Patents

Literature

230 results about "Pipe wrench" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pipe wrench is any of several types of wrench that are designed to turn threaded pipe and pipe fittings for assembly (tightening) or disassembly (loosening). The Stillson wrench, or Stillson-pattern wrench, is the usual form of pipe wrench, especially in North America. The Stillson name is that of the original patent holder, who licensed the design to a number of manufacturers. The patent expired decades ago. Another type of wrench often used on pipes, the plumber wrench, is also called a pipe wrench in some places.

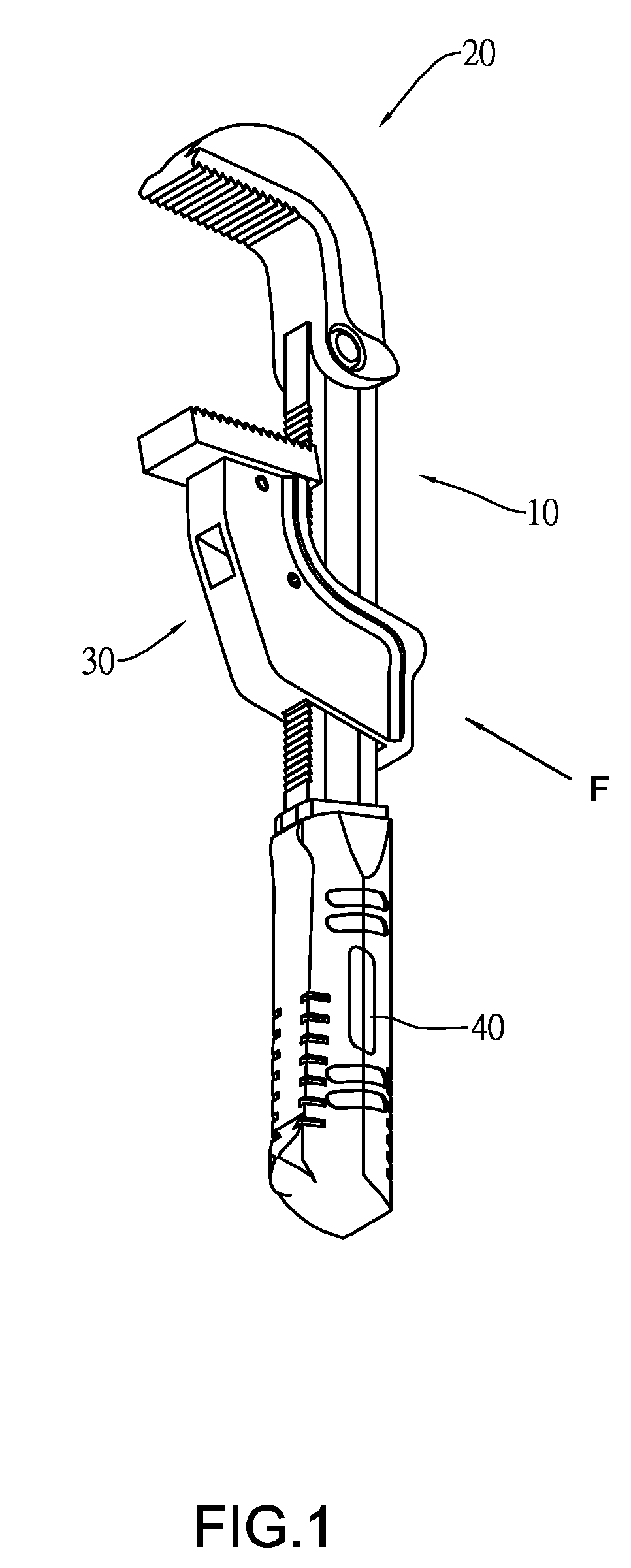

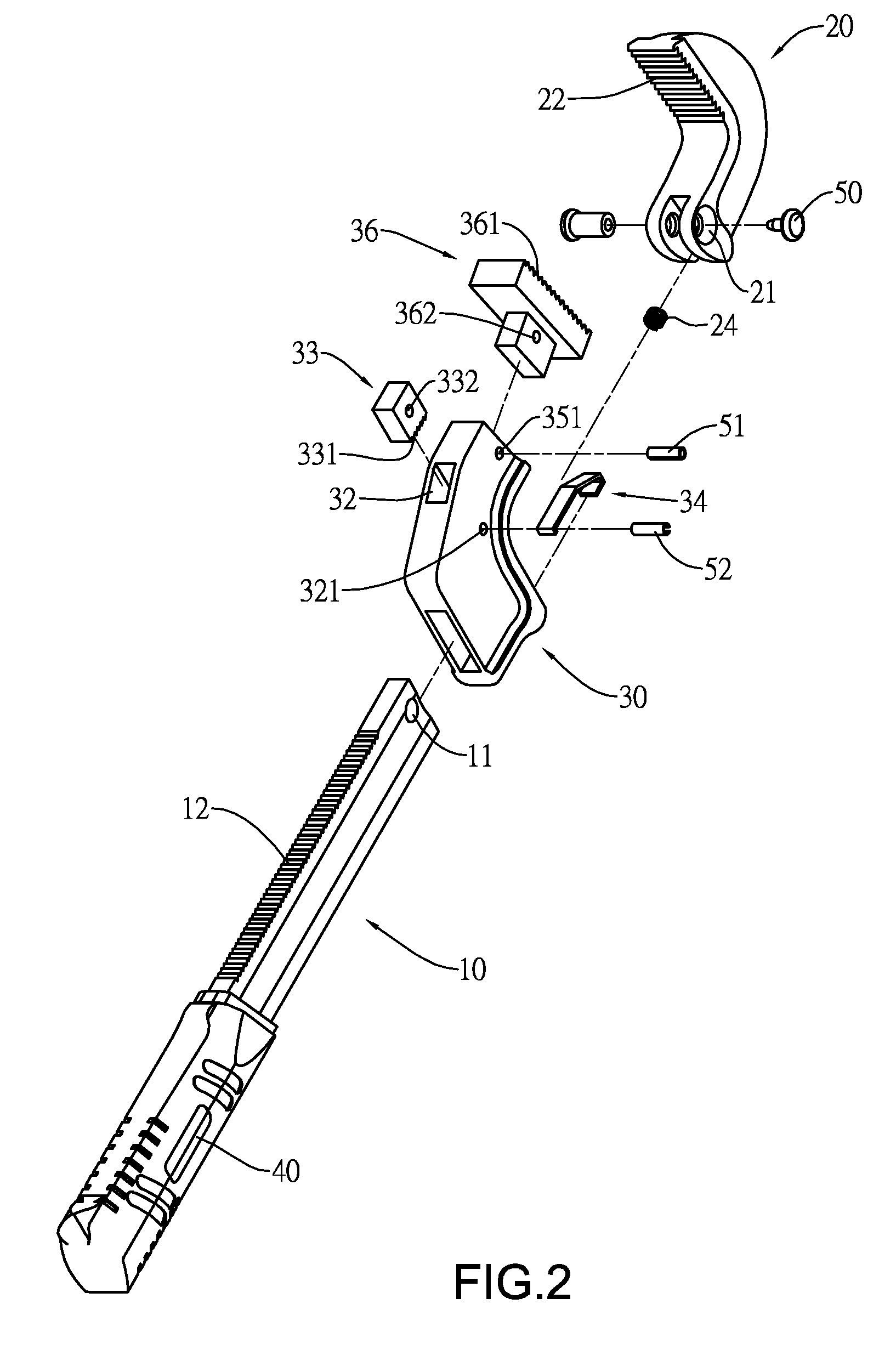

Pipe wrench assembly

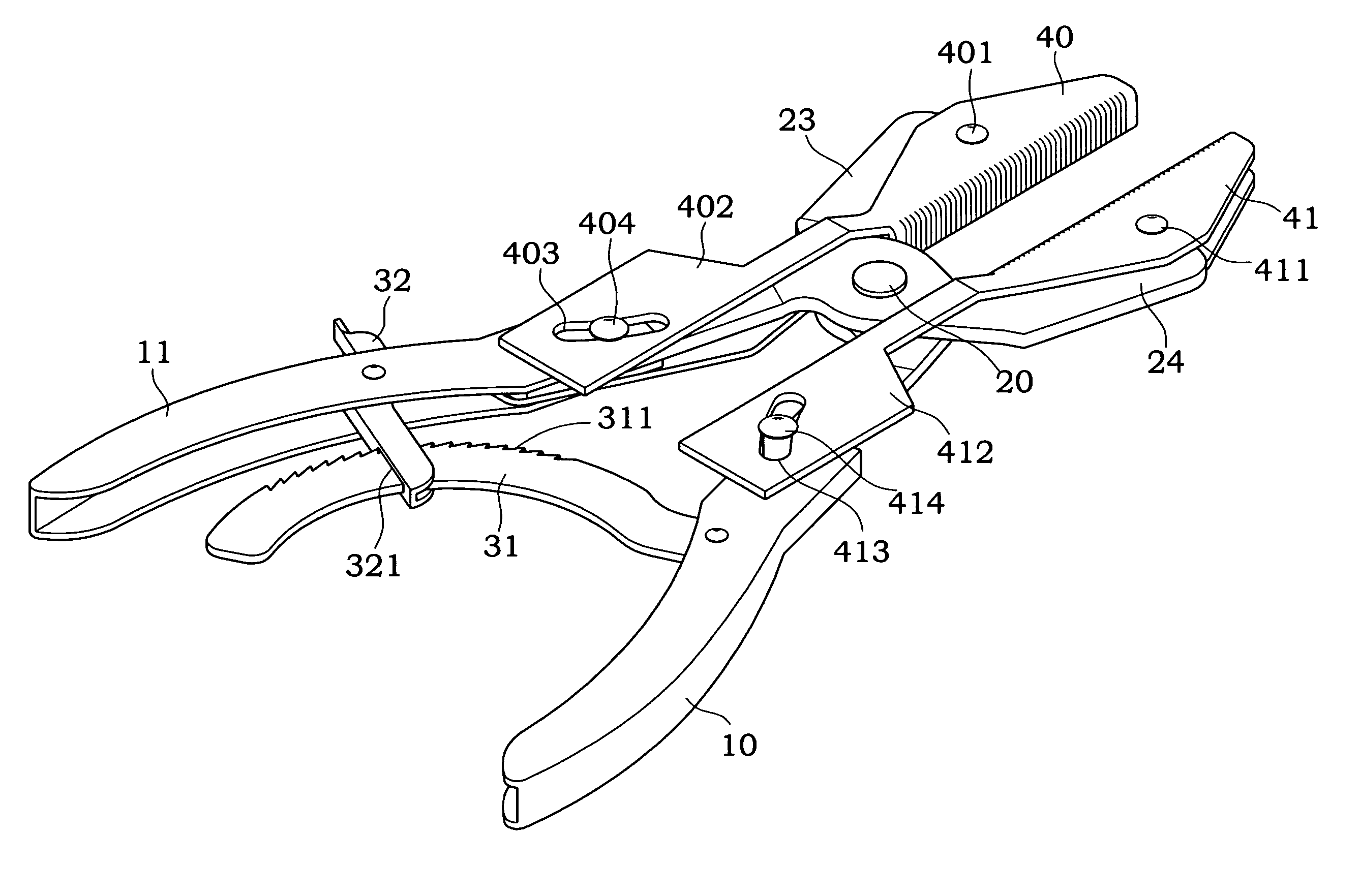

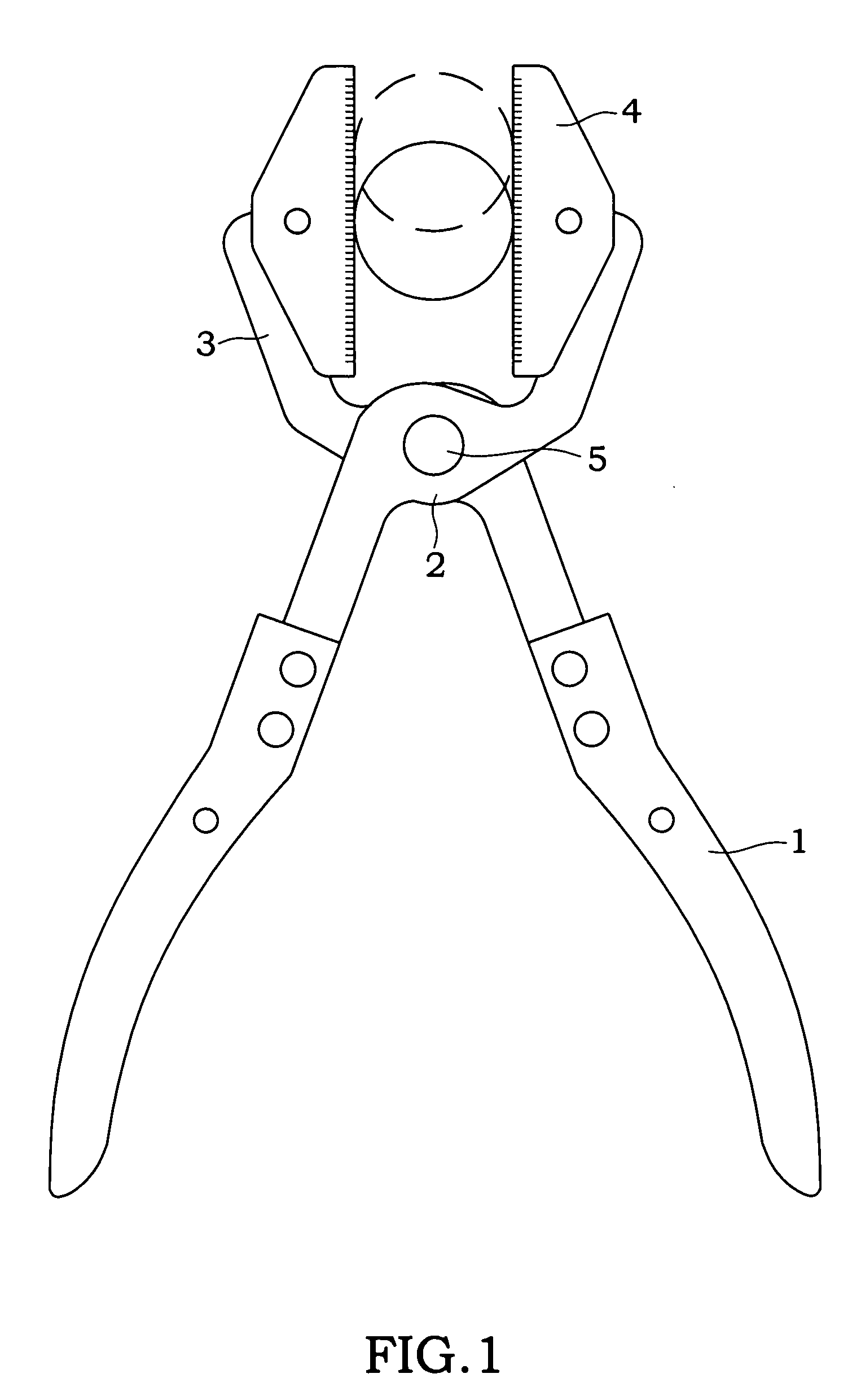

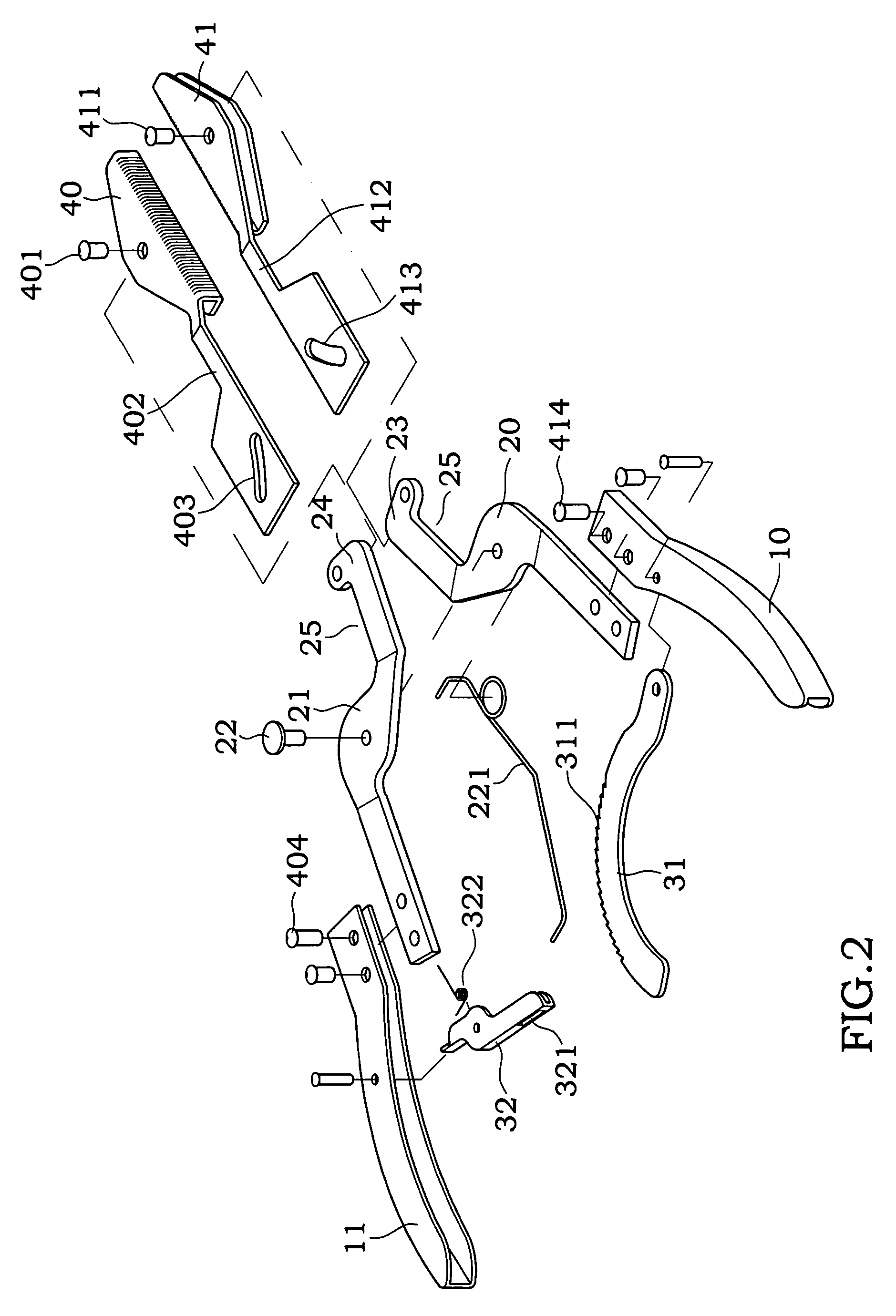

InactiveUS20060162509A1The method is simple and convenientGuaranteed clamping effectPliersPipe wrenchEngineering

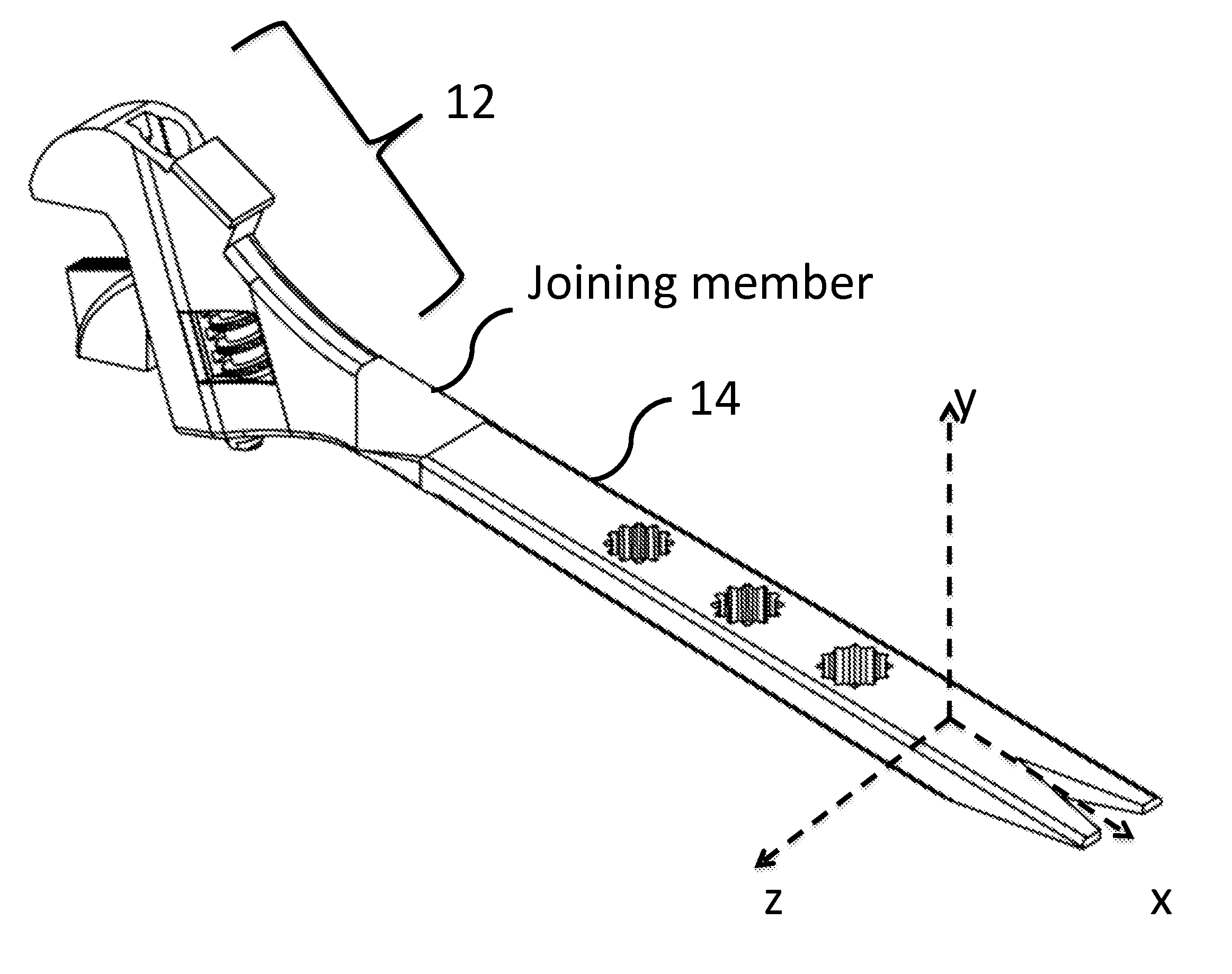

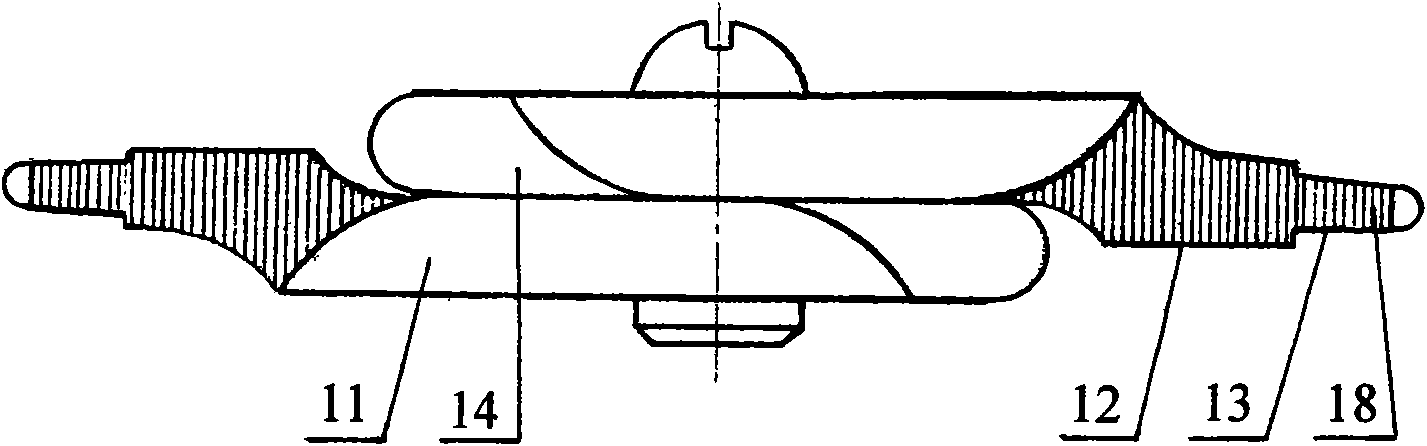

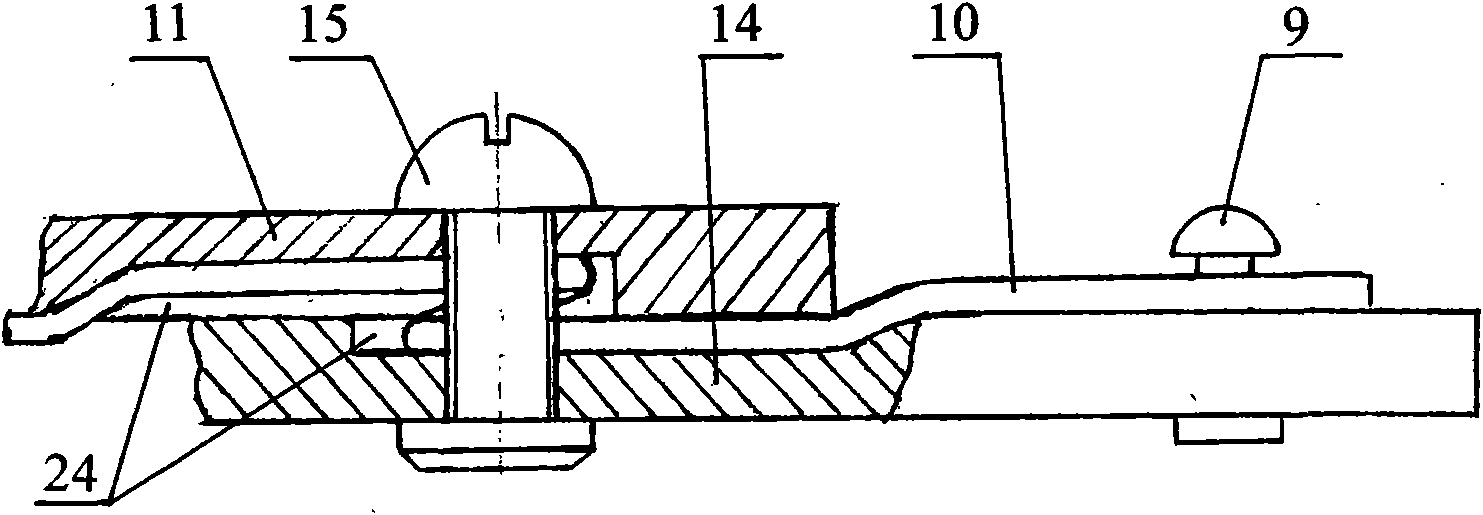

An improved pipe wrench assembly includes a first and a second arms, a first and a second movable wrench members disposed on the front ends of the first and second arms respectively, a guide plate separately extended from the rear ends of the first and second movable wrench members, a sliding groove disposed on the guide plate, and an insert pin pivotally coupled in the sliding groove; wherein another end of the insert pin of the first movable wrench member is fixed to a second handle and another end of the insert pin of the second movable wrench member is fixed to a first handle. With the insert pin and the sliding groove, the first and second movable wrench members can produce a parallel clamping movement when the pipe wrench is clamped and released.

Owner:WANG CHING SHU

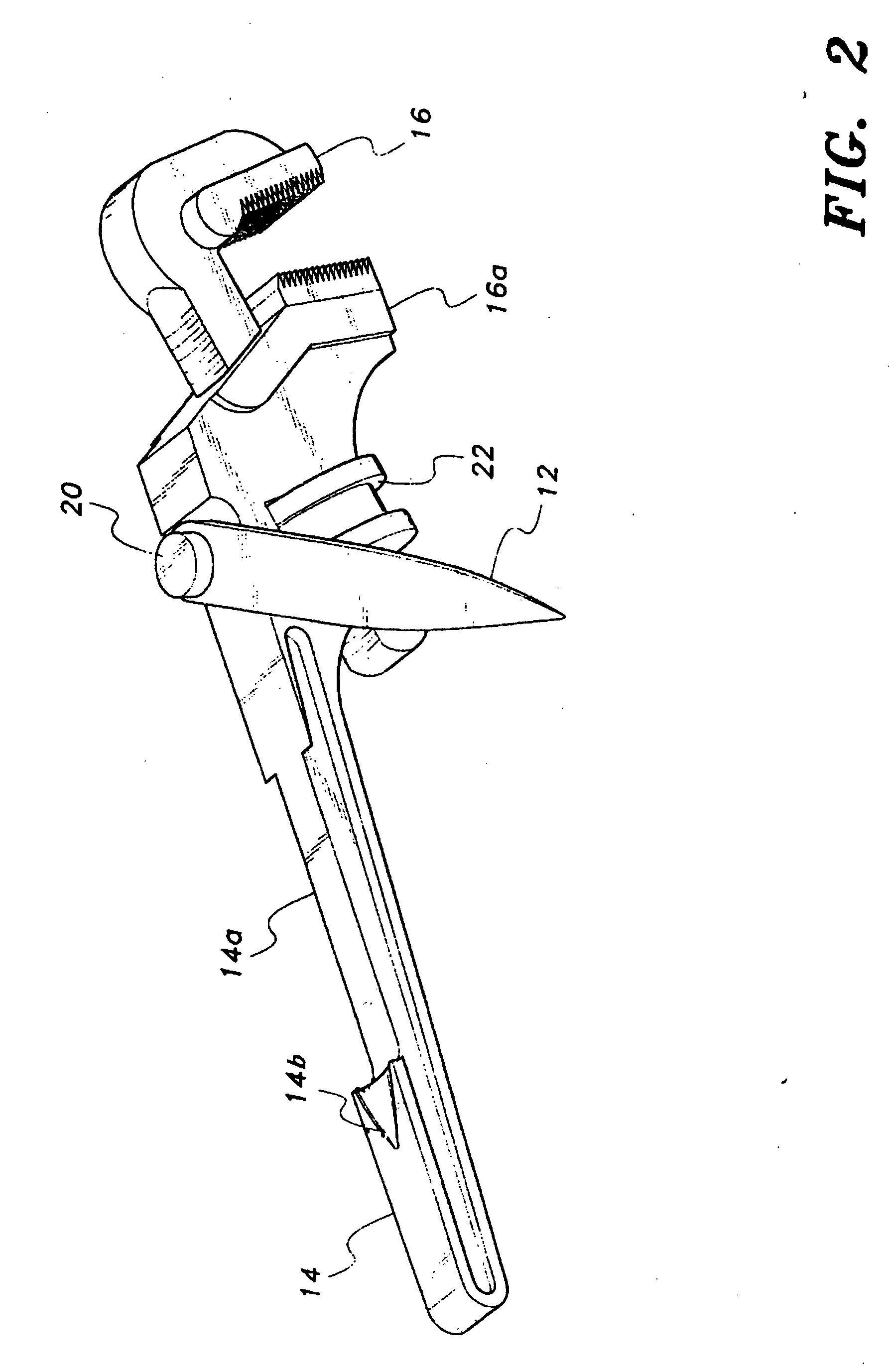

Combination tool with hammer head, crescent wrench and pipe wrench

A combination tool comprising a hammer head portion, a pipe wrench, a crescent wrench and a handle, wherein the pipe wrench and crescent wrench are located on opposite ends of the tool. The pipe wrench comprises an adjustable jaw and a fixed jaw, and the fixed jaw of the pipe wrench lies directly on top of the hammer head portion. The handle optionally comprises finger grips that can be formed out of the same material as the handle or a separate piece of material, such as rubber, that is wrapped around the outside of the handle. In the preferred embodiment, the length of the handle is in the range of four to ten inches, and the overall length of the tool is in the range of ten to twenty-four inches. The tool is preferably made of chrome-plated forged steel.

