Patents

Literature

417results about How to "Reduce supporting costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

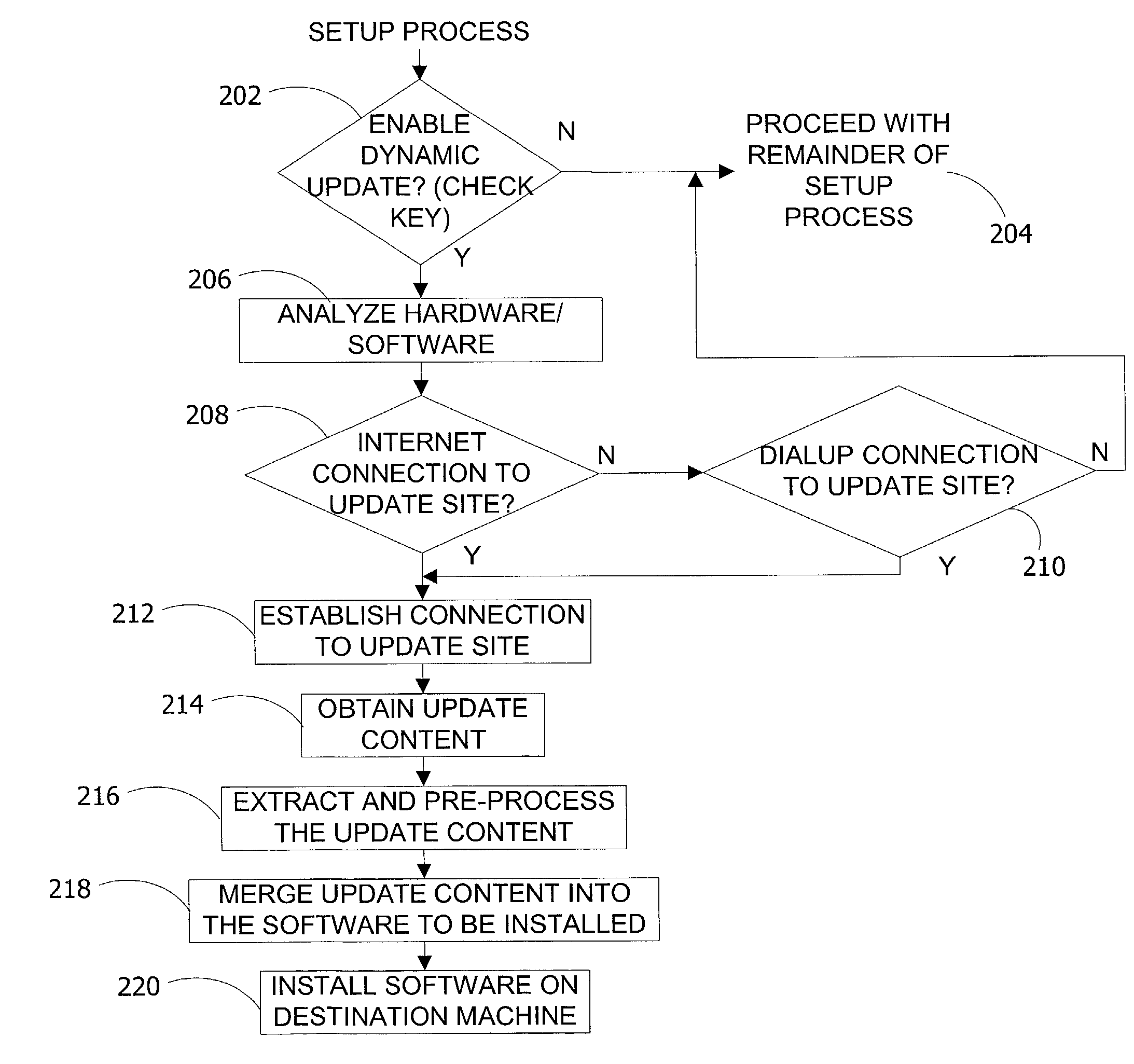

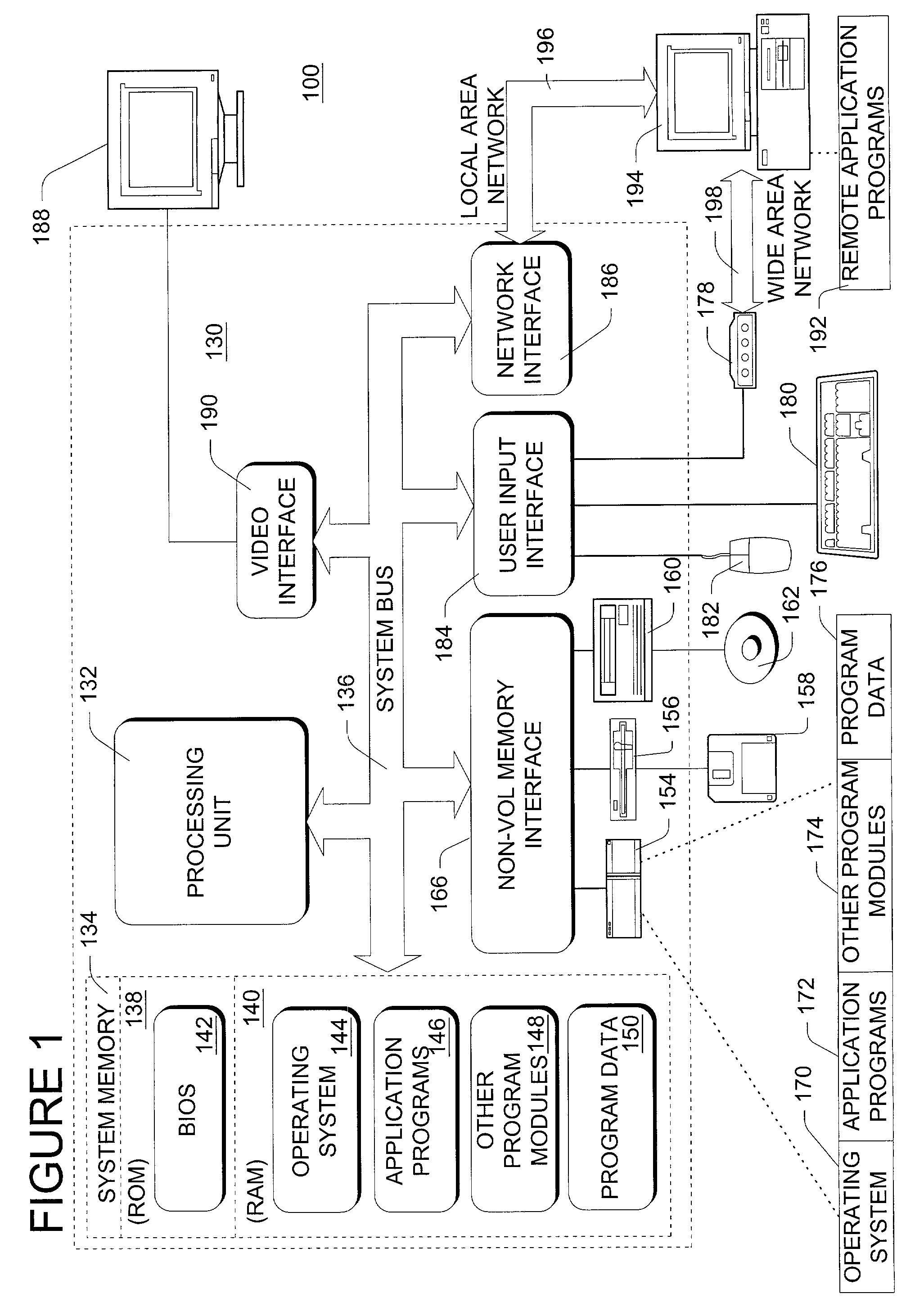

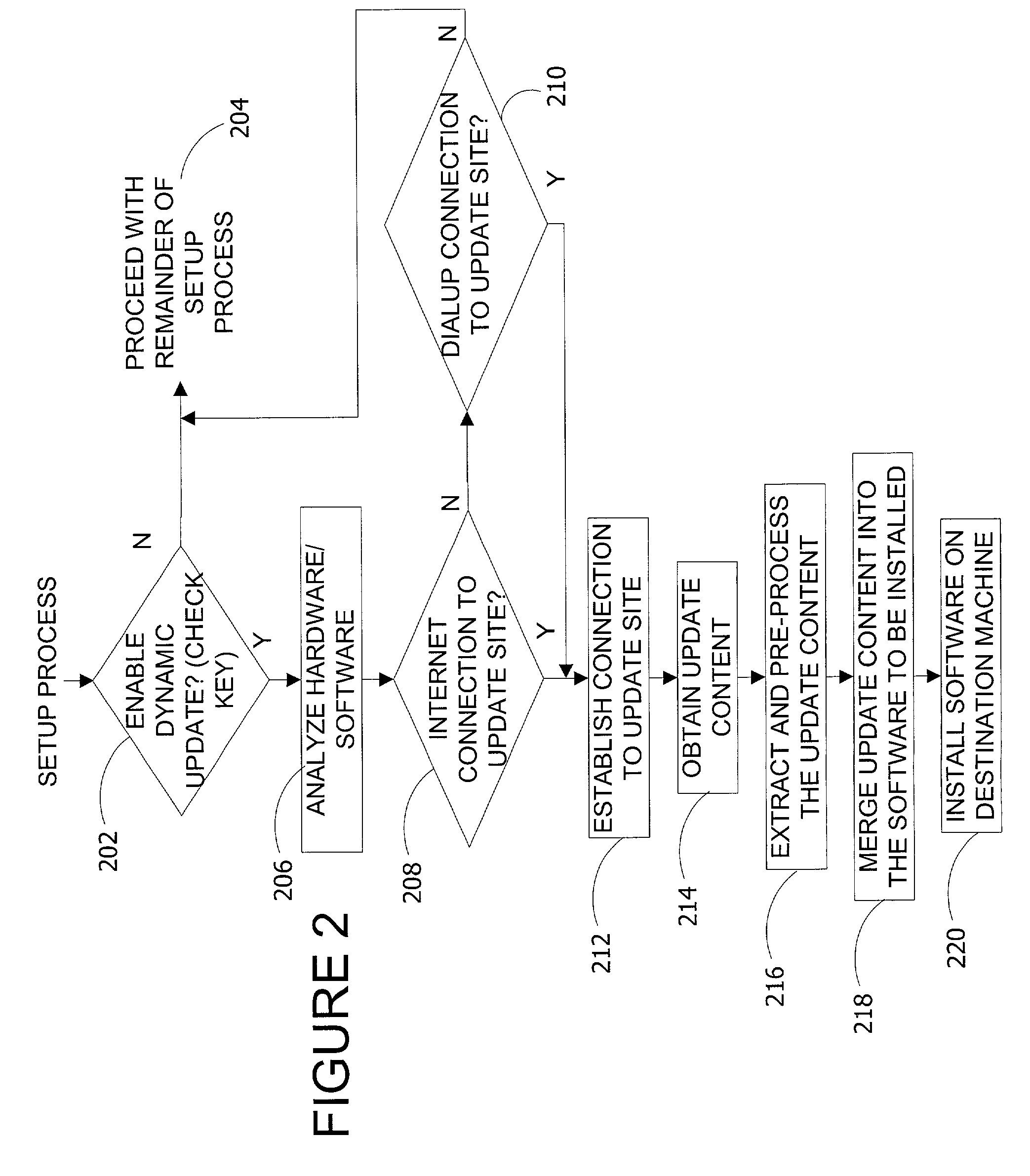

Dynamic software update

InactiveUS7251812B1Improve stabilityImprove responsivenessDigital computer detailsData resettingOperational systemDynamic software updating

A system and method for dynamically updating software on one or more installation media for installation on at least one destination machine. The invention obtains update content from one or more update media and merges the update content with the software on the installation media prior to installing the software on the destination machine. The software to be installed includes application programs and operating system software.

Owner:MICROSOFT TECH LICENSING LLC

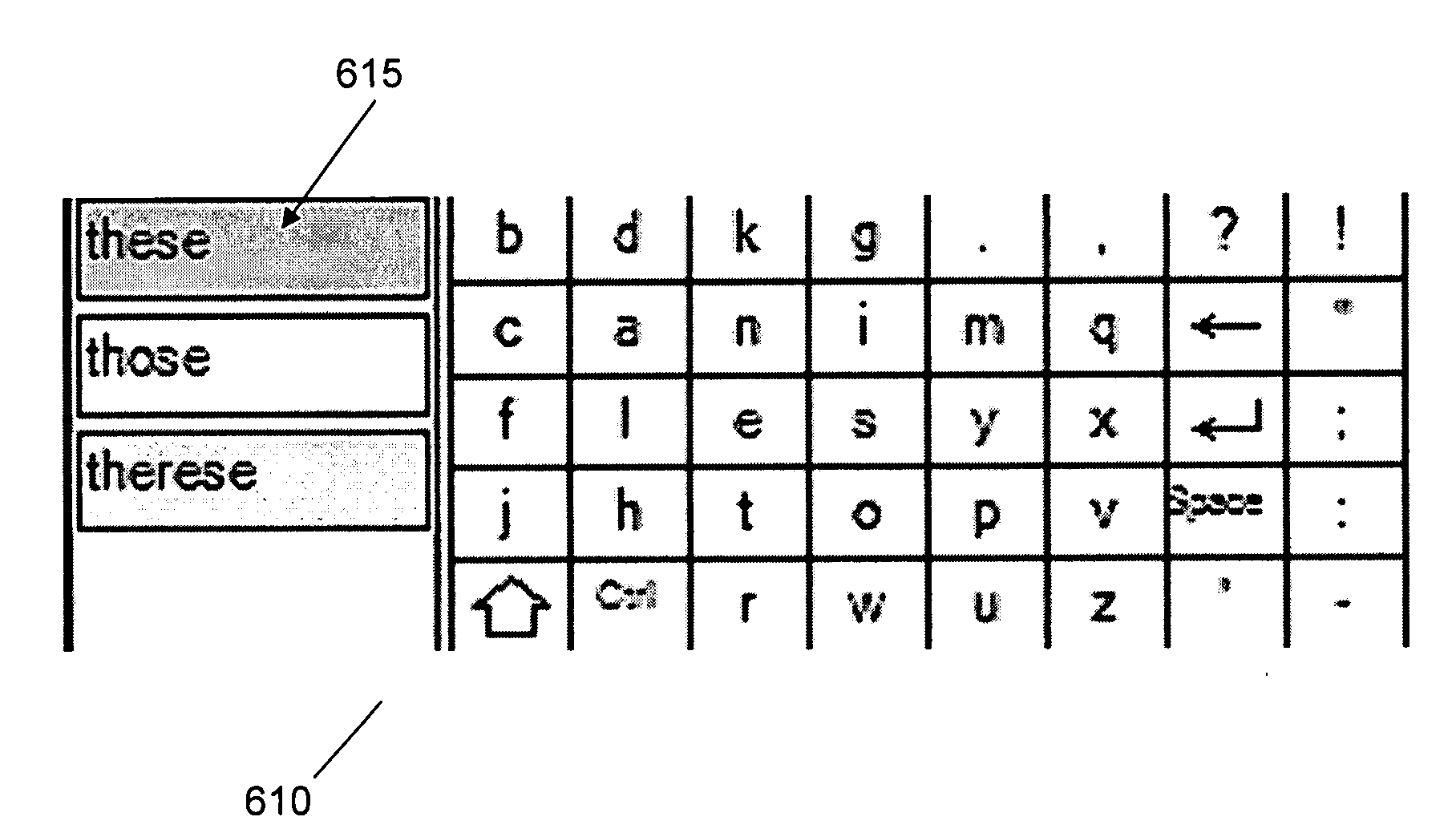

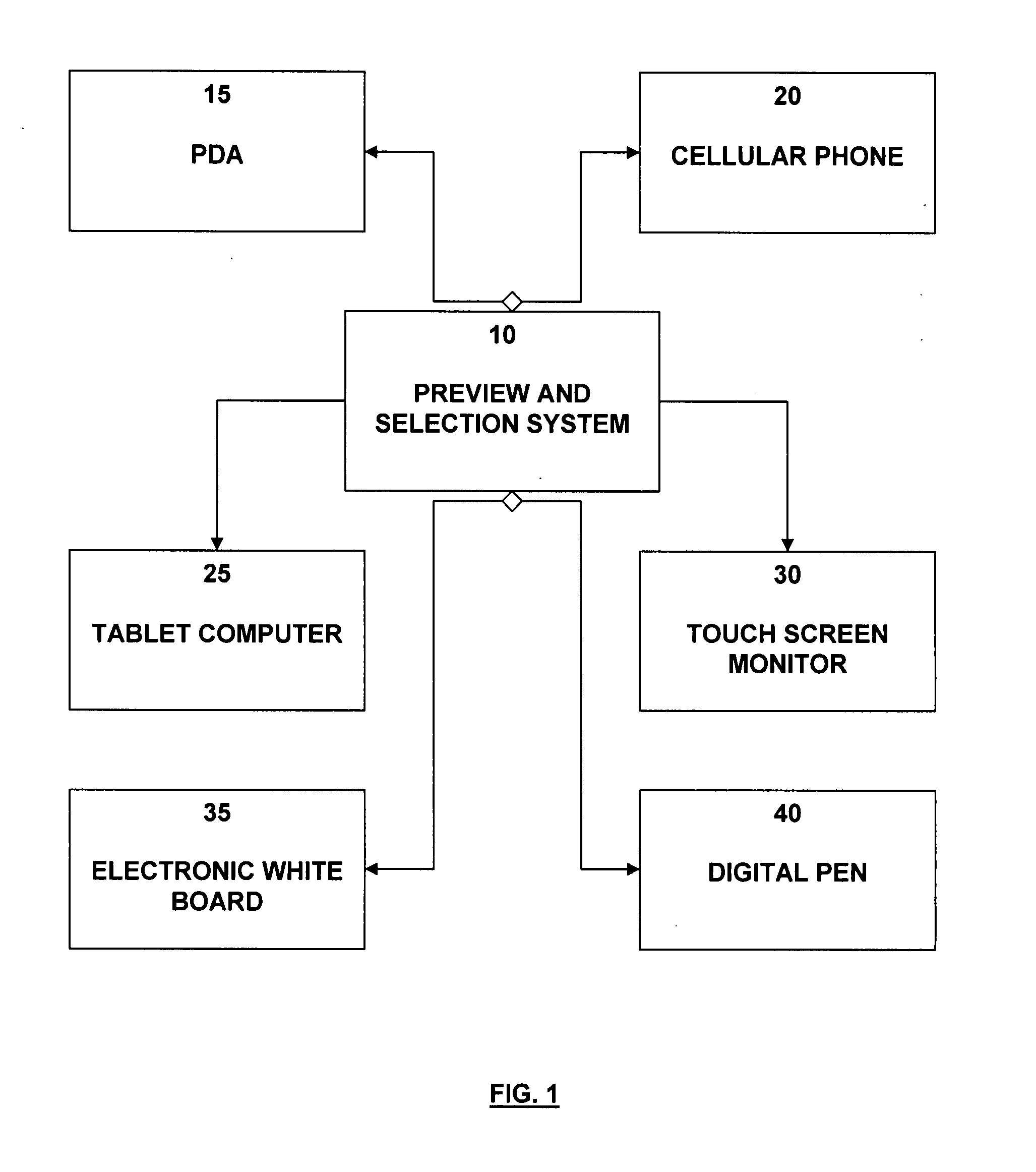

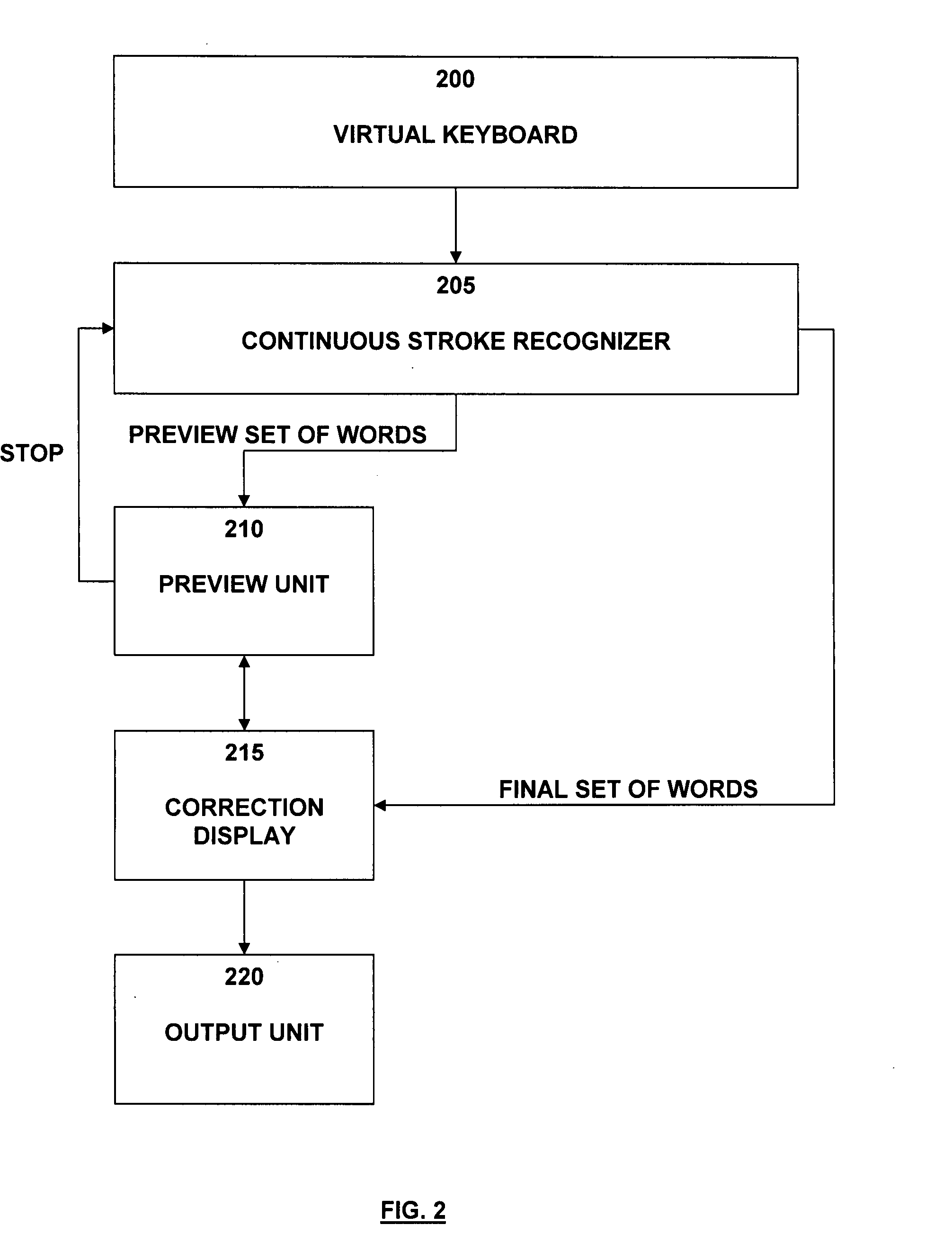

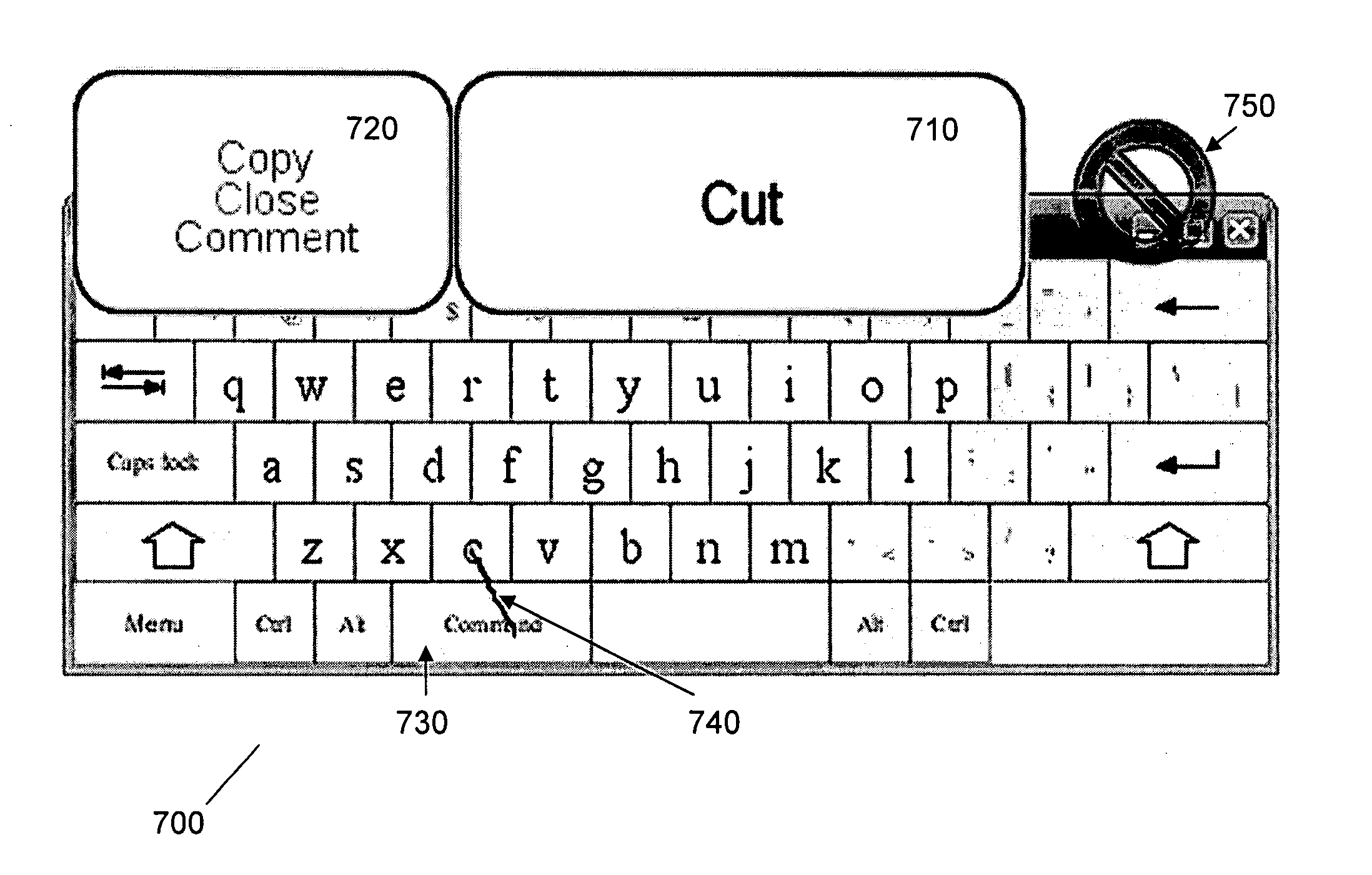

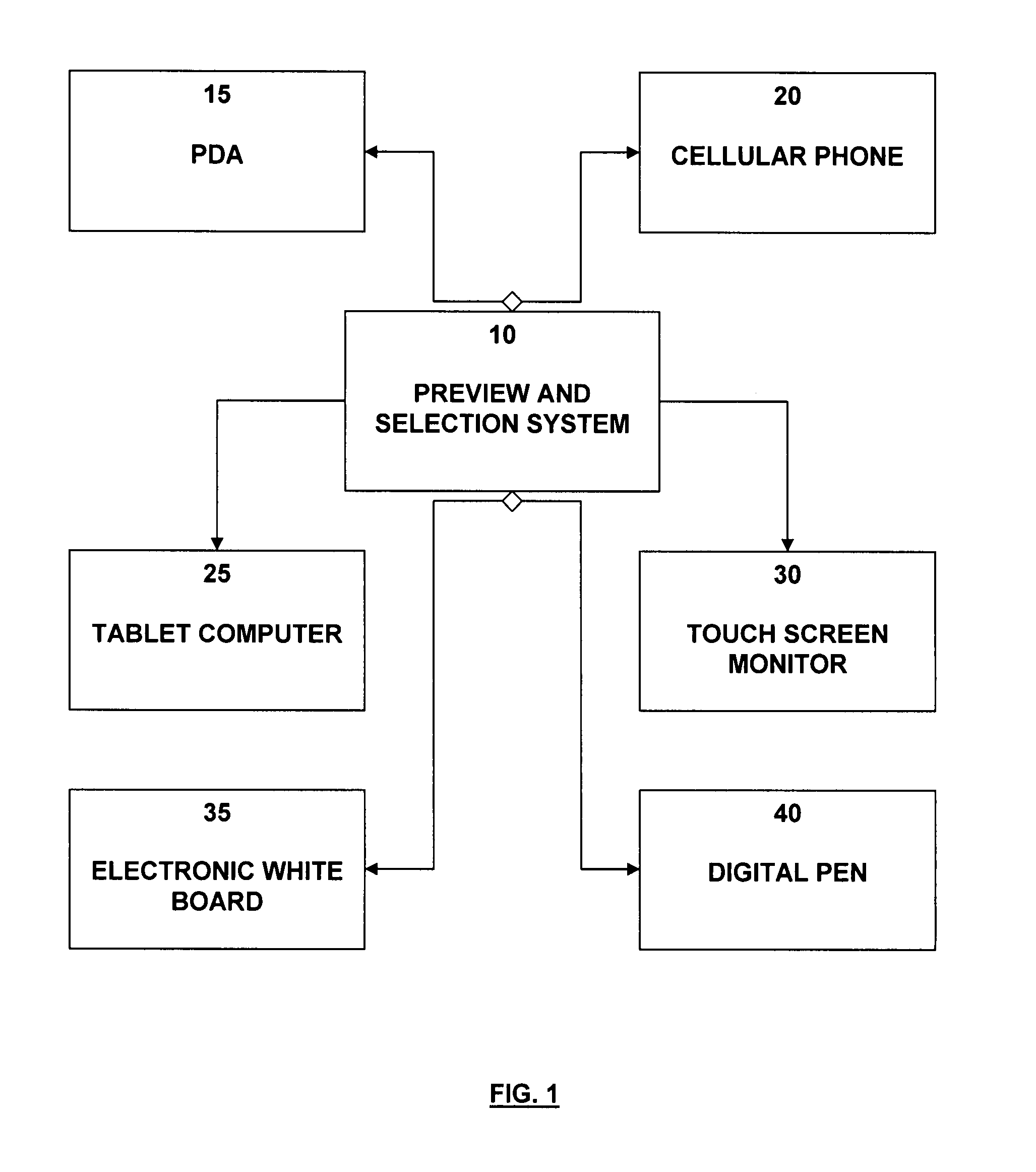

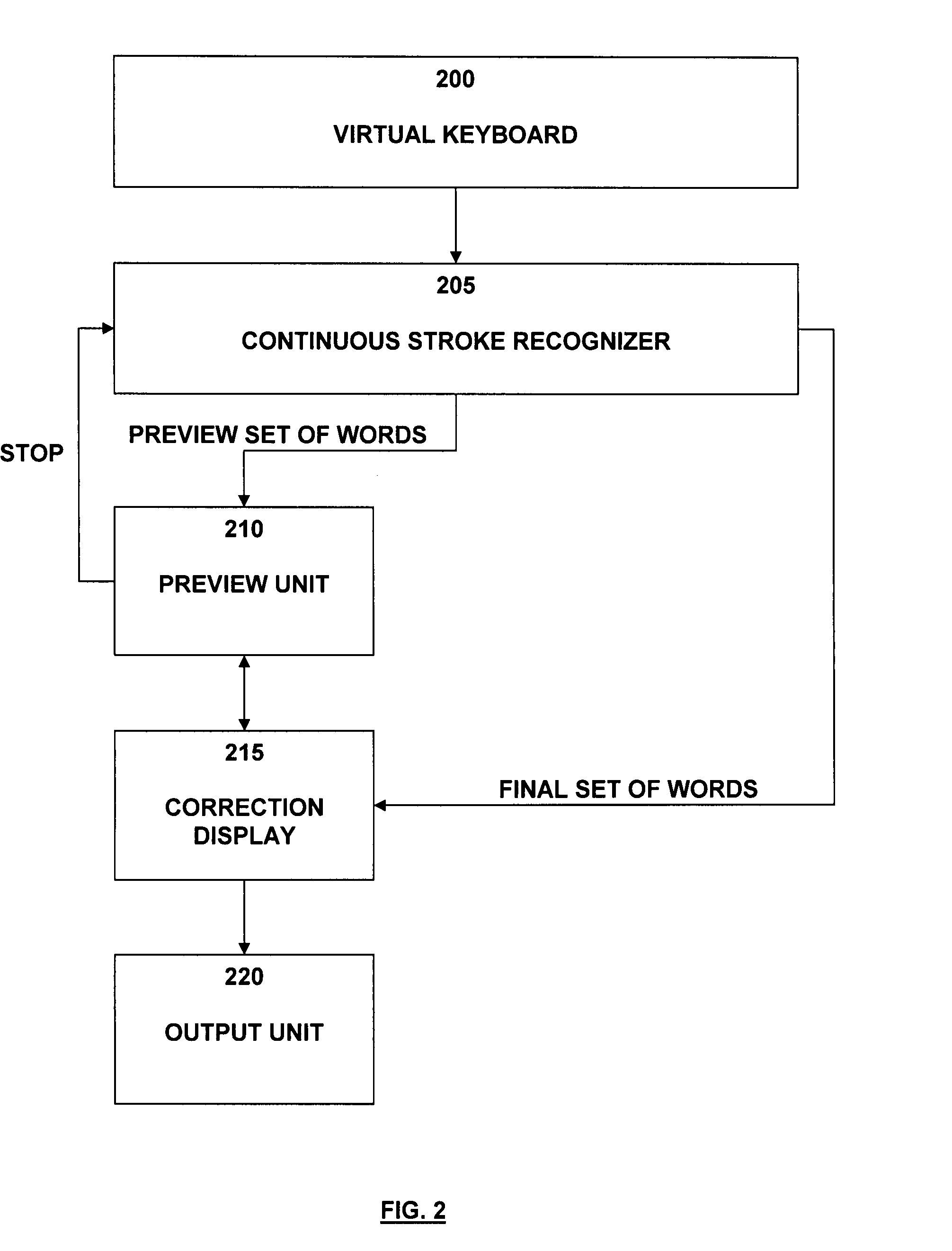

System and method for preview and selection of words

InactiveUS20080270896A1ConfidenceReduce supporting costsDigital computer detailsNatural language data processingDisplay deviceVirtual keyboard

A system, method and computer-readable medium that previews words and commands recognized by a continuous stroke recognizer based on input into a virtual keyboard layout is presented. The system and method allows a user to see the word that will be recognized or output before the user commits the continuous stroke input to the system. Further, after recognition and output, the system presents the recognized output word and the closest word candidates in a correction display integrated with the virtual keyboard layout. Among other things, the user is provided with options to change the current output word by selecting another word candidate on the correction display, and to delete the current output word by selecting the representation of the current output word on the correction display.

