Patents

Literature

277 results about "OCTYL ACRYLATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface sizing agent for paper making

InactiveCN101225623AImprove qualityMeet quality requirementsWater-repelling agents additionNon-macromolecular organic additionIsooctyl acrylateEmulsion

The invention relates to a surface sizing agent for paper making, which has the material formula with a plurality of components and weight percentages as follows: starch 6.5-8%, styrene 4.5-6%, acrylonitrile 4-5%, n-butyl methacrylate 5.5-6.5, methacrylic acid iso-octyl 2-3.5, iso-octyl acrylate 0.4-1%, hydrogen peroxide 0.2-0.5%, formic acid0.5-1%, ferrous sulfate 0.5-4%, n-dodecyl mercaptan 0.5-3%, amylase 0-0.2% and water the rest, wherein at least one is chosen from n-butyl methacrylate, methacrylic acid iso-octyl and iso-octyl acrylate. The appearance of the surface sizing agent is slight yellow emulsion, and the main component is styrene-acrylic copolymer which is easily soluble at normal temperature. The surface sizing agent for paper making has the advantages of greatly increasing paper surface intensity, decreasing hair and powder shedding, and improving the sizing degree, smoothness and printability of paper.

Owner:杨春先

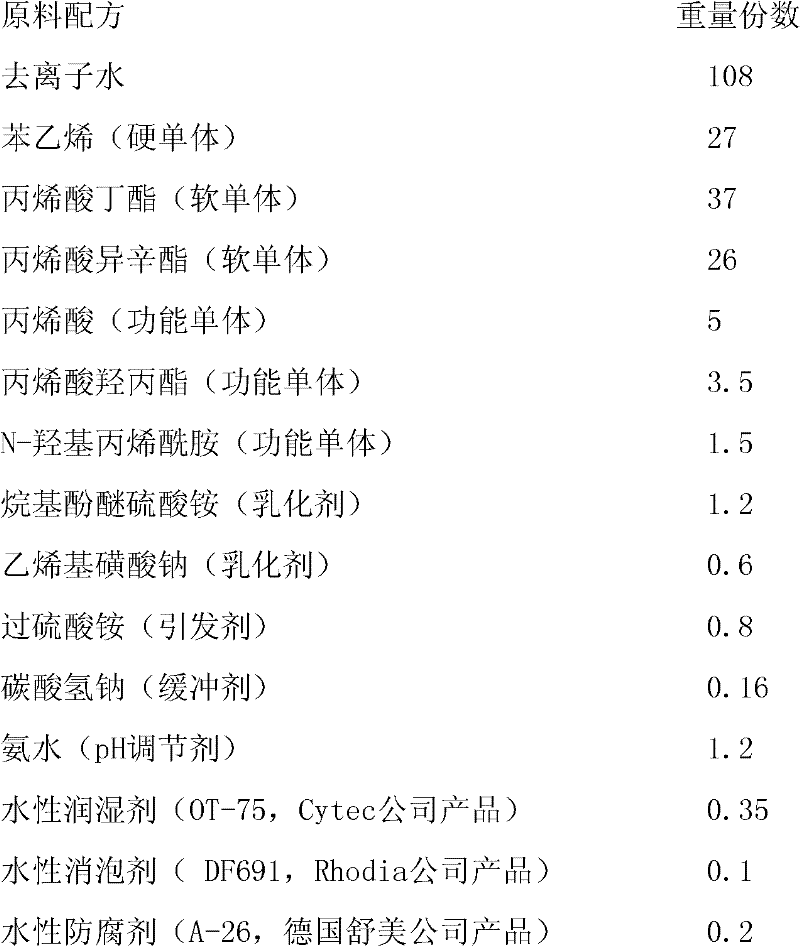

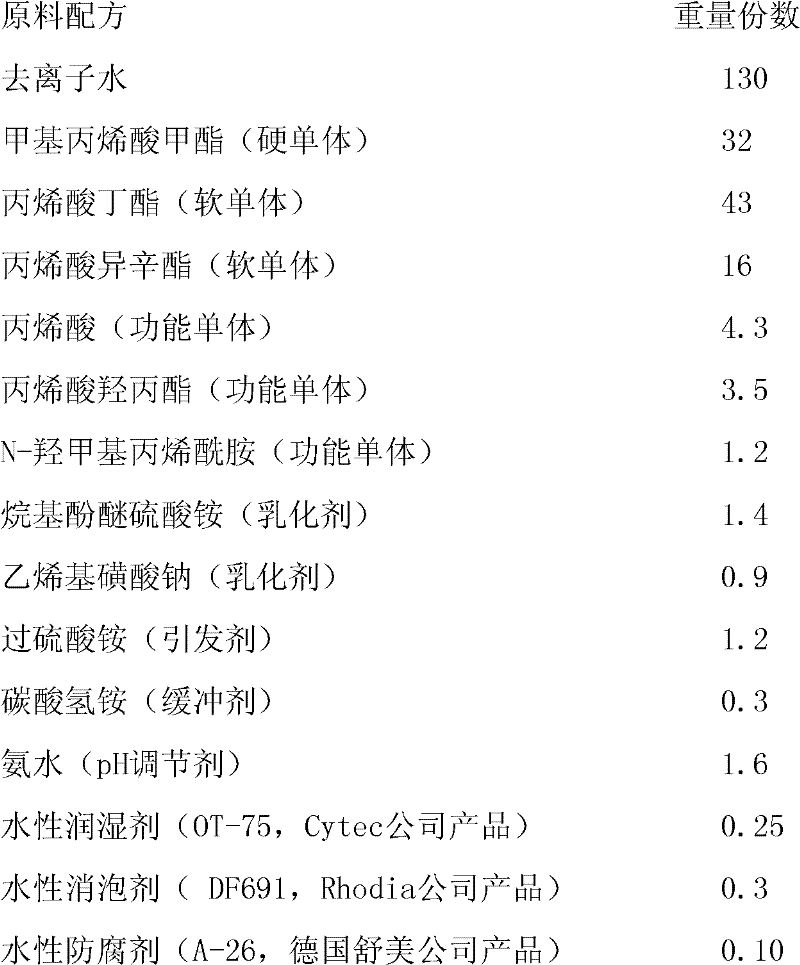

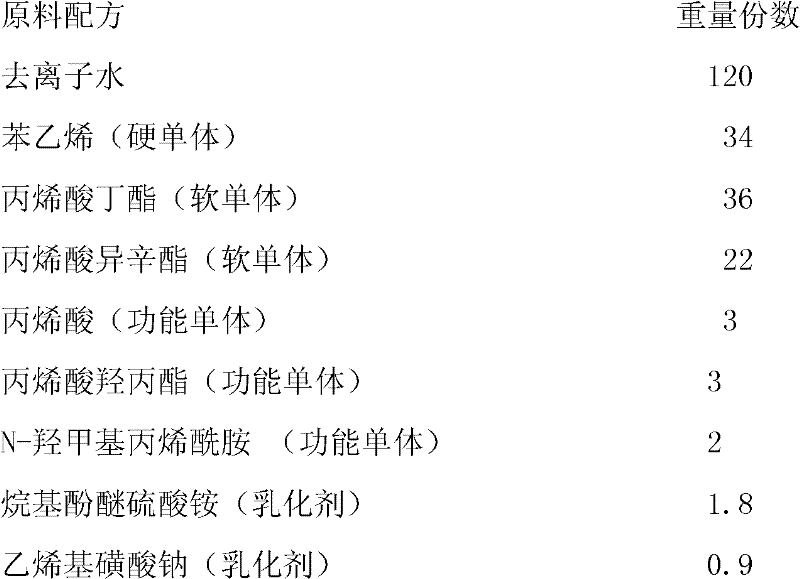

Aqueous adhesive for non-woven fabric composite membrane and preparation method of aqueous adhesive

InactiveCN102443367AImprove stabilityGood adhesionEster polymer adhesivesHydrocarbon polymer adhesivesIsooctyl acrylateFunctional monomer

The invention discloses an aqueous adhesive for a non-woven fabric composite membrane and a preparation method of the aqueous adhesive, belonging to the field of manufacturing of adhesives. The adhesive comprises the following components of: deionized water, monomers, a composite emulsifier, an initiator, a buffering agent, a pH regulator and an aqueous addition agent, and the solid content of the adhesive is 40-50%. The monomers in the components of the adhesive comprise a hard monomer, soft monomers and functional monomers, wherein the hard monomer is styrene or methyl methacrylate, the soft monomers are butyl acrylate and iso-octyl acrylate, and the functional monomers are composed of crylic acid, hydroxy-propyl acrylate and N-methylol acrylamide. The monomers comprise the following components in percentage by mass: 20-40% of styrene or methyl methacrylate, 10-30% of iso-octyl acrylate, 30-50% of butyl acrylate, 1-5% of crylic acid, 1-5% of hydroxy-propyl acrylate and 1-5% of N-methylol acrylamide. The aqueous adhesive has the advantages of effectively improving wetting and flatting properties on the surface of a plastic film, ensuring that the plastic film has a better wettingproperty with the non-woven fabric, and enhancing the peeling strength.

