Patents

Literature

4664results about How to "Lower impedance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

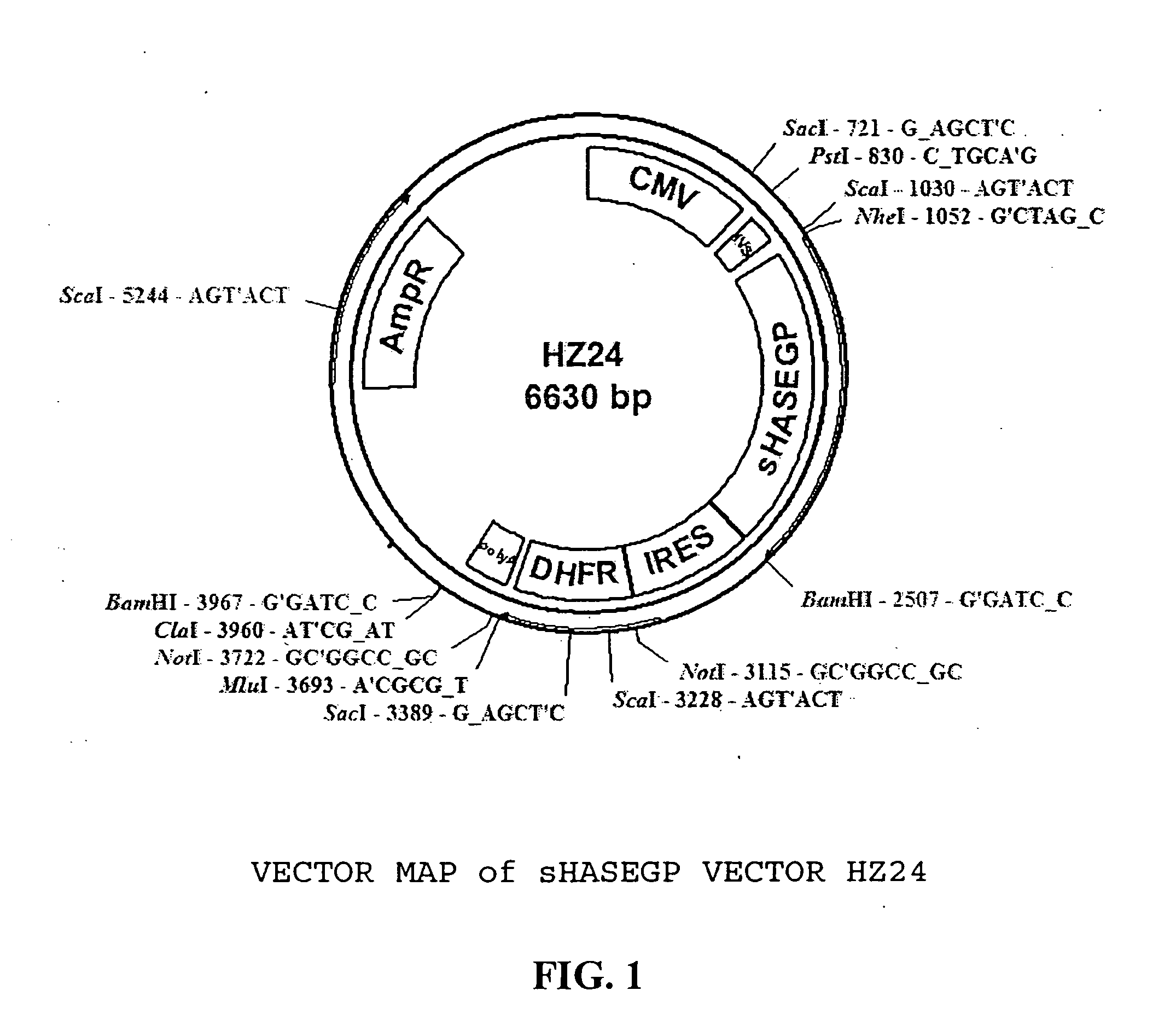

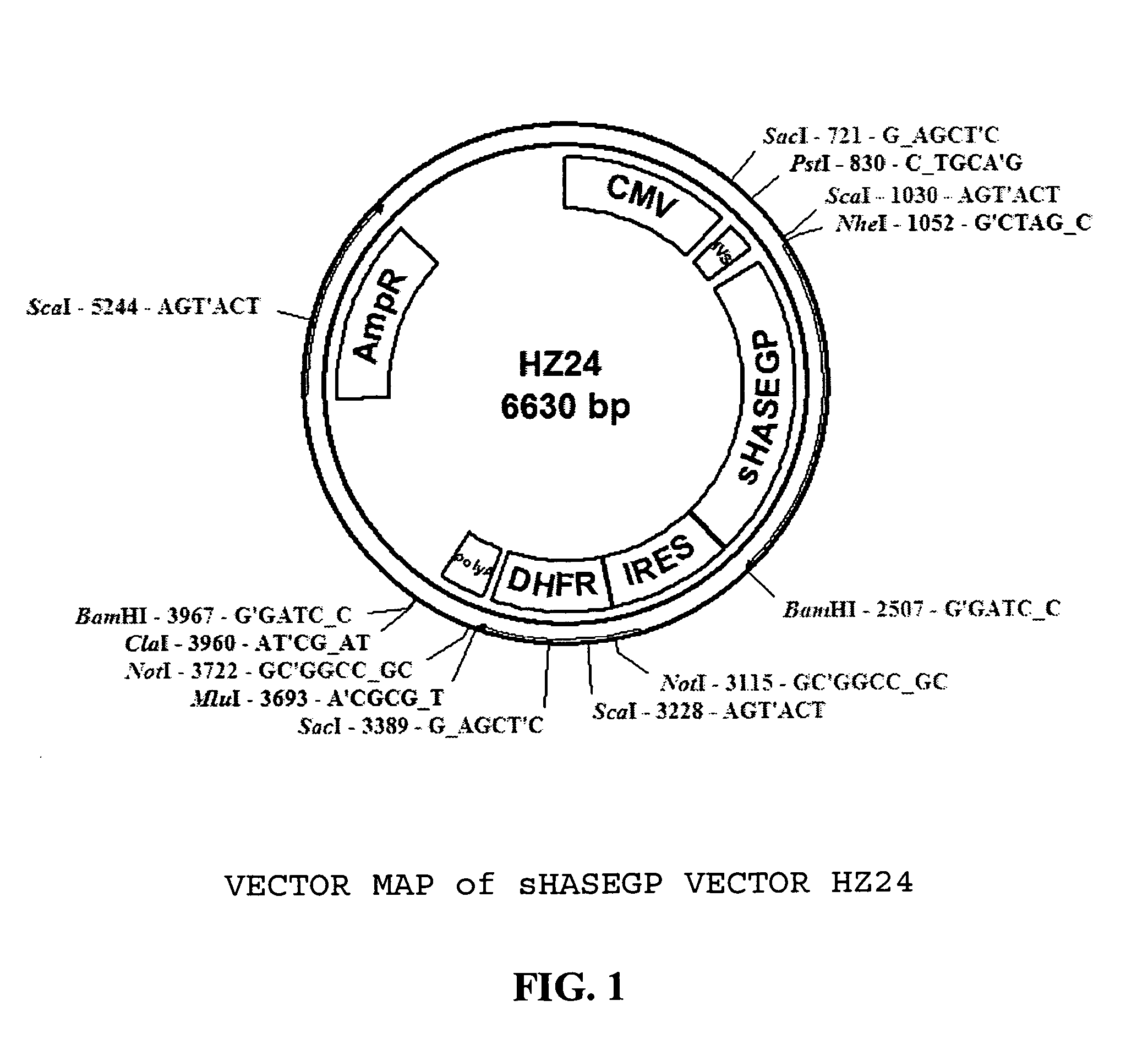

Soluble glycosaminoglycanases and methods of preparing and using soluble glycosaminogly ycanases

PendingUS20060104968A1Improve extentIncrease ratingsSenses disorderNervous disorderHyaluronidaseRecombinant glycoprotein

The invention relates to the discovery of novel soluble neutral active Hyaluronidase Glycoproteins (sHASEGPs), methods of manufacture, and their use to facilitate administration of other molecules or to alleviate glycosaminoglycan associated pathologies. Minimally active polypeptide domains of the soluble, neutral active sHASEGP domains are described that include asparagine-linked sugar moieties required for a functional neutral active hyaluronidase domain. Included are modified amino-terminal leader peptides that enhance secretion of sHASEGP. The invention further comprises sialated and pegylated forms of a recombinant sHASEGP to enhance stability and serum pharmacokinetics over naturally occurring slaughterhouse enzymes. Further described are suitable formulations of a substantially purified recombinant sHASEGP glycoprotein derived from a eukaryotic cell that generate the proper glycosylation required for its optimal activity.

Owner:HALOZYME

Soluble glycosaminoglycanases and methods of preparing and using soluble glycosaminoglycanases

ActiveUS20050260186A1Improve extentIncrease ratingsAntibacterial agentsSenses disorderHyaluronidasePathology diagnosis

The invention relates to the discovery of novel soluble neutral active Hyaluronidase Glycoproteins (sHASEGPs), methods of manufacture, and their use to facilitate administration of other molecules or to alleviate glycosaminoglycan associated pathologies. Minimally active polypeptide domains of the soluble, neutral active sHASEGP domains are described that include asparagine-linked sugar moieties required for a functional neutral active hyaluronidase domain. Included are modified amino-terminal leader peptides that enhance secretion of sHASEGP. The invention further comprises sialated and pegylated forms of a recombinant sHASEGP to enhance stability and serum pharmacokinetics over naturally occurring slaughterhouse enzymes. Further described are suitable formulations of a substantially purified recombinant sHASEGP glycoprotein derived from a eukaryotic cell that generate the proper glycosylation required for its optimal activity.

Owner:HALOZYME

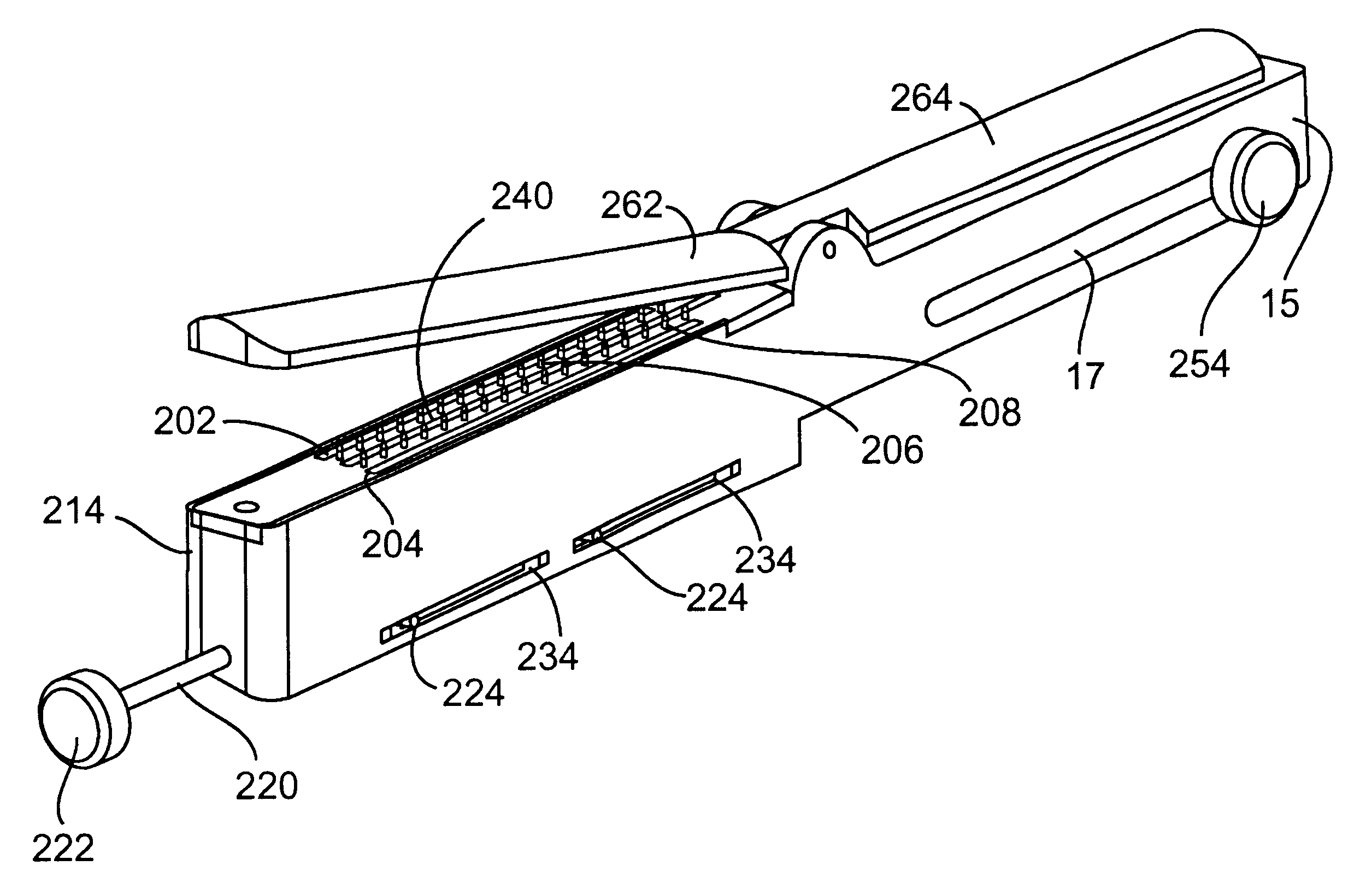

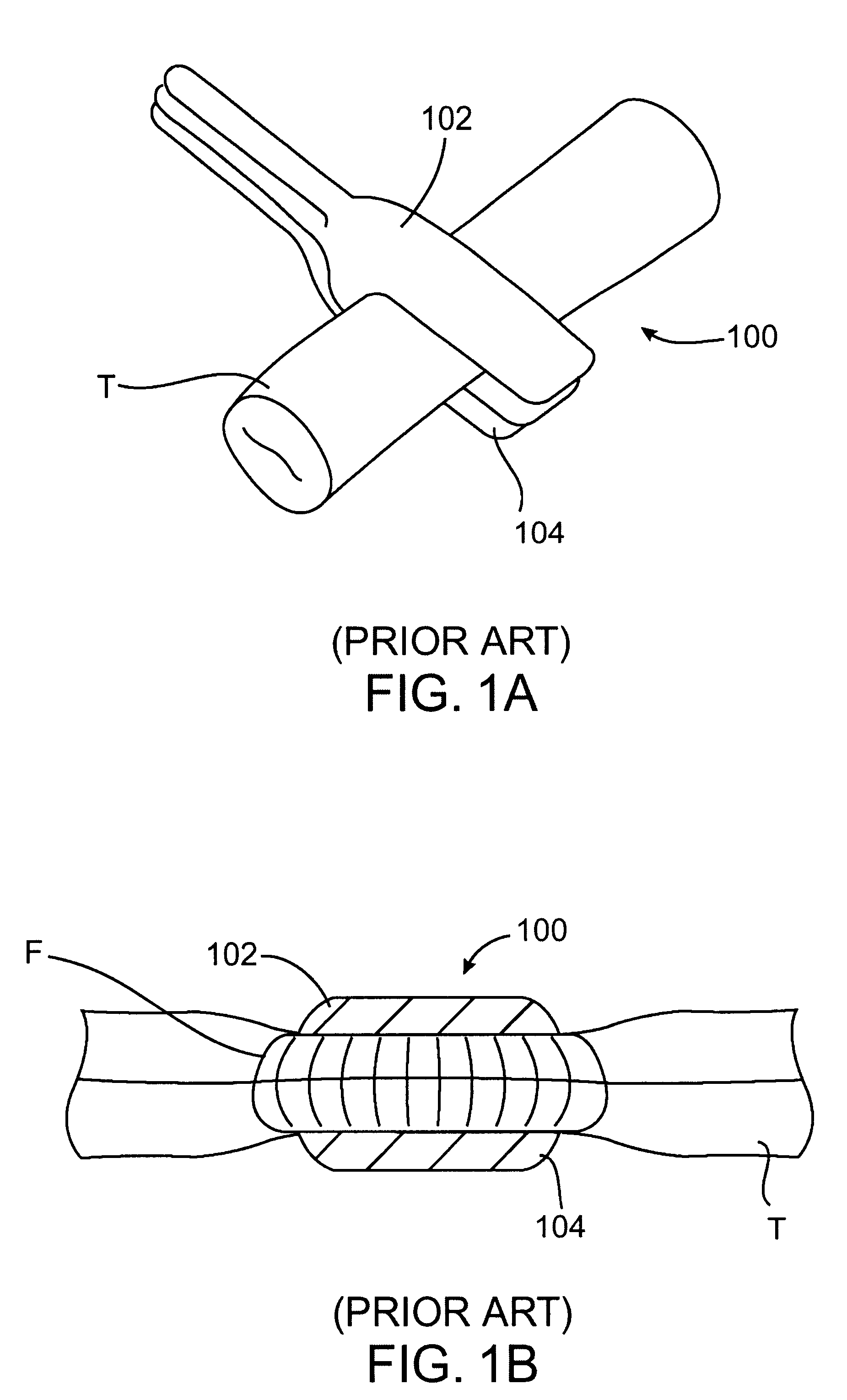

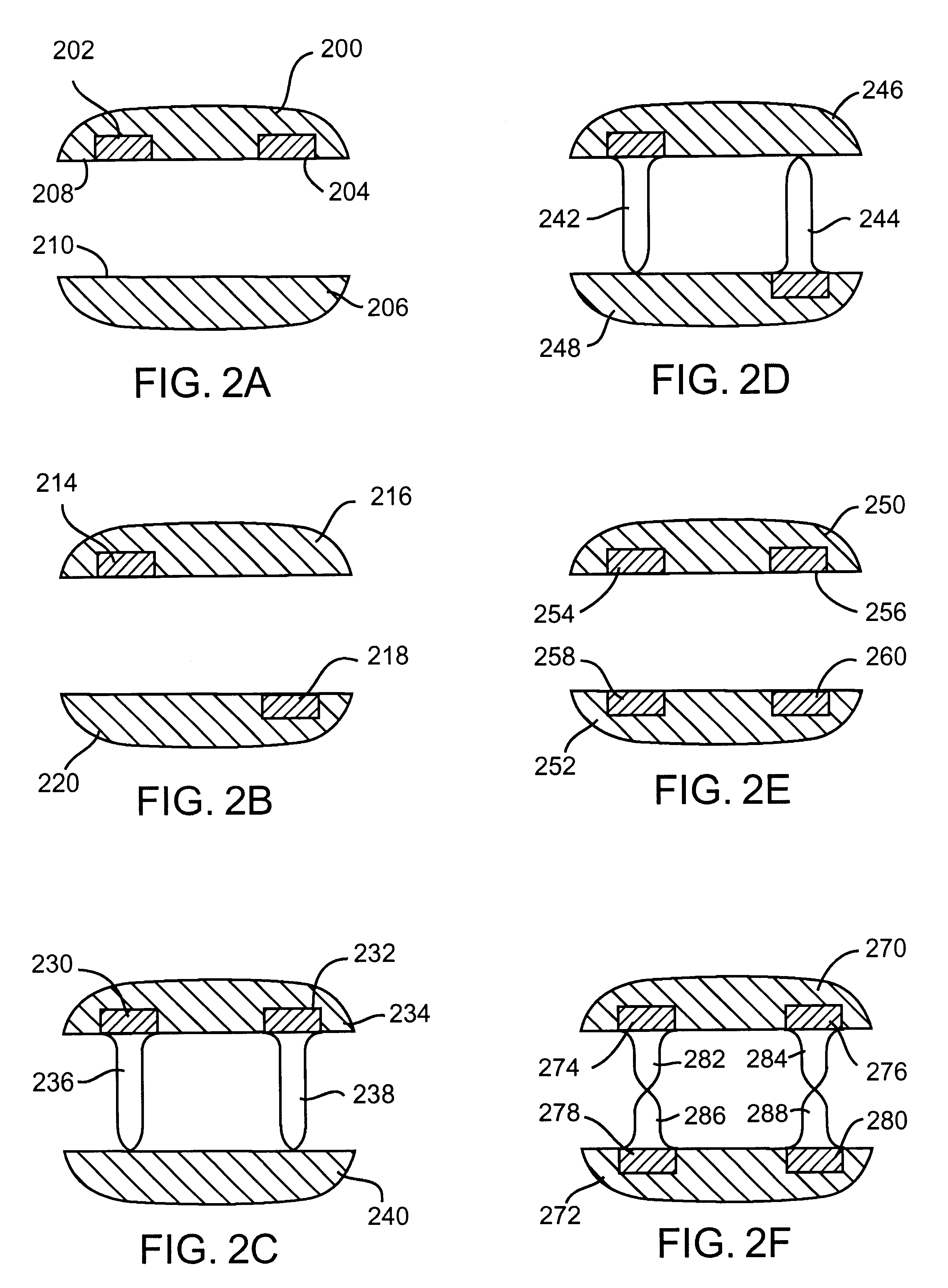

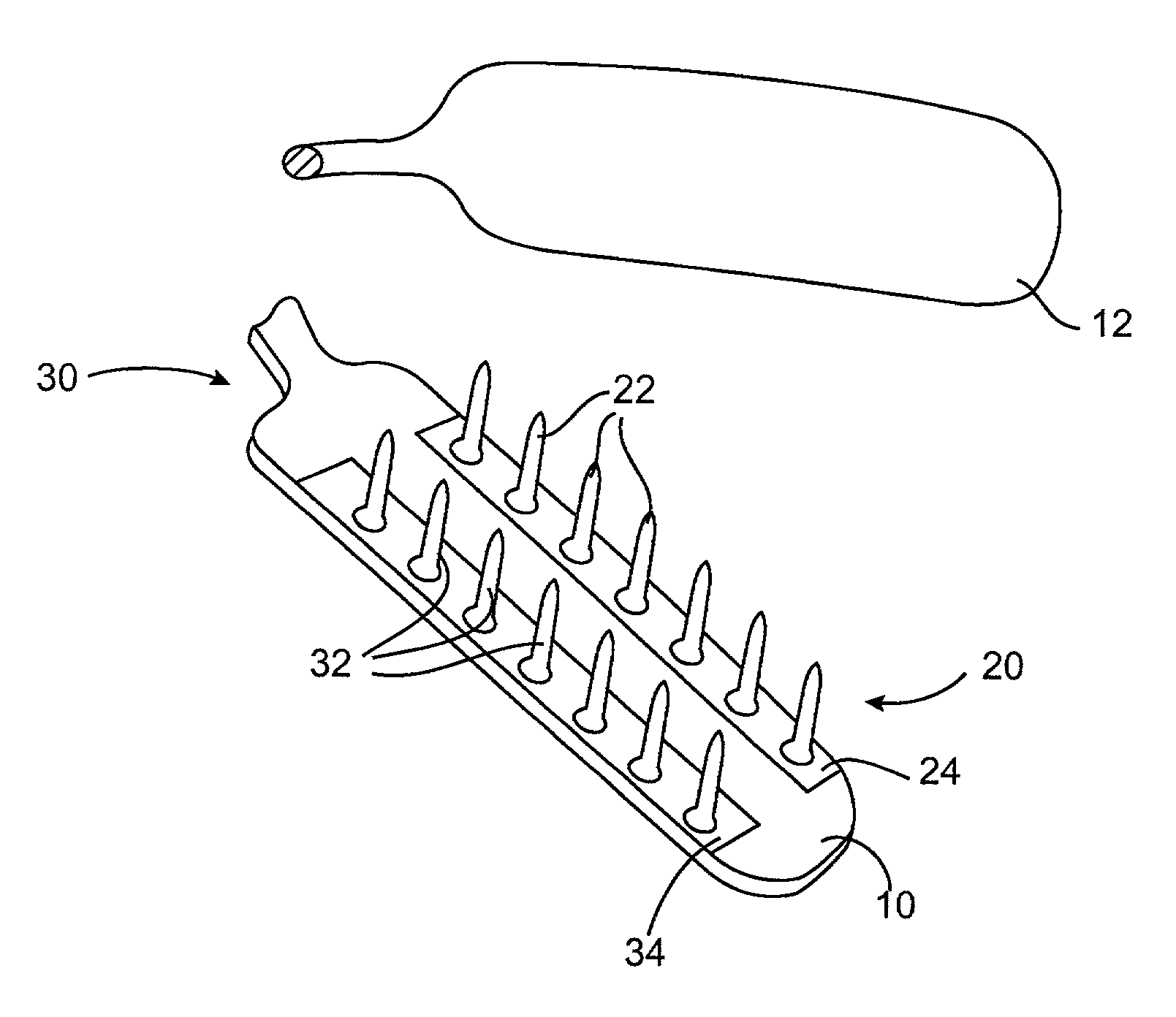

Bipolar surgical instruments having focused electrical fields

InactiveUS6514252B2Reduce capacityLower impedanceSurgical needlesSurgical instruments for heatingElectricitySurgical device

A bipolar surgical device comprises a pair of actuable jaws. A first electrode member which optionally includes a line of electrically coupled tissue-penetrating elements is formed on one of the jaws, and a second electrode member which optionally includes a line of electrically coupled tissue-penetrating elements is formed on the same or the other jaw. The electrode members are laterally spaced-apart and arranged in a parallel, usually linear manner so that the lateral distance therebetween remains generally constant. In operation, tissue may be grasped between the jaws so that the electrode members contact and / or the tissue-penetrating elements enter into the tissue. By energizing the electrode members at opposite polarities using a high frequency energy source, tissue between the jaws will be heated, coagulated, and / or necrosed, while heating of tissue outside of the lines will be minimized.

