Patents

Literature

98results about How to "Improve grip performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

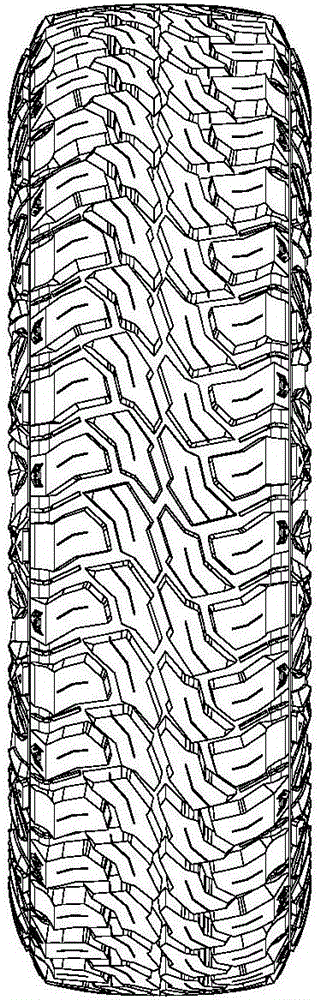

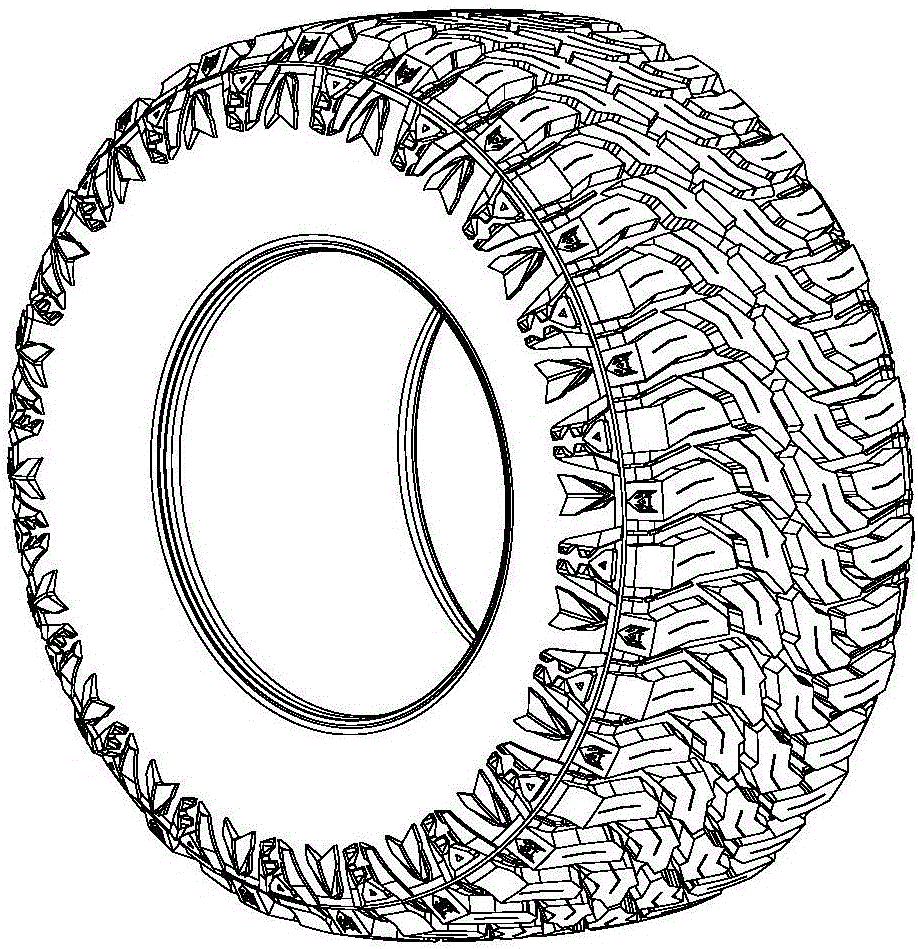

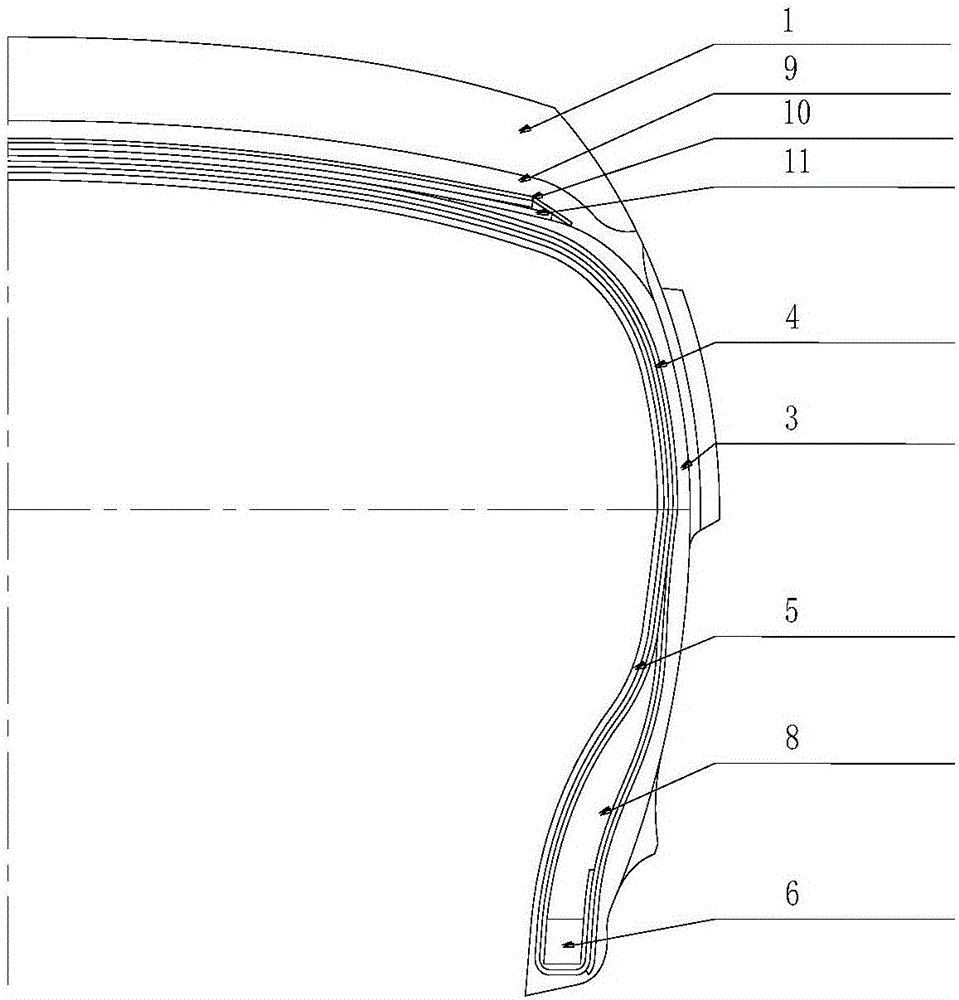

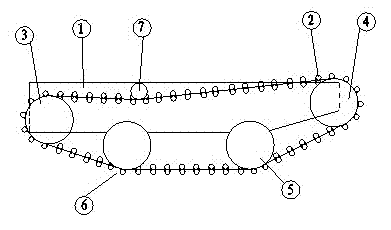

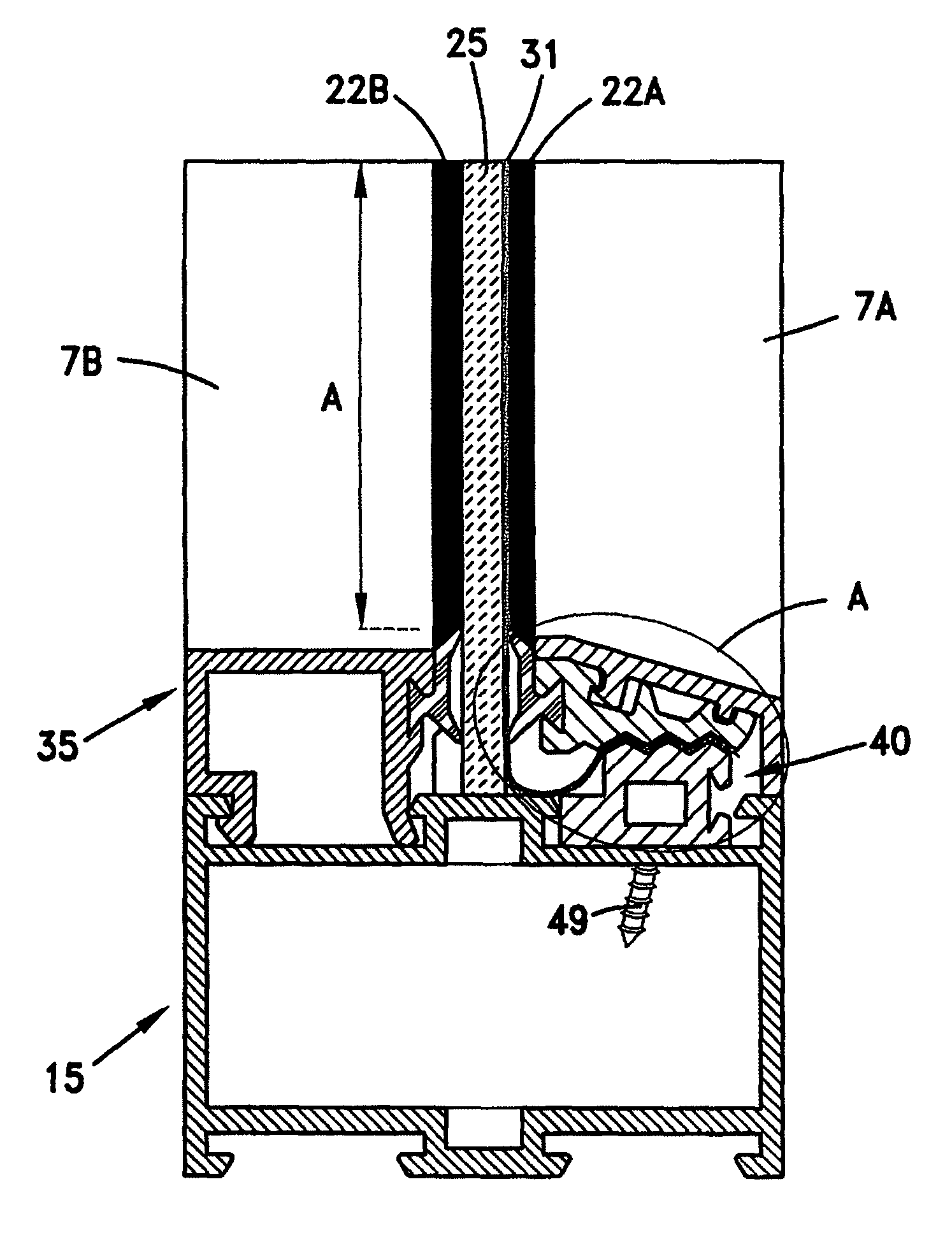

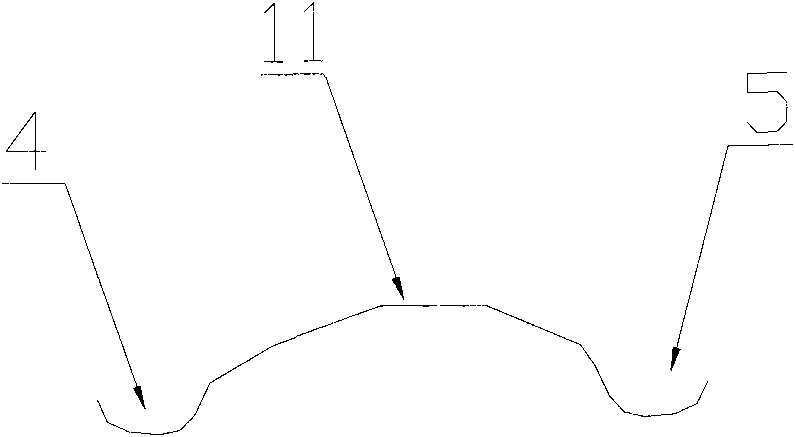

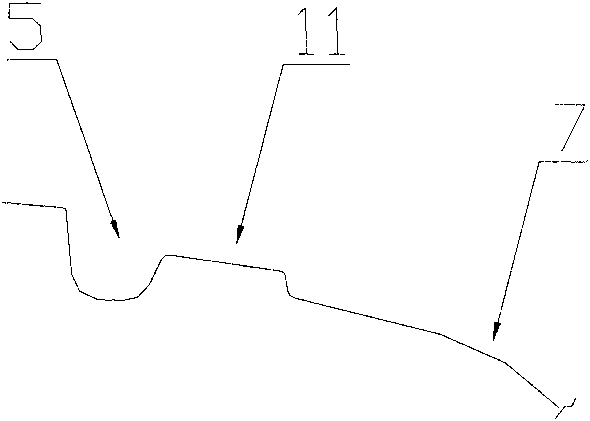

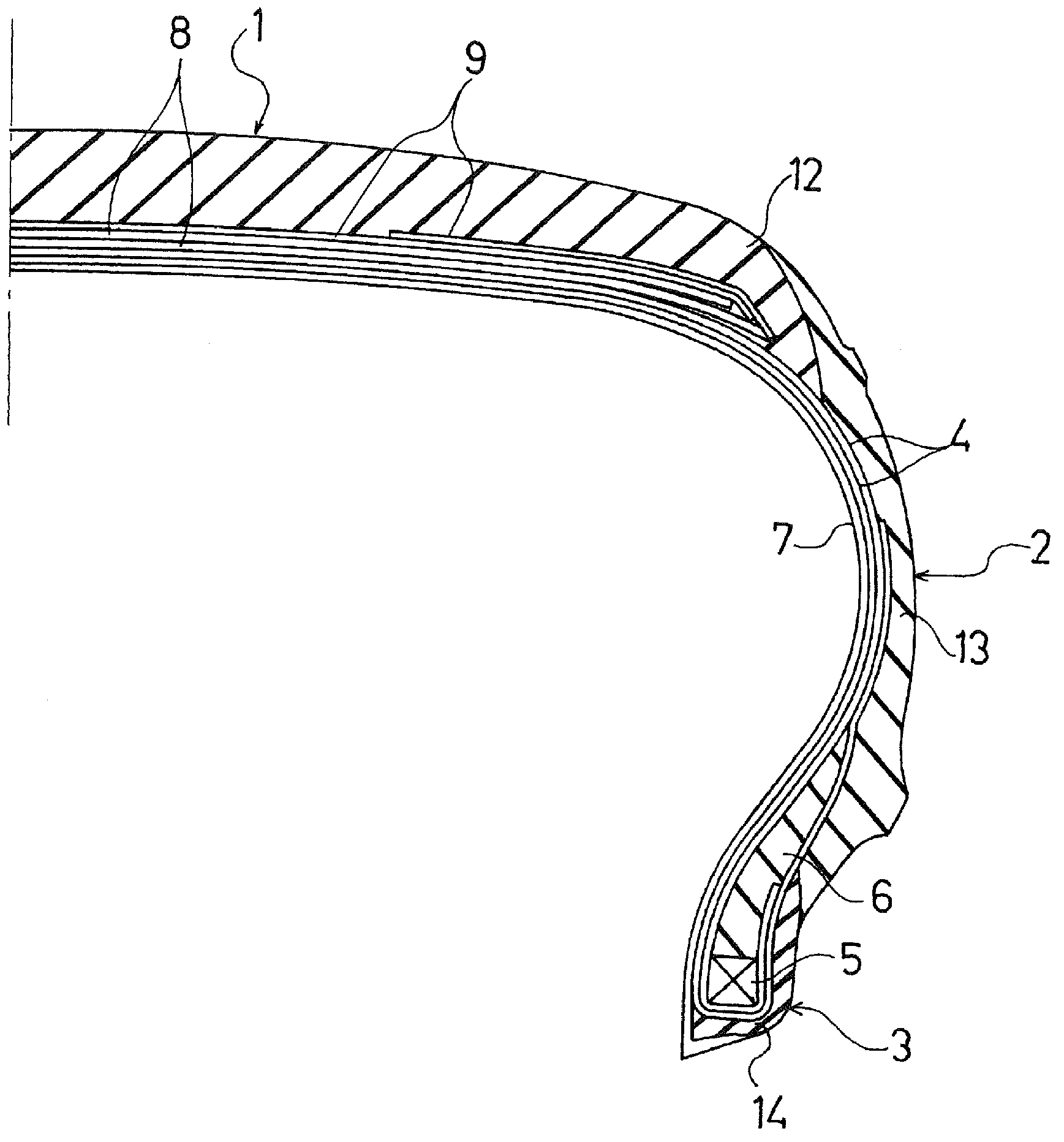

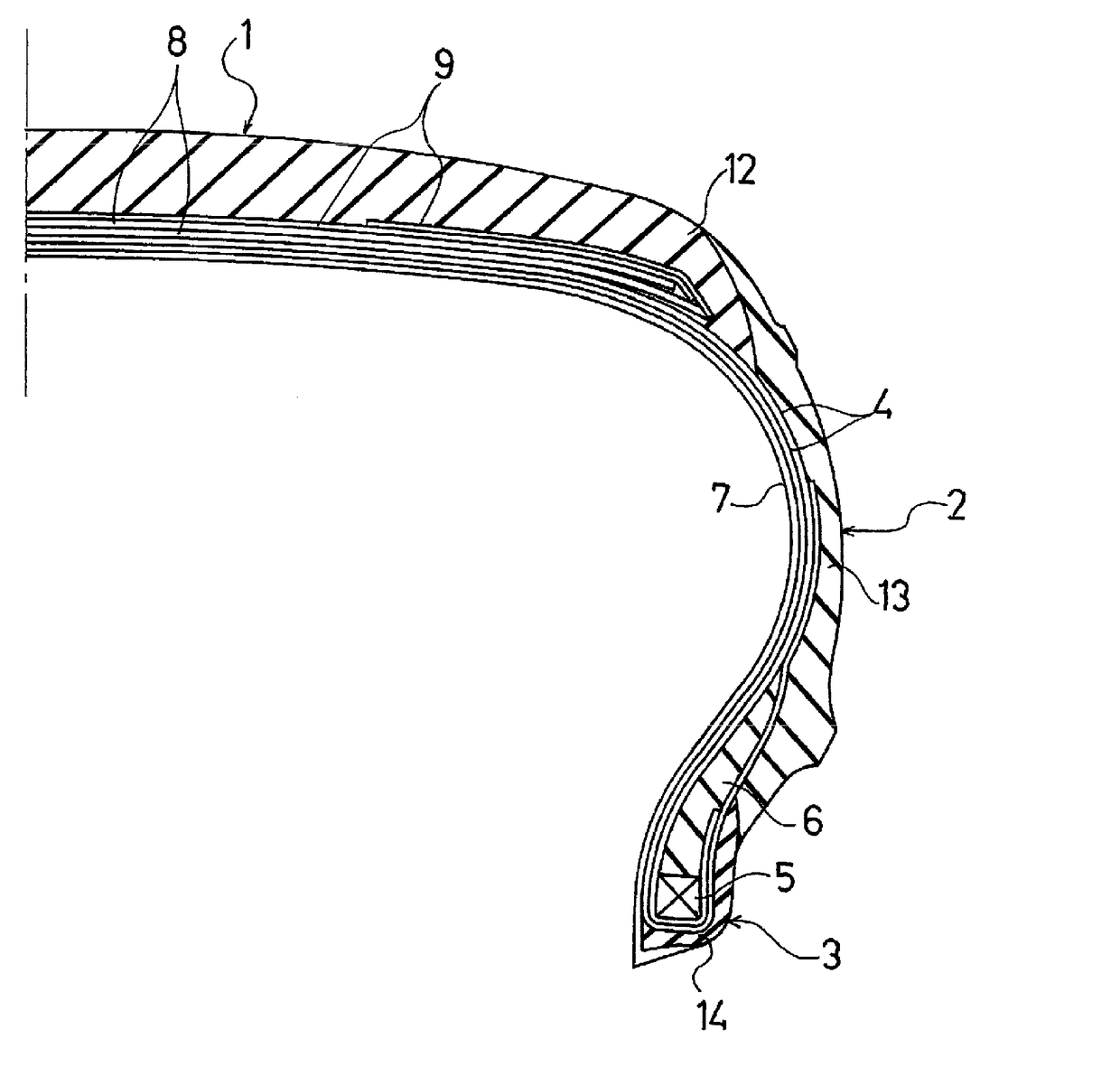

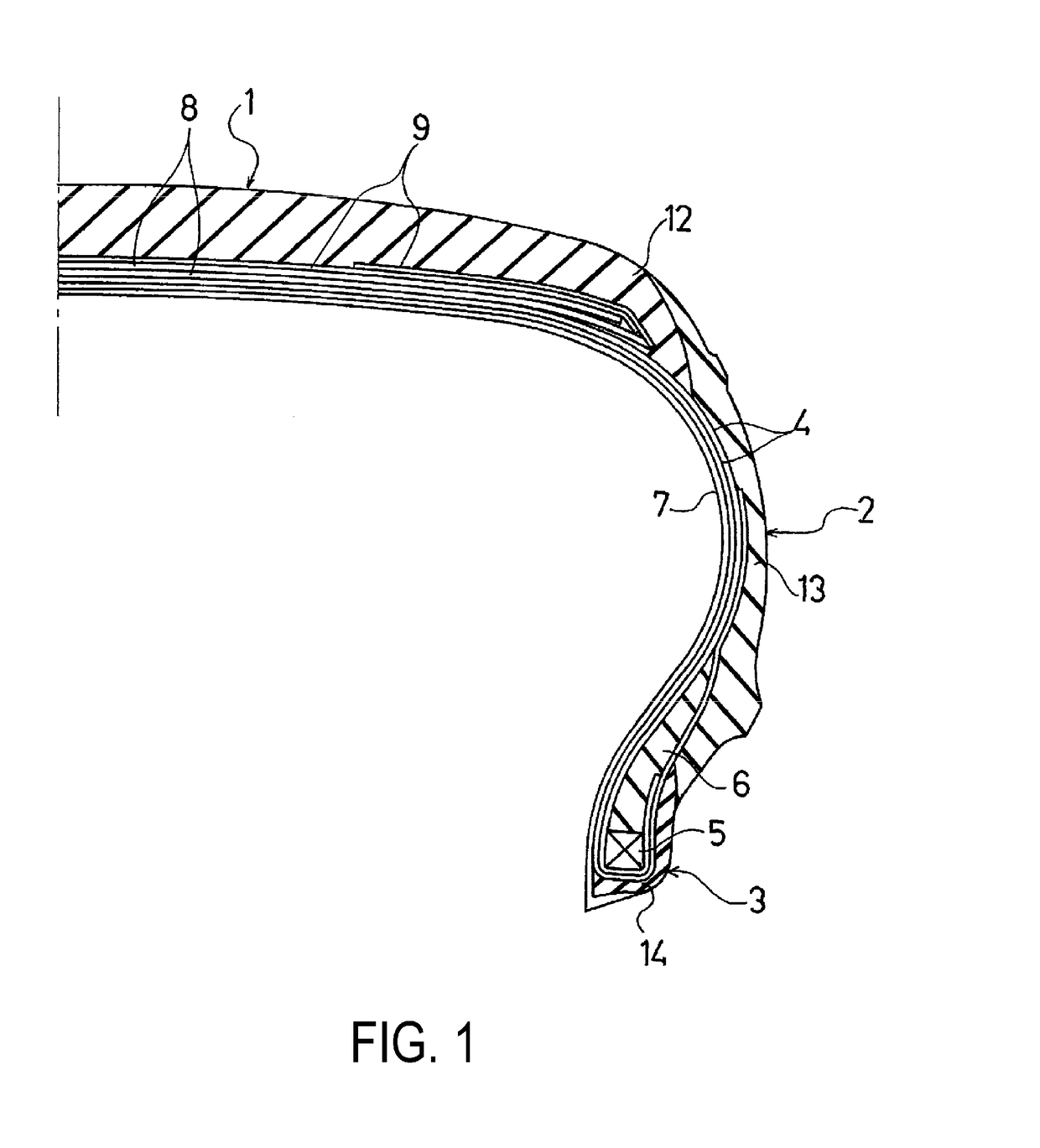

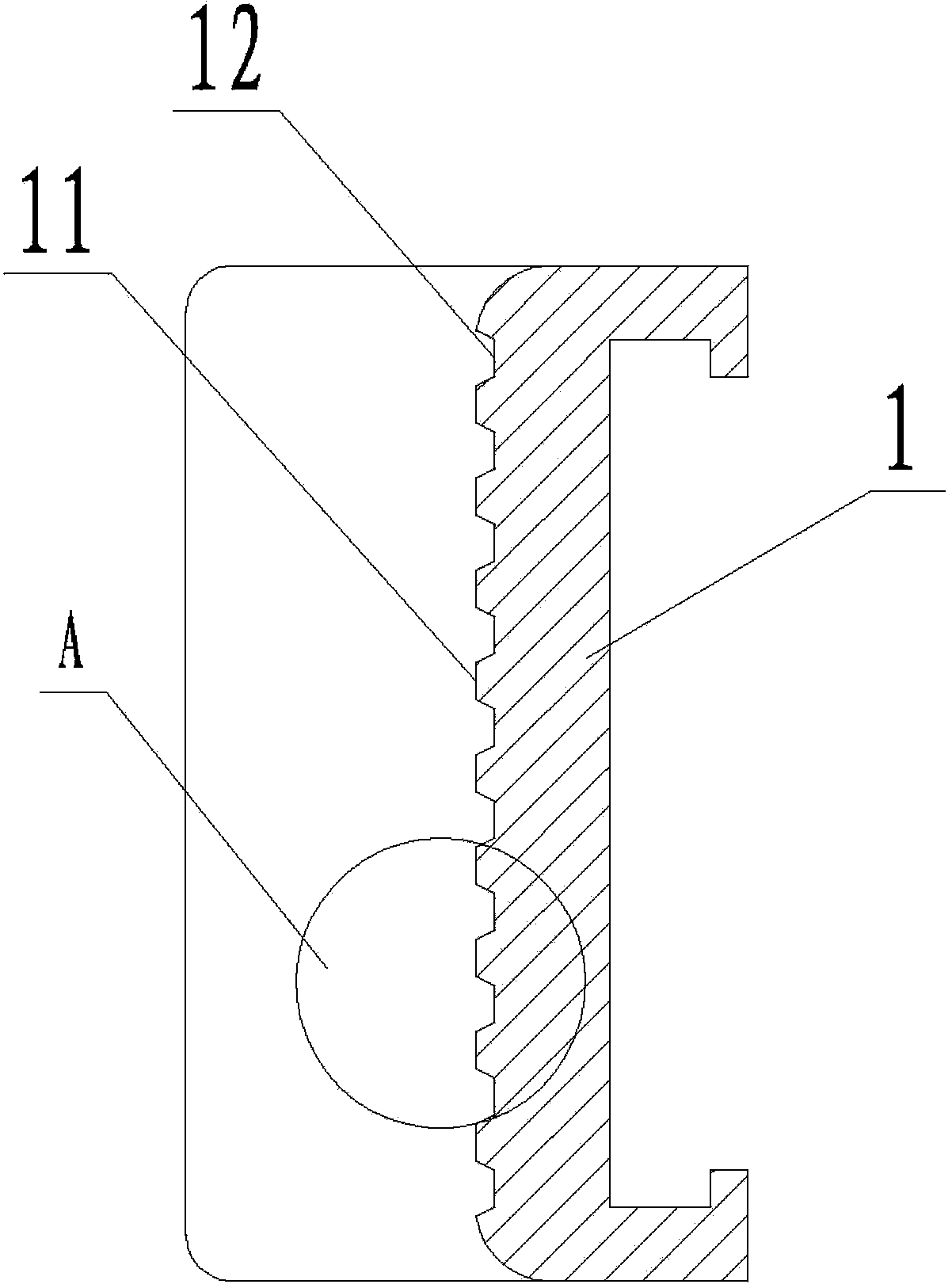

All-steel mud-field tire

InactiveCN106394128AHigh strengthImprove securityOff-road vehicle tyresPneumatic tyre reinforcementsUltimate tensile strengthTire iron

The invention provides a novel all-steel mud-field tire, and belongs to the field of tires. Through the adoption of the novel all-steel mud-field tire disclosed by the invention, improving tire strength is facilitated, impact resistance and durability of the tire are improved, and the service life of the tire is prolonged. A longitudinal section of the all-steel mud-field tire comprises a tire crown (1), a tire shoulder (2), a tire sidewall (3), a tire bead (6), and a tire body (4), wherein the tire crown (1) is located on the outer side of the upper part of the longitudinal section; the tire shoulder (2) is connected with the tire crown (1); the tire sidewall (3) is connected with the tire shoulder (2); the tire bead (6) connected with a wheel rim is arranged at the lower part of the tire sidewall (3); the tire body (4) is located on the inner side of the section of the tire; a tire shoulder pad (21) is arranged on the tire shoulder (2); a convex rib (31) is circumferentially and annularly arranged on the outer part of the tire sidewall (3); and the tire body (4) is a layer of all-steel tire body.