Owner:NUANCE COMM INC

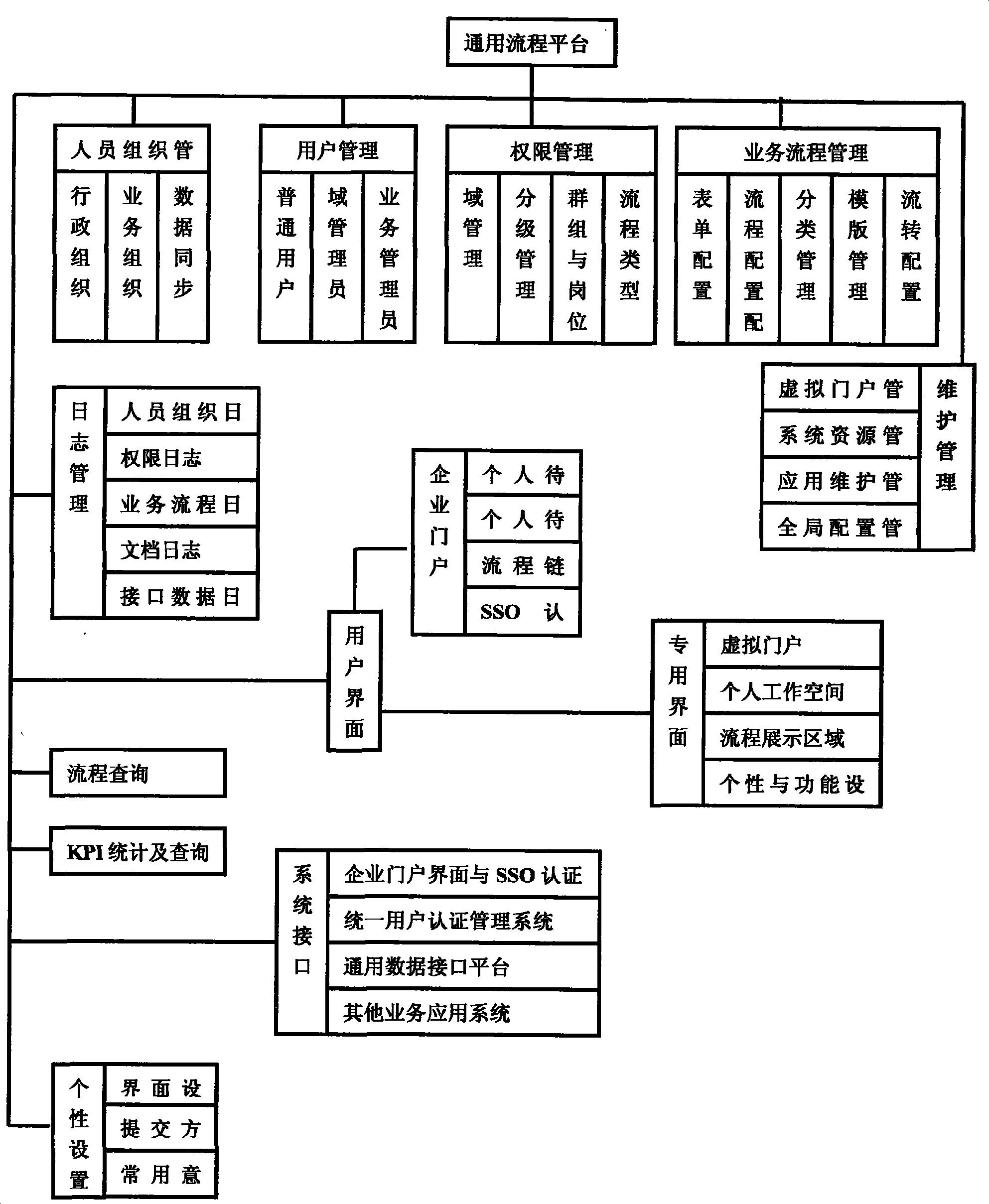

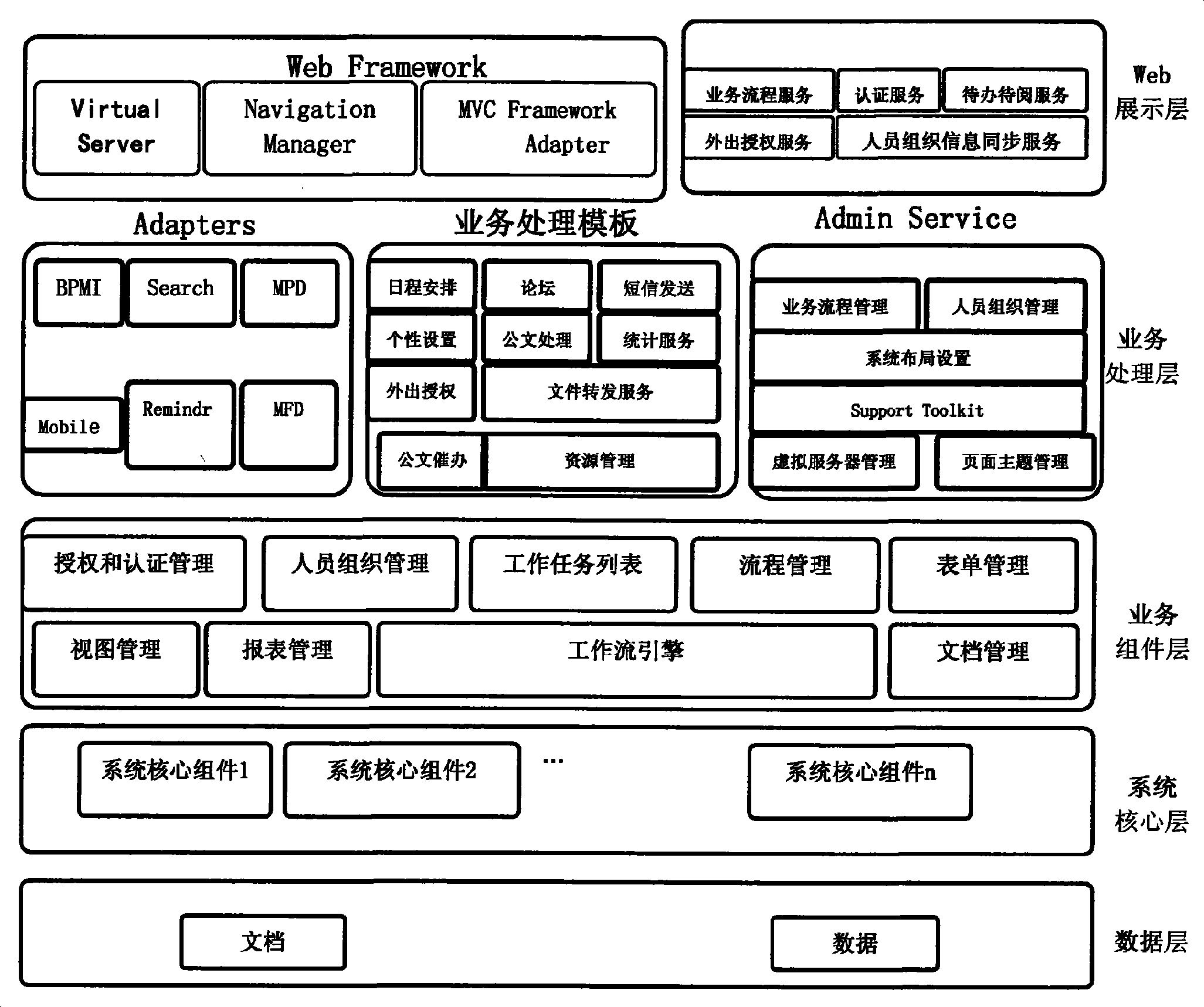

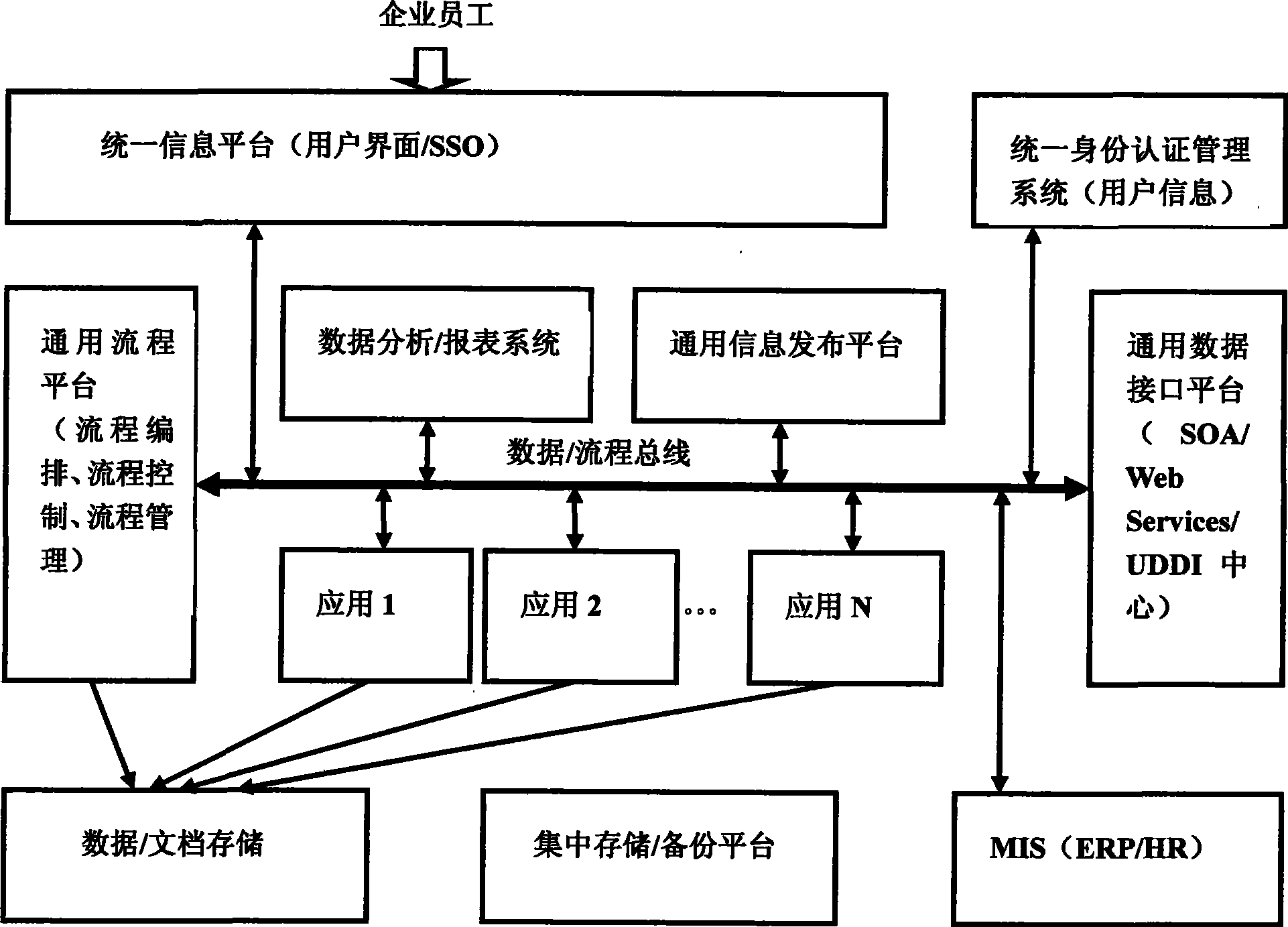

Generalized flowsheet platform for corporation

InactiveCN101364289ARealize unified managementReduce complexityResourcesCurrent managementEnterprise level

The invention relates to a generalized flowsheet platform technique under an enterprise-oriented information system structure. Aiming at current management and transaction processing, a provincial universal electronic workflow platform is built through an advanced workflow technique according to the principle of centralization, standardization and integration; therefore, unified management and centralized monitoring for various managements and operation flows can be realized on one hand, and on the other hand, a general workflow application model independent of application is built from the standpoint of the enterprise-oriented information system structure; the configurable componentized model is utilized to conform or transform the existing application and dispose the new application; one or multiple sets of system platforms are built in a concentrative or distributed manner; therefore, the complexity of a workflow system is reduced, the workflow application is enabled to be developed and deployed rapidly, and the management maintenance work is simplified and the cost of later technical support is lowered at the same time.

Owner:CHINA MOBILE GRP FUJIAN CO LTD

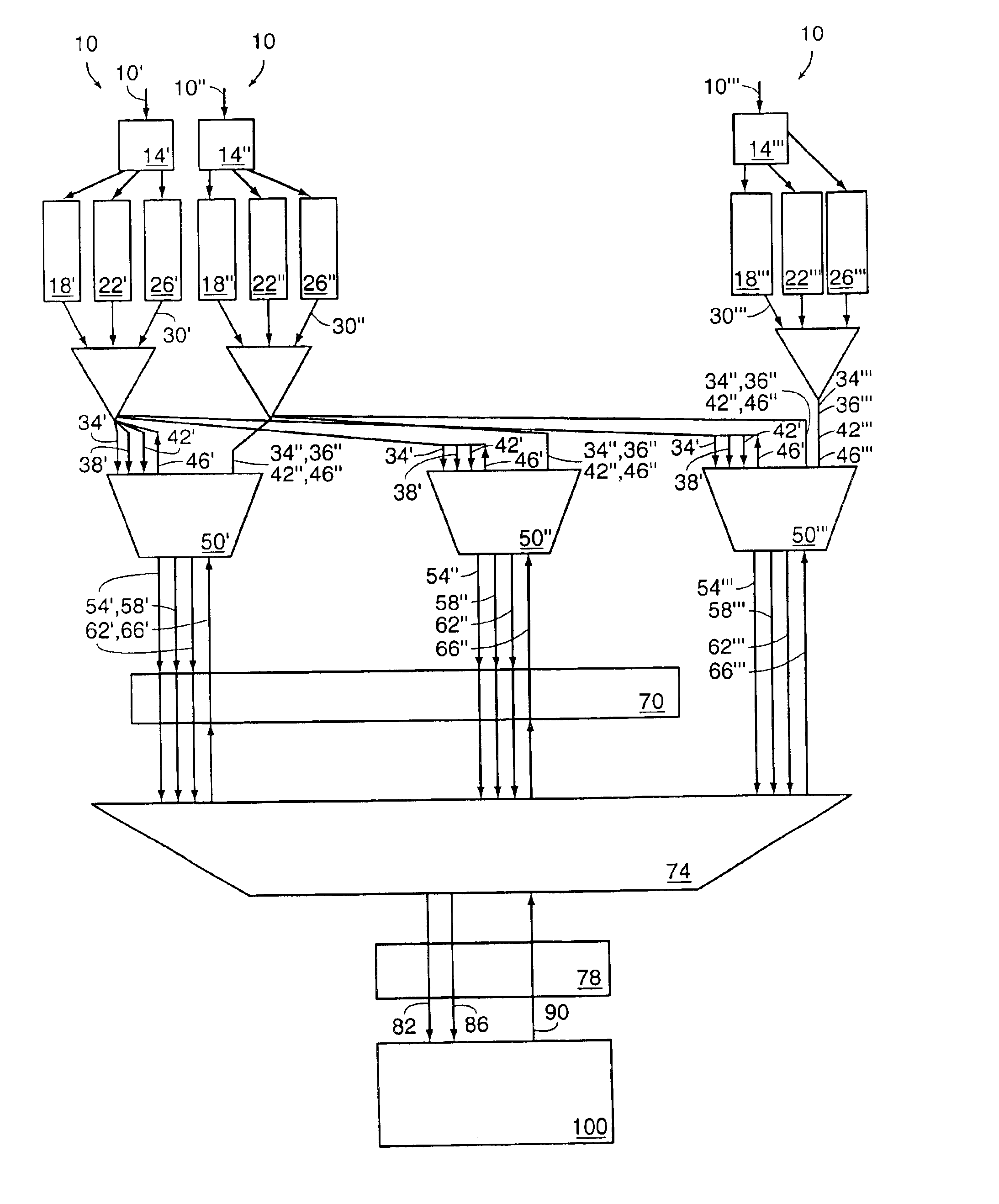

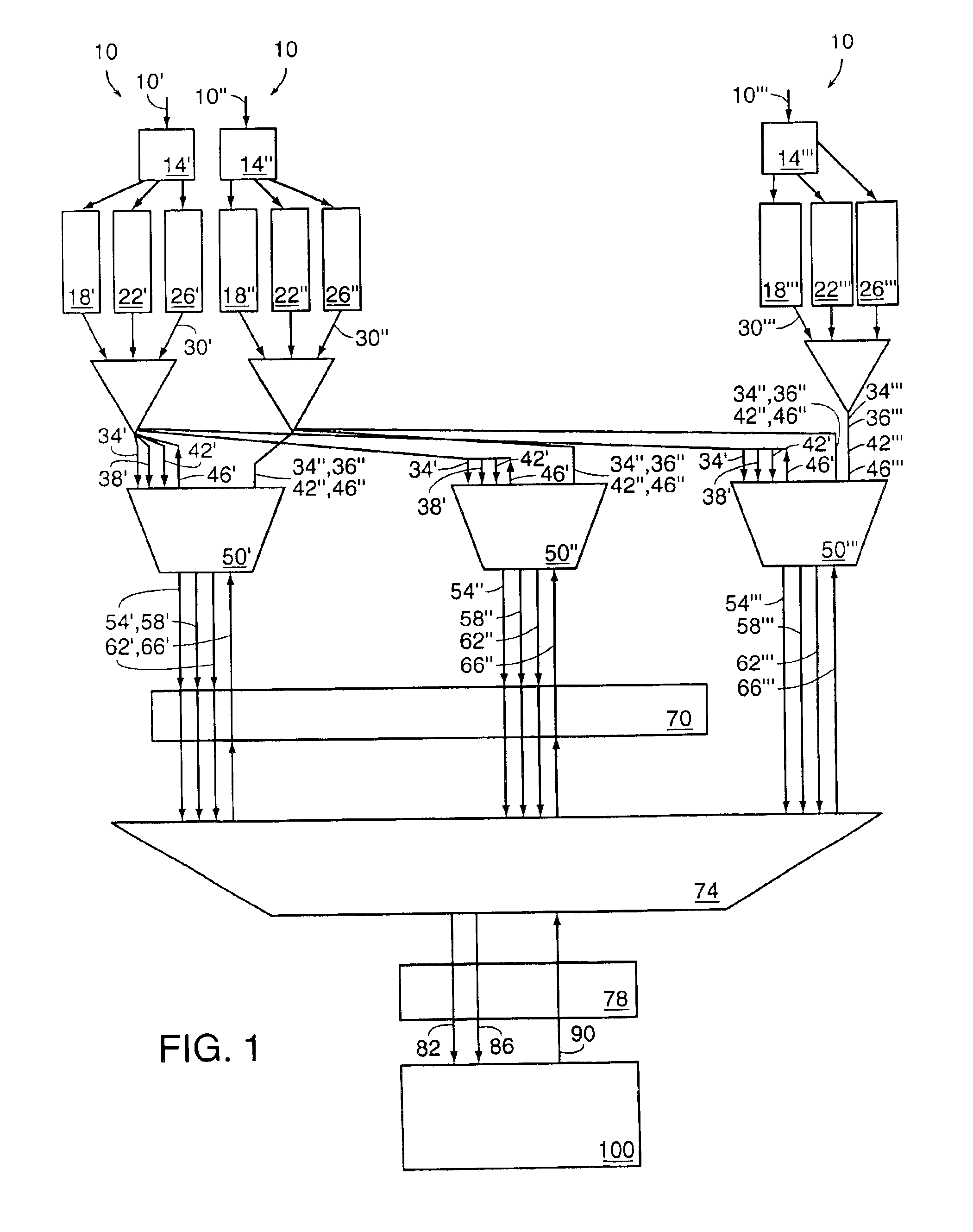

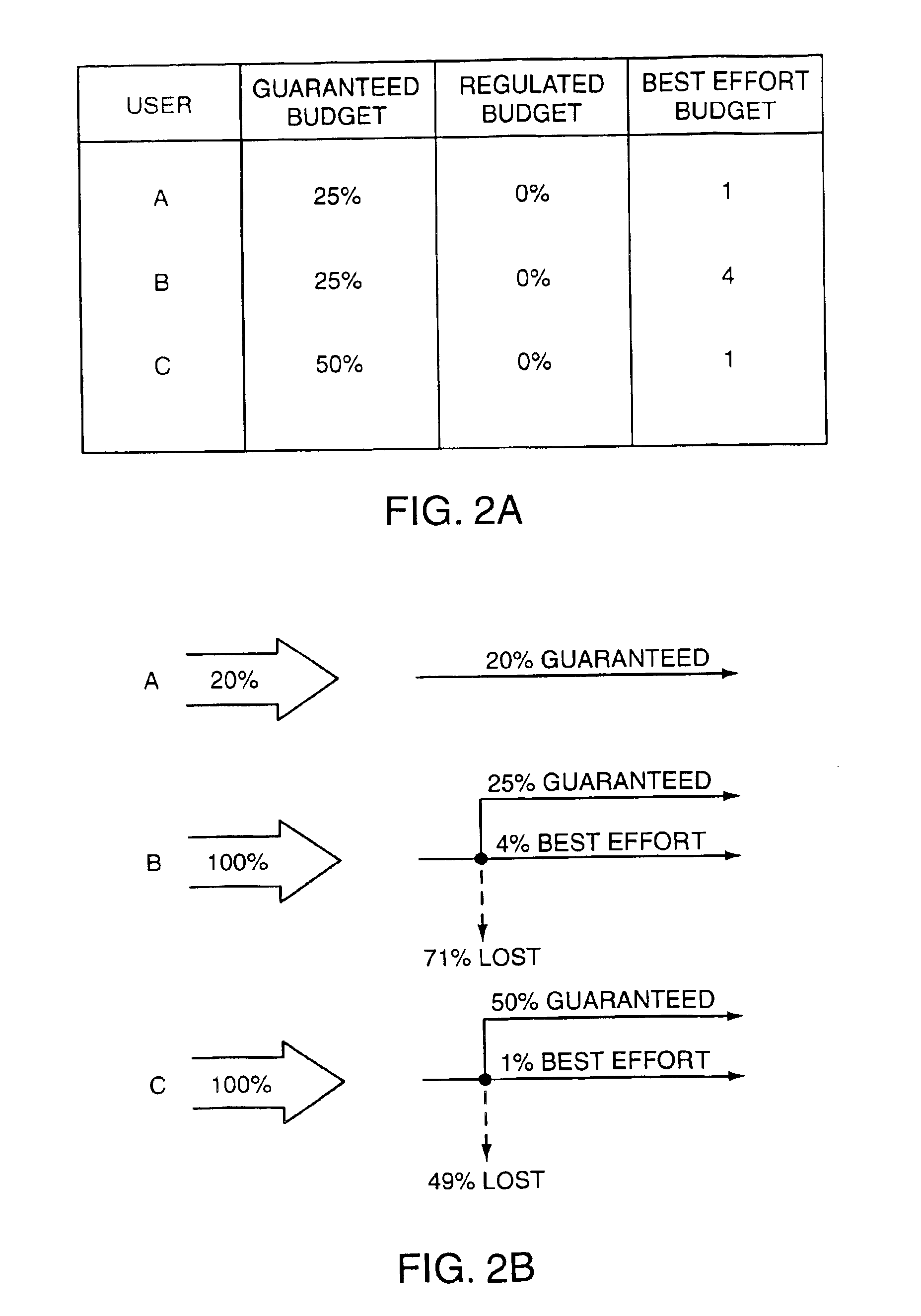

Multi-level scheduling method for multiplexing packets in a communications network

InactiveUS6882623B1Easy to useReduce communication costsError preventionTransmission systemsTraffic capacityData stream

A method and system for data traffic management in telecommunications networks is presented. End user data streams are aggregated to achieve more efficient use of a communication channel. Bandwidth is dynamically allocated to the data streams of the various users, effectively reducing their communications costs. The system includes a class of service selector and a plurality of stream selectors. Each stream selector is associated with a single budget category. Data is placed into queues according to a priority assigned by the end user. Data packets are transmitted from their queues through the class of service selector and through one of the stream selectors in response to the traffic provided by the end users and the budget category subscriptions of the end users.

Owner:NATIVE NETWORKS TECH +1

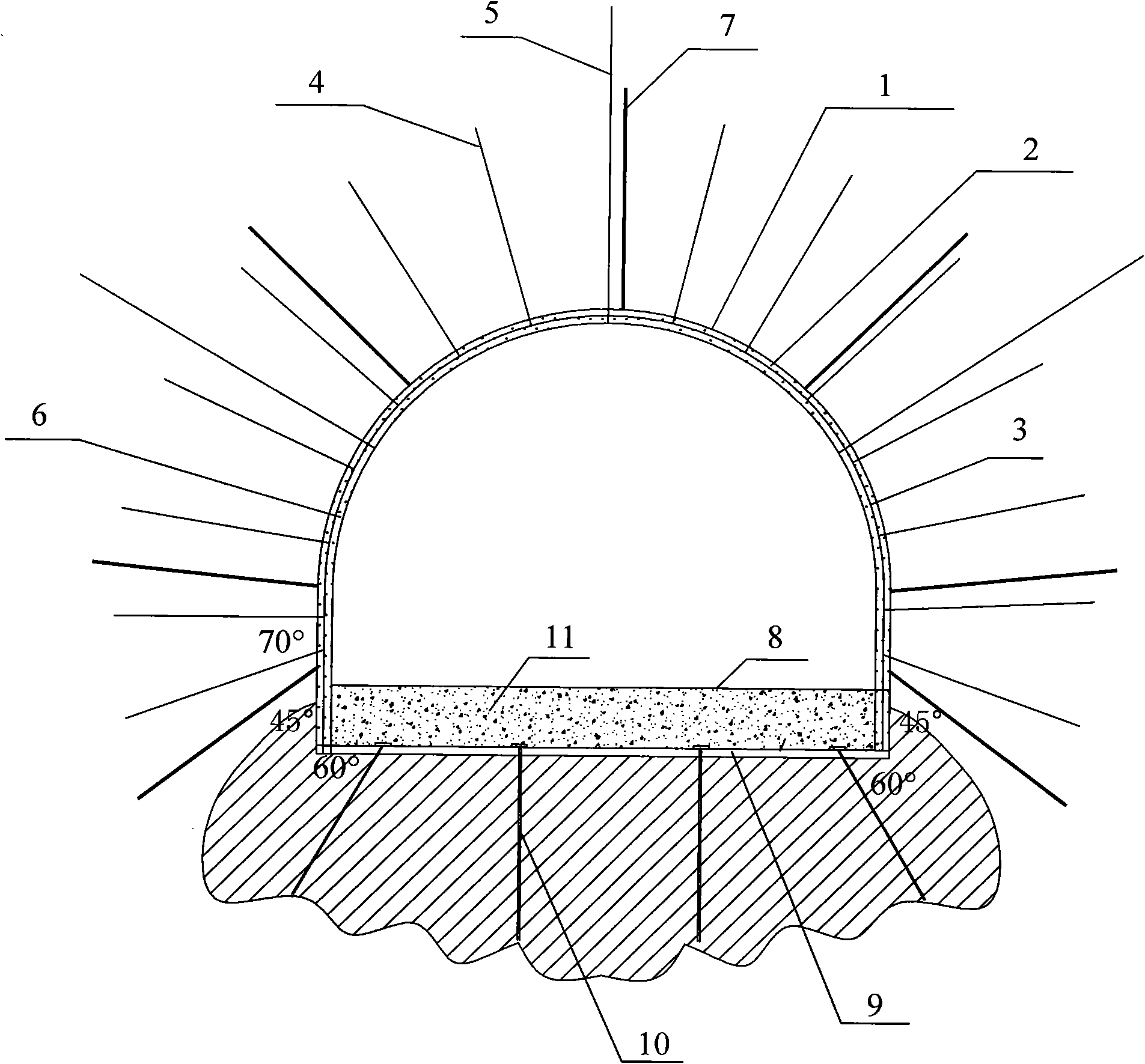

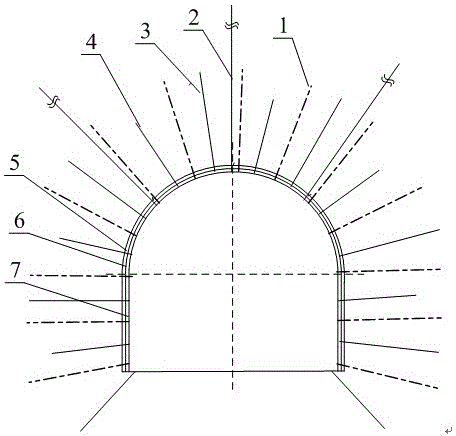

Deep well tunnel cable anchor rigid-flexible coupling support and surrounding rock overall reinforced support method

InactiveCN101967984AImprove carrying capacityPrevent shear deformationUnderground chambersTunnel liningPre stressCoupling

Owner:ANHUI UNIV OF SCI & TECH

System and method for preview and selection of words

InactiveUS7895518B2ConfidenceReduce supporting costsNatural language data processingSpecial data processing applicationsDisplay deviceVirtual keyboard

