Patents

Literature

5771results about How to "Low water absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

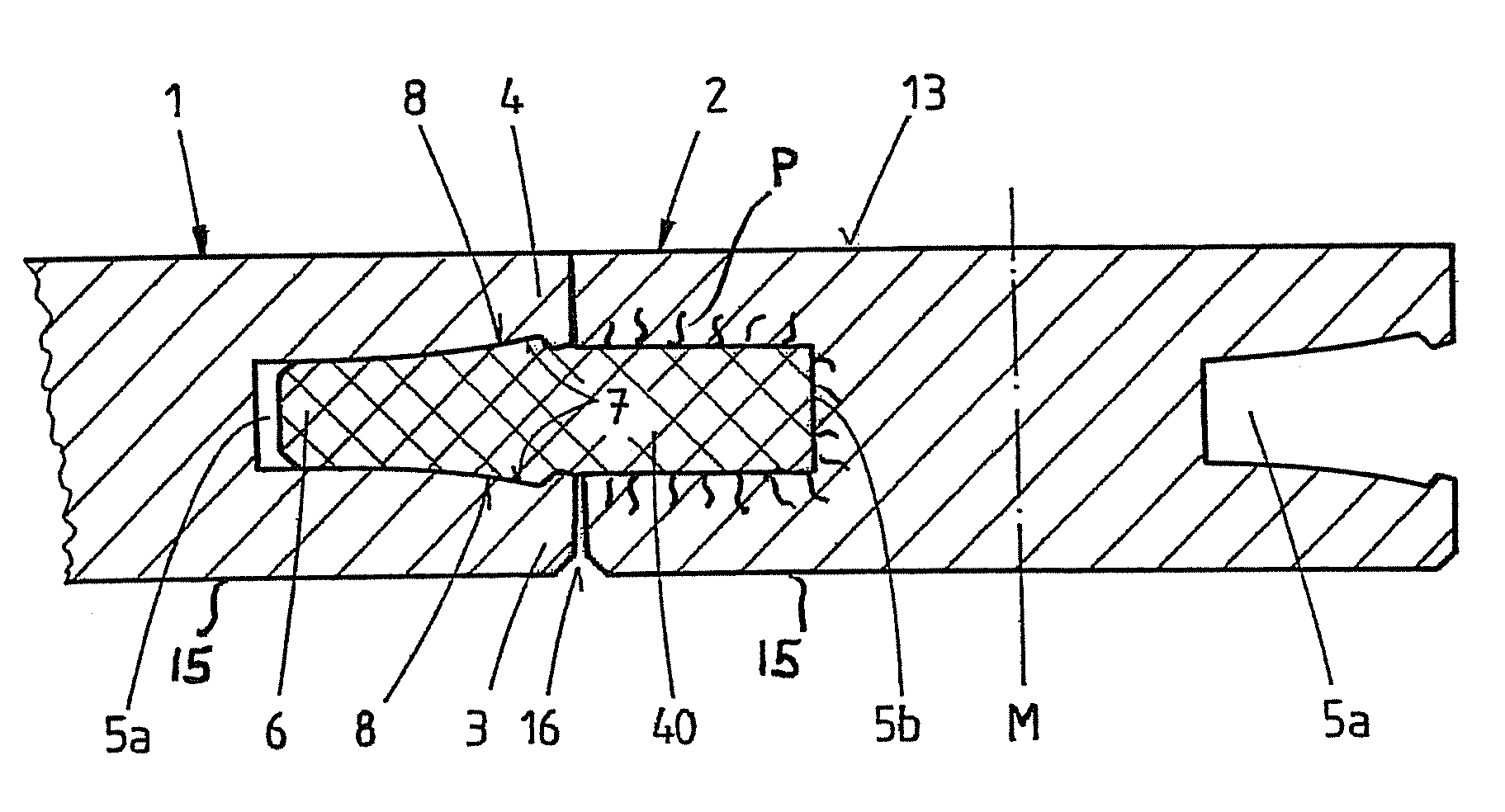

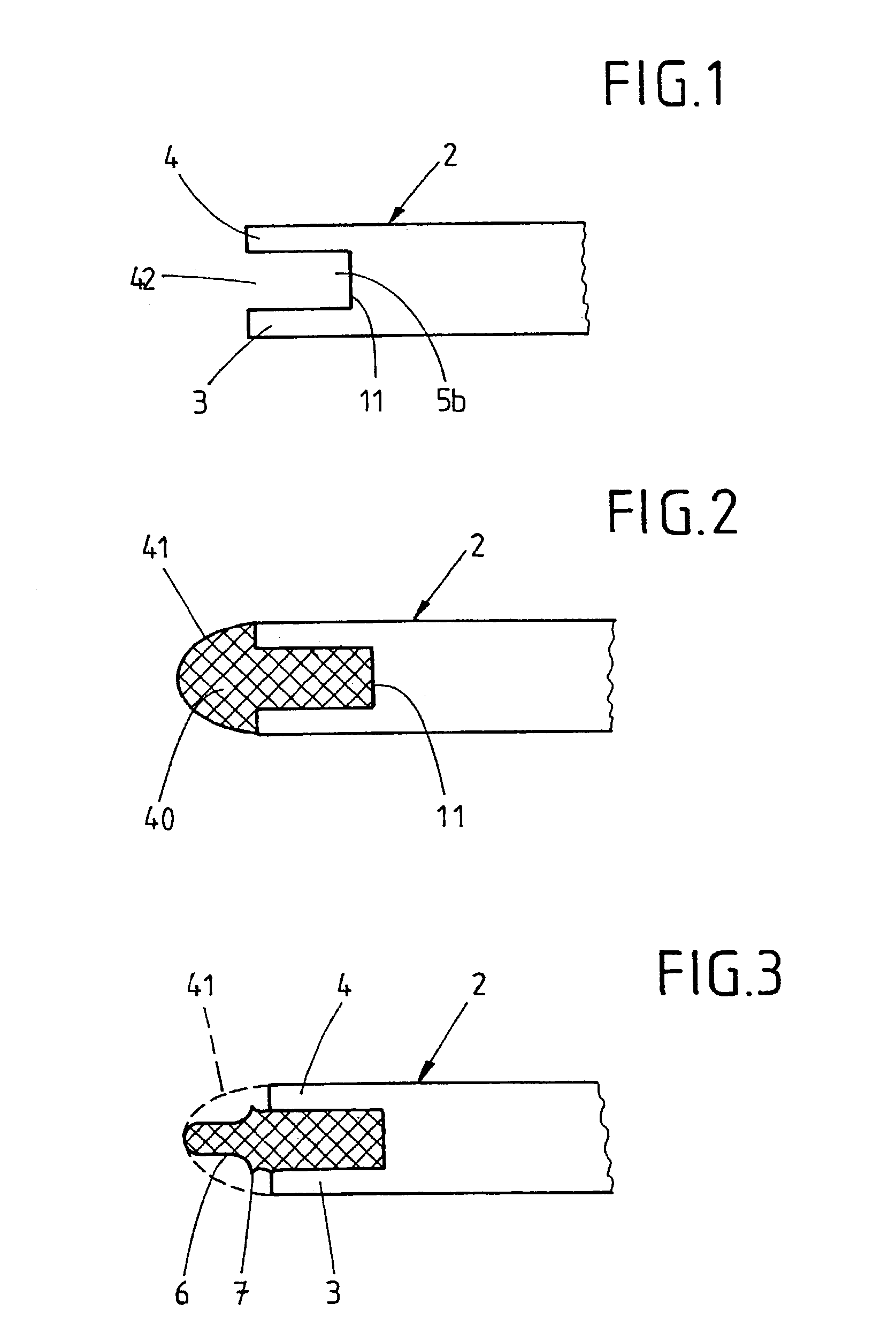

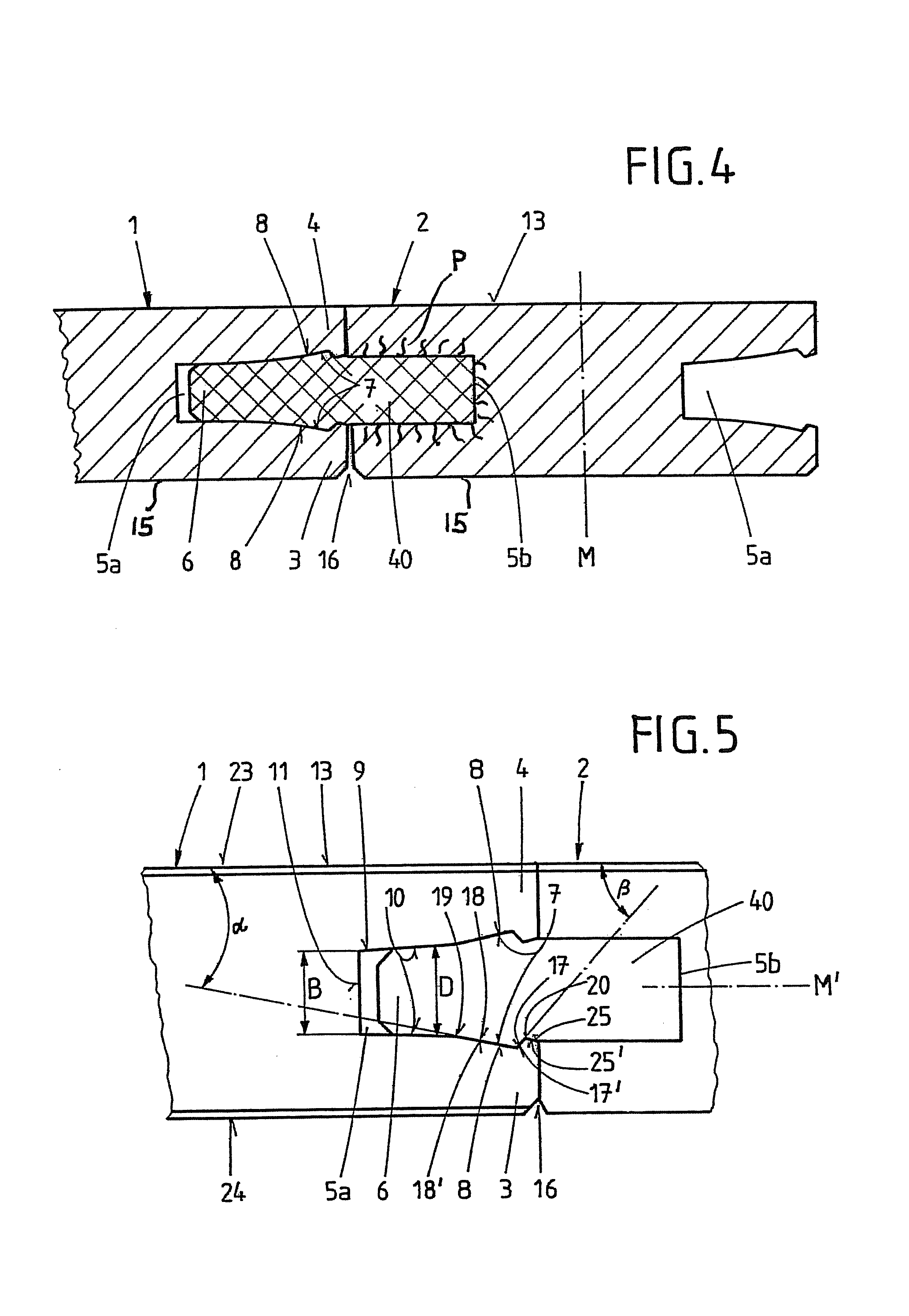

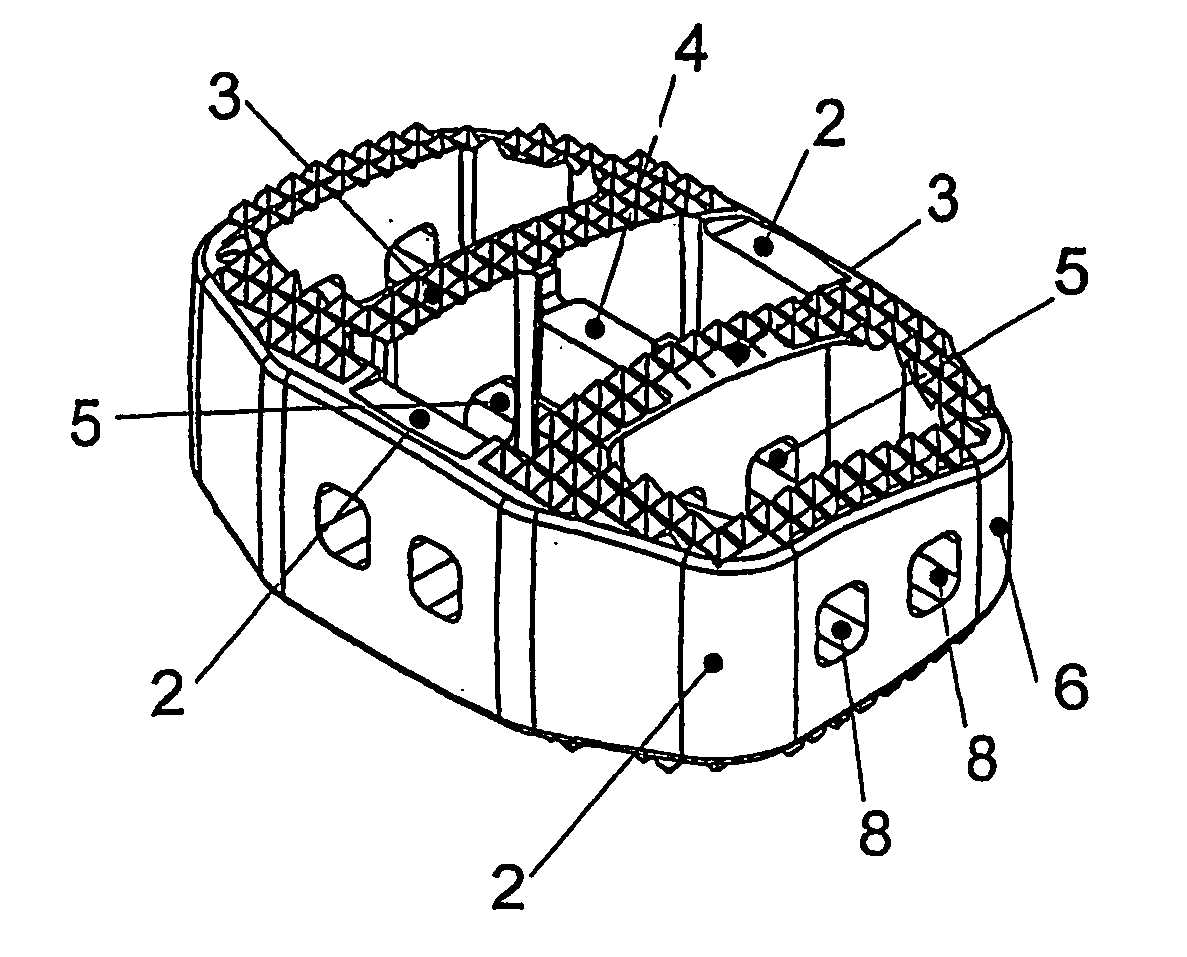

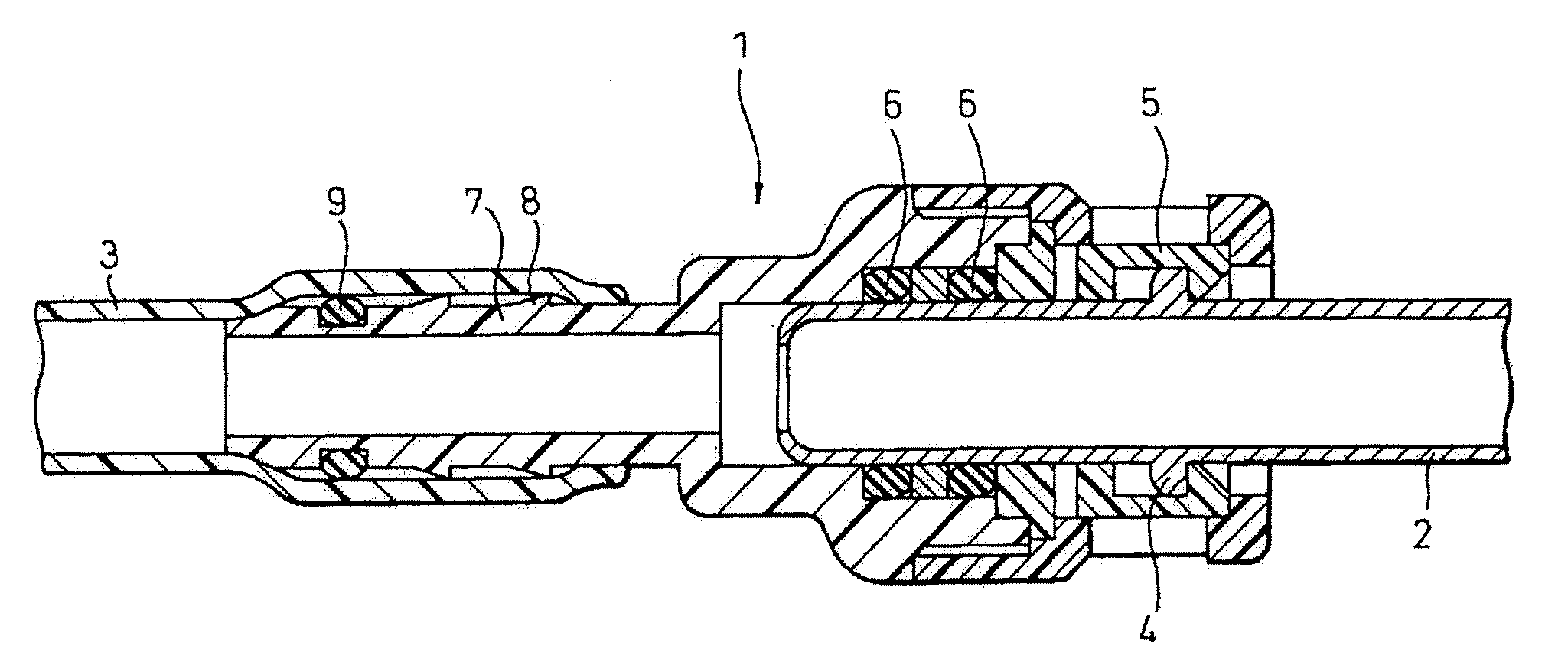

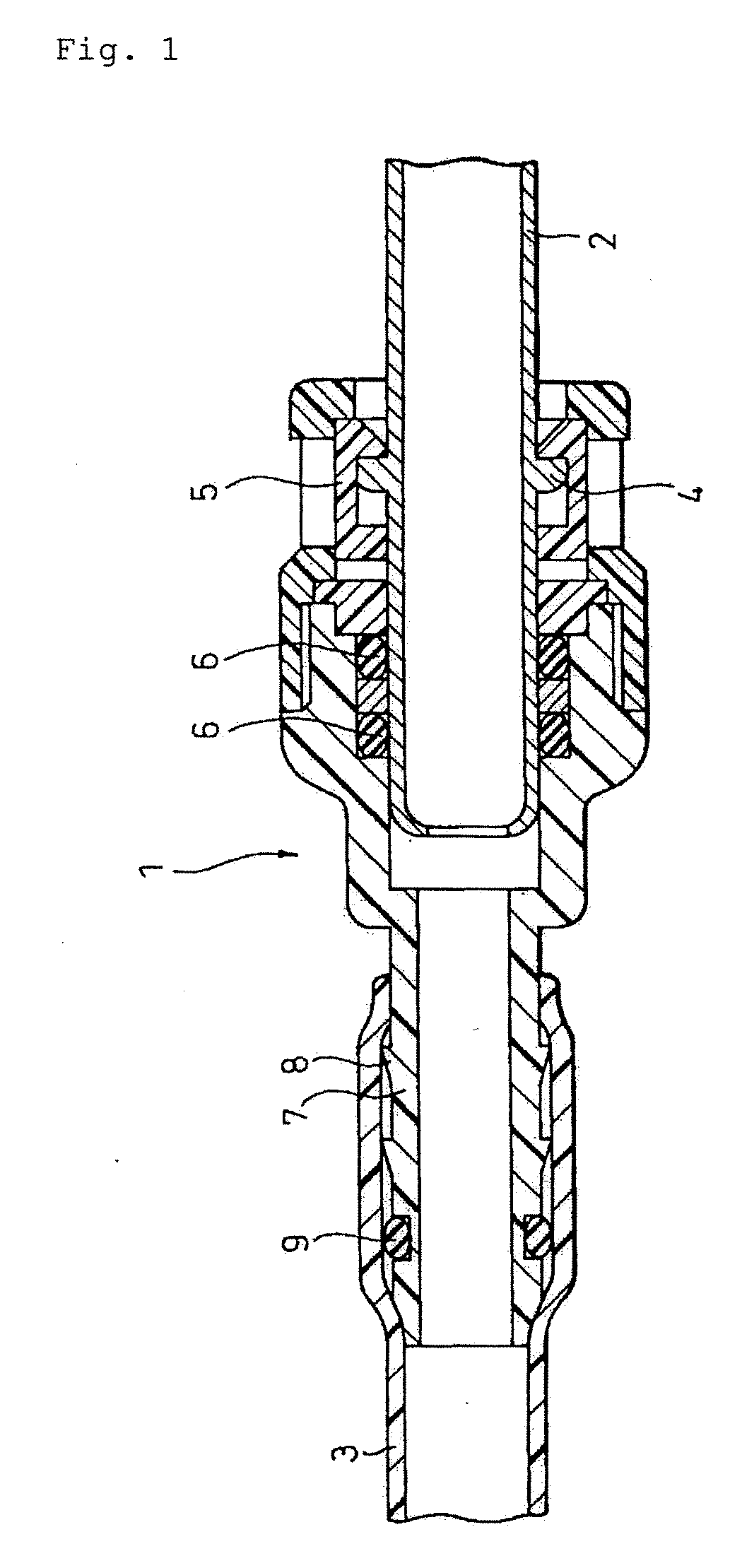

Arrangement of building elements with connecting means

InactiveUS7377081B2Potential savingAccurately processStrutsWallsArchitectural engineeringInterconnection

An arrangement of building elements capable of a snap-fastening interconnection comprises an element, especially the tongue, consisting of a different material from the other building elements. An MDF / HDF panel, is initially milled along the longitudinal and / or transverse sides, and the resulting groove is then provided and / or foam-filled with extrudates. Finally, the free ends of the extrudates are milled to form the profile of the tongue. Alternatively, or additionally, a groove may also be milled into the extrudates.

Owner:KAINDL FLOORING GMBH

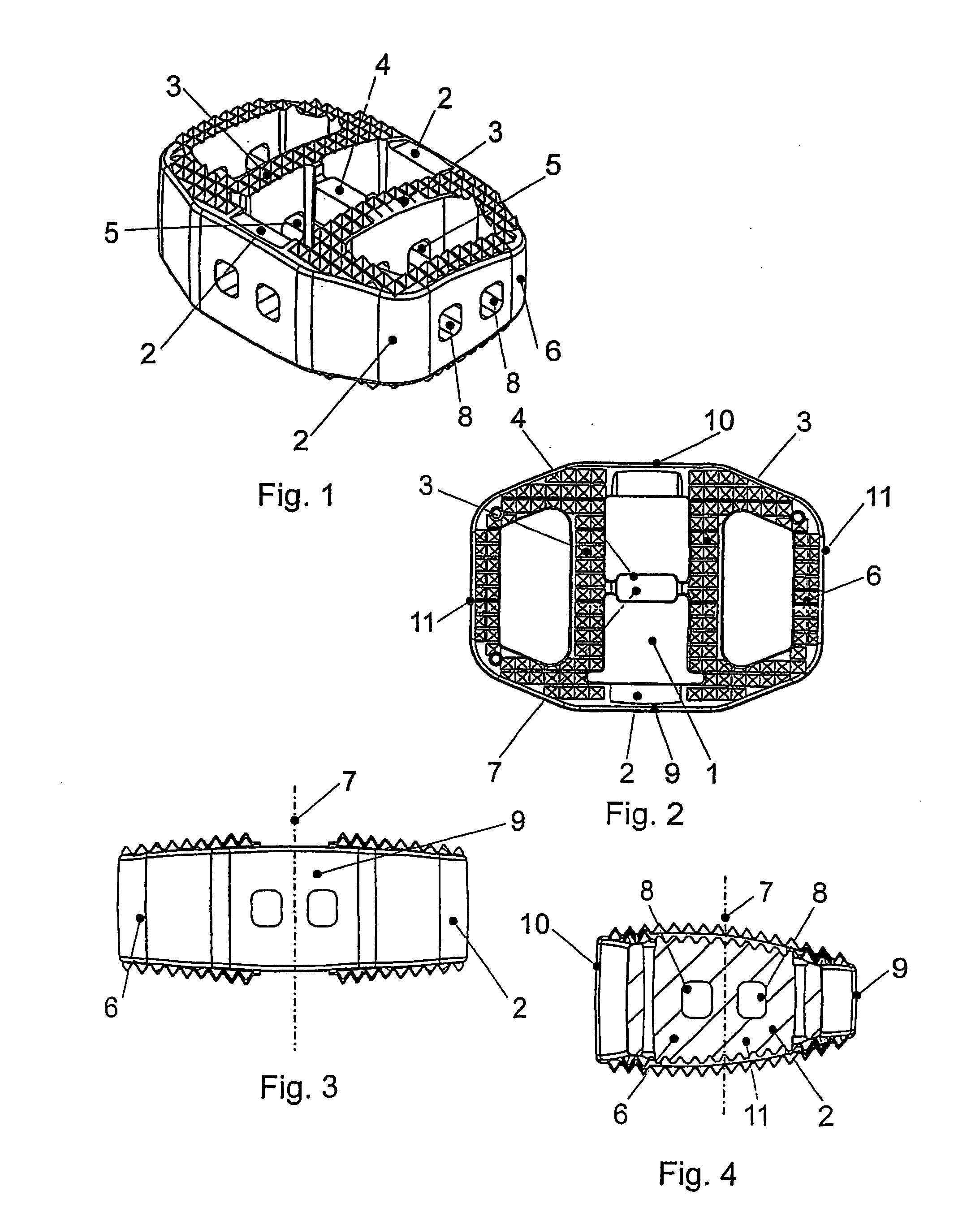

Bone implant, in particular, an inter-vertebral implant

InactiveUS20060167549A1Low water absorptionPreventing the filler from falling outBone implantJoint implantsBone implantEngineering

A bone implant and the method of manufacturing thereof, the bone implant, in particular an inter-vertebral implant, made of a radiation-permeable material. The inter-vertebral implant defining a surface and comprising a front section, a back section, two lateral sections defining a central axis, and a substantially hollow interior chamber, each section having a superior and inferior vertebral contacting surface. The hollow chamber is subdivided by at least two partitions running essentially parallel to the central axis and which connect the front section to the back section.

