Patents

Literature

428 results about "Continuous injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

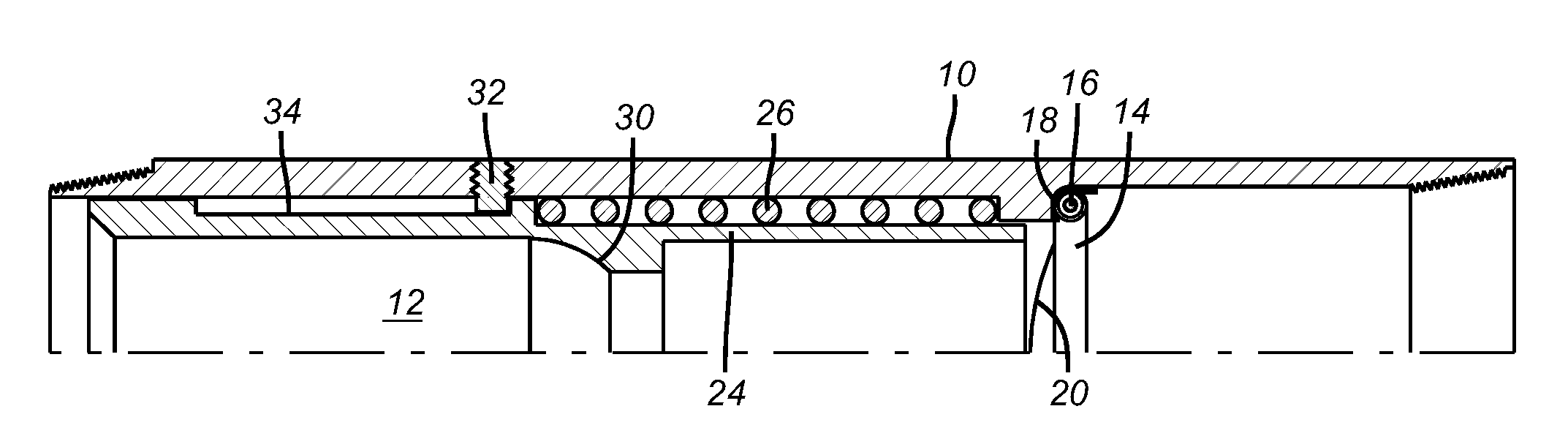

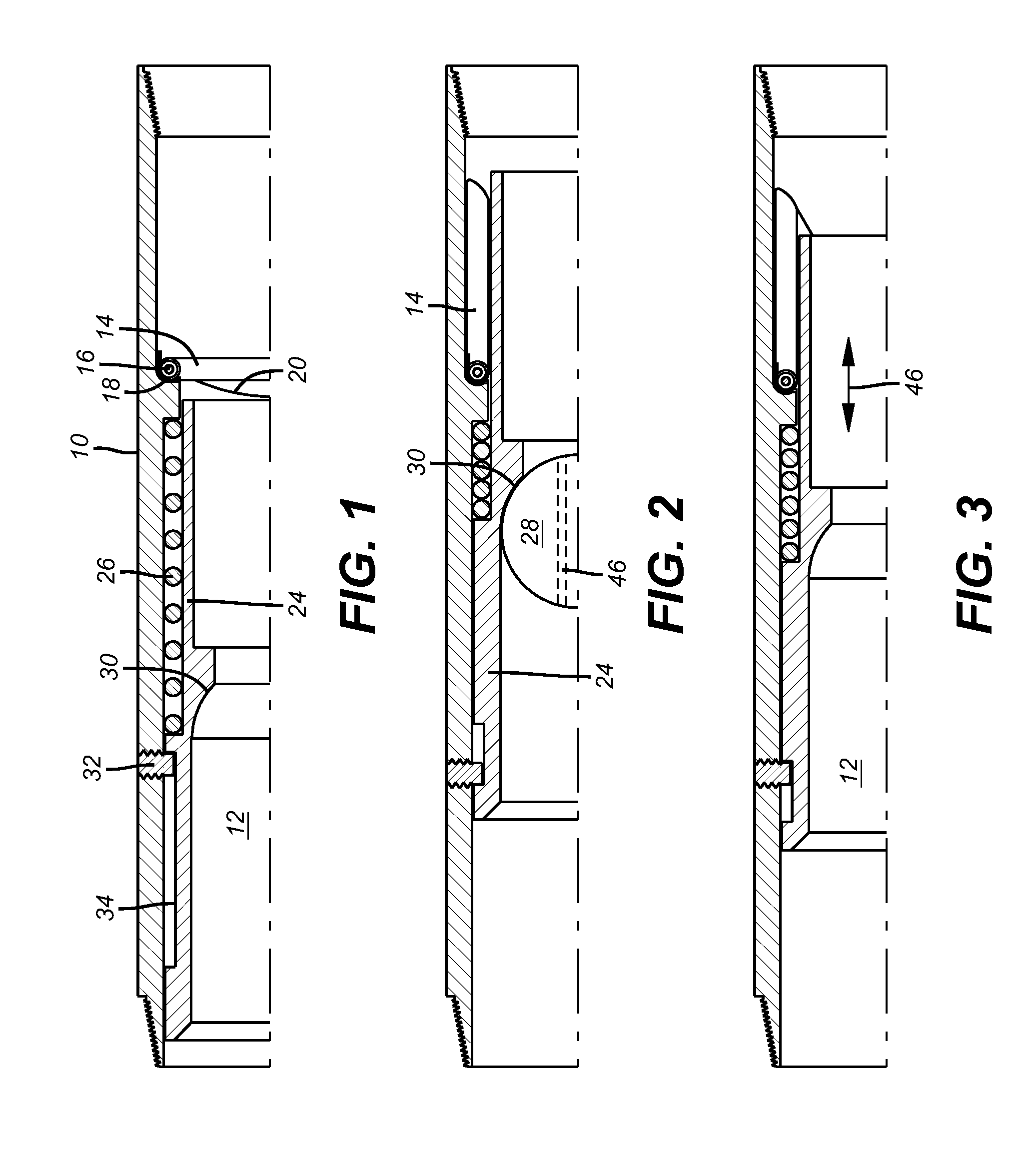

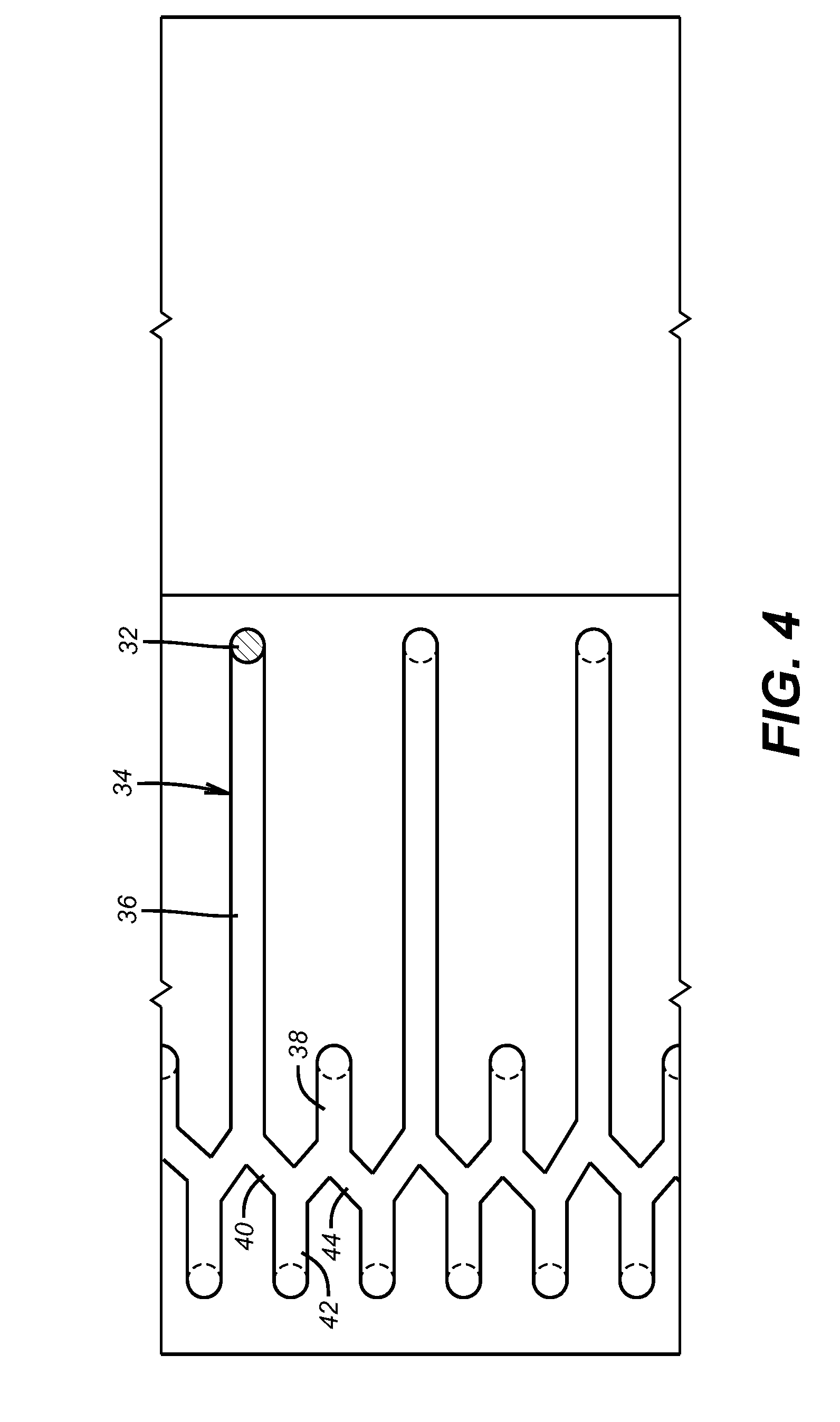

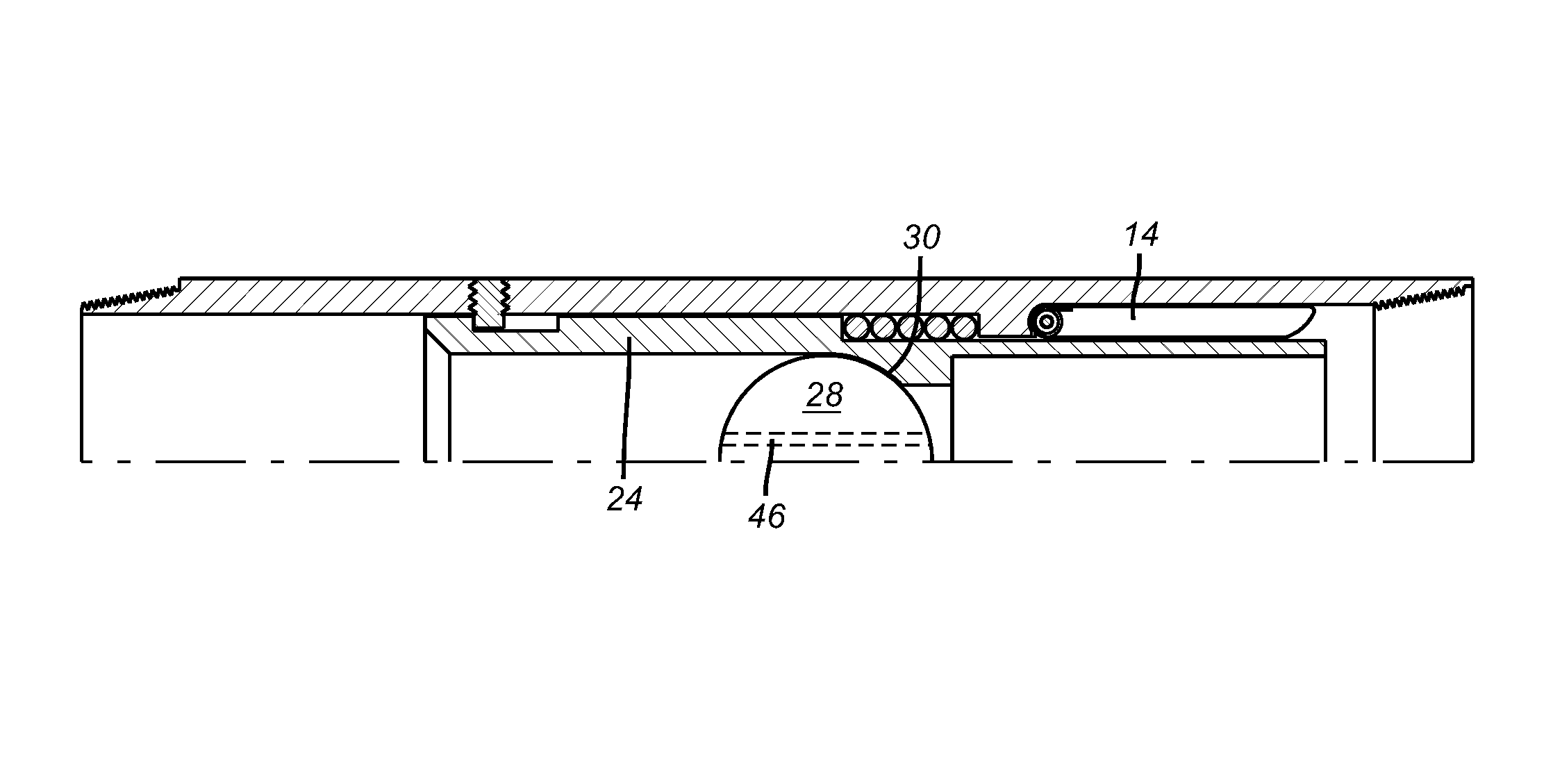

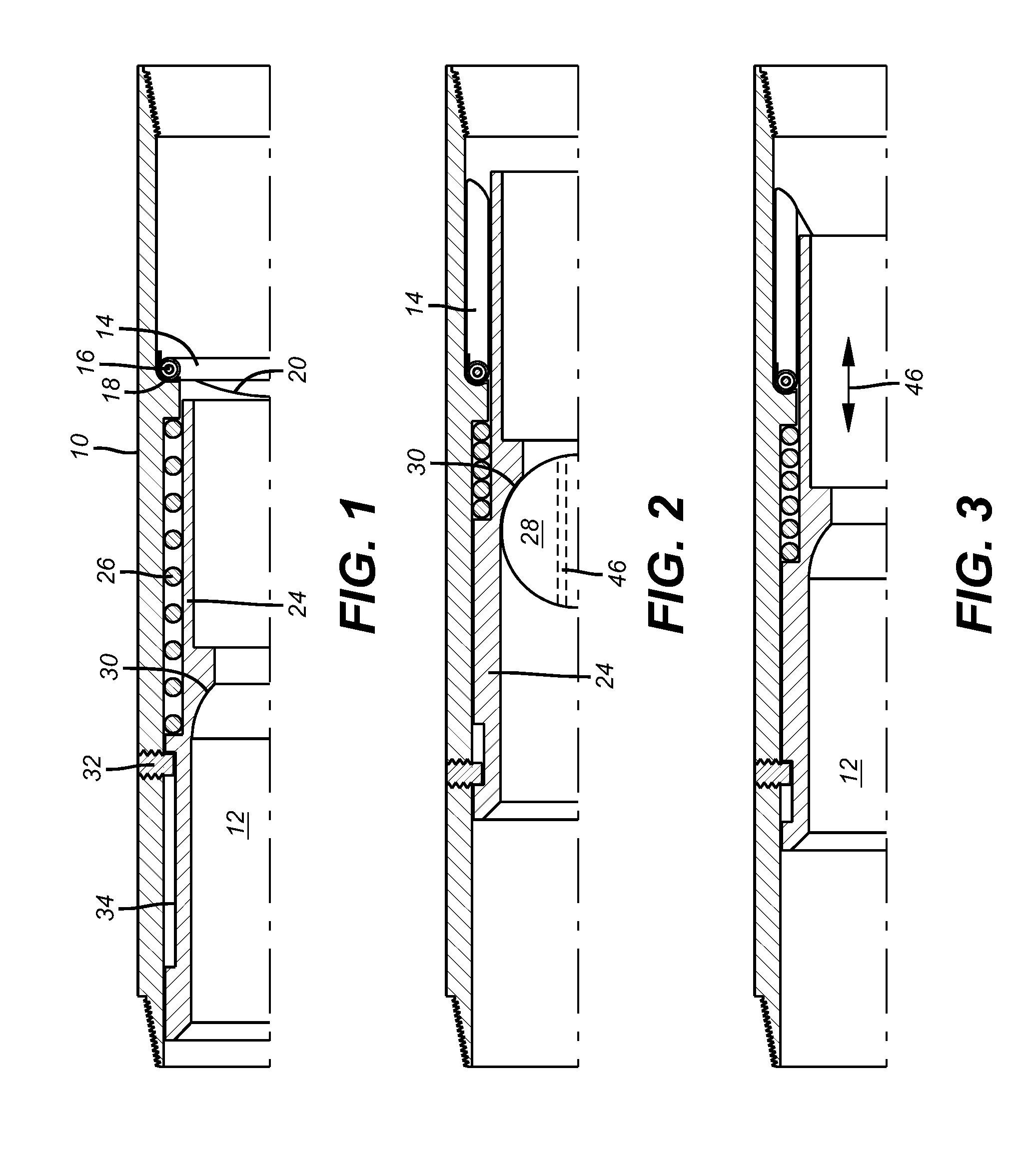

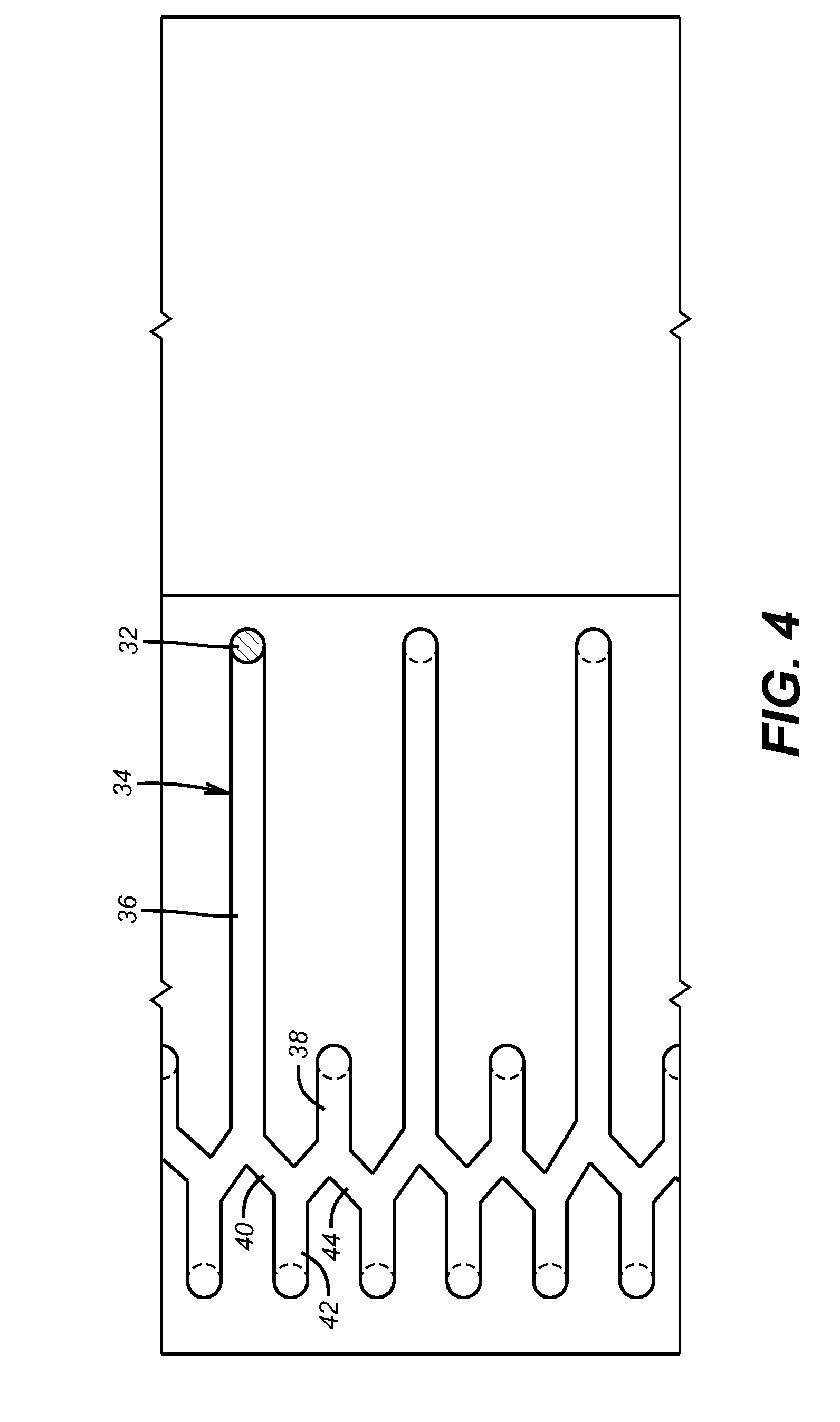

Injection Valve with Indexing Mechanism

A flapper valve preferably used in injection application in deep subterranean locations has an actuating sleeve with a seat to accept an object. A j-slot connects the actuation sleeve movement to the housing so that with an object on the seat and an applied pressure cycle the sleeve moves the flapper to the open position. The plug is dissolved and the injection begins. The plug can have an opening so as to allow continuous injection flow as the flapper is operated. Closing the flapper involves a second object on the same seat and a pressure cycle so that a spring can push the sleeve away from the flapper to allow a torsion spring on the flapper to close it.

