Patents

Literature

226 results about "Polymer bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This reference indicates that primary bonds in a polymer are the intramolecular bonds (the covalent bonds) that hold the polymer together. Cross-linking different chains of polymer together does occur through a covalent bond, such as a disulfide bond.

Control of polymer surface molecular architecture via amphipathic endgroups

ActiveUS20050282997A1Promote resultsReduce signal to noise ratioSurgeryCatheterPolymeric surfacePolyethylene oxide

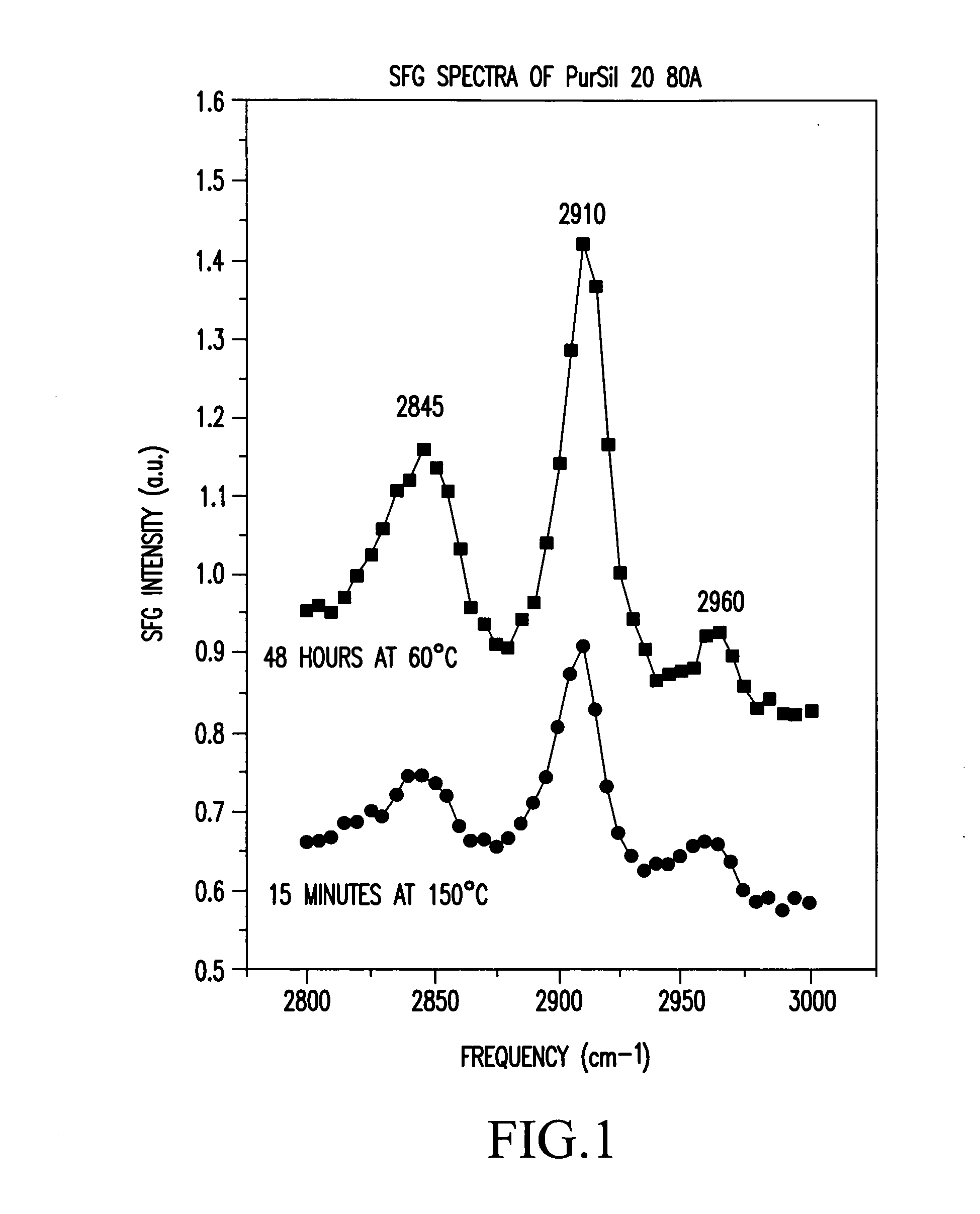

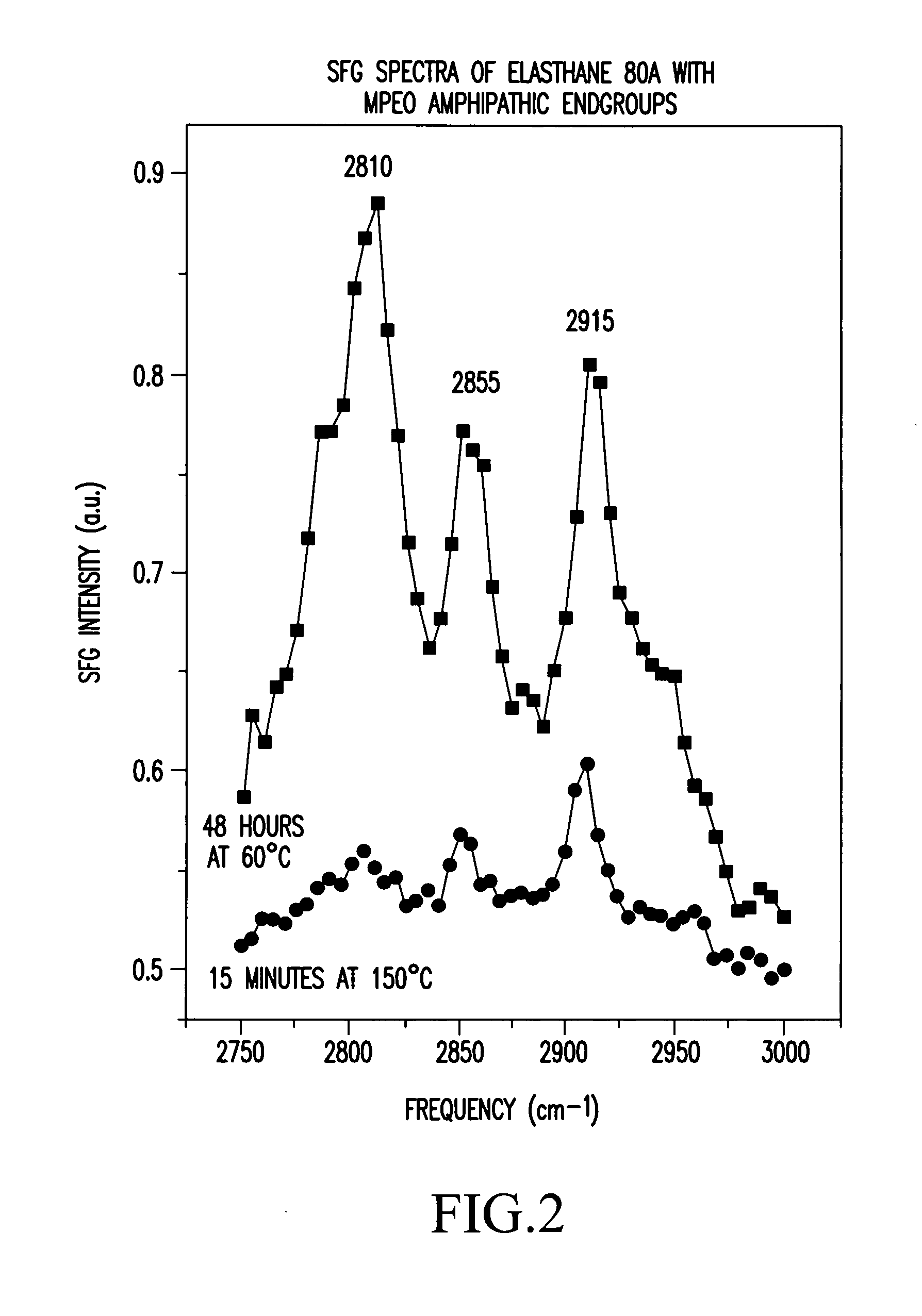

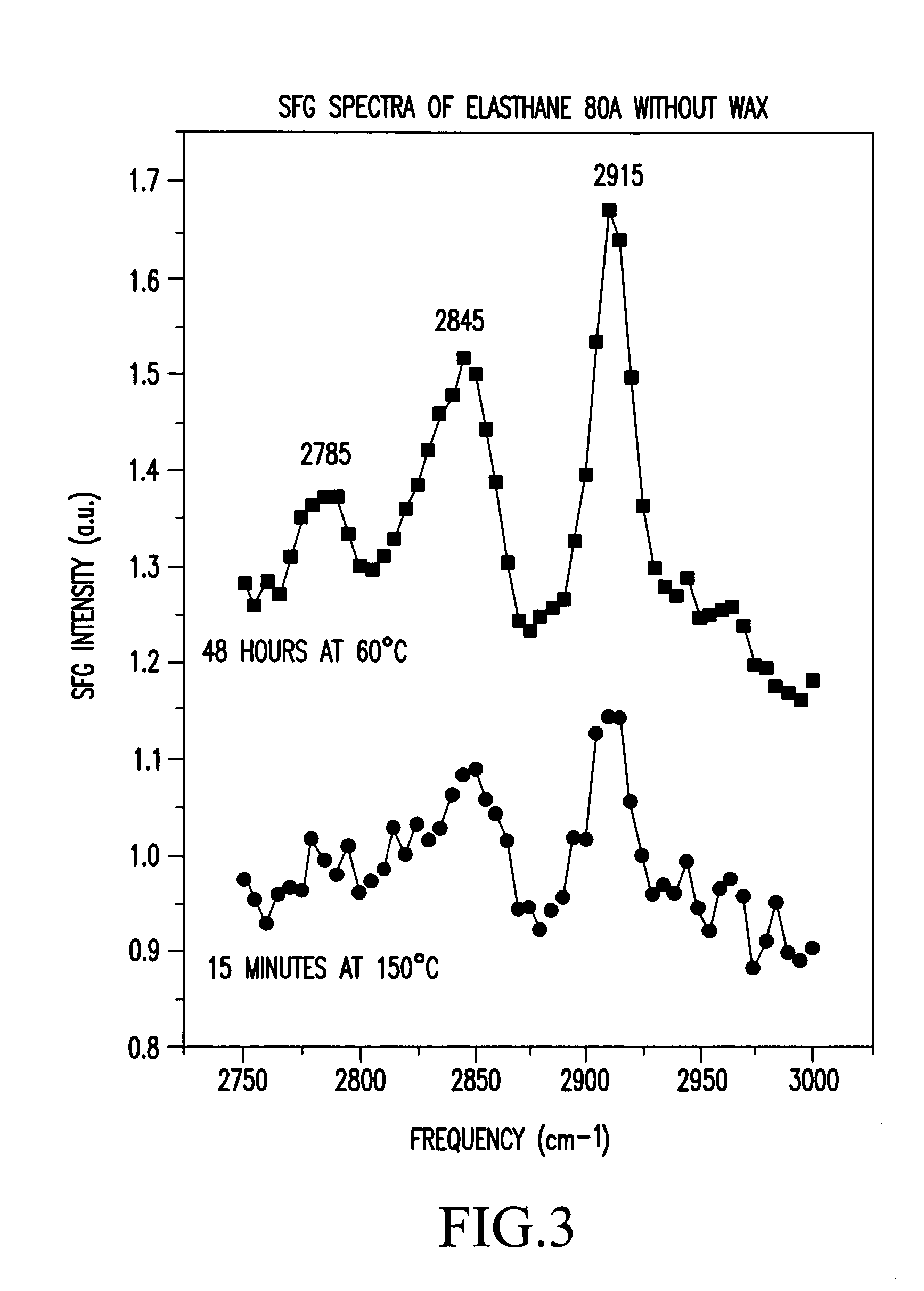

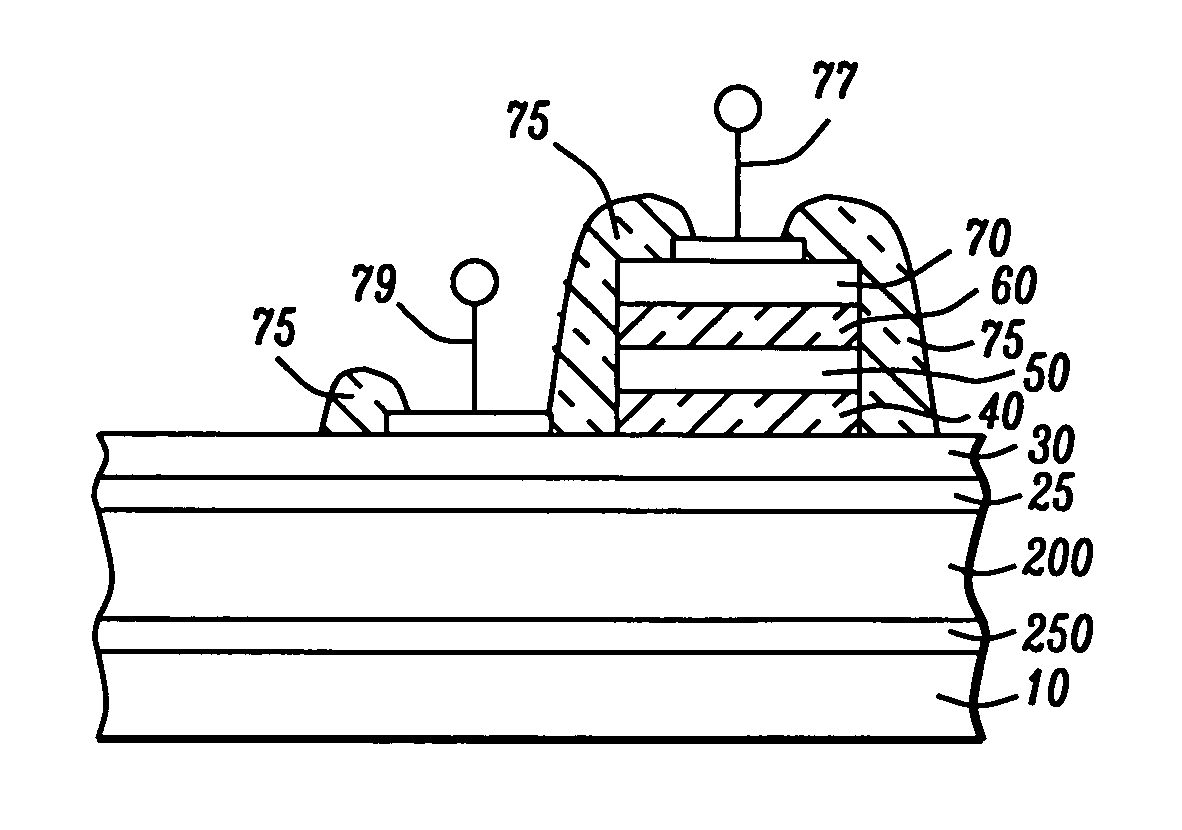

Polymers whose surfaces are modified by endgroups that include amphipathic surface-modifying moieties. An amphipathic endgroup of a polymer molecule is an endgroup that contains at least two moieties of significantly differing composition, such that the amphipathic endgroup spontaneously rearranges its positioning in a polymer body to position the moiety on the surface of the body, depending upon the composition of the medium with which the body is in contact, when that re-positioning causes a reduction in interfacial energy. An example of an amphipathic surface-modifying endgroup is one that has both a hydrophobic moiety and a hydrophilic moiety in a single endgroup. For instance, a hydrophilic poly(ethylene oxide) terminated with a hydrophilic hydroxyl group is not surface active in air when the surface-modifying endgroup is bonded to a more hydrophobic base polymer. If the hydroxyl group on the oligomeric poly(ethylene oxide) is replaced by a hydrophobic methoxy ether terminus, the poly(ethylene oxide) becomes surface active in air, and allows the poly(ethylene oxide) groups to crystallize in the air-facing surface. In this example, immersion in water destroys the crystallinity as the poly(ethylene oxide) sorbs water and the hydrophobic methoxy group retreats below the surface of the polymer. Also disclosed are methods and articles of manufacture that make use of these polymers.

Owner:THE POLYMER TECH GROUP

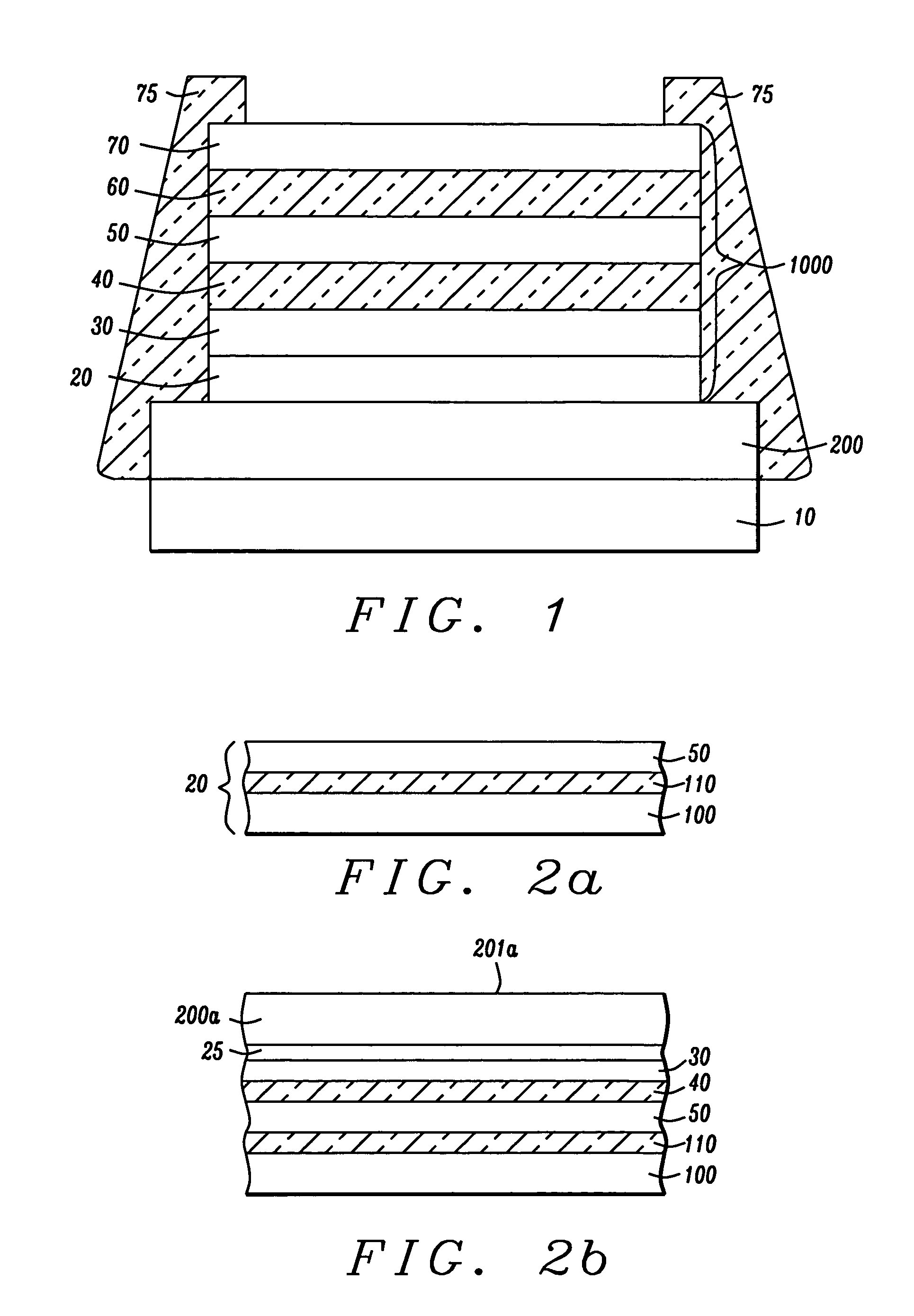

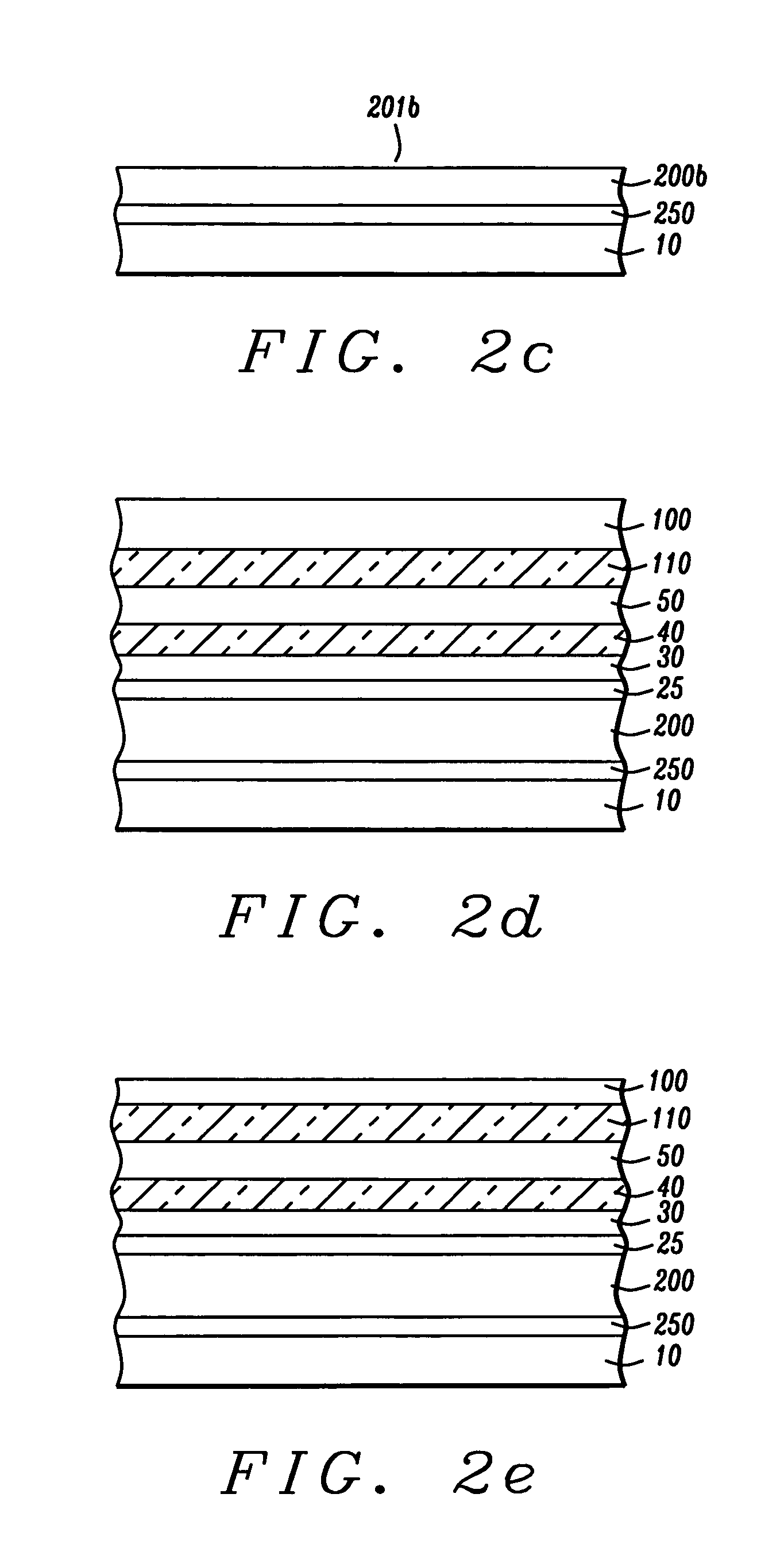

Method of making resonant tunneling diodes and CMOS backend-process-compatible three dimensional (3-D) integration

InactiveUS7002175B1Improve performanceEase of fabricationSemiconductor/solid-state device detailsNanoinformaticsLow noiseElectrical connection

A double barrier resonant tunneling diode (RTD) is formed and integrated with a level of CMOS / BJT / SiGe devices and circuits through processes such as metal-to-metal thermocompressional bonding, anodic bonding, eutectic bonding, plasma bonding, silicon-to-silicon bonding, silicon dioxide bonding, silicon nitride bonding and polymer bonding or plasma bonding. The electrical connections are made using conducting interconnects aligned during the bonding process. The resulting circuitry has a three-dimensional architecture. The tunneling barrier layers of the RTD are formed of high-K dielectric materials such as SiO2, Si3N4, Al2O3, Y2O3, Ta2O5, TiO2, HfO2, Pr2O3, ZrO2, or their alloys and laminates, having higher band-gaps than the material forming the quantum well, which includes Si, Ge or SiGe. The inherently fast operational speed of the RTD, combined with the 3-D integrated architecture that reduces interconnect delays, will produce ultra-fast circuits with low noise characteristics.