Owner:PERFECT SURGICAL TECHN

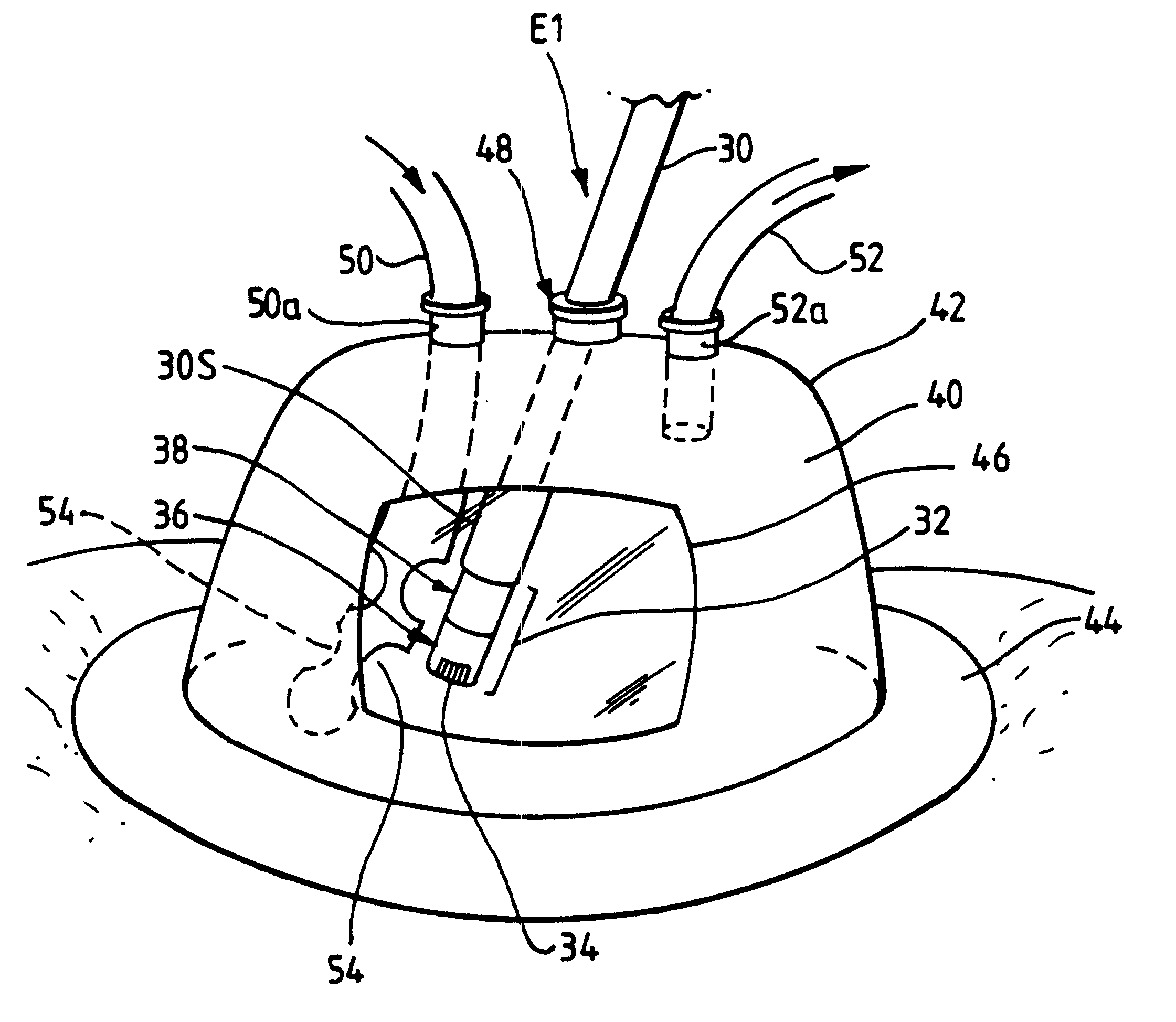

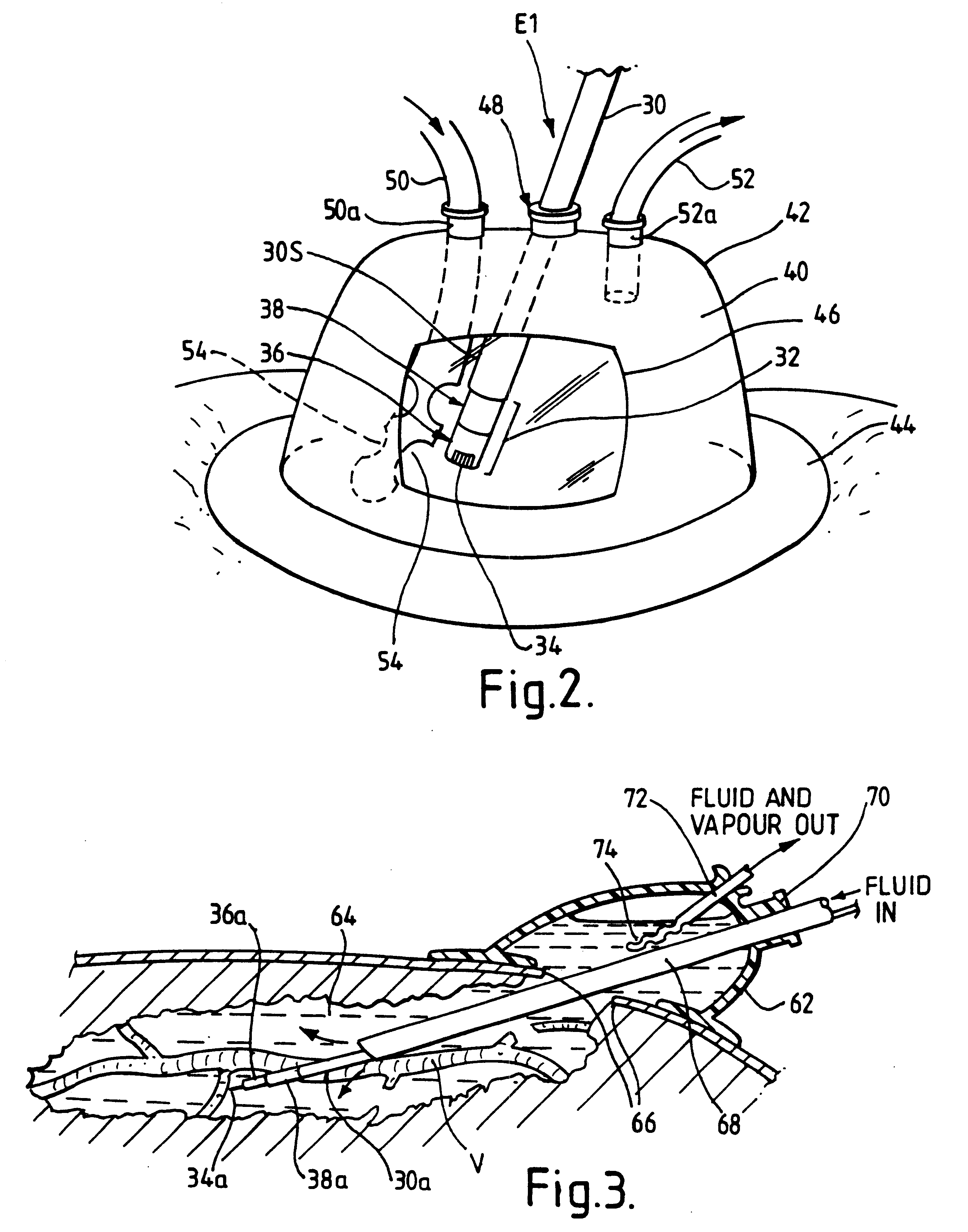

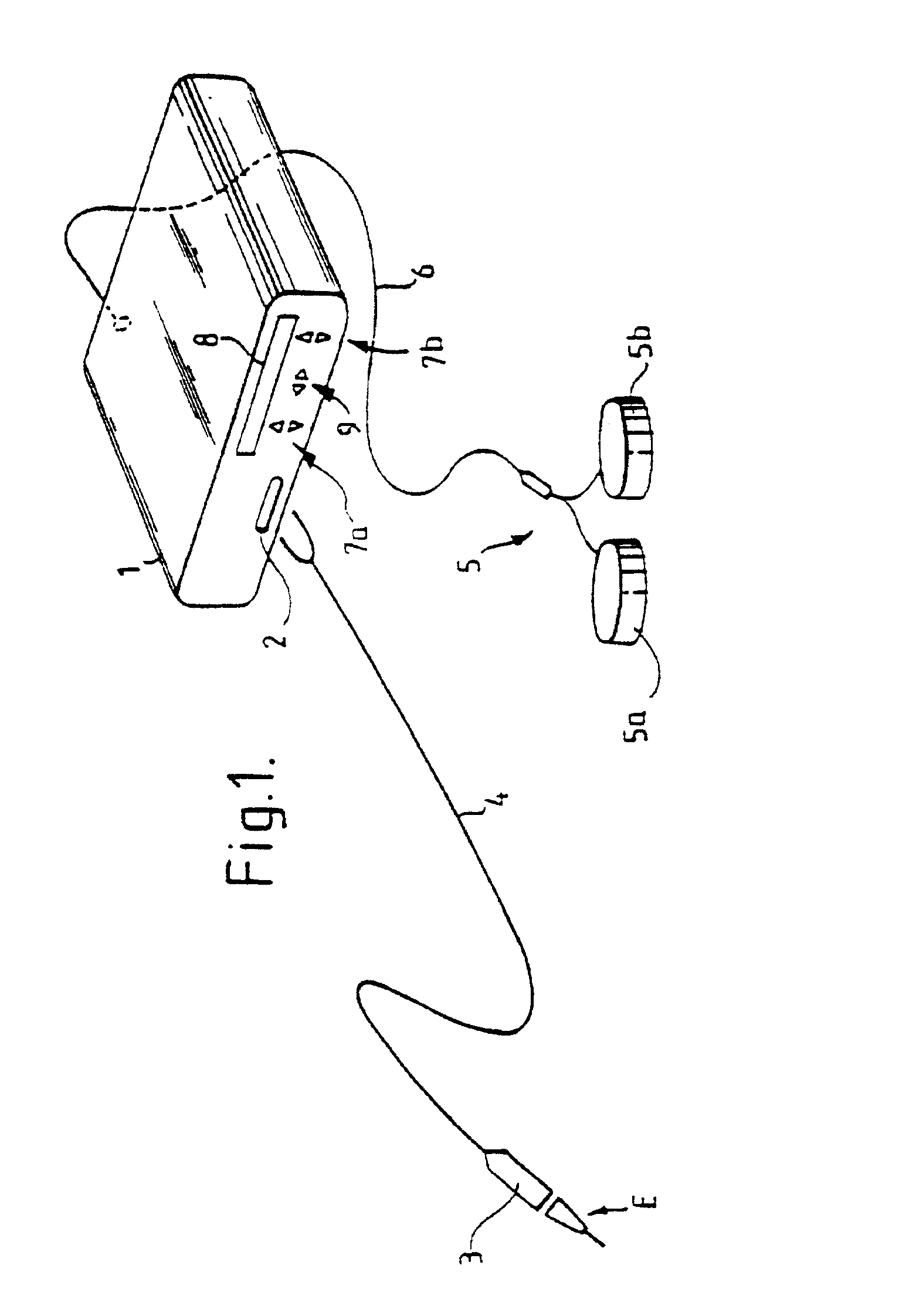

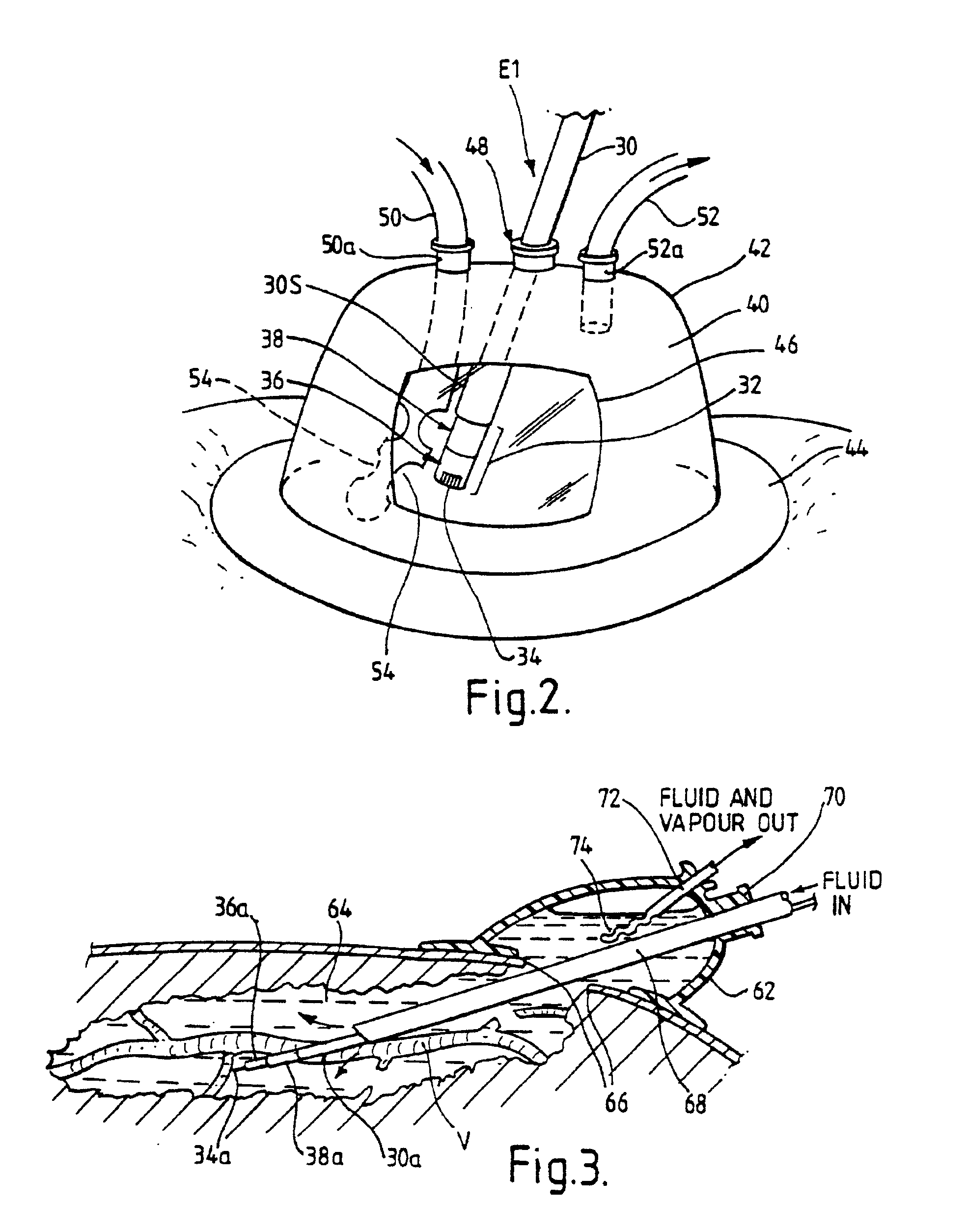

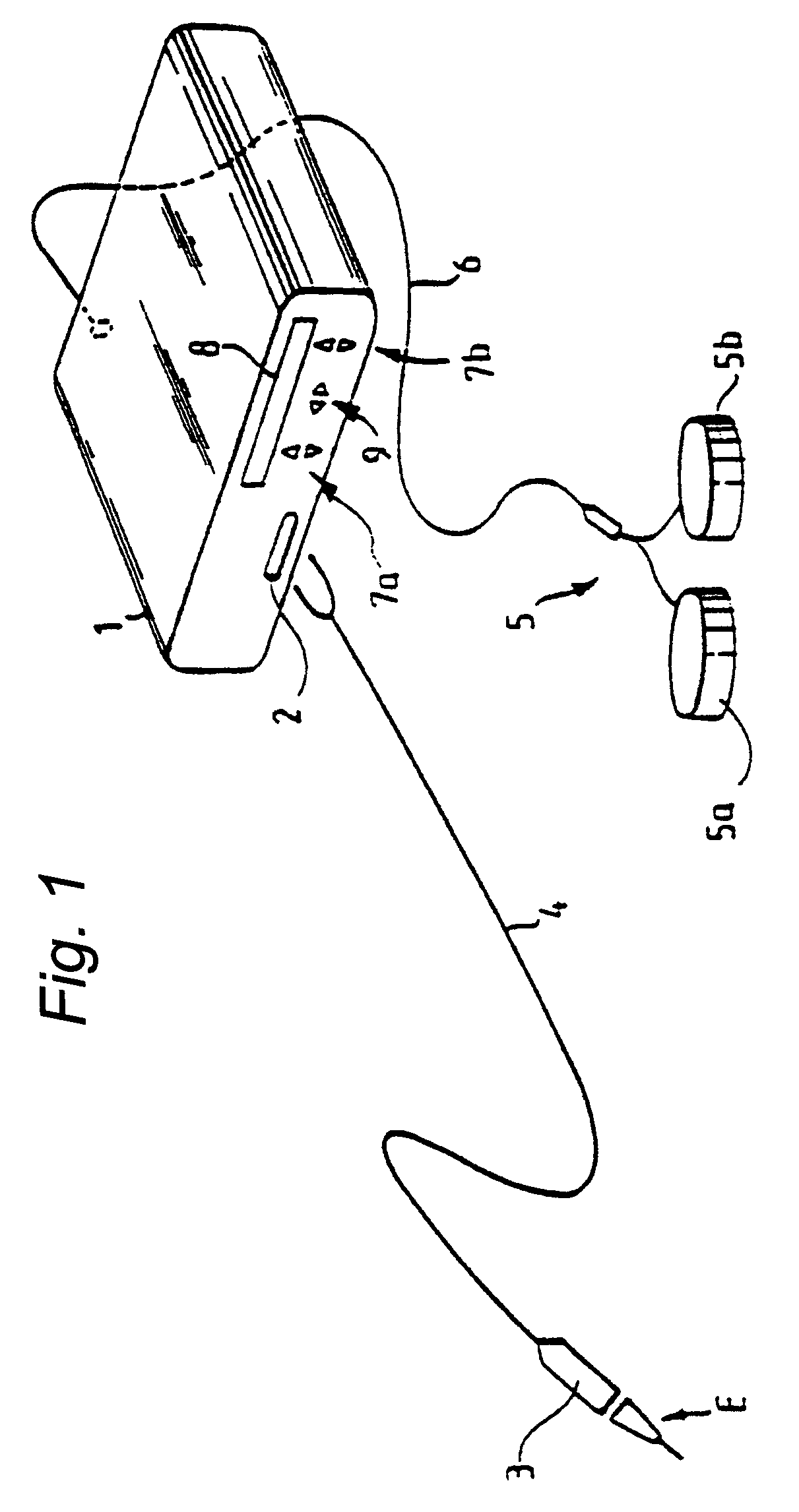

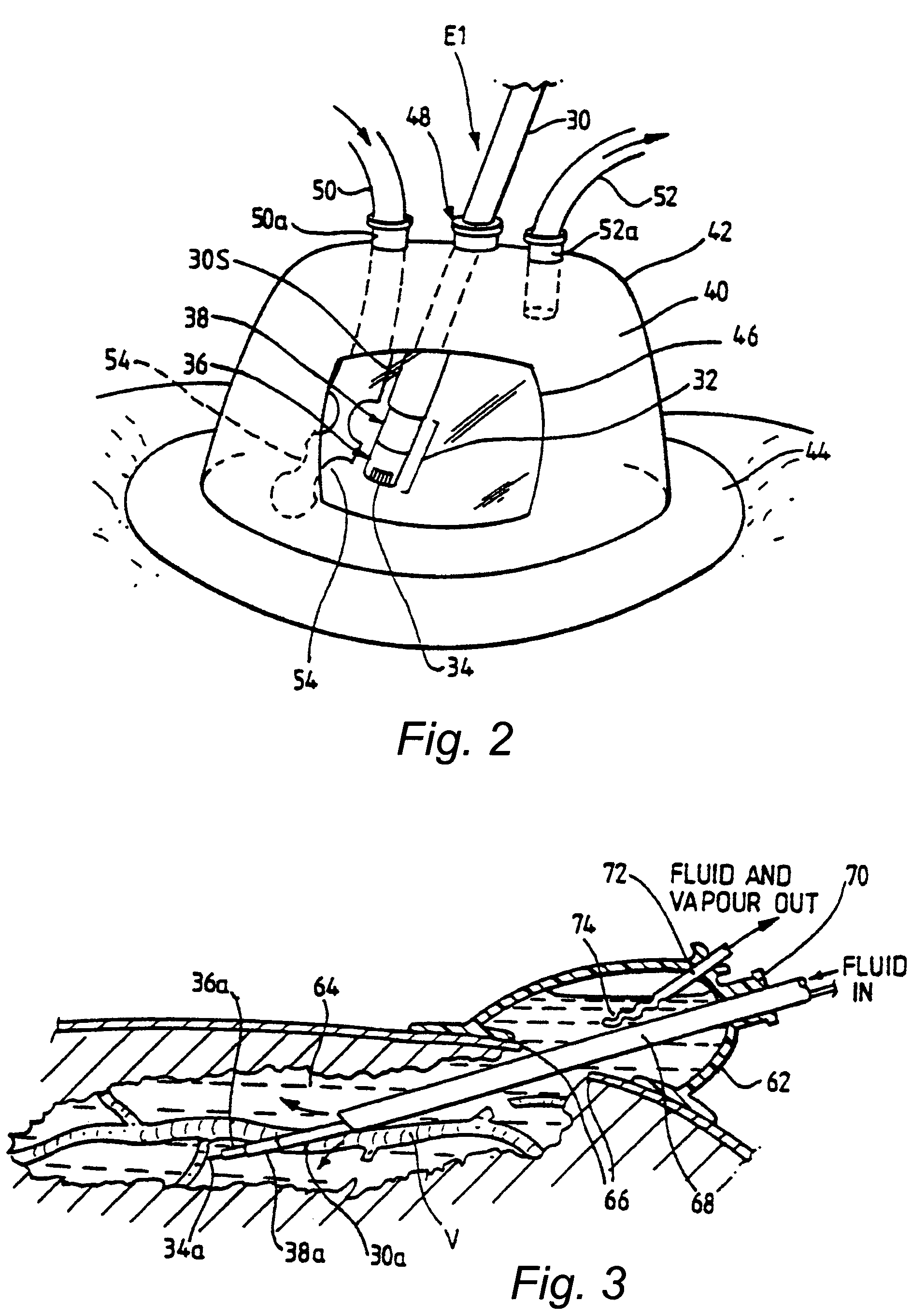

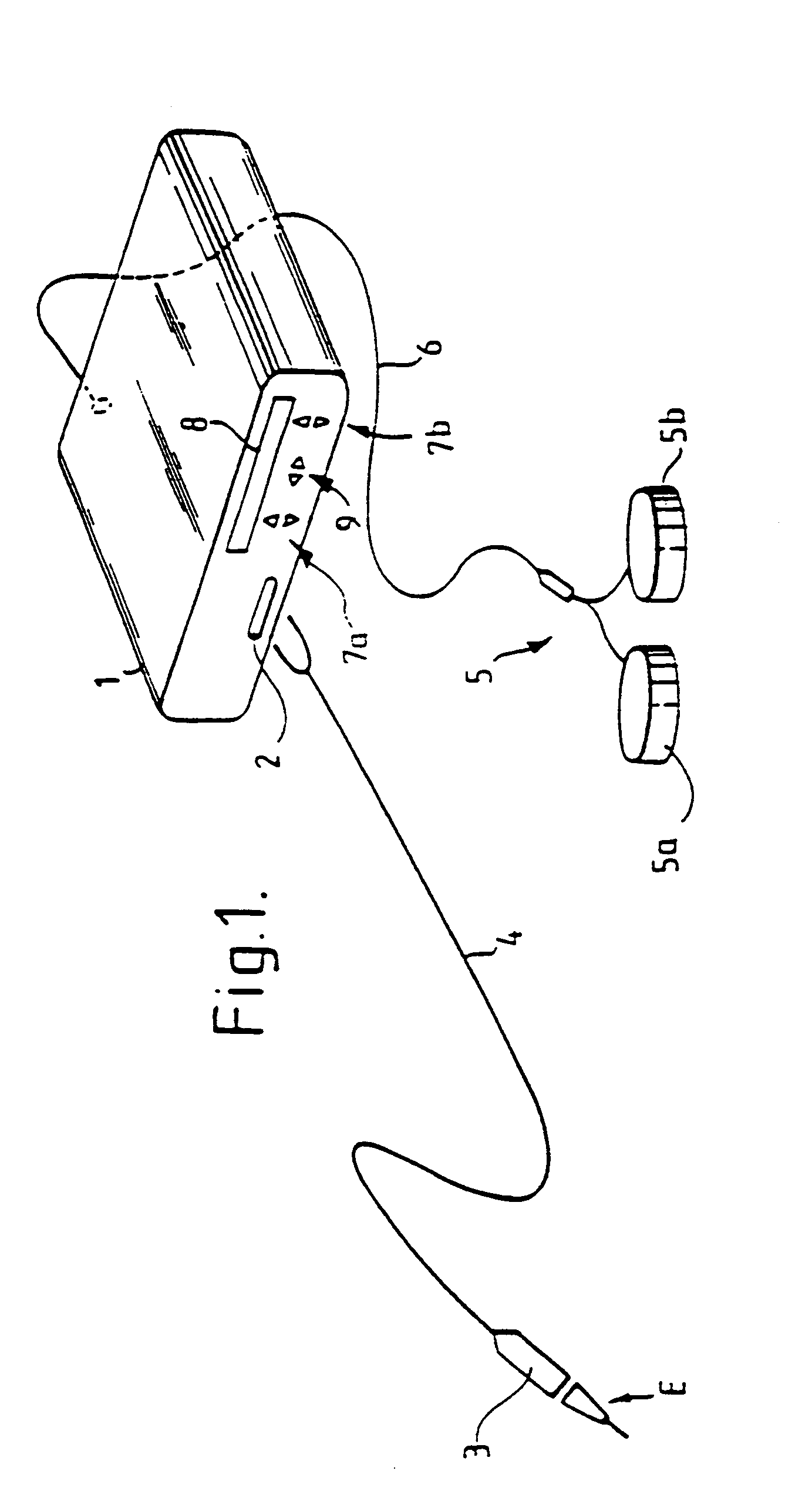

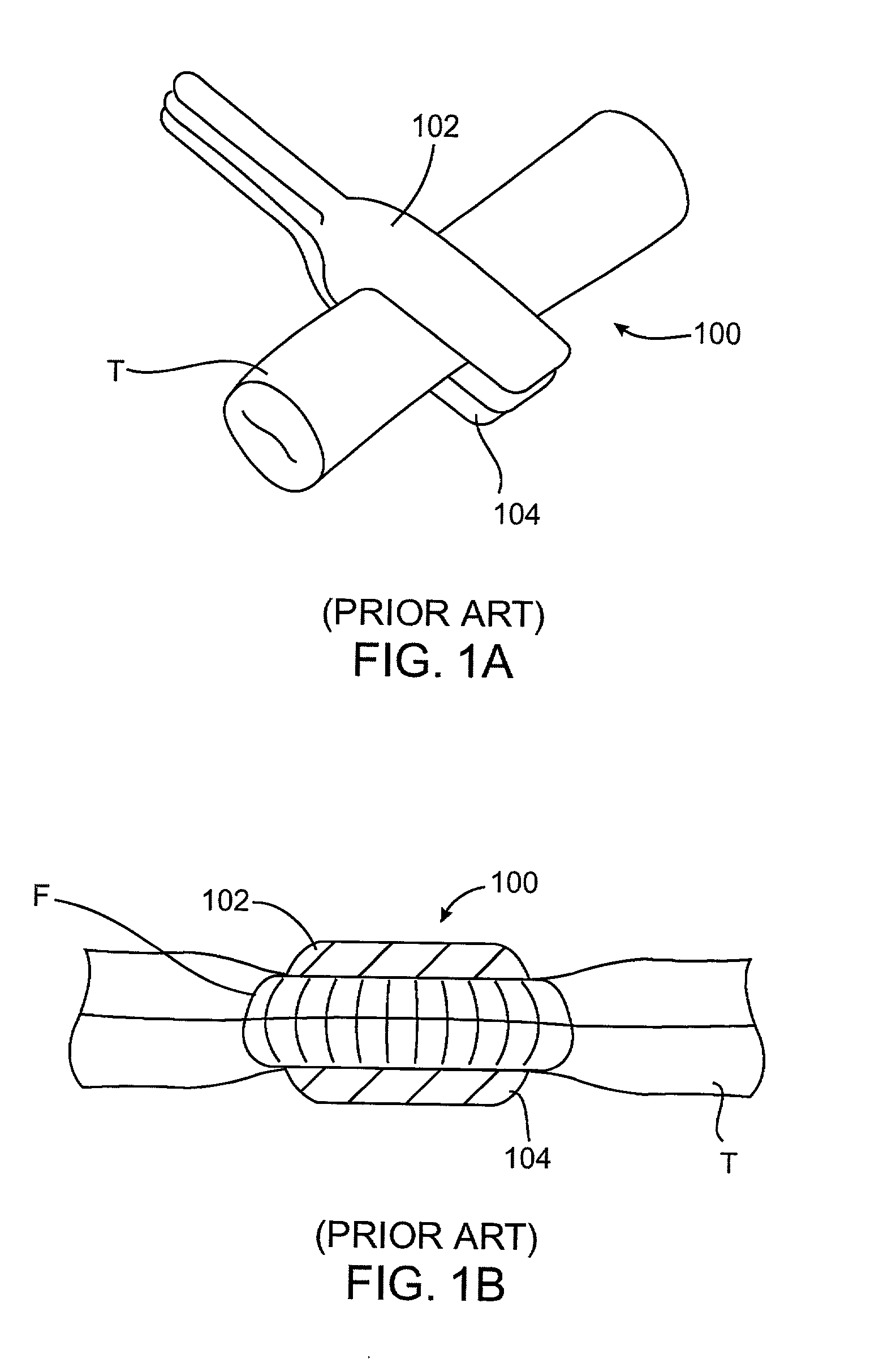

Electrosurgical system

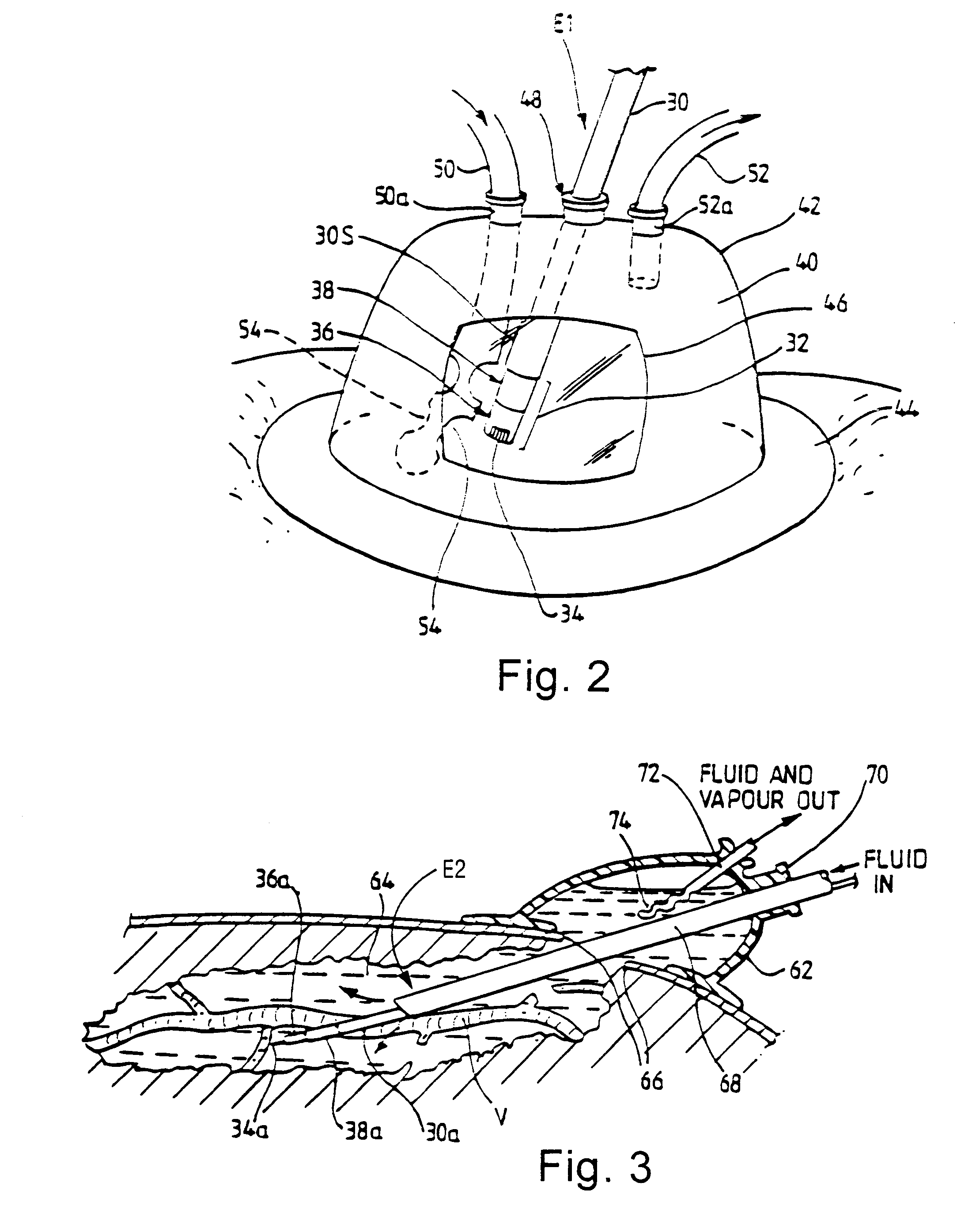

An electrosurgical system comprises a radio frequency generator (1), an electrosurgical instrument (E1), and a fluid enclosure (42). The generator (1) has a radio frequency output for delivery of power to the electrosurgical instrument (E1) when immersed in an electrically-conductive fluid. The electrosurgical instrument (E1) has an electrode assembly (32) at the distal end thereof, the electrode assembly comprising a tissue treatment electrode (34), and a return electrode (38) axially spaced therefrom in such a manner as to define, in use, a conductive fluid path that completes an electrical circuit between the tissue treatment electrode and the return electrode. The fluid enclosure (42) is adapted to surround an operation site on the skin of a patient or an incision leading to a cavity surgically created within the patient's body. The fluid enclosure (42) includes sealing means (44) for sealing against the patient's tissue, and the fluid enclosure includes at least one port (50a, 52a) through which the electrosurgical (E1) is insertable, and through which the electrically-conductive fluid can enter and / or leave the enclosure.

Owner:GYRUS MEDICAL LTD

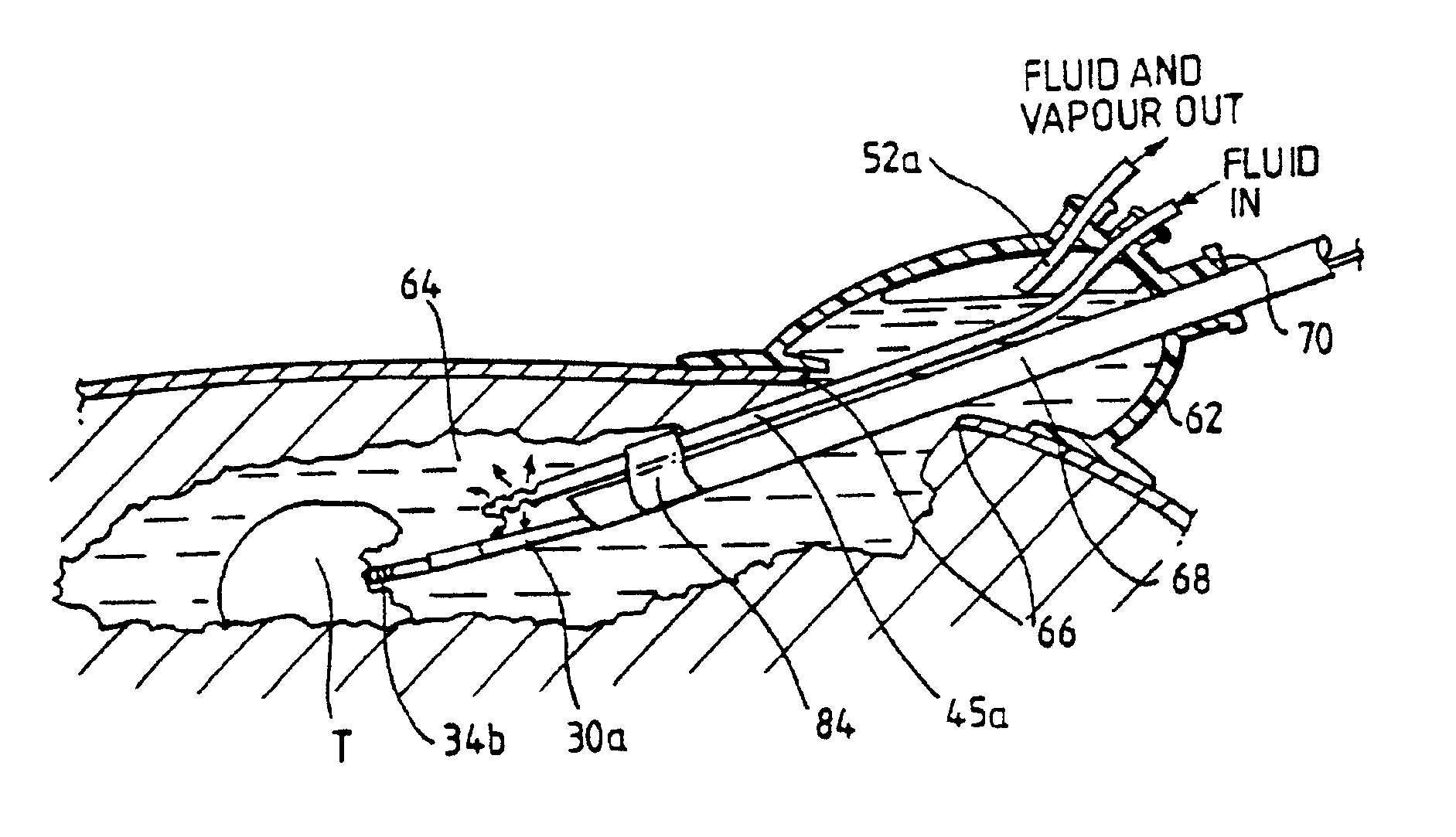

Electrosurgical system and method

An electrosurgical system comprises a radio frequency generator (1), an electrosurgical instrument (E1), and a fluid enclosure (42). The generator (1) has a radio frequency output for delivery of power to the electrosurgical instrument (E1) when immersed in an electrically-conductive fluid. The electrosurgical instrument (E1) has an electrode assembly (32) at the distal end thereof, the electrode assembly comprising a tissue treatment electrode (34), and a return electrode (38) axially spaced therefrom in such a manner as to define, in use, a conductive fluid path that completes an electrical circuit between the tissue treatment electrode and the return electrode. The fluid enclosure (42) is adapted to surround an operation site on the skin of a patient or an incision leading to a cavity surgically created within the patient's body. The fluid enclosure (42) includes sealing means (44) for sealing against the patient's tissue, and the fluid enclosure includes at least one port (50a, 52a) through which the electrosurgical (E1) is insertable, and through which the electrically-conductive fluid can enter and / or leave the enclosure. The fluid enclosure device of the present invention can also be used to treat tumours within the colon. The enclosure, which includes a proximal and a distal bung, is inserted into the colon in a deflated condition and then inflated with a conductive fluid or gas. The colon can be supported against the pressure of the fluid or gas with a pressure sleeve that has been inserted to surround the region of the colon being treated. An electrosurgical instrument is then inserted into the colon and manipulated to vaporize the tumor.

Owner:GYRUS MEDICAL LTD

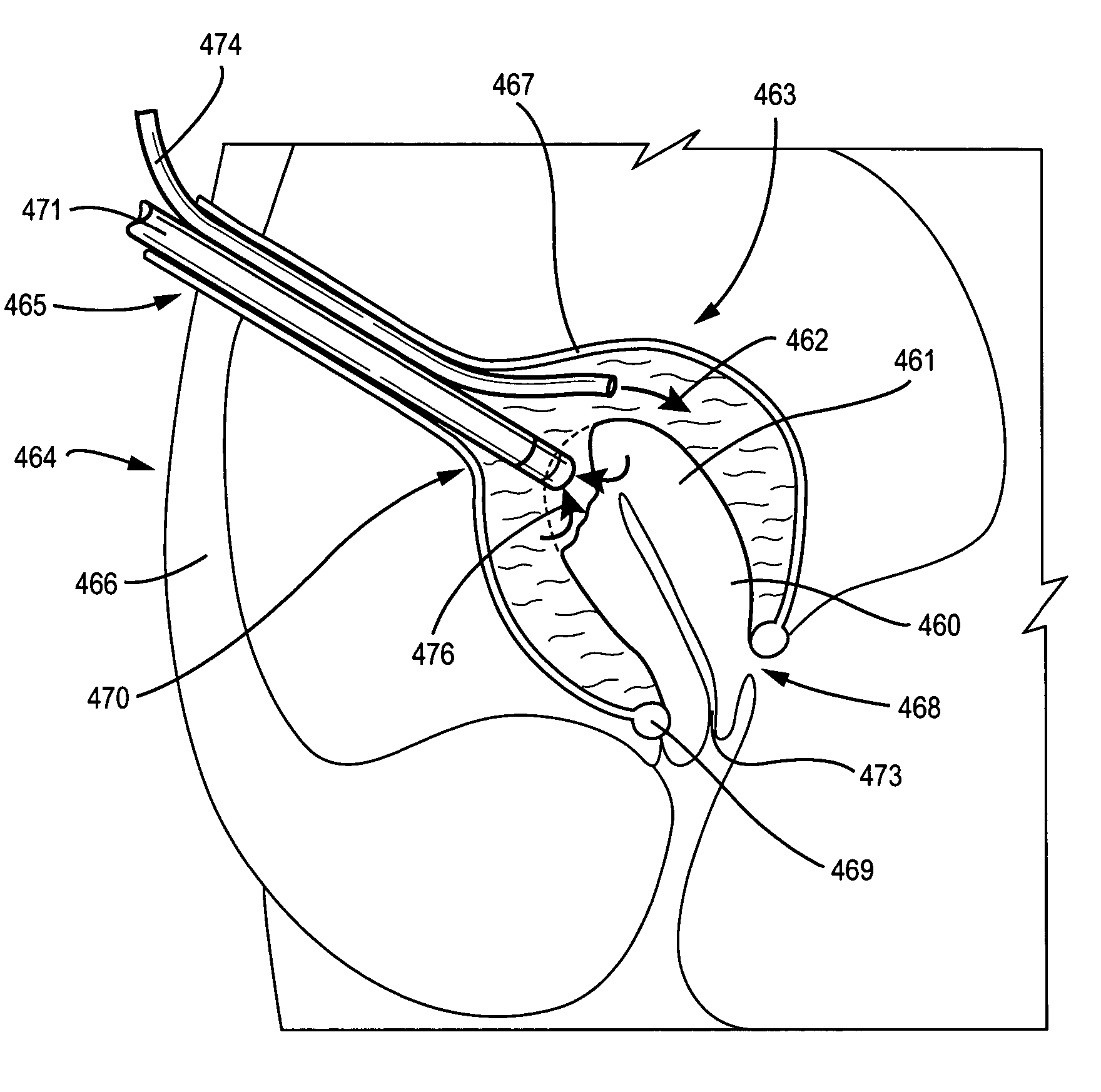

Electrosurgical instrument

InactiveUS7278994B2Lower impedanceReduced effectivenessCannulasDiagnosticsGynecologyPeritoneal cavity

A system and method are disclosed for removing a uterus using a fluid enclosure inserted in the peritoneal cavity of a patient so as to enclose the uterus. The fluid enclosure includes a distal open end surrounded by an adjustable loop, that can be tightened, a first proximal opening for inserting an electrosurgical instrument into the fluid enclosure, and a second proximal opening for inserting an endoscope. The loop is either a resilient band extending around the edge of the distal open end or a drawstring type of arrangement that can be tightened and released. The fluid enclosure is partially inserted into the peritoneal cavity of a patient in a deflated condition and then manipulated within the peritoneal cavity over the body and fundus of the uterus to the level of the uterocervical junction. The loop is tightened around the uterocervical junction, after which the enclosure is inflated using a conductive fluid. The loop forms a pressure seal against the uterocervical junction to contain the conductive fluid used to fill the fluid enclosure. Endoscopically inserted into the fluid enclosure is an electrosurgical instrument that is manipulated to vaporize and morcellate the fundus and body of the uterus. The fundus and body tissue that is vaporized and morcellated is then removed from the fluid enclosure through the shaft of the instrument, which includes a hollow interior that is connected to a suction pump The fundus and body are removed after the uterus has been disconnected from the tissue surrounding uterus.

Owner:GYRUS MEDICAL LTD

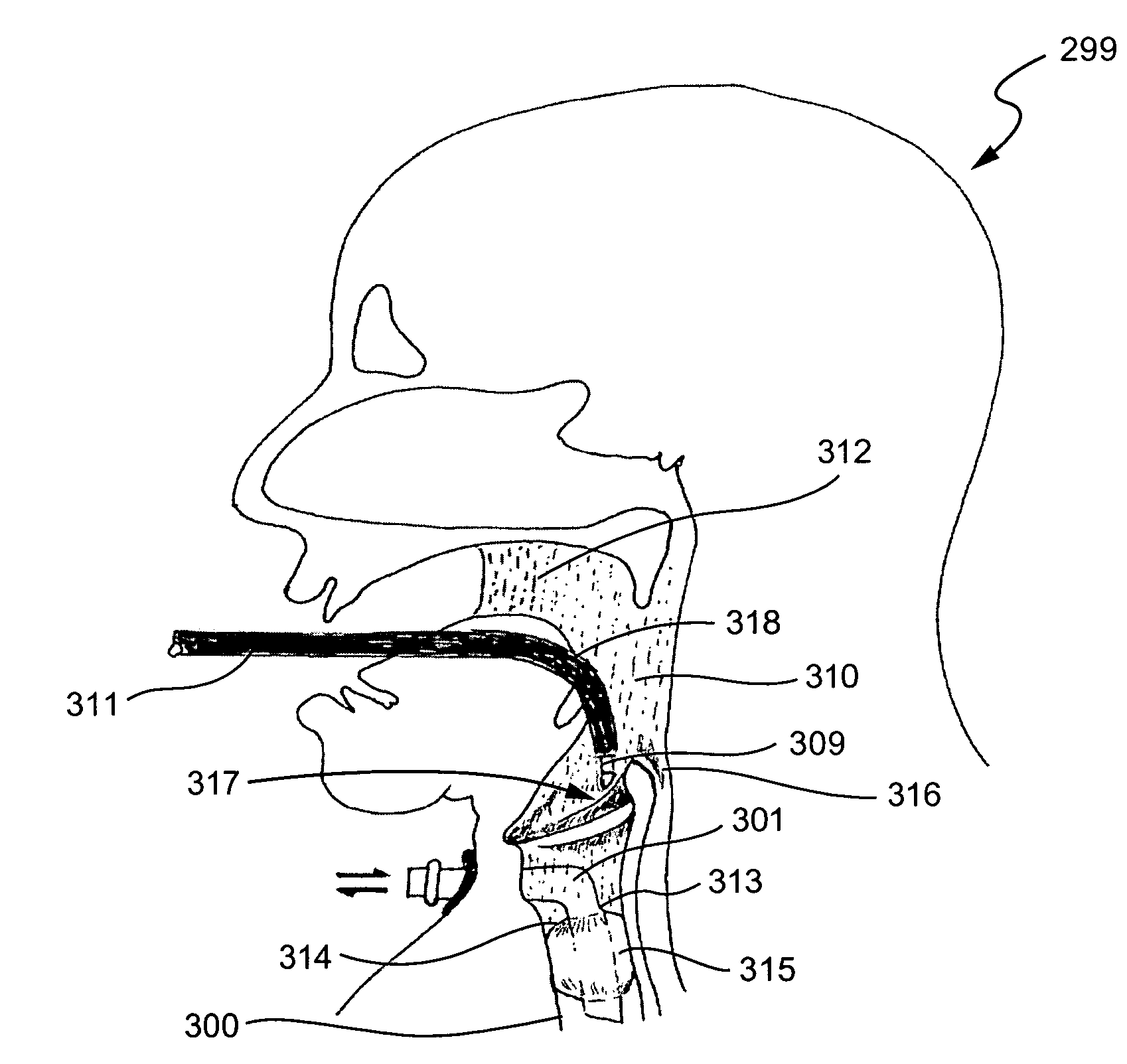

Electrosurgical system and method

InactiveUS7001380B2Lower impedanceMinimizing char formationCannulasDiagnosticsBenign conditionEnlarged tonsils

A method is disclosed for treating benign conditions, such as enlarged tonsils and / or adenoids located in a patient's throat or nasopharynx, or soft tissue lesions located in a patient's oropharynx or larynx. According to the method, a space containing the patient's nasopharynx, oropharynx or pharynx and larynx is isolated from the patient's trachea and lungs using an inflatable cuff tracheostomy tube or nasotracheal tube inserted in the patient's trachea. The cuff is inflated to occlude the trachea. The patient is placed in a supine position, whereupon at least a portion of the space containing the nasopharynx and / or oropharynx and larynx is filled with saline. An endoscope is then inserted into the space to view the operative site in which the tonsils or tissue lesion are to be treated. An electrosurgical instrument having an active tissue treatment electrode and a return electrode connected to an electrosurgical generator is then inserted into the space, either along side the endoscope or through the endoscope's working channel. The generator is then operated to apply a radio frequency voltage between the active and return electrodes of the electrosurgical instrument, whereby a conduction path is formed between the active and return electrodes, at least partially through the saline, whereupon the active electrode is manipulated to debulk or otherwise treat the soft tissue lesion or enlarged tonsils and / or adenoids.

Owner:GYRUS MEDICAL LTD

Bipolar surgical instruments having focused electrical fields

InactiveUS6162220AReduce capacityLess of a tendency to cause bleedingSurgical needlesSurgical instruments for heatingElectricityEngineering

A bipolar surgical device includes a pair of actuable jaws. A first electrode member which optionally includes a line of electrically coupled tissue-penetrating elements is formed on one of the jaws, and a second electrode member which optionally includes a line of electrically coupled tissue-penetrating elements is formed on the same or the other jaw. The electrode members are laterally spaced-apart and arranged in a parallel, usually linear manner so that the lateral distance therebetween remains generally constant. In operation, tissue may be grasped between the jaws so that the electrode members contact and / or the tissue-penetrating elements enter into the tissue. By energizing the electrode members at opposite polarities using a high frequency energy source, tissue between the jaws will be heated, coagulated, and / or necrosed, while heating of tissue outside of the lines will be minimized.

