Polyarylenesulfidesulfone/sulfonated polymer composite separation membrane and preparation method thereof

A technology of sulfonated polymer and polyarylene sulfide sulfone, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve the problems of limited application scope, low porosity, small flux, etc. Simple, high-porosity, high-throughput effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

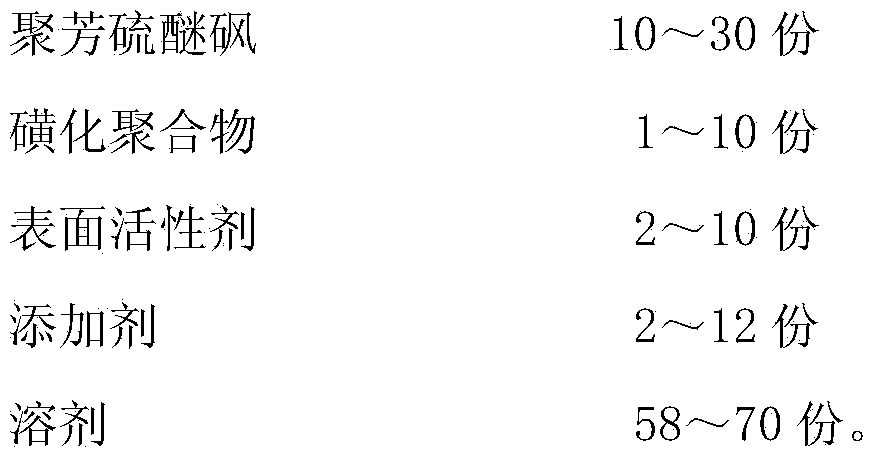

[0035] Add 10g of polyarylene sulfide sulfone resin, 10g of sulfonated polyarylene sulfide sulfone, 10g of Tween 80, 8g of polyvinylpyrrolidone, 4g of polyethylene glycol, and 58g of N-methylpyrrolidone into a dissolving solution with a stirrer and a thermometer. Stir and dissolve in the kettle at a temperature of 120°C, centrifuge at a speed of 5000r / min for 10min in a centrifuge, filter to remove impurities, and stand for 2 hours for defoaming to make a uniform membrane-forming solution. Scrape the film-making solution evenly on a quartz glass plate at a temperature of 20°C with a flat-plate scraping machine, and then immerse the nascent film in deionized water at a temperature of 20°C, and the gel will solidify into a polyarylene sulfide sulfone / sulfonated polymer composite separation membrane. After water washing, the polyarylene sulfide sulfone / sulfonated polymer composite separation membrane is soaked in an aqueous solution containing 30% glycerol to preserve pores, and ...

Embodiment 2

[0037] Put 14g of polyarylene sulfide sulfone resin into 8g of sulfonated polyarylene sulfide sulfone, 4g of Tween 80, 4g of polyvinylpyrrolidone, and 70g of N-methylpyrrolidone into a dissolution kettle equipped with a stirrer and a thermometer, at a temperature of 160°C Stir to dissolve, centrifuge at a speed of 5000r / min for 10min in a centrifuge, filter to remove impurities, and stand for 4h for defoaming to make a uniform membrane-forming solution. Scrape the film-making solution evenly on a quartz glass plate at a temperature of 60°C with a flat-plate scraping machine, and then immerse the primary film in a mixed solution of deionized water and ethanol at a temperature of 60°C, and the gel will solidify into polyarylene sulfide sulfone / sulfonated polymer composite separation membrane. After water washing, the polyarylene sulfide sulfone / sulfonated polymer composite separation membrane is soaked in an aqueous solution containing 30% glycerol to preserve pores, and dried ...

Embodiment 3

[0039] Add 18 g of polyarylene sulfide sulfone resin, 6 g of sulfonated polyarylene sulfide sulfone, 5 g of Tween 80, 8 g of polyethylene glycol, and 63 g of N-methylpyrrolidone into a dissolution kettle with a stirrer and a thermometer. Stir to dissolve at ℃, centrifuge at a speed of 5000r / min for 10min in a centrifuge, filter to remove impurities, and stand for 4h to prepare a uniform membrane-forming solution. Scrape the film-making solution evenly on a quartz glass plate at a temperature of 40°C with a flat-plate scraping machine, and then immerse the nascent film in a mixed solution of deionized water and N-methylpyrrolidone at a temperature of 40°C, and the gel solidifies into a polymer Arylsulfide sulfone / sulfonated polymer composite separation membrane. After water washing, the polyarylene sulfide sulfone / sulfonated polymer composite separation membrane is soaked in an aqueous solution containing 30% glycerol to preserve pores, and dried to obtain the polyarylene sulfi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com