Patents

Literature

982results about How to "Load minimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

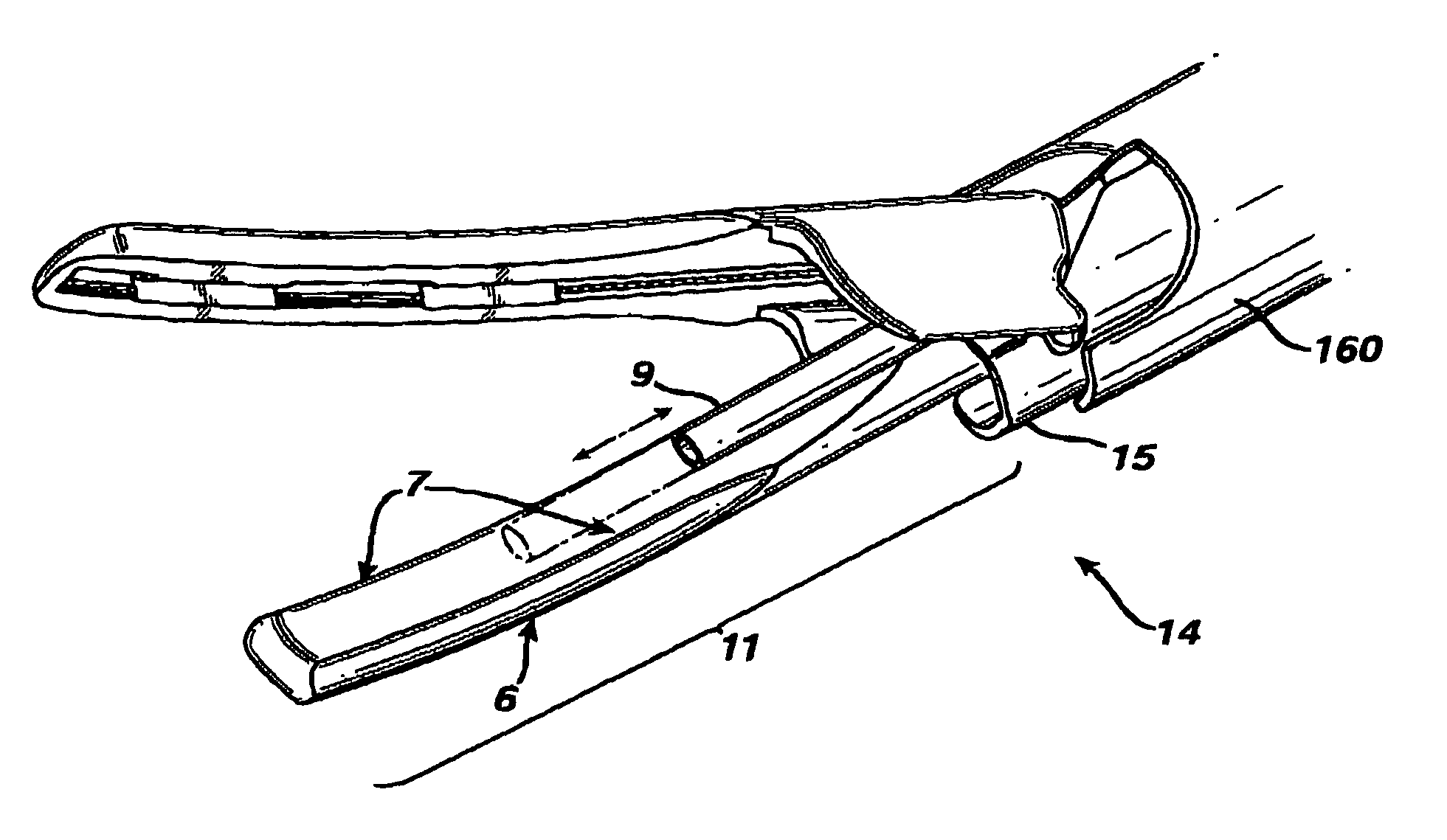

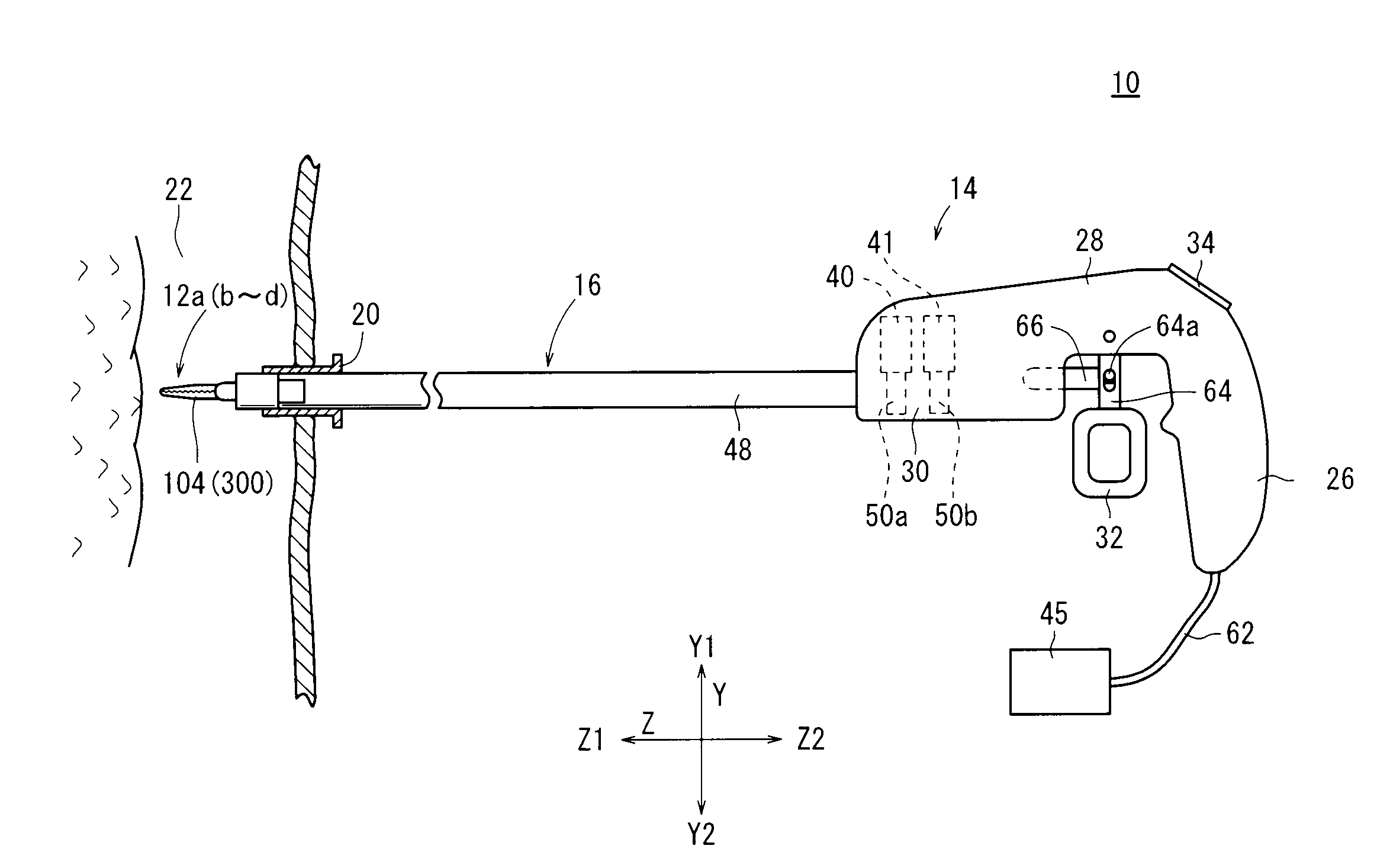

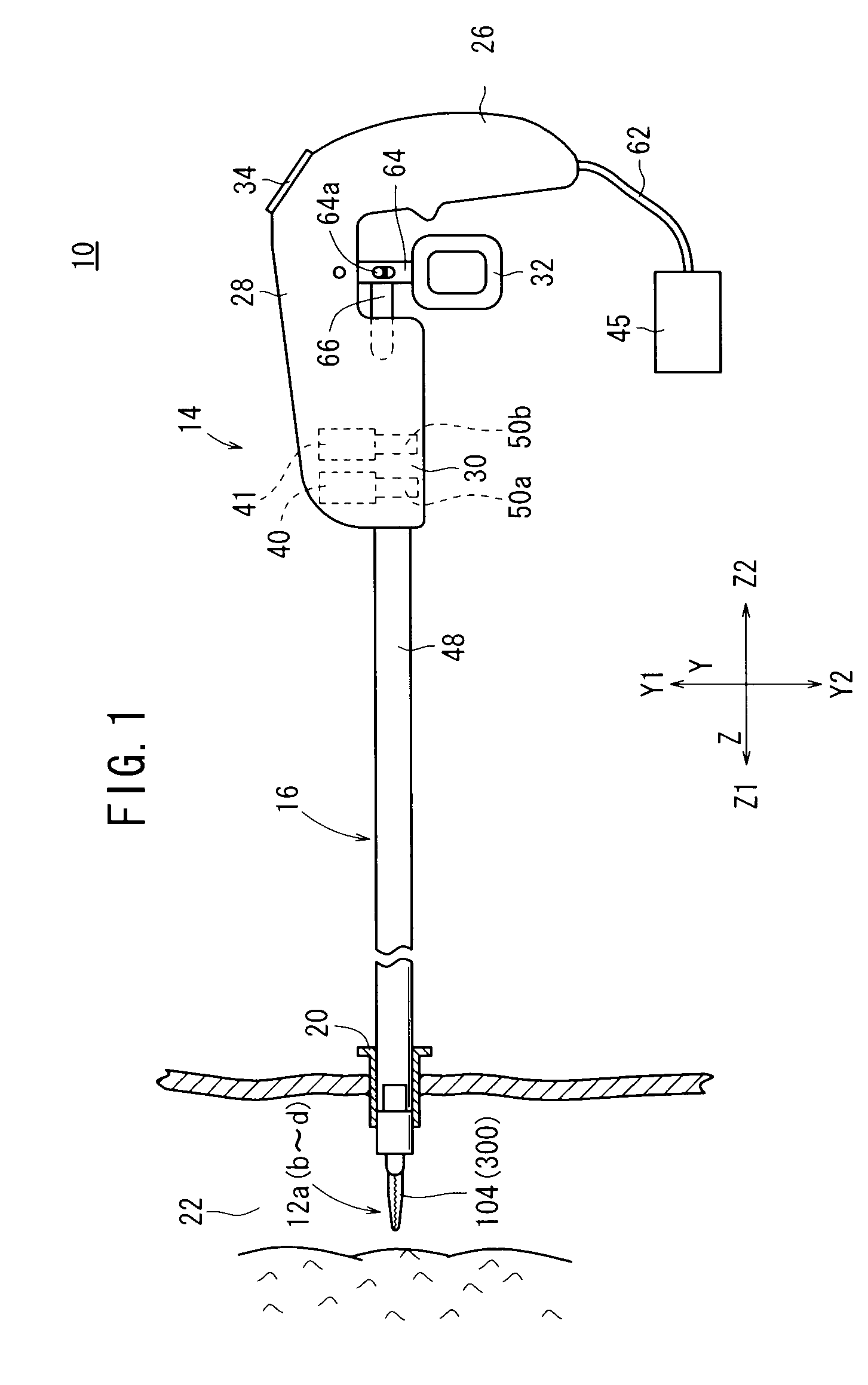

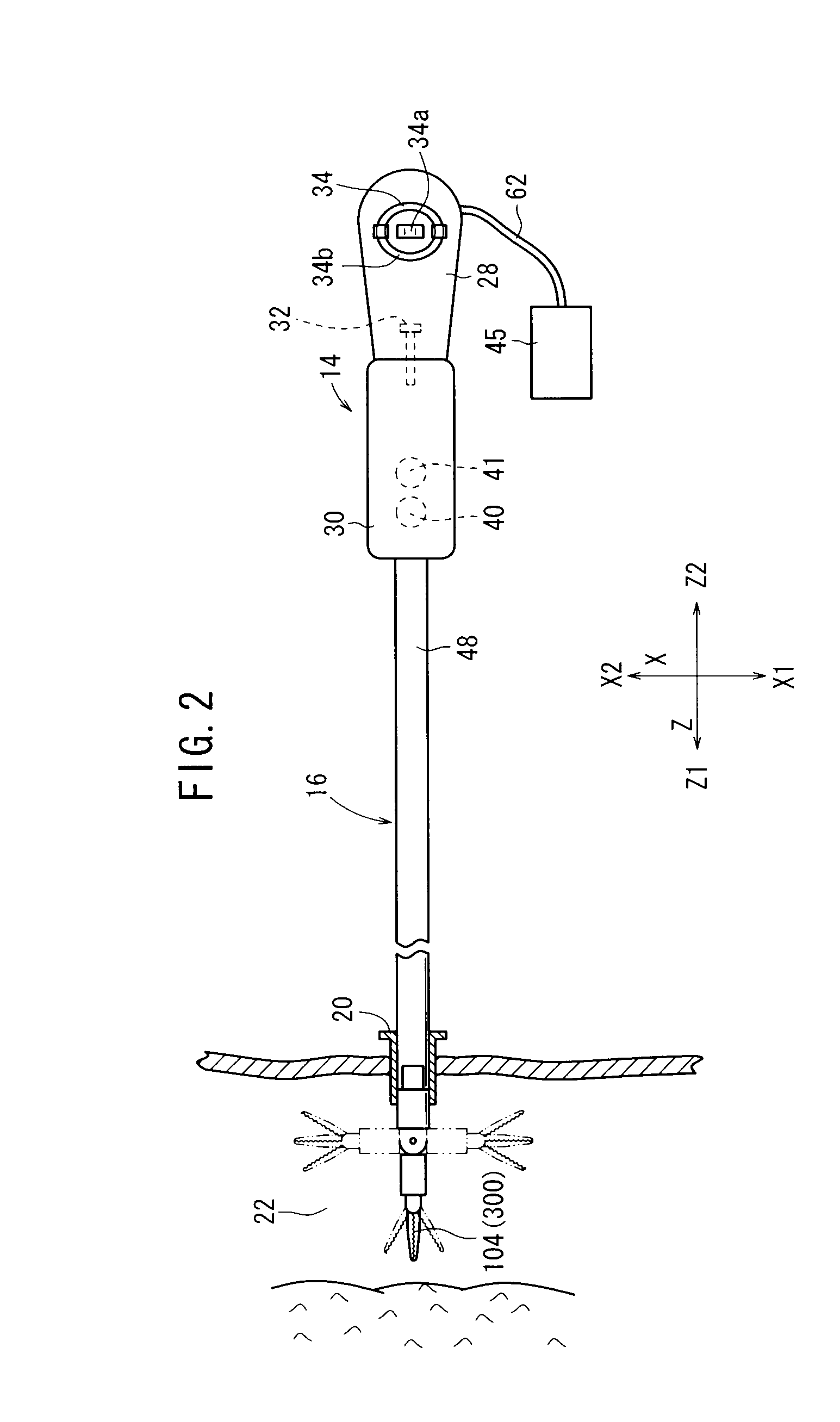

Medical manipulator

ActiveUS8523900B2Load minimizationReduce contractionDiagnosticsSurgical manipulatorsWork unitActuator

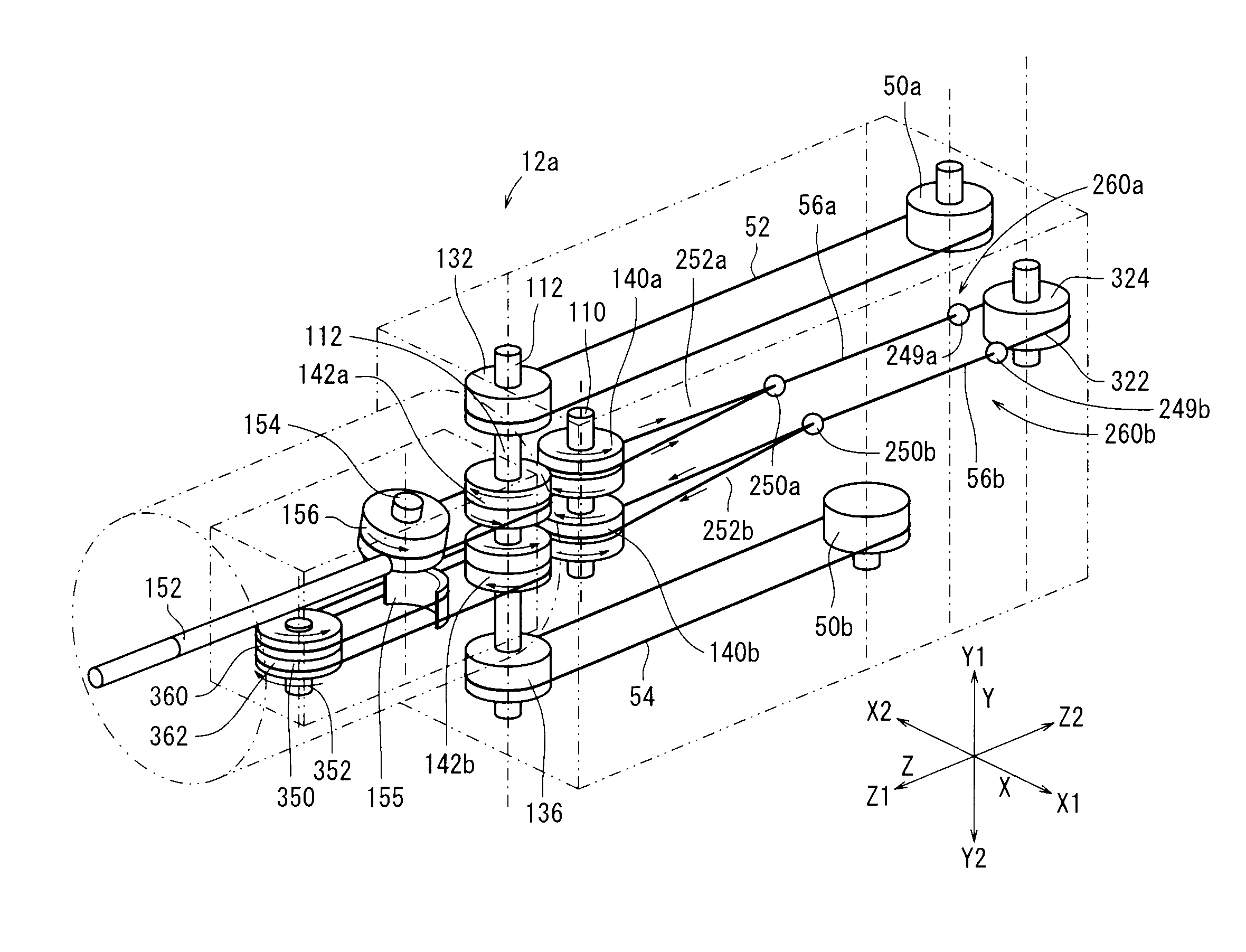

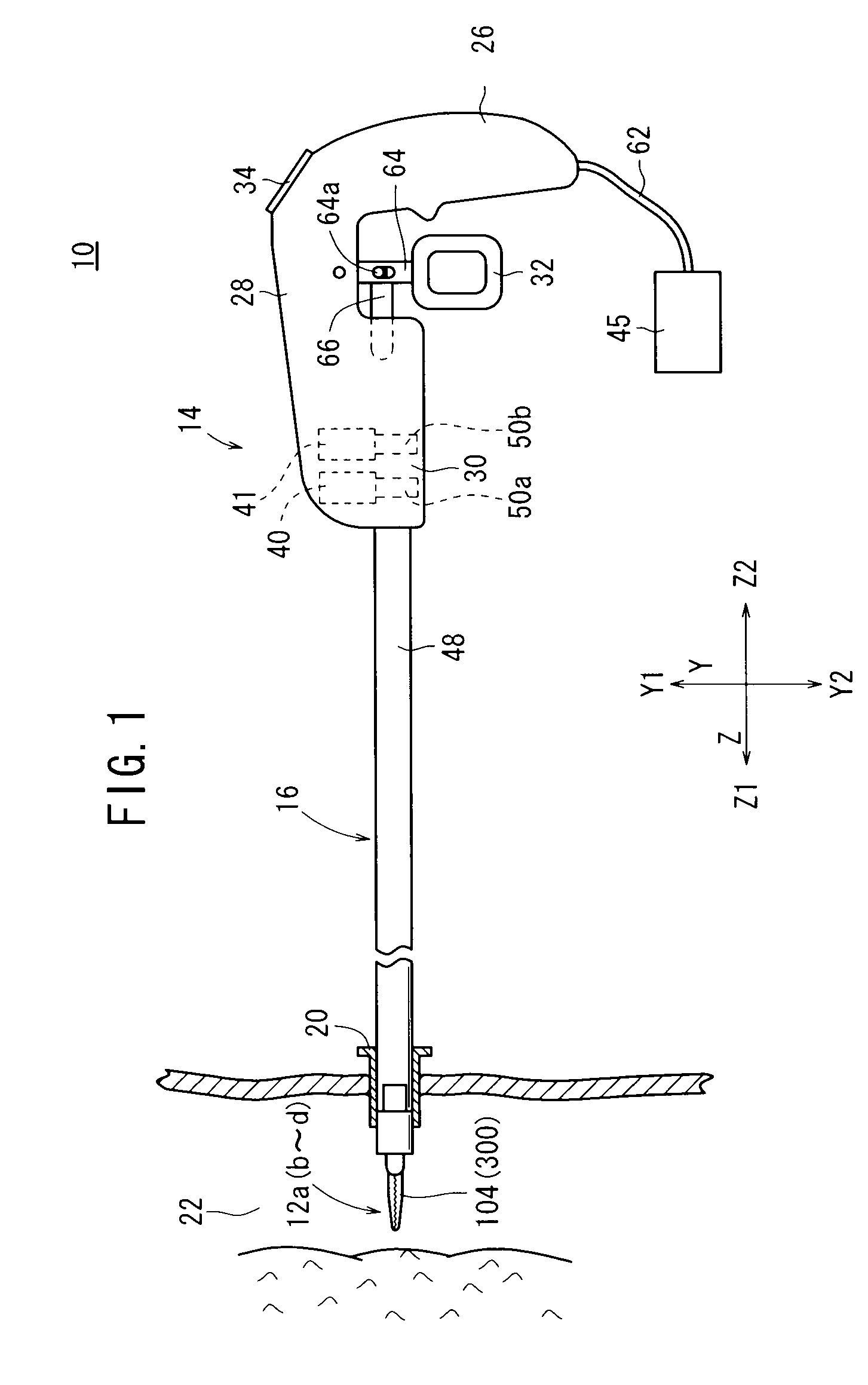

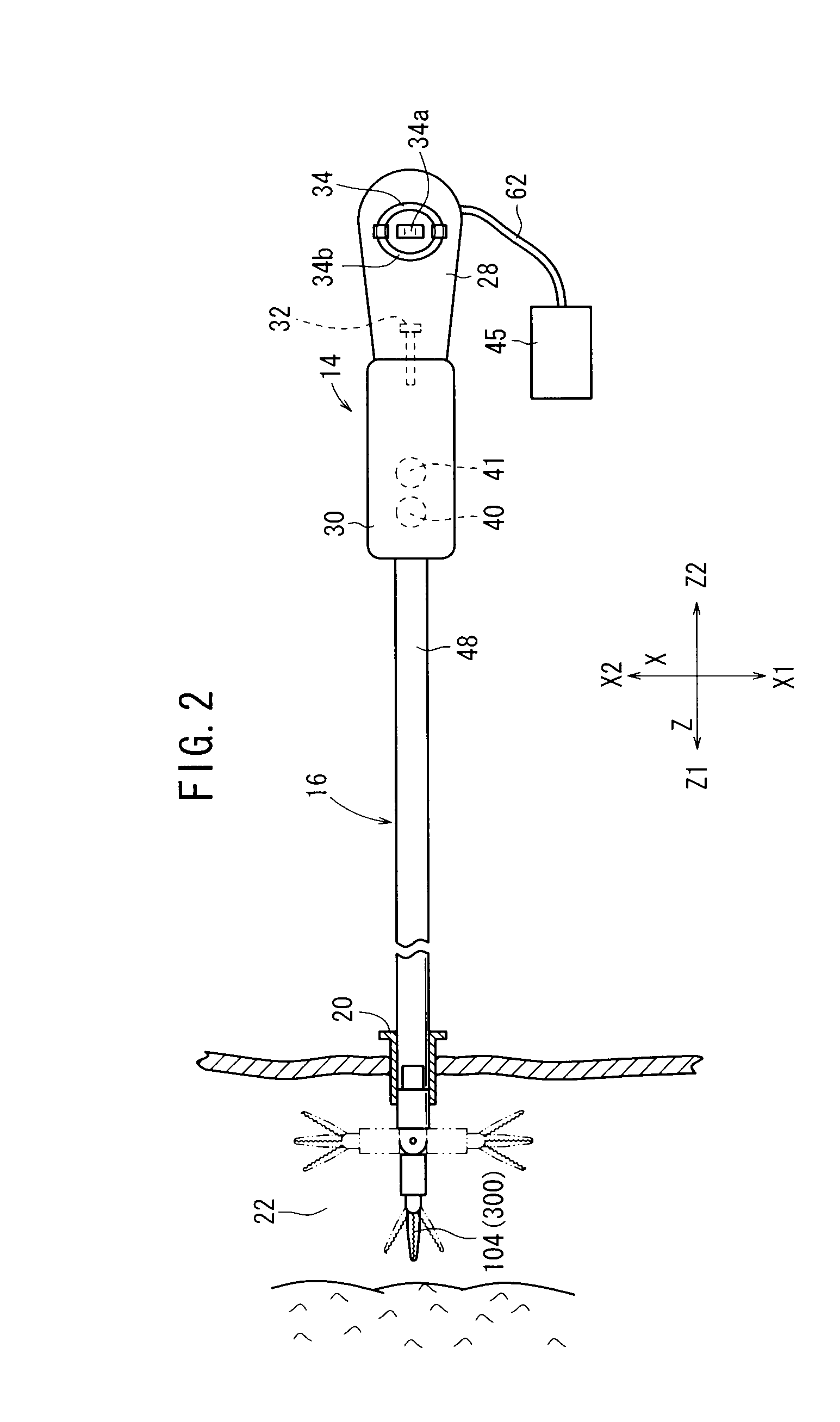

A medical manipulator includes a wire movable in opposite directions, a driven wire having both ends thereof connected to the wire, an end effector of a distal-end working unit, a transmitting member, a crescent driven member integral with the transmitting member, and a return pulley. The transmitting member, the crescent driven member, and the return pulley are successively arranged in this order from the proximal end of the medical manipulator. When the driven wire is moved in opposite directions, the transmitting member also moves in opposite directions. At this time, the crescent driven member moves toward the return pulley, and the proximal-end portion of the return pulley enters a cavity of the crescent driven member.

Owner:KARL STORZ GMBH & CO KG

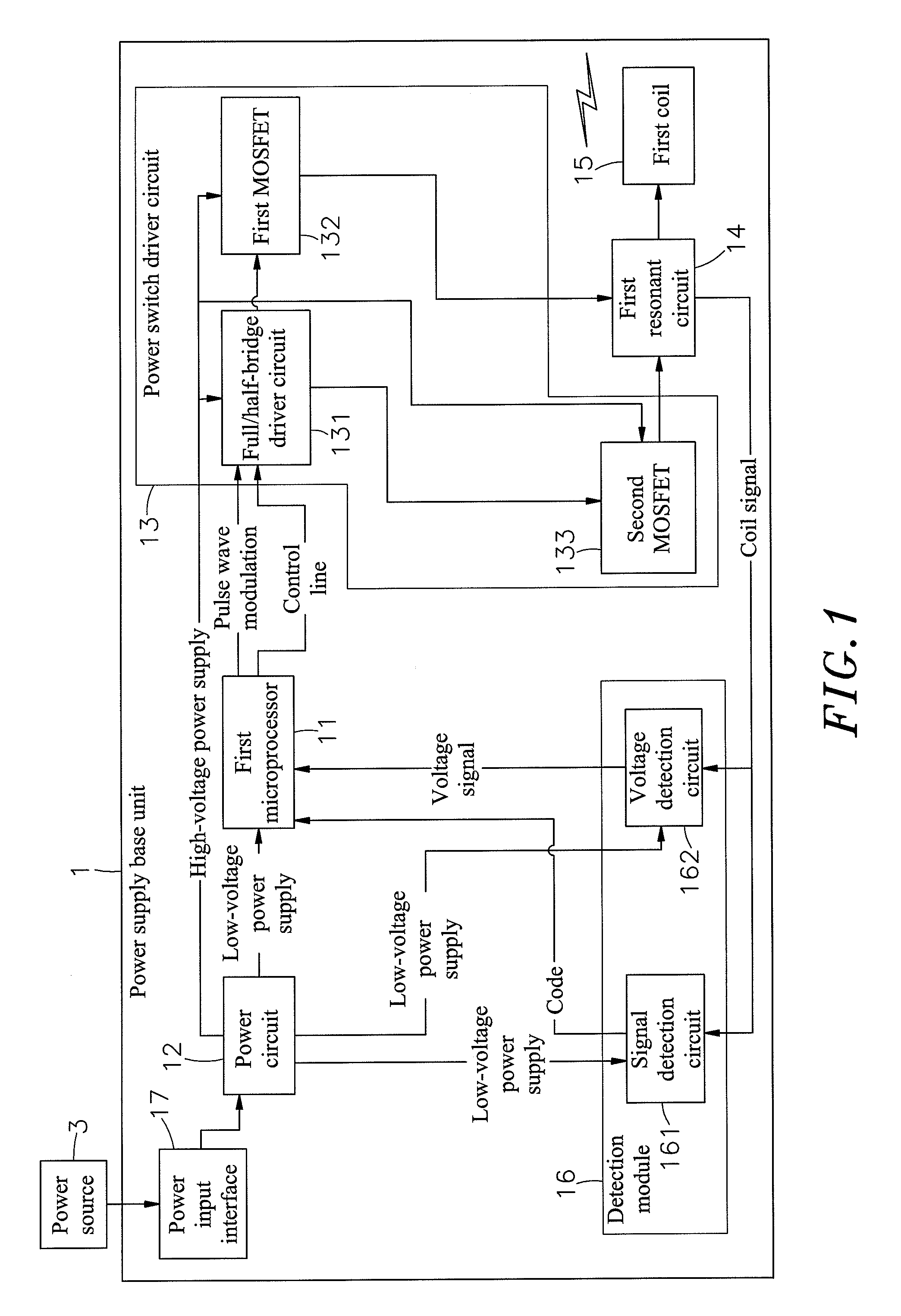

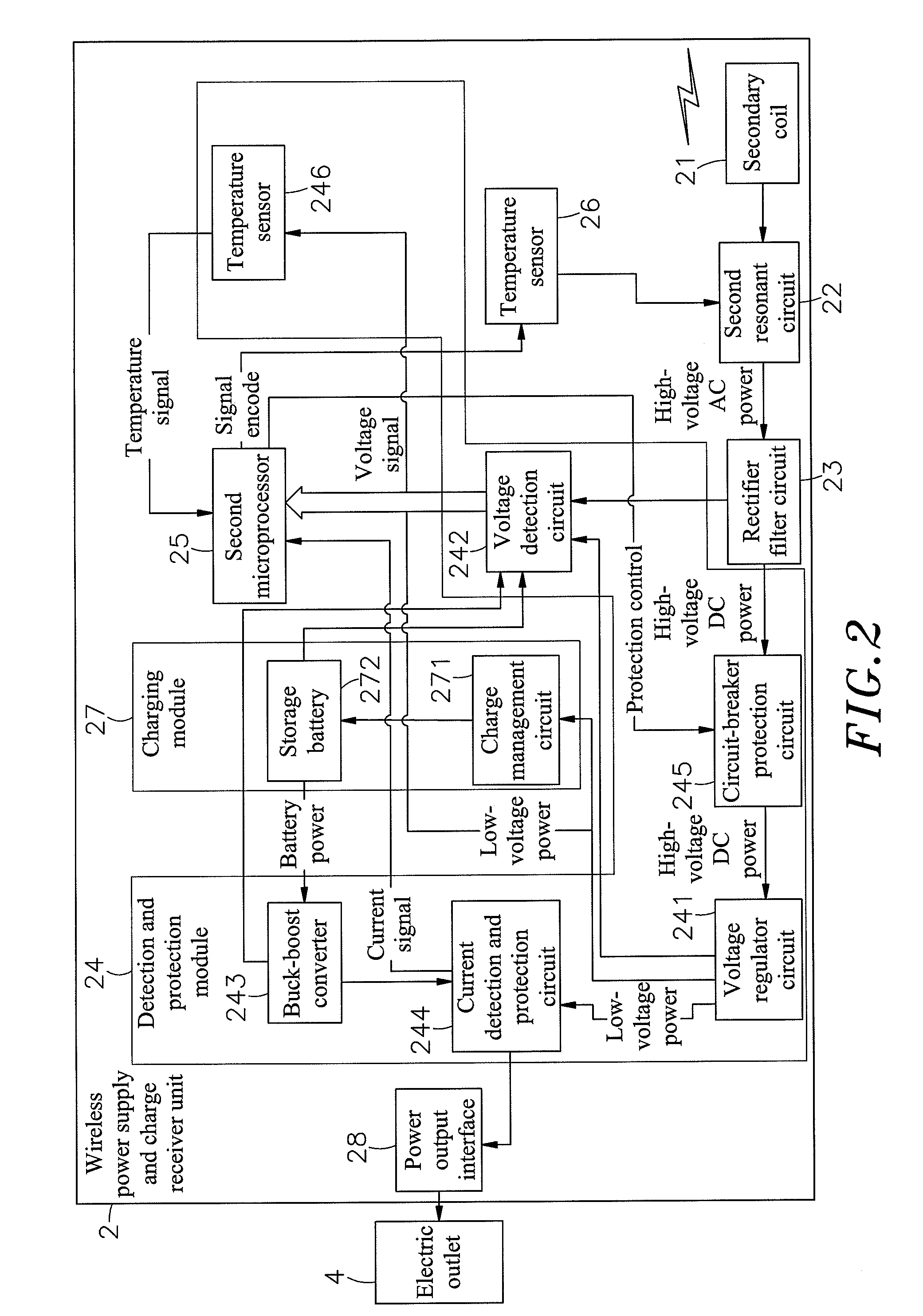

Frequency modulation type wirelss power supply and charger system

ActiveUS20110199046A1Double safety protectionLoad minimizationElectric signal transmission systemsNear-field transmissionEngineeringFrequency modulation

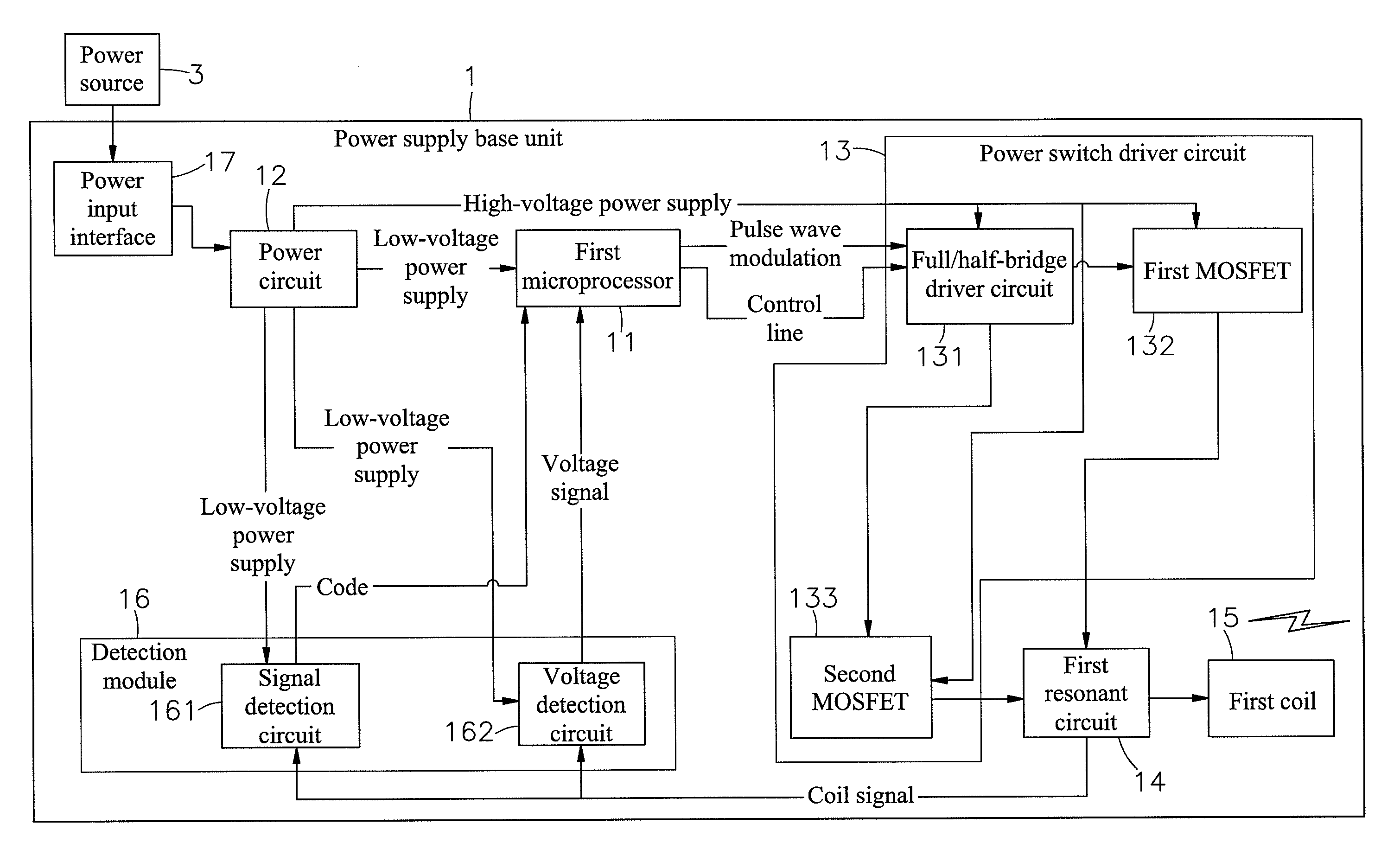

A frequency modulation type wireless power supply and charger system includes a power supply base unit consisting of a first microprocessor, a power circuit, a power switch driver circuit, a first resonant circuit, a first coil, a detection module and a power input interface, and a wireless power supply and charge receiver unit consisting of a secondary coil, a second resonant circuit, a rectifier filter circuit, a detection and protection module, a second microprocessor, a temperature sensor, a charging module and a power output interface and adapted for receiving electrical power from the power supply base unit wirelessly for charging an external electronic device. The detection and protection module of the wireless power supply and charge receiver unit detects the supply of the electrical power, and the second microprocessor sends a feedback signal to the power supply base unit through the signal generator circuit and the second resonant circuit subject to the detection of the detection and protection module for enabling the power supply base unit to control the power switch driver circuit to regulate its output power automatically, thereby minimizing power transmission loss and the load of the internal components of the wireless power supply and charge receiver unit.