Owner:PERFECT SURGICAL TECHN

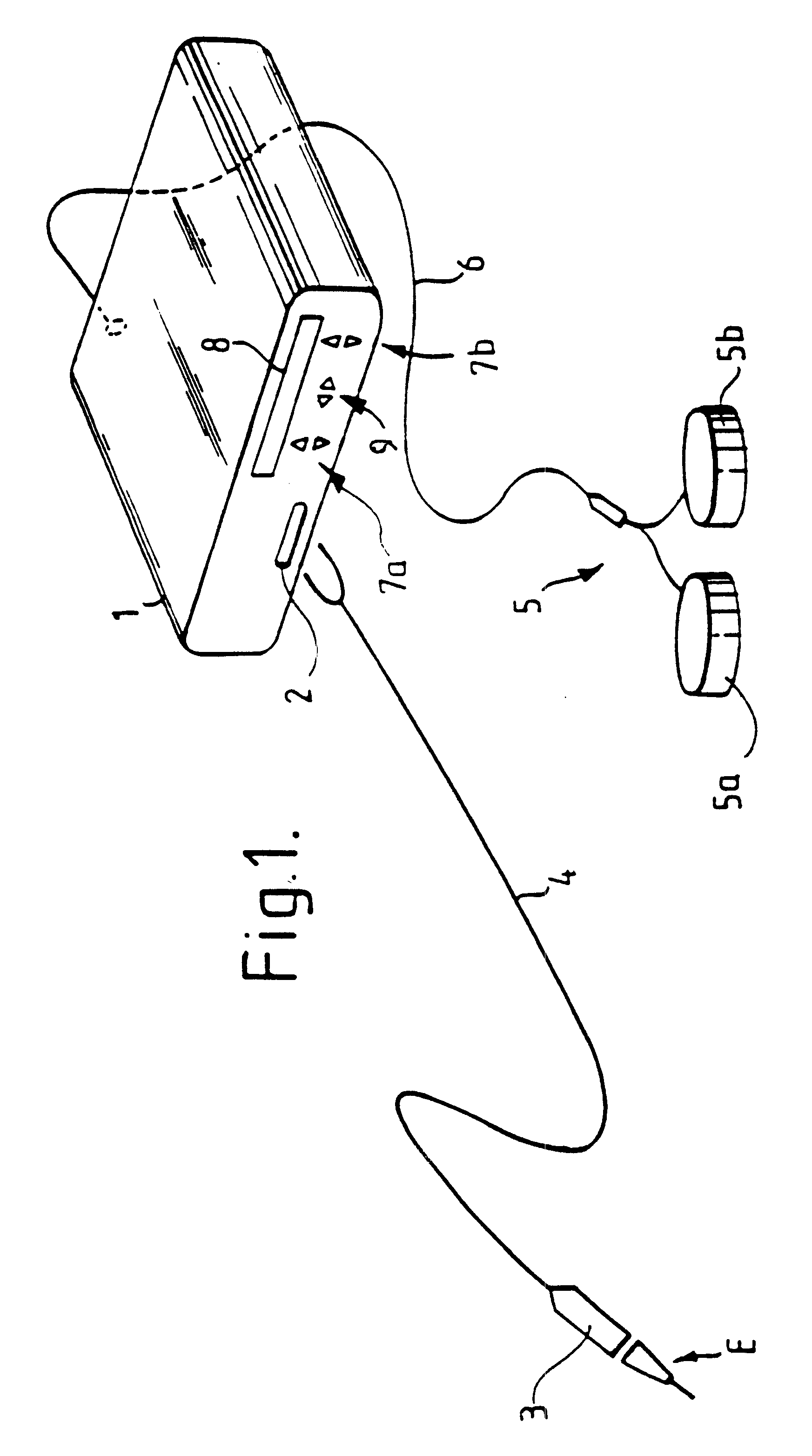

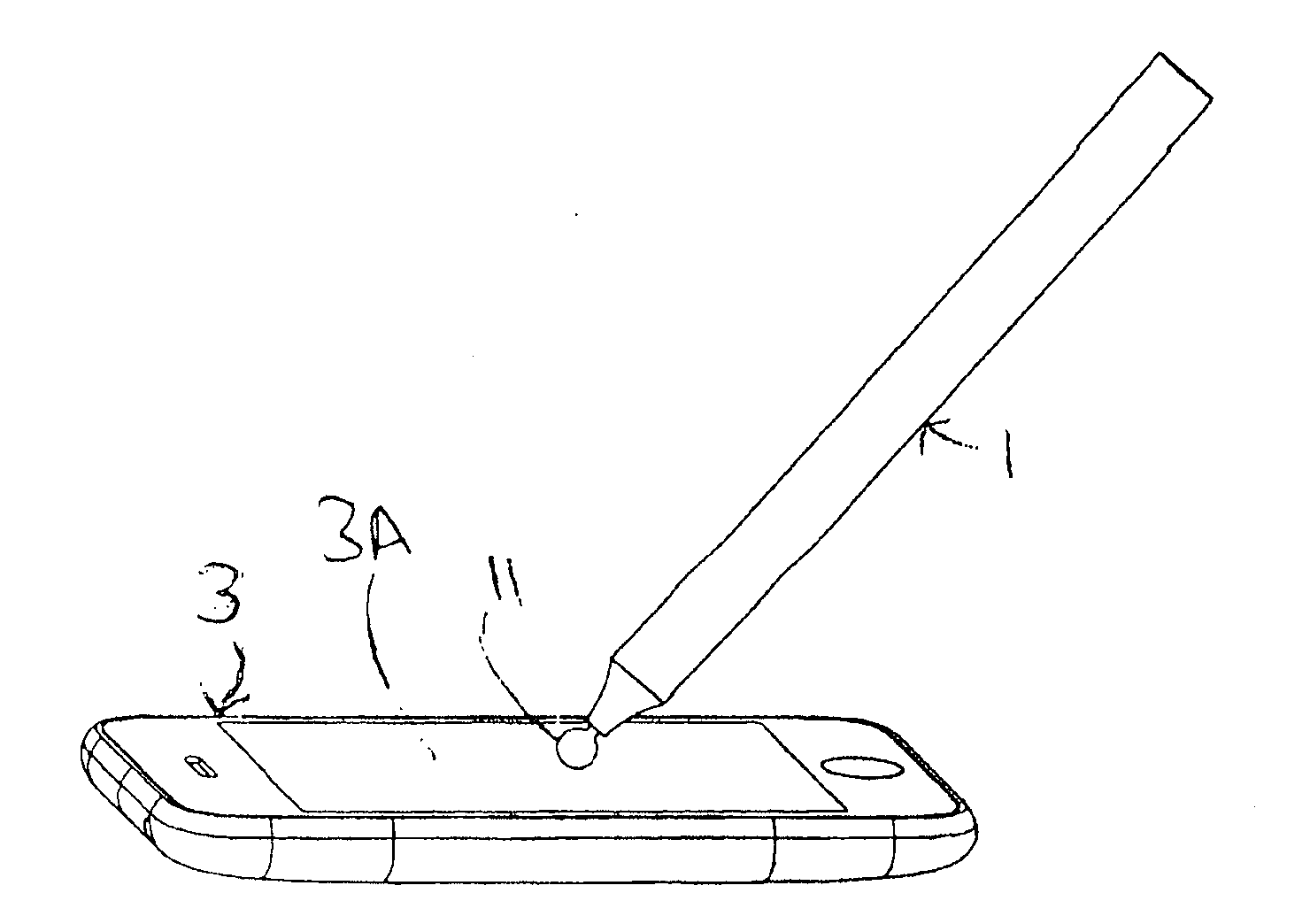

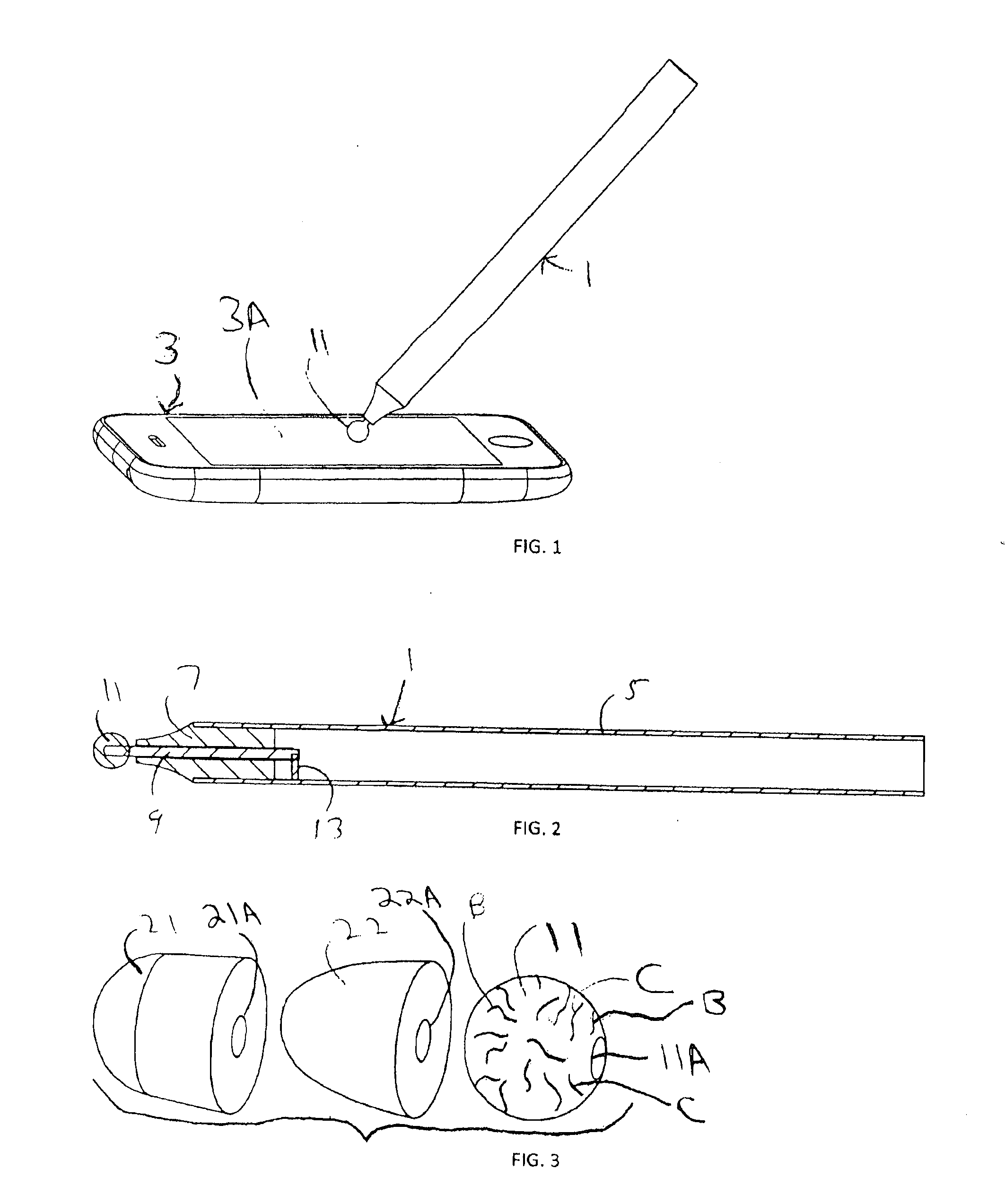

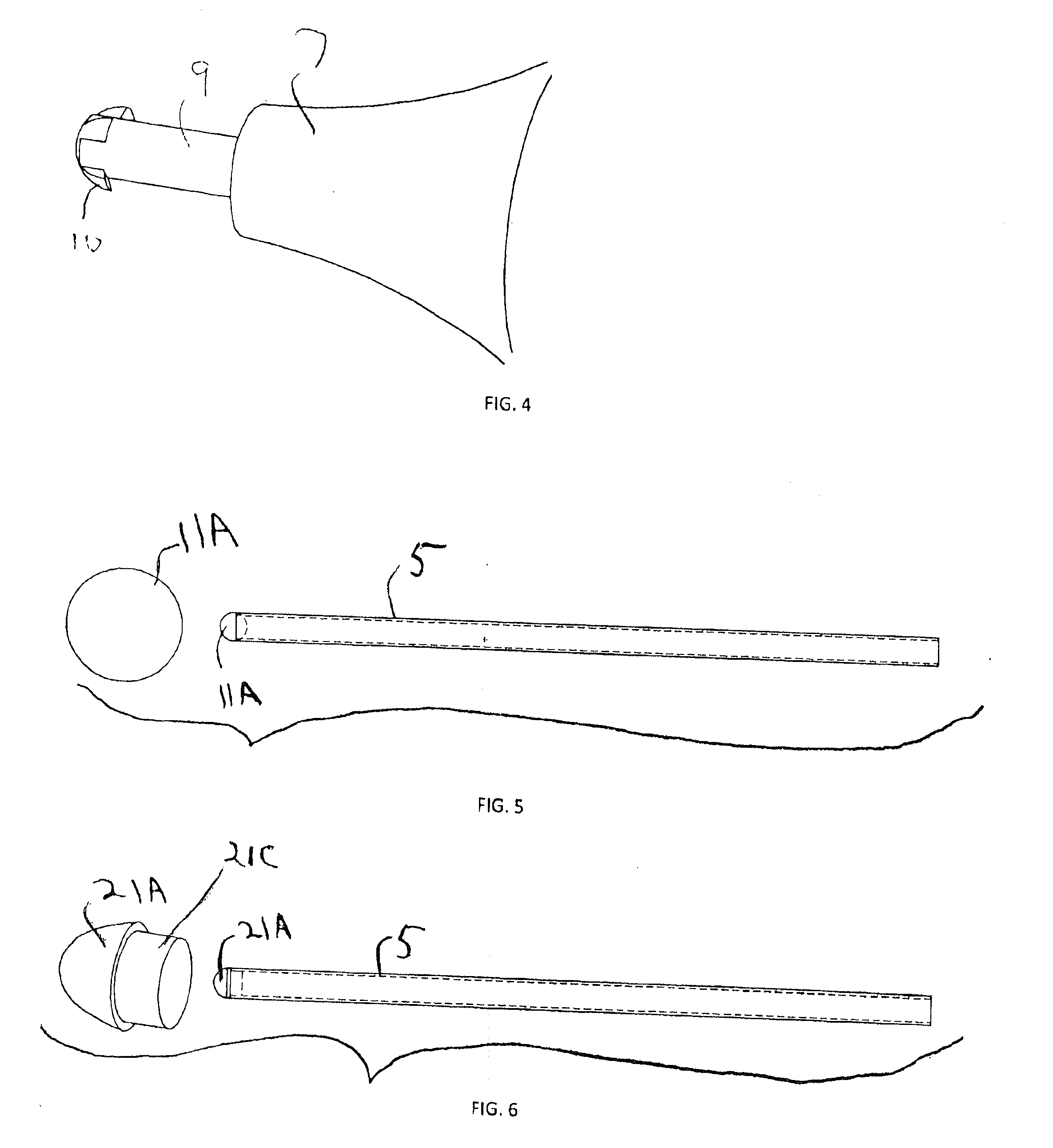

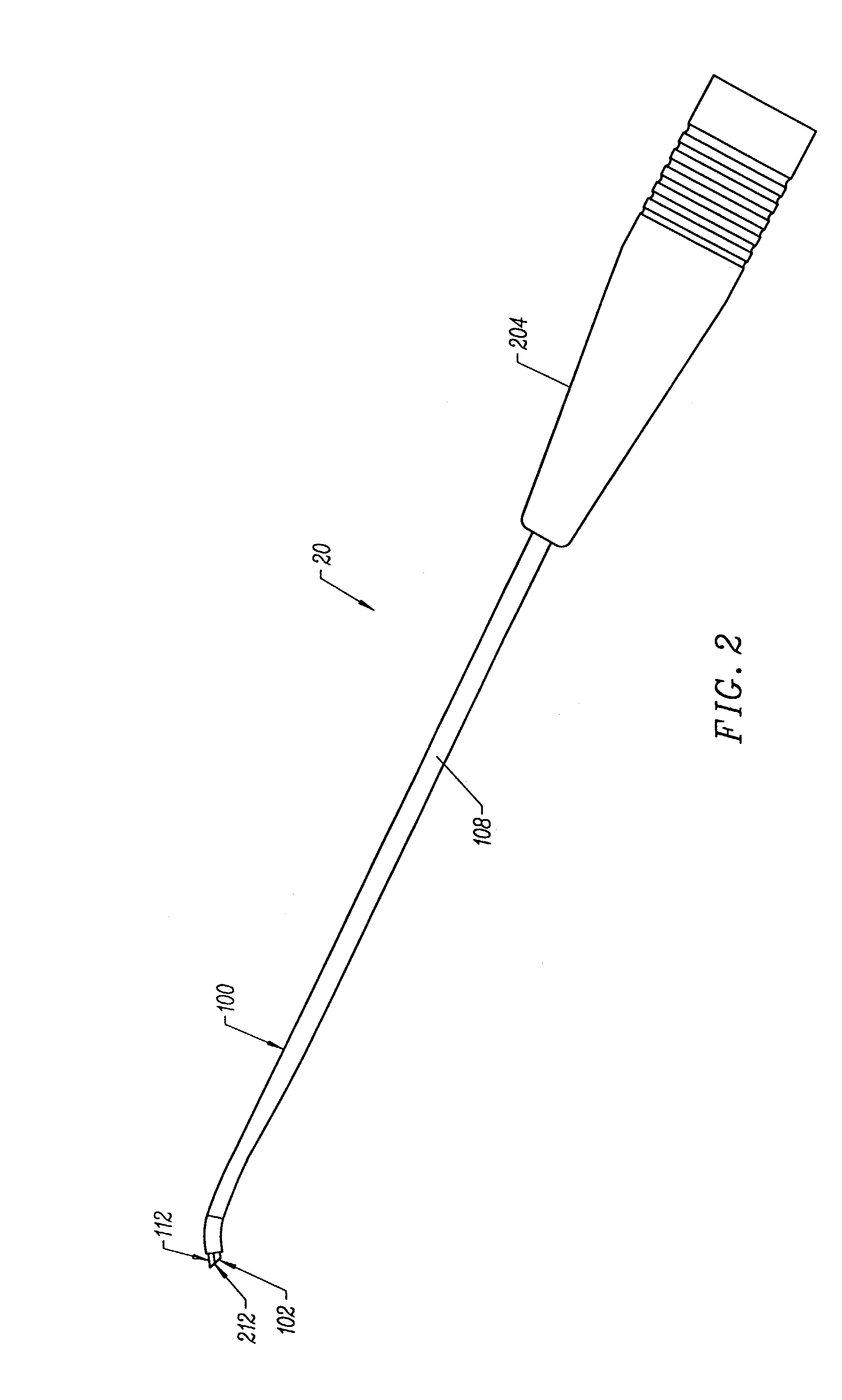

Capacitive touch screen stylus

InactiveUS20110304577A1Reduce coefficient of frictionLower impedanceInput/output processes for data processingCapacitanceFiber

In some embodiments, a stylus for providing input to a capacitive touch screen, having a tip including or consisting of conductive felt, which provides a deformable conductive surface for contacting the touch screen. The tip is produced by felting base fibers (which are typically non-conductive) with conductive fibers. In other embodiments, a capacitive touch stylus having at least a first mode of operation and a second mode of operation, and including at least one conductive tip and switched circuitry (preferably, passive circuitry) including at least one switch biased in a default state indicative of the first mode of operation but switchable into a second state indicative of the second mode of operation in response to movement of the tip (typically, in response to exertion of not less than a threshold force on the tip). In some embodiments, a stylus having a conductive tip (e.g., a conductive, felted tip) and including switched circuitry (preferably, passive circuitry) having a first state which couples a capacitance to the tip, where the capacitance is sufficient to allow a capacitive touch screen device to recognize (as a touch) simple contact of the tip on the screen of the touch screen device, and a second state which decouples the capacitance from the tip, thereby preventing the touch screen device from recognizing (as a touch) simple contact of the tip on the screen.

Owner:RB CONTROLS CO

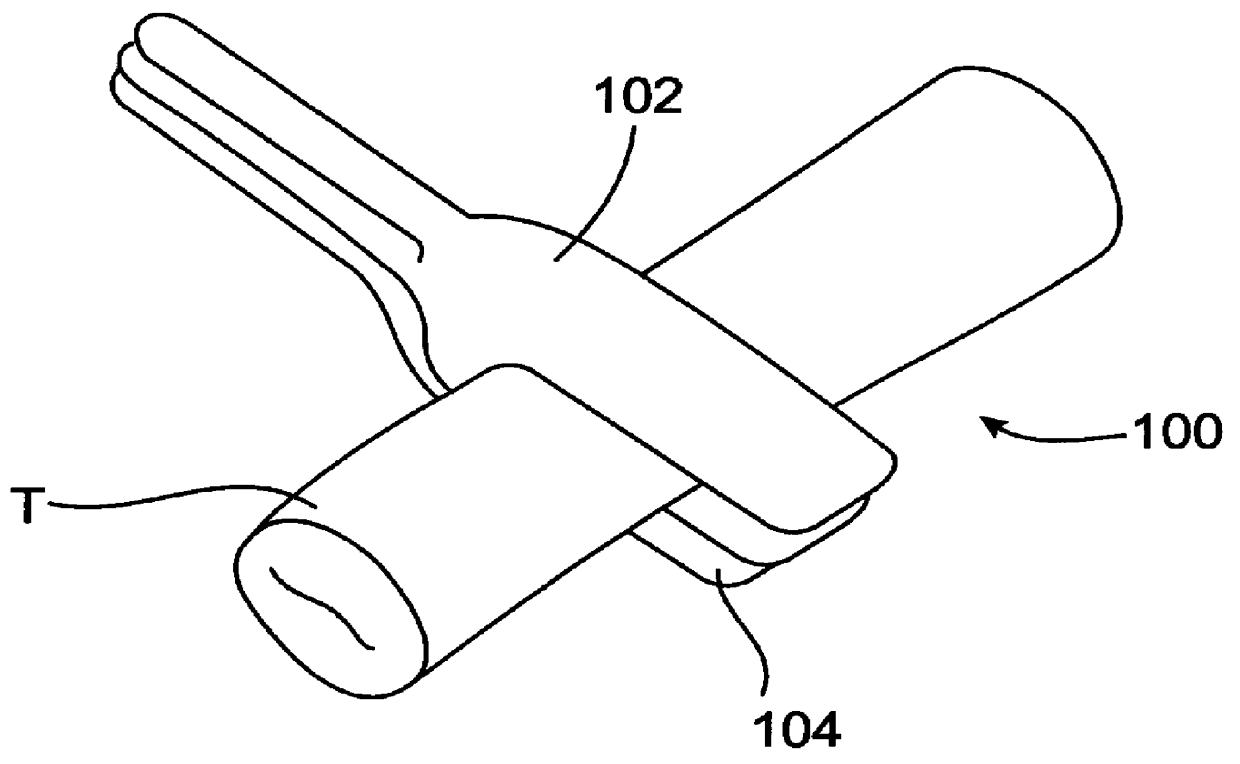

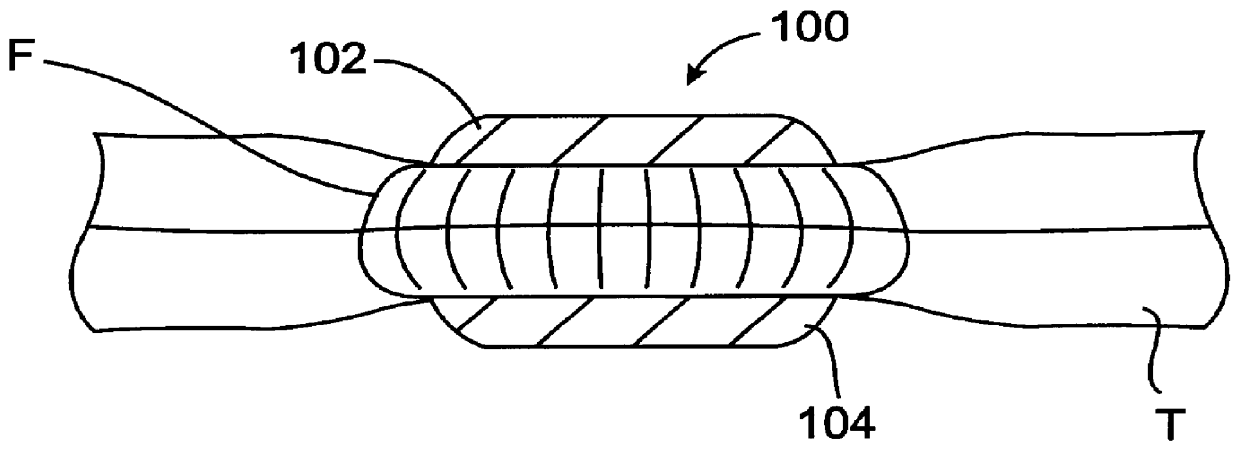

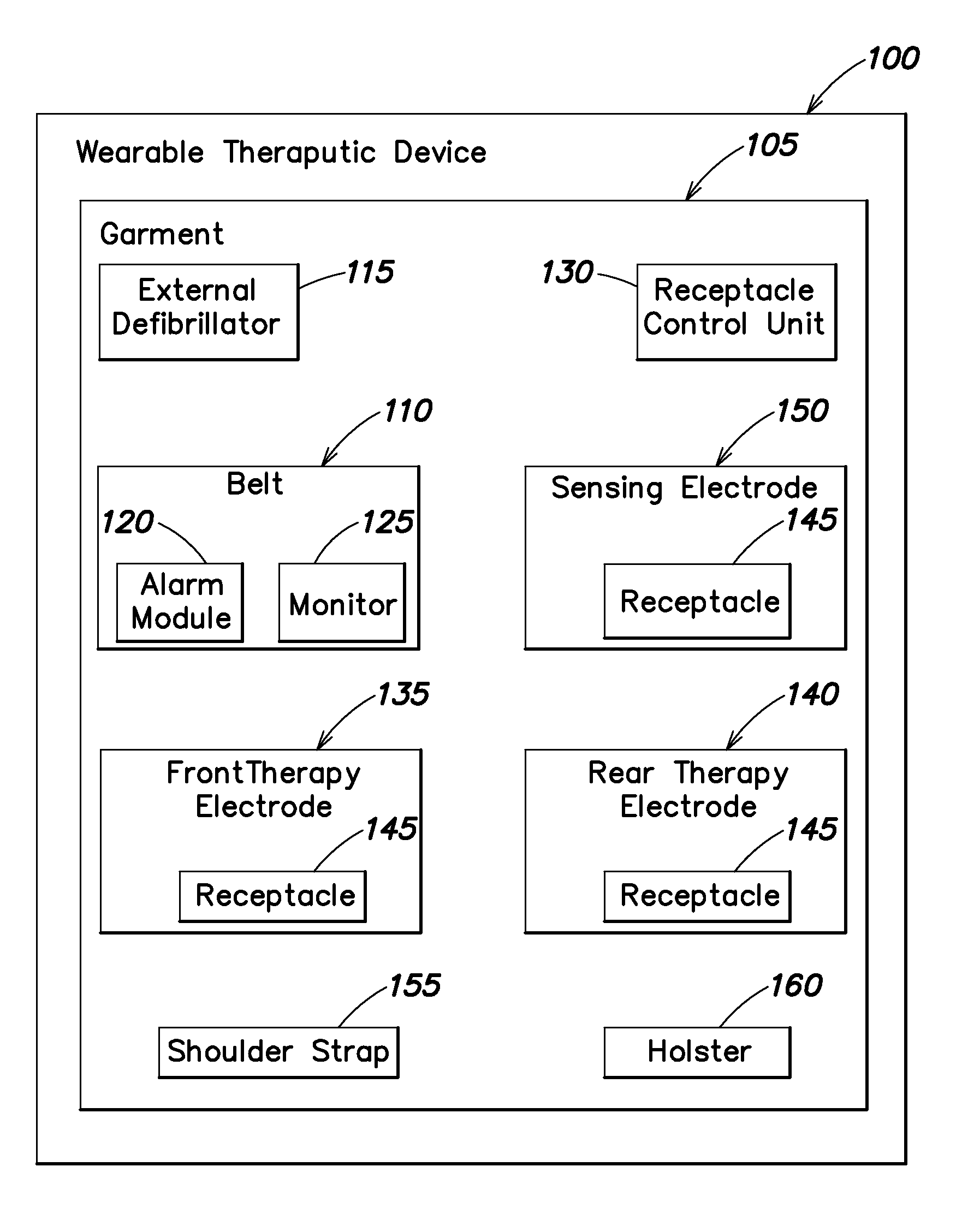

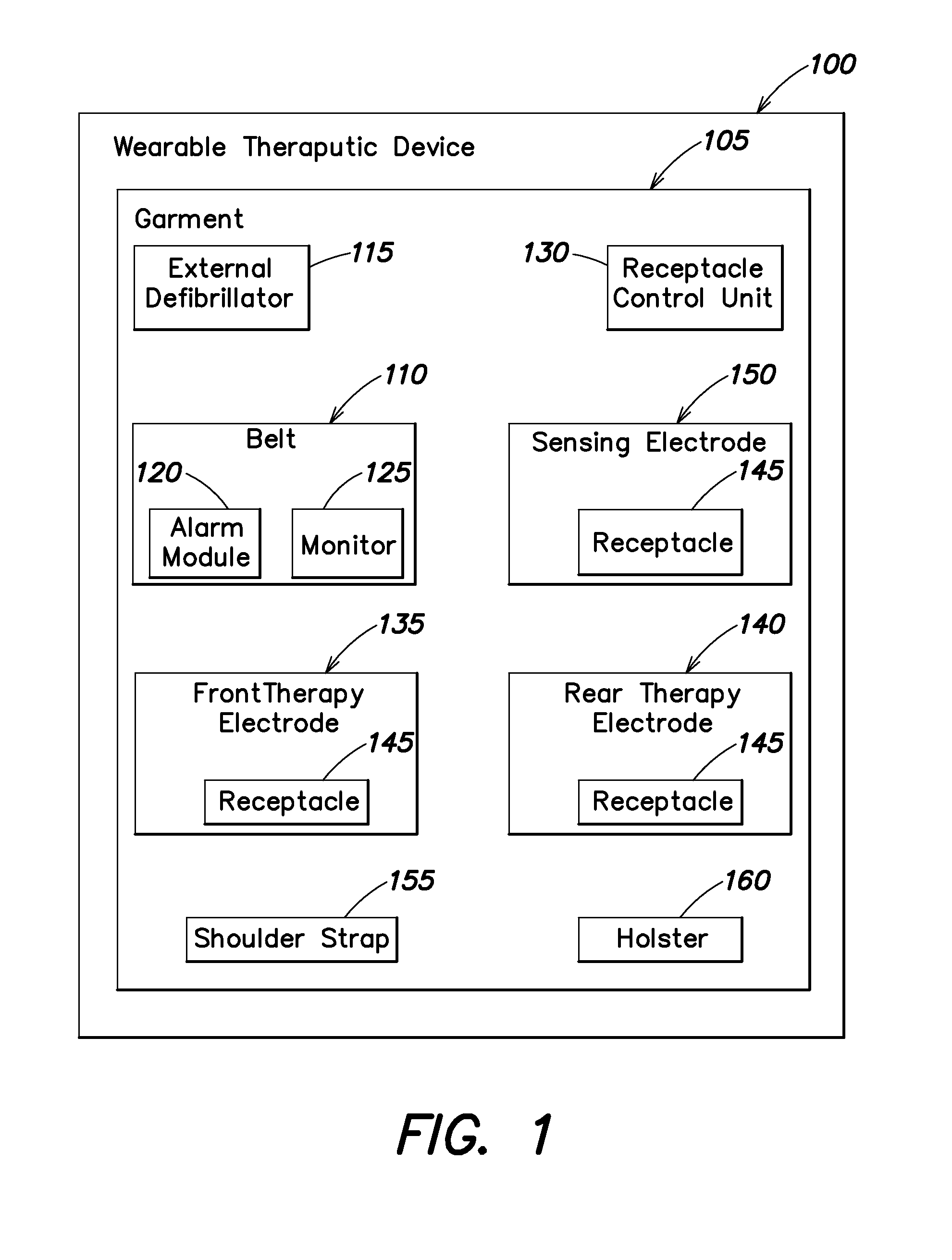

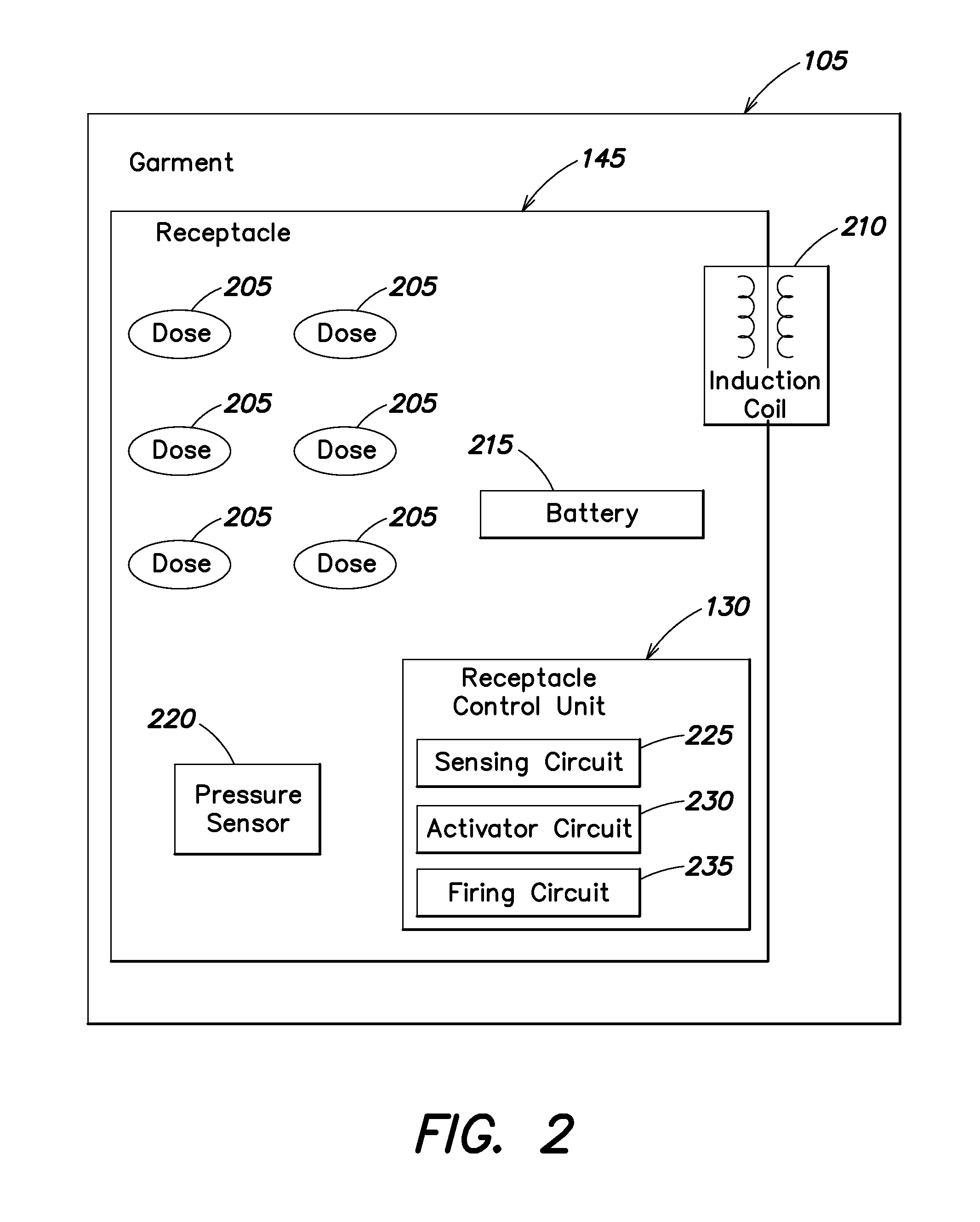

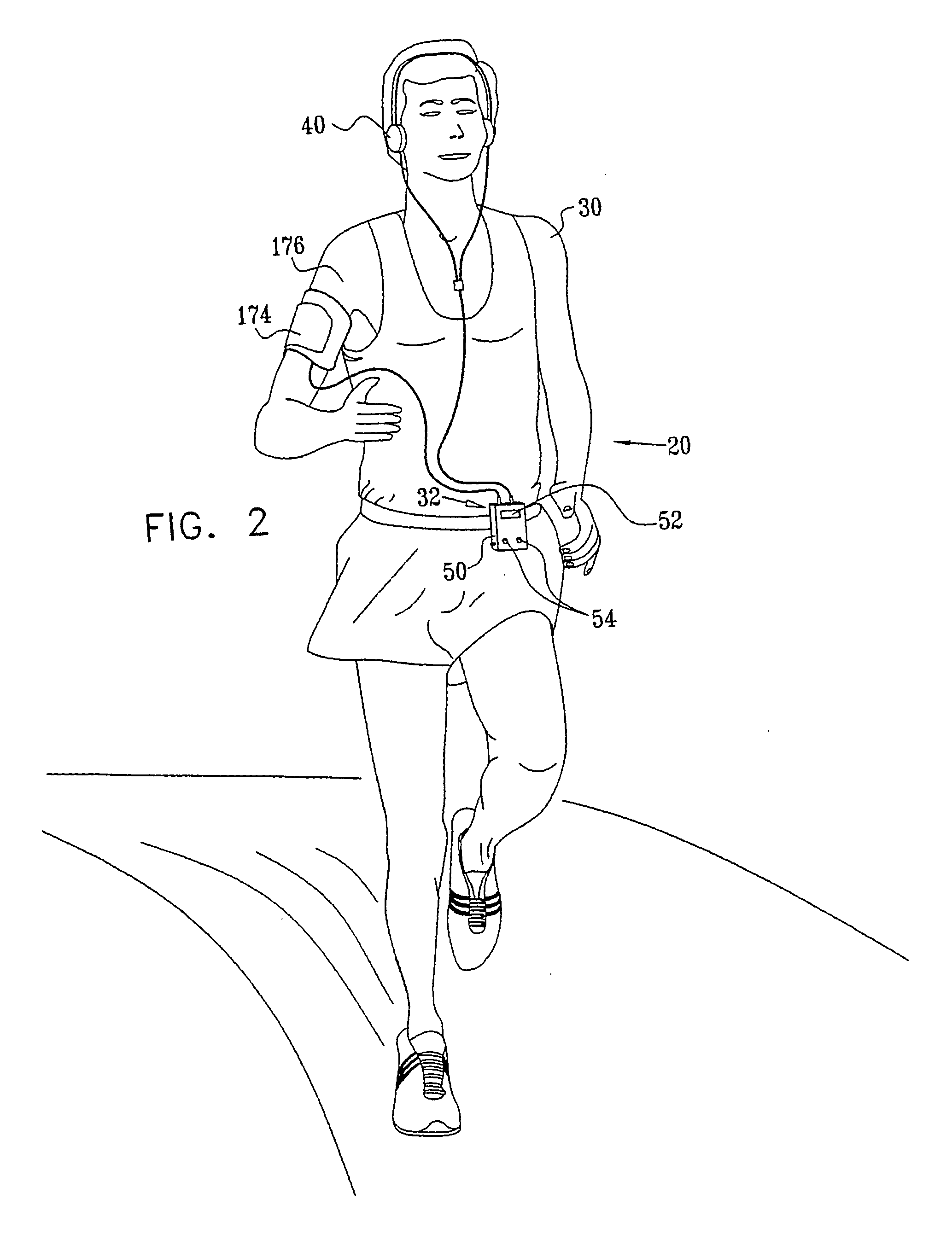

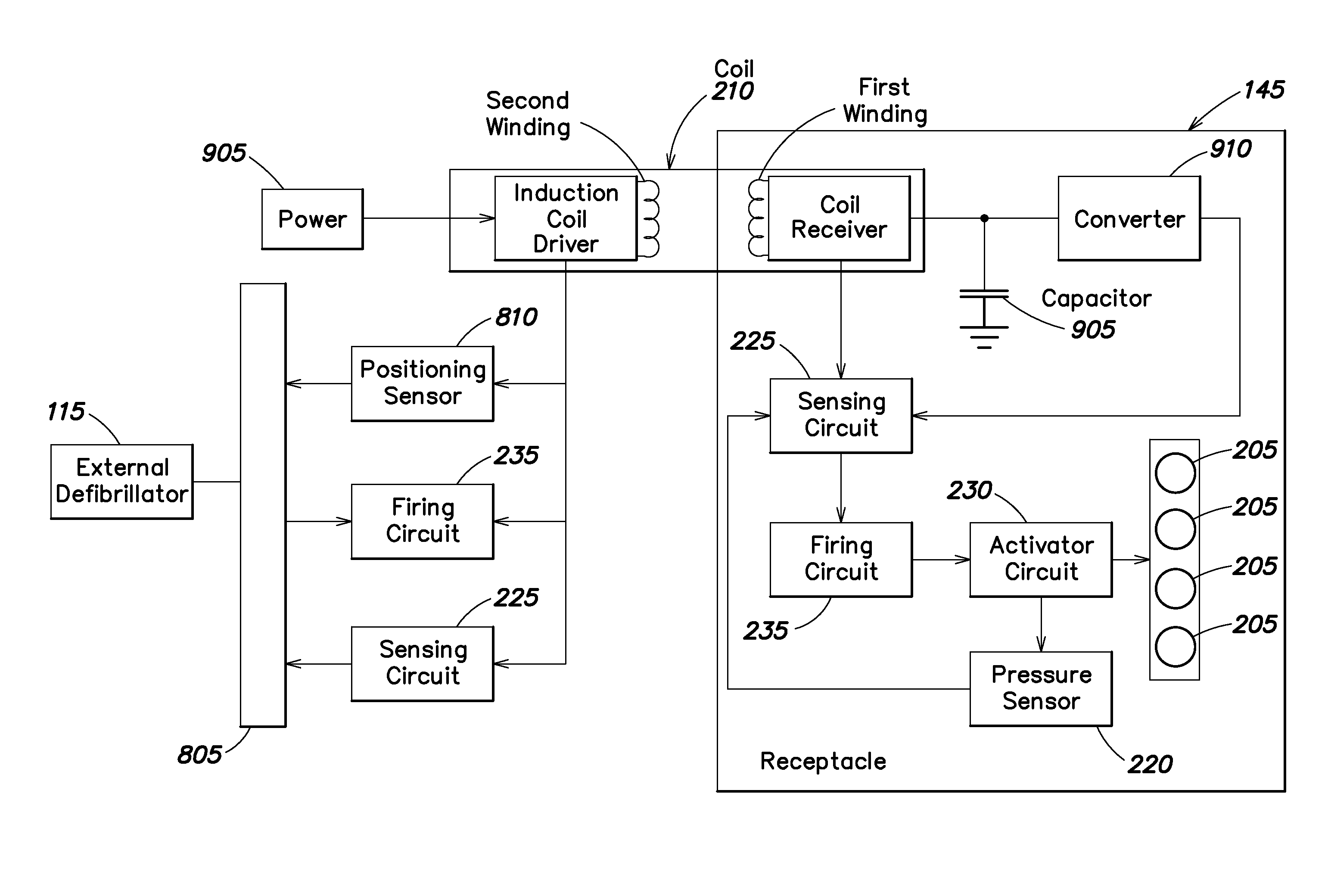

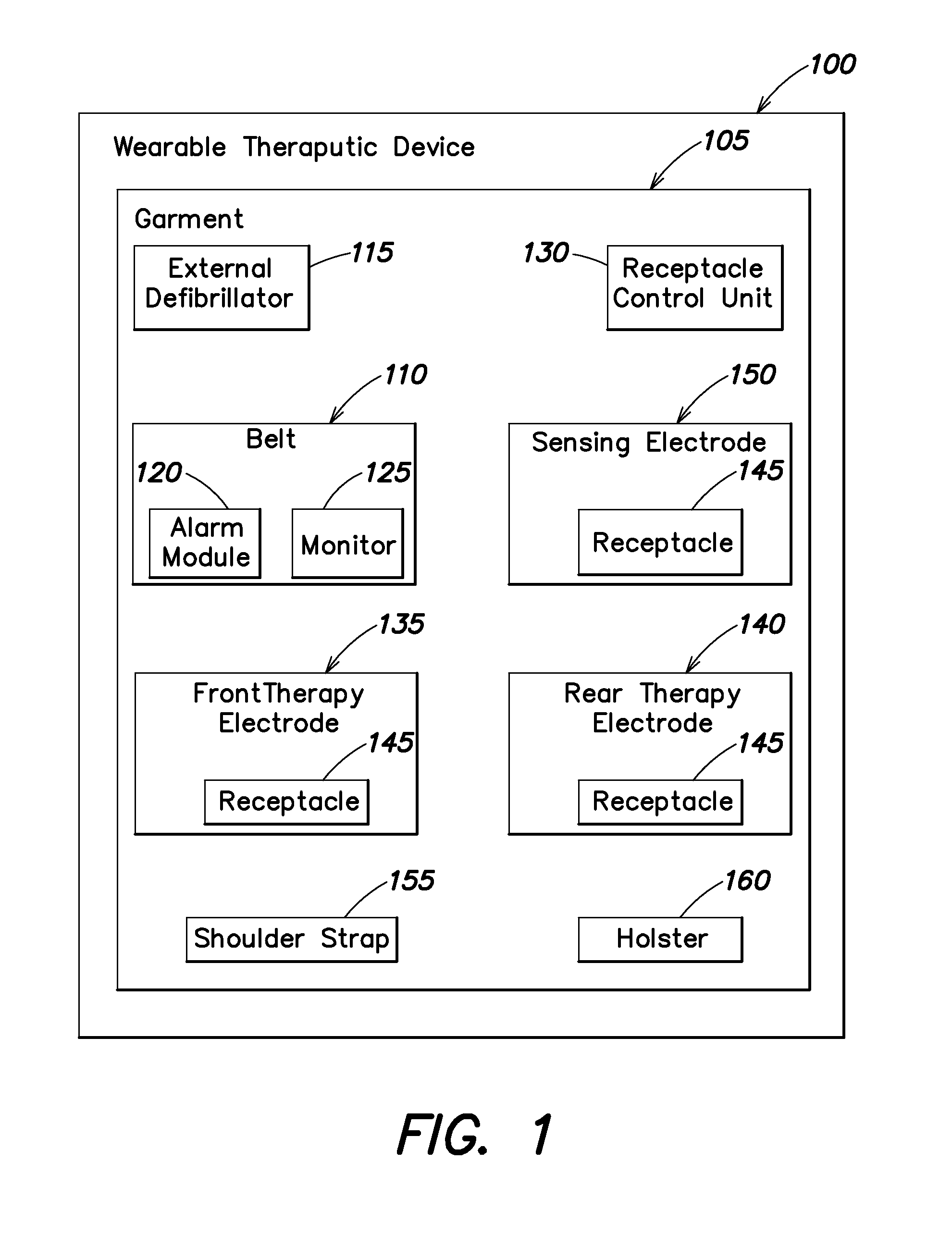

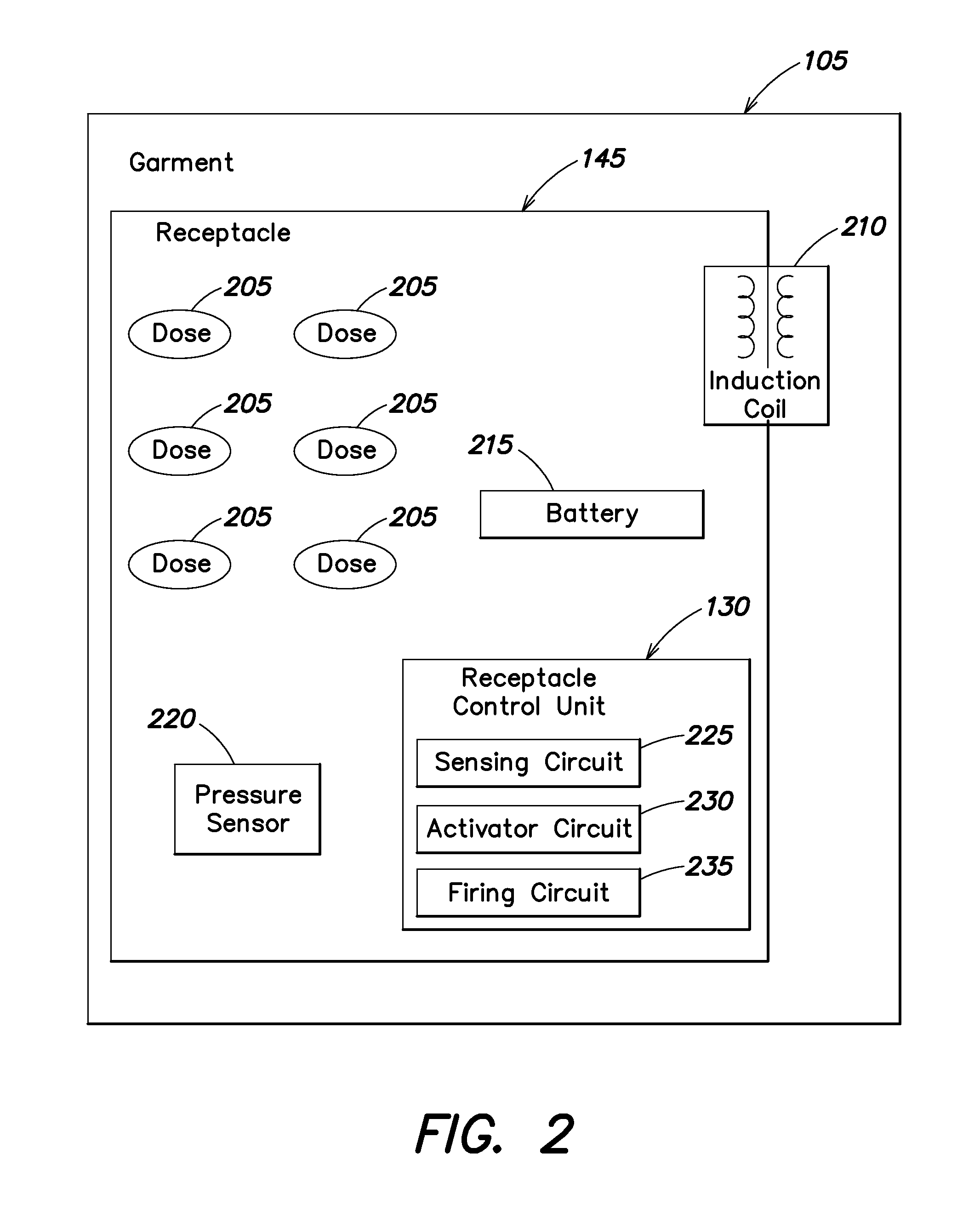

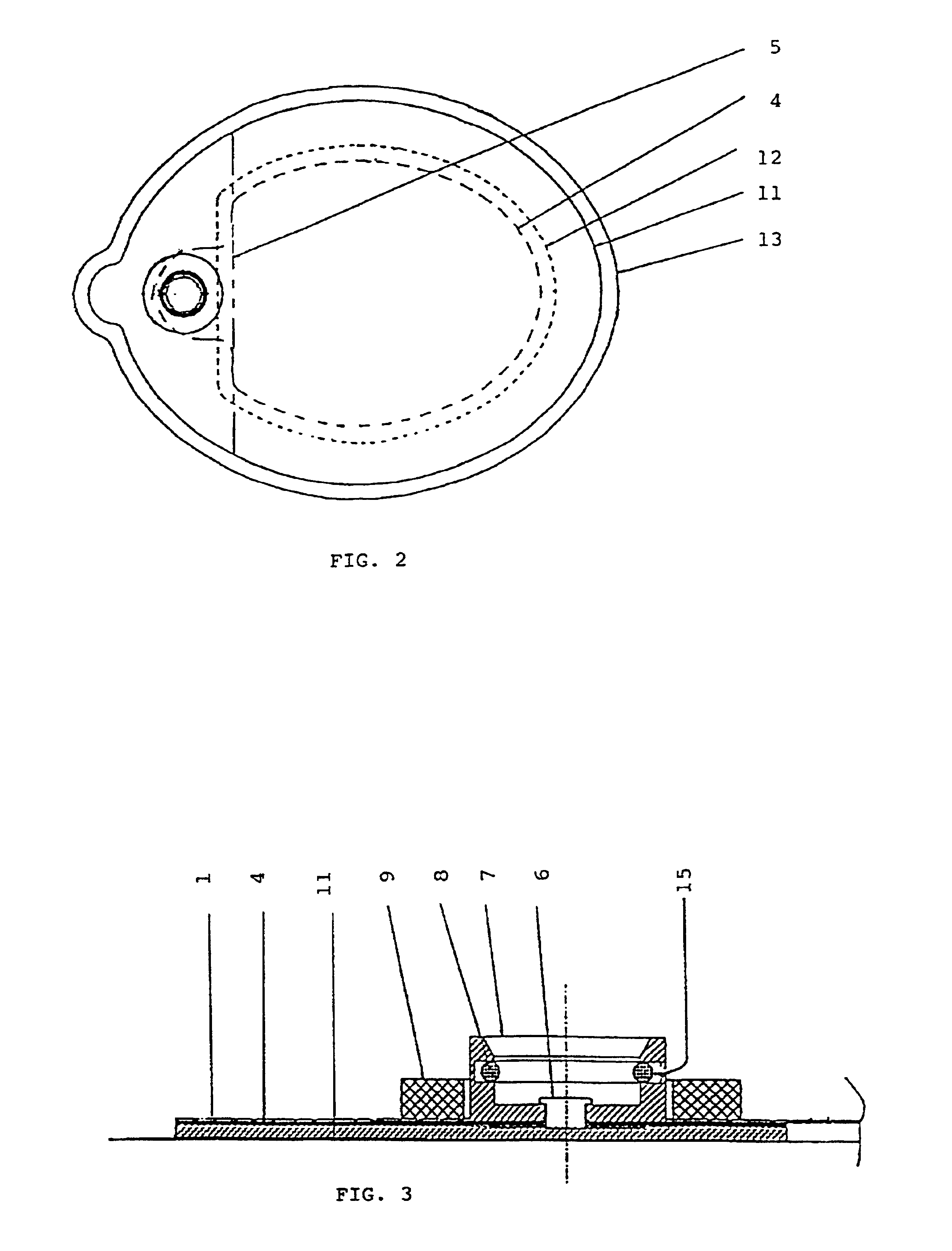

Wearable therapeutic device

ActiveUS20110288604A1Reduce impedanceLower impedanceHeart defibrillatorsExternal electrodesEngineeringExternal defibrillators

A wearable therapeutic device that includes a garment configured to contain an external defibrillator. The garment is configured to house at least one of an alarm module and a monitor and to house a first therapy electrode and a second therapy electrode. The garment is also configured to releasably receive a receptacle that contains a conductive fluid proximate to at least one of the first therapy electrode and the second therapy electrode, and to electrically couple the receptacle with the garment.

