Patents

Literature

244results about How to "Low film forming temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

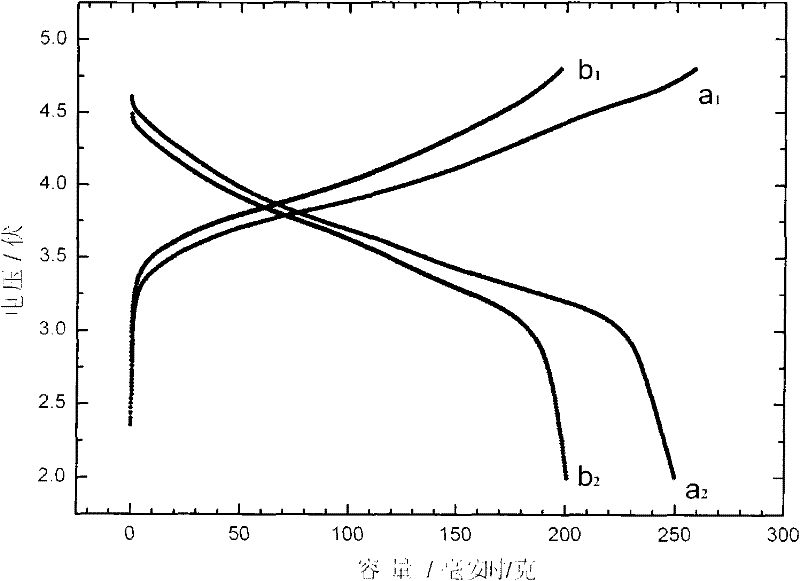

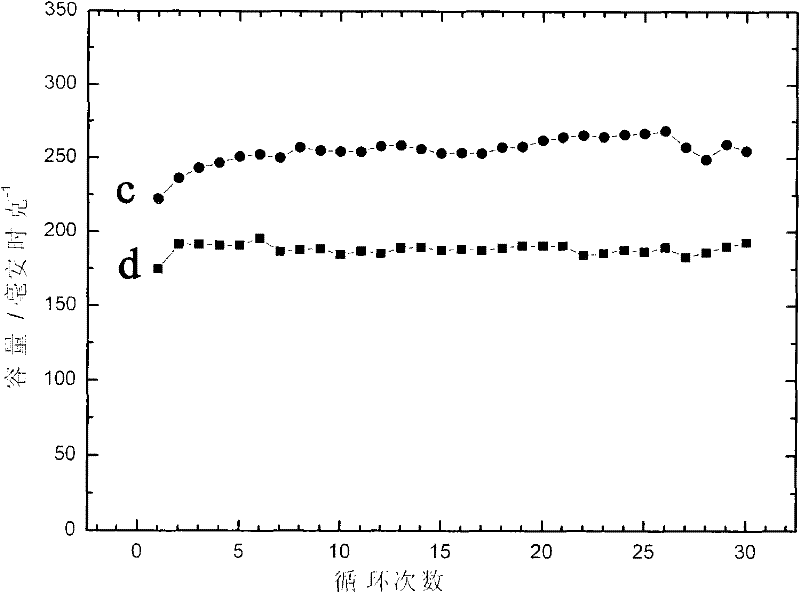

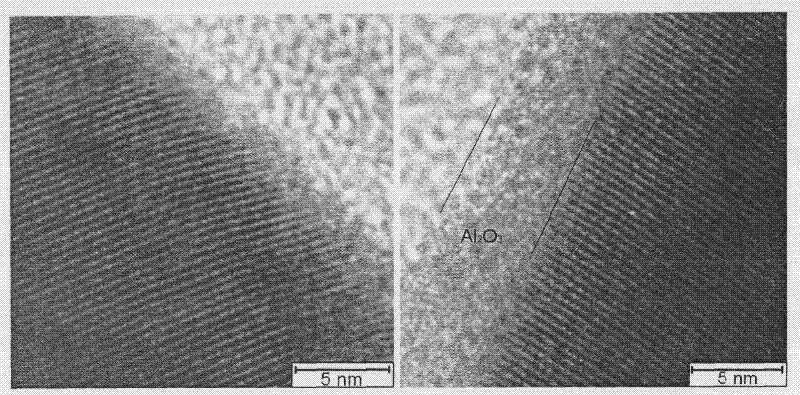

Method for cladding surfaces of active material of anode and/or anode and methods manufacturing anode and battery

InactiveCN102244231AStructurally intactStable structureNon-aqueous electrolyte accumulator electrodesMetallurgyLithium-ion battery

The invention provides a method for cladding surfaces of an active material of an anode and / or the anode and methods for manufacturing the anode and a battery. In the cladding method, an atomic layer deposition technology is adopted to deposit surface modification substances on the surfaces of the active material of the anode and / or the anode of a lithium battery. According to the invention, the cycle performance and the specific capacity of the lithium-ion battery can be improved obviously and electrode materials are more stable.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

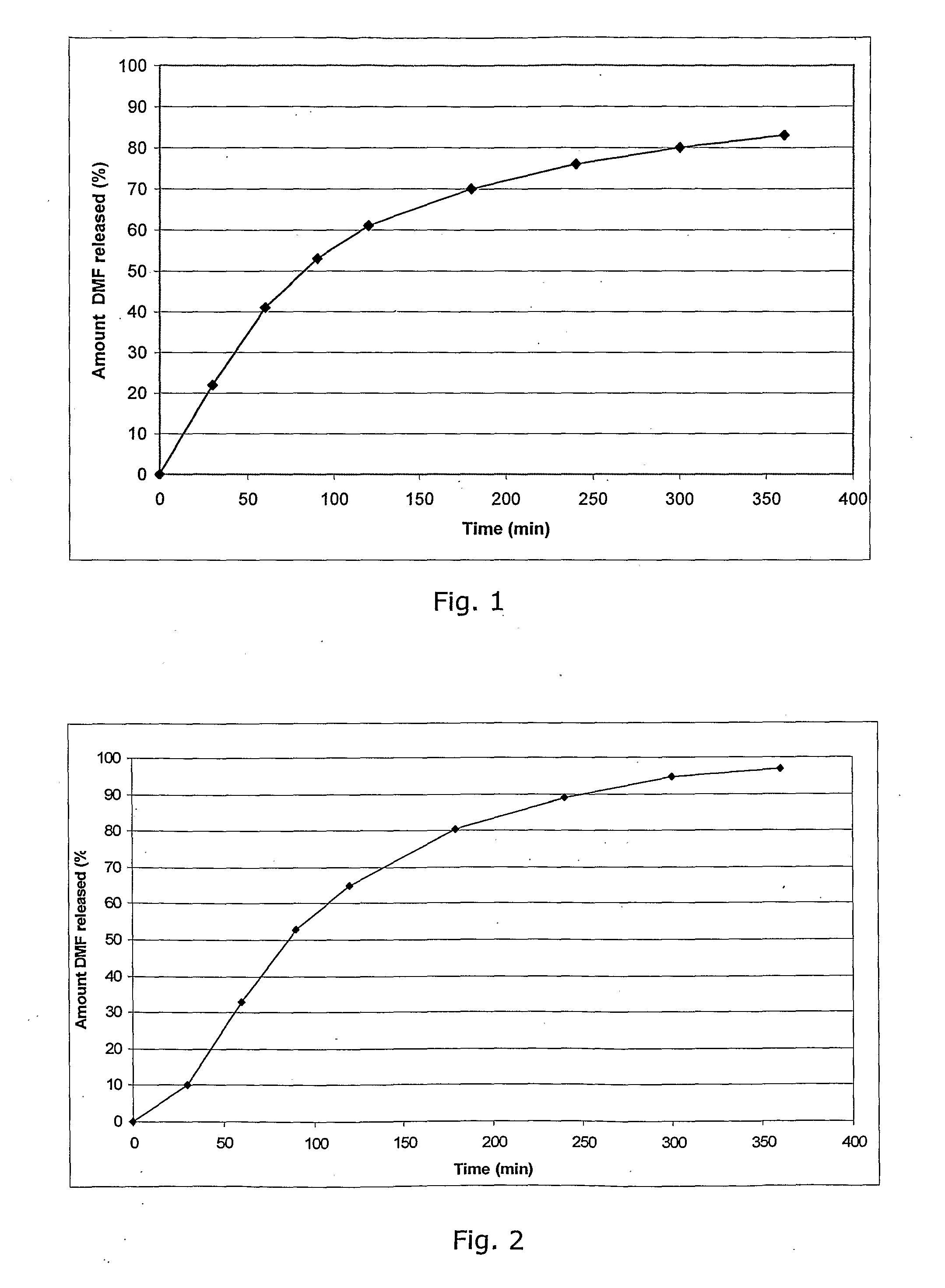

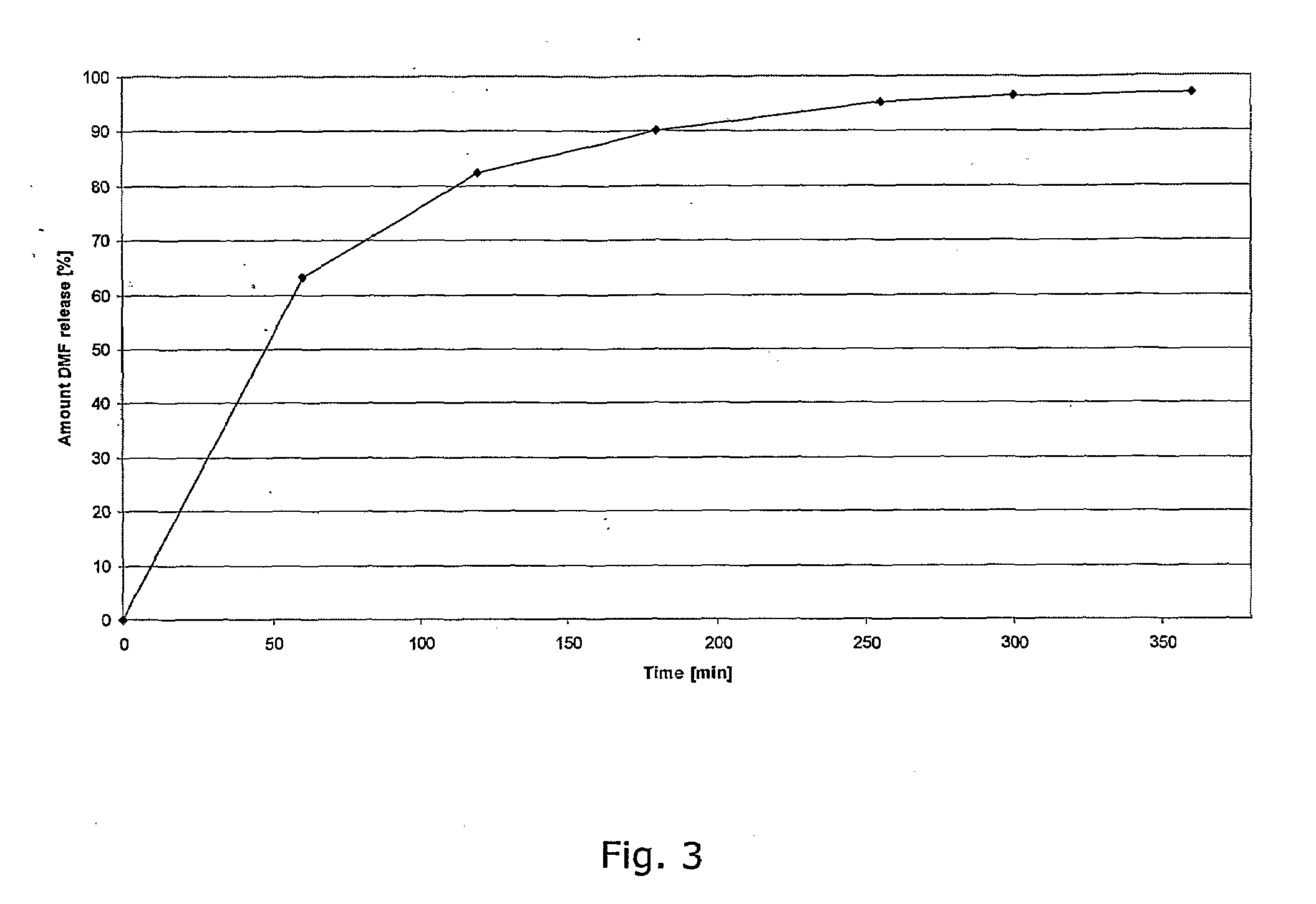

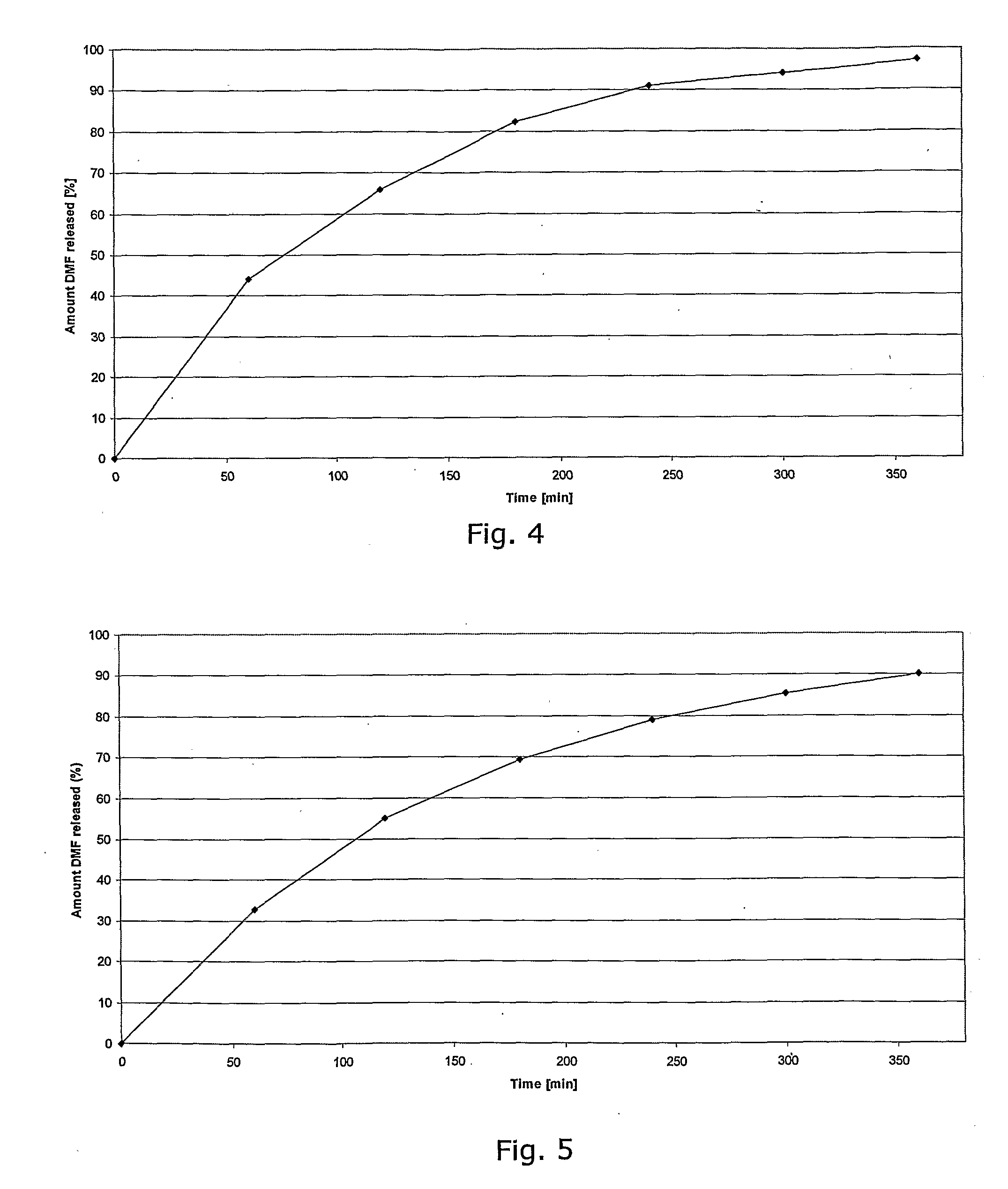

Controlled Release Pharmaceutical Compositions Comprising a Fumaric Acid Ester

InactiveUS20080299196A1Decrease glass transition pointLow film forming temperatureBiocideSenses disorderDiseaseHigh concentration

The present invention relates to controlled release pharmaceutical compositions comprising fumaric acid ester(s) as active substance(s). The compositions are suitable for use in the treatment of e.g. psoriasis or other hyperproliferative, inflammatory or autoimmune disorders and are designed to release the fumaric acid ester in a controlled manner so that local high concentrations of the active substance within the gastrointestinal tract upon oral administration can be avoided and, thereby, enabling a reduction in gastro-intestinal related side-effects.

