Patents

Literature

60results about How to "Improve rolling resistance performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

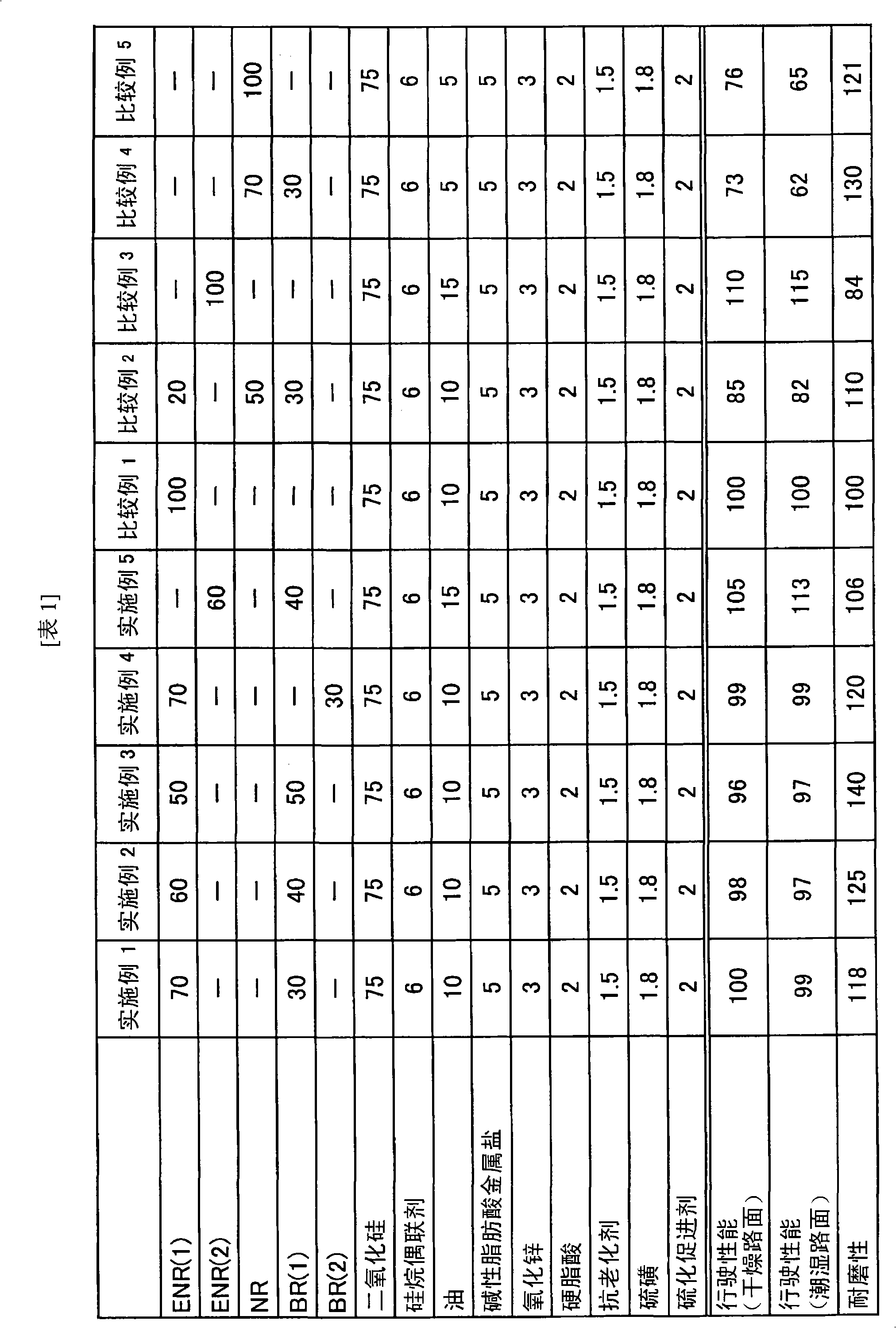

Rubber composition and tire having tread comprising thereof

InactiveUS20060173118A1Improve rolling resistance performanceReduce fuel consumptionSpecial tyresRolling resistance optimizationRolling resistanceNitrogen

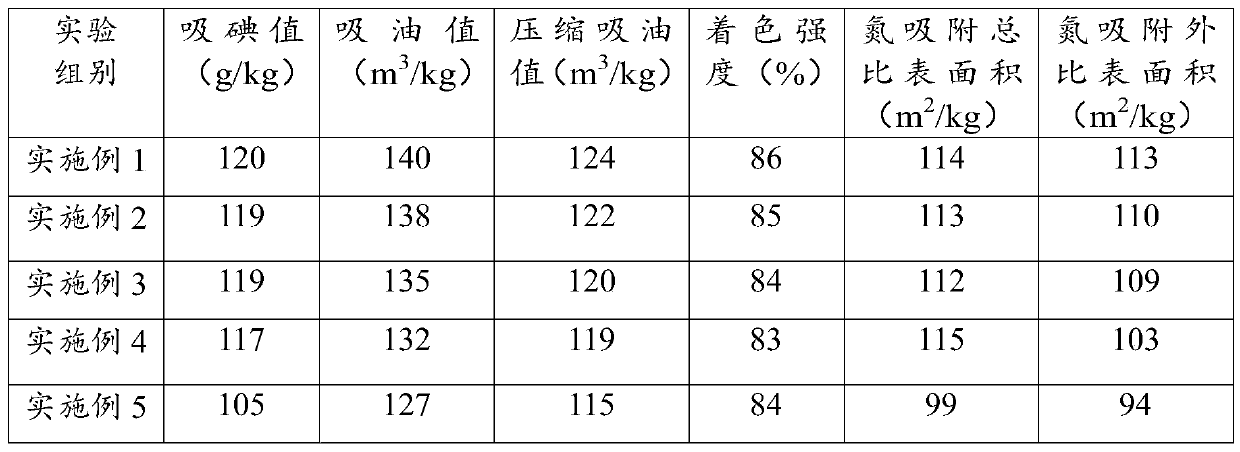

There is provided a rubber composition capable of producing a tire which improves rolling resistance performance, wet skid performance and drivability of a vehicle in good balance, and a tire having a tread comprising thereof. A rubber composition comprising 30 to 150 parts by weight of the total of (1) silica with a nitrogen adsorption specific area of 100 m2 / g or less and (2) silica with a nitrogen adsorption specific area of 180 m2 / g or more based on 100 parts by weight of a rubber component, wherein the content of silica (1) and silica (2) satisfies the following formula, and a tire having a tread comprising thereof: [Content of silica (1)]×0.2≦[content of silica (2)]≦[content of silica (1)]×6.5.

Owner:SUMITOMO RUBBER IND LTD

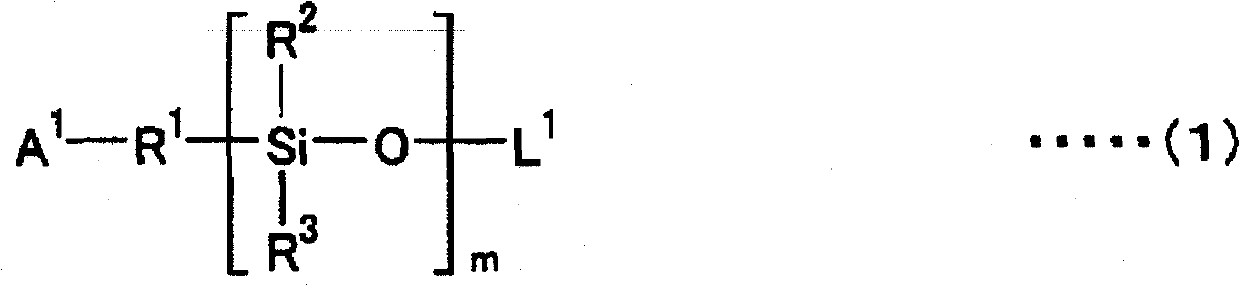

Method for producing modified conjugated diene polymer/copolymer, modified conjugated diene polymer/copolymer, and rubber composition and tier using the same

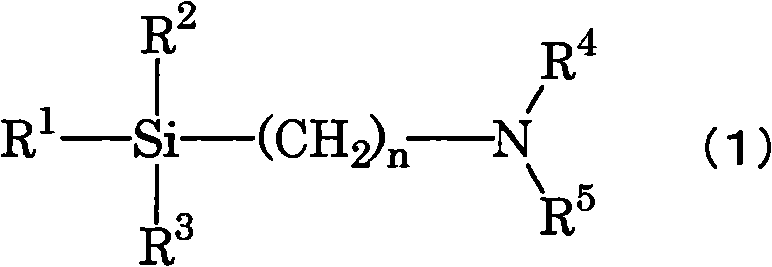

ActiveCN102026826AImprove rolling resistance performanceIncreased durabilitySpecial tyresWheelsPolymer sciencePolymer bonding

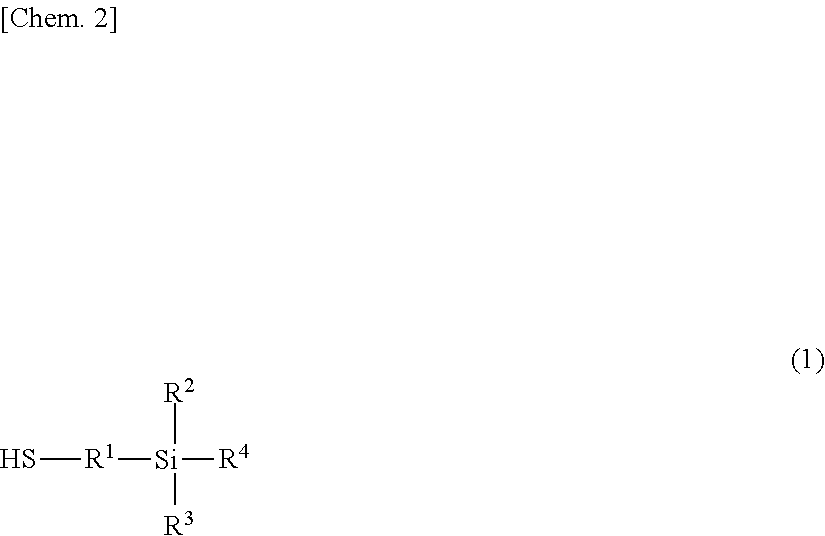

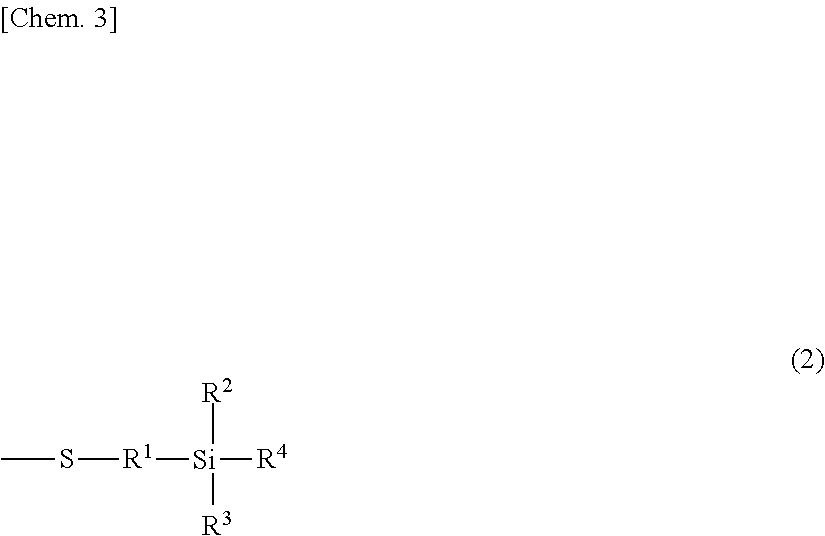

Provided are a method for producing a modified conjugated diene polymer / copolymer including a modified reaction step for causing an organosilane compound having a characteristic group for producing a silanol group by hydrolysis and, in the vicinity of the characteristic group, (i) a functional group for combining the organosilane compound with the conjugated dione polymer / copolymer by performing an addition or substitutive reaction on an active site and, after the reaction, prompting a reaction between the silanol group and a reinforcing filler or (ii) a functional group for prompting the reaction between the silanol group and the reinforcing filler to react with the active site of a conjugated dione polymer / copolymer having the active site, and a hydrosis step performed after completing the modified reaction step; a modified conjugated diene polymer / copolymer having, at an end of a molecular of a conjugated diene polymer / copolymer, a silanol group and, in the vicinity of the silanol group, a functional group for prompting a reaction between the silanolgroup and a reinforcing filler; and a rubber composition having the modified conjugated polymer / copolymer and carbon black of a specific property; and a tier using the rubber composition.

Owner:BRIDGESTONE CORP

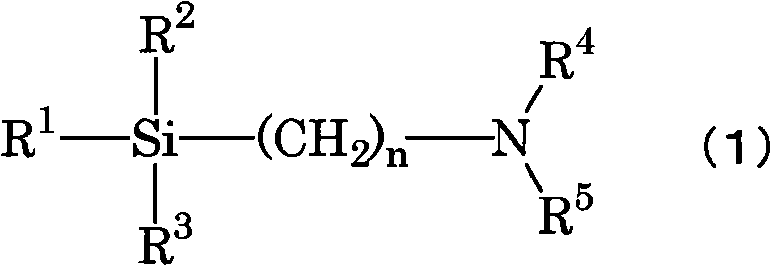

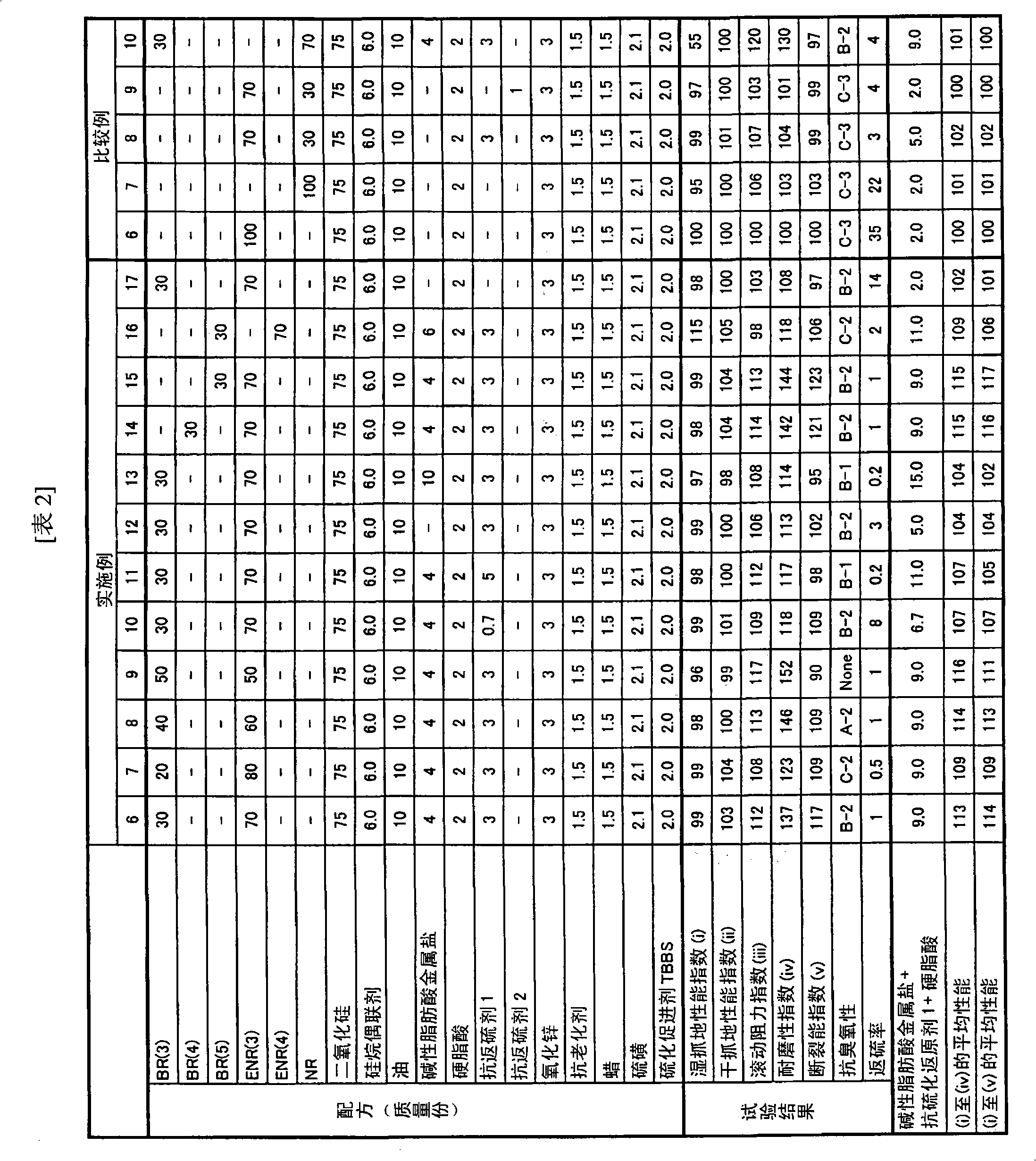

Tire rubber composition and pneumatic tire

ActiveCN102199316AImprove gripGood balance of abrasion resistanceSpecial tyresRolling resistance optimizationRolling resistanceSulfur

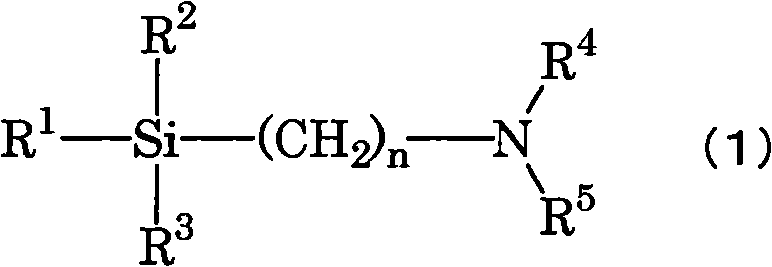

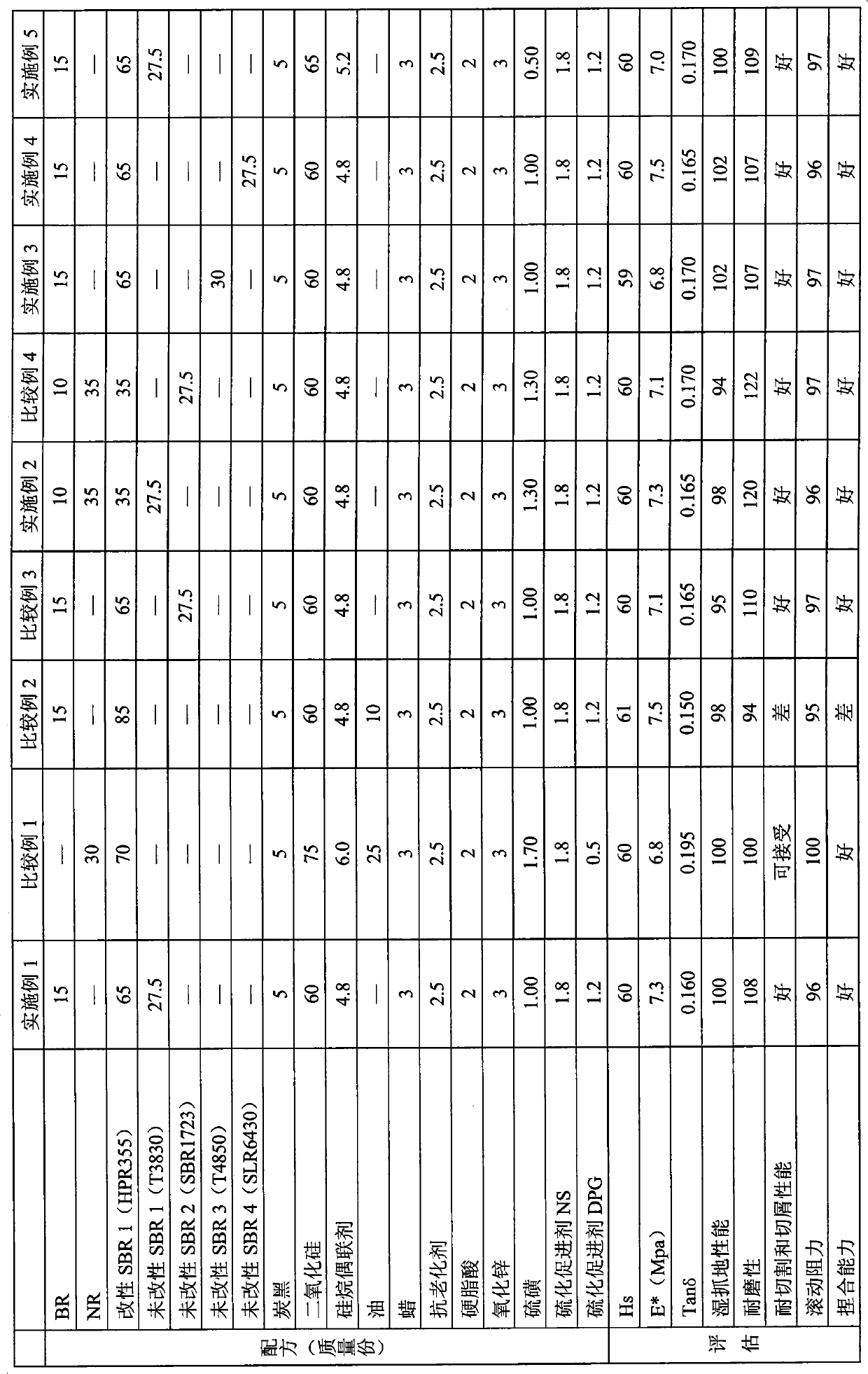

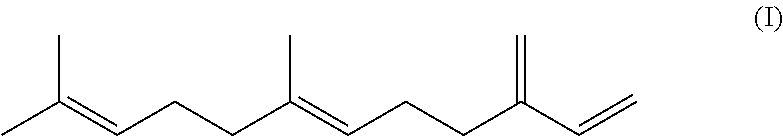

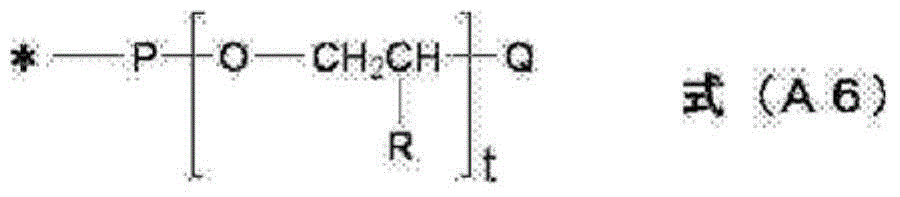

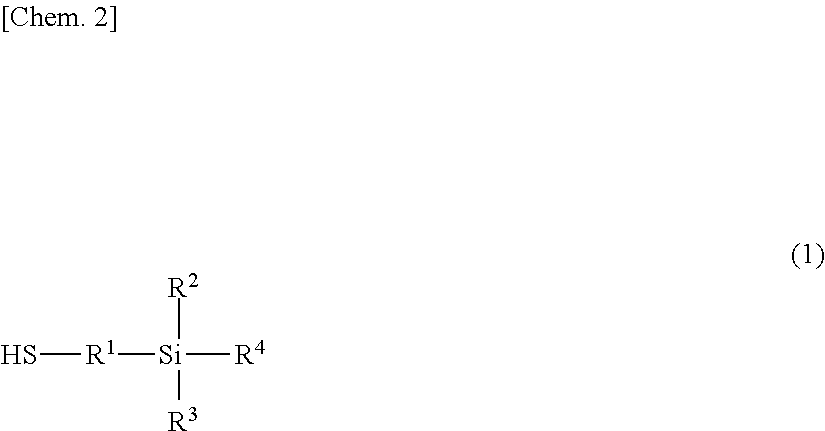

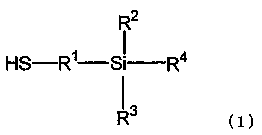

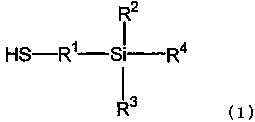

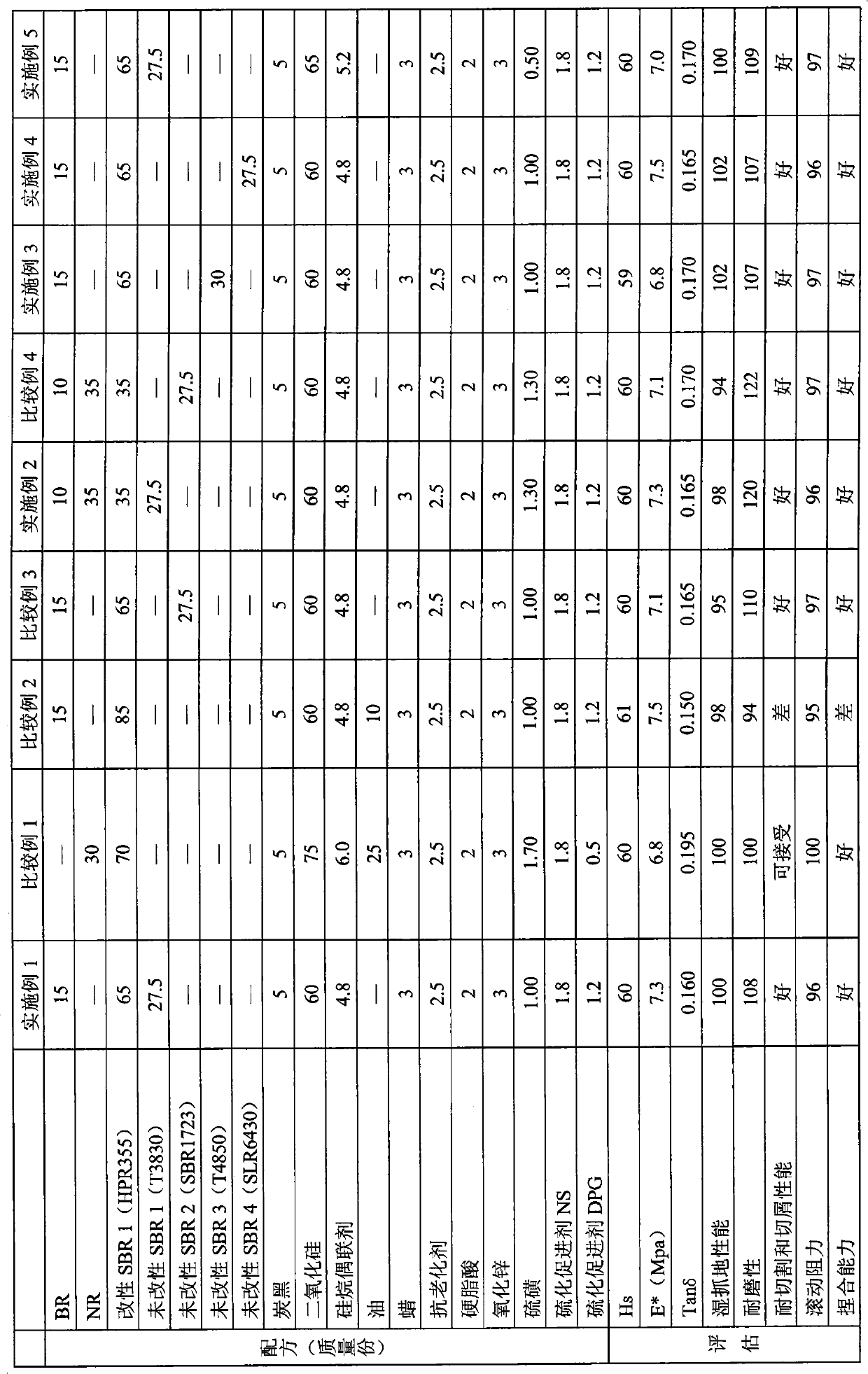

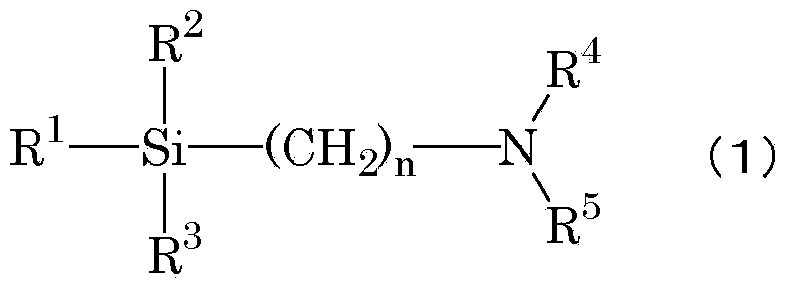

The present invention aims to provide a tire rubber composition that achieves a good balance of grip performance (especially, wet grip performance), abrasion resistance, cut and chip resistance, low rolling resistance, and kneadability, and a pneumatic tire using the same. The composition comprise: a rubber component including a styrene-butadiene rubber modified by a compound of formula (1): and a non-modified styrene-butadiene rubber; a filler including silica, the filler being in an amount of 80 parts by mass or less per 100 parts by mass of the rubber component; and sulfur in an amount of 0.5-1.5 parts by mass per 100 parts by mass of the rubber component, the modified styrene-butadiene rubber having a bound styrene content of 20-40% by mass and a vinyl content of 30-65% by mass, and the non-modified styrene-butadiene rubber having a bound styrene content of 25-45% by mass and a vinyl content of 10-50% by mass.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition and tire having tread comprising thereof

InactiveCN1821293AImprove rolling resistance performanceImprove drivabilitySpecial tyresTyre tread bands/patternsRolling resistanceSilicon dioxide

Owner:SUMITOMO RUBBER IND LTD

Tire rubber composite and pneumatic tire

ActiveCN104245817AGood dispersionLow wear resistanceSpecial tyresRolling resistance optimizationRolling resistancePolymer science

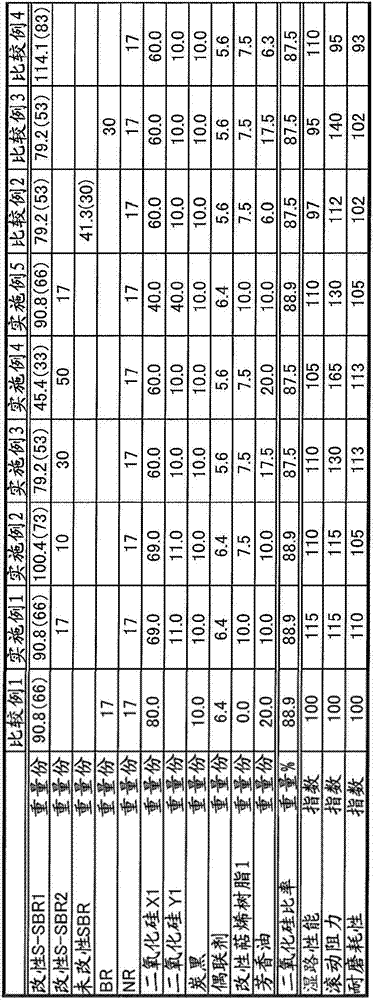

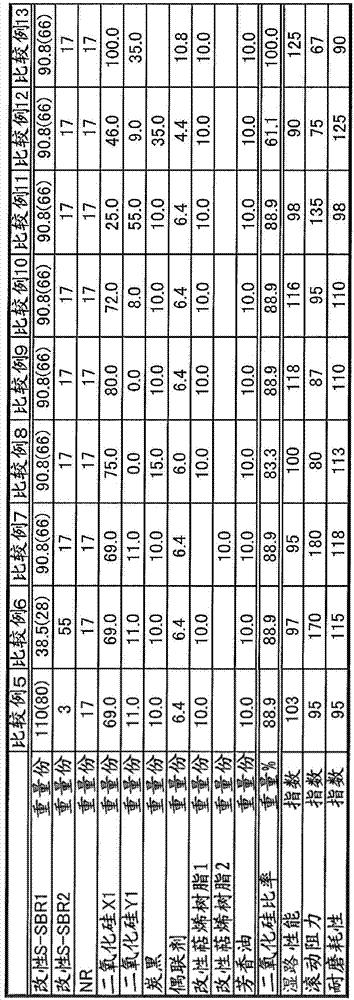

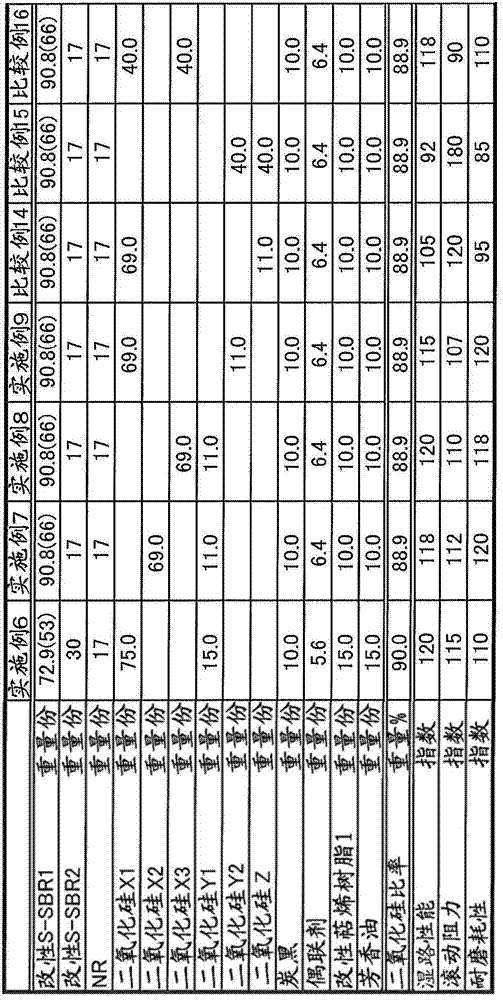

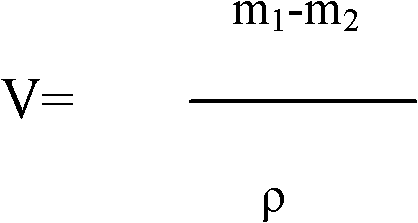

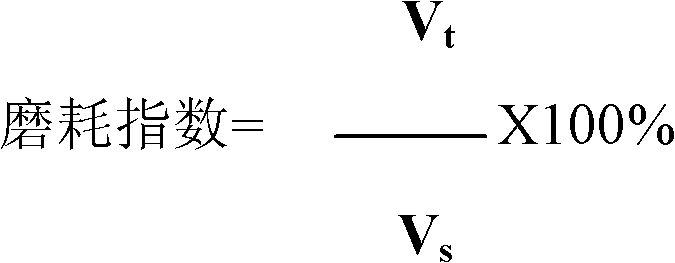

Provided is a tire rubber composition that has lower rolling resistance, and improved wet performance and abrasion resistance compared to conventional levels. The composition is characterized in that: 2-50 parts by weight of an aromatic modified terpene resin with a softening point of at least 100 DEG C and a total of 60-130 parts by weight of two types of silica, silica X and silica Y, are added to 100 parts by weight of a diene rubber that includes 5-50 wt% of a terminal-modified S-SBR having a vinyl unit content of at least 25 wt% and a glass transition temperature of - 50 DEG C or below; the functional group of the modified S-SBR is reactive with a silanol group; a reinforcing filler comprising of silica X, silica Y and optionally added carbon black includes the silica at a proportion of at least 85 wt%; the specific surface area of silica X as determined by nitrogen absorption is at least 140m<2> / g; the specific surface area of silica Y as determined by nitrogen absorption is 100-140m<2> / g exclusive; and if the respective masses of silica X and silica Y per 100 parts by weight of the diene rubber are expressed as x parts by weight and y parts by weight, the relationship x / 7 < y <=x is satisfied.