Owner:NUANCE COMM INC

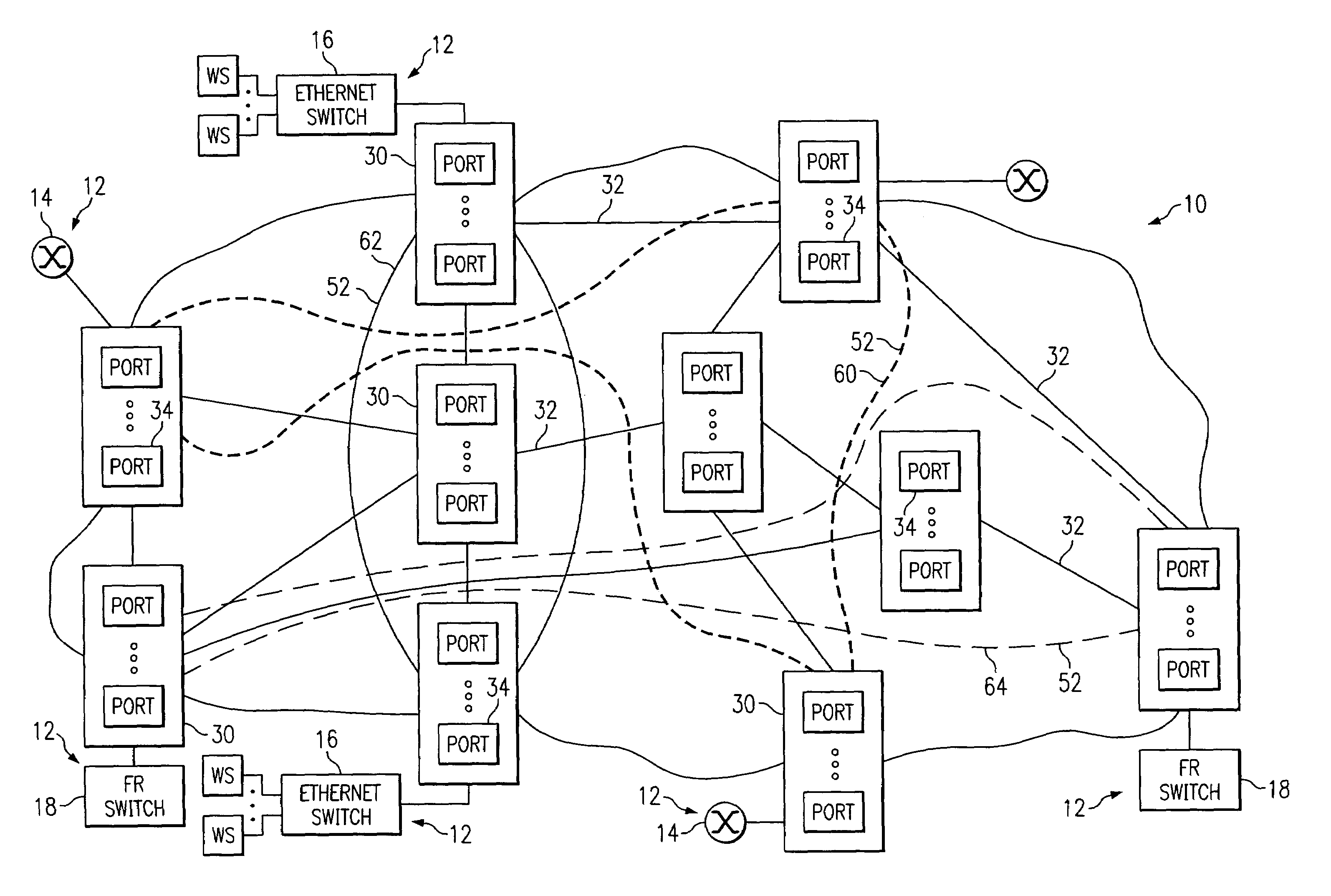

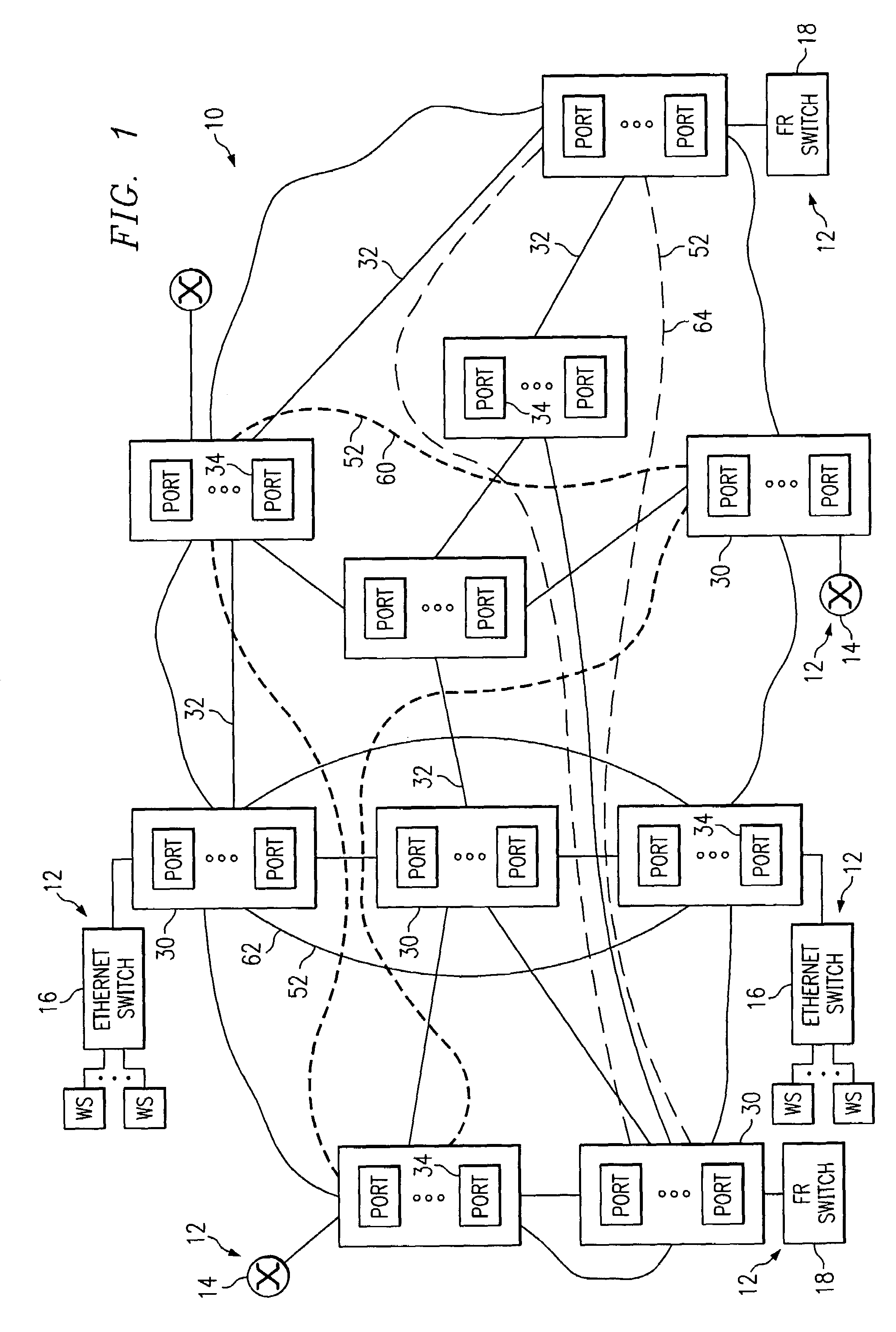

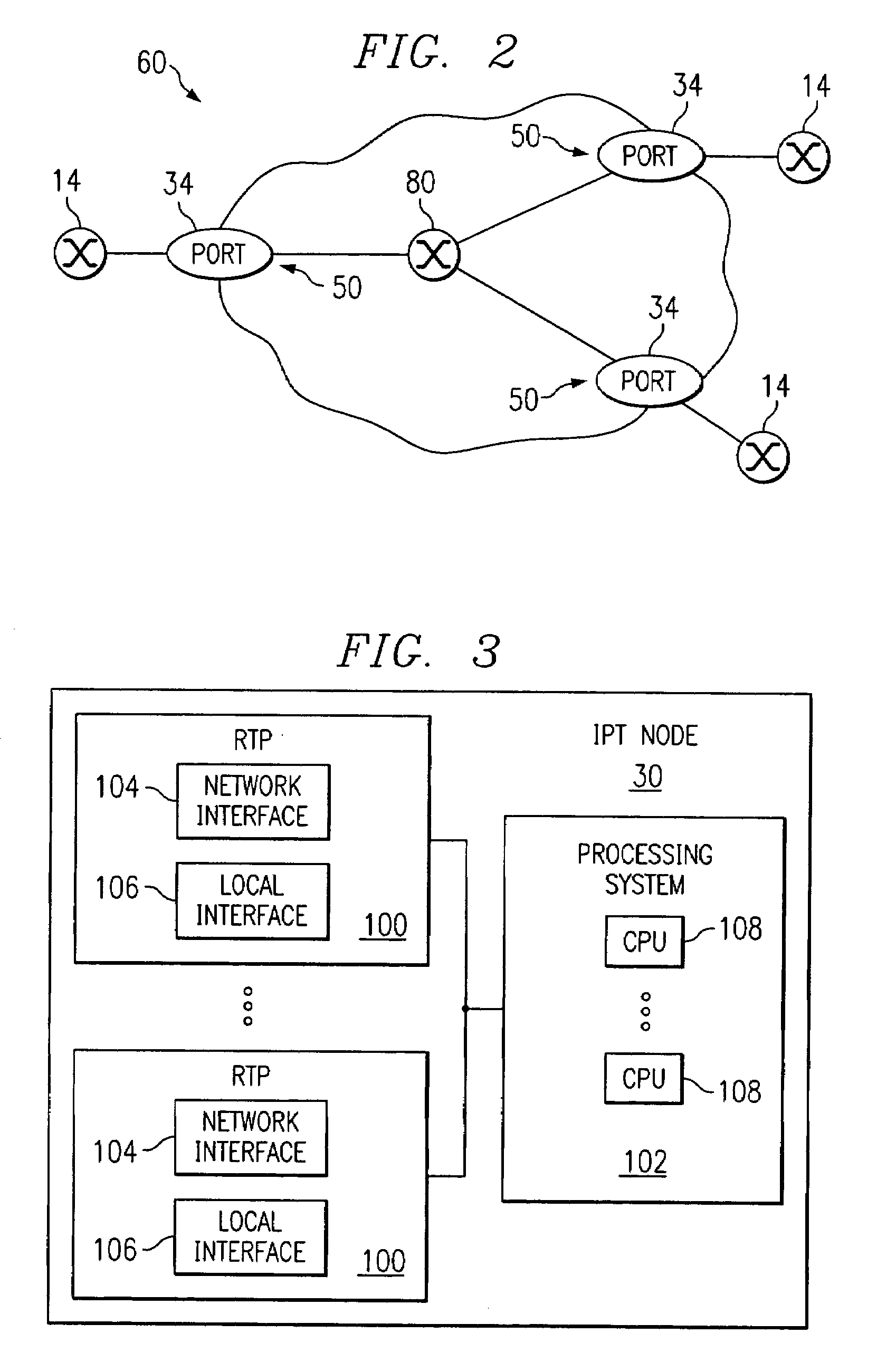

Transport network and method

InactiveUS7133403B1Improved external representationEasy to optimizeData switching by path configurationTime-division multiplexing selectionSingle elementEngineering

A transport network includes a flexible topology for internally defining transport elements. The transport elements each include a port group having a plurality of geographically distributed ports from the transport network. Point-to-multipoint connectivity is defined between the ports in a port group. An identifier represents the port group as a single element to internal and / or external elements for protocol exchanges.

Owner:FUJITSU LTD

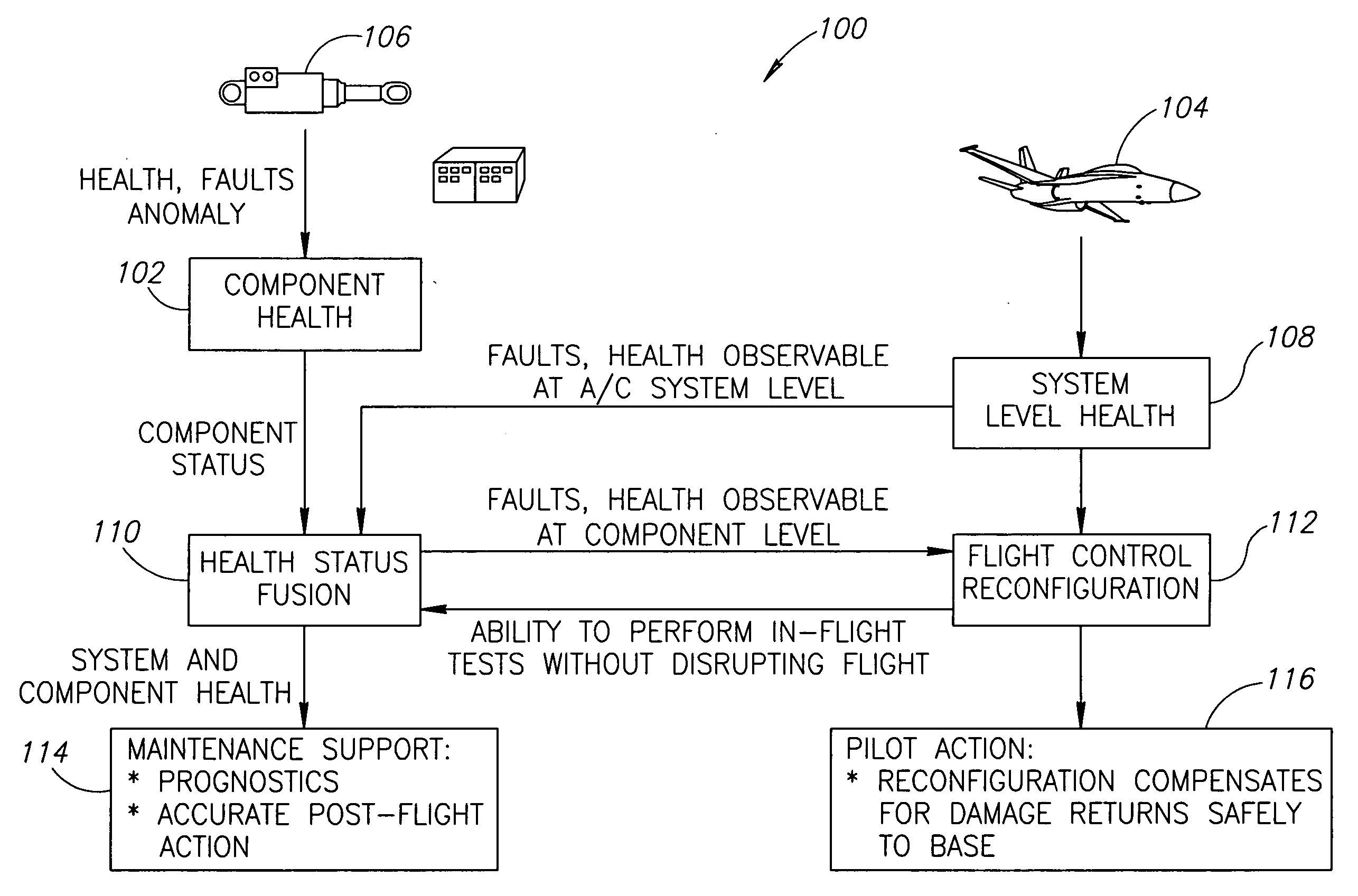

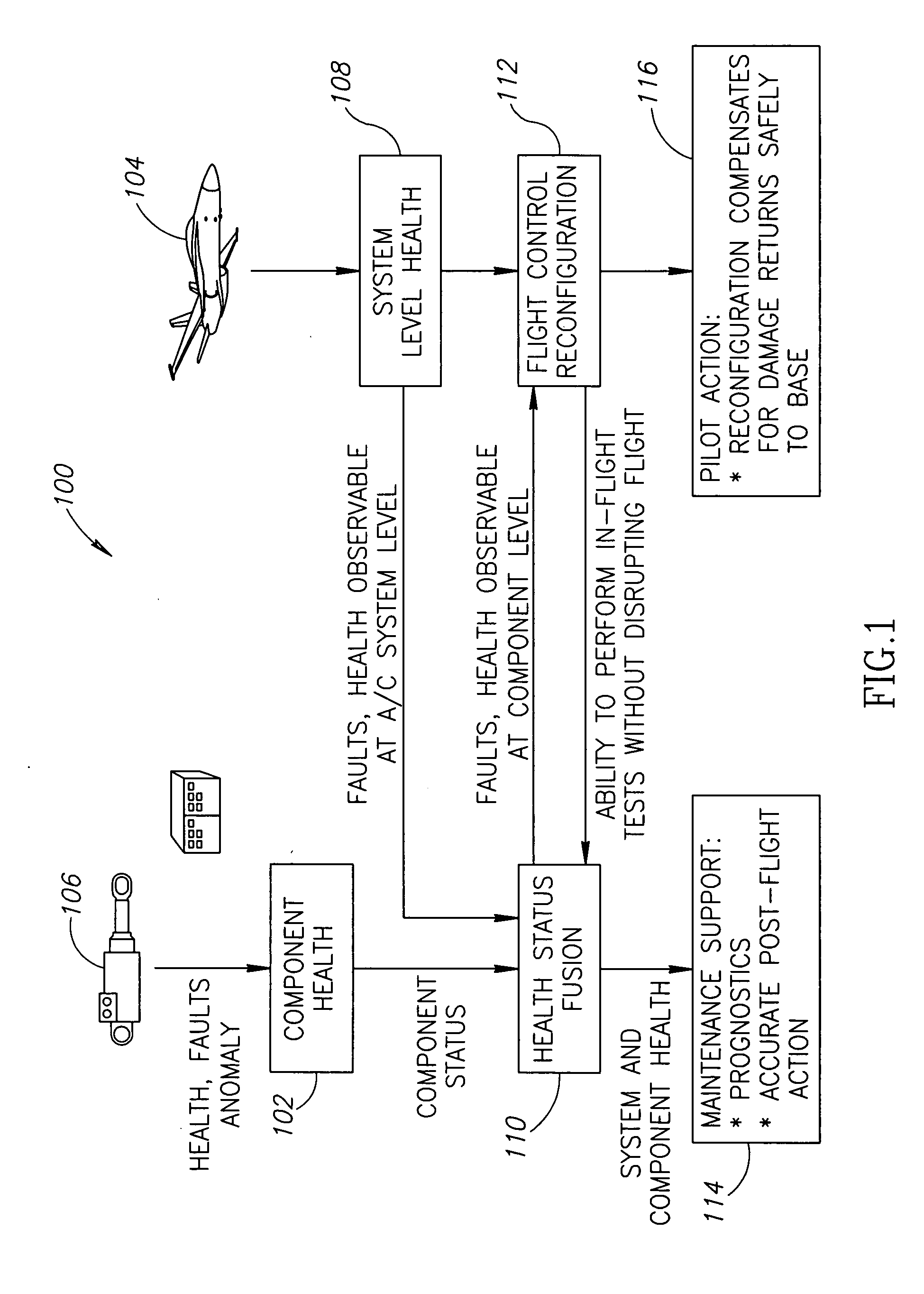

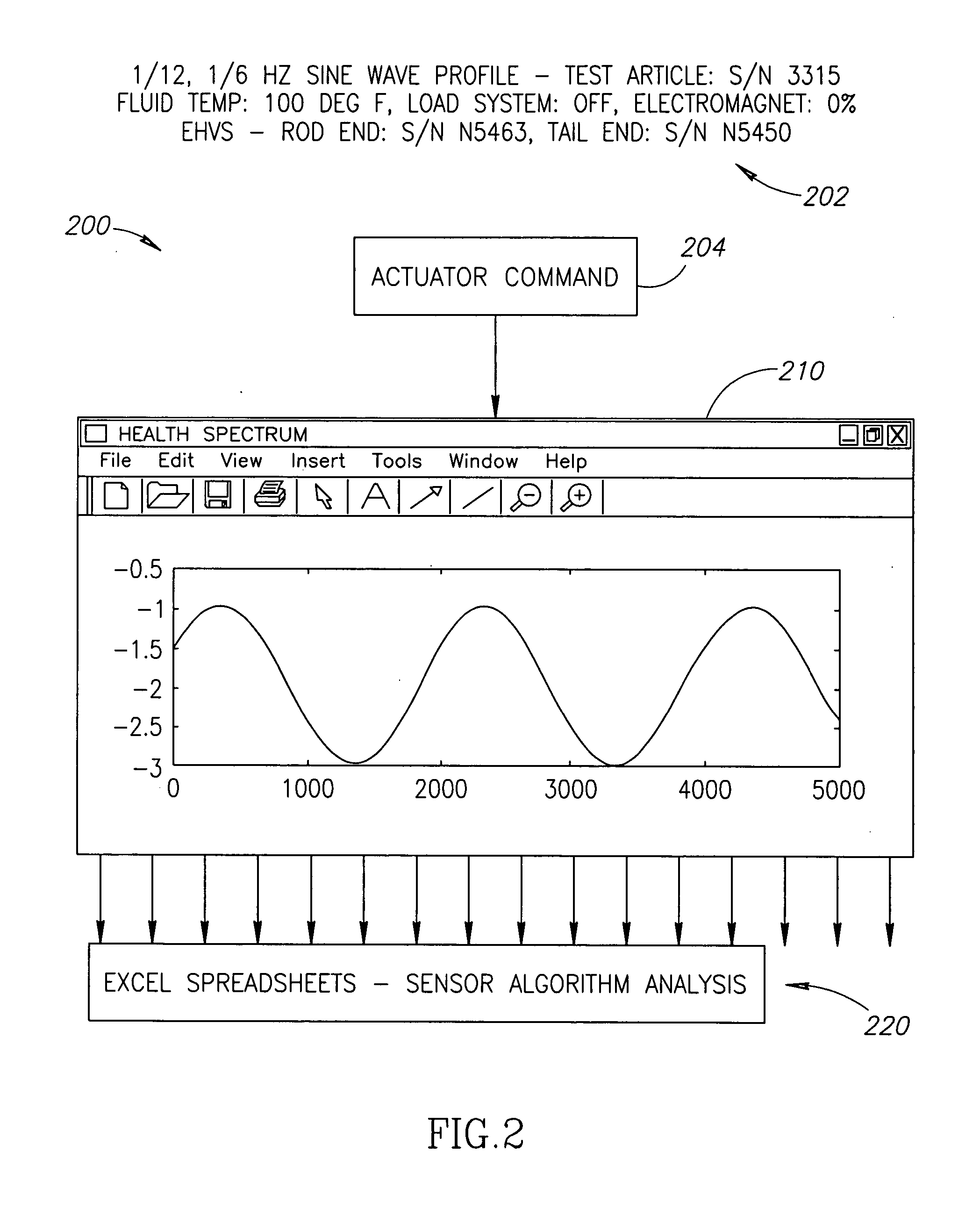

Component health assessment for reconfigurable control

ActiveUS20050114090A1Improve rendering capabilitiesImprove performanceRegistering/indicating working of vehiclesElectric testing/monitoringDiagnostic informationReliability engineering

Apparatus and methods for assessing component health for reconfigurable control are disclosed. In one embodiment, a method of operating a product includes monitoring a first diagnostic information of a component of the product, and monitoring a second diagnostic information of a system that includes the component. The first and second diagnostic informations are then combined, and based at least partially on the combined first and second diagnostic information at least one of the component and the system are reconfigured.

Owner:THE BOEING CO

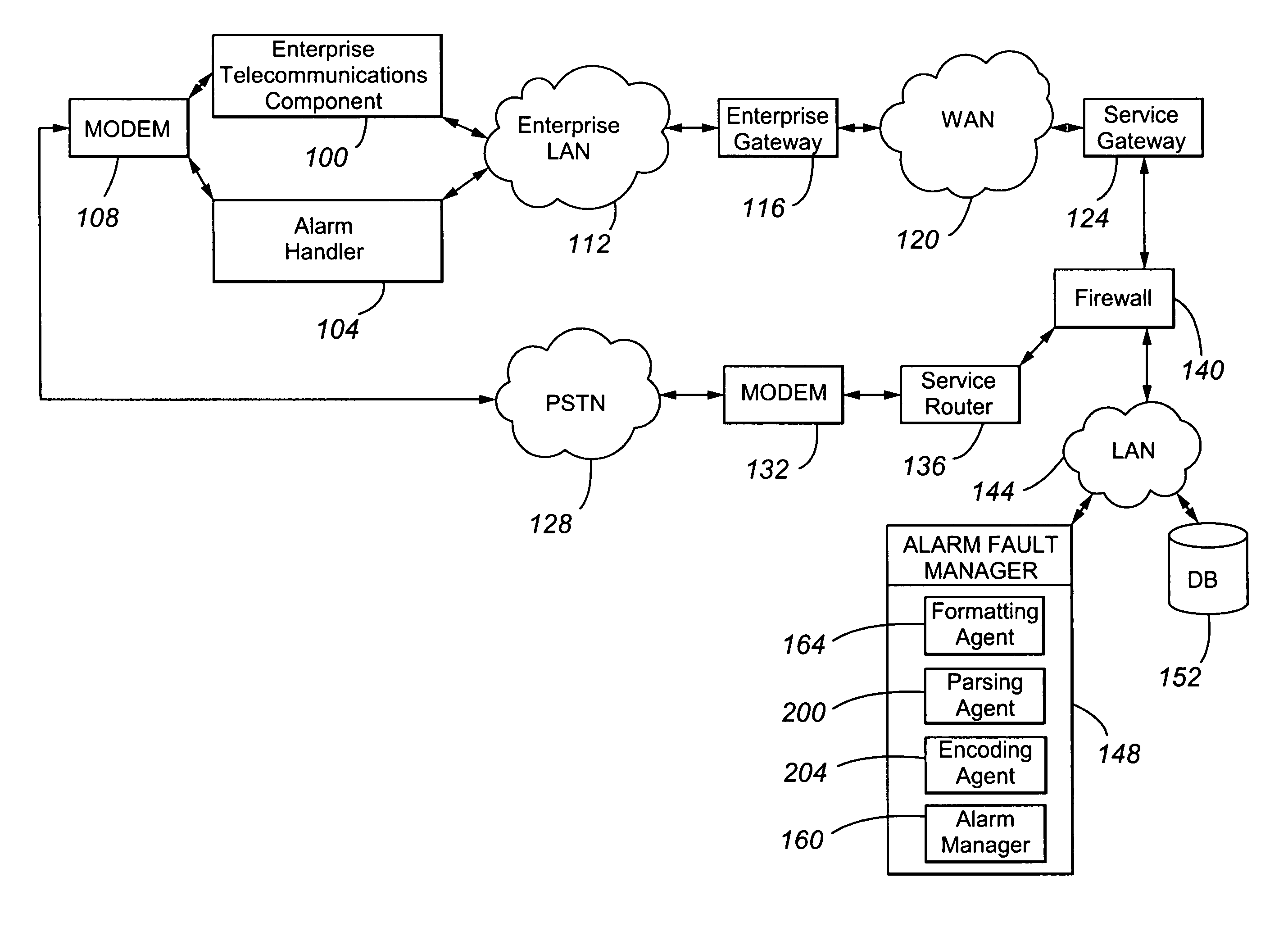

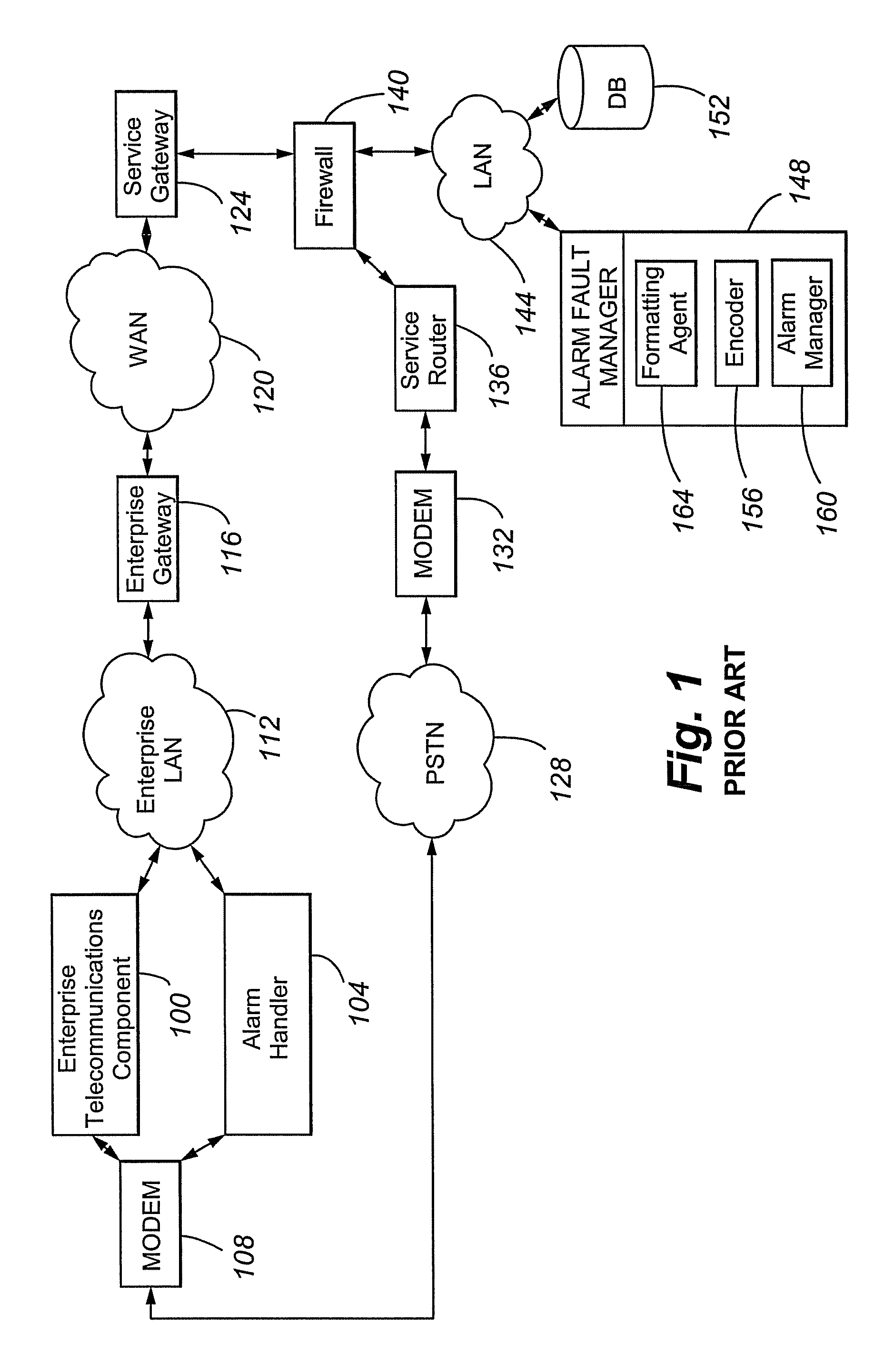

Dynamic system of autonomous parsers for interpreting arbitrary telecommunication equipment streams

InactiveUS7873992B1Easy to addImprove maintainabilityMemory loss protectionError detection/correctionNatural language processingTelecommunications equipment

A system for parsing an arbitrary input stream is provided that includes a plurality of parsers 304a-n operable to parse an input stream, each parser corresponding to a unique input structure, and a parser selection agent 300 operable to receive the input stream and select a subset of the plurality of parsers to parse the input stream.

Owner:AVAYA INC

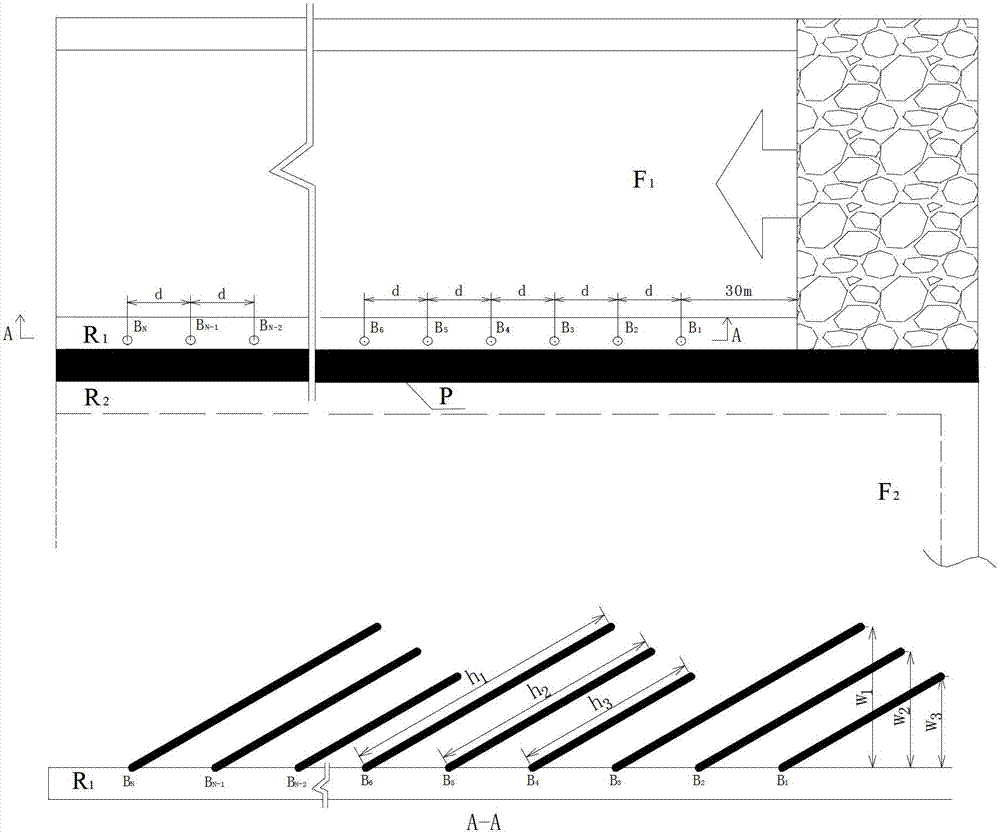

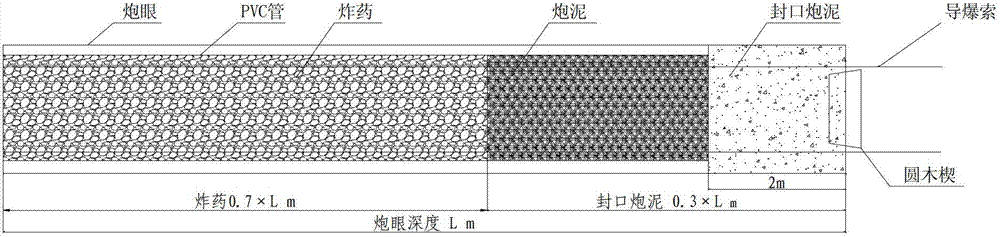

Beside-roadway escribing pressure relief method of roadway driving along gob of small coal pillar influenced by dynamic pressure

InactiveCN102778182AShorten exercise timeEliminate mining dynamic pressureBlastingEngineeringCoal pillar

The invention discloses a beside-roadway escribing pressure relief method of roadway driving along a gob of a small coal pillar influenced by dynamic pressure. The method includes the following steps: adopting roadway roof deep hole blasting as the escribing method, arranging escribing shot holes within the overall length range of an adjacent working surface crossheading of the roadway driving along the gob, and implementing stage blasting operation during back production of the working surface, wherein the escribing shot holes need to be close to the small coal pillar as far as possible, the depth of the escribing shot holes is determined according to the mining height of the back production working surface and the free caving height of the roof of the working surface, the shot holes need to be arranged with a distance away from the working surface, and the distance among the shot holes need to be determined reasonably; then performing explosive filling and hole blocking; performing ahead blasting operation in front of the working surface or lag blasting operation after the shot holes enter a gob area; and instantly performing roadway driving along the gob when the bad influence on the essence of the roadway driving along the gob of the small coal pillar caused by dynamic pressure of the working surface can be basically eliminated when back production of the adjacent working surface is finished. By means of the beside-roadway escribing pressure relief method, normal production of a back production working surface is ensured, and the cost and difficulty in roadway support along the gob are greatly reduced.

Owner:SHANDONG UNIV OF SCI & TECH

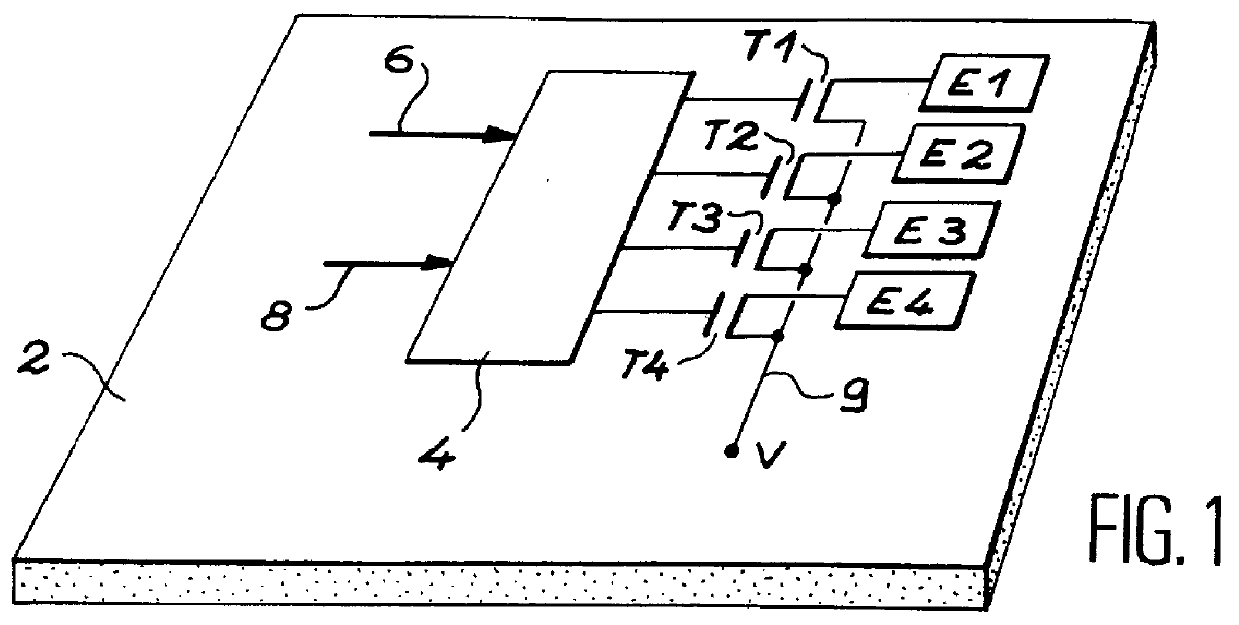

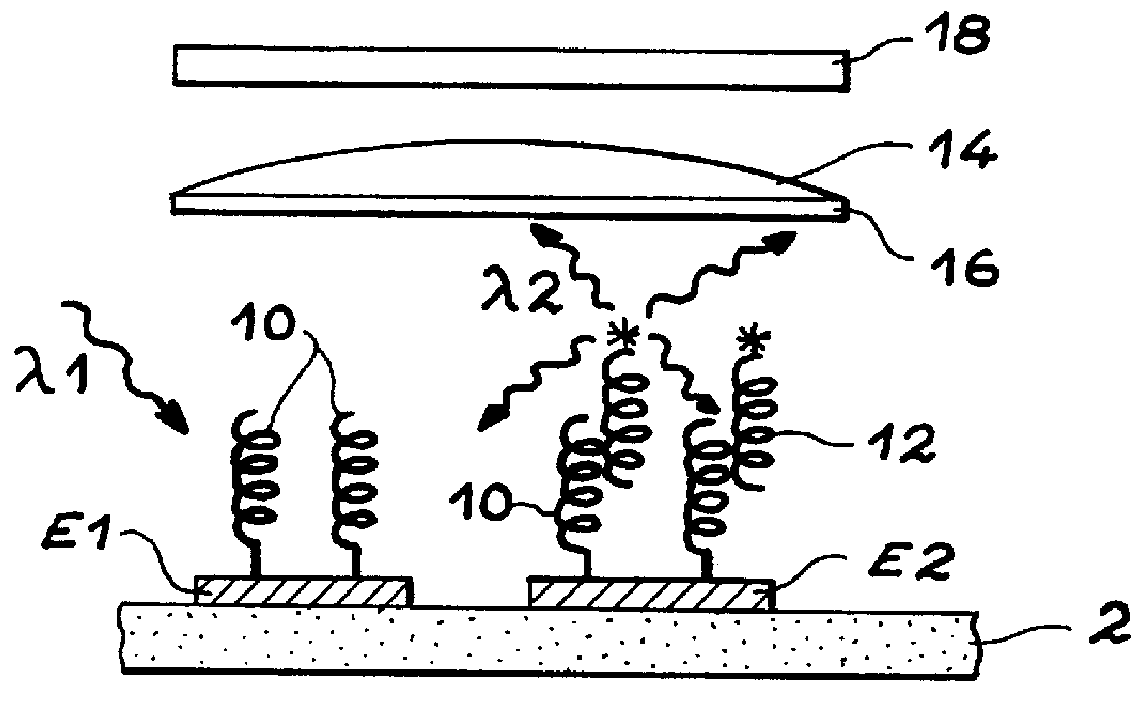

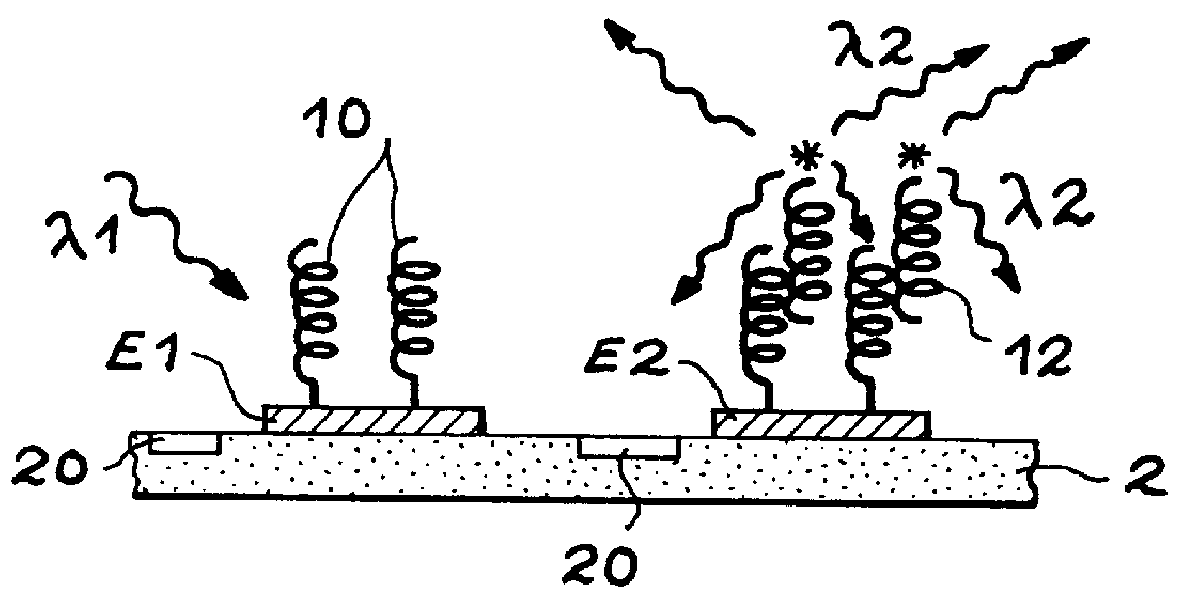

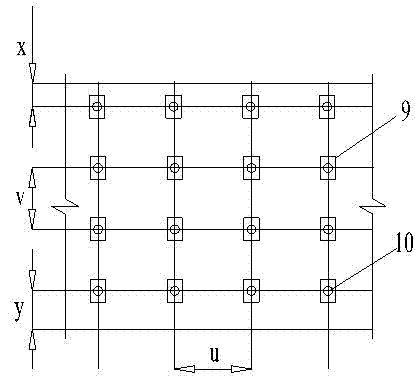

Electrode support comprising at least one electrode covered by a deposit and system for reading this support

InactiveUS6144023AReduce supporting costsBioreactor/fermenter combinationsBiological substance pretreatmentsOptoelectronicsLight source

Support comprising electrodes covered by a deposit and a system for reading this support. This support comprising a substrate (22) and electrodes (24) on this substrate, at least one of these electrodes being designed to be covered by a deposit capable of recognizing and capturing molecule-targets that are sensitive to a first light and that are capable of emitting a second light when they are excited by the first light. The substrate and electrodes are transparent to at least the first or the second light. The system comprises a light source (60) emitting the first light and means (62) of detecting the second light. Application to biological sensors.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

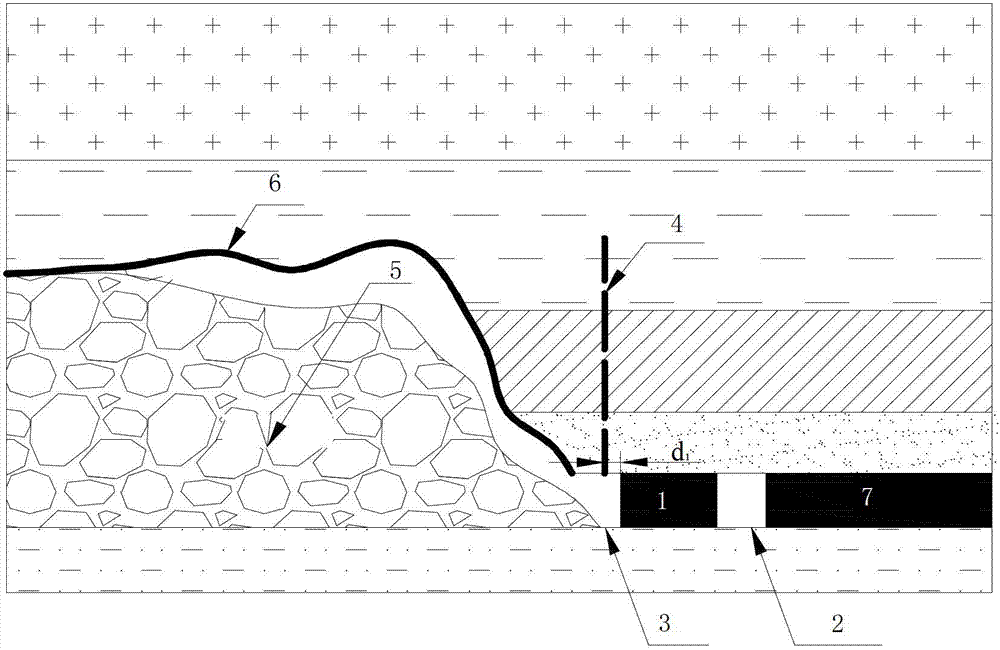

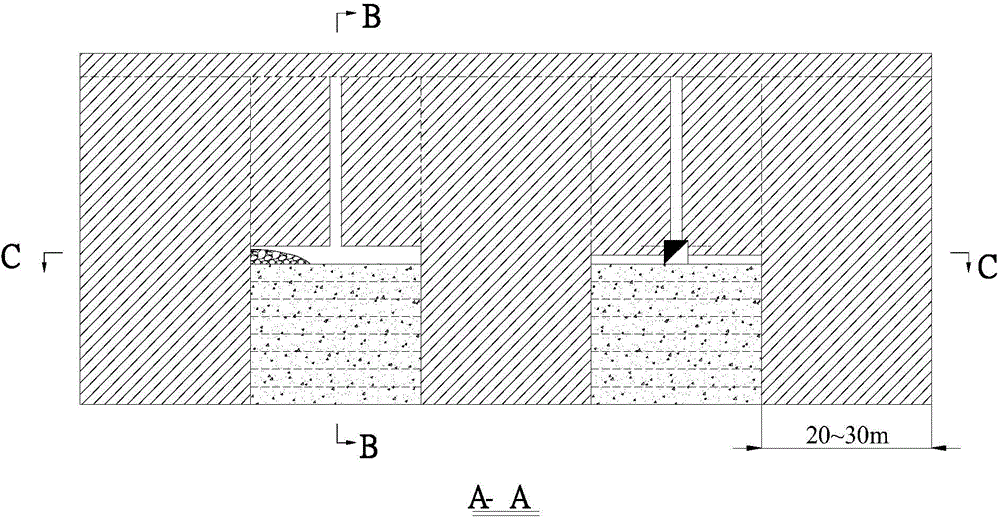

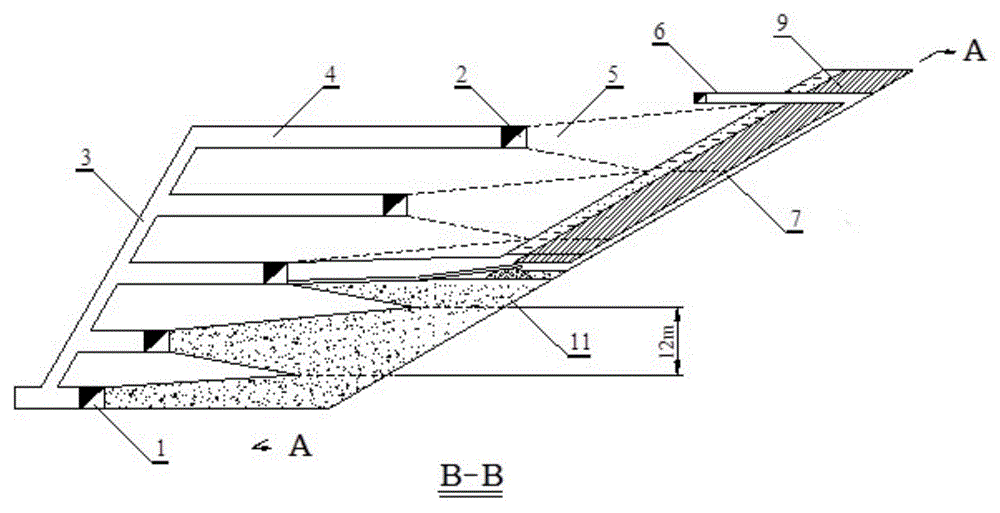

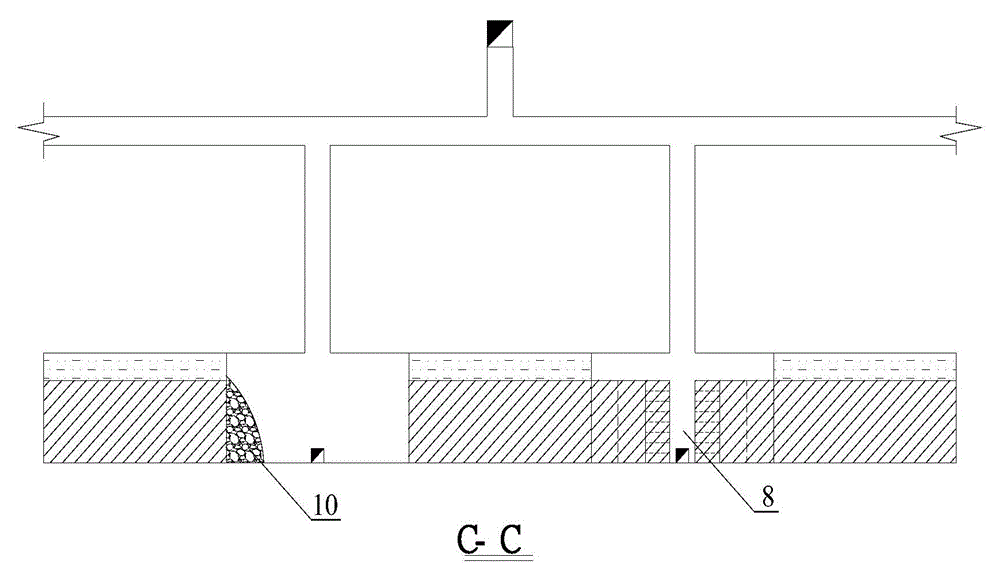

Roadside packing gob-side entry retaining top-cutting explosion pressure relief method

InactiveCN104790954ARelieve pressureEliminate problems such as support difficultiesUnderground miningSurface miningStructural engineeringDeep hole

The invention discloses a roadside packing gob-side entry retaining top-cutting explosion pressure relief method which comprises the following four steps: I, confirming a top-cutting method, the drilling construction time and a drilling construction site; II, confirming top-cutting pressure relief explosion drilling parameters; III, drilling deep-hole explosion holes and explosive filling and sealing holes; IV, performing explosion top-cutting pressure relief. The roadside packing gob-side entry retaining top-cutting explosion pressure relief method is applied to roadside packing gob-side entry retaining top-cutting explosion pressure relief.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

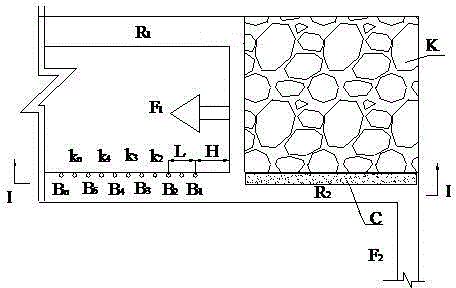

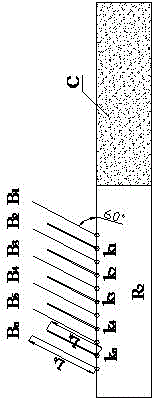

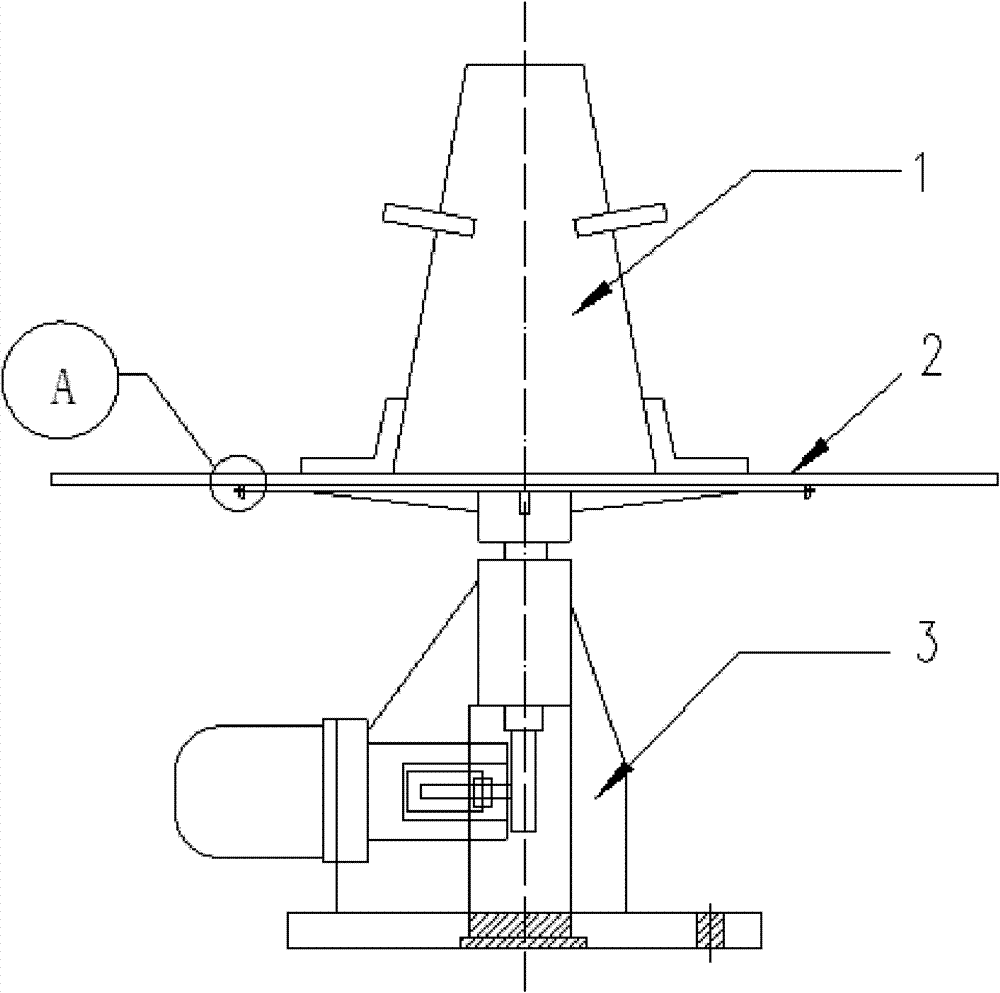

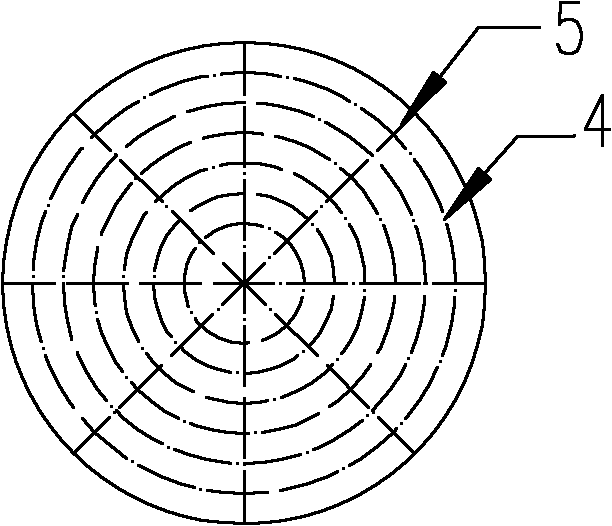

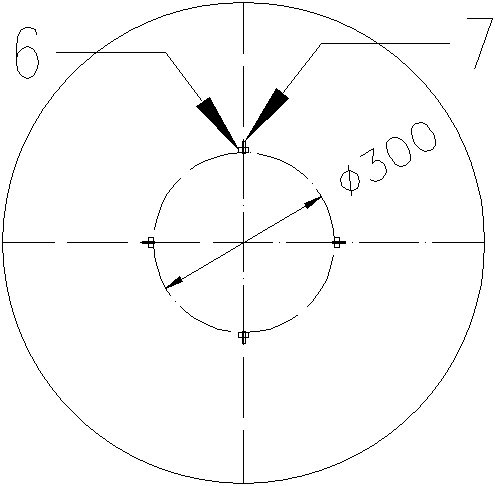

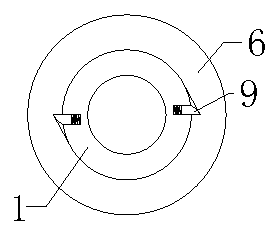

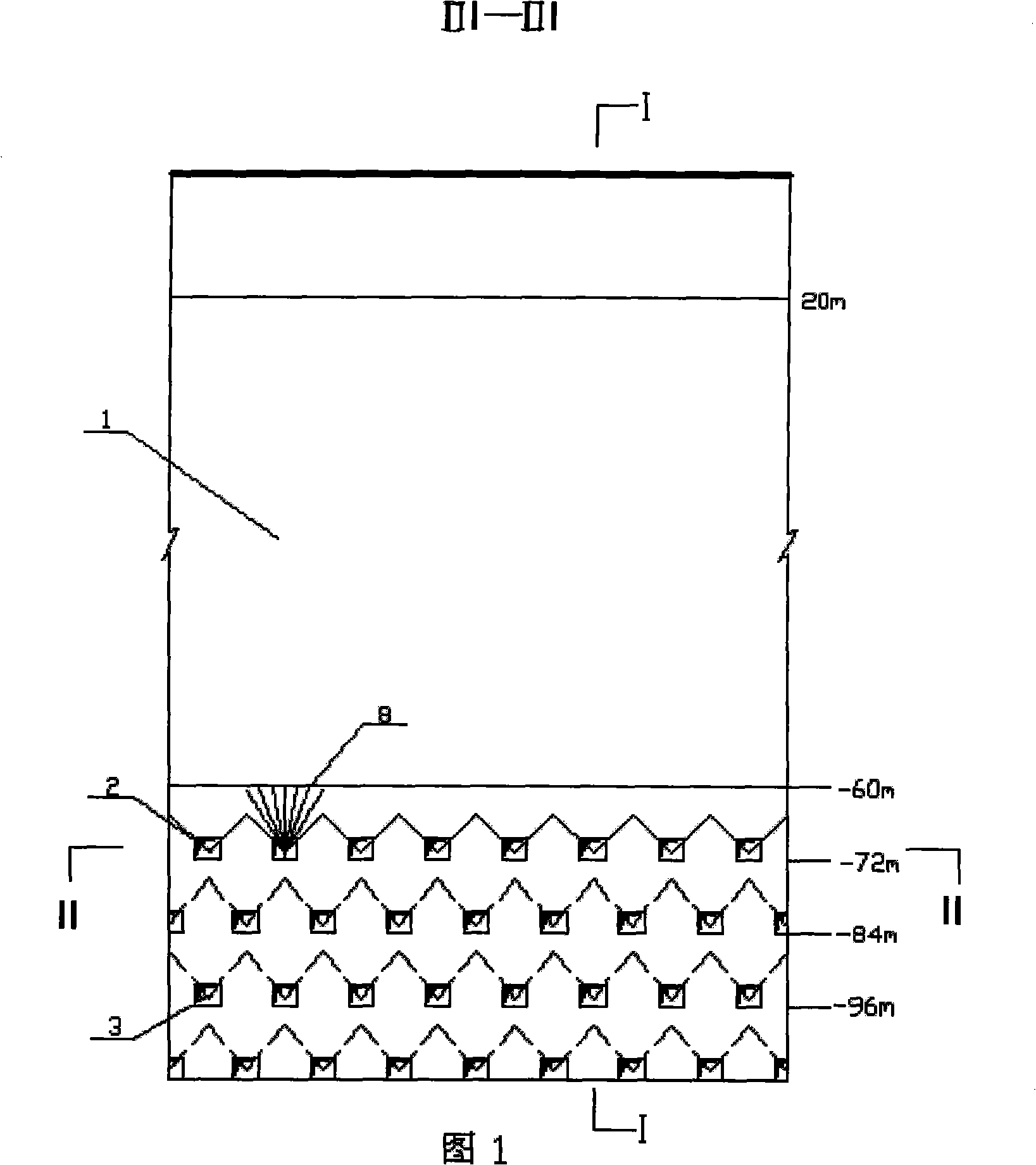

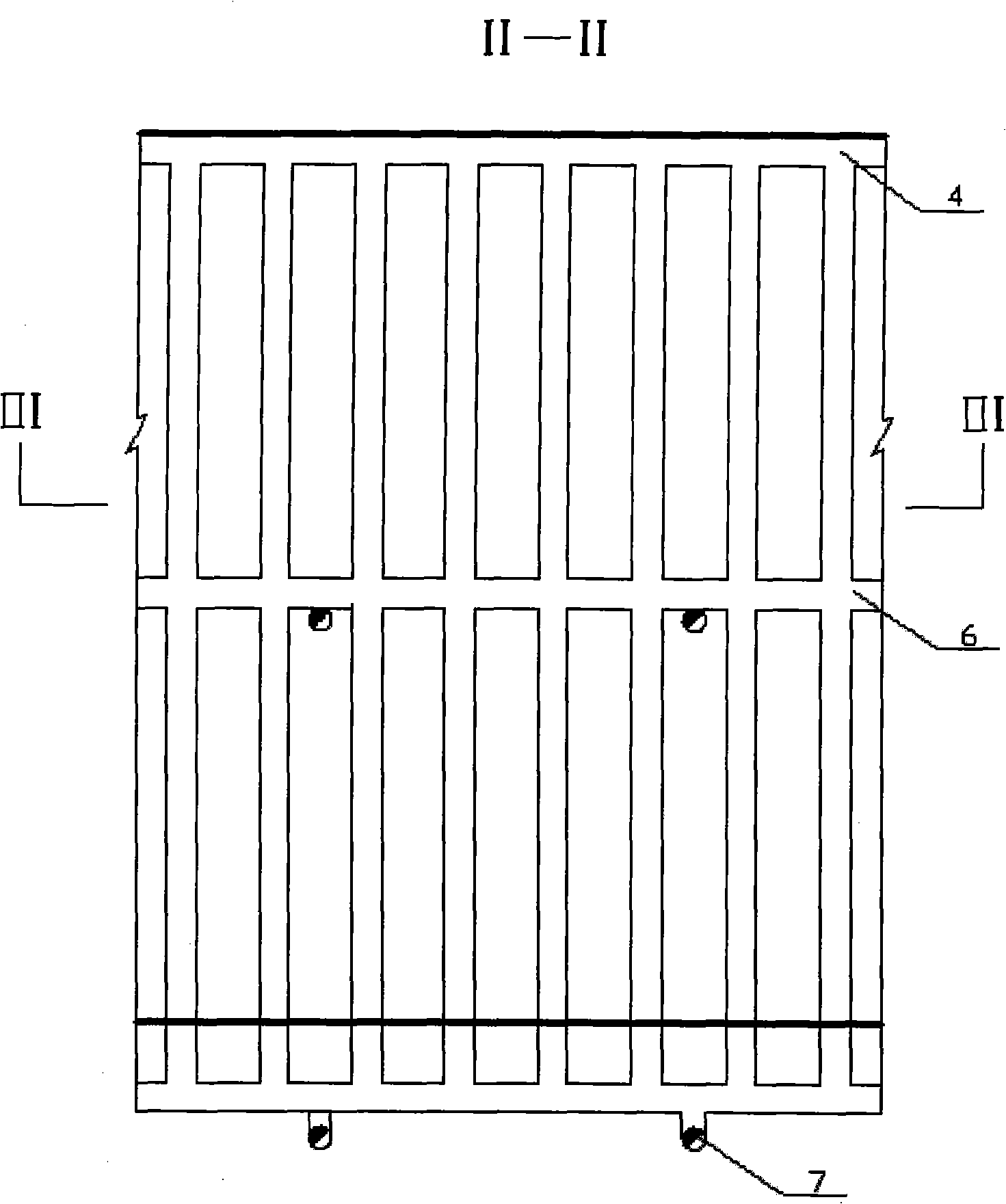

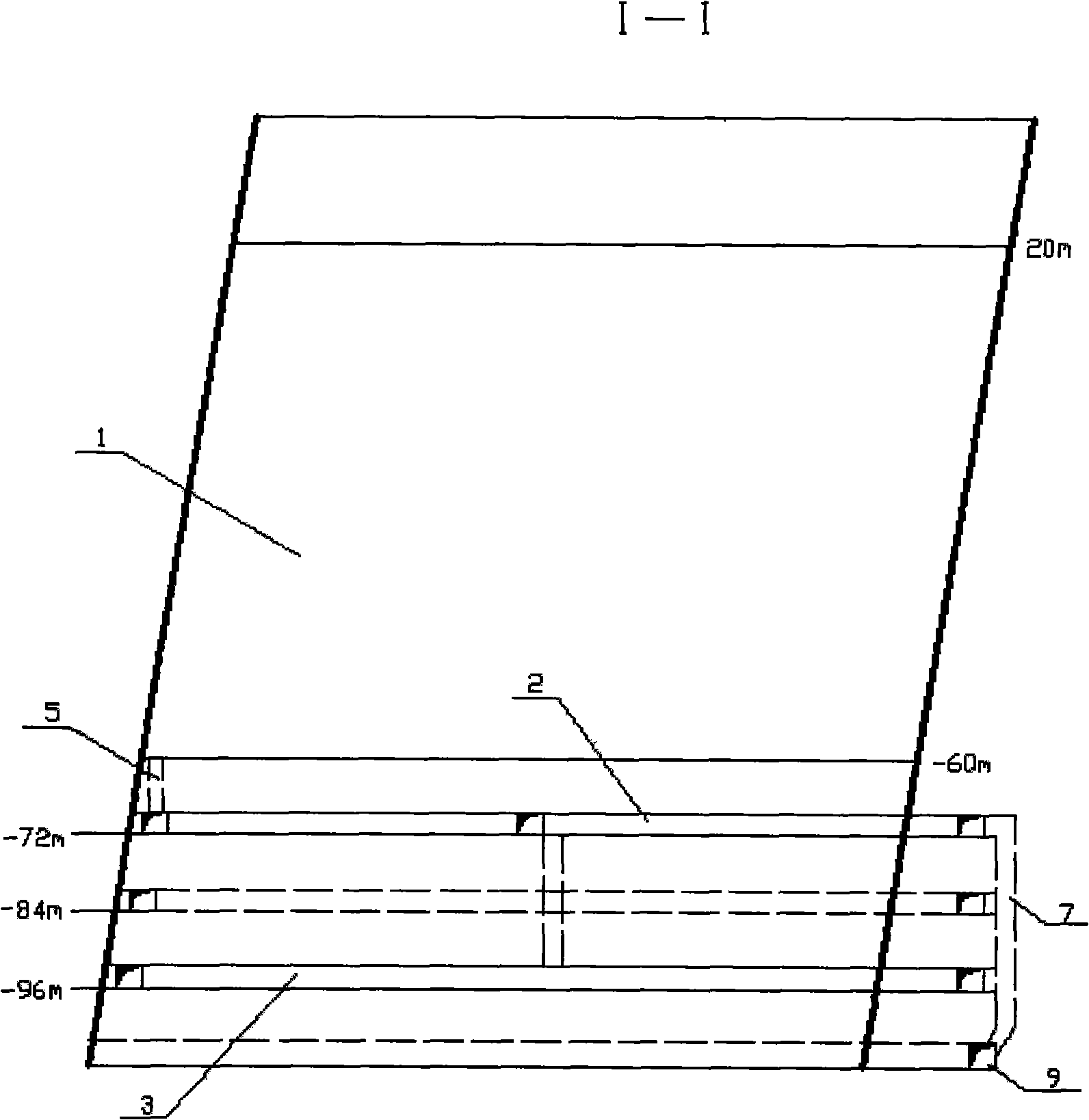

Testing method for working performance of concrete and apparatus implementing same

The invention relates to a testing method for working performance of concrete and an apparatus implementing the same. The testing apparatus comprises a concrete slump tester, a cement mortar fluidity testing jumping table and a circular extending table. In similar testing of the slump of concrete disposed on a large table-board, the jumping table vibrates preset times according to certain frequency and certain vibration amplitude after a slump cylinder is hoisted, which enables the slump and flowing of the concrete to be improved and the concrete to form a circular truncated cone shape with a larger area; the slump H after vibration, the mobile extended diameter D of the concrete, center thickness h1 and edge thickness h2 after vibration are measured, the inclination angle theta of a frustum after slump of the concrete is calculated through conversion, bleeding and the segregation degree of the concrete are observed, and thus, working performance of the concrete can be comprehensively estimated. Compared with the prior art, the invention has the following advantages: working performance of fresh concrete can be conveniently and quickly tested and distinguished, and the method and the apparatus are applicable to a wide variety of concrete.

Owner:TONGJI UNIV

Inverse Y-shaped ventilation method for coal mining working face

InactiveCN102071958ASolve accumulated puzzlesConcentration controllableTunnel/mines ventillationGas removalEconomic benefitsCoal pillar

The invention relates to an inverse Y-shaped ventilation method for a coal mining working face. In the method, a transportation roadway is arranged on one side of the coal mining working face; a railway roadway and a return air roadway are sequentially arranged on the other side of the coal mining working face; coal pillars are positioned between the railway roadway and the return air roadway; contact roadways are formed at certain intervals; sealed partition walls are arranged among the contact roadways; before the working face is actually mined, the contact roadways near the working face are communicated so as to form a return air contact roadway; a beside-roadway wall body is built along the border of a gob, which is close to the back of the working face; a sealing wall is constructed at the position which is 1 to 2m away from the back of the return air contact roadway so as to seal a gob-side entry and the return air roadway; when the working face is actually mined, air flow passes through the railway roadway and the transportation roadway to enter the coal mining work face and returns to the return air roadway through the gob-side entry and the return air contact roadway; and the stroke of the air flow forms an inverse Y shape. The ventilation method is characterized by simple structure and stable air flow, solves the problem of gas accumulation at the upper corner of an actual mining working face and the problem that the god-side entry is difficult to maintain, and has obvious social and economic benefits.

Owner:CHINA UNIV OF MINING & TECH +1

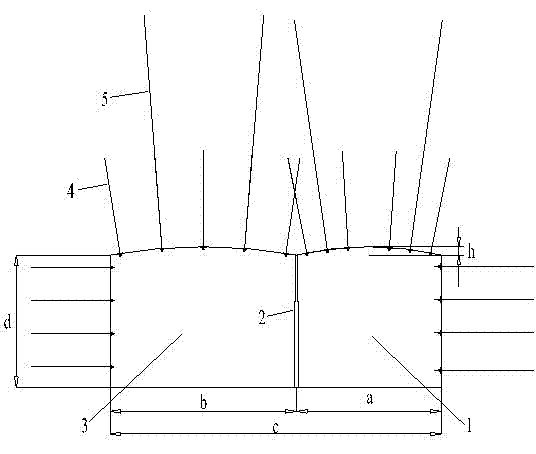

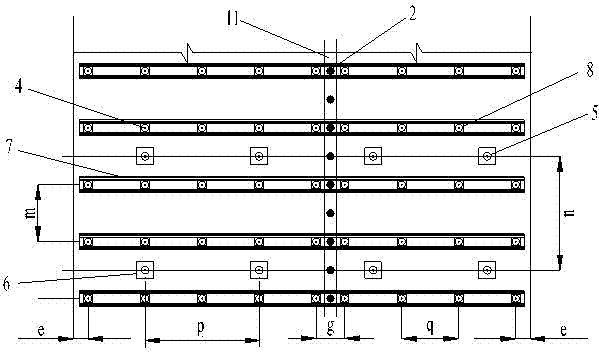

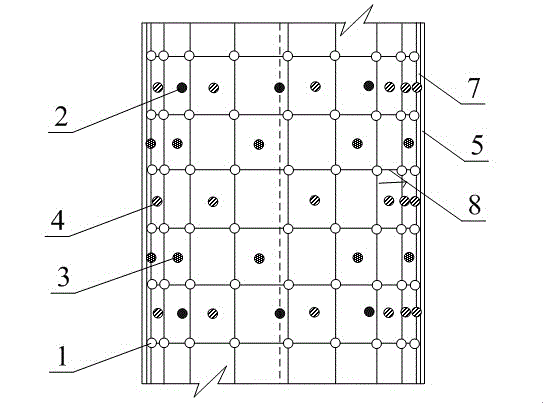

Support method for span reduction with double micro-arches in large-span cut-outs

InactiveCN102268998ASolve the problem of difficult to control the stability of the roofImprove top control effectTunnelsMine roof capsLong spanMonomer

The invention discloses a span-reducing support method with double micro-arches for large-span cutouts, which is suitable for span-reduction support in areas with complex structures and deep composite roofs with large-span cutouts. The secondary roadway is used instead of the first roadway, and the double micro-arch cutout is used to replace the traditional one-time long-span rectangular cutout, and the prestressed anchor / cable is used to strengthen the surrounding rock of the cutout. The distribution law of the plastic zone of the surrounding rock of the micro-arch cutout, select reasonable support parameters, give full play to the support function of the prestressed anchor rod / cable, add a row of single pillars and top beams to reduce the span support in the double micro-arch cutout protection, the top control effect is obvious. For large-span cutouts, the span reduction support method of secondary roadway formation + double micro-arch sections + anchor net cables + single pillars and hinged roof beams was adopted to solve the problem of difficult control of the roof of long-span rectangular cutouts and realize The large-span cutting eye is fast, safe and economical to construct, and its method is simple and easy to implement, with low support cost and good support effect.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

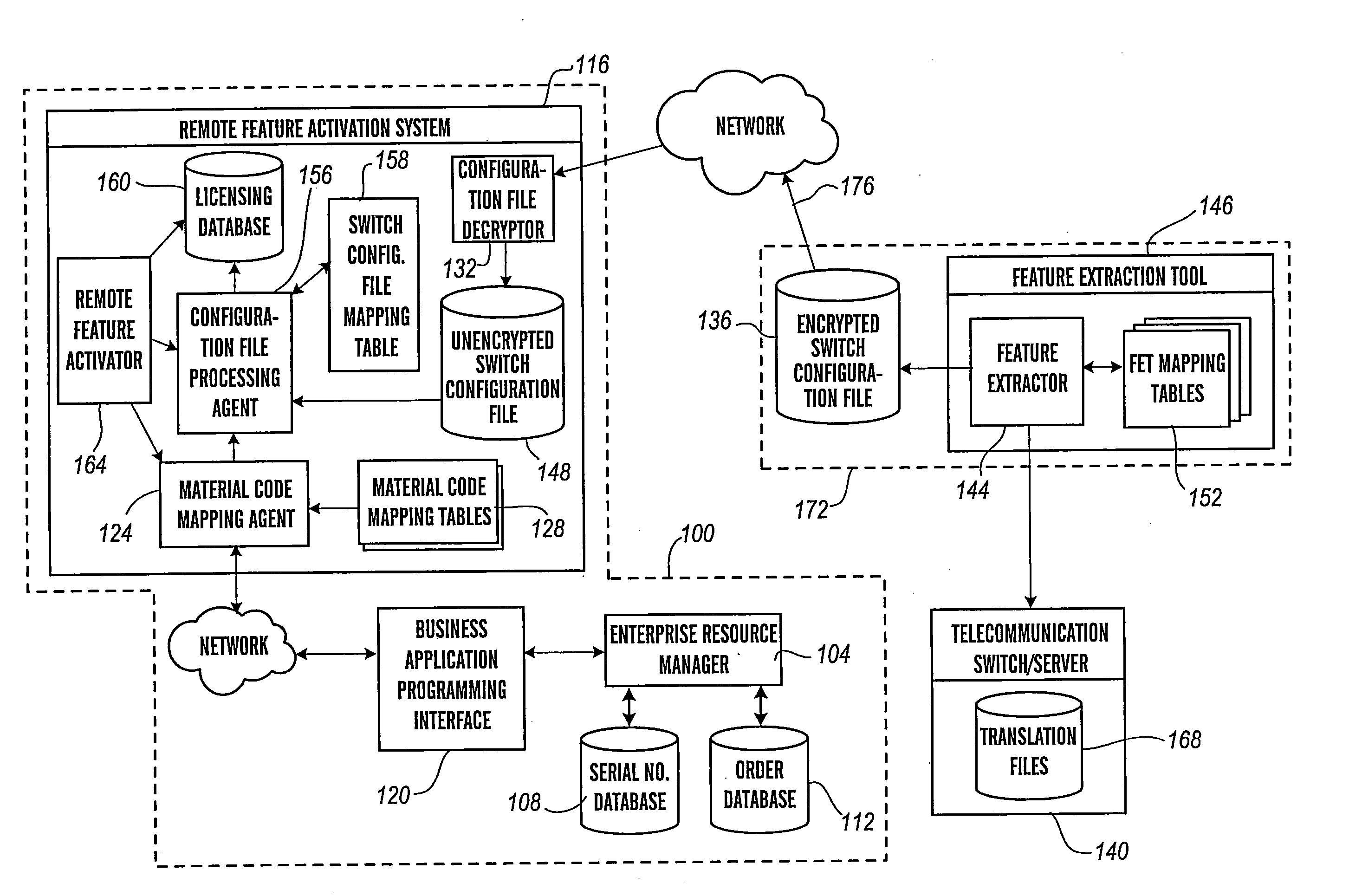

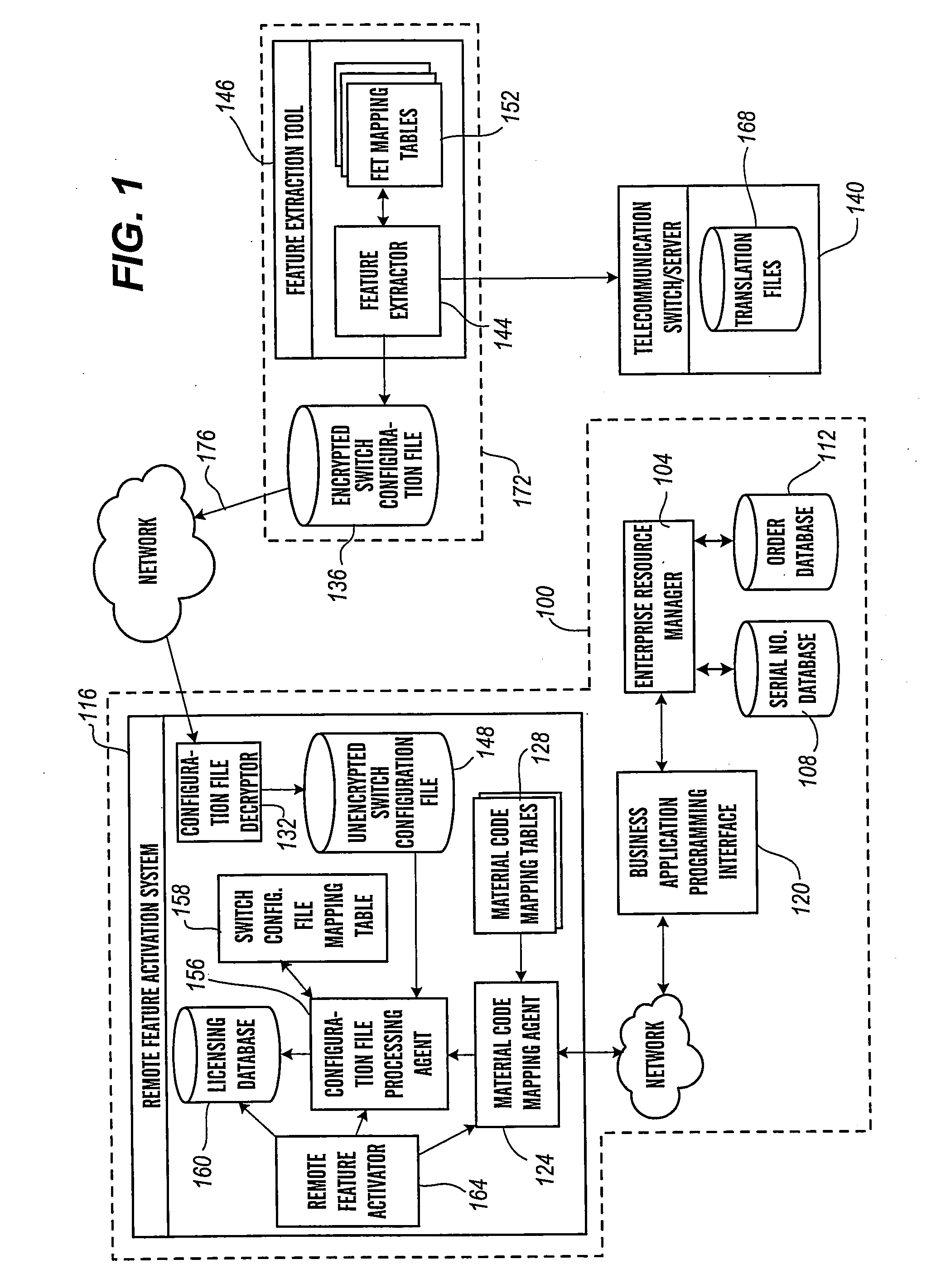

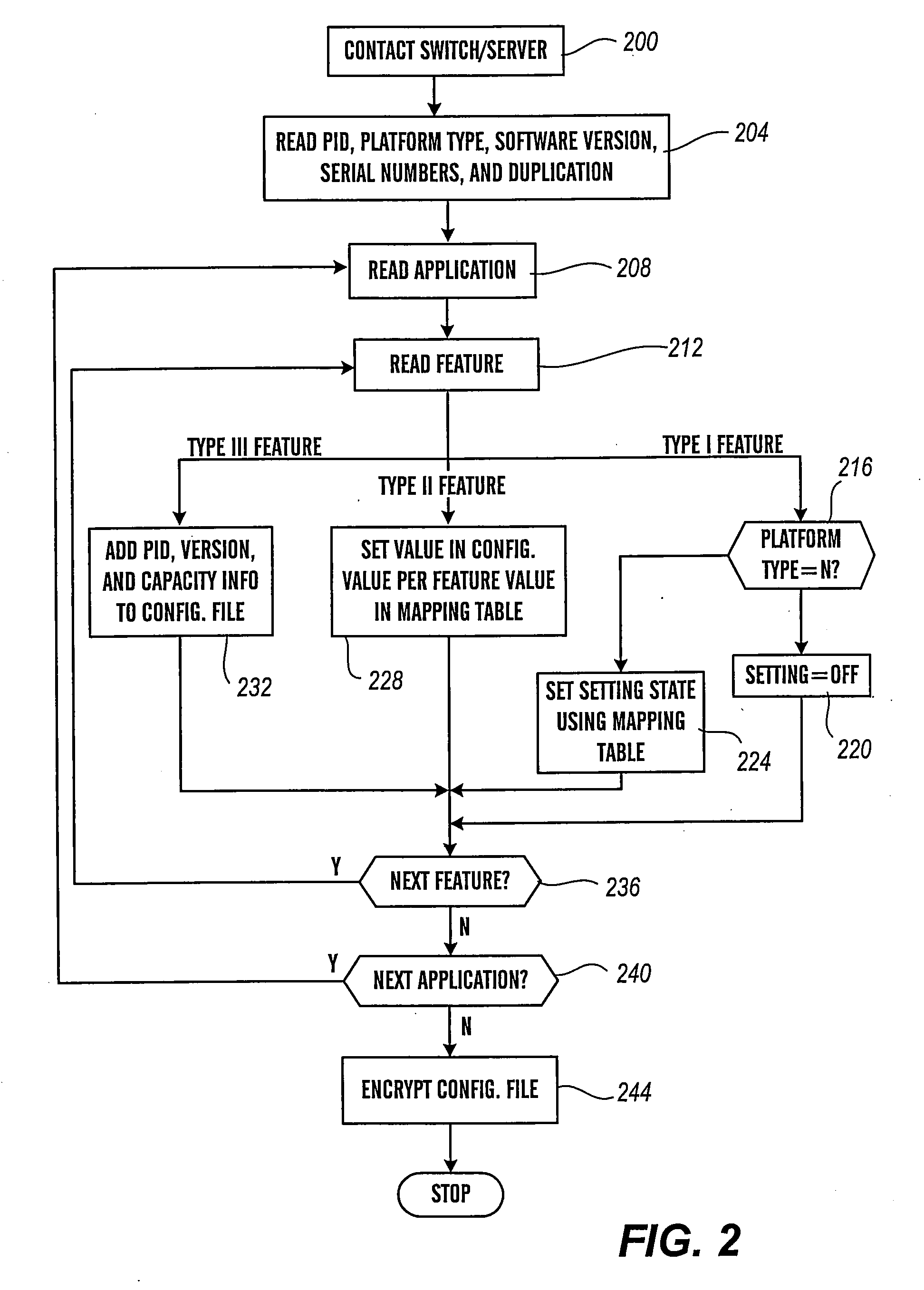

Remote feature activator feature extraction

InactiveUS20080052295A1Shorten the timeReduce errorsDigital data processing detailsAnalogue secracy/subscription systemsFeature extractionComputer science

A database record controls a license to use a computational component. An input receives an order identifier associated with an order related to a computational component and an interface retrieves order information associated with the identifier. The order information comprises at least one material code. A material code mapping agent compares the material code with at least one material code mapping table to identify corresponding computational component information associated with the material code. In another configuration, a transaction record includes first information associated with the order, the order relates to at least a first computational component and / or feature thereof, a configuration file includes second information different from the first information, the configuration file relates to at least one telecommunication switch / server, and a configuration file processing agent compares some of the first information with some of the second information to form a system record having both first and second information.

Owner:AVAYA TECH LLC

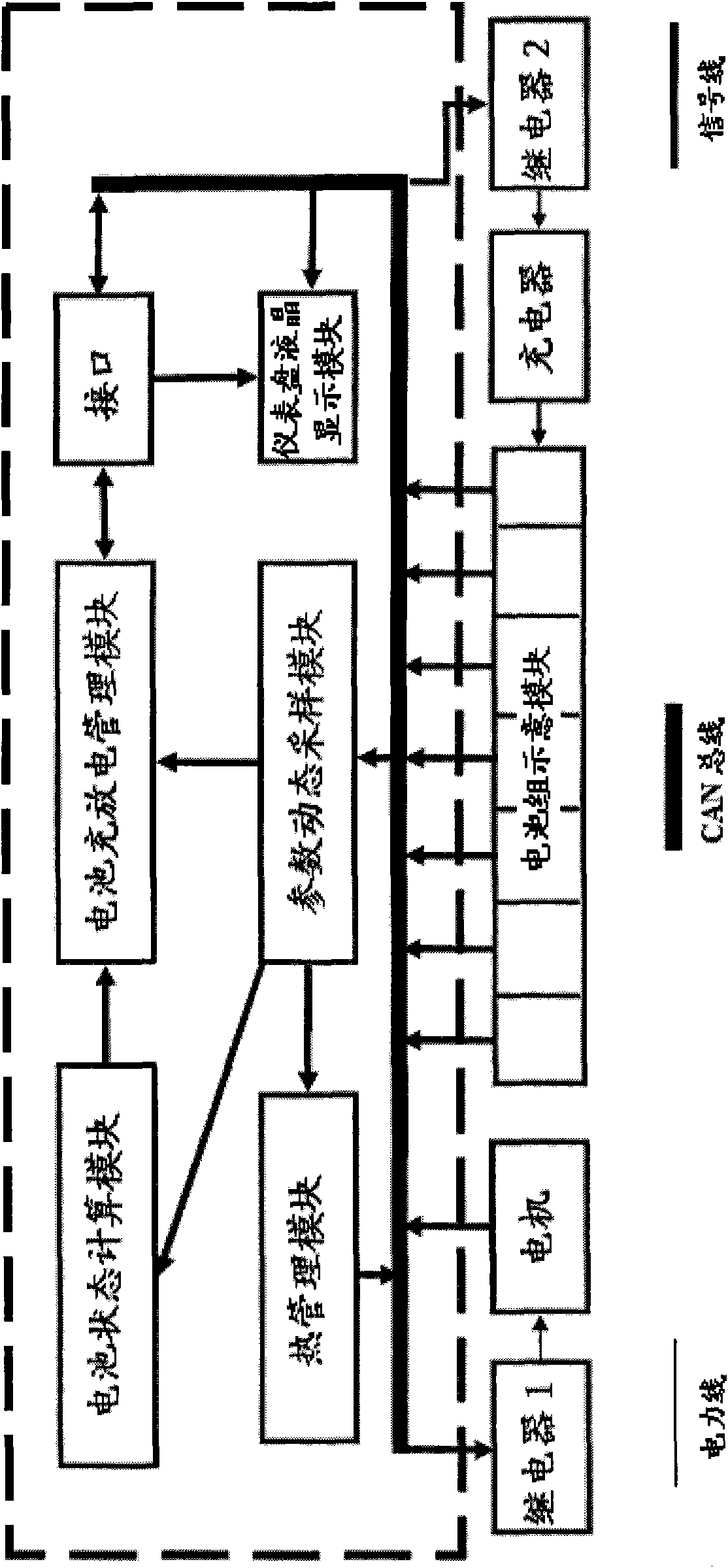

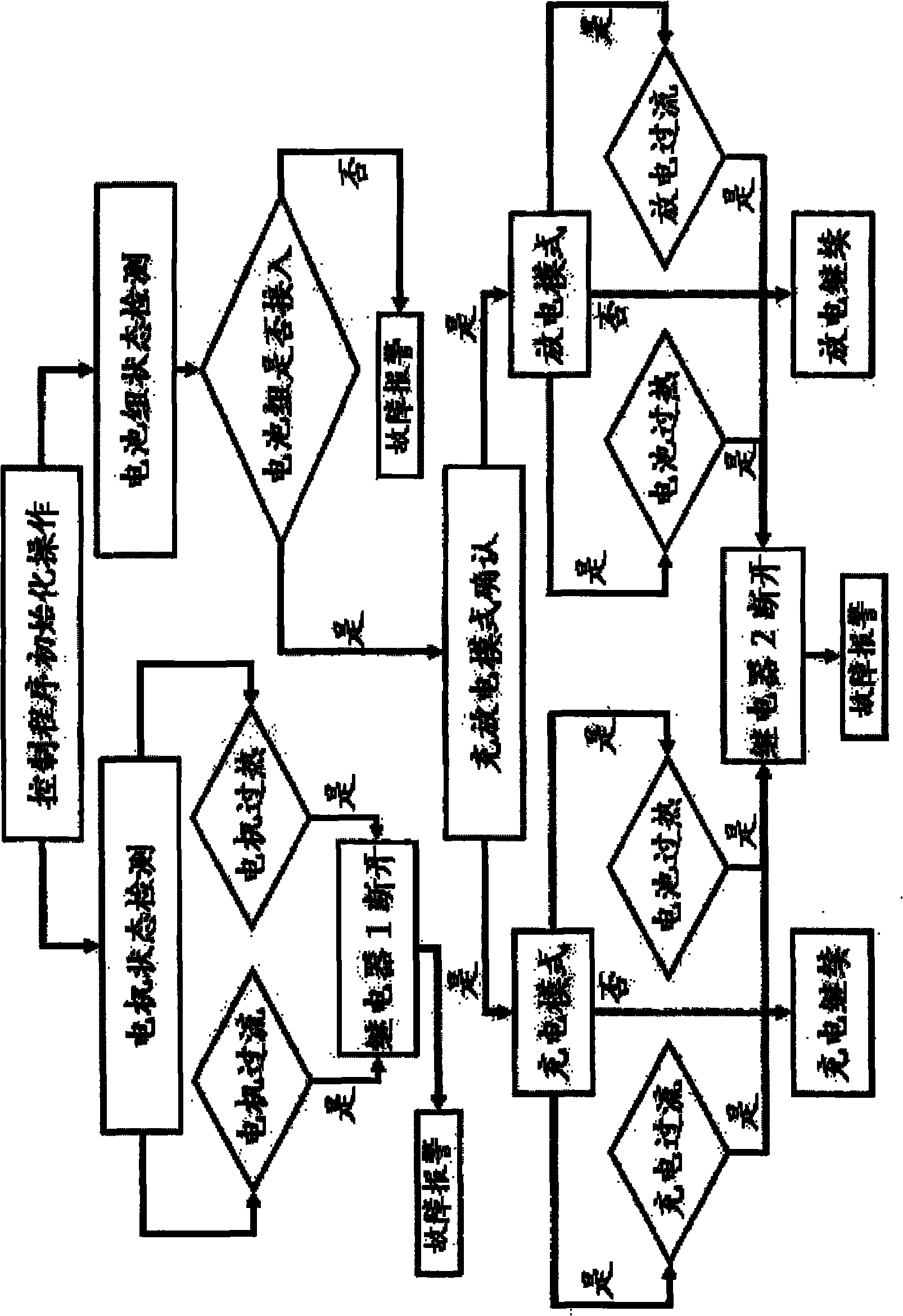

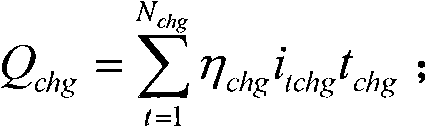

Vehicle power battery pack management system integrated into electric vehicle instrument and control method thereof

InactiveCN102013529AGuaranteed uptimeExtended service lifeElectric devicesElectrical testingArea networkElectrical battery

The invention relates to a vehicle power battery pack management system integrated into an electric vehicle instrument and a control method thereof, and belongs to the field of integrated management of power battery packs. The vehicle power battery pack management system comprises a parameter dynamic sampling module, a heat management module, a battery state calculation module, a battery chargingand discharging management module, an instrument panel liquid crystal display module and an interface. The battery charging and discharging management module is respectively connected with a controller area network (CAN) bus and the instrument panel liquid crystal display module through the interface. The instrument panel liquid crystal display module is connected with the CAN bus. The heat management module and the parameter dynamic sampling module are also respectively connected with the CAN bus. The control method is to monitor a battery state and faults through a control program. The power battery pack management system is convenient to maintain when integrated into the electric vehicle instrument; the work reliability of the system is improved; a remote control interface of an instrument panel can change the management strategy at any time according to the working state of a power battery pack so as to guarantee that the battery pack operates in the optimal state and prolong the service life of a motor.

Owner:李玉堂

Supporting method of permeable soft broken rock stratum roadway

InactiveCN103603675AEffective deformationEffectively closedUnderground chambersTunnel liningSteel barCement slurry

The invention relates to a supporting method of a roadway in a coal mime, particularly to a supporting method of a permeable soft broken rock stratum roadway. The supporting method aims at solving the problems that soft broken rock stratum roadways especially permeable soft broken rock stratum roadways are poor in supporting effect, high in cost and the like. The supporting method comprises the steps of first concrete spraying; combined support through high strength deformed steel bar anchor rods and diamond metal nets; anchor cable installation; secondary concrete spraying; installation of chemical pulp grouting anchor rods; installation of cement slurry grouting anchor rods.

