Patents

Literature

242 results about "Poor control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

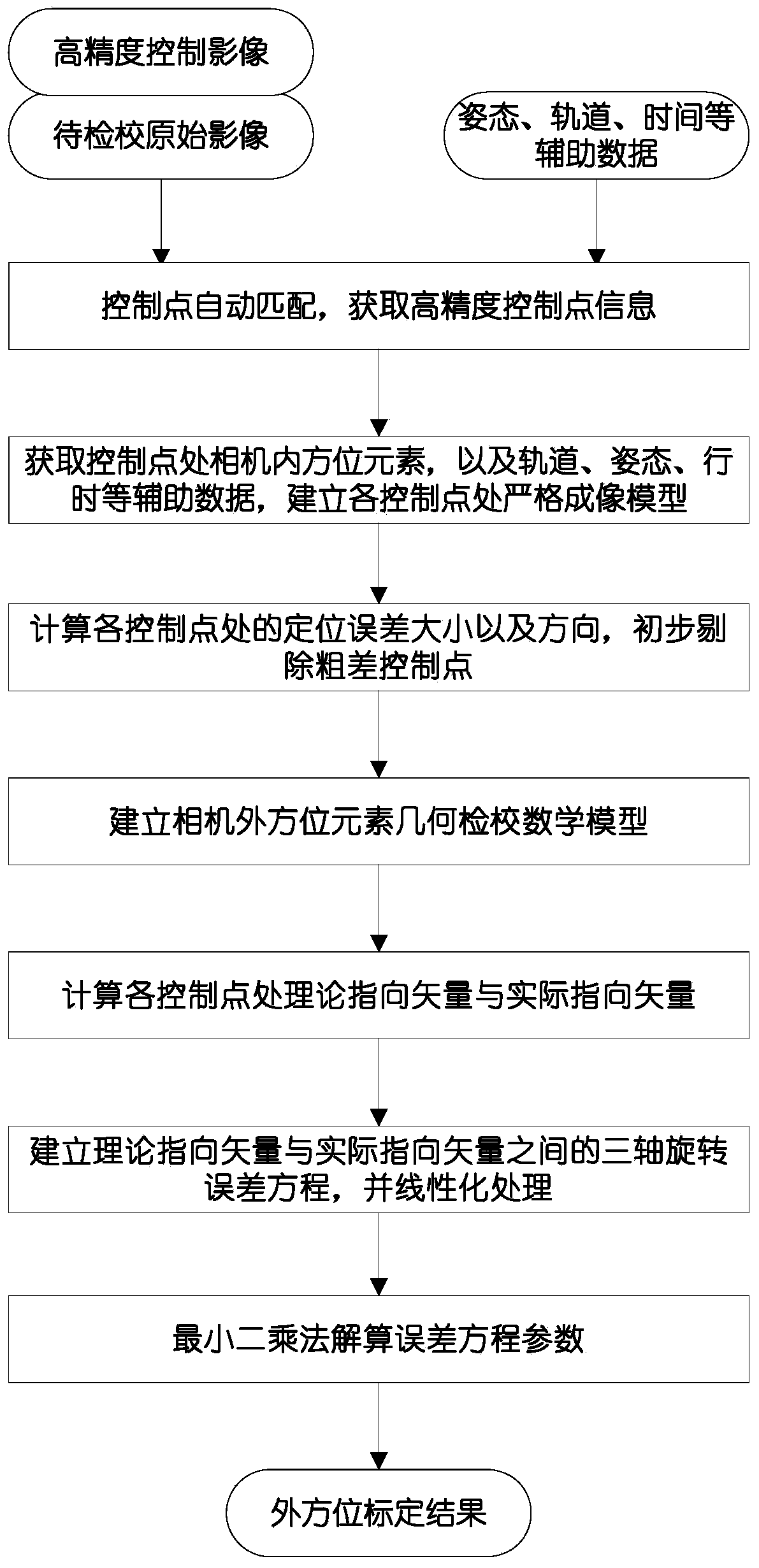

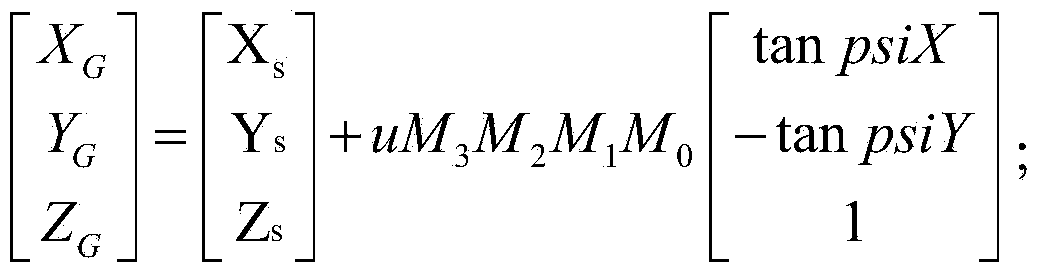

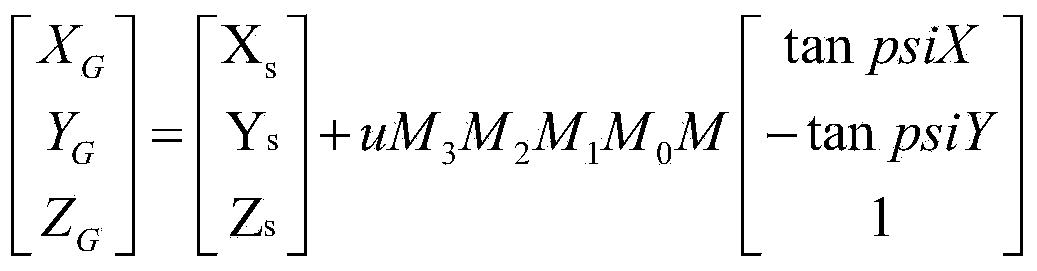

Method for calibrating in-orbit exterior orientation parameters of push-broom optical cameras of remote sensing satellite linear arrays

ActiveCN103679711AMeet the needs of on-orbit geometry calibrationImprove accuracyImage analysisMathematical modelOrbit

The invention discloses a method for calibrating in-orbit exterior orientation parameters of push-broom optical cameras of remote sensing satellite linear arrays. The method includes steps of (1), acquiring information of high-precision control points; (2), acquiring interior orientation elements of the cameras at the control points, acquiring auxiliary data of orbits and the like and building rigorous imaging geometric models of various control points; (3), computing positioning errors of the various control points, eliminating coarse and poor control points and acquiring information of preliminarily calibrated control points; (4), building geometric calibration mathematical models of exterior orientation elements of the cameras, and computing theoretical pointing vectors and actual pointing vectors of the various control points; (5), creating three-axis rotation error equations among the theoretical pointing vectors and the actual pointing vectors and linearly processing the equations; (6), solving parameters of the error equations by a least square process to acquire calibration exterior parameters. The method has the advantage that after errors of a system are compensated by the aid of the calibration exterior parameters, the cameras are stable in non-control positioning precision.

Owner:SPACE STAR TECH CO LTD

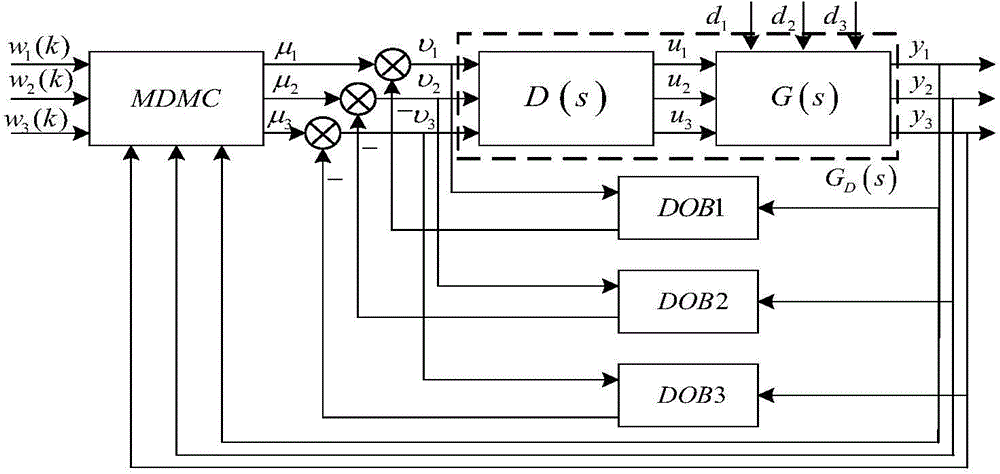

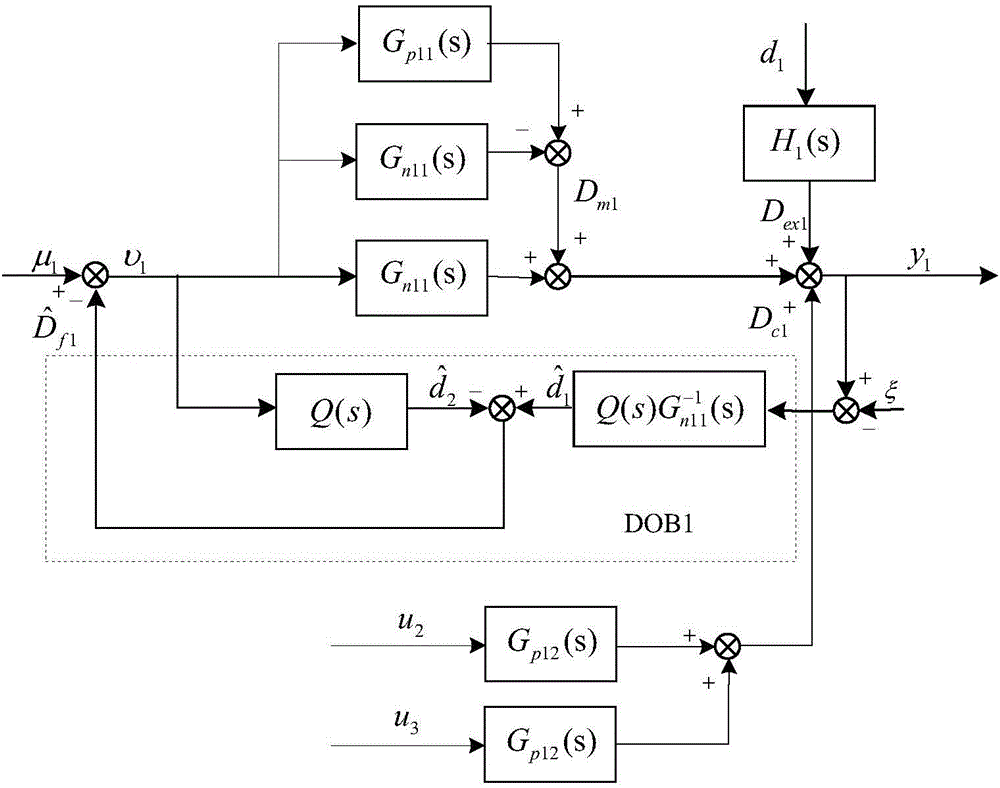

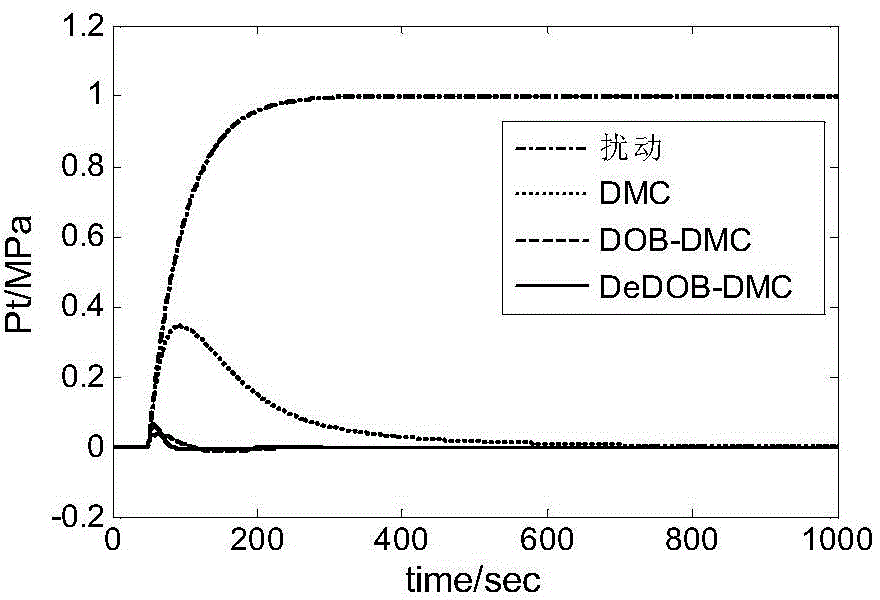

Predictive control method for supercritical set based on decoupling and disturbance observation

The invention discloses a predictive control method for a supercritical set based on decoupling and disturbance observation. According to the method, a supercritical thermal power generating set is adopted as a controlled object, the fuel amount, the water supply amount, and the openness of an adjusting valve of a steam turbine are adopted as inputs, the main steam pressure, the middle point temperature, and the loads of the set are adopted as outputs, the controlled object is enabled to be similar to decoupling through a feedforward compensator, and then disturbance is observed through disturbance observers which are respectively arranged at channels, so that the multivariate predictive control to the controlled object is realized, the problem of poor control effects caused by the disturbance influences of a coordinative control system of the supercritical set is solved, the external influence that the disturbance cannot be measured can be effectively inhibited, and besides, the internal disturbance caused by the coupling between input varies can be inhibited, so that the control property of the coordinative control system of the supercritical set is improved.

Owner:SOUTHEAST UNIV

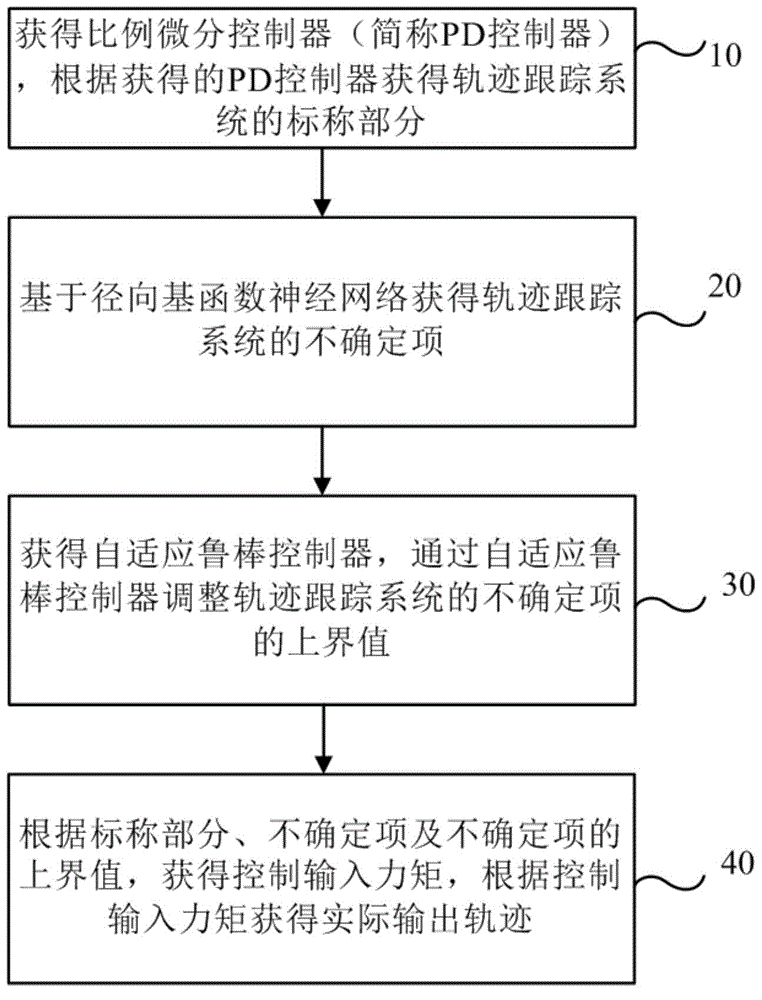

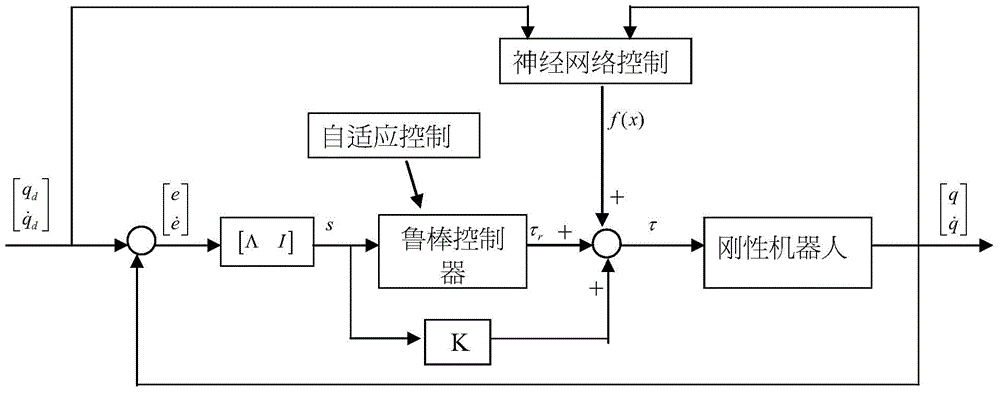

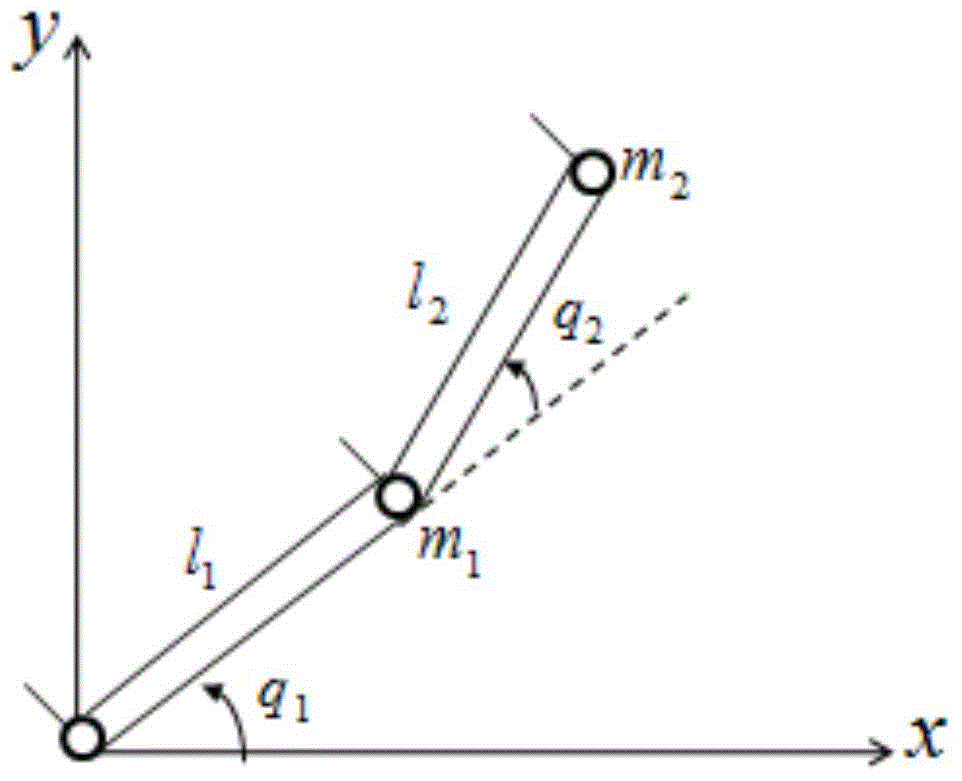

Neural network adaptive robust trajectory tracking method and controller

InactiveCN104808487AGuaranteed stabilityImprove dynamic performanceAdaptive controlRadial basis function neuralLimit value

The embodiment of the invention discloses a neural network adaptive robust trajectory tracking method and a controller applied to the technical field of robot trajectory tracking control, so as to solve the problems of poor stability and poor control effects of the prior robot trajectory tracking control technology. The method comprises steps: a proportion-derivative (PD) controller is acquired, and according to the acquired PD controller, a nominal part of the trajectory tracking system is acquired; on the basis of a radial basis function neural network, uncertain items of the trajectory tracking system are acquired; an adaptive robust controller is acquired, and the uncertain items of the trajectory tracking system are adjusted via the adaptive robust controller; and according to the nominal part, the uncertain items and an uncertain upper limit value of the uncertain items, total control input is acquired, and according to the total control input, an actual output trajectory is acquired.

Owner:TAIZHOU UNIV

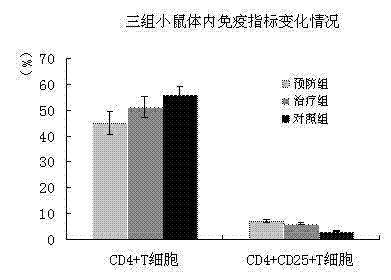

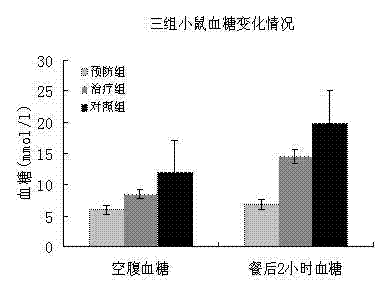

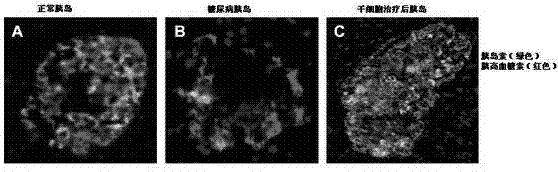

Mesenchymal stem cell injection, preparation method and application thereof in preparing medicine for treating diabetes

InactiveCN102920735AIncrease productionEasy quality controlCell dissociation methodsPeptide/protein ingredientsVitamin CSide effect

The invention discloses a mesenchymal stem cell injection, a preparation method and application of the mesenchymal stem cell injection in preparing a medicine for treating diabetes; the mesenchymal stem cells are derived from human umbilical cord and placenta; the mesenchymal stem cell injection consists of components: human mesenchymal stem cells, human albumin, low molecular heparin calcium, compound amino acid, vitamin C of 0.5% and dissolving medium; and the dissolving medium can be a compound electrolyte solution or glucose or normal saline. According to the mesenchymal stem cell injection, the preparation method and the application of the mesenchymal stem cell injection in preparing the medicine for treating the diabetes, the mesenchymal stem cell injection is used for repairing injured islet beta cells, and the blood sugar is reduced by secretion of the endogenous insulin, therefore, a purpose of foundational treating the diabetes is achieved. A disease course of the diabetes can be reversed, patients are helped in escaping out of inconvenience and toxic and side effects of taking the endogenous drug and injecting the insulin as well as serious complications caused by poor control of the blood sugar; and the 1-type and 2-type diabetes are treated thoroughly.