Owner:NANTONG GAOMENG NEW MATERIAL

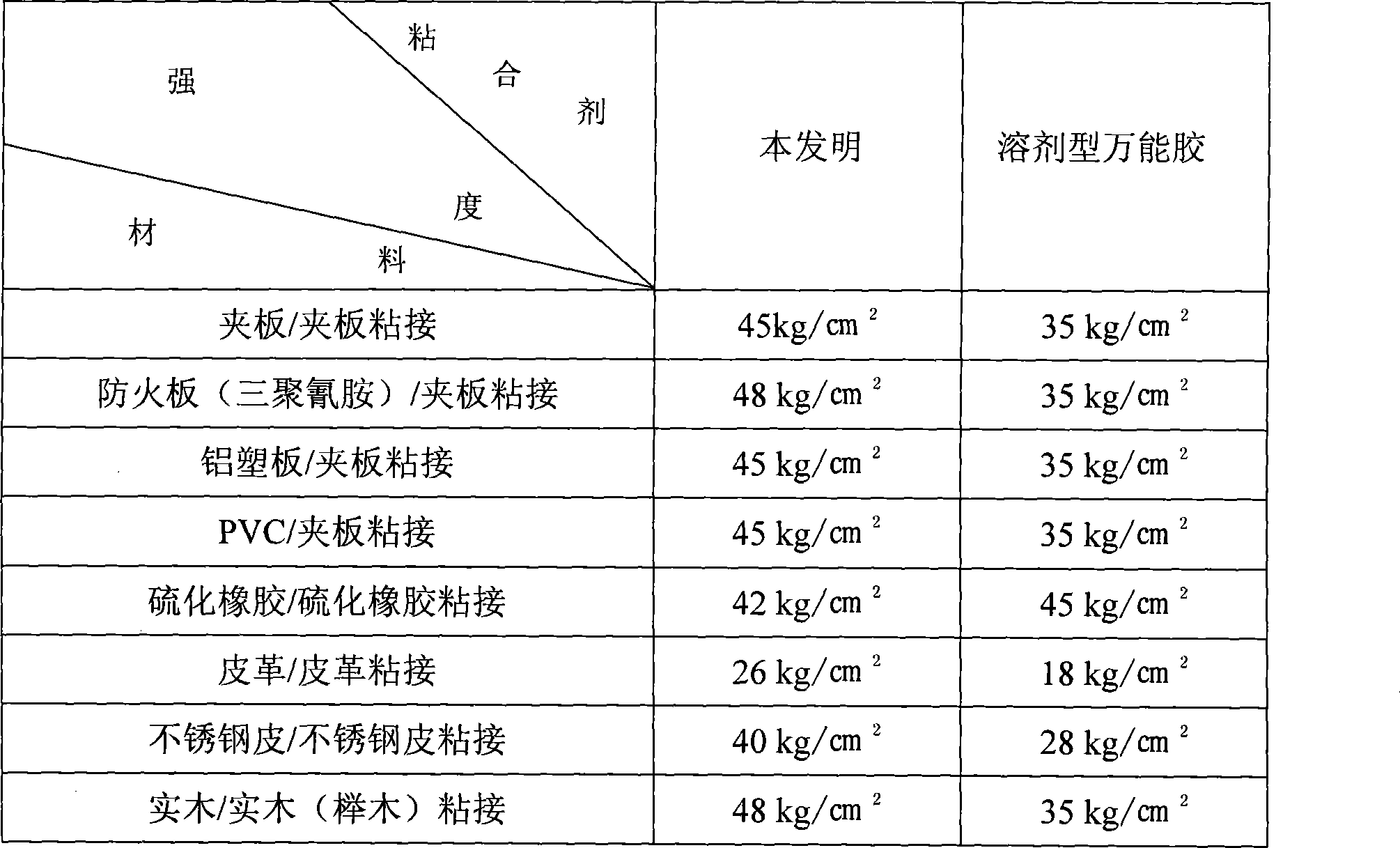

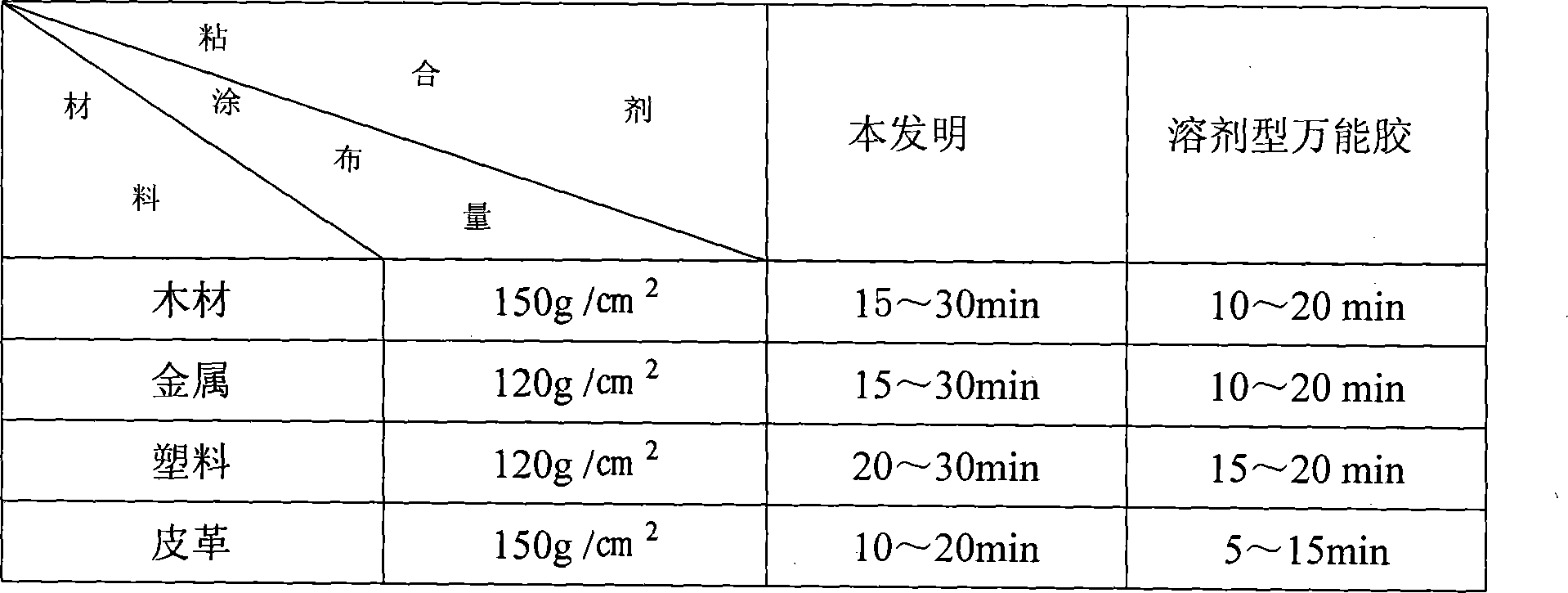

Water-based all-purpose adhesive and method for preparing same

InactiveCN101225271AWith adhesive strengthImprove stabilityInksCoatingsIsooctyl acrylatePolymer science

The invention discloses a water-based all purpose adhesive and the preparation method, which belongs to the field of water-based adhesive, the technical proposal is a copolymer emulsion of 120 to 300 portions of vinyl acetate, 15 to 50 portions of organic silicon monomer with unsaturated double bond, 60 to 150 portions of ethylene tertiary carbonate, 80 to 120 portions of butyl acrylate, 90 to 150 portions of iso-octyl acrylate, 5 to 15 portions of acrylic acid; the emulsion also comprises 20 to 80 portions of tackifying resin, 3 to 8 portions of sodium salt decocting mixture, 50 to 150 portions of plasticizer, 15 to 50 portions of polyvinyl alcohol, 2 to 8 portions of silane coupling agent, 8 to 12 portions of hydrochloric acid, 3 to 15 portions of anionic emulsifier and 3 to 12 portions of nonionic emulsifier. The preparation method is that the mixed monomer is dropped by the manner of emulsion polymerization, and should be completed in three to five hours; warming up to 85 to 95 DEG C to cure for 40 to 60 minutes; then discharging and filtering and packaging after cooling down to 45 to 35 DEG C. The water-based all purpose adhesive has the advantages of convenient use, wide applicability, and can be used for the manufacturing of furniture, luggage and construction decoration.

Owner:唐浩

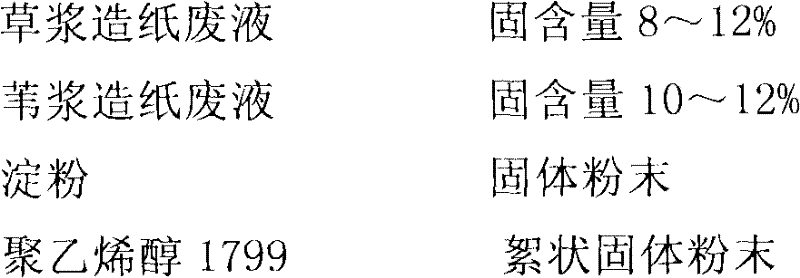

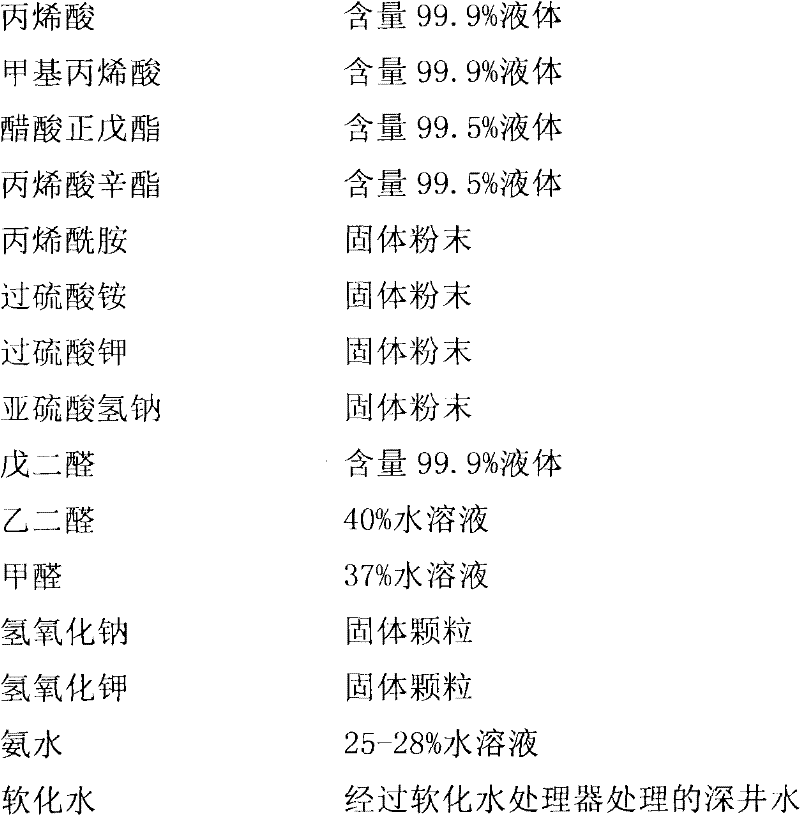

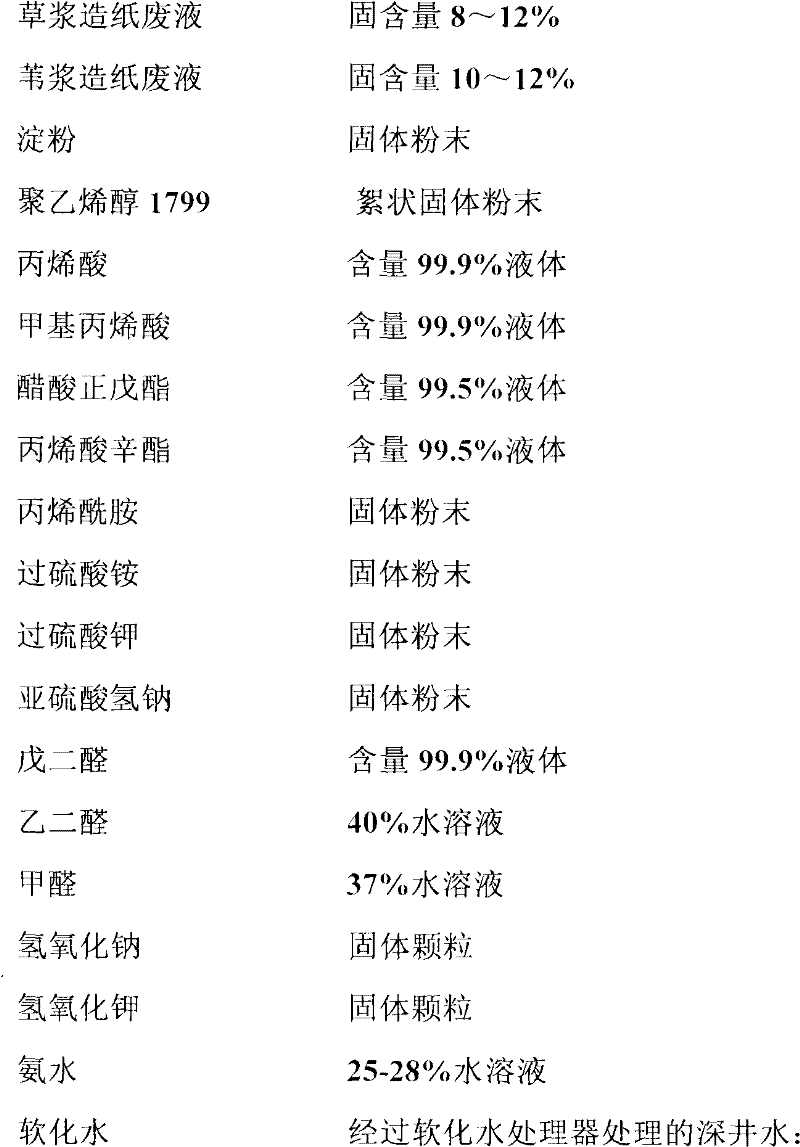

Biodegradable liquid mulch film produced from papermaking waste liquid, and production method thereof

InactiveCN102337138AReduce pollutionImprove production environmentAgriculture tools and machinesClimate change adaptationLiquid wasteChemical reaction

The invention relates to a biodegradable liquid mulch film produced from papermaking waste liquid, and a production method thereof. The film is produced from papermaking waste liquid discharged from paper making industries, starch, polyvinyl alcohol, acrylic acid or methacrylic acid or acrylamide, amyl acrylate or octyl acrylate, formaldehyde or glutaral or glyoxal, and the like. According to the method, lignin is grafted with acryl; starch is grafted with acryl; lignin, starch and polyethylene glycol hydroxyl are processed through a series chemical reactions of condensation, cross-linking, and copolymerization, such that an aqueous polymer with lignin as a basic material is synthesized. Therefore, the biodegradable liquid mulch film is obtained. According to the invention, industrial papermaking waste liquid is adopted as a main material, such that the pollution caused by papermaking waste liquid is reduced, environment is protected, cost is saved, irrigation water is saved, and crop yield is improved. With the wide popularization of the biodegradable liquid mulch film, a positive effect is provided for increasing the crop yield in our nation.

Owner:刘长福

Preparation method of optical transparent two-sided sticky tape

ActiveCN103773260AImprove heat resistanceImprove aging resistanceFilm/foil adhesivesSynthetic resin layered productsMethacrylateIsooctyl acrylate

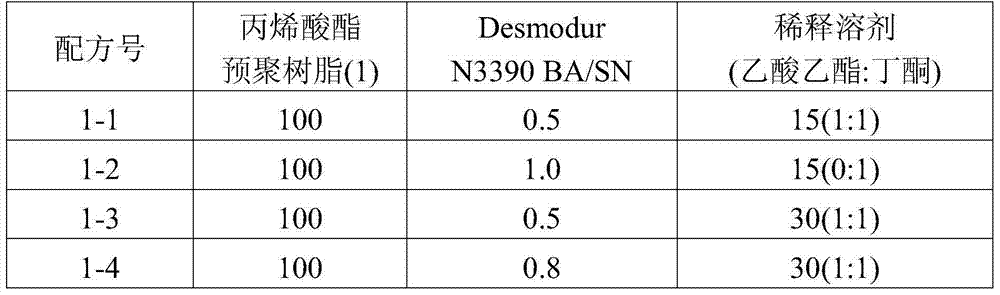

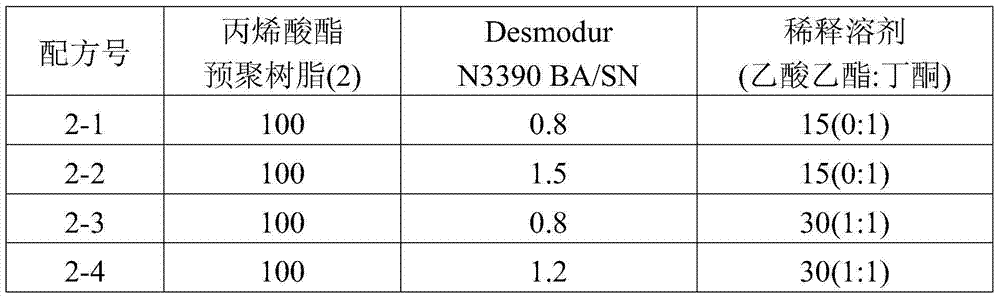

The invention discloses a preparation method of an optical transparent two-sided sticky tape. The preparation method is characterized by comprising the following steps: adding butyl acrylate, iso-octyl acrylate, ethyl methacrylate, functional monomers, glycidyl methacrylate, solvent I and an initiator to a reaction kettle to carry out copolymerization for 4-6h under the protection of nitrogen, thus obtaining acrylate prepolymer resin; mixing the acrylate prepolymer resin with a curing agent and a diluting solvent to obtain an acrylate optical glue; uniformly spreading the acrylate optical glue on polyester release film A with a comma blade by a coating machine and then feeding the polyester release film A coated with the acrylate optical glue into a six-section drying channel at a linear velocity of 5-15m / min, wherein the length of the drying channel is 20-25m and the temperature of the drying channel is 65-100 DEG C; compounding the polyester release film A and polyester release film B which are the same in width under the pressure of a compression roller being 0.4MPa; curing in a 40-45 DEG C drying room, thus obtaining the optical transparent two-sided sticky tape. The optical transparent two-sided sticky tape has extremely low viscosity and excellent performance.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Acrylic copolymers with improved low temperature performance

InactiveUS20060276587A1Reduce temperature riseImprove low temperature impact performanceCoatingsCore shell2-ethylhexyl acrylate

This invention relates to a core / shell impact modifier having as a core a copolymer or terpolymer having from 25 to 75 percent by weight of 2-ethylhexyl acrylate (2-EHA) monomer units with from 25 and 75 percent by weight of n-octyl acrylate (n-OA) monomer units. This core-shell impact modifier is used in performance polymers to improve low temperature impact performance.

