Method for disposing urban sludge through combustion

A technology of municipal sludge and treatment method, applied in combustion method, combustion type, incinerator, etc., can solve the problems of long processing time, low combustion rate of municipal sludge, and inability to deal with municipal sludge energy consumption. , to increase the processing time without wasting energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

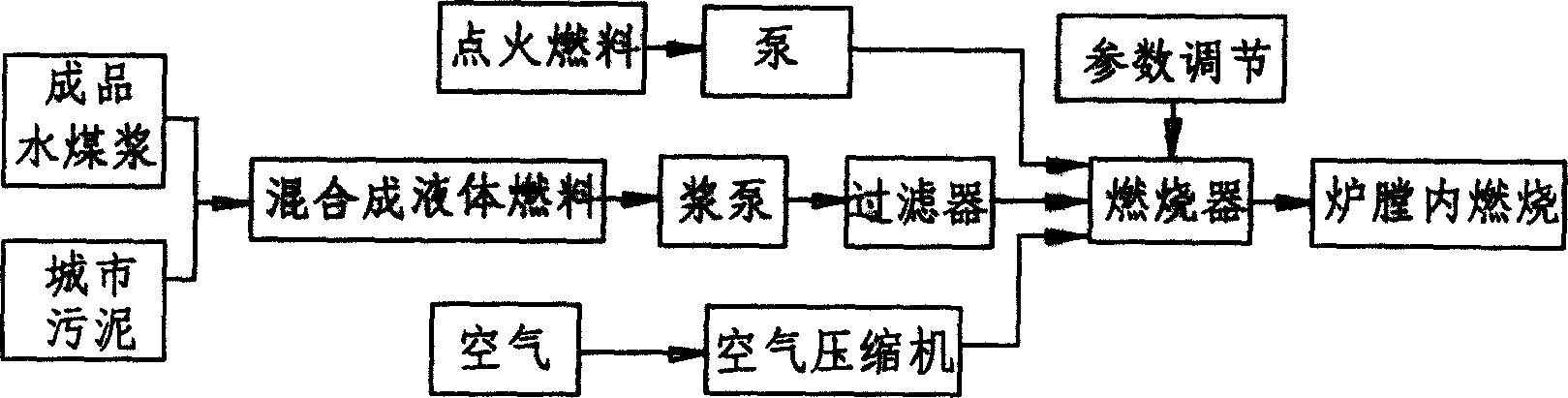

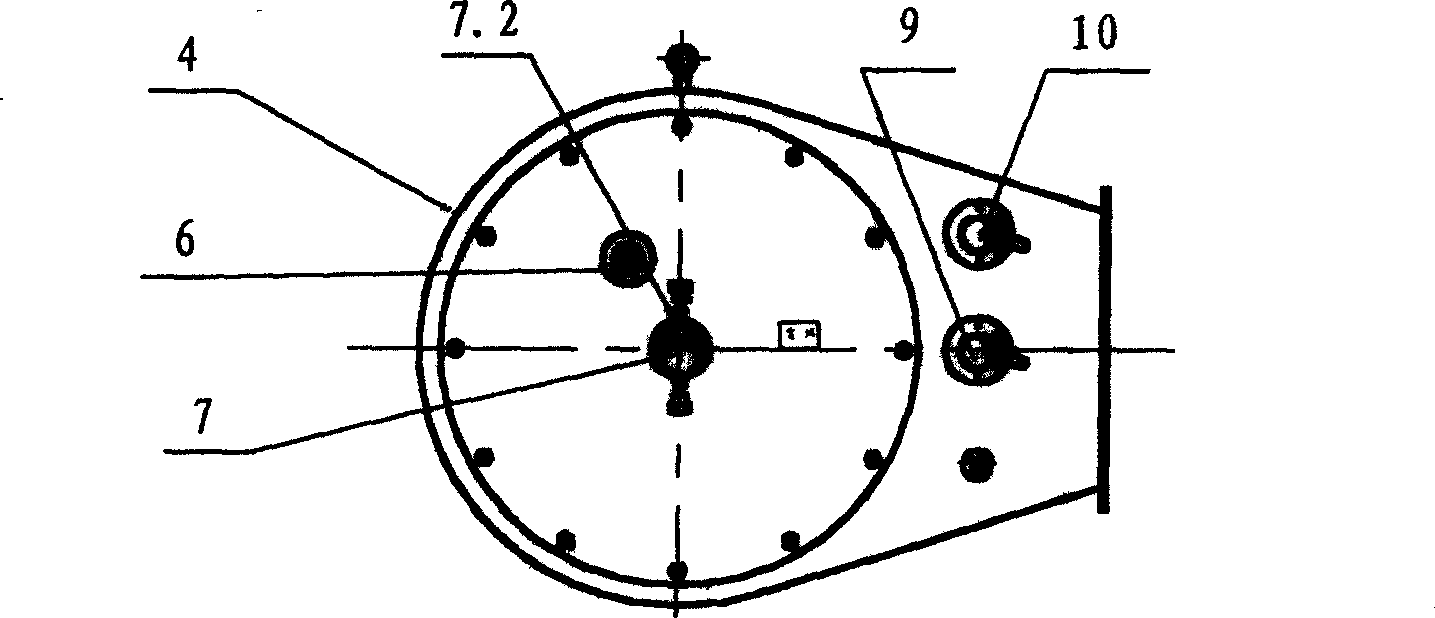

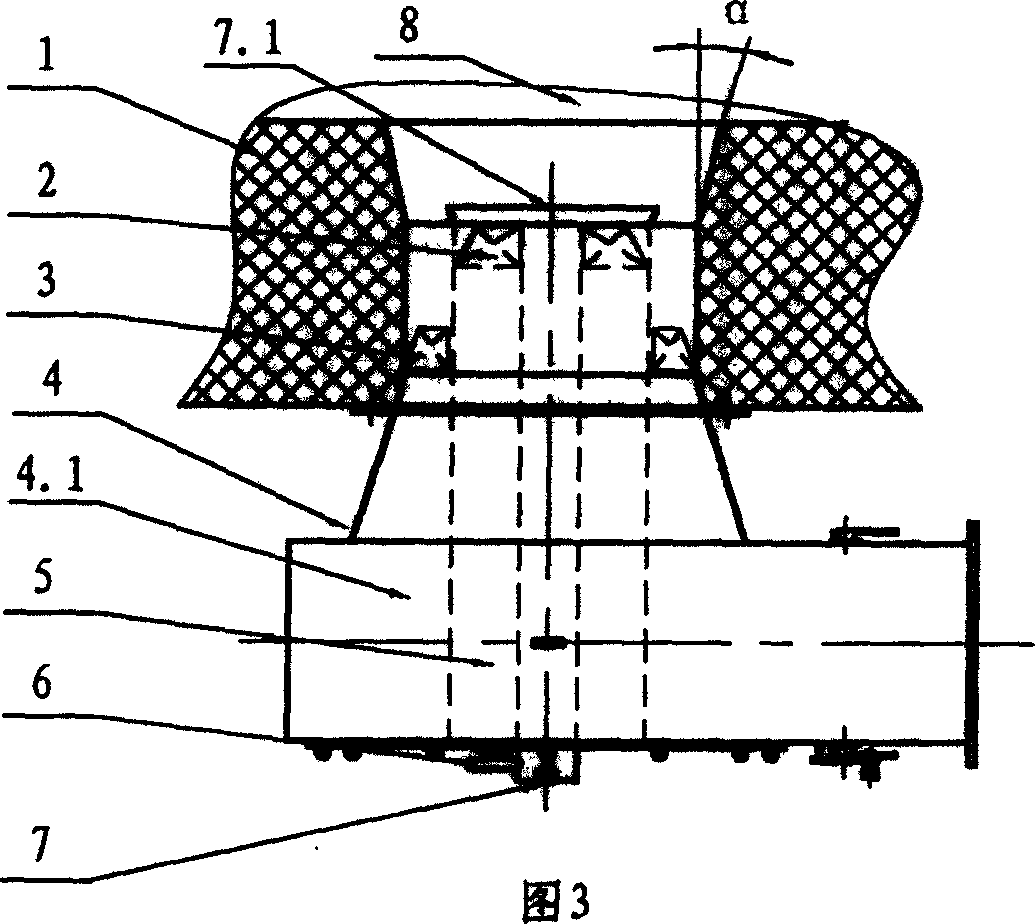

[0020] Embodiment 1: (see figure 1 , figure 2 ,image 3)

[0021] Use a pump to send the ignition fuel through the ignition channel 7.2 on the burner 4, and send it to the furnace 8 in an atomized state. Turn on the primary and secondary air switches 9 and 10 of the burner 4, so that the primary and secondary air pass through the air respectively. The wheels 2 and 3 are rotated and sent in, and the air enters the nozzle 7.1 of the burner 4 spray gun 7 through the primary and secondary air ducts 5 and 4.1, and then ignites the ignition fuel to raise the temperature of the furnace to 650°C. Ignition fuel can be easy to ignite and safe to use such as diesel or gas (the same below);

[0022] Then the municipal sludge with water content of 70-85% and the finished product coal-water slurry with water content of 30-40% are stirred and mixed into liquid fuel with a volume ratio of 2: 3.5, pressurized to 0.6Mpa with a slurry pump and sent into the burner 4 center The spray gun 7 sen...

Embodiment 2

[0027] Use a pump to send the ignition fuel through the ignition channel 7.2 on the burner 4, and send it to the furnace 8 in an atomized state. Turn on the primary and secondary air switches 9 and 10 of the burner 4, so that the primary and secondary air pass through the air respectively. The wheels 2 and 3 are rotated and sent in, and the air enters the nozzle 7.1 of the burner 4 spray gun 7 through the primary and secondary air ducts 5 and 4.1, and then ignites the ignition fuel to raise the temperature of the furnace to 700°C;

[0028] Then the municipal sludge with water content of 70-85% and the finished product coal water slurry with water content of 30-40% are stirred and mixed into liquid fuel with a volume ratio of 2:3, and then pressurized to 0.65Mpa with a slurry pump and sent to the center of the burner 4 The spray gun 7 sends the compressed air of 0.7Mpa to the spray gun 7 on the burner 4 at the same time, and injects it into the furnace 8 through the nozzle 7.1, ...

Embodiment 3

[0032] Use a pump to pump the ignition fuel through the ignition channel 7.2 on the burner 4, and send it to the furnace 8 in an atomized state. Turn on the primary and secondary air switches 9 and 10 of the burner 4 to make the primary and secondary air flow through the air respectively. The wheels 2 and 3 are rotated and sent in, and the air enters the nozzle 7.1 of the burner 4 spray gun 7 through the primary and secondary air ducts 5 and 4.1, and then ignites the ignition fuel to raise the temperature of the furnace to 700°C;

[0033] Then the city sludge with water content of 70-85% and the finished product coal water slurry with water content of 30-40% are stirred and mixed into liquid fuel with a volume ratio of 2: 3.5, pressurized to 0.6Mpa with a slurry pump and sent into the burner 4 center The spray gun 7 sends 0.6Mpa compressed air to the spray gun 7 on the burner 4 at the same time, and injects it into the furnace 8 through the nozzle 7.1, so that the liquid fuel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com