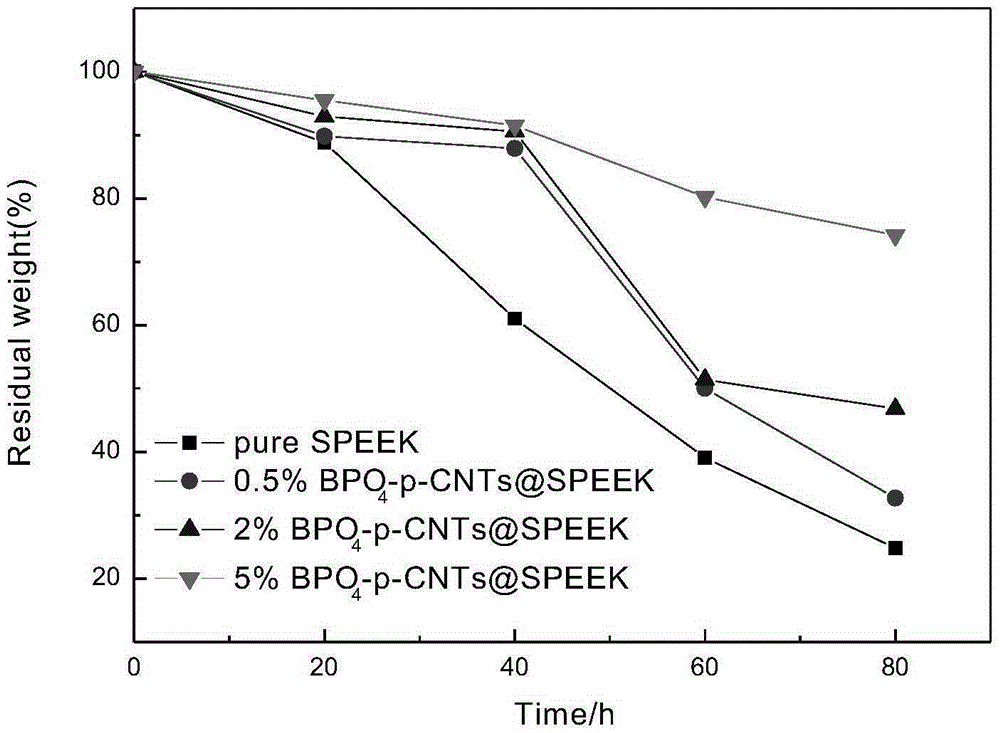

Method for preparing boron phosphate coated carbon nanotube composite proton exchange membrane

A proton exchange membrane and nanotube composite technology is applied in the field of preparation of boron phosphate-coated carbon nanotube composite proton exchange membrane, which can solve the problems of poor compatibility of organic phase and inorganic phase, decrease of uniformity and physical and chemical properties, etc. , to achieve the effect of good compatibility, simple method and avoid chemical treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