Owner:张瀚

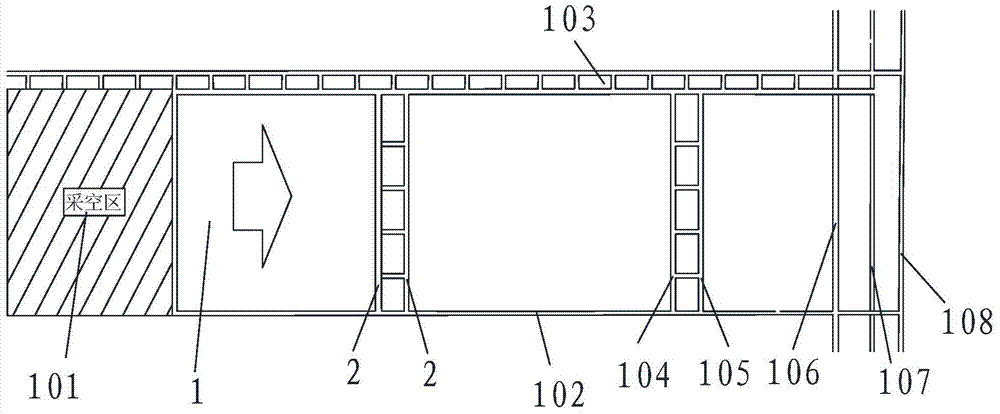

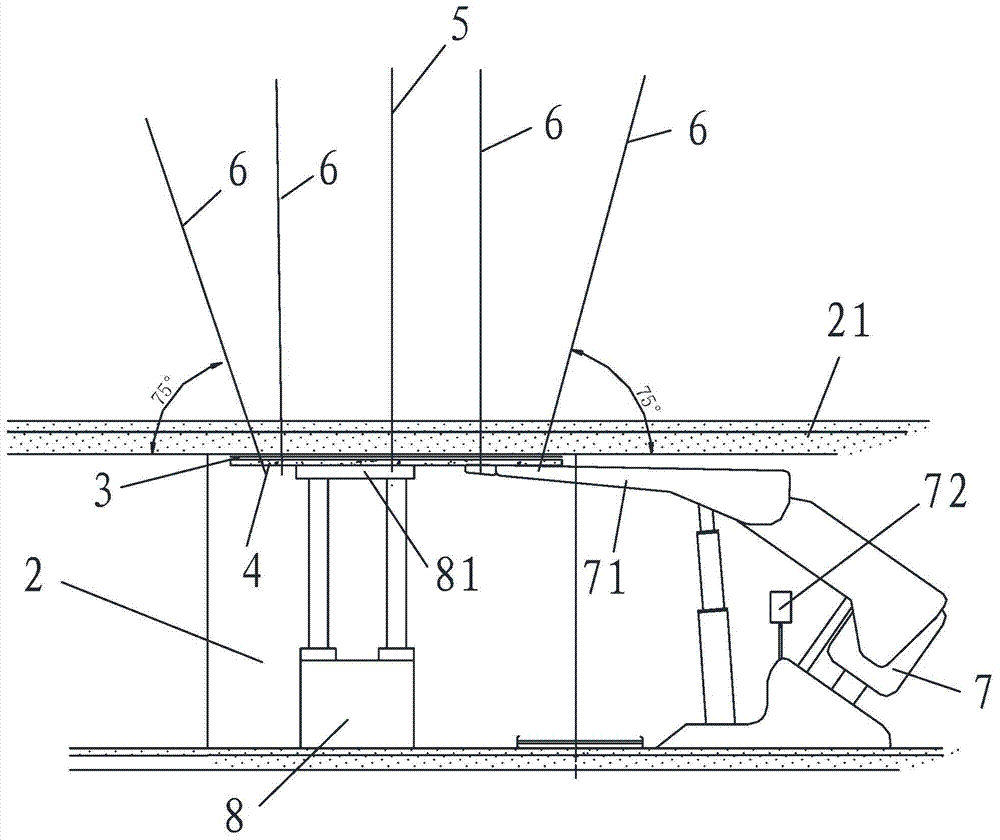

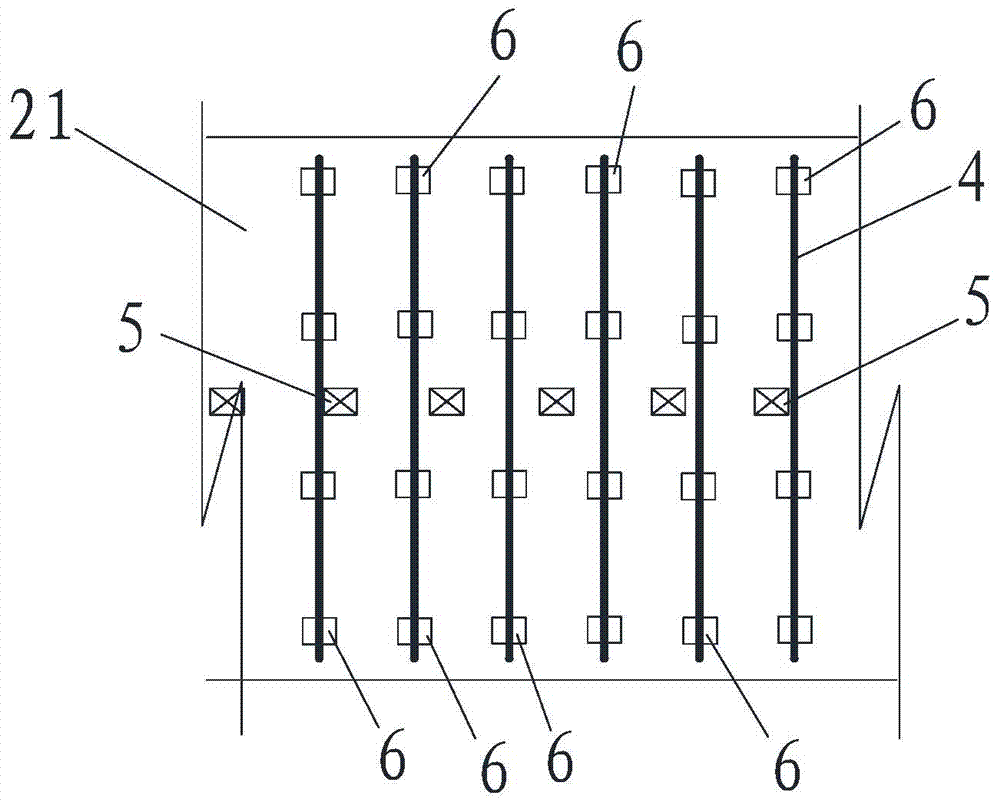

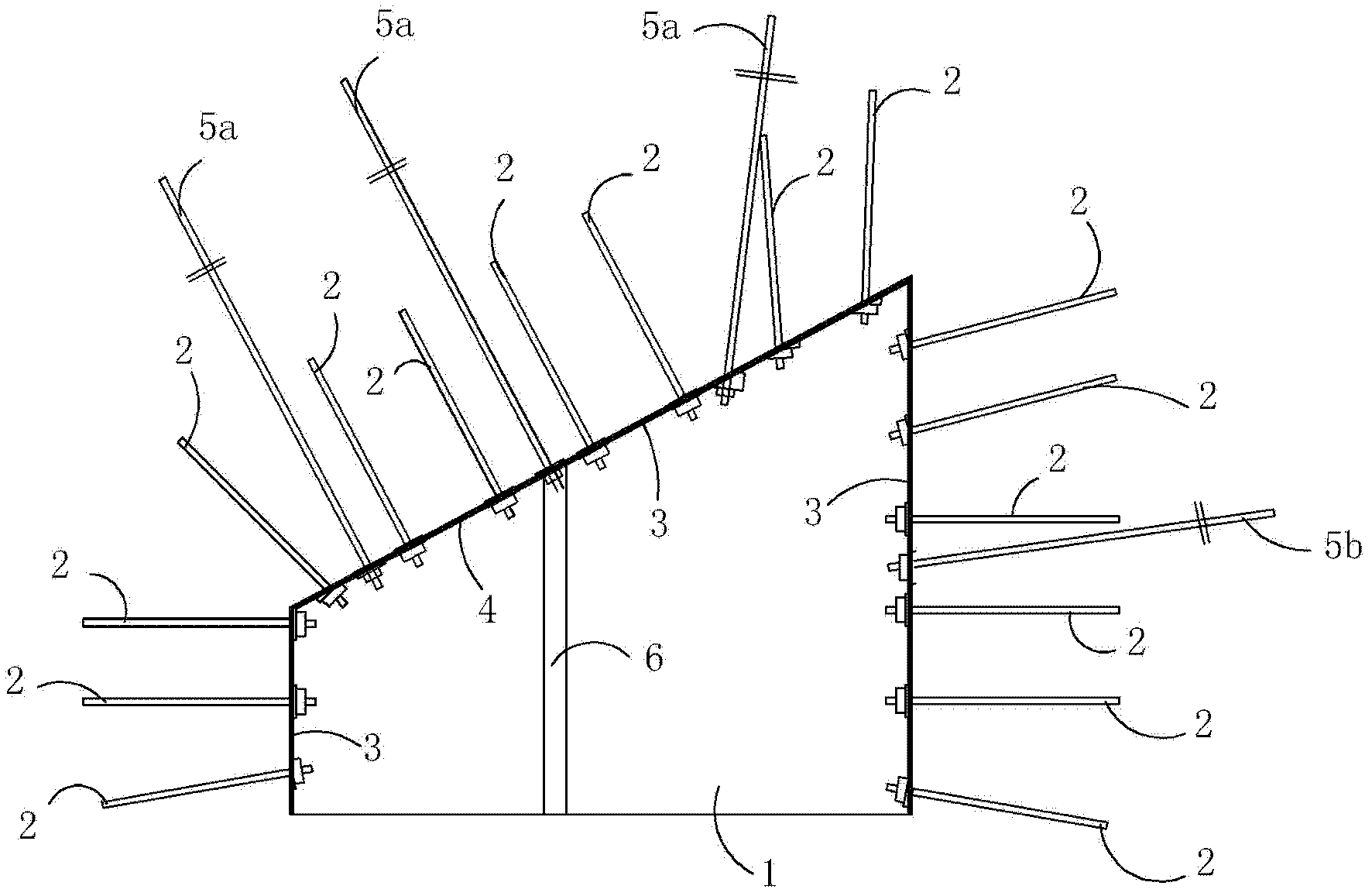

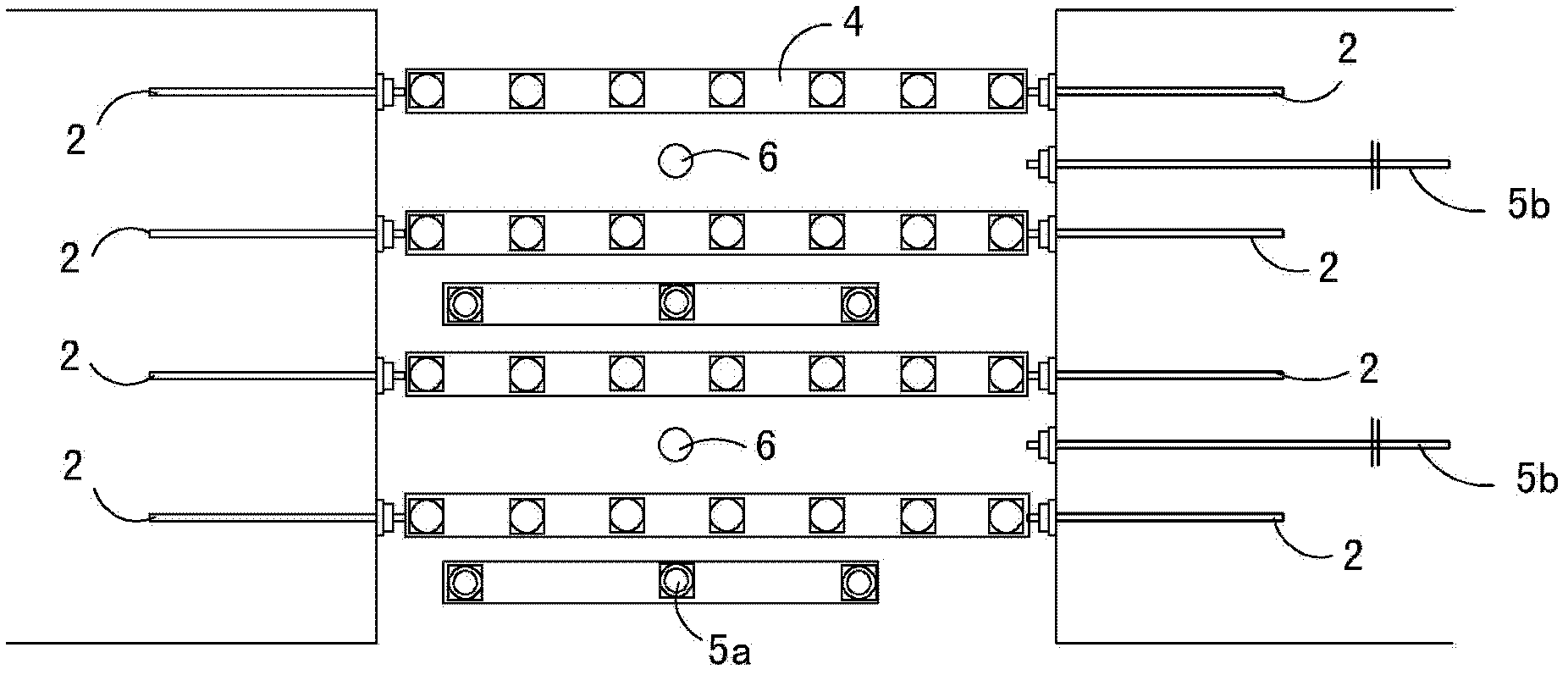

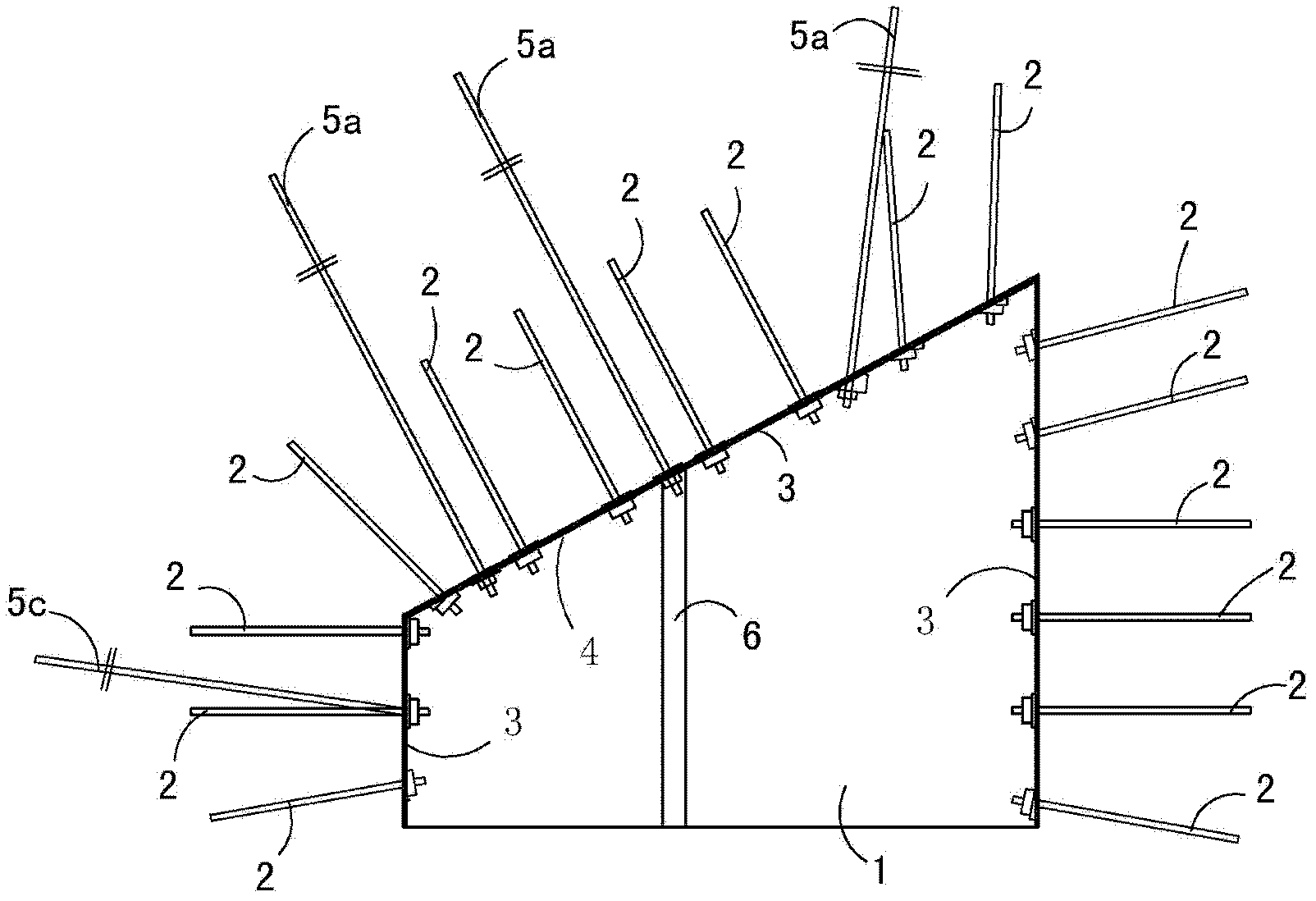

Abandoned roadway timbering device and construction method of fully mechanized coal mining face passed through abandoned roadway

ActiveCN103696788AReduce roof fall accidentsImprove support strengthUnderground miningSurface miningStructural engineeringCoal mining

The invention discloses an abandoned roadway timbering device which comprises a metal net, a steel belt, a protective net, timbering anchor ropes, hanging timbering anchor ropes, anchor rods and a hydraulic support. The steel belt is installed on a top plate of an abandoned roadway through multiple hanging timbering anchor ropes, the hanging timbering anchor ropes located at two ends of the steel belt and the top plate form an included angle alpha, the metal net is fixed under the top plate through the hanging timbering anchor ropes and the timbering anchor ropes, the steel belt is located under the metal net, multiple timbering anchor ropes are installed on the top plate located on a central line of the abandoned roadway, a hydraulic chock is located in the abandoned roadway, a top beam of the hydraulic chock abuts against the top plate, and the protective net is installed on the roadway side of the abandoned roadway through the anchor rods. The invention further discloses a construction method of a fully mechanized coal mining face passed through the abandoned roadway.

Owner:CHINA SHENHUA ENERGY CO LTD +1

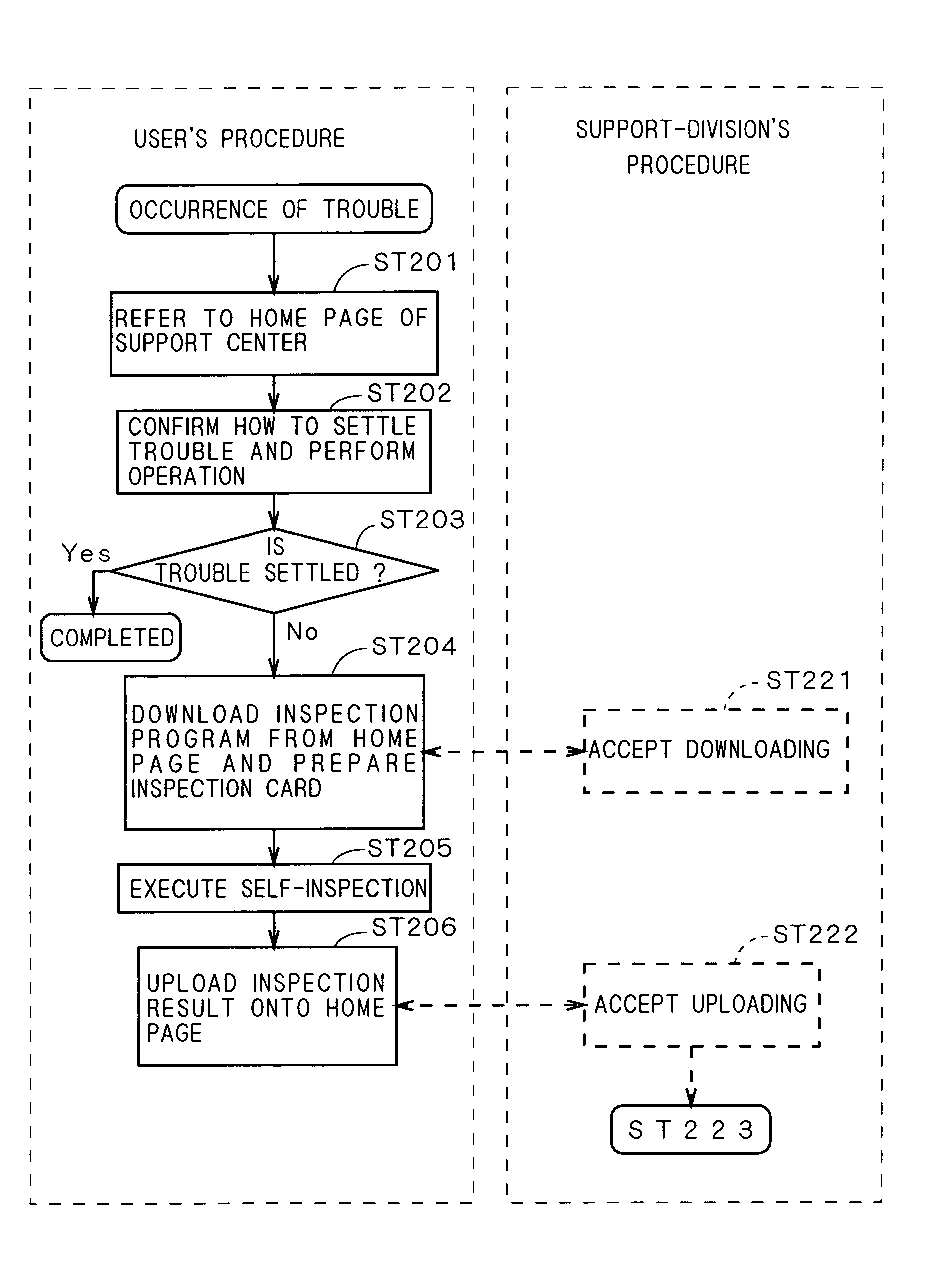

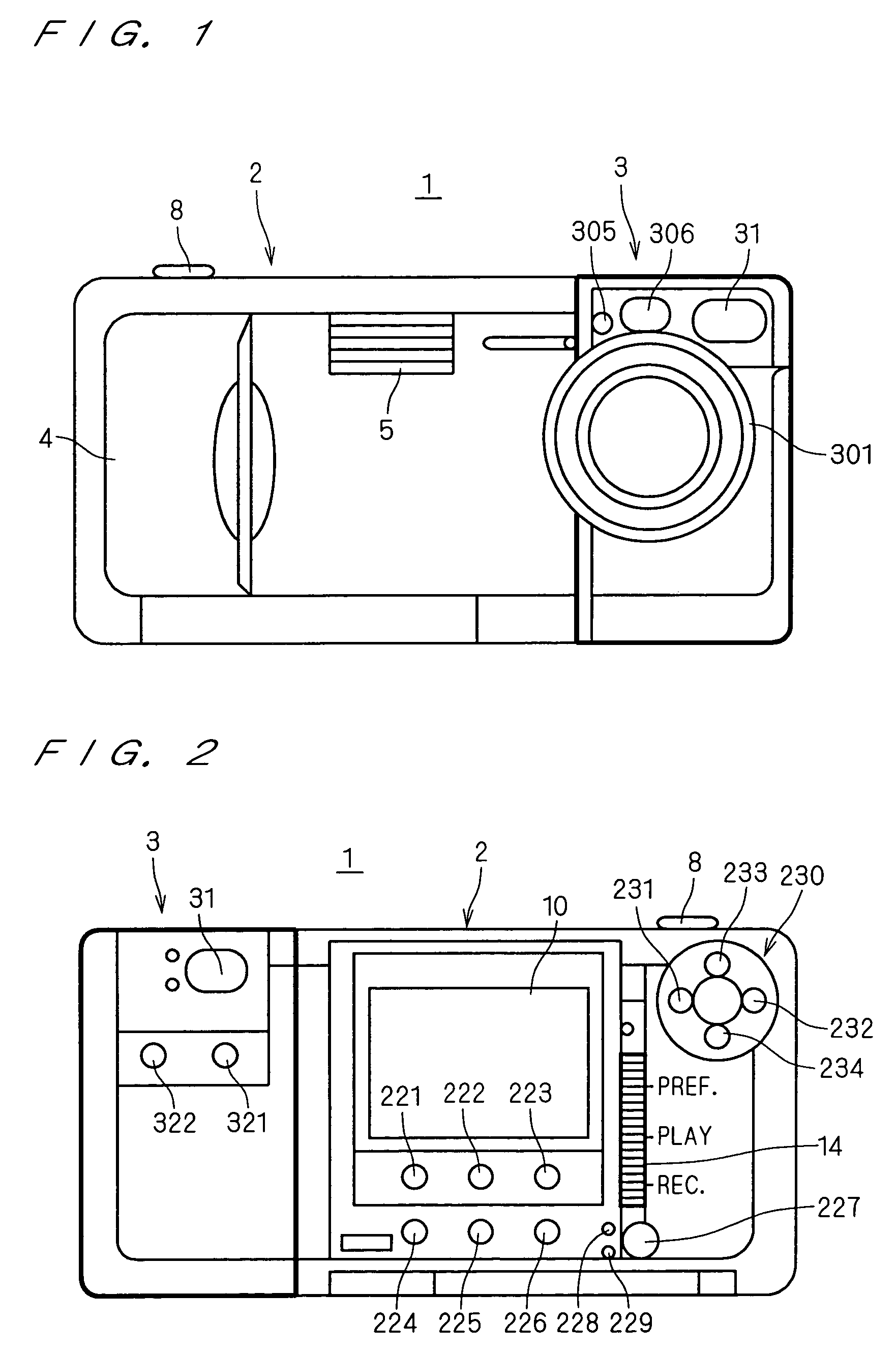

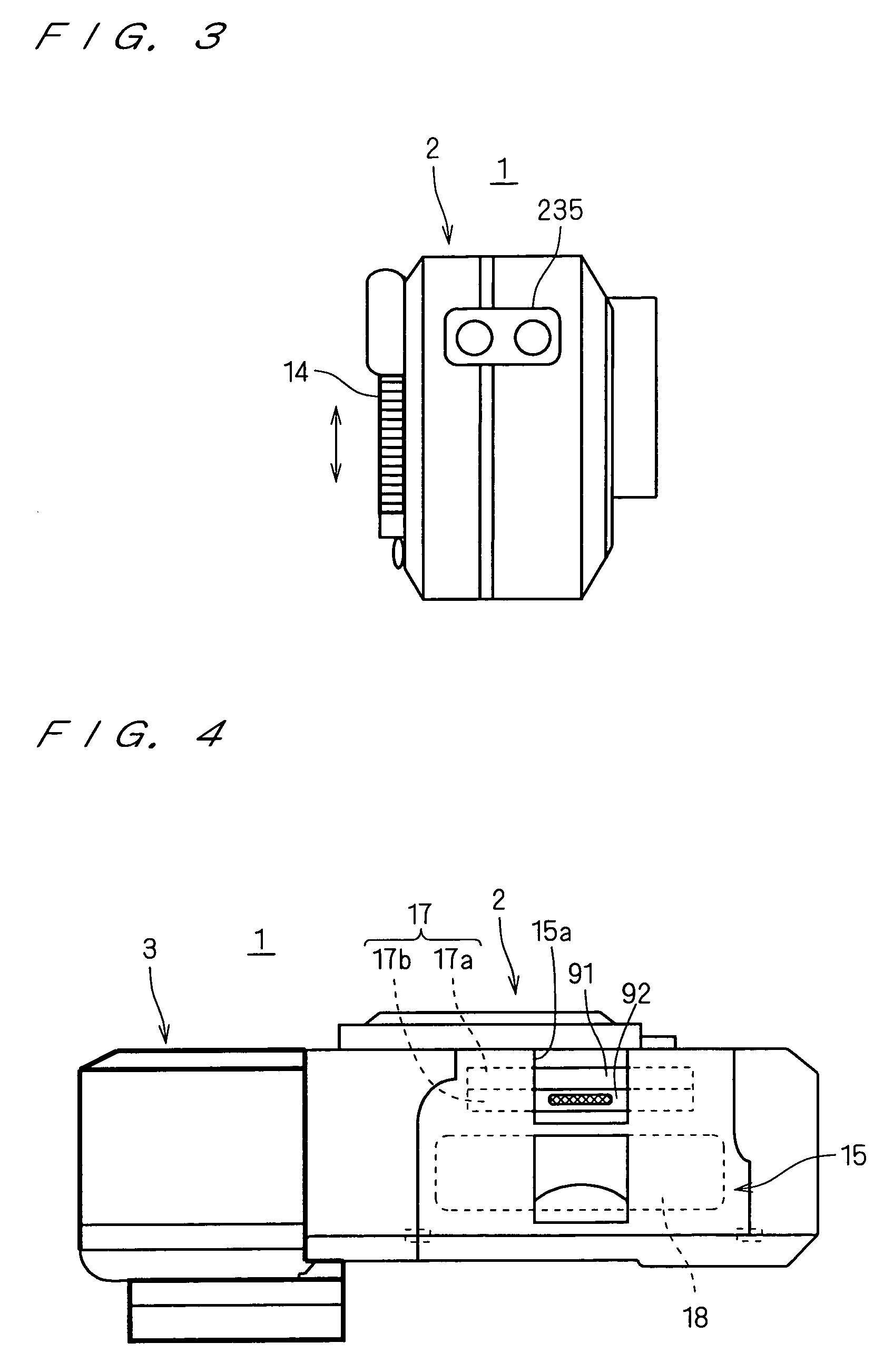

Method and apparatus for diagnosing electronic device

InactiveUS7124326B1Accurate diagnosisEasy to receiveData processing applicationsDigital computer detailsComputer hardwareHome page

Downloading of an inspection program for an electronic device to be supported is accepted on the home page of the support center. The user executes the downloaded inspection program on the electronic device to generate inspection results. Then, uploading of the inspection results is accepted on the home page, a computer of the support center analyzes the uploaded inspection results to generate a diagnosis result, and the diagnosis result including necessity of repair is transferred to the user. Thereby, it is possible to properly and quickly diagnose the electronic device on the user's side and reduce the support cost by preventing unnecessary transport of the electronic device.

