Special epoxy-cotton-oil-containing binding agent for automobile interior ornament surface composite leather

A technology for epoxy cottonseed oil and automotive interior parts, which is used in mineral oil hydrocarbon copolymer adhesives, aldehyde/ketone condensation polymer adhesives, adhesives, etc. The problem of low production efficiency of the molding process, to achieve the effect of smooth composite effect and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

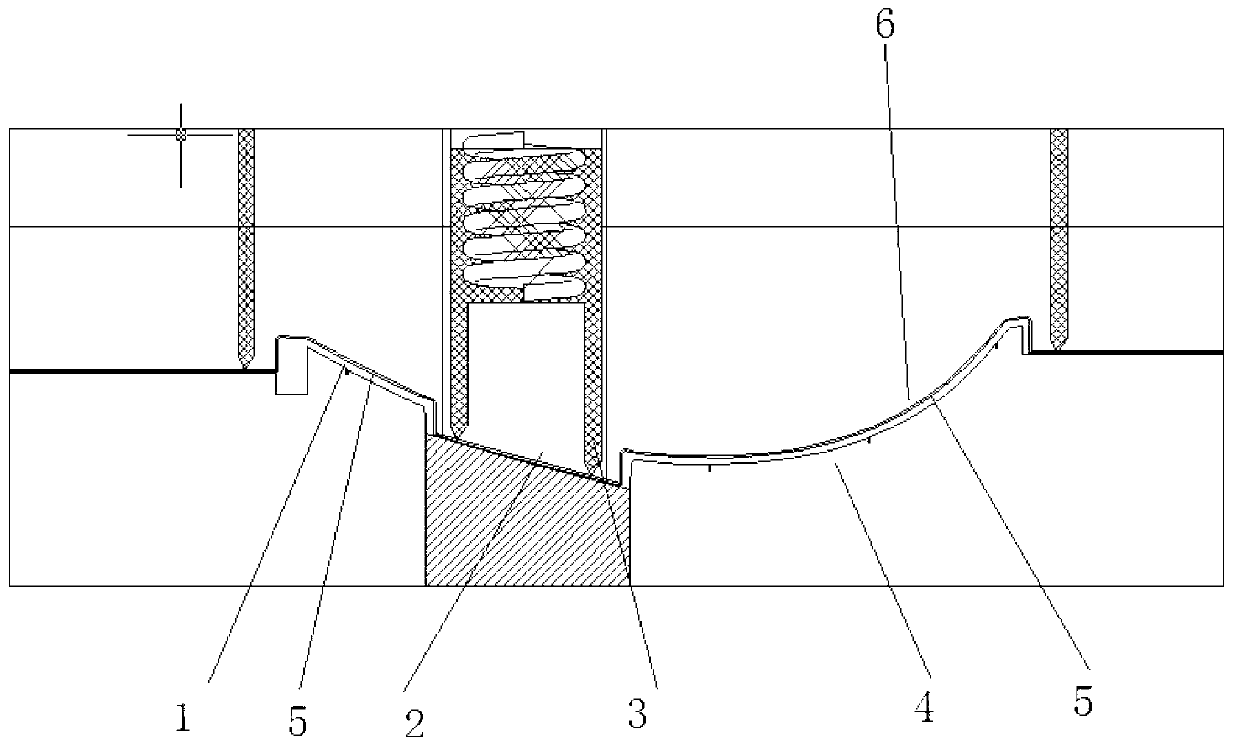

Image

Examples

Embodiment Construction

[0024] A special adhesive for composite leather on the surface of automotive interior parts containing epoxy cottonseed oil, which is made from the following raw materials in parts by weight (kg): Japan Sumitomo KA-31 EVA 58, octyl phenolic resin 203 14, C5 petroleum resin 12, WPP type polypropylene wax 0.6, oxidized polyethylene wax 5.7, modified bamboo charcoal powder 8, rice husk ash 3, nano carbon 1, silane coupling agent KH550 0.9, antioxidant 264 0.2, antioxidant 3010 1.2, n-butyl methacrylate 2, hydroxyethyl methacrylate 0.7, dibutyl maleate 0.5, epoxy cottonseed oil 0.6, triethyl citrate 0.2;

[0025] The preparation method of modified bamboo charcoal powder is:

[0026] (1) Soak bamboo charcoal powder in 14% hydrogen peroxide solution for 4 hours, then wash with deionized water until neutral, and dry;

[0027] (2) Add 1% dioctyl maleate and 3% a-cyanoacrylate equivalent to the weight of the dried bamboo charcoal powder, stir at 3000 rpm for 40 minutes, then dry Crus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com