Owner:ZOLL MEDICAL CORPORATION

Bipolar surgical instruments having focused electrical fields

InactiveUS20020013583A1Reduce capacityLower impedanceSurgical needlesSurgical instruments for heatingElectricitySurgical device

A bipolar surgical device comprises a pair of actuable jaws. A first electrode member which optionally includes a line of electrically coupled tissue-penetrating elements is formed on one of the jaws, and a second electrode member which optionally includes a line of electrically coupled tissue-penetrating elements is formed on the same or the other jaw. The electrode members are laterally spaced-apart and arranged in a parallel, usually linear manner so that the lateral distance therebetween remains generally constant. In operation, tissue may be grasped between the jaws so that the electrode members contact and / or the tissue-penetrating elements enter into the tissue. By energizing the electrode members at opposite polarities using a high frequency energy source, tissue between the jaws will be heated, coagulated, and / or necrosed, while heating of tissue outside of the lines will be minimized.

Owner:PERFECT SURGICAL TECHN

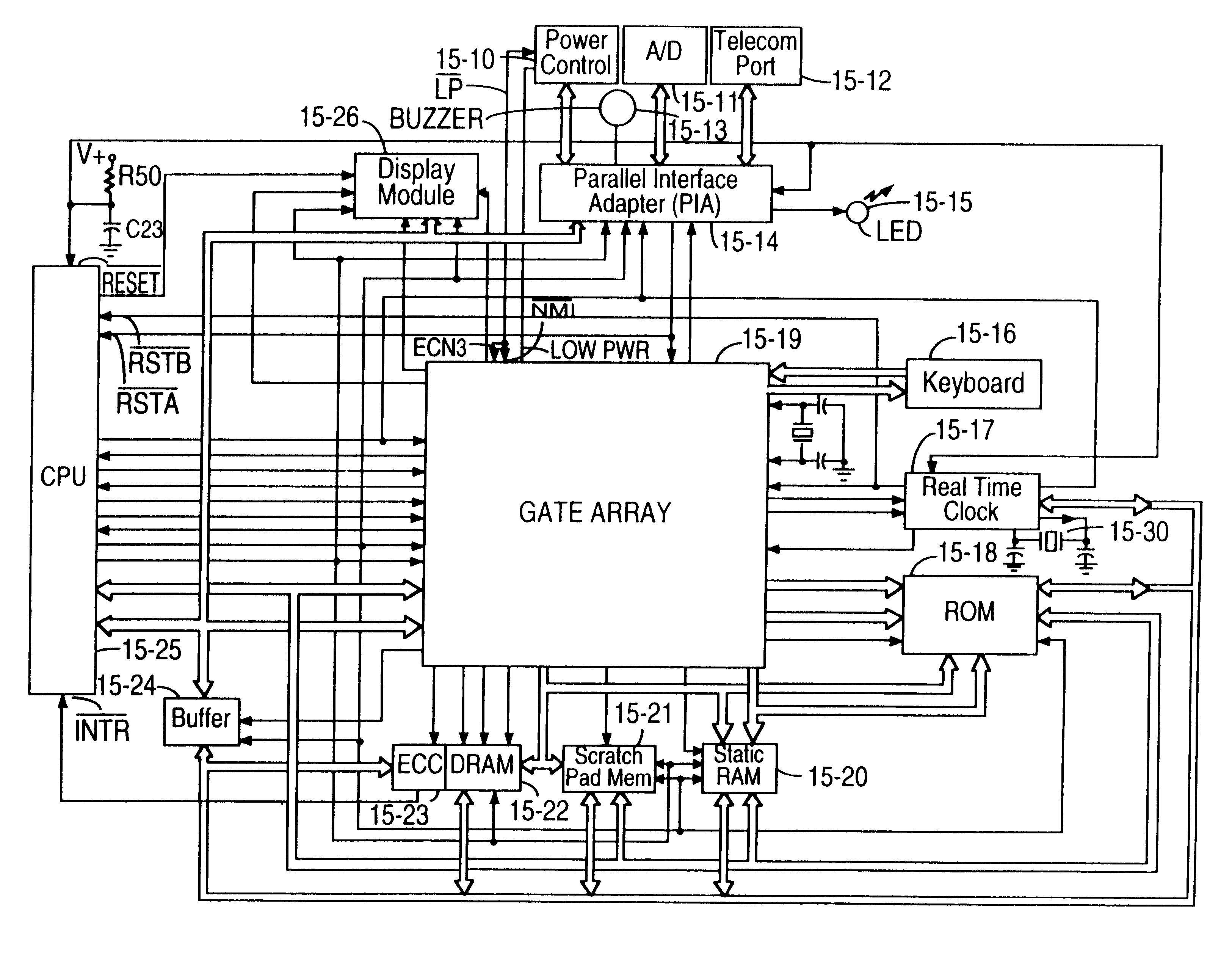

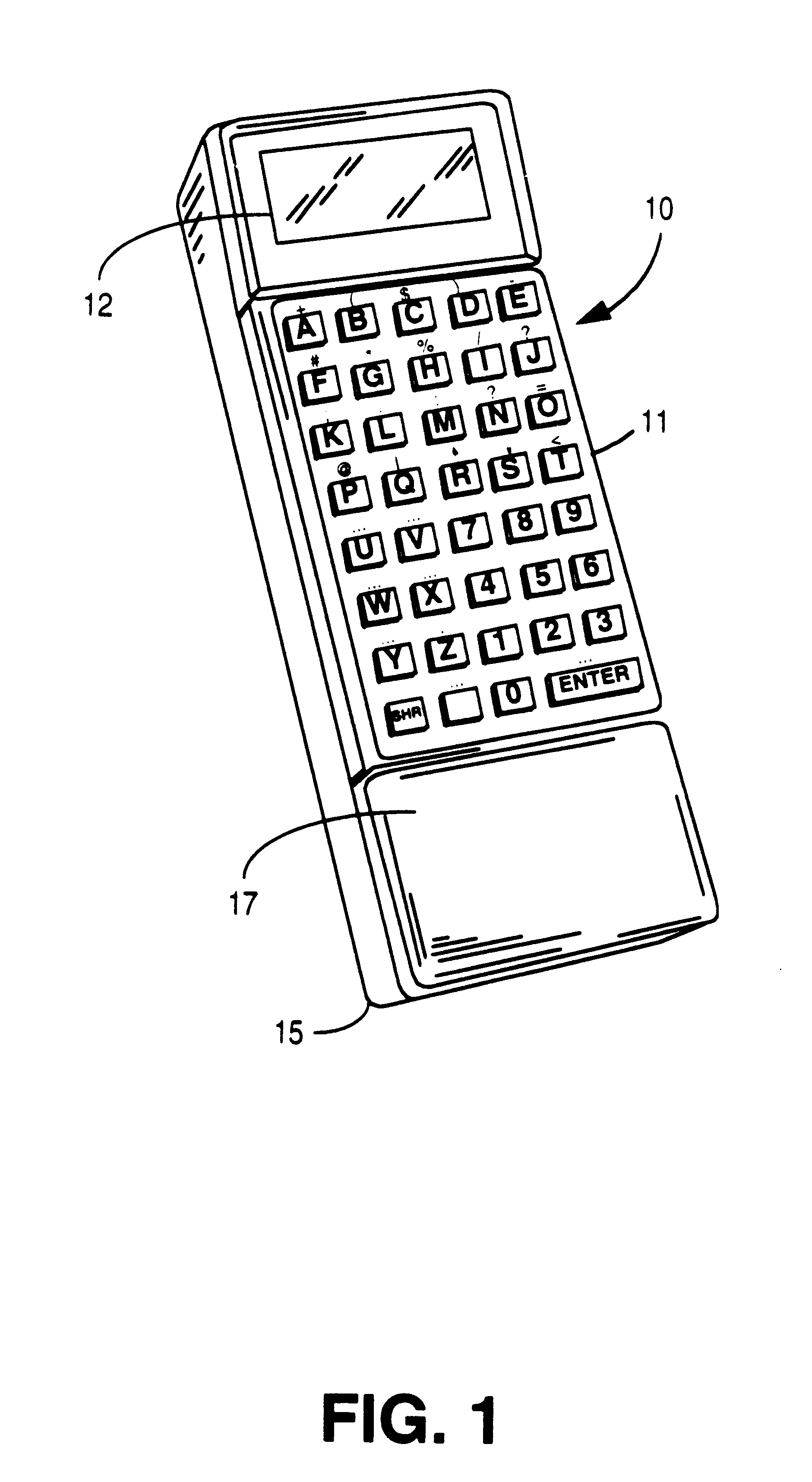

Battery pack having memory

InactiveUS6307349B1Reduce eliminateDecreasing the turn on potentialCircuit monitoring/indicationElectrical testingElectrical batteryCombined use

In an exemplary embodiment, a battery conditioning system monitors battery conditioning and includes a memory for storing data based thereon; for example, data may be stored representative of available battery capacity as measured during a deep discharge cycle. With a microprocessor monitoring battery operation of a portable unit, a measure of remaining battery capacity can be calculated and displayed. Where the microprocessor and battery conditioning system memory are permanently secured to the battery so as to receive operating power therefrom during storage and handling, the performance of a given battery in actual use can be accurately judged since the battery system can itself maintain a count of accumulated hours of use and other relevant parameters. In the case of a nonportable conditioning system, two-way communication may be established with a memory associated with the portable unit so that the portable unit can transmit to the conditioning system information concerning battery parameters (e.g. rated battery capacity) and / or battery usage (e.g. numbers of shallow discharge and recharge cycles), and after a conditioning operation, the conditioning system can transmit to the portable unit a measured value of battery capacity, for example. A battery pack having memory stores battery history and identifying data to be retrieved by a portable battery powered device. Battery status information may be utilized in conjunction with characteristic battery history data in order to optimize charging and discharging functions and to maximize the useful life of a battery pack.

Owner:INTERMEC

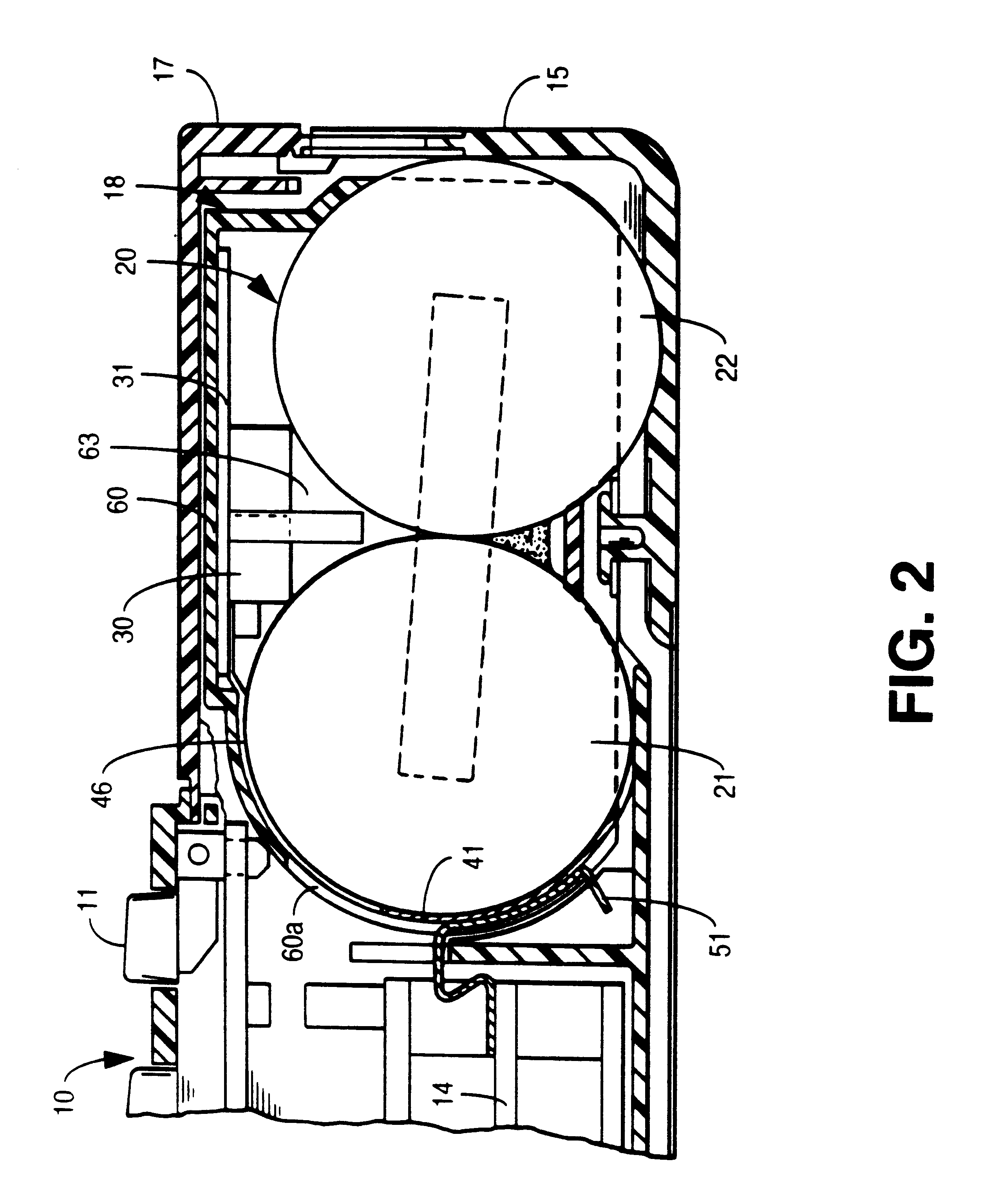

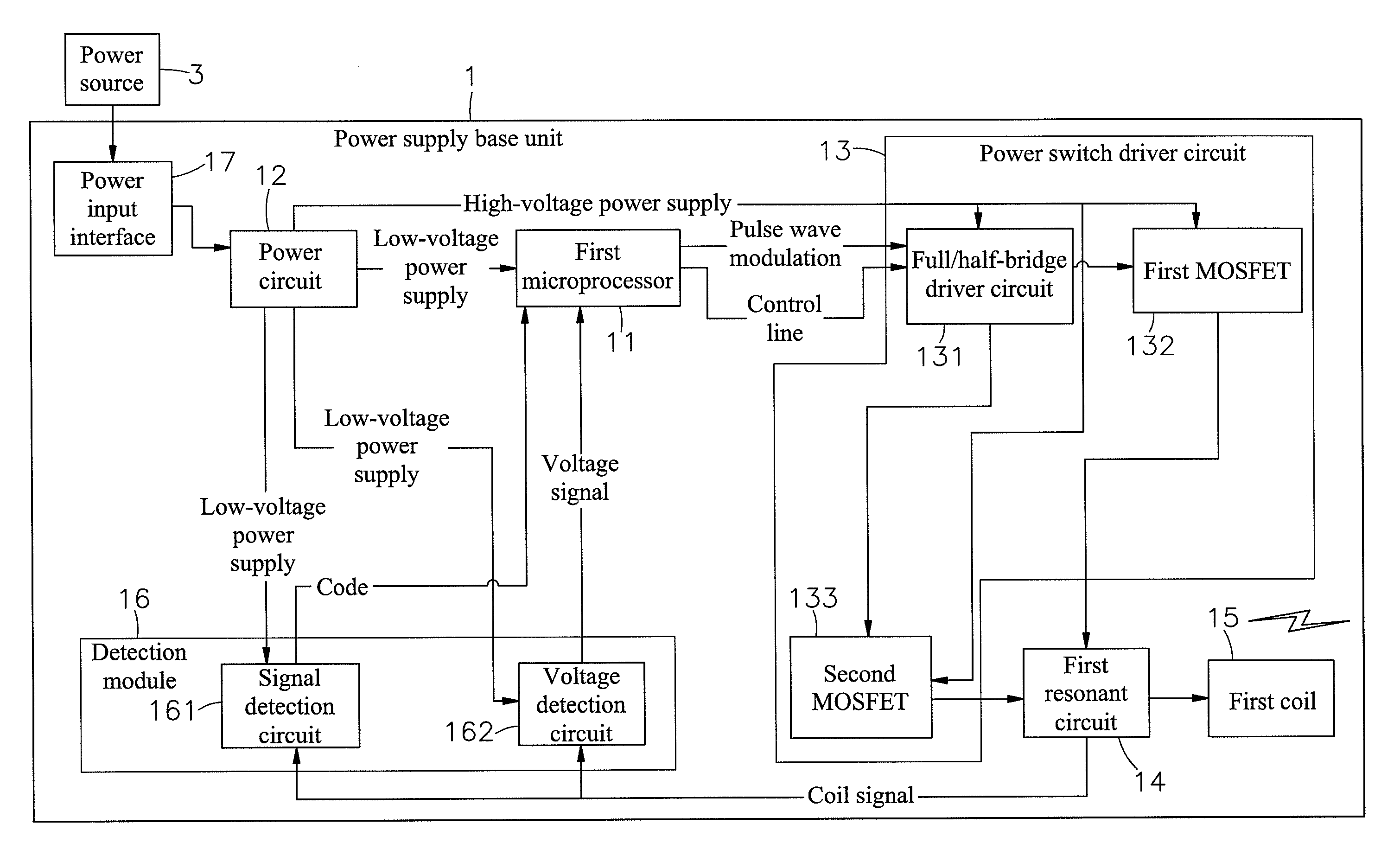

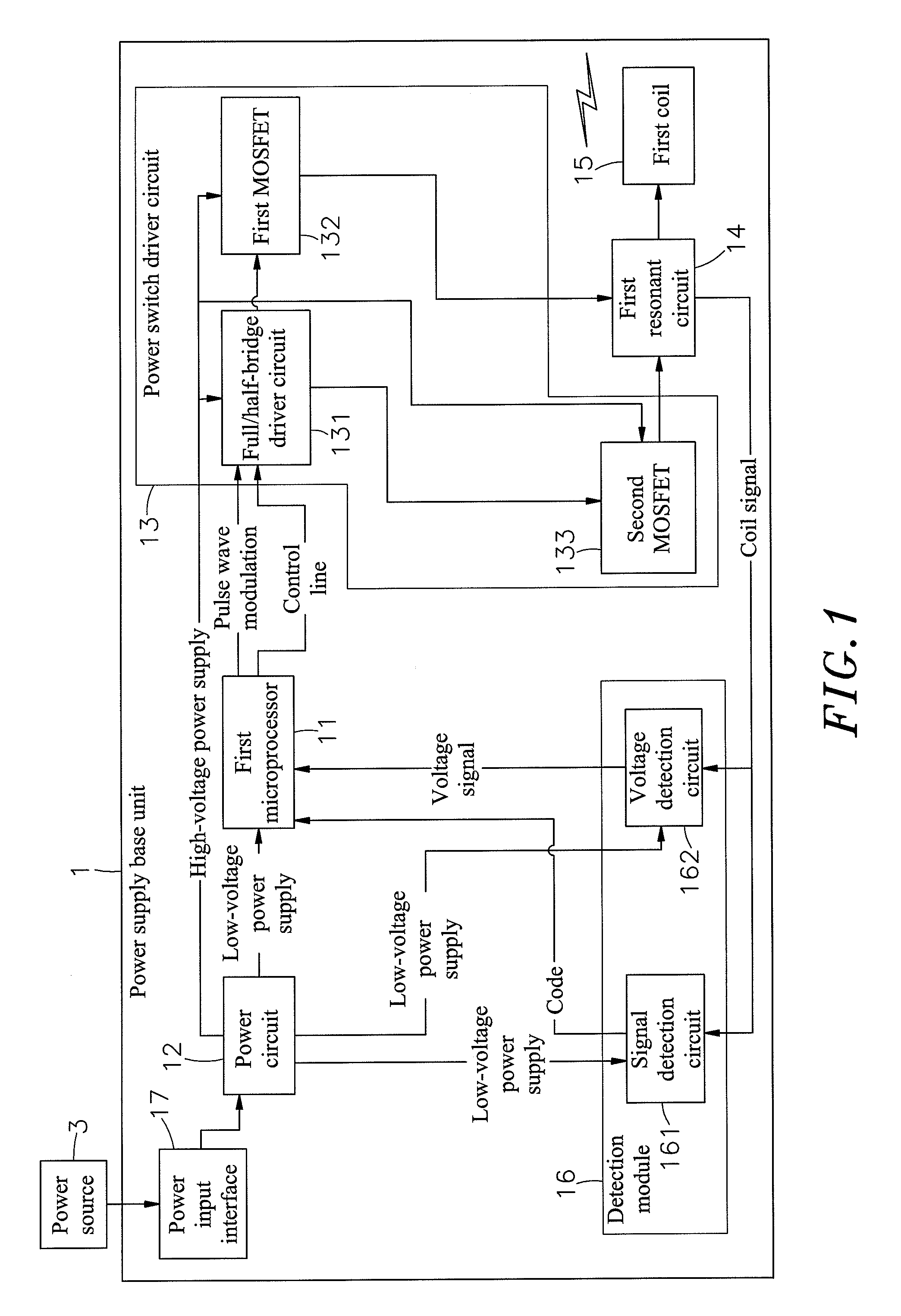

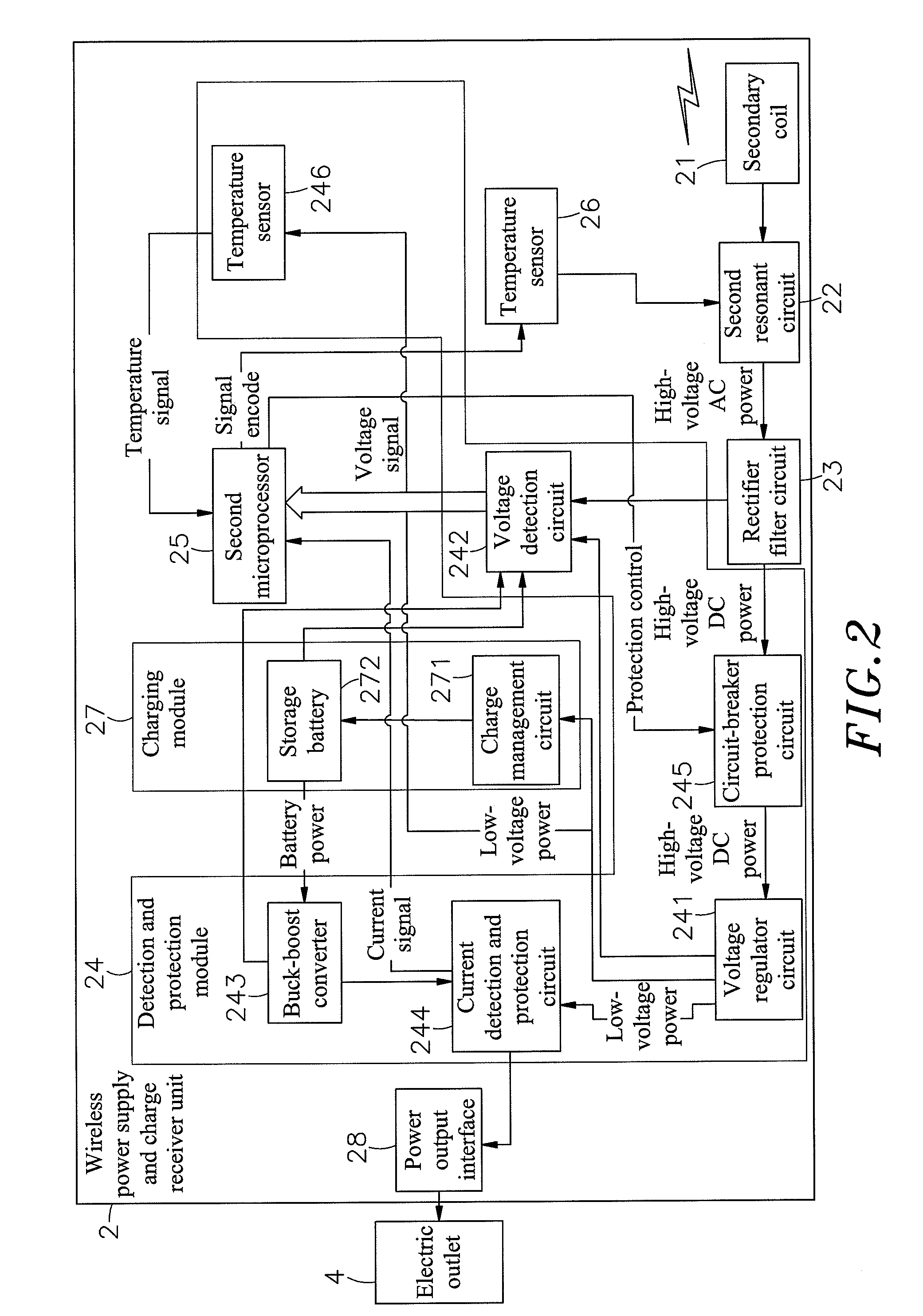

Frequency modulation type wirelss power supply and charger system

ActiveUS20110199046A1Double safety protectionLoad minimizationElectric signal transmission systemsNear-field transmissionEngineeringFrequency modulation

A frequency modulation type wireless power supply and charger system includes a power supply base unit consisting of a first microprocessor, a power circuit, a power switch driver circuit, a first resonant circuit, a first coil, a detection module and a power input interface, and a wireless power supply and charge receiver unit consisting of a secondary coil, a second resonant circuit, a rectifier filter circuit, a detection and protection module, a second microprocessor, a temperature sensor, a charging module and a power output interface and adapted for receiving electrical power from the power supply base unit wirelessly for charging an external electronic device. The detection and protection module of the wireless power supply and charge receiver unit detects the supply of the electrical power, and the second microprocessor sends a feedback signal to the power supply base unit through the signal generator circuit and the second resonant circuit subject to the detection of the detection and protection module for enabling the power supply base unit to control the power switch driver circuit to regulate its output power automatically, thereby minimizing power transmission loss and the load of the internal components of the wireless power supply and charge receiver unit.

Owner:FU TONG TECH

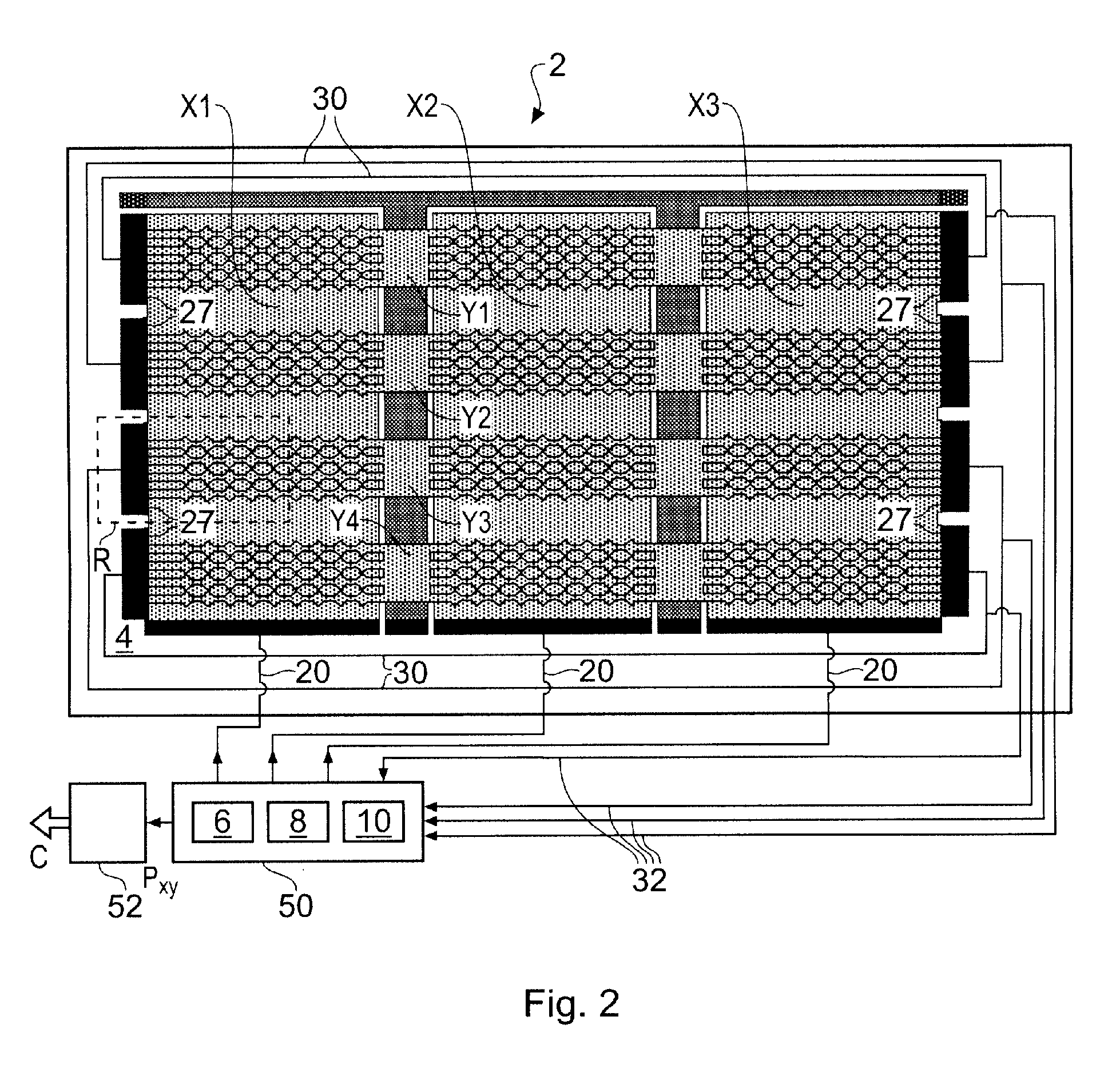

Touch Sensitive Screen

ActiveUS20070062739A1Lower impedanceEfficient couplingTransmission systemsInput/output processes for data processingElectrical resistance and conductancePlastic materials

A capacitive sensor for determining the presence of an object, such as a user's finger or a stylus, is provided. The sensor comprises a substrate, for example made of transparent plastics material, such as PET, on which electrodes are deposited. A resistive drive electrode for example formed of transparent ITO, is arranged on one side of the substrate and a resistive sense electrode, which again may be of transparent ITO, is arranged on the other side of the substrate. Thus an overall transparent sensor may be provided. A shorting connection is also provided which is configured to connect between two locations on one of the electrodes. The electrodes are connected to respective drive and sense channels. By providing the shorting connection between two locations on one or other (or both) of the electrodes, a lower resistance connection is provided between other locations on the electrode and the corresponding drive or sense channel.

