Positive electrode for secondary battery and manufacturing method of positive electrode for secondary battery

a technology of secondary batteries and manufacturing methods, which is applied in the manufacturing process of electrodes, cell components, coatings, etc., to achieve the effect of increasing the proportion of positive electrode active materials and increasing the capacity per unit volume of secondary batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

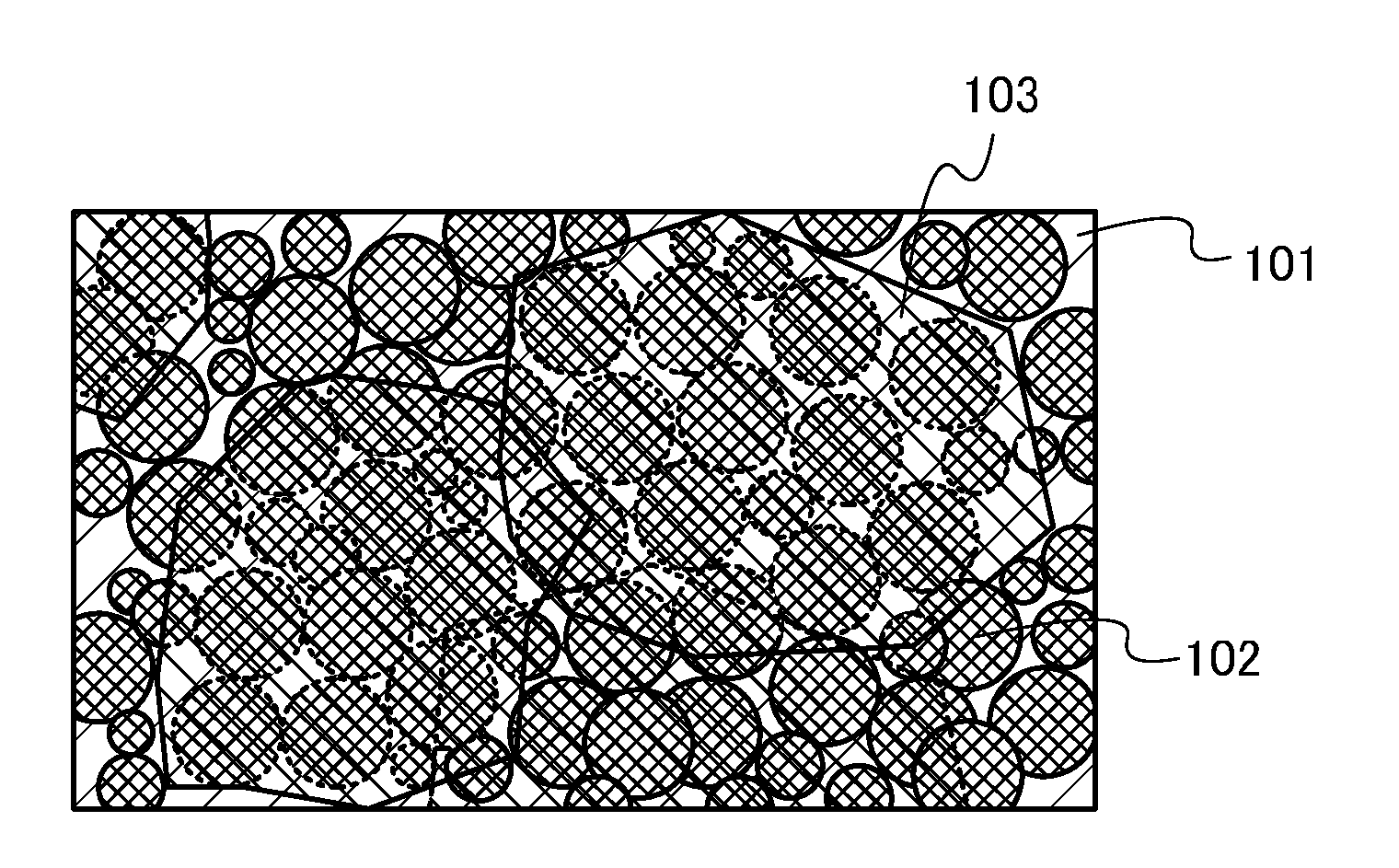

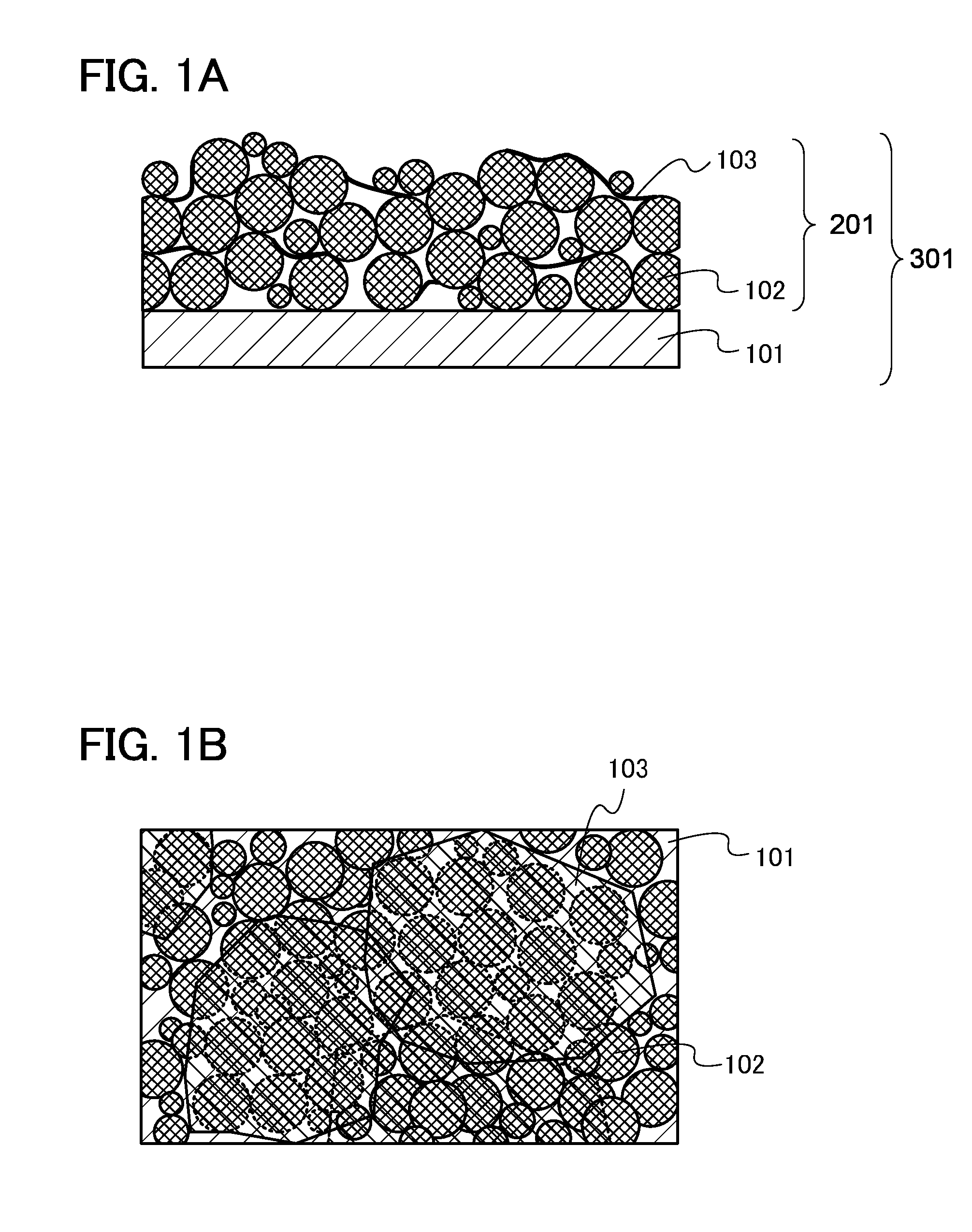

[0045]In this embodiment, an example of a positive electrode for a lithium secondary battery of one embodiment of the present invention will be described with reference to FIGS. 1A and 1B and FIG. 2.

[0046]FIG. 1A is a cross-sectional view of an example of a positive electrode 301, and FIG. 1B is a top view thereof. In the positive electrode 301, a positive electrode active material layer 201 is provided over a current collector 101. The positive electrode active material layer 201 includes a positive electrode active material 102 and a reaction mixture 103 where reduced graphene oxide and a polymer having a functional group as a side chain are bonded to each other.

[0047]In the positive electrode 301, the reaction mixture 103 functions as a binder. As for the bond between the reduced graphene oxide and the polymer having the functional group as the side chain in the reaction mixture 103, a covalent bond is preferable because of its high bonding strength. Note that a polymer in this s...

embodiment 2

[0061]In this embodiment, an example of a method for manufacturing a positive electrode for a lithium secondary battery of one embodiment of the present invention will be described.

