Patents

Literature

839 results about "Perfluorosulfonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

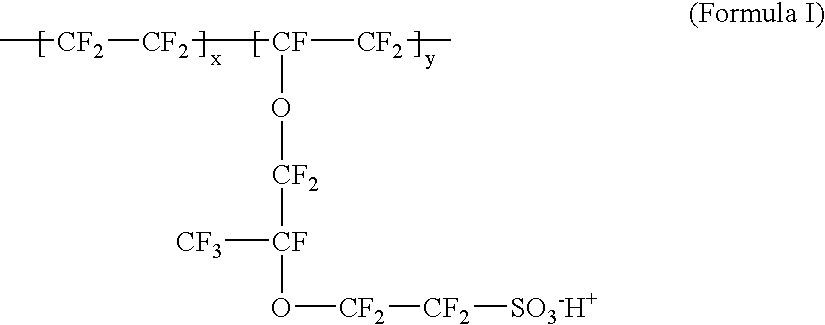

Perfluorosulfonic Acid Membranes for Fuel Cell and Electrolyser Applications. ... acid functionalized non-fluorinated polyaromatics 1 and polymer materials comprising protogenic functions other than sulfonic acid (typically phosphonic and heterocycle functionalized materials). These endeavors have also notably advanced perfluorosulfonic acid ...

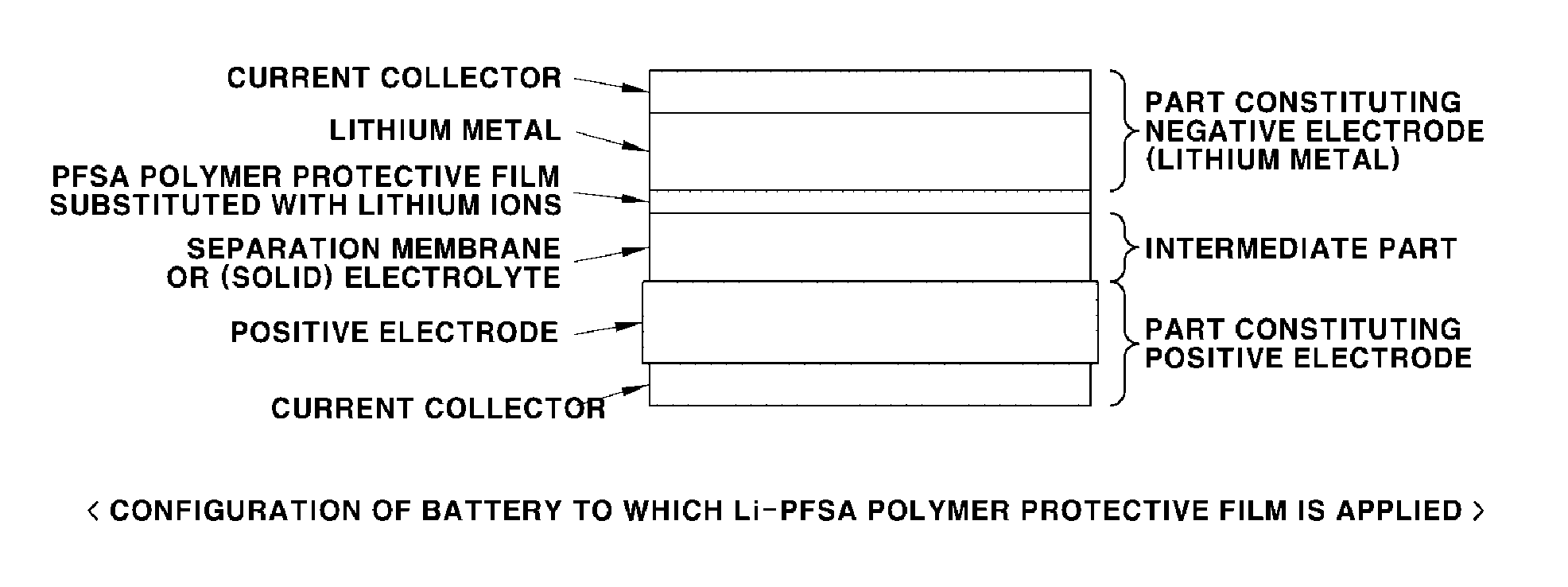

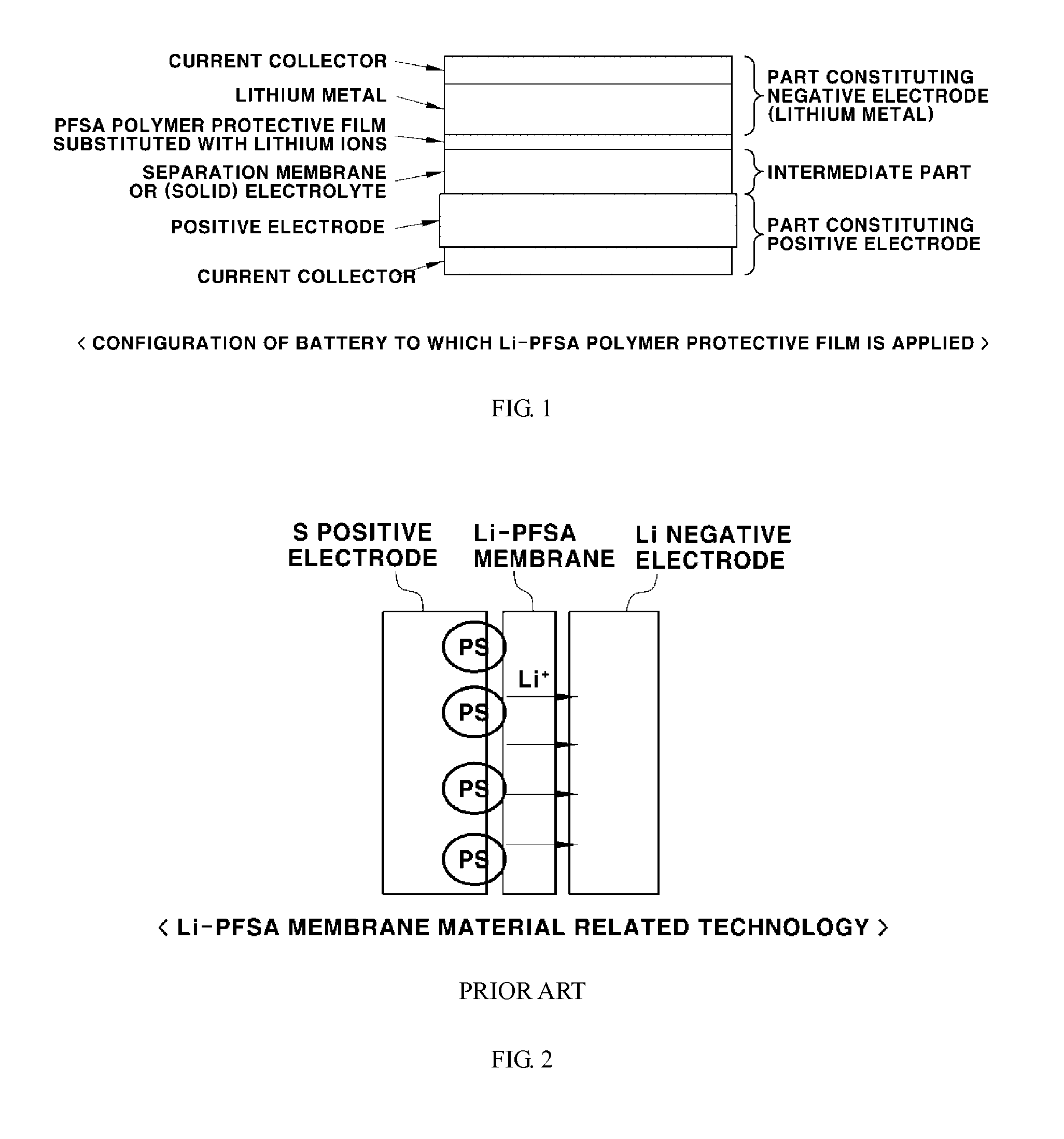

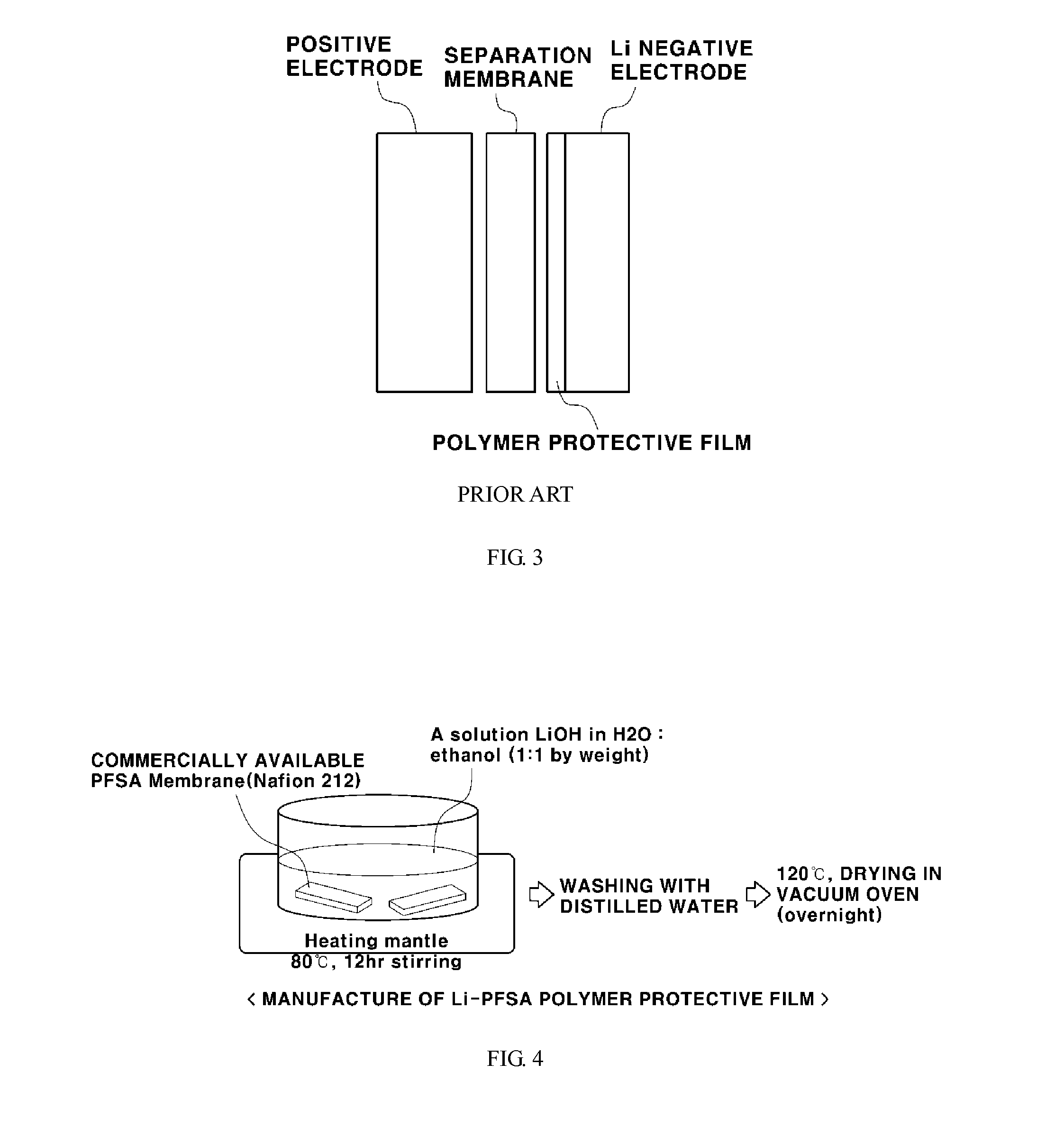

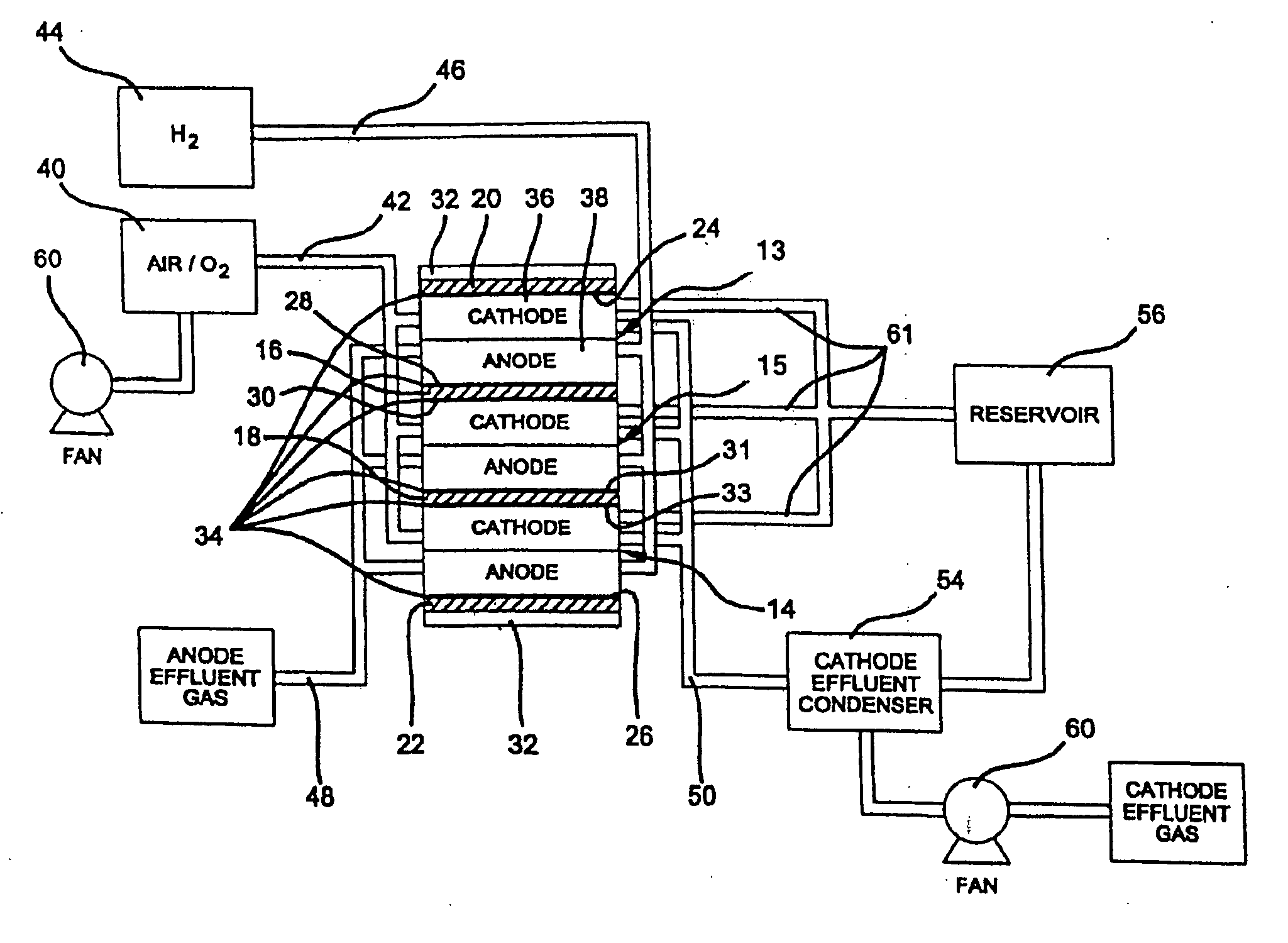

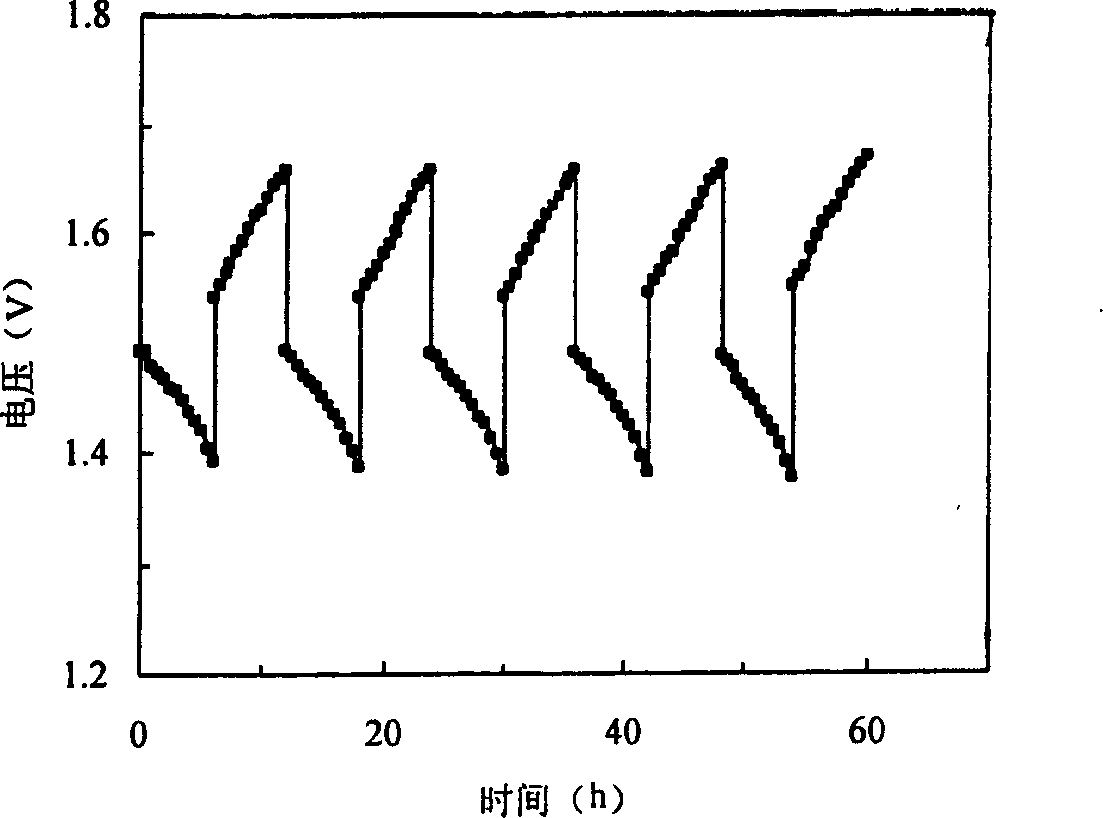

Separation membrane for lithium sulfur batteries

InactiveUS20150255782A1Improve lithium ion conductivityImprove stabilityFuel and secondary cellsElectrode thermal treatmentLithium–sulfur batteryLithium metal

Disclosed is a material which enhances stability for lithium in all the batteries, which use the lithium metal as an electrode material, by using and applying a lithium-substituted perfluoro sulfonic acid (PFSA) material in the form of a membrane or a powder to a lithium anode. Methods of manufacturing the material are also enclosed.

Owner:HYUNDAI MOTOR CO LTD

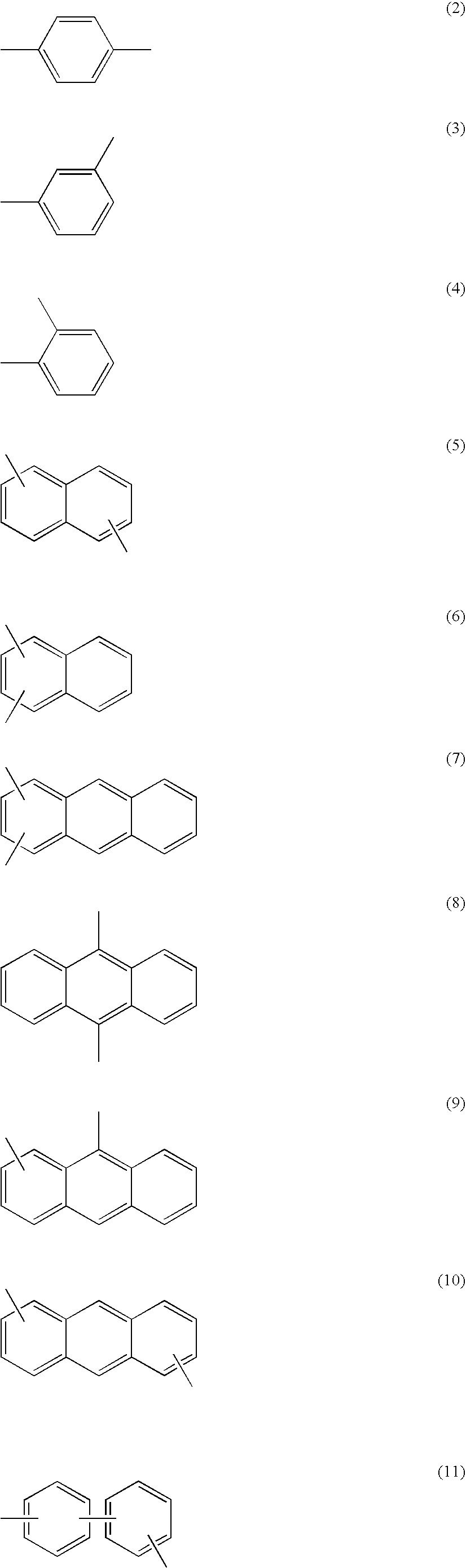

Sulfonated polyelectrolyte membranes containing perfluorosulfonate ionomers

ActiveUS20060177719A1Ion-exchanger regenerationFinal product manufactureIon exchangePolymer chemistry

New proton conducting membranes are made of sulfonated poly(arylene sulfide) polymers (SPAS) and a perfluorosulfonic acid polymer. A preferred poly(arylene sulfide) polymer is poly(p-phenylene sulfide). The membranes are used as a proton exchange membrane in PEM fuel cells operating at temperatures above 60° C., or at low relative humidity. According to methods of the invention, sulfonated poly(phenylene sulfide) (SPPS) films may be provided with a wide range of physical properties, which depend in part on the ion exchange capacity of the films. In particular, the degree or level of sulfonation can be tailored by adjusting reaction conditions such as temperature and time. In a preferred embodiment, an ionomer comprising perfluorosulfonic acid polymer is imbibed into the insoluble SPAS films by immersing the films in a solution or dispersion of the ionomers.

Owner:GM GLOBAL TECH OPERATIONS LLC

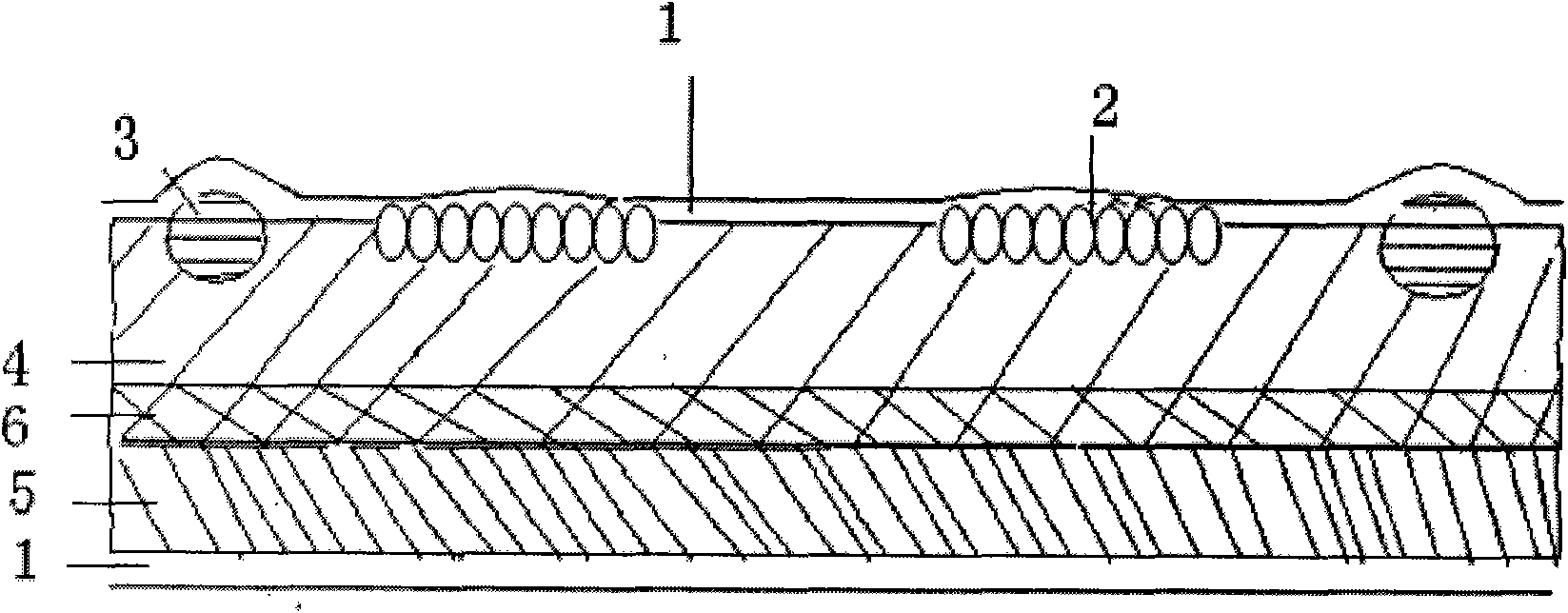

Fluorine-containing ion exchange membrane with reinforced sacrificial fiber mesh cloth

InactiveCN101773788AImprove electrochemical performanceLower resistanceSemi-permeable membranesHydrophilic coatingFiber

The invention relates to a fluorine-containing ion exchange membrane with reinforced sacrificial fiber mesh cloth, which comprises a fluorine-containing ion exchange resin base membrane, mesh cloth with sacrificial fiber and a hydrophilic coating, wherein the fluorine-containing ion exchange resin base membrane comprises a perfluorocarboxylic acid resin membrane layer of 5-10 micrometers, a perfluorosulfonic acid resin membrane layer of 90-120 micrometers, and a perfluorosulfonic acid / perfluorocarboxylic acid copolymerization or blending resin membrane layer of 0-40 micrometers, which is positioned between the perfluorocarboxylic acid membrane layer and the perfluorosulfonic acid membrane layer; and the mesh cloth with the sacrificial fiber comprises reinforced fiber and sacrificial fiber. In the invention, the fluorine-containing ion exchange membrane with the reinforced sacrificial fiber mesh cloth can improve the electrochemical properties of the membrane and can effectively reduce the resistance of the membrane.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