Owner:QINGDAO DOUBLESTAR TIRE IND CO LTD

Tire tread-use rubber composition

A tire tread-use rubber composition includes from 10 to 50 parts by weight of a tackifying resin having a softening point of from 100° C. to 150° C.; from 70 to 130 parts by weight of a carbon black having a nitrogen specific surface area of from 250 to 400 m2 / g; from 1 to 3 parts by weight of sulfur; from 0.5 to 4.0 parts by weight of a sulfenamide vulcanization accelerator; and from 1.5 to 5.0 parts by weight of a thiuram vulcanization accelerator per 100 parts by weight of a rubber component; wherein when A is a compounded amount in parts by weight of the sulfenamide vulcanization accelerator, T is a compounded amount in parts by weight of the thiuram vulcanization accelerator, and S is a compounded amount in parts by weight of the sulfur, a weight ratio (A+T) / S is from 2 to 4.

Owner:YOKOHAMA RUBBER CO LTD

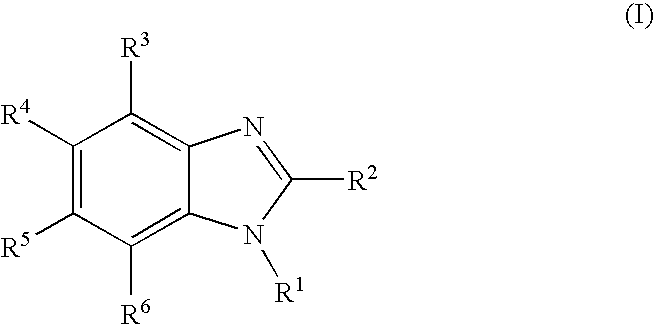

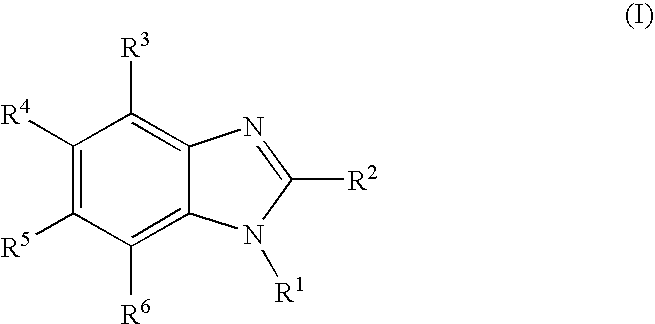

Rubber composition and pneumatic tire made therefrom

InactiveUS20050176858A1Improve grip performanceImprove gripSpecial tyresBenzimidazole derivativeProduction rate

A rubber composition comprising 100 parts by weight of a rubber ingredient comprising natural rubber and / or a synthetic rubber, 0.1 to 50 parts by weight of at least one nitrogenous compound selected among benzimidazole derivatives having a specific structure and hydrazide derivatives having a specific structure, and 0.1 to 50 parts by weight of a protonic acid; and a pneumatic tire including a member formed from this rubber composition. The rubber composition enables excellent gripping performance while attaining intact productivity. The pneumatic tire produced from this rubber composition, in particular, the tire whose tread has been formed from the composition, has significantly improved gripping performance in high-speed driving, etc.

Owner:BRIDGESTONE CORP +1

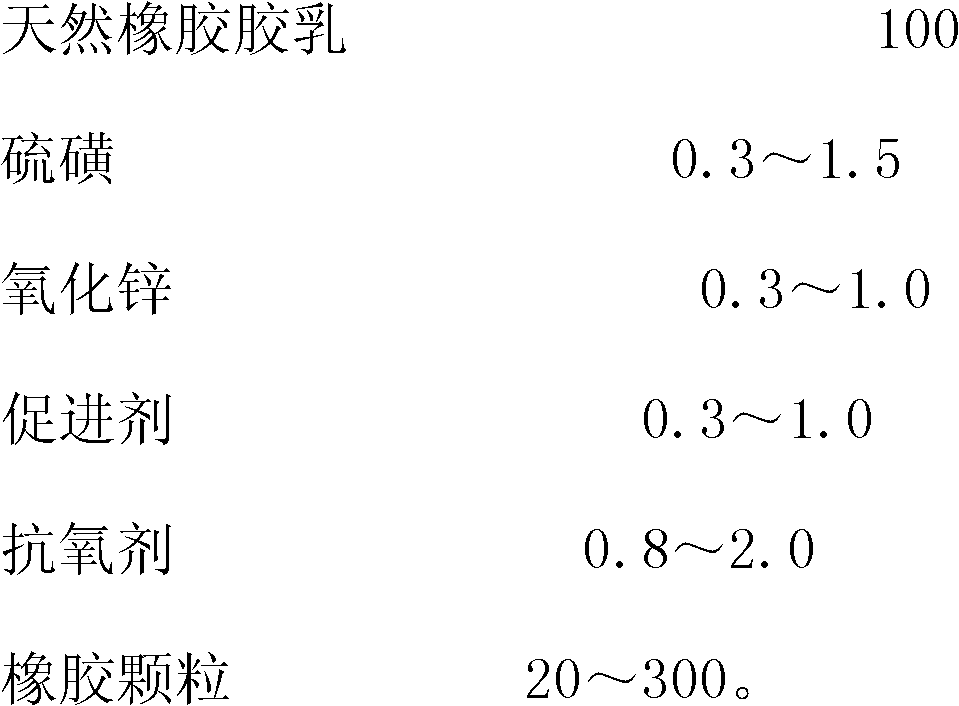

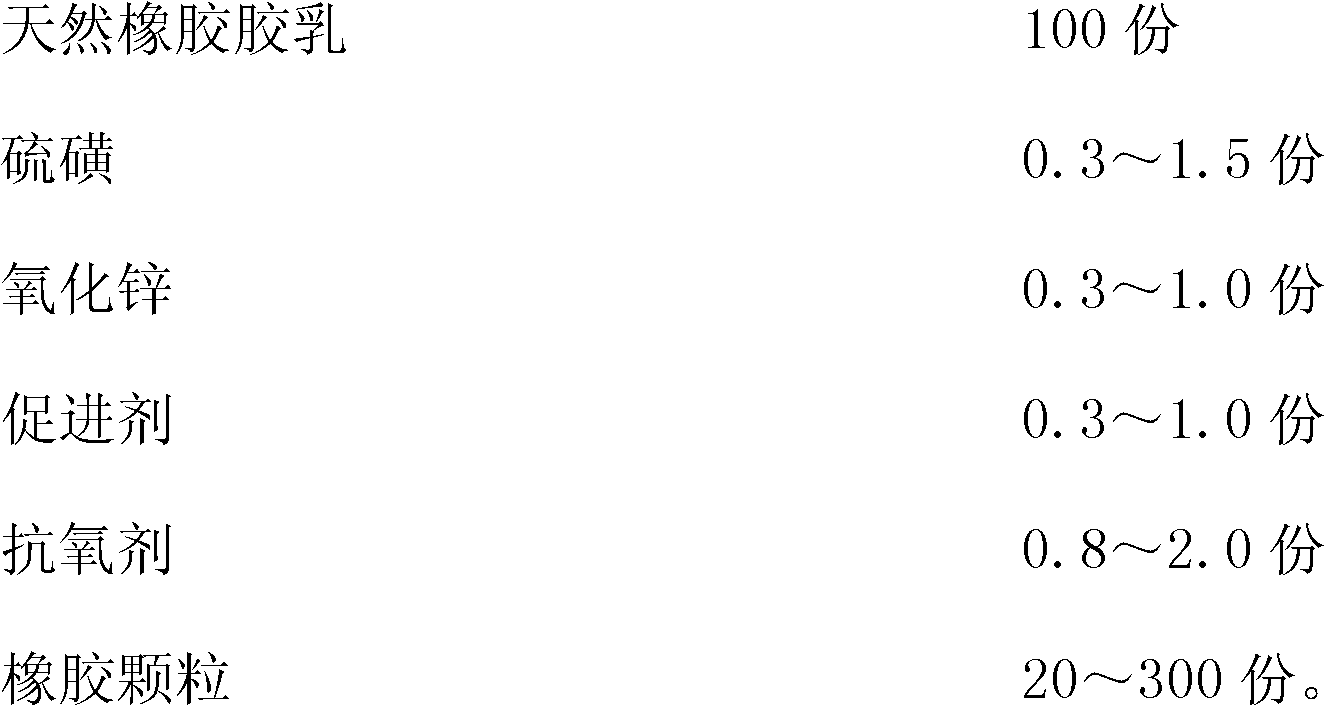

Antiskid rubber gloves and processing method thereof

InactiveCN102488340AIncrease coefficient of frictionImprove grip performanceCoatingsProtective garmentPolymer scienceSulfur

The invention discloses a pair of antiskid rubber gloves and a processing method thereof. Each antiskid rubber glove comprises rubber latex forming a glove body and antiskid rubber latex forming an antiskid layer, wherein the antiskid rubber latex consists of natural rubber latex, sulfur, zinc oxide, an accelerator, an antioxidant and rubber particles. According to the antiskid rubber gloves disclosed by the invention, rubber particles are arranged on the outer surfaces of the gloves in a processing course of the gloves so as to increase the friction coefficient of the gloves, enhance the catching power of the gloves and largely improve the antiskid effect of the gloves; in addition, the gloves have no special requirement on production moulds and equipment and only the traditional production mould is needed in a production process, therefore the production input is low and the production cost of enterprises can be reduced greatly. The gloves processed with the processing method disclosed by the invention have the advantages of good antiskid effect, capability of solving the problem that defective holes possibly appear on the gloves caused by mould bumps in the production process and high yield; and the processing method disclosed by the invention has the advantage of simple operation.

Owner:ZHENJIANG SUHUI LATEX PROD

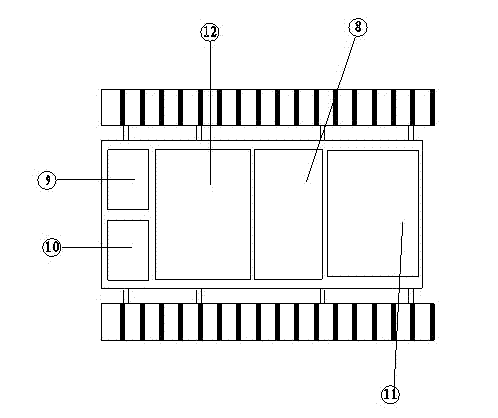

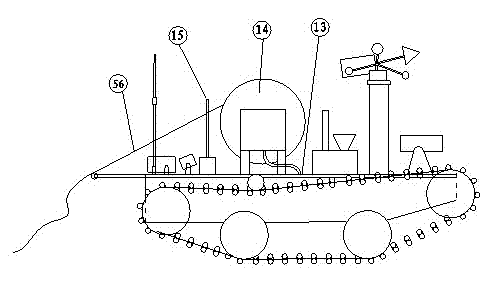

Crawler type walking robot workstation

InactiveCN102211621AHigh strengthDoes not affect strengthTelevision system detailsColor television detailsBrushless motorsProgrammable logic controller

The invention discloses a crawler type walking robot workstation, which belongs to the field of electromechanical integral robots. The crawler type walking robot workstation comprises an upper computer, a main control primary vehicle and multiple controlled secondary vehicles; the main control primary vehicle comprises a vehicle body, a crawler type walking mechanism and a PLC (Programmable Logic Controller). The crawler type walking robot workstation is characterized in that the vehicle bodies of both the main control primary vehicle and the controlled secondary vehicles are closed and inflatable boxes; the crawler type walking mechanism consists of a rubber double-sided toothed crawler, a rear driving wheel, a front guiding wheel, a front bearing wheel, a rear bearing wheel and a tension wheel; a left driving speed regulating rotor and a right driving motor are respectively driven by a storage battery as a power; the PLC is mounted on the main control primary vehicle; and the operation is executed by a speed regulating brushless motor driving module. In the invention, multiple rotor vehicles are combined together according to different functions and coordinate on the whole, thereby forming a robot workstation.

Owner:山西亚佳机电集团有限公司

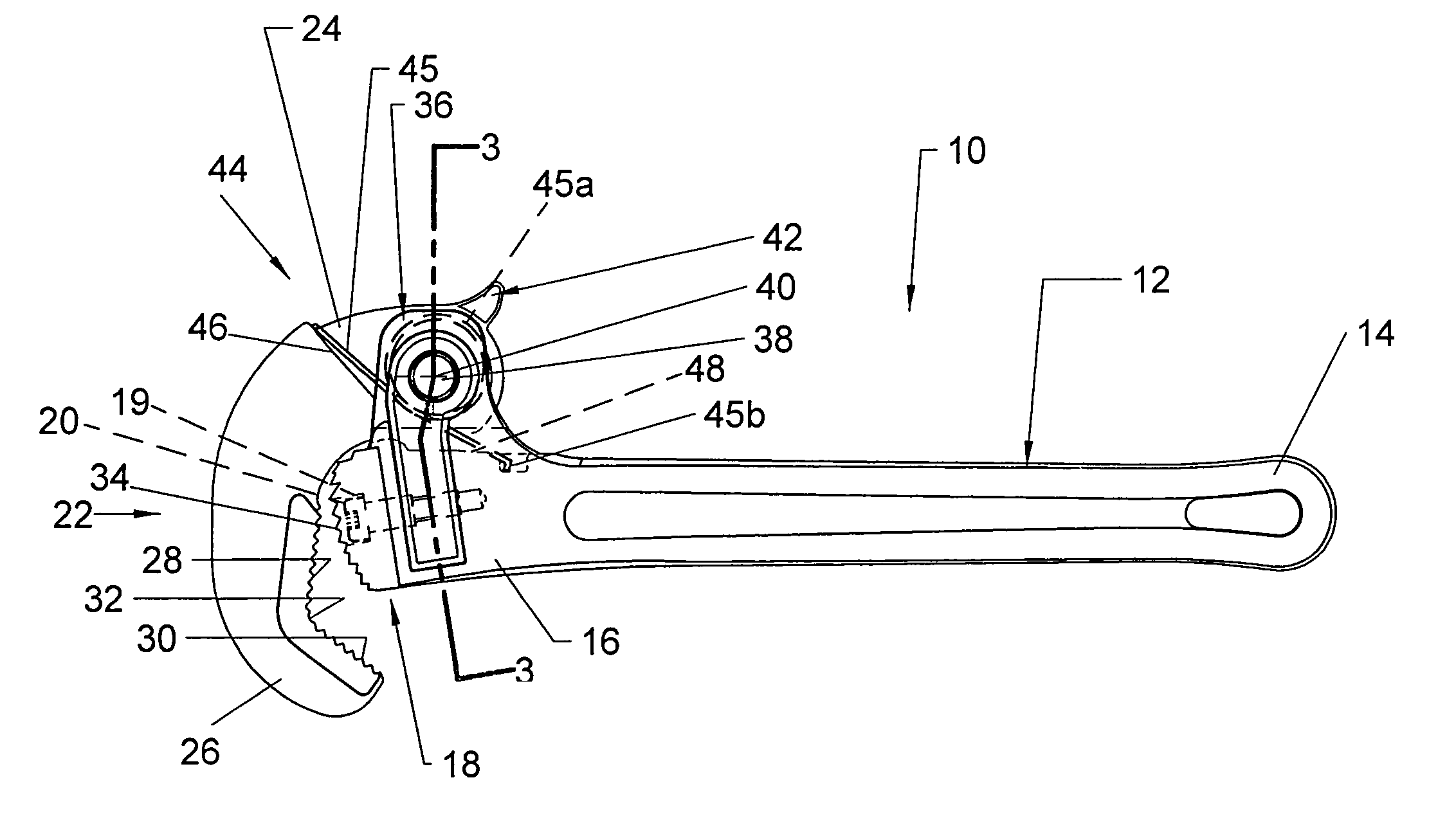

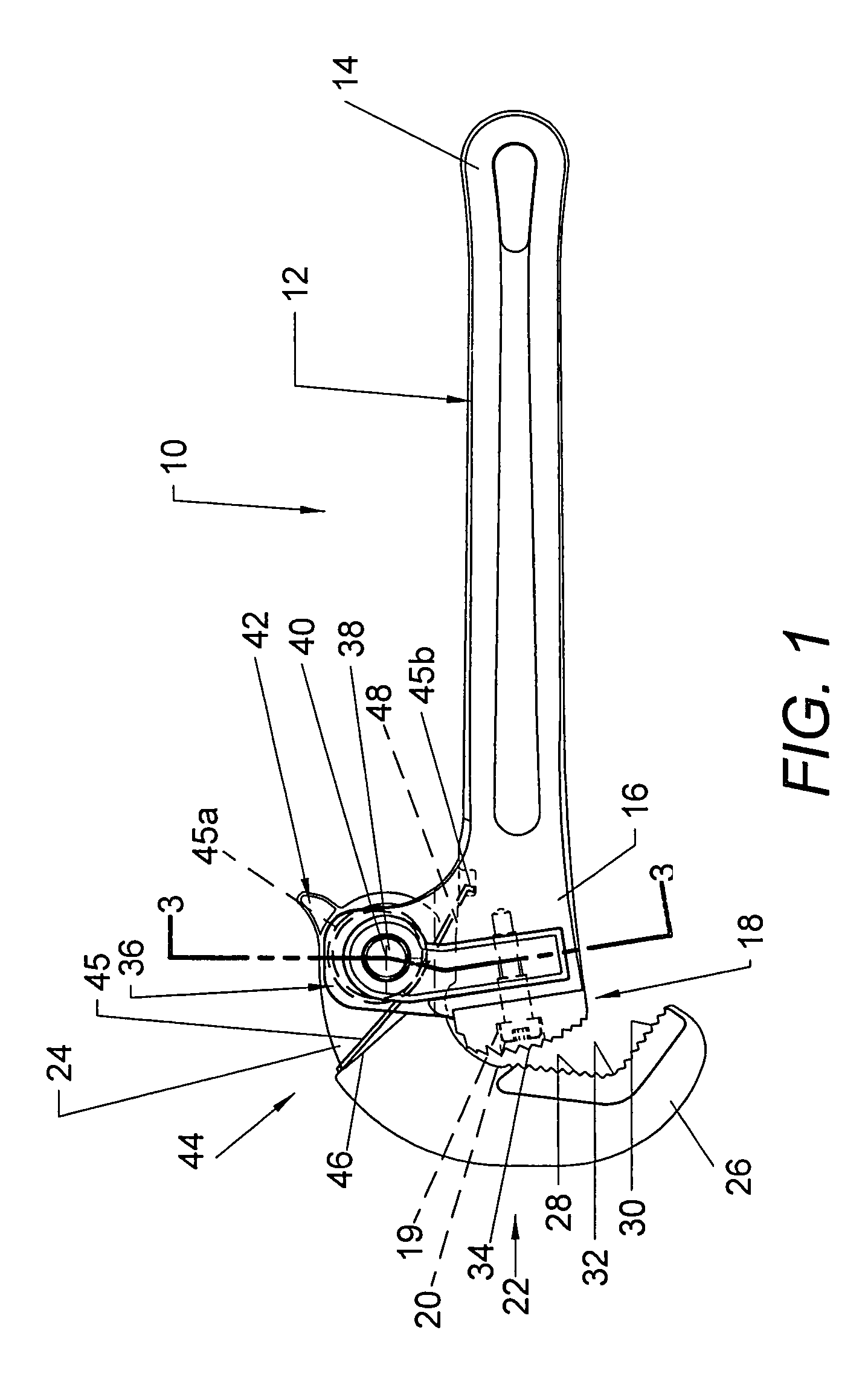

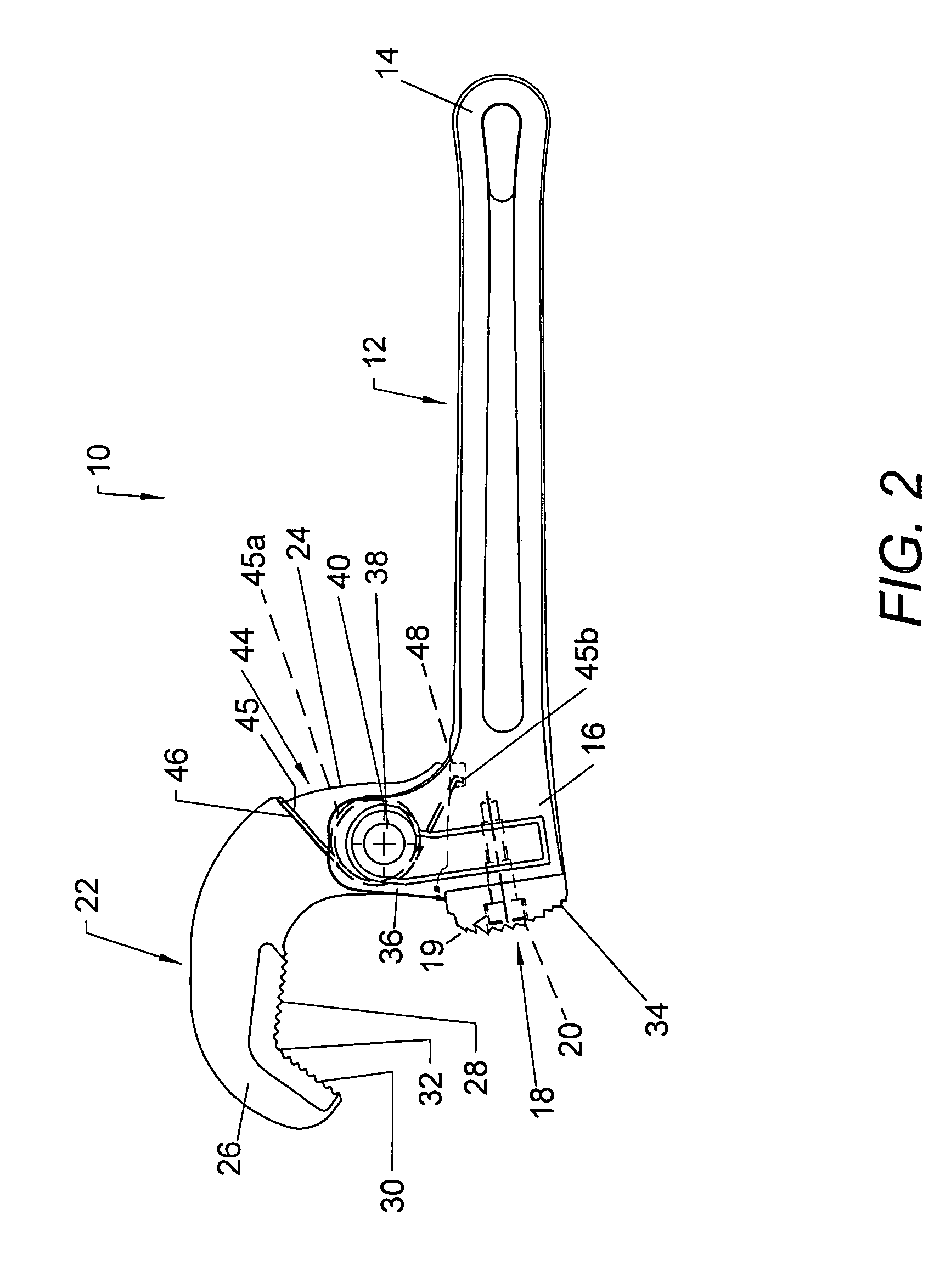

Pivoting jaw pipe wrench

A pivoting jaw pipe wrench comprises a fixed jaw including a plurality of discrete teeth, each for a different one of a plurality of pipes having different diameters. A pivotal jaw member has first and second jaw faces at an obtuse angle to one another and displaceable toward and away from the fixed jaw, whereby a pipe of given diameter to be gripped by the wrench is cradled between the first and second jaw surfaces and engaged by the one of the discrete teeth provided on the arcuate jaw for the pipe of given diameter.