Owner:DEPUY SYNTHES PROD INC

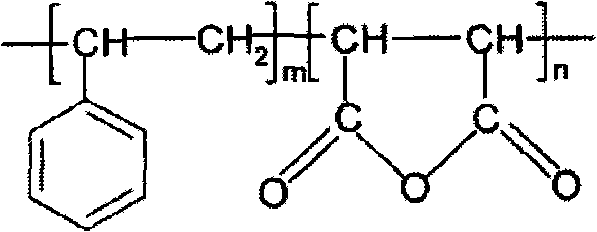

Halogen-free resin composition and its application for copper clad laminate and printed circuit board

ActiveUS20130161080A1Low dielectric constantImprove heat resistancePlastic/resin/waxes insulatorsGroup 5/15 element organic compoundsEpoxyLow dissipation

A halogen-free resin composition includes (A) 100 parts per hundred resin of epoxy resin; (B) 1 to 100 parts per hundred resin of benzoxazine resin; (C) 1 to 100 parts per hundred resin of styrene-maleic anhydride; (D) 0.5 to 30 parts per hundred resin of amine curing agent; and (E) 5 to 150 parts per hundred resin of halogen-free flame retardant. The composition obtains properties of low dielectric constant, low dissipation factor, high heat resistance and flame retardancy by specific composition and ratio. Thus, a prepreg or a resin film, which can be applied to a copper clad laminate and a printed circuit board, is formed.

Owner:ELITE MATERIAL

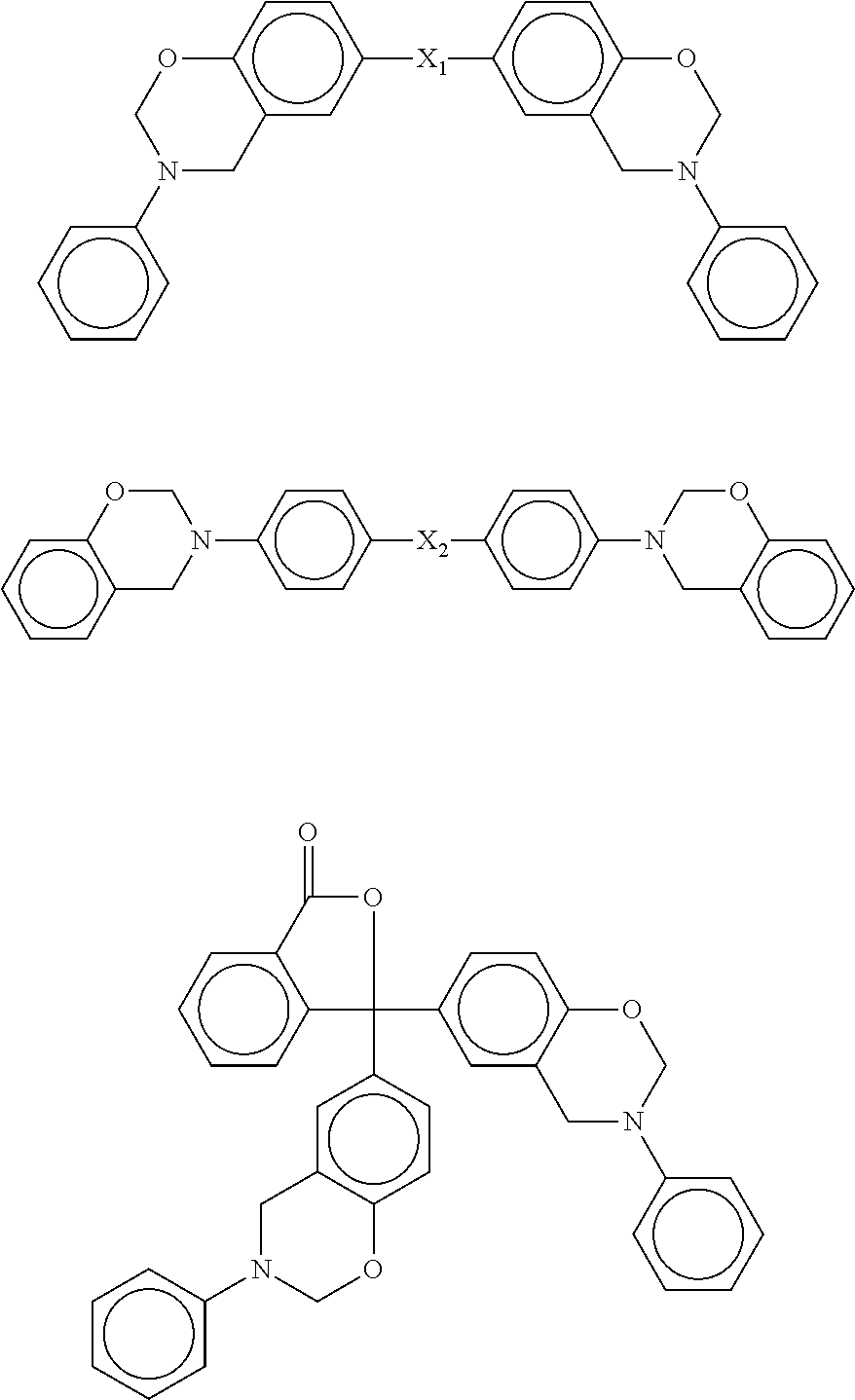

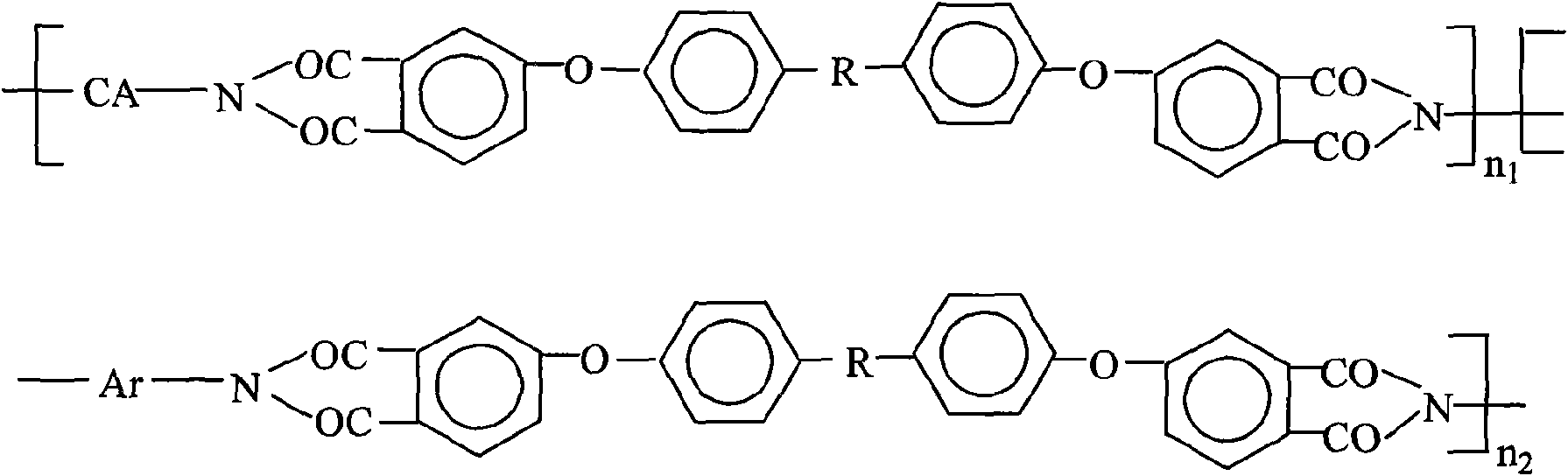

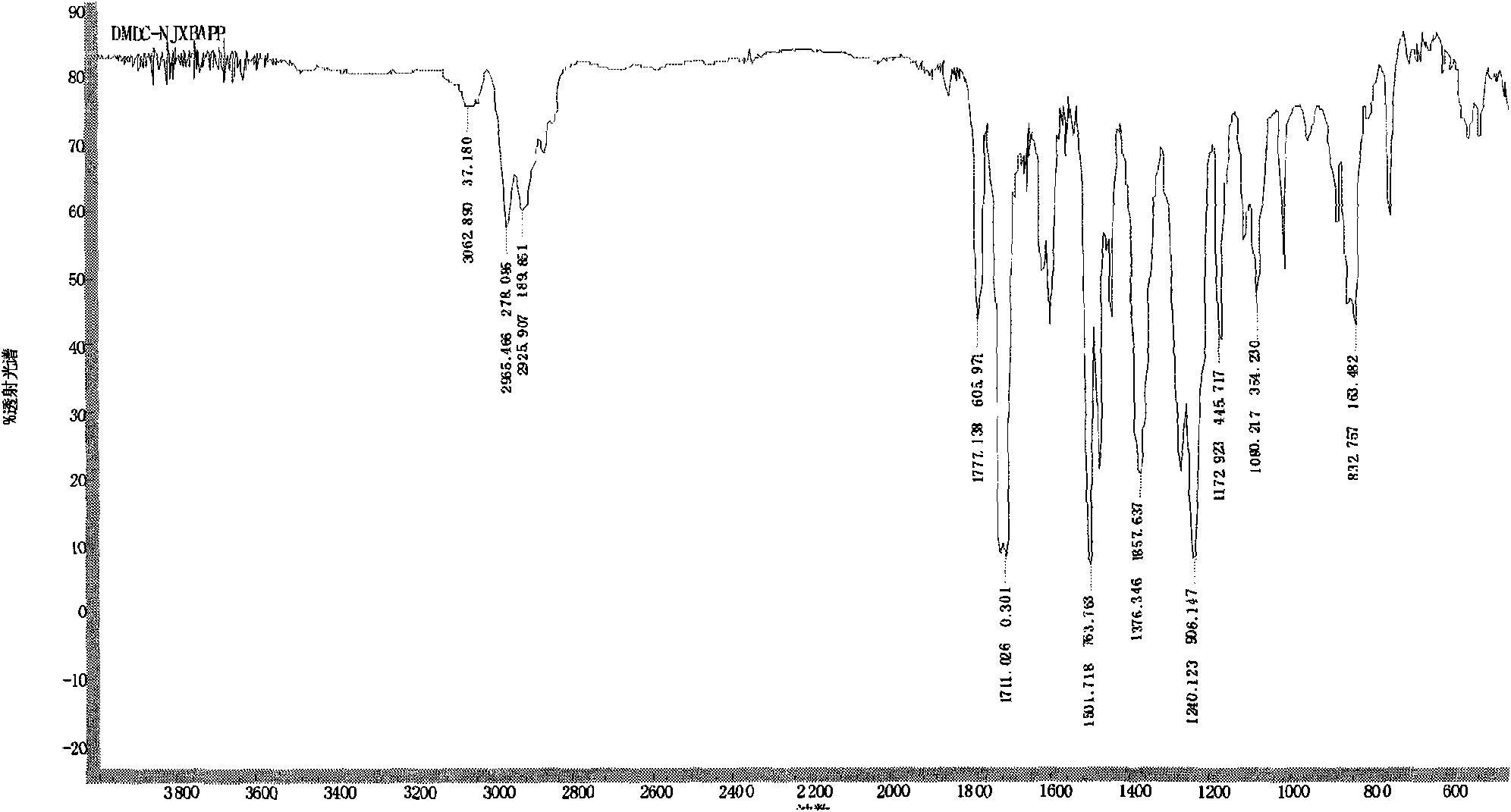

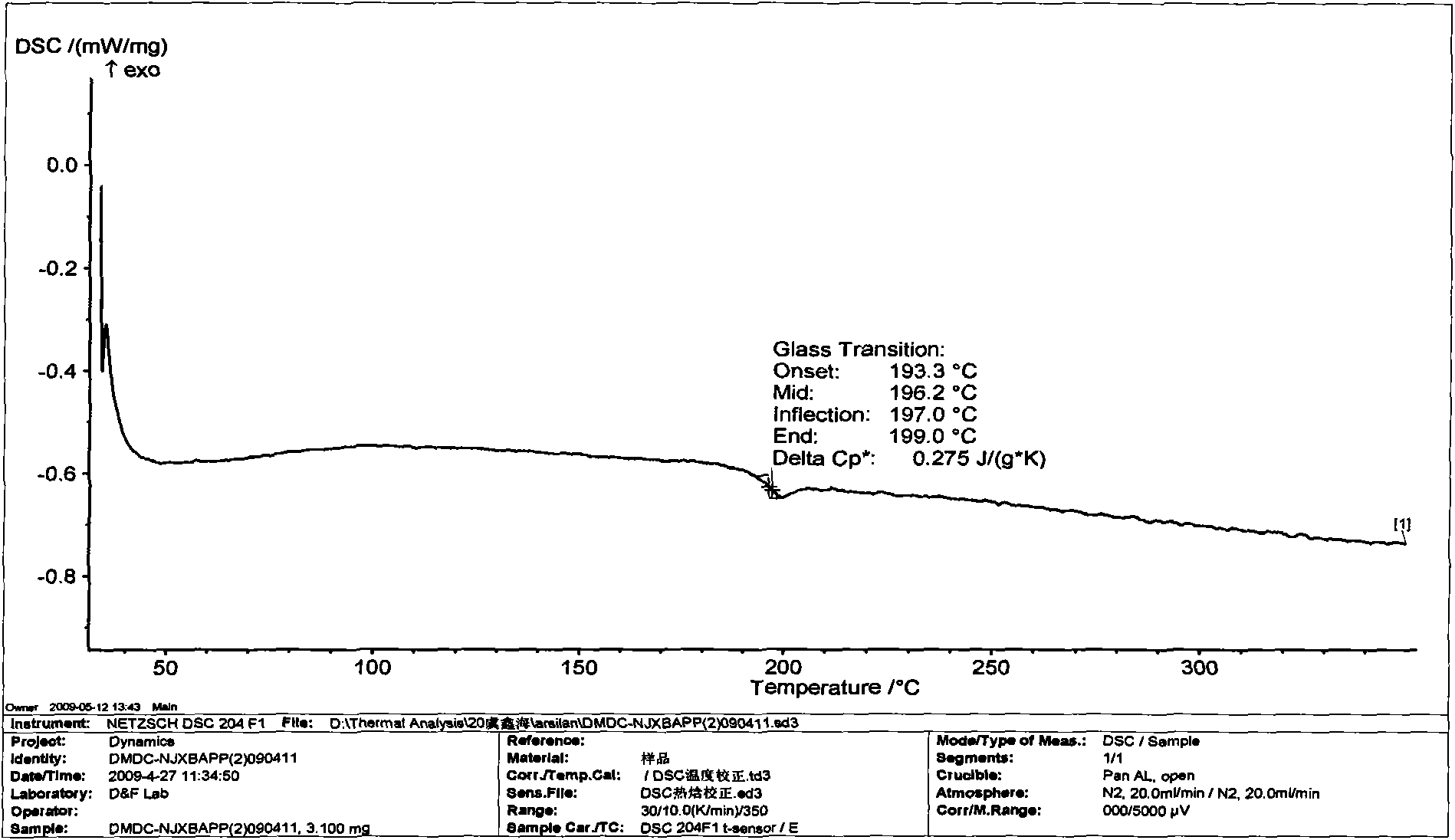

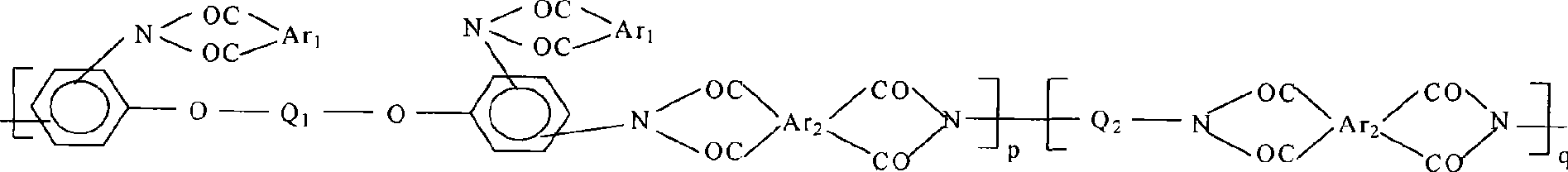

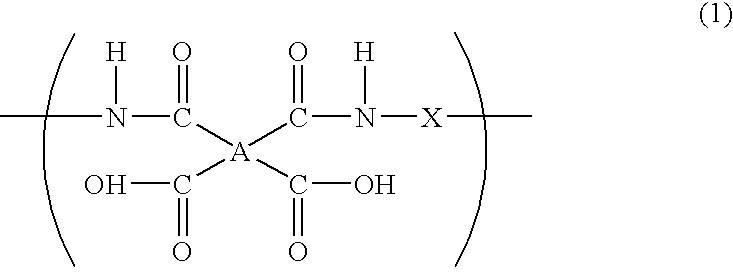

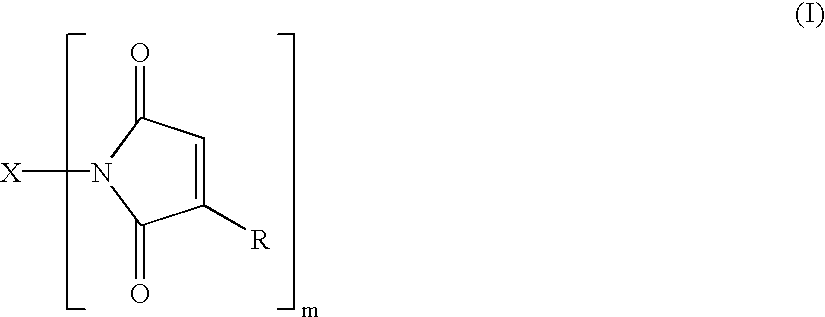

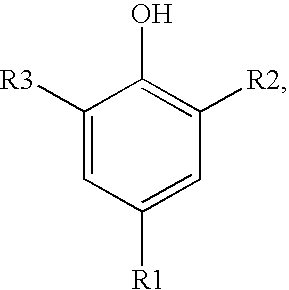

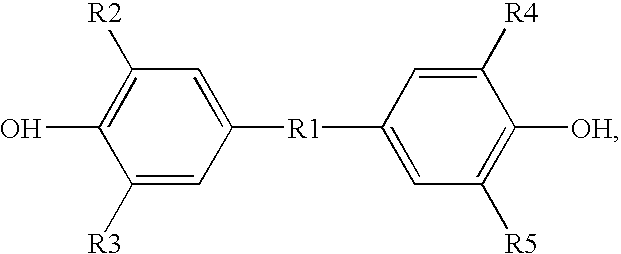

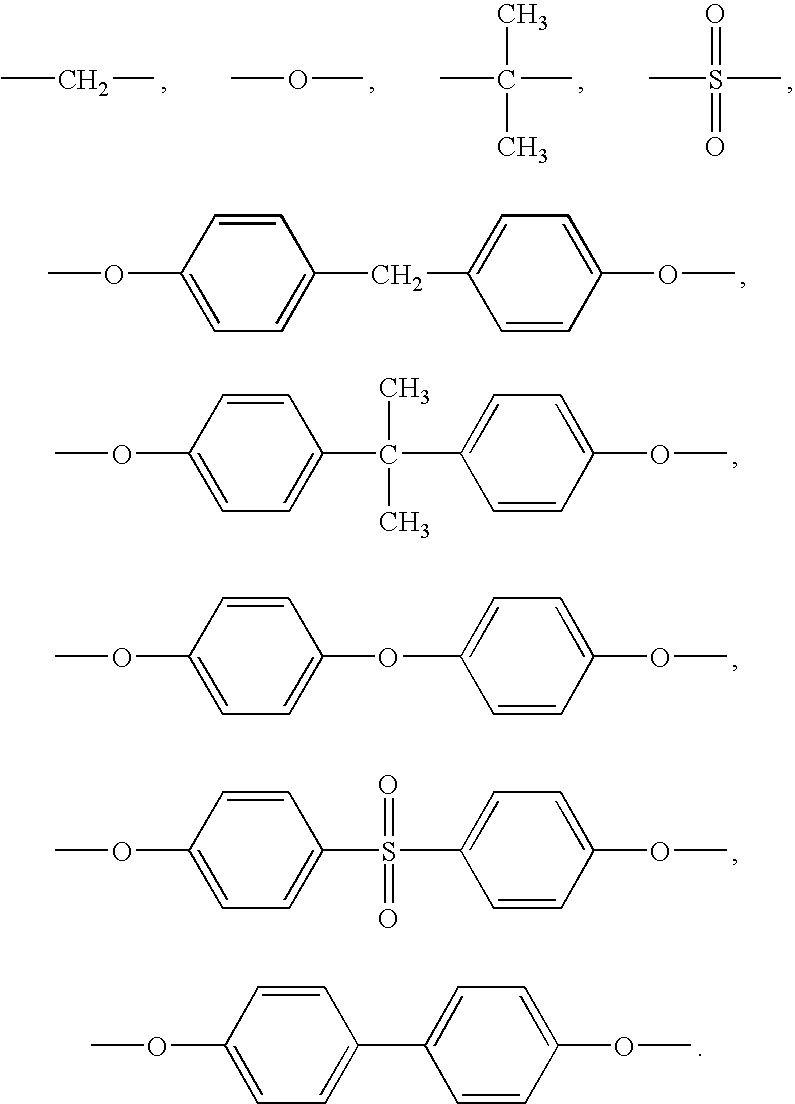

Alicyclic-containing polyimide film and preparation method thereof

InactiveCN101580637AConvenient sourceLow costTelescopesNon-linear opticsOptical communicationPhotochemistry

The invention relates to an alicyclic-containing polyimide film. The molecular structure general formula of the film is the right formula, wherein, -CA- is a bivalence connection group of an alicyclic dibasic primary amine, -Ar- is a bivalence connection group of an aromatic dibasic primary amine, and -R- is a bivalence connection group of an aromatic dibasic estolide. The preparation thereof includes: the alicyclic dibasic primary amine and the aromatic dibasic primary amine are dissolved in non-proton organic solvent with strong polarity, the aromatic dibasic estolide is added, the non-proton organic solvent with strong polarity is used for regulating the viscosity of the alicyclic-containing polyamic acid resin solution after reaction for 1-3 hours, forming is carried out in a curtain coating machine, and dehydration fever imidization, cooling and demoulding are carried out so as to obtain the film. The preparation method has mild reaction condition and low cost and is environmentally friendly; and meanwhile, the alicyclic-containing polyimide film has excellent mechanic property and heat resistant property and low water absorption, and the visible light transmission thereof is as high as more than 97%. The film has good application prospect in the fields of optical waveguide material, photorefractive material and photoelectric material in optical communication field and direct action membrane material in the liquid crystal display field and the like.

