Tire rubber composition and pneumatic tire

A rubber composition, rubber technology, applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as the decline of kneading ability, and achieve the effect of good kneading ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

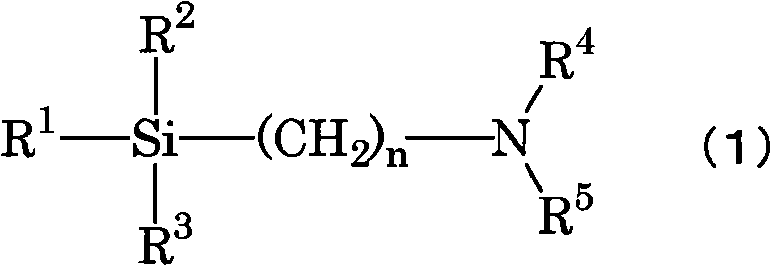

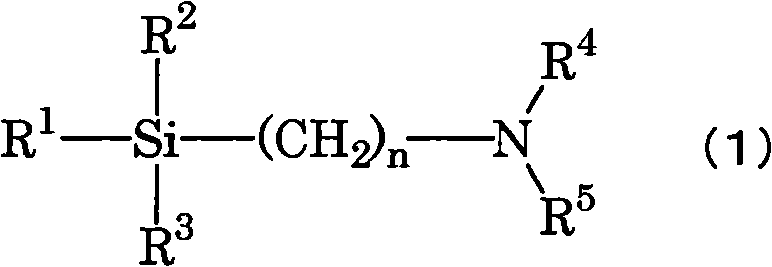

Method used

Image

Examples

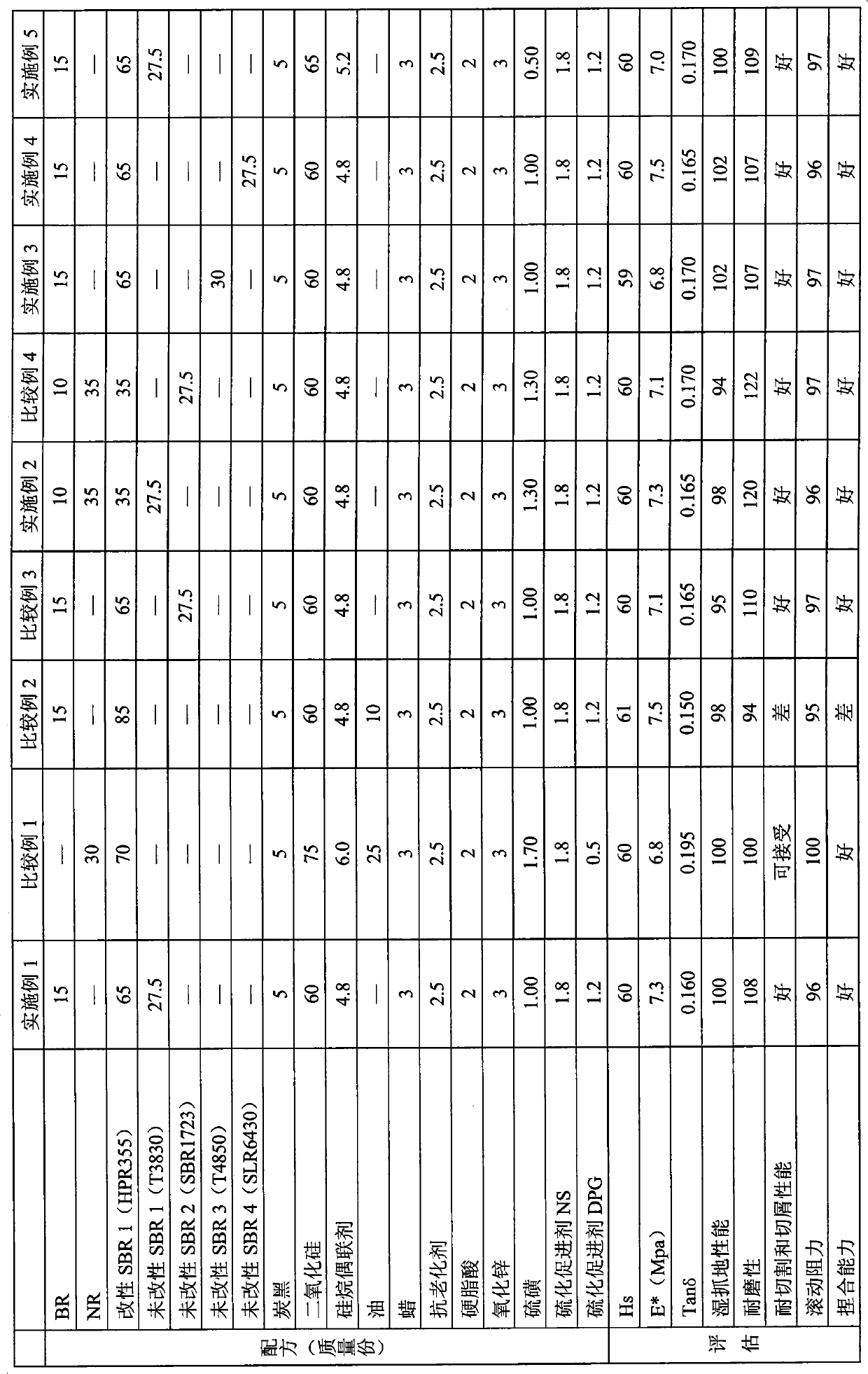

Embodiment 1~5 and comparative example 1~4

[0093] According to each formulation shown in Table 1, raw materials other than sulfur and a vulcanization accelerator were charged into a 1.7 L Banbury mixer and kneaded at 150° C. for 5 minutes to provide kneaded materials. Sulfur and a vulcanization accelerator were kneaded into the obtained kneaded mixture at 80° C. using an open two-roll mill for 5 minutes. Thus an unvulcanized rubber composition was prepared. A rubber sheet is formed from the prepared unvulcanized rubber composition. This rubber sheet was vulcanized under pressure at 150°C and 25 kgf for 5 minutes to prepare a vulcanized rubber composition.

[0094] In addition, the prepared unvulcanized rubber composition is molded into a tread shape and combined with other tire components to form an unvulcanized tire. The unvulcanized tire was vulcanized at 150° C. for 35 minutes to prepare a test tire (tire size: 175 / 65R15).

[0095] The unvulcanized rubber composition, vulcanized rubber composition, and test tire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com