Owner:BAKER HUGHES INC

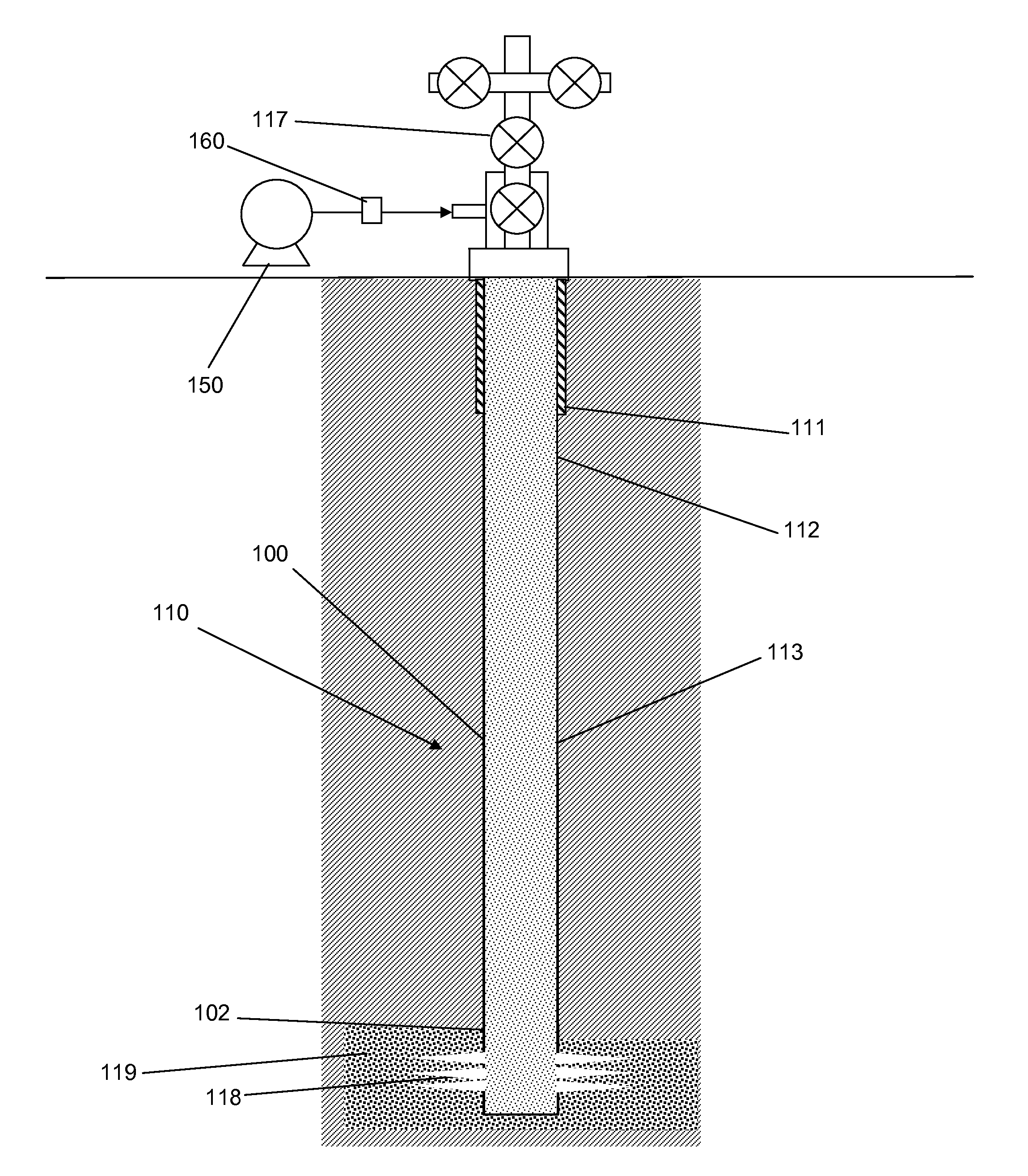

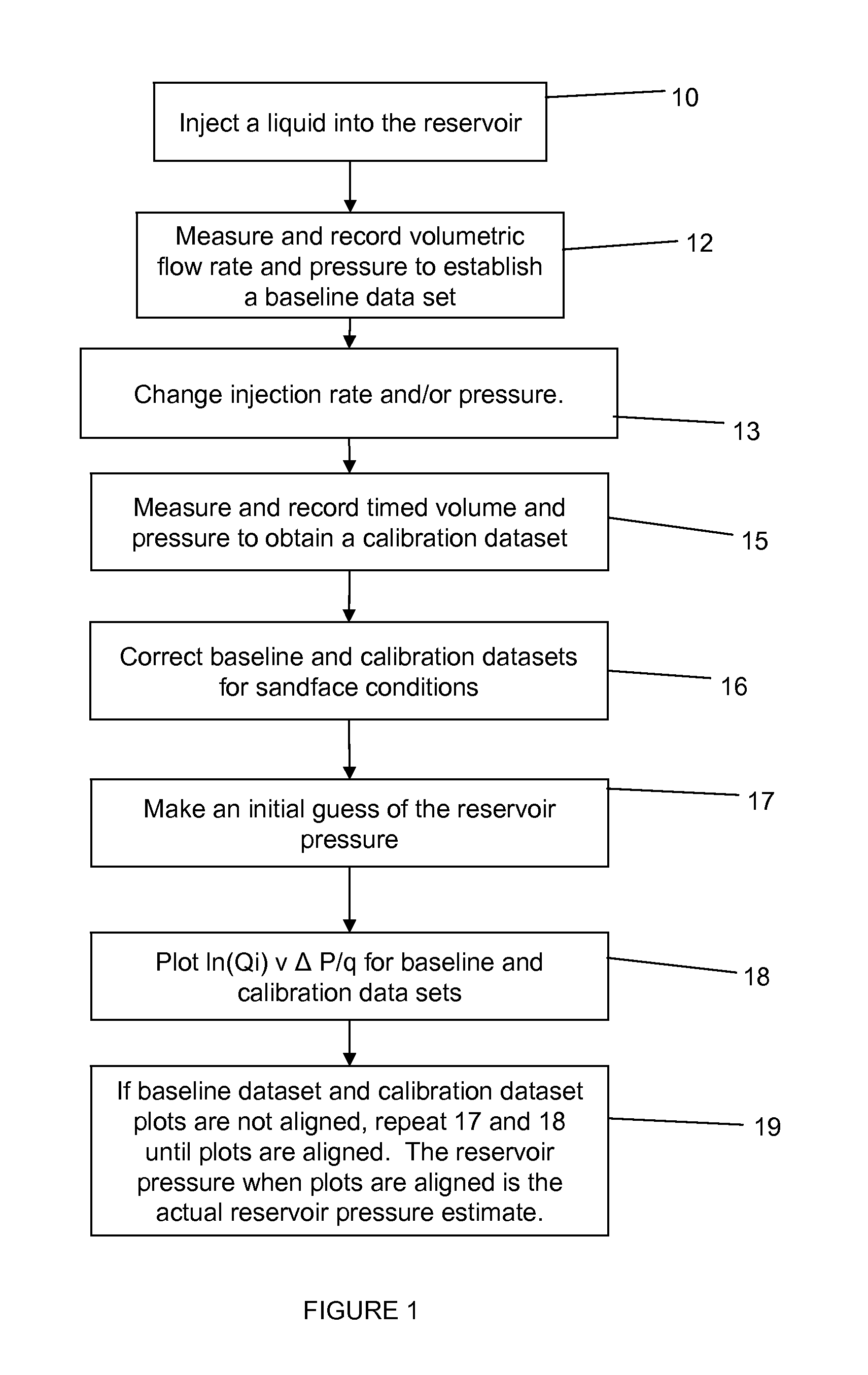

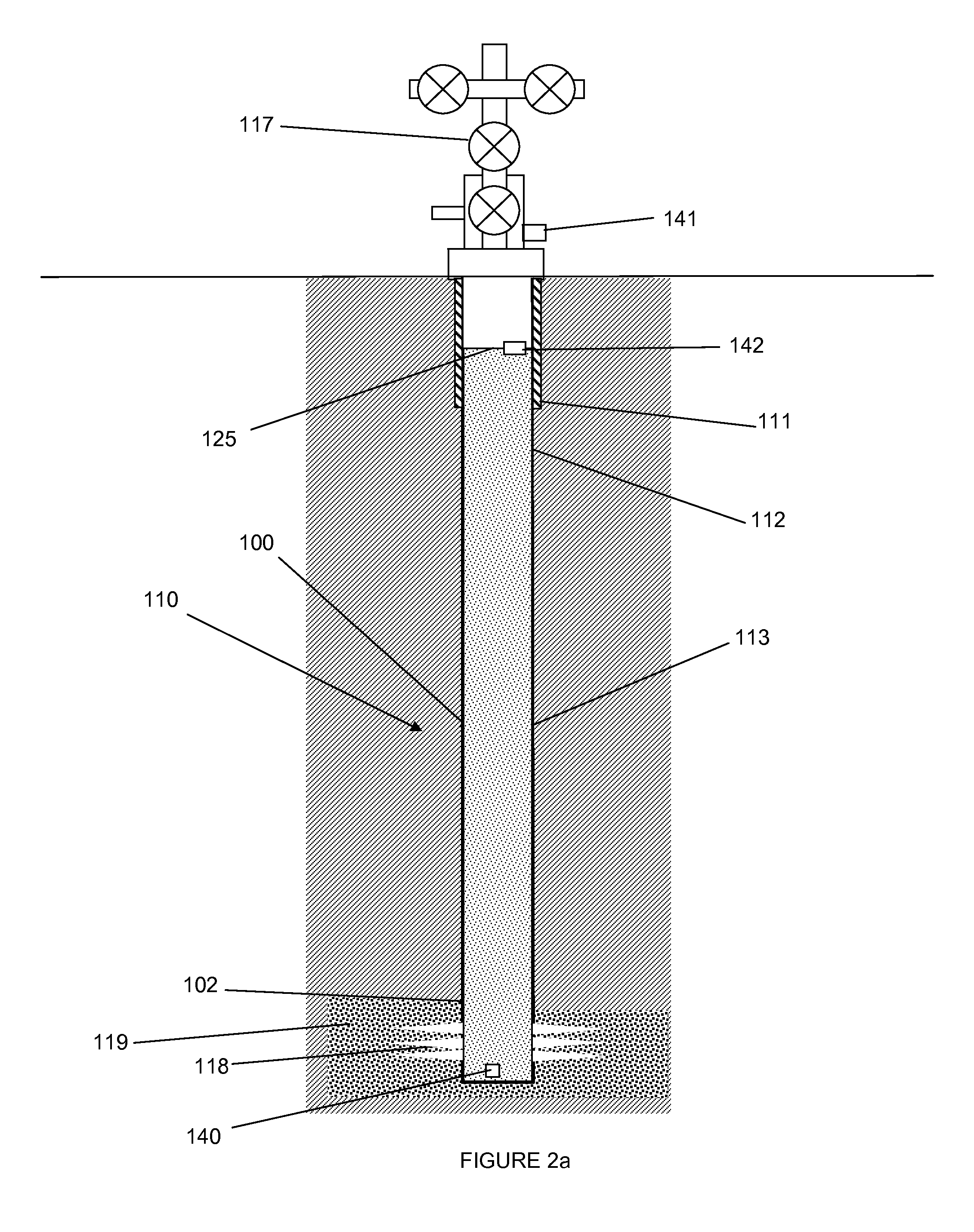

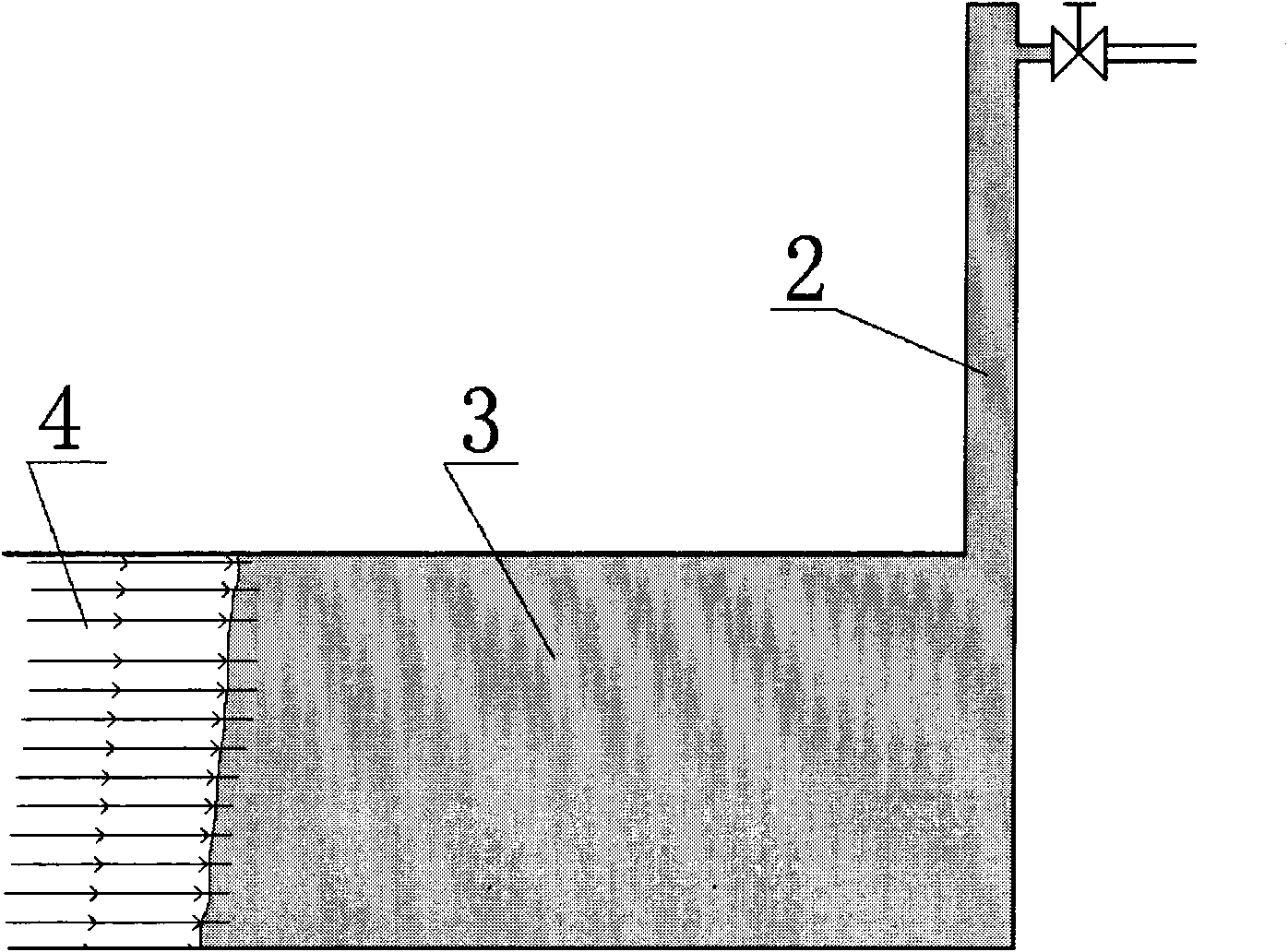

Method of determining reservoir pressure

ActiveUS20120158310A1Reduce penetrationElectric/magnetic detection for well-loggingSurveyBaseline dataInjection pressure

A new approach is disclosed for measuring the pressure of tight gas reservoirs, using information obtain from continuous injection prior to hydraulic fracture stimulation. The technique can be obtained utilizing either bottom-hole or surface pressure gauges and properly instrumented surface injection pumps. The analysis is completed by plotting injection and rate data in a specialized form from terms arranged in Darcy's radial flow equation to obtain a curve or trend. The key component to proper application of this technique is to obtain both baseline and one or more calibration data sets. These calibration data sets are obtained by either increasing or decreasing the injection pressure and / or rate from the baseline data. Initial reservoir pressure is assumed, but the calibration data indicates if the guess was too high or low. Accurate estimates of reservoir pressure may be obtained in a few iterations.

Owner:BP CORP NORTH AMERICA INC

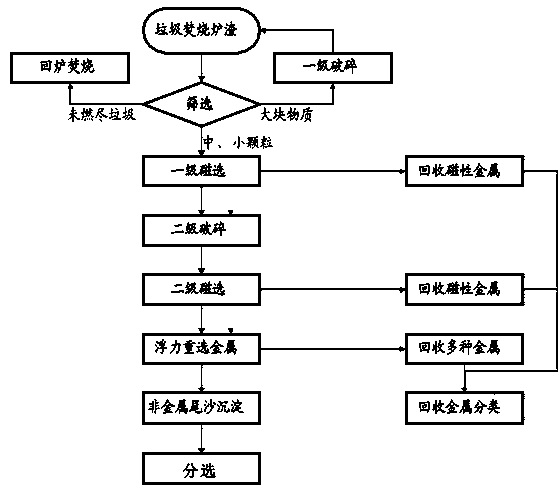

Method for comprehensively treating and utilizing household garbage incineration slag

The invention discloses a method for comprehensively treating and utilizing household garbage incineration slag.. The method comprises the following steps: A. screening and primary crushing of slag; B. primary magnetic separation; C. secondary crushing: the slag subjected to the primary magnetic separation is conveyed into a flushing water continuous injection type sanding machine through a conveying belt, the slag is crushed in the sanding machine, and the crushed slag granules flow out of the sanding machine together with the flushing water; D. secondary magnetic separation: the mixture of the slag and the flushing water flowing out of the outlet of the sanding machine flows by a drum magnetic iron remover, and magnetic metals contained in the slag are picked out by secondary magnetic separation; E. buoyancy gravity concentration on other metals; and F. precipitation of non-metallic tailings. Since other metals are picked up by secondary magnetic separation and buoyancy gravity concentration, the metal content in the slag is effectively decreased, the quality of bricks or cement is guaranteed when the treated slag is used to make bricks or cement; and since the flushing water is continuously injected into the sanding machine, most of disgusting odor can be removed and dust is eliminated, and the water circulation manner is adopted, the advantages of saving energy and protecting the environment are achieved.

Owner:山东环兴再生资源科技有限公司

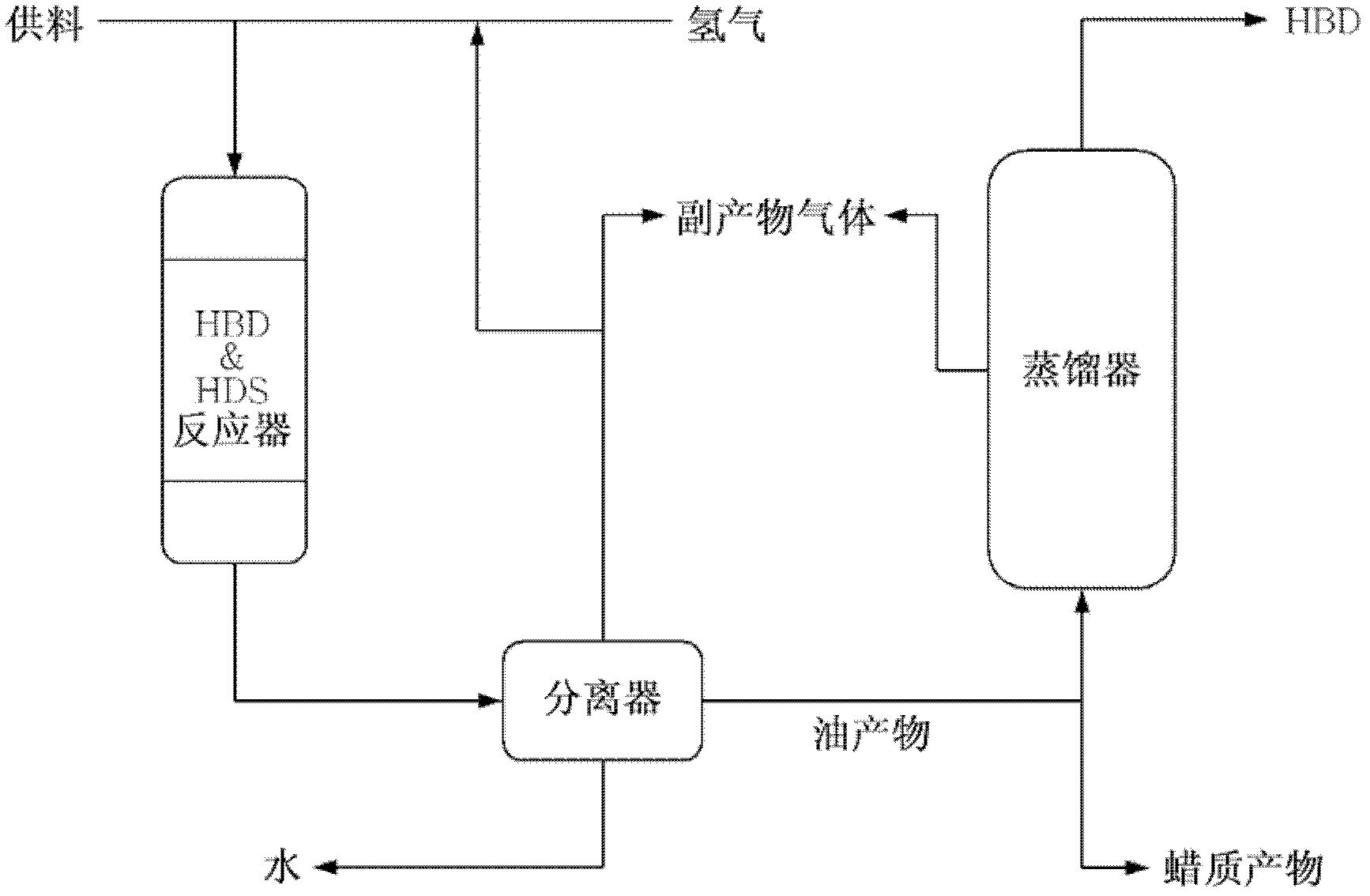

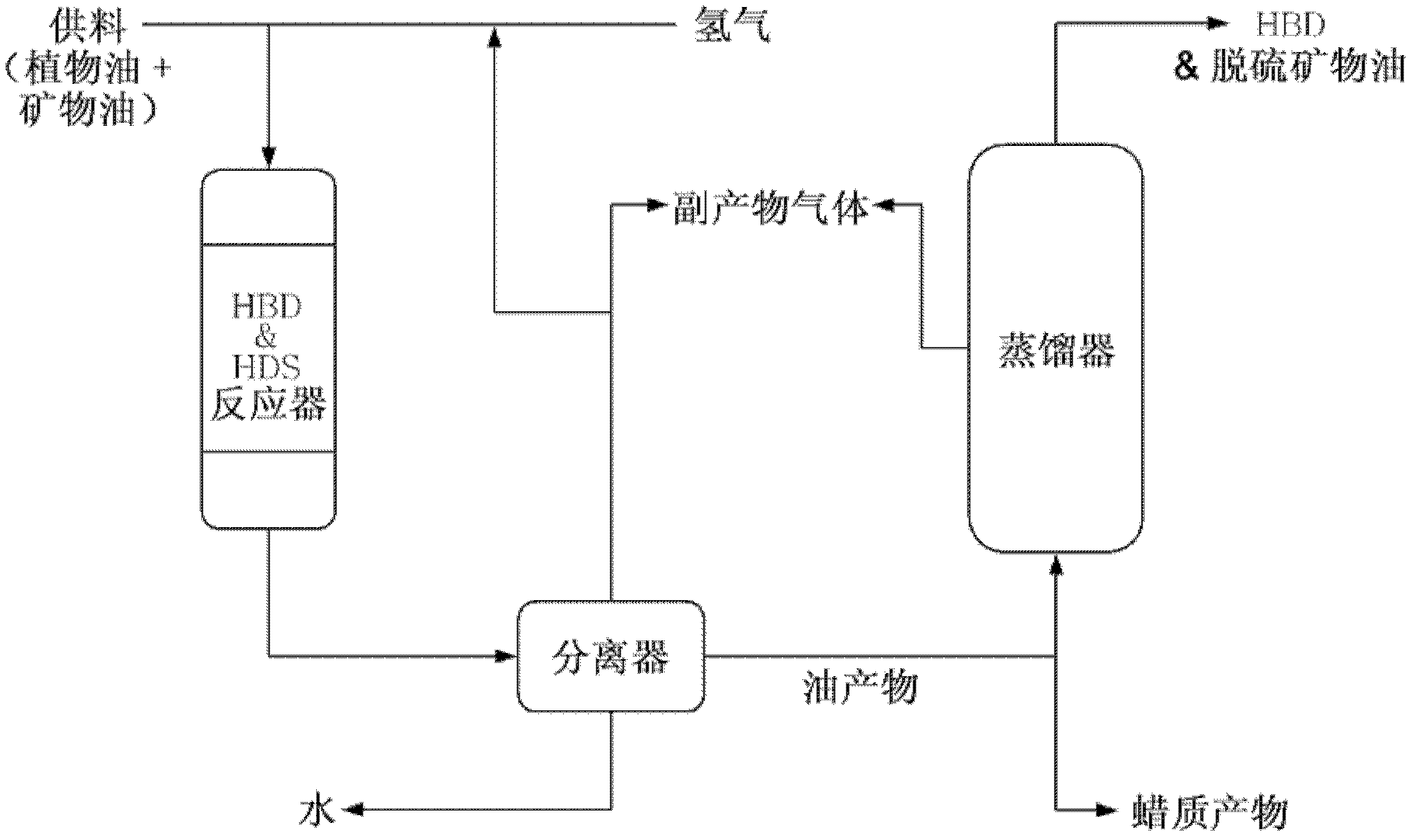

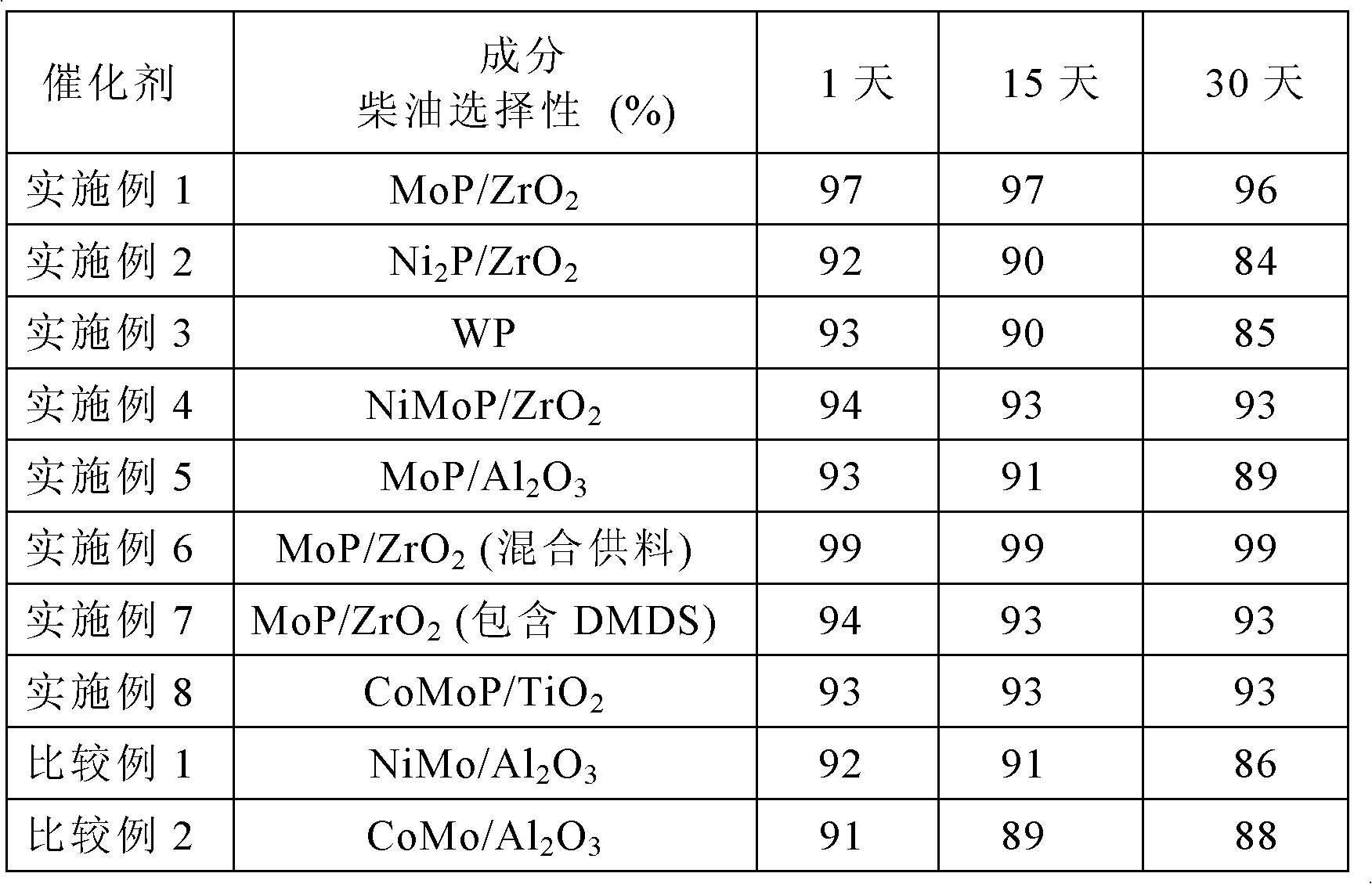

Metal phosphorus compound for preparing biodiesel and method for preparing biodiesel using the same

ActiveCN102427880AIncreased hydrotreating activityHigh activityPhysical/chemical process catalystsBiofuelsVegetable oilIsomerization

The present invention relates to a catalyst for preparing biodiesel, and a method for preparing biodiesel using the same. More specifically, the present invention relates to a catalyst for preparing biodiesel, which prepares biodiesel from a feed containing vegetable oil using a catalyst containing a metal phosphorus compound. The catalyst for preparing biodiesel according to the present invention uses a metal phosphorus compound, thereby enhancing preparation activity of HBD even without continuous injection of sulfides, and enabling production of high quality HBD with a low pour point due to the simultaneous procession of hydrogenation and isomerization reactions.

Owner:SK INNOVATION CO LTD +1

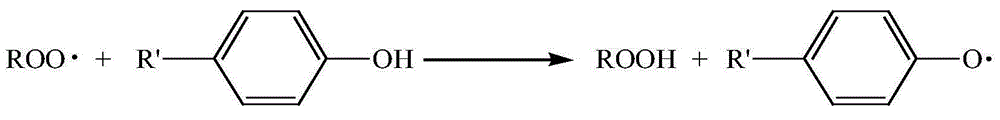

Method of rubbery polymer and rubber reinforced thermoplastics using the same

ActiveCN102311527AExcellent polymerization productivityImprove impact resistanceProduction rateThermoplastic

Disclosed is a method of manufacturing a rubbery polymer having an excellent impact resistance and heat stability, and a rubber reinforced thermoplastic resin composition using the same, in which for the method of manufacturing the rubbery polymer having an average particle diameter of 2500 to 4000 AA, a gel content of 70 to 90 %, and a glass transition temperature up to 0 DEG C, 5 to 70 parts by weight of monomers are injected in one time and 30 to 95 parts by weight of the monomers are added by continuous injection, based on 100 parts by weight of total monomer that is injected for manufacturing the rubbery polymer. Therefore, using the method of the present invention easily performs the control of the particle diameter and the distribution the heat of polymerization. In addition, the polymerization productivity and the production stability of the rubbery resin can be improved and also the impact resistance and the processing heat stability of the rubber reinforced thermoplastic resin composition using the same can be largely improved.