Owner:FU TONG TECH

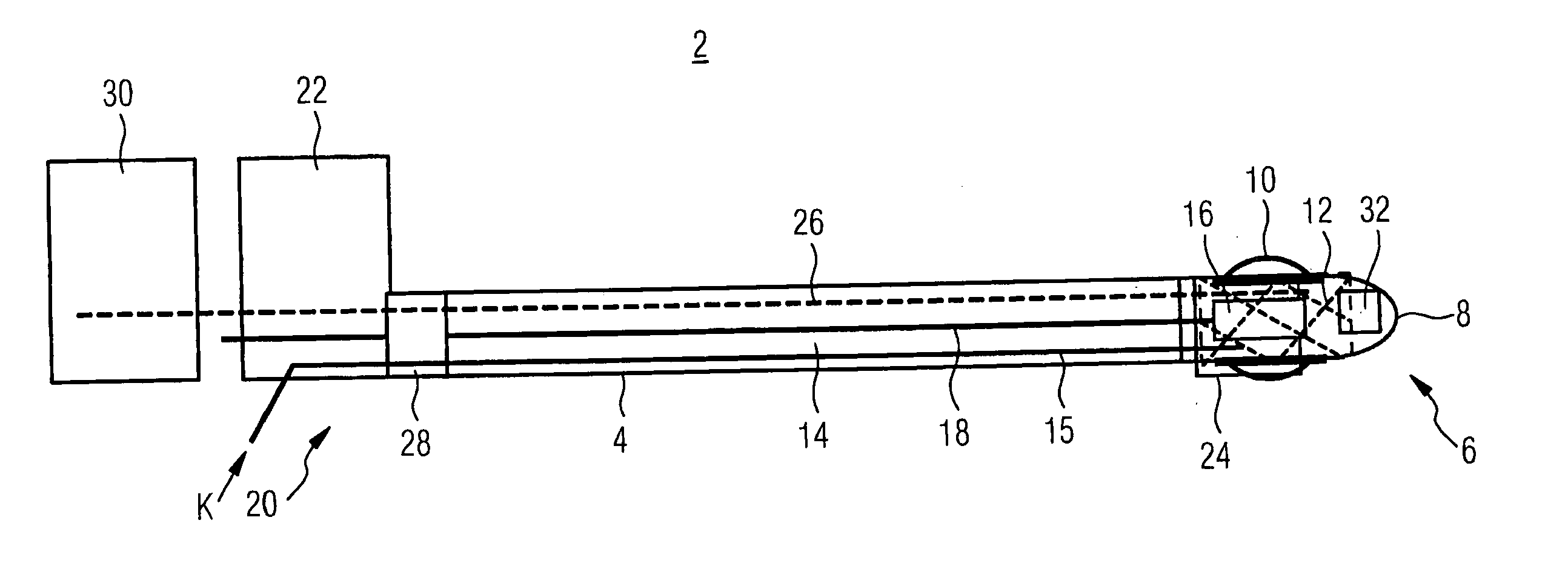

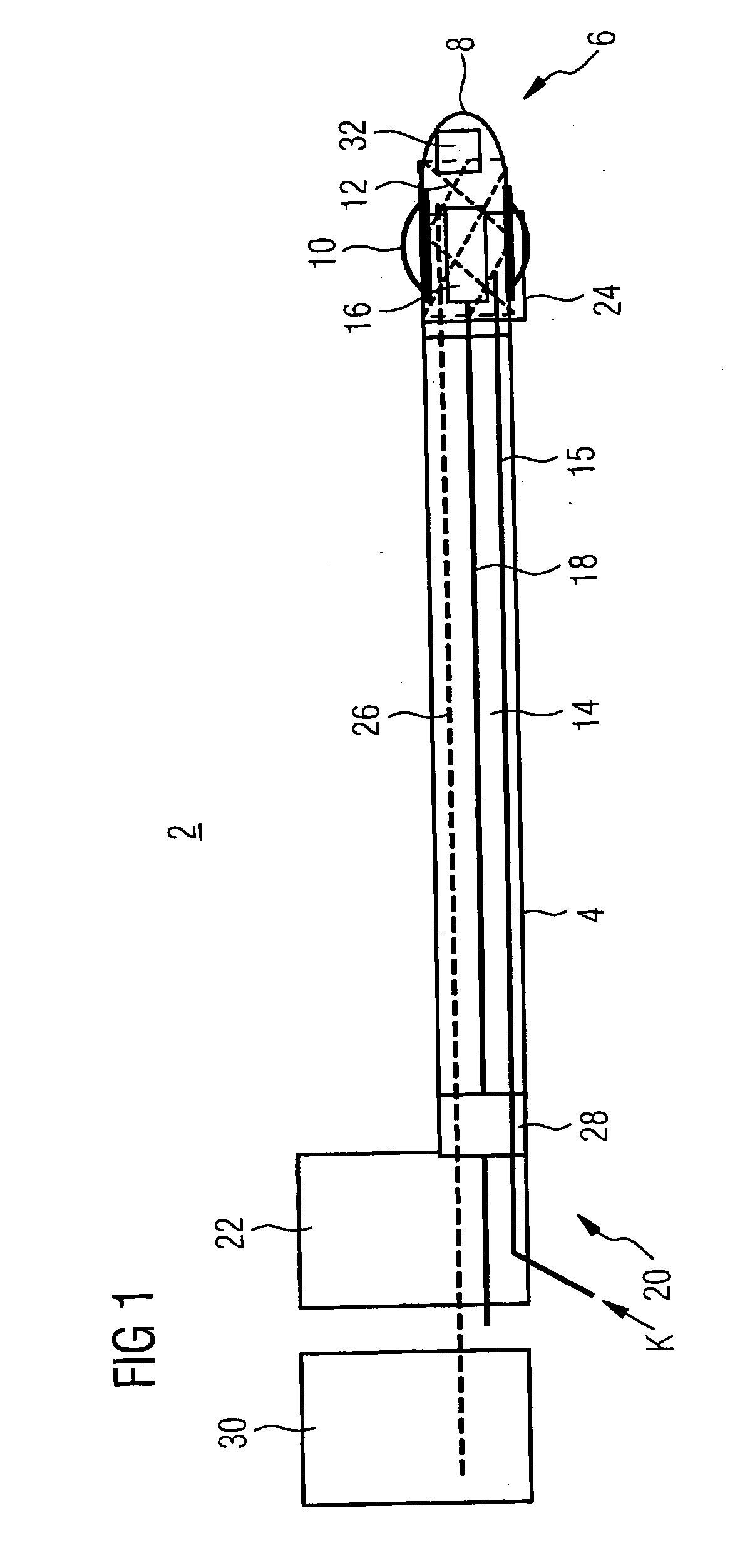

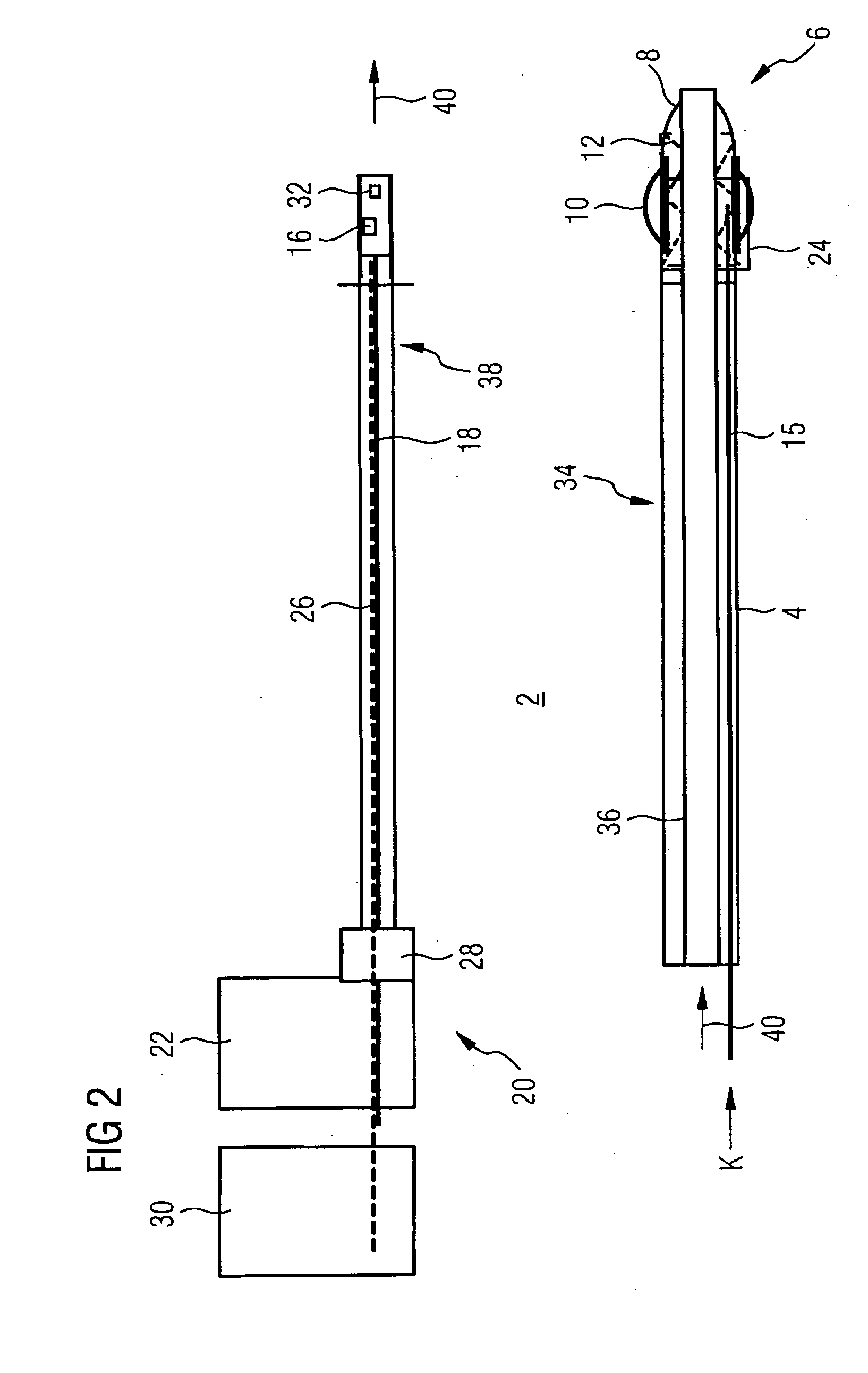

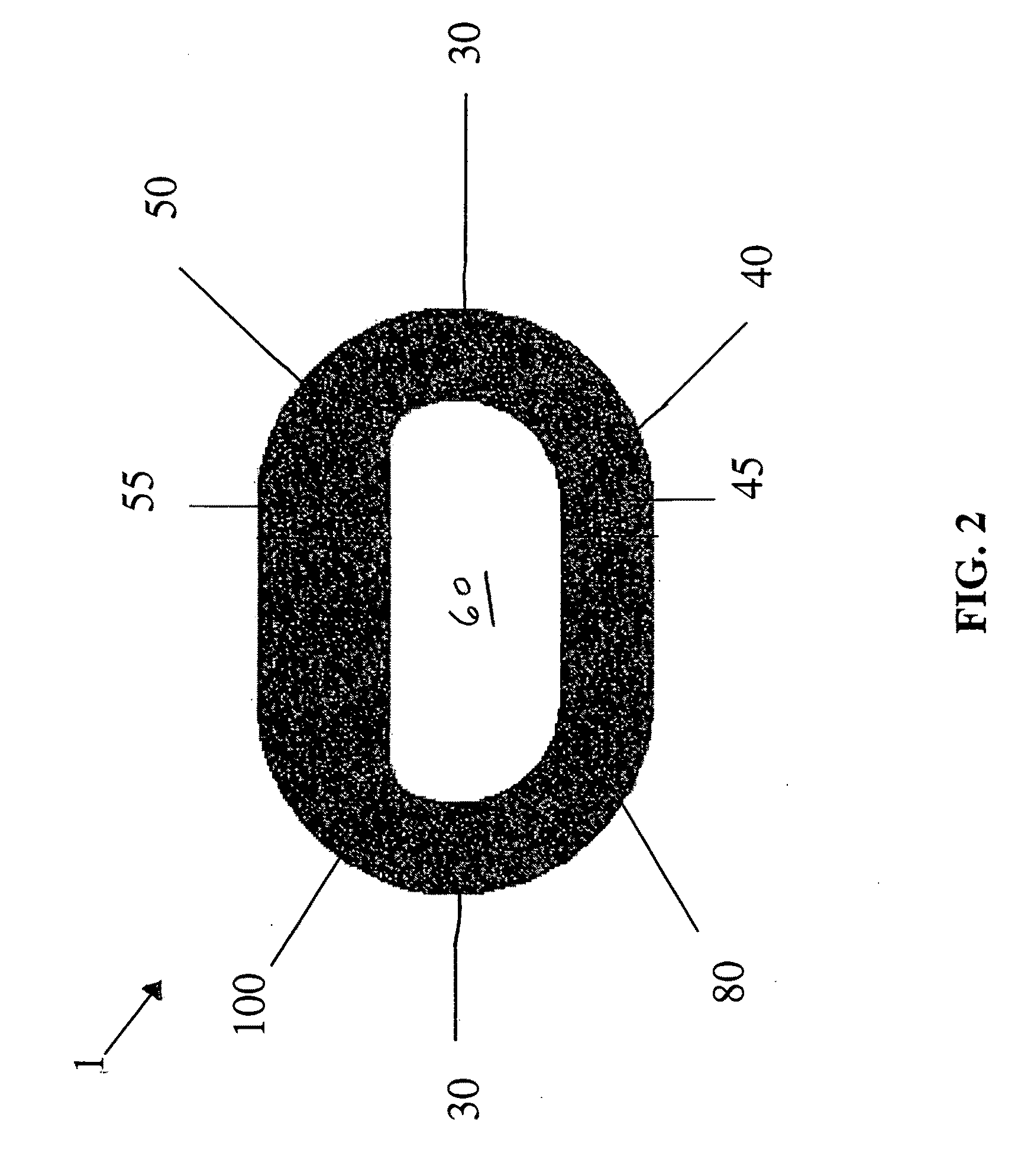

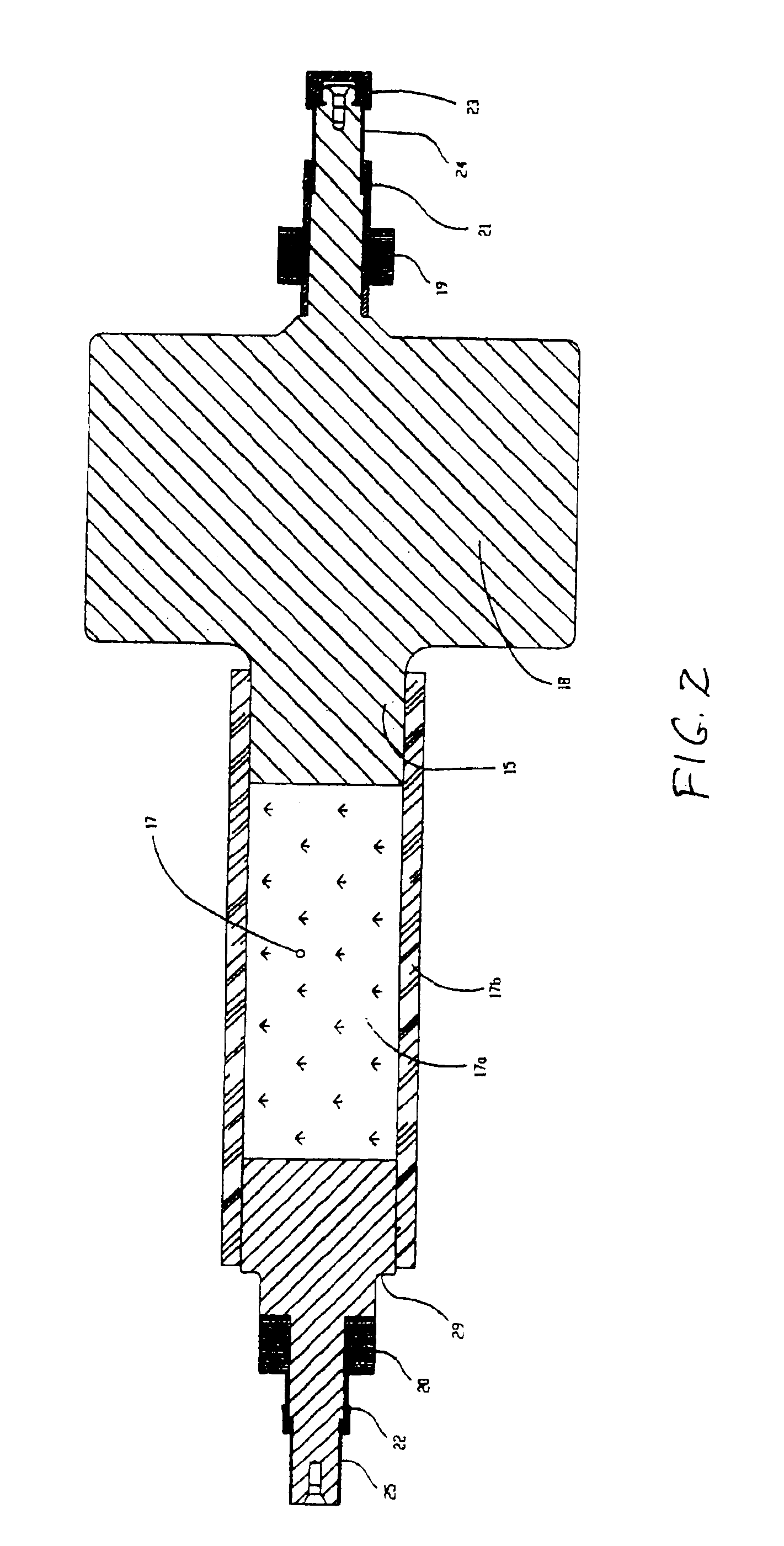

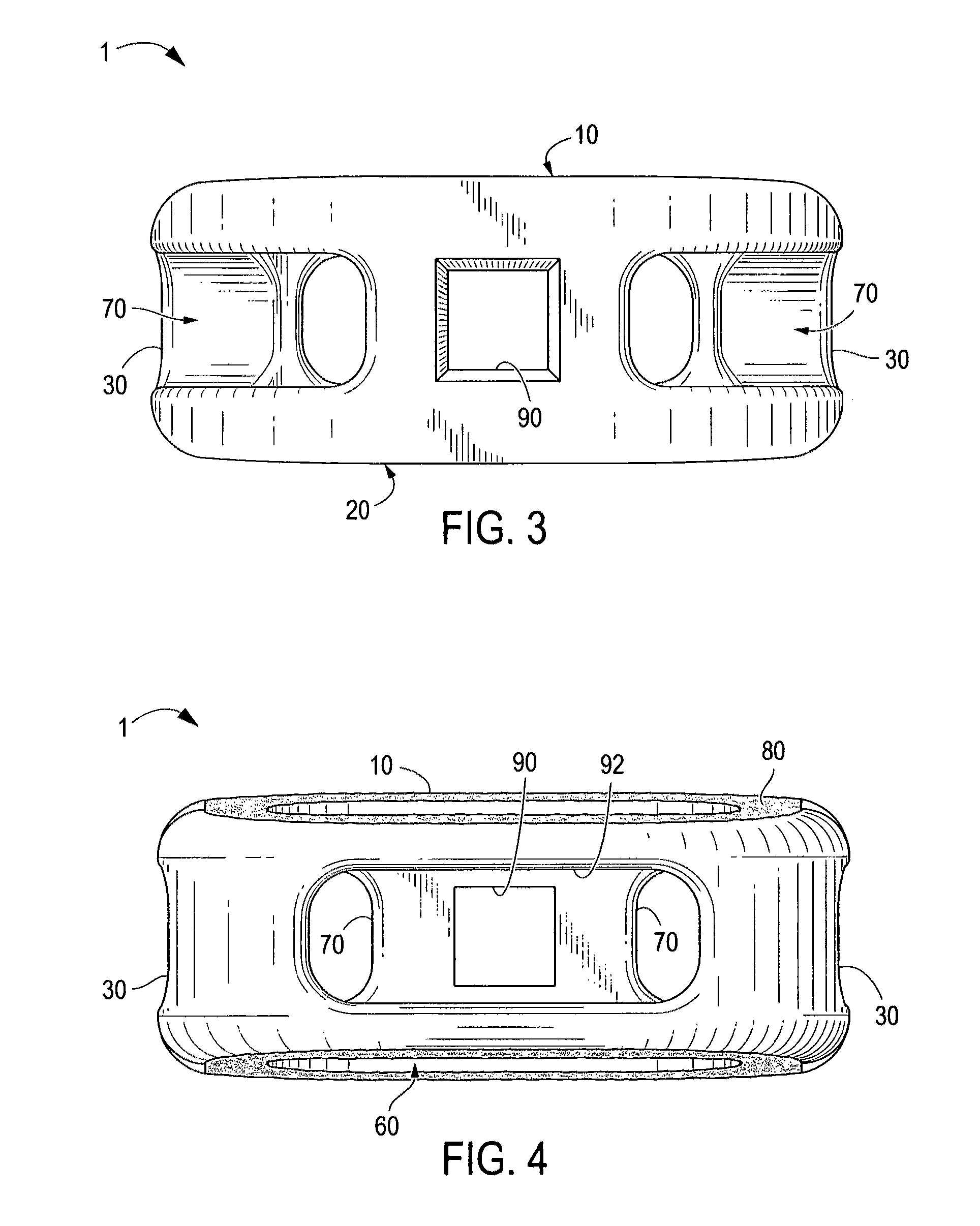

Cryocatheter for introduction into a body vessel together with medical investigation and treatment equipment

ActiveUS20070093710A1Load minimizationUltrasonic/sonic/infrasonic diagnosticsGuide needlesTherapeutic DevicesBlood vessel

A cryocatheter for introduction into a body vessel or into an organ, with a catheter inner surrounded by a catheter sheath, and with a catheter tip arranged at its distal end, with a feed line for an expansion or cooling agent arranged in the catheter sheath or the catheter inner, and with a balloon, arranged close to the catheter tip, which can be expanded and contracted again by means of the expansion and cooling agent, is to be constructed in such a way that by simple manipulation it can be positioned at a precise target position in the body vessel and, in addition, it minimizes the burden on the patient from invasive interventions. For this purpose, in accordance with the invention an image capture device, with at least one imaging sensor for mapping the region of the vessel around the balloon, is positioned in the region of the catheter tip.

Owner:SIEMENS HEALTHCARE GMBH

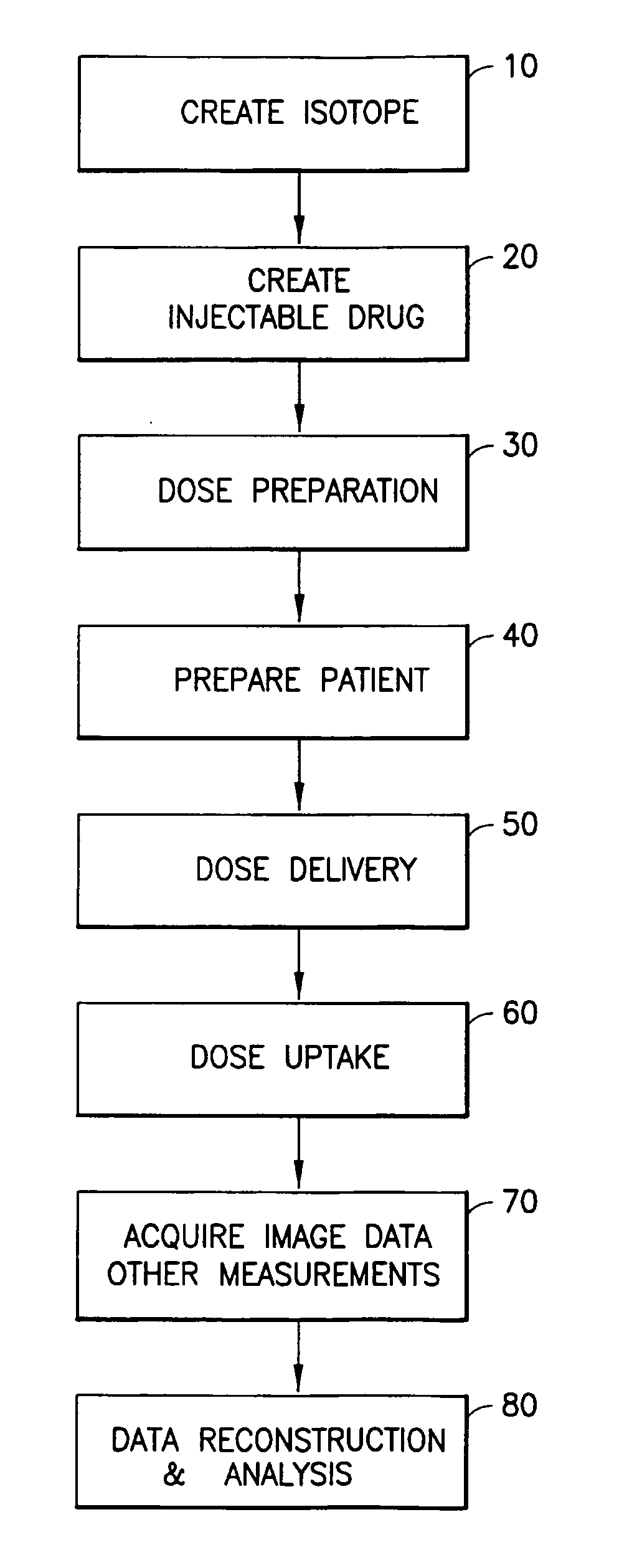

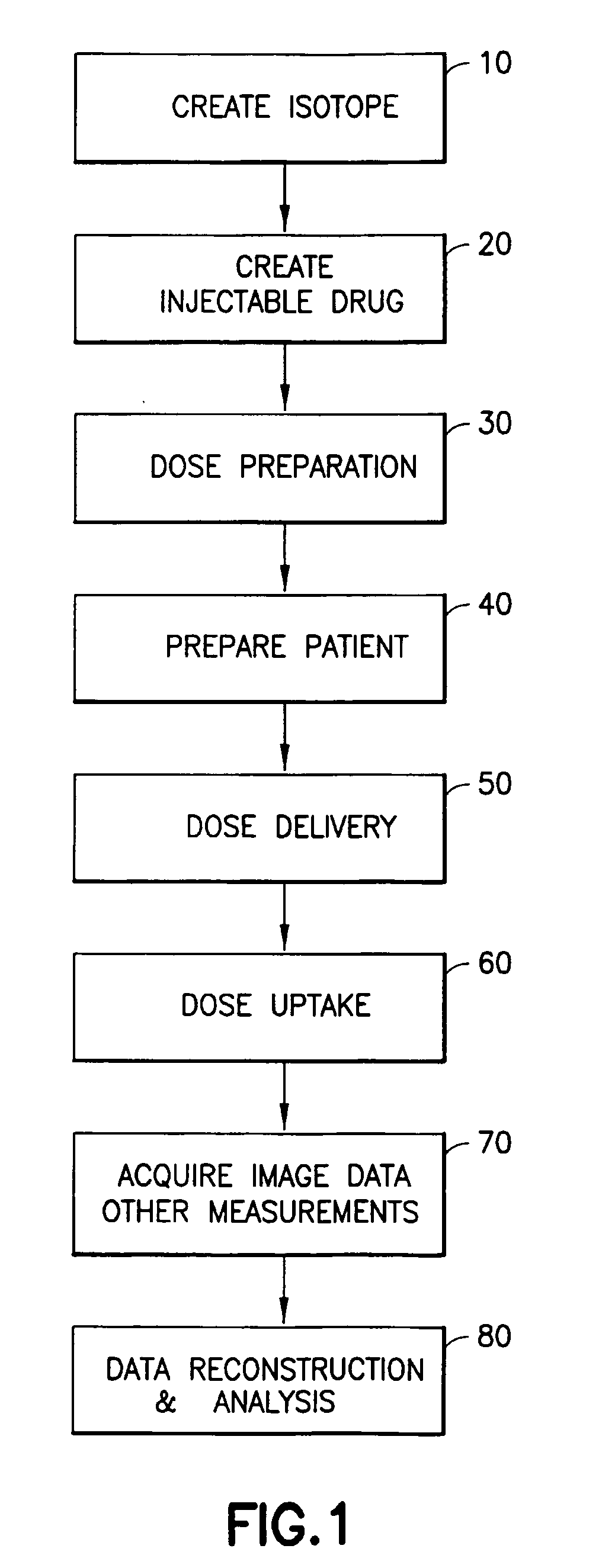

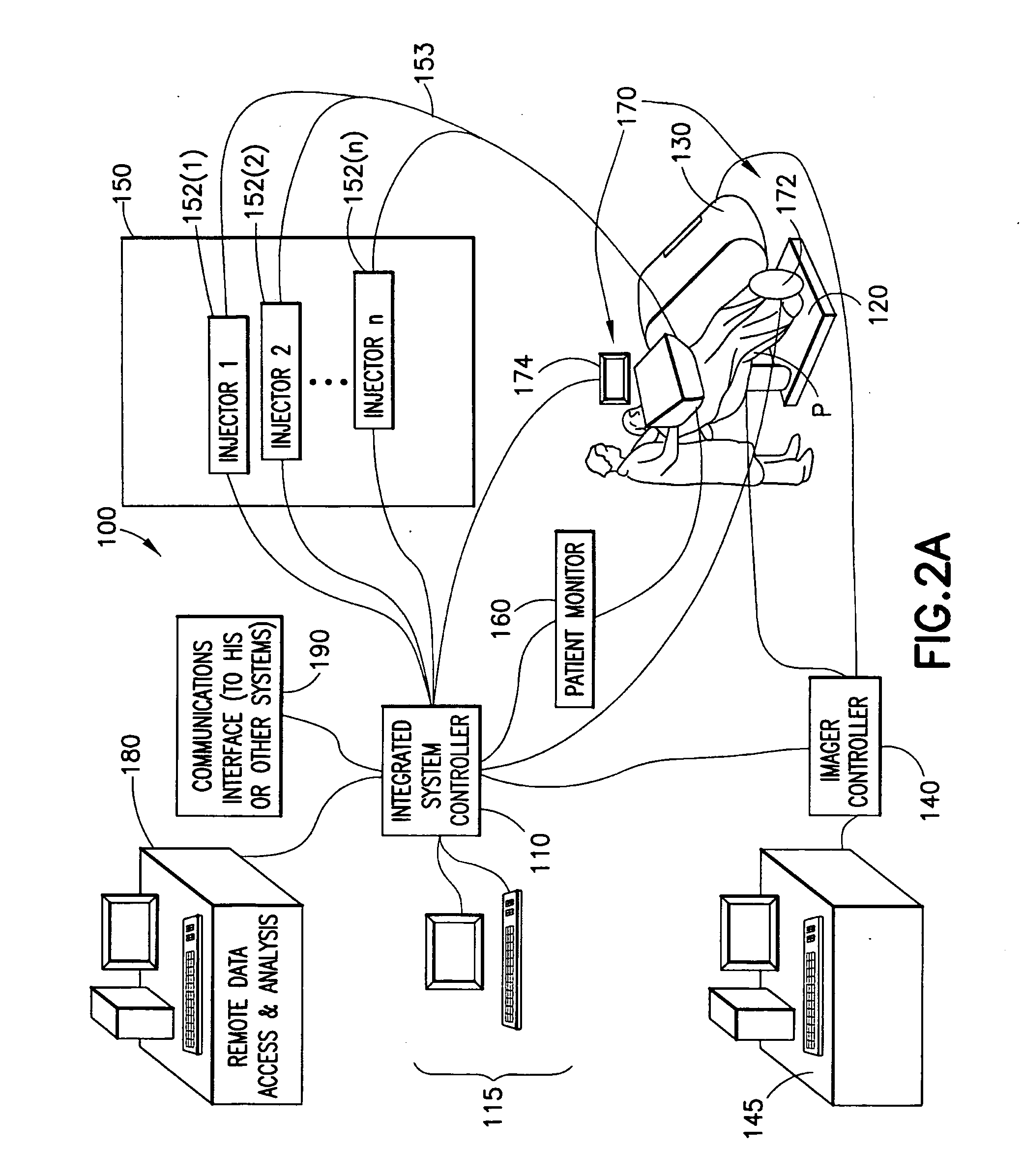

Systems For Integrated Radiopharmaceutical Generation, Preparation, Transportation and Administration

ActiveUS20110178359A1Reduce wasteEliminate needDrug and medicationsMedical devicesDocking stationFluid transport

An integrated radiopharmaceutical patient treatment system is disclosed including a patient support platform with an associated patient stimulus apparatus, an imager proximate the patient support platform, a radiopharmaceutical fluid delivery system for infusing a radiopharmaceutical fluid into a patient, a patient monitor to be associated with a patient, and an integrated system controller operably associated with the patient stimulus apparatus, imager, radiopharmaceutical fluid delivery system, and patient monitor to control and coordinate their operations. Within the patient treatment system the radiopharmaceutical fluid delivery system may be included comprising a radionuclide supply module, a radiopharmaceutical processing module, a quality control module, a patient injection module, and a controller. A hazardous fluid handling system including a docking station and a hazardous fluid transport device adapted to detachably dock with the docking station is further disclosed.

Owner:BAYER HEALTHCARE LLC

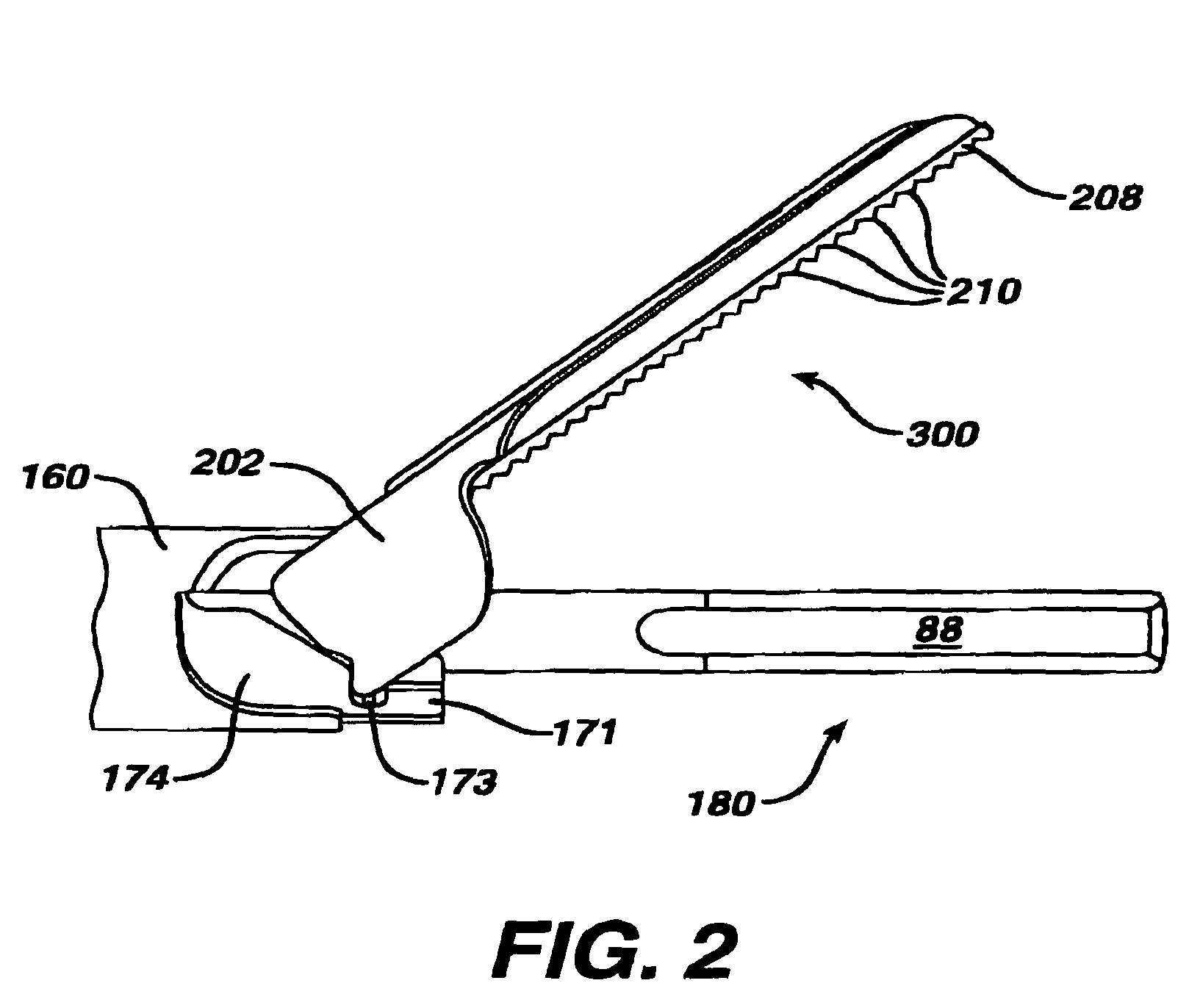

Ultrasonic surgical instrument incorporating fluid management

ActiveUS8348880B2Load minimizationEfficient removalDiaphragm valvesEngine diaphragmsSurgical operationSurgical blade

Disclosed is an ultrasonic surgical device having a distally / proximally movable fluid management system consisting of single lumen or multiple lumens. The invention provides for the delivery of irrigation fluid or the removal of fluid, debris or vapor from the tissue-effecting portion of the blade while minimizing the loading on the blade. The blades of the surgical device, when excited at a natural blade system frequency, will have modal shapes characterized by longitudinal, transverse and / or torsional motion and will have nodal locations for these motions at positions along the tissue effecting length of the blade. The instrument is designed to allow for the fluid management system to be positioned at one or more motion nodes to facilitate efficient removal of tissue or fluid, which tends to accumulate at such nodes of the ultrasonic surgical blades.

Owner:ETHICON ENDO SURGERY INC

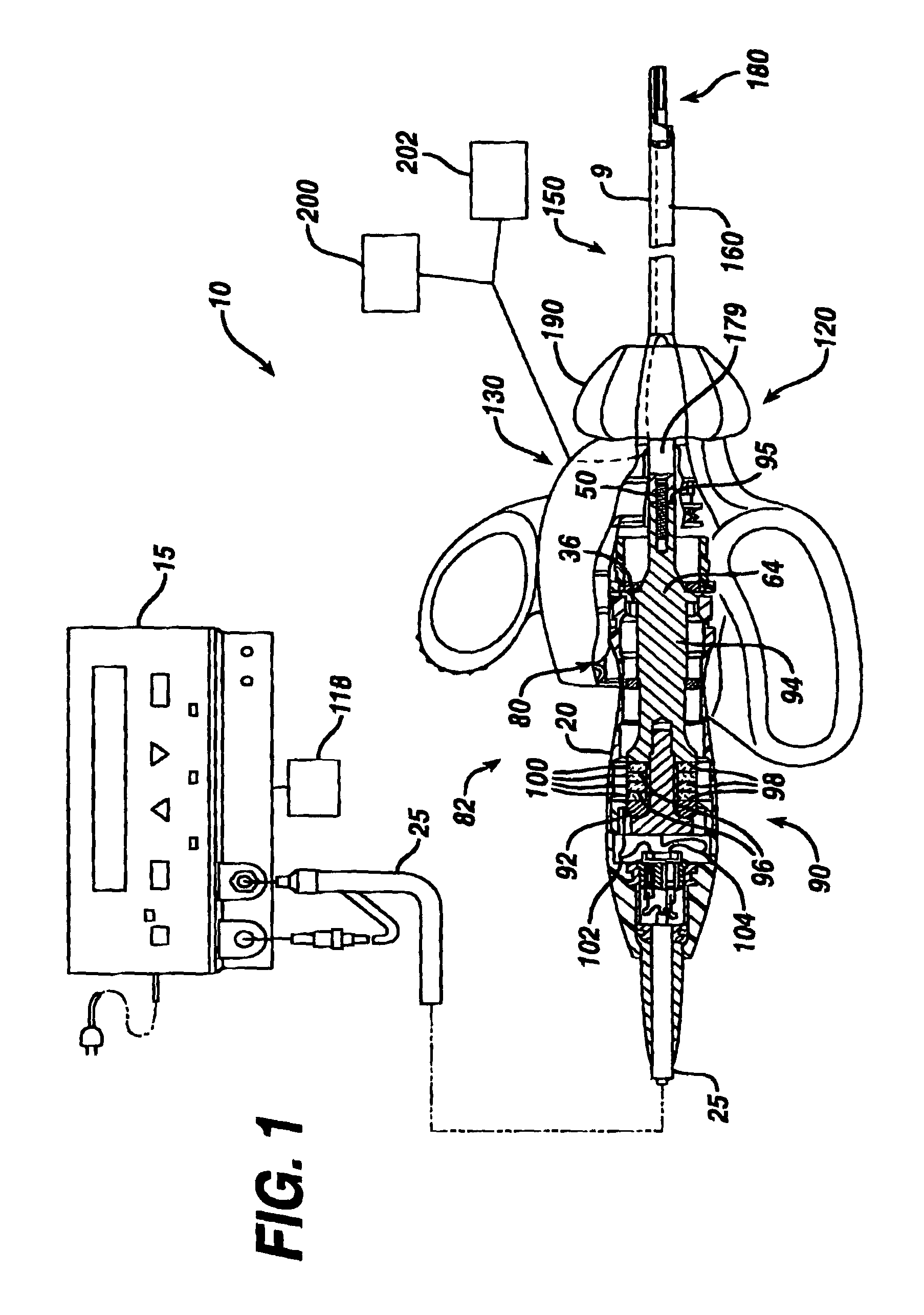

Vehicle communication, analysis and operation system

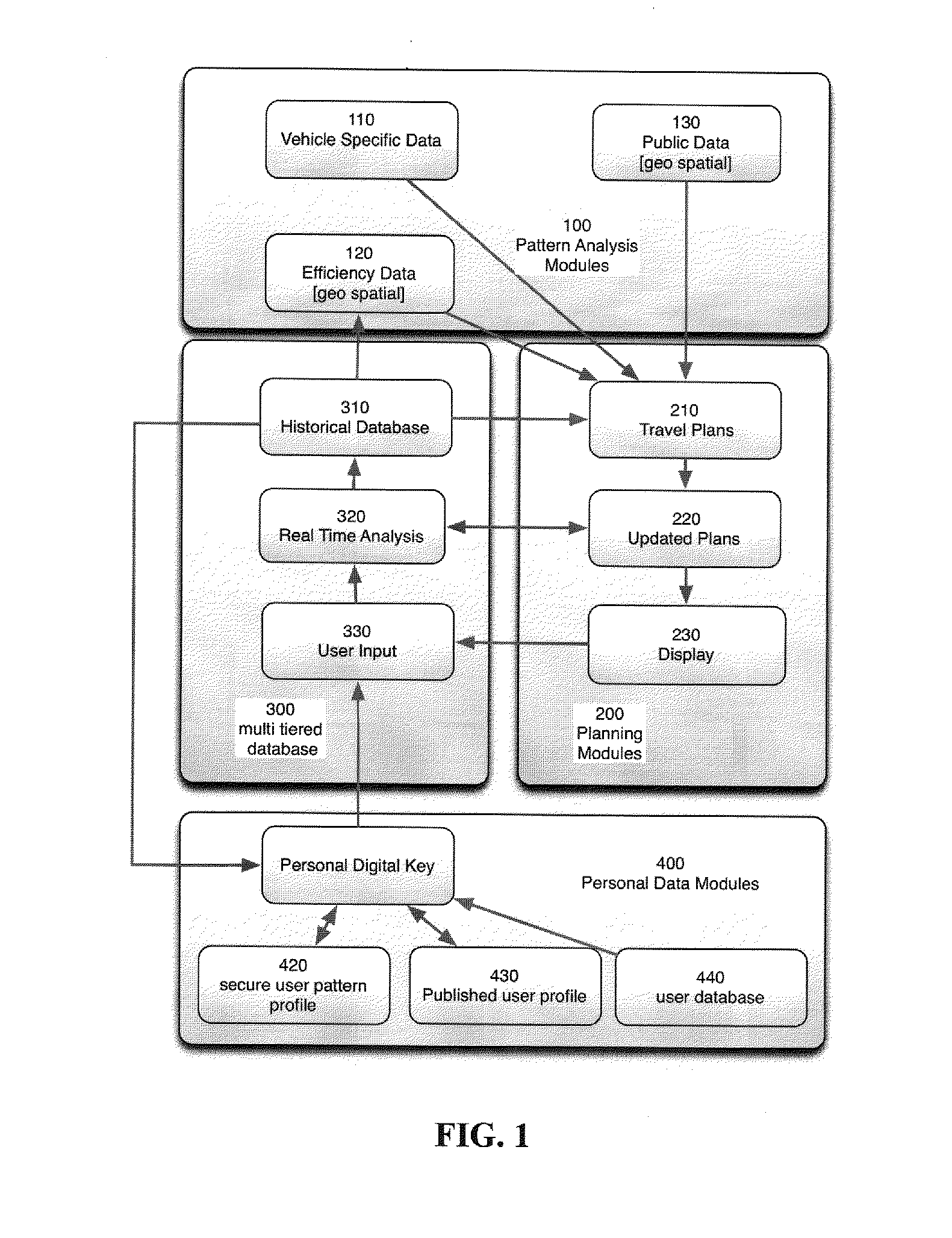

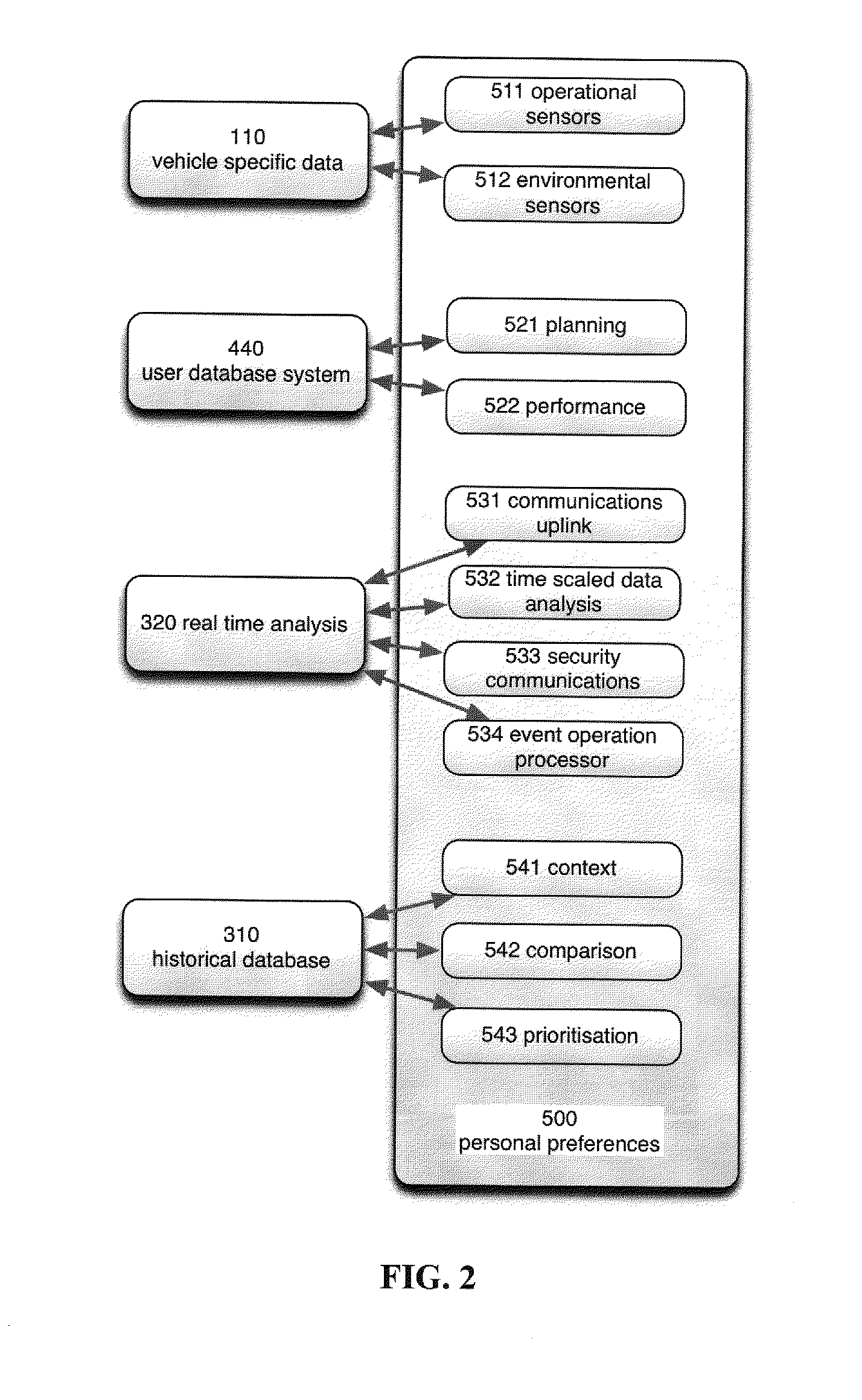

InactiveUS20130079964A1Minimizes computation loadLoad minimizationDigital data processing detailsNavigation instrumentsFuel conservationOperational system

The present invention provides a communication and analysis system that can manage data operations with a vehicle centric system with a planned route path. A vehicle that is in a communications link with a network can also manage its activities based on real time, historical and predictive knowledge, without having this all knowledge processing on board. Such data processing would include a cluster analysis of geo-spatial, internal functions and operator specific requirements. The rule based system would also incorporate the use patterns of a specific vehicle, or a specific user. A vehicle operator or vehicle multiple operators could share or upload information that would assist with efficient data processing and display, including fuel conservation and time management. Cluster weighting patterns can be assigned based on activities as efficient operation, safe travel and navigation.