Owner:SMITH COLE J

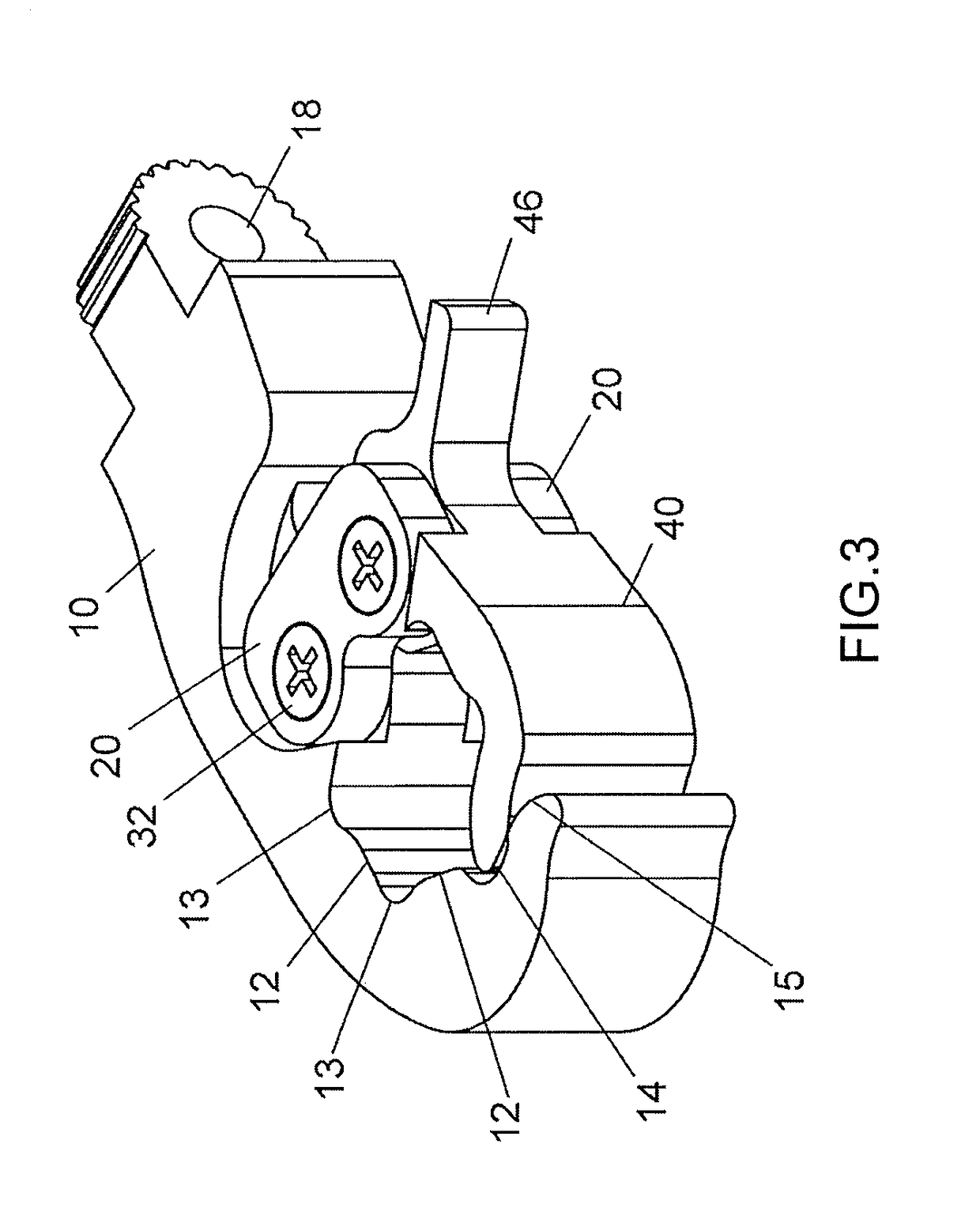

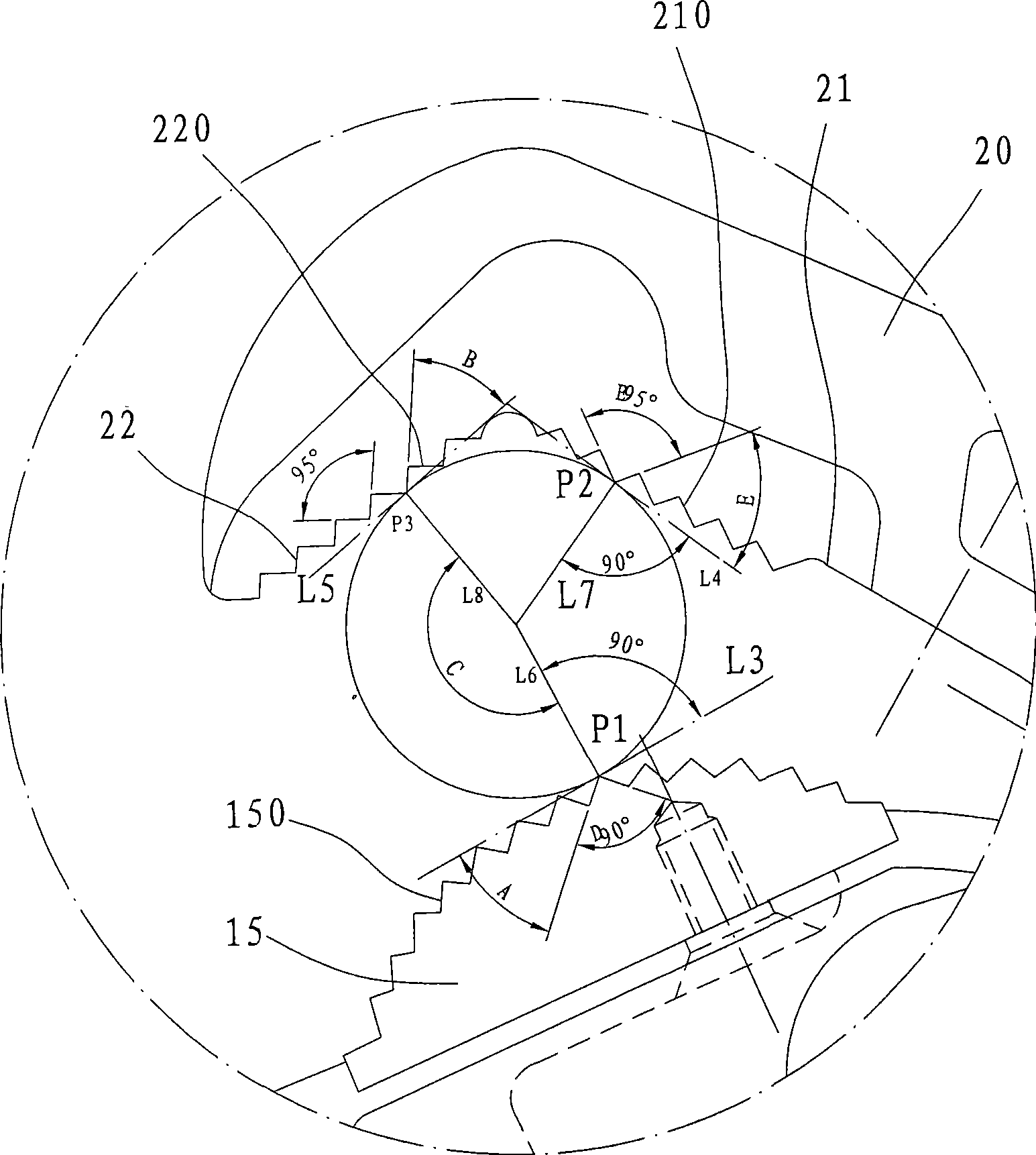

Pivoting jaw pipe wrench

A pivoting jaw pipe wrench comprises a fixed jaw including a plurality of discrete teeth, each for a different one of a plurality of pipes having different diameters. A pivotal jaw member has first and second jaw faces at an obtuse angle to one another and displaceable toward and away from the fixed jaw, whereby a pipe of given diameter to be gripped by the wrench is cradled between the first and second jaw surfaces and engaged by the one of the discrete teeth provided on the arcuate jaw for the pipe of given diameter.