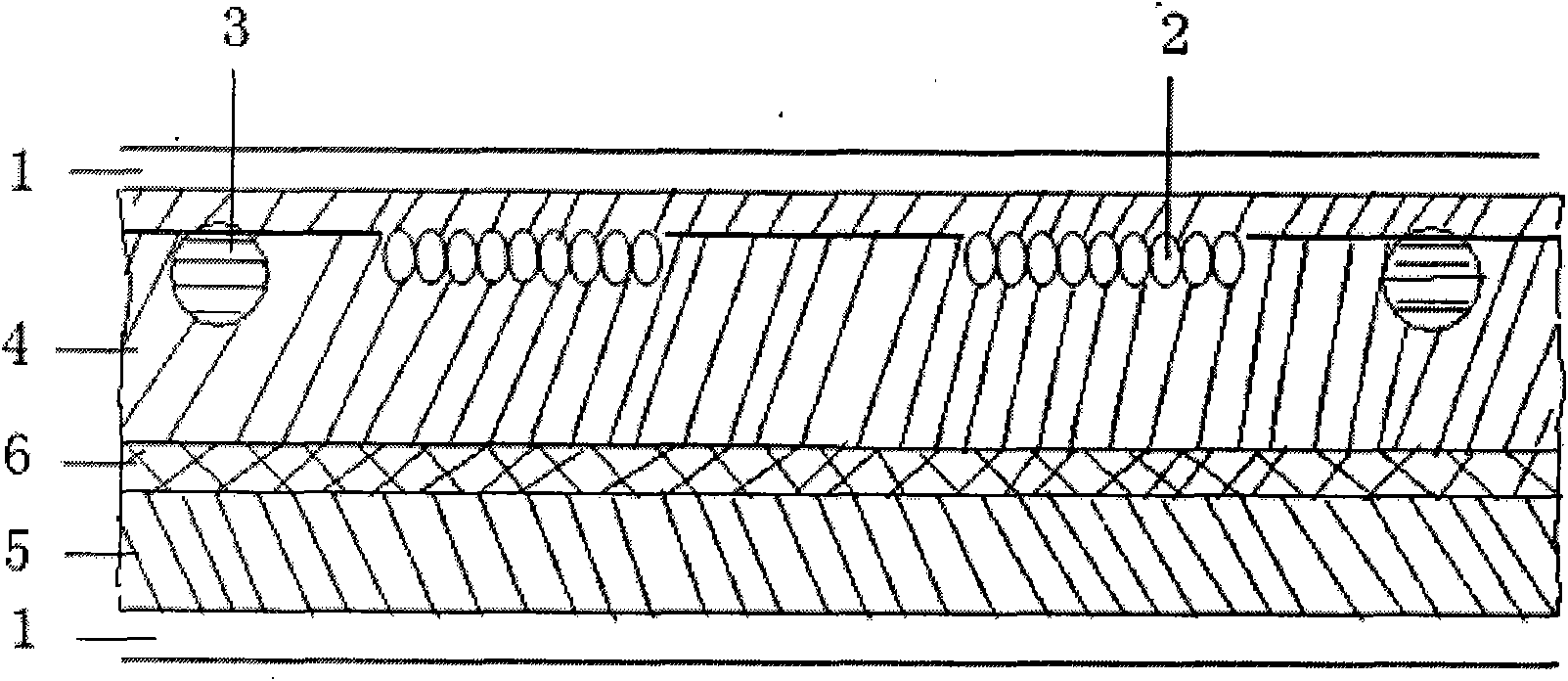

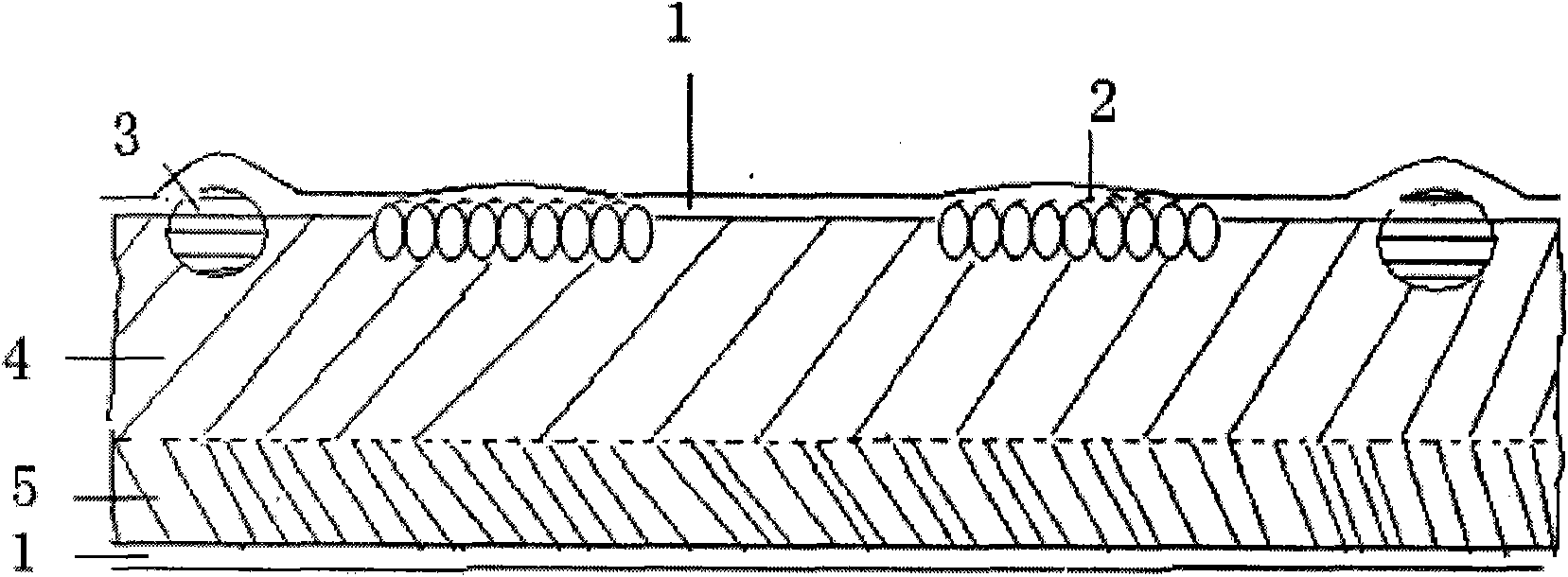

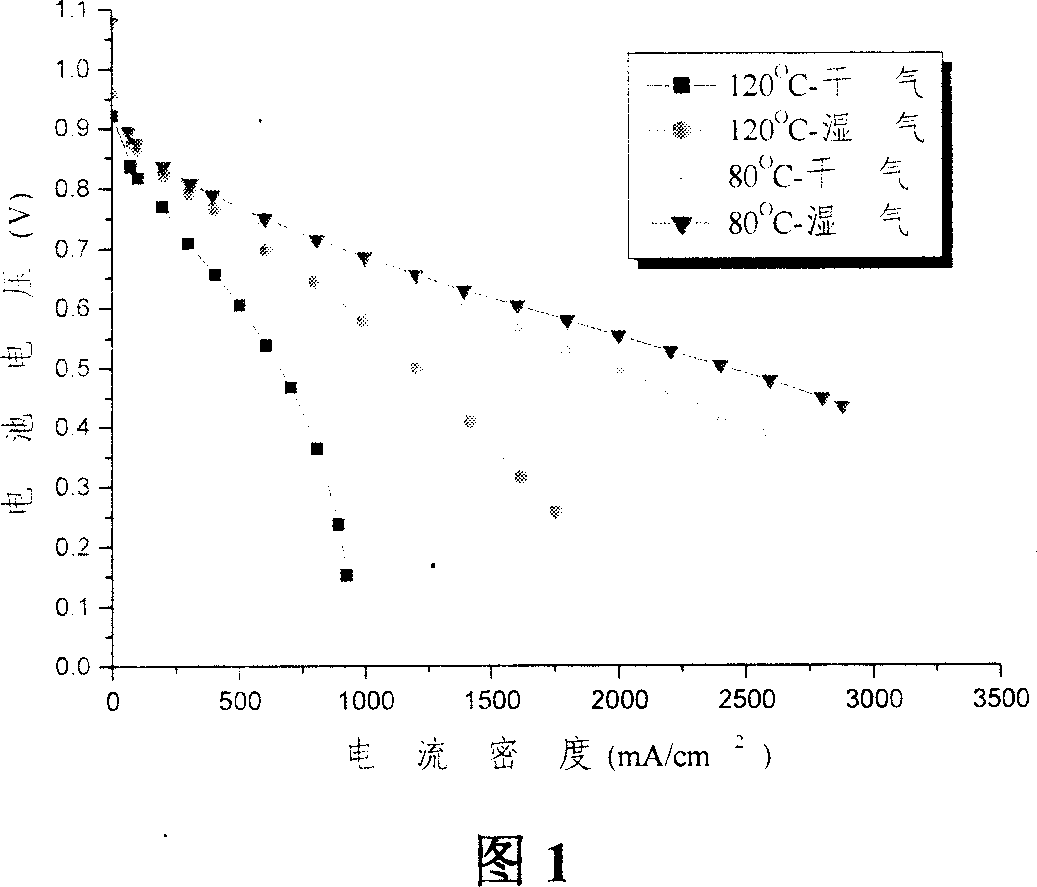

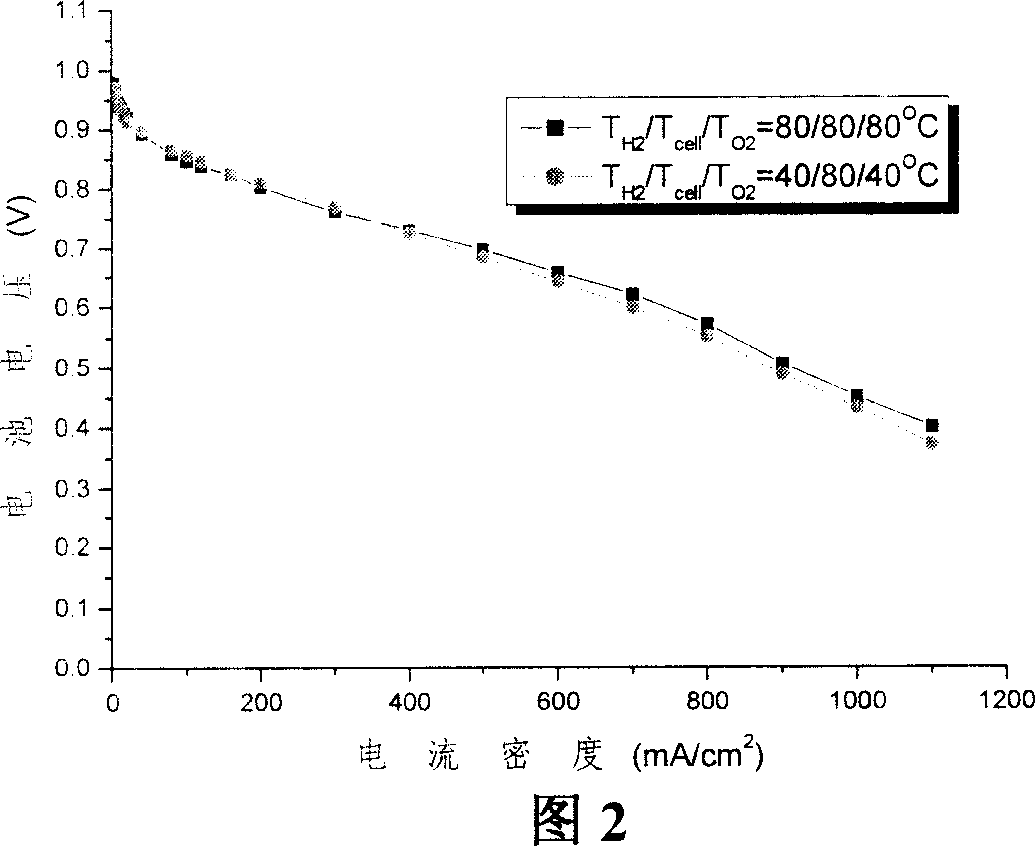

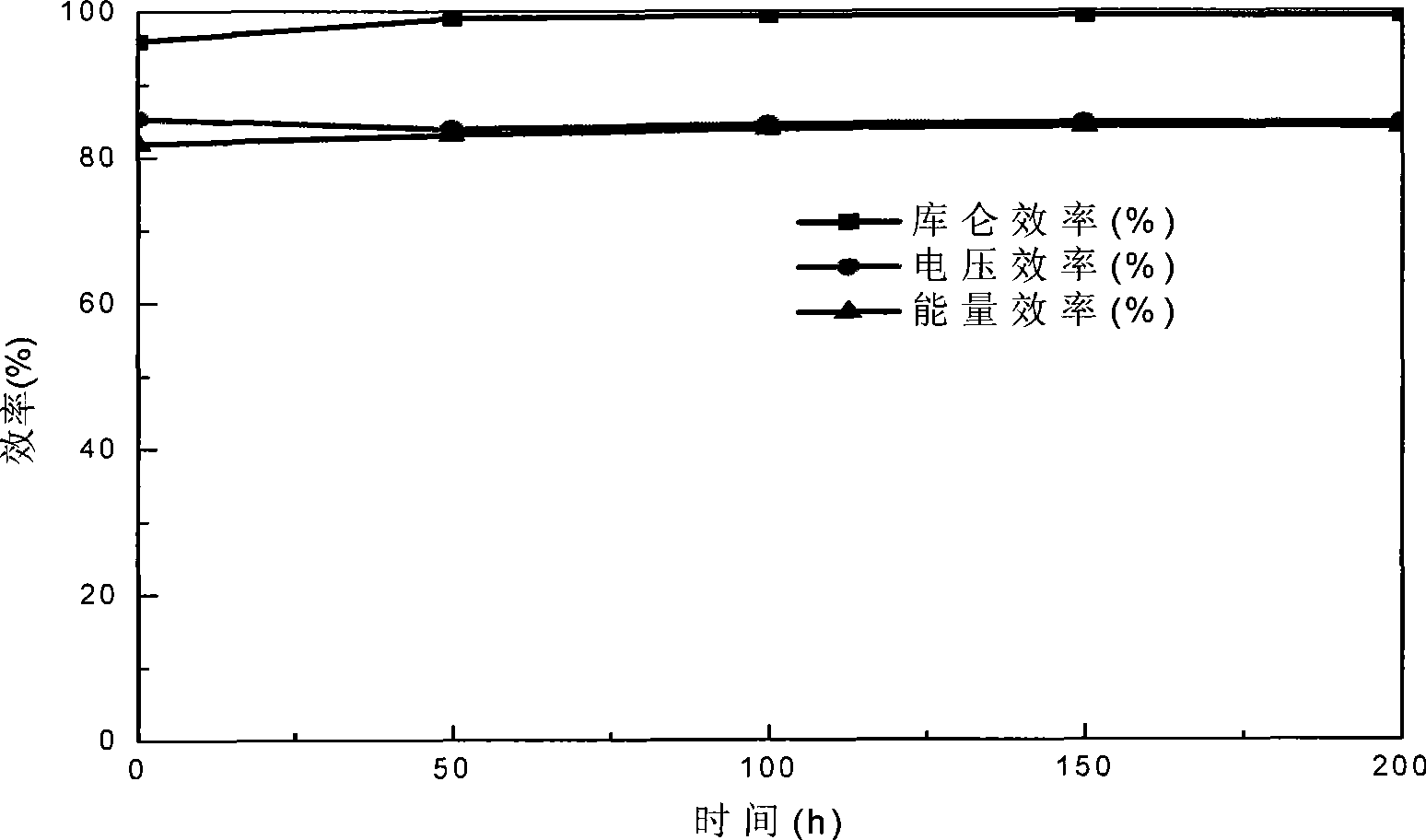

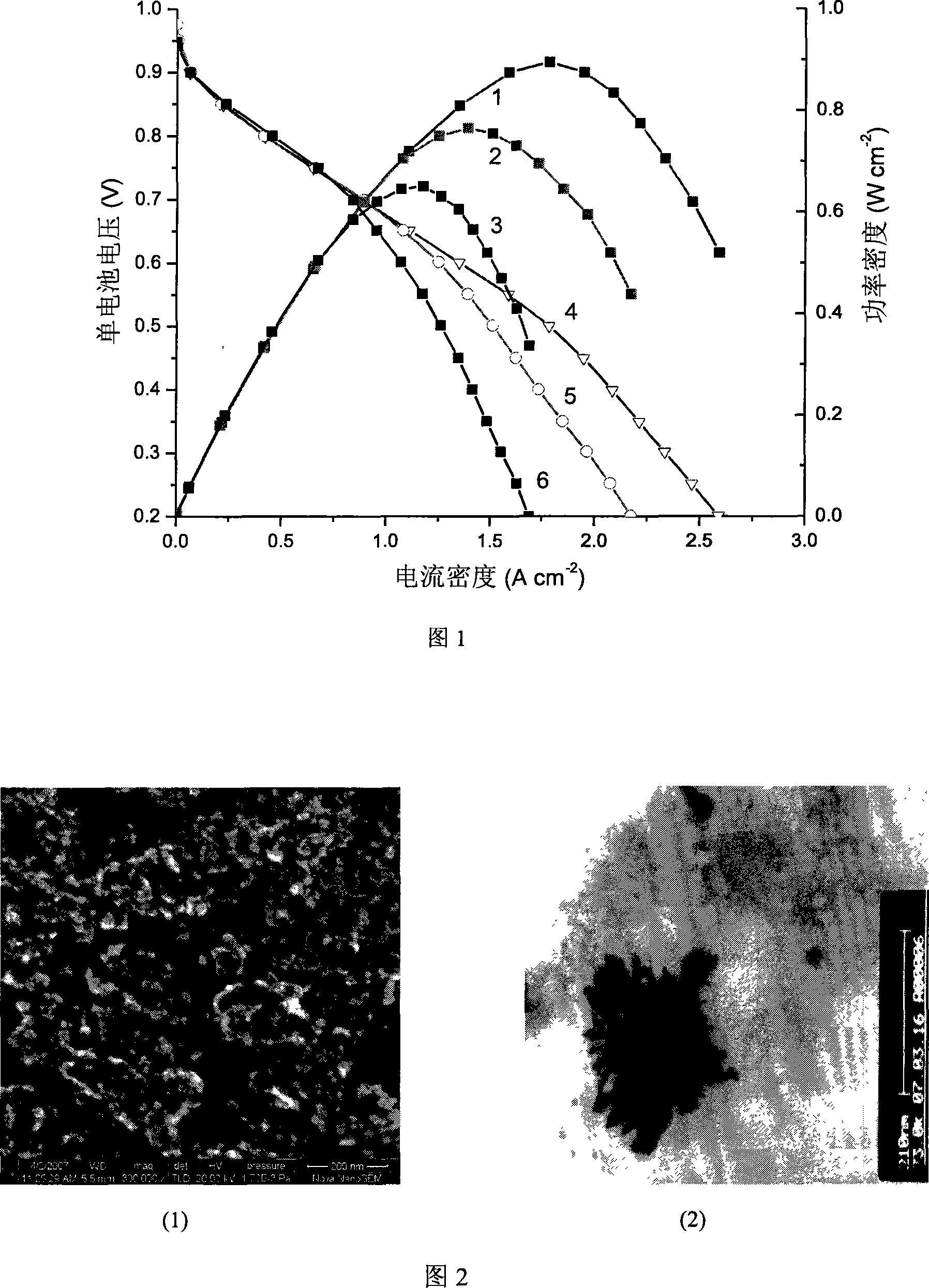

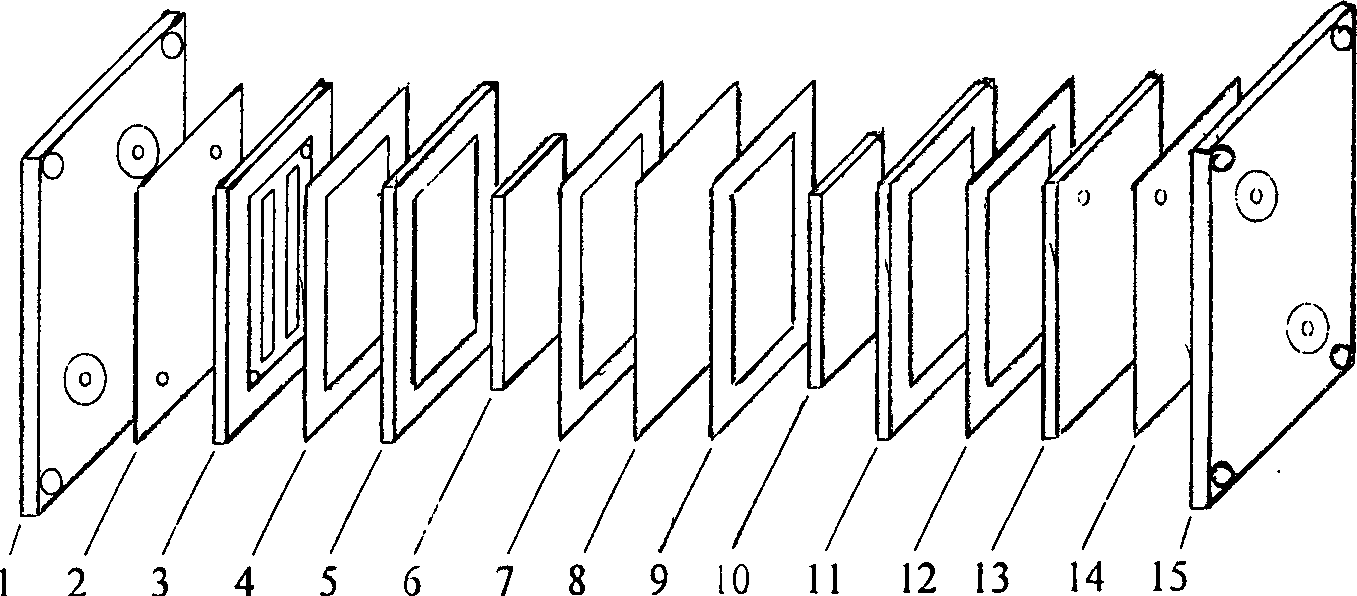

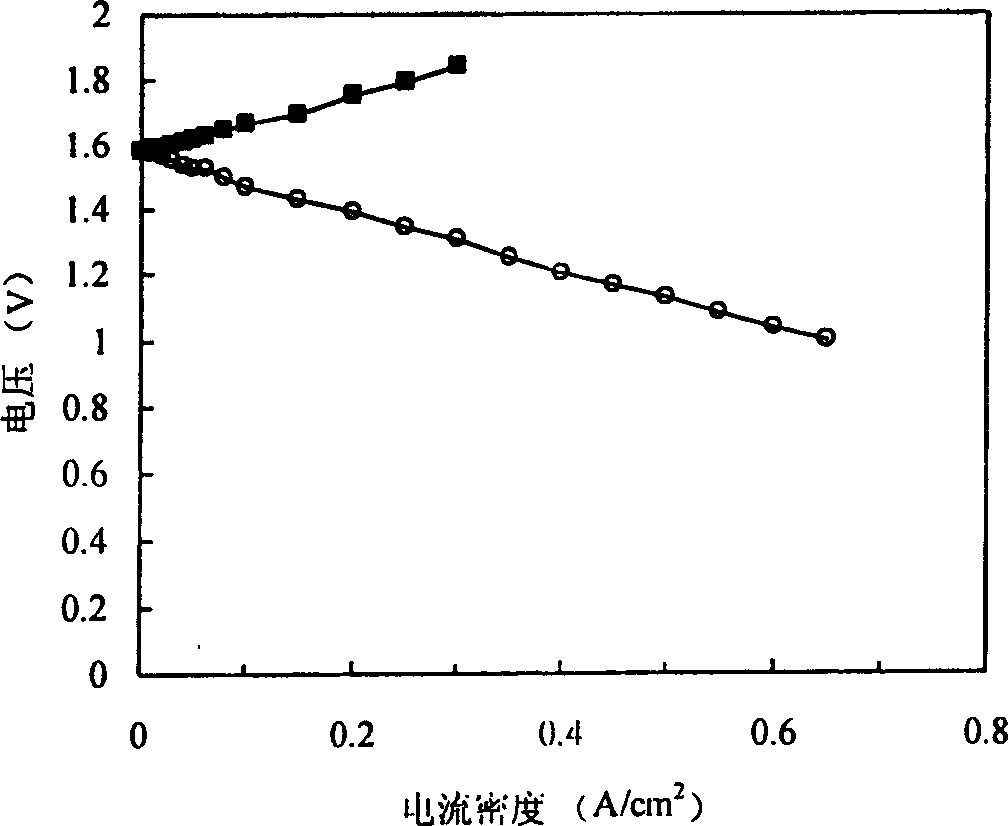

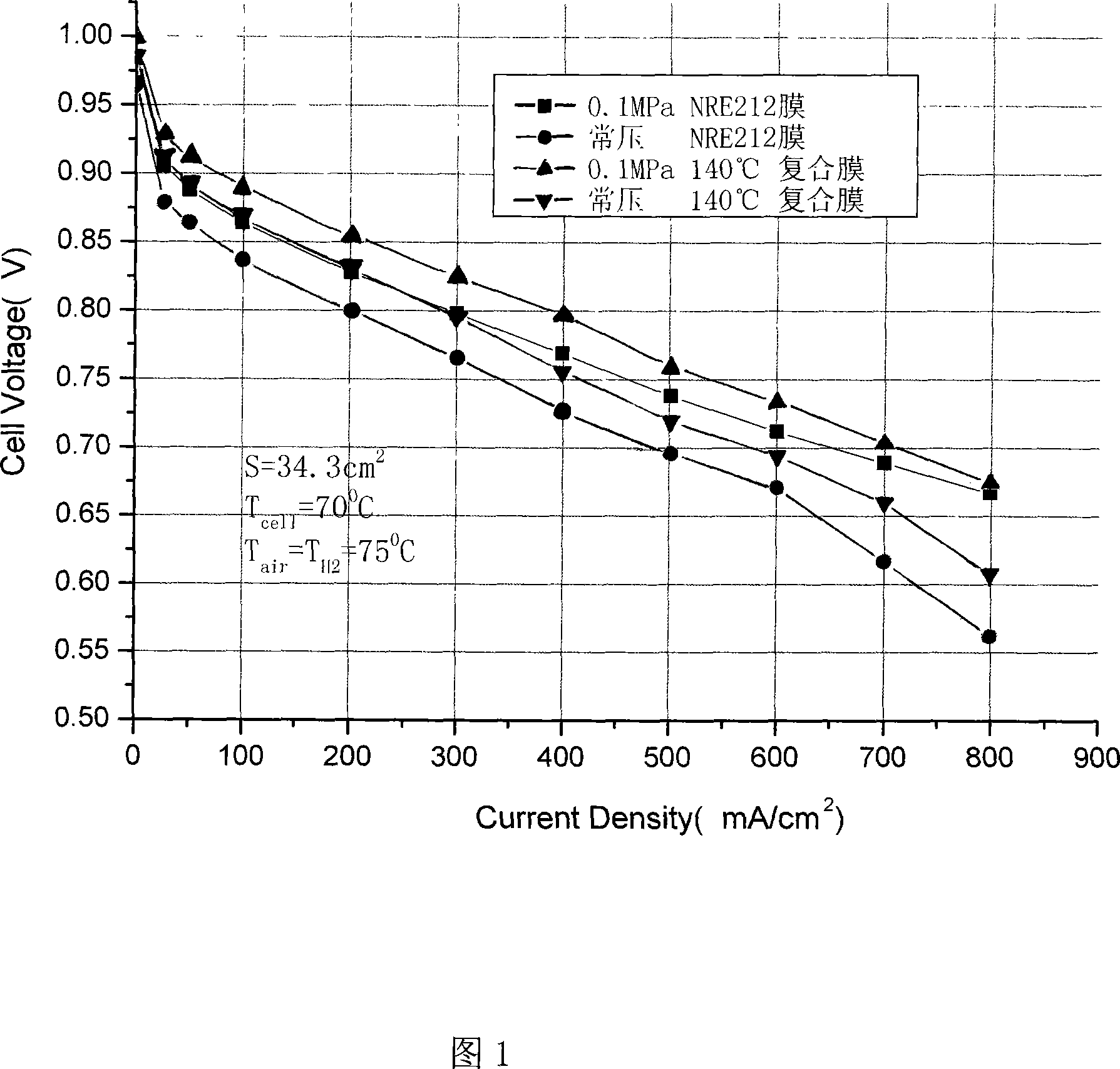

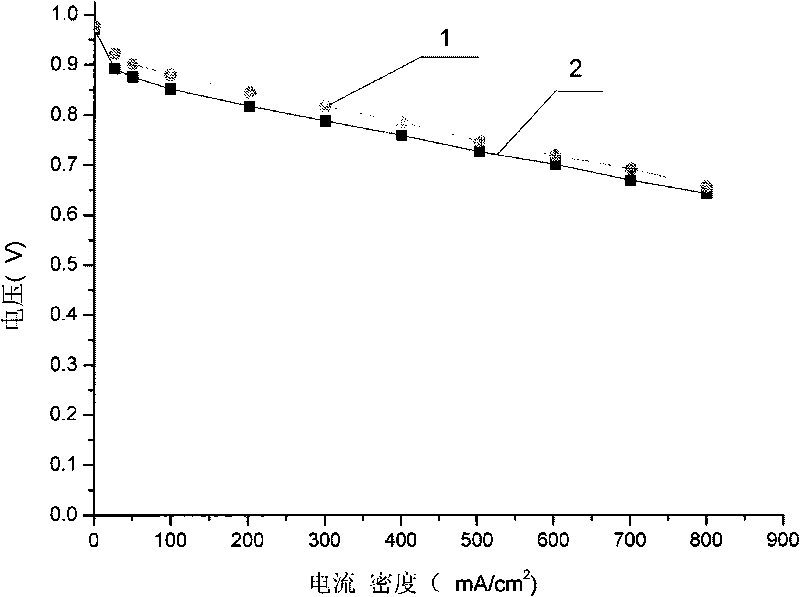

Multi-layer moisture making compound film for proton exchange film fuel cell and its making method