Owner:NEODRON LTD

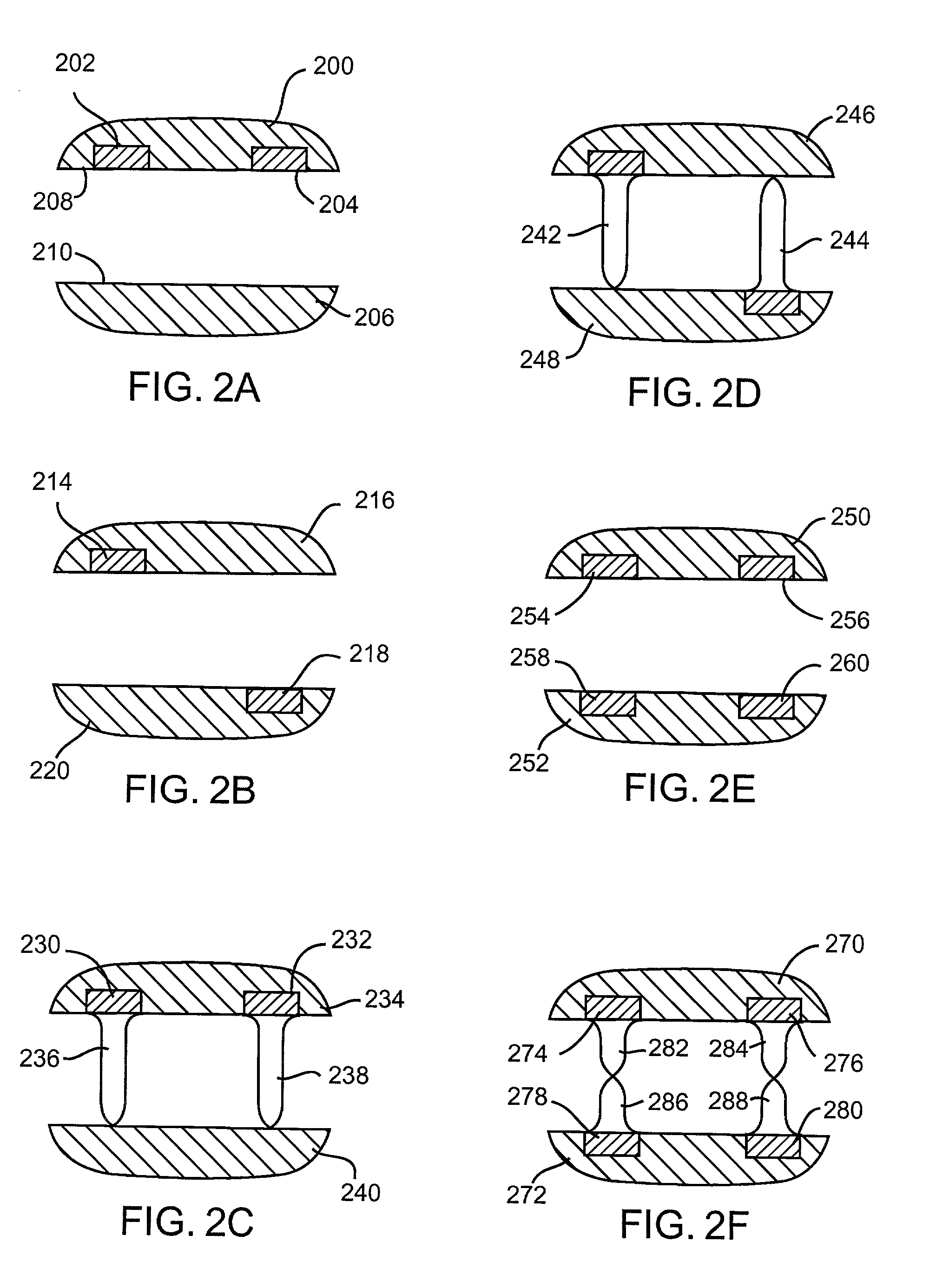

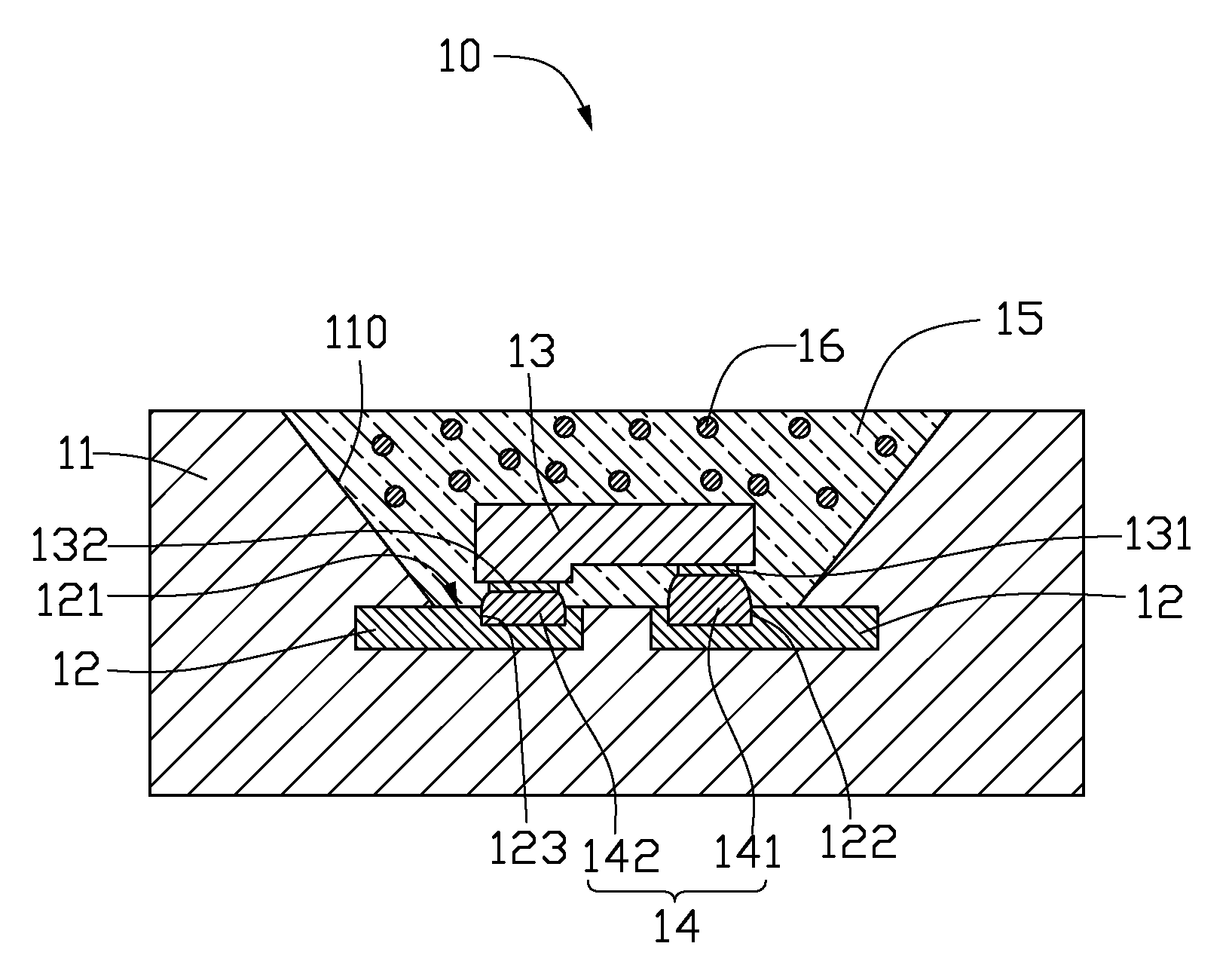

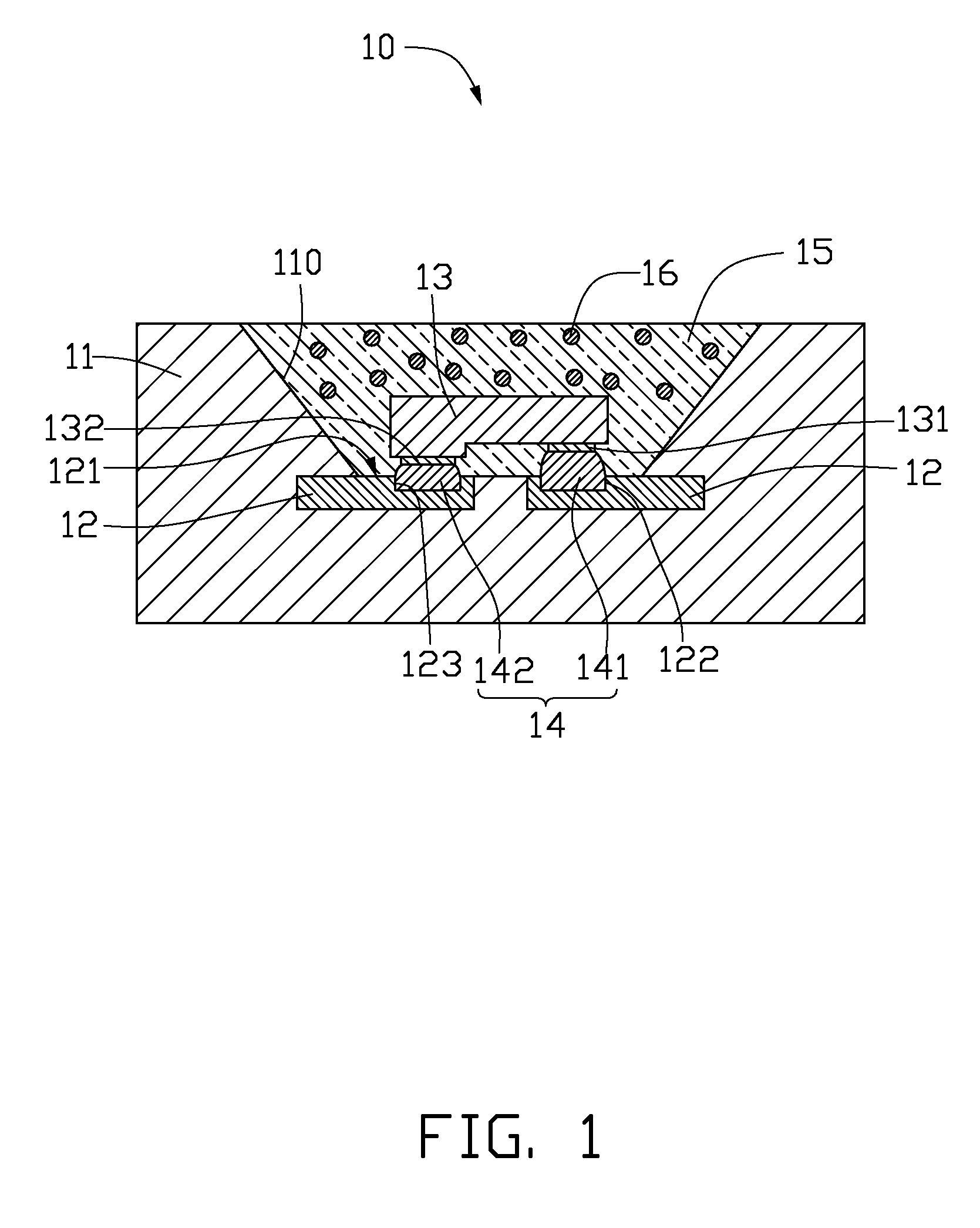

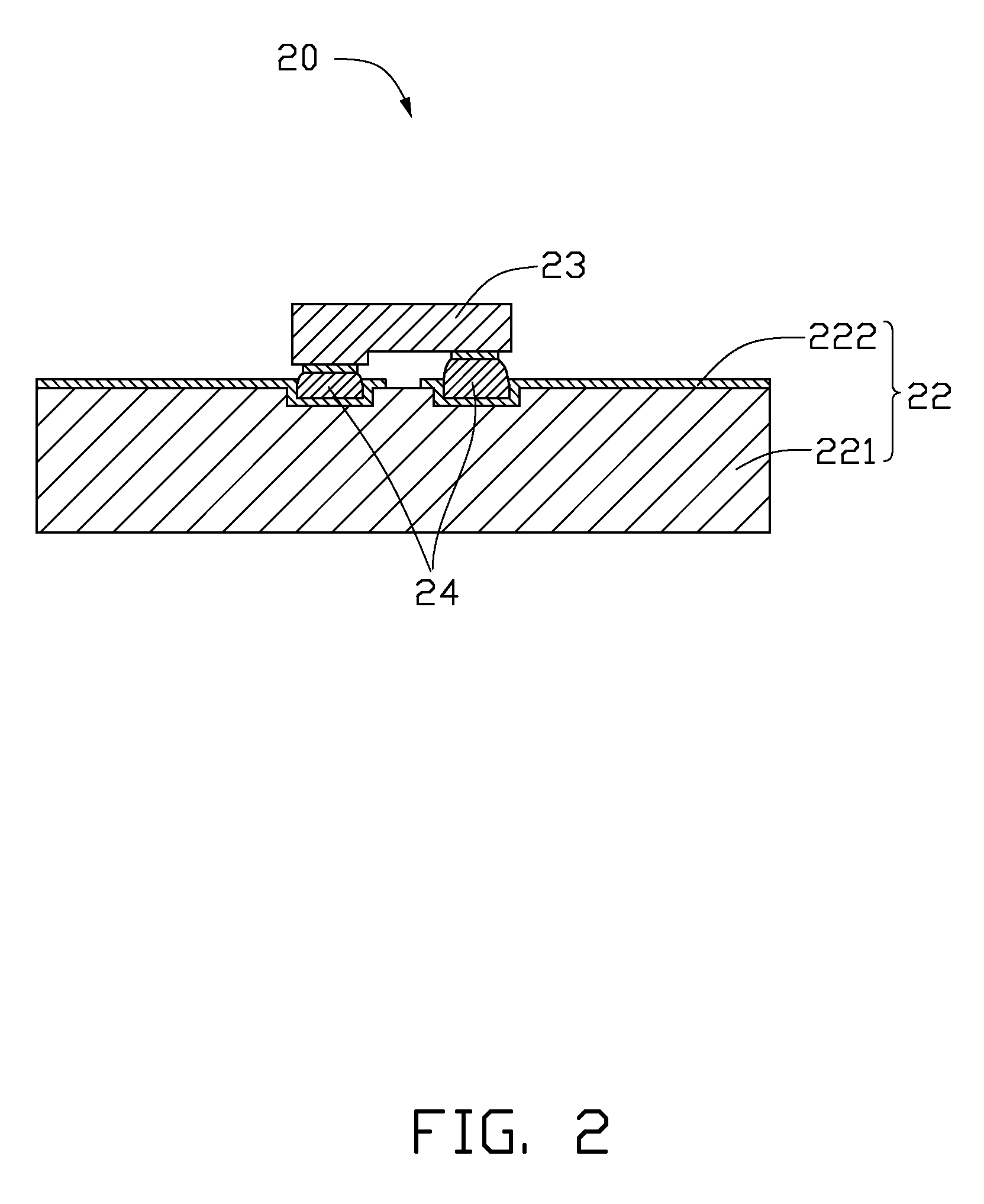

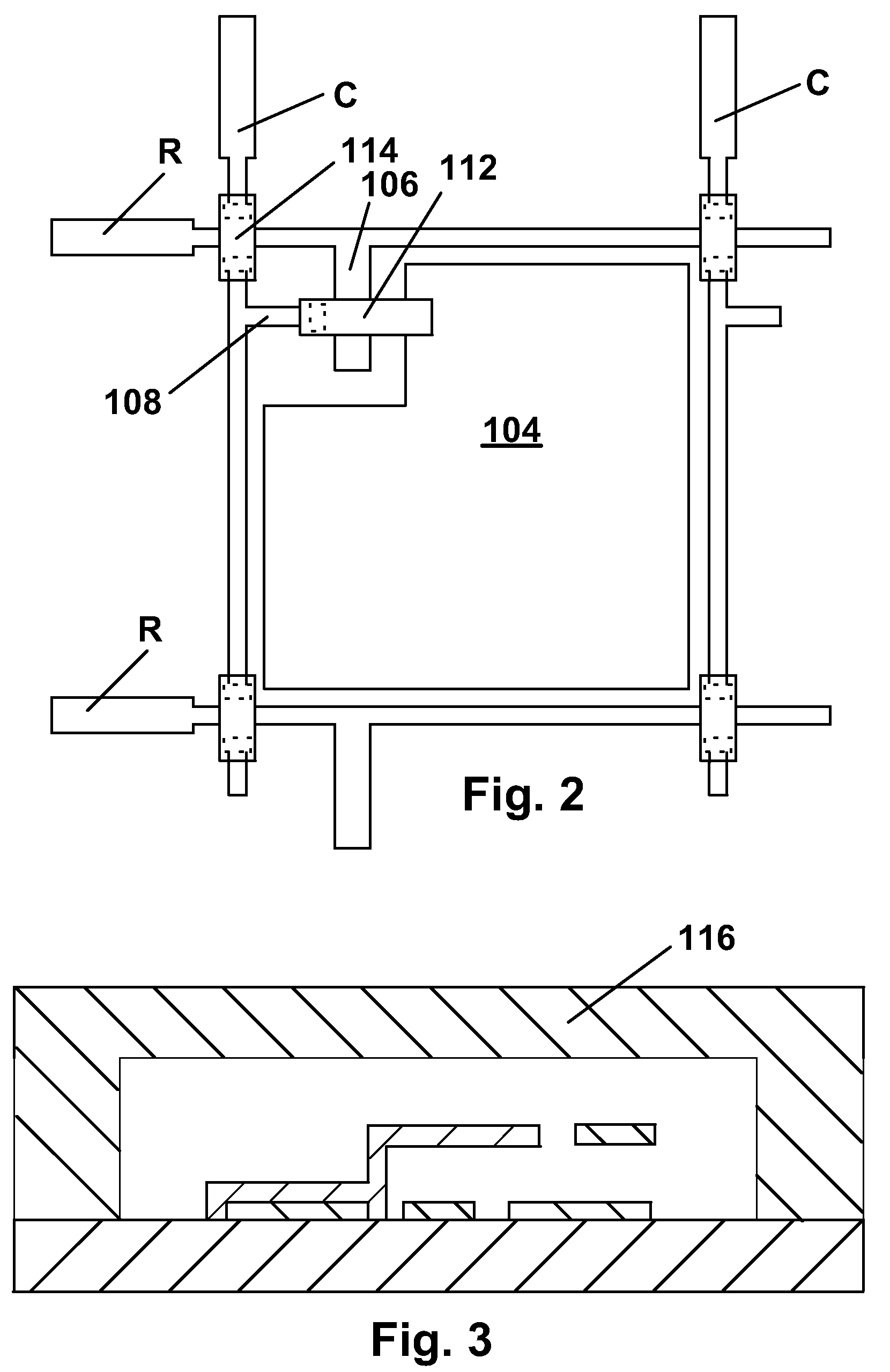

Flip-chip light emitting diode and method for fabricating the same

InactiveUS20090321778A1Small sizeLower impedanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFlip chip

A flip-chip light emitting diode includes a substrate, an LED chip and a plurality of conductive bumps. The substrate has at least one recess defined in the surface of the substrate, and at least a part of the conductive bumps is embedded the at least one recess. The LED chip is mounted on a surface of the substrate by a flip-chip mounting process. The conductive bumps are sandwiched between the substrate and the LED chip to bond and electrically connect the LED chip to the substrate.

Owner:ADVANCED OPTOELECTRONICS TECH

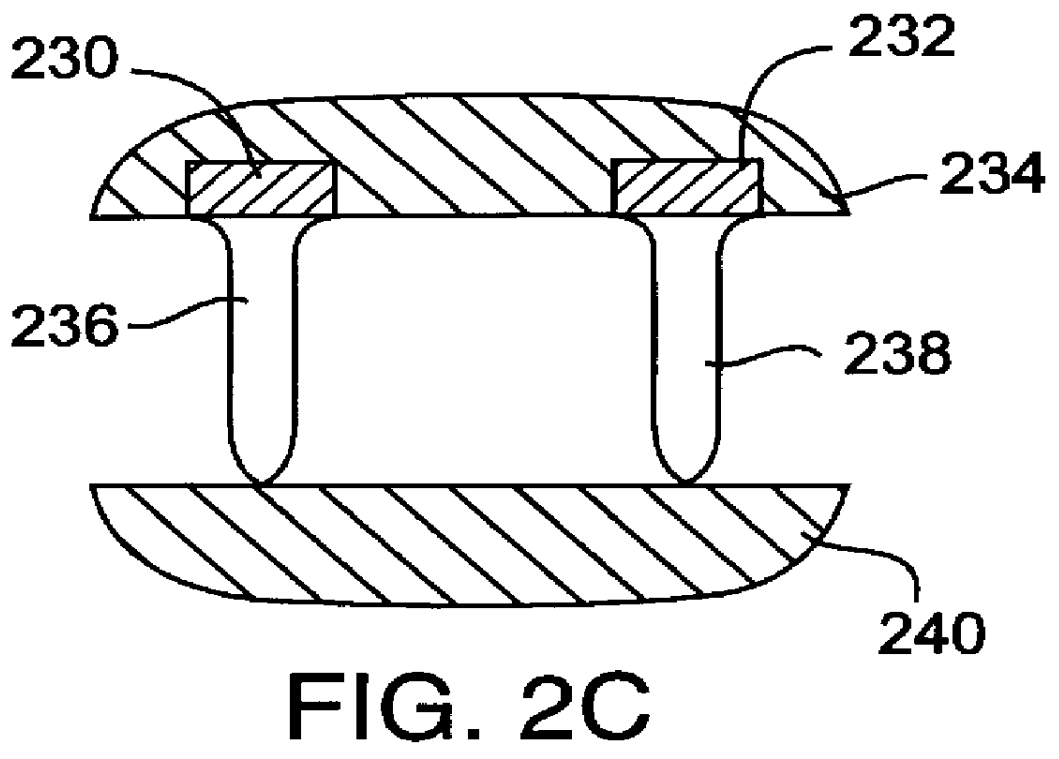

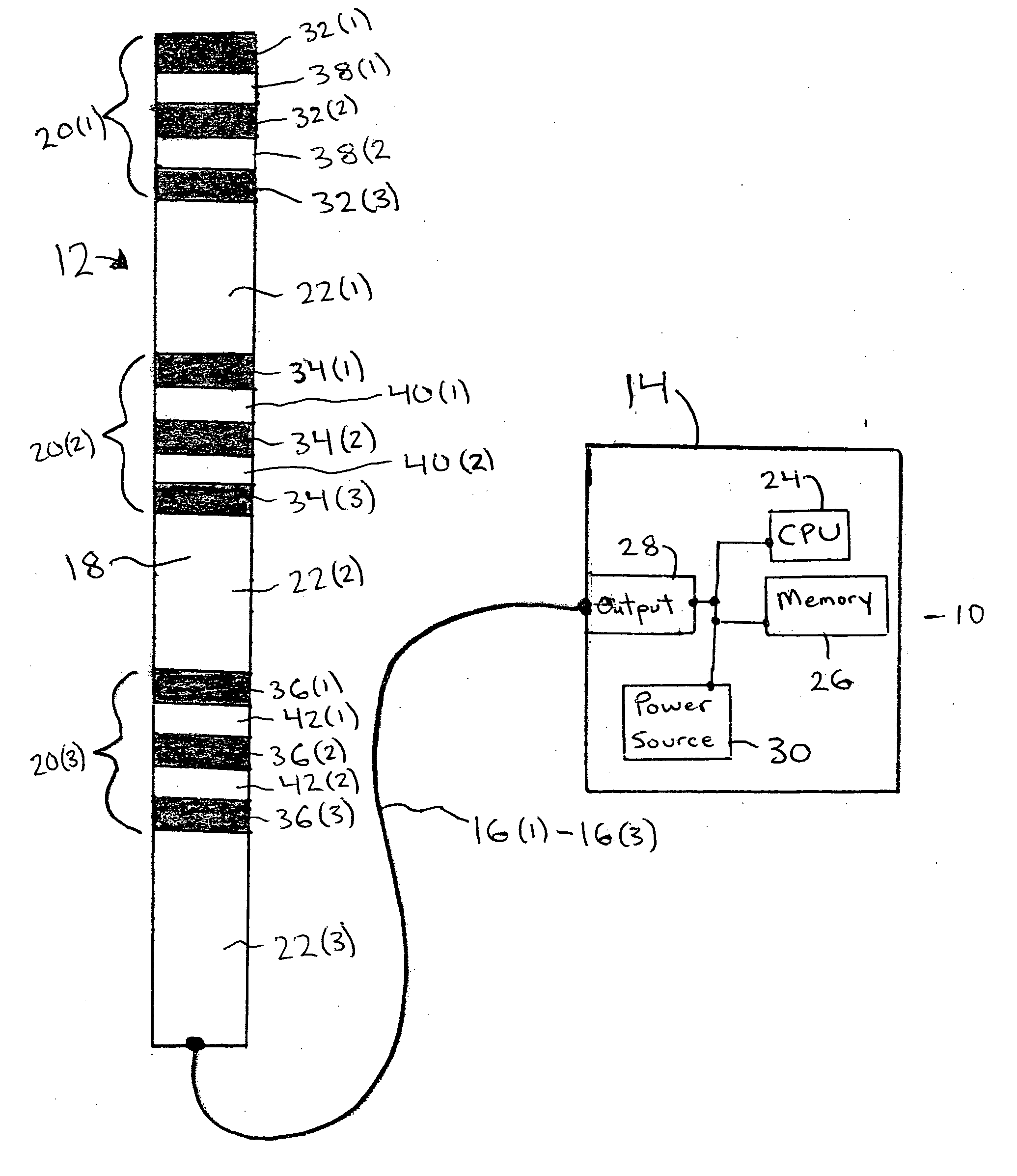

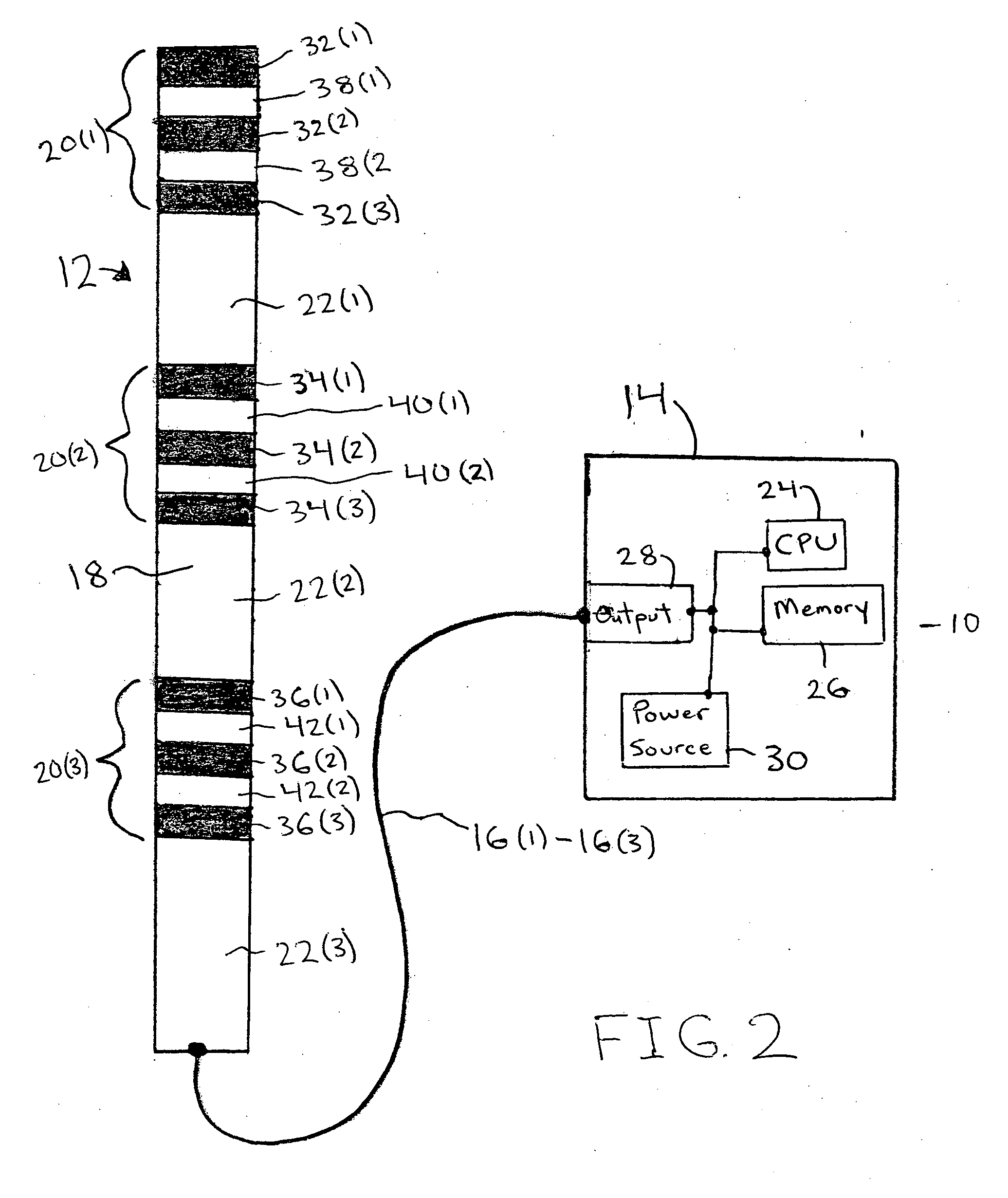

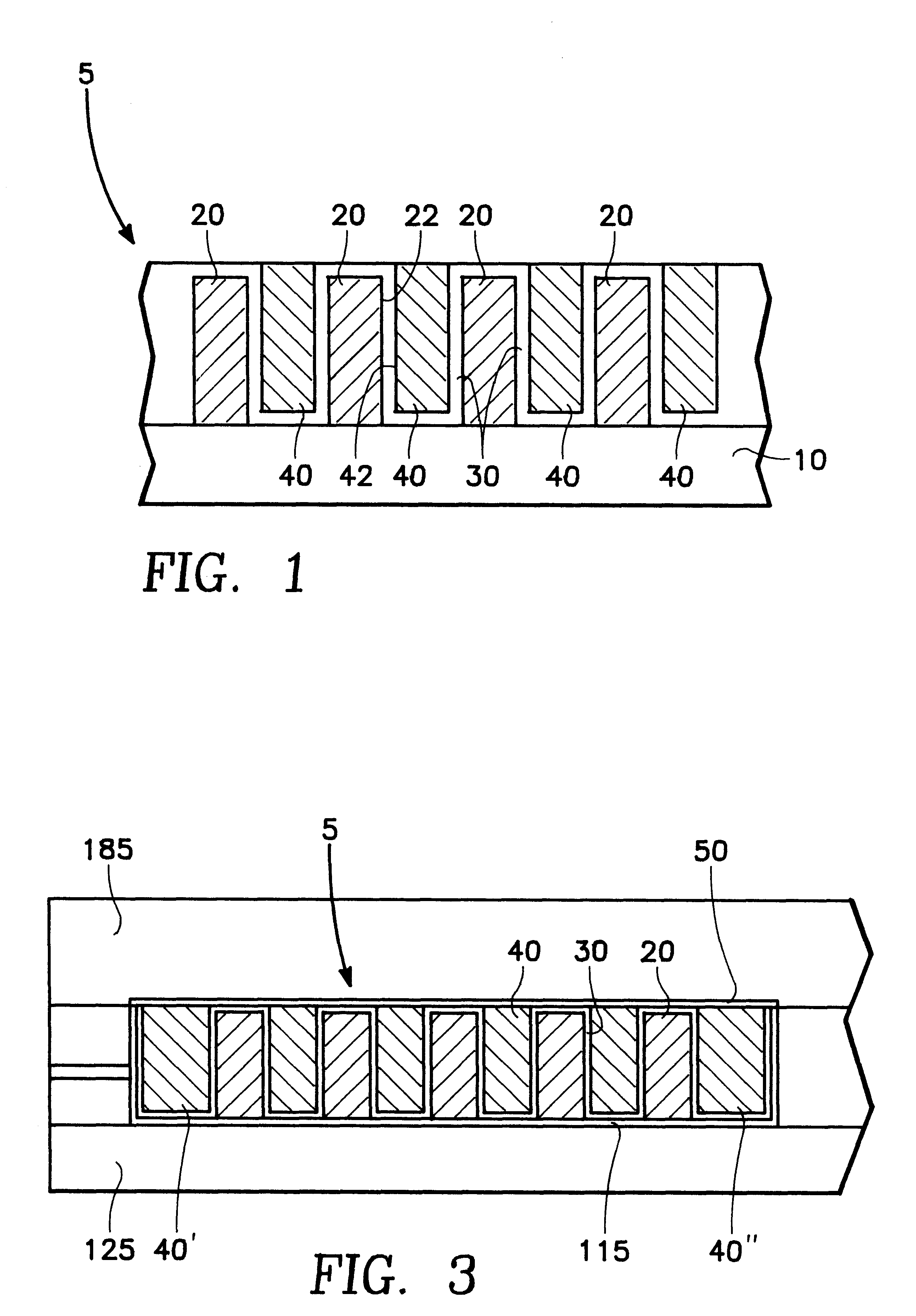

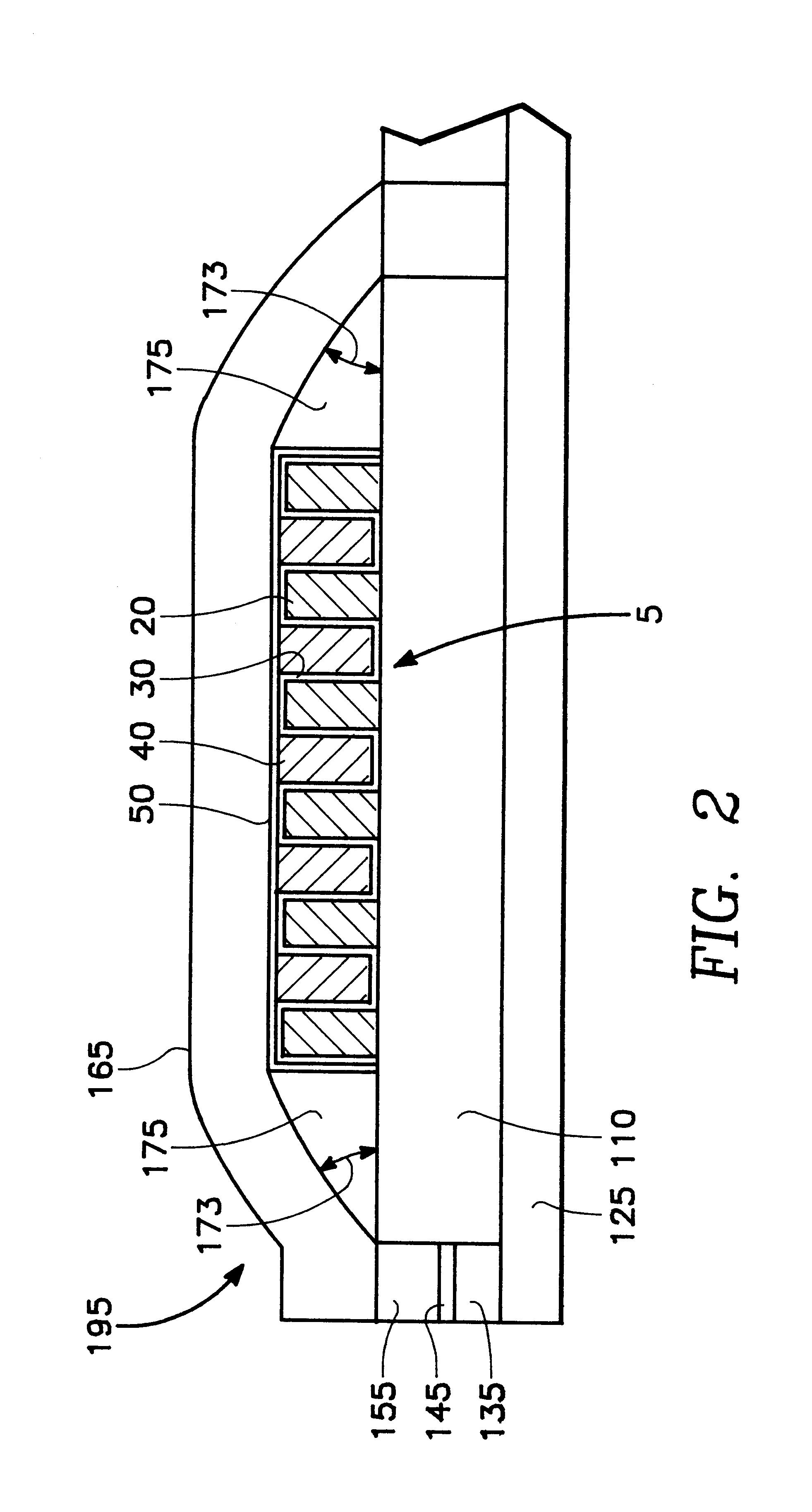

Electrode array for use in medical stimulation and methods thereof

InactiveUS20050038489A1Reduce power consumptionIncrease battery lifeSpinal electrodesExternal electrodesElectrode arrayBiomedical engineering

An electrode array for use in medical stimulation includes one or more electrodes along an array body and one or more leads. Each of the electrodes has one or more conductive sections and each of the conductive sections has an outer surface which is substantially exposed from the array body for coupling to tissue. At least one of the electrodes has at least one of: adjacent pairs of the conductive sections separated by an insulating section; the conductive section having at least one portion which is spaced in from other portions of the conductive section and which substantially extends all the way around or all along a length of the conductive section; at least one substantially non-planar end; and a substantially planar shape with a substantially non-linear outer edge. Each of the electrodes has at least one of the leads coupled to each of the conductive sections of the electrode.

Owner:CASE WESTERN RESERVE UNIV

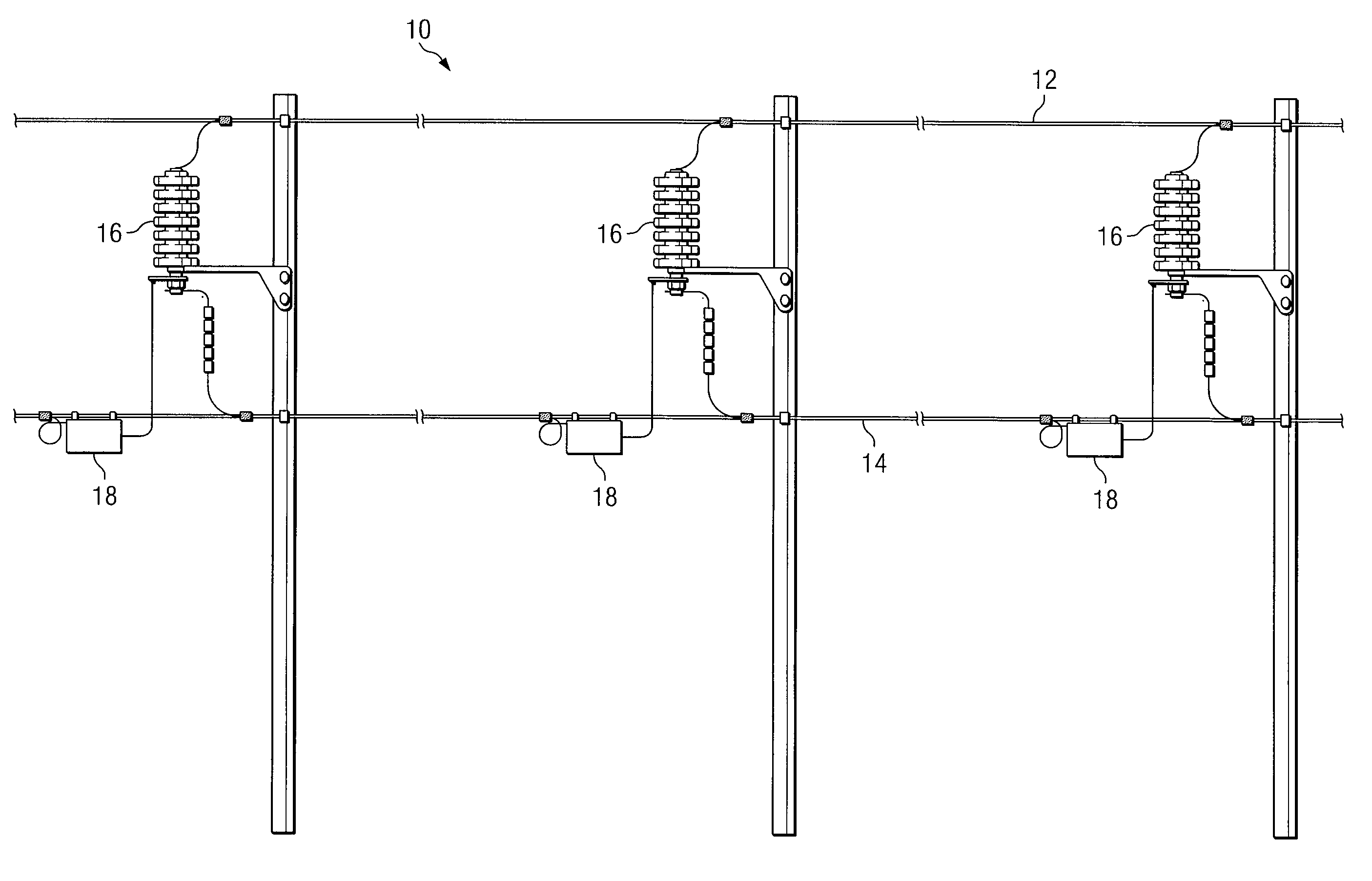

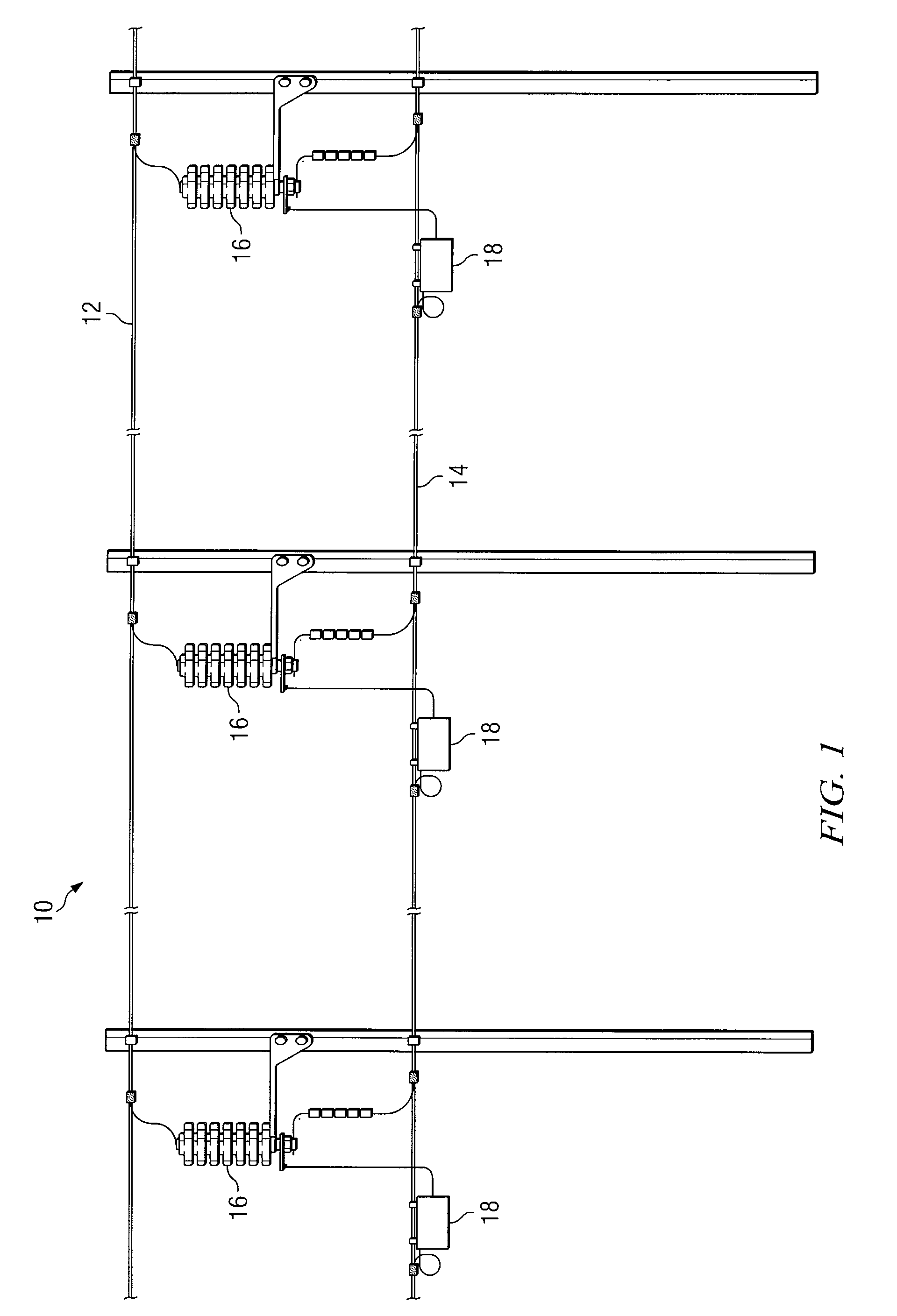

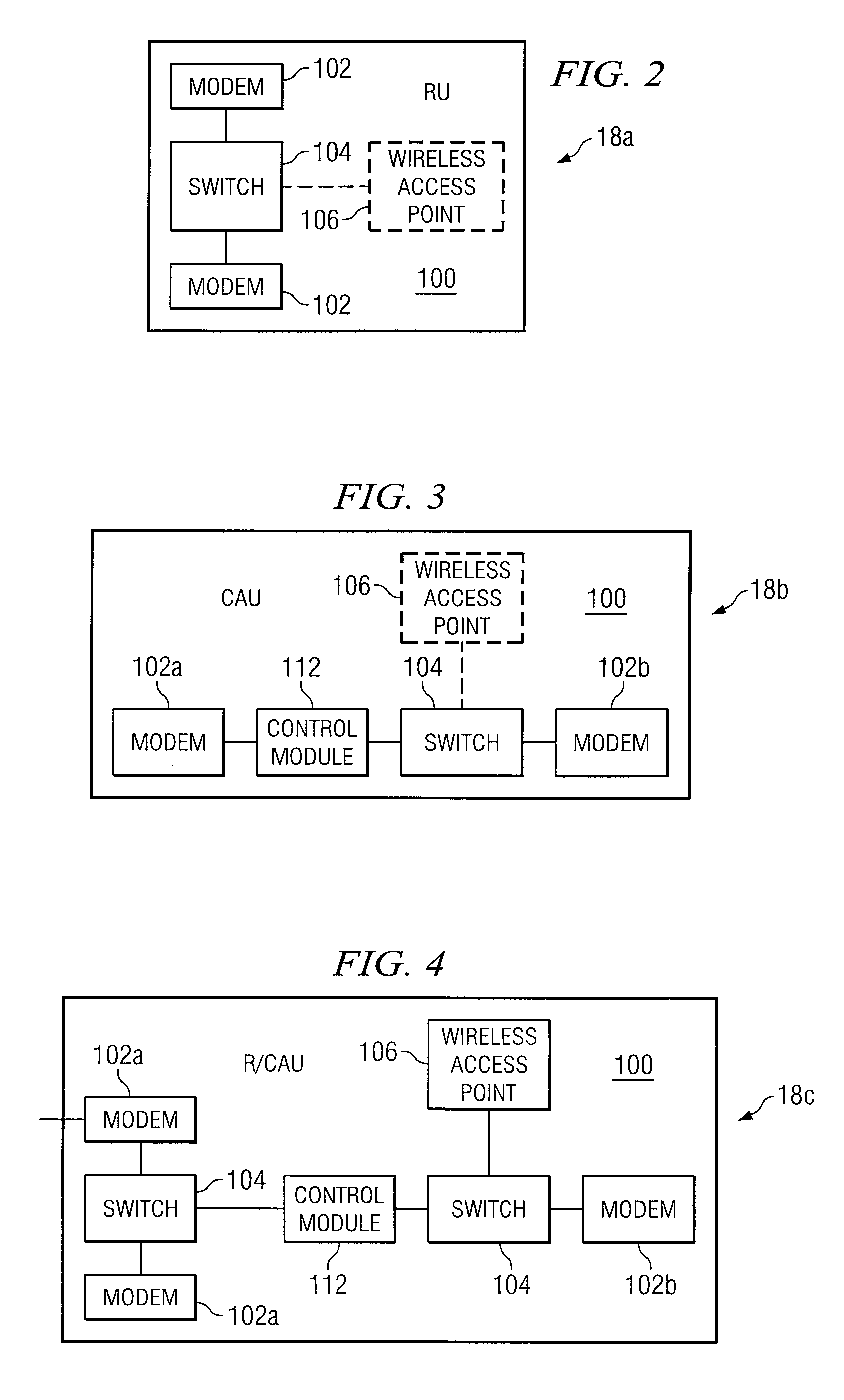

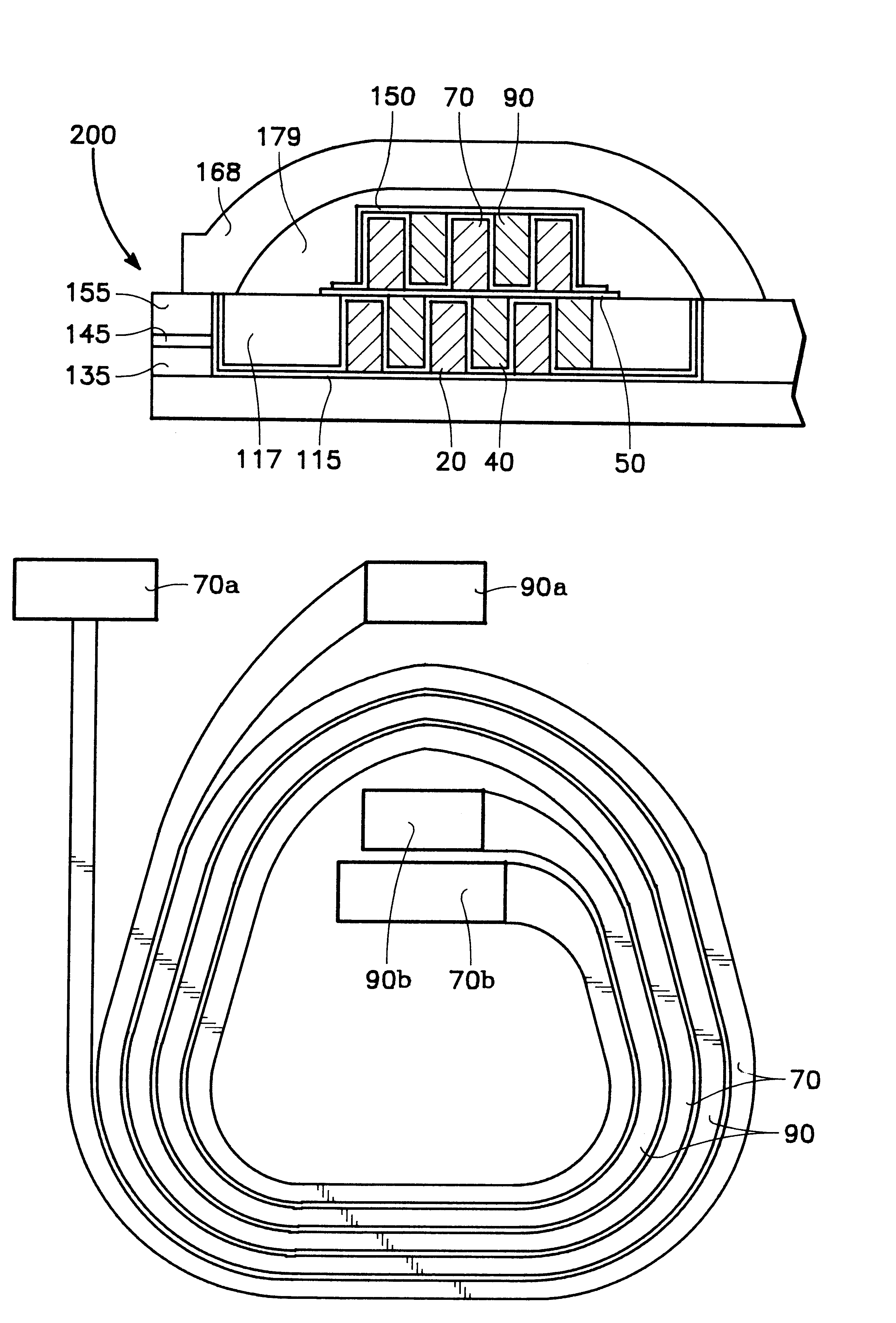

Coupling of communications signals to a power line

InactiveUS7522812B2Improved transmission and throughputQuick installationPower distribution line transmissionGaseous cathodesLow voltageEngineering

In one embodiment, a device for coupling communications signals onto a medium-voltage power line includes a first connector, a second connector and one or more components. The first connector is adapted to couple to a low-voltage communications line. The second connector is adapted to couple to a surge arrester. The one or more components are operable to substantially match the impedances between the surge arrester and the low-voltage communications line.

