Tire rubber composite and pneumatic tire

A technology for rubber composition and tire, applied in the field of rubber composition for tires and pneumatic tires, can solve the problems of reduced wear resistance, poor dispersibility, low carbon black reinforcement, etc., and achieves improved wear resistance and improved dispersion. improved performance, wet grip and abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

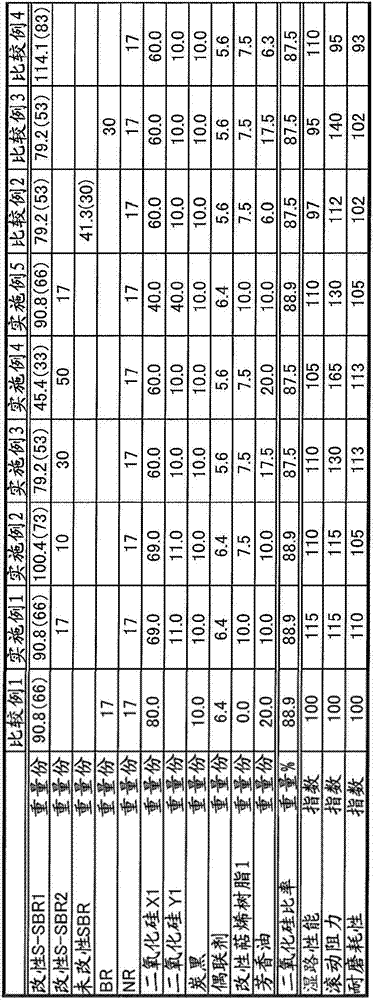

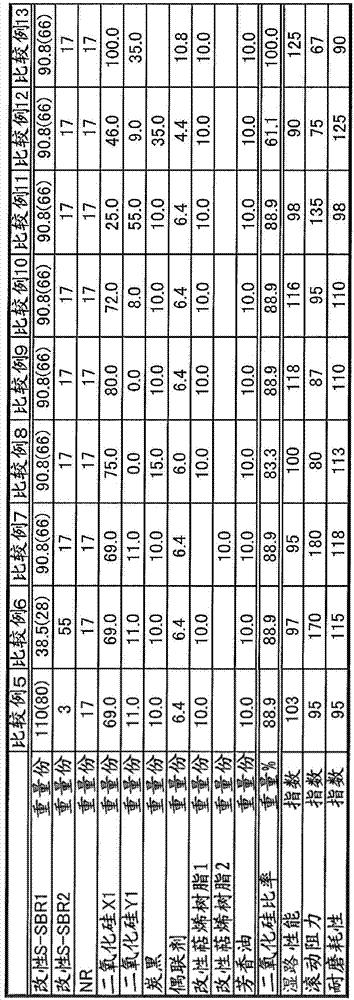

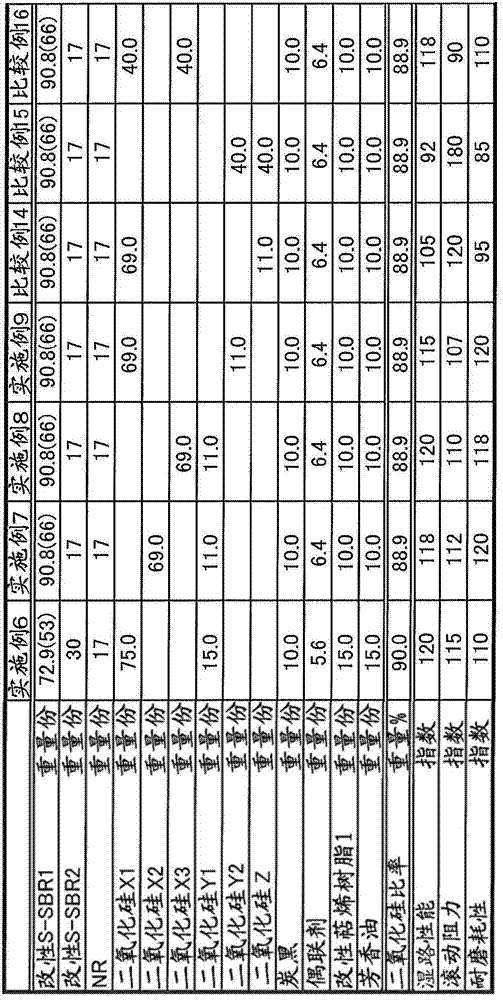

[0043] Will Figure 4 The shown complexing agents are used as common complexes by Figure 1~3 The 25 kinds of rubber compositions for tires (Examples 1-9, Comparative Examples 1-16) formed by the compounding shown are prepared in the following manner: put the ingredients except sulfur and vulcanization accelerator in a 1.8L internal mixer Mix for 5 minutes, add sulfur and vulcanization accelerator to the discharged masterbatch, and mix with an open mill. in addition, Figure 1~3 In, since the modified S-SBR1 and the unmodified SBR contain 37.5 parts by weight of oil-extending oil, the actual compounding amount is shown in the column of compounding amount, and the net weight of each SBR after removing the oil-extending oil is shown in parentheses. With the amount. In addition, the compounding quantity of aromatic oil was adjusted suitably so that the total oil quantity and / or rubber hardness in a rubber composition may become a comparable level. The ratio of silica to the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com