InactiveCN101079487ALow costImprove thermal stabilityFinal product manufactureSolid electrolyte fuel cellsPolystyreneAccelerant

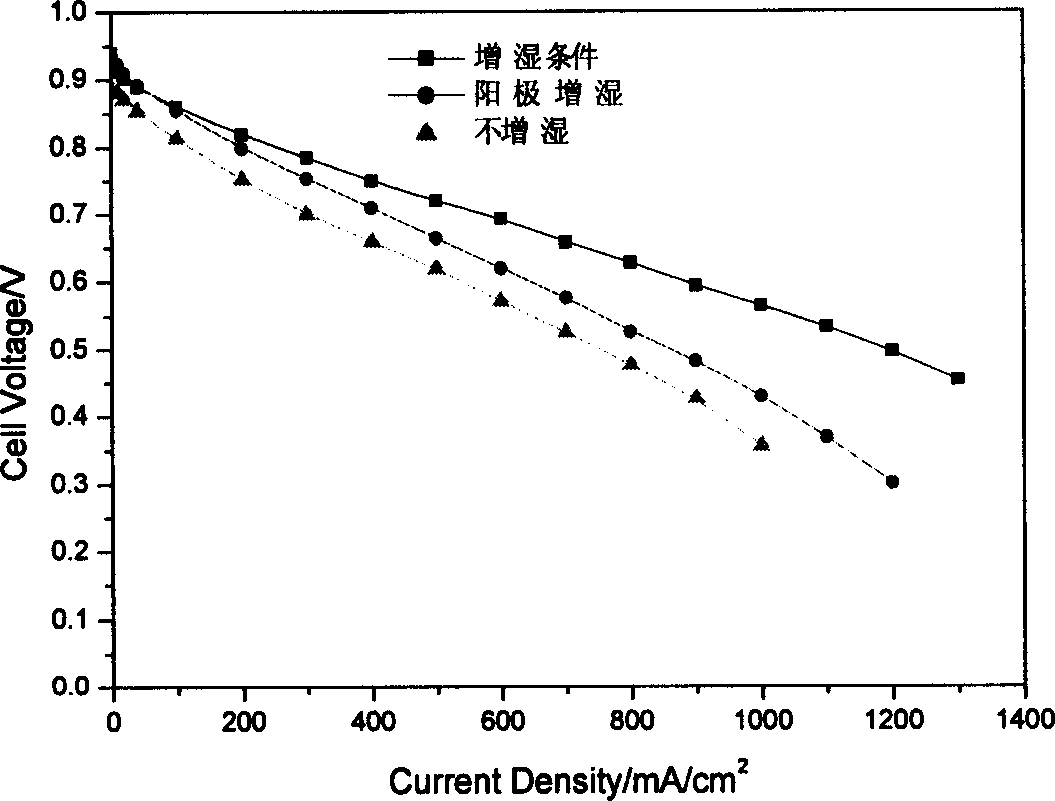

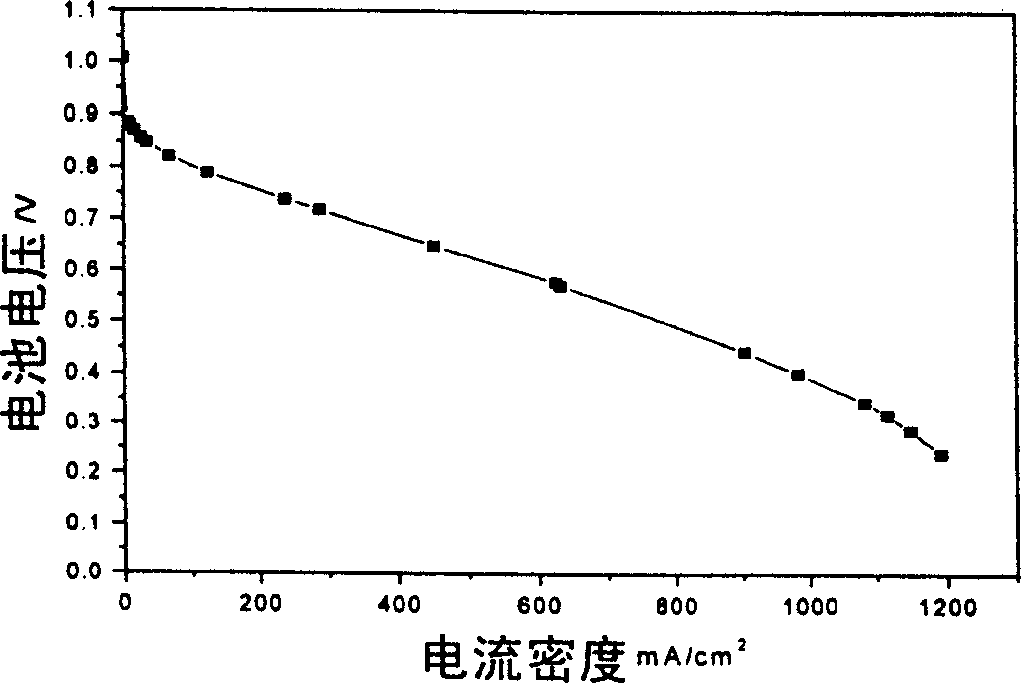

The invention relates to a multiple-layer complex proton exchange film for the fuel battery in particular to a multiple-layer self-humidifying complex film and preparing method for the proton exchange film fuel battery. The complex film comprises the following parts: a porous strengthening film and a self-humidifying complex layer, wherein the proton exchange film resin is poured and painted on the porous strengthening film and the strengthening complex film is formed, the self-humidifying complex layer is poured and painted at two sides of the strengthening complex film, the self-humidifying complex layer is comprised by the metal accelerant and the proton exchange film resin(the mass ratio of the accelerant(pt) and the proton exchange film resin is 0.0005:1-0.01:1), the proton exchange film resin can be perfluorine sulfonic acid resin, sulfonated polyarylethersulfone, sulfonated polyetheretherketone, partial sulfonated polystyrene fluoride, partial sulfonated polyarylethersulfone fluoride, or partial polyaryletheretherketone fluoride. The multiple-layer self-humidifying complex film is provided with the good steady, the high proton conductivity and the good self-humidifying property.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

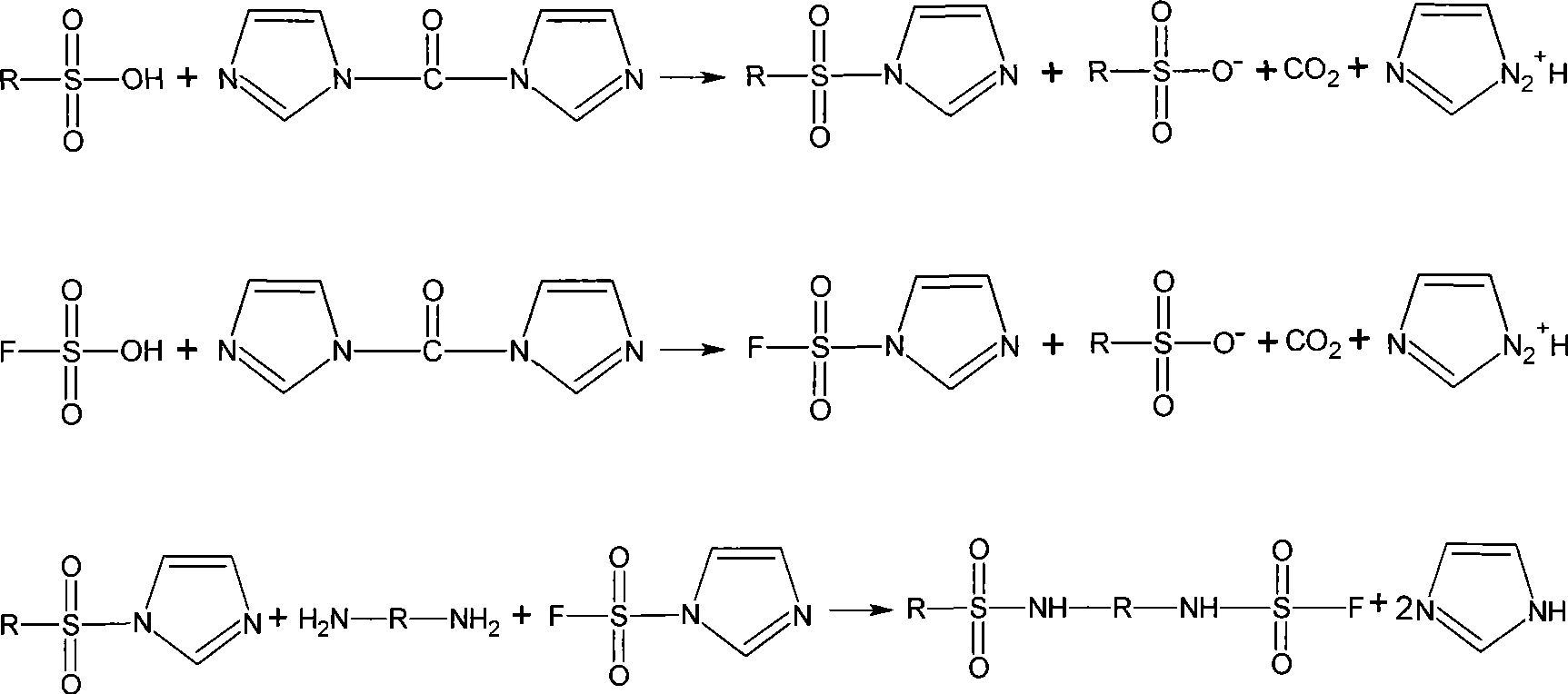

Fluorine/hydrocarbon composite ion exchange film and preparation thereof

InactiveCN101383404AHigh degree of bindingImprove performanceSemi-permeable membranesCell component detailsCross-linkChemical stability

The invention relates to a fluorine / hydrocarbon composite ion exchange membrane and a preparation method thereof. The membrane is formed by compounding a layer of hydrocarbon sulfonic acid type ion exchange membrane and a layer of perfluorinated sulfonic acid type ion exchange membrane; compared with the perfluorinated sulfonic acid type ion exchange membrane, the composite ion exchange membrane has low price, and compared with the hydrocarbon sulfonic acid type ion exchange membrane, the chemical stability of the composite ion exchange membrane is remarkably improved. The preparation method of the membrane is as follow: the sulfonic acid radical of the hydrocarbon sulfonic acid type ion exchange membrane is cross-linked with the sulfonic acid group of the perfluorinated sulfonic acid type ion exchange membrane through chemical cross-linking reaction, and thereby the composite ion exchange membrane is obtained. The membrane is used as the battery diaphragm of the all-vanadium redox flow battery (VRB), and can effectively reduce the cost of the battery on the basis of keeping good oxidation resistance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for preparing self-humidifying composite proton exchange film for fuel cell

InactiveCN1464580AEasy to operateSimple preparation processSolid electrolyte fuel cellsFuel cell detailsAlcoholOrganic solvent

The present invention discloses a process for preparing self-humidifying composite proton exchange membrane for fueling battery comprising, adding heat dissolving all fluorosulfuric acid film into the low boiling point organic alcohol and water dissolvent, forming all fluorosulfuric acid resin solution, adding the carrying type catalyst and high boiling point organic dissolvent containing Pt into the all fluorosulfuric acid resin solution, dropping the solution on the surface of the organic porous membrane, heating up and storing under vacuum.

Owner:SUNRISE POWER CO LTD

Method for preparing complex film of proton exchange film for fuel cell

InactiveCN1416186ADip easyReduce surface tensionCell electrodesCell component detailsOrganic solventBoiling point

The method includes following steps. The porous membrane of high polymer is dipped in ethanol solution in order to remove the organic matter on the surface. The organic solvent with high boiling point is added to the porous membrane, which is then put to the vacuum oven heating to obtain the composite proton exchange membrane of perfluorosulfuric acid. The thickness of the membrane is 10-100 micron m. The invention possessesthe advantages of easy to control the thickness of the composite membrane and the immersion quantity of the perfluoro resin, providing the membrane with the proporties of airtight and good intensity. It is safe to be used in the fuel cell.

