Corn threshing roller set and corn threshing machine

A technology of corn threshing and threshing rollers, which is applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of low cleaning rate, broken corn kernels and corncobs, and low work efficiency, and achieves the improvement of cleaning rate, Reduce breakage and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

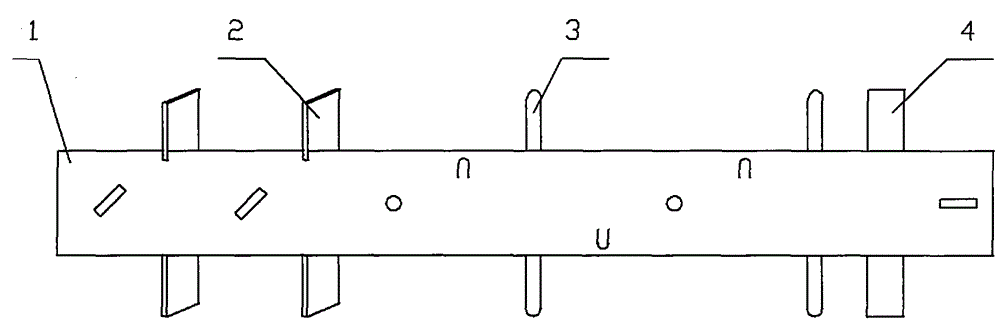

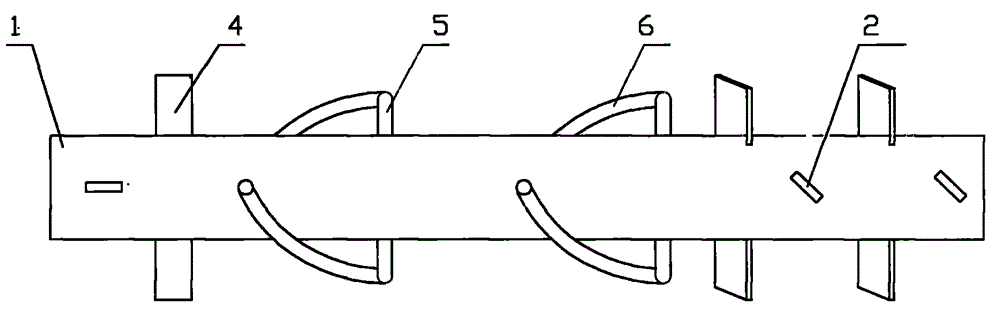

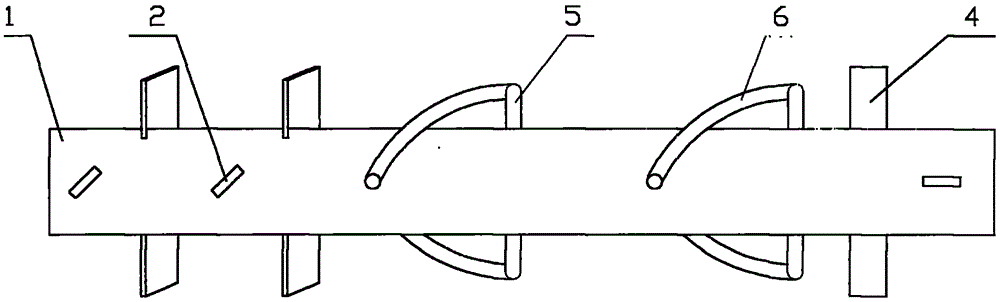

[0041] like figure 1 , figure 2 and image 3 As shown, the corn threshing roller group is composed of several threshing rollers arranged side by side. There are several pusher plates on the driving ends of the first threshing roller and the second threshing roller, and the pushing direction is from the driving end to the driven end. There are several threshing plates at the driven end, and a plurality of threshing columns on the main body of the roller core; a pusher plate is set at the driven end of the third threshing roller, and its advancing direction is from the driven end to the driving At the driving end, there is a shifting plate at its active end, and a number of threshing ribs are set on its main part, and the threshing ribs are fixed on the roller core through the support column; The advancing direction of the las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com