Tyre comprising a tread containing circumferential reinforcing elements in the sublayer

A technology of reinforcing elements and crown reinforcements, applied in tire tread/tread pattern, tire parts, vehicle parts, etc., can solve the problem of reducing tire rolling resistance and achieve excellent reinforcement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

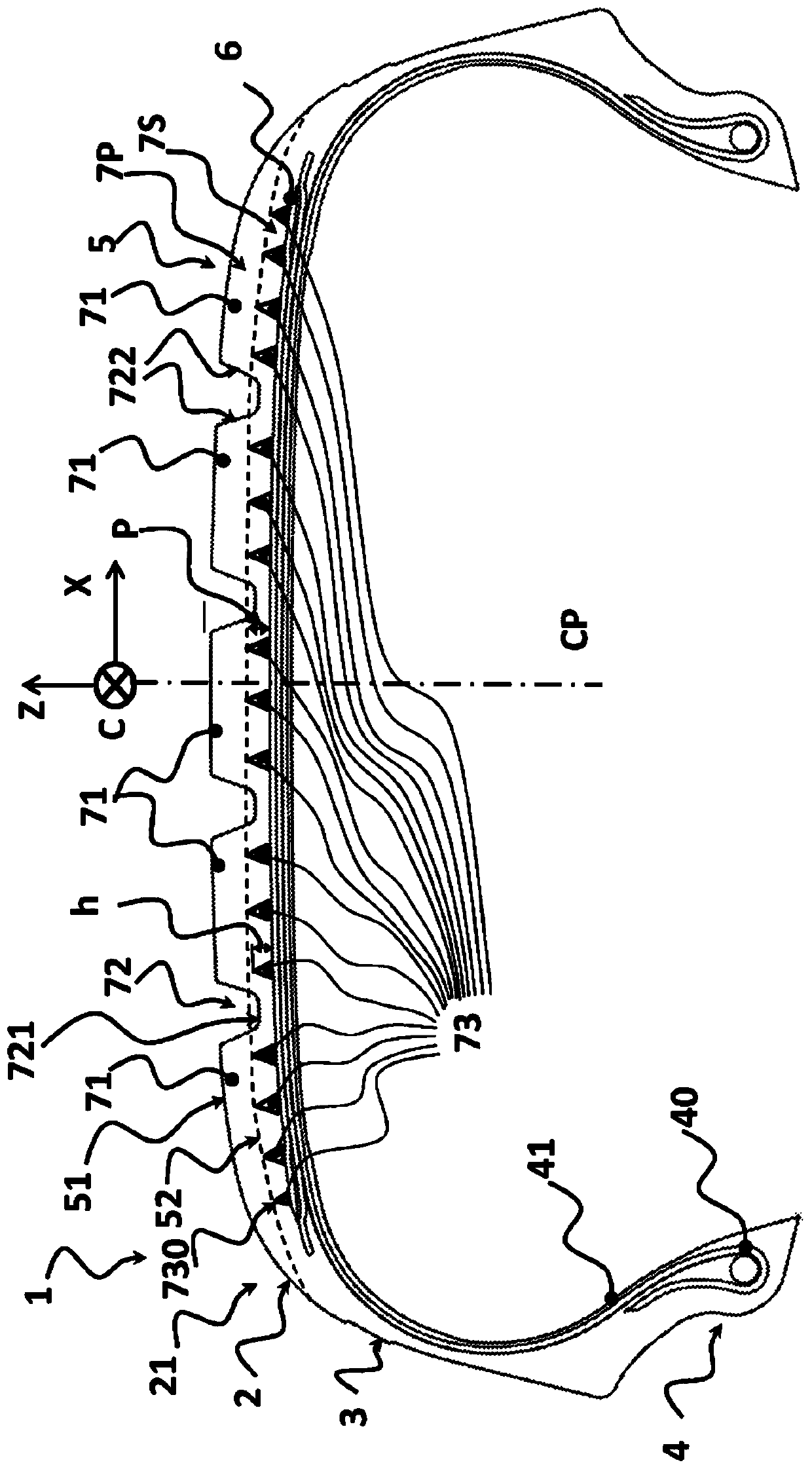

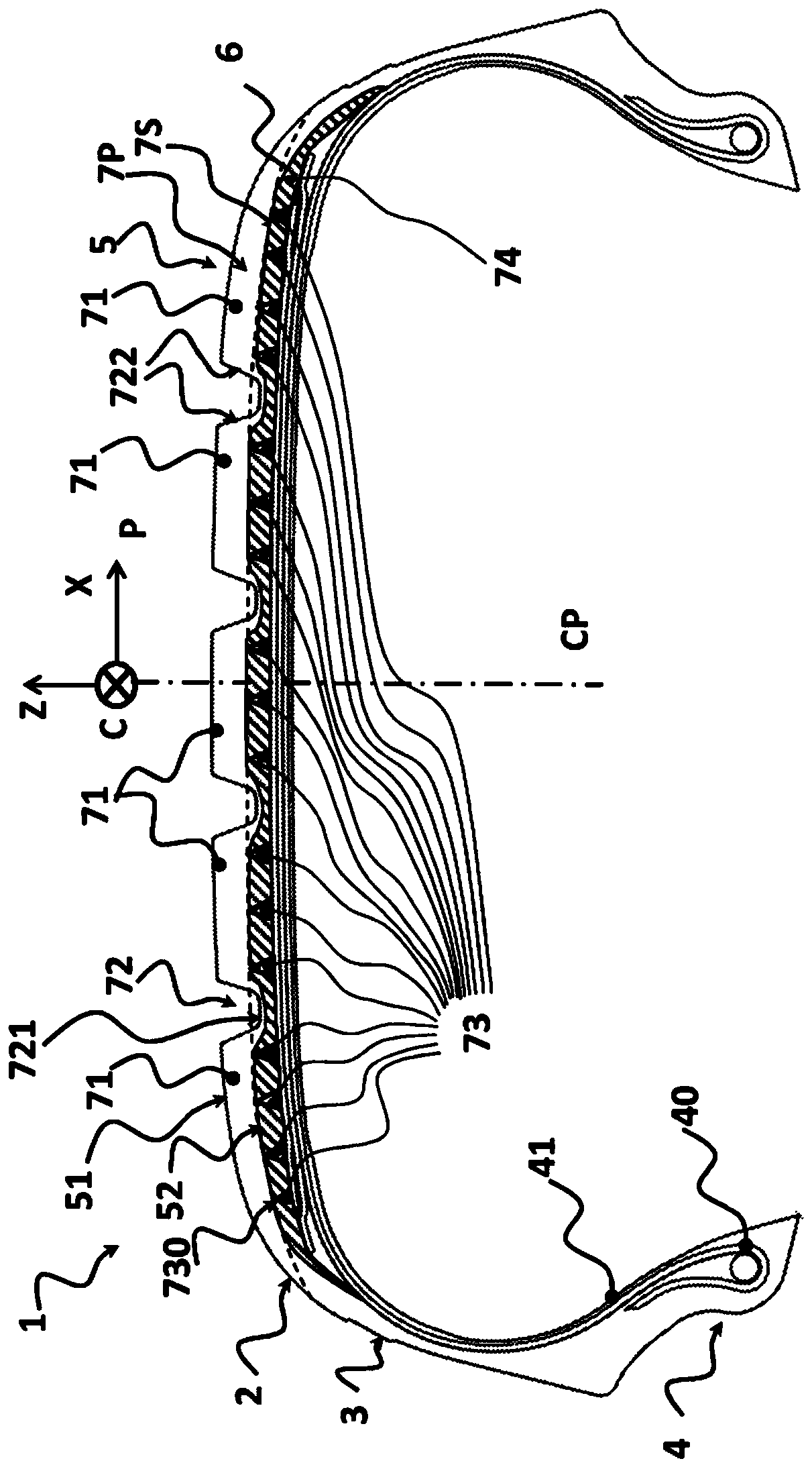

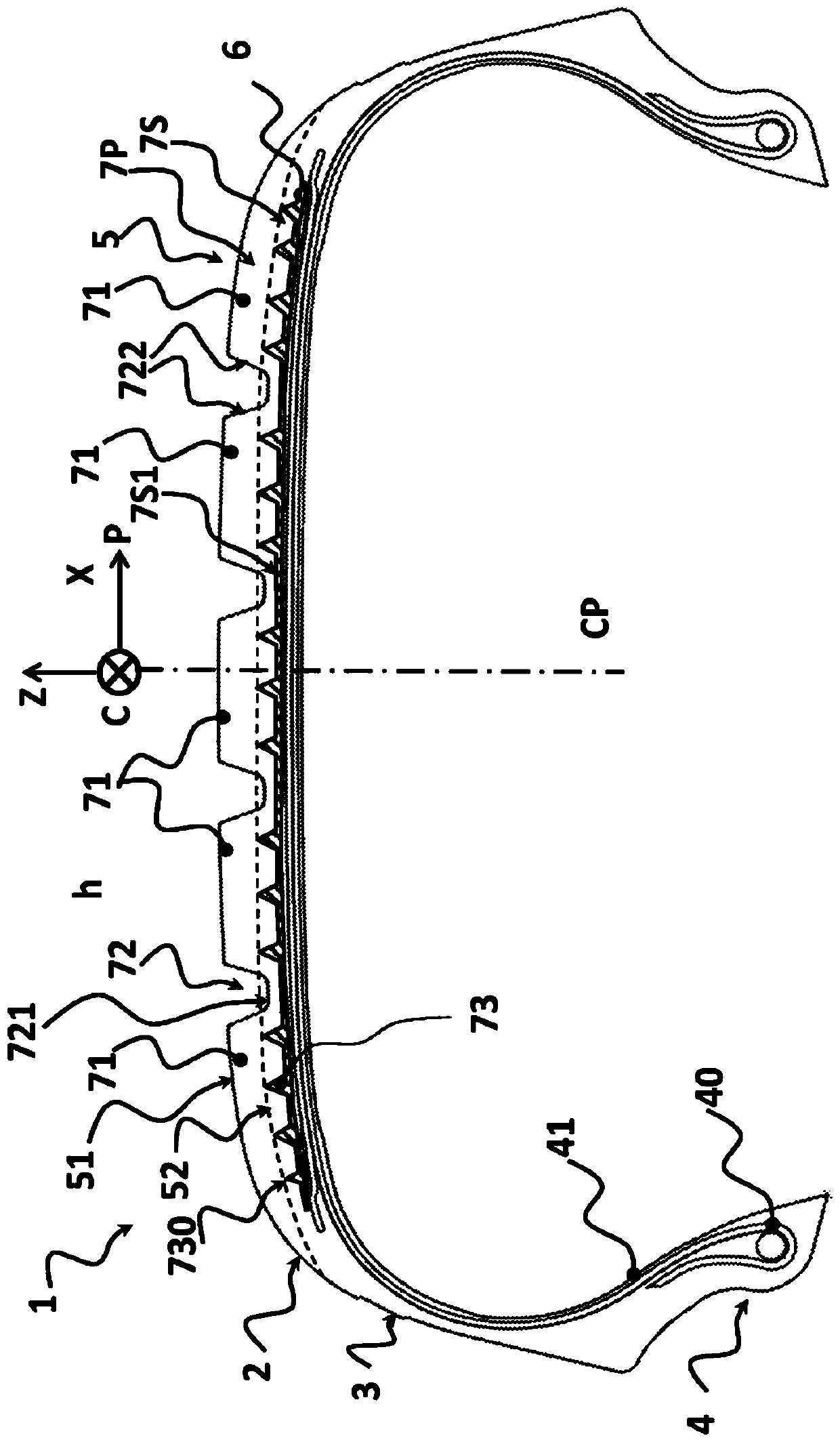

[0033] figure 1 A tire 1 is shown comprising a crown 2 and two sidewalls 3 each connected to a bead 4 . A crown 2 is connected on each side to the radially outer end of each of the two sidewalls. The crown 2 includes a tread 5 . figure 1 shows the equatorial plane CP, perpendicular to the axis of rotation of the tyre, halfway between the two beads 4 (mounted on the rim) and passing through the middle of the axial width of the crown 2; figure 1 The axial X, circumferential C and radial Z directions on the equatorial plane CP are also indicated by arrows located directly above the tread 5 .

[0034] Each bead has a bead wire 40 . A carcass ply 41 is wound around each bead wire 40 . The carcass ply 41 is radial and is formed, in a manner known per se, of cords; in this implementation, of textile cords; these cords are arranged substantially parallel to each other and formed at angles 80° and 80° to the equatorial plane CP. The way of the angle between 90° extends from one be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com