Owner:SUNRISE POWER CO LTD

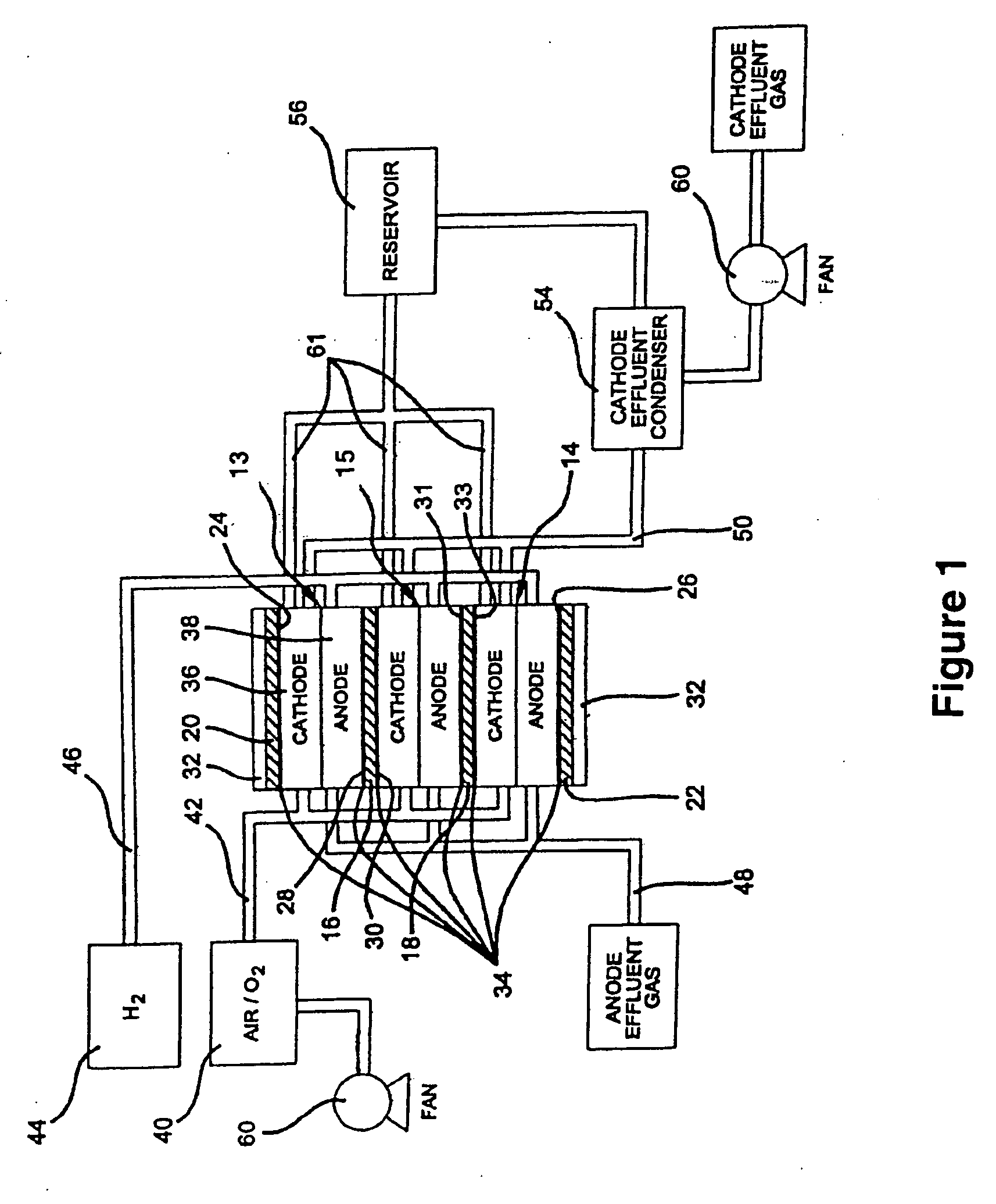

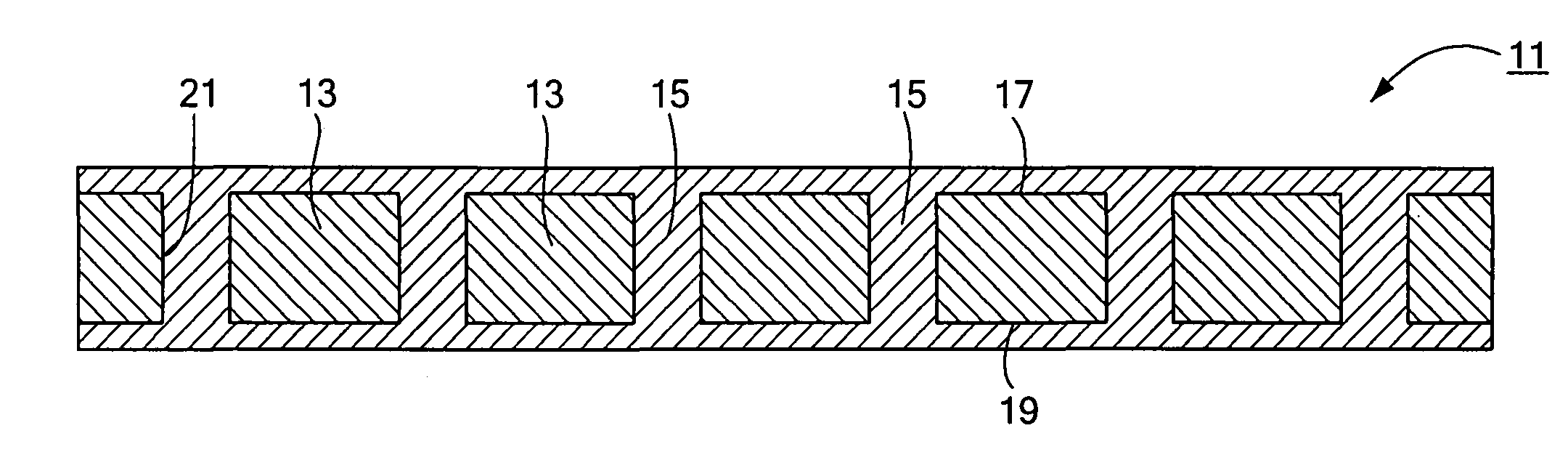

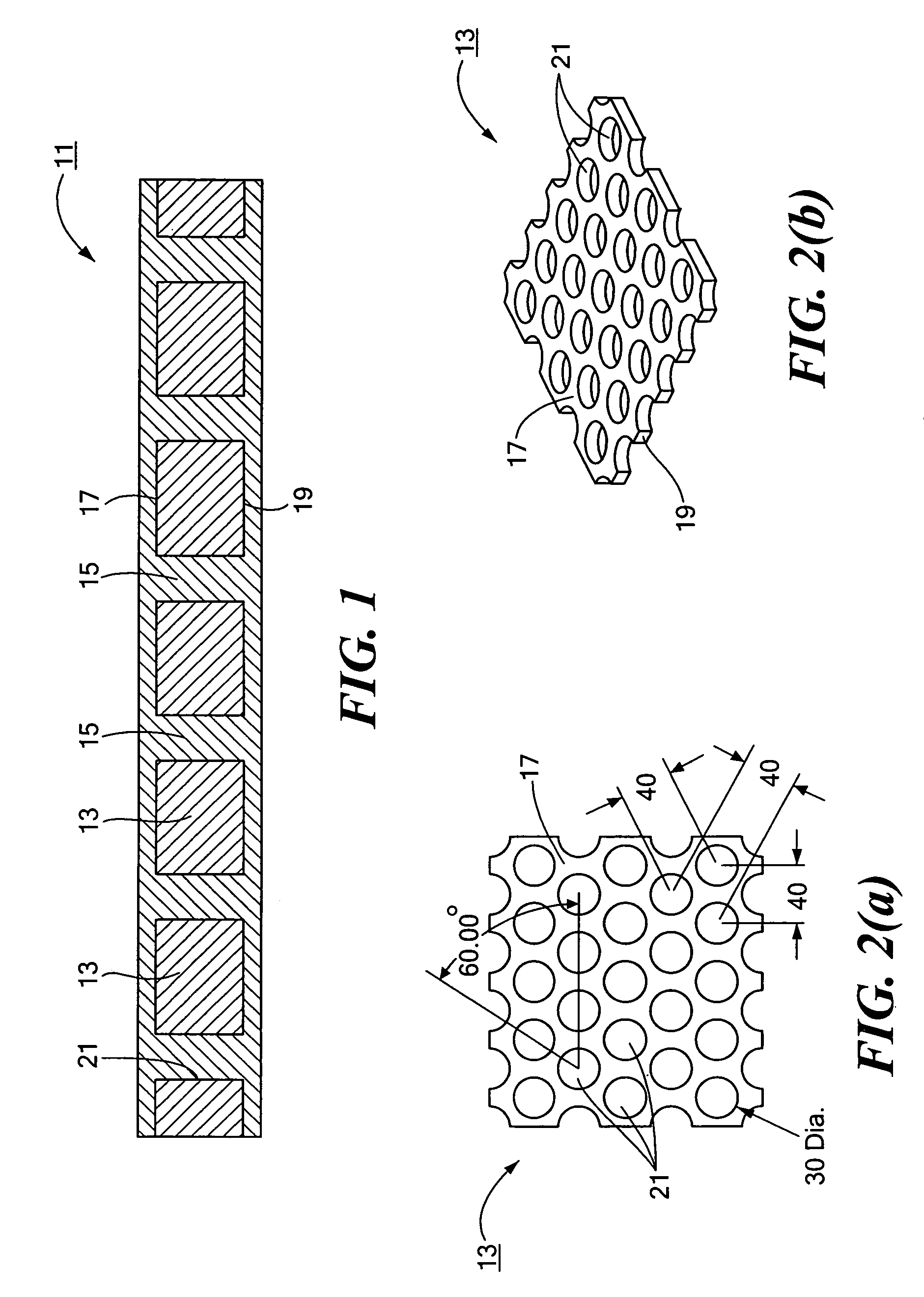

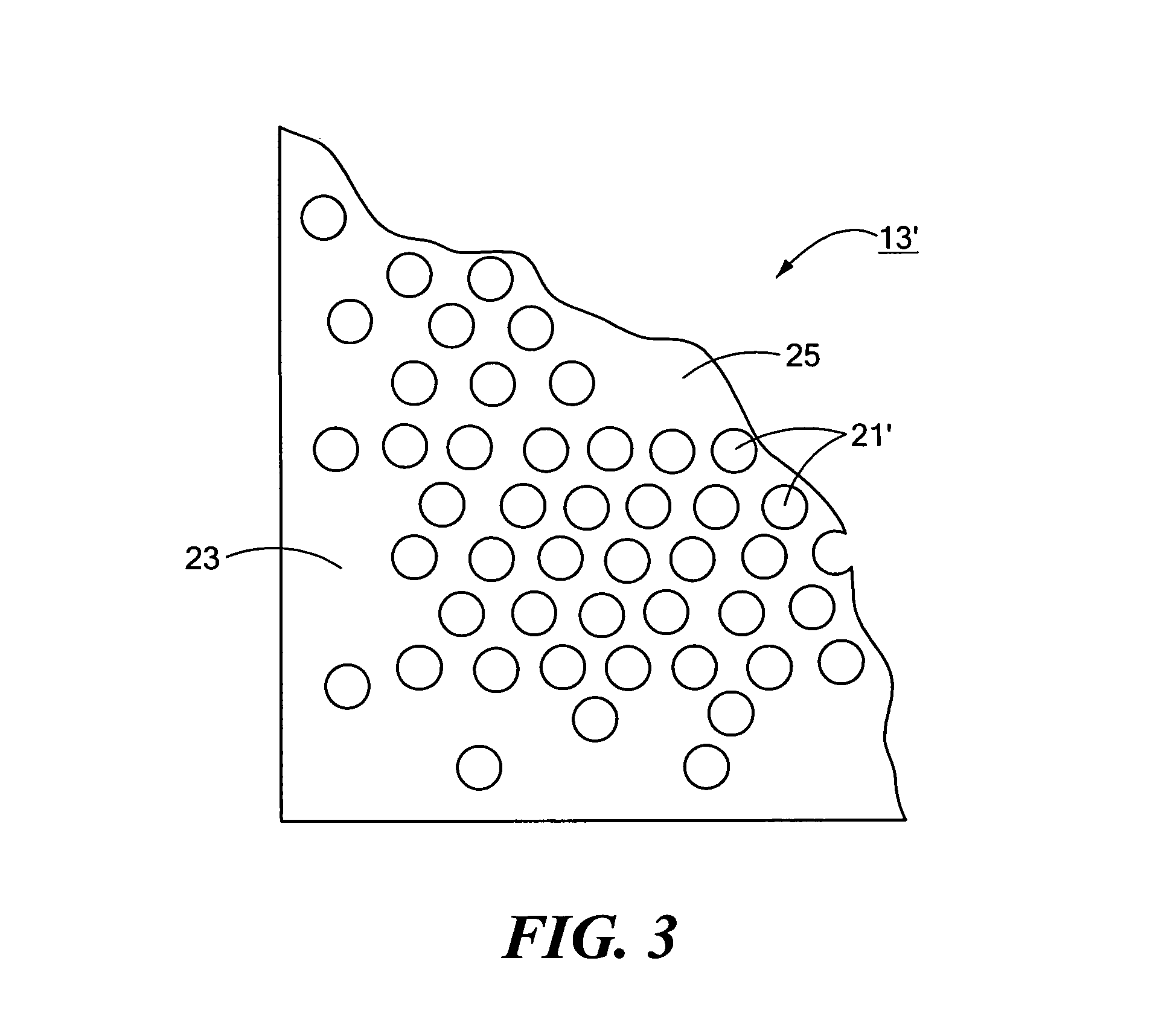

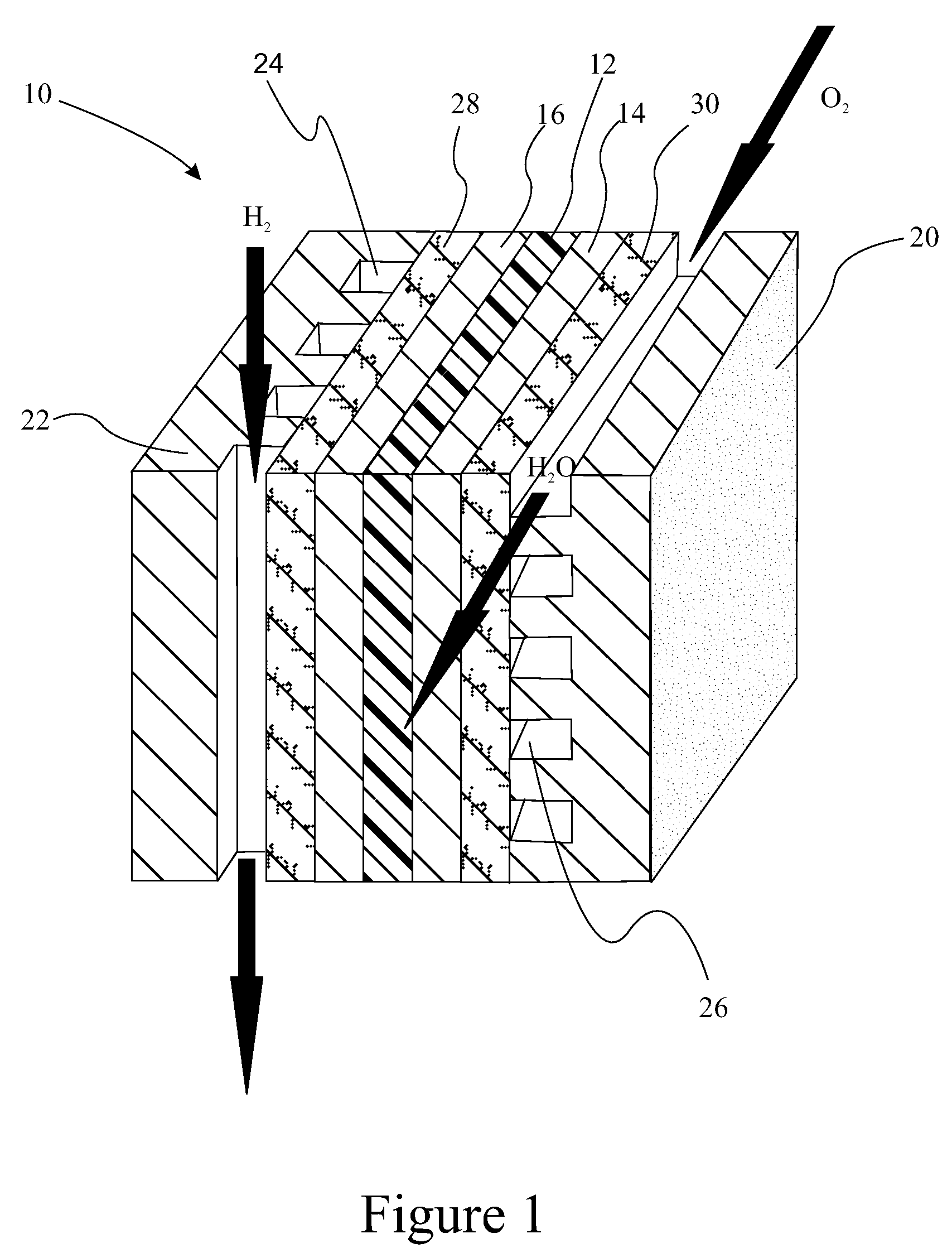

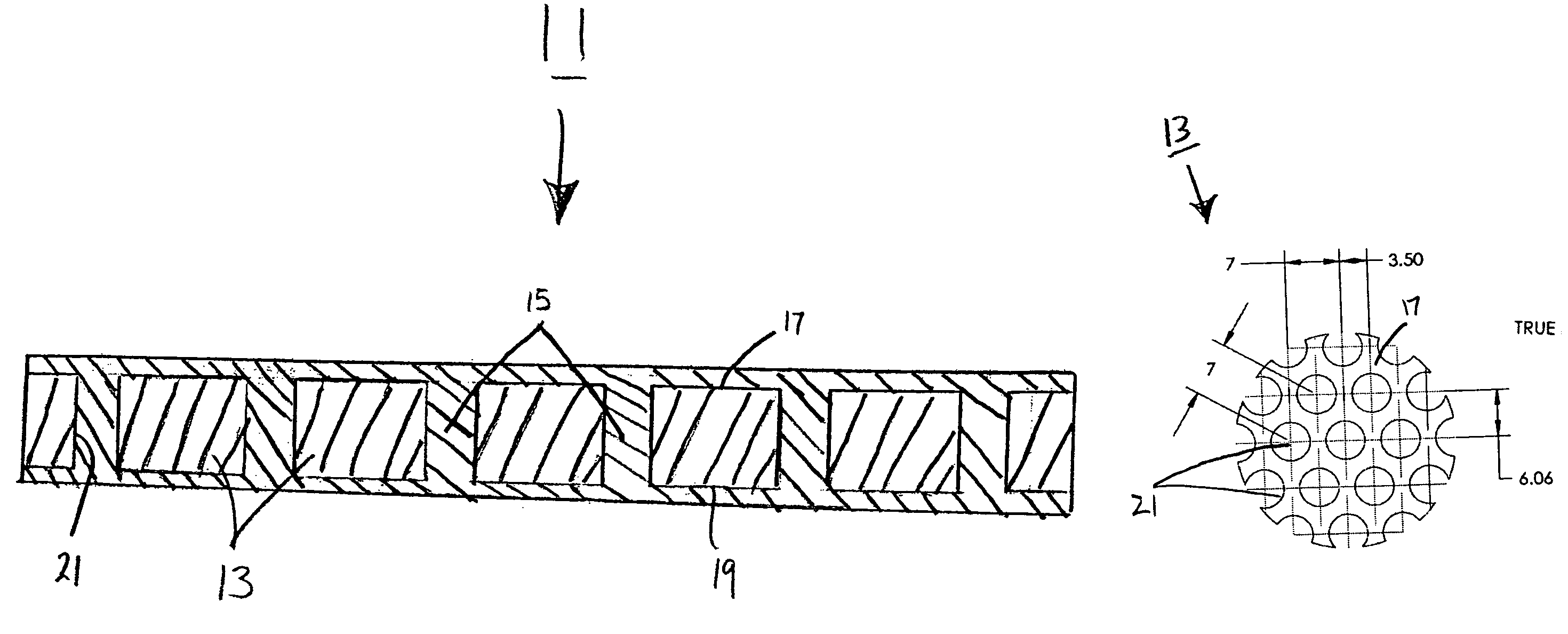

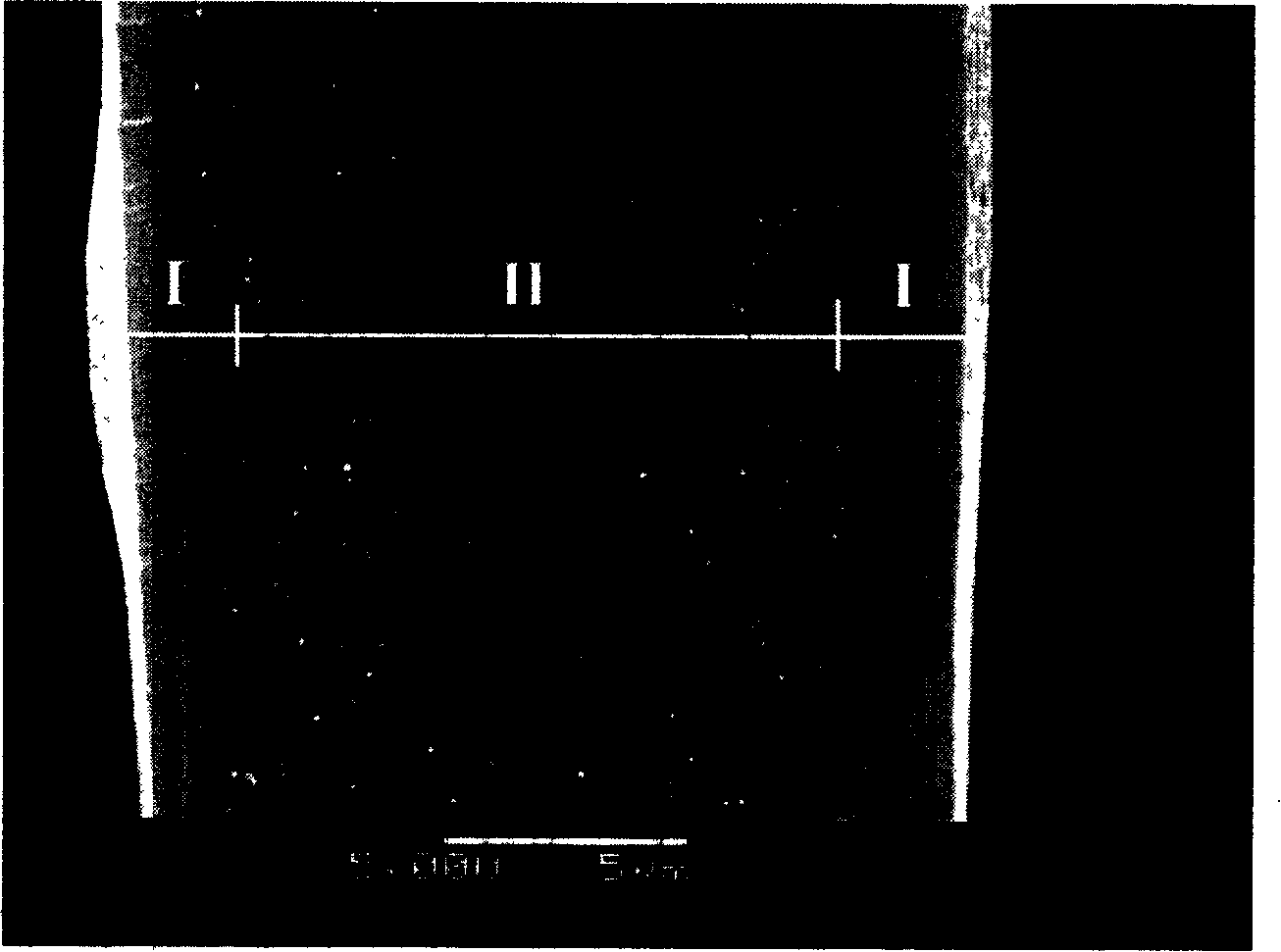

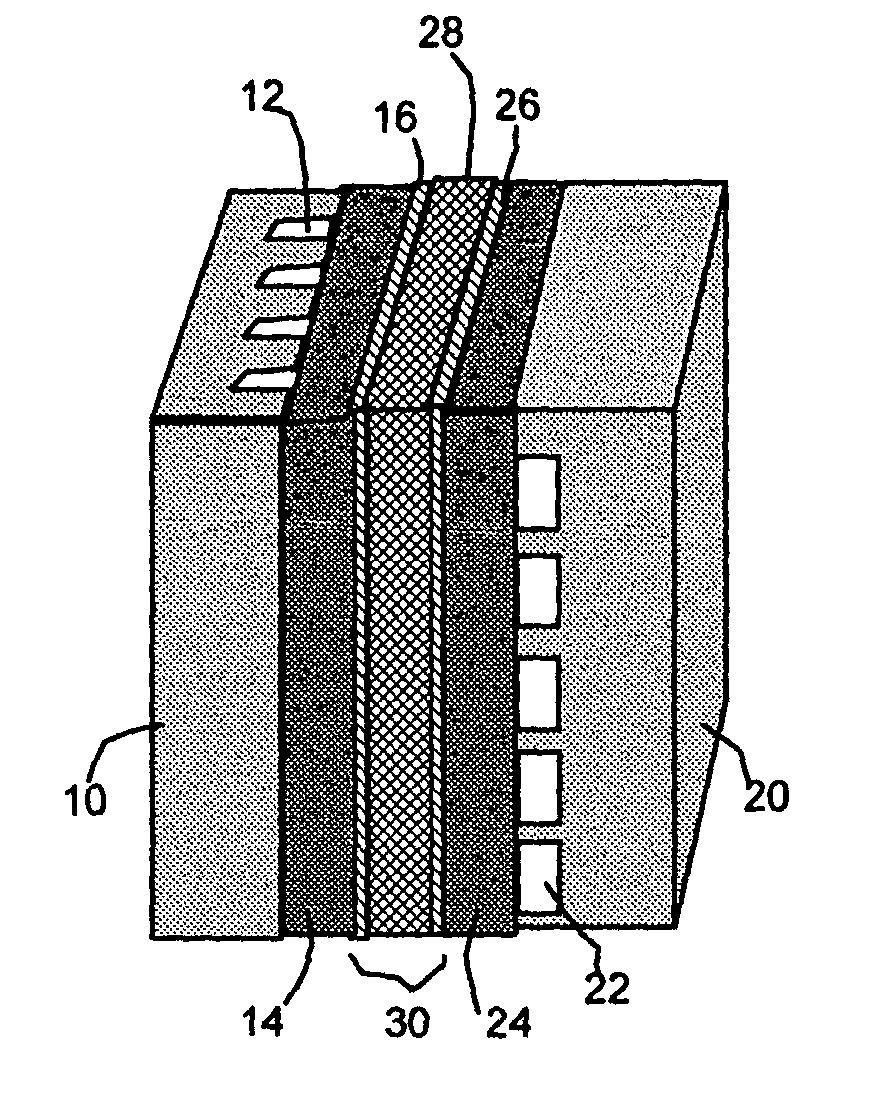

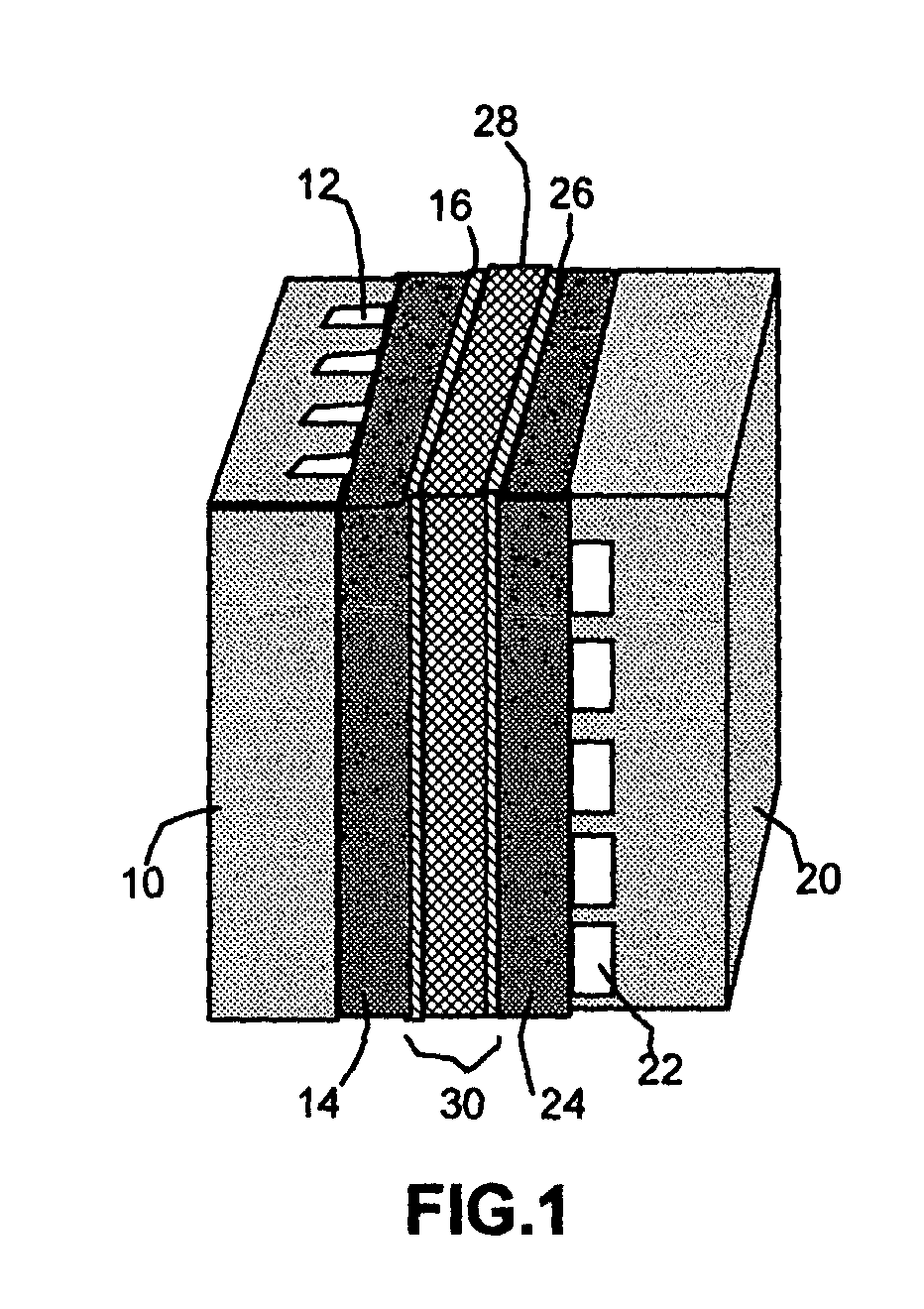

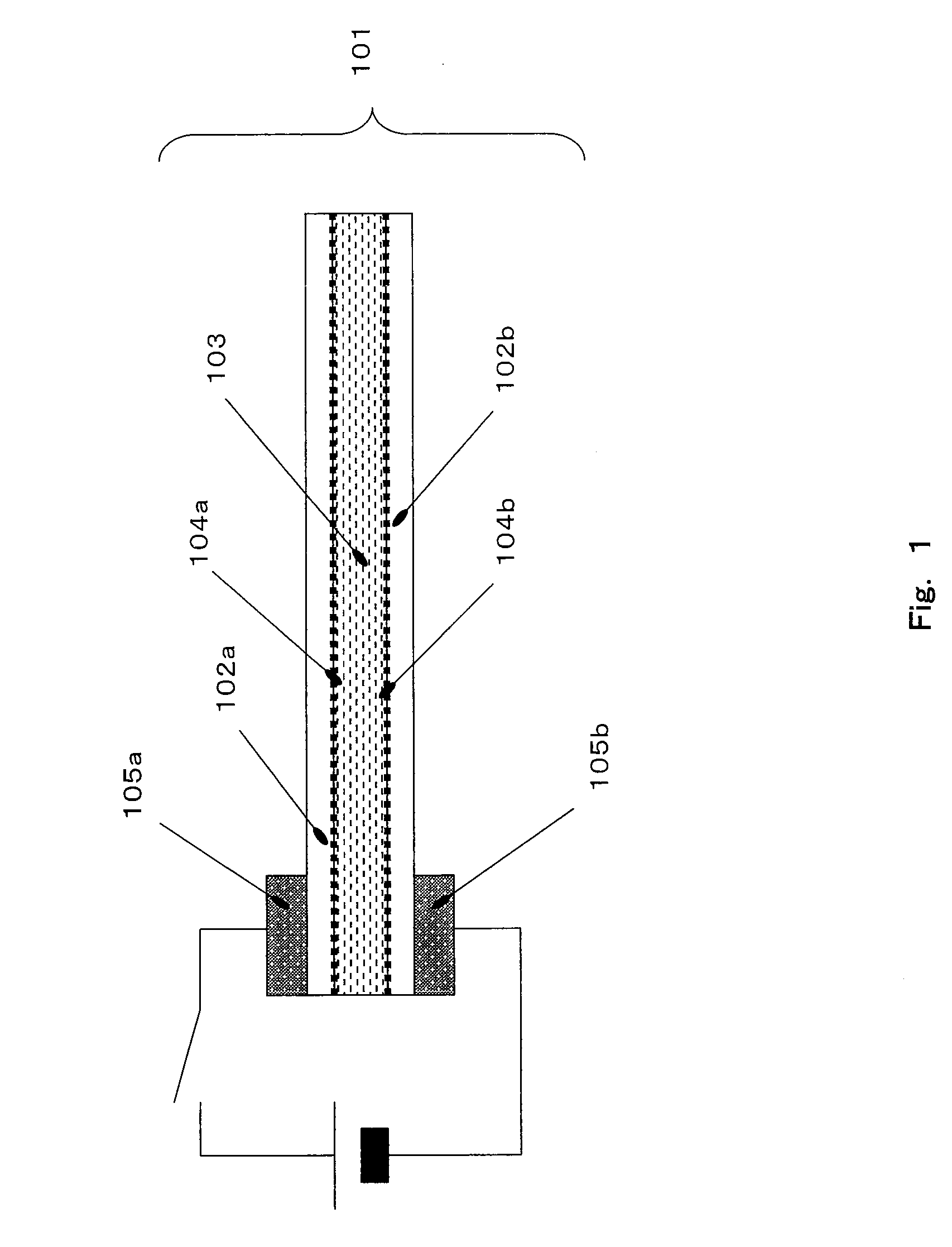

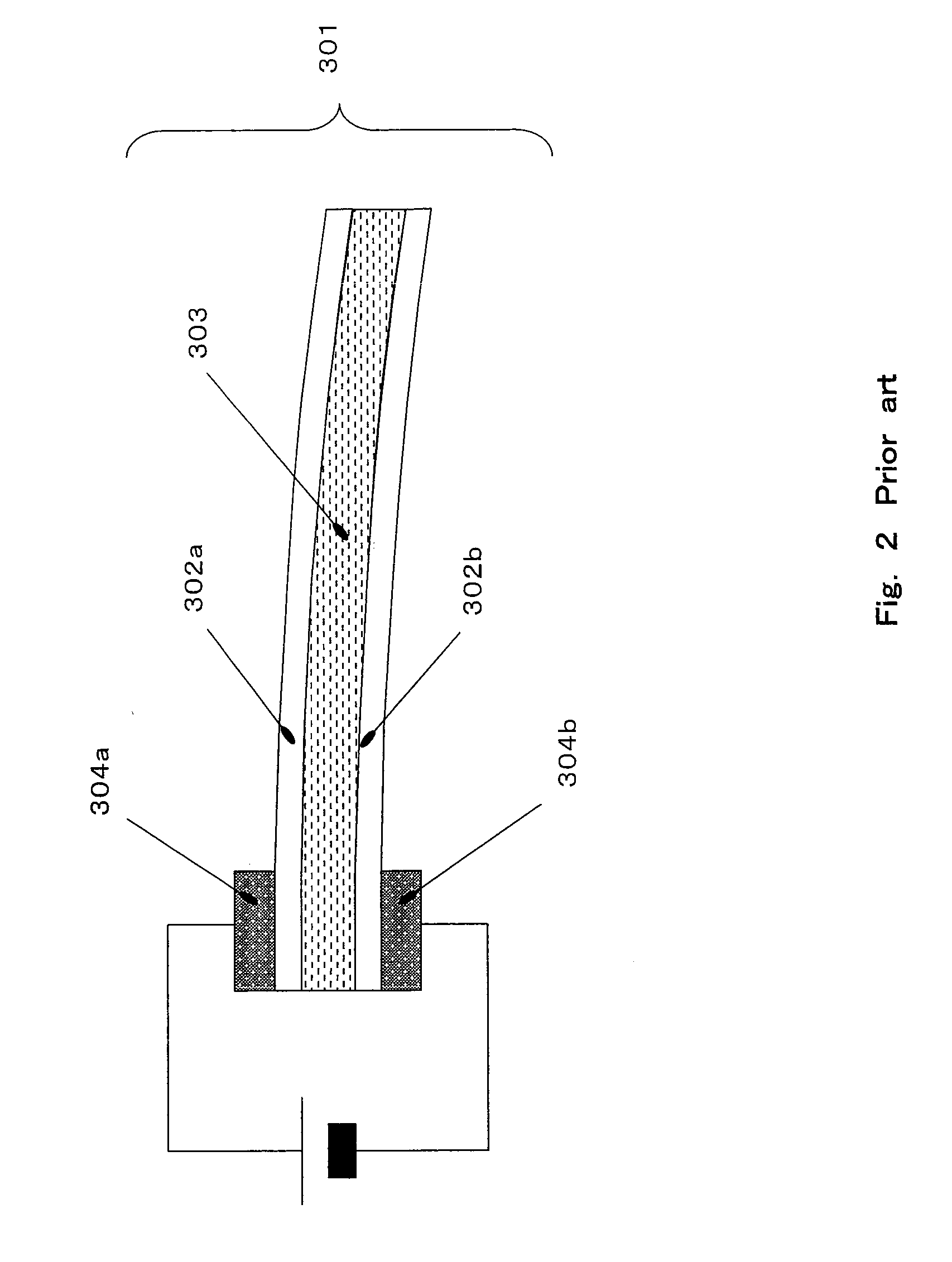

Solid polymer electrolyte composite membrane comprising laser micromachined porous support

A solid polymer electrolyte composite membrane and method of manufacturing the same. According to one embodiment, the composite membrane comprises a rigid, non-electrically-conducting support, the support preferably being a sheet of polyimide having a thickness of about 7.5 to 15 microns. The support has a plurality of cylindrical pores extending perpendicularly between opposing top and bottom surfaces of the support. The pores, which preferably have a diameter of about 5 microns, are made by laser micromachining and preferably are arranged in a defined pattern, for example, with fewer pores located in areas of high membrane stress and more pores located in areas of low membrane stress. The pores are filled with a first solid polymer electrolyte, such as a perfluorosulfonic acid (PFSA) polymer. A second solid polymer electrolyte, which may be the same as or different than the first solid polymer electrolyte, may be deposited over the top and / or bottom of the first solid polymer electrolyte.

Owner:PLUG POWER

Polyelectrolyte membranes made of poly(perfluorocyclobutanes) with pendant perfluorosulfonic acid groups and blends with poly(vinylidene fluoride)

A polymer useful as an ion conductor in fuel cells includes a perfluorocyclobutyl moiety and pendant PFSA side groups. The polymer is made by a variation of the Ullmann reaction. Ion conducting membranes incorporating the polymer are provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

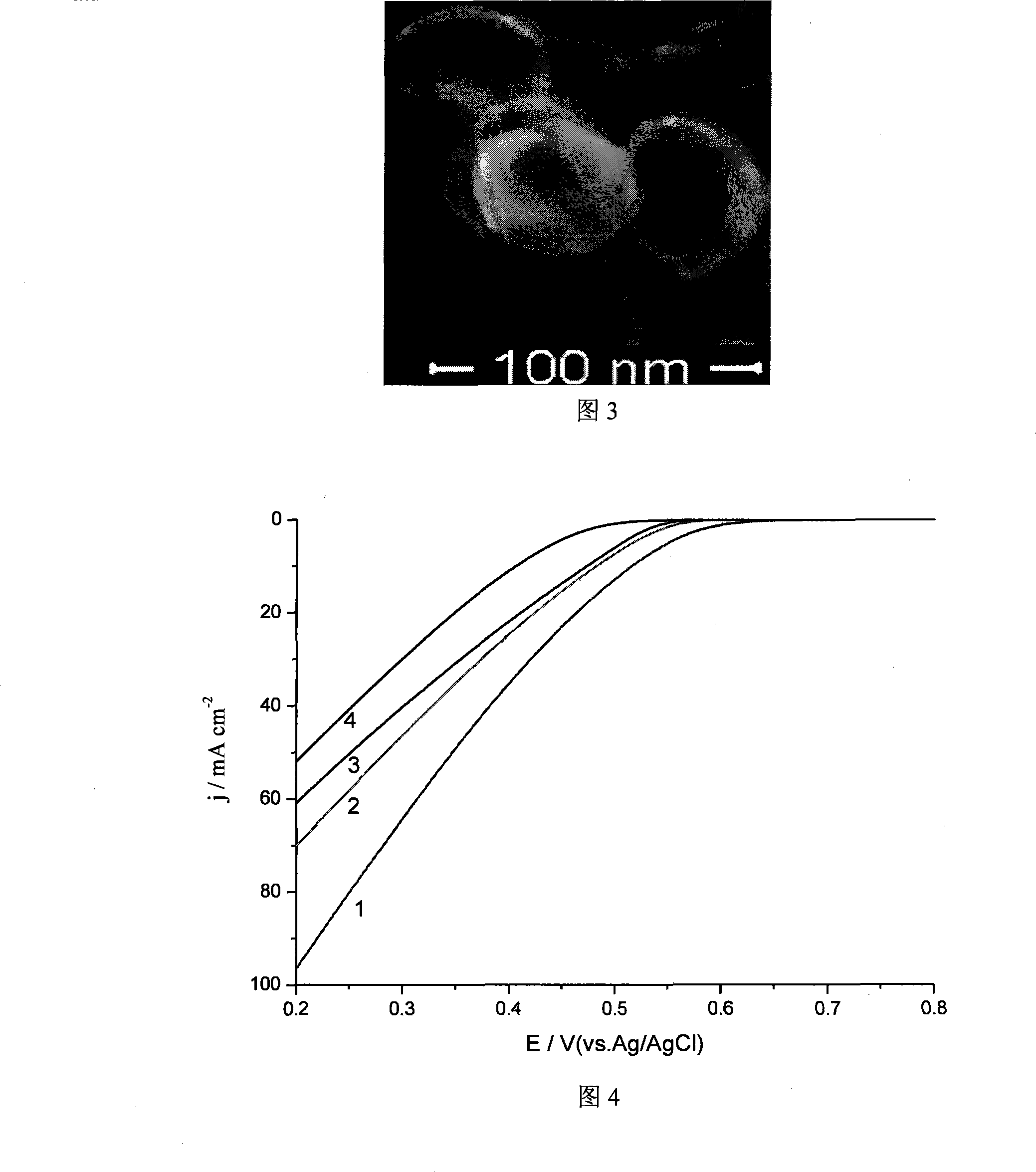

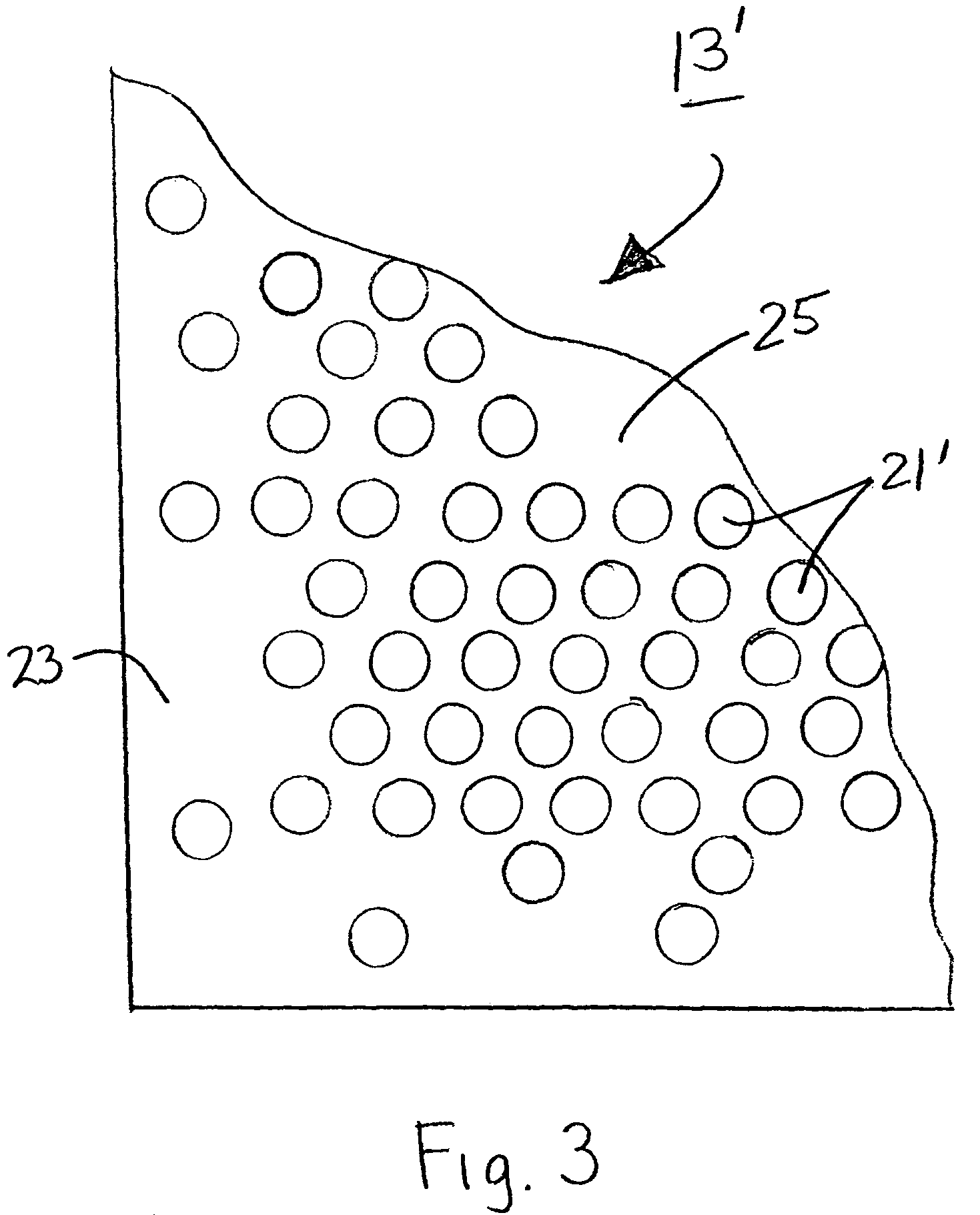

Process for preparation of gas perforated electrode catalyst of nucleus-shell structure

InactiveCN101227000AOvercoming the hydrogen evolution problemOvercome hydrolysisCell electrodesCatalyst activation/preparationPlatinum saltsNon platinum

The invention provides a method for preparing a core-shell structure gas porous electrode catalyst, which belongs to the field of fuel cells. First, a homogeneously dispersed non-platinum-group transition metal M core is optionally deposited on a gas porous electrode which is bonded on perfluoro sulfonic acid resin, and then a M@Pt core-shell type catalyst is made through a chemical replacement reaction between the deposited non-platinum-group transition metal M core and a platinum salt solution. The invention has the advantages of simple process and low cost. The M@Pt core-shell type catalyst which is prepared by the invention is capable of effectively reducing the amount of precious metal platinum, improving the utilization ratio of the catalyst, and the catalyst is capable of replacing a prior commercial Pt / C catalyst.

Owner:CHONGQING UNIV

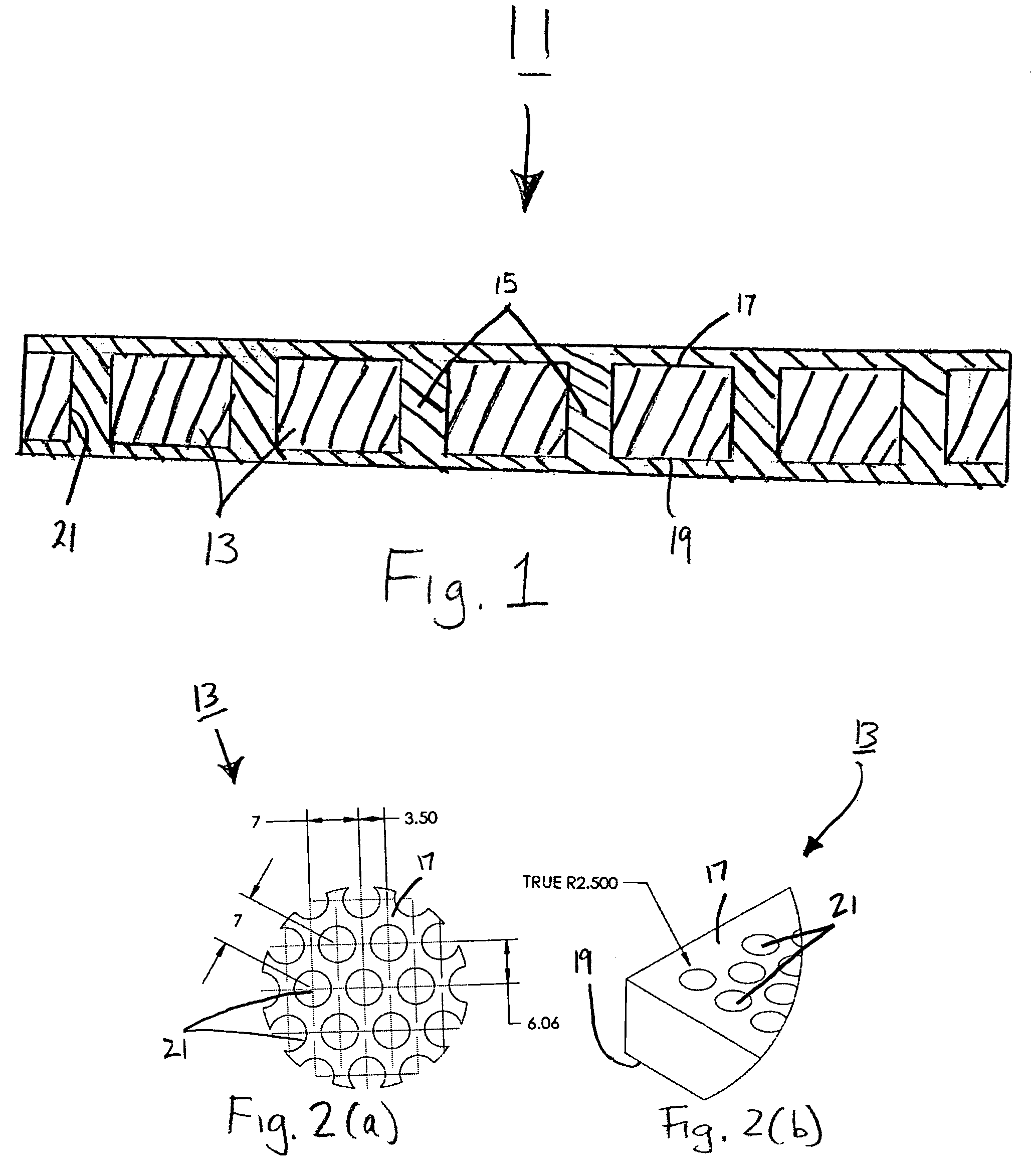

Solid polymer electrolyte composite membrane comprising plasma etched porous support

ActiveUS7807063B2Hybrid capacitor electrolytesPaper/cardboard articlesPolymer electrolytesPolymer science

A solid polymer electrolyte composite membrane and method of manufacturing the same. According to one embodiment, the composite membrane comprises a rigid, non-electrically-conducting support, the support preferably being a sheet of polyimide having a thickness of about 7.5 to 15 microns. The support has a plurality of cylindrical pores extending perpendicularly between opposing top and bottom surfaces of the support. The pores, which preferably have a diameter of about 0.1 to 5 microns, are made by plasma etching and preferably are arranged in a defined pattern, for example, with fewer pores located in areas of high membrane stress and more pores located in areas of low membrane stress. The pores are filled with a first solid polymer electrolyte, such as a perfluorosulfonic acid (PFSA) polymer. A second solid polymer electrolyte, which may be the same as or different than the first solid polymer electrolyte, may be deposited over the top and / or bottom of the first solid polymer electrolyte.

Owner:PLUG POWER

SiO2/perfluorinated sulfonic resin compound proton exchange membrane and preparation method thereof

ActiveCN101773793AHigh strengthImprove conductivitySemi-permeable membranesCell electrodesHydrogenCerium

The invention relates to a SiO2 / perfluorinated sulfonic resin compound proton exchange membrane and a preparation method thereof, which is composed of perfluorinated sulfonic resin and SiO2 doped with cerium or / and manganese. The perfluorinated sulfonic resin is H-type resin with sulfonic acid groups or F type resin with sulfuryl fluoride groups with the equivalent value of 600-1,300g / mmol. The compound proton exchange membrane prepared in the invention has higher proton conductivity and mechanical strength, can effectively prevent penetration of hydrogen and methanol, and is favor of improvement of fuel cell property.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

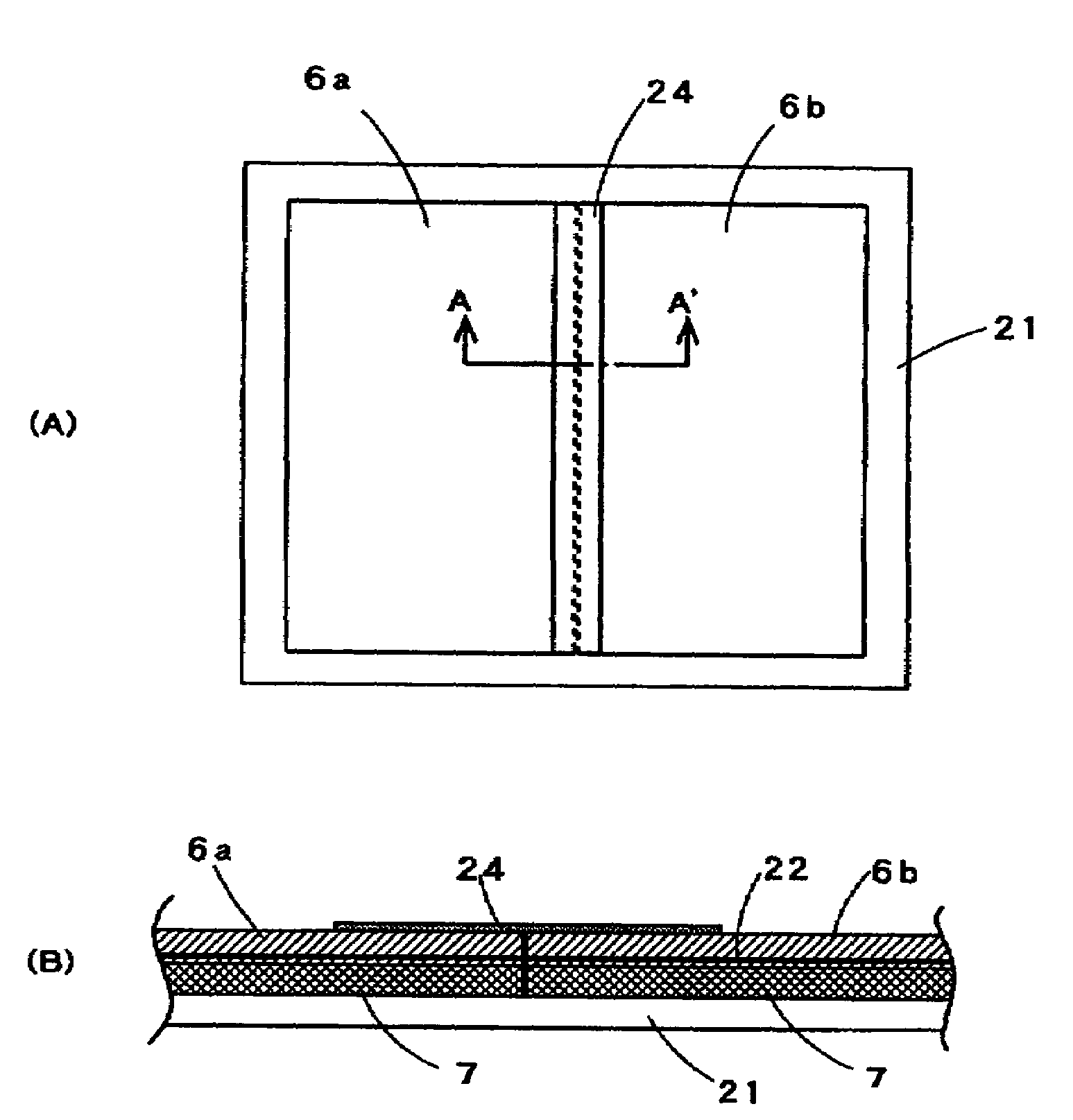

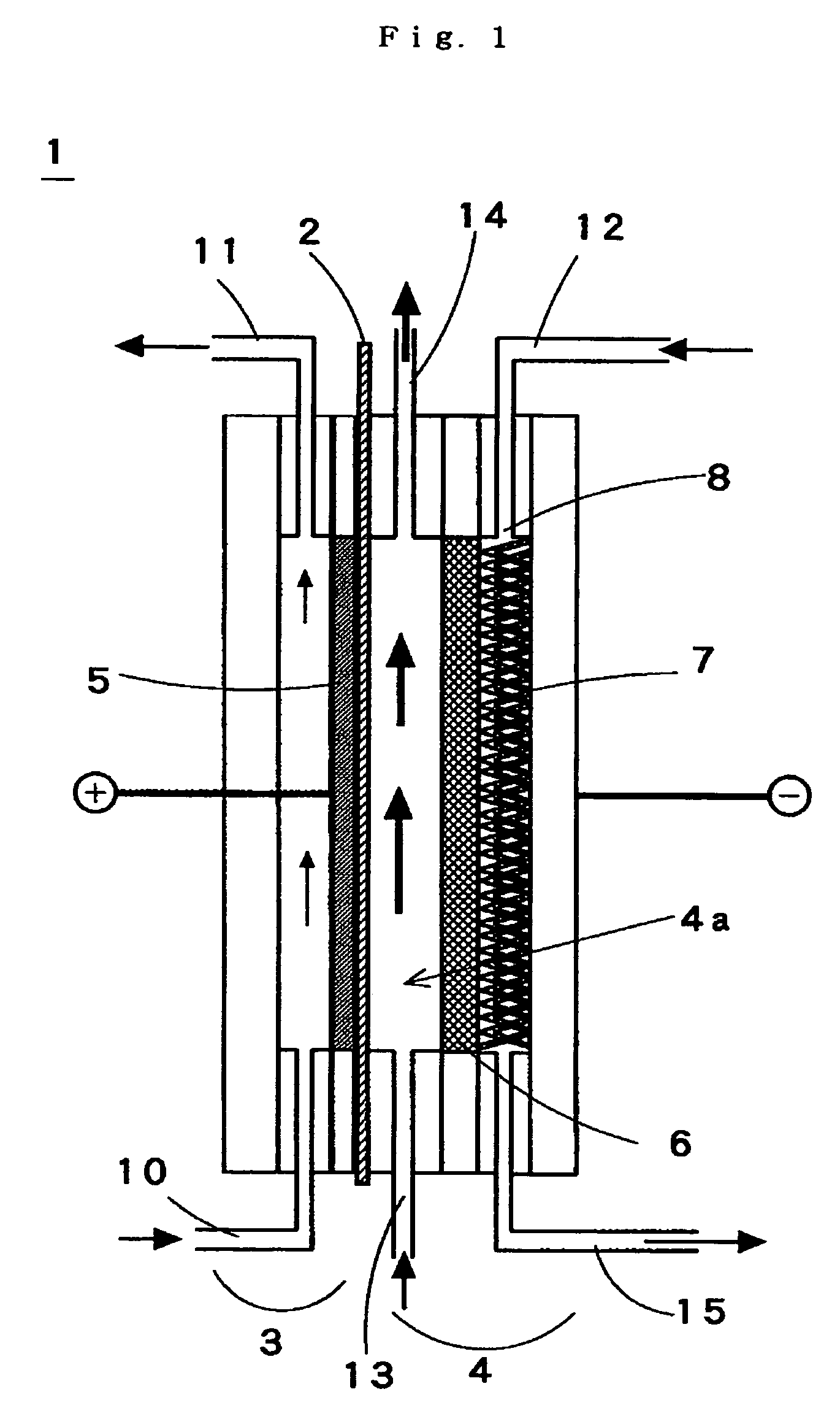

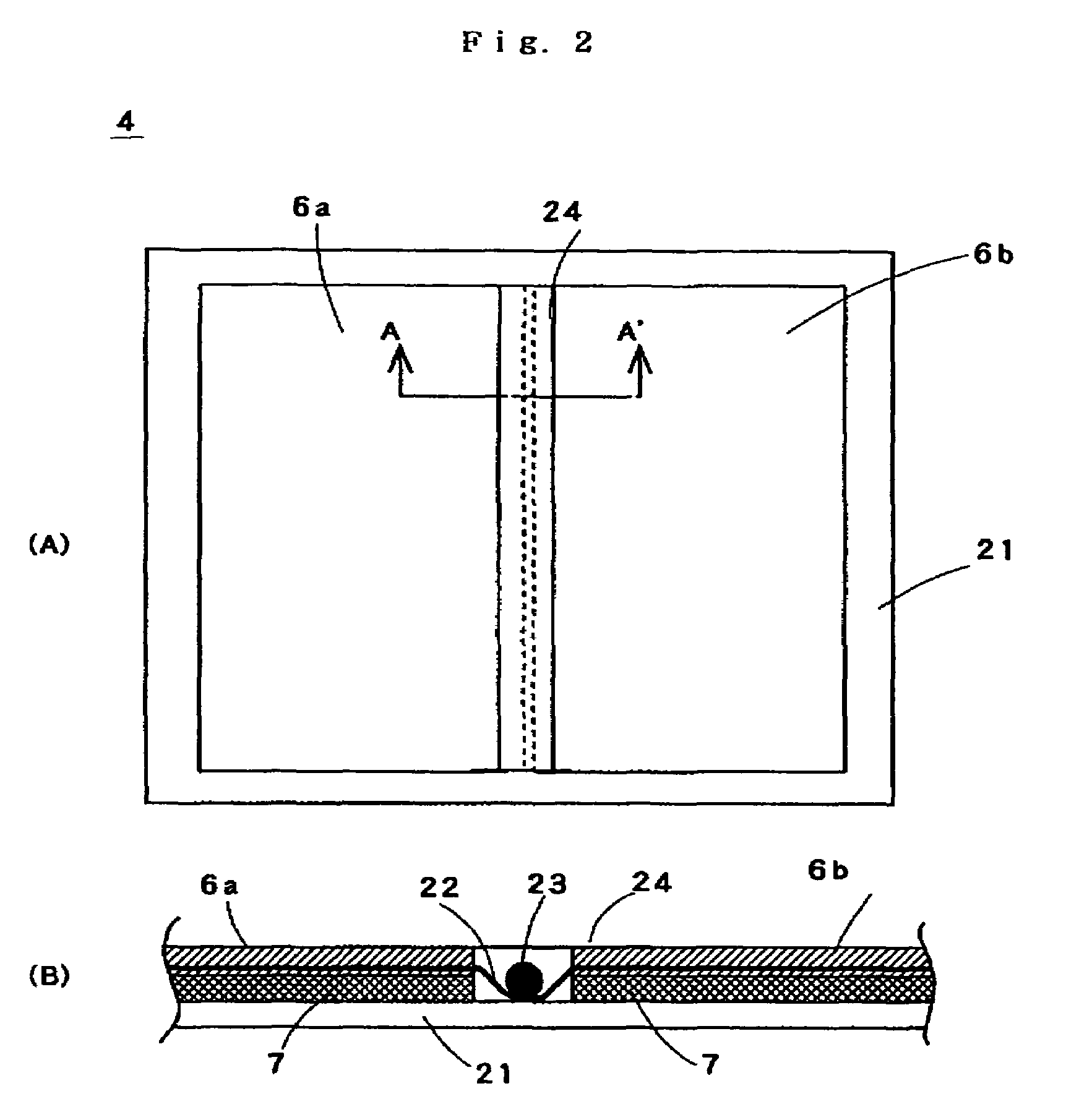

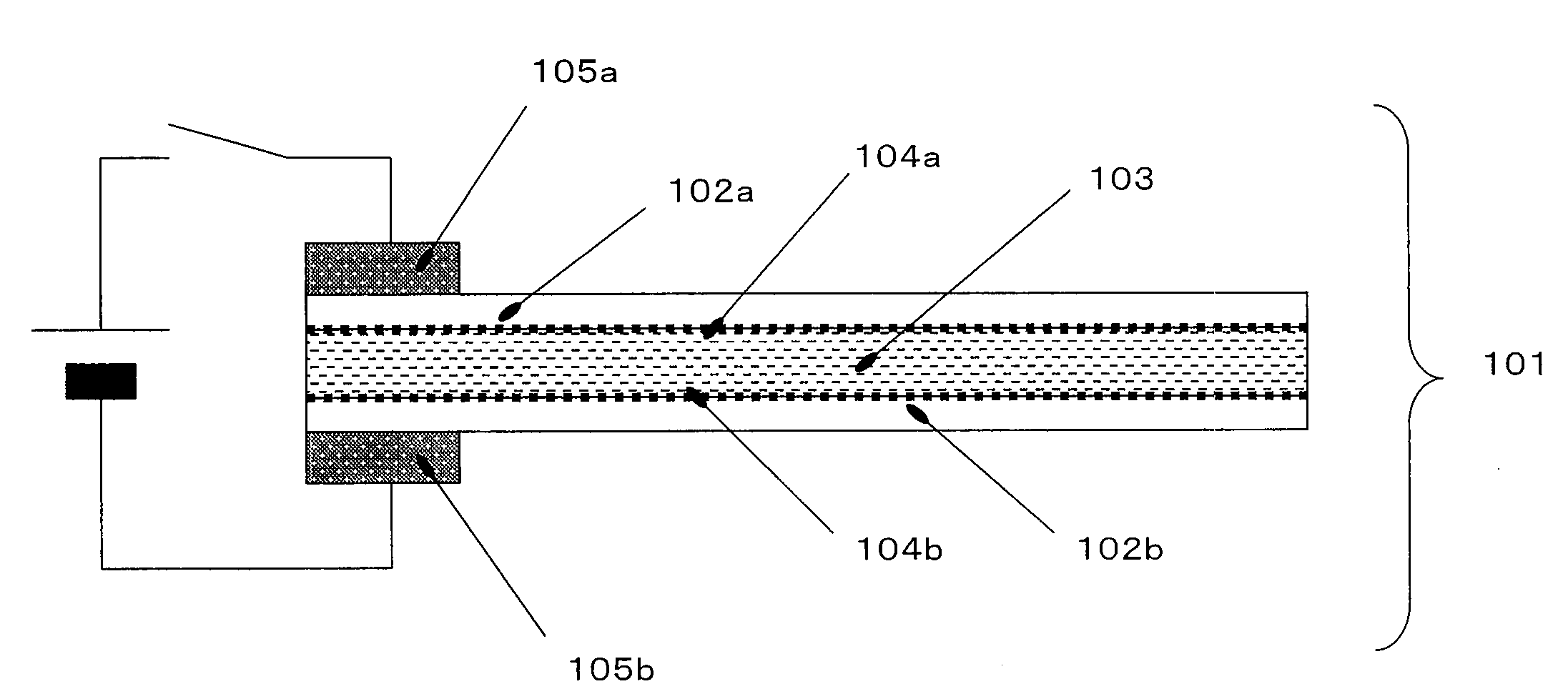

Gas diffusion electrode assembly, bonding method for gas diffusion electrodes, and electrolyzer comprising gas diffusion electrodes

In a gas diffusion electrode assembly, and in an electrolyzer using the same, a bonding piece having on at least one surface a perfluorosulfonic acid layer, a perfluorosulfonyl fluoride layer or an alkyl ester of perfluorocarboxylic acid layer is positioned at its perfluoro compound layer surface with respect to the gas diffusion electrode assembly. Adjacent gas diffusion electrodes are heat fusion bonded together, or heat fusion bonding is carried out using the bonding piece in a frame form. Adjacent gas diffusion electrodes are sealed up by heat fusion bonding, using a material that is similar to the material that forms the gas diffusion electrodes.