Owner:EMERSON ELECTRIC CO

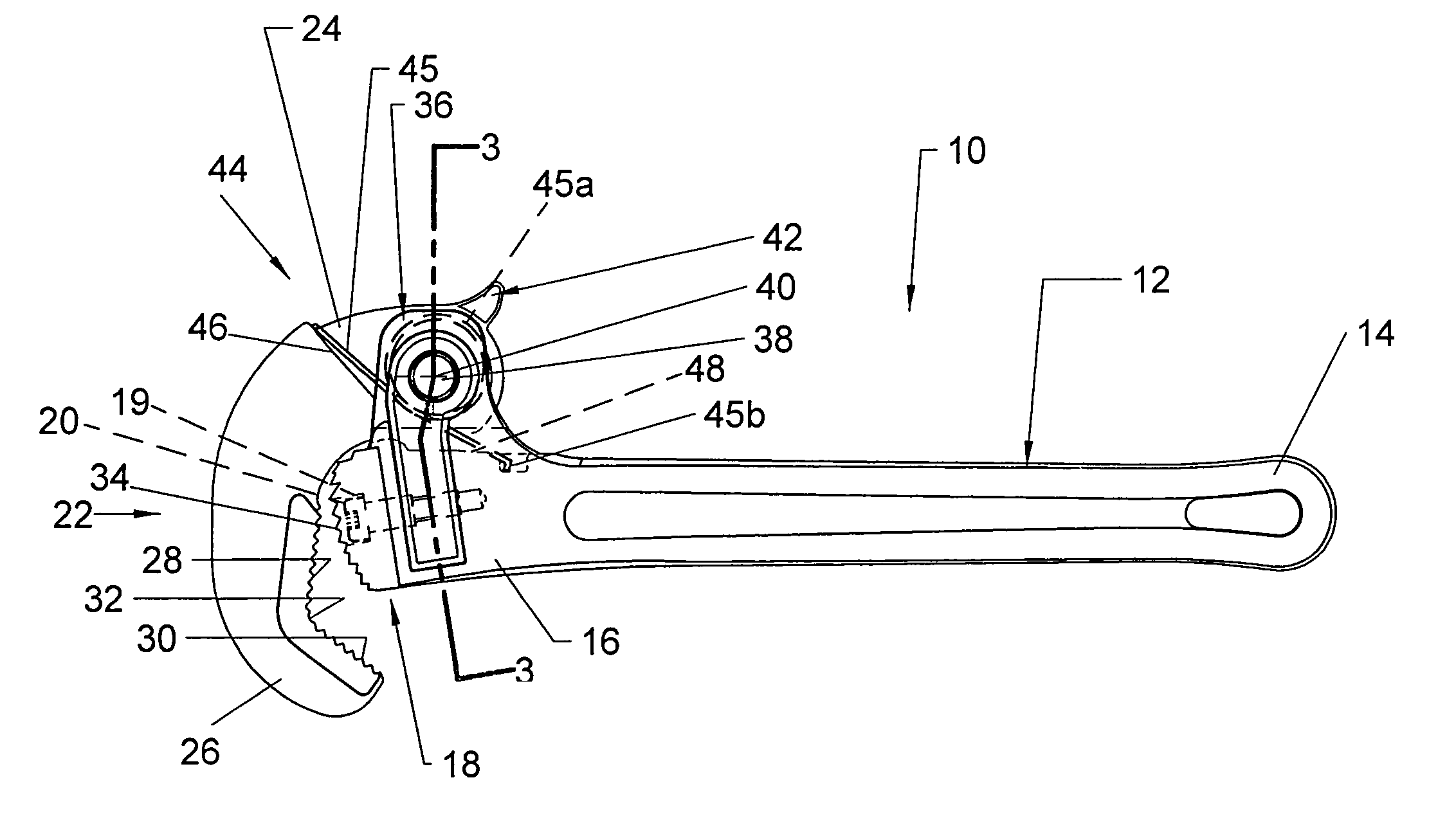

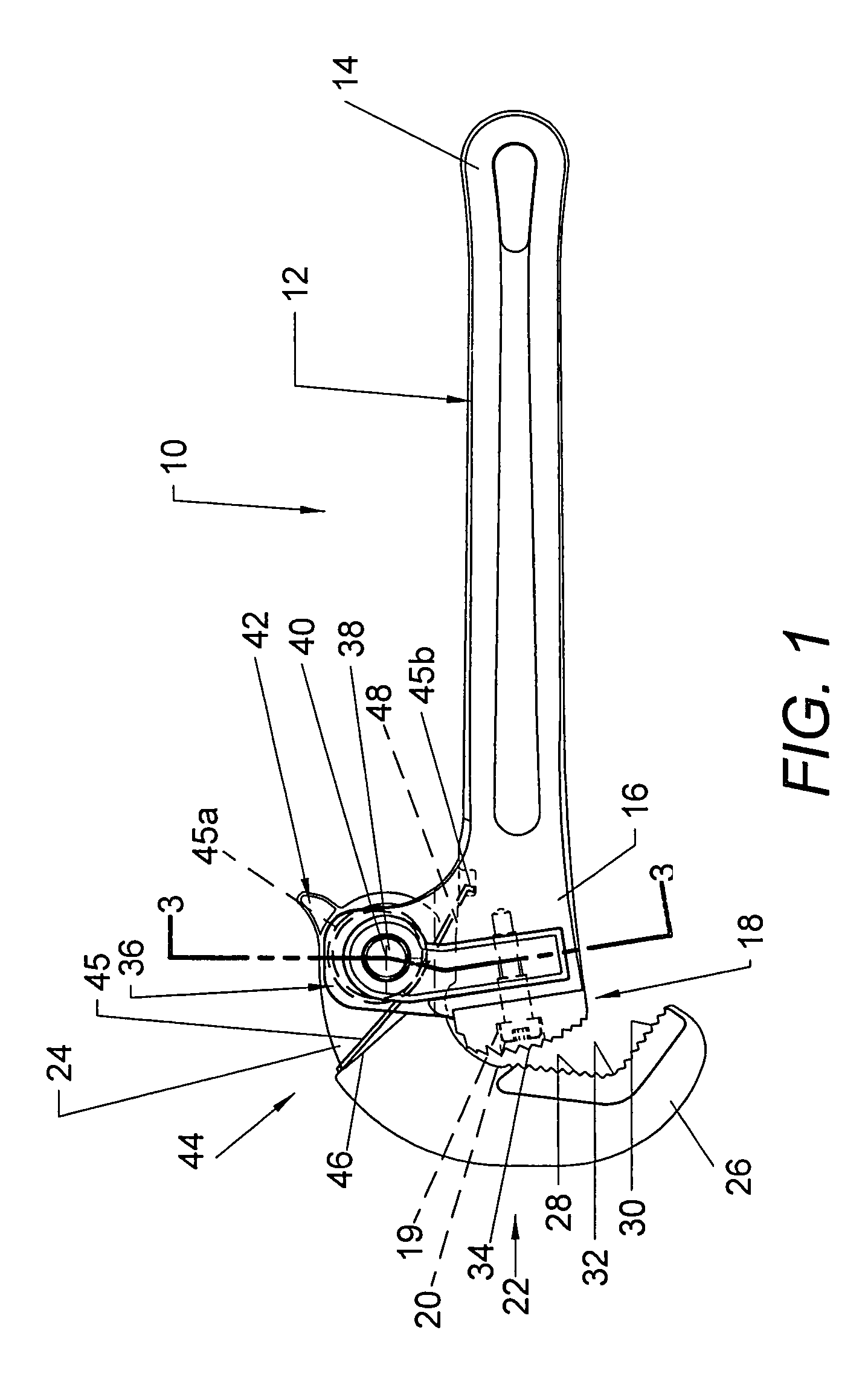

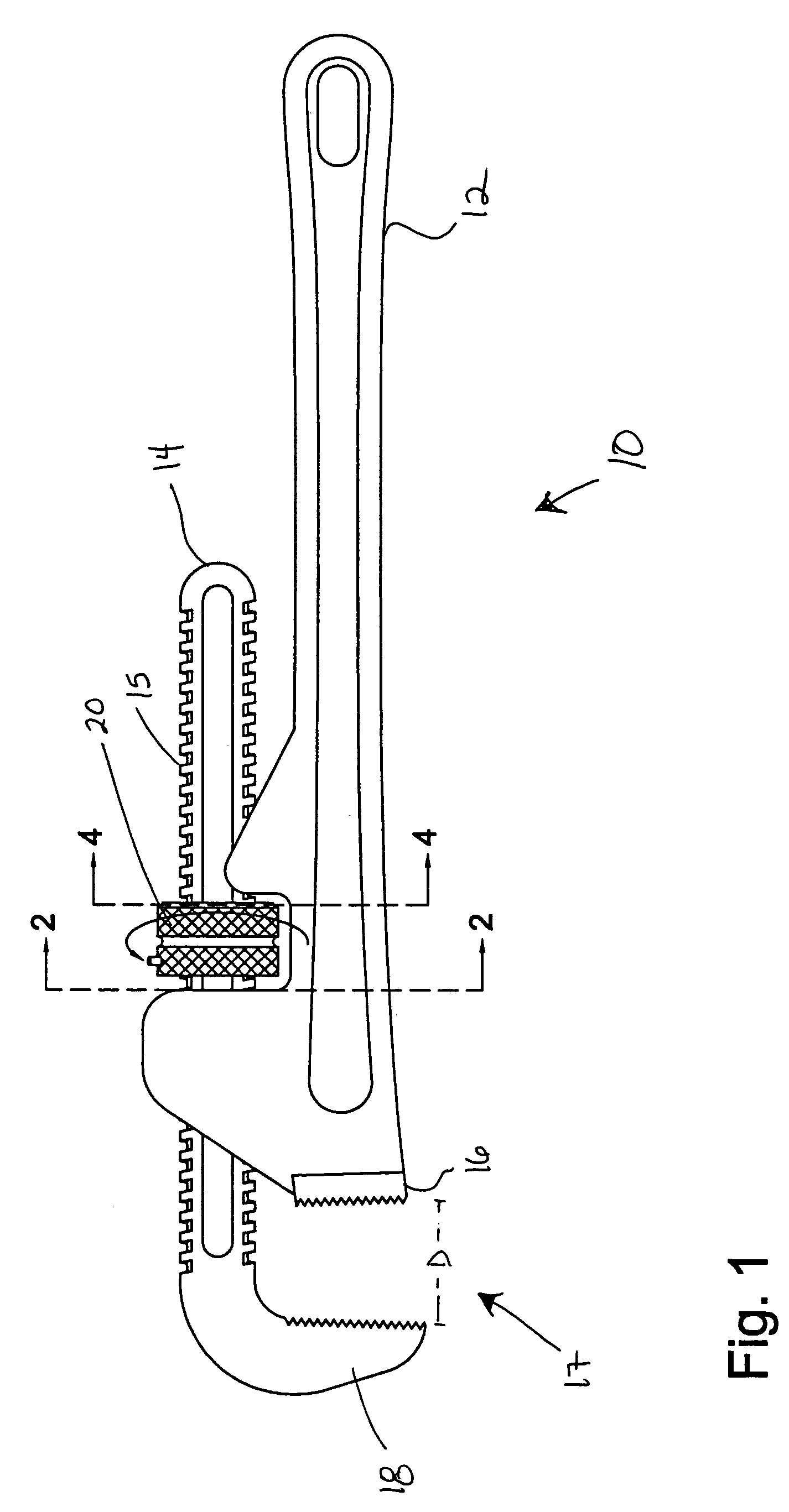

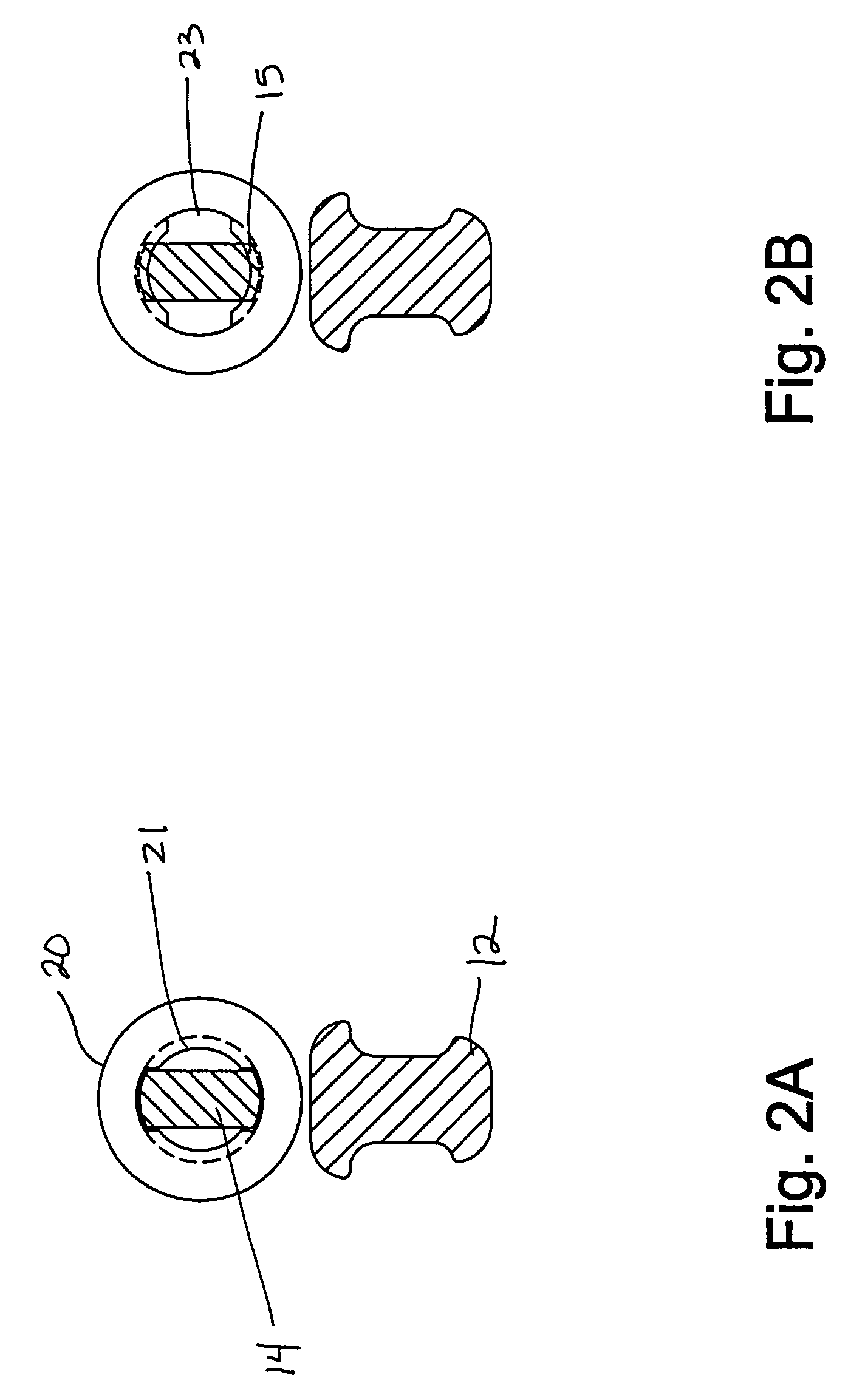

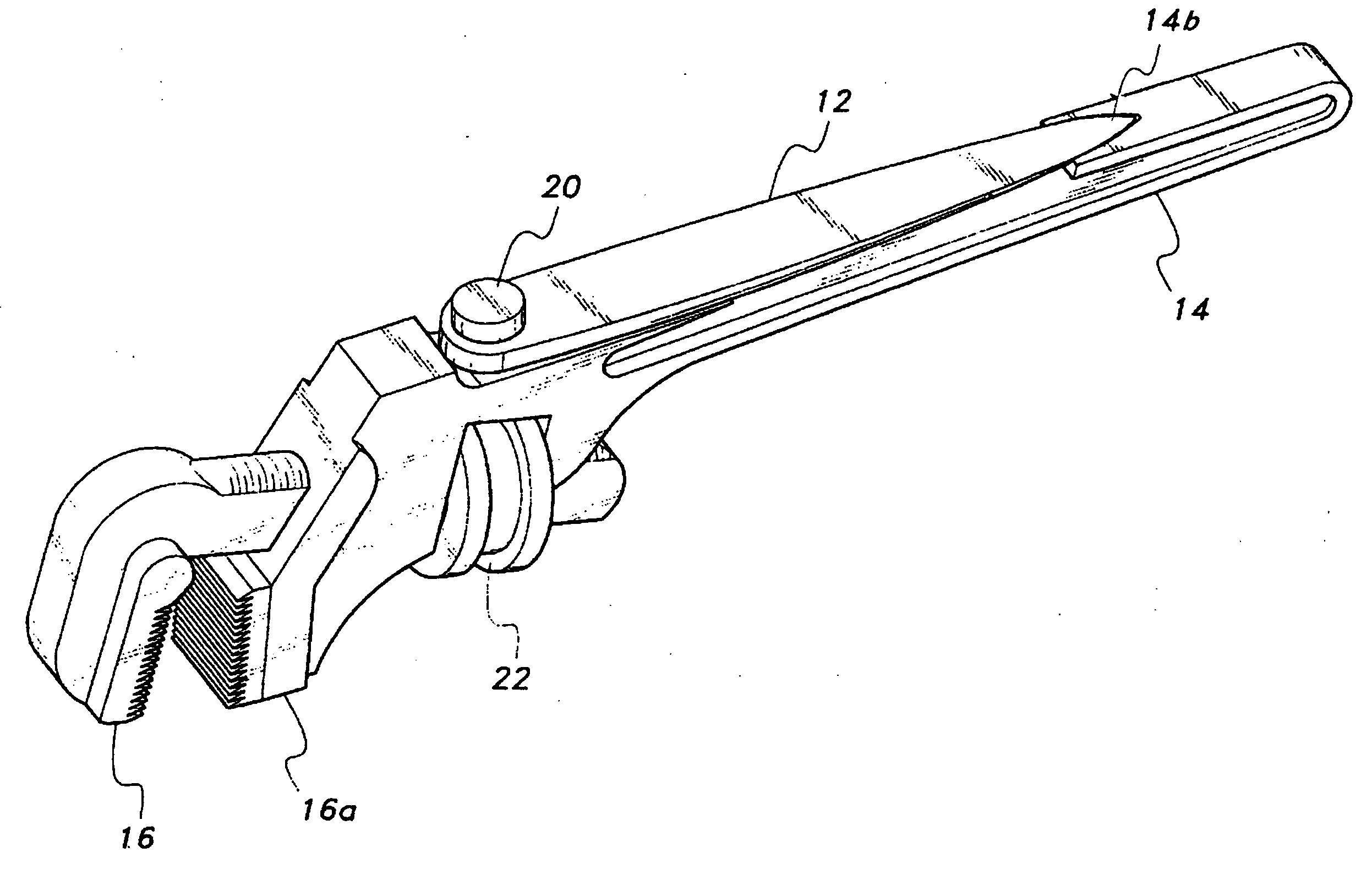

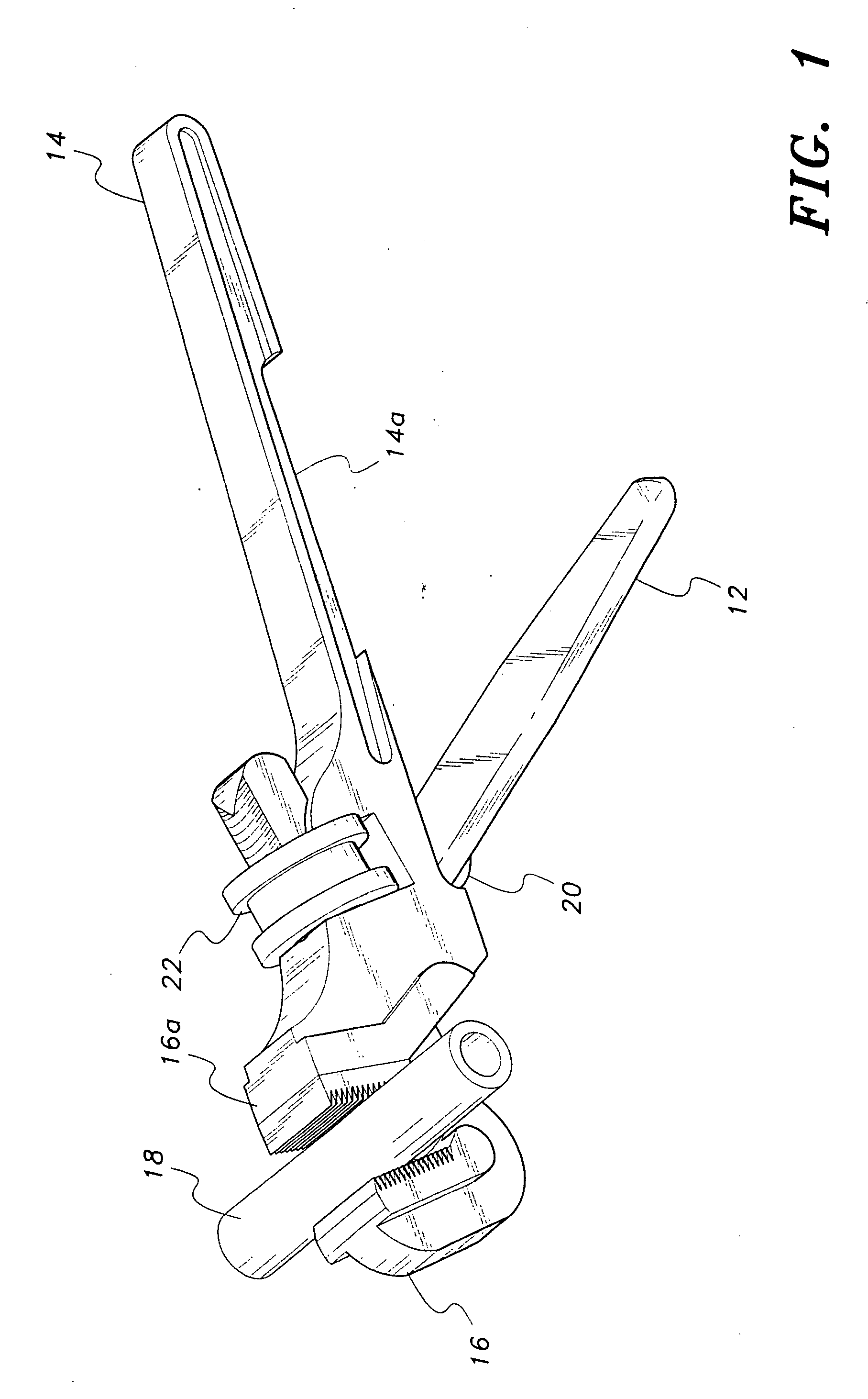

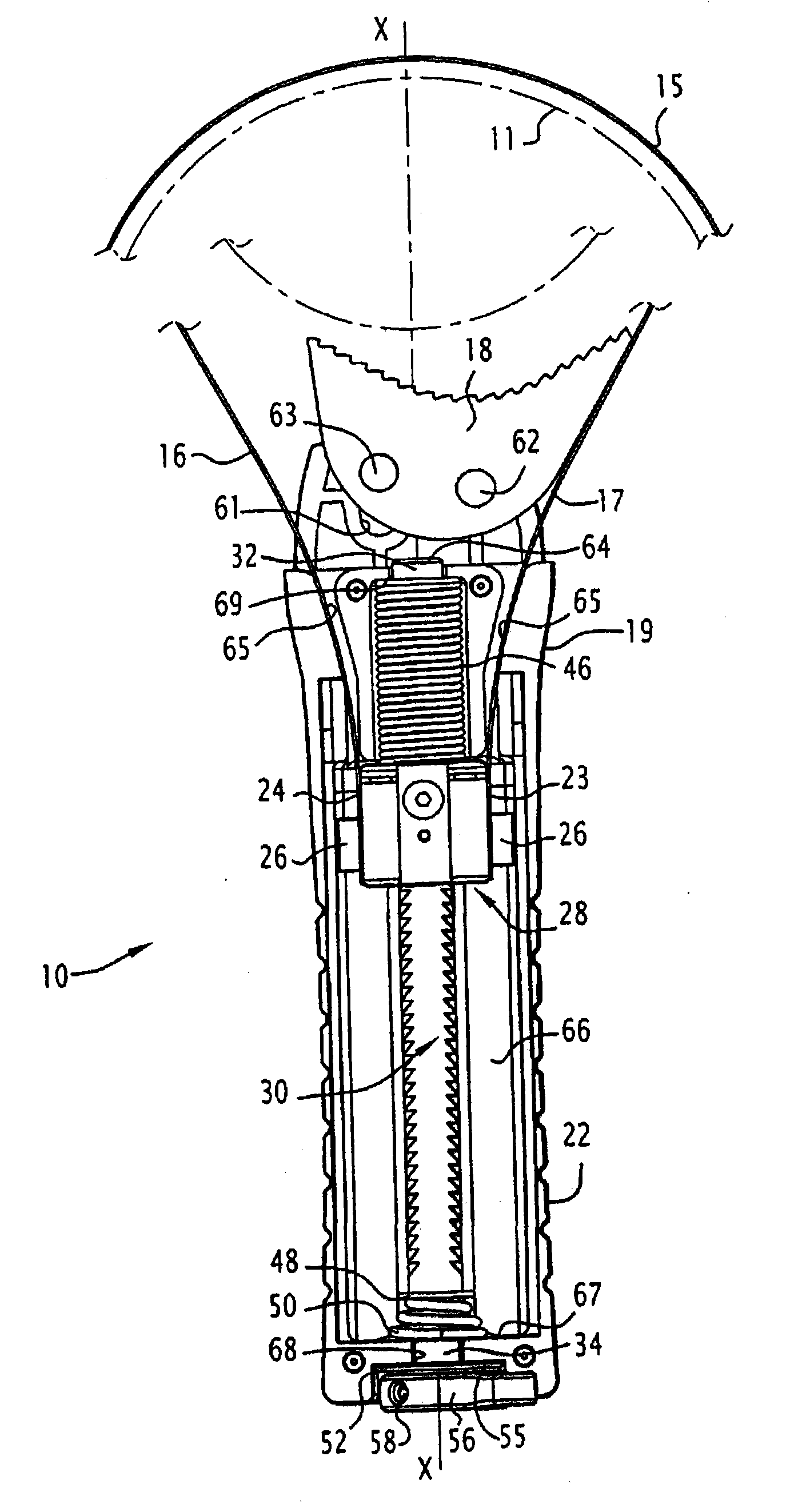

One hand pipe wrench

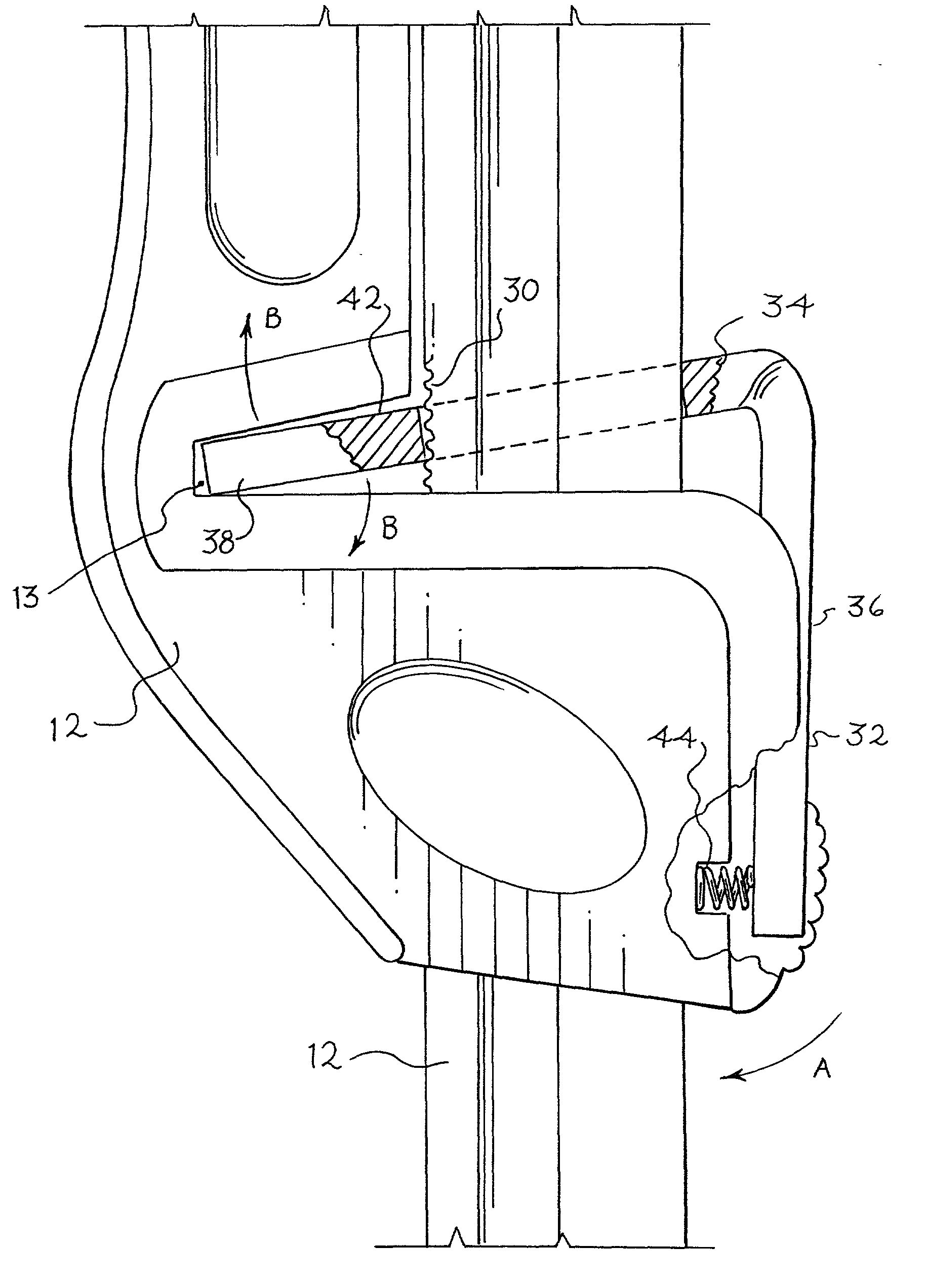

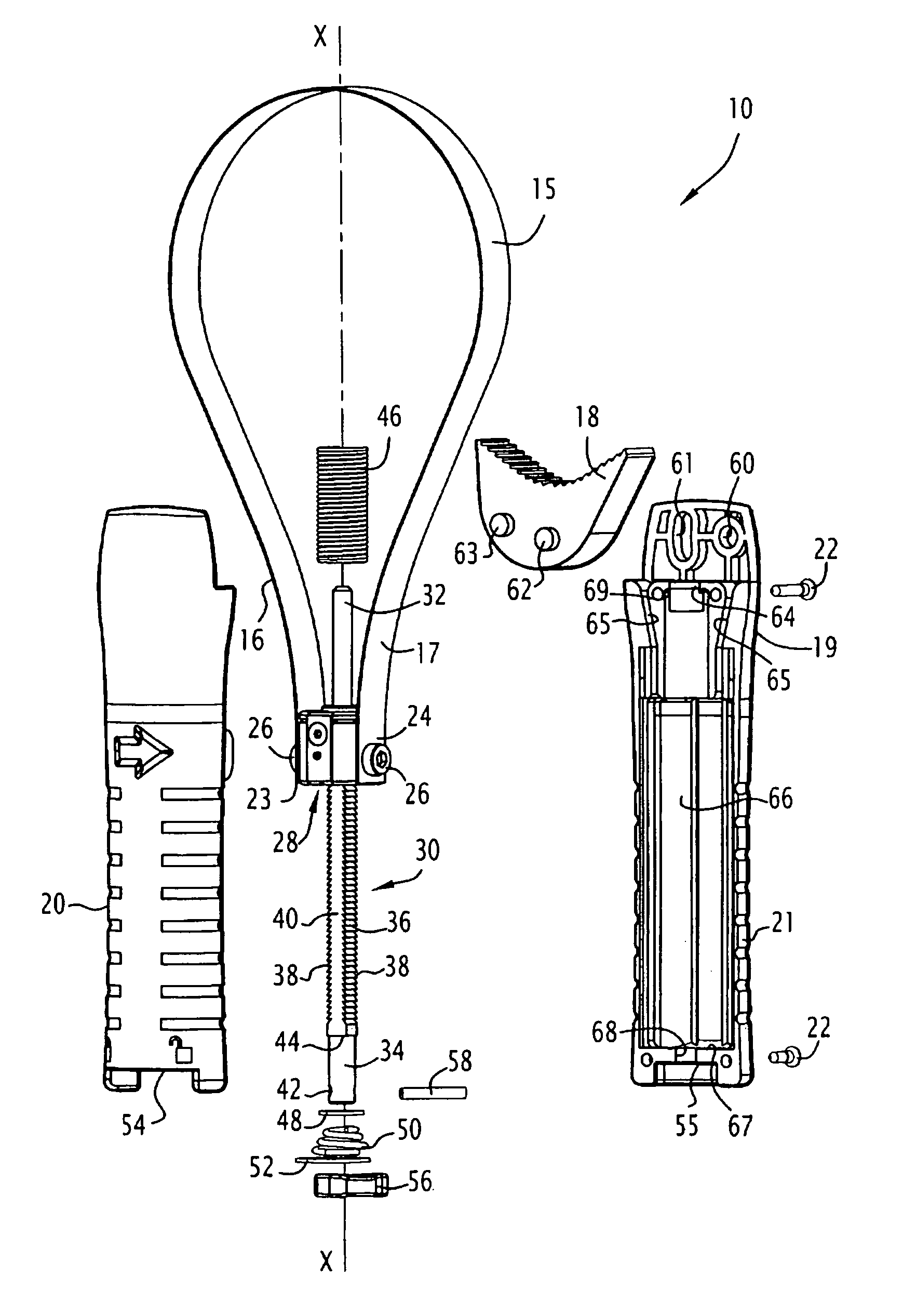

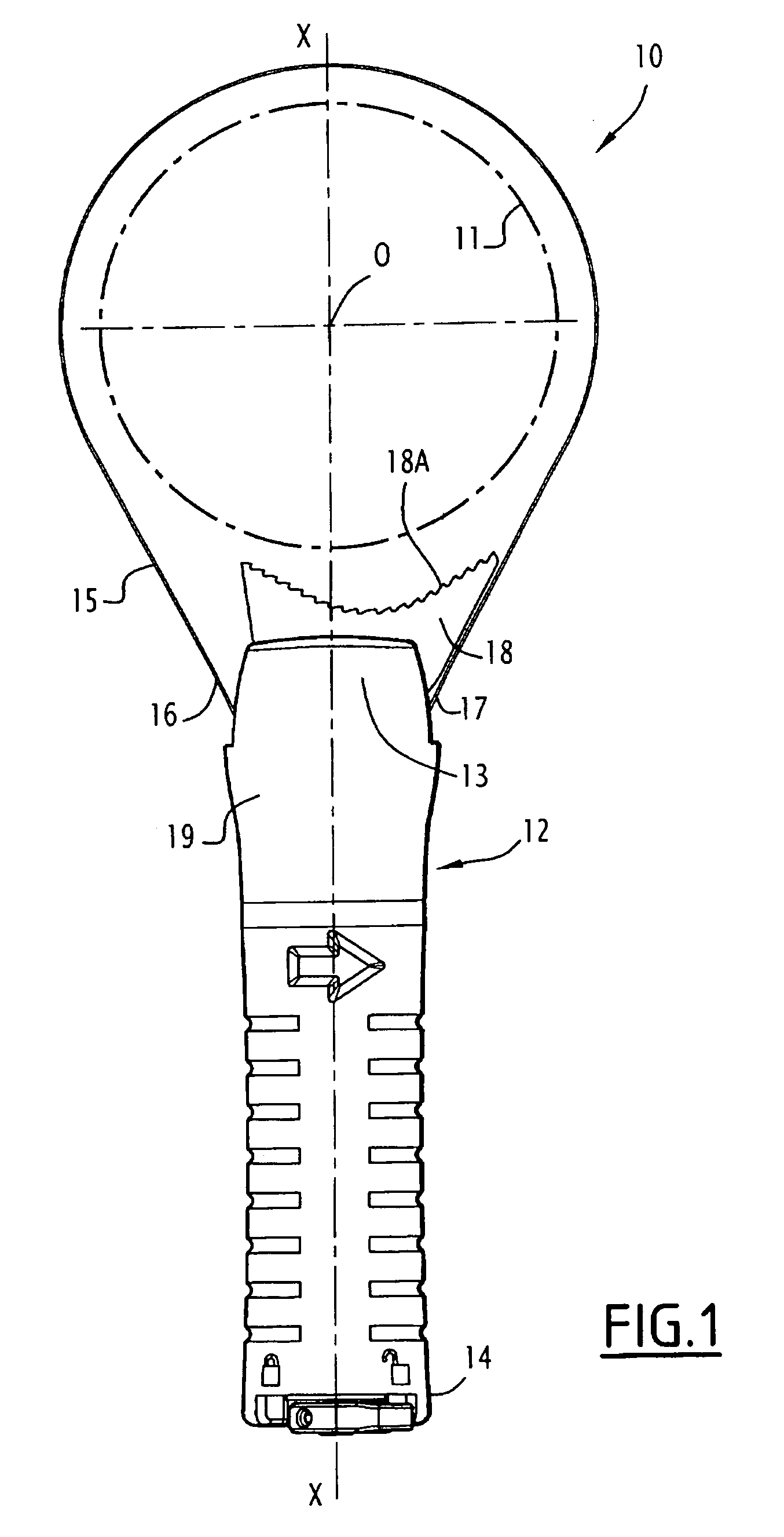

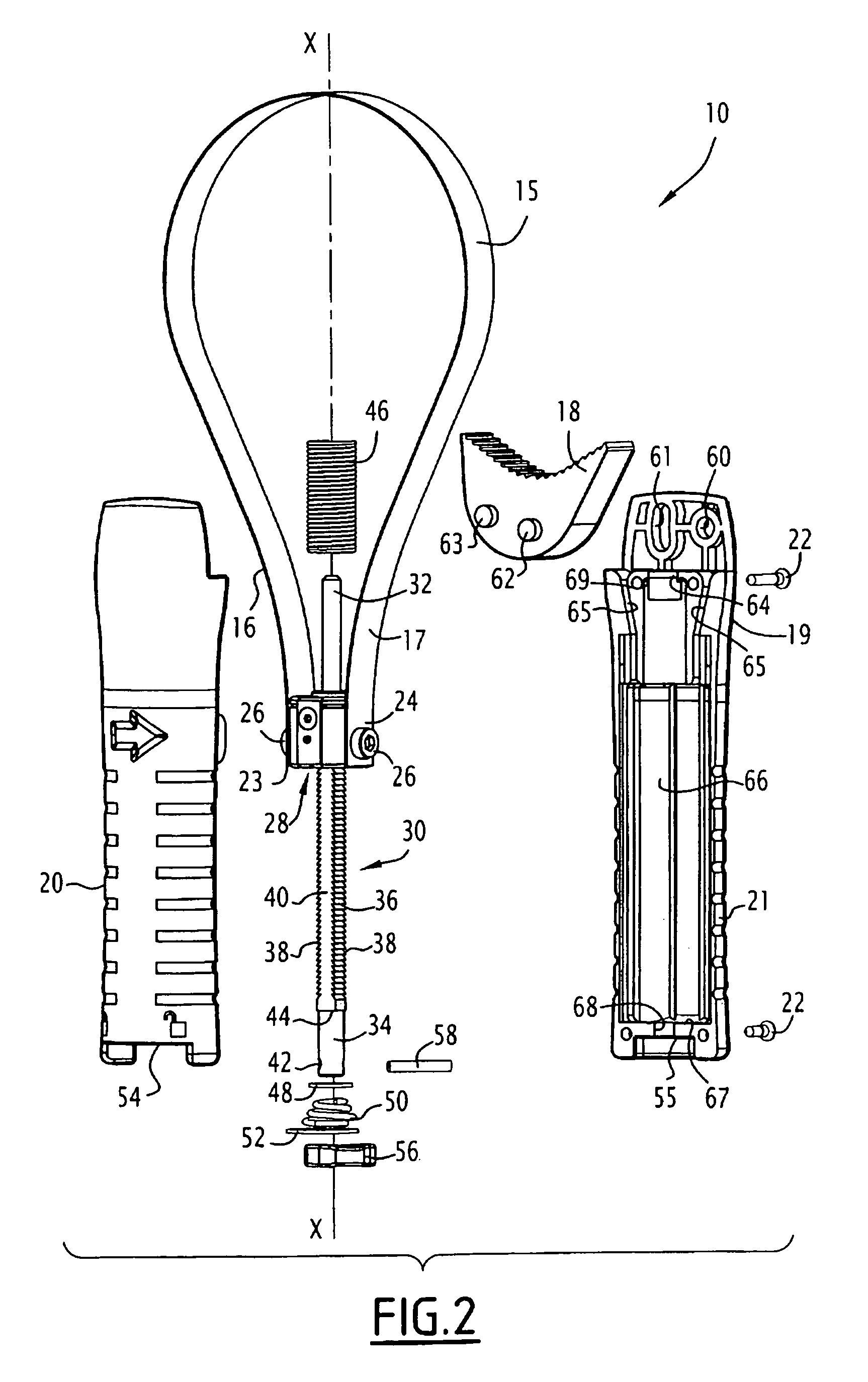

A pipe wrench is disclosed, the pipe wrench having a uniquely handy control lever and one-way ratchet for very rapid adjustment of wrench position. The wrench also has a pivoting upper jaw that further aids a user in adjusting and tightening the wrench while using only one hand. The wrench may also be used as a hand tool, for instance for clamping an object or workpiece for performing work on the object.

Owner:BLACK & DECKER INC

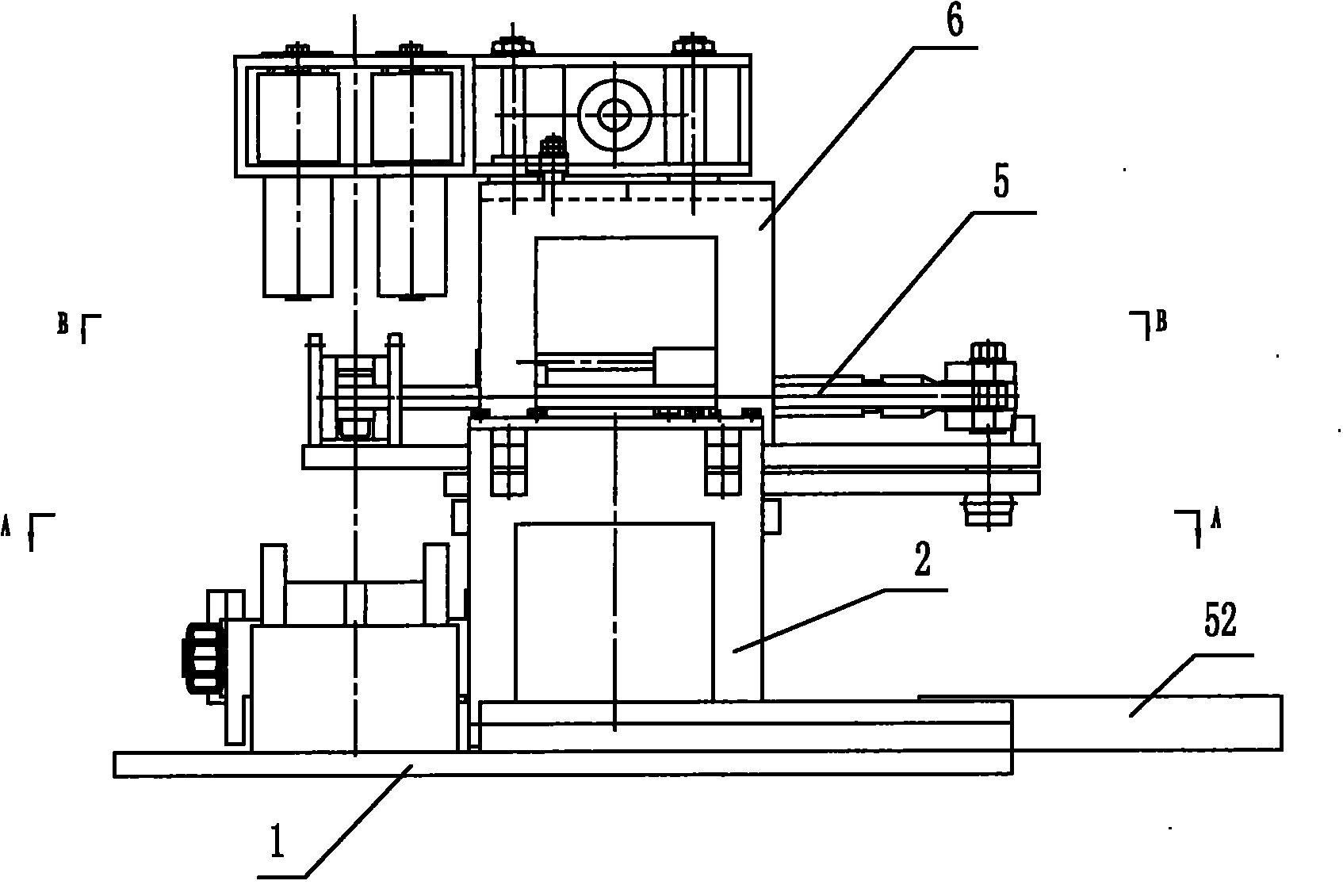

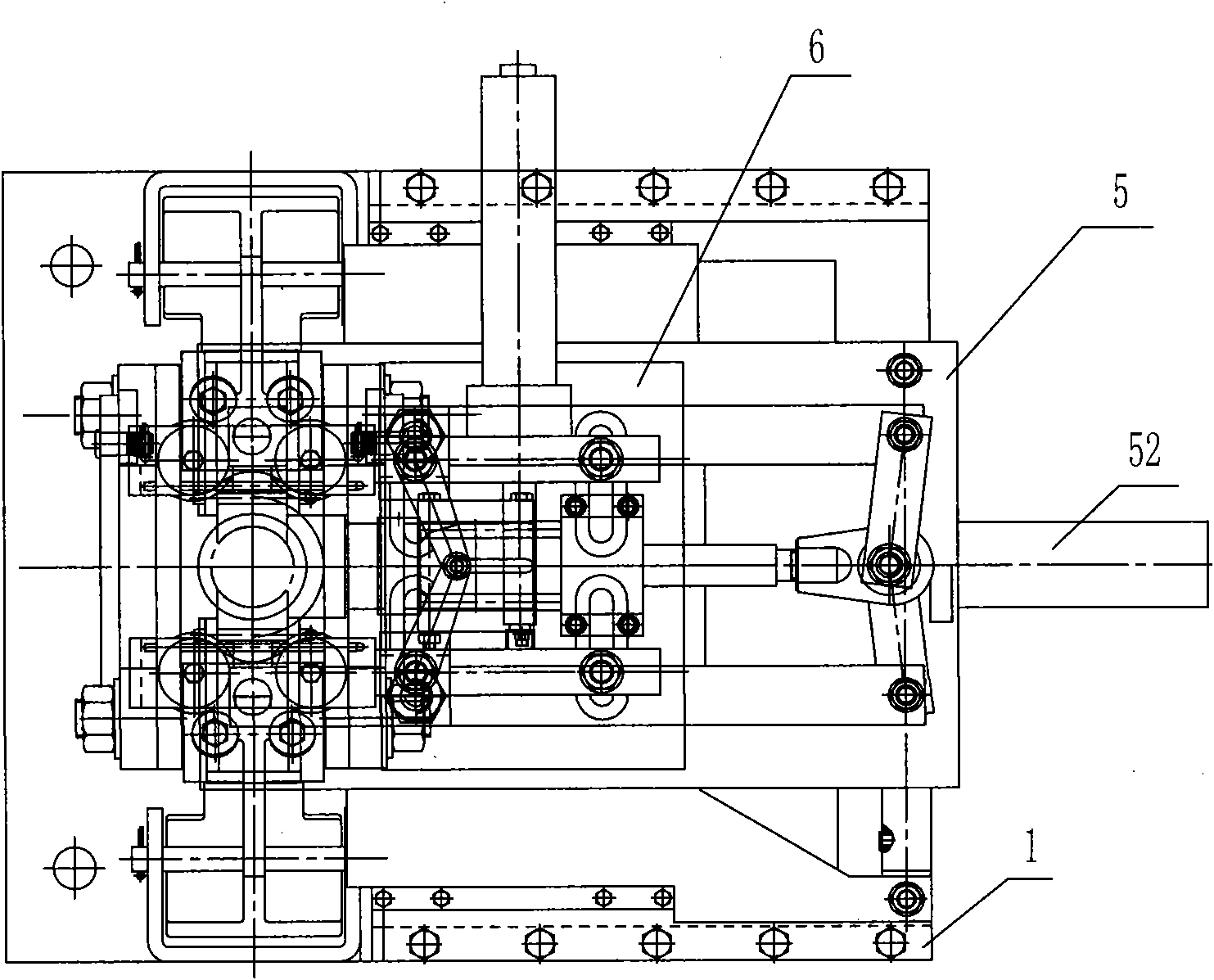

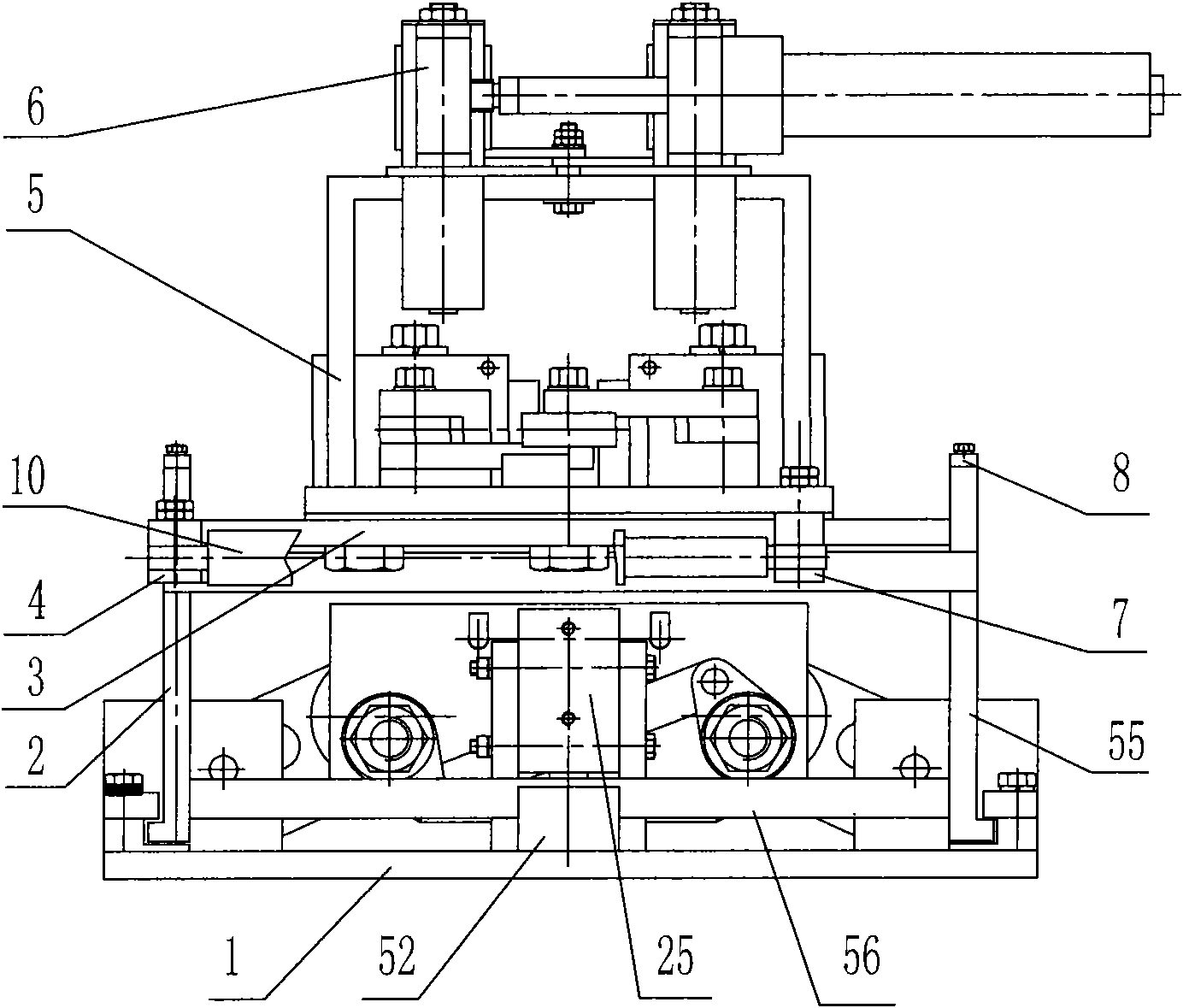

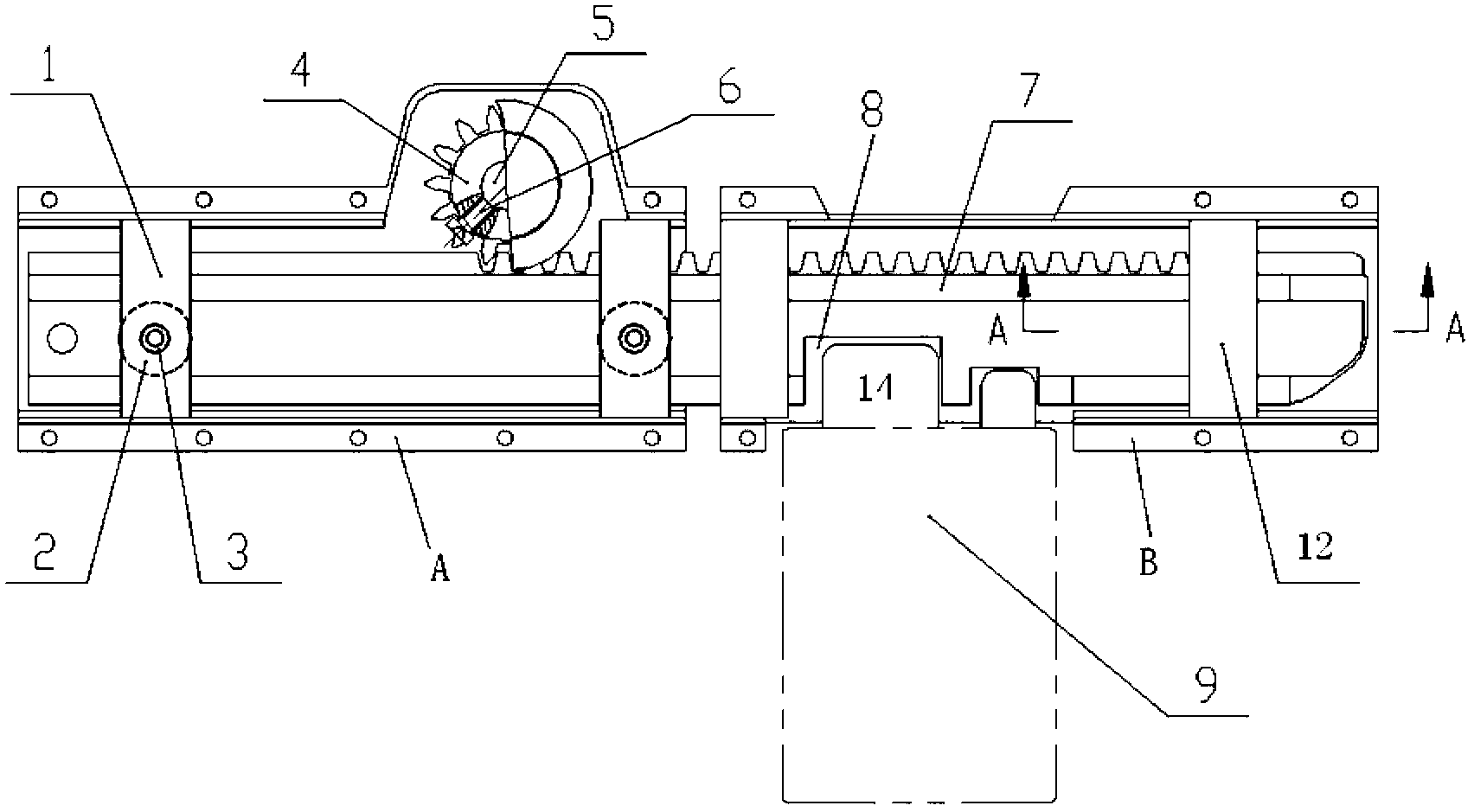

High-torque hydraulic pipe-wrenching machine for wrenching and disassembling outer-flat drilling rod

The invention relates to high-torque hydraulic wrenching and disassembling equipment suitable for an outer-flat drilling rod, belonging to the field of drilling and exploring machineries. The high-torque hydraulic pipe-wrenching machine for wrenching and disassembling the outer-flat drilling rod is characterized by comprising lower clamping tongs, a floating device, clasp punching tongs, an orifice leaving oil cylinder, a sliding block at the lower end part of a left floating post and a sliding block at the lower end part of the right floating post of the floating device respectively correspond to the insides of a left chute and a right chute of a lower clamping tongs support of the lower clamping tongs, the body of the orifice leaving oil cylinder is fixed at the rear end part of the lower clamping tongs support, and a piston rod of the orifice leaving oil cylinder is articulated with a floating frame; and the clasp punching tongs are arranged on a floating plate of the floating device, and clasp turning tongs are arranged on a bottom plate of the clasp punching tongs. The invention adopts an integral structure of clamping, clasp turning, clasp punching / pre-tightening and is suitable for the wrenching and the disassembling of the outer-flat drilling rod.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