Owner:DONGHUA UNIV

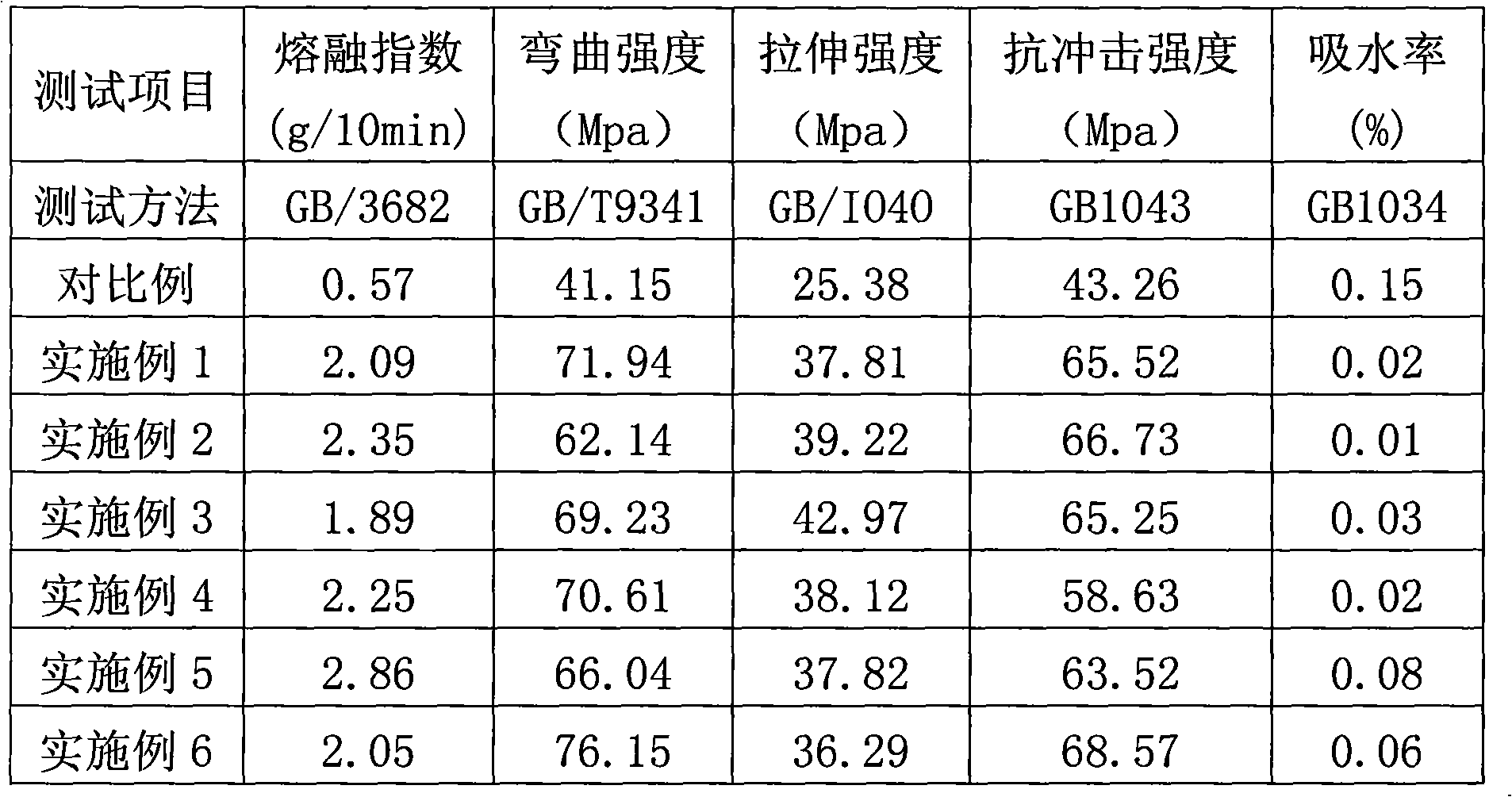

Wood plastic composite material

The invention relates to a wood plastic composite material comprising the following materials in parts by weight: 100 parts of wood meals, 20-80 parts of waste plastics, 5-50 parts of waste rubbers, 10-60 parts of high-melt index thermoplastic resins, 1-12 parts of surface active agents, 2-8 parts of lubricating agents, 0.1-4 parts of cross-linking agents, 0.1-4 parts of antioxygens and 0.05-1.5 parts of processing agents, wherein the grain diameter of the wood meals ranges from 10 meshes to 325 meshes; the flow velocity of the high-melt index thermoplastic resins is higher than 20 g / 10 minutes; the cross-linking agents are peroxides, thus the invention improves the dispersibility and the flowability of the wood meals contained in the composite and the compatibility of plastics by adding the high-melt index thermoplastic resins, can not only better utilize the resources, but also enhances the mechanical strength (such as tensile strength, bending strength, impact strength, and the like) of the composite material by adding the waste rubbers, has the advantages of good processing property, low water absorption rate, good stability of products, and the like and is suitable for injection moulding and beneficial to market promotion.

Owner:东莞市启原实业有限公司

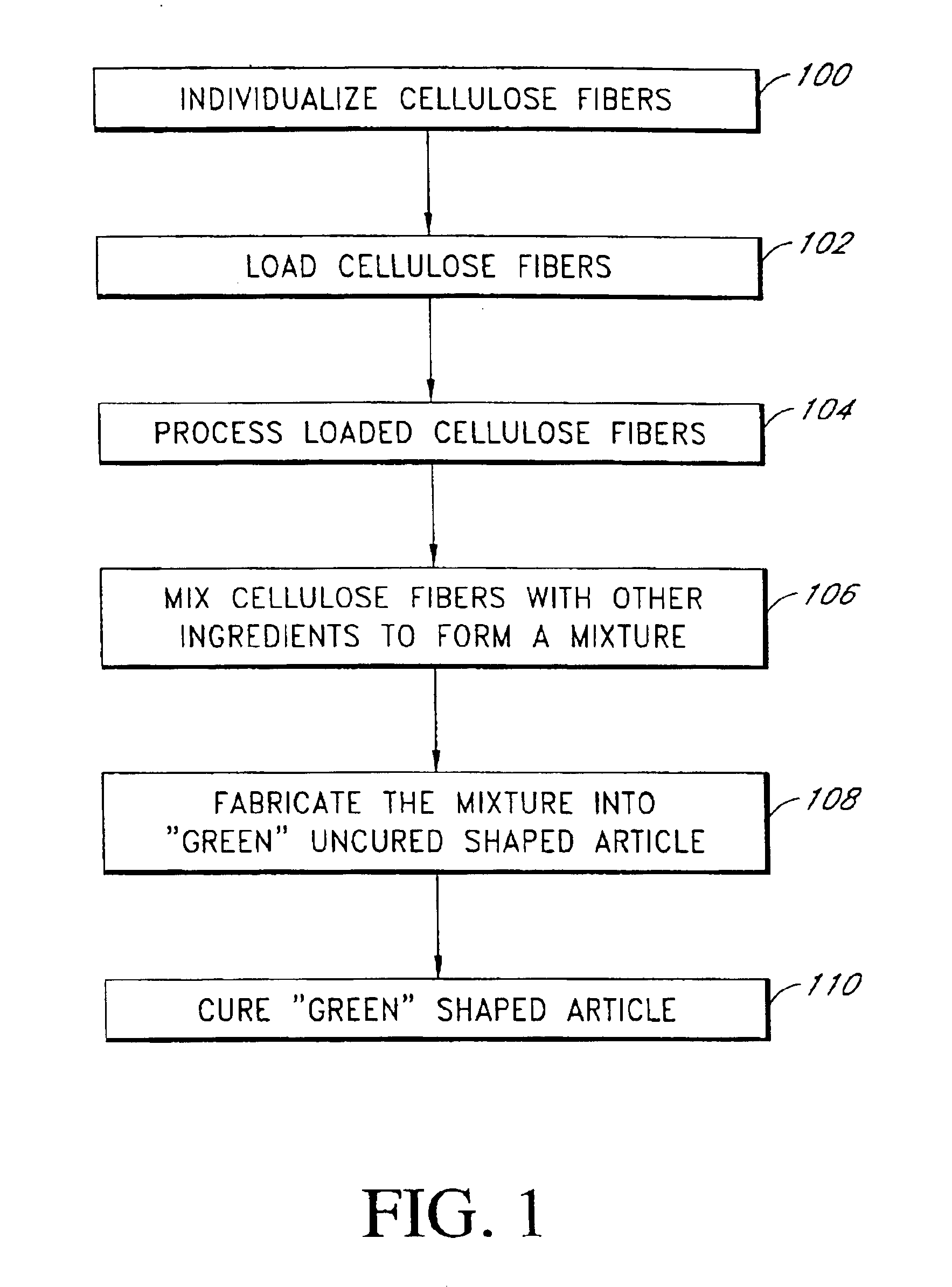

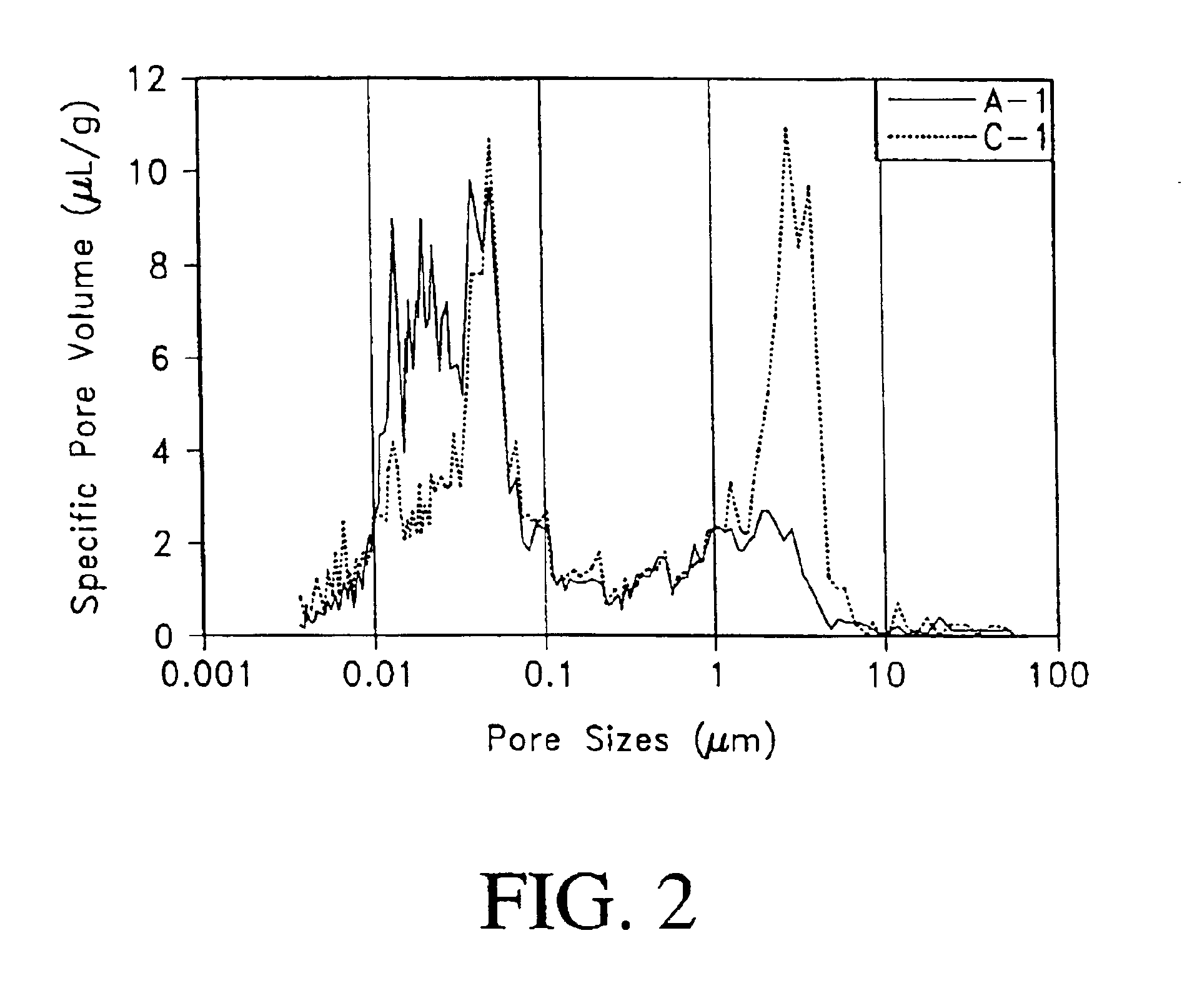

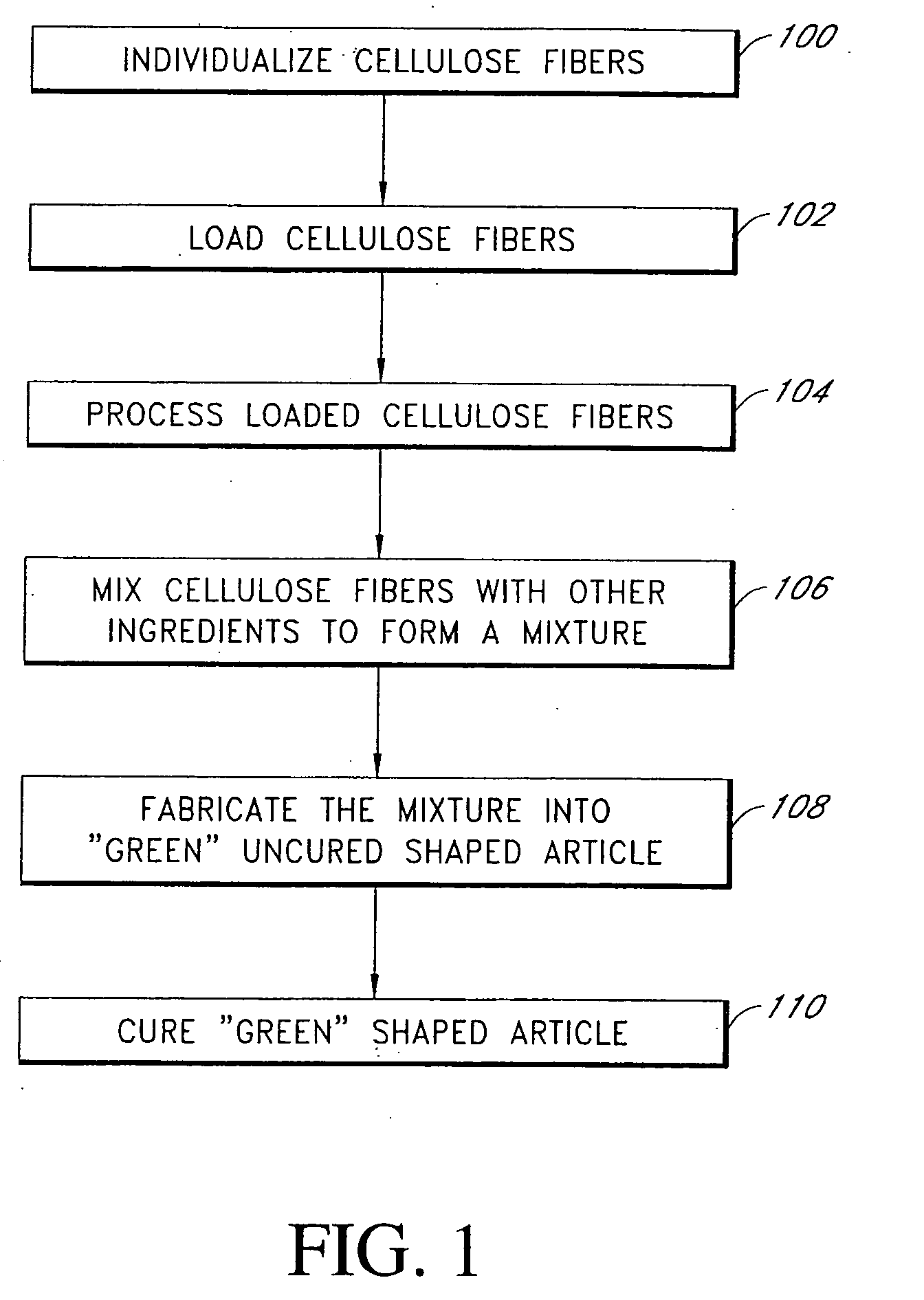

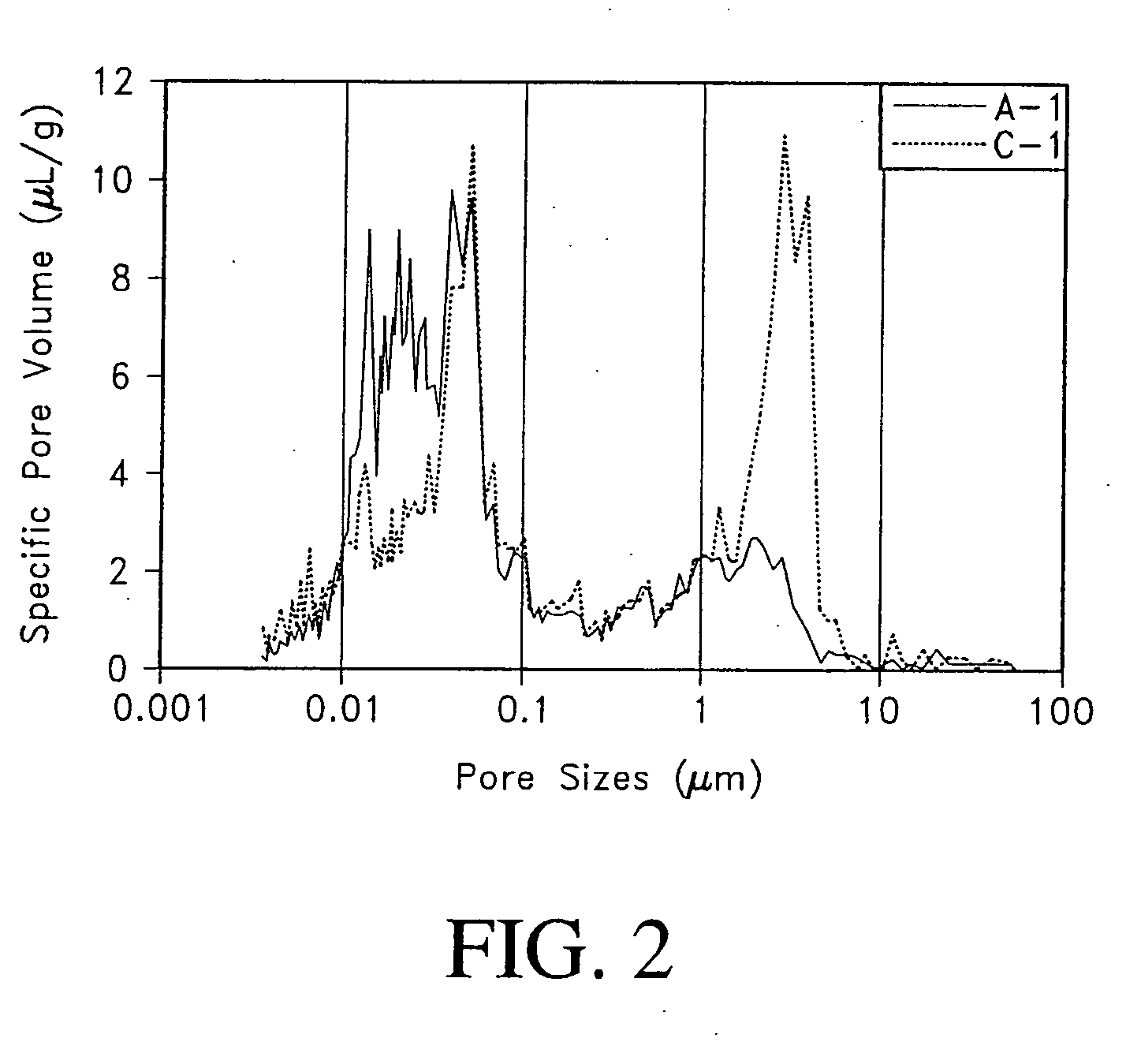

Fiber cement composite materials using cellulose fibers loaded with inorganic and/or organic substances

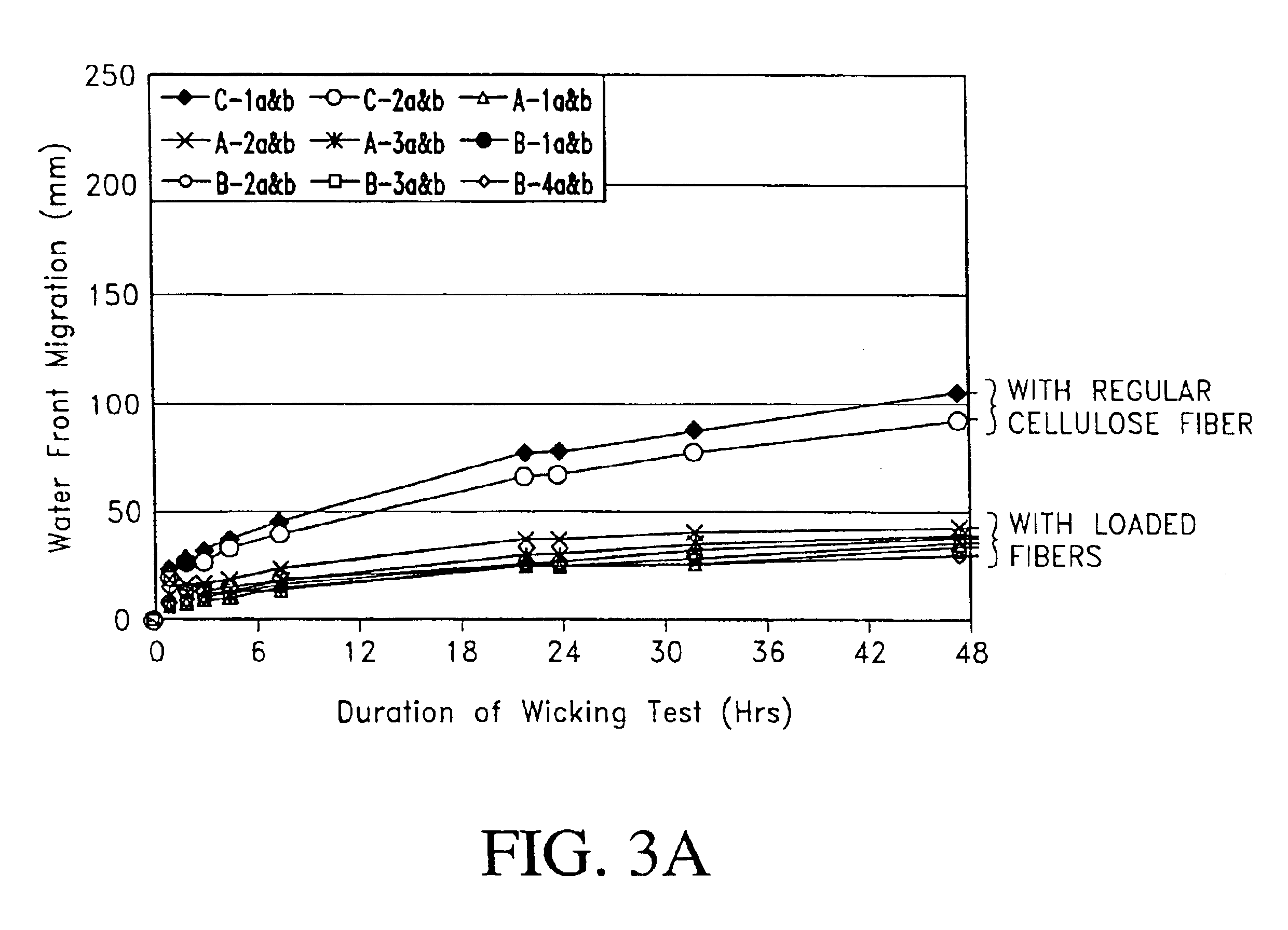

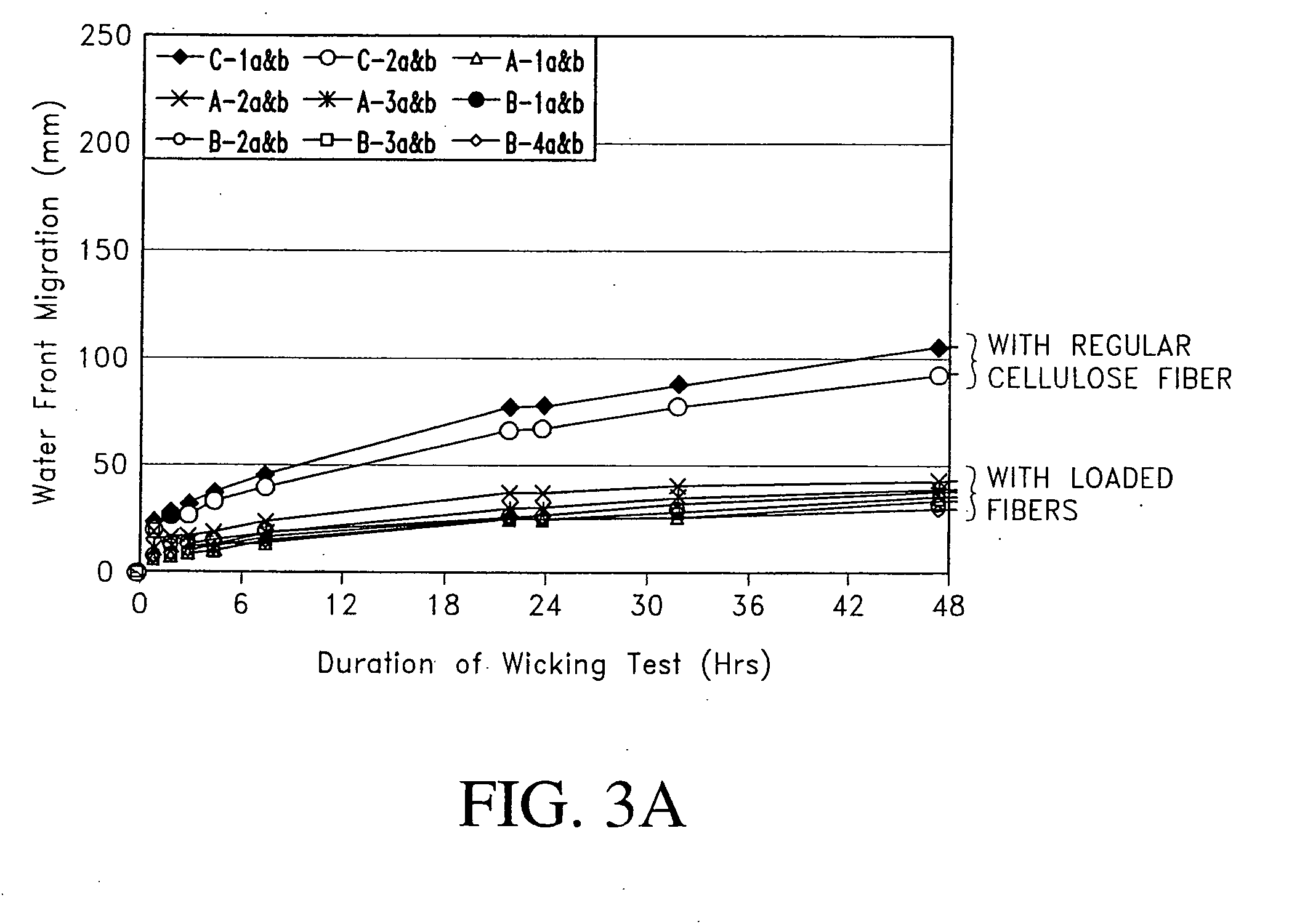

InactiveUS6872246B2Reduction of it pore volumeIncrease toughnessNatural cellulose pulp/paperSpecial paperFreeze thaw resistanceChemical dissolution

This invention discloses a new technology related to cellulose fiber reinforced cement composite materials using the loaded cellulose fibers. This invention discloses four aspects of the technology: fiber treatment, formulation, method and final product. This technology advantageously provides fiber cement building materials with the desirable characteristics of reduced water absorption, reduced rate of water absorption, lower water migration, and lower water permeability. This invention also impart the final products improved freeze-thaw resistance, reduced efflorescence, reduced chemical dissolution and re-deposition, and improved rot and fire resistances, compared to conventional fiber cement products. These improved attributes are gained without loss in dimensional stability, strength, strain or toughness.