Owner:ARKEMA INC

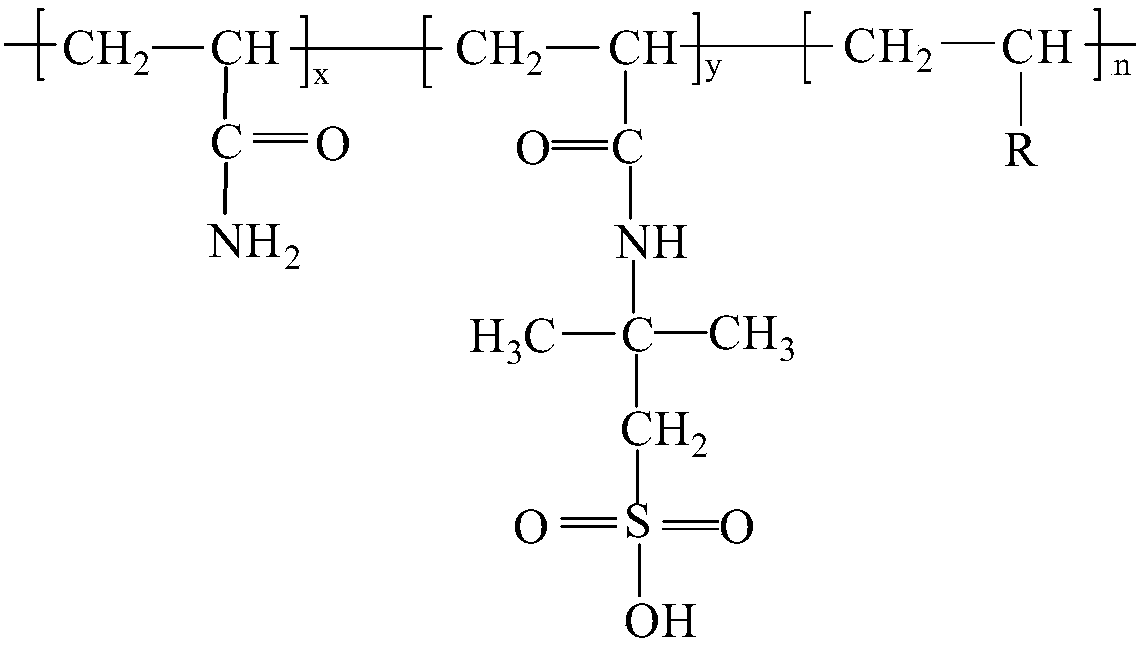

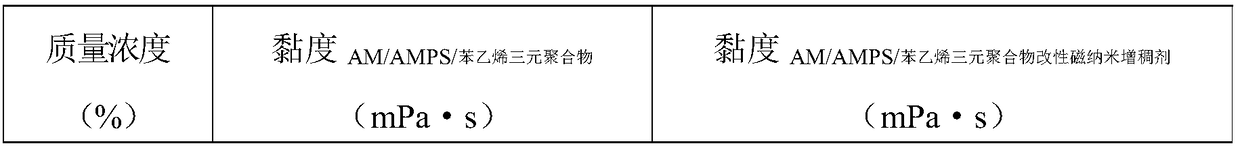

Hydrophobic associated polymer modified magnetic nano-thickener and preparation method thereof

InactiveCN109456740AEfficient viscosity increaseEfficient functionFluid removalDrilling compositionPolymer modifiedPolymer science

The invention discloses a hydrophobic associated polymer modified magnetic nano-thickener and a preparation method thereof. The hydrophobic associated polymer modified magnetic nano-thickener is a core-shell structured nanocomposite prepared by taking nanometer Fe3O4 as the core, modifying the Fe3O4 through oleic surfactants and grafting an amphiphilic high-polymer compound, wherein the amphiphilic high-polymer compound is a hydrophobic associated water-soluble ternary polymer prepared by copolymerizing a water-soluble monomer, a heat-resistant and anti-salt monomer and a hydrophobic monomer,the water-soluble monomer is acrylamide, the heat-resistant and anti-salt monomer is 2-acrylamide-2-methylpropanesulfonic acid, and the hydrophobic monomer is styrene, n-octyl acrylate or octadecyl dimethyl allyl ammonium chloride. The hydrophobic associated polymer modified magnetic nano-thickener helps solve the problems of high cost and poor thickening performance of nano-thickeners and reutilization difficulty of polymer thickeners and is an efficient thickening and recycling integrated nano-thickener obtained by modifying low-toxicity magnetic nanometer materials and amphiphilic high-polymers; the preparation method of the hydrophobic associated polymer modified magnetic nano-thickener has no need for high-temperature and high-pressure reaction conditions and helps reduce the operation difficulty and the production cost.

Owner:XI'AN PETROLEUM UNIVERSITY

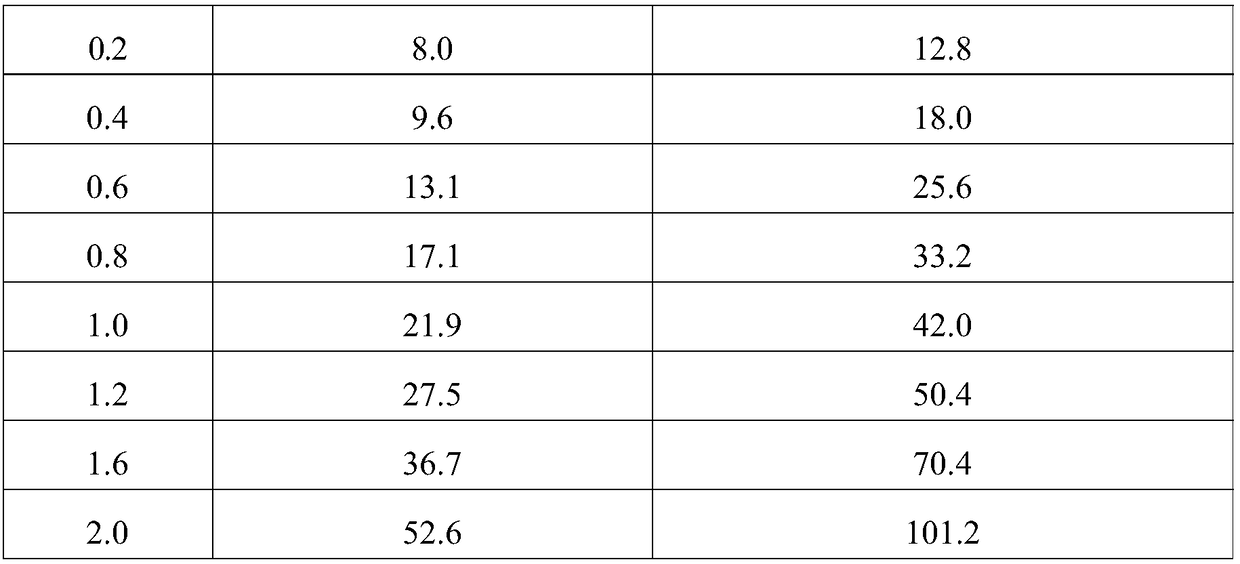

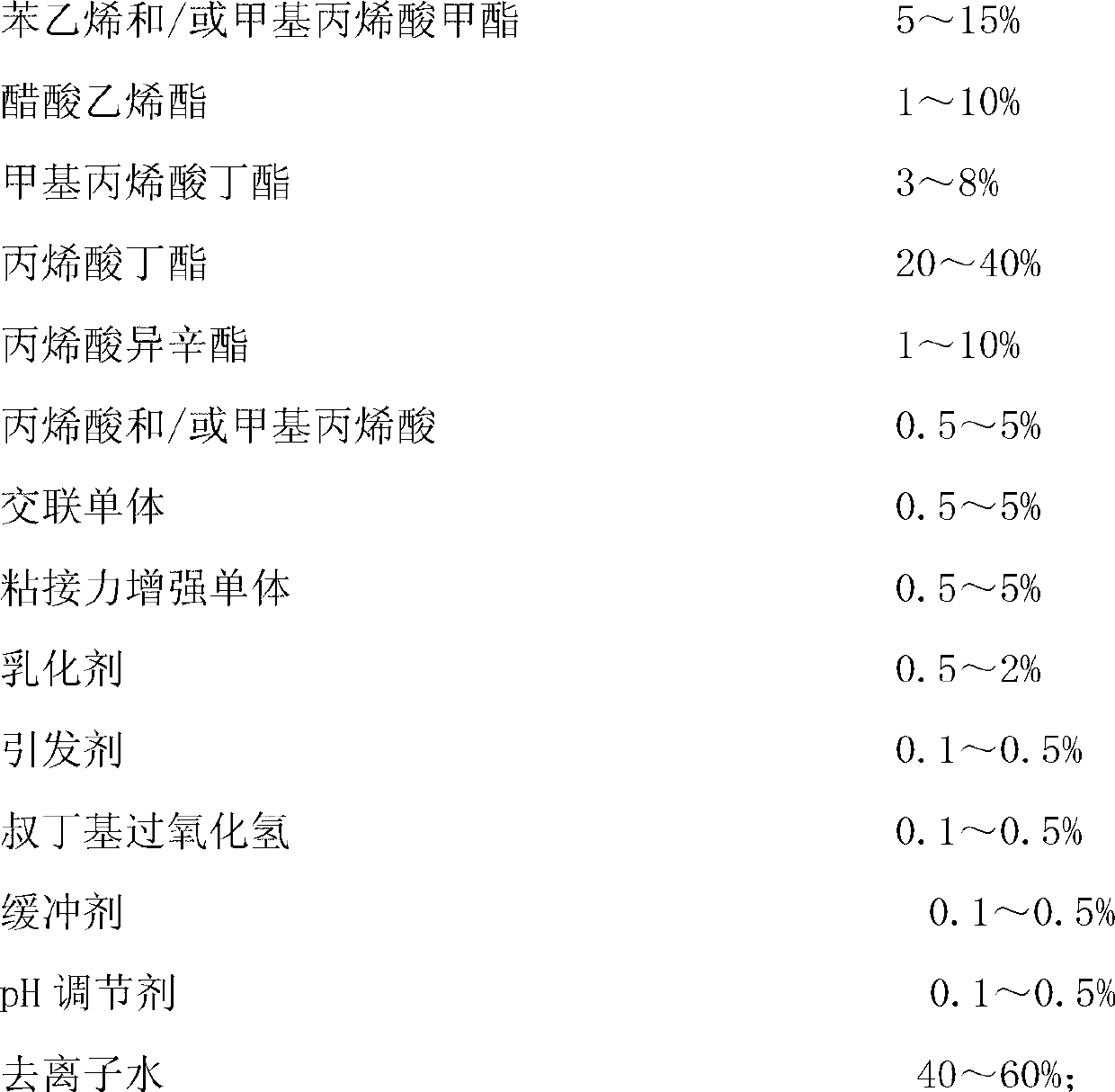

Water emulsion type plant adhesive and preparation method thereof

ActiveCN102925085AEliminate pollutionEliminate diversionEster polymer adhesivesIsooctyl acrylateAdhesive

The invention discloses a water emulsion type plant adhesive and a preparation method thereof, belonging to the field of adhesives. The adhesive consists of styrene or methyl methacrylate, vinyl acetate, butyl methacrylate, butyl acrylate, iso-octyl acrylate, acrylic acid, crosslinking monomer, adhesion reinforcing monomer, emulsifier, initiator, tert-butyl hydroperoxide, buffer agent, pH regulator and deionized water; and through a seeded emulsion polymerization technology, the homopolymer of styrene or methyl methacrylate is synthesized firstly as seed, the pre-emulsion is dropwise added to the seed polymerization particles to synthesize a shell polymer, and finally a core-shell structure with a hard core and a soft shell is formed. After the film formation of the polymer particles, the initial adhesion is high, and the sticking of glass beads on an adhesive layer is facilitated; and moreover, the cohesion is great, thus no adhesive residue is transferred to the base fabric during the transfer of the plant particles, and the washing effect of the reflective fabric is improved.

Owner:NANTONG GAOMENG NEW MATERIAL

Acrylic epoxy core-shell emulsion and preparation method thereof

The invention discloses acrylic epoxy core-shell emulsion and a preparation method thereof. The acrylic epoxy core-shell emulsion is prepared from the following components in parts by mass: 150 to 300 parts of water, 30 to 60 parts of styrene, 30 to 60 parts of methyl methacrylate, 20 to 75 parts of iso-octyl acrylate, 20 to 75 parts of butyl acrylate, 0.5 to 5 parts of acrylic acid, 0.5 to 5 parts of methacrylic acid, 5 to 10 parts of epoxy resin, 5 to 20 parts of an anionic emulsifier, 1 to 5 parts of a cross-linking monomer, 5 to 15 parts of a waterborne epoxy curing agent, 0.5 to 2 parts of an initiator, 0.1 to 0.5 part of an oxidant and 0.1 to 0.5 part of a reductant. According to the acrylic epoxy core-shell emulsion disclosed by the invention, acrylic emulsion is combined with the epoxy resin, so that the disadvantages of easiness in yellowing, poor damp heat resistance, poor toughness and the like of the epoxy resin are remedied, and the properties of hardness, wear resistance and the like of the acrylic emulsion are increased.