Owner:BIOGEN SWISS MFG GMBH

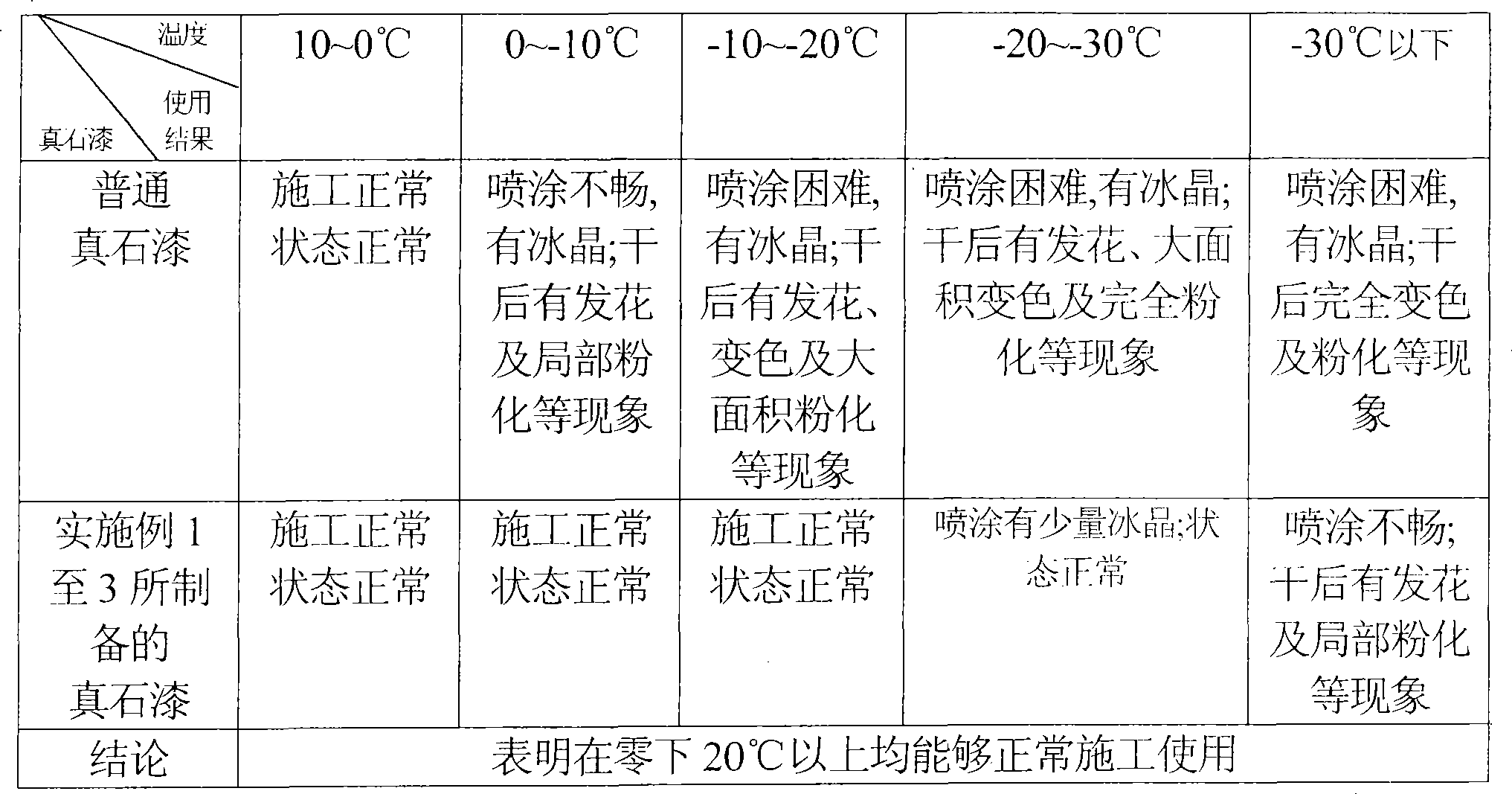

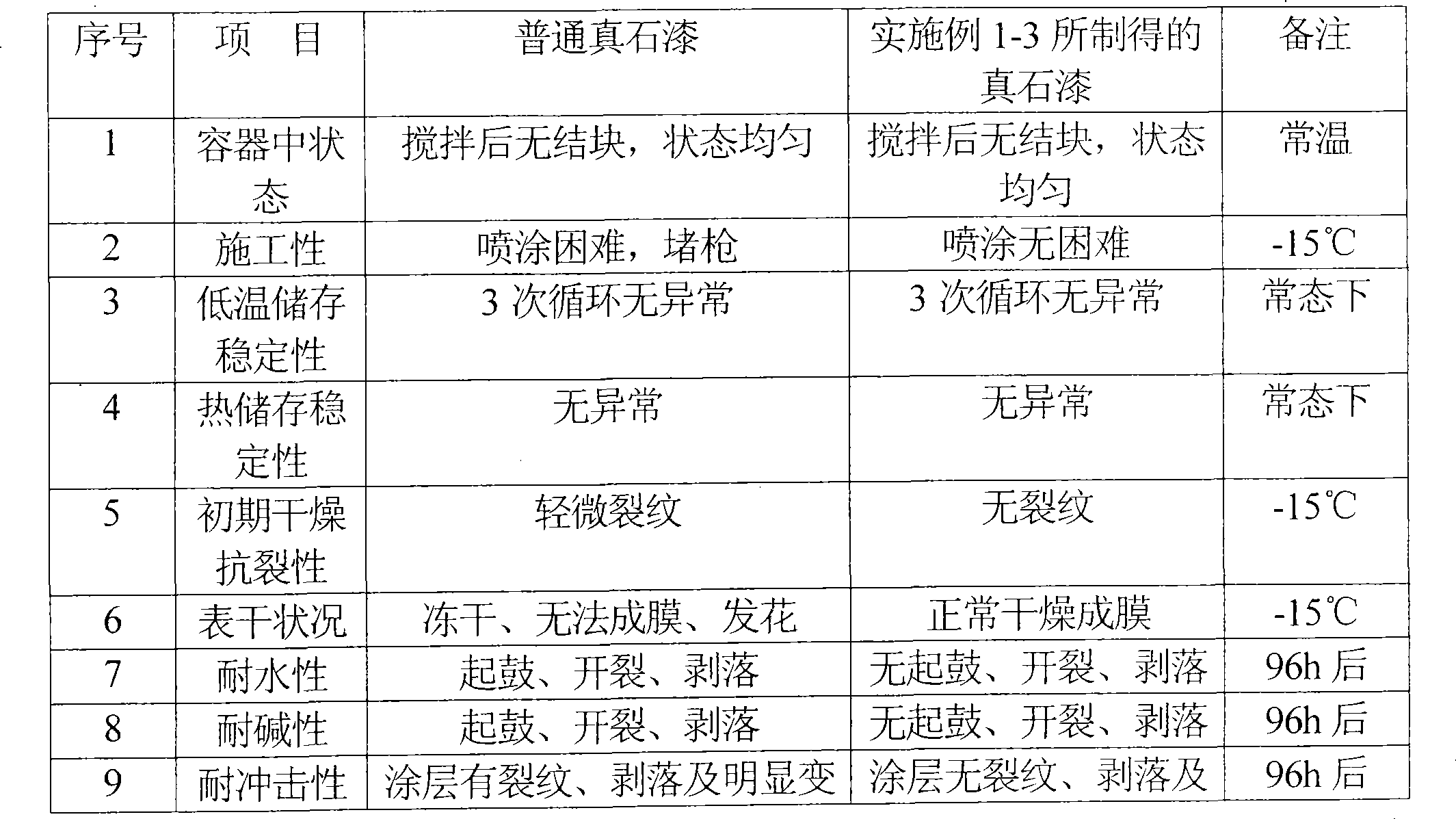

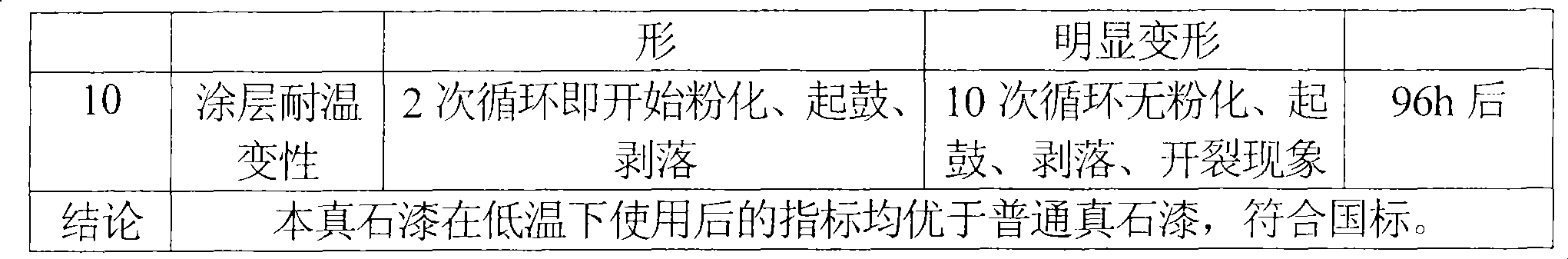

Environment friendly antifreezing stone-like paint and preparation thereof

The invention discloses an environment freeze protection stone paint, which comprises the following raw material components according to the parts by weight: 0.1-5 of fibrin aqueous solution of 1-4% concentration, 0.8-1.2 of glycol, 50-70 of colored sand of 41-80 mesh, 5-25 of colored sand of 81-120, 17-23 of KE025 acrylic emulsion, 0.6-0.9 of alcohol ester-12 addition agent, 0.02-0.06 of foam killer, 0.01-0.1 of thickness agent and 0.02-0.06 of neutralizing agent. Meanwhile, the invention also discloses a preparation method for the stone paint. The stone paint has the environment and freeze protection performance, provides powerful guarantee for being suitable for winter construction, in particular to various severe conditions of winter construction in the northern area of our country.

Owner:许军 +1

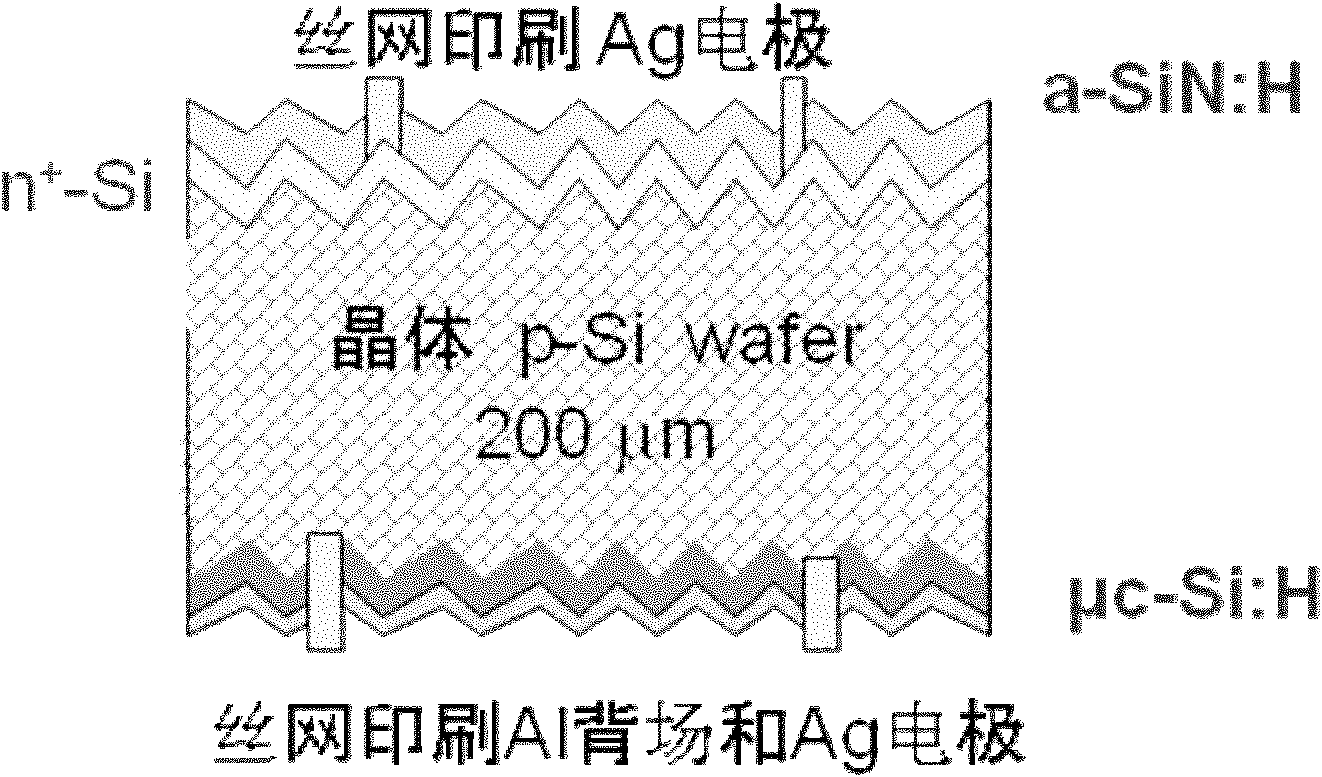

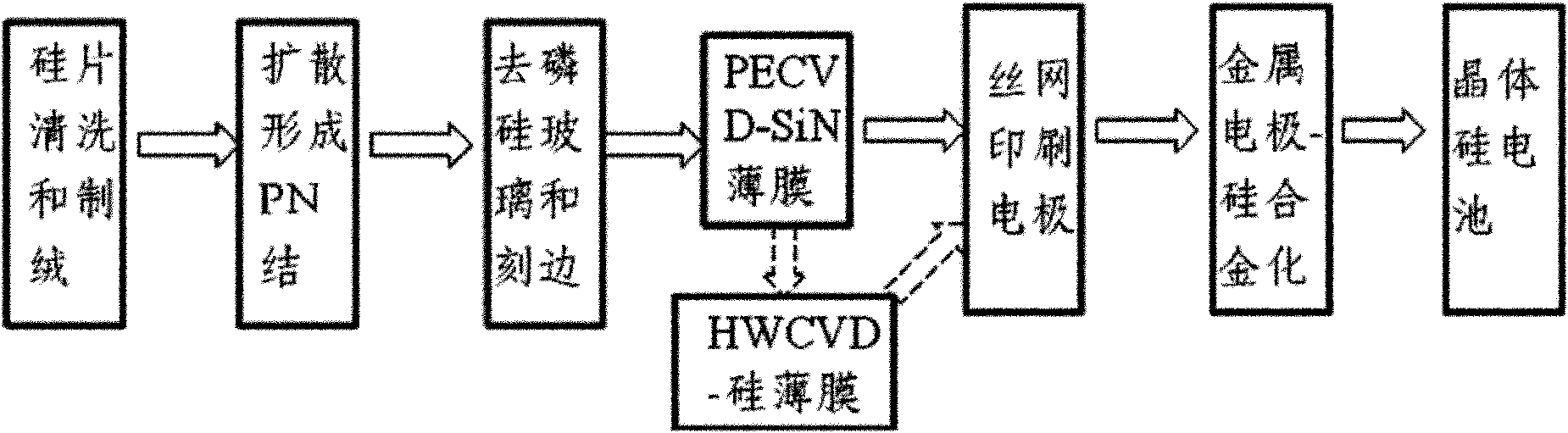

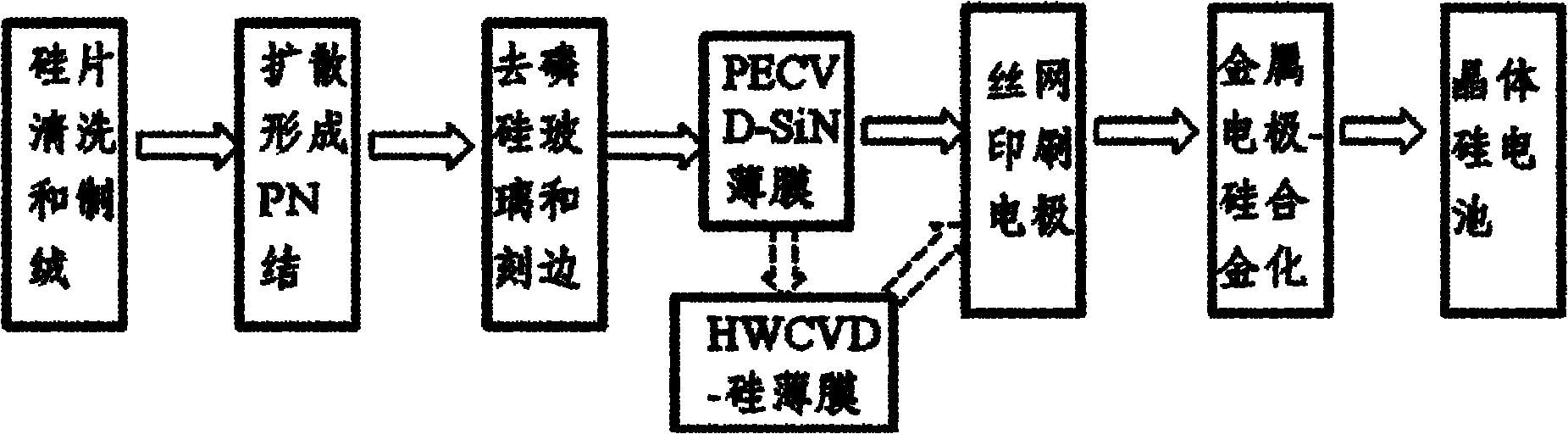

Preparation method of double-sided passivated crystalline silicon solar cell

InactiveCN101937944APrevent escapeAdjustable bandgapSemiconductor devicesP type siliconMicrocrystalline silicon

The invention discloses a preparation method of a double-sided passivated crystalline silicon solar cell, belonging to the technical field of photovoltaic power generation. The preparation method comprises the following steps of: firstly, respectively carrying out surface precleaning and surface texturing on P-shaped single crystal silicon and a polycrystalline silicon wafer by adopting an alkaline solution and an acid solution; secondly, diffusing by using phosphorus oxychloride as a diffusion source to form a PN junction; thirdly, removing a phosphosilicate glass on the surface of the silicon wafer by adopting a chemical wet method, and etching the edge of the silicon wafer by adopting a plasma; fourthly, preparing a silicon nitride film on the surface of an emitting region of a P-type silicon wafer by adopting a plasma enhanced chemical vapor deposition method; fifthly, preparing a mixed phase film material of hydrogenated microcrystalline silicon and amorphous silicon by adopting a hot filament chemical vapor deposition method, depositing a film at one side of the P-type silicon wafer, and passivating the defects and a dangling bond on the surface of the P-type silicon wafer; and sixthly, sintering a screen printing back electrode and a screen printing positive electrode to form the solar cell. The invention lowers the probability of compounding photo-generated minority carriers on the back surface, enhances the long-wave light quantum efficiency and creates the conditions of transportation and collection of the photo-generated carriers.