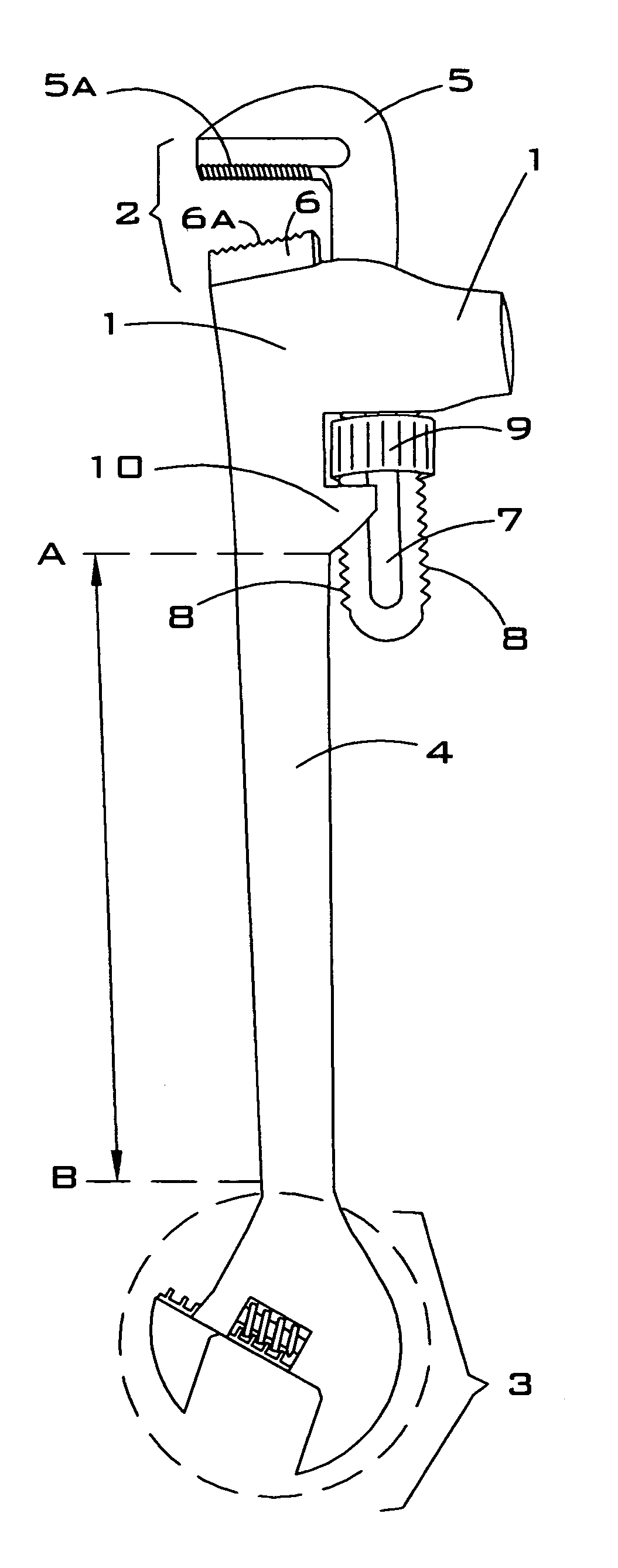

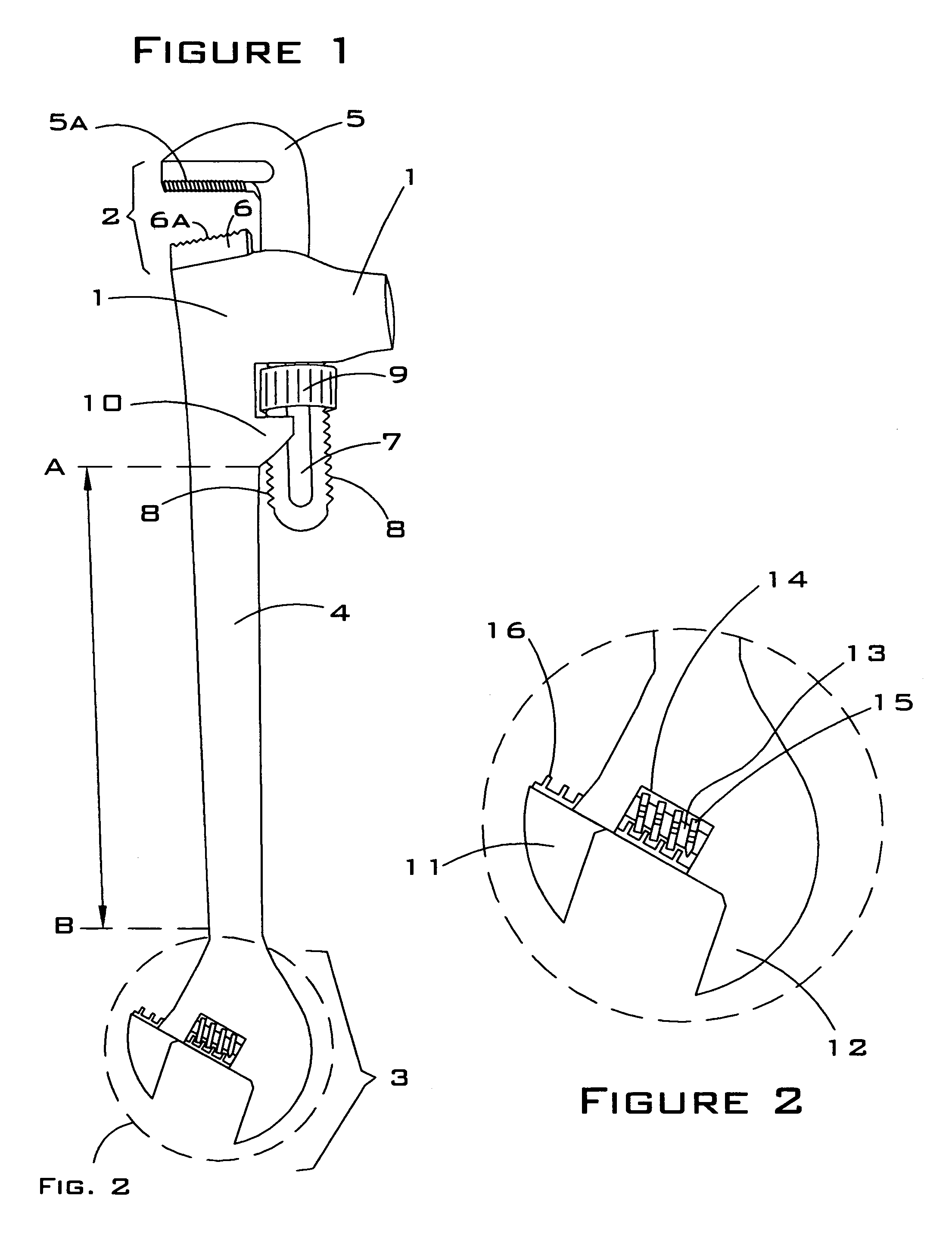

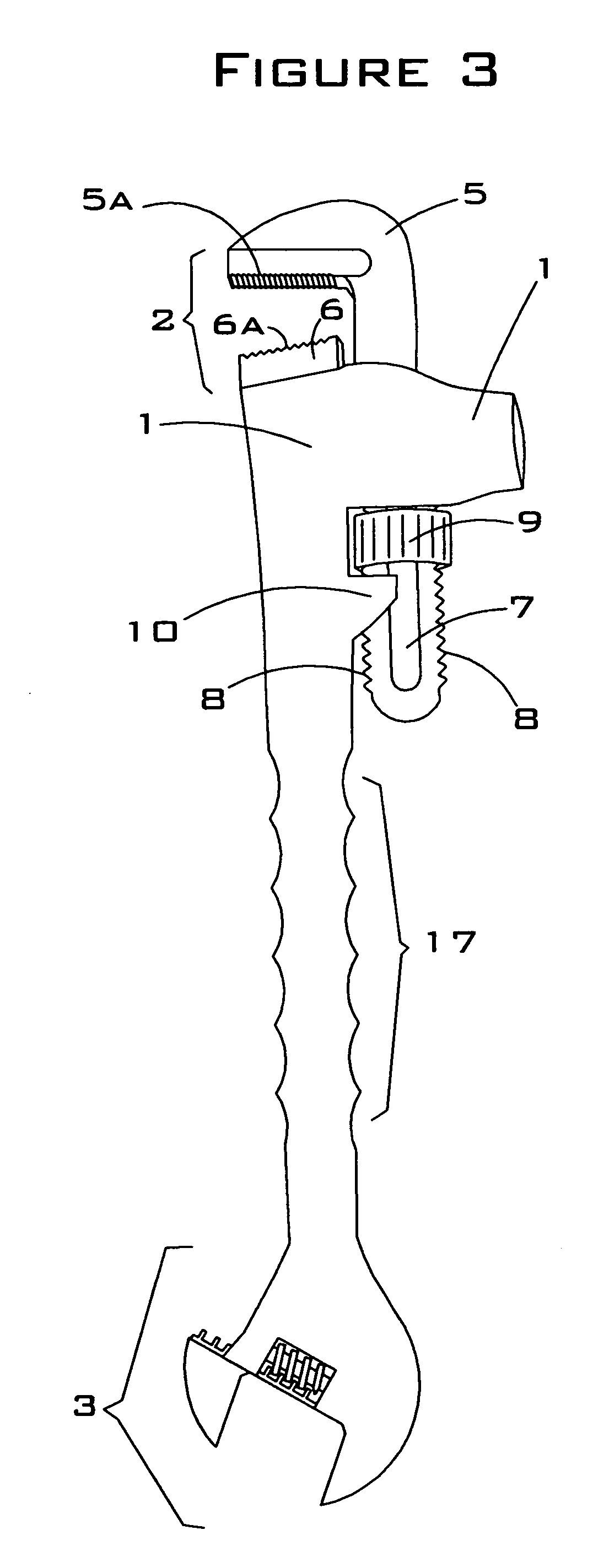

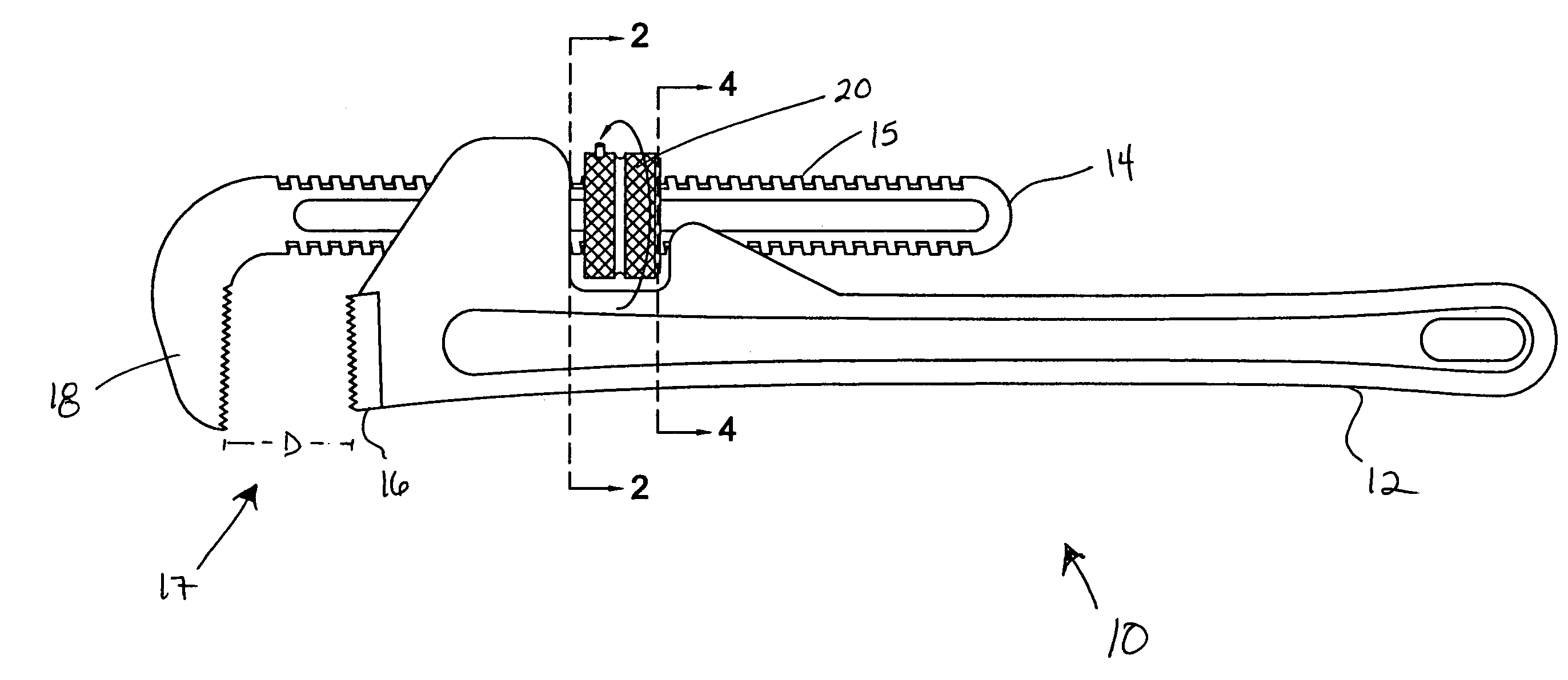

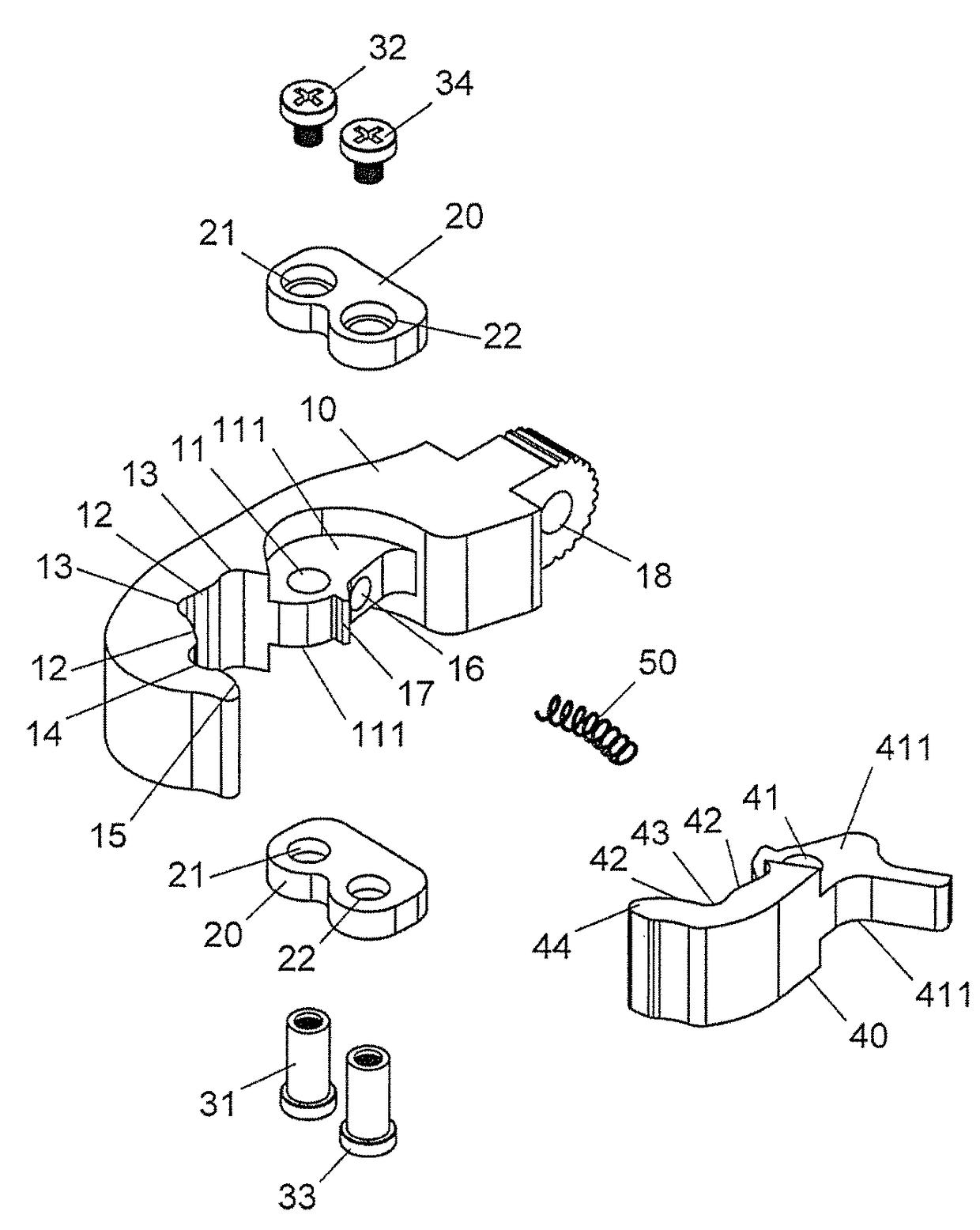

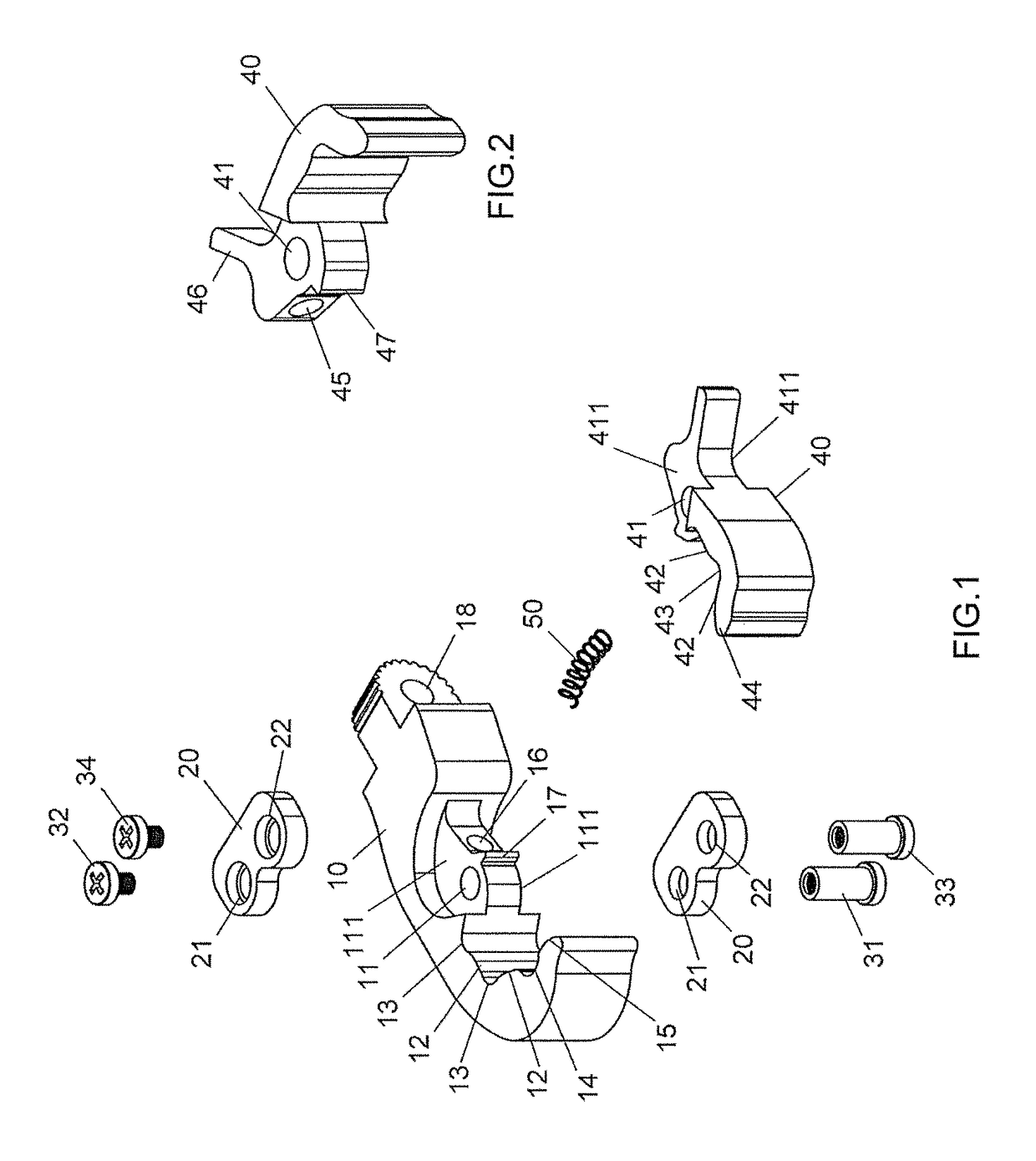

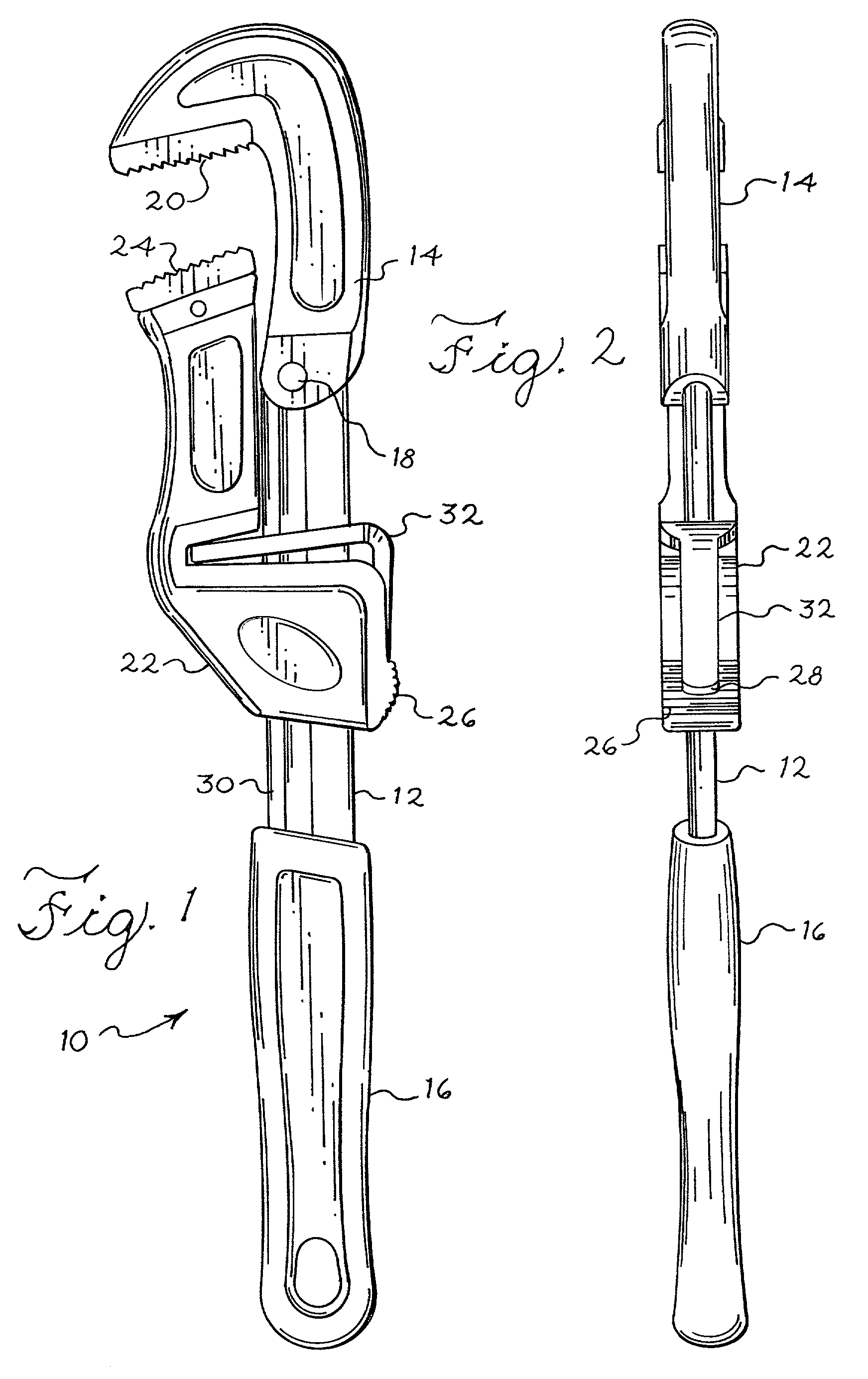

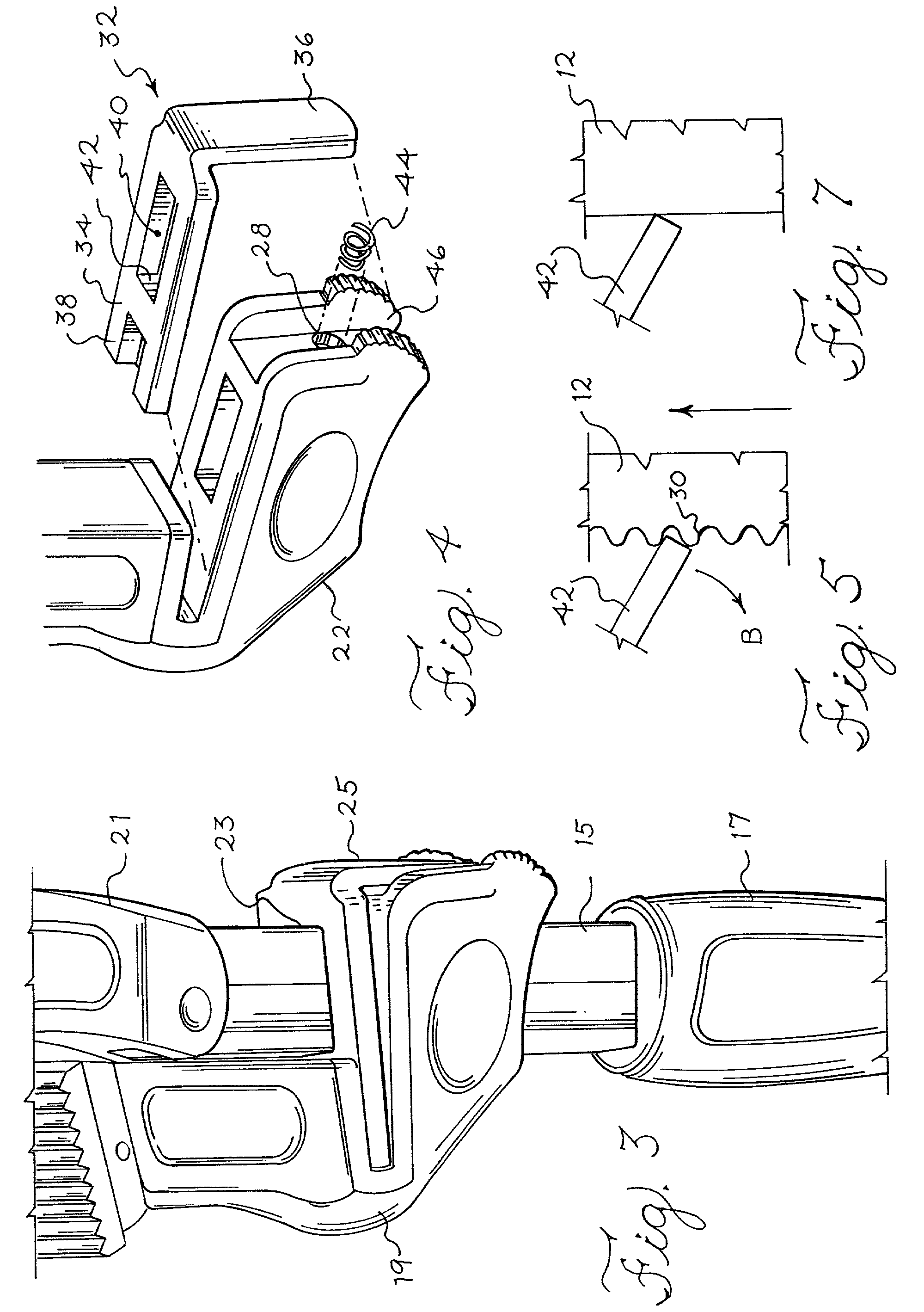

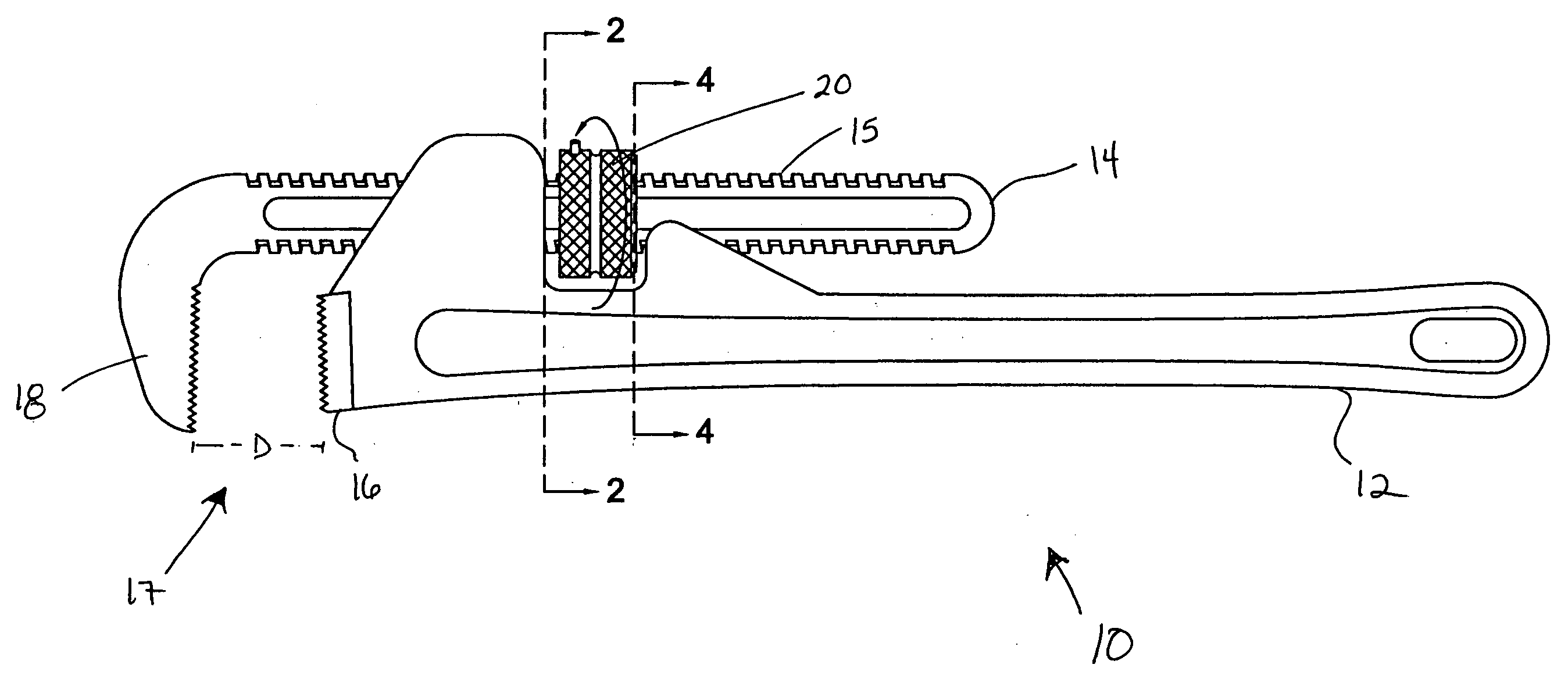

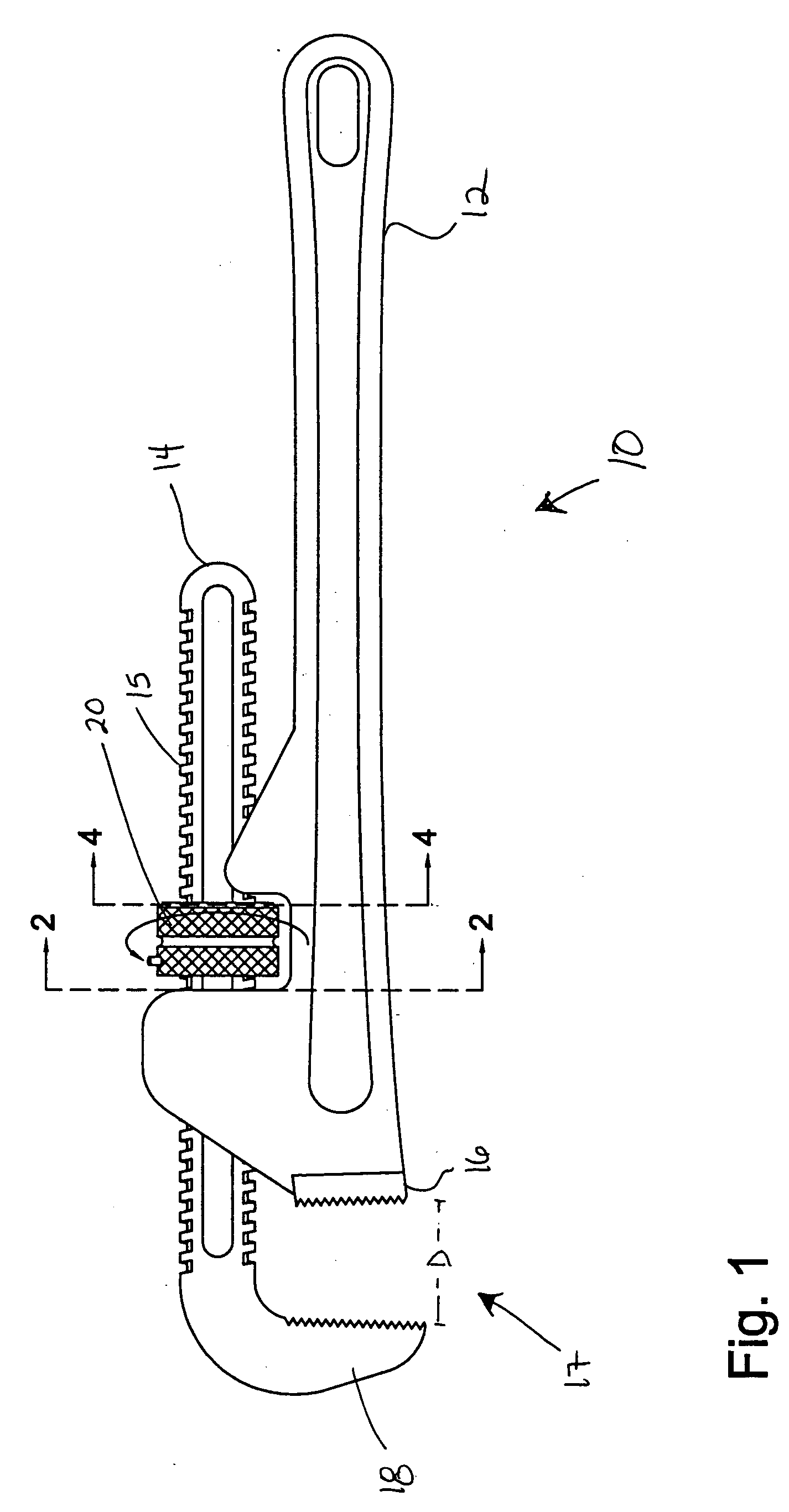

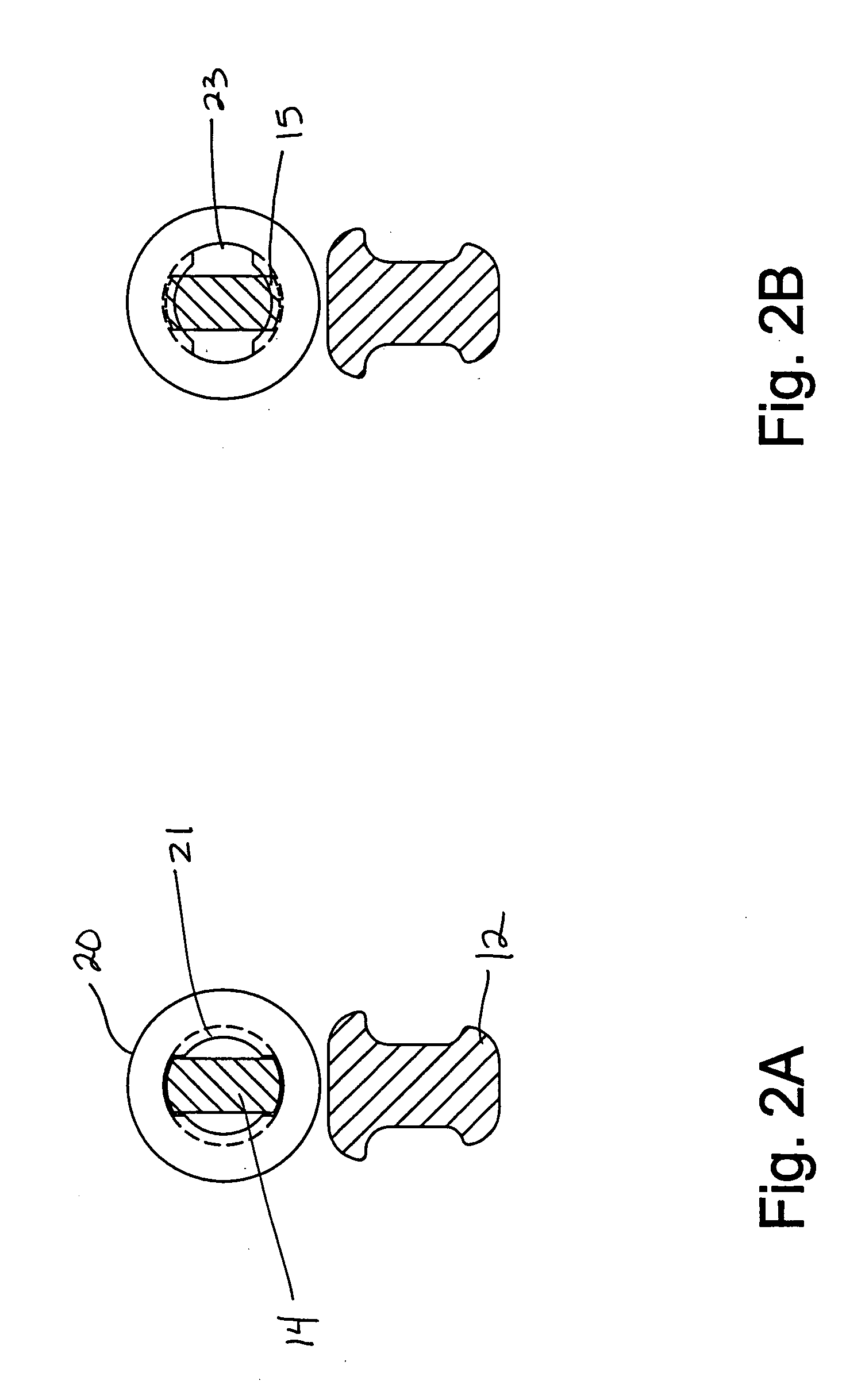

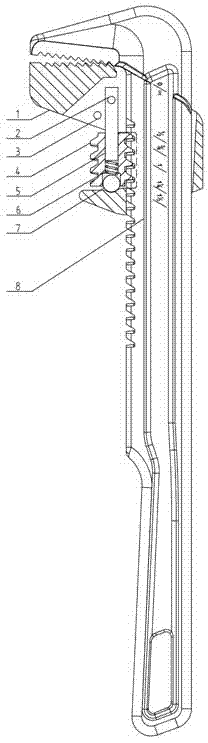

Pipe wrench retrofit

The specification discloses a modified nut assembly and locking assembly for locking the shank of a wrench in place. The nut assembly preferably includes a nut for engaging and disengaging the shank of the wrench and a spring for biasing the nut to a position where the shank of the wrench is locked in place. Threads internal to the nut matingly engage threads on the shank of the wrench when in a locked position, and grooves internal to the nut allow the shank of the wrench to slide freely through the nut when in an unlocked position. The locking assembly preferably includes a housing, a sliding portion, a locking portion, and a spring. The sliding portion and locking portion preferably abut each other within the housing. The spring is preferably located in the sliding portion and extends from the sliding portion to the shank of the wrench.