Owner:LG CHEM LTD

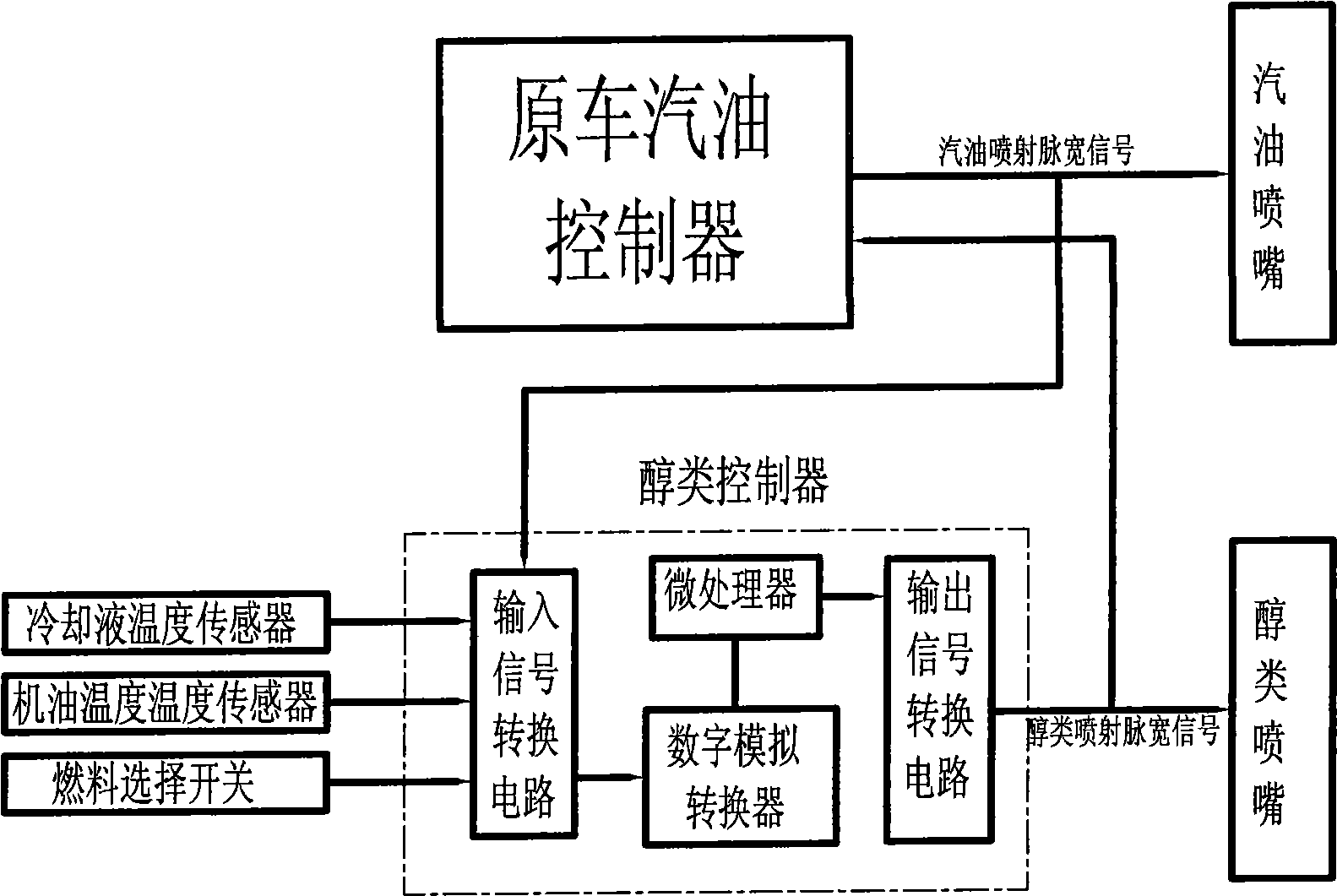

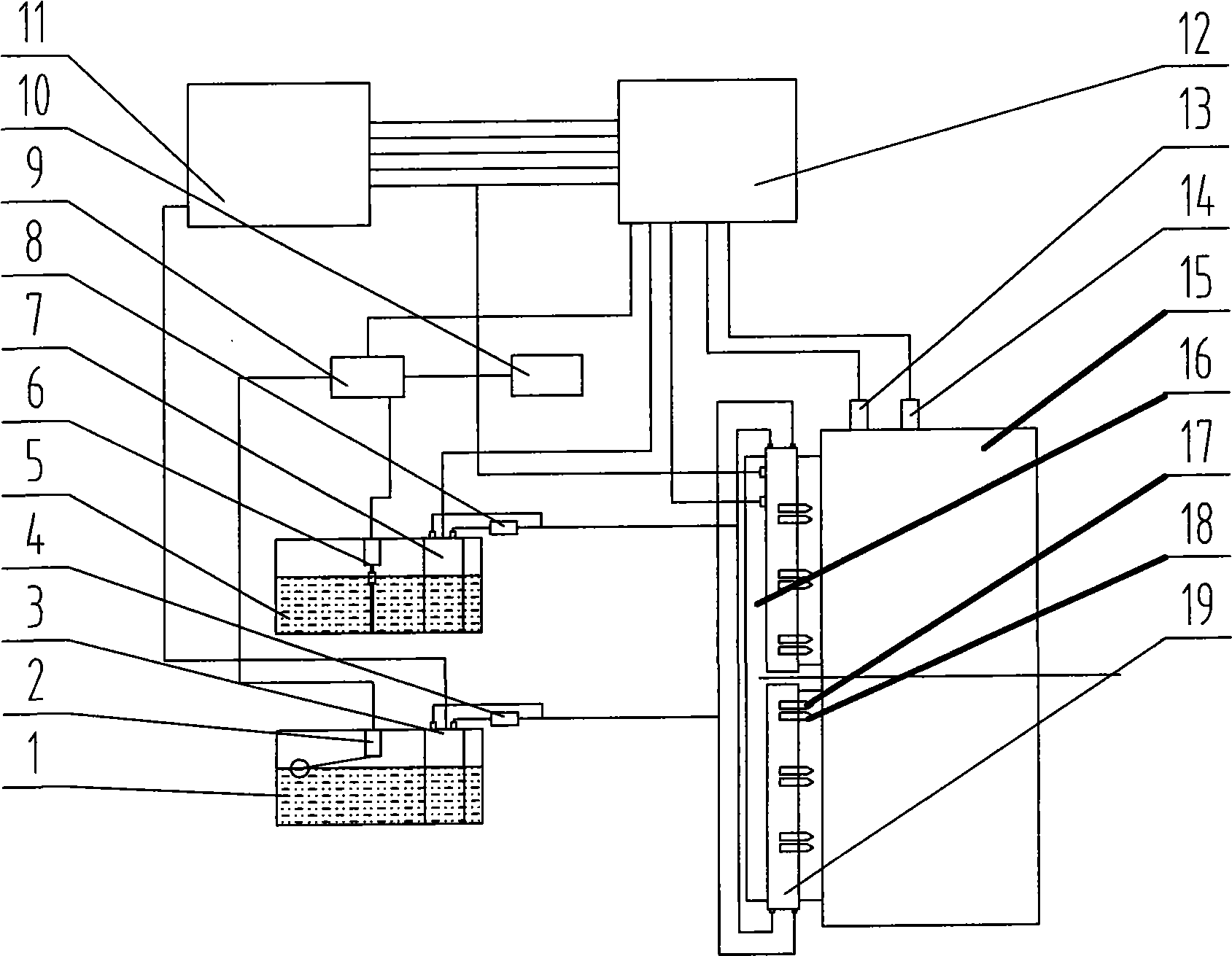

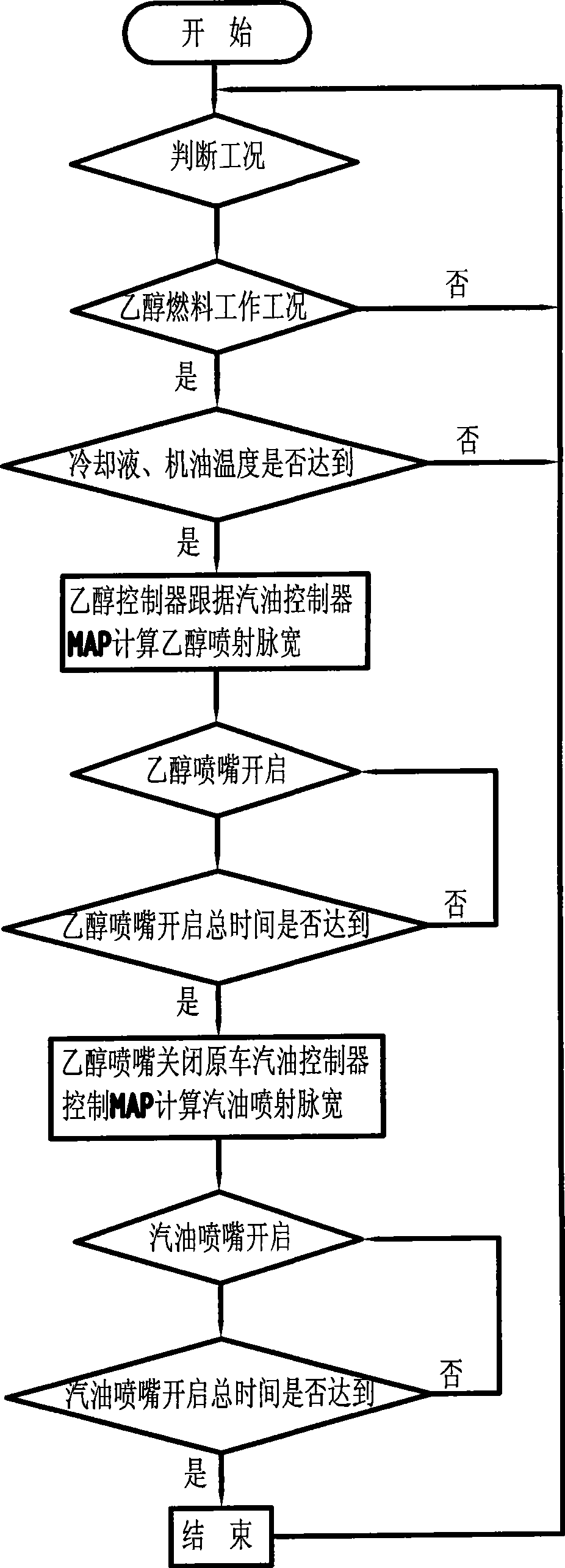

Control method and apparatus for gasohol flexible fuel engine

InactiveCN101503979ASolve insolubleImprove consumption structureElectrical controlInternal combustion piston enginesLiquid temperatureAlcohol

The invention discloses a method and a device for controlling a gasoline alcohol flexible fuel engine, wherein the method comprises supply and injection of gasoline and supply and injection of alcohols; the working mode comprises that the engine is started by using a mode of original vehicle gasoline and a gasoline nozzle injects gasoline to keep the engine working normally; when a select switch of the alcohol fuel is closed, an alcohol controller detects the cooling liquid temperature and the engine oil temperature of the engine: if the cooling liquid temperature and the engine oil temperature reach the evaporation point of the alcohols, the alcohol controller starts to receive an oil injection pulse sent by an gasoline controller and convert the oil injection pulse into the injection pulse width of the alcohol fuel; the alcohol controller converts the oil injection pulse into an alcohol injection pulse and controls an alcohol nozzle to work; the modes that the gasoline controller controls the gasoline injection and the alcohol controller controls the alcohol injection are switched in proportion and are performed alternately; and after the alcohol nozzle finishes 8 to 10 seconds of working cycle of the engine through continuous injection, the gasoline nozzle finishes 1 to 2 seconds of working cycle through injection, and the operations are repeated alternately.

Owner:DONGFENG MOTOR CORP HUBEI

Method for increasing production by compounding microorganism and biologically active agent

ActiveCN101839126AEffectively remove fouling and cloggingRemove fouling and cloggingFluid removalMicroorganismCompound a

The invention discloses a method for increasing production by compounding a microorganism and a biologically active agent, which comprises the following steps of: injecting prepared aqueous solution of a microorganism blockage-removing oil-displacing bacterial agent and aqueous solution of the biologically active agent into an oil layer in a continuous injection mode or a compounding mode in a ratio of 1:1 or 1:2; and closing a well for 7 to 15 days and then exploiting the well. In the method, the microorganism and the biologically active agent are matched with each other, so that the aim of effect superposition is fulfilled and the petroleum recovery ratio is enhanced.

Owner:SUNCOO PETROLEUM TECH

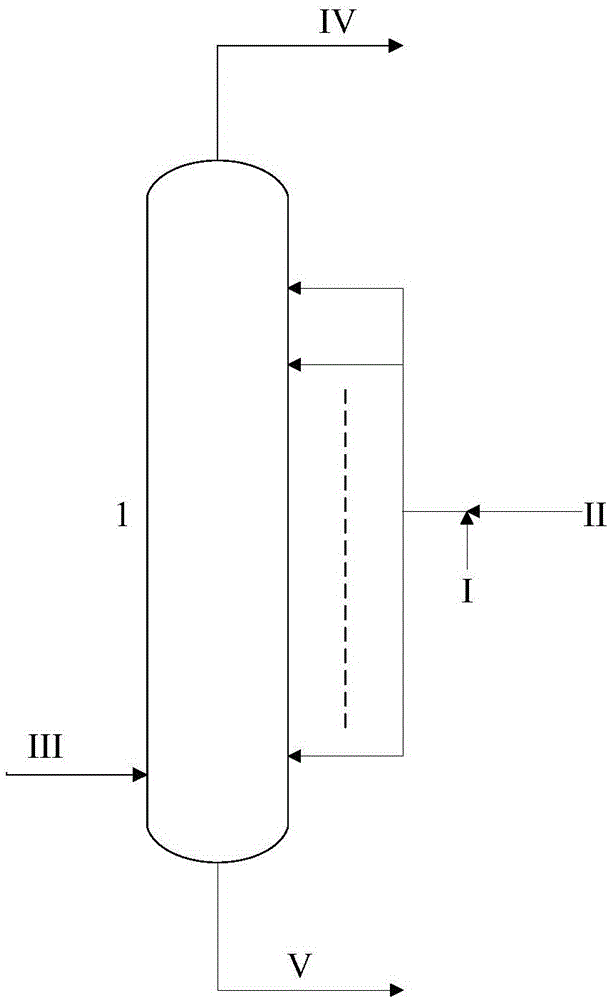

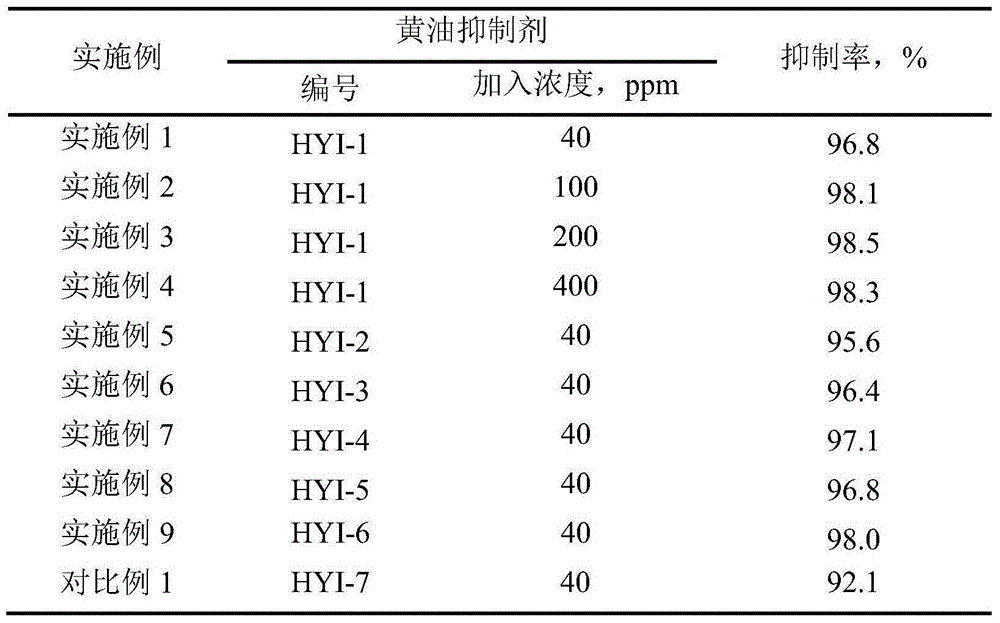

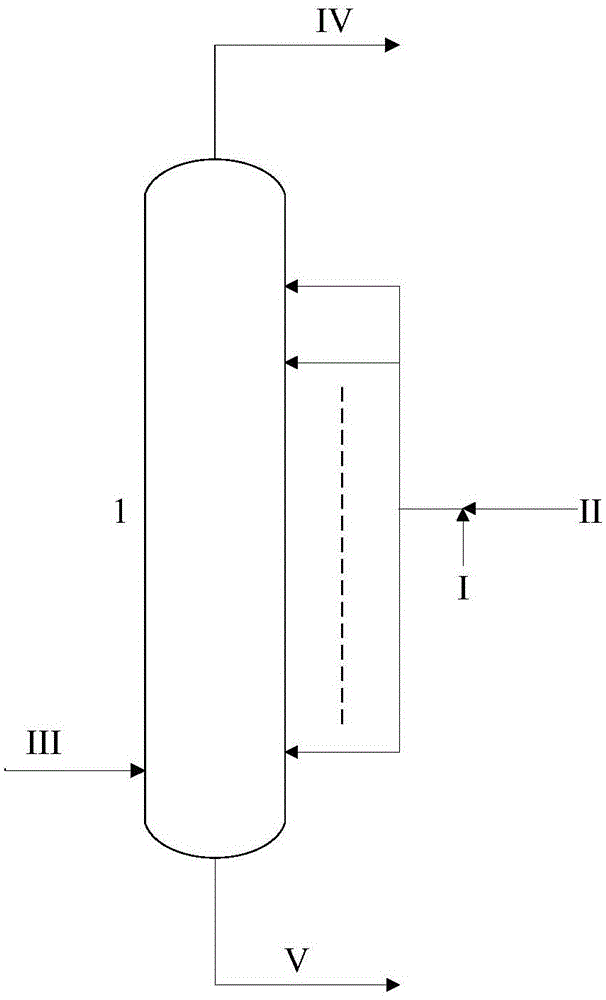

Method for inhibiting generation of grease

ActiveCN106467444ASuppress generationOrganic compounds purification/separation/stabilisationHydrocarbon purification/separationAlcoholInstability

The invention relates to a method for inhibiting generation of grease, which solves the technical problems of poor grease inhibition effect, tower blockage due to instability, tedious operation and high cost in the previous caustic wash towers. The method solves the problems by employing a following technical scheme: 1) a grease inhibitor (I) is employed by comprising the following components in parts by weight: 0.5-10 parts of aminated compounds and 0-5 parts of alcohols compounds; and b) the inhibitor (I) and alkali lye (II) are subjected to on-line continuous injection through an alkali lye injection line of the caustic wash tower into the caustic wash tower (1). The method can be used for inhibiting massive generation of grease in the industrial apparatus caustic wash tower such as petroleum ethylene, ethylene produced by ethanol, alkene produced by methanol, vinyl acetate, dichloroethylene and epoxypropane, as well as tower blockage.