Owner:SATURNA GREEN SYST

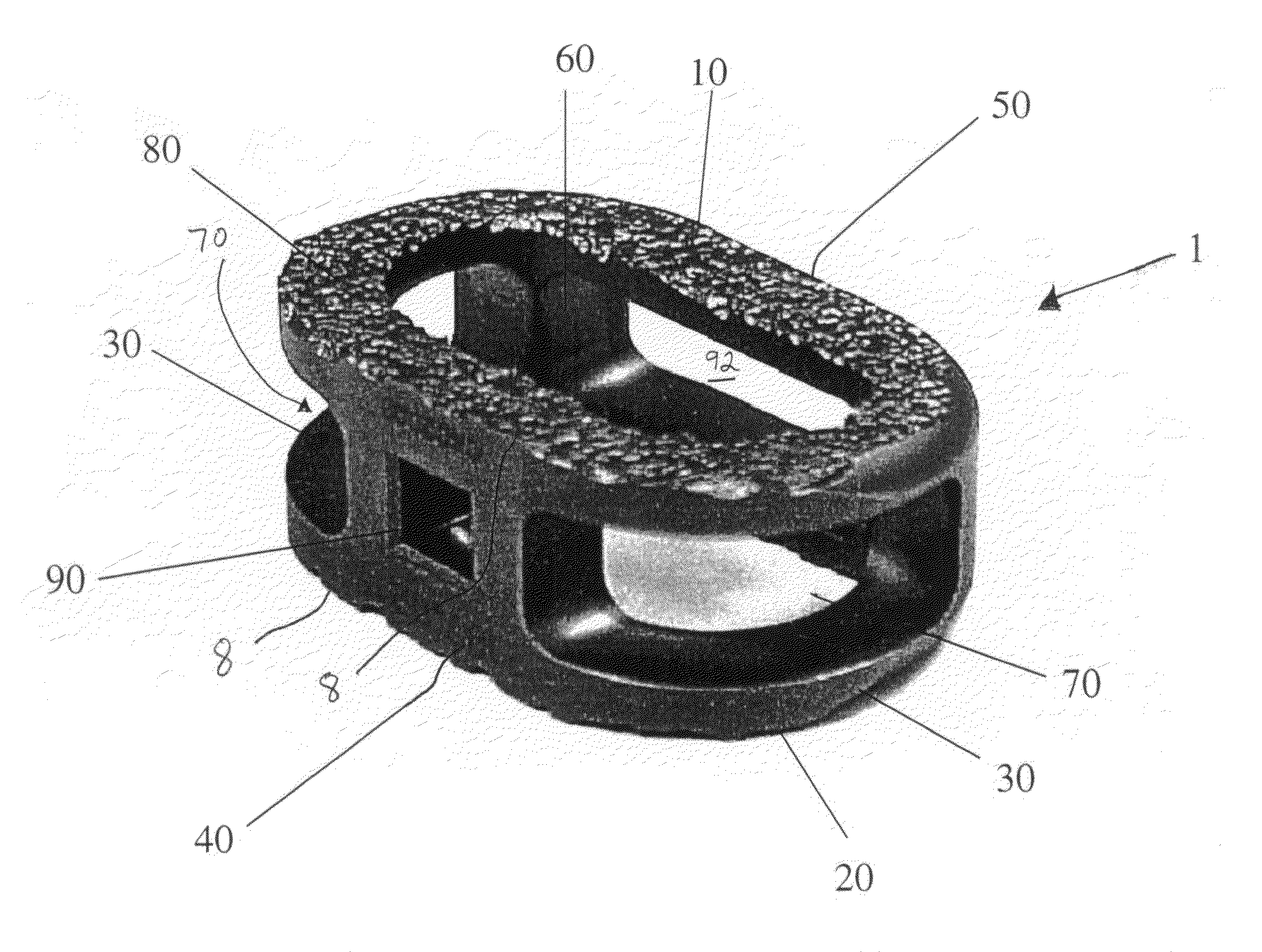

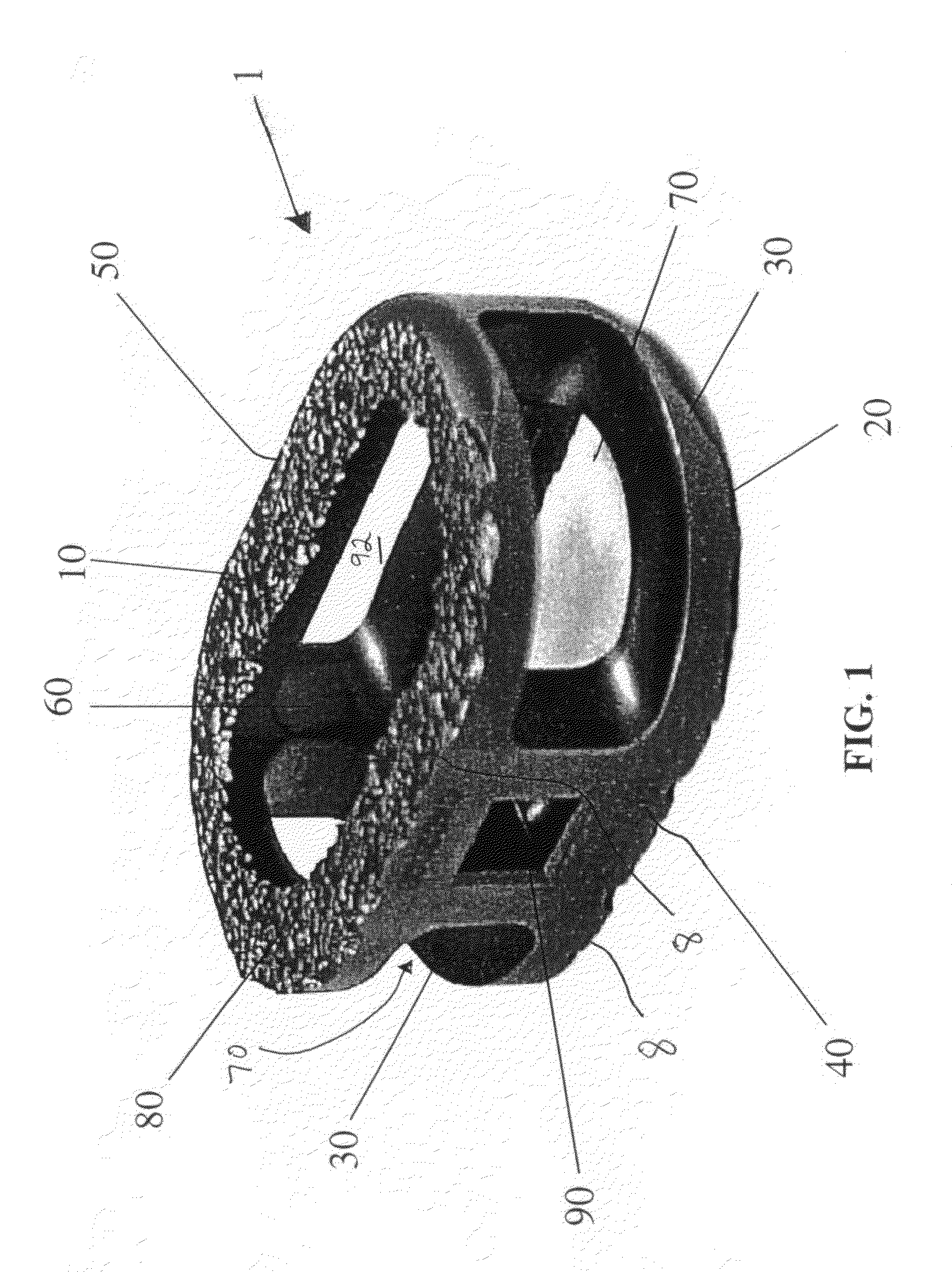

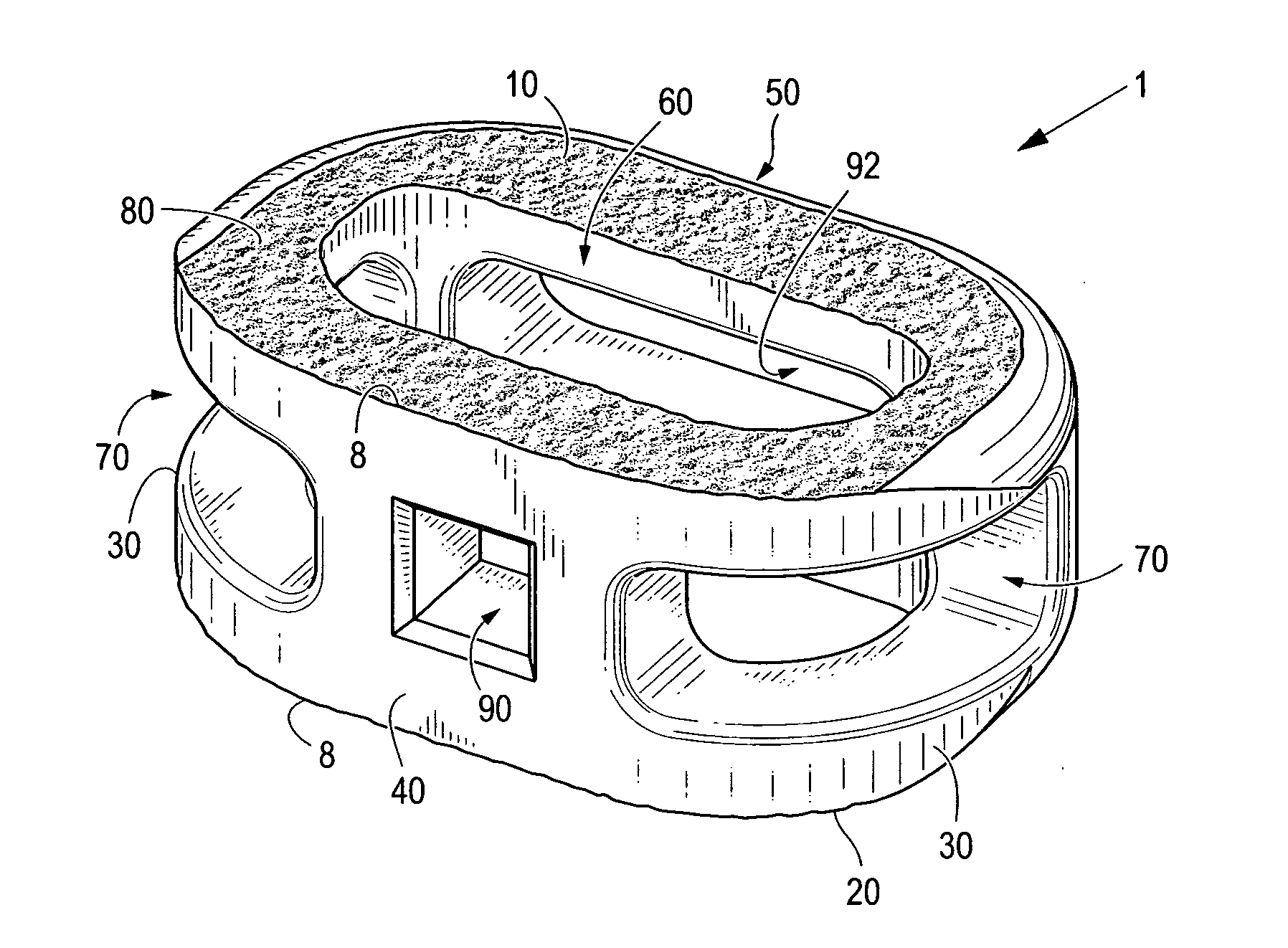

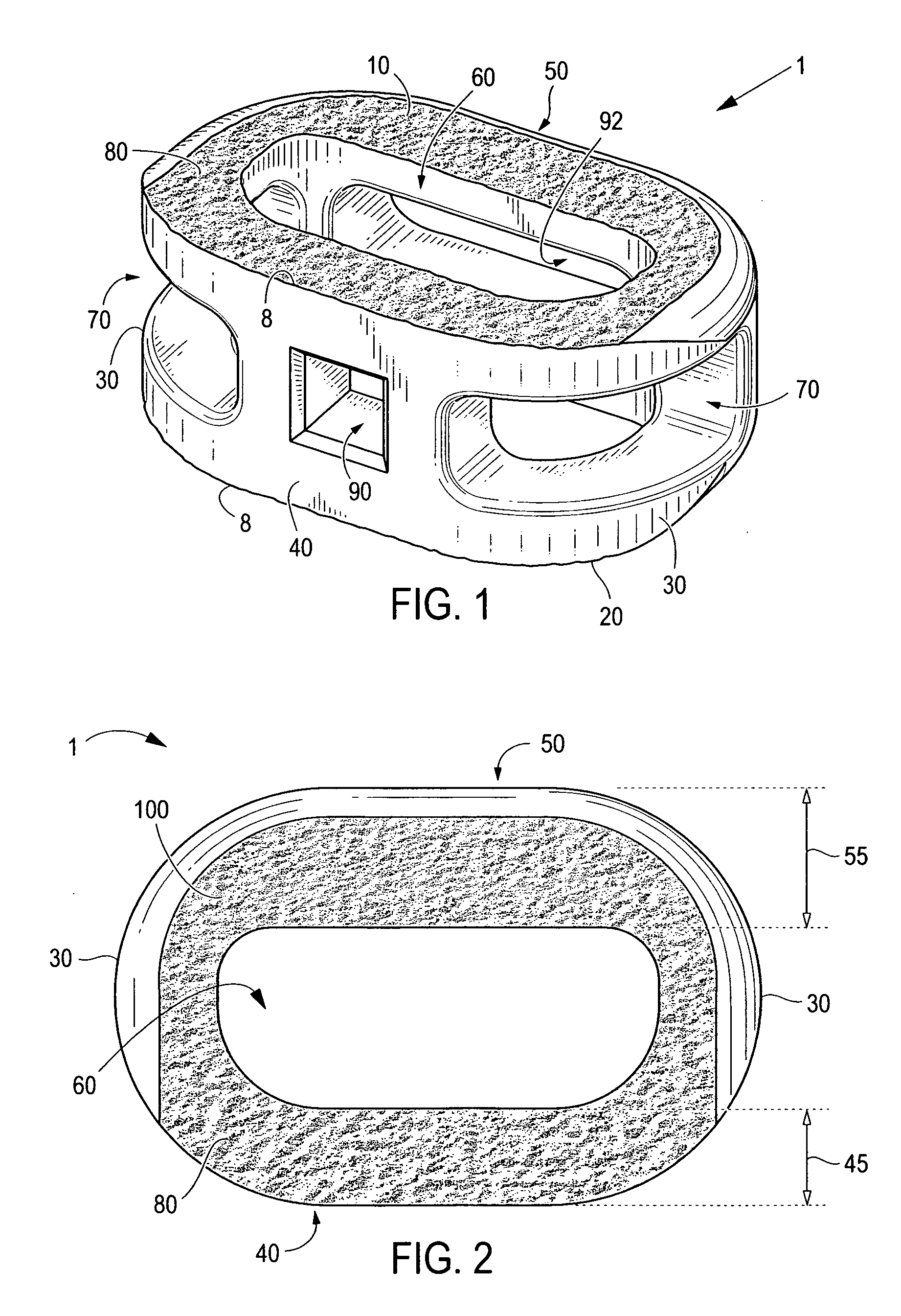

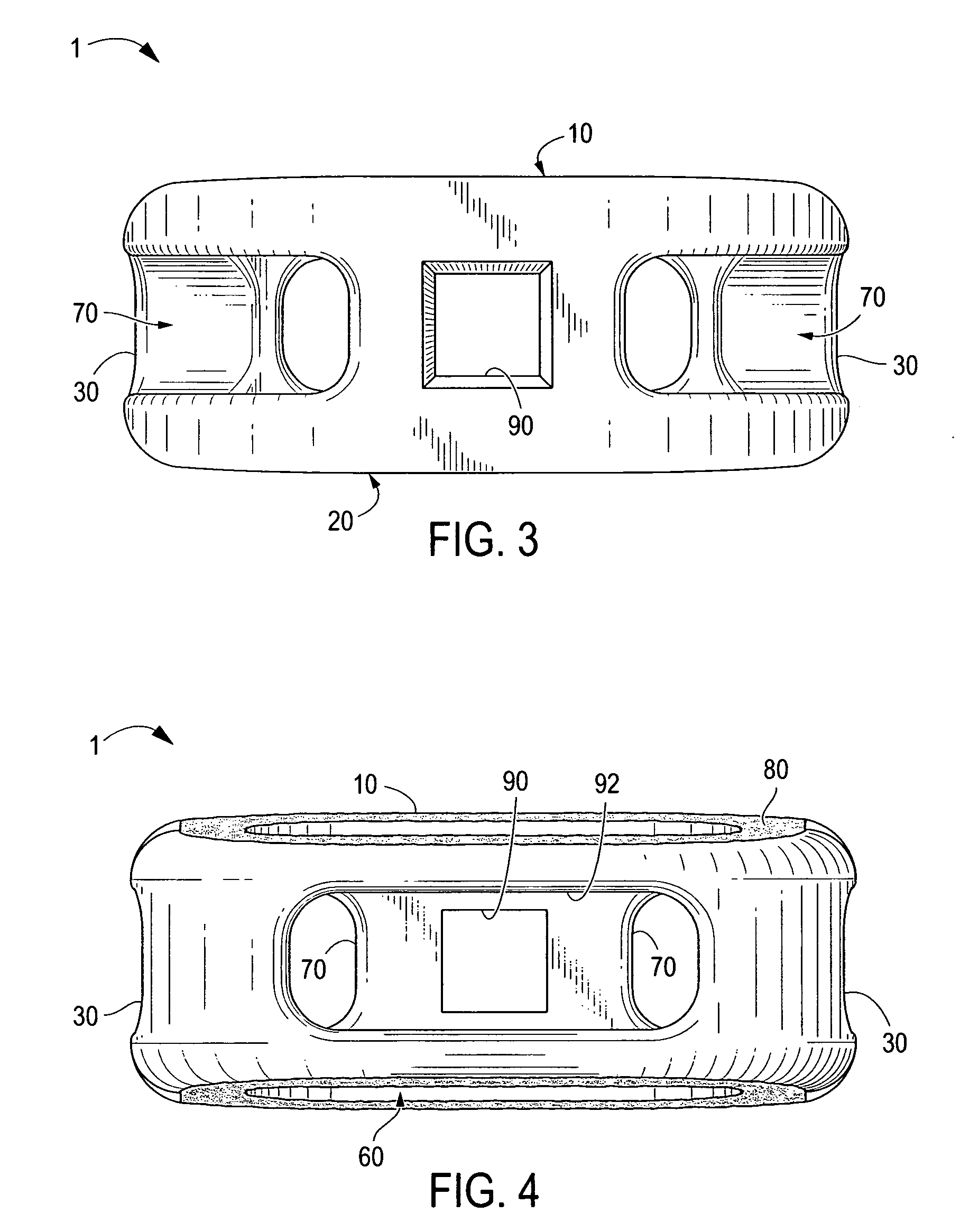

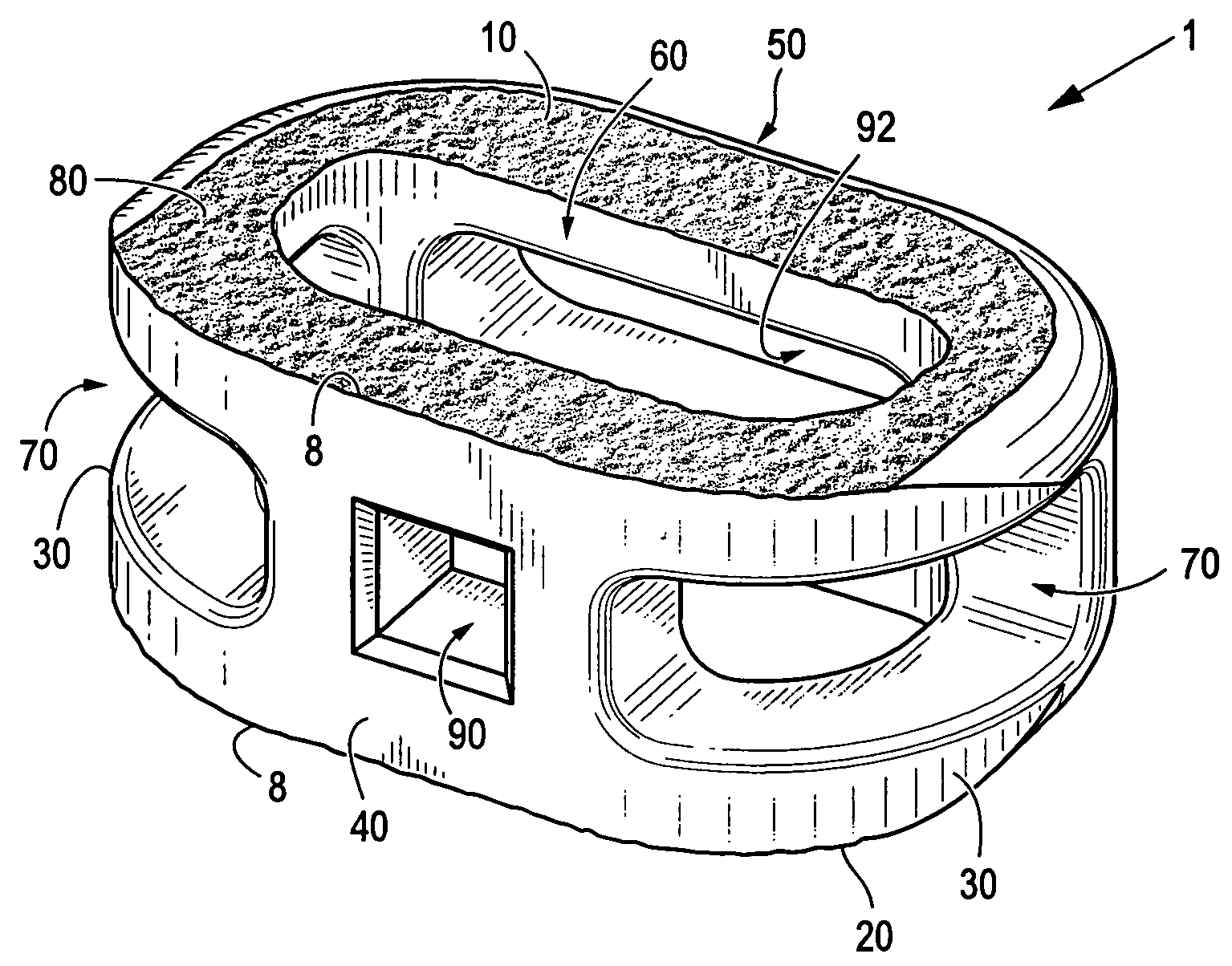

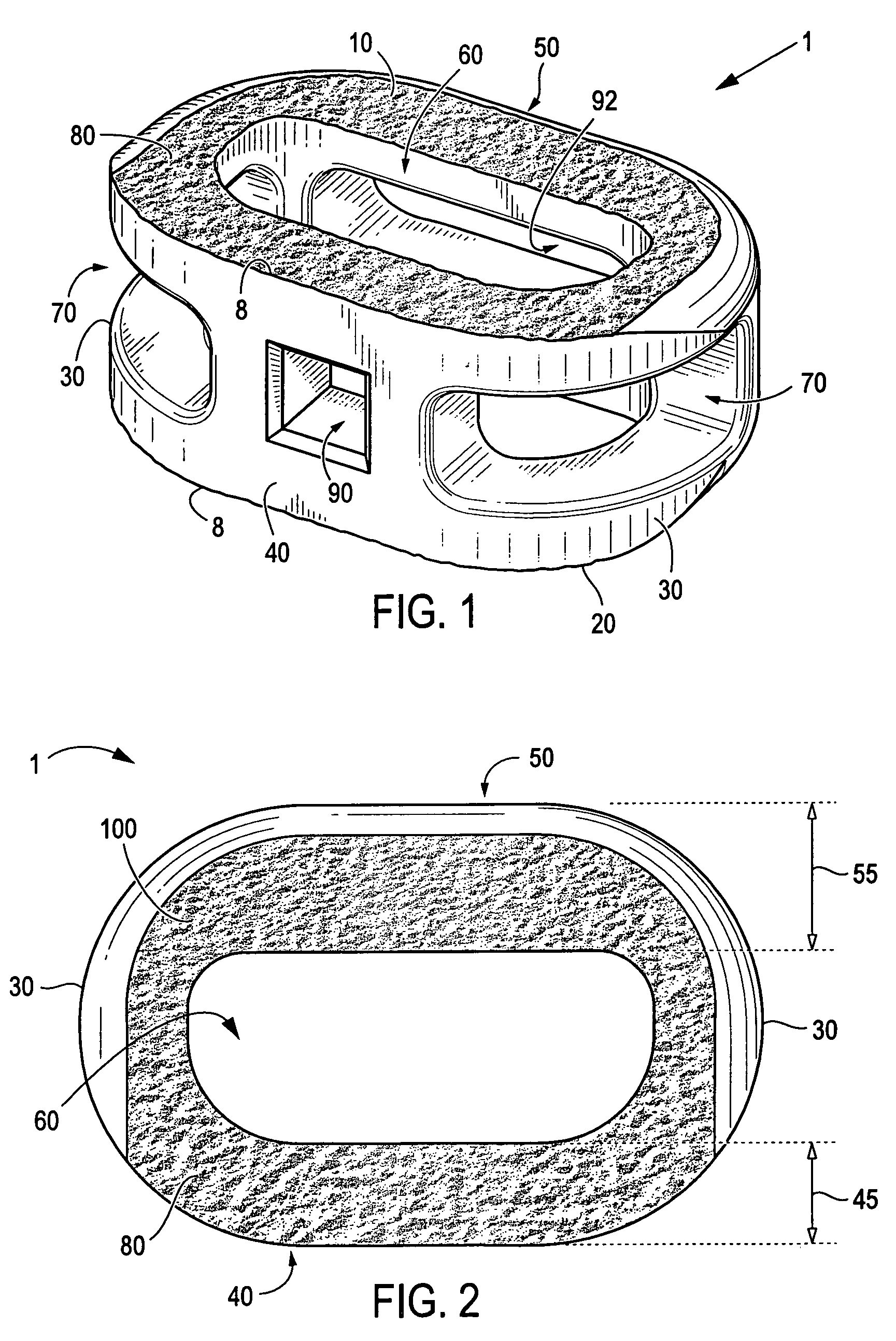

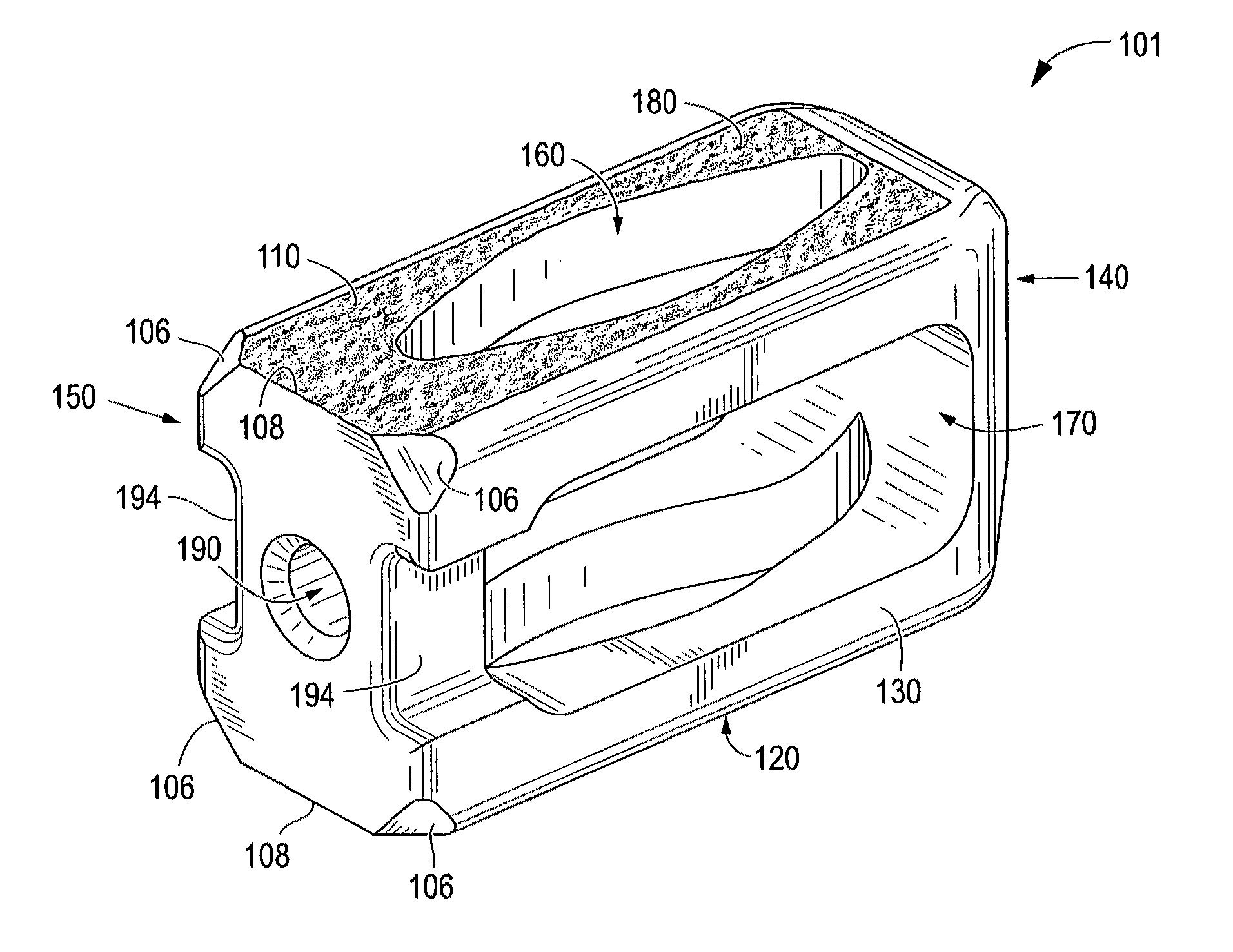

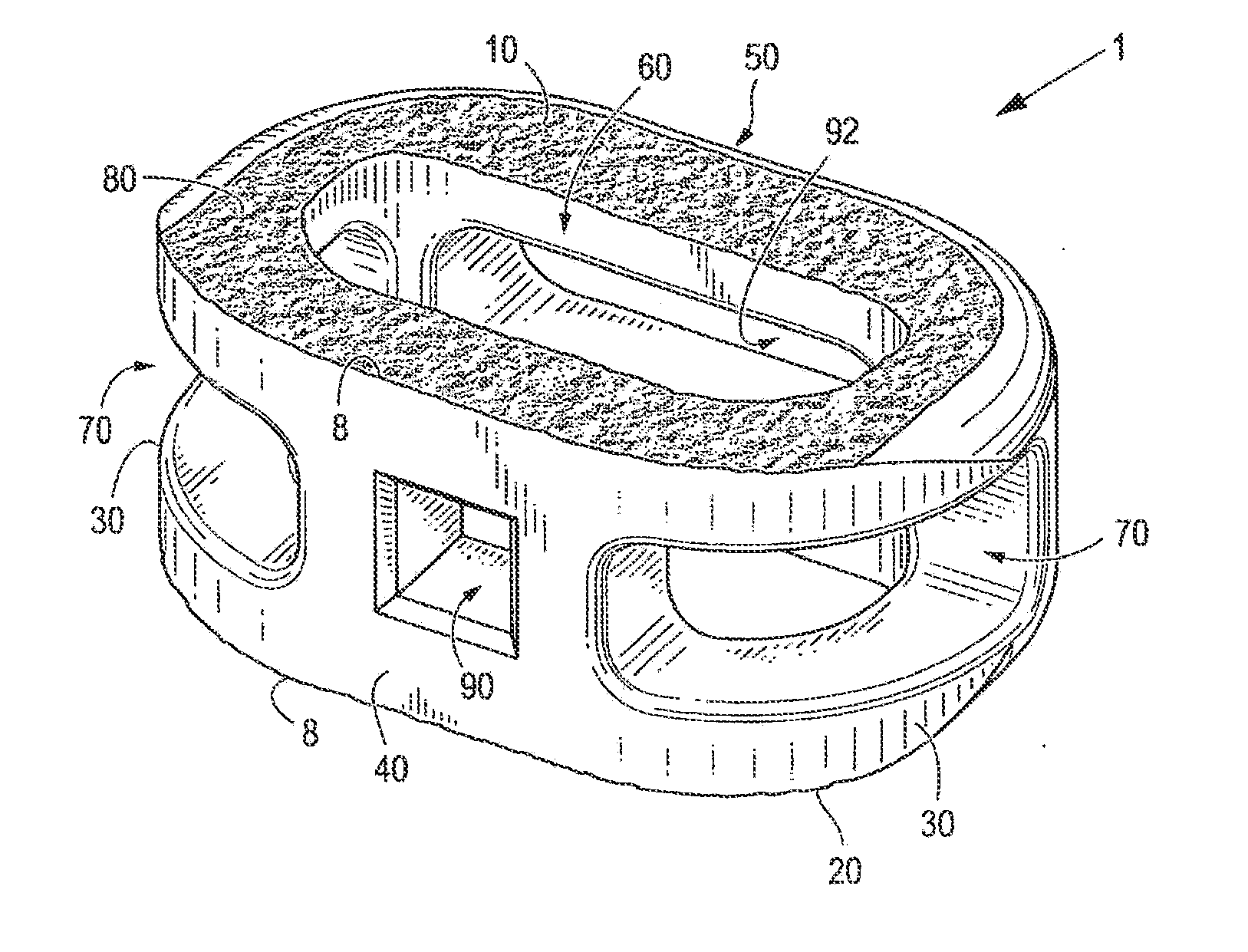

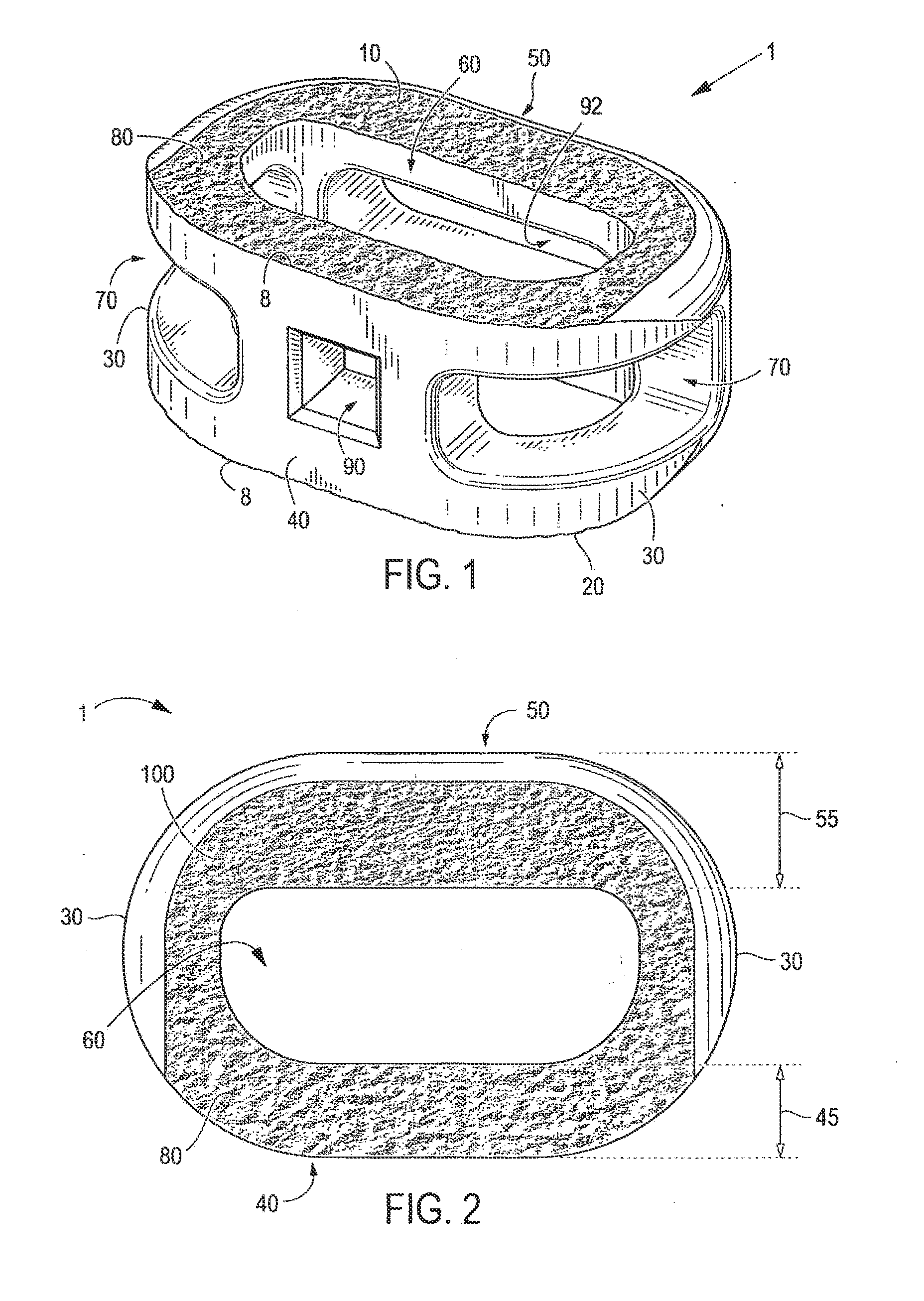

Composite telescoping anterior interbody spinal implant

InactiveUS20100076559A1Add seatsImprove visualizationBone implantSpinal implantsMetal alloySpinal implant

A composite telescoping interbody spinal implant and method of using the implant. The implant includes a cage formed of metal, a metal alloy, or both. The cage is able to change size following manufacture, and has a top plate with a plurality of posts and a bottom plate with a corresponding plurality of columns. The posts telescopically engage the columns upon assembly of the top plate with the bottom plate. The posts extend partially outside the columns when the top plate is in a raised first position with respect to the bottom plate; the posts and columns are fully engaged when the top plate is in a second position closest to the bottom plate. The implant also includes a non-metallic body inserted between the top plate and the bottom plate and defining the adjustable height of the implant.