Owner:SHANGHAI JIAO TONG UNIV

Double-component water-based polyurethane high-abrasion-resistance matte varnish and preparation thereof

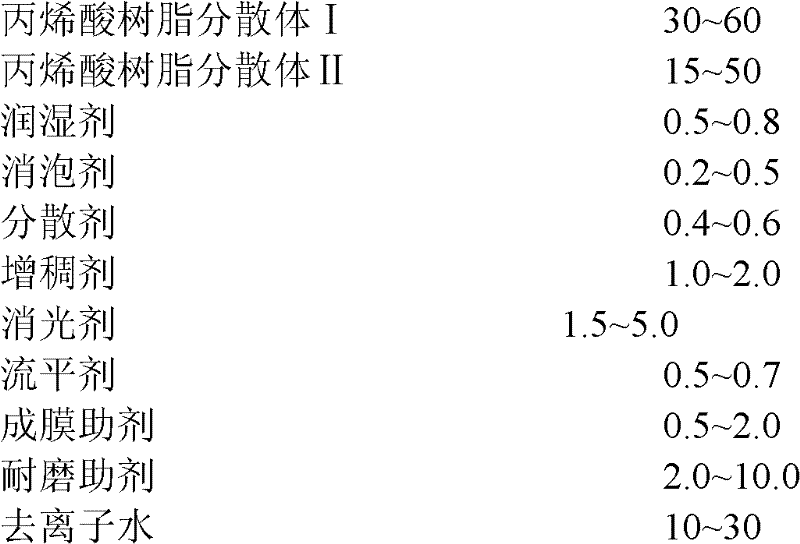

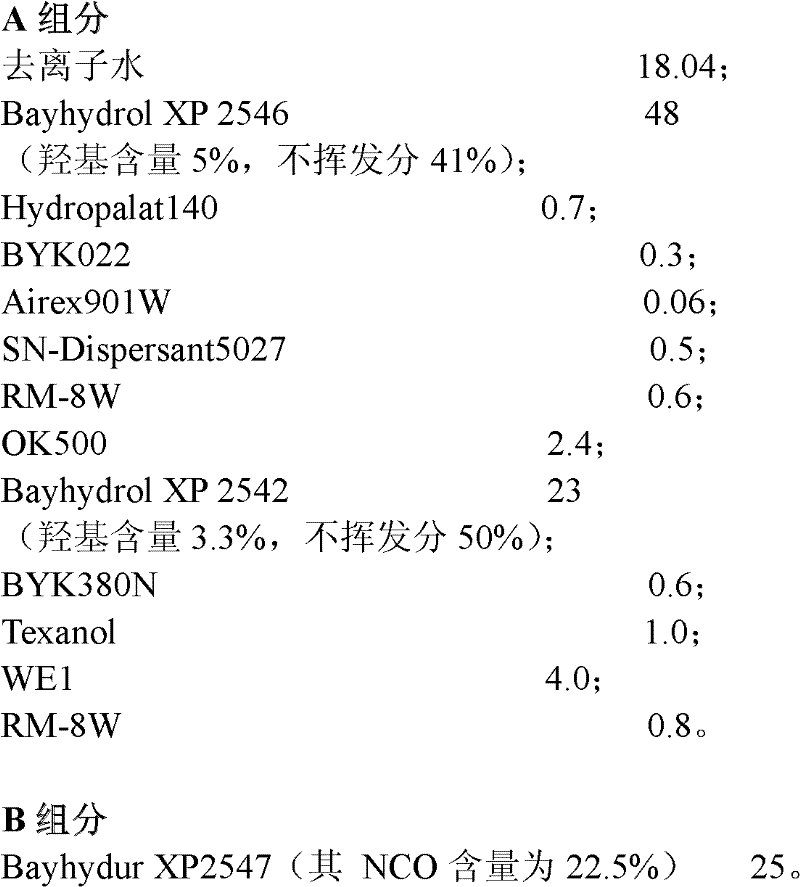

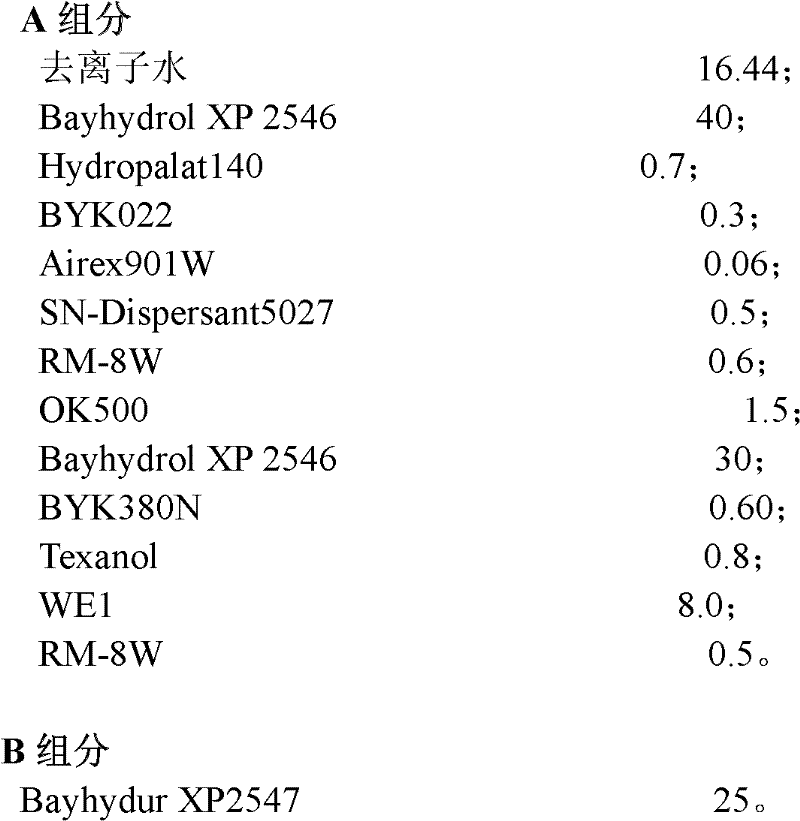

InactiveCN102533077AReduce glossOvercome the disadvantage of uneven mattingPolyurea/polyurethane coatingsEpoxyAcrylic resin

The invention discloses a double-component water-based polyurethane high-abrasion-resistance matte coating and a preparation thereof. The coating comprises two components A and B, wherein the component A is prepared by using an acrylic resin dispersion body as a basic component and adding deionized water, a wetting agent, a defoaming agent, a dispersing agent, a thickening agent, a delustering agent, a leveling agent, a film forming additive and a water resistant additive to the acrylic resin dispersion body to disperse the acrylic resin dispersion body; and the component B is aliphatic polyisocyanate. The invention provides a water-based matte coating with low VOC (Volatile Organic Compounds), low gloss, good adhesion force, wear resistance and corrosion resistance; and the water-based matte coating can be very well combined with a water-based or solvent type epoxy resin floor coating and a polyurethane floor coating. The water-based matte coating disclosed by the invention has the advantages of low delustering agent adding quantity and stability in storage; the gloss of the coating system can be effectively reduced; and the comprehensive performance of the coating system is improved. By using the double-component water-based polyurethane high-abrasion-resistance matte coating disclosed by the invention, the water-based coating system solution with environment friendliness, high performance, stability in storage and low cost can be provided.

Owner:CENT SOUTH UNIV +1

Dendritic organic-inorganic hybrid water-borne nano polyurethane-epoxy anticorrosive coating and preparation method thereof

InactiveCN101798484ASolve pollutionNo pollution in the processAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedCross-link

The invention discloses a dendritic organic-inorganic hybrid water-borne nano polyurethane-epoxy anticorrosive coating and a preparation method thereof. Compositions of the coating mainly comprise dendritic organic-inorganic hybrid water-borne nano polyurethane-epoxy emulsion, anticorrosive pigment and filler, pigment dispersing agent, a film forming aid, a water-based additive, a cross-linking curing agent and deionized water, wherein the dendritic organic-inorganic hybrid water-borne nano polyurethane-epoxy emulsion is prepared by the following steps: prepolymerizing a polyurethane hydrophilic branch; preparing a dendritic polyurethane intermediate product by adopting hyperbranched synthesis technology; inoculating organic-inorganic hybrid into a nano material by adopting a in-situ polymerization; and simultaneously grafting epoxy resin with hydroxyl; and the prepared emulsion is compounded with the anticorrosive pigment and filler and the like to prepare the anticorrosive coating. The anticorrosive coating radically solves the VOC pollution problem of solvent-type anticorrosive coating, and simultaneously solves a series of problems such as poor roughness, weatherability, ageing resistance, alkali resistance and solvent resistance of the conventional water-borne anticorrosive coating.

Owner:SICHUAN UNIV +1

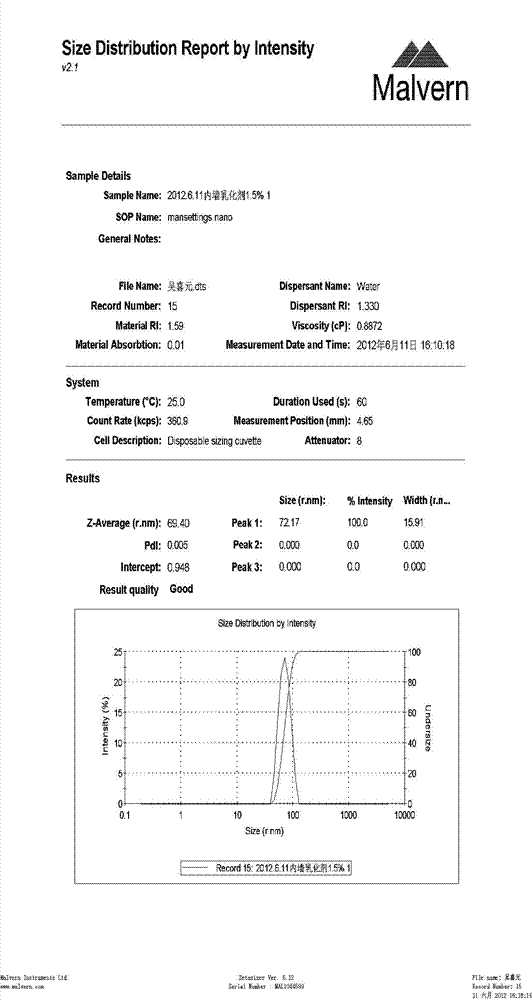

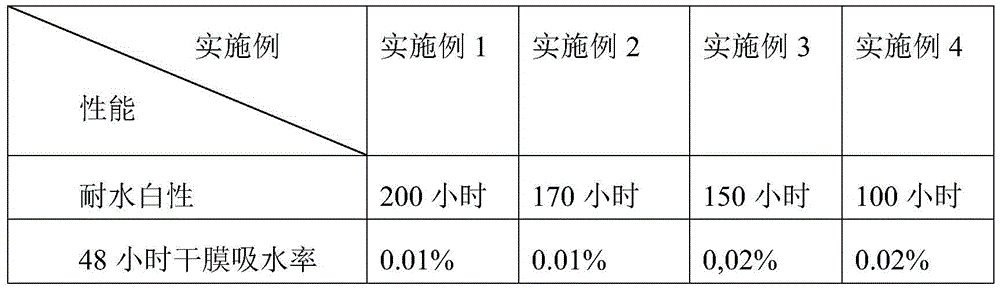

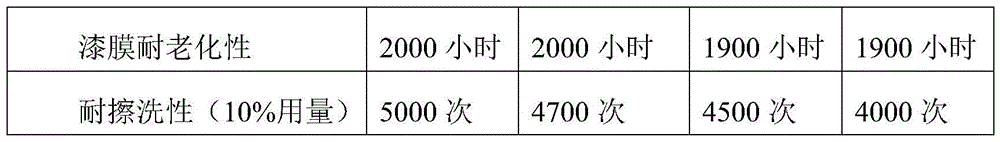

Preparation method of waterproof and whiting-resistant silicon-acrylic composite emulsion for interior wall latex coatings

InactiveCN102924646AGood weather resistanceImprove adhesionEmulsion paintsPolymer scienceLatex rubber

The invention relates to a preparation method of a waterproof and whiting-resistant silicon-acrylic composite emulsion for interior wall latex coatings. The emulsion comprises the following raw materials: monomers, emulsifiers, initiators such as ammonium persulfate and deionized water. The raw materials are orderly processed through steps of pre-emulsifying the monomer, polymerizing seed emulsion, polymerizing semi-continuous emulsion and finally filtering and discharging. According to the preparation method, vinyl organic silicon, a self-crosslinking system and assistant cross-linking agents are copolymerized with acrylic esters monomers by using pre-emulsification semi-continuous seed emulsion polymerizing method to prepare the silicon-acrylic composite emulsion. Entire preparation process is stable and convenient and is beneficial to achieving mass production. The obtained composite emulsion has the advantages of monomer conversion rate of more than 96%, average emulsion particle size of less than 100 nanometers (nm), good mechanical stability and storage stability, high hardness of film, low lowest film-forming temperature and excellent whiting resistance in water and water resistance.

Owner:SHAANXI UNIV OF SCI & TECH

Water soluble acrylic resin and its prepn

The present invention relates to one kind of water soluble acrylic resin for ink, polish oil and paint and its preparation process. The organic silicone oil modified acrylic resin is prepared with acrylic acid monomer 15-57 wt%, organic silicone oil with double bond 1-15 wt%, organic solvent 20-60 wt% and initiator 0.1-10 wt%, and through free radical solution polymerization at 60-160 deg.c to obtain organic silicone oil modified acrylic resin, adding neutralizing agent and water through stirring, distilling to eliminate organic solvent, further adding neutralizing agent and water to reach solid content of 20-60 wt%. The organic silicone oil modified acrylic resin has high vitrification point, low filming temperature, high water tolerance and other advantages.

Owner:JIANGSU SANMU GROUP CORPORATION

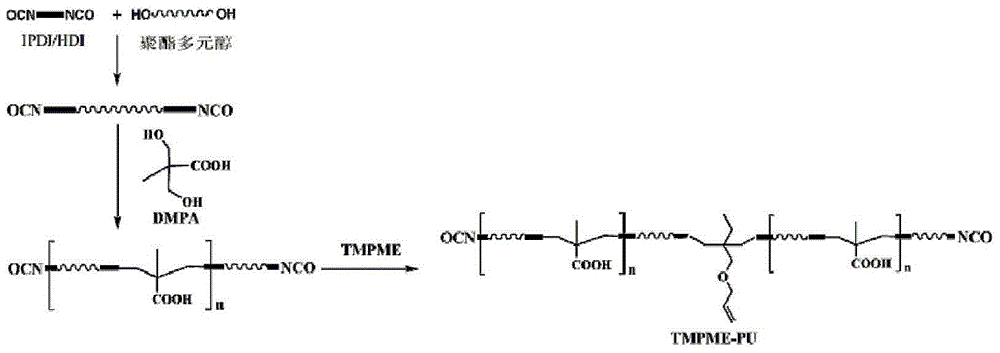

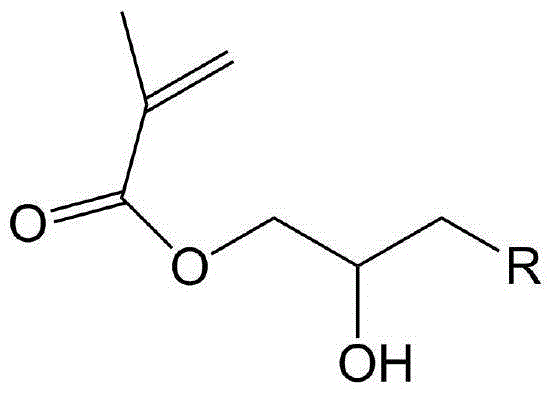

Water-based polyurethane composite emulsion and preparation method thereof

ActiveCN102838713ASpeed up evaporationLower glass transition temperatureGraft polymer adhesivesWater basedPolyester

The invention discloses a water-based polyurethane composite emulsion and a preparation method thereof. The preparation method is characterized by comprising the following steps: by using acetone or butanone and acrylic monomer as solvents, polymerizing diisocyanate (HDI), isophorone diisocyanate (IPDI), mixed polyester polyalcohol, dihydroxymethylpropionic acid, 1,4-butanediol, trimethylolpropane monoene propyl ether, 2-hydroxypropyl acrylate and 2-hydroxyethyl acrylate to obtain carboxylic polyurethane; neutralizing with tertiary amine, and removing the solvents to obtain a self-emulsified double-bond-containing water-based polyurethane anionic emulsion; and by using the emulsion as a seed, adding acrylate monomer and a right amount interpenetrating-network crosslinking agent monomer to carry out pre-emulsification, and carrying out seed emulsion polymerization to obtain the composite emulsion in an interpenetrating network structure. The invention has the advantages of energy saving, environmental protection, high early bonding force, safe and reliable technique and stable product quality.

