Method for cladding surfaces of active material of anode and/or anode and methods manufacturing anode and battery

A positive electrode active material and surface coating technology, which is applied to the surface coating of positive electrode active materials and/or positive electrodes and the preparation of positive electrodes and batteries, can solve the problems of difficult control of the thickness and uniformity of the coating layer, and achieve Uniform and complete coverage, low shape requirements, high specific capacity and specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

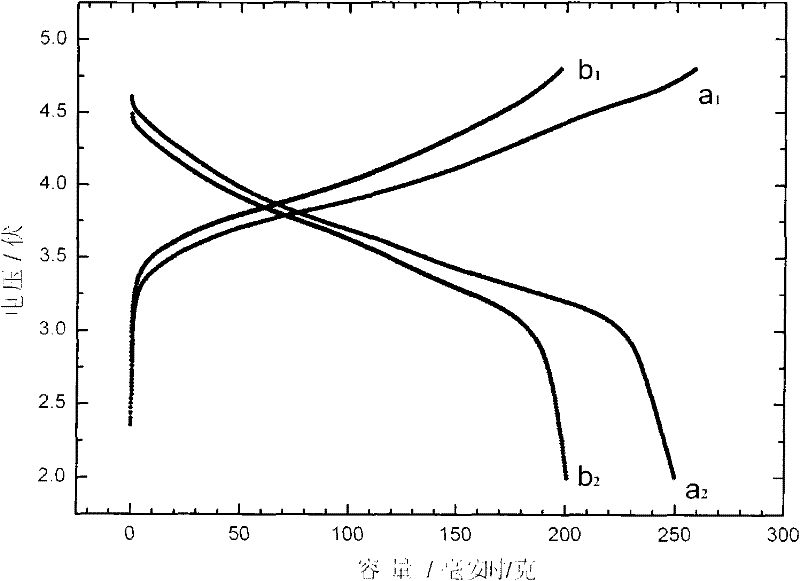

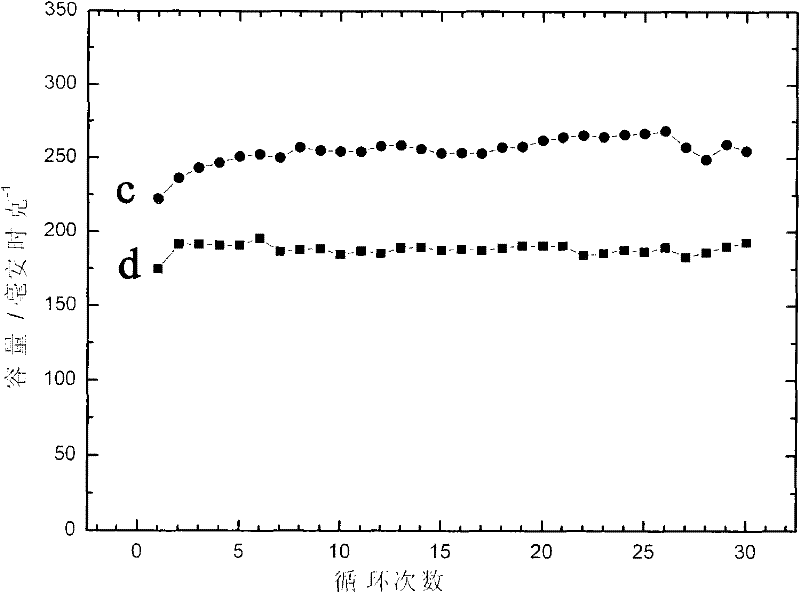

Embodiment 1

[0037] This embodiment is used to illustrate the method for surface coating the positive electrode and the preparation method of the positive electrode of the present invention.

[0038] (1) Preparation of positive electrode sheet:

[0039] 70 parts by weight of Li 1.2 Ni 0.17 Mn 0.54 Co 0.07 O 2 , 10 parts by weight of polyvinylidene fluoride (PVDF) and 20 parts by weight of acetylene black are added to 50 parts by weight of N-methylpyrrolidone (NMP) and stirred to form a slurry. The slurry was evenly coated on both sides of a 16 μm thick aluminum foil, and dried at 120° C. for 5 minutes to obtain a pole piece with a thickness of 200 μm (including the aluminum foil), and then the pole piece was pressed into a positive electrode sheet by a tablet press.

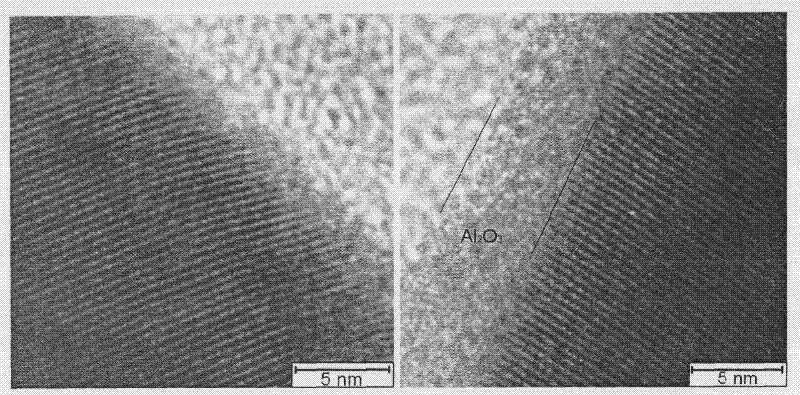

[0040] (2) Surface coated with Al 2 O 3 :

[0041] Using ALD deposition system (Savannah-100, Shijia Technology Co., Ltd.), when the reaction chamber vacuum reaches about 10 -2 During torr, the components of the atomic layer depositi...

Embodiment 2

[0059] This embodiment is used to illustrate the method for surface coating the positive electrode and the preparation method of the positive electrode of the present invention.

[0060] (1) Preparation of positive electrode sheet:

[0061] Put 85 parts by weight of LiMn 2 O 4 , 5 parts by weight of PVDF and 10 parts by weight of acetylene black are added to 50 parts by weight of NMP and mixed uniformly to form a slurry. The slurry was evenly coated on both sides of a 16 μm thick aluminum foil, and dried at 120° C. for 5 minutes to obtain a pole piece with a thickness of 200 μm (including the aluminum foil), and then the pole piece was pressed into a positive electrode sheet by a tablet press.

[0062] (2) Surface coated with ZrO 2 :

[0063] Using ALD deposition system (Savannah-100, Shijia Technology Co., Ltd.), when the reaction chamber vacuum reaches about 10 -2 During torr, the components of the atomic layer deposition system are heated. The temperature of the reaction chamber is...

Embodiment 3

[0076] This embodiment is used to illustrate the method for surface coating the positive electrode and the preparation method of the positive electrode of the present invention.

[0077] (1) Preparation of positive electrode sheet:

[0078] 75 parts by weight of LiFePO 4 , 10 parts by weight of PVDF and 15 parts by weight of acetylene black are added to 50 parts by weight of NMP and mixed uniformly to form a slurry. The slurry was evenly coated on both sides of a 16 μm thick aluminum foil, and dried at 120° C. for 5 minutes to obtain a pole piece with a thickness of 200 μm (including the aluminum foil), and then the pole piece was pressed into a positive electrode sheet by a tablet press.

[0079] (2) Surface coated with Si:

[0080] Using ALD deposition system (Savannah-100, Shijia Technology Co., Ltd.), when the reaction chamber vacuum reaches about 10 -2 When torr, the components of the atomic layer deposition system are heated, and the temperature of the reaction chamber is contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com