Owner:CHINA PETROLEUM & CHEM CORP +1

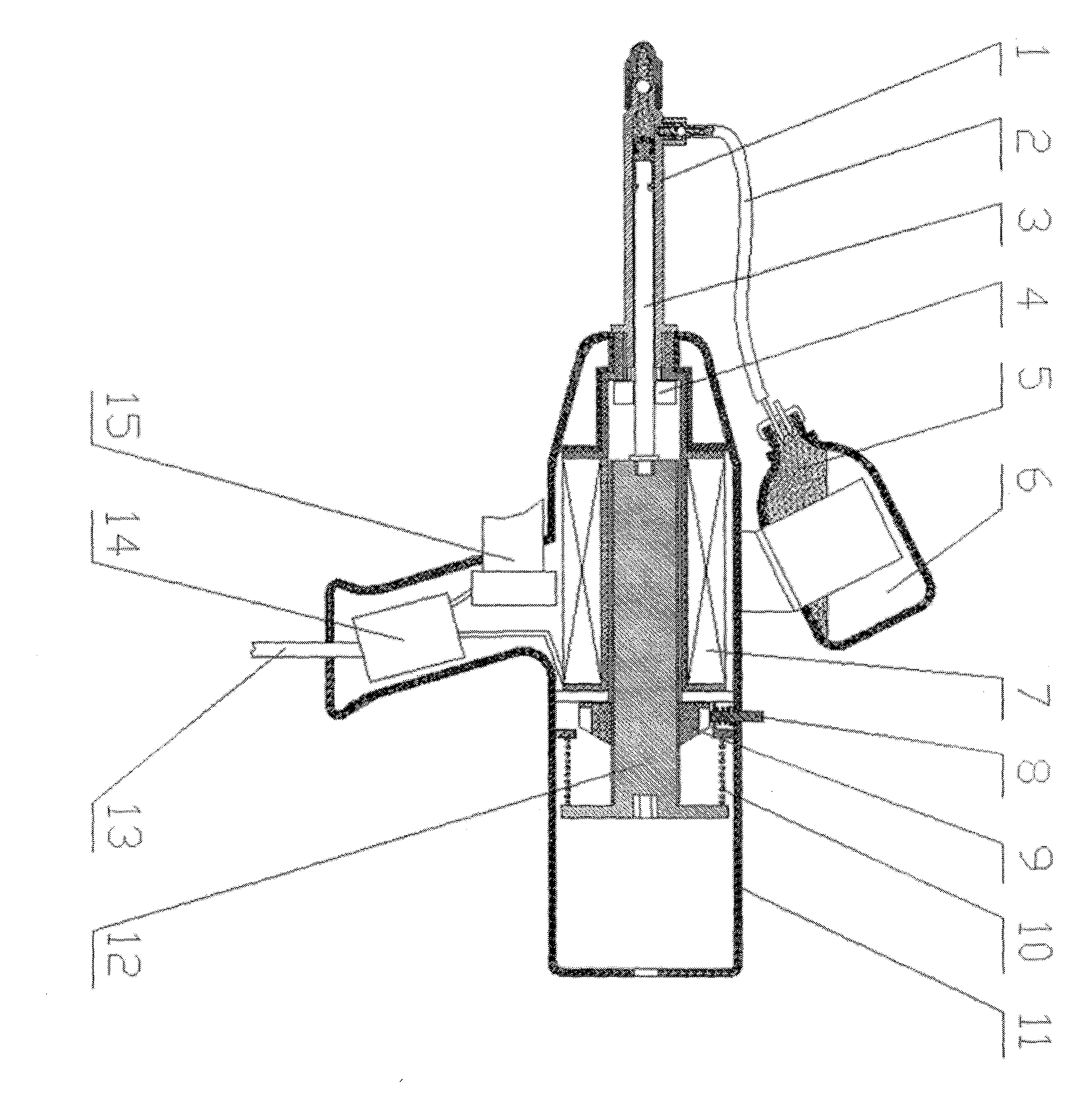

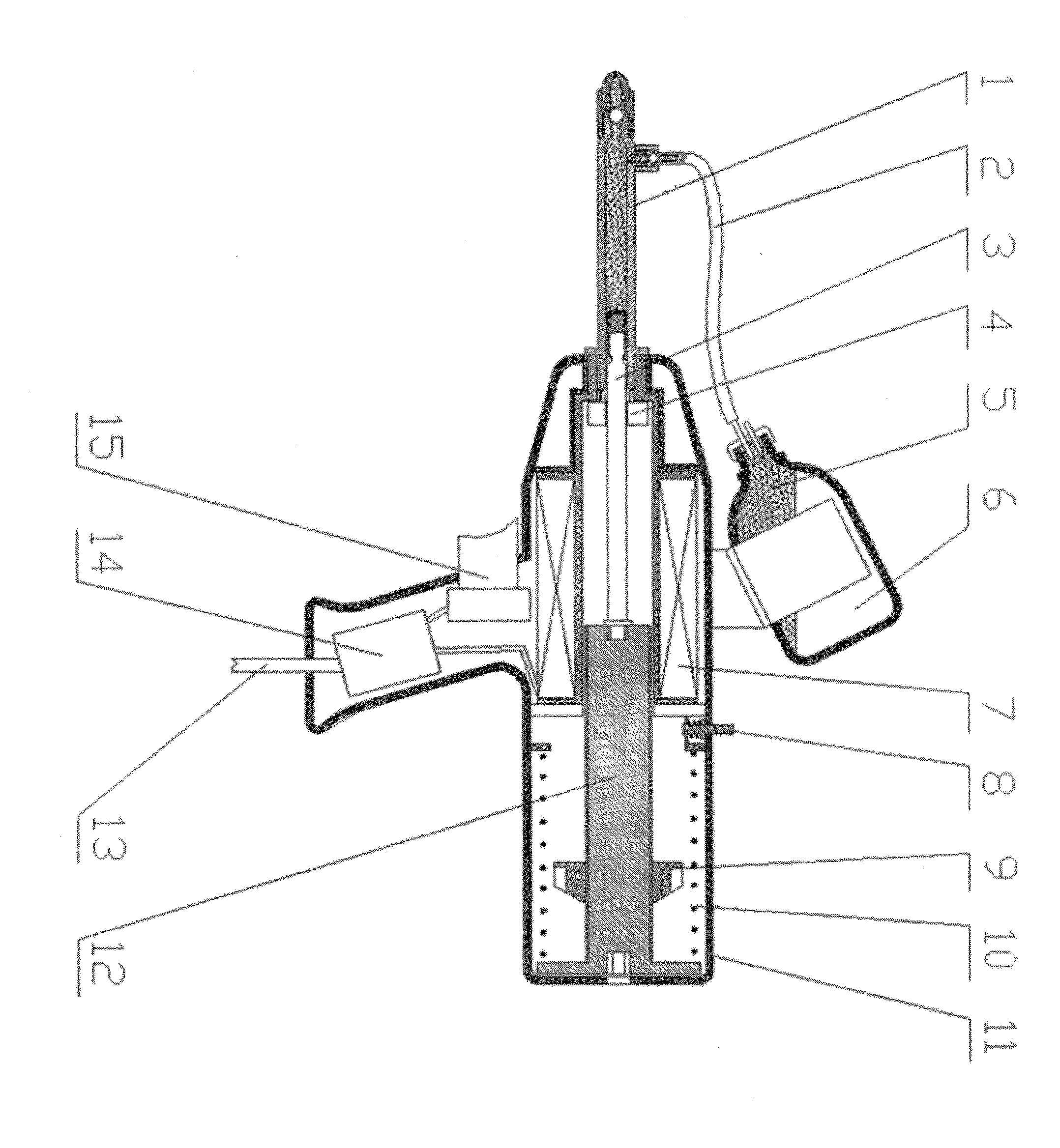

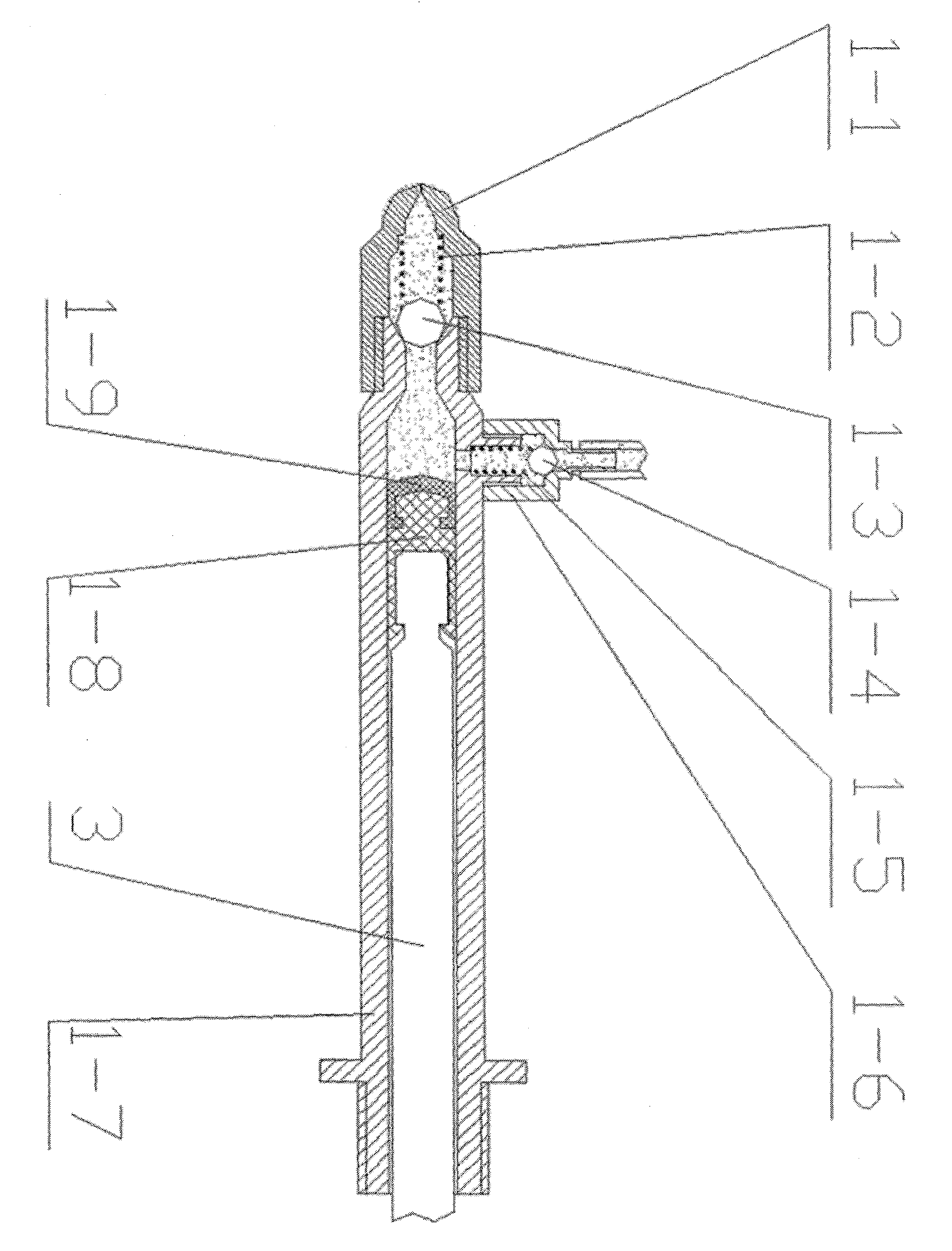

Injector without needle for animals

InactiveCN101428159AEasy to controlNo painJet injection syringesVeterinary instrumentsInjection pressurePipe fitting

The invention relates to a veterinary needleless injector comprising drug containing tube components, an injector and a high pressure air supply; the injector includes a magnetic thrust piston arranged inside a cavity on a housing; a pure iron locating part corresponding to the magnetic thrust piston is arranged in the cavity; a tail rod end protrudes out of the housing; the rod end of the magnetic thrust piston is movably connected with a piston rod of an injection piston inside an injection syringe arranged at the front end of the housing; an injection head is arranged at the front end of the injection syringe; a drug inlet port on one side is connected with the outlet port of the drug containing tube components through pipe fittings; a switch plug is arranged at one end of the inside of a through cavity at the lower part of the housing; the outer end is in contact with the side surface of a trigger; a hollow gas circuit movable switch plug corresponding to the switch plug is arranged on the other side in the cavity; and a spring is arranged at the tail end which is connected with the high pressure air supply through pipe fittings. The invention has the advantages of rapidity, high efficiency, no infliction of pain on animals, continuous injection, accurate control of dosage, controllable and adjustable injection pressure for livestock, effective prohibition against cross infection and good safety.

Owner:沈阳航天新光低温容器制造有限责任公司

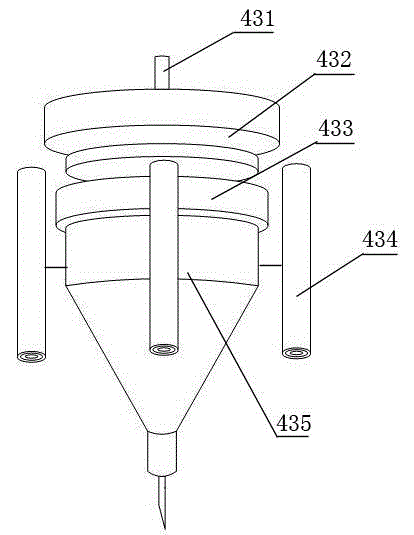

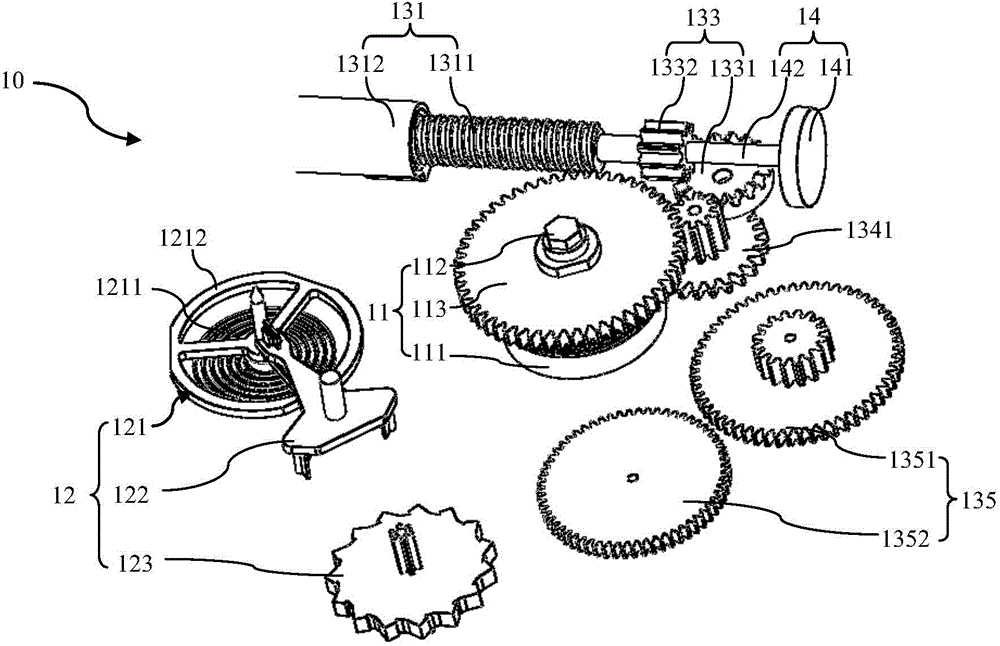

Electromagnetic continuous needleless injector with dose and injection depth adjusting faction

The invention provides an electromagnetic continuous needleless injector with a dose and injection depth adjusting faction. The injector mainly comprises the following parts: a drug tube, coils, an iron core, a dose adjusting device and an electronic control system, wherein the drug tube is used for carrying and injecting drugs. The injector depends on the electromagnetic coils and the iron core to provide driving forces, realizes continuous injection through working of two check valves, adjusts the injected dose by relatively rotating the iron core and a stop and adjusts the injection depth by adopting a switch arranged on a shell to adjust the voltage output by a control circuit. The injector has the advantages of small product volume, light weight, simple structure, large single injected dose and low production cost.

Owner:BEIJING QS MEDICAL TECH

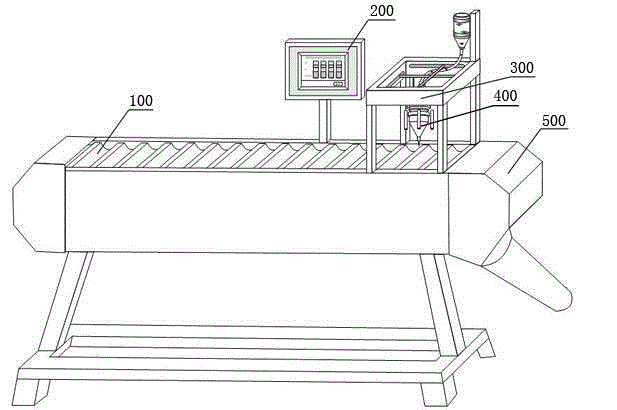

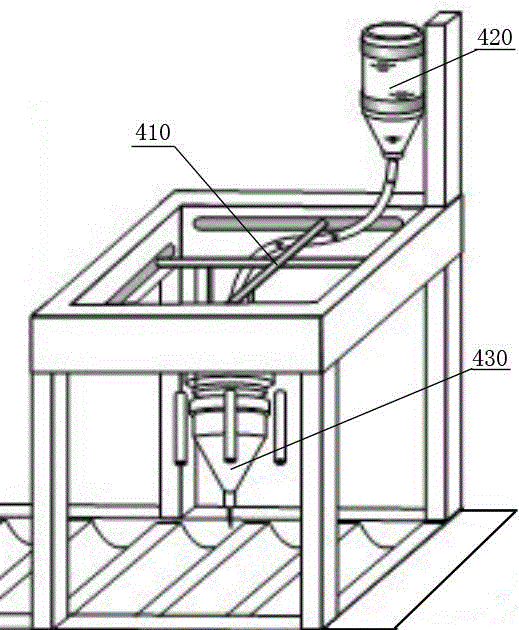

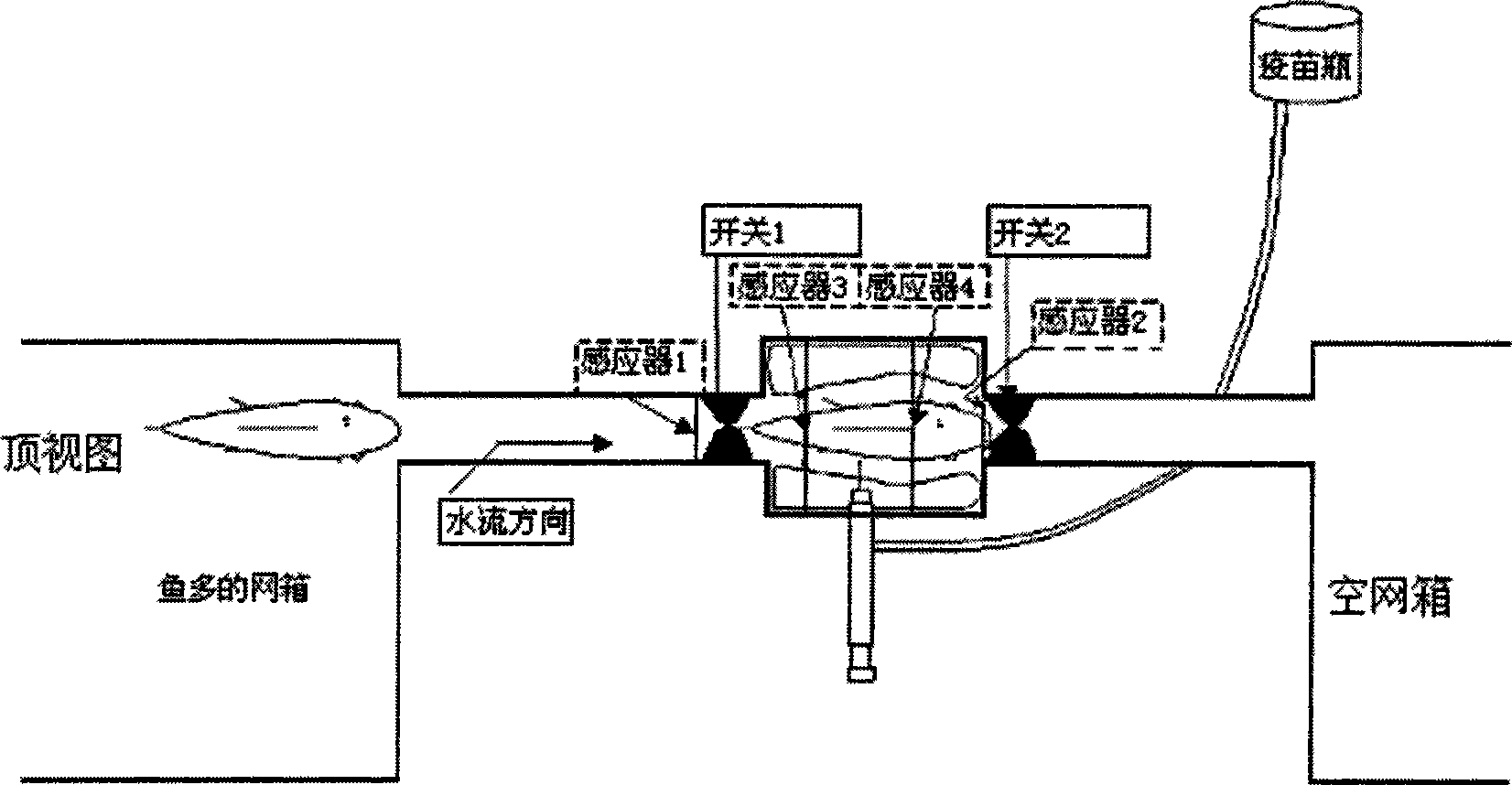

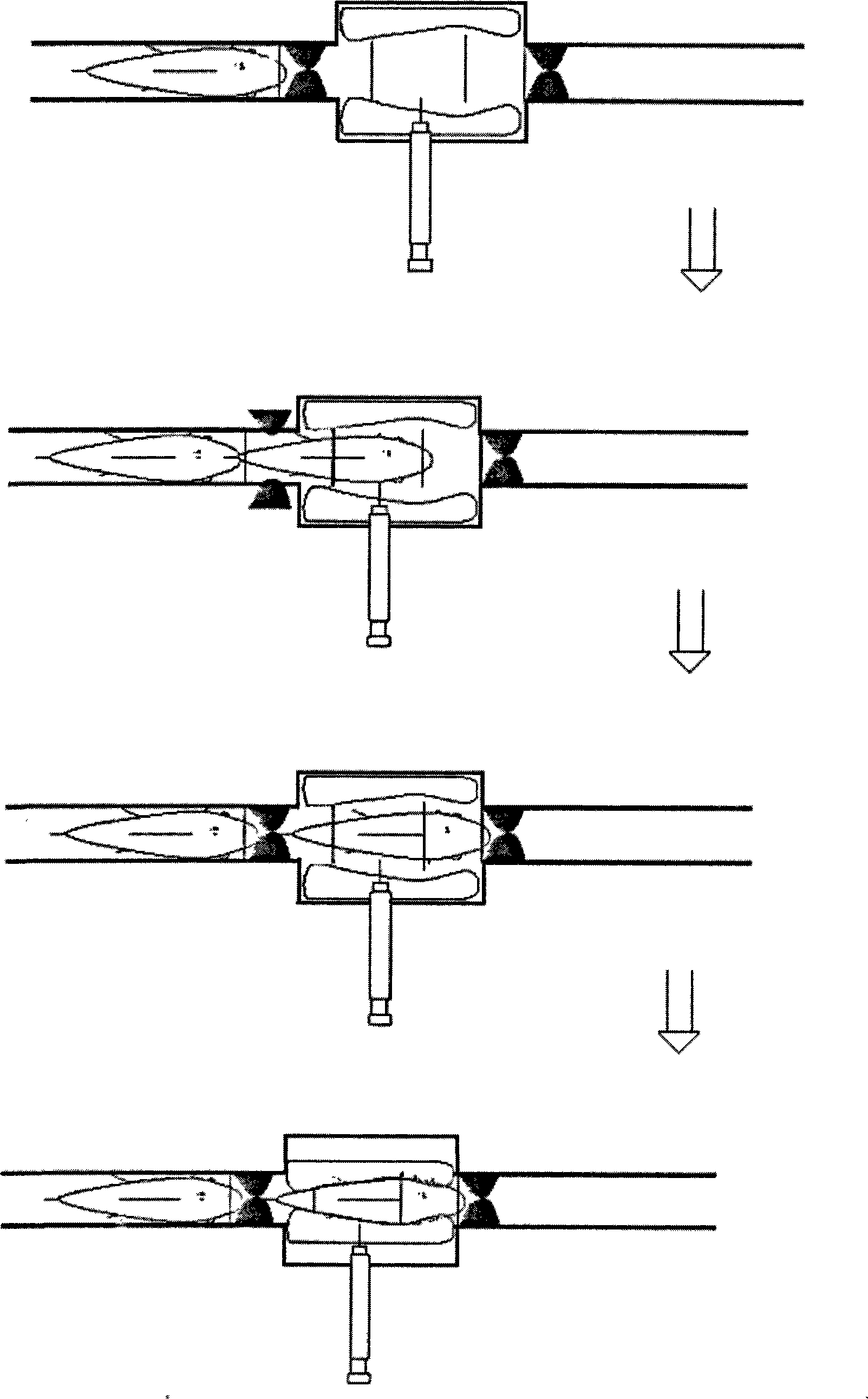

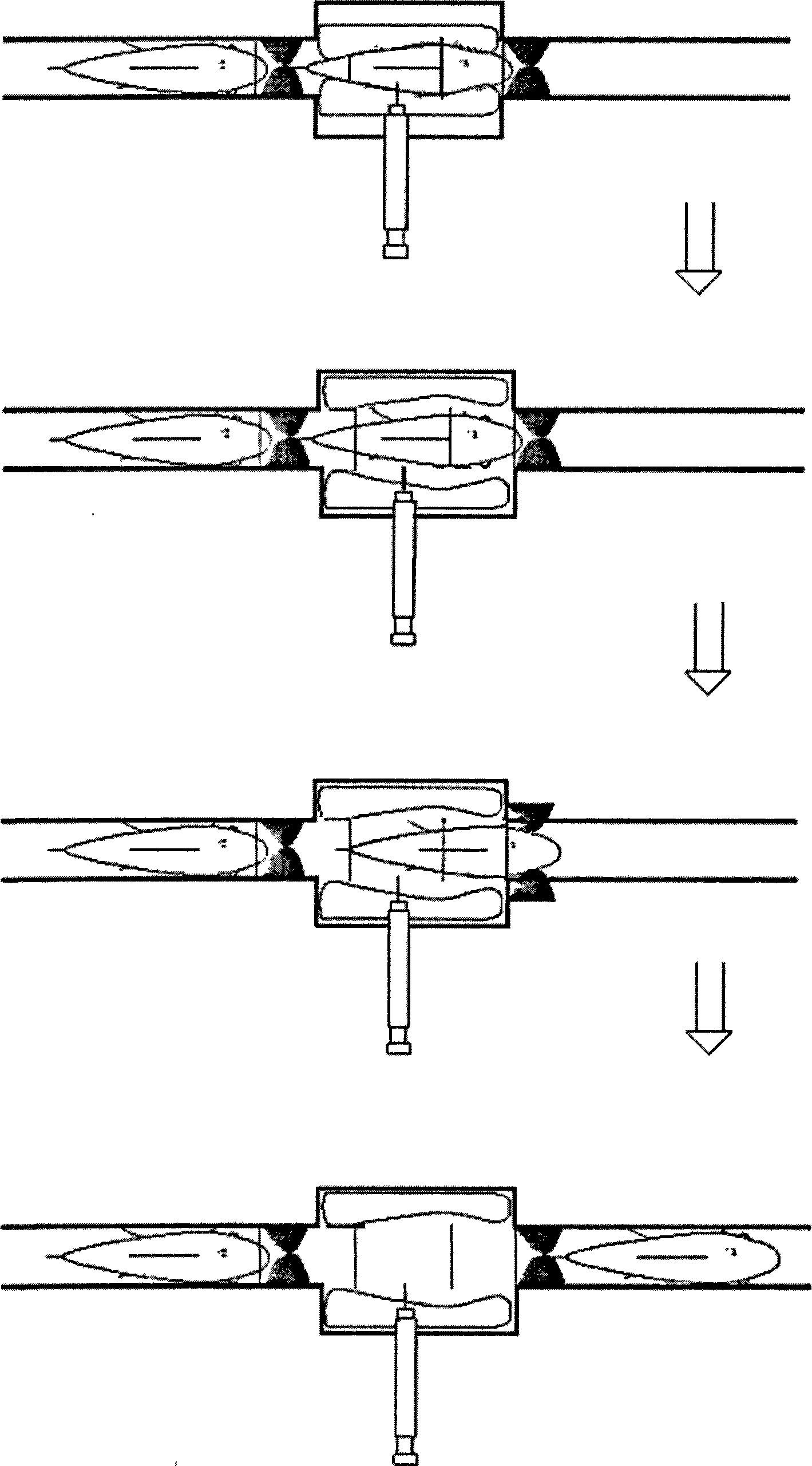

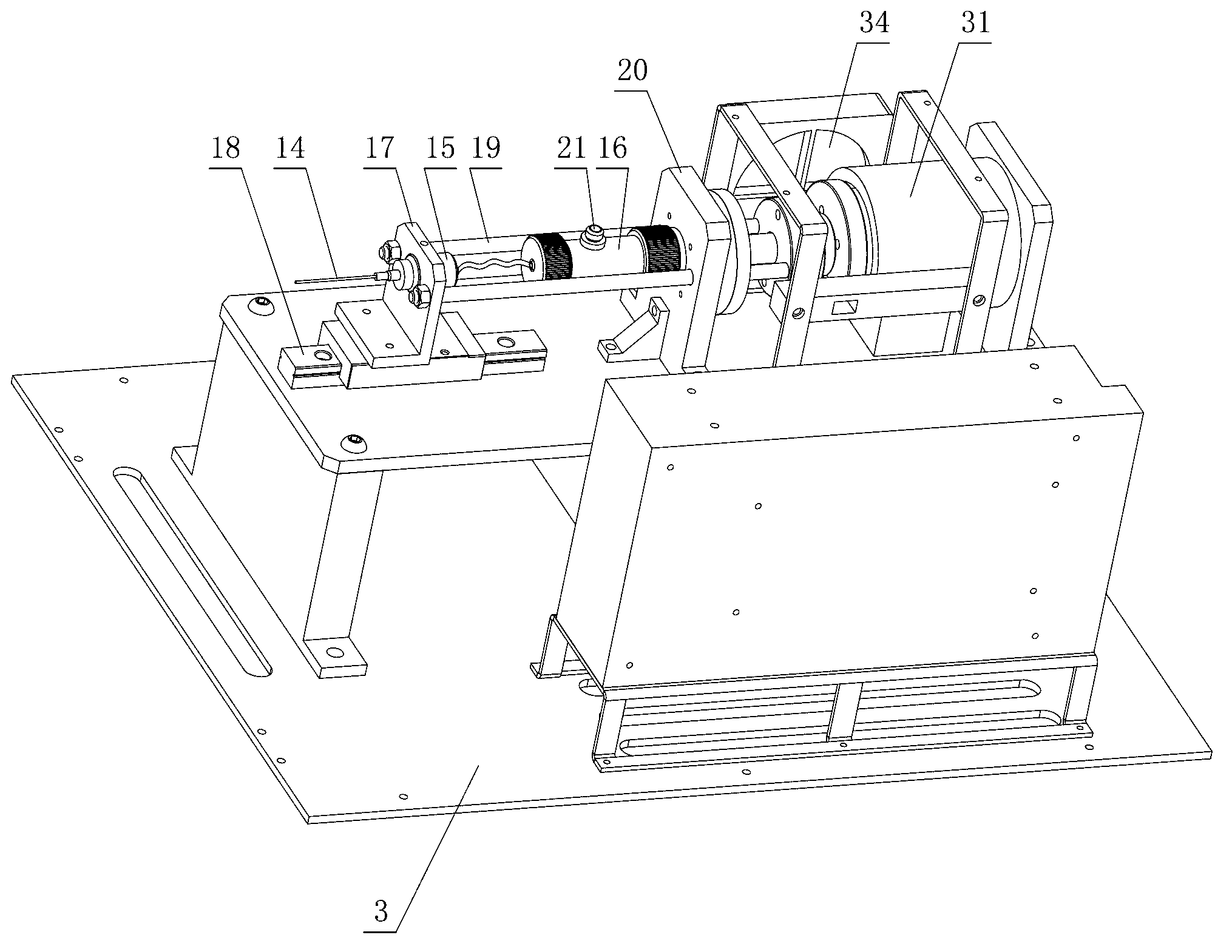

Automatic and continuous fish vaccine injection device

ActiveCN104367396AEasy injectionEliminate the complexity of manual manual vaccinationClimate change adaptationPisciculture and aquariaLiquid-crystal displayEngineering

The invention relates to the technical field of aquaculture, in particular to an automatic and continuous fish vaccine injection device. According to the specific production requirements of aquaculture in China and the production requirements of multi-type fish culture, the automatic and continuous fish vaccine injection device is developed, and the mode of track conveying serves as the main mode of the automatic and continuous fish vaccine injection device. The automatic and continuous fish vaccine injection device works in cooperation with a modularized three-axis fish body laser positioning system, a vaccine injection device body and a programmed man-machined operation control system with a touch liquid crystal display serving as a carrier to realize the purpose of injecting vaccine to multi-type fish bodies automatically and continuously in fishery production. Thus, the complexity of manual vaccine injection is avoided, high labor intensity is avoided, and vaccine injection in large-scale culture is facilitated.

Owner:SUN YAT SEN UNIV

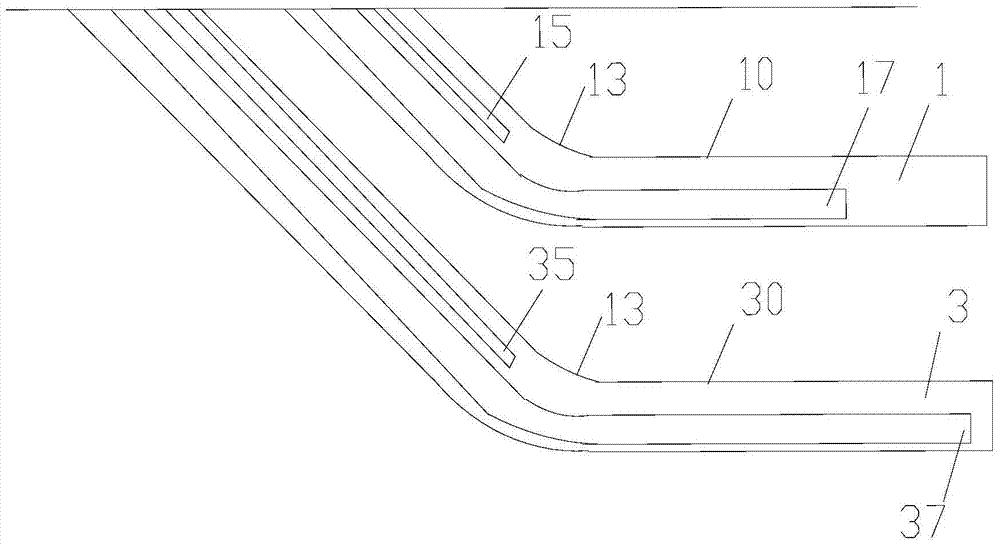

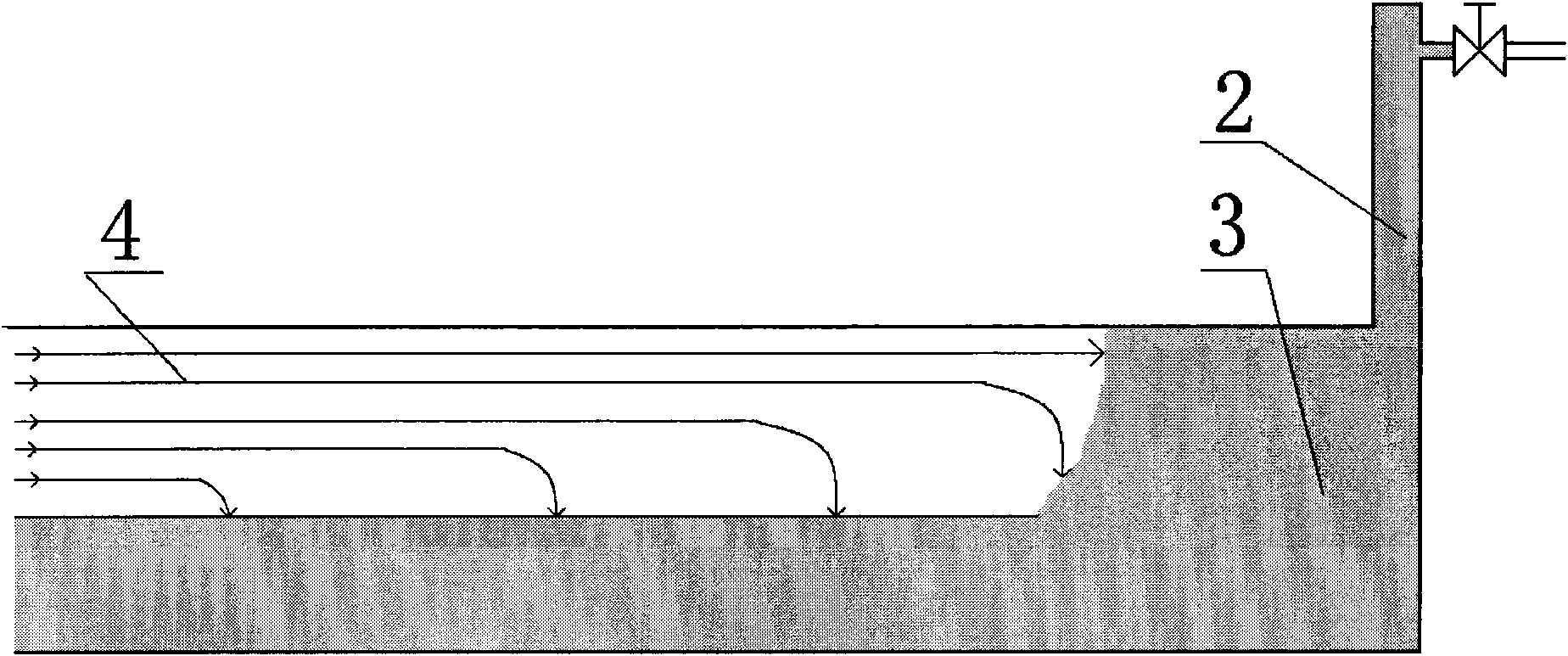

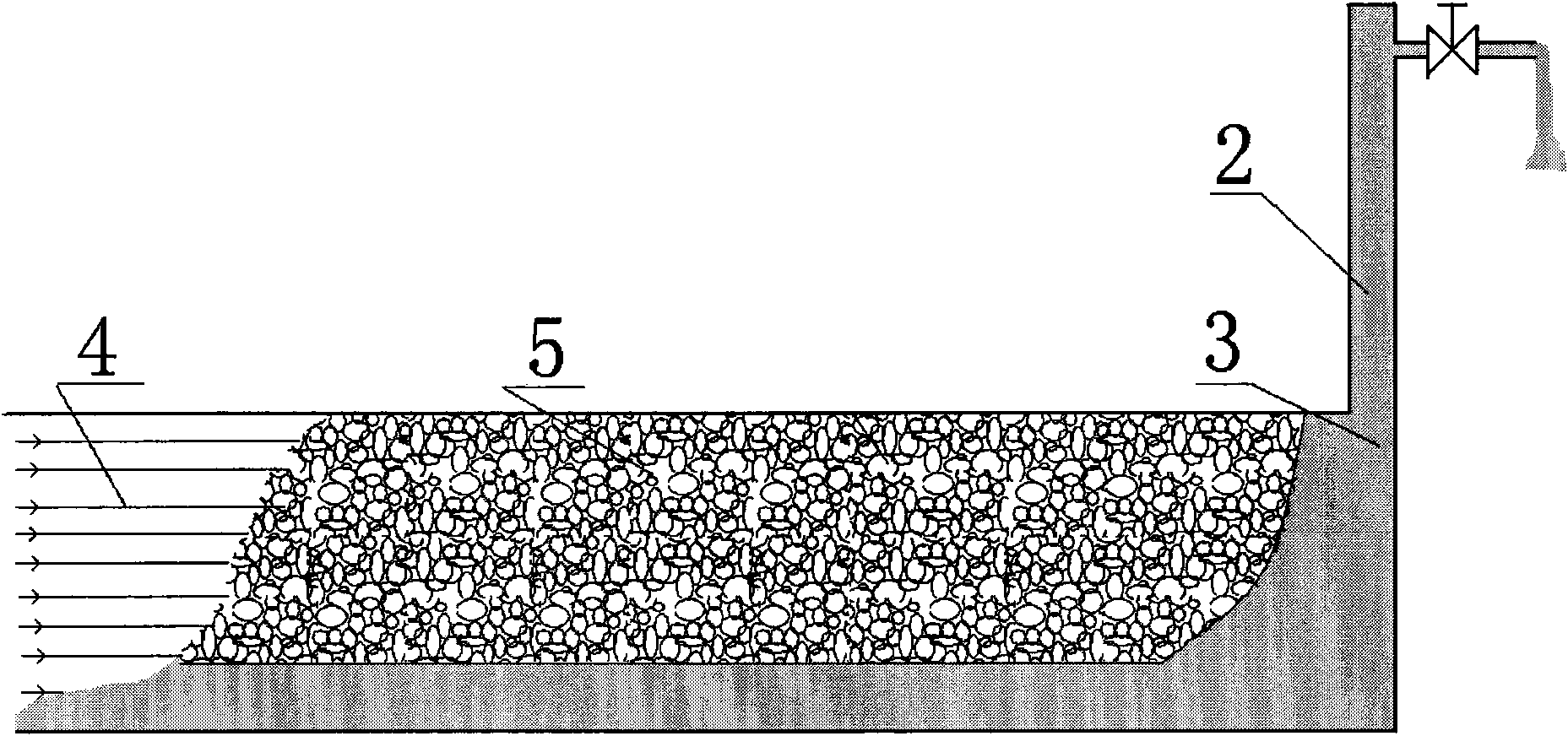

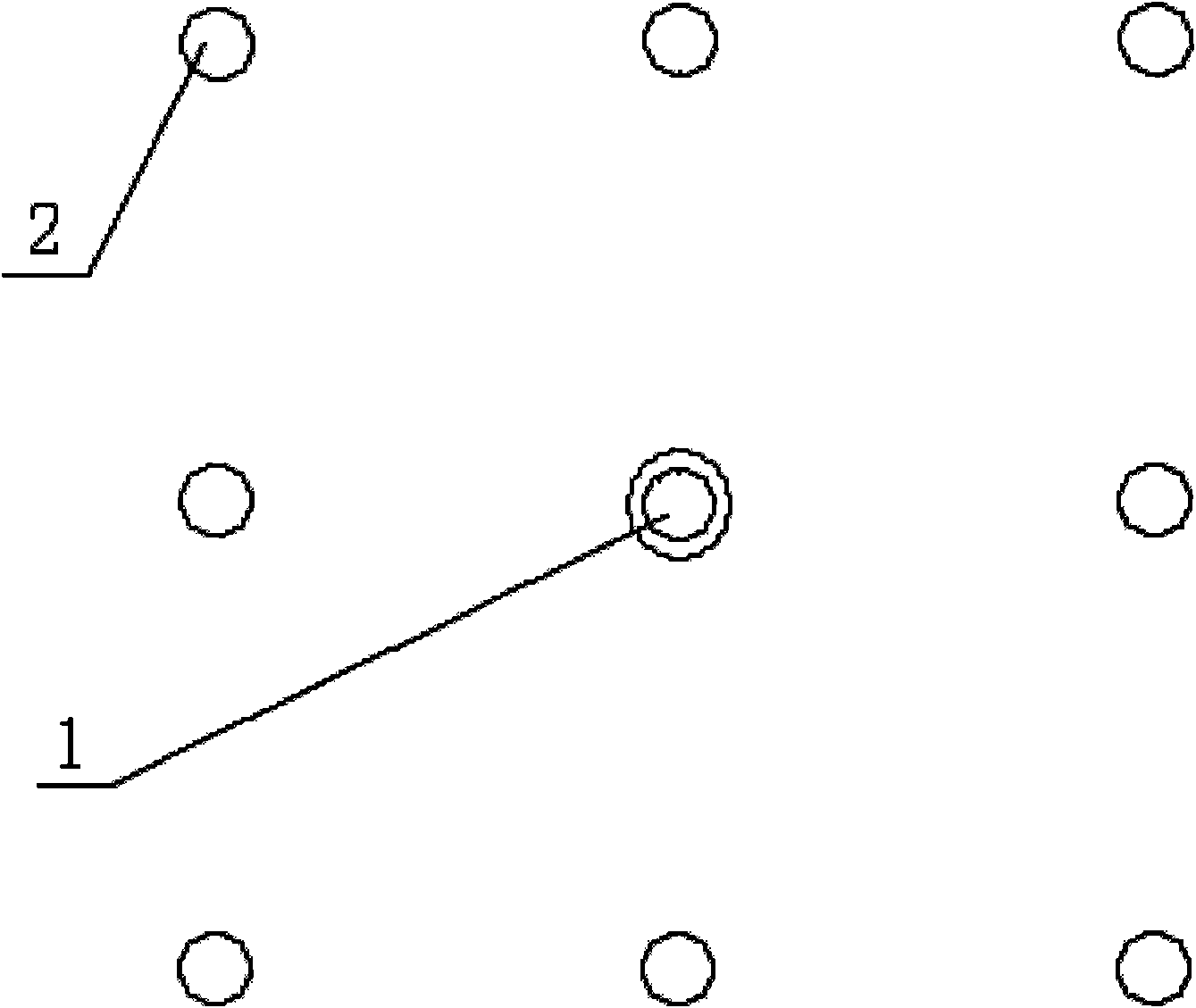

Mid-depth layer oil reservoir double-horizontal-well equal-temperature-difference forced steam circulation preheating method

ActiveCN103615225AOvercome the disadvantages that it is difficult to achieve cycle preheatingFluid removalHorizontal wellsMechanical lift

The invention provides a mid-depth layer oil reservoir double-horizontal-well equal-temperature-difference forced steam circulation preheating method. The mid-depth layer oil reservoir double-horizontal-well equal-temperature-difference forced steam circulation preheating method comprises the steps: A, selecting a qualified oil reservoir; B, deploying double horizontal wells in the qualified oil reservoir; C, conducting steam huff and puff development on the upper horizontal well and the lower horizontal well at the same time to enable the pressure of the qualified oil reservoir to be decreased to be lower than 3.5MPa; D, placing an upper horizontal well steam injection pipe column and an upper horizontal well mechanical lifting pipe column down to the upper horizontal well of the double horizontal wells, and placing a lower horizontal well steam injection pipe column and a lower horizontal well mechanical lifting pipe column down to the lower horizontal well of the double horizontal wells; E, conducting circulation preheating, conducting continuous injection and extraction on the upper horizontal well and the lower horizontal well at the same time, injecting steam in the upper horizontal well and the lower horizontal well at the same time, and utilizing mechanical lifting for extracting condensed fluid at the same time, wherein the condensed fluid in the upper horizontal well is extracted from the upper horizontal well, and the condensed fluid in the lower horizontal well is extracted from the lower horizontal well.

Owner:PETROCHINA CO LTD

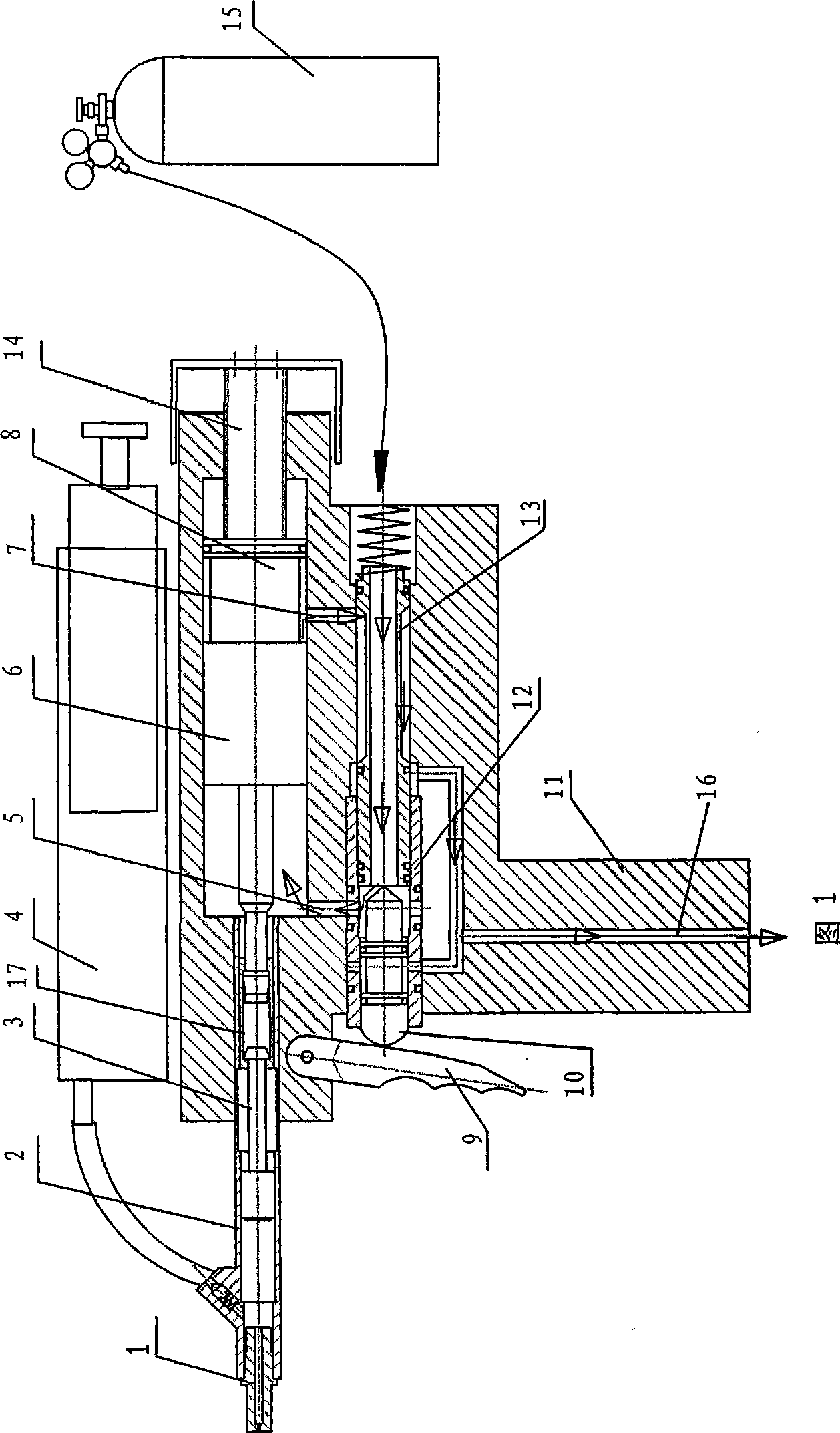

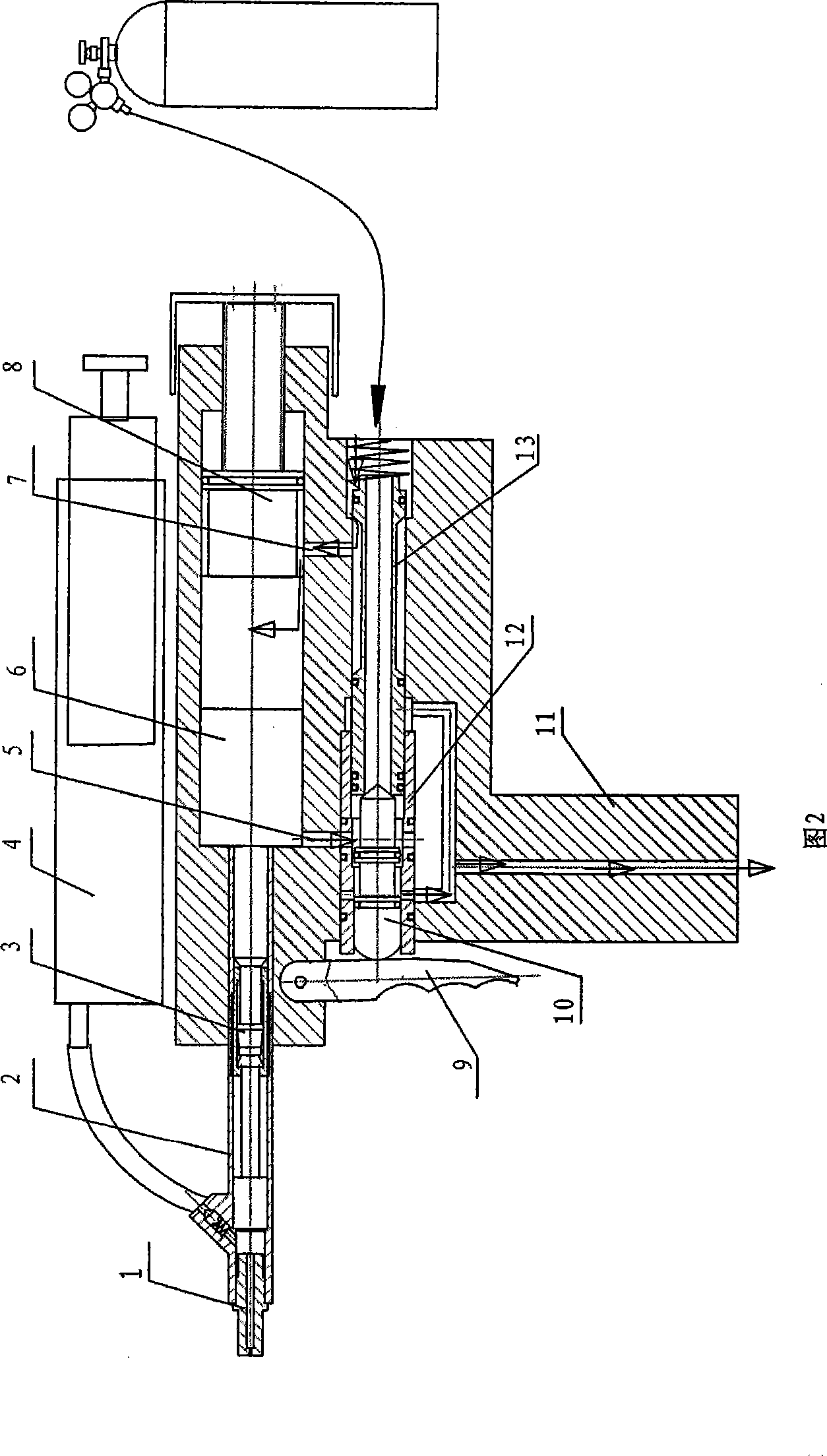

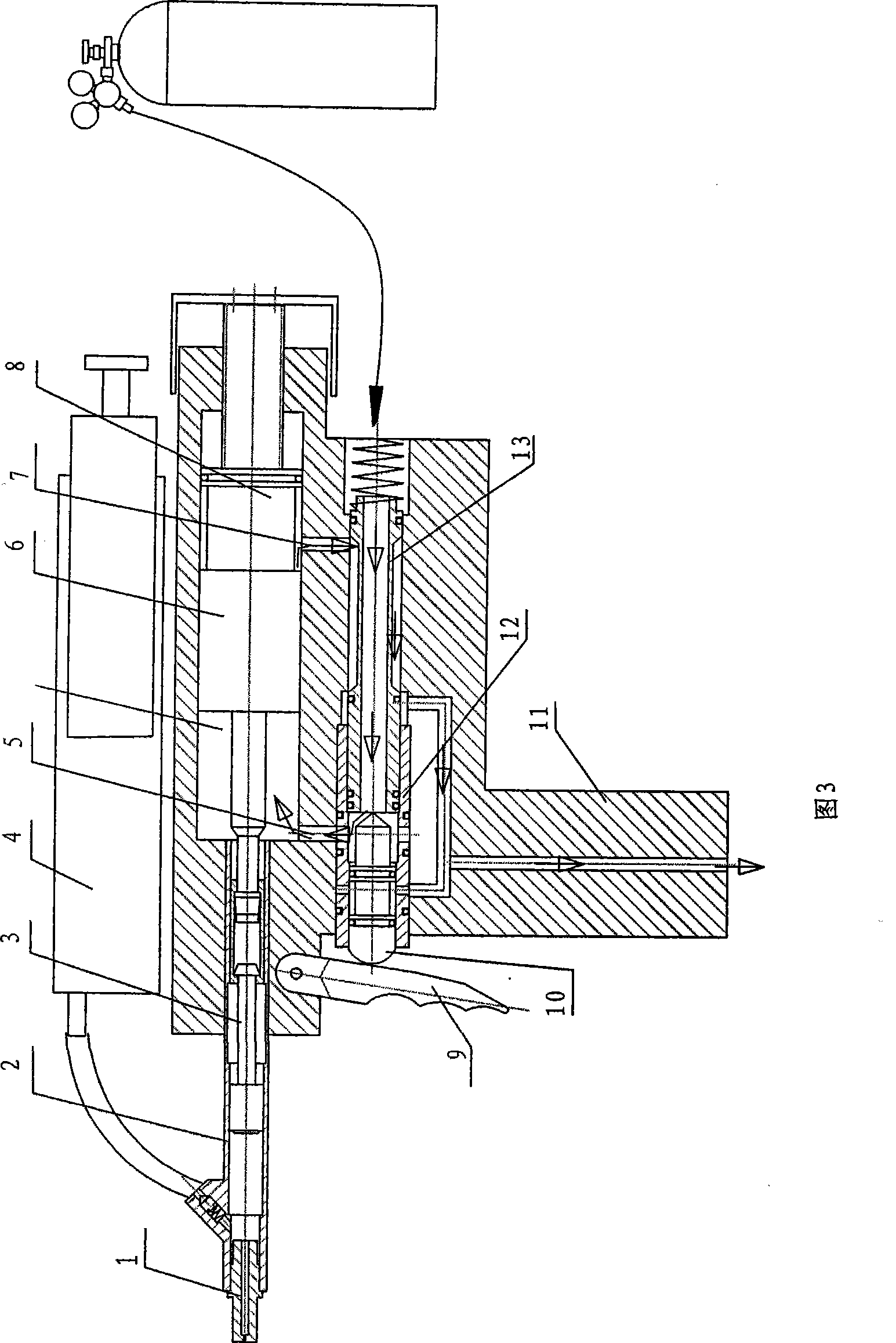

Injection valve with indexing mechanism

A flapper valve preferably used in injection application in deep subterranean locations has an actuating sleeve with a seat to accept an object. A j-slot connects the actuation sleeve movement to the housing so that with an object on the seat and an applied pressure cycle the sleeve moves the flapper to the open position. The plug is dissolved and the injection begins. The plug can have an opening so as to allow continuous injection flow as the flapper is operated. Closing the flapper involves a second object on the same seat and a pressure cycle so that a spring can push the sleeve away from the flapper to allow a torsion spring on the flapper to close it.