Owner:青岛奥克生物开发有限公司

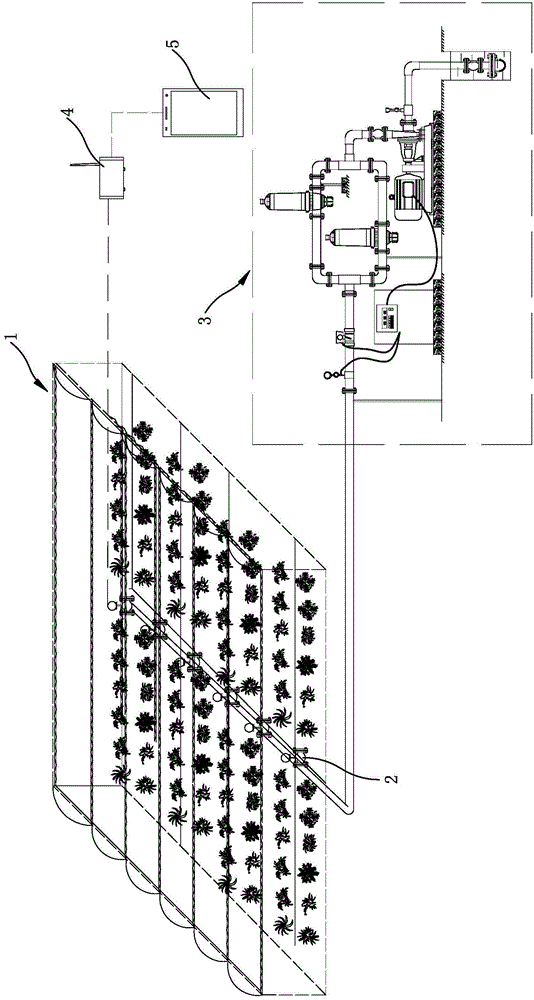

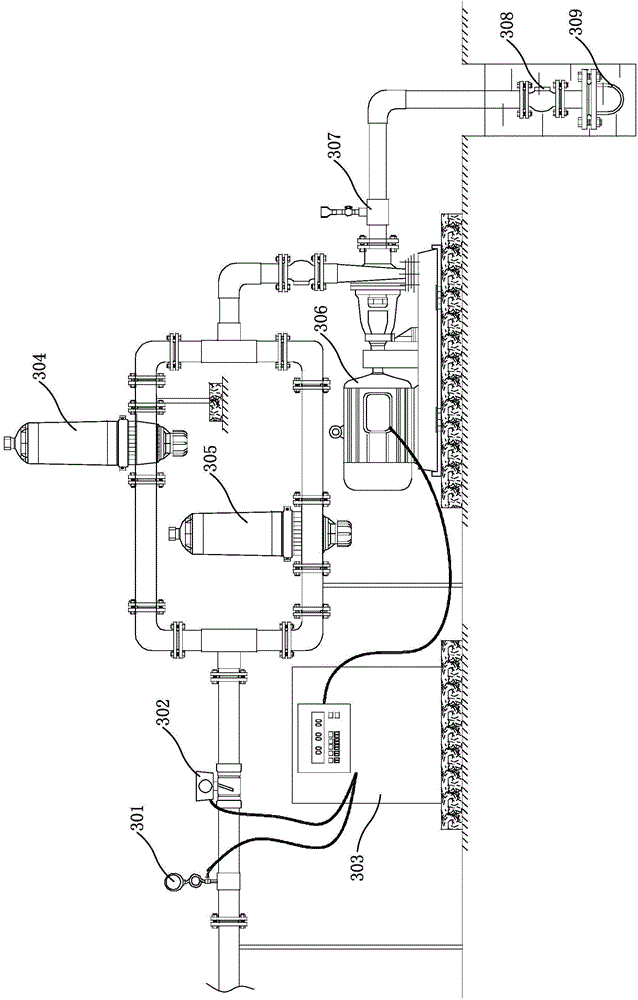

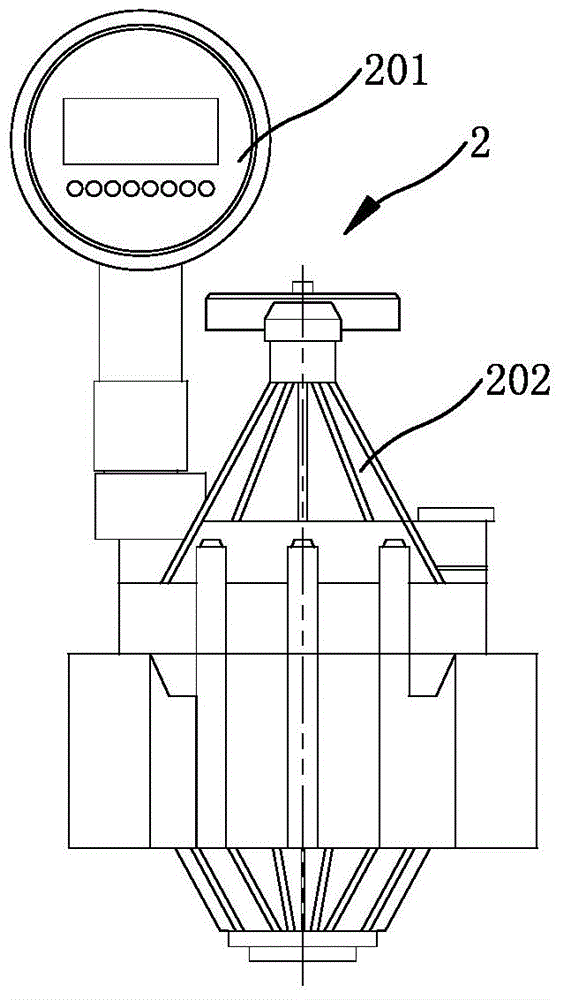

Mobile phone remote intelligent irrigation system

InactiveCN104584988AExpand spaceReasonable structural designProgramme controlWatering devicesStopped workRemote control

The invention relates to a mobile phone remote intelligent irrigation system, which is designed so as to solve the technical problem that the existing similar intelligent irrigation system has a poor control mode and a poor structural design and lacks of smart mobile phone remote control. The intelligent irrigation system comprises a network data processor and a smart mobile phone; APP (application) intelligent irrigation software is installed in the smart mobile phone; an electromagnetic valve controller is a wireless electromagnetic valve controller; a water flow touch sensor is arranged in a water flow switch valve; the electromagnetic valve controller automatically starts to work according to setting, and the work is controlled remotely through the APP intelligent irrigation software in the smart mobile phone, and a signal that water flows is sensed by the water flow sensor, and a water pump is started to work; the work of the electromagnetic valve controller is controlled through the mode, and after sensing a signal that the water hardly flows, the water flow sensor automatically turns off, and the water pump automatically stops working; therefore the goal that the work of an intelligent frequency conversion control cabinet at a head part is intelligently controlled and triggered through the electromagnetic valve controller at a tail end is achieved through the process.

Owner:宁波市富金园艺灌溉设备有限公司

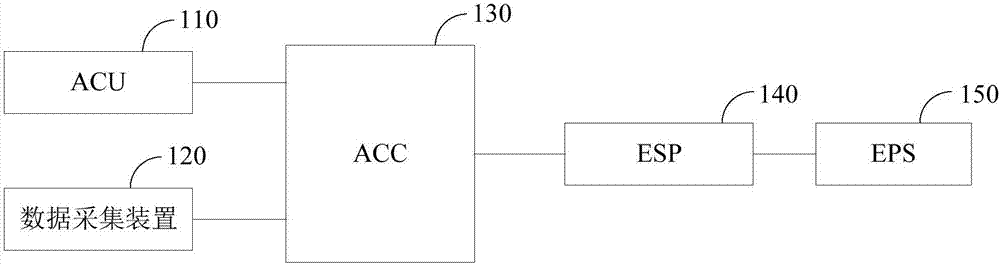

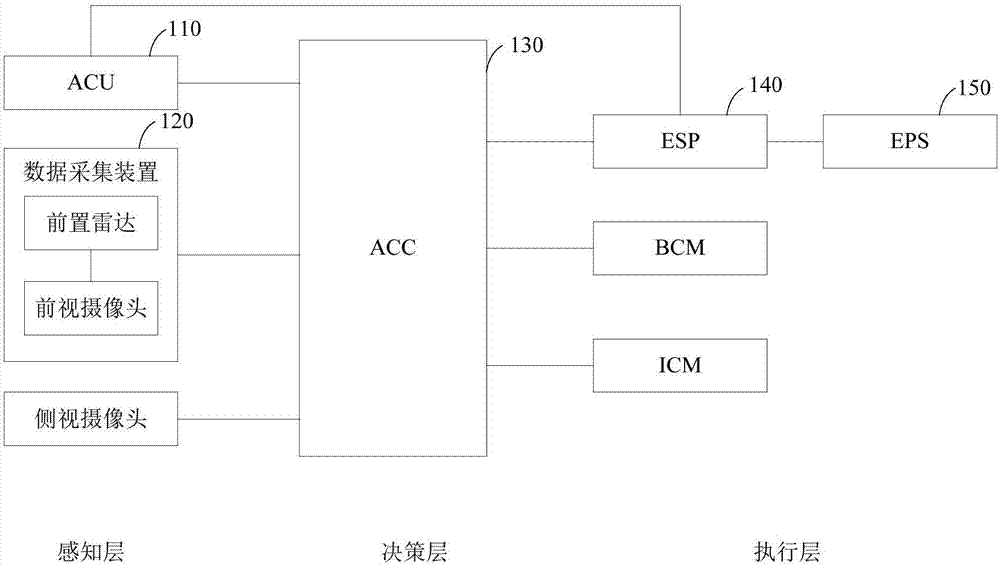

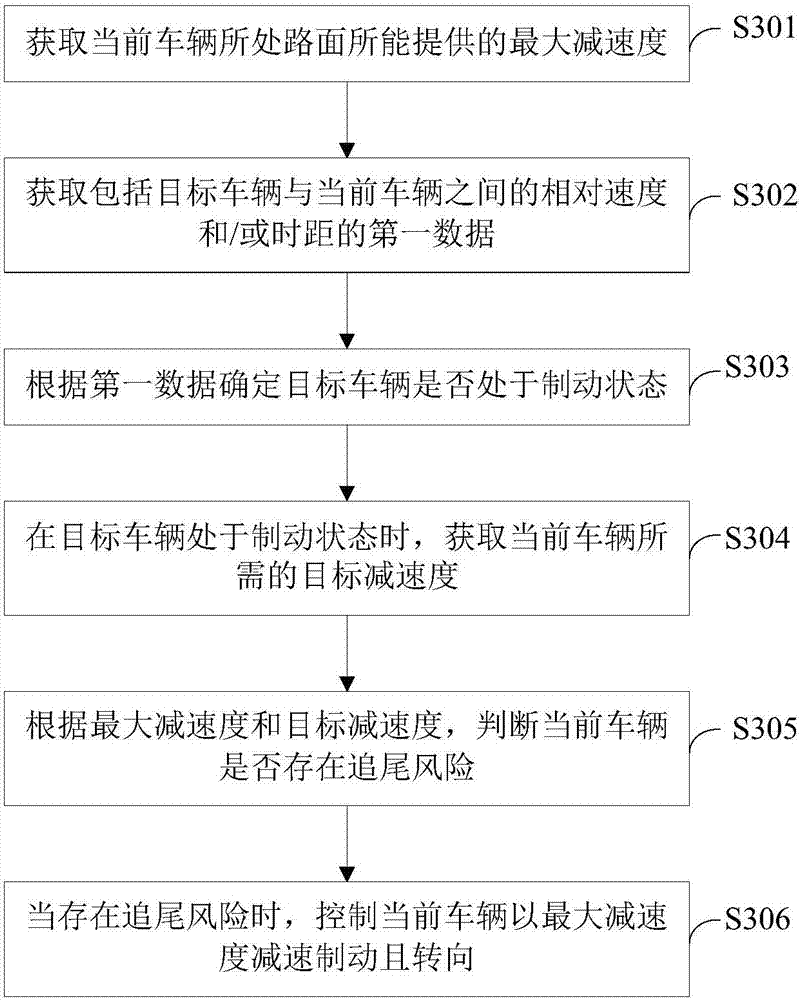

Vehicle control method and system

The invention provides a vehicle control method and system. The method comprises the following steps of: acquiring a maximum deceleration provided by a road surface on which a current vehicle is located; acquiring first data including a relative speed and / or a time interval between a target vehicle and the current vehicle, wherein the target vehicle is a vehicle which is located in front of the current vehicle and closest to the current vehicle; judging whether the target vehicle is in a braking state or not according to the first data; acquiring a target deceleration required by the current vehicle when the target vehicle is in the braking state; according to the maximum deceleration and the target deceleration, judging whether the current vehicle has a rear-end collision risk; and when the rear-end collision risk exists, controlling the current vehicle to perform decelerating, braking and steering at the maximum deceleration. According to the method disclosed by the invention, the maximum deceleration provided by the road surface on which the current vehicle is located and the required target deceleration are used as a basis for judging whether the rear-end collision risk exists, and the problems of poor control effect and low safety caused by that adhesion conditions of the road surface are not considered in an existing ACC control process are solved.

Owner:成都前锋电子股份有限公司

Secondary cooling water amplitude-cutting control method of slab continuous casting machine

ActiveCN102430733AAvoid the third brittle temperature zoneRealize collection and diversionSlab casterField tests

The invention provides a method for carrying out online automatic accurate amplitude-cutting control on spraying width of secondary cooling water of a wide and thick slab, belonging to the technical field of control over cooling water for continuous casting and aiming at overcoming the defects of large engineering modification of a cooling water supply loop, higher cost or poorer control precision of manually adjusting spraying width and the like existing in the prior art. The method mainly comprises the following steps of: taking secondary cooling water spraying widths of different steel types and different width specifications of casting blanks, which are determined through temperature field simulation computation of secondary cooling water regions of the casting blanks and field tests,as references, driving a guide device mainly consisting of a support frame and a collecting guide pipe to collect and guide out redundant cooling water which is sprayed from spray pipes at edge partsof rows of the inner arc of the sector section so as to realize online accurate amplitude-cutting to spraying width of the secondary cooling water of the inner arc of the sector section. Due to adoption of the method disclosed by the invention, temperature of the corner of a continuous casting blank can be stably controlled at 870-900 DEG C, a third brittleness temperature region of steel is effectively avoided, the micro transverse crack defect rate of the corner of the micro alloy steel continuous casting blank is controlled within 1 percent.

Owner:TIANJIN IRON & STEEL GRP

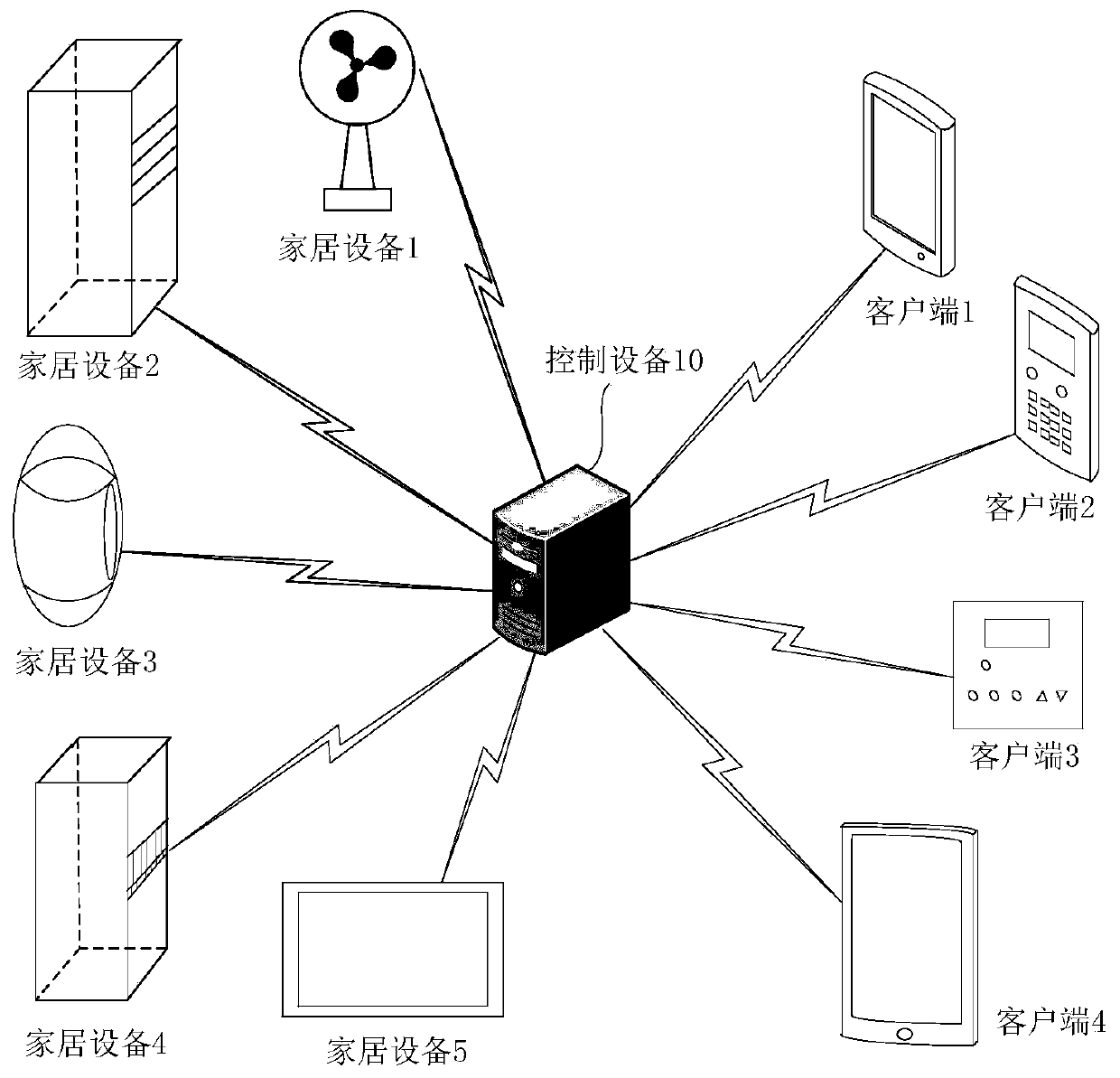

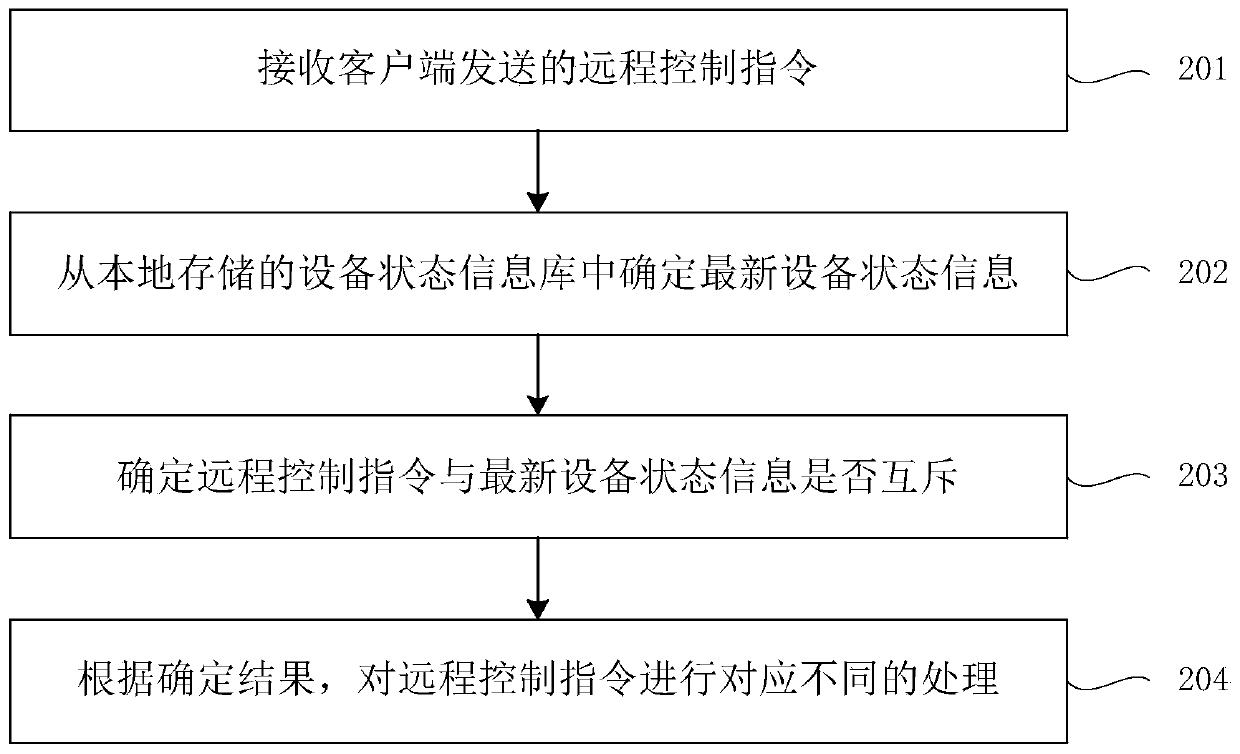

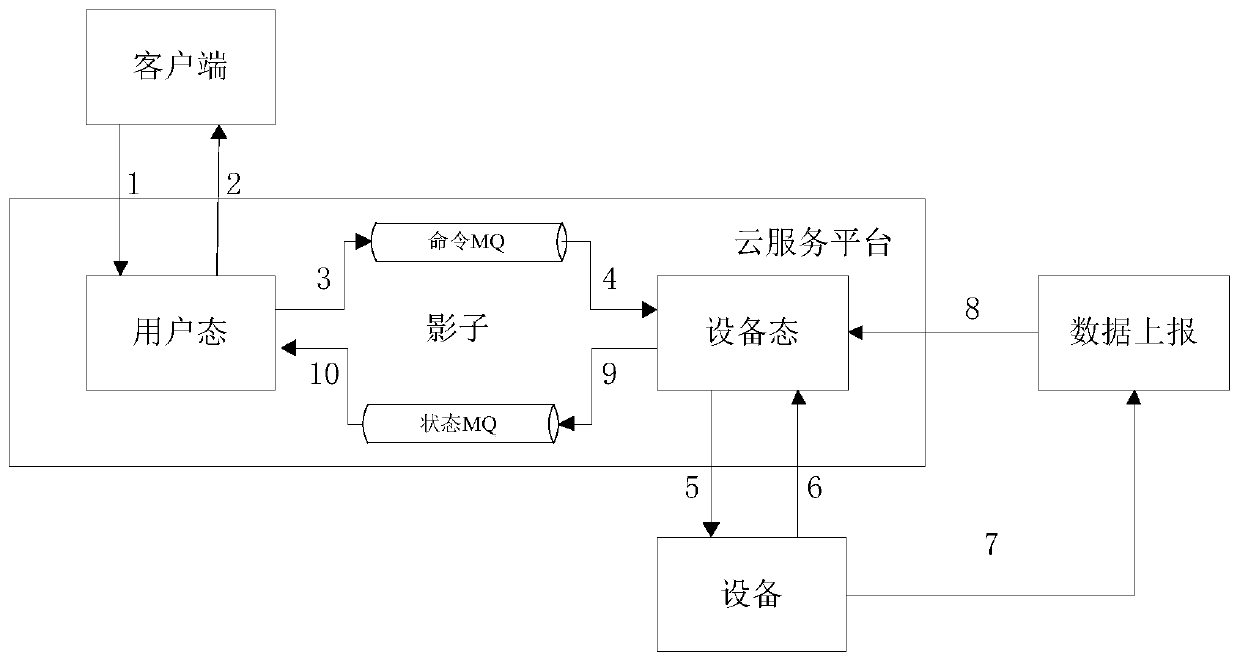

Method and device for controlling equipment, computing equipment and storage medium

InactiveCN110545222AImmediateImprove accuracyData switching by path configurationInformation repositoryRemote control

The invention discloses a method and device for controlling equipment, computing equipment and a storage medium. The method and the device are used for solving the technical problem of poor control accuracy of intelligent household equipment so as to realize effective control of the intelligent household equipment and improve the control accuracy of the intelligent household equipment, and the method comprises the following steps: receiving a remote control instruction for the intelligent household equipment sent by a client; determining latest equipment state information of the smart home equipment from a locally stored equipment state information base; determining whether the remote control instruction and the latest equipment state information are mutually exclusive or not; if the intelligent household equipment cannot execute the remote control instruction in the equipment state corresponding to the latest equipment state information, determining that the remote control instructionand the latest equipment state information are mutually exclusive; and carrying out corresponding different processing on the remote control instruction according to a determination result.

Owner:GREE ELECTRIC APPLIANCES INC +1

Cracking furnace exit temperature hybrid control method

ActiveCN102053562ASimple designImprove controlThermal non-catalytic crackingAdaptive controlProcess engineeringIntegral controller

The invention relates to a cracking furnace exit temperature hybrid control method which aims at solving the problems that the existing method has poor control effect and can not meet the requirements for energy conservation, emission reduction and environment protection. The method provided by the invention comprises the following steps: firstly, designing a proportional integral controller of a cracking furnace exit temperature process by using a typical response curve method; then, establishing a process model required by a non-minimum model prediction function controller based on cracking furnace exit temperature real-time process data; and finally, designing a proportional integral controller of a non-minimum model prediction function, and obtaining current control parameter values in accordance with an objective function. In the method provided by the invention, the error between cracking furnace exit temperature process parameters and practical cracking furnace exit temperature process parameters can be effectively reduced, the defects of the traditional controller is further made up and the control device is ensured to be in the optimal operation state, thereby strictly controlling the cracking furnace exit temperature process parameters in the production process.