Owner:JAMES HARDIE TECH

Silicon dioxide aerogel material and preparation method thereof

The invention relates to a silicon dioxide aerogel material and a preparation method thereof. The method comprises the following steps: by using water glass as silicon source, adding an acid-containing organic solvent free of chlorine ions and fluorine ions to generate a precipitate of sodium ions, potassium ions and other metal salt ions, filtering to remove the precipitate to obtain high-purity silica sol, carrying out a sol-gel process, aging, acidifying, modifying, and drying to obtain the silicon dioxide aerogel material. The acidification before modification enhances the surface reaction activity of the silicon gel, thereby obviously enhancing the modification effect and efficiency. The method has the advantages of low cost and simple and efficient technique, is beneficial to mass high-efficiency production, is free of chlorine ions and fluorine ions in the whole technical process, and enhances the equipment operation safety and reliability; and the product can be used for heat preservation and thermal insulation of nuclear power and liquefied natural gas equipment and pipelines with higher requirement for corrosion resistance, and can also be used for thermal insulation in the field of aerospace, petrochemical engineering, track transportation, ships, automobiles, construction and the like.

Owner:浙江圣润纳米科技有限公司

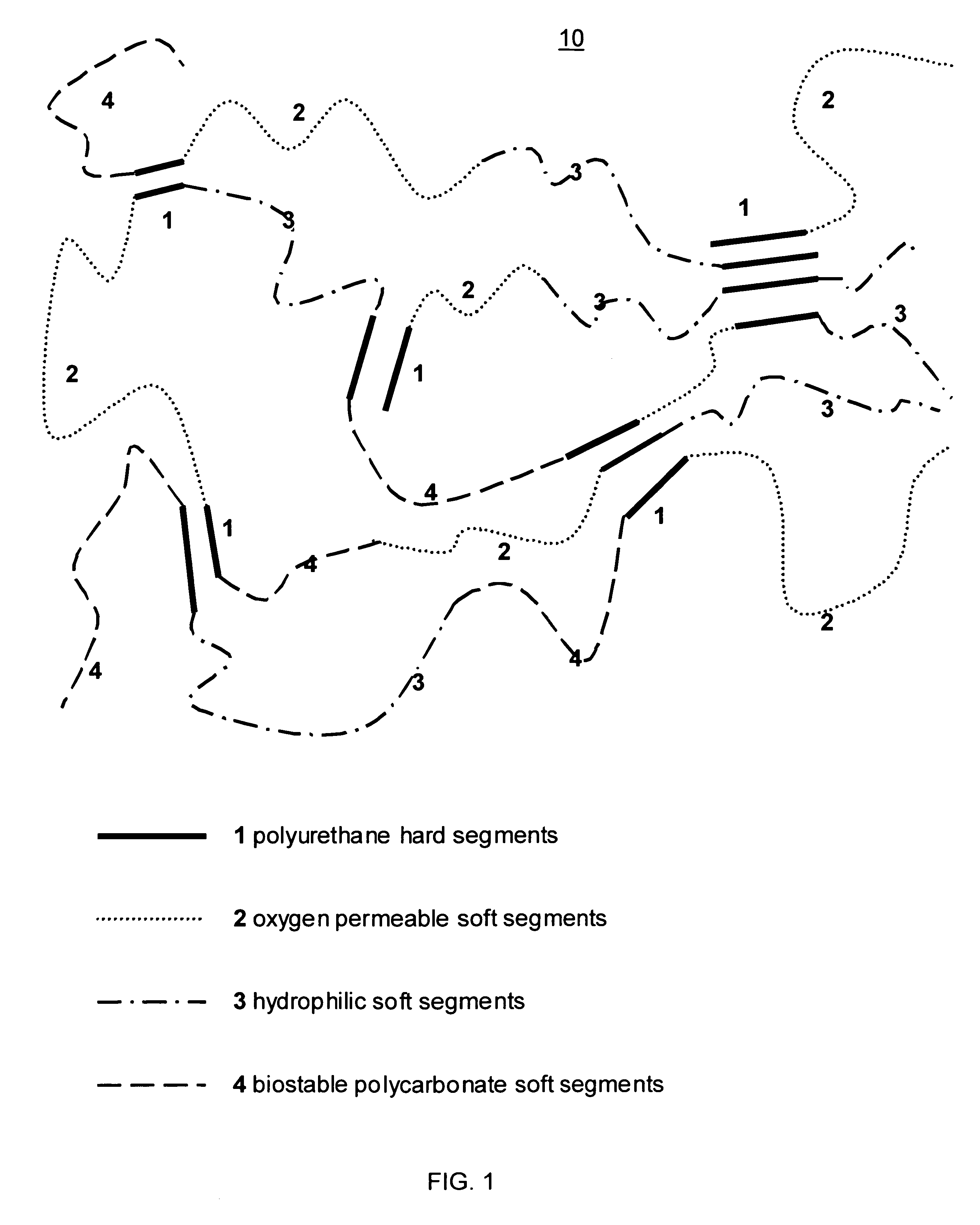

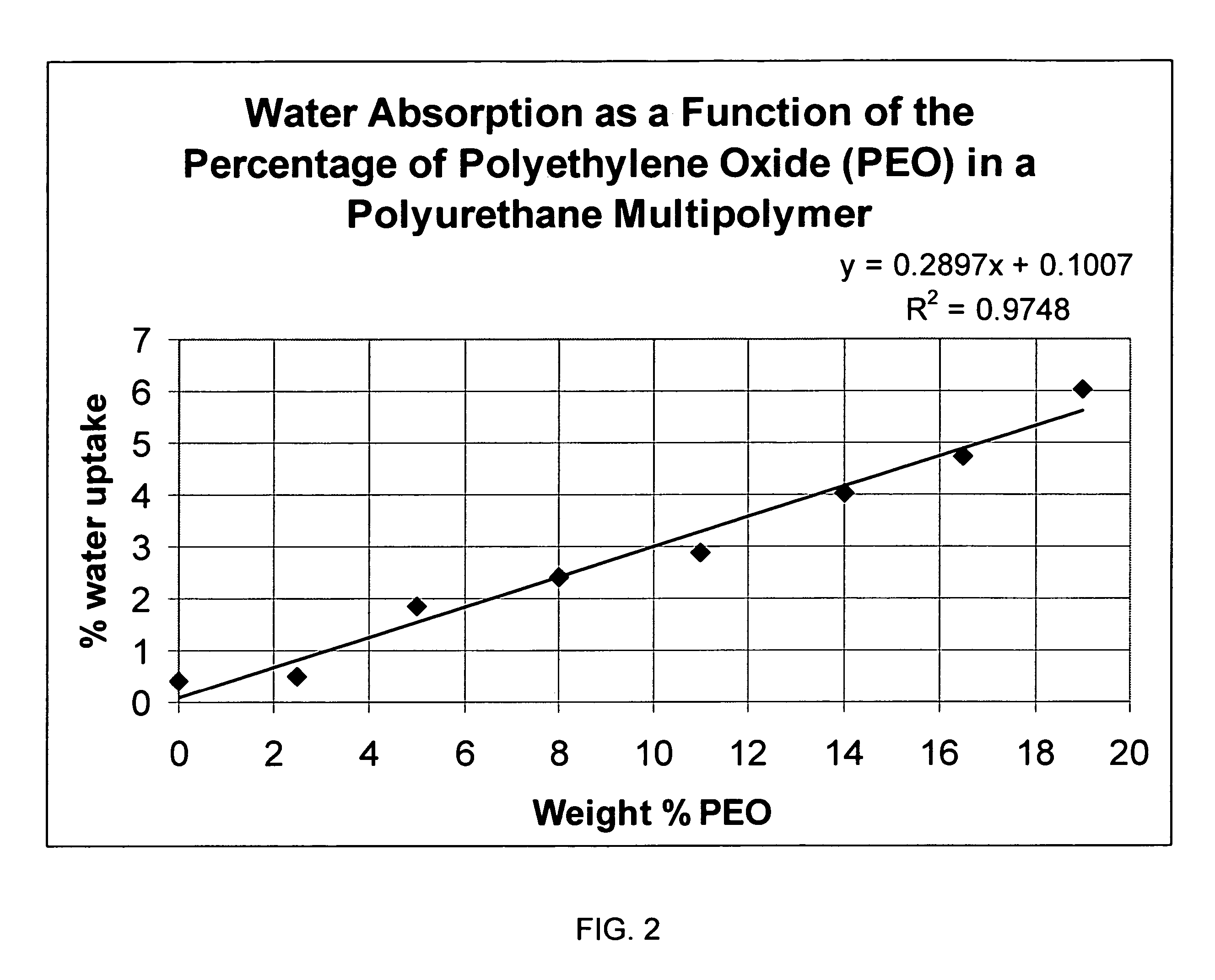

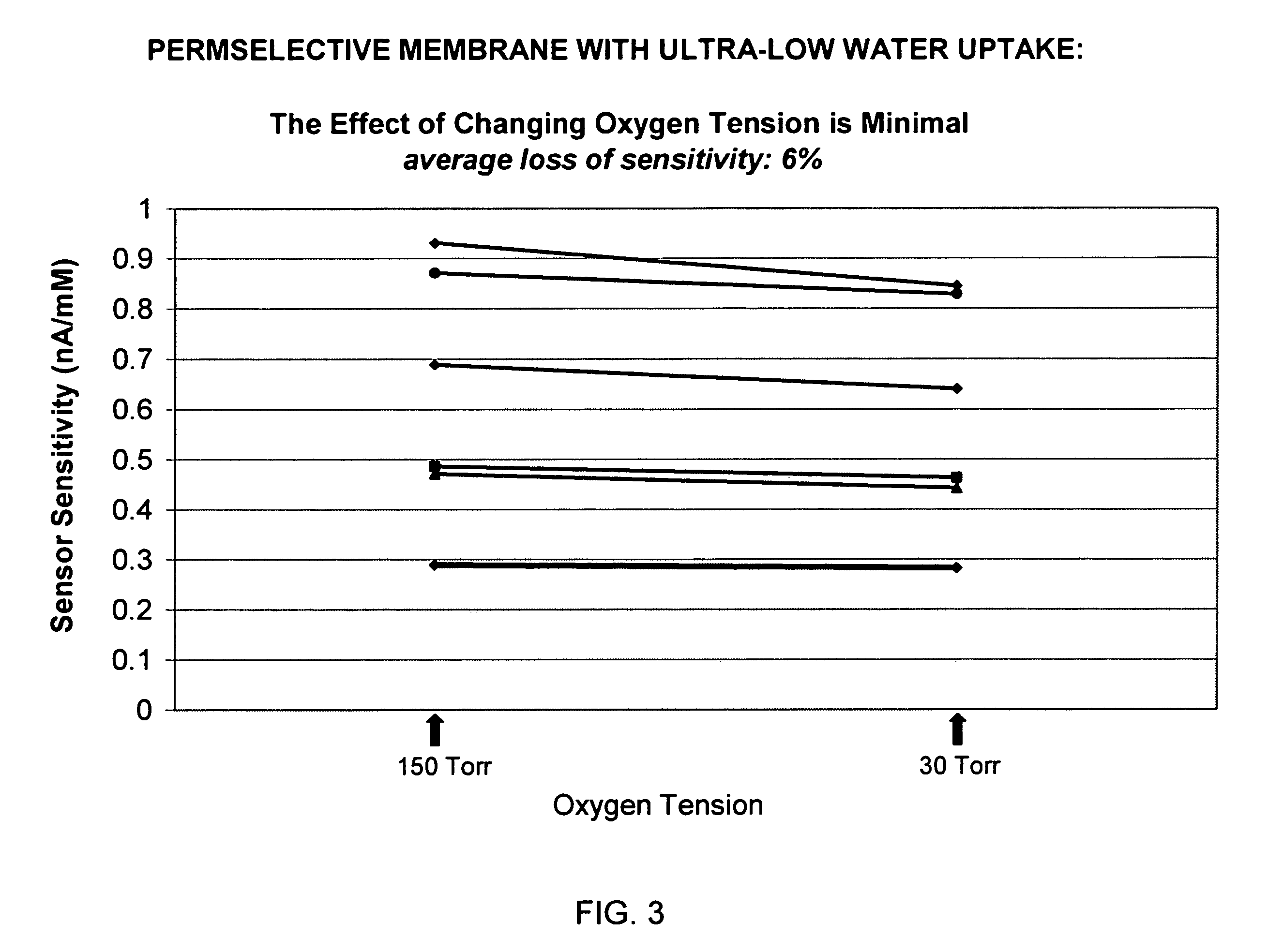

Biosensor membrane material

ActiveUS7687586B2Plateau in their responseLoss of integrityImmobilised enzymesBioreactor/fermenter combinationsProsthesisD-Glucose

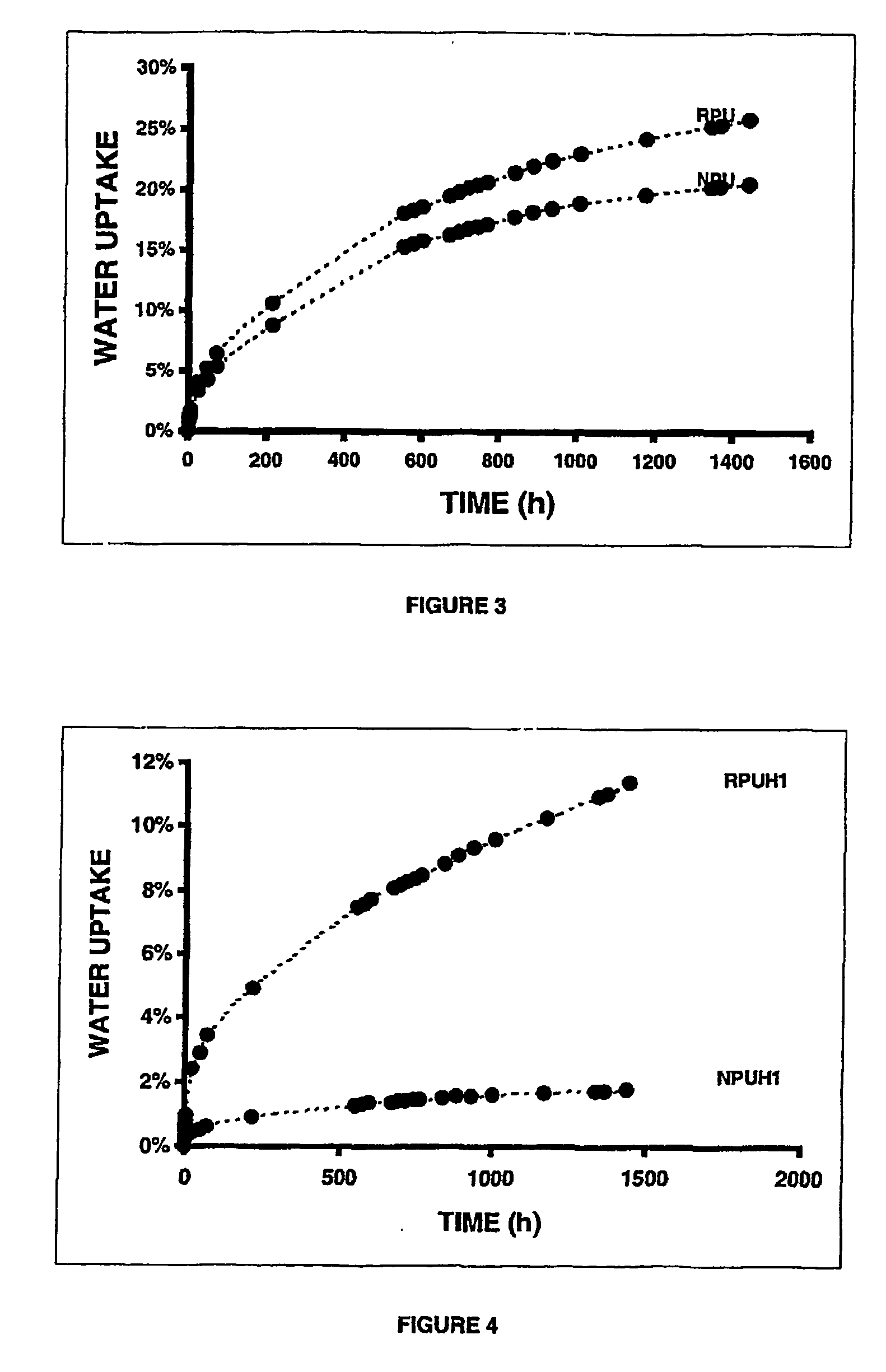

Embodiments of the present invention provide various multipolymers and permselective membranes for use with biosensors and other implantable medical devices and prostheses. Embodiments of the present invention may provide structural strength and integrity, and further may control the influx of glucose, oxygen and / or water. Embodiments of the present invention may, for example, minimize or reduce the influx of glucose by minimizing the percentage of hydrophilic segments, which in turn minimizes the percentage of water uptake and the degree of glucose transport.