Owner:BAKER HUGHES INC

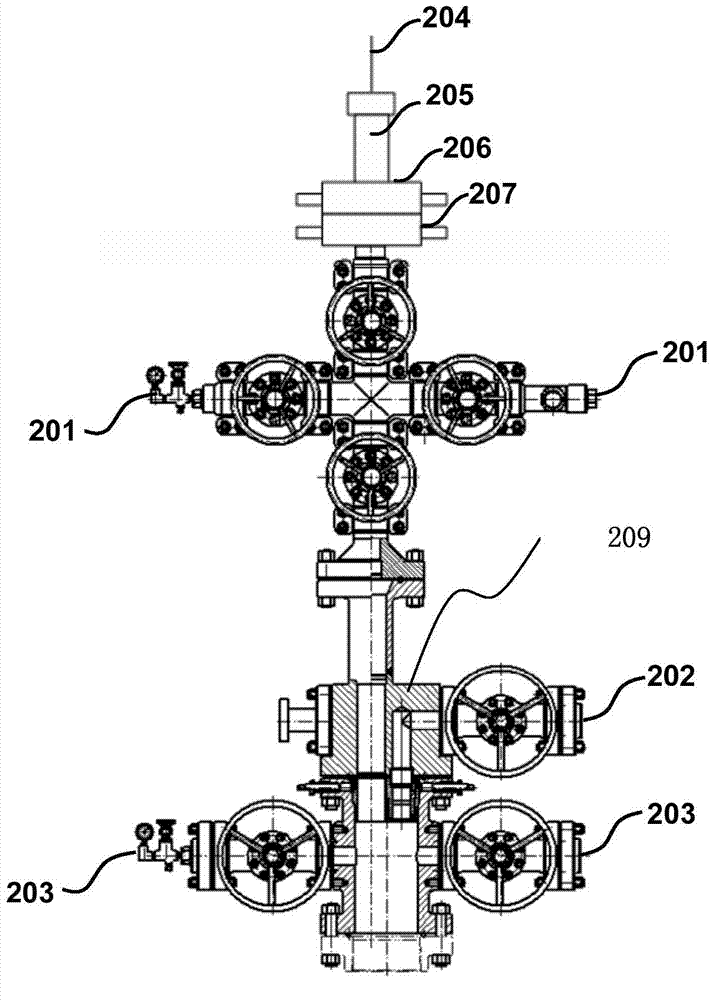

Improved carbon dioxide drive oil production method

ActiveCN101555785AAvoid wastingEffective displacement of crude oilFluid removalPressure decreaseOil field

The invention relates to an improved carbon dioxide drive oil production method which is applied to oil production in oil fields. The invention is characterized in that A. carbon dioxide is injected into a gas injection well; and B. under the condition of continuous injection of carbon dioxide, peripheral production wells are opened for production and closed discontinuously. In the period of closing the well, the pressure of an oil pool at the periphery of the gas injection well raises, and when the pressure raises to a certain extent, the production wells are opened for production; with the production of the opened production wells, the pressure of the oil pool at the periphery of the gas injection well decreases and when the pressure decreases to a certain extent, the production wells are closed; and the above steps are repeatedly circulated. The method has the effects that the drive oil effect can be improved and the recovery ratio of the oil pool is improved; and when the pressureraises, part of carbon dioxide can be dissolved into the crude oil; when the pressure decreases, the carbon dioxide can be separated from the crude oil so as to form small bubbles and the volume of the crude oil is obviously expanded compared with the volume of the crude oil when the carbon dioxide is not separated. As the carbon dioxide is injected continuously, the expanded crude oil expands todownstream, thus driving the downstream crude oil to flow to the production wells.

Owner:PETROCHINA CO LTD

Method of inhibiting olefin polymerization in alkaline washing column of methanol-to-olefin (MTO) device

InactiveCN106467447AReduce pollutionInhibit aggregationHydrocarbon purification/separationHydrocarbonsOrganic chemistryPoor control

The invention relates to a method of inhibiting olefin polymerization in an alkaline washing column of a methanol-to-olefin device and mainly solves the technical problems of poor control effect on olefin polymerization, poor targeted applications, instability, complex operations, high toxicity and high cost in an alkaline wash column of an MTO apparatus in the prior art. In the technical scheme, a) an olefin polymerization inhibitor (I) is employed and includes, by weight, 0-20 parts of an amine compound and 0-10 parts of an alcohol compound; and b) the olefin polymerization inhibitor (I) is injected to the alkaline wash column (1) along with an alkaline solution (II) in an online continuous injection manner through an alkaline solution injection line on the alkaline wash column. The method solves the technical difficult problems and can be used for controlling and preventing the olefin polymerization in the MTO apparatus.

Owner:CHINA PETROLEUM & CHEM CORP +1

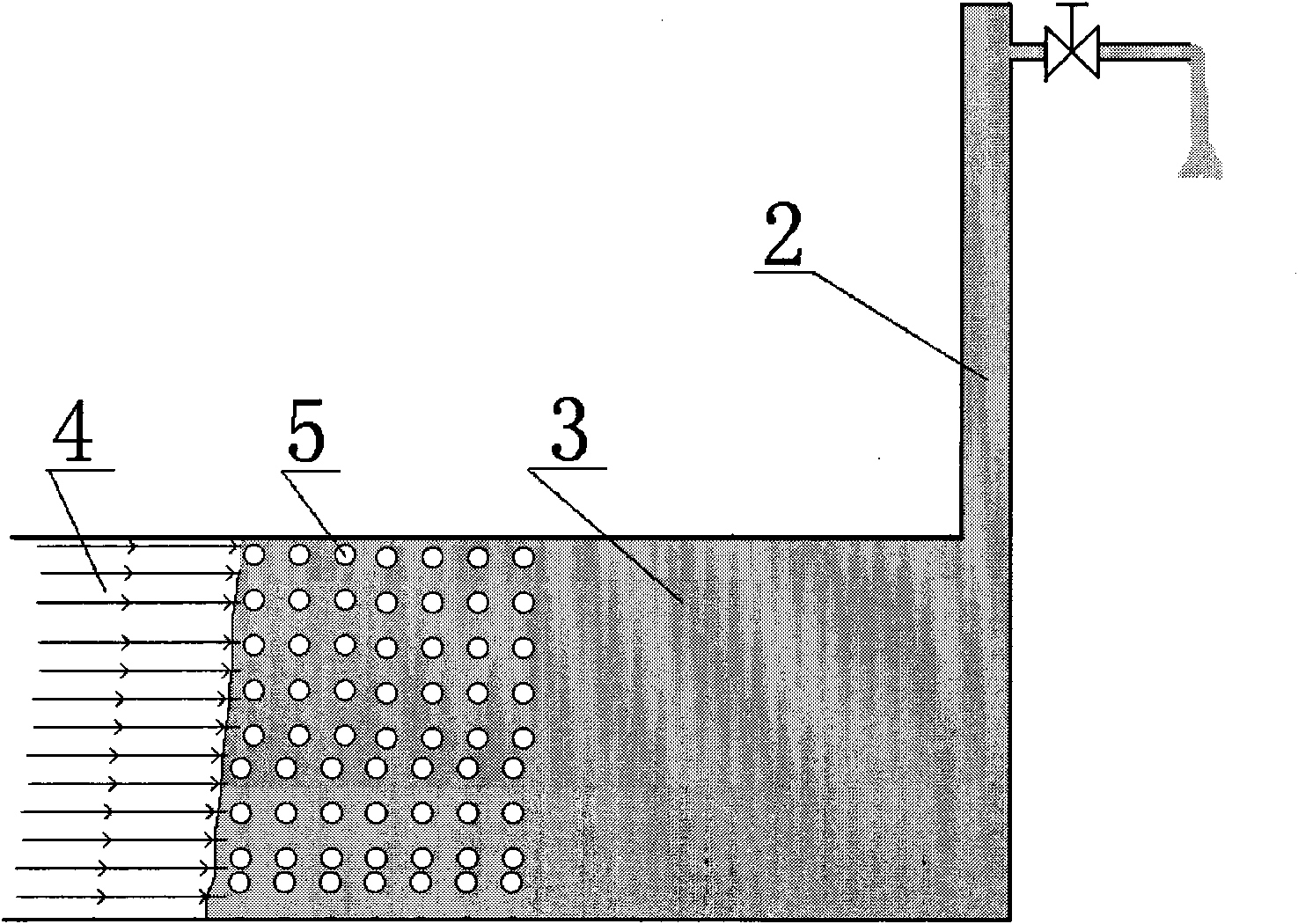

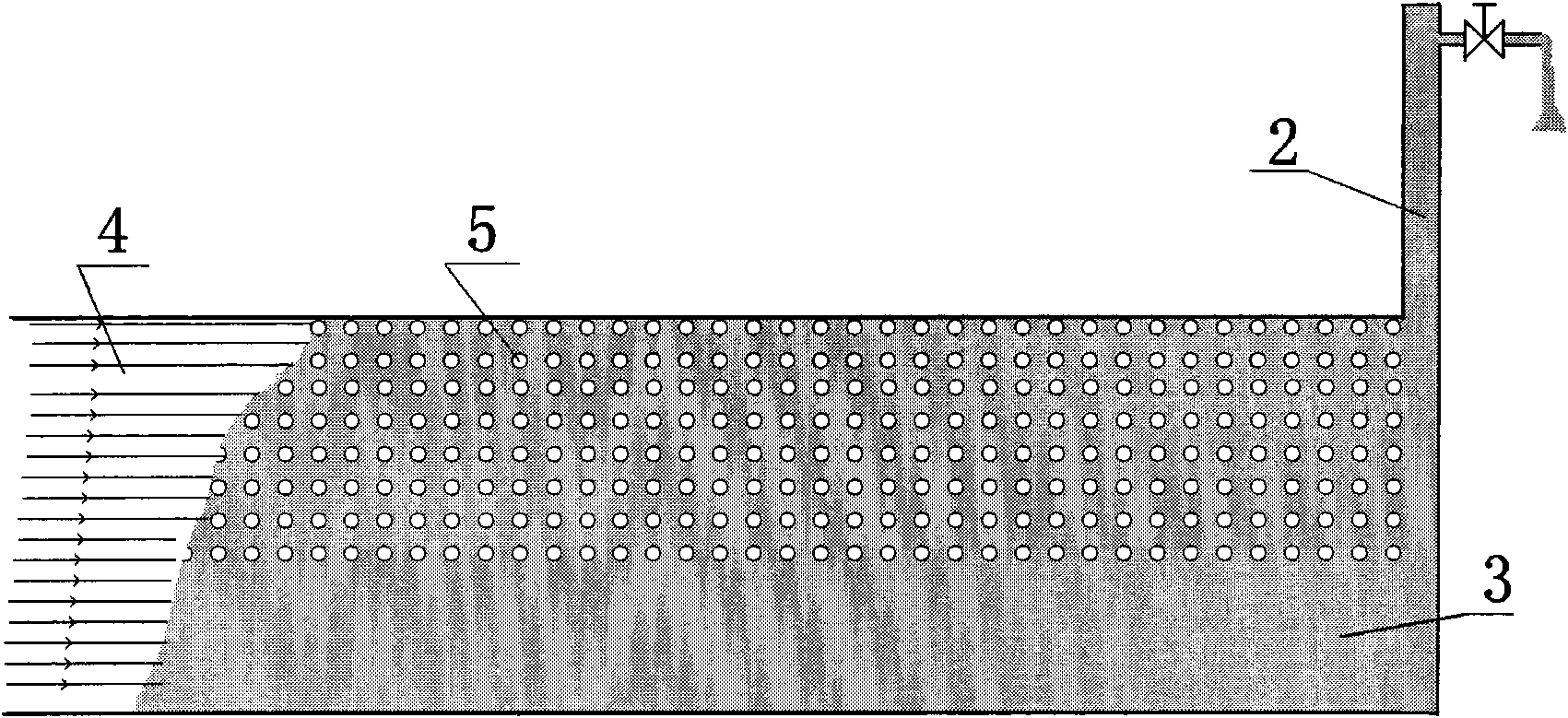

Ultralow permeability oil filed water injection well multicomponent chemical microemulsion pressure reduction and injection gain method

ActiveCN101691838AUnblockImprove seepage environmentFluid removalDrilling compositionPhosphatePressure reduction

The invention relates to an ultra-low permeability oil filed water injection well chemical pressure reduction and injection gain technology. In the technology, micellar acid microemulsion and alkalis-CO2 microemulsion are combined together; the alkalis-CO2 microemulsion component refers to inorganic alkalis which comprises 3-15% of sodium hydroxide and sodium carbonate solutions, 0.5-5% of inorganic complex blocking remover, 0.5-1.5% of stabilizer IS-2, 0.2-2% of sulfonate surfactant and 0.1-1.5% of fluorocarbon surfactant; the micellar acid microemulsion component comprises 10-25% of mixed acid liquor composed of inorganic acid salt and organic acid, 5-15% of phosphate microemulsion micellar agent, 0.5-1.5% of imidazoline inhibitor and 1-2.5% of stabilizer IS-2. When using the technology, sectional plug continuous injection is adopted; the injection pressure is lower than the formation fracture pressure; and the injection speed: the delivery capacity is controlled to 150-300L / min. The microemulsion of the invention can generate new supercritical carbon dioxide (SC-CO2) microemulsion under the condition of floodable formation so as to effectively solve the reservoir choke of the ultra-low permeability oil filed water injection well, improve liquid phase seepage environment, realize pressure reduction and injection gain to the water injection well, increase the recovery rate of petroleum and obviously increase the economic benefit of oil extraction.

Owner:XIAN ZHONGFU KAIHONG GASOLINEEUM TECH

Method for injecting live fish

InactiveCN101496503ASolve the disadvantages of leaving the water bodyInjection is effectiveClimate change adaptationPisciculture and aquariaEngineeringInjection device

The invention relates to a live fish injection device, which is characterized by comprising a live fish leading channel which is provided with a first gate and a second gate, wherein a soft cushion clip which is controlled by a singlechip and moves in a direction perpendicular to the leading channel for clipping the live fish is arranged between the first and the second gates., the live fish leading channel is also provided with four sensors respectively arranged at the front end of the two gate switches and between the two gate switches for detecting the position and size of the live fish; and the channels of the first and the second gates are also provided with continuous injection syringes. The inventive device has simple structure, facilitates the live fish injection, and improves the efficiency and safety of the live fish injection work.

Owner:BIOLOGICAL TECH INST OF FUJIAN ACADEMY OF AGRI SCI

Improved steam drive oil production method

ActiveCN101555787AImprovement of driving effectFacilitate exothermic chemical reactionsFluid removalPressure decreaseOil field

The invention relates to a steam drive oil production method which is applied to oil production in oil fields. The method comprises the following steps: enough steam amount is injected continuously in a steam injection well; under the condition of continuous injection of steam, peripheral production wells are opened for production and closed discontinuously; in the period of closing the well, the pressure of an oil pool at the periphery of the steam injection well raises, and when the pressure raises to a certain extent, the production wells are opened for production; with the opening of the production wells, the pressure of the oil pool at the periphery of the steam injection well decreases, and when the pressure decreases to a certain extent, the production wells are closed; the above steps are repeatedly circulated; when the pressure raises, the saturation temperature of the steam can raise, the heat can be transferred to the rock and crude oil of the reservoir and the temperature of the rock and the crude oil in the reservoir can also raise; when the pressure decreases, the saturation temperature of the steam can decrease, and when the pressure of the rock and the crude oil in the reservoir raises, the temperature formed is higher than the saturation temperature of the steam; and part of water contained in the crude oil and on the surface of the rock is flash-evaporated into steam so as to form foam oil which displaces the crude oil.

Owner:PETROCHINA CO LTD

Method for preparing cerealose or maltose syrup with crushed rice enzyme method

The invention discloses a method for preparing cerealose or maltose syrup with a crushed rice enzyme method, comprising the following steps: adding water in crushed rice for washing and immersing, carrying out pulp refining, regulating the pH value of the slurry, adding thermostable alfa-amylase to carry out two times continuous injection liquefaction, keeping warm to obtain the emulsion; adjusting the temperature of the emulsion to 55-60 DEG C, regulating the pH value to 5.0-5.6, adding beta-amylase to carry out saccharification to obtain a sacchariferous liquor with the DE value of more than 40 and the maltose content of more than 40% even 50%, and processing the sacchariferous liquor to obtain a maltose syrup product; or after adjusting the temperature of the emulsion to 55-60 DEG C, regulating the pH value to 5.2-5.7, adding crushed malt with stirring to carry out saccharification until the DE value of the material exceeds 40%, and filtering and condensing the sacchariferous liquor to obtain a cerealose product. The prepared products can be edible directly, and can be used as raw material for processing cake, candy and other Chinese traditional food and as carbon source of a microbe medium.

Owner:GUANGZHOU SHUANGQIAO +1

Method for quickly starting short-cut nitrification and denitrification of ammonia-containing wastewater

ActiveCN103373764AReduce the difficulty of startingImprove processing efficiencyTreatment with aerobic and anaerobic processesHigh concentrationActivated sludge

The invention relates to a method for quickly starting short-cut nitrification and denitrification of ammonia-containing wastewater. The method comprises the following steps of: firstly putting inocula into a bioreactor, wherein the inocula are enriched nitrobacteria or mixtures of the nitrobacteria and aerobic activated sludge in sewage plants; adopting the two operation modes including batch injection and continuous injection to start a system; and adding the nitrobacteria during batch injection, and adding denitrifiers during continuous injection. Compared with the prior art, the method has the advantages of low start requirement, high start speed, capability of treating high-concentration ammonia-containing wastewater and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