Owner:EMERSON ELECTRIC CO

Pneumatic tire

ActiveCN101734109AImprove braking effectEnhance the edge effectTyre tread bands/patternsGround contactTread

A pneumatic tire has a tread pattern including a plurality of main grooves extending along a tire circumferential direction, and a shoulder land portion constructed by a rib or a block row formed in an outer side in a tire width direction of the main groove positioned in an outermost side. A circumferential sipe is provided in each of the shoulder land portions in both sides in the tire width direction. The number of the circumferential sipes provided in the shoulder land portion in a vehicle inner side is larger than the number of the circumferential sipes provided in the shoulder land portion in a vehicle outer side.

Owner:TOYO TIRE & RUBBER CO LTD

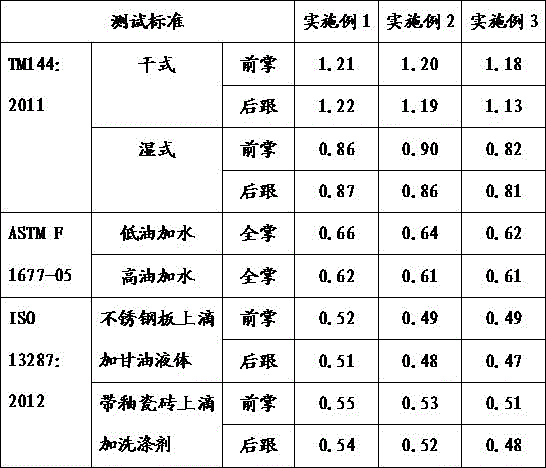

Antiskid rubber outsole and manufacturing method of same

ActiveCN106589491AImprove grip performanceEasy to processSolesDomestic footwearPolymer scienceVulcanization

The invention relates to shoe soles and provides an antiskid rubber outsole which is specially used on surfaces containing surfactants and oil stains and a manufacturing process of the outsole. The antiskid rubber outsole is prepared from nitrile butadiene rubber, integrated rubber, solution polymerized styrene-butadiene rubber, modified liquid polybutadiene rubber, fumed silica, a plasticizer, an anti-aging agent, petroleum resin, a white smoke activator, a silane coupling agent, polyethylene wax, zinc oxide, sulfur, and a vulcanization accelerator. The antiskid rubber outsole has excellent antiskid effect not only on a regular dry or wet surface or a surface containing surfactants, for example, detergents, and an oil stain surface. People can walk safely and stably on the outsoles. The manufacturing process has simple processes and is easy to carry out, and is suitable for large-scale production.

Owner:MAOTAI FUJIAN SOLES CO LTD +1

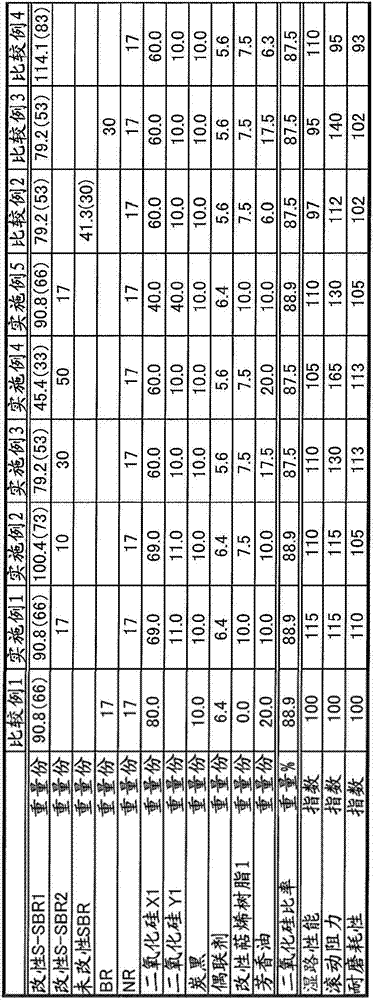

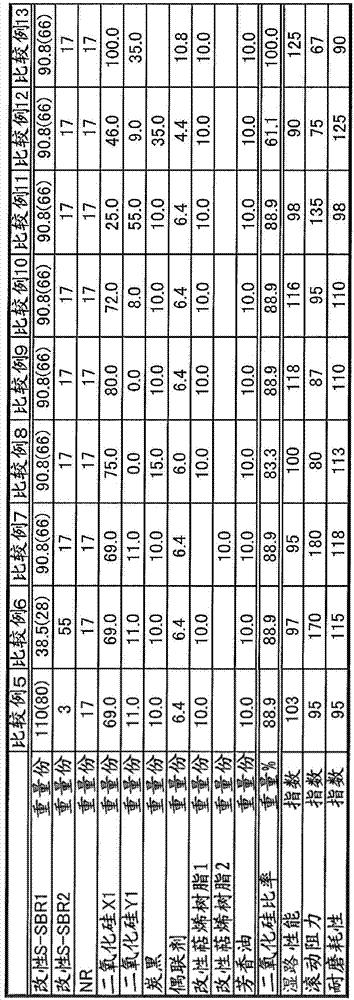

Tire rubber composite and pneumatic tire

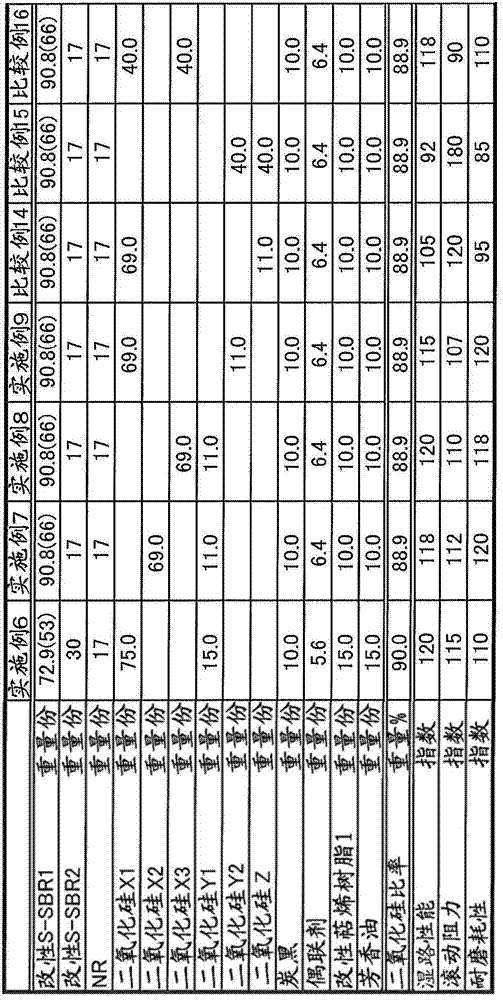

ActiveCN104245817AGood dispersionLow wear resistanceSpecial tyresRolling resistance optimizationRolling resistancePolymer science

Provided is a tire rubber composition that has lower rolling resistance, and improved wet performance and abrasion resistance compared to conventional levels. The composition is characterized in that: 2-50 parts by weight of an aromatic modified terpene resin with a softening point of at least 100 DEG C and a total of 60-130 parts by weight of two types of silica, silica X and silica Y, are added to 100 parts by weight of a diene rubber that includes 5-50 wt% of a terminal-modified S-SBR having a vinyl unit content of at least 25 wt% and a glass transition temperature of - 50 DEG C or below; the functional group of the modified S-SBR is reactive with a silanol group; a reinforcing filler comprising of silica X, silica Y and optionally added carbon black includes the silica at a proportion of at least 85 wt%; the specific surface area of silica X as determined by nitrogen absorption is at least 140m<2> / g; the specific surface area of silica Y as determined by nitrogen absorption is 100-140m<2> / g exclusive; and if the respective masses of silica X and silica Y per 100 parts by weight of the diene rubber are expressed as x parts by weight and y parts by weight, the relationship x / 7 < y <=x is satisfied.

Owner:THE YOKOHAMA RUBBER CO LTD

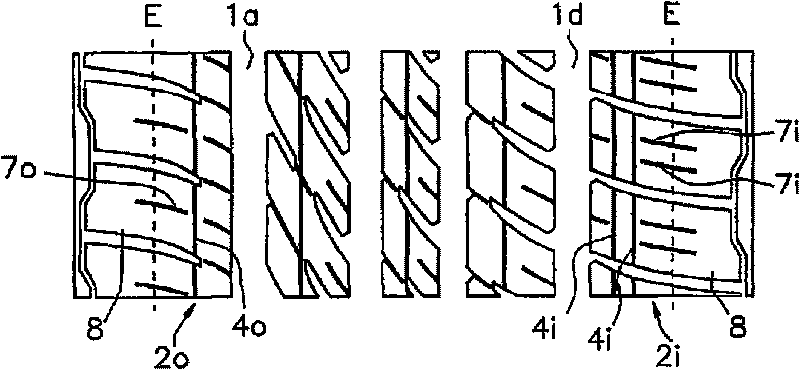

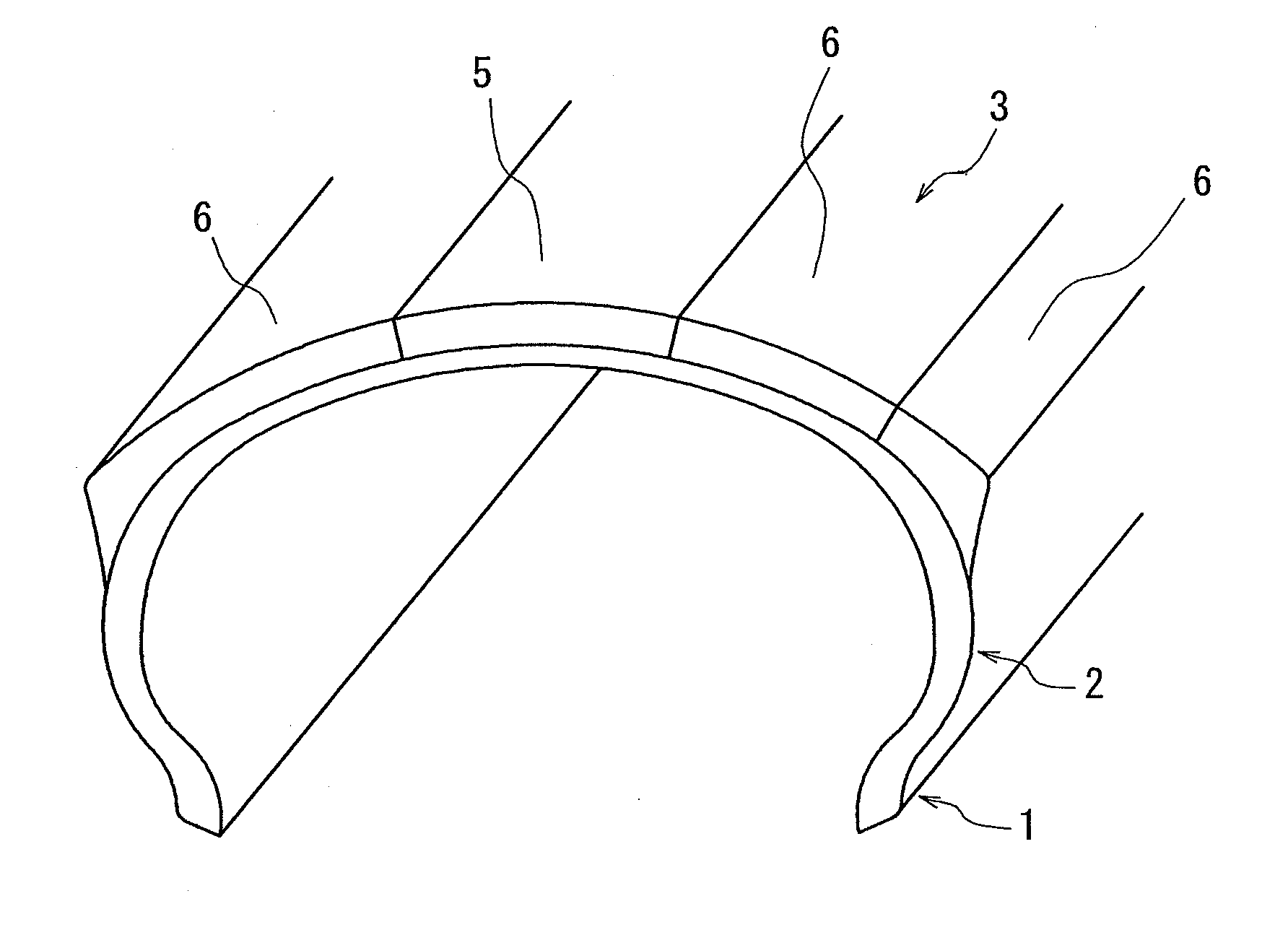

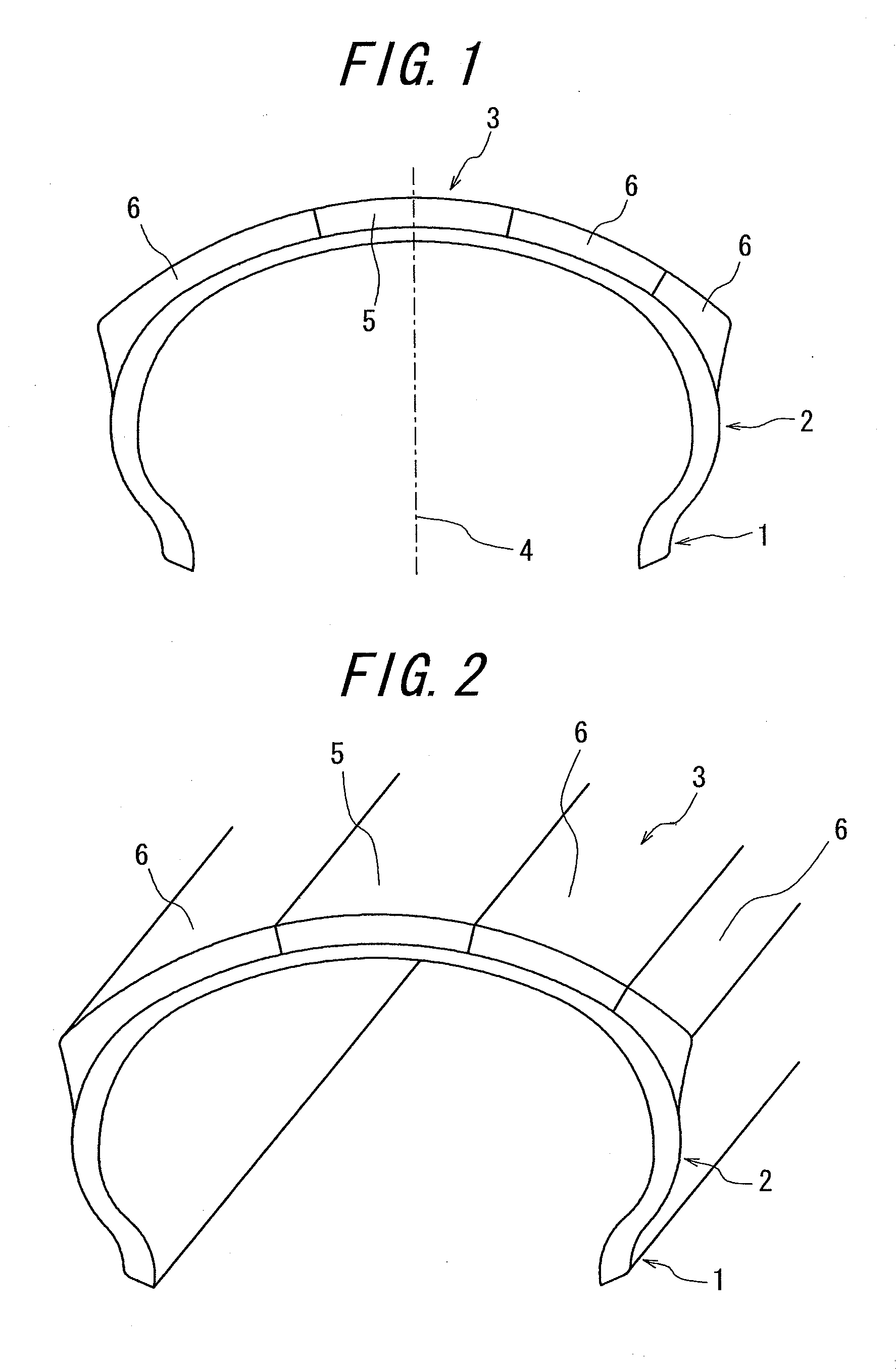

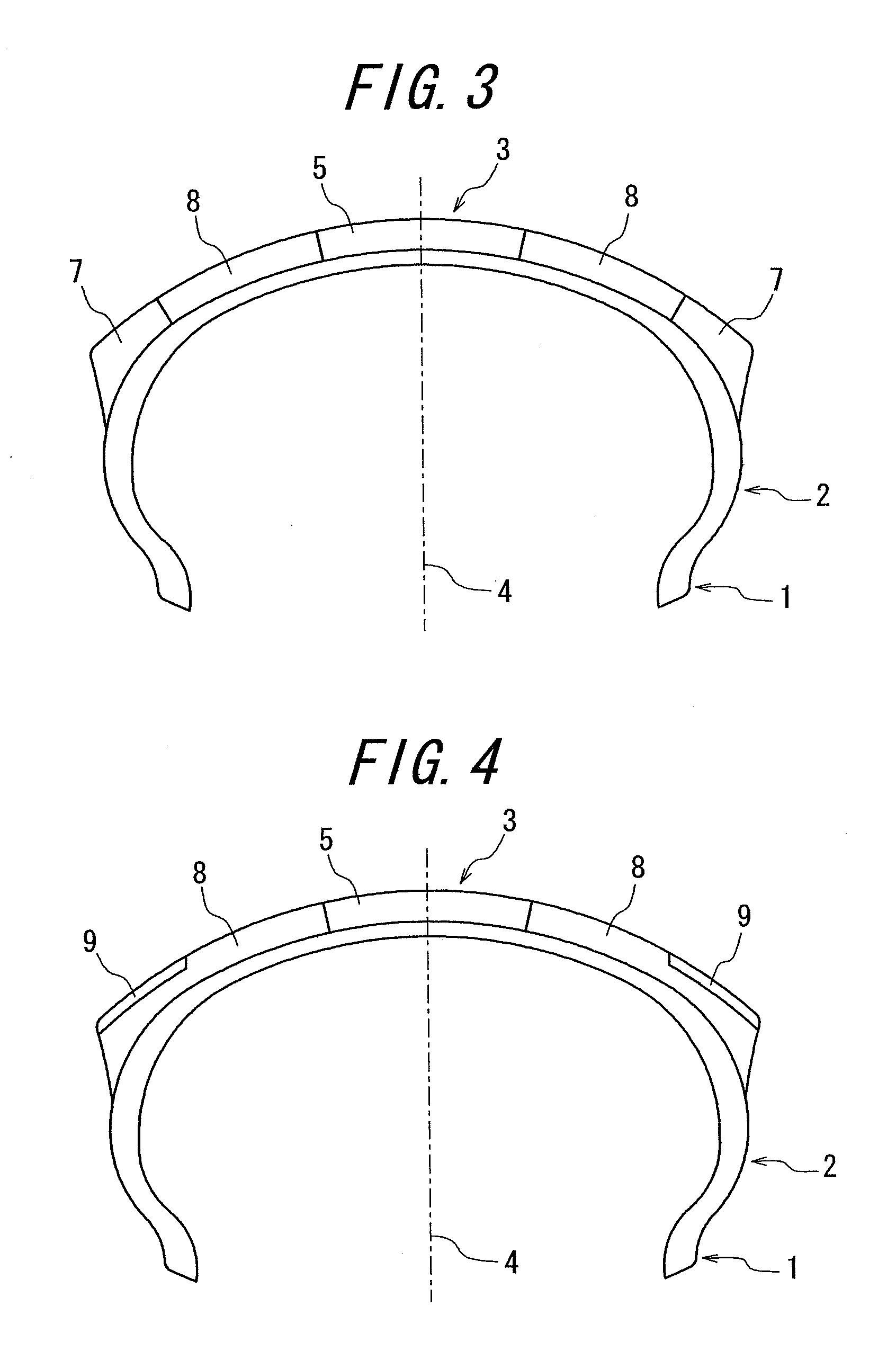

Pneumatic tire for motorcycle

ActiveUS20100132862A1Improve grip performanceIncreased durabilityMotorcycle tyresTyre tread bands/patternsMechanical engineeringTread

The present invention provides a pneumatic tire for a motorcycle, in which tire durability at a relatively high speed in running straight is enhanced with maintaining good gripping performances in cornering situation by optimizing the distribution of loss tangent in tread rubbers constituting a tread portion. The pneumatic tire for a motorcycle includes a pair of bead portions 1 having bead cores embedded therein, a pair of sidewalls 2 extending on the outer side in the tire radial direction from the bead portions 1, and a tread portion 3 extending over the respective sidewall portions 2, wherein the tread portion 3 is constituted of at least four tread regions such that, when the tread regions are viewed in a section in the tire widthwise direction, loss tangent values of rubbers constituting the adjacent tread regions are different from each other, and a loss tangent value of a rubber constituting a center tread region 5 as a tread region including the tire equatorial plane 4, of the tread regions, is smaller than a loss tangent value of each of rubbers constituting other tread regions 6.

Owner:BRIDGESTONE CORP

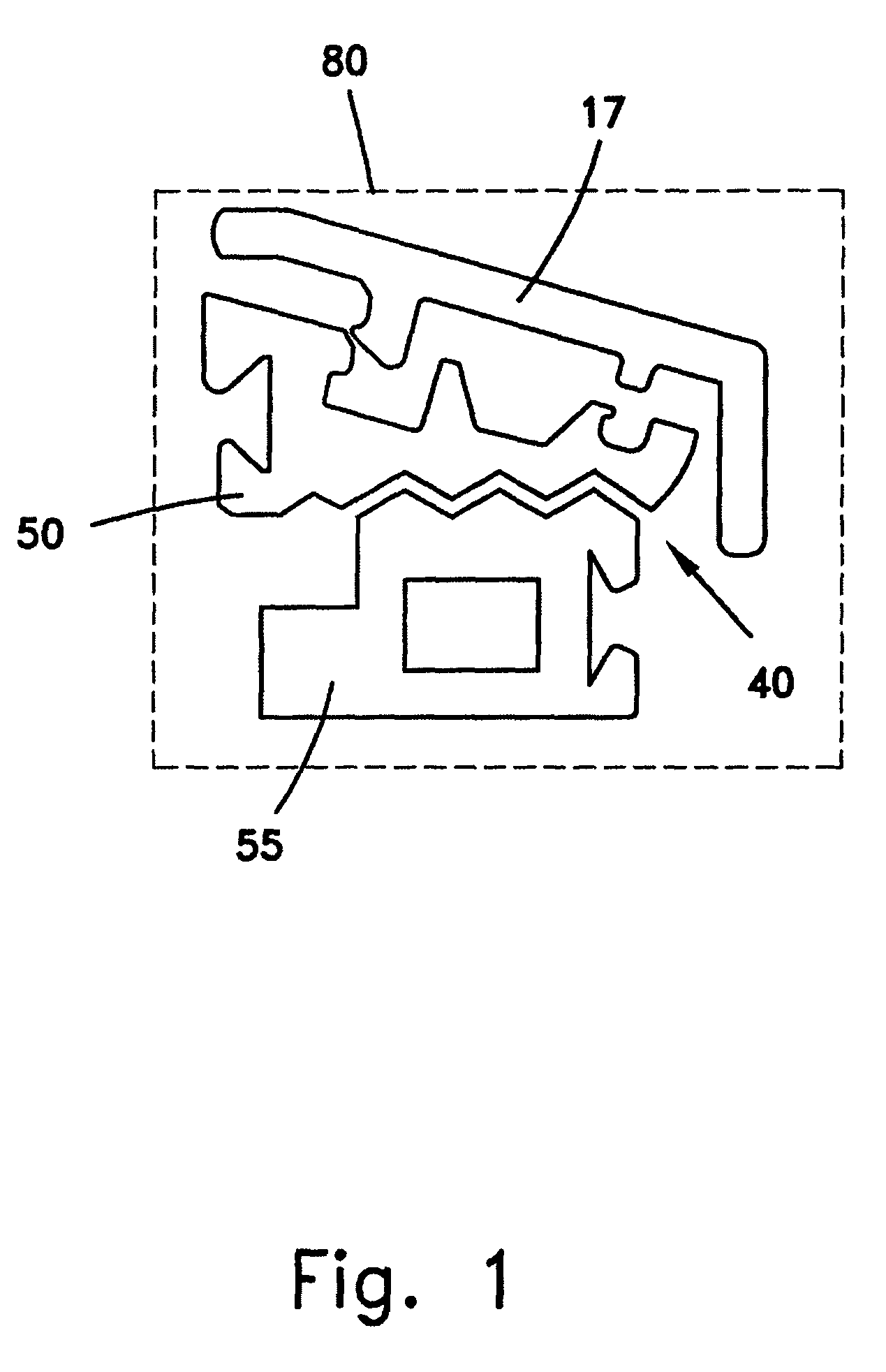

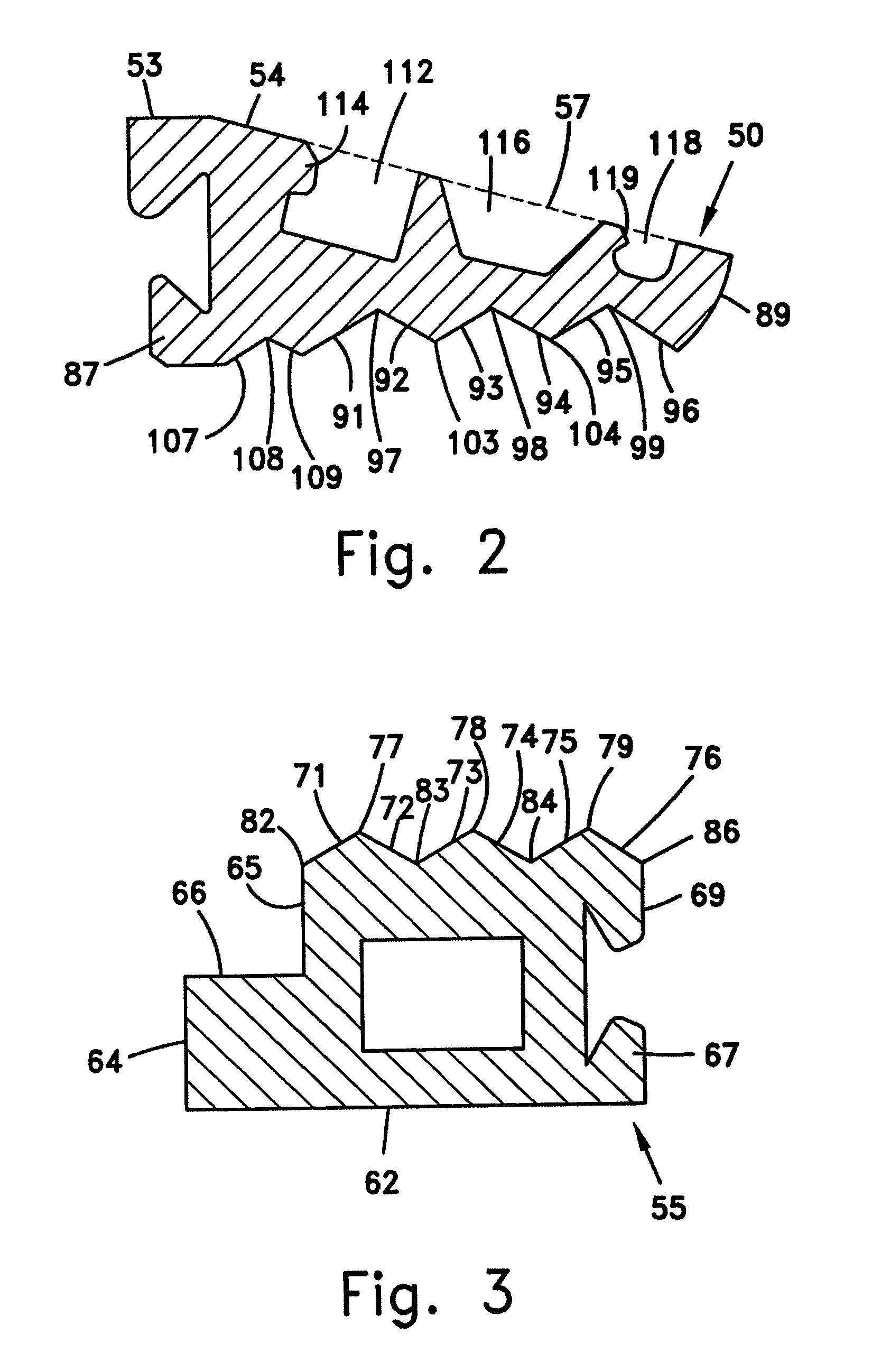

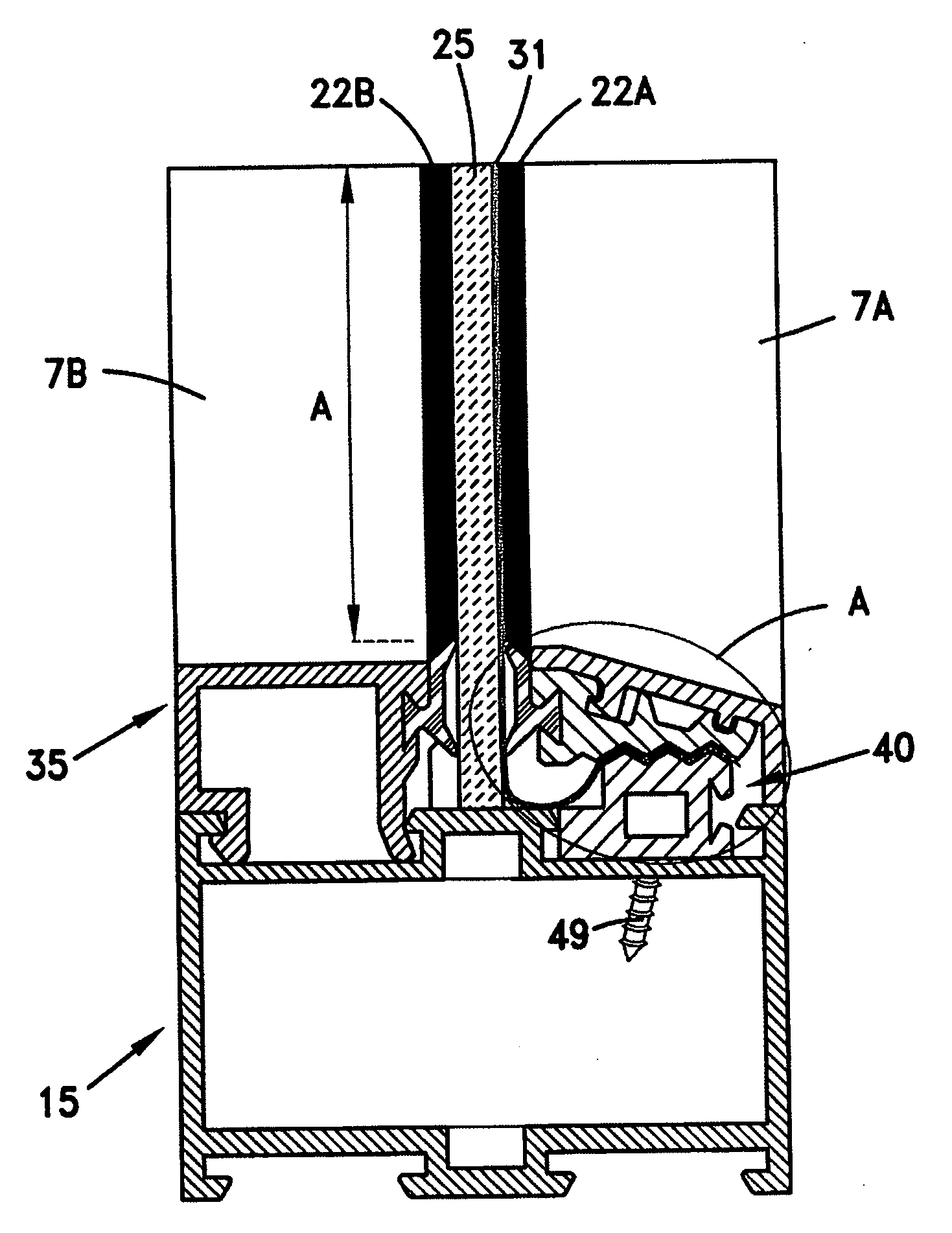

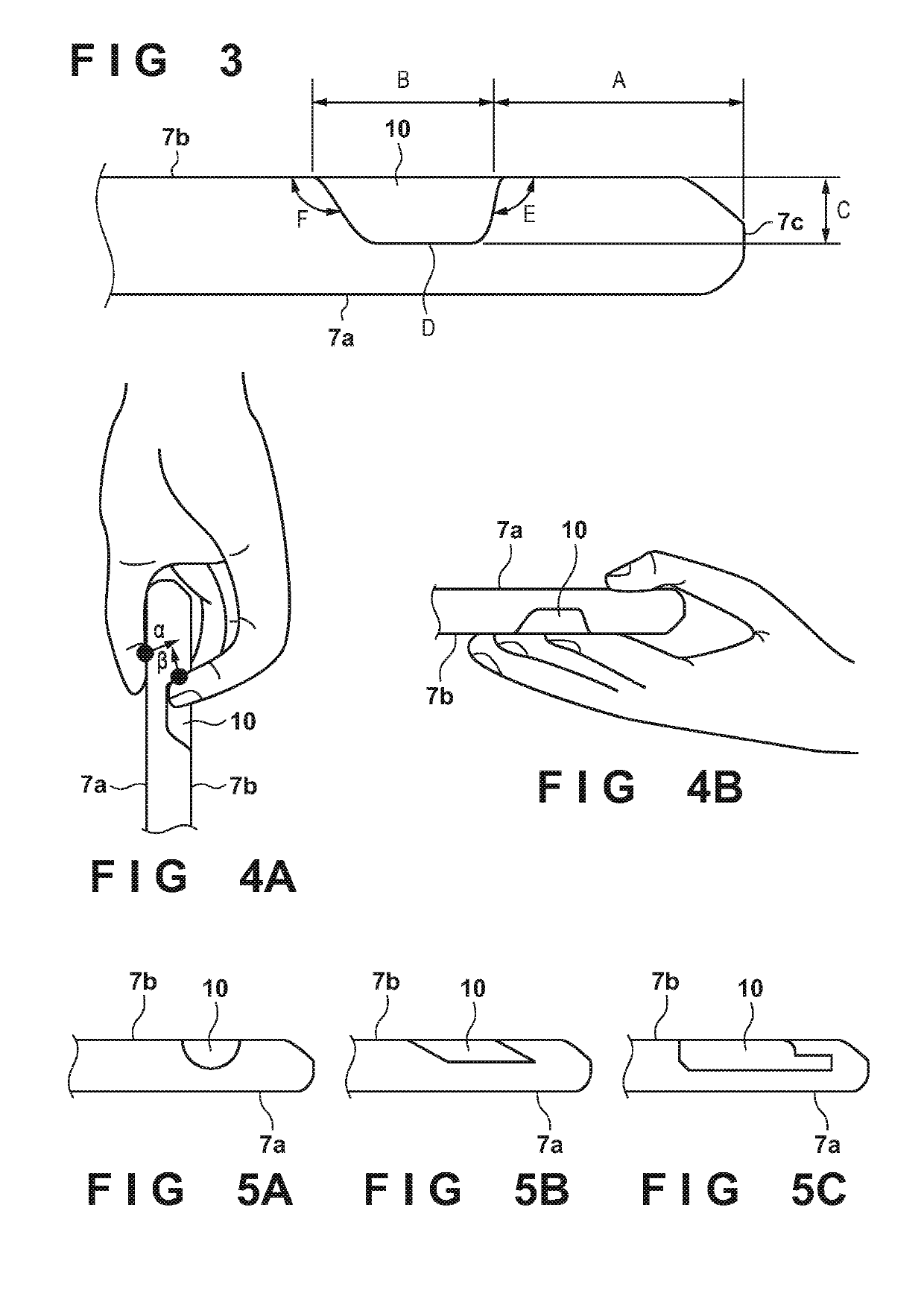

Window film anchoring device

ActiveUS8151540B2Improve impact resistanceAvoid relative motionBuilding repairsBuilding material handlingMechanical engineering