Owner:THE POLYMER TECH GROUP +1

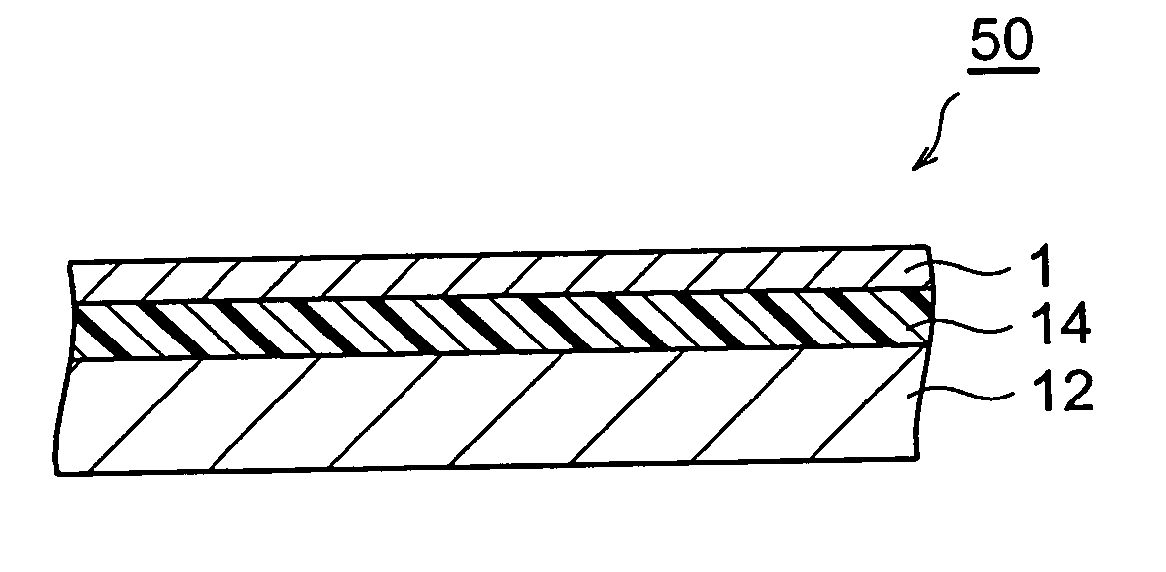

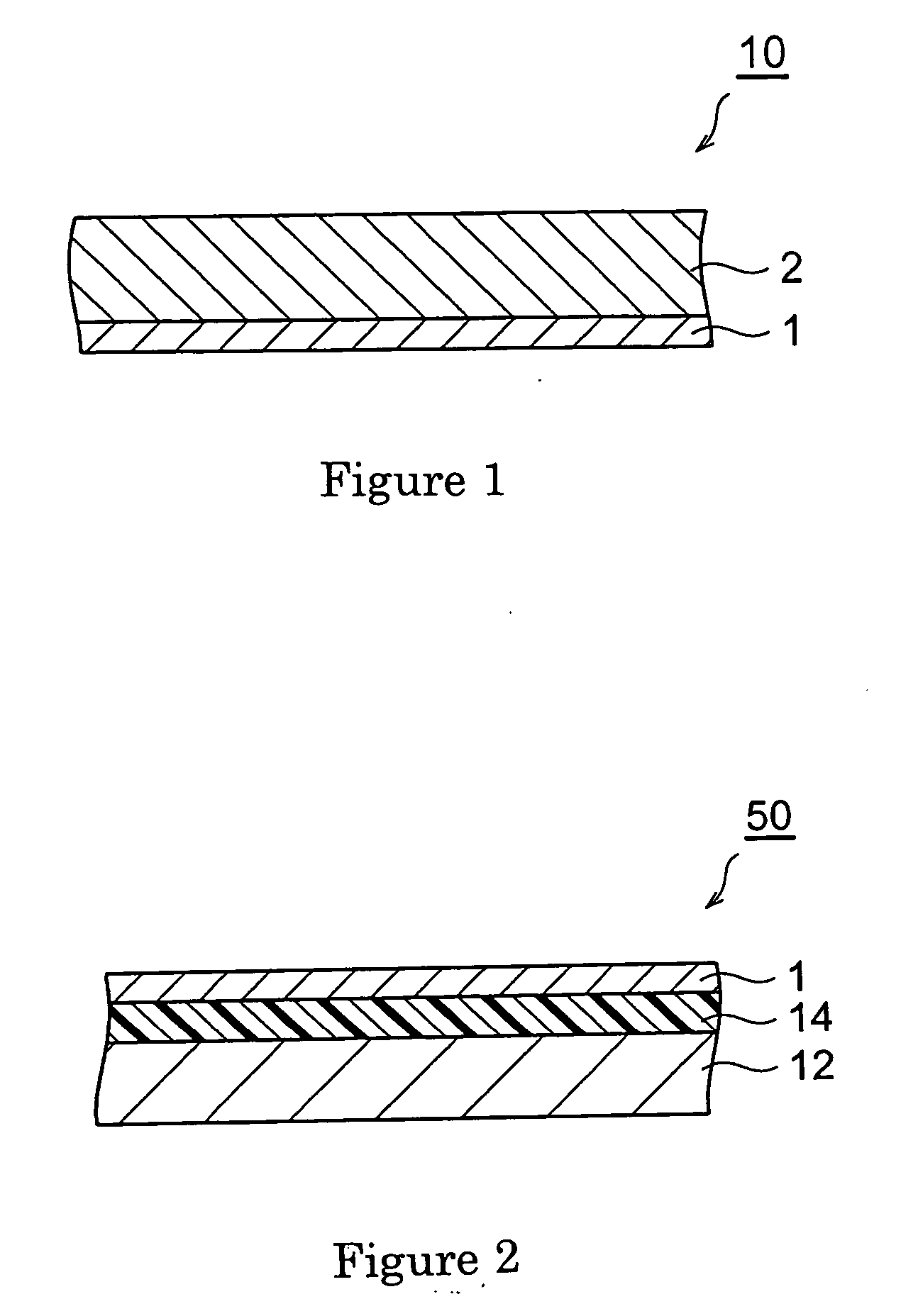

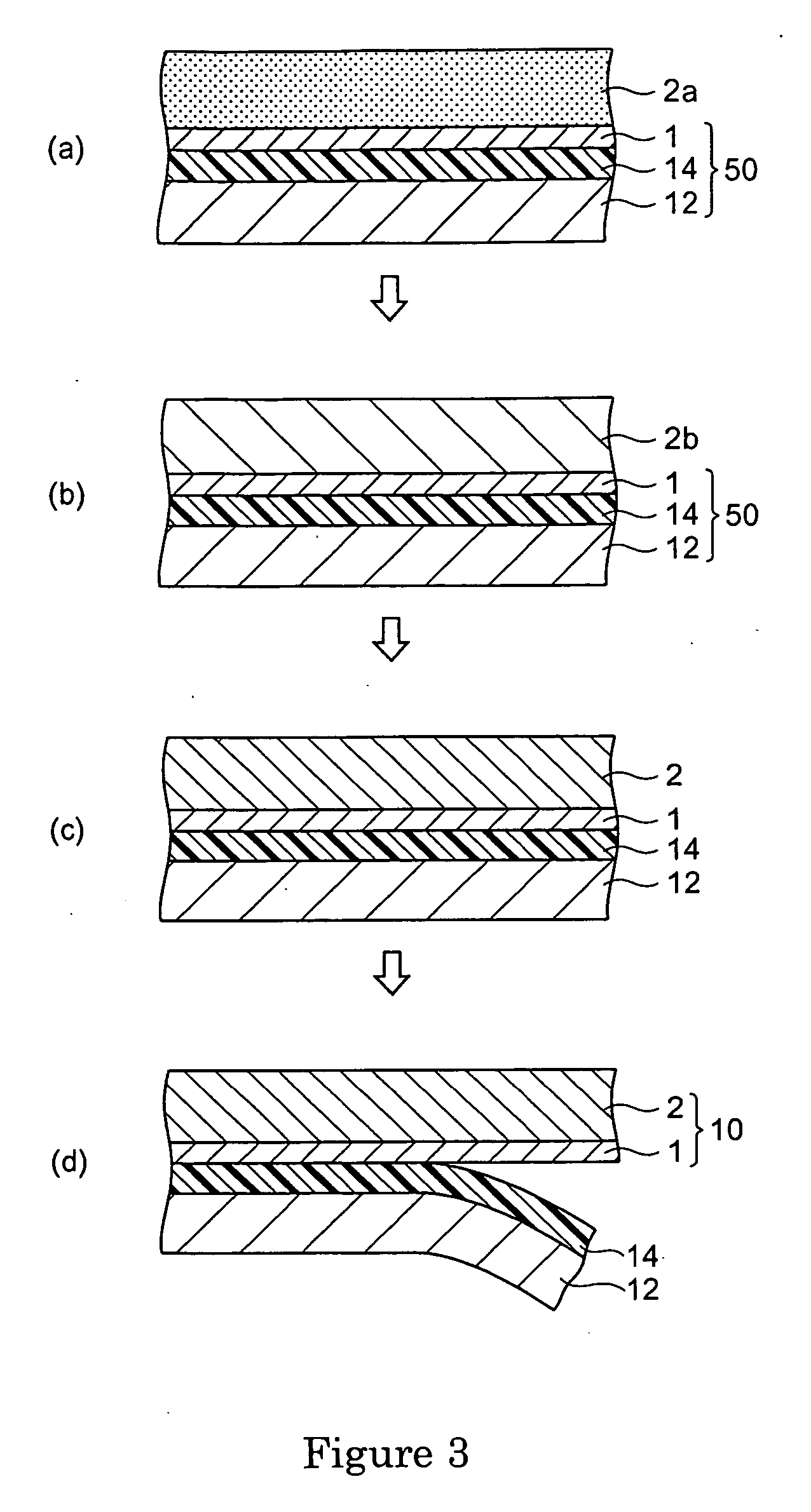

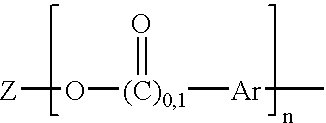

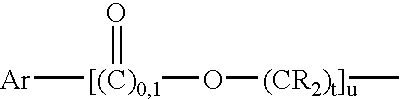

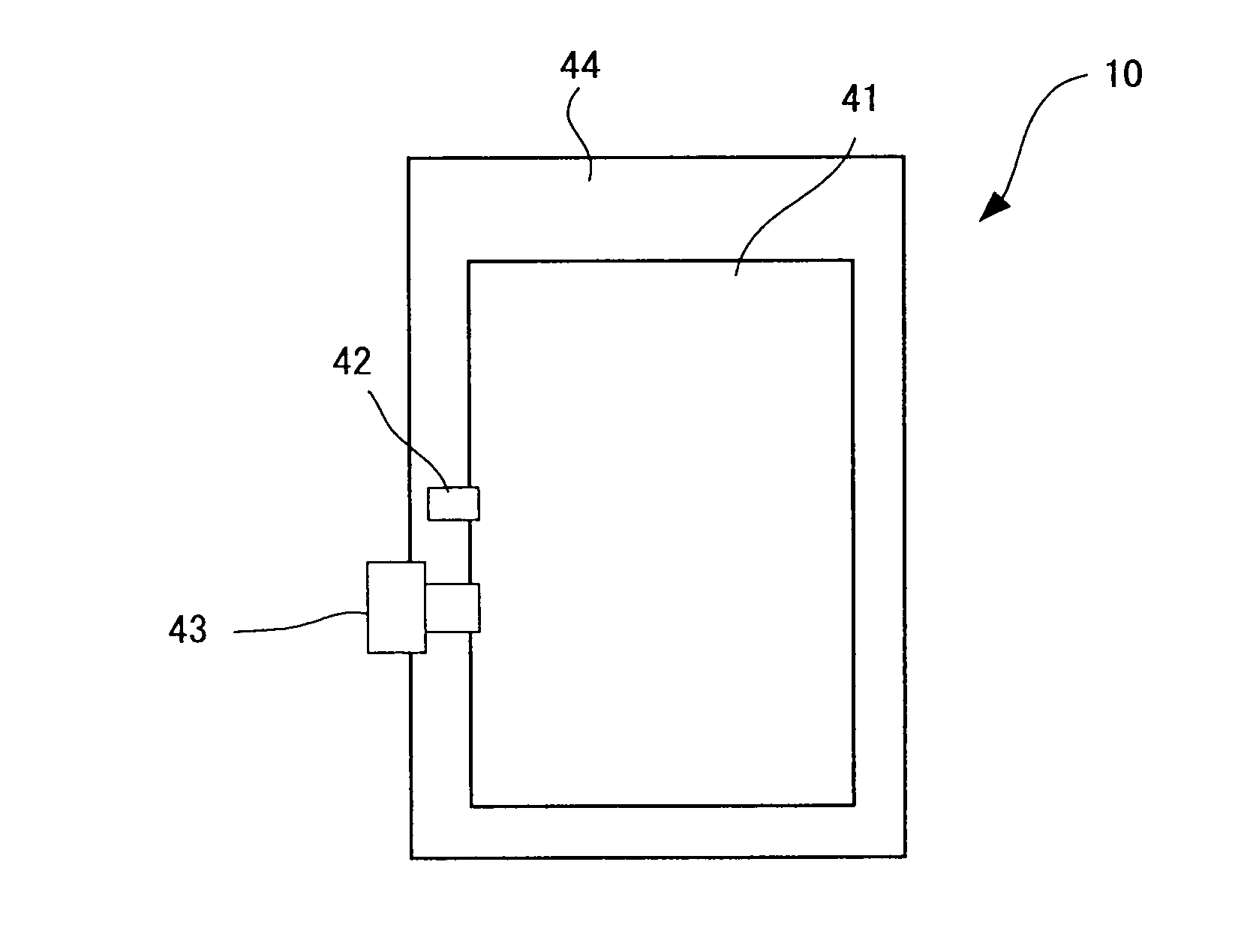

Substrate for flexible wiring and method for producing the same

InactiveUS20070077416A1Low water absorptionLayer be enoughPretreated surfacesGlass/slag layered productsPolyesterLiquid crystalline

The present invention provides a substrate for flexible wiring comprises a liquid crystalline polyester layer and a copper foil with a thickness of 5 μm or less. The substrate has a large adhesion between the resin layer and the copper foil, and is sufficient in water absorbing property and electrical properties.

Owner:SUMITOMO CHEM CO LTD

Fiber composite

InactiveUS20100272980A1High transparencyLow water absorptionMonocomponent cellulose artificial filamentRecord information storageThermal expansionCellulose fiber

To provide a cellulose fiber composite having high transparency, low water absorption and low coefficient of linear thermal expansion.A fiber composite which comprises fibers having an average fiber diameter of at most 30 nm and a matrix material and which has a haze of at most 5 according to JIS K-7136 when the fiber composite has a thickness of 100 μm.

Owner:MITSUBISHI CHEM CORP

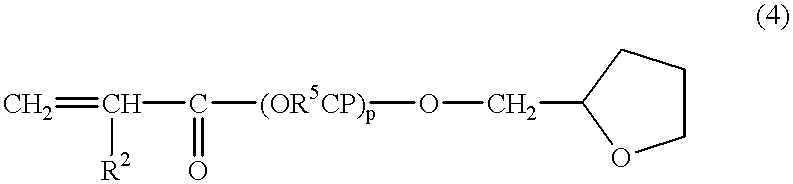

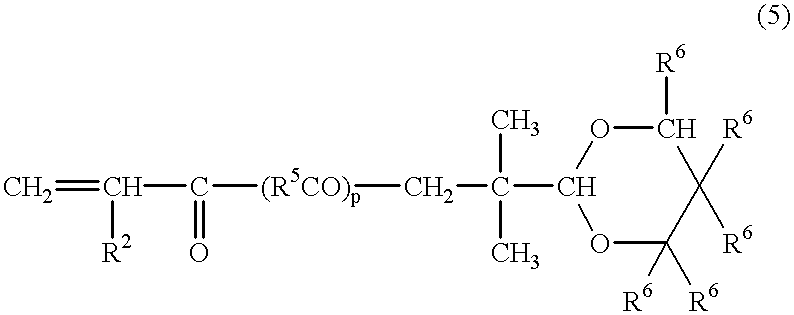

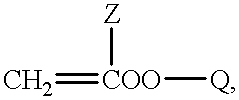

Liquid curable resin composition

InactiveUS6180741B1Low water absorptionEasy to disassembleCladded optical fibreFibre mechanical structuresFiberMeth-

A liquid curable resin composition exhibiting superior storing stability and suitable for use as a material for optical fiber ribbon matrix, a bundling material, and a material for up-jacketing fibers. The composition contains a first polydimethylsiloxane compound which contains (i) at least two urethane bonds, (ii) an unreactive organic group attached to at least one end of the first polydimethyl-siloxane, and (iii) a (meth)acrylol group attached to at least one end of the first polydimethylsiloxane, and a second polydimethylsiloxane compound which contains (i) at least two urethane bonds and (ii) an unreactive organic group attached to at least one end of the second polydimethylsiloxane, and optionally a third polysiloxane compound which does not contain urethane bonds.

Owner:DSM NV +1

Semi-aromatic polyamide resin

InactiveUS20090098325A1Good adhesive propertyHigh residence stability and hot water resistanceSynthetic resin layered productsFlexible pipesDiamineCarboxylic group

A semi-aromatic polyamide resin is provided which has a high level of residence stability, hot-water resistance and chemical resistance and is also excellent in adhesive properties and compatibility with other resins and the like.The semi-aromatic polyamide resin comprises: dicarboxylic acid units in which 50 to 100 mol % of the dicarboxylic acid units are aromatic dicarboxylic acid units; and diamine units in which 60 to 100 mol % of the diamine units are aliphatic diamine units having 9 to 13 carbon atoms. Furthermore, at least 10% of terminal groups of molecular chains of the polyamide resin are blocked with a terminal-blocking agent, and the amount of terminal amino groups of the molecular chains is 60 μeq / g or more and 120 μeq / g or less. In addition, [NH2] / [COOH]≧6 is satisfied, where [NH2] (μeq / g) represents the amount of the terminal amino groups and [COOH] (μeq / g) represents the amount of terminal carboxyl groups.

Owner:KURARAY CO LTD

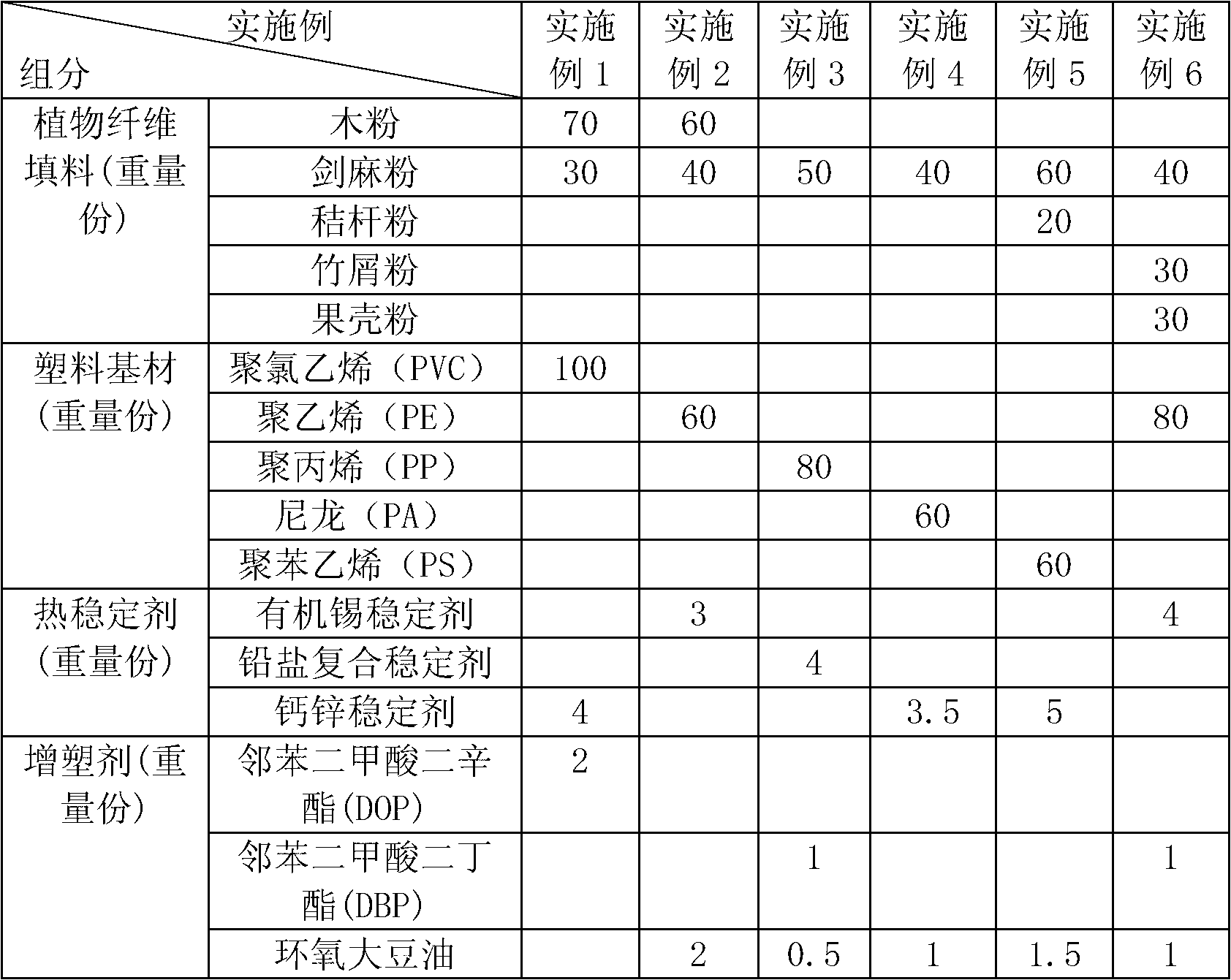

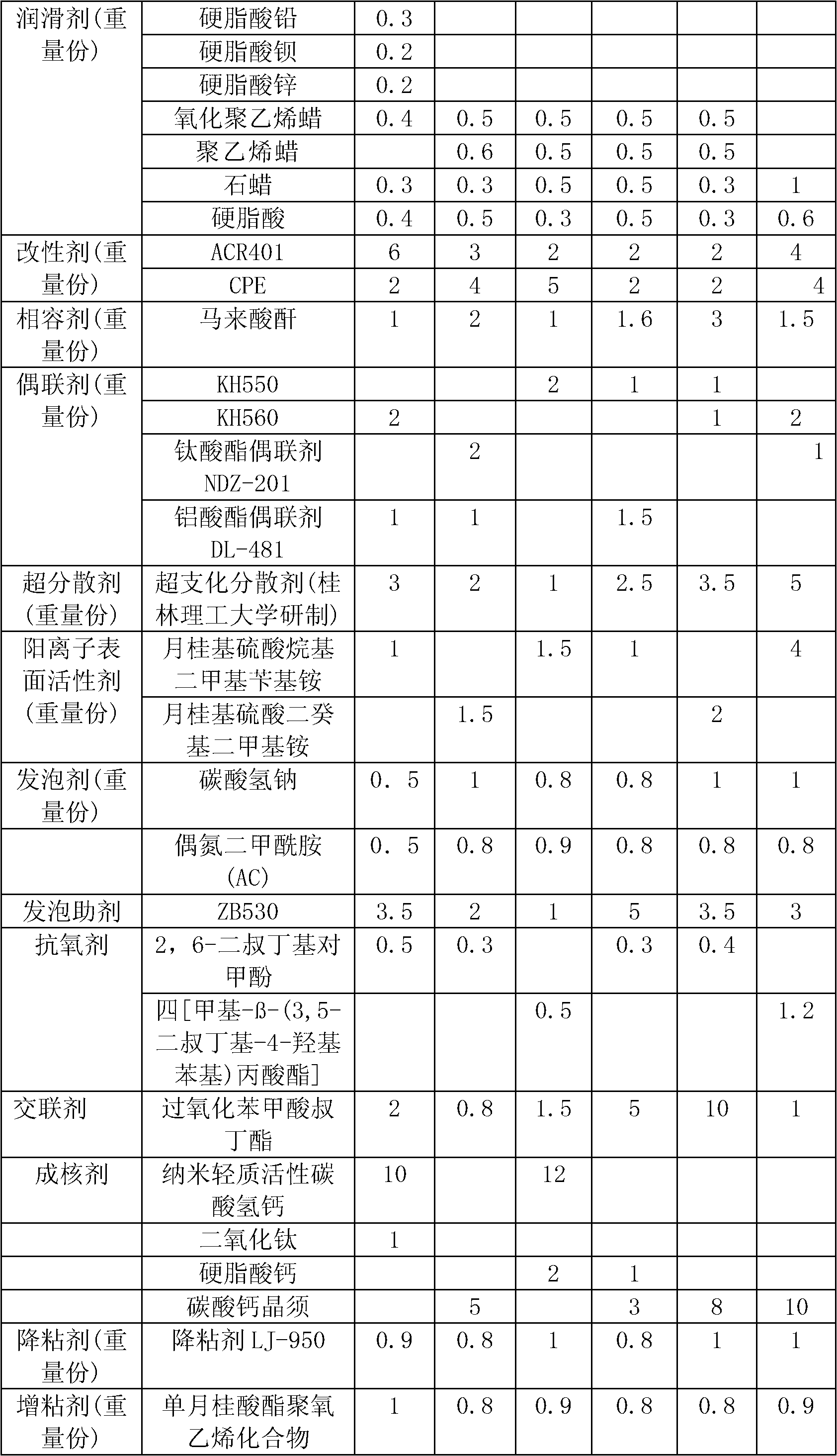

New macromolecule fiber composite material

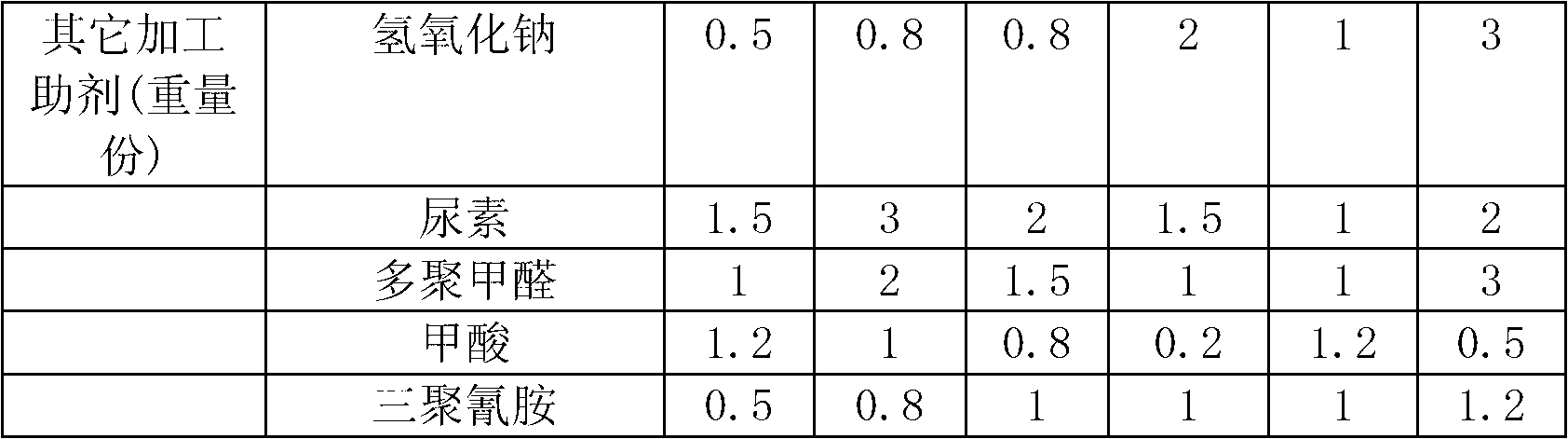

The invention discloses a new macromolecule fiber composite material which is prepared by the following components in parts by weight, 40-100 parts of plant fiberfill, 60-100 parts of plastic base material, 3.5-5 parts of heat stabilizer, 1-2 parts of plasticizer, 1.6-2 parts of lubricating agent, 4-8 parts of modifying agent, 1-3 parts of compatilizer, 2-3 parts of coupling reagent, 1-5 parts of super dispersing agent, 1-4 parts of positive ion surface active agent, 1-1.8 parts of foaming agent, 1-5 parts of blowing promoter, 0.3-1.2 parts of antioxygen, 1-10 parts of cross-linking agent, 1-20 parts of nucleating agent, 0.8-1 part of viscosity reducer, 0.8-1 part of tackifier and 3.2-13.4 parts of other auxiliaries. The new composite material can not easily cause wet swelling and air shrinkage, and is low in expansibility and water absorbability, so that the prepared product has good stability.