Owner:THE YOKOHAMA RUBBER CO LTD

Solution polymerized styrene-butadiene rubber composition, preparation method thereof, and vulcanized rubber thereof

ActiveCN103073759AImproved wet skid resistanceImprove wear indexSpecial tyresRolling resistance optimizationRolling resistancePolymer science

The invention provides a solution polymerized styrene-butadiene rubber (SSBR) composition, a preparation method thereof, and a vulcanized rubber thereof. The solution polymerized styrene-butadiene rubber composition comprises blended modified rubber component and solution polymerized styrene-butadiene rubber. Calculated according to the weight of solution polymerized styrene-butadiene rubber as 100 parts, the composition comprises 1-70 parts of the modified rubber component. The modified rubber component comprises uncrosslinked rubber and rubber particles with crosslinked structures, which are dispersed in the uncrosslinked rubber. The rubber particles with crosslinked structures are nitrile rubber particles with an average particle size of 50-200nm and a gel content of 60wt% or higher. The uncrosslinked rubber is styrene-butadiene rubber. A weight ratio of the rubber particles with crosslinked structures to the uncrosslinked rubber is 80:20-30:70. The wet skid performance and wear resistance of the vulcanized rubber of the solution styrene-butadiene rubber composition can both be improved; the vulcanized rubber has low rolling resistance, and can be used for preparing high-efficiency automobile tread rubber.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rubber composition and process for preparing the same

InactiveUS20070015861A1Efficient couplingReduce rolling resistanceSpecial tyresRolling resistance optimizationRolling resistancePolymer science

A rubber composition improving the reaction efficiency of a silane coupling agent in kneading, suppressing generation of air bubbles, improving processability and abrasion resistance and lowering rolling resistance, and a process for preparing the same are provided. A rubber composition comprising silica, wherein 3 to 15 parts by weight of a silane coupling agent based on 100 parts by weight of silica and 0.3 to 1.45 parts by weight of a potassium salt based on 100 parts by weight of silica are contained.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition

InactiveCN106068302AHigh hardnessGood dispersionSpecial tyresRolling resistance optimizationRolling resistancePolymer science

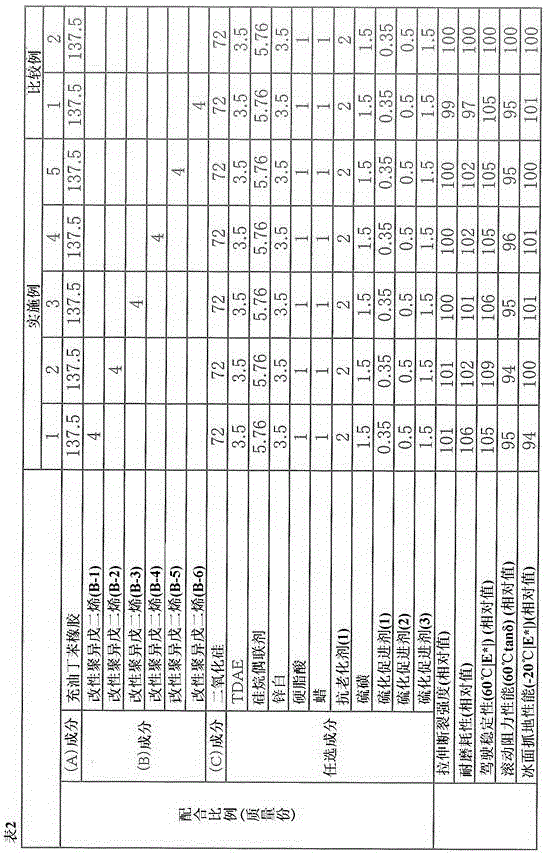

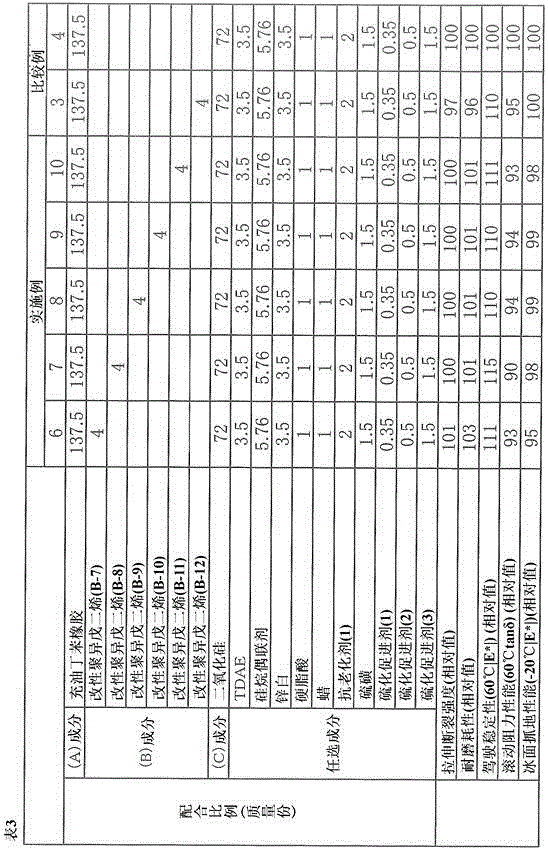

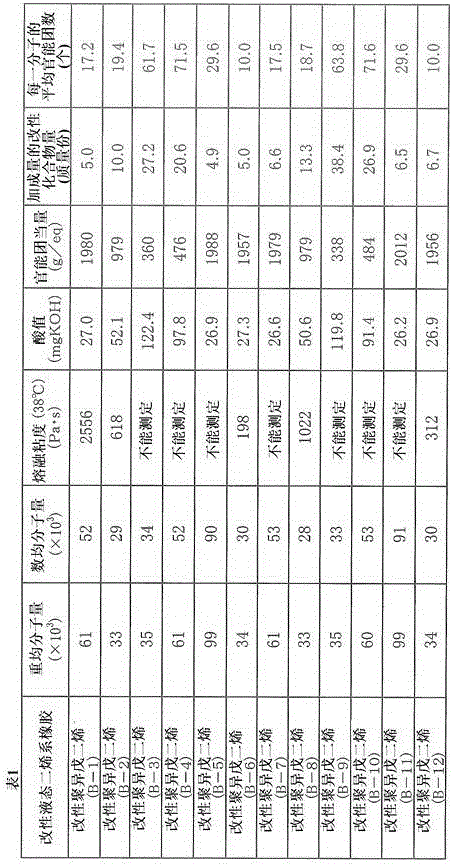

To provide a rubber composition having excellent filler dispersability, a crosslinked product having excellent wear resistance and other properties, and a tire using said composition or said crosslinked product in a portion thereof and enabling improved rolling resistance performance, as well as improved steering stability and improved ice grip performance. A rubber composition containing, with respect to 100 parts by mass of a solid rubber (A): 0.1-10 parts by mass of a modified liquid diene rubber (B) obtained by adding a modified compound to a native liquid diene rubber (B') and having a functional group derived from said modified compound; and 20-150 parts by mass of a filler (C). The modified liquid diene rubber (B) satisfies the following (i)-(iv): (i) isoprene units are included in the amount of 50 mass% or more with respect to the total monomer units; (ii) the weight-average molecular weight (Mw) is 25,000-120,000; (iii) the modified compound is added in the amount of 3-40 parts by mass with respect to 100 parts by mass of the native liquid diene rubber (B'); and (iv) the average number of functional groups per molecule of the modified liquid diene rubber (B) is 15-80 groups.

Owner:KURARAY CO LTD

Rubber composition and tire

ActiveUS20140213715A1Easy to processImprove rolling resistance performanceSpecial tyresRolling resistance optimizationCarbon blackFarnesene

The present invention relates to a rubber composition including (A) at least one rubber component selected from the group consisting of a synthetic rubber and a natural rubber; (B) a polymer of farnesene; and (C) carbon black having an average particle size of from 5 to 100 nm, a content of the carbon black (C) in the rubber composition being from 20 to 100 parts by mass on the basis of 100 parts by mass of the rubber component (A).

Owner:KURARAY CO LTD +1

Rubber composition and pneumatic tire

ActiveUS20170107360A1Good effectIncrease polaritySpecial tyresInflatable tyresNitrile rubberPolymer science

A rubber composition comprises 100 parts by mass of a diene rubber component comprising at least one selected from the group consisting of styrene-butadiene rubber, polybutadiene rubber, natural rubber and polyisoprene rubber, the diene rubber component containing modified styrene-butadiene rubber modified with a functional group having an interaction with a silanol group on a surface of silica, from 20 to 120 parts by mass of silica, and from 3 to 30 parts by mass of hydrogenated non-modified nitrile rubber. A pneumatic tire has a rubber part comprising the rubber composition.

Owner:TOYO TIRE & RUBBER CO LTD

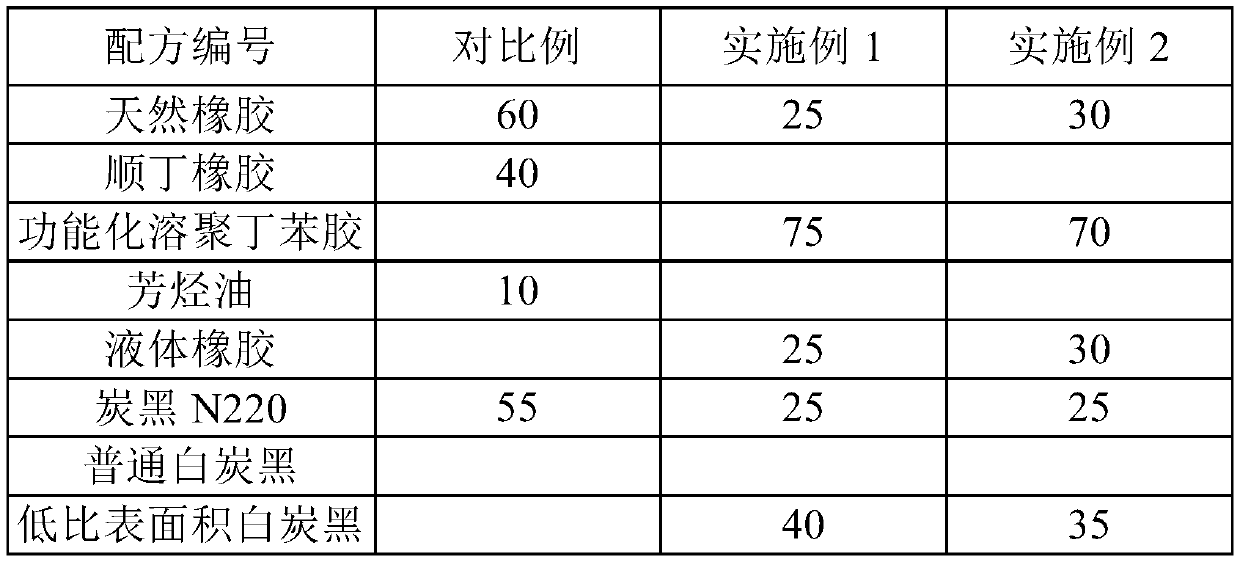

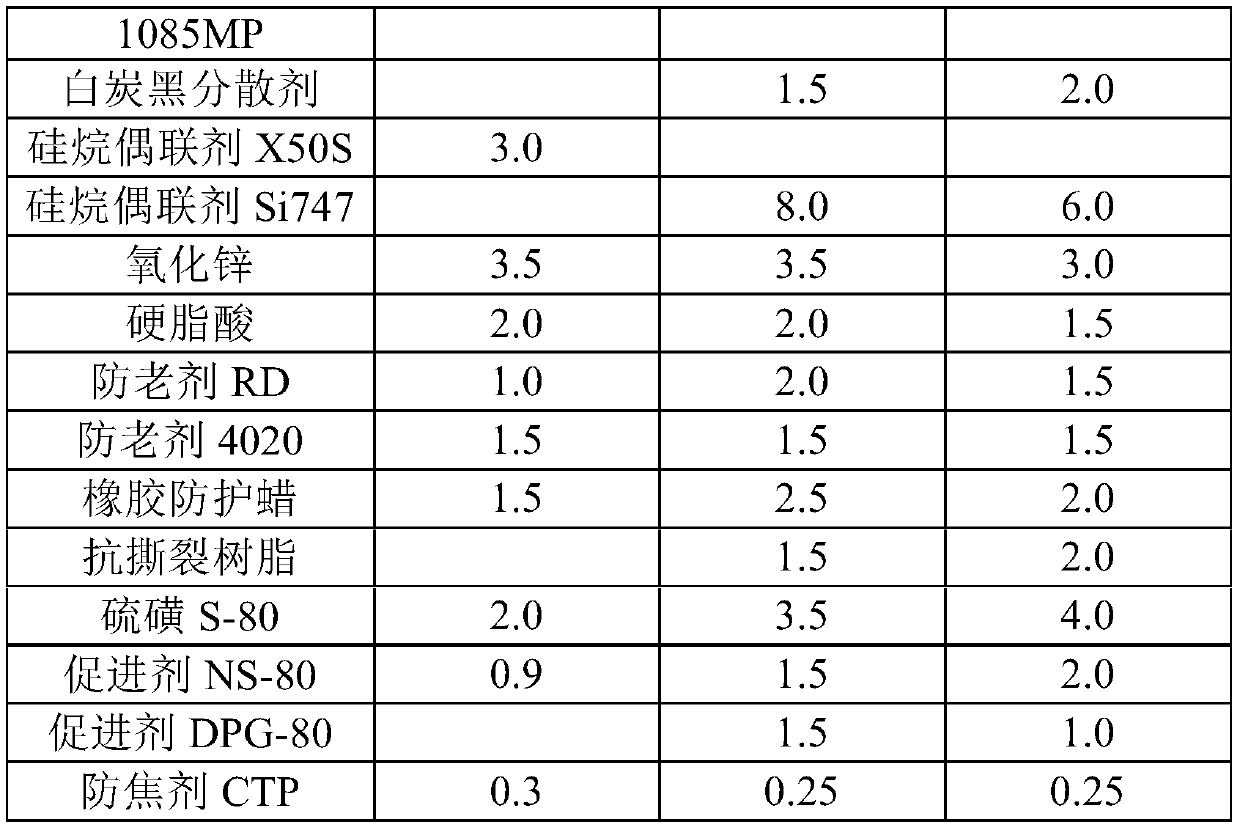

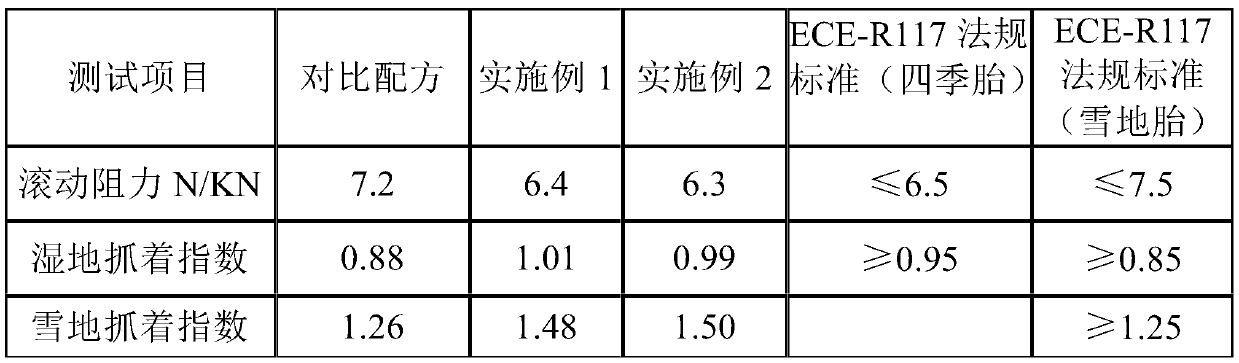

Four-season all-steel ice and snow tire tread rubber composition

ActiveCN111333934AImprove low temperature resistanceImprove cold resistanceSpecial tyresRolling resistance optimizationPolymer scienceRolling resistance

The invention relates to the technical field of tire rubber, in particular to a four-season all-steel ice and snow tire tread rubber composition. The composition comprises the following steps, by weight, after mixing: 10-30 parts of natural rubber, 10-35 parts of liquid rubber, 65-80 parts of functionalized solution polymerized styrene-butadiene rubber, 5-25 parts of carbon black, 20-55 parts of white carbon black with a low specific surface area, 4.0 -12.0 parts of a silane coupling agent ranges, 1.5-3.0 parts of white carbon black dispersing agent, 2.0-5.0 parts of zinc oxide, 1.0-3.0 partsof stearic acid, 1.0-3.0 parts of an anti-aging agent 4020, 1.5-2.5 parts of an anti-aging agent RD, 1.0-4.0 parts of rubber protective wax, 1.5-2.5 parts of sulfur S-80, 1.0-3.5 parts of tear-resistant resin, 1.0-2.5 parts of an accelerant NS-80 and 0-0.5 part of an accelerant DPG-80. The tire tread produced by the invention not only has excellent snowfield grip on a snowfield pavement, but alsokeeps excellent grip on an all-ice pavement, and has excellent rolling resistance, wet skid resistance and wear resistance.