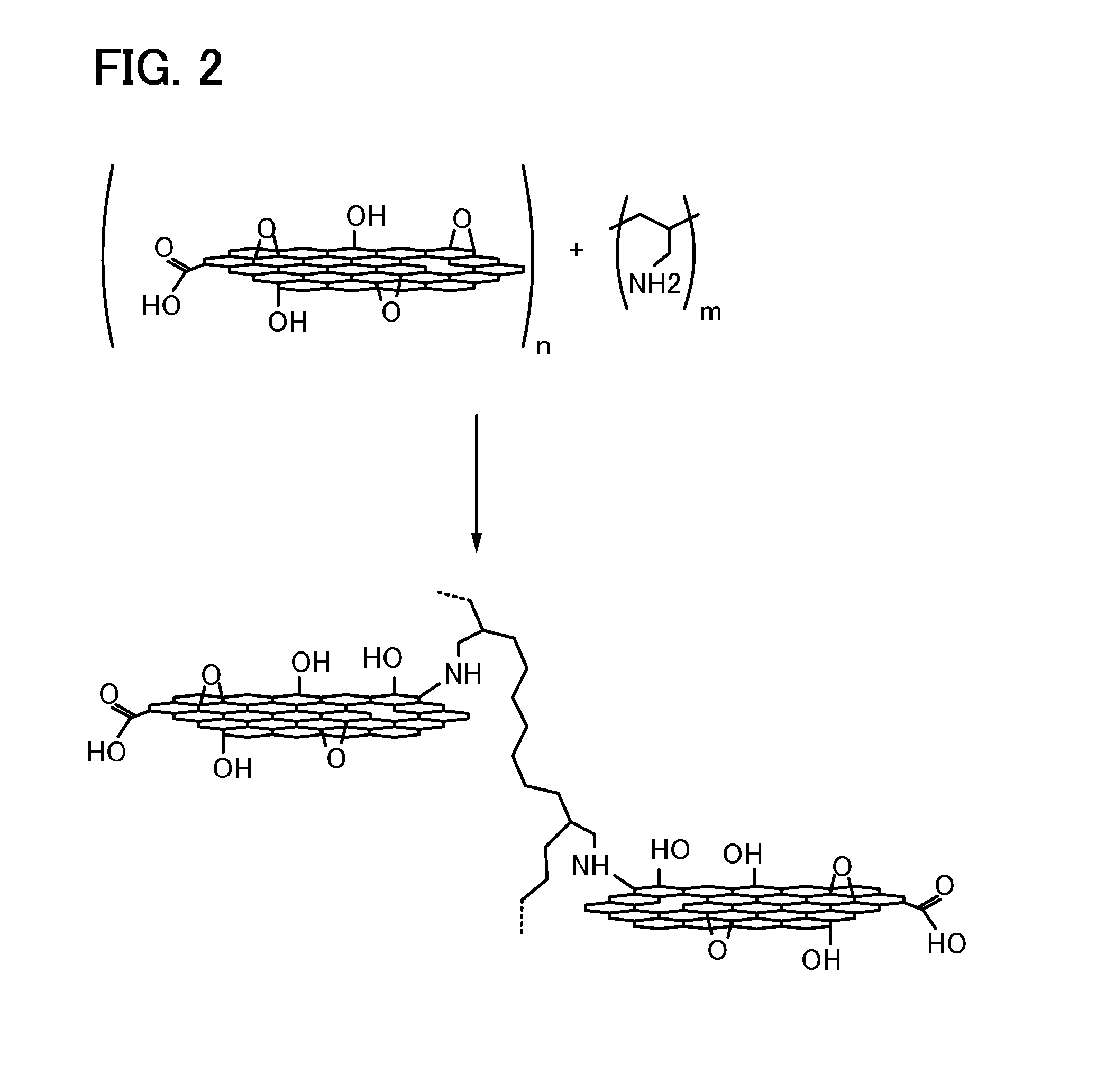

[0062]First, a method for forming graphene oxide will be described. Graphene oxide can be formed by an oxidation method called a modified Hummers method. A modified Hummers method is as follows: a sulfuric acid solution of potassium permanganate, hydrogen peroxide water, or the like is mixed into single crystal graphite powder to cause oxidation reaction; thus, a suspension containing graphite oxide is formed. Then, the graphite oxide is cleaved to form a dispersion containing graphene. The graphite oxide has a functional group such as an epoxy group, a carbonyl group, a carboxyl group, or a hydroxy group due to the oxidation of carbon in graphite. By transmitting ultrasonic vibration to the suspension containing graphite oxide, the graphite oxide whose interlayer distance is long can be cleaved to separa...

embodiment 3

[0095]In this embodiment, an example of a lithium secondary battery of one embodiment of the present invention and an example of a manufacturing method thereof will be described with reference to FIGS. 3A and 3B.

[0096]FIG. 3A is an external view of a coin-type (single-layer and flat) lithium secondary battery, and FIG. 3B is a cross-sectional view thereof.

[0097]In a coin-type lithium secondary battery 6000, a positive electrode can 6003 doubling as a positive electrode terminal and a negative electrode can 6001 doubling as a negative electrode terminal are insulated from each other and sealed by a gasket 6002 made of polypropylene or the like. As in the above description, a positive electrode 6010 includes a positive electrode current collector 6008 and a positive electrode active material layer 6007 provided in contact with the positive electrode current collector 6008. A negative electrode 6009 includes a negative electrode current collector 6004 and a negative electrode active ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric conductivity | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com