Owner:GREGORY N SCOTT

Pipe wrench

A pipe wrench includes a fixed jaw with alternatively located first recesses and first driving faces defined in the inner side thereof. A pivotal member is pivotably connected to the fixed jaw and a resilient member is biased between the fixed jaw and the pivotal member. The pivotal member has alternatively located third recesses and second driving faces. A hexagonal space is defined between the first and second driving faces. The end portion of the pivotal member is inserted into a second recess defined in the inner side of the fixed jaw. The object is clamped in the hexagonal space, and the pivotal member can be pivoted away from the fixed jaw. The pipe wrench is able to quickly clamp and dismounted from the object.

Owner:ZHEJIANG YIYANG TOOL MFG +2

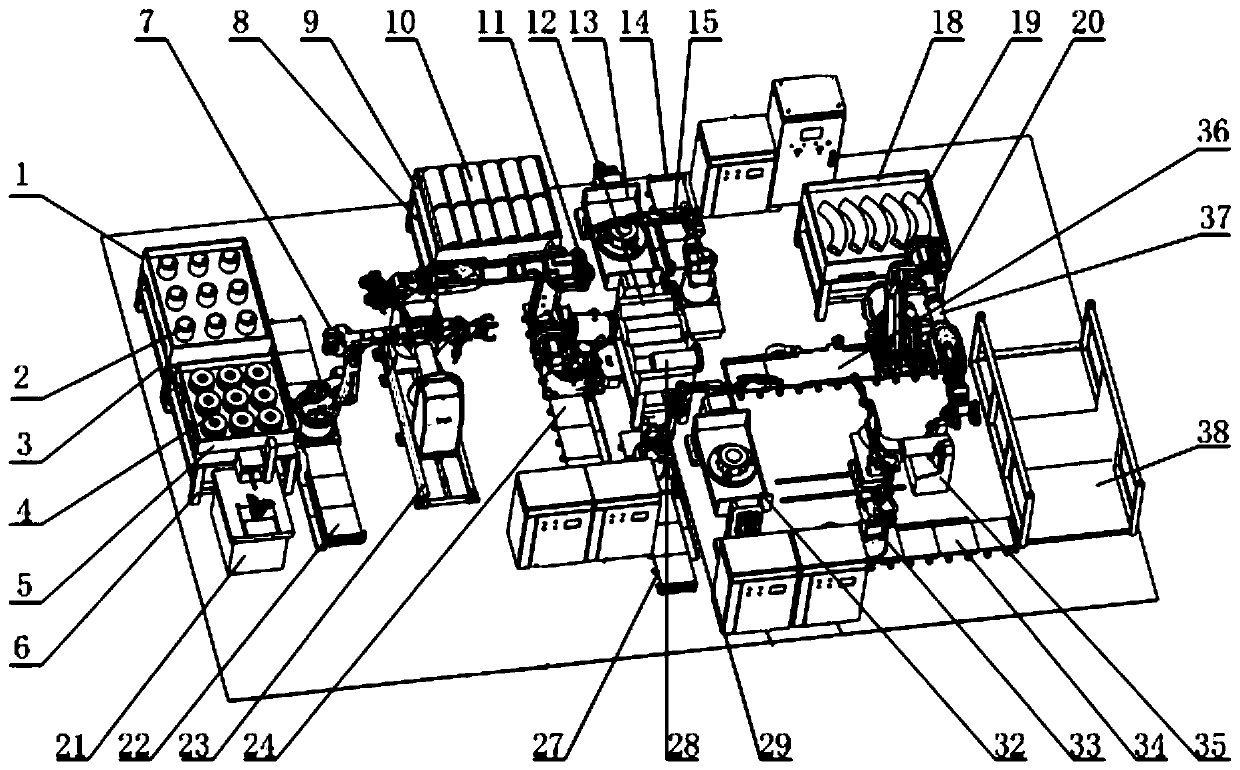

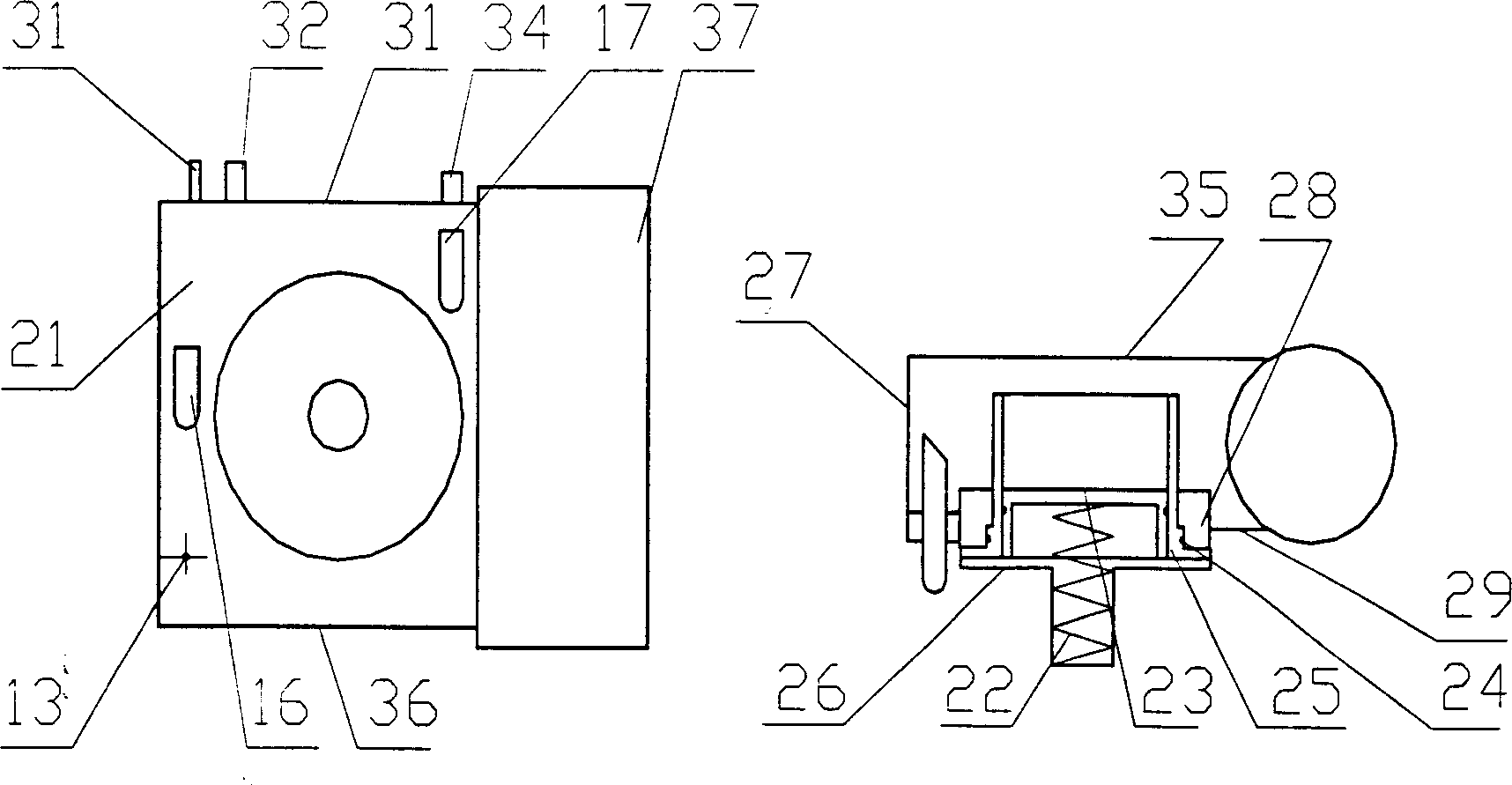

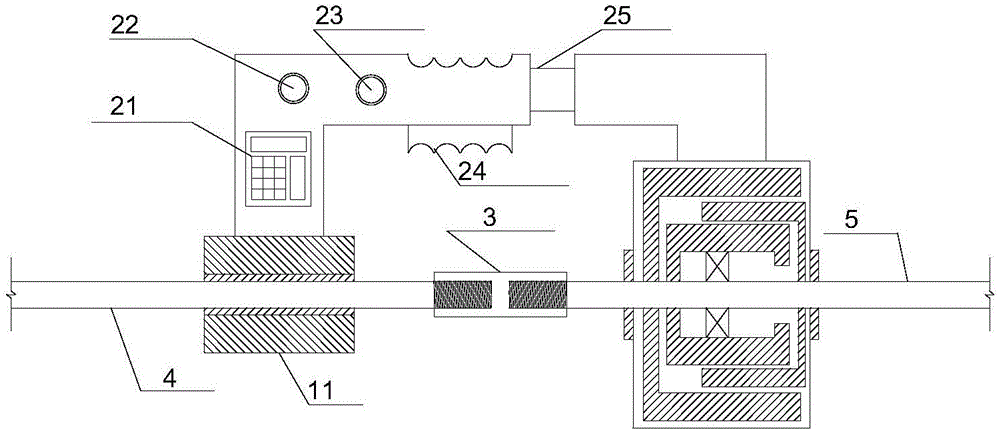

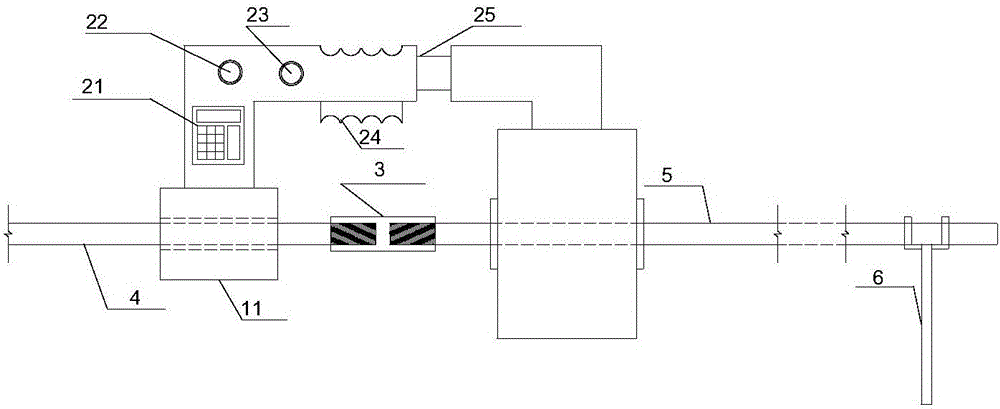

Short pipe-flange/sleeve/elbow full-automatic coupling and welding workstation

InactiveCN110757033ARealize fully automatic logisticsEnsure consistencyWelding/cutting auxillary devicesAuxillary welding devicesPipe wrenchPipe fitting

The invention discloses a short pipe-flange / sleeve / elbow full-automatic coupling and welding workstation. The short pipe-flange / sleeve / elbow full-automatic coupling and welding workstation comprises ashort pipe-flange / sleeve coupling station, a short pipe-flange / sleeve welding station and a short pipe-elbow coupling and welding station. The short pipe-flange / sleeve coupling station comprises a grabbing / welding robot, a head and tail type automatic coupling machine, carrying robots, an automatic marking machine, a flange material platform, a sleeve material platform and a short pipe material platform. The feeding operation of short pipes, flanges and sleeves, the marking operation of the flanges and the assembly and spot welding operation of the short pipes and the flanges / sleeves are achieved. The short pipe-flange / sleeve welding station comprises welding robots, rotary type position changing machines and a transfer locating platform. The feeding, welding and discharging operation ofthe short pipes to be welded is achieved. The short pipe-elbow coupling and welding station comprises a carrying robot, a pipe wrench type position changing machine, a welding robot, an elbow materialplatform and a finished product material frame. The feeding, coupling and welding operation of the short pipes and elbows and the discharging operation of welded finished products are achieved. The short pipe-flange / sleeve / elbow full-automatic coupling and welding workstation can improve the automation level of short pipe and pipe fitting coupling and welding operation.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP +1

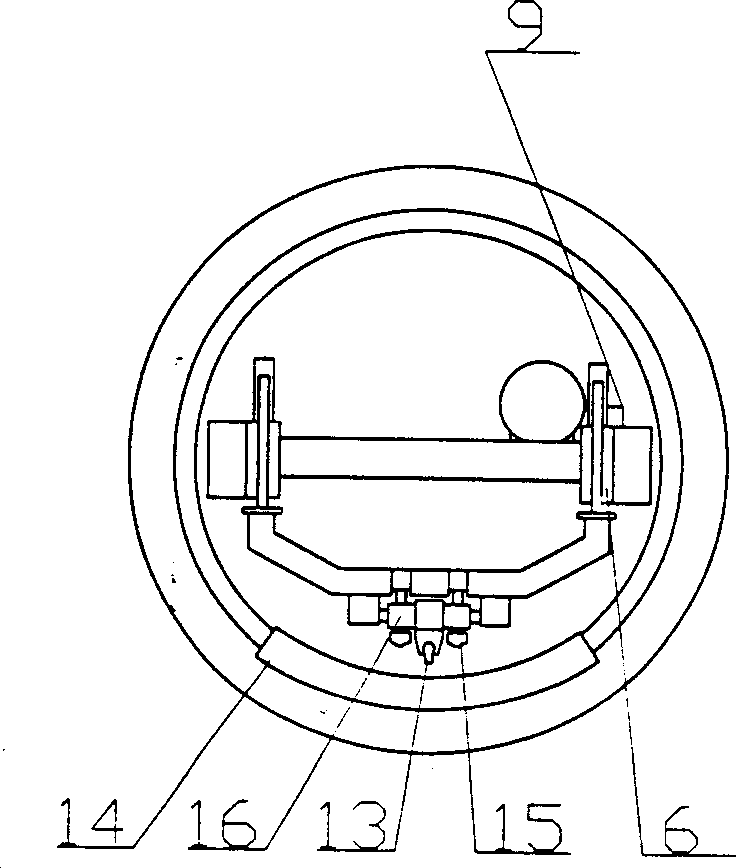

Lining assembling machine having pressure type total leak-proof fuel cell

InactiveCN1448616AEnsure safetySimple structureUnderground chambersTunnel liningPipe wrenchFuel cells

The lining and assembling machine with pressurized sealed oil tank belongs to tunnel engineering constructing machinery. The connecting mode includes setting the cantilever beam and the oil tank cantilever beam in the same side of the disk, driving the disk with the rotating driver, setting the electric control assembly on the top of the oil tank steel structure, setting the hydraulic pump set on the top of the oil tank cantilever beam, setting the pressurized sealed oil tank inside the steel structure of the oil tank steel structure, welding the guide barrel on one side of the cantilever beam, fixing the elevating oil cylinder onto the outside of the guide barrel, setting the elevating beam below the elevating oil cylinder, screwing the translating mechanism in the lower part of the elevating beam, setting the translating oil cylinder in the middle of the translating mechanism, and setting two pipe wrench beside the translating oil cylinder. The present invention has simple structure and high construction speed.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

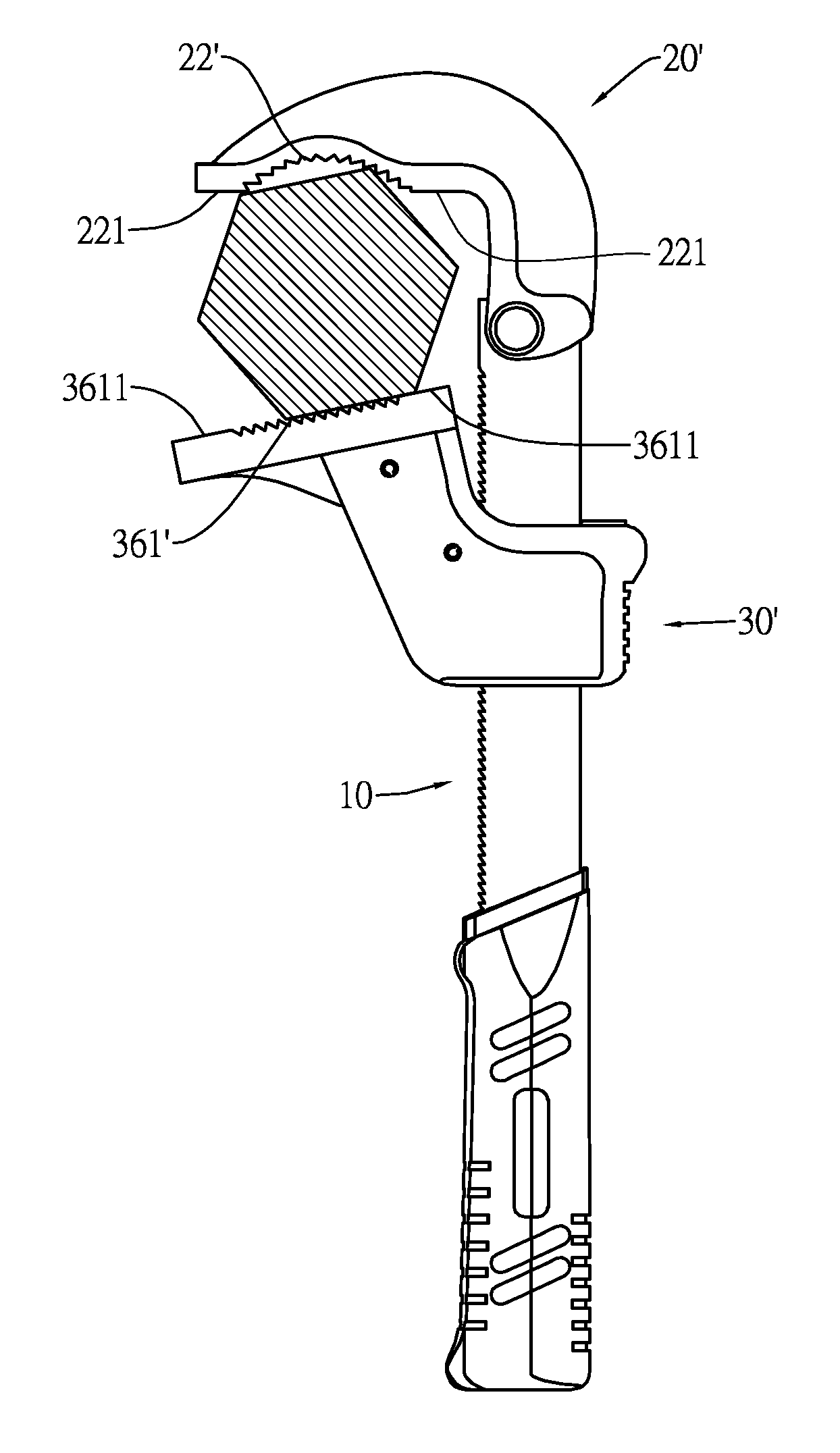

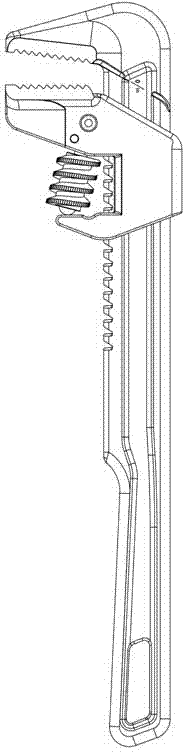

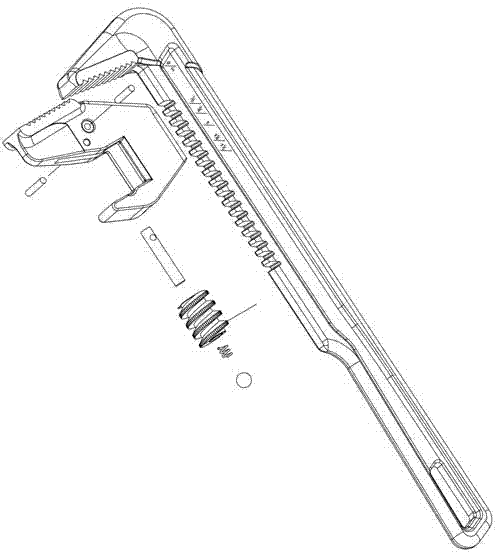

Jaw pipe wrench with resilient member

InactiveUS20090193940A1Improve convenienceIncrease competitionSpannersWrenchesPipe wrenchEngineering

The present invention pertains to a jaw pipe wrench with resilient member comprising a wrench body penetrating through an actuating jaw, where a resilient member mounted and provides with one flat surface leans against said wrench body, so as to drive a serrated section of the wrench body firmly contacting with a serrated section of actuating jaw. While in manipulation, users initially propel the actuating jaw and synchronically compress the resilient member, the serrated section of the wrench body thus moves away from the serrated section of the actuating jaw, whereby users can freely raise or descend the actuating jaw in time of clamping, thus increasing the convenience of using.

