Pneumatic tire

A technology of pneumatic tires and tires, applied in tire parts, tire tread/tread pattern, rolling resistance optimization, etc., can solve problems such as partial wear, poor rolling resistance, etc. The effect of suppressing uneven wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

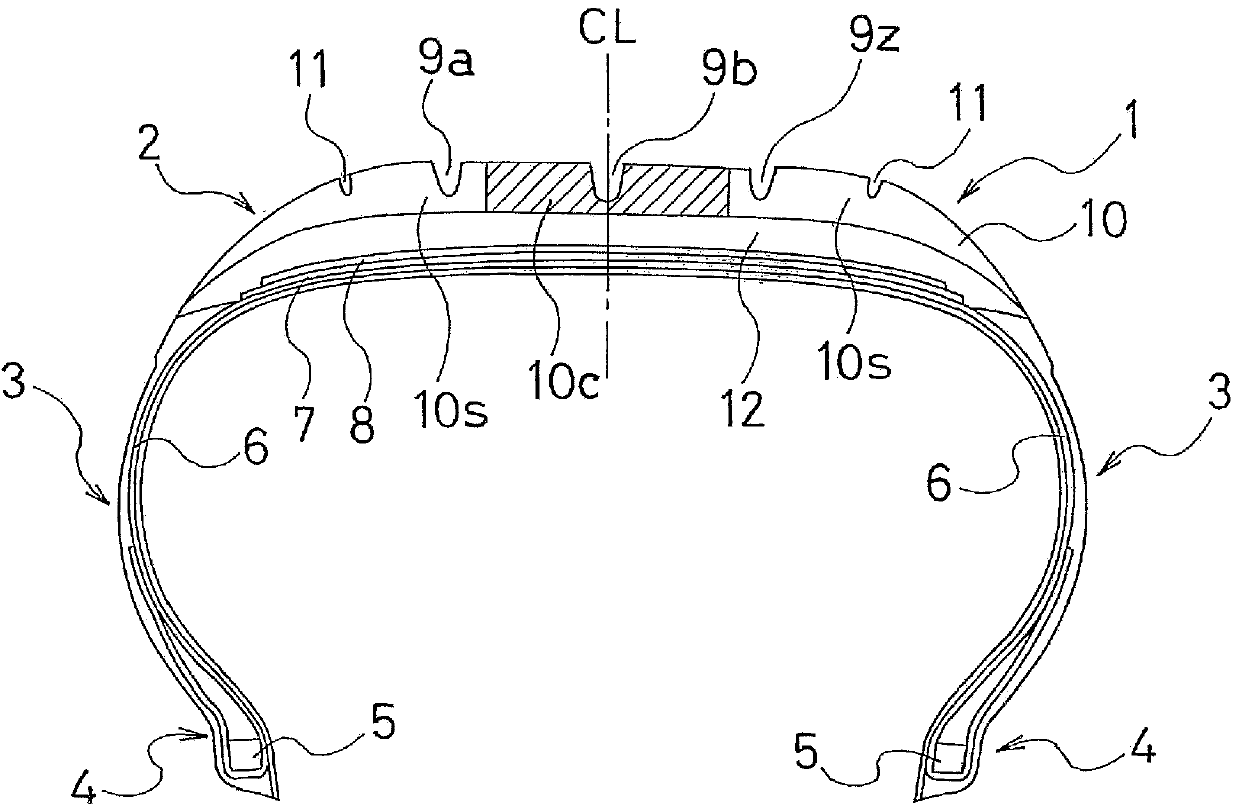

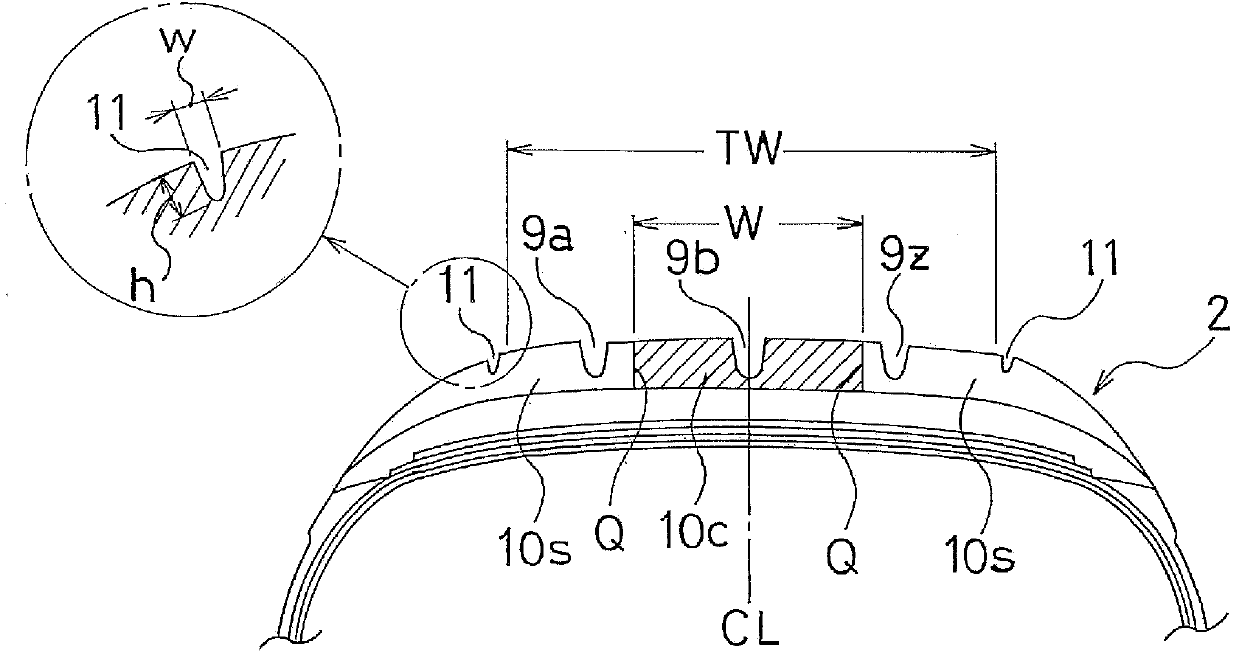

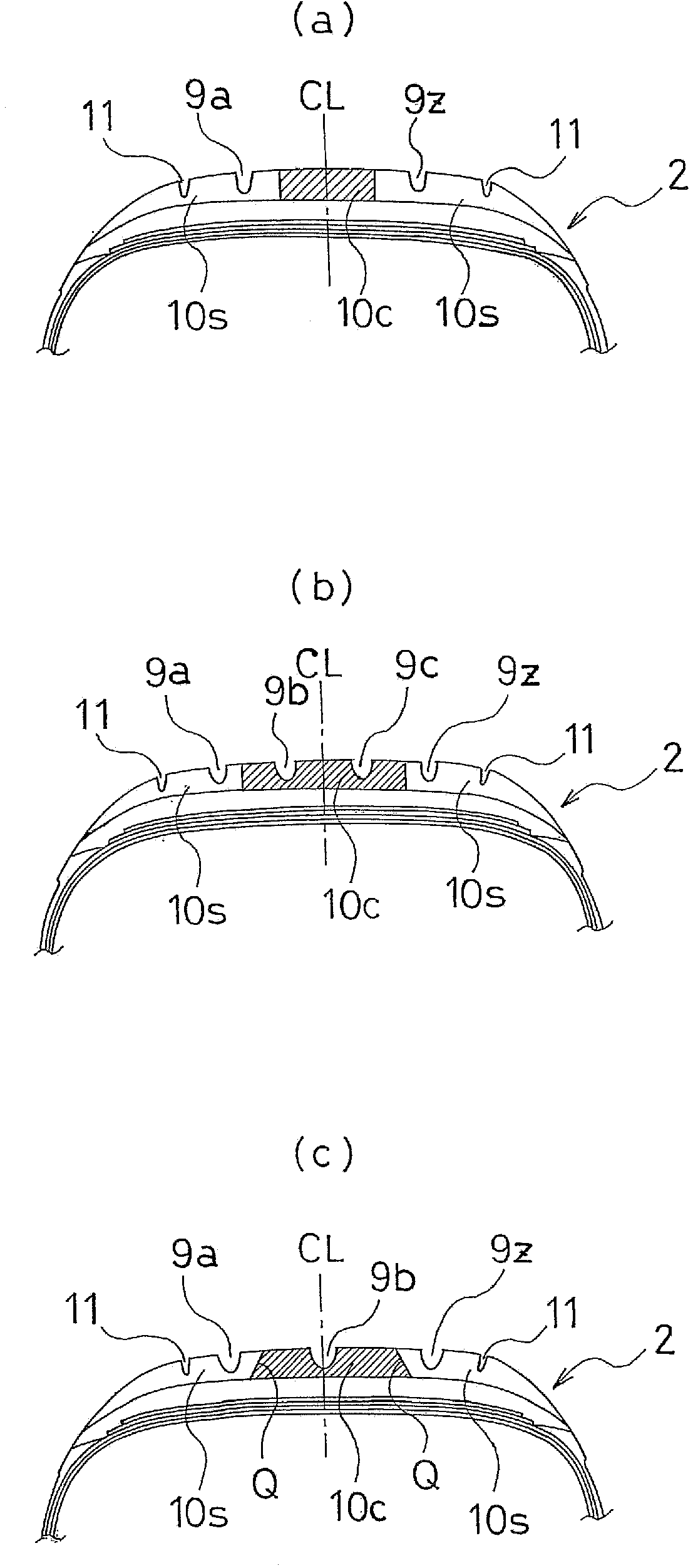

[0050] The tire size is 195 / 65R15, and the tire structure is figure 1 A conventional tire (conventional example) composed of a compound of a medium structure and a compound of the tread cap with a low tan δ at 60°C with emphasis on rolling resistance, and the arrangement of the compound of the tread cap, between the tread and both sides The tires of the present invention (Examples 1 to 4) and comparative tires (Comparative Examples 1 to 5) with different physical properties, presence or absence of circumferential fine grooves, and specifications of the compound disposed on each shoulder portion are as shown in Table 1. In addition, in each tire, all specifications except the specification of Table 1 are the same.

[0051] For these 10 types of tires, the rolling resistance, wet grip performance and partial wear performance were evaluated by the following methods, and the results are collectively described in Table 1 with an index of 100 for conventional tires. Indicates that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com