Owner:AGC INC +8

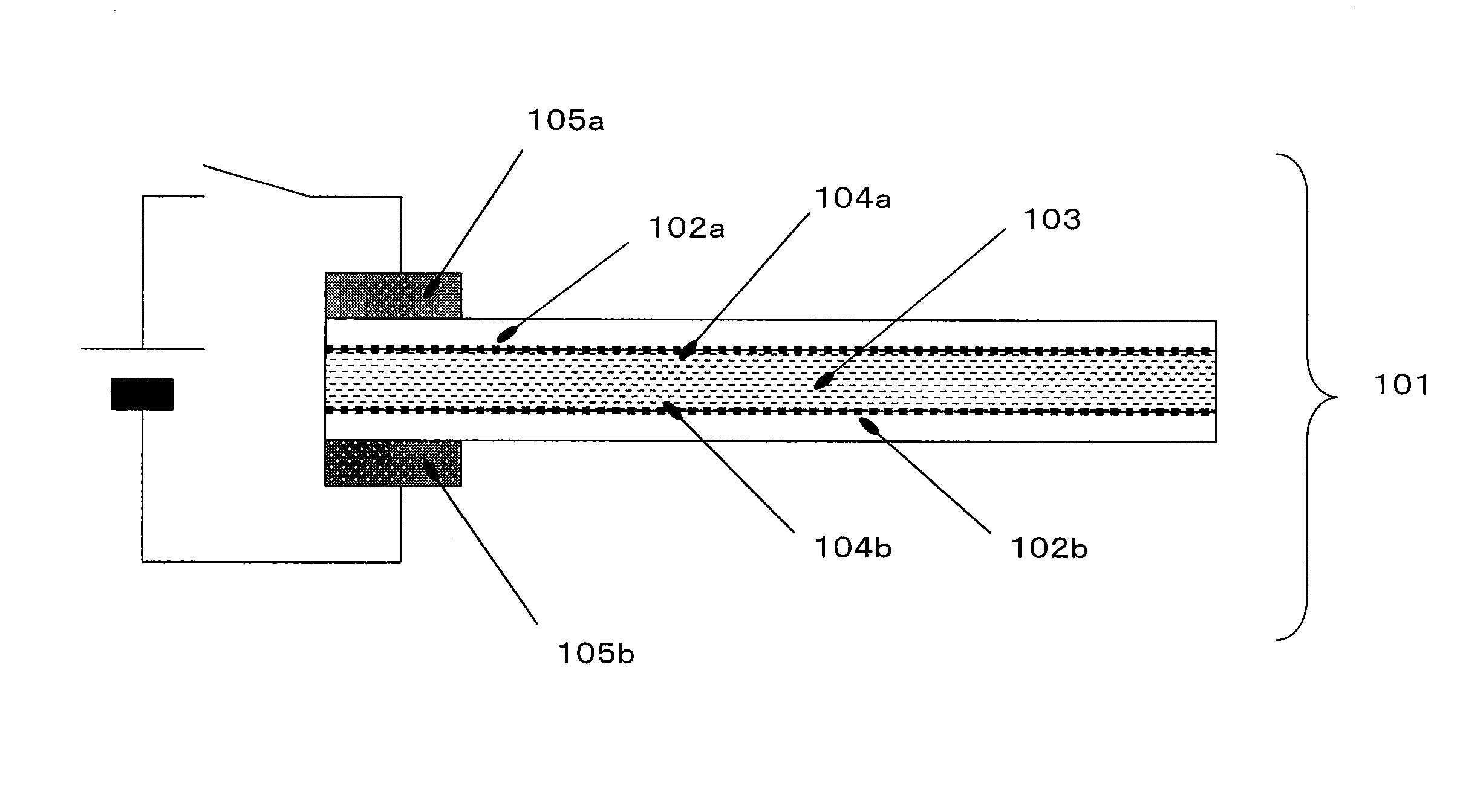

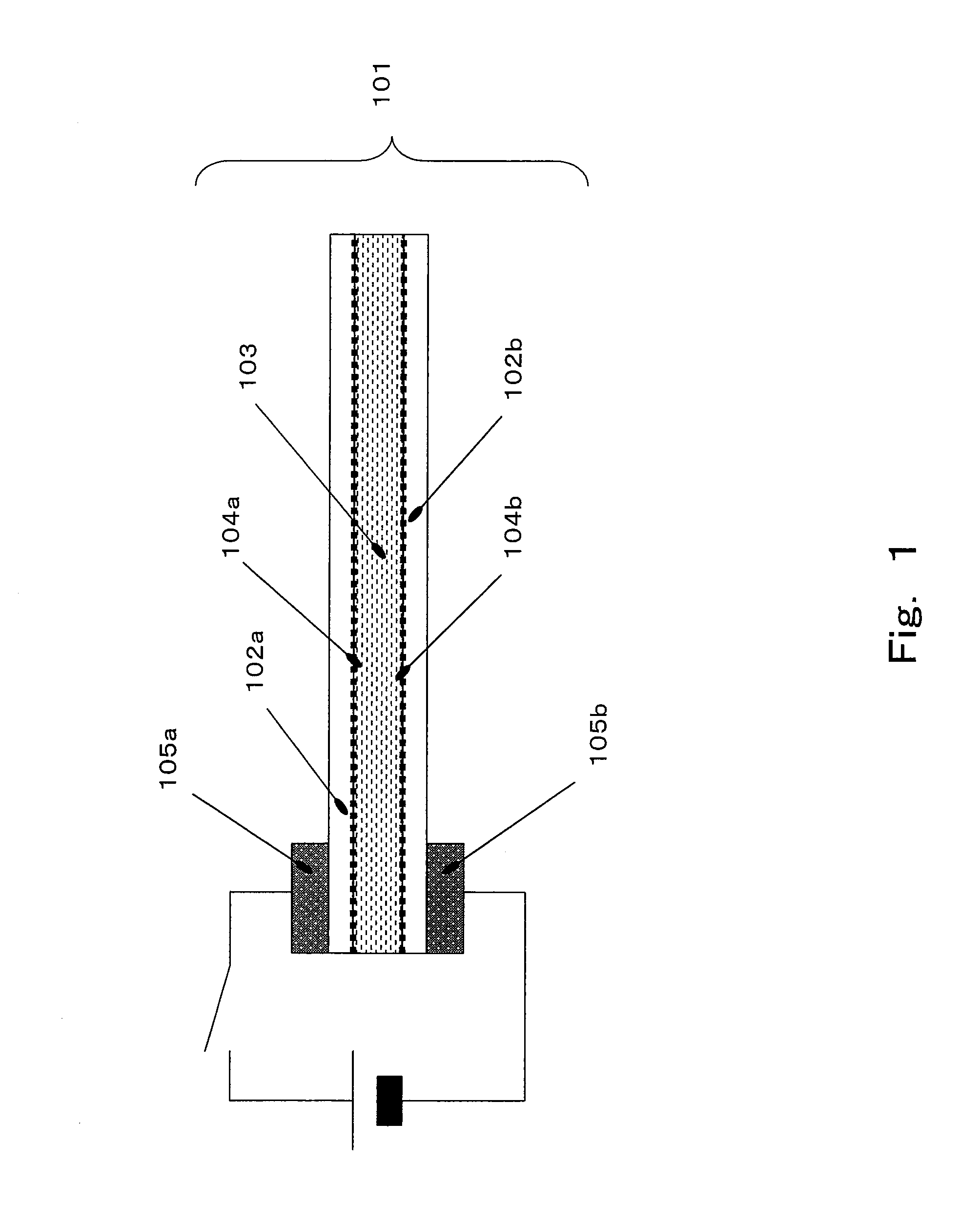

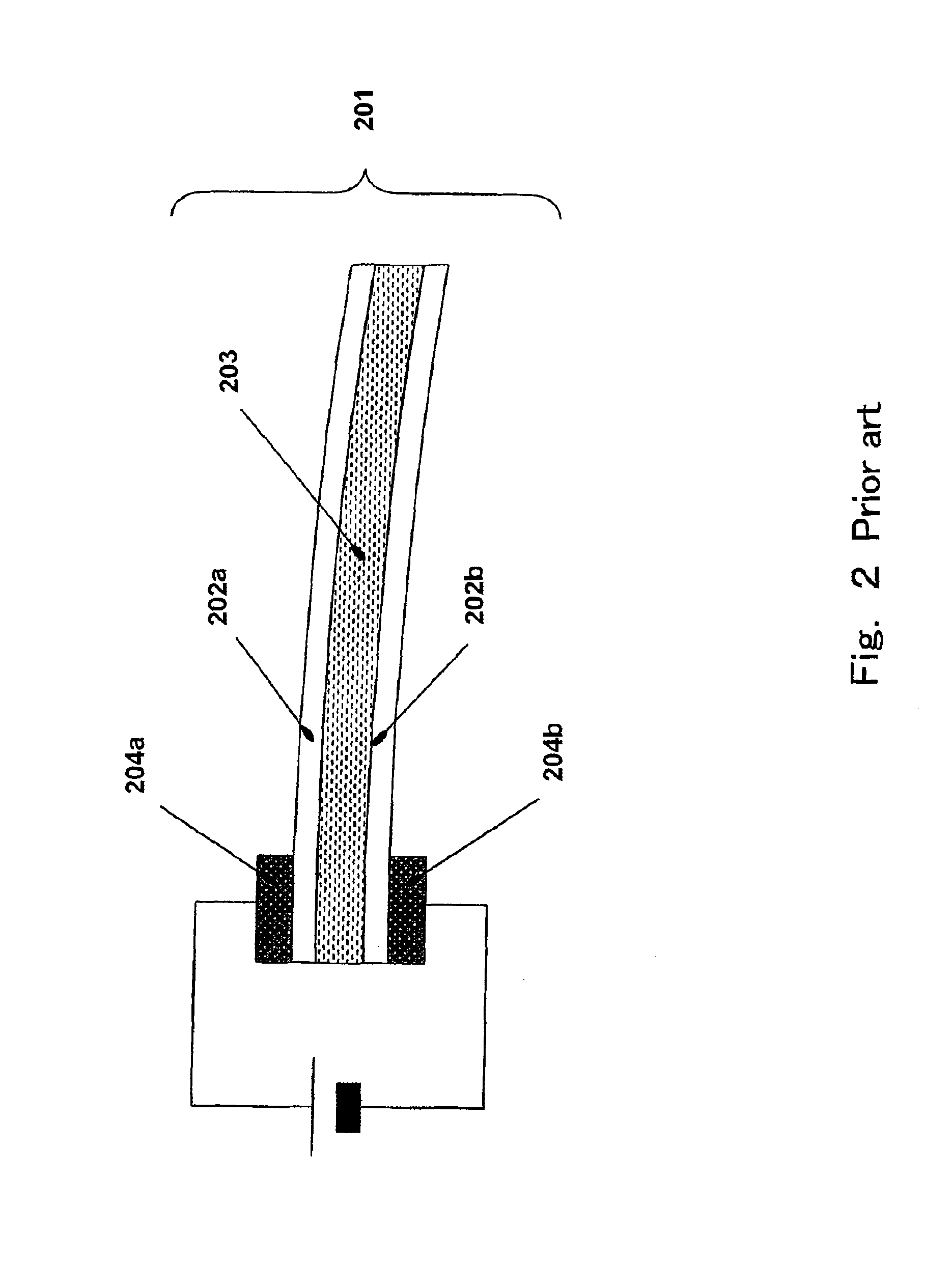

Electrically conductive polymer actuator, and method for manufacturing the same

ActiveUS7733000B2Improve adhesionCellsPiezoelectric/electrostrictive device manufacture/assemblyPolyethylene oxideConductive polymer

To improve adhesive properties between an electrically conductive polymer membrane and a solid electrolyte membrane to each other, and thus to ensure the operation of an electrically conductive polymer actuator which effects a bending motion is aimed.The bendable electrically conductive polymer actuator of the present invention is an electrically conductive polymer actuator having a laminate structure of: a first organic polymer including at least one or more of a vinylidene fluoride / hexafluoropropylene copolymer, polyvinylidene fluoride, a perfluorosulfonic acid / PTFE copolymer, polymethyl methacrylate, polyethylene oxide, and polyacrylonitrile; a solid electrolyte membrane including a mixture with an ionic liquid; and an electrically conductive polymer membrane including a mixture of polyethylenedioxythiophene and polystyrene sulfonic acid on at least one face of the solid electrolyte membrane, in which a second organic polymer including a vinylidene fluoride / hexafluoropropylene copolymer is embedded in the electrically conductive polymer membrane surface in the state being dispersed.

Owner:PANASONIC CORP

Method for producing electrode of sodium polysulfide/bromine novel energy storage cell

InactiveCN1474470AHigh mechanical strengthImprove conductivityCell electrodesSodium polysulfideChemistry

An electrode process method for multiple Na / Br sulfide type energy storage battery is to mix carbon loading transition metal catalyst and perfluorinated sulfonic acid resin uniformly to be coated on the supporting carbon paper or felts as the negative pole, and mix carbon loading Pt catalyst and perfluorinated sulfonic acid resin evenly to be coated on carbon paper or felts as the positive pole. The inverted electrodes have rather high mechanical strength, good conductance.

Owner:DALIAN RONGKE POWER

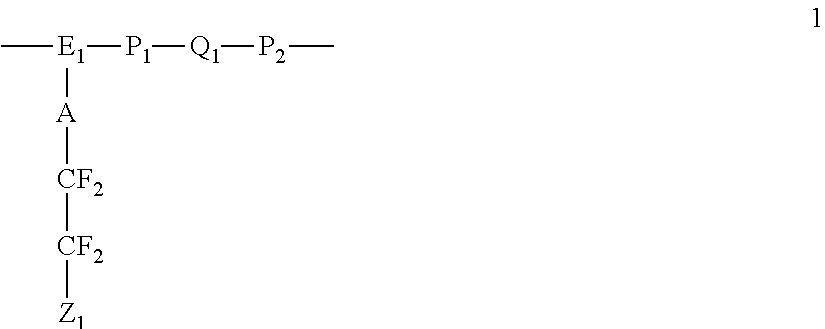

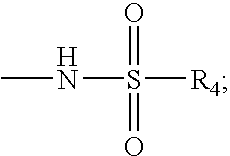

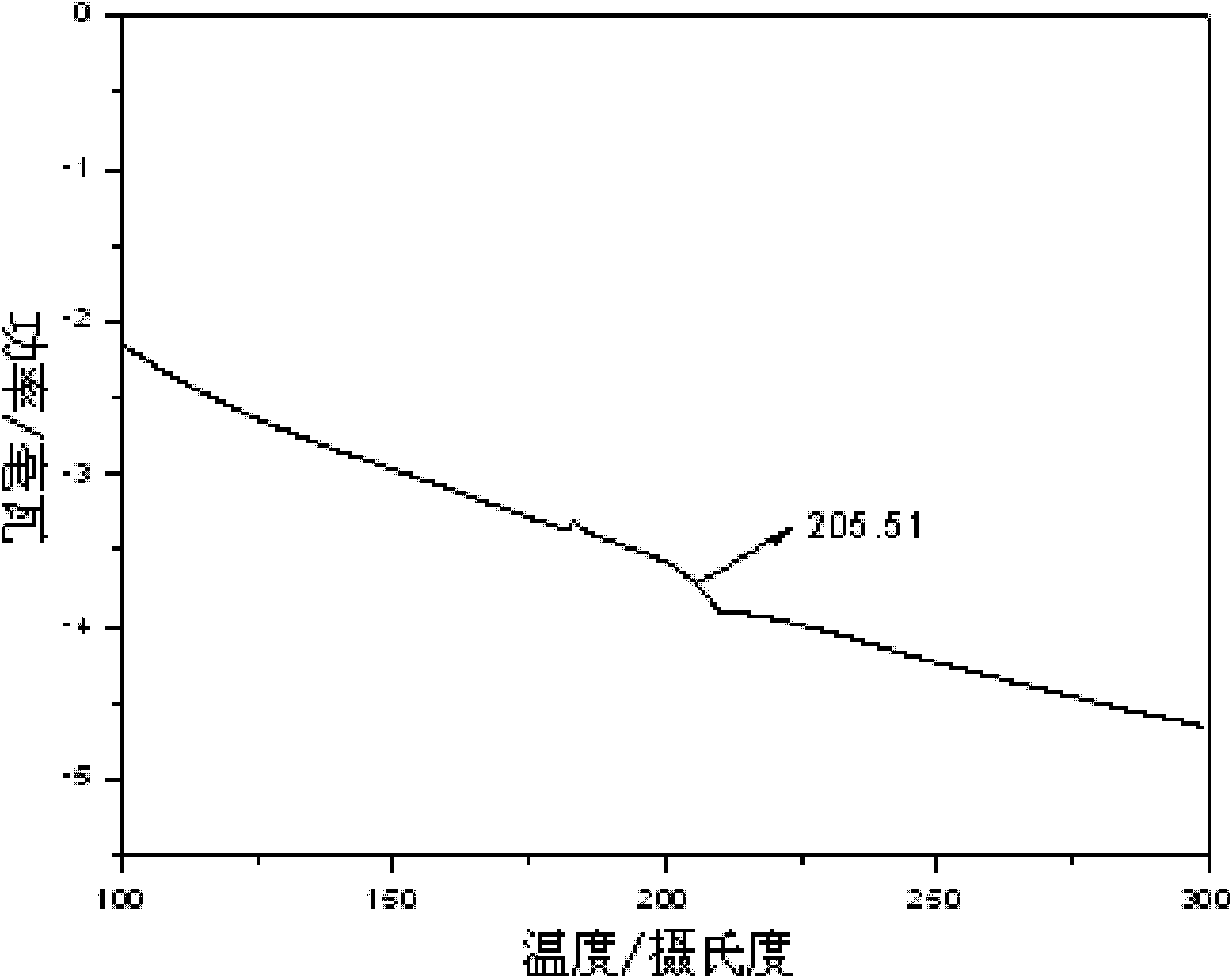

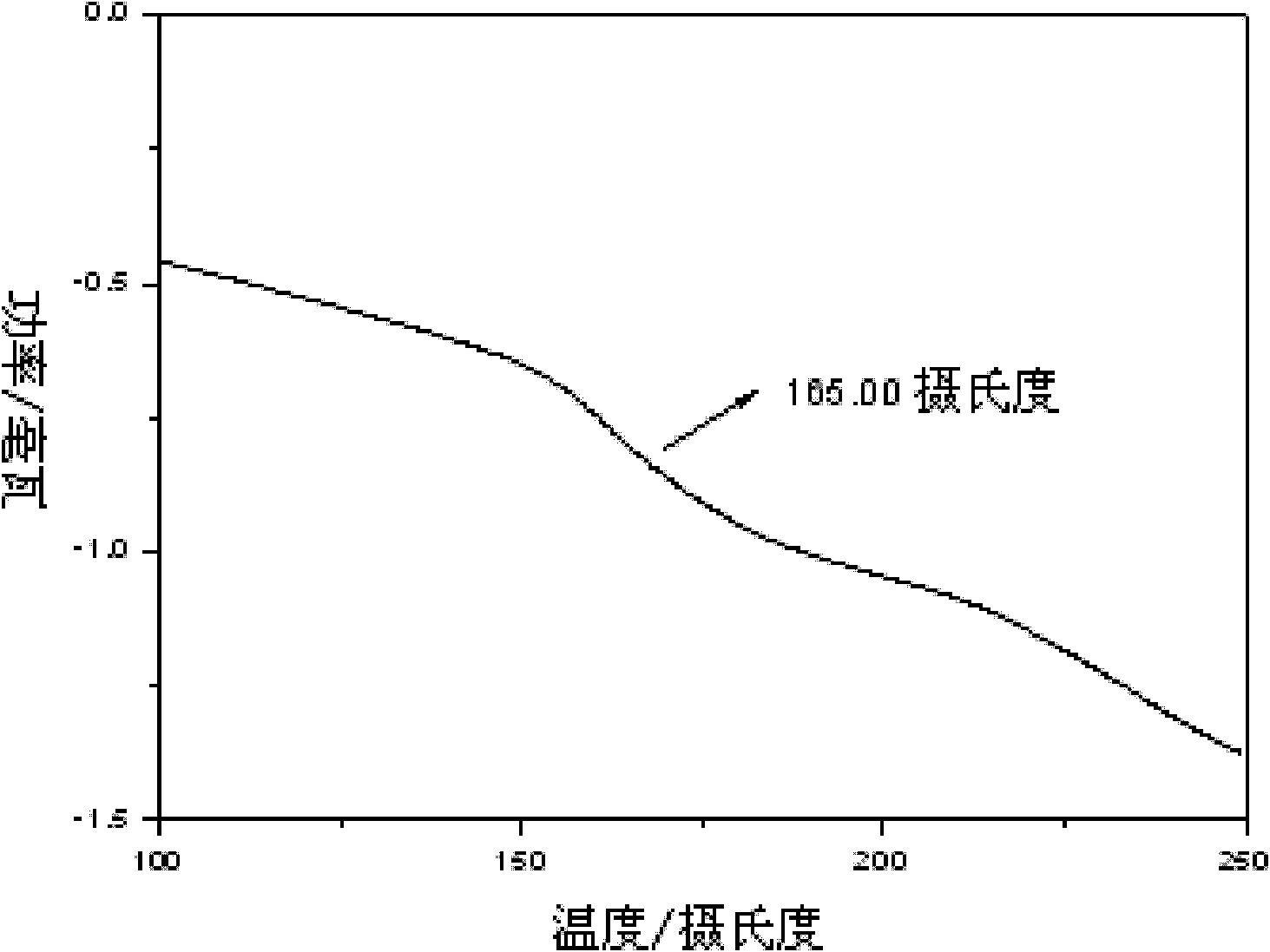

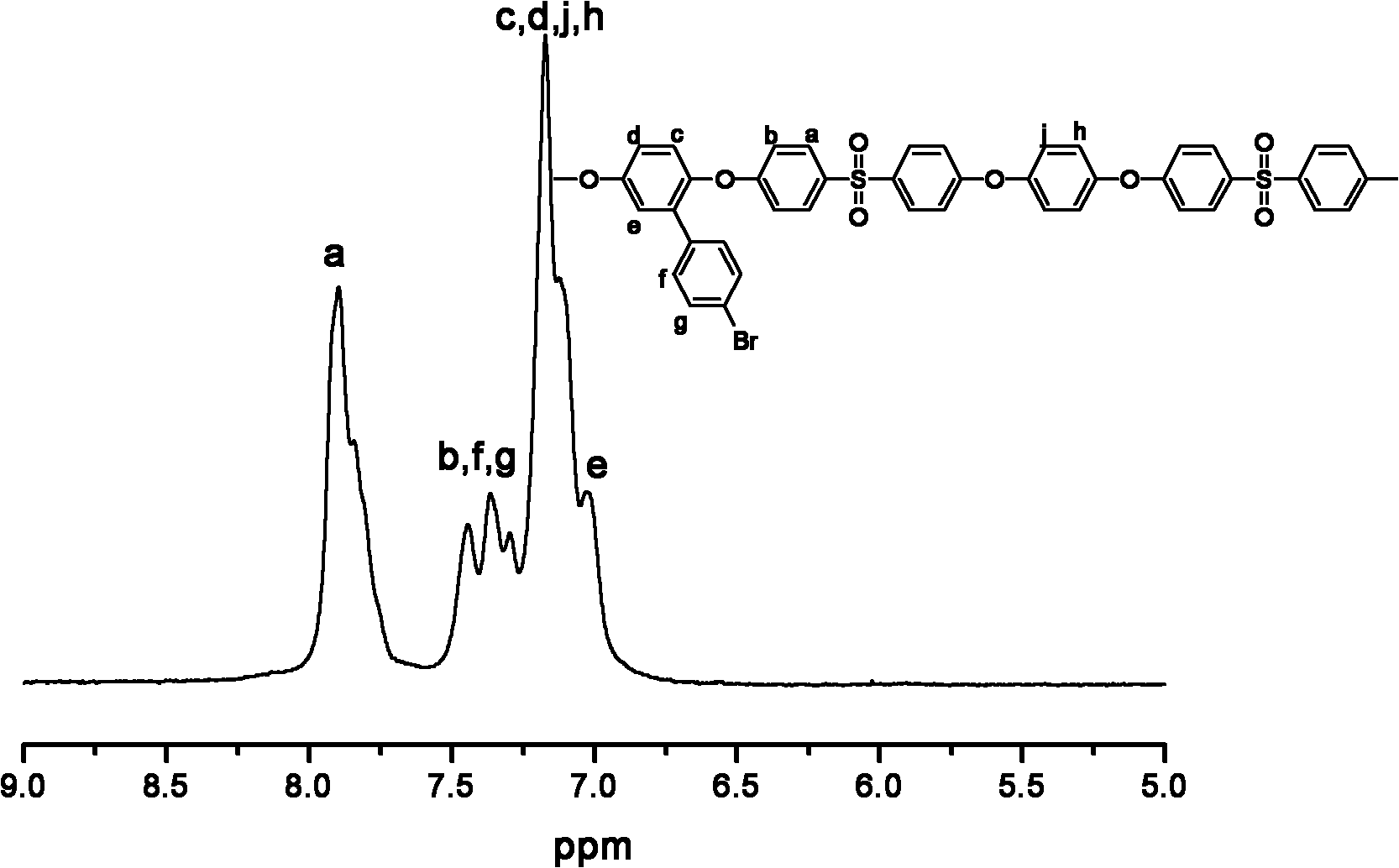

Perfluorosulfonic acidcontaining polyarylethersulfone proton exchange membrane material and preparation method thereof

InactiveCN102174258AImprove proton conductivityImprove thermal stabilityCell component detailsFuel cell detailsHalogenSide chain

The invention discloses a perfluorosulfonic acidcontaining polyarylethersulfone proton exchange membrane material and a preparation method as well as application thereof, belonging to the field of high molecular materials. The proton exchange membrane film is a polymer which consists of a polyarylethersulfone main chain and a 1,1,2,2-tetrafluoro-2-(1,1,2,2-tetrafluoro-2-phenylethyoxyl) ethane sulfonic acid side chain. The method comprises the following steps of: synthesizing para-bromophenyl lateral group containing polyarylethersulfone; performing halogen decoupling on the para-bromophenyl lateral group containing polyarylethersulfone and 1,1,2,2-tetrafluoro-2-(1,1,2,2-tetrafluoro-2-iodoethyoxyl) ethane potassium sulfonate under the action of copper; and performing hydrochloric acid treatment to obtain the perfluorosulfonic acid containing polyarylethersulfone proton exchange membrane material. Since a perfluorosulfonic acid serving as a super acid is introduced, meanwhile, a benzene ring is introduced between the polyarylethersulfone main chain and the perfluorosulfonic acid side chain, the proton exchange membrane has higher proton conductivity at the temperature of 80 DEG C and a necessary foundation is provided for preparing the proton exchange membrane with low swelling property and high proton conductivity.