Owner:INTERNATIONAL BROADBAND ELECTRIC COMMUNICATIONS INC

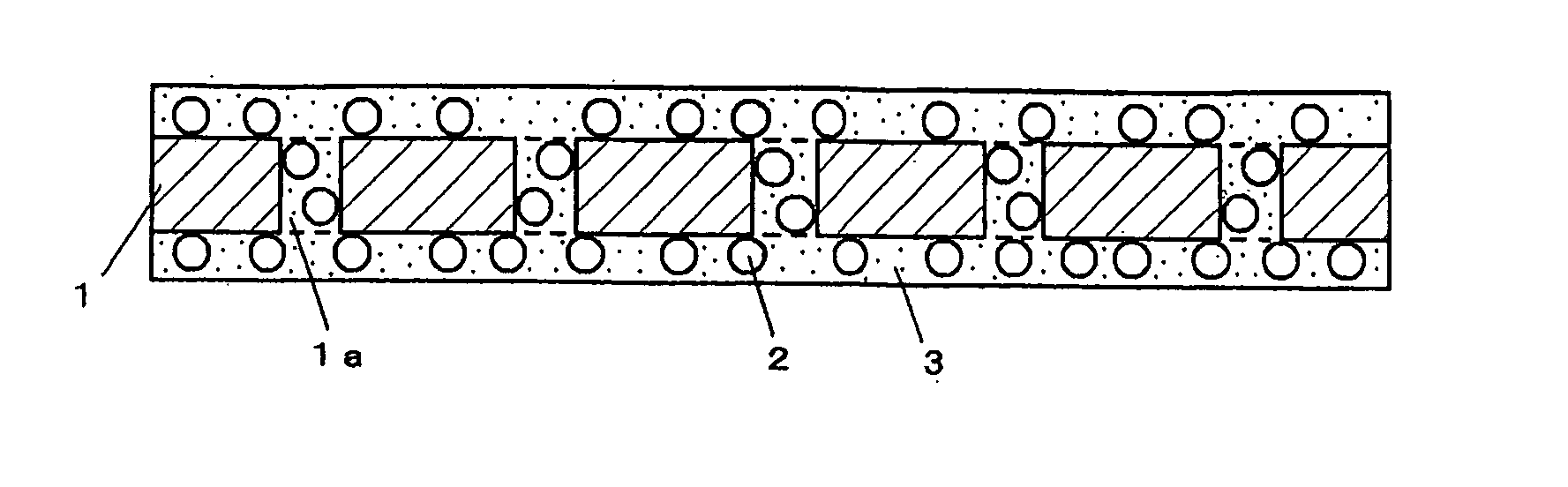

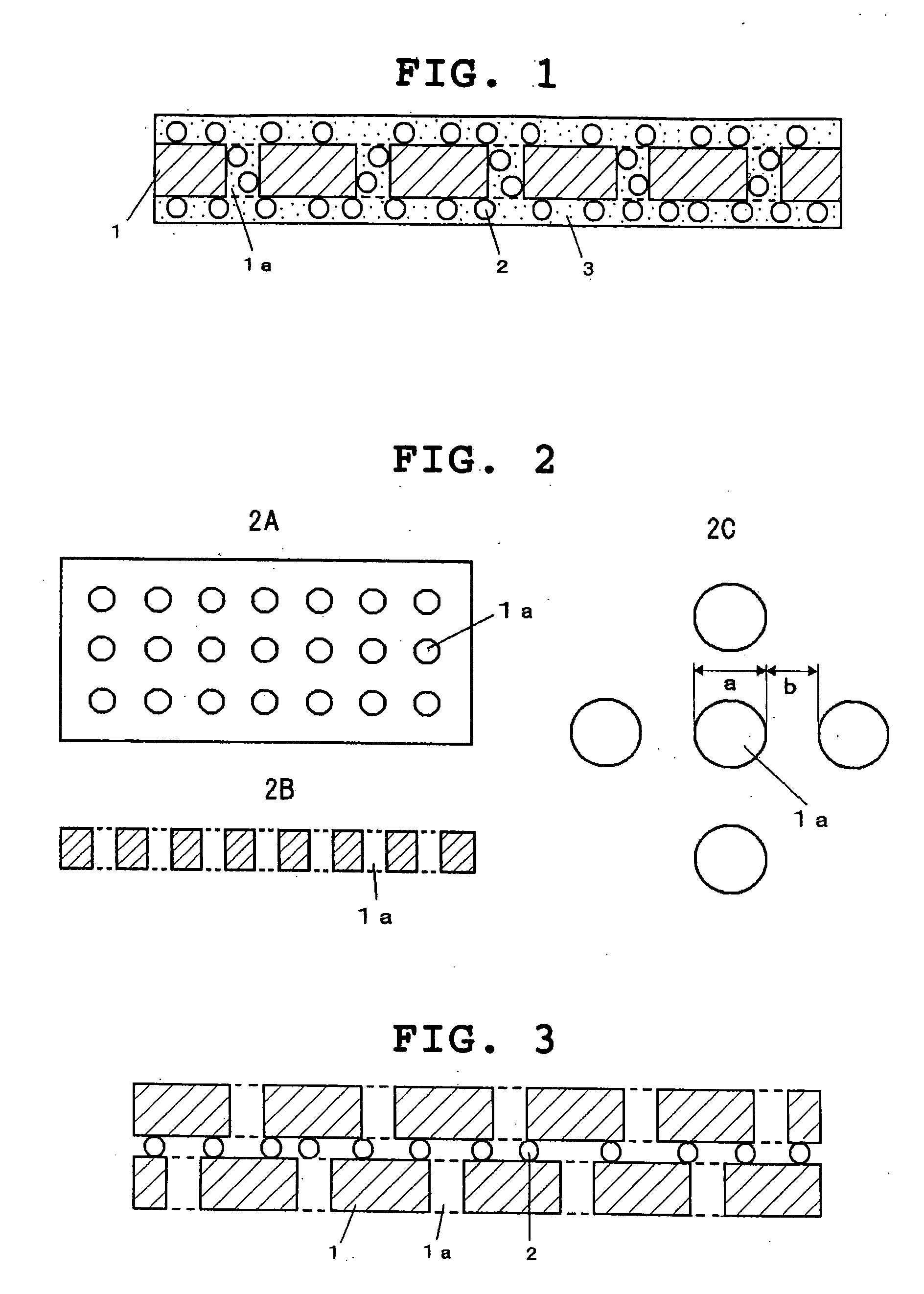

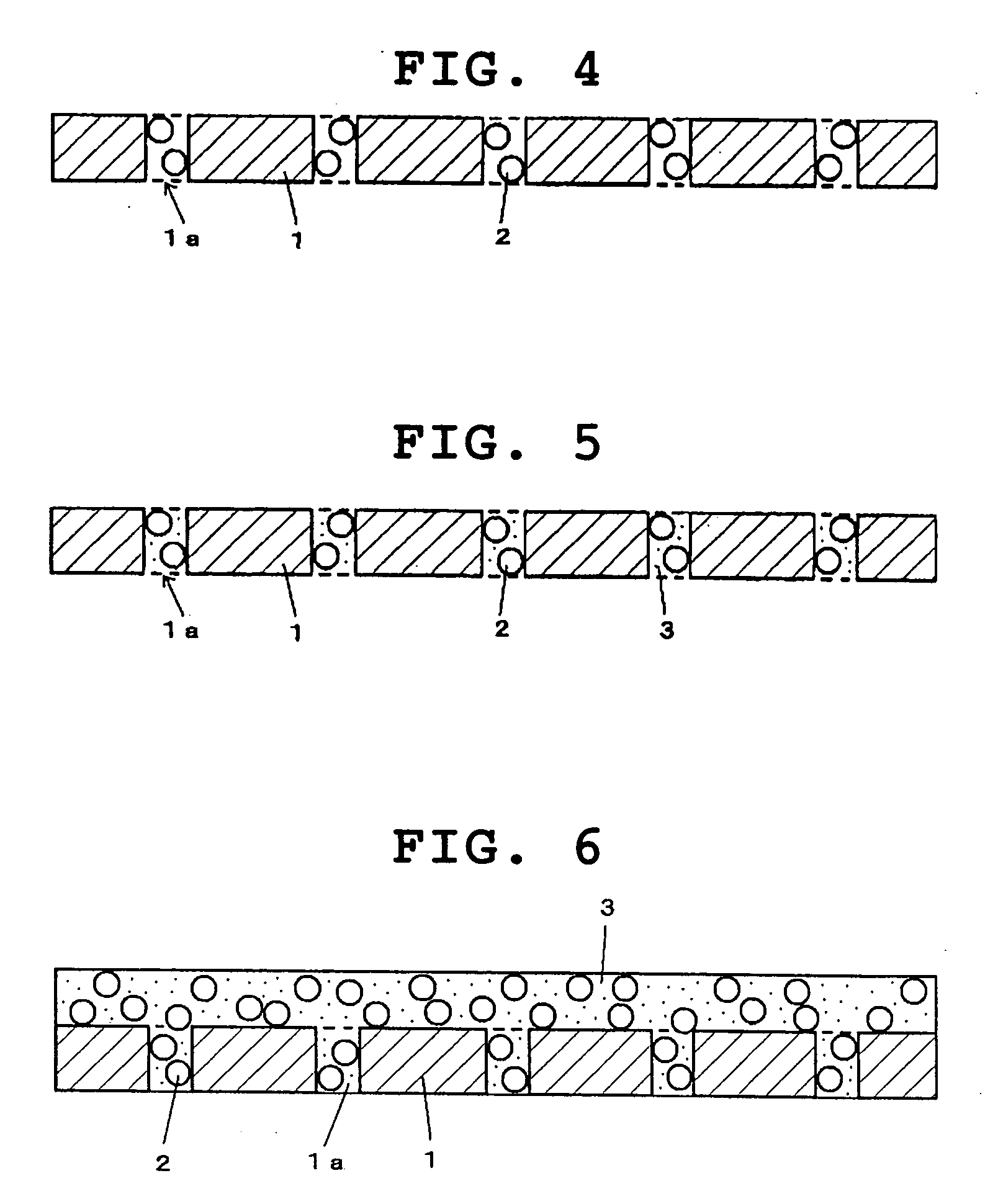

Thin film write head with interlaced coil winding and method of fabrication

InactiveUS6466401B1Increase working frequencySeparationConstruction of head windingsHeads using thin filmsResistConductive materials

The preferred embodiment of the present invention provides a write head having an interlaced conductor coil winding and method of fabrication. The interlaced winding of the present invention may have alternating turns of a first and a second coil. In the preferred embodiment, the side walls of successive coil turns are separated by an ultra thin inorganic insulation which defines the distance between successive turns of the first and second coil. In one method of fabrication, a conductive seed layer is deposited on a generally planar insulative surface, a resist mask is formed on the seed layer, and a conductive material deposited on the exposed seed layer to form the turns of the first coil. The masked portions of the seed layer are removed, after resist mask removal, to electrically isolate the turns of the first coil. The inorganic insulation may be formed in a layer conformal with the first coil. The second coil is formed between the turns of the first coil. A seed layer and mask may be used to facilitate second coil deposition. Etching, or planarization, may be used to electrically isolate the turns of the second coil. A capping layer may be formed over any exposed conductor material to insulate the winding from an upper pole structure or other overlying structure. Embodiments of the present invention may have multiple layers of conductor winding having some conventional, or all interlaced coil structure.

Owner:WESTERN DIGITAL TECH INC

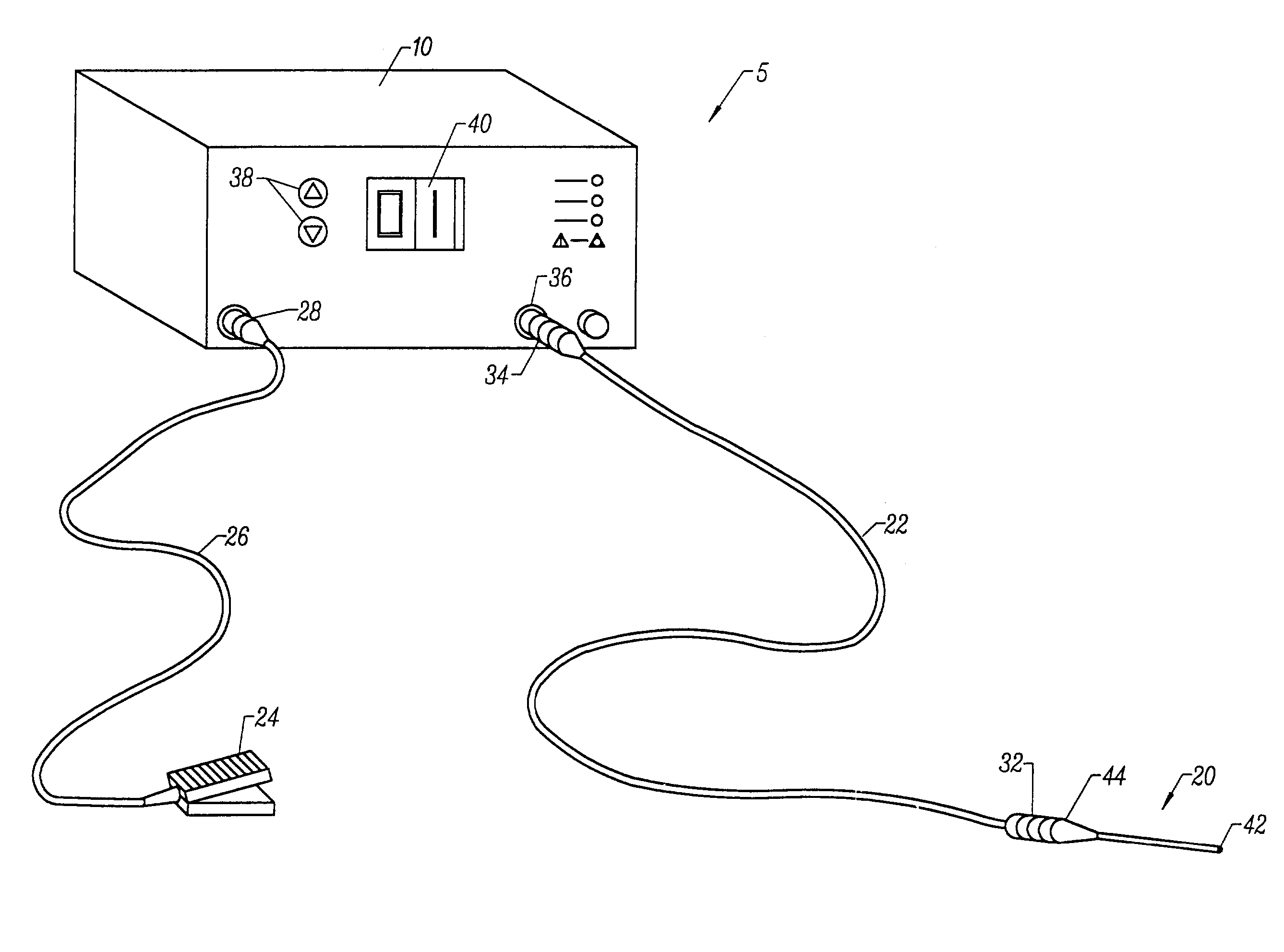

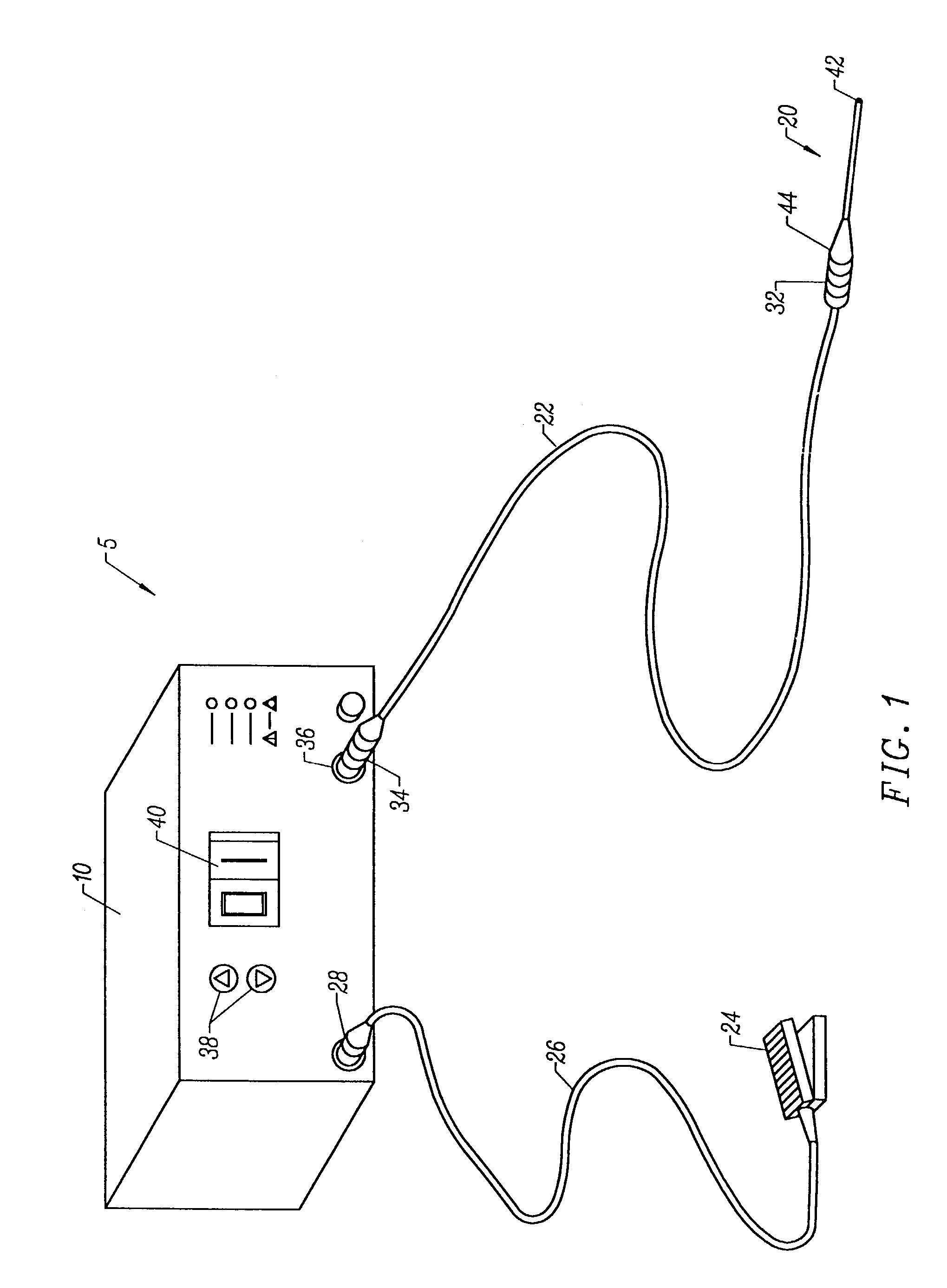

Systems and methods for electrosurgical tissue contraction

InactiveUS7094215B2Limiting thermal damage and dissociationSuppress thermal damageEye treatmentSurgical instruments for heatingSacroiliac jointSurgical department

Systems and methods are provided for performing electrosurgical interventions, such as selectively contracting soft collagen tissue and other body structures, while limiting thermal damage or molecular dissociation of such tissue and limiting the thermal damage to tissue adjacent to and underlying the treatment site. The systems and methods of the present invention are particularly useful for surgical procedures in electrically conducting environments, such as arthroscopic procedures in the joints, e.g., shoulder, knee, hip, hand, foot, elbow or the like. The present invention is also useful in relatively dry environments, such as treating and shaping the cornea, and dermatological procedures involving surface tissue contraction of tissue underlying the surface of the skin for tissue rejuvenation, wrinkle removal and the like.

Owner:ARTHROCARE

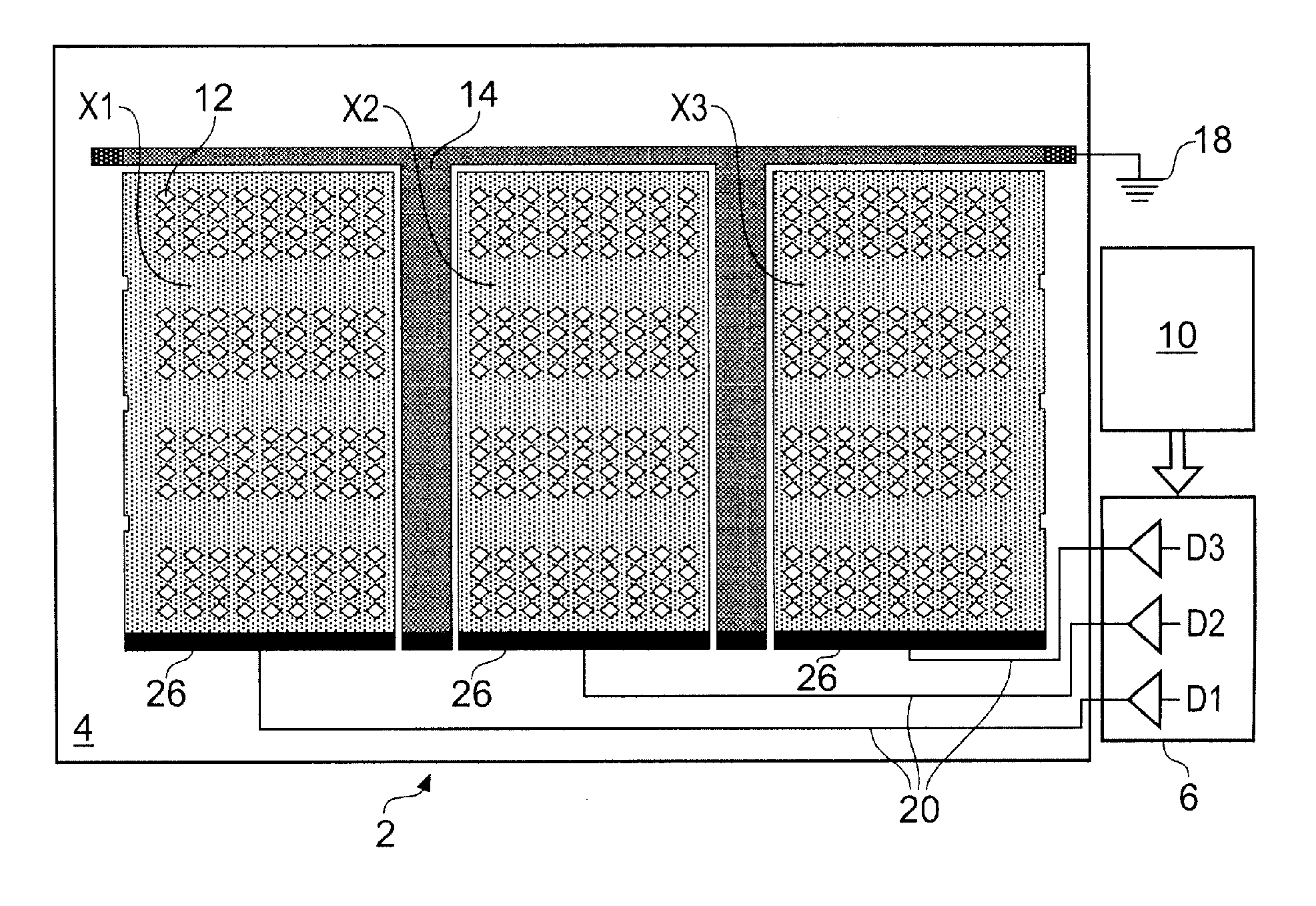

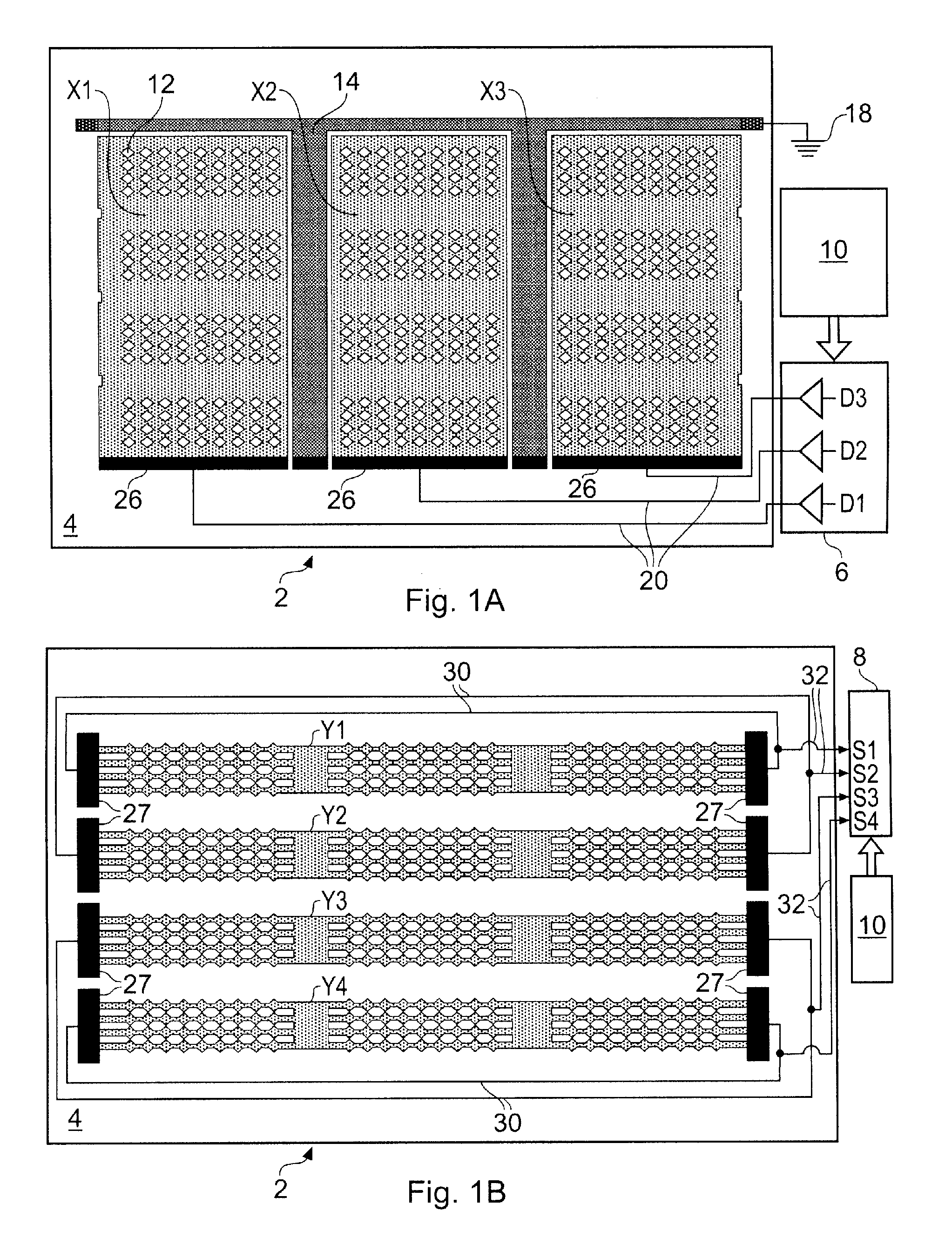

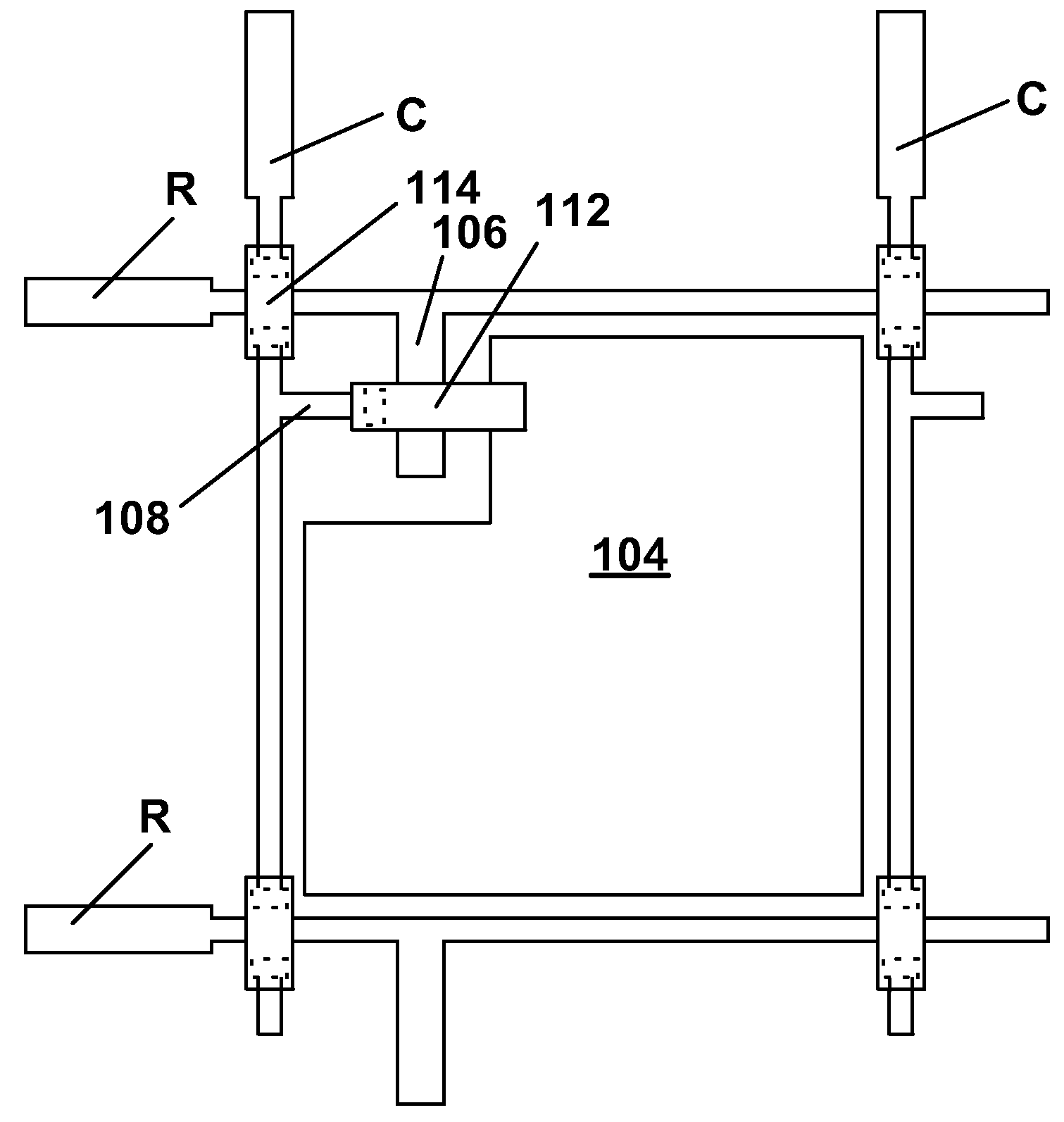

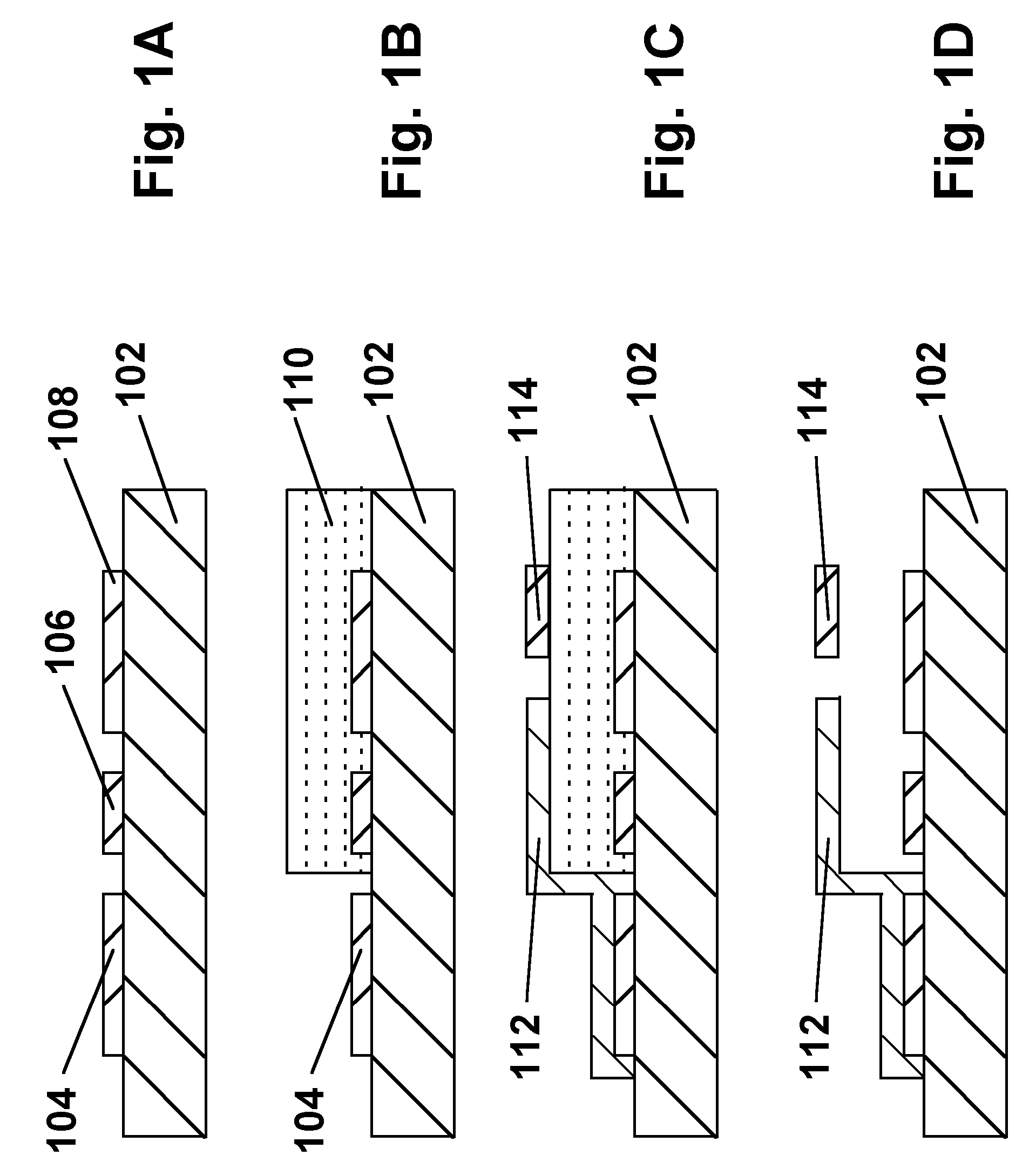

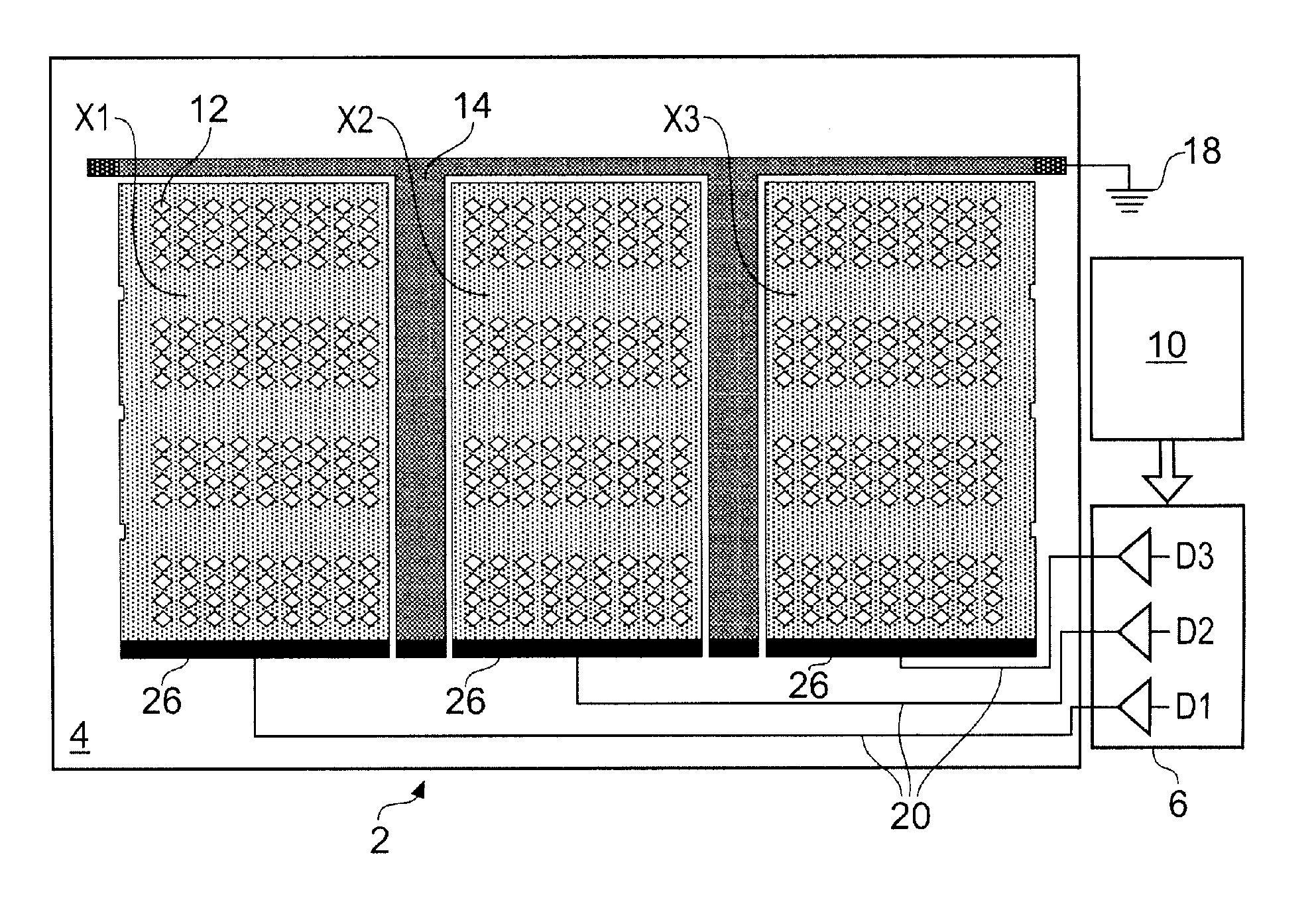

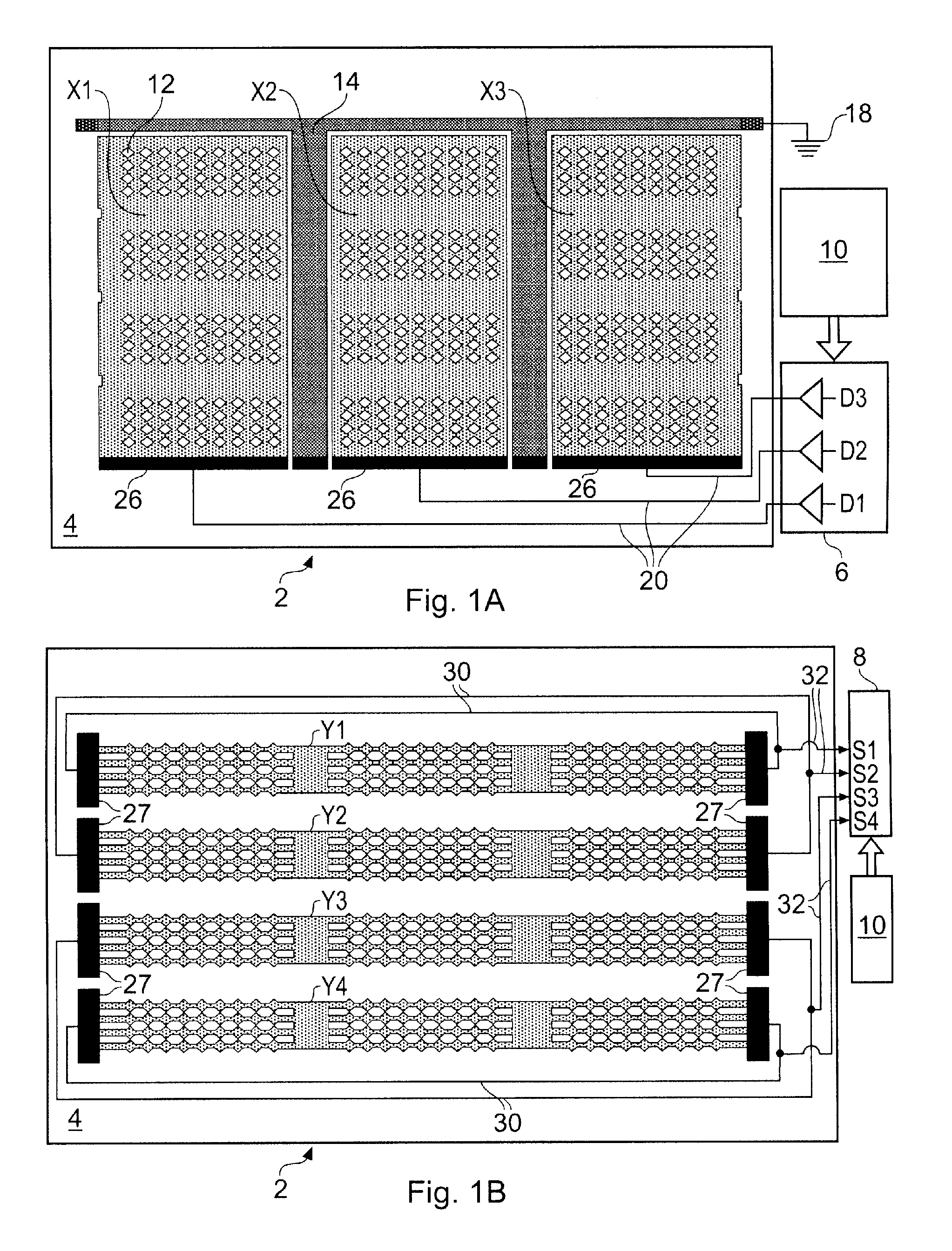

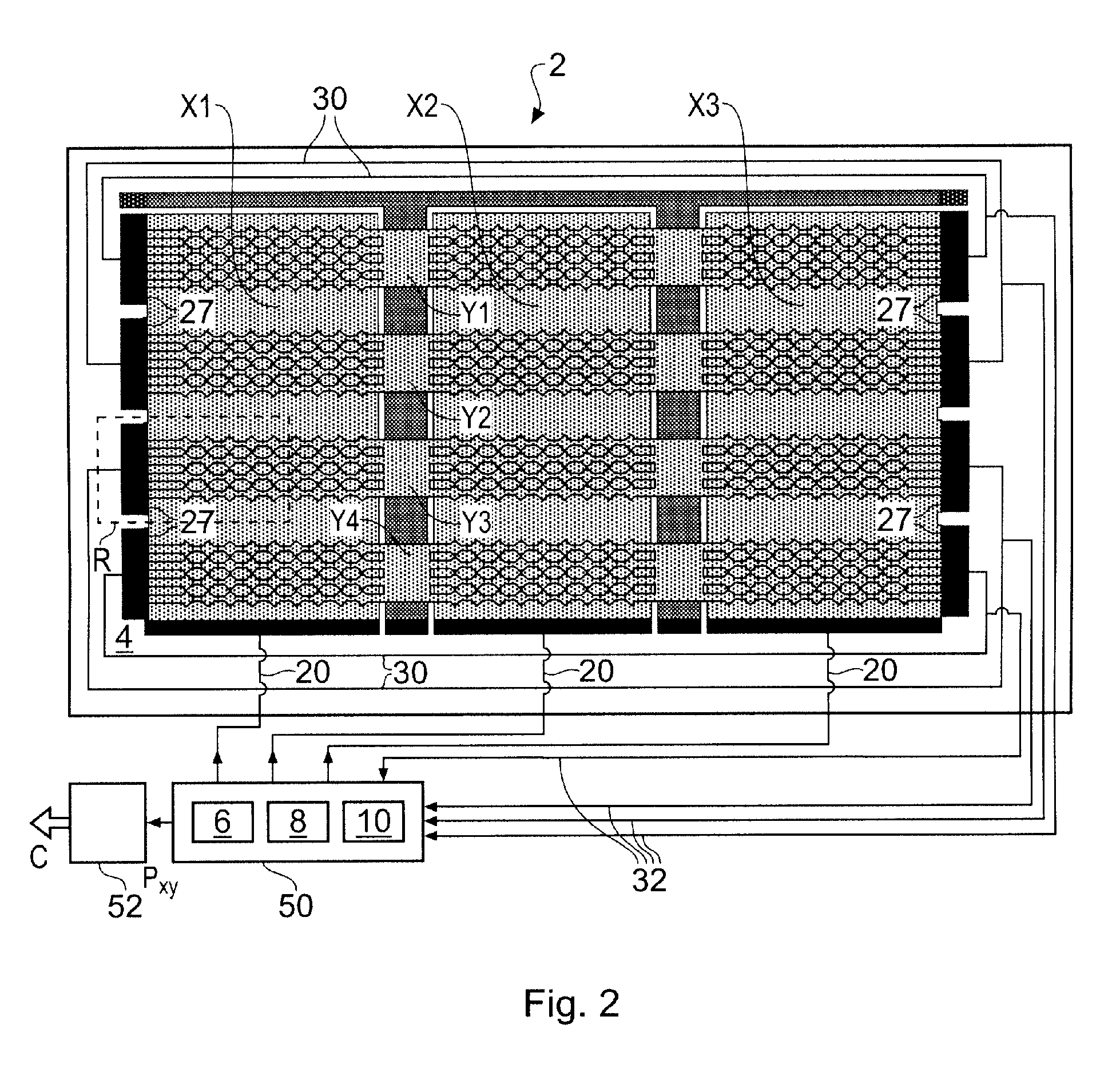

Backplanes for electro-optic displays

InactiveUS7365733B2Low costLower impedanceElectrostatic/electro-adhesion relaysCathode-ray tube indicatorsElectricityDisplay device

A backplane for an electro-optic display comprises a pixel electrode (104), a voltage supply line (C) arranged to supply a voltage to the pixel electrode (104), and a micromechanical switch (106, 112) disposed between the voltage supply line (C) and the pixel electrode (104), the micromechanical switch (106, 112) having an open state, in which the voltage supply line (C) is not electrically connected to the pixel electrode (104), and a closed state, in which the voltage supply line (C) is electrically connected to the pixel electrode (104).