Owner:衢州远景资源再生科技有限公司

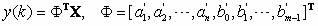

Region intelligent protection system of transformer substation

InactiveCN103107603ARealize intelligent operation managementImprove protectionCircuit arrangementsInformation technology support systemSmart substationTransformer

The invention discloses a region intelligent protection system of a transformer substation and relates to the technical field of control over transformer substation, and the region intelligent protection system is used for solving the problems of poor control flexibility and poor harmony among power grids at different levels in an existing intelligent transformer substation. The region Intelligent protection system comprises maintenance work station server, three region intelligent protection mainframes, a plurality of instation preprocessing units, and a plurality of interval submachines, wherein the plurality of instation preprocessing units achieve transferring data together with each region intelligent protection mainframe and the maintenance work station server by virtue of through high speed data and a control network; each transformer substation is correspondingly provided with one instation preprocessing unit and one or more interval submachine; each interval submachine is used for achieving the collection of analog quantity data and discrete data and sending the collected data to the corresponding instation preprocessing unit by adopting the protocol of IEC61850-9-2; and the instation preprocessing units are used for sending control commands received from the high speed data and the control network to the corresponding interval submachines. The region intelligent protection system disclosed by the invention is suitable for the existing transformer substation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

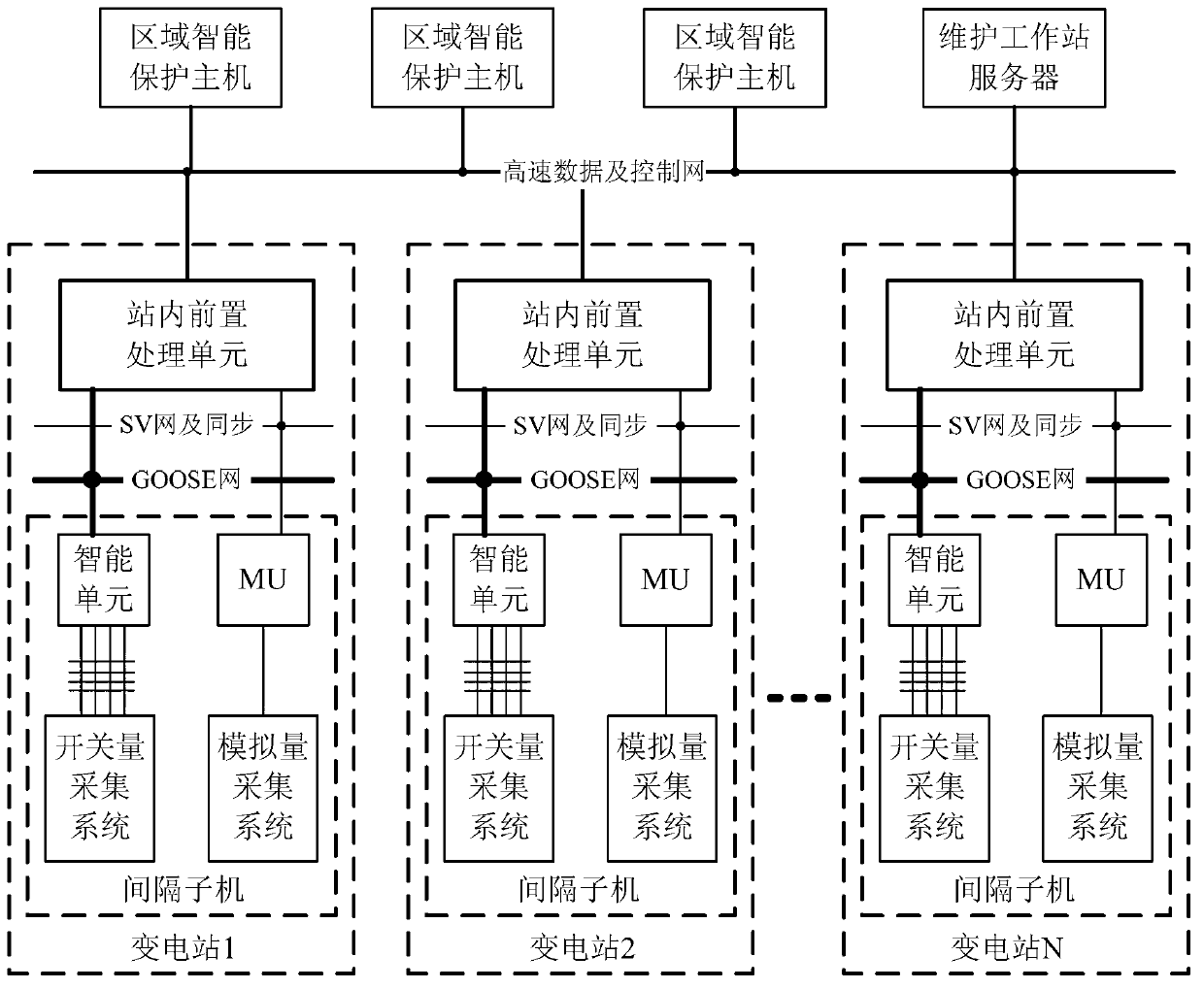

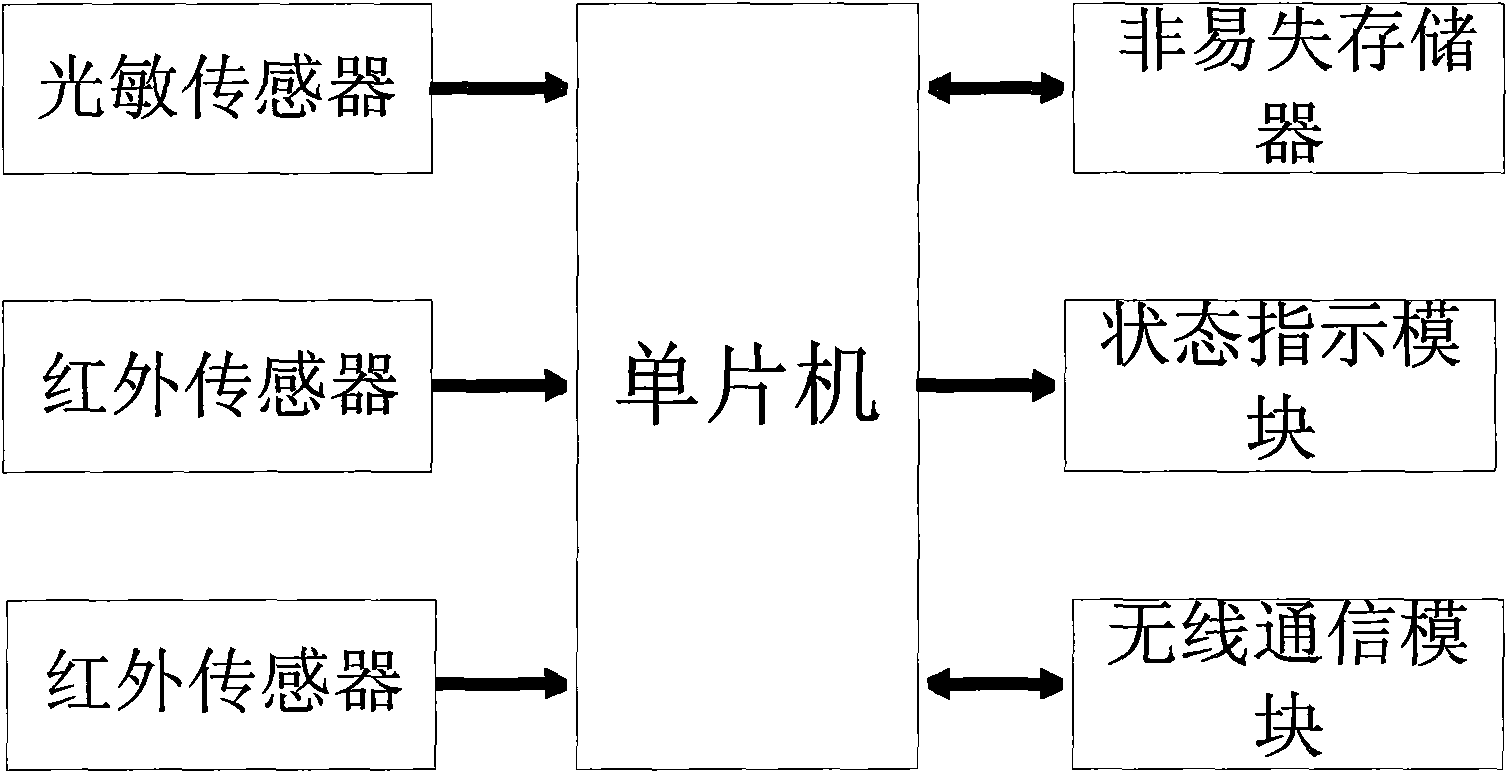

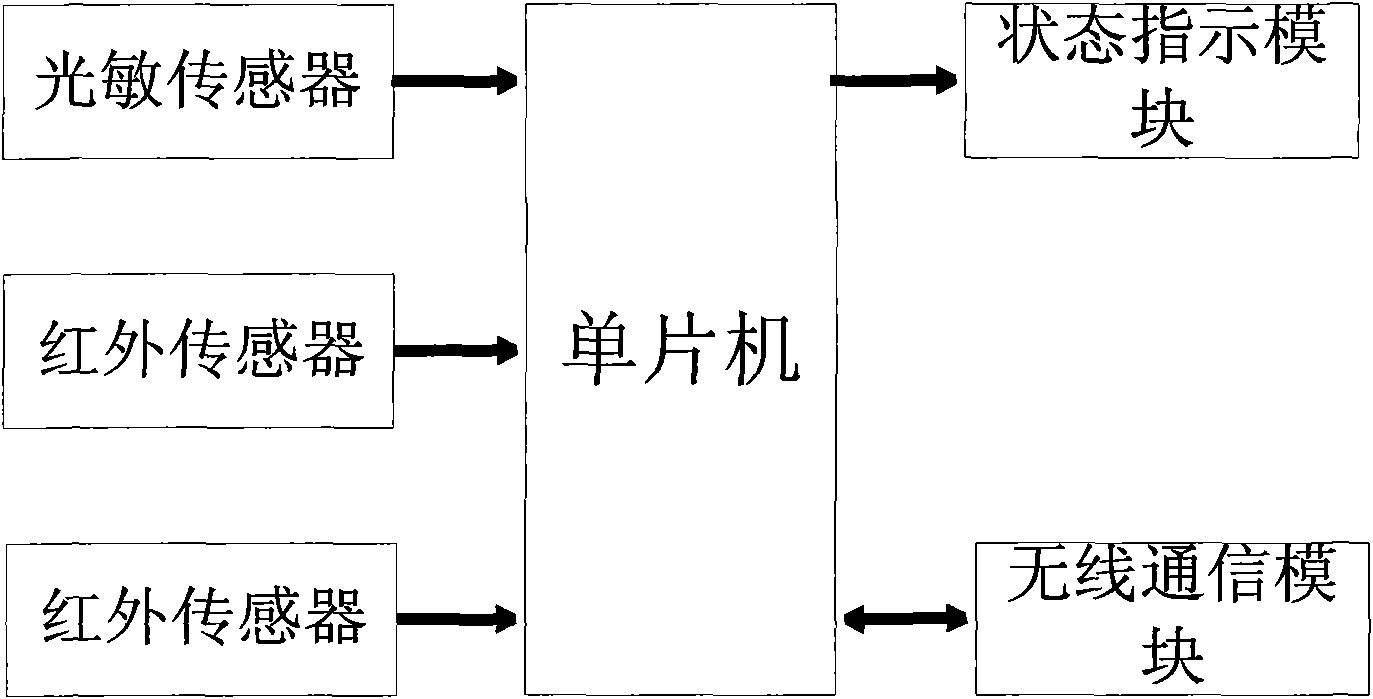

Intelligent lighting control system based on wireless sensor network technology

InactiveCN101562930AEasy to controlQuick layoutEnergy efficient ICTTransmission systemsMicrocontrollerIntelligent lighting

The invention relates to the field of lighting control, in particular to an intelligent lighting control system based on wireless sensor network technology, and solves the problems that the prior lighting system in a building is unreasonable, has poor control effect and the like. The intelligent lighting control system comprises a lighting control node connected with the lighting system in the building, and a plurality of condition acquisition nodes which are arranged in rooms or corridors in the building and perform wireless communication with the lighting control node; each node comprises a singlechip, a light sensor, two infrared sensors parallelly arranged on an entrance of a room or a connecting position of corridors between floors, and a wireless communication module connected with the I / O port of the singlechip; the output end of the sensor is connected with the A / D acquisition port of the singlechip; and the lighting control node is provided with a nonvolatile storage. The intelligent lighting control system has simple and reasonable structure, small volume, stable operation, convenient arrangement, easy maintenance and good control effect, adopts short distance wireless communication for information interaction, realizes intelligent lighting control in low cost and high efficiency, and can save electric energy furthest.

Owner:ZHONGBEI UNIV

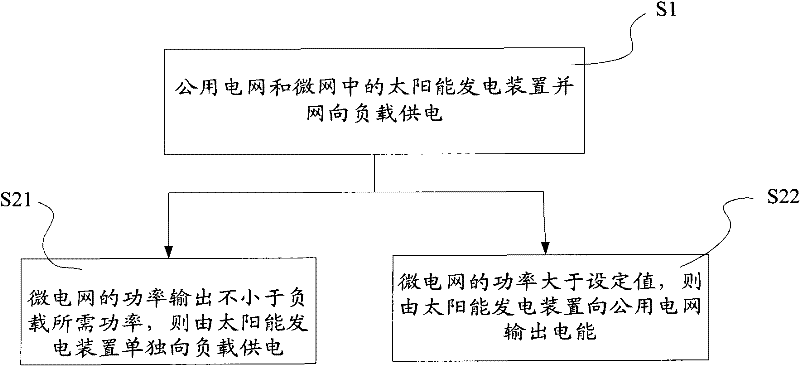

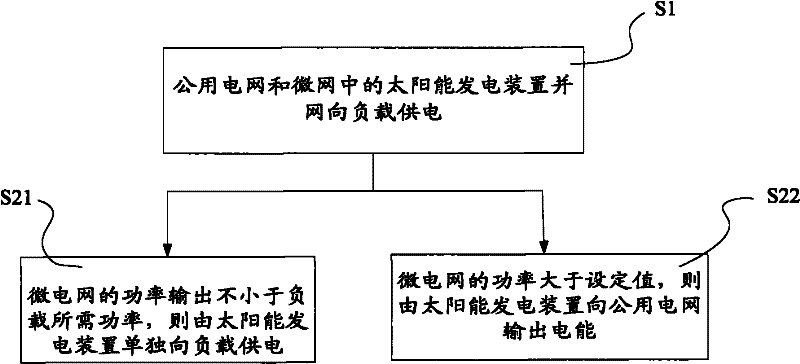

Micro grid control method

InactiveCN102347620AReduce loadReduce electricity billsBatteries circuit arrangementsPower network operation systems integrationElectricitySolar generator

The invention discloses a micro grid control method, which aims at solving the problem of poor control effect of a micro grid system in the prior art. The micro grid control method comprises the following steps that: when a solar generator in a micro grid and a public grid supply electricity to a load in a grid-connected way, the solar generator singly supplies electricity to the load when the power output of the micro grid is not smaller than the required power of the load, and the solar generator outputs electric energy to the public grid when the power of the micro grid is greater than the set value. The method provided by the invention has the advantages that the solar energy can be utilized to the furthest degree, the electricity consumption cost of users is reduced, in addition, users obtain certain economic benefits in a mode of outputting excessive electric energy to the public grid, the economy and the environment protection are realized, and the electricity consumption requirements can also be met.

Owner:STATE GRID CORP OF CHINA +2

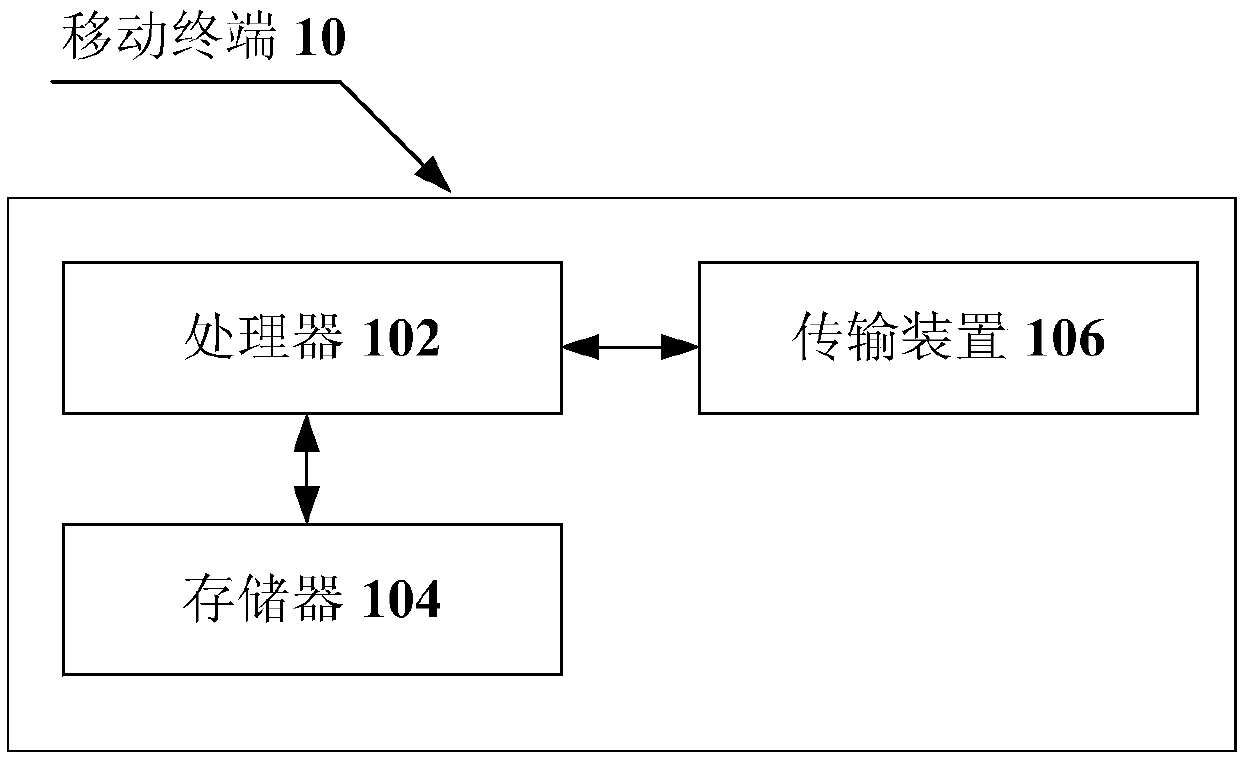

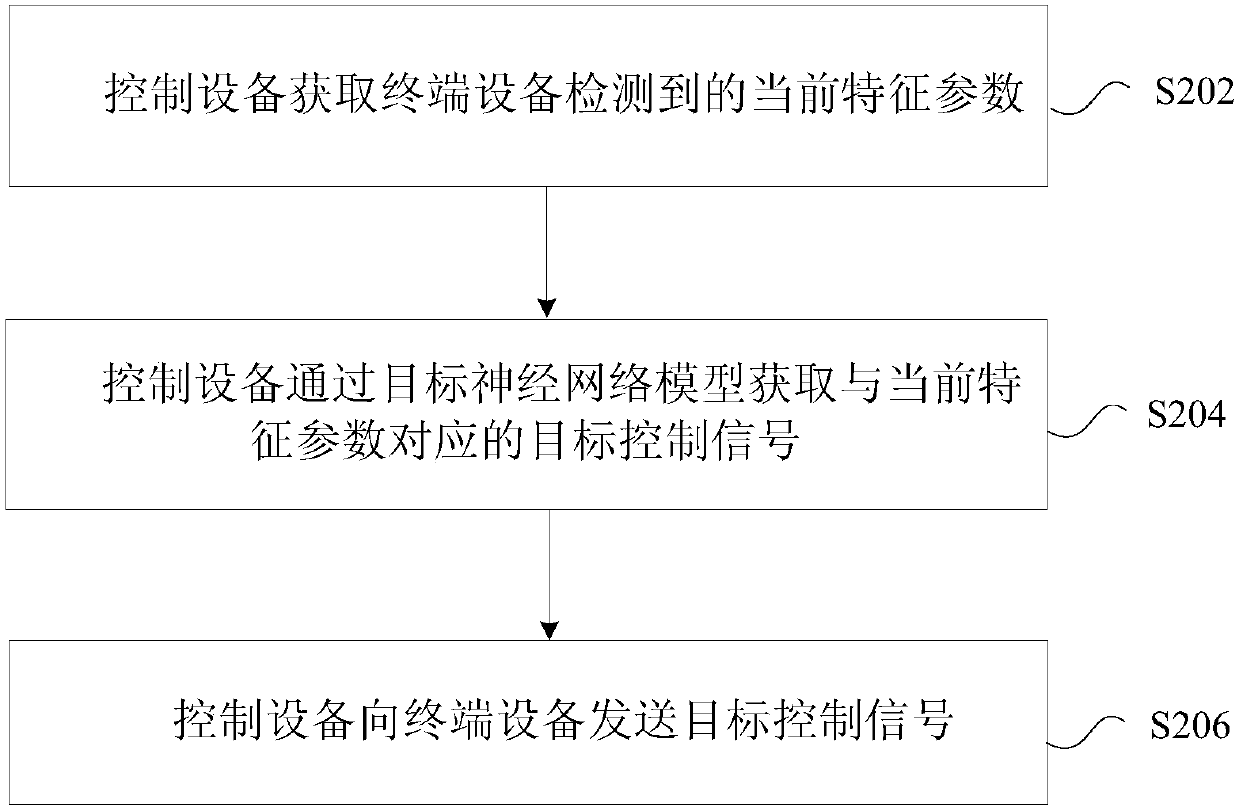

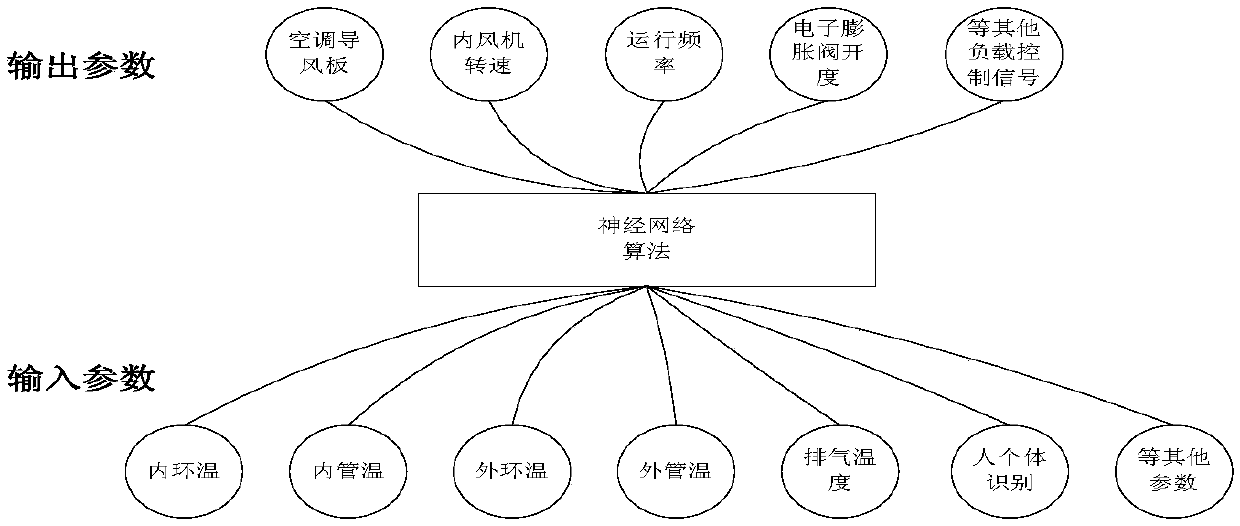

Method and apparatus for controlling terminal device, storage medium, and processor

ActiveCN107797459AImprove rationalityImprove comfortComputer controlNeural architecturesTarget controlTerminal equipment

The invention provides a method and apparatus for controlling a terminal device, a storage medium, and a processor. The method comprises: a control device acquires a current feature parameter detectedby a terminal device; the control device acquires a target control signal corresponding to the current feature parameter by a target neural network model; and the control terminal sends the target control signal to the terminal device. Therefore, a problem of poor comfort sensing experience of the user because of poor control reasonability of the terminal device according to the related technology is solved; the reasonability of the terminal device is improved; and the user feels comfortable in a current environment.