Owner:AGENCY FOR SCI TECH & RES

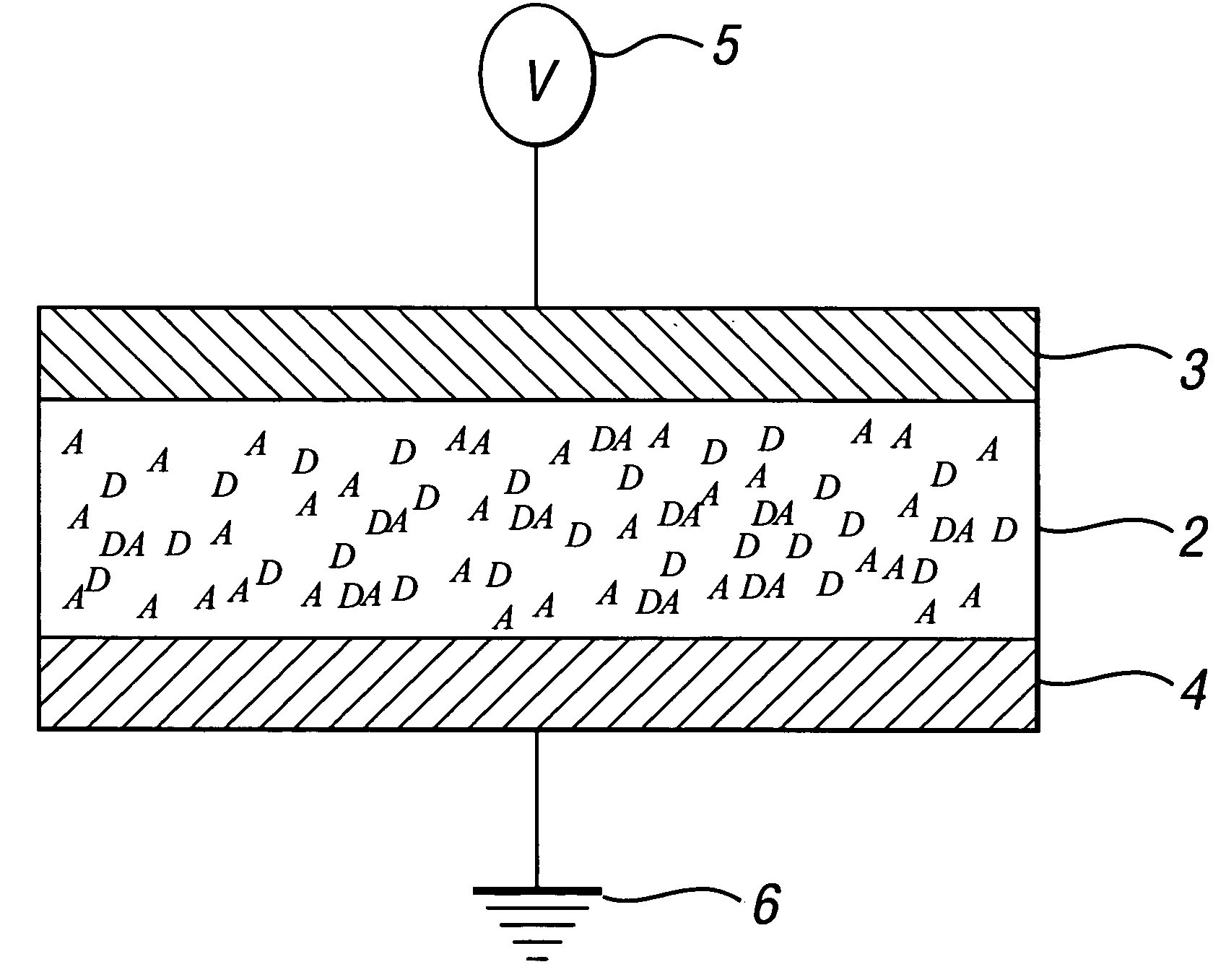

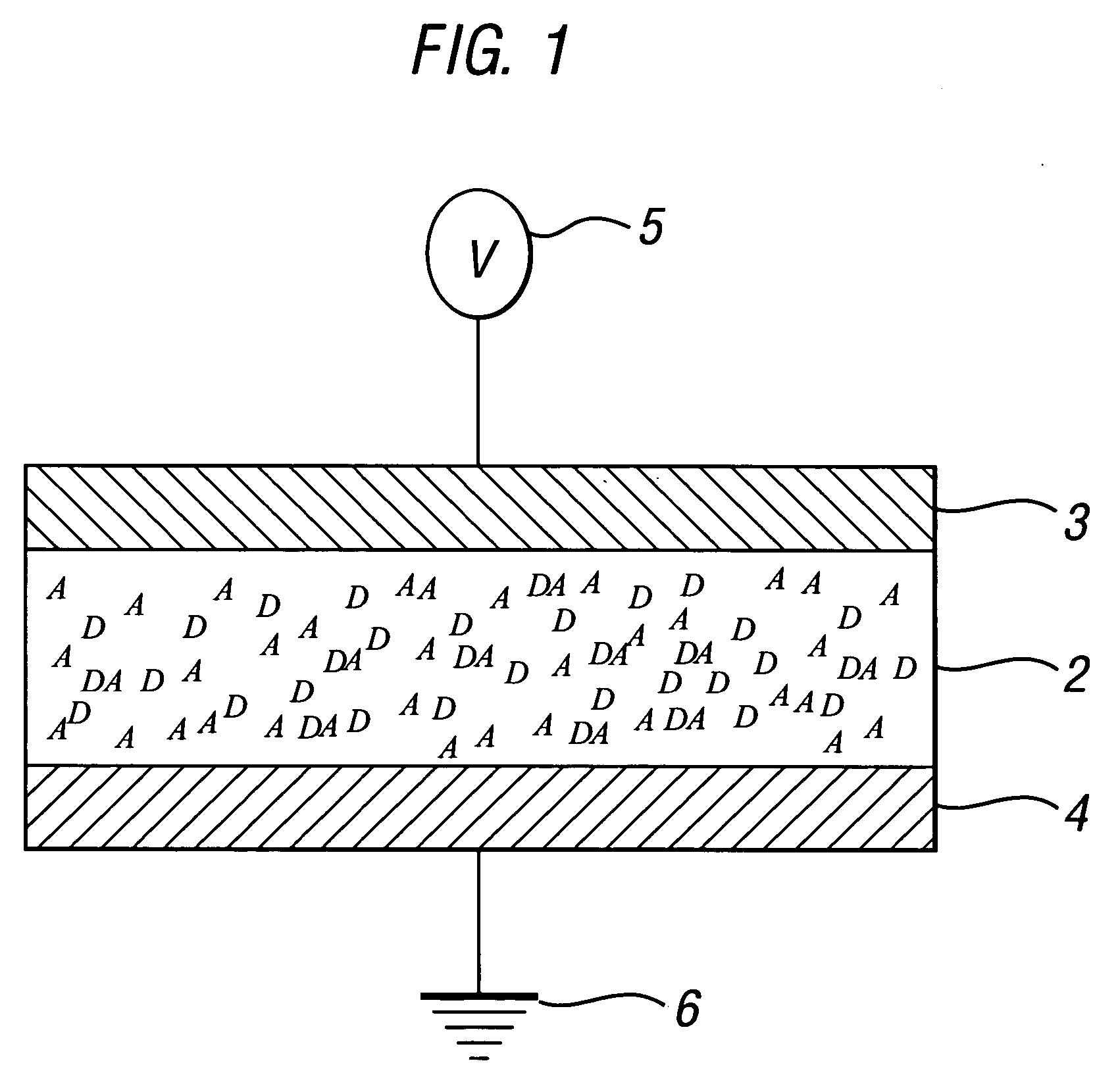

Memory devices based on electric field programmable films

Disclosed herein is an electric field programmable film comprising a polymer bonded to an electroactive moiety. Disclosed herein too is a method of manufacturing an electric field programmable film comprising depositing upon a substrate, a composition comprising a polymer and an electroactive moiety that is bonded to the polymer. Disclosed herein too is a data processing machine comprising a processor for executing an instruction; and a memory device comprising an electric field programmable film, wherein the electric field programmable film comprises a polymer bonded to an electroactive moiety, and further wherein the memory device is in electrical and / or optical communication with the processor.

Owner:BU LUJIA +4

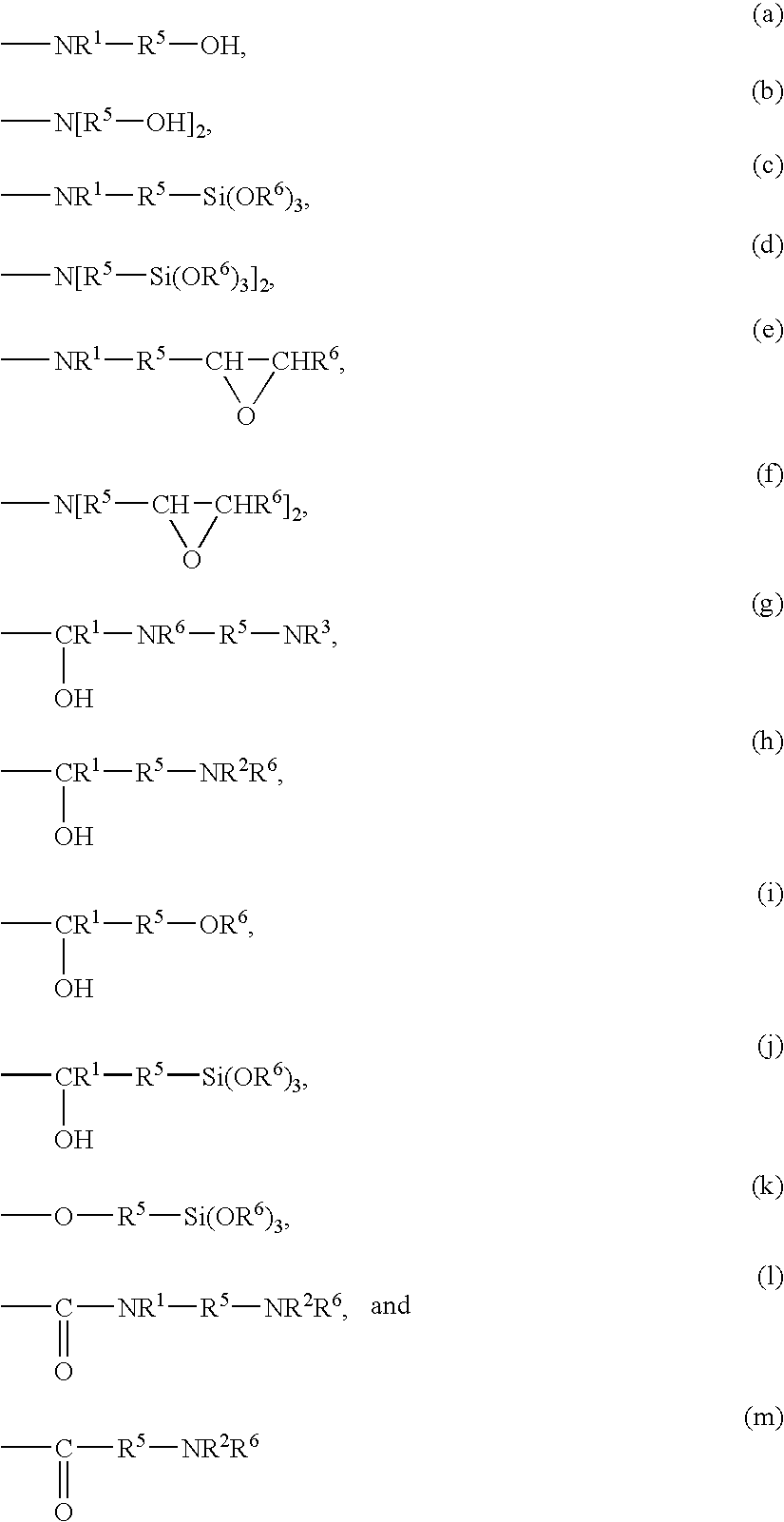

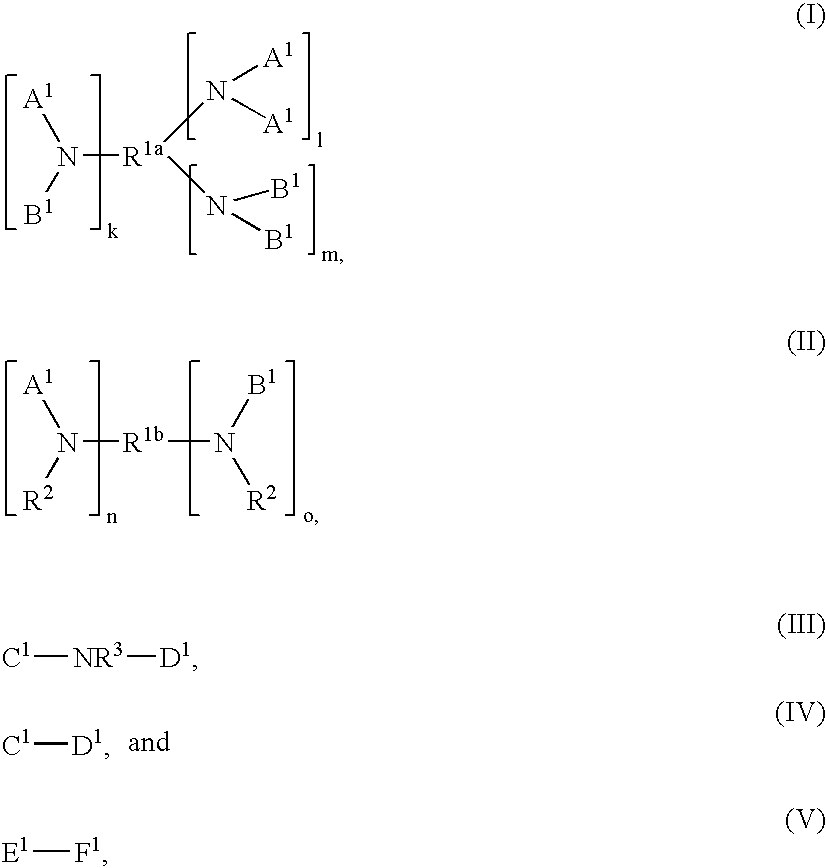

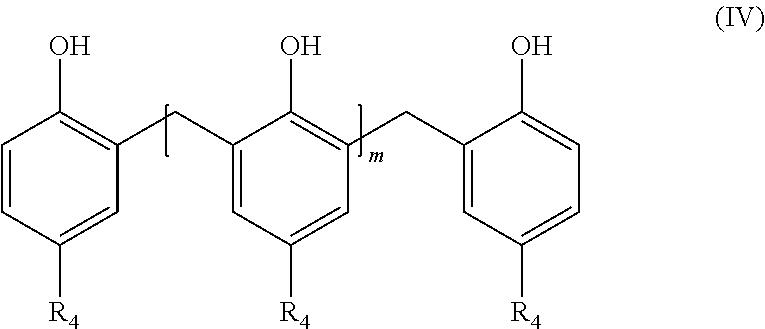

Modified polymers and compositions containing the same

ActiveUS20050171276A1Maintain good propertiesBuilding insulationsGraft polymer adhesivesPolymer sciencePolymer bonding

A first-order modified, hydrogenated polymer comprising (1) a hydrogenated polymer obtained by hydrogenating at least one unhydrogenated polymer selected from the group consisting of a polymer comprising conjugated diene monomer units and a copolymer comprising conjugated diene monomer units and vinyl aromatic hydrocarbon monomer units, and (2) a functional group-containing first-order modifier group bonded to the hydrogenated polymer (1), wherein the content of the vinyl aromatic hydrocarbon monomer units, vinyl aromatic hydrocarbon block ratio, weight average molecular weight, and hydrogenation ratio (as measured with respect to the double bonds in the conjugated diene monomer units) of the first-order modified, hydrogenated polymer are, respectively, within specific ranges. A second-order modified polymer obtained by reacting a second-order modifier with a first-order modified polymer comprising (β) a base polymer and (γ) a functional group-containing first-order modifier group bonded to the base polymer (β). A composition comprising the above-mentioned first-order modified, hydrogenated polymer or second-order modified polymer and at least one functional component other than the modified polymer.

Owner:ASAHI KASEI CHEM CORP

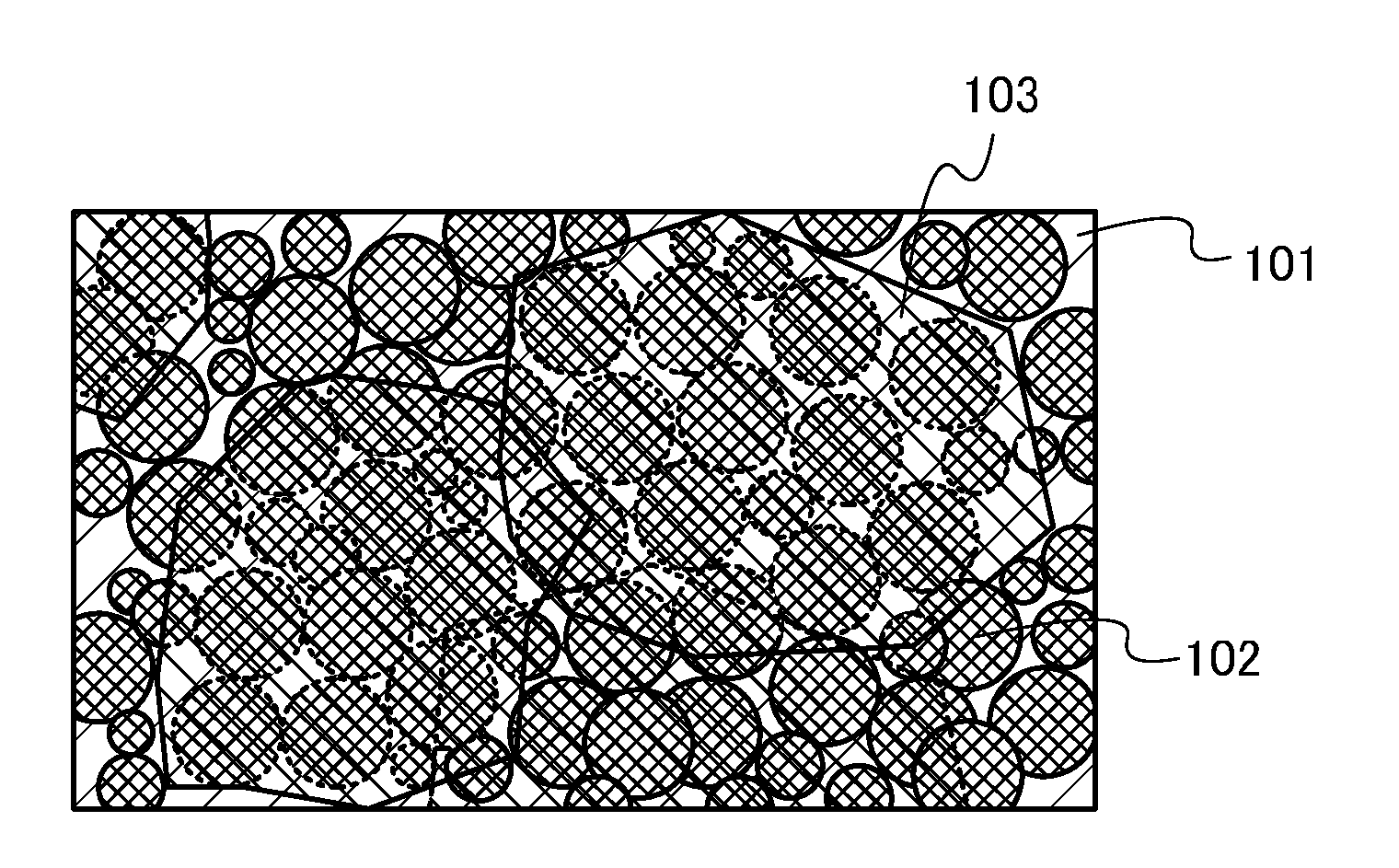

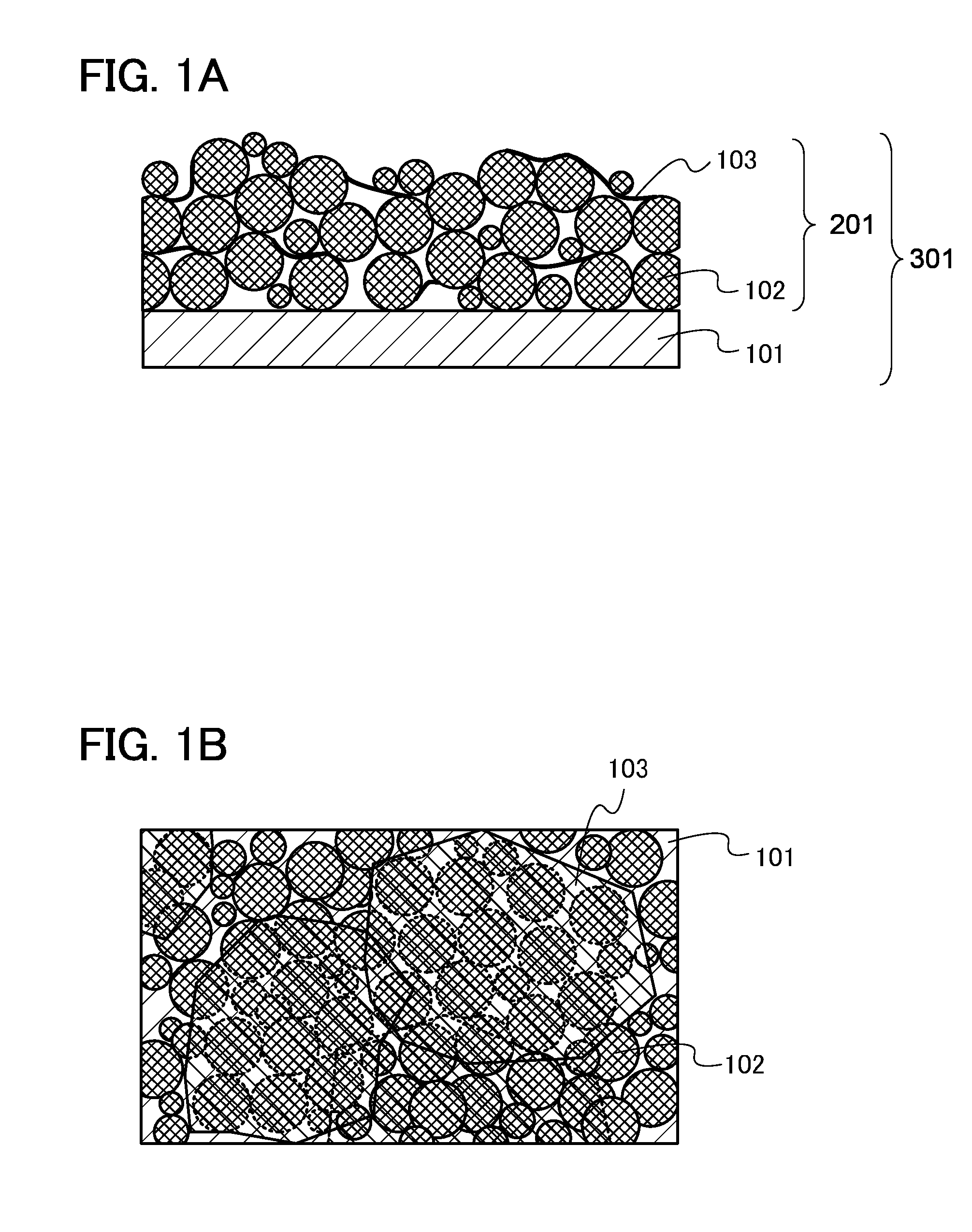

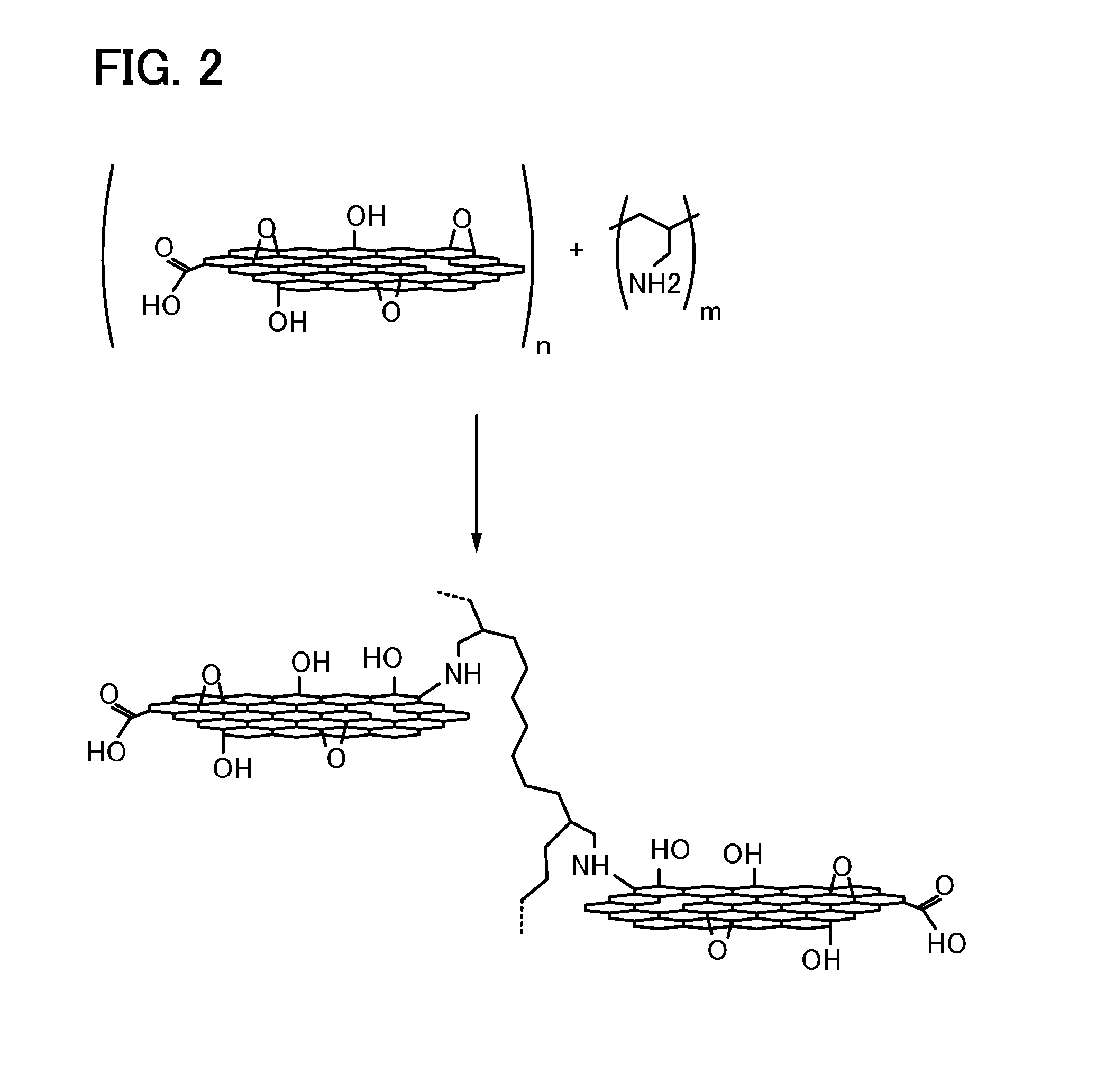

Positive electrode for secondary battery and manufacturing method of positive electrode for secondary battery

InactiveUS20130164619A1Raise the ratioIncrease capacityActive material electrodesElectrode collector coatingSide chainPolymer bonding

The positive electrode active material layer includes a plurality of particles of a positive electrode active material and a reaction mixture where reduced graphene oxide is bonded to a polymer having a functional group as a side chain. The reduced graphene oxide has a sheet-like shape and high conductivity and thus functions as a conductive additive by being in contact with the plurality of particles of the positive electrode active material. The reaction mixture serves as an excellent binder since the reduced graphene oxide is bonded to the polymer. Therefore, even a small amount of the reaction mixture where the reduced graphene oxide is covalently bonded to the polymer excellently serves as a conductive additive and a binder.