Owner:TITAN SPINE

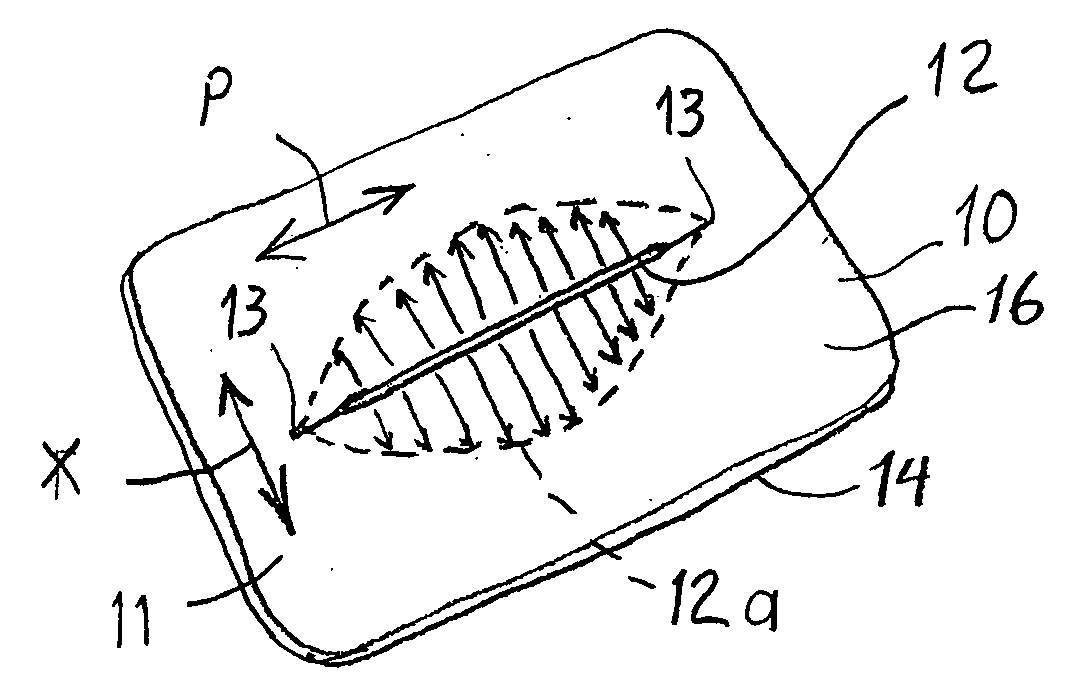

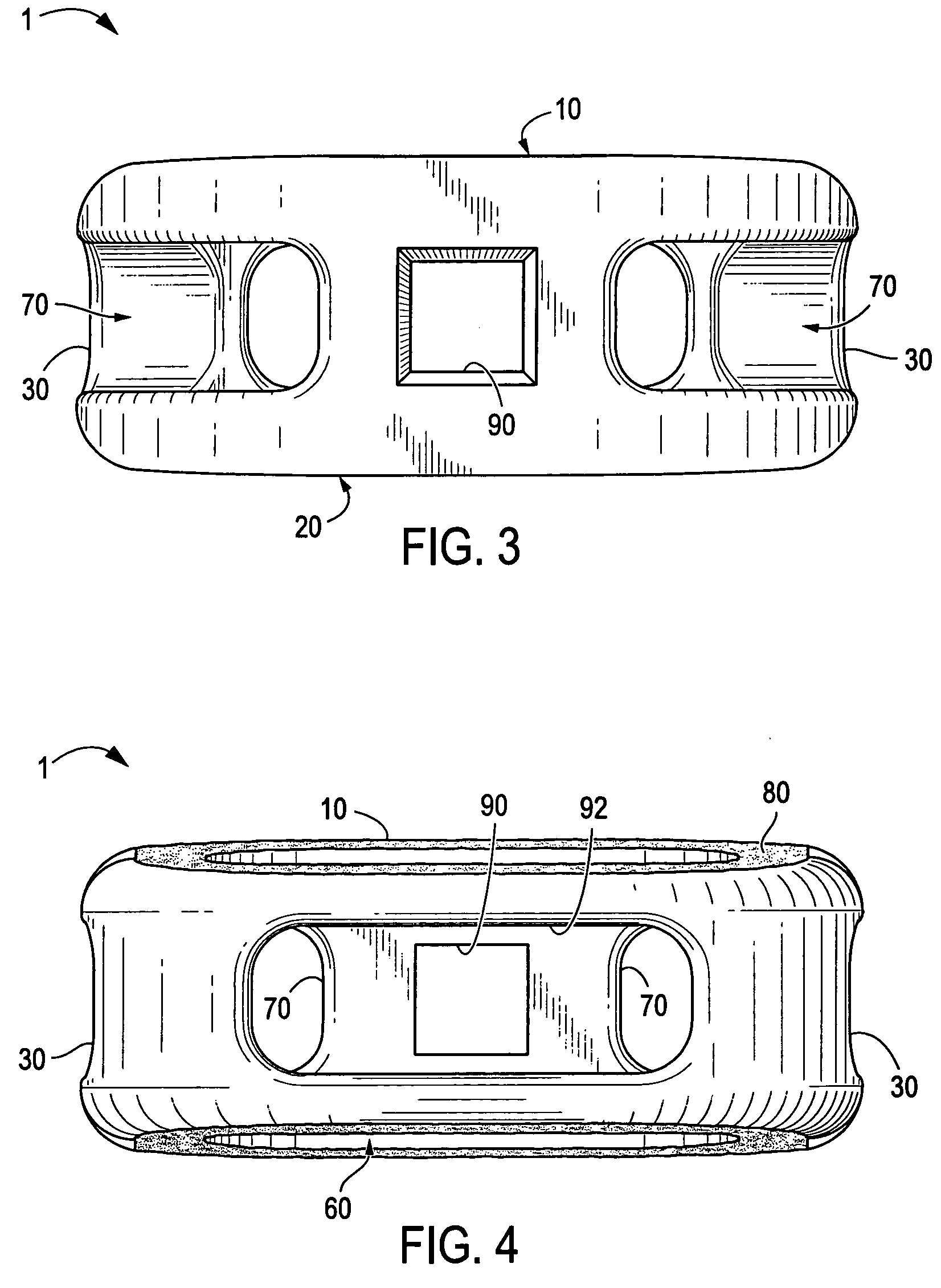

Devices and methods for protecting tissue at a surgical site

ActiveUS20050283050A1Minimize local loadingDissipate forceCannulasDiagnosticsWear resistantSurgical site

A tissue protector is adapted to be positioned on the skin surrounding an incision. The tissue protector provides a load bearing surface for surgical tools and instruments to prevent blunt force and pressure trauma to the skin and soft tissues within the incision. In one embodiment, the tissue protector is a sheet of wear-resistant material having an opening corresponding to the incision and expandable as the incision is retracted. In another embodiment, a tissue protector device includes a continuous expandable arrangement of interconnected L-shaped links. In still another embodiment, a one-piece tissue protector includes a flexible panel supported on the skin and a flexible sleeve extending into the incision. Yet another embodiment of the invention resides in a track that is supported about the incision. An instrument support platform is slidably mounted to the track to support a surgical tool relative to the incision.

Owner:DEPUY SYNTHES PROD INC

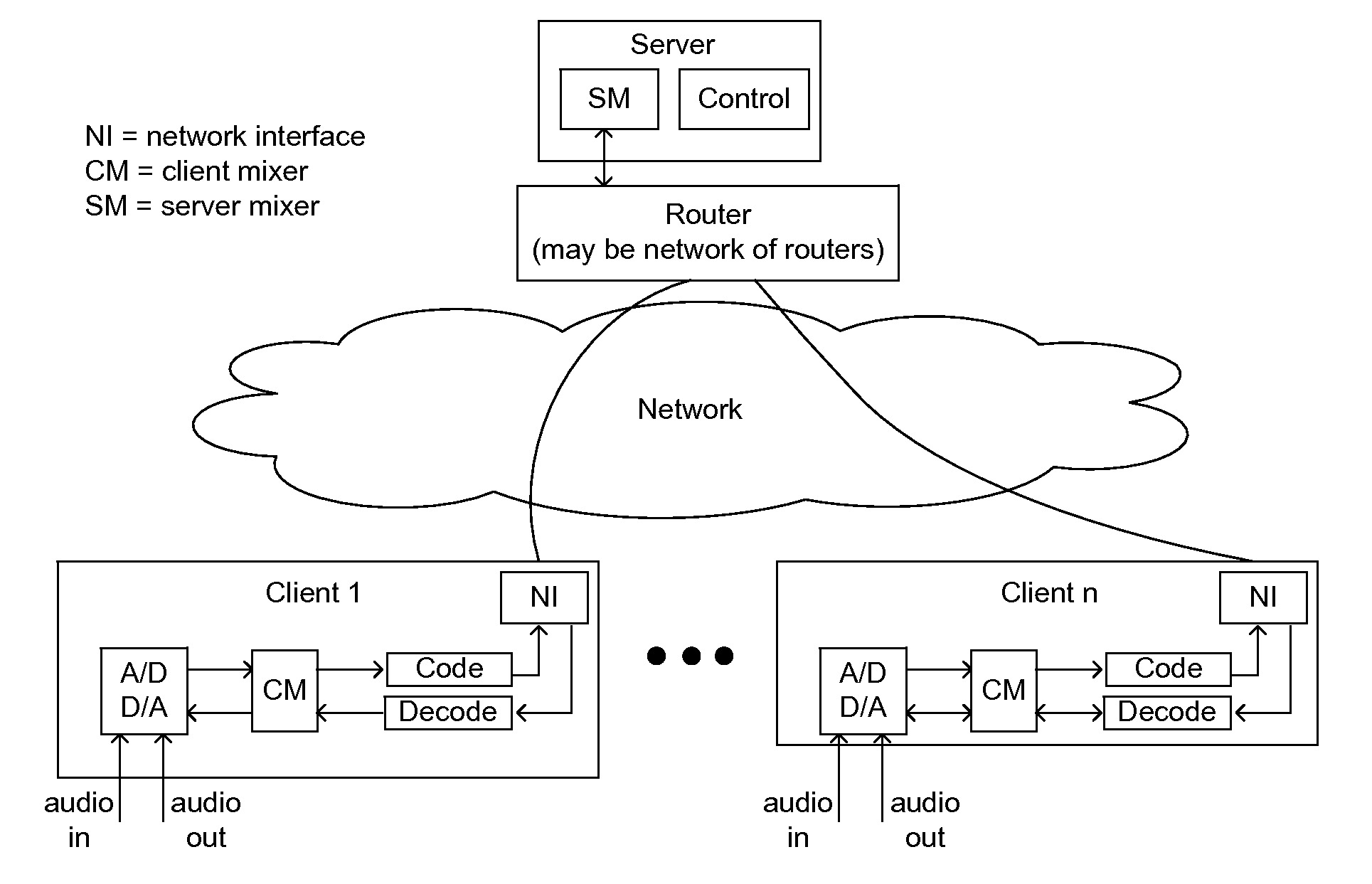

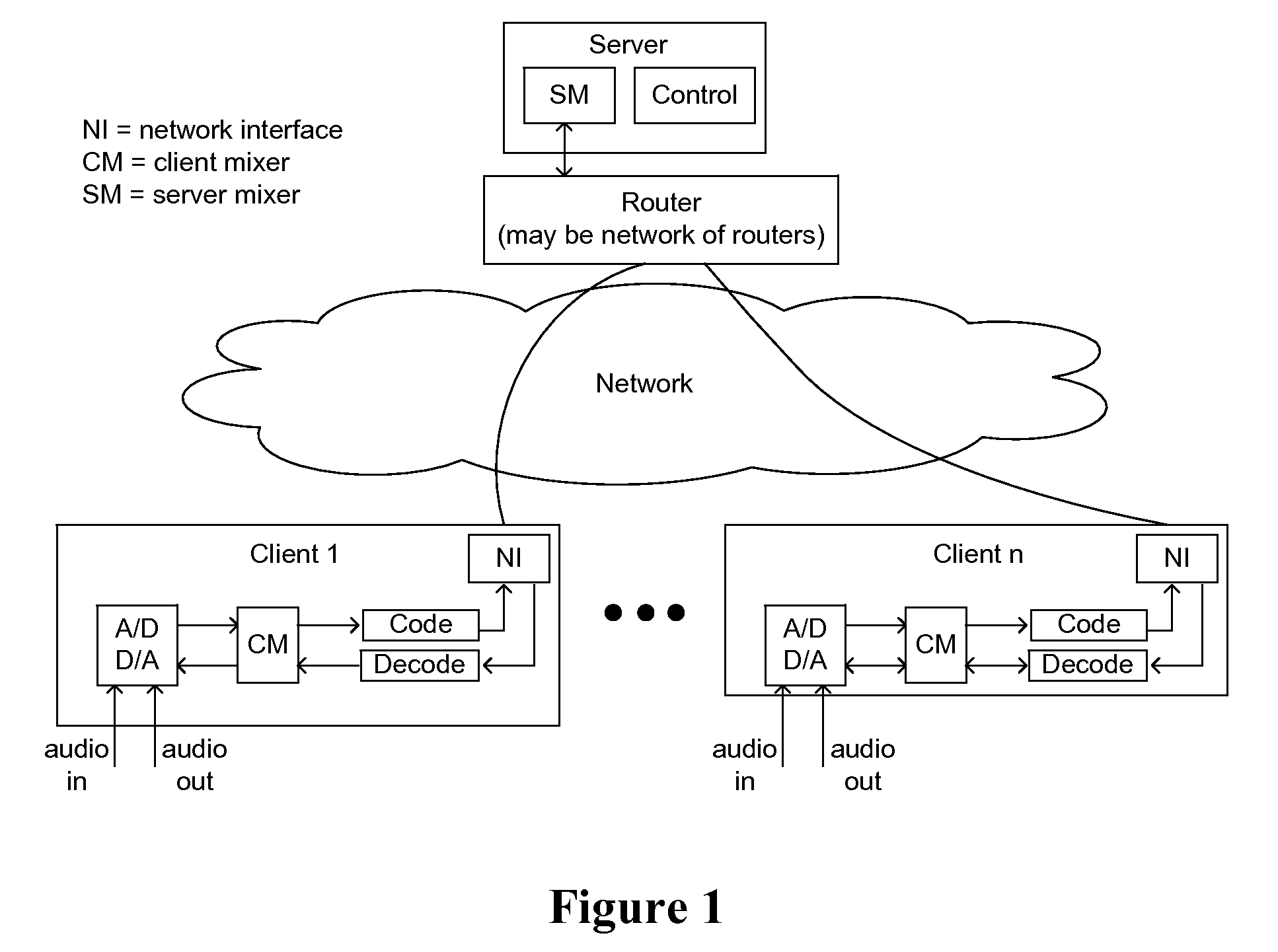

Distributed mixer for on-line audio collaboration

InactiveUS20080201426A1Effective balanceMinimizes computation loadMultiple digital computer combinationsTransmissionBandwidth constraintData signal

Embodiments of the present invention generally relate to a system and method of processing data signals. More specifically, in one embodiment, system architecture splits mixing functions between client and server to enable dynamic switching between a client-server and a peer-to-peer paradigm. In another embodiment, architecture allows one to efficiently trade-off computation in the server and link bandwidth in the network. In another embodiment a system is provided to minimize computational load on server subject to link bandwidth constraint. In another embodiment a system is provided to maximize use of client computational resources. In another embodiment a system is provided to adapt to changing network environments and changing service requirements (e.g. number of clients).

Owner:DARCIE THOMAS

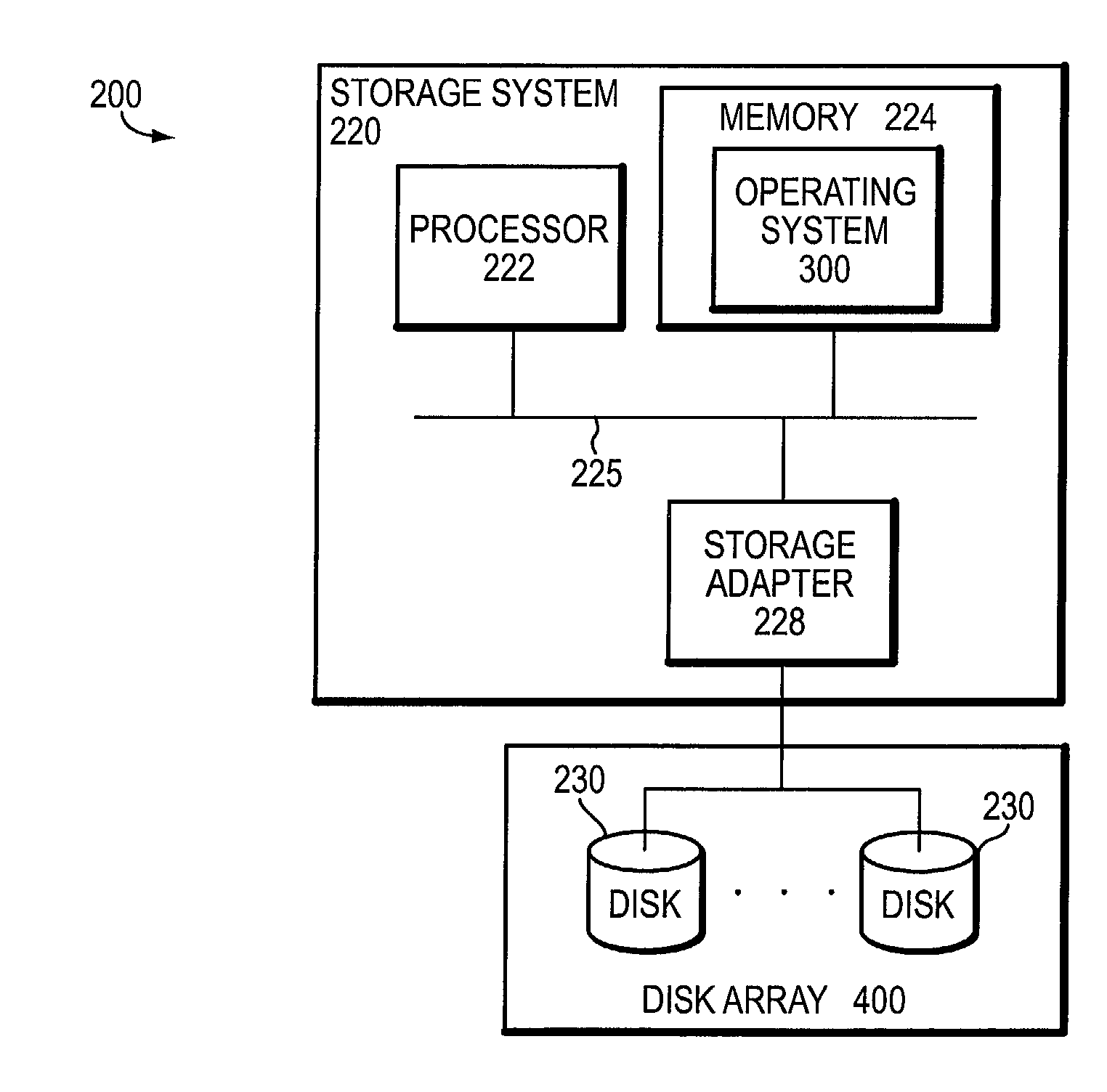

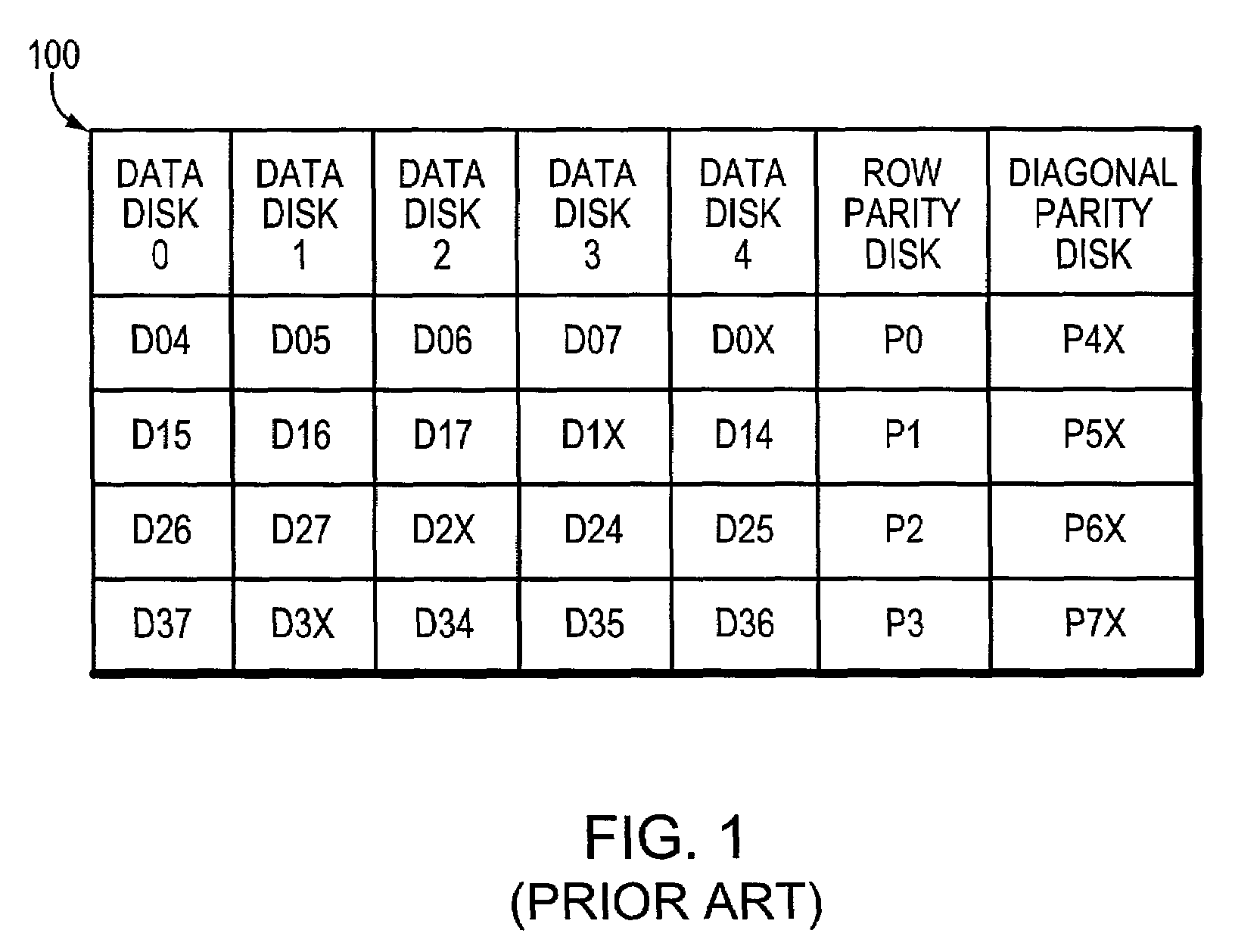

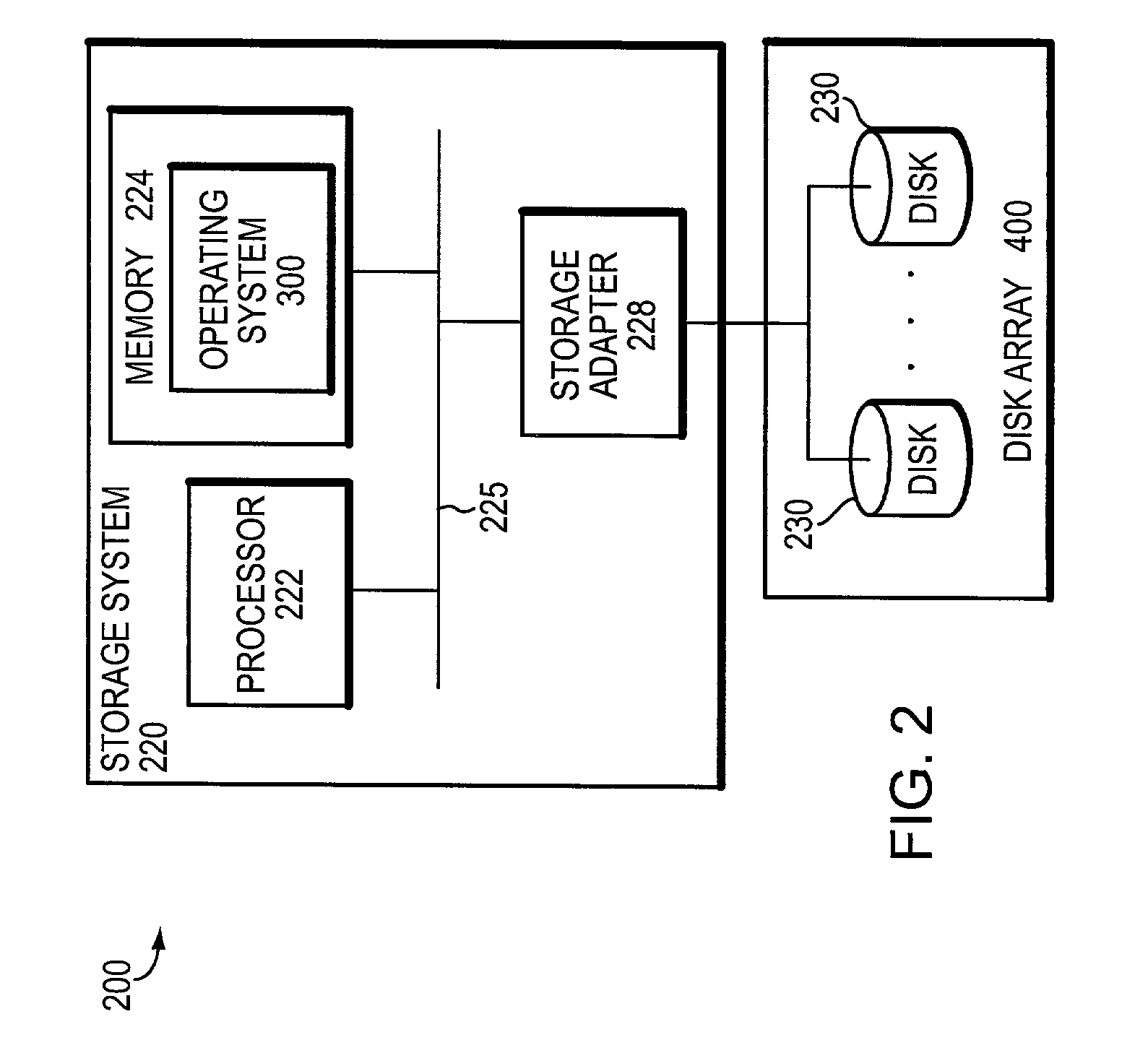

Row-diagonal parity technique for enabling efficient recovery from double failures in a storage array

ActiveUS6993701B2Reduce overheadEffective recoveryInput/output to record carriersStatic storageTheoretical computer scienceDouble fault

A “row-diagonal” (R-D) parity technique reduces overhead of computing diagonal parity for a storage array adapted to enable efficient recovery from the concurrent failure of two storage devices in the array. The diagonal parity is computed along diagonal parity sets that collectively span all data disks and a row parity disk of the array. The parity for all of the diagonal parity sets except one is stored on the diagonal parity disk. The R-D parity technique provides a uniform stripe depth and an optimal amount of parity information.

Owner:NETWORK APPLIANCE INC

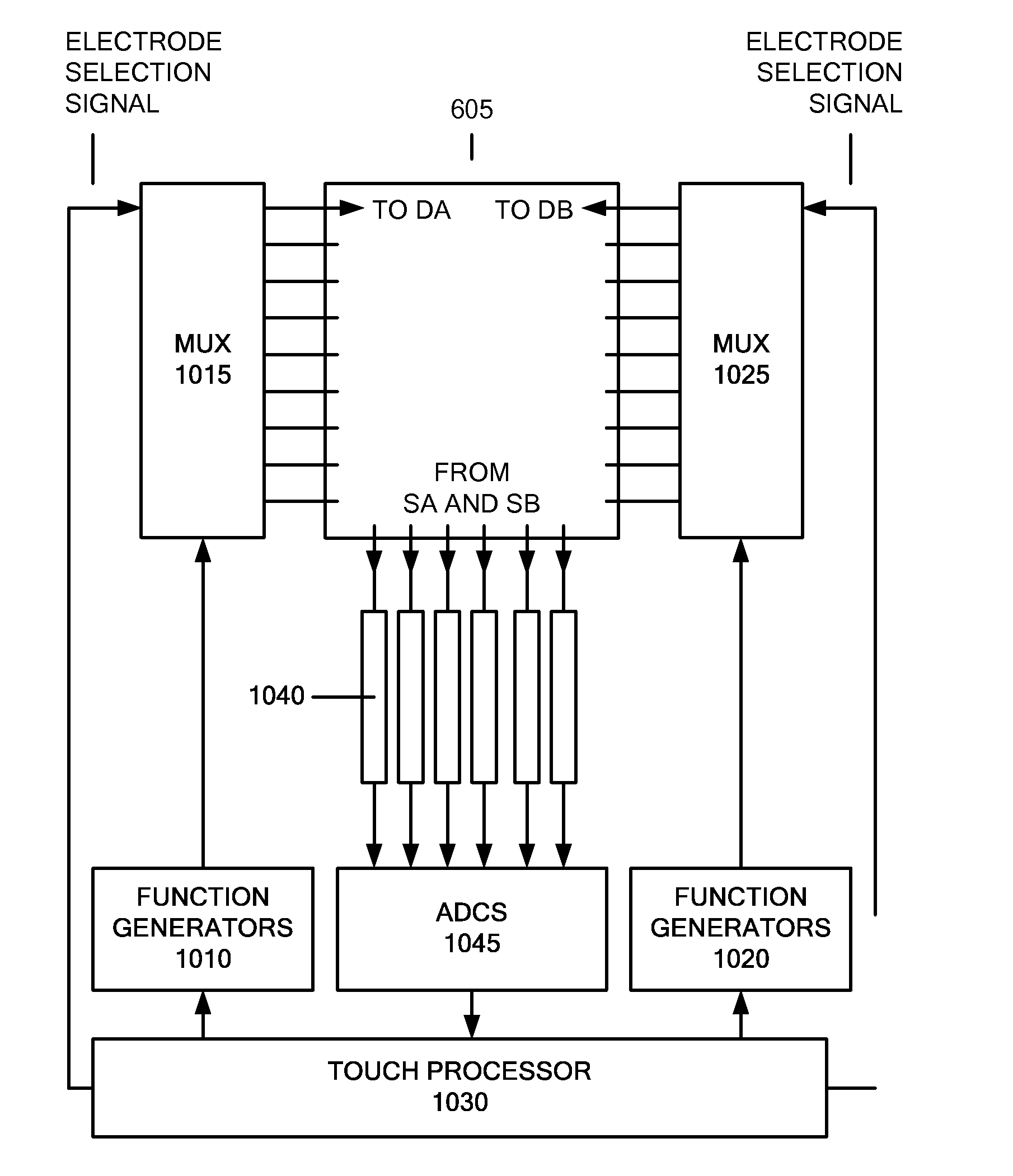

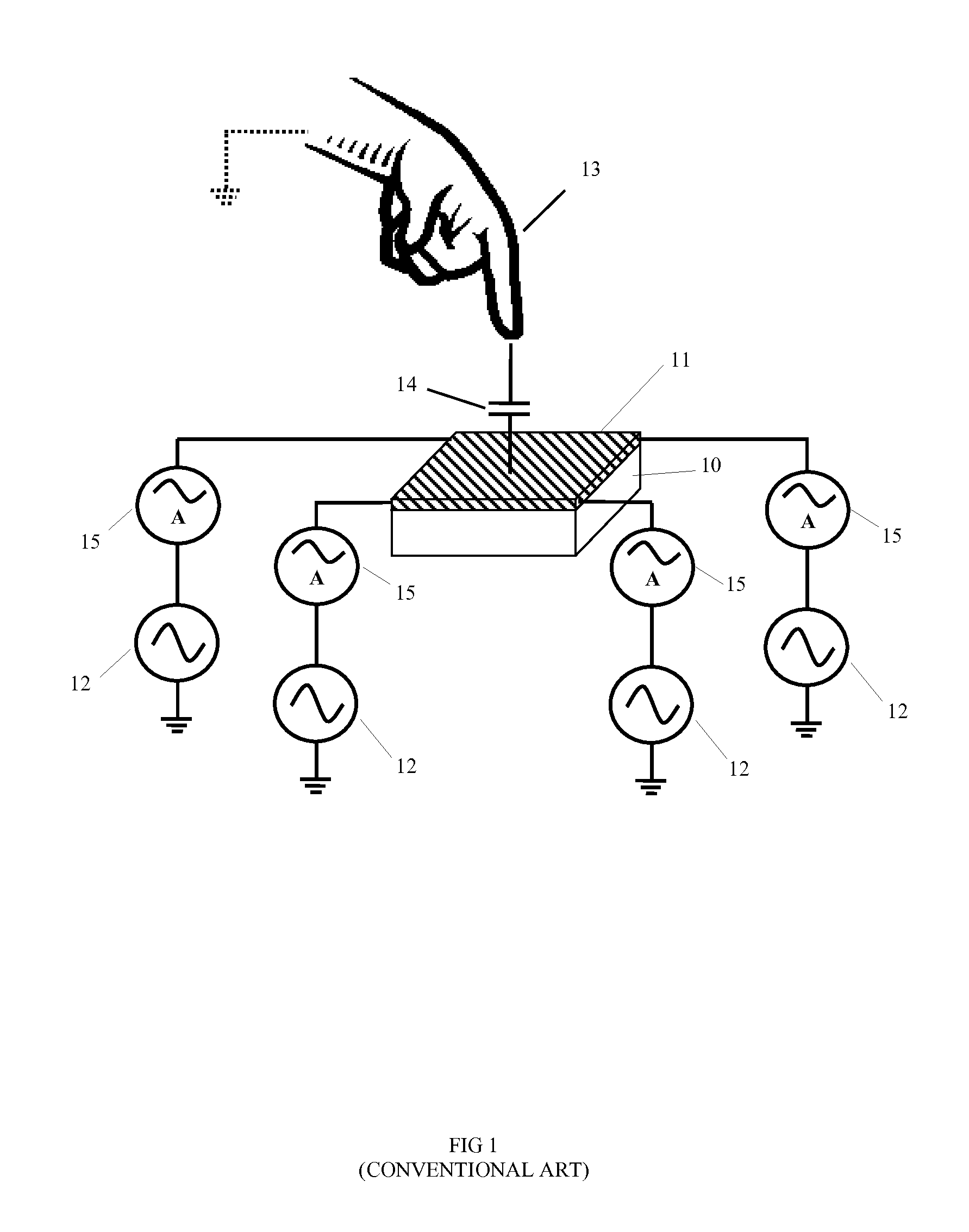

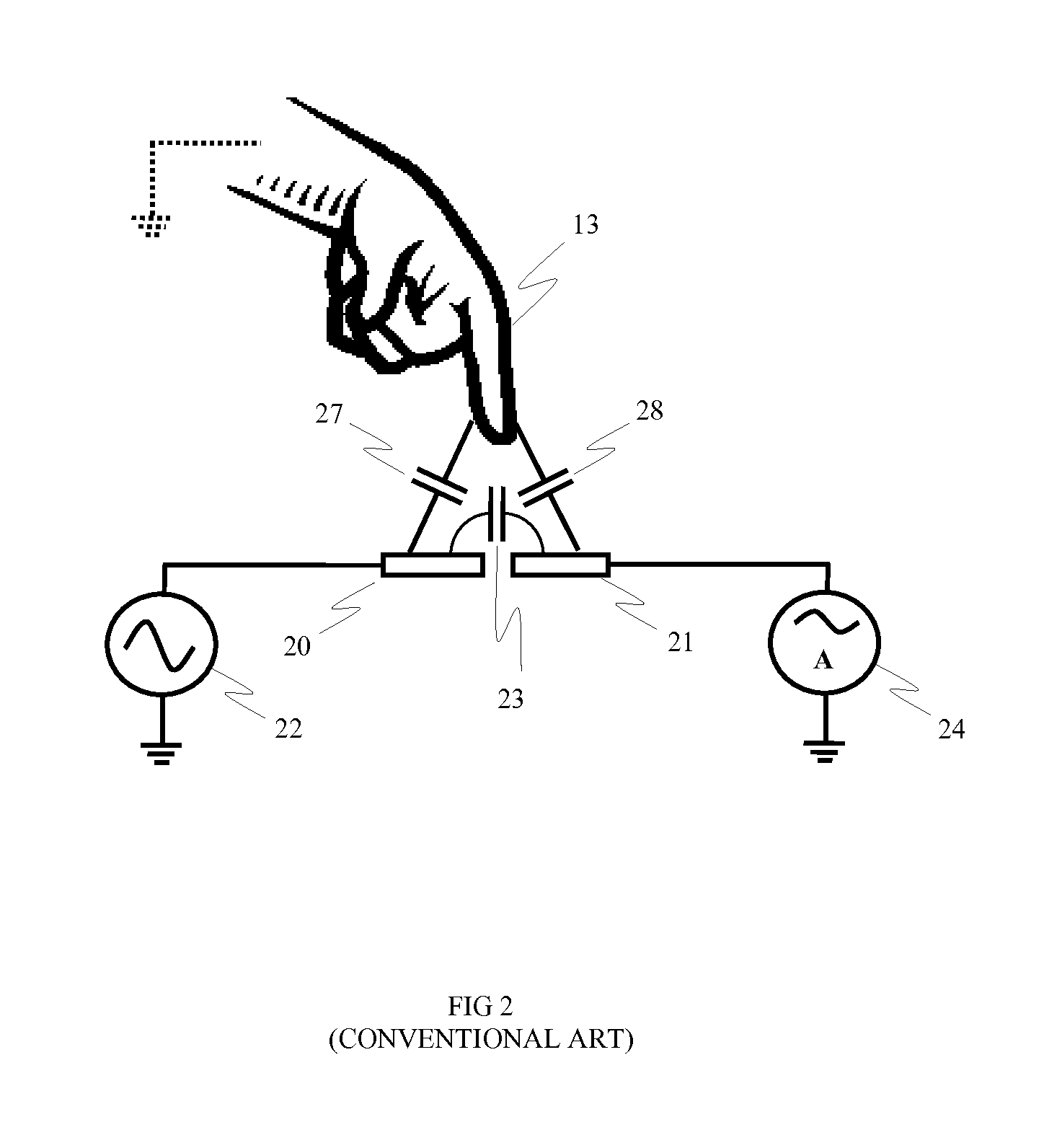

Capacitive touch panel with a 'dual layer' force sensor

ActiveUS20140062933A1Minimizing load capacitanceHigh-frequency signalInput/output processes for data processingCapacitanceCoupling

A capacitive touch panel includes a first substrate and a second substrate arranged relative to the first substrate. A plurality of drive electrodes are arranged on the first substrate, wherein each drive electrode comprises a first drive electrode section and a second drive electrode section. In addition, a plurality of sense electrodes are arranged on the second substrate, the plurality of sense electrodes including touch sensing electrodes and force sensing electrodes. At least part of a sense electrode of the plurality of sense electrodes forms a force sensitive coupling capacitance with a second drive electrode section and not with a first drive electrode section.