Owner:佛山市顺德区巴德富实业有限公司

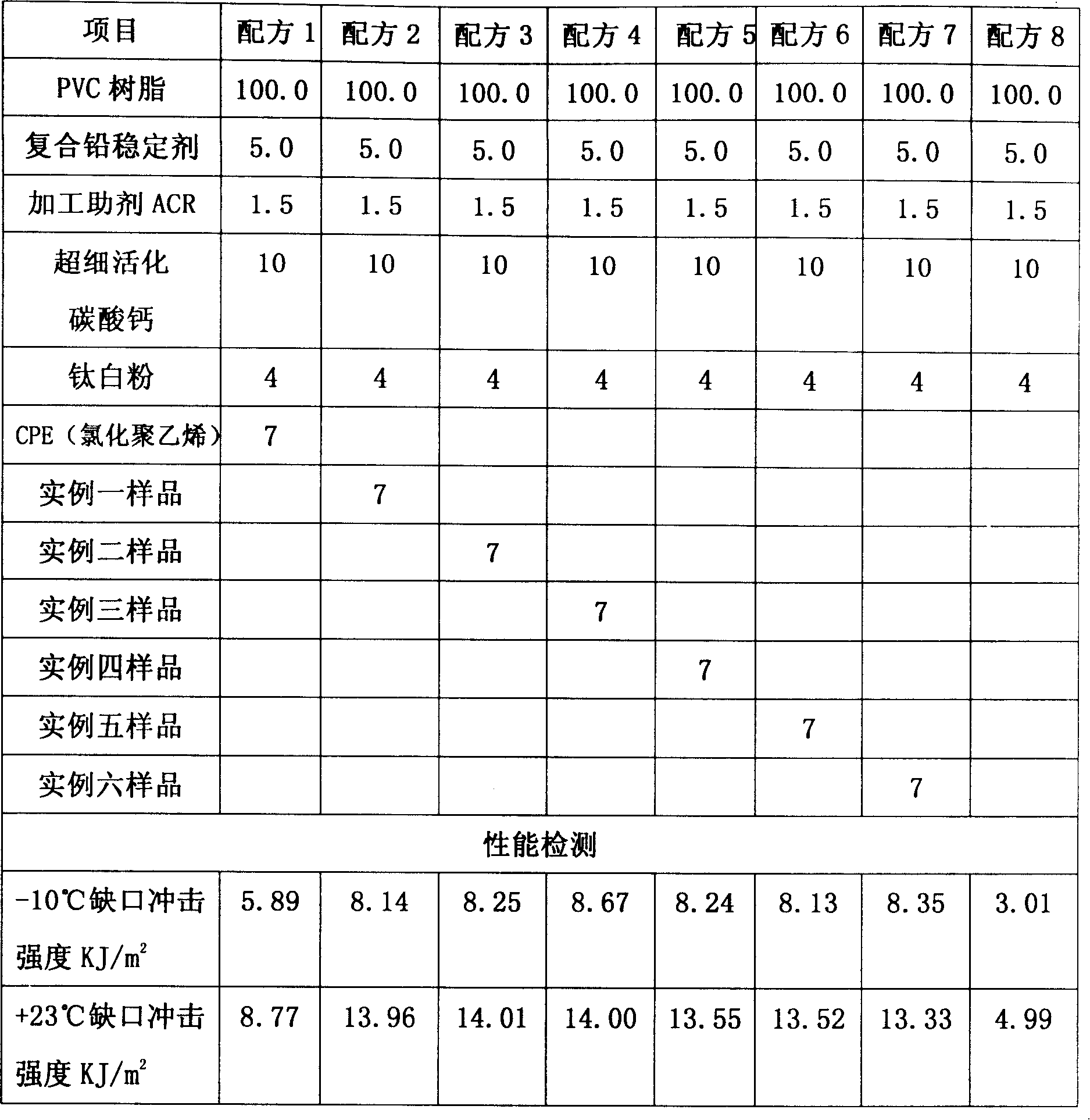

High cold-resistance ultra-high impact strength resistance modified for PVC

The invention relates to high cold resistant and super-high-impact strength impact modifier, which is core-shell structural copolymer. Crosslinking agent is added into polymeric monomer butyl acrylate and iso-octyl acrylate to carry out emulsion polymerization, thus obtaining the core layer. The total weight of the core-layer polymeric monomer is calculated in 100 percent, wherein, the butyl acrylate accounts for 20-50 percent and the iso-octyl acrylate accounts for 50-80 percent; the shell layer is obtained through continuous emulsion polymerization of methyl methacrylate on the core layer. The amount of the core-layer polymeric monomer accounts for 90-95 percent of total polymeric monomer and the amount of the shell-layer polymeric monomer accounts for 5-10 percent of the total polymeric monomer. The core-shell copolymer of the invention comprises that the content of core-layer acryl elastomer is more than 90 percent, thus greatly improving the impact strength; the glass transition temperature of the core can be reduced lower than minus 60 DEG C, thus ensuring the high cold resistance of the products. The invention has super-high impact strength in the PVC and can be widely used in PVC exterior boardy products.

Owner:SHANDONG RUIFENG CHEM

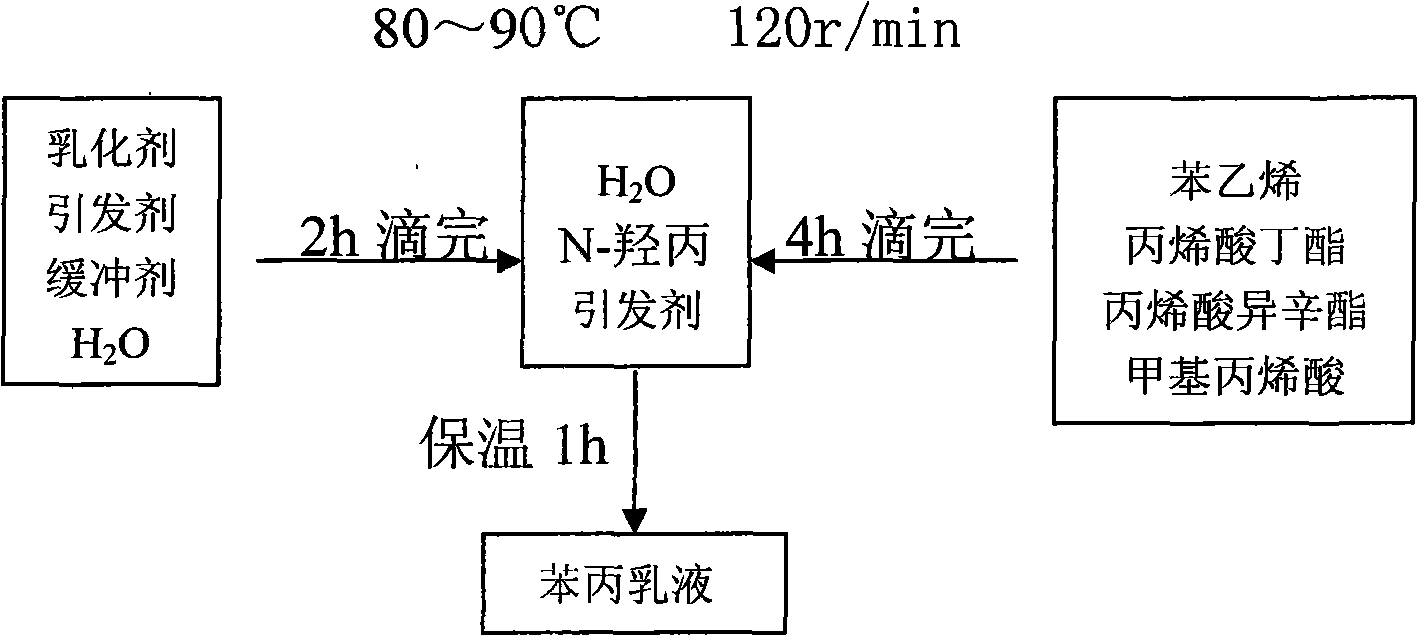

Synthetic styrene-acrylic latex

The invention discloses synthetic styrene-acrylic latex, which includes components by weight: 2-4 parts of crylic acid, 5-8 parts of iso-octyl acrylate, 10-15 parts of styrene, 6-9 parts of butyl acrylate, 0.4-0.8 part of emulsifying agent, 0.1-0.4 part of ammonium persulfate and 65-80 parts of ionic water. Because soft monomer and hard monomer proportion MAA:St:BA is 36:25:36, the obtained emulsion has high hardness, and good anti-aging performance, when amount of seed emulsion is 10-12%, comprehensive properties of the obtained emulsion are best, and proper amount of carboxyl functional monomer is added to significantly improve polymerization stability of the emulsion, calcium ionic stability, emulsion viscosity and film water absorption rate.

Owner:QUANZHOU DELI CHEM

Termination adhesive tape and manufacture method thereof

InactiveCN102250562AMeet application needsLow costFilm/foil adhesivesEster polymer adhesivesIsooctyl acrylateBenzoyl peroxide

The invention relates to the technical field of adhesive tapes, and particularly relates to a termination adhesive tape and a manufacture method thereof. The termination adhesive tape comprises a base tape and a glue layer located on the base tape, wherein the glue layer is an acrylic glue layer, which is composed of the following raw materials in parts by weight: 1-5 parts of butyl acrylate, 5-12 parts of vinyl acetate, 40-60 parts of ethyl acetate, 20-35 parts of iso-octyl acrylate, 0.5-2 parts of hydroxyethyl methacrylate, 1-3 parts of acrylic acid, 2-4 parts of toluene and 0.1-0.4 part of benzoyl peroxide. The manufacture method sequentially comprises the following steps: A. preparing the acrylic glue: titrating toluene-dissolved benzoyl peroxide used as an initiator to a mixed solution of butyl acrylate, vinyl acetate, ethyl acetate, iso-octyl acrylate, hydroxyethyl methacrylate and acrylic acid at the temperature of 80 DEG C, and ensuring the titration time of 2 hours and self-reaction time of 2.5 hours; and B. applying the acrylic glue on the base tape, sequentially drying, cooling and coiling. The termination adhesive tape provided by the invention has the advantages of low cost, beautiful appearance, simple manufacture process and good electrolyte resistance.

Owner:东莞市苏粤电子包装材料有限公司

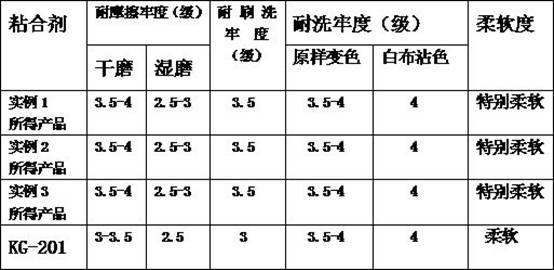

Pigment printing imitated reactive printing adhesive and preparation method thereof

ActiveCN102619103AGood flexibilityImprove adhesion fastnessEster polymer adhesivesDyeing processIsooctyl acrylateTextile printer

The invention relates to pigment printing imitated reactive printing adhesive and a preparation method thereof. The pigment printing imitated reactive printing adhesive is polymer emulsion prepared from fatty alcohol-polyoxyethylene ether (peregal O-25), sodium dodecyl benzene sulfonate, butyl acrylate, dimethyl aminopropyl methacrylamide, glycidyl methacrylate, iso-octyl acrylate, methyl methacrylate, acrylic acid, ammonium persulphate, sodium hydrogensulfite and deionized water through polymerization by using seeded emulsion. The pigment printing imitated reactive printing adhesive product has obvious advantages in indexes such as softness, rub fastness and fastness to washing, and quality of the pigment printing imitated reactive printing product can be obviously improved.

Owner:LIAONING FIXED STAR FINE CHEM

Environment-friendly exterior wall paint and preparation method thereof

The invention discloses an exterior wall paint prepared from the following raw materials in parts by weight: 86-90 parts of waterborne acrylic emulsion, 17-20 parts of styrene-acrylic emulsion, 20-50 parts of wollastonite powder, 2-3 parts of iso-octyl acrylate, 1-2 parts of potassium borate, 0.4-1 part of ethylene glycol dimethacrylate, 3-4 parts of tungsten boride, 1-2 parts of sodium dodecyl sulfate, 0.6-1 part of dibenzoyl peroxide, 3-4 parts of absolute ethyl alcohol, 0.8-1 part of gamma-aminopropyltriethoxysilane, 0.1-0.2 part of polyoxyethylene polyoxypropylene ether, 3-5 parts of coalescing agent and 10-20 parts of deionized water. The paint produced by the invention is low in raw material loss, less in gel generation, simple in process, firm in paint film, good in glossiness, strong in impact force resistance, not easy to crack, soft in texture, strong in decoration, high in weather and scrubbing resistance, strong in adhesive force, long in service life, free of special smell, heavy metals such as mercury, lead and the like and formaldehyde volatiles, and capable of meeting the technical requirement of an environment-friendly paint; and the added coalescing agent has very high stability, efficient adhesiveness and film forming property, so that the density of the paint film is increased, the film forming quality is improved, and a film layer has the advantages of strong adhesive force, no hole and rift, densification, uniformity and the like.