Owner:SEMICON ENERGY LAB CO LTD

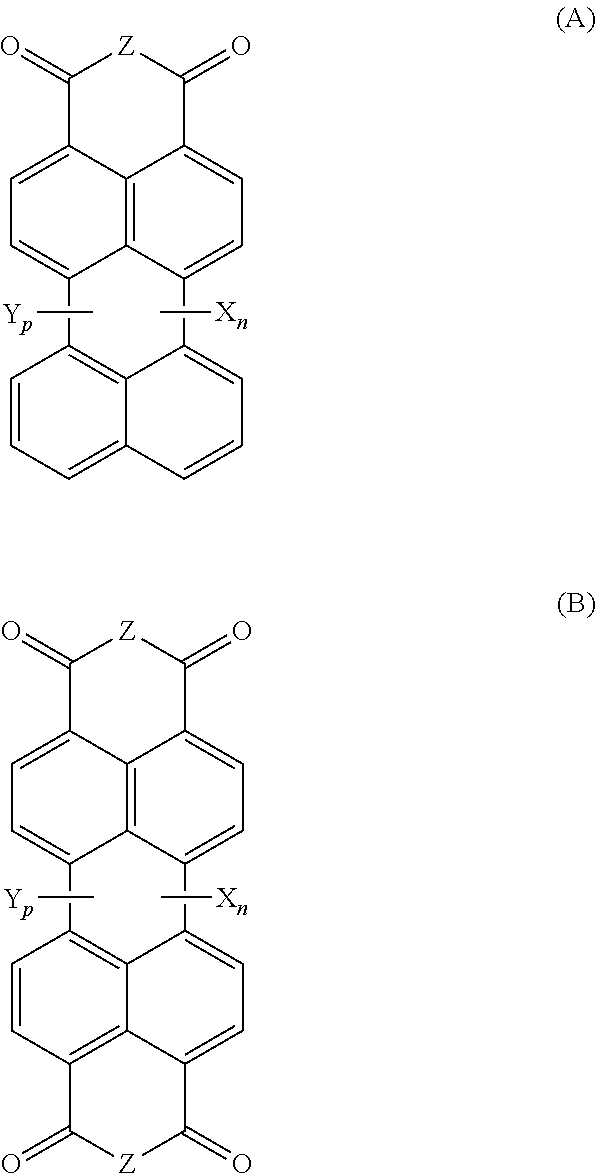

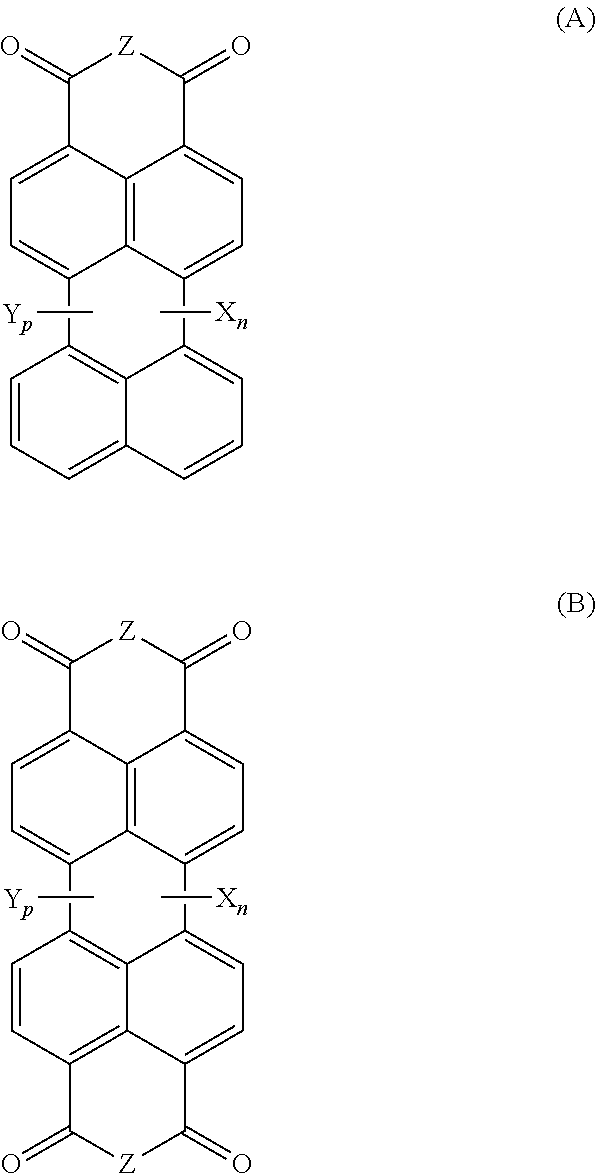

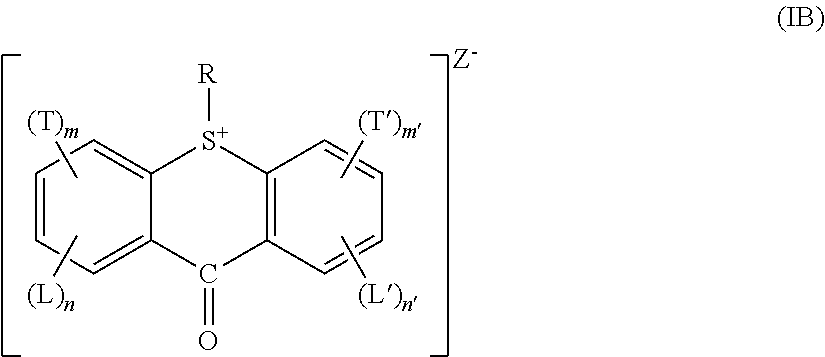

Polymer-bonded perylene dyes and compositions containing same

ActiveUS20110293899A1Improve solubilityGood dispersibilityOrganic chemistryLayered productsSolubilityLiquid medium

A method of increasing the solubility and / or dispersibility of a perylene dye in a liquid medium. The method comprises binding the perylene dye to a polymer which is soluble in the liquid medium. This abstract is neither intended to define the invention disclosed in this specification nor intended to limit the scope of the invention in any way.

Owner:SICPA HLDG SA

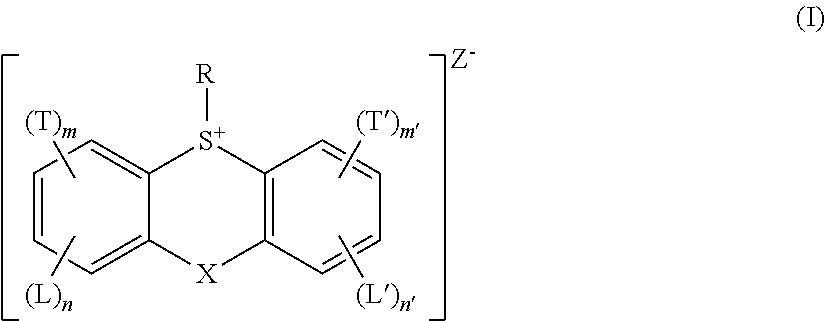

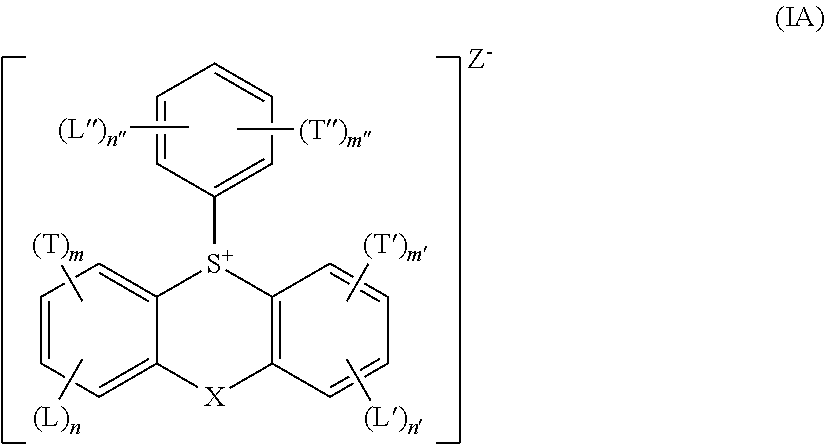

Photoresists comprising multiple acid generator compounds

PendingUS20140080062A1Weight increaseImprove photolithographic effectPhotosensitive materialsElectric discharge tubesPolymer bondingCompound (substance)

The present invention relates to new photoresist compositions that comprise (a) a polymer comprising an acid generator bonded thereto; and (b) an acid generator compound that is not bonded to the polymer and that comprises one or more acid-labile groups.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

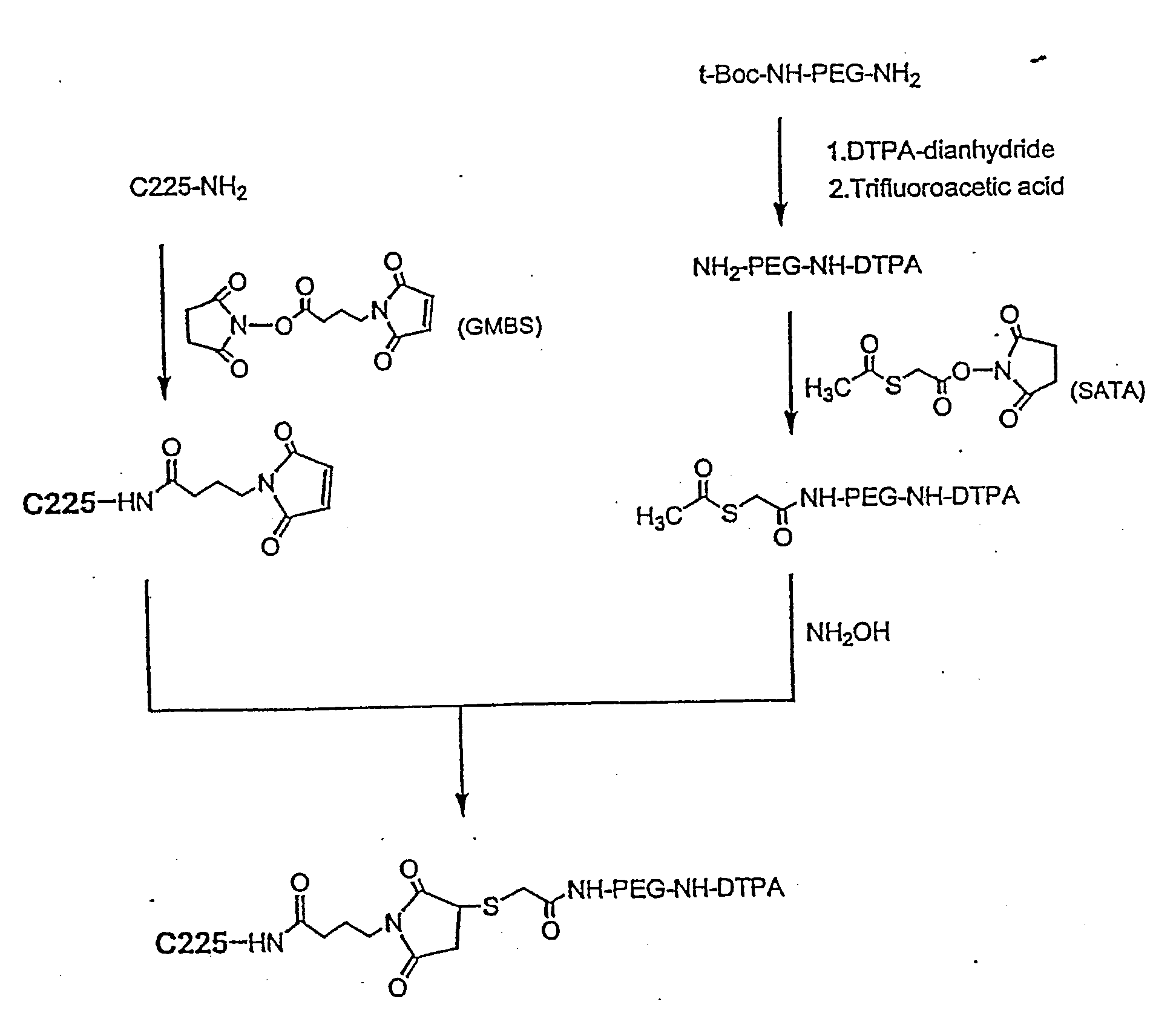

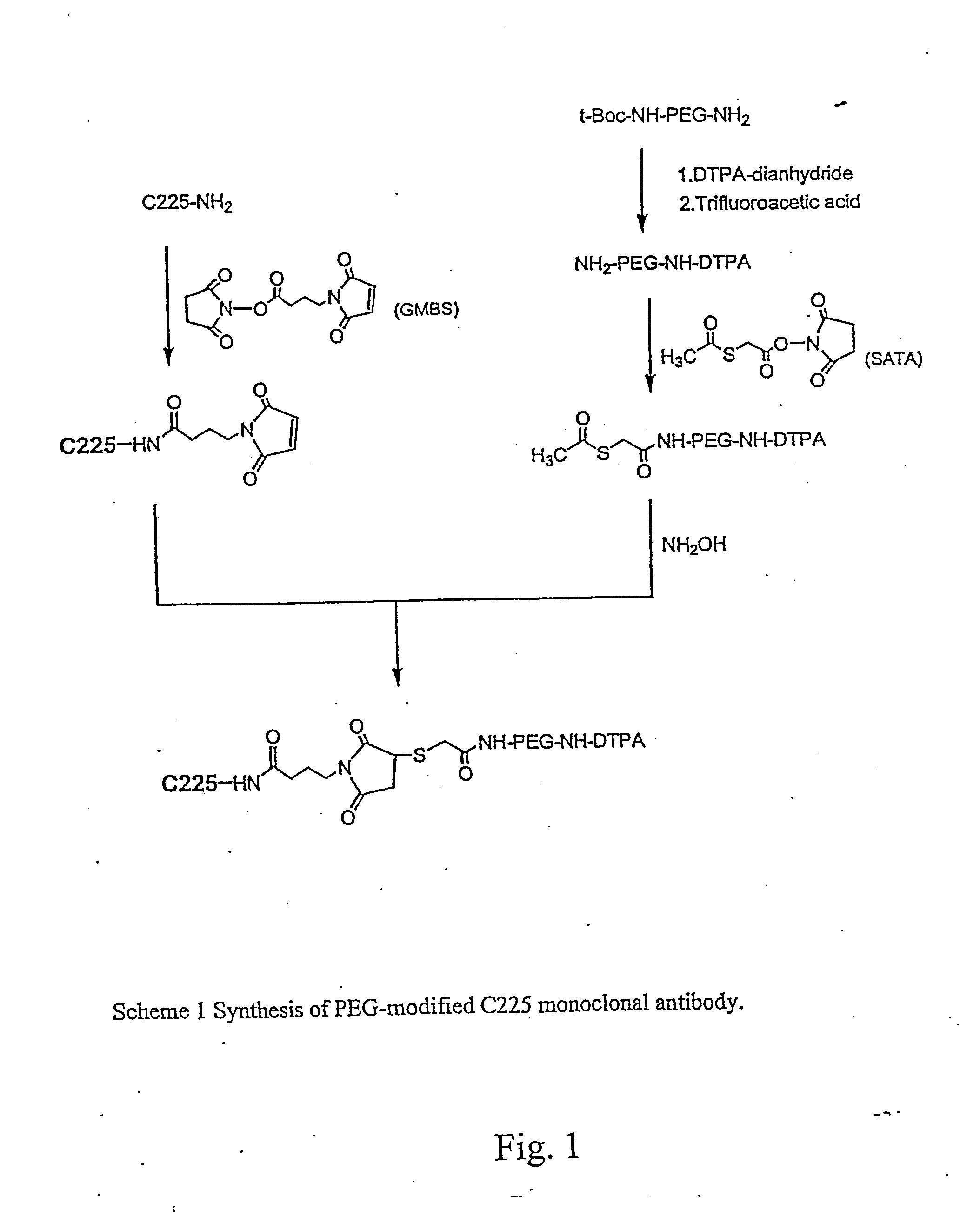

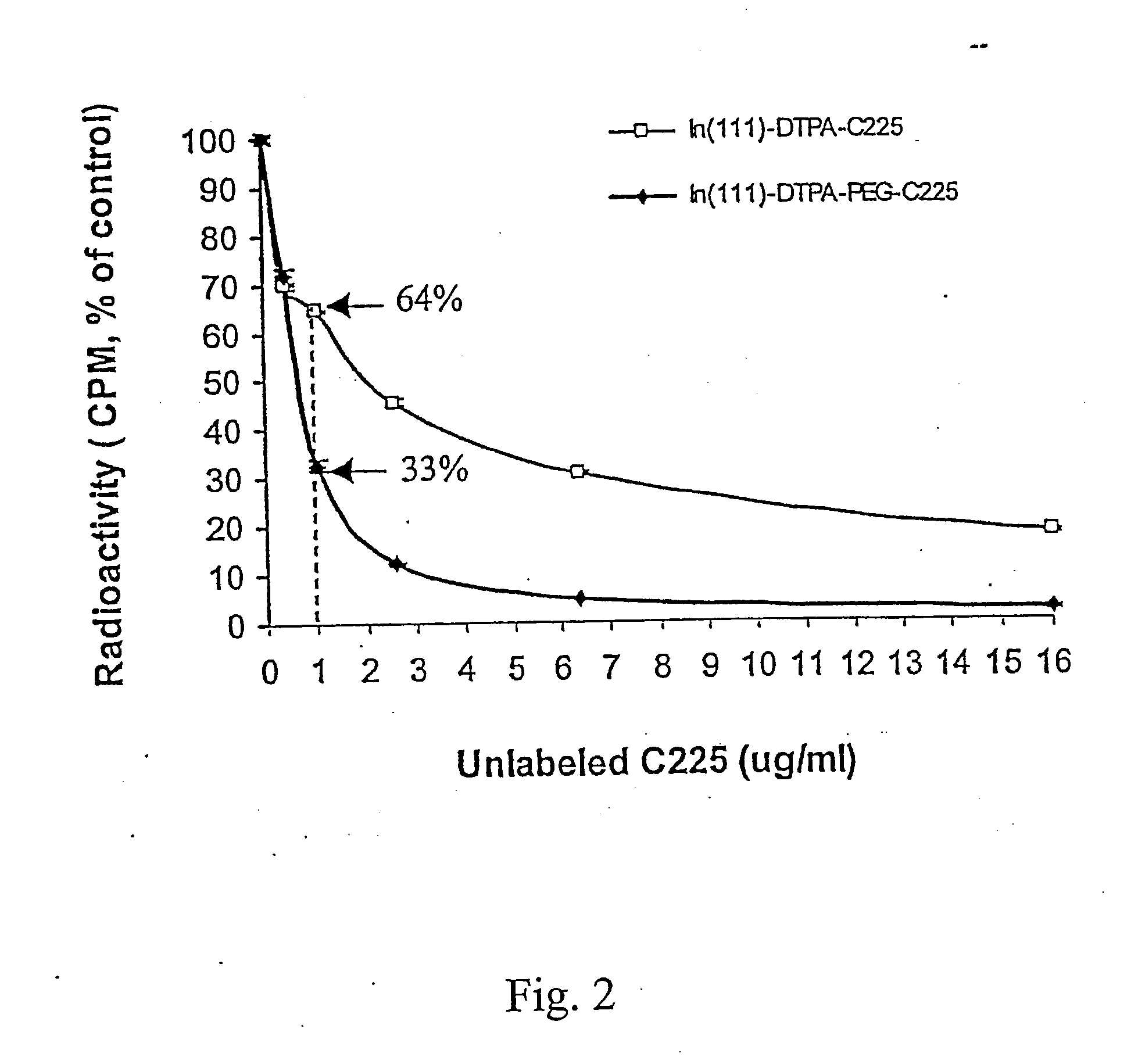

Diagnostic Imaging Compositions, Their Methods Of Synthesis And Use

InactiveUS20070196275A1Longer in vivo half lifeReduced liver uptakeRadioactive preparation carriersPharmaceutical non-active ingredientsPolymer bondingAnnexin

Conjugate molecules comprising a ligand bonded to a polymer are disclosed. One such conjugate molecule comprises a ligand bonded to a polymer, a chelating agent bonded to the polymer, and a radioisotope chelated to the chelating agent. The conjugate molecules may be useful in detecting and / or treating tumors or biological receptors. These conjugate molecules may be synthesized without the necessity of preactivation of the ligand using an SCN-polymer-chelating agent precursor. Conjugate molecules incorporating an annexin V ligand are particularly useful for visualizing apoptotic cells. Conjugate molecules incorporating a C225 ligand are particularly useful for targeting tumors expressing EGFR.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