Owner:SORAG

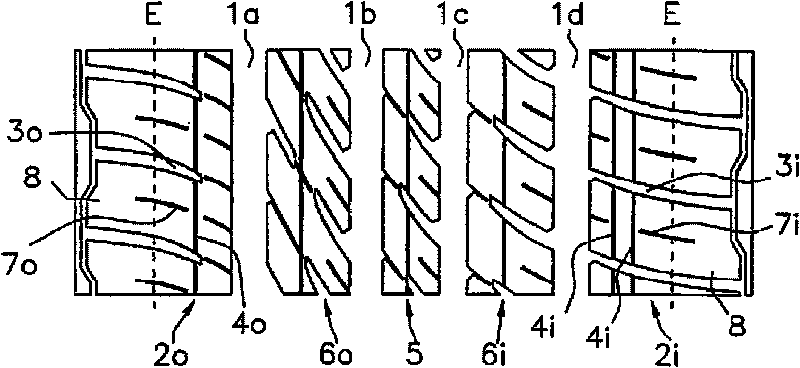

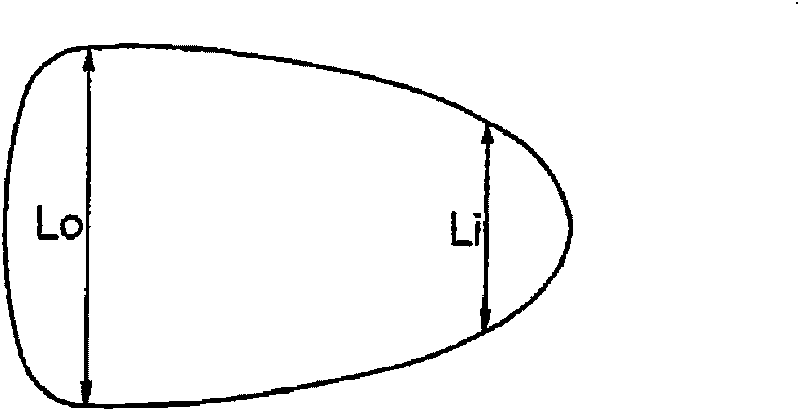

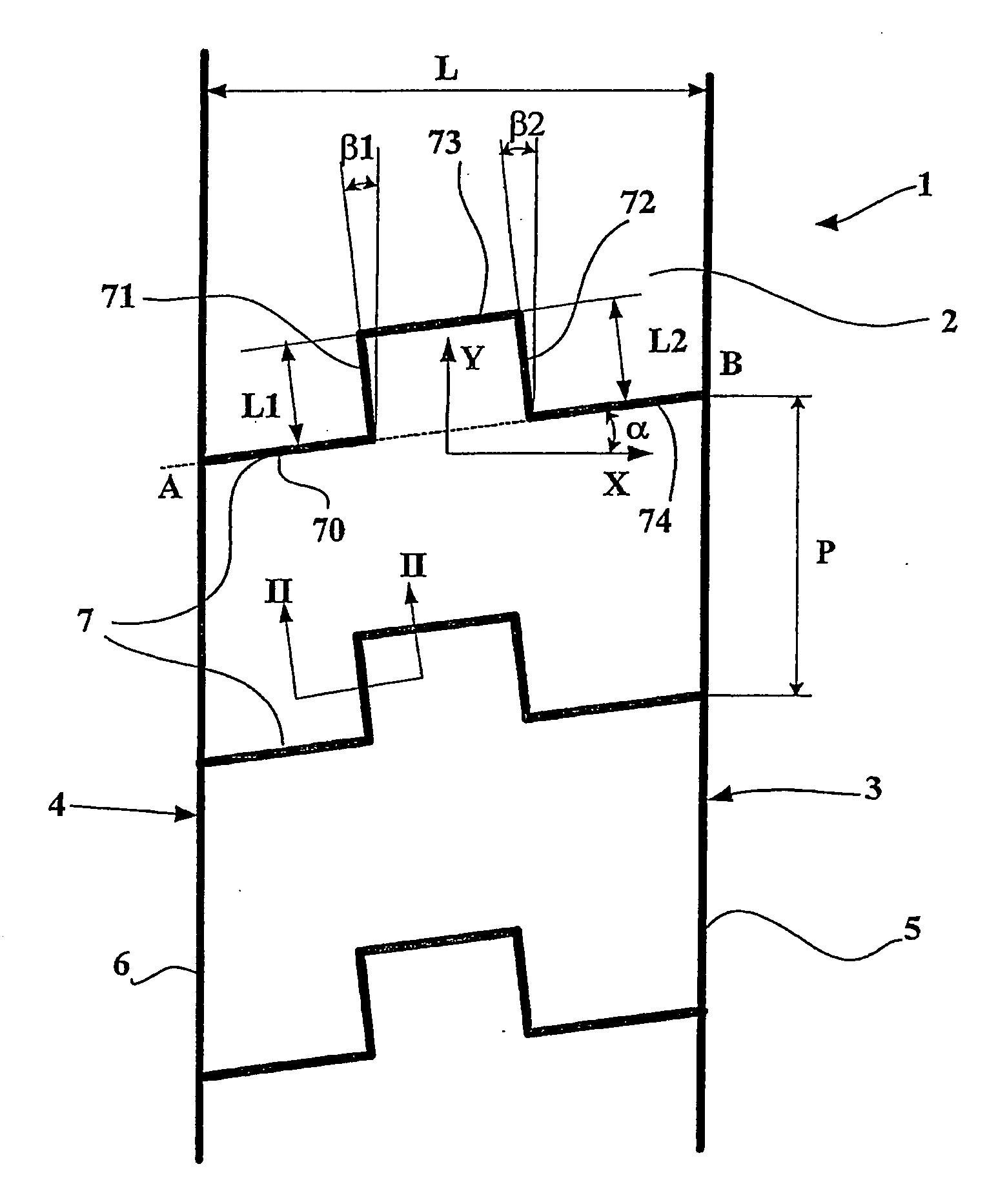

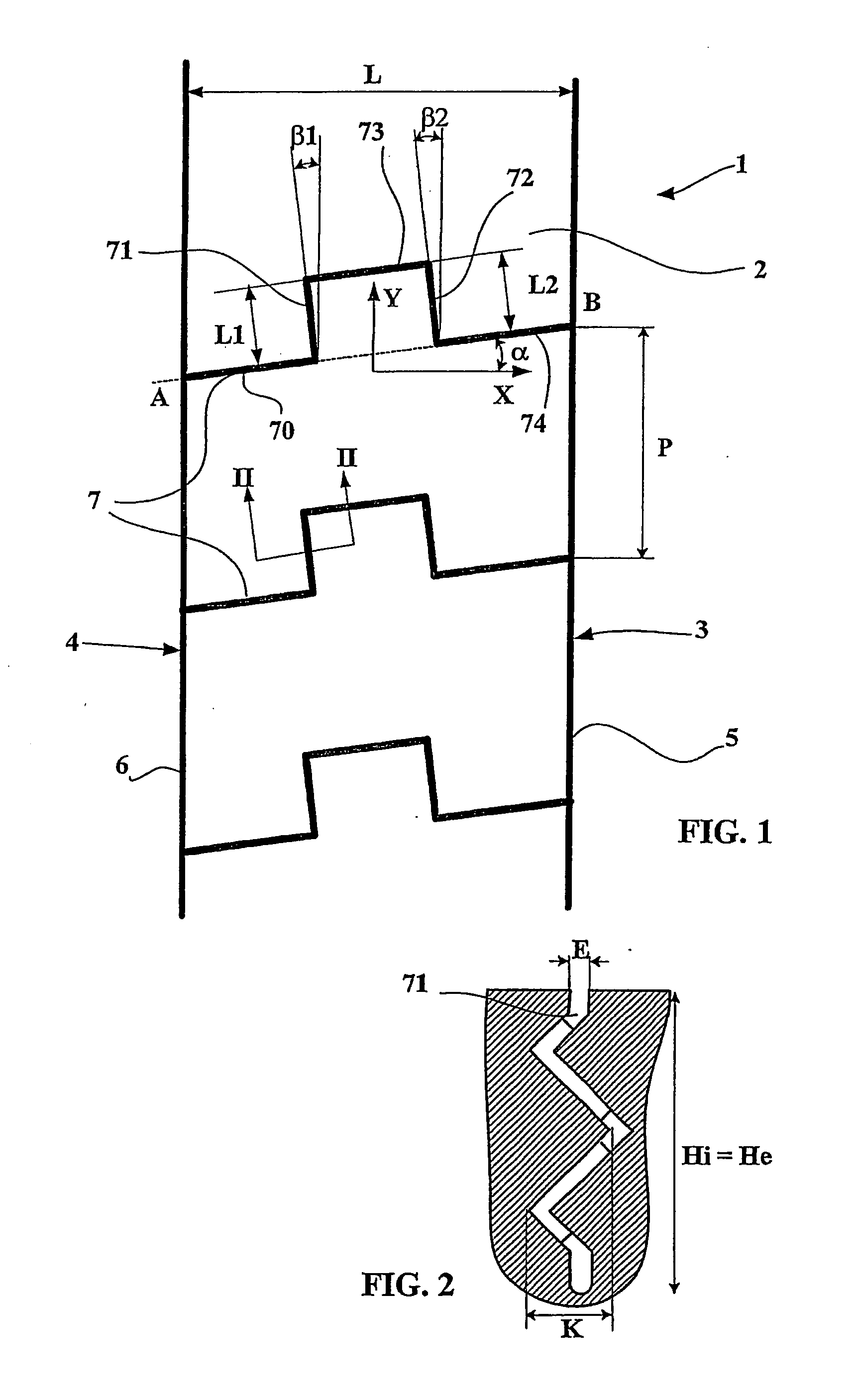

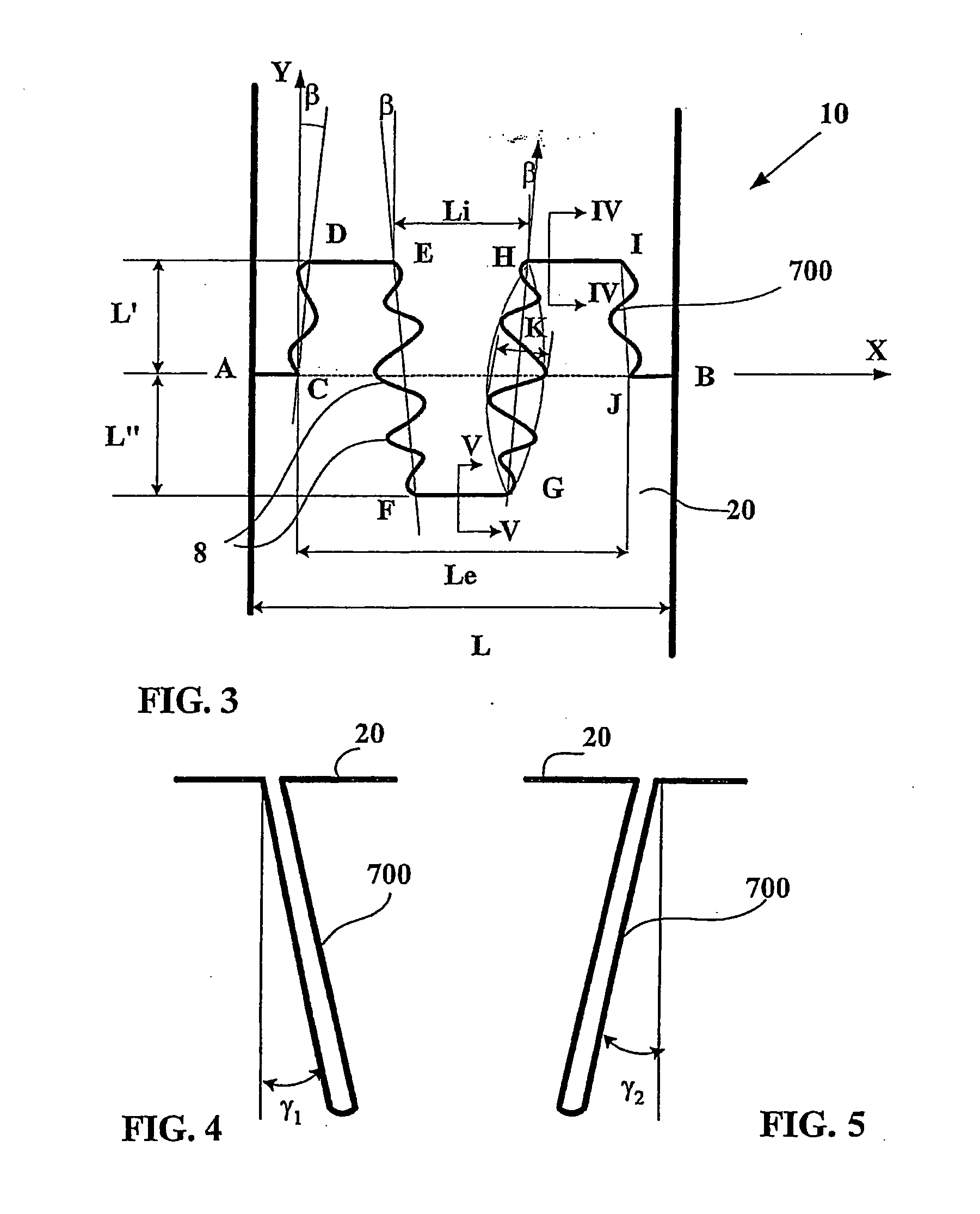

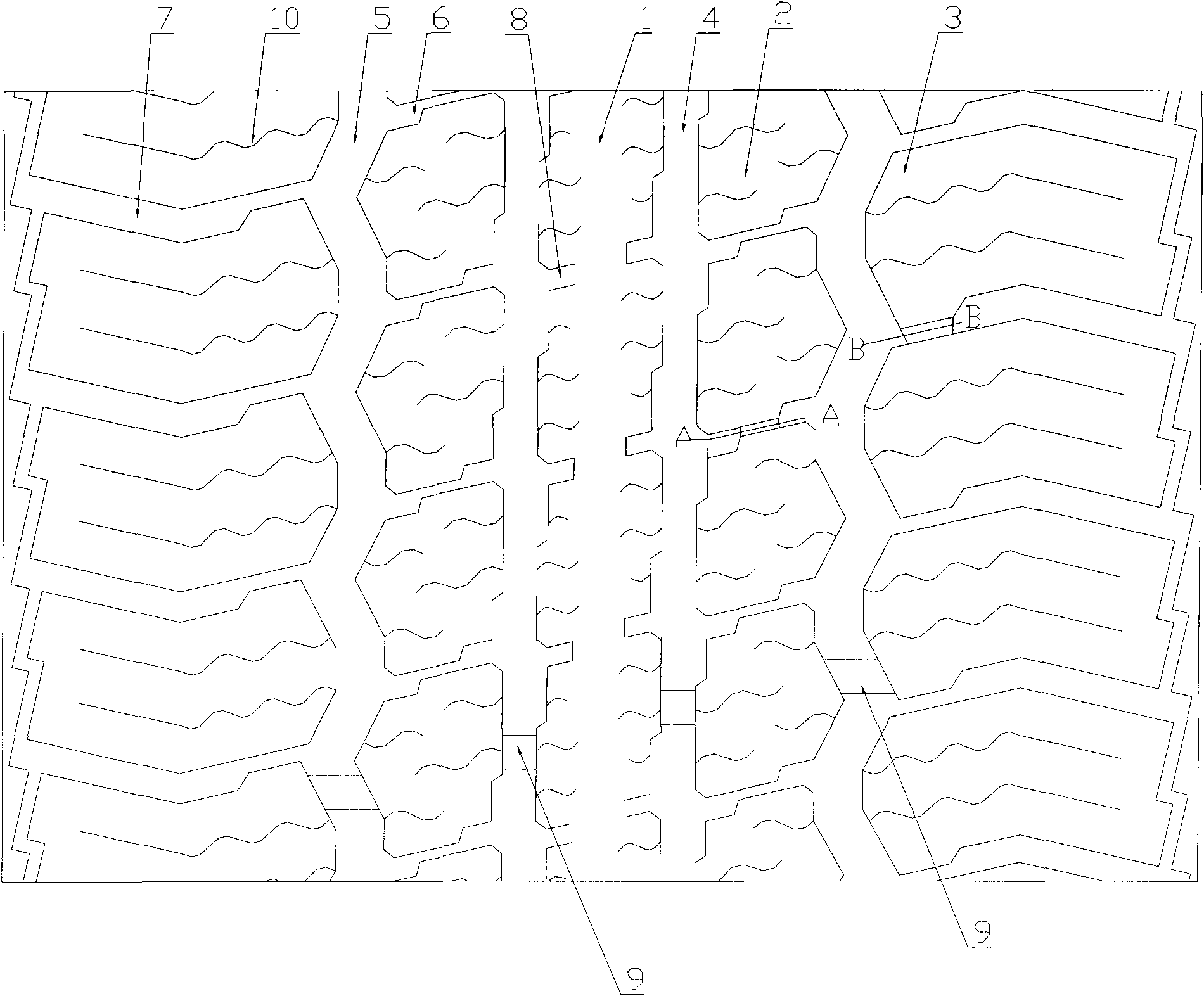

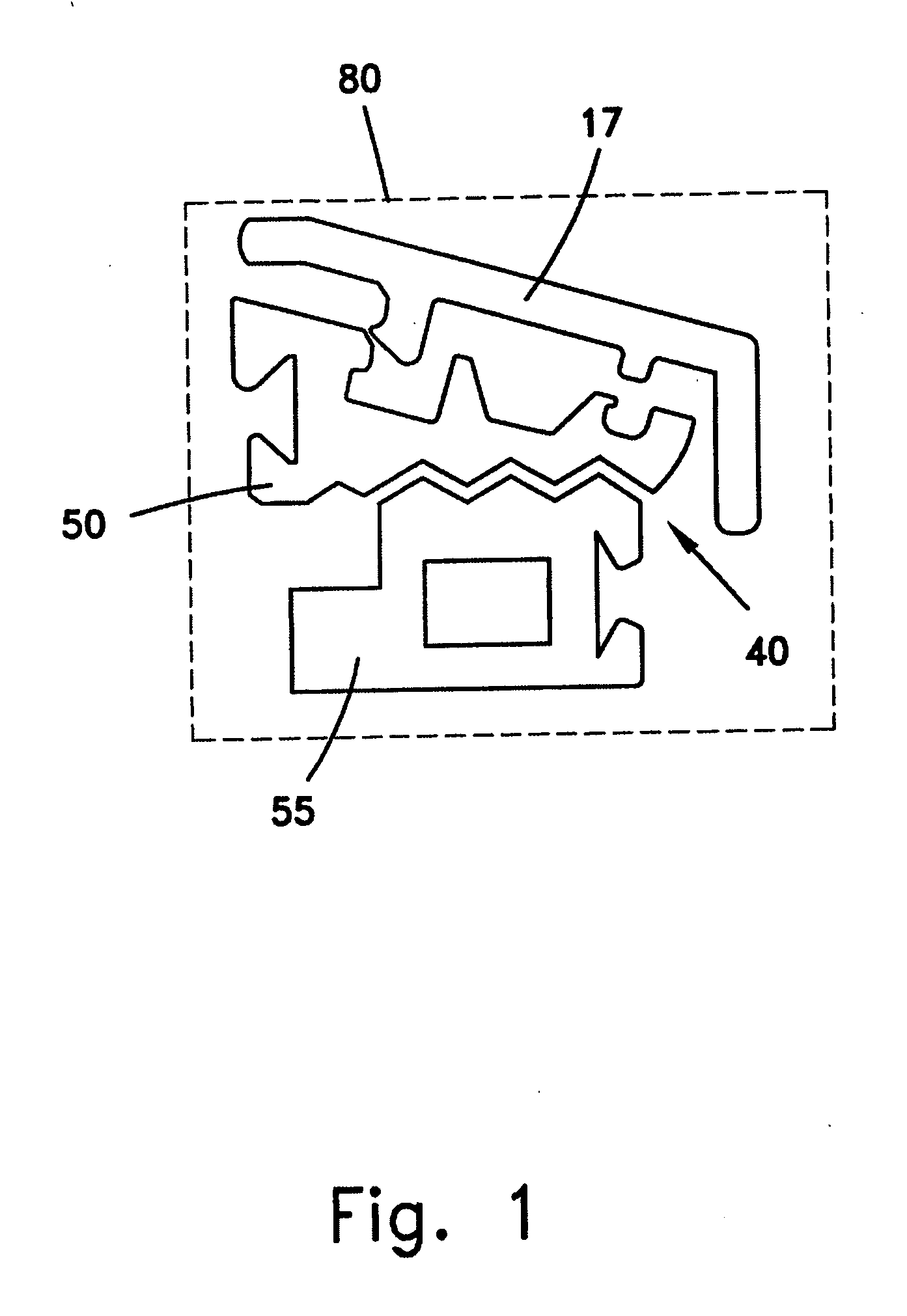

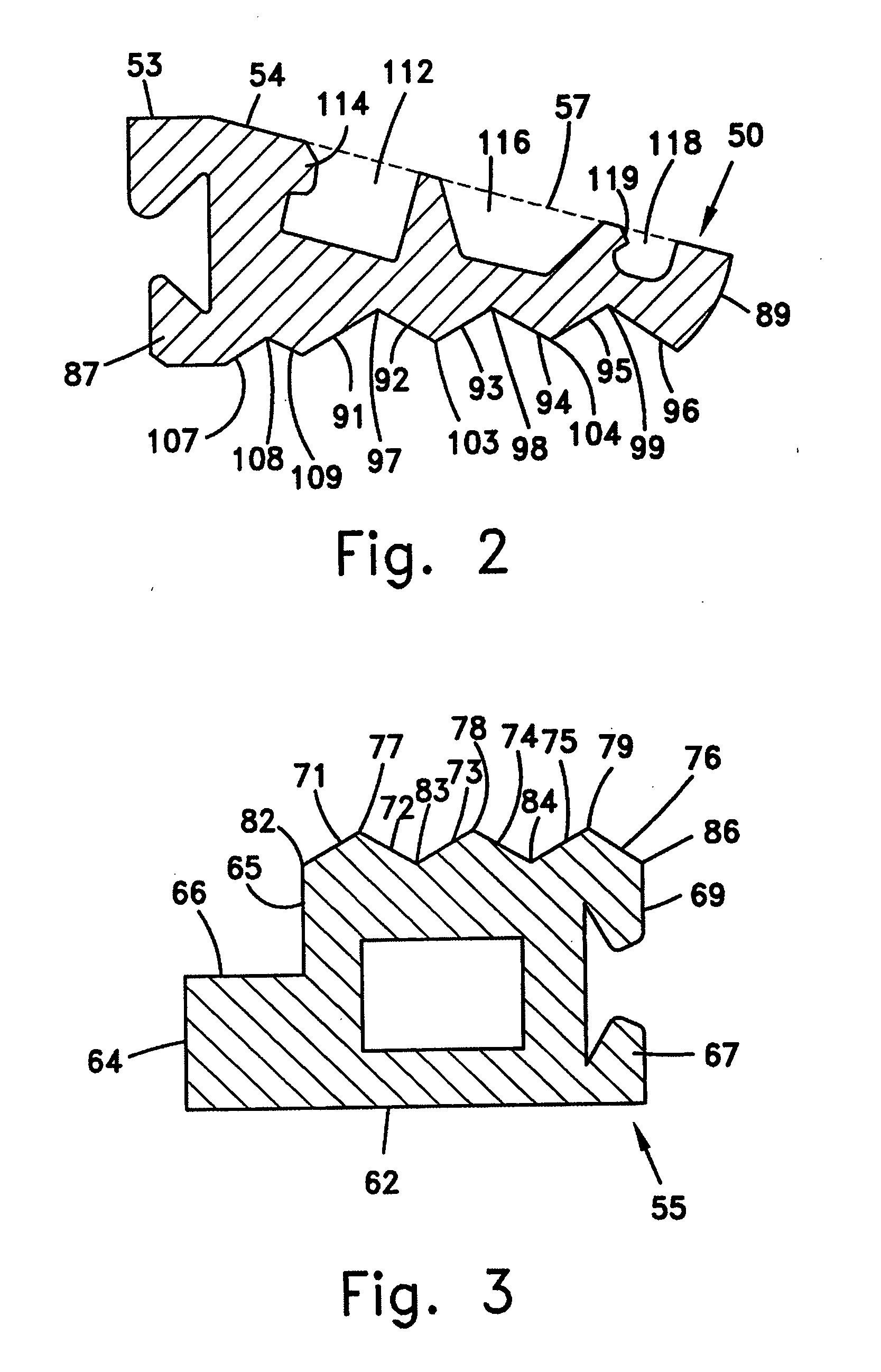

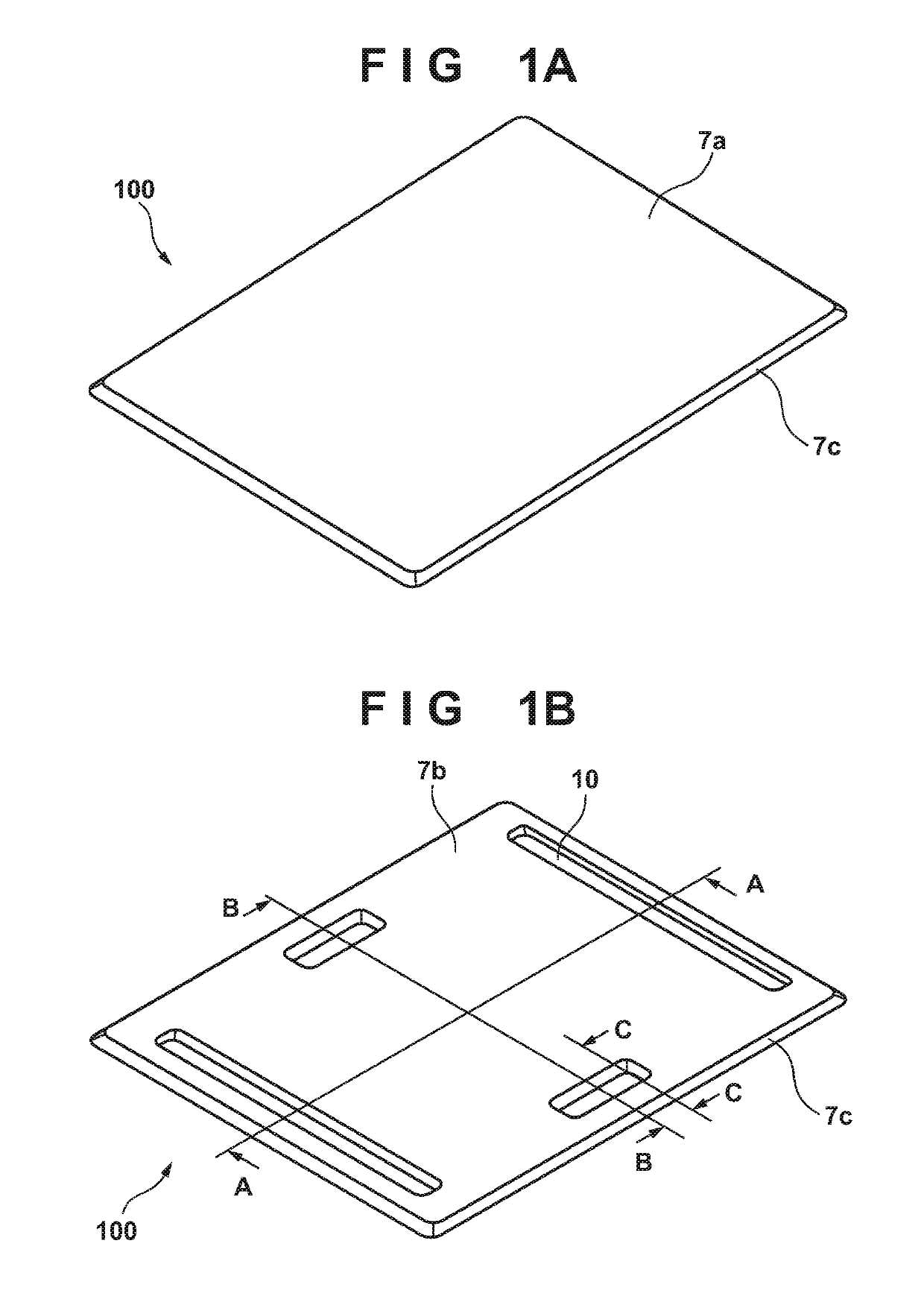

Tire tread provided with incisions

InactiveUS20070187014A1Effective blockingImprove grip performanceTyre tread bands/patternsNon-skid devicesMaximum depthEngineering

Tire tread including a pattern formed by at two ridges of mean width L, which include a plurality of incisions whose traces on the contact surface extend between two points of intersection A and B, the segment AB making an angle with the transverse direction of the tread at most equal to 40°, the tread wherein each incision, of mean width E, includes a succession of incision portions, some of said incision portions having, on any surface parallel to the contact surface in the new condition and located between said surface in the new condition and ⅔ of the maximum depth of the incision, traces that make an average angle β at most equal to 15° with the longitudinal direction of the tread, said portions having a total length Lt which is at least equal to one-fifth of the ridge width; and in that the incision portions whose traces make an average angle β are provided on their opposite walls with relief elements of amplitude K designed to cooperate with one another to block relative movements between one incision wall and the opposite wall, the amplitude K of said relief elements being between 4 and 10 times the mean width E of the incision.

Owner:MICHELIN RECH & TECH SA

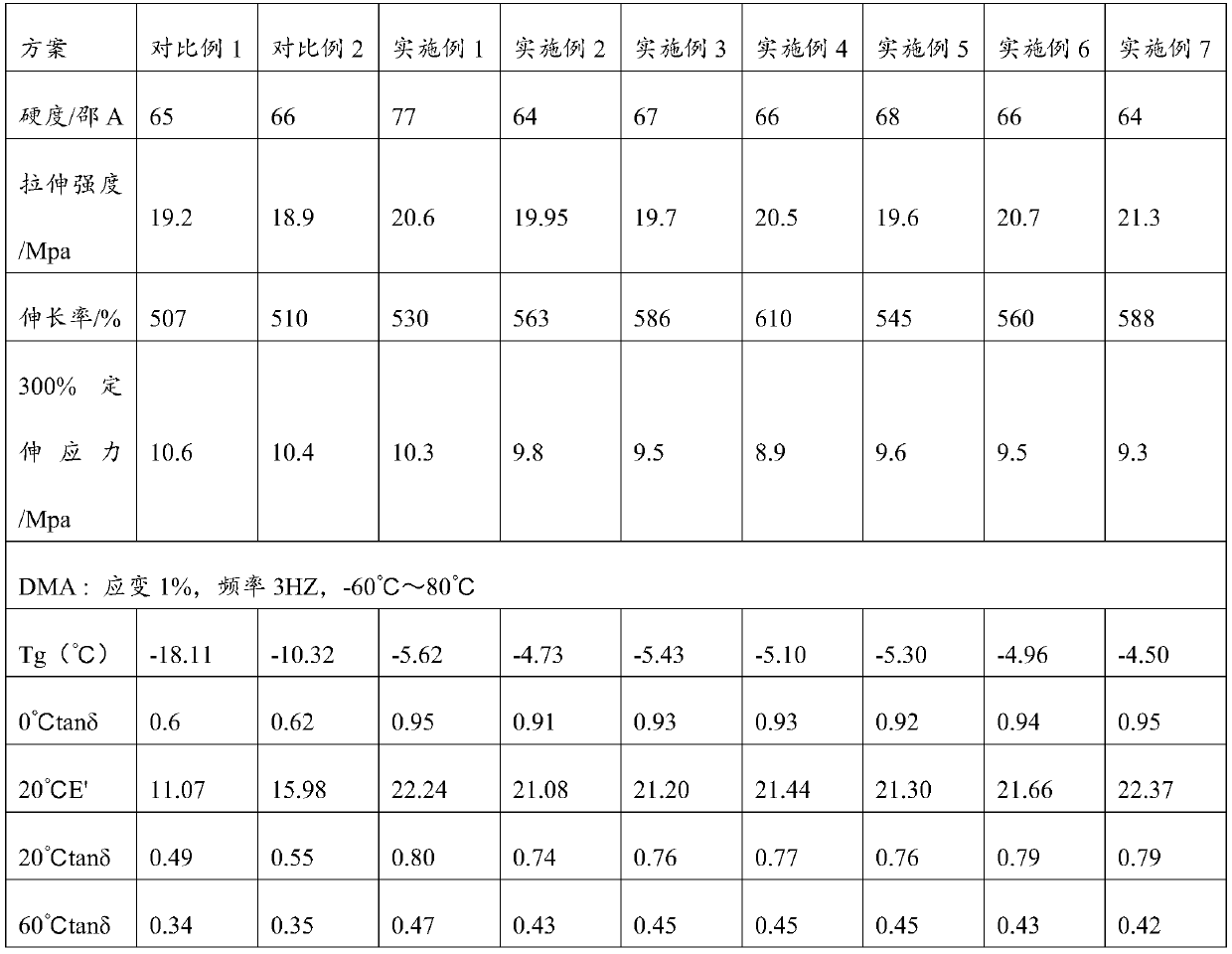

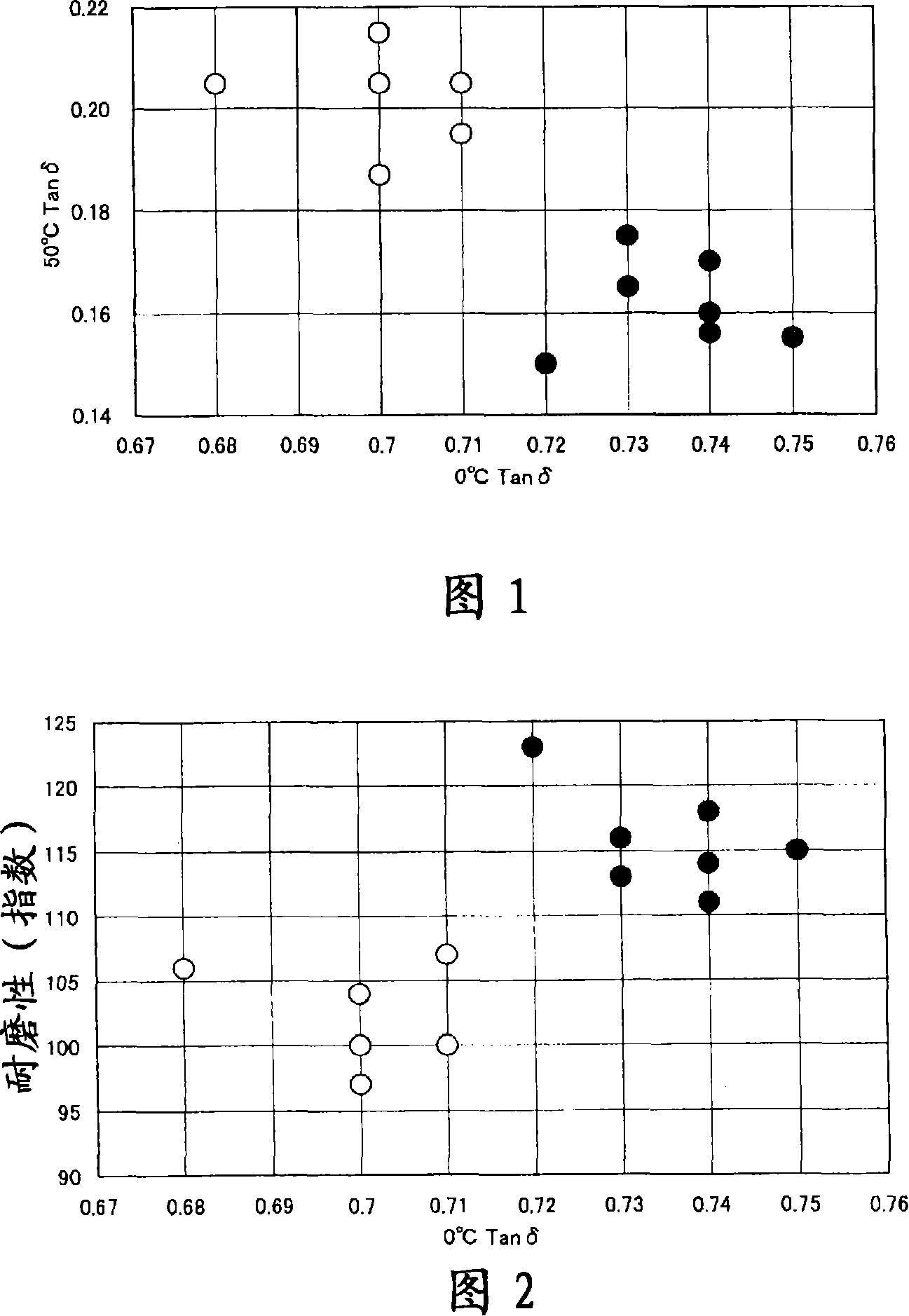

Tread compound for passenger tyre with high wet skid resistance and preparation method thereof

InactiveCN105001475AImproved wet grip performanceImproves wet grip performanceSpecial tyresButadiene-styrene rubberAntioxidant

The invention relates to a tread compound for a passenger tyre with high wet skid resistance and a preparation method thereof. The tread compound comprises, by weight, 13 to 16 parts of natural rubber, 61 to 83 parts of first solution-polymerized styrene butadiene rubber, 25 to 40 parts of second solution-polymerized styrene butadiene rubber, 10 to 20 parts of carbon black, 45 to 55 parts of white carbon black, 2 to 7 parts of a softener, 5 to 6 parts of an activator, 3 to 4 parts of an antioxidant, 1.8 to 2.2 parts of a wet skid resistance reinforcing agent, 4.5 to 5.5 parts of resin with high wet skid resistance, 7 to 9 parts of a coupling agent and 3 to 3.5 parts of a vulcanizing agent. The tyre prepared from the raw materials provided by the invention has wet skid resistance reaching grade A or above and is a high quality tyre with superhigh wet skid resistance.

Owner:山东盛世泰来橡胶科技有限公司

Grip for sporting goods and golf club

ActiveUS20170182386A1Improve grip performanceLower performance requirementsSnowboard bindingsSkisPolymer scienceSurface layer

An object of the present invention is to provide a grip for sporting goods containing an acrylonitrile-butadiene based rubber as a base rubber and having an excellent grip performance and sustainability of grip performance under a wet condition. The present invention provides a grip for sporting goods comprising an outermost surface layer formed from a surface layer rubber composition, wherein the surface layer rubber composition contains (A) a base rubber and (B) a resin having a softening point in a range from 5° C. to 120° C., (A) the base rubber contains an acrylonitrile-butadiene based rubber, and (B) the resin is at least one type selected from the group consisting of a hydrogenated rosin ester, a disproportionated rosin ester, an ethylene-vinyl acetate copolymer, a coumarone resin, a phenol resin, a xylene resin and a styrene resin.

Owner:SUMITOMO RUBBER IND LTD

Saloon car tyre surface

InactiveCN102398478AGood maneuverabilityStrong performanceTyre tread bands/patternsEngineeringBrake force

The invention relates to a saloon car tyre surface and specially, relates to patterns of the saloon car tyre surface. The saloon car tyre surface comprises a centre pattern block, side pattern blocks and shoulder pattern blocks. The side pattern blocks and the shoulder pattern blocks are orderly and regularly arranged at left and right sides of the centre pattern block from inside to outside. The saloon car tyre surface is divided into left and right symmetrical parts by the centre pattern block. The centre pattern block is a vertical one-piece pattern block and is located in the center of the saloon car tyre surface. The centre pattern block is separated from the side pattern blocks through main vertical circle pattern channels located between the centre pattern block and the side pattern blocks. The side pattern blocks are separated from the shoulder pattern blocks through auxiliary vertical circle pattern channels located between the side pattern blocks and the shoulder pattern blocks. Adjacent two of the side pattern blocks are separated through an inclined side pattern channel and two ends of the inclined side pattern channel are respectively communicated with the main vertical circle pattern channel and the auxiliary vertical circle pattern channel. Adjacent two of the shoulder pattern blocks are separated through a shoulder pattern channel and the shoulder pattern channel is communicated with the auxiliary vertical circle pattern channel. The patterns of the saloon car tyre surface are mixed patterns and thus the saloon car tyre surface can produce an enough braking force and has good control performances and a beautiful appearance.

