Patents

Literature

61results about How to "Won't foam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inorganic powder texture coating, and its applying method

ActiveCN1757688AEasy constructionUnique texturePowdery paintsCement coatingsInorganic pigmentsMaterials science

A inorganic dry powder paint with good mass sensation is prepared proportionally from cement, color sand, re-dispersed emulsoid powder, hydrophobic agent, inorganic pigment and filler. Its advantages are high adhesion to concrete, high weatherability, good air permeability, and no pollution. Its application method is also disclosed.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

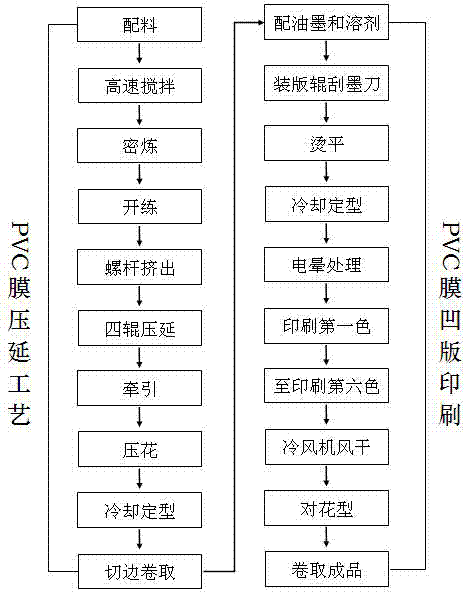

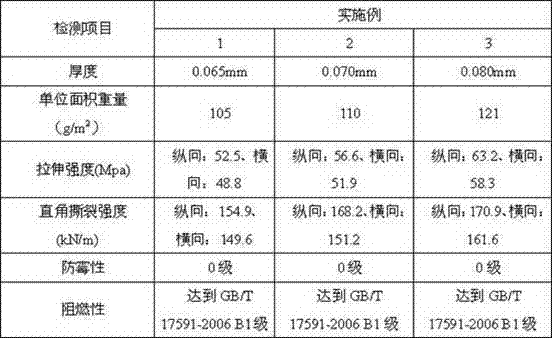

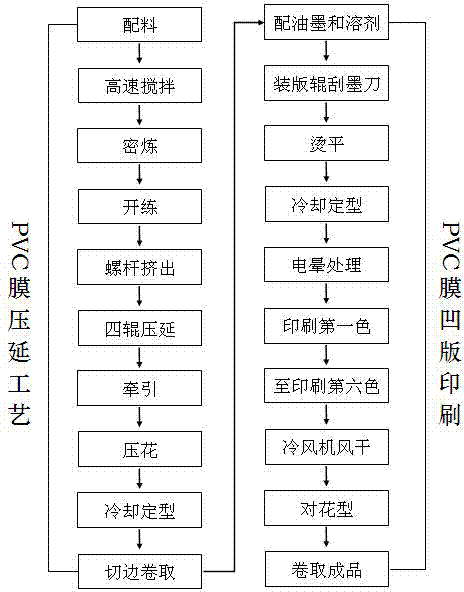

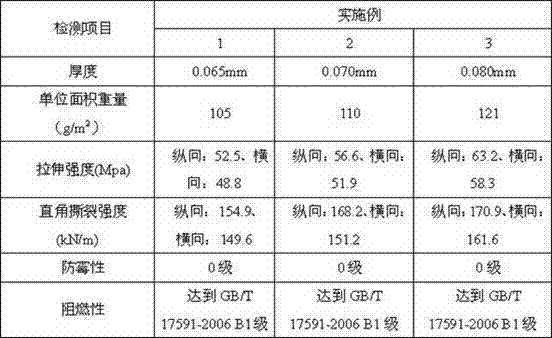

Semi-rigid PVC (polyvinyl chloride) decorative membrane

The invention relates to a semi-rigid PVC (polyvinyl chloride) decorative membrane. The semi-rigid PVC decorative membrane comprises the following main raw materials in parts by weight: 100 parts of PVC resin powder, 18-23 parts of plasticizer, 3-5 parts of stabilizer, 25-35 parts of calcium carbonate, 4-6 parts of flame retardant, 6-9 parts of titanium white, 2-4 parts of soybean oil and 0.1-0.3 part of mold preventive; and the semi-rigid PVC decorative membrane is prepared through a calendering stage and an intaglio printing stage. The product provided by the invention is thin and semi-rigid, can not bubble in case of being laminated with glass and other materials, and can prevent broken glass from splashing and falling when the glass is broken; the addition of the flame retardant and the mold preventive endows the product with high-efficiency flame-retardant and mold-resistant properties, and the flame-retardant property and the mold-resistant property can be respectively up to B1 level and 0 level; and the product has long color retention time and long service life, and can soften bright light, partition space, enhance privacy and create a mild atmosphere.

Owner:ZHEJIANG BOTAI PLASTIC

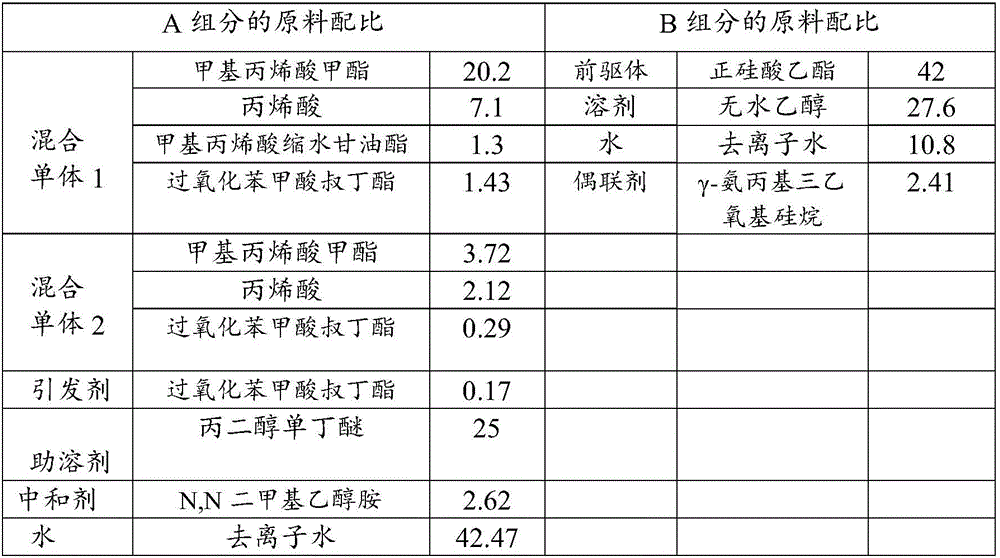

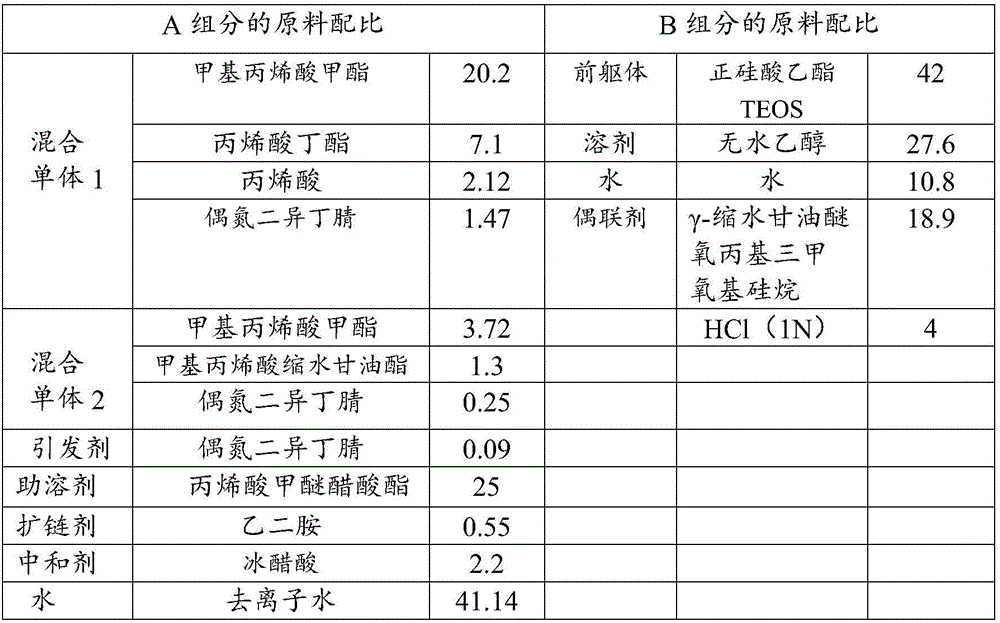

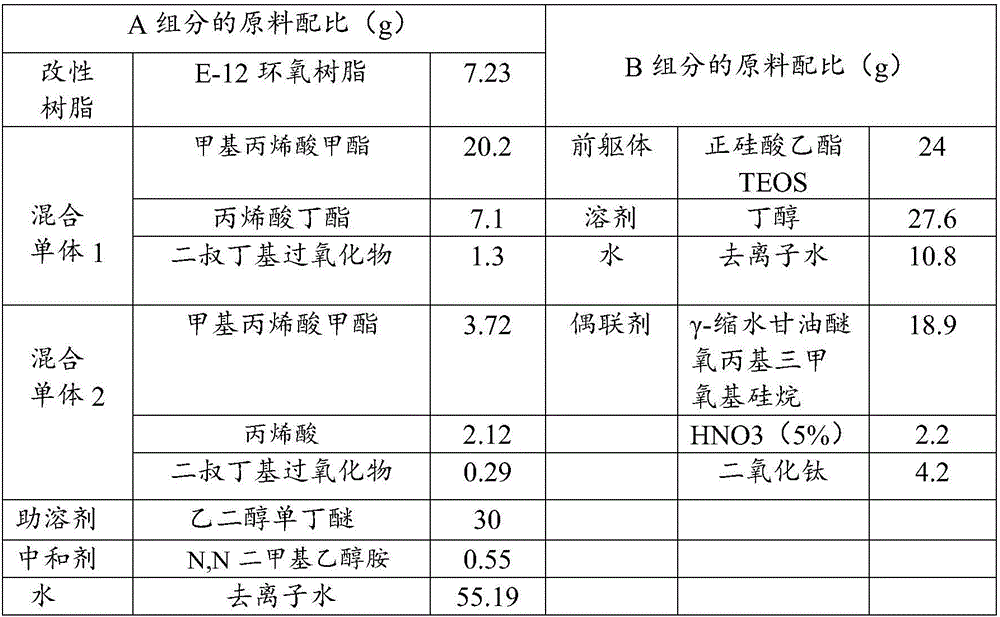

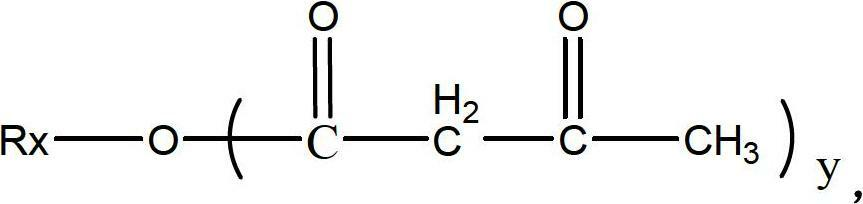

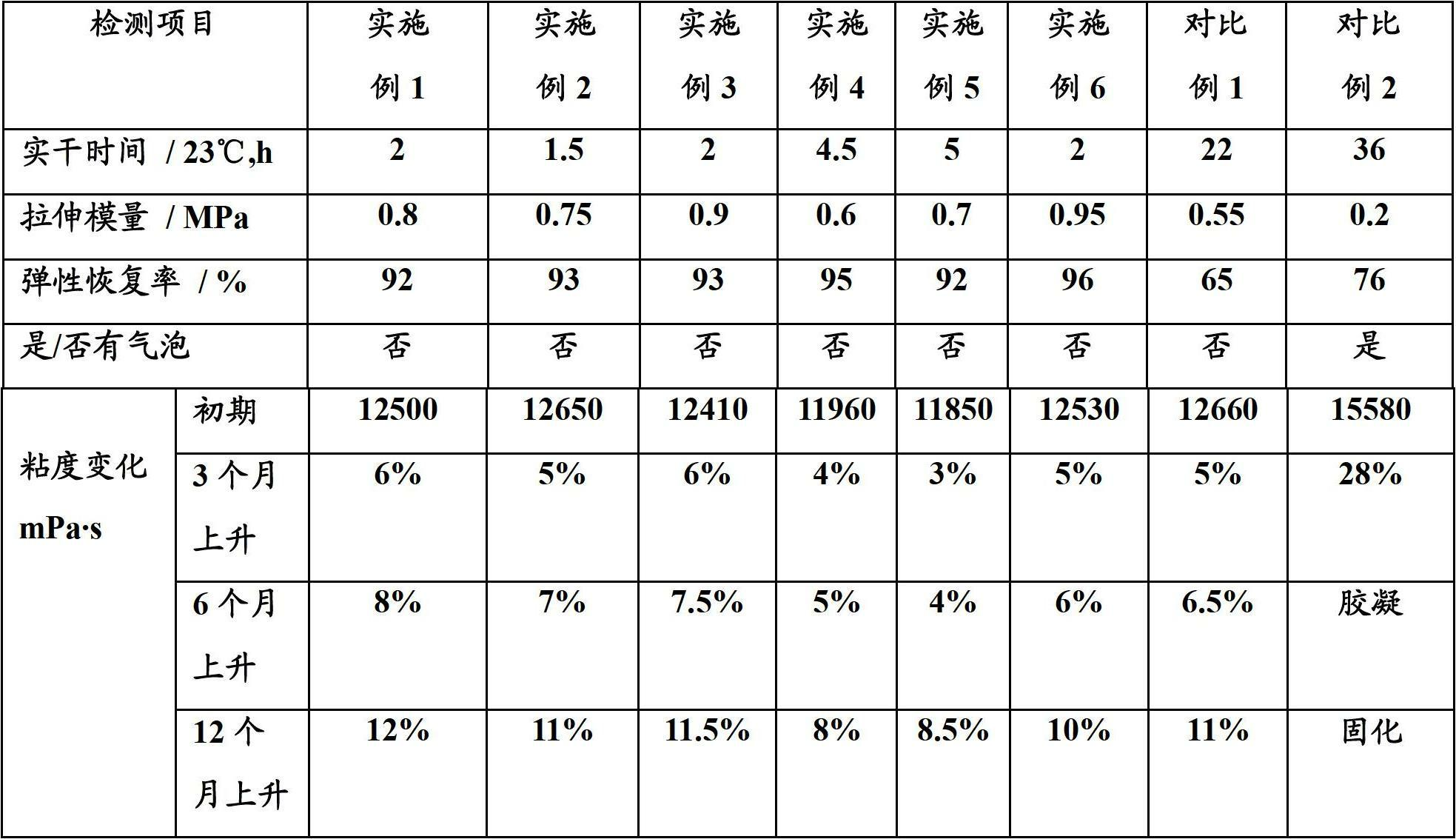

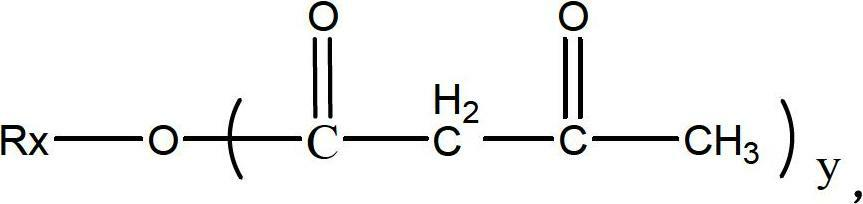

Resin for novel waterborne double-component organic-inorganic hybrid coating and preparation method of resin

The invention belongs to the field of waterborne coatings and discloses resin for a novel waterborne double-component organic-inorganic hybrid coating and a preparation method of the resin. For a component A, acrylic acid is used as a main body, polyester, alcohol acid, polyurethane, epoxy and organosilicon are utilized to modify the acrylic acid, and a waterborne acrylic resin dispersion with one or several functional groups is synthesized. For a component B, nano oxide sol with one or several functional groups is synthesized through a sol-gel method. Through inorganic modifying, antiaging performance, waterproofness and wear resistance of common double-component materials are improved, an organic-inorganic composite material with an inorganic portion accounting for a higher portion can be obtained, and stability of the organic-inorganic composite material in water is ensured; water is used as a diluent, so that VOC of a system is lowered, and the resin has excellent environment friendliness.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD

Single-component polyurethane sealant capable of quickly curing moisture and preparation method thereof

ActiveCN102690626AFast curingWon't foamNon-macromolecular adhesive additivesOther chemical processesAcetoacetatesCyclodextrin

The invention relates to a single-component polyurethane sealant capable of quickly curing moisture and a preparation method thereof. The polyurethane sealant comprises the following raw materials in percentage by weight: 10 to 20 percent of polyisocyanate monomer, 20 to 45 percent of polyether polyol, 1 to 10 percent of acetoacetic ester sealed end polyether prepolymer, 5 to 20 percent of plasticizer, 25 to 40 percent of modified mineral powder, 1 to 5 percent of latent curing agent, 0.1 to 2 percent of cyclodextrin wrapped environment-friendly catalyst, 0.1 to 1 percent of defoaming agent and 0.1 to 1 percent of water-removing agent, wherein the water-removing agent is one or more of mono-isocyanate compound or functionalized silane compound. The single-component polyurethane sealant avoids bubble fundamentally, can be quickly cured, is stable in storage, and can be applied to construction on damp interfaces.