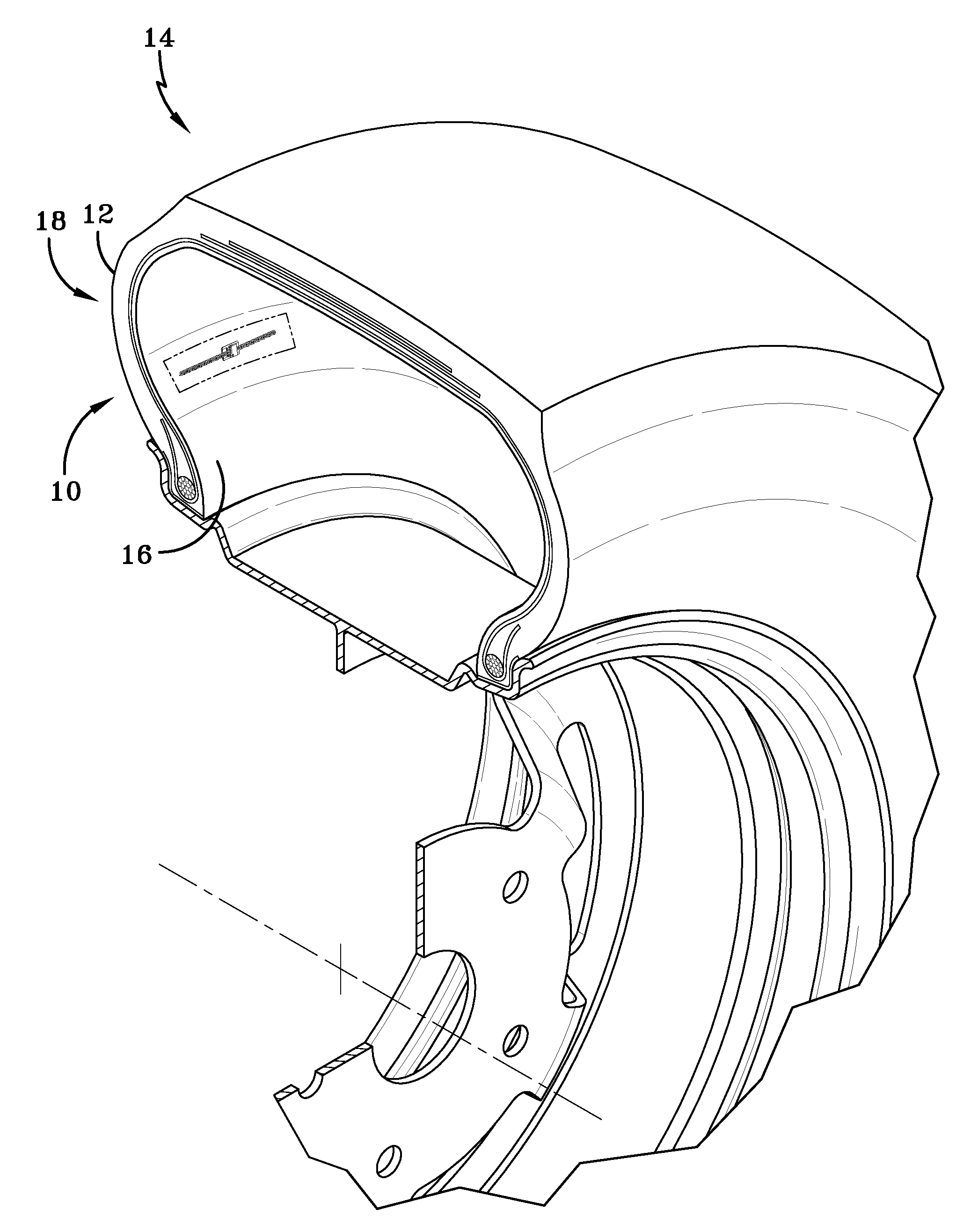

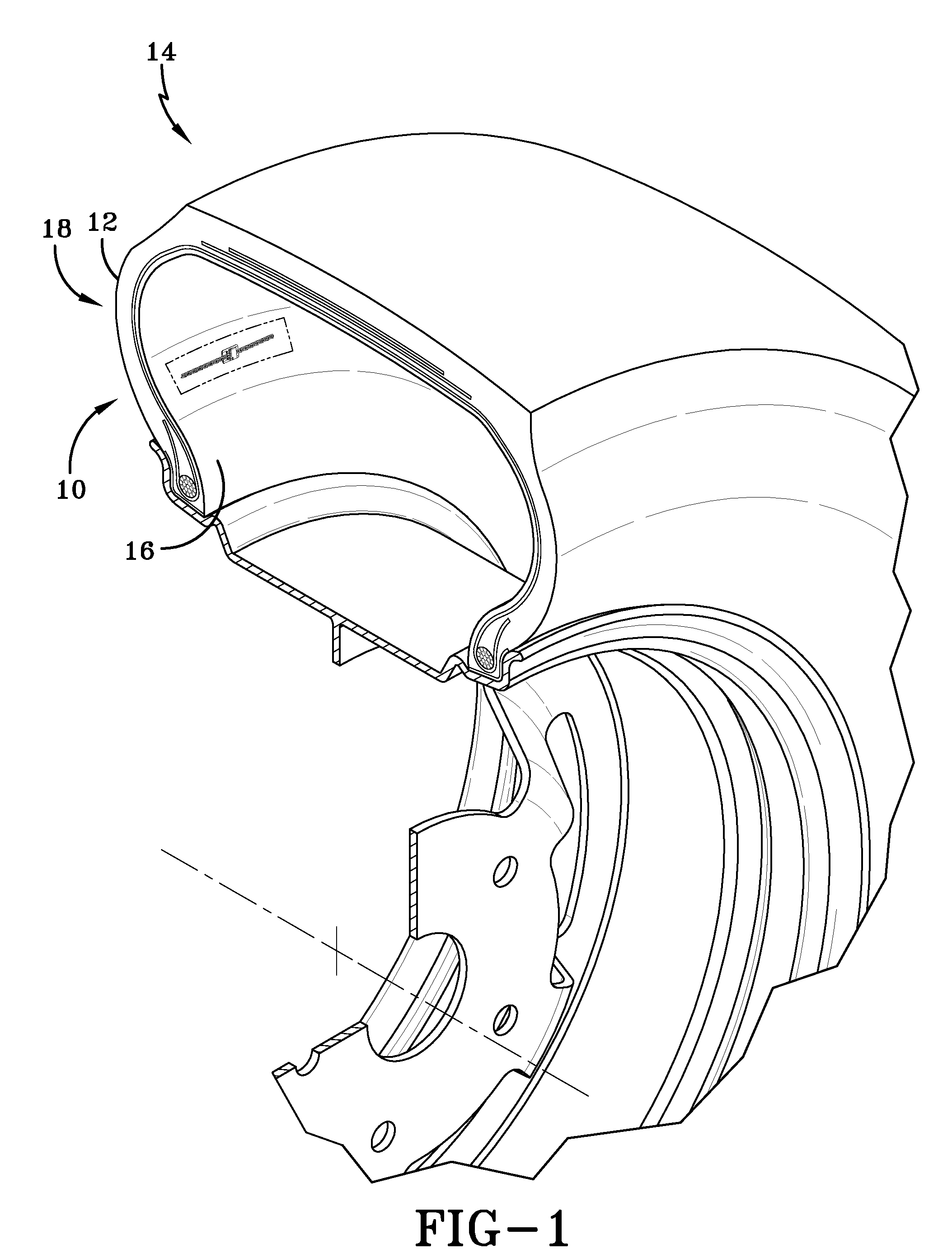

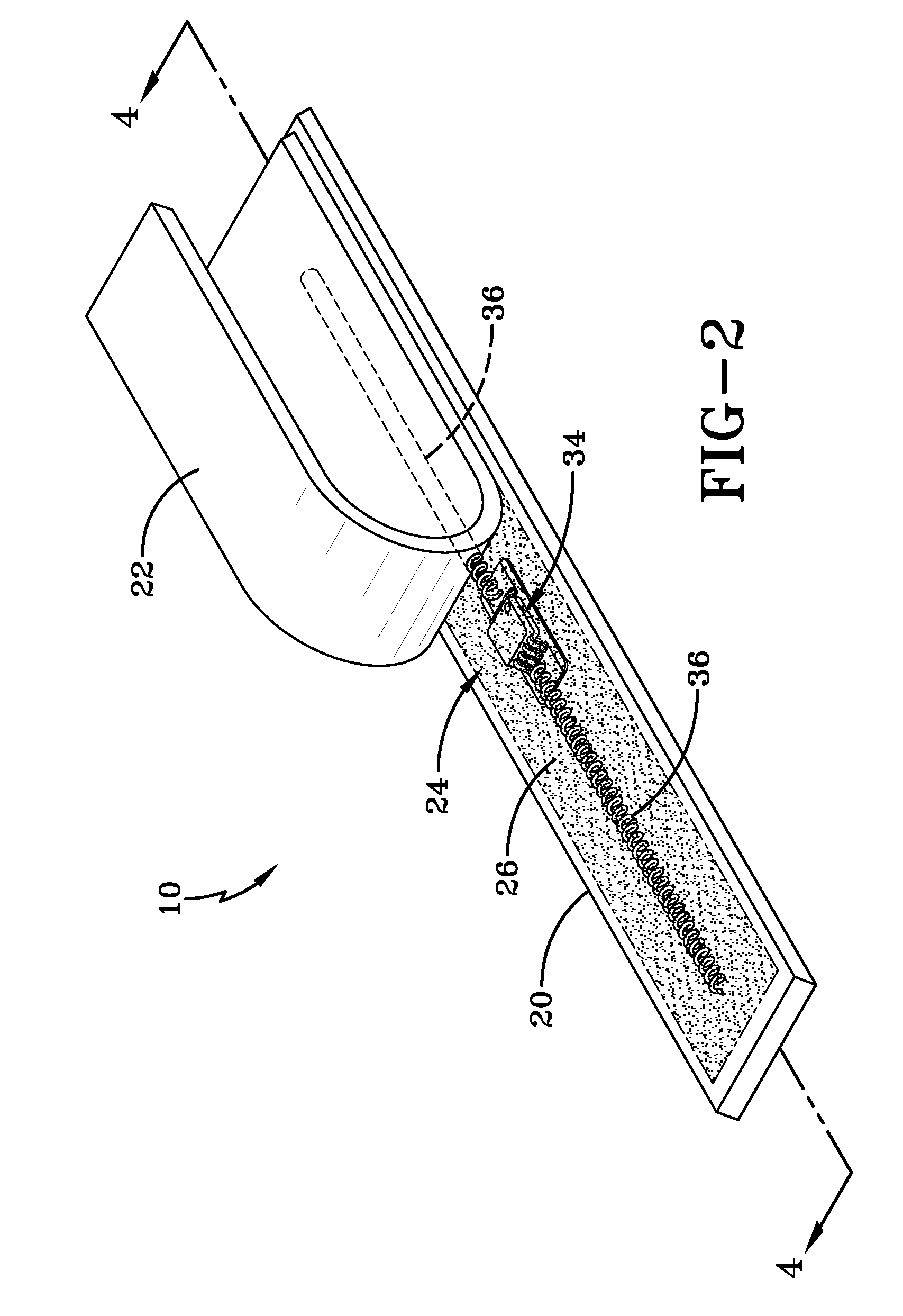

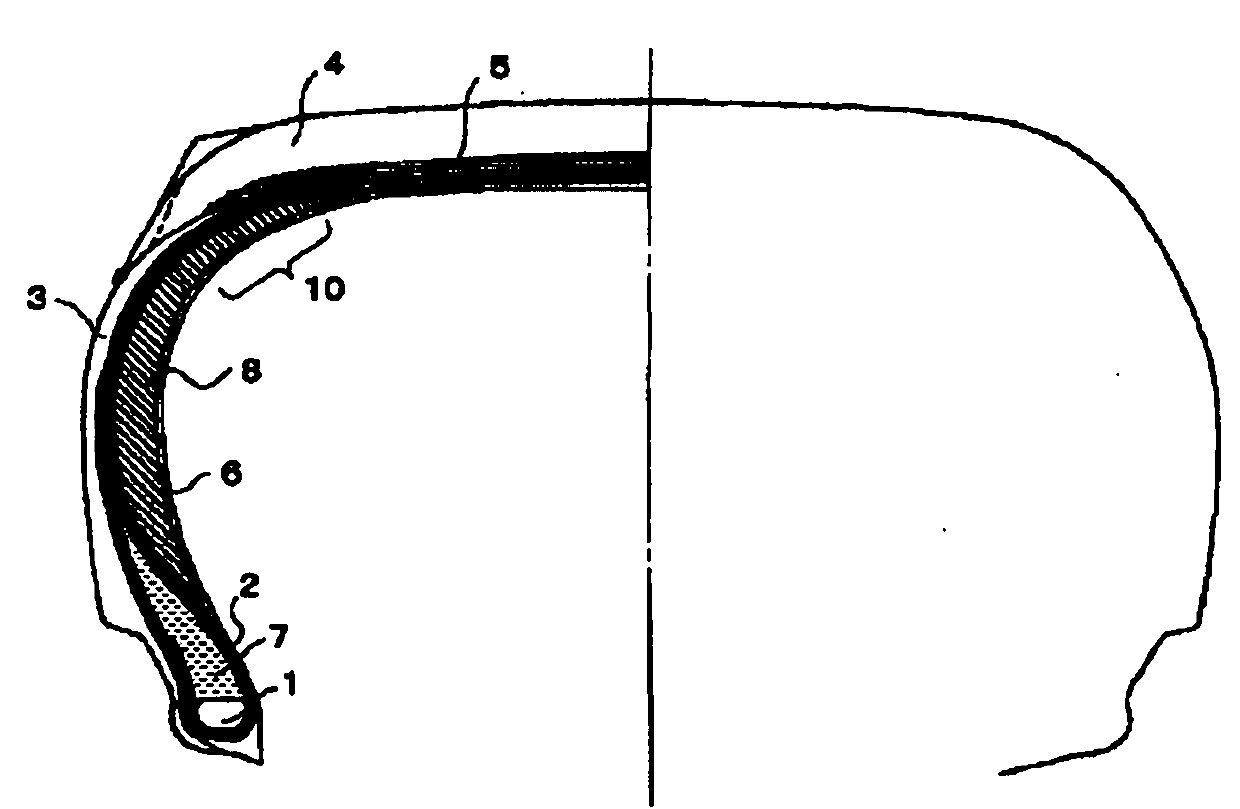

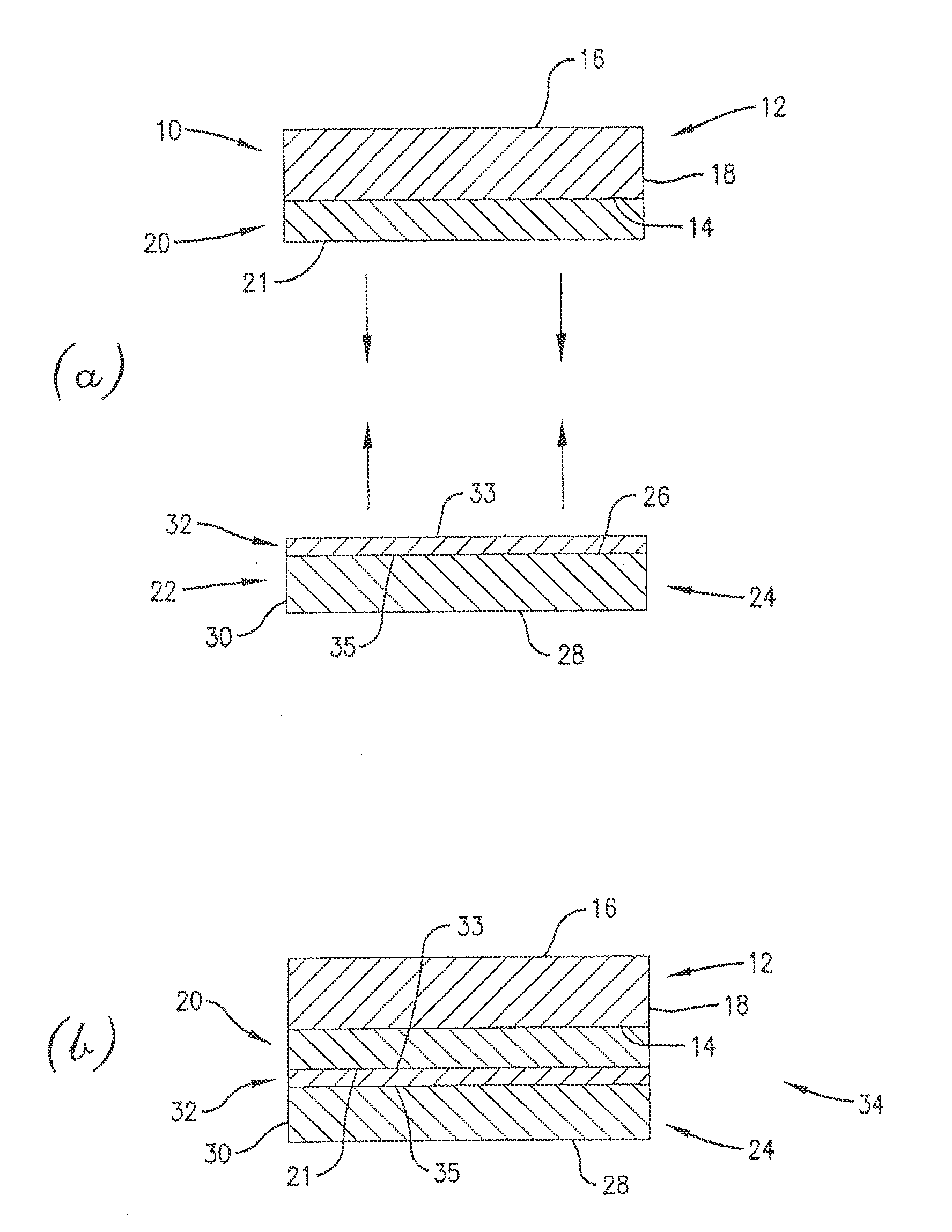

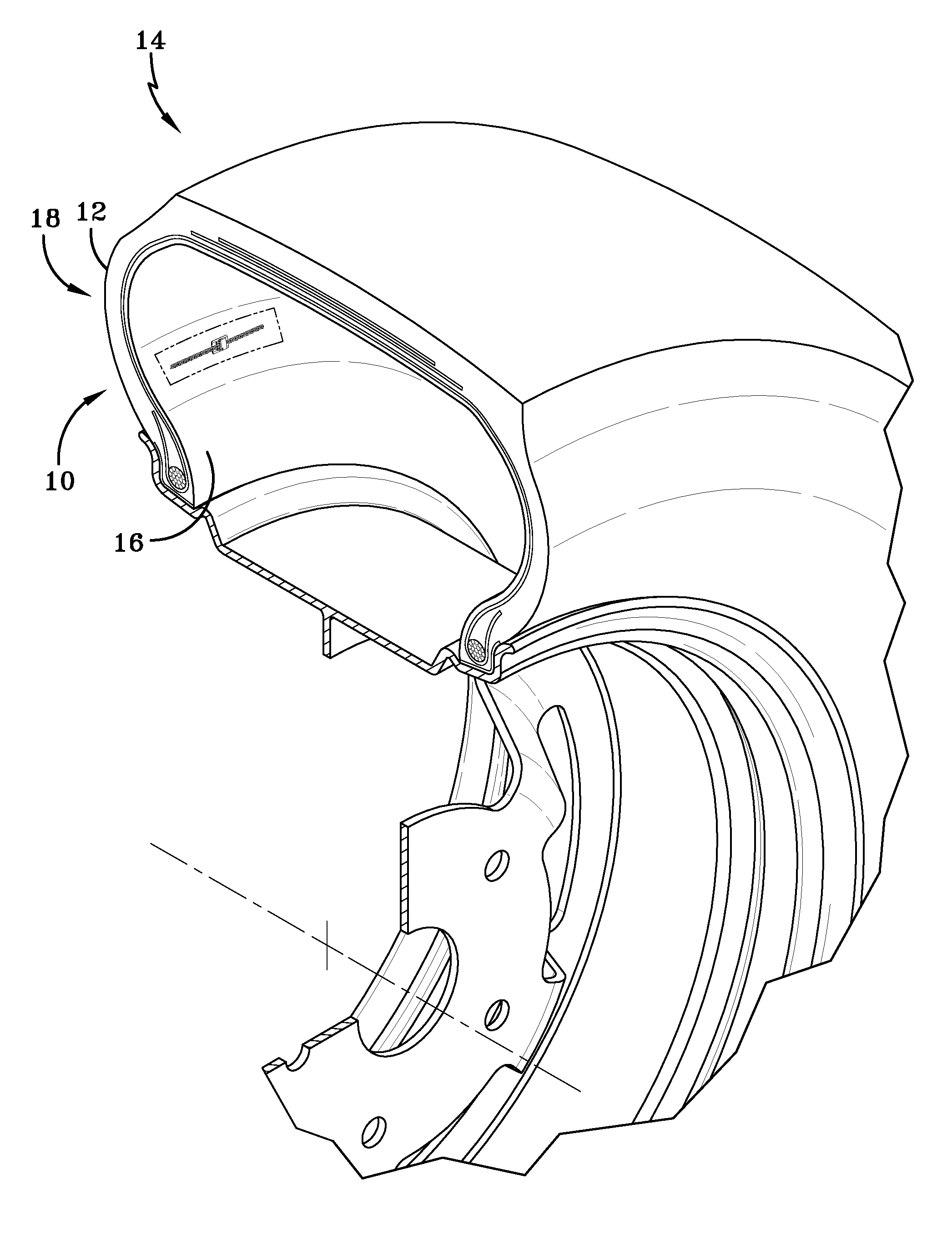

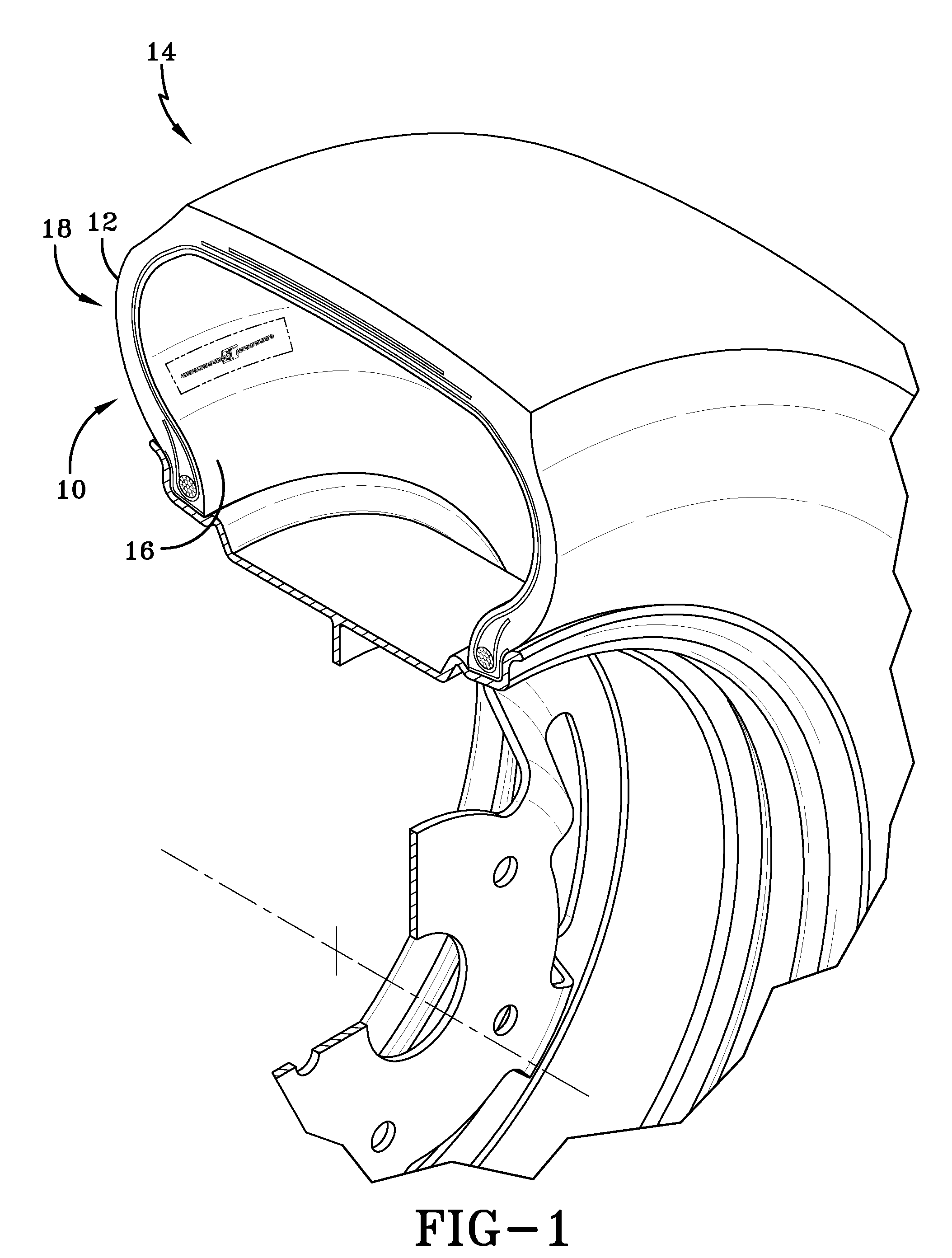

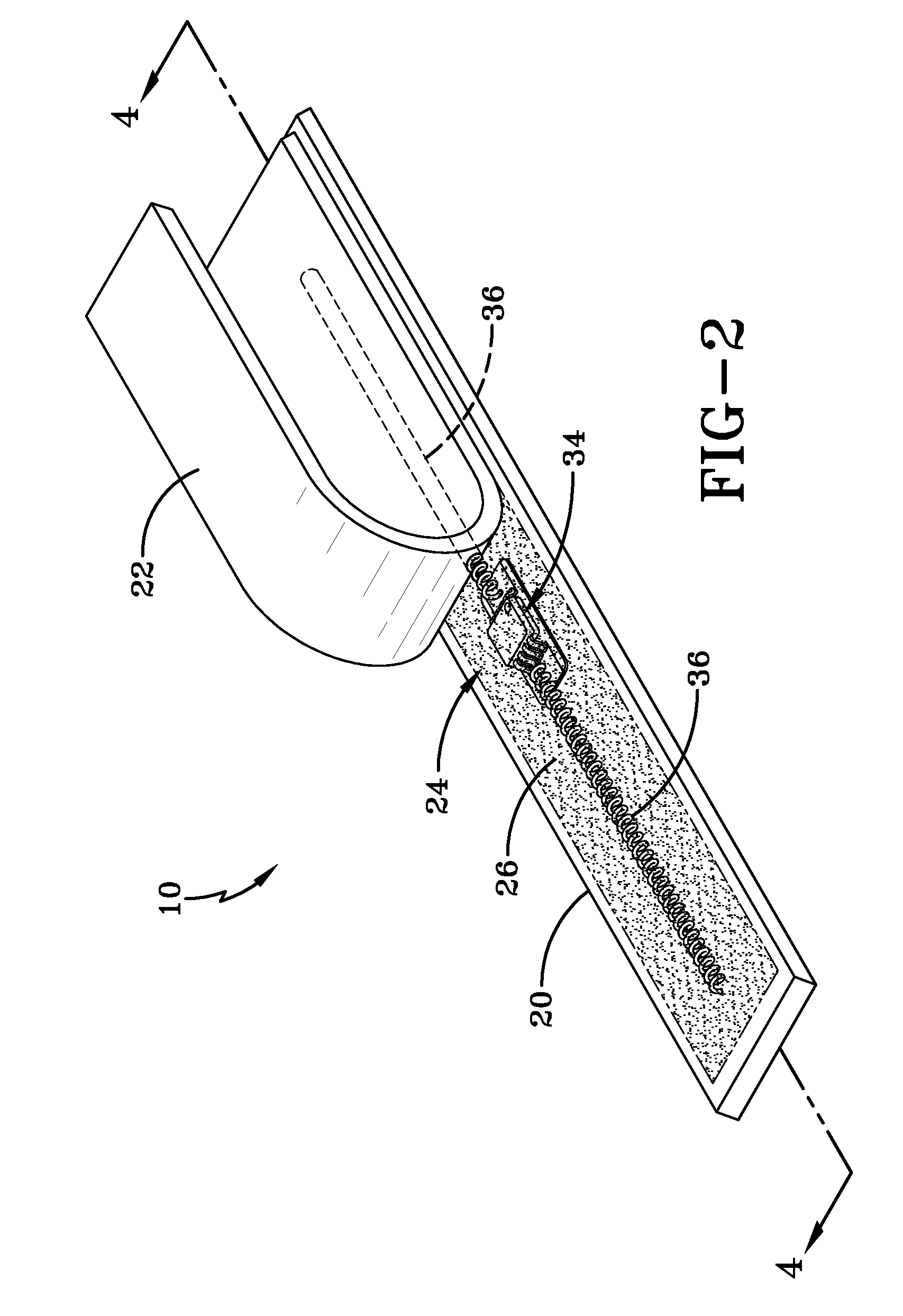

Environmentally resistant assembly containing an electronic device for use in a tire

An assembly for use in or on a tire. The assembly comprises an electronic device having a body and an adhesive coating on at least the body of the electronic device. The body is at least partially made of a plastic material or a fiber reinforced plastic (FRP). The adhesive coating comprises an imide-based adhesive. The adhesive coating may have a polymer bonding group comprising at least one of natural rubber, butyl rubber, a chlorinated elastomer, polybutadiene, synthetic polyisoprene, or styrene-butadiene rubber or a combination thereof. In one embodiment, the assembly further comprises a first elastomeric layer and a second elastomeric layer. The adhesive coating secures the body to the first and the second elastomeric layers. The first and second elastomeric layers may comprise a butyl-containing compound or natural rubber compound. In one embodiment, the electronic device is a radio frequency identification tag having the body and an antenna.

Owner:THE GOODYEAR TIRE & RUBBER CO

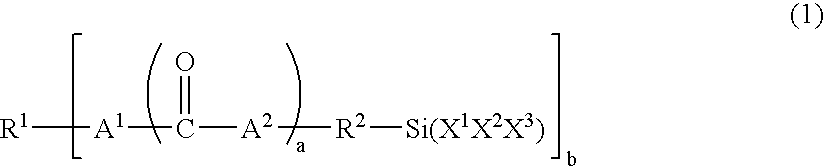

Method for producing modified conjugated diene polymer/copolymer, modified conjugated diene polymer/copolymer, and rubber composition and tier using the same

ActiveCN102026826AImprove rolling resistance performanceIncreased durabilitySpecial tyresWheelsPolymer sciencePolymer bonding

Provided are a method for producing a modified conjugated diene polymer / copolymer including a modified reaction step for causing an organosilane compound having a characteristic group for producing a silanol group by hydrolysis and, in the vicinity of the characteristic group, (i) a functional group for combining the organosilane compound with the conjugated dione polymer / copolymer by performing an addition or substitutive reaction on an active site and, after the reaction, prompting a reaction between the silanol group and a reinforcing filler or (ii) a functional group for prompting the reaction between the silanol group and the reinforcing filler to react with the active site of a conjugated dione polymer / copolymer having the active site, and a hydrosis step performed after completing the modified reaction step; a modified conjugated diene polymer / copolymer having, at an end of a molecular of a conjugated diene polymer / copolymer, a silanol group and, in the vicinity of the silanol group, a functional group for prompting a reaction between the silanolgroup and a reinforcing filler; and a rubber composition having the modified conjugated polymer / copolymer and carbon black of a specific property; and a tier using the rubber composition.