Owner:SHARP KK

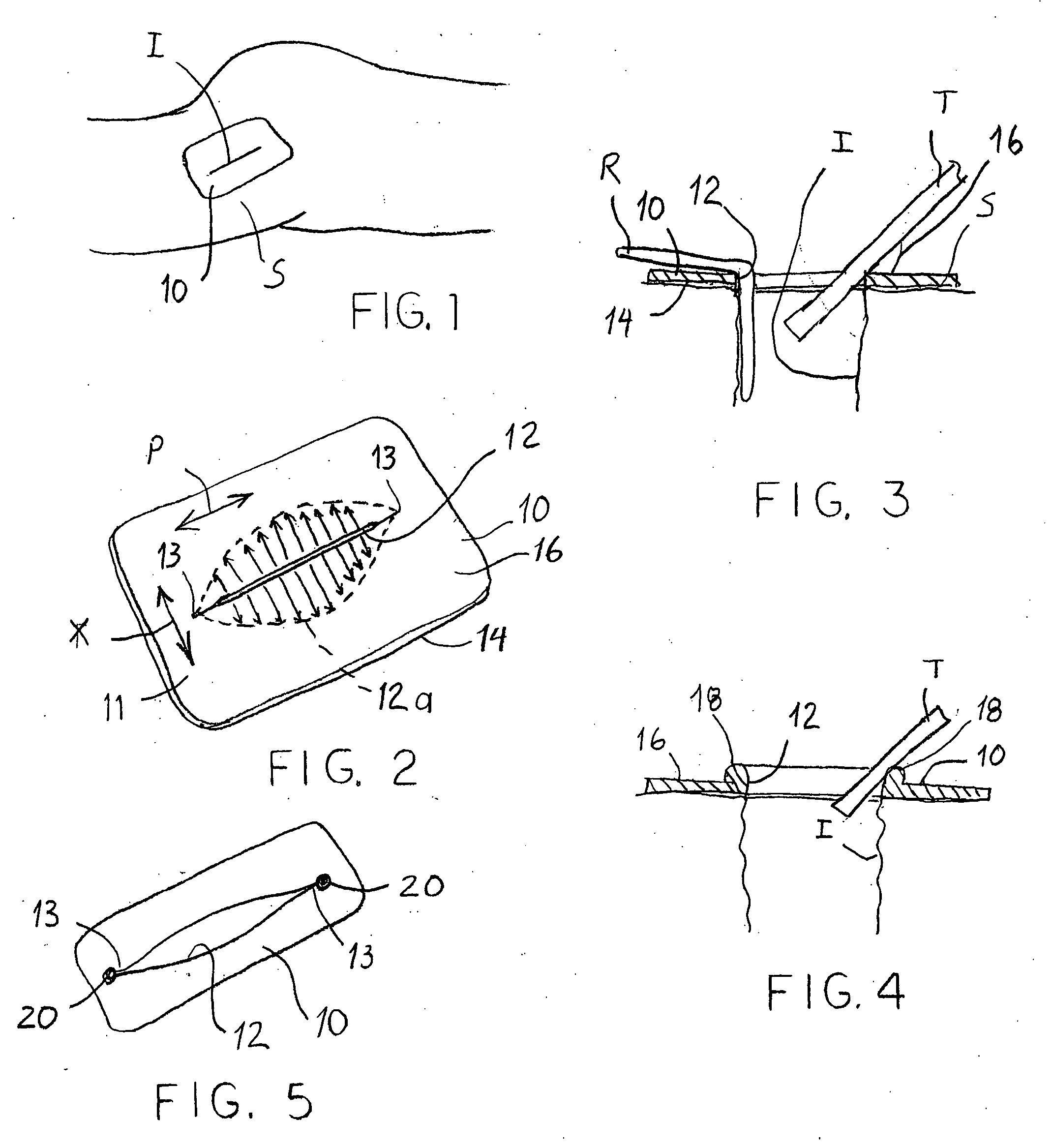

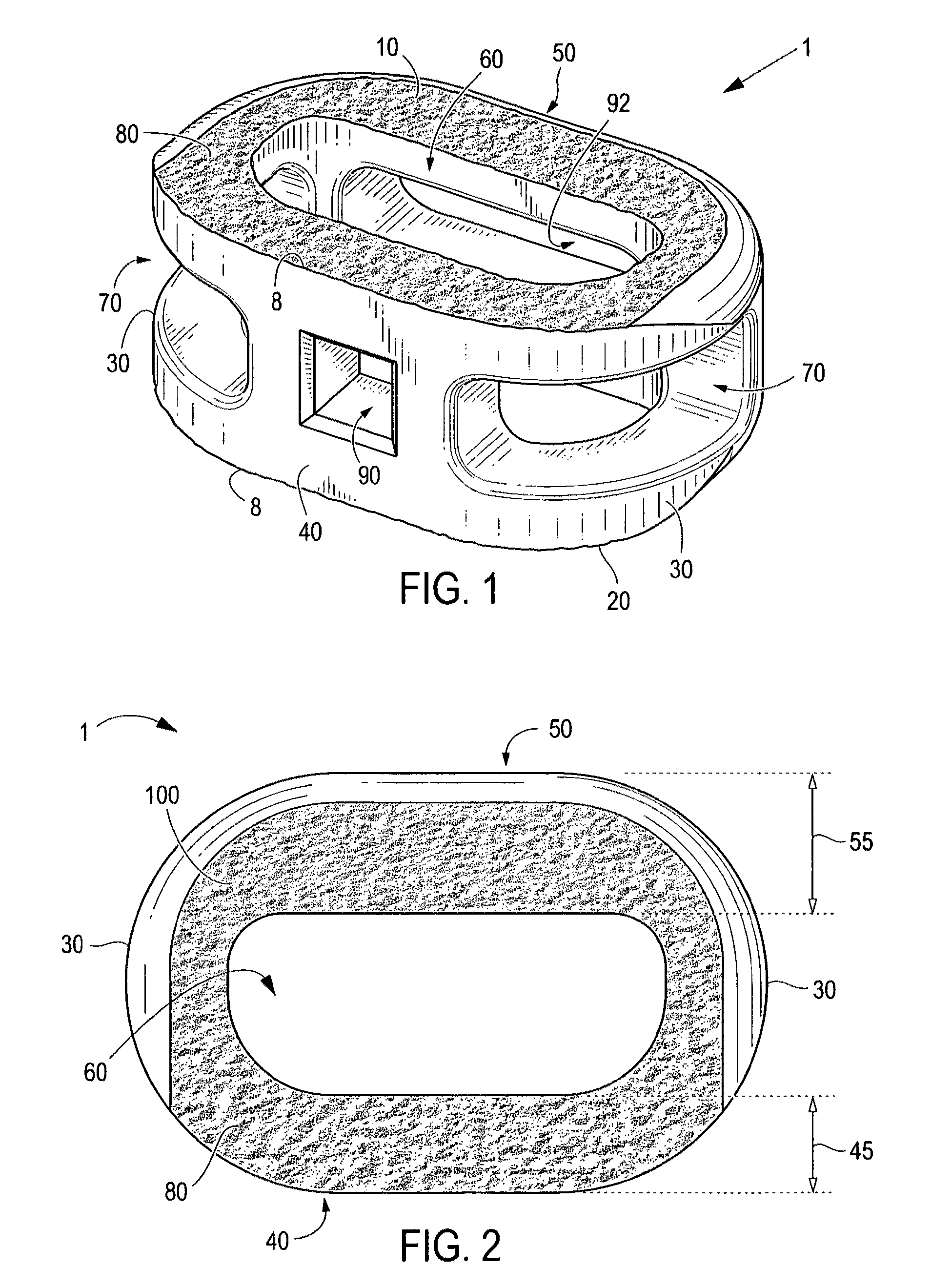

Composite interbody spinal implant having openings of predetermined size and shape

ActiveUS20080262623A1Add seatsImprove visualizationBone implantSpinal implantsSpinal implantBiomedical engineering

An interbody spinal implant including a body having a top surface, a bottom surface, opposing lateral sides, opposing anterior and posterior portions, a substantially hollow center, and a single vertical aperture. The single vertical aperture extends from the top surface to the bottom surface, has a size and shape predetermined to maximize the surface area of the top surface and the bottom surface available proximate the anterior and posterior portions while maximizing both radiographic visualization and access to the substantially hollow center, and defines a transverse rim. The body may be non-metallic and may form one component of a composite implant; the other component is a metal plate disposed on at least one of the top and bottom surfaces of the body.

Owner:TITAN SPINE

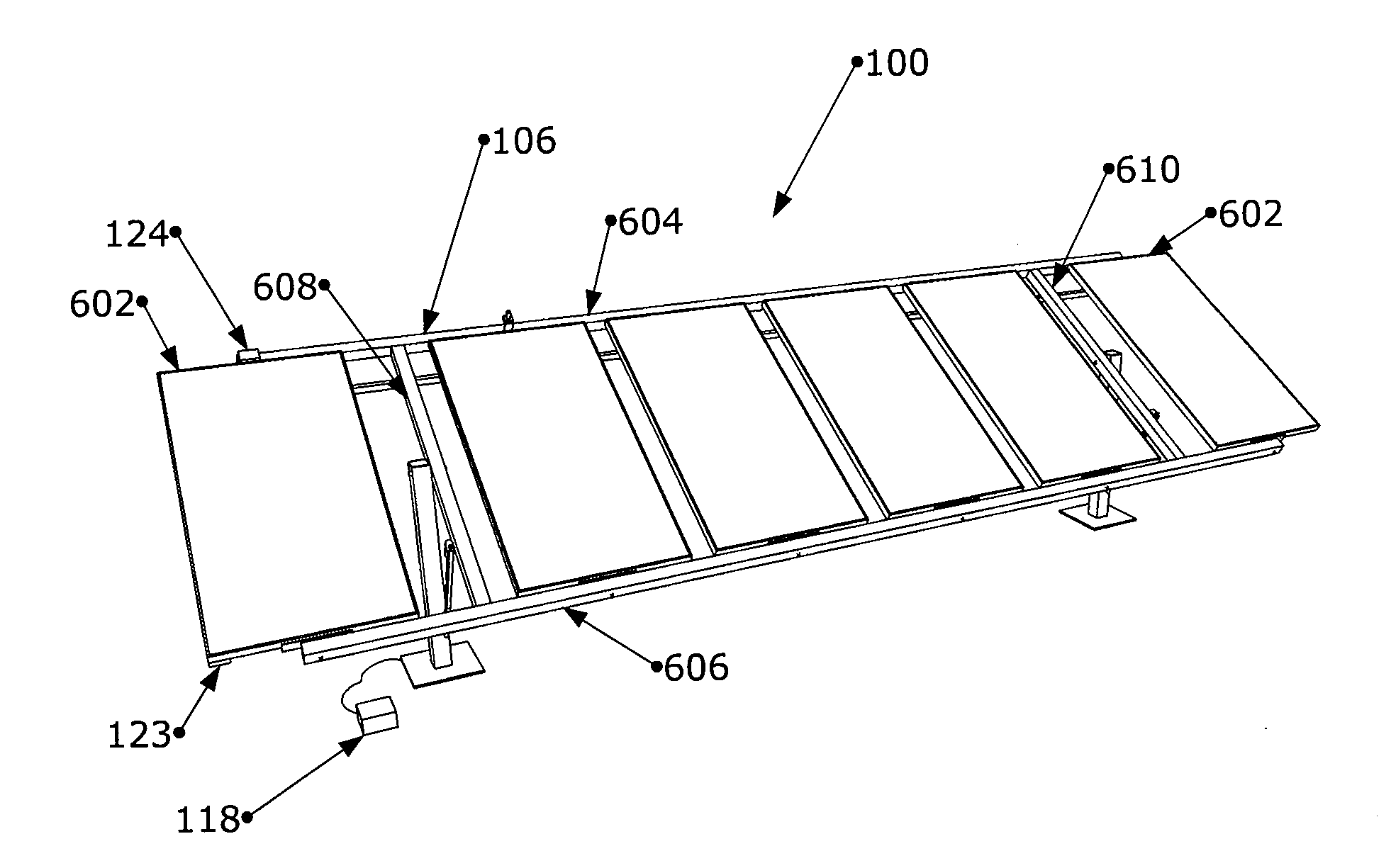

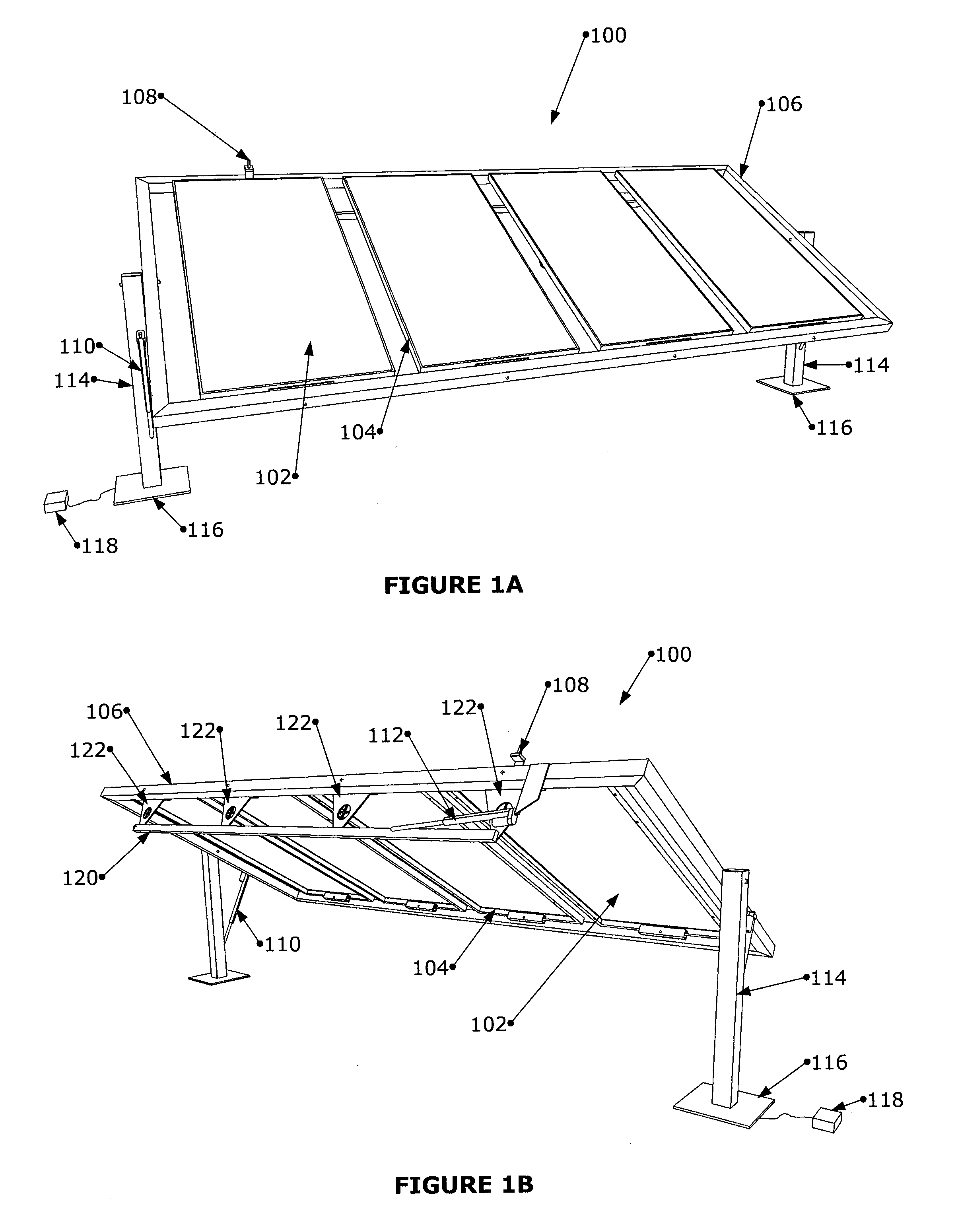

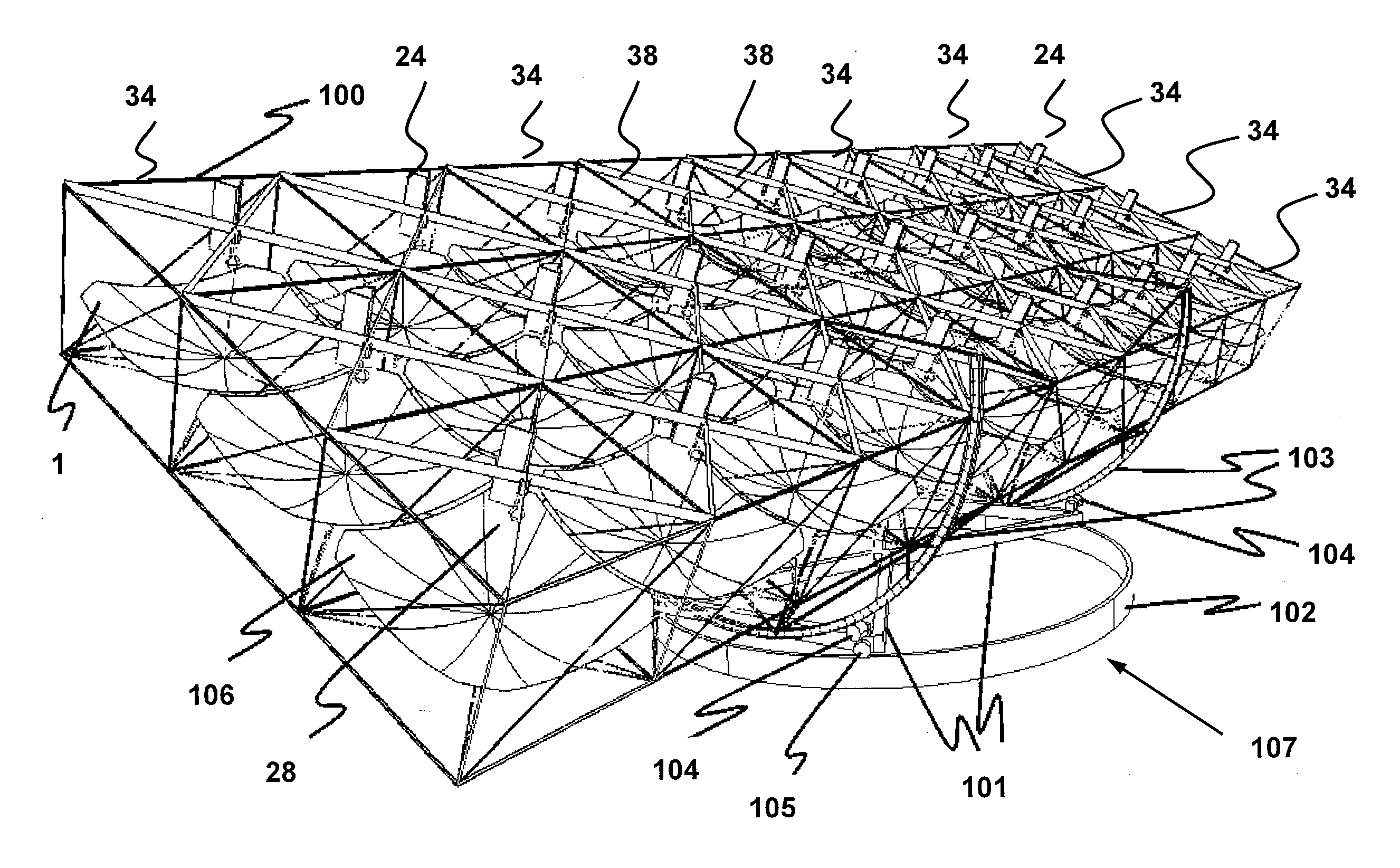

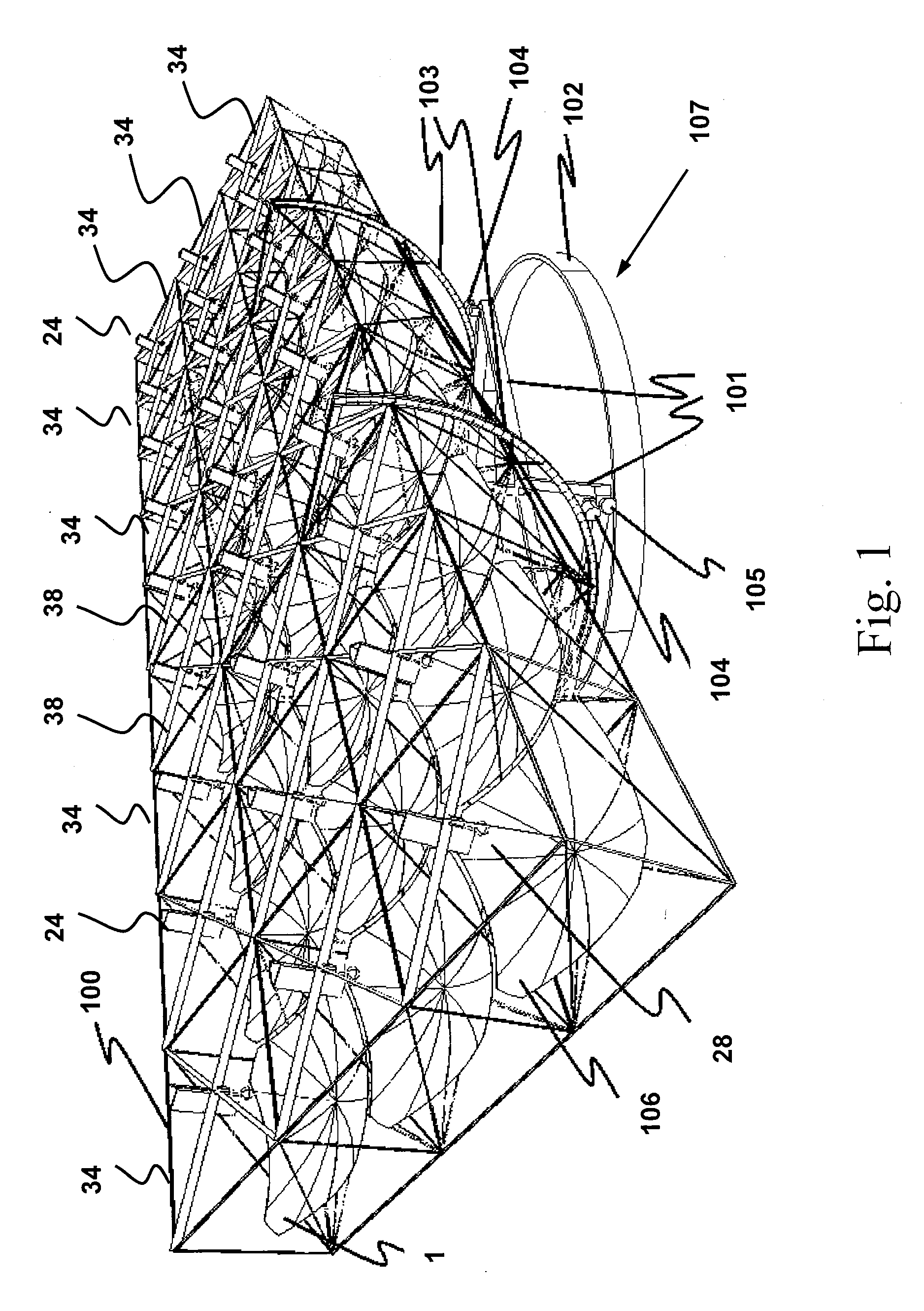

High efficiency counterbalanced dual axis solar tracking array frame system

ActiveUS20110073161A1Minimizes wind loadingReduce windOptical radiation measurementSolar heating energyPhotovoltaic solar energyShadowings

A high efficiency, environmentally friendly system comprising a plurality of photovoltaic solar collecting panels (PV panels) is disclosed. The system comprises an outer frame to which a plurality of inner frames are mounted to which the plurality of PV panels are attached. To minimize shadowing by the outer frame upon one or more PV panels, at least one PV panel may extend beyond an endpoint of the main frame. The system also comprises an outer frame rotation actuator that rotates the outer frame and an inner frame rotation actuator that rotates the inner frames and the plurality of PV panels. The solar tracking array frames disclosed herein help to improve the quality of the environment by conserving a variety of energy resources (e.g., fossil fuels, hydroelectric energy, etc.) The solar tracking array frames disclosed herein also help to reduce greenhouse gas emissions, as solar tracking array frames do not produce carbon dioxide byproducts.

Owner:SCANLON MARK +1

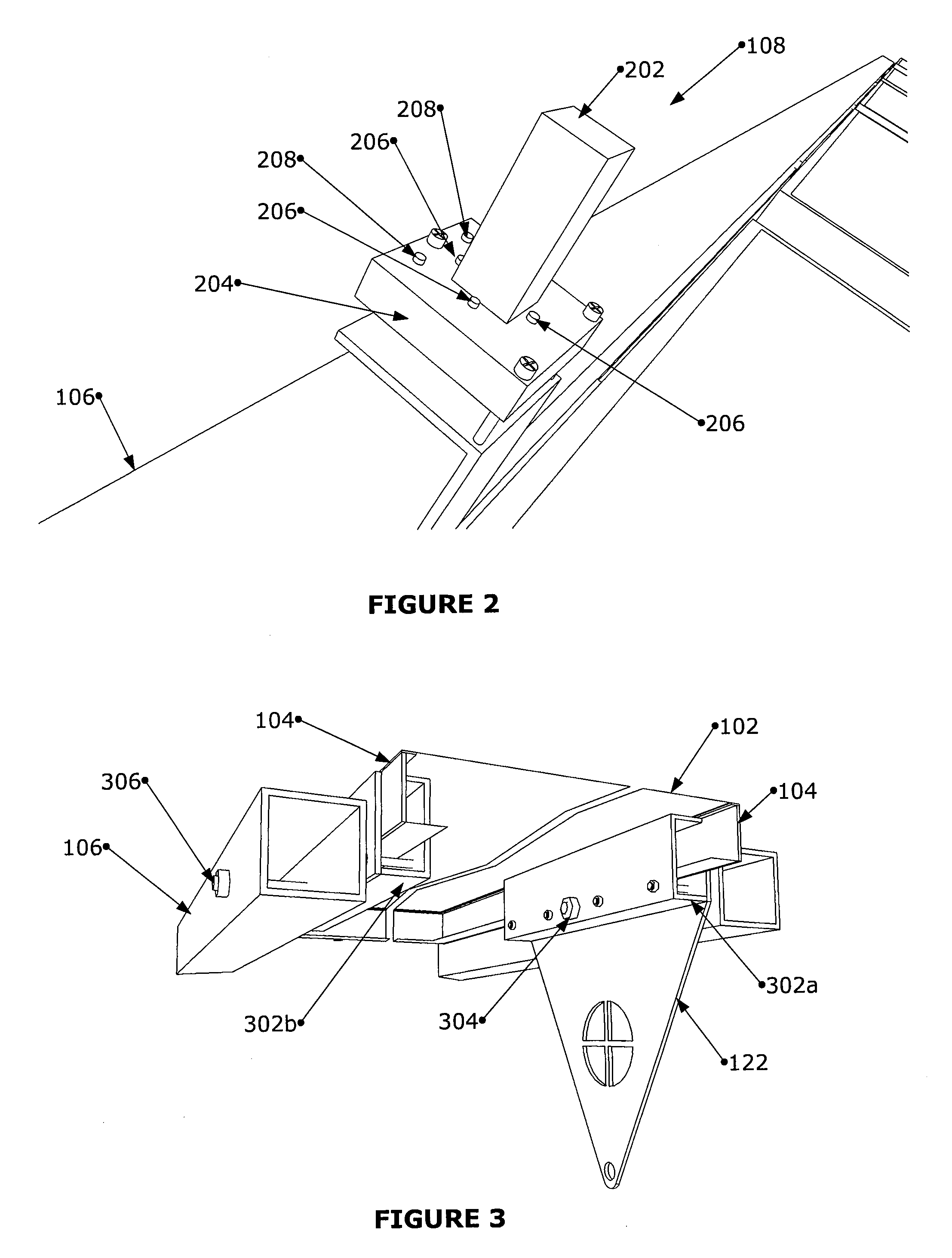

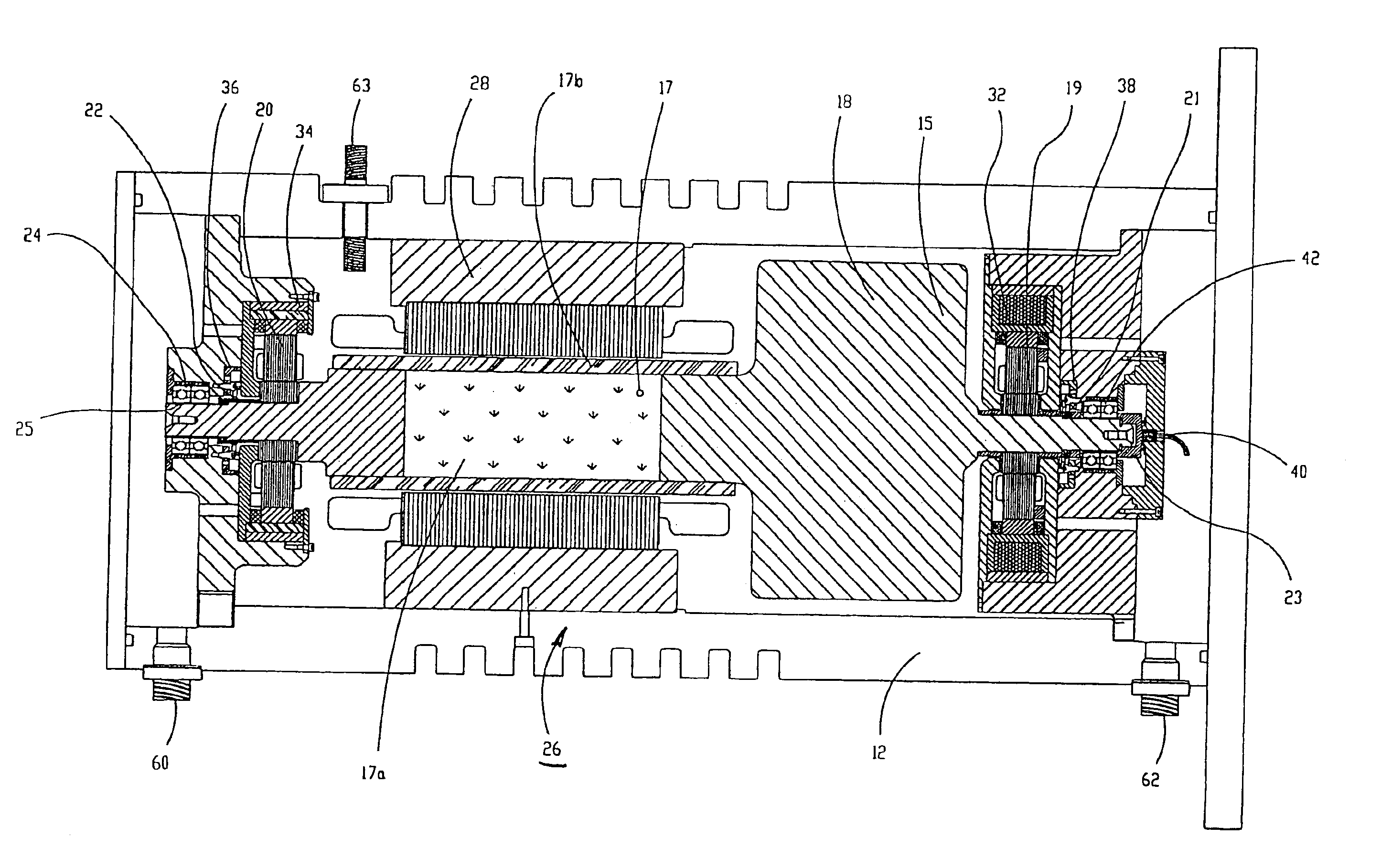

Energy storage flywheel with minimum power magnetic bearings and motor/generator

InactiveUS6897587B1Minimum rotor lossLow maintenanceMagnetic circuit rotating partsEngine componentsFlywheel energy storage systemAutomotive engineering

An optimized flywheel energy storage system utilizing magnetic bearings, a high speed permanent magnet motor / generator, and a flywheel member. The flywheel system is constructed using a high strength steel wheel for kinetic energy storage, high efficiency magnetic bearings configured with dual thrust acting permanent magnet combination bearings, and a high efficiency permanent magnet motor generator. The steel wheel provides a cost effective, high speed construction for the energy storage rotor.

Owner:VYCON ENERGY INC

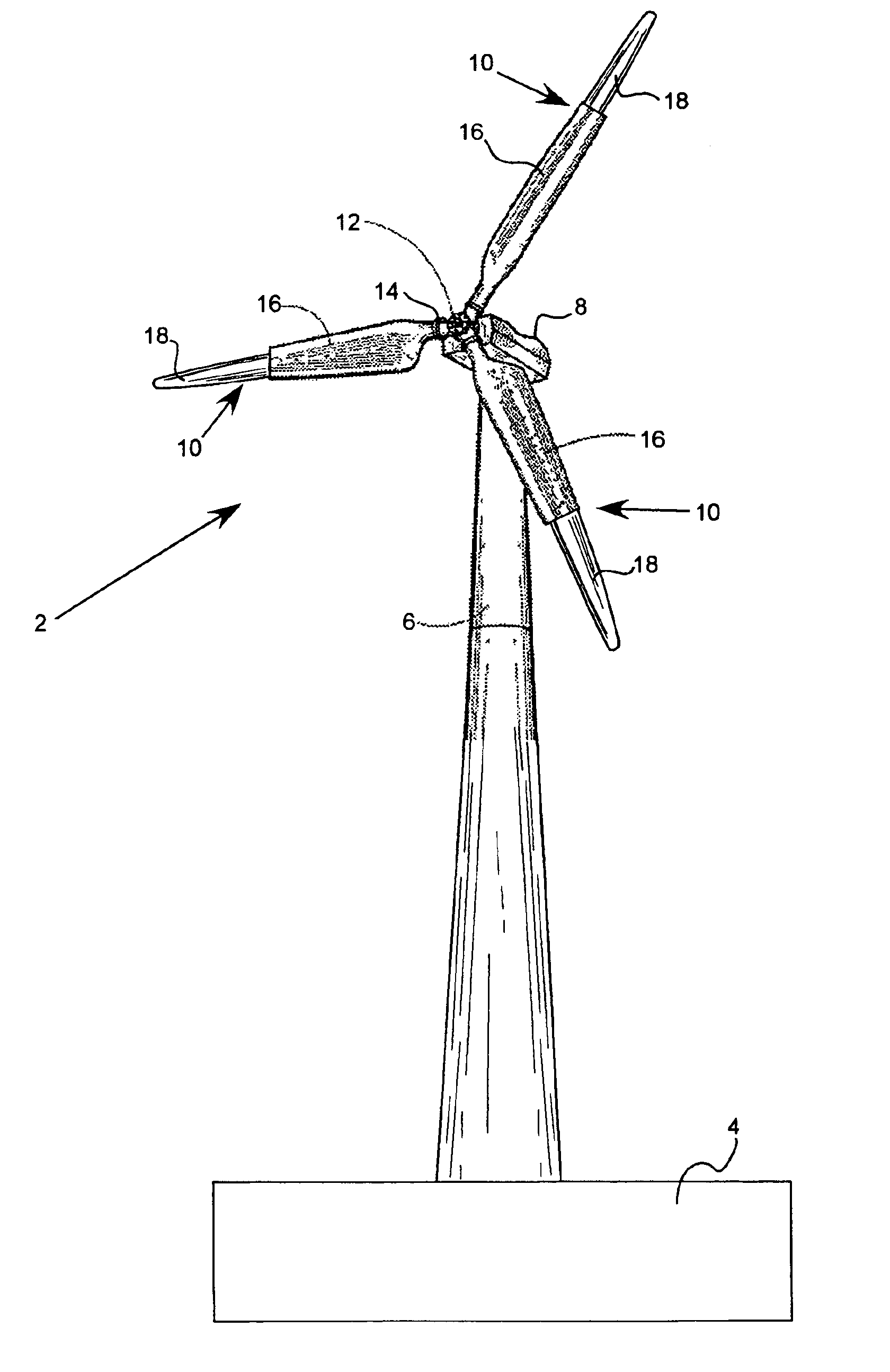

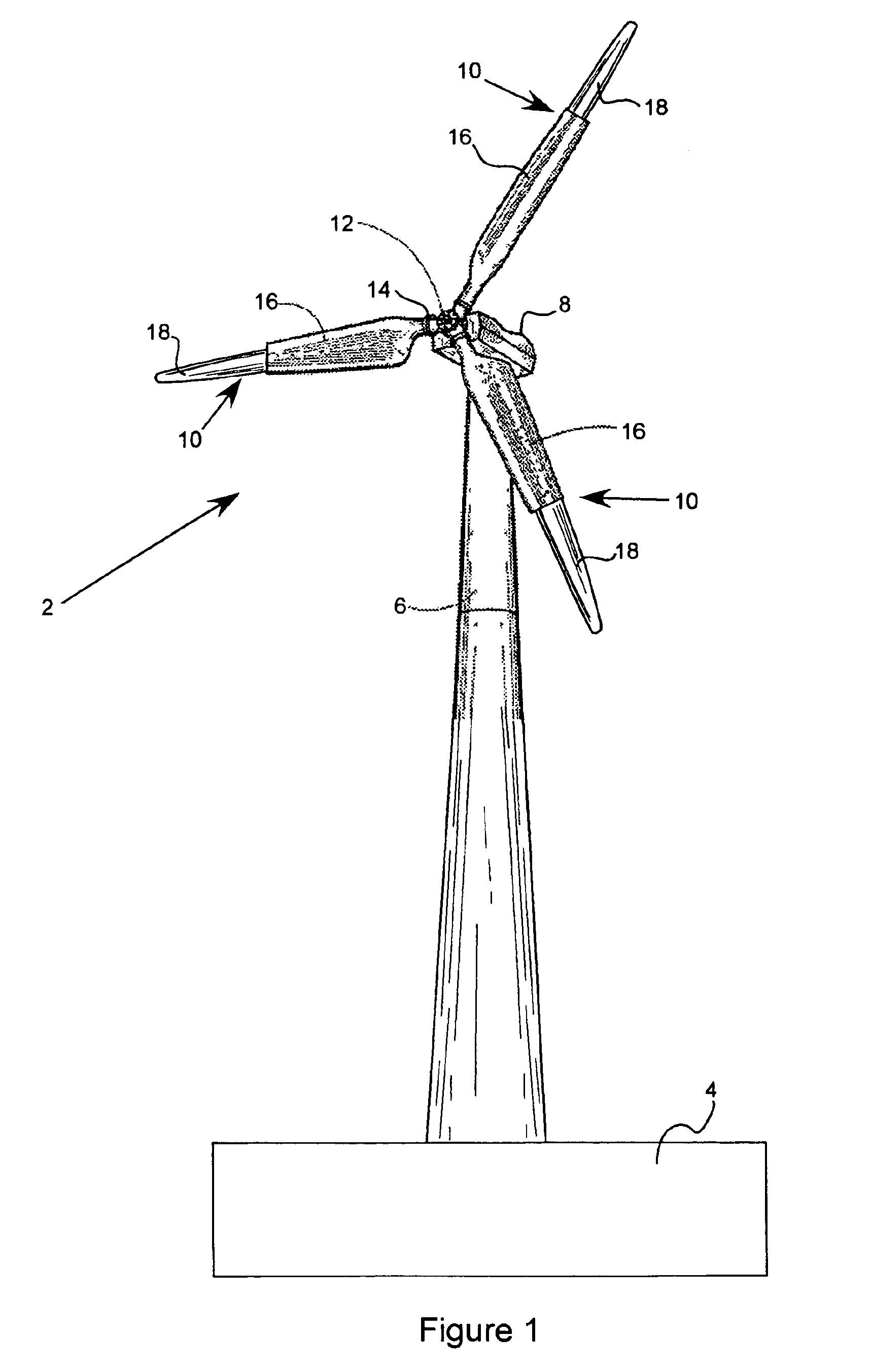

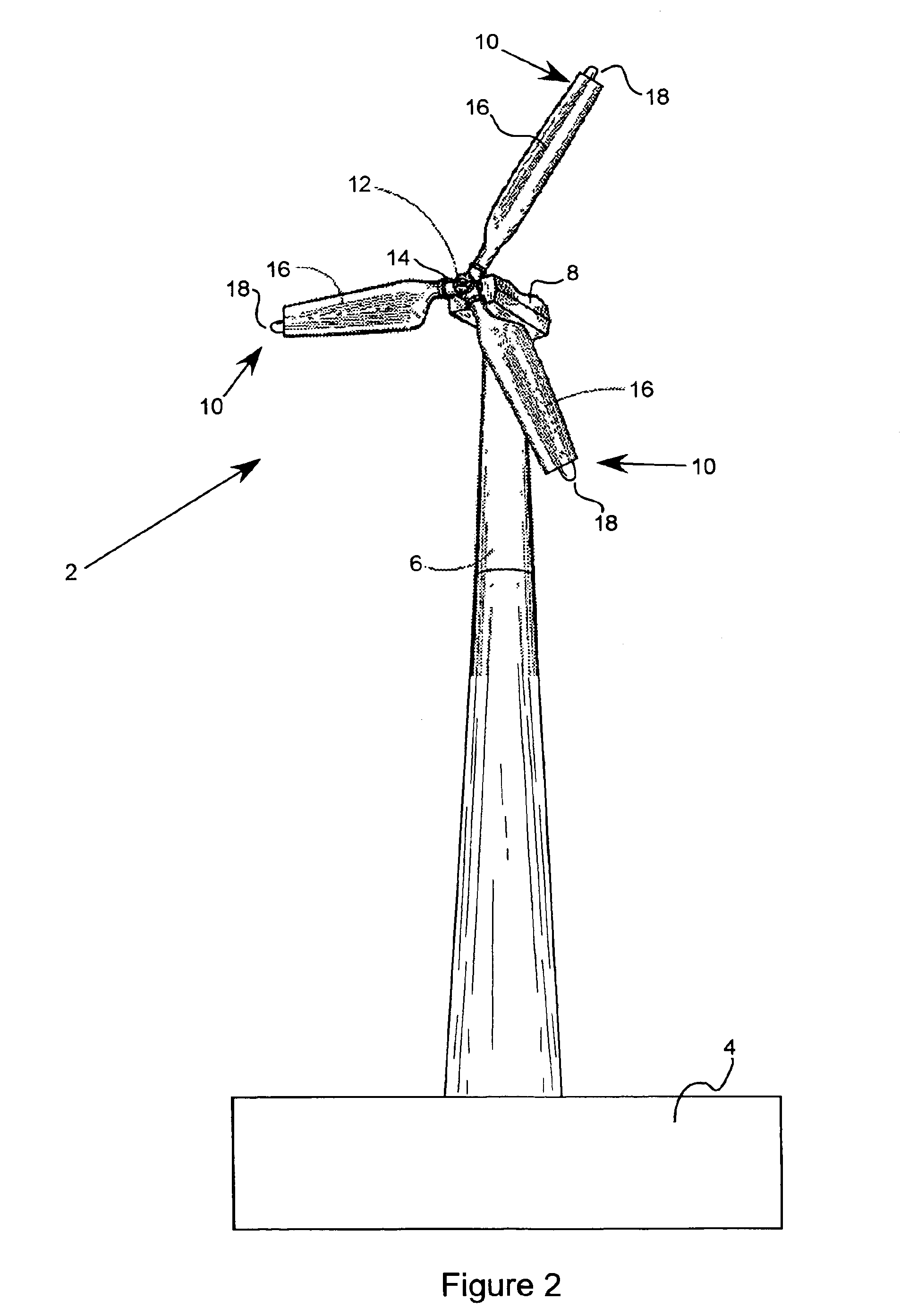

Telescoping wind turbine blade

A wind turbine blade made of a fixed blade section with an integral mounting flange for attachment to a wind turbine hub. A moveable blade section is attached to the fixed blade section and is free to move in a longitudinal direction relative to the fixed blade section. A positioning device controllably positions the moveable blade section to vary the overall length of the blade. This allows the wind turbine's rotor diameter to be adjusted. The rotor diameter can be increased in order to provide high power output in low wind conditions and it can be decreased in order to minimize loads in high wind conditions.

