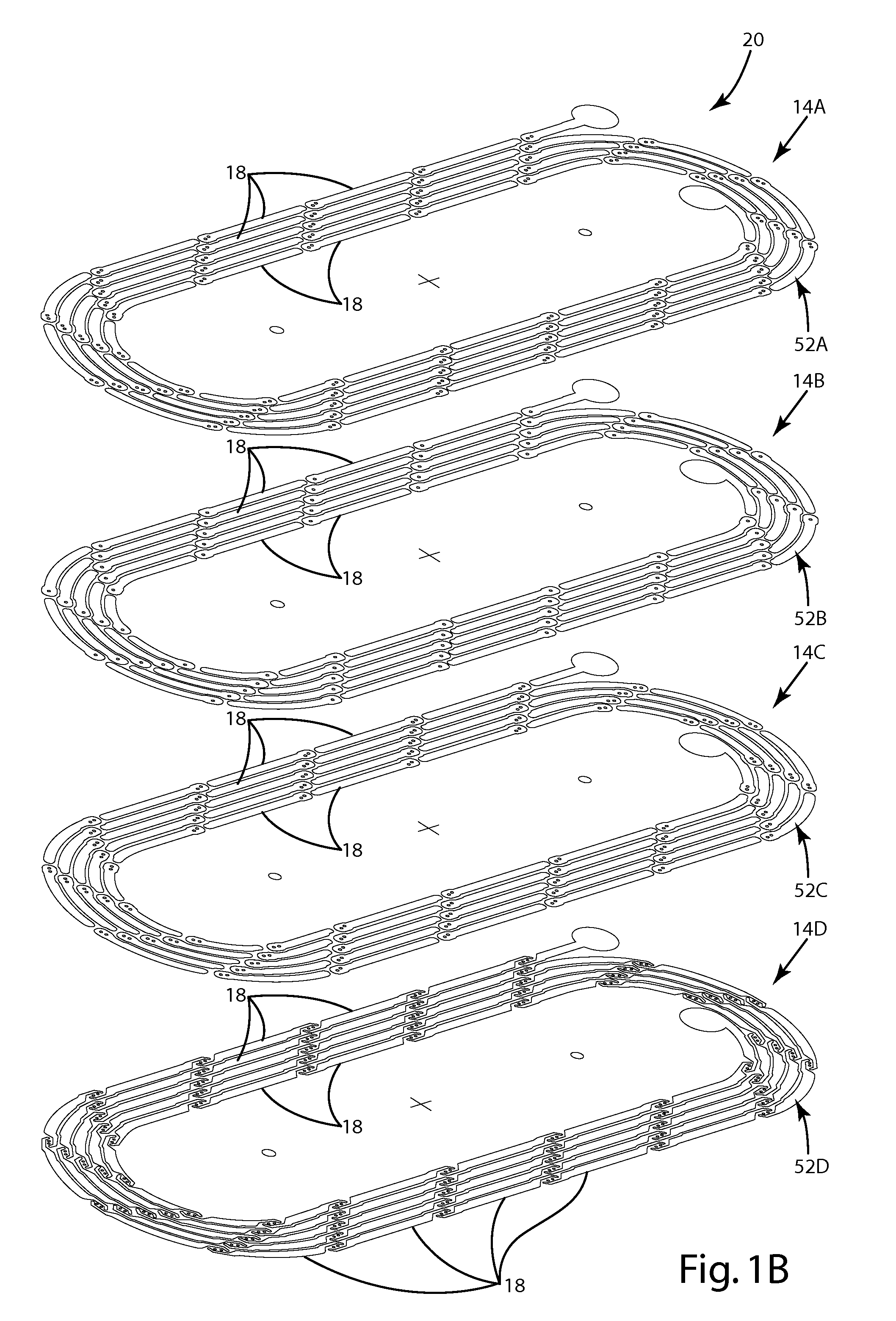

Printed circuit board coil

ActiveUS20090085706A1Reduce skin effectReduce lossTransformersTransformers/inductances coils/windings/connectionsElectrical conductorLitz wire

A multilayer printed circuit board (“PCB”) coil that simulates a coil formed from litz wire. The PCB includes a plurality of alternating conductor and insulating layers interconnected to cooperatively form the coil. Each conductor layer includes a trace that follows the desired coil shape and is divided into a plurality of discrete conductor segments. The segments are electrically connected across layers to provide a plurality of current flow paths (or filaments) that undulate between the layers in a regular, repeating pattern. The coil may be configured so that each filament spends a substantially equal amount of time in proximity to the paired coil and therefore contributes substantially equally to the self or mutual inductance of the coil. Each conductor layer may include a plurality of associated traces and intralayer connector that interconnected so that each filament undulates not only upwardly / downwardly, but also inwardly / outwardly in a regular, repeating pattern.

Owner:PHILIPS IP VENTURES BV

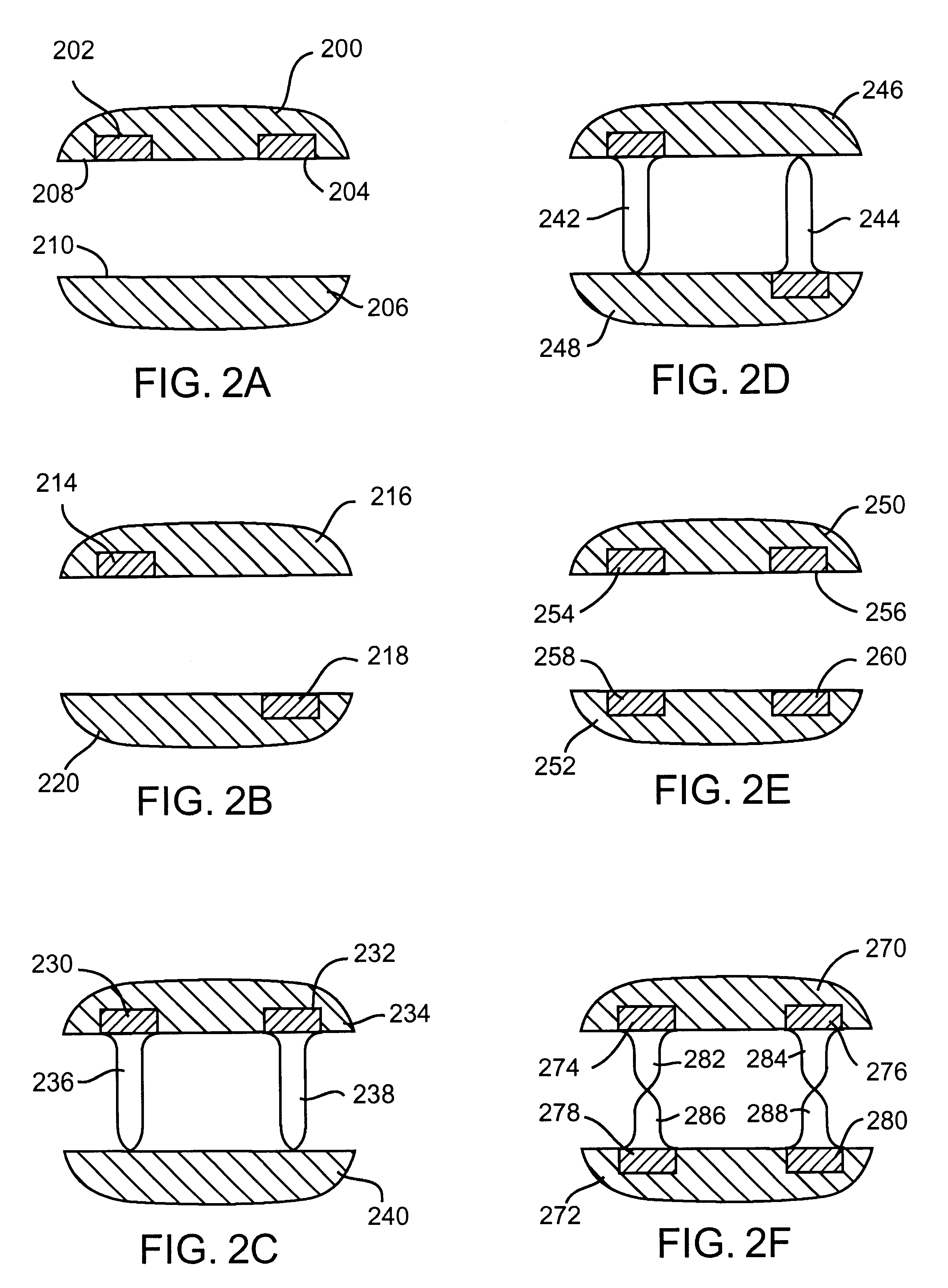

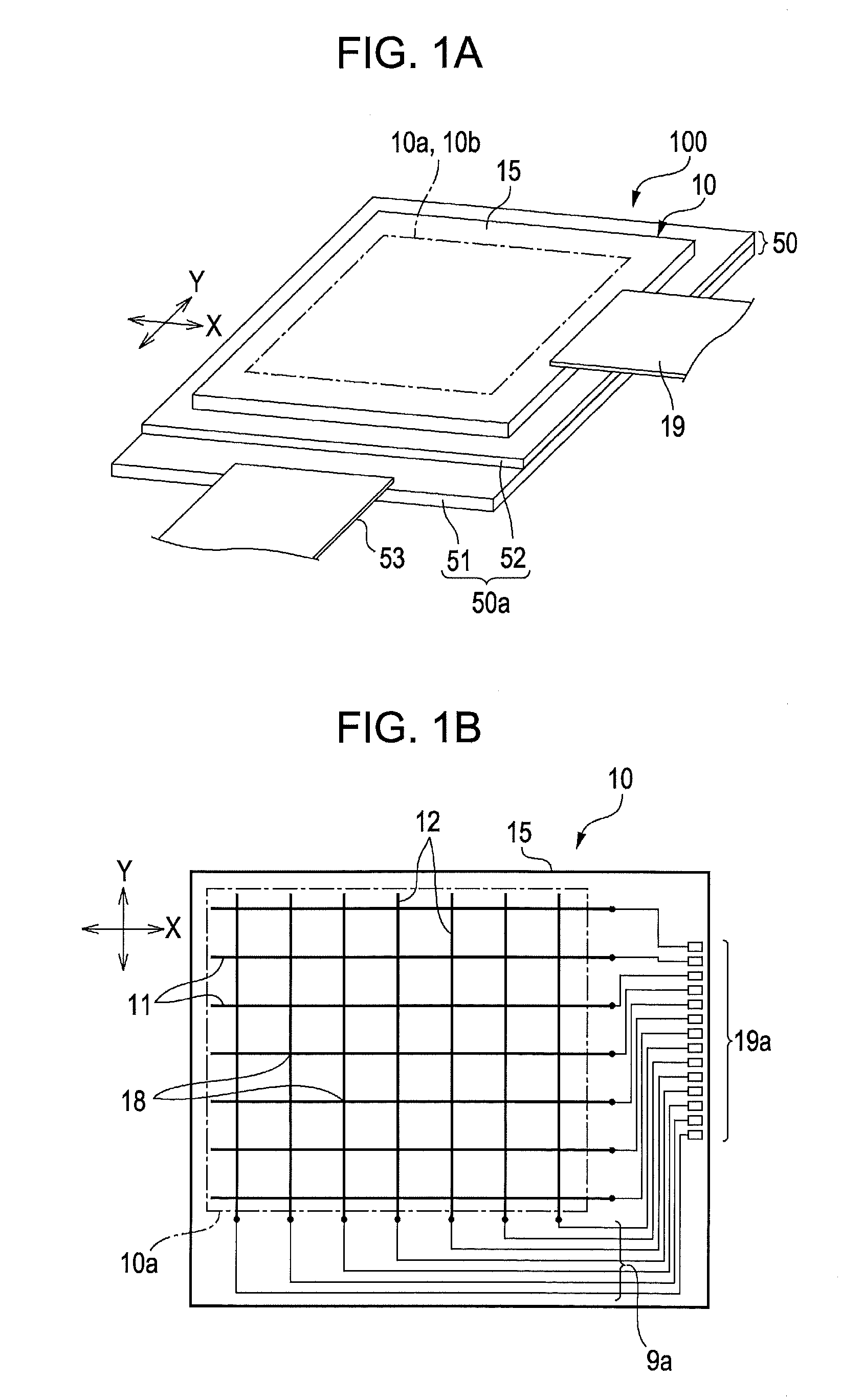

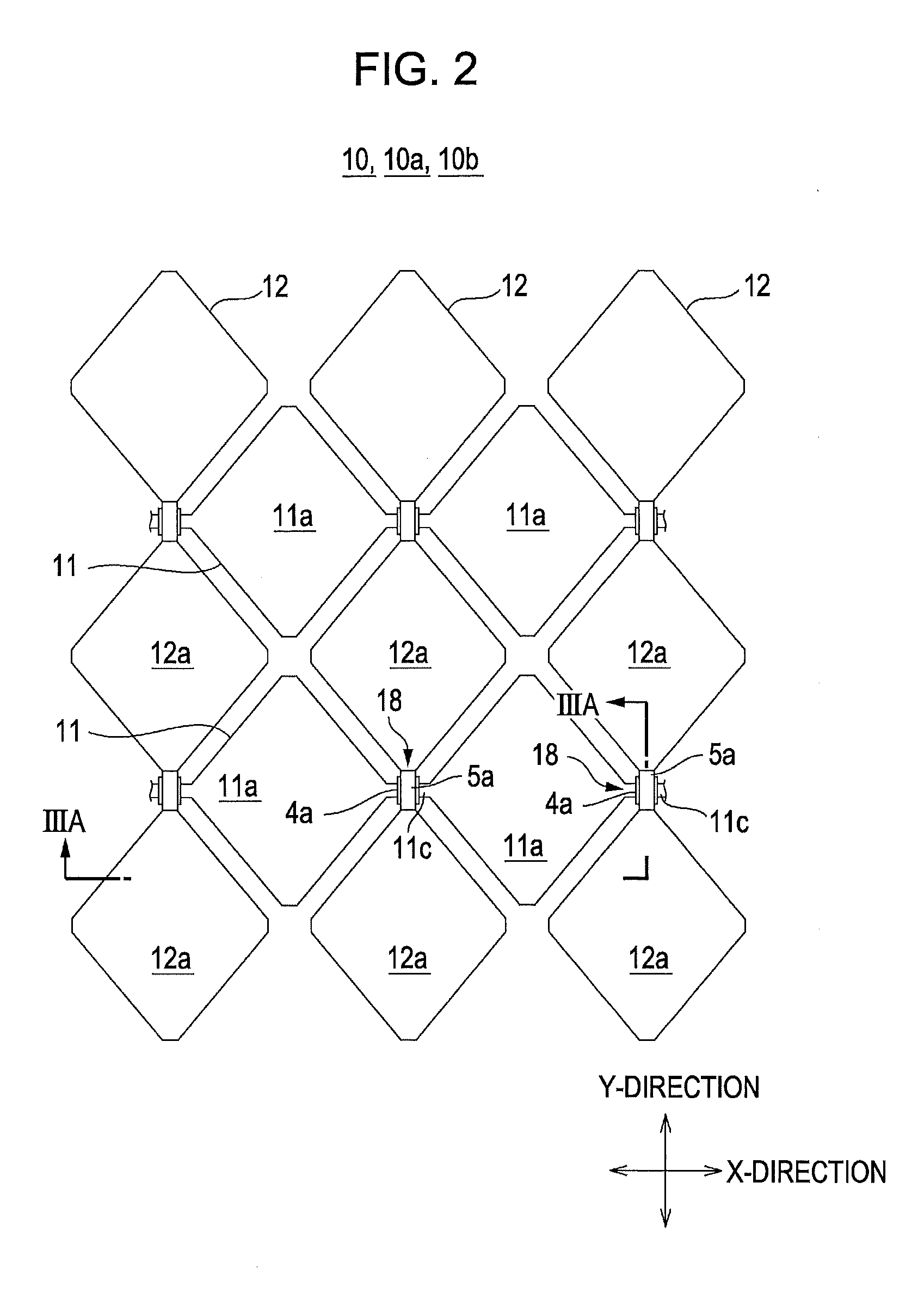

Capacitive input device

ActiveUS20080309635A1Reduce resistanceSimple processInput/output processes for data processingCapacitanceEngineering

A capacitive input device includes a translucent substrate; first translucent electrode lines, extending in a first direction; second translucent electrode lines, extending in a second direction intersecting with the first direction; interlayer insulating layers; and relay electrodes. The first translucent electrode lines intersect with the second translucent electrode lines at intersecting portions. Portions of one of each first translucent electrode line and each second translucent electrode line are connected to each other with the intersecting portions. Portions of the other are separated from each other with the intersecting portions. The translucent interlayer insulating layers overlie the first or second translucent electrode line portions connected to each other with the intersecting portions. The translucent relay electrodes overlie the interlayer insulating layers to electrically connect the first or second translucent electrode line portions, separated from each other with the intersecting portions, to each other.