Owner:苏州中材非金属矿工业设计研究院有限公司 +1

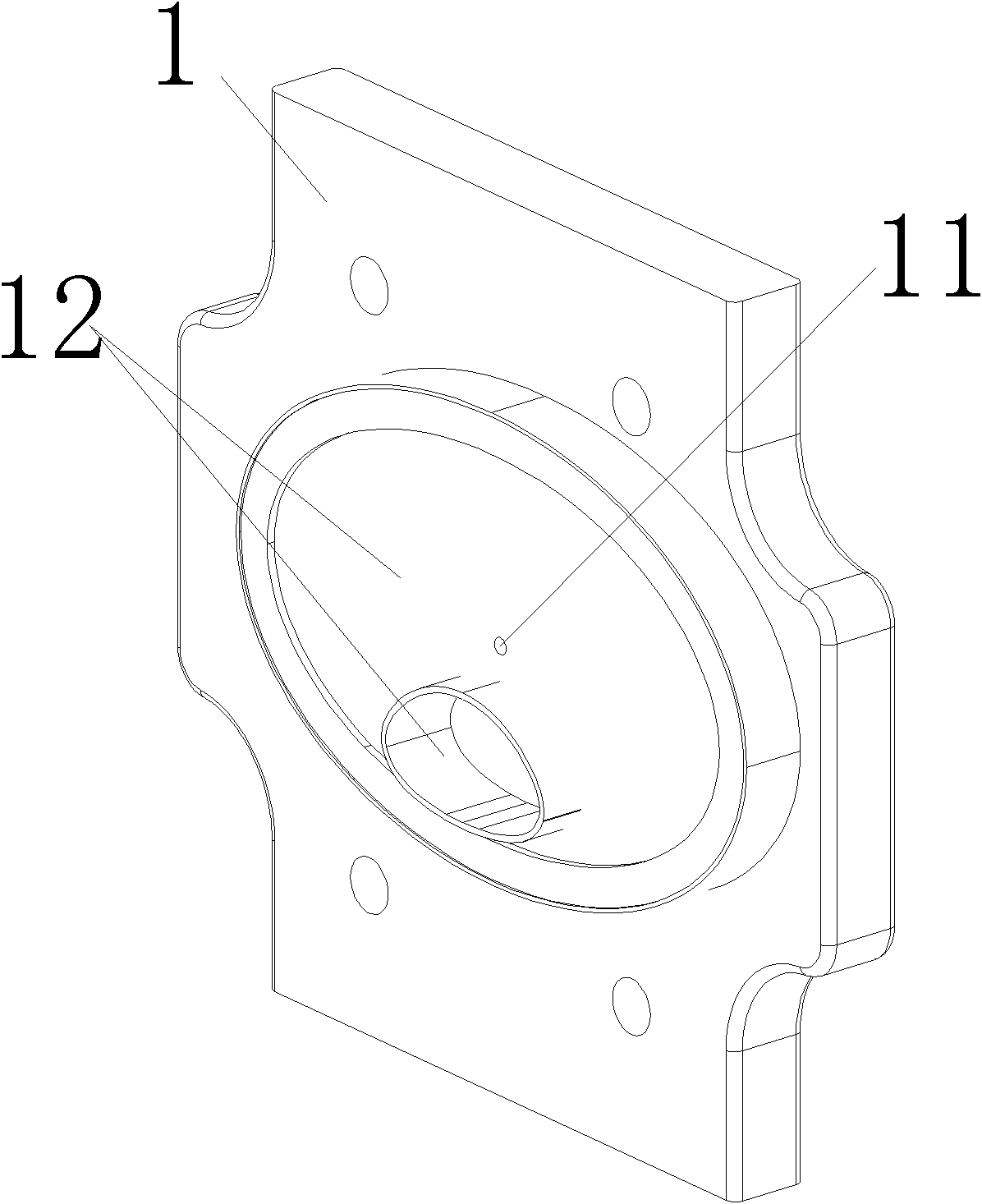

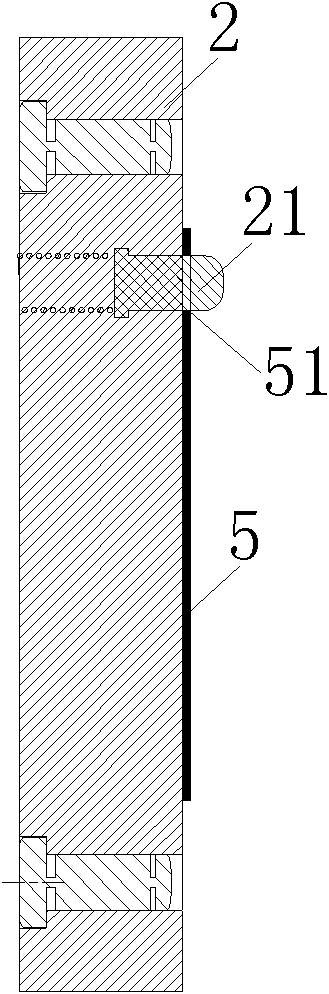

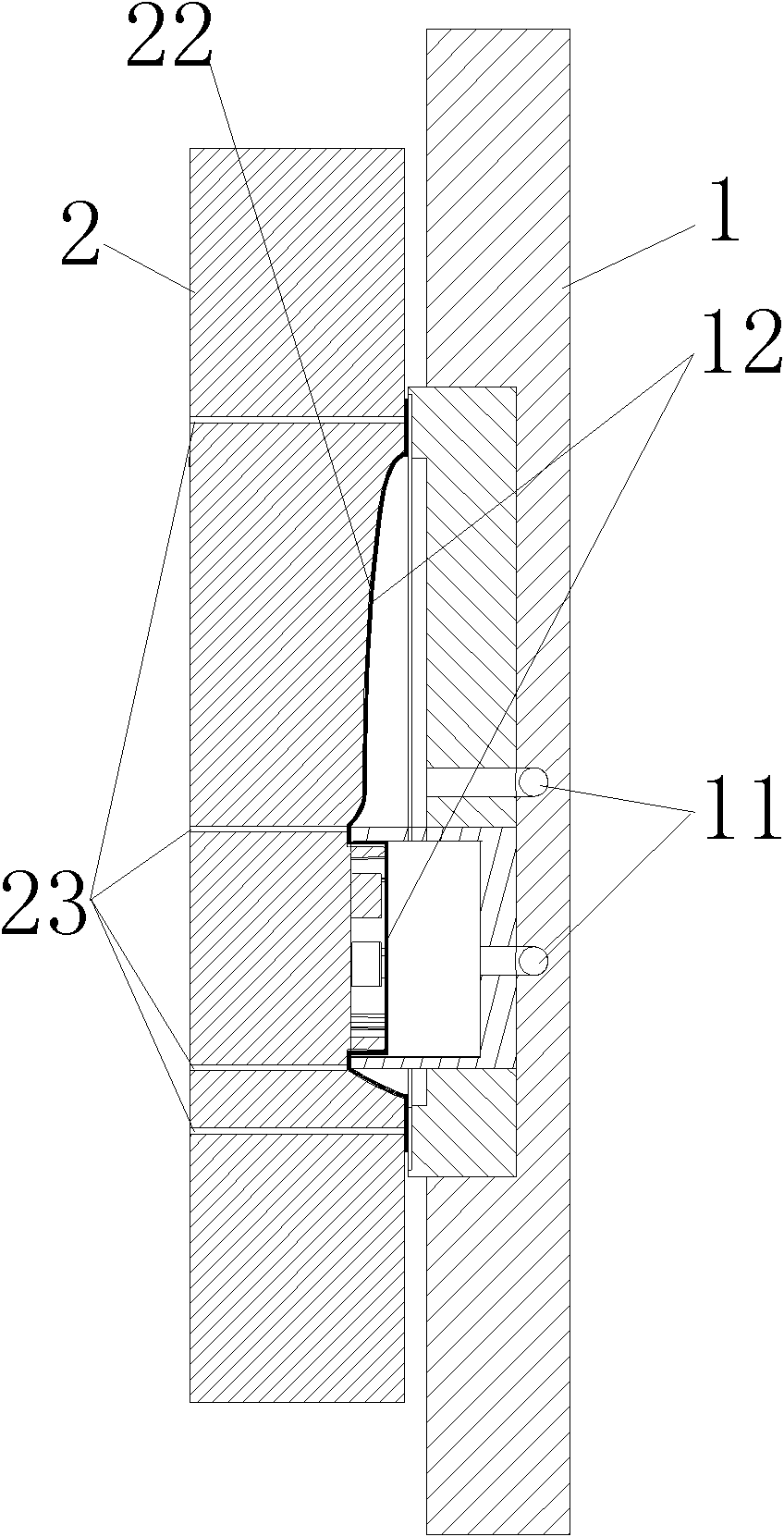

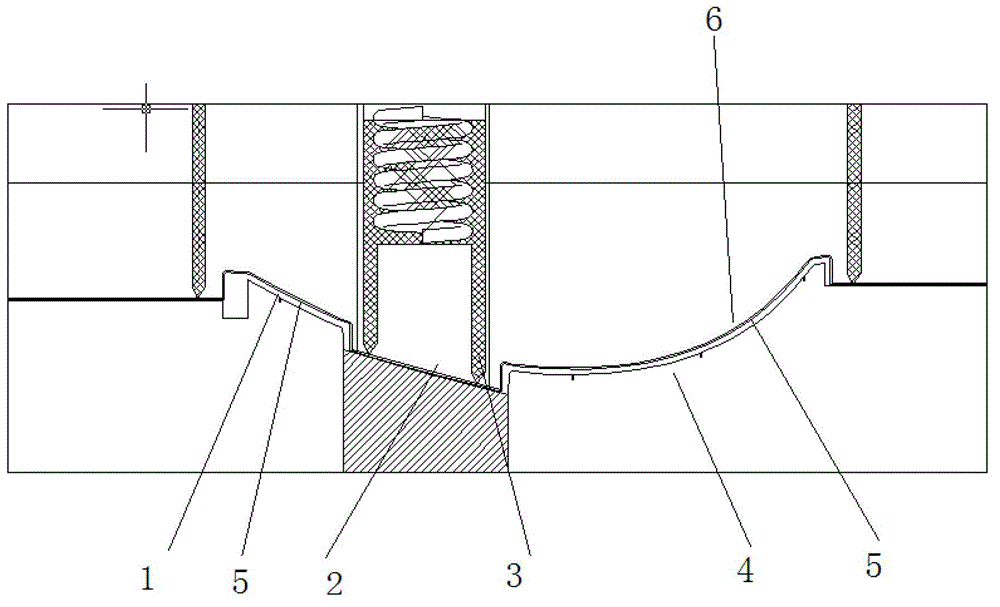

In-mould film lamination process for plastic product and forming mould thereof

The invention discloses an in-mould film lamination process for a plastic product and a forming mould for the in-mould film lamination process. The invention provides the in-mould film lamination process for the plastic product, which can simultaneously finish injection moulding and film lamination operation of the plastic product in a one-time forming process; and the invention also provides theforming mould for the in-mould film lamination process. The in-mould film lamination process for the plastic product comprises the following steps of: arranging a film forming module on the forming die, forming a film on a female mould of the forming mould through the film forming module before injection moulding, and then performing injection moulding so that the film lamination and the injection moulding are finished at the same time and the film has good attachment on an injection moulding part. In order to ensure smooth implementation of the in-mould film lamination process, the inventionalso provides the forming mould comprising the film forming module, a film cutter module and a movable slipway for mounting the film forming module and the film cutter module.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