Owner:FRONTIER WIND LLC

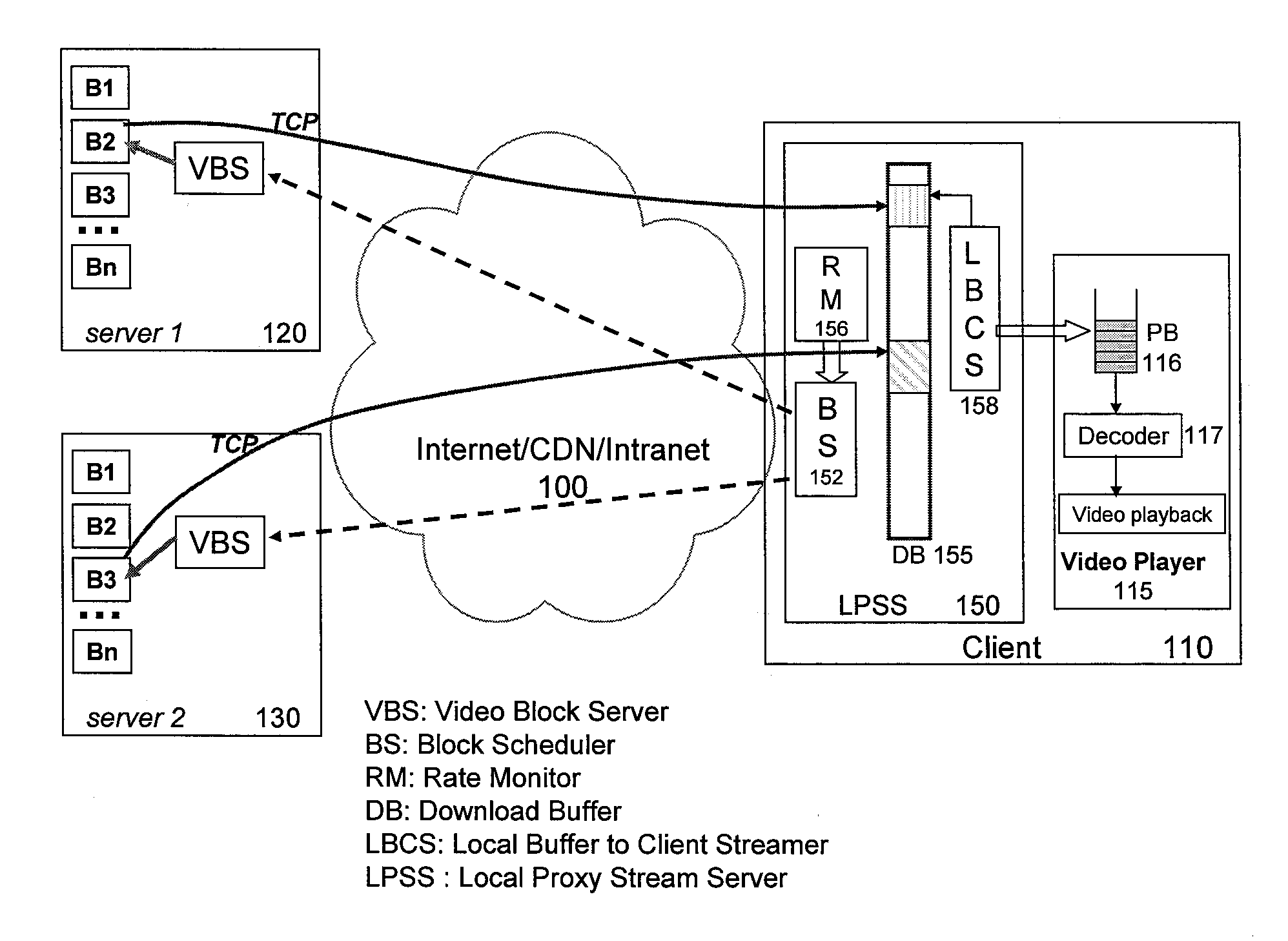

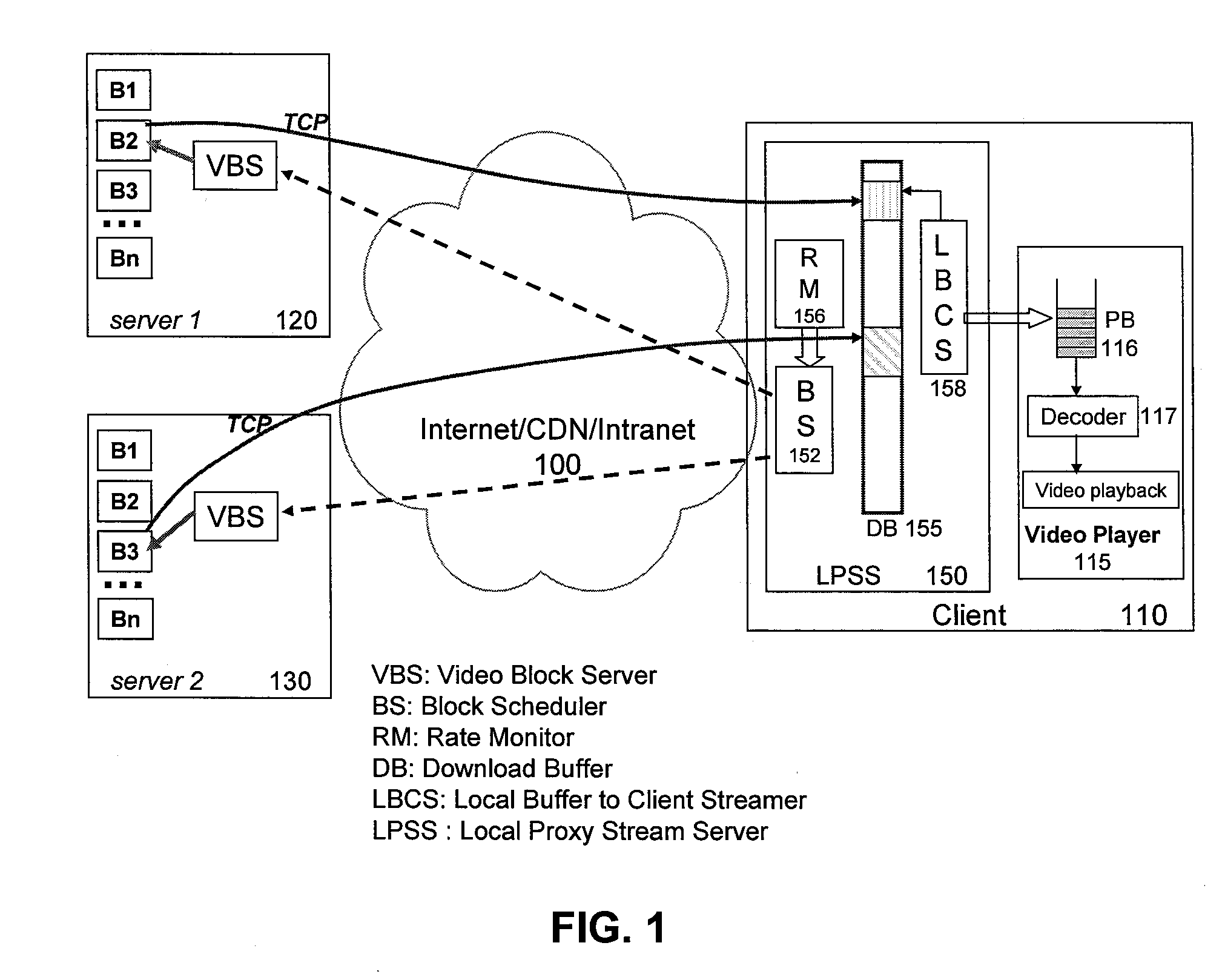

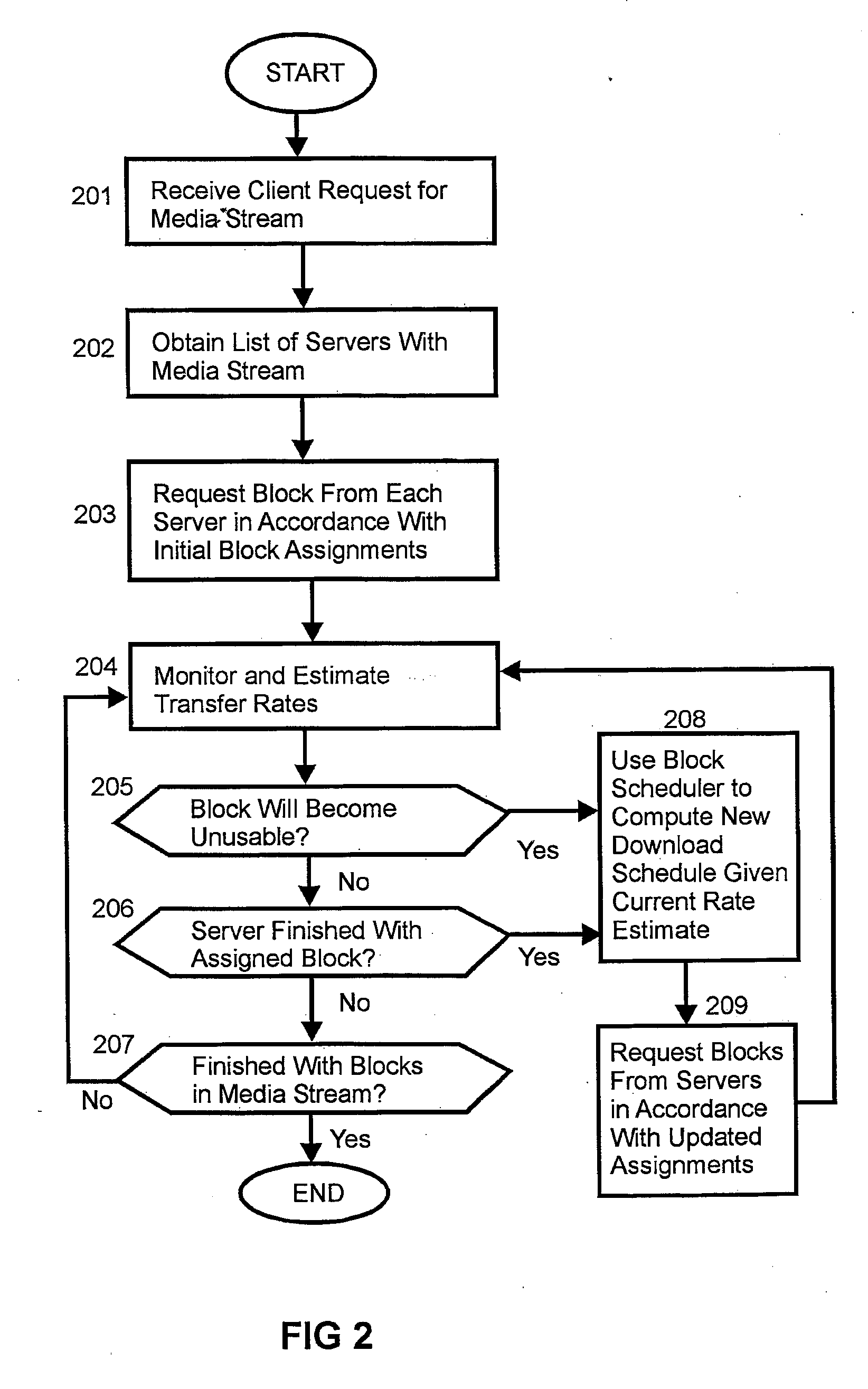

System and Method for Parallel Indirect Streaming of Stored Media from Multiple Sources

InactiveUS20060184688A1Facilitates protocol independenceLoad minimizationMultiple digital computer combinationsTransmissionComputer network

A system and method are herein disclosed for parallel streaming of stored media from multiple sources. The architecture utilizes the notion of indirect streaming and provides a local proxy streaming server which is responsible for interacting with the multiple servers and scheduling downloads of media blocks and for dealing with possible rate fluctuations and server failures.

Owner:NEC LAB AMERICA

Anterior interbody spinal implant

ActiveUS7662186B2Improved seating in the discImprove visualizationBone implantSpinal implantsSurgical approachAnterior surgery

This present invention relates to interbody spinal implants and methods of using such implants. Certain embodiments of the present invention are particularly suitable for placement using an anterior surgical approach. Certain embodiments of the present invention include a body having a top surface, a bottom surface, opposing lateral sides, and opposing anterior and posterior portions. Interbody spinal implants, as now taught, further include roughened surface topography on at least a portion of its top surface and / or bottom surface. Preferred embodiments of the interbody spinal implant are substantially hollow and have a generally oval-shaped transverse cross-sectional area. Preferred embodiments of further include at least one aperture that extends the entire height of the implant body. This vertical aperture also defines a transverse rim having greater posterior thickness than anterior thickness. Certain embodiments also preferably include at least one aperture that extends the entire transverse length of the implant body.

Owner:TITAN SPINE

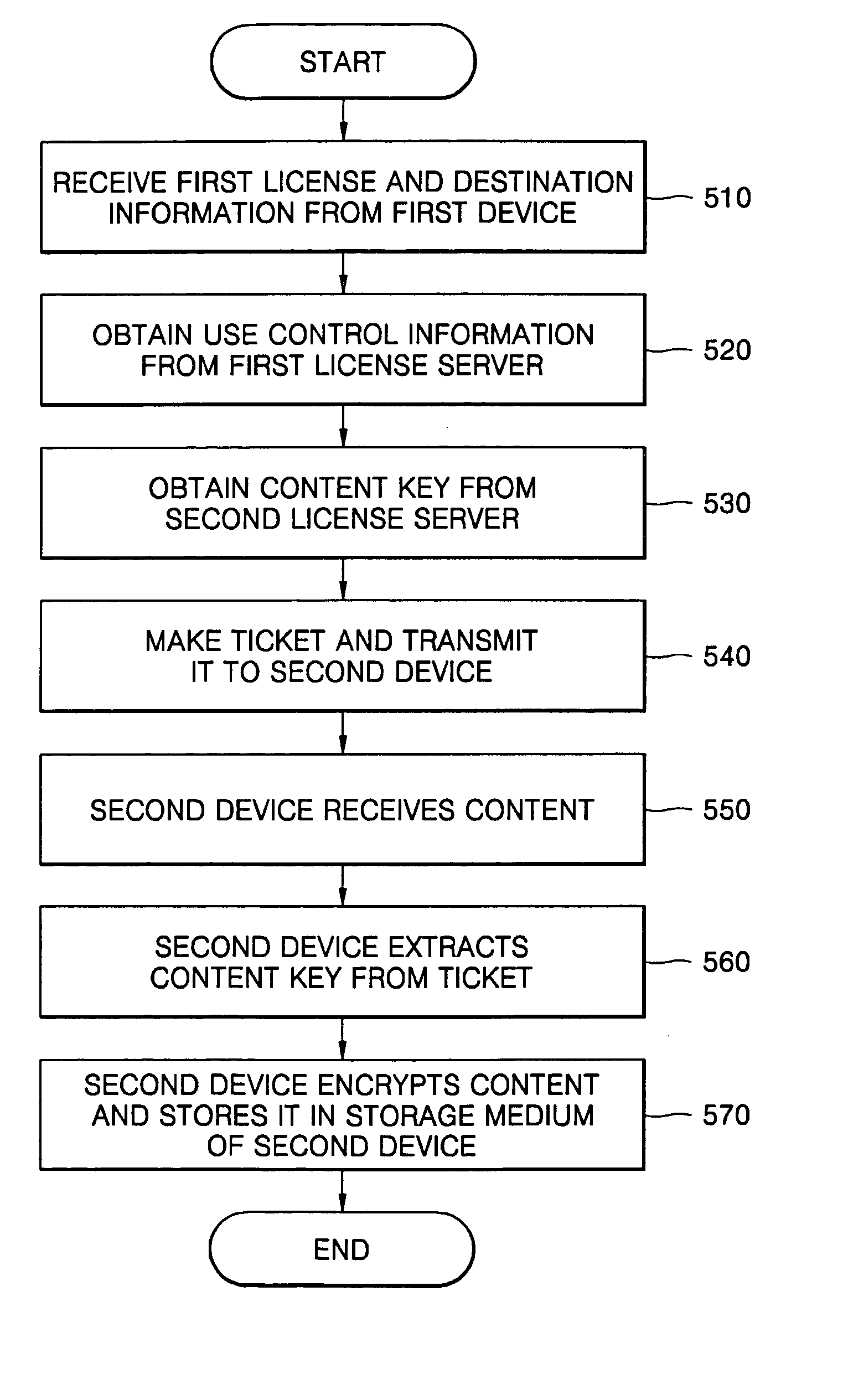

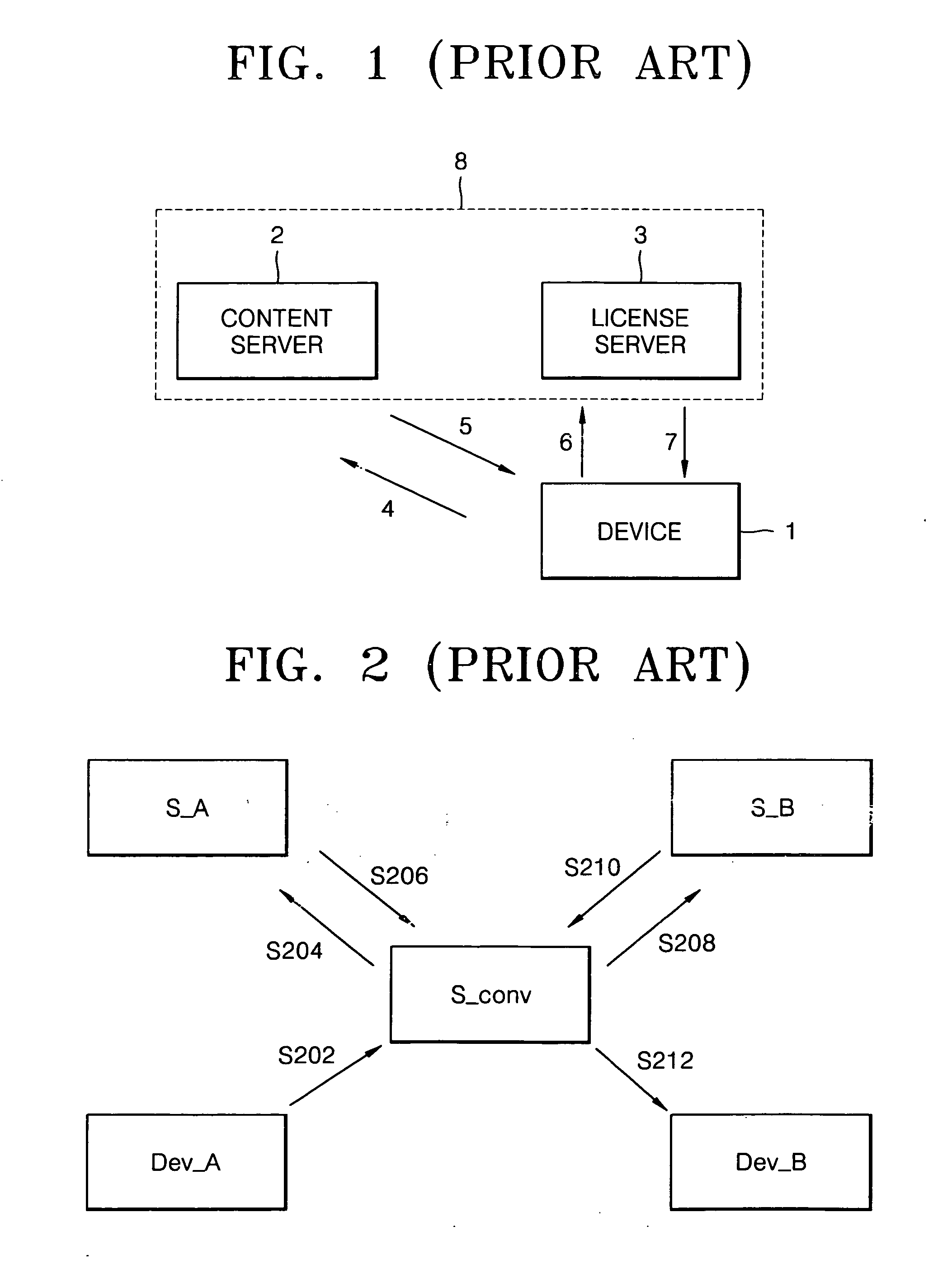

Method of transmitting and reproducing content processed by various DRM systems

ActiveUS20060026691A1Load minimizationDigital data processing detailsUser identity/authority verificationTicketEngineering

Provided is a method of transmitting content processed according to first digital rights management (DRM) to a device that uses second DRM. The method includes generating a ticket using a first license server and a second license server, the first license server issuing a first license for use in the first DRM and the second license server issuing a second license for use in the second DRM; the second device obtaining a second content key required to process the content using the ticket and the second DRM; and the second device receiving the content from the first device and processing the content using the second content key and the second DRM. The ticket includes use control information that specifies a restriction of use of the content, and the second content key required to process the content using the second DRM.

Owner:SAMSUNG ELECTRONICS CO LTD

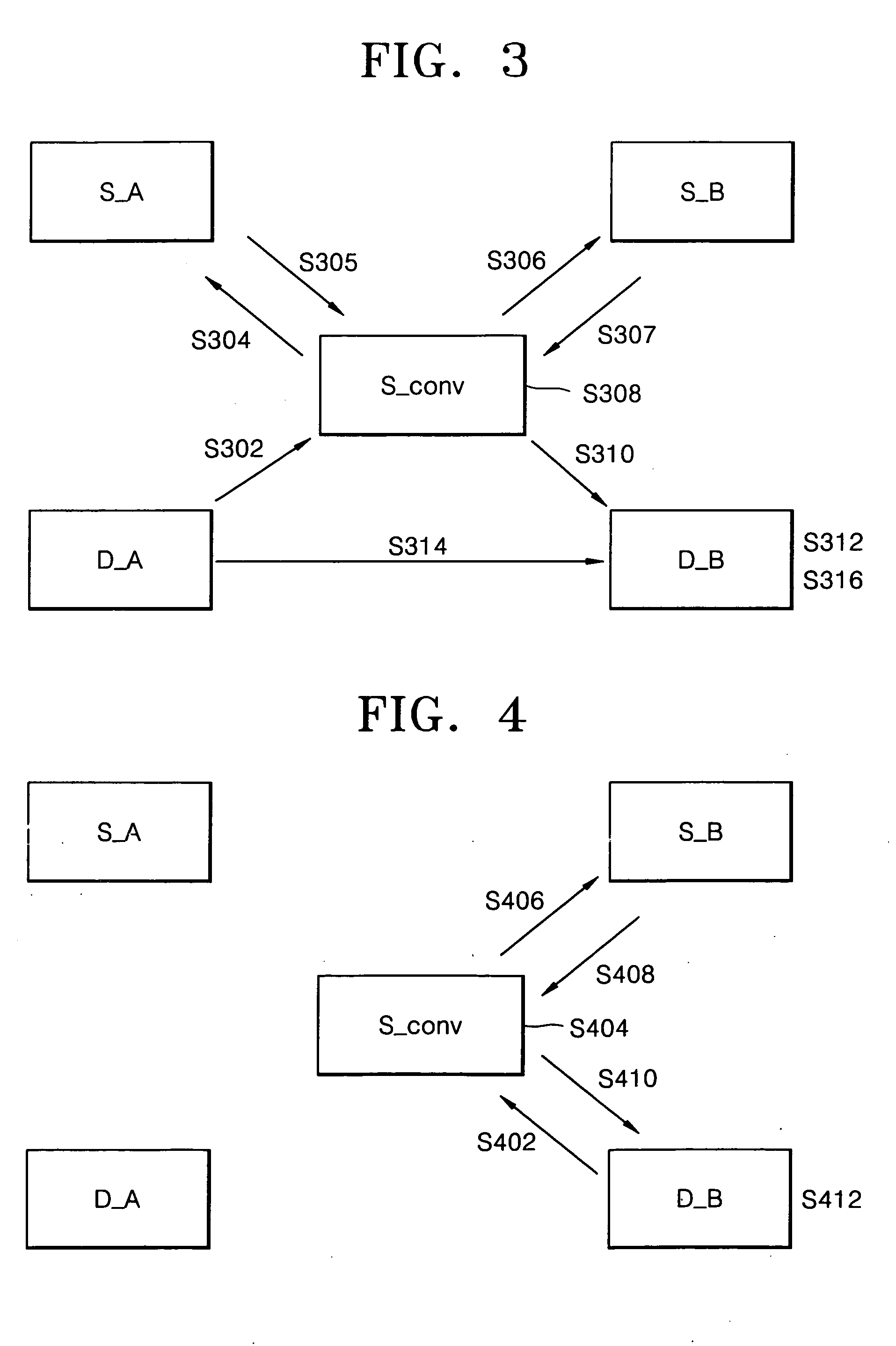

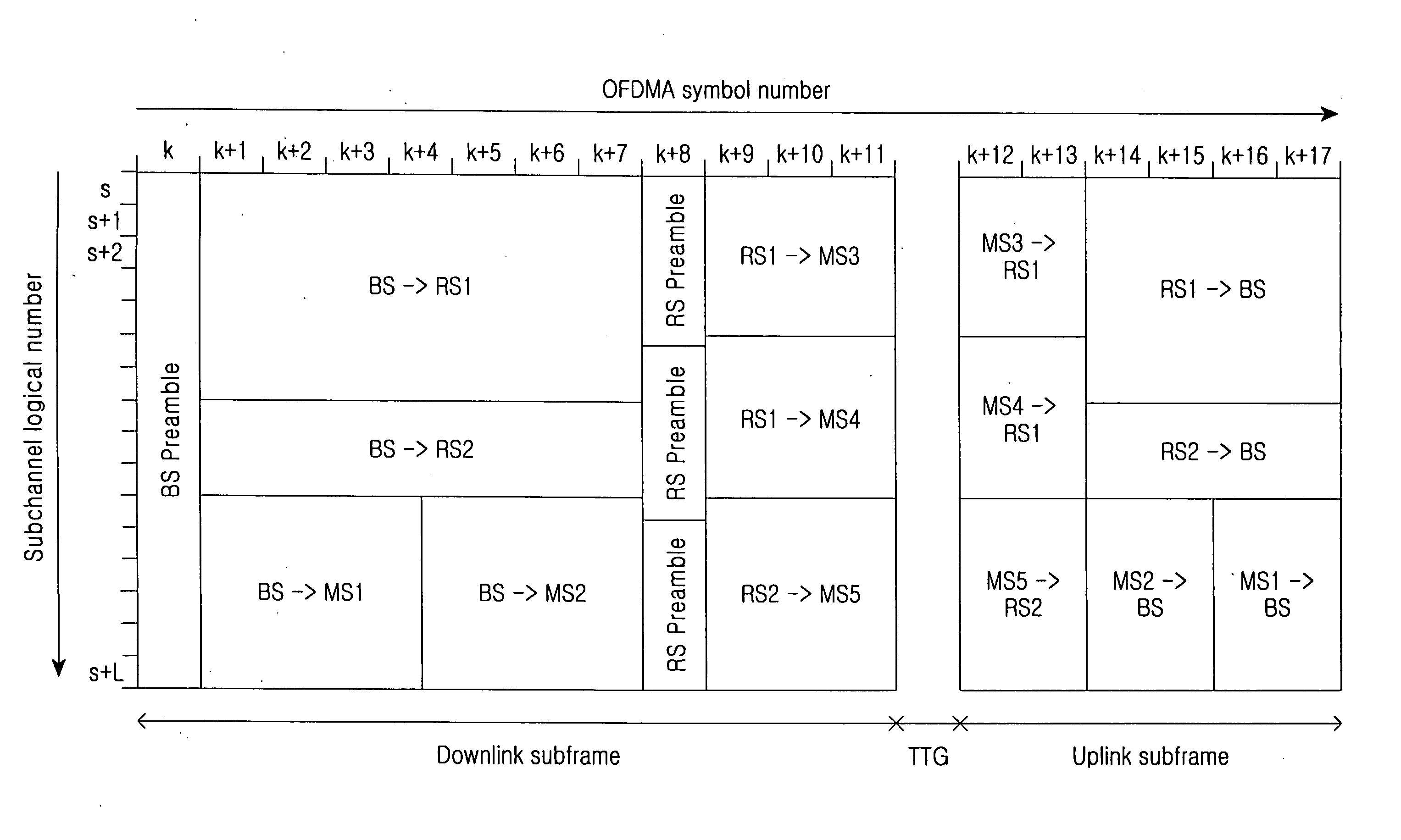

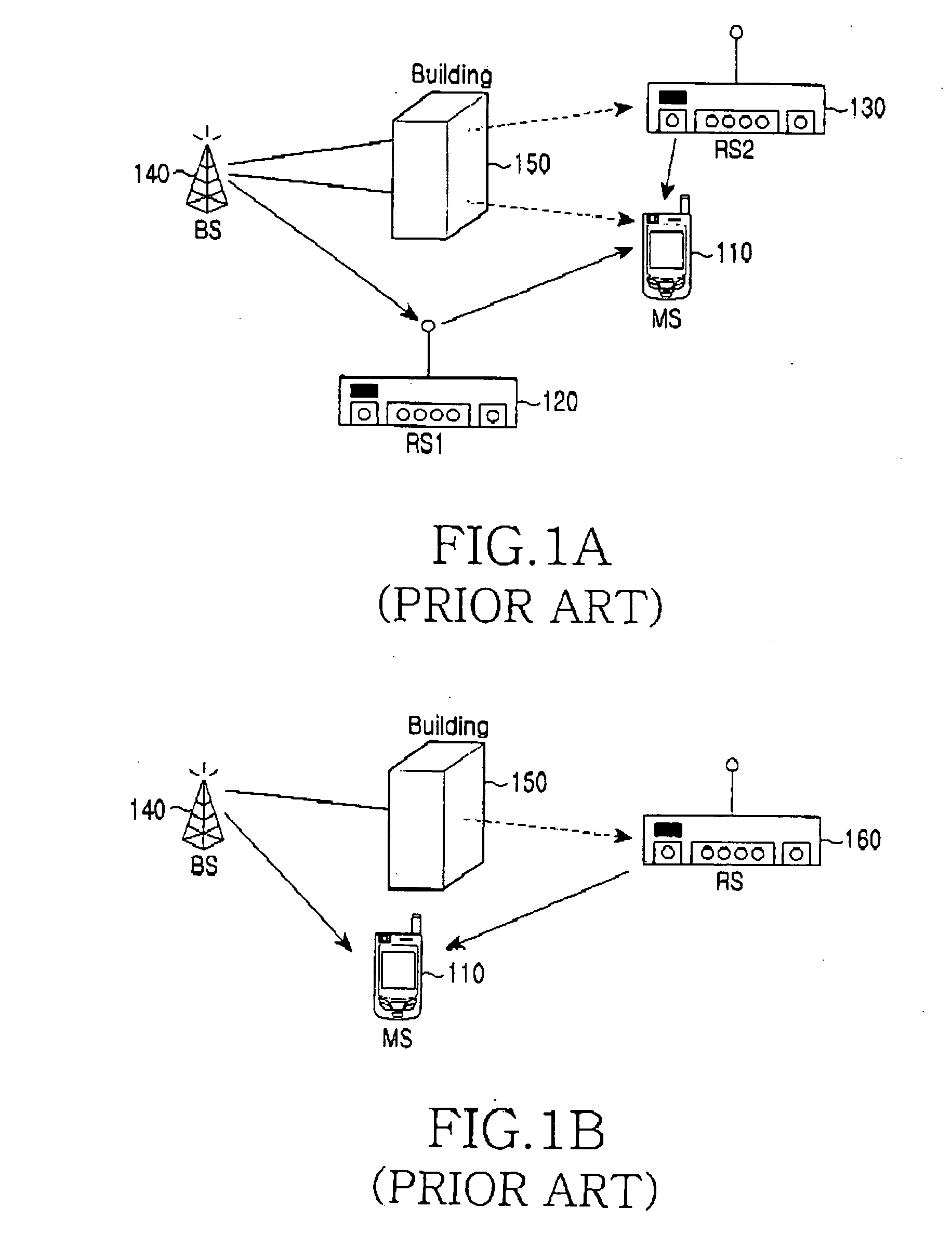

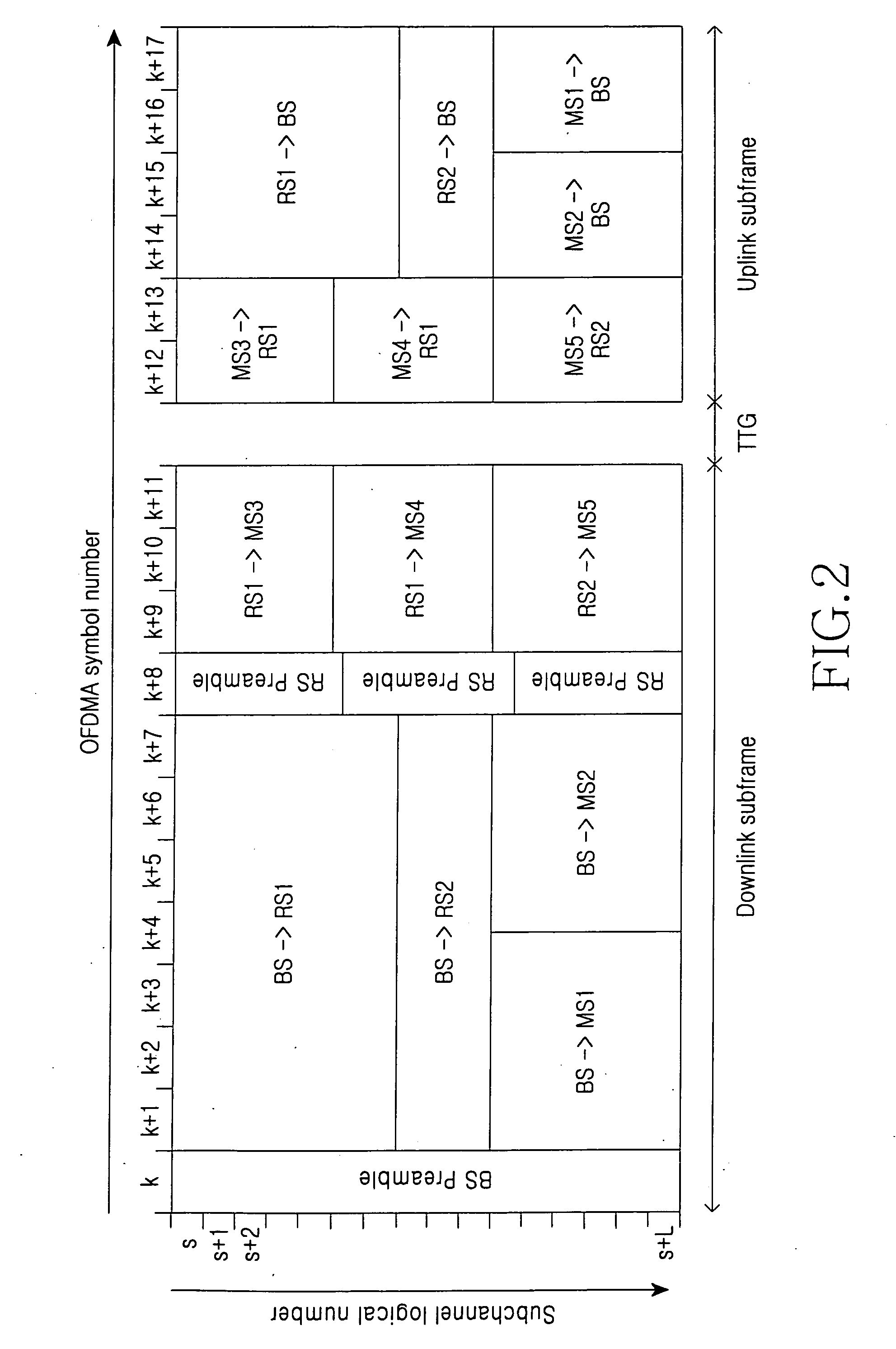

Routing apparatus and method in a multi-hop relay cellular network

InactiveUS20060285505A1Minimize message loadLoad minimizationNetwork topologiesData switching by path configurationCellular networkRSS

Owner:SAMSUNG ELECTRONICS CO LTD

Medical manipulator

ActiveUS20100198253A1Small sizeWide operating angleDiagnosticsSurgical manipulatorsManipulatorEngineering

A medical manipulator includes a wire movable in opposite directions, a driven wire having both ends thereof connected to the wire, an end effector of a distal-end working unit, a transmitting member, a crescent driven member integral with the transmitting member, and a return pulley. The transmitting member, the crescent driven member, and the return pulley are successively arranged in this order from the proximal end of the medical manipulator. When the driven wire is moved in opposite directions, the transmitting member also moves in opposite directions. At this time, the crescent driven member moves toward the return pulley, and the proximal-end portion of the return pulley enters a cavity of the crescent driven member.