Owner:CHUZHOU MAISITE NEW BUILDING MATERIAL

Water-based acrylic emulsion adhesive capable of releasing negative ions and preparing method

ActiveCN106085303AEliminate pollutionEliminate odorNon-macromolecular adhesive additivesEster polymer adhesivesIsooctyl acrylateCross-link

The invention discloses a water-based acrylic emulsion adhesive capable of releasing negative ions. The water-based acrylic emulsion adhesive capable of releasing negative ions is prepared from acrylic acid, iso-octyl acrylate, methyl methacrylate, styrene, anionic emulsifying agent, non-ionic emulsifying agent, initiating agent, pH buffering agent, cross-linking agent, modified nanometer negative ion powder and deionized water. According to the water-based acrylic emulsion adhesive capable of releasing the negative ions, the modified nanometer negative ion powder is grafted to a water-based acrylic adhesive with the chemical method, and the water-based acrylic adhesive capable of releasing negative ions is obtained; the water-based acrylic adhesive can be used for bonding between non-porous materials such as all kinds of cloth and wood and porous materials such as sponges, and pollution caused by an organic solvent adhesive to the environment is eliminated; meanwhile, the negative ions can be further released, the effects of purifying air and eliminating peculiar smell are achieved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

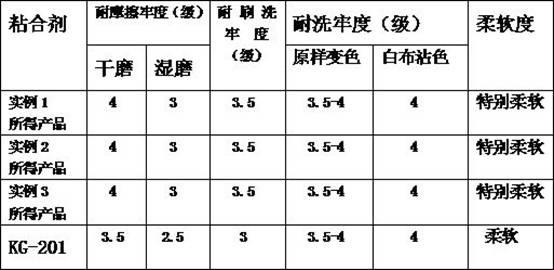

Modified white latex and preparation method thereof

ActiveCN106047223AImprove water resistanceGood adhesionMonocarboxylic acid ester polymer adhesivesIsooctyl acrylateFunctional monomer

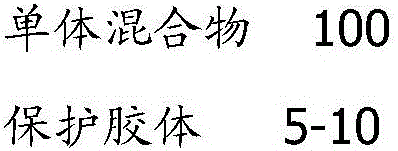

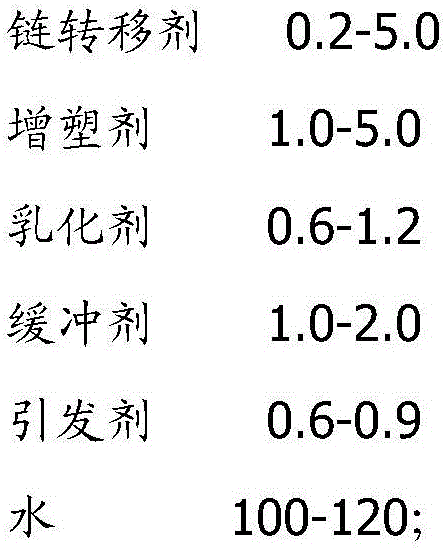

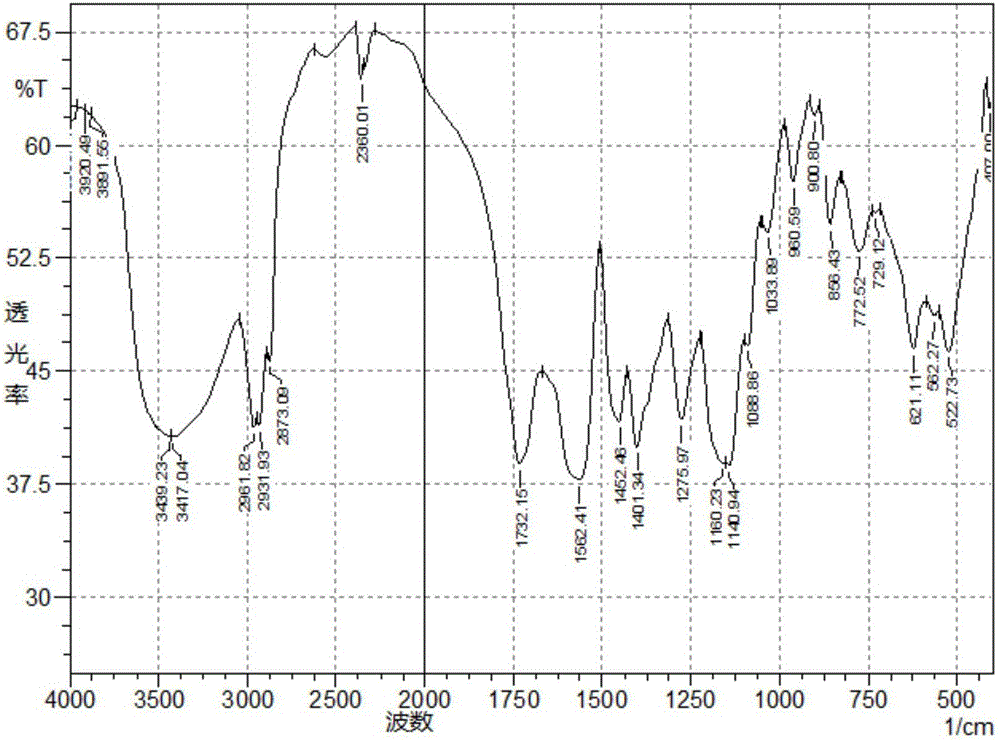

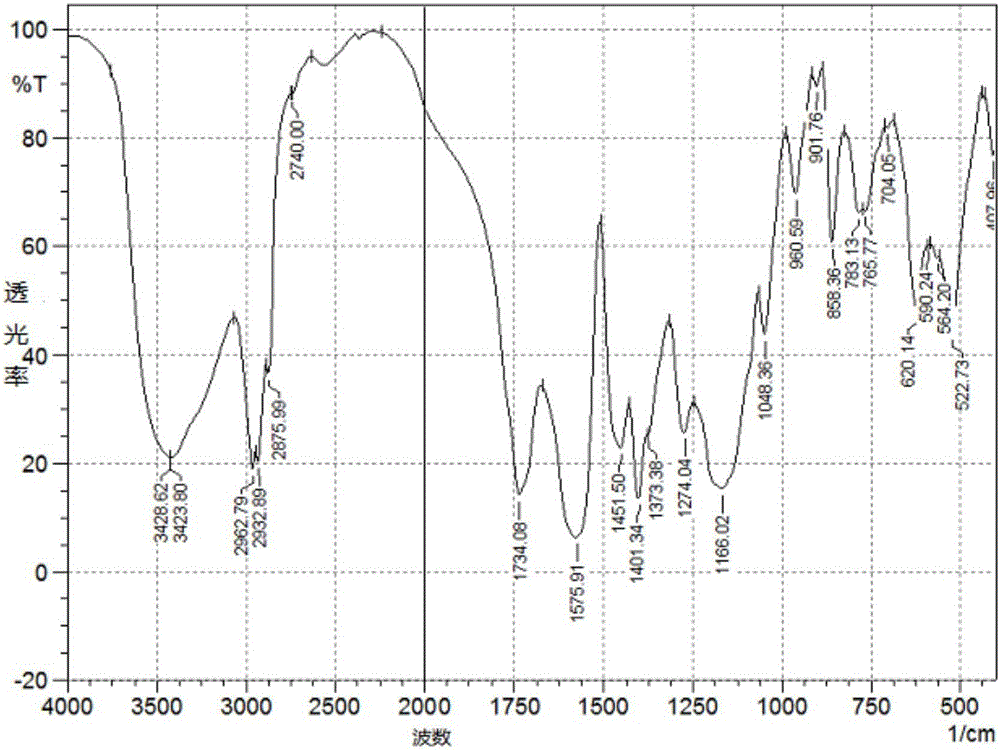

The invention provides modified white latex and a preparation method thereof. The modified white latex is prepared from, by weight, 100 parts of monomer mixture, 5-10 parts of protective colloid, 0.2-5.0 parts of chain transfer agent, 1.0-5.0 parts of plasticizer, 0.6-1.2 parts of emulsifier, 1.0-2.0 parts of buffering agent, 0.6-0.9 part of initiator and 100-120 parts of water. The monomer mixture comprises main monomers and functional monomers. The weight of main monomers accounts for 80%-95% of the total quantity of the monomer mixture. The main monomers are vinyl acetate, and the functional monomers comprise iso-octyl acrylate and vinyl versatate. The water tolerance and bonding performance of the white latex are improved, and the prepared white latex has the advantages that a coating is good in water tolerance and high in bonding strength.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Freeze-tolerant acrylate pressure-sensitive adhesive, preparation method thereof, and application thereof in production of freeze-tolerant acrylate pressure-sensitive labels

ActiveCN105400464AImprove performanceMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesIsooctyl acrylateBenzoyl peroxide

The invention discloses a freeze-tolerant acrylate pressure-sensitive adhesive, a preparation method thereof, and an application thereof in the production of freeze-tolerant acrylate pressure-sensitive labels. The adhesive is prepared through free radical polymerization of copolymerization monomers, and the copolymerization monomers comprise, by weight, 20-50 parts of iso-octyl acrylate, 150-200 parts of butyl acrylate, 50-100 parts of acrylic acid, 10-70 parts of 2-ethylhexyl acrylate, 100-200 parts of ethyl acetate, 300-450 parts of toluene and 3-5 parts of benzoyl peroxide. The problems of low molecular weight, insufficient cohesive energy and adhesive overflow due to softness are solved through improving a formula and combing a new label production technology; and the freeze-tolerant acrylate pressure-sensitive adhesive labels disclosed in the invention have the advantages of soft adhesive, stable performances, avoiding of warping, opening and other phenomena when used to label refrigerated blood bags and other refrigerated products, and solving of the problem of difficult automatic labeling of -30DEG C blood bags with present blood bag labels.

Owner:GUANGZHOU JINWANZHENG PRINTING MATERIAL CO LTD

Method for loading drugs on drug eluting balloon catheter

ActiveCN104174073ARelease stabilityUniform drug coatingSurgeryCoatingsDrug eluting balloonDrug release

The invention relates to a method for loading drugs on a drug eluting balloon catheter. The method comprises the following steps: (1) swelling a balloon for 0.5-3 hours; (2) spraying a mixed liquid composed of therapeutic drugs, additives and a solvent onto the surface of the swelled balloon by adopting a vacuum spraying technology, and naturally drying by air for 10-30 minutes, wherein the weight ratio of the solvent, the therapeutic drugs and the additives in the mixed liquid is (10-90) to (0.5-30) to (5-60); and the solution for swelling the balloon in the step (1) is any one or more of methyl formate, ethyl acetate, ethyl formate, methyl acetate, propyl formate, methyl propionate, ethyl propionate, phenyl acetate, n-octyl acrylate and methyl benzoate. According to the method for loading drugs on the drug eluting balloon catheter, a drug coating can be uniform and firm, and drugs can be released quickly and stably.

Owner:LIAONING YINYI BIOTECH CO LTD

Amphiphilic copolymer dispersant, preparation method and application

ActiveCN105777973AGood dispersionGuaranteed water solubilityTransportation and packagingMixingIsooctyl acrylateFunctional monomer

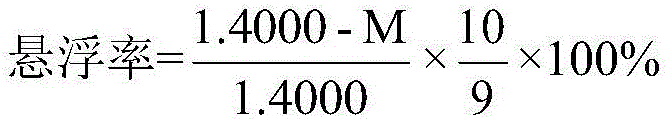

The invention discloses amphiphilic copolymer dispersant, a preparation method and application.Firstly, a water-alcohol solution is configured, chain transfer and polyvinyl alcohol is added for preheating, then initiator, methacrylic acid, iso-octyl acrylate and a functional monomer are added, after a reaction is conducted, neutralization reagent with the carboxyl carboxyl being 80-100% is added, then pressure reduction, distillation and alcohol removal are conducted, and after pH is adjusted, liquid dispersant is obtained; the liquid dispersant is dried, and solid dispersant is obtained; the functional monomer is hydroxyethyl acrylate or sodium ethylenesulphonate or combination of the hydroxyethyl acrylate and the sodium ethylenesulphonate, and the functional monomer is composed of, by mass, 20-80 parts of methacrylic acid, 10-50 parts of iso-octyl acrylate, 10-40 parts of hydroxyethyl acrylate and 10-20 parts of sodium ethylenesulphonate.According to the preparation method, a water-alcohol system is adopted, distilled and recovered solvent can be directly used without being processed, emission of waste water, waste gas and solid waste is avoided, and the production cost is lowered.The dispersant prepared from the method is good in dispersing agent, and suspension percentage can reach 98.5%.

