A mining method for mining steeply inclined thick ore bodies with broken hanging wall rocks

A mining method and thick ore body technology, applied in surface mining, underground mining, special mining, etc., can solve problems such as unfavorable mining of sub-marginal economic minerals, inability to select ore from waste rock, and poor control of ore-rock boundaries, etc., to achieve The effect of optimizing the layout of the mining project, reducing the mixing of waste rocks, and reducing the amount of ore occupied by the bottom pillar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

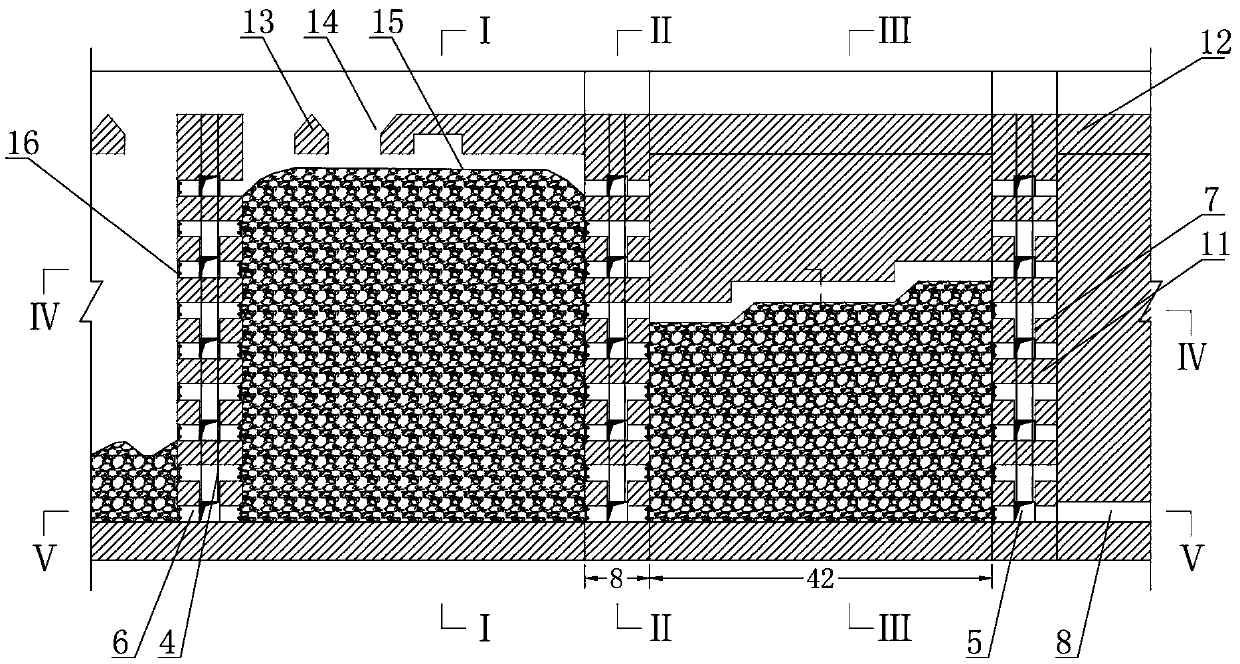

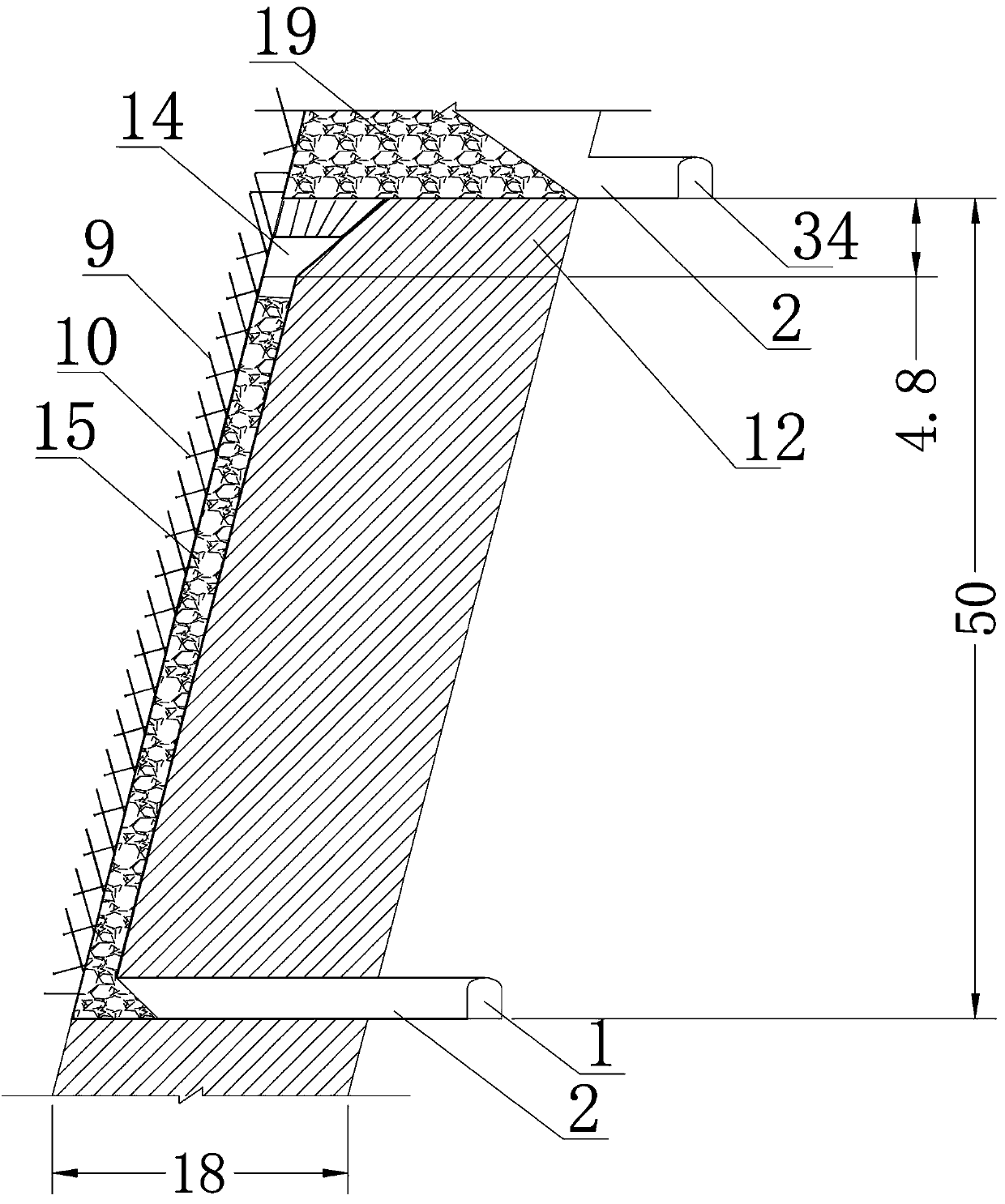

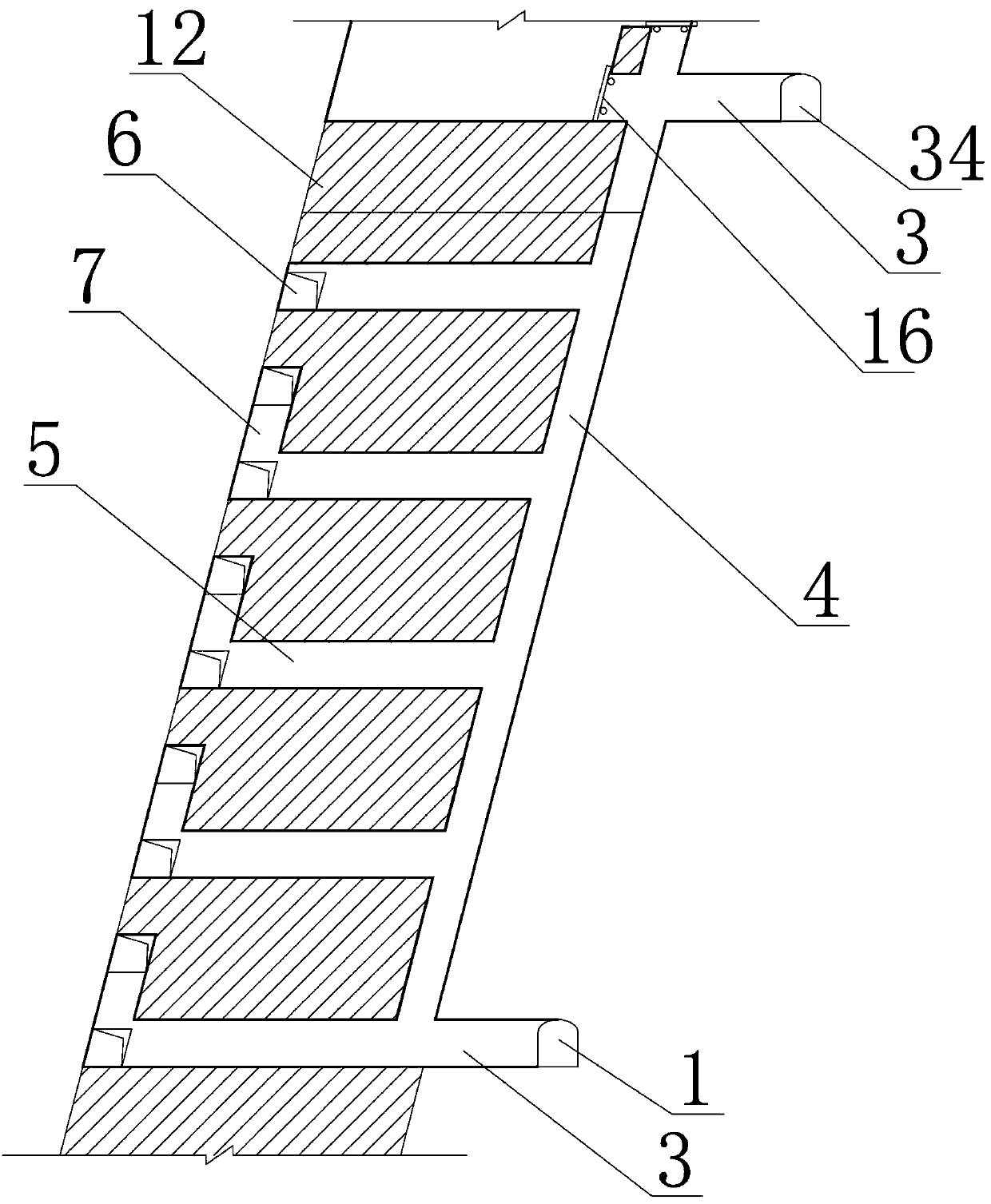

[0044] Such as Figure 1 to Figure 17 As shown, a mining method for mining a steeply inclined thick ore body with broken hanging wall rocks is described in this embodiment. The inclination angle of the ore body is 76° and the thickness is 18m. less than 40m 2 , the ore body is a sulfide tunnel ore with an average grade of 0.6%. Adopt mining method provided by the invention to mine, its main technology is as follows:

[0045] Divide the ore block: Divide the ore body into the middle section from top to bottom, the height difference between the transport entryway 1 and the return air entryway in the middle section is the middle section height, and the middle section height is 50m. The ore blocks are arranged along the strike of the ore body, with a length of 50m, of which the mine house is 42m long and the ore pillar is 8m wide. The height of the top pillar is 4.8m, and there is no bottom pillar, that is, the height of the mine house is 45.2m, and the width of the mine house ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com