Owner:GUILIN SHUKANG BUILDING MATERIAL

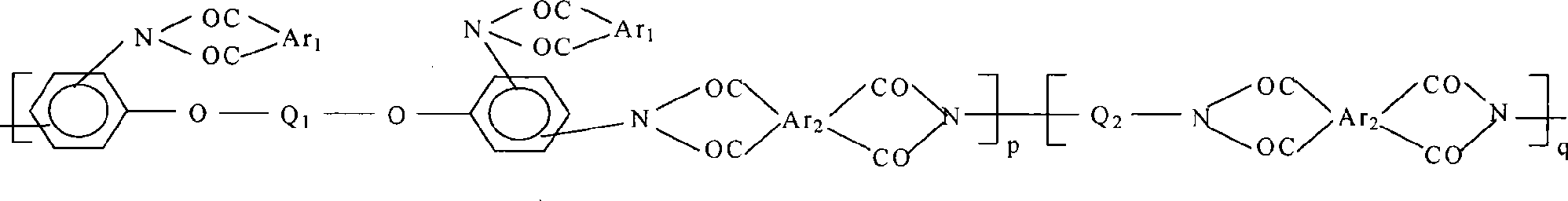

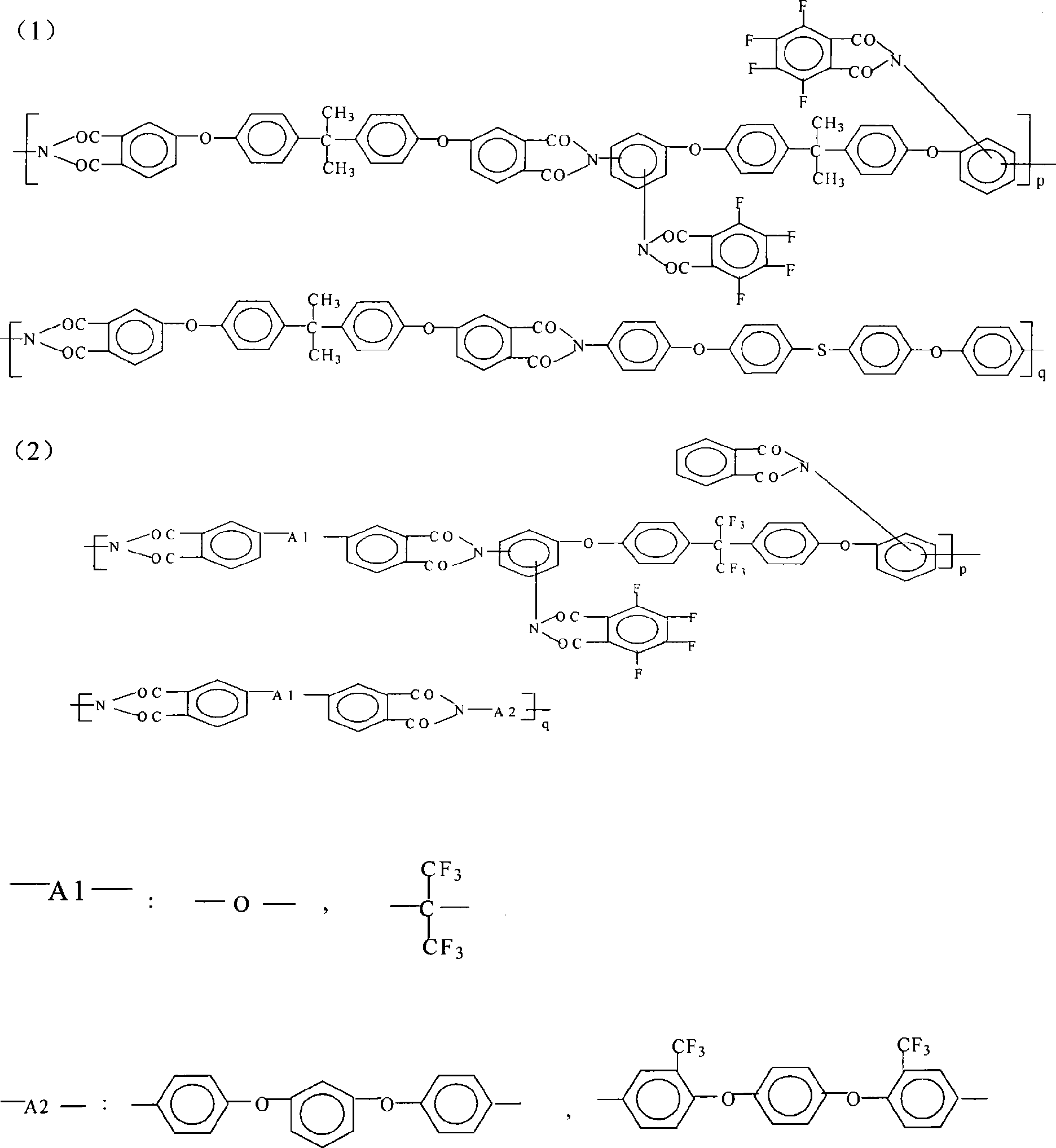

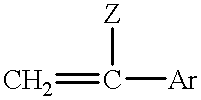

Colorless transparent aromatic polyimide film and preparation method thereof

The invention discloses a colorless and transparent aromatic polyimide film which has the general formula of molecular structure as follows; the preparation thereof includes: aromatic primary amine and aromatic acid anhydride with specific molecular structures are adopted for polymerization in a strong polar aprotic organic solvent system within the temperature range of 0 DEG C to 35 DEG C to prepare a colorless and transparent viscous polyamide acid solution with homogeneous phase. Viscosity adjustment, casting for forming the film, heating for rising temperature and solvent removal are carried out simultaneously when partial imidization reaction is carried out, and then demoulding and stretching, further deep thermal imidization and rolling are carried out to obtain the colorless and transparent aromatic polyimide film. No special production equipment is required by the invention so that production can be carried out on the conventional production line of the polyimide film and the polyimide film is applicable to industrialized production.

Owner:DONGHUA UNIV +3

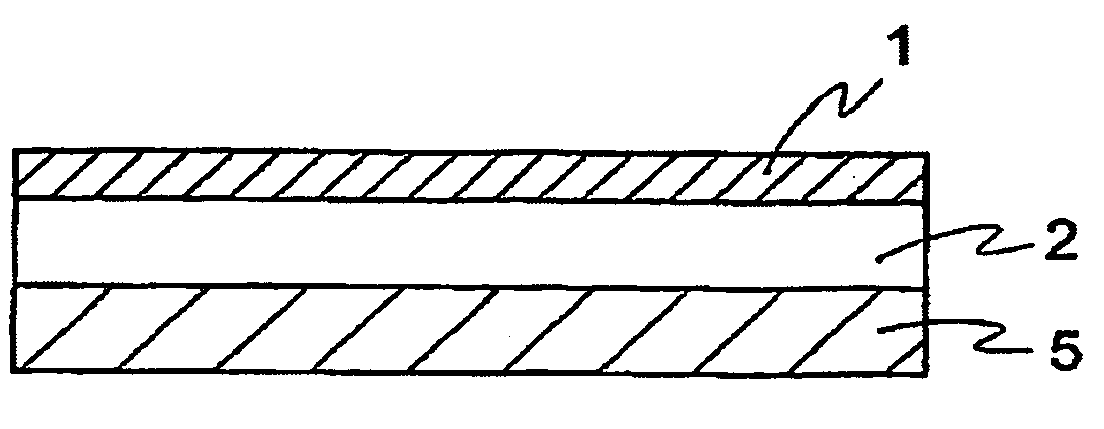

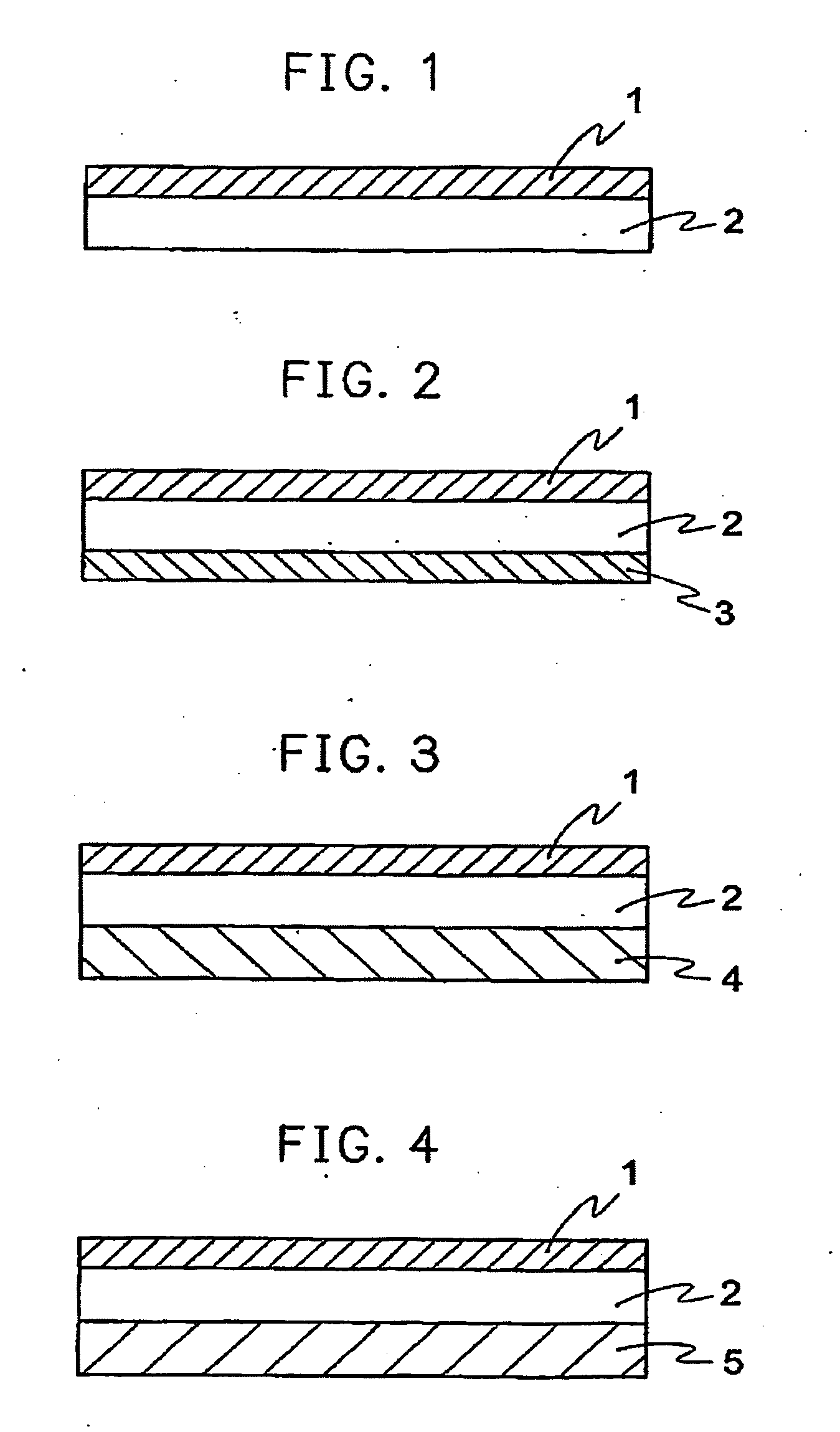

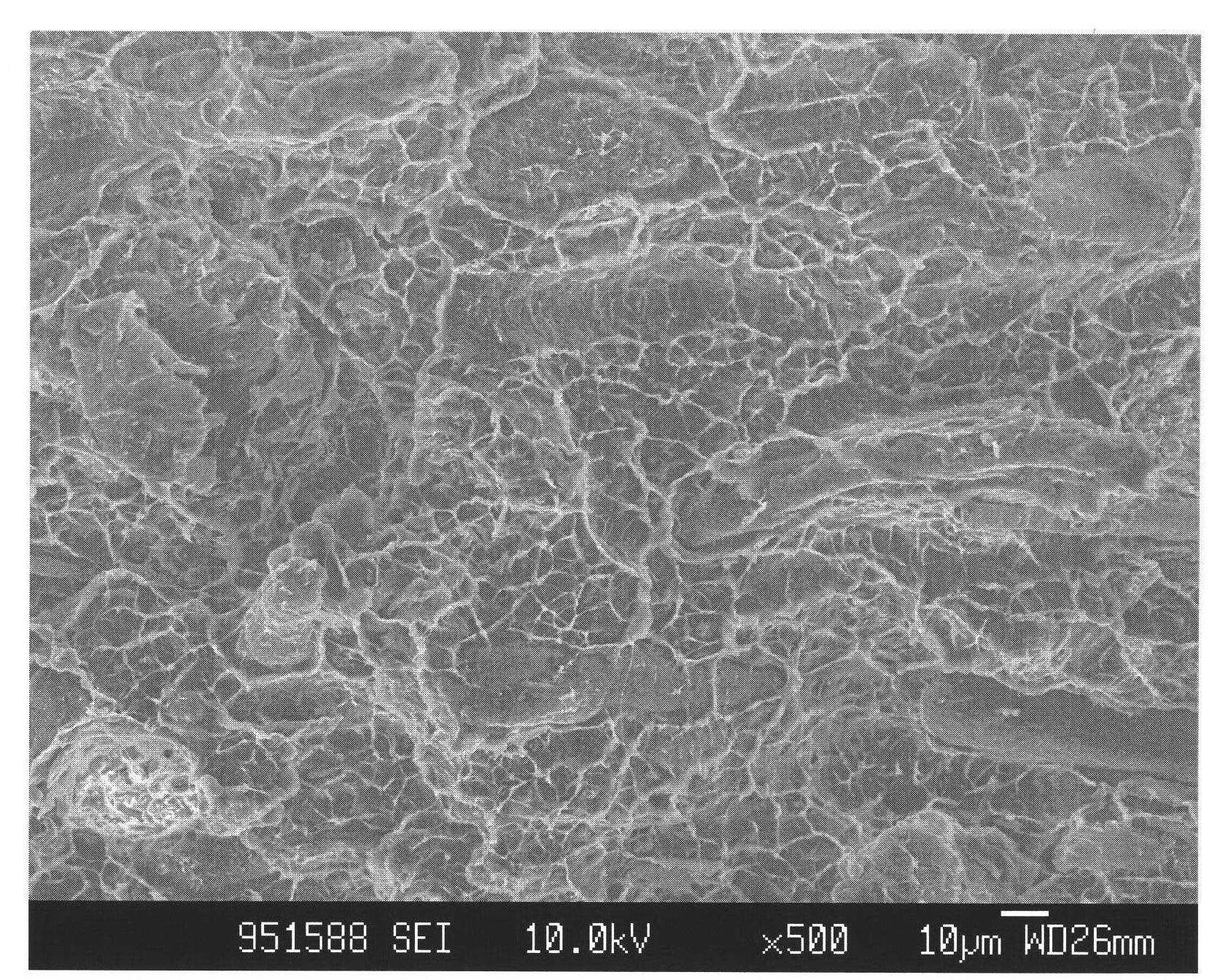

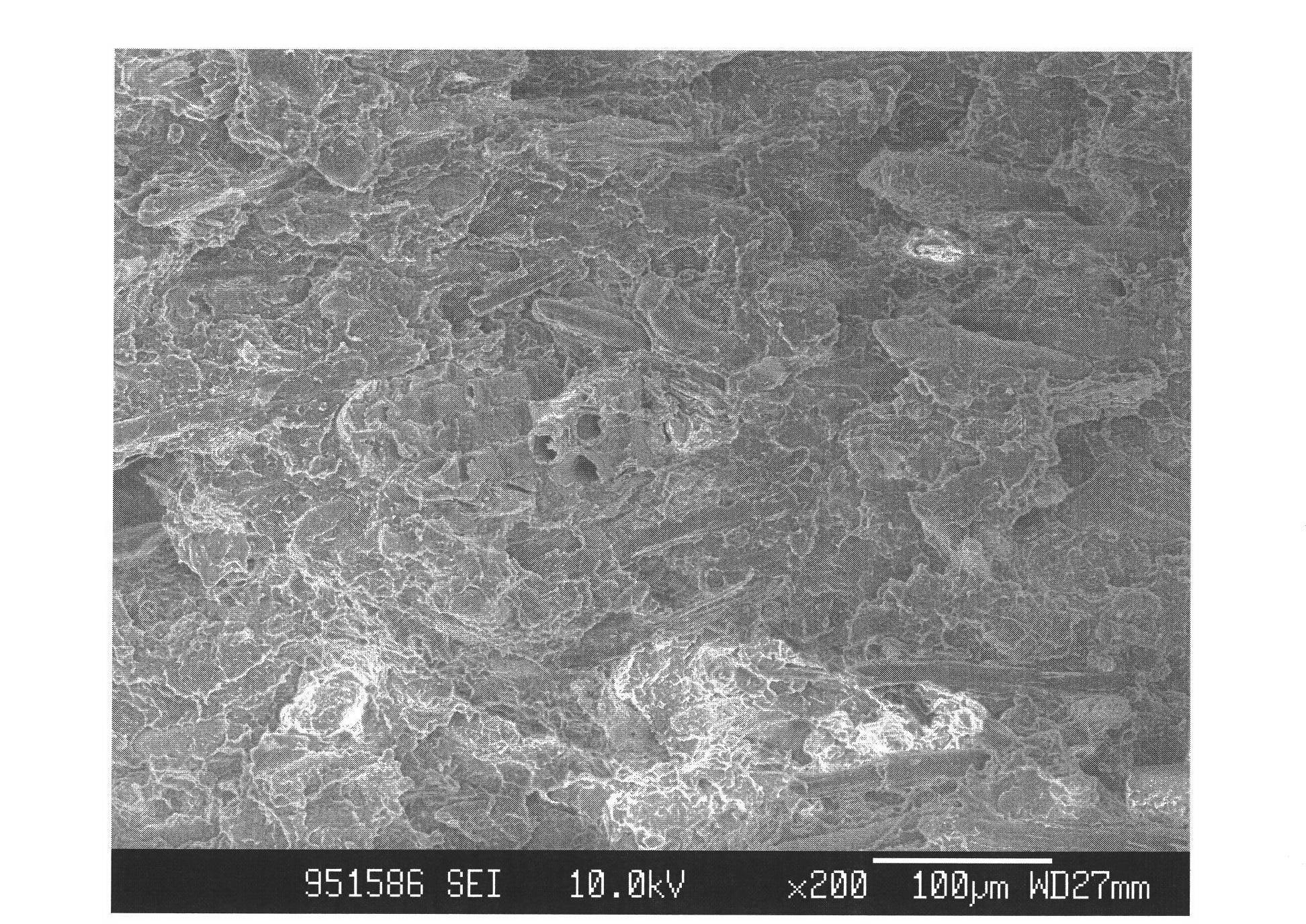

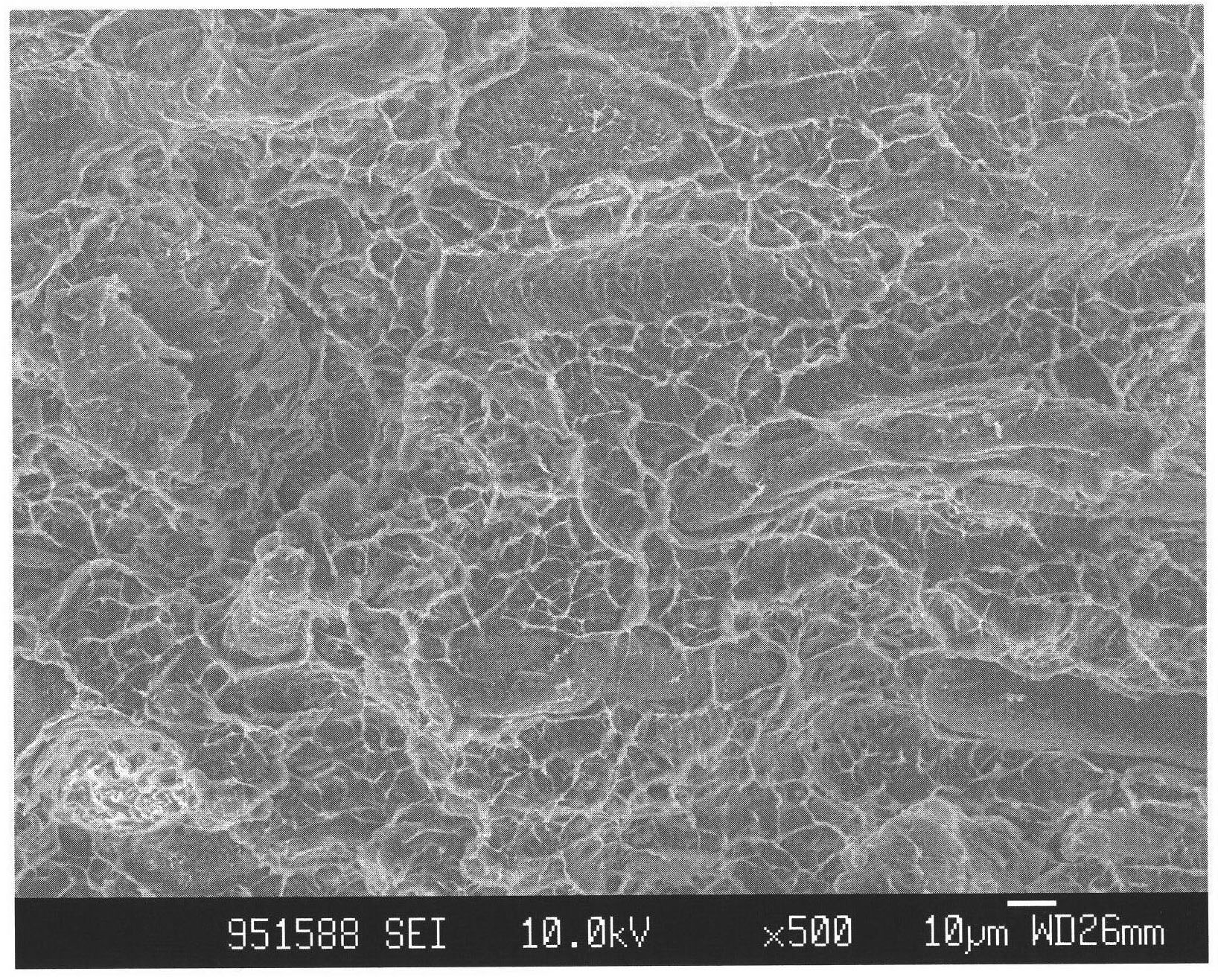

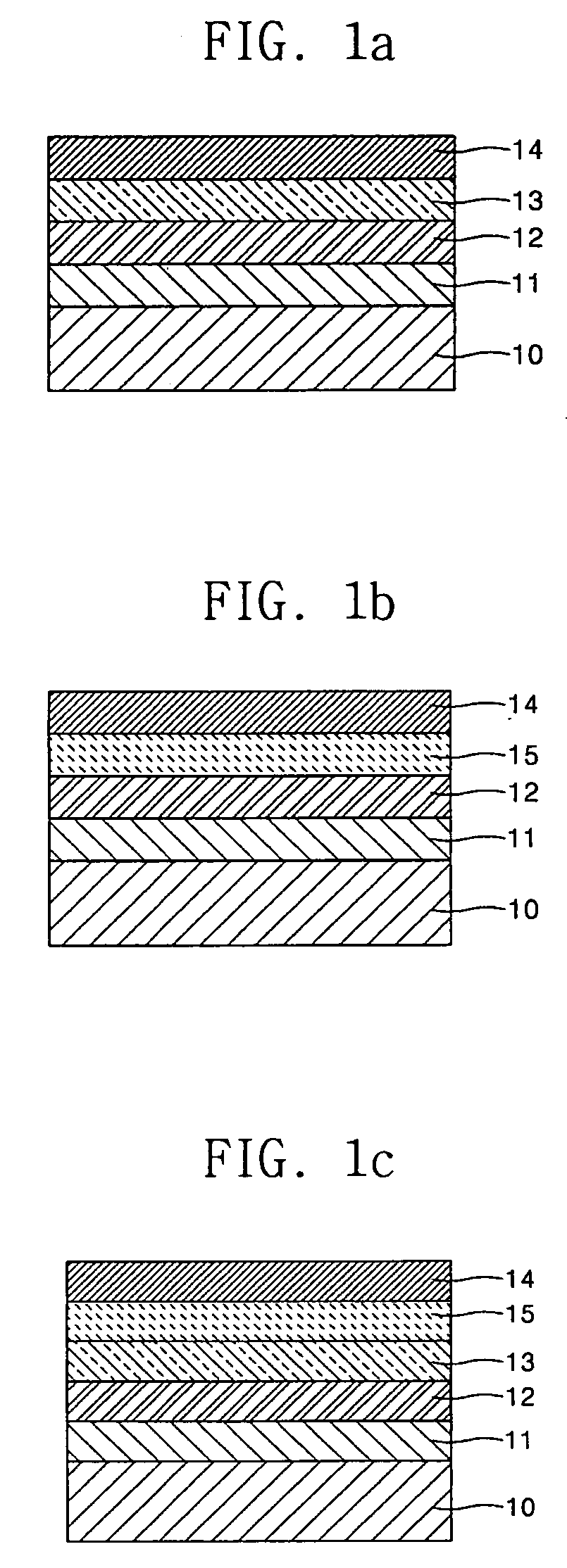

Thermoplastic polyimide resin film, multilayer body and method for manufacturing printed wiring board composed of same

ActiveUS20060115670A1Maintain good propertiesHigh bonding strengthPrinted circuit assemblingSynthetic resin layered productsPrinted circuit boardThermoplastic polyimide

The present invention provides a laminate having a two-layer or three-layer structure including a non-thermoplastic polyimide film and a thermoplastic polyimide layer provided on one or both of the surfaces thereof, the surface of the thermoplastic polyimide layer being surface-treated; a laminate including a polymer film and a layer provided on one or both of the surfaces thereof, the layer including a polyimide resin composition comprising a polyimide resin with a specified structure and a thermosetting component; and a resin film and a laminate including the same which provided one, at least, of surface having a Ra1 value of arithmetic mean roughness of 0.05 μm to 1 μm measured with a cutoff value of 0.002 mm, and a Ra1 / Ra2 ratio of 0.4 to 1, Ra2 being a value measured with a cutoff value of 0.1 mm. These laminates can provide a printed circuit board with excellent adhesiveness, on which a micro-wiring circuit can be formed.