Owner:KUO SHAO FAN

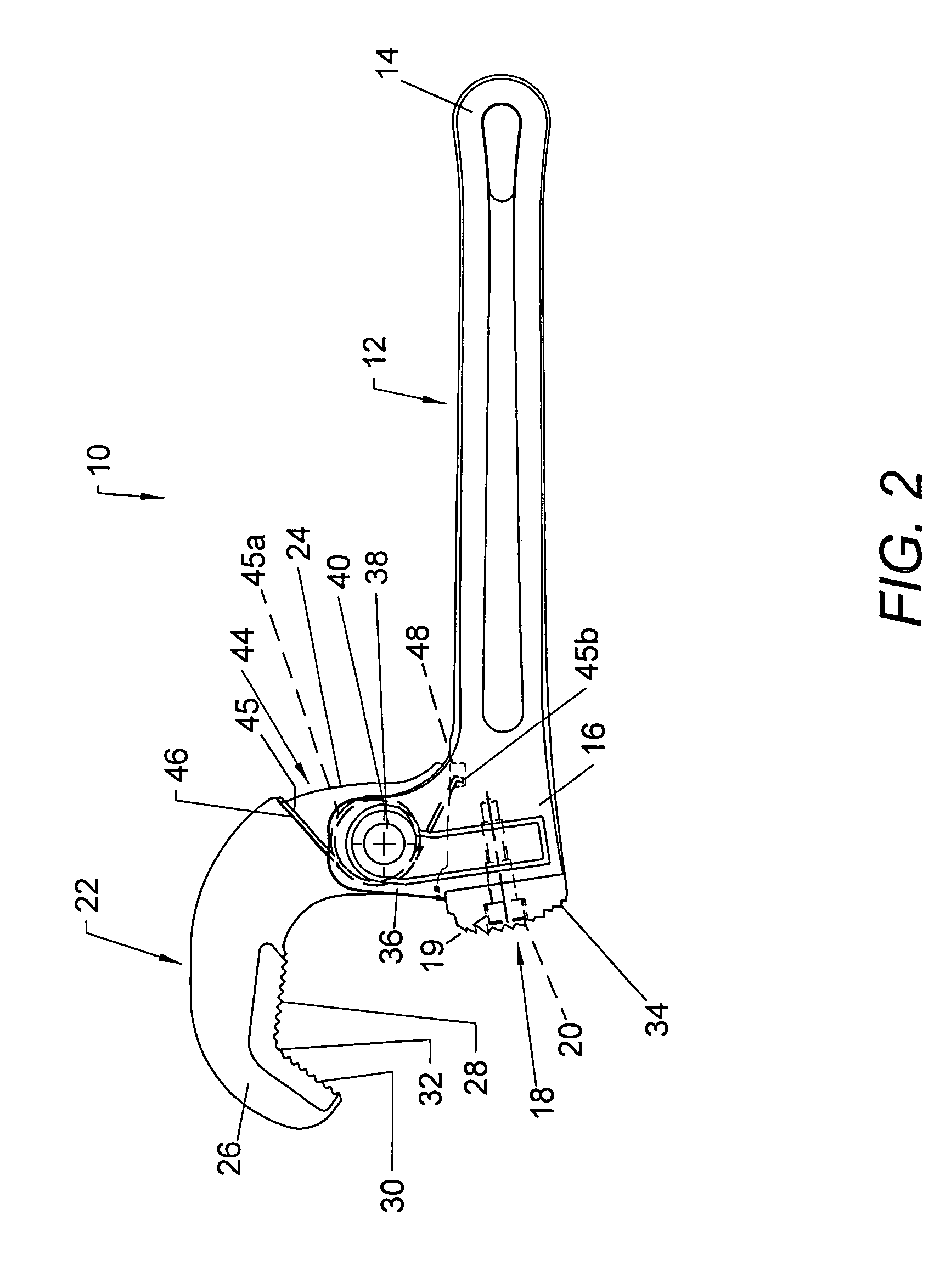

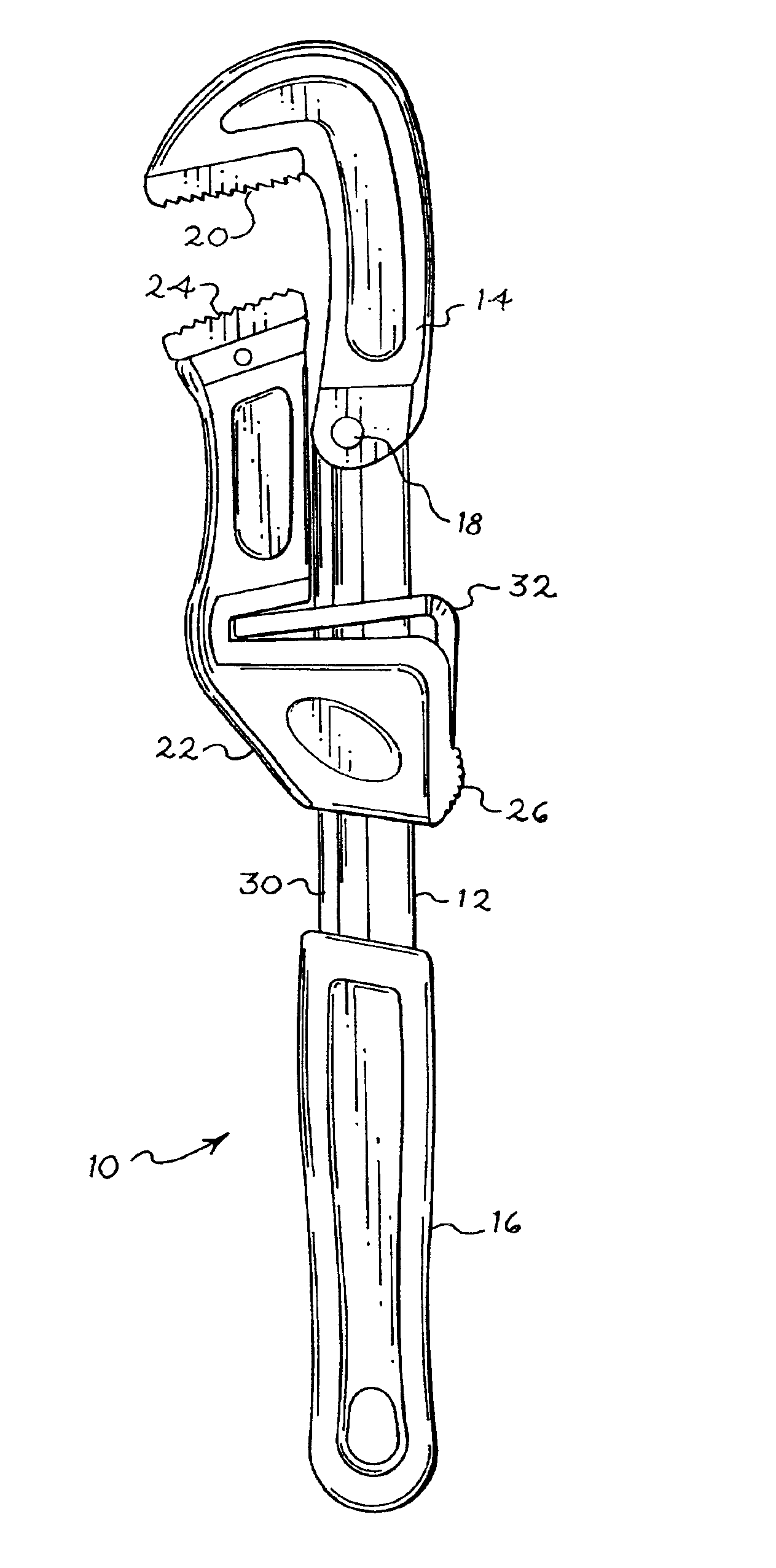

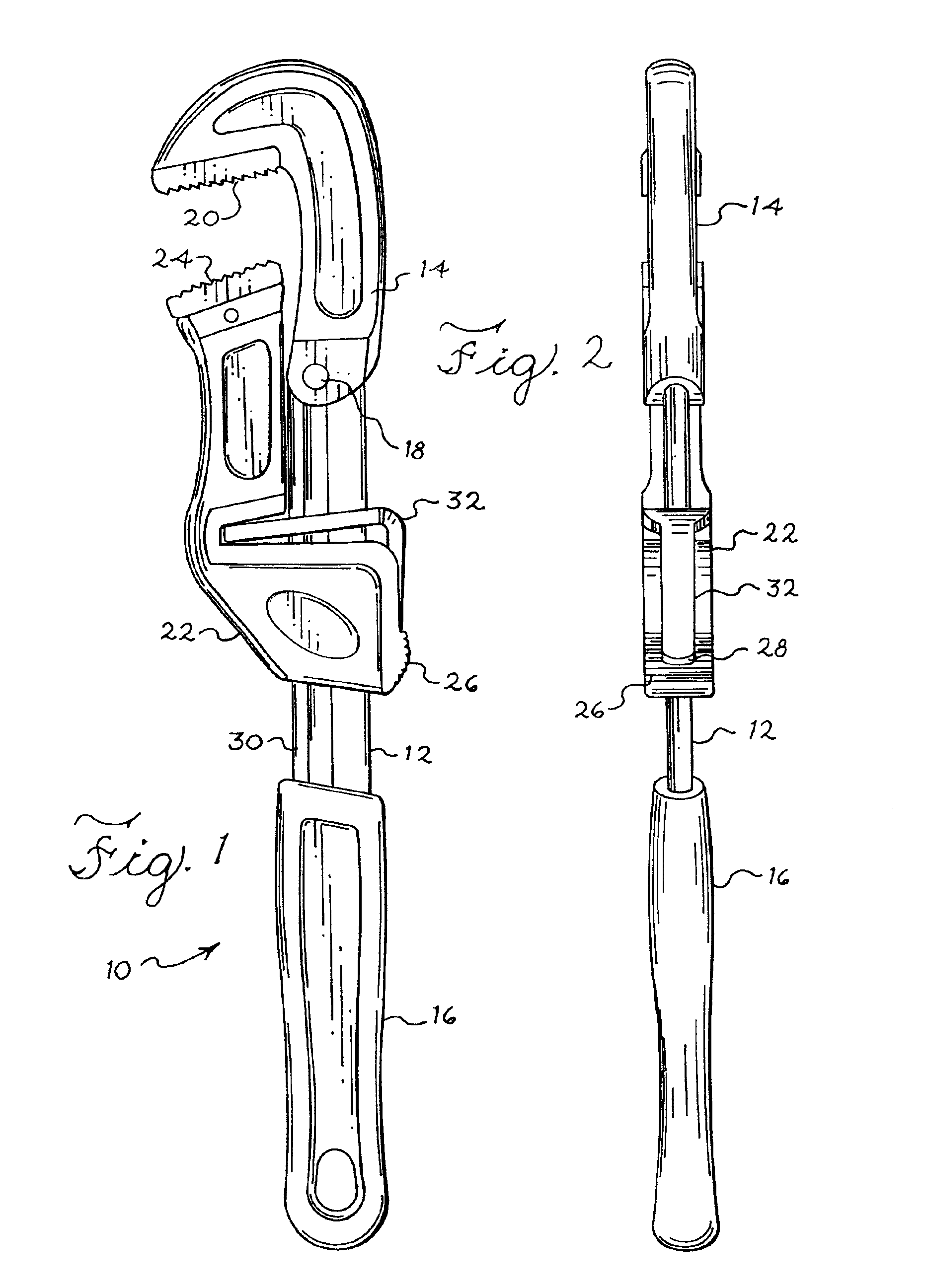

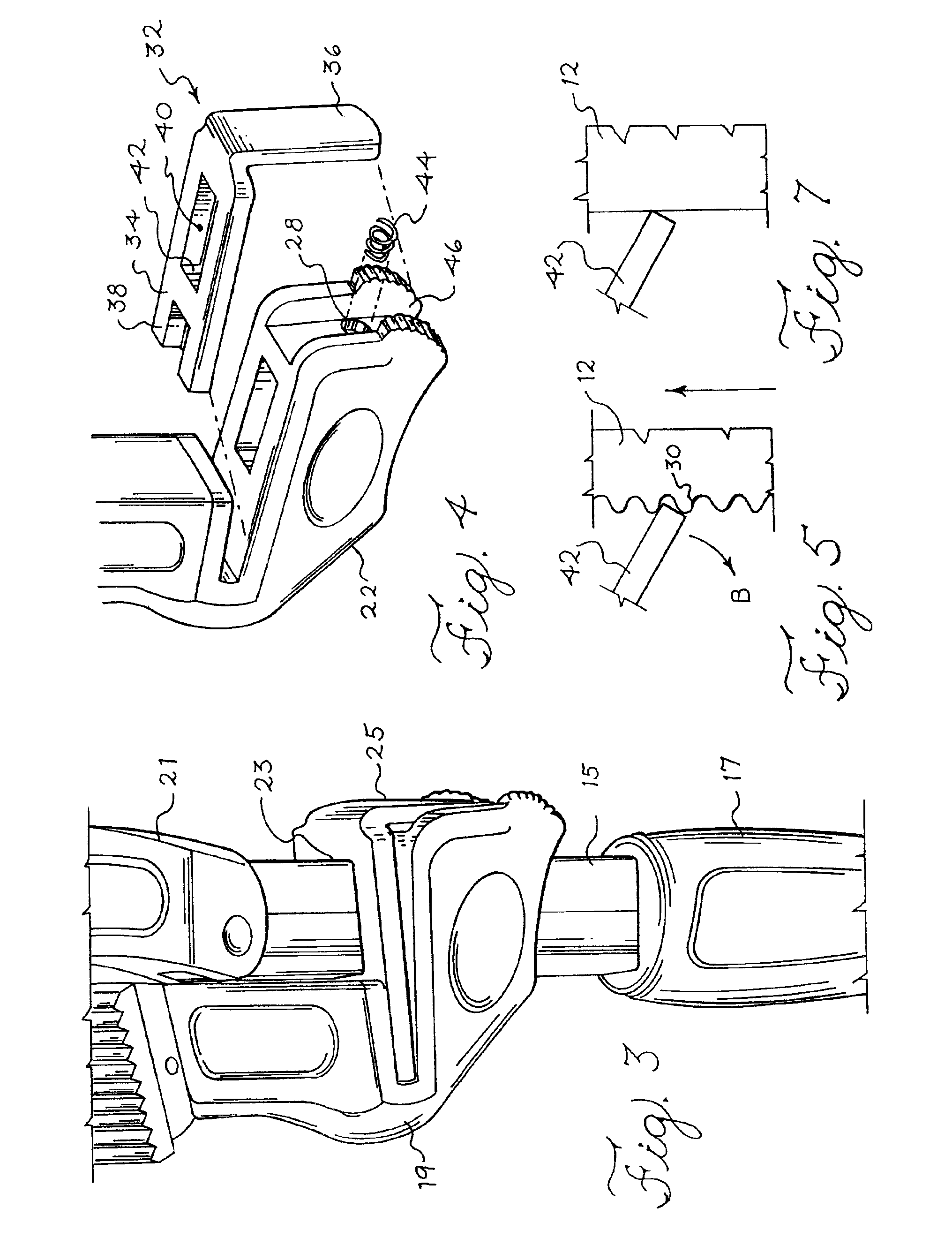

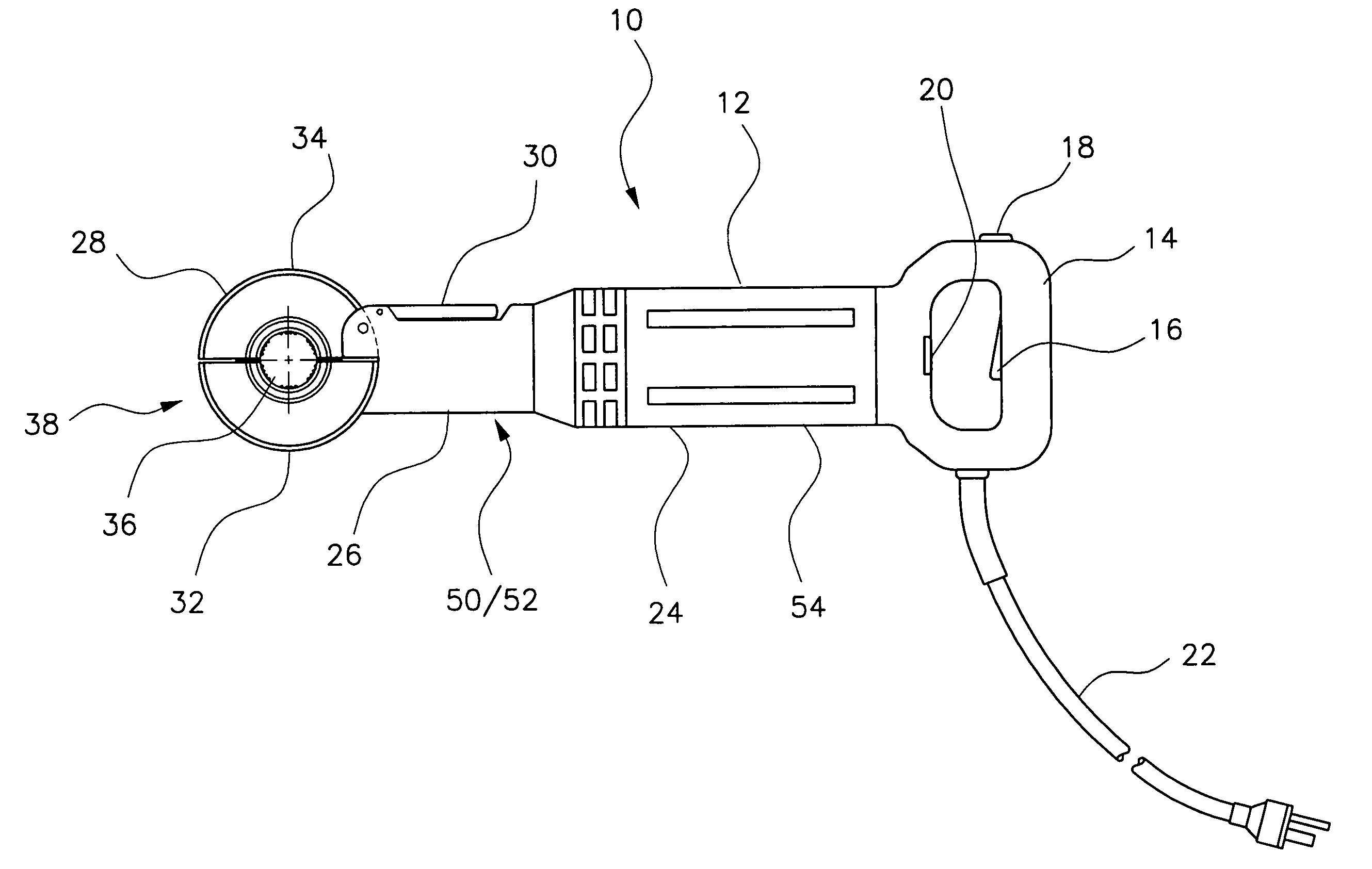

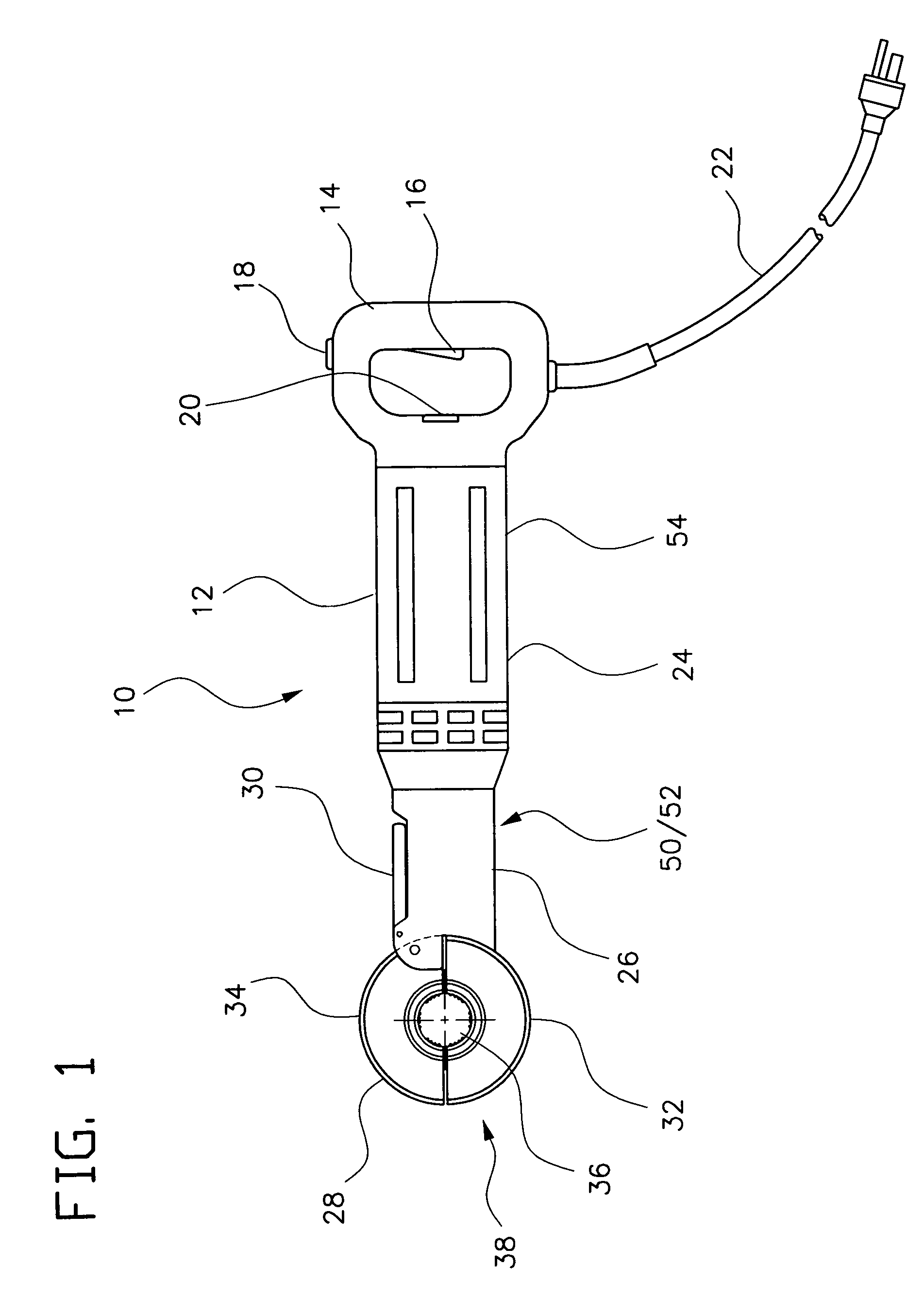

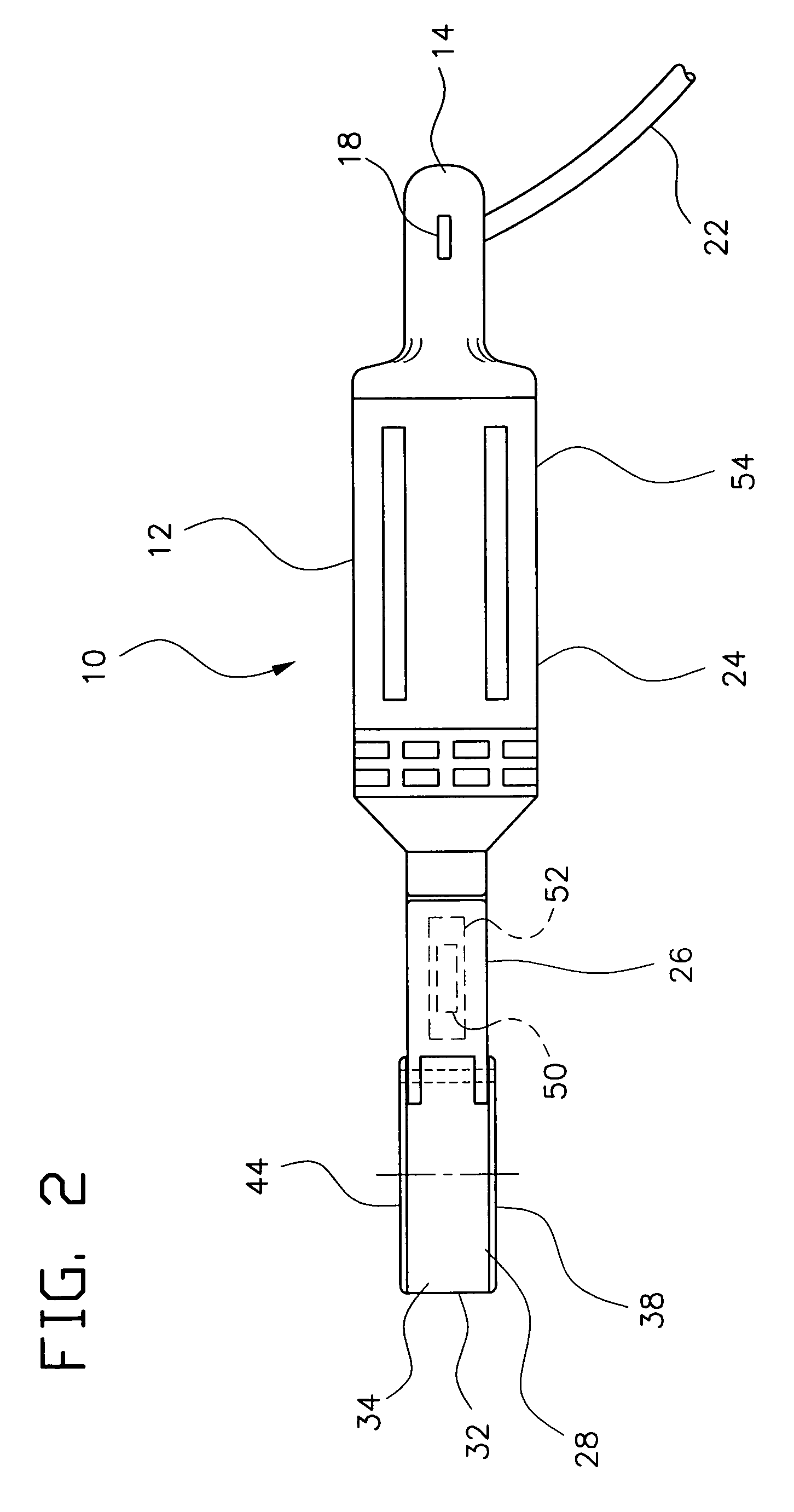

One hand pipe wrench

A pipe wrench is disclosed, the pipe wrench having a uniquely handy control lever and one-way ratchet for very rapid adjustment of wrench position. The wrench also has a pivoting upper jaw that further aids a user in adjusting and tightening the wrench while using only one hand. The wrench may also be used as a hand tool, for instance for clamping an object or workpiece for performing work on the object.