Owner:JILIN UNIV

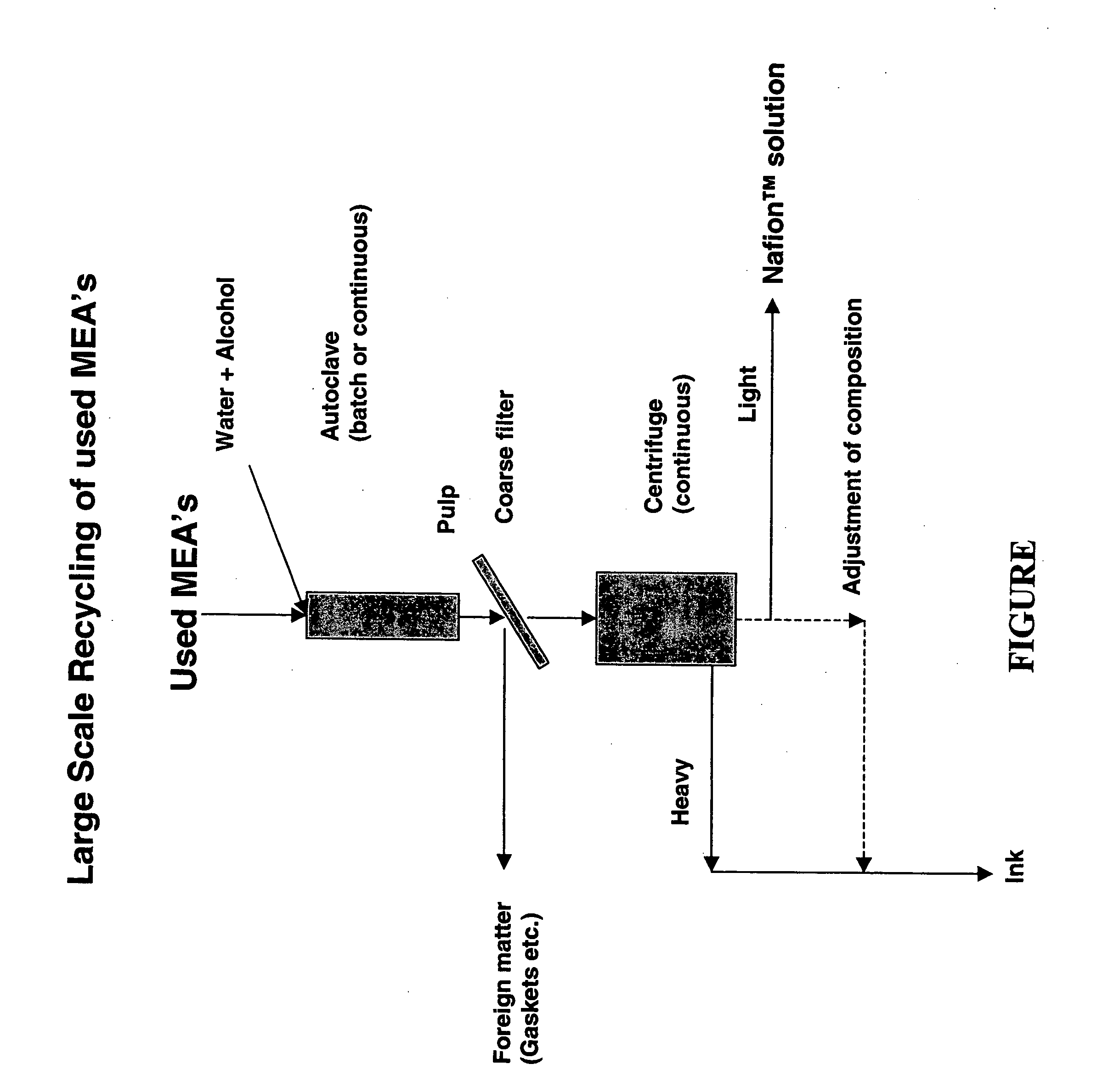

Recycling of used perfluorosulfonic acid membranes

InactiveUS20050211630A1Guaranteed long-term availabilityIncrease consumptionTransuranic element compoundsActive material electrodesSolventMembrane configuration

Owner:ION POWER

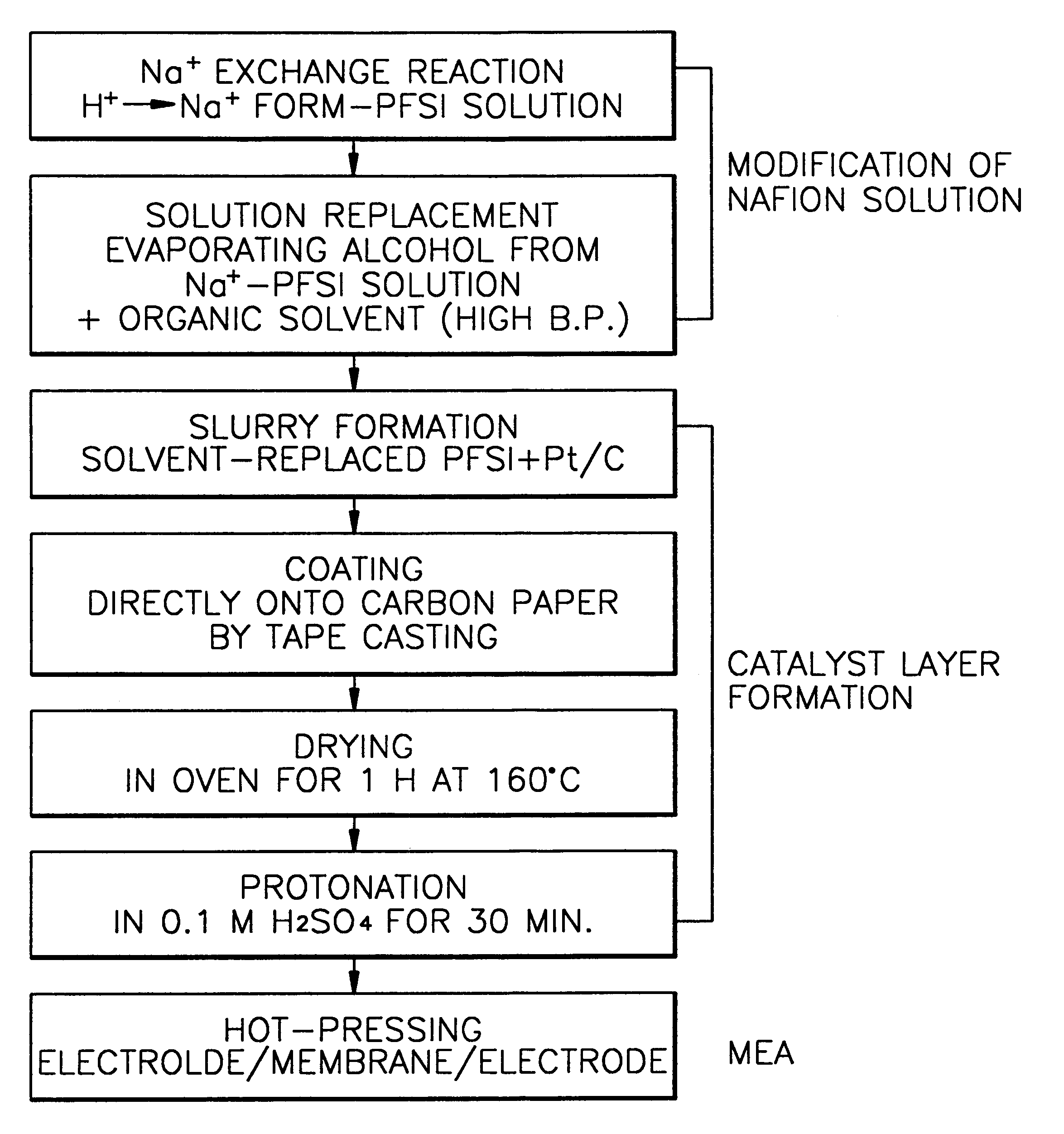

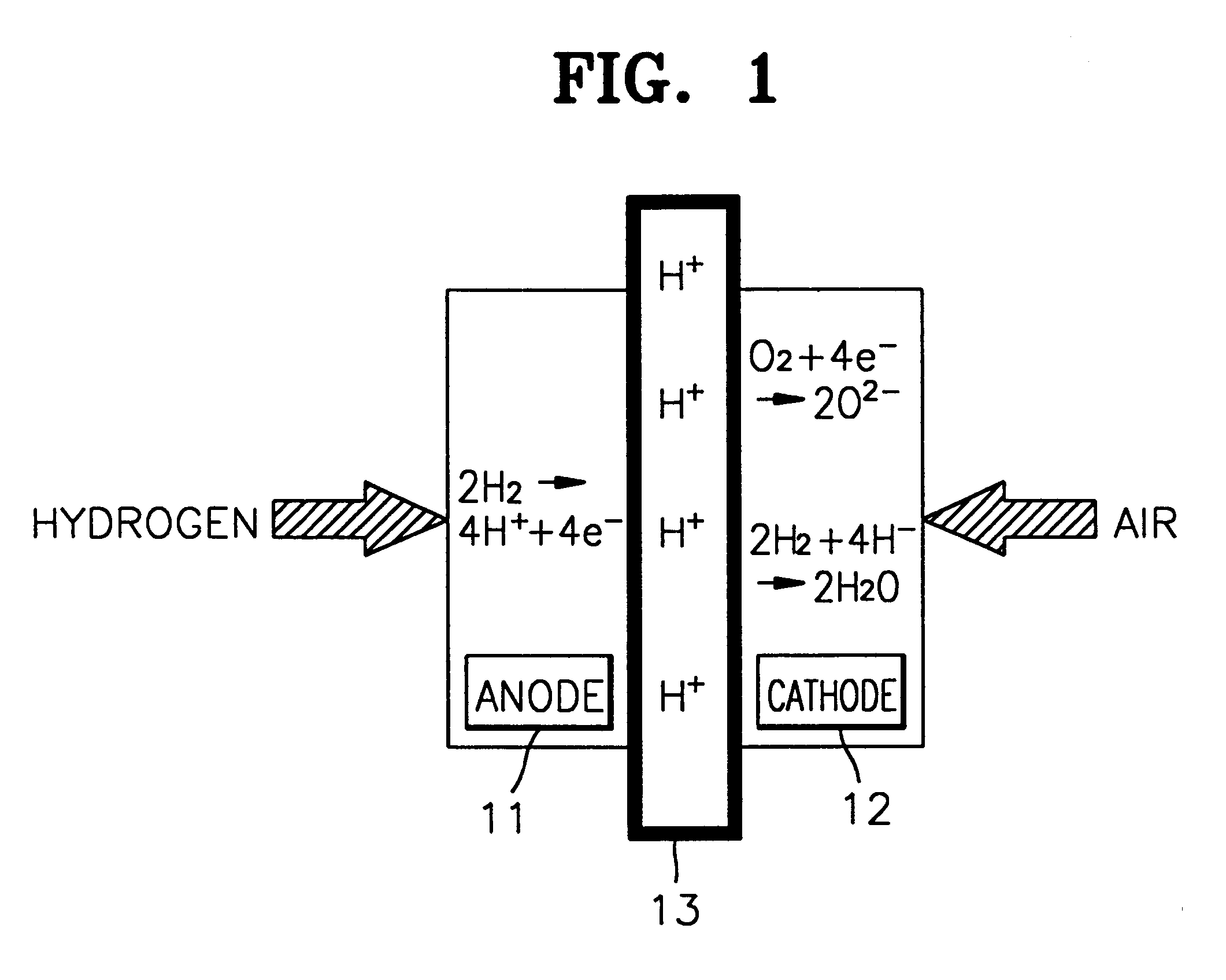

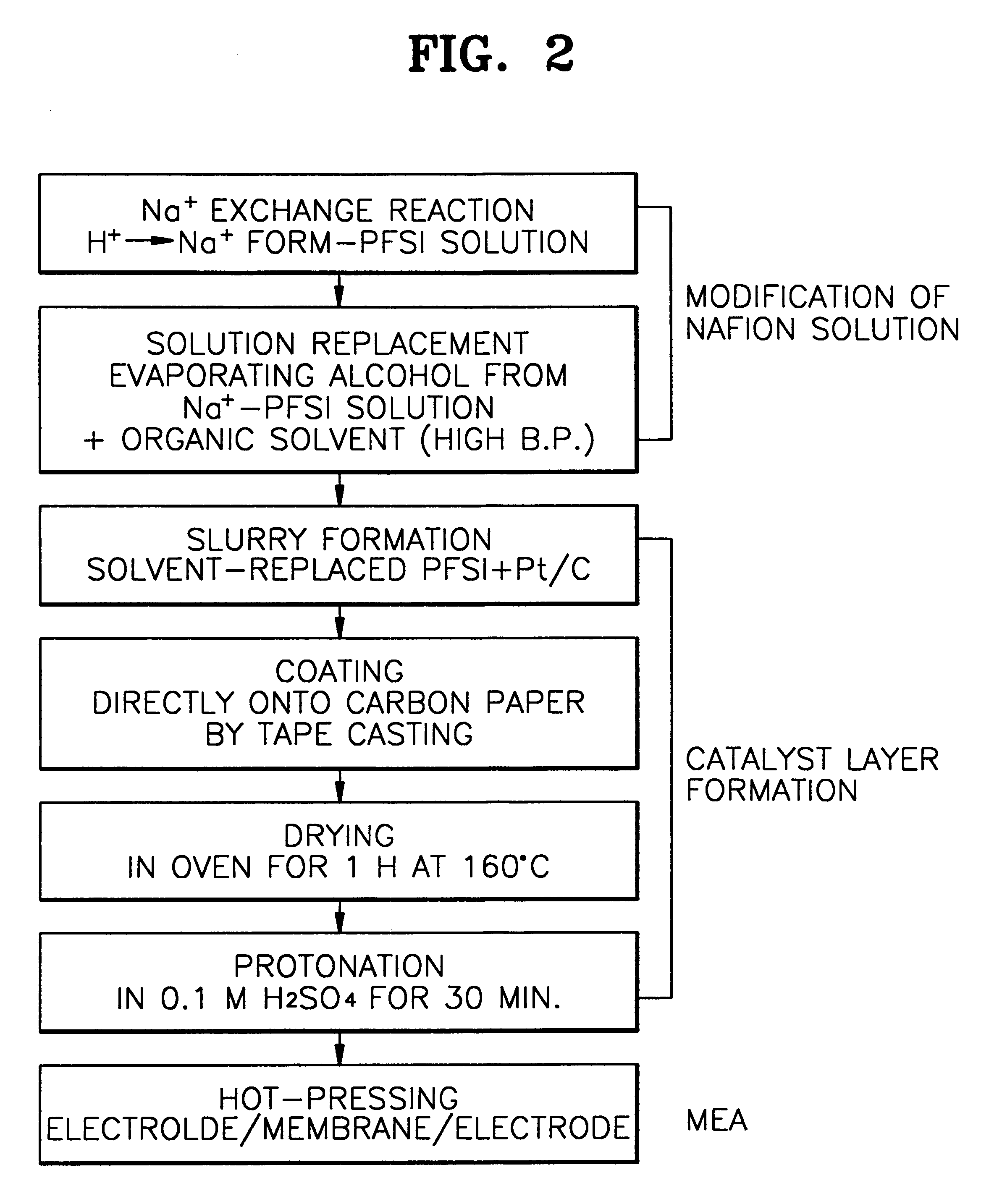

Method of forming catalyst layer for fuel cell

A method for preparing a slurry for forming a catalyst layer of a PEM fuel cell electrode and a method for fabricating the PEM fuel cell produced thereby are provided. The method for preparing a slurry for forming a catalyst layer of a proton exchange membrane (PEM) fuel cell according to the present invention comprises the steps of (a) adding an MOH solution to a perfluorosulfonate ionomer (PFSI) solution to convert PFSI in the PFSI solution into an M+ form-PFSI solution, wherein M is an alkaline metal selected from the group consisting of Li, Na and K; (b) adding an organic polar solvent having a higher boiling point than that of alcohol remaining in the PFSI solution to a mixed solution obtained in step (a) and heating the mixture at a temperature range of the boiling point of the alcohol to 20° C. higher than the boiling point to remove the remaining alcohol to obtain a pretreated PFSI solution; and (c) mixing the pretreated PFSI solution with Pt / C to form a slurry for forming a catalyst layer of a PEM fuel cell. Since processing stability is improved and the slurry can be easily prepared, Pt loading greater than a conventional level can be achieved by a single coating step by preventing a Pt catalyst from penetrating into a backing layer, the electrode characteristics are improved. Also, mass production of the PEM fuel cells is possible.

Owner:SAMSUNG SDI CO LTD

Technique for molding new type proton exchange membrane

ActiveCN101050285ASimple process routeFacilitate large-scale productionHigh concentrationSilicon dioxide

This invention discloses a process for shaping a novel composite proton exchange membrane. The process comprises: dissolving perfluorosulfonic acid in aqueous solution of low-boiling-point organic alcohol, adding high-boiling-point organic solvent and silica sol to obtain membrane-forming solution, dragging base membrane-expanded PTFE microporous membrane on the carry roller of a membrane-forming machine, soaking the base membrane in the low-concentration resin solution, drying at 40-100 deg.C, soaking in the high-concentration resin solution, drying at 40-100 deg.C, soaking and drying repeatedly until the thickness of the composite membrane reaches the predetermined value, and shaping the composite membrane in a drier at 120-200 deg.C. The process is simple, and suitable for mass production. The obtained composite proton exchange membrane has such advantages as high self-water-generating and water-retaining ability, high environmental adaptability, high strength and size stability, and long service life.

Owner:SUNRISE POWER CO LTD

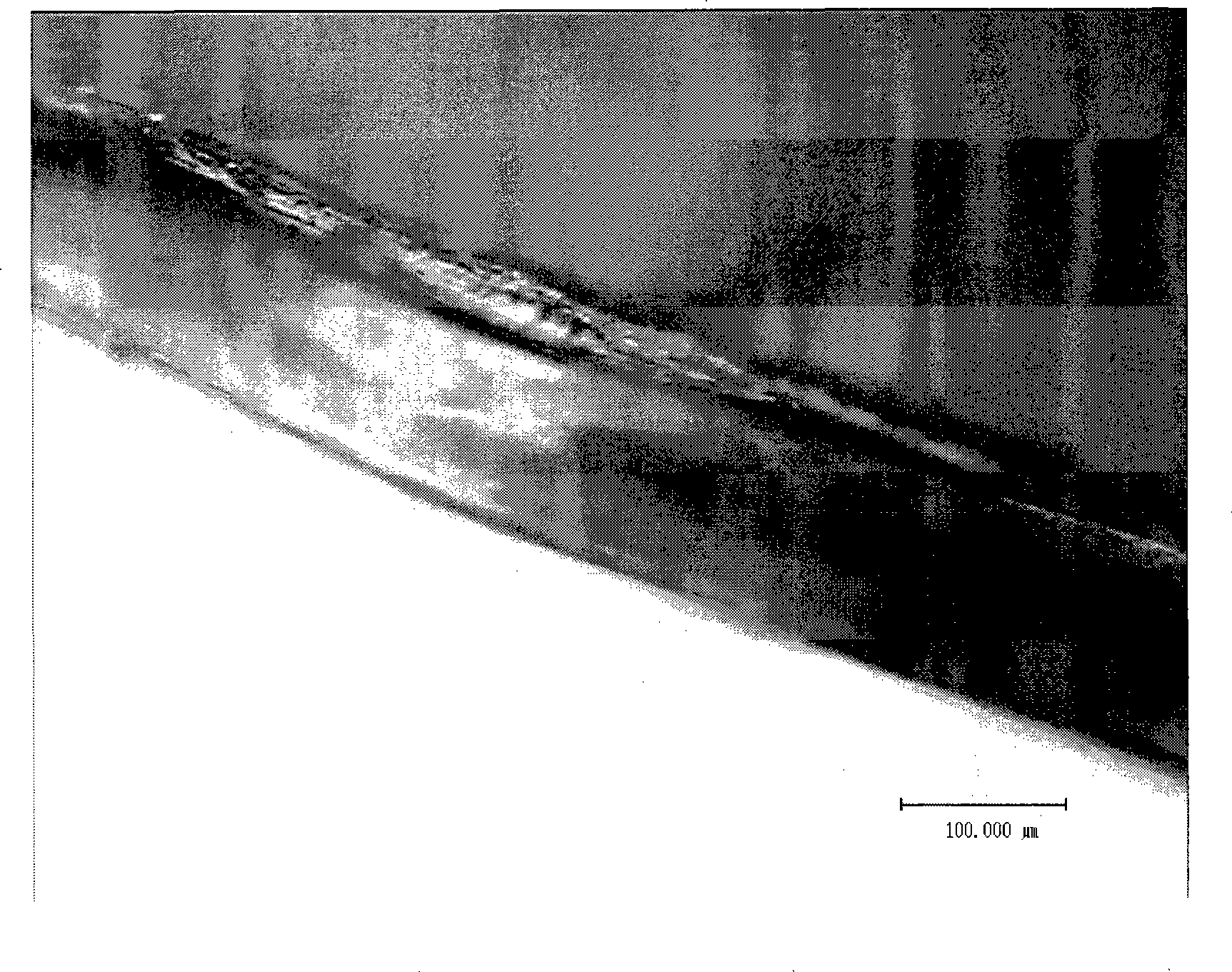

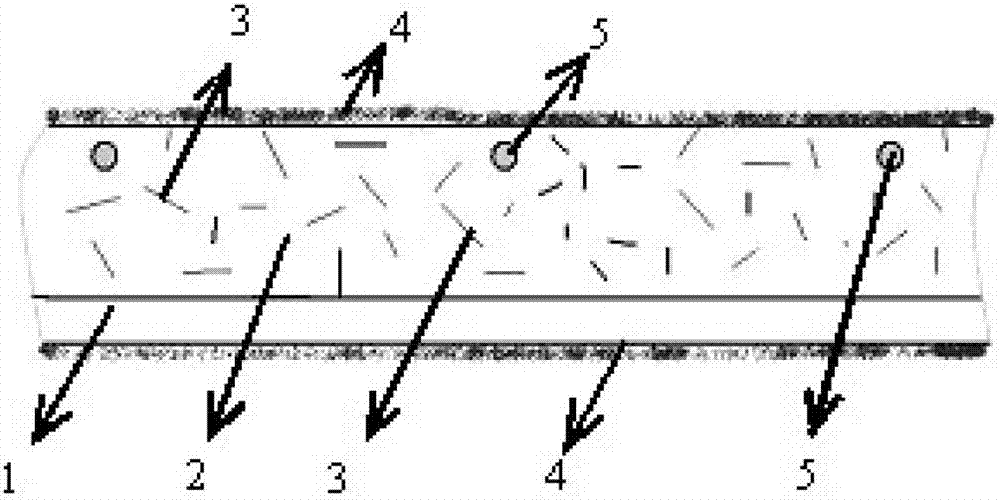

Fiber-reinforced perfluorinated ion exchange membrane containing non-continuous nano-pore canal and preparation method thereof

ActiveCN103031566AImprove electrochemical performanceImprove mechanical propertiesOrganic diaphragmsFiberPhysical chemistry

The invention relates to a fiber-reinforced perfluorinated ion exchange membrane containing a non-continuous nano-pore canal and a preparation method thereof. A basic membrane of the membrane comprises a perfluorosulfonic acid ion exchange resin layer and a perfluorocarboxylic acid ion exchange resin layer, reinforcing fiber mesh cloth is arranged in the perfluorosulfonic acid resin layer, and gas release coatings are sprayed on the surfaces on the two outer sides of the basic membrane; and the fiber-reinforced perfluorinated ion exchange membrane is characterized in that the non-continuous nano-pore canal is further contained in the perfluorosulfonic acid resin layer. The membrane is prepared through a melting co-extrusion or multi-layer hot-pressing compounding process. The membrane is used for the ion exchange membrane in the chlor-alkali industry and has better mechanical properties and electrochemical properties.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

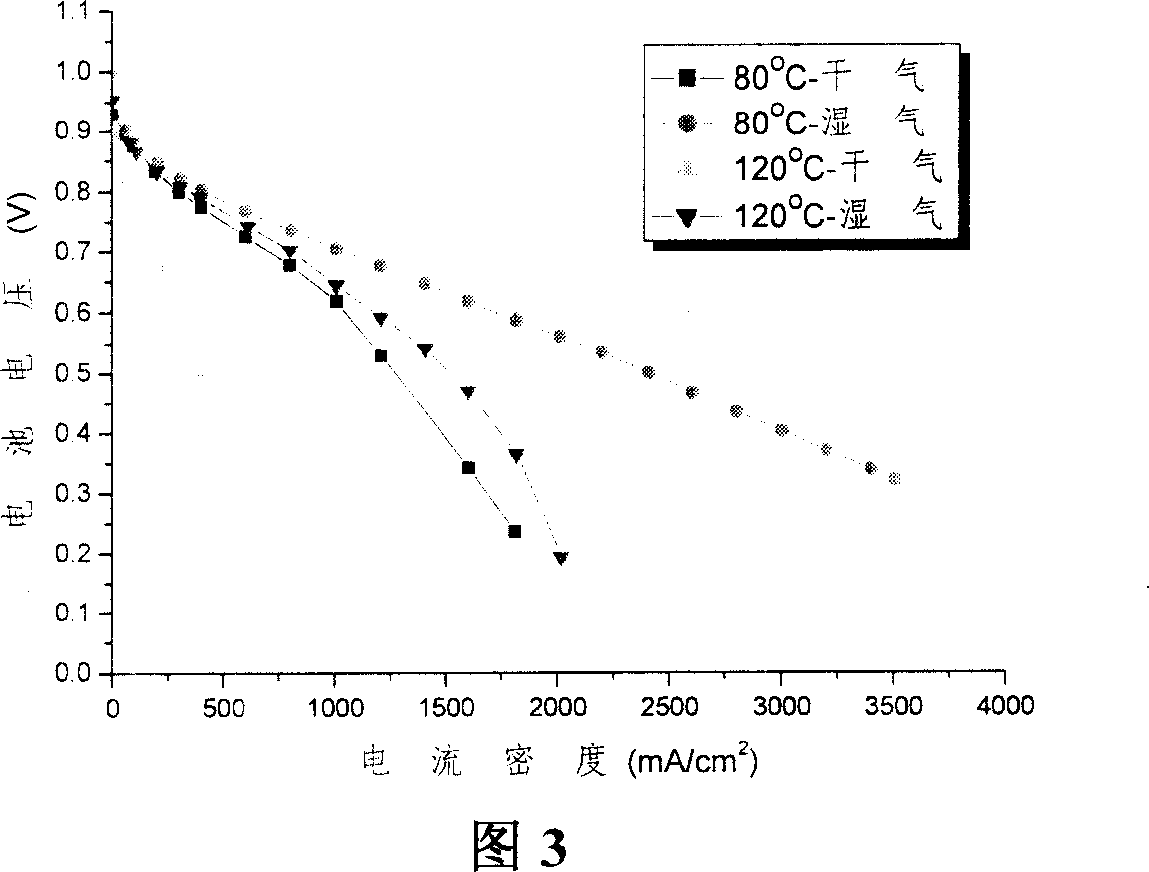

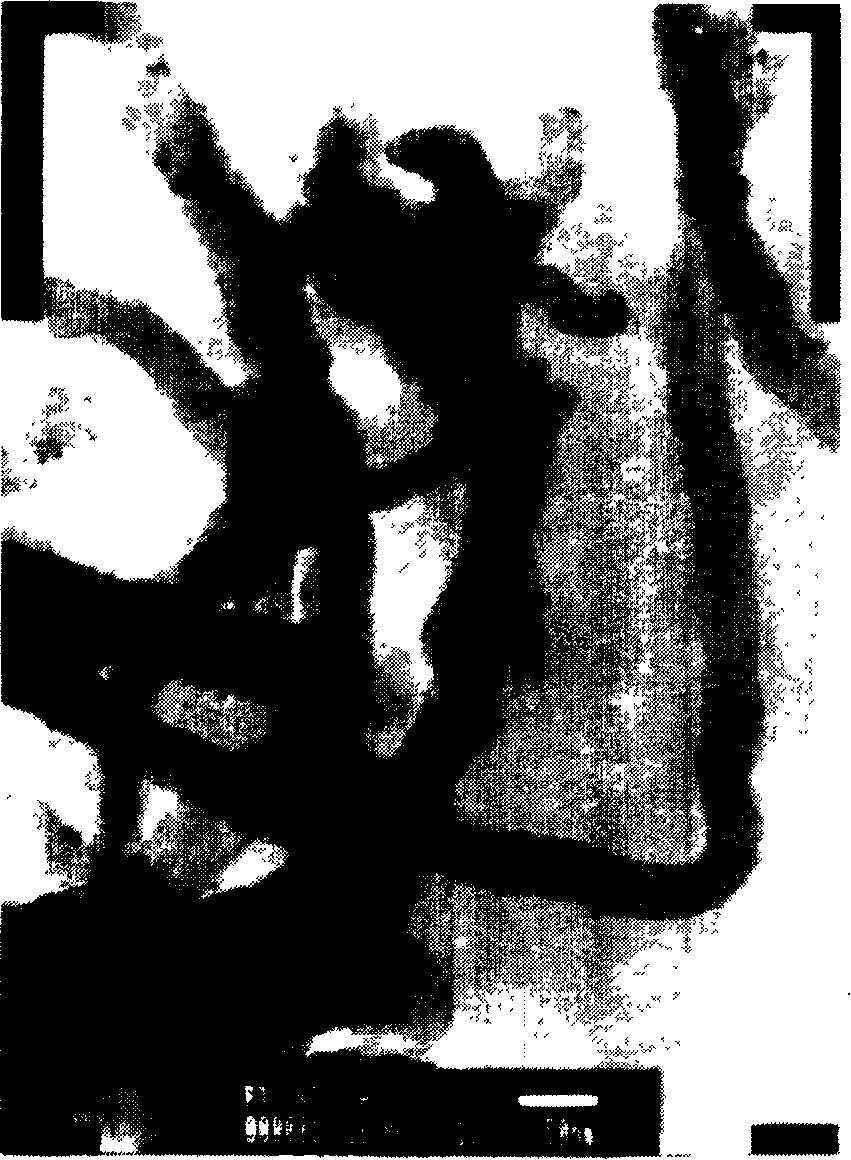

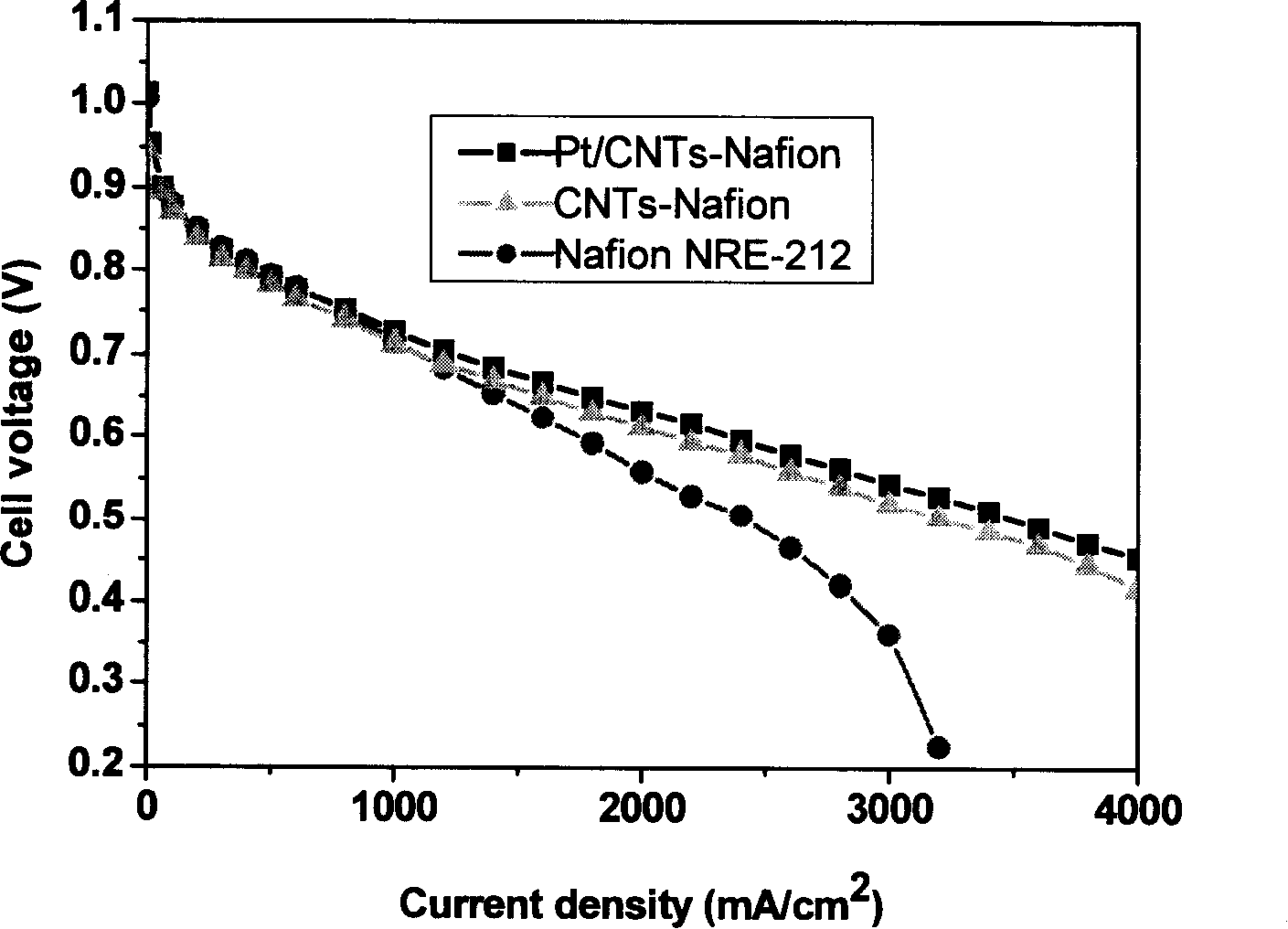

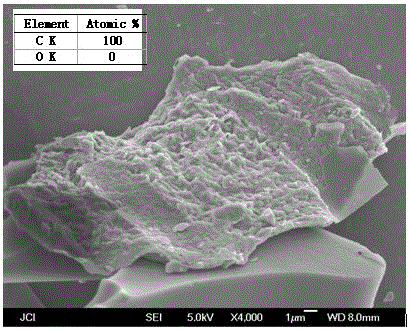

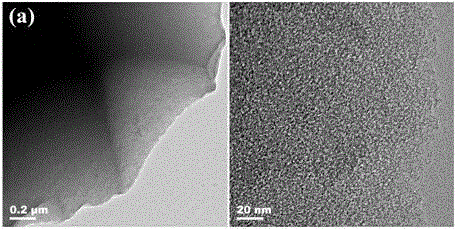

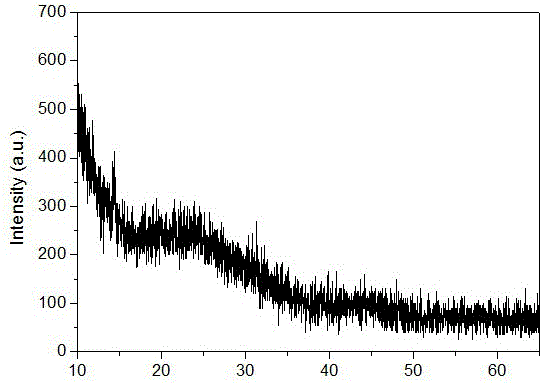

A carbon nano tube enhanced self-humidity increase compound proton exchange film and its preparation

ActiveCN101170183AEasy to operateHigh strengthFinal product manufactureSolid electrolyte fuel cellsNano sio2Carbon nanotube

The invention relates to a fuel cell, in particular to a self-humidifying combined proton exchange membrane for a strengthening fuel cell based on a carbon nanotube and a preparation method thereof, which comprises the following steps: a solution casting method is utilized to prepare and obtain a strengthened perfluorosulfonic resin membrane of the carbon nanotube, and Pt is introduced into the membrane as self-humidifying catalyst, wherein, Pt can be directly carried on the carbon nanotube or carried on nano SiO2 particle, and the prepared membrane is 10-100 [mu]m thick. The prepared combined membrane thickness and nanotube content can be easily controlled, the manufactured membrane surface is level and smooth, not ventilate, has no short-circuit with good intensity, has better cell performance on self-humidifying operation, and can be safely applied to the fuel cell.

Owner:SUNRISE POWER CO LTD

Method for preparing high-specific surface area porous carbon material based on oil tea seed husk and application thereof

ActiveCN105664847AWide variety of sourcesLow priceCarbon compoundsOther chemical processesPorous carbonFiltration

The invention relates to a method for preparing a high-specific surface area porous carbon material based on oil tea seed husks and an application thereof. The preparation method of the carbon material comprises the following steps: performing hydrothermal carbonization on the oil tea seed husk powder to obtain a black solid, using water and ethanol for cleaning the black solid and drying the black solid, adding KOH and grinding and performing hole expanding, then placing a mixing sample in inert gas flow atmosphere, separately using dilute hydrochloric acid and water for washing an obtained grey solid until the grey solid is neutral, performing pumping filtration, and naturally drying the product in air to obtain the high-specific surface area porous carbon material. The carbon material has excellent adsorption performance on heavy metal, a dye and perfluorinated sulfonic acid pollutants in water. The method has the advantages that the raw material is biomass waste, the source is wide, the cost is low; processes for preparing the carbon material is simple, the used reagents are conventional chemical reagents, the production cost is low; and the adsorptivity of the carbon material on a plurality of pollutants in water is better than that of the reported materials.

Owner:NANCHANG HANGKONG UNIVERSITY

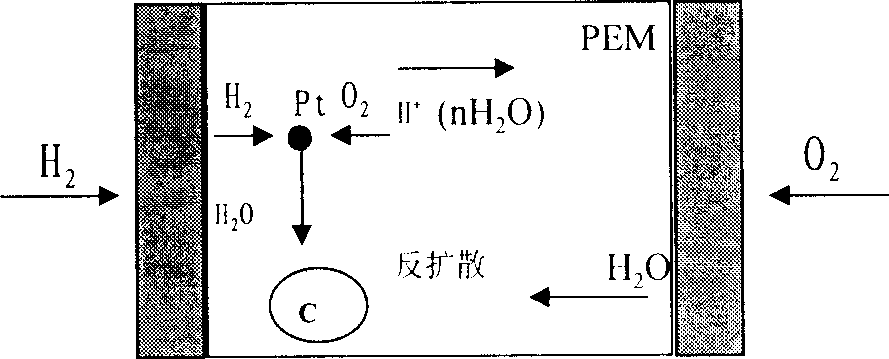

Self-moisturizing proton exchange membrane, membrane-electrode assembly and fuel cell

A self-moisturizing polymer electrolyte membrane (PEM) composition, a membrane-electrode assembly, and a fuel cell. The PEM composition comprises (a) a proton-conducting polymer containing a detachable hydrogen ion and a counter-ion bonded to the polymer; and (b) a deliquescent material for keeping the membrane wet and for detaching the hydrogen ion to facilitate proton transport in the membrane. Alternatively, the deliquescent material may be strategically located on the gas flow field channels, gas-diffusion electrode or backing layers, and / or electro-catalyst layers. A preferred PEM polymer is poly(perfluoro sulfonic acid). This self-moisturizing PEM obviates the need to have a pre-humidifying structure or a complex flow field design in a fuel cell.

Owner:JANG BOR Z

Electrically conductive polymer actuator and method for manufacturing the same

ActiveUS20090308737A1Deterioration of characteristicImprove adhesionPiezoelectric/electrostriction/magnetostriction machinesSoldering apparatusPolyethylene oxideHexafluoropropylene

To improve adhesive properties between an electrically conductive polymer membrane and a solid electrolyte membrane to each other, and thus to ensure the operation of an electrically conductive polymer actuator which effects a bending motion is aimed.The bendable electrically conductive polymer actuator of the present invention is an electrically conductive polymer actuator having a laminating structure of: a first organic polymer including at least one or more of a vinylidene fluoride / hexafluoropropylene copolymer, polyvinylidene fluoride, a perfluorosulfonic acid / polytetrafluoroethylene copolymer, polymethyl methacrylate, polyethylene oxide, and polyacrylonitrile; a solid electrolyte membrane including a mixture with an ionic liquid; and an electrically conductive polymer membrane including a mixture of polyethylenedioxythiophene and polystyrene sulfonic acid on at least one face of the solid electrolyte membrane, in which a second organic polymer including polyvinylphenol is embedded in the electrically conductive polymer membrane surface in the state being dispersed.

Owner:PANASONIC CORP

Porous proton exchange membrane material and preparation method thereof

InactiveCN101240079AImprove hydrophilic abilitySimple materialCation exchangersPolymer sciencePorous membrane

The invention provides a polymerized porous membrane with a hydrophilic body, which is composed of proton exchange resin monomer containing sulfonic acid group, wherein the proton exchange resin monomer is perfluorinated sulfonic acid resin or sulfonated heat stable polymer with proton exchange function. The porous membrane is prepared by casting solution of proton exchange resin to form a membrane, cutting to strips after heat-pressing, extending the strips in longitudinal and transversal direction, and heat-setting finally. The inventive membrane material can be used as multi-functional membrane material and be applied to fuel cell material.

Owner:WUHAN UNIV OF TECH

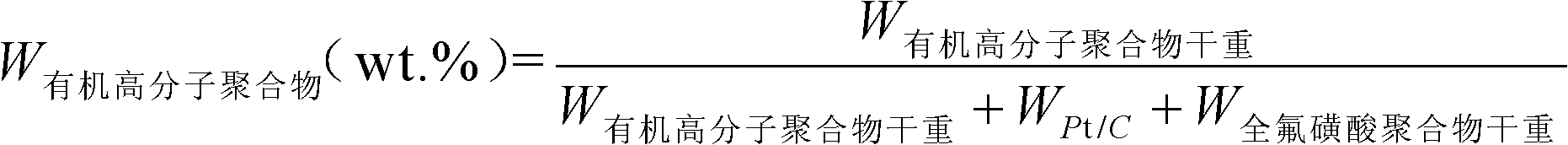

Membrane electrode containing hydrophilic high polymer in anode catalytic layer and preparation method thereof

InactiveCN102437343AGood moisturizing effectIncreased counter-diffusion dynamicsCell electrodesSlurrySolvent

Owner:SOUTH CHINA UNIV OF TECH

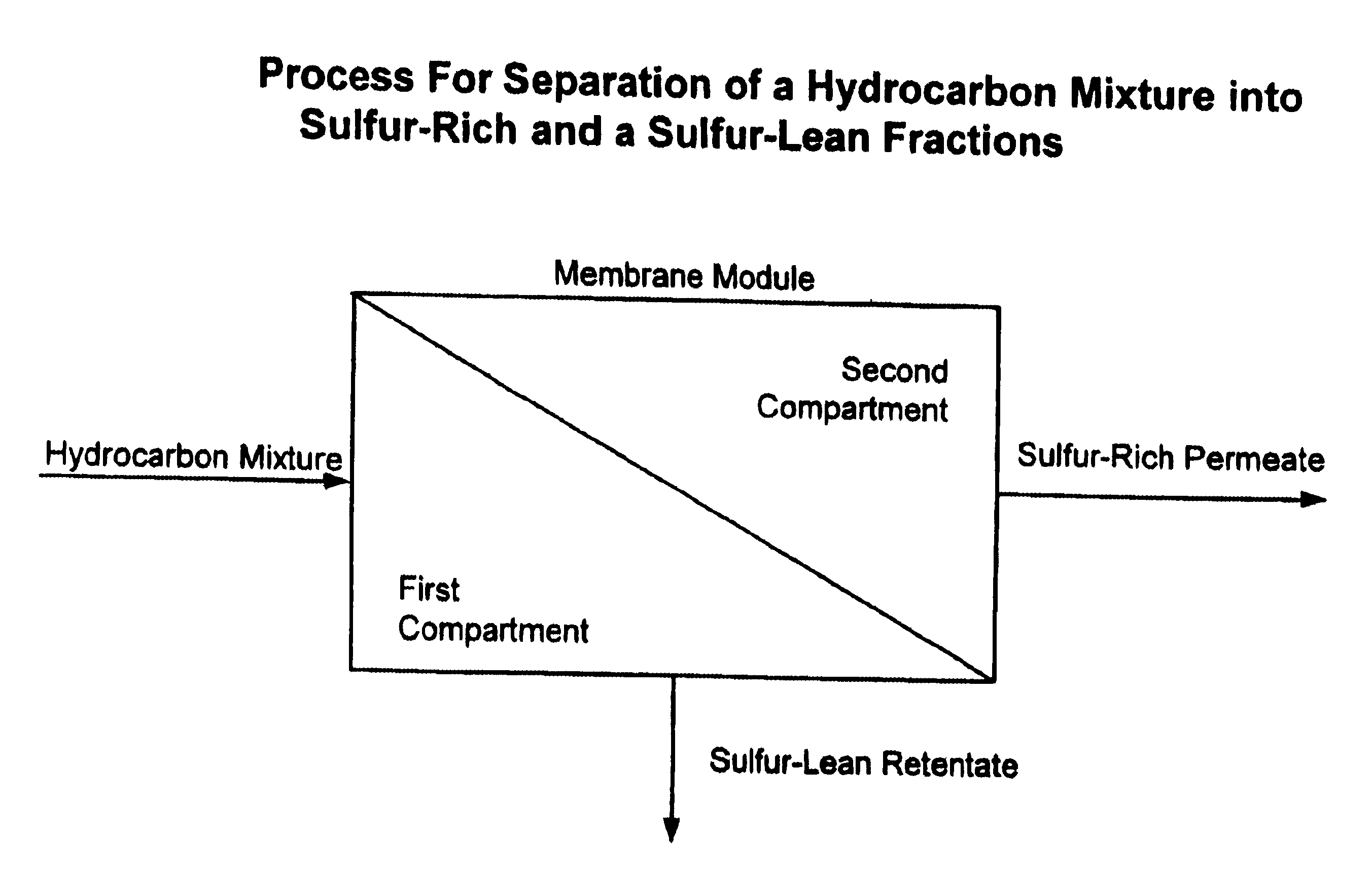

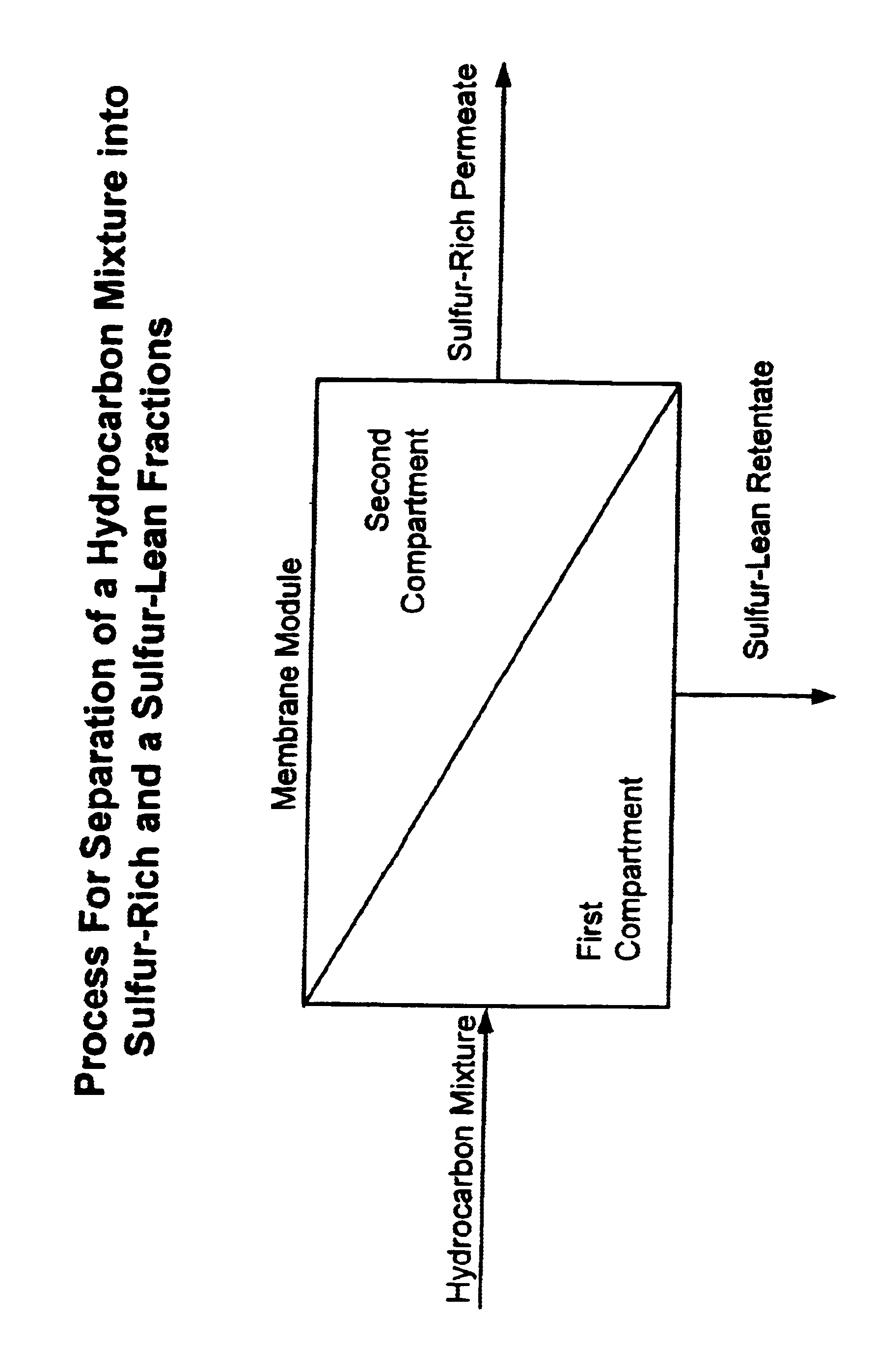

Ionic membranes for organic sulfur separation from liquid hydrocarbon solutions

Methods for the separation of sulfur compounds from a hydrocarbon mixture using an ionic membrane are provided. Preferred ionic membranes are Nafion(R)-type (polymers of perfluorosulfonic acid) membranes and derivatives thereof. Preferred applications include the removal of sulfur contaminants from light cracked naphthas.

Owner:EXXON RES & ENG CO

Method for preparing low-permeability proton exchange membrane for fuel cell

ActiveCN101692487APrecise thickness controlRepeatableFinal product manufactureCell component detailsTetrafluoroethyleneProton

The invention discloses a method for preparing a low-permeability proton exchange membrane for a fuel cell, which compounds perfluorinated sulfonic acid resin on the surface of an expanded polytetrafluoroethylene microporous membrane by combining ultrasonic soaking and spraying, wherein the ultrasonic soaking comprises of soaking the expanded polytetrafluoroethylene microporous membrane in ultrasonic oscillated perfluorinated sulfonic acid resin solution; and the spraying comprises covering, spraying and loading two lateral surfaces of the ultrasonically-soaked expanded polytetrafluoroethylene microporous membrane repeatedly till the thickness of the proton exchange membrane reaches the predetermined requirement. The method has the following characteristics that: perfluorinated sulfonic acid resin components can fully and effectively fill micropores of the expanded polytetrafluoroethylene microporous membrane through twice ultrasonic soaking in the perfluorinated sulfonic acid resin solution of different thicknesses so as to reduce air permeability; the thickness of the membrane can be accurately controlled with repeatability; the strength and dimensional stability of the membrane can be improved so as to improve the service life of the membrane; and the method can easily realize mass production.

Owner:SUNRISE POWER CO LTD

Process for preparing perfluorinated sulfonic resin solution by using waste perfluorinated ion membrane

The invention relates to a process for preparing perfluorinated sulfonic resin solution by using discarded total-fluorinion film as raw material, loading in turn into 3-60% inorganic acid, water solution of ethylenediaminetetraacetic acid disodium salt having a concentration of 0.05-0.3mol / L, steeping in water solution of sodium hydroxide having a concentration of 0.1-2mol / L, loading into container with solvent, thermal insulating 0.5-18 hours at 150-280 deg. C at the presence of inactive gas.

Owner:EAST CHINA UNIV OF SCI & TECH

Method of preparing membrane electrode using recasted perfluro sulfonic acid proton exchange film

InactiveCN1414652AReduce use costPromote commercial applicationCell electrodesFinal product manufactureOrganic solventGaseous diffusion

A method to prepare membrane electrode by remaking quantum exchange membrane of perfluorosulphonic acid includes the following steps: 1) to placing the substance of perfluorsulphonic acid into water containing organic polarity solvent with low boiling point and dissolving it by heating in a sealed reactor, 2) drying the solution of perfluorosulphonic acid by heating, 3) adding high-boiling point organic solvent for dissolving the dried substance of perfluorosulphonic acid and placing it in the dryer for 24 hour for obtaining the membrane making liquid, 4) pouring the membrane making liquid into a mould after the mould being warmed and producing the membrance by vacuum heat drying, 5) spraying the membrane making liquid on the catalytic layer surface of multihole gaseous diffusion electrode and drying it by heating after it being airdried.

Owner:SUNRISE POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com