Owner:TRIANGLE TIRE

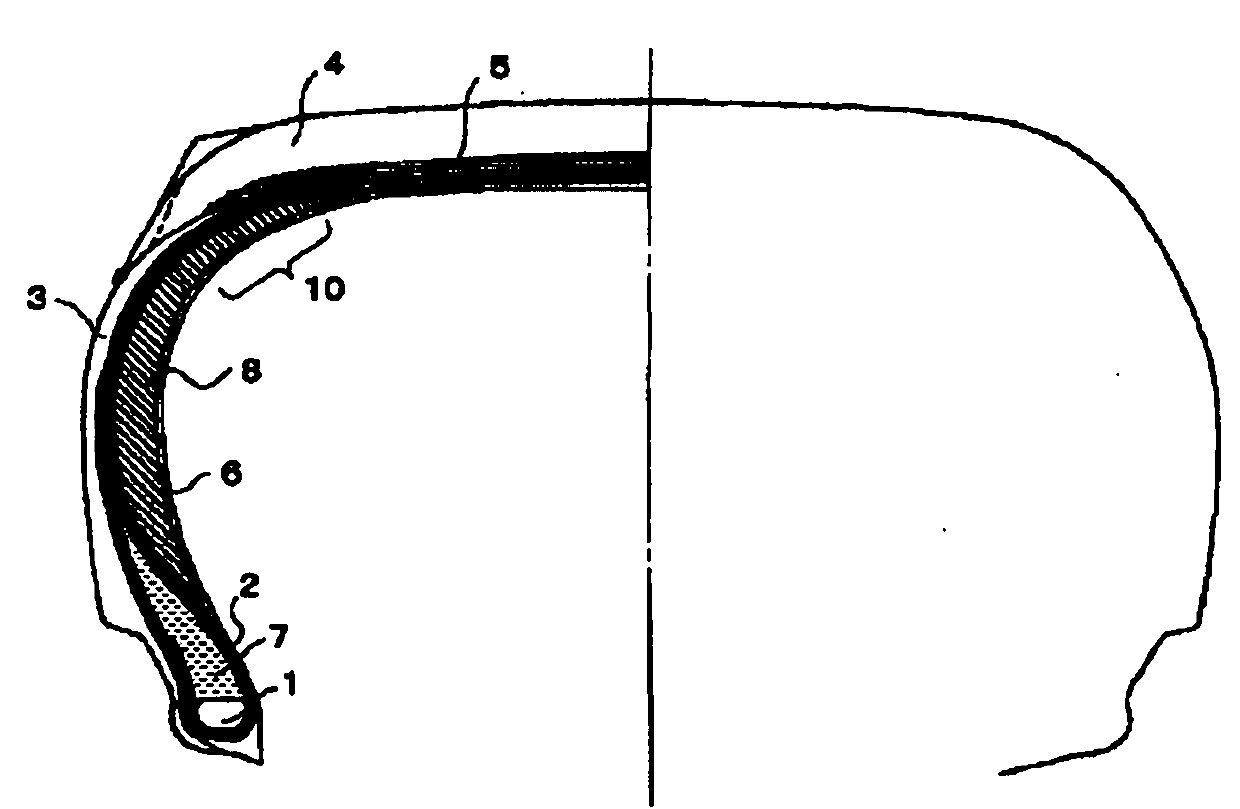

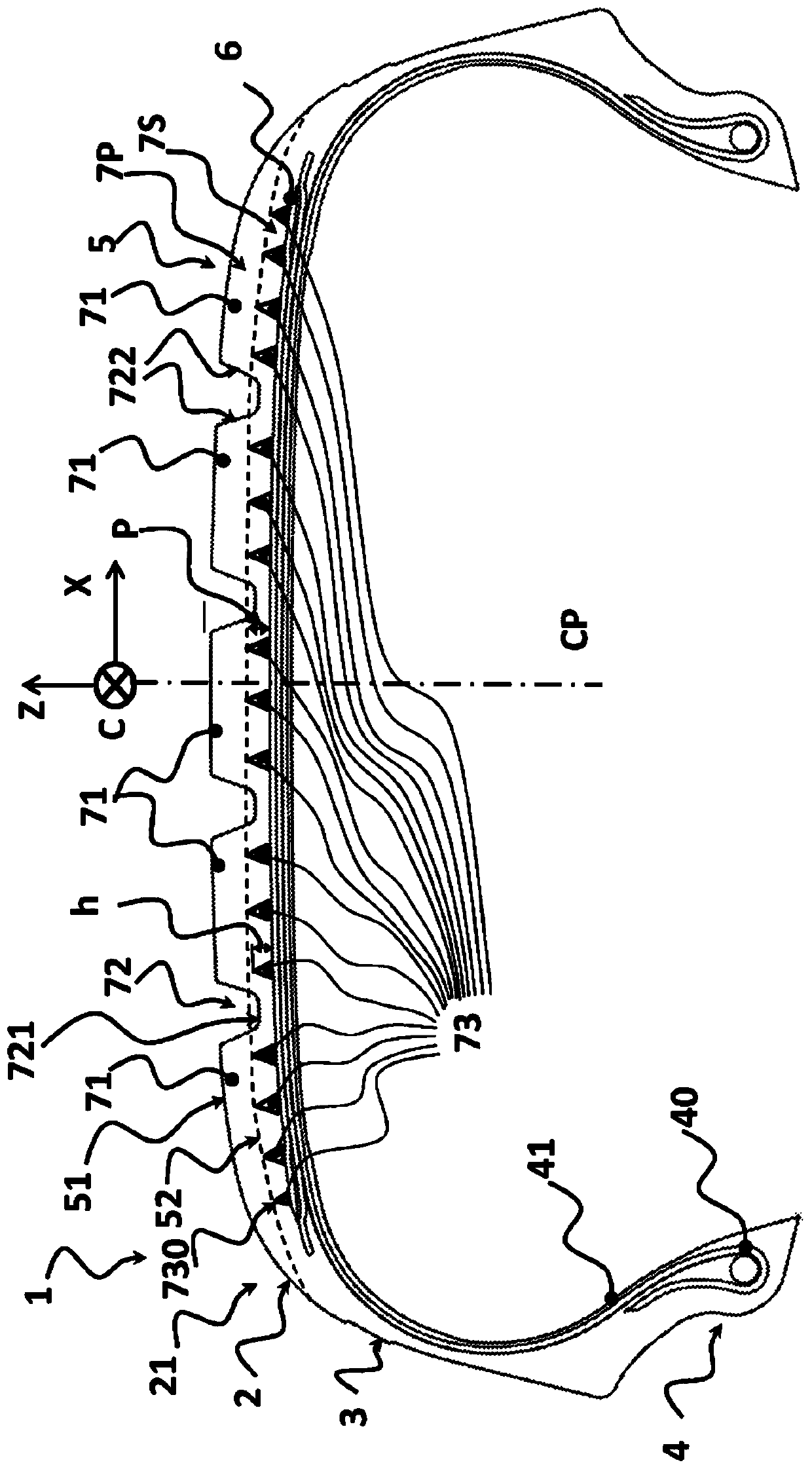

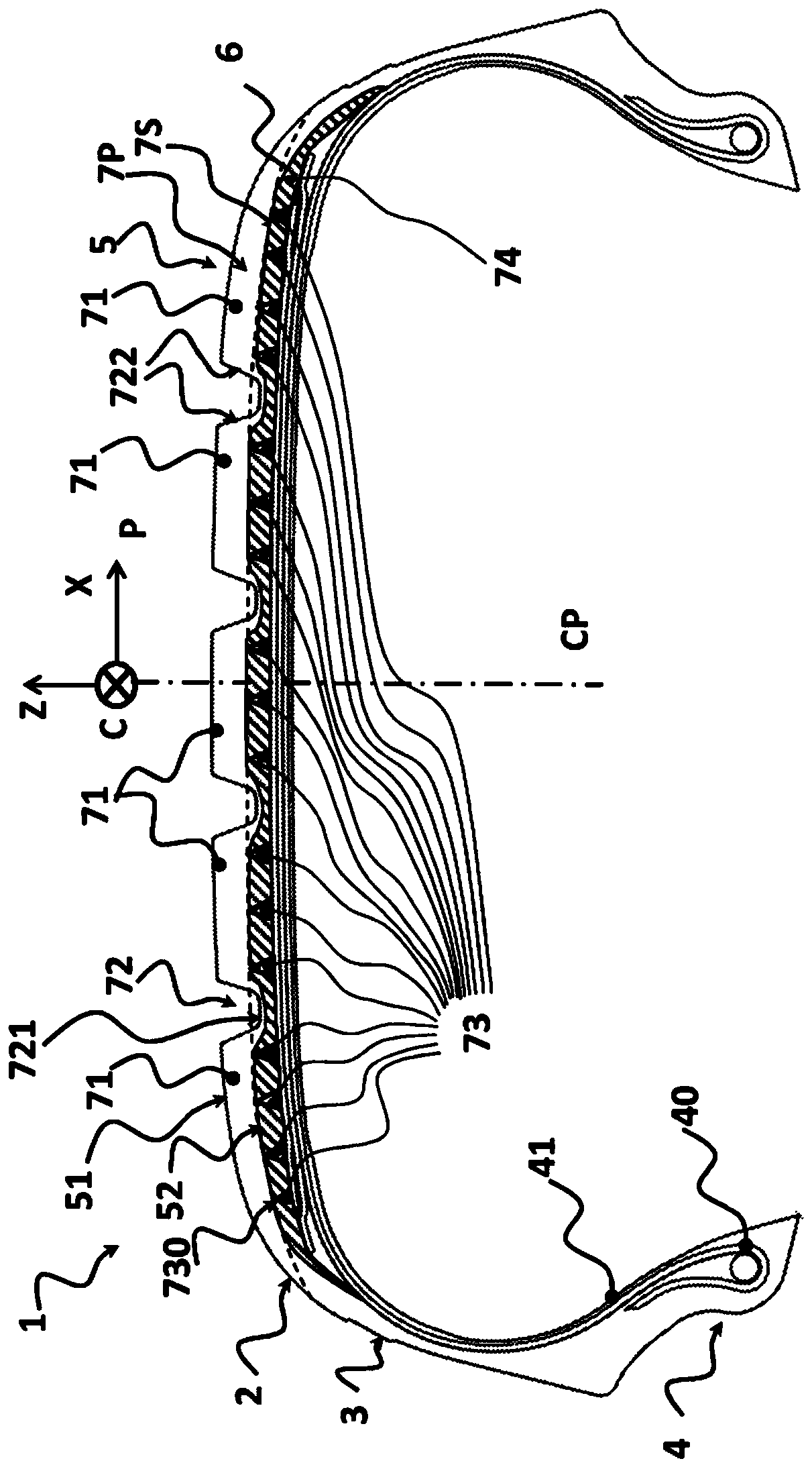

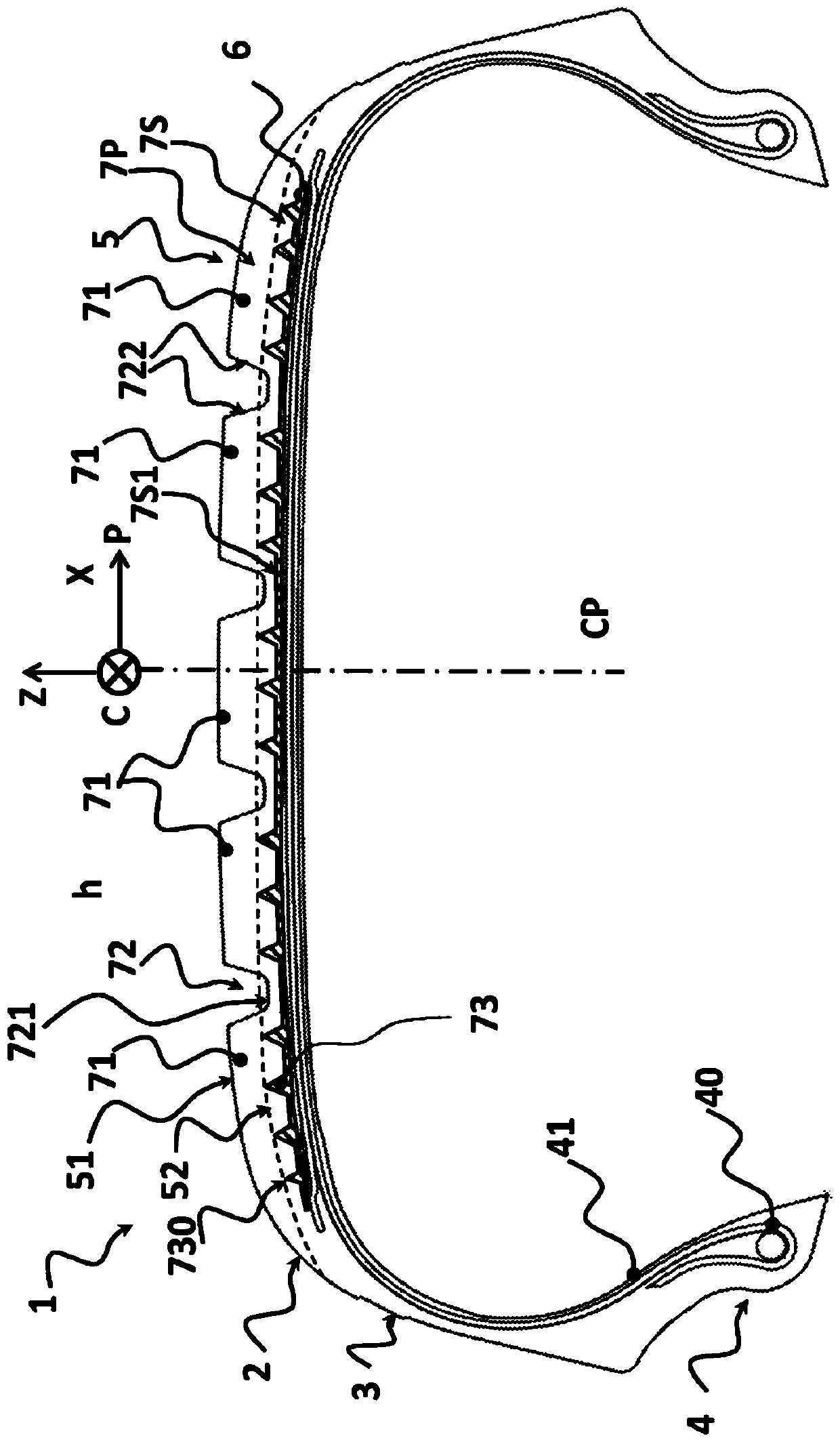

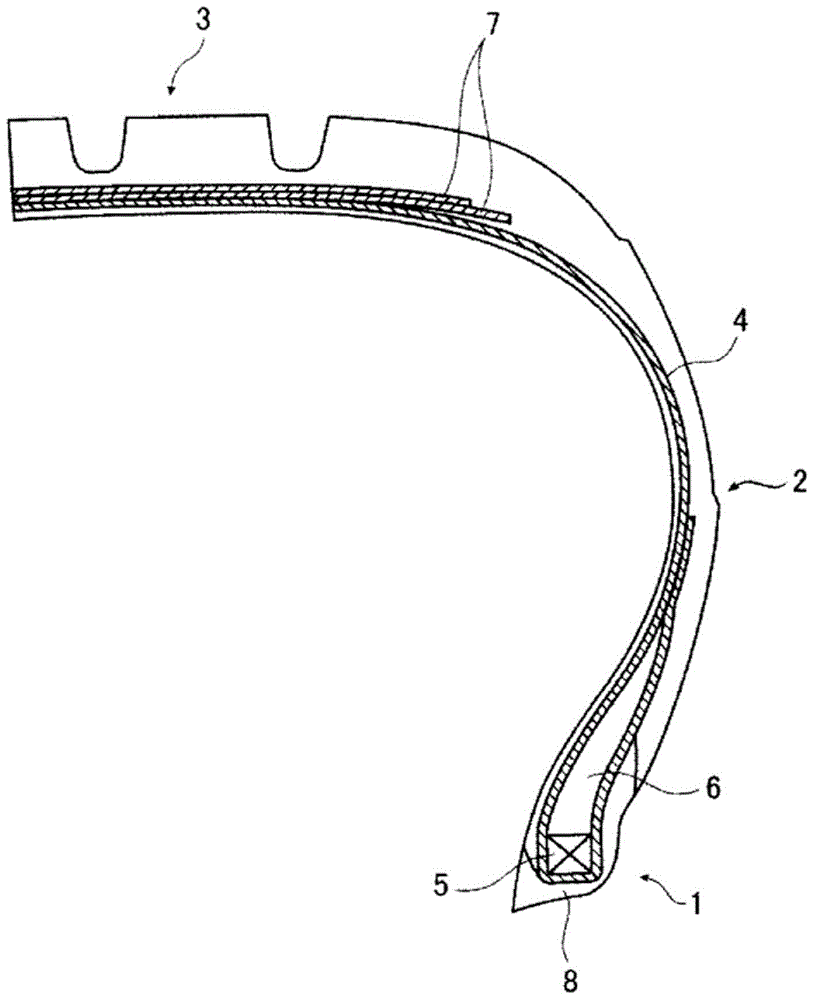

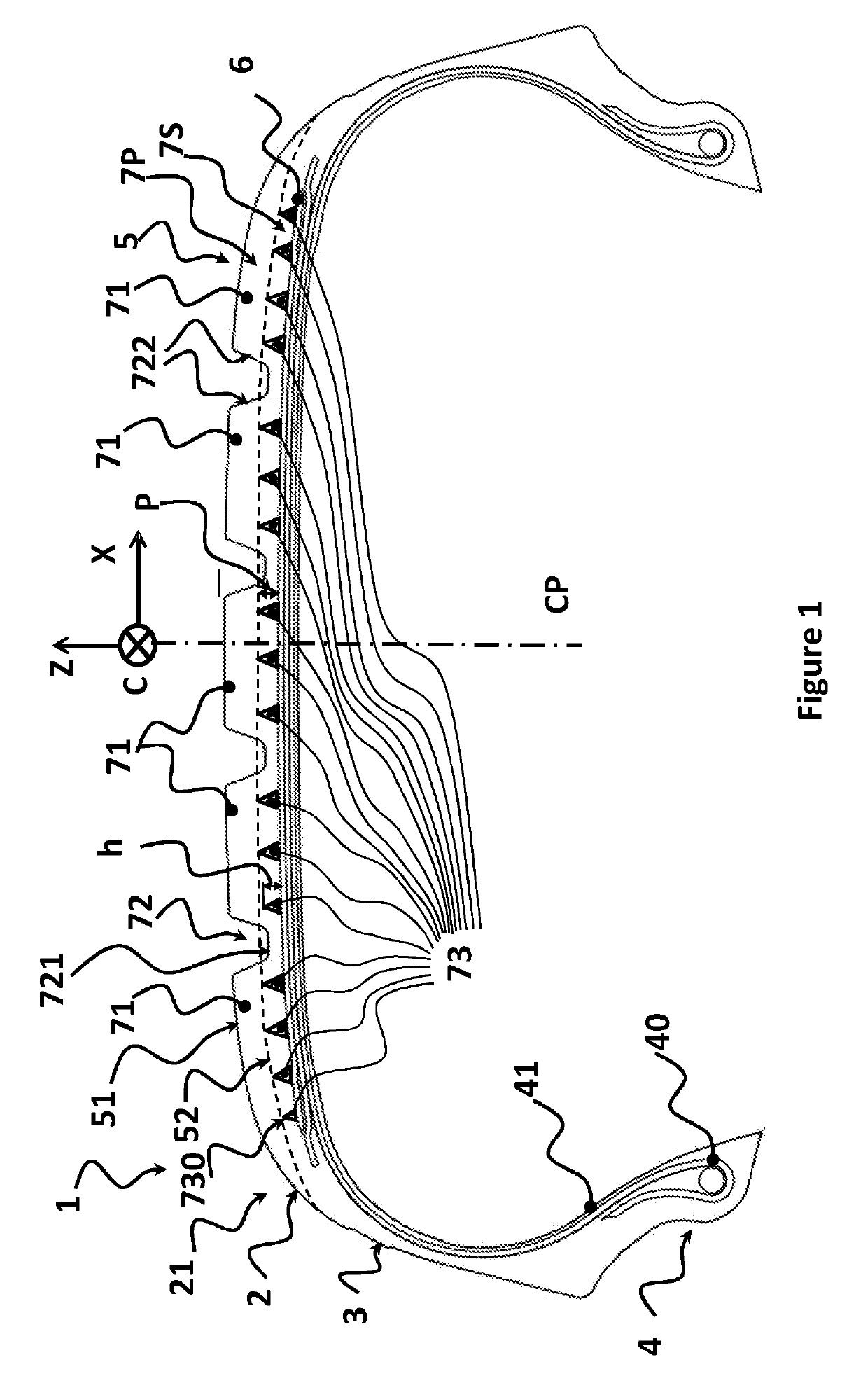

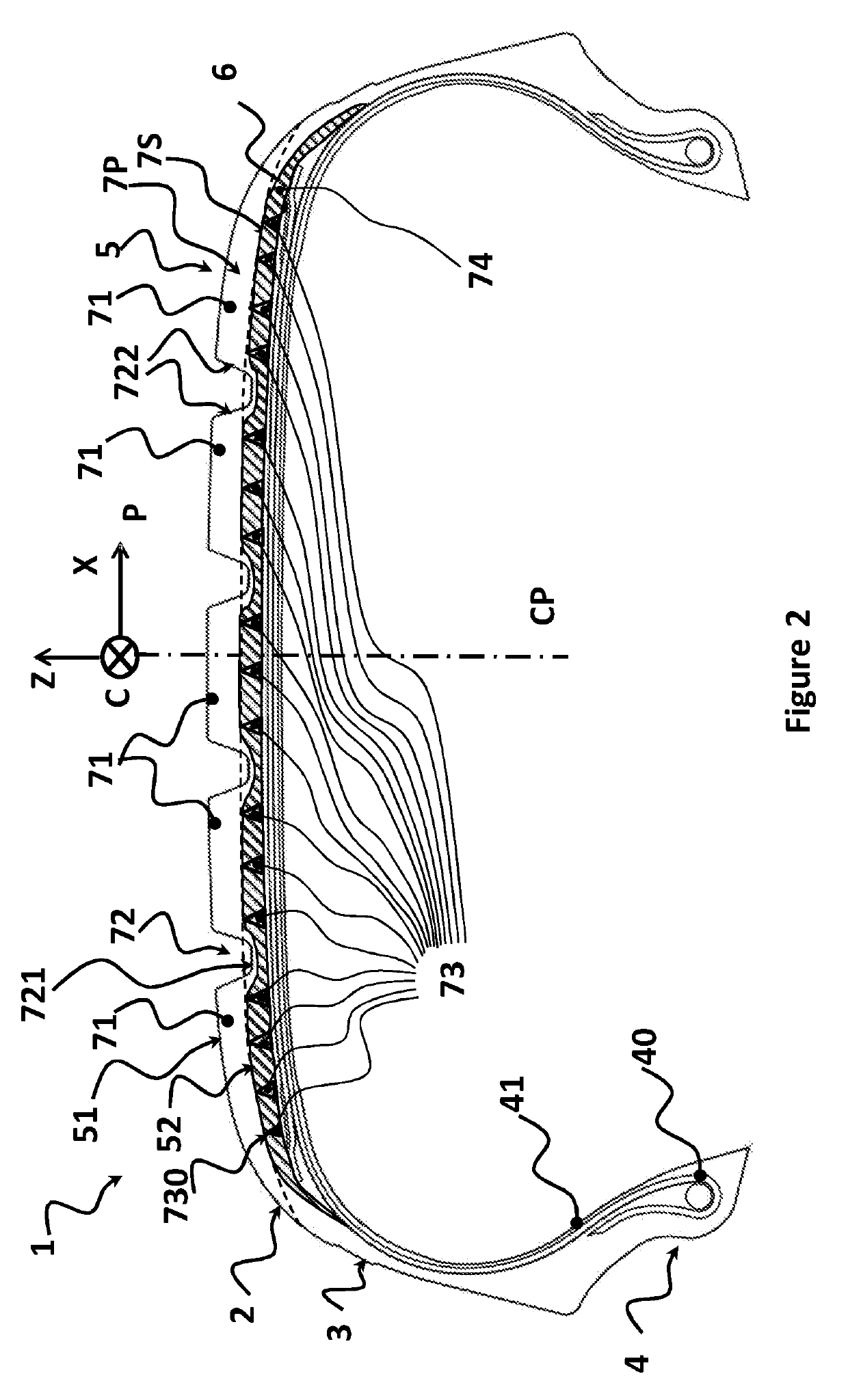

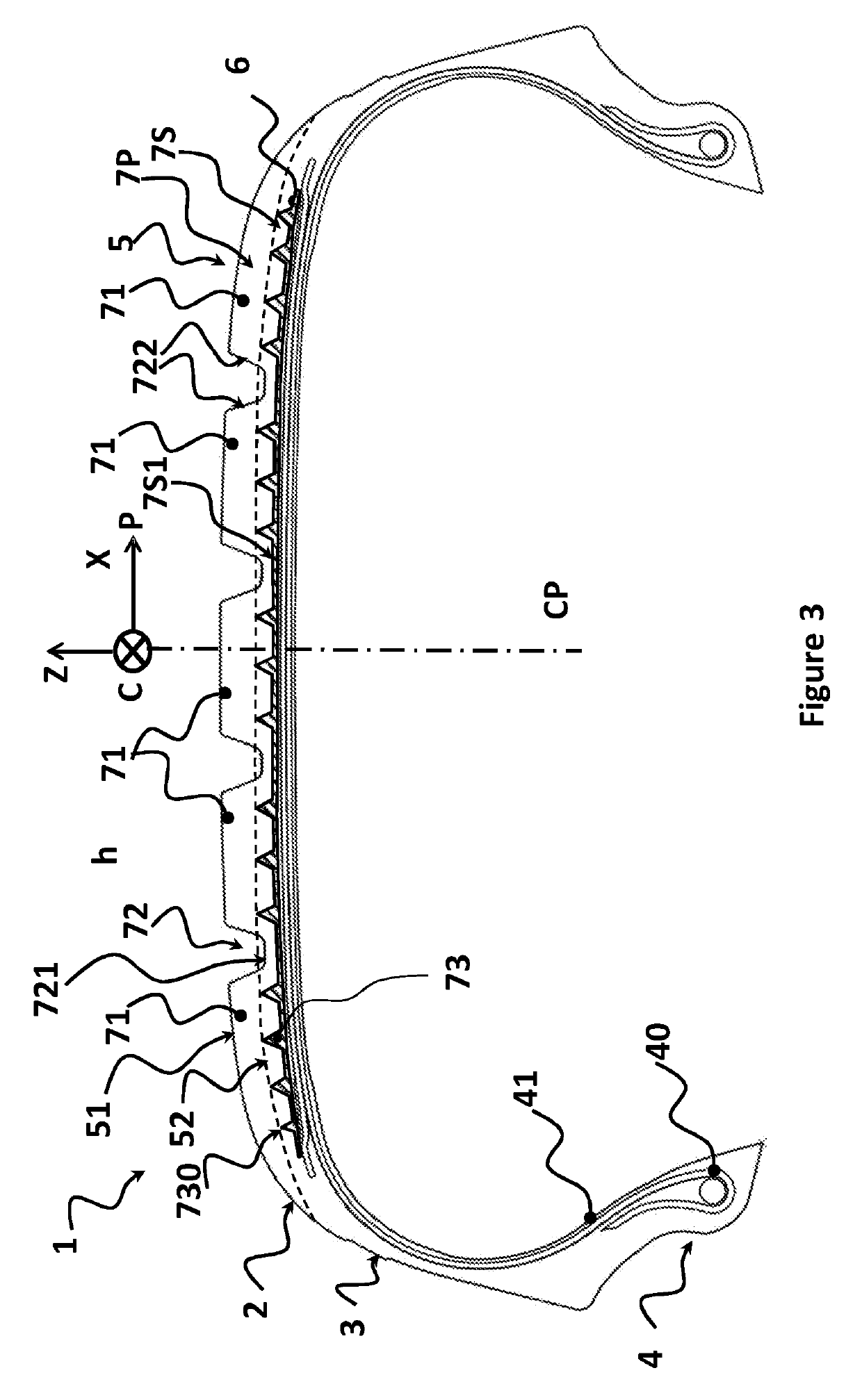

Tyre comprising a tread containing circumferential reinforcing elements in the sublayer

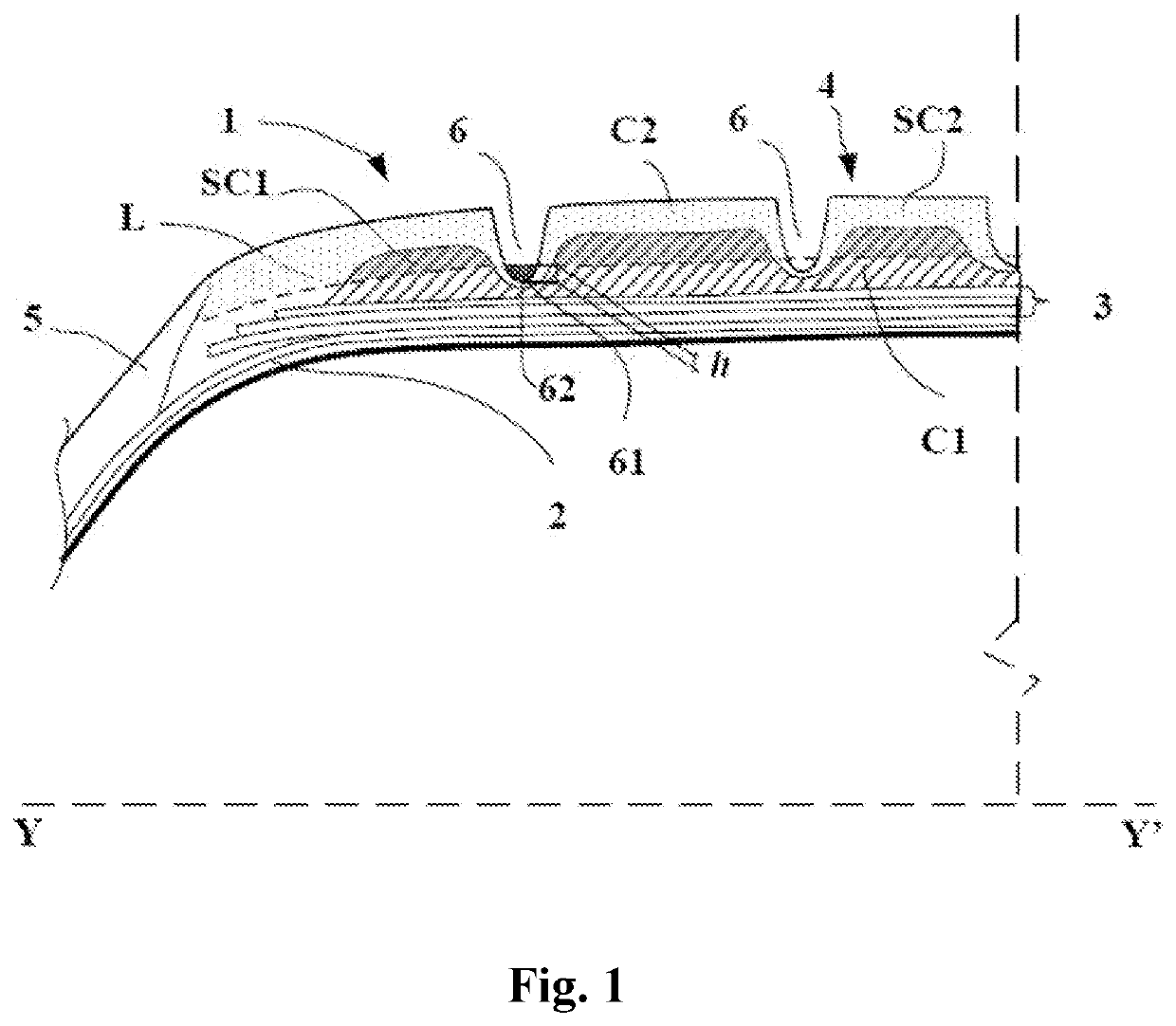

Tire (1) comprising two beads (4), two sidewalls (3) connected to the beads and a crown (2) connected to the ends of the two sidewalls, the crown comprising a crown reinforcement (6) and a tread (5) radially on the outside of the crown reinforcement (6), said tread (7) comprising a plurality of tread blocks (71), at least two radially superposed layers: a sub-layer (7S) covering the crown reinforcement (6) and a main layer (7P) radially on top of the crown reinforcement (6), the sub-layer comprising a plurality of circumferential reinforcing elements (73) made up of a rubber compound of a rigidity that is higher than the rigidity of the rubber compound of the rest of the sub-layer, the circumferential reinforcing elements (73) extending radially from the radially exterior surface of said crown reinforcement (6) toward the interface between the sub-layer (7S) and the main layer (7P), said circumferential reinforcing elements having axial width that decreases progressively in a radiallyoutwards direction.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

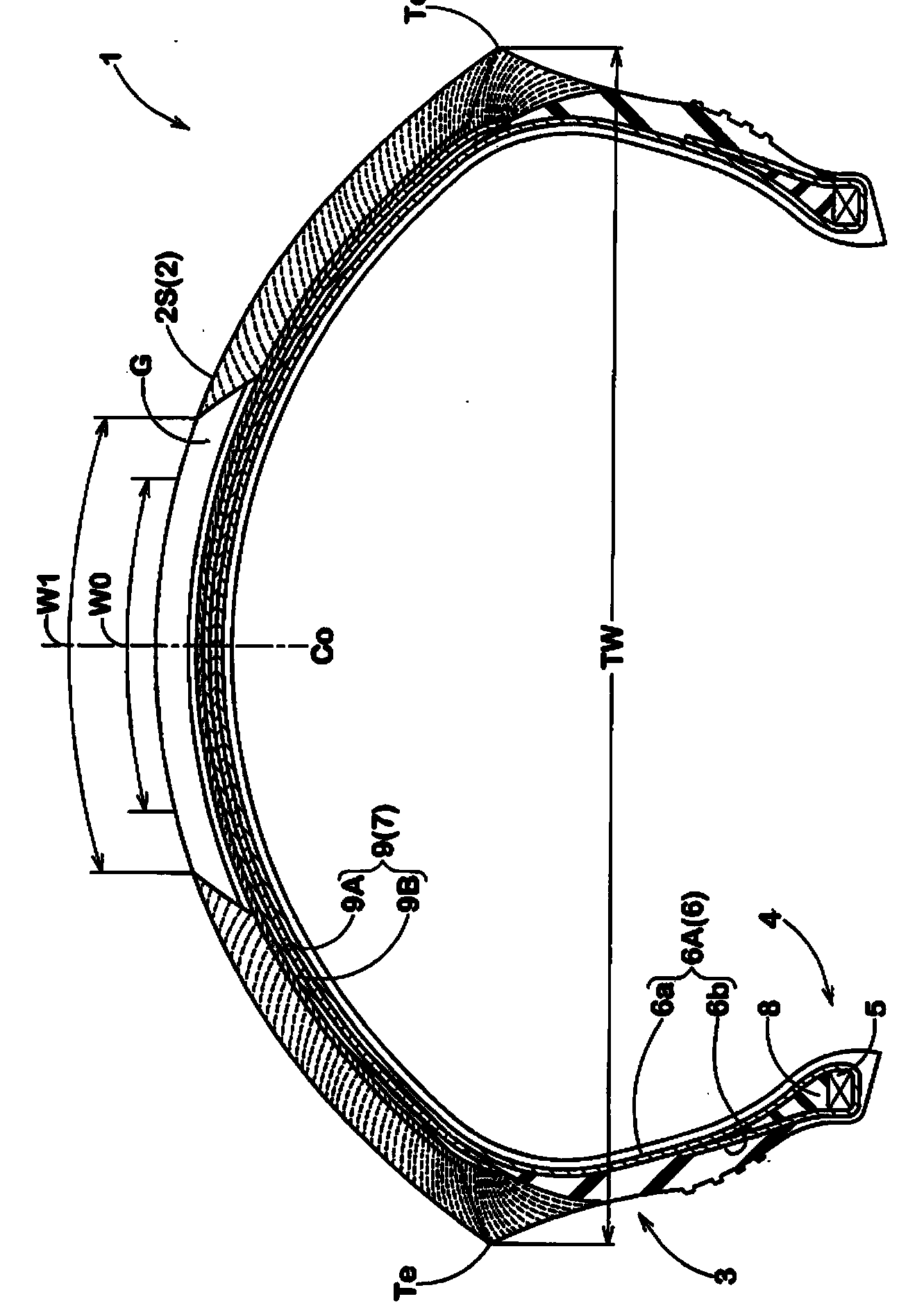

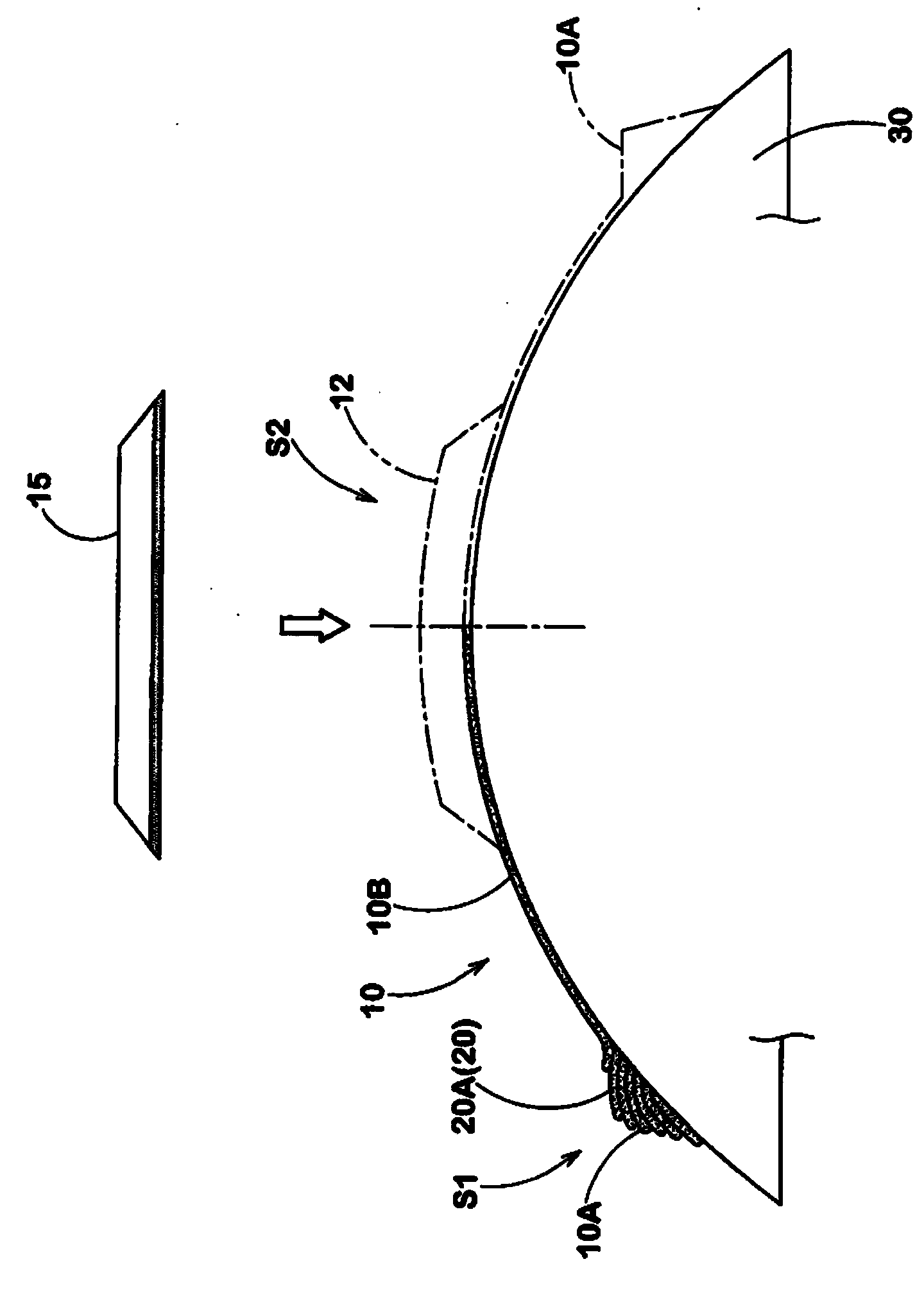

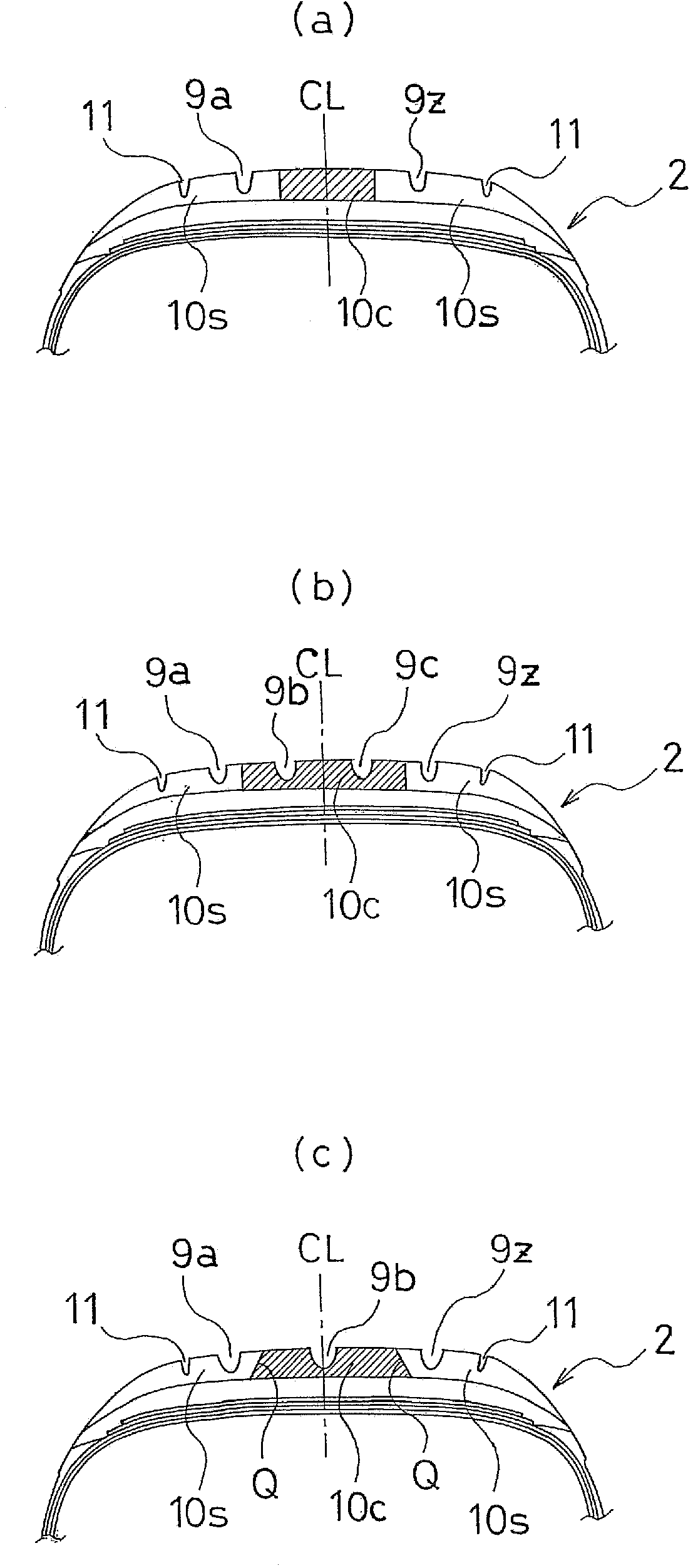

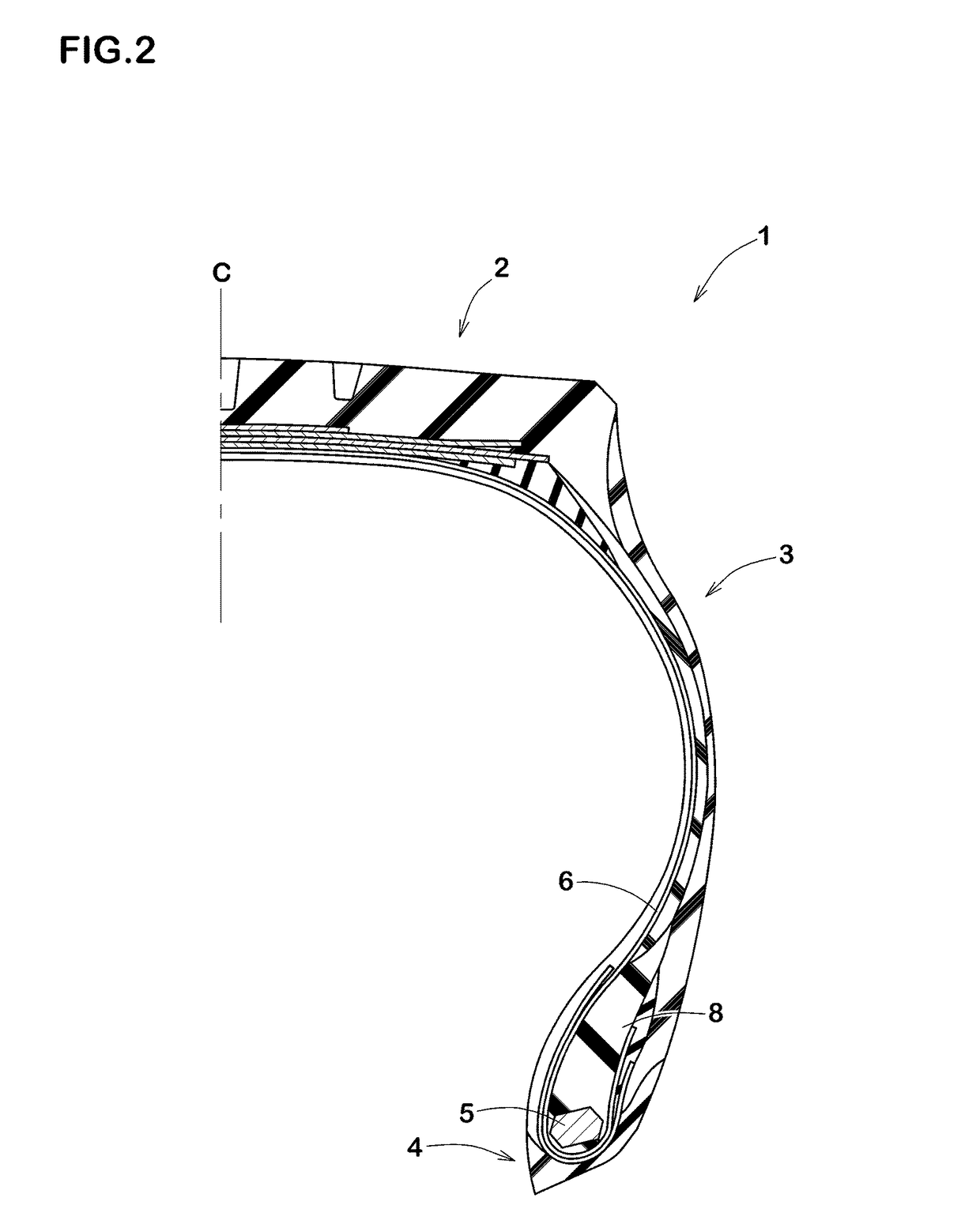

Motorcycle tyre and making method thereof

ActiveCN103660799AImprove rolling resistance performanceImprove cornering performanceTyresPneumatic tyre reinforcementsRolling resistanceMotorcycle tyre

The invention provides a motorcycle tyre and a making method thereof; the rolling resistance performance, operation stability and transition performance of steering from straight to a corner can be simultaneously improved; tread rubber comprises the following structures: a bottom layer having tread rubber side portions on two ends and a connecting rubber portion connecting the two tread rubber side portions; and a top layer configured on an outer side in a radial direction. The top layer comprises a central top on a tyre equatorial face side and shoulder tops configured on two outer sides of the central top; the central top comprises a central top main body portion forming a tyre surface and a central top base portion on a radial inner side of the central top main body portion; a cross section of the central top is a similar trapezoid with a base angle [theta] under 45 degrees, and rubber is employed to form a ring through extrusion molding so as to form the central top. A rubber strip is winded in a spiral shape so as to form the bottom layer and the shoulder tops.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition and tire

ActiveUS9228077B2Easy to processGood dispersionSpecial tyresRolling resistance optimizationPolymer scienceSilicon dioxide

Owner:KURARAY CO LTD +1

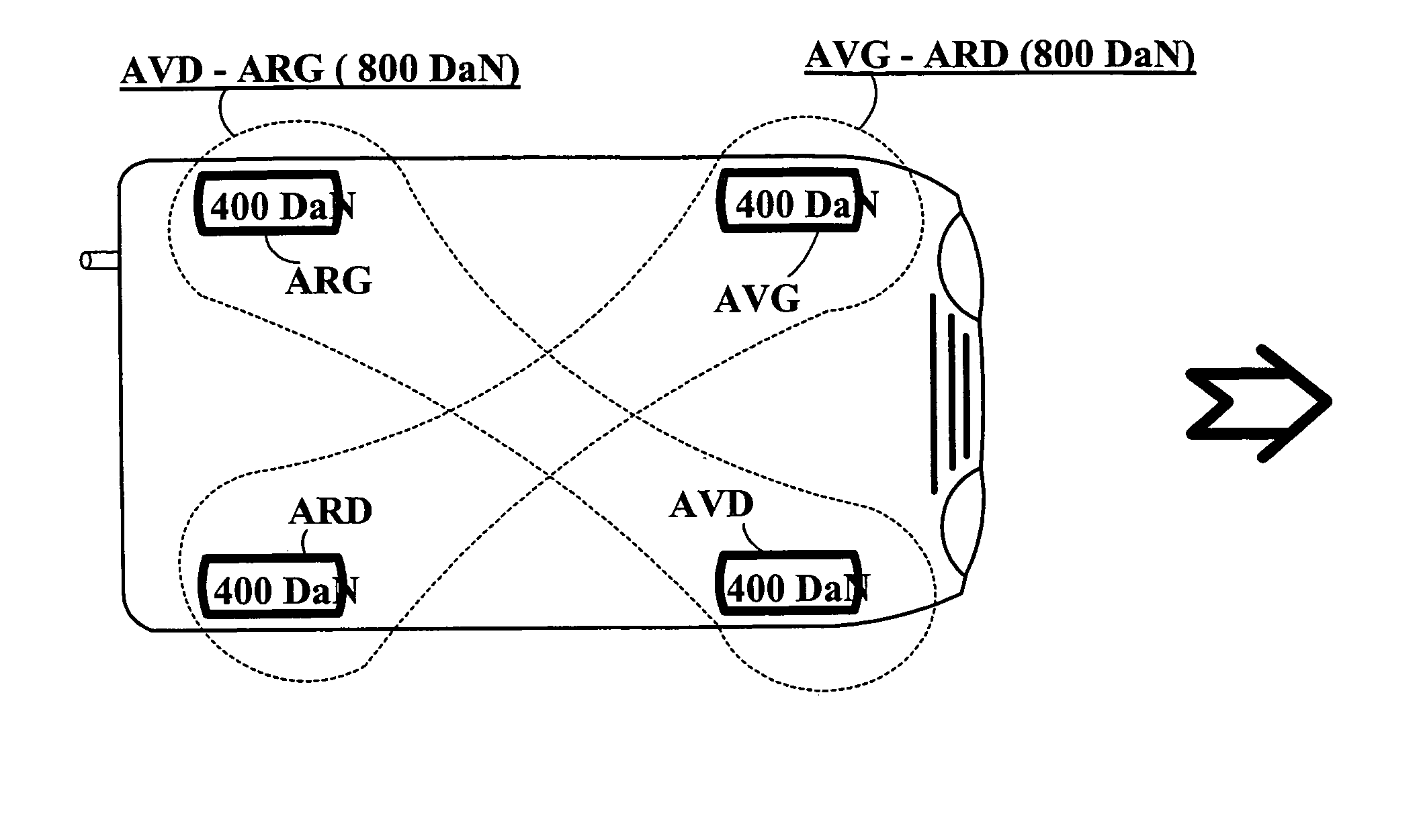

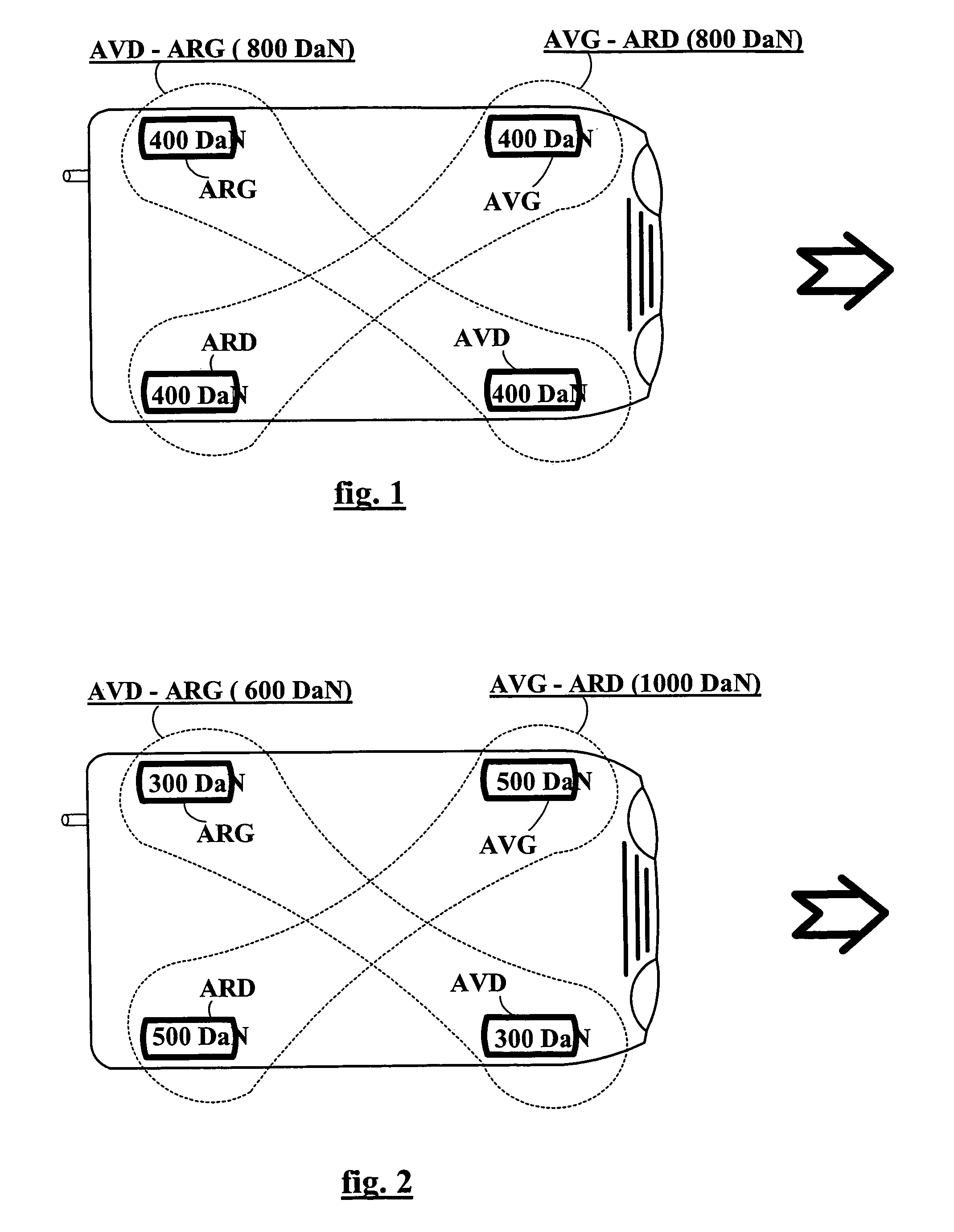

Method and system for extending the mobility of a vehicle

InactiveUS7546763B2Improve mobilityPreserve current performanceUnderstructuresTyre measurementsDiagonalActuator

The mobility of a vehicle having first and second pairs of diagonally opposite wheels is extended when the pressure on a given wheel is abnormally low. A load on the first pair of wheels defines a first load diagonal, and a load on the second pair of wheels defines a second load diagonal. A disequilibrium between the first and second load diagonals is induced by actuation of a level corrector comprised of at least two actuators each acting on a respective side of the vehicle, for reducing a load borne by said given wheel and thereby extending the mobility thereof.