Owner:JAPAN DISPLAY WEST

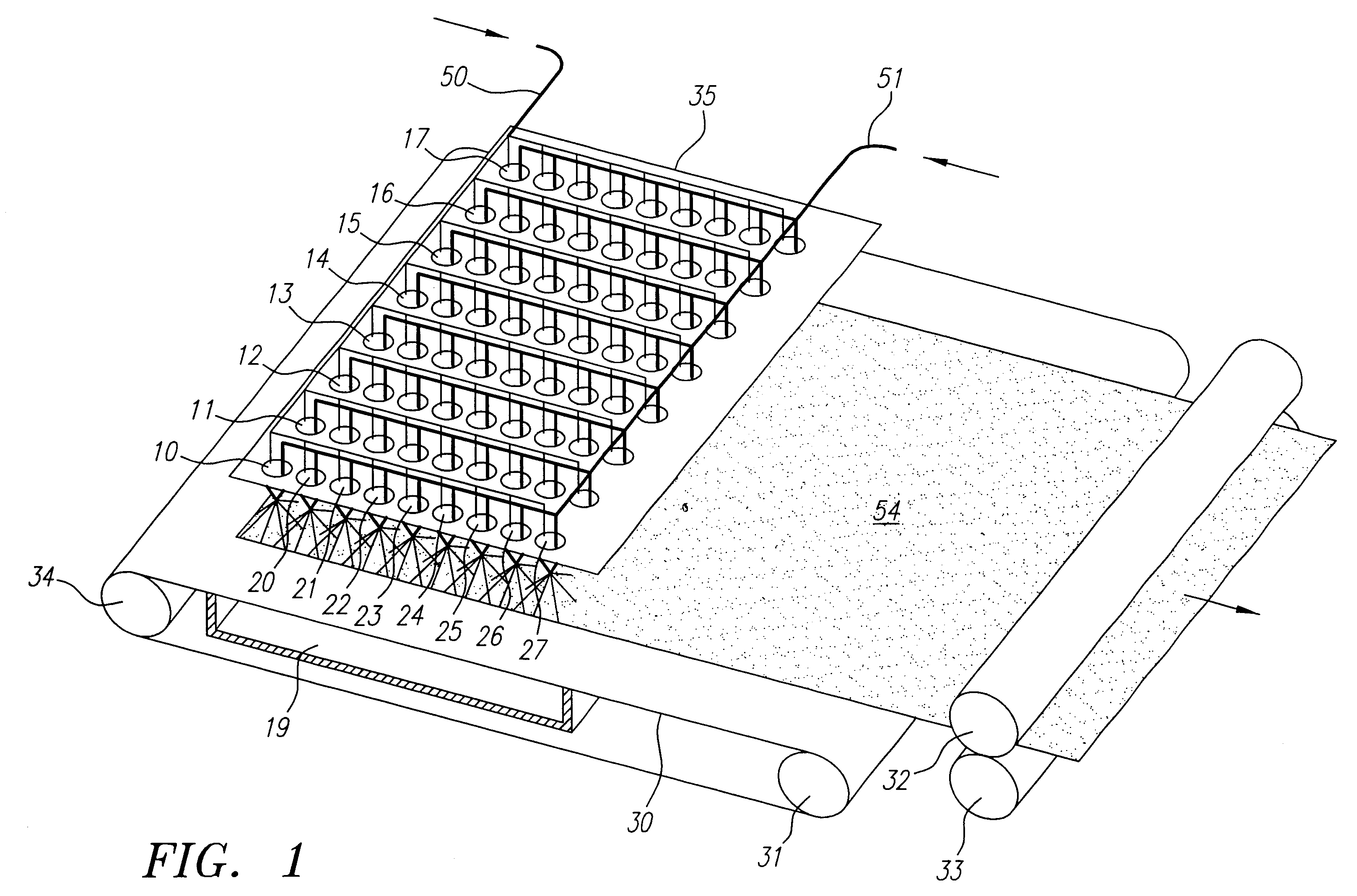

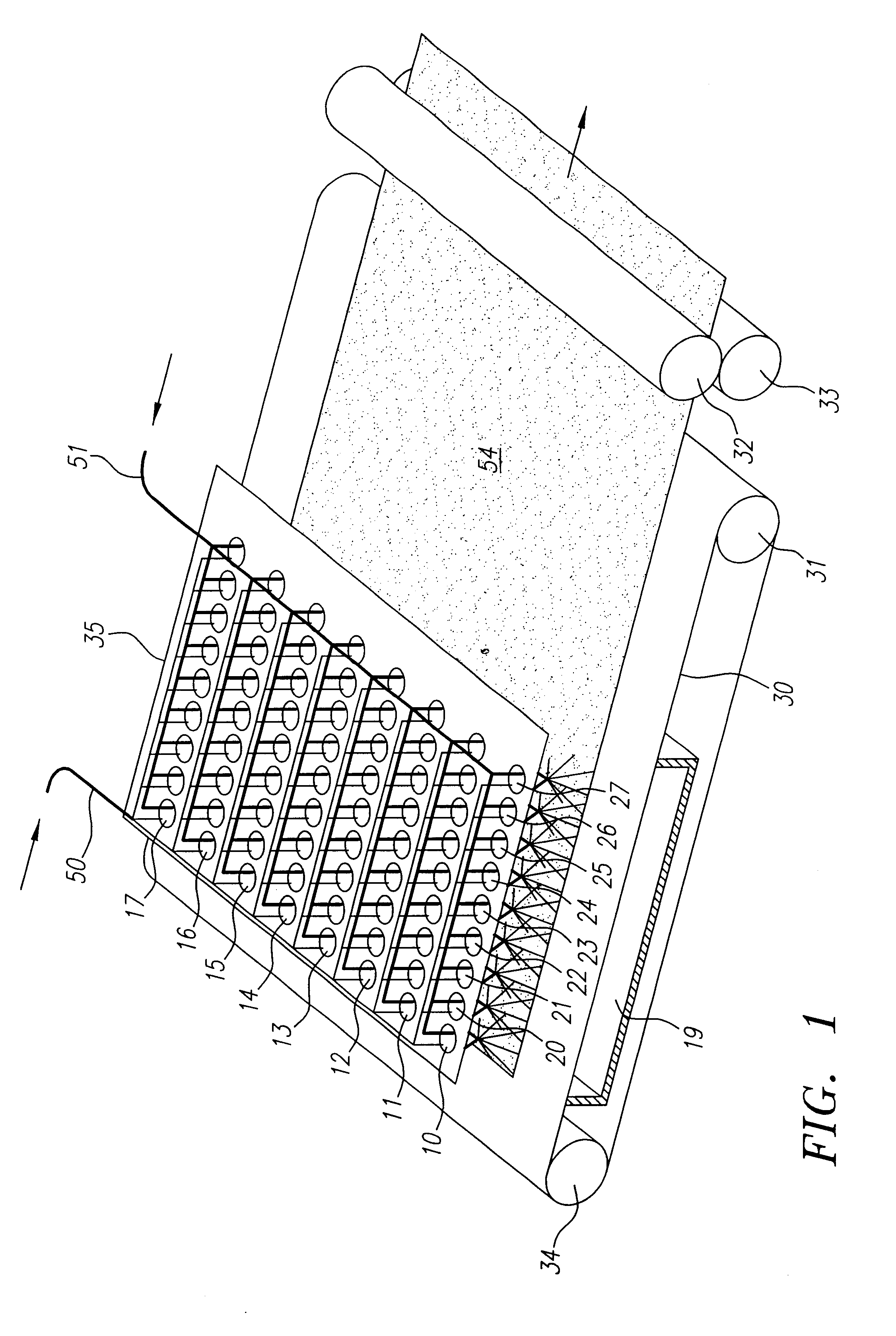

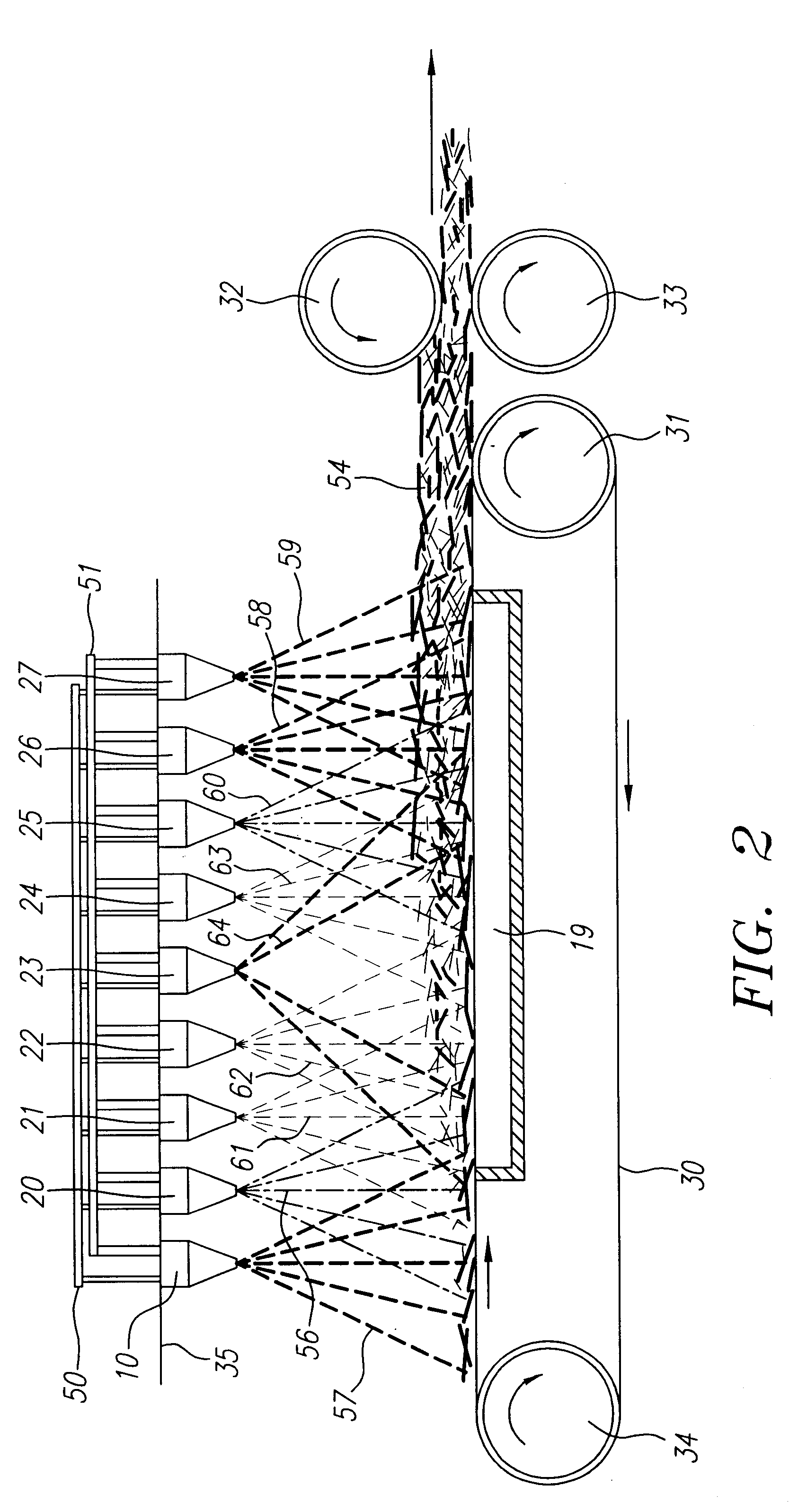

Method and apparatus for producing high efficiency fibrous media incorporating discontinuous sub-micron diameter fibers, and web media formed thereby

InactiveUS6315806B1Increase distanceReduce resistanceFilament/thread formingLoose filtering material filtersMean diameterFiber

A composite filtration medium web of fibers containing a controlled dispersion of a mixture of sub-micron and greater than sub-micron diameter polymeric fibers is described. The filtration medium is made by a two dimensional array of cells, each of which produces a single high velocity two-phase solids-gas jet of discontinuous fibers entrained in air. The cells are arranged so that the individual jets are induced to collide in flight with neighboring jets in their region of fiber formation, to cause the individual nascent fibers of adjacent jets to deform and become entangled with and partially wrap around each other at high velocity and in a localized fine scale manner before they have had an opportunity to cool to a relatively rigid state. The cells are individually adjusted to control the mean diameters, lengths and trajectories of the fibers they produce. Certain cells are adjusted to generate a significant percentage of fibers having diameters less than one micron diameter, and which are relatively shorter in length and certain other cells are adjusted to generate a significant percentage of structure-forming reinforcing fibers having diameters greater than one micron diameter which are relatively longer in length. By employing appropriate close positioning and orientation of the cells in the array, the sub-micron fibers are caused to promptly entangle with and partially wrap around the larger reinforcing fibers. The larger fibers thereby trap and immobilize the sub-micron diameter fibers in the region of formation, to minimize the tendency of sub-micron diameter fibers to clump, agglomerate, or rope together in flight. Also, the larger fibers in flight are made to form a protective curtain to prevent the sub-micron fibers from being carried off by stray air currents.

Owner:THE PROCTER & GAMBLE COMPANY

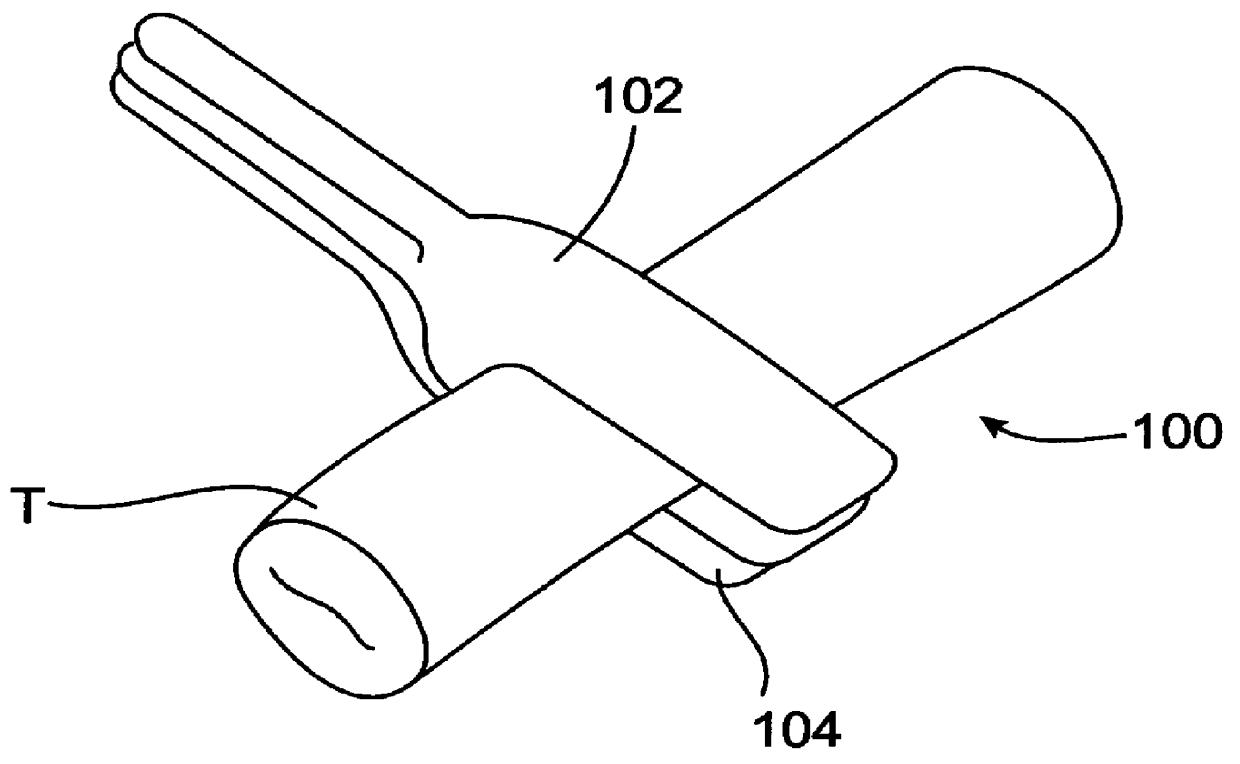

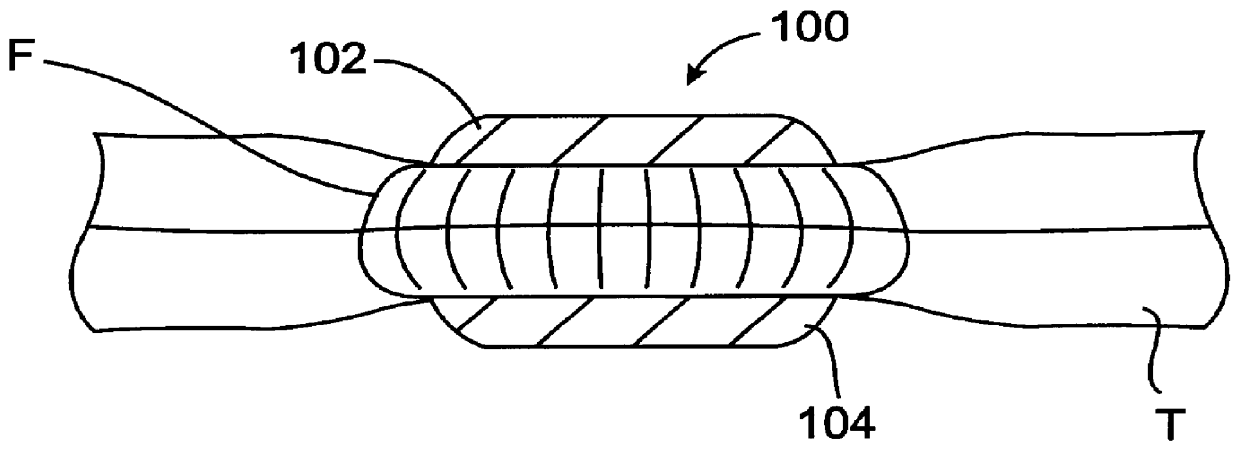

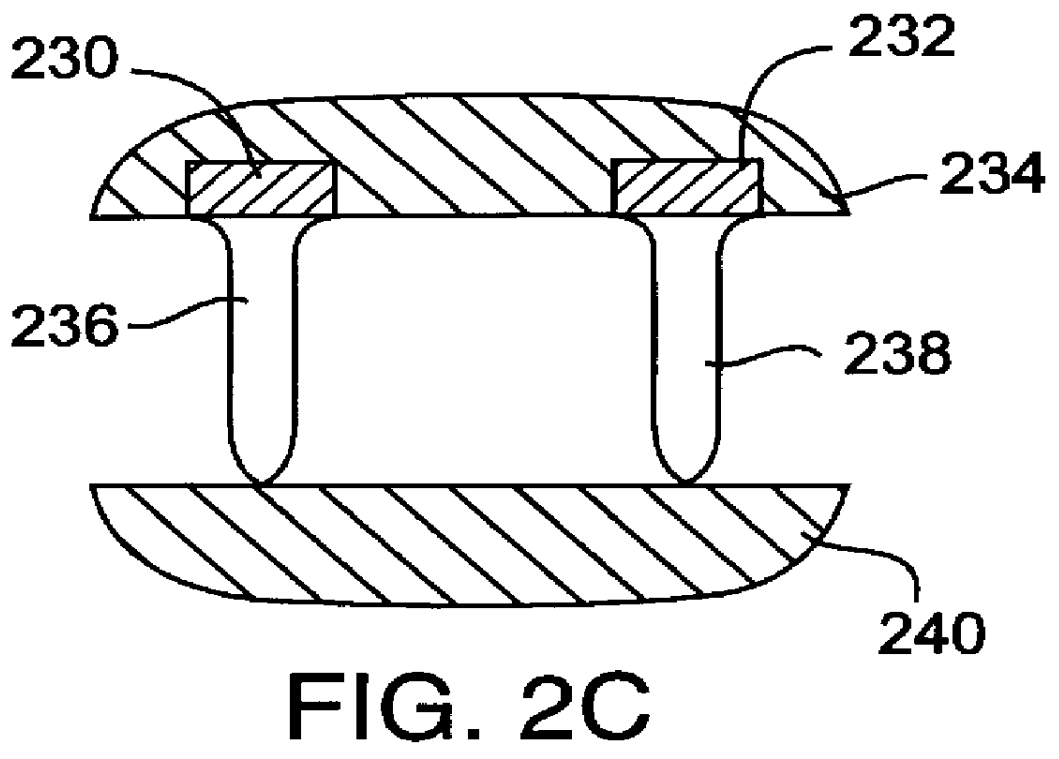

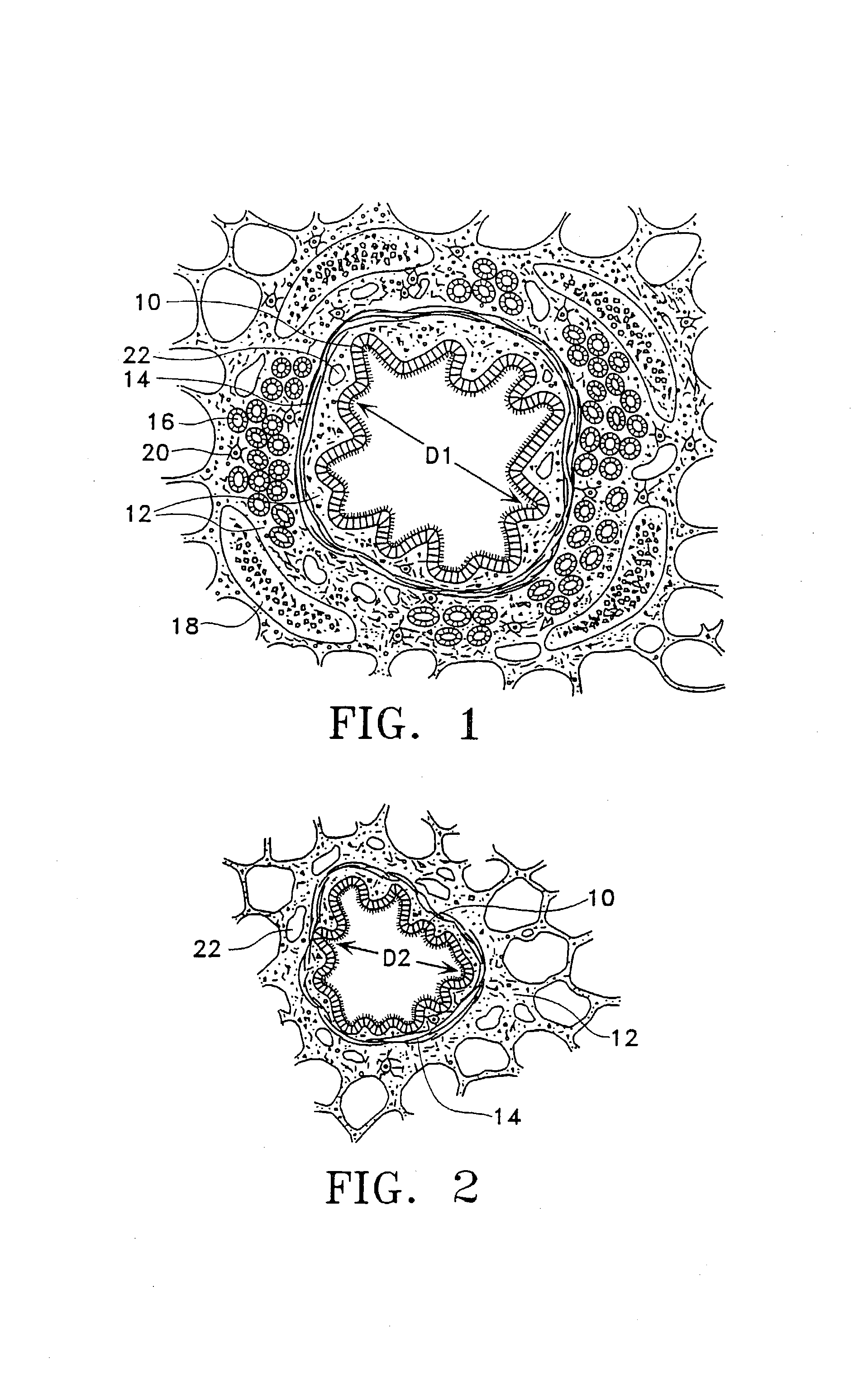

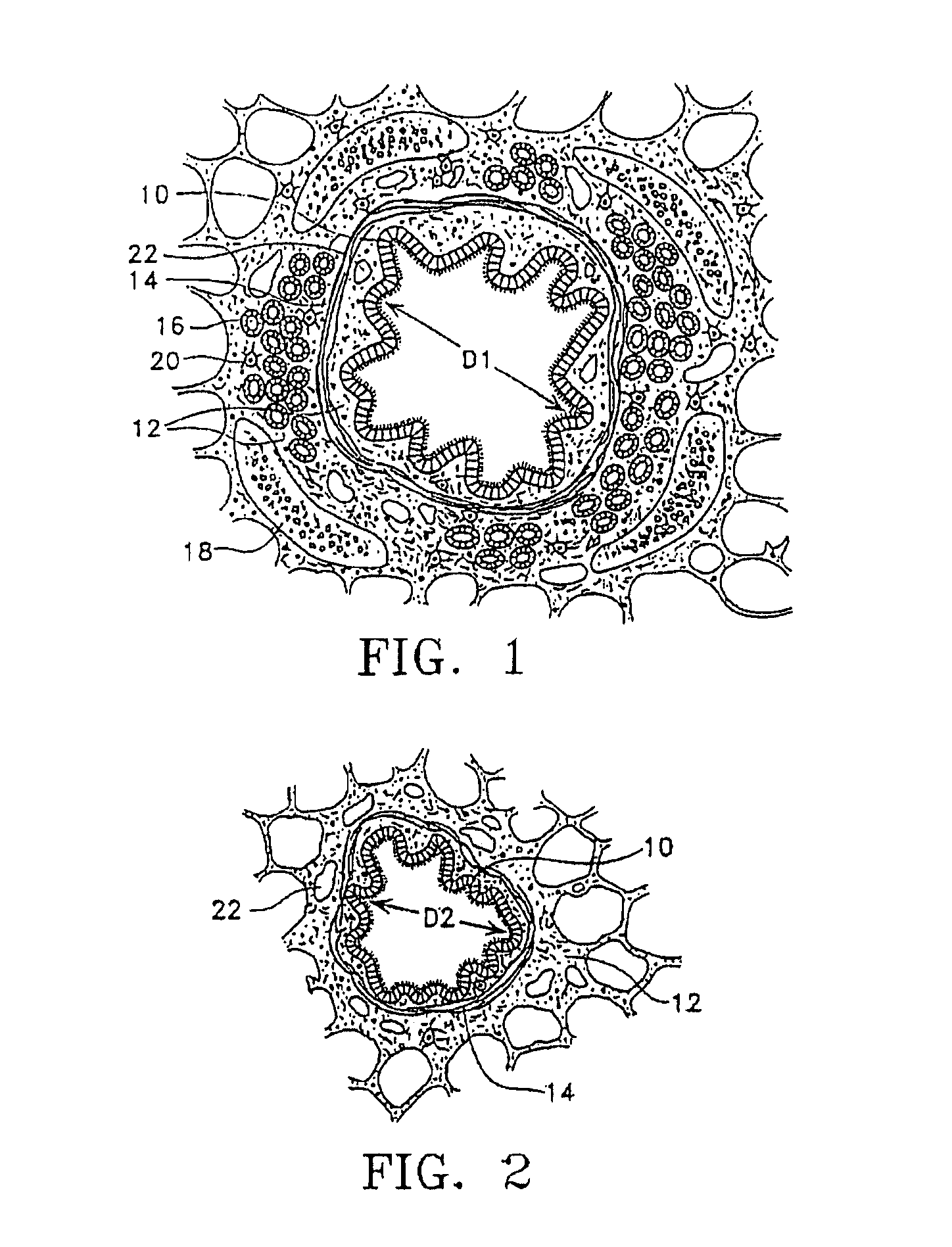

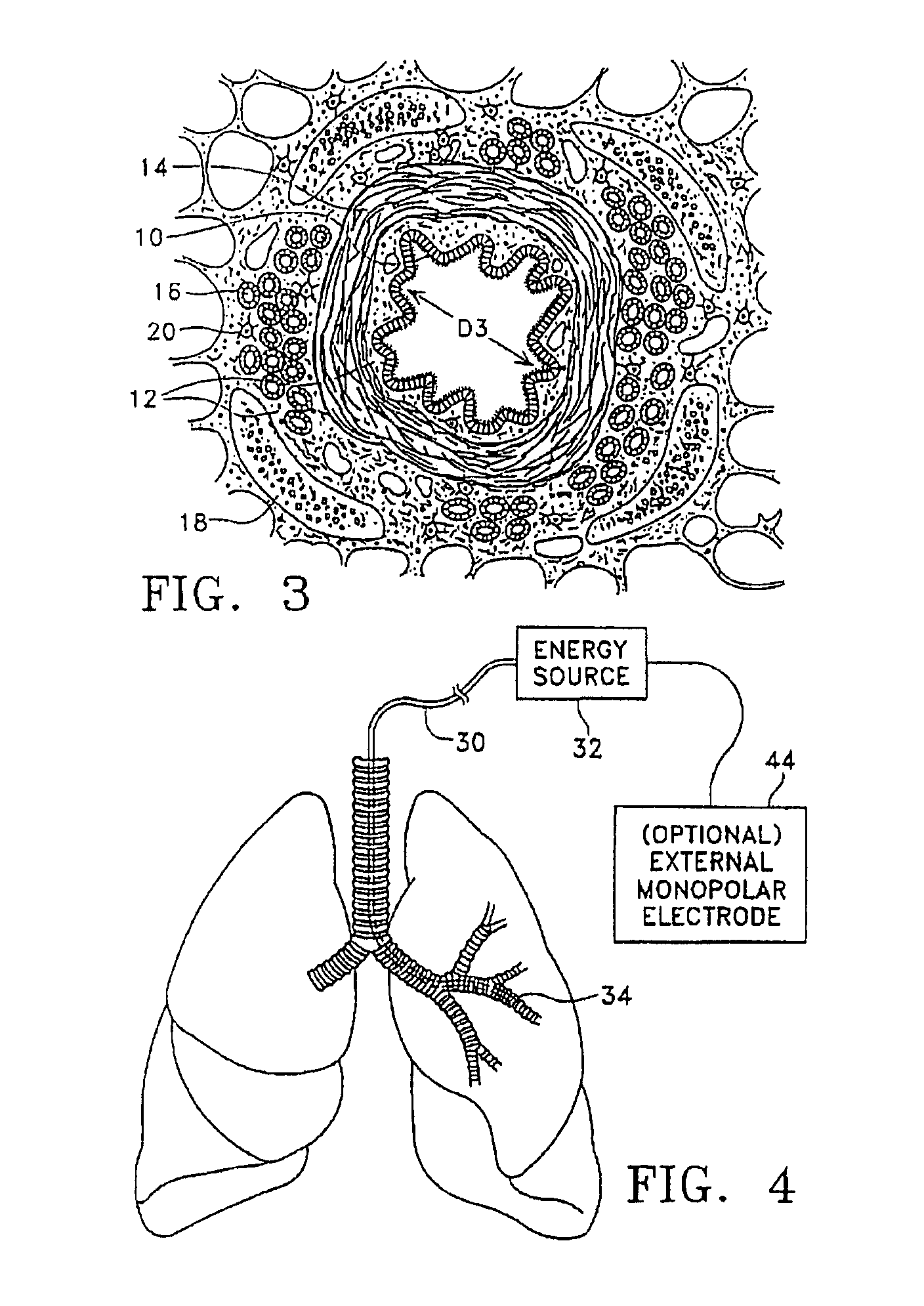

Modification of airways by application of energy

InactiveUS7198635B2Reduce plugging of the airwayPrevent the airway from being able to constrictElectrotherapySurgical needlesPatient complianceObstructive Pulmonary Diseases

This relates to methods and devices for treating reversible chronic obstructive pulmonary disease, and more particularly, relates to a device for exchanging energy with airway tissue such as that found in the airway of human lungs. The exchange of energy with this airway tissue in the airways reduces the ability of the air ways to constrict and / or reduces the resistance within the airway to the flow of air through the airway. This also relates to a method for decreasing responsiveness or decreasing resistance to airflow of airways involves the transfer of energy to or from the airway walls to prevent or reduce airway constriction and other symptoms of lung diseases. The treatment reduces the ability of the airway to contract during an acute narrowing of the airways, reduces mucus plugging of the airways, and / or increases the airway diameter. The methods according to the present invention provide a longer duration and / or more effective treatment for lung diseases than currently used drug treatments, and obviate patient compliance issues. This also includes additional steps that reduce the ability of the lung to produce at least one of the symptoms of reversible obstructive pulmonary disease and to reduce the resistance to the flow of air through a lung.

Owner:BOSTON SCI SCIMED INC

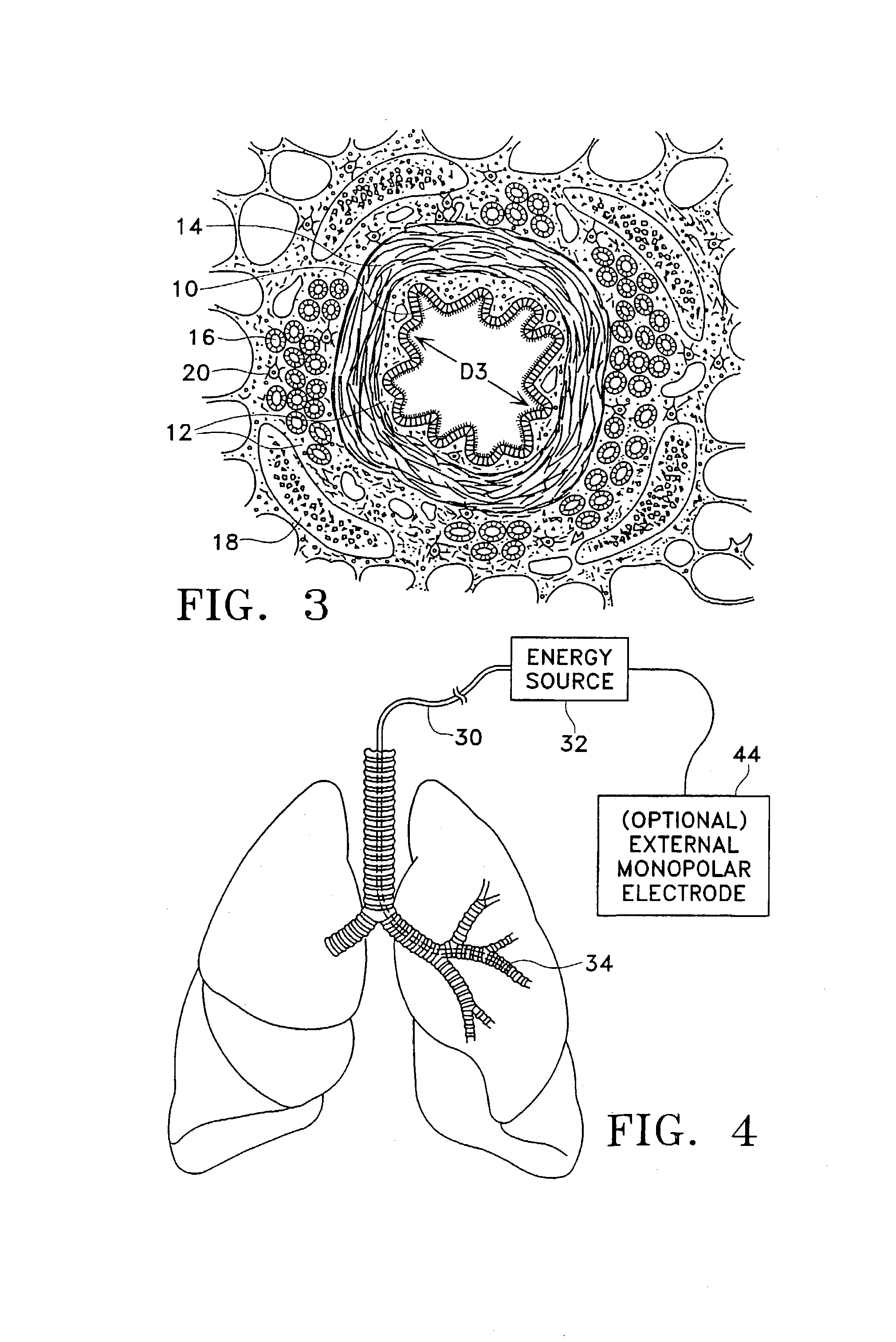

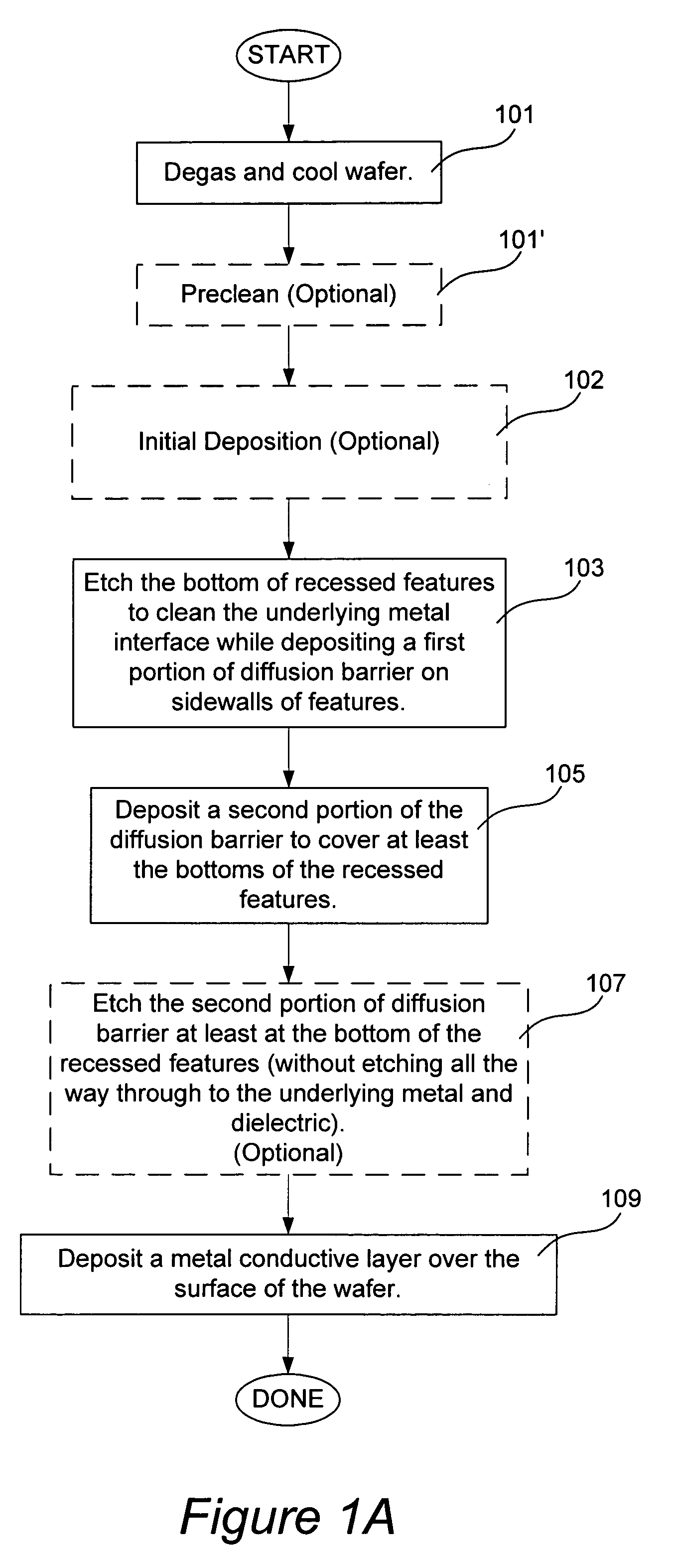

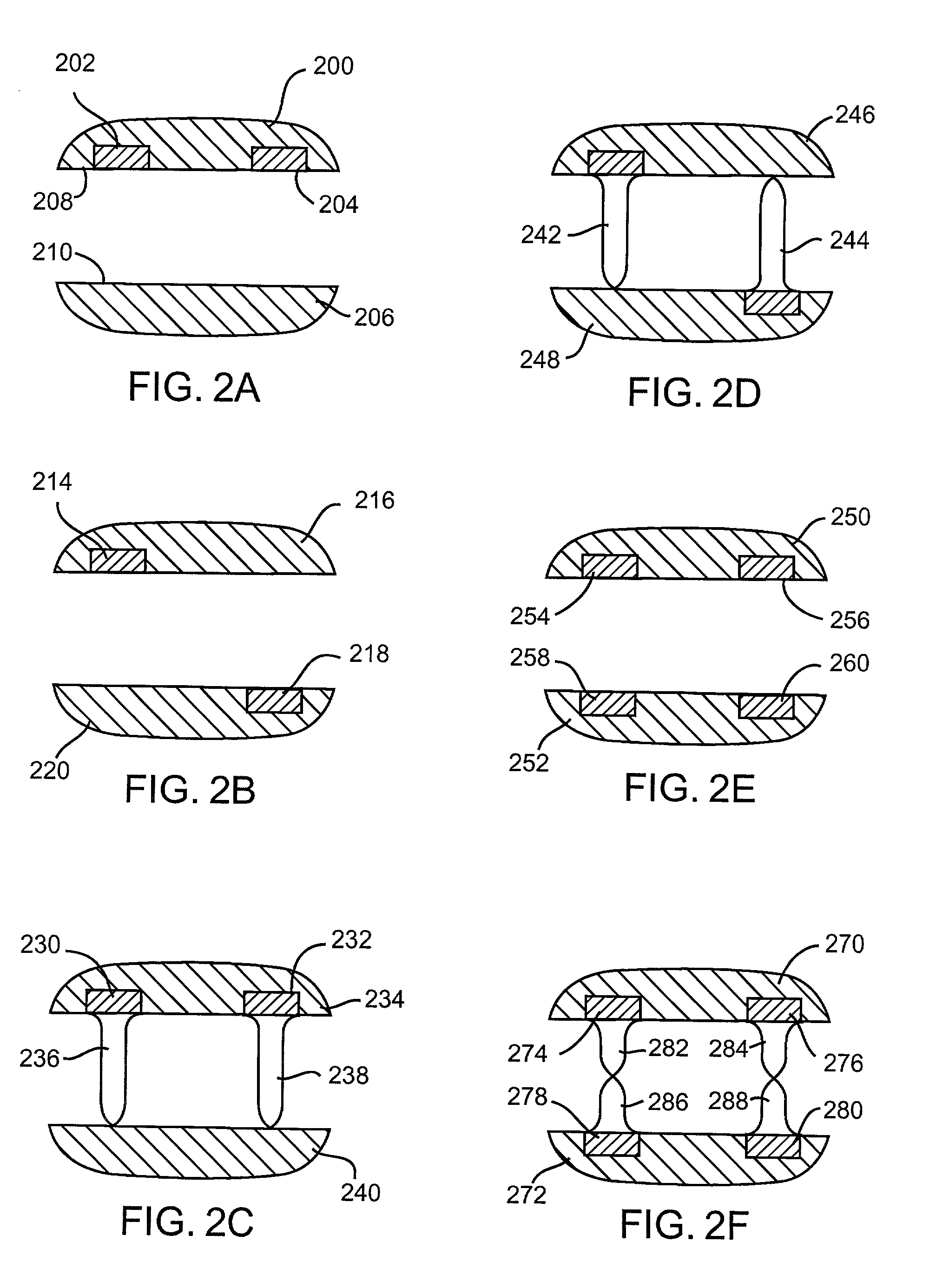

Barrier first method for single damascene trench applications

InactiveUS7186648B1Increase throughputHigh throughputSemiconductor/solid-state device manufacturingMetal interconnectEtching

Methods for forming a diffusion barrier on low aspect features of an integrated circuit include at least three operations. The first operation deposits a barrier material and simultaneously etches a portion of an underlying metal at the bottoms of recessed features of the integrated circuit. The second operation deposits barrier material to provide some minimal coverage over the bottoms of the recessed features. The third operation deposits a metal conductive layer. Controlled etching is used to selectively remove barrier material from the bottom of the recessed features, either completely or partially, thus reducing the resistance of subsequently formed metal interconnects.

Owner:NOVELLUS SYSTEMS

Bipolar surgical instruments having focused electrical fields

InactiveUS20020013583A1Reduce capacityLower impedanceSurgical needlesSurgical instruments for heatingElectricitySurgical device

A bipolar surgical device comprises a pair of actuable jaws. A first electrode member which optionally includes a line of electrically coupled tissue-penetrating elements is formed on one of the jaws, and a second electrode member which optionally includes a line of electrically coupled tissue-penetrating elements is formed on the same or the other jaw. The electrode members are laterally spaced-apart and arranged in a parallel, usually linear manner so that the lateral distance therebetween remains generally constant. In operation, tissue may be grasped between the jaws so that the electrode members contact and / or the tissue-penetrating elements enter into the tissue. By energizing the electrode members at opposite polarities using a high frequency energy source, tissue between the jaws will be heated, coagulated, and / or necrosed, while heating of tissue outside of the lines will be minimized.

Owner:PERFECT SURGICAL TECHN

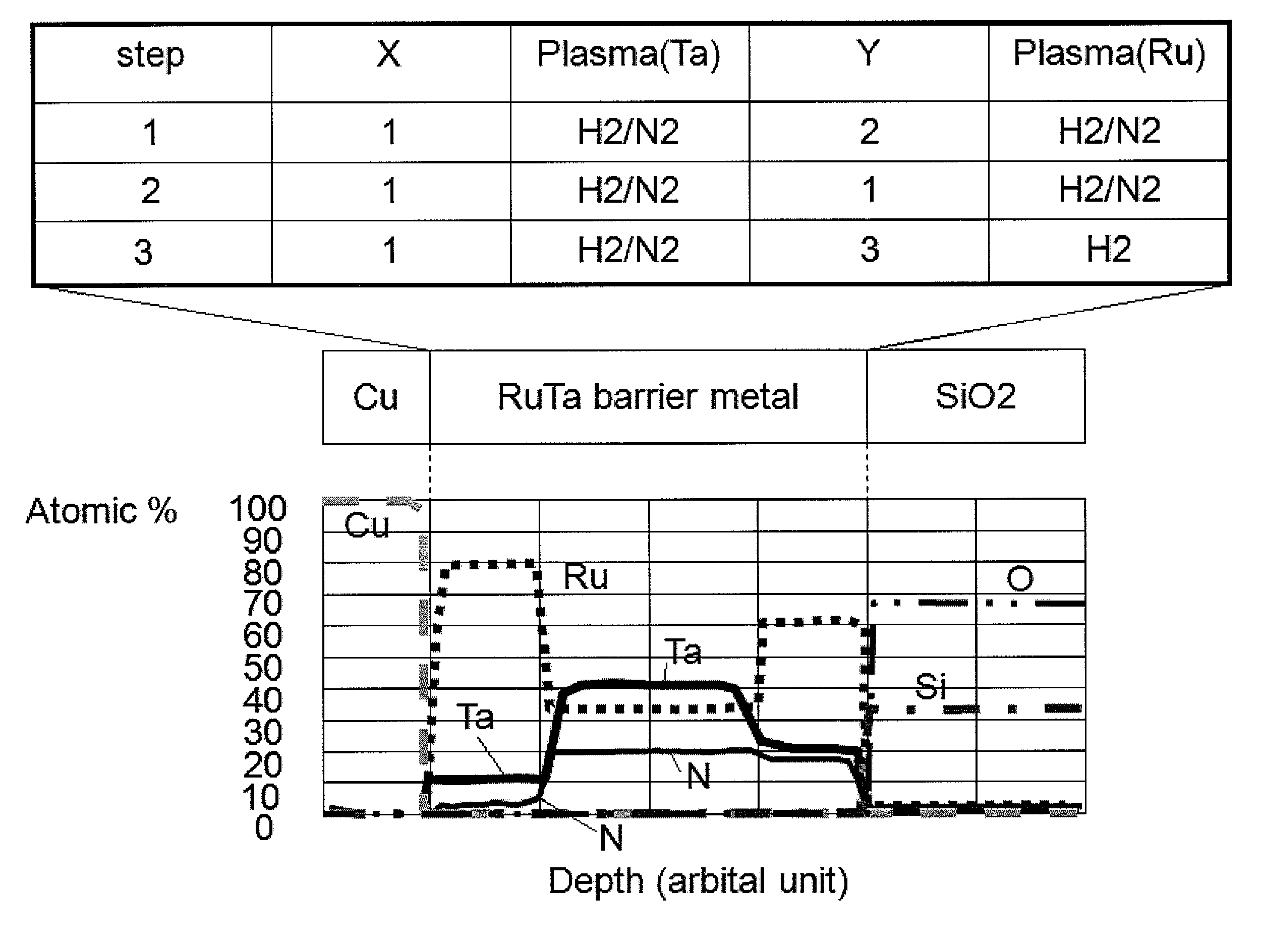

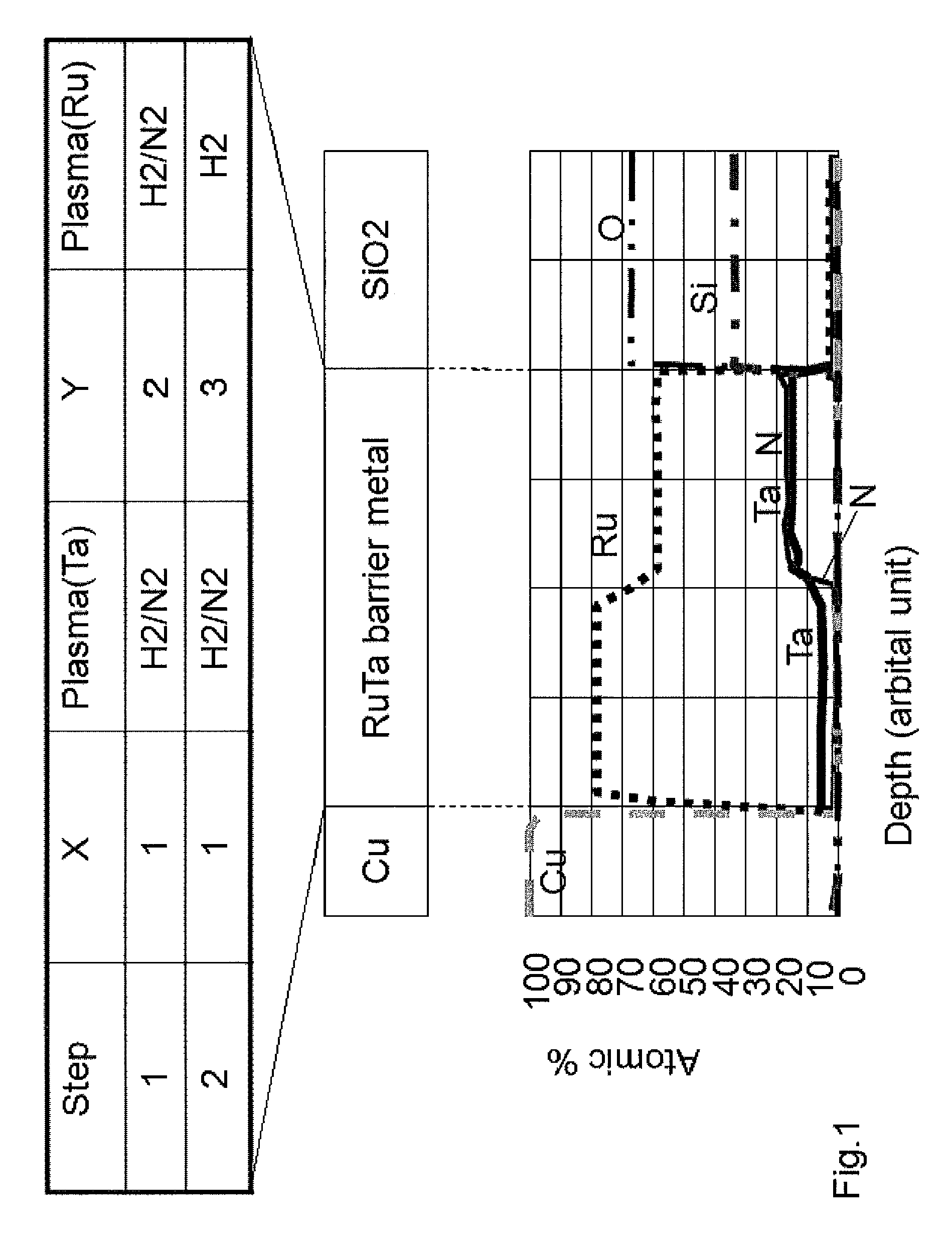

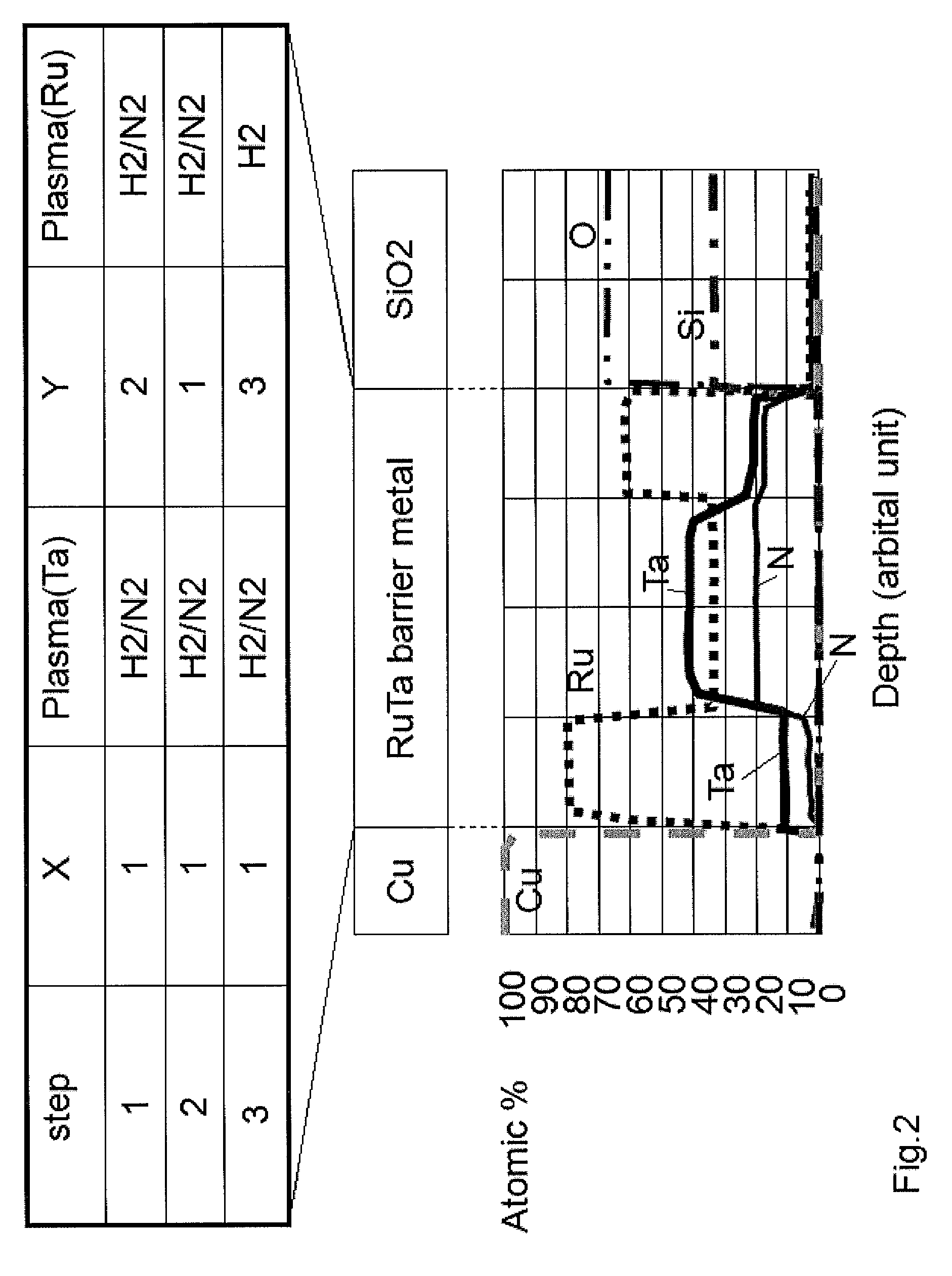

Atomic composition controlled ruthenium alloy film formed by plasma-enhanced atomic layer deposition

ActiveUS8084104B2Reduce resistanceLow densitySemiconductor/solid-state device detailsSynthetic resin layered productsRutheniumAlloy

A metal film composed of multiple atomic layers continuously formed by atomic layer deposition of Ru and Ta or Ti includes at least a top section and a bottom section, wherein an atomic composition of Ru, Ta or Ti, and N varies in a thickness direction of the metal film. The atomic composition of Ru, Ta or Ti, and N in the top section is represented as Ru(x1)Ta / Ti(y1)N(z1) wherein an atomic ratio of Ru(x1) / (Ta / Ti(y1)) is no less than 15, and z1 is 0.05 or less. The atomic composition of Ru, Ta or Ti, and N in the bottom section is represented as Ru(x2)Ta / Ti(y2)N(z2) wherein an atomic ratio of Ru(x2) / (Ta / Ti(y2)) is more than zero but less than 15, and z2 is 0.10 or greater.

Owner:ASM JAPAN

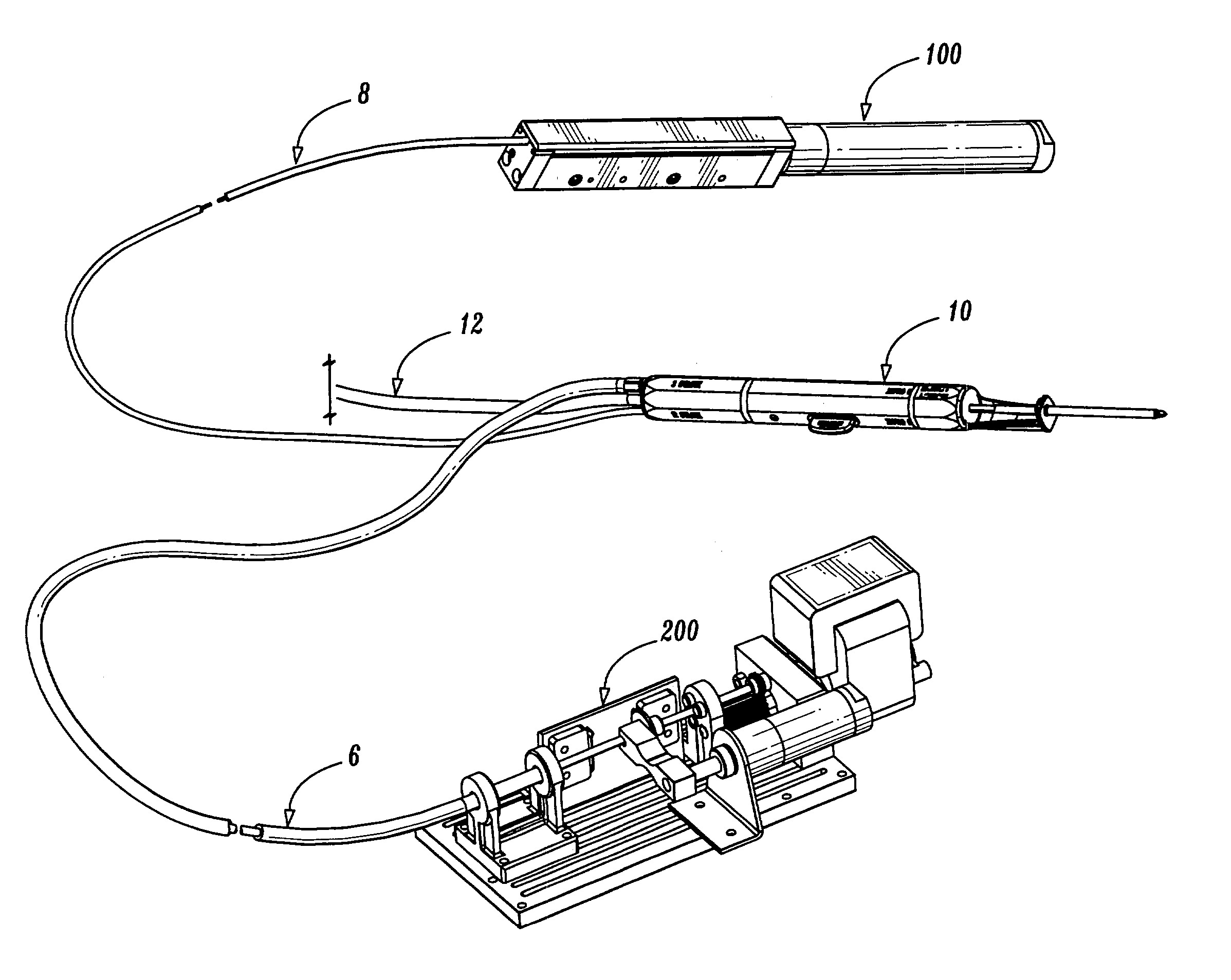

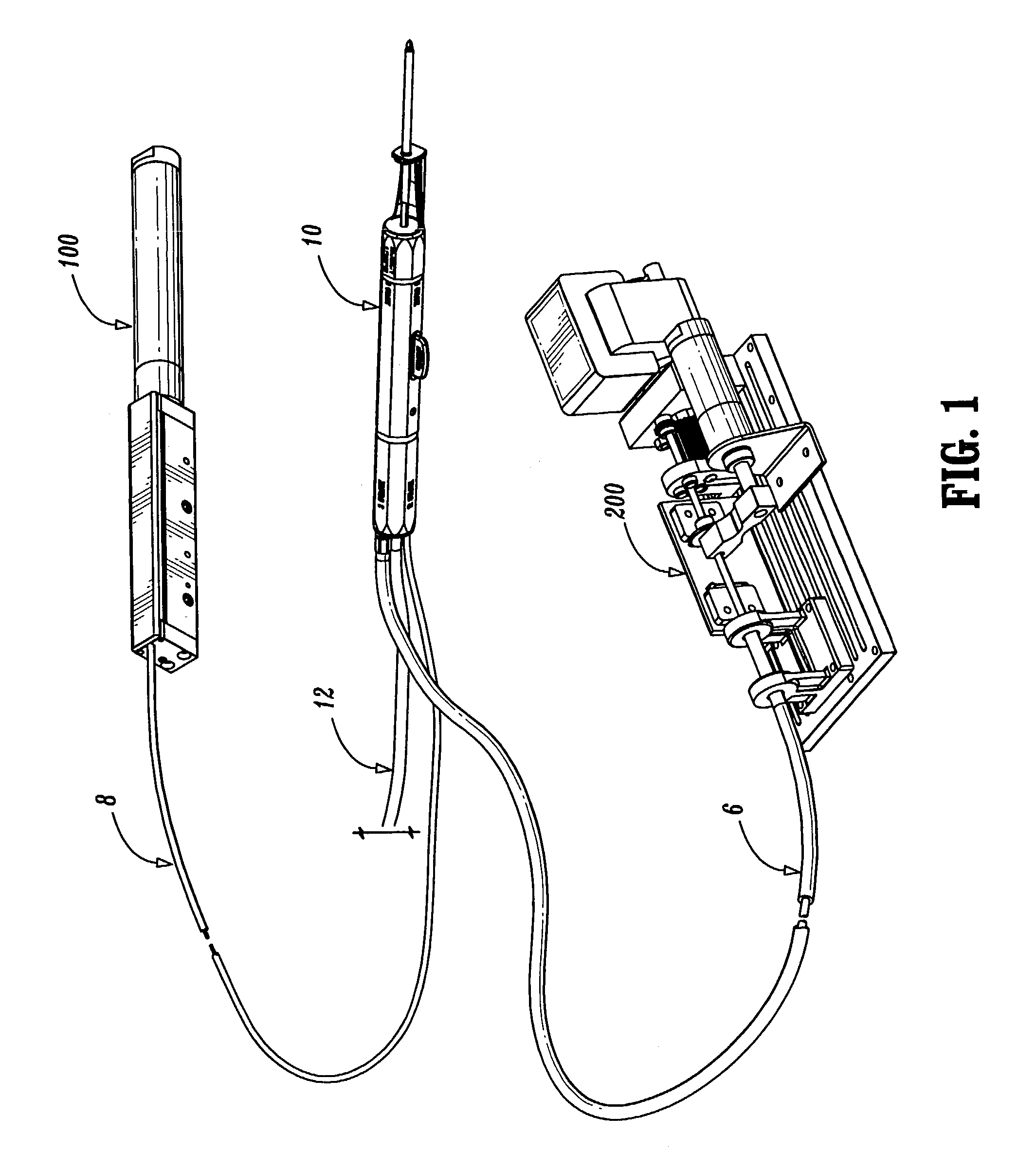

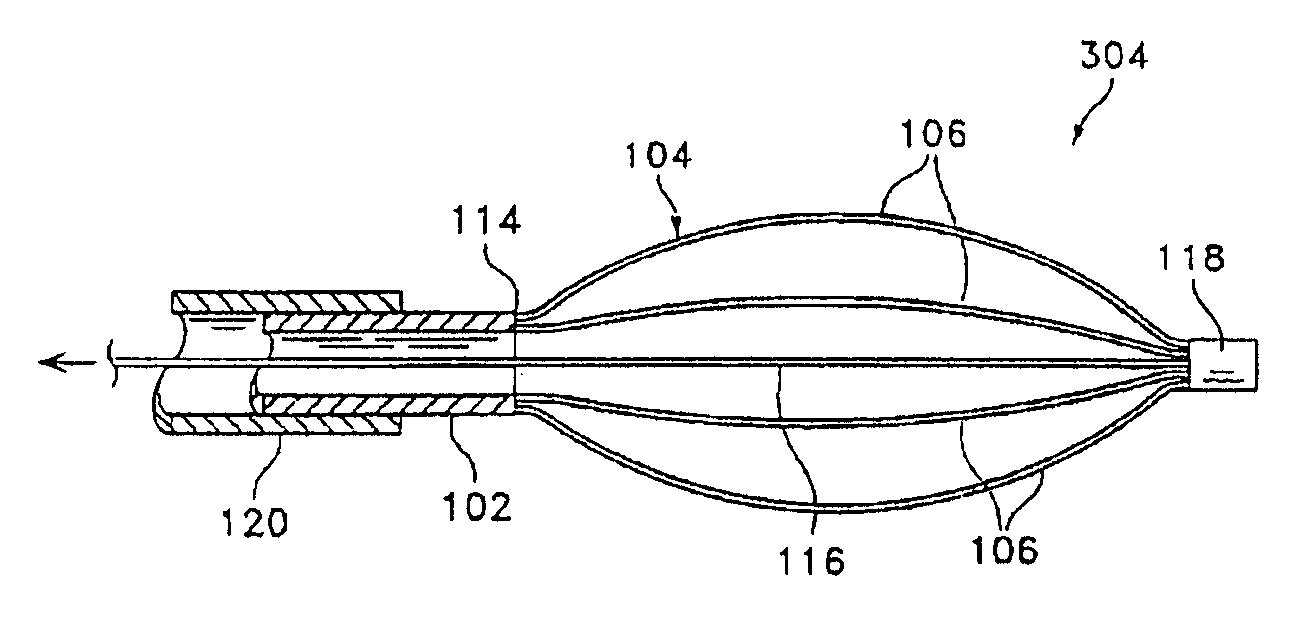

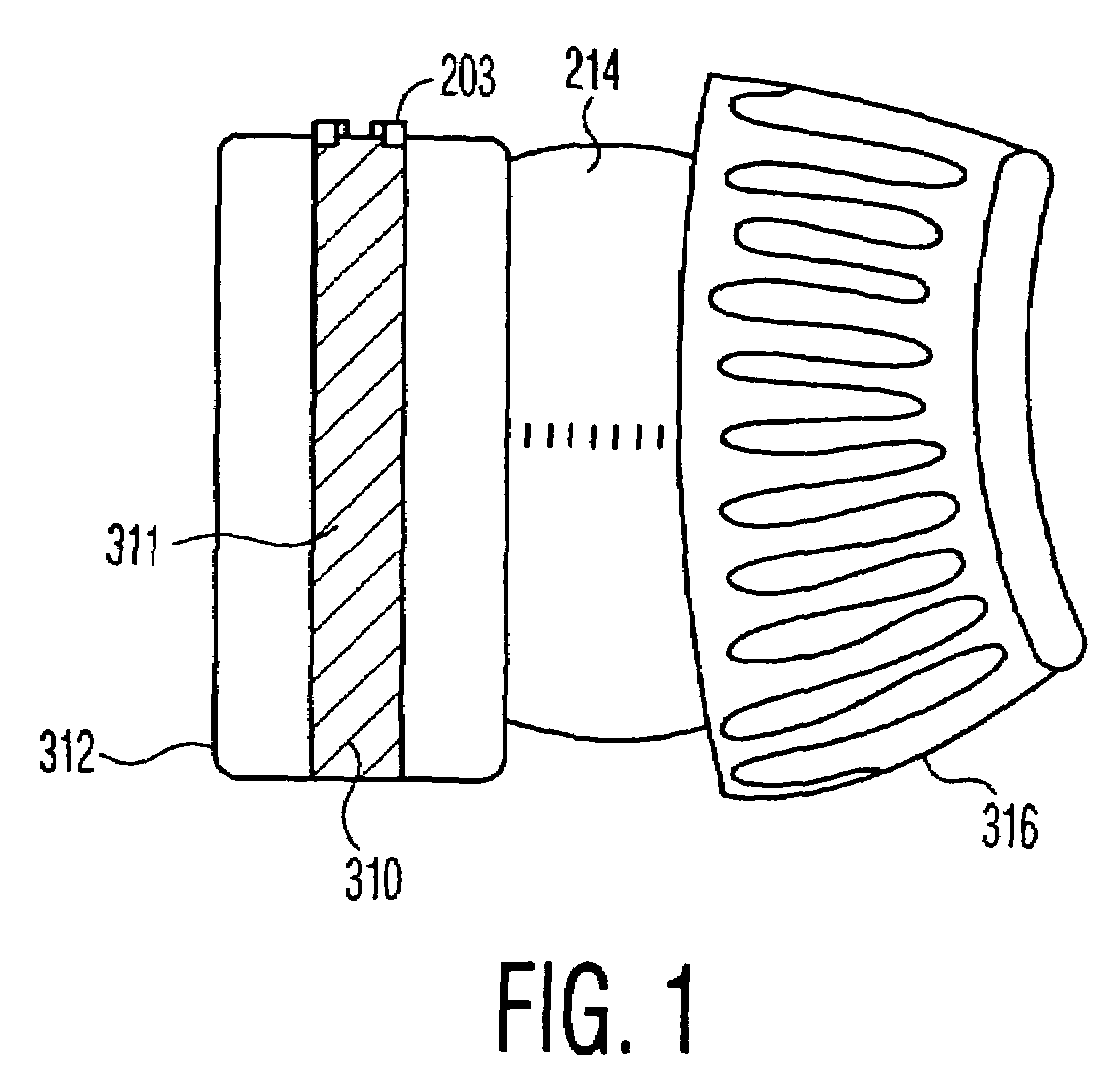

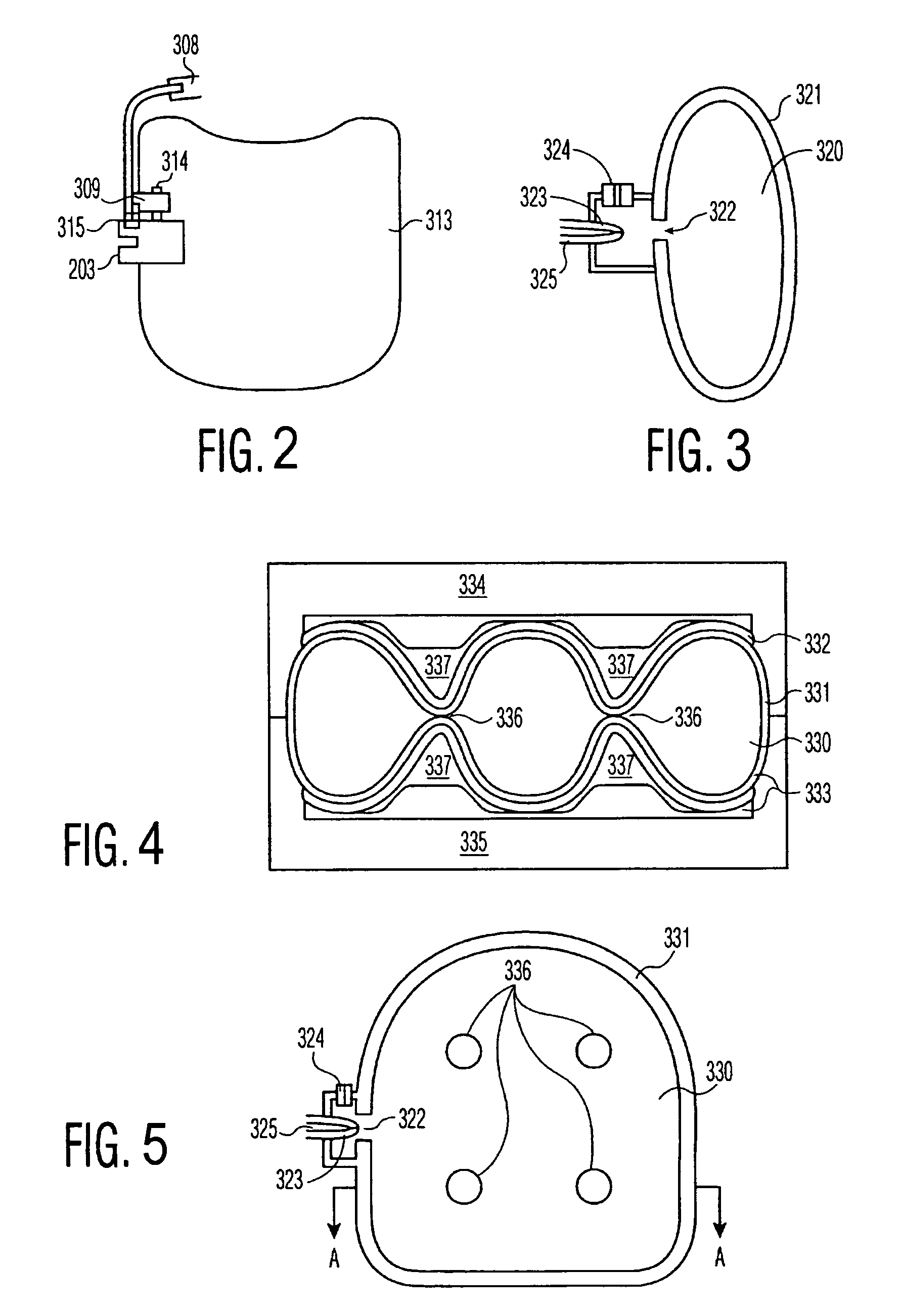

Devices for modification of airways by transfer of energy

InactiveUS7425212B1Reduced ability to constrictIncreased airway diameterElectrotherapySurgical instruments for heatingEnergy transferDisease

This relates to a device for treating lung disease, and more particularly, relates to a device for exchanging energy with airway tissue such as that found in the airways of human lungs. The exchange of energy with this airway tissue in the airways reduces the ability of the airways to constrict and / or reduces the resistance within the airway to the flow of air through the airway.

Owner:BOSTON SCI SCIMED INC

Vertical-type non-volatile memory devices

ActiveUS20090121271A1Reduce the possibilityReduce in quantityTransistorSolid-state devicesSemiconductor materialsDevice material

In a semiconductor device, and a method of manufacturing thereof, the device comprises a substrate of single-crystal semiconductor material extending in a horizontal direction and a plurality of interlayer dielectric layers on the substrate. A plurality of gate patterns are provided, each gate pattern being between a neighboring lower interlayer dielectric layer and a neighboring upper interlayer dielectric layer. A vertical channel of single-crystal semiconductor material extends in a vertical direction through the plurality of interlayer dielectric layers and the plurality of gate patterns, a gate insulating layer being between each gate pattern and the vertical channel that insulates the gate pattern from the vertical channel.

Owner:SAMSUNG ELECTRONICS CO LTD

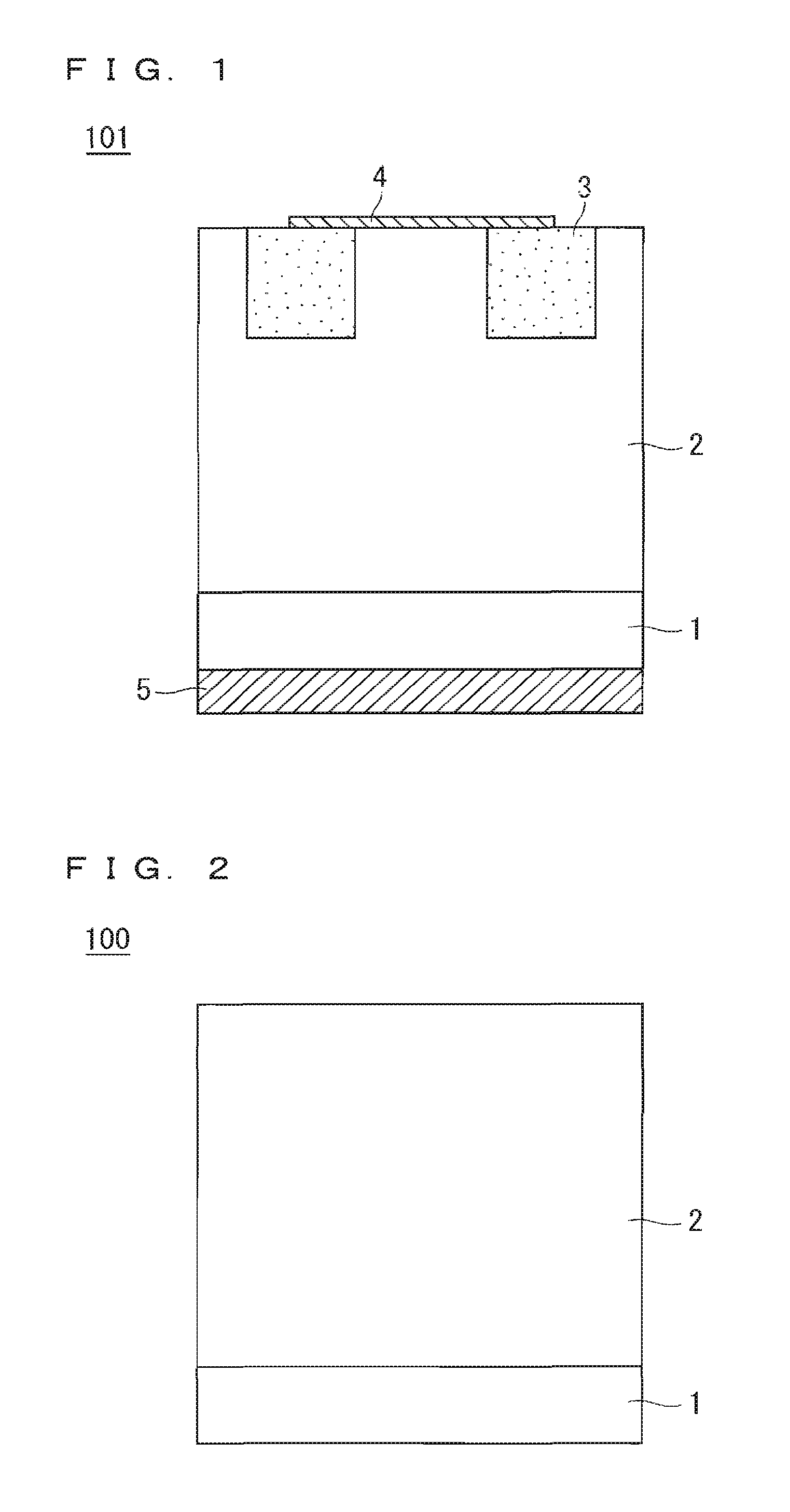

Silicon carbide semiconductor device and silicon carbide semiconductor device manufacturing method

ActiveUS20160336392A1Lower on-resistanceImprove breakdown voltageSemiconductor devicesDevice materialSemiconductor

A silicon carbide semiconductor device capable of achieving a decrease in ON resistance and an increase in breakdown voltage and a method for manufacturing a silicon carbide semiconductor device. A silicon carbide semiconductor device includes a silicon carbide substrate and a drift layer. The drift layer includes a breakdown voltage holding layer extending from a point where a doping concentration has a predetermined value to a surface of the drift layer. The doping concentration in the breakdown voltage holding layer continuously decreases from the point where the doping concentration has the predetermined value to a modulation point located further toward the surface of the drift layer than a midpoint in a film thickness direction of the breakdown voltage holding layer. The doping concentration in the breakdown voltage holding layer continuously increases from the modulation point to the surface of the drift layer.

Owner:MITSUBISHI ELECTRIC CORP

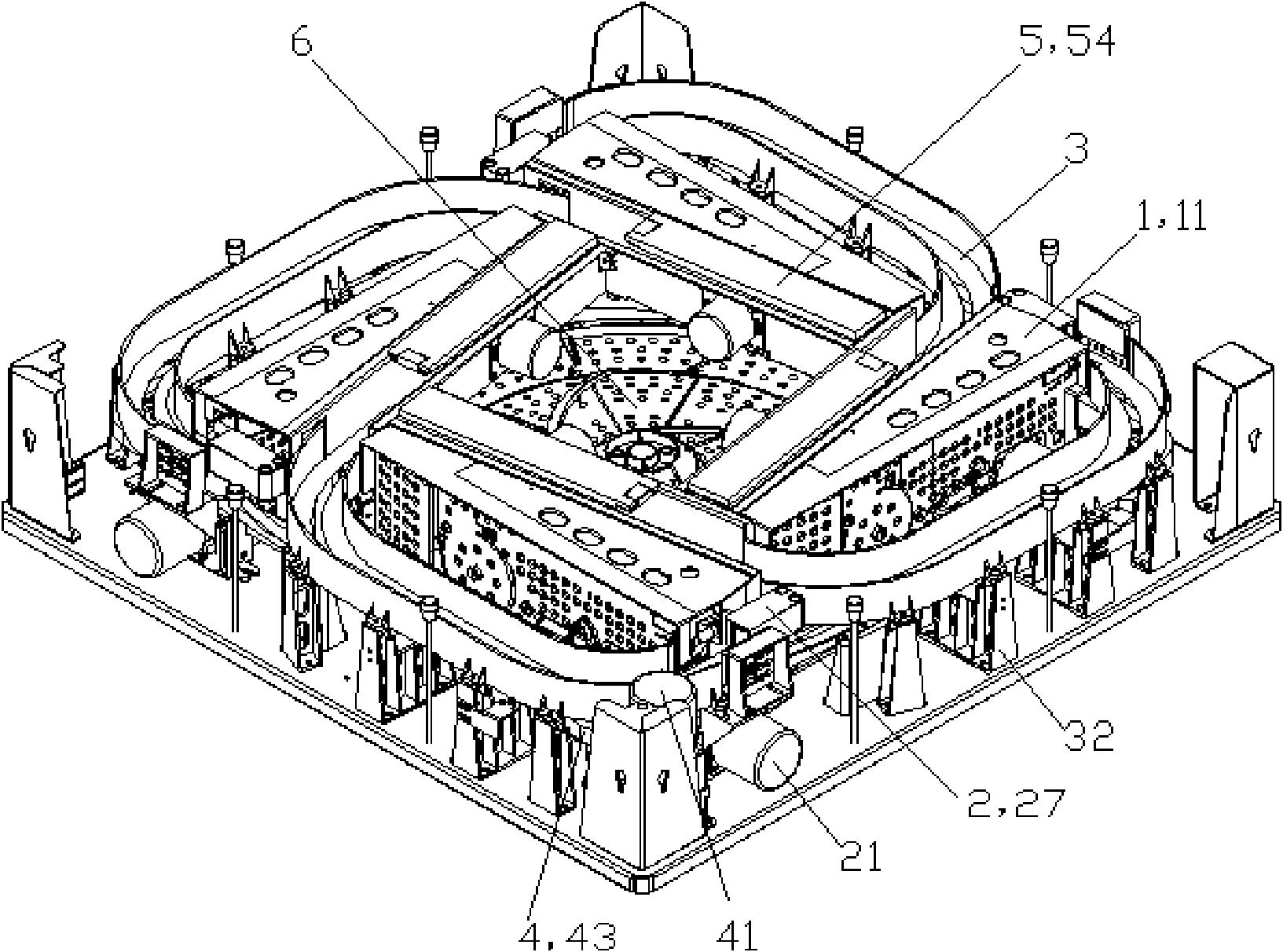

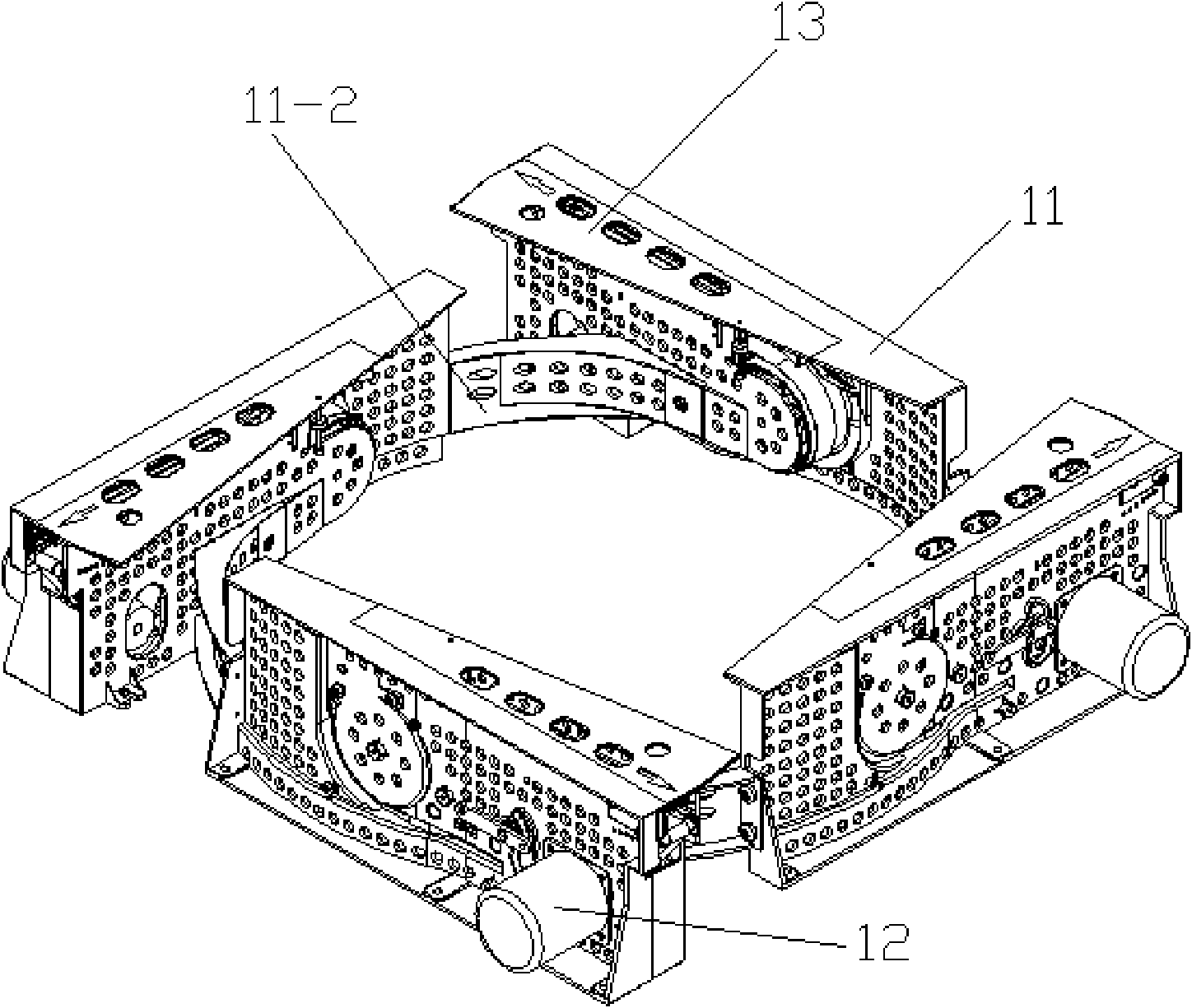

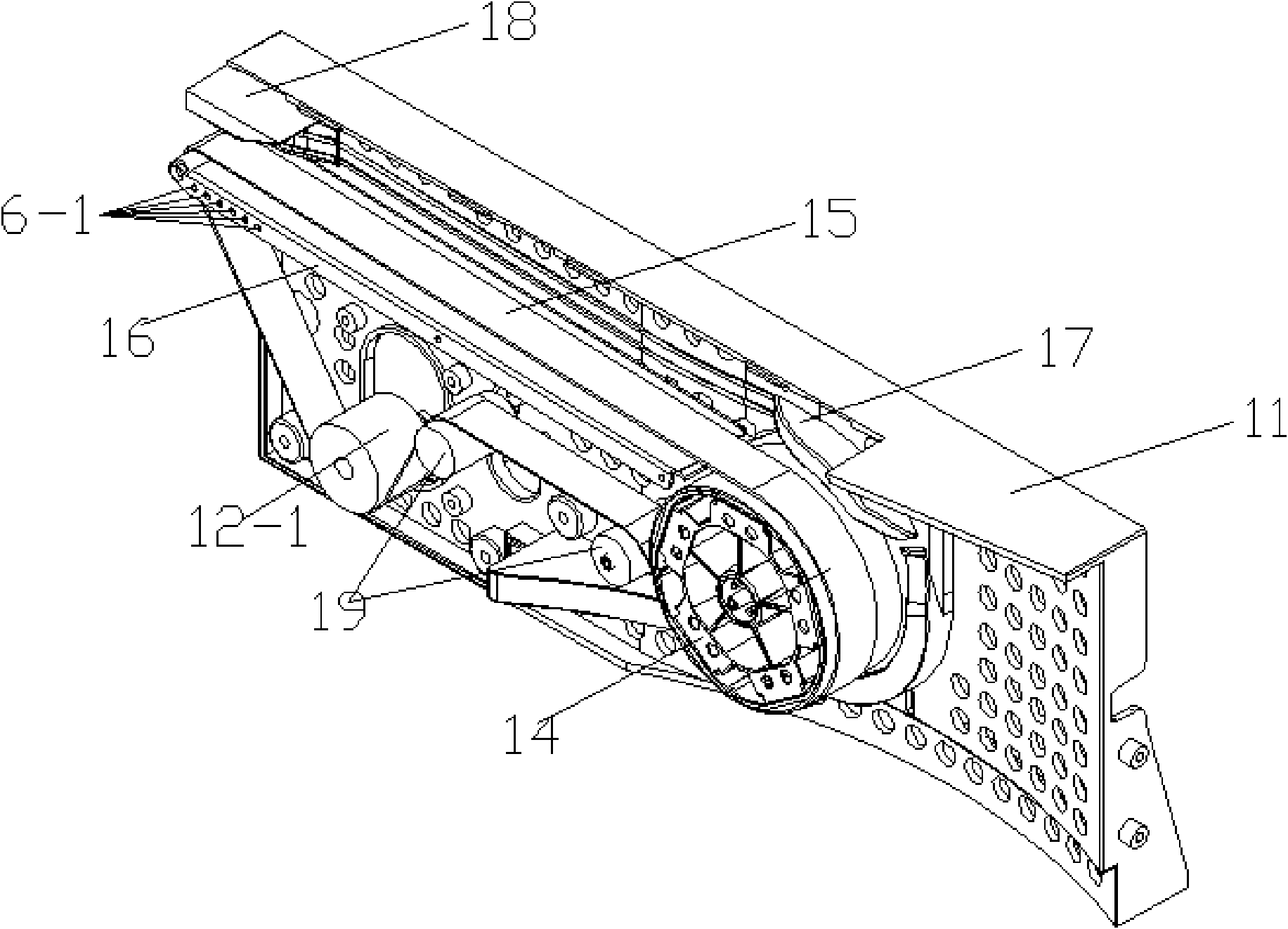

Fully-automatic mahjong machine

InactiveCN102133480AReduce manufacturing costGuaranteed uptimeIndoor gamesInlet channelTransmission belt

The invention relates to a fully-automatic mahjong machine comprising a board sending system, a board loading system, a board lifting system and a large shuffling disc. The board sending system comprises four board sending mechanisms, each board sending mechanism comprises a transmission rack, and a board sending motor, a board absorbing wheel, a transmission belt, a transmission platform, a board inlet guiding piece and a board outlet guiding piece fixed on the transmission rack; a board sending channel is arranged at the upper end of the transmission platform, the board absorbing wheel is tightly attached at the lower end of a board inlet opening of the board sending channel, the board inlet guiding piece is positioned above the board absorbing wheel, the board outlet guiding piece is positioned at a board outlet opening of the board inlet channel, the board sending motor is used for driving a motor guiding wheel, the motor guiding wheel is positioned below the transmission platform, and the transmission belt loops the motor guiding wheel, the board absorbing wheel and the transmission platform. In the invention, for the mahjong boards with different widths, the board sending mechanism of the mahjong machine can run normally by only replacing the corresponding board inlet guiding piece and the board outlet guiding piece, and a transmission rack cover does not need to be changed, so that the operation is simple and convenient, and the board inlet guiding piece and the board outlet guiding piece has extremely low production cost relative to the transmission rack cover.

Owner:程亮星

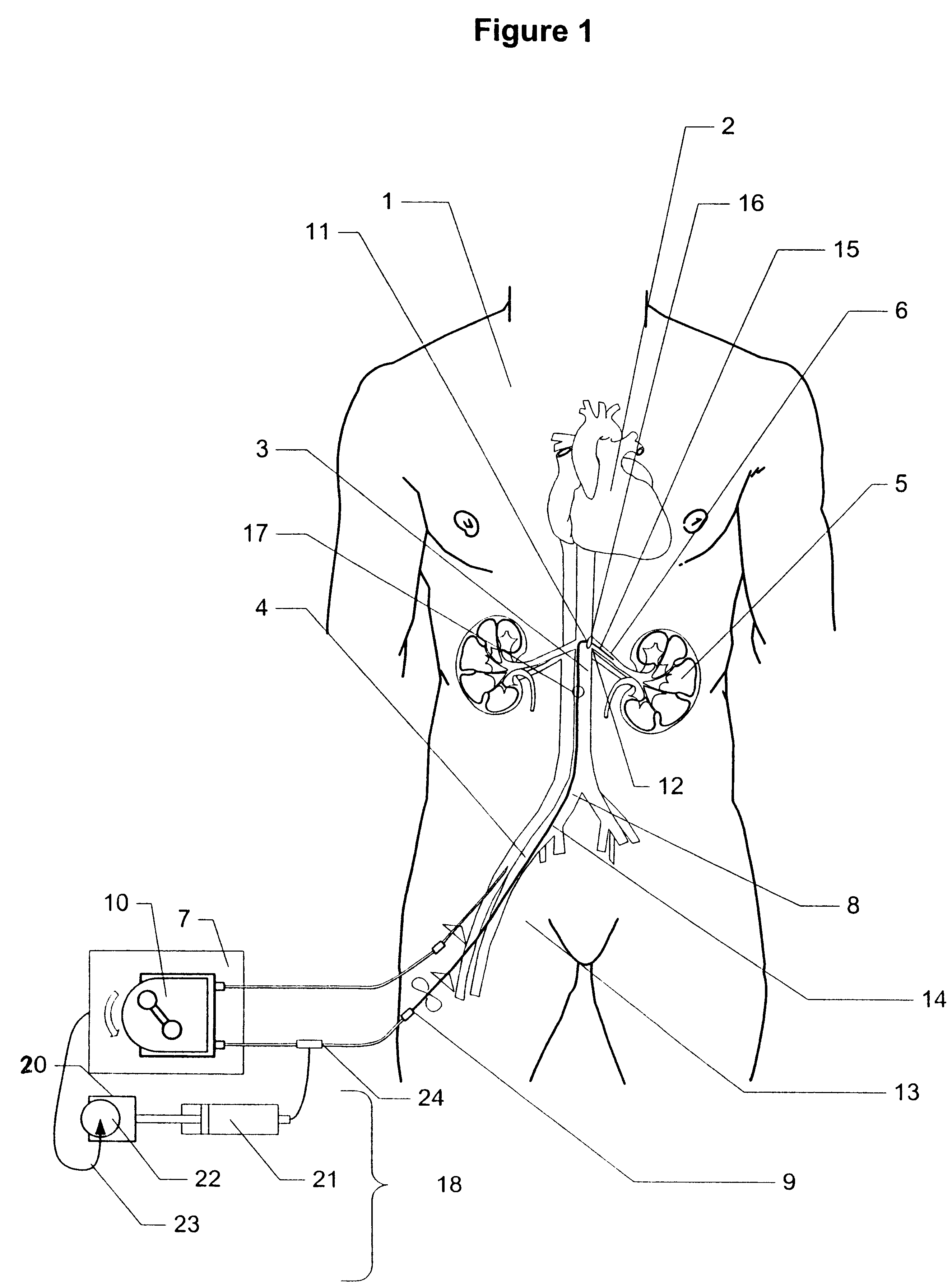

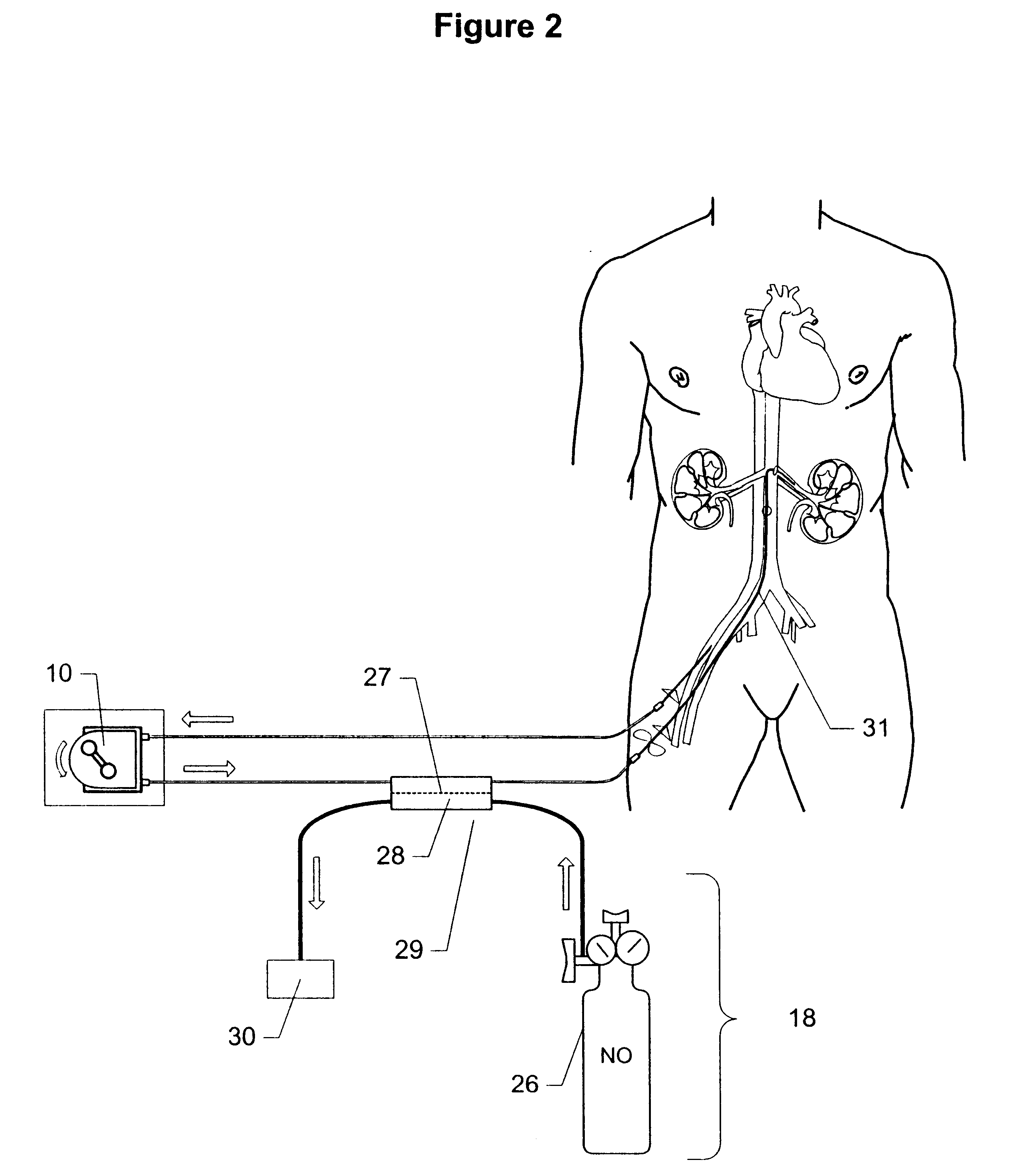

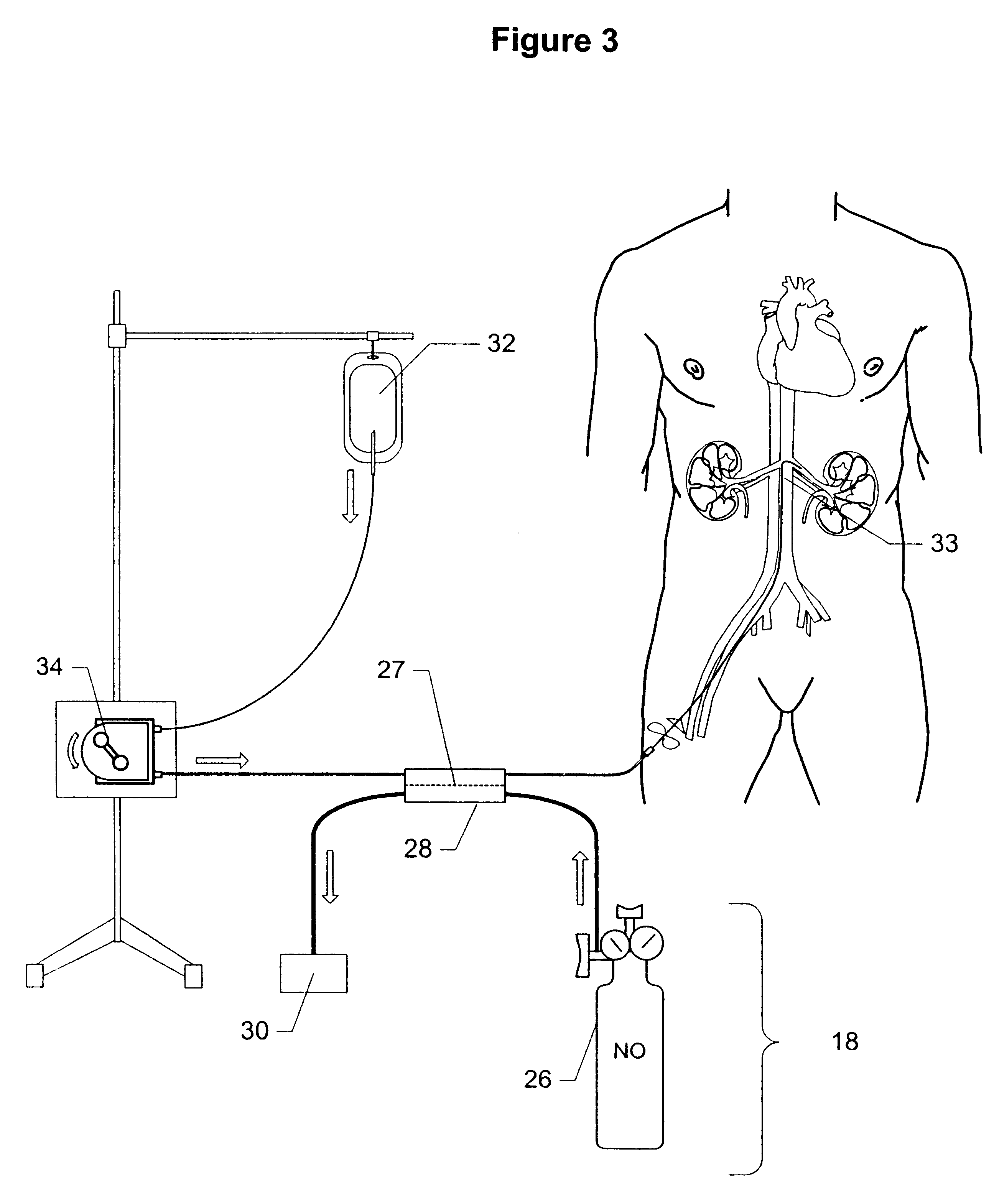

Method and apparatus for treatment of congestive heart failure by improving perfusion of the kidney by infusion of a vasodilator

InactiveUS6287608B1Improve the quality of lifeImprove survival rateBiocideInorganic active ingredientsRenin–angiotensin systemVascular dilatation

A method for treating congestive heart failure (CHF) has been developed that restores kidney renal functions by artificial vasodilation of at least one kidney. A vasodilator drug is locally delivered to the kidney via a kidney perfusion catheter. The drug can be mixed with the patient's blood, saline or other suitable solvent and the mixture directly applied to the kidney through the catheter. The restoration of kidney function assists the heart by removing excess fluid, urine and toxin from the patient, and by normalizing the patient's renin-angiotensin system and other neurohormonal substances. The method is applicable to treat chronic and acute CHF.

Owner:GAMBRO LUNDIA AB

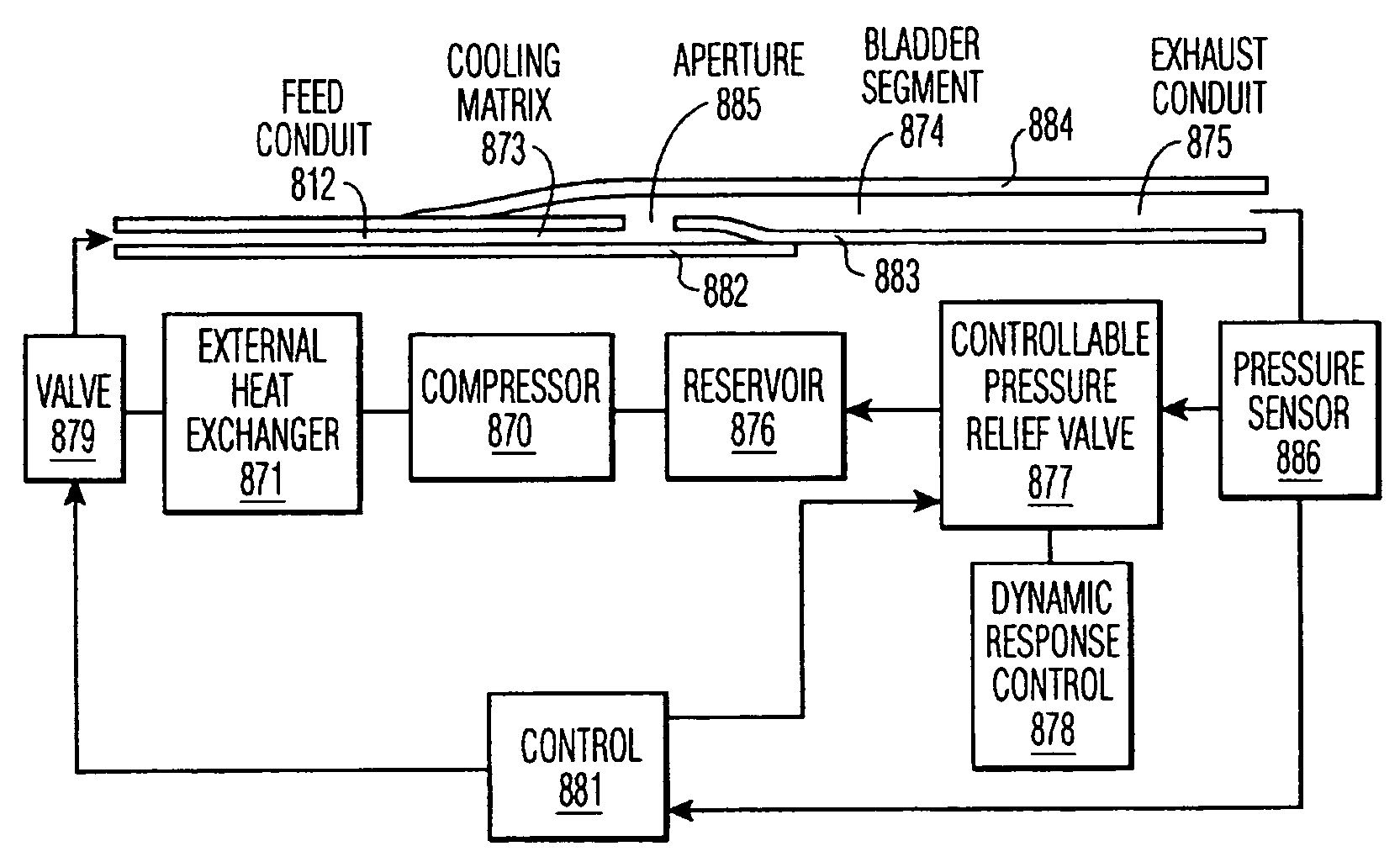

Adaptively controlled footwear

A method for controlling footwear, comprising cushioning a transient force during use of the footwear at a first period of a gait cycle, storing energy from said cushioning, and releasing the stored energy during use of the footwear at a second period of the gait cycle, and after said transient force has subsided. The control can be electronic, mechanical or hydraulic, and is preferably dependent on a sensed gait cycle phase. The control may be adaptive to the user or the use of the footwear. The stored energy can be used to assist in locomotion, to generate electrical energy, to drive a heat pump, or simply dissipated.

Owner:PROMDX TECH

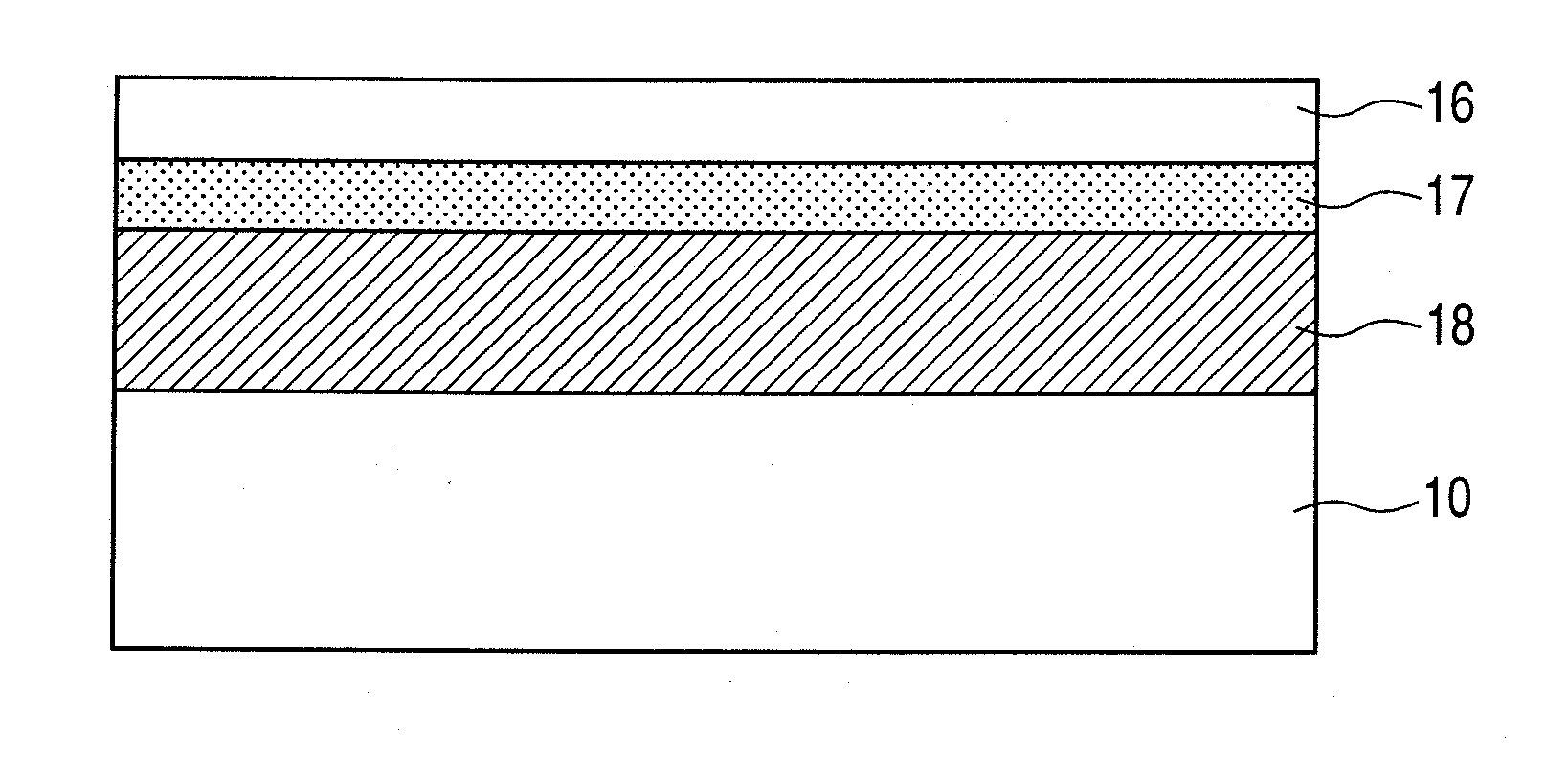

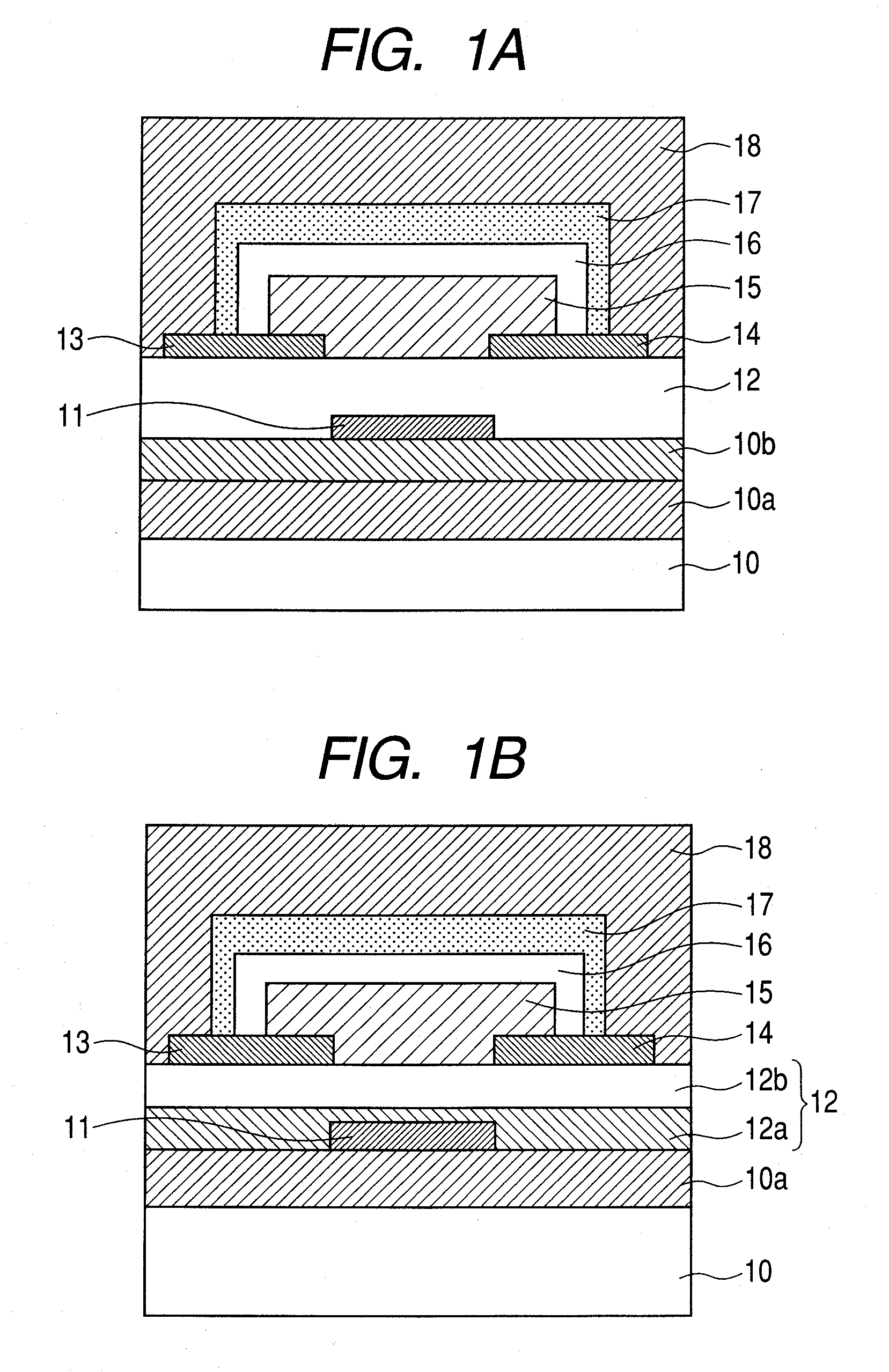

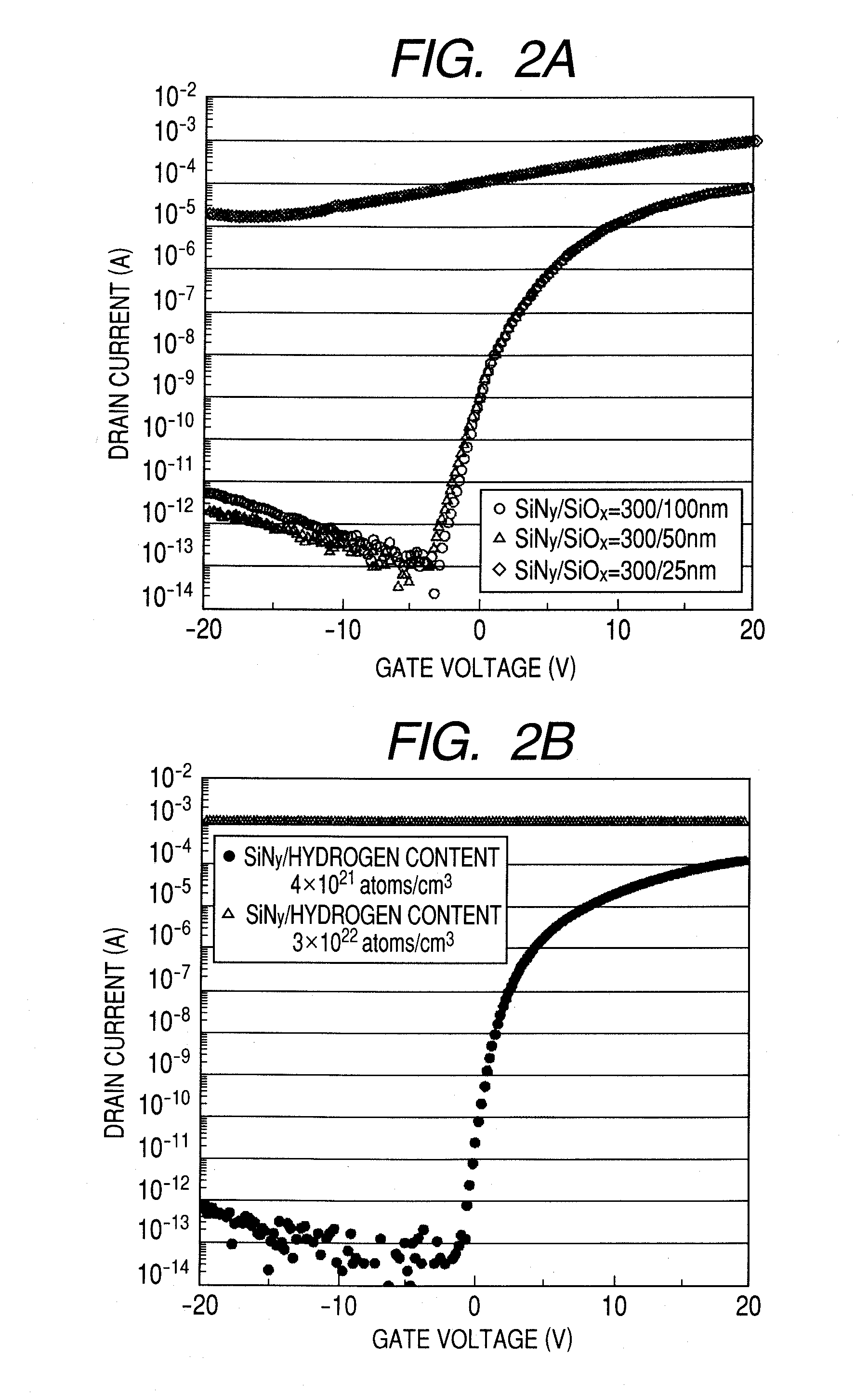

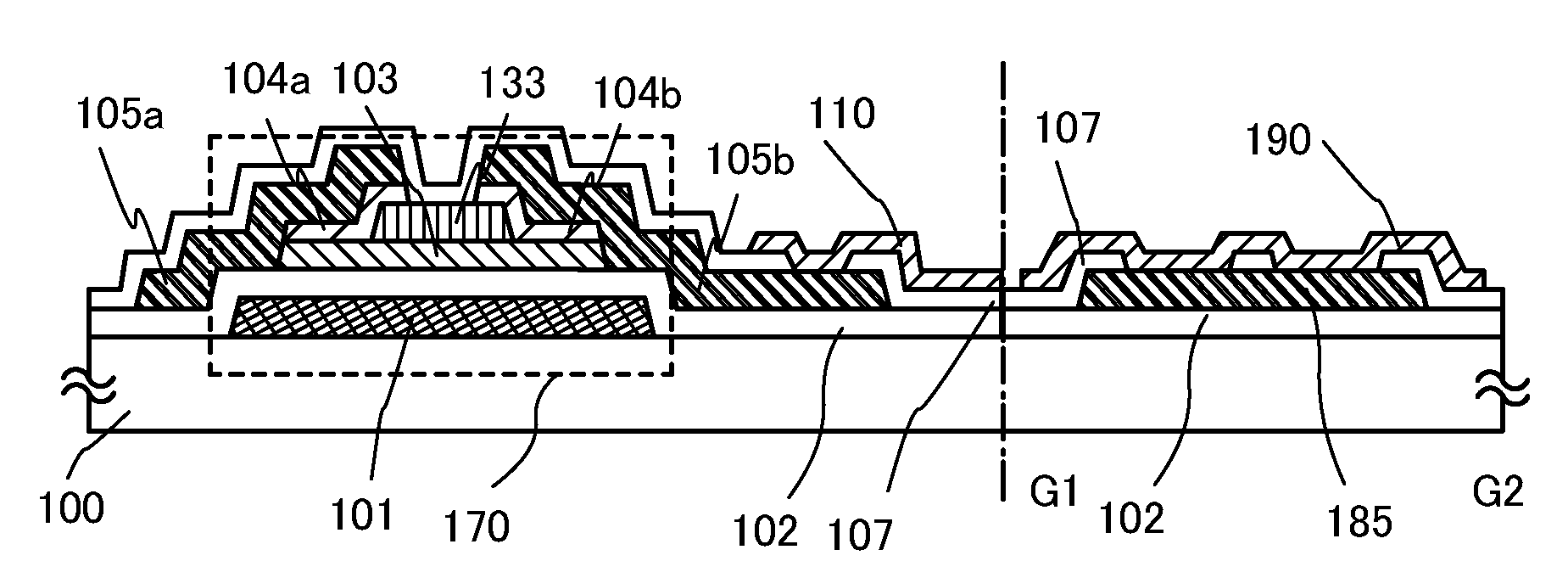

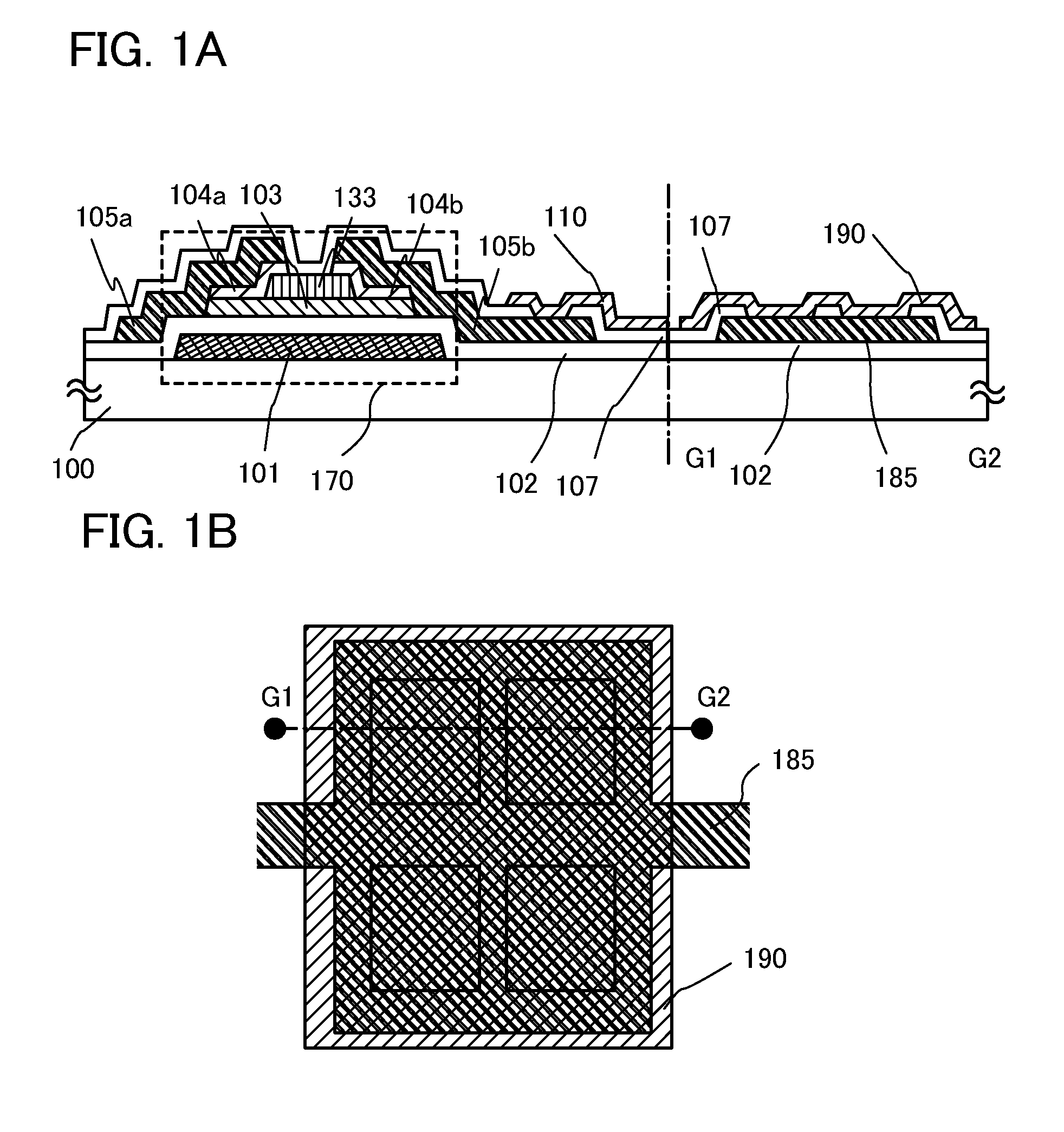

Oxide semiconductor device including insulating layer and display apparatus using the same

ActiveUS20100283049A1Lowering of the resistance of the semiconductor layerImprove productivityTransistorSolid-state devicesHydrogen contentNitride

Provided is an oxide semiconductor device including an oxide semiconductor layer and an insulating layer coming into contact with the oxide semiconductor layer in which the insulating layer includes: a first insulating layer coming into contact with an oxide semiconductor, having a thickness of 50 nm or more, and including an oxide containing Si and O; a second insulating layer coming into contact with the first insulating layer, having a thickness of 50 nm or more, and including a nitride containing Si and N; and a third insulating layer coming into contact with the second insulating layer, the first insulating layer and the second insulating layer having hydrogen contents of 4×1021 atoms / cm3 or less, and the third insulating layer having a hydrogen content of more than 4×1021 atoms / cm3.