Owner:GREE ELECTRIC APPLIANCES INC

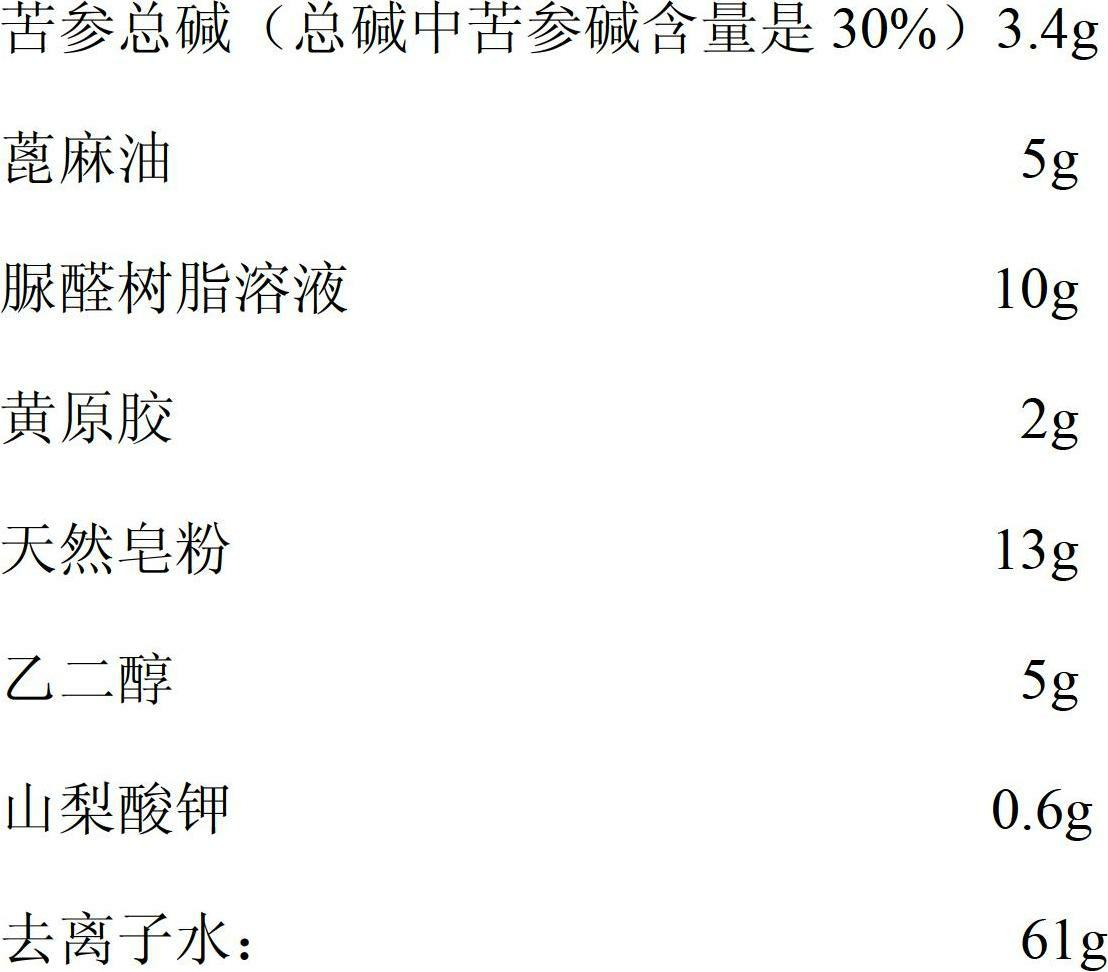

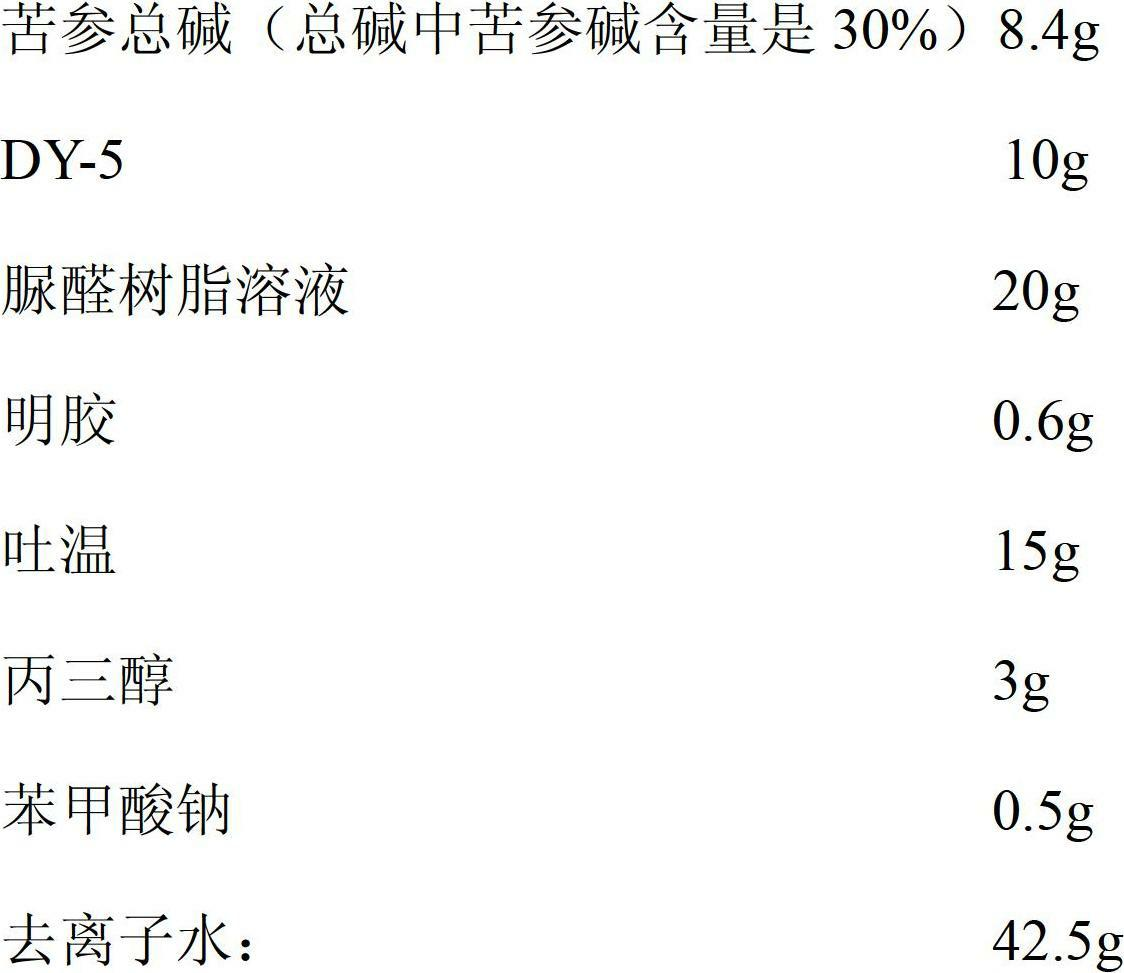

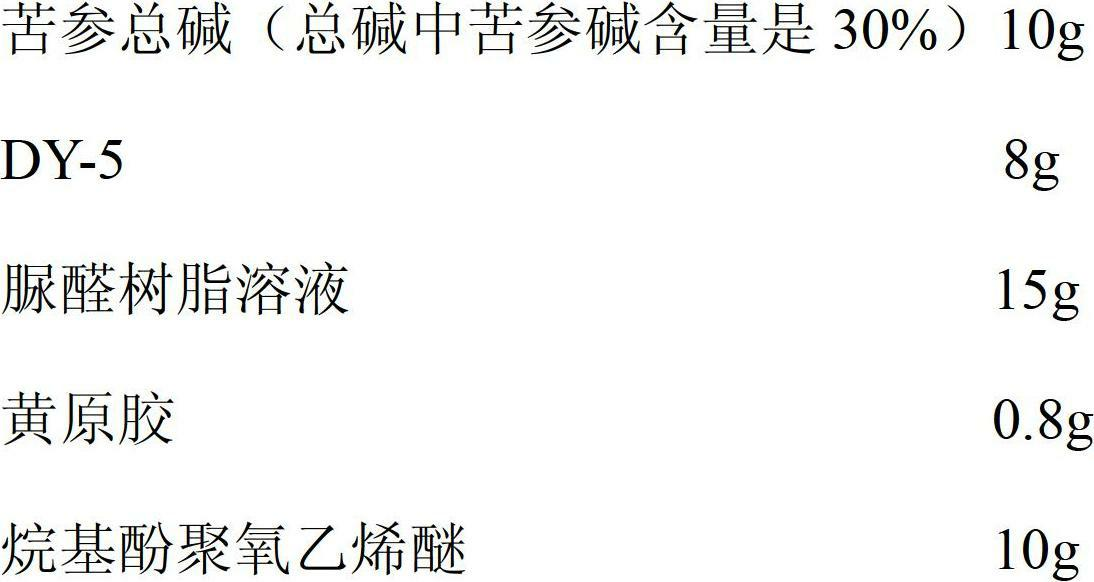

Matrine microcapsule suspension agent and preparation method thereof

InactiveCN102669192AImprove effective utilizationLong-lasting effectBiocideFungicidesAdditive ingredientSuspending Agents

The invention belongs to the technical field of biological pesticides, and more particularly relates to a matrine-containing pesticide and a preparation method thereof. The matrine-containing pesticide is characterized in that a suspension agent mainly comprises the following components in parts by weight: 1-25 parts of matrine, 5-20 parts of organic solvent, 1-25 parts of capsule wall material, 0.1-3 parts of colloid, 1-20 parts of emulsifier and the balance of de-ionized water to 100 parts. The matrine microcapsule suspension agent and the preparation method thereof aim to solve insufficient dosage form of biological pesticides in China, pollution to the environment and a poor control effect on insect pests. All active components in the scheme are naturally extracted from single-composition sophora flavescens plants, do not contain any chemical pesticides and are safe to natural enemies and the environment; and the novel matrine pesticide has the advantages of long duration of efficacy, anti-photolysis, improvement of utilization rate of pesticides and the like.

Owner:沈阳东大迪克化工药业有限公司

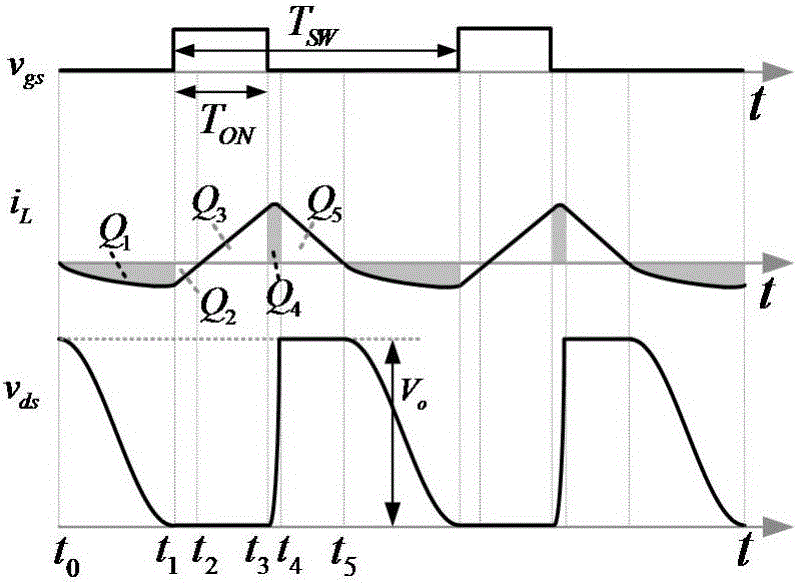

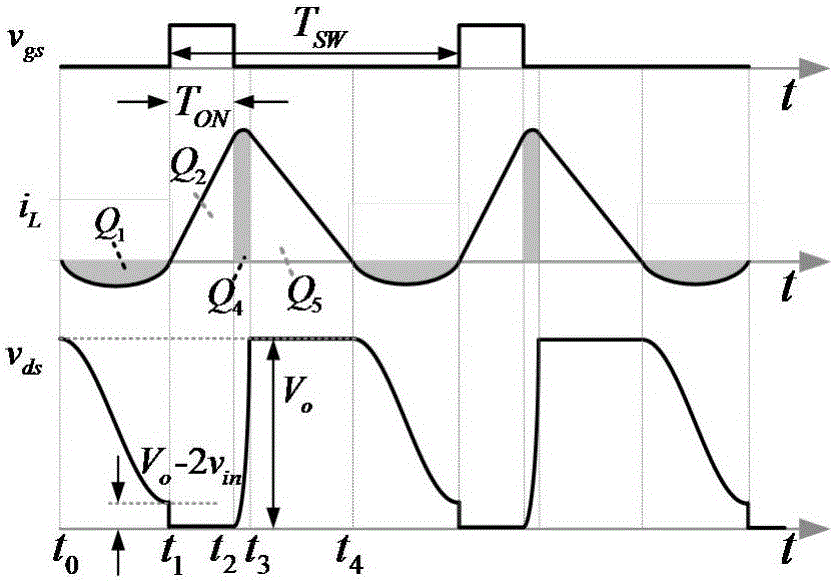

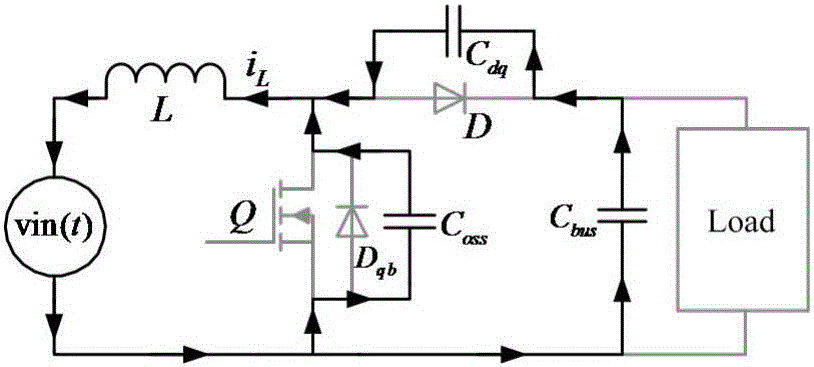

High-frequency CRM boost type PFC converter capable of adaptively optimizing THD (total harmonic distortion)

ActiveCN106100373AAchieving Adaptive OptimizationReduce data capacityEfficient power electronics conversionAc-dc conversionTotal harmonic distortionConduction time

The invention provides a high-frequency CRM boost type PFC converter capable of adaptively optimizing the THD (total harmonic distortion) of input current and belongs to the AC-DC power conversion field. According to the high-frequency CRM boost type PFC converter, the THD (total harmonic distortion) of the input current is decreased based on a charge conduction time control mode; a digital table look-up mode is adopted to generate modulation wave signals, charge conduction time control is realized through a preset conduction time data table, and therefore, the problems of poor control precision and high cost of a digital real-time calculation mode of an analog control mode can be solved; all circuits except a modulation wave signal generating circuit, are realized by an analog mode, so that the defect that a digital controller is limited in MHz high-frequency signal response speed can be eliminated, and performance requirements for the digital controller can be lowered; preset limited data in the data table are transformed, so that the charge conduction time control can be adaptively adjusted with input voltage and output power with output power detection not required, and therefore, the THD (total harmonic distortion) of the input current can be adaptively optimized, and system cost can be significantly reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

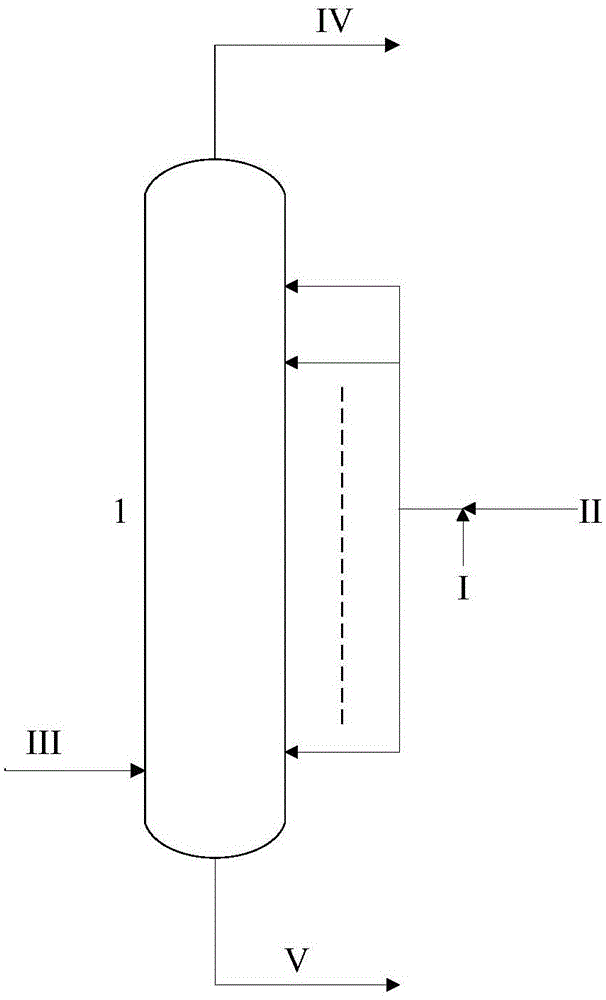

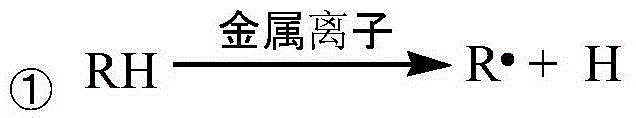

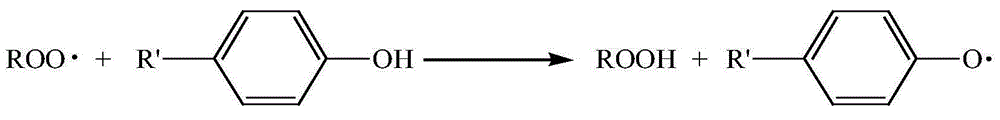

Method of inhibiting olefin polymerization in alkaline washing column of methanol-to-olefin (MTO) device

InactiveCN106467447AReduce pollutionInhibit aggregationHydrocarbon purification/separationHydrocarbonsOrganic chemistryPoor control

The invention relates to a method of inhibiting olefin polymerization in an alkaline washing column of a methanol-to-olefin device and mainly solves the technical problems of poor control effect on olefin polymerization, poor targeted applications, instability, complex operations, high toxicity and high cost in an alkaline wash column of an MTO apparatus in the prior art. In the technical scheme, a) an olefin polymerization inhibitor (I) is employed and includes, by weight, 0-20 parts of an amine compound and 0-10 parts of an alcohol compound; and b) the olefin polymerization inhibitor (I) is injected to the alkaline wash column (1) along with an alkaline solution (II) in an online continuous injection manner through an alkaline solution injection line on the alkaline wash column. The method solves the technical difficult problems and can be used for controlling and preventing the olefin polymerization in the MTO apparatus.

Owner:CHINA PETROLEUM & CHEM CORP +1

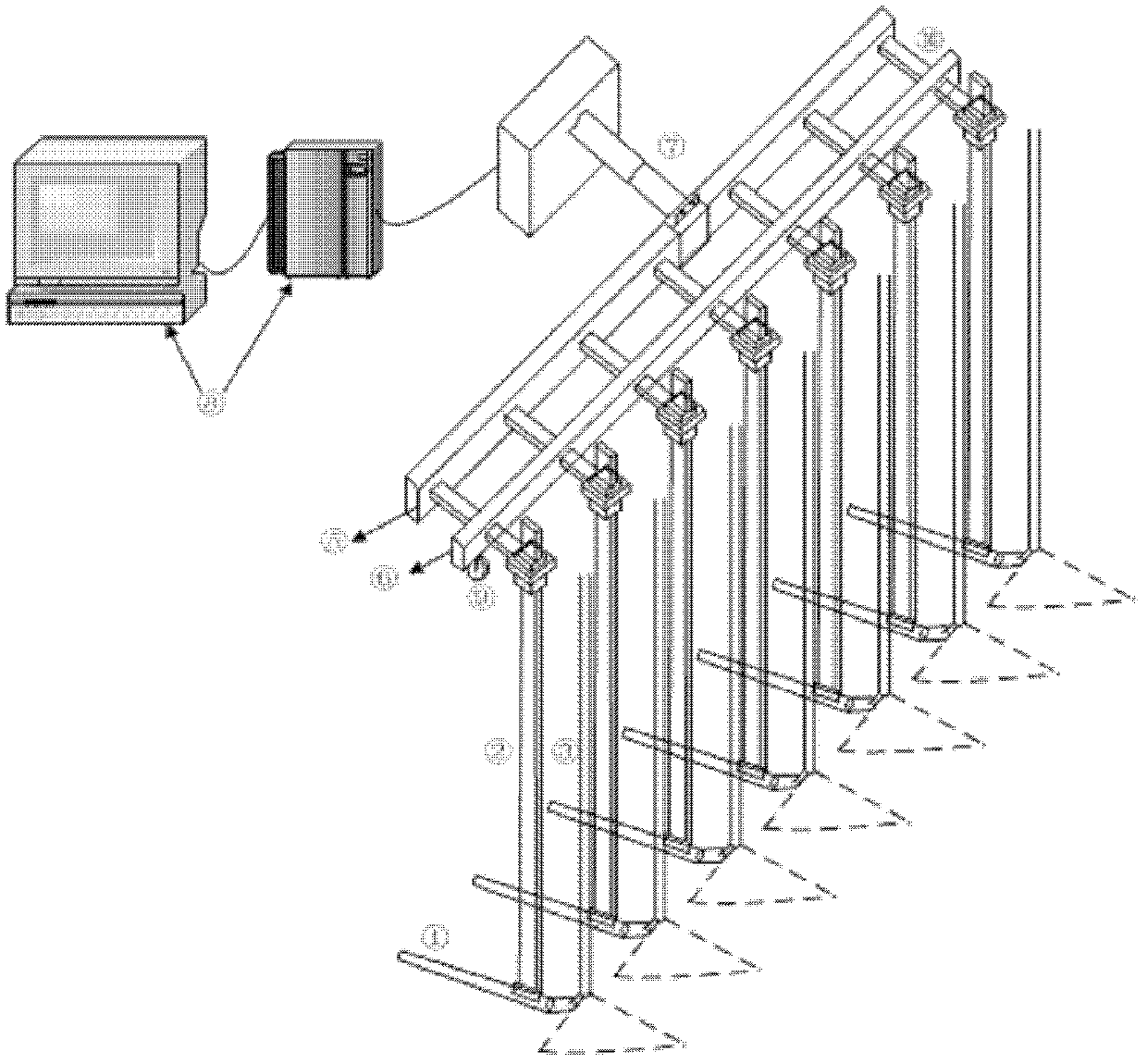

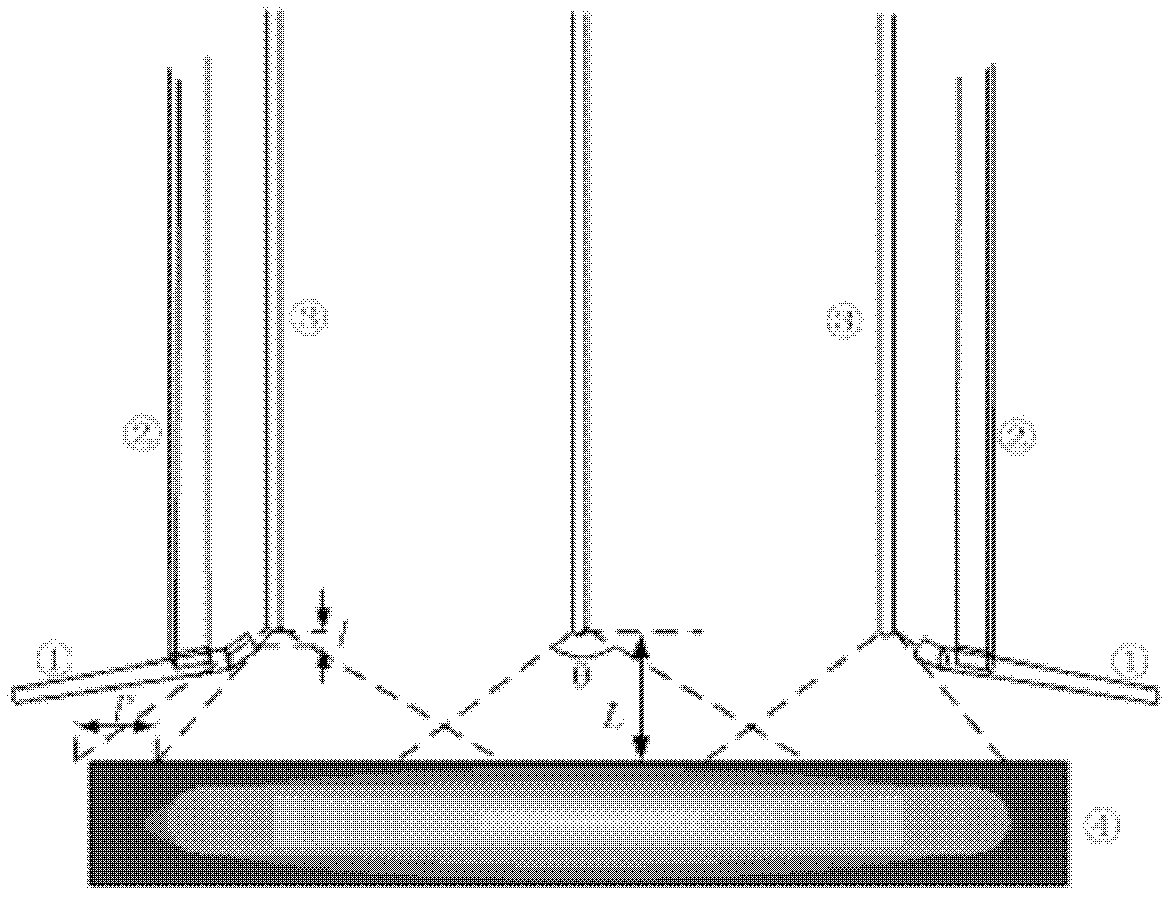

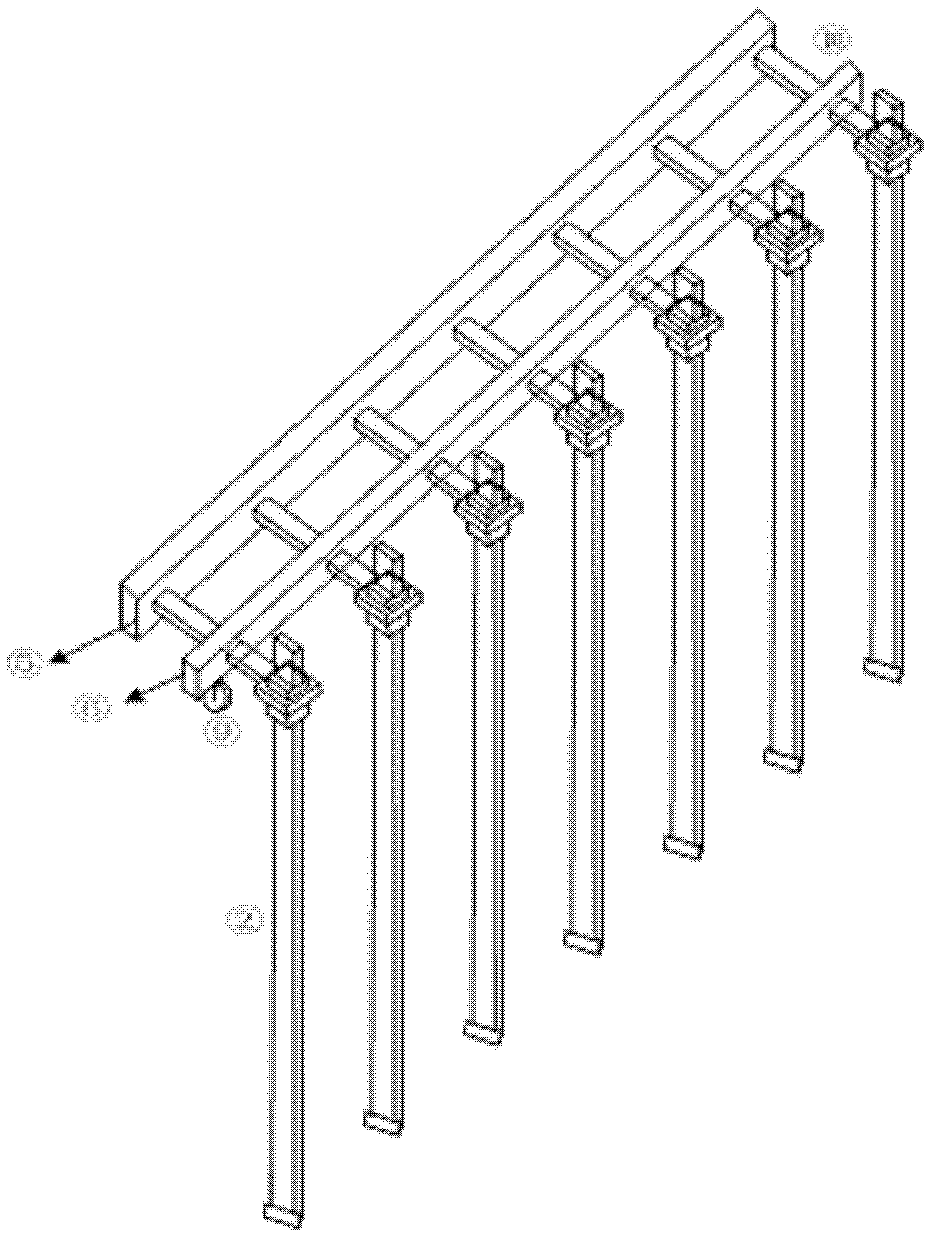

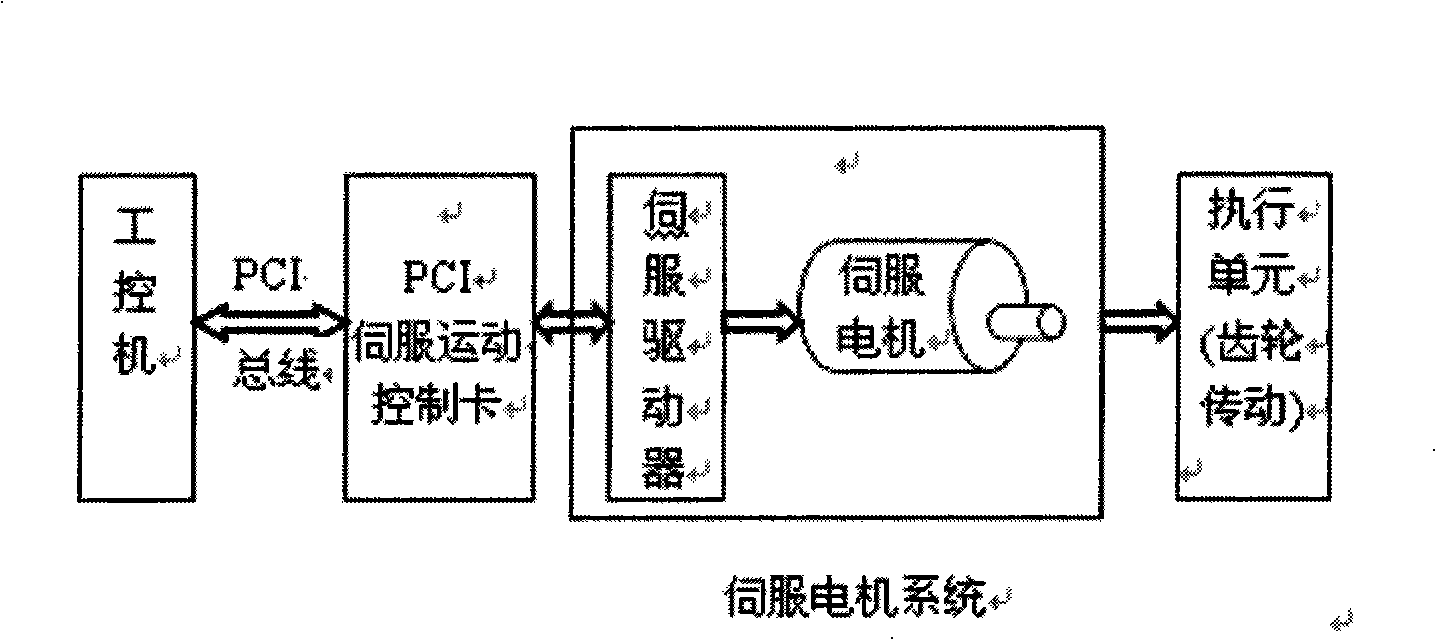

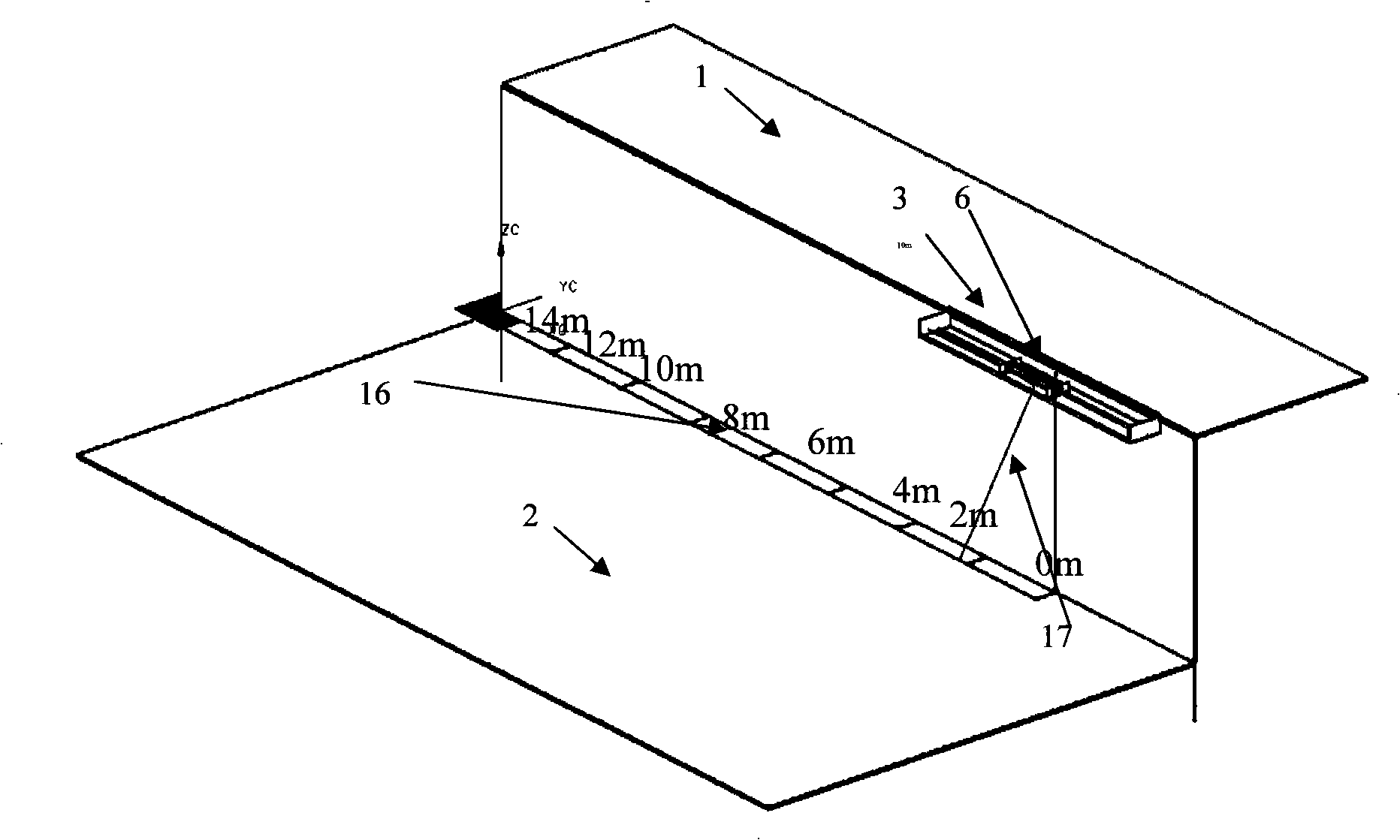

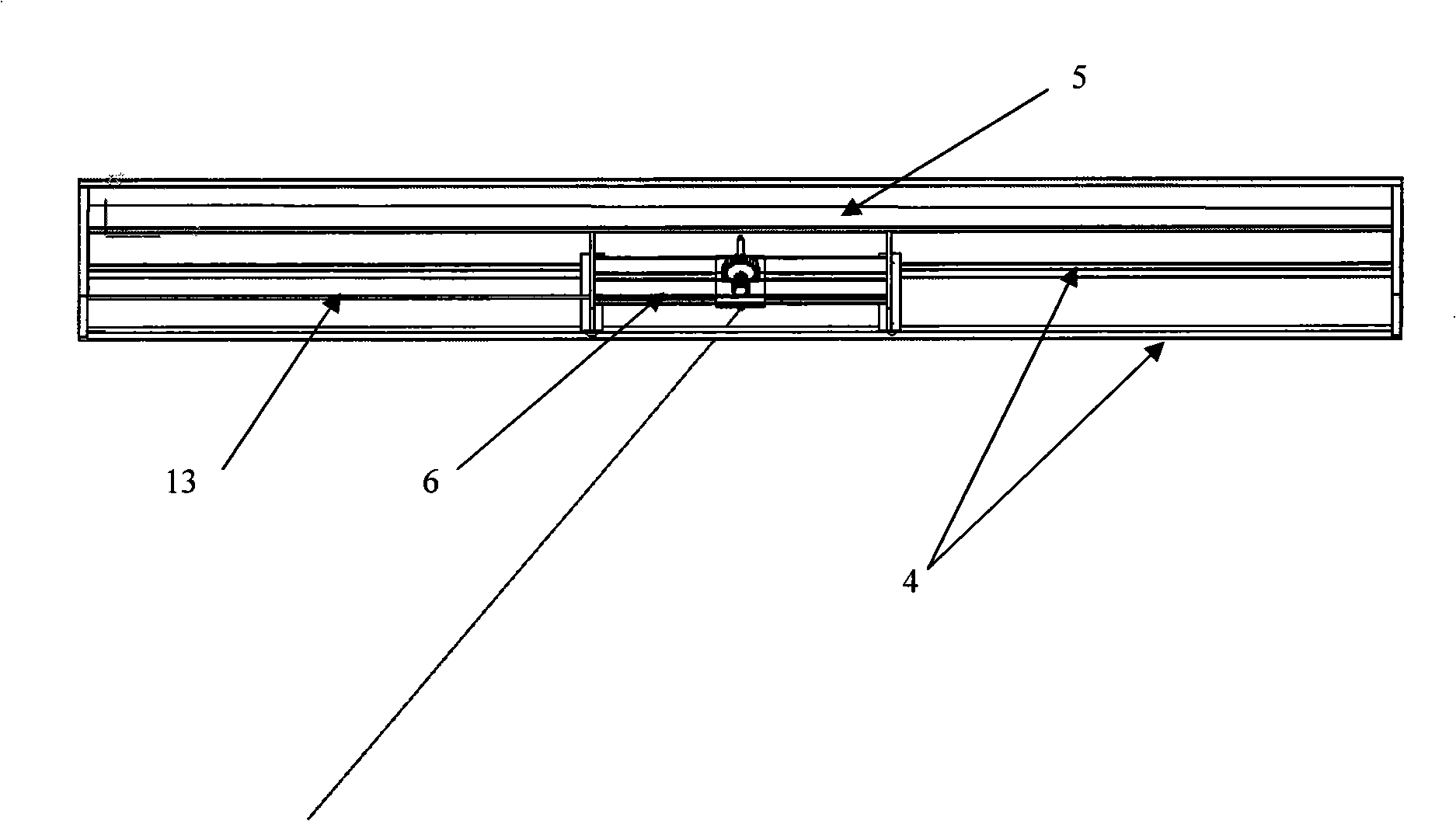

One-dimensional anchoring rope and vertical tube dynamic characteristics test device

The invention provides a mooring rope and a riser dynamic characteristic testing device for an ocean structure, belonging to the ocean engineering technical field, comprising a sliding mooring rope and riser testing platform, a shoreside rail-mounted bracket, a replaceable brake bar, an AC servo motor control system, a bottom equidistant anchor point and so on, wherein, the shoreside rail-mounted bracket is fixed on the bank of a water pool; the sliding mooring rope and riser testing platform is arranged in rails of the shore-side rail mounted bracket on the bank; the shoreside rail-mounted bracket and the sliding mooring rope and riser testing platform are horizontally connected through the replaceable brake bar, so that the sliding mooring rope and riser testing platform can be fixed; the AC servo motor control system controls a slide block on the sliding mooring rope and riser testing platform to slide; a mooring rope model or a riser model is hung on the lower end of the slide block of the sliding mooring rope and riser testing platform, and the other end of the mooring rope model or the riser model is fixed on the bottom equidistant anchor point. The device overcomes the defects of difficulty of changing wide horizontal spans, poor control accuracy, difficult operation and so on.

Owner:SHANGHAI JIAO TONG UNIV

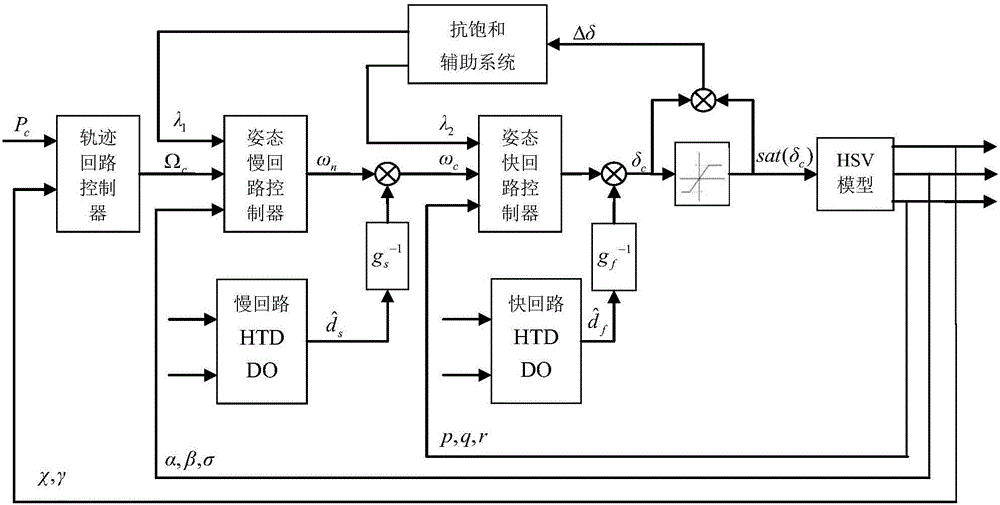

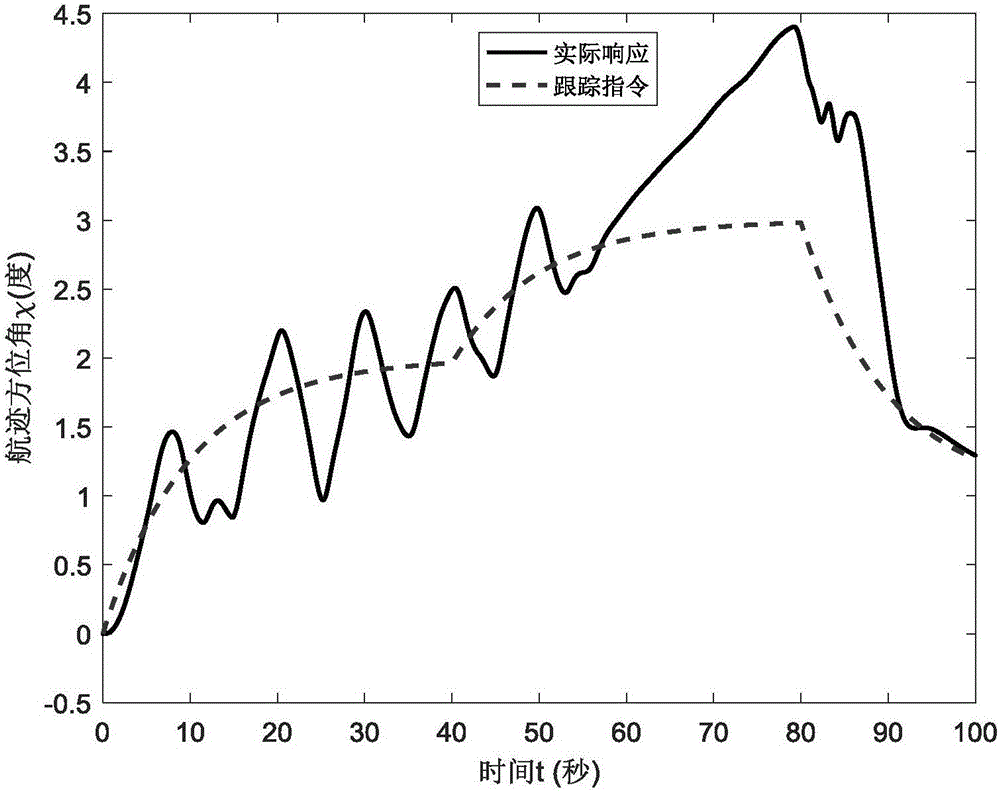

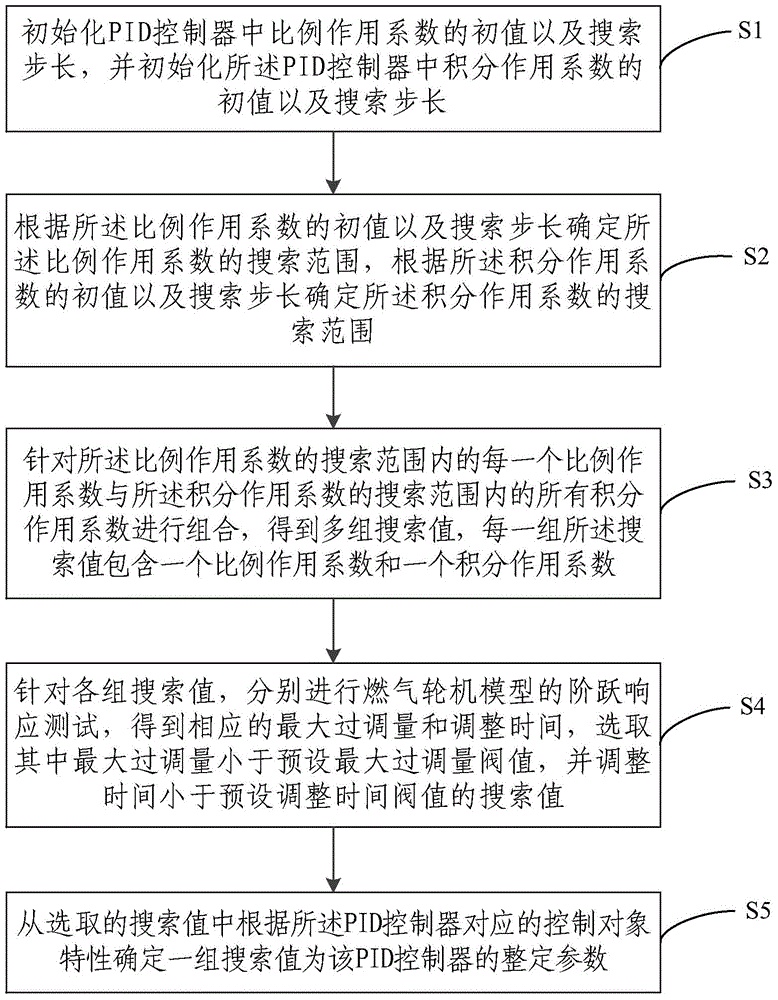

Hypersonic speed maneuvering flight anti-rudder surface saturation resistance robust control method

The invention discloses a hypersonic speed maneuvering flight anti-rudder surface saturation resistance robust control method, belongs to flight control methods in the technical field of aviation and aerospace, and aims to solve the problem of poor control system performance of a HSV (hypersonic vehicle) caused by operating control surface amplitude saturation and composite disturbance in the hypersonic speed maneuvering flight process. The method provides a novel saturation resistance auxiliary design system, the order of the system is as same as that of an attitude control system, and the system is applicable to an SISO (single input single output) system and an MIMO (multiple input multiple output) system. Variables of the auxiliary system is led into a back-stepping method error variables, HSV maneuvering flight control laws are designed by the aid of the back-stepping method ideologies, and the closed loop stability of a system is ensured. The invention provides a disturbance observer based on a mixed tracking differentiator, tracking and approach for composite disturbance are performed by the disturbance observer, and compensation control laws are designed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

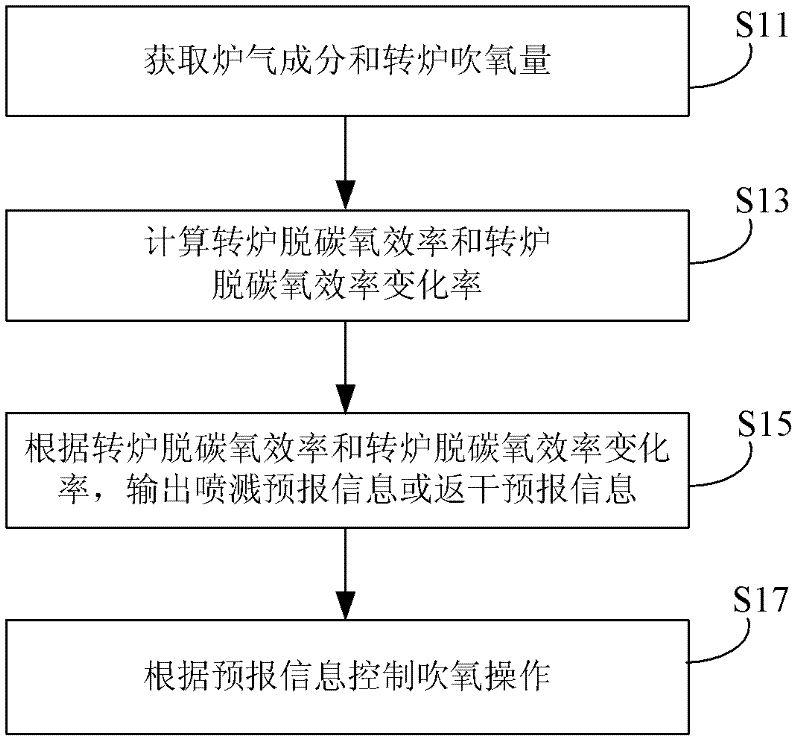

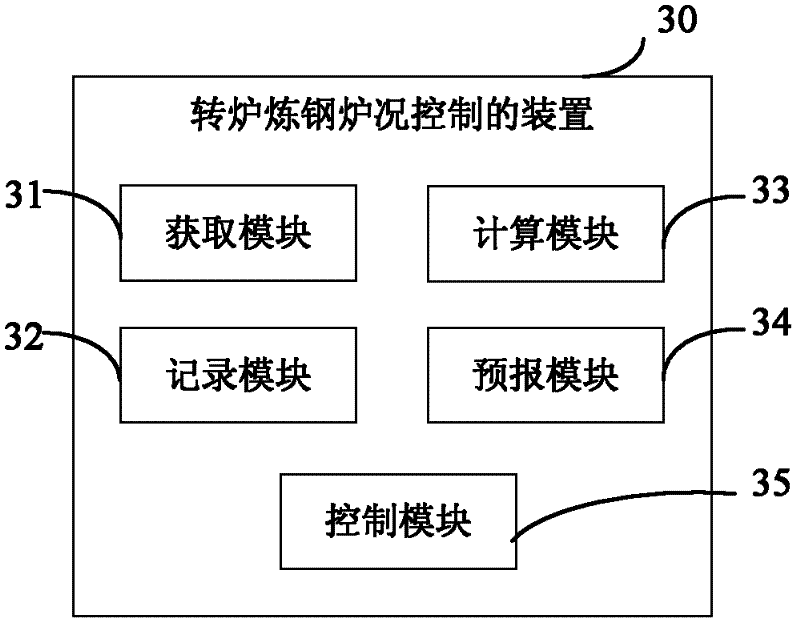

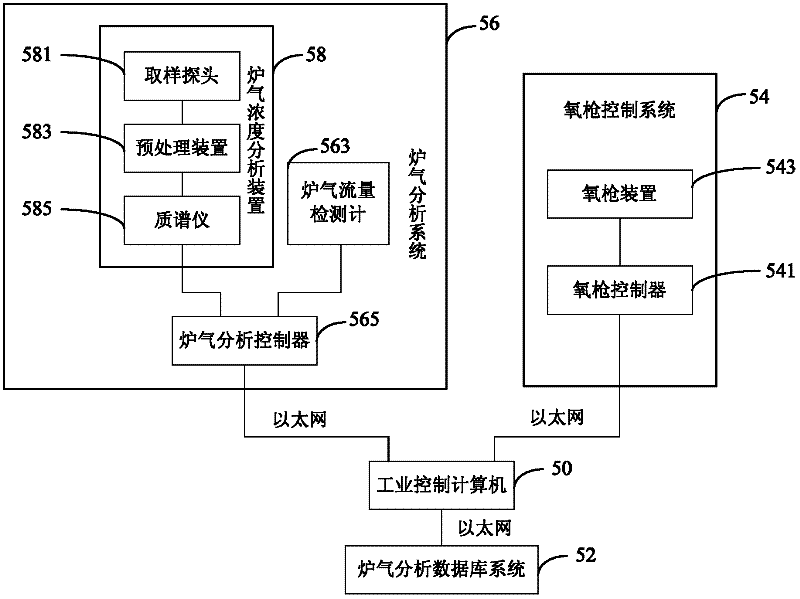

Method, device and system for controlling steel-making process of converter

InactiveCN102344985AOvercome the disadvantage of poor stability of artificial experience controlEasy to controlManufacturing convertersSmelting processInstability

The invention provides a method, a device and a system for controlling the steel-making process of a converter, which are used for solving the problems of influence of descending of a converter gas hood and the slag accumulation at a converter mouth on the control effect and poor control precision in the prior art. The method comprises the following steps of: a step S11 of obtaining content of CO and CO2 in converter gas and recording the oxygen blowing amount of the converter; a step S13 of calculating the oxygen decarburization efficiency of the converter and the change rate of the oxygen decarburization efficiency of the converter according to the content of CO and CO2 and the oxygen blowing amount of the converter; a step S15 of outputting splashing forecast information or drying return forecast information according to the oxygen decarburization efficiency of the converter and the change rate of the oxygen decarburization efficiency of the converter; and a step S17 of controlling the oxygen blowing operation according to the splashing forecast information or the drying return forecast information. Due to the adoption of the technical scheme, the instability of control by artificial experience is eliminated; and compared with the existing sonar slag-forming monitoring method, the method is not influenced by the descending of the converter gas hood and the slag accumulation at the converter mouth, is more accurate to control and ensures the stability of the smelting process to be improved.

Owner:田陆

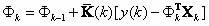

Control method of three-phase grid-connected inverter

InactiveCN105515430AReduce computationReliable controlAc-dc conversionSingle network parallel feeding arrangementsPrediction algorithmsGrid connected inverter

The invention discloses a control method of a three-phase grid-connected inverter, which is used for solving the problems of large computation and poor control performance of an existing control method. The technical scheme is characterized in that the control method comprises the following steps: firstly, building an output current prediction model of the three-phase grid-connected inverter under an alpha-beta coordinate system; secondly, obtaining an optimal switching function combination which is used for controlling the three-phase grid-connected inverter by utilizing the built output current prediction model and adopting a two-step prediction algorithm; finally, controlling all switching devices of the three-phase grid-connected inverter by utilizing the optimal switching function combination of the three-phase grid-connected inverter. According to the control method of the three-phase grid-connected inverter, disclosed by the invention, the three-phase grid-connected inverter is controlled by adopting the two-step prediction control algorithm on the basis of the built output current prediction model of the three-phase grid-connected inverter; compared with an existing inverter control method, the control method has the advantages that the computation is small, and the control performance is ideal.

Owner:STATE GRID QINGHAI ELECTRIC POWER +2

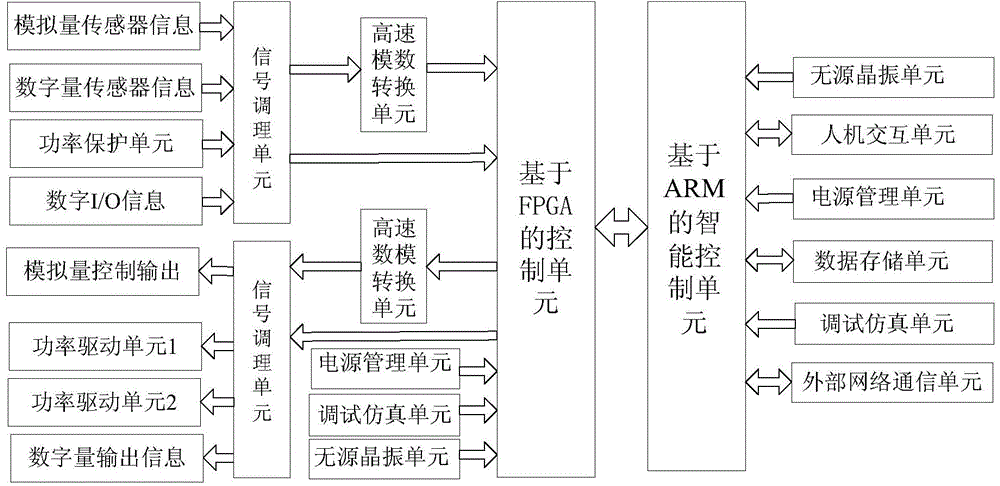

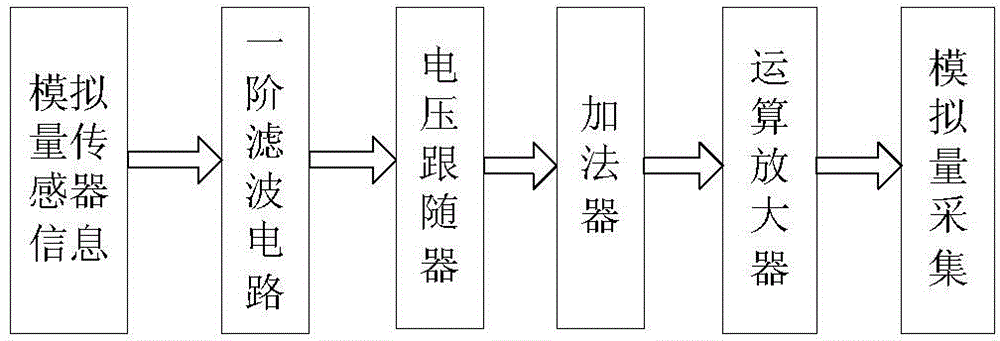

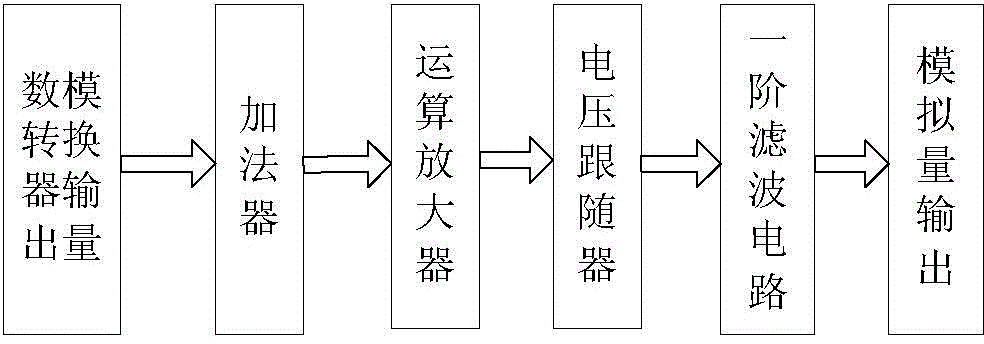

Double-drive hybrid direct-current and low-voltage intelligent servo driver circuit

ActiveCN105242587AReduce power consumptionPowerfulProgramme controlComputer controlHigh resistanceLow voltage

The invention belongs to the technical field of servo driver circuit design, and specifically relates to a double-drive hybrid direct-current and low-voltage intelligent servo driver circuit. The circuit of the invention comprises an ARM-based intelligent control unit, an FPGA-based control unit, a high-speed analog-to-digital conversion unit, a high-speed digital-to-analog conversion unit, a data storage unit, a signal conditioning unit, an external network communication unit, a power management unit, a debugging and simulation unit, a passive crystal oscillation unit, a human-computer interaction unit, a sensor information unit, an intelligent control output unit, a power protection unit, and a power drive unit. The technical problem that the existing servo driver has poor control performance, occupies a large space and is hard to achieve a networked mode is solved. By adopting the design of 'ARM + FPGA + double power drive units', the double-drive hybrid direct-current and low-voltage intelligent servo driver circuit of the invention has the characteristics of double drive, small size, low power consumption, high precision, high reliability, good real-time performance, high scalability, good networking performance, and high resistance to electromagnetic interference.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

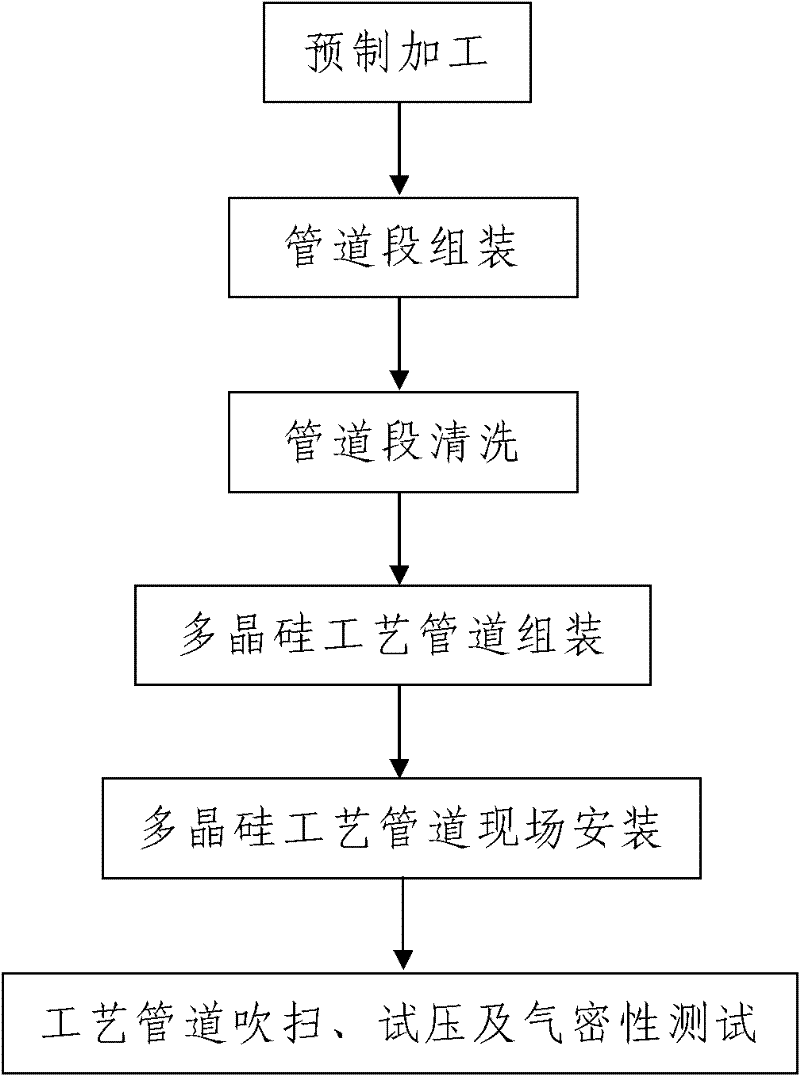

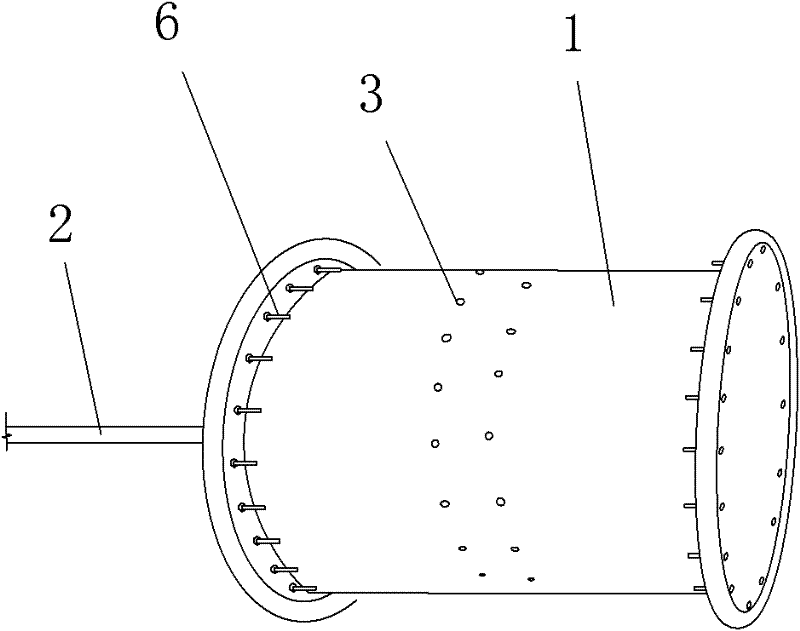

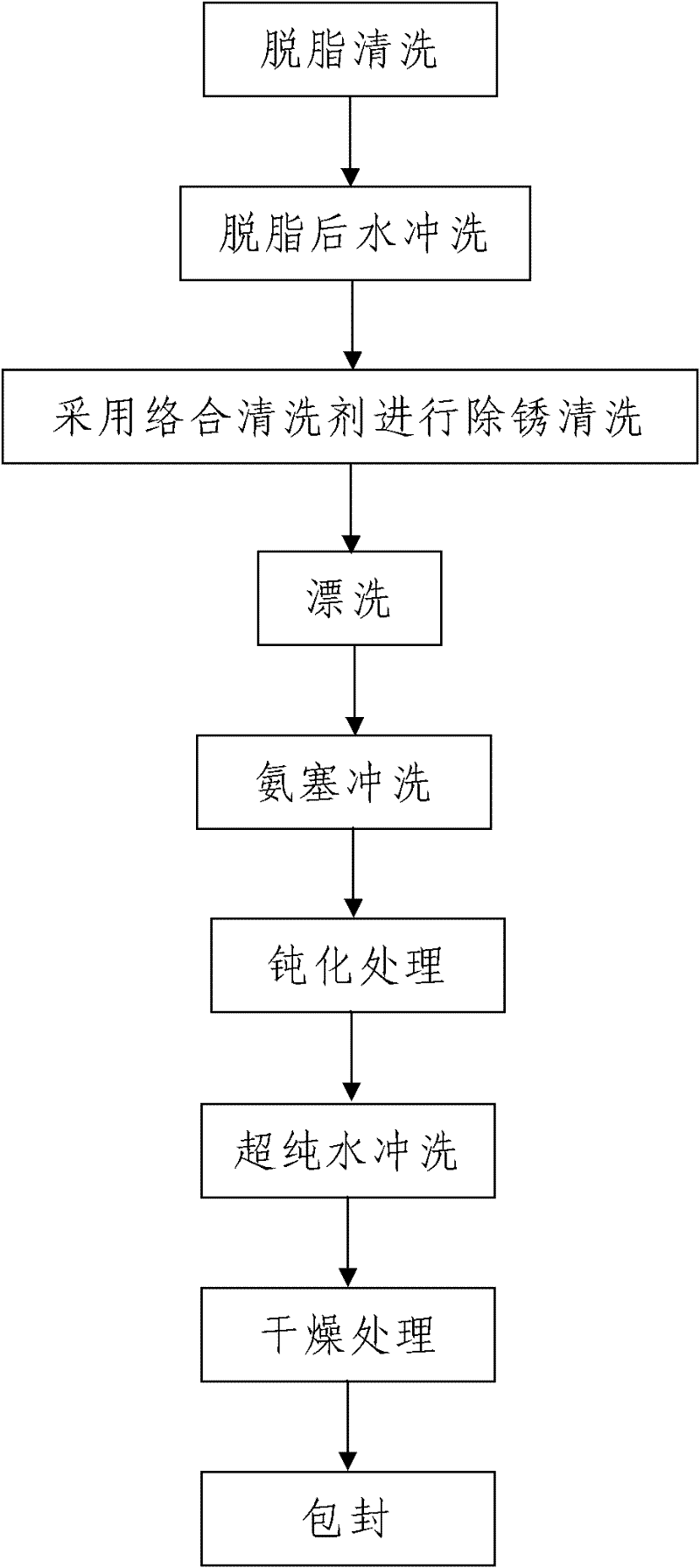

Construction method for controlling cleanliness of electronic-grade multicrystal-silicon process pipe

ActiveCN102231357AReasonable designEasy and simple to implementHollow article cleaningSemiconductor/solid-state device manufacturingEngineeringAmmonia

The invention discloses a construction method for controlling the cleanliness of an electronic-grade multicrystal-silicon process pipe. The construction method comprises the following steps of: (1) prefabrication machining; (2) pipe section assembling: finishing an assembly procedure of pipe sections by utilizing an interior gas protection device and an argon arc welding machine; (3) pipe section cleaning comprising the following steps of: degrease cleaning, water flushing after degreasing, complexing and derusting, rinsing, ammonia-plugging flushing, passivation processing, ultra-pure water flushing, dry processing and packaging; (4) multicrystal-silicon process pipe assembling; (5) field assembling of the multicrystal-silicon process pipe; and (6) process pipe blowing, pressure testing and airtightness testing. The invention has the advantages of reasonable design, simplicity and convenience in operation, convenience for realizing and good pipe cleanliness control effect, can solve various problems such as complex factors influencing the cleanliness of the interior of the multicrystal-silicon process pipe, difficulty in control of the cleanliness of the interior of the pipe, poor control effect of the cleanliness and the like in a multicrystal-silicon process pipe construction process.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

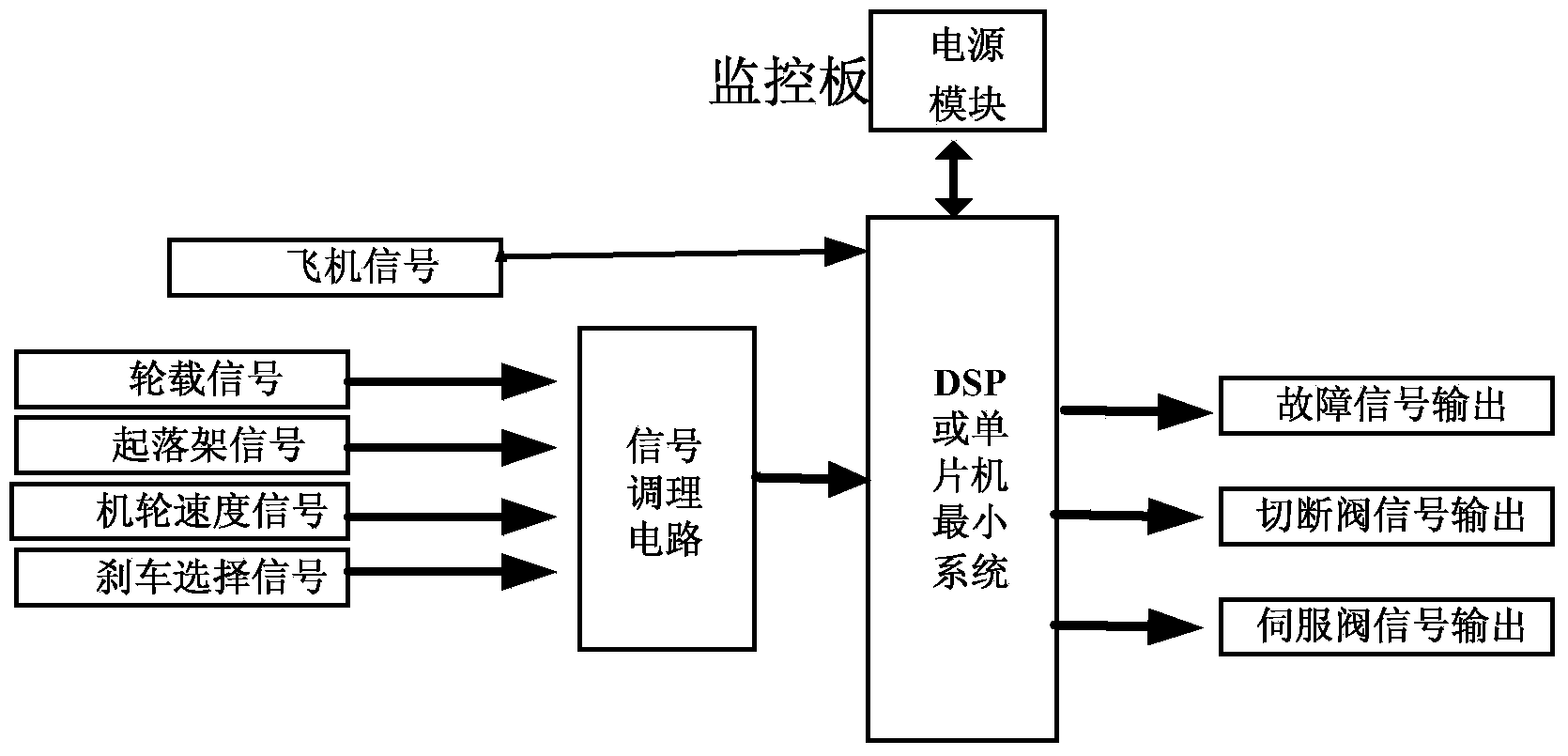

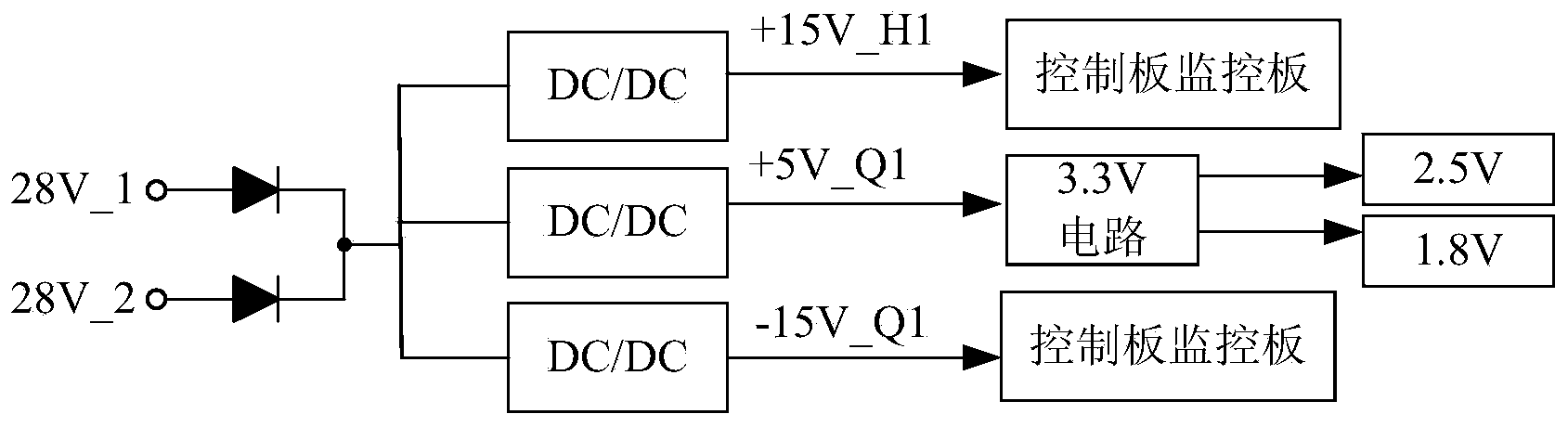

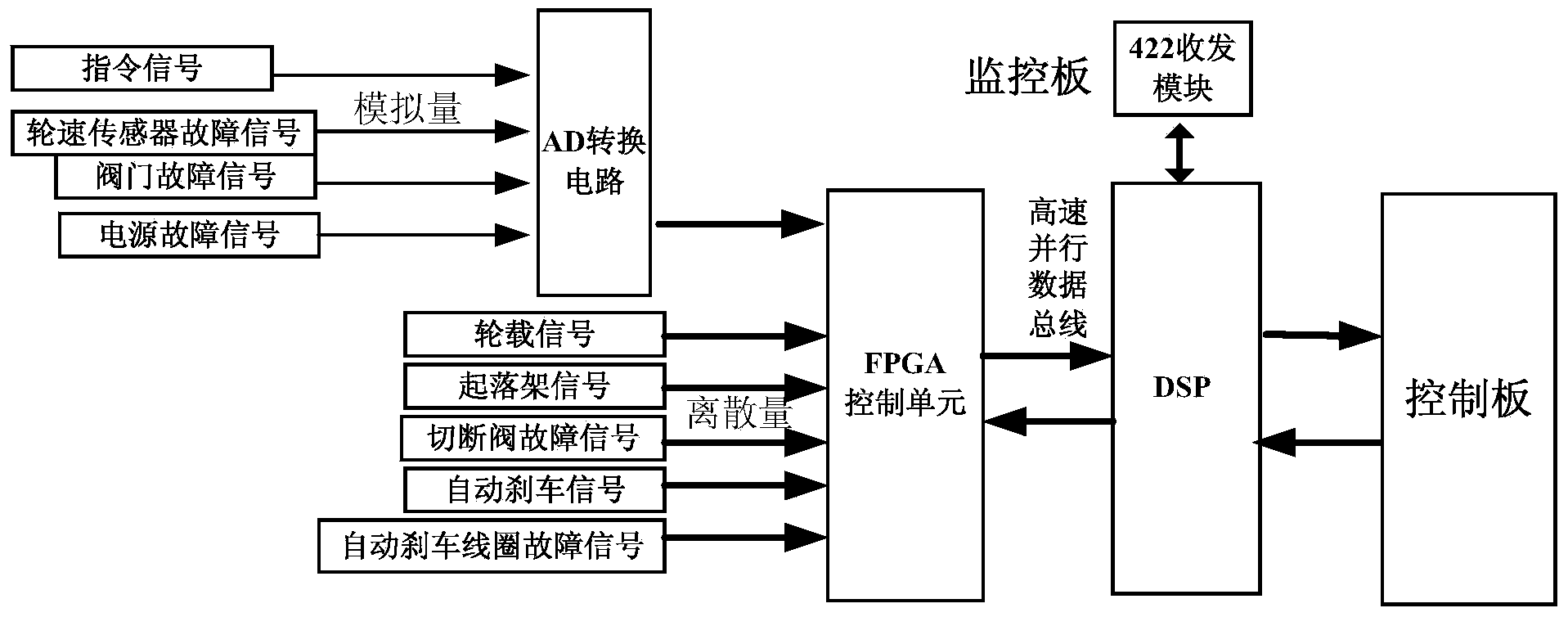

DSP+FPGA (digital signal processor and field programmable gate array)-based anti-skid brake control box of aircraft brake system

ActiveCN103640693AAchieve integrationAchieve modularityBrake regulatorsDigital signal processingField-programmable gate array

The invention discloses a DSP+FPGA (digital signal processor and field programmable gate array)-based anti-skid brake control box of an aircraft brake system, and aims at solving the technical problem that a conventional DSP-based anti-skid brake controller of an aircraft has the poor control accuracy. The technical scheme is that the control box comprises a power panel, a control panel and a monitoring panel, wherein the control panel and the monitoring panel adopt high-performance DSP+FPGA as a control core, and the complex control operation capacity of the DSP and the high-efficiency data processing capacity of the FPGA are combined, so that the number of discrete elements in the panels is reduced, the number of the panels in the brake control box is reduced, the system operation speed is increased, and the control accuracy is high. The integration and the modularization of the anti-skid brake control system of the aircraft are realized, and the reliability of the system is relatively high. According to the anti-skid brake control box of the aircraft brake system, the complex control operation capacity of the DSP and the high-efficiency data processing capacity of the FPGA are combined, so that the system operation speed is increased and the control accuracy is improved; the control accuracy is improved from 1 percent in the prior art to 0.5 percent.

Owner:XIAN AVIATION BRAKE TECH

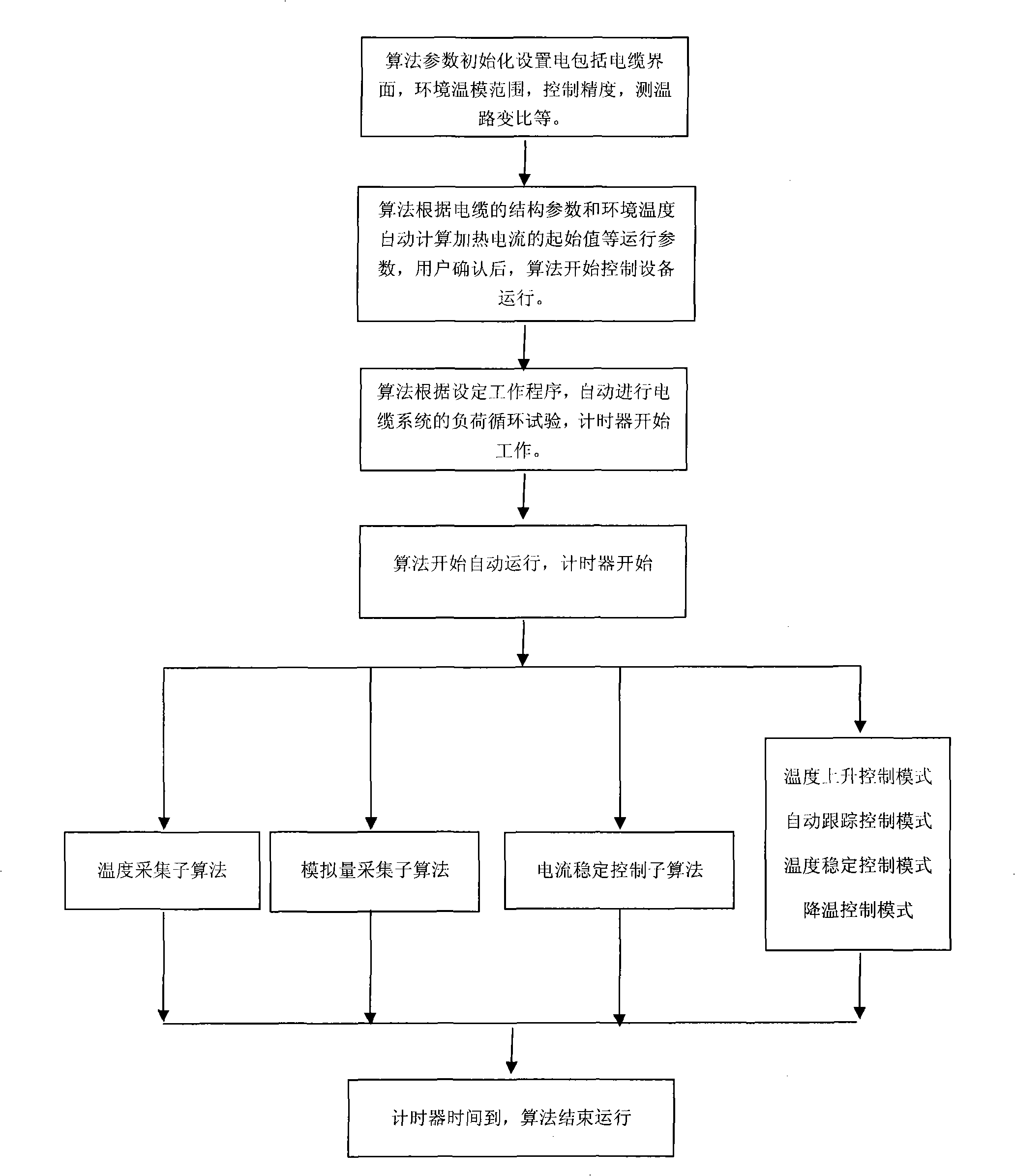

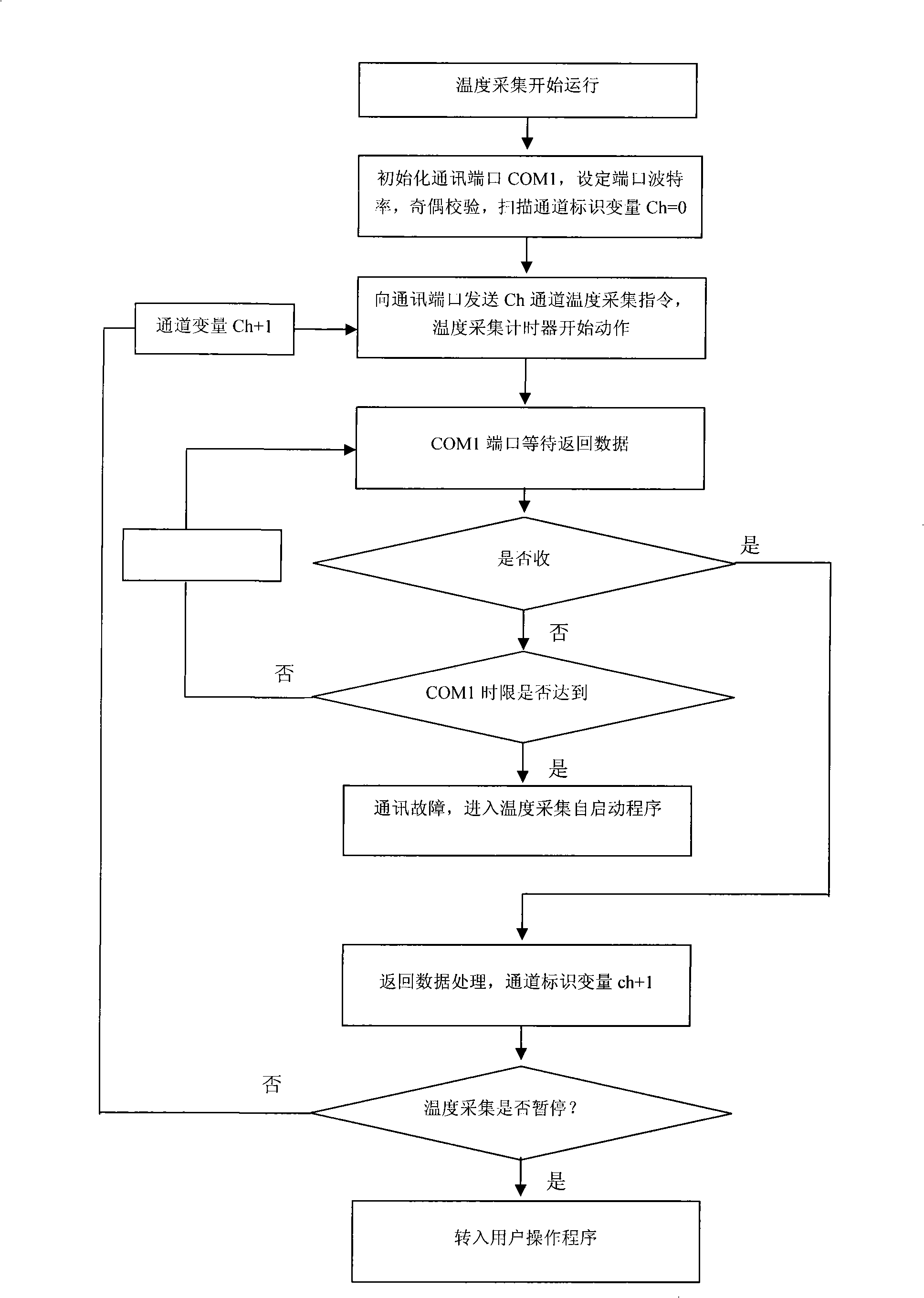

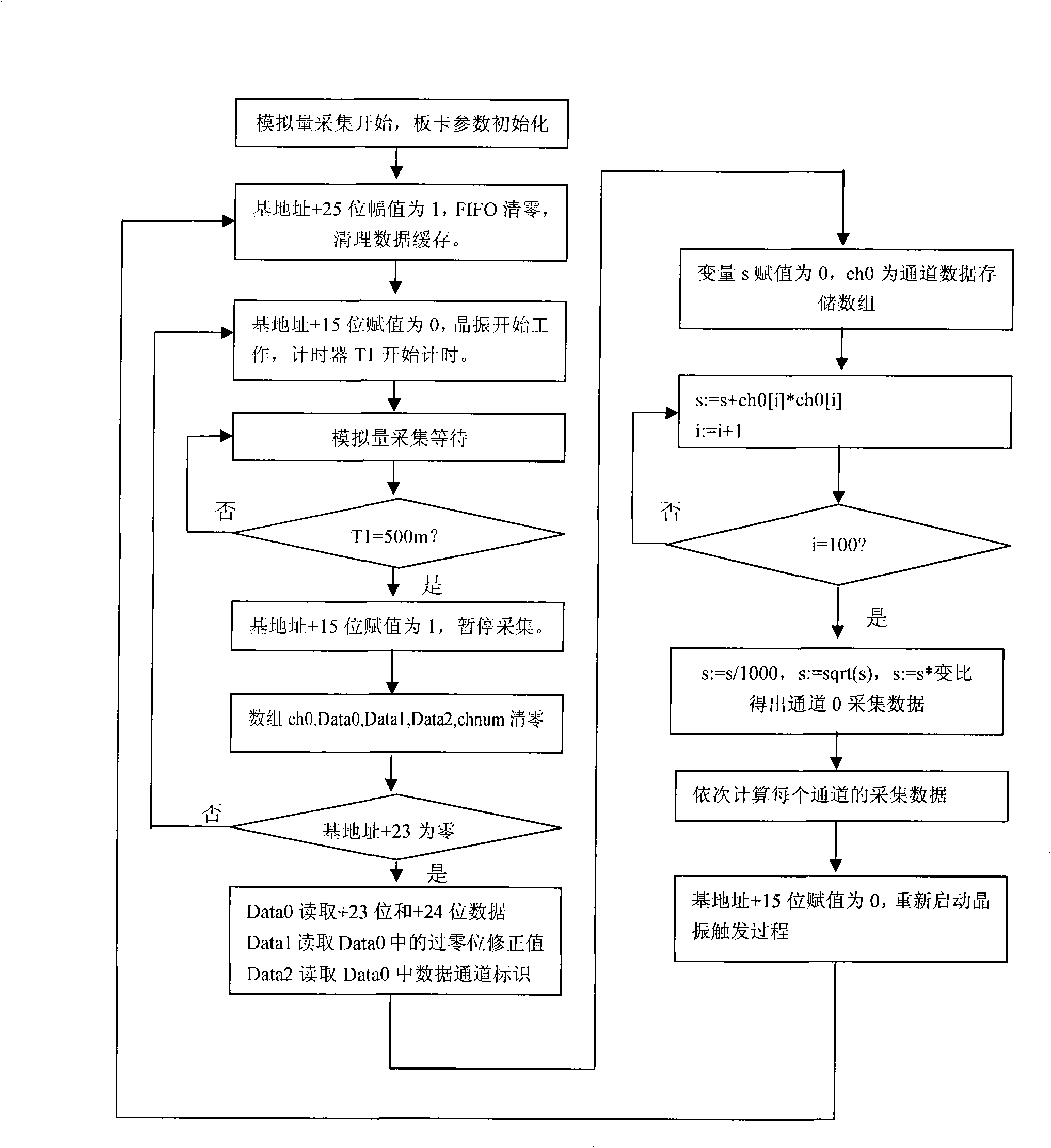

Power cable conductor temperature automatic following and control method

InactiveCN101339442AAvoid precisionAvoid process problemsTemperature control using electric meansElectrical conductorEngineering

The invention relates to a power cable conductor temperature automatic following and controlling method, which is composed of a data processing unit, a data acquisition unit and a control output unit related to the aspect of the hardware, and is logically constituted by a temperature rise controlling mode, an automatic tracking and control mode, a temperature stable control mode and a temperature drop controlling mode comprising: the data acquisition unit real-timely collects the current data and the temperature data of the cable and feeds back to the data processing unit, which determines the implementary adjustment amplitude according to the software algorithm, and the control output unit completes the practical performance, completes the full automatic tracking control of the cable conductor temperature. The invention realizes the temperature control process of the cable conductor with full automation and high precision, completes the automatic track and control on the temperature of the conductor with high precision, thereby effectively avoiding the defects of poor control precision and fussy technology in the traditional hand control method, and the controlling effect is excellent.

Owner:WUHAN HIGH VOLTAGE RESEARCH INSTITUTE OF STATE GRID

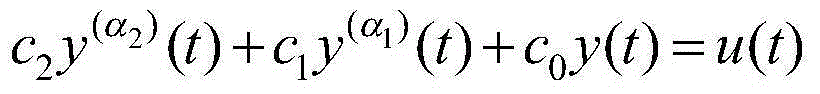

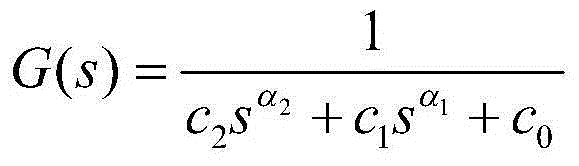

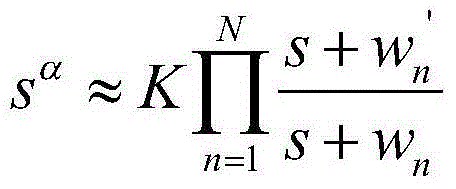

Fractional order PFC method of industrial heating furnace system

The invention discloses a fractional order PFC method of an industrial heating furnace system. A traditional PID control method and an integer order PFC method have poor control effects on a kind of fractional order system. The control method of the invention comprises: firstly employing an Oustaloup approximation method to approximate a fractional order system into an integer order system; building a prediction output model based on an Oustaloup approximation model; expanding an integer order PFC method to a fractional order PFC method; introducing a fractional order calculus operator into an object function; and furthermore designing a fractional order prediction function controller based on the prediction model and selected performance indexes. The fractional order PFC method can be well applied to the real process objects described by a fractional order model, omit the order reduction step of the integer order PFC method to control a high order system model, meanwhile increase the flexibility of adjusting controller parameters, and obtain good control performances.

Owner:HANGZHOU DIANZI UNIV +1

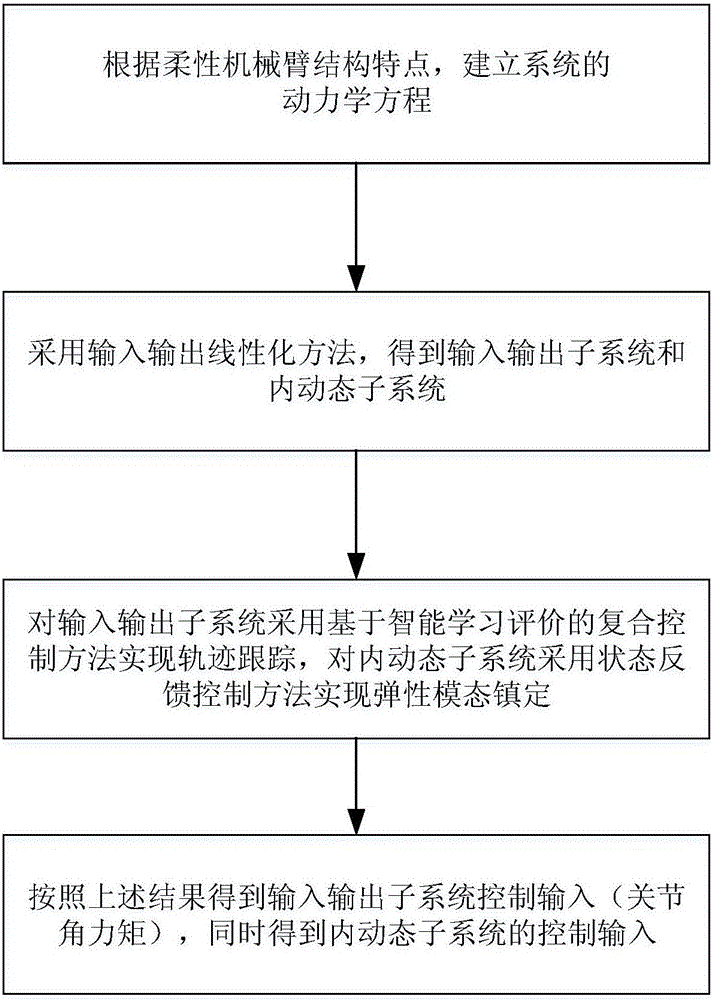

Flexible mechanical arm composite control method based on intelligent learning evaluation

ActiveCN106773684AHigh control precisionApplicable Engineering RequirementsAdaptive controlSimulationSelf adaptive

The invention discloses a flexible mechanical arm composite control method based on intelligent learning evaluation. A technical problem of poor control precision of the current flexible mechanical arm control method is solved. The method comprises steps that linear processing is performed on the existing flexible mechanical arm model; nondeterminacy of lumping of the system is considered by a controller; nondeterminacy of a neural network approximate system is introduced; modeling errors are further considered; a system prediction model is designed; and the modeling errors are introduced into neural network weight self-adaption updating rule. Thus, feedback information is quire comprehensive, control precision is improved and engineering requirements are met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

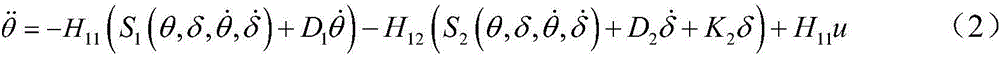

Piano playing musical note correction system and method

InactiveCN108364528AReduce workloadImprove accuracyMusicElectrical appliancesComputer moduleData recording

The invention provides a piano playing musical note correction system. The system comprises a track display module, a note picking module, a sound picking module, a comparison module, and a data recording module. The comparison module is connected to the track display module. The similarity values of the notes are instantly marked by the track display module, so that the students can correct in real time during the practice. In this way, during the practice of playing, the student picks up the playing sound through the sound pickup device and converts the sound digital signal. At the same time, comparing the similarity between the above-mentioned sound digital signal and the note digital signal greatly improves the accuracy of the identification. The comparison result is marked in real time by the track display module on the notes of the practice playing track, so that the students can understand the playing situation. The timely detection of the notes with poor control makes the training process targeted, so that the students can practice on their own without the help of a teacher.

Owner:NANTONG INST OF TECH

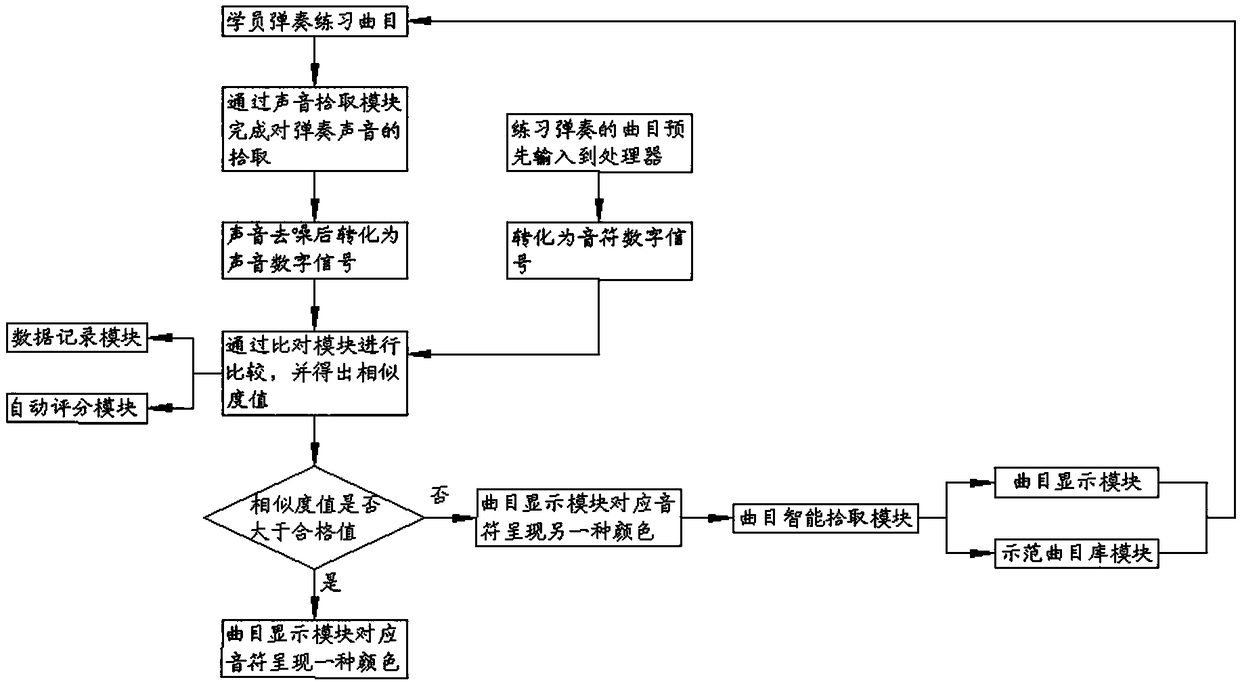

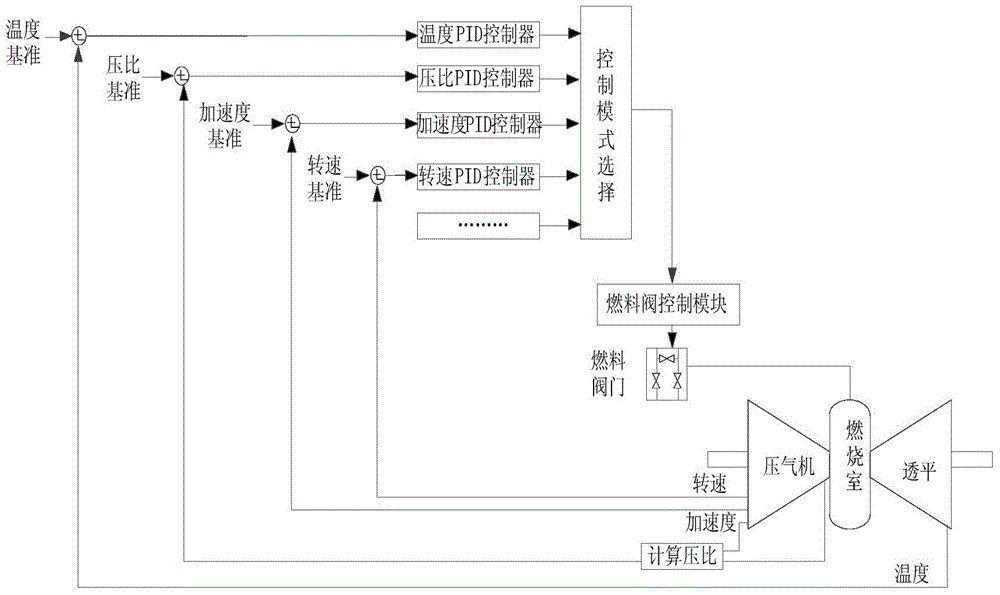

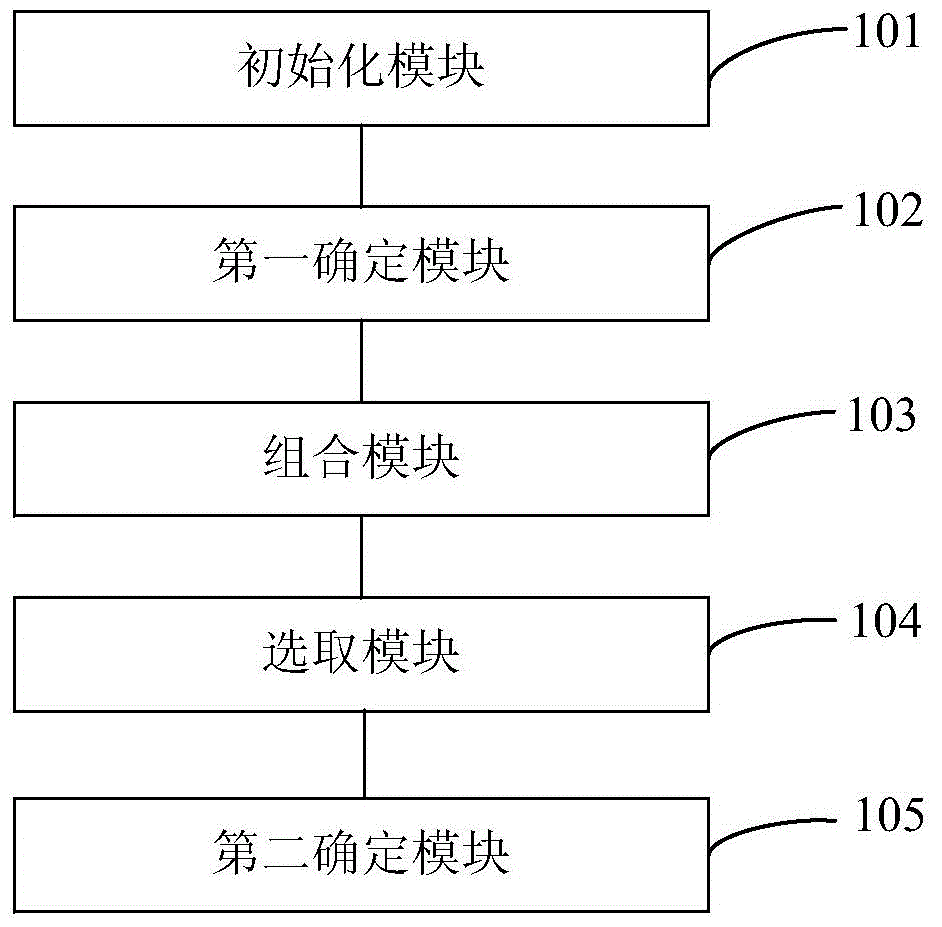

Method and device for setting parameters of closed-loop PID (proportion integration differentiation) controller of gas turbine

InactiveCN104635486AOvercome efficiencyOvercome the defect that it is difficult to obtain the optimal tuning parametersControllers with particular characteristicsProportion integration differentiationClosed loop

The invention relates to a method and a device for setting parameters of a closed-loop PID (proportion integration differentiation) controller of a gas turbine. The method comprises the following steps of initializing the initial values of a proportion action coefficient and an integration action coefficient of the PID controller, and researching the step length; determining the researching ranges of the proportion action coefficient and the integration action coefficient; performing the step response testing of a gas turbine model on all combinations of searching values of the proportion action coefficient and the integration action coefficient within the searching range, and selecting all searching values meeting the maximum overshoot and time adjusting requirements; determining one group of setting parameters. The method has the advantages that the defects of low parameter setting effect and poor control effect because of reliance on experiences of engineers in the prior art are overcome; a plurality of controller parameters meeting the dynamic property indexes of the controller can be automatically obtained, the setting parameters are determined, the control effect better than the effect of the manual setting method is obtained, the service life of the gas turbine unit is effectively prolonged, and the fuel consumption of the gas turbine unit is decreased.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

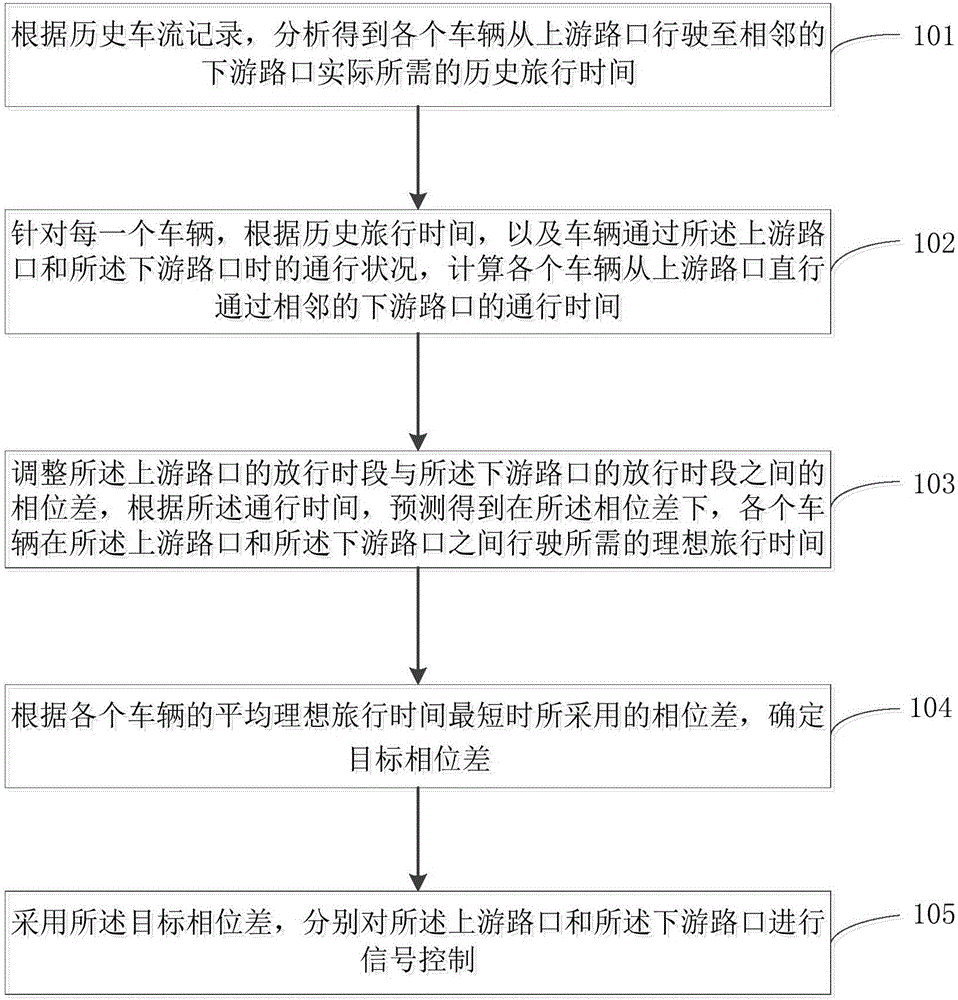

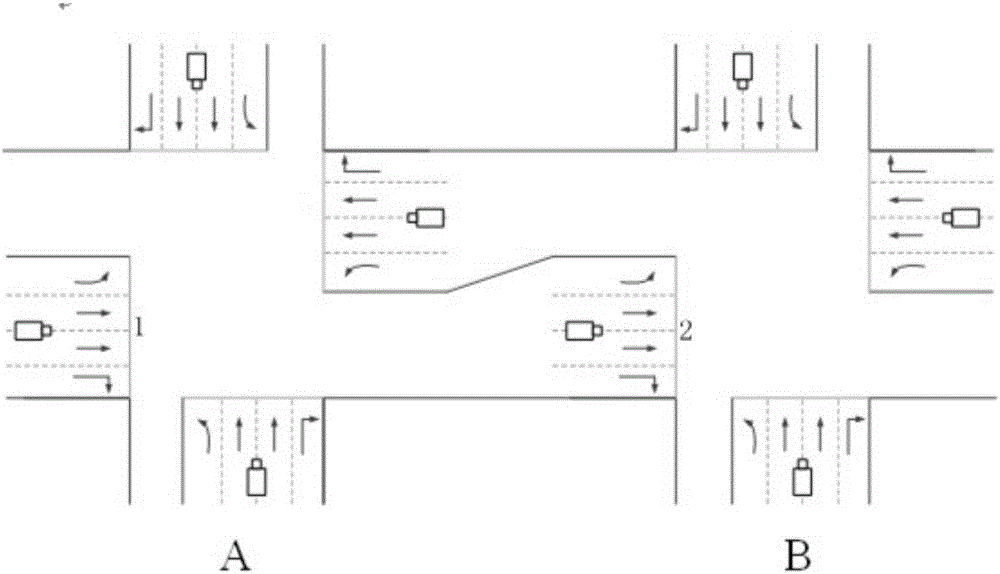

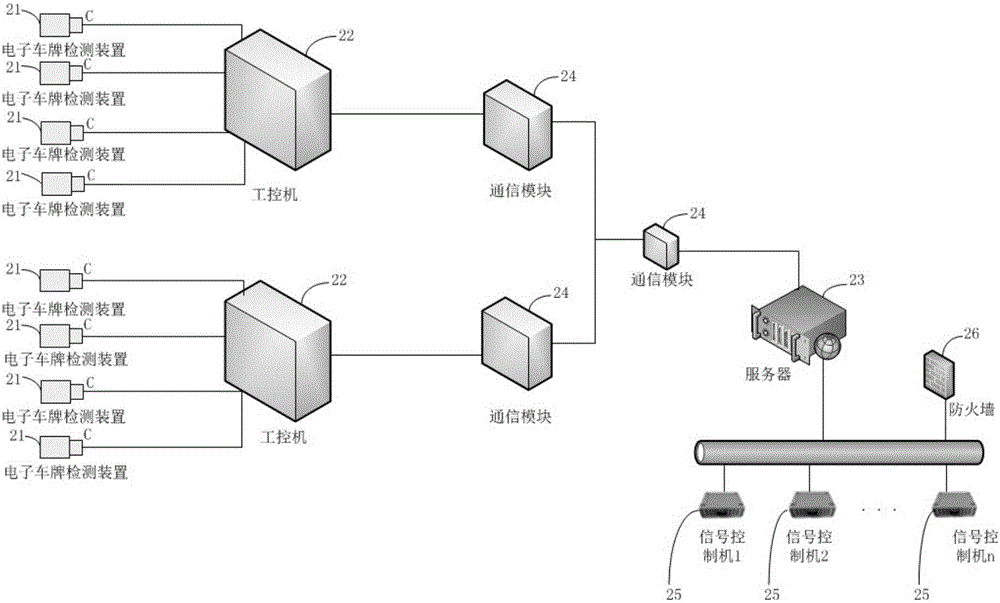

Control method and device for traffic signal and traffic signal system

The invention provides a control method and device for a traffic signal and a traffic signal system. The method comprises the following steps: adjusting a phase difference between a permitting time frame of an upstream intersection and the permitting time frame of a downstream intersection after acquiring the passing time between each vehicle upstream intersection and the adjacent downstream intersection; forecasting an ideal traveling time for driving between the upstream intersection and the downstream intersection of each vehicle under the phase difference according to the passing time; confirming a target phase difference according to the adopted phase difference at the shortest average ideal traveling time of each vehicle; and adopting the target phase difference for respectively controlling the signals at the upstream intersection and the downstream intersection. Under the condition of unchanged permitting duration at the adjacent intersections, the effectiveness of the signal control can be promoted by only changing the phase difference, the passing efficiency is promoted and the technical problems of extensive control and poor control effect of the prior art can be solved.

Owner:TSINGHUA UNIV

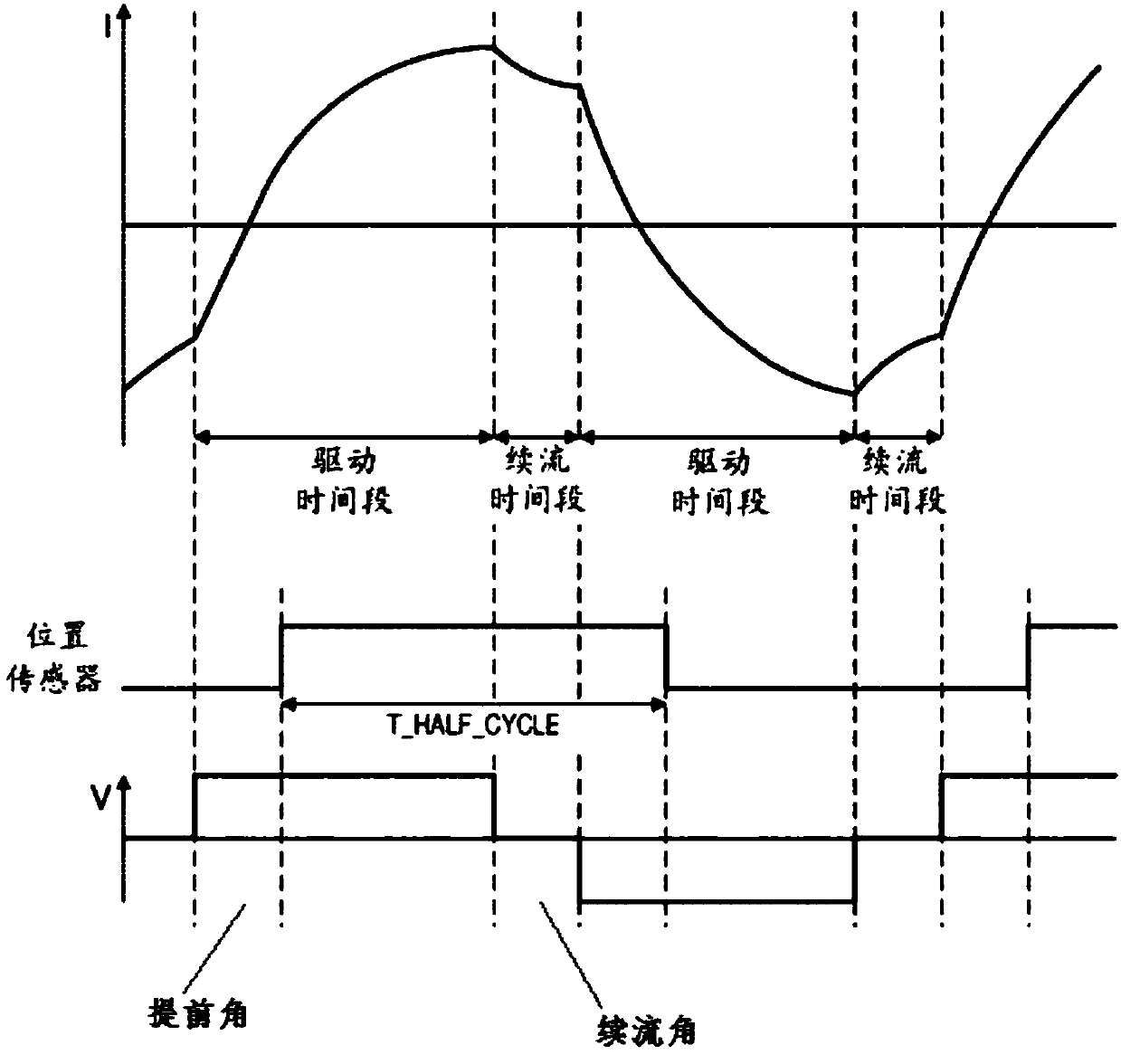

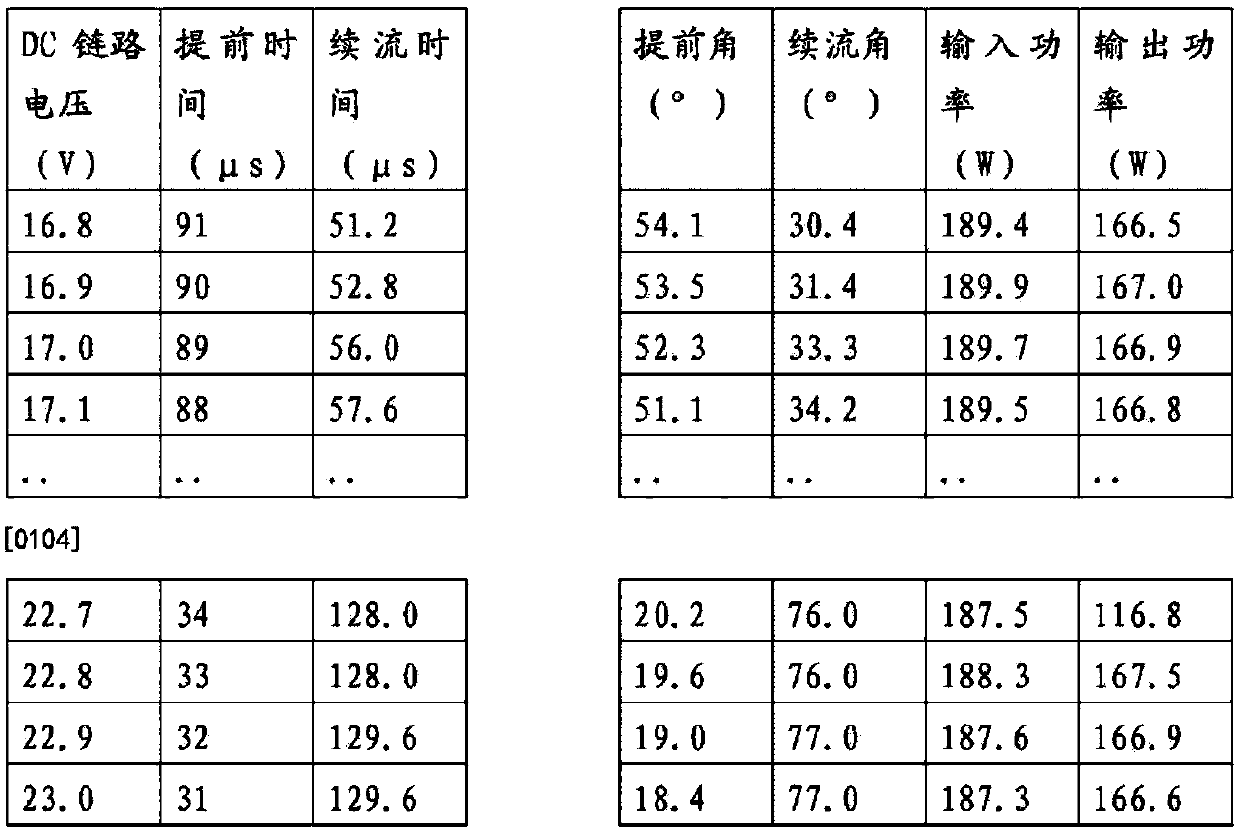

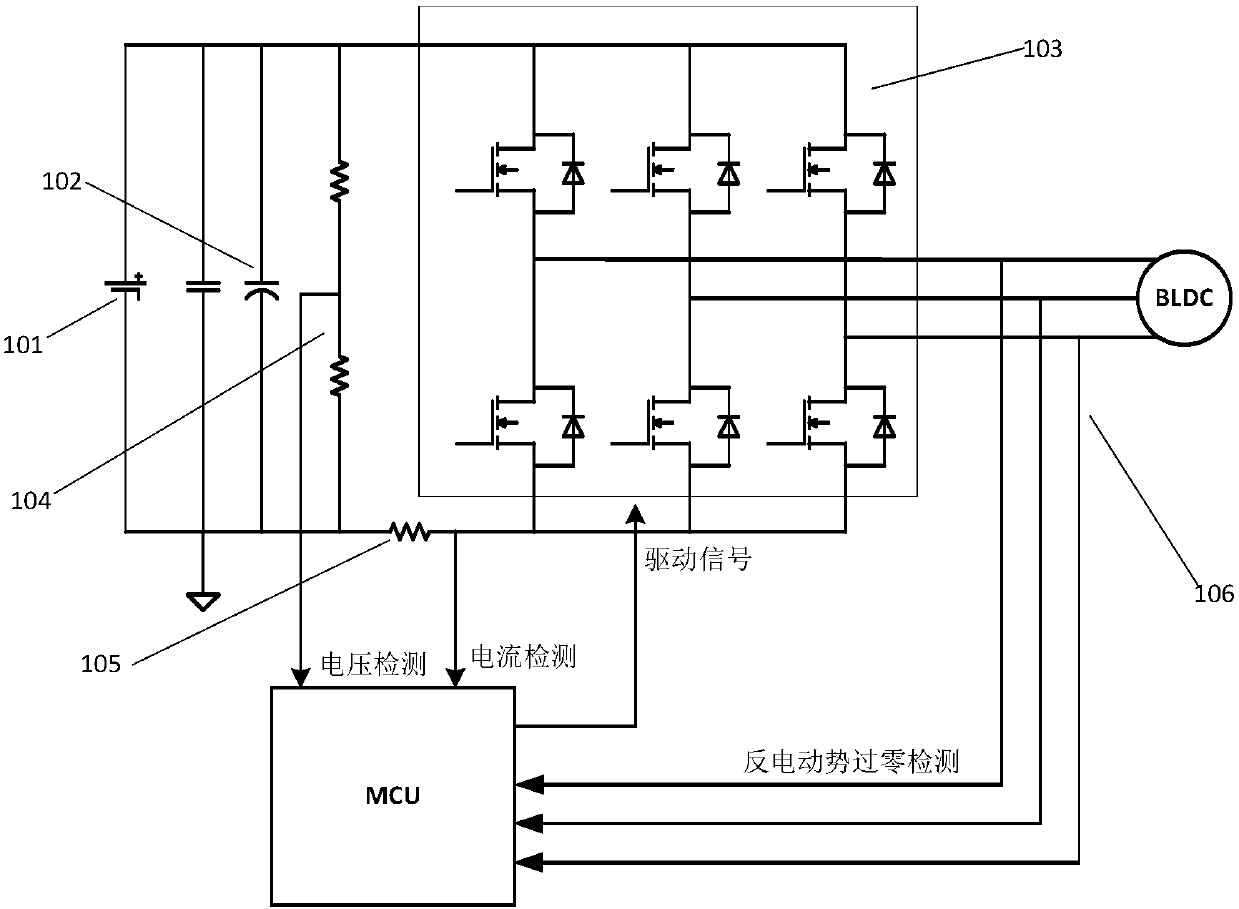

Dust collector, motor and constant power control method and apparatus

InactiveCN107612444ALow costImprove the problem of poor control effectElectronic commutation motor controlVector control systemsConstant powerEngineering

The invention discloses a dust collector, a motor and a constant power control method and apparatus. The constant power control method comprises the following steps: obtaining a direct current bus voltage and a direct current bus current of the motor; obtaining a direct current bus current given value of the motor according to the direct current bus voltage and a power given value of the motor; obtaining a current difference value between the direct current bus current given value and the direct current bus current; and performing PI adjustment on the current difference value so as to obtain aduty ratio signal for controlling the motor, and performing constant power control on the motor according to the duty ratio signal. According to the method, by performing PI control on the direct current bus current so as to implement the constant power control on the motor, not only is the hardware cost not increased, but a position sensor also does not need to be used and the effects of large-range power adjustment and continuous control can be implemented; and meanwhile, the problem of poor control effect due to influence of environmental factors in a production process can be effectivelyimproved, and the universality is strong.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com