Owner:广东多正树脂科技有限公司

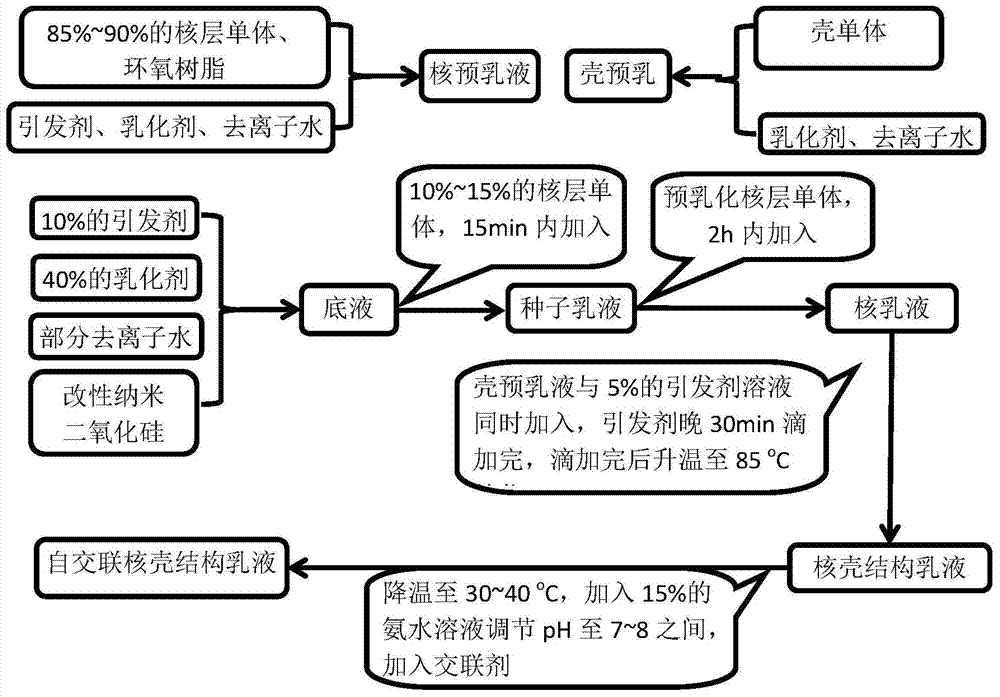

Room temperature self-crosslinking water-based paint as well as preparation method and application thereof

ActiveCN104497777AImprove scrub resistanceGood Diffuse Reflection PerformanceCoatingsDouble bondEmulsion

The invention provides room temperature self-crosslinking water-based paint as well as a preparation method and an application thereof. The paint has high hardness, high scrubbing resistance and good diffuse reflection performance. The preparation method of the paint comprises the following steps: performing graft modification on alkaline silica sol by utilizing a silane coupling agent containing unsaturated double bonds, thereby obtaining nanosilicon dioxide of which the surface is provided with the unsaturated double bonds; by taking the nanosilicon dioxide as a seed, mixing an acrylate monomer and an epoxy resin in the presence of an initiator, and preparing the room temperature self-crosslinking acrylate emulsion which is subjected to epoxy resin and inorganic particle double modification and has a core-shell structure by utilizing a semi-continuous seeded emulsion polymerization process; and by taking the emulsion as a base material, adding a delustering agent, glass powder, body pigment and paint aids, thereby obtaining the room temperature self-crosslinking water-based paint. The paint is coated on the wall surface or board and can be simultaneously taken as a writing board of a doodling pen and a projection screen of a projector, and the problem that the teaching board and the projection screen are independent from each other and cannot be simultaneously used in the prior art is solved.

Owner:山西奇色环保科技股份有限公司

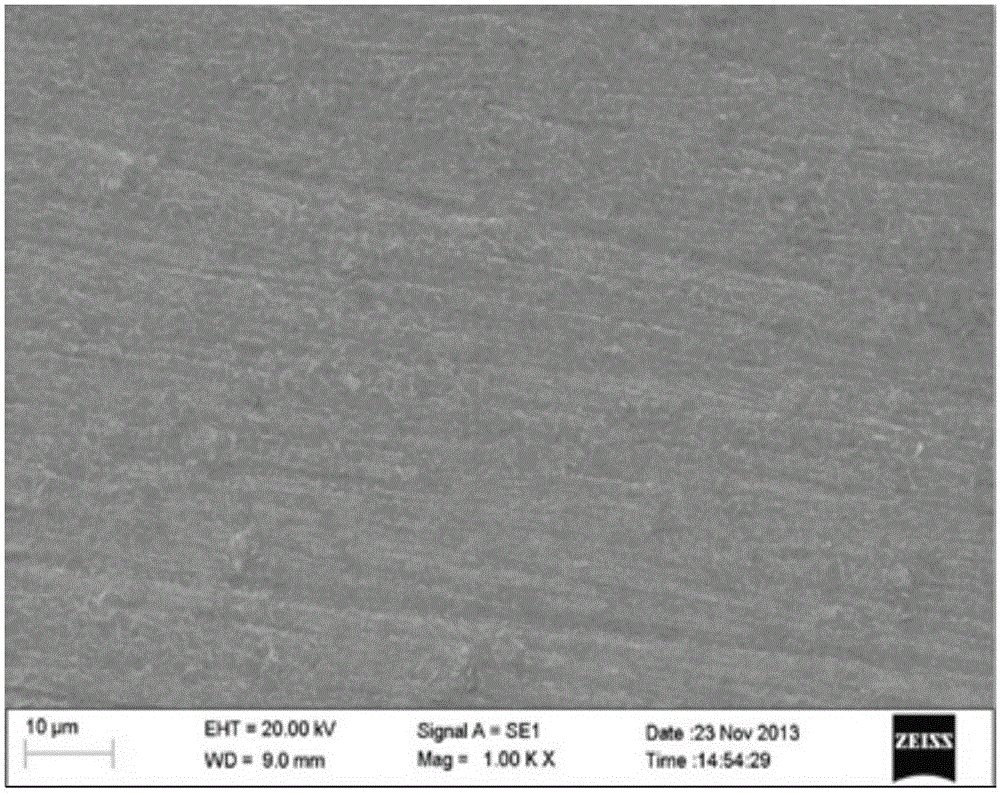

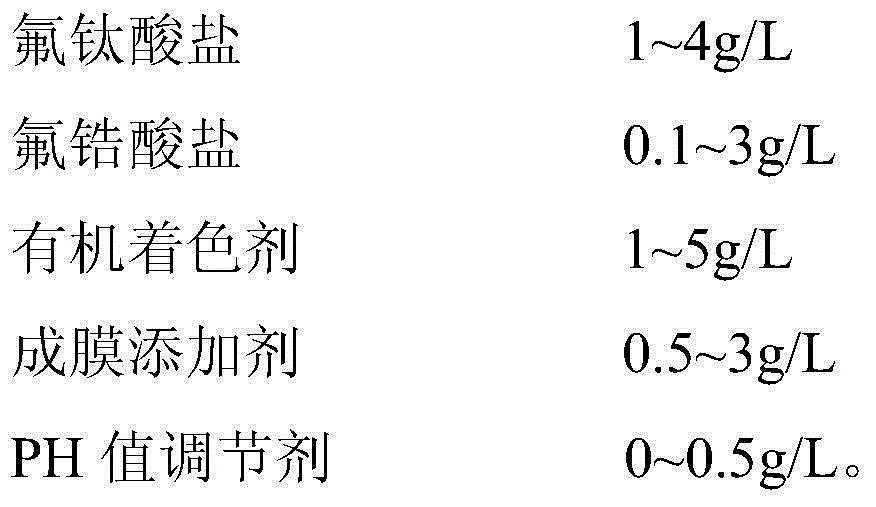

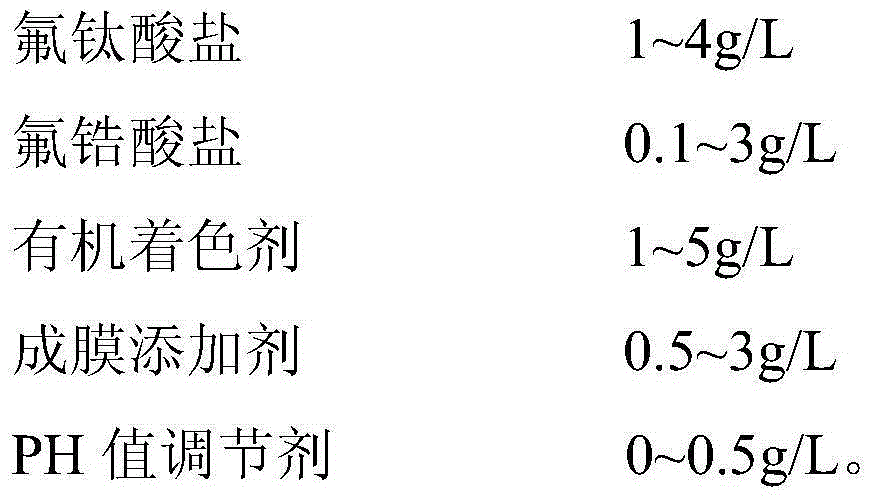

Anticorrosion treatment process for converting/electro-statically spraying environment-friendly zirconium titanate on surfaces of aluminum alloys

ActiveCN105132900AEasy to operateLow film forming temperatureLiquid surface applicatorsMetallic material coating processesCompound (substance)Titanium

The invention belongs to the technical field of chemical materials and discloses an anticorrosion treatment process for converting / electro-statically spraying environment-friendly zirconium titanate on surfaces of aluminum alloys. The anticorrosion treatment process comprises the following steps: (1) carrying out surface pretreatment on the aluminum alloys; (2) converting the surfaces of the aluminum alloys, putting the aluminum alloys subjected to surface pretreatment into a zirconium titanate converting solution, soaking, washing, standing and drying the aluminum alloys to obtain conversion films; (3) suspending the dried aluminum alloys in a powder spraying room and electro-statically spraying organic powder on the aluminum alloys; and (4) standing, preserving heat at 180-200 DEG C, then cooling to obtain anticorrosion coatings. According to the anticorrosion treatment process, the conversion treatment is low in film-forming temperature and short in film-forming time; the zirconium titanate treatment solution is stable, chromium-free and environmentally-friendly; through the treatment process, the surfaces of the aluminum alloys are high in corrosion resistance; the conversion films are excellent in combination with the aluminum alloys and the organic coatings.

Owner:SOUTH CHINA UNIV OF TECH

Waterborne rusted paint and preparation method thereof

InactiveCN101638541ALow film forming temperatureStable storageLiquid surface applicatorsAnti-corrosive paintsDefoamerEmulsion

The invention provides waterborne rusted paint, which mainly comprises transforming agent, transformation accelerator, water, film-forming additives, freeze-thaw stabilizer, ethylene-propylene emulsion, thickener, defoamer and preservatives. The invention also provides a method for preparing the waterborne rusted paint. The waterborne rusted paint has the characteristics of low film-forming temperature, good storage stability, good film properties, high film water resistance and the like, and completely meets the antirust protection requirements of the shipbuilding industry, petroleum industry, machinery industry, construction industry and other various industries needing steel antirust protection.

Owner:上海奇想青晨新材料科技股份有限公司

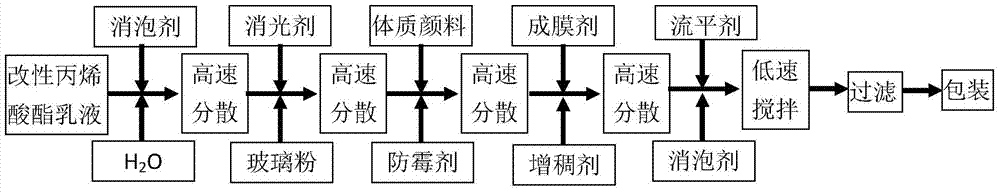

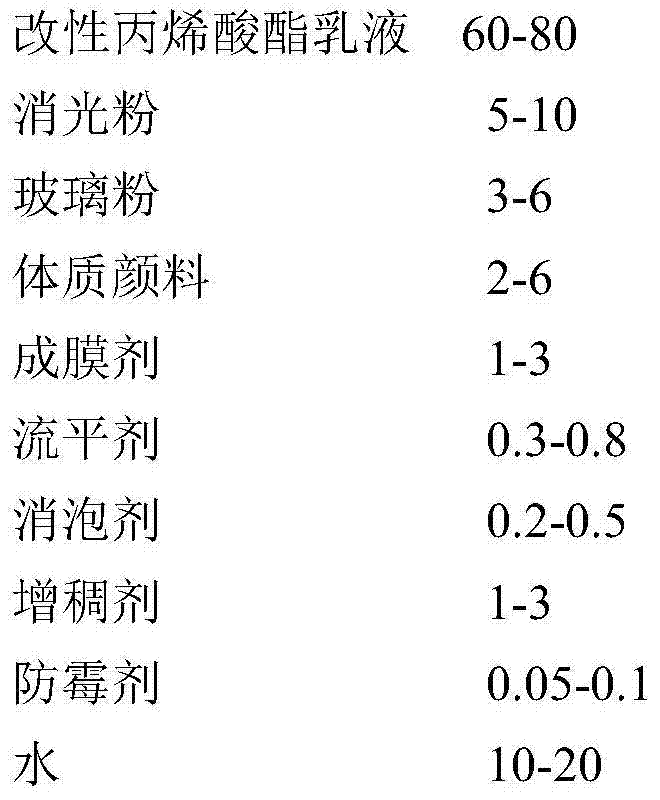

Nano self-crosslinked acrylate paint for external wall and method for making same

InactiveCN1632015AImprove surface energyLow film forming temperatureCoatingsHydrophilic coatingLow speed

The invention relates to a method to prepare a new hydrophilic coating for outside wall containing nmself-crosslinking acrylic ester latices and nm inorganic powder. Its dispensation is:nm indoor crosslinking acrylic ester latex(5-40%), indoor crosslinking acrylic ester latex(20-50%),inorganic nm powder(0.1-20%),inorganic filler(10-50%),film-forming assistant(0.05-5.0%) and the other is water without ion. Its preparing method is:firstly use high speed dispersion and sand grinding method to prepare nm disperseion and filler color which are then mixed with nm self-crosslinking acrylic ester latex and general acrylic ester latex, add into assistant and stir them by media-low speed for 0.5-1.5h,filter and package. The coating has good stability and film-forming performance,strong adhesive force and resistance to pollution, outstanding thermo insulating property, as well as self-cleaning performance.