Owner:CANON KK

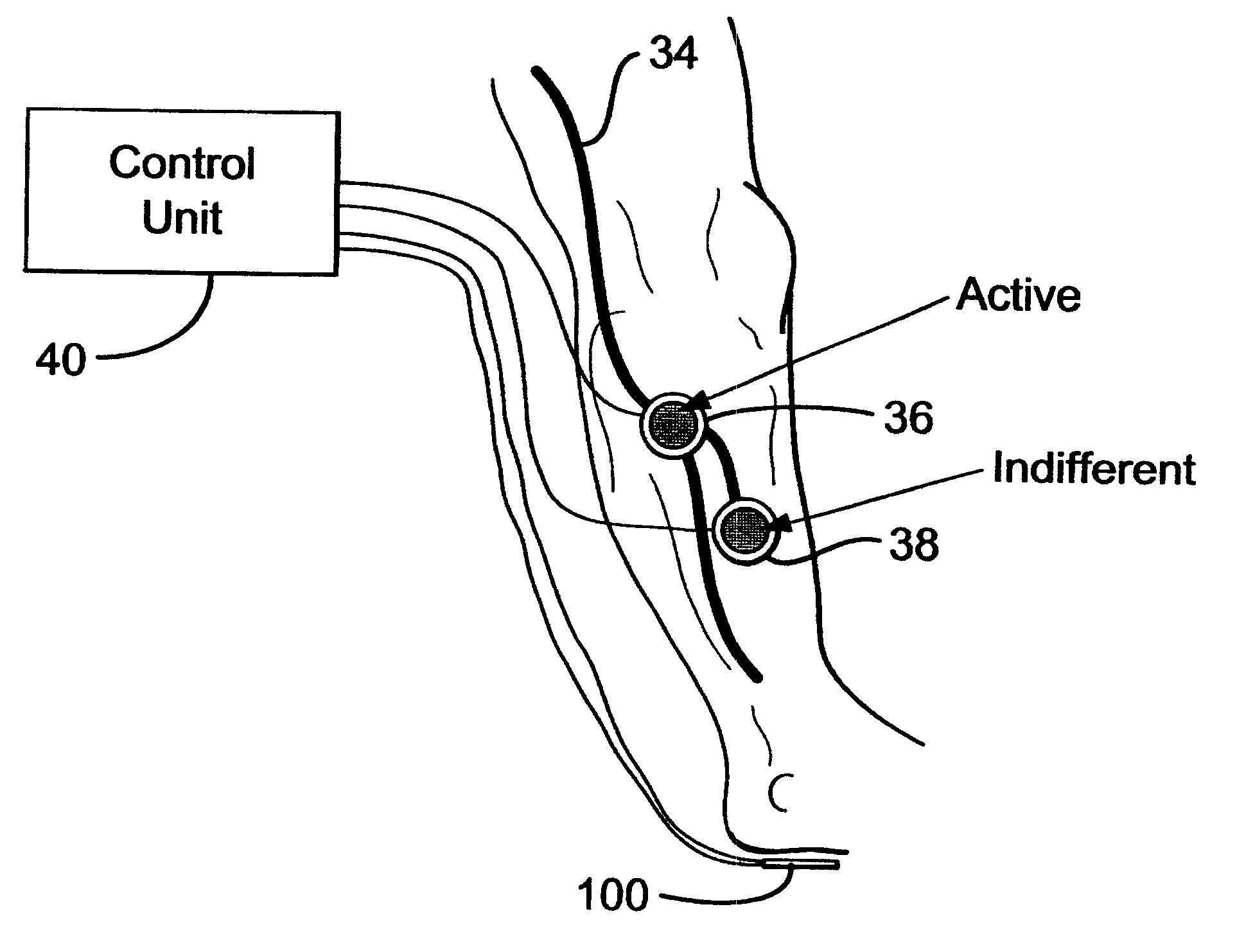

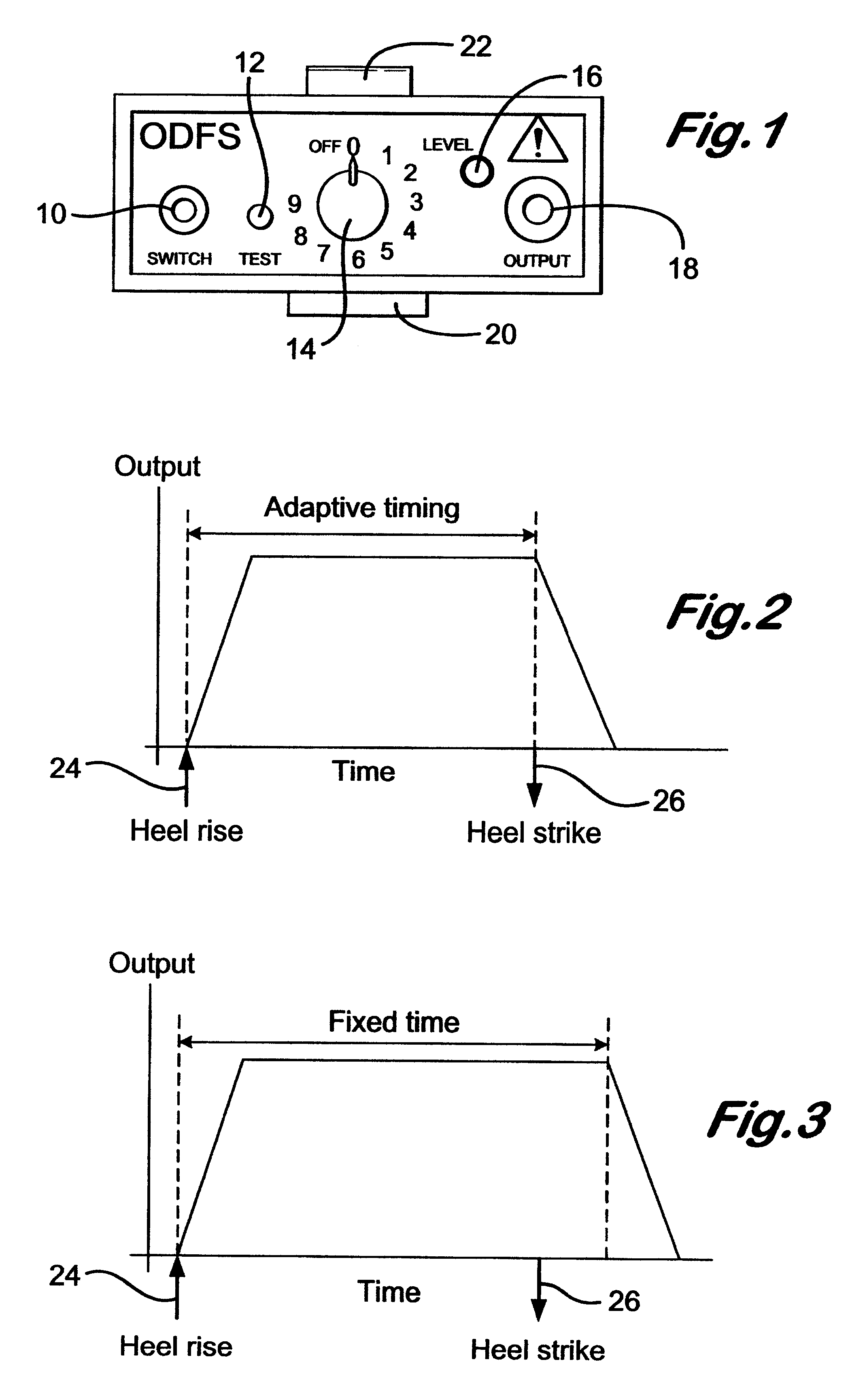

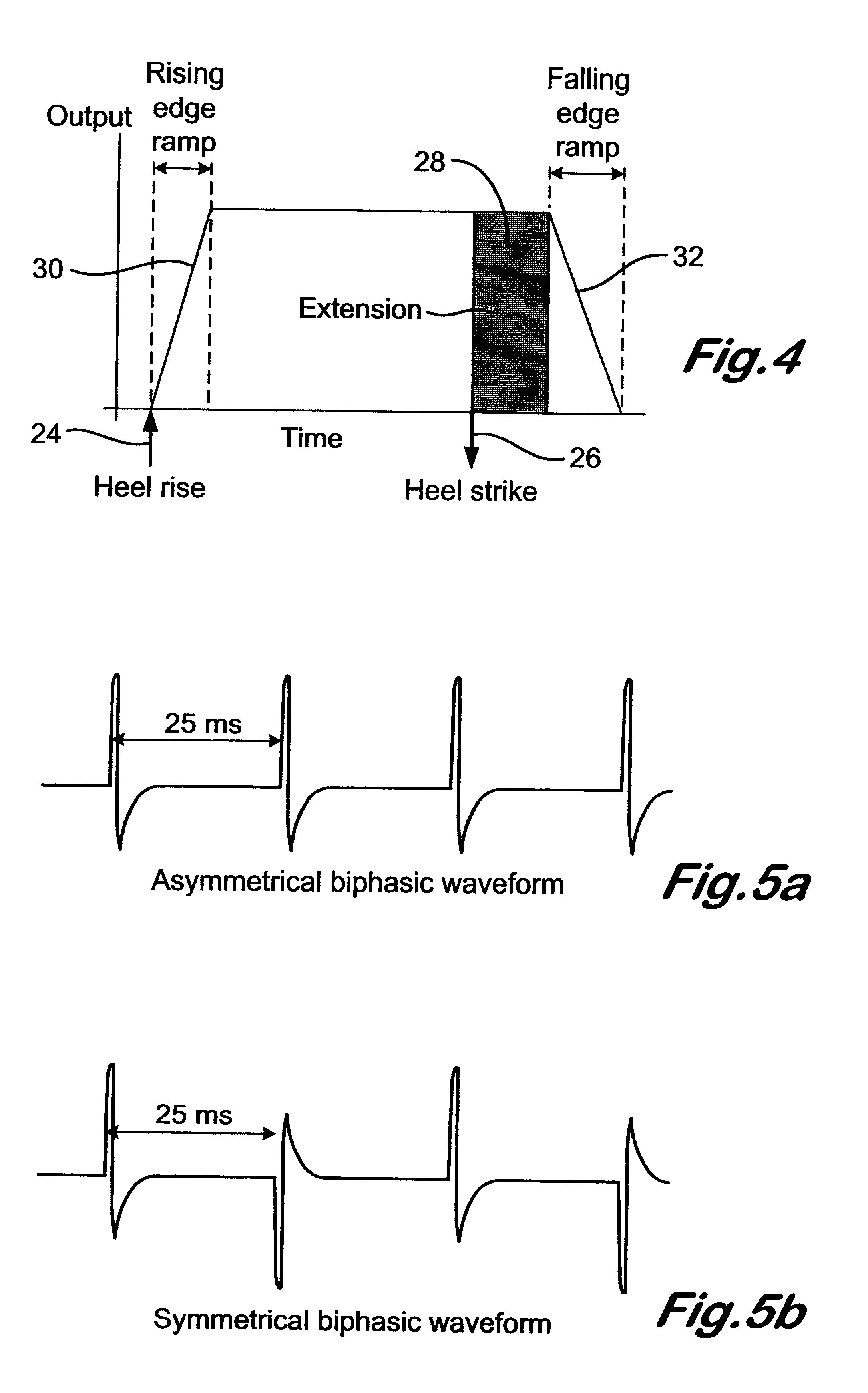

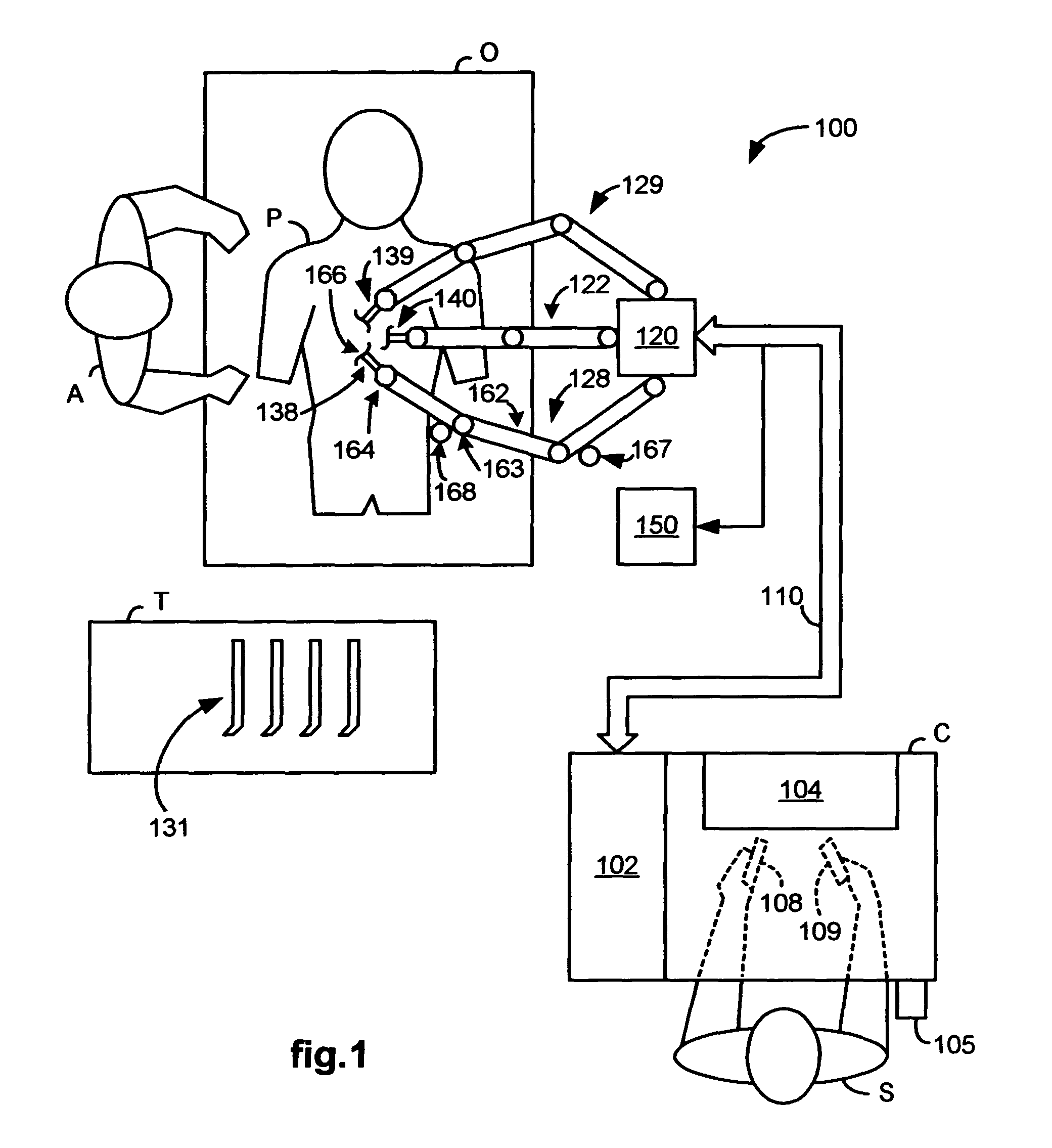

Apparatus for electrical stimulation of the body

InactiveUS6507757B1Inhibition effectReduce distanceElectrotherapyDiagnostic recording/measuringElectrical resistance and conductanceFoot strike

A stimulator for stimulating the leg or other parts of the body e.g. the leg in a patient with drop foot is provided, the stimulator being controlled by e.g a foot switch but being reliable in use and therefore commanding acceptance by users. The foot switch has to work in adverse environmental conditions and is subject to repeated use so that its characteristics vary with time. The invention provides a functional electrical stimulator for attachment to the leg that has adaptive characteristics and comprises first and second electrodes for attachment to the leg to apply an electrical stimulus, a foot switch for sensing foot rise or foot strike, a circuit responsive to said foot switch for generating stimulation pulses; and means forming part of said circuit for responding to changes in the resistance characteristics of said switch means by adjusting a corresponding response threshold of said circuit.The invention also provides a two-channel stimulator that offers various possibilities for controlling the signals to be supplied to different muscle groups. For example, means may be provided defining a signal pathway between the first and second channels so that the supply of stimulation pulses in one of said first and second channels can be controlled by the state of switch means associated with the other of said first and second channels. In a further embodiment means defining a signal pathway between the first and second channels is arranged so that the supply of stimulation pulses in one of said first and second channels can be controlled by the state of activity of the other of said first and second channels. In a yet further embodiment the first channel has means arranged to cause the stimulation pulses to time-out after a predetermined period and the second channel having no or disabled timing means so that supply of stimulation pulses is continuous in a predetermined state of limb position responsive switch means associated with that channel. The two-channel stimulator can be used e.g., to treat bilateral dropped foot.

Owner:BOURNEMOUTH UNIV HIGHER EDUCATION CORP +1

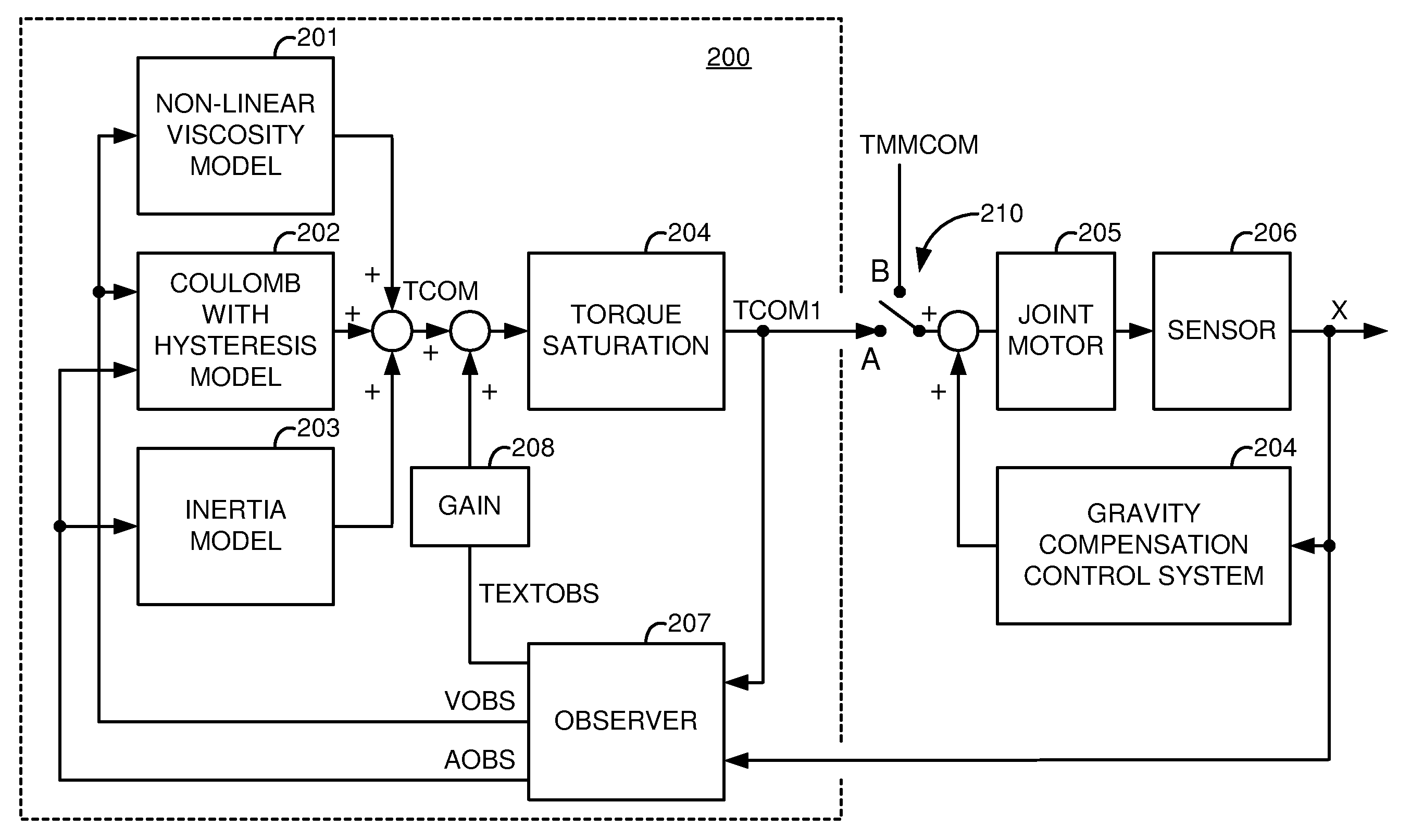

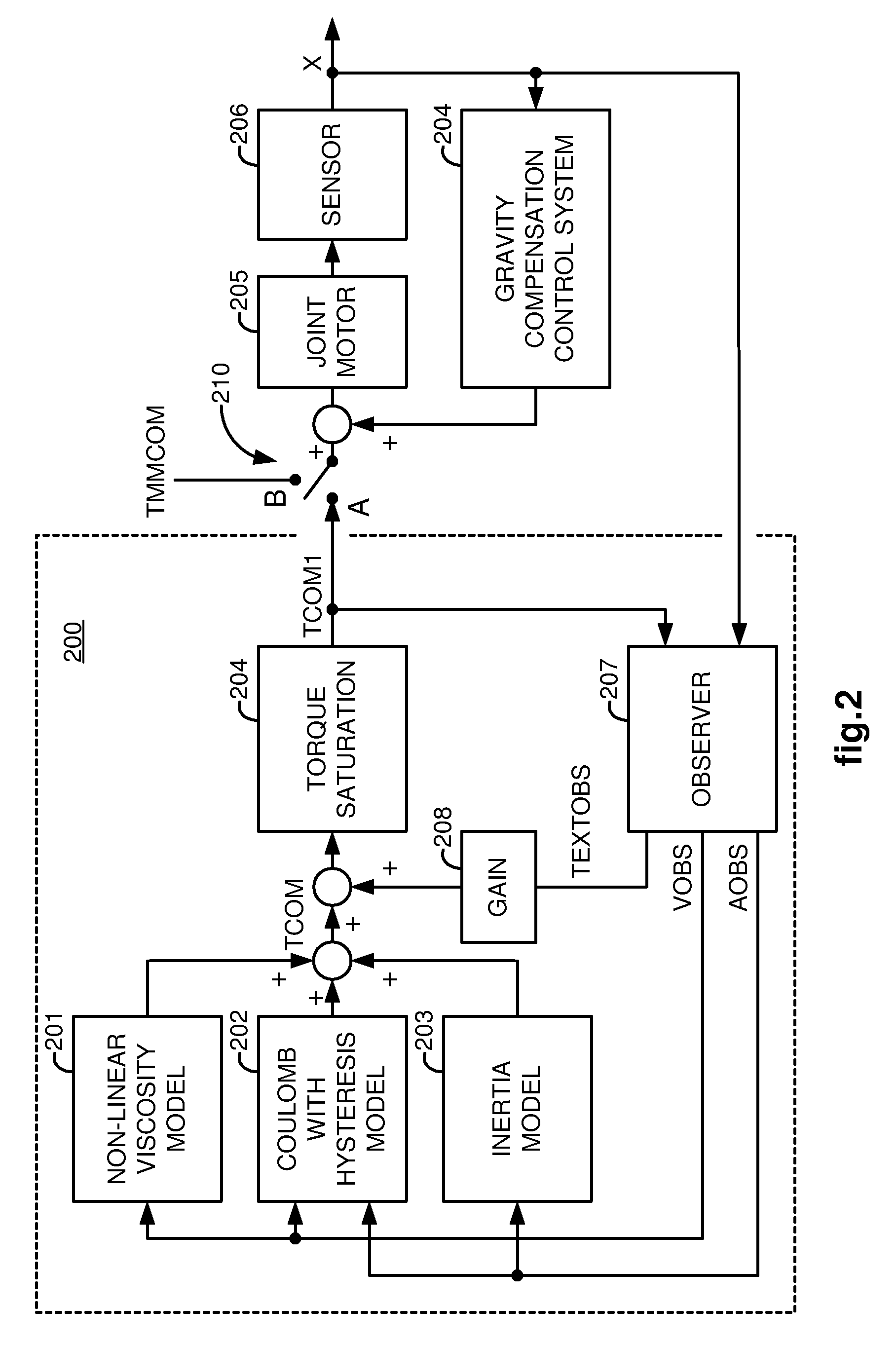

Control system for reducing internally generated frictional and inertial resistance to manual positioning of a surgical manipulator

ActiveUS7819859B2Friction is generatedReduce resistanceProgramme controlProgramme-controlled manipulatorSurgical siteAngular velocity