Owner:BRIDGESTONE CORP

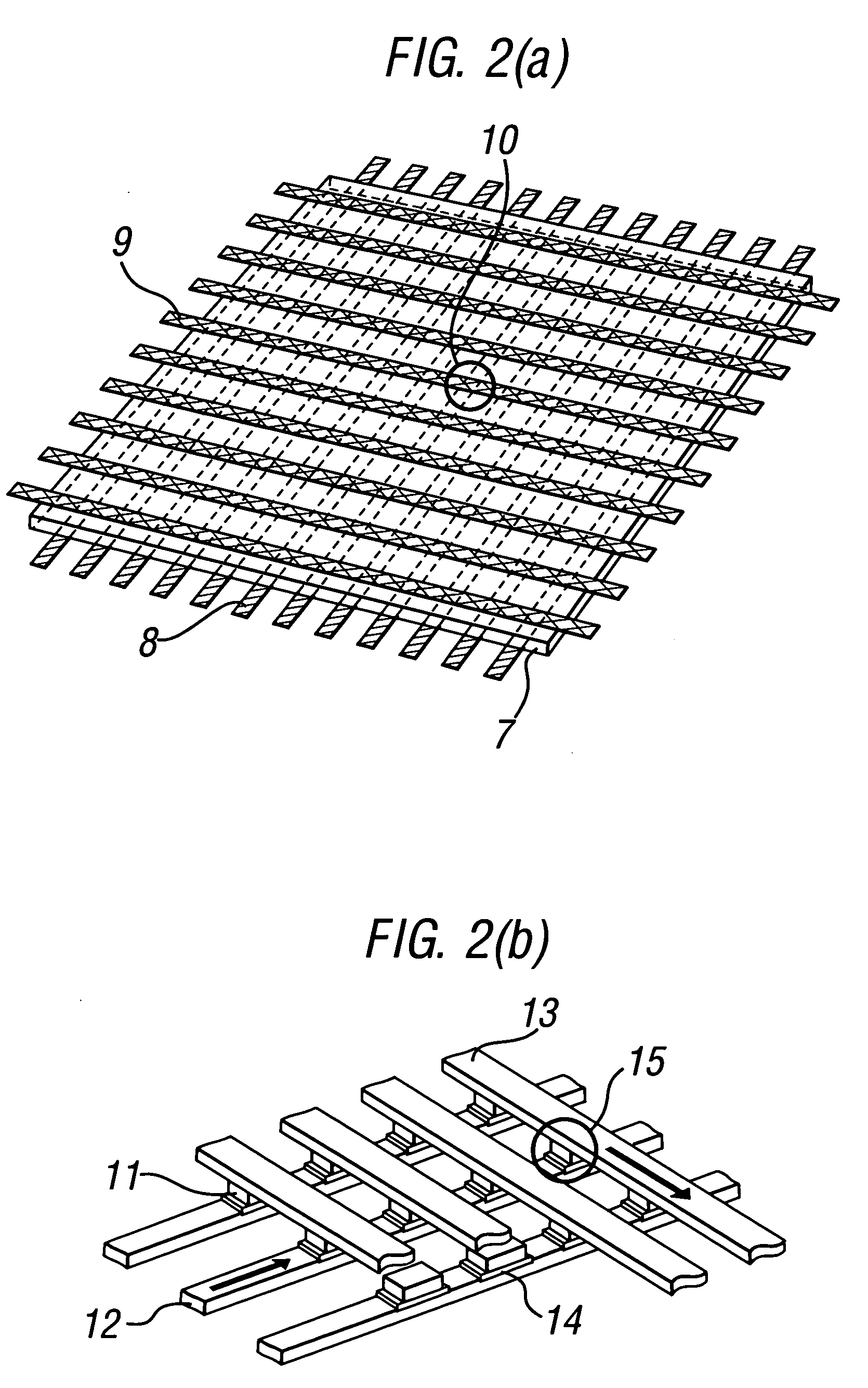

Inkjet printer and printer head

InactiveUS20030197758A1Reduce surface tensionReduce moisturePrintingColloidal silicaVena contracta diameter

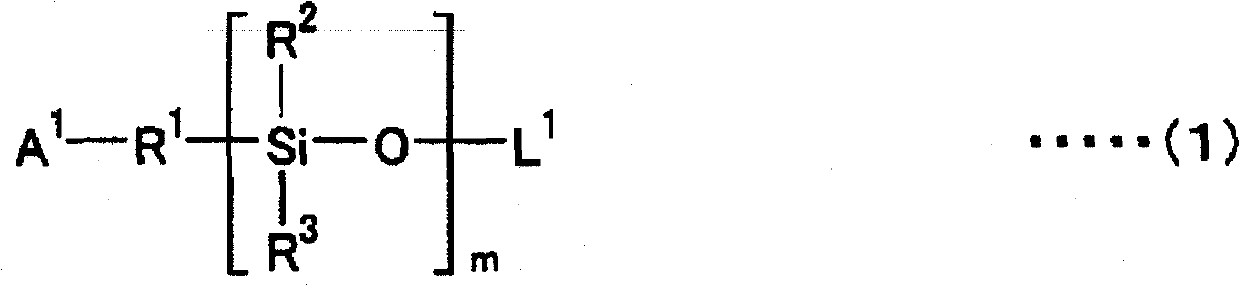

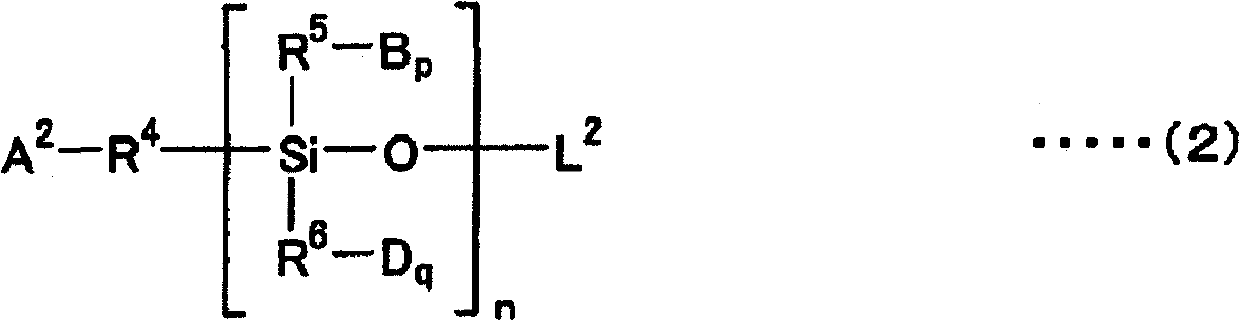

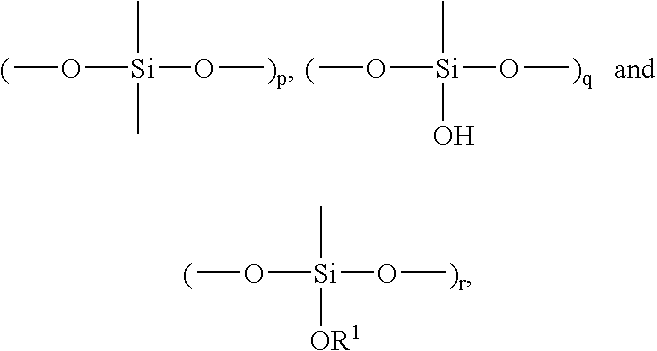

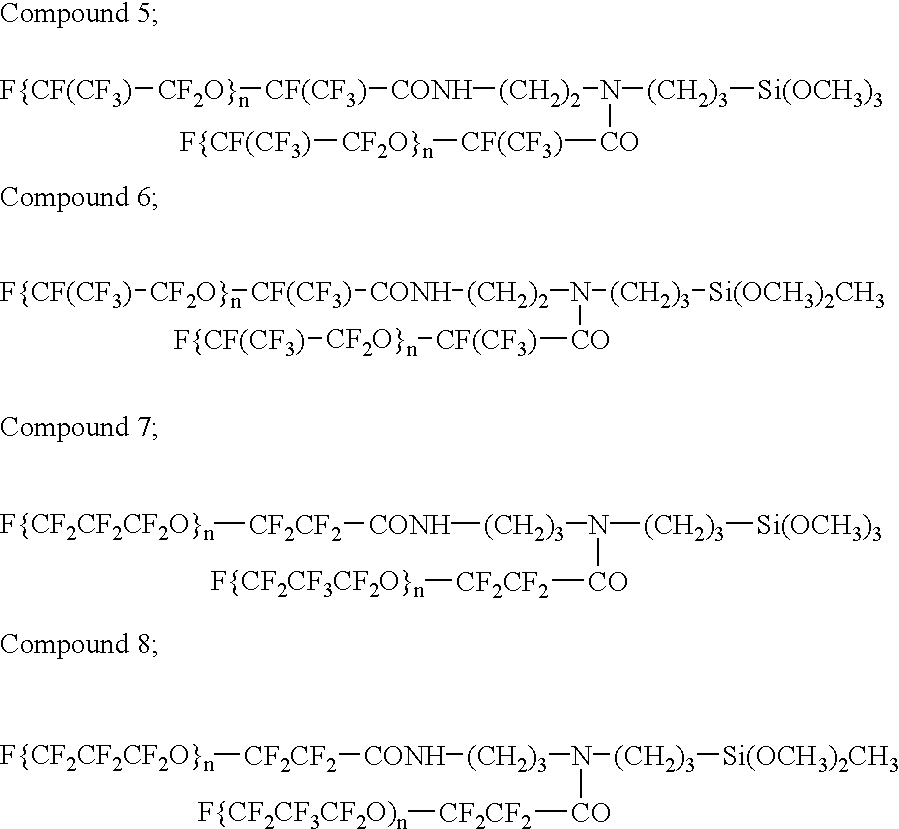

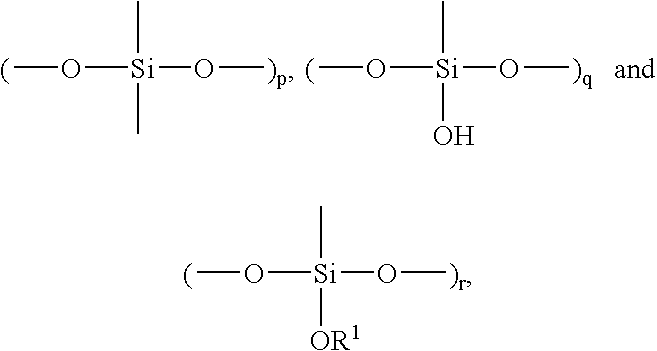

An inkjet head having an ink flow path communicated with an ink chamber to an inkjet nozzle and having an orifice plate to which the nozzle is formed. An ink-philic layer is formed on the surface of the ink flow path, and an ink repellent layer is formed on the surface of the orifice plate where the nozzle is formed. The ink-philic layer is made of amorphous silica or inorganic polymer of colloidal silica bonded with a polymer of (SiOR), and the ink repellent layer contains a compound having perfluoropolyether chain and alkoxysilane residue as a terminal.

Owner:RICOH KK +2

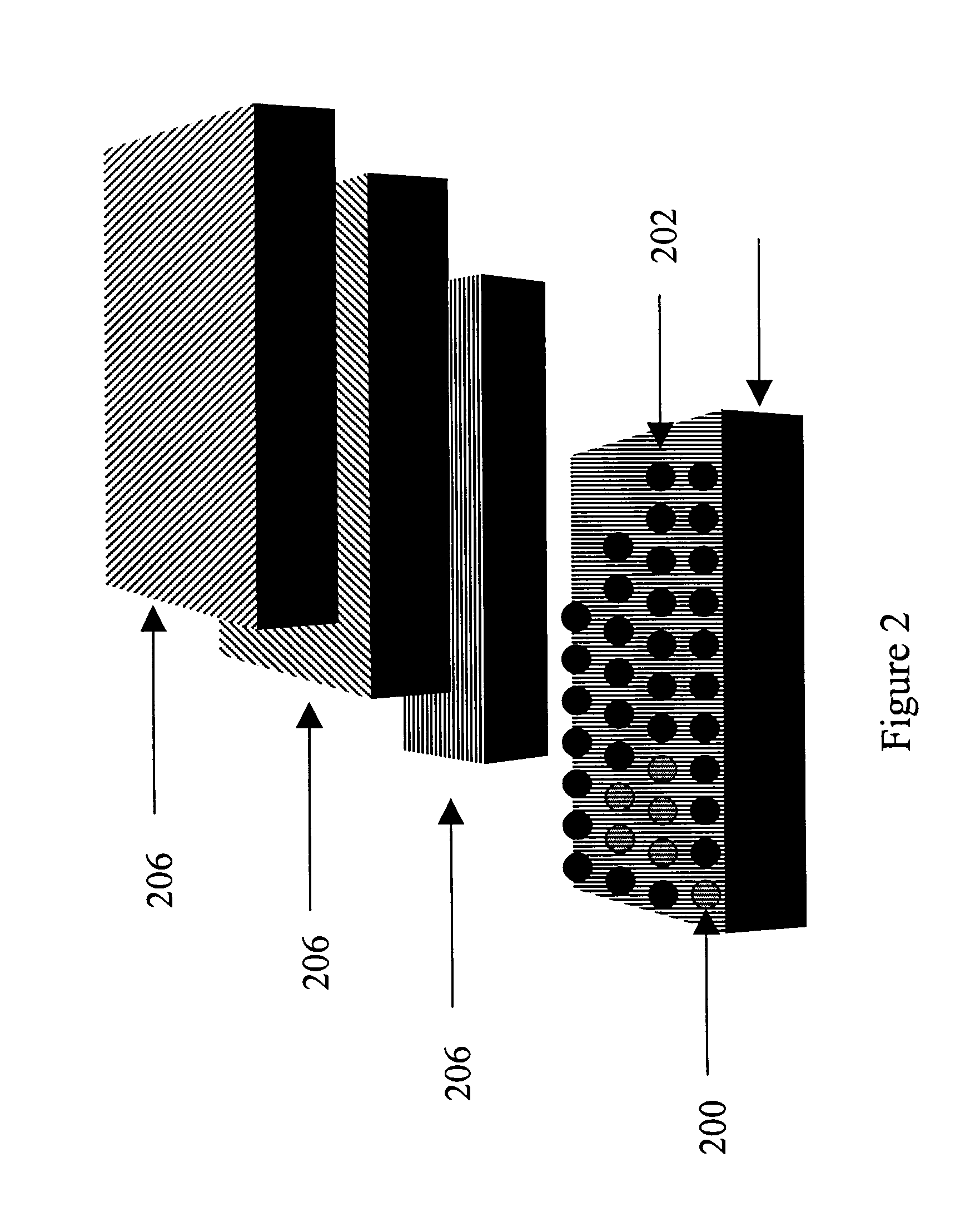

Methods and materials for the reduction and control of moisture and oxygen in OLED devices

InactiveUS20050186123A1Extend your lifeImprove efficiencySamplingOther chemical processesChange colorPolymer bonding

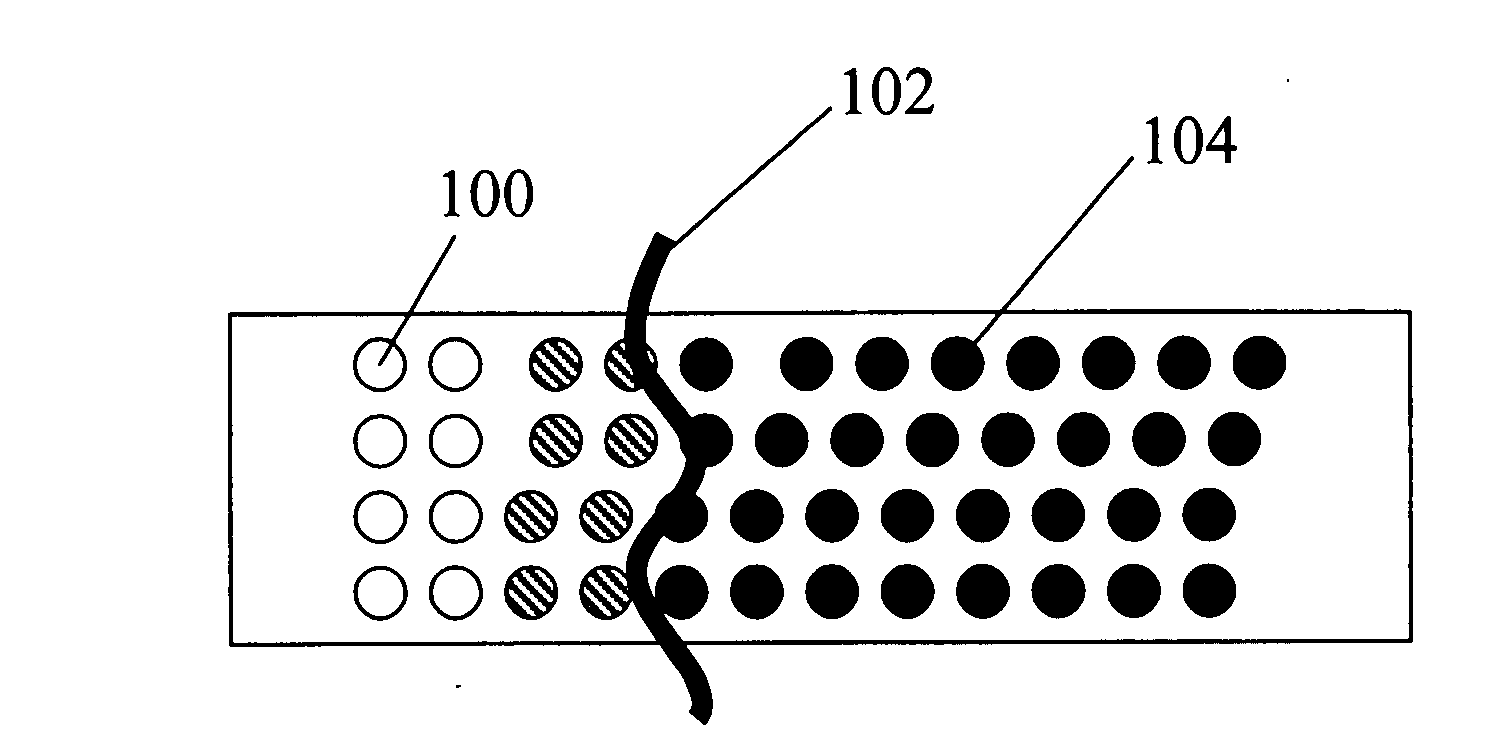

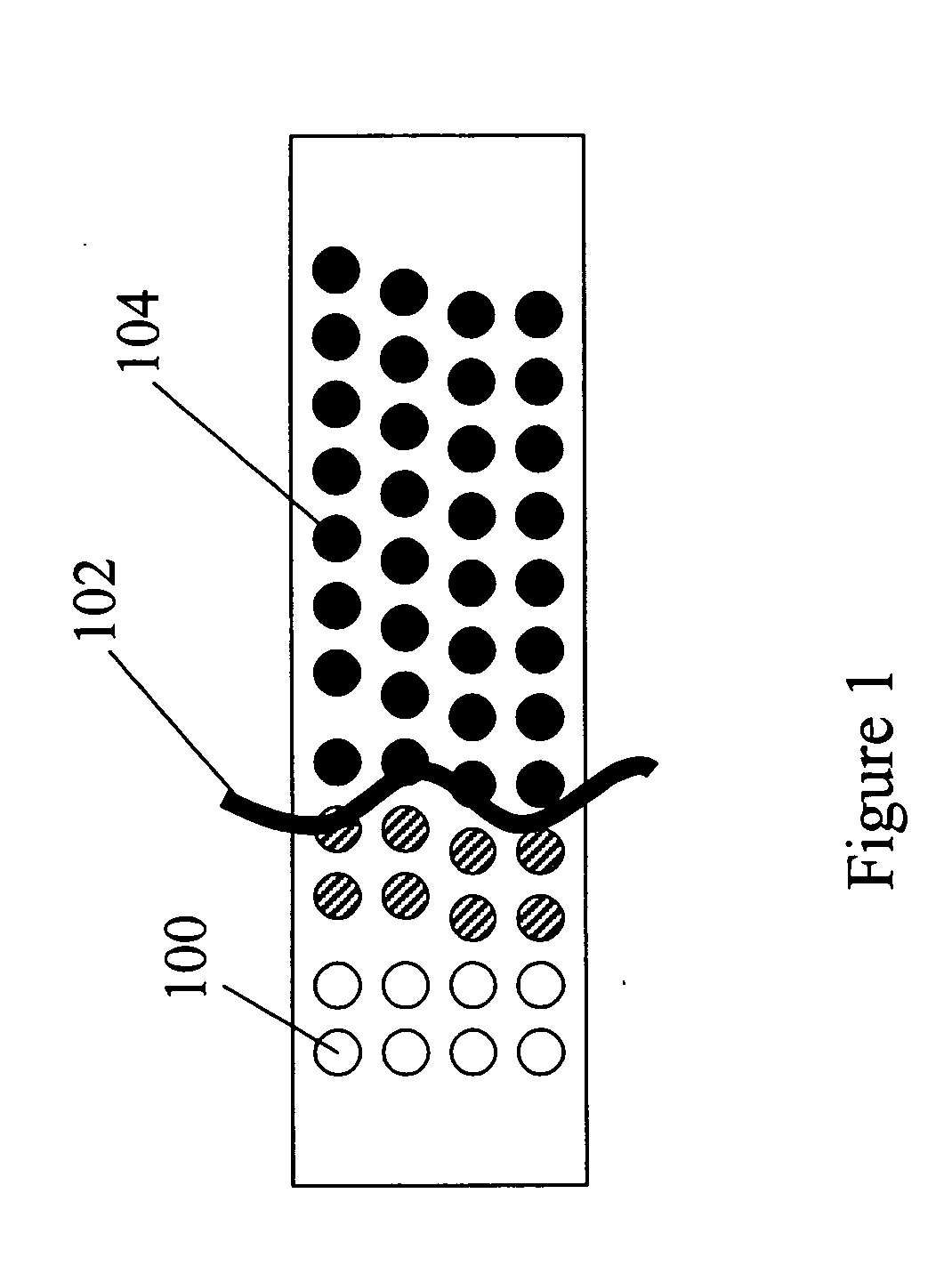

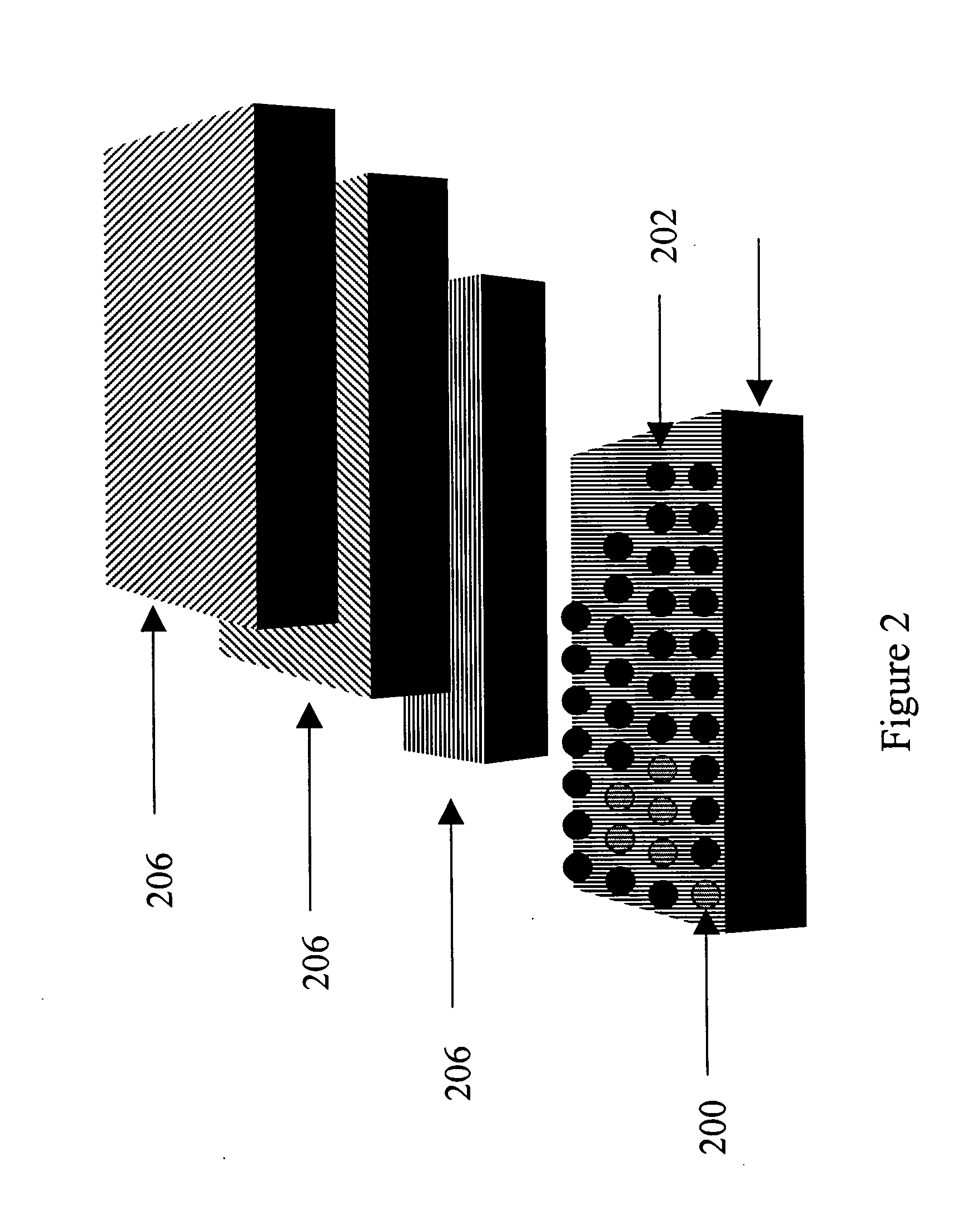

Novel uses and methods of use for inorganic and macroreticulate polymer bonding to metals to control moisture and oxygen in OLED, and other like devices, are provided. Materials having color change capacity are also provided for the removal of moisture from an OLED, where the material changes color upon reaching its capacity and thereby signals the user that the OLED is no longer protected from moisture damage.