Owner:上海梅盛企业发展有限公司

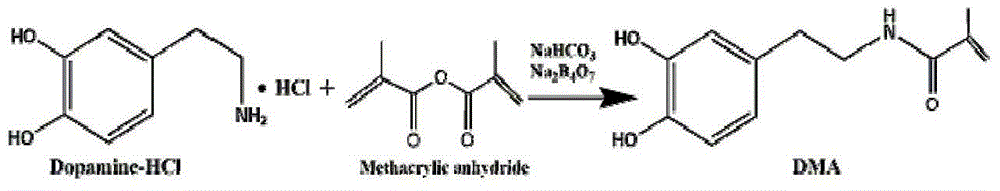

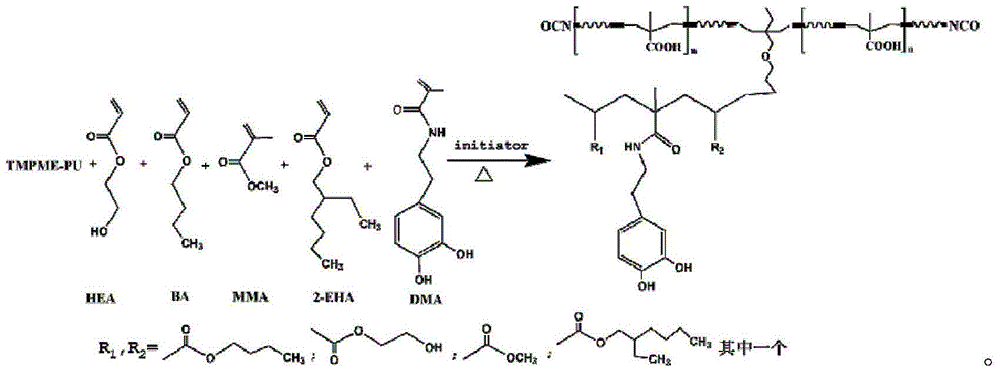

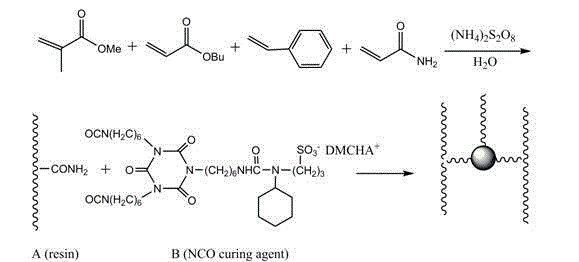

Bionically designed waterborne polyacrylate modified polyurethane composite emulsion and preparation method thereof

The invention discloses a bionically designed waterborne polyacrylate modified polyurethane composite emulsion and a preparation method thereof. The method is characterized by: using acetone or butanone and acrylic monomer as the solvent, subjecting diisocyanate HDI and IPDI, mixed polyester polyol, dimethylolpropionic acid, 1, 4-butanediol, trimethylolpropane monoallyl ether, hydroxypropy, and hydroxyethyl acrylate to polymerization to obtain polyurethane with carboxyl, and conducting neutralization with tertiary amine, removing the solvent to obtain self-emulsifying waterborne polyurethane anionic emulsion containing double bonds; then taking the emulsion as seed, adding acrylate monomer, dopamine methacrylamide and a proper amount of crosslinking agent monomer to carry out pre-emulsification, then performing seeded emulsion polymerization to obtain the bionically designed waterborne polyacrylate modified polyurethane composite emulsion. The composite emulsion provided by the invention has the advantages of energy saving and environmental protection, adaptation to various material surfaces, safe and reliable process, and stable product quality.

Owner:广东多正树脂科技有限公司

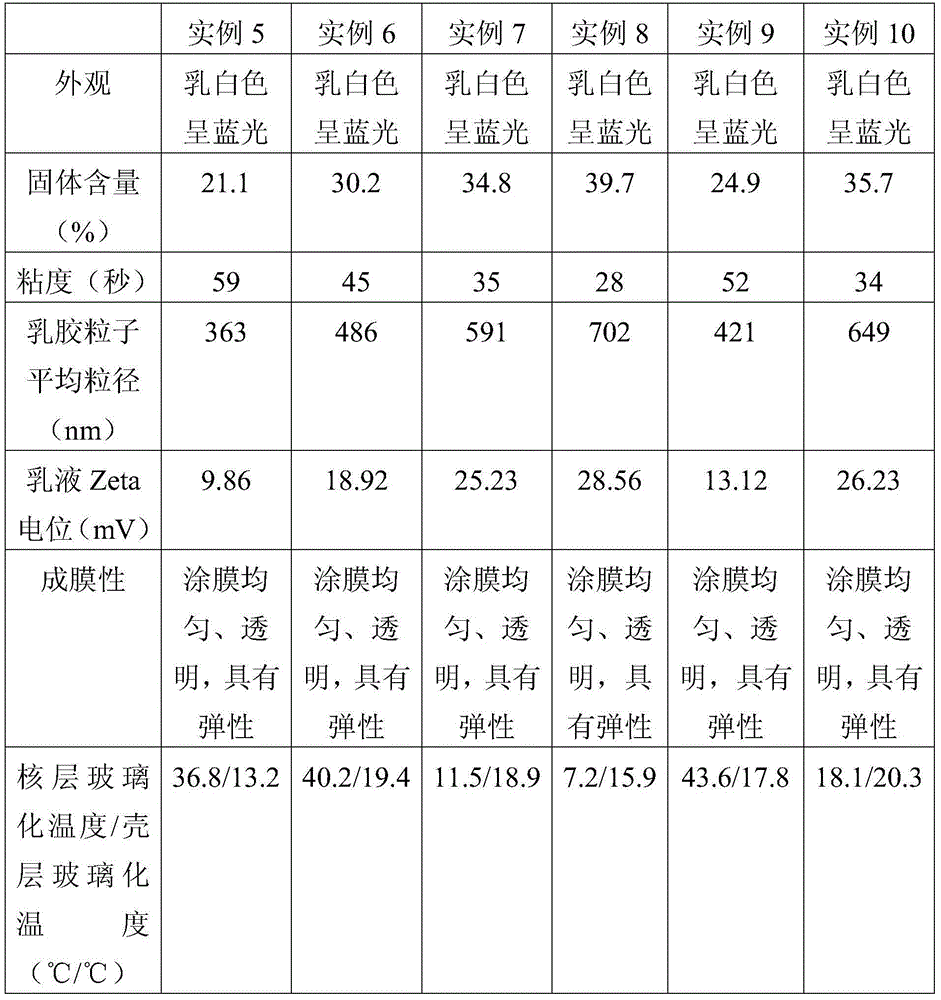

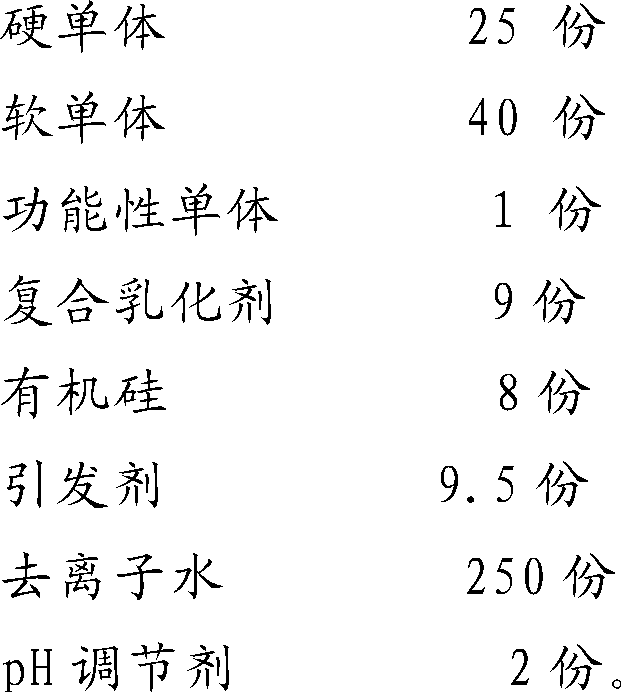

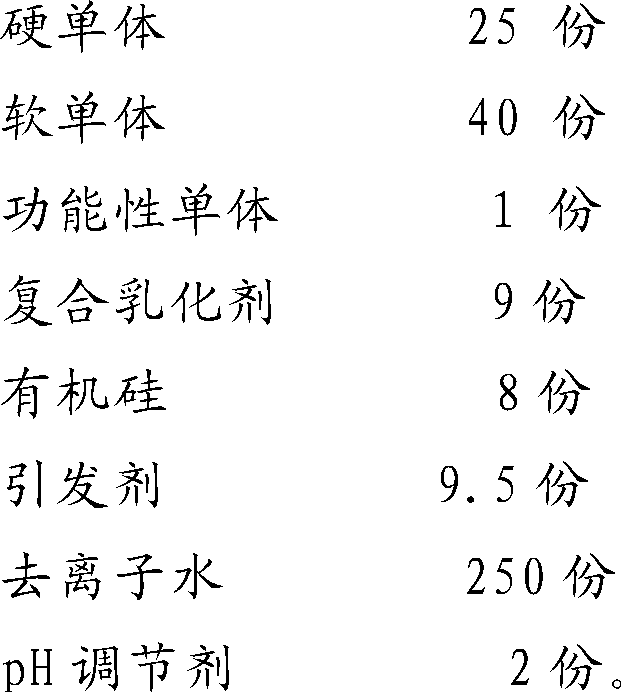

Coating emulsion and preparation method thereof

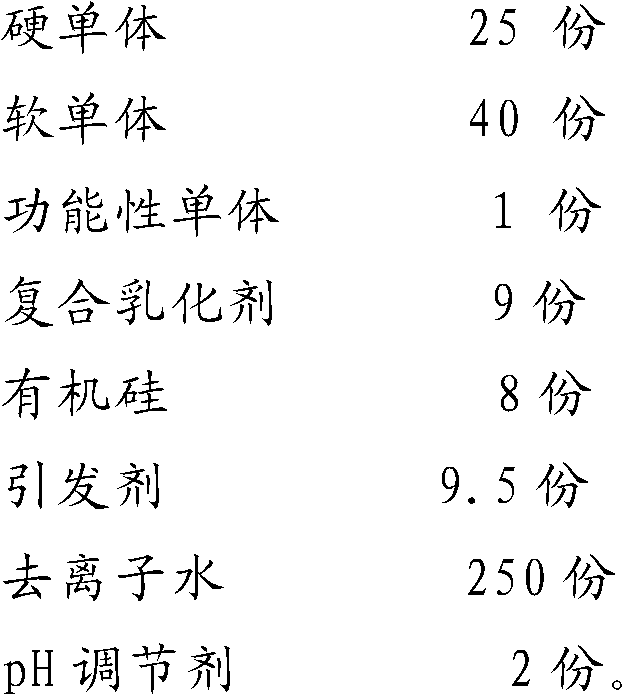

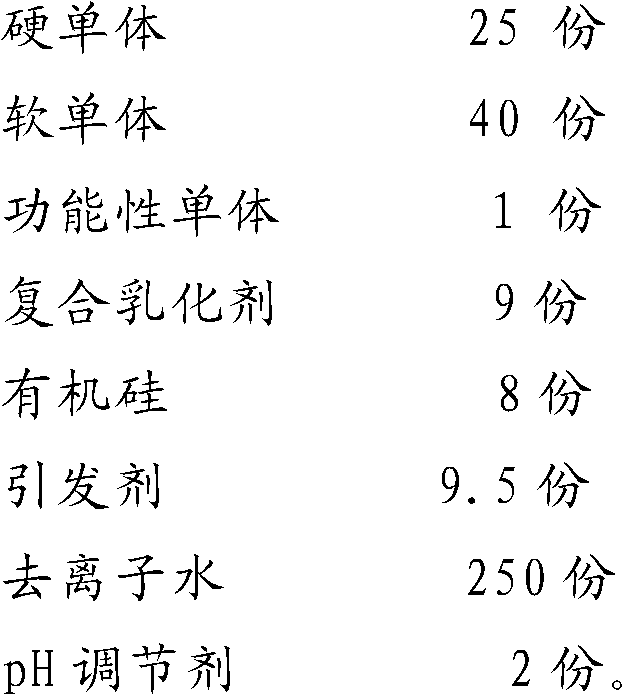

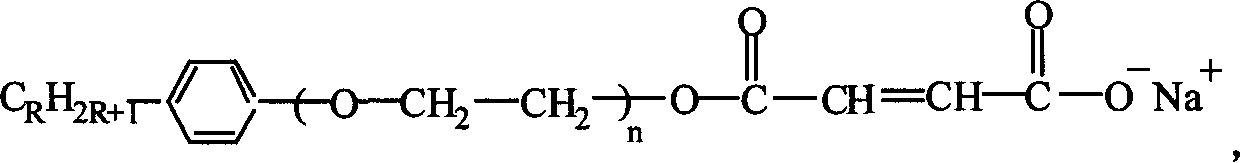

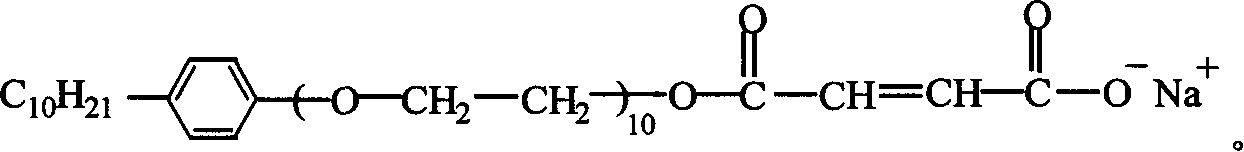

InactiveCN102585084ALow film forming temperatureImprove water resistanceCoatingsEmulsionFunctional monomer

The invention relates to coating emulsion and also provides a preparation method of the coating emulsion. The coating emulsion is formed by the polymerization of the following raw materials: hard monomers, soft monomers, functional monomers, compound emulsifier, organic silicon, initiators, PH regulator and deionized water. According the preparation method, the proper proportion of the soft monomers and the hard monomers is selected, the anion and nonionic emulsifier is applied for mixing, and the coating emulsion is prepared by core-shell polymerization, so that the coating emulsion is lower in film forming temperature, good in water resistance, good in washing resistance, good in calcium ion stability, and can be widely applied to the preparation process of building coatings.

Owner:上海奇想青晨新材料科技股份有限公司

Fluoride core-shell acrylic-resin emulsion, its production and use

InactiveCN101029110AGood flexibilityImprove the finishAntifouling/underwater paintsPaints with biocidesAcrylic resinPliability

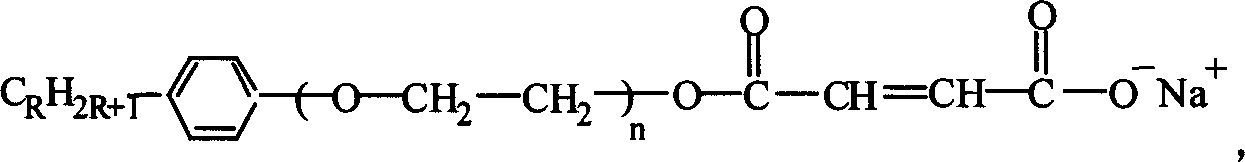

An acrylate emulsion containing fluorine nuclear shell, its production and use are disclosed. The process is carried out by reacting maleic anhydride with alkyl phenolic polyethenoxy ether, regulating to indifference by sodium carbonate, copolymerizing for reactive emulsion and 2-4 kinds acrylate proportionally, adding into 2-4 kinds acrylate and methyl-acrylic dodecafluoptyl esters while polymerizing nuclear monomer, reacting for 1-4hrs and drying for 10mins. It has excellent weather-resistance, water-proof and anti-fouling performances and costs low.

Owner:JILIN UNIV

Method for producing resin emulsion used for water-based metallic paint and produced resin emulsion thereof

ActiveCN102432730AHigh glass transition temperatureImprove water resistanceCoatingsWater basedDouble bond

The invention discloses a method for producing a resin emulsion used for water-based metallic paint and a produced resin emulsion thereof. The resin emulsion is prepared by the following raw materials by weight: 0-260 parts of styrene, 40-310 parts of methyl methacrylate, 3.0-5.0 parts of acrylamide, 16.5-23.5 parts of acrylic acid, 182-202 parts of butyl acrylate, 18-38 parts of functional unsaturated monomers, 1.1-2.1 parts of an emulsifier, 5.4-7.4 parts of a phosphorus and double bond-containing polymerizable surfactant, 8-12 parts of organosilicon monomers, and 45-55 parts of a Zn<2+> solution with a mass concentration of 12-16%. The method of the invention employs a core-shell emulsion polymerization technology to make the emulsion has an overall high vitrification temperature and alow film-forming temperature. By adopting a phosphorus and double bond-containing polymerizable surfactant, the water proofness and corrosion resistance of the emulsion are enhanced. By using a dual normal-temperature self-crosslinking technology, a compact netted polymer structure can be formed, so that the emulsion can has good adhesive force, hear resistance, wear resistance, as well as the advantages of energy saving, environmental protection, nontoxicity and harmlessness.

Owner:山东宝达新材料有限公司

Nuclear shell type long-acting antibacterial emulsion and preparation method thereof

ActiveCN104592459ANot easy to scrub and dissolveLow film forming temperatureAntifouling/underwater paintsPaints with biocidesEmulsionChemistry

The invention relates to a nuclear shell type long-acting antibacterial emulsion. The nuclear shell type long-acting antibacterial emulsion comprises the following raw material components: water, n-butyl acrylate, isobutyl acrylate, isooctyl acrylate, styrene, methyl methacrylate, vinyl acetate, guanidinium oligomer macromonomers, an emulsifying agent, an initiating agent, a cross-linking agent and sodium bicarbonate. The preparation method comprises the following steps: preparing each raw material component; adding water, the emulsifying agent and isooctyl acrylate into a reactor, stirring, heating to 60-70 DEG C, adding the initiating agent to initiate reaction, and after the emulsion becomes blue, maintaining for 60-120 minutes, so as to obtain a nuclear layer emulsion; maintaining the temperature at 70-80 DEG C, adding n-butyl acrylate, heating to 81-85 DEG C, maintaining the temperature, cooling, and discharging, so as to obtain the nuclear shell type long-acting antibacterial emulsion. According to the preparation method, guanidinium and guazatine oligomers are taken as antibacterial functional groups, and guanidyl serves as a main antimicrobial group, has an obvious antibacterial effect and is very safe to human bodies. The preparation method for the nuclear shell type long-acting antibacterial emulsion is simple, rapid, environmentally friendly and suitable for industrial production, and the operation is easy.

