Novel grain corn combine harvester

A technology for combine harvesters and corn, applied in harvesters, threshing equipment, crop processors, etc., can solve the problems of low degree of automation, waste of resources, low threshing efficiency, etc., achieve complete automation and systematization, extend the walking route, The effect of improving threshing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

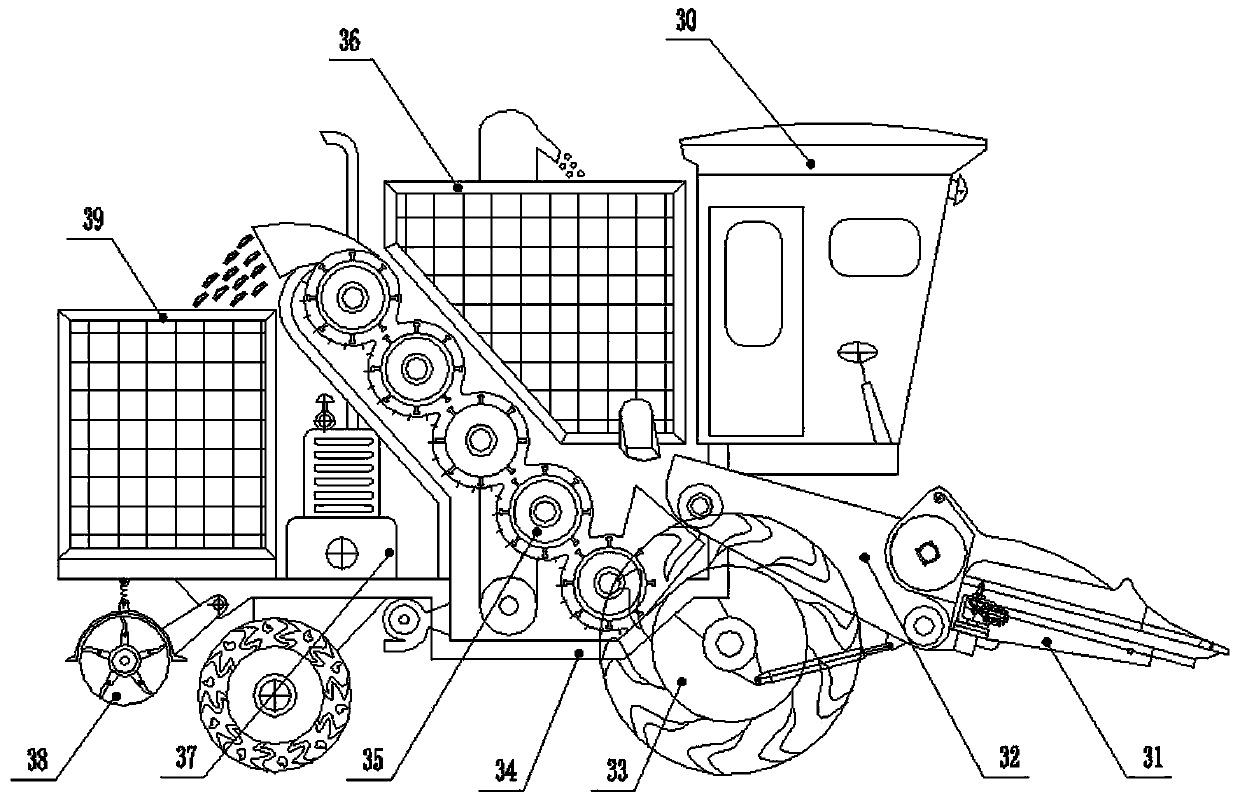

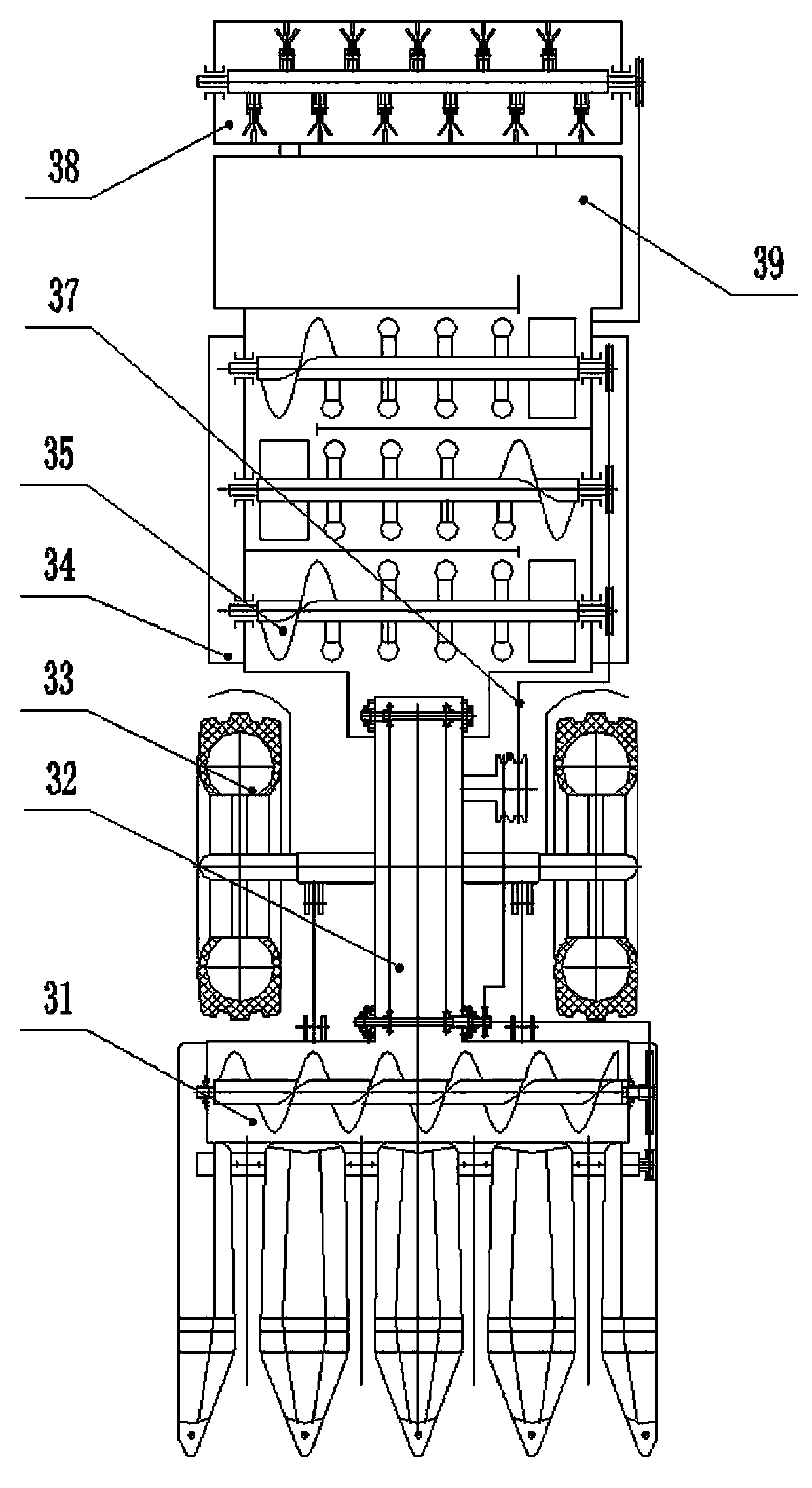

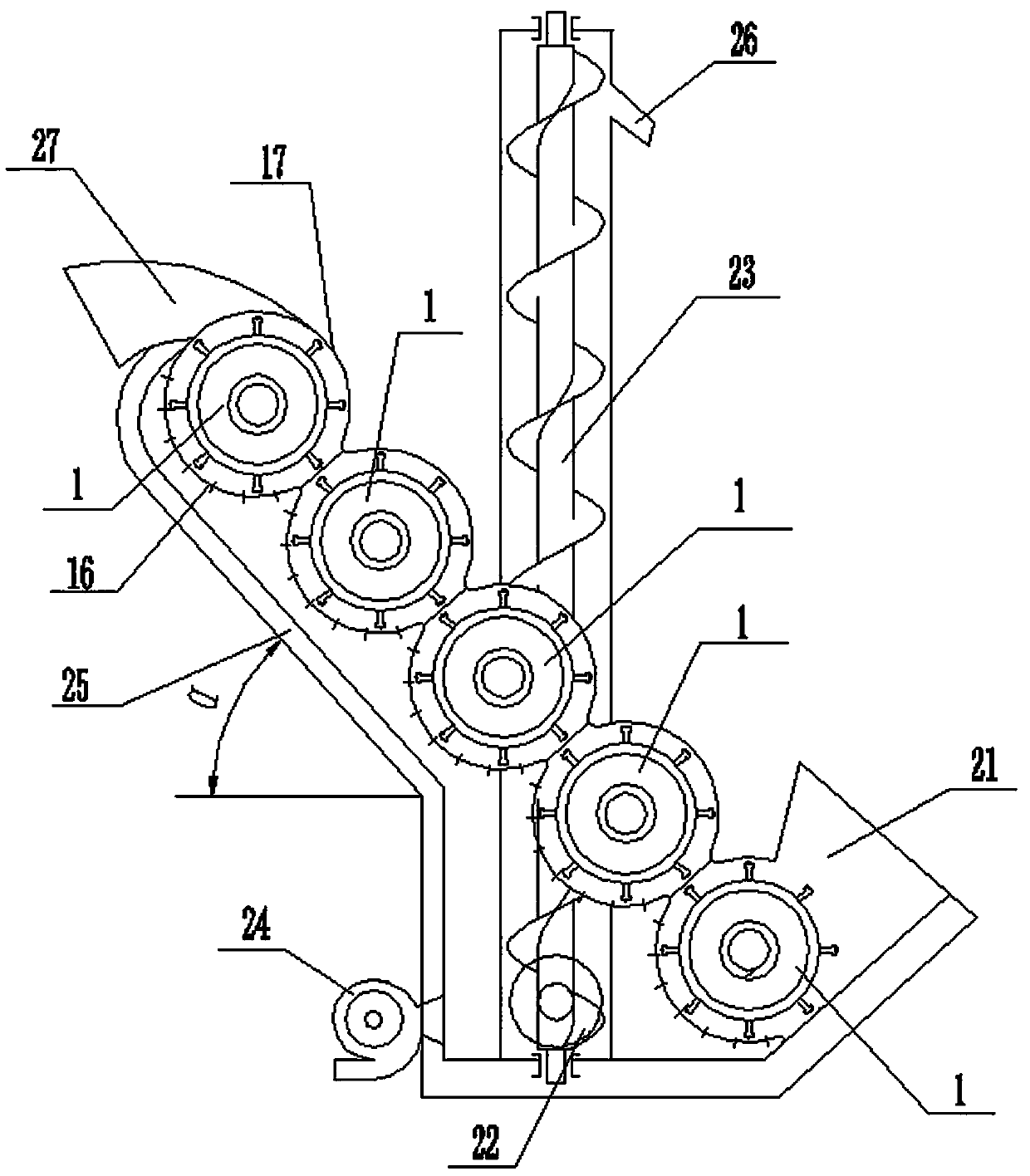

[0019] like Figure 1 to Figure 4 As shown, a new type of grain corn combine harvester includes a body 34, a driving control system 30, a transmission system 37, a walking system 33, a header unit 31 and a threshing unit 35. The rear end of the table unit 31 is connected to the lift bridge 32 , the rear end of the lift bridge 32 is connected to the threshing unit 35 , and the threshing unit 35 and the header unit 31 are connected through the lift bridge 32 . The threshing unit 35 is connected with a collection box 39 and a grain recovery box 36, a straw returning device 38 is installed at the rear of the body 34, the collection box 39 is turned over by the hydraulic system for unloading, and the outlet of the grain recovery box 36 is unloaded by an opening mechanism. , the working parts of the whole corn combine harvester are connected by the transmission system 37, and the control of the machine is achieved through the joint action of the driving control system 30 and the wal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com