Owner:INTUITIVE SURGICAL OPERATIONS INC

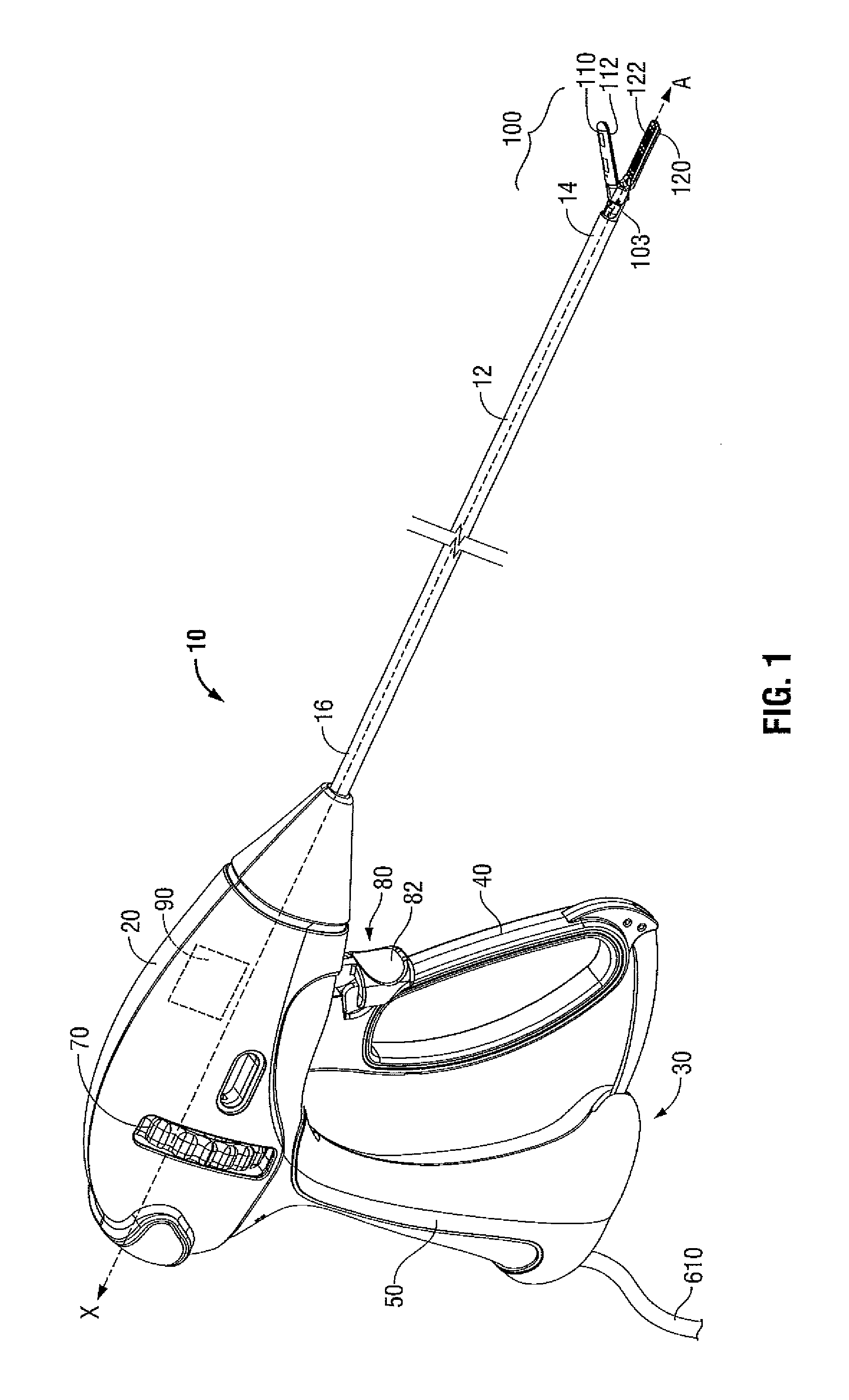

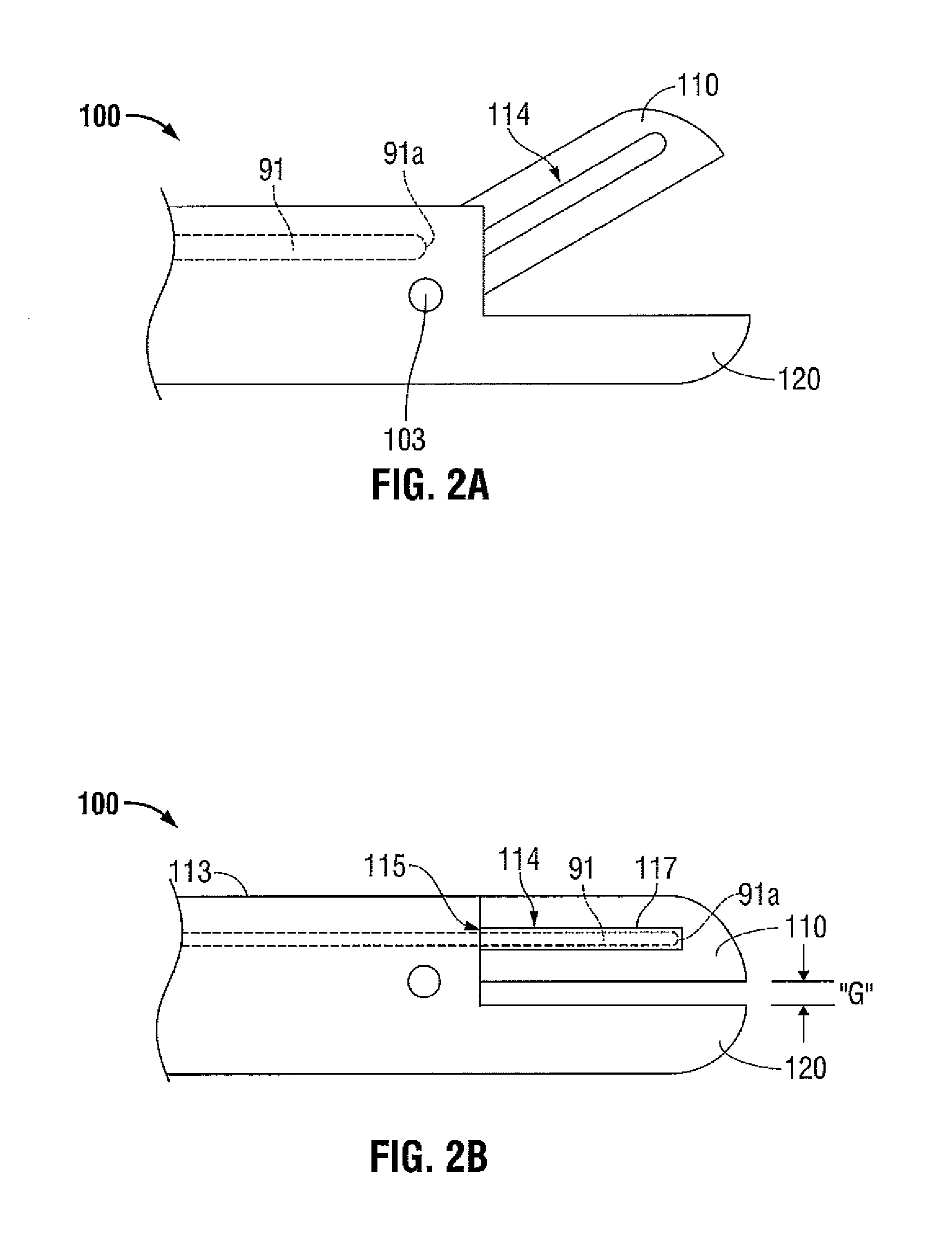

Electrosurgical instrument

ActiveUS8961515B2Promote sportsReduce resistanceSurgical instruments for heatingSurgical forcepsForcepsEngineering

An electrosurgical forceps is provided with a shaft that extends from a housing of the electrosurgical forceps. An end effector assembly operably coupled to a distal end of the shaft includes a pair of first and second jaw members each having jaw housing and an electrosurgical seal plate. One or both of the first and second jaw members is movable from an open configuration, to a clamping configuration. The moveable jaw member includes an elongated channel defined in its respective jaw housing and extends along a length thereof. A drive assembly operably couples to the moveable jaw member via a drive rod that is engageable with the elongated channel to move the movable jaw member from the open configuration to the clamping configuration and to provide a closure force between the first and second jaw members when the jaw members are in the clamping configuration.

Owner:TYCO HEALTHCARE GRP LP

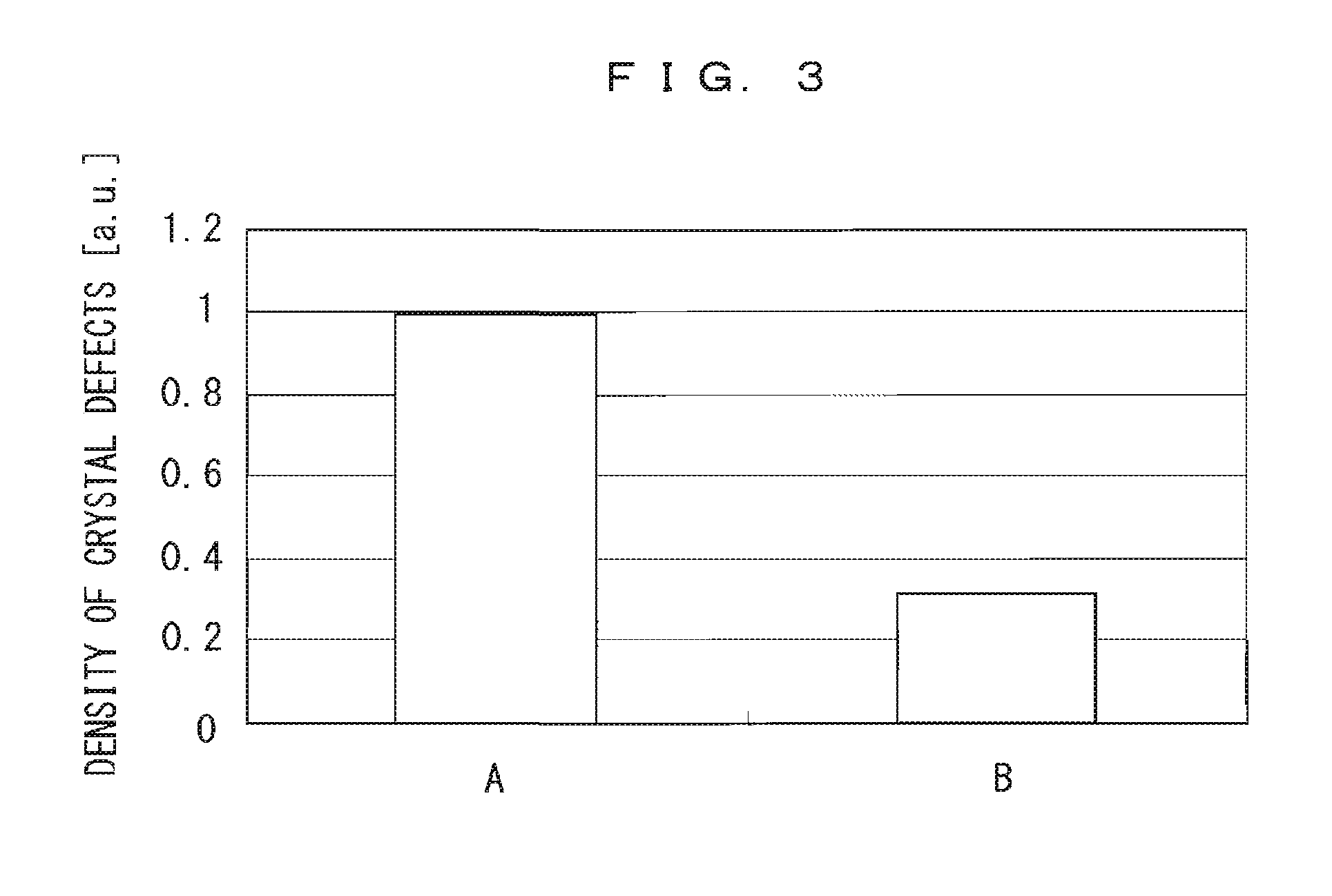

Nitride semiconductor laser device

ActiveUS20090141765A1Improve life characteristicsLow densityOptical wave guidanceLaser detailsElectron blocking layerLaser

A nitride semiconductor laser device has a group III nitride semiconductor multilayer structure. The group III nitride semiconductor multilayer structure includes an n-type semiconductor layer, a p-type semiconductor layer and a light emitting layer held between the n-type semiconductor layer and the p-type semiconductor layer, and the p-type semiconductor layer is formed by successively stacking a p-side guide layer, a p-type electron blocking layer in contact with the p-side guide layer and a p-type cladding layer in contact with the p-type electron blocking layer from the side closer to the light emitting layer. The p-side guide layer is formed by stacking a layer made of a group III nitride semiconductor containing Al and a layer made of a group III nitride semiconductor containing no Al. The p-type cladding layer is made of a group III nitride semiconductor containing Al, and the p-type electron blocking layer is made of a group III nitride semiconductor having a larger Al composition than the p-type cladding layer.

Owner:ROHM CO LTD

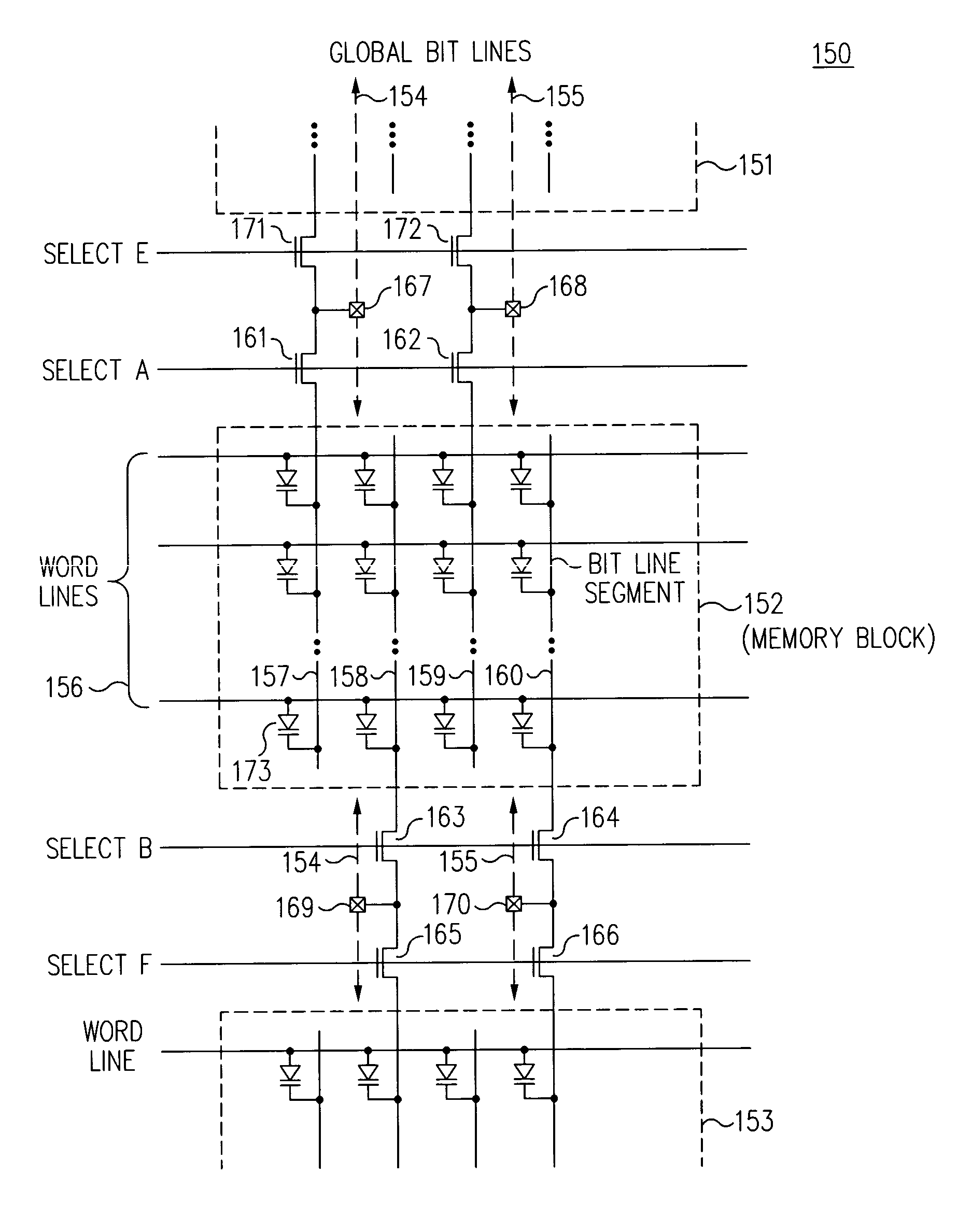

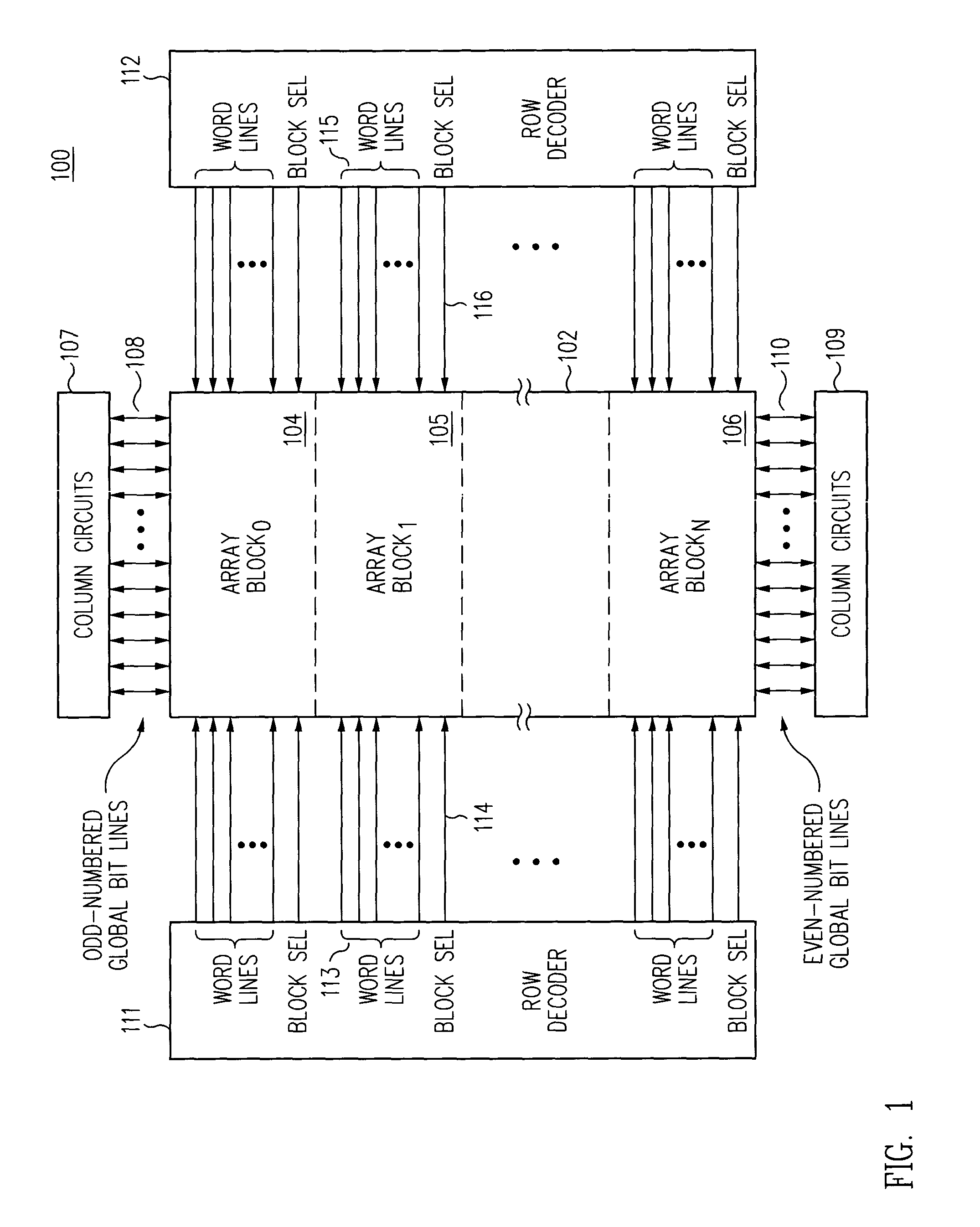

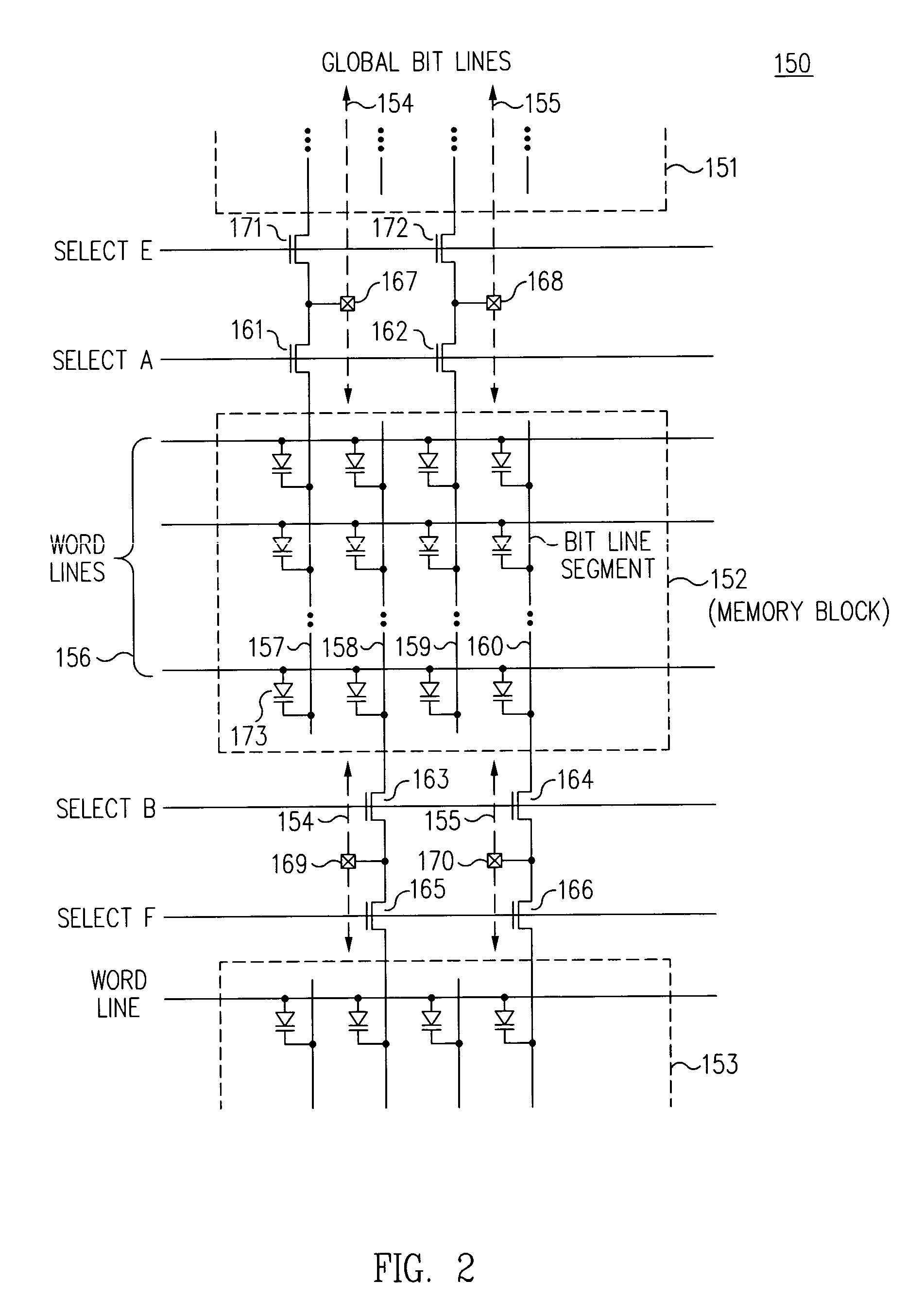

Three-dimensional memory device incorporating segmented bit line memory array

InactiveUS7233024B2Reduce capacitanceShorten overall length of unitSolid-state devicesRead-only memoriesBit lineHigh density

A three-dimensional (3D) high density memory array includes multiple layers of segmented bit lines (i.e., sense lines) with segment switch devices within the memory array that connect the segments to global bit lines. The segment switch devices reside on one or more layers of the integrated circuit, preferably residing on each bit line layer. The global bit lines reside preferably on one layer below the memory array, but may reside on more than one layer. The bit line segments preferably share vertical connections to an associated global bit line. In certain EEPROM embodiments, the array includes multiple layers of segmented bit lines with segment connection switches on multiple layers and shared vertical connections to a global bit line layer. Such memory arrays may be realized with much less write-disturb effects for half selected memory cells, and may be realized with a much smaller block of cells to be erased.

Owner:WODEN TECH INC

Semiconductor device

ActiveUS20100072467A1Increasing the thicknessAvoid separationTransistorElectroluminescent light sourcesDisplay deviceSemiconductor package

A display device includes a pixel portion in which a pixel is arranged in a matrix, the pixel including an inverted staggered thin film transistor having a combination of at least two kinds of oxide semiconductor layers with different amounts of oxygen and having a channel protective layer over a semiconductor layer to be a channel formation region overlapping a gate electrode layer and a pixel electrode layer electrically connected to the inverted staggered thin film transistor. In the periphery of the pixel portion in this display device, a pad portion including a conductive layer made of the same material as the pixel electrode layer is provided. In addition, the conductive layer is electrically connected to a common electrode layer formed on a counter substrate.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com