Owner:山东德胜精细化工研究院有限公司

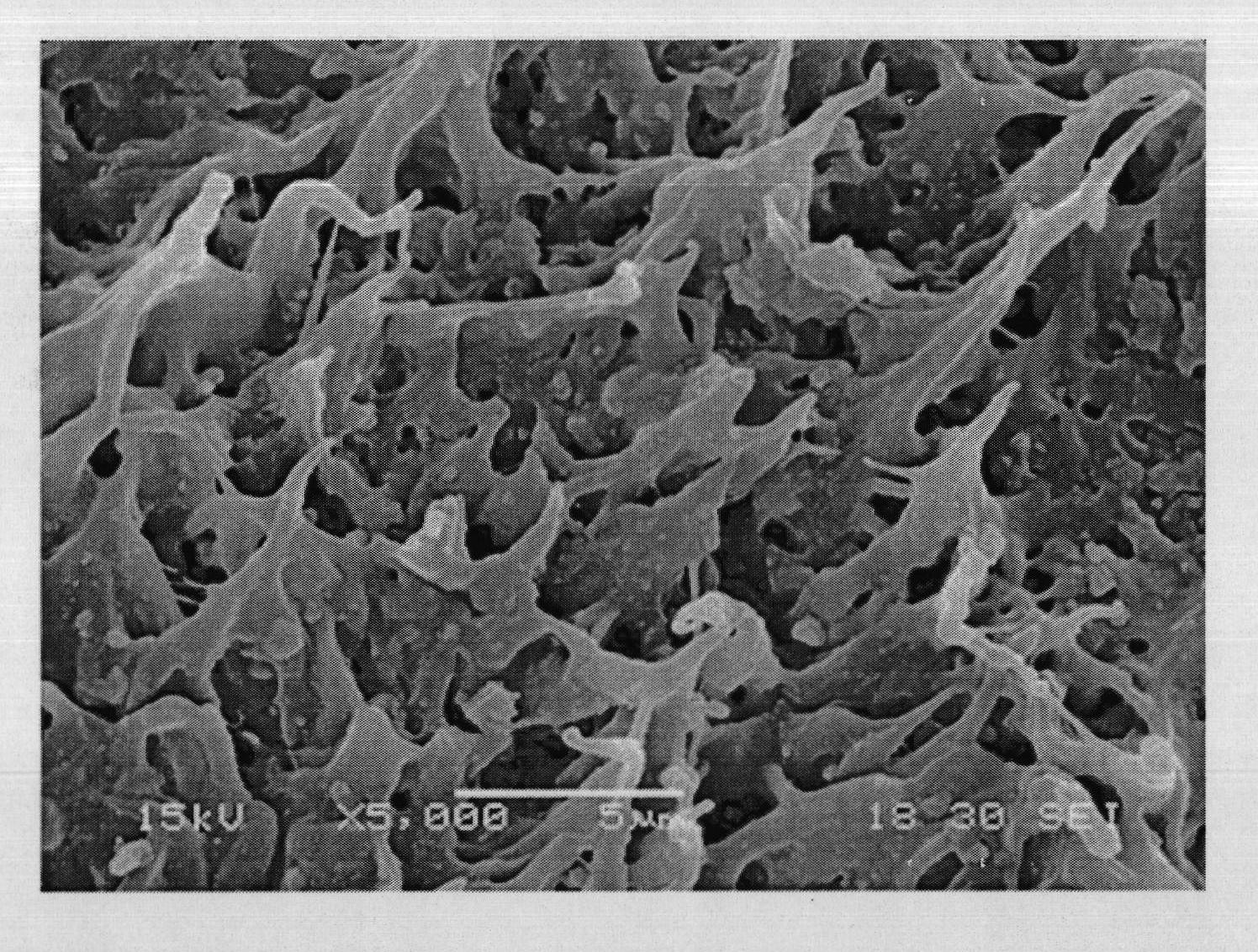

Polyacrylate elastomer emulsion and preparation method thereof

The invention provides a polyacrylate elastomer emulsion and a preparation method thereof. The polyacrylate elastomer emulsion is prepared from a soft monomer and a hard monomer with an emulsion polymerization method, wherein the soft monomer is more than one of n-butyl acrylate, isobutyl acrylate, octyl acrylate or n-octyl methacrylate; and the hard monomer is more than one of methyl methacrylate, styrene or vinyl acetate. The polyacrylate elastomer emulsion can be used for preparing a composite toughening modifier for plastic. The composite toughening modifier for plastic serving as a filler for a rubber material can be used for toughening together with CPE (Chlorinated Polyethylene), so that the impact resistance of the material is enhanced by over five times, and is enhanced by over 10 times in comparison to that of non-toughened PVC (Polyvinyl Chloride). The plasticizing capacity of a substrate is improved, the hardness and rigidity of a product can be enhanced, and the heat resistance, wear resistance and size stability of the material are enhanced. The application field of nano-calcium carbonate is enlarged greatly, and the cost of a rubber product can be lowered remarkably.

Owner:SHANGHAI HUAMING HI TECH GRP

Pilling resistant agent emulsion for wool fabrics and preparation method thereof

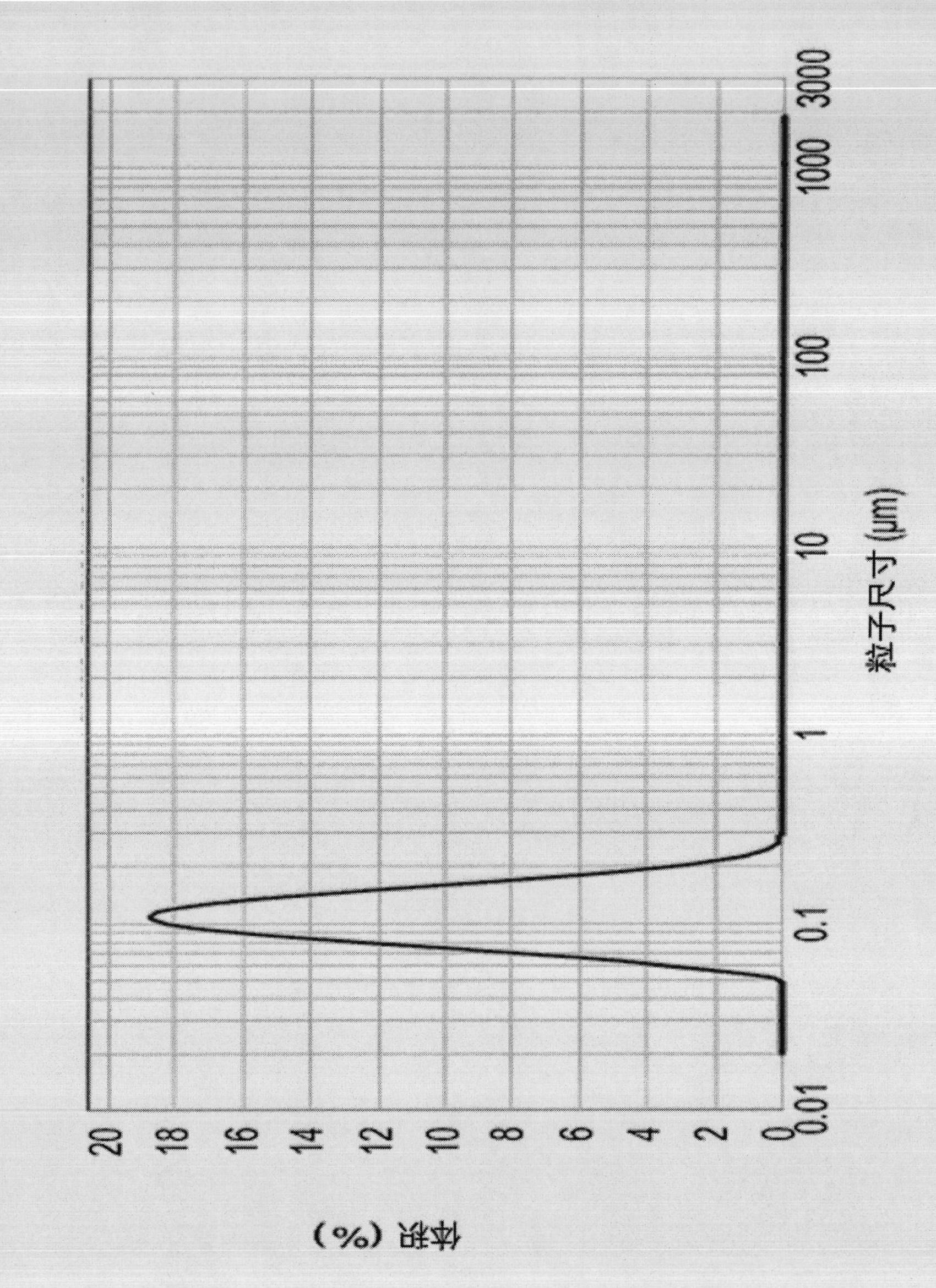

InactiveCN103044627AGood anti-pillingNo emissionsAnimal fibresPolymer scienceEmulsion polymerization

The invention discloses pilling resistant agent emulsion for wool fabrics and a preparation method thereof. The emulsion comprises the following raw materials in percentage by weight: 2-8 percent of ethyl hexyl acrylate monomer, 6-16 percent of butyl acrylate monomer, 2-8percent of hydroxyl ester acrylate monomer, 0.1-1.5 percent of anionic surfactant, 0.1-1.5 percent of non-ionic emulsifier, 0.01-0.1 percent of initiator, 0.8-5 percent of siloxane monomer, 5-15 percent of vinyl-contained silane coupling agent, 0.1-1 percent of silane hydrolysis inhibitor and 50-70 percent of de-ionized water; and the emulsion is prepared by adopting the semi-continuous seed emulsion polymerization technique. The pilling resistant agent emulsion has the characteristics of small particle size, low emulsion dosage, easy control of reaction process, no environmental pollution and the like. The pilling resistant grade of the wool fabrics which are treated by the pilling resistant agent emulsion is improved by more than 2 grades; the hydrophily is basically not changed; and the original hand feel and style of the fabrics are little influenced.

Owner:SUZHOU UNIV +1

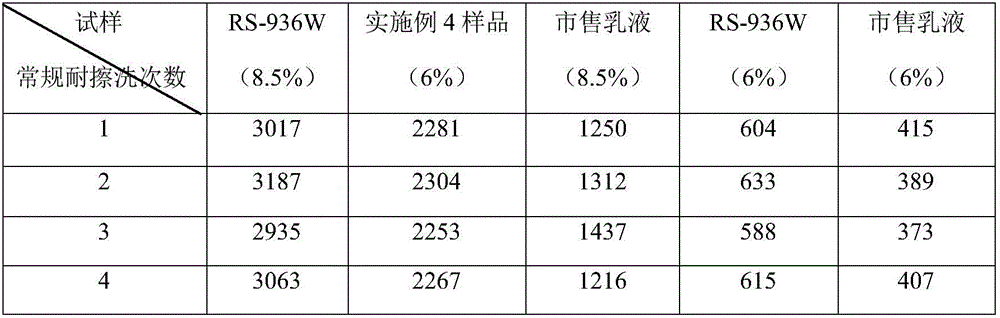

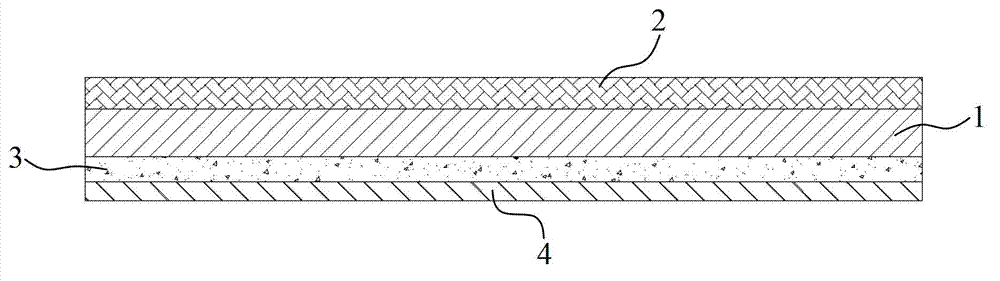

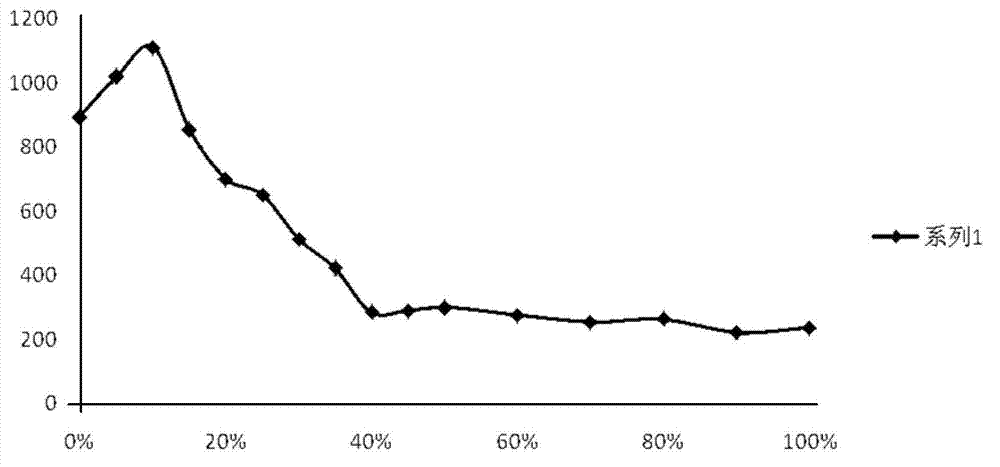

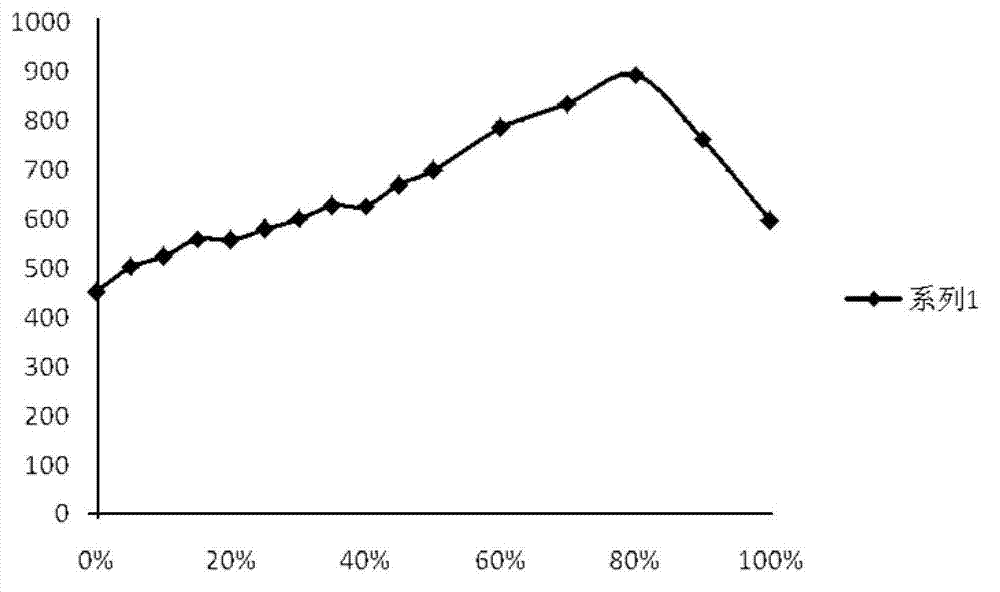

Low-emulsion-addition and high-scrubbing-resistance water-based interior wall emulsion and preparation thereof

The invention belongs to the field of latex coatings, and particularly relates to low-emulsion-addition and high-scrubbing-resistance water-based interior wall emulsion and preparation thereof. The water-based interior wall emulsion is prepared from the following raw materials in parts by weight: 10 to 25 parts of styrene, 5 to 20 parts of butyl acrylate, 5 to 20 parts of iso-octyl acrylate, 0.5 to 5 parts of an alkyl carboxylic acid cross-linking monomer, 0.5 to 5 parts of siloxane, 1 to 5 parts of organic matter oil, 1.0 to 2.5 parts of an emulsifier, 0.1 to 0.5 part of persulfate and 50 to 55 parts of water. The prepared emulsion has extremely high wetting, dispersing and wrapping capability for a pigment filler, so that a latex paint obtained under the condition of low emulsion addition is endowed with high scrubbing resistance.