Owner:GUANGXI UNIV

Preparation method of and product of modified polyvinyl acetate emulsion adhesive

InactiveCN105111975AImprove water resistanceImprove cold resistanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesChemical industryPolyvinyl acetate

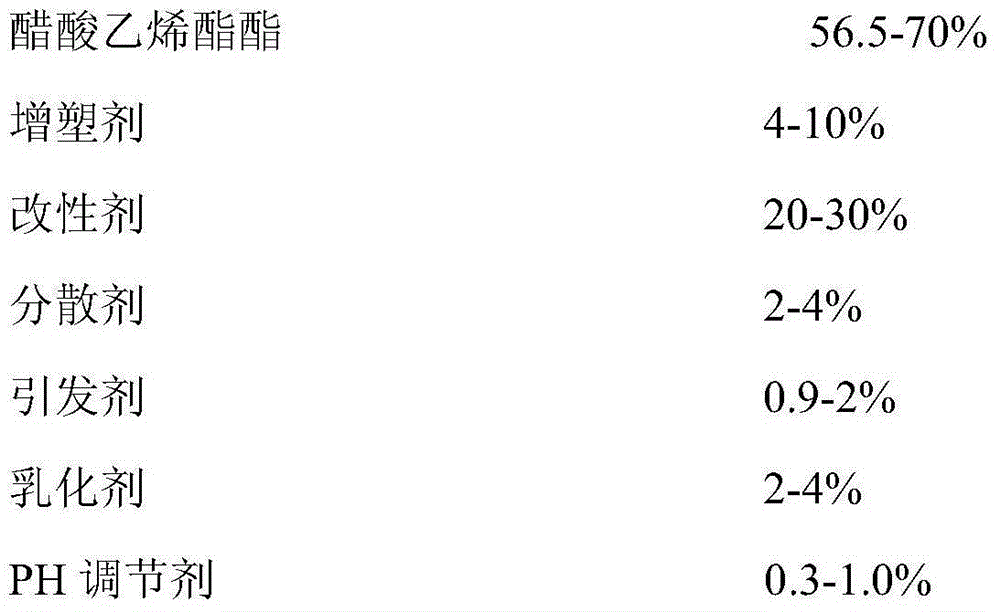

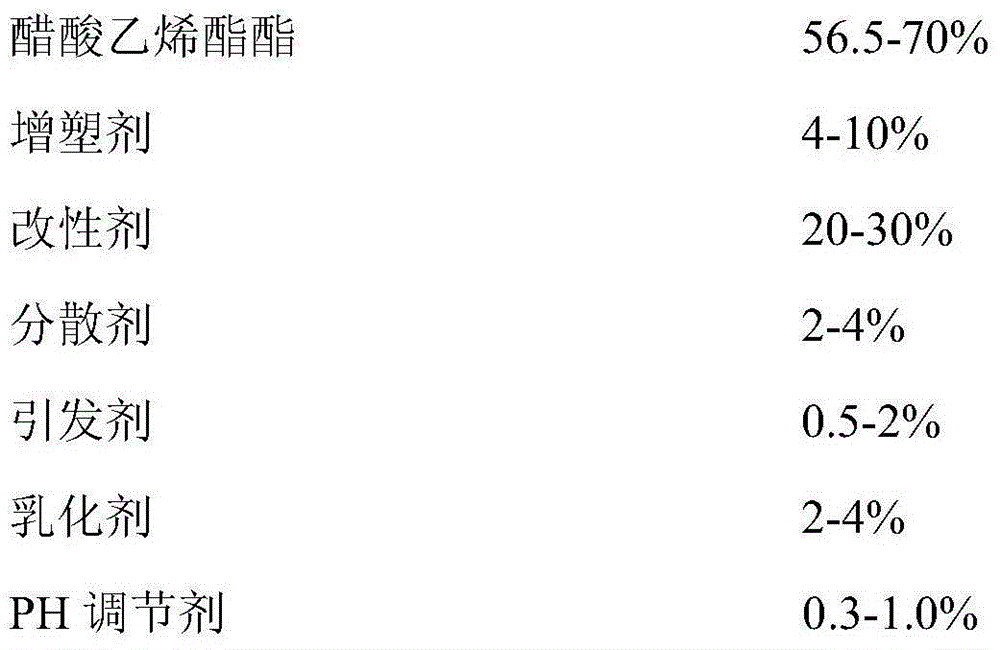

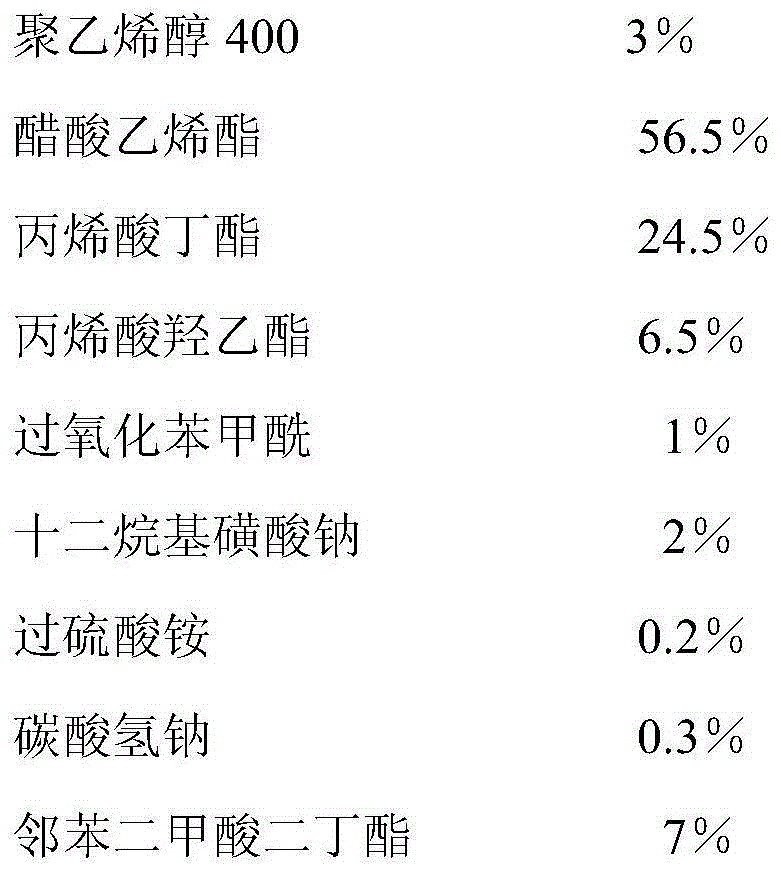

The invention discloses a preparation method of a modified polyvinyl acetate emulsion adhesive. The preparation method includes: adding reaction agents including, by mass, 56.5-70% of vinyl acetate, 4-10% of plasticizer, 20-30% of modifier, 2-4% of dispersant, 0.9-2% of initiator, 2-4% of emulsifier and 0.3-1.0% of PH adjuster for emulsion polymerization. The invention further provides the adhesive prepared by the method. The adhesive is nontoxic and harmless, can realize adhesive effect and meets standards of chemical industry, waterproofness and cold resistance of polyvinyl acetate are improved, and using range of the emulsion adhesive of polyvinyl acetate is widened.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

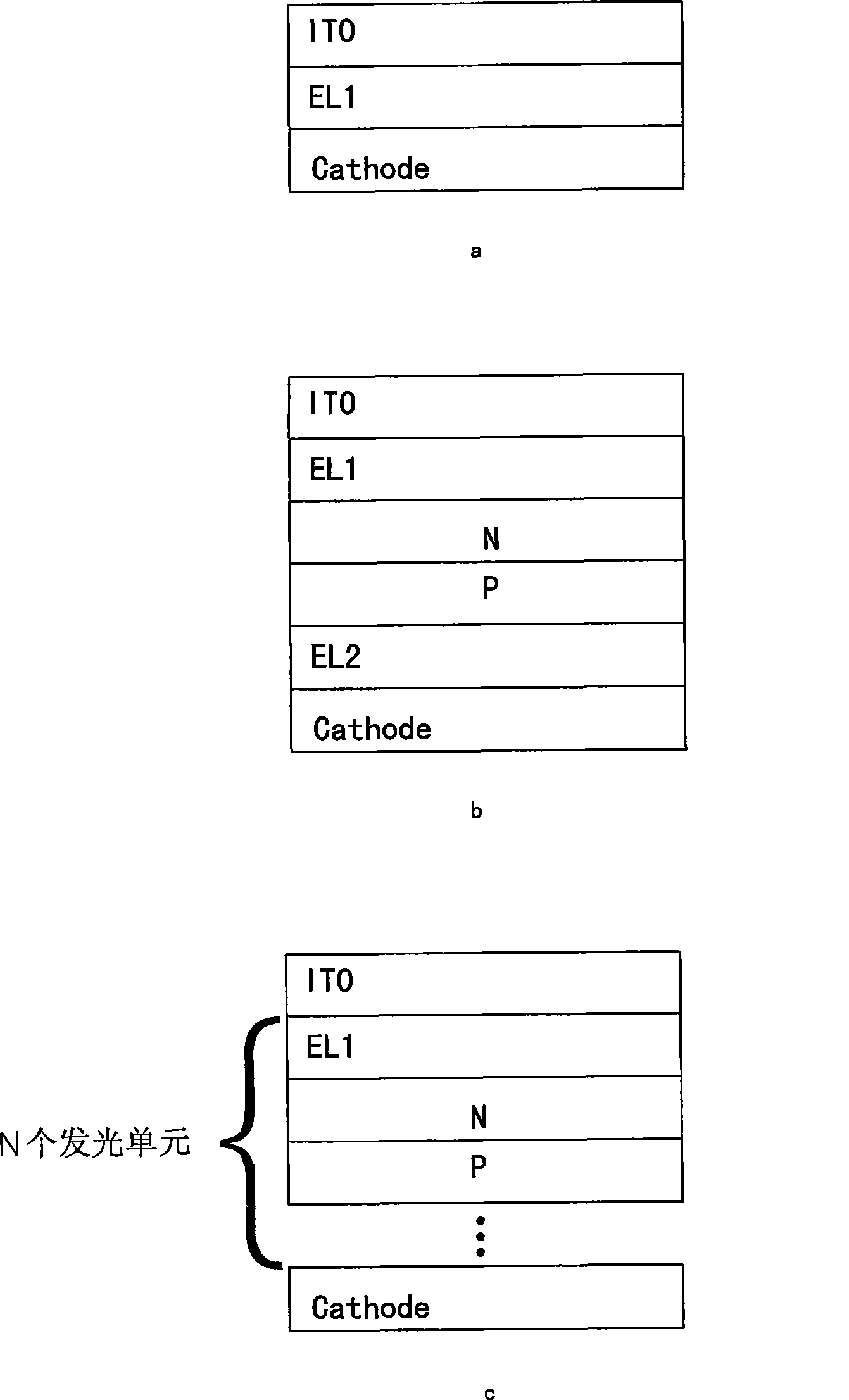

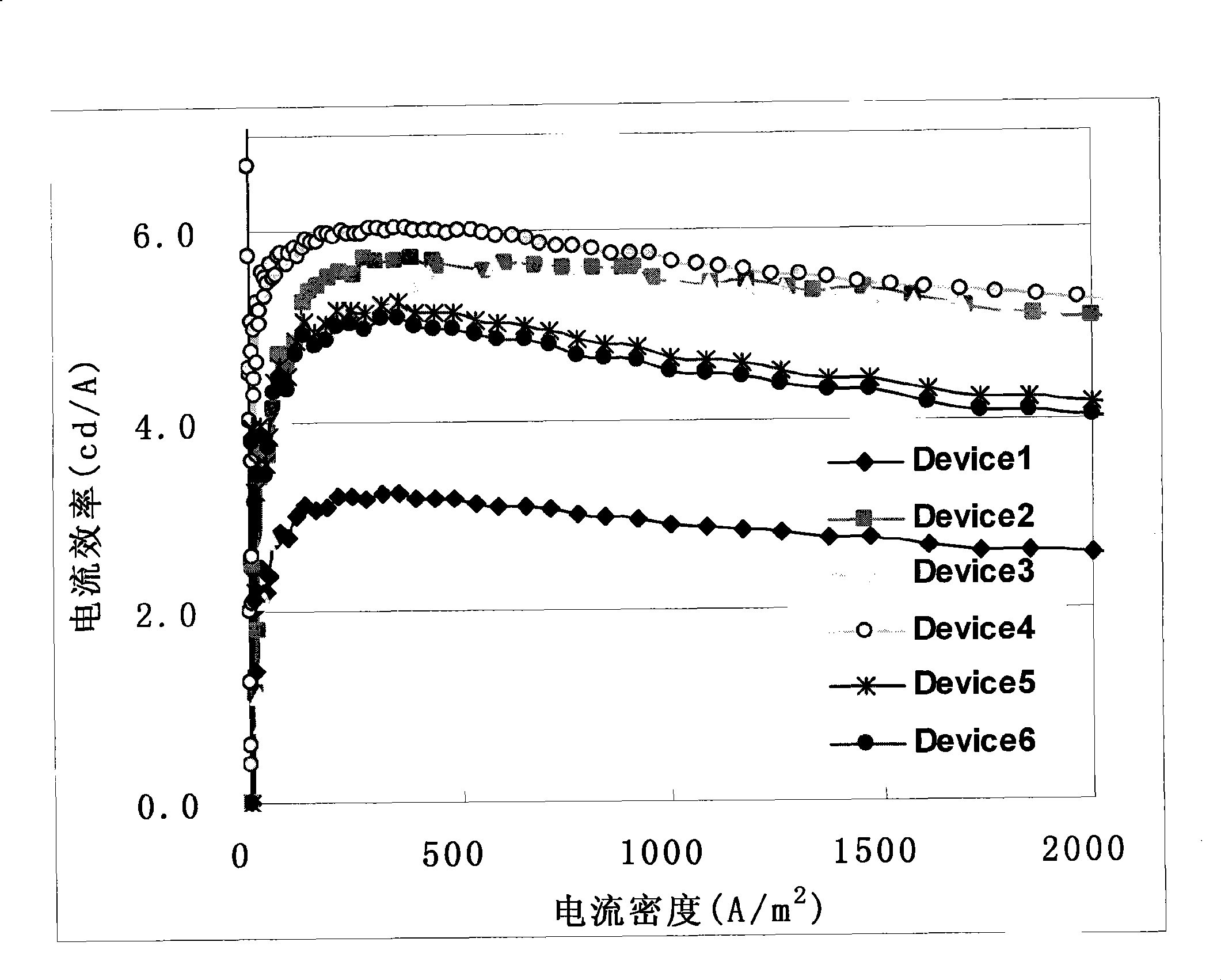

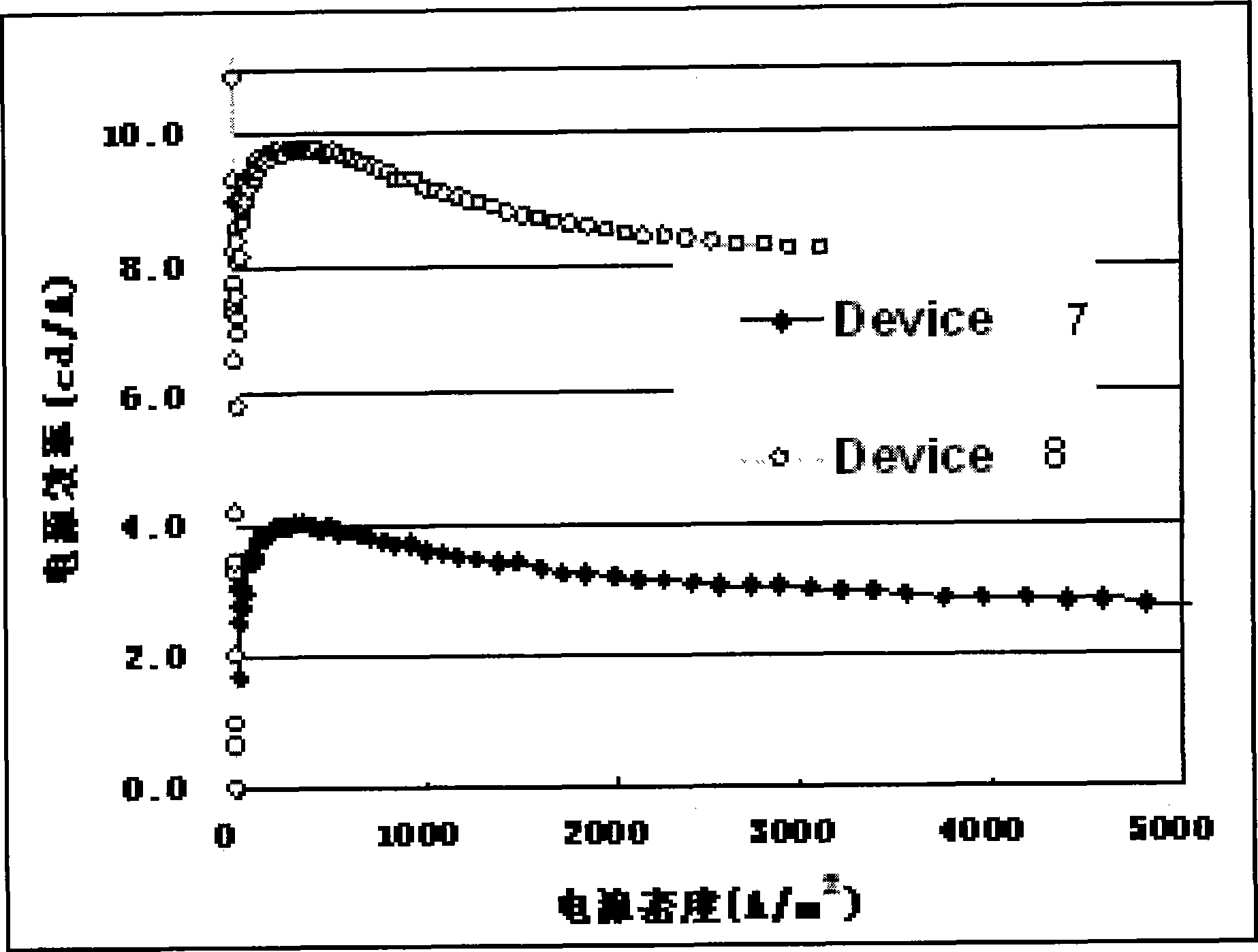

Organic electroluminescent devices of laminated construction

ActiveCN101452997AImproved device power efficiencyLow film forming temperatureOrganic chemistrySolid-state devicesOrganic electroluminescenceChemistry