Owner:KANEKA CORP

Halogen-less high frequency resin composition, and prepreg and laminate manufacturing by using same

ActiveCN101684191ALow heat resistanceImprove heat resistanceSynthetic resin layered productsWoven fabricsStyrene maleic anhydrideAbsorbance

The invention relates to a halogen-less high frequency resin composition, and a prepreg and a laminate manufactured by using the same. The halogen-less high frequency resin composition comprises the following components based on weight part of the organic solids: (A) 10 to 50 parts of styrene-maleic anhydride oligomer; (B) 10 to 50 parts of at least one compound containing dihydro-benzoxazine ring; (C) 10 to 50 parts of at least one polyepoxide; and (D) 5 to 30 parts of at least one phosphorus-containing flame retardant. The prepreg and the laminate manufactured by using the halogen-less highfrequency resin composition has low dielectric constant, low dielectric loss factor, high glass transition temperature, good heat resistance, low water absorbance, and simple and convenient technological operation.

Owner:GUANGDONG SHENGYI SCI TECH

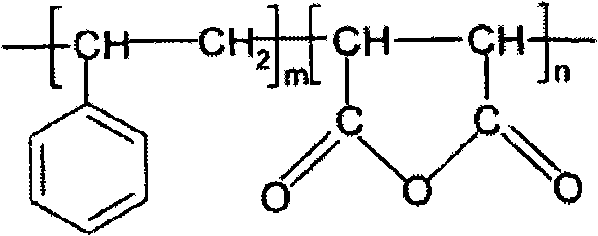

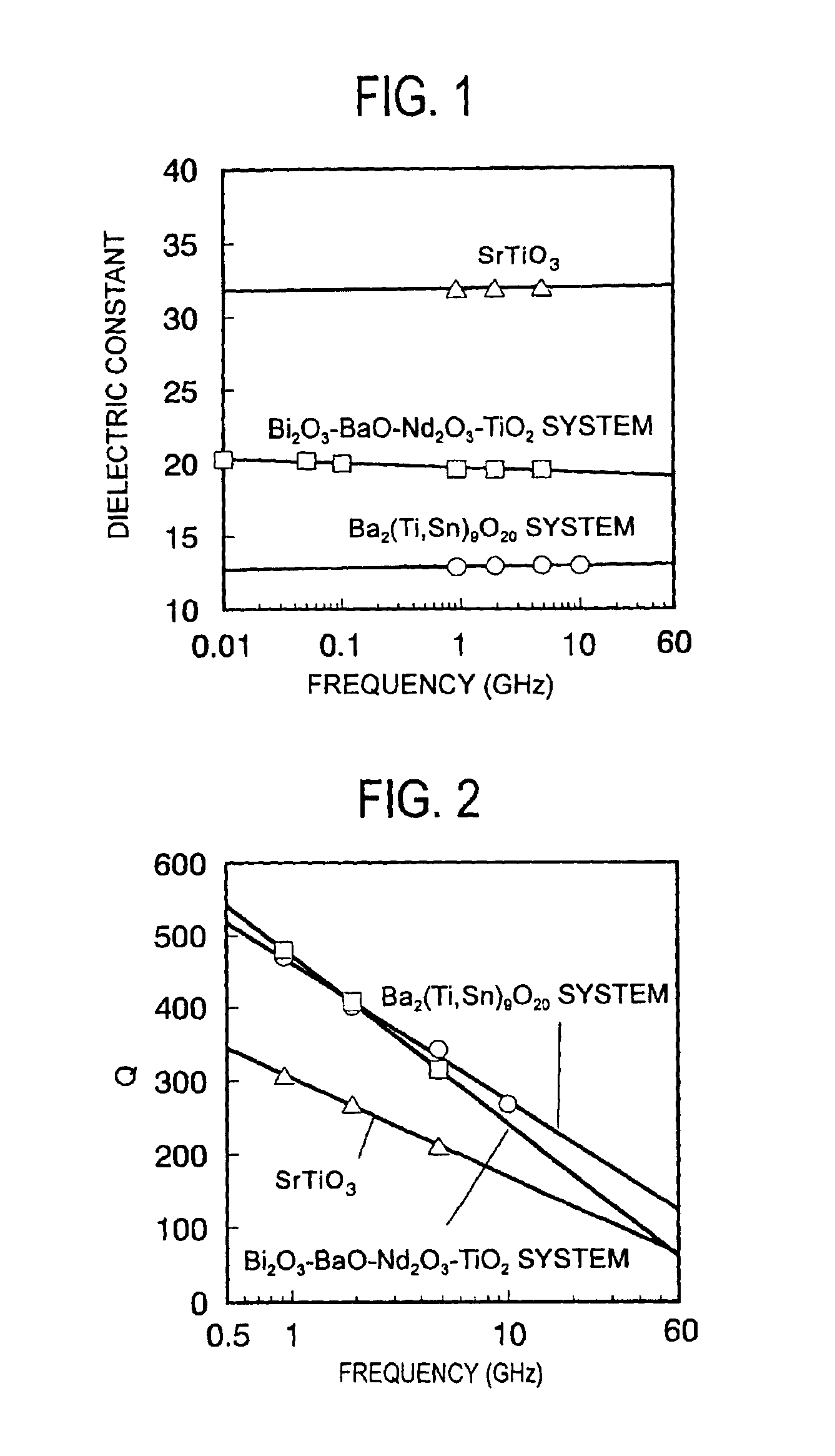

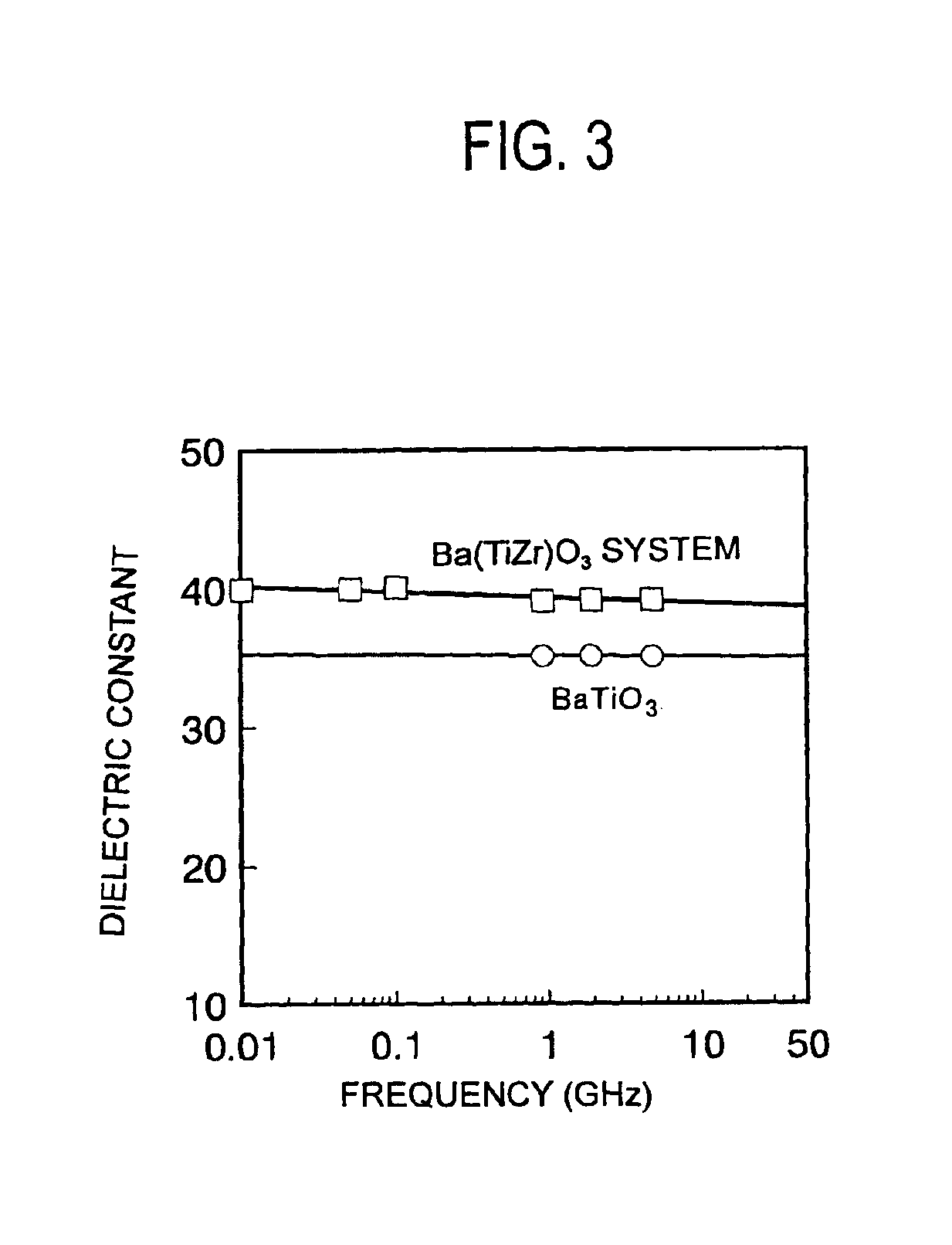

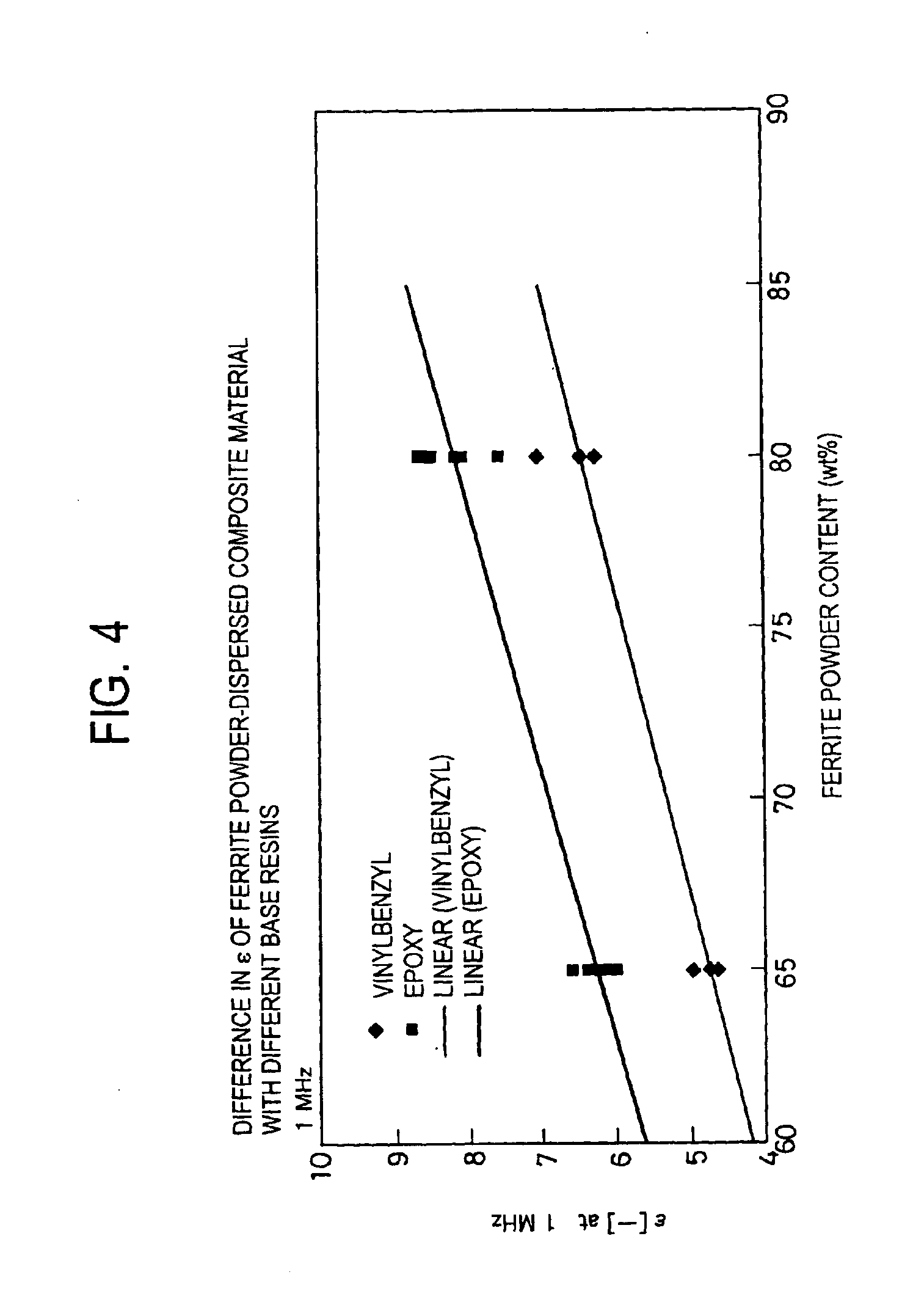

Composite dielectric material, composite dielectric substrate, prepreg, coated metal foil, molded sheet, composite magnetic substrate, substrate, double side metal foil-clad substrate, flame retardant substrate, polyvinylbenzyl ether resin composition, thermosettin

InactiveUS6908960B2Low dielectric constantMinimized of constantShielding materialsPrinted capacitor incorporationShell moldingMetal foil

Owner:TDK CORPARATION

High wear-resistant wood-plastic composite and preparation method thereof

The invention provides a high wear-resistant wood-plastic composite and a preparation method thereof, and relates to a composite obtained by mixing modified plant fiber powder, modified nano ceramics particles and plastic powder. The high wear-resistant wood-plastic composite comprises the modified plant fiber powder, the modified nano ceramics particles, the recycled plastic powder and the like, wherein the modified nano ceramics particles comprises modified nano Al2O3, modified nano Si3N4, modified nano SiC or the mixture thereof, which can obviously improve the microhardness of the wood-plastic composite, reduce the wear rate and improve the mechanical property. The high wear-resistant wood-plastic composite is prepared from the components by the common melt-mixing method in the plastic processing. The surface hardness and the wearability of the wood-plastic composite are greatly increased, and the strength and the toughness are also greatly improved, so that the overall performance of the wood-plastic composite is greatly enhanced. The wood-plastic composite can be used in the fields of construction material, furniture, package and the like.

