Method and equipment for detecting burning rate of pulverized coal

A technology of combustion rate and combustion rate of pulverized coal, which is applied in the direction of chemical analysis by combustion, can solve the problems of unsatisfactory quality, cumbersome operation procedures, and large error of combustion rate, etc., to achieve the maximum benefit of coal injection and good repeatability , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

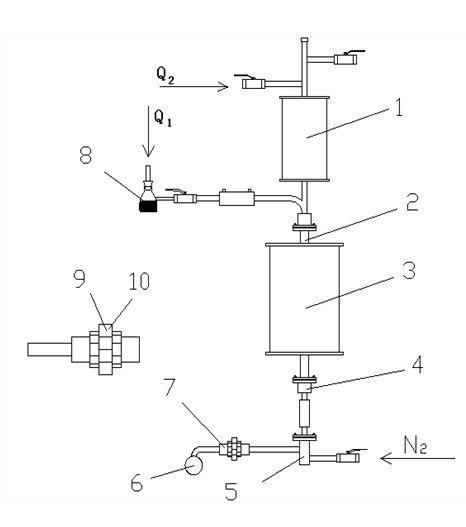

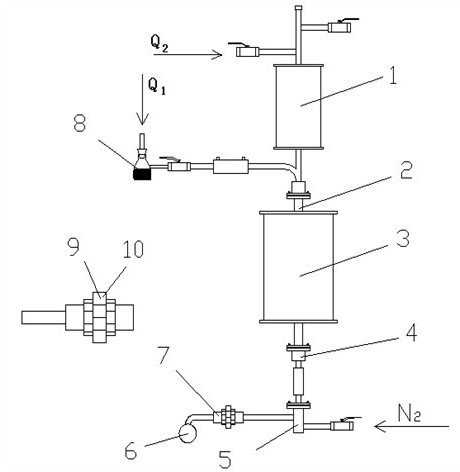

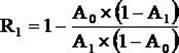

[0041] Embodiment 1: take by weighing 4# bituminous coal 40 + 0.5g (baked at 110°C for 3h) and put it into the spray bottle, weigh the total weight of the blow bottle (268.02g) and coal powder, record m 1 It is 308.02g. Turn on the air compressor, turn on the Q 1 , Q 2 Flow meter control valve, flow control is 1.0m 3 / h, 0.8m 3 / h. open N 2 device, flow control 2L / min. When blowing continuously for 8 minutes, cover the end of the dust collector with a rubber bag to collect gas and collect double samples. The injection time is set to 15min, and then turn off the N 2 device, Q 2 , Q 1 The flow meter controls the valve, weighs and records m 2 It is 289.64g. Remove the dust collector and ash collection tank in turn, collect unburned coal powder, and weigh m 3 It is 1.56g. Air blowing gas, control flow Q 1 2.0m 3 / h,Q 2 1.5m 3 / h, the time is 3 minutes. After the experiment is completed, turn off the air compressor. After the heating furnace cools down to below ...

Embodiment 2

[0057] Embodiment 2: take by weighing 2# anthracite 40g + 0.5 (baked at 105°C for 2h) and put it into the spray bottle, weigh the total weight of the spray bottle (268.02g) and coal powder, and record it as m 1 It is 308.37g. Open Q in sequence 1 , Q 2 Control valve, flow control is 0.8m 3 / h, 0.5m 3 / h, finally open N 2 device, flow control 2L / min. When blowing continuously for 5 minutes, start to collect gas and collect double samples. The injection time is set to 10min, and then turn off the N 2 device, Q 2 , Q 1 The flow meter controls the valve. Weigh and record m 2 It is 295.36g. Remove the dust collector and ash collection tank in turn, collect unburned coal powder, and weigh m 3 It is 1.13g. Air blowing gas, control flow Q 1 1.5m 3 / h,Q 2 1.0m 3 / h, the time is 2 minutes. After the experiment is completed, turn off the air compressor. After the furnace cools down to below 200°C (about 6h), turn off the main switch of the heating furnace, hot blast f...

Embodiment 3

[0070] Example 3: Weigh 40g of mixed coal (the ratio of 2 and 4# pulverized coal is 45:55) + 0.5 and put it into the blowing bottle, weigh the total weight of the blowing bottle (268.02g) and coal powder, and record it as m 1 It is 308.25g. Open Q in turn 1 , Q 2 Control valve, flow control is 0.9m 3 / h, 0.7m 3 / h, finally open N 2device, flow control 2L / min. When spraying continuously for 7 minutes, start to collect gas and collect double samples. The injection time is set to 12min, and then turn off the N 2 device, Q 2 , Q 1 The flow meter controls the valve. Weigh and record m 2 It is 294.18g. Remove the dust collector and ash collection tank in turn, collect unburned coal powder, and weigh m 3 It is 1.53g. Air blowing gas, control flow Q 1 1.8m 3 / h,Q 2 1.2m 3 / h, the time is 2.5 minutes. After the experiment is completed, turn off the air compressor. After the furnace cools down to below 250°C (about 5.5h), turn off the main switch of the heating furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com