Owner:QINGDAO YELLOWSEA RUBBER

Rubber composition for tire treads

ActiveCN103237841AGood dispersionHigh affinitySpecial tyresRolling resistance optimizationHydrocarbon solventsPolymer science

Provided is a rubber composition for tire treads, and the rubber composition brings about lower rolling resistance and better control stability than the conventional levels. The rubber composition is characterized by comprising 100 parts by weight of a diene rubber containing at least 40 wt% of a modified conjugated-diene polymer rubber, and 66-110 parts by weight of a filler comprising at least 50 wt% of silica. The composition is further characterized in that the modified conjugated-diene polymer rubber has modifying end groups obtained by reacting at least one compound with active conjugated-diene polymer chains obtained by copolymerizing a conjugated-diene monomer and an aromatic vinyl monomer in a hydrocarbon solvent by using an organic active metal compound as an initiator, the at least one compound having a functional group reactive with the active ends of the polymer chains, the modifying end groups including a functional group that interacts with silica, and that the modified conjugated-diene polymer rubber has an aromatic-vinyl unit content of 38-48 wt%, a vinyl unit content of 20-35%, and a weight-average molecular weight of 600,000-1,000,000.

Owner:YOKOHAMA RUBBER CO LTD

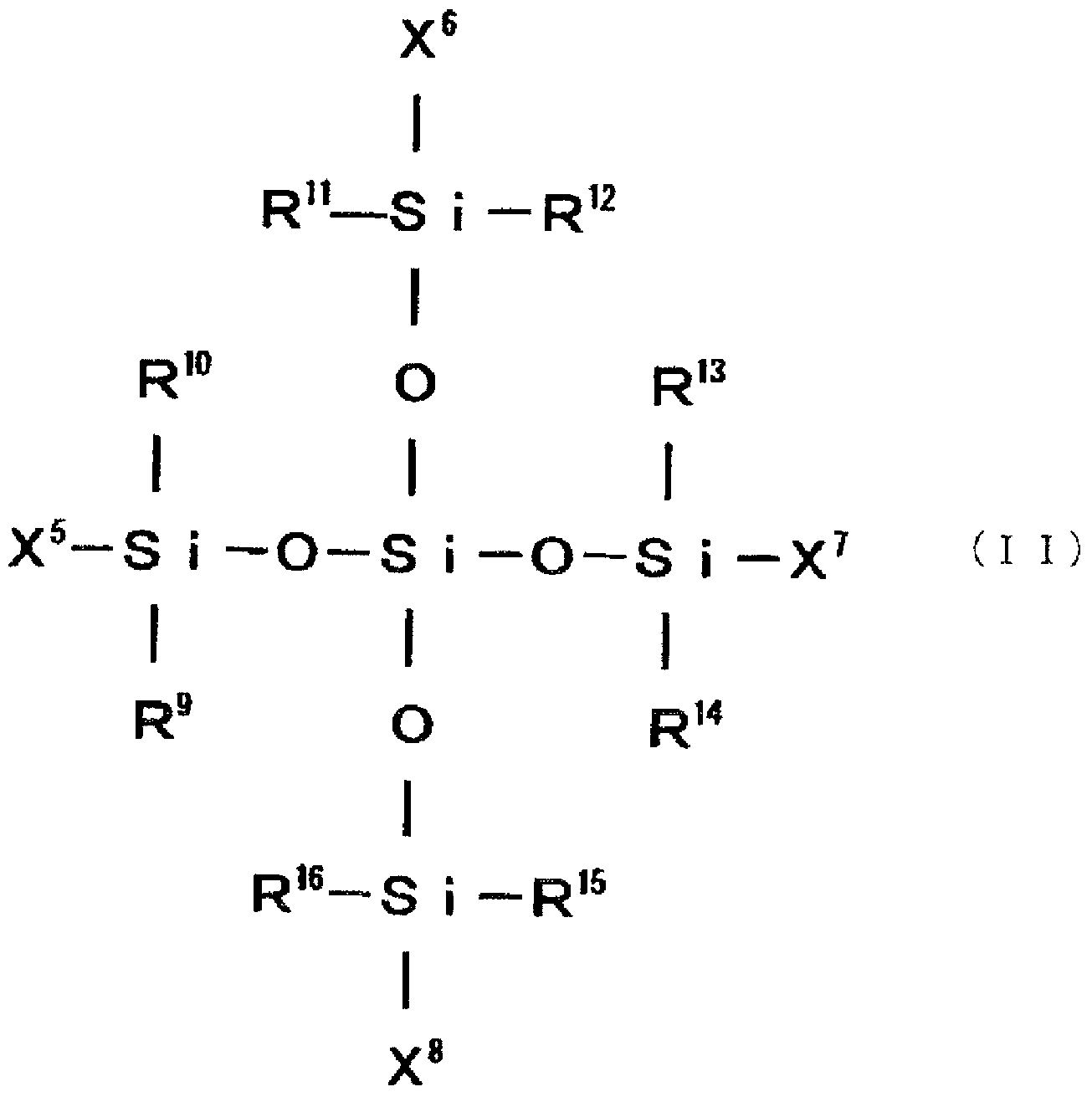

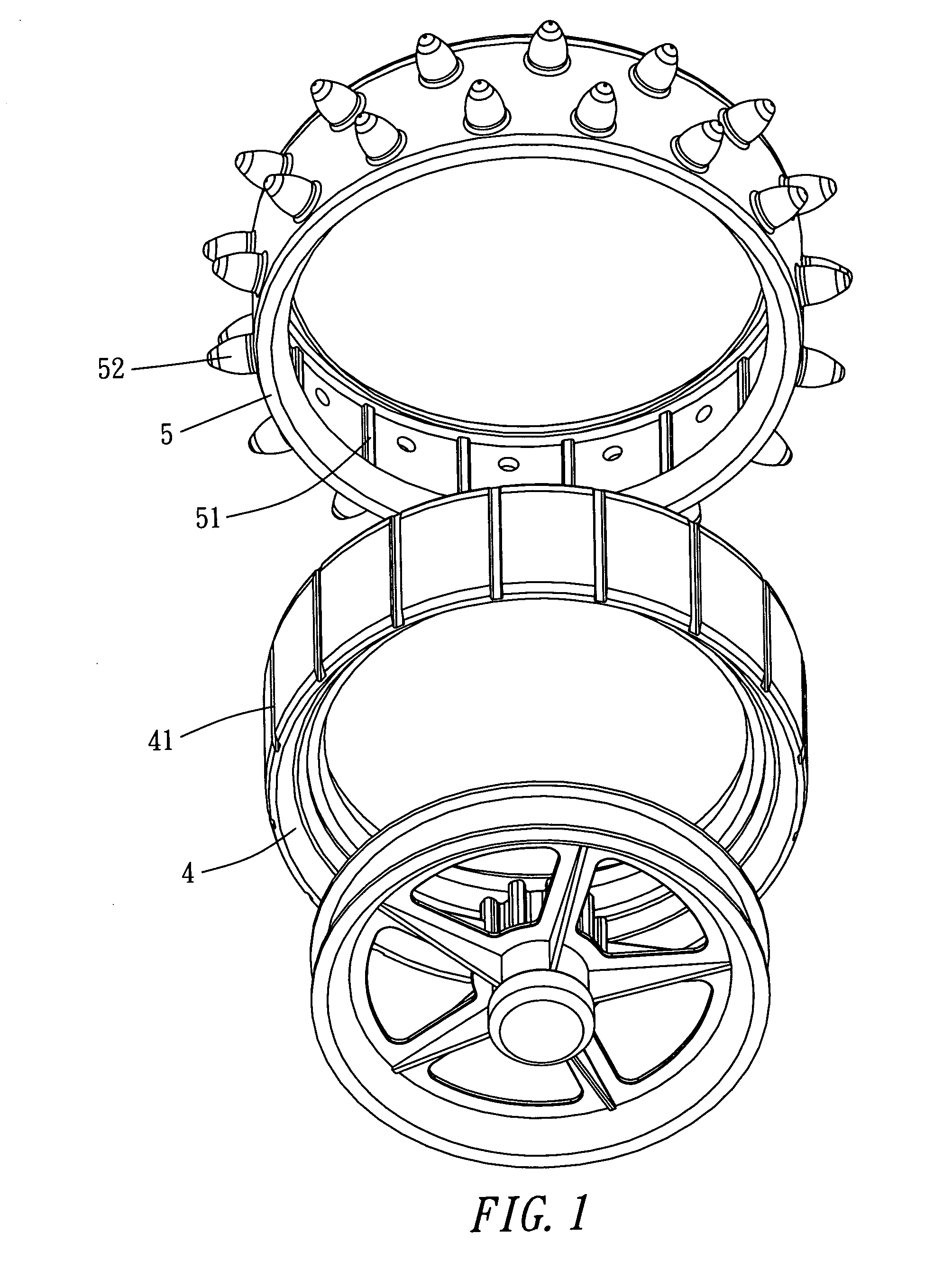

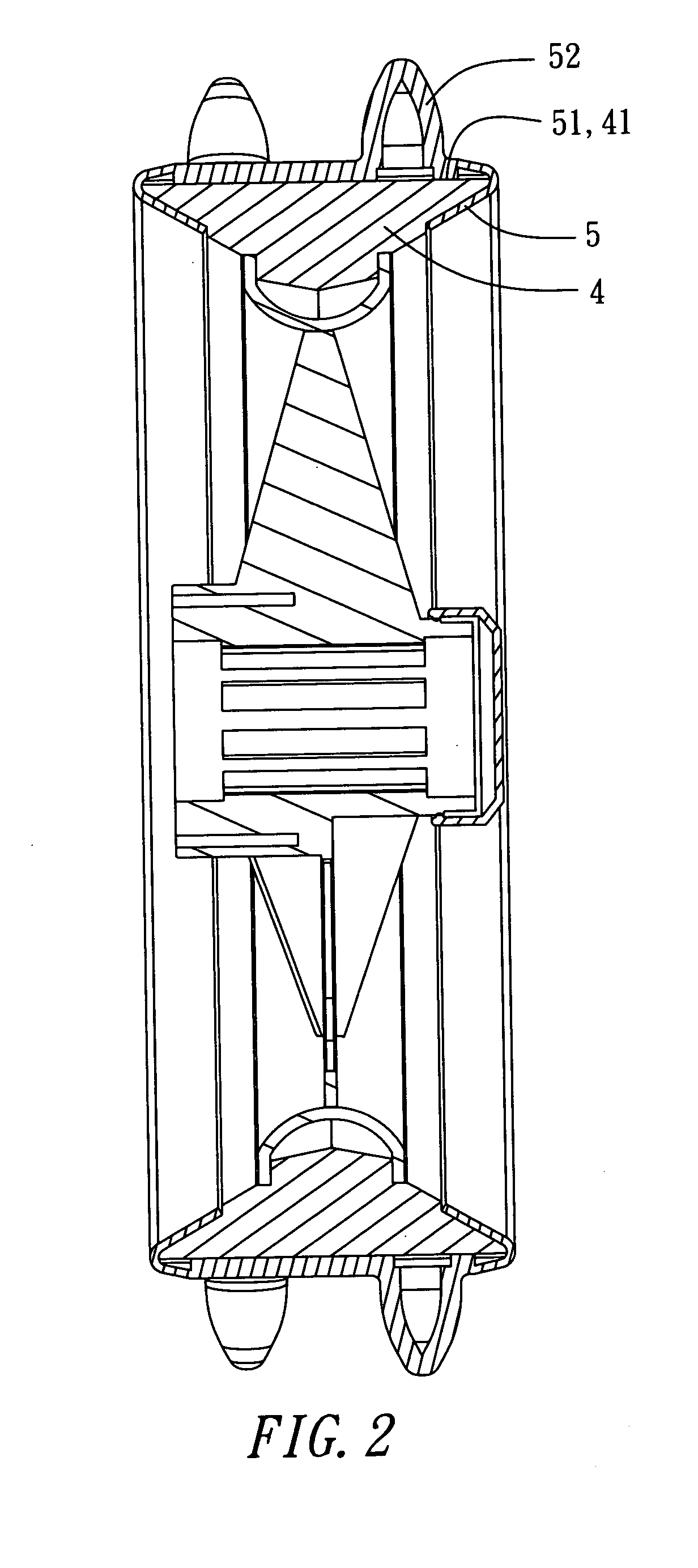

Tire for golf cart

InactiveUS20070044880A1Improve grip performanceLight weightNon-inflatable tyresPneumatic tyre reinforcementsShock resistanceGolf Ball

A tire for a golf cart includes an inner tire, and a thin outer tire mounted around the inner tire. The inner tire made of EVA solid foam material co-operates with the thin outer tire having a plurality of protruding bosses to construct a solid composite tire, so that the tire has a light weight, needs not to be inflated and has a better shock-absorbing effect. In addition, the pointed cylindrical shaped protruding bosses of the thin outer tire can be extended into the muddy or snowy ground to provide an excellent grip effect, so that the golf cart can be moved smoothly and conveniently. Thus, the tire has an excellent ground grip effect, so that the tire is available for the muddy or snowy ground.

Owner:UNIQUE PRODS & DESIGN

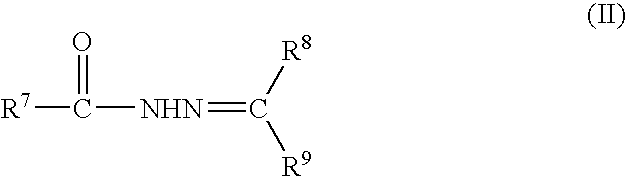

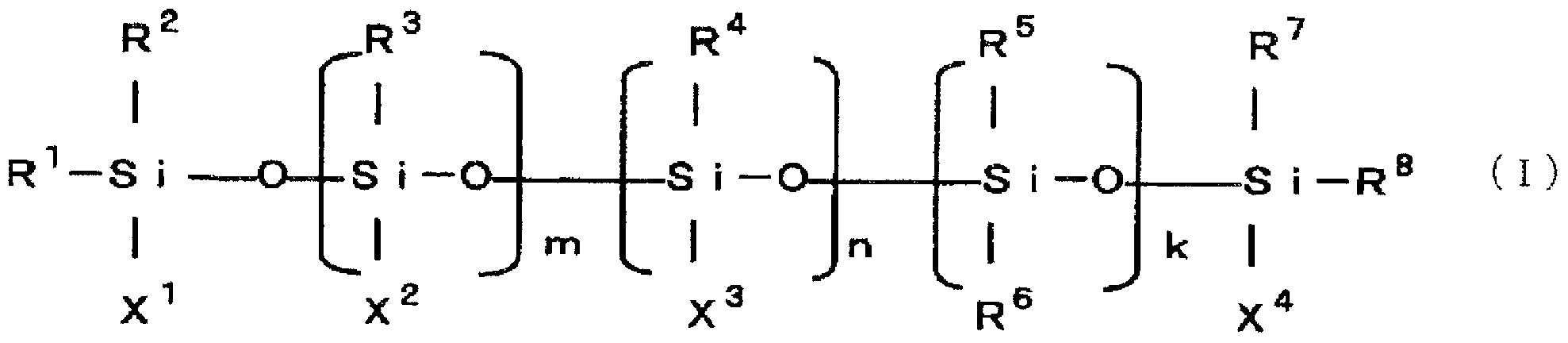

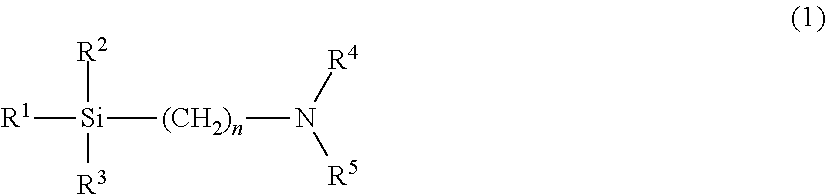

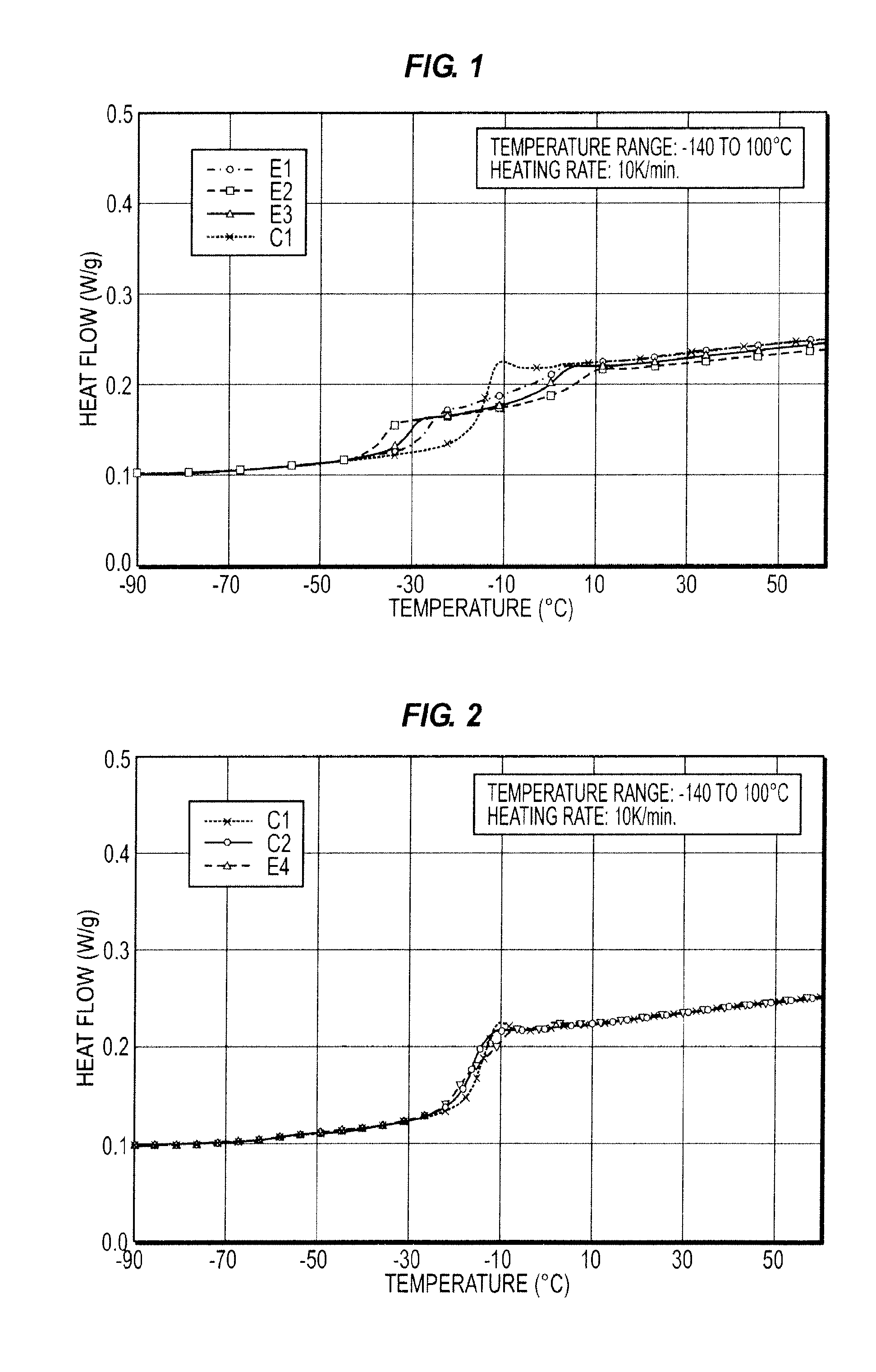

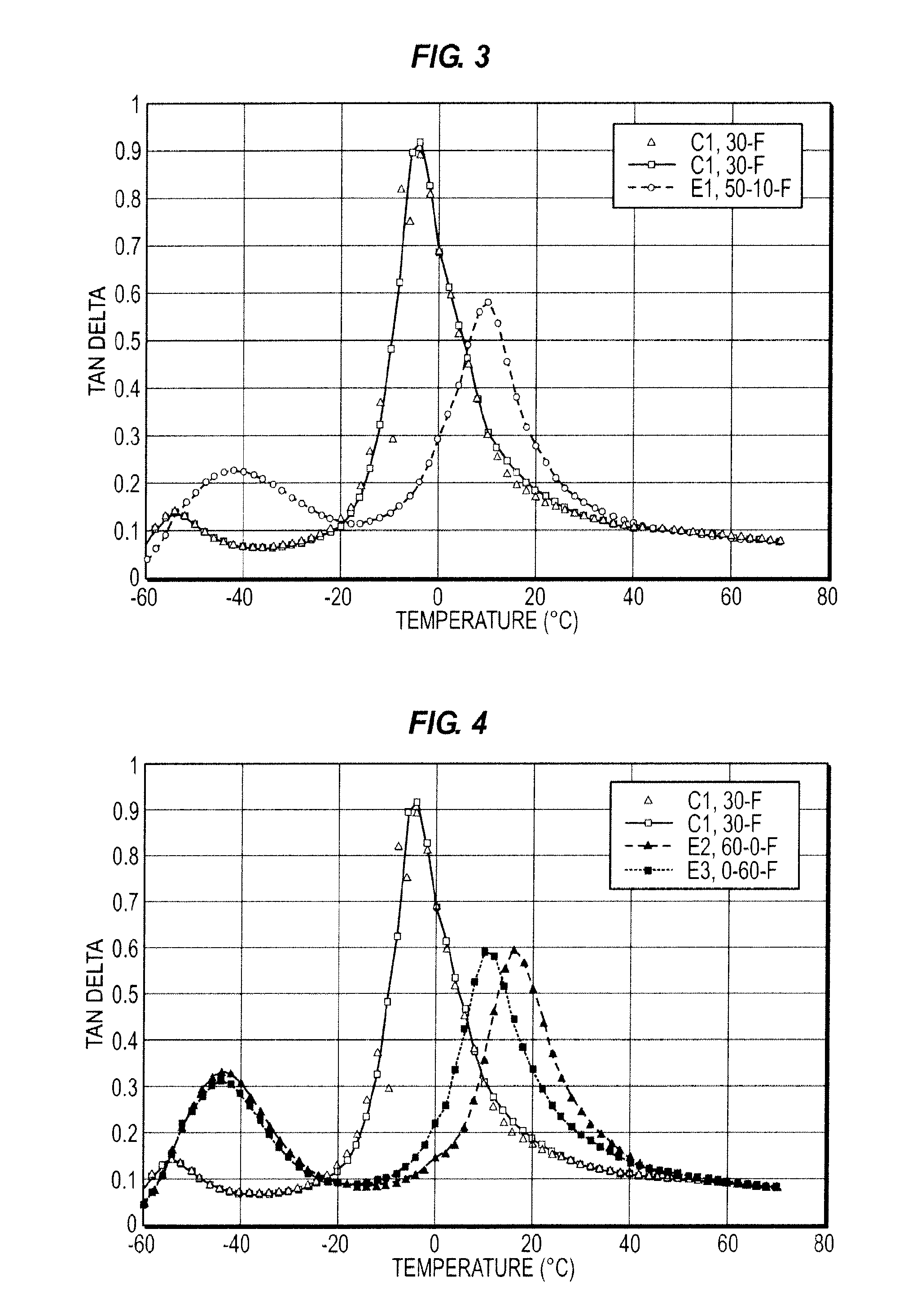

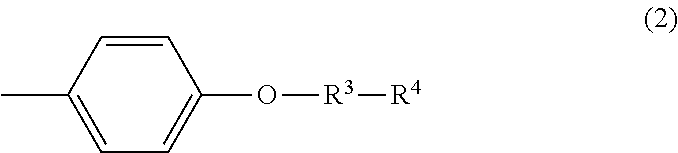

Tire rubber composition and pneumatic tire

InactiveUS20110230593A1Improve balanceImprove grip performanceSpecial tyresRolling resistance optimizationRolling resistanceSulfur

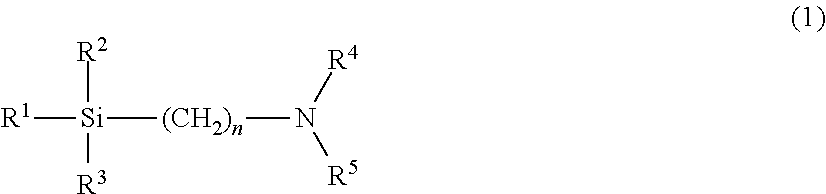

The present invention aims to provide a tire rubber composition that achieves a good balance of grip performance (especially, wet grip performance), abrasion resistance, cut and chip resistance, low rolling resistance, and kneadability, and a pneumatic tire using the same. The composition comprise: a rubber component including a styrene-butadiene rubber modified by a compound of formula (1):and a non-modified styrene-butadiene rubber; a filler including silica, the filler being in an amount of 80 parts by mass or less per 100 parts by mass of the rubber component; and sulfur in an amount of 0.5-1.5 parts by mass per 100 parts by mass of the rubber component, the modified styrene-butadiene rubber having a bound styrene content of 20-40% by mass and a vinyl content of 30-65% by mass, and the non-modified styrene-butadiene rubber having a bound styrene content of 25-45% by mass and a vinyl content of 10-50% by mass.

Owner:SUMITOMO RUBBER IND LTD

Racing car tire tread rubber composition with high road holding and high control performance

ActiveCN110372929AImprove wet skid resistanceImprove grip performanceSpecial tyresAntioxidantPolystyrene

The invention relates to a racing car tire tread rubber composition with high road holding and high control performance. The racing car tire tread rubber composition is prepared from the following components in parts by weight: 27.5-68.75 parts of high styrene emulsion polybutadiene rubber, 27.5-68.75 parts of high styrene soluble polystyrene butadiene rubber, 20-40 parts of styrene-soluble styrene-butadiene rubber, 60-90 parts of super-abrasive-resisting carbon black, 30-50 parts of white carbon black, 2-8 parts of a silane coupling agent, 0-30 parts of aromatic oil, 2-4 parts of zinc oxide,1-3 parts of stearic acid, 2-6 parts of an antioxidant, 5-10 parts of road holding resin, 5-20 parts of liquid styrene-butadiene rubber, 1-2 parts of sulfur and 1.6-4.0 parts of an accelerator. The racing car tire tread rubber composition is excellent in wet road holding performance and dry road holding performance, the control performance is further excellent, the racing car tire tread rubber composition is superior than all of tread rubber compositions in the prior art, and the problem of insufficient road holding of tires during high-speed turning or lane-changing is solved.