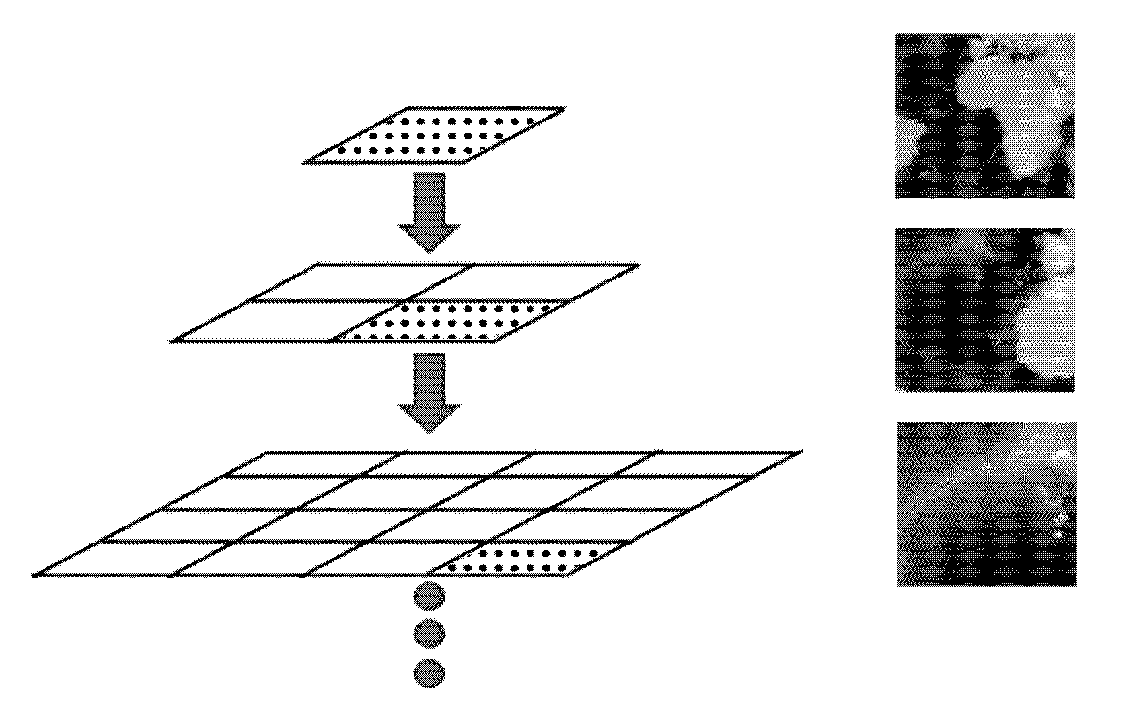

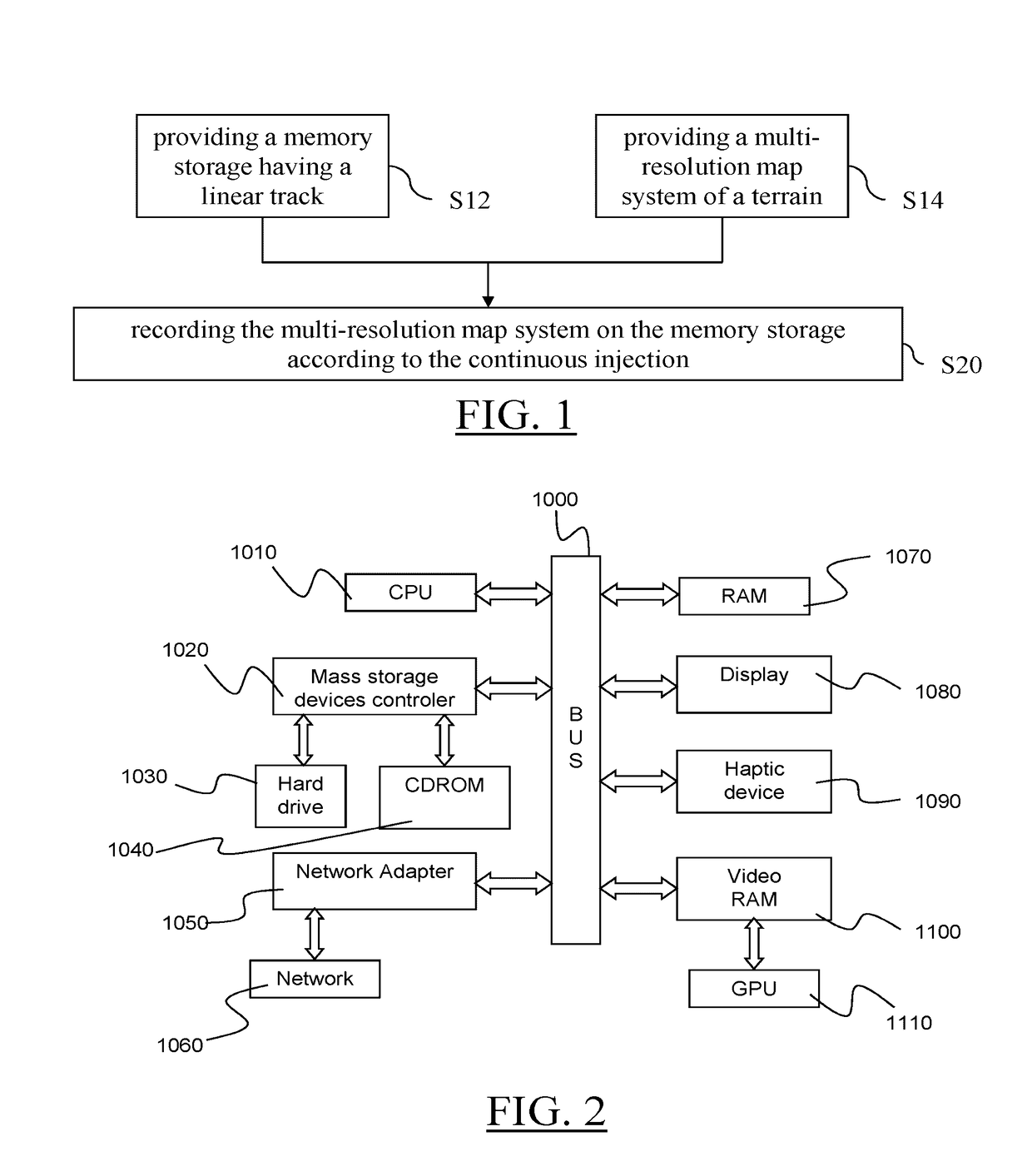

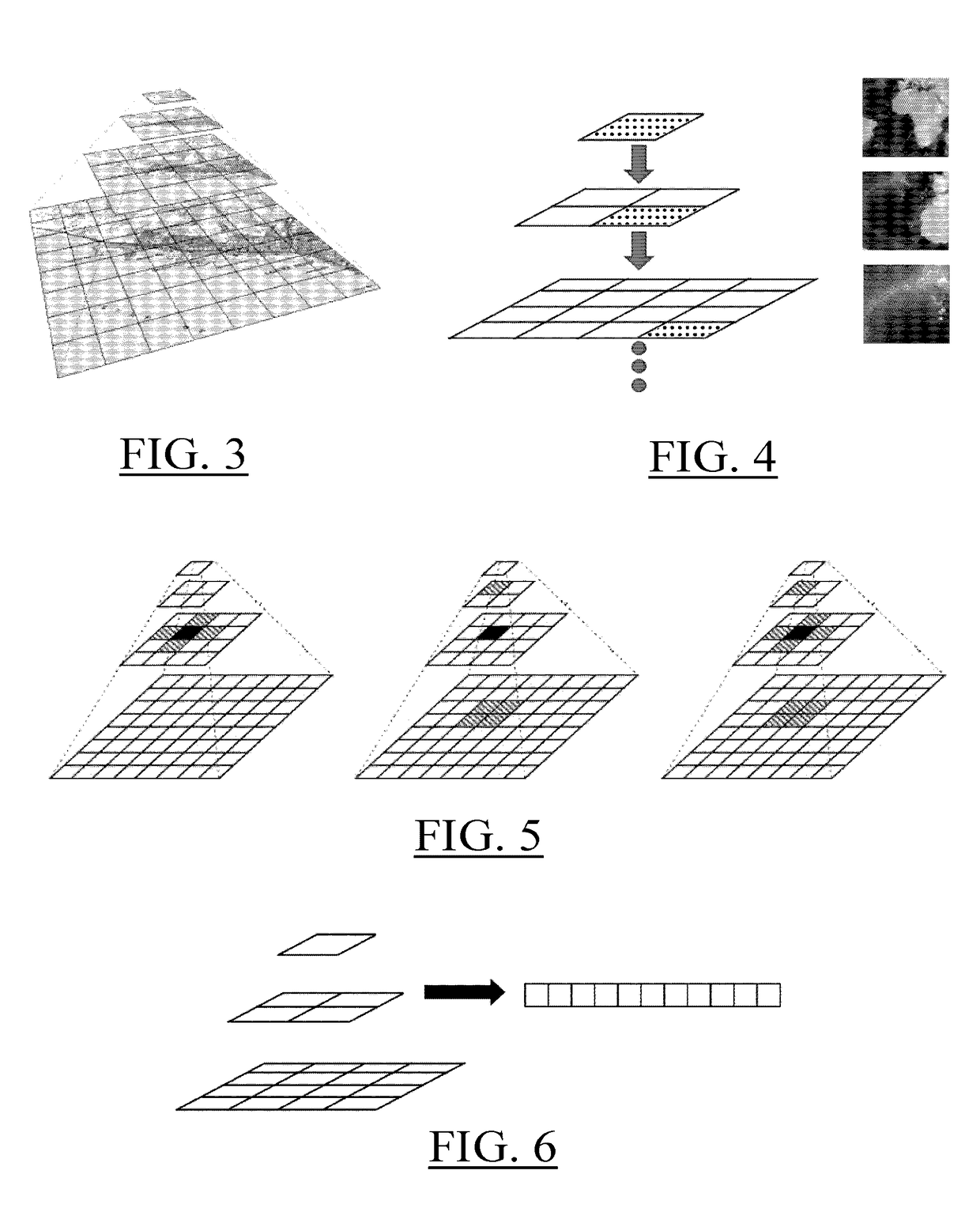

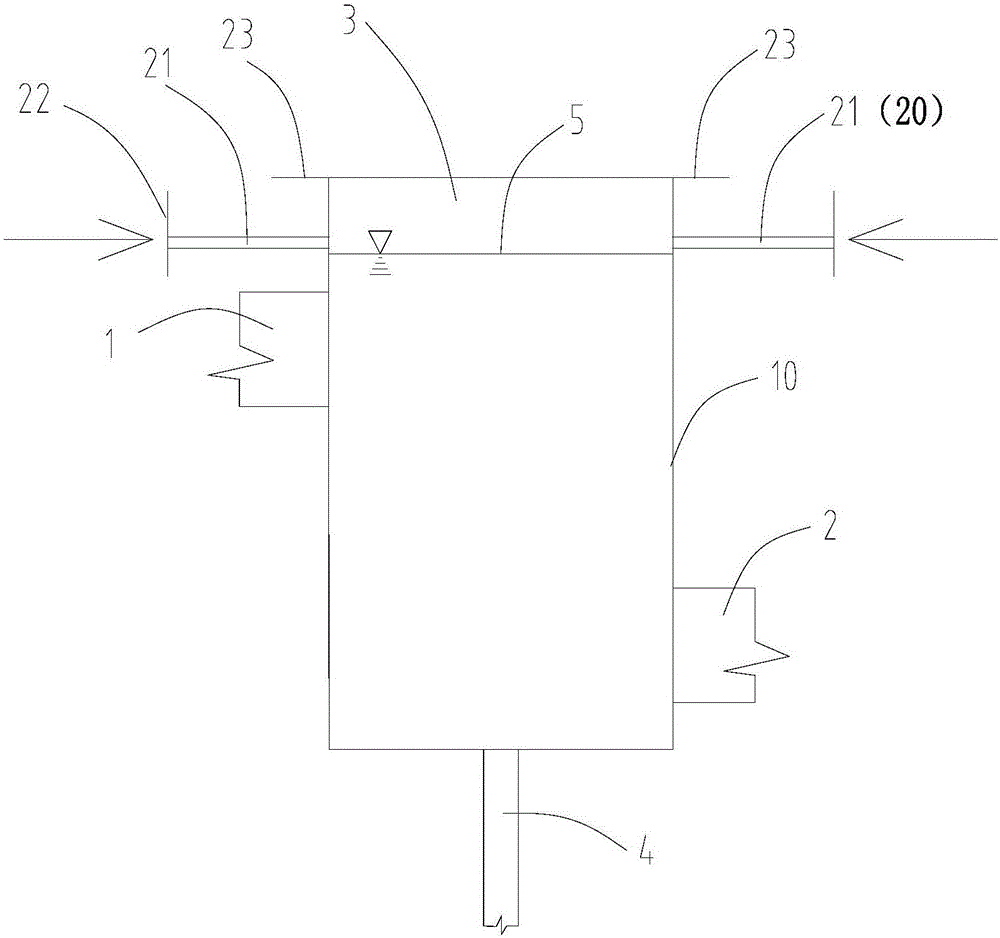

Multi-resolution image system

ActiveUS20170169544A1Geometric image transformationImage memory managementImage resolutionMulti resolution

The invention notably relates to a memory storage having a linear track and having recorded thereon a multi-resolution image system of an object, the multi-resolution image system including a set of images, each image representing the object and having a respective resolution, wherein the recording is according to a continuous injection from a space-filling curve of the set of images to the linear track, the space-filling curve interlaces the different images, and the intersection between the space-filling curve and each image is on a Hilbert curve.The invention improves the way to record a multi-resolution image system of an object on a memory storage.

Owner:DASSAULT SYSTEMES

Platinum channel mixing barrel and platinum channel mixing barrel device

ActiveCN106746497ALower oxygen levelsReduce condensationGlass furnace apparatusGlass productionPlatinumEngineering

The invention relates to a platinum channel mixing barrel and a platinum channel mixing barrel device. The platinum channel mixing barrel comprises a stirring barrel body with a barrel opening, a molten glass inlet and a molten glass outlet, wherein the mixing barrel body is also communicated with a hot-gas supply device for blowing an inert hot gas into a space above a free water surface in the mixing barrel body, so that the inert hot gas blown by the hot-gas supply device flows into the space above the free water surface and then is sent out from the barrel opening. Oxygen in the space is diluted and discharged by blowing the inert hot gas into the space above the free water surface in the mixing barrel body, so that volatilization of a precious metal component exposed in the space is inhibited and a precious metal volatile matter of generating precious metal defects is reduced from the source. The generated precious metal volatile matter can be taken out of the space along with continuous injection of the inert hot gas into the space above the free water surface, and the condensation of the precious metal volatile matter can be reduced, so that the probability of generating the precious metal defects in a glass substrate is reduced and the yield and the quality of a product are improved.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

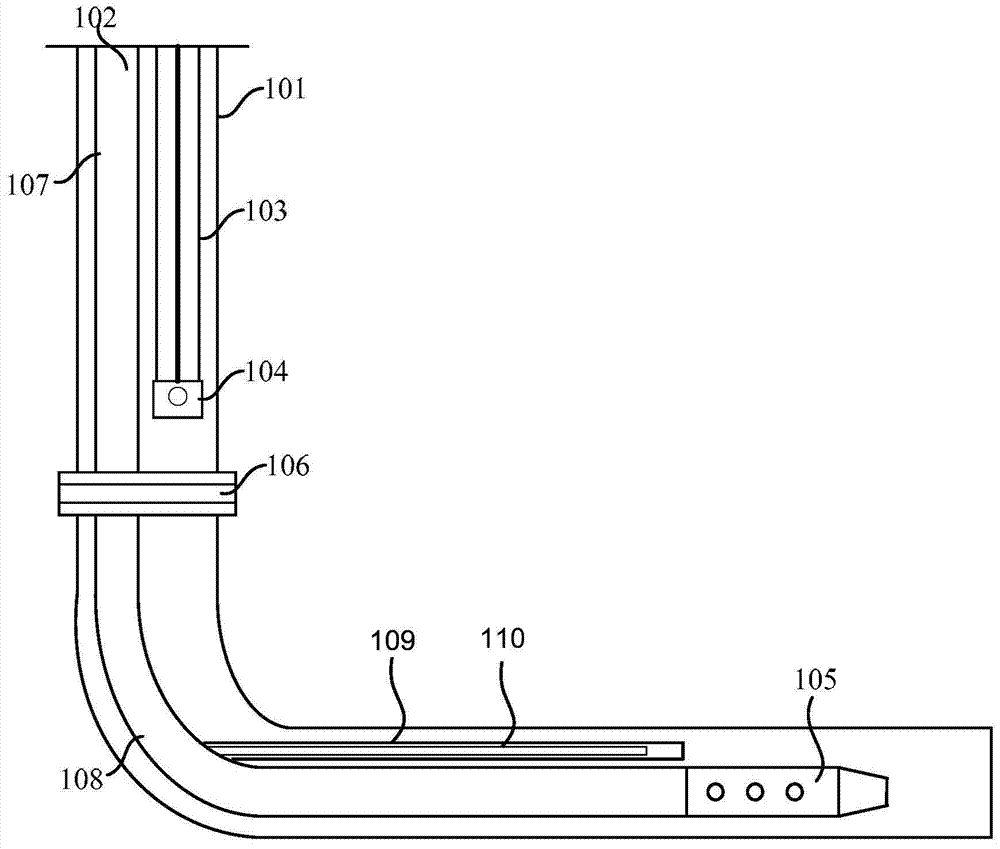

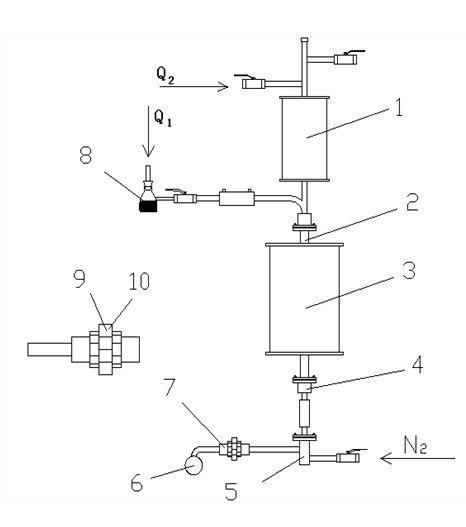

Method and equipment for detecting burning rate of pulverized coal

InactiveCN102539621AIncrease burn rateImprove accuracyChemical analysis using combustionProcess engineeringNational standard

The invention relates to a method and equipment for detecting burning rate of pulverized coal, belonging to the technical field of physical and chemical detection in metallurgical engineering. The method comprises the steps of: preparing coal samples, continuously blowing air, collecting unburned pulverized coal, collecting mixed gas, detecting by using a gas analyzer, burning in a muffle furnace and calculating burning rate. The equipment comprises a hot air furnace (1), a coal injection bottle (8), a burning furnace (3), an N2 gas source, a three-way ash collection groove (5), a gas collection bag (6) and a dust collector (7). The method and the equipment for detecting the burning rate of pulverized coal solve the problems that the burning rate of the equipment of the background technique is generally low and the unburned pulverized coal is difficult to collect, continuous injection is realized, and enough unburned pulverized coal (1g required by the national standard) and mixed gas can be collected. The accuracy of the detected burning rate of pulverized coal is high, the operation is simple and convenient, the repeatability is good, reference data for flammability of the kind of the injected pulverized coal can be provided for a blast furnace, and on the premise that the condition of the blast furnace is smooth, the benefit of coal injection is maximized by improving the burning rate of the pulverized coal.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

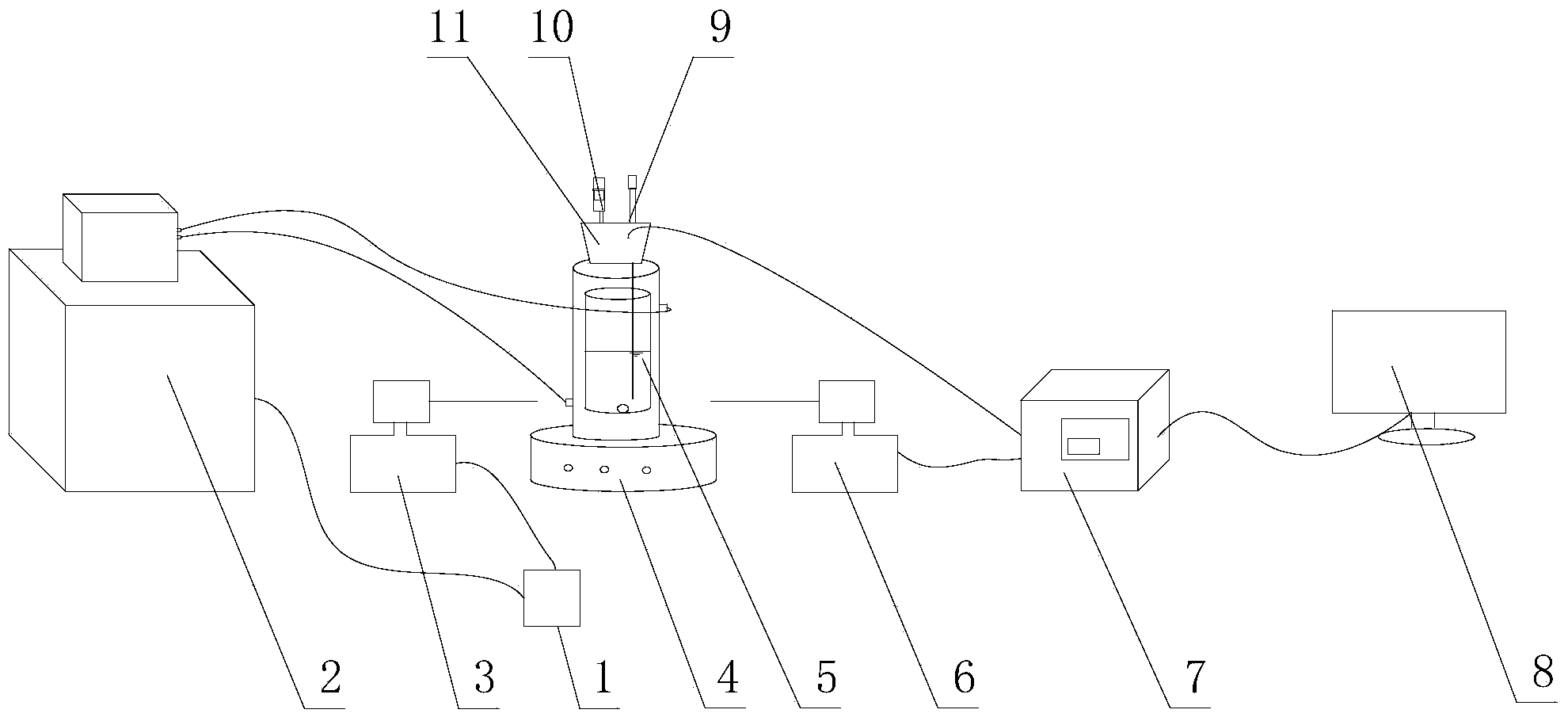

Device for detecting solid-liquid solubility by laser intensity

InactiveCN103940693ATroubleshooting the Attachment WallRealize real-time monitoringMaterial weighingWater bathsSolubility

The invention relates to a device for detecting solid-liquid solubility by laser intensity. According to the device, a thermostatic circulating water bath and a laser emitter are connected with a power supply by conductive wires; the thermostatic circulating water bath is communicated with a glass jacket bottle; magnetons are arranged in a test sample bottle in the glass jacket bottle; a magnetic stirrer is arranged at the bottom of the glass jacket bottle; a sample loading injector extending into the test sample bottle, and a contact-type temperature sensor are arranged on a rubber plug at the top of the glass jacket bottle; the laser emitter and a laser receiver are arranged at the both sides of the glass jacket bottle, respectively; the laser receiver and the temperature sensor are connected with a digital light intensity display by conductive wires, respectively; the digital light intensity display is connected with a computer by a conductive wire. The device disclosed by the invention overcomes the problems of high error, instability and poor repeatability generated by observation with naked eyes during the process of measuring solubility by a traditional turbidity point method, realizes quantitative and continuous injection of a solvent, and solves the problem of attachment of a sample to the wall of a container during sample injection.

Owner:SHAANXI NORMAL UNIV

Chemical pressure decreasing and augmented injection technology for strong sensitivity oil layer water injection well

InactiveCN101705811AImprove interpenetration relationshipIncrease temperatureFluid removalDrilling compositionPressure decreaseInjection pressure

The invention relates to a petroleum extraction technology, aiming at a strong sensitivity oil layer water injection well. In the technology, chemical injection agent is prepared by the four components in parts by weight: 10-25% of acid, 3-15% of alkali, 0.3-8.5% of surfactant, 1-7% of oxidant, and the balance water. When in use, an on-site injection manner of segmented plug continuous injection is adopted, the injection pressure is lower than petroleum layer fracture pressure, and the injection speed is controlled to be 150-300L / min based on the output volume. The invention integrates the technical principals of various oil layer plugging relief and oil displacement technologies of acid, alkali, surface active agent, oxidant, autogenous CO2 and the like to generate technical addictive effect, thereby realizing to solve the technical problems of comprehensive chemical plugging relief and pressure decreasing and augmented injection of the strong sensitivity oil layer water injection well.

Owner:XIAN ZHONGFU KAIHONG GASOLINEEUM TECH

Quick start method for treating ammonia-containing wastewater by A/O process

ActiveCN103373760AReduce the difficulty of startingImprove processing efficiencyTreatment with aerobic and anaerobic processesHigh concentrationActivated sludge

The invention relates to a method for quickly starting short-cut nitrification and denitrification of an A / O system. The method comprises the following steps of: firstly putting inocula into a bioreactor, wherein the inocula are enriched nitrobacteria and nitrous acid denitrifiers or mixtures of aerobic activated sludge in sewage plants; adopting two operation modes including batch injection and continuous injection to start a system; and adding the nitrobacteria during batch injection, and adding the denitrifiers during continuous injection. Compared with the prior art, the method has the advantages of low start requirement, high start speed, capability of treating high-concentration ammonia-containing wastewater and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

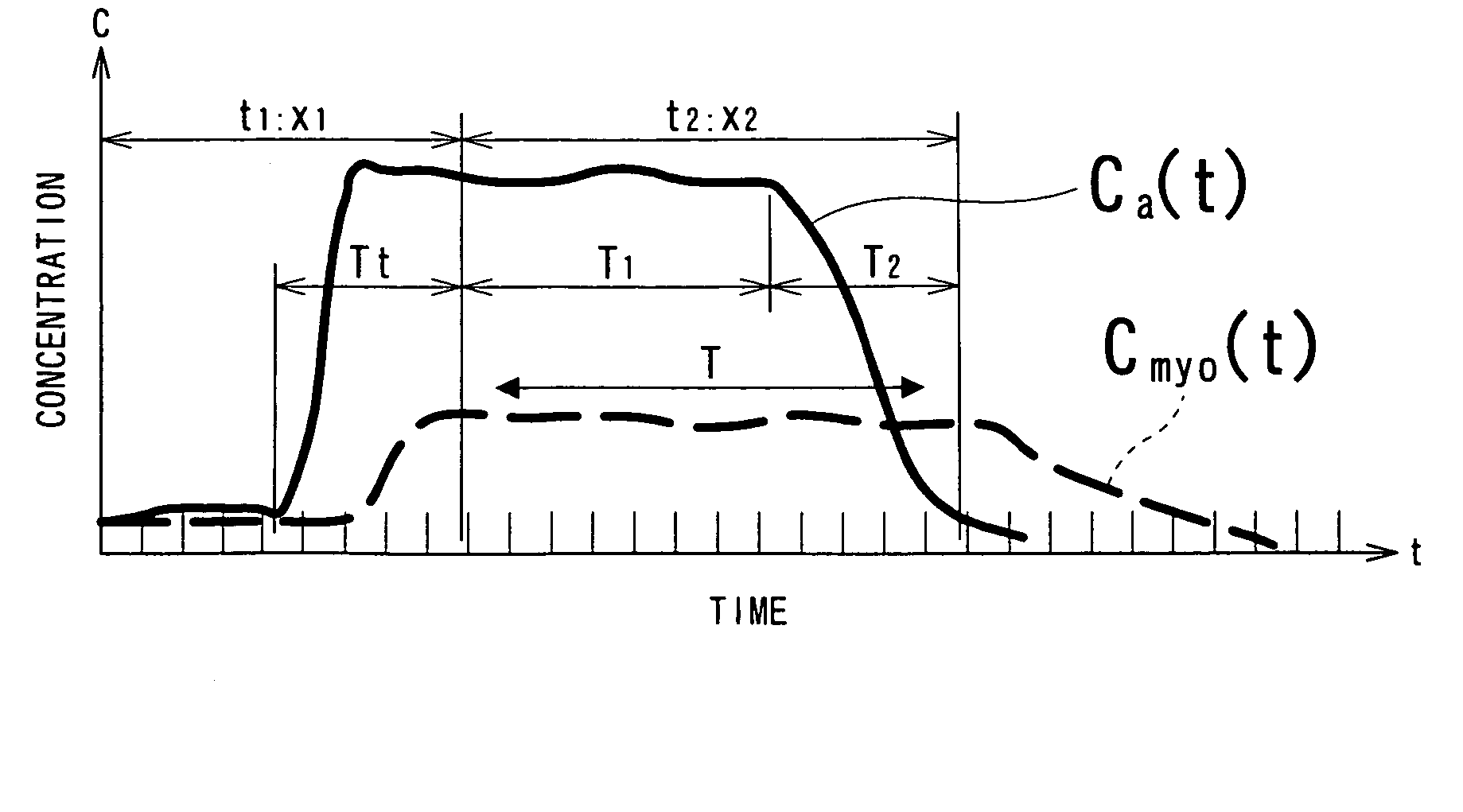

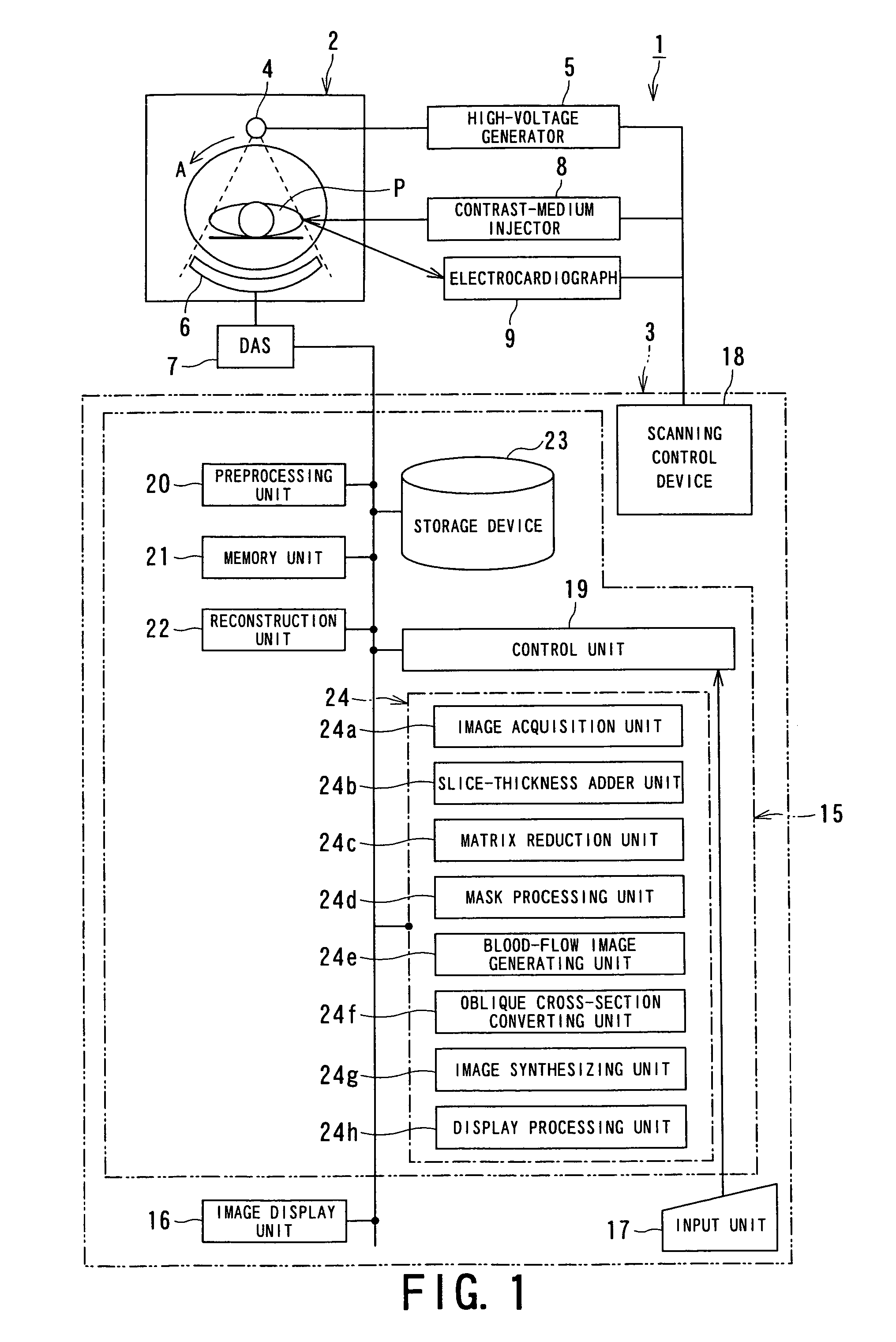

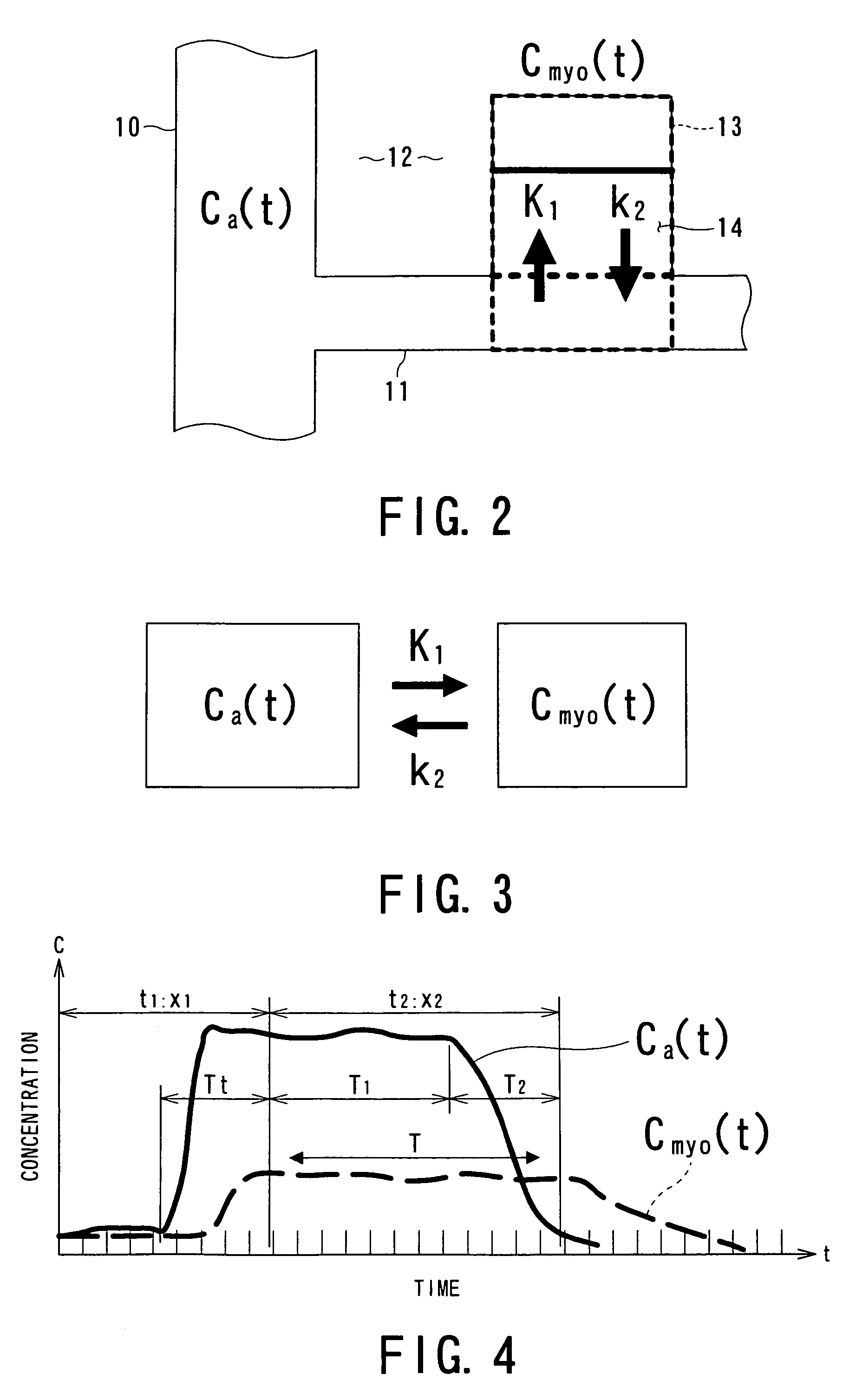

X-ray CT apparatus and myocardial perfusion image generating system

ActiveUS7853309B2Reduce injection volumeShort timeDiagnostic recording/measuringTomographyCardiac muscleX-ray