Owner:中山市巴德富化工科技有限公司

Heat dissipation adhesive tape applied to electronic device and preparation process of same

ActiveCN103045117AAvoid local overheatingFacilitated DiffusionNon-macromolecular adhesive additivesFilm/foil adhesivesIsooctyl acrylateBenzoyl peroxide

The invention discloses a heat dissipation adhesive tape applied to an electronic device, which is characterized by comprising a PET (polyethylene terephthalate) thin film with the thickness of 0.004 mm to 0.025 mm, wherein the lower surface of the PET thin film is coated with a heat conduction adhesive layer; the heat conduction adhesive layer is prepared from the following components in part by weight by baking after mixing: 100 parts of acrylic ester adhesive, 50 to 150 parts of graphite powder, 200 to 300 parts of solvent, 0.1 to 1 part of curing agent and 0.01 to 0.1 part of coupling agent; and the acrylic ester adhesive consists of the following components in part by weight: 100 parts of butyl acrylate, 0.1 to 1 part of benzoyl peroxide, 50 to 150 parts of iso-octyl acrylate, 2 to 5 parts of acrylic acid, 10 to 30 parts of methyl methacrylate, 0 to 10 parts of vinyl acetate and 0.1 to 1 part of 2-hydroxyethyl methacrylate. According to the invention, the effect that thermal conductivity is improved in both length and thickness directions is ensured; uniformity of thermal conductivity of the adhesive tape is realized; not only is the heat dissipation adhesive tape beneficial for dissipating heat, but also local overheating of the adhesive tape is avoided; and performance and service life of the product are improved.

Owner:斯迪克新型材料(江苏)有限公司

Weather resistant, impact resistant and economical PVC promoter

The invention relates to a PVC auxiliary agent with good weathering resistance, shock resistance and economical efficiency, which is characterized in that: the PVC auxiliary agent is a copolymer with a nuclear shell structure, wherein, a nuclear layer of the PVC auxiliary agent is formed by emulsion polymerization of butyl acrylate, chlorinated polyethylene and 2-ethyl hexyl acrylate under the protection of a surfactant and nitrogen and through initiation of an initiator, and a core shell is formed by continuous emulsion polymerization and grafting reaction of methyl methacrylate on the nuclear layer. By adoption of the total weight of a monomer polymer as 100 percent, the butyl acrylate occupies 30 to 40 percent; the chlorinated polyethylene occupies 30 to 40 percent; the 2-ethyl hexyl acrylate occupies 15 to 35 percent; and the methyl methacrylate occupies 5 to 20 percent. The PVC auxiliary agent has superior shock resistance and weathering resistance and simultaneously has superior powder fluidity, and the shock resistance of the PVC auxiliary agent is higher than that of MBS and acrylic ester shock modifiers which are widely applied in the industry.

Owner:SHANDONG RUIFENG CHEM

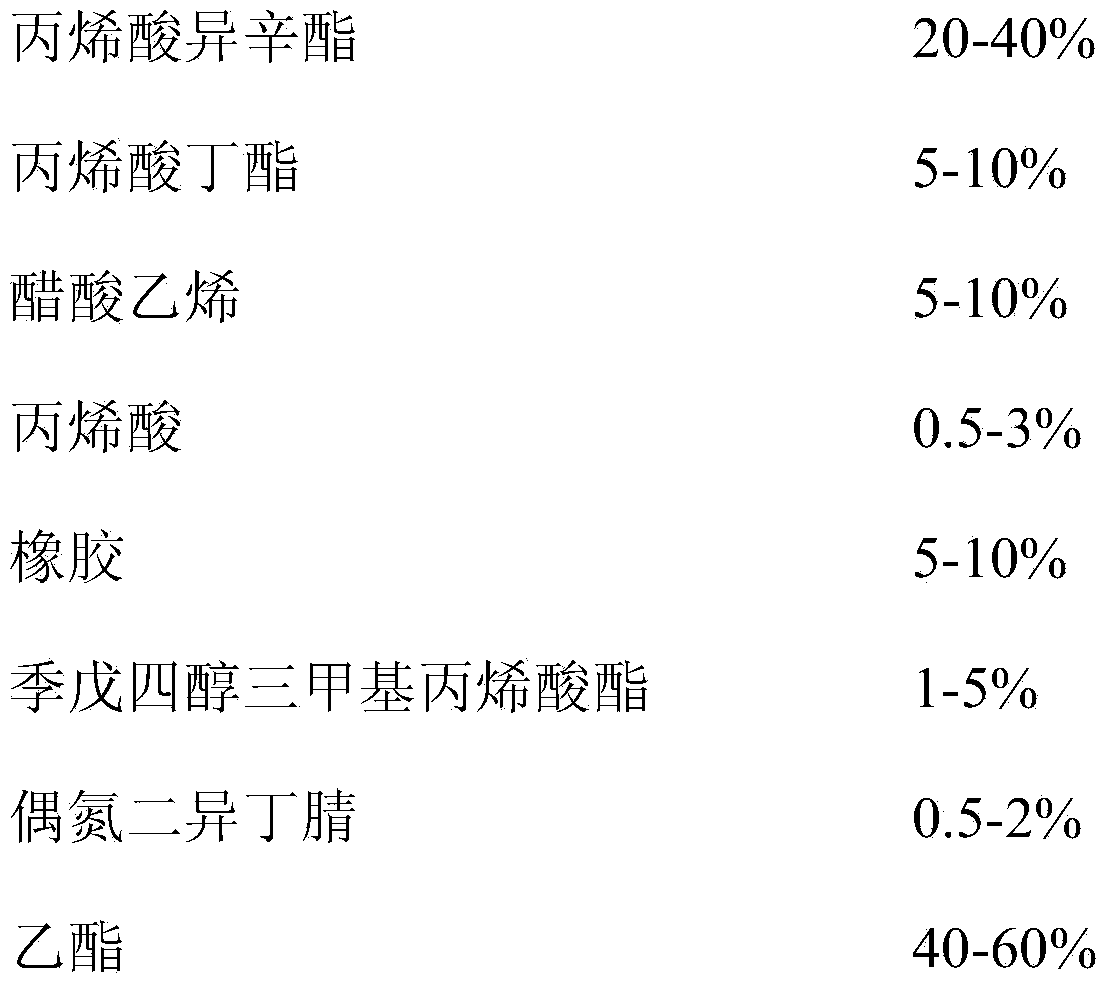

Special-purpose acrylic glue of lithium battery and preparation method thereof

ActiveCN103468177AExtended service lifeImprove working conditionEster polymer adhesivesConjugated diene hydrocarbon adhesivesIsooctyl acrylateMethacrylate

The invention relates to the technical field of lithium battery materials, and in particular relates to special-purpose acrylic glue of a lithium battery and a preparation method thereof. The special-purpose acrylic glue of the lithium battery comprises the following materials in percentage by weight: 20%-40% of iso-octyl acrylate, 5%-10% of butyl acrylate, 5%-10% of vinyl acetate, 0.5%-3% of acrylic acid, 5%-10% of rubber, 1%-5% of pentaerythritol trimethyl acrylate, 0.5%-2% of azodiisobutyronitrile and 40%-60% of ethyl ester. An adhesive tape which is prepared by using the glue does not lose viscosity due to chemical reaction after being soaked in electrolyte, and can keep good viscosity, so that a metal strap of a lug can be effectively fixed, and the metal strap of the lug is enabled to be not infiltrated by the electrolyte, thereby prolonging the service life of the battery and eliminating potential safety hazards. Besides, the glue can resist a high temperature of 150 DEG C at most, so that the battery can keeping a good working state under the high-temperature condition, the service life of the battery is prolonged, and the potential safety hazards are eliminated.

Owner:澳中新材料科技(韶关)有限公司

Water-based acrylate emulsion for water-based woodware paint and preparation method thereof

The invention discloses water-based acrylate emulsion for water-based woodware paint and a preparation method thereof. The water-based acrylate emulsion is prepared from the following materials in parts by weight: 0.1-5 parts of butyl acrylate, 10-30 parts of methyl methacrylate, 5-15 parts of iso-octyl acrylate, 3-15 parts of oligomer, 0.1-3 parts of an emulsifying agent, 0.1-5 parts of crosslinking monomer, 0.05-0.2 part of a chain transferring agent, 0.1-5 parts of carboxylic monomer, 0.1-0.3 part of persulfate, 1.4-3 parts of ammonia water, 0.1-5 parts of adipic acid dihydrazide and 43-67 parts of water. The preparation process comprises the steps of emulsifying, polymerizing and discharging. The preparation method disclosed by the invention has the advantages of simple equipment, convenience in operation, low cost and short period. The prepared emulsion has the characteristics of low film-forming temperature, high paint-film fullness and good cohesion resistance and has good application prospect in the field of the water-based woodware paint.

Owner:中山市巴德富化工科技有限公司

Preparation method of emulsion type pressure-sensitive adhesive

InactiveCN105175620AImprove stabilityNarrow particle size distributionEster polymer adhesivesSodium bicarbonateIsooctyl acrylate

A preparation method of an emulsion type pressure-sensitive adhesive comprises, by weight, 60-65 parts of a soft monomer, 20-25 parts of iso-octyl acrylate, 10-15 parts of a hard monomer, 1-3 parts of acrylic acid, 100 parts of deionized water, 0.1-0.2 parts of dodecyl mercaptan, 0.4-0.5 parts of an initiator, 0.2-0.5 parts of sodium bicarbonate, 0.8-1.2 parts of an anionic emulsifier, 1.8-2.2 parts of a nonionic emulsifier, and a proper amount of ammonia water, wherein the soft monomer is selected from one or a mixture of two of butyl acrylate and ethyl acrylate; the hard monomer is selected from one or a mixture of more of vinyl acetate, styrene and methyl methacrylate; the anionic emulsifier is one or a combination of more of CO-436, k-12 and DB-45; and the nonionic emulsifier is one or a combination of two of OP-10 and TA300-70. The preparation method adopting a seed emulsion technology makes an emulsion have good stability, narrow particle size distribution and easy control property, and the pressure-sensitive adhesive obtained in the invention improves the initial adhesion and the peel strength under large permanent adhesion.