Owner:SAILUN GRP CO LTD

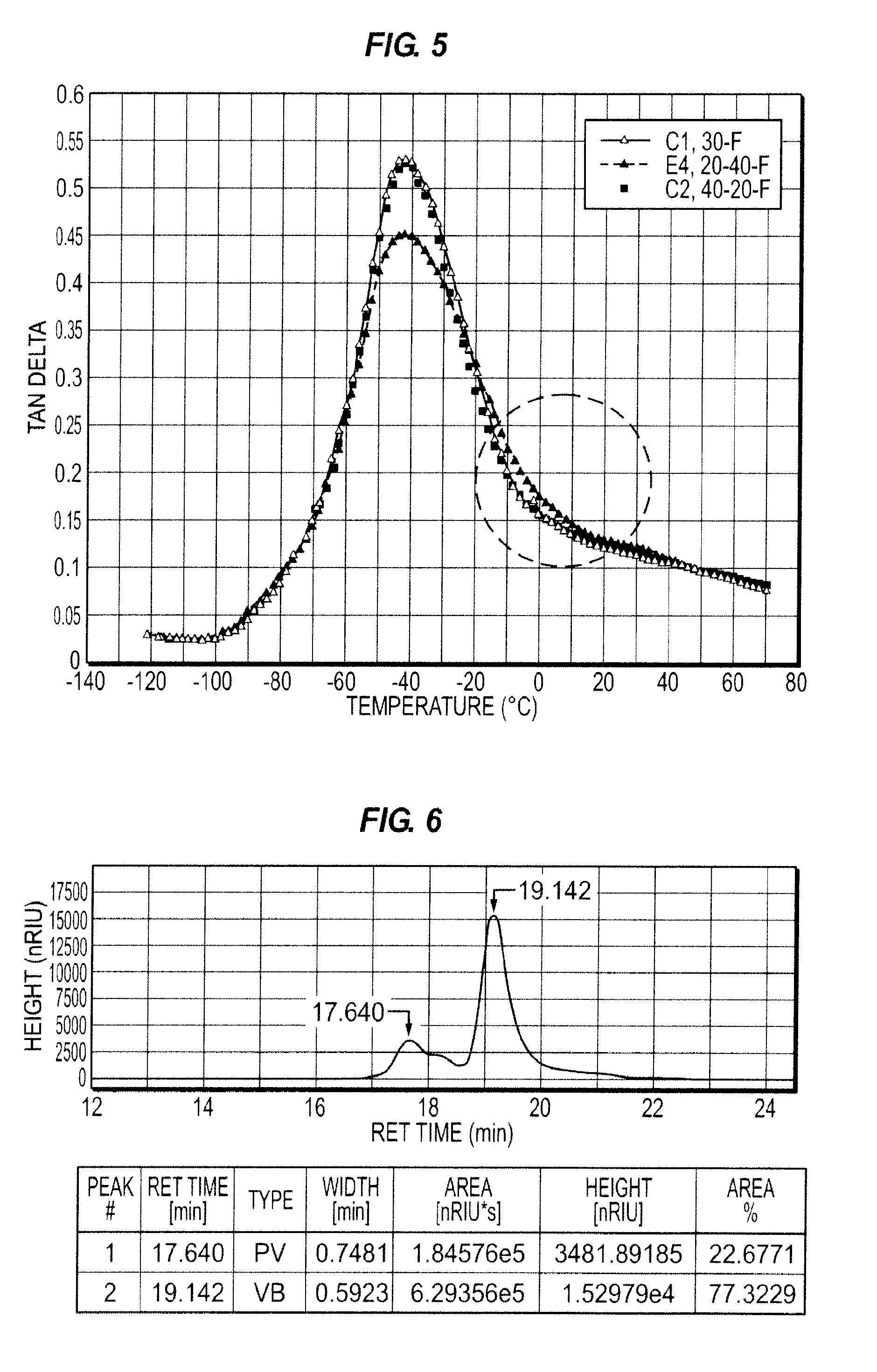

Modified butadiene polymer composition

InactiveCN101155868AHigh strengthImprove grip performanceRolling resistance optimizationPolymer scienceRolling resistance

An object of the present invention is to improve, in the raw material rubber compound particularly using a silica-based filler, which is used for tire tread, the balance between the rolling resistance and the skid resistance on a wet road surface and at the same time, improve the wear resistance is enhanced. The present invention provides an oil-extended polymer composition comprising 100 parts by weight of (A) a polymer having a number average molecular weight Mn of 500,000 to 700,000 and a content of a functional group-containing polymer component to be adsorbed to silica of 50 wt% or more, and from 20 to 60 parts by weight of (B) an extender oil.

Owner:ASAHI KASEI CHEM CORP

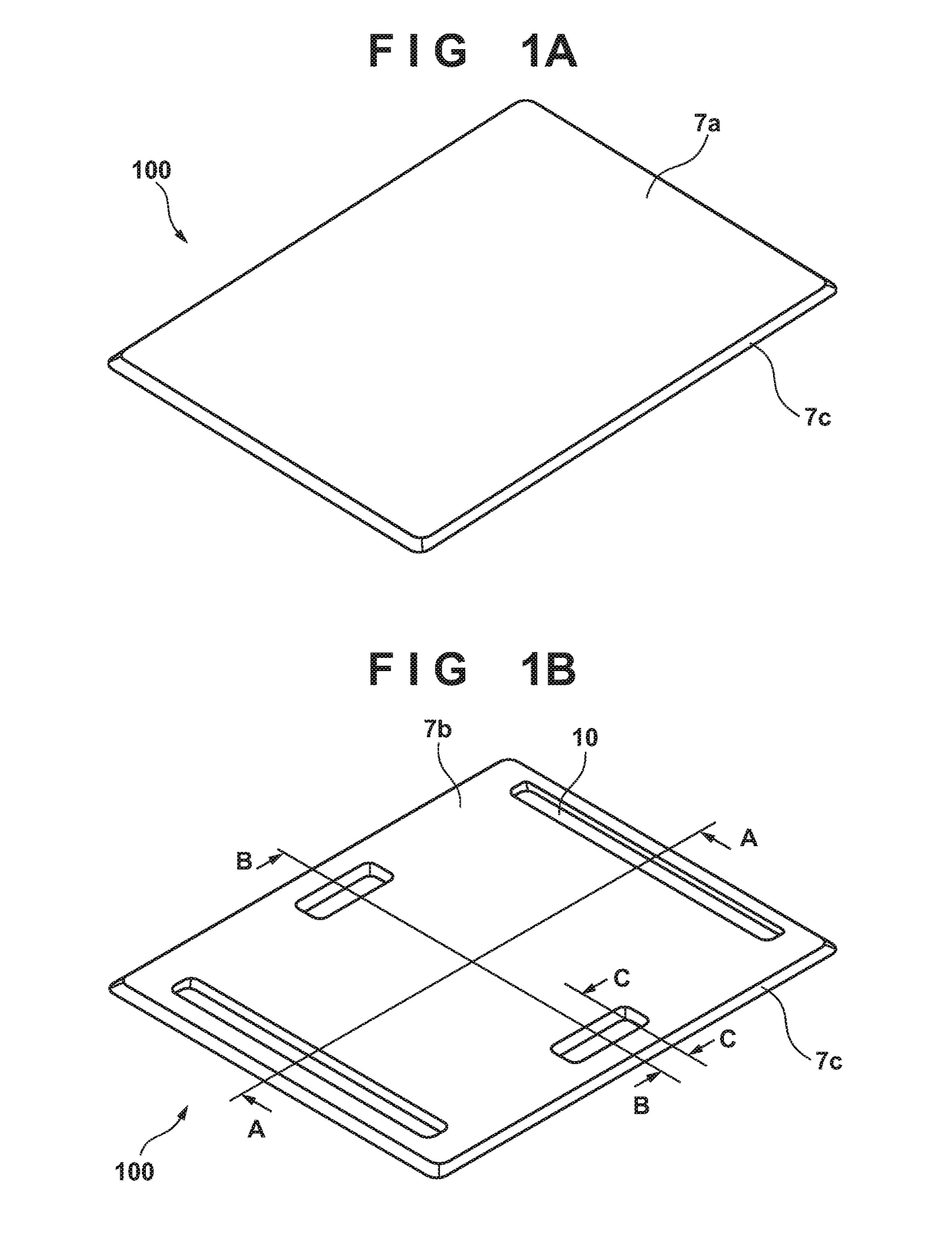

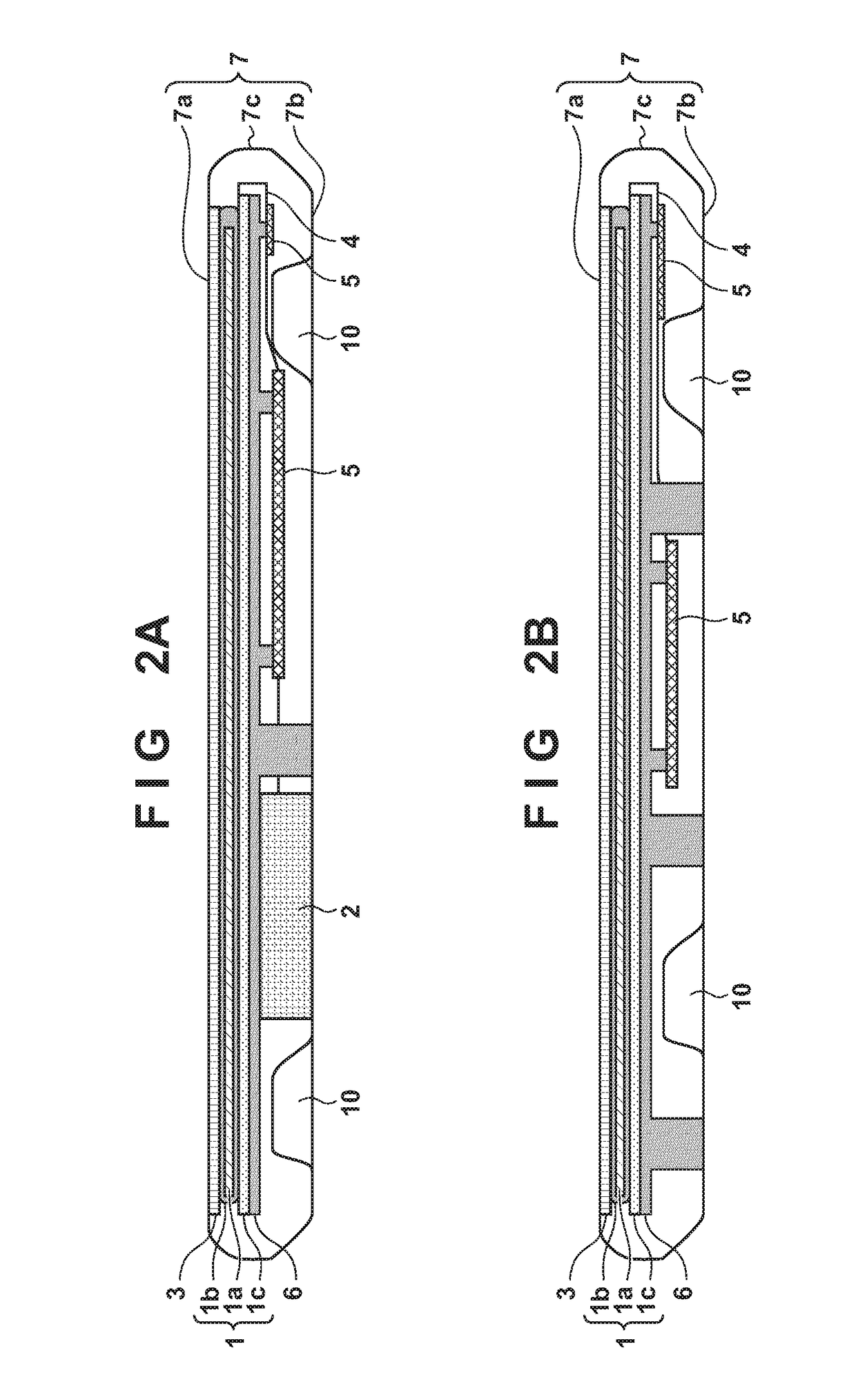

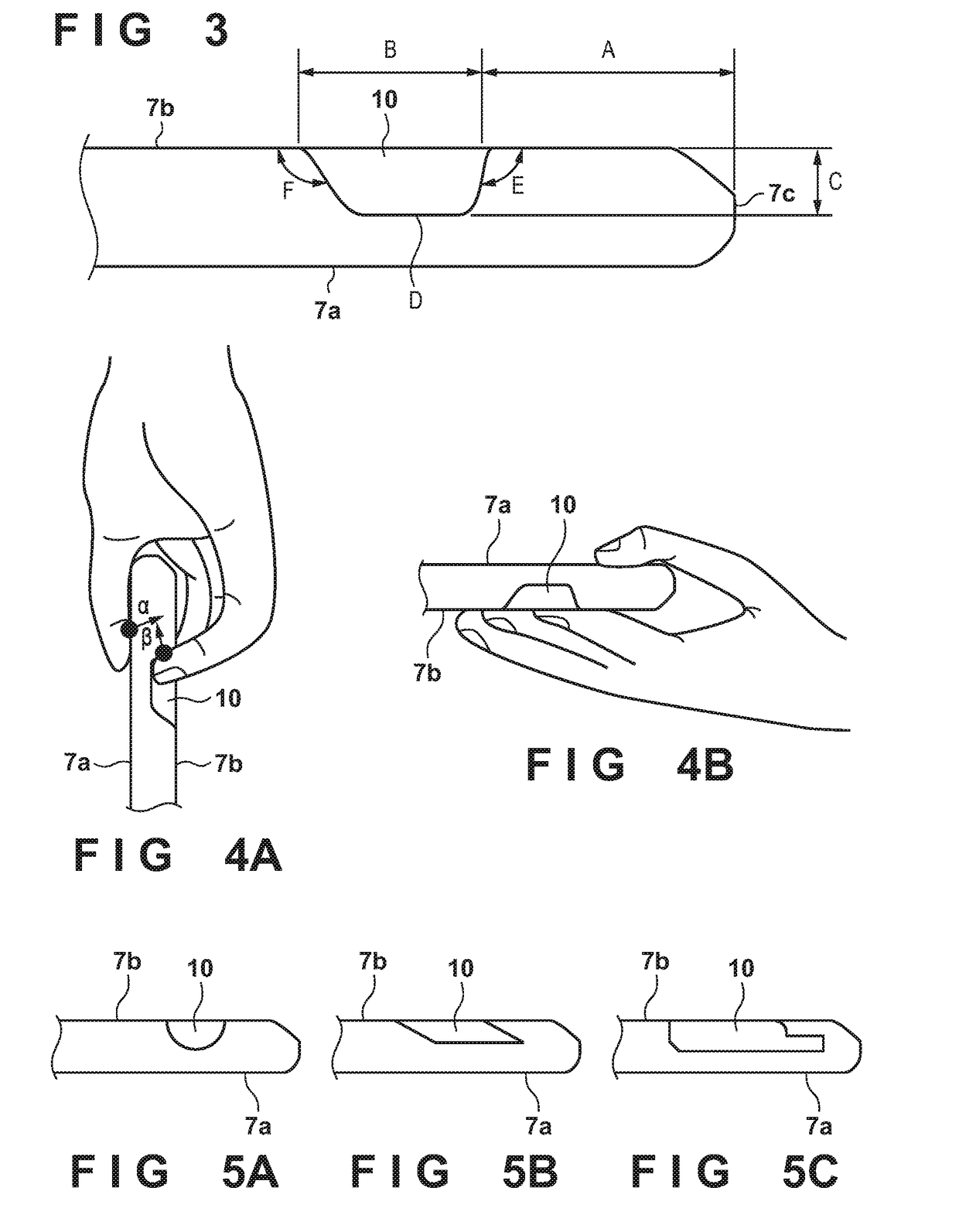

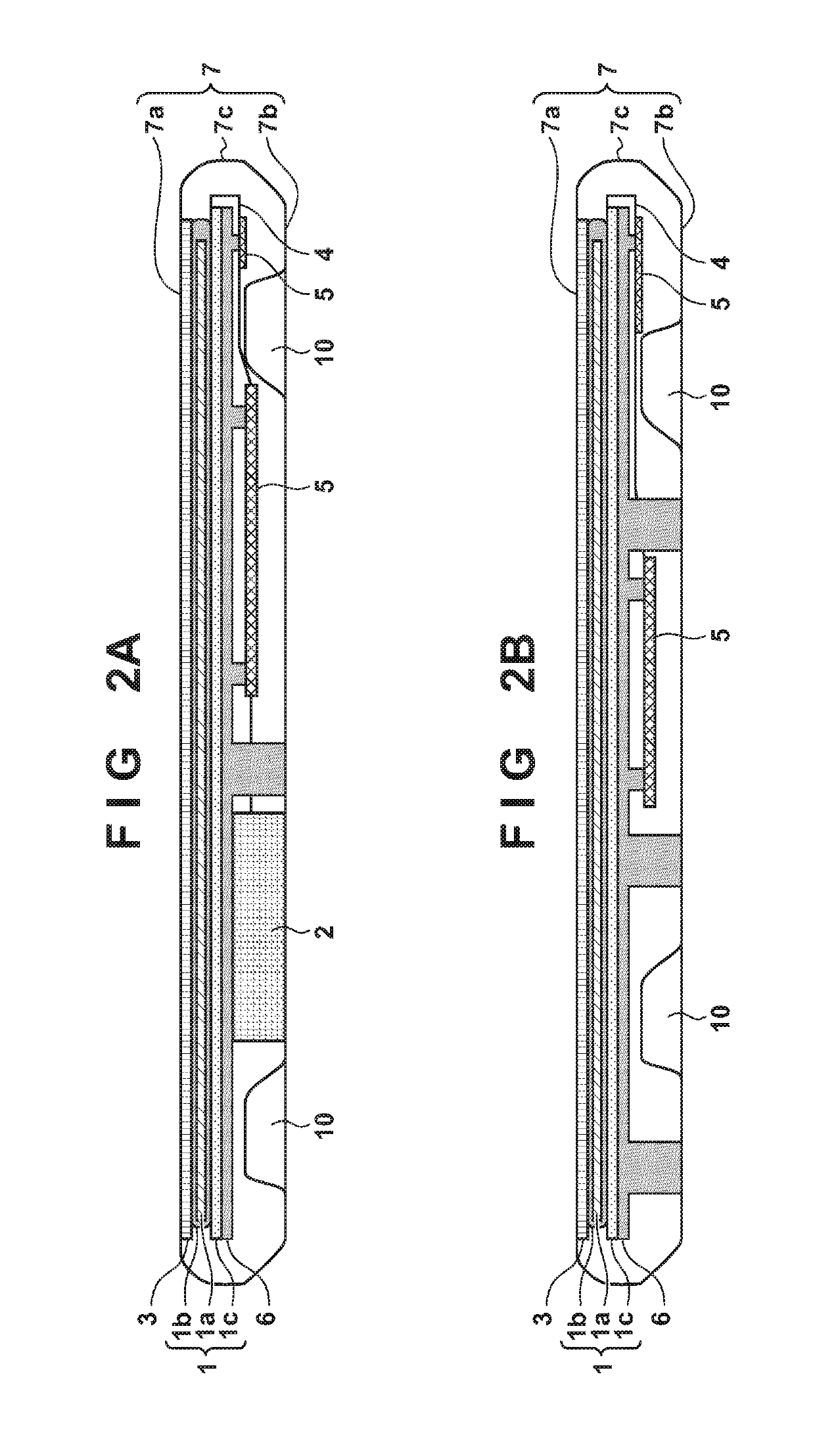

Radiation imaging apparatus and radiation imaging system

ActiveUS20170090044A1Improve grip performanceRadiation detection arrangementsMaterial analysis by transmitting radiationRadiation imagingImaging equipment

A radiation imaging apparatus is provided. The apparatus includes a radiation detection panel, a housing of a cuboid shape that accommodates the radiation detection panel. The housing has a front surface that the radiation enters, a rectangular back surface arranged on a side opposite to a side of the front surface, and four side surfaces configured to connect the front surface and the back surface. The apparatus further includes a grip portion which is concave toward the radiation detection panel, formed in a peripheral region on the back surface. The grip portion has at least one of a depth not less than one-half a distance between the front surface and the back surface, and a depth not less than a distance between the back surface and a center of gravity of the radiation imaging apparatus.