Owner:KARL STORZ GMBH & CO KG

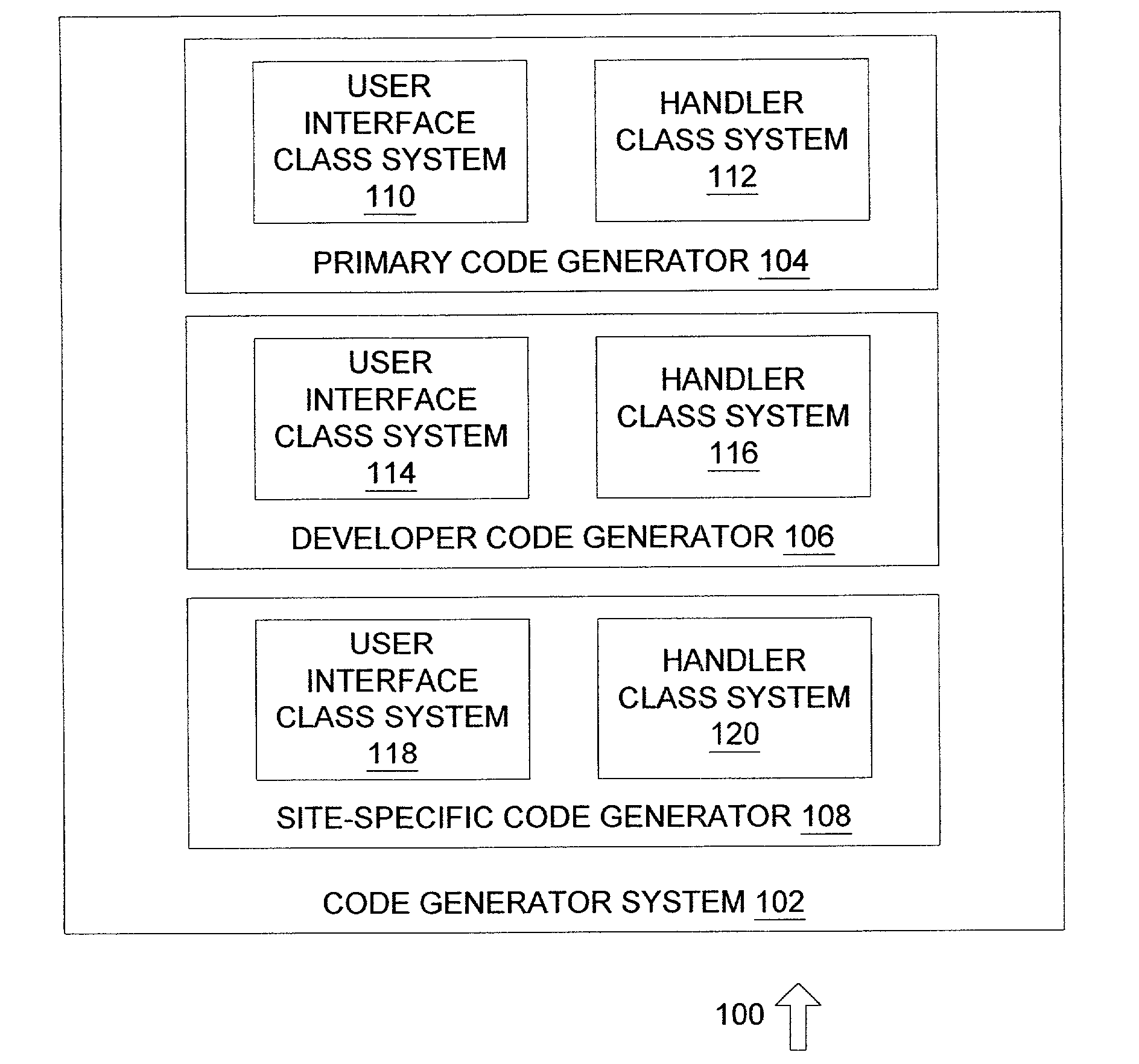

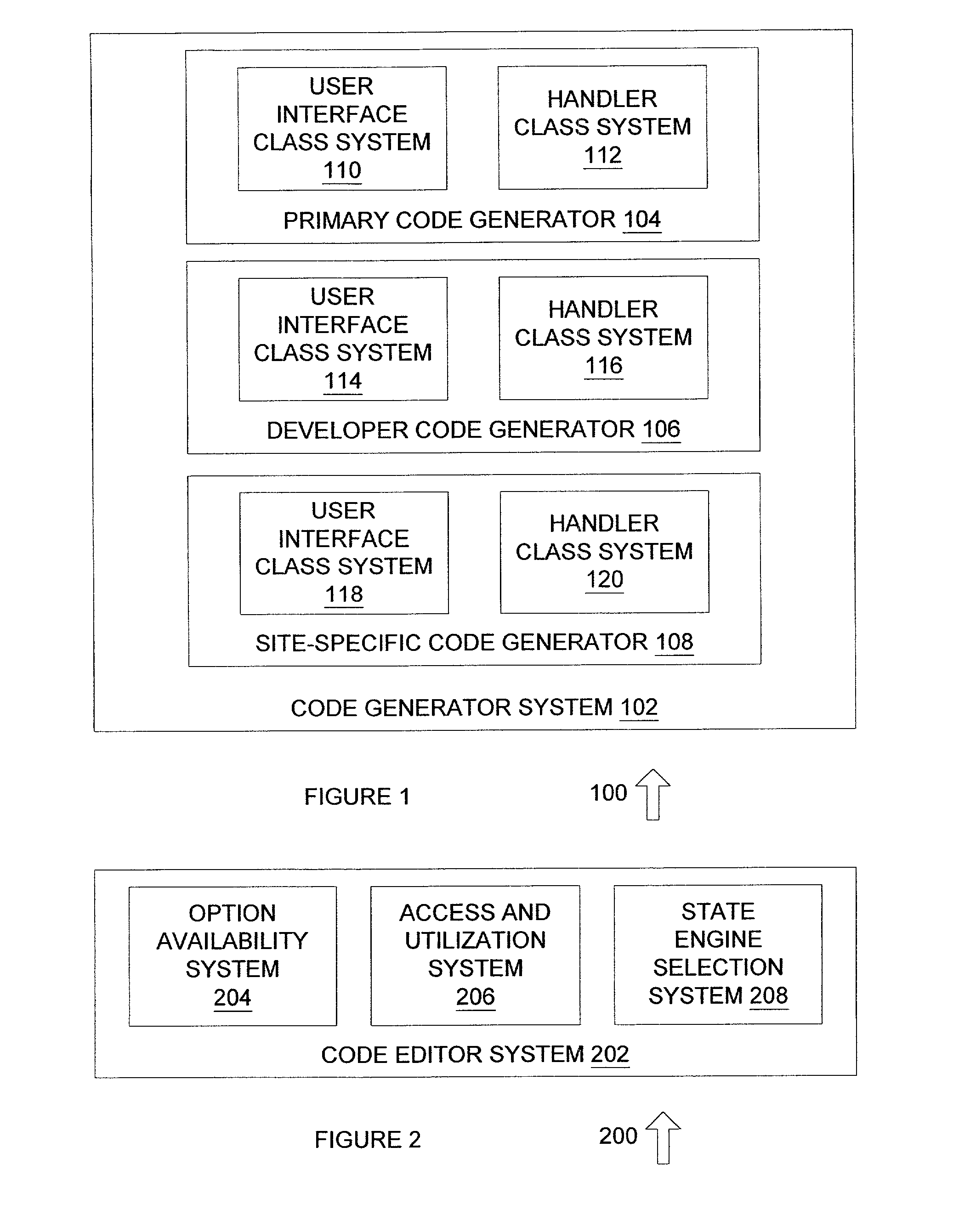

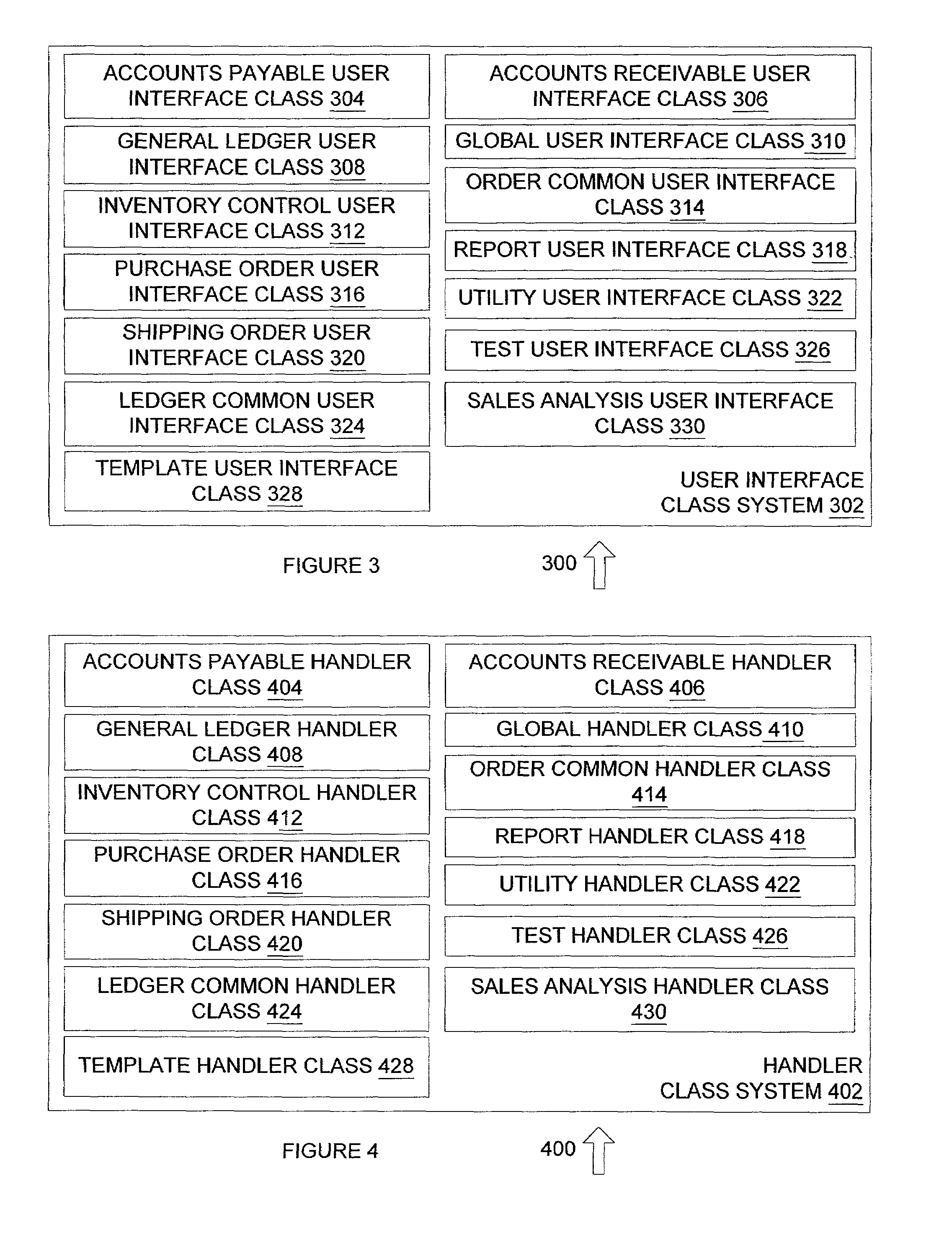

System and method for generating user interface code

ActiveUS7243334B1Execution of minimizedGeneration of minimizedComplete banking machinesFinanceData displayHuman–computer interaction

A system for generating user interface code is provided. The system includes a user interface class system generating a user interface class that has two or more user interface features that can be assembled into a user interface by an operator, such as field entry prompts and data display fields. The system also includes a handler class system generating one or more states for each user interface feature of the user interface class, such as to navigate through the field entry prompts and data display fields. The user interface class system, in conjunction with the handler class system, generates the user interface code that causes the selected user interface features and associated states for the user interface features to be generated.

Owner:EPICOR SOFTWARE CORP

Composite interbody spinal implant having openings of predetermined size and shape

ActiveUS8262737B2Add seatsImprove visualizationBone implantSpinal implantsSpinal implantBiomedical engineering

Owner:TITAN SPINE

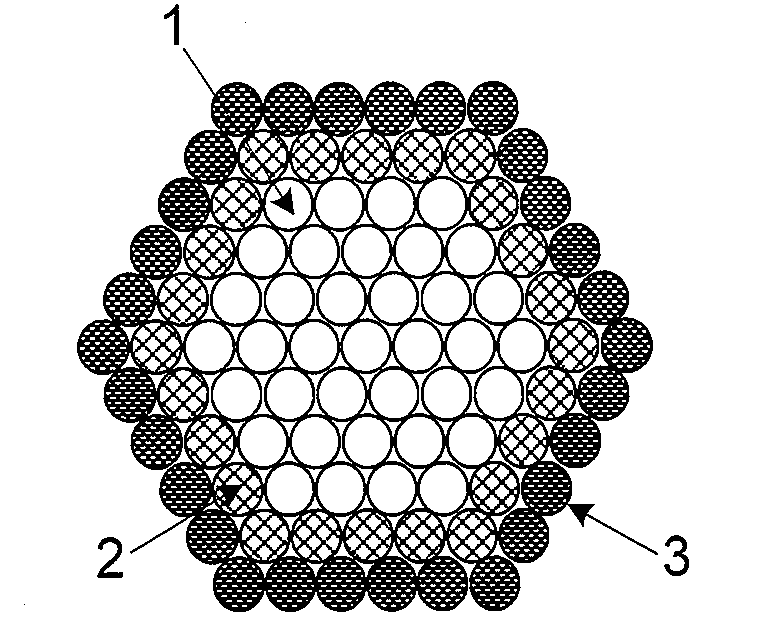

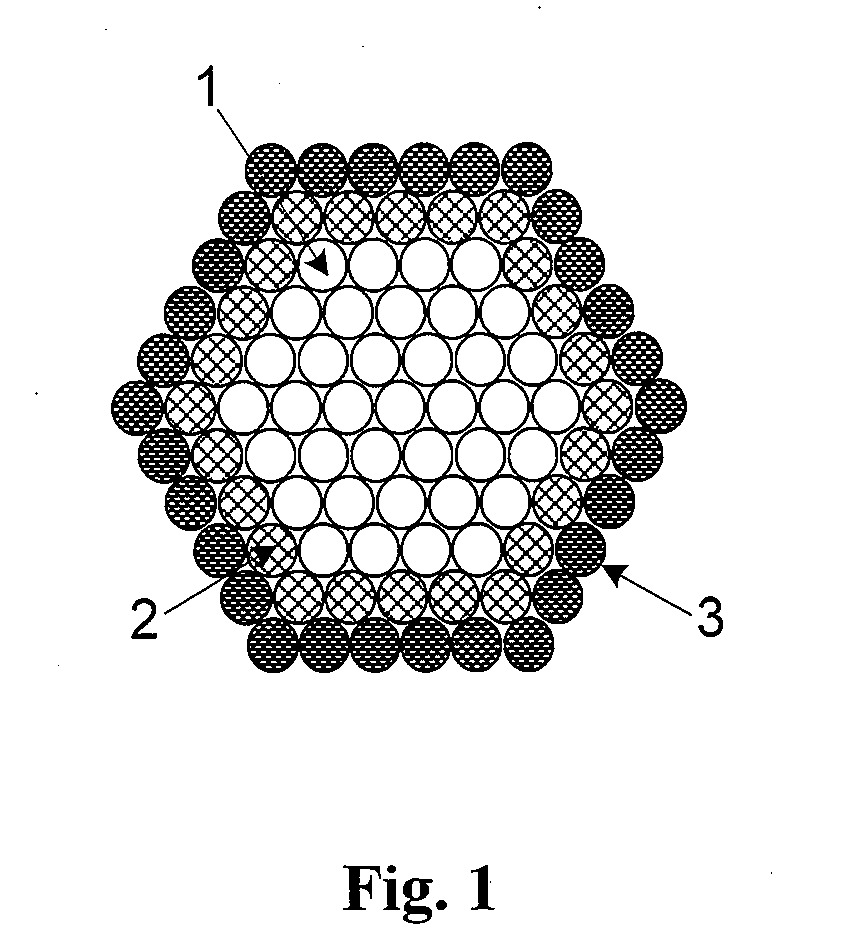

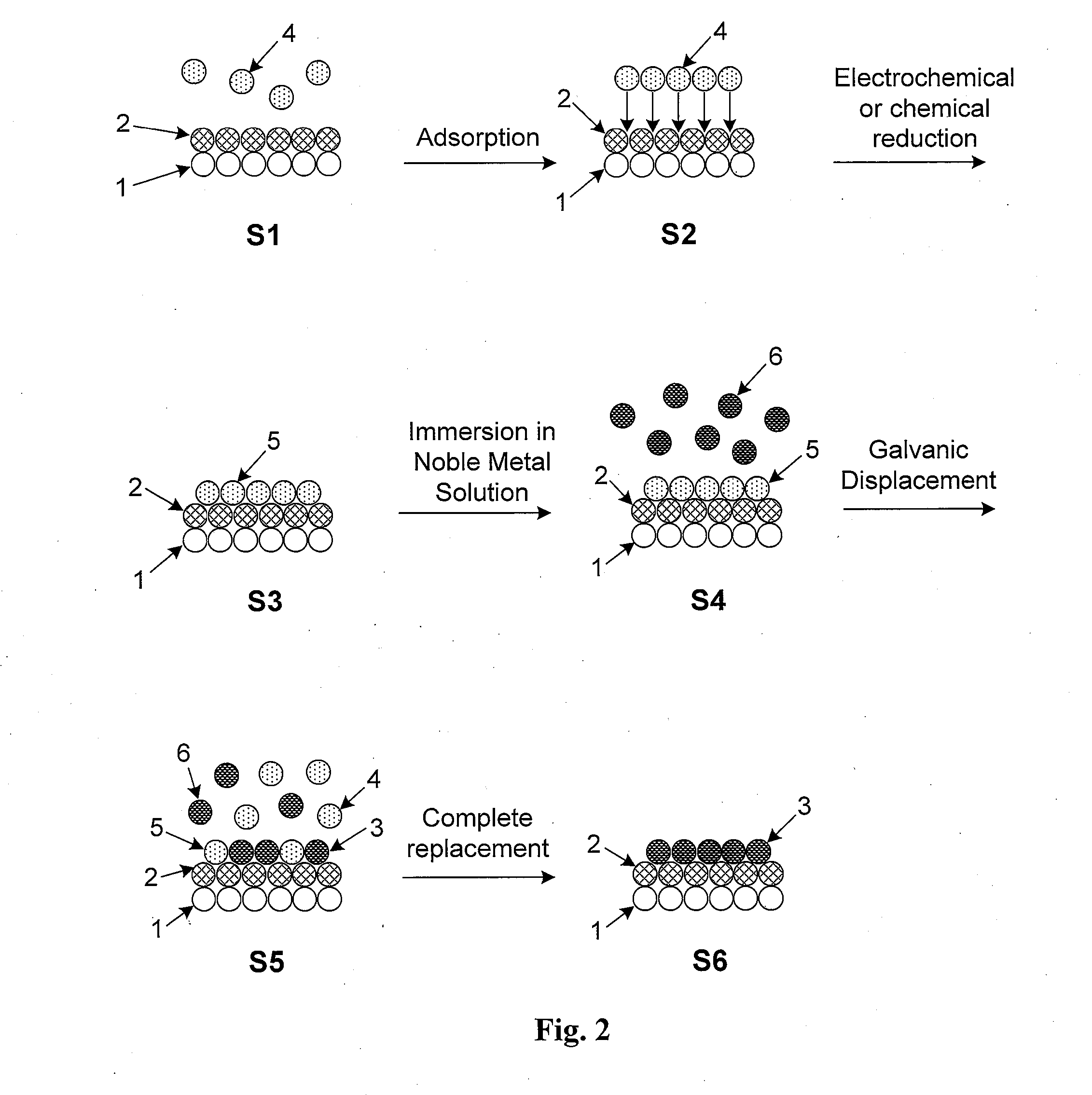

Platinum-Coated Non-Noble Metal-Noble Metal Core-Shell Electrocatalysts

InactiveUS20100197490A1Minimal loadingEfficiently formedMaterial nanotechnologyCell electrodesAlloyPt element

Core-shell particles encapsulated by a thin film of a catalytically active metal are described. The particles are preferably nanoparticles comprising a non-noble core with a noble metal shell which preferably do not include Pt. The non-noble metal-noble metal core-shell nanoparticles are encapsulated by a catalytically active metal which is preferably Pt. The core-shell nanoparticles are preferably formed by prolonged elevated-temperature annealing of nanoparticle alloys in an inert environment. This causes the noble metal component to surface segregate and form an atomically thin shell. The Pt overlayer is formed by a process involving the underpotential deposition of a monolayer of a non-noble metal followed by immersion in a solution comprising a Pt salt. A thin Pt layer forms via the galvanic displacement of non-noble surface atoms by more noble Pt atoms in the salt. The overall process is a robust and cost-efficient method for forming Pt-coated non-noble metal-noble metal core-shell nanoparticles.

Owner:BROOKHAVEN SCI ASSOCS

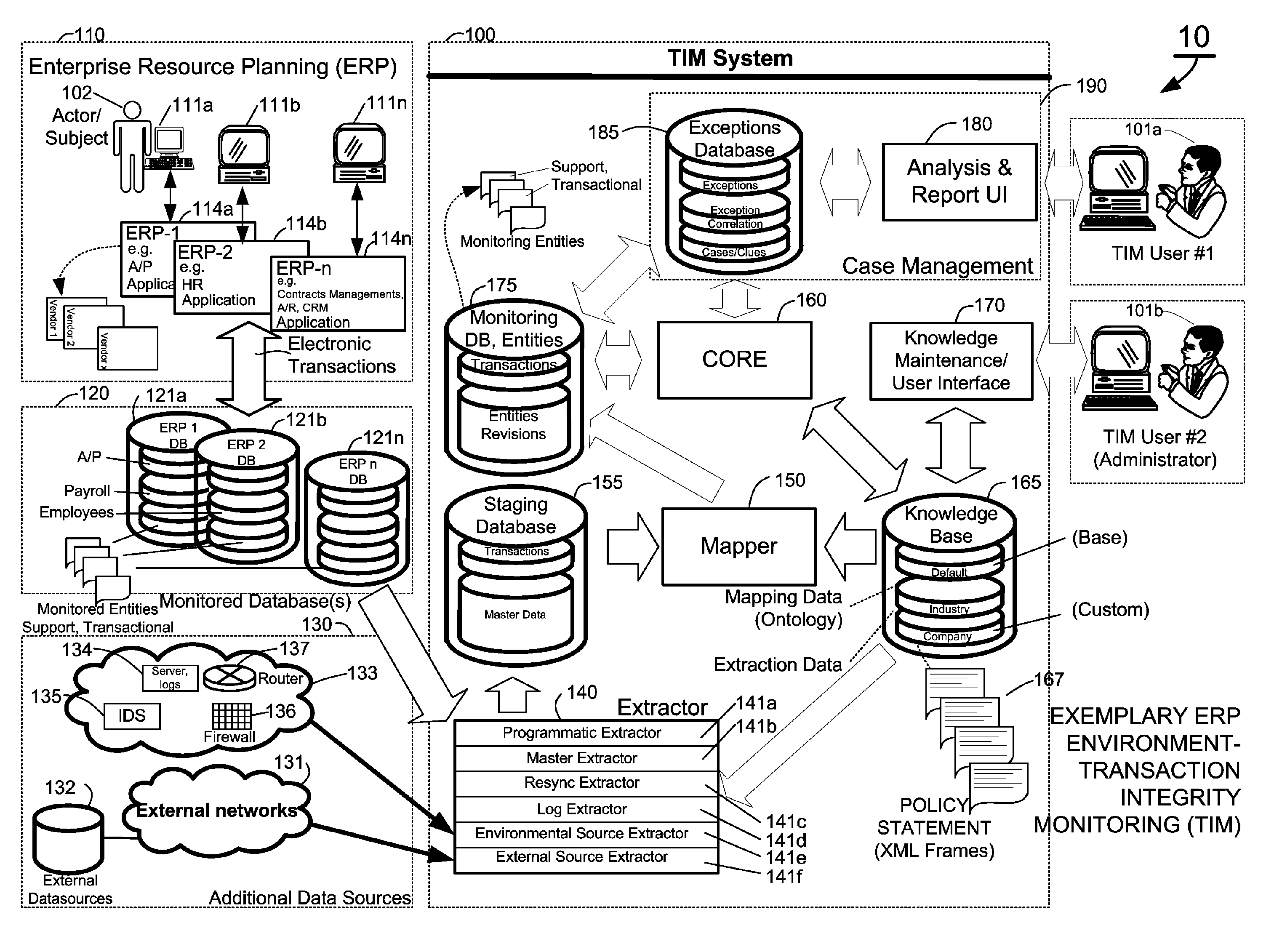

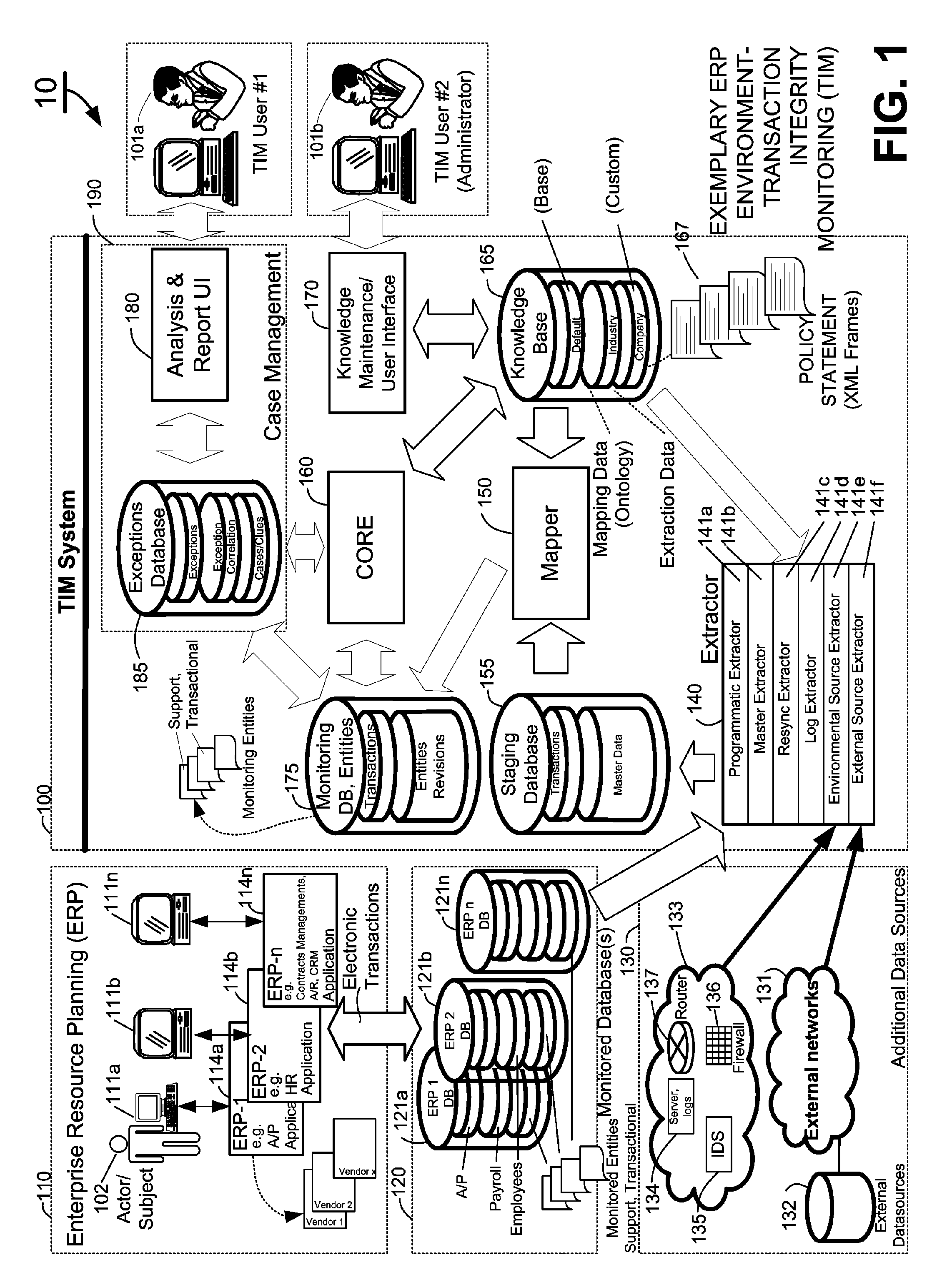

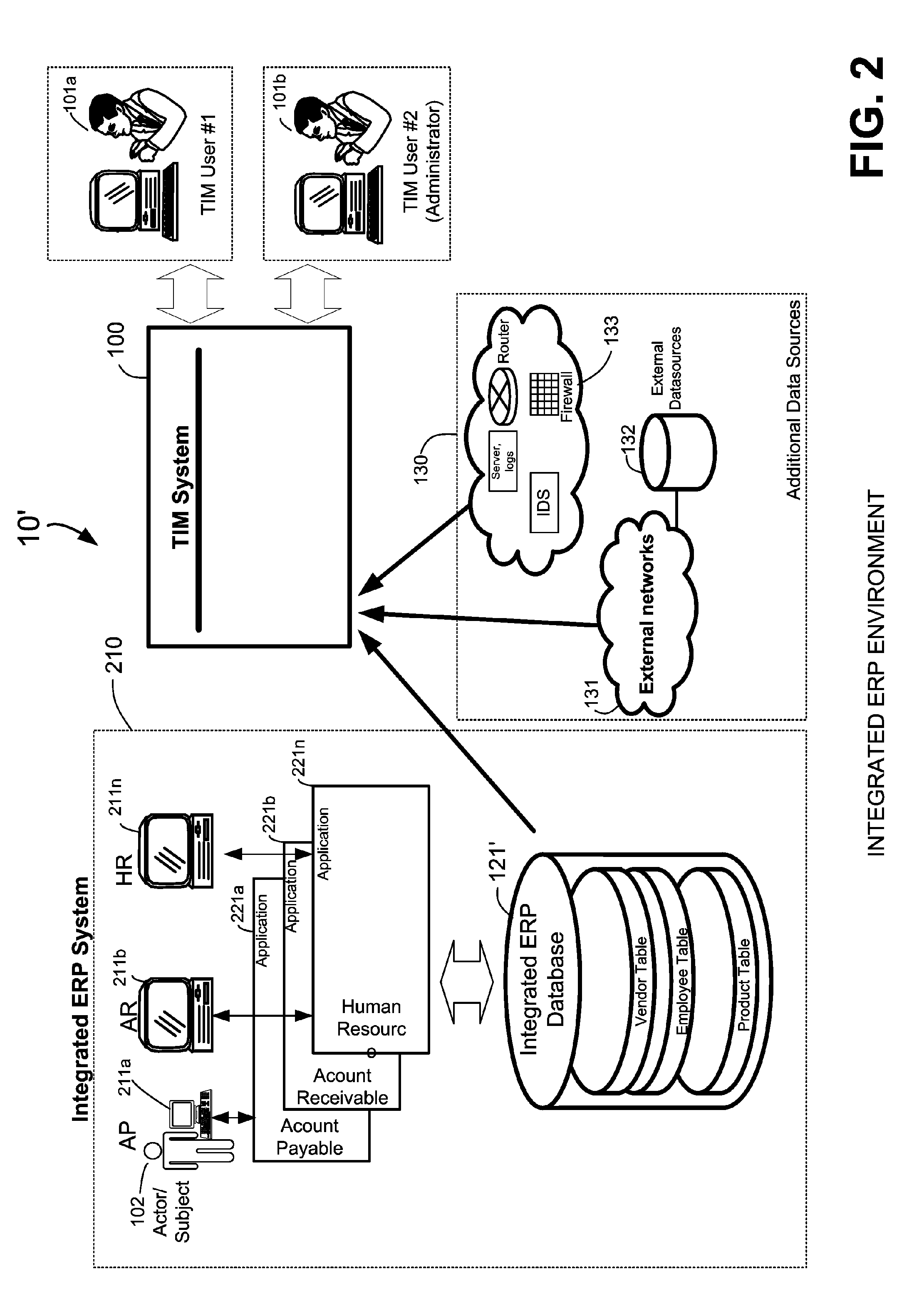

Methods and systems for extraction of transaction data for compliance monitoring

InactiveUS20080195579A1Load minimizationMinimizes financial lossDigital data information retrievalFinanceData ingestionCompliance Monitoring

Methods and systems for extraction of transaction data for compliance monitoring, particularly useful in a system for monitoring electronic transactions of an enterprise and detecting exceptions indicating noncompliance with enterprise policies. Data extractors obtain data from various data sources and provide the data for use by a transaction analysis engine that executes computer-executable compliance policy statements against extracted data. Data extractors include one or more of following: a master extractor, a log extractor, a resync extractor, a programmatic extractor, an environmental source extractor, and an external source extractor. Data extraction is effected by using the master extractor and / or programmatic extractor to extract an initial subset of information about monitored transactions from an enterprise system, and then using the log extractor, the resync extractor, the programmatic extractor, the environmental source extractor, and / or the external source extractor to extract a second subset of information about changed data.

Owner:KENNIS PETER H +7

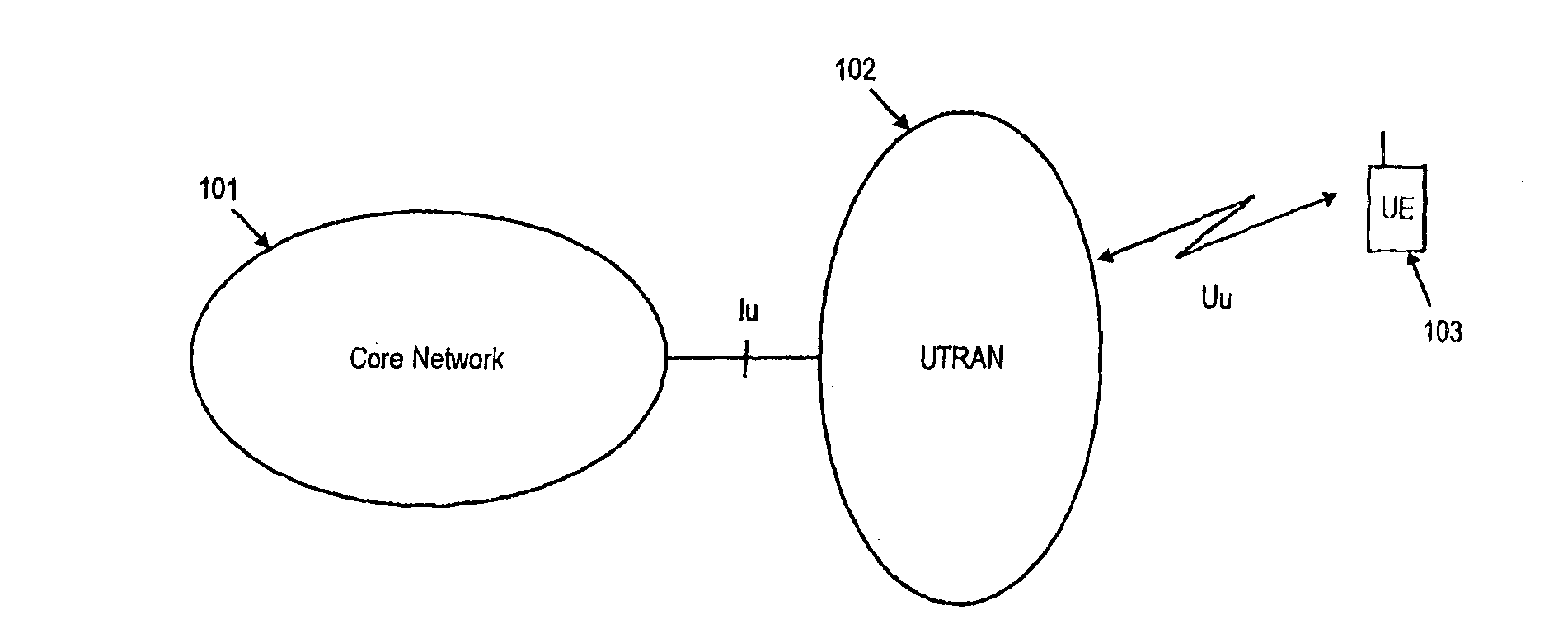

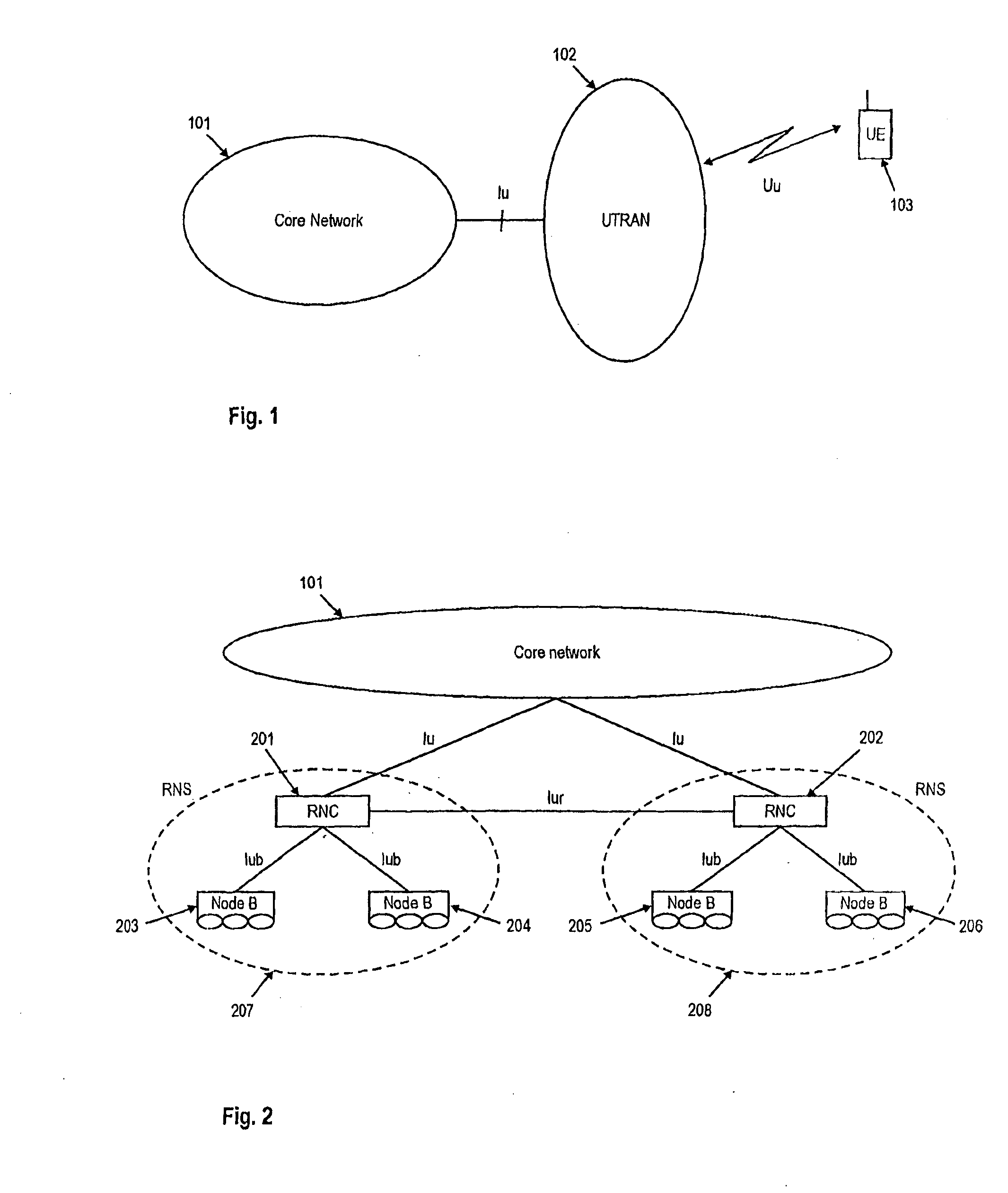

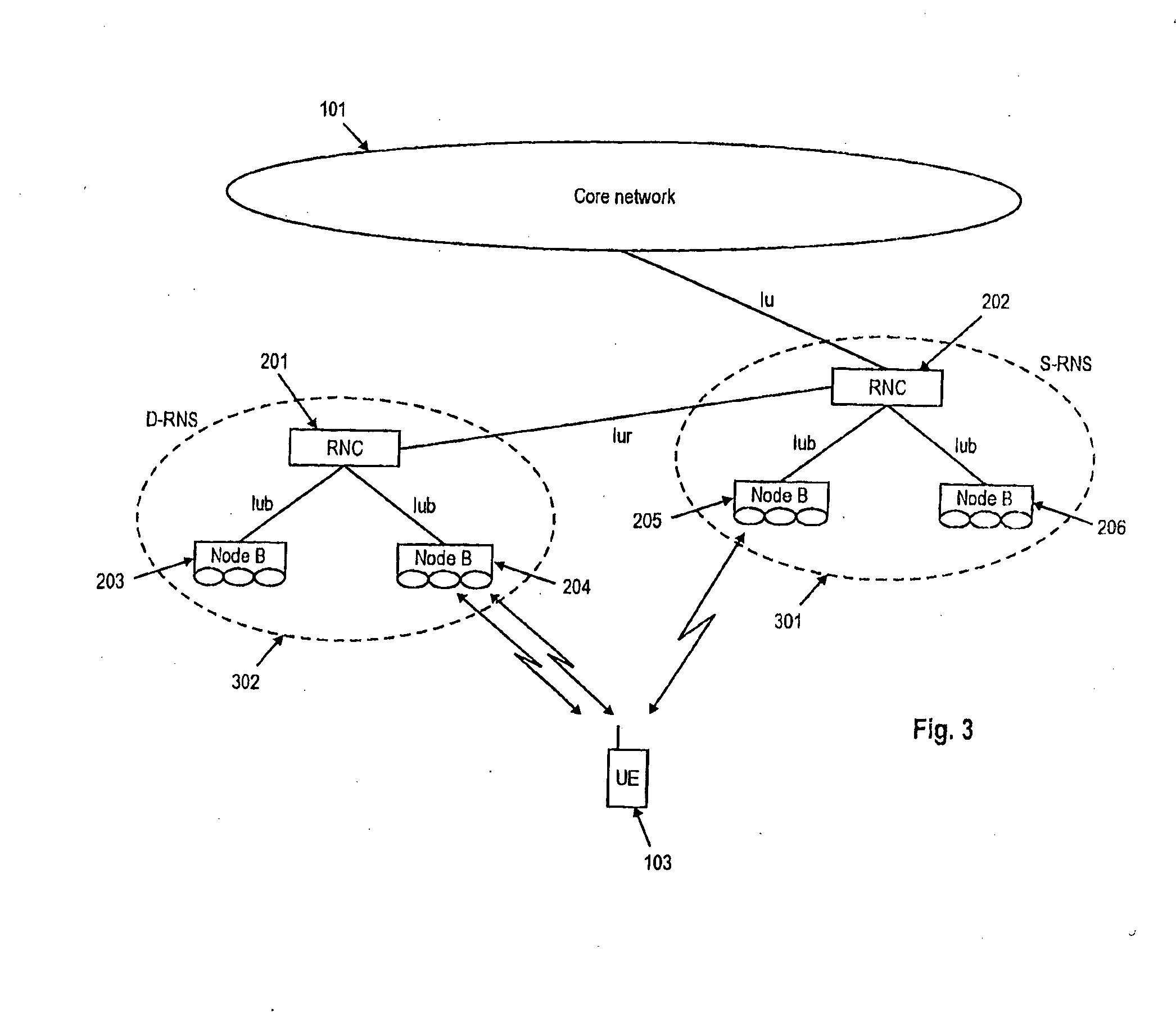

Delayed Base Station Relocation in Distributed Radio Access Networks

InactiveUS20080268852A1Load minimizationProcedure is slowRadio/inductive link selection arrangementsData switching networksCommunications systemControl signal

The present invention relates to a method for relocating control plane functionality of a serving base station in a mobile communication system comprising a mobile terminal and a plurality of base stations. Further, the present invention relates to a base station in a mobile communication system and to the mobile communication system. To tackle potentially intolerable delay of control signaling due to frequent serving network element relocations in the network architecture the present invention suggests a partial relocation of a serving network element wherein the control plane functionality is relocated but connection to the core network via a gateway is maintained through the previous serving network element. A further aspect of the present invention suggests a total relocation, where control plane functionalities are relocated and where a new connection to the core network is established between the new serving network element and the gateway. Also decision criteria on whether to perform partial or total relocation are provided.

