Patents

Literature

443 results about "CORN GRAIN" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

However, each of the individual kernels of corn is considered a whole grain, so using a strict definition of corn as a vegetable isn’t totally true. By definition, a whole grain is a small, hard, dry seed of a grass plant.

Method of producing fermentation-based products from corn

InactiveUS7083954B2Excellent extractabilityIncrease usable surface areaProtein composition from vegetable seedsClimate change adaptationCorn mealFermentation

Corn oil and corn meal obtained from corn are included in useful products. A method for producing fermentation-based products comprises combining corn meal with water and an enzyme, and mixing the combination with a micro-organism capable of fermenting a carbon source to produce a fermentation-based product. The corn meal is produced by cracking whole corn, conditioning the whole corn and extracting the whole corn to produce corn meal without flaking the corn during processing. The corn grain process generally includes the steps of cracking corn grain having a total oil content of from about 3% by weight to about 30% by weight and extracting a corn oil from the cracked corn grain.

Owner:RENESSEN

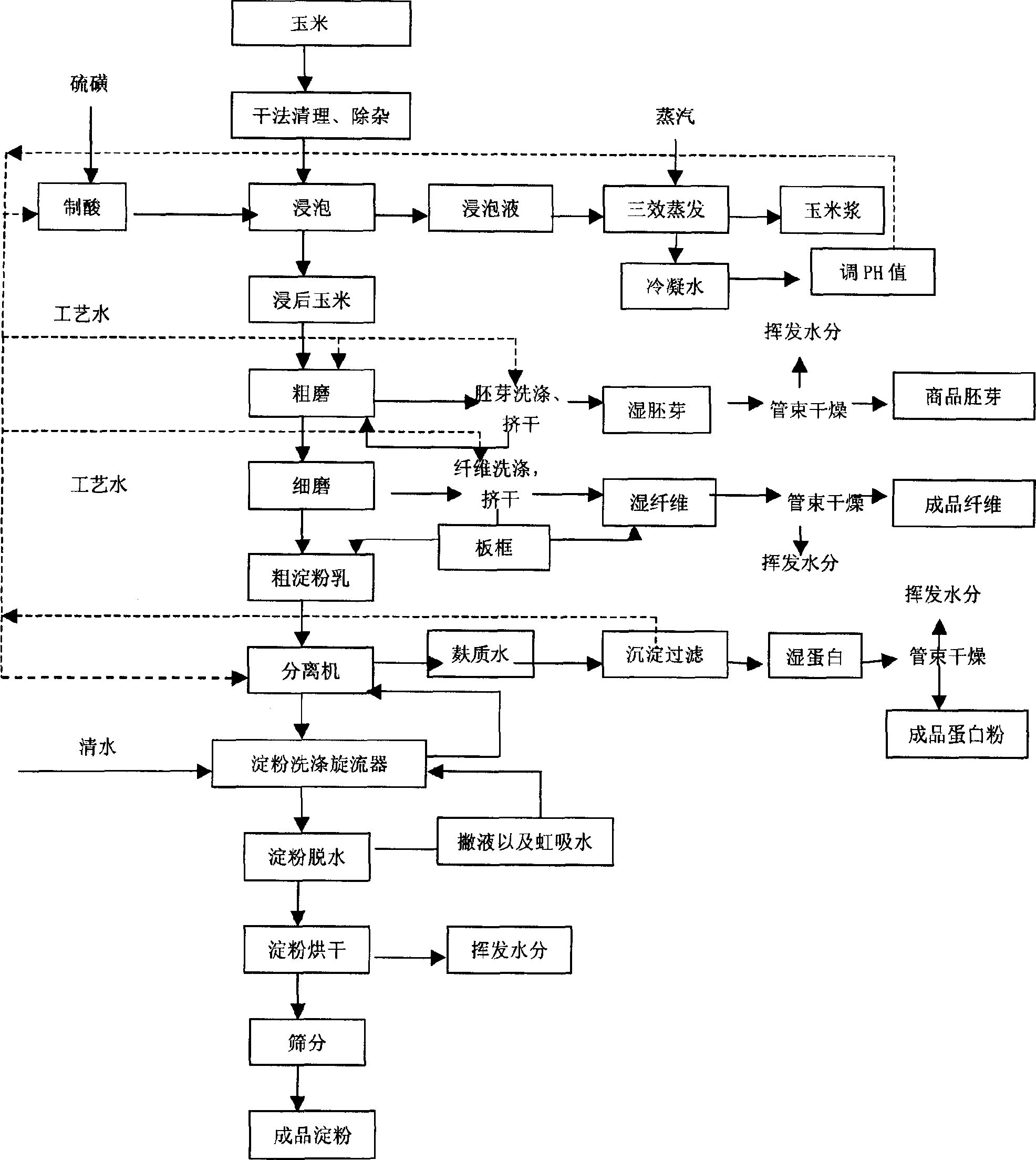

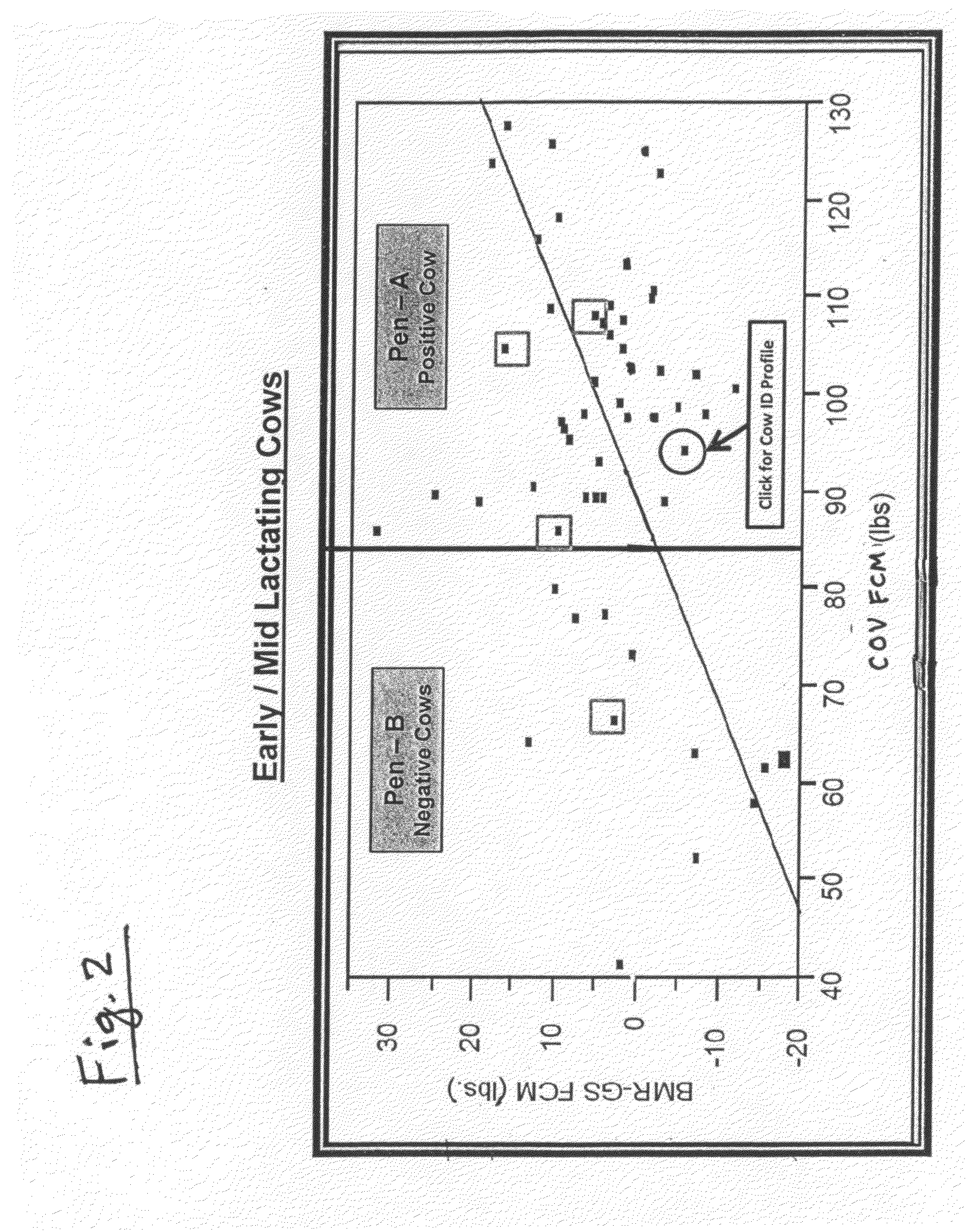

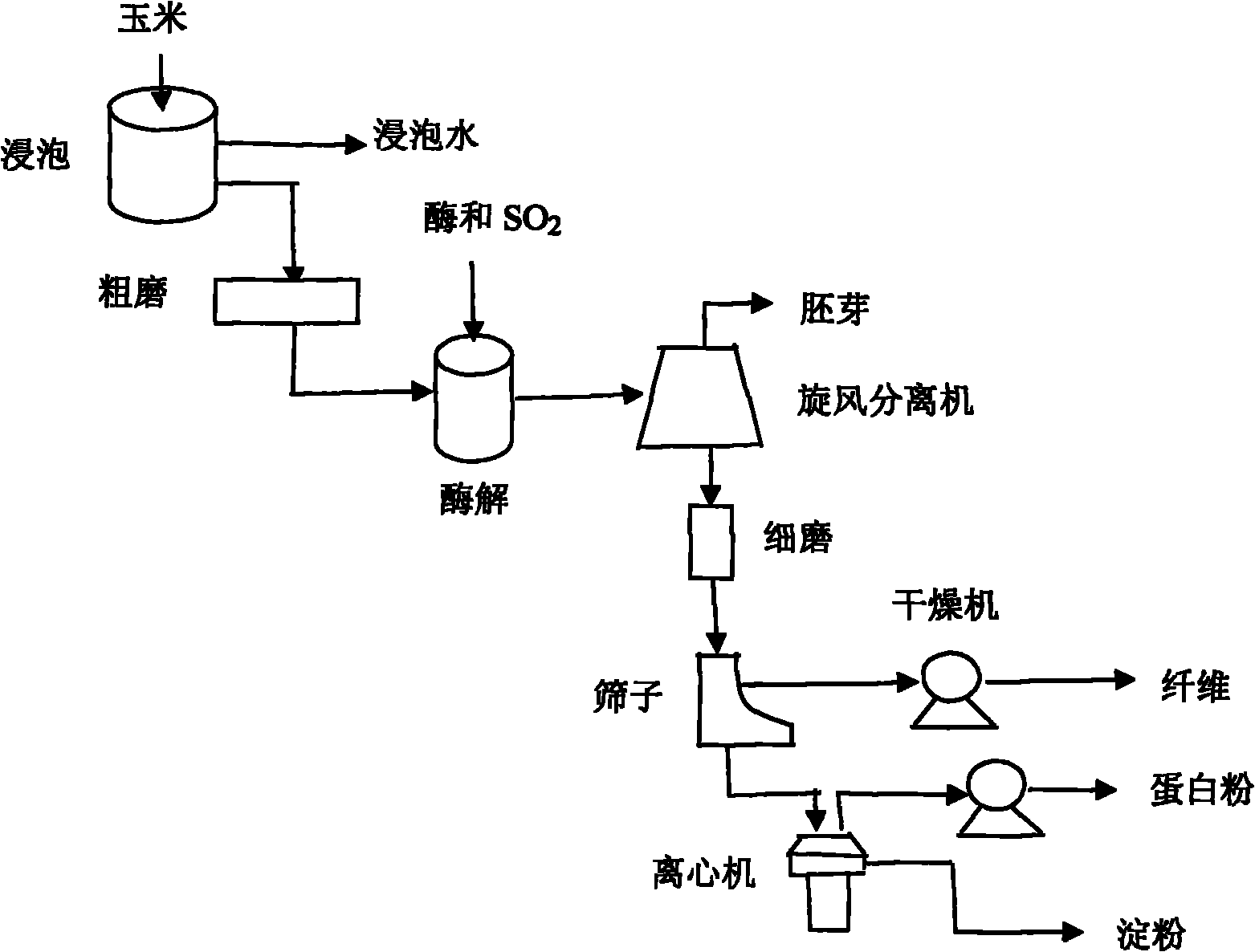

Tech. of closed water circulation in maize starch prodn. process

InactiveCN1792221AReduce water consumptionGuarantee product qualityProteins working-up by texturisingVegetable proteins working-upFiberEvaporation

A closed-loop cyclic utilization technology for the technological water in the procedure of preparing corn starch is disclosed. After the technological water is used to prepare sulfurous acid and immerse corn grains in it, it flows in technological water pool behind evaporation, condensing and regulating pH value. The technological water is also used for coarse grinding, fine grinding, and washing germinal buds and fibers. After two-stage air-floating separation, the water containing bran flows in protein depositing tank. The supernatant is drained in technological water pool and the protein deposit is recovered.

Owner:鲁洲生物科技(山东)有限公司

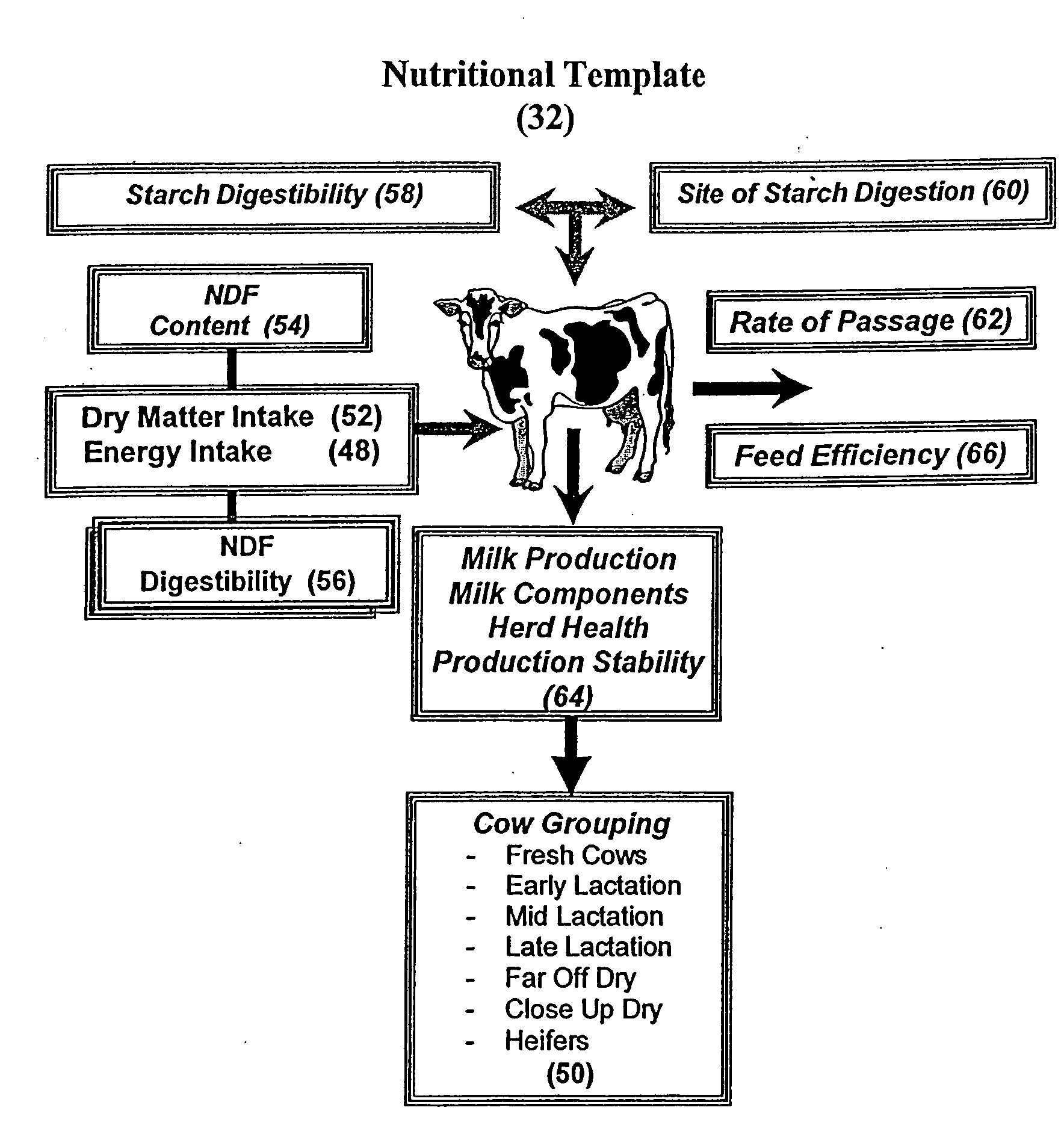

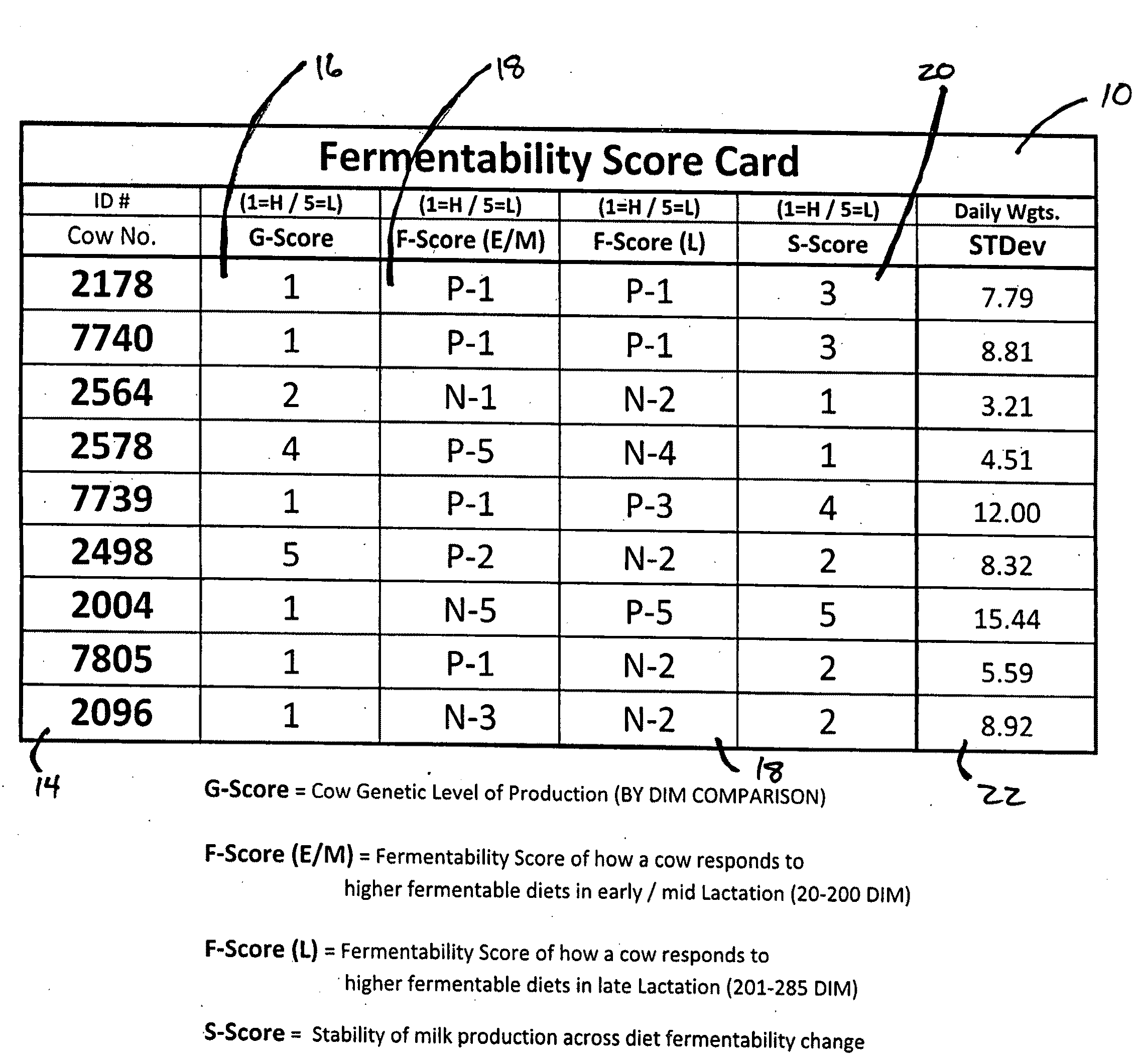

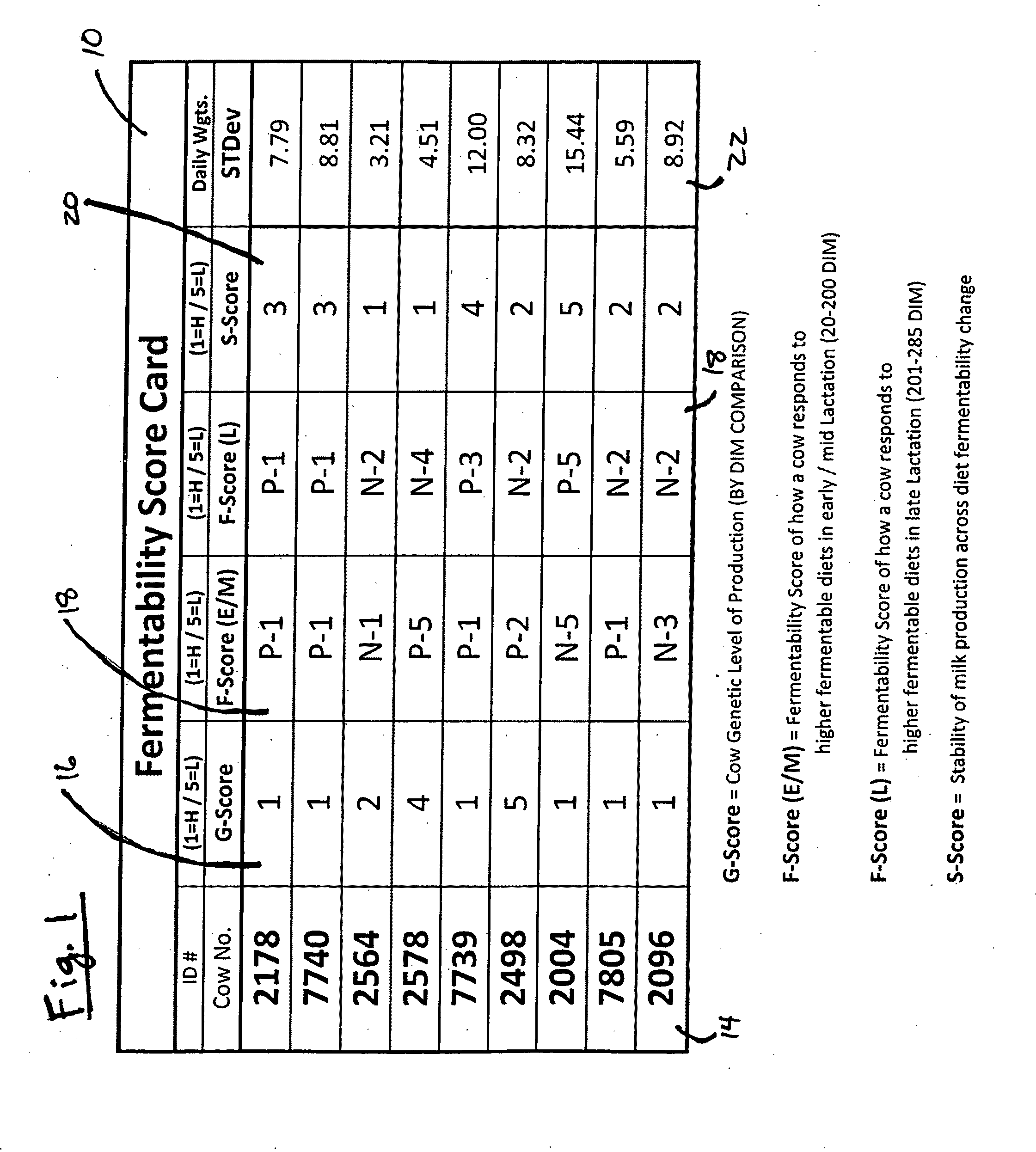

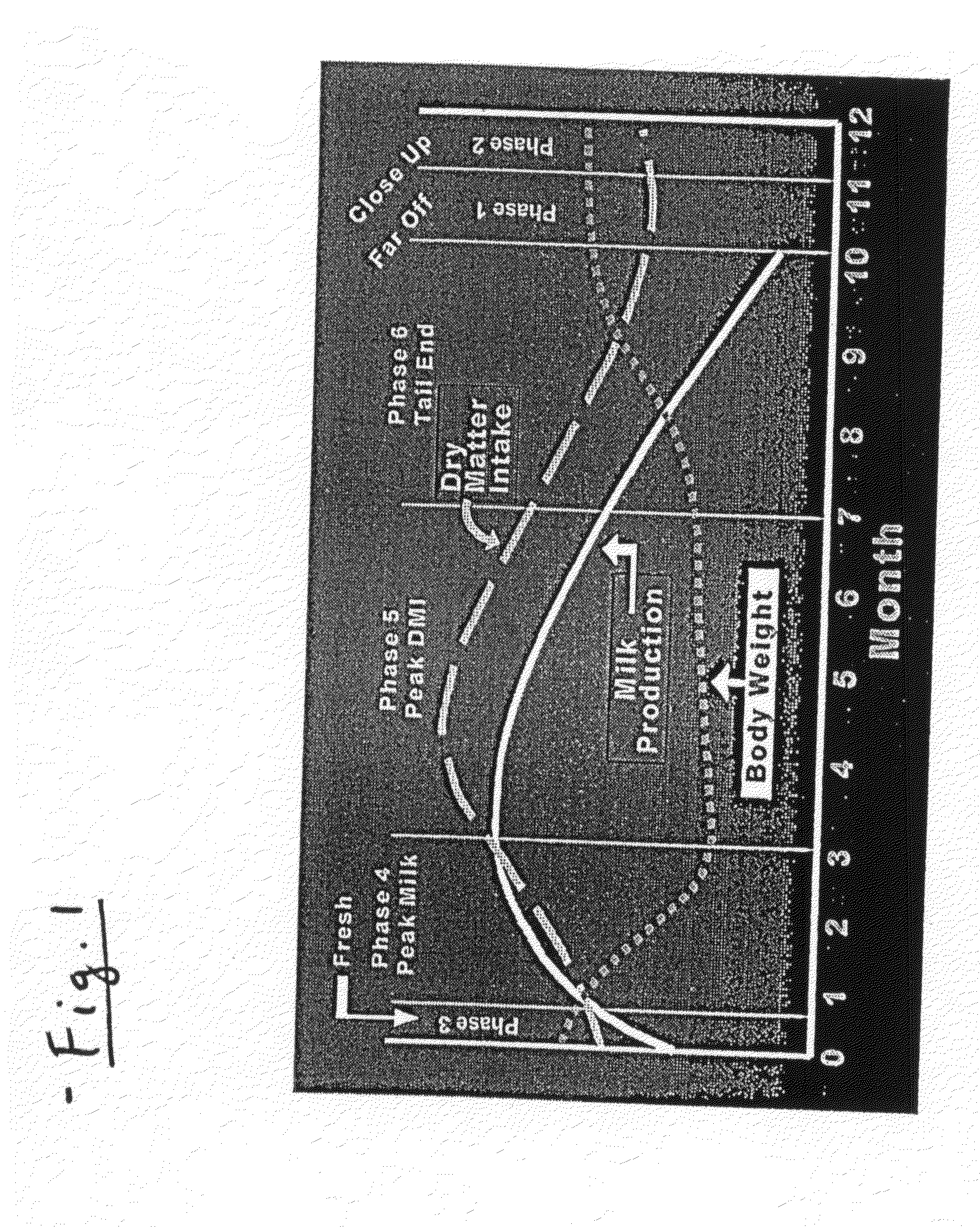

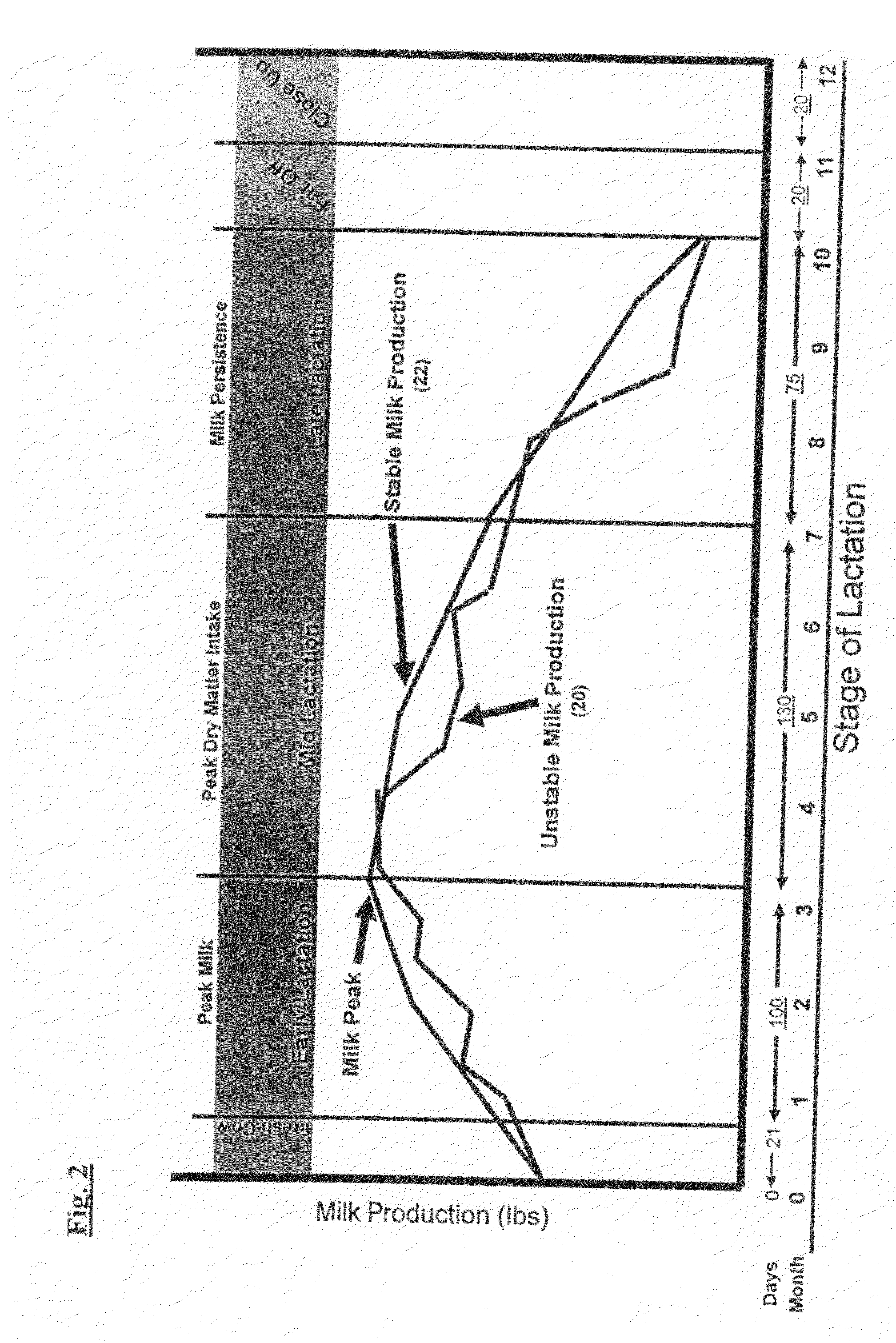

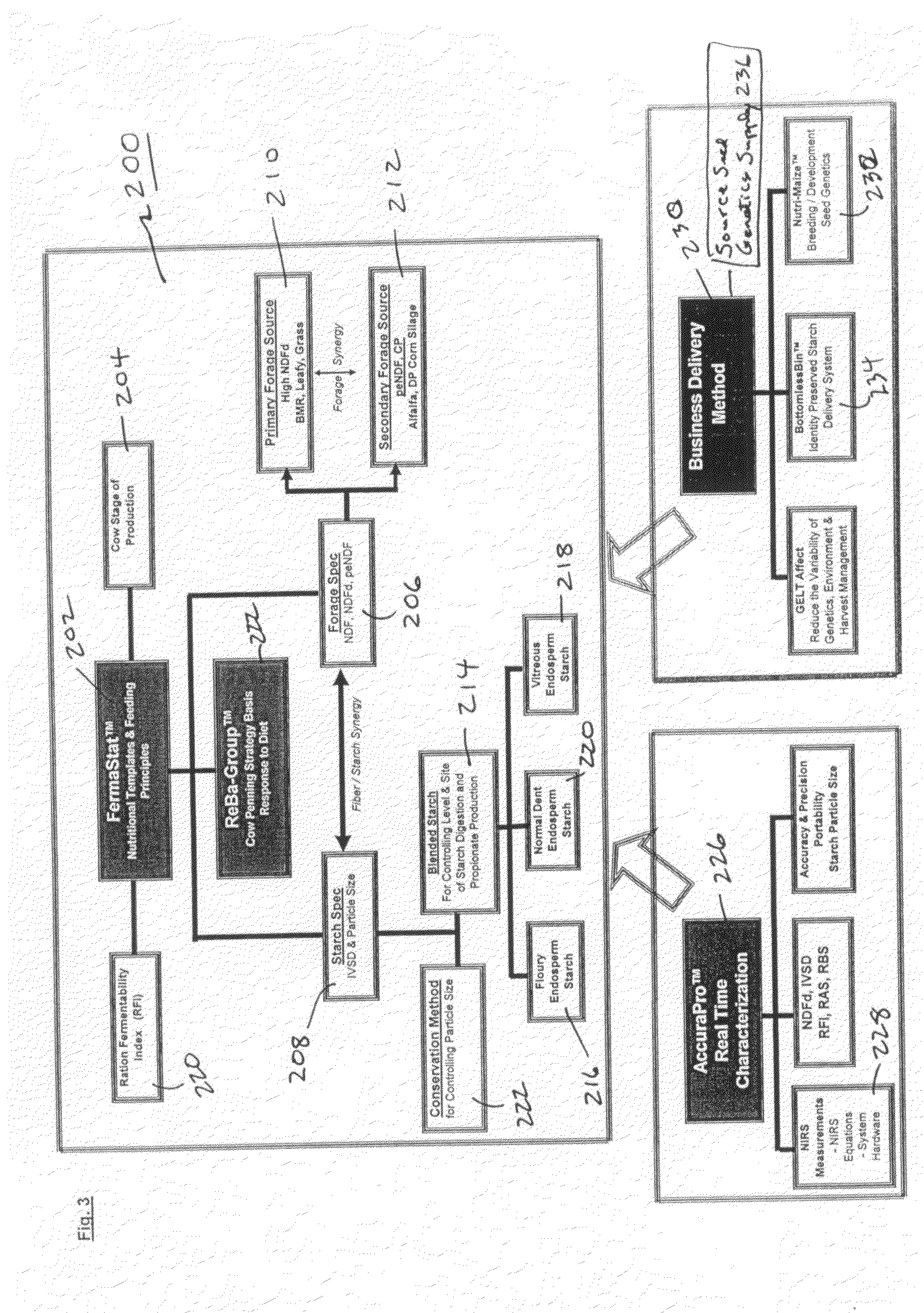

Feed delivery system for enhancing ruminant animal nutrition

InactiveUS20080215167A1Precisely formulatedImprove production stabilityAnimal feeding stuffSpecial data processing applicationsAgricultural scienceAnimal Foraging

A feed delivery system for a dairy farm wherein a third-party supplier of the system can provide the dairy farm with lists of approved hybrids for the feed components, necessary information inputs for practicing the feed method, and all or a portion of its component needs for the feed ration corresponding to a feed ration that contains: at least one primary forge source selected from the group consisting of brown midrib corn silage, dual-purpose corn silage, leafy corn silage, and grass silage; a secondary forage source selected from the group consisting of dual-purpose corn silage, alfalfa haylage, alfalfa dry hay, grass silage, and alfalfa / grass mix; a corn grain of floury and / or vitreous endosperm starch grain into which normal dent corn or mutt corn may be blended in order to achieve a predetermined level of in vitro starch digestibility; such grain component being further processed to produce a specific particle size of the blended starch. The feed delivery system can also provide the dairy farm with real-time characterizations of at least some of its feed ingredients, and re-penning strategies for maximizing the milk productivity of the cows.

Owner:NUTRI INNOVATIONS LLC

System for real-time characterization of ruminant feed rations

InactiveUS20090092715A1Improve energy efficiencyHealth be optimizedMaterial analysis by optical meansAnimal feeding stuffAgricultural scienceAdditive ingredient

Owner:NUTRI INNOVATIONS LLC

Soaking technology for preparing corn starch

The invention relates to a soaking technology for preparing corn starch, belonging to the technical field of grain deep processing. The technological steps comprise: 1. soaking: corn grains are soaked in water to soften embryos; 2. pulp grinding: the soaked corn grains are coarsely ground to obtain corn pulp; 3. enzymolysis: one of acid protease and pepsin is added in the obtained corn pulp after coarse grinding to conduct enzymolysis to the corn pulp, and SO2 is fed at the same time to mainly take the effect of inhibiting activities of microorganisms on the premise that the enzymatic activity is not affected; and 4. fine grinding, separation and drying to obtain starch finished product. Through shortening soaking time and reducing the used amount of SO2, the invention has the advantages that the corrosion of equipment, the underground water pollution, the residual sulfurous acid in the product and the like are obviously reduced, the obstacles restricting enzyme to enter endosperm to react with protein particles are eliminated, the total soaking time is only 8-12h, the soaking time is shortened, the cost is reduced, the effect is good, and the popularization value and the application value are high.

Owner:山东福田糖醇有限公司

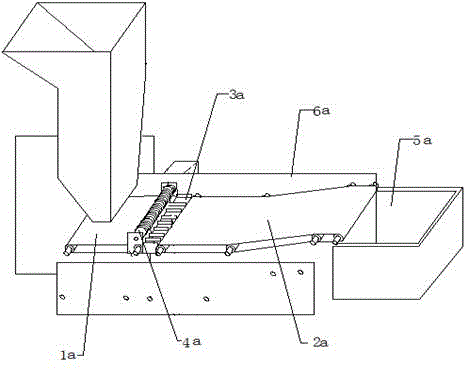

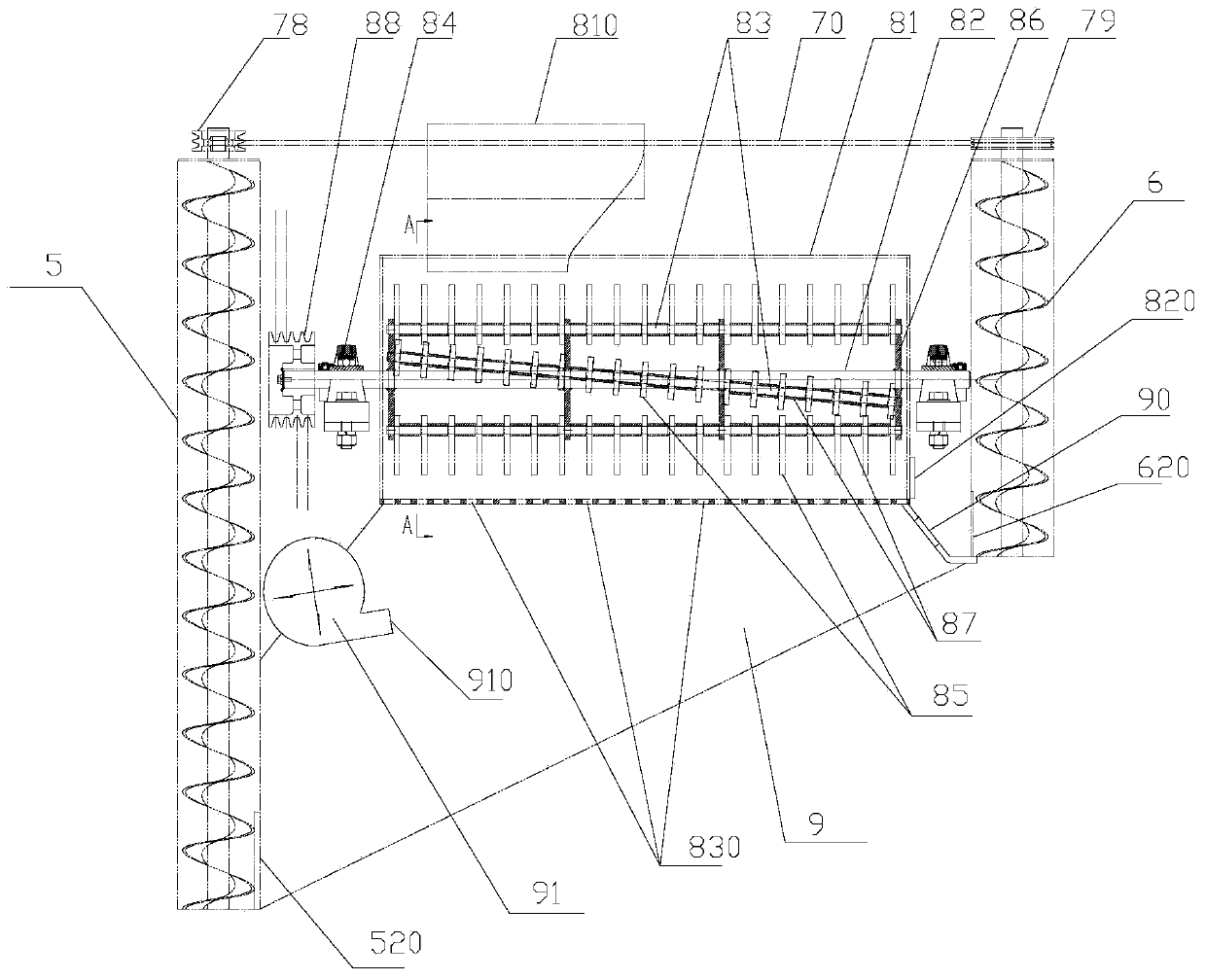

Sweet corn grain production line and sweet corn grain production process

InactiveCN104799172AImprove qualityGuaranteed freshSeed preservation by freezing/coolingFood preparationProduction lineAgricultural science

The invention discloses a sweet corn grain production line and a sweet corn grain production process. The sweet corn grain production line comprises a withering system, a peeling machine, a threshing machine, a sweet corn grain uniform spreading and selection device, a sweet corn grain processing rinsing machine, a sweet corn grain processing blanching device, a cooling system, a sweet corn grain processing draining device, a quick-freezing system, a sweet corn grain selection mechanism, a sweet corn grain processing last-stage metal detection mechanism, a packaging mechanism and a metal detector, which are sequentially arranged in the material conveying direction. The sweet corn grain production process comprises the steps of raw material acceptance check, withering, peeling, threshing, selection, rinsing, blanching, cooling, draining, quick-freezing, selection, gold detection before packaging, packaging, gold detection after packaging and warehousing. By adopting the sweet corn grain production line and the sweet corn production process, the sweet corn grains with good quality can be produced, the freshness of the corn grain can be guaranteed, the nutrition of the corn can be prevented from being lost, the automation degree is high in the processing process, the labor intensity can be alleviated, and the streamline operation can be realized.

Owner:HENAN KEXI FOOD

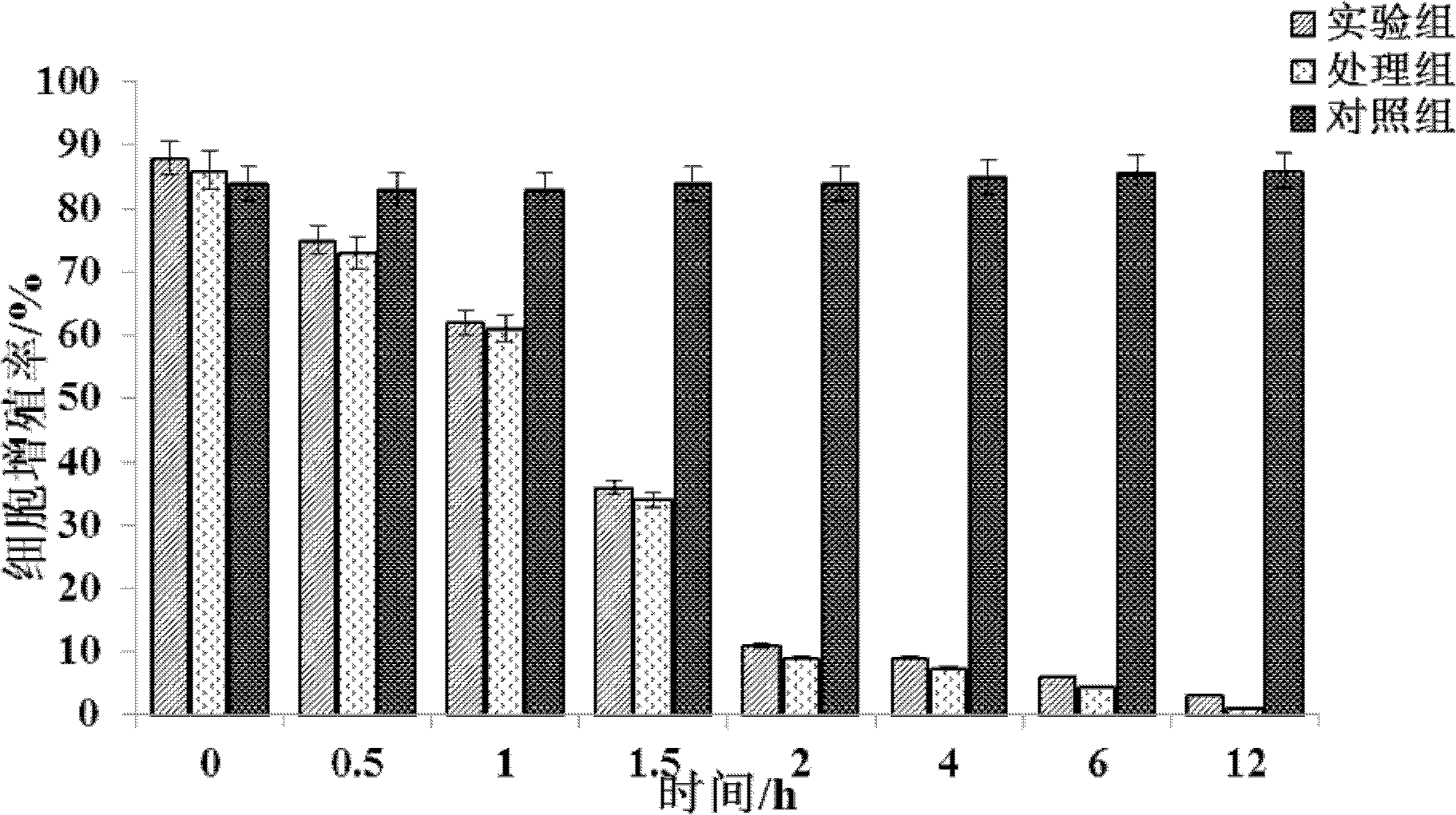

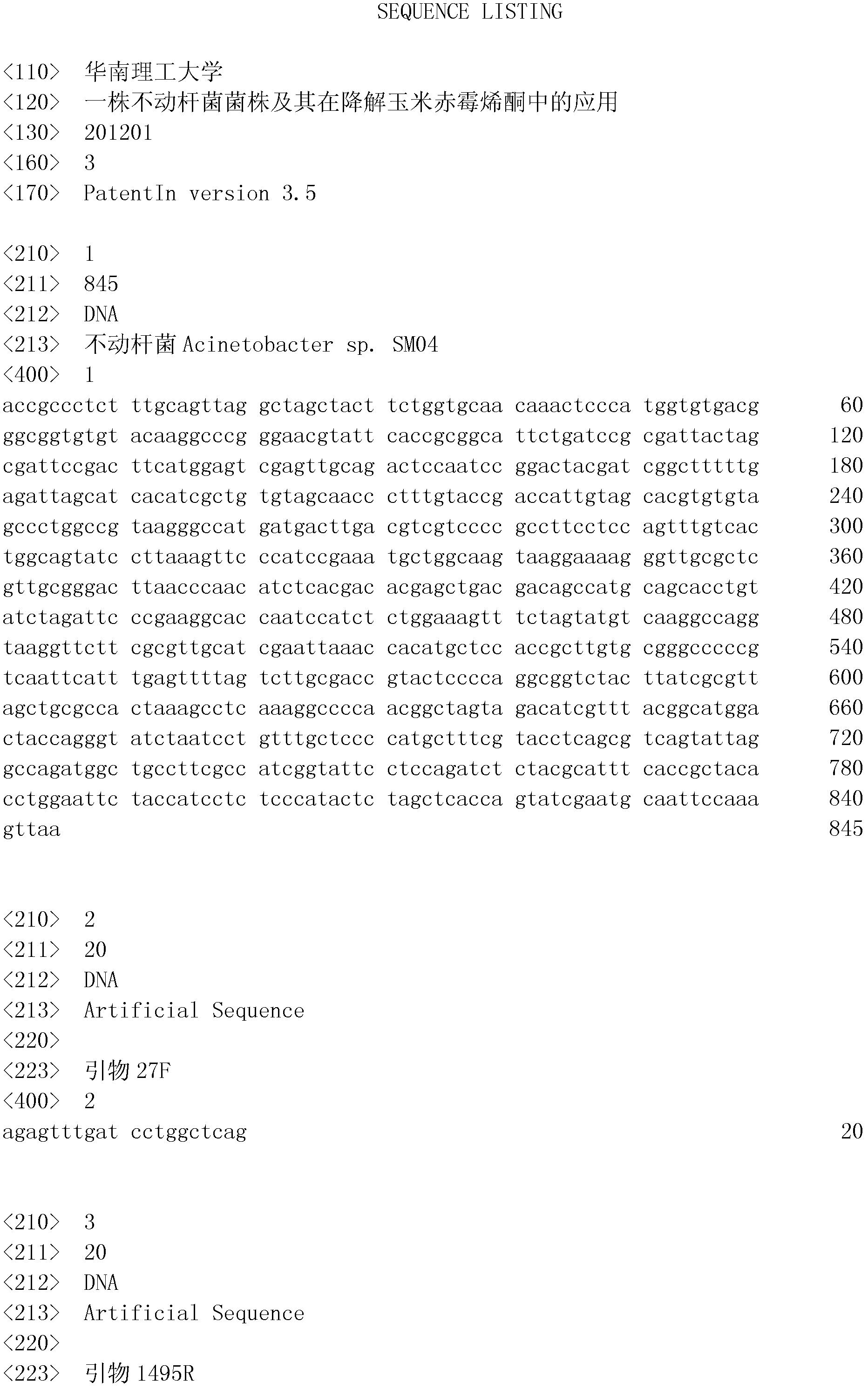

Acinetobacter strain and application thereof to degradation of zearalenone

InactiveCN102559555APromote degradationLow costBacteriaAnimal feeding stuffZeranolMicrobiological culture

The invention discloses an acinetobacter strain and application thereof to degradation of zearalenone. The acinetobacter strain disclosed by the invention is Acinetobacter sp. SM04, and is preserved in the China General Microbiological Culture Collection Center on December 5th, 2011, and the preservation number is CGMCC No. 5524. The Acinetobacter sp. SM04 disclosed by the invention has stronger degradation capability towards mycotoxins ZEN, can degrade more than 98% of zearalenone into low-estrogenic-activity product within 36 hours, cannot produce high-estrogenic-activity analogues such as zearalenone and zeranol, and has real detoxification capability. The acinetobacter strain can be applied to the treatment of corn grains, corn alcohol residues or other mycotoxin contaminated feed, so that safe food and animal feed are obtained, and further, a zearalenone degradation strain which has low cost and high efficiency and avoids secondary pollution is provided for the environment-friendly processing and treatment of the grains and feed.

Owner:SOUTH CHINA UNIV OF TECH

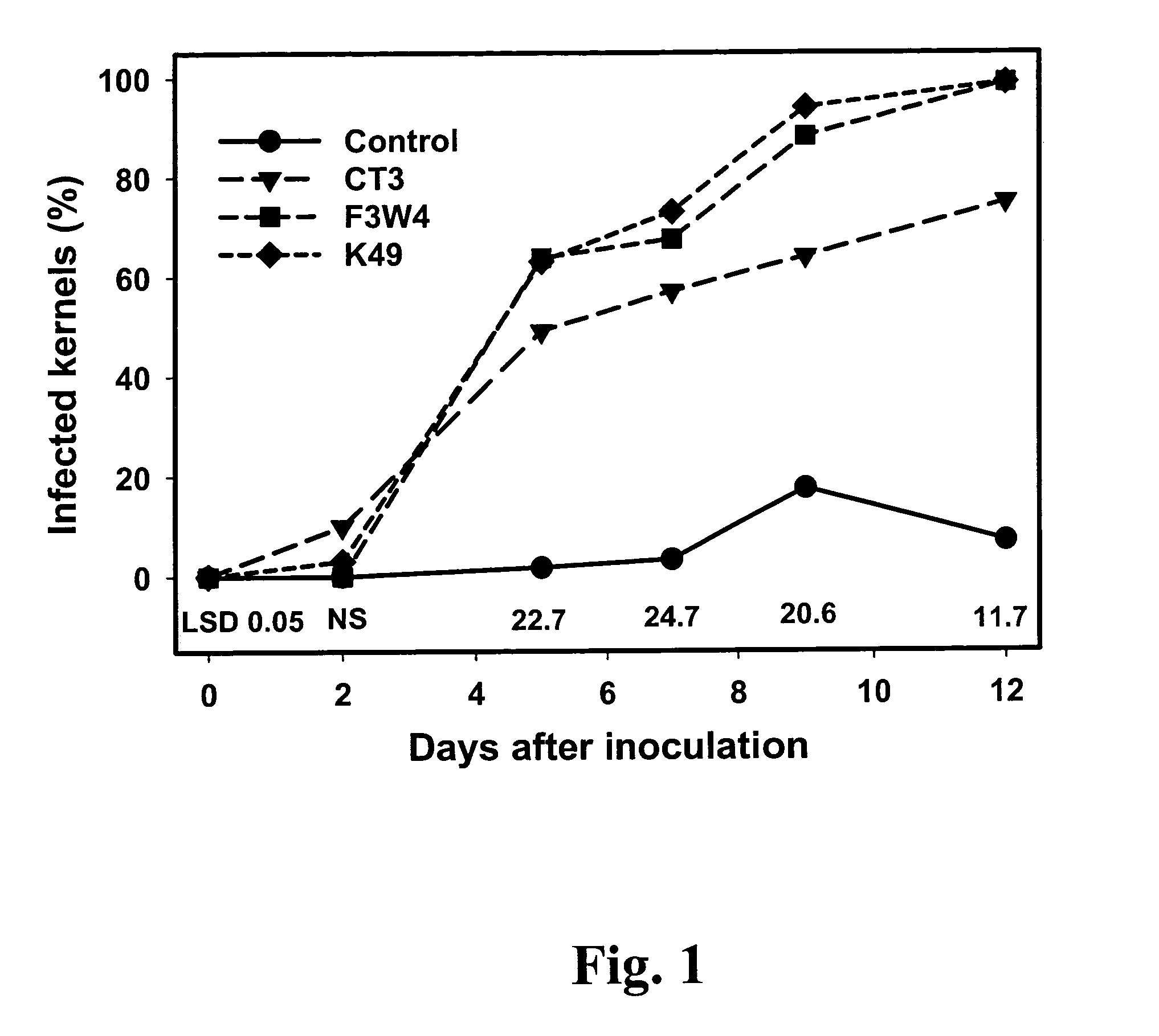

Non-aflatoxigenic Aspergillus flavus isolates

InactiveUS7361499B1Reduce aflatoxin contaminationReduce contaminationBiocideMicroorganismsAflatoxin contaminationToxin

The ability of two Aspergillus flavus Link isolates (CT3 and K49) to reduce aflatoxin contamination of corn was assessed in a four-year field study (2001 to 2004). Soil was treated with six wheat inoculant treatments: toxigenic isolate F3W4; the non-toxigenic isolate K49; the non-aflatoxigenic isolate CT3, two mixtures of CT3 or K49 with F3W4; and an autoclaved wheat control, applied at 20 kg / ha. In 2001, inoculation with the toxigenic isolate increased corn grain aflatoxin levels by 167% compared to the non-inoculated control, while CT3 and K49 inoculation reduced aflatoxin levels in corn grain by 86% & 60%, respectively. In 2002, inoculation of CT3 and K49 reduced aflatoxin levels by 61% and 76% compared to non-inoculated controls, respectively. In 2001 mixtures of toxigenic and non-toxigenic isolates had little effect on aflatoxin levels, but in 2002 inoculation with mixtures of K49 and CT3 reduced aflatoxin levels 68 and 37% compared to non-inoculated controls, respectively. In 2003 and 2004, a low level of natural aflatoxin contamination was observed (8 ng / g). However, inoculation with mixtures of K49+F3W4 and CT3+F3W4, reduced levels of aflatoxin 65 to 94% compared to the toxigenic strain alone. Compared to the non-sclerotia producing CT3, strain K49 produces large sclerotia, has more rapid in vitro radial growth, and a greater ability to colonize corn when artificially inoculated, perhaps indicating greater ecological competence. Results indicate that non-toxigenic, indigenous A. flavus isolates, such as strain K49, have potential use for biocontrol of aflatoxin contamination in southern U.S. corn.

Owner:US SEC AGRI

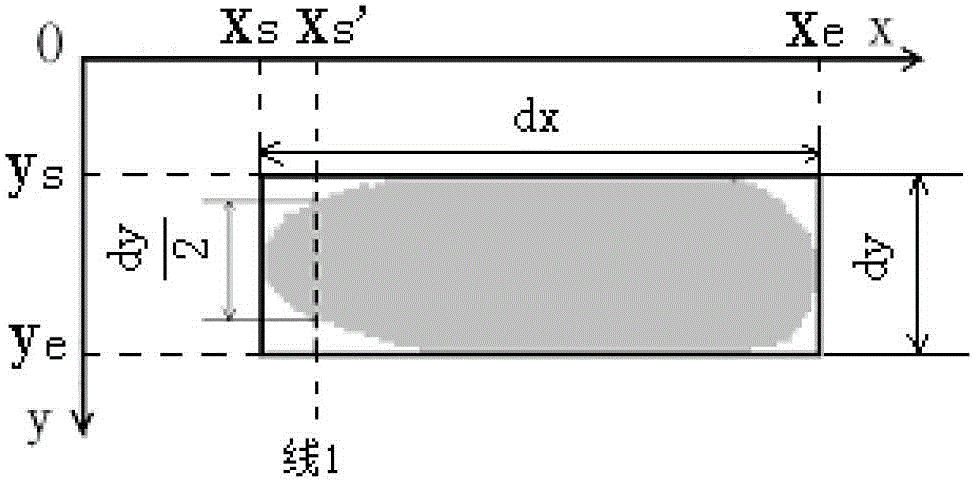

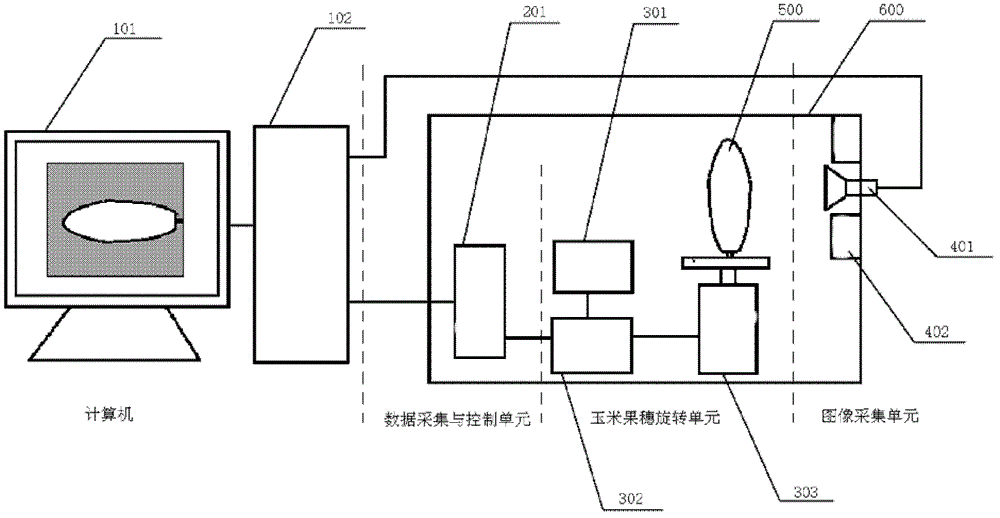

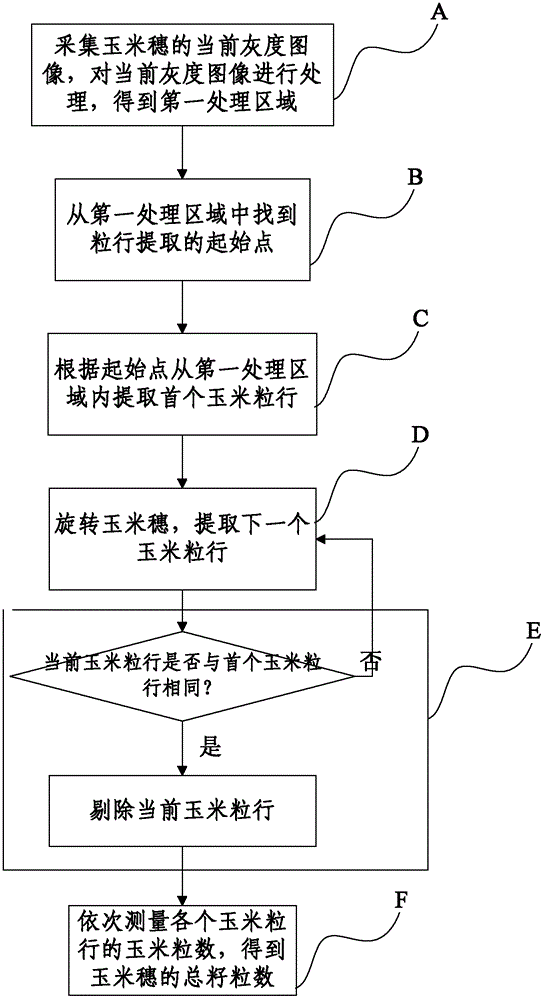

On-corncob corn niblet counting method

InactiveCN102750584AQuick measurementAccurate measurementCharacter and pattern recognitionCounting objects with random distributionMachine visionPanicle

The invention discloses an on-corncob corn niblet counting method and relates to the field of machine vision. The method comprises the steps of A, collecting a current gray level image of a corn panicle and processing the current gray level image to obtain a first processing area; B, finding a starting point of niblet row extraction in a first processing area; C, extracting a first corn niblet row in the first processing area according to the starting point; D, rotating the corn panicle and extracting a next corn niblet row; E, judging whether the current corn niblet row is the same with the first corn niblet row, if the current corn niblet row is the same with the first corn niblet row, eliminating the current corn niblet row and performing the step F; otherwise, performing the step D; and F, measuring the number of the corn niblets of all corn niblet rows sequentially to obtain a total number of all the corn niblets of the corn panicle. According to the method, a counting device with the high cost is not required, the implementation cost is low, the number of the the niblets of the corn panicle can be measured rapidly, accurately and stably, the detection method has the advantages of being flexible, good in timeliness and accuracy and the like.

Owner:CHINA AGRI UNIV

Method for producing corn and pine nut rice dumpling

The invention relates to a method for producing a corn and pine nut rice dumpling, and belongs to a food processing technology. The method comprises the following steps of: screening fresh corn grains to remove impurities, and softening and performing aging resistance treatment; performing fragrance-enhancing treatment on pine nuts; and mixing the fresh corn grains and the pine nuts in a certain ratio for the production of the rice dumping. The product has good organoleptic quality and a special nutrition effect. The produced rice dumpling product has unique flavor and excellent mouthfeel.

Owner:JILIN WEIYIKANG BIOLOGICAL SCI & TECH

Grain production method for maize starch with novel functionality

A novel method of producing maize grain with desirable functionality has been developed involving planting two different maize hybrids within the same field. The two maize hybrids are planted in alternating blocks of rows. One hybrid is male sterile such that the second hybrid provides pollen for the entire field. This leads to blocks of two separate types of grain which may be harvested and processed separately.

Owner:CORN PROD DEV INC

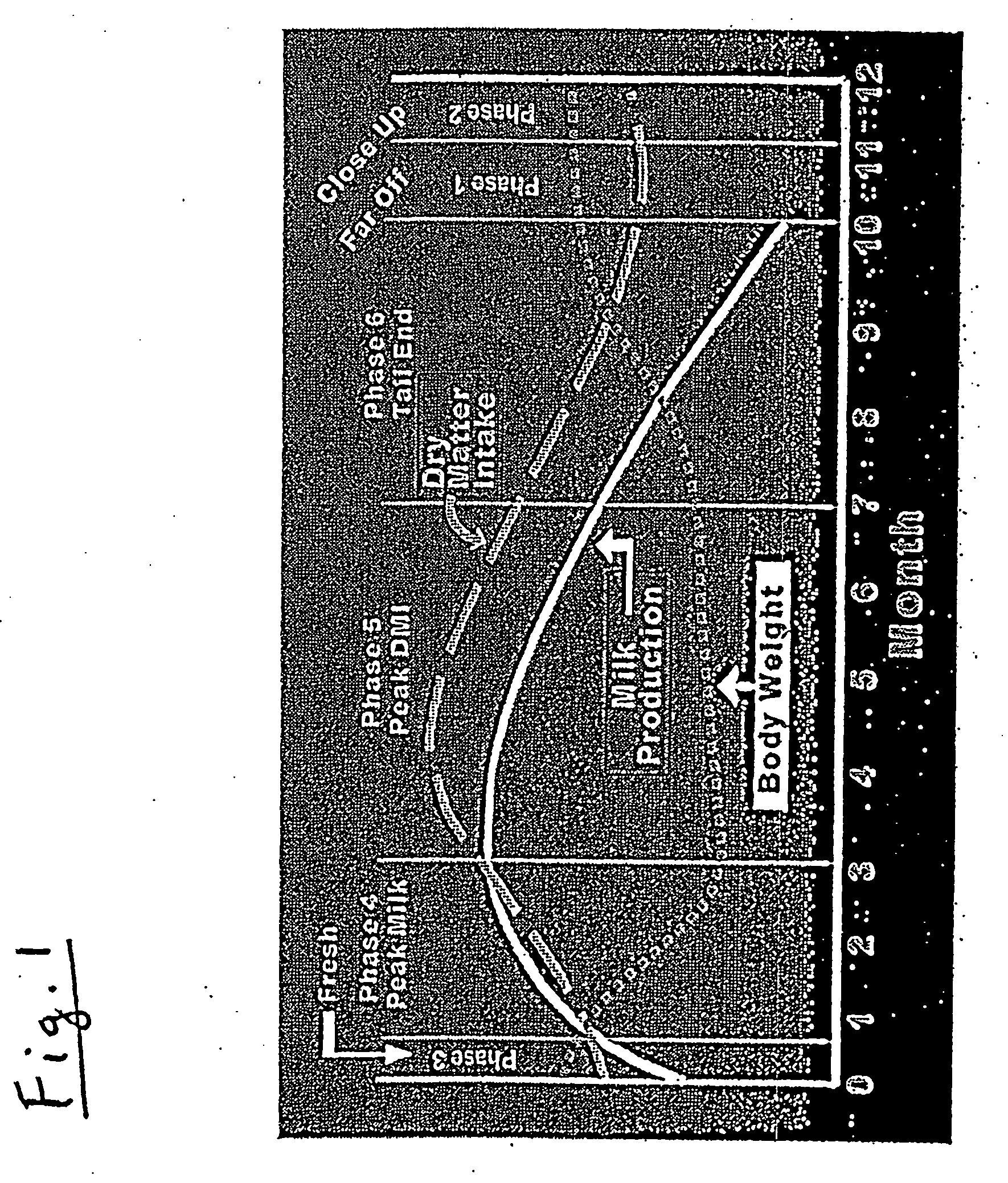

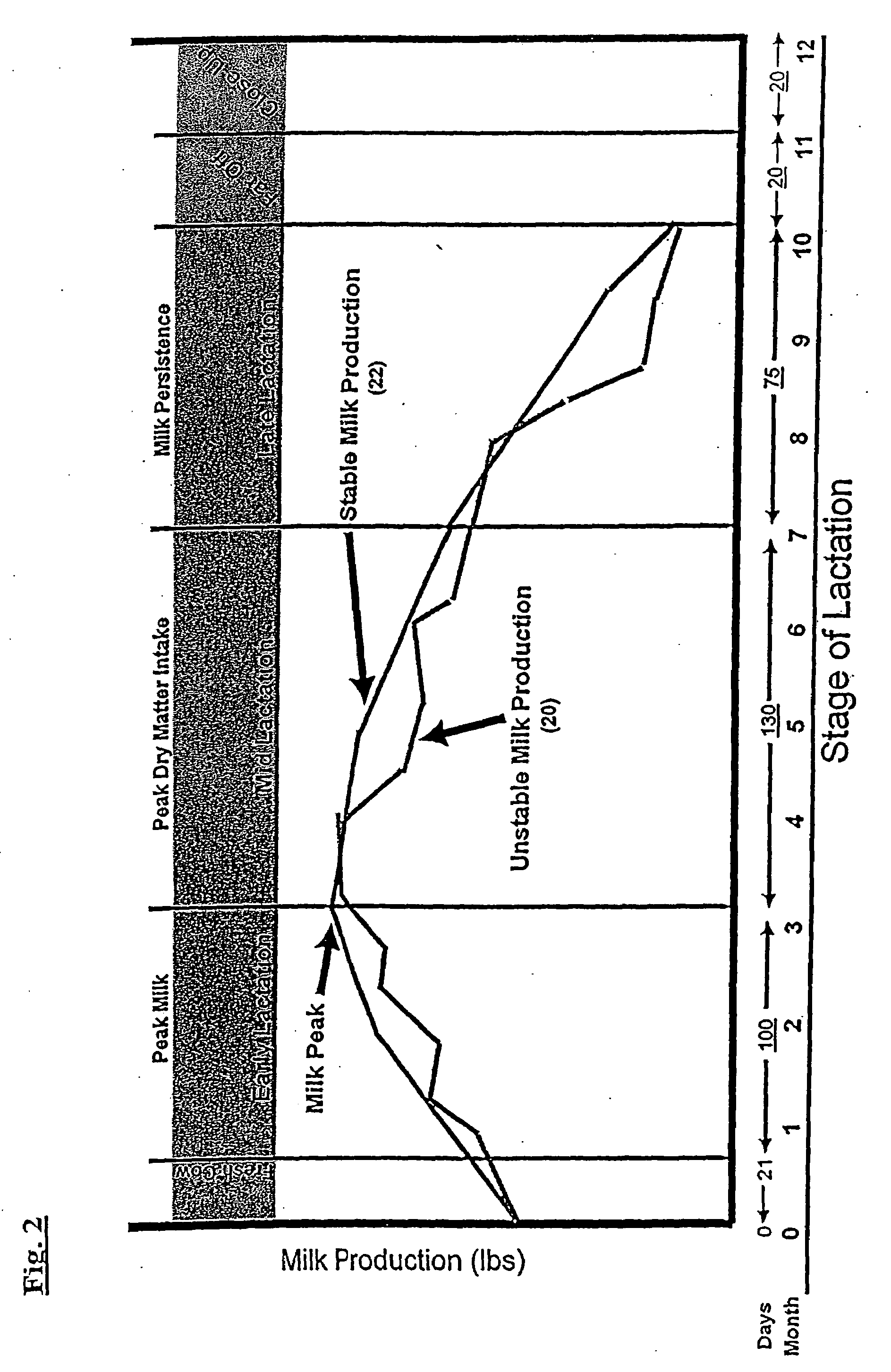

Method and feed for enhancing ruminant animal nutrition

InactiveUS20080145476A1Improve production stabilityImprove the level ofAnimal feeding stuffAgricultural scienceAnimal Foraging

A method for feeding a ruminant animal a feed ration for enhancing its milk production stability across a multiple-stage lactation cycle is provided according to the invention. The feed ration should contain: at least one primary forge source selected from the group consisting of brown midrib corn silage, dual-purpose corn silage, leafy corn silage, and grass silage; a secondary forage source selected from the group consisting of dual-purpose corn silage, alfalfa haylage, alfalfa dry hay, grass silage, and alfalfa / grass mix; a corn grain blend of opaque / floury and vitreous / hard endosperm starch grain into which normal dent corn or mutt corn may be blended in order to achieve a predetermined level of in vitro starch digestibility; such blended grain component being further processed to produce a specific particle size of the blended starch. A feed ration prepared in accordance with this method optimizes the ruminal environment inside the cow that consumes the feed ration for producing the enhanced milk production stability.

Owner:NUTRI INNOVATIONS LLC

Products comprising corn oil and corn meal obtained from high oil corn

Corn oil and corn meal obtained from high oil corn are included in useful products. The corn oil is extracted from the high oil corn to form the corn meal. The corn oil generally comprises levels of nutrients not found in commercially available corn oils, since most or all of the corn grain, rather than just the germ, is exposed to the extraction process. The corn grain generally includes the steps of flaking corn grain having a total oil content of at least about 8% and extracting a corn oil from the flaked corn grain. The corn oil is useful for making nutritionally enhanced edible oil or cooking oil, lubricants, biodiesel, fuel, cosmetics and oil-based or oil-containing chemical products. The extracted corn meal is useful for making enhanced animal feed rations, snack food, blended food products, cosmetics, and fermentation broth additive.

Owner:RENESSEN

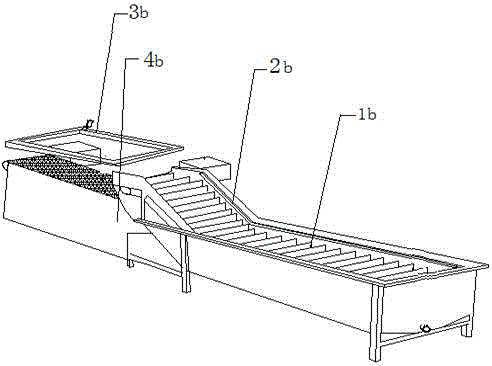

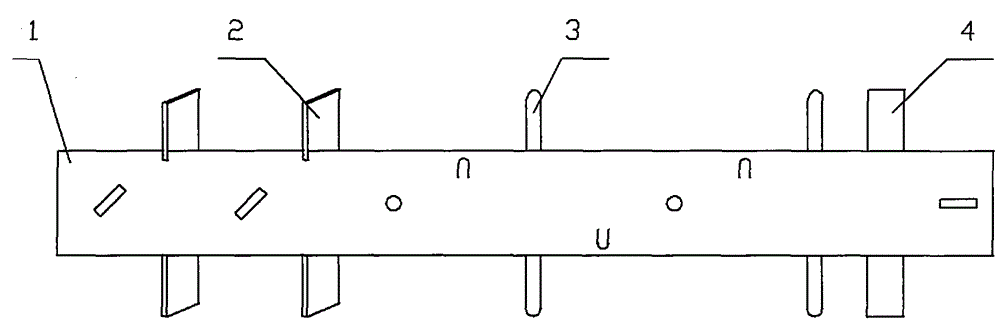

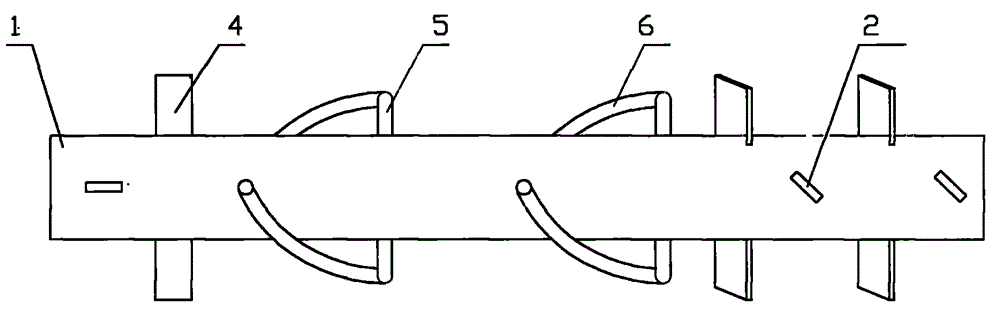

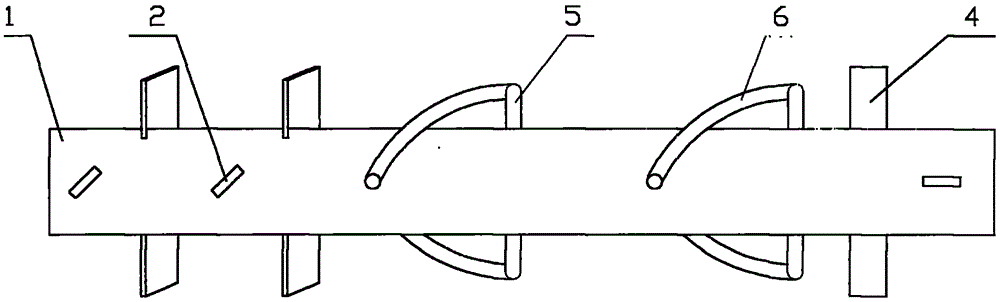

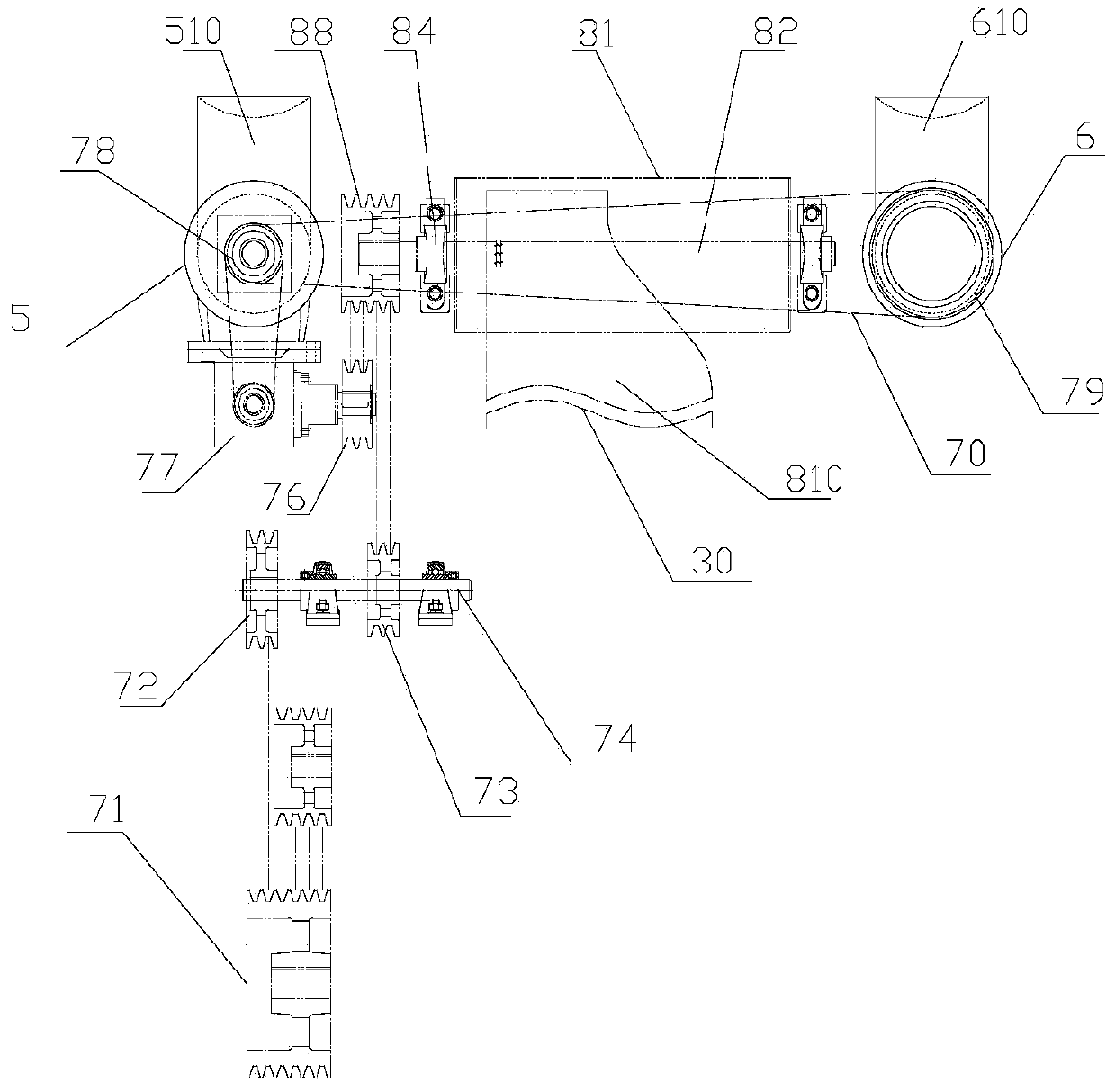

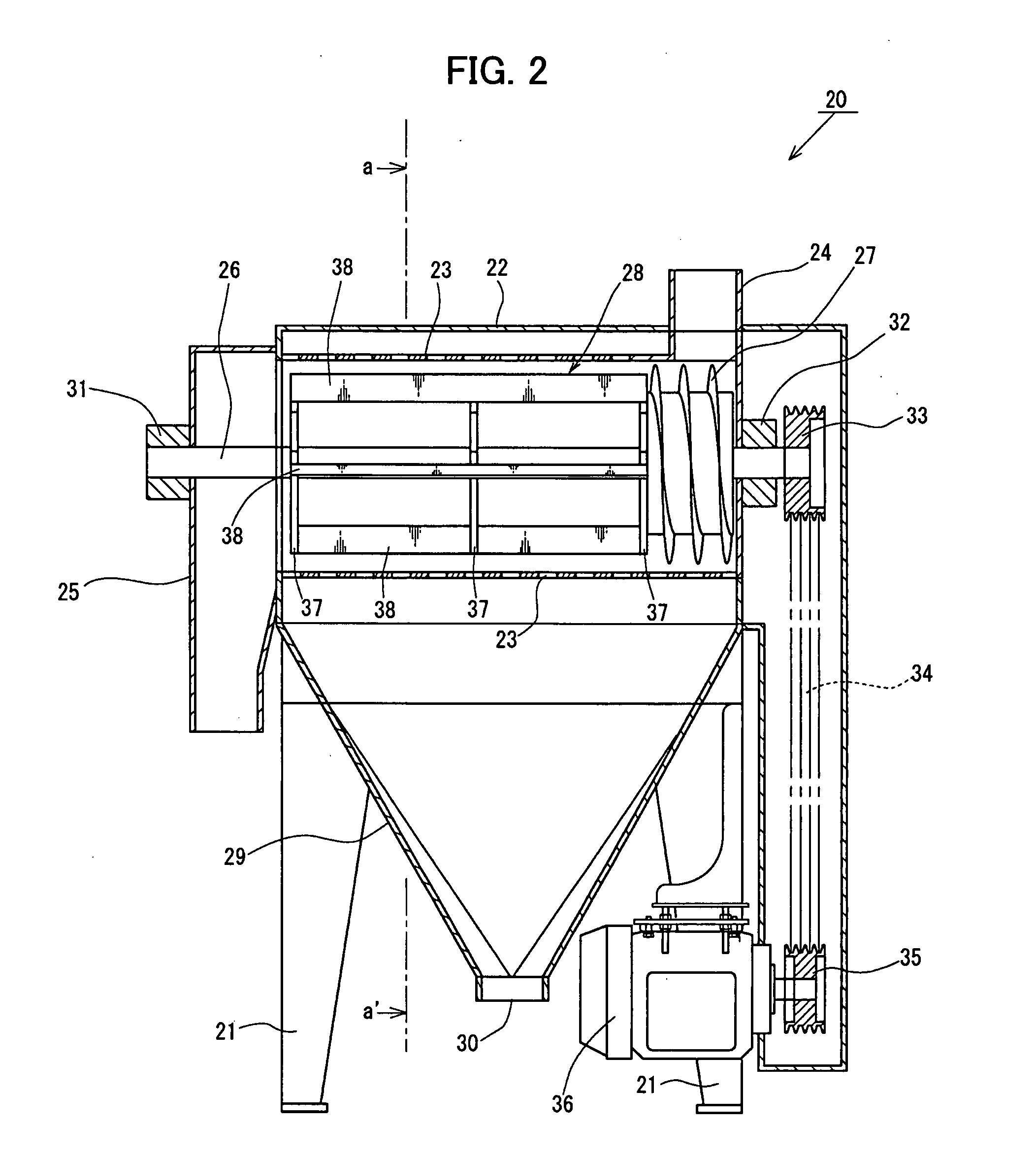

Corn threshing roller set and corn threshing machine

The invention relates to a corn threshing roller set and a corn threshing machine. The corn threshing roller set is composed of a plurality of threshing rollers arranged side by side, driving end of first and second threshing rollers are provided with a pushing board, driven ends of the first and second threshing rollers are provided with a plurality of stirring plates, a roller core body is provided with a plurality of threshing rods. A driven end of a third threshing roller is provided with a pushing board, a driving end of the third threshing roller is provided with a stirring plate, the body of the third threshing roller is provided with threshing ribs. The corn threshing machine comprises a machine body, a power device, a feed device and a plurality of threshing chambers arranged side by side, each threshing machine is composed of an upper cover and a screen mesh, two ends of the first threshing chamber communicate with two ends of the second threshing chamber, and pushing tails of other threshing chambers communicate with pushing heads of next adjacent threshing chambers. The corn threshing roller set and the corn threshing machine are high in work efficiency, corn grains and cobs will not be severely broken, and the threshing rate is high.

Owner:杜红军

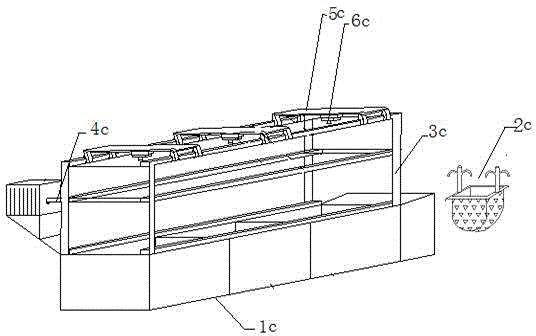

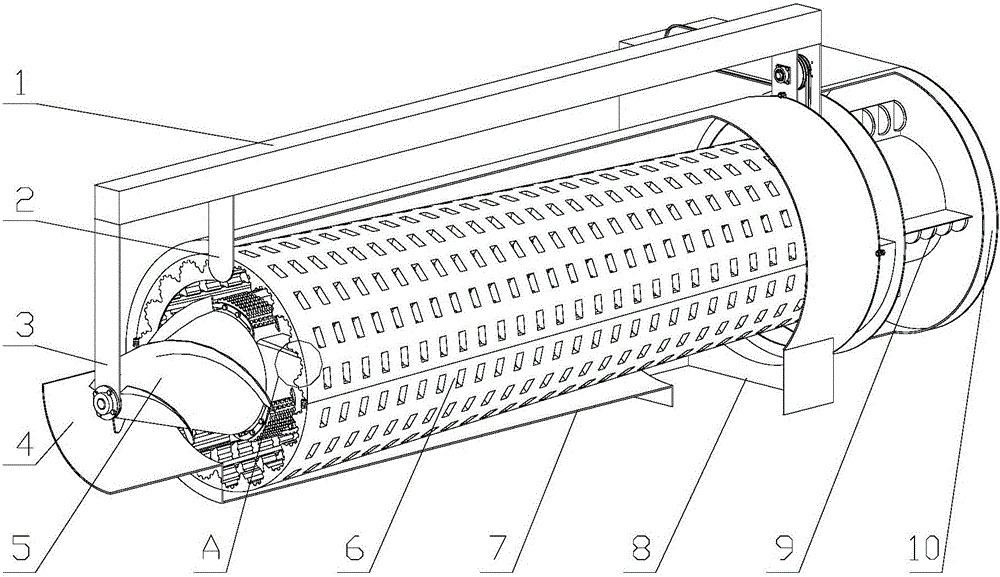

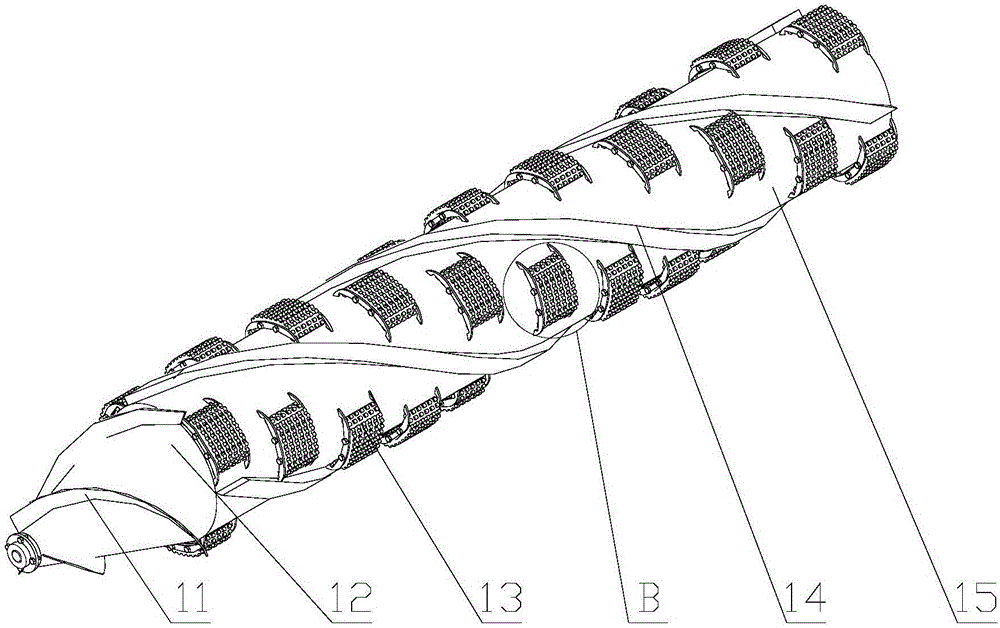

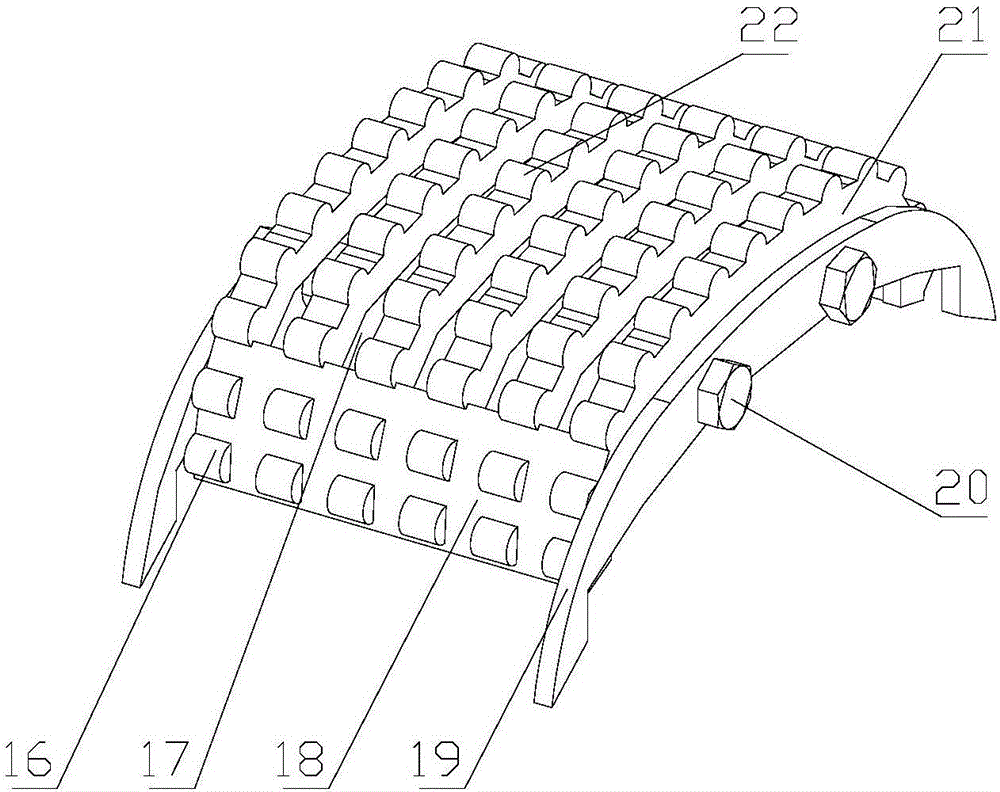

Axial rheological gap bionic corn threshing device

The invention discloses an axial rheological gap bionic corn threshing device. The axial rheological gap bionic corn threshing device comprises a machine frame, a threshing roller, a concave plate sieve, a machine cover and a corncob recycling mechanism, wherein the machine cover is fixed at the lower part of the machine frame; the concave plate sieve is fixed in the machine cover; the threshing roller is fixed in the concave plate sieve; the corncob recycling mechanism is fixed ar the back part of the machine cover; the cylindrical threshing roller and the conical concave plate sieve jointly form threshing gaps which are continuously changed from big to small to promote that corn ears are subjected to effective threshing action all the time; and threshing teeth on the outer surface of a bionic threshing bridge and threshing columns which are distributed on the inner surface of the concave plate sieve in a copying arc form jointly form the threshing functional surface, microscopic threshing moment is applied to corn grains, and the removed corn grains are separated out timely through a grain leaking groove in the surface of the bionic threshing bridge and a separating port in the surface of the concave plate sieve. The axial rheological gap bionic corn threshing device has high threshing efficiency and few crushed grains, and can synchronously collect the corncobs.

Owner:SHANDONG JUMING MASCH CO LTD

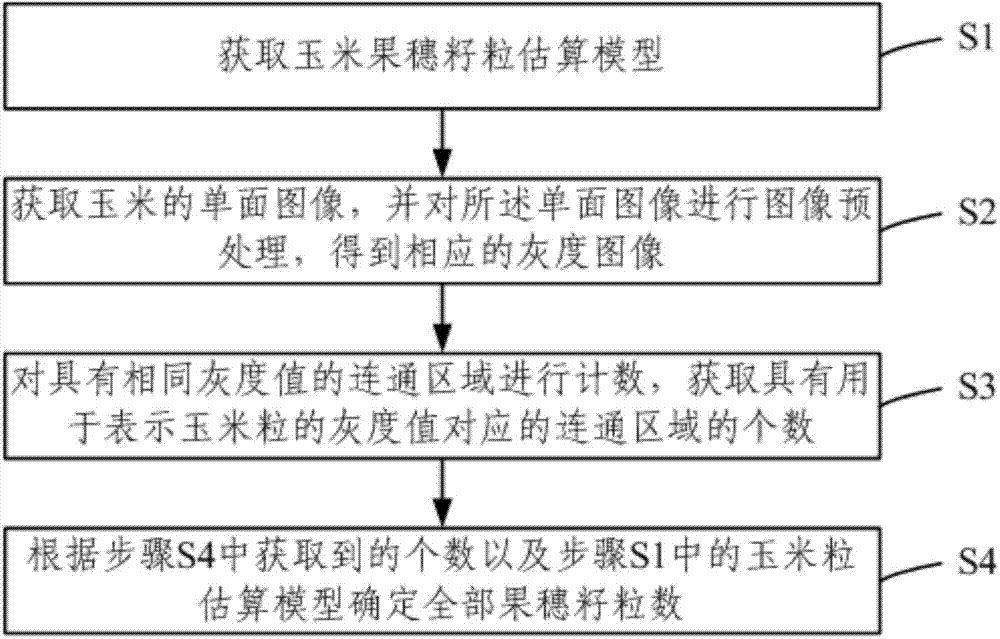

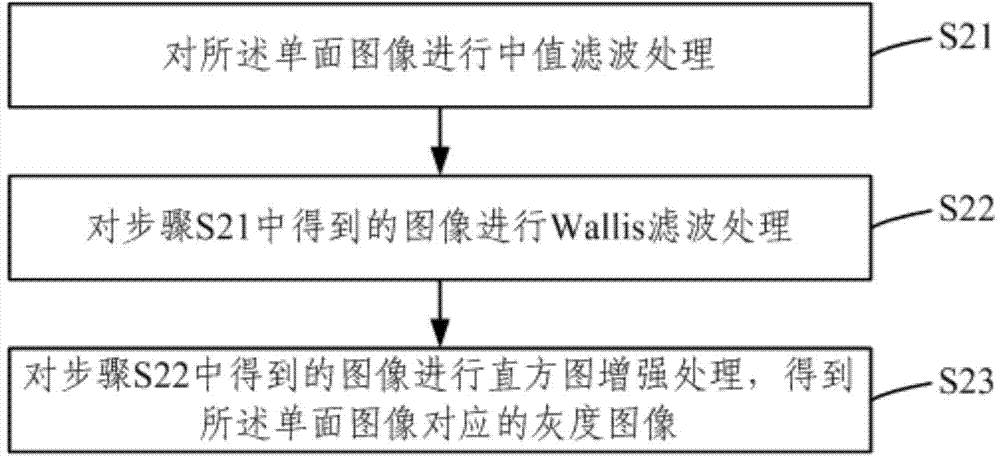

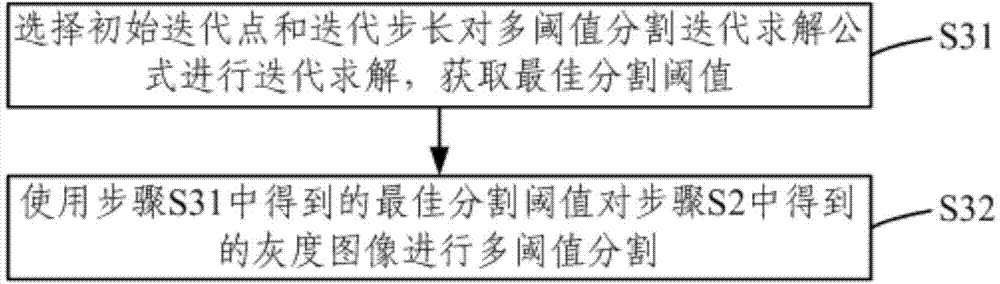

Counting method and device for corn ear grains

ActiveCN103810522ACounting simpleCounting objects with random distributionComputer scienceCORN GRAIN

The invention provides a counting method and a counting device for corn ear grains. The method comprises the following steps: step S1, obtaining an estimation model for the corn ear grains, wherein the estimation model for the corn ear grains is used for showing a function relation between the number of the ear grains on the single surface of corn and the number of all ear grains; step 2, obtaining the single sided image of the corn, and preprocessing the single sided image to obtain a corresponding gray level image; step S3, performing multi-threshold segmentation on the gray level image obtained in the step S2, so as to obtain a corresponding binary image; step S4, counting communicating areas with the same gray values, and obtaining the number of the communication areas corresponding to the grey values for showing the corn grains; and step S5, determining all ear grains according to the number obtained in the step S4 and the corn grain estimation model in the step S1. By adopting the counting method for the corn ear grains, the corn ear grains can be quickly and conveniently counted.

Owner:CHINA AGRI UNIV

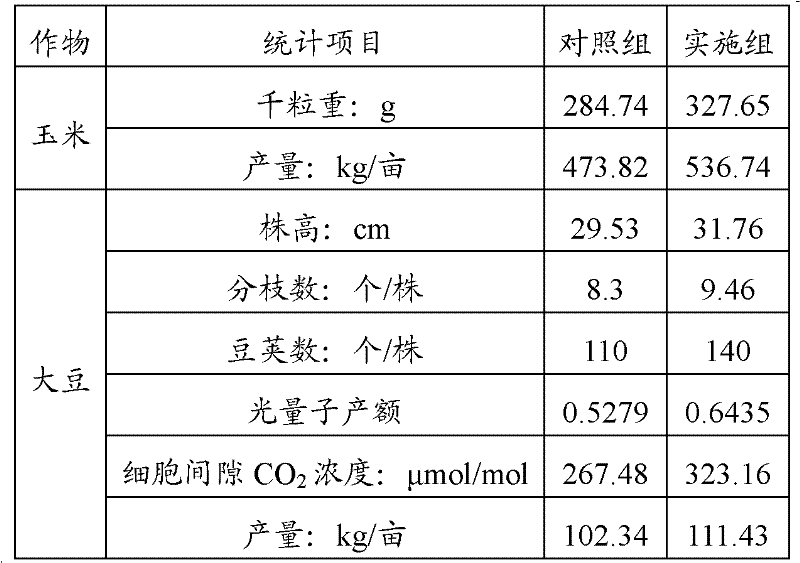

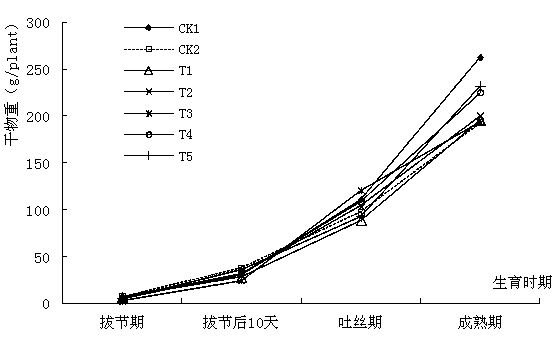

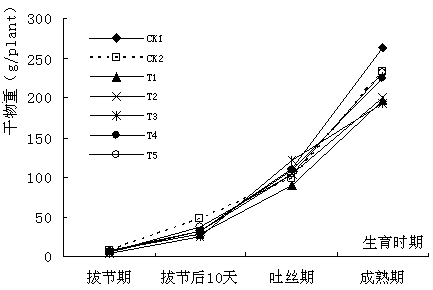

Method for corn-soybean strip type interplanting

The invention relates to the technical field of agricultural cultivation, and discloses a method for corn-soybean strip type interplanting. With the adoption of the method, corns and soybeans are planted alternately in a strip type. When corn grain milk lines reach 1 / 2 to 3 / 4, a stalk and leaves above three leaves of an ear are removed, the three leaves of the ear are reserved, and all leaves below the three leaves of the ear are sheared off adopting a leaf ring as a basic standard. According to the invention, the leaves below the three leaves of the ear, and the stalk and the leaves above the three leaves of the ear are removed timely and suitably, the original source library relationship of corn plants is broken, the transport direction of organics is changed, a new source library relationship is established, a carbon pool effect of source leaves is enhanced, nutrition provided for grains is improved, simultaneously, the growing environment of the soybeans in a strip type interplanting mode is improved, and the corns and soybeans have high yield at the same time.

Owner:SICHUAN AGRI UNIV

Comprehensive prevention and control technology of corn waterlogging disaster

ActiveCN103814779AReduce reducing substancesToxic reductionPlant protectionSoil-working methodsAbsorption capacityRoot growth

The invention discloses a comprehensive prevention and control technology of a corn waterlogging disaster, wherein soil ridging or compartment ridging regulation and control are utilized. The comprehensive prevention and control technology comprises the following steps: sowing in a wide and narrow row spacing manner during corn sowing, carrying out intertillage ridging or ditching during the five-leaf stage of corn, ditching in wide rows of corn and ridging in narrow rods of corn, or ditching in wide rows on the two sides of a compartment consisting of four or six rows, additionally applying nitrogen-oxygen mixed fertilizer instantly after the corn waterlogging disaster occurs, and spraying spermidine chemical modifier on leaf surfaces at the same time, wherein spraying is carried out once in the morning and night for 2-3 days continuously; other steps are the same as that during normal management, corn is harvested until bracts of corn clusters are dried up, corn grain milk lines disappear, and a black layer appears, namely when grains are completely and physiologically matured. According to the comprehensive prevention and control technology, through comprehensive precontrol advantages of prevention in advance and remedy after the disaster, the root oxygen deficiency after waterlogging can be effectively reduced and retarded, accumulated toxic effect of hazardous substances of soil is reduced, and the root growth and absorption capacity is strengthened, so that the symplastic growth of overground part and root system is promoted, and the yield is improved.

Owner:HENAN AGRICULTURAL UNIVERSITY

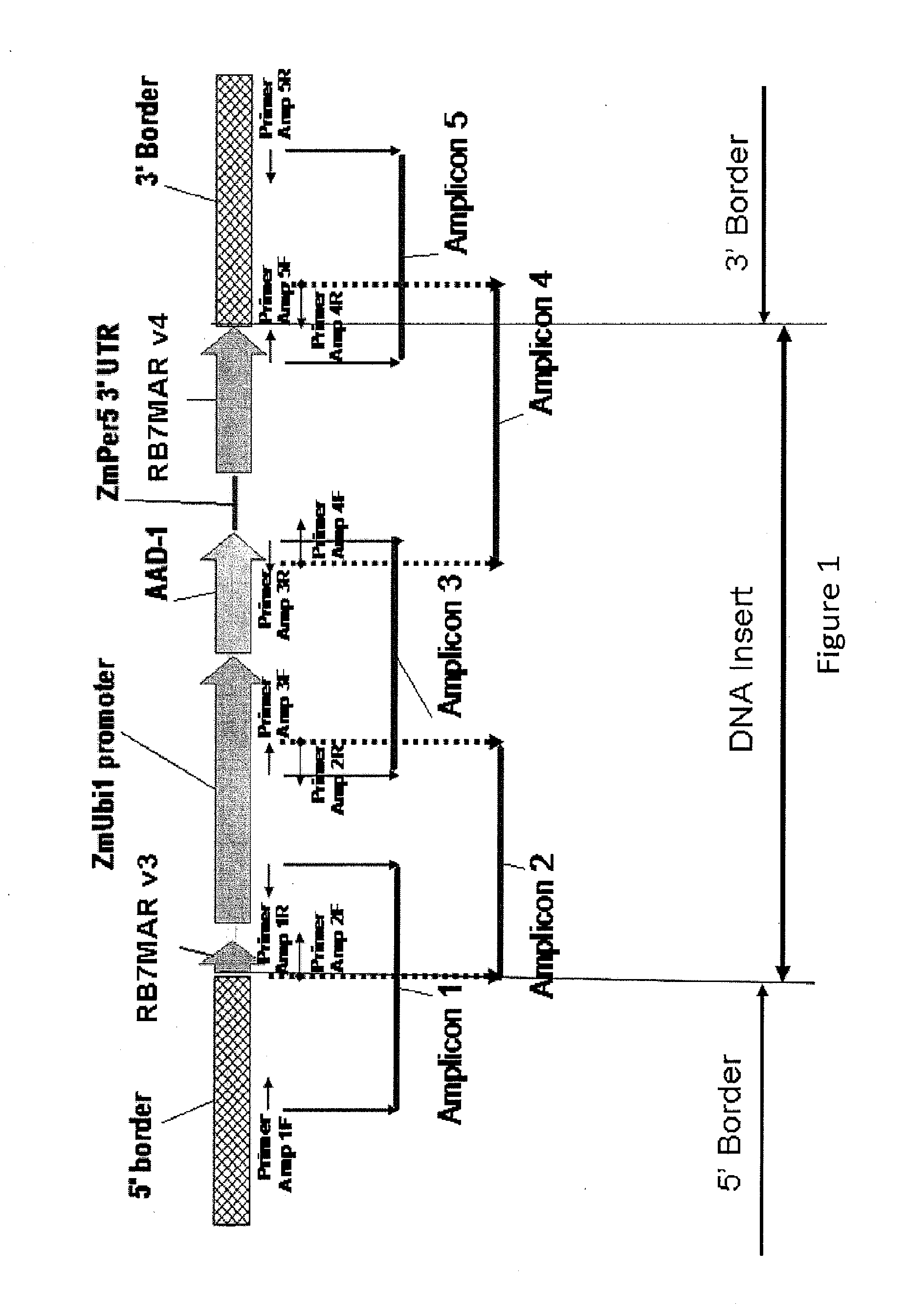

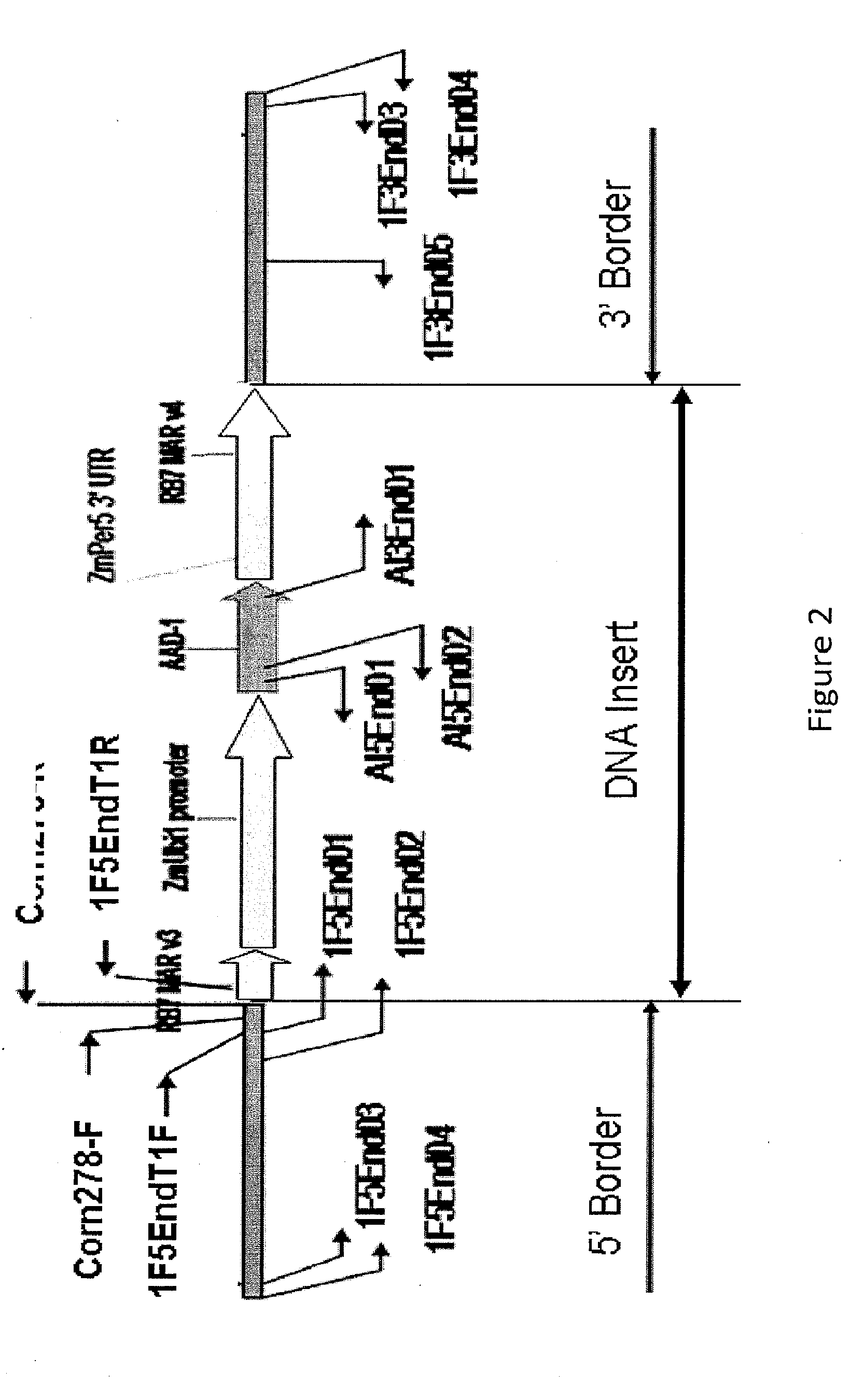

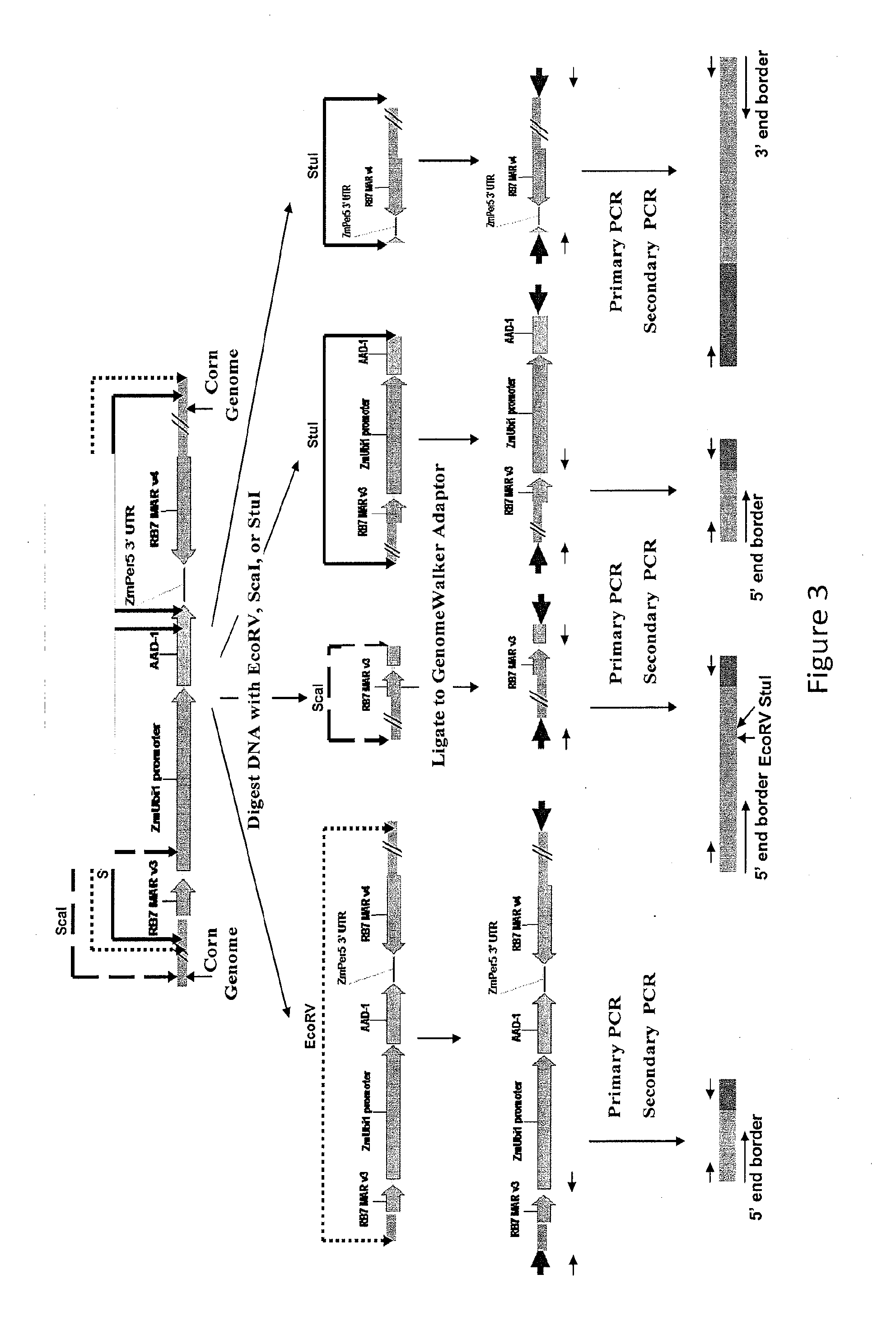

Detection of aad1 event das-40278-9

ActiveUS20120244533A1Microbiological testing/measurementFluorescence/phosphorescenceBiotechnologyReference genes

This invention relates in part to detecting herbicide tolerant plants—more specifically, an aad-1 transformation event in corn plants. The subject invention also provides assays for detecting the presence of the subject event in a sample (of corn grain, for example). Kits and conditions useful in conducting the assays are also provided. The subject invention also relates in part to plant breeding using the subject methods. In some embodiments, said event / polynucleotide sequence can be “stacked” with other traits. More specifically, the invention relates in part to an endpoint TaqMan PCR assay for AAD-1 corn event 40278-9. Some embodiments are directed to assays that are capable of high throughput zygosity analysis. The subject invention further relates, in part, to the use of a preferred reference gene for use in determining zygosity.

Owner:CORTEVA AGRISCIENCE LLC

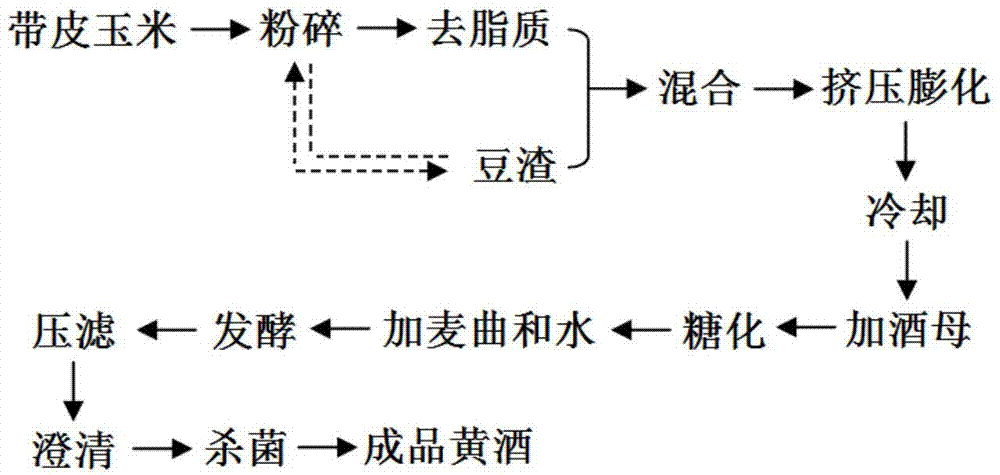

Method for brewing yellow wine rich in soluble dietary fiber

The invention discloses a method for brewing yellow wine rich in soluble dietary fiber. The method comprises the following steps: removing or not removing lipids of corn with husks, carrying out enzymatic or non-enzymatic extrusion swelling treatment on the corn together with bean dregs, and then fermenting and brewing yellow wine. The method disclosed by the invention, by creatively carrying out enzymatic or non-enzymatic extrusion treatment on the mixture of the corn with husks and the bean dregs and by combining with a multi-enzyme system yellow wine fermenting technology, has the characteristics that the product has high yield, good quality, low cost and rich nutrition; in addition, the method disclosed by the invention not only widens the utilization way of corn grains but also realizes the full use of by-products from the processing of such agricultural products as corn husks, bean dregs and the like, so that waste materials are recycled, and resource waste and environmental pollution are reduced.

Owner:JIANGNAN UNIV

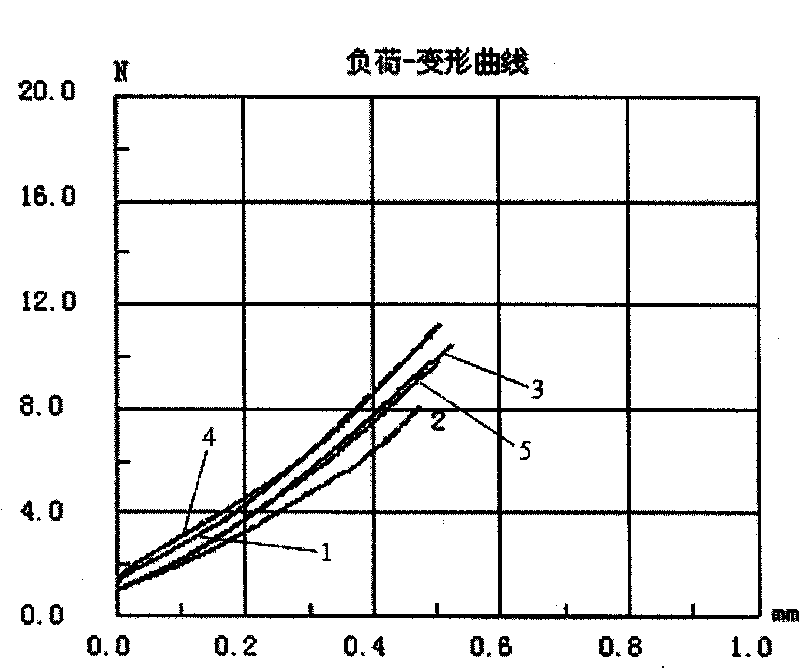

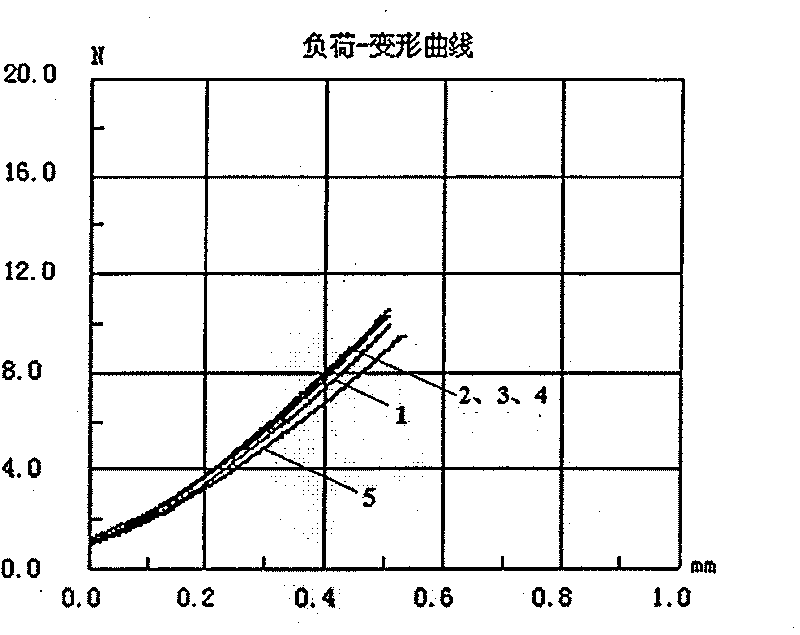

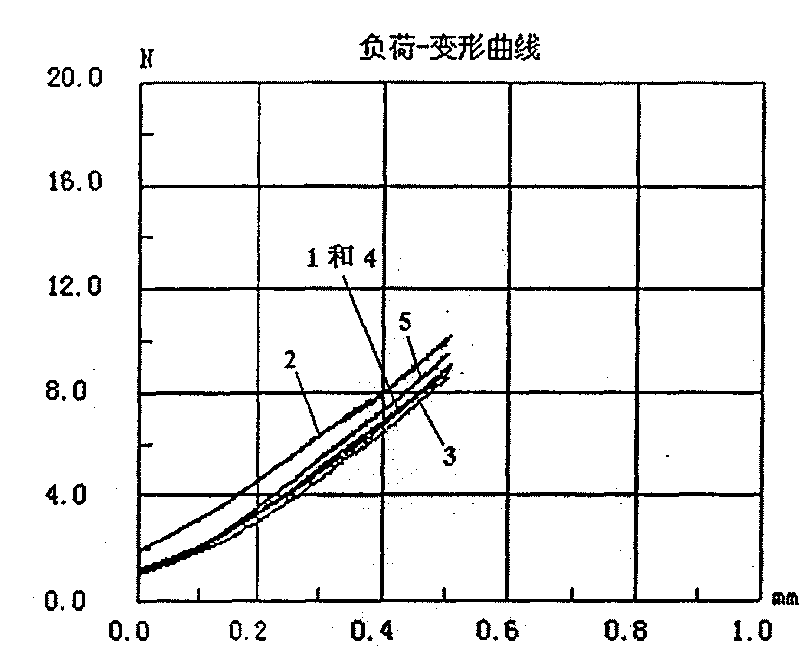

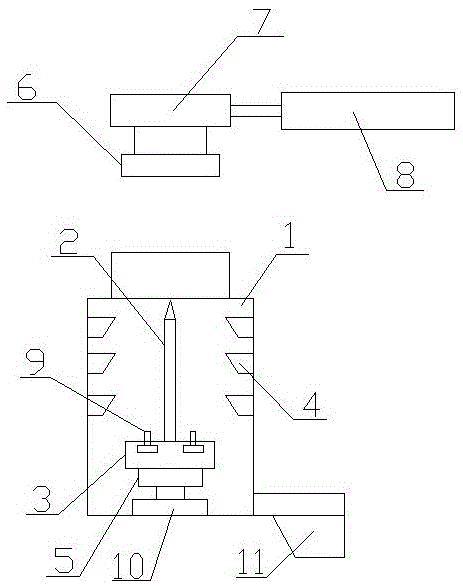

Method for determining corn grain hardness

InactiveCN101713718AGood hardness measurement resolutionHigh hardness resolutionInvestigating material hardnessMicrocomputerMachine selection

The invention relates to a general method for determining corn grain hardness. The method for determining the corn grain hardness is characterized by comprising the following determining steps of: (1) preparation before corn determination; (2) testing machine selection; (3) selection and clamping of a steel needle; (4) determining process; and (5) hardness determination. The invention has the advantages of high hardness resolution, wide application range, convenient operation and high detection speed. The method can determine the hardness of different components of the same corn and the hardness of any different corn grains by using a uniform standard and a method and realize the hardness comparability of different objects determined. The invention can determine the hardness of different positions of the outside and the inside of corn grains and use the general microcomputer universal material testing machine within 500N and the general steel needle as apparatuses without additional special equipment.

Owner:GANSU AGRI UNIV

Preparation method of corn flour

InactiveCN106722065AFast absorptionSolve problems such as sticky mouthfeelMilk preparationOther dairy technologySodium bicarbonateFiltration

The invention discloses a preparation method of starch-free enzymolysis corn flour. The preparation method comprises the following steps: pre-crushing, cooking, defibrination, enzymolysis, filtration, concentration, homogenization, sterilization, spray drying, and packaging. The preparation method provided by the invention specifically comprises the steps of pre-crushing corn grains firstly, then putting the crushed corn grains into a cooking kettle for preliminary cooking, then adding sodium tripolyphosphate and sodium citrate, and passing the mixture through a colloid mill; and adding medium-temperature alpha-amylase into an enzymolysis tank for enzymolysis, lowering the temperature, adding cellulase for enzymolysis, adding sodium D-isoascorbate and sodium bicarbonate after enzymolysis, performing filtration, concentration, homogenization and sterilization, and finally, performing spray drying to prepare the enzymolysis corn flour. The starch in corns is thoroughly removed from the enzymolysis corn flour prepared by the method, the mouthfeel is significantly improved, and the phenomenon of retrogradation agglomeration in a later period of a corn beverage can also be solved.

Owner:南昌泰康食品科技有限公司

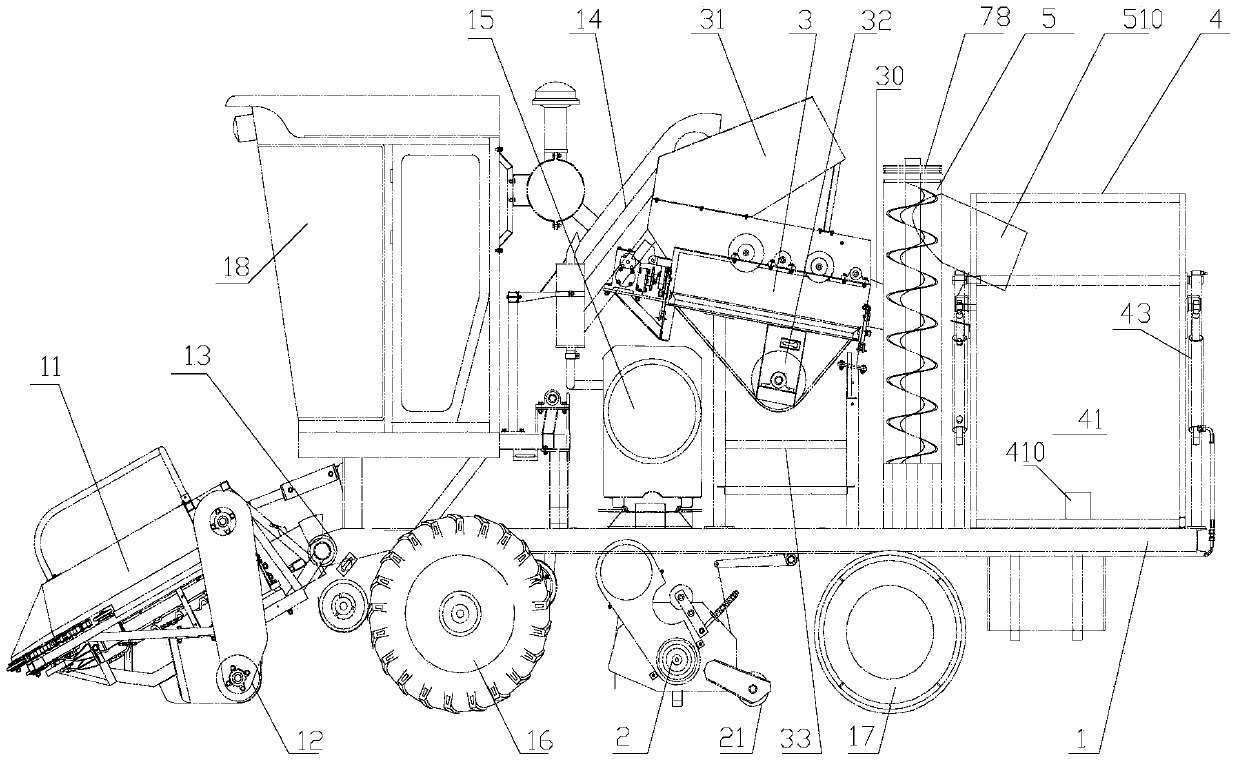

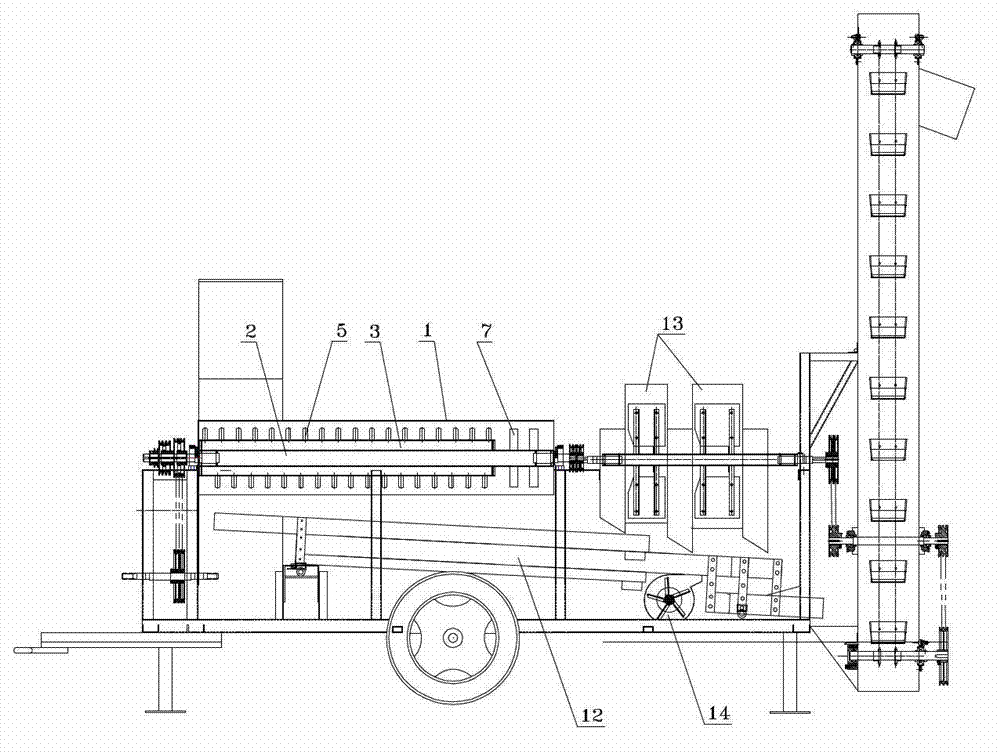

Self-propelled shelled corn and corncob classification harvester

InactiveCN103548483AIncrease the level of mechanizationIncrease productivityMowersSteering wheelDrive wheel

The invention provides a self-propelled shelled corn and corncob classification harvester, which comprises a chassis, a cab, a diesel, a barn, driving wheels, steering wheels, a header, a small elevator, a big elevator, a front chopper, a peeling machine, a threshing machine, a shelled corn packing auger and a corncob packing anger, wherein the threshing machine is positioned above the chassis between the peeling machine and the barn and is used for peeling shelled corns on the corncob and separating the shelled corns from the corncob; the corncob discharging hole of the peeling machine is in butt joint with the corncob feeding hole of the threshing machine; the shelled corn packing auger is used for upwards conveying the shelled corns; the corncob packing anger is used for upwards conveying the corncob; a vertical clapboard is arranged in the barn to divide the barn into a shelled corn cabin and a corncob cabin; the shelled corns are fed into the shelled corn cabin via the shelled corn packing auger; the corncob is fed into the corncob cabin via the corncob packing anger. According to the self-propelled shelled corn and corncob classification harvester disclosed by the invention, the effect of one machine with multiple functions of stripping, peeling and threshing corn as well as classifying, storing and transporting the shelled corns and corncobs can be achieved.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

Corn compound cultivation method for improving corn yield and land productivity

InactiveCN102498859AImprove land productivityIncreased land productivity (income)HorticultureLand productivityMushroom

A corn compound cultivation method for improving corn yield and land productivity relates to a corn compound cultivation method and aims at solving the problems that corn grain yield is low and the land productivity is poor in an existing cultivation method. The method comprises the following steps: performing stubble cleaning, rotary tillage, subsoiling and ridging by using a complete soil preparation machine; performing three-dimensional compound cultivation of corn, early-ripe potatoes, early-ripe wild cabbage, hot peppers or shitake mushroom; applying cured organic fertilizer before seeding; seeding the corn, the early-ripe potatoes, the early-ripe wild cabbage, the hot peppers or the shitake mushroom when the soil is stabilized and reaches 7 DEG C; deeply loosening or plowing furrows before corn seedlingscome up out of the ground; removing weeds and keeping one corn seedling each hole for sowing the seedling when the corn seedlings grow at a state of two leaves and one heart performing sun exposure for one day after removing the weeds and performing deep plowing and ridge lifting; removing tiller buds and the weeds, loosening ridge bodies and then performing the deep plowing and ridge sealing when the height of corn seedlings reaches 32-40 cm; and preventing and curing ostrinia nubilalis by adopting a biological prevention and control technology. The corn grain yield is increased compared with common micro-ridges, and the land productivity is improved obviously.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

Special iodine-enriched fertilizer for rice and preparation method thereof

InactiveCN104446745AIncrease productionImprove qualityBio-organic fraction processingAlkali orthophosphate fertiliserDiseaseMicrobial agent

The invention discloses a special iodine-enriched fertilizer for rice and a preparation method thereof. The special iodine-enriched fertilizer is prepared from the following raw materials in parts by weight: 40-50 parts of chicken manure, 12-16 parts of laver powder, 20-30 parts of cobs without corn grains, 6-8 parts of shrimp shell powder, 6-8 parts of shell powder, 5-6 parts of sawdust from wide-leaf trees, 4-6 parts of nitratite, 2-3 parts of sodium selenite, 4-7 parts of urea, 3-4 parts of medical stone powder, 4-5 parts of potassium nitrate, 6-7 parts of diammonium phosphate, 5-6 parts of residual tea dregs, 8-10 parts of rice chaff ash, 6-8 parts of biogas liquid, 2-3 parts of VA mycorrhizas, 5-6 parts of ammonium sulfate, 3-4 parts of calcium nitrate, 1-2 parts of EDTA cheating iron, 1-3 parts of a compound microbial agent, and a proper amount of water. The organic fertilizer for rice is prepared from easily available raw materials and has the functions that the soil disease is effectively prevented, the root development of rice can be promoted, the yield of rice can be improved, and the quality of rice can be increased.

Owner:六安亿牛生物科技有限公司

Corn threshing machine

The invention provides a corn threshing machine comprising a machine body; a placing rod is arranged in middle of the machine body, and positioned on a placing table; threshing blocks are arranged on the inner side of the machine body; a rotate motor is arranged below the placing table; a holddown device is arranged above the machine body, and connected with a press down cylinder; the right side of the press down cylinder is provided with a lateral shifting device; the corn is placed on the placing rod, and the press down cylinder presses the holddown device so as to fix the corn niblets on the placing rod; the rotate motor rotates so the threshing blocks can thresh the rotating corn; when the threshing work is done, a lifting motor can push up the placing table, and a push cylinder can push out the corn stalk fixed on the placing rod; the corn niblets directly enter a preset device through a feed trough; the whole process is convenient, safe and fast, and the corn niblets are less in damages, thus increasing farmer economical benefits.

Owner:WUHU BOKE ELECTROMECHANICAL

Efficient corn-threshing method

An efficient corn-threshing method mainly solves the problems that existing corn-threshing methods are low in threshing efficiency and poor in threshing and separating effect. The efficient corn-threshing method is characterized by comprising conveying corn cobs or corn cobs with skins to a main threshing barrel (1) through a feeding device; performing primary threshing on the corn cobs, and performed primary screening; performing secondary threshing on the corn cobs through an auxiliary threshing roller (4), and performing primary screening; performing secondary screening out of corns by swinging an upper sieve plate (9), a middle screen (10) and a lower sieve plate (11); performing third screening out of the corns above the upper sieve plate (9), the middle screen (10) and the lower sieve plate (11) through a suction fan (13) of a careful selection device; performing fourth screening out of the corns through a blower (14) of a cleaning device; and finally bagging the corns or loading the corns to a vehicle through an output loading device. The efficient corn-threshing method has the advantages of being high in efficiency and guaranteeing quality.

Owner:QIQIHAR BEIKUN AGRI MACHINERY MFG

High-oil corn high-yield cultivation method

The invention discloses a high-oil corn high-yield cultivation method and belongs to the technical field of special corn cultivation. The high-oil corn high-yield cultivation method is characterized in that the method integrates several high-yield efficient corn cultivation technologies, and includes the steps of selecting high-oil corn varieties, deeply ploughing, applying sufficient basic fertilizers, additionally applying slow release fertilizers, ridging and planting, mulching films, controlling corn borers and harvesting in time. Using the method for planting high-oil corns is timesaving and laborsaving, average yield per mu is above 600 kilograms, corn grains are above 9% in oil content and can be processed for use as well as used as feed, economic and social benefits are remarkable.

Owner:SHANDONG TIANTAI SEED

Method for producing corn flour

The corn flour producing process includes the following steps: soaking corn grains in water, blanching at 80-100deg.c for 1-3 min, soaking in water with sodium percarbonate in 0.1 wt% of corn and water at 28-60deg.c for 30-60 min, water washing, soaking in water with lactic acid bacteria in 0.01 wt% of corn and water at 28-60deg.c for 24-72 hr, water washing, milling into milk in a mill, taking 80 mesh below slurry, dewatering and drying to obtain corn flour in 3-8 %, cooling and packing. Thus produced corn flour is delicious, and has the whole nutritious components of corn maintained, and is favorable to transportation and storage.

Owner:张子飚

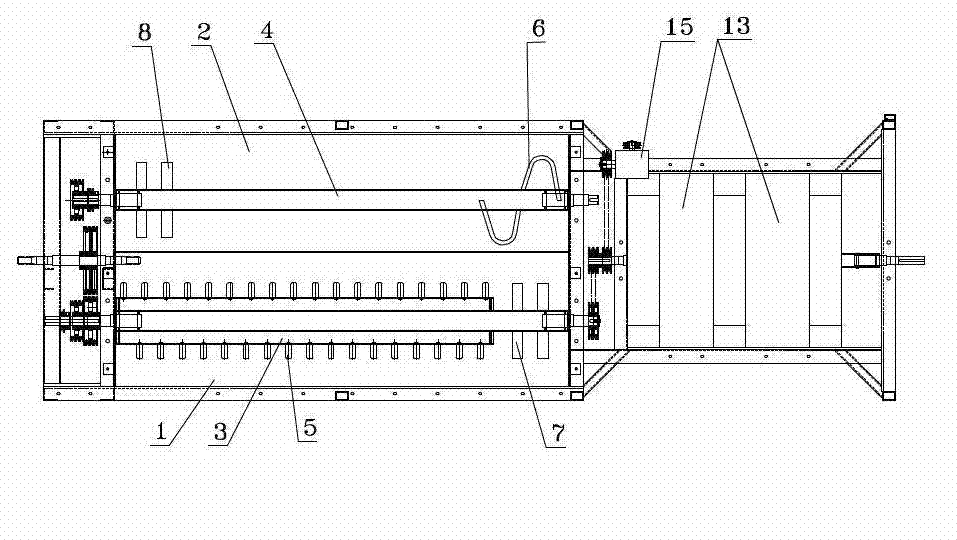

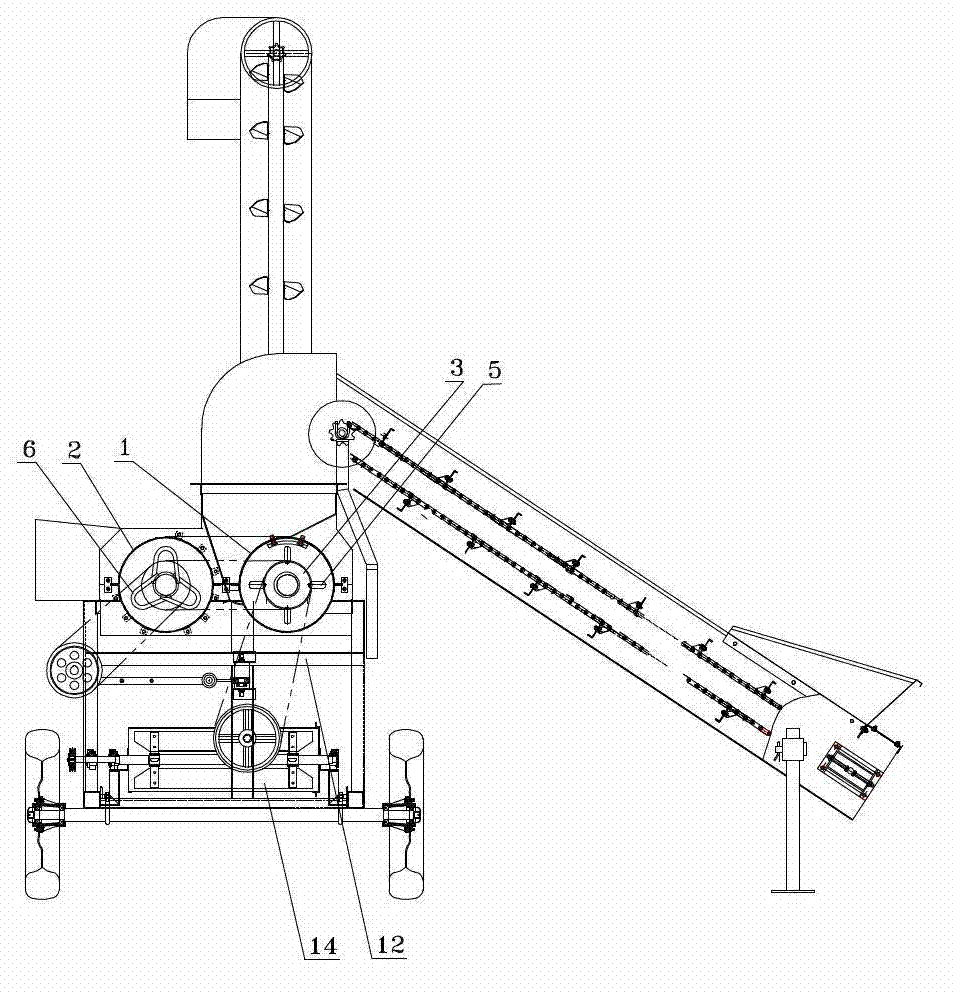

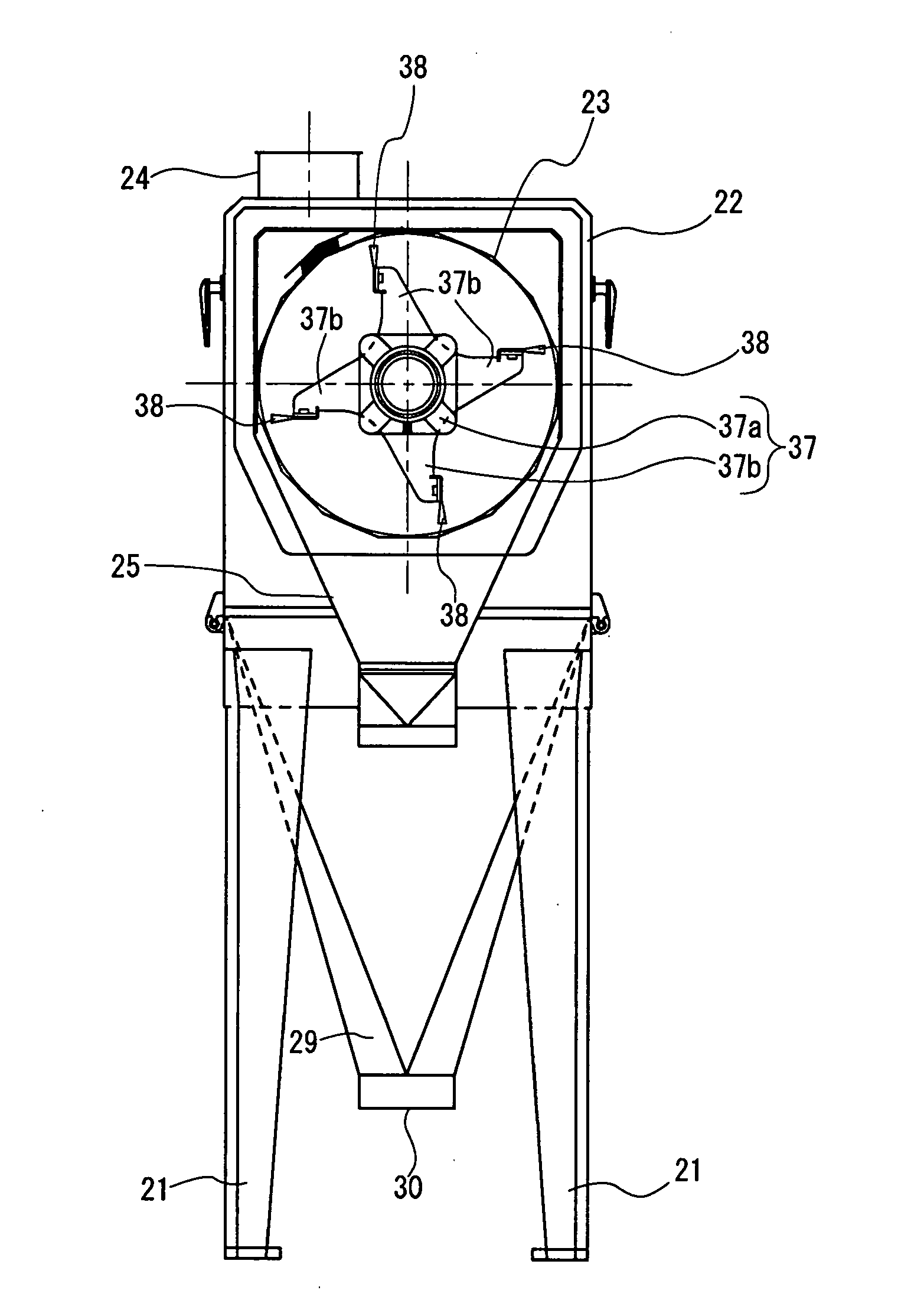

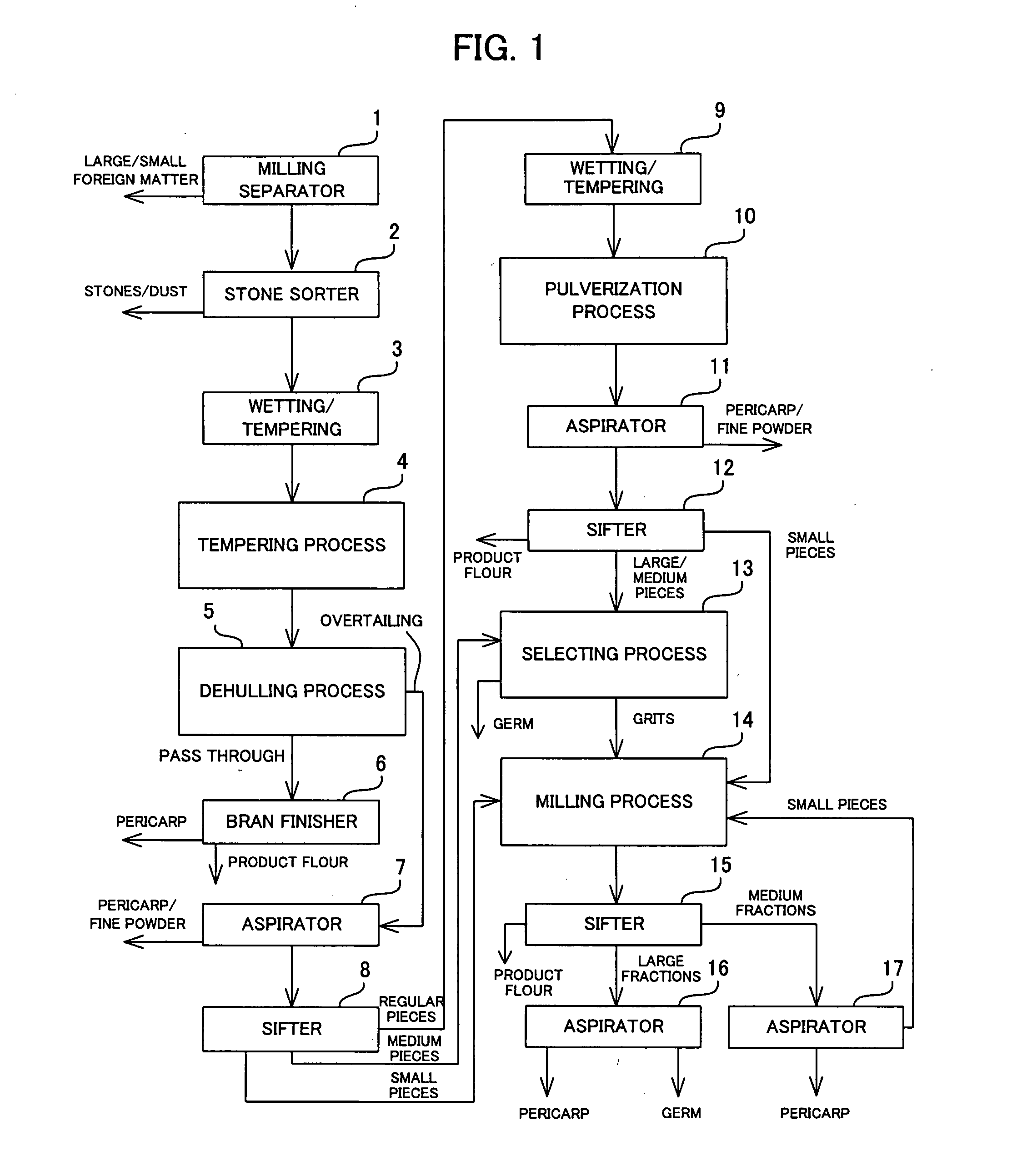

Method of and apparatus for processing corn grains for production of ethanol

A processing method and an apparatus for producing ethanol that reduces the number of separation steps to the maximum extent possible and simplifies the production configuration while enabling the grits, pericarp and germ to be extracted with ease. The method includes a tempering step of wetting corn grains with a certain amount of water, a dehulling step of dehulling the corn grains while maintaining their shape without breaking the wetted grains, a pulverization step of pulverizing the dehulled corn grains into pieces, a separation step of separating grits and bran from the broken pieces, and a milling step of further milling the separated grits.

Owner:SATAKE CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com