Divided mining method for inclined medium-thick ore body with unstable false roof

A technology with thick ore bodies and false roofs, which is applied in ground mining, earth square drilling, underground mining, etc., can solve the problems of difficult construction, affecting operation safety, poor operation safety, etc., and achieves low ore dilution loss rate and mechanization High degree of effect with low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

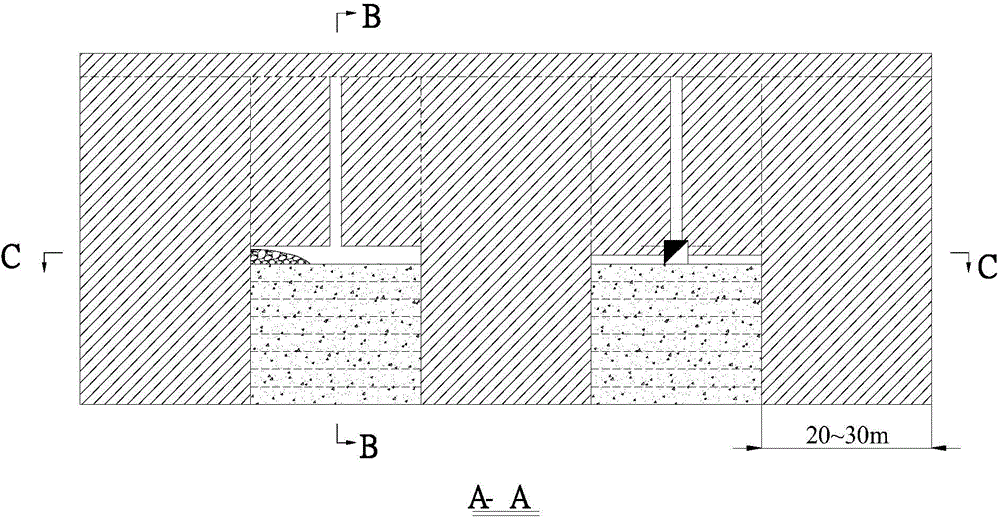

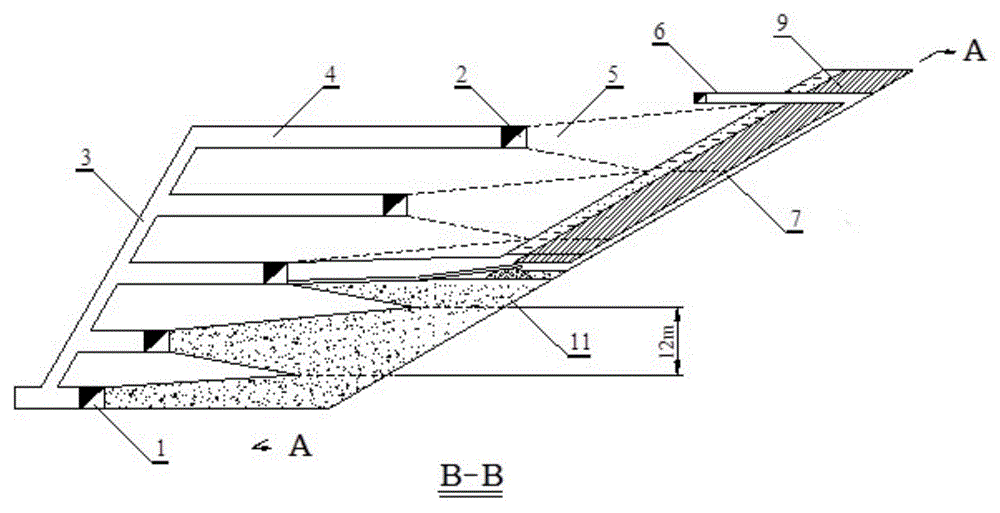

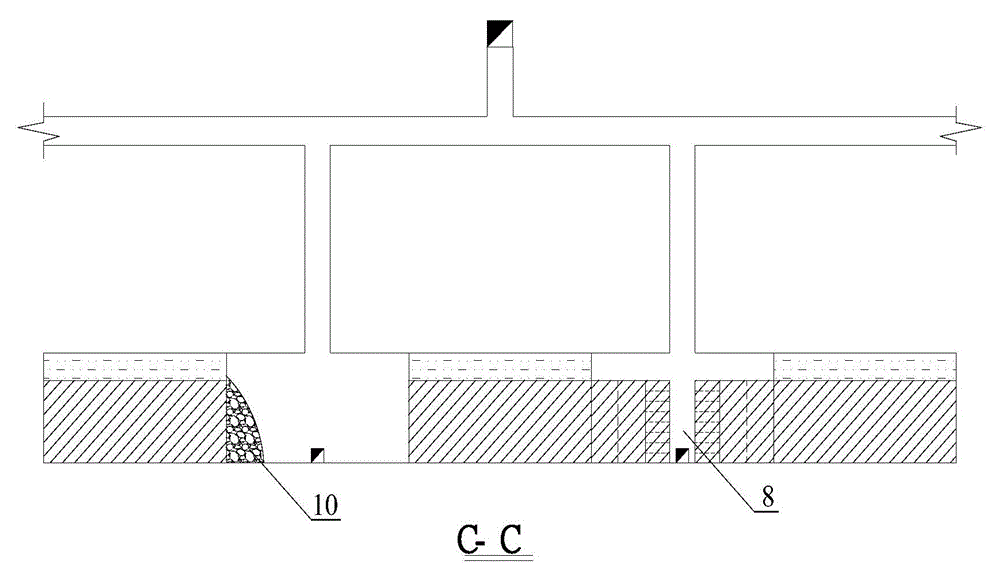

[0022] The separate mining method of inclined medium-thick ore body with unstable false roof provided by the present invention divides the panel area along the ore body trend, divides the ore house and pillars in the panel area, and reserves the top column when mining; the ore body upper wall is arranged outside the veins For the subsection level roadway, layered connecting road, and mine shaft trackless mining standard project, the filling return air is arranged up the mountain at the position near the lower wall in the center of the mine pillar; the mining room is first in the panel area, and then the mining pillar. Bottom-to-top sequential layered mining; mining starts from the ore-exiting horizontal roadway, and the false roof and ore body are mined in stages, that is, the first layer adopts the roadway mining method to collapse the false roof and ore body. The shallow hole collapses ahead of time to form a layered false roof, and the false roof waste rock is retained in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com