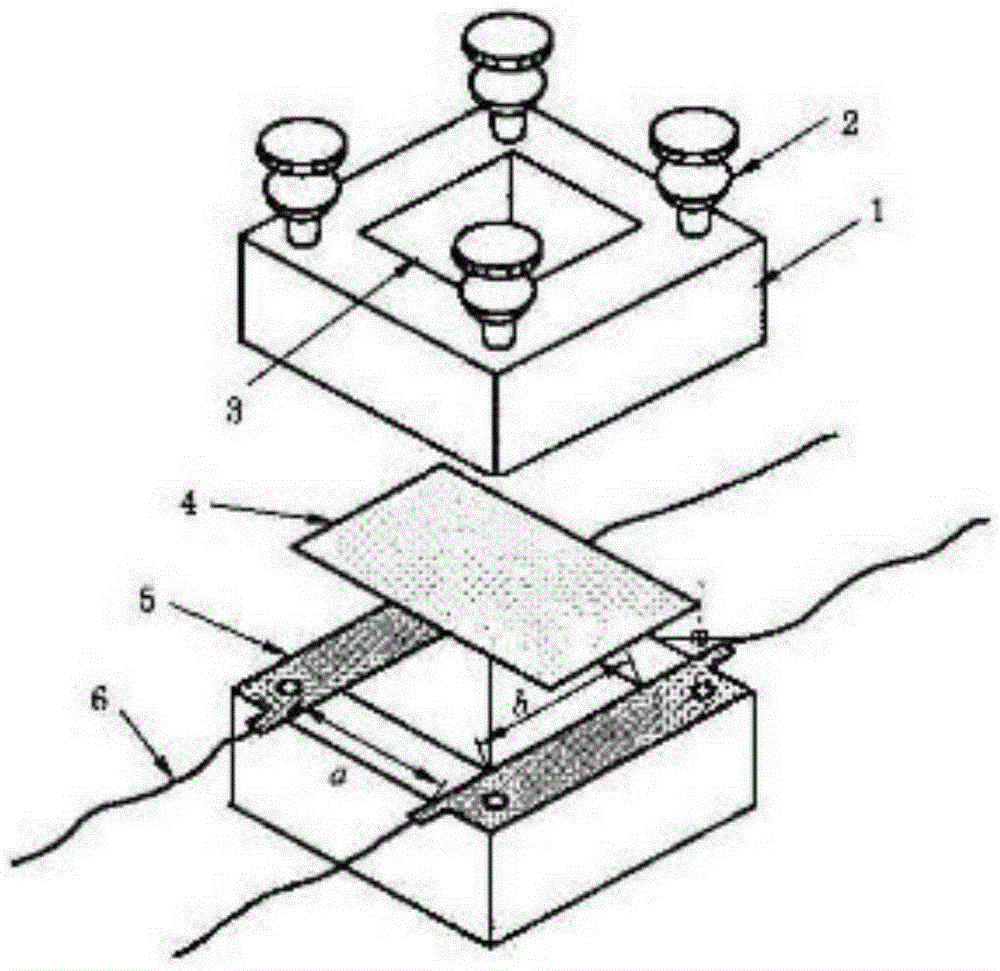

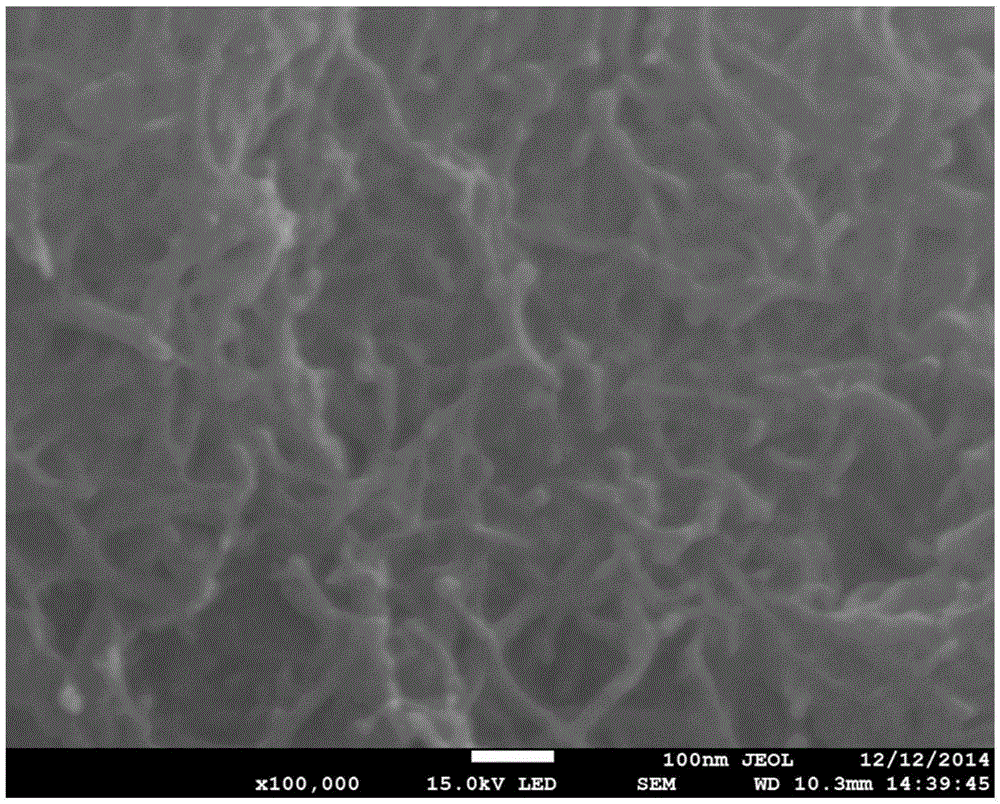

[0035]A preparation method of boron phosphate coated carbon nanotube composite proton exchange membrane, the steps are as follows:

[0036] 1) Preparation of sulfonated polyether ether ketone:

[0037] Put the polyetheretherketone powder in 98wt% concentrated sulfuric acid (solid-to-liquid ratio: 1g:20mL), the reaction temperature is 50°C, fully stir the reaction for 3h, and then pour the reaction solution into a large amount of ice-water mixture and stir for 1h, statically The resulting solid was washed with deionized water several times until the pH of the eluate was 6.5-7.0, and the precipitated polymer was filtered out, and finally dried at 60°C for 24 hours to obtain sulfonated polyether ether ketone;

[0038] 2) Preparation of boron phosphate-coated carbon nanotubes:

[0039] (1) preparation concentration is the Tris (trishydroxymethylaminomethane) solution of 50mmol / L, adds the hydrochloric acid adjustment solution pH value of 0.1mol / L to be 8, obtains 100mlTris-HCl bu...

Embodiment 2

[0048] A preparation method of boron phosphate coated carbon nanotube composite proton exchange membrane, the steps are as follows:

[0049] 1) Preparation of sulfonated polyether ether ketone:

[0050] Put the polyetheretherketone powder in 98wt% concentrated sulfuric acid (solid-to-liquid ratio: 1g:20mL) at a reaction temperature of 50°C and fully react for 3 hours, then pour the reaction solution into a large amount of ice-water mixture and stir for 1 hour, then let stand Filtrate, and wash the obtained solid with deionized water several times until the pH of the eluate is 6.5-7.0, filter out the precipitated polymer, and finally dry at 60°C for 24 hours to obtain sulfonated polyether ether ketone;

[0051] 2) Preparation of boron phosphate-coated carbon nanotubes:

[0052] (1) preparation concentration is the Tris (trishydroxymethylaminomethane) solution of 50mmol / L, adds the hydrochloric acid adjustment solution pH value of 0.1mol / L to be 8, obtains 100mlTris-HCl buffer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com