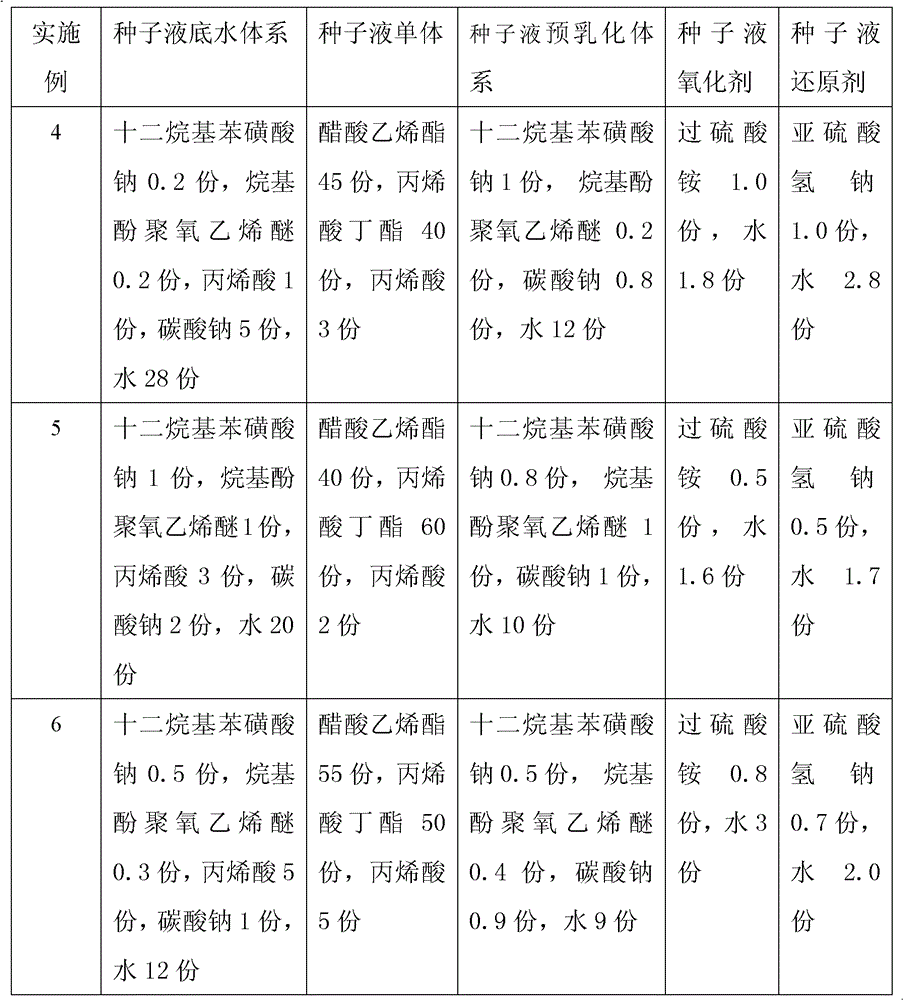

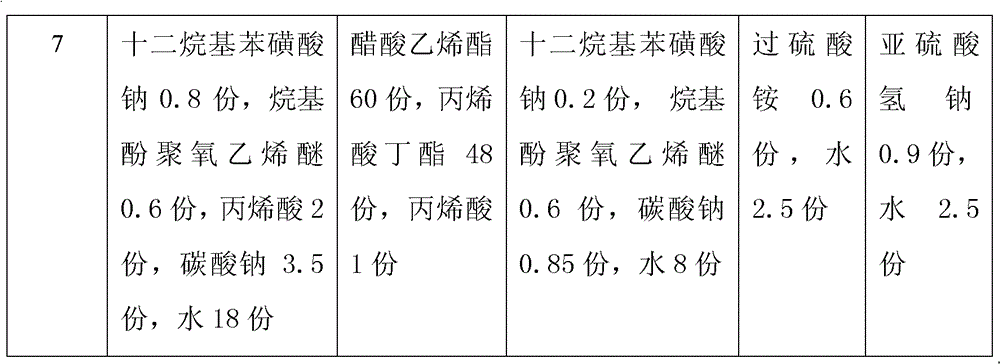

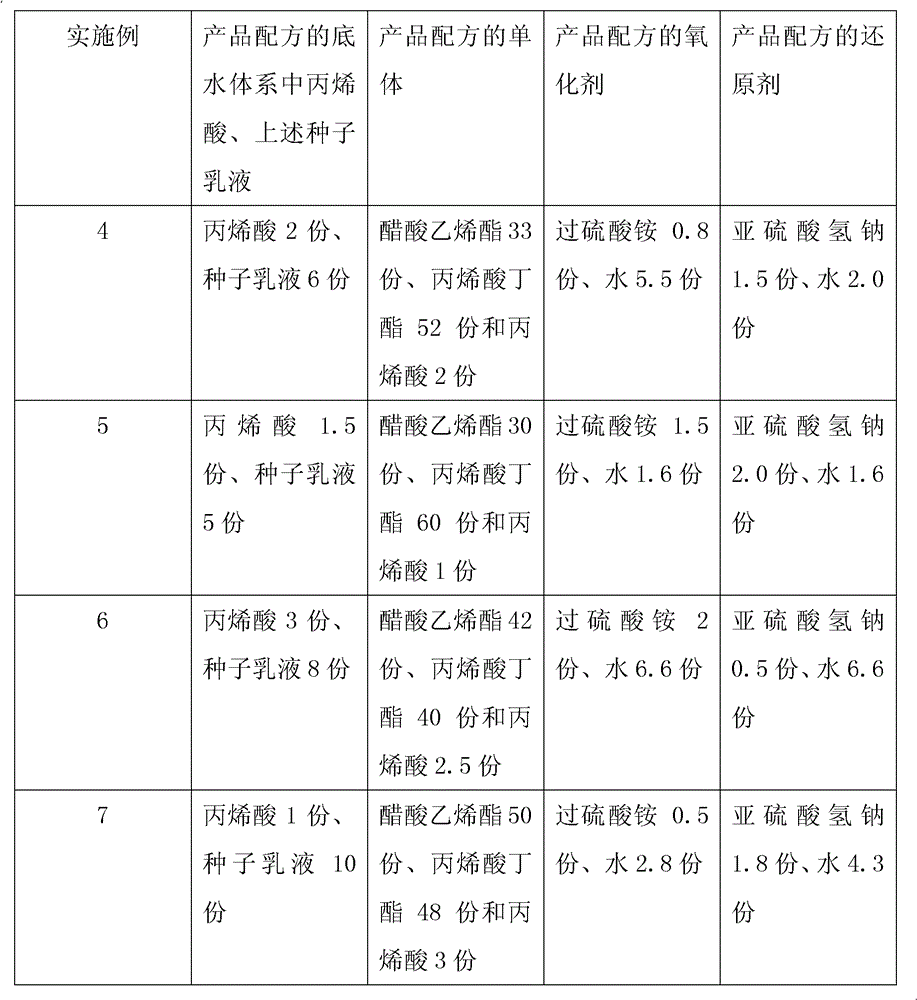

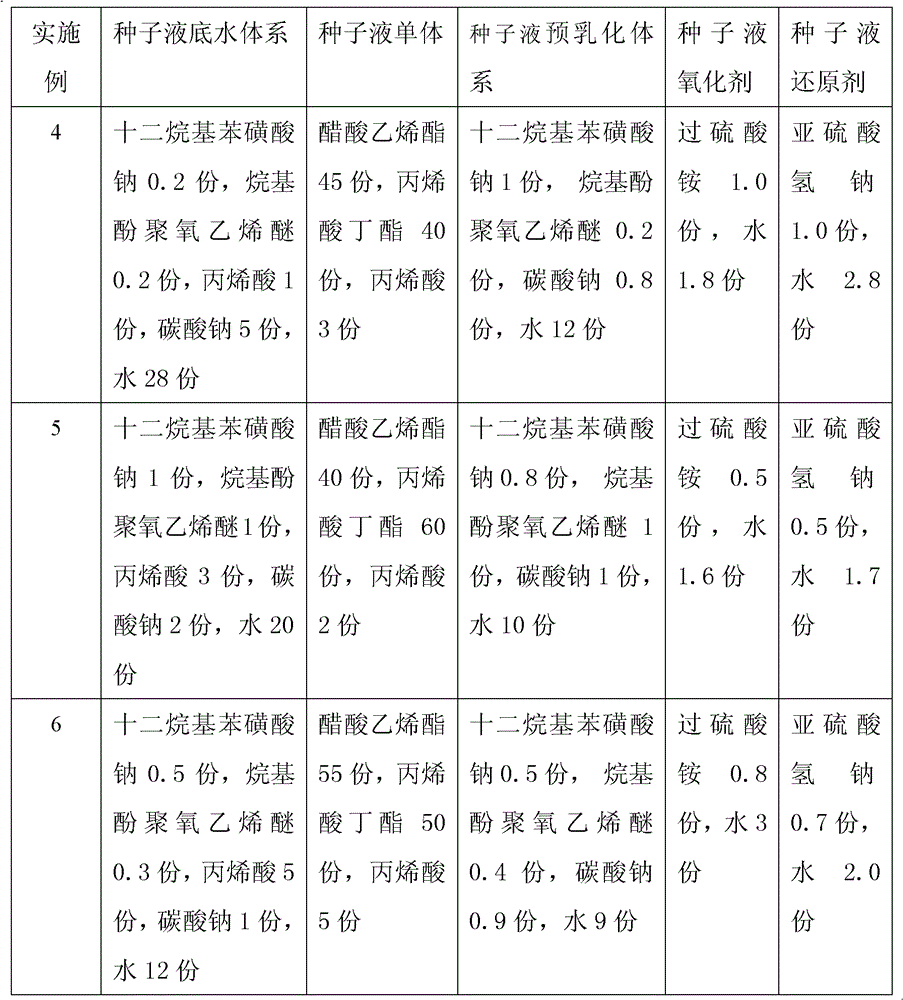

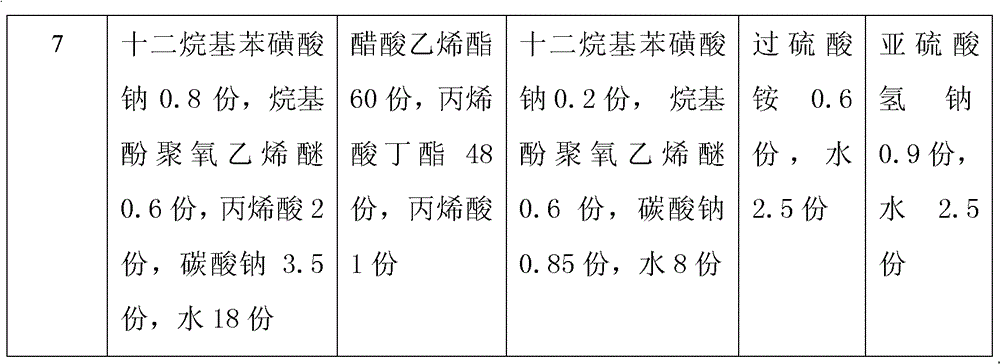

Vinyl acetate-acrylate copolymer emulsion, its synthesis method and application

ActiveCN103059211ALow coating viscosityHigh bonding strengthMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesAdhesiveSynthesis methods

The invention relates to a vinyl acetate-acrylate copolymer emulsion, which is prepared by adopting OP-10, SDBS, SVS, water, acrylic acid and a seed emulsion as the bottom water system, taking VAc, BA and AA as the monomer, employing ammonium persulfate as the oxidant, and using sodium bisulfite as the reducing agent. Specifically, the seed emulsion in the bottom water system is prepared by using SDBS, OP-10, AA, sodium carbonate and water as the base solution, adopting VAc, BA and AA as the monomer, employing SDBS, OP-10, sodium carbonate and water as the pre-emulsification system, taking ammonium persulfate as the oxidant, and adopting sodium bisulfite as the reducing agent. The emulsion provided in the invention has a solid content of 40%-45%, viscosity (in terms of a 4-cup application amount) of 20S-26S, bonding peel strength (N / 2.5cm) of 1.4-2.5, a surface tension force of 32-37 dyne, and a film contact angle of 25-29 degrees, thus being particularly suitable for application in dry paper-plastic or plastic-plastic composite adhesives. The preparation method of the vinyl acetate-acrylate copolymer emulsion has the characteristics of mild reaction conditions and safety reaction system, thus being conducive to factory mass production.

Owner:CHINA PETROCHEMICAL CORP +2

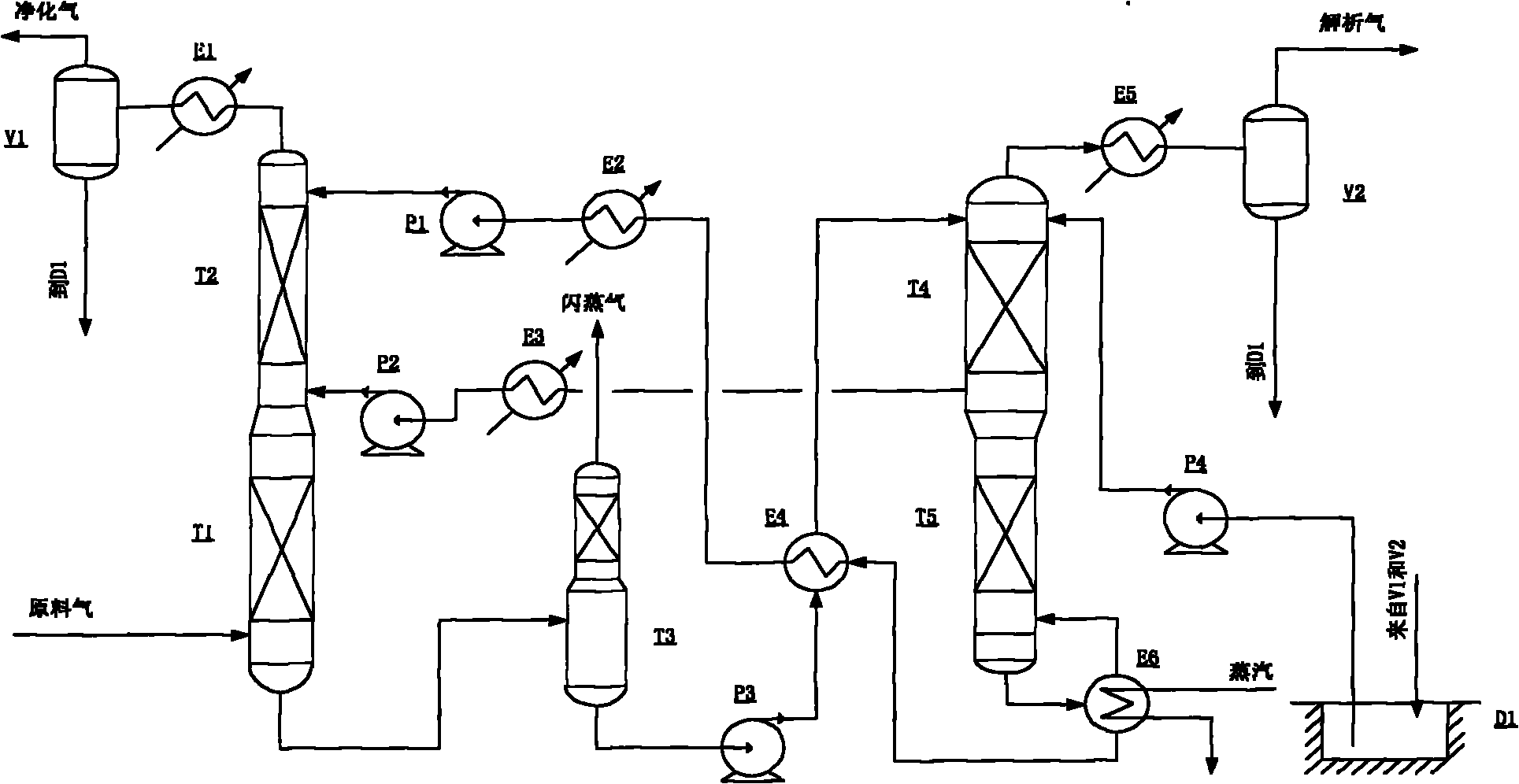

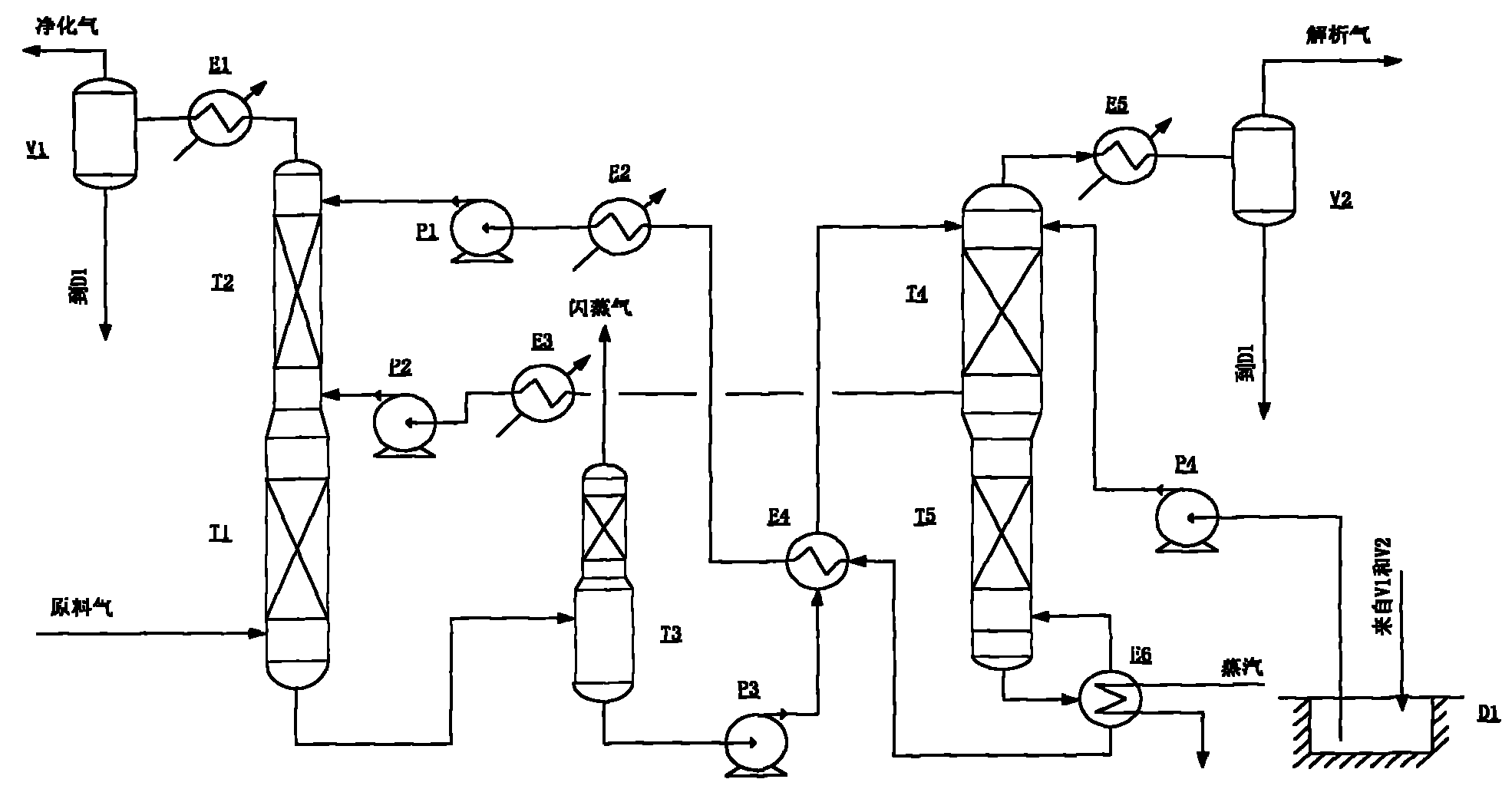

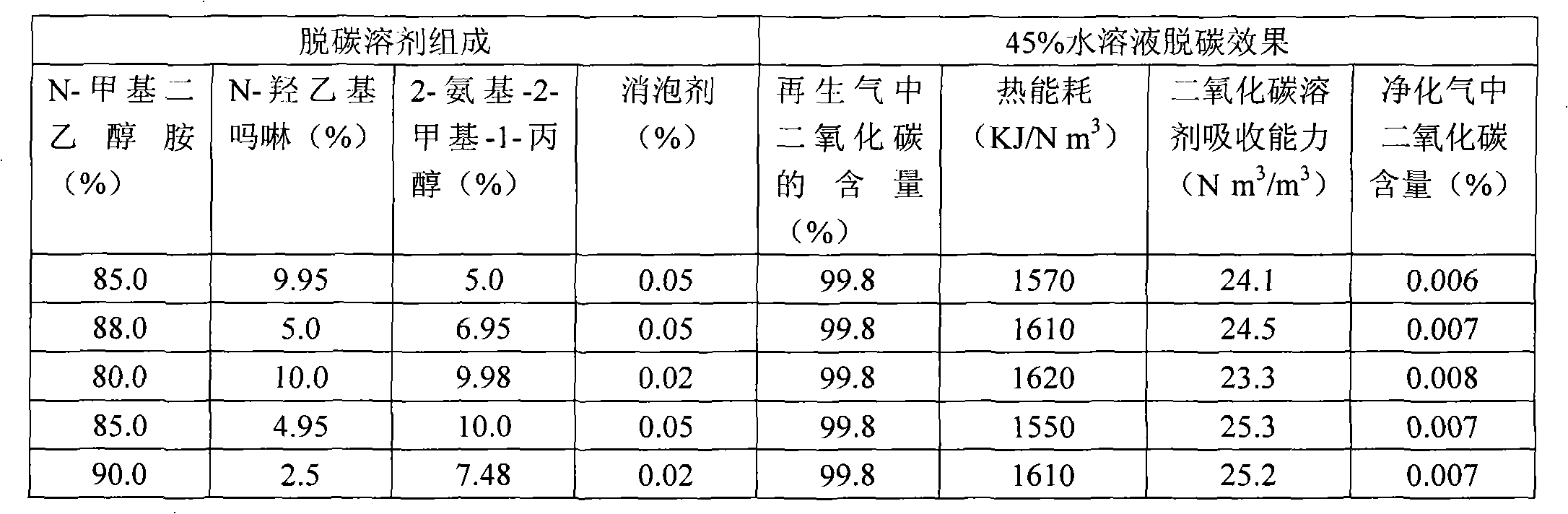

Novel high-efficient compound decarbonization solvent

ActiveCN101816878AHigh boiling pointReduce volatilityProductsCarbon compoundsAbsorption capacityCo2 absorption

The invention discloses a novel high-efficient compound decarbonization solvent which comprises N-methyldiethanolamine and an active agent. The active agent is a mixture which consists of at least two of N-hydroxyethyl morpholine, 2-amino-2-methyl-1-propanol and piperazine, wherein the weight ratio of the N-hydroxyethyl morpholine is 80 to 90 percent; the weight ratio of the active agent is 10 to 20 percent and a defoaming agent is also added into the compound decarbonization solvent. The novel high-efficient compound decarbonization solvent has the advantages of high carbon dioxide absorption capacity, high purification degree, low regeneration energy consumption, and no foams after long-term use of the decarbonization solvent.

Owner:四川精事达科技有限公司

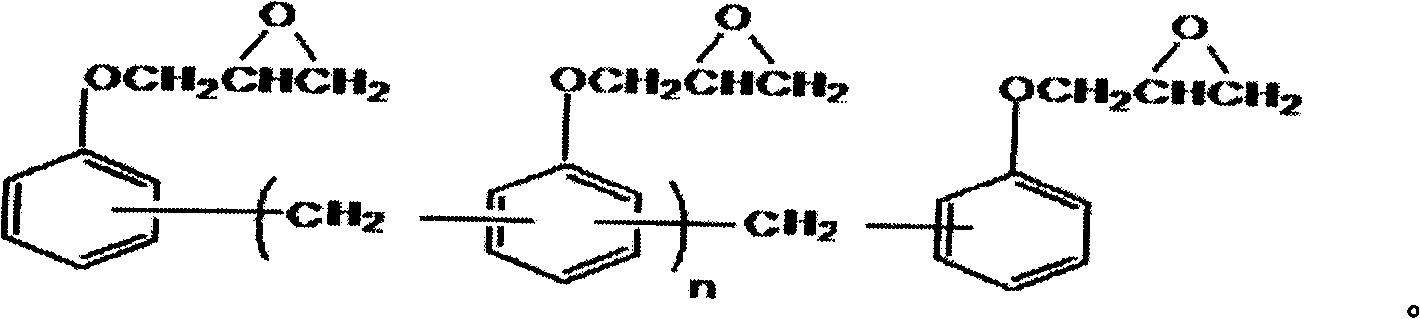

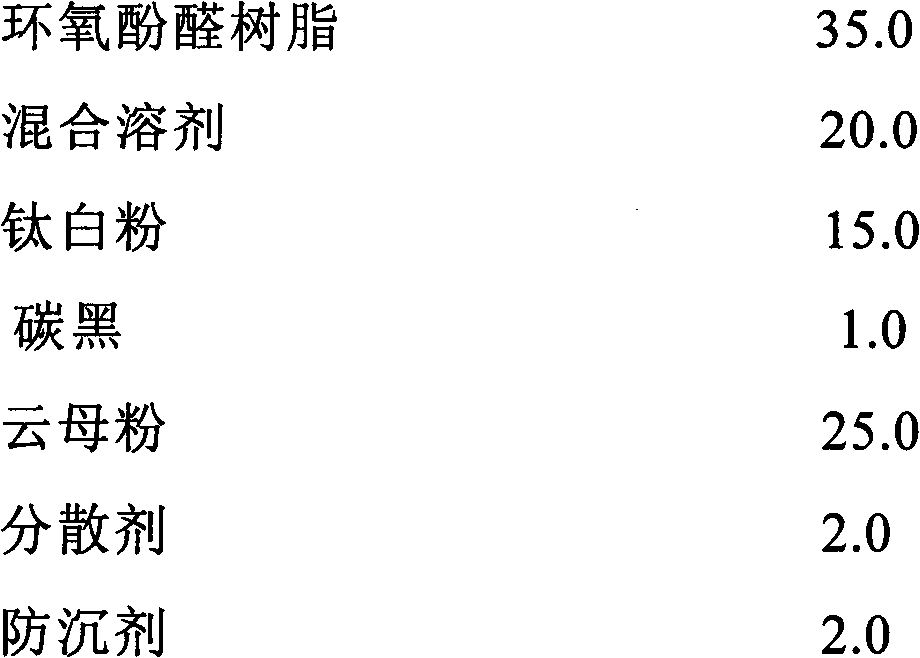

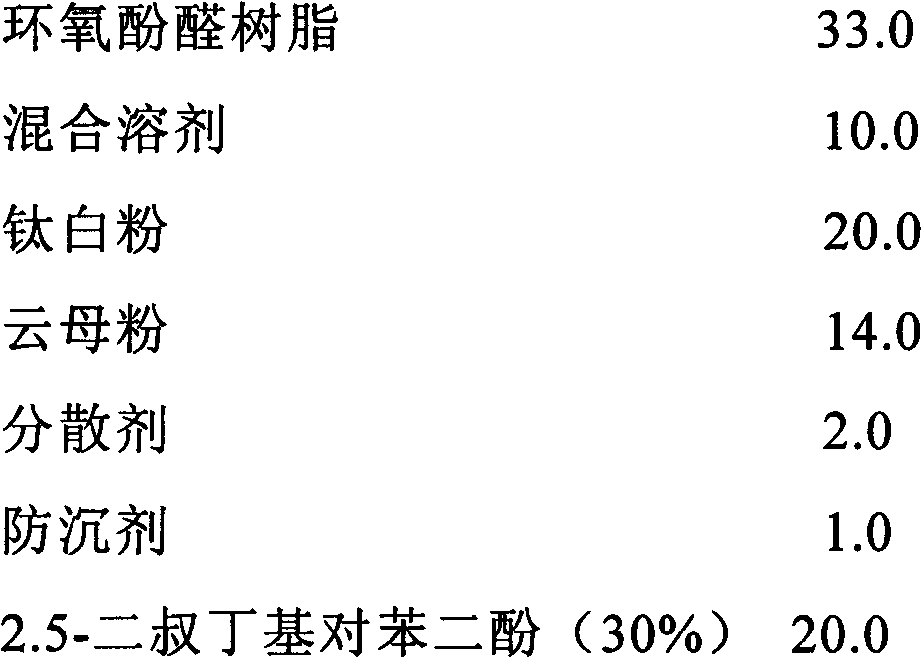

Coating for inner wall of styrene tank

The invention relates to a coating for an inner wall of a styrene tank. The coating consists of a component A and a component B in a weight ratio of 4:1, wherein the component A comprises the following components in part by weight: 30 to 55 parts of epoxy phenolic resin, 10 to 20 parts of mixed solvent, 10 to 30 parts of pigment, 10 to 25 parts of packing, 0 to 20 parts of polymerization inhibitor, 0.5 to 2 pars of dispersing agent and 1 to 3 parts of anti-settling agent; and the component B comprises the following components in part by weight: 15 to 25 parts of epoxy hardener and 1 to 10 parts of n-butyl alcohol. Compared with the prior art, the invention has the advantages that the coating can prevent styrene from gradually automatically agglutinating on the surface of the inner wall of the storage tank, has ideal reaction activity and high crosslinking density and can resist corrosion of benzene, styrene and the like, and a film cannot foam, crack or fall off.

Owner:SHANGHAI DATONG HIGH TECH MATERIALS

Preparation method of silicone resin for adhesion of solvent-free environment-friendly glass fiber

ActiveCN103484057AWill not polluteReduce consumptionNon-macromolecular adhesive additivesGlass fiberPlatinum complex

The invention provides a preparation method of silicone resin for adhesion of solvent-free environment-friendly glass fiber. The preparation method comprises the steps of (1) preparing solvent-free vinyl MDTQ silicone resin; (2) preparing vinyl phenyl silicone oil; (3) adding the vinyl MDTQ silicone resin, the vinyl phenyl silicone oil and precipitation method silicon dioxide into a reaction kettle according to the proportion of (2-4): (5-7): (1-2) in parts by weight, heating to 150-200 DEG C under stirring conditions, performing heat preservation for 2h, cooling and discharging to obtain base glue; (4) taking 100 parts by weight of the base glue, adding 8-6 parts by weight of hydrogen-containing silicone oil with the hydrogen content of 0.2-1%, uniformly stirring, and then packaging to obtain a component A; (5) taking 100 parts by weight of the base glue, adding 0.5-2 parts by weight of platinum complex catalyst, uniformly stirring, and then packaging to obtain a component B. When the A-B dual-component solvent-free silicone resin prepared by the preparation method provided by the invention is coated, organic solvents do not need to be added, the coating efficiency is improved, and the environmental pollution can be avoided.

Owner:襄阳玖润氟硅材料有限公司

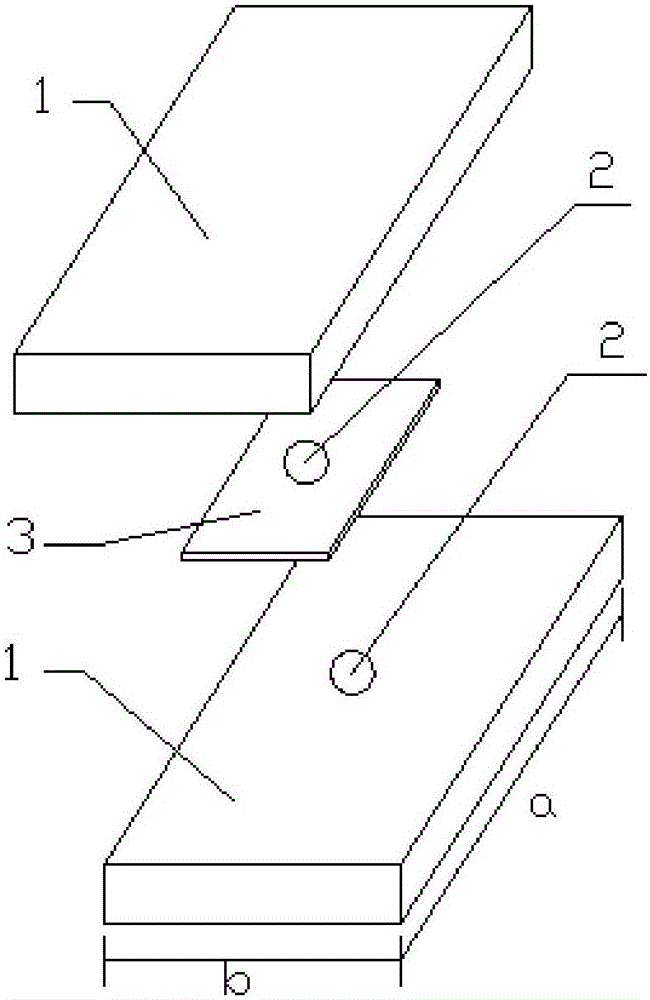

Melamine decorative veneer hot-pressing concavo-convex forming process

InactiveCN102139496ADifficult to fall offAvoid crackingLayered productsWood veneer joiningWater vaporEngineering

The invention provides a melamine decorative veneer hot-pressing concavo-convex forming process. By the process, the problems that compaction degree of the product produced by the process is low, the melamine decorative veneer is easy to drop off, the product is fragile and is susceptible to bending deformation, a base plate generates displacement, and the melamine decorative veneer is bubbled easily caused by water vapor are solved. The process comprises the following steps of: softening the base plate; paving the melamine decorative veneer with double surfaces coated with melamine resin glue on the base plate; placing the base plate on a mould-pressing mould to perform mould pressing, wherein the mould-pressing mould comprises an upper template and a lower template, a convex plate is arranged on the upper template, and a groove is formed on the lower template; placing the base plate, where the melamine decorative veneer is paved, on the lower template of the mould-pressing mould; and settling the upper template to press until the convex plate on the upper template and the groove on the lower template are closed and pressed, so that the base plate with the melamine decorative veneer forms a concavo-convex shape under the action of the convex plate and the groove.

Owner:陈亮

Method for preparing eucommia seed oil by low-temperature cold-pressing technology

InactiveCN103146472AImprove oil yieldAvoid pollutionFatty-oils/fats refiningFatty-oils/fats productionBiotechnologyEngineering

The invention provides a method for preparing eucommia seed oil by a low-temperature cold-pressing technology and purifying high-content a-linolenic acid. The method comprises the following steps of careful selection, husking, drying, metering charging, pressing, filtration, purification, examination and sterilization packaging processes on eucommia fruits. The method is carried out at a normal temperature, guarantees relative stability of active substances such as a-linolenic acid in eucommia seed oil in processing, does not adopt any chemical substances in pressing, effectively avoids the pollution produced by a solvent on eucommia seed oil, adopts a nanofiltration purification technology and improves a-linolenic acid content. The method for extracting eucommia seed is simple, can be realized easily, has a low production cost, low energy consumption and high a-linolenic acid content, and can provide a good raw material for development of foods, health-care foods or medicine products. Various nutrients in slag cake subjected to pressing are not destroyed and produce active effects on further development of eucommia products.

Owner:HANZHONG YONGYANG HI TECH PHARMA CO LTD

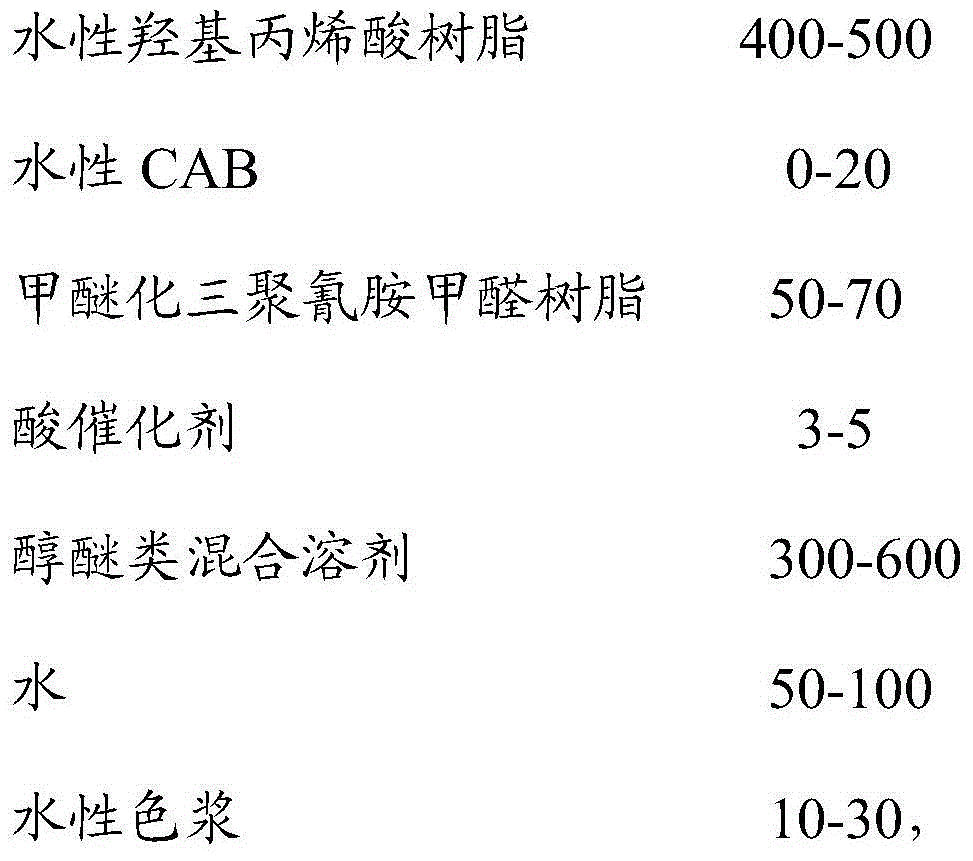

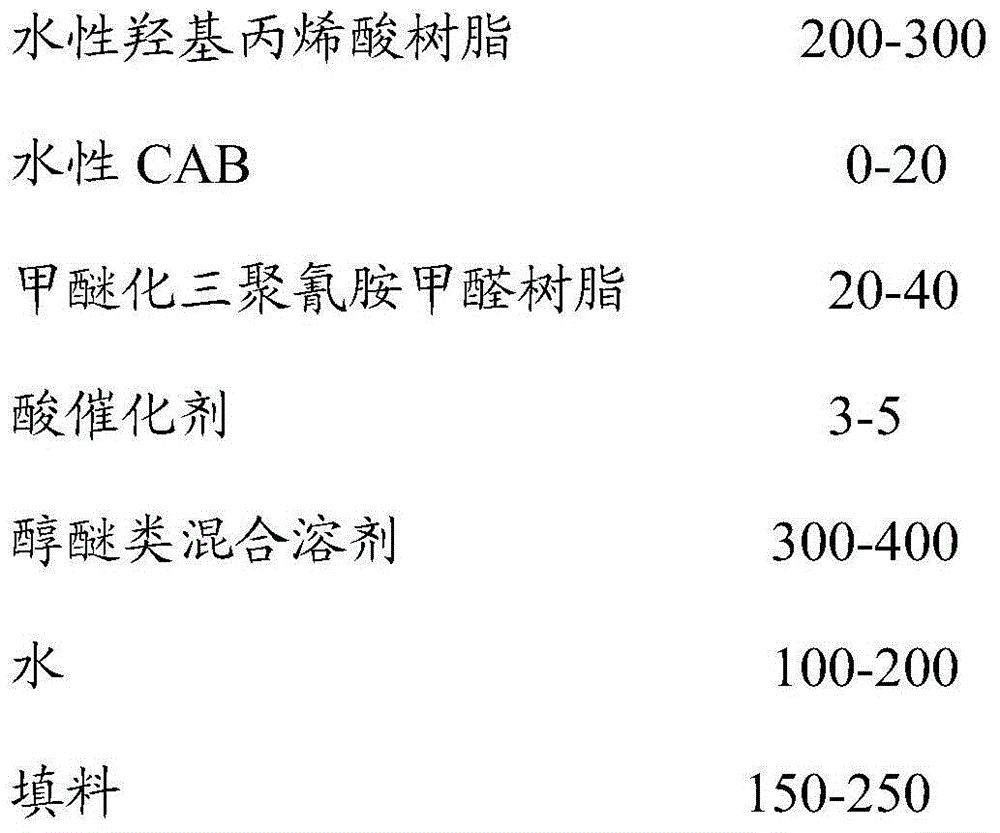

Aqueous crackle paint and coating technology thereof

ActiveCN104130648ASolve the problem of water-basedReduce pollutionPretreated surfacesCoatingsLacquerAcrylic resin

An aqueous crackle paint is prepared by using an aqueous crackle primer, an aqueous crackle finish and an aqueous enamel through a coating technology, the primer and the finish form a crackle shape, and the enamel has color modification and crackle effect finish protection effects. The above three coatings use aqueous acrylic resin as a main body resin of a film and contain methylated melamine formaldehyde resin as a high temperature crosslinking agent, aqueous CAB and parts of an alcoholic solvent are introduced to a formula system in order to achieve an ideal surface drying speed, and fumed silica, talcum powder and other high oil absorbing fillers are used to adjust the critical PVC concentration of the formula system and adjust the shrinkage stress of the film. The coating technology of the aqueous crackle paint comprises the following steps: spring the aqueous crackle primer, carrying out surface drying at normal temperature for 5min, spraying the aqueous crackle finish, carrying out constant temperature treatment at 150DEG C for 20min, spraying the aqueous crackle enamel, and carrying out constant temperature treatment at 150DEG C for 20min to obtain the aqueous crackle paint.

Owner:XINHE NEW MATERIALS CO LTD

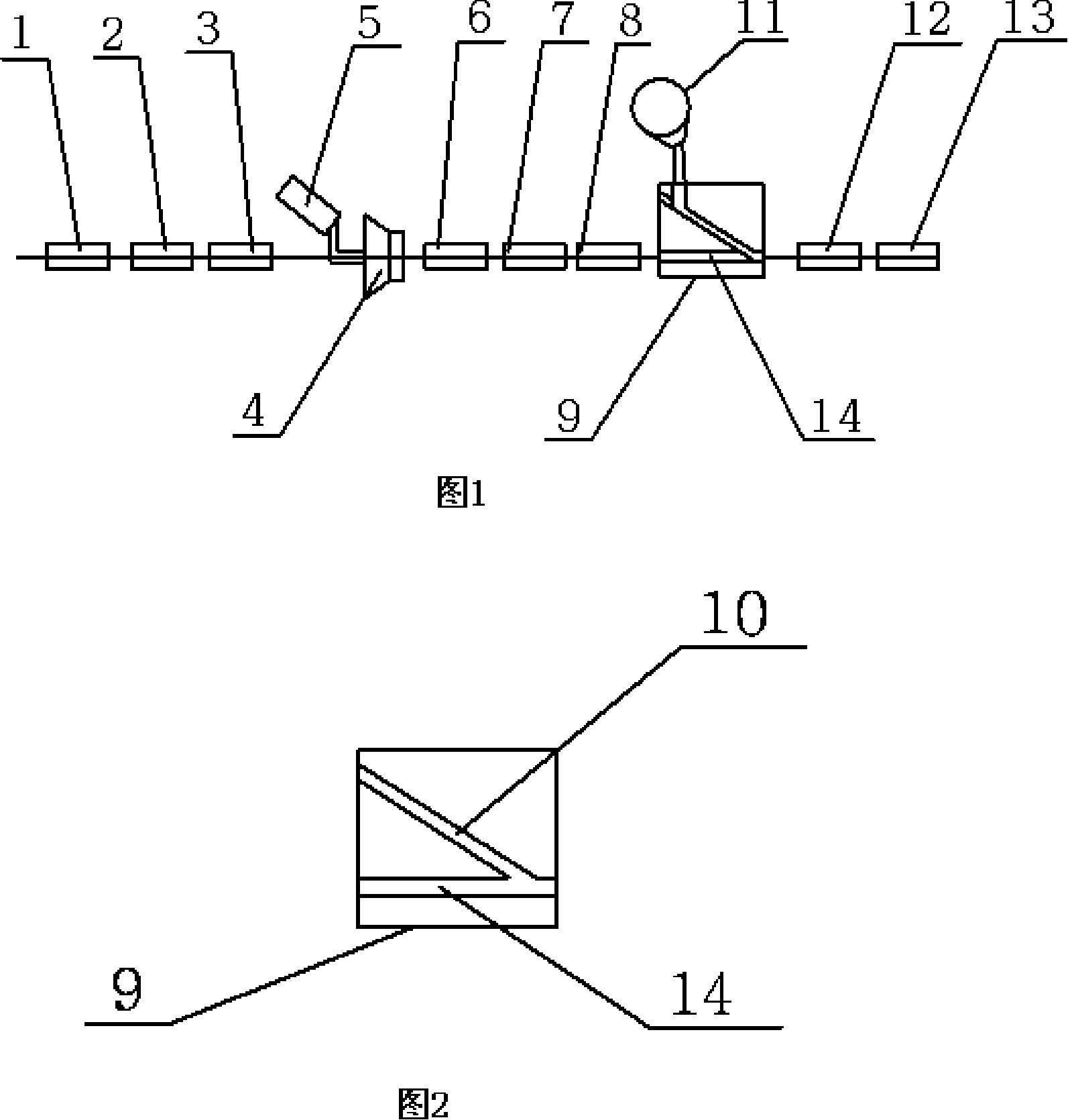

Technology for manufacturing automobile door and window sealing strip

The invention discloses a production process of a stamping steel ribbon for car doors and windows. After the processing and delivering of a steel strip uncoiler, a spot welder and a steel storage rack, the stamping steel ribbon is combined with the ejection of compact from the EPDM extruder in a composite head and then has a processing in a microwave vulcanizing slot and a hot air vulcanizing slot. A traction sends the stamping steel ribbon into a coating mold. The upper side in the coating mold is provided with a tilt flow passage and the lower side in the coating mold is provided with a horizontal flow passage, so as to result in a 15 degree to 45 degree angle between TPE and the composite EPDM of the three stamping ribbon vulcanized. The composite temperature range is from 80 Celsius system to 200 Celsius system. With the processing of a cooling tank and a cutting machine, the stamping steel ribbon with TPE composite layer is produced out. The invention makes the TPE be composite evenly and firmly with the composite EPDM of the three stamping ribbon. The invention has the advantages that the TPE composite layer has no expansion scab, no sparkling, no indentation, a curling stability and a even thickness. The invention is easy to be debugged for operators and has a high reliability, stability and production efficiency.

Owner:天津贵航红阳密封件有限公司

Special epoxy-cotton-oil-containing binding agent for automobile interior ornament surface composite leather

InactiveCN103087655AImprove temperature resistanceComposite effect levelingMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer science(Hydroxyethyl)methacrylate

The invention discloses a special epoxy-cotton-oil-containing binding agent for automobile interior ornament surface composite leather, which is prepared from the following raw materials in parts by weight: 58-62 parts of EVA (ethylene-vinyl acetate), 14-18 parts of octyl phenolic resin 203, 10-12 parts of C5 petroleum resin, 0.5-1 part of WPP polypropylene wax, 5-7 parts of oxidized polyethylene wax, 6-8 parts of modified bamboo charcoal powder, 2-3 parts of rice hull ash, 1-2 parts of nano carbon, 0.8-1.3 parts of silane coupling agent KH550, 0.1-0.2 part of antioxidant 264, 0.8-1.2 parts of antioxidant 3010, 1-2 parts of n-butyl methylacrylate, 0.5-1 part of hydroxyethyl methacrylate, 0.3-0.5 part of dibutyl maleate, 0.3-0.6 part of epoxy cotton oil and 0.1-0.2 part of triethyl citrate. The raw materials for preparing the binding agent contain the modified bamboo charcoal powder, rice hull ash and nano carbon, and thus, the binding agent has the advantages of favorable temperature tolerance and flat composite effect, can not bubble after long-term usage, and is very suitable for automobile interior ornament surface composite leather.

Owner:WUHU ZHONGLI PARTS

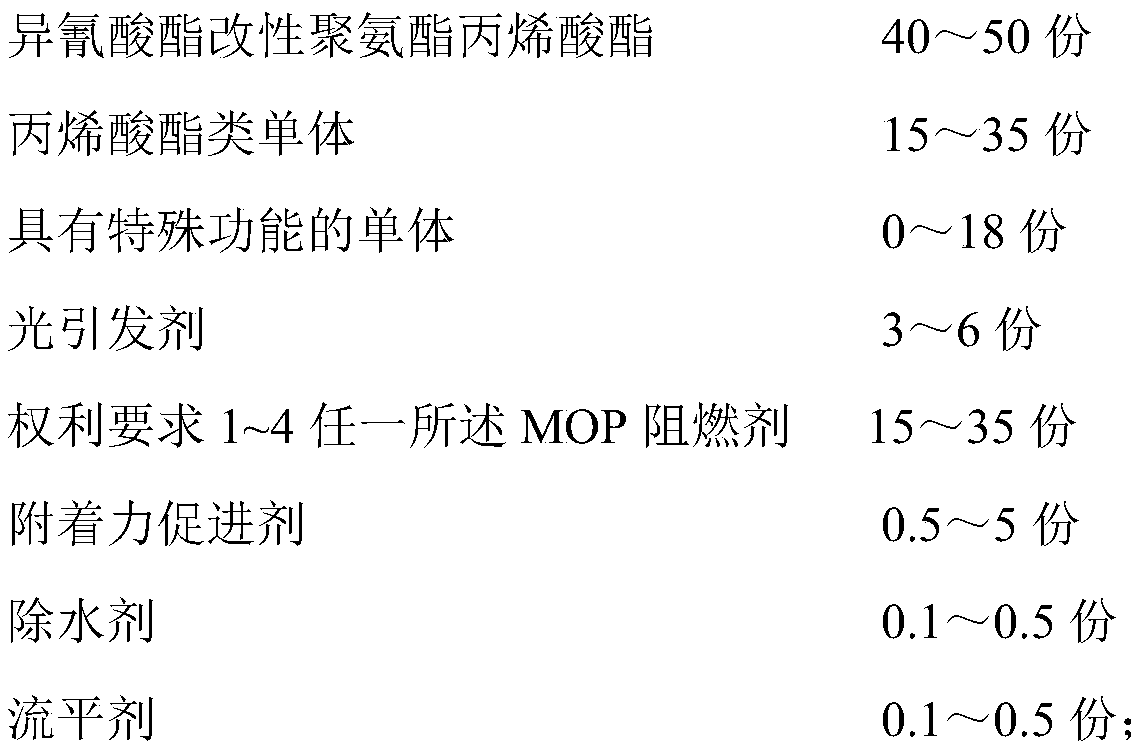

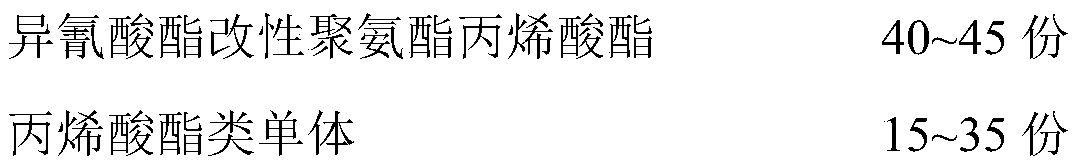

MOP flame retardant, flame-retardant UV/moisture dually-cured conformal coating, and preparation method and application of flame-retardant UV/moisture dually-cured conformal coating

ActiveCN111548726AImprove flame retardant performanceOther performance is not affectedFireproof paintsPolyurea/polyurethane coatingsEndcappingPolymer science

The invention relates to an MOP flame retardant, a flame-retardant UV / moisture dually-cured conformal coating, and a preparation method and application of the flame-retardant UV / moisture dually-curedconformal coating. The MOP flame retardant is obtained through the end-capping reaction of non-halogenated phosphorus polyol and isocyanate acrylate. The MOP flame retardant provided by the inventionis excellent in flame retardant effect and can be used in a UV / moisture cured system; the flame-retardant UV / moisture dually-cured conformal coating provided by the invention has excellent flame retardancy, can be cured by UV and moisture, and has no influence on other properties. Besides, the monomer with a special function is added into the flame-retardant UV / moisture dually-cured conformal coating, so that the viscosity of the conformal coating can be stabilized during long-time placement, the stability of the conformal coating is improved, and the conformal coating does not foam when beingcured.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD

Punching press shaped high sealing tropical type plastic aluminium composite hard sheet and production technology

Owner:刘继福

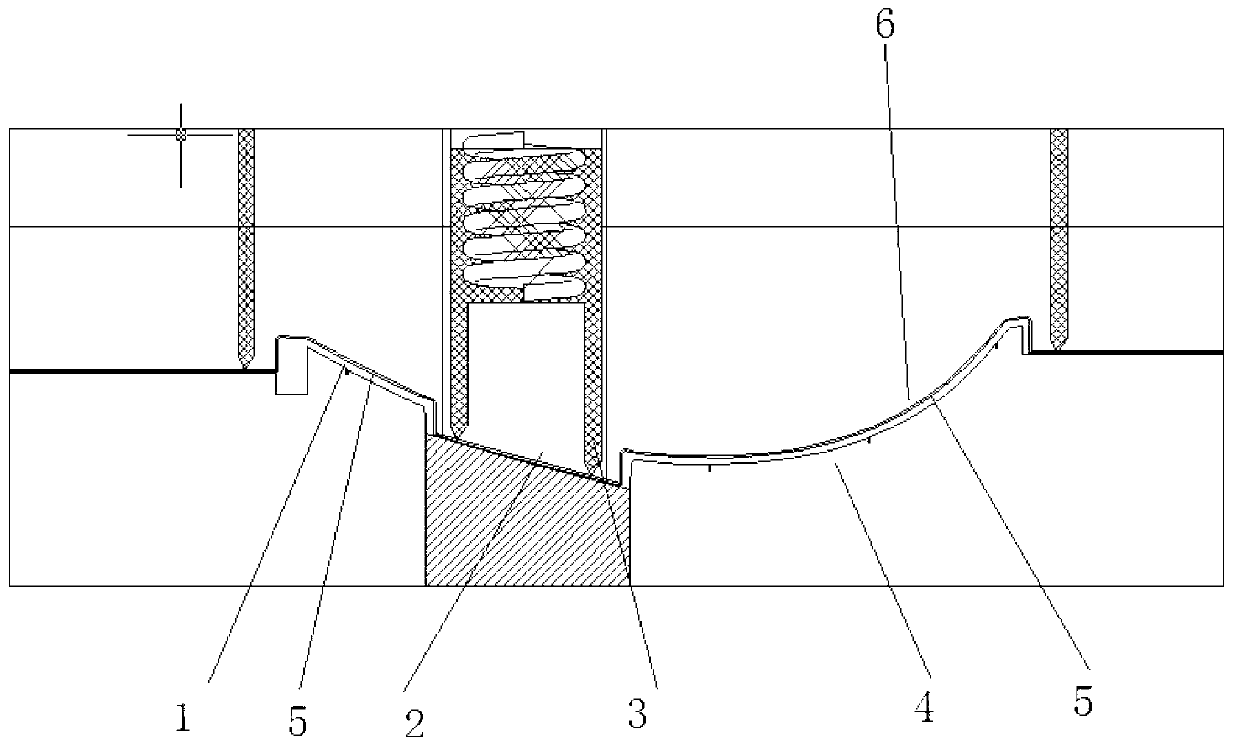

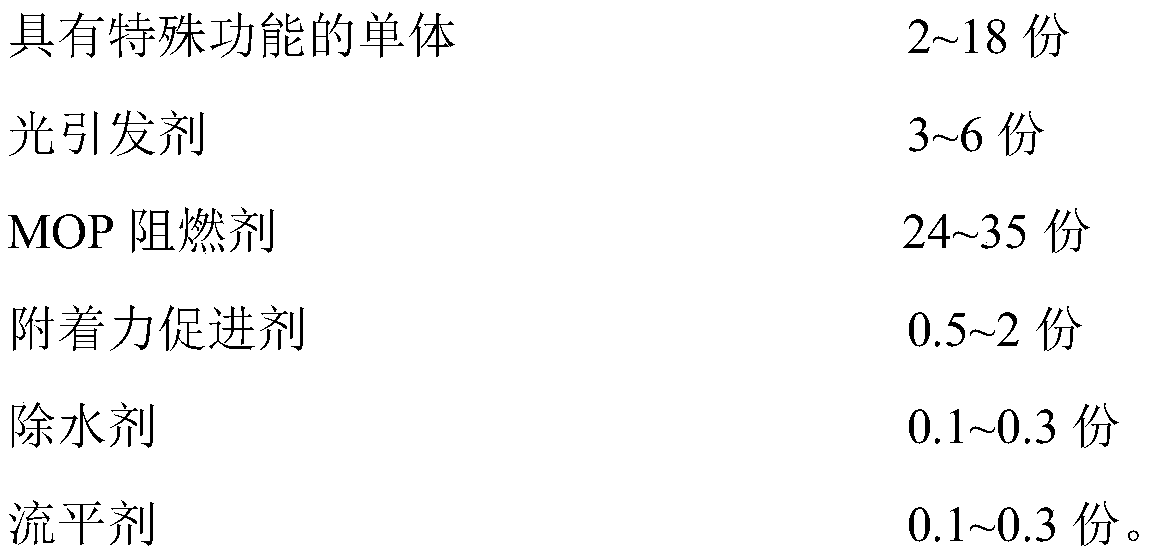

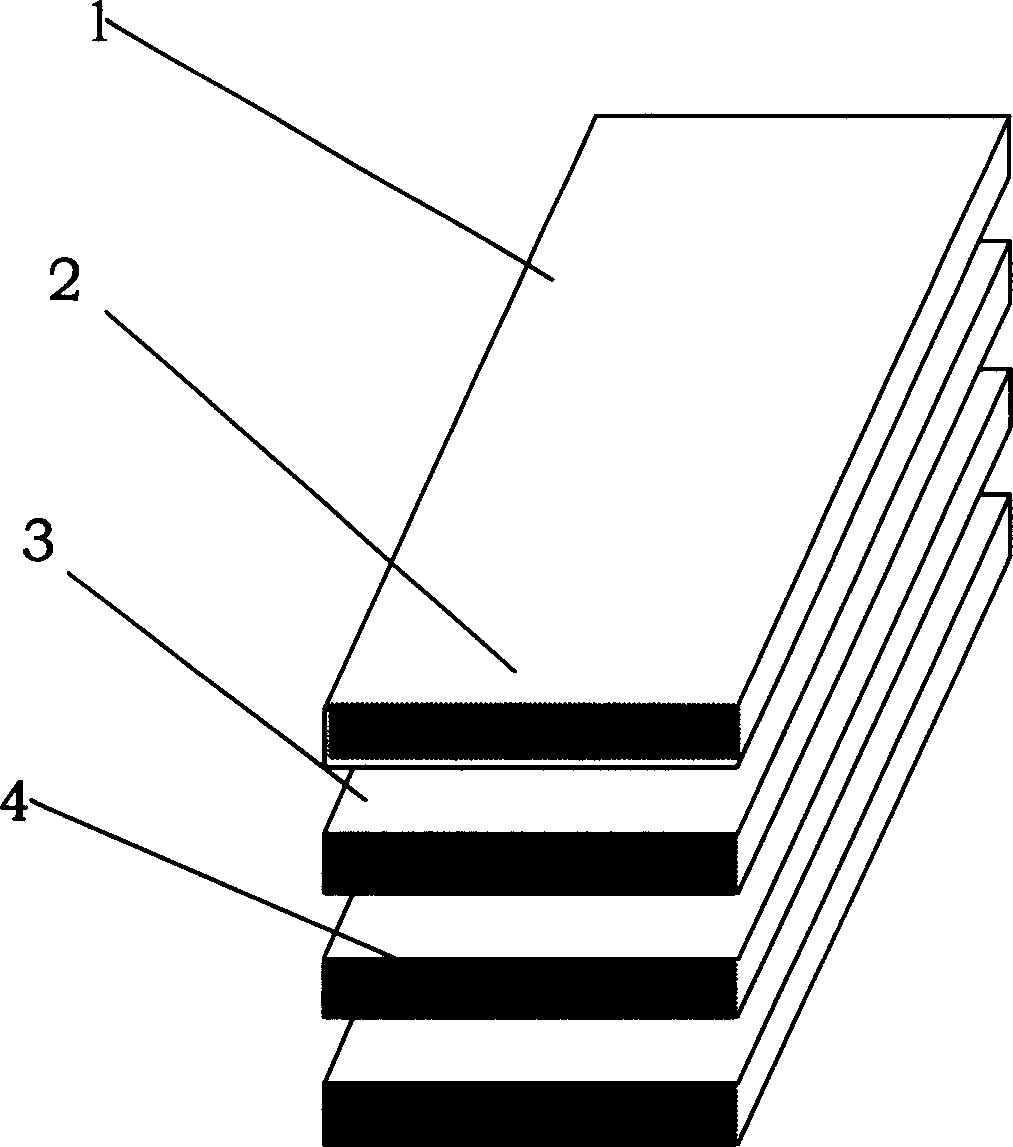

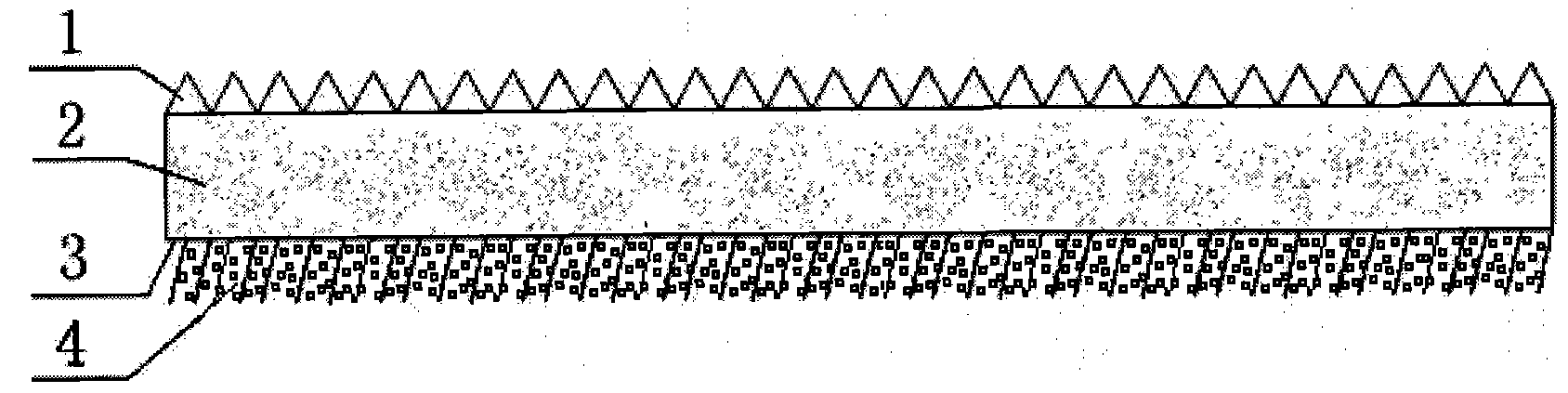

Manufacturing process for cement-base plastic track coiled material

The invention relates to a manufacturing process for a cement-base plastic track coiled material, which comprises the steps of pouring colorful polyurethane elastomer liquid on a silica gel base belt which runs annularly and is provided with convex-concave grains, scraping and filling through a straight-strip-shaped silica gel plate, then sequentially arranging a venting watertight rubber particle coiled material and polymer fiber geotextile coated with polyurethane glue into an oven to be heated and cured, and side cutting, cutting down and coiling to form the plastic track coiled material. The plastic track coiled material is of a three-layer structure, wherein an upper layer is a colorful polyurethane elastomer layer, a middle layer is a rubber particle coiled material layer, and the lower layer is the polymer fiber geotextile. Due to the facts that a surface layer of antiskid colorful polyurethane elastomer is hollowed, and the rubber particle coiled material is venting and watertight, moisture contained in a cement base can escape. Therefore, the plastic track coiled material cannot foam or delaminate and is suitable for cement bases.

Owner:欧阳鹰湘

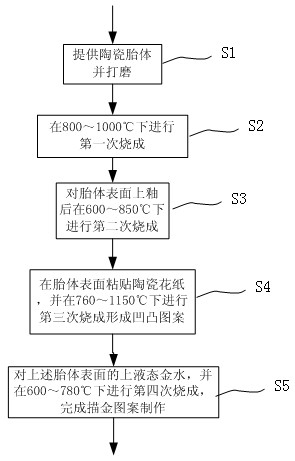

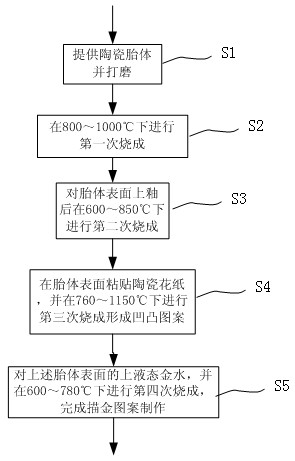

Manufacture method of ceramic wine bottle with liquid gold

The invention discloses a manufacture method of a ceramic wine bottle with liquid gold, which sequentially comprises the following steps of: offering and polishing a ceramic blank body; firstly burning the blank body at the temperature of 800-1000 DEG C to remove the water gas and the organic matter impurity in the blank body; glazing the surface of the blank body; secondarily burning at the temperature of 1180-1320 DEG C; offering a ceramic stained paper with concave-convex patterns, adhering the ceramic stained paper on the surface of the blank body, thirdly burning at the temperature of 760-1150 DEG C, and removing an adhesive film in a baking way to lead the ceramic stained paper to be completely adhered to the surface of the blank body to form into the concave-convex pattern; and spraying the liquid gold on the surface of the blank body, fourthly burning at the temperature of 600-700 DEG C to manufacture the pattern with the liquid gold. By repeatedly burning and controlling the burning temperature, the manufacture method of the ceramic wine bottle with the liquid gold can form into colorful, hierarchical and abundant liquid gold patterns at the outer surface of the whole ceramic wine bottle, and avoiding foaming, discoloring and cracking.

Owner:SHANGHAI GAOCHENG CREATIVE TECH GRP

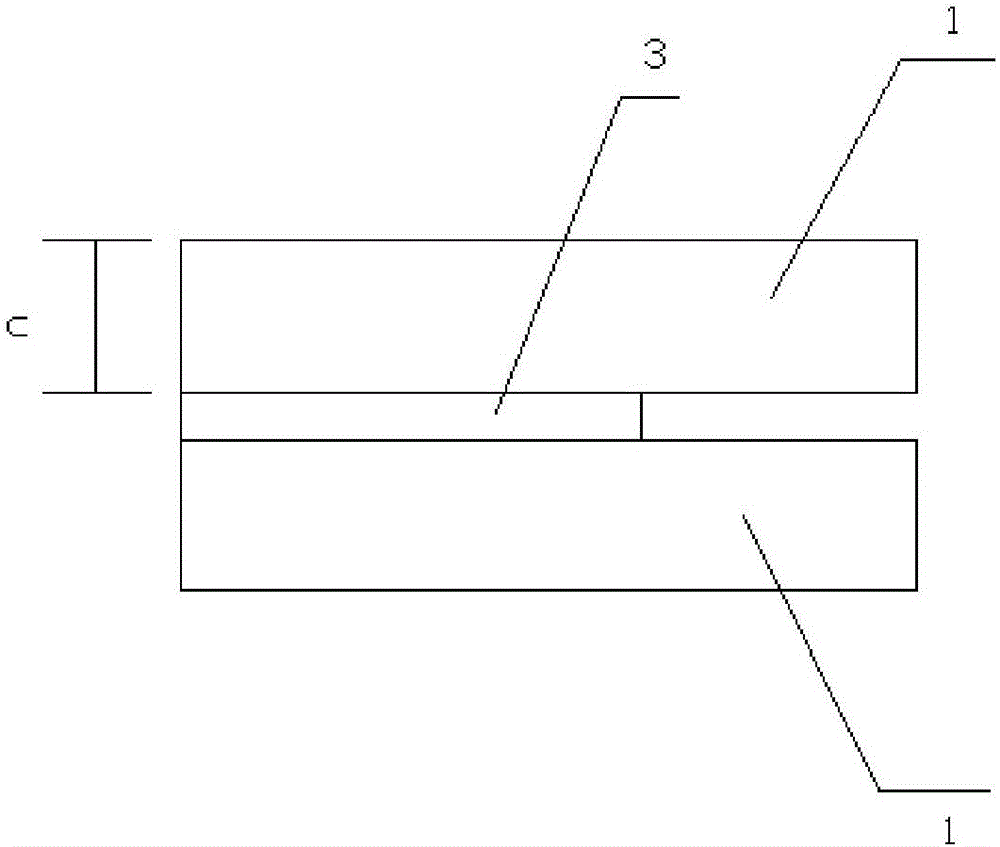

Cross-section making method

InactiveCN106546459AIncrease success rateShort timePreparing sample for investigationAdhesiveEngineering

The invention relates to a cross-section making method. The method particularly comprises the following steps that 1, two organic glass plates of a cuboid structure are prepared, and 502 glue is prepared to serve as an adhesive; 2, a measured object is taken as a sample; 3, one piece of organic glass plate is placed on an operating platform, and the adhesive is dropwise added to the center of the organic glass for the first time; 4, the measured object is placed on the organic glass on which the adhesive is dropwise added; 5, the adhesive is dropwise added to the measured object for the second time; 6, the other piece of organic glass is placed on the measured object in a press-fit mode, and the two pieces of organic glass are adhered into a whole to form an initial blank of a section; 7, the initial blank of the section is ground till the observation position is ground. According to the cross-section making method, the time of the whole process is greatly shortened, the making cost is greatly reduced, bubbling cannot be generated, and the section success rate is high.

Owner:江苏弘信华印电路科技有限公司

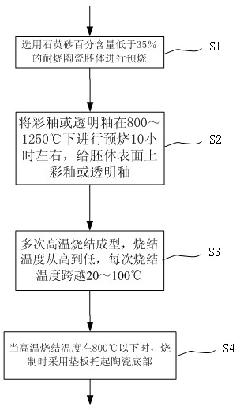

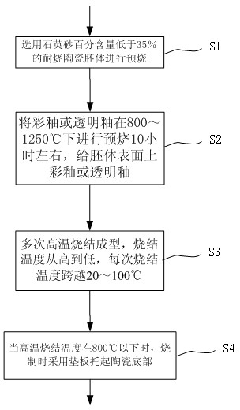

Multi-temperature sintering method for ceramic

The invention discloses a multi-temperature sintering method for ceramic. The method comprises the steps: pre-sintering a ceramic blank body, and coating colour ceramic glaze or transparent glaze on the surface of the blank body; and carrying out multi-high-temperature sintering molding, wherein the percentage content of quartz sand in the ceramic blank body is less than 35%, the colour ceramic glaze or transparent glaze is pre-fired for about 10 hours at the temperature of 800-1250 DEG C; during the multi-high-temperature sintering molding, from high to low, sintering temperature spans over 20-100 DEG C each time. In the multi-temperature sintering method for the ceramic, the blank material with low quartz sand percentage content is used, the calcined colour ceramic glaze or transparent glaze is coated on the surface of the blank body, and multi-high-temperature sintering temperature is controlled, and finally, a decorative ceramic pattern with diverse color levels and bright gloss is formed, and the decorative ceramic pattern does not has the problems of foaming, decoloring and cracking.

Owner:SHANGHAI GAOCHENG CREATIVE TECH GRP

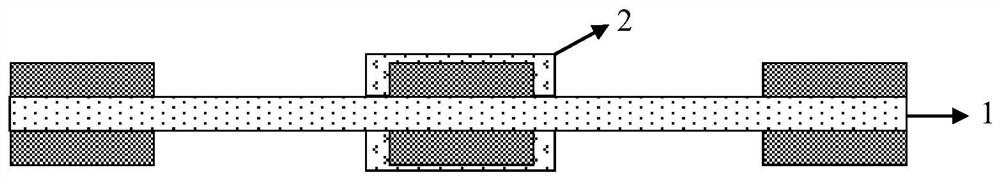

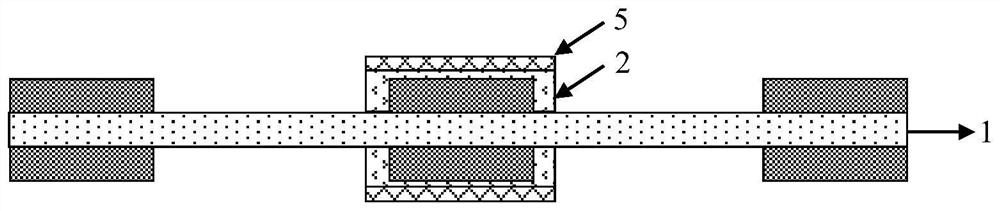

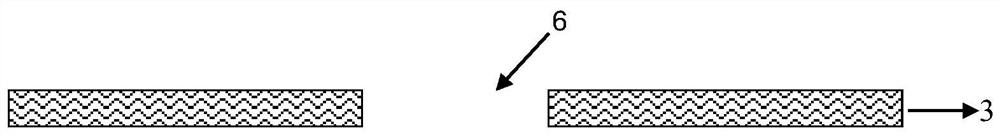

Processing method for resin hole plugging of rigid-flex board of ultrathin printed circuit

PendingCN112672510AWon't foamPrinted circuit detailsConductive material chemical/electrolytical removalPolymer scienceCopper foil

The invention relates to a processing method for resin hole plugging of a rigid-flex board of an ultrathin printed circuit. According to the invention, cover films are attached to the bent parts of the upper surface layer and the lower surface layer of a flexible board, and a PFG protective film and pure glue which are pre-pressed together are attached to the cover films; then windowing treatment is carried out on the bent parts of the flexible board; then a copper foil, a prepreg, the flexible board, another prepreg and another copper foil are laminated in sequence from bottom to top; a layer of an RP190 auxiliary buffer pressing material is added to the each of the upper layer and the lower layer of the obtained laminated board, and then pressing is conducted so as to obtain a semi-finished product of the rigid-flex board; and the prepared ultrathin board can be subjected to a resin hole plugging process. Since the PFG protective film and the copper foil are bonded by pure glue carried in the bending area of the flexible board, so the copper foil in the flexible area does not foam during baking, the semi-finished product production of uncovering after resin hole plugging of the rigid-flex board combined board is completed, uncovering can be directly conducted before uncovering, the problem that copper foams in a baking flexible board area are poor after resin hole plugging in the prior art can be solved, product yield is increased, and production cost is reduced.

Owner:GULTECH WUXI ELECTRONICS CO LTD

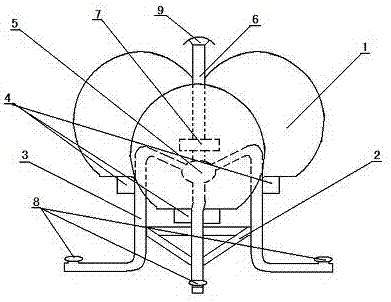

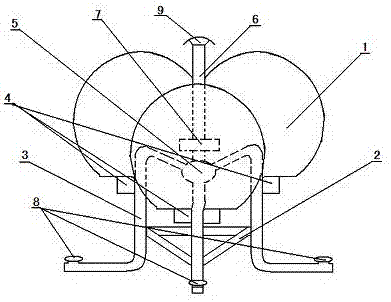

Ball float type aerator for fishpond

The invention discloses a ball float type aerator for a fishpond. The aerator is composed of three float balls, a triangular bracket, three air outlet pipelines, a gas buffering spherical channel, anair inlet pipeline and an air pump, wherein the three air outlet pipelines made from stainless steel are fixed together by virtue of the triangular bracket; counter weights are respectively arranged on the three float balls; the air inlet pipeline is connected with the air pump; the air pump is communicated with the gas buffering spherical channel by virtue of a pipeline; and the gas buffering spherical channel is communicated with the three air outlet pipelines. Due to aeration of the float ball in an equal distance, even if it is stormy, the balls float stably; due to the design of the gas buffering spherical channel, the floating state is static (without external force) in the air pump operating process; due to adjustment of the counter weights, stress of the float balls is kept uniform, and the float balls are prevented from turning over due to the external force; due to a bubble ball, oxygen pumped into water is uniformly dispersed, and bubbles are not produced on the water surface; and the air pump is connected with a sealed speed regulation and control module, so that the oxygen inlet amount is remotely controlled, and excessive aeration is avoided.

Owner:钱光芸

Method for laminating woven shell fabric to surface of interior trim part of automobile roof plate

ActiveCN103144400AImprove efficiencyHigh bonding strengthMineral oil hydrocarbon copolymer adhesivesLamination ancillary operationsMicrocrystalline waxMethyl carbonate

The invention relates to a method for laminating a woven shell fabric to the surface of an interior trim part of an automobile roof plate. The method comprises the steps of: spraying a binder to the surface of the interior trim part where the woven shell fabric is required for being laminated, and then, laminating the woven shell fabric, wherein the binder is prepared from the following raw materials in parts by weight: 50-55 parts of EVA (Ethylene Vinylacetate), 5-7 parts of pentalyn, 1-2 parts of dimethyl carbonate, 15-20 parts of terpene resin, 20-25 parts of petroleum resin C5, 3-5 parts of microcrystalline wax, 1-2 parts of styrene, 1-2 parts of polyethylene glycol adipate, 0.3-0.5 part of chlorinated polyethylene, 0.2-0.3 part of N-2-(aminoethyl)-3-aminopropyl trimethoxysilane, 2-3 parts of polyisobutylene, 1-2 parts of calcium carbonate, 3-5 parts of modified nano potassium feldspar powder, 1-2 parts of wood ash, 0.5-1 part of ferrocene, 1-2 parts of antioxidant 168, 0.3-0.8 part of antioxidant 1076 and 1-2 parts of silane coupling agent kh5501. According to the method, a die pressing process is adopted, the edge cutting is automatic, and the efficiency is high; and meanwhile, the specific binder is adopted, so that the binding is high in strength and is flat, and the bubbling cannot occur during long-term use.

Owner:如皋市金轶纺织有限公司

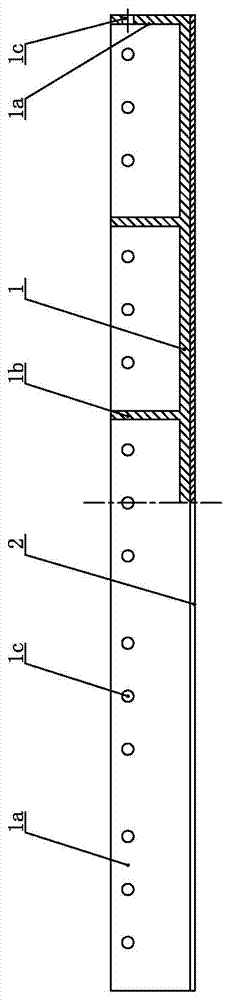

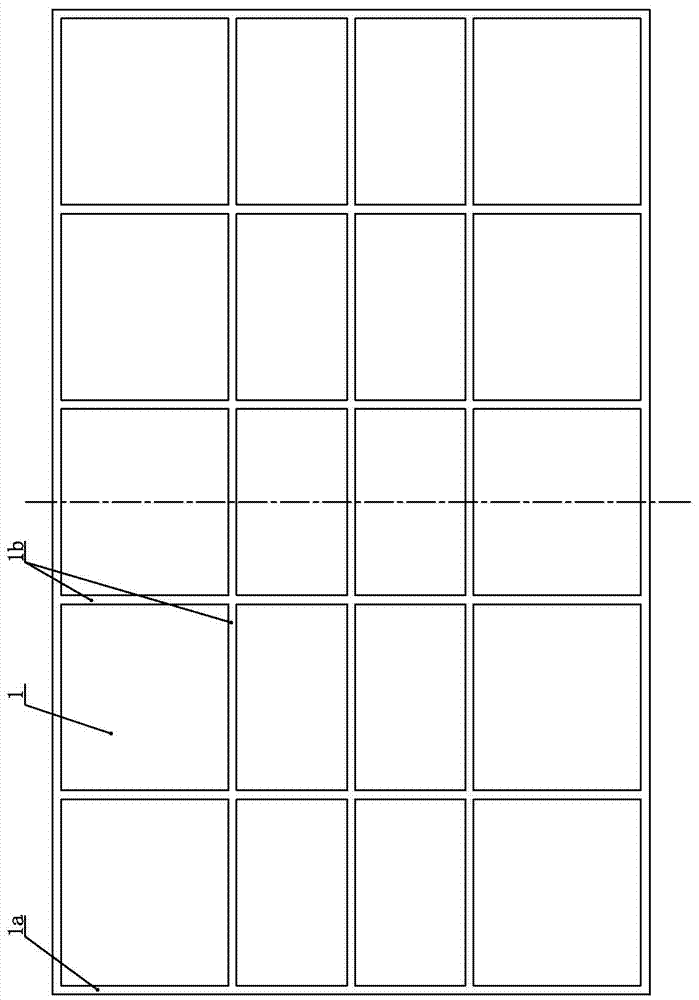

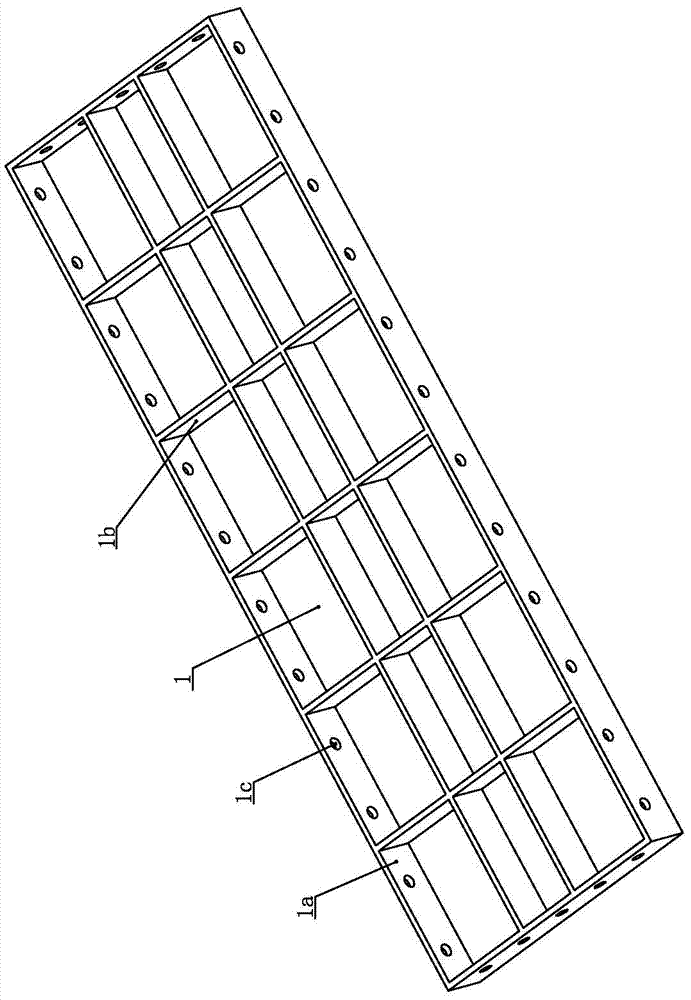

Composite type building framework and manufacturing method thereof

ActiveCN107060318AGuaranteed isolation effectPlay the role of isolationFlat articlesForming/stuttering elementsGlass fiberEngineering

The invention discloses a composite type building framework and a manufacturing method thereof. The composite type building framework comprises a plastic framework base material. A PP composite layer sheet is connected with a working face of the plastic framework base material in a hot mode, the PP composite layer sheet comprises a non-woven layer, a PP mixture laminated layer and a pure PP film layer which are connected into a whole part, and the pure PP film layer is connected with the upper surface of the PP mixture laminated layer in a hot mode; and the non-woven layer is connected with the lower surface of the PP mixture laminated layer in a hot mode, and the non-woven layer faces to the working face of the plastic framework base material and is connected with the working face of the plastic framework base material together in a hot mode. Firstly PP particles are extruded and melted, the PP particles are mixed with 30-50 mm fiberglass evenly to be co-extruded and enter a thermal insulated cylinder to be stored temporarily, then quantitative extrusion is conducted to fall on the PP composite layer sheet located at the bottom of a lower mould and a parison is formed after an upper mould and a lower mould are assembled, pressure-maintained and cooled; vertical walls extending upwards are arranged on the periphery of the parison, a rib plate is arranged on the upper end surface, and a composite type building framework finished product is formed after the upper mould is pressure-released and backhauled, and the parison breaks away from the upper mould and is deburred. The composite type building framework can be used repeatedly, is low in construction cost, and does not stick with concrete.