The invention discloses a laminated organic electroluminescent device, which comprises a pair of electrodes and an organic luminescent medium arranged between the electrodes. The organic luminescent medium comprises at least two luminescent units. A connection layer is arranged between the luminescent units. The connection layer comprises at least one selected from compounds in the general formula I or II, wherein Ar is mid-condensed-nuclei aromatics of which the number of carbon atoms is selected from 6 to 30, or mid-fused-heterocycle aromatics of which the number of carbon atoms is selected from 6 to 30; n is an integer selected from 2 to 4; and alkali metal materials or alkali metal compounds are simultaneously doped. The device connects two or more than two luminescent units together so as to play a role as a charge generation layer. The device with N laminated luminescent units is N times the current efficiency of a single luminescent-layer device, and gains certain improvement of power efficiency as well. In addition, compared with the prior laminated device, the connection-layer material selected by the electroluminescent device has the advantages of lower film-forming temperature and relatively simple preparation process.

Owner:TSINGHUA UNIV +2

Polyacrylate binder for pigment printing and preparation method of polyacrylate binder

InactiveCN103103820ALow film forming temperatureImprove water resistanceDyeing processFunctional monomerCore shell

The invention discloses a polyacrylate binder for pigment printing. The binder is prepared by polymerizing the following raw materials: a hard monomer, a soft monomer, a functional monomer, a compound emulsifying agent, organic silicone, an initiator, a pH regulating agent and deionized water. The invention also provides a preparation method of the polyacrylate binder for the pigment printing. According to the binder and the preparation method disclosed by the invention, proper proportion of the soft monomer to the hard monomer is selected, the mixture of a negative ion emulsifying agent and a nonionic emulsifying agent is used, and the binder is obtained through core-shell polymerization reaction so as to ensure that the binder for the pigment printing disclosed by the invention has pretty low film forming temperature, pretty good water resistance, and good scrubbing resistance, and can be widely applied to a pigment printing process in a dyeing and printing industry.

Owner:上海奇想青晨新材料科技股份有限公司

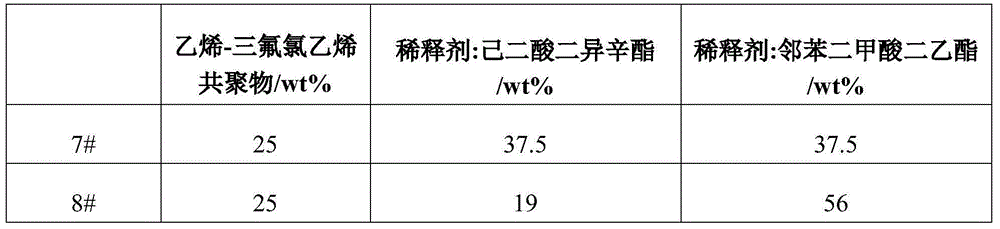

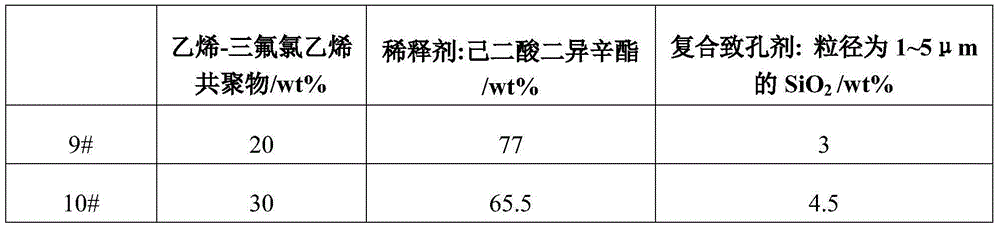

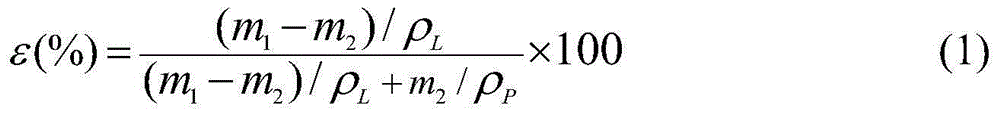

Formula for preparing fluorocopolymer porous membranes and method for preparing porous membranes according to formula

ActiveCN104607062ALow film forming temperatureSuitable for industrial implementationMembranesSemi-permeable membranesHollow fibreFiber

Owner:苏州孝义家光电科技有限公司

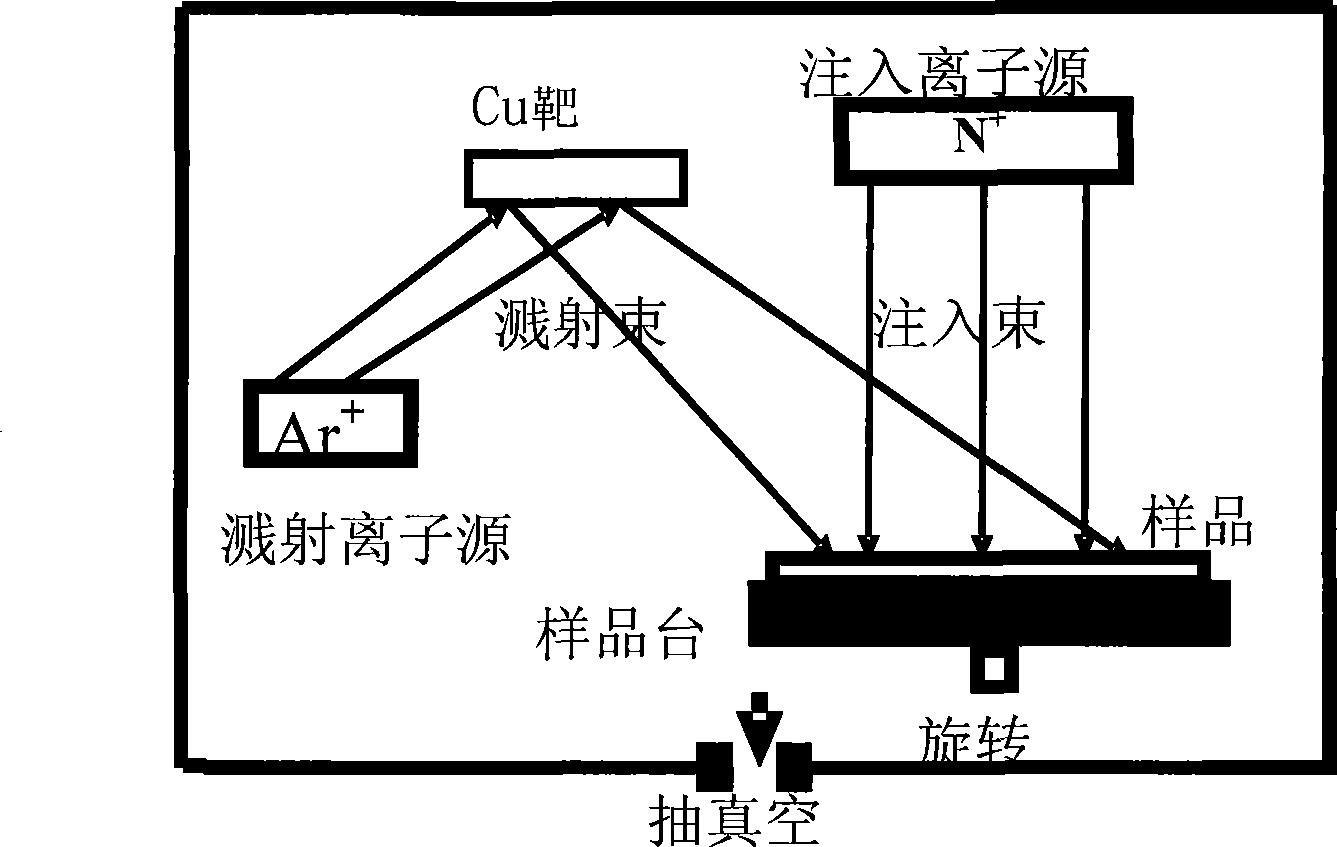

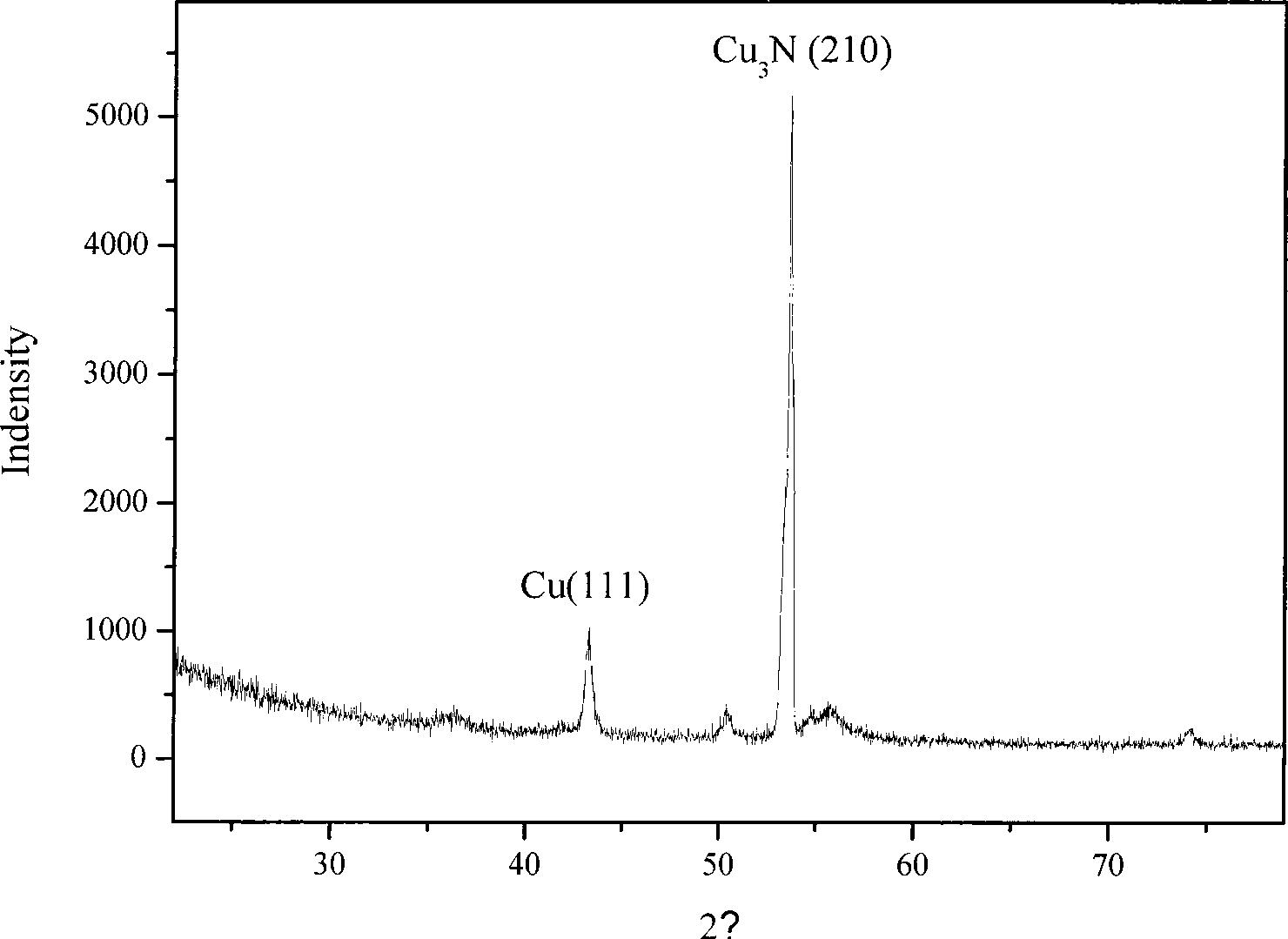

Method for preparing copper nitride film by ion beam enhanced deposition

InactiveCN101413104AMeet the requirements of industrial productionLow film forming temperatureVacuum evaporation coatingSputtering coatingIon beamCopper

The invention discloses a method for preparing a copper nitride film through the enhanced deposition of ion beams. Copper with high purity is used as a sputtering target; mixed ion beams produced by pure N2 or mixed high-purity gas with the ratio of Ar to N2 of 1 to 5 attacks a deposition film and are vertically injected to the sputtering deposition film; the accelerating voltage of the ion beam is between 10 and 50kV; the strength of beam current is between 1 and 4 mA; even injection is realized through revolution of a sample table and autorotation of a sample to ensure that the film has an even Cu3N polycrystalline structure with high tropism in subsequent crystallization and heat treatment; at the same time, polycrystalline structure is deposited on a SiO2 / Si underlayer to prepare the even and compact copper nitride film which has good adhesion with an underlayer and has resistivity of more than 1.0*10<3> omega.cm. The method for preparing a copper nitride film meets the requirement of industrialized production, has low film forming temperature, is compatible with a semiconductor process and has no emission of waste.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

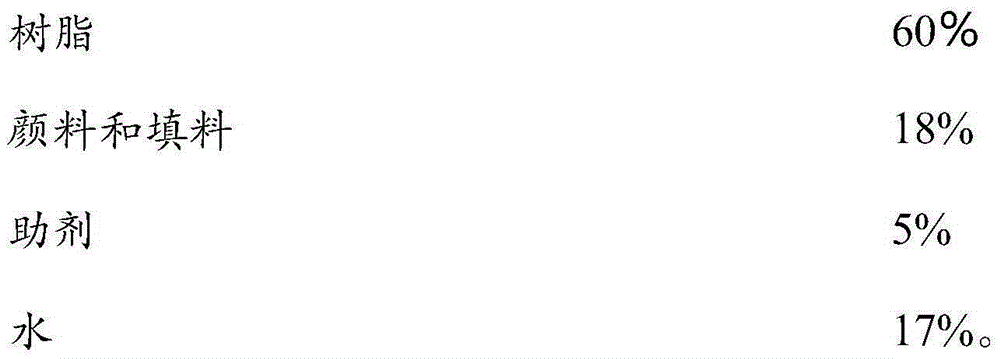

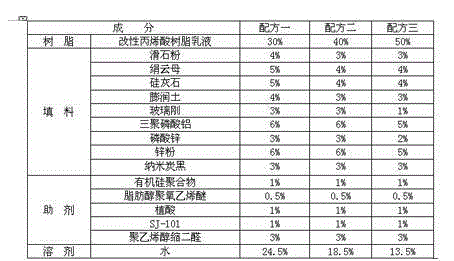

Water-borne wood paint and preparation method thereof

InactiveCN105348961AImprove wear resistanceGood flexibilityAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedAcrylic resin

The invention discloses a water-borne wood paint, and a preparation method thereof. The water-borne wood paint is prepared from following raw materials: a resin, a pigment, a filling material, an auxiliary agent, and water, wherein the resin is a mixed resin of water-based acrylic resin and acrylic acid modified waterborne polyurethane resin, or a mixed resin of water-based acrylic resin and waterborne polyurethane resin. The water-borne wood paint is high in strength, possesses excellent chemical resistance, gloss retention, colour retention, and base material permeability, high transparency; obtained films possess water resistance, boiling water resistance, low film forming temperature, and excellent levelling properties; after-tack is not caused; solid content is high; a plurality of steps are avoided; the water-born wood paint is dried quickly at normal temperature; the obtained films are flat and well-rounded; polyurethane paint possesses excellent adhesive force and wear resistance, and is bright and well-rounded, so that the water-born wood paint can be used for painting as a wooden floor paint.