Owner:CANON KK

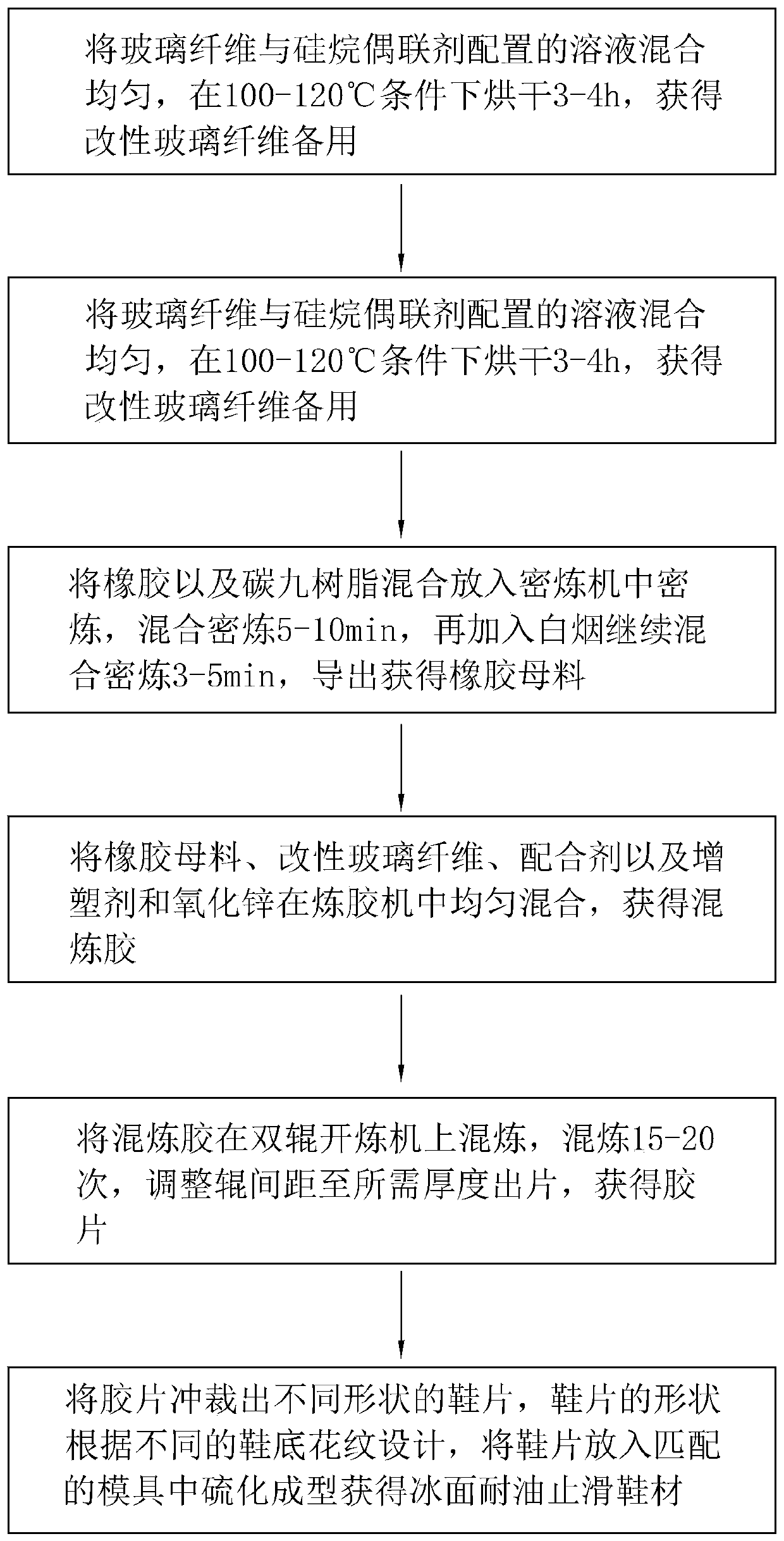

Ice-surface oil-resistant non-slip shoe material and preparation method thereof

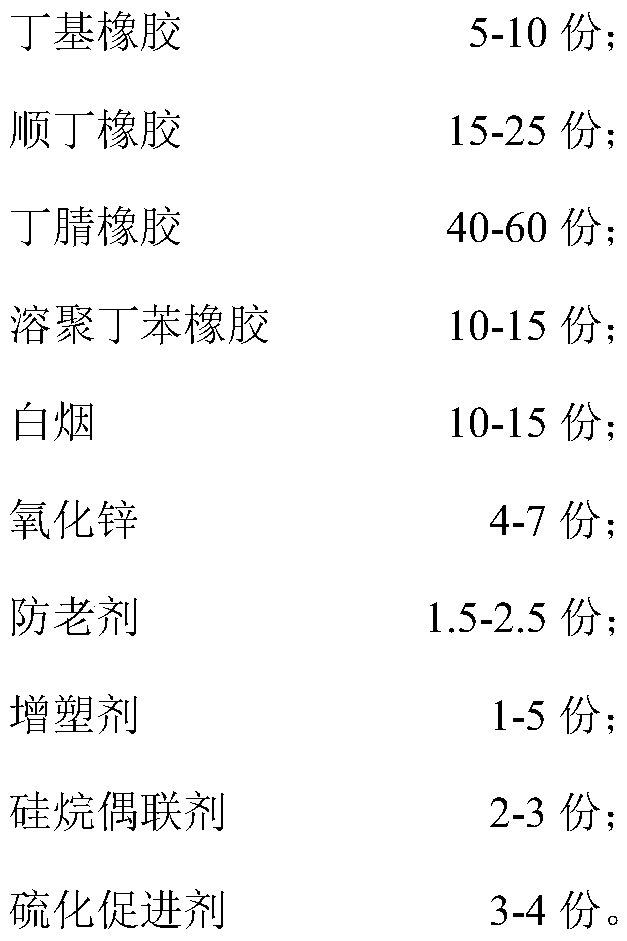

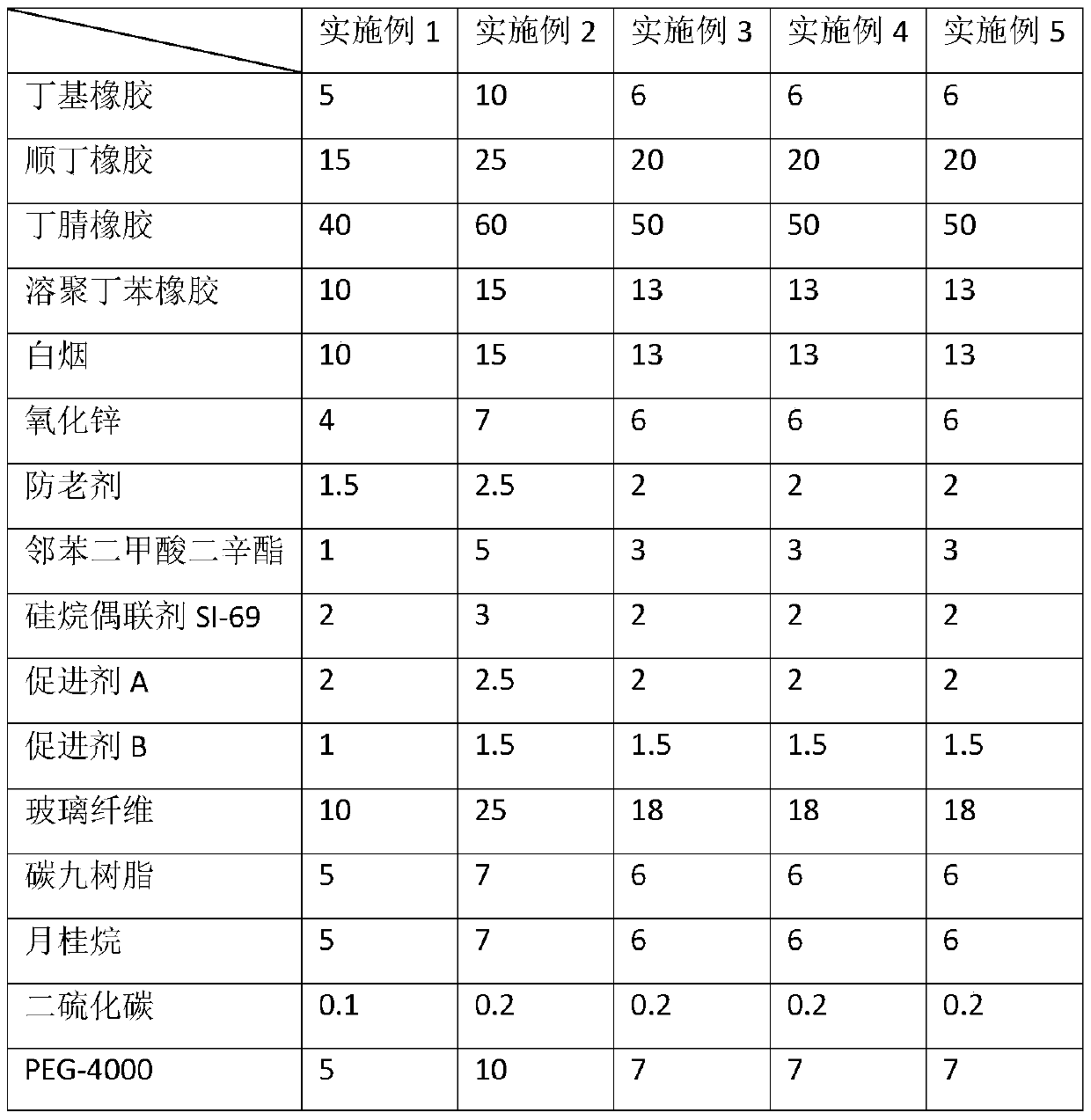

The invention discloses an ice-surface oil-resistant non-slip shoe material and a preparation method thereof, and relates to the technical field of shoe materials. The shoe material is prepared from butyl rubber, butadiene rubber, nitrile rubber, solution polymerized styrene-butadiene rubber, white smoke, zinc oxide, an anti-ageing agent, a plasticizer, a silane coupling agent and a vulcanizationaccelerator. The shoe material prepared through the formula is combined with the specific pattern of an outsole and integrally formed or adhered to the outsole, and the obtained sole has the advantages of being resistant to oil and slip, good in mechanical performance, free of fog return and the like. The anti-slip performance is excellent, and the shoe material is suitable for being used on the ice and snow ground.

Owner:WENZHOU YIHE SHOE MATERIAL CO LTD

Rubber Composition for Tire Treads

ActiveUS20170362415A1Quality improvementImprove grip performanceSpecial tyresEmulsionPolymer science

A rubber composition contains: a diene rubber; 1 to 25 parts by weight of aromatic modified terpene resin; 80 to 150 parts by weight of silica; 5 to 50 parts by weight of carbon black; an oil component; and 0.1 to 20 wt. % of the weight of the silica of alkyltriethoxysilane having an alkyl group having 3 to 20 carbons, the diene rubber containing 10 to 30 wt. % of natural rubber, 10 to 30 wt. % of solution polymerized styrene butadiene rubber having a styrene unit content of 30 to 40 wt. % and 80 to 40 wt. % of emulsion polymerized styrene butadiene rubber, and a ratio of a total amount of an oil-extending component in the solution polymerized styrene butadiene rubber and / or the emulsion polymerized styrene butadiene rubber, the aromatic modified terpene resin, and the oil component to a weight of the natural rubber being 3.0 to 4.0.

Owner:THE YOKOHAMA RUBBER CO LTD

Styrene butadiene rubber with novel styrene incorporation

InactiveUS20120010356A1Improve braking performanceImprove grip performanceSpecial tyresRolling resistance optimizationRolling resistanceButadiene-styrene rubber

The present invention relates to improved compositions of SSBR rubber. The improved compositions exhibit sufficient or improved balance of characteristics such as rolling resistance, HBU, abrasion, grip, and / or tear. The compositions may be made in an efficient, cost-effective manner.

Owner:TRINSEO EURO GMBH

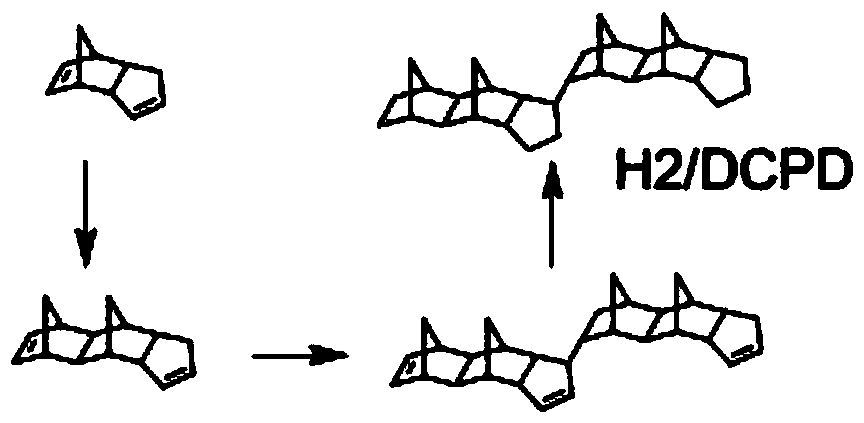

Branched conjugated diene copolymer, rubber composition and pneumatic tire

ActiveUS20140371415A1Easy to processExcellent abrasion resistanceSpecial tyresPolymer scienceAliphatic hydrocarbon

There is provided a branched conjugated diene copolymer prepared by copolymerizing 1 to 99% by weight of a branched conjugated diene compound (1):wherein R1 is an aliphatic hydrocarbon having 6 to 11 carbon atoms, and 99 to 1% by weight of a conjugated diene compound (2):wherein R2 and R3 are the same or different and each is a hydrogen atom, or the like. The branched conjugated diene copolymer is useful as a rubber component of a rubber composition for a tire enhancing both of abrasion resistance and grip performance to a high level and exhibiting excellent processability.

Owner:SUMITOMO RUBBER IND LTD

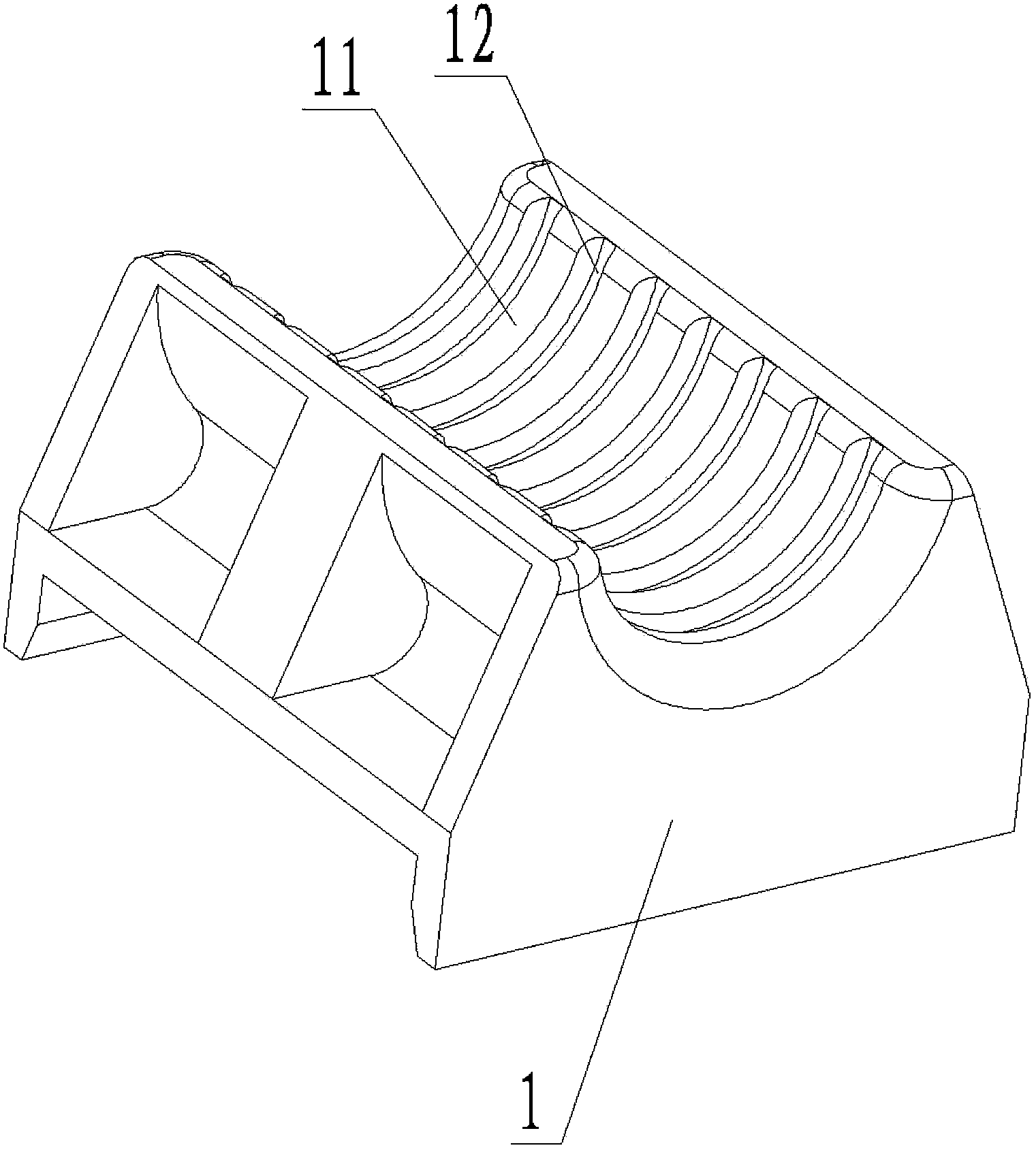

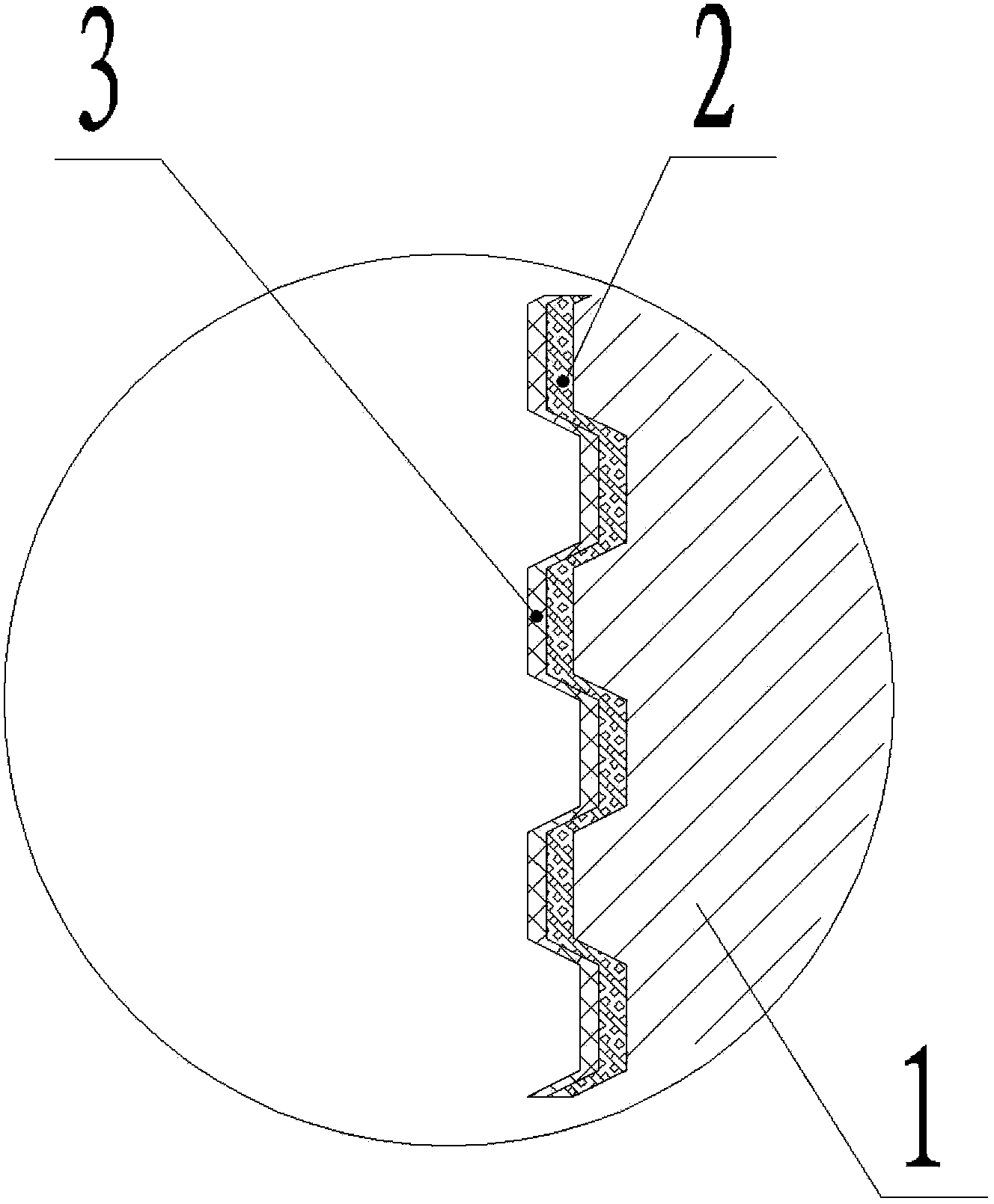

Antifouling clamping block of continuous tube injection head and manufacturing method thereof

InactiveCN103670305AImprove grip performanceGuarantee the stability of clamping performanceMolten spray coatingDrilling rodsLubricationEngineering

The invention discloses an antifouling clamping block of a continuous tube injection head. The antifouling clamping block comprises a clamping block body (1) which is provided with a concave arc clamping face (11), a transverse groove (12) is formed in the concave arc clamping face (11), and a friction coating layer (2) and an anticorrosion and antifouling coating layer (3) are arranged on the concave arc clamping face (11) in sequence. The invention further discloses a manufacturing method of the antifouling clamping block of the continuous tube injection head, and belongs to the field of well drilling device corollary equipment. Due to the fact that the transverse groove is formed in the concave arc clamping face, the clamping contact area is reduced, unit pressure on the contact face is increased, the continuous lubrication film layer formed by underground media on the clamping surface can be effectively blocked and damaged, and stability of clamping performance is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Rubber composition and pneumatic tire

Provided is a rubber composition that can improve hysteresis loss to allow for simultaneous improvement in initial grip performance and stable grip performance during mid and late running while ensuring good abrasion resistance. The present invention relates to a rubber composition containing: a rubber component; sulfur; and a specific compound, the rubber composition containing 60% to 100% by mass of a diene rubber based on 100% by mass of the rubber component, the rubber composition containing 0.1 to 30 parts by mass of the specific compound per 100 parts by mass of the rubber component.

Owner:SUMITOMO RUBBER IND LTD

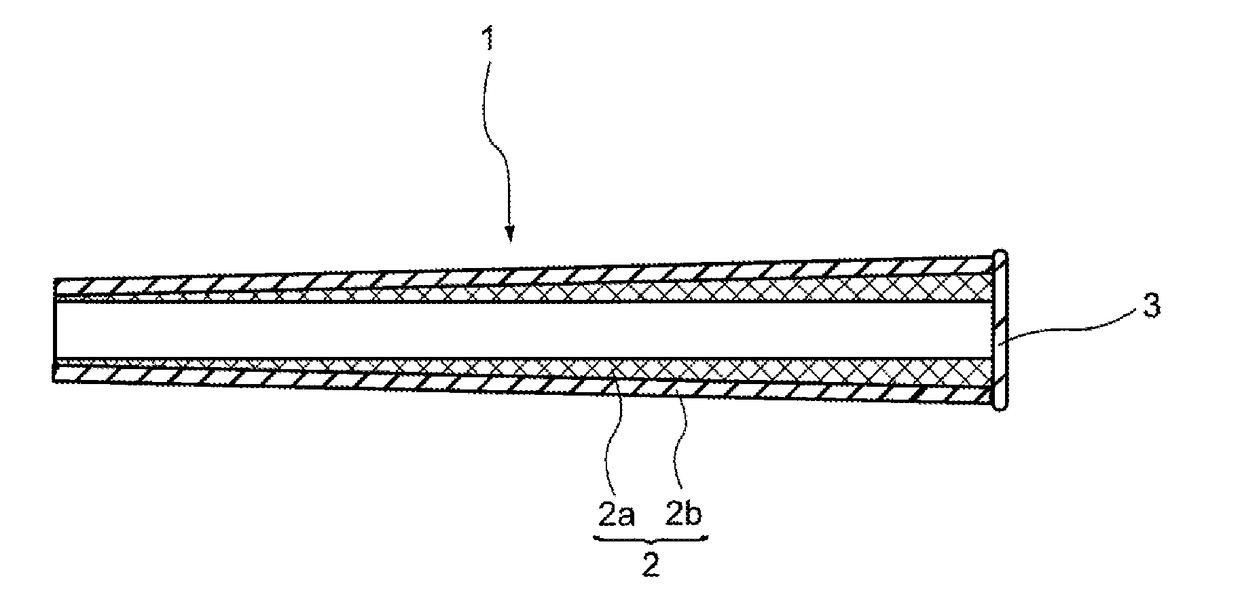

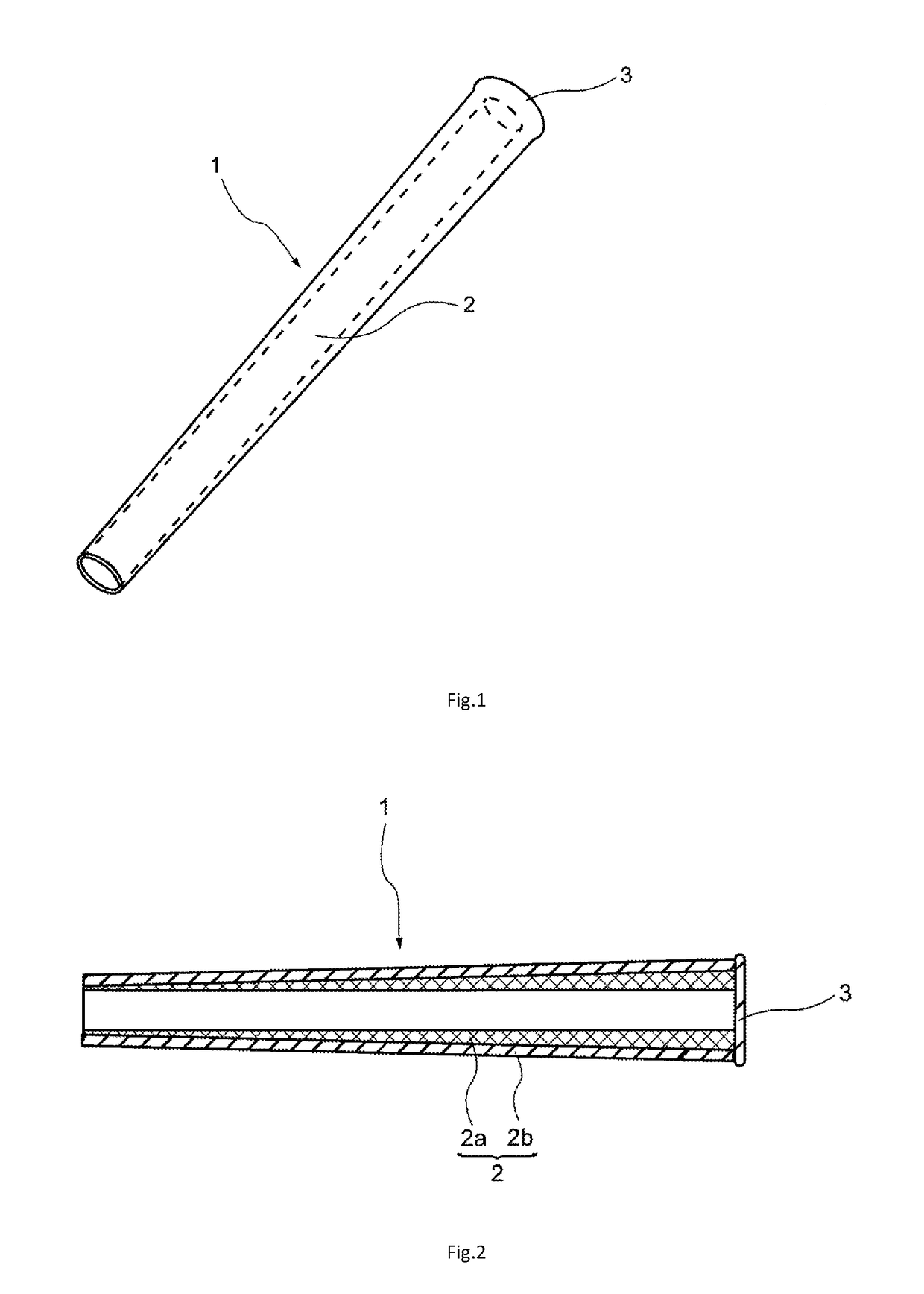

Window film anchoring device

ActiveUS20070209302A1Improve impact resistanceImpede free motionWindow/door framesBuilding repairsEngineeringMechanical engineering

A window film anchoring device is disclosed which comprises a first engagement member and a second engagement member between which a free film portion of a film affixed to a window pane is inserted. The first and second engagement members are attached to a corresponding window frame portion, and film engaging surfaces of the first engagement member are in interlocking and lateral motion preventing relation with complementary film engaging surfaces of the second engagement member so as to maintain a constant pressing force on the free film portion. The anchoring device is adapted to be a retrofit kit, and is able to be easily attached to an existing window frame, in order to increase the impact or impulse resistance of the window pane. The anchoring device may also be factory assembled to a newly produced frame.

Owner:SORAG

Radiation imaging apparatus and radiation imaging system

ActiveUS10274613B2Improve grip performanceImage-conversion/image-amplification tubesRadiation detection arrangementsRadiation imagingPhysics

A radiation imaging apparatus is provided. The apparatus includes a radiation detection panel, a housing of a cuboid shape that accommodates the radiation detection panel. The housing has a front surface that the radiation enters, a rectangular back surface arranged on a side opposite to a side of the front surface, and four side surfaces configured to connect the front surface and the back surface. The apparatus further includes a grip portion which is concave toward the radiation detection panel, formed in a peripheral region on the back surface. The grip portion has at least one of a depth not less than one-half a distance between the front surface and the back surface, and a depth not less than a distance between the back surface and a center of gravity of the radiation imaging apparatus.

Owner:CANON KK

Tire tread-use rubber composition

A tire tread-use rubber composition includes from 10 to 50 parts by weight of a tackifying resin having a softening point of from 100° C. to 150° C.; from 70 to 130 parts by weight of a carbon black having a nitrogen specific surface area of from 250 to 400 m2 / g; from 1 to 3 parts by weight of sulfur; from 0.5 to 4.0 parts by weight of a sulfenamide vulcanization accelerator; and from 1.5 to 5.0 parts by weight of a thiuram vulcanization accelerator per 100 parts by weight of a rubber component; wherein when A is a compounded amount in parts by weight of the sulfenamide vulcanization accelerator, T is a compounded amount in parts by weight of the thiuram vulcanization accelerator, and S is a compounded amount in parts by weight of the sulfur, a weight ratio (A+T) / S is from 2 to 4.

Owner:THE YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com