Owner:MINOLTA CO LTD

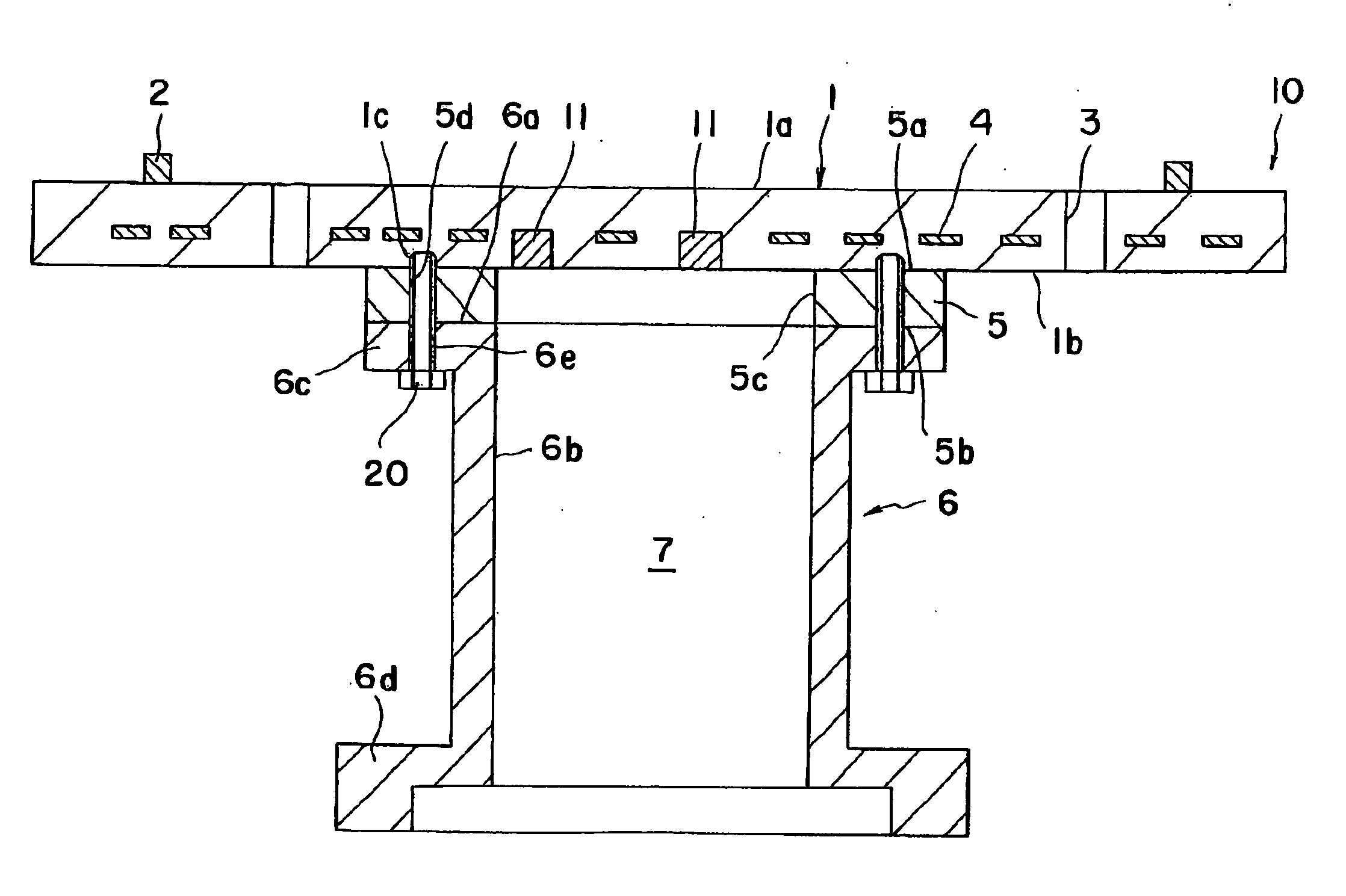

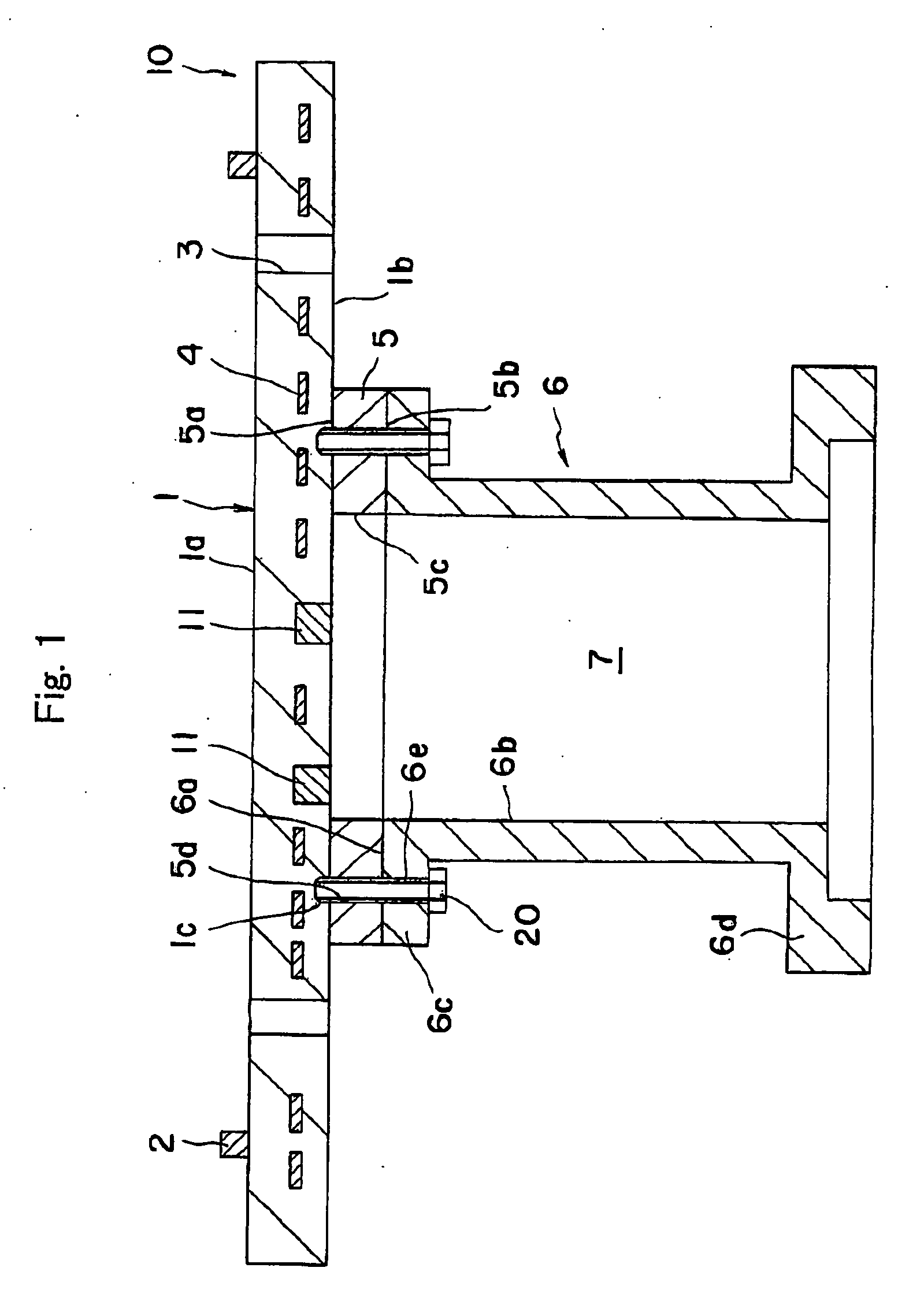

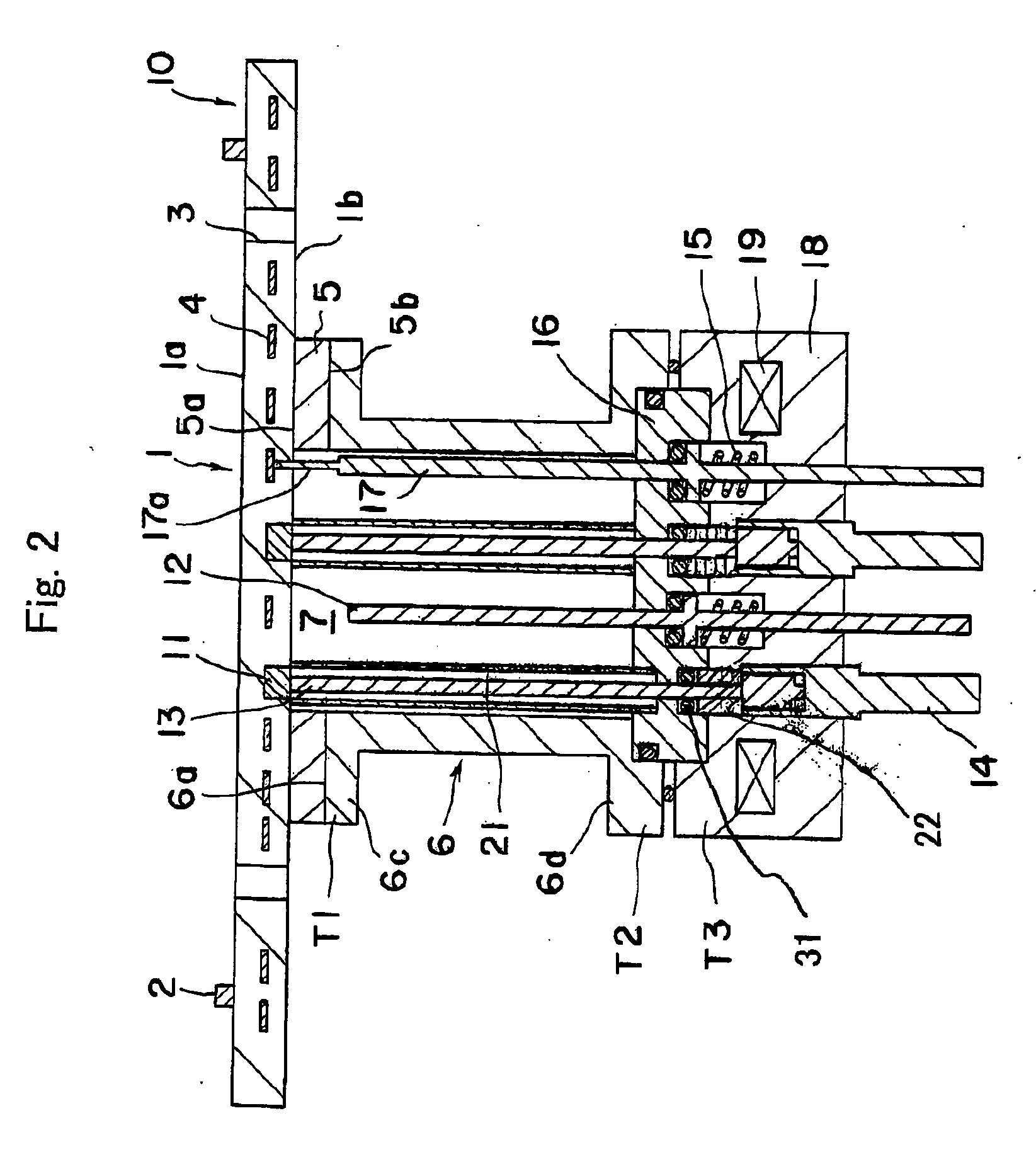

Heating systems

ActiveUS20060186109A1Deterioration flatness and inclination can be preventedEasy to carrySemiconductor/solid-state device manufacturingHot plates heating arrangementsHeating systemEngineering

An object of the present invention is to provide a heating system having a ceramic heater and a supporting member supporting the back face of the heater, so that the cost of the supporting member can be reduced, the design change of the heater is made easier and excellent flatness of the heating face on use can be maintained. The heating system has a ceramic substrate 1 having a heating face 1a and a back face 1b, a heating means 4 for generating heat from the heating face 1a of the substrate 1, a metal supporting member 6 supporting The back face 1b of the substrate 1, and a heat insulating plate 5 provided between the back face 1b of the substrate 1 and the supporting member 6.

Owner:NGK INSULATORS LTD

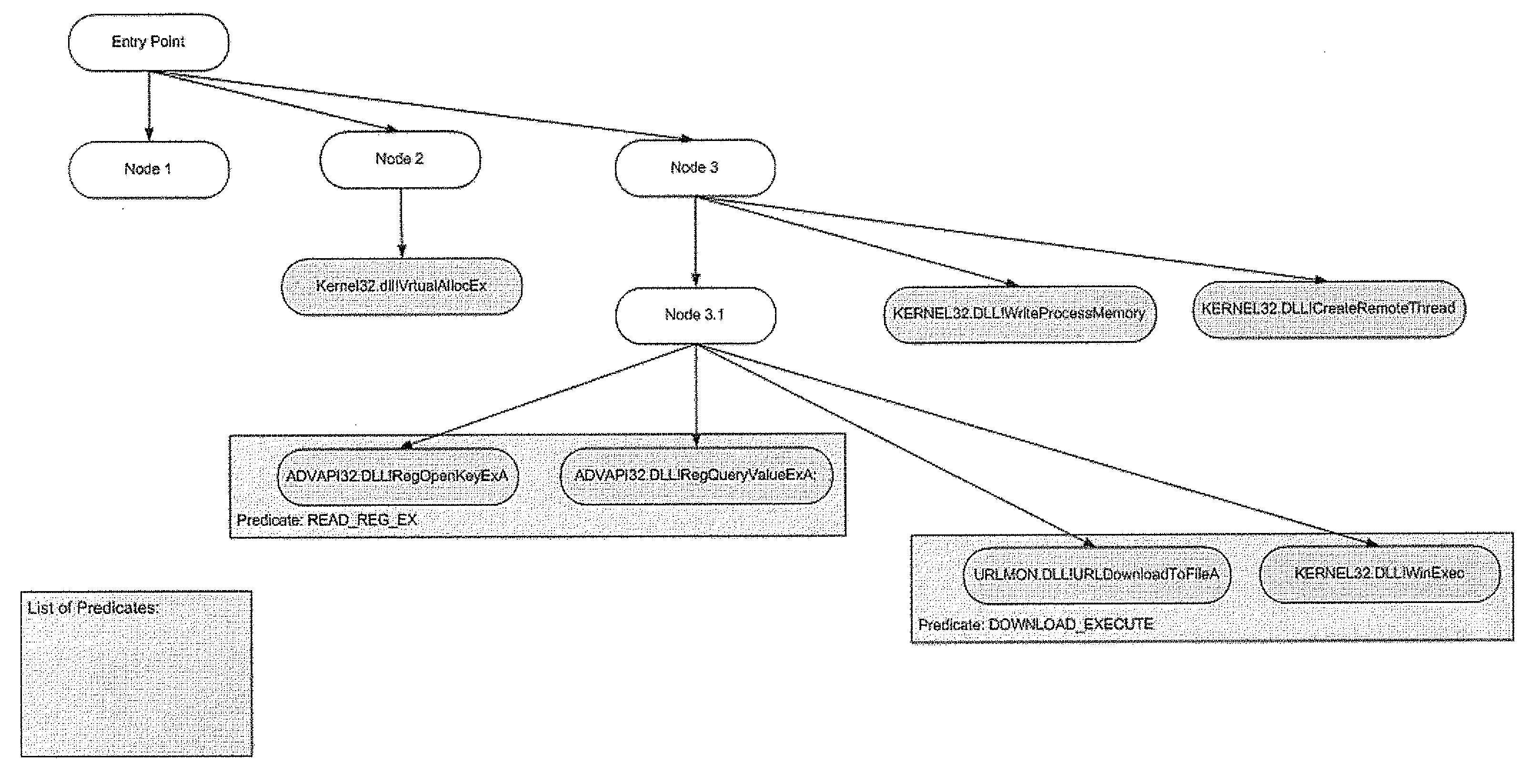

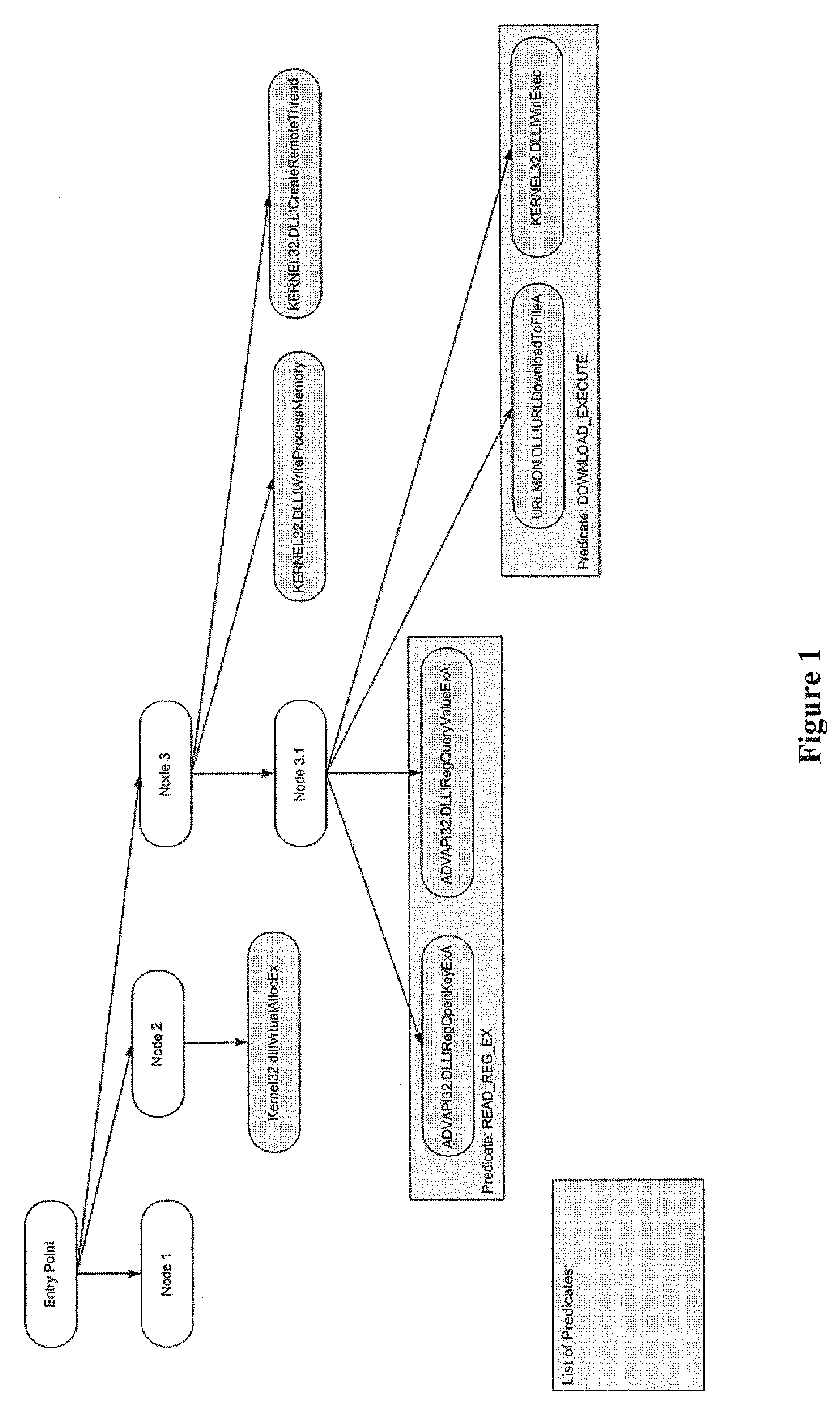

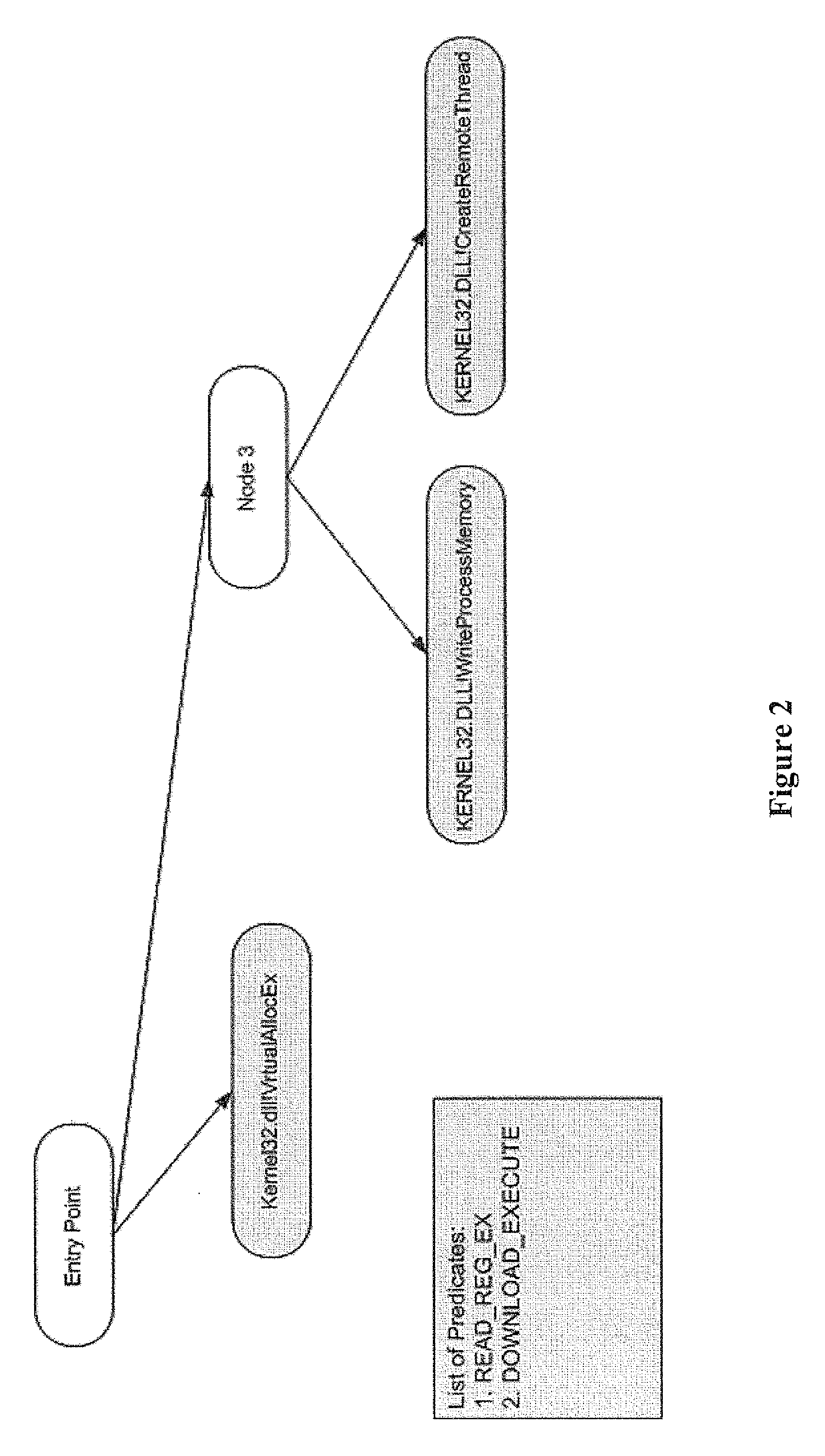

Methods for detecting malicious programs using a multilayered heuristics approach

ActiveUS20100333203A1Reduce supporting costsFunction increaseMemory loss protectionDigital data processing detailsHeuristicMalware

Three heuristic layers are used to determine whether suspicious code received at a port of a data processing device is malware. First, static analysis is applied to the suspicious code. If the suspicious code passes the static analysis, dissembling analysis is applied to the suspicious code. Preferably, if the suspicious code passes the dissembling analysis, dynamic analysis is applied to the suspicious code.

Owner:CHECK POINT SOFTWARE TECH LTD

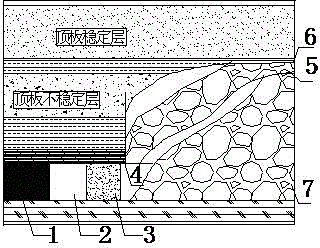

Divided mining method for inclined medium-thick ore body with unstable false roof

ActiveCN104018836AOut of stopeReduce the dilution loss rateUnderground miningSurface miningEngineeringNo removal

The invention discloses a divided mining method for an inclined medium-thick ore body with an unstable false roof. The ore body is divided into panels along the strike, ore pillars of chambers are divided in the panels and a top pillar is reserved during stoping; an outside-vein slice drift, a layered linking roadway and a trackless stope preparation project of a chute mine are distributed on the upper panel of the ore body, and an upward air roadway is filled and is distributed at a position at the center of the ore pillars of the chambers and close to the lower panel; chambers are mined firstly and the ore pillars are mined secondly in the panels, and the chambers and the ore pillars are mined in an up-down layering manner; the stoping is performed from an ore removal crossdrift, the false roof and the ore body are mined in sequence, after ores are conveyed out by a carry-scraper, the false roof at the lower sub-layer is subjected to caving in advance by shallow holes, waste stones of the false roof are reserved in a stoping field, and the ore breaking compensation height is compensated in a layering filling manner, the stoping is performed on the lower sub-layer, and the laying caving is performed on the false roof after layering ore breaking and ore conveyed out, the operation is repeated for multiple times until the stoping field is stoped completely, and the bottom layer of the stoping field is filled to close to the back. By using the method, the operating safety, high mechanical degree, no removal of the waste stones of the false roof, low production cost, and low ore dilution loss can be realized.

Owner:CENT SOUTH UNIV

Asymmetric bolt-mesh-cable combination support method for special-shaped mining roadway in large dip angle coal seam

InactiveCN102296976ASolve the characteristicsSolve the drum gang strongAnchoring boltsPre stressCoal

The invention discloses an asymmetrical bolt-net-cable combined supporting method for a special-shaped recovery tunnel of a large inclination angle coal bed. The method is characterized by comprising the following steps of: digging the tunnel according to the shape of the tunnel section, and supporting tunnel top plates, tunnel high-cut surrounding rock and tunnel low-cut surrounding rock by using prestressed anchor rods, steel bar nets and steel strips; arranging top plate prestressed anchor cables on the tunnel top plates; for the solid coal recovery tunnel, arranging high-cut prestressed anchor cables on the tunnel high-cut surrounding rock when the tunnel is dug for 5 to 7 days, and arranging struts in the center of the tunnel towards one side of the low-cut surrounding rock; and for the small coal post reserved recovery tunnel, arranging low-cut prestressed anchor cables on the tunnel low-cut surrounding rock when the tunnel is dug for 5 to 7 days, and arranging struts in the center of the tunnel towards one side of the low-cut surrounding rock. The combined asymmetrical supporting method has good application effect of stability control of the special-shaped recovery tunnel of the large inclination angle coal bed, the repair frequency of the tunnel is greatly reduced, and the supporting cost of the tunnel is reduced.

Owner:ANHUI UNIV OF SCI & TECH

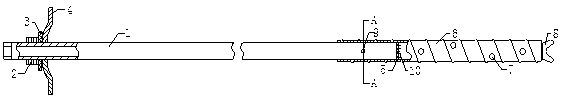

Recoverable anchor rod for drilling, anchoring and grouting and supporting method thereof

The invention relates to a recoverable anchor rod for drilling, anchoring and grouting and a supporting method thereof. The anchor rod comprises a hollow grouting rod body, a nut, a gasket, a tray and a hollow threaded rod body. A drill bit is arranged at the front end of the hollow threaded rod body, and the hollow threaded rod body is provided with multi-purpose holes; the hollow grouting rod body advances inwards through threads, metal nails welded to the internal surface of the front end of the hollow grouting rod body pierce an anchoring agent package inside the hollow threaded rod body, and then, an anchoring agent is mixed and is then discharged through the holes, so as to play an anchoring role; the hollow grouting rod body is used for grouting, and slurry is exported through the multi-purpose holes, so as to cement and solidify loose coal rock bodies; and the hollow threaded rod body is snapped with the wall of a drilled hole through threads on the external surface of the hollow threaded rod body, so as to strengthen an anchoring role in end parts. The one-time drilling, anchoring and grouting supporting of loose coal rocks is realized through tightening and tensioning the tail of the hollow anchor rod, so that the difficult problem that the anchor rod dose not easily enter the loose coal and rocks caused by the fact that the loose coal rocks are subjected to hole collapsing after the loose coal and rocks are subjected to drilling is solved, the load capacity of a coal body is increased, and the supporting strength for surrounding rock of a roadway is enhanced. The recoverable anchor rod for drilling, anchoring and grouting and the supporting method thereof have the advantages of simple structure, low cost, little waste, easiness in construction, and good supporting effect.

Owner:CHINA UNIV OF MINING & TECH

Large dead zone residual ore recovery method

InactiveCN101403304AHigh recovery rateImprove safety conditionsUnderground miningBlastingSpelunkingRecovery method

The invention relates to a recovery method of residual ores in a large mined out space. The method comprises the steps of sublevel caving method without sill pillar, rock drilling and blasting in an inlet passage and ore removal; and is characterized in that: forced caving and induced inbreak are adopted by ore break down, a recycling inlet passage is arranged at the bottom of the mined out space, residual orebody inside and at the periphery of the mined out space to be recycled is divided into an induced inbreak area and a forced caving area from top to bottom, the continuous mined out space formed after the blasting is utilized to induce the inbreak of the ore at the upper part, and the recycling inlet passage is arranged in the ore body at the lower part of the mined out space. The method solves the problems of poor safety condition and low recovery rate and the like of the traditional residual ore recovery in the mined out space, realizes high degree of safety, low production cost and high recovery rate and the like of the residual ore recovery, and improves the production efficiency and economic efficiency of mines.