An X-ray CT apparatus comprises a blood-flow information acquisition unit, a correction value calculating unit and a blood-flow image generating unit. The blood-flow information acquisition unit obtains information of a relative blood flow rate in the myocardium of the subject based on the CT image. The correction value calculating unit obtains a correction value based on the CT image in a concentration transition period defined to be a period from immediately after start of a continuous injection of a contrast medium into the subject until the contrast medium reaching the myocardium increases and is be in a state where it can be considered that the contrast medium is saturated at a constant value. The blood-flow image generating unit generates a blood flow value image in the myocardium by correcting the information of the relative blood flow rate with the correction value.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE +1

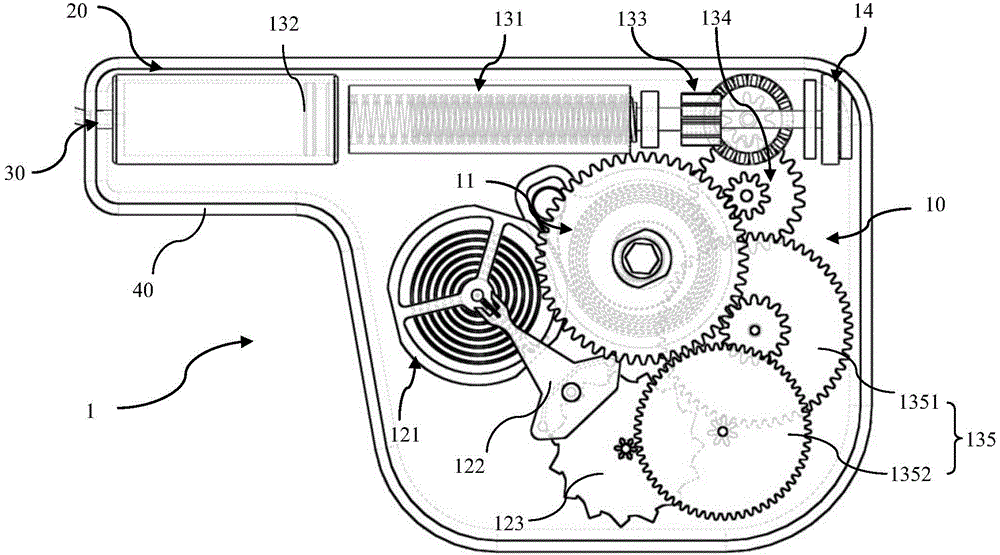

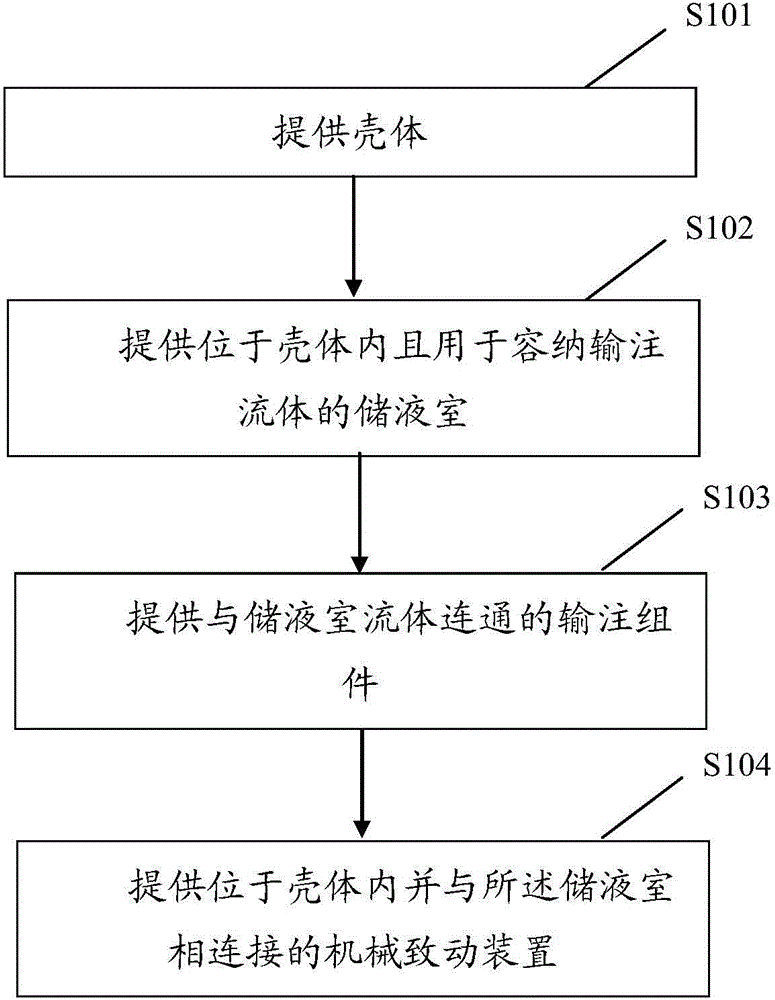

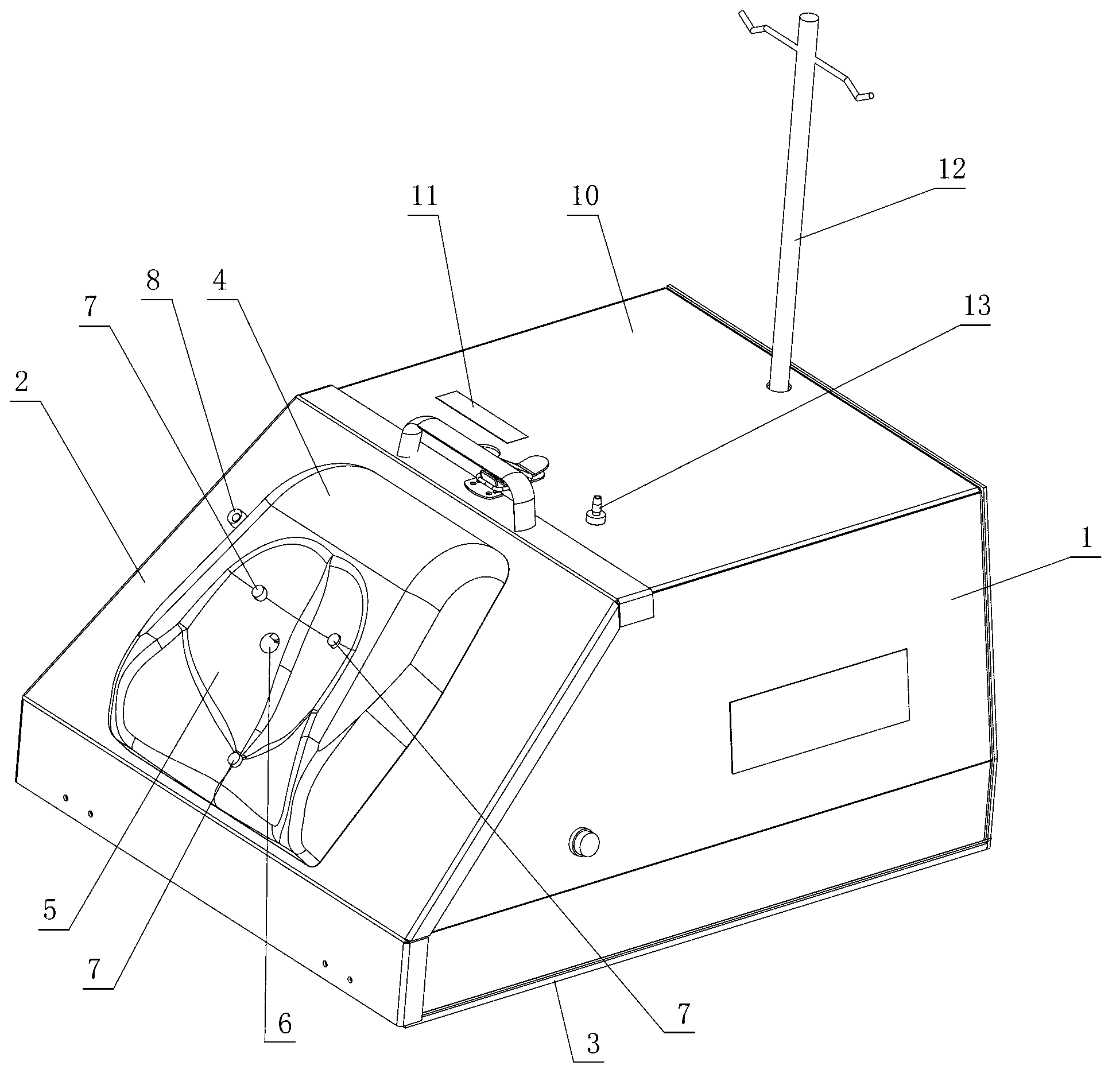

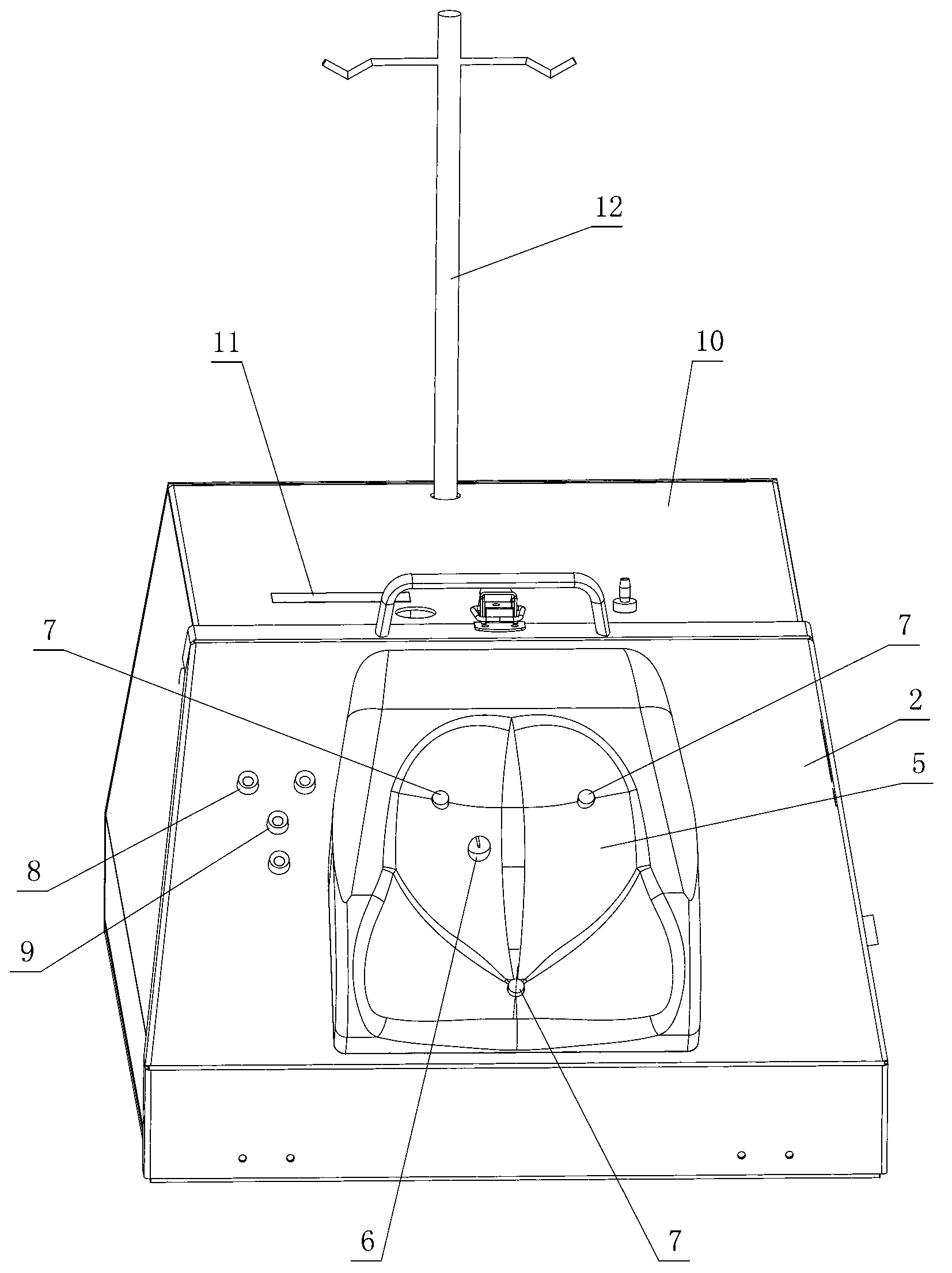

Fluid perfusion equipment comprising mechanical actuating device and manufacturing method of fluid perfusion equipment

InactiveCN106267459AReduce volumeRealize automatic continuous injectionPressure infusionInsulin pumpBiomedical engineering

The invention provides fluid perfusion equipment which is used for medicating patients and comprises a mechanical actuating device and a manufacturing method of the fluid perfusion equipment. The fluid perfusion equipment can comprises a shell, a fluid storage chamber, a perfusion component and the mechanical actuating device, wherein the fluid storage chamber is arranged in the shell and is used for accommodating a perfusion fluid; the perfusion component communicates with the fluid in the fluid storage chamber and is used for conveying the perfusion fluid in the fluid storage chamber into the body of the patients; and the mechanical actuating device is arranged in the shell and is connected to the fluid storage chamber, and the mechanical actuating device is used for providing kinetic energy by which the perfusion fluid in the fluid storage chamber is conveyed to the patients by virtue of the perfusion component and controlling the flow of the perfusion fluid conveyed to the patients by controlling the size of the kinetic energy. With the implementation of the equipment and the method, the automatic continuous injection of the perfusion fluid within a short period (for example, 1-7 days) is achieved, and the conveying flow is stabilized; in addition, the size of an insulin pump is diminished; and moreover, the fluid perfusion equipment is more conducive to the patients to wear.

Owner:MEDTRONIC INC

Automatic continuous injection device for drug injection of adult chicken

InactiveCN103222901AEasy to operateHigh injection safety factorVeterinary instrumentsDrug injectionEngineering

The invention discloses an automatic continuous injection device for drug injection of an adult chicken, and belongs to the technical field of poultry injectors. The automatic continuous injection device comprises an injection part mounted in a housing and provided with a power part, wherein a front cover plate of the housing and a bottom plate of the housing are obliquely mounted; an injection panel is mounted on the outer wall of the front cover plate; the outer wall of the injection panel is of a concave curved surface; and a needle outlet communicated with the interior of the housing is formed in the concave curved surface. The automatic continuous injection device is simple in operation and high in safety coefficient of injection.

Owner:HUZHOU ZHONGAN AGRI INTELLIGENT TECH

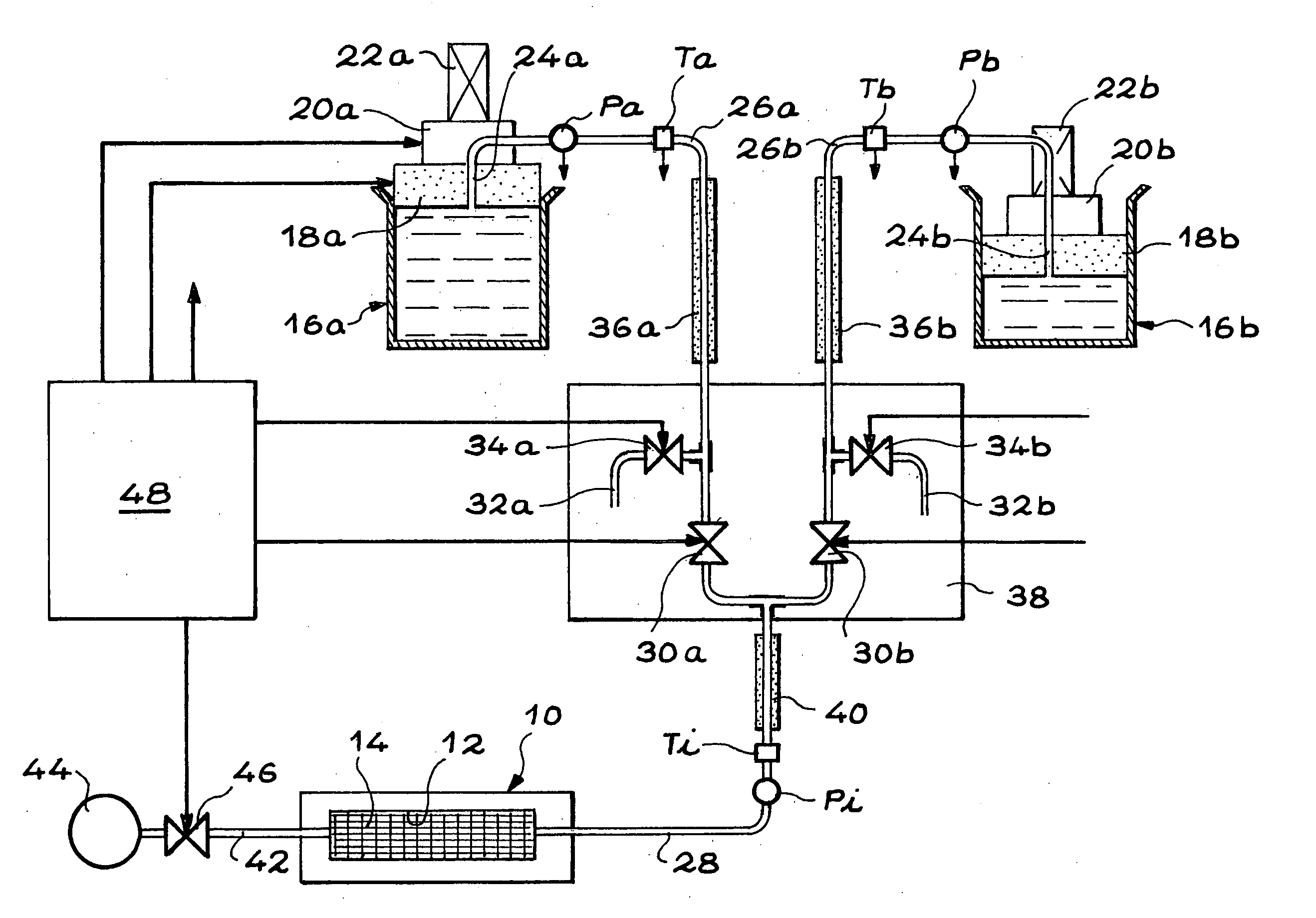

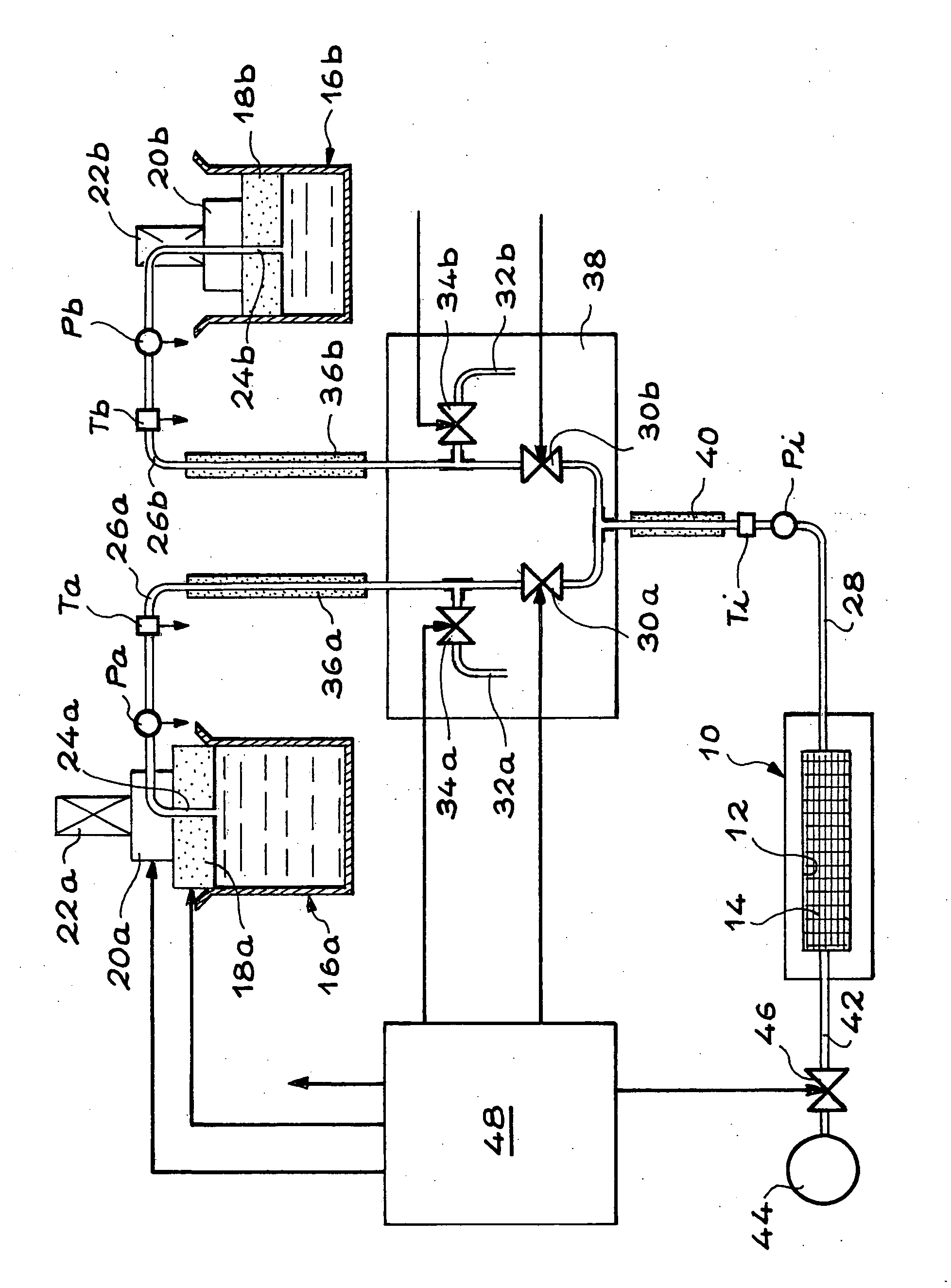

Method for injecting resin in a mould containing a fibrous preform

To produce a large-size item using the RTM technique, only two reservoirs (16a, 16b) are used which are alternately connected to the mould (10). When one of the reservoirs is empty, it is replaced by another reservoir full of resin while the resin contained in the other reservoir is injected into mould (10). Therefore continuous injection is made into mould (10) of a quantity of resin that is greater than the accumulated capacity of the first and second reservoirs (16a, 16b).

Owner:EADS CCR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com