Owner:PANASONIC CORP

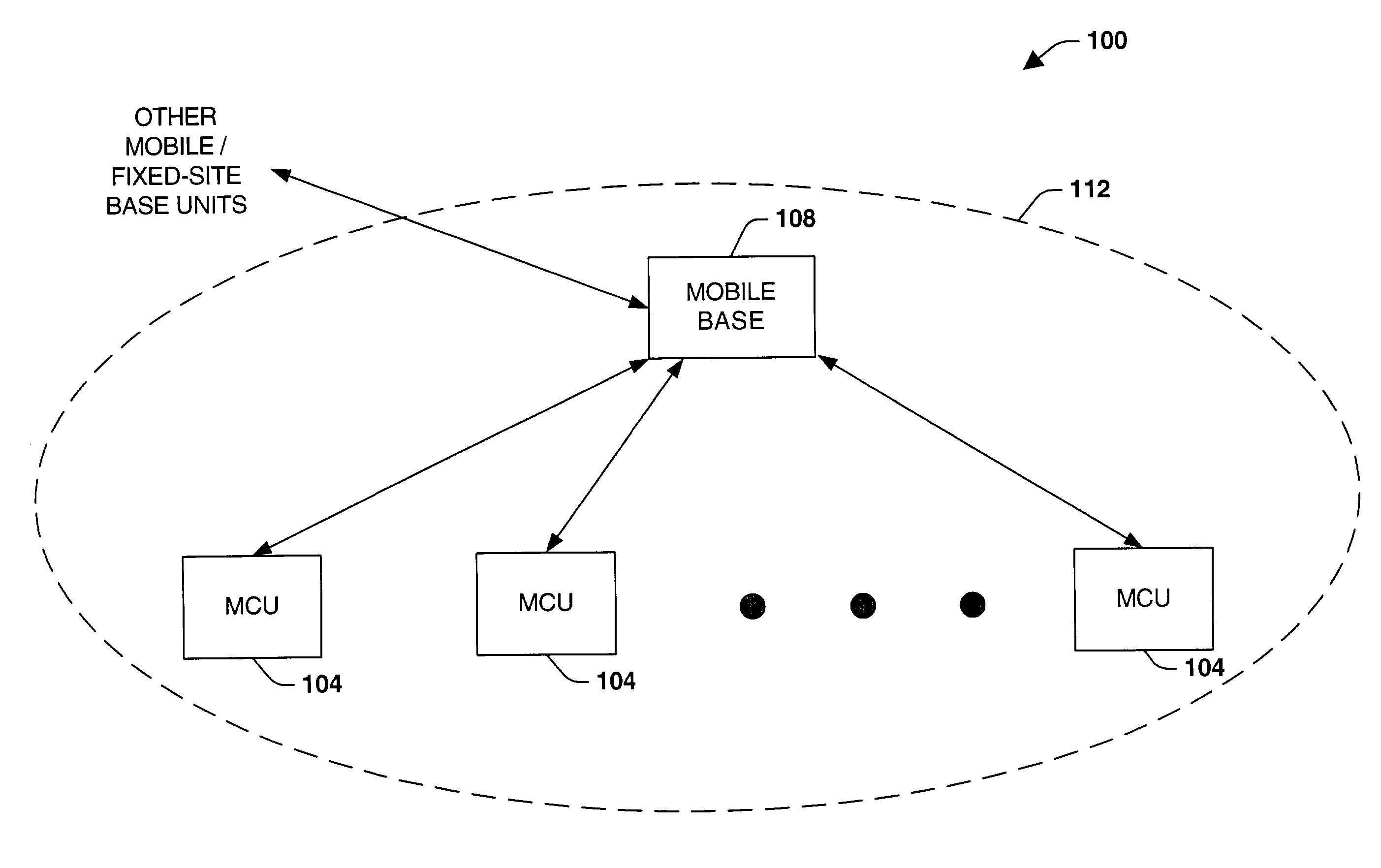

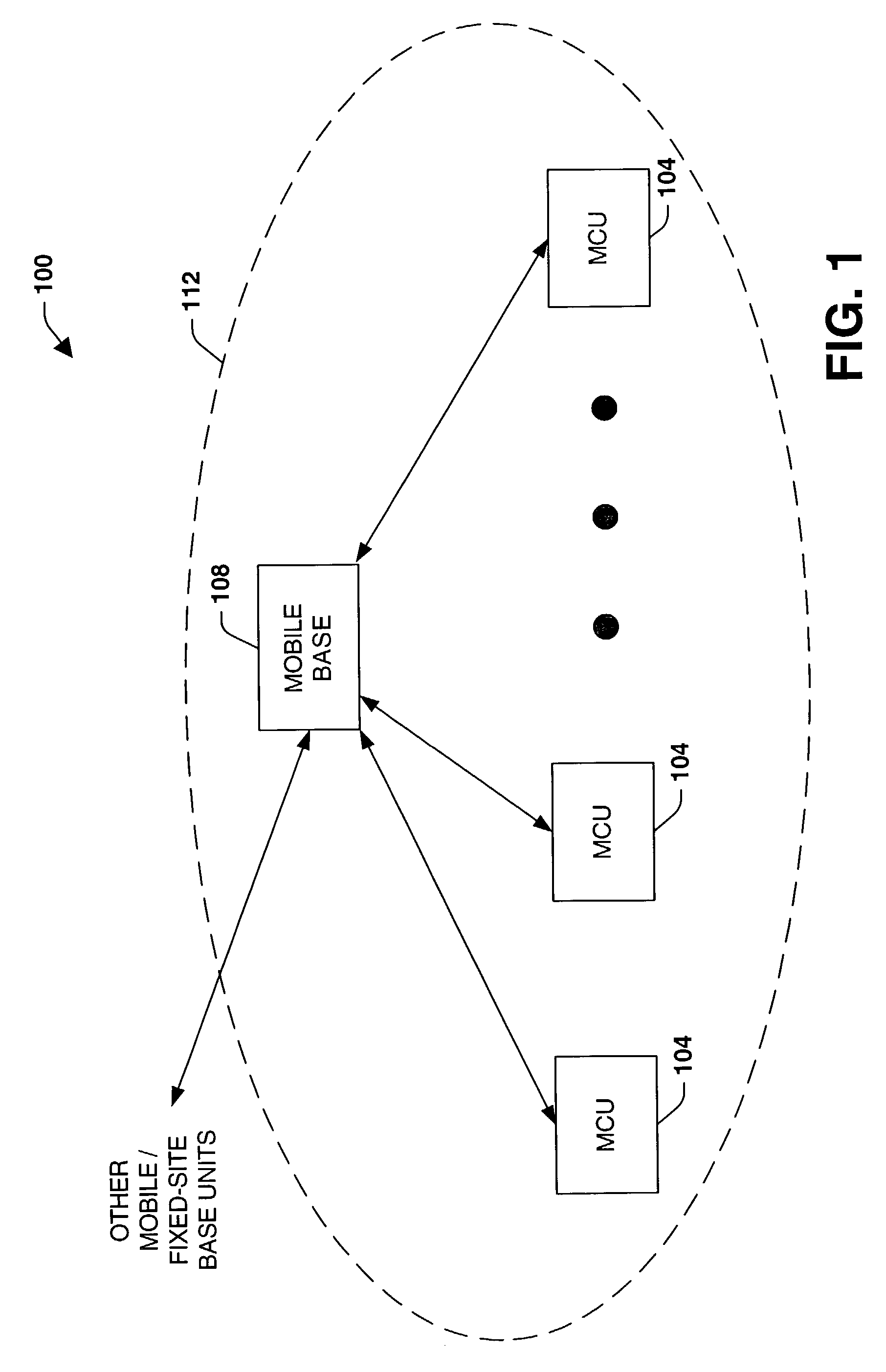

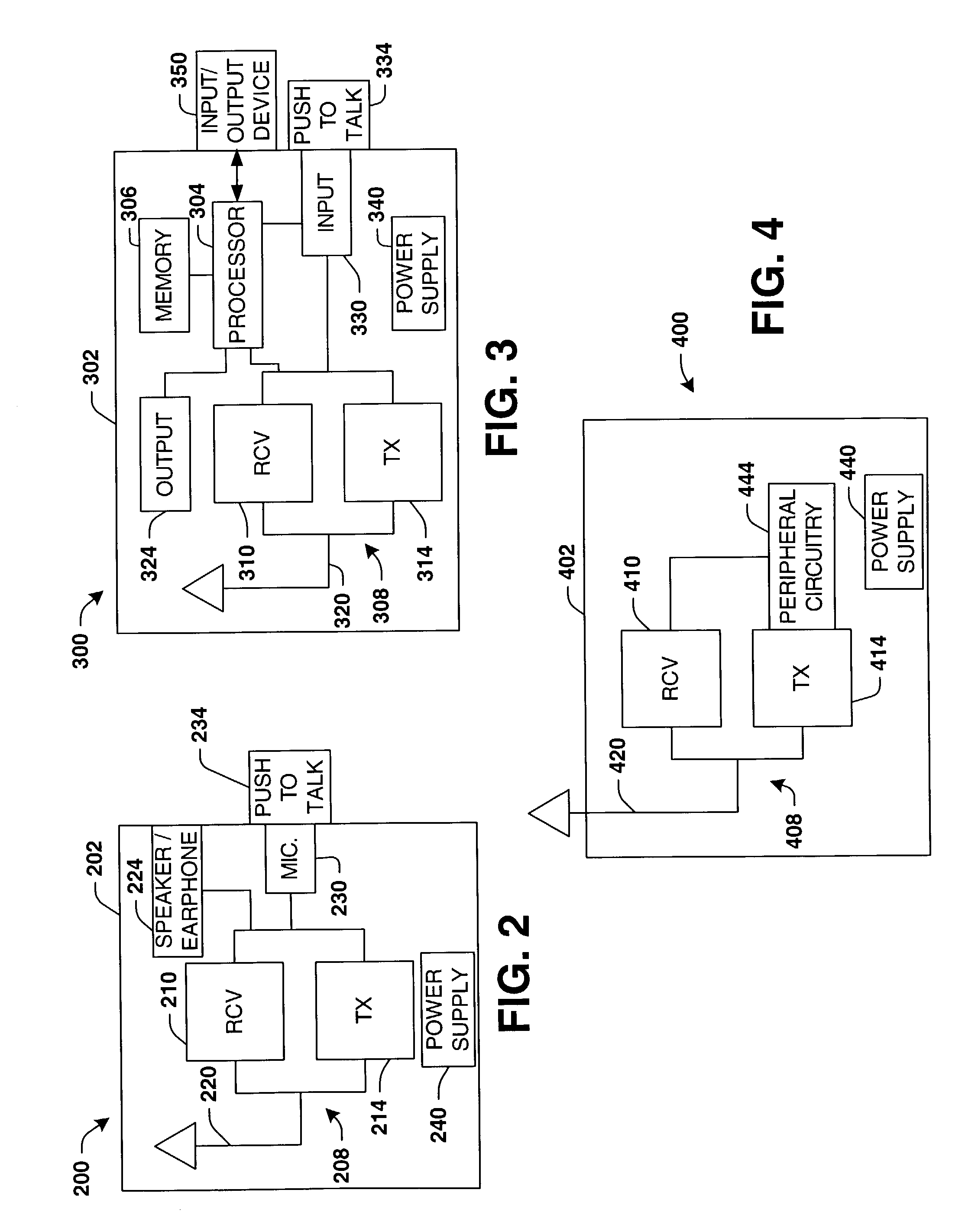

Communication system with mobile coverage area

InactiveUS20040097227A1Avoid accidentsMitigating one or more line-of-sight issuesAngle measurementNetwork topologiesCommunications systemCommunication unit

Systems and methods are disclosed for establishing and utilizing a mobile communication system having a mobile communication coverage area. The mobile communication system includes a plurality of mobile communication devices or units and a mobile base. The mobile base establishes a communication coverage area and provides mobility with respect to the coverage area. Communications between the plurality of mobile communication devices are transmitted to the mobile base, and retransmitted or re-broadcast from the mobile base to the destination mobile communication units.

Owner:NORTHROP GRUMMAN SYST CORP

Implant with critical ratio of load bearing surface area to central opening area

ActiveUS20120158144A1Easy to implantMaximizes visualizationBone implantSpinal implantsBody shapeVertebral bone

An implant that has a predefined ratio of load bearing surface area to the overall size of the implant body and specifically to the surface area of a centrally located opening of a vertical aperture which connects to a center void area or passage defined by the implant body shape. This invention discloses a critical ratio or balance between loading of contained graft material through the hollow center or central passage of the implant and the implant's frictional load bearing or contact area with e.g., adjacent vertebral bones. Application of this invention to a spinal implant provides an improved integration and integration rate of the graft material or the fusion of the adjacent vertebral bone structures. The ratio between implant load bearing surface area and implant central opening area maximizes implant internal volume and allows a large passage disposed medial laterally to allow for radiographic verification of fusion growth.

Owner:TITAN SPINE

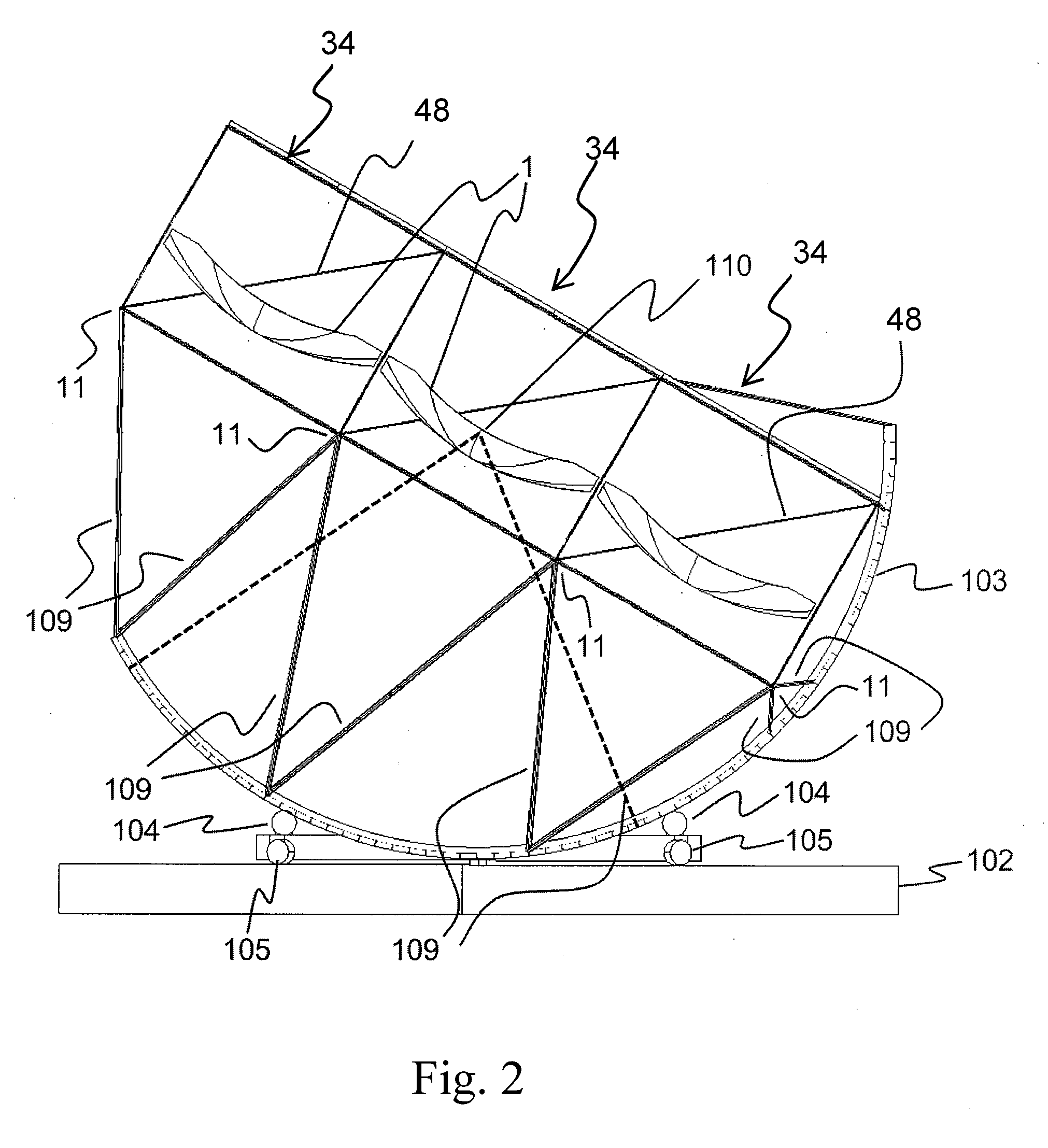

Method of manufacturing large dish reflectors for a solar concentrator apparatus

ActiveUS20090277224A1Reduce supporting costsMaximizes stiffnessSolar heating energySolar heat devicesProduction rateProduction line

A method of manufacturing monolithic glass reflectors for concentrating sunlight in a solar energy system is disclosed. The method of manufacturing allows large monolithic glass reflectors to be made from float glass in order to realize significant cost savings on the total system cost for a solar energy system. The method of manufacture includes steps of heating a sheet of float glass positioned over a concave mold until the sheet of glass sags and stretches to conform to the shape of the mold. The edges of the dish-shaped glass are rolled for structural stiffening around the periphery. The dish-shaped glass is then silvered to create a dish-shaped mirror that reflects solar radiation to a focus. The surface of the mold that contacts the float glass preferably has a grooved surface profile comprising a plurality of cusps and concave valleys. This grooved profile minimizes the contact area and marring of the specular glass surface, reduces parasitic heat transfer into the mold and increases mold lifetime. The disclosed method of manufacture is capable of high production rates sufficiently fast to accommodate the output of a conventional float glass production line so that monolithic glass reflectors can be produced as quickly as a float glass production can make sheets of float glass to be used in the process.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

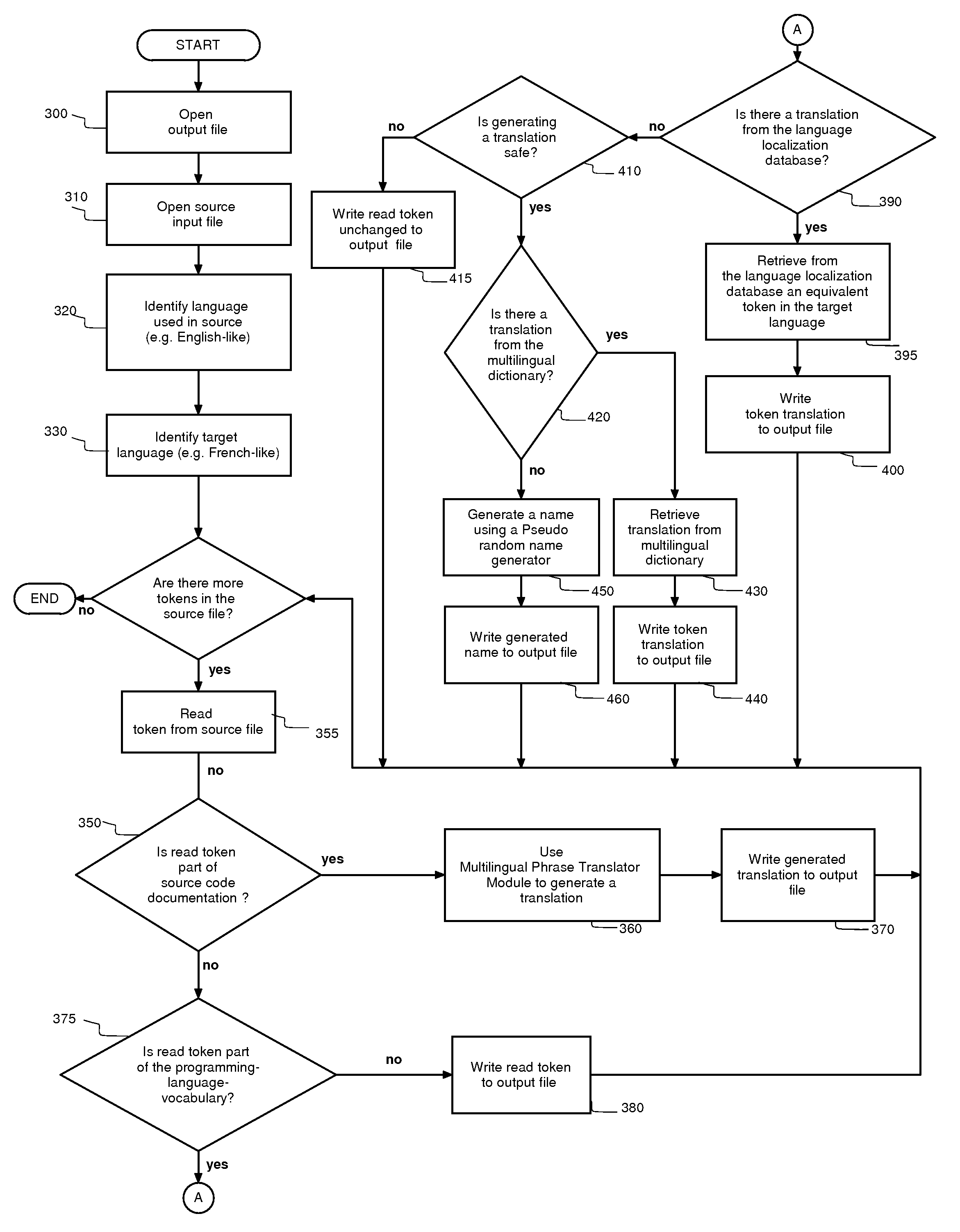

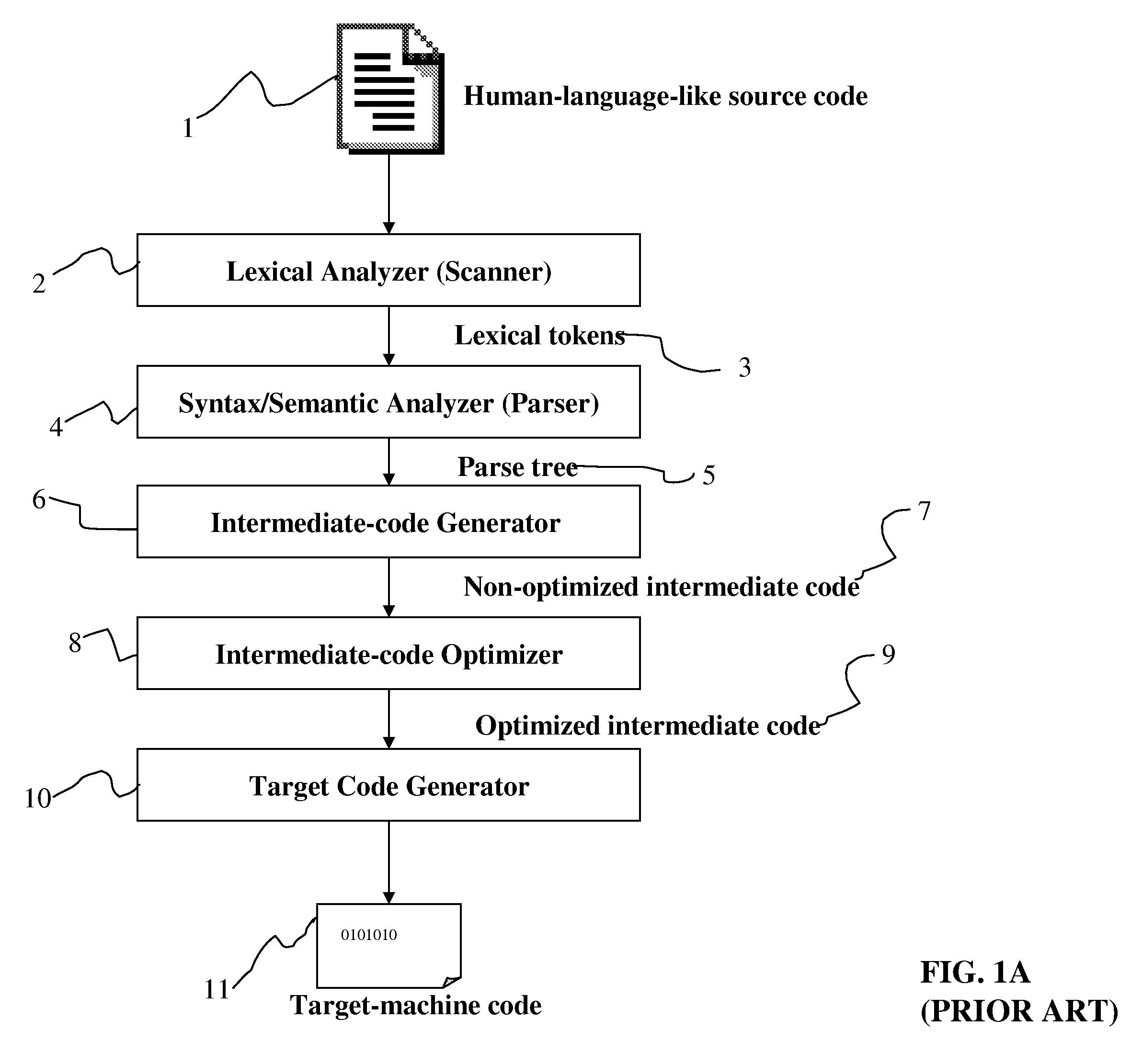

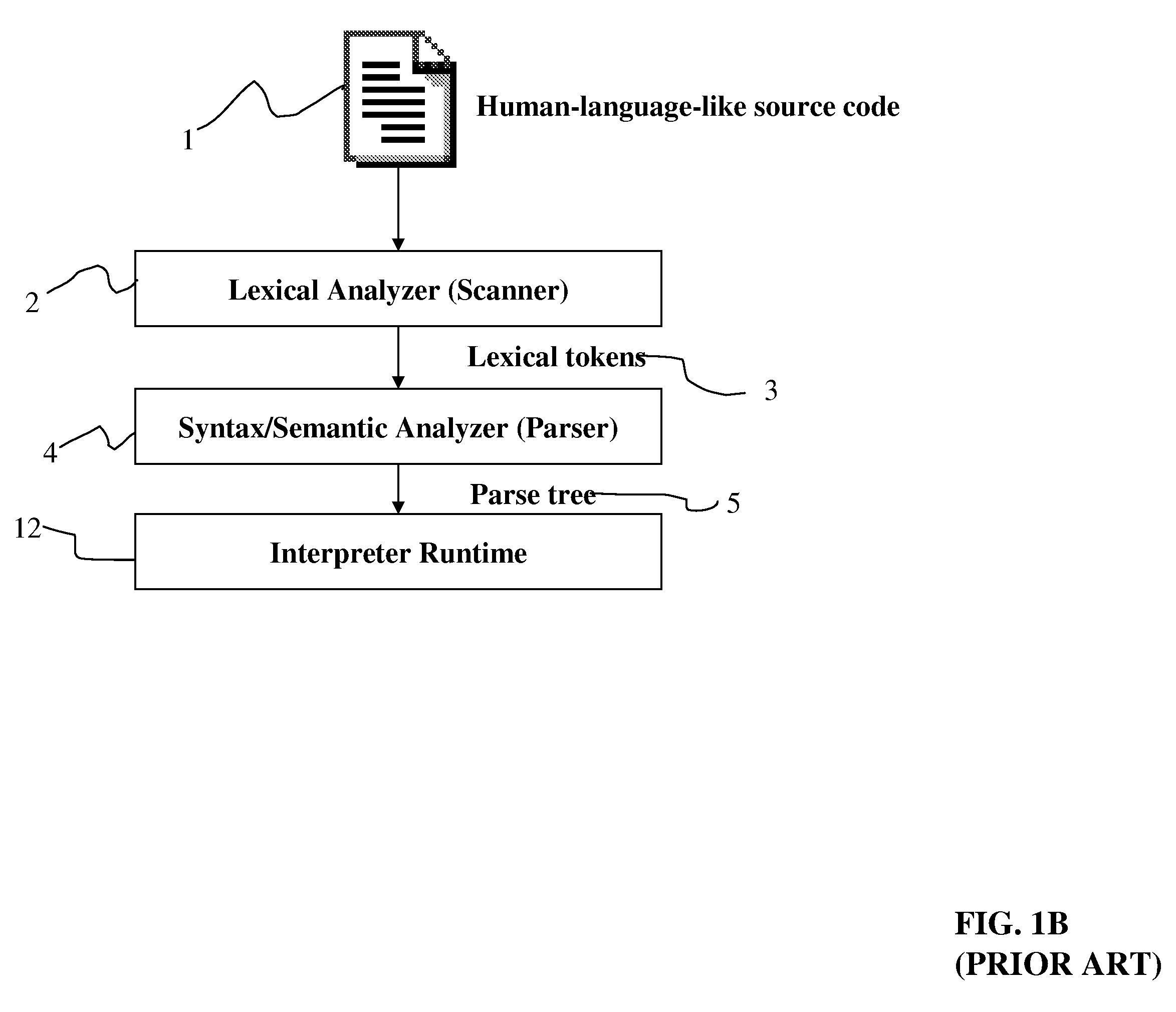

Multilingual compiler system and method

InactiveUS20060271920A1Overcome problemsMinimize programmer 's cognitive loadExecution for user interfacesMemory systemsHuman languageSoftware

A method and system are provided for creating multilingual computer programs. Programmers use their own native language in writing software instructions and commands and the invention translates those either to another native language or to a native-language-independent representation. The invention supports having a single computer program with multiple native languages.

Owner:ABOUELSAADAT WAEL

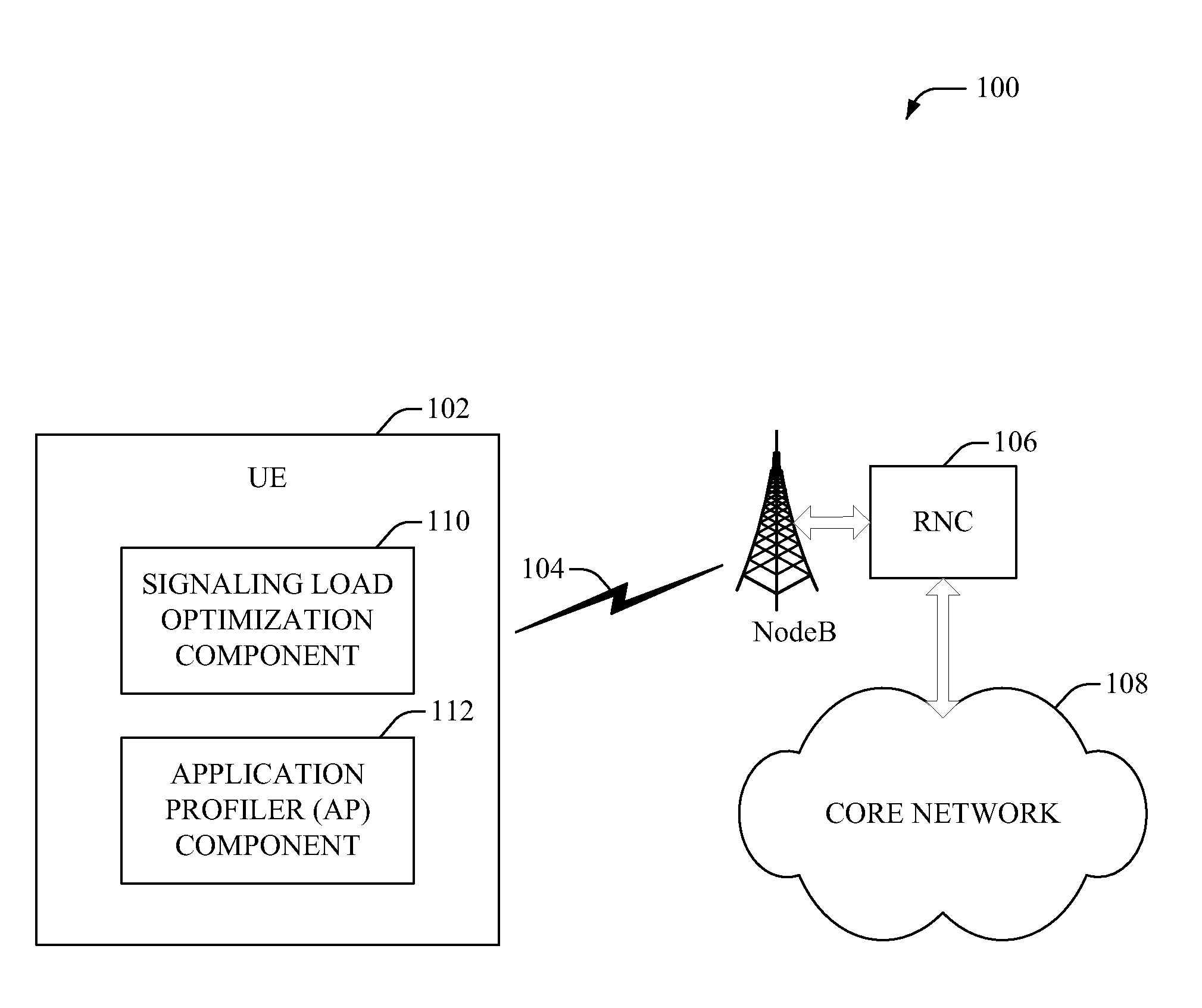

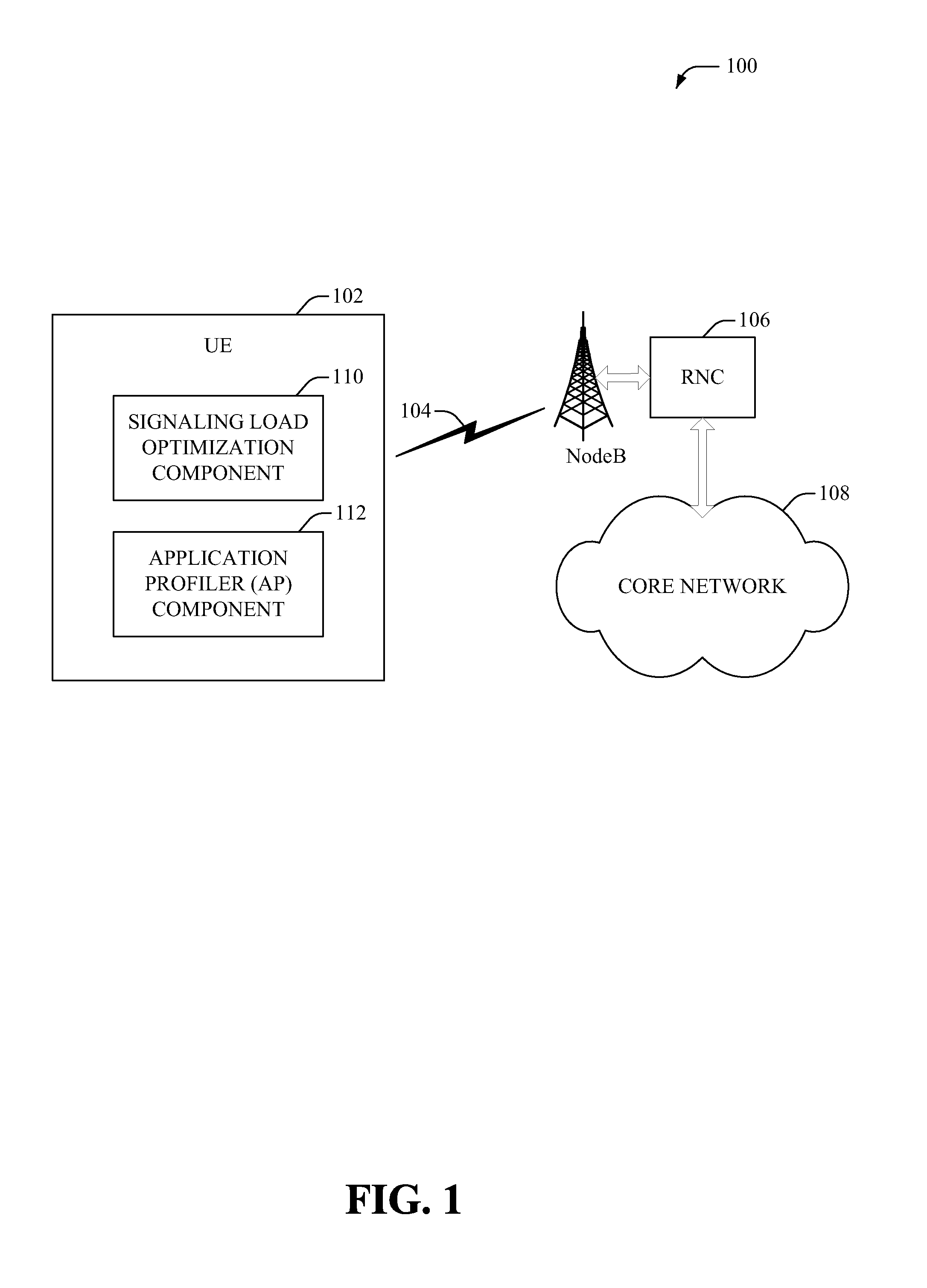

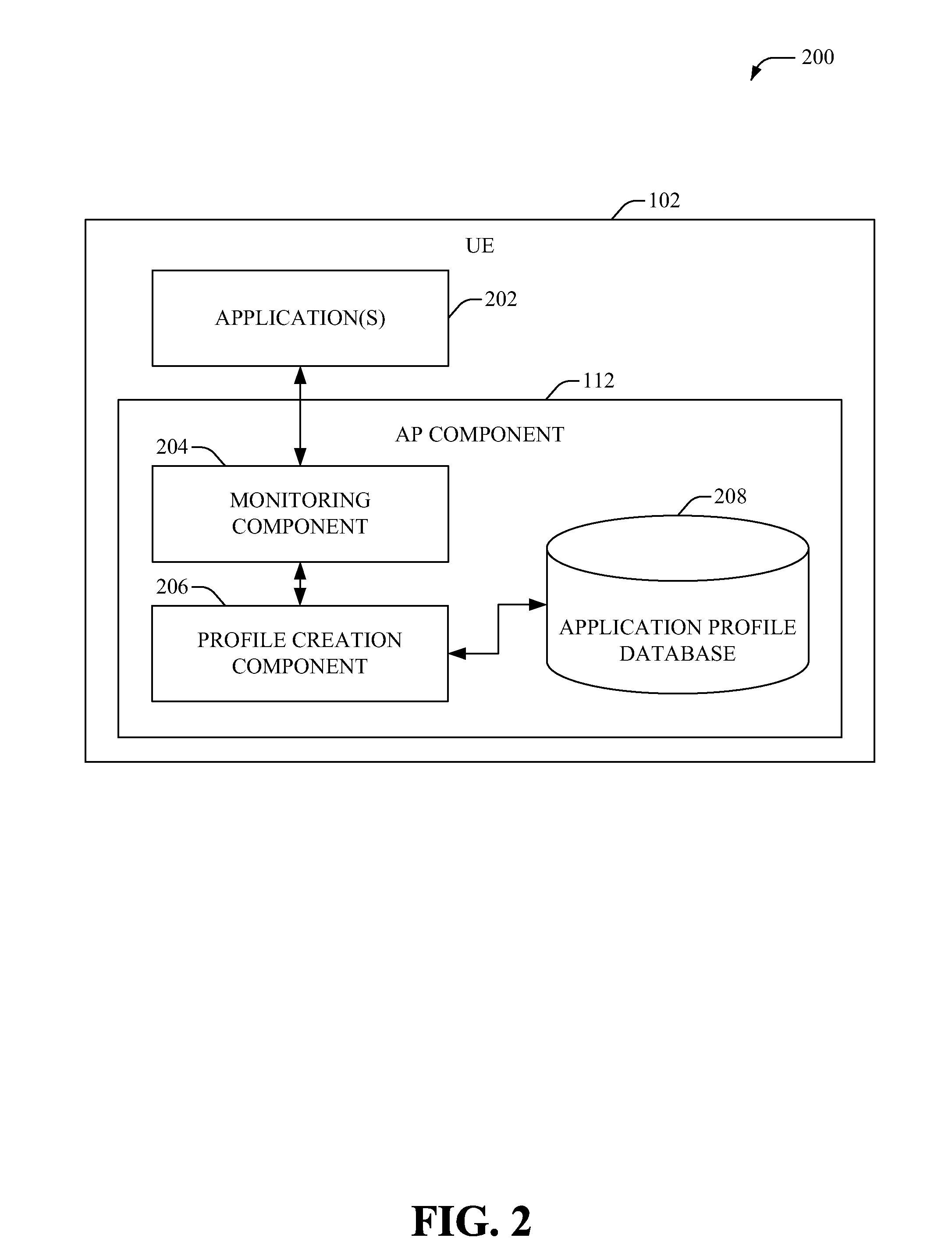

Data bundling and fast dormancy based upon intelligent application learning

ActiveUS20120124196A1Facilitate bundling data sessionQuick controlPower managementEnergy efficient ICTData streamArrival time

A system and methodology that performs data bundling and controls fast dormancy based on application monitoring and classification is provided. Moreover, the system provides a balance between saving battery power of a user equipment (UE) and reducing signaling and processing load in a radio resource controller (RRC). Specifically, the system observes data flow related behavior of applications on the UE. On receiving a first data flow request, an arrival time of a next data flow request is predicted based on an analysis of the behavior, and the system determines whether the two data flows can be bundled together and transmitted over a single connection. Additionally, on completion of the first data flow, the arrival time of the next data flow request is predicted based on the analysis, and the system determines whether a fast dormancy timer can be disabled to transmit the next data flow over the current connection.

Owner:AT&T MOBILITY II LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com