Owner:广东嘉宝莉科技材料有限公司

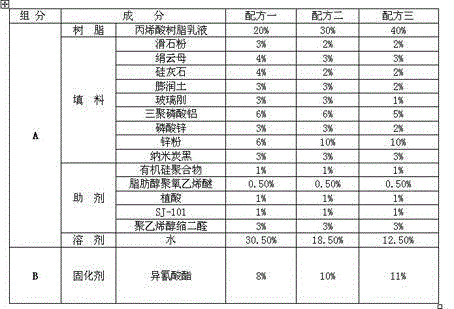

Preparation method of isocyanate curing agent-modified water-based acrylate composite metal anticorrosive paint

InactiveCN104017452AImprove densification performanceLow film forming temperatureAnti-corrosive paintsActivated carbonPolymer science

The invention discloses a preparation method of an isocyanate curing agent-modified water-based acrylate composite metal anticorrosive paint. According to the preparation method, the water-based acrylate composite metal anticorrosive paint can be matched with water-based epoxy or acrylic primer and intermediate coat and also can be applied to a solvent type paint to form a crossed composite type paint anticorrosive system in a single-component or dual-component manner; isocyanate curing agent-modified acrylic resin is adopted to form a crossed netty structure; the density of the paint is improved, the film-forming temperature of the paint is reduced, thus the construction is facilitated; an activated carbon-based powder reducing auxiliary is adopted to be matched up with a zinc-containing compound to realize relatively strong reducibility, the anticorrosive effect of the water-based paint (especially to steel components) is greatly improved, and good construction performance is displayed in the construction process; compared with a traditional alcohol acid system, the preparation method has the advantages that little dry dust is generated, good surface sagging resistance can be displayed when the wet film thickness is 400-500 microns.

Owner:ZHOUSHAN HENGTAI PAINT IND

Water-based lotus-leaf-structured hydrophobic over-printing varnish for wallpaper and preparation method of over-printing varnish

The invention specifically relates to water-based lotus-leaf-structured hydrophobic over-printing varnish for wallpaper and a preparation method of the over-printing varnish, and belongs to the technical field of ink. The technical problem to be solved is to provide an over-printing varnish by using which the surface of a wallpaper product can be smooth, bright and wear-proof and the lotus leaf type waterproof and moisture-roof effects can be realized, and a preparation method of the over-printing varnish. In order to solving the technical problem, the technical scheme adopted is as follows: the water-based lotus-leaf-structured hydrophobic over-printing varnish for the wallpaper is prepared from raw materials including a modified organic silicon polymer emulsion, a non-film-forming acrylate emulsion, an styrene-acrylic emulsion, neutralizing amine, propylene glycol, a water-based coalescing agent, a water-based leveling wetting agent, a mineral defoamer, a water-based nanoscale organosilicon waterproofing agent, a waterborne polyurethane thickening agent, deionized water and an organic silicon defoamer; the raw materials are stirred and mixed in a specific order to form the over-printing varnish.

Owner:山西金博雅油墨科技有限责任公司

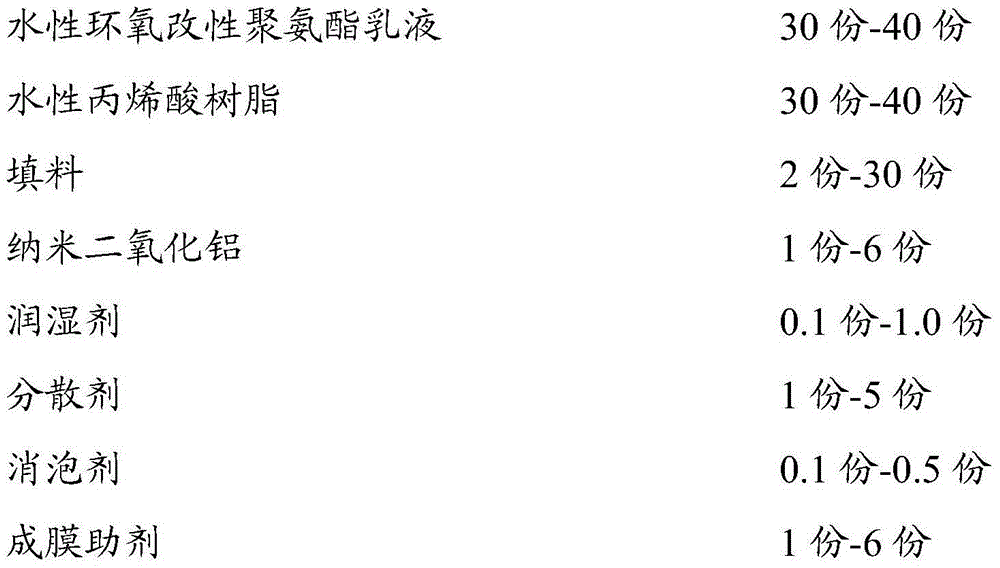

Single-component water-based wood paint

InactiveCN104817946AHigh glass transition temperatureHigh hardnessPolyurea/polyurethane coatingsTripropylene glycolEpoxy

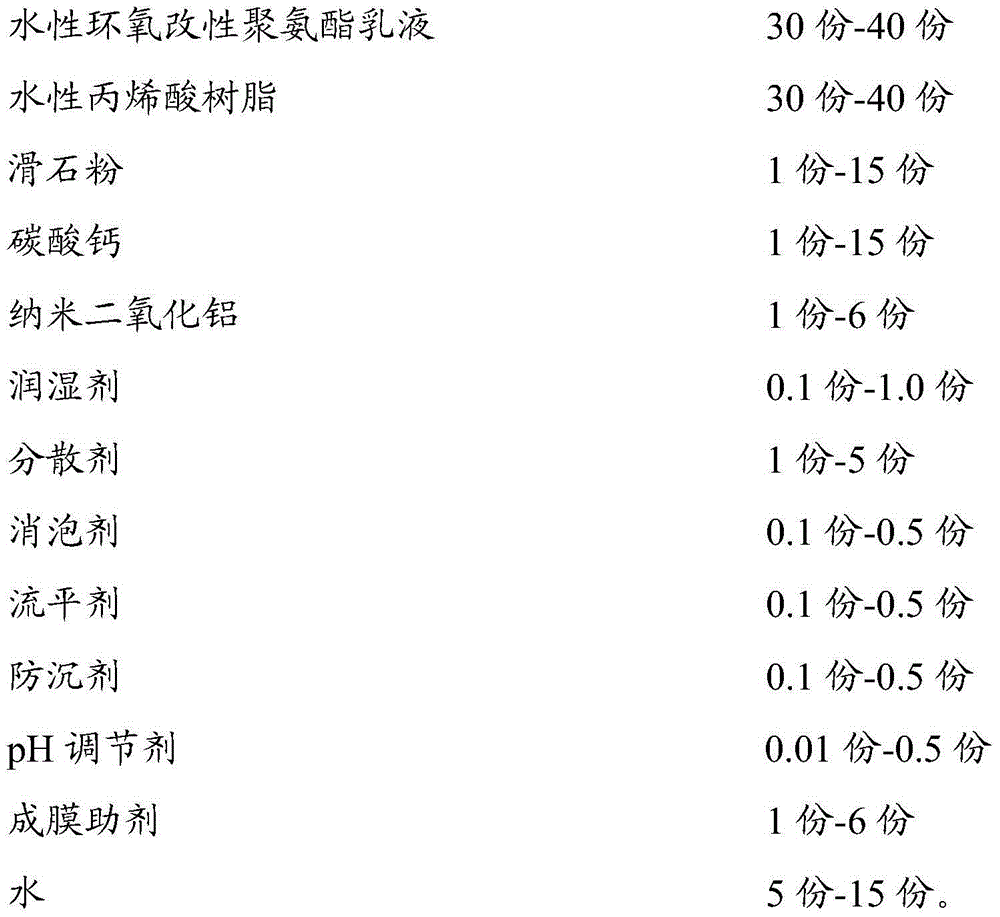

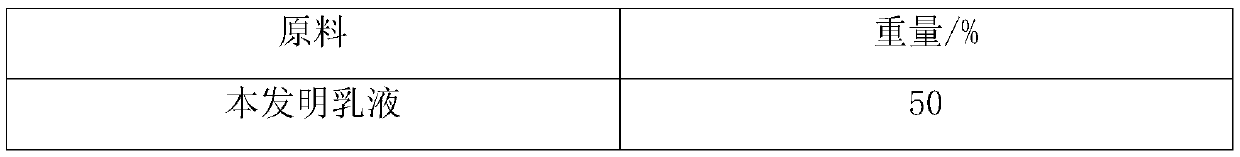

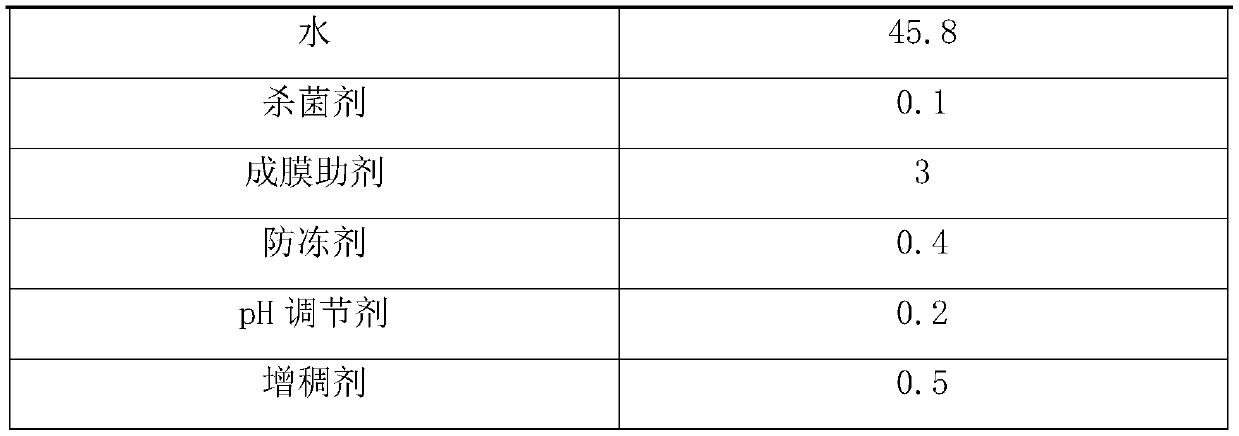

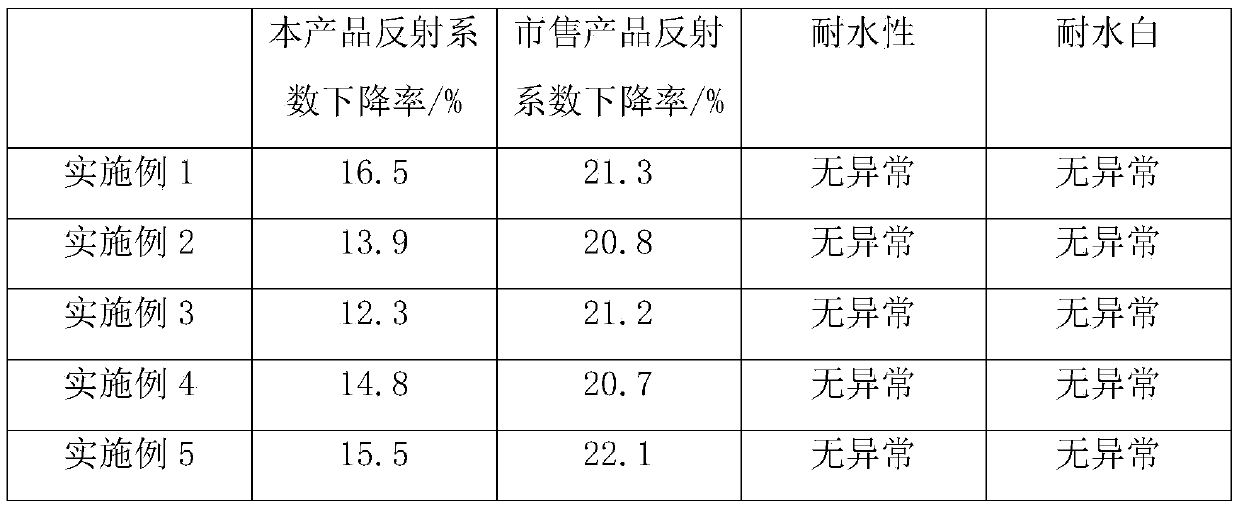

The invention relates to a single-component water-based wood paint which comprises the following components in parts by weight: 30-40 parts of water-based epoxy modified polyurethane emulsion, 30-40 parts of water-based acrylic resin, 2-30 parts of filler, 1-6 parts of nano aluminum dioxide, 0.1-1.0 part of wetting agent, 1-5 parts of dispersing agent, 0.1-0.5 part of defoaming agent, 1-6 parts of film-forming assistant and the balance of water. The water-based acrylic resin is a hydroxy acrylic resin in which the mass content of hydroxy group is 0-2-0.4 part. The film-forming assistant is prepared by mixing the following components in parts by weight: 60-90 parts of tripropylene glycol monobutyl ether and 10-40 parts of alcohol ester-12. The single-component water-based wood paint has the advantages of excellent water resistance, excellent wear resistance, excellent adhesive force, favorable film effect, high film hardness, high drying speed and low cost.

Owner:广东朗法博涂装新材料科技有限公司

Acrylate emulsion for high-gloss water-based finish varnish with lotus leaf effect and preparation method of acrylate emulsion

ActiveCN109705256AImprove deformationImprove stabilityAntifouling/underwater paintsPaints with biocidesIsooctyl acrylateWater based

The invention discloses an acrylate emulsion for the high-gloss water-based finish varnish with a lotus leaf effect and a preparation method of the acrylate emulsion. The acrylate emulsion is composedof the following raw materials in parts by weight: 20-30 parts of methyl methacrylate, 10-20 parts of isooctyl acrylate, 0.1-3 parts of cross-linking monomers, 1-3 parts of carboxyl monomers, 1-3 parts of organic silicon monomers, 1.1-3 parts of an emulsifier, 0.2-1 part of an initiator, 1-5 parts of a coalescing agent, 0.5-5.5 parts of a pH regulator and 50-65 parts of deionized water. Through aproper core-shell ratio, Tg difference, complete hydrophobicity of a hard core and relative hydrophobicity of a soft shell, a paint film is provided with a structure of ''lotus leaf effect'', and useof inorganic compounds is completely avoided, so that the finish varnish prepared from the emulsion has excellent water resistance, stain resistance, yellowing resistance, stability and universality.

Owner:佛山市顺德区巴德富实业有限公司

Preparation method of acrylic acid organic silicon soap-free copolymerization emulsion

The invention discloses a preparation method of acrylic acid organic silicon soap-free copolymerization emulsion. Unsaturated monomers, organic silicon, a reactive emulsifier, an initiator and water are adopted as raw materials, temperature of a reaction kettle is controlled by virtue of core-shell polymerization and soap-free polymerization technologies, then treatment is carried out for removing residual monomers, and a neutralizing agent is added for neutralization, so that emulsion is obtained. By virtue of the soap-free polymerization technology, better water white resistance can be realized with less expensive organic silicon monomer, and water absorption of a paint film is reduced. By virtue of the core-shell polymerization technology, a core layer with high glass transition temperature and a shell layer with lower glass transition temperature are obtained, so that synthetic emulsion has lower film formation temperature under the condition that the average glass transition temperature is the same with a homopolymerization technology, usage amount of a coalescing agent is reduced, and influence of solvent volatilization on atmospheric environment is reduced. The acrylic acid organic silicon soap-free copolymerization emulsion product does not contain a free emulsifying agent, so that influence of the acrylic acid organic silicon soap-free copolymerization emulsion product on the environment is greatly reduced, and the acrylic acid organic silicon soap-free copolymerization emulsion product is environmentally friendly; and the acrylic acid organic silicon soap-free copolymerization emulsion has excellent weather resistance, water resistance and pollution resistance.

Owner:江苏三瑞生物技术有限公司

Terpolymer-modified neoprene latex adhesive and preparation method thereof

ActiveCN104017522ALow film forming temperatureImprove initial tackMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesButyl acrylateMethacrylate methyl

The invention relates to a terpolymer-modified neoprene latex adhesive and a preparation method thereof. The adhesive comprises the following components in parts by weight: 100 parts of neoprene latex, 10-90 parts of methyl methacrylate, 10-90 parts of butyl acrylate, 0.5-8 parts of emulsifier, 0.2-5 parts of catalyst, 10-50 parts of tackifying emulsion, 0.5-2 parts of anti-aging agent, 0.5-4 parts of thickener, 0.1-1 part of preservative and 2-8 parts of zinc oxide. The prepared adhesive has obviously lower film-forming temperature and higher initial viscosity, and satisfies the operating requirements of various climates. By adopting the redox catalytic system, the adhesive has the advantages of low synthesis temperature and high grafting ratio.

Owner:重庆中科力泰高分子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com