Owner:MICHELIN RECH & TECH SA

Rubber composition for tread and pneumatic tire

InactiveCN101987890AImprove driving performanceIncrease contentSpecial tyresRolling resistance optimizationRoad surfaceEngineering

Owner:SUMITOMO RUBBER IND LTD

Low-temperature-resistant wet-skid-resistant tire tread and preparation method thereof

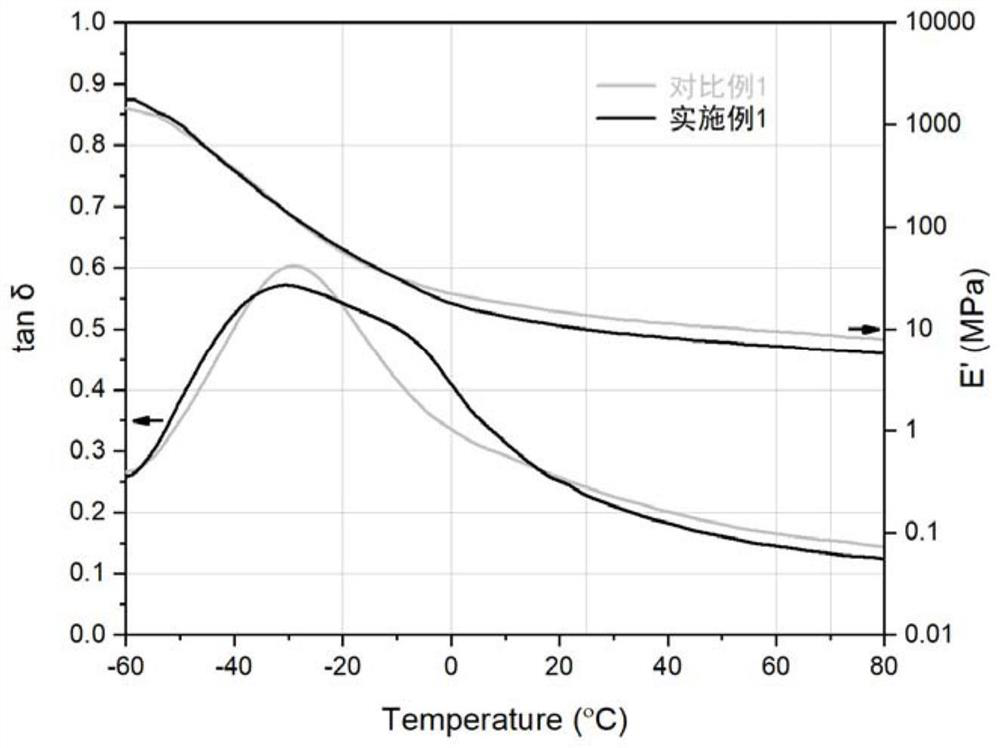

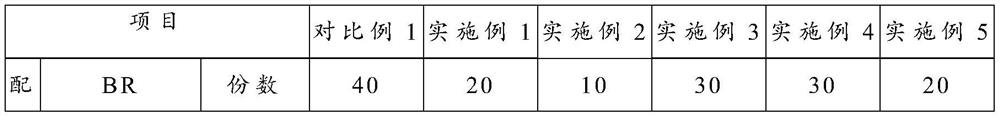

ActiveCN112280127AImprove low temperature resistanceImprove wet skid resistanceSpecial tyresRolling resistance optimizationRolling resistancePolybutadiene

The invention discloses a low-temperature-resistant wet-skid-resistant tire tread and a preparation method thereof, and belongs to the technical field of tire tread rubber compositions, the tire treadcomprises a low-temperature-resistant wet-skid-resistant tire tread rubber composition, and the tire tread rubber composition comprises 10-30 parts of polybutadiene rubber, 40-70 parts of medium-lowstyrene low-Tg SSBR, 10-30 parts of SSBR with high styrene and high Tg, 5-20 parts of anti-slippery resin, 80-120 parts of white carbon black, 5-15 parts of a silane coupling agent and 20-60 parts ofenvironment-friendly oil. The product is applied to tires, solves the problem that the existing tread rubber composition cannot well improve the wet skid resistance and the low temperature resistance,and has the characteristics that the low temperature resistance, the wet skid resistance and the rolling resistance of the tires can be improved at the same time, and the cost is reduced.

Owner:QINGDAO DOUBLESTAR TIRE IND CO LTD

Rubber composition for tire tread, and pneumatic tire

ActiveCN105073873AExcellent wet performance and low rolling resistanceGood processabilitySpecial tyresRolling resistance optimizationChemistryConjugated diene

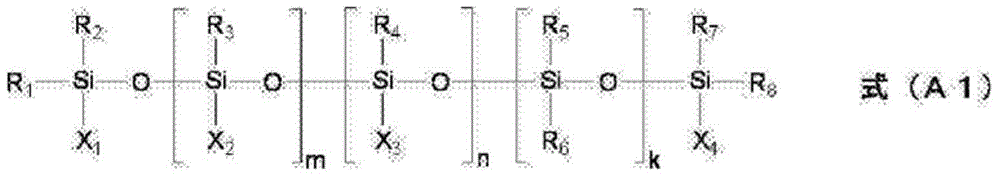

Provided is a rubber composition for tire tread, comprising: a diene rubber component containing 20 mass% or more of a specific denatured conjugated diene rubber; silica contained in the quantity of 60-200 parts by mass with respect to 100 parts by mass of said rubber component; and polysiloxane represented by averaged compositional formula (1), and contained in the quantity of 1-20 mass% with respect to the quantity of silica. Formula (1): (A)a(B)b(C)c(D)d(R1)eSiO(4-2a-b-c-d-e) / 2 (In the formula, A represents a bivalent organic group containing a sulfide group, B represents a C5-10 monovalent hydrocarbon group, C represents a hydrolyzable group, D represents an organic group containing a mercapto group, R1 represents a C1-4 monovalent hydrocarbon group, and a-e satisfy the conditional formulae 0≤a<1, 0≤b<1, 0<c<3, 0<d<1, 0≤e<2, and 0<2a+b+c+d+e<4, with the caveat that either a or b is not 0.) Also provided is a pneumatic tire using said composition in tire tread.

Owner:YOKOHAMA RUBBER CO LTD

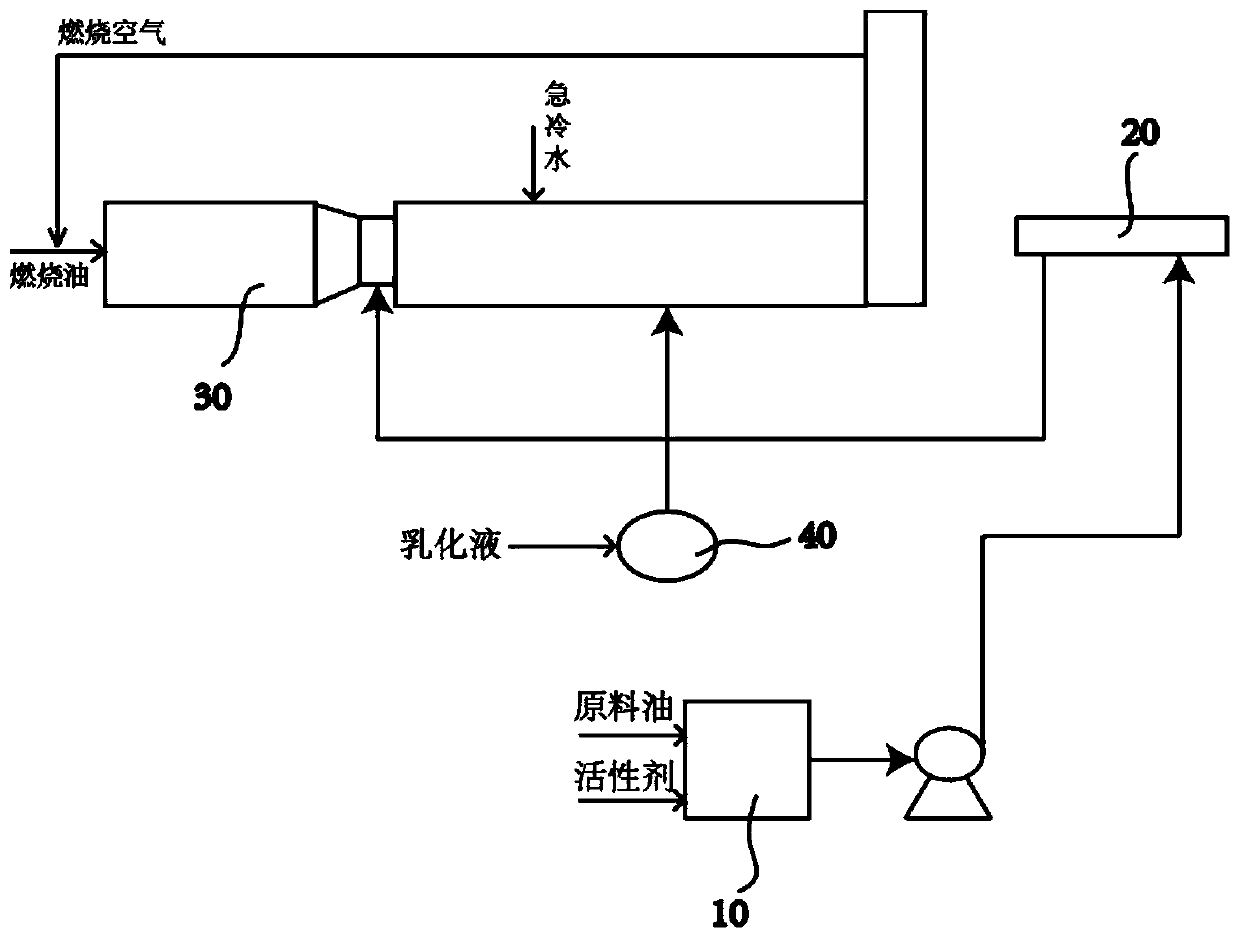

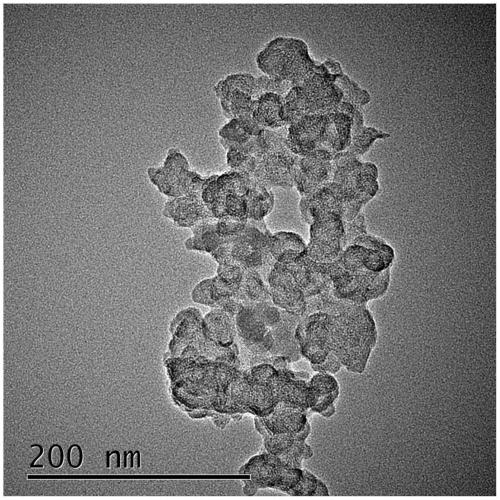

Composite carbon material and preparation method thereof, rubber composite material and tire

The invention provides a composite carbon material and a preparation method thereof, a rubber composite material and a tire, and relates to the technical field of carbon materials. According to the composite carbon material preparation method, an emulsifying liquid with a specific composition is sprayed to form atomized liquid droplets, the atomized liquid droplets react with primary structurally-modified carbon black existing in the form of flue gas, and by using a reinforcing filler and surface characteristics of the primary structurally-modified carbon black, the reinforcing filler reacts with and links to the primary structurally-modified carbon black to form the integration so as to obtain the composite carbon material. According to the present invention, the preparation method has simple and convenient operation, and is suitable for industrial-scale production, and the prepared composite carbon material has good low-hysteresis property. The present invention further provides a composite carbon material, which is prepared by using the composite carbon material preparation method, can meet the low-hysteresis performance requirement and the requirements of large-scale tire mixing, can be filled into different types of rubbers, is not limited to specific rubber latex, and has wide application range.

Owner:青岛黑猫新材料研究院有限公司

Tire rubber compositions

InactiveUS20200332089A1Enhance roll resistance performanceEnhance steer stabilitySpecial tyresTyre beadsComposite materialPolymer chemistry

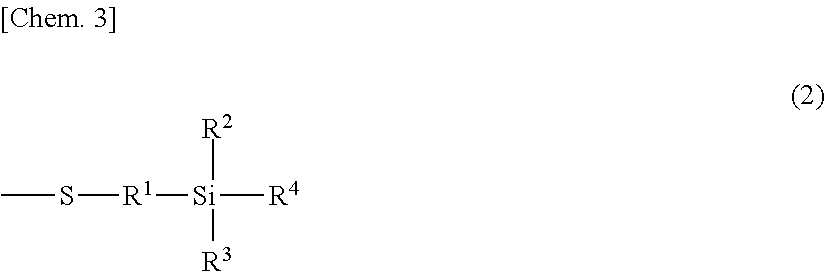

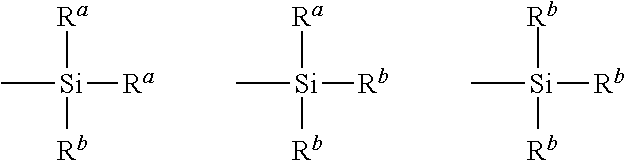

The tire rubber composition includes 100 parts by mass of a solid rubber (A) having a glass transition temperature (Tg) of not more than −10° C., 0.1 to 50 parts by mass of a modified liquid diene rubber (B) having a functional group derived from a silane compound with a specific structure, and 20 to 200 parts by mass of a filler (C), the modified liquid diene rubber (B) satisfying the following (i) to (iv): (i) the weight average molecular weight (Mw) is 15,000 to 120,000, (ii) the vinyl content is not more than 70 mol %, (iii) the average number of the functional groups per molecule of the modified liquid diene rubber (B) is 1 to 30, and (iv) the glass transition temperature (Tg) is not more than 0° C.

Owner:KURARAY CO LTD

Rubber composition

InactiveUS20070060686A1Excellent abrasion resistanceReduce rolling resistanceSpecial tyresTyre tread bands/patternsSilane couplingAir bubble

A rubber composition, wherein a reaction efficiency of a silane coupling agent at kneading is improved, generation of air bubbles is suppressed, abrasion resistance is improved, and rolling resistance is lowered, is provided. A rubber composition containing silica, which comprises 3 to 15 parts by weight of a silane coupling agent based on 100 parts by weight of silica, and boric acid.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition and process for preparing the same

InactiveUS7569632B2Efficient couplingSuppress the generation of air bubblesSpecial tyresRolling resistance optimizationPolymer scienceRolling resistance

A rubber composition which is effective in improving the reaction efficiency of a silane coupling agent in kneading, suppressing generation of air bubbles, improving processability and abrasion resistance and lowering rolling resistance, and a process for preparing the same, wherein the rubber composition includes silica, 3 to 15 parts by weight of a silane coupling agent based on 100 parts by weight of the silica and 0.3 to 1.45 parts by weight of a potassium salt based on 100 parts by weight of silica.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

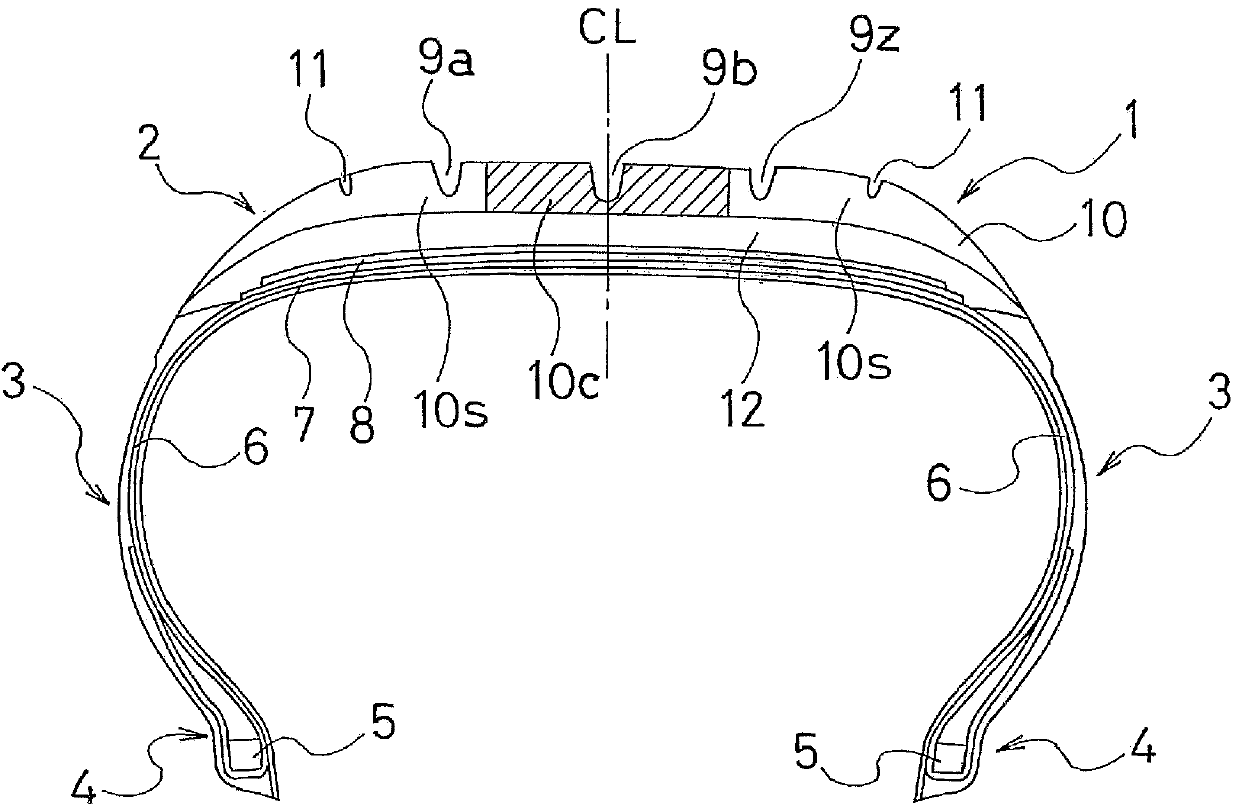

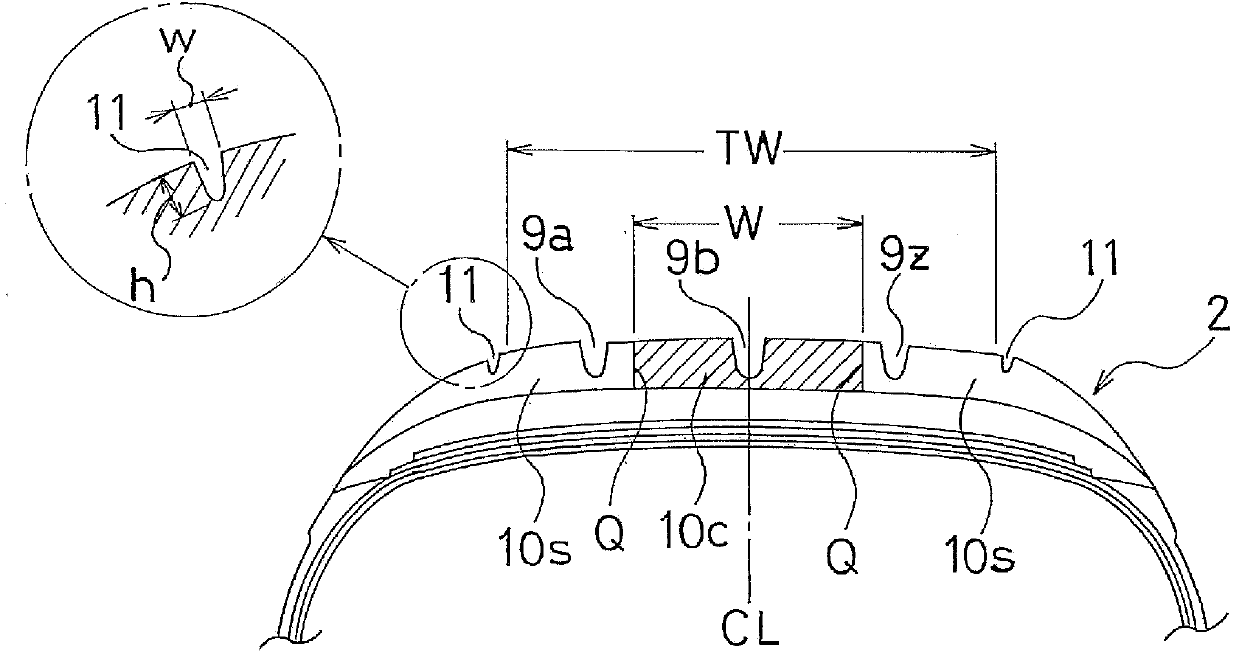

ActiveCN104220277AImprove grip characteristicsImprove rolling resistance performanceTyre tread bands/patternsRolling resistance optimizationRolling resistanceEngineering

The present invention provides a pneumatic tire which has both rolling resistance and wet grip performance while suppressing the occurrence of uneven wear. This pneumatic tire has a configuration in which cap rubber (10) is divided into a center part (10c) that extends across a tire equator line (CL) and shoulder parts (10s, 10s) located on both sides thereof, a compound having a higher tandelta at 0 DEG C compared to the shoulder part (10s) and focusing on wet grip performance is disposed in the center part (10c), a compound having a lower tandelta at 60 DEG C compared to the center part (10c) and focusing on rolling resistance is disposed in both the shoulder parts (10s, 10s), and circumferential fine grooves (11, 11) are formed on the respective shoulder sides of outermost main grooves (9a, 9z) in both the shoulder parts (10s, 10s).