Owner:E INK CORPORATION

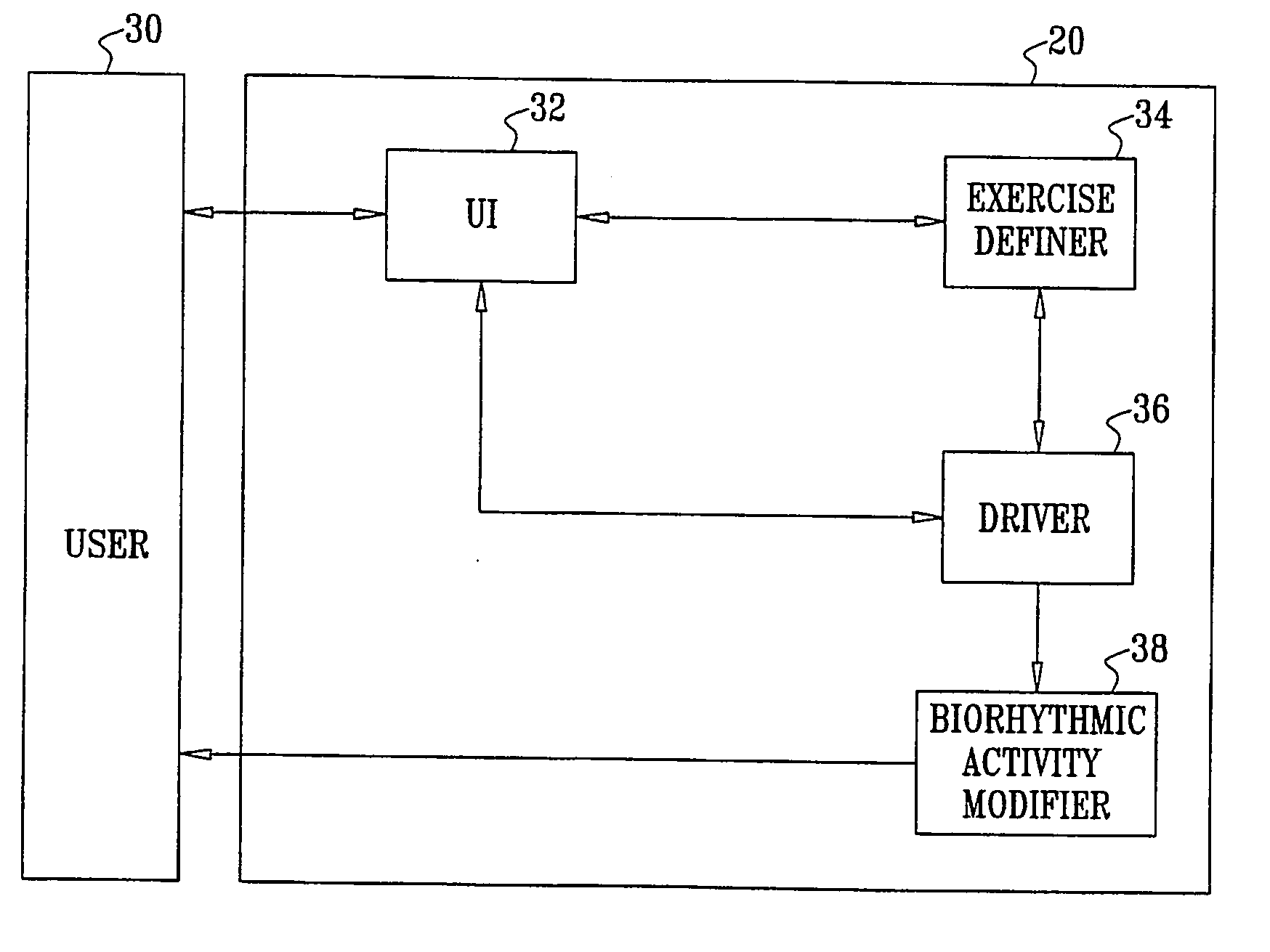

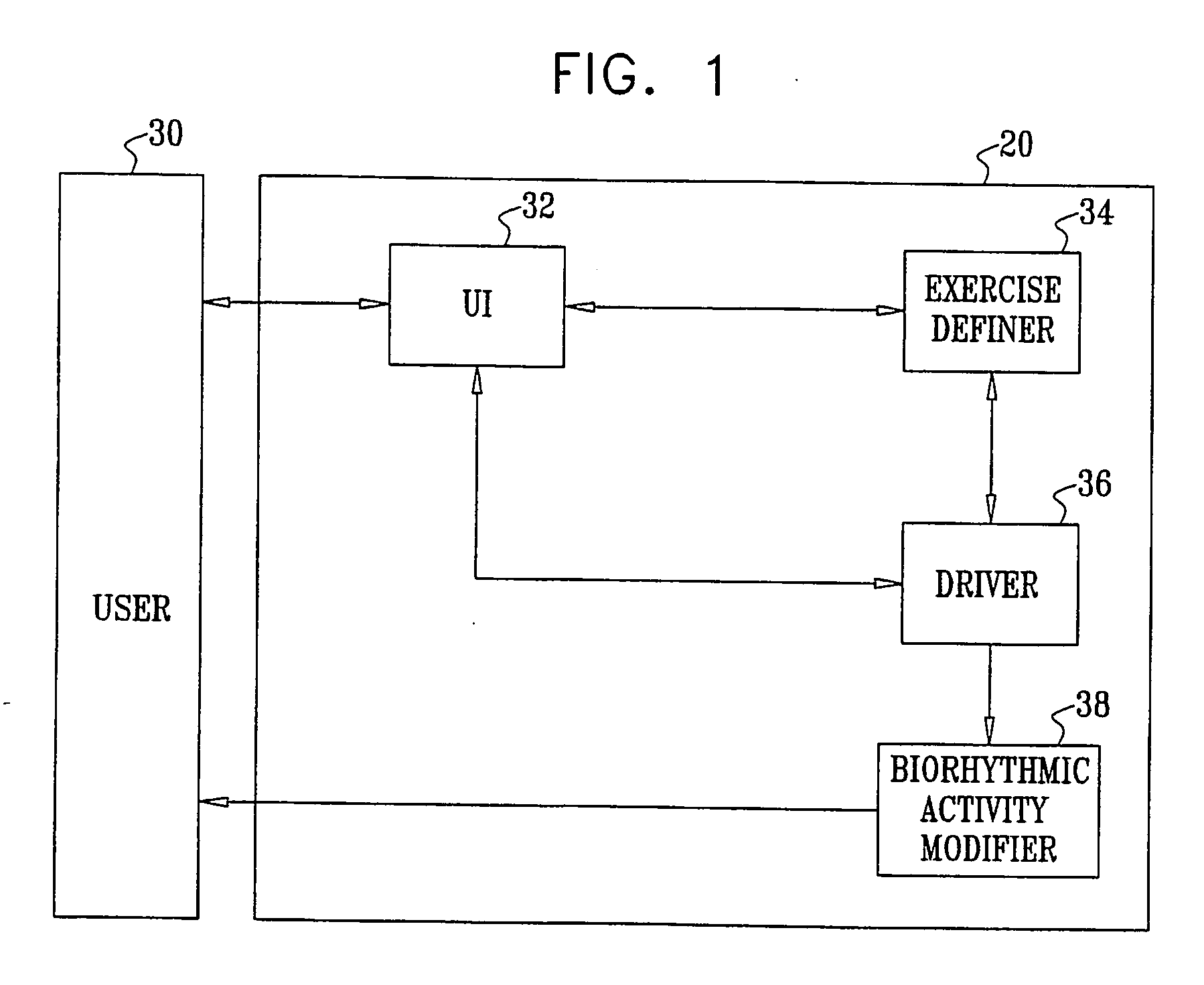

Generalized metronome for modification of biorhythmic activity

ActiveUS20060102171A1Increasing tissue oxygenationReduce peripheral impedanceGymnastic exercisingVibration massageMedicineMetronome

Owner:2BREATHE TECHOGIES LTD

Wearable therapeutic device

A wearable therapeutic device that includes a garment configured to contain an external defibrillator. The garment is configured to house at least one of an alarm module and a monitor and to house a first therapy electrode and a second therapy electrode. The garment is also configured to releasably receive a receptacle that contains a conductive fluid proximate to at least one of the first therapy electrode and the second therapy electrode, and to electrically couple the receptacle with the garment.

Owner:ZOLL MEDICAL CORPORATION

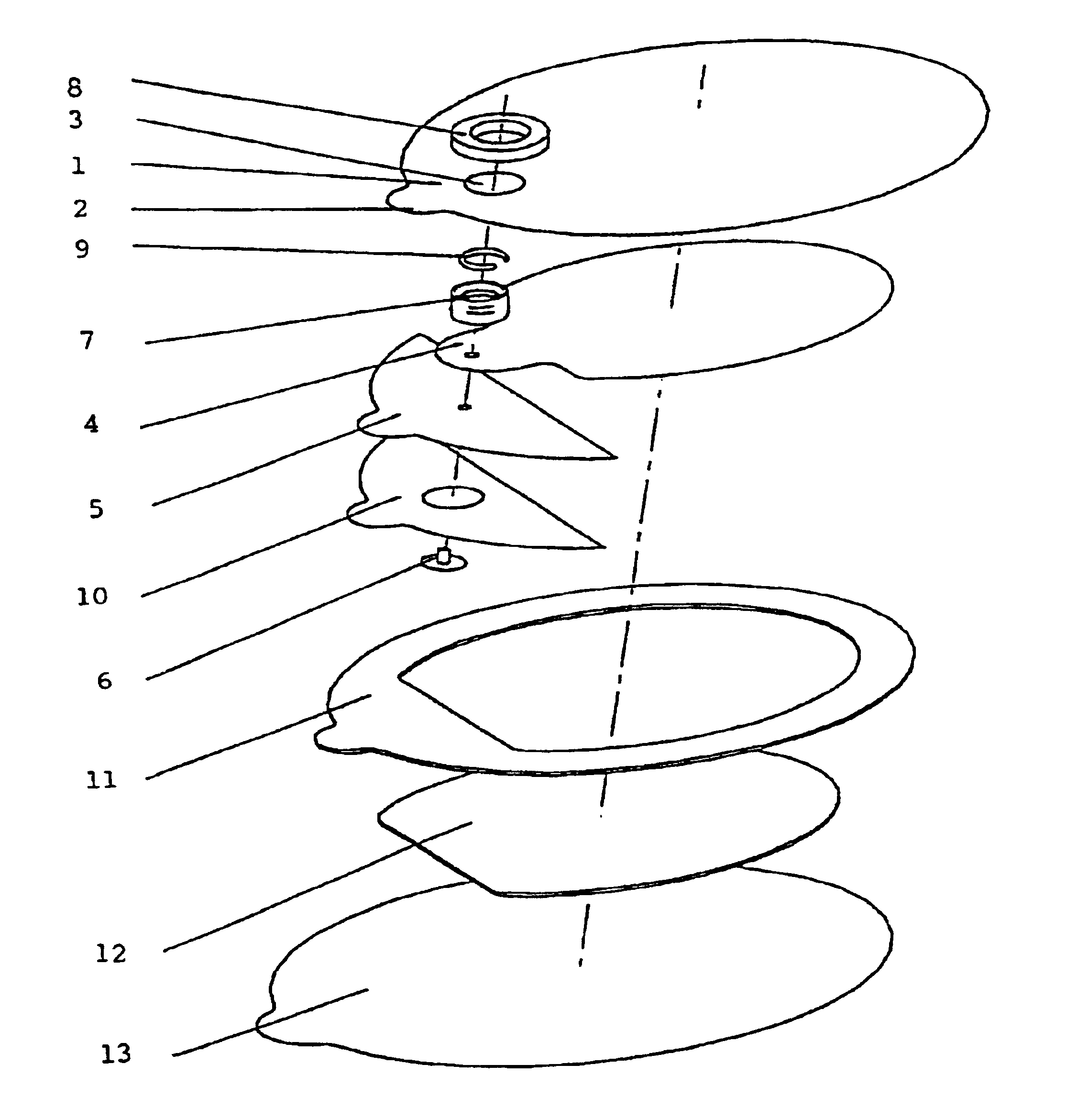

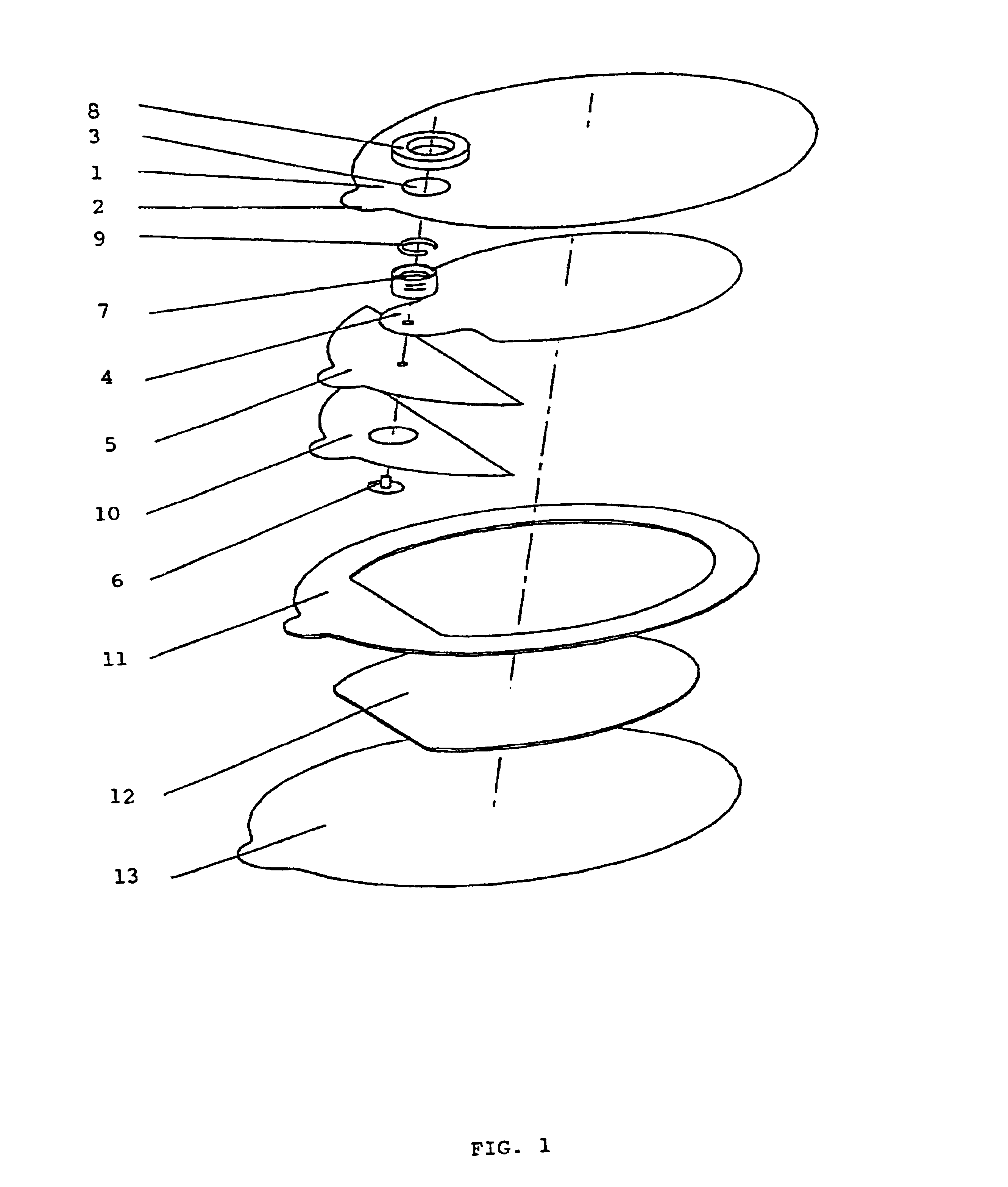

Skin electrode

InactiveUS6845272B1Reduced shelf lifeExtended shelf lifeElectrocardiographySensorsMaterials scienceMetal

An electrode for establishing electrical contact with the skin is disclosed, said electrode having a low impedance and comprising an electrically conductive metallic layer (4) and an electrically conductive gel (12) attached to said metallic layer, wherein the pH of the electrically conductive gel (12) is chosen so as to provide a corrosion of the metallic layer (4).

Owner:MEDICOTEST SYSTR

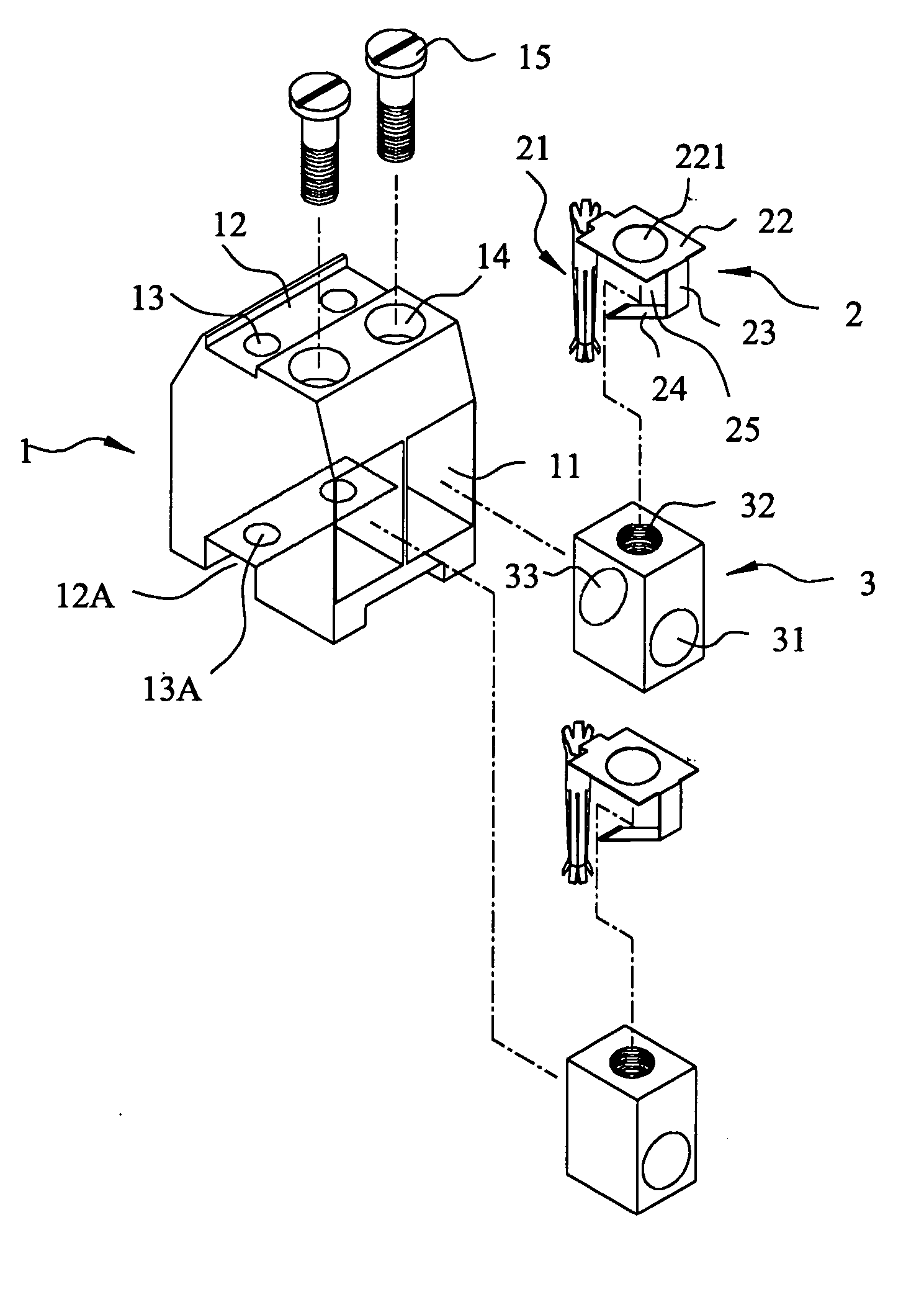

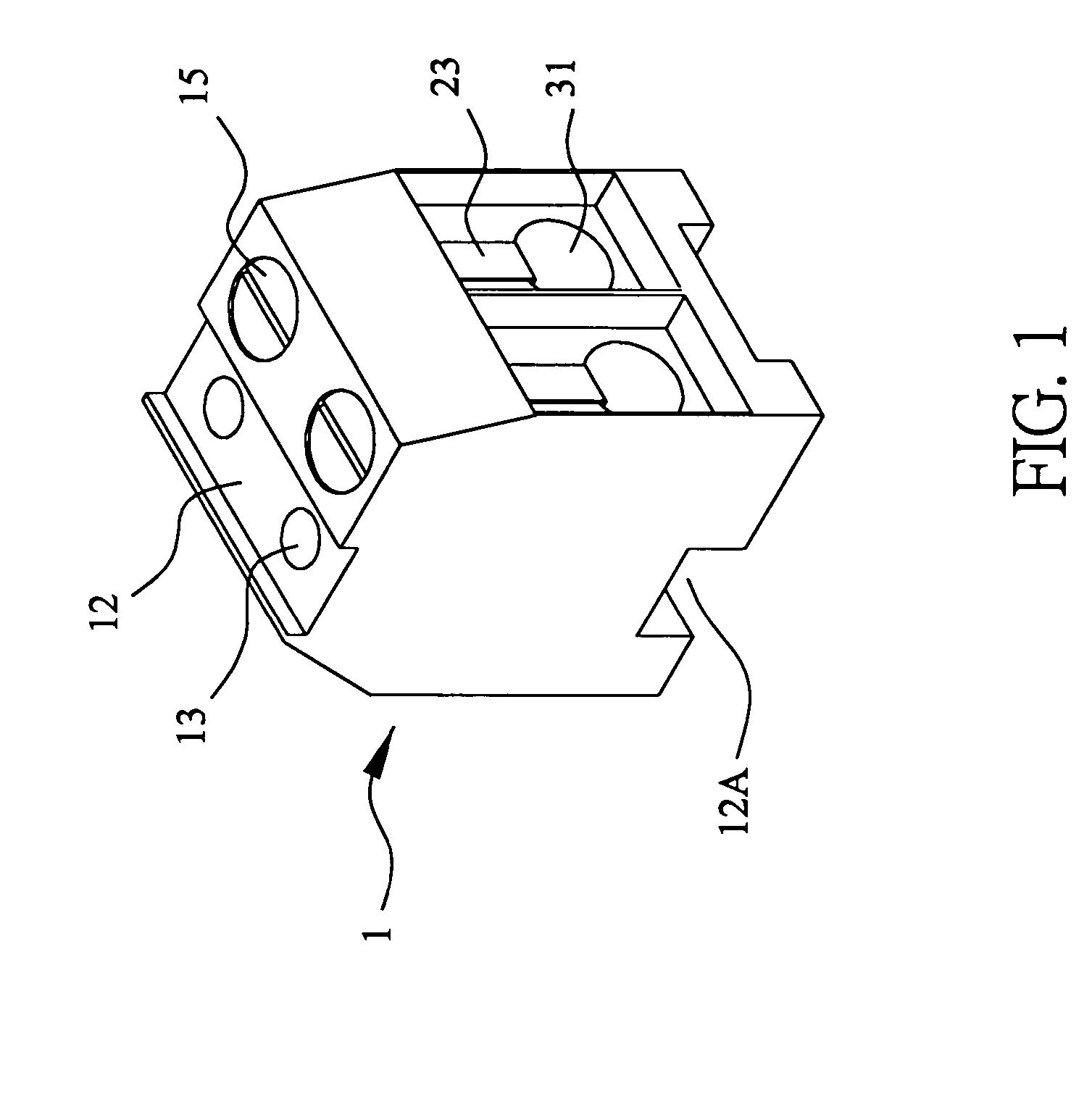

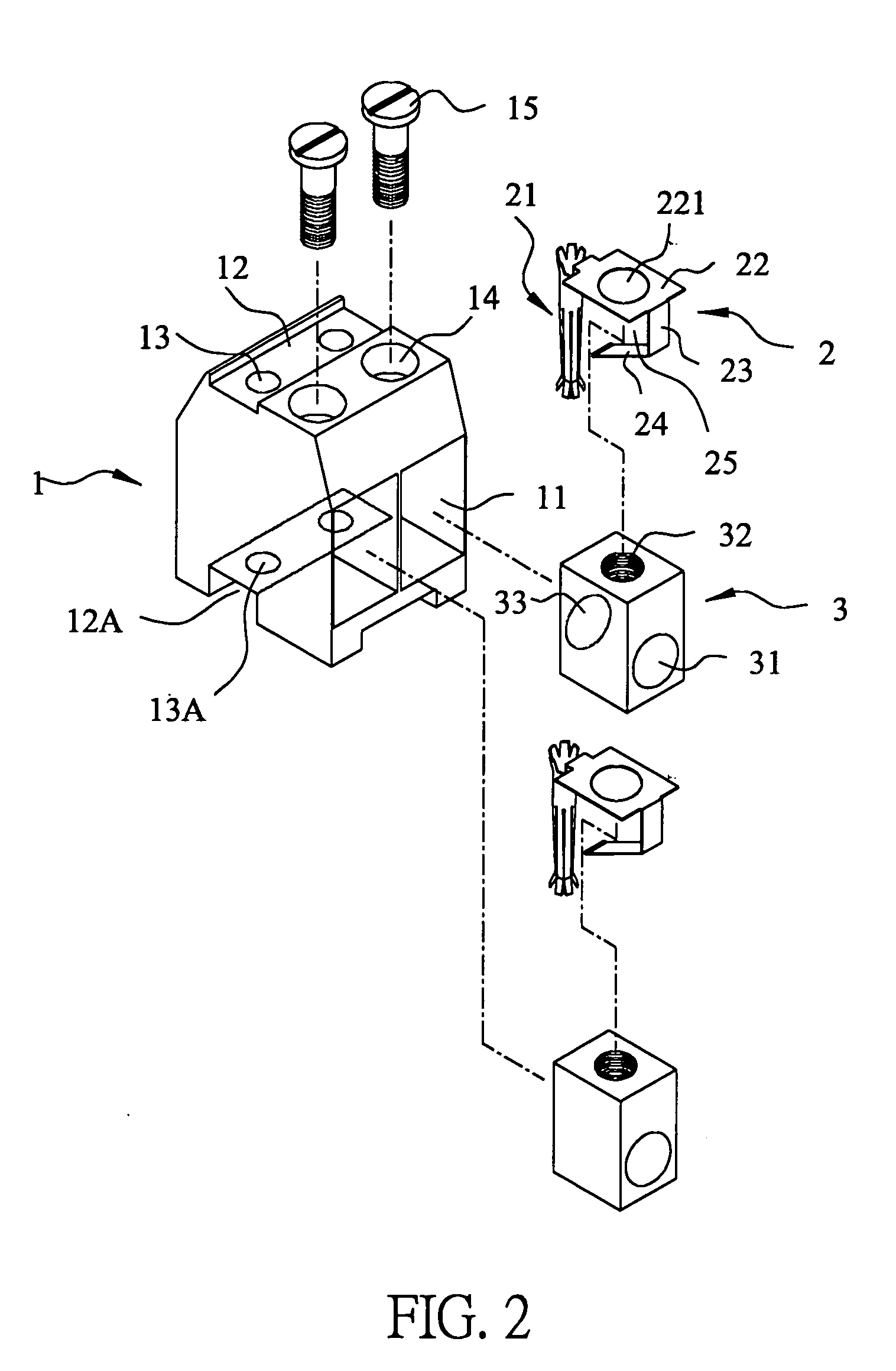

Structure of connector

InactiveUS20050130508A1Low insertion forceLarge contact areaClamped/spring connectionsLower faceHeat generation

A connector includes a housing forming at least one receptacle and a terminal received in each receptacle. The housing has upper and lower faces in which opposite slots are defined. Through holes are defined in the slots and extending to the receptacle. The terminal has an engagement section, a retention section extending from the engagement section, an extension section extending from the retention section and opposite to the engagement section and a wire engaging section projecting from the extension section. The engagement section includes a plurality of circumferentially spaced resilient leaves forming a cylinder axially aligned with the holes defined in the upper and lower faces of the housing. Thus, when a pin of a mating connector is fit into the cylinder of the engagement section through either one of the holes of the housing, the pin is completely surrounded by the leaves and a large contact area is formed between the pin and the engagement section. Due to the resiliency of the leaves, only a low insertion force is needed in completing insertion of the pin into the engagement section. Firm engagement, low impedance and low noise, as well as reduced heat generation, can be realized between the pin and the engagement section.

Owner:YEH SHENG HSING

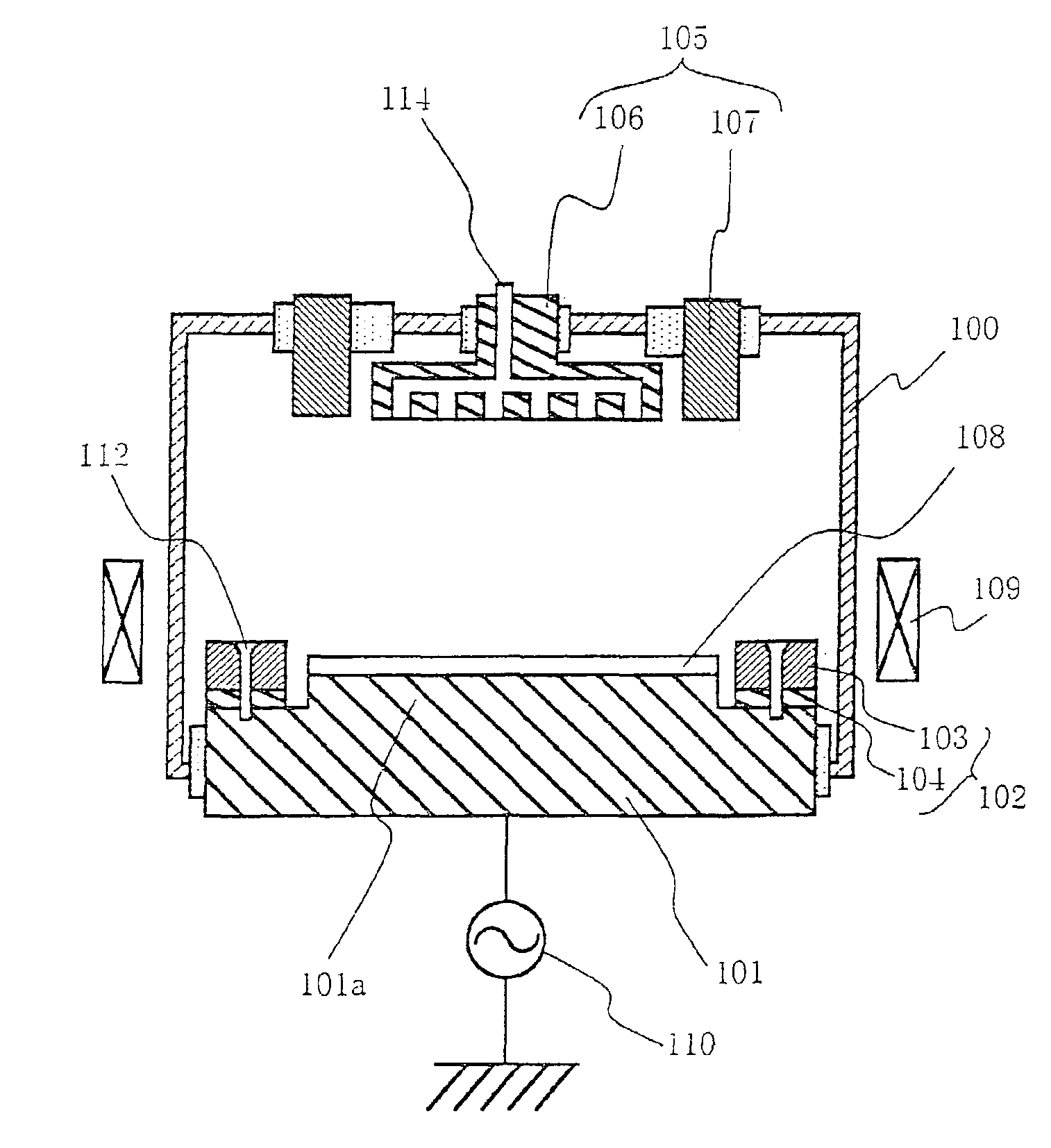

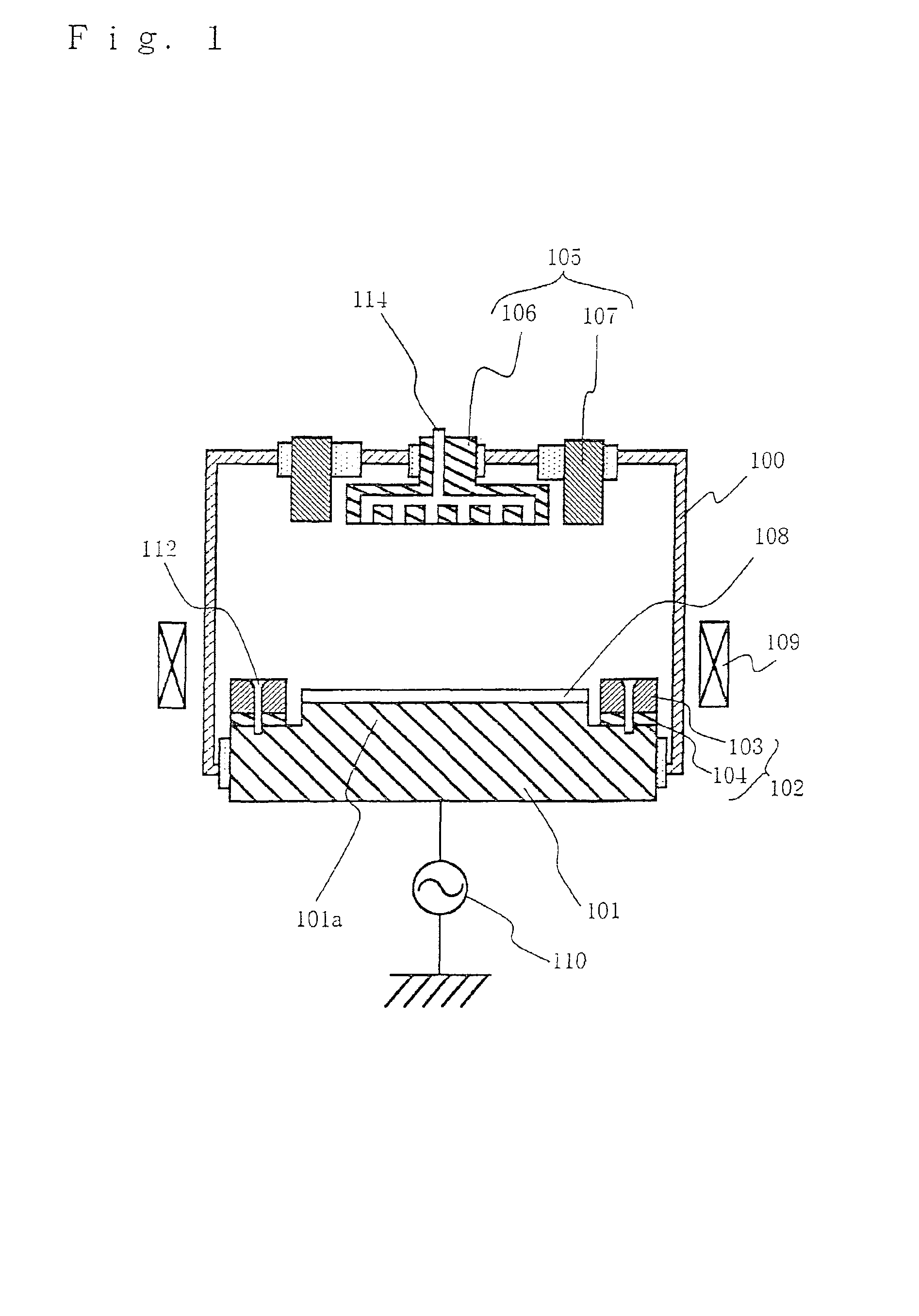

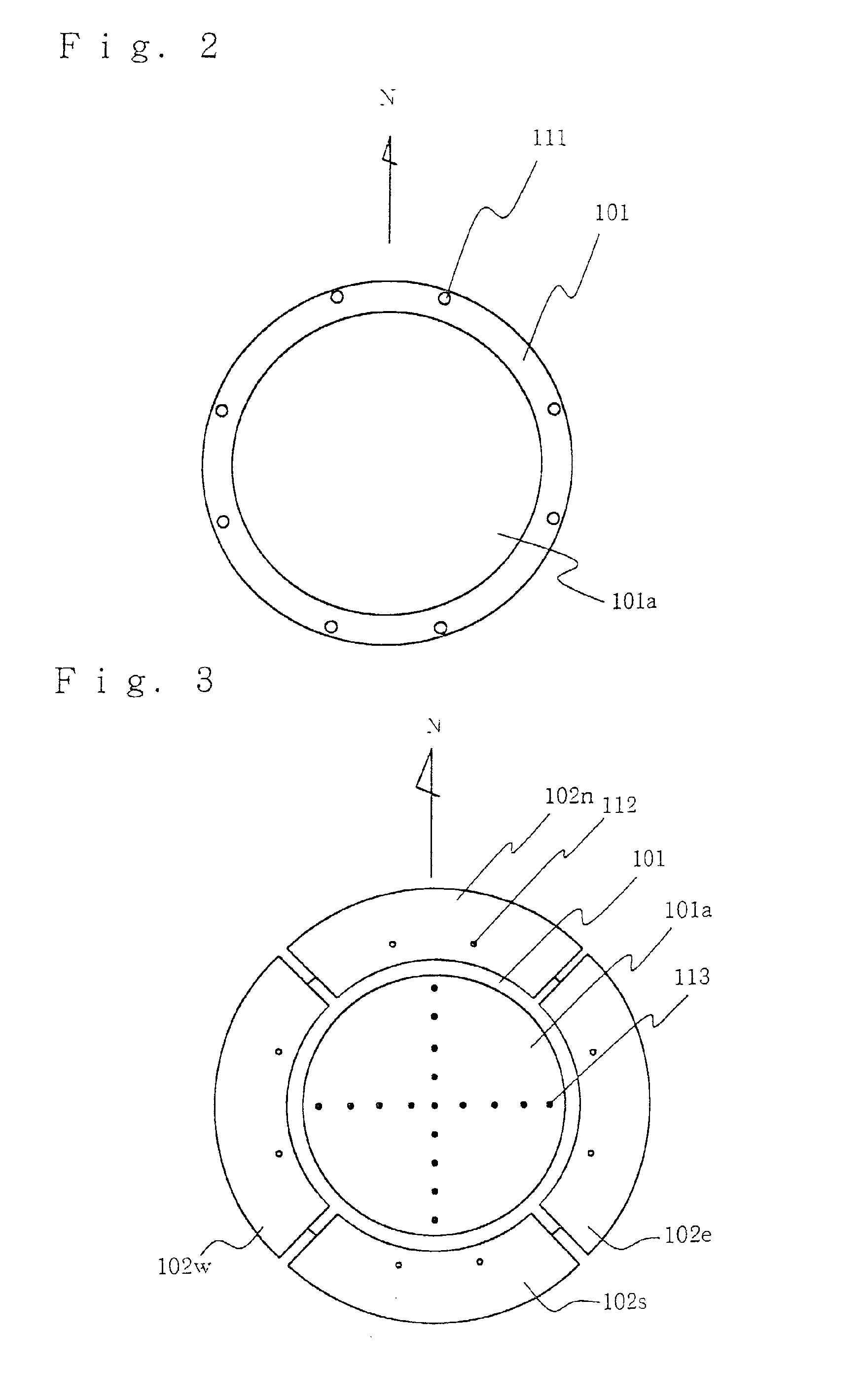

Plasma etching device

InactiveUS8114245B2Lower impedanceLiquid surface applicatorsElectric discharge tubesElectron currentElectricity

A plasma etching device which has an auxiliary electrode enabling realization of a uniform plasma density of generated plasma on the surface of a base and which enables uniform etching with respect to the base without depending upon pressure and without rotating a magnetic field applying means. The plasma etching device has magnetic field applying means which has two parallel plate electrodes I and II and RF power applying means, with the base set on the electrode I, and which is horizontal and unidirectional with respect to the surface of the base where plasma etching is carried out. In this plasma etching device, an auxiliary electrode is provided at least on the upstream side of the base in a flow of electron current generated by the magnetic field applying means. The auxiliary electrode includes a local electrode arranged on the side facing the electrode II and means for adjusting impedance provided at a part of the local electrode to be electrically connected with the electrode I.