Owner:KUNMING UNIV OF SCI & TECH

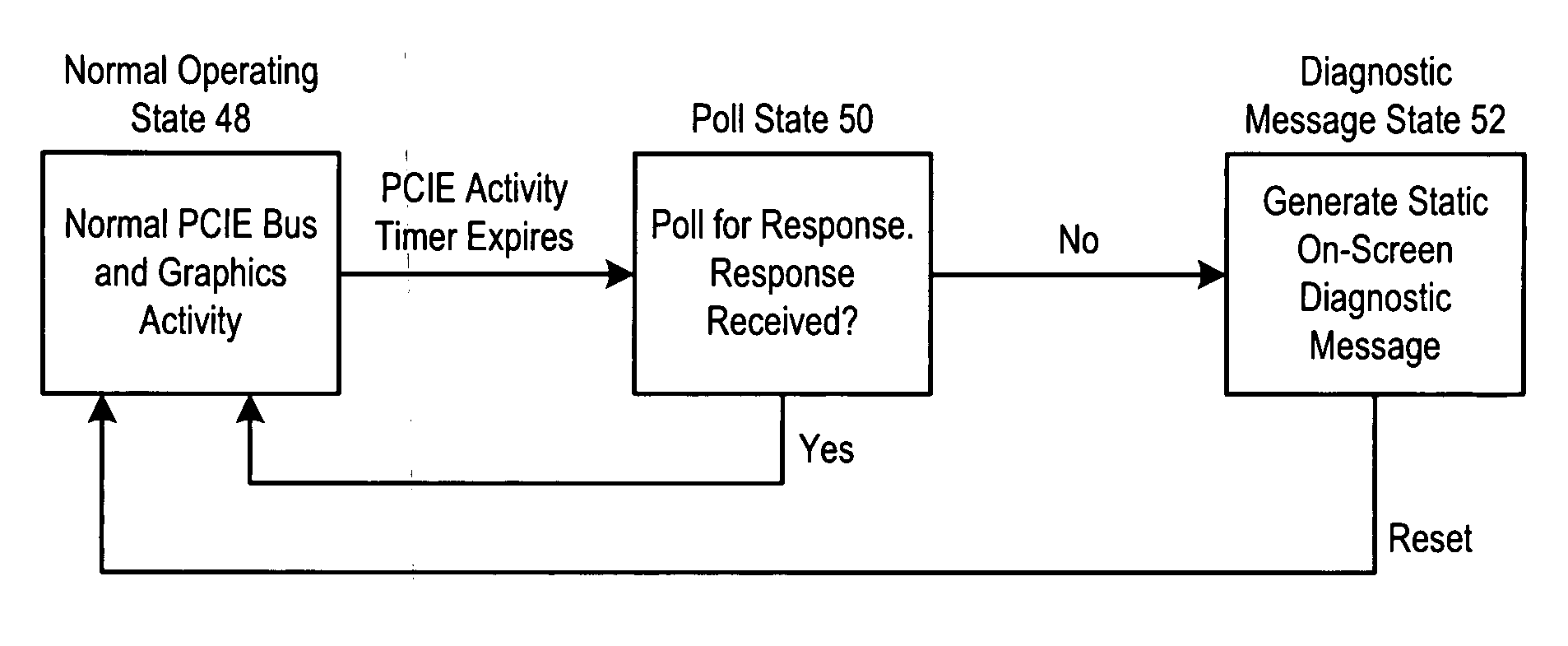

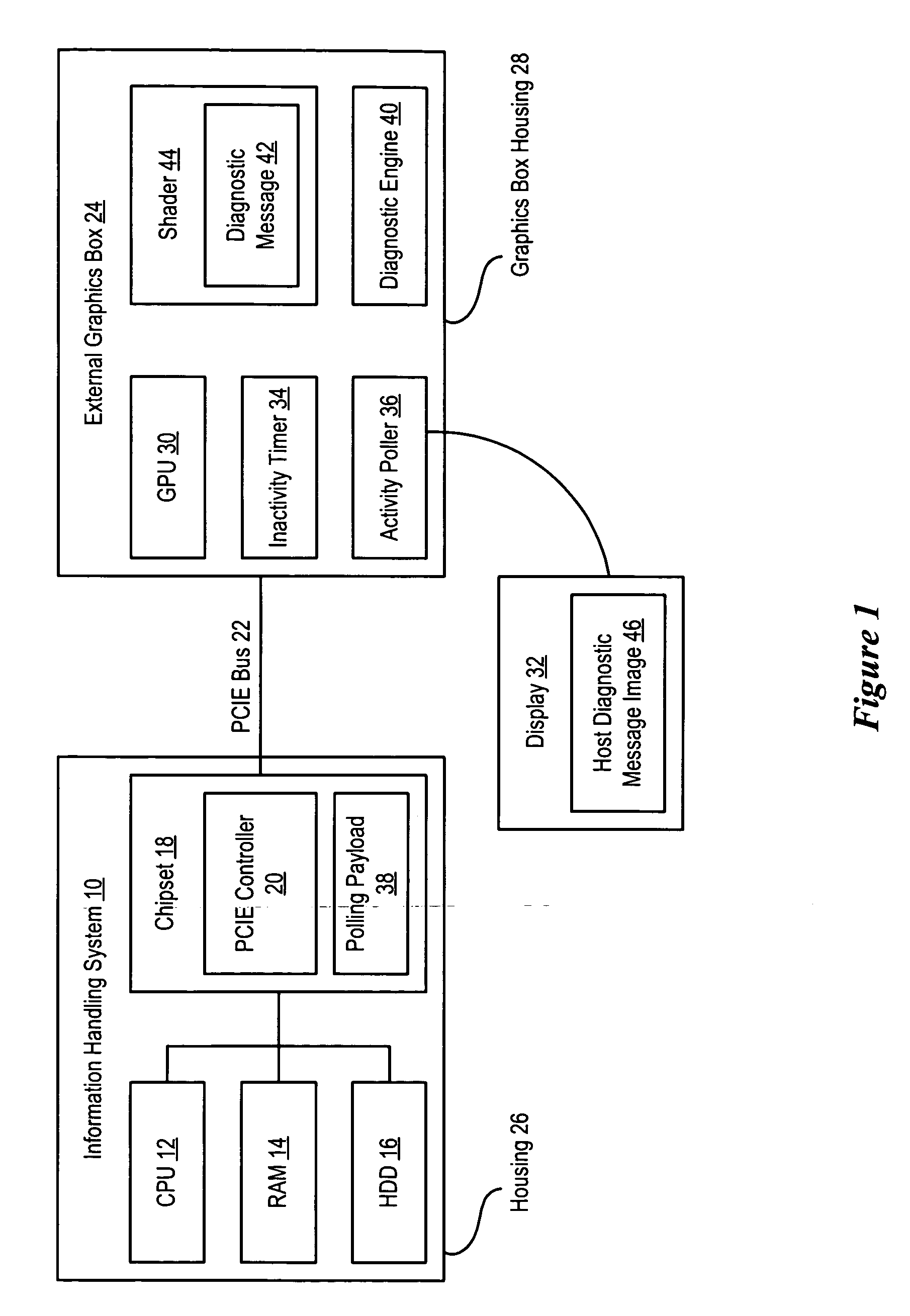

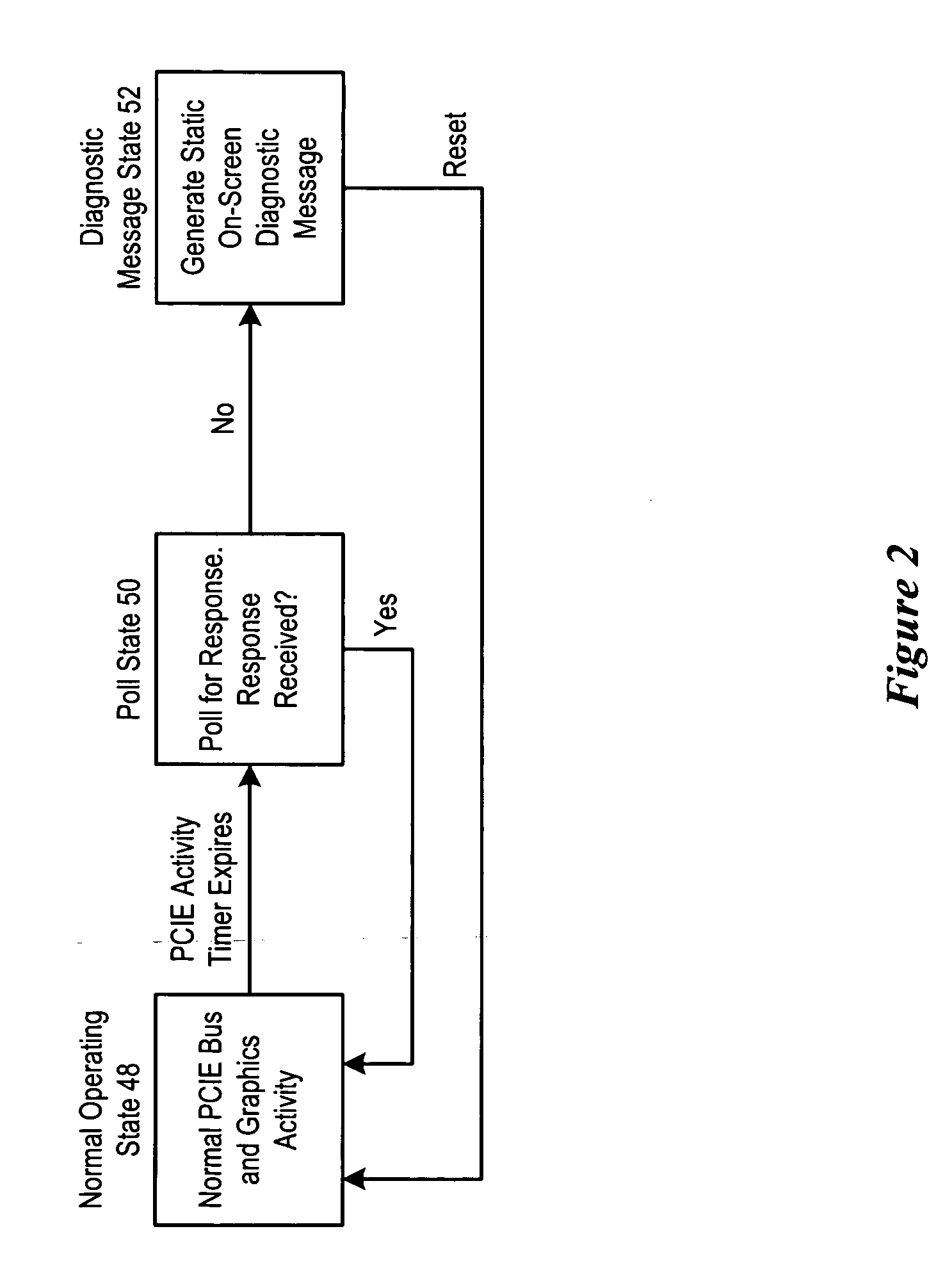

System and method for information handling system external graphics box local diagnostic message

ActiveUS20070159489A1Minimal impactShorten the timeError detection/correctionDigital computer detailsInformation processingPCI Express

An activity poller on an external graphics box is activated during inactivity in communication from a host information handling system to the external graphics box, such as over an external PCI Express cable. The activity poller periodically sends a memory read request from the external graphics box to the host information handling system through the PCI Express cable and analyzes the response to determine the operational state of the host information handling system. Failure of the host information handling system to respond to the polling for a predetermined time results in presentation of a locally generated diagnostic message at the external graphics box, such as message stored in shader instructions of the external graphics box.

Owner:DELL PROD LP

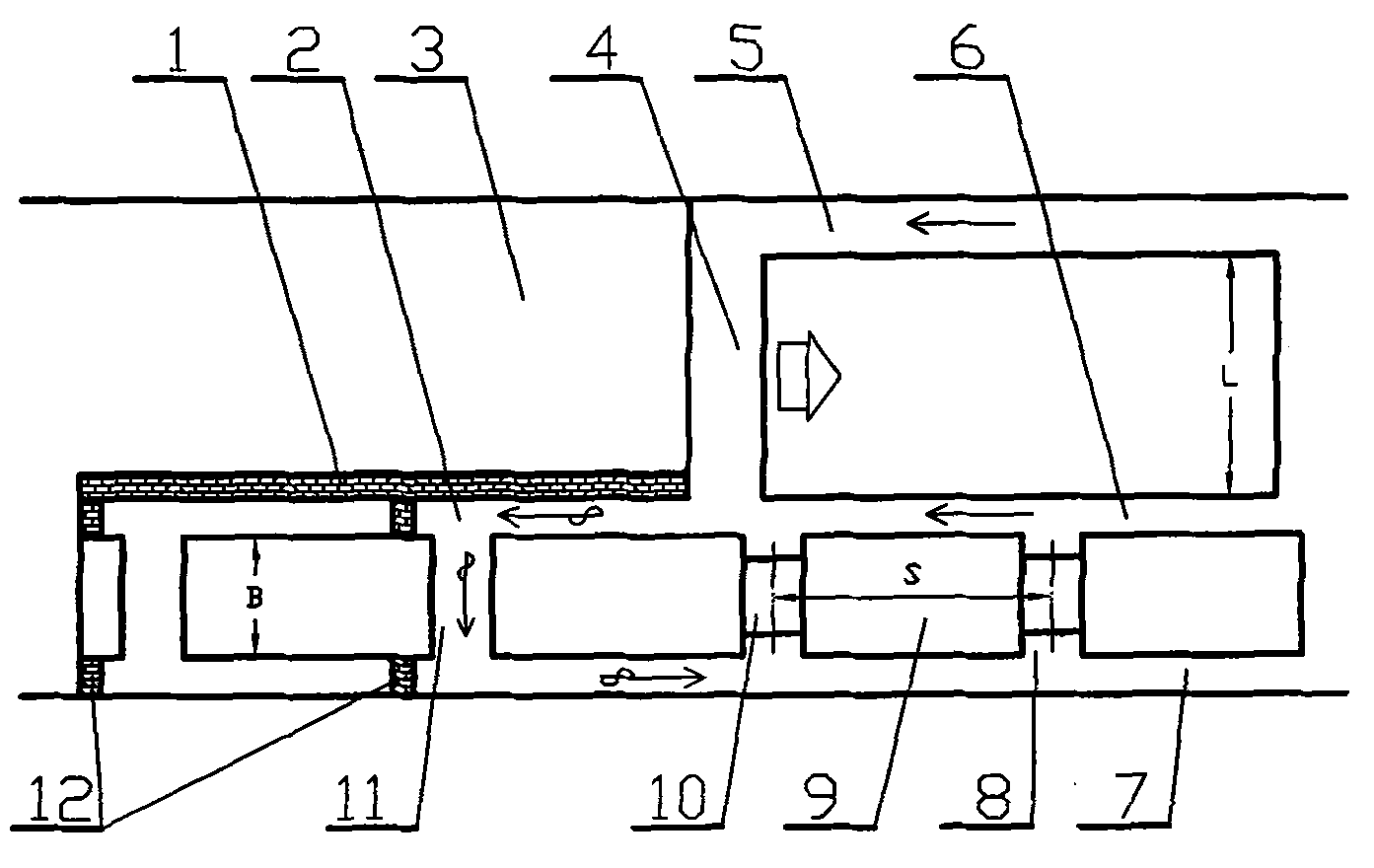

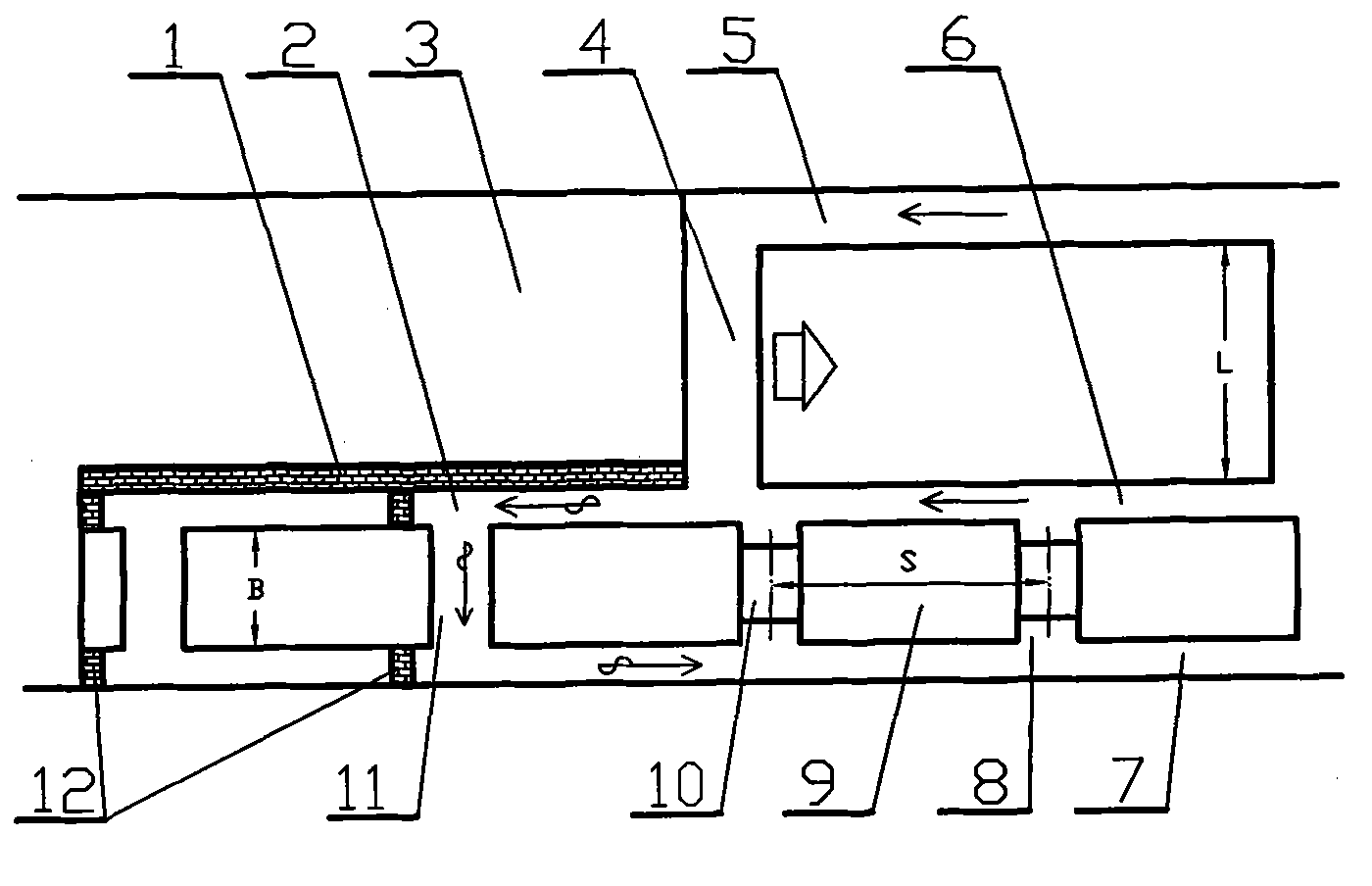

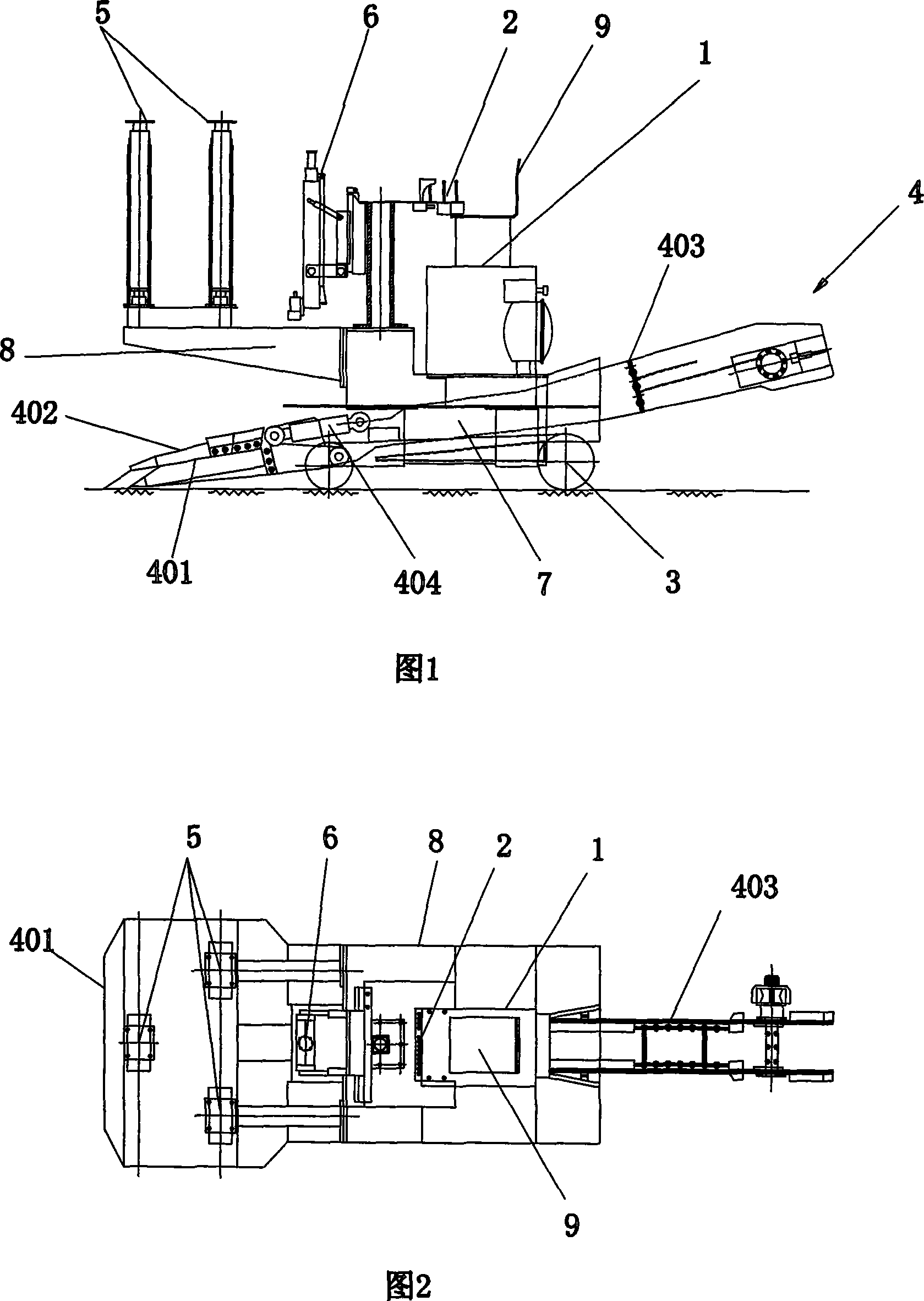

Explosion coal-falling, coal-loading, coal-conveying and anchor-rod supporting mechanism integration operation method and apparatus

InactiveCN101025086AIncrease the speed of excavationExcavation section is largeUnderground miningSurface miningResource recoveryEngineering

The invention provides a blast-winning, coal loading, coal conveying and anchor rod-timbering mechanical integrated operating method and device. And the device mainly comprises: hydraulic system, hydraulic control table, track walking part, coal loading and conveying part, timbering part, and hydraulic anchor rod machine, and the method uses integrated device, scraper conveyor and gate coal conveyor; and its drivage circulating speed is 1m to 1.5 m, blast-winning and after the fumes have settled, making the integrated device enter into the operating site, and after completing coal loading and conveying, making anchor rod timbering; after completing the anchor rod timbering operation, making the integrated device exit the operating site and over 20 meters distant from the operating site, and then making drilling and blasting operation. And it improves explosion level of blast winning and resources recovery, and reduces operators.

Owner:闫振东

High-strength full-thread equal-strong resin bolting reinforcing bar and production method thereof

The invention provides a high-strength full-thread equal-strong resin bolting reinforcing bar and a production method thereof. The high-strength full-thread equal-strong resin bolting reinforcing bar comprises the following chemical components: 0.18-0.27wt% of C, 0.30-0.75wt% of Si, 1.35-1.60wt% of Mn, 0.06-0.09wt% of V, less than or equal to 0.035wt% of P, less than or equal to 0.035wt% of S and the balance of Fe and inevitable impurities. During a smelting process, a vanadium nitrogen alloy is micro-alloyed, so as to increase the strength and toughness of the reinforcing bar. Due to the high strength of the high-strength full-thread equal-strong resin bolting reinforcing bar according to the invention, the steel material can be saved, the shoring cost is lowered, the structure strength is enhanced and the safety storage is increased.

Owner:LAIWU IRON & STEEL GRP

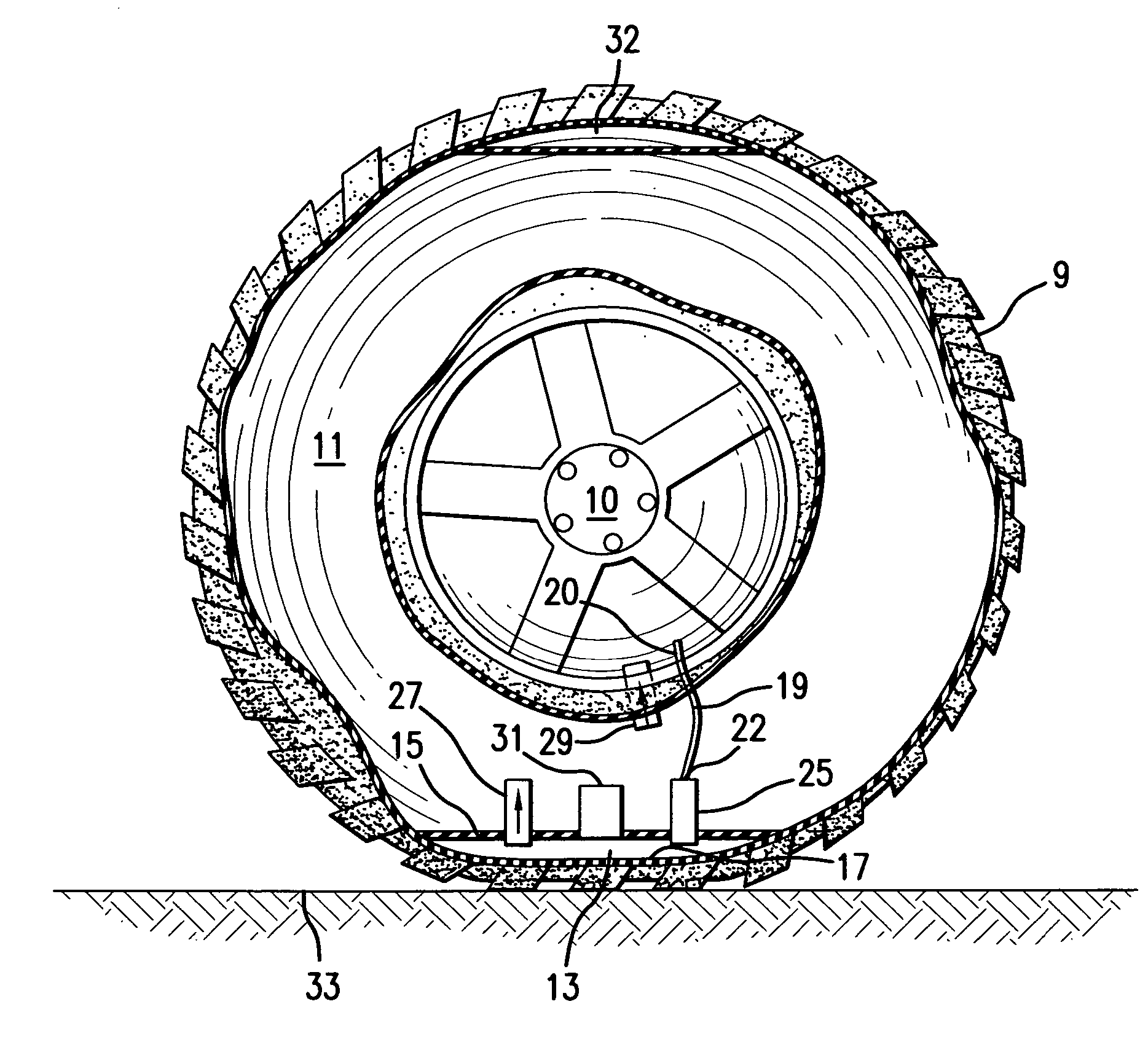

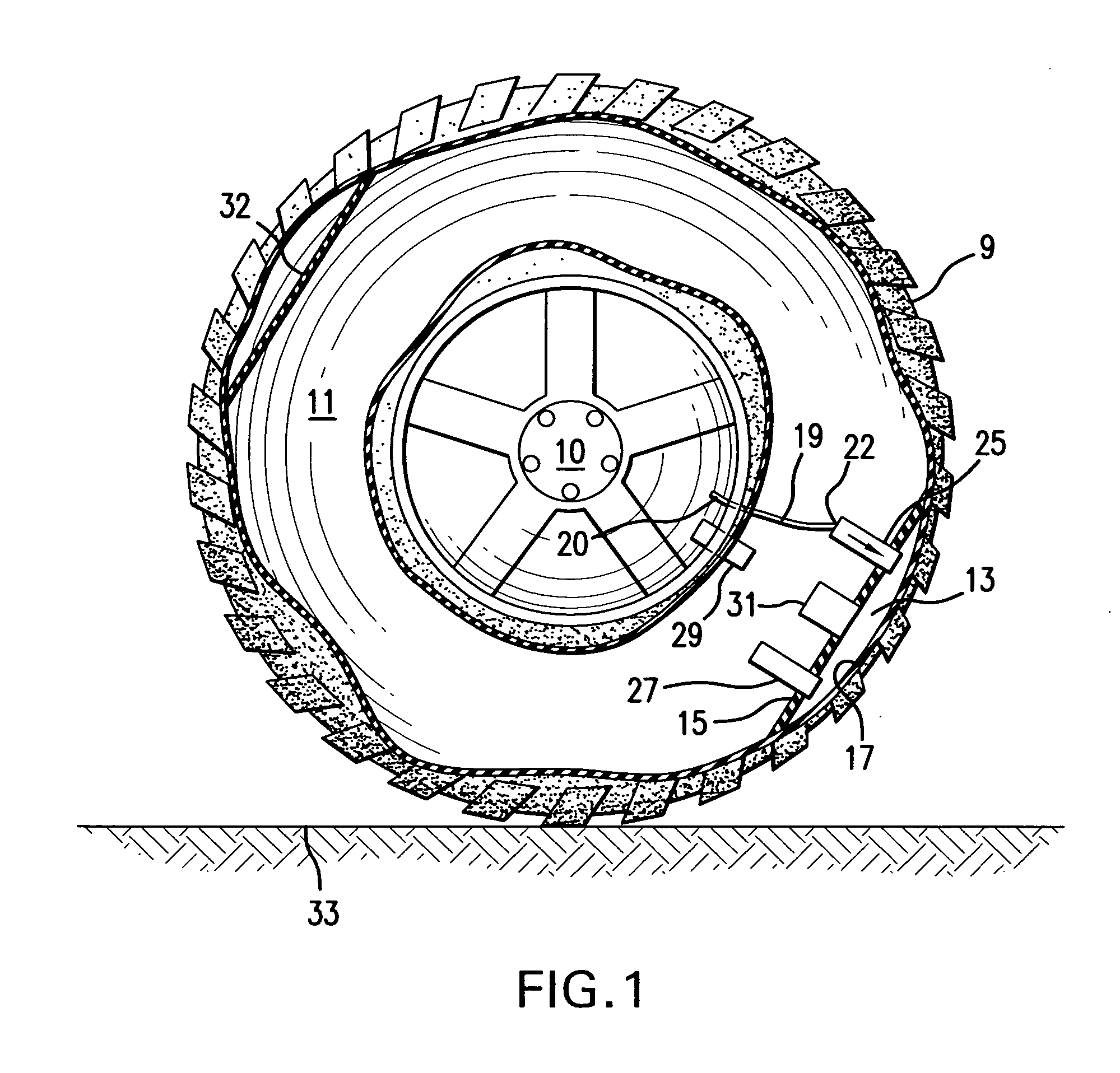

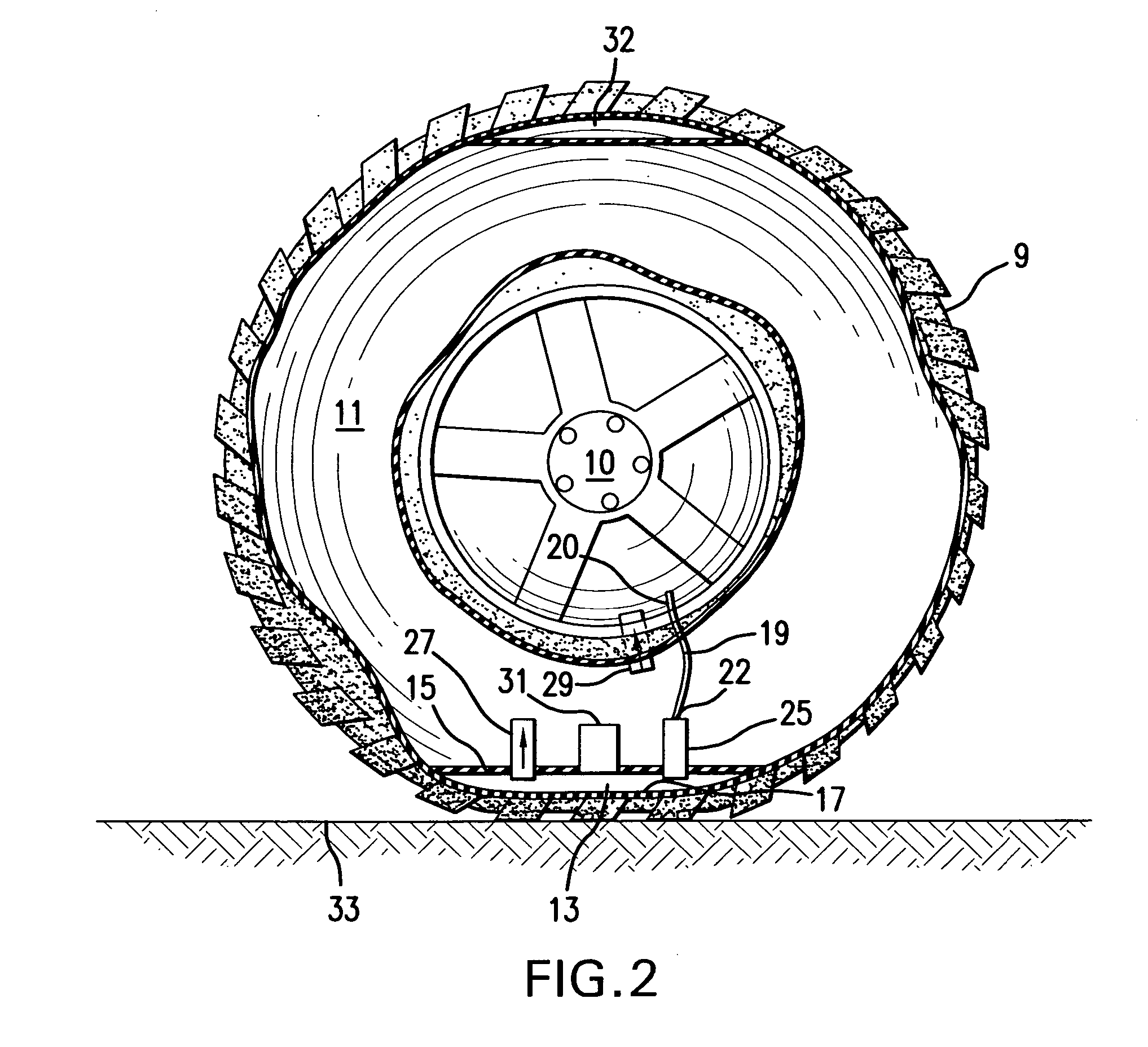

Integral pressure regulation system for tires and other vessels containing compressible fluids

ActiveUS20060021690A1Block fluid flowKeep the pressureTyre measurementsTyre-inflating valvesPump chamberCheck valve

An inflation and pressure regulation system for inflatable vessels, such as tires, has a main chamber containing a volume of compressible fluid, such as air, and a pump chamber which acts to maintain the fluid in the vessel at a desired pressure. The pump chamber has a rigid, fluid-tight wall facing the main chamber and a flexible wall which is part of, or adjacent to, the wall of the vessel that can be deformed under use. A fluid channel extending between the pump chamber and a source of ambient fluid admits fluid into the pump chamber. A first check valve positioned between the fluid channel and the pump chamber permits one-way flow of fluid from the exterior of the vessel into the pump chamber while it is uncompressed. A second check valve permits one-way passage of fluid from the pump chamber, when it is compressed, into the main chamber. One or more valves can be used to prevent over-inflation of the main chamber.

Owner:BUNKER GRANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com