Owner:JUSHI GRP CO

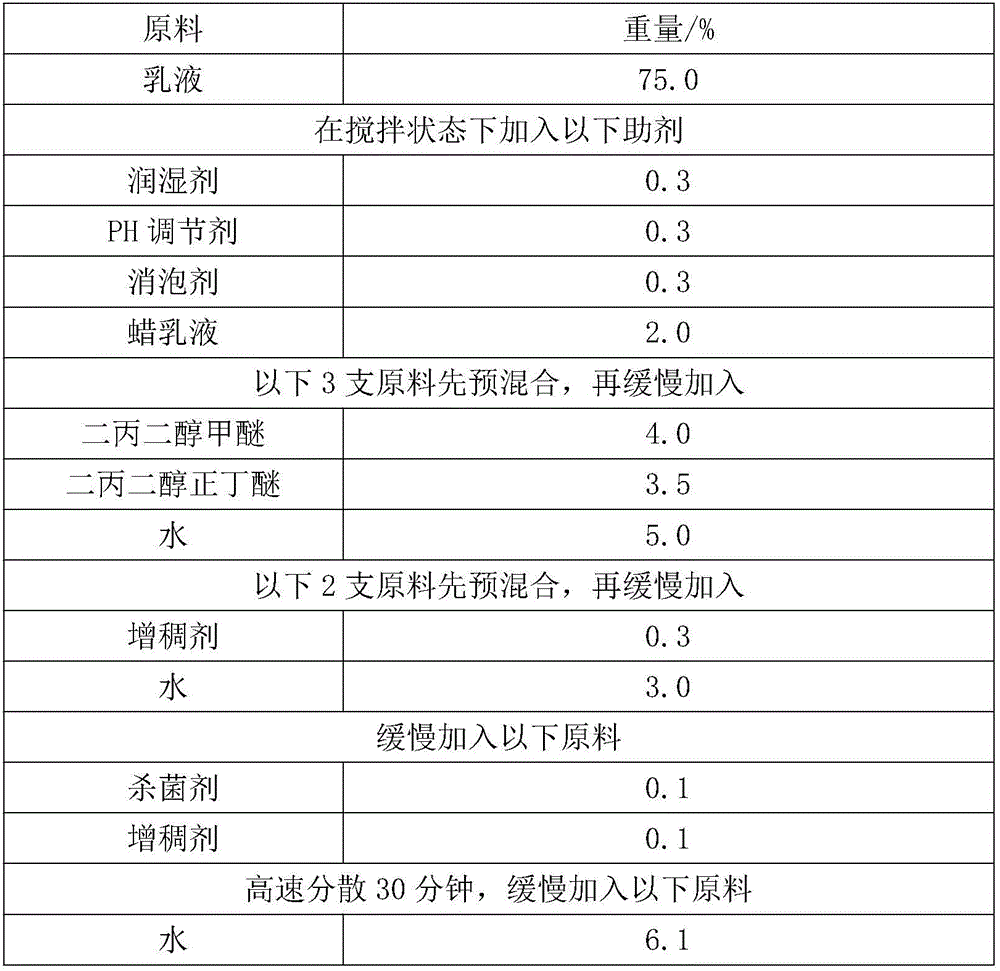

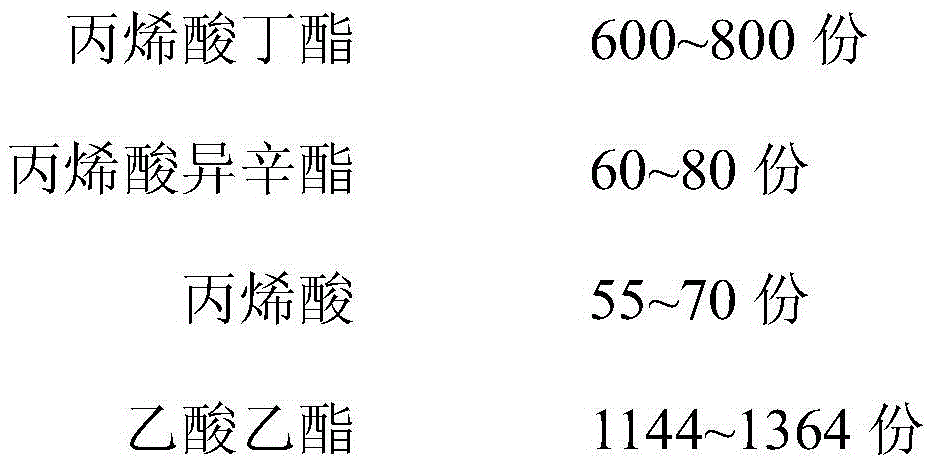

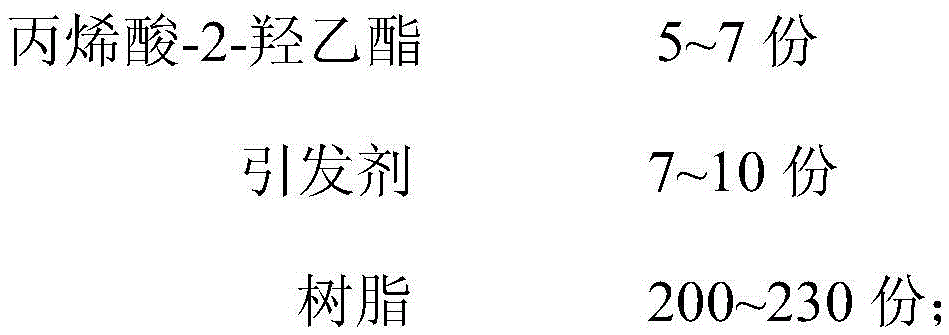

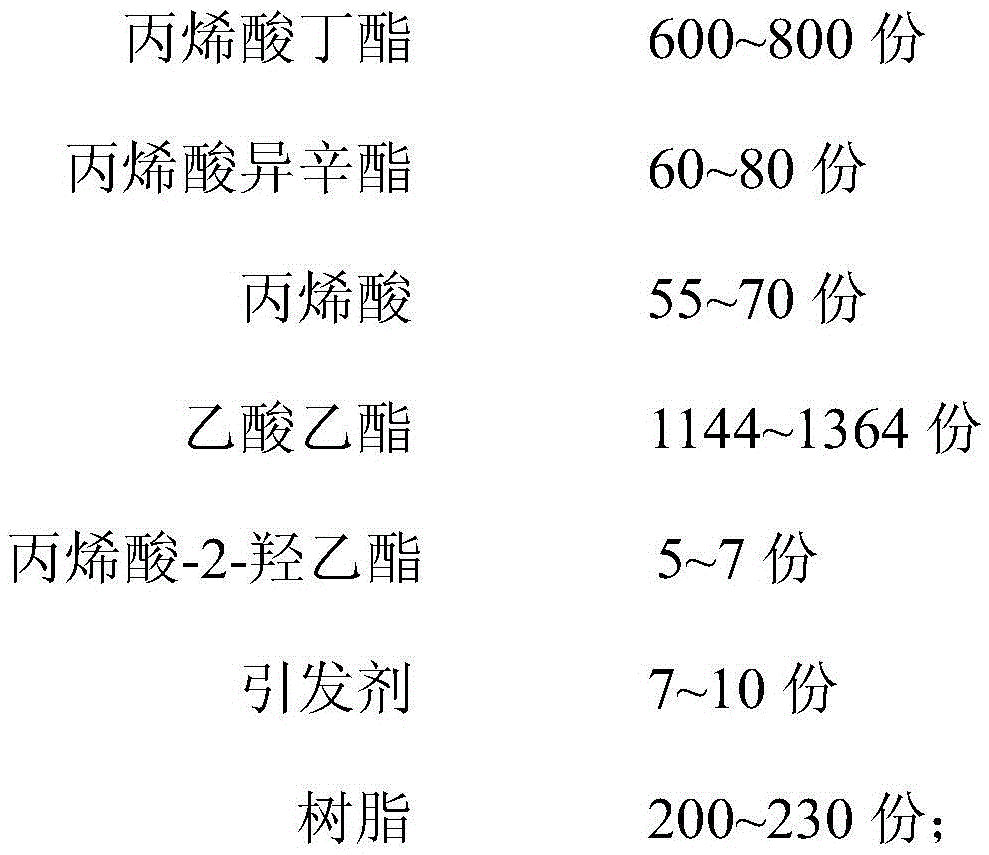

Preparation technology of acrylate adhesive and acrylate adhesive product

ActiveCN105542687AAvoid being unfriendlyImprove performanceMacromolecular adhesive additivesEster polymer adhesivesIsooctyl acrylateAdhesive

A preparation technology of an acrylate adhesive comprises the following steps: a, raw materials are taken in a weight ratio; b, part of butyl acrylate, iso-octyl acrylate and ethyl acetate are taken and added to a reactor and stirred; c, part of acrylic acid and 2-hydroxyethyl acrylate are taken and added to the reactor in the step b and stirred; d, part of butyl acrylate, ethyl acetate, acrylic acid and 2-hydroxyethyl acrylate are taken and added to the reactor in the step c and stirred; e, an initiator is taken, divided into 6 parts and dissolved in ethyl acetate respectively, six solutions are added to the reactor in the step d sequentially, and after addition, the mixture is stirred; f, resin is taken and dissolved in ethyl acetate, the mixture after dissolution is added to the reactor in the step e and stirred, and the acrylate adhesive is obtained. According to the preparation technology, a non-toluene solvent is used, environment-friendliness is realized, the technology is optimized, the polymer dispersion is improved, and a down-stream product meets the environmental protection requirements for low VOC (volatile organic compounds) quantity and low total carbon on the premise that the performance is guaranteed.

Owner:YASUSA CHEM CO LTD

Lyophobic high-hardness water resistant acrylic ester emulsion and preparation method thereof

The invention discloses lyophobic high-hardness water resistant acrylic ester emulsion and a preparation method thereof, and belongs to the field of acrylic ester emulsion. The emulsion is prepared from the following raw materials in parts by mass: 80 to 120 parts of water, 10 to 30 parts of methyl methacrylate, 20 to 40 parts of styrene, 0 to 30 parts of iso-octyl acrylate, 2 to 10 parts of functional monomers, 0 to 2 parts of crosslinking monomers, 2 to 10 parts of protection glue, 2 to 6 parts of emulsifying agents, 1 to 5 parts of initiating agents and 0 to 3 parts of oxidation-reduction agents. The lyophobic high-hardness water resistant acrylic ester emulsion is prepared by a warming self-reaction method; the whole reaction is performed at the temperature of 25 to 95 DEG C, so that the whole reaction system can be performed in relative mild environment; the reaction stability is ensured; meanwhile, the whole reaction is performed in a reaction kettle; the preparation can be realized through heating and stirring; the processing work procedures are very simple; the processing cost of the acrylic ester emulsion is greatly reduced.

Owner:中山市巴德富化工科技有限公司

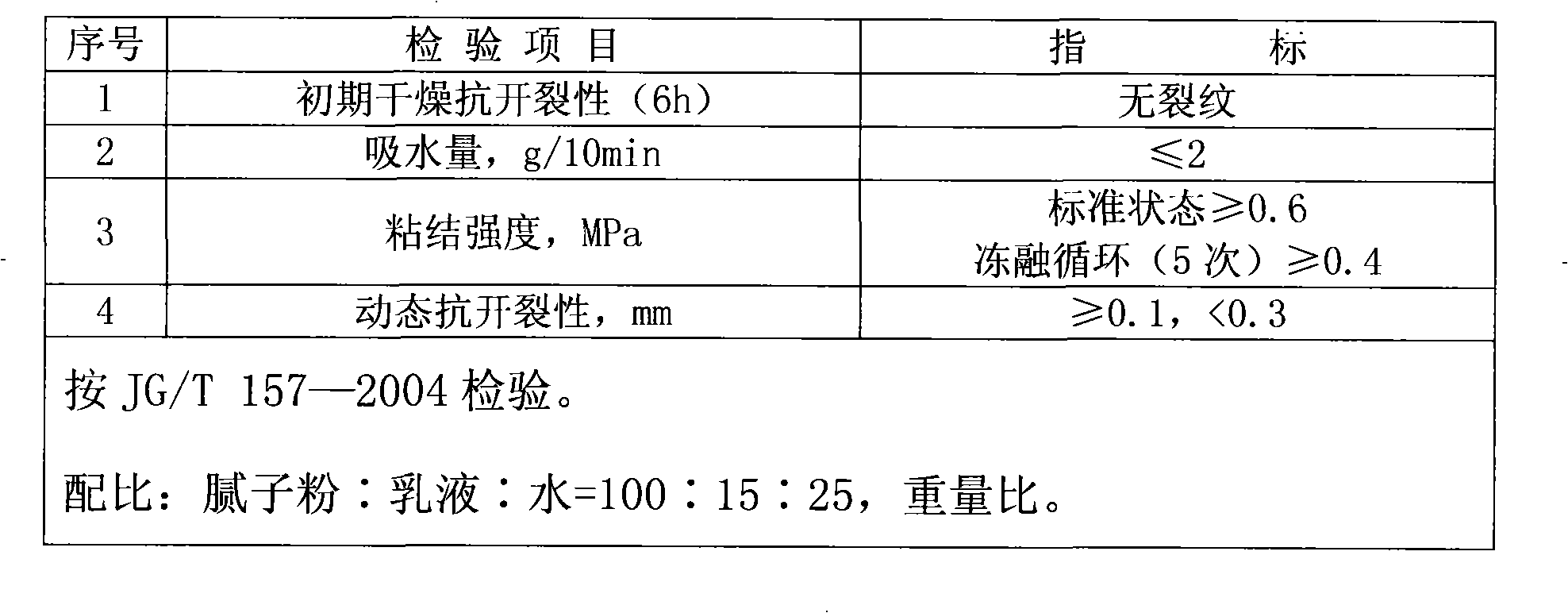

Elastic emulsion for curing building putty and preparation method thereof

InactiveCN101358049AImprove crack resistanceGood dynamic crack resistanceFilling pastesIsooctyl acrylatePutty

The invention discloses an elastic emulsion used to cure construction putty and a preparation method thereof. The elastic emulsion contains the components with the following weight portion: 80 to 100 portions of methyl methacrylate, 0 to 60 portions of styrene, 70 to 90 portions of butyl acrylate, 135 to 165 portions of iso-octyl acrylate, 3 to 11 portions of acrylic acid, 0.2 to 1.2 portions of anionic emulsifier, 0.6 to 2.6 portions of non-ionic emulsifier, 1.0 to 2.2 portions of reactive emulsifier, 1.0 to 2.2 portions of buffer, 1.6 to 2.5 portions of initiator, 0.4 to 1.2 portions of sodium formaldehyde sulfoxylate, 0.4 to 1.2 portions of tert-butyl hydroperoxide, 2.0 to 6.0 portions of pH value regulator, 0.4 to 1.2 portions of defoamer, 0.4 to 1.2 portions of thickener, and 290 to 350 portions of water. The invention is rationally designed, the process is simple, putty layer cured by the product has high anti-cracking and dynamic anti-cracking performance at the early stage, which meets the needs of the construction industry.

Owner:上海展辰涂料有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com