Method for carbon dioxide strengthening of recycled concrete aggregate

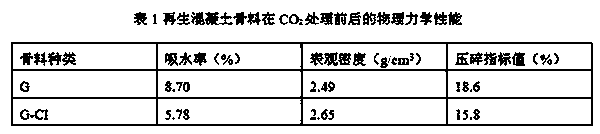

A technology of recycled concrete and carbon dioxide, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of reducing the water absorption rate of recycled concrete aggregates, affecting the pH value of the attached mortar, and limited strength improvement. Achieve the effect of increasing strength, increasing compactness, reducing water absorption and crushing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment includes the following steps:

[0022] (1) Recycled concrete aggregate: C30 concrete beams are crushed and screened to obtain recycled concrete fine aggregate (G) with a particle size range of 0.16-2.5mm, which is sealed and stored;

[0023] (2) CO 2 Strengthening treatment: put the recycled concrete fine aggregate (G) in a closed container, and control the relative humidity of the container to 60%, CO 2 The volume concentration is 20%, carbonized for 6 days; the incompletely carbonized recycled concrete aggregate is 4%, and the obtained CO 2 The strengthened recycled concrete aggregate (G-CI) is sealed and preserved;

[0024] (3) Preparation of recycled mortar: The treated recycled concrete aggregate particles are made into recycled mortar.

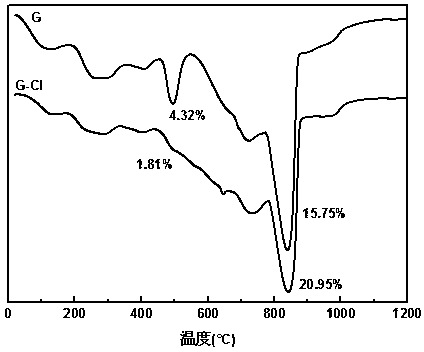

[0025] via CO 2 The differential thermal curves of recycled concrete aggregate before and after strengthening treatment are as follows: figure 1 shown. from figure 1 Visible: Via CO 2 After strengthening tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com