Owner:GUANGDONG XINXIU NEW MATERIAL CO LTD

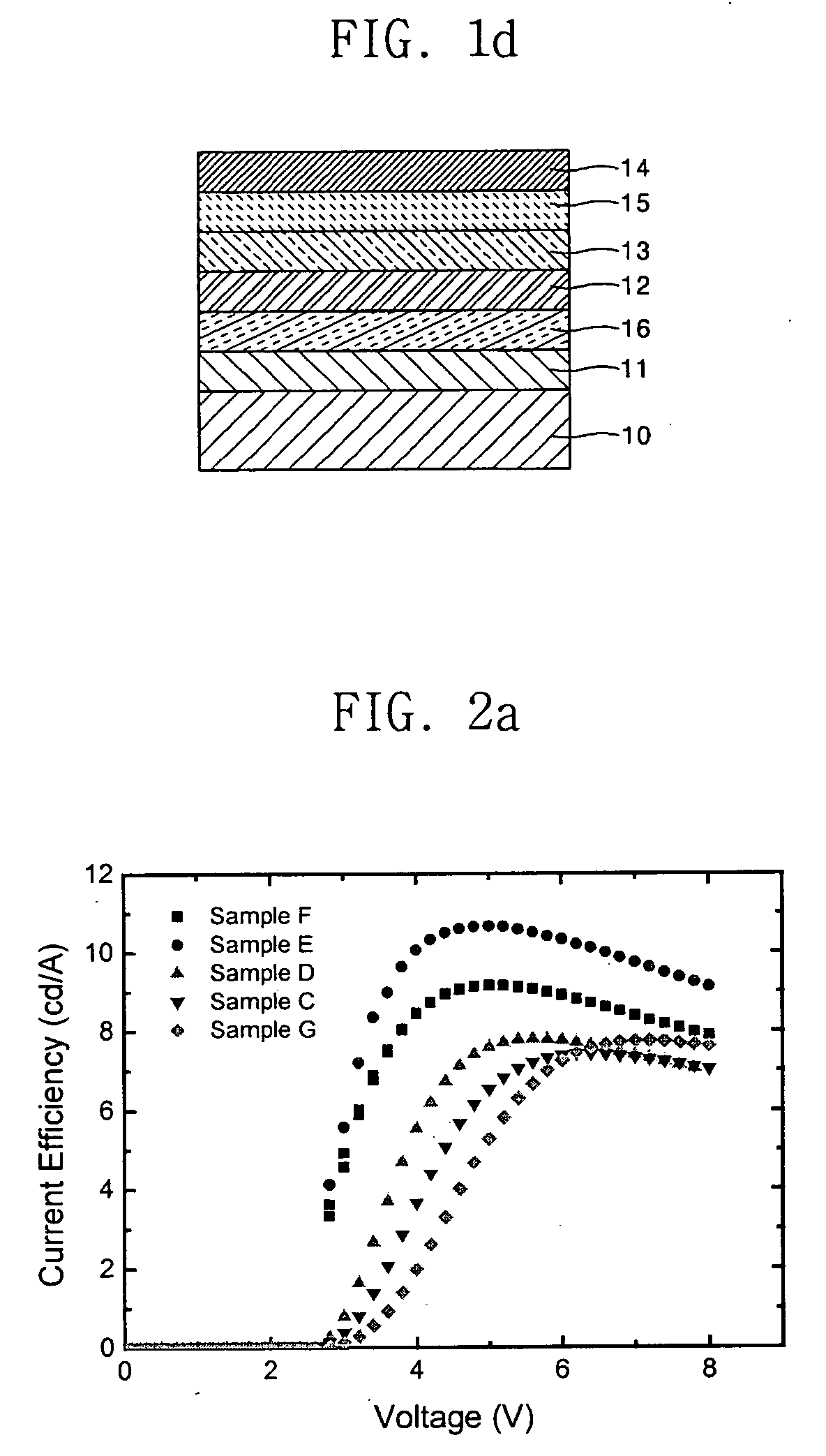

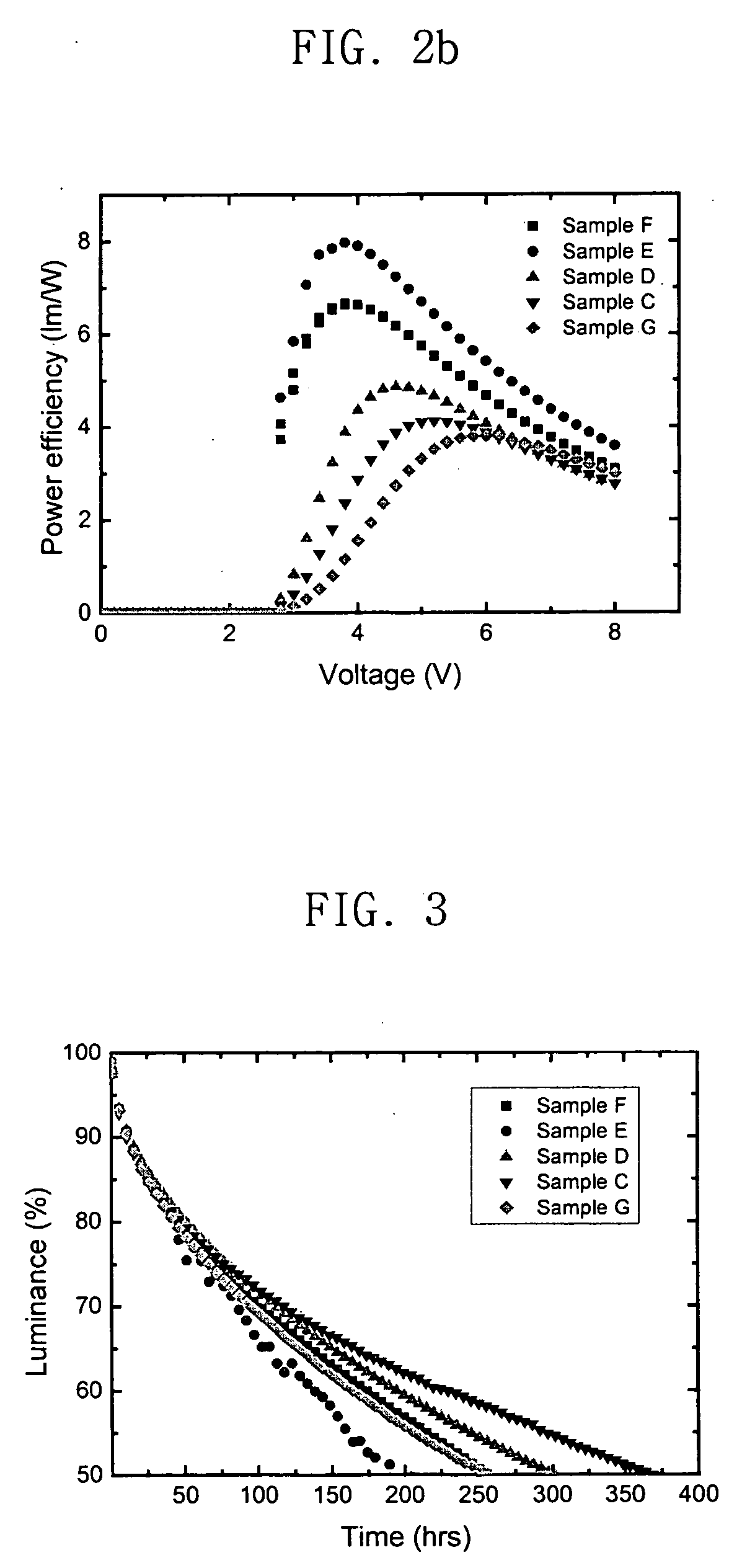

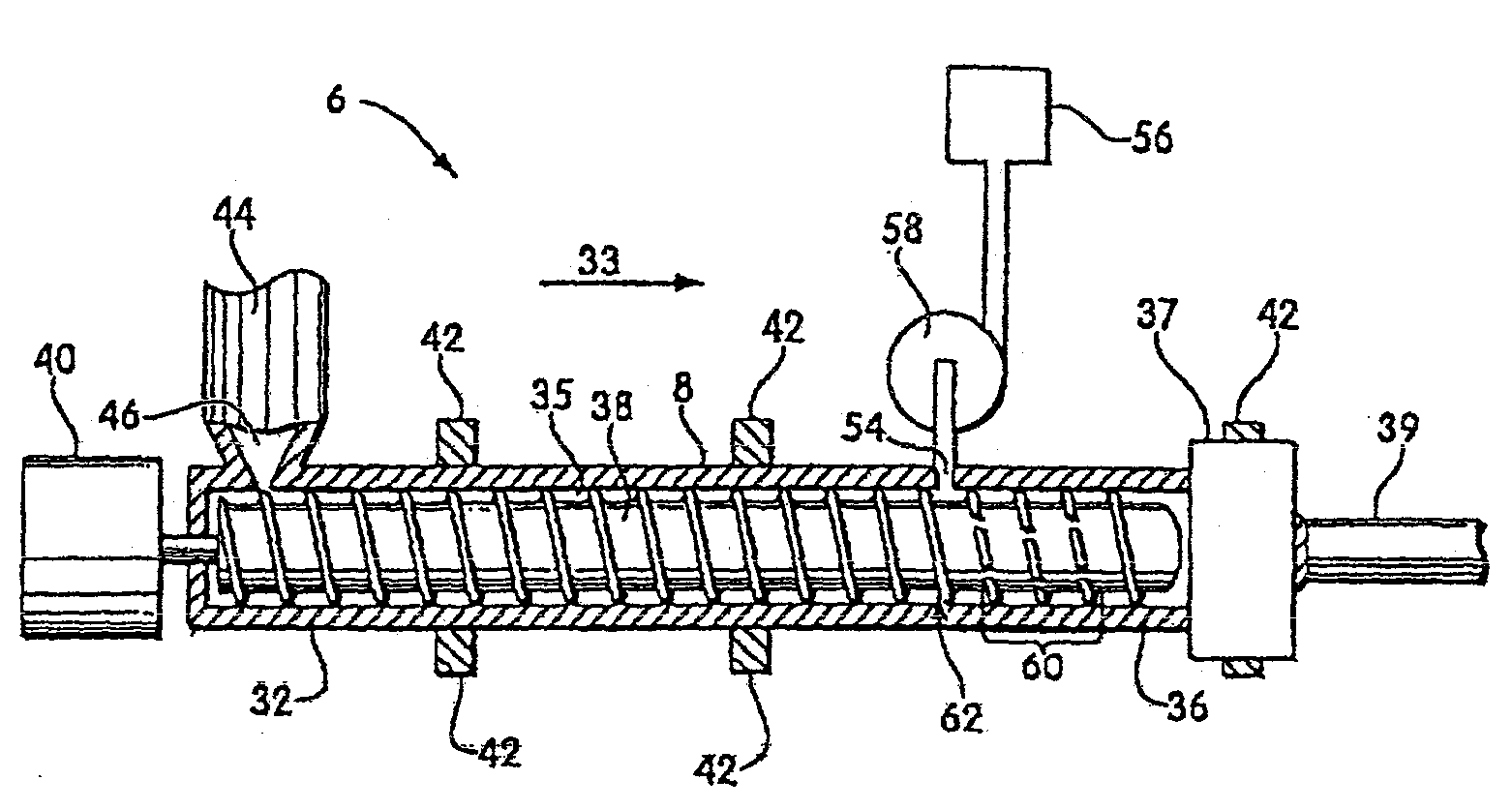

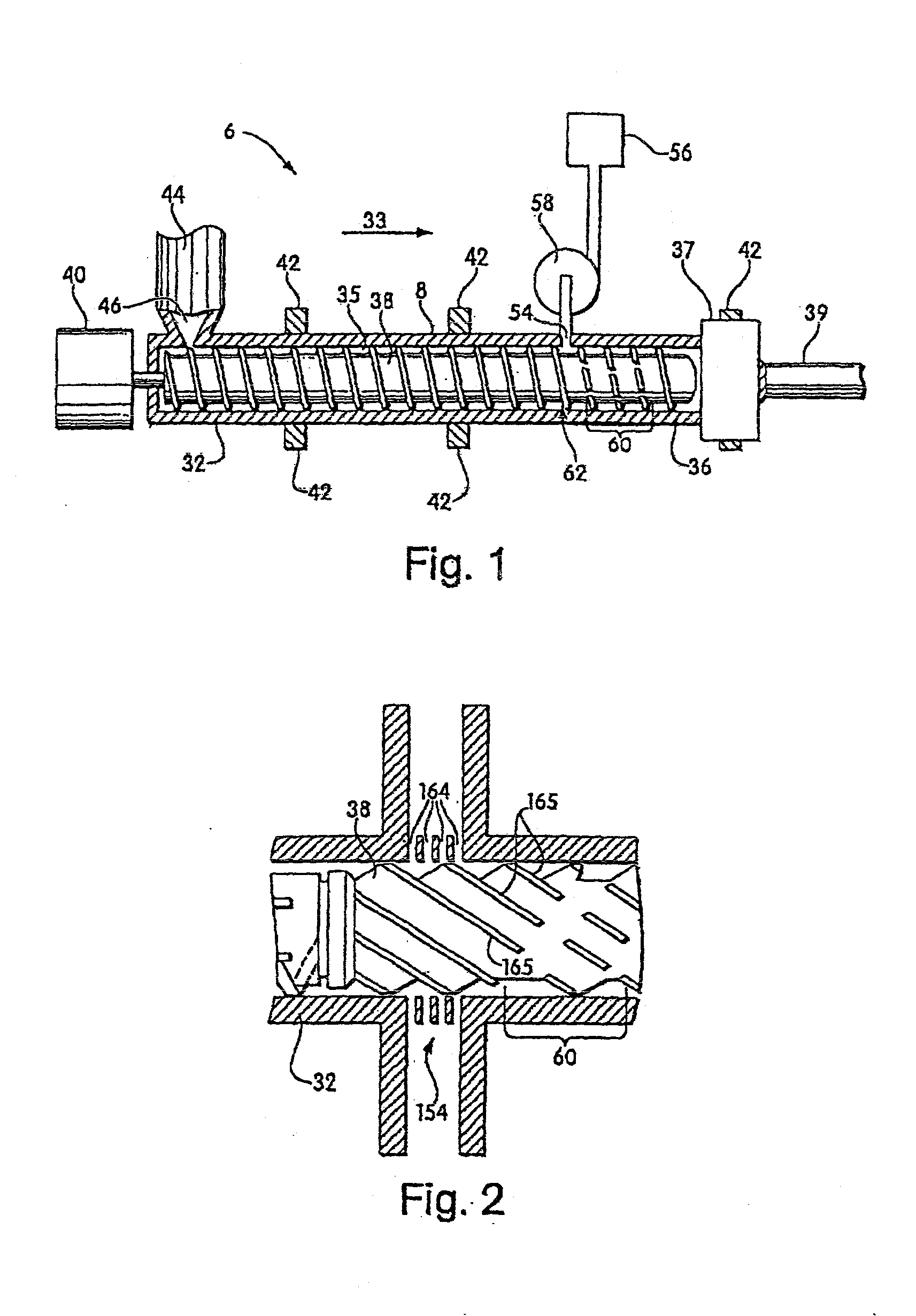

Composition of conducting polymer and organic opto-electronic device employing the same

ActiveUS20060180810A1Low water uptakeLow contentDischarge tube luminescnet screensConductive materialIonOpto electronic

A composition including a conducting polymer and an ionomer, and an opto-electronic and an electronic device including the composition are provided. The composition is prepared by doping a conducting polymer with an ionomer which has a low water uptake, has a low content of by-products decomposed by a reaction with electrons, and can crosslink with the conducting polymer. Thus, the opto-electronic device including the composition has improved device performance such as device efficiency and lifetime.

Owner:SAMSUNG DISPLAY CO LTD

Heat-preservation sound-proof low-density foamed concrete

The invention discloses heat-preservation sound-proof low-density foamed concrete. The heat-preservation sound-proof low-density foamed concrete is characterized by being prepared from, by weight, 40-100 parts of cement, 5-40 parts of carbide slags, 5-40 parts of active powder, 1-20 parts of foaming agents, 0.1-8 parts of foam stabilizers, 0-8 parts of water reducing agents, 0-8 parts of coagulation accelerator, 0-25 parts of waterproof agents, 0.1-5 parts of anti-cracking agents and 25-150 parts of water, and the foamed concrete is prepared from the materials through mixing, foam molding and maintenance. The heat-preservation sound-proof low-density foamed concrete has the advantages of being low in dry density, low in heat conductivity coefficient, high in strength, wide in raw material source, low in cost, simple in preparation technology, convenient to prefabricate in factories or pour on site and the like; the heat-preservation sound-proof low-density foamed concrete is suitable for building exterior wall heat-preservation engineering, roof heat-preservation engineering, floor heating heat-preservation engineering, composite heat-preservation wall engineering, backfilling engineering, retaining wall slab engineering and the like.

Owner:株洲大禹恒基新材料有限公司

Thermoplastic elastomeric foam materials and methods of forming the same

InactiveUS20040038018A1Low water absorptionImprove water absorptionLayered productsThin material handlingThermoplastic elastomerMelt temperature

Foams with low water absorption are provided, along with thermoplastic elastomeric foam materials and methods of forming the same. In some embodiments, the TPE foams have a low water absorption. Microcellular foams are included. Processing conditions (e.g., blowing agent type and content, die geometry, exit melt temperature, among others) may be controlled to produce foams having desirable characteristics, such as low water absorption.

Owner:MUCELL EXTRUSION

Thermosetting resin compositions containing maleimide and/or vinyl compounds

InactiveUS6852814B2Low water absorptionImprove adhesionOrganic chemistryLayered productsPliabilitySolvent

In accordance with the present invention, there are provided novel thermosetting resin compositions which do not require solvent to provide a system having suitable viscosity for convenient handling. Invention compositions have the benefit of undergoing rapid cure. The resulting thermosets are stable to elevated temperatures, are highly flexible, have low moisture uptake and are consequently useful in a variety of applictions, e.g., in adhesive applications since they display good adhesion to both the substrate and the device attached thereto.

Owner:HENKEL CORP

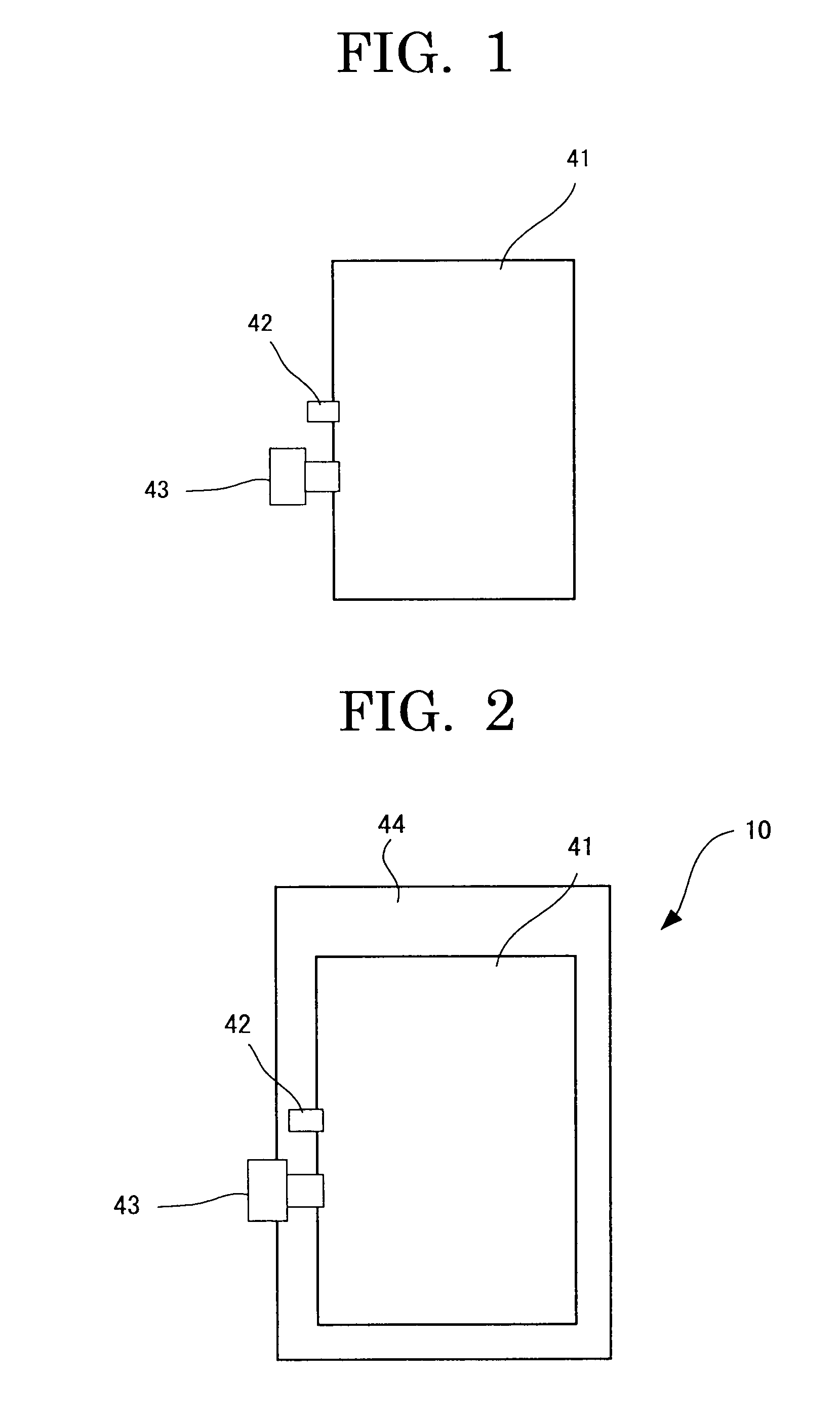

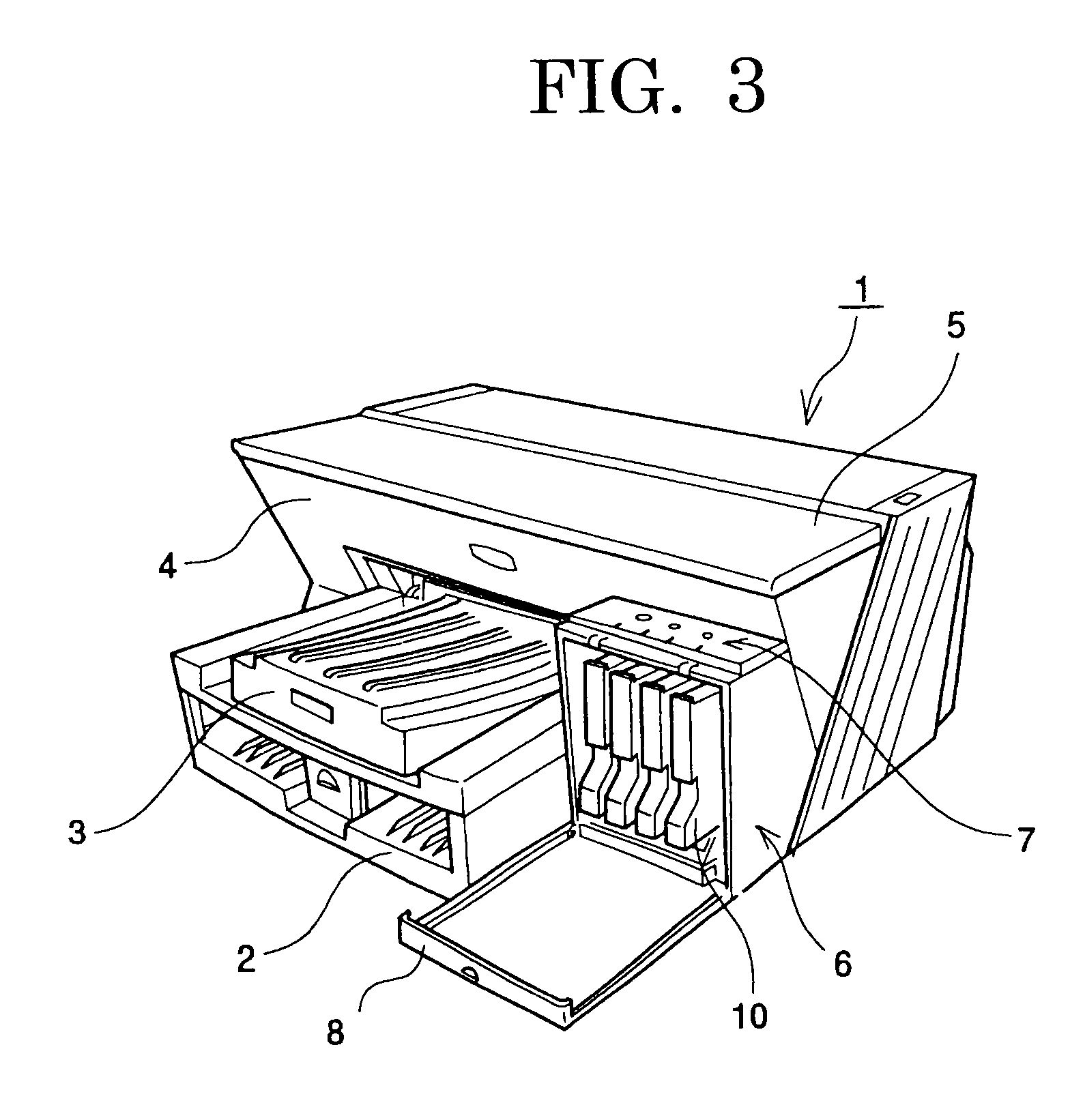

Recording ink as well as ink media set, ink cartridge, ink recorded matter, inkjet recording apparatus and inkjet recording method

ActiveUS20110057981A1High image densityLow densityOther chemical processesMeasurement apparatus componentsSolid componentPolymer science

A recording ink containing at least a solid component which contains a colorant and a resin and is a solid at 25° C., a liquid component which has a higher boiling point than that of water and is a liquid at 25° C. and water, wherein the total content of the liquid component in the recording ink is 20% by mass or less, the total content of the solid component in the recording ink is 20% by mass or more, and the total content of a resin component in the solid component is 40% by mass to 95% by mass relative to a total amount of the solid component is provided.

Owner:RICOH KK

Thermosetting Resin Composition and Application Thereof

InactiveUS20100240811A1Excellent dielectric propertiesIncrease thermal resistanceBiocideOrganic chemistryTetrabromobisphenol ASolvent

The present invention discloses a thermosetting resin composition including: a bi-functional or multi-functional epoxy resin, a SMA uses as a curing agent, an allyl phenol such as diallyl bisphenol A used as a co-curing agent and a toughening agent a low-bromine or high-bromine BPA epoxy resin or tetrabromobispheno A (TBBPA or TBBA) uses as a flame retardant agent, and an appropriate solvent. After the resin composition of the invention is cured, the resin composition has lower dielectric property and better thermal reliability and tenacity. A copper clad laminate made of an enhanced material such as glass fiber has lower dielectric constant (Dk) and loss tangent (Df), high Tg, high thermal decomposition temperature (Td), better tenacity and PCB manufacturability, and thus very suitable to be used as a copper clad laminate and a prepreg for manufacturing PCBs or applied as a molding resin material for contraction, automobile and air navigation.

Owner:ITEQ DONGGUAN +1

Fiber cement composite materials using cellulose fibers loaded with inorganic and/or organic substances

InactiveUS20050235883A1Low water absorptionLow water migrationConstruction materialWater-repelling agents additionCement compositesCellulose fiber

This invention discloses a new technology related to cellulose fiber reinforced cement composite materials using the loaded cellulose fibers. This invention discloses four aspects of the technology: fiber treatment, formulation, method and final product. This technology advantageously provides fiber cement building materials with the desirable characteristics of reduced water absorption, reduced rate of water absorption, lower water migration, and lower water permeability. This invention also impart the final products improved freeze-thaw resistance, reduced efflorescence, reduced chemical dissolution and re-deposition, and improved rot and fire resistances, compared to conventional fiber cement products. These improved attributes are gained without loss in dimensional stability, strength, strain or toughness.

Owner:MERKLEY DONALD J +1

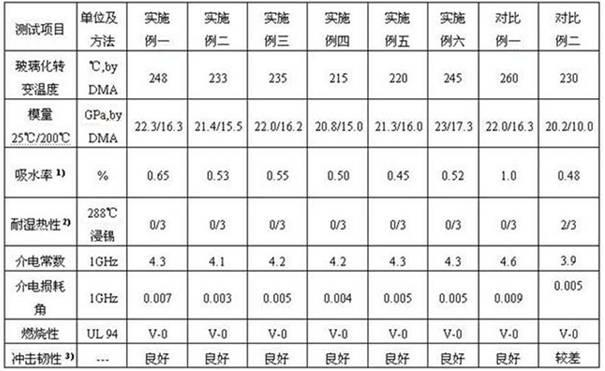

Thermosetting resin composition, prepreg and laminated board

ActiveCN102115600AExcellent heat and humidity resistanceImprove heat resistanceGlass/slag layered productsMetal layered productsEpoxyDielectric loss

The invention discloses a thermosetting resin composition, which is characterized by comprising the following components in part by weight: 8 to 80 parts of allyl modified bismaleimide resin prepolymer, 15 to 60 parts of cyanate resin and 5 to 40 parts of halogen-free epoxy resin, wherein the allyl modified bismaleimide resin prepolymer is prepared by reacting bismaleimide resin with an allylcompound at the temperature of between 110 and 160DEG C for 20 to 100 minutes, and a weight ratio of the bismaleimide resin to the allylcompound is 100:(30-120). The composition can be used for preparing a prepreg and a laminated board. The composition and the laminated board have excellent humidity resistance, high heat resistance, low water absorption rate, high modulus, lower dielectric constant and dielectric loss, and good processing toughness, and can realize halogen-free flame retardancy.

Owner:SHENGYI TECH SUZHOU

Water plasticized high refractive index polymer for ophthalmic applications

InactiveUS6281319B1High glass transitionHigh water contentTissue regenerationIntraocular lensAcrylateHigh-refractive-index polymer

A high refractive index, foldable polymer suitable for use in ophthalmic devices, such as intraocular lenses, is provided. The polymer may be produced from a polymerization reaction of first, second and third monomeric components and a crosslinking agent. The first monomeric component includes an aryl acrylate or an aryl methacrylate. The second monomeric component, which is not an acrylate, includes a monomer having an aromatic ring with a substituent having at least one site of ethylenic unsaturation. The third monomeric component includes a high water content hydrogel-forming monomer. The resulting high refractive index copolymer is durable enough to be cut and polished when dry, and becomes soft and foldable when hydrated.

Owner:ADVANCED VISION SCI

Nanocomposites based on polyurethane or polyurethane-epoxy hybrid resins prepared avoiding isocyanates

ActiveUS20070135588A1Beneficial physicochemical and mechanical propertyAvoid damageMaterial nanotechnologySynthetic resin layered productsNanometreAspect ratio

A fast curable non-isocyanate-based polyurethane- and polyurethane-epoxy network nanocomposite polymeric compositions are derived upon crosslinking a mixture comprising of natural or modified nano-clay [ionic phyllosilicate] with platelet thickness in the scale of A (˜1 nm) and aspect ratio (length / thickness) higher than 10 (nm)] preferably natural or modified montmorillonite with either a monomer(s) or oligomer(s) bearing at least one cyclocarbonate group or a mixture of the latter with an epoxy resin, with a hardener, which is a monomer or oligomer or mixtures therefrom, bearing primary and / or secondary amino groups. The use of the nanoclays reduces the gel time and increases the adhesion of the cured polyurethane and polyurethane / epoxy hybrid and also reduces its water absorption.

Owner:HUNTSMAN ADVANCED MATERIALS AMERICAS INC

Water repellent compositions for wood preservatives

InactiveUS7264886B2Improve permeabilityImprove waterproof performanceFireproof paintsWax coatingsWaxWater based

Water-based wax emulsions, optionally for use in conjunction with alkaline copper and / or quaternary ammonium based preservatives systems, are described. These emulsions are comprised of natural or synthetic wax, nonionic surfactants having HL B values greater than 11, anionic surfactants, and water. Certain emulsion compositions as described in this specification posses the unique property of maintaining emulsion stability in wood preservatives during extended use in typical wood treatment processes. Water-repellant wood treated with the wax emulsions are described. A method of treating wood, comprising providing wood and treating the wood with the wax emulsion under conditions effective to increase its water repellency is also disclosed.

Owner:VIANCE

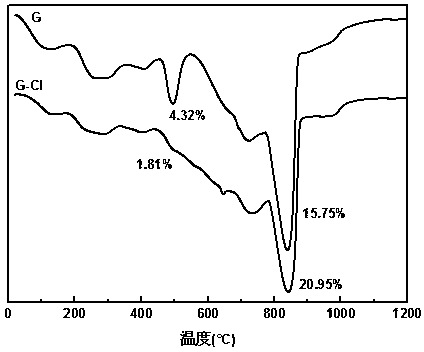

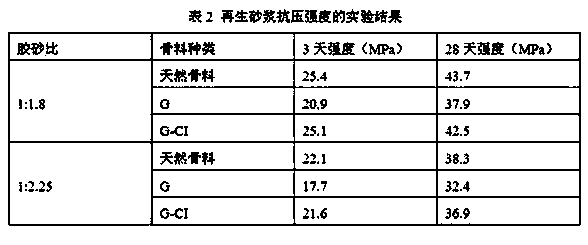

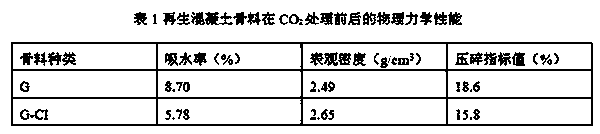

Method for carbon dioxide strengthening of recycled concrete aggregate

ActiveCN104045251AImprove physical and mechanical propertiesImprove early strengthSolid waste managementCarbonizationAbsorption rate

A method for carbon dioxide strengthening of a recycled concrete aggregate comprises the following steps: (1) crushing and sieving waste concrete; (2) placing the sieved recycled concrete aggregate in a sealed container, controlling the relative humidity of 30-90% and the CO2 concentration of 5-90%, and carrying out carbonization treatment; and (3) making the treated recycled concrete aggregate particles into recycled mortar and concrete. Compared with mortar prepared from a recycled concrete aggregate without treatment, the mortar prepared from the obtained recycled concrete aggregate after CO2 strengthening treatment enables the mortar early strength to be improved by 20.1%-22.0% and the later strength to be improved by 12.1%-13.9%; the 28 d drying shrinkage value can be reduced by 7.8%-16.7%; and the 28 d water absorption rate can be reduced by 7.7%-13.3%.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com