Tech. of closed water circulation in maize starch prodn. process

A processing process, corn starch technology, applied in vegetable protein processing, texturing, food science and other directions, can solve the problems of affecting starch quality, secondary pollution, large equipment investment, etc., to improve dry matter yield, reduce Water consumption, the effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

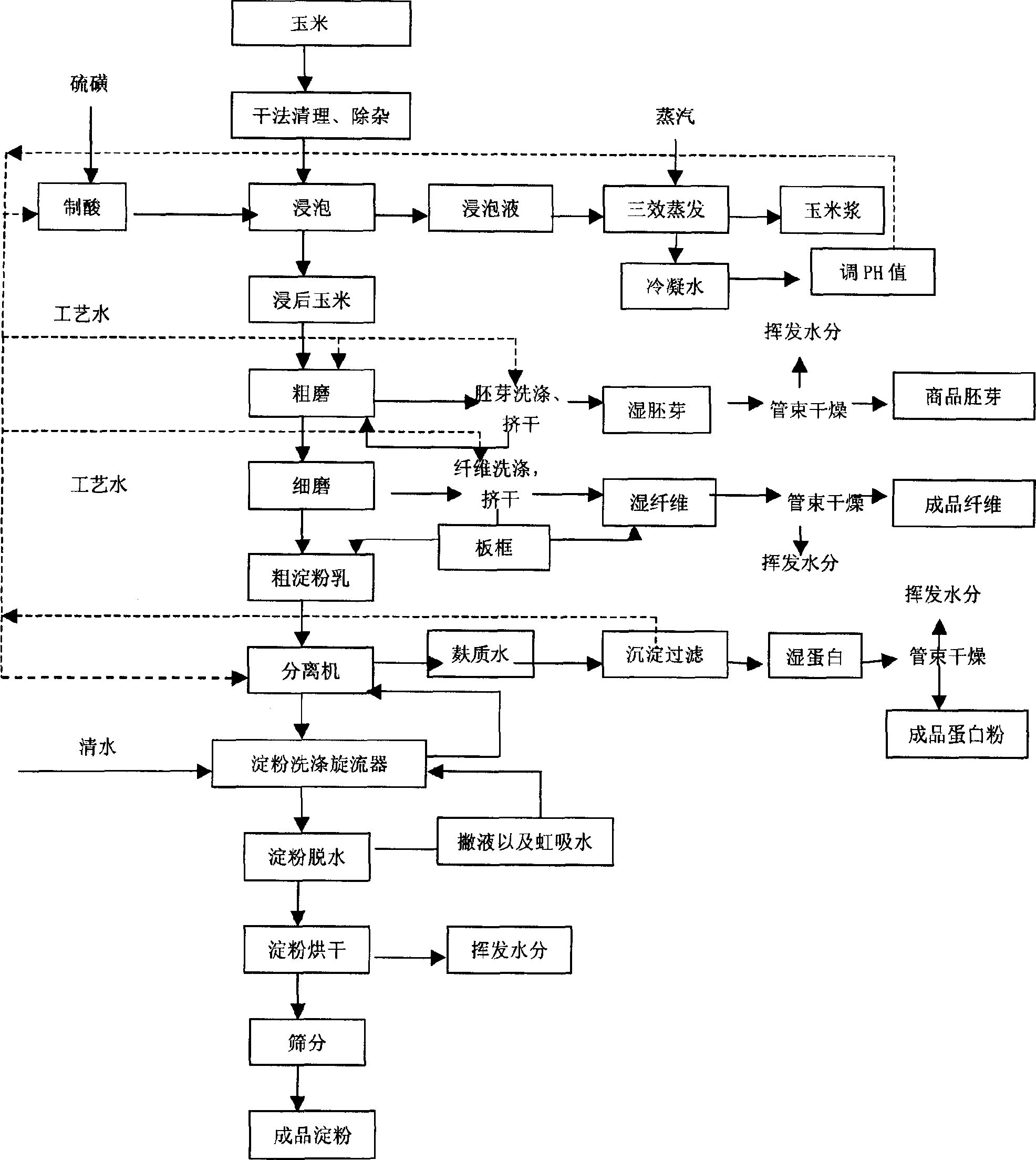

[0016] The whole process is shown in the figure. After the corn has been cleaned, it is transported to the soaking workshop by dry method for soaking. The water used in the soaking workshop is mainly for acid production. The process water for acid production does not affect the soaking effect. After soaking, the thin corn steep liquor is evaporated by three-effect. The condensed water produced during the evaporation of corn steep liquor is returned to the process pool by adjusting the pH value to between 4-7. After soaking, the corn is sent to the grinding process with process water for grinding. The corn germ is extracted in the grinding stage, and when the germ is washed The water from the process pond and the waste water from the germ washing and squeezing process are all reused in the coarse grinding process. The fiber washing water is process water. The waste water generated during the washing and squeezing process contains a certain amount of fine fibers and cannot be direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com