Owner:YOKOHAMA RUBBER CO LTD

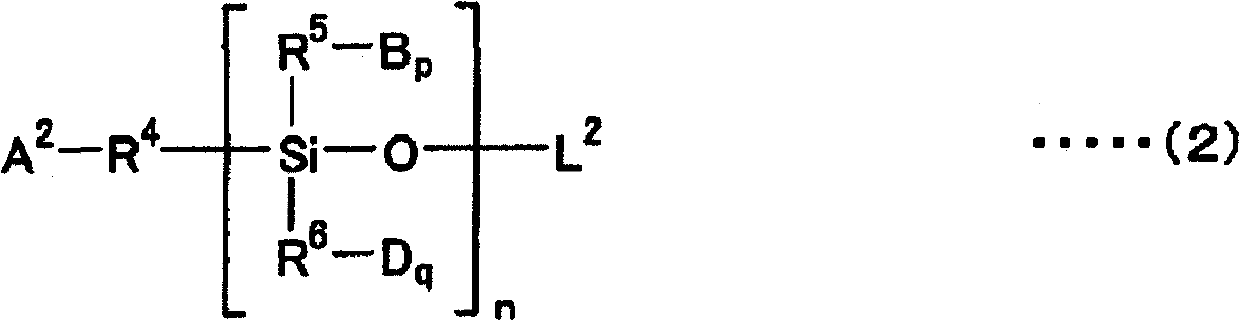

Rubber compositions

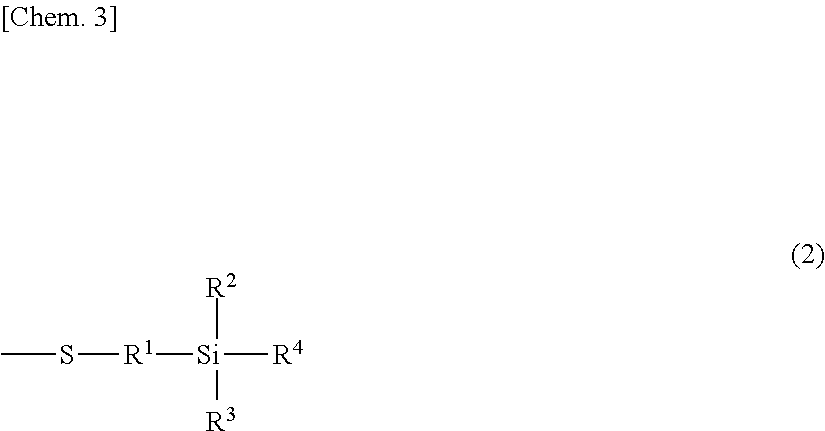

ActiveUS20190194429A1Maintain good propertiesImprove steering stabilitySpecial tyresRolling resistance optimizationSilane compoundsPolymer science

Disclosed herein is a rubber composition containing 100 parts by mass of a solid rubber (A), 0.1 to 50 parts by mass of a modified liquid diene rubber (B) having a functional group derived from a silane compound represented by the formula (1), and 20 to 200 parts by mass of a filler (C), the modified liquid diene rubber (B) satisfying (i) to (iii): (i) a weight average molecular weight (Mw) is not less than 1,000 and less than 15,000; (ii) a vinyl content is not more than 70 mol %; and (iii) an average number of functional groups per molecule of the modified liquid diene rubber (B) is 1 to 20.

Owner:KURARAY CO LTD

Tire comprising a tread containing circumferential reinforcing elements in the sublayer

A tire (1) comprises two beads (4), two sidewalls (3) connected to the beads and a crown (2) connected to the ends of the two sidewalls, the crown comprising a crown reinforcement (6) and a tread (5) radially outside the crown reinforcement (6), said tread (7) comprising a plurality of tread pattern blocks (71), at least two radially superposed layers: a sublayer (7S) covering the crown reinforcement (6), and a main layer (7P) radially above the crown reinforcement (6), the sublayer comprising a plurality of circumferential reinforcing elements (73) being formed of a rubber compound having greater stiffness than the stiffness of the rubber compound of the rest of the sublayer, the circumferential reinforcing elements (73) extending radially from the radially exterior surface of said crown reinforcement (6) in the direction of the interface between the sublayer (7S) and the main layer (7P), said circumferential reinforcing elements having an axial width which decreases gradually with increasing radial proximity to the outside.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

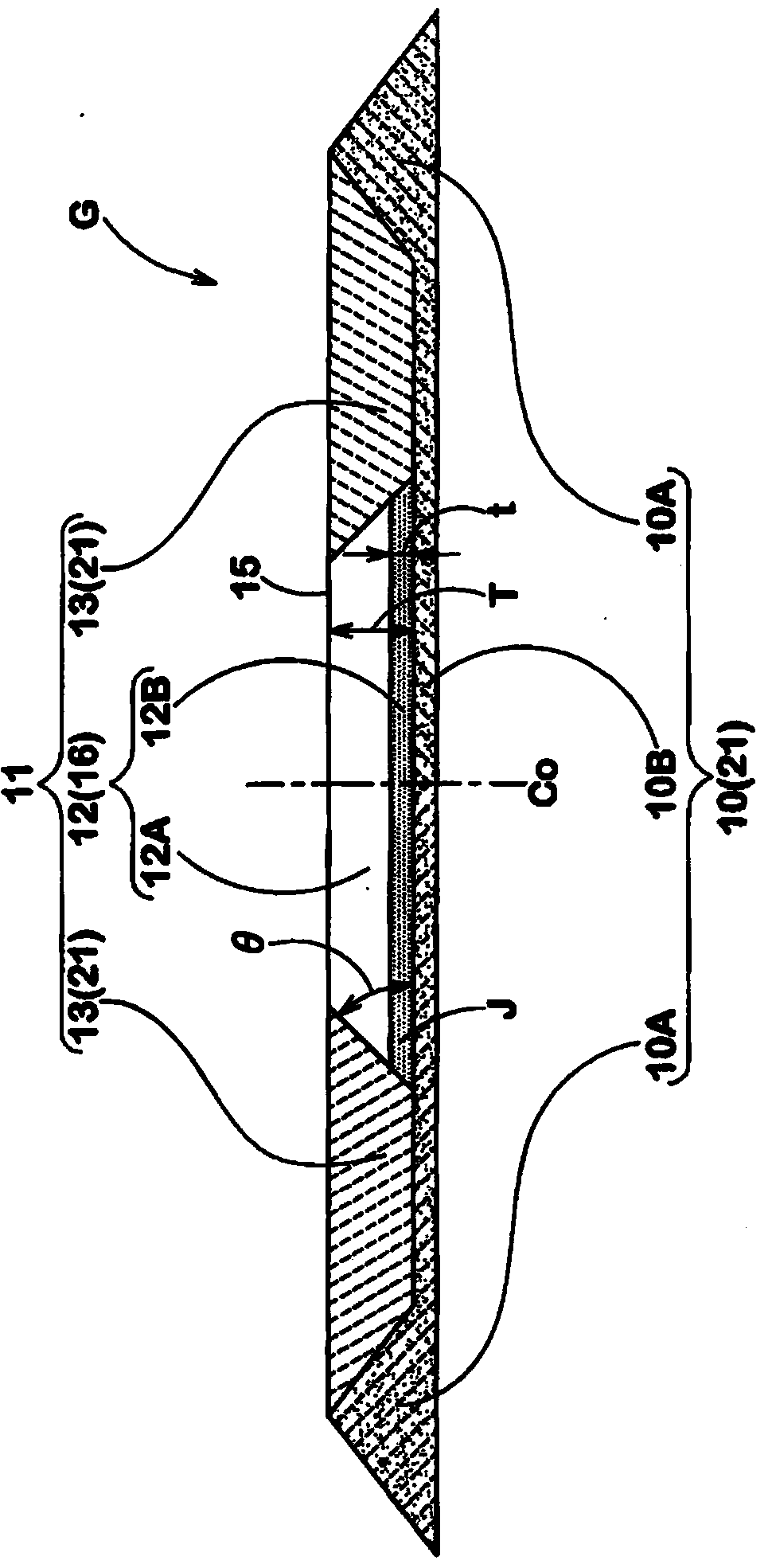

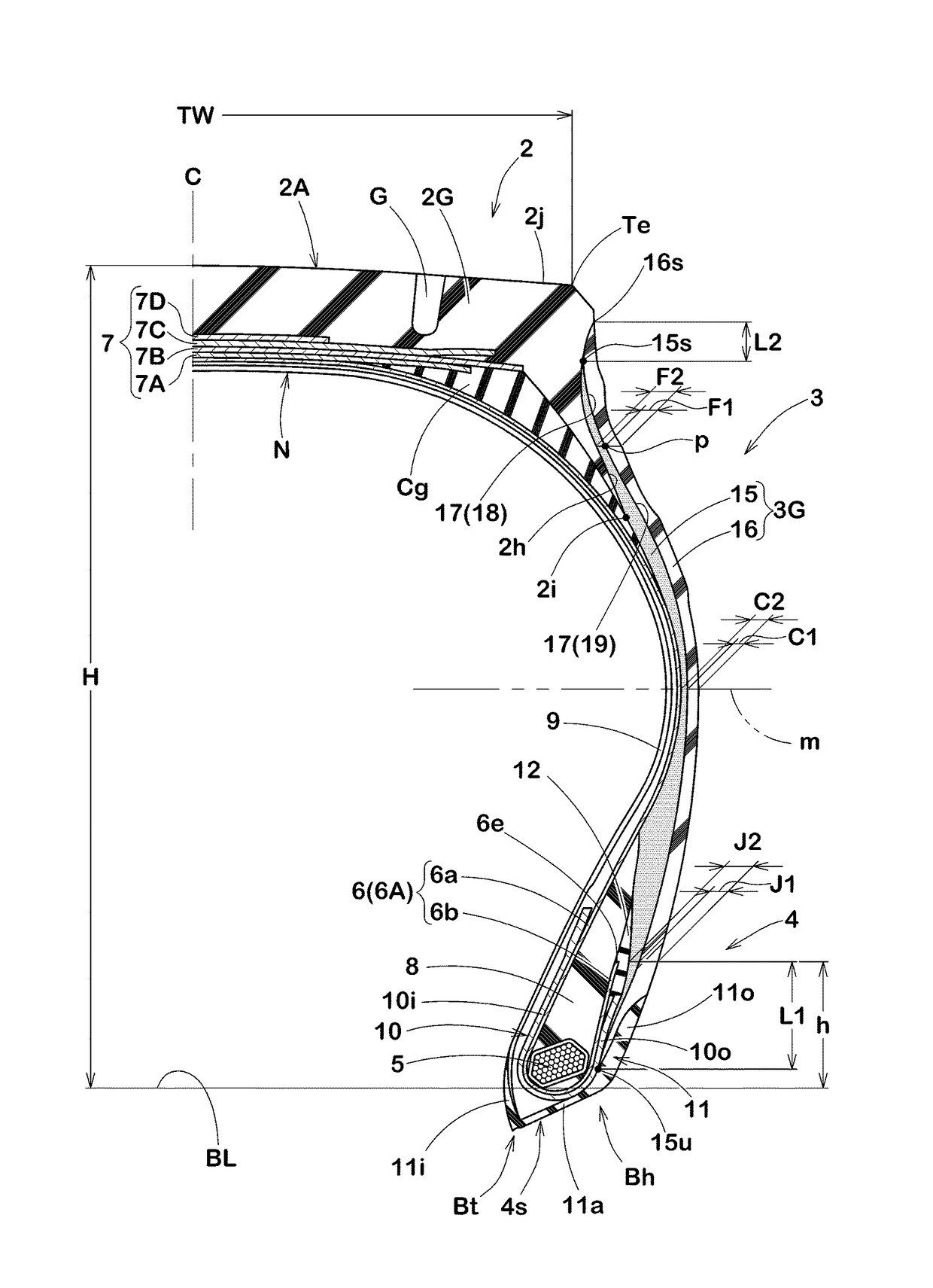

Tire for heavy loads

ActiveUS9815338B2Weaken energyReduce generationHeavy duty tyresHeavy duty vehicleRolling resistanceEngineering

To improve durability performance and rolling resistance performance in a well-balanced manner. It is a tire for heavy loads including a carcass ply (6A). A sidewall rubber (3G) includes an inside rubber part (15) on the carcass (6) side, and an outside rubber part (16) disposed on the outside thereof and forming a tire outer surface. The inside rubber part (15) has a loss tangent tan δ1 less than the outside rubber part (16), and their difference is 0.010 to 0.035. The inside rubber part (15) has a complex elastic modulus less than the outside rubber part (16), their difference is 0.5 to 1.4 (MPa). The outer end (15s) in the tire radial direction of the inside rubber part (15) contacts with the outer surface (2h) in the tire axial direction of the tread rubber (2G), and the inner end (15u) in the tire radial direction is disposed radially inside the outer end (6e) in the tire radial direction of the turned up portion (6b) of the carcass ply (6A).

Owner:SUMITOMO RUBBER IND LTD

Rubber composition

ActiveCN109642055AImprove handling stabilityImprove rolling resistance performanceSpecial tyresRolling resistance optimizationSilane compoundsPolymer science

To provide: a rubber composition from which a crosslinked product having excellent wear resistance and mechanical strength, such as tensile strength, can be obtained, the state of dispersion of a filler in the crosslinked product obtained from the rubber composition being ideal for improving physical properties; said crosslinked product; and a tire that uses, in a portion thereof, said compositionor said crosslinked product, and that is capable of achieving an improvement in rolling resistance and steering stability. [Solution] Disclosed is a rubber composition comprising, per 100 parts by mass of a solid rubber (A): from 0.1 to 50 parts by mass of a modified liquid diene rubber (B) having a functional group derived from a silane compound represented by formula (1); and from 20 to 200 parts by mass of a filler (C). The modified liquid diene rubber (B) satisfies the following (i) to (iii): (i) the weight-average molecular weight (Mw) is greater than or equal to 1,000 to less than 15,000; (ii) the vinyl content is less than or equal to 70 mol%; and (iii) the average number of functional groups per molecule of the modified liquid diene rubber (B) is from 1 to 20.

Owner:KURARAY CO LTD

Tire rubber composition and pneumatic tire

ActiveCN102199316BImprove gripGood balance of abrasion resistanceSpecial tyresRolling resistance optimizationRolling resistanceSulfur

The present invention aims to provide a tire rubber composition that achieves a good balance of grip performance (especially, wet grip performance), abrasion resistance, cut and chip resistance, low rolling resistance, and kneadability, and a pneumatic tire using the same. The composition comprise: a rubber component including a styrene-butadiene rubber modified by a compound of formula (1) : and a non-modified styrene-butadiene rubber; a filler including silica, the filler being in an amount of 80 parts by mass or less per 100 parts by mass of the rubber component; and sulfur in an amount of 0.5-1.5 parts by mass per 100 parts by mass of the rubber component, the modified styrene-butadiene rubber having a bound styrene content of 20-40% by mass and a vinyl content of 30-65% by mass, and the non-modified styrene-butadiene rubber having a bound styrene content of 25-45% by mass and a vinyl content of 10-50% by mass.

Owner:SUMITOMO RUBBER IND LTD

Tread for a tire

PendingUS20220072903A1Improve gripImprove rolling resistance performanceSpecial tyresTyre tread bands/patternsPolymer scienceButadiene Dioxide

A tire having a rubber tread comprises a first radially inner layer C1 and a second radially outer layer C2, the first and second layers being intended to be in contact with a ground on which they are running, in new or worn condition, in which the rubber composition of the first layer C1 comprises more than 50 phr of a copolymer of ethylene and of a 1,3-diene, a reinforcing filler and a plasticizing system, the 1,3-diene being 1,3-butadiene or isoprene and the ethylene units in the copolymer representing more than 50 mol % of all the monomer units of the copolymer.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Rubber compositions

ActiveUS20190218376A1Improve steering stabilityImprove rolling resistance performanceSpecial tyresRolling resistance optimizationSilane compoundsPolymer science

A rubber composition includes 100 parts by mass of a solid rubber (A), 0.1 to 50 parts by mass of a modified liquid diene rubber (B) having a functional group derived from a silane compound represented by the formula (1), and 20 to 200 parts by mass of a filler (C), the modified liquid diene rubber (B) satisfying (i) to (iii) below: (i) The weight average molecular weight (Mw) is 15,000 to 120,000. (ii) The vinyl content is not more than 70 mol %. (iii) The average number of functional groups per molecule of the modified liquid diene rubber (B) is 1 to 30.

Owner:KURARAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com