Owner:BLACK & DECKER INC

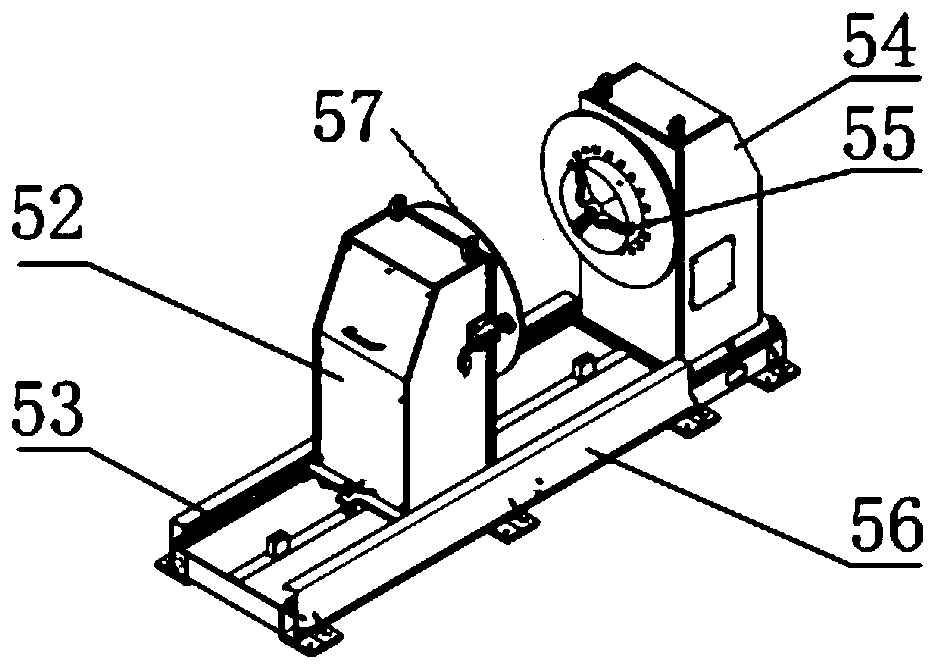

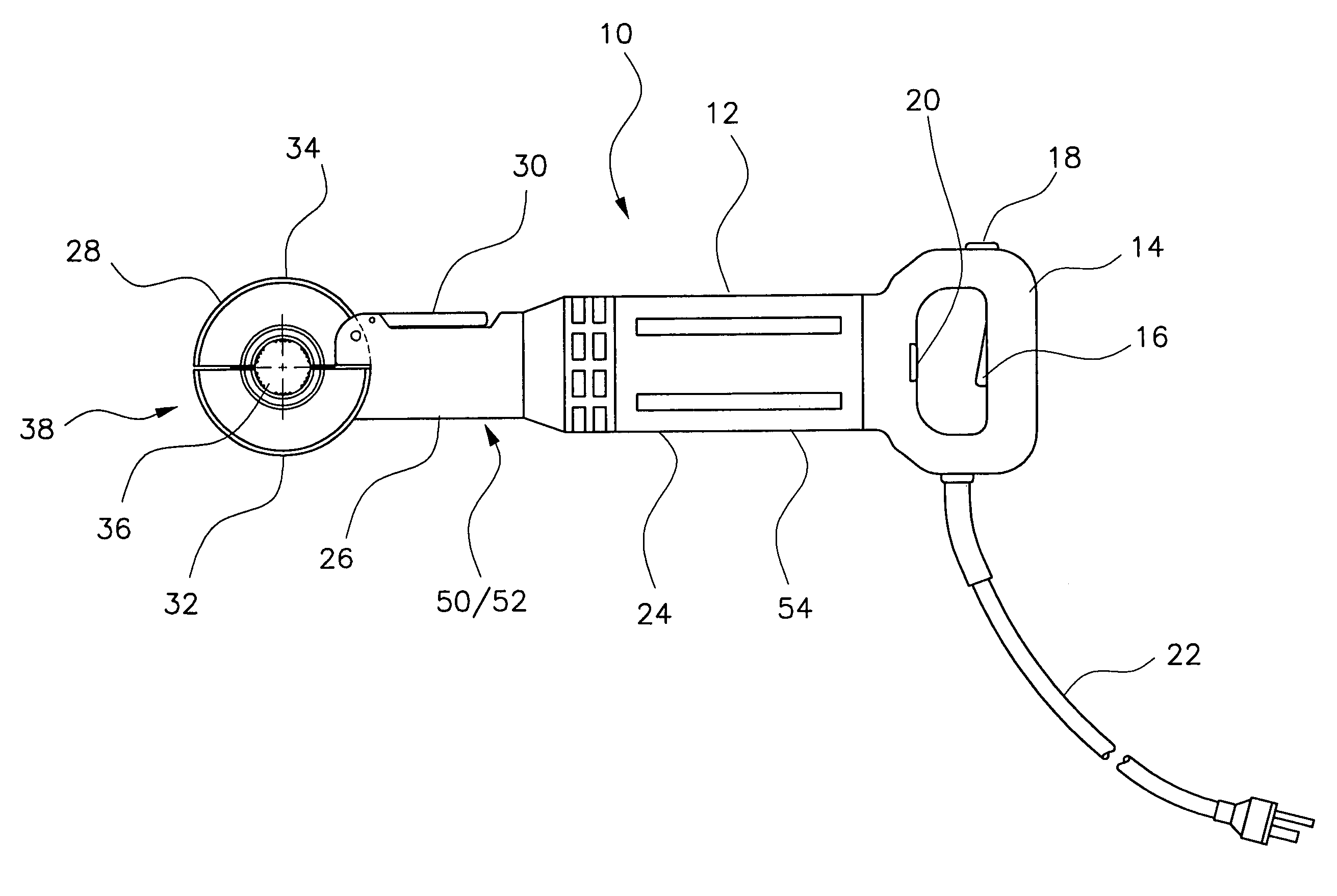

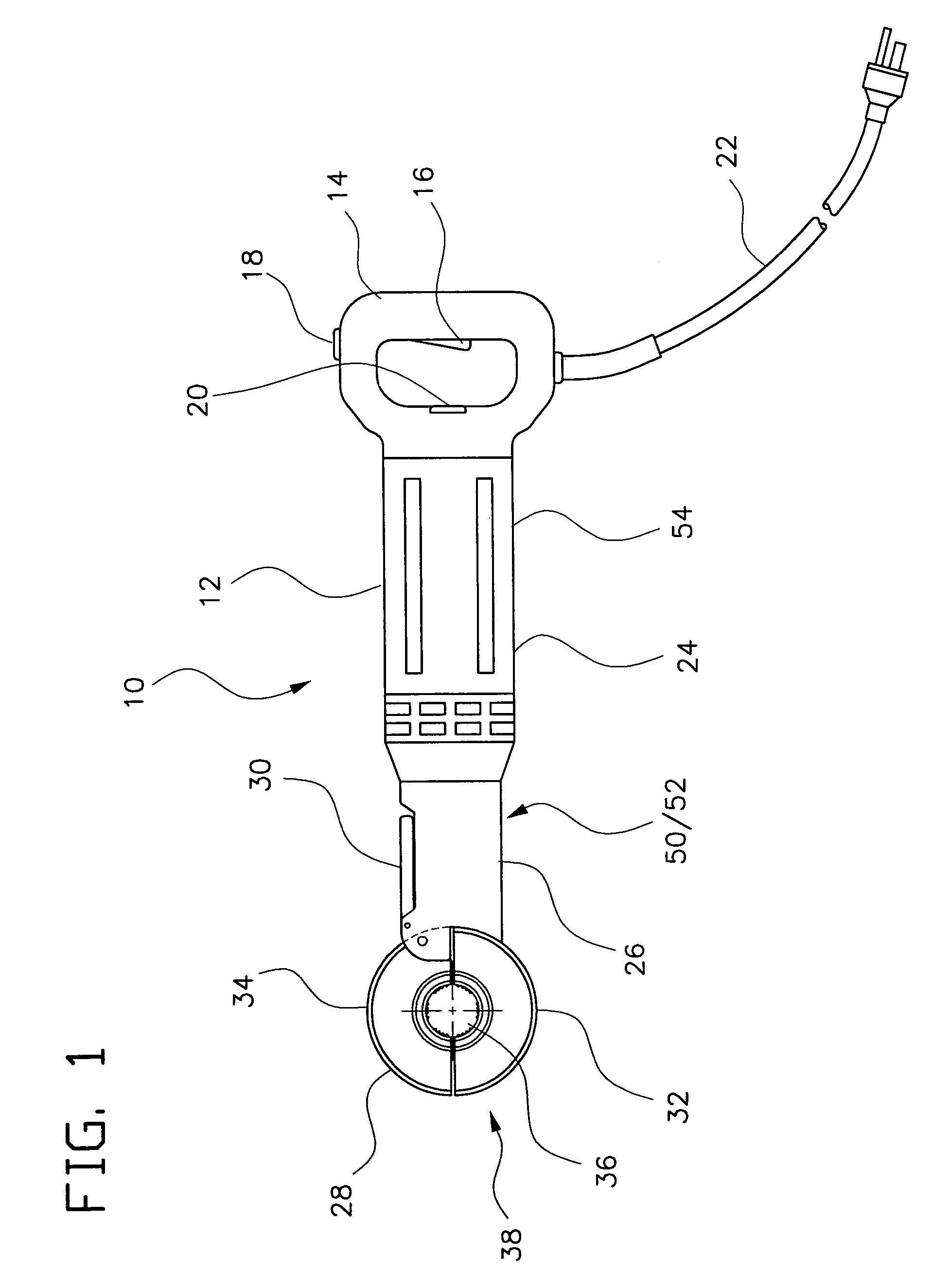

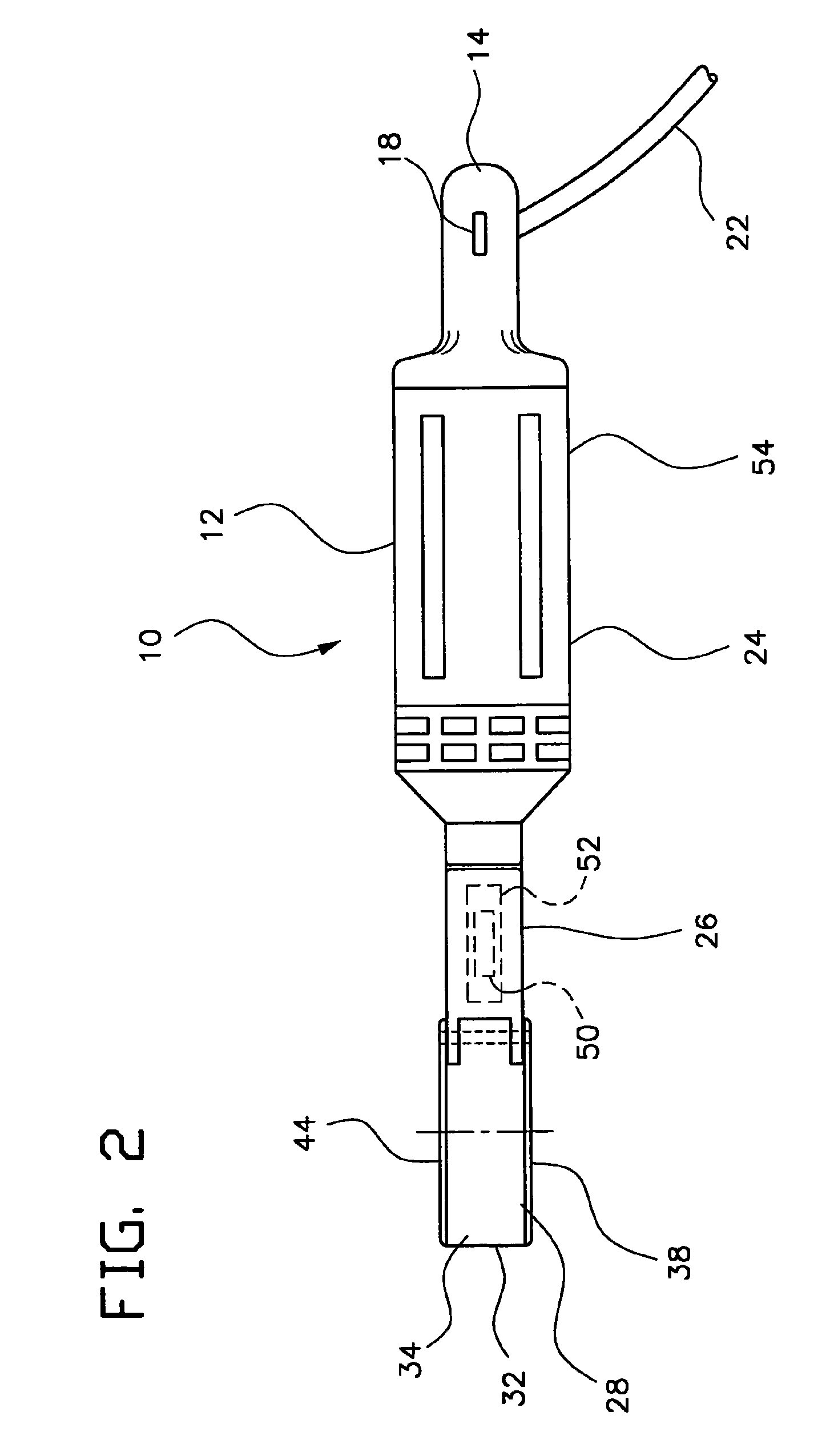

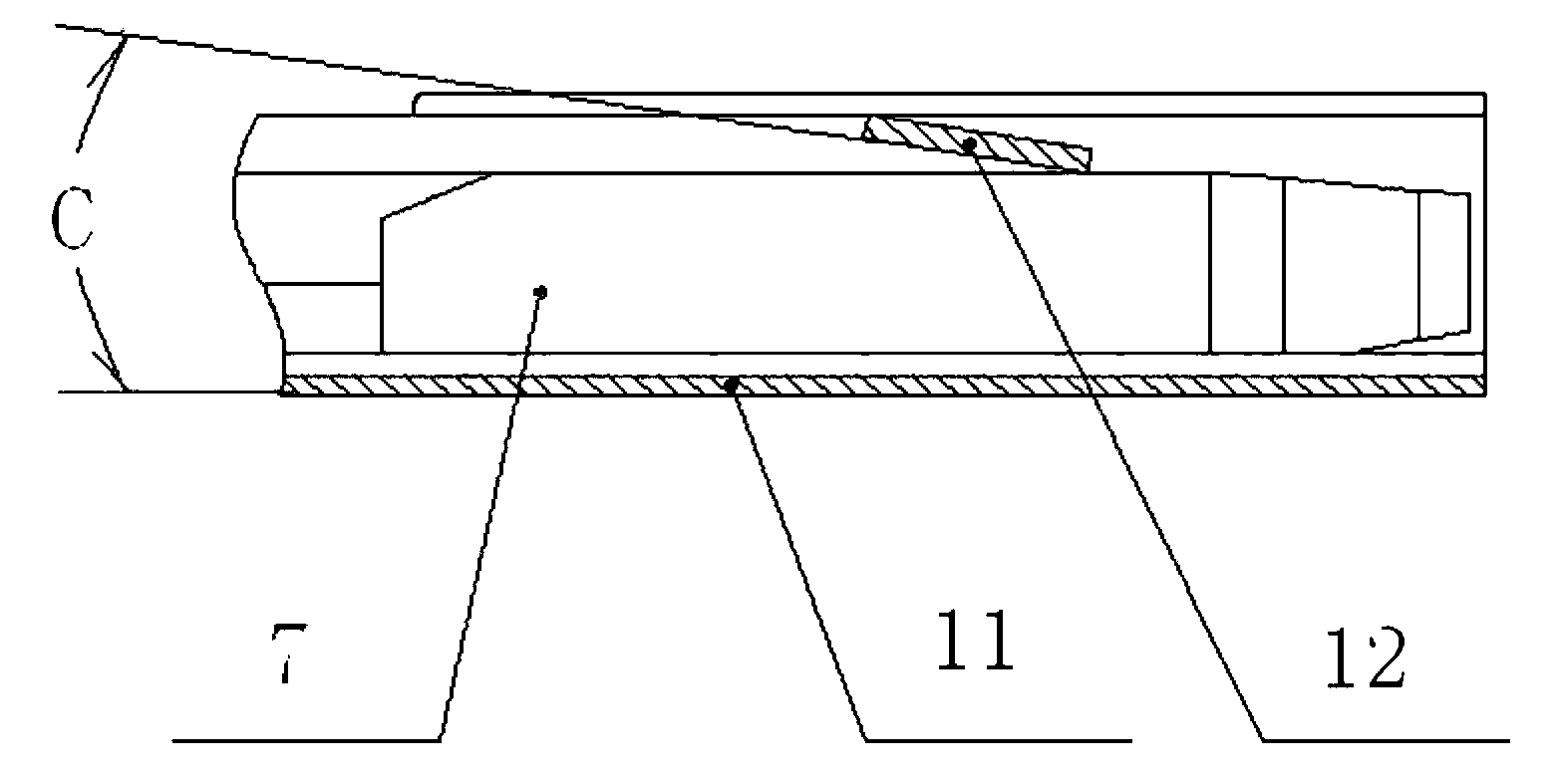

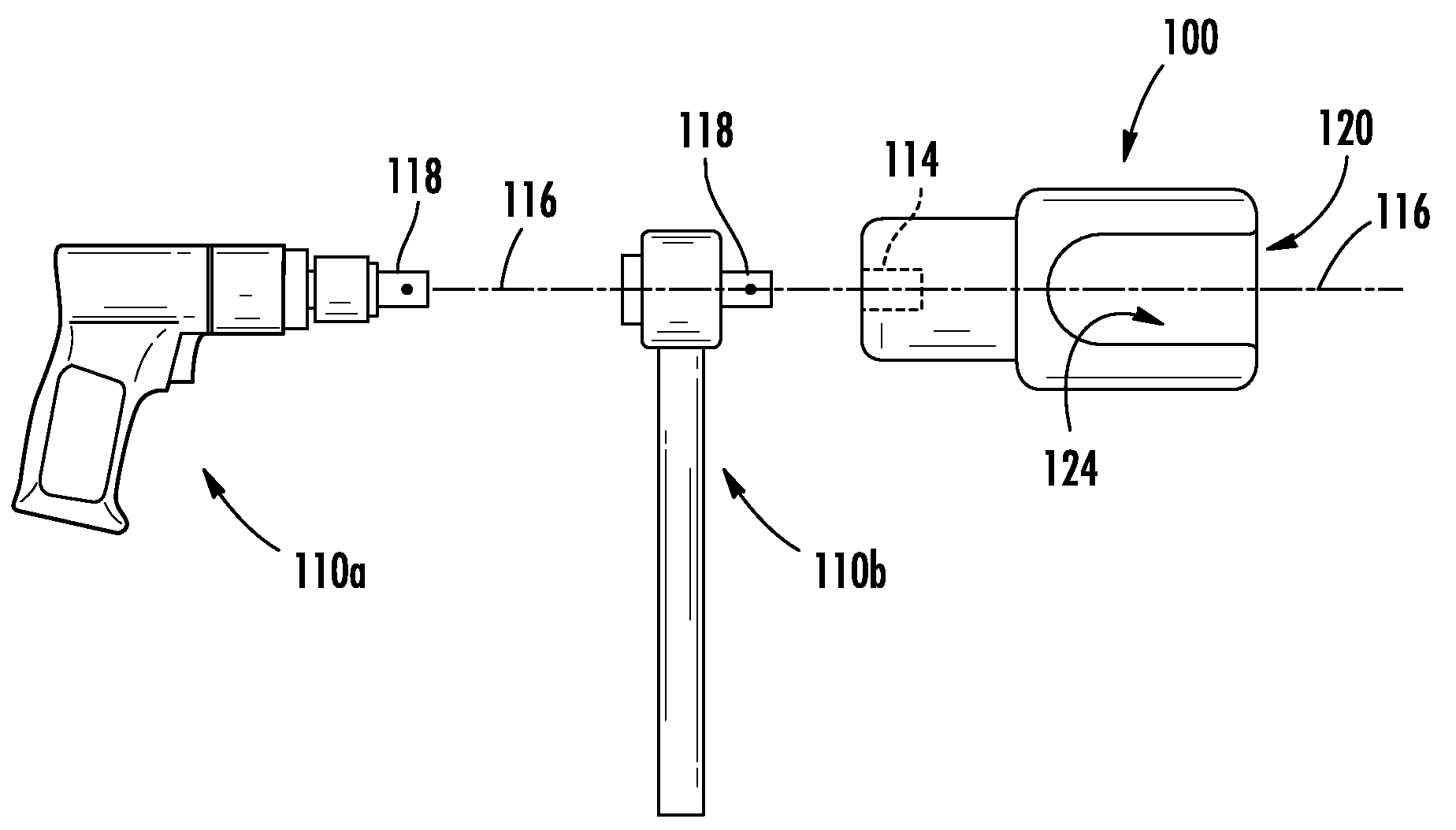

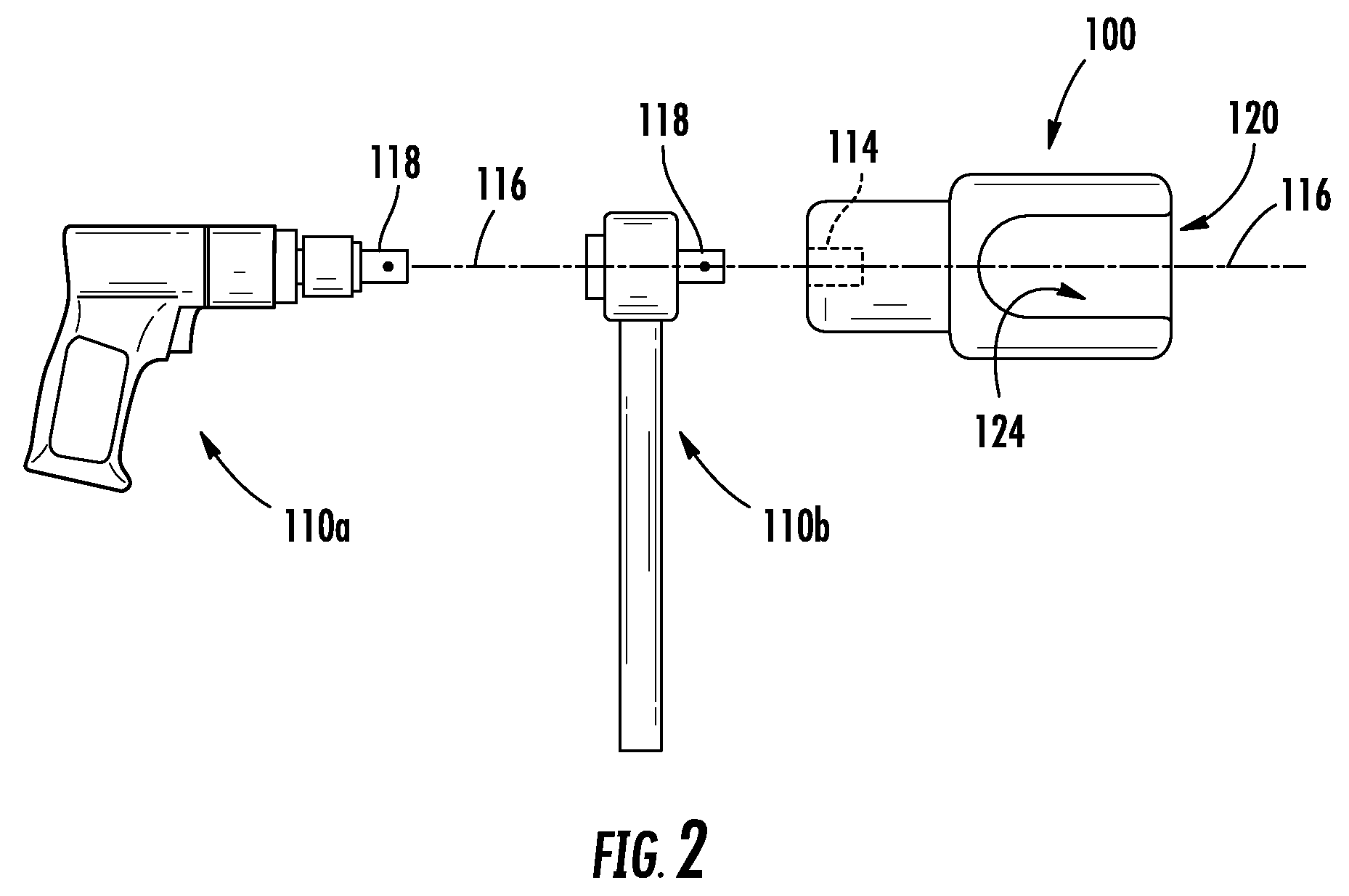

Powered adjustable pipe wrench

The powered adjustable pipe wrench has a motorized rotary grip to rotate a pipe component clamped therein and a laterally spaced stationary grip to hold a second pipe component stationary relative to the first as it is being rotated. The pipe wrench may have a cylindrical jaw housing with semicylindrical fixed and openable portions hinged to one another. One end of the housing includes a powered component to rotate the pipe component held therein, while the other housing end includes fixed jaw components holding the second pipe component stationary. Alternatively, the pipe wrench may have a powered component extending from the fixed jaw of the wrench body to rotate the first pipe component, and a rectilinearly adjustable jaw portion extending from the wrench body. A set of fixed jaw components is axially spaced from the rotary component to hold the second pipe component stationary.

Owner:HERMAN MYBURGH PRESERVATION TRUST

Steel reinforcement sleeve connection device and application method thereof

InactiveCN106760225AReduce work intensitySave manpower and material resourcesBuilding reinforcementsBuilding material handlingPipe wrenchElectricity

The invention provides a steel reinforcement sleeve connection device and an application method thereof, belongs to the technical field of building construction, and aims to solve the problems of high labor intensity and low efficiency in the traditional pipe wrench based manual connection between a steel reinforcement sleeve and a steel reinforcement. The connection device comprises a clamp, a manipulation device, a transmission device and a motor which are electrically connected with each other sequentially, wherein the clamp comprises a fixed end clamp and a free end clamp matching with each other for use; the free end clamp can slide along the clamped steel reinforcement under the action of the transmission device; and the manipulation device comprises an intelligent regulation and control device, a master switch, a direction switch, a handle switch and a distance regulation bar. The application method comprises the following steps: 1, driving a steel reinforcement sleeve to rotate by means of the connection device, so that one end of the steel reinforcement sleeve is fixedly connected with a first steel reinforcement; and 2, driving a second steel reinforcement to rotate by means of the connection device, so that the other end of the steel reinforcement sleeve is fixedly connected with the second steel reinforcement.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

Powered adjustable pipe wrench

The powered adjustable pipe wrench has a motorized rotary grip to rotate a pipe component clamped therein and a laterally spaced stationary grip to hold a second pipe component stationary relative to the first as it is being rotated. The pipe wrench may have a cylindrical jaw housing with semicylindrical fixed and openable portions hinged to one another. One end of the housing includes a powered component to rotate the pipe component held therein, while the other housing end includes jaw components holding the second pipe component stationary. Alternatively, the pipe wrench may have a powered component extending from the jaw of the wrench body to rotate the first pipe component, and a rectilinearly adjustable jaw portion extending from the wrench body. A set of jaw components is axially spaced from the rotary component to hold the second pipe component stationary.

Owner:MYBURGH HERMAN

Pipe wrench retrofit

The specification discloses a modified nut assembly and locking assembly for locking the shank of a wrench in place. The nut assembly preferably includes a nut for engaging and disengaging the shank of the wrench and a spring for biasing the nut to a position where the shank of the wrench is locked in place. Threads internal to the nut matingly engage threads on the shank of the wrench when in a locked position, and grooves internal to the nut allow the shank of the wrench to slide freely through the nut when in an unlocked position. The locking assembly preferably includes a housing, a sliding portion, a locking portion, and a spring. The sliding portion and locking portion preferably abut each other within the housing. The spring is preferably located in the sliding portion and extends from the sliding portion to the shank of the wrench.

Owner:GREGORY N SCOTT

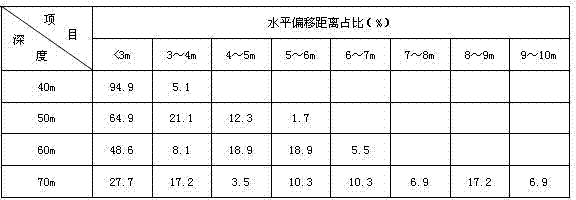

Injection method for static sounding probe rod

ActiveCN103088804AImprove verticalityIncrease the penetration depthIn situ soil foundationPipe wrenchClockwise

The invention belongs to the field of geotechnical engineering investigation in-situ tests and particularly relates to an injection method for a static sounding probe rod. The injection method for the static sounding probe rod is characterized in that after the probe rod is injected into a static sounding hole at an angle smaller than 0.3 degree, injection is stopped every time the probe rod is injected at a center distance. The probe rod conducts clockwise rotation through a pipe wrench. Angle data of a probe is observed. When the trend that the angle data becomes small occurs, rotation and continuous injection of the probe rod is stopped when the angle data is the smallest; and when the trend that the angle data becomes large occurs, the probe rod continues to rotate along the clockwise direction and continues to be injected after returning to an original position. The injection method for the static sounding probe rod has the advantages of improving perpendicularity of the static sounding probe rod, improving the injection depth of the probe rod at one time as much as possible under restriction of permitted inclined degree of the probe rod and without adoption of traditional means of placing the guide protective sleeve downwards to improve the perpendicularity of the of the probe rod and reducing working intensity of static sounding field operation.

Owner:SHANGHAI GEOTECHN INVESTIGATIONS & DESIGN INST

10-in-1 multiple function wrench

A multifunctional hand tool is provided, having an adjustable wrench head and an elongated handle extending from the wrench head. The handle is oriented transverse to the wrench head and that defines a plurality of wrench apertures of different sizes. Each wrench aperture defines an axis of rotation for operable use oriented substantially transverse to the first axis of rotation. The wrench head further comprises a hammer and the elongated handle further comprises a nail pull structure. The wrench head can further include a grip texture on an outer surface thereof to facilitate use of the wrench apertures or the nail pull defined by the wrench handle. The outer surface of the handle further includes grip features or textures to facilitate use of the hammer. The adjustable wrench can be changed to a pipe wrench.

Owner:TEST RITE INT

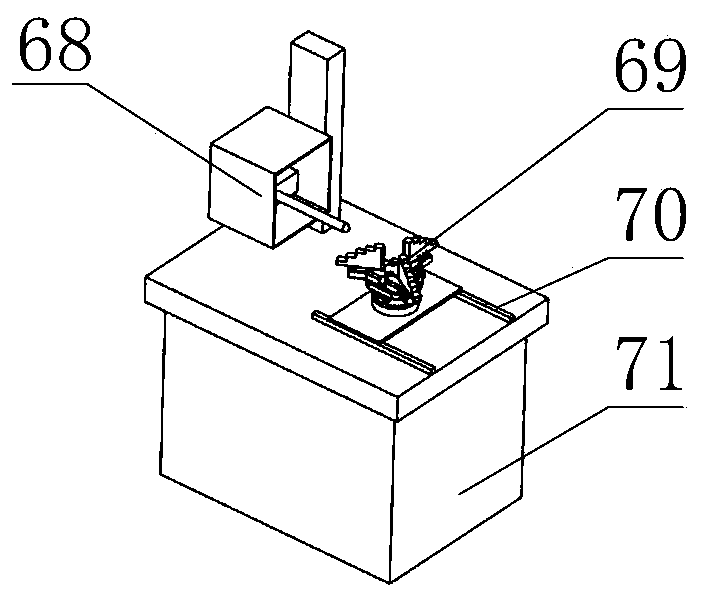

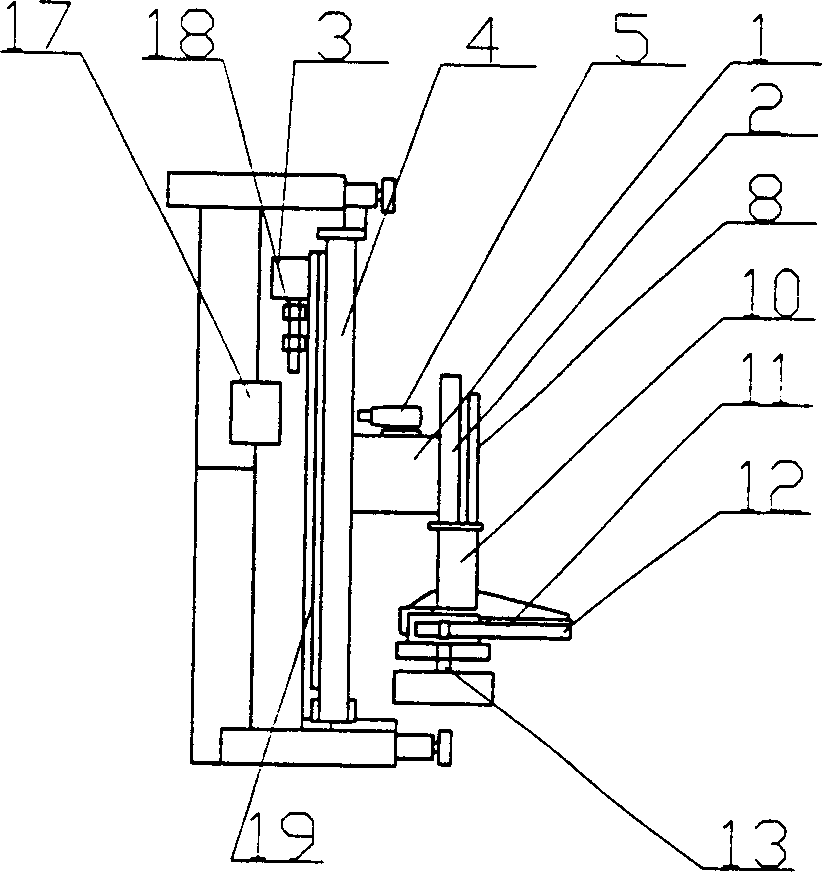

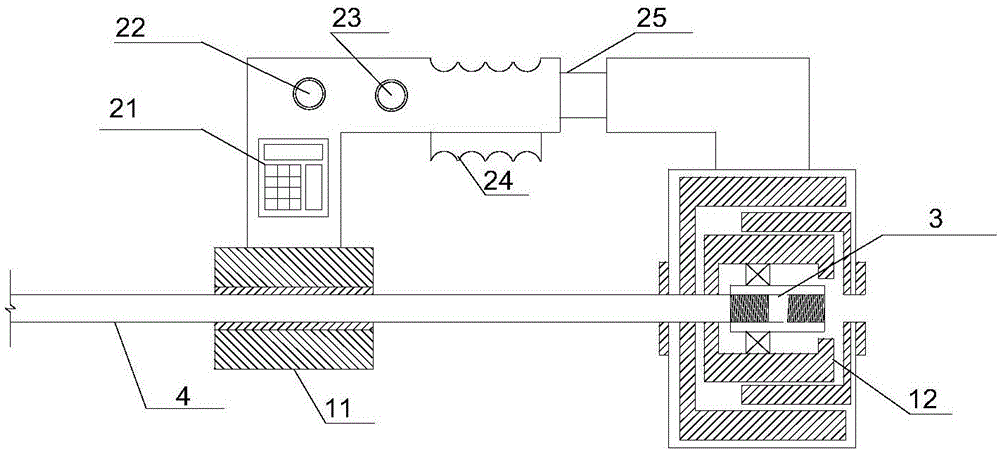

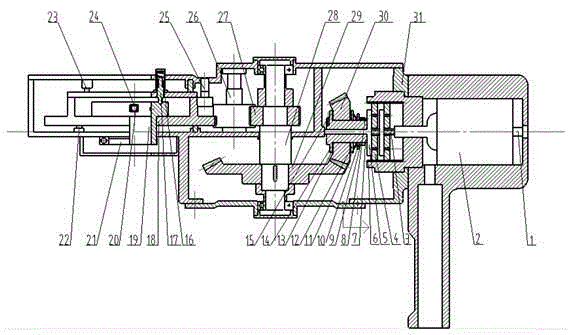

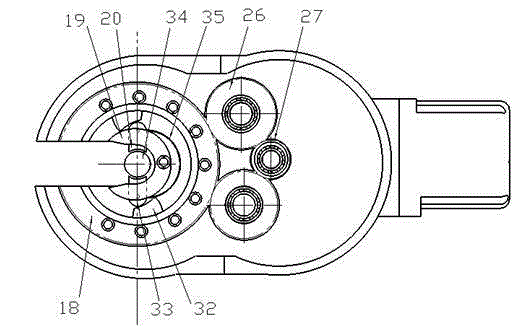

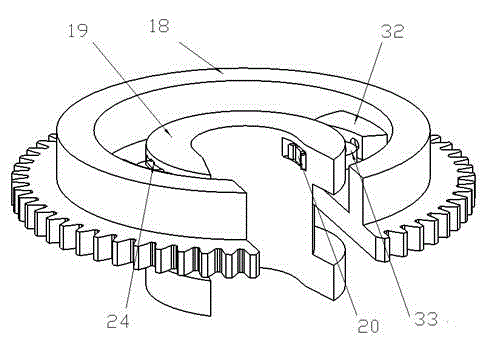

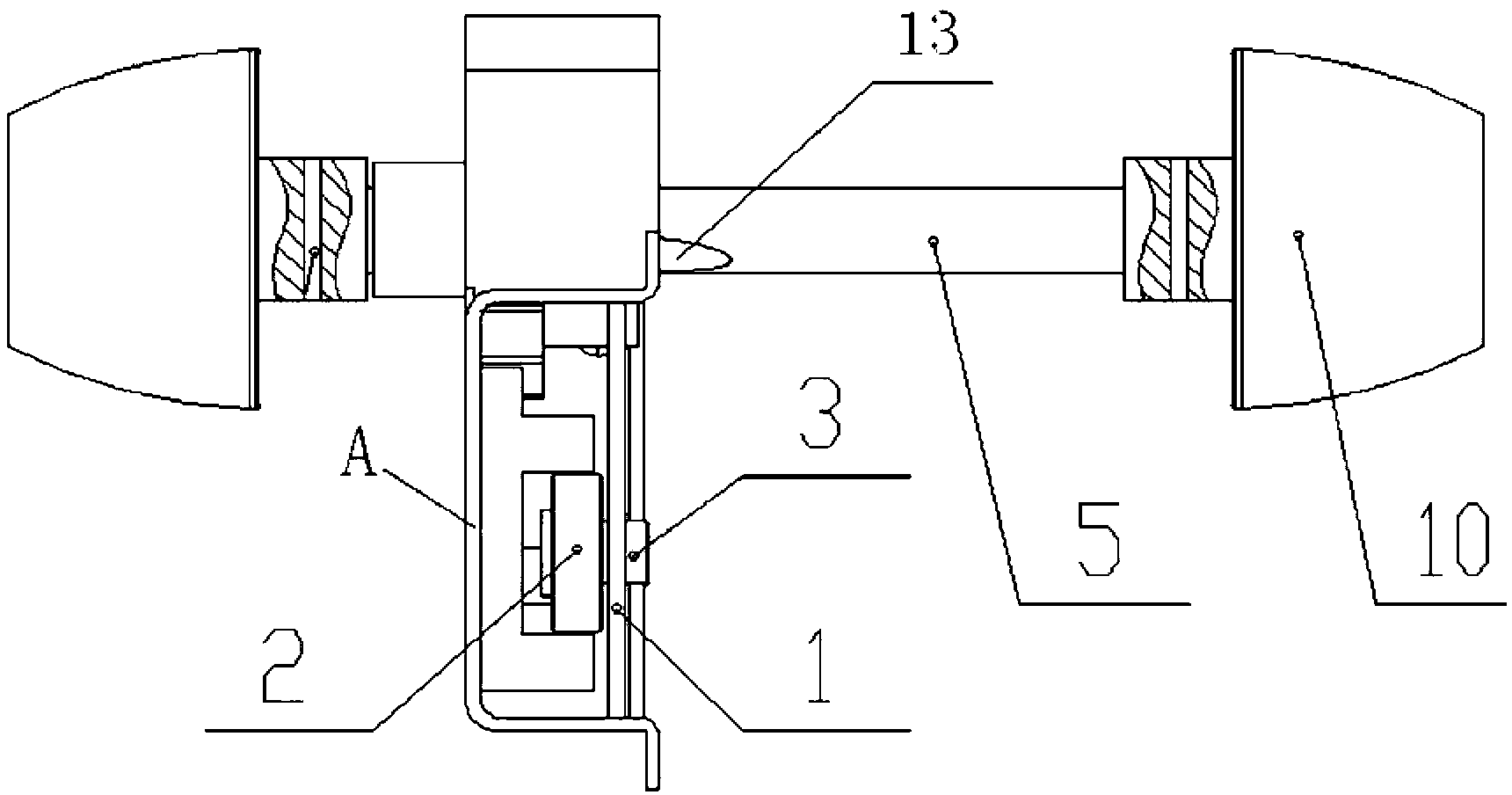

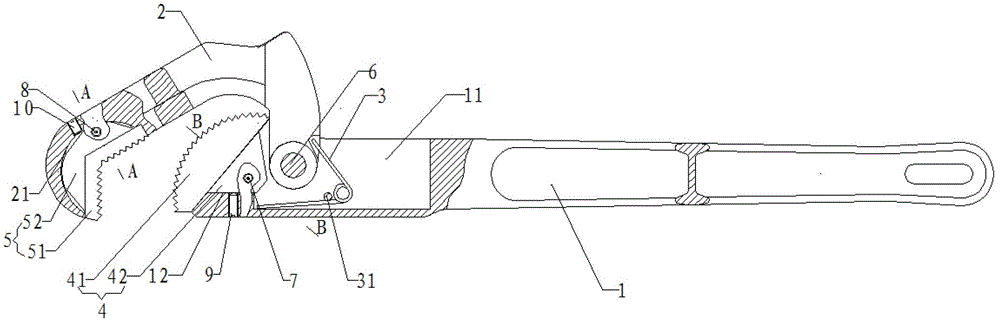

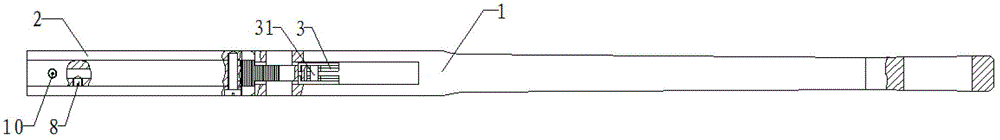

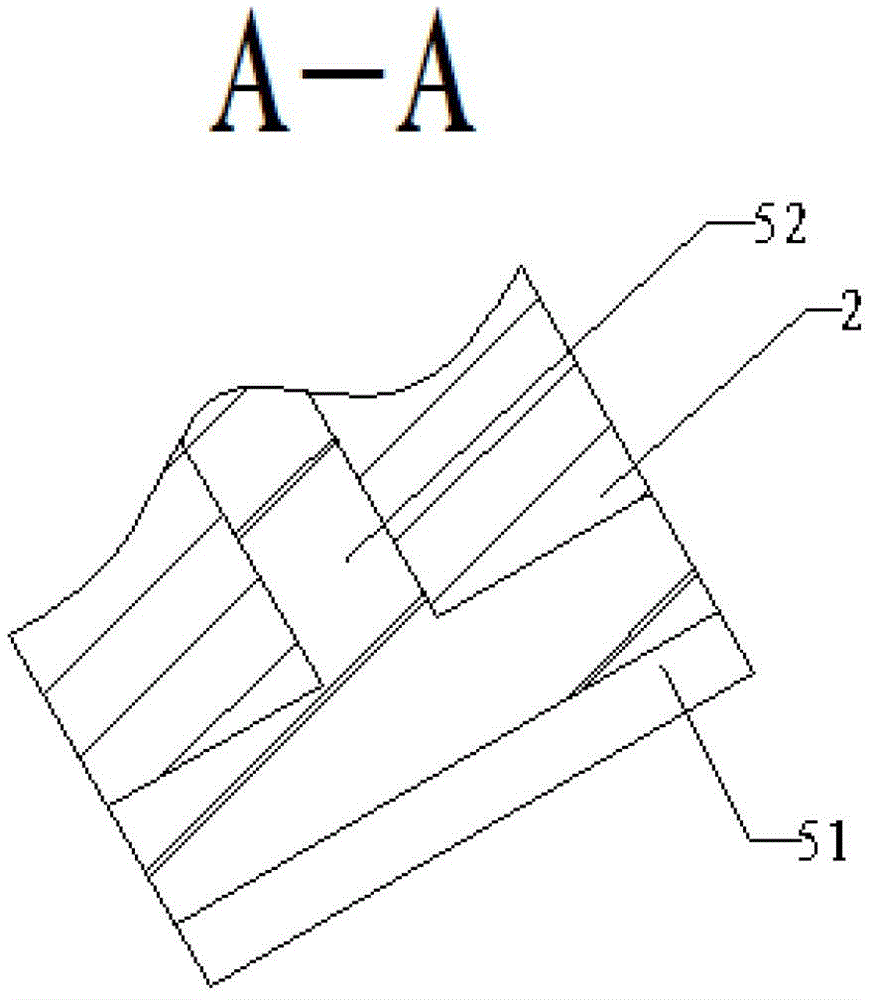

Electric pipe wrench for threaded connection of reinforcing steel bar and connecting sleeve

InactiveCN104889919AFirmly connectedReliable tightening torqueSpannersWrenchesPipe wrenchEngineering

The invention discloses an electric pipe wrench for threaded connection of a reinforcing steel bar and a connecting sleeve in a building industry, and belongs to the technical field of reinforcing steel bar connecting devices. The technical scheme includes the electric pipe wrench comprises a shell, a power device, a transmission device, a torque device and a rotating and connecting device, the tightening torque outputted by the power device is transmitted to the rotating and connecting device through the transmission device, the rotating and connecting device realizes orientation rotation of the connecting sleeve through an opening gear and a palate plate, a torque adjusting device can set tightening torque of the connecting sleeve, so that reliable threaded connection is achieved, and overload can be avoided. The electric pipe wrench provides a proper electric tool for threaded connection technology of the thick reinforcing steel bar and the connecting sleeve and has the advantages that a mechanism is small, simple and convenient, the tightening torque can be adjusted, the electric pipe wrench is safe and reliable in running, labor intensity of operators is greatly reduced, working efficiency is remarkably improved, traditional manual operations can be replaced, and the electric pipe wrench is a pioneered and special electric tool in the field of threaded connection of the reinforcing steel bar and the connecting sleeve.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

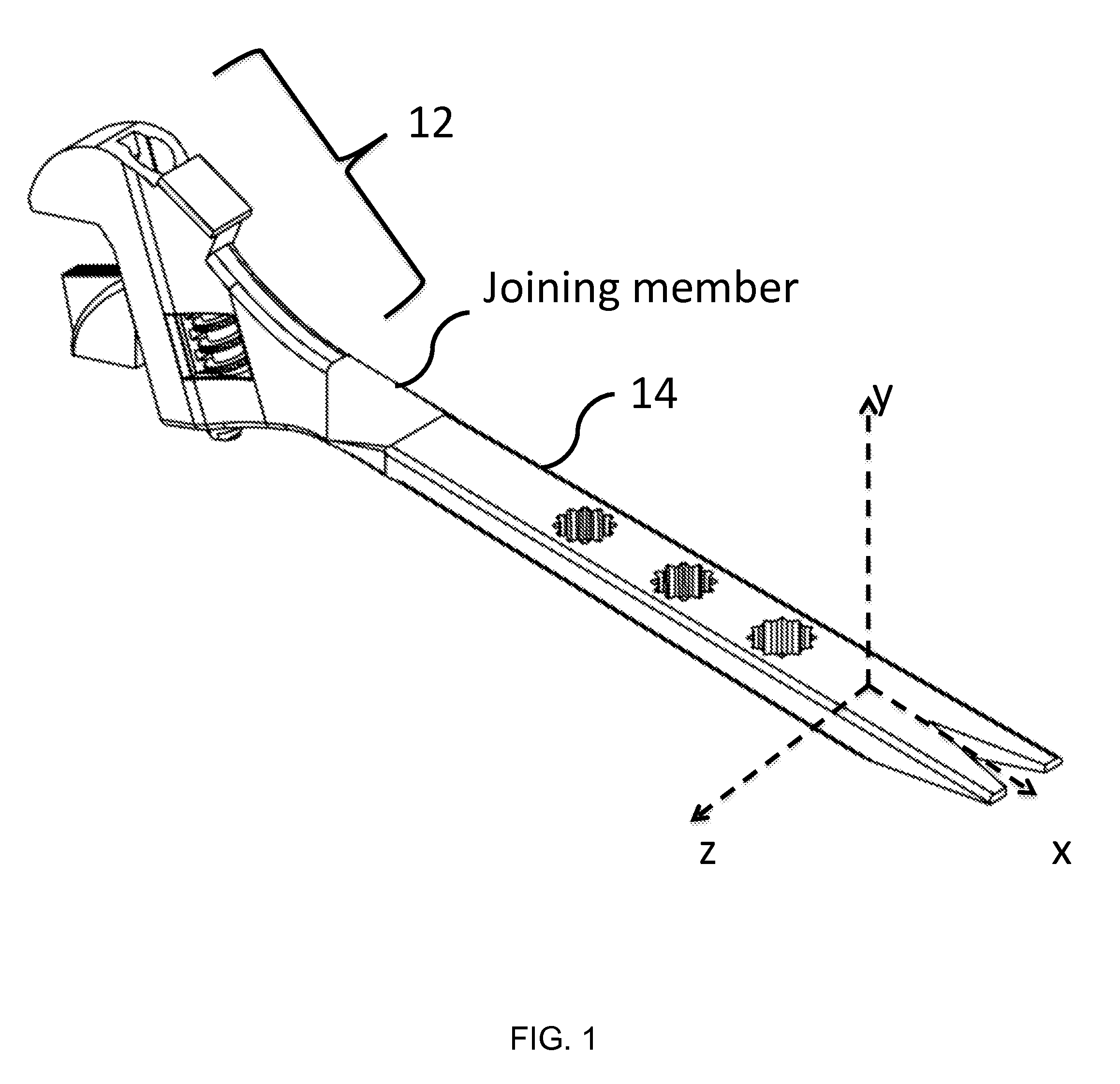

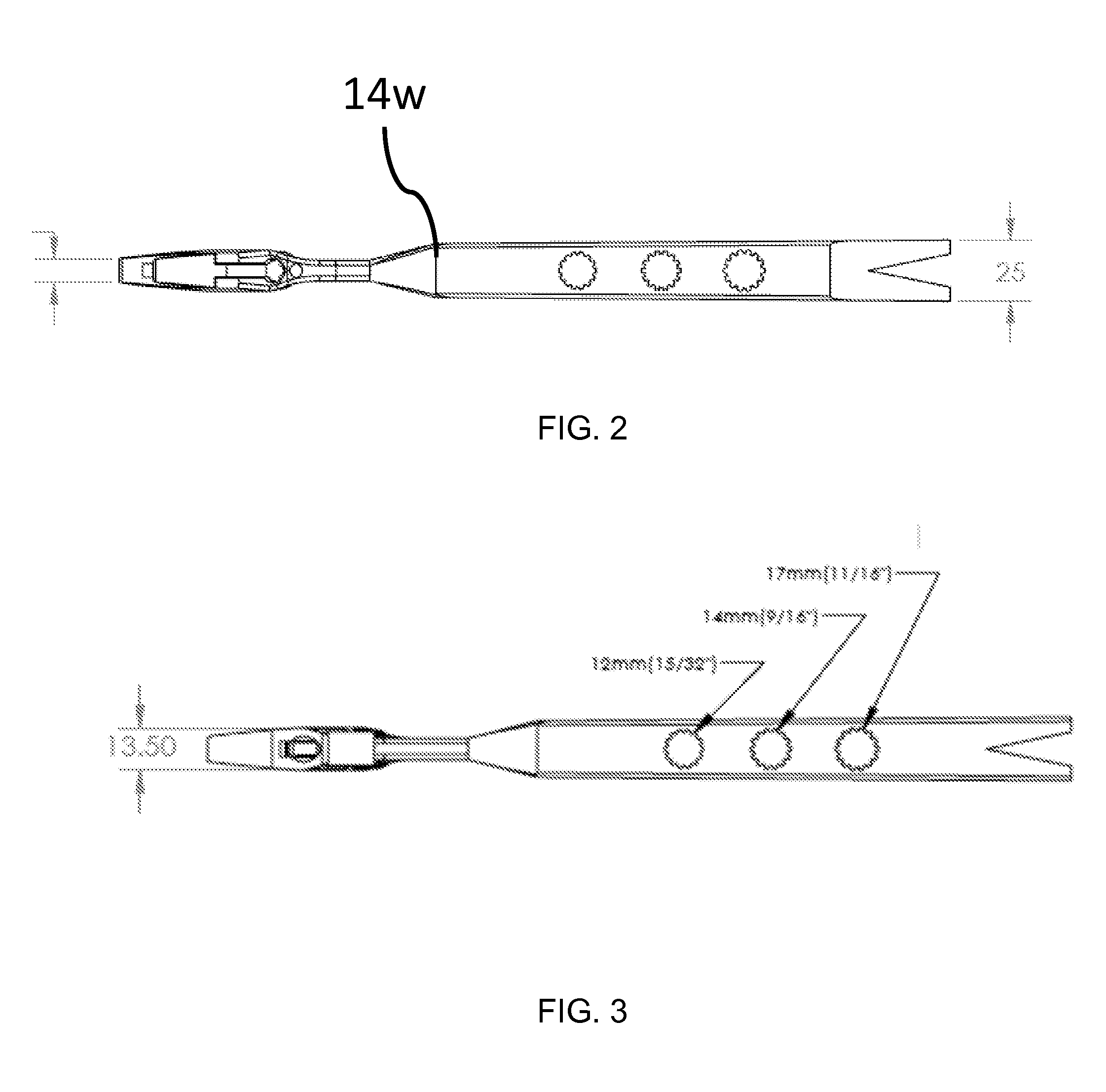

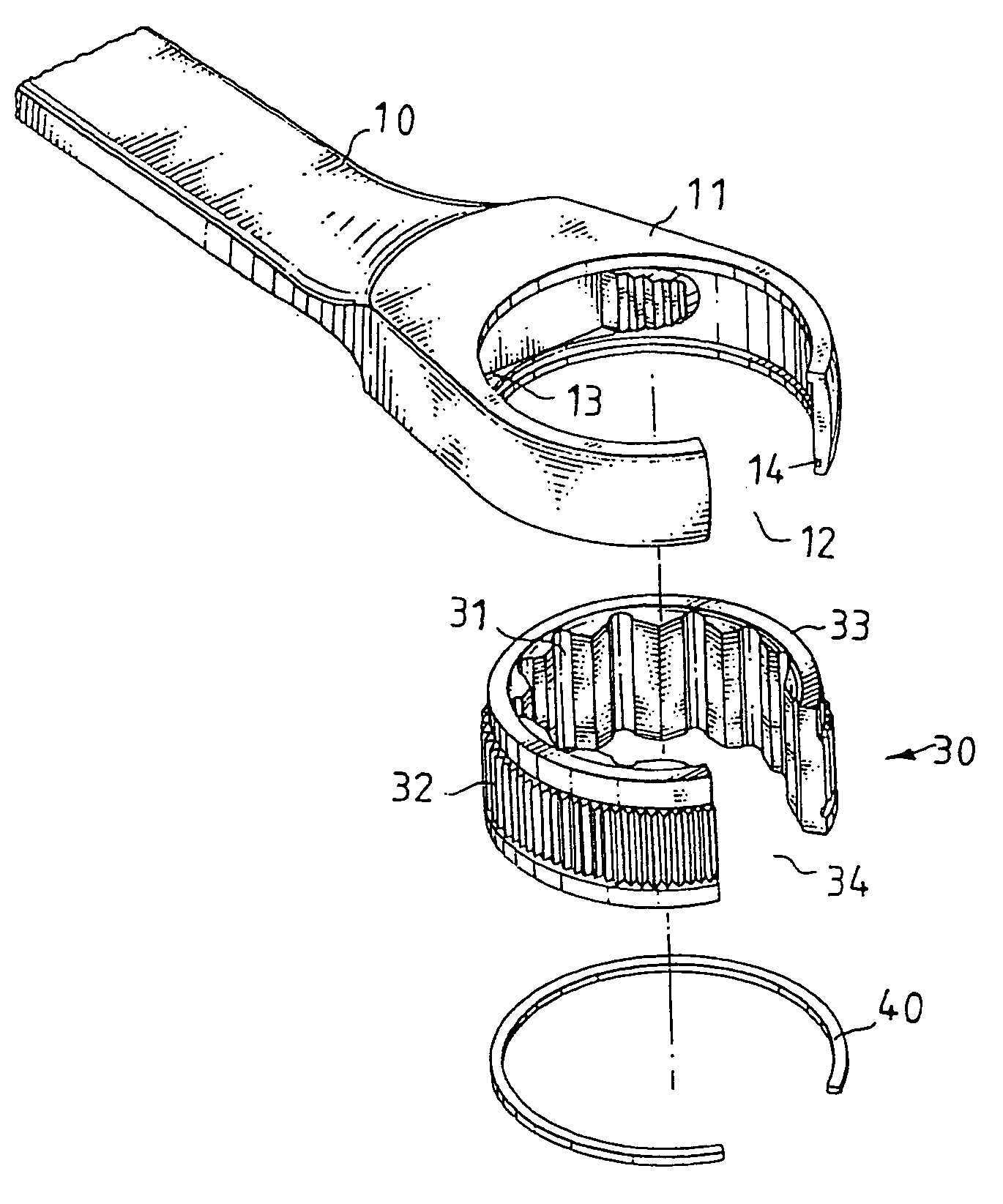

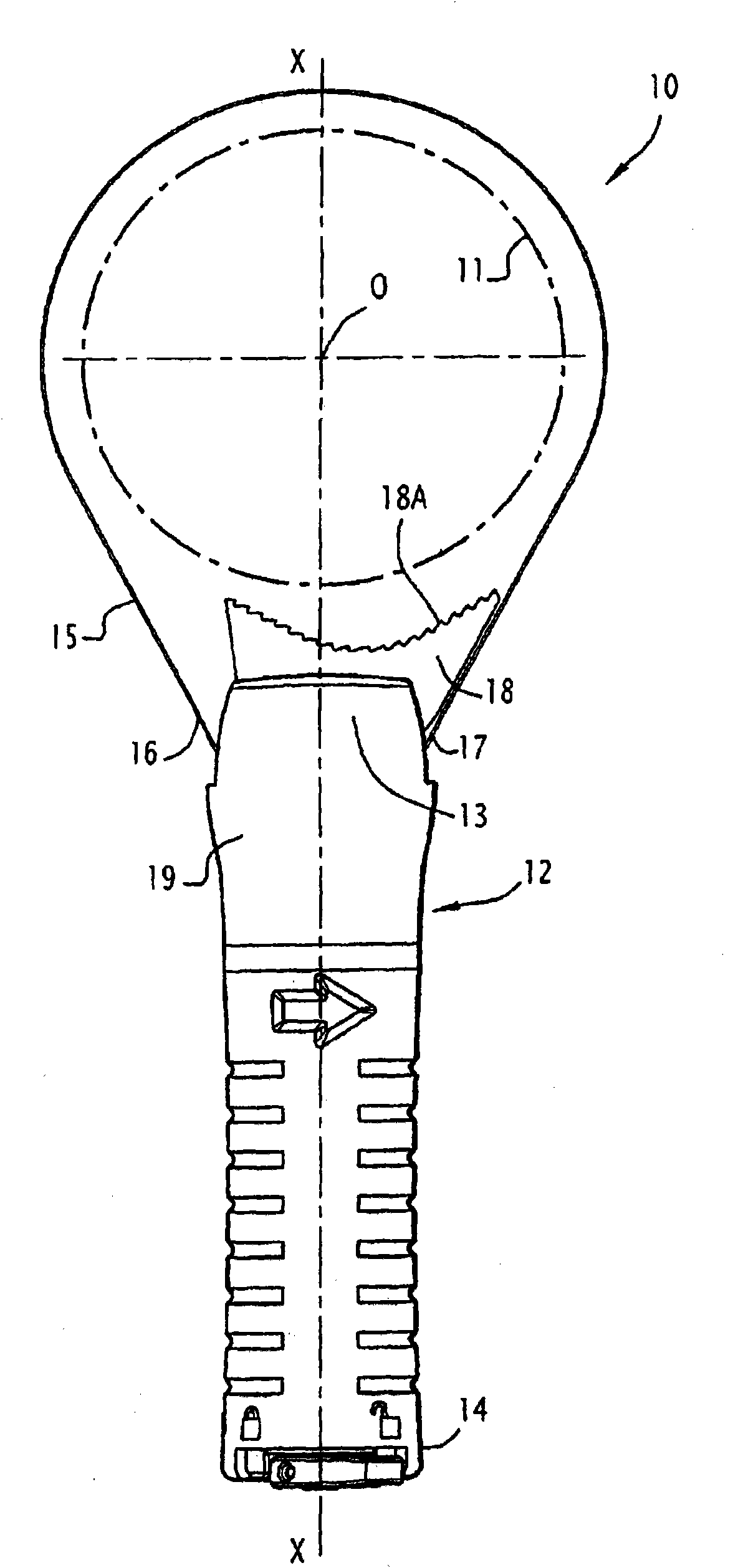

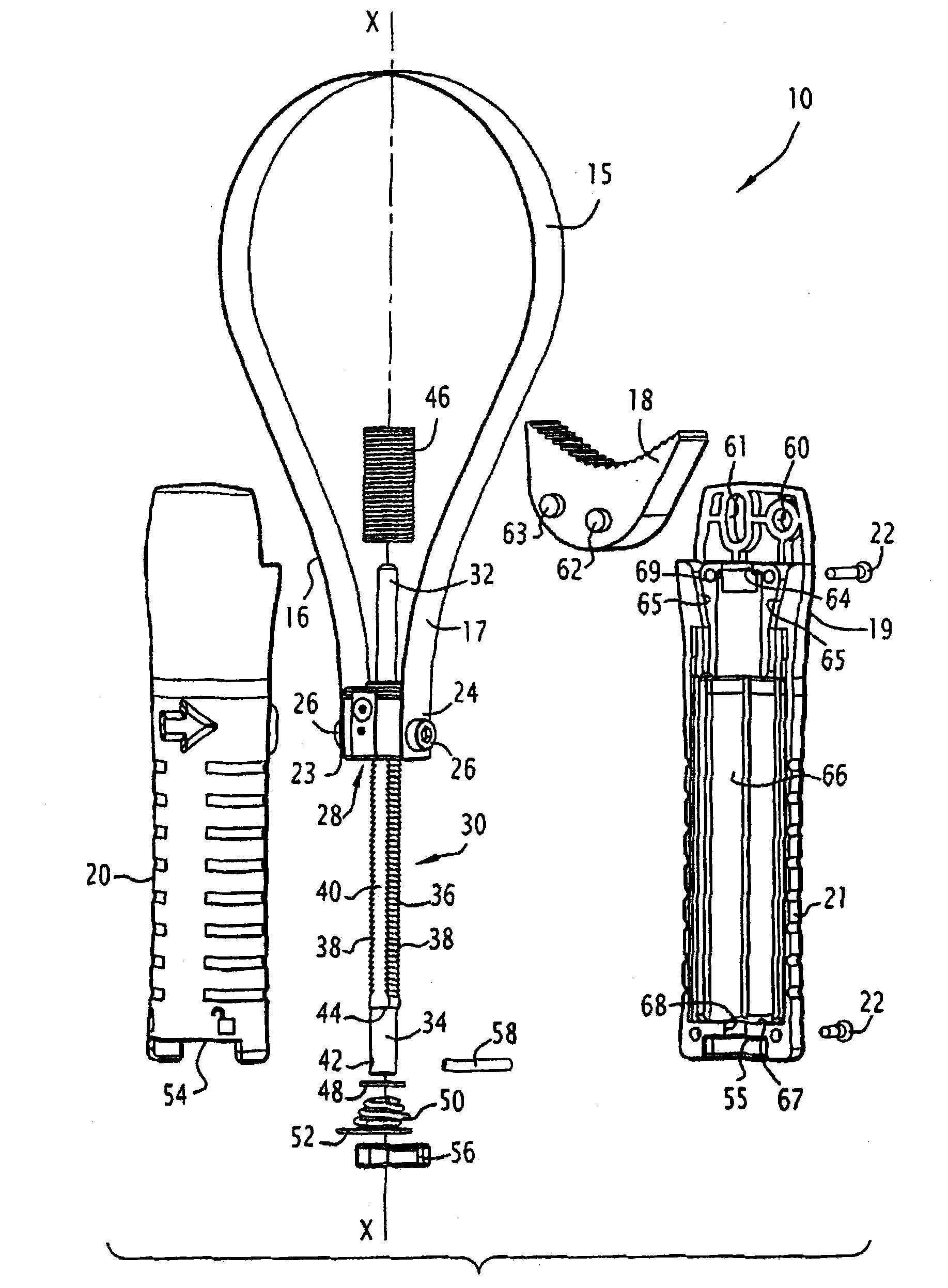

Strap pipe wrench for driving an object having a generally cylindrical shape

ActiveUS8316740B2Easy to adjustReduce tensionBottle/container closurePower operated devicesPipe wrenchAbutment

A strap pipe wrench for driving an object having a generally cylindrical shape includes a handle which extends along a longitudinal axis, a connecting member which is movable relative to the handle in a direction parallel to the longitudinal axis, and a strap formed in a loop and having two opposing end portions which cooperate with two zones integral with the handle when the strap surrounds the object tightly, the two opposing end portions of the strap being attached to the connecting member, a displacement device for displacing said connecting member, and enabling the size of the loop of the strap to be adjusted and the strap to be tensioned when it surrounds the object tightly, and a shoe disposed between the two zones for abutment on the object, the shoe having an abutment face of generally arcuate shape.

Owner:STANLEY BLACK & DECKER MEA FZE

Gate lock with gear rack bolt

The invention discloses a gate lock with a gear rack bolt. The gate lock comprises a main casing, a bearing, a riveting nut, a driving gear, a rotating shaft, a driven gear, an auxiliary casing, an externally installed lock and a handle. The main casing and the auxiliary casing and the externally installed lock (externally installed locks produced by various manufacturers can be matched) are directly embedded on a door plate, a lock cylinder of the externally installed lock rotates an unlocking bolt by means of driving of a key, and extension and contraction of a spring bolt can be controlled to be matched with a clamping groove of the driven rack to control locking and unlocking of the gate lock. The handle drives the rotating shaft to control the driving gear to rotate, and unlocking or locking can be performed through meshing of a gear and a rack. The danger that the gate lock can be unlocked by tools of pipe wrenches and the like can be effectively avoided, the anti-theft effect of the gate lock is ensured, and safety is improved.

Owner:白水清

Pipe wrench having a fixed positioning ring

Owner:HSIEN CHIH CHING

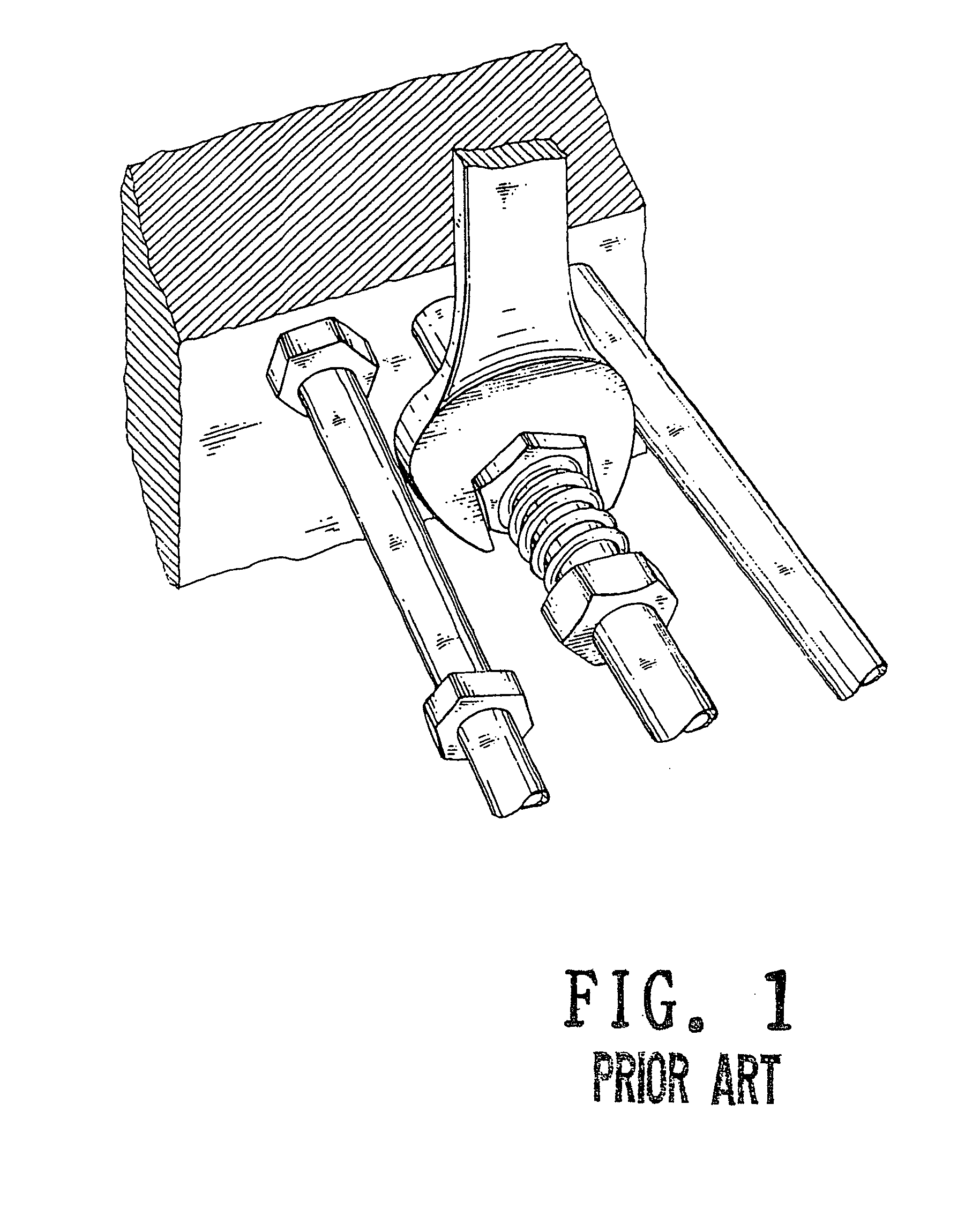

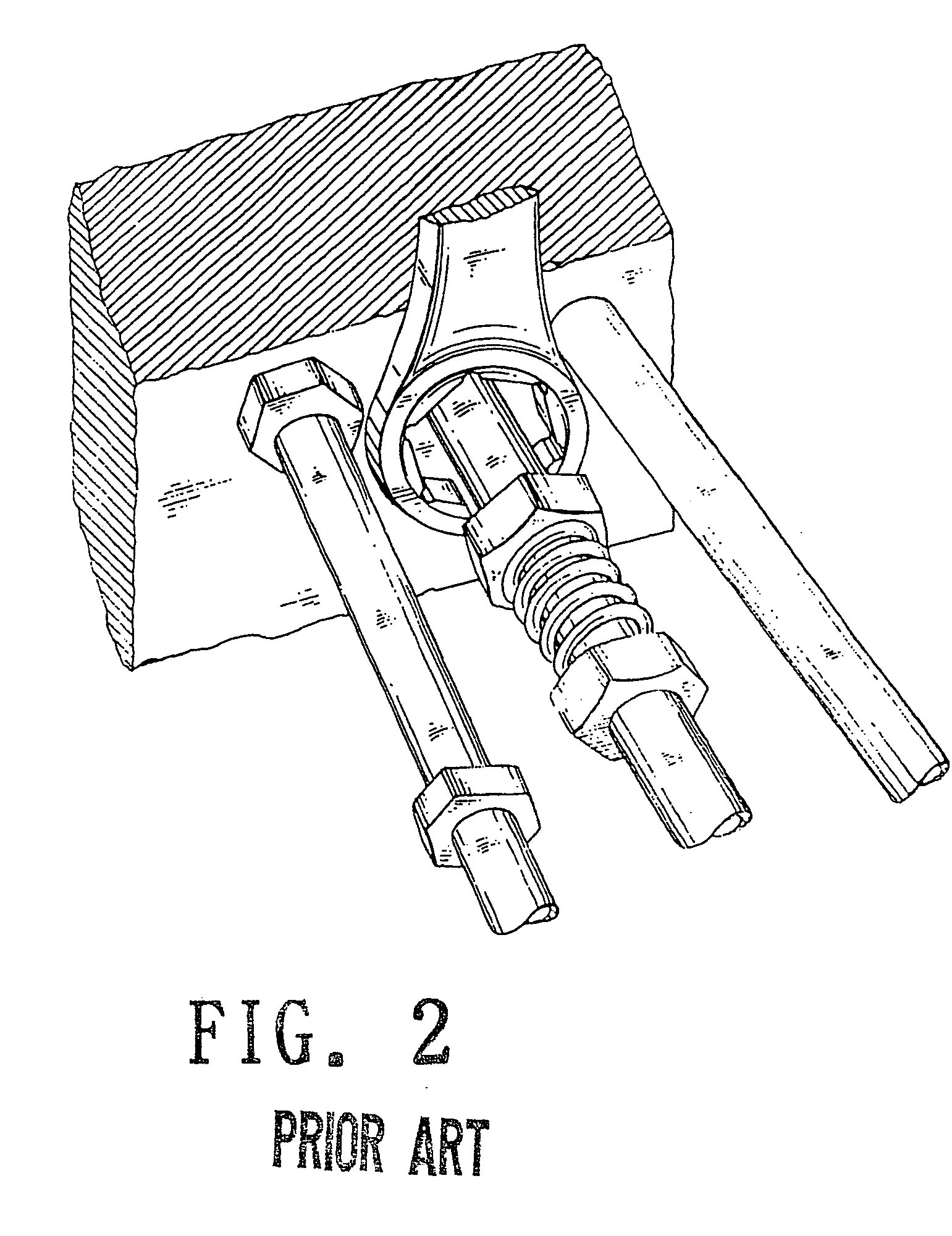

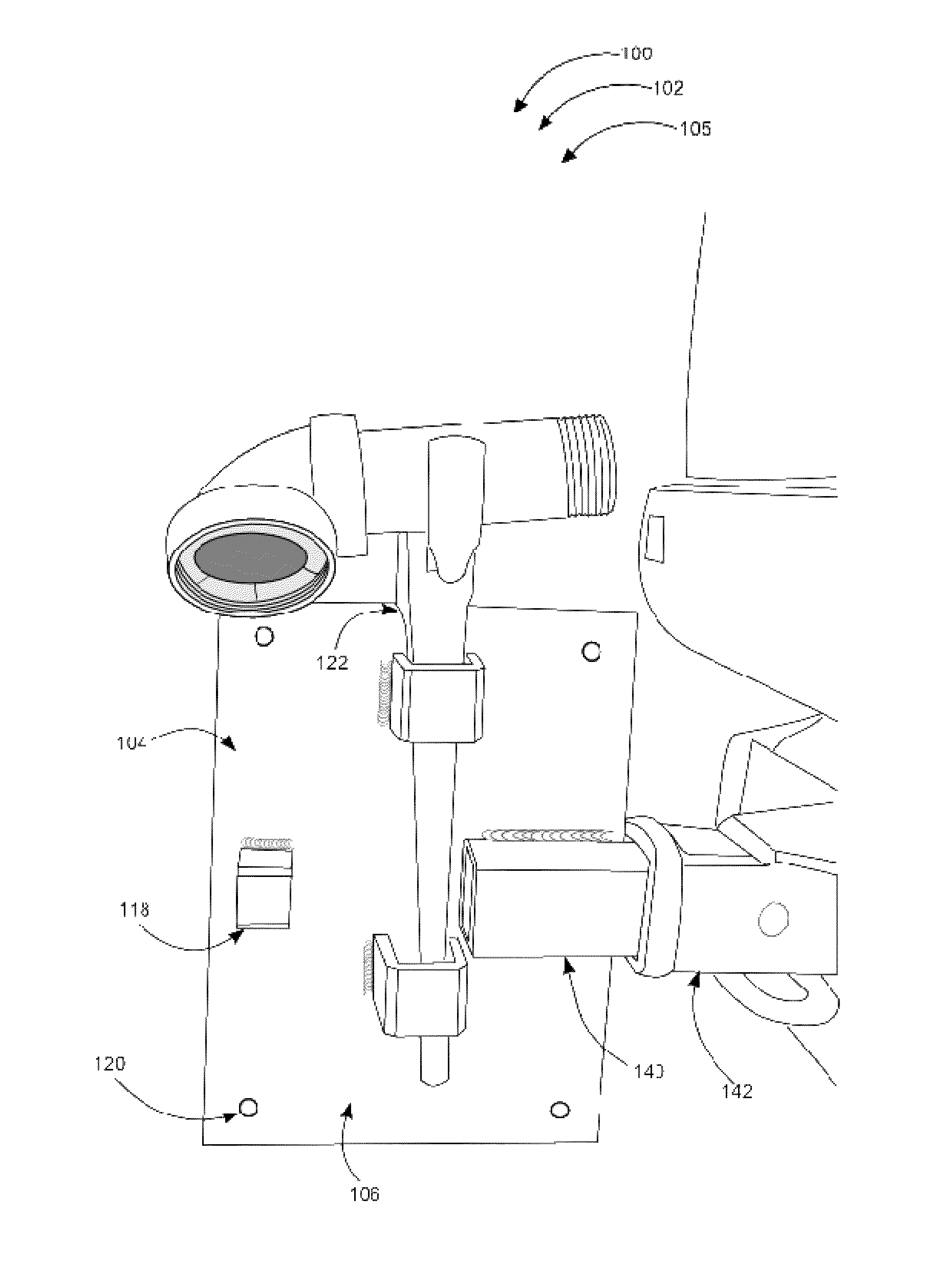

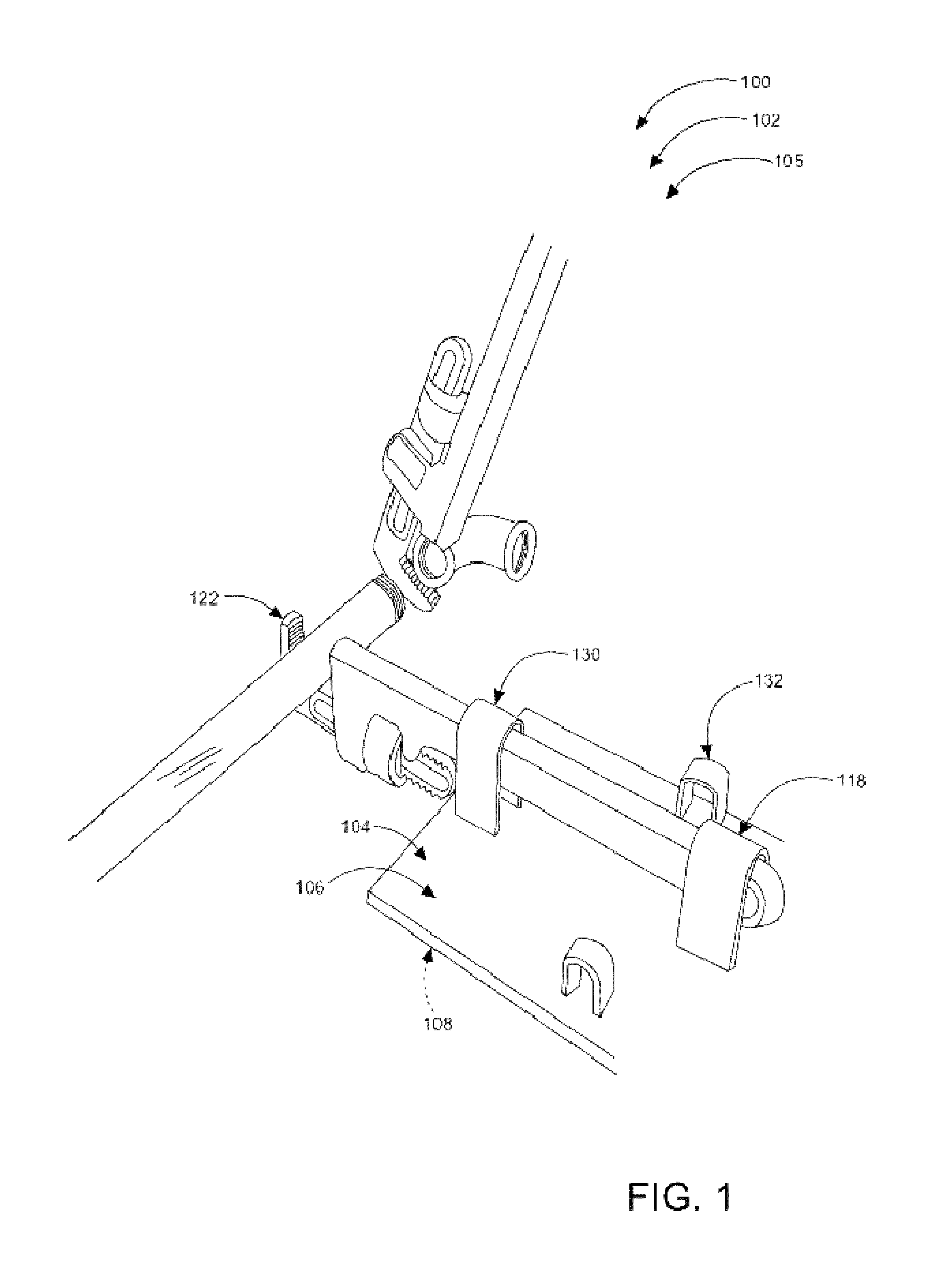

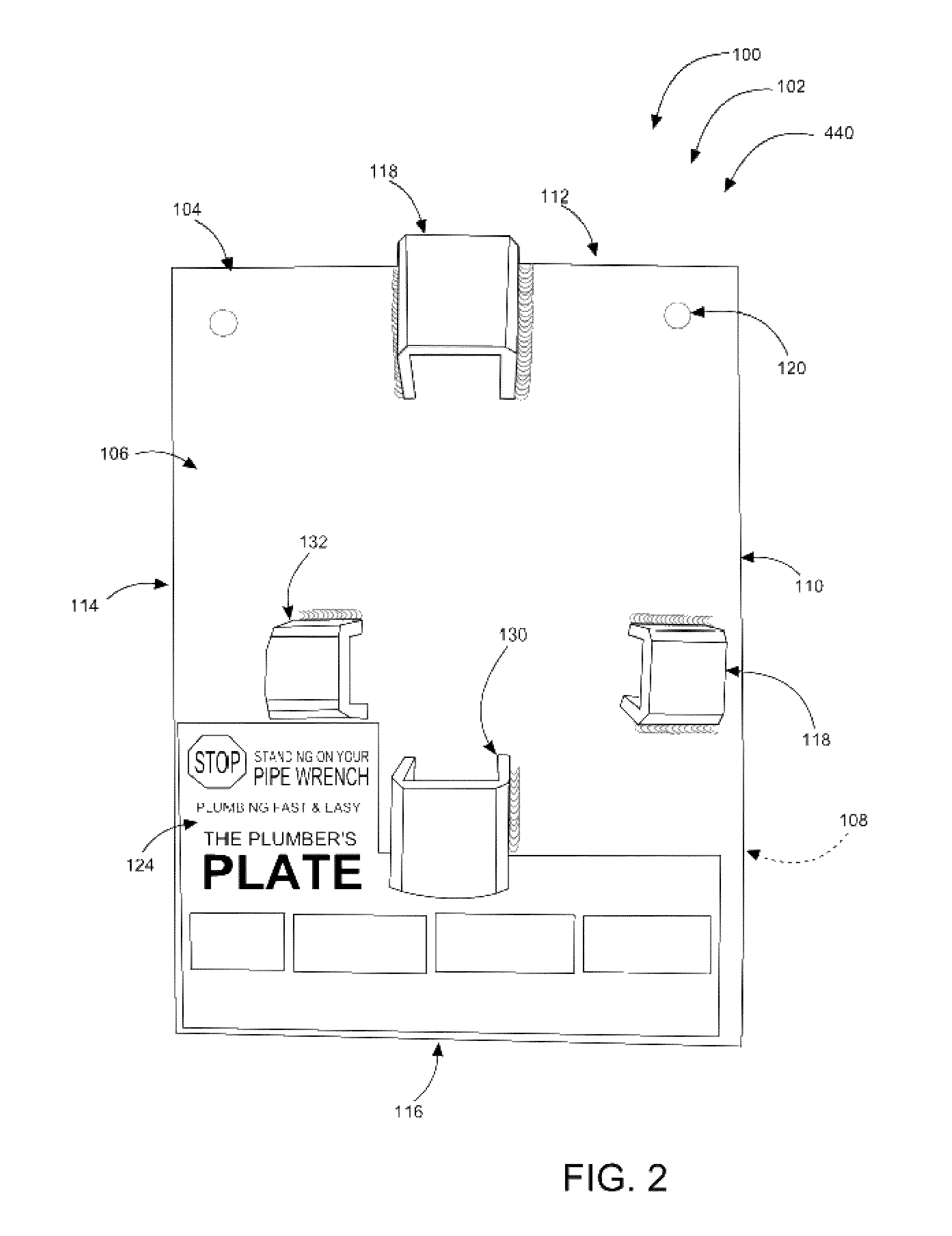

Wrench securing plate systems

A specialty tool for holding a pipe wrench stable when assembling or disