Method of inhibiting olefin polymerization in alkaline washing column of methanol-to-olefin (MTO) device

A methanol-to-olefin and olefin polymerization technology, applied in the purification/separation of hydrocarbons, chemical instruments and methods, ethylene production, etc., can solve the problems of cumbersome operation, high cost, instability, etc., to extend the operation cycle and reduce environmental pollution , the effect of inhibiting the production of butter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

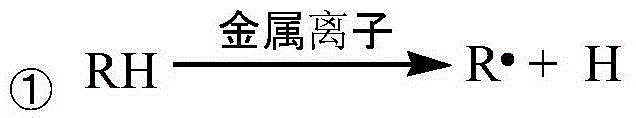

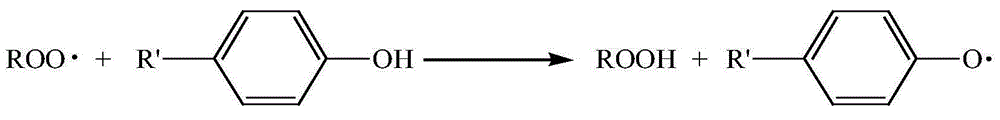

Problems solved by technology

Method used

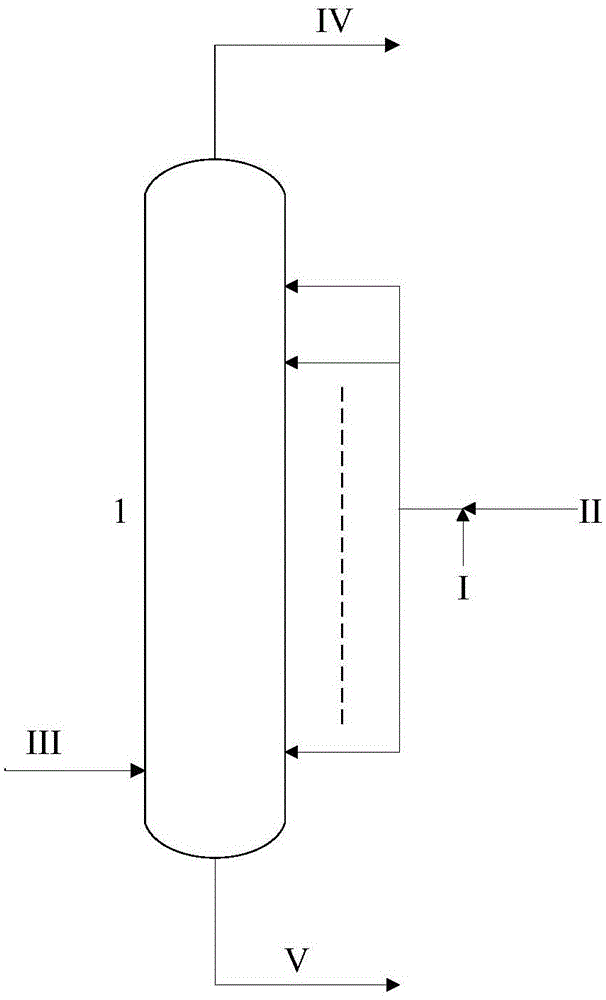

Image

Examples

Embodiment 1

[0031] Dissolve 45g of monosuccinimide in 260g of deionized water, stir well, then add 50g of hydroquinone, heat and stir evenly, then cool and filter, the filtrate is the olefin polymerization inhibitor, called ZJI-1.

[0032] The above-mentioned ZJI-1 polymerization inhibitor is applied to the simulated alkali washing tower of the methanol-to-olefins plant, and the feed composition of the alkali washing tower is 41.1% of ethylene, 40.2% of propylene, C 4 11.2%, Acetaldehyde 0.05%, Butanone 0.03%, C 5 + Hydrocarbons 5.58%, CO 2 0.02%, temperature 45°C, sodium hydroxide concentration 10%. Use a piston pump to continuously add the inhibitor into the circulating alkali liquor and then enter the alkali washing tower, the addition amount is 100ppm (relative to the alkali washing tower feed). After 30 days of continuous operation of the device, no tower blockage was found, and the weight of butter in the lye was calculated. And compared with the amount of butter produced when ...

Embodiment 2

[0037] Prepare the olefin polymerization inhibitor ZJI-1 according to the method of Example 1, change the addition amount of the olefin polymerization inhibitor to 300ppm, and evaluate its inhibitory effect on butter production according to the method of Example 1, see Table 1 for details.

Embodiment 3

[0039] Prepare the olefin polymerization inhibitor ZJI-1 according to the method of Example 1, change the addition amount of the olefin polymerization inhibitor to 600ppm, and evaluate its inhibitory effect on butter production according to the method of Example 1, see Table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com