Owner:OHMI TADAHIRO +1

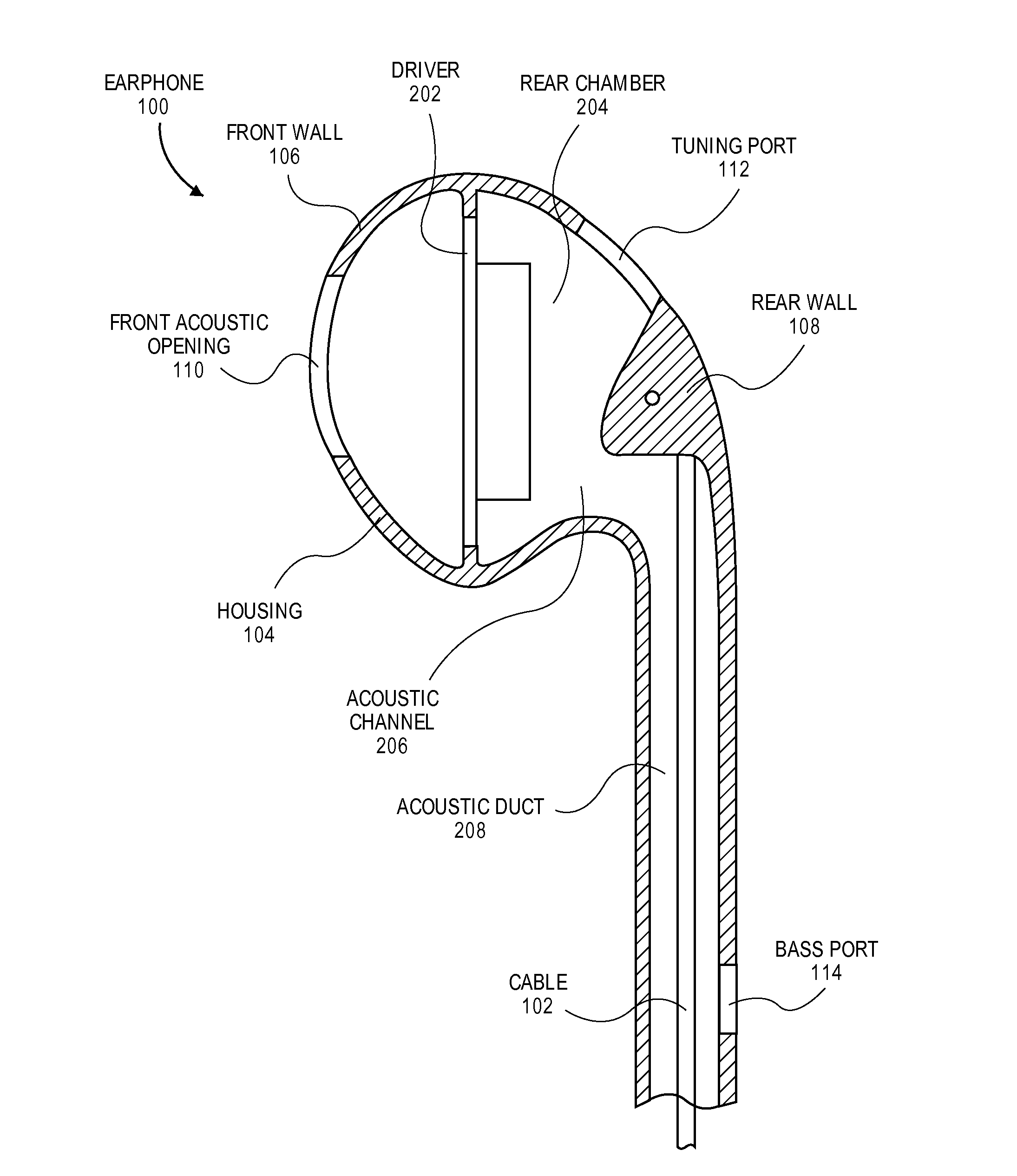

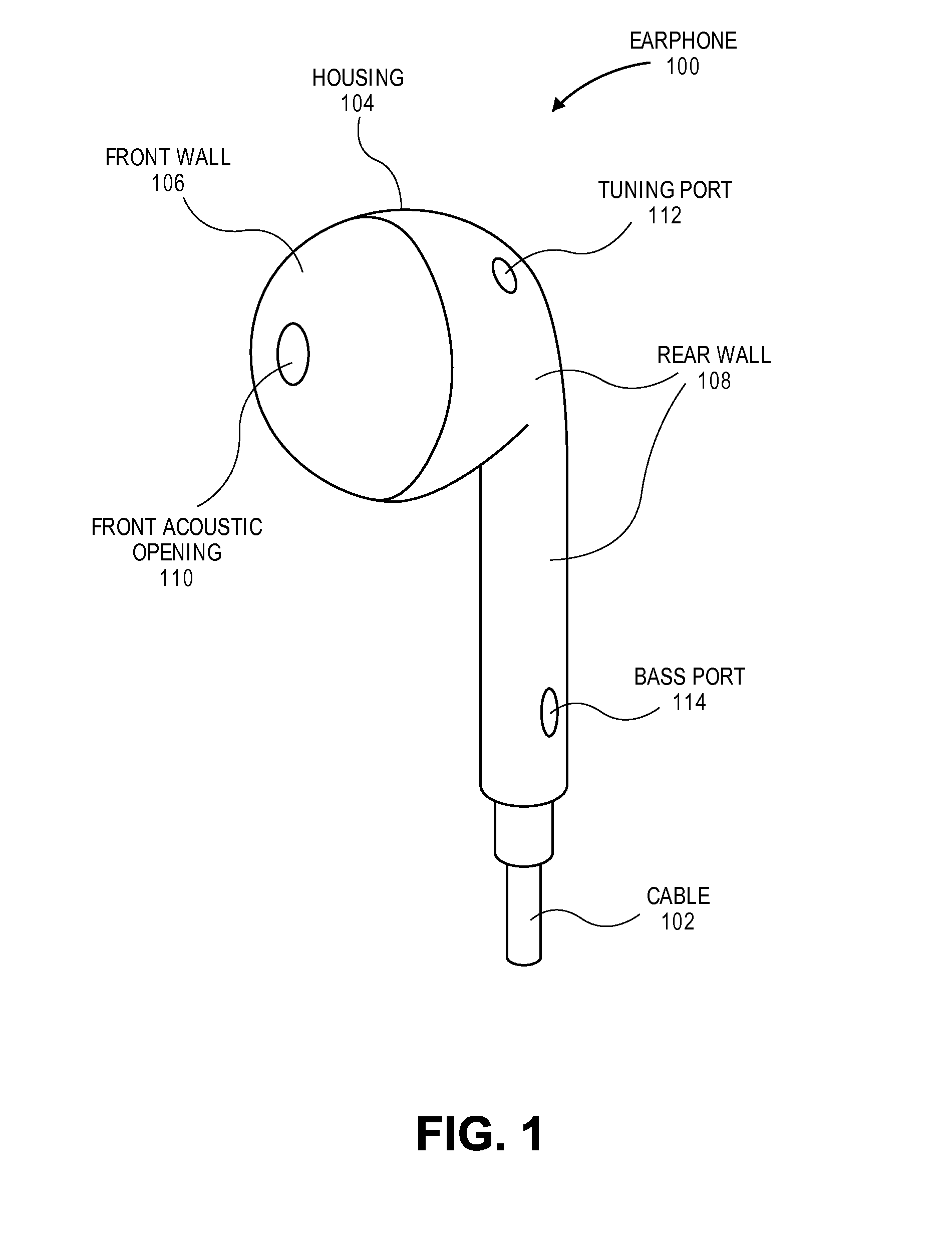

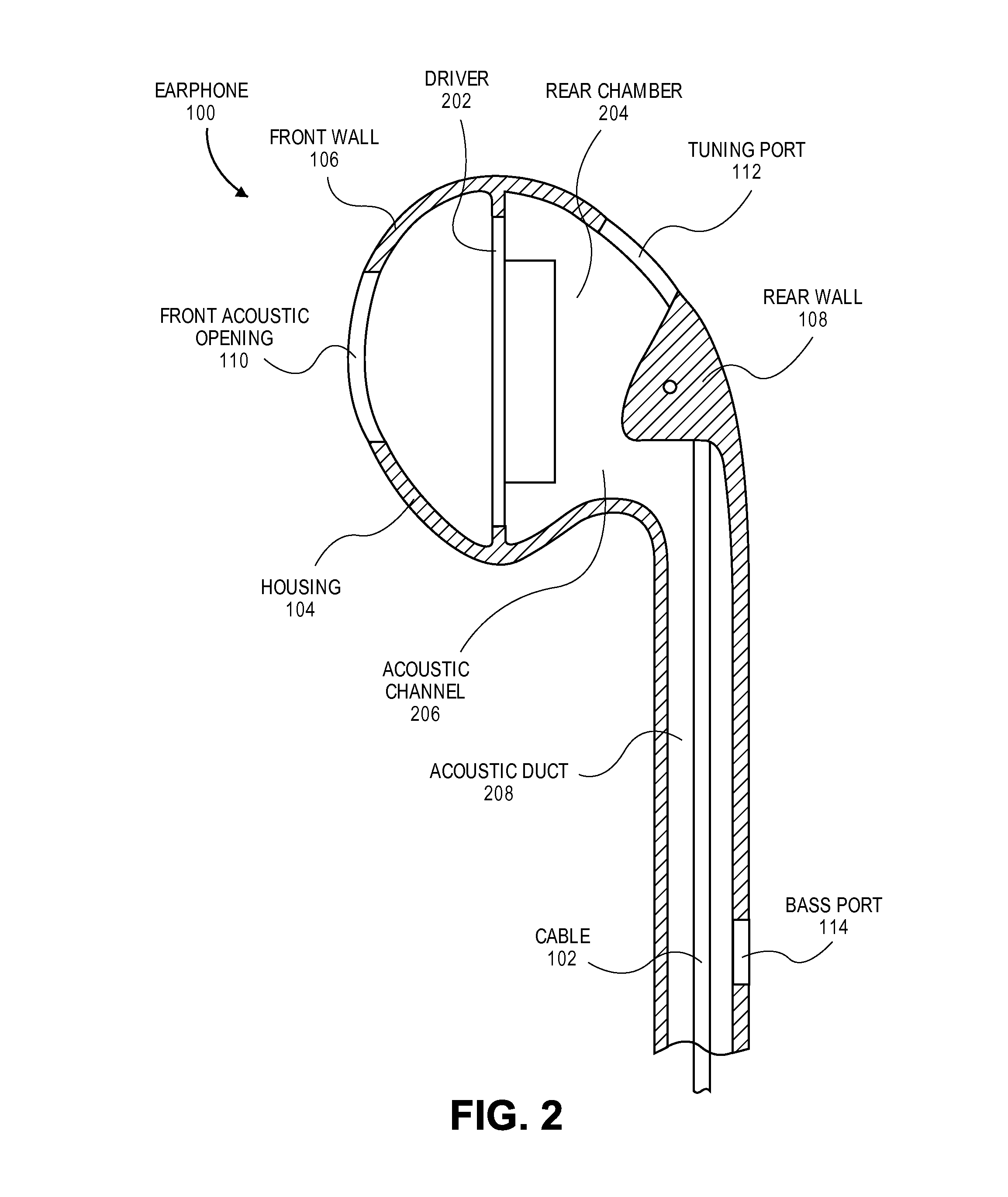

Mass loaded earbud with vent chamber

ActiveUS20150382100A1Lower acoustic impedanceReduce the possibilityIntra aural earpiecesFrequency/directions obtaining arrangementsEngineeringHeadphones

Owner:APPLE INC

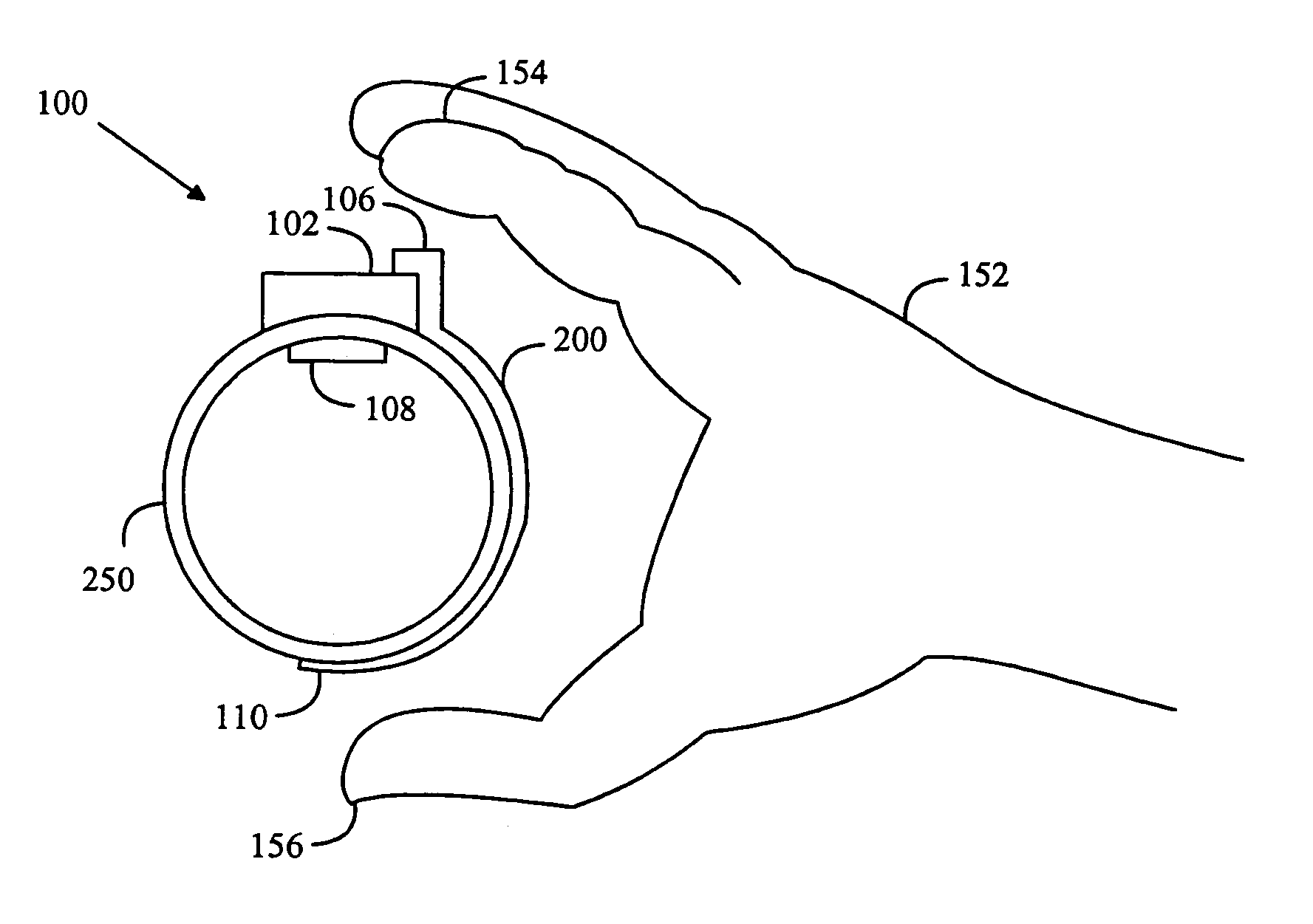

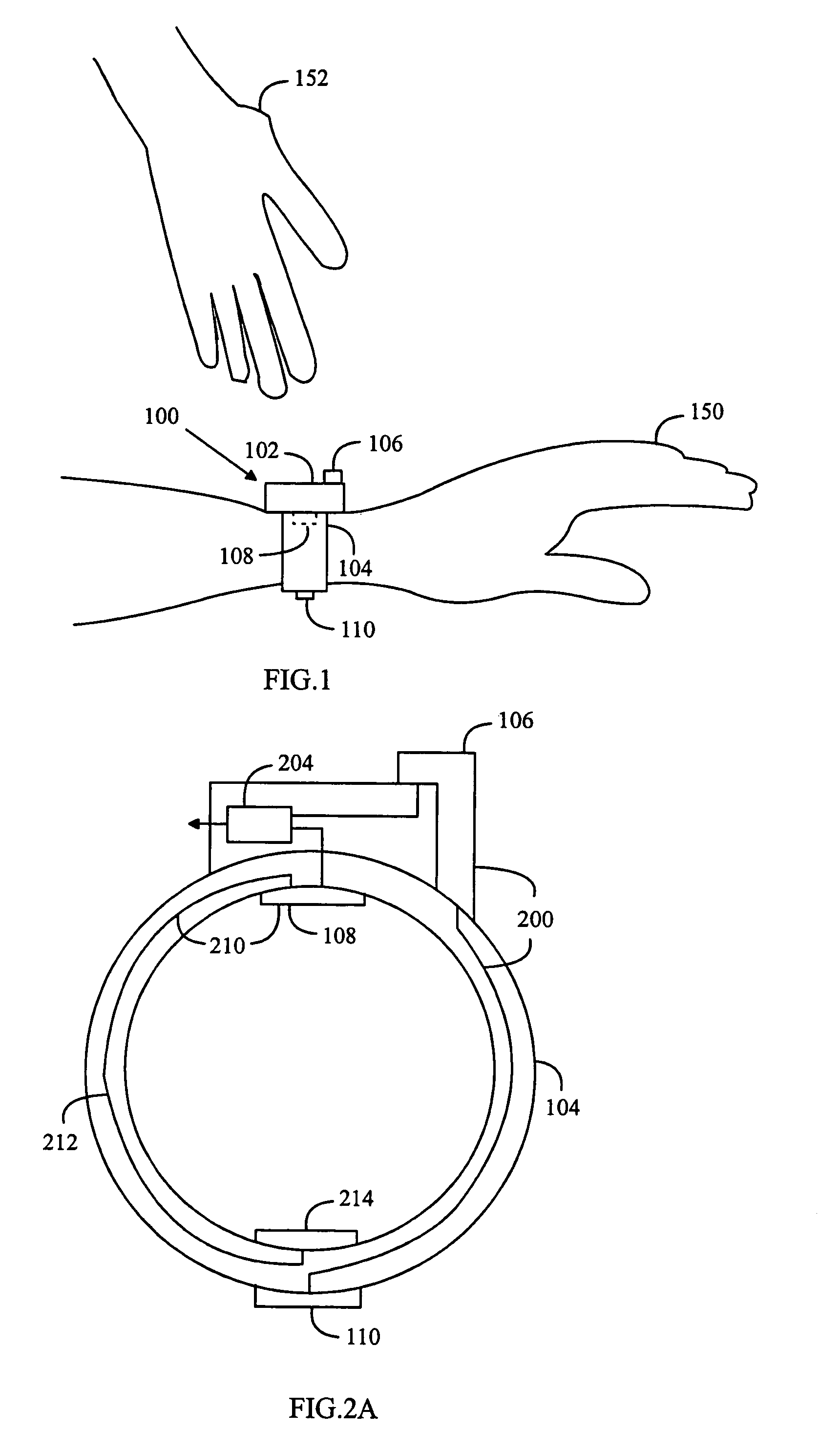

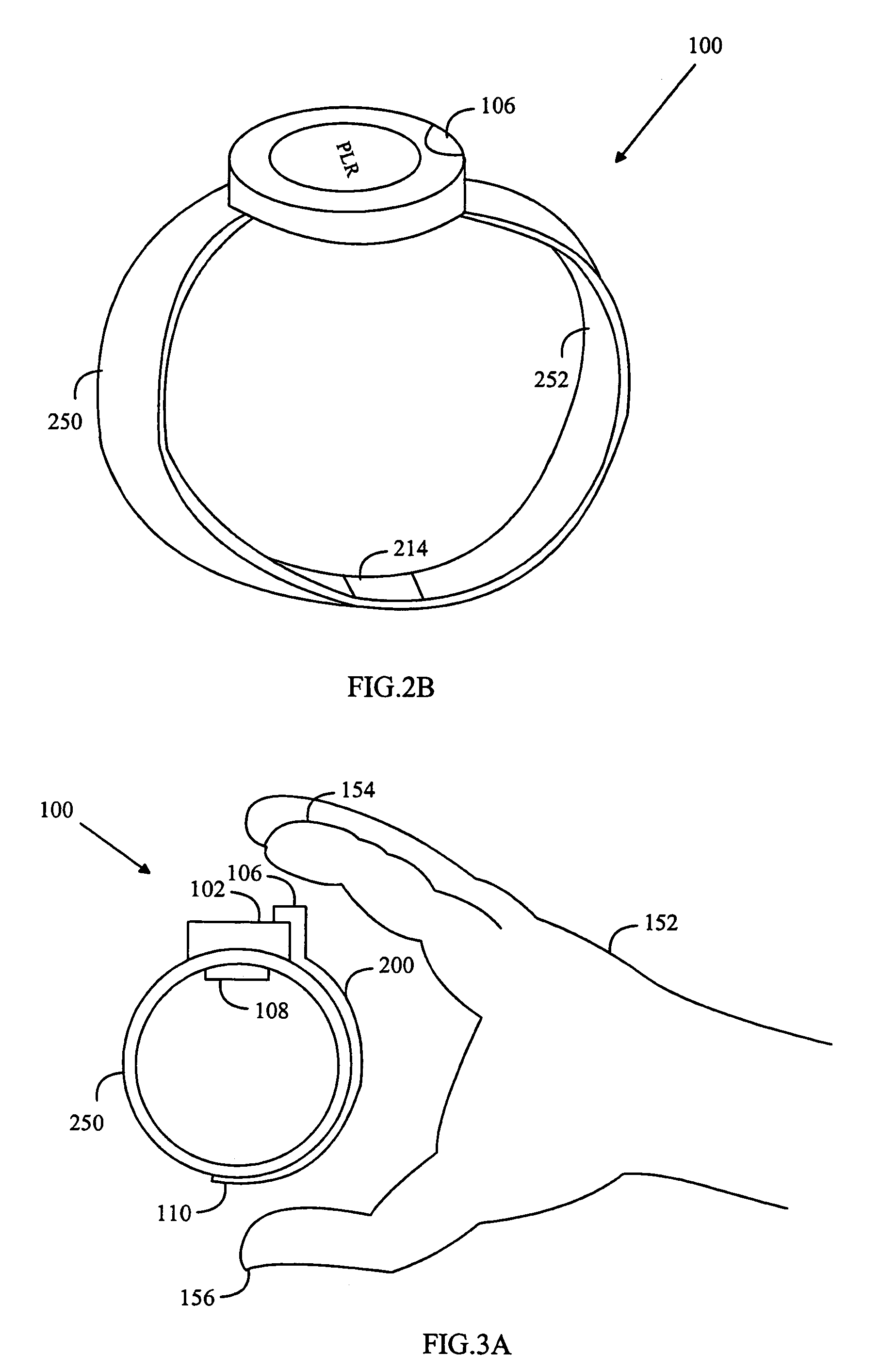

Method and device for measuring heart rate, and method for manufacturing the device

ActiveUS7171259B2Firm and convenient gripLower impedanceElectrocardiographySensorsMeasurement deviceStructure function

A heart rate measuring device is attached around a user's hand, the device having an inner surface, which is in contact with the skin on the hand to which it is attached, and an outer surface, which is other than the inner surface. The inner surface of the measuring device is provided with an electrically conductive inner structure, which functions as an electrode for a contact with the skin of the hand to which the device is attached. An electrically conductive outer structure functions as an electrode for a contact with the user's other hand and it is electrically isolated from the electrically conductive inner structure. The electrically conductive outer structure on the measuring device extends at least to opposite sides of the hand to which the device is attached, and at least part of the electrically conductive outer surface is on the outer surface of the measuring device, on opposite sides of the hand to which the device is attached. The electrically conductive outer structure and inner structure are connected to a measuring unit for heart rate measurement.

Owner:POLAR ELECTRO

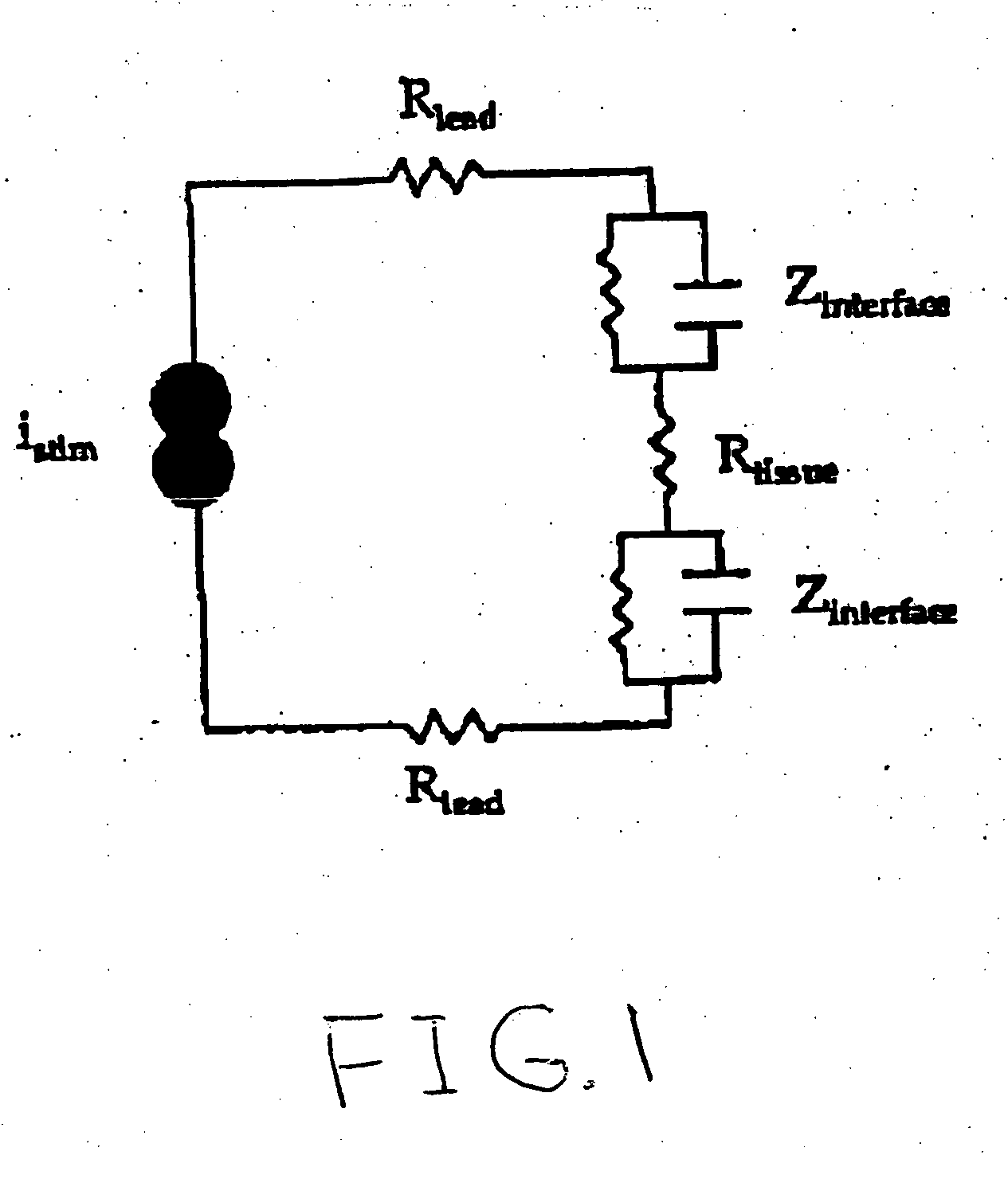

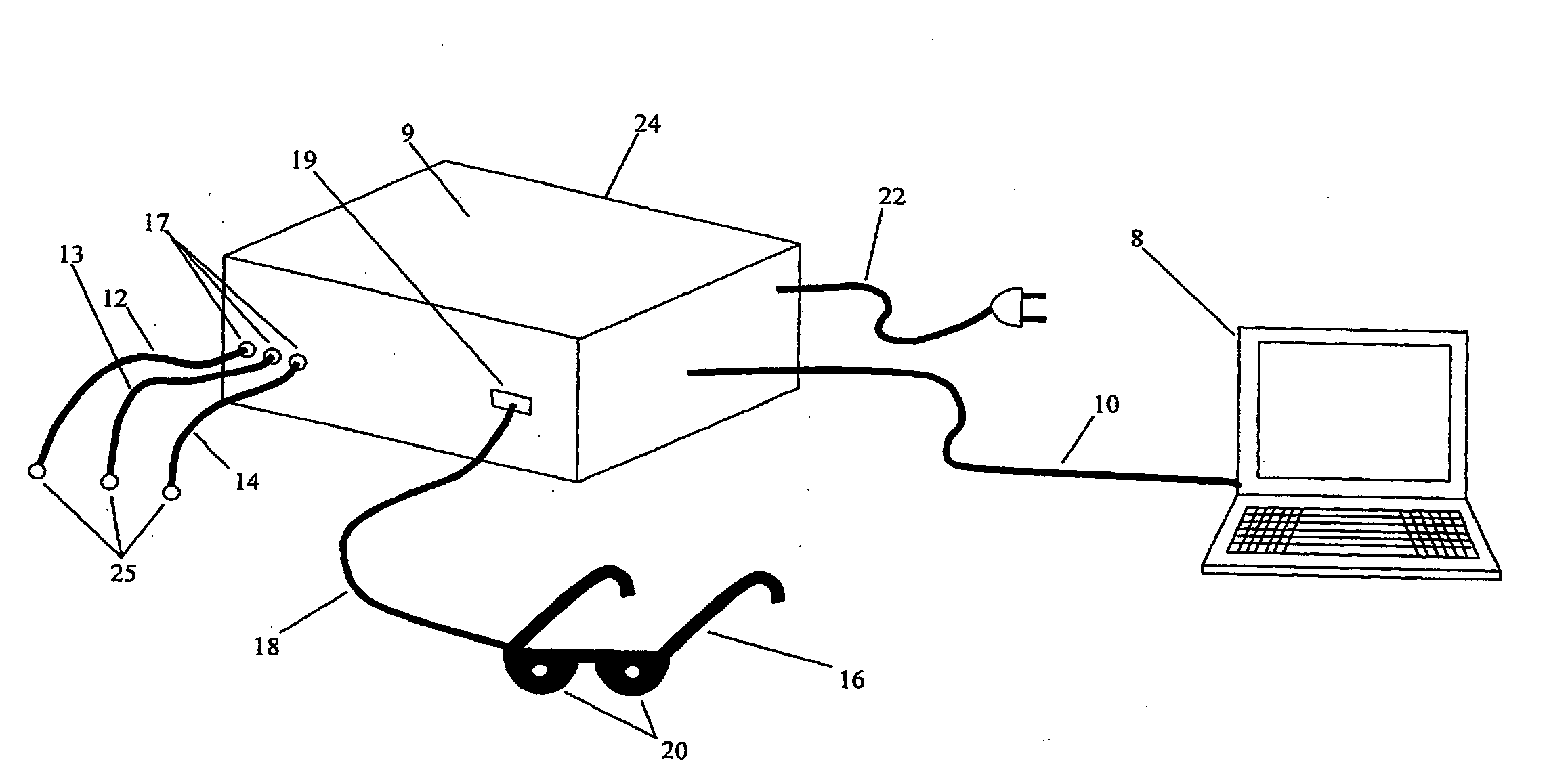

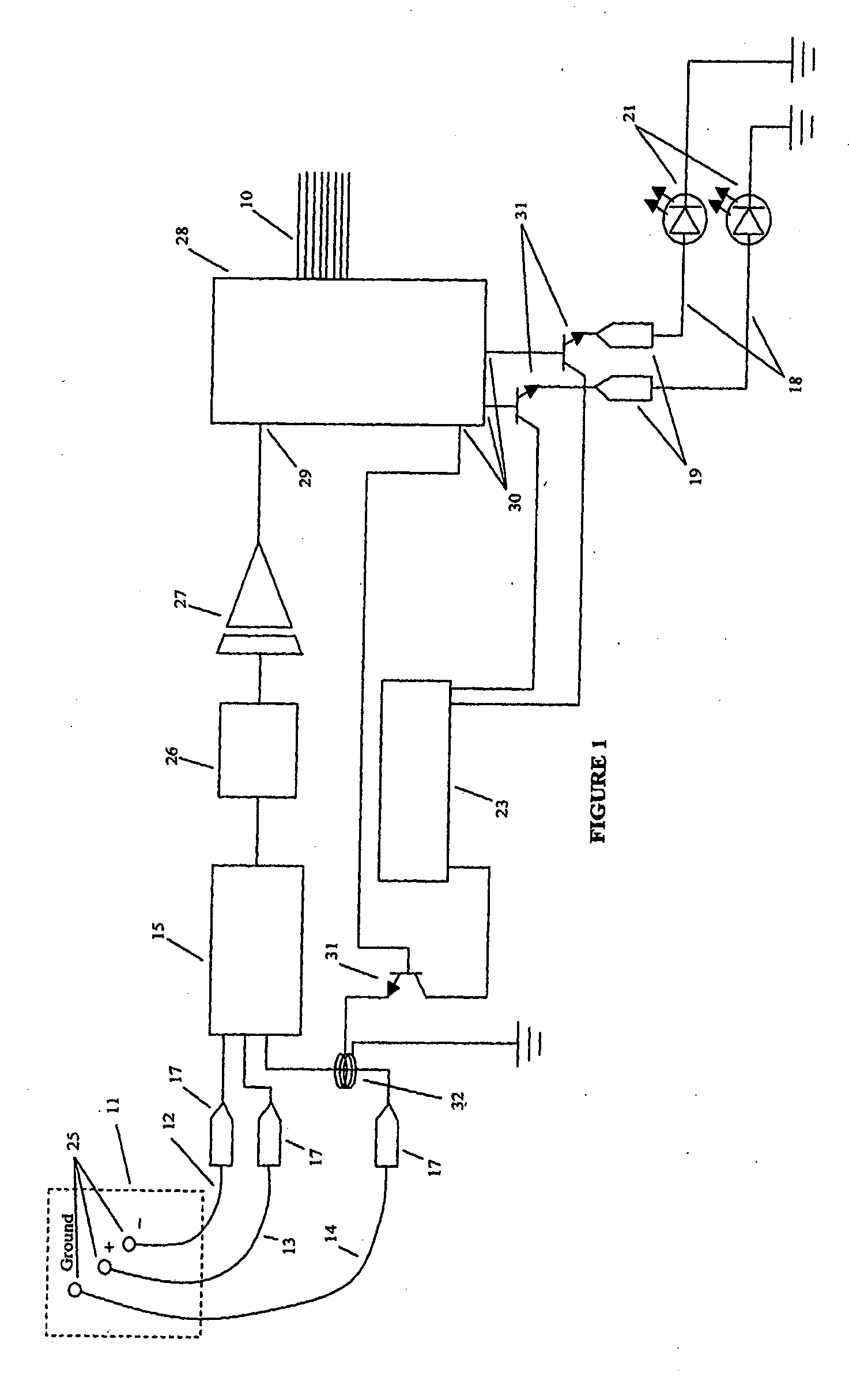

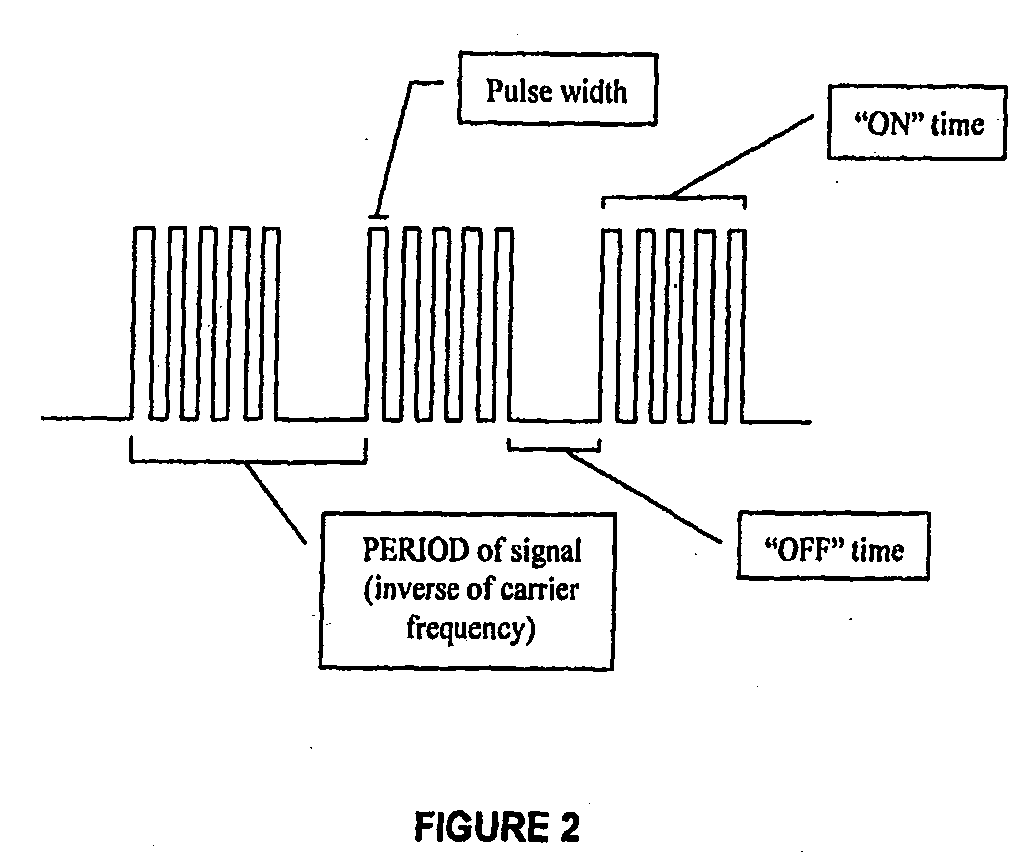

Methods and Apparatus for Electrical Stimulation of Tissues Using Signals that Minimize the Effects of Tissue Impedance

InactiveUS20090030476A1Optimization mechanismFunction increaseElectroencephalographyElectrotherapyElectricityMedicine

A tissue stimulation system that generates an electrical tissue stimulation signal configured to reduce tissue impedance and increase depth of signal penetration. The use of leads is dynamically controlled and altered between conducting biopotential voltages, conducting electrical tissue stimulation signals, and grounding, in response to a computational analysis of biopotential data acquired from a region of tissue to be stimulated.

Owner:HARGROVE JEFFREY B

Electronic component separator and method for producing the same

InactiveUS20050208383A1Improve reliabilityImprove machinabilityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersLithiumElectronic component

The present invention provides a separator that, when used in a lithium ion secondary battery, polymer lithium secondary battery, aluminum electrolytic capacitor or electric double-layer capacitor, offers desired levels of various practical characteristics, undergoes minimal heat shrinkage even when overheated, and exhibits high reliability and excellent workability. The electronic component separator proposed by the present invention comprises a porous base made of a substance having a melting point of 180° C. or above, and a resin structure provided on at least one side of and / or inside the porous base, and the porous base and / or resin structure contains filler grains.

Owner:TOMOEGAWA PAPER CO LTD

Touch sensitive screen

ActiveUS7932898B2Lower impedanceEfficient couplingTransmission systemsCathode-ray tube indicatorsElectrical resistance and conductancePlastic materials

A capacitive sensor for determining the presence of an object, such as a user's finger or a stylus, is provided. The sensor comprises a substrate, for example made of transparent plastics material, such as PET, on which electrodes are deposited. A resistive drive electrode for example formed of transparent ITO, is arranged on one side of the substrate and a resistive sense electrode, which again may be of transparent ITO, is arranged on the other side of the substrate. Thus an overall transparent sensor may be provided. A shorting connection is also provided which is configured to connect between two locations on one of the electrodes. The electrodes are connected to respective drive and sense channels. By providing the shorting connection between two locations on one or other (or both) of the electrodes, a lower resistance connection is provided between other locations on the electrode and the corresponding drive or sense channel.

Owner:NEODRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com