Owner:YANGZHOU SAICHUANG NEW MATERIAL TECH

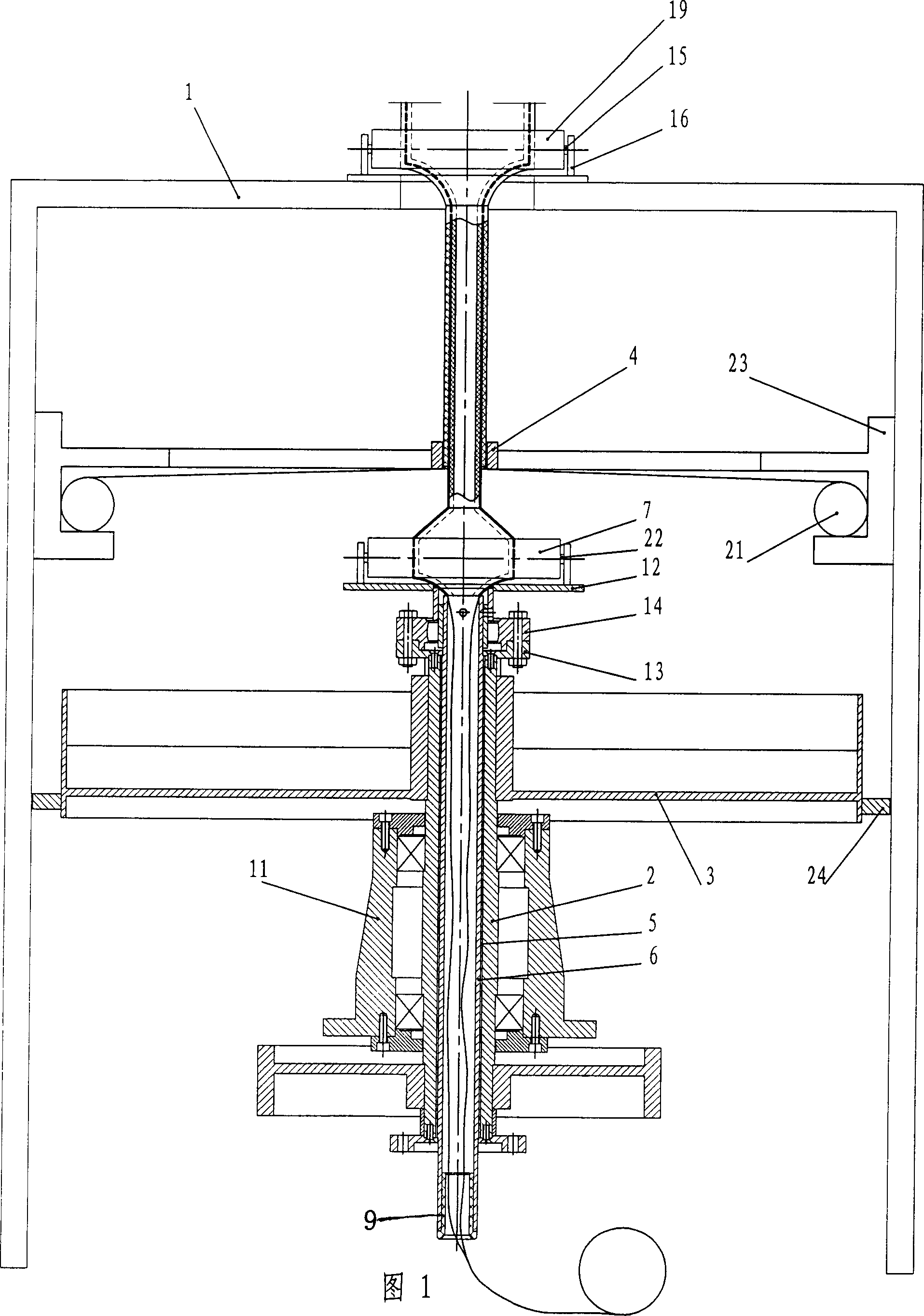

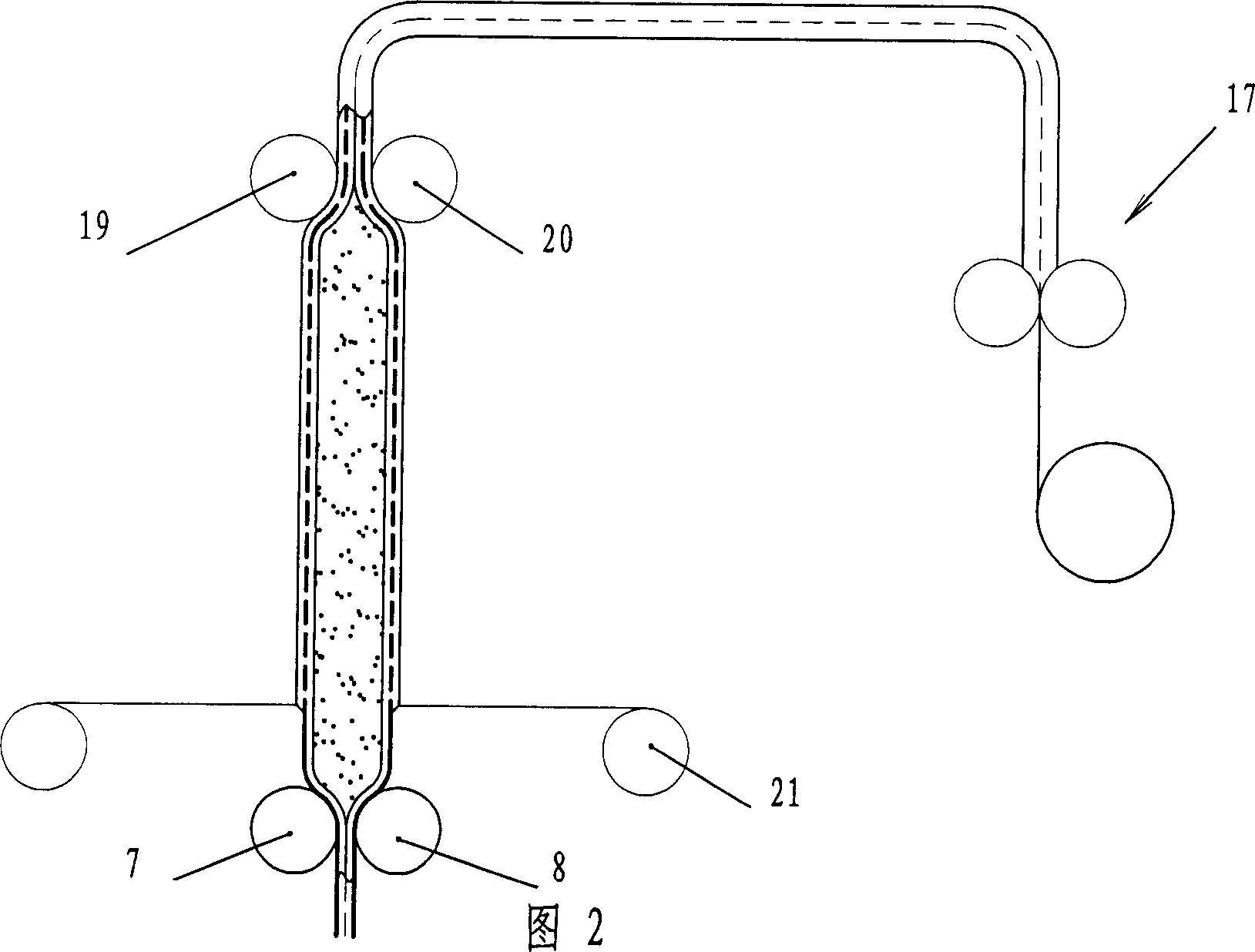

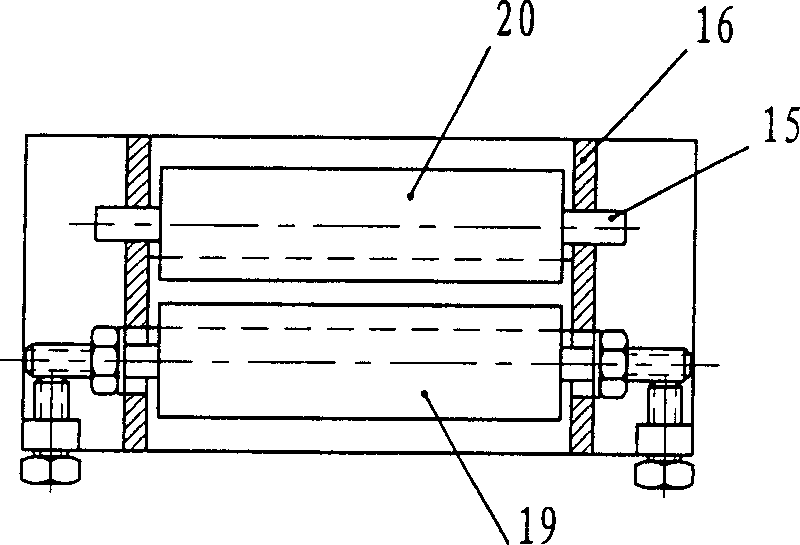

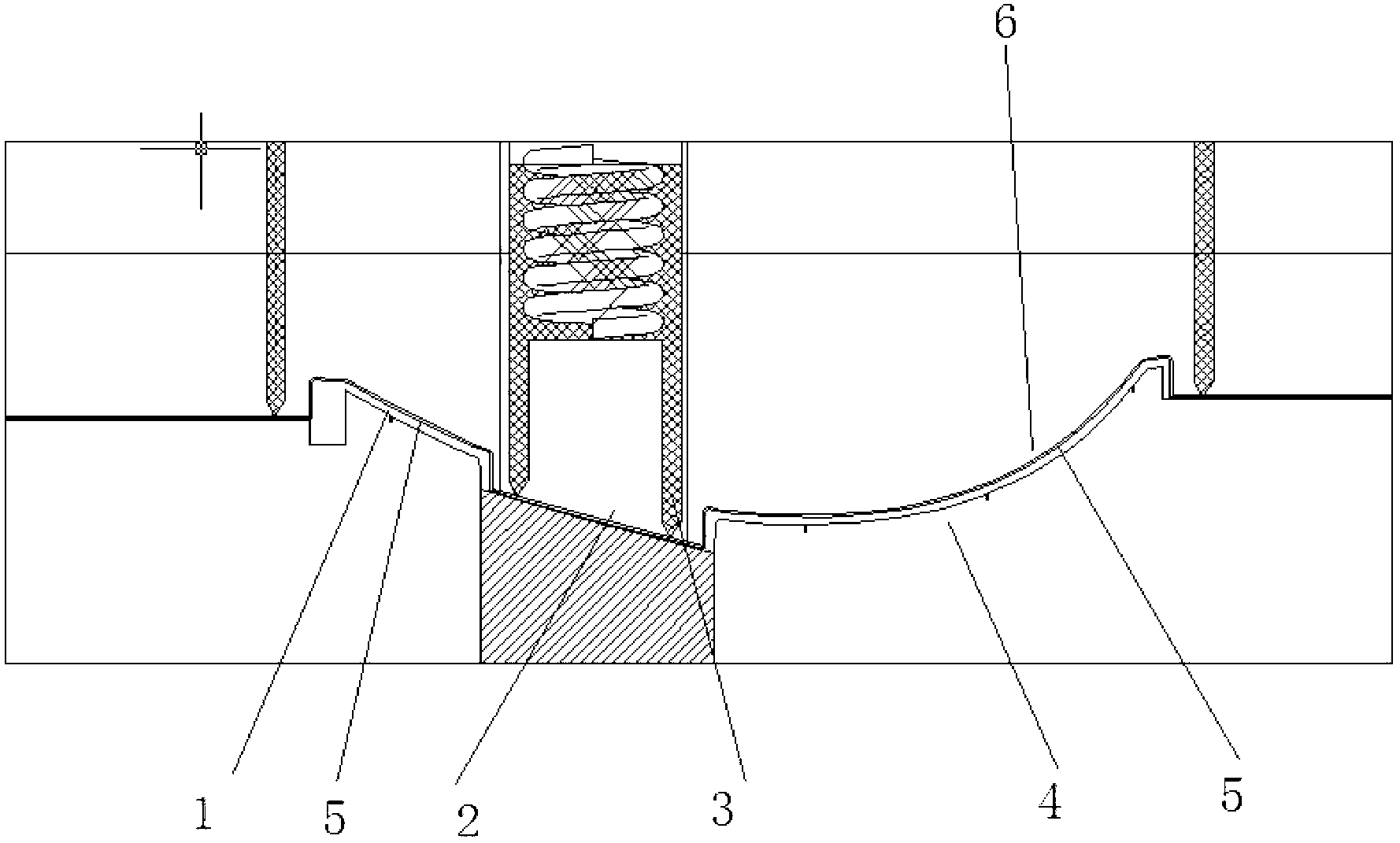

Round loom for producing inner external wall film coated water delivery flexible pipes

The invention comprises a frame, a vertical shaft in the centre of the frame, a cam disc sleeved in the upper part of the vertical shaft, several rollers mounted on the rail of the cam disc and a measurement ring disposed above the vertical shaft. The measurement ring is mounted on the frame through at least one connecting-rod. A through-hole is disposed in the vertical shaft, and in the through-hole is disposed a double-pipe. Above the double-pipe are disposed two air-extruding rollers, between which there is an adjustable gap. Above the measurement ring are disposed two hose-lifting rollers, between which there is an adjustable gap.

Owner:罗衍宾

Method for compositing leather on surface of bonder used by car door interior parts and containing modified diatomite

ActiveCN103171232AImprove efficiencyHigh bonding strengthMineral oil hydrocarbon copolymer adhesivesLamination ancillary operationsEpoxyMicrocrystalline wax

The invention provides a method for compositing leather on the surface of a bonder used by car door interior parts and containing modified diatomite. The method is characterized by spraying the bonder on the interior part surface needing leather compositing and then composting leather, wherein the bonder is prepared from the following raw materials in parts by weight: 57-62 parts of EVA (ethylene-vinyl acetate copolymer), 8-12 parts of epoxy resin, 12-16 parts of C5 petroleum resin, 3-5 parts of microcrystalline wax, 0.5-1 part of WPP type polypropylene wax, 1-2 parts of dimethyl carbonate, 2-4 parts of nanometer celestite powder, 7-10 parts of modified diatomite, 2-3 parts of modified rice hull ash, 1.3-1.6 parts of a silane coupling agent KH560, 0.2-0.4 part of ferrocene, 0.3-0.6 part of n-butyl methacrylate, 0.4-0.6 part of epoxidized soybean oil, 0.4-0.6 part of an antioxidant 264, 0.2-0.4 part of an antioxidant 616 and 0.2-0.4 part of an antioxidant 333. The method has the beneficial effects that the method adopts a molding process, achieves automatic trimming and is high in efficiency; and meanwhile, the specific bonder is adopted, has high bonding strength, is flat and can not bubble after being used for a long time.

Owner:TAIZHOU JINSONG

Vinyl acetate-acrylate copolymer emulsion, its synthesis method and application

ActiveCN103059211BLow coating viscosityHigh bonding strengthMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesSodium bisulfateSodium acid carbonate

Owner:CHINA PETROCHEMICAL CORP +2

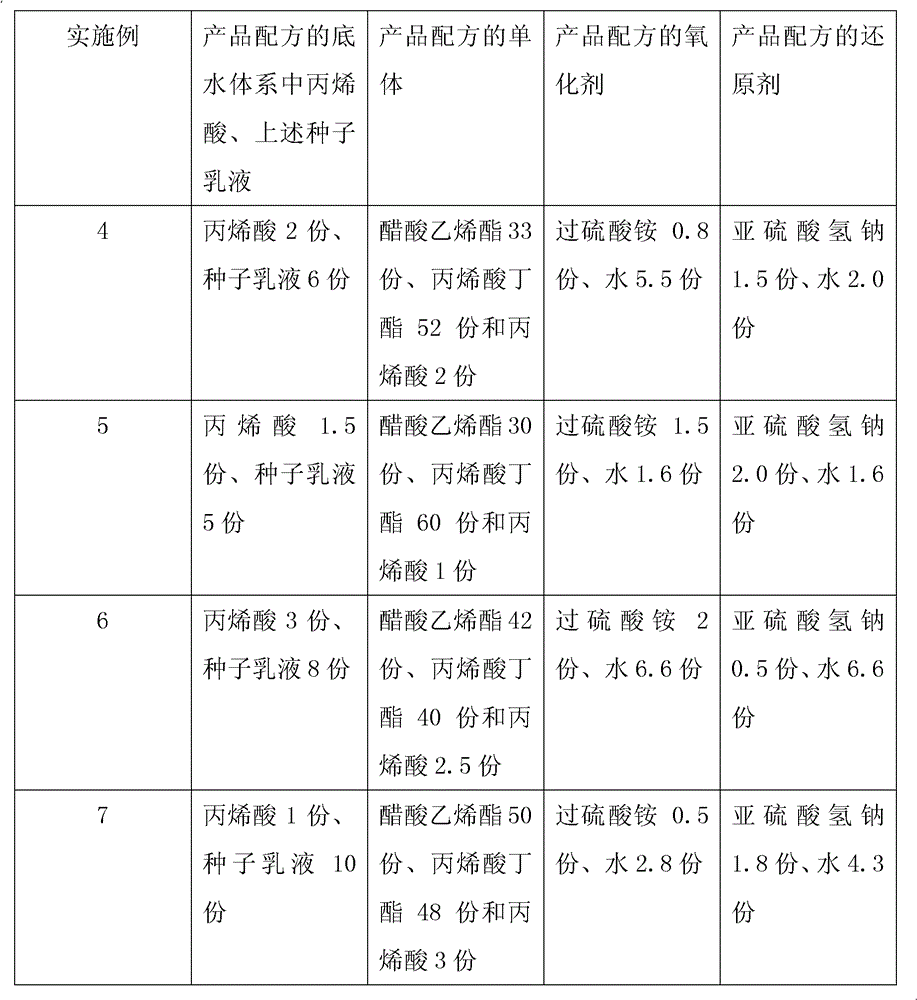

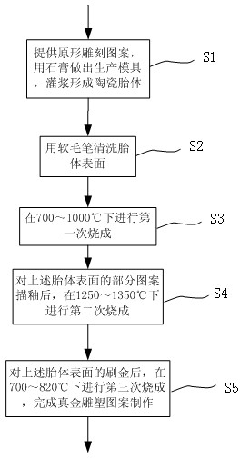

Golden sculpture method for wine bottle

The invention discloses a golden sculpture method for a wine bottle. The method successively comprises the following steps: providing an original sculpture pattern, making a production mould with gypsum, and grouting so as to form a ceramic body; washing the surface of the ceramic body with a soft brush; sintering the ceramic body at the temperature of 700-1000 DEG C for the first time for removing water steam and organic impurities out of the ceramic body so as to increase the surface strength of the ceramic body; coating glaze on partial patterns on the surface of the ceramic body, and then sintering the ceramic body at the temperature of 1250-1350 DEG C for the second time; and after brushing gold on the surface of the ceramic body, sintering the ceramic body at the temperature of 700-820 DEG C for the third time to complete the manufacturing of the golden sculpture pattern. In the golden sculpture method for the wine bottle, glaze coating is used for replacing traditional glaze spraying, gold coating is used for replacing traditional gold spraying, and finally the golden sculpture pattern with diverse color levels, and no defects of foaming, decoloring and crazing can be obtained by carrying multiple sintering processes and controlling sintering temperature.

Owner:SHANGHAI GAOCHENG CREATIVE TECH GRP

Semi-rigid PVC (polyvinyl chloride) decorative membrane

The invention relates to a semi-rigid PVC (polyvinyl chloride) decorative membrane. The semi-rigid PVC decorative membrane comprises the following main raw materials in parts by weight: 100 parts of PVC resin powder, 18-23 parts of plasticizer, 3-5 parts of stabilizer, 25-35 parts of calcium carbonate, 4-6 parts of flame retardant, 6-9 parts of titanium white, 2-4 parts of soybean oil and 0.1-0.3 part of mold preventive; and the semi-rigid PVC decorative membrane is prepared through a calendering stage and an intaglio printing stage. The product provided by the invention is thin and semi-rigid, can not bubble in case of being laminated with glass and other materials, and can prevent broken glass from splashing and falling when the glass is broken; the addition of the flame retardant and the mold preventive endows the product with high-efficiency flame-retardant and mold-resistant properties, and the flame-retardant property and the mold-resistant property can be respectively up to B1 level and 0 level; and the product has long color retention time and long service life, and can soften bright light, partition space, enhance privacy and create a mild atmosphere.

Owner:ZHEJIANG BOTAI PLASTIC

Super silica PU and preparation method thereof

InactiveCN104004356AShorten construction timeWon't foamGround pavingsCoatingsSuspending AgentsSilica gel

The invention discloses super silica PU, comprising the following components by mass: 4 to 6% of a rubber vulcanizing agent, 20 to 30% of silica gel, 1 to 2% of an antioxidant, 1 to 2% of a mildew inhibitor, 1 to 3% of an ultraviolet ray absorber, 1 to 3% of a suspending agent, 1 to 3% of a thickening agent, 35 to 40% of a filler, 5 to 7% of a pull agent, 3 to 5% of an anti-oxidant, 3 to 5% of a leveling agent and 8 to 12% of a pigment, wherein the mass percents of the components sum to 100%. The invention has the following beneficial effects: construction time can be shortened, 3-to-10-mm-thick super silica PU can be laid in one shot forming, and the laid super silica PU never bubbles, has no oil return and can be used for a long time.

Owner:邱能聪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com