Owner:MATHESON TRI GAS

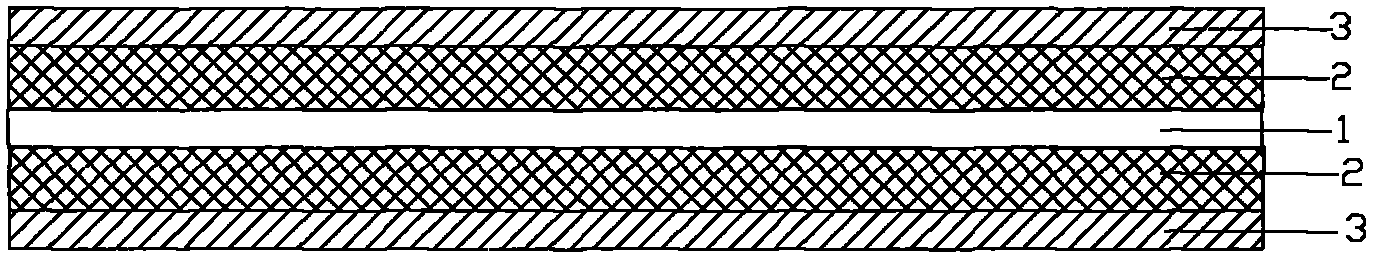

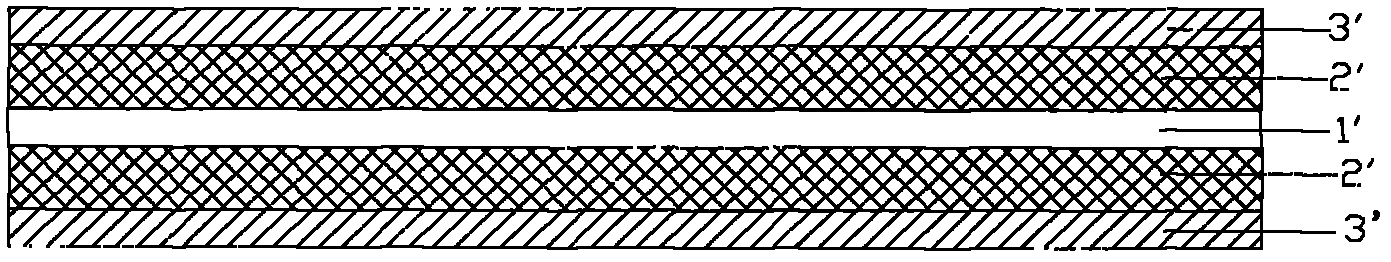

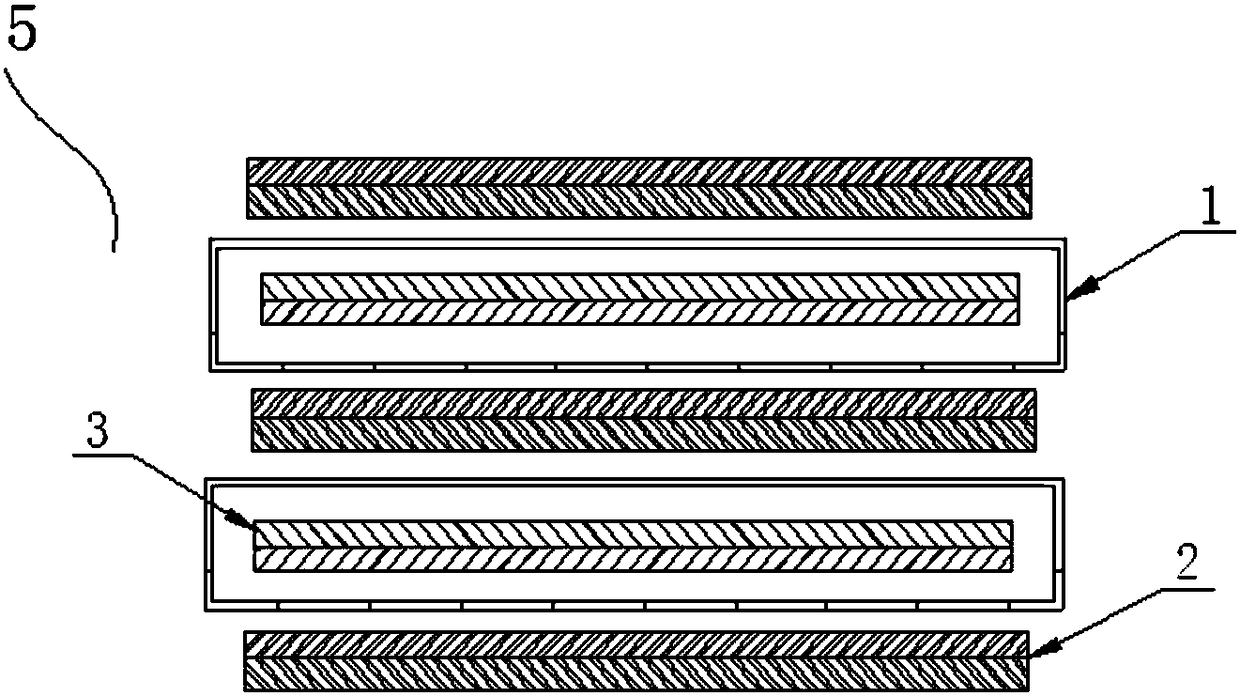

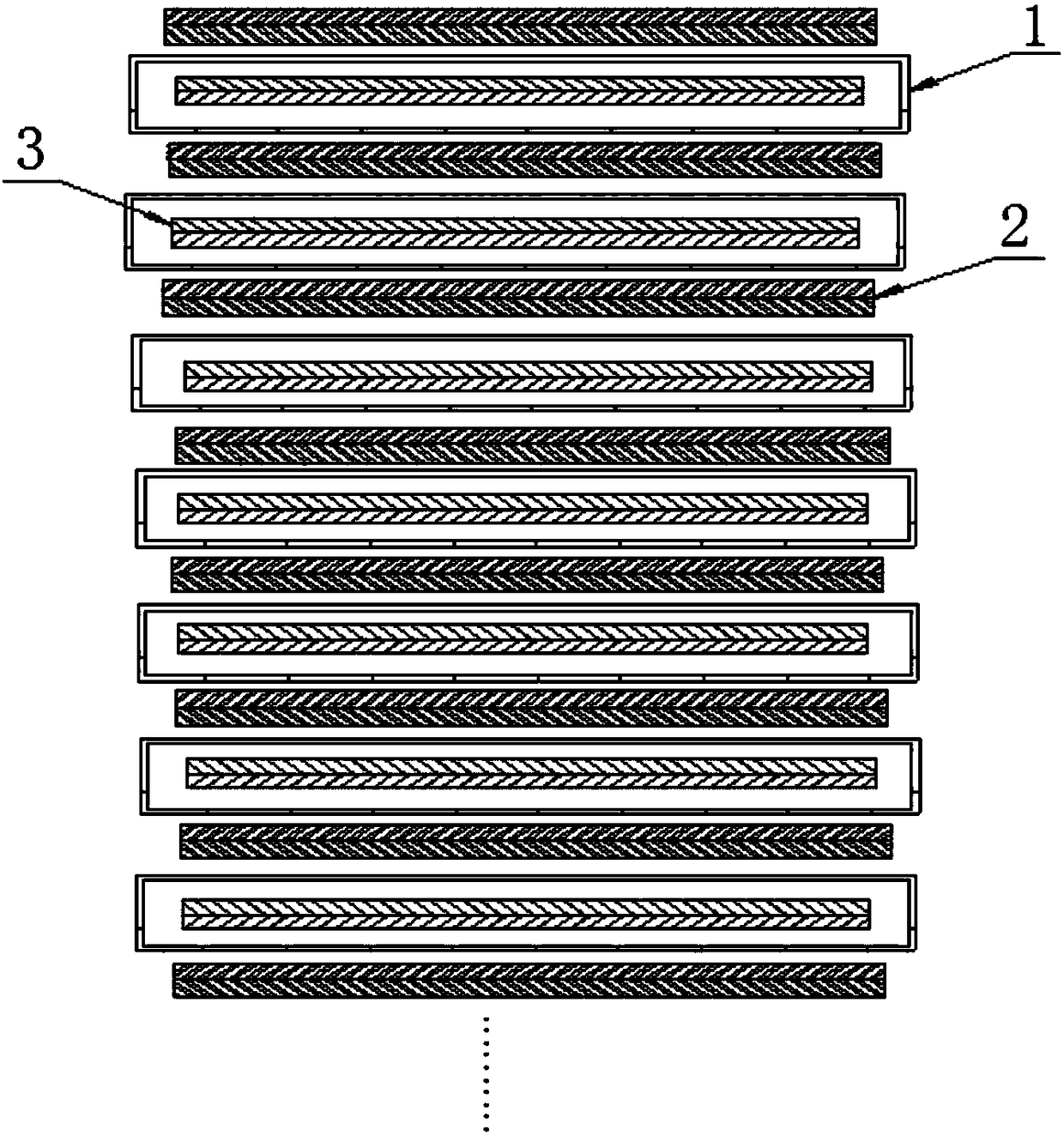

Lithium ion battery

InactiveCN102569881AIncrease surface tensionGood adhesionSecondary cellsNon-aqueous electrolyte accumulator electrodesSurface layerPolymer bonding

The invention relates to the technical field of lithium ion batteries, in particular to a lithium ion battery with good safety performance, overcharge resistance and mechanical properties. The lithium ion battery comprises a positive electrode plate, a negative electrode plate, a diaphragm between the positive electrode plate and the negative electrode plate, and an electrolyte, wherein the diaphragm comprises a porous film base material and a ceramic material layer which is coated on the surface of the porous film base material; the positive electrode plate comprises a positive current collector, a positive active material layer coated on the surface of the positive current collector, and a positive polymer bonding layer coated on the positive active material layer and positioned on the surface layer; and the negative electrode plate comprises a negative current collector, a negative active material layer coated on the surface of the negative current collector, and a negative polymer bonding layer coated on the negative active material layer and positioned on the surface layer. Compared with the prior art, the lithium ion battery has good safety performance, overcharge resistance and mechanical properties.

Owner:NINGDE AMPEREX TECH

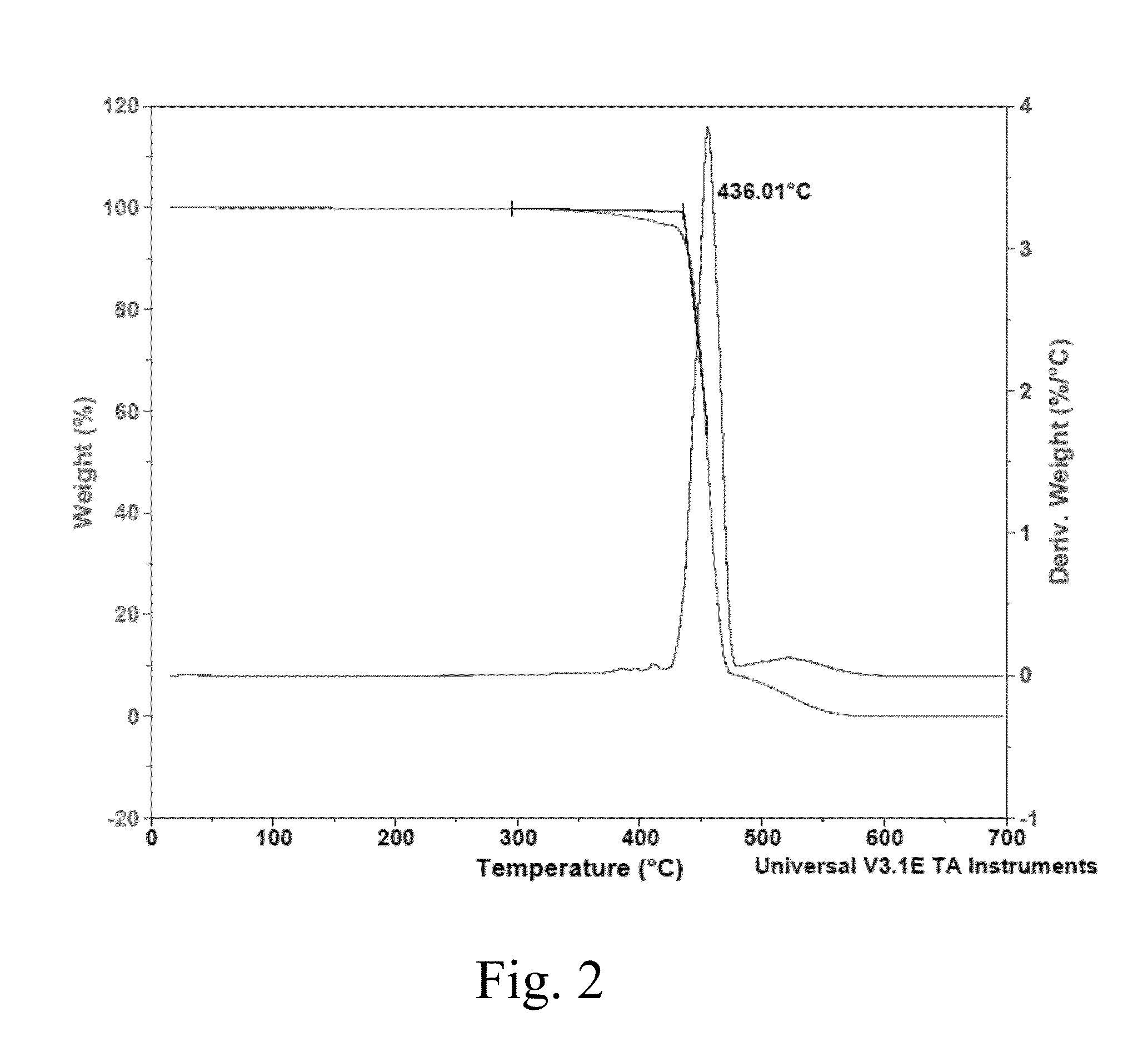

Cyclic olefin polymer compositions and polysiloxane release layers for use in temporary wafer bonding processes

ActiveUS20150194331A1Semiconductor/solid-state device detailsSynthetic resin layered productsCyclo olefin polymerWafer bonding

The invention broadly relates to cyclic olefin polymer bonding compositions and release compositions, to be used independently or together, that enable thin wafer handling during microelectronics manufacturing, especially during a full-wafer mechanical debonding process. The release compositions comprise compositions made from siloxane polymers and copolymers blended in a polar solvent, and that are stable at room temperature for longer than one month. The cyclic olefin polymer bonding compositions provide high thermal stability, can be bonded to fully-treated carrier wafers, can be mechanically or laser debonded after high-temperature heat treatment, and are easily removed with an industrially-acceptable solvent. Wafers bonded according to the invention demonstrate lower overall post-grind stack TTV compared to other commercial bonding materials and can survive 200° C. PECVD processing.

Owner:BREWER SCI

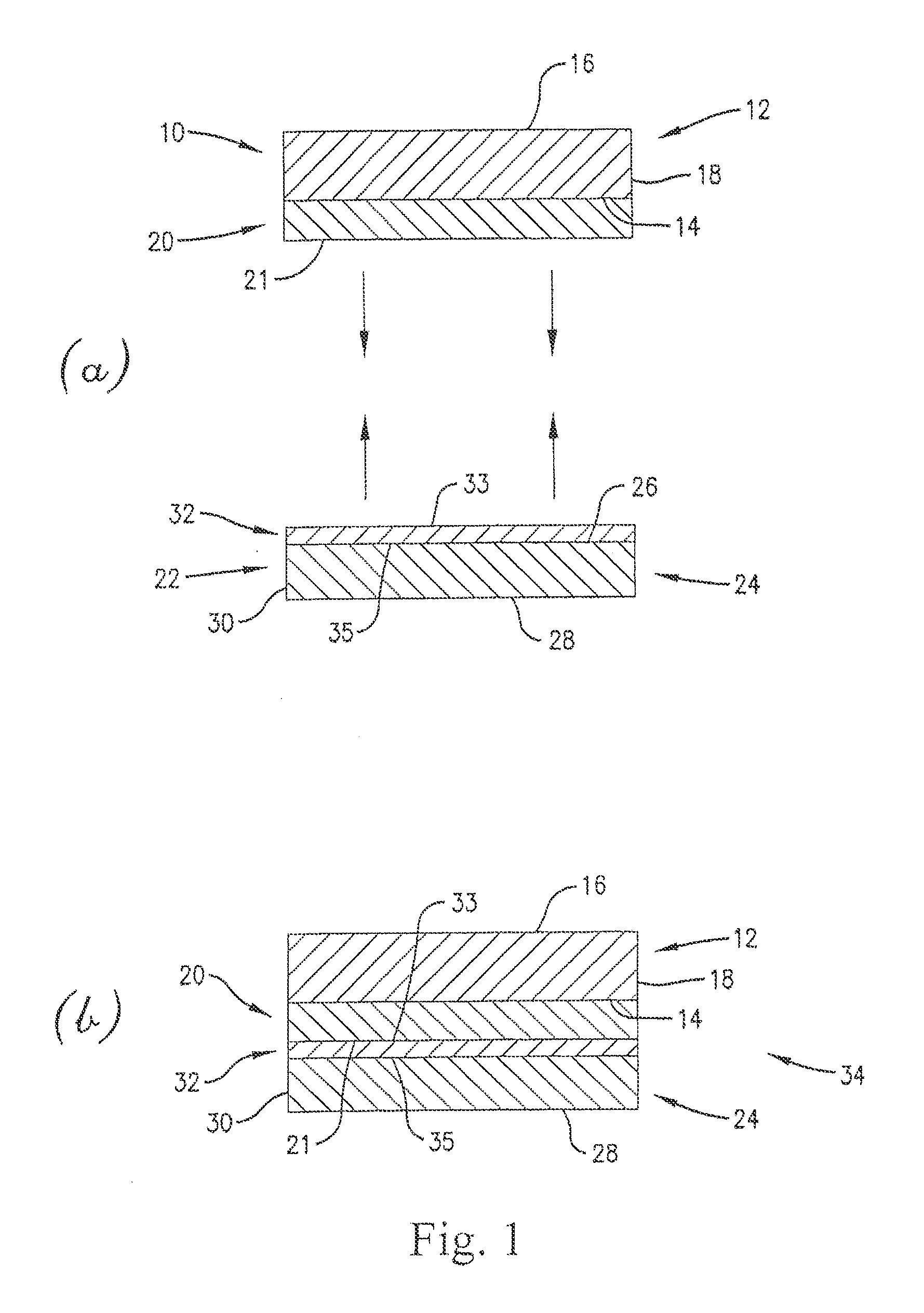

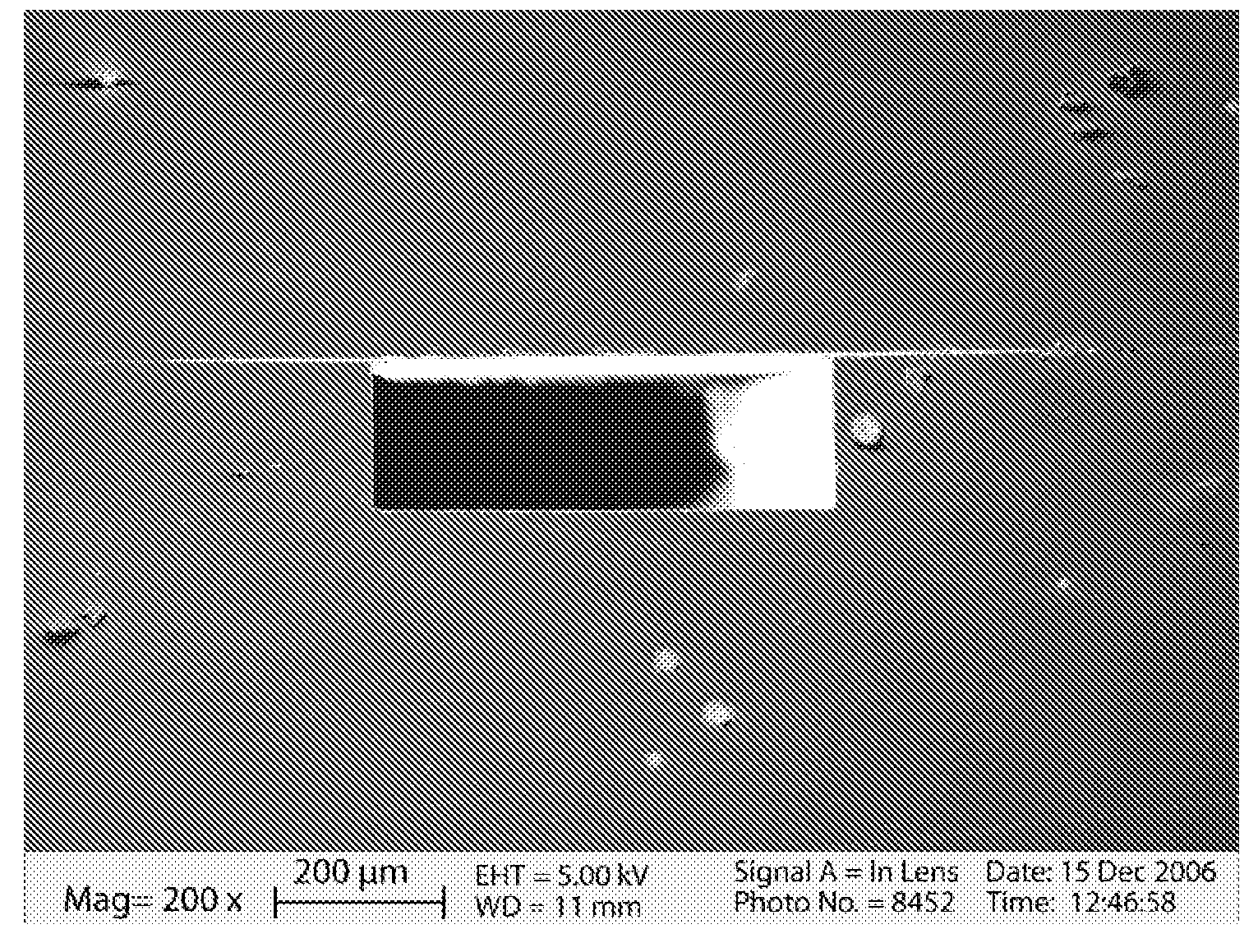

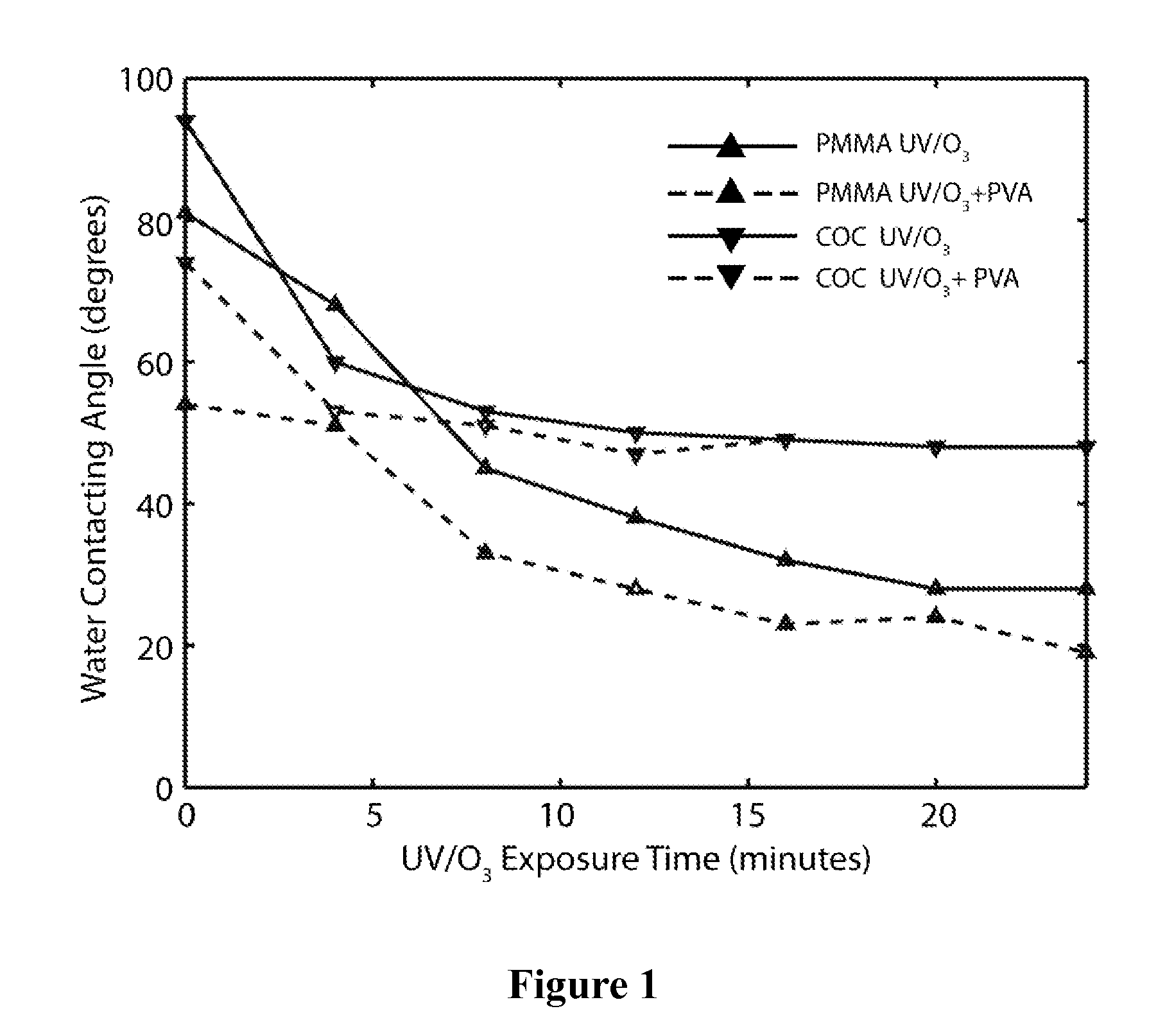

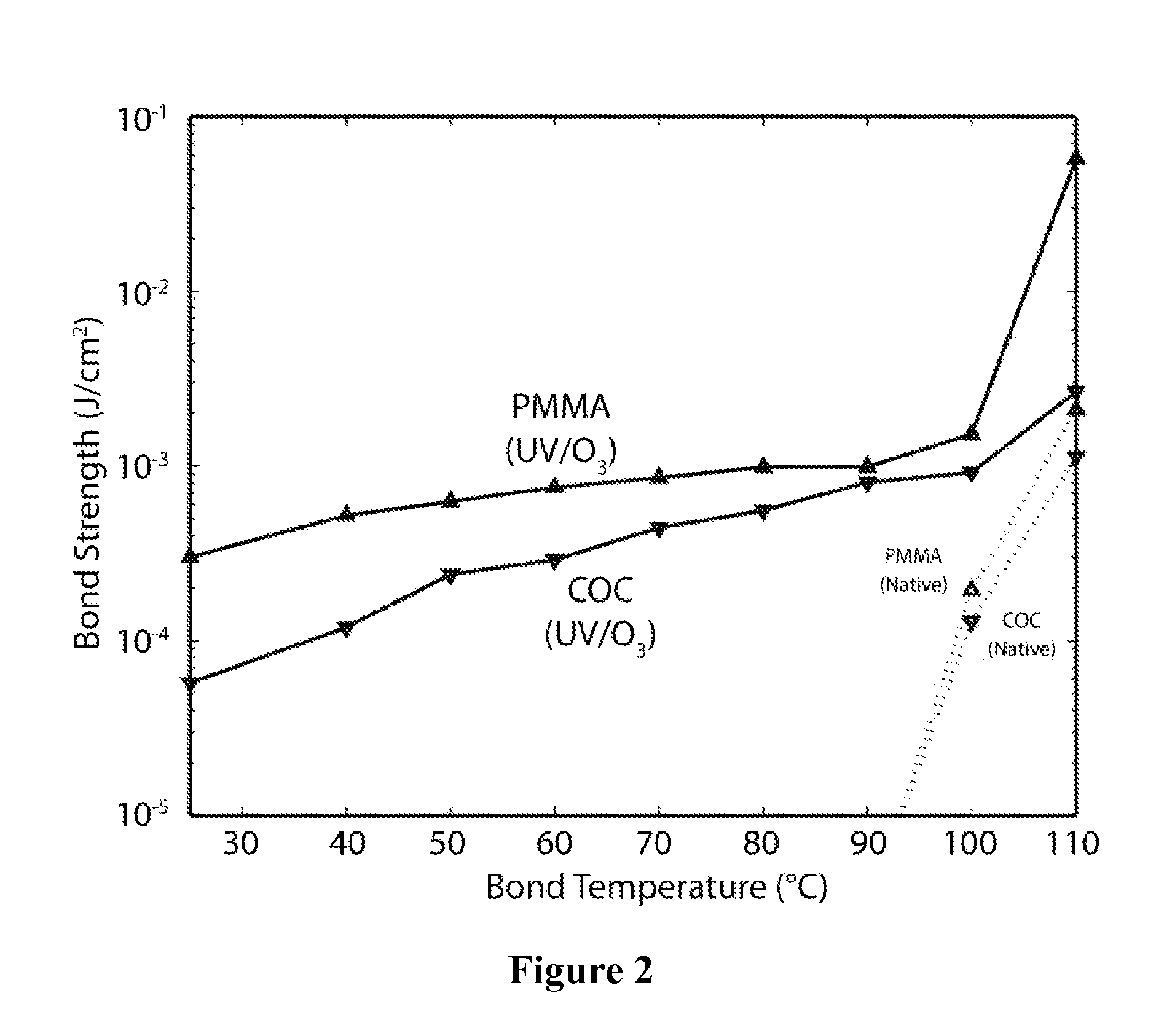

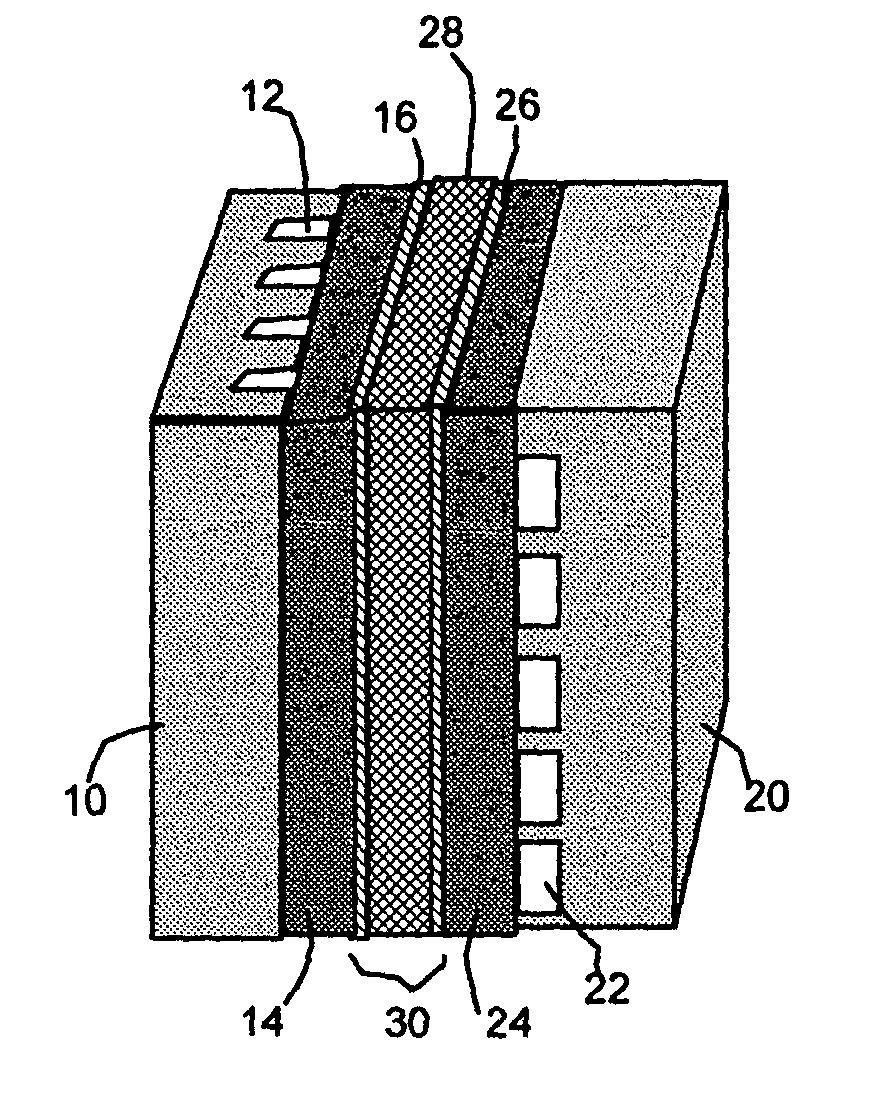

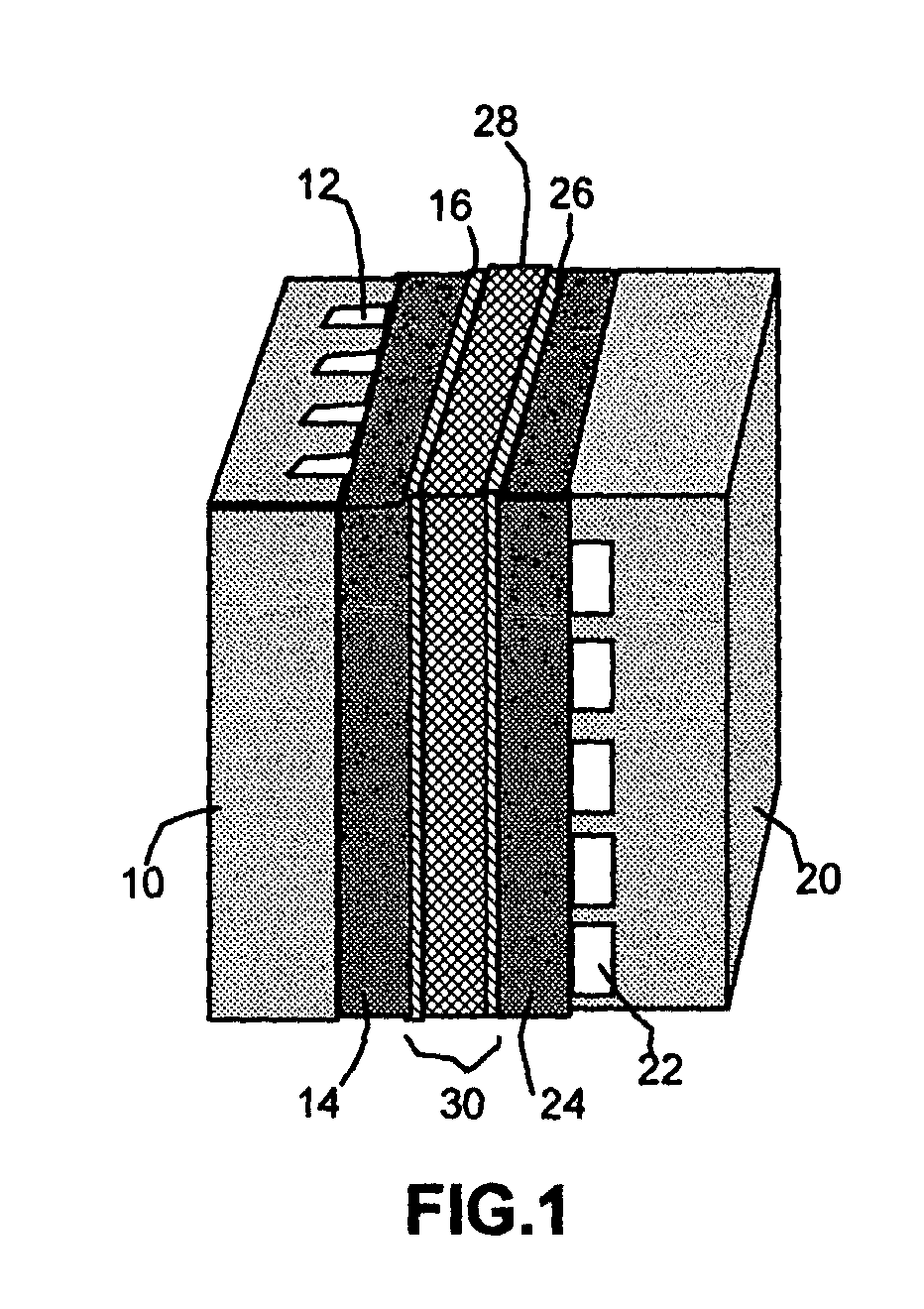

Low Temperature Polymer Bonding Using UV/Ozone Surface Treatment

InactiveUS20090227755A1High bonding strengthLow costPretreated surfacesGroup 3/13 element organic compoundsThermoplasticVitrification

The present invention relates to a method for bonding two surfaces to one another. The invention particularly pertains to the use of such method in which one of the surfaces is a polymeric plastic (and more preferably a polymeric thermoplastic (especially poly-(methyl methacrylate) (“PMMA”) or cyclic olefin copolymer (“COC”)). More particularly, the invention relates to treating at least one of the contacting surfaces with UV in the presence of oxygen to thereby generate ozone (O3) and atomic oxygen under conditions of temperature below that of the glass transition temperature of the polymeric plastic. The UV / O3-mediated bonding results in high bond strength and zero-deformation method. This bonding method can be applied to micro / nano-scale polymer devices, and particularly to microfluidic devices, for a low cost, high throughput, high yield advantage.

Owner:UNIV OF MARYLAND

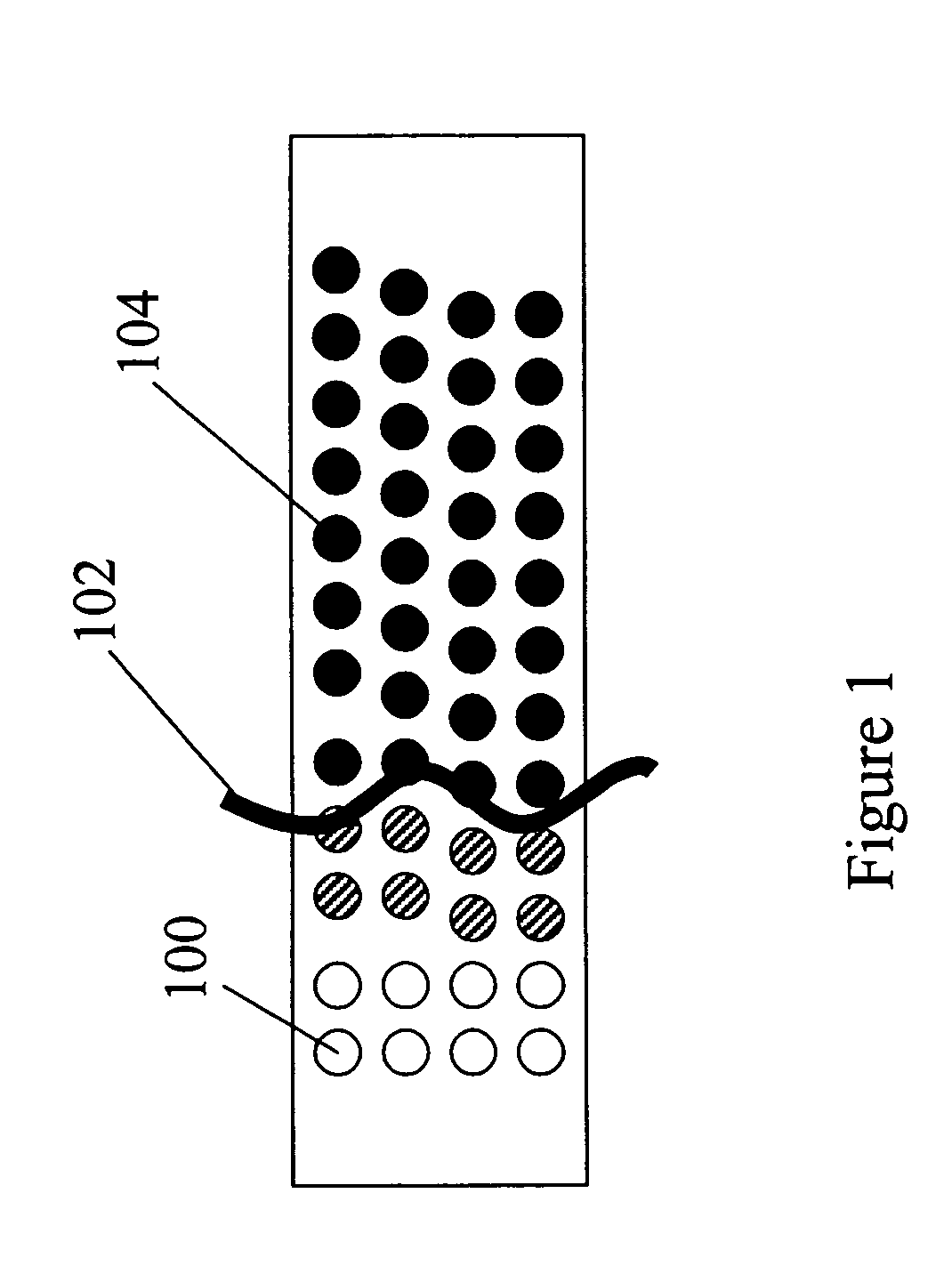

Hydrophilic polymeric coatings for medical articles

ActiveUS7691476B2Extension of timeKeep for a long timeSynthetic resin layered productsPharmaceutical delivery mechanismEthylene oxidePolymer bonding

The invention provides a durable, lubricious coating for a medical article that can be prepared from a first polymer that is synthetic, soluble in a polar liquid, and having first reactive groups, and a second polymer that is synthetic, hydrophilic, and that includes second reactive groups. The first reactive groups and a portion of the second reactive groups react to bond the first polymer to the second polymer. A portion of the second reactive groups remains unbonded which, upon neutralization, provide lubricious properties to the coating. In some aspects the coating is formed using a crosslinking agent having latent reactive groups. The coatings provide particularly long dry out times and are very useful for catheterization processes. In addition, the coatings can be subject to sterilization with ethylene oxide and retain very good durable and lubricious properties.

Owner:SURMODICS INC

Hydrophilic polymeric coatings for medical articles

ActiveUS20060276894A1Improve the lubrication effectImprove adhesionSynthetic resin layered productsPharmaceutical containersEthylene oxidePolymer bonding

The invention provides a durable, lubricious coating for a medical article that can be prepared from a first polymer that is synthetic, soluble in a polar liquid, and having first reactive groups, and a second polymer that is synthetic, hydrophilic, and that includes second reactive groups. The first reactive groups and a portion of the second reactive groups react to bond the first polymer to the second polymer. A portion of the second reactive groups remains unbonded which, upon neutralization, provide lubricious properties to the coating. In some aspects the coating is formed using a crosslinking agent having latent reactive groups. The coatings provide particularly long dry out times and are very useful for catheterization processes. In addition, the coatings can be subject to sterilization with ethylene oxide and retain very good durable and lubricious properties.

Owner:SURMODICS INC

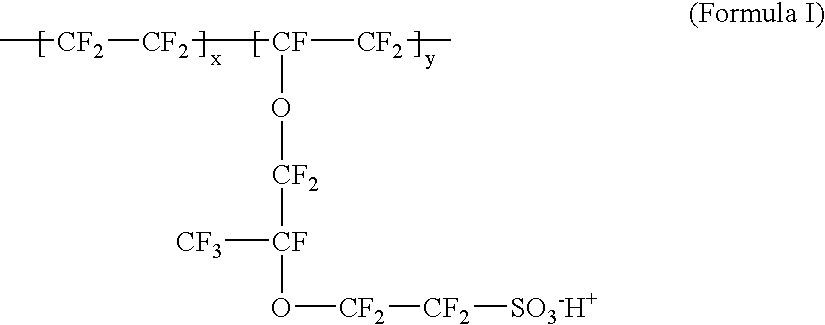

Self-moisturizing proton exchange membrane, membrane-electrode assembly and fuel cell

A self-moisturizing polymer electrolyte membrane (PEM) composition, a membrane-electrode assembly, and a fuel cell. The PEM composition comprises (a) a proton-conducting polymer containing a detachable hydrogen ion and a counter-ion bonded to the polymer; and (b) a deliquescent material for keeping the membrane wet and for detaching the hydrogen ion to facilitate proton transport in the membrane. Alternatively, the deliquescent material may be strategically located on the gas flow field channels, gas-diffusion electrode or backing layers, and / or electro-catalyst layers. A preferred PEM polymer is poly(perfluoro sulfonic acid). This self-moisturizing PEM obviates the need to have a pre-humidifying structure or a complex flow field design in a fuel cell.

Owner:JANG BOR Z

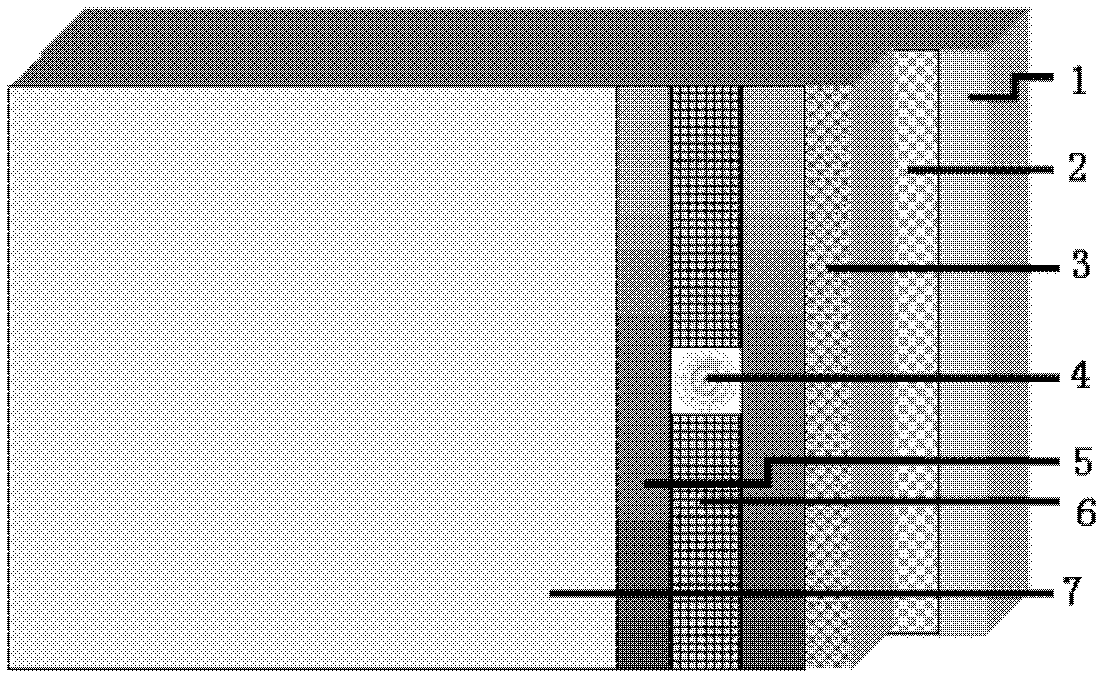

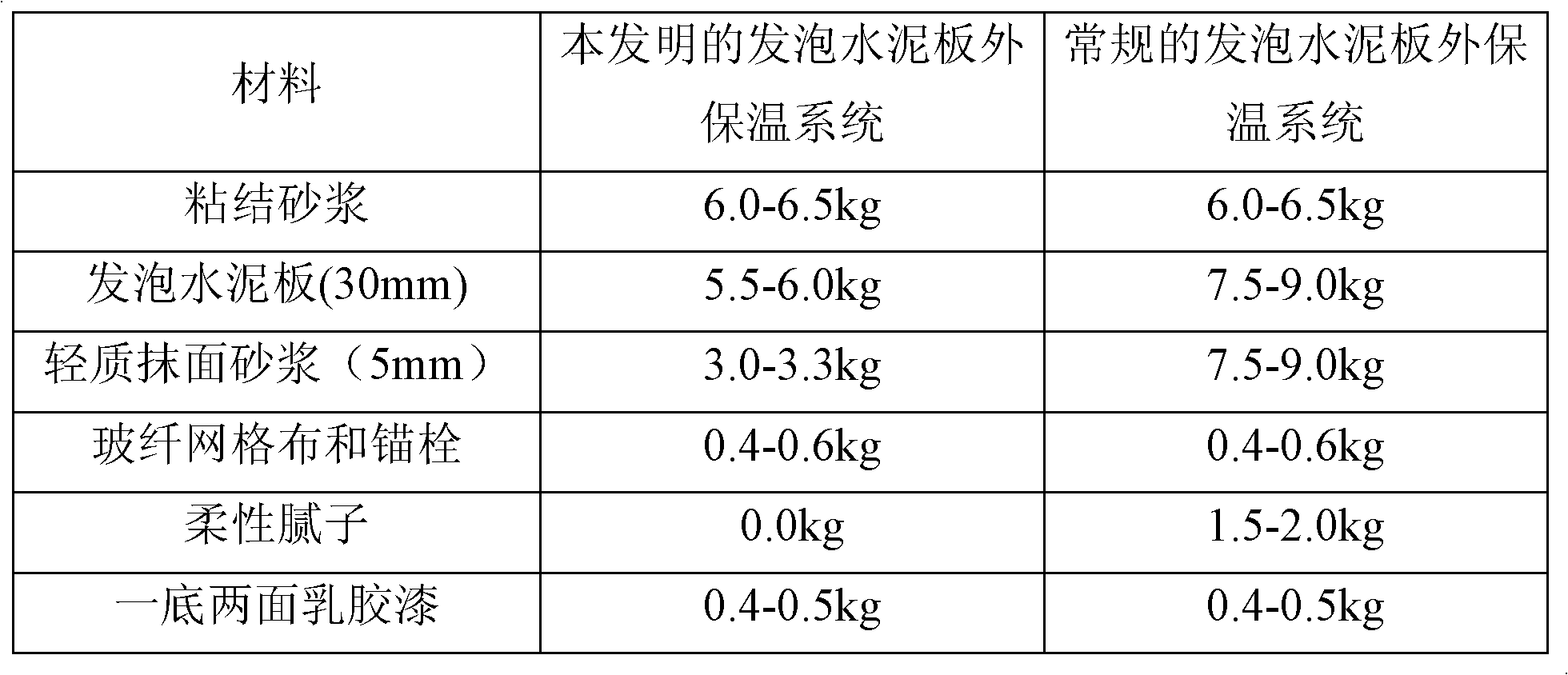

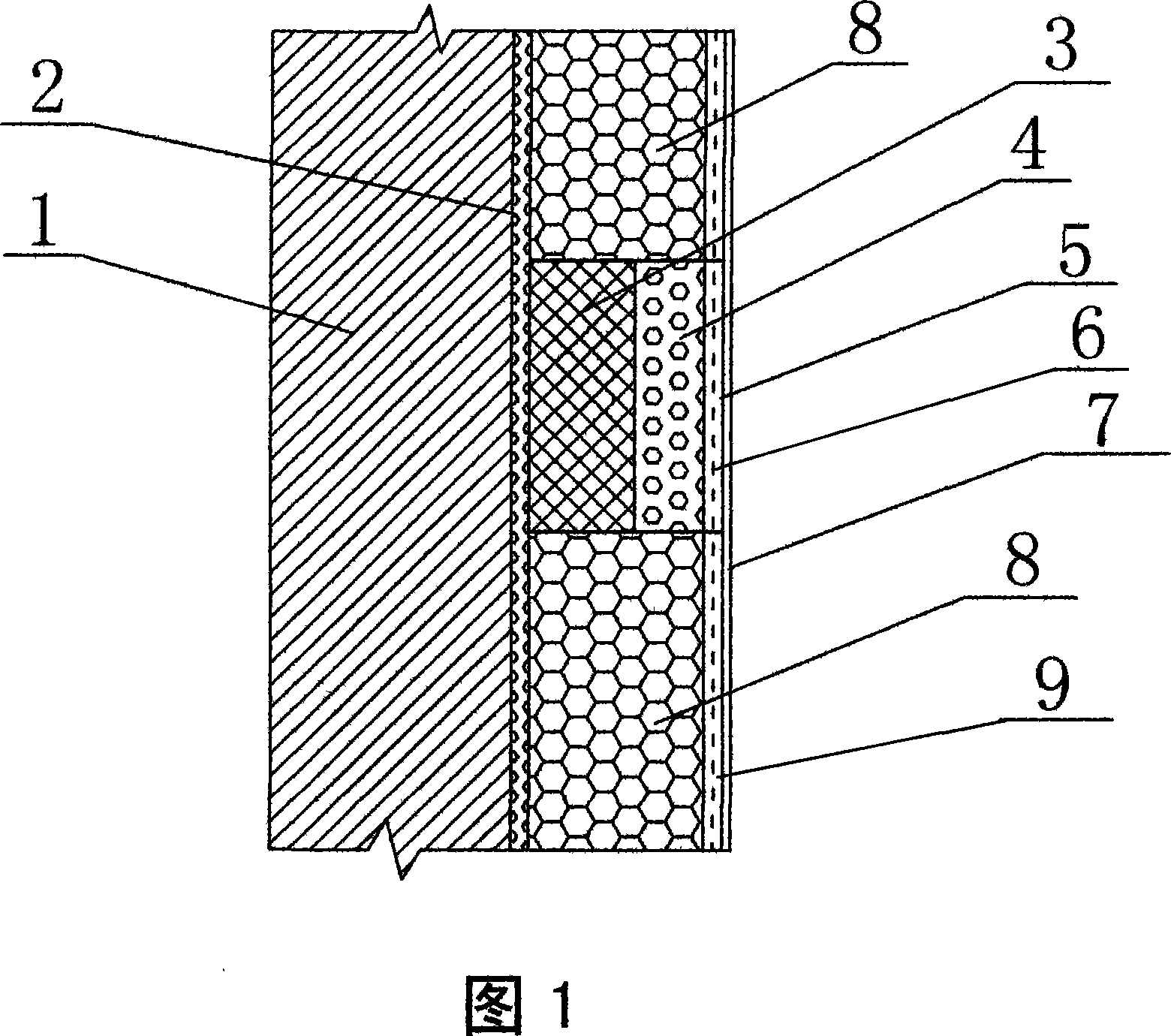

External wall insulation structure through foaming cement board and construction method thereof

ActiveCN102605867ALess affected by heat shrinkageReduce temperature differenceClimate change adaptationHeat proofingCelluloseCement board

The invention relates to an external wall insulation structure through a foaming cement board and a construction method of the external wall insulation structure through the foaming cement board. Polymer bonding mortar, a foaming cement board, an anti-cracking layer and a decorating layer are arranged in sequence from the surface of a base wall body, the anti-cracking layer is formed by light plastering mortar and glass fiber gridding cloth, and the external wall insulation structure is characterized in that the light plastering mortar consists of the following components by weight percent: 12-25% of polyacrylic emulsion, 0.15-0.24% of cellulose ether, 0.1-0.5% of polypropylene fiber, 0.1-0.2% of dispersing agent, 0.1-0.2% of mildew preventive, 15-25% of ordinary portland cement, 15-30% of glazed hollow bead, 5-20% of quartz sand, 0-30% of coal ash and 0.5-1% of water reducing agent.

Owner:上海天补科技有限公司

Nano-gold catalyst and preparation method thereof

InactiveCN104128199AAvoid elevationPrevent sinteringMaterial nanotechnologyMolecular sieve catalystsMolecular sievePolymer bonding

The invention relates to a nano-gold catalyst and a preparation method thereof. The preparation method of the catalyst comprises the following steps: reducing an acid containing gold into nano-Au; mixing the nanoAu with a polymer bonding agent, adding a silicon source and an aluminum source for reacting to obtain a catalyst precursor; and adding a template agent into the catalyst precursor for performing a hydrothermal reaction to obtain the nano-gold catalyst with a core-shell structure, wherein the core is the nano-Au, and the shell is an A type, X type, Y type or ZSM-5 type silicon-aluminum mesoporous molecular sieve of one or more of compounds. The catalyst has high thermal stability and high catalytic activity.

Owner:SOUTHEAST UNIV

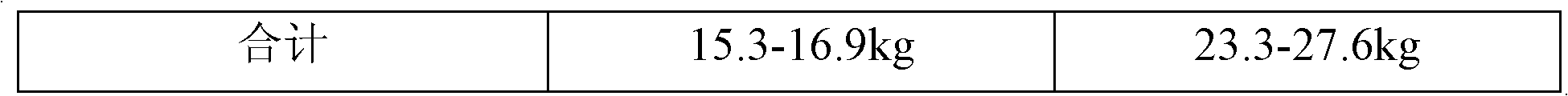

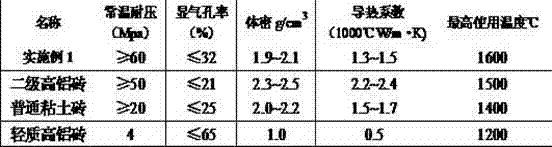

Novel lightweight mullite brick and fabrication method thereof

The invention discloses a novel lightweight mullite brick and a fabrication method thereof. According to the fabrication method, partial high-strength lightweight mullite aggregate, composite organic pore forming material and a high-polymer bonding agent are added to mullite which is used as a main raw material. The novel lightweight mullite brick has a lower heat conductivity coefficient, high compressive strength, high service temperature and certain erosion resistance, and can be extensively applied to parts of various sets of thermal equipment, which are not in direct contact with melt and materials. The novel lightweight mullite brick can replace a heavyweight high-alumina brick and a clay brick to be used as a working layer at some parts of various sets of thermal equipment, the deadweight of the thermal equipment can be reduced by more than 20%, and energy can be saved by above 25%.

Owner:郑州瑞泰耐火科技有限公司

Environmentally resistant assembly containing an electronic device for use in a tire

An assembly for use in or on a tire. The assembly comprises an electronic device having a body and an adhesive coating on at least the body of the electronic device. The body is at least partially made of a plastic material or a fiber reinforced plastic (FRP). The adhesive coating comprises an imide-based adhesive. The adhesive coating may have a polymer bonding group comprising at least one of natural rubber, butyl rubber, a chlorinated elastomer, polybutadiene, synthetic polyisoprene, or styrene-butadiene rubber or a combination thereof. In one embodiment, the assembly further comprises a first elastomeric layer and a second elastomeric layer. The adhesive coating secures the body to the first and the second elastomeric layers. The first and second elastomeric layers may comprise a butyl-containing compound or natural rubber compound. In one embodiment, the electronic device is a radio frequency identification tag having the body and an antenna.

Owner:THE GOODYEAR TIRE & RUBBER CO

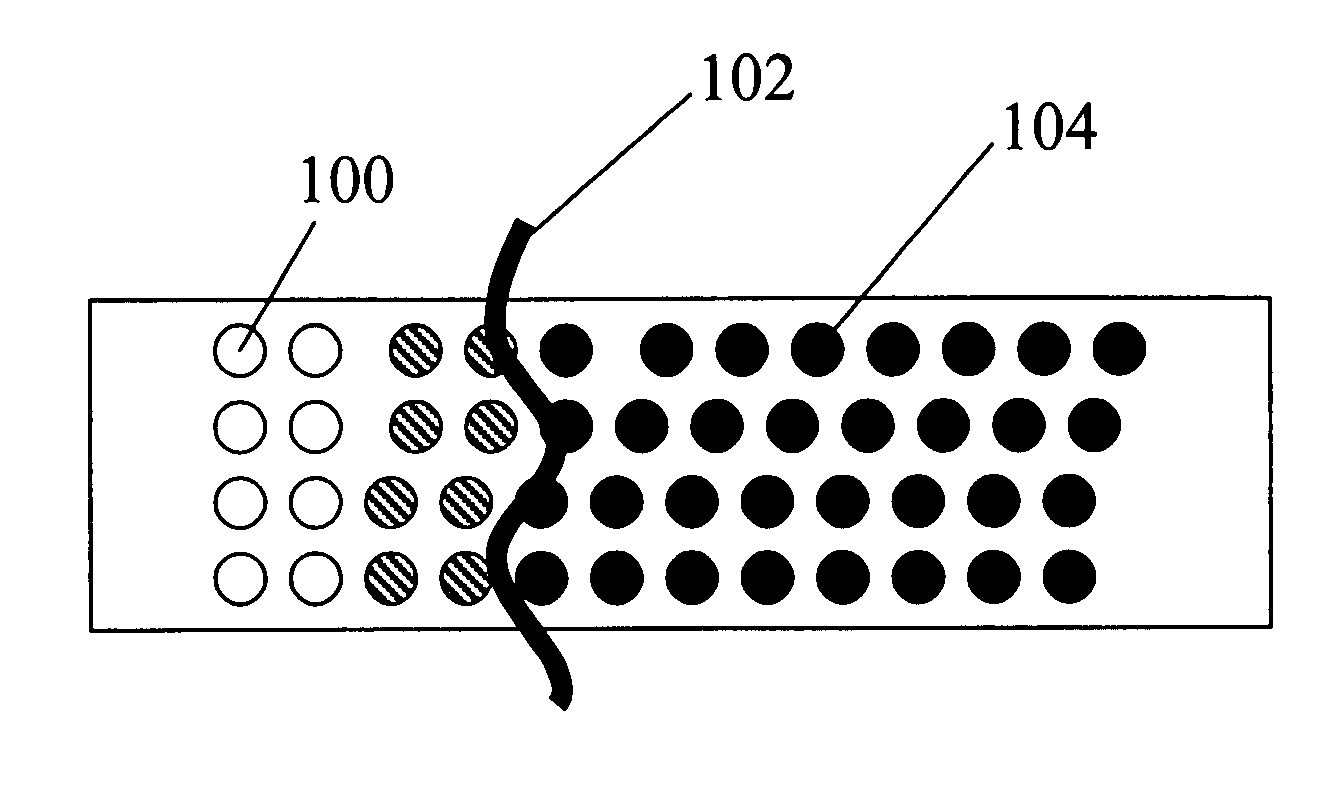

High-stability polymer bonding inorganic oxide battery diaphragm coating and preparation method thereof

InactiveCN106340604AImprove bindingSimple processCell seperators/membranes/diaphragms/spacersNew energySide chain

The invention belongs to the field of new energy resource material and particularly relates to a high-stability polymer bonding inorganic oxide battery diaphragm coating and a preparation method thereof. The high-stability polymer bonding inorganic oxide battery diaphragm coating is characterized in that the characteristic that a surface zata potential is a positive value when the pH value of an aluminum oxide and silicon oxide dual-property inorganic oxide is smaller than an equipotential point is utilized, a polymer binder with negative charge on functional groups and inorganic oxide perform electrostatic self-assembly to form tight chemical bonds, and the inorganic oxide coating stable in structure is formed after coating. The preparation method comprises the main process steps that preparing inorganic oxide-water dispersion solution, measuring the oxide of the solution, regulating the pH value of the inorganic oxide-water dispersion solution to be below the equipotential point, making a polymer with sulfonate radical side chains and the inorganic oxide perform electrostatic self-assembly to form slurry, and performing coating and drying. By the adoption of the method, the bonding power of the binder and the inorganic oxide is strengthened, the slurry coating process of the inorganic oxide battery diaphragm coating is completely consistent with a traditional coating technology, the process is simple, and the cost is controllable.

Owner:武汉格物天成新材料科技有限公司

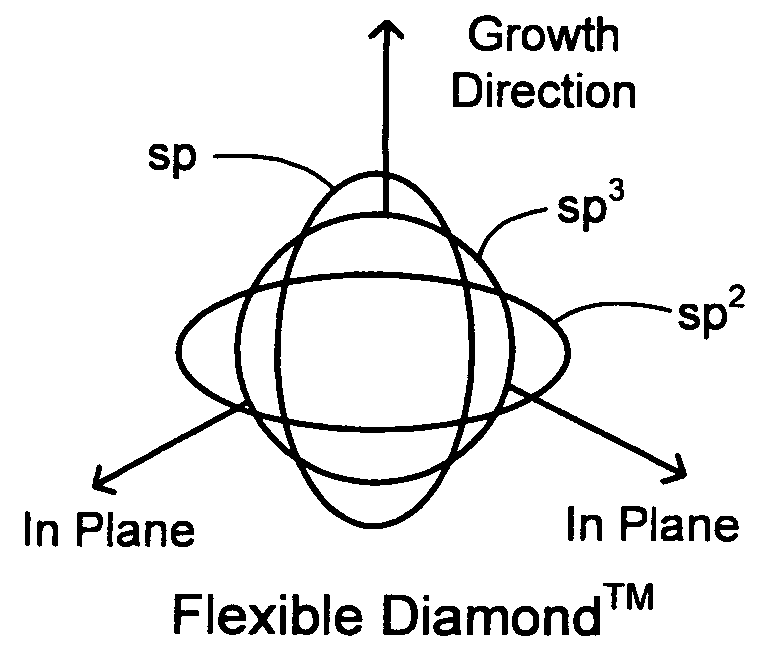

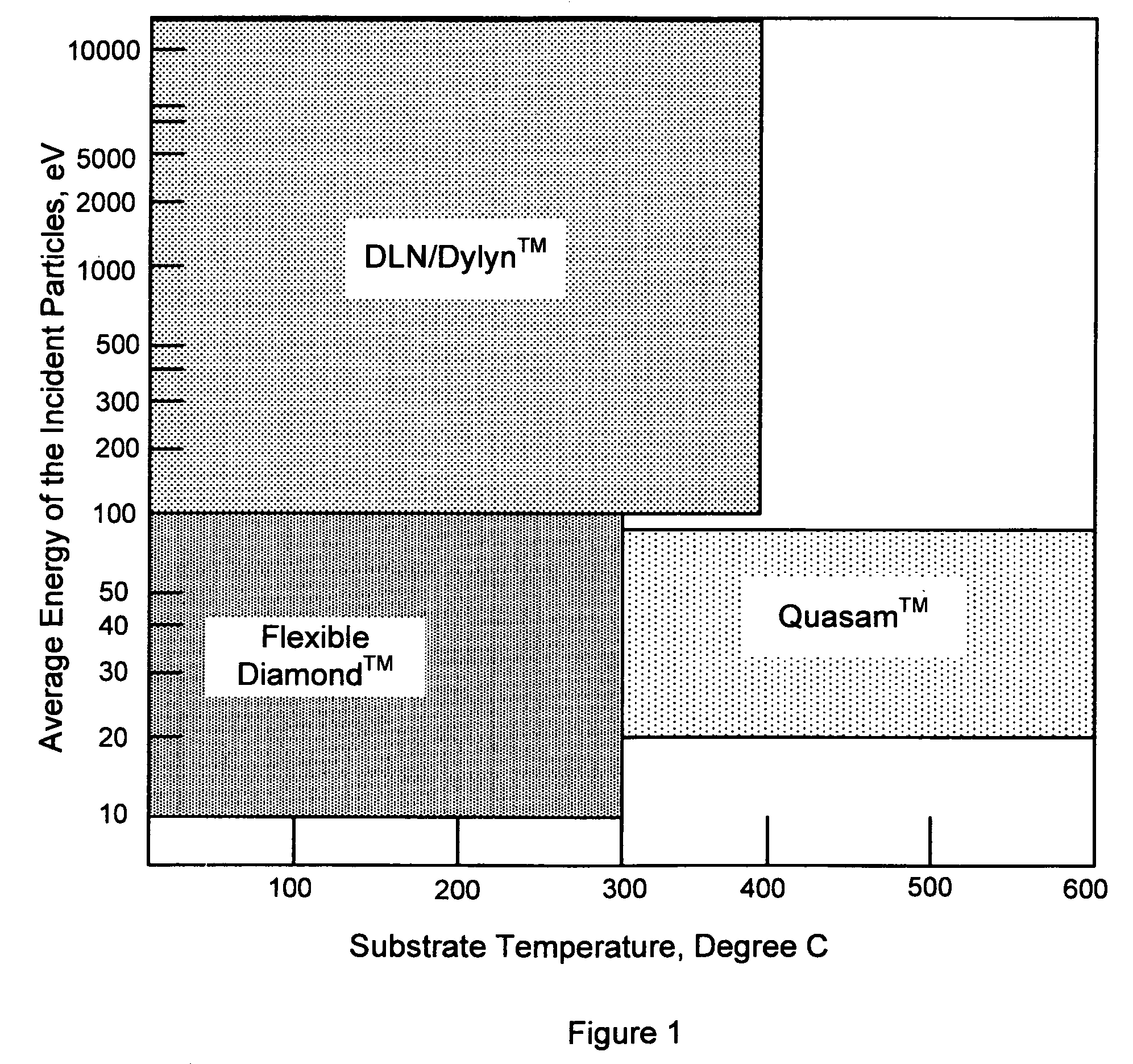

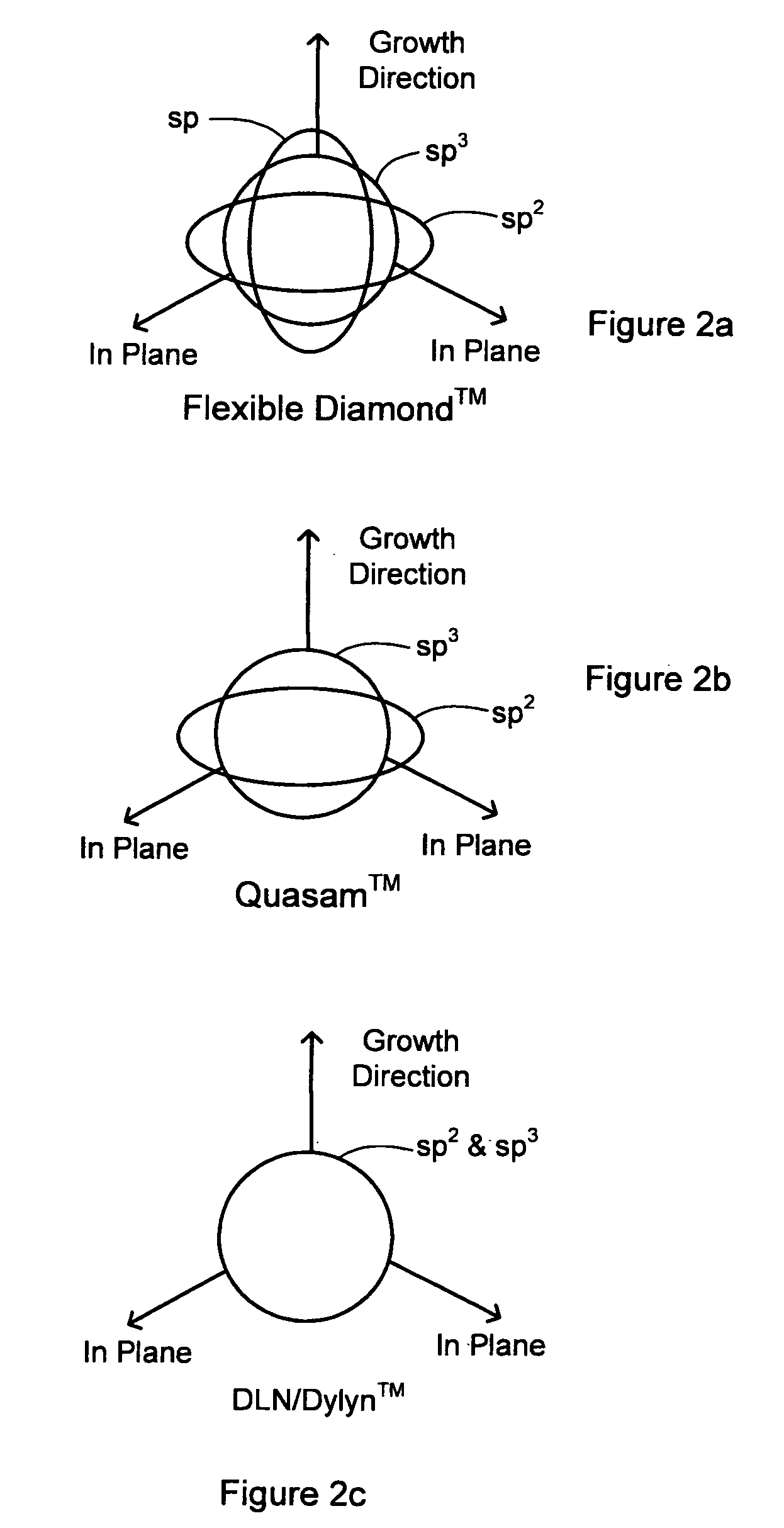

Synergetic SP-SP2-SP3 carbon materials and deposition methods thereof

InactiveUS20050163985A1Simple materialImprove fracture toughnessPolycrystalline material growthUltra-high pressure processesSurface reactionHydrogen

The present invention generally provides carbon materials and methods for producing the carbon materials that include a polymer-like bonded carbon network, a diamond-like bonded carbon network, a graphene-like bonded carbon network, and at least one stabilizing network of at least one alloying element. The material may further include hydrogen, silicone, and oxygen. The carbon materials are generally produced using plasma deposition while accounting for both thermal and incident particle impact activation for surface reactions, which beneficially enables the production of the carbon material at relevantly low incident flux energy and / or relatively low substrate temperatures.

Owner:NANODYNAMICS INC

Lithium ion battery core and preparation method thereof, and lithium ion battery

ActiveCN108390101AAchieve initial integrationImprove adhesionFinal product manufactureCell component detailsBond interfacePolymer bonding

The invention relates to a lithium ion battery core and a preparation method thereof, and a lithium ion battery. The preparation method comprises: assembling a positive electrode sheet, a negative electrode sheet and a separation membrane, and carrying out hot pressing at least twice to prepare the battery core, wherein the separation membrane comprises a base membrane and a polymer bonding substance coated on the base membrane. According to the present invention, the lithium ion battery core is prepared through the multiple hot pressing, wherein the first hot pressing provides the pre-pressing effect so as to achieve the primary bonding of the separation membrane and the electrode sheet and expose the gap at the bonding interface position, and the second hot pressing provides the supplementing effect, such that the polymer bonding substance can fully fill the gap generated by the pre-pressing, and the bonding effect of the bonding interface can be enhanced; and with the at least two hot pressing, the bonding effect at the bonding interface can be improved in a targeted manner, and the clogging of the separation membrane due to the infiltrating of the molten polymer bonding substance into the pores of the separation membrane can be avoided.

Owner:DO FLUORIDE NEW ENERGY TECHNOLOGY CO LTD

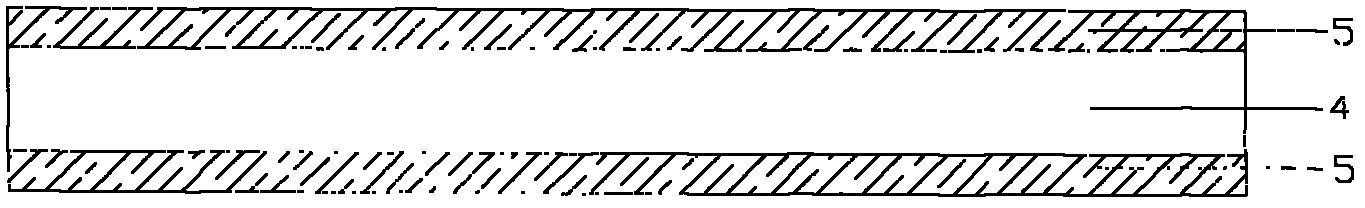

Fire-resistant hard foamed polyurethane composite board and fire protection strip preparation method

ActiveCN101214750AWith heat preservation functionImprove flame retardant performanceFibre treatmentPolyureas/polyurethane adhesivesAdhesive cementPolyol

The invention discloses a method to make fire retardant hard foam polyurethane composite plates and fire protection strips. Firstly, fire retardant polymeric sheets are made. While a polyurethane foaming machine is used to foam polyisocyanate and flame retardant premixed polyether polyol into hard foam polyurethane plates, the fire retardant polymeric sheets are compounded onto both sides of the hard foam polyurethane plates to make the fire retardant hard foam polyurethane composite plates. The method to make the fire protection strips is that polymer bonding adhesive cement is used to stick the fire retardant hard foam polyurethane composite plates on base wall; fire retardant polyurethane leveling slurry is applied on the surface layer of the fire retardant hard foam polyurethane composite plates for leveling; after the leveling layer is dried, a fire retardant finishing adhesive cement layer is applied on the leveling layer; a piece of inorganic grid cloth is laid on the fire retardant finishing adhesive cement layer; subsequently, the fire retardant finishing adhesive cement is used for leveling. The invention can effectively retard flame; the process is simple; the product is used conveniently. The fire protection strips can bring fireproof function to the complete wall with excellent fireproof effect.

Owner:烟台同化防水保温工程有限公司

Methods and materials for the reduction and control of moisture and oxygen in OLED devices

InactiveUS7553355B2Extend your lifeImprove efficiencyCombination devicesAuxillary pretreatmentPolymer bondingChange color

Novel uses and methods of use for inorganic and macroreticulate polymer bonding to metals to control moisture and oxygen in OLED, and other like devices, are provided. Materials having color change capacity are also provided for the removal of moisture from an OLED, where the material changes color upon reaching its capacity and thereby signals the user that the OLED is no longer protected from moisture damage.

Owner:MATHESON TRI GAS INC

Fabricating method and construction method of seamless composite board integrating insulation, decoration and waterproofing

InactiveCN101839045AImprove waterproof performanceImprove crack resistanceCovering/liningsProduction lineGlass fiber

The invention relates to a fabricating method and a construction method of a seamless composite board integrating insulation, decoration and waterproofing. The technical scheme is that the fabricating method comprises the following steps of: (1) prefabricating a polymer cement adhesive for later use, selecting a glass fiber mesh, selecting an insulation board with a certain thickness and size for spraying a surfactant on two sides of the board for later use, selecting a veneer for later use and prefabricating a polymer waterproof bonding adhesive for later use; and (2) introducing the insulation board into a production line, coating the polymer cement adhesive on the insulation board, pressing the glass fiber mesh in the insulation board, and curing, dehydrating and drying by using a device transmission system for curing the polymer bonding adhesive to complete the fabrication. The methods have the advantages of greatly improving the waterproofing, anti-cracking and anti-impact performance of board seams, realizing the continuousness and integrity of a decoration layer of an insulation system of the seamless integrated composite board by the pasting of the polymer waterproofing bonding adhesive and pressing and realizing the insulation, decoration and waterproofing of the whole system.

Owner:DONGYING RUIYUAN SPECIAL BUILDING MATERIALS

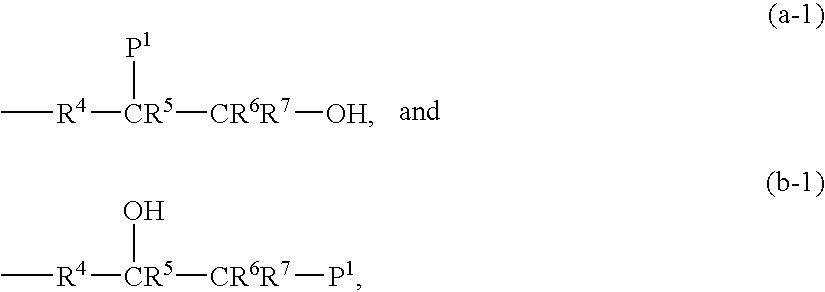

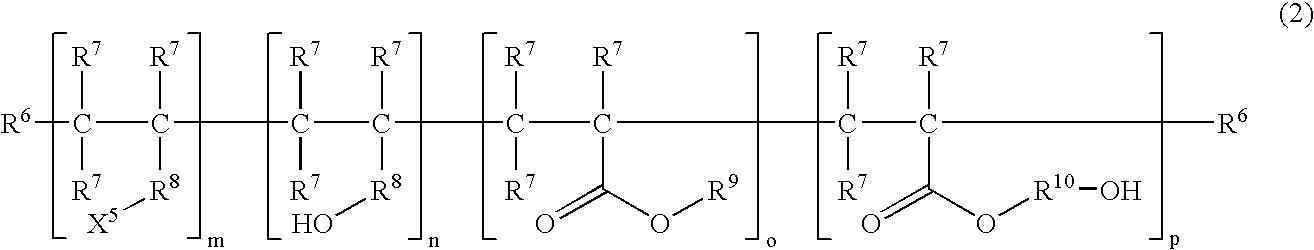

Moisture-curable, graft-modified resin composition, process for its manufacture and process for bonding substrates employing the resin composition

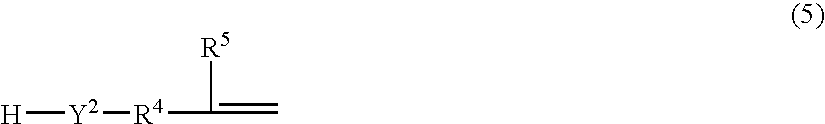

ActiveUS20080311419A1High modulusHigh strengthAdhesive processesFilm/foil adhesivesSilylenePolymer bonding

A moisture-curable, graft-modified resin composition includes at least one thermoplastic polymer (i) and at least one silyl group containing polymer (ii) possessing at least one hydrolyzable silyl group that is bonded to the polymer through a linking group containing at least one heteroatom selected from the group consisting of oxygen and nitrogen, each of polymers (i) and (ii) having grafted thereto at least one same or different silane (iii) which, prior to being grafted, possesses at least one reactive carbon-carbon unsaturated bond.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Process for clinkering anisotropic permanent ferrite through polymer bonding and modeling

InactiveCN1664964AImprove magnetismLow costInorganic material magnetismInductances/transformers/magnets manufacturePolymer bondingFerrite powder

The invention discloses a method for sintering anisotropic permanent ferrite by binding molding of polymer, comprising the following preparing steps: fully mixing ferrite powder with polymer binder accounting for 0.1-3.0% of the total weight of raw materials to obtain molding powder; then heating the molding material and a mould to 60-150 deg.C, placing the molding powder in the mould and making pressure molding under external oriented magnetic field so as to obtain blanks; finally sintering the blanks at the stable temperature of 1200-1280 deg.C to make it. The invention is low-cost, and the obtained ferrite has high magnetic property and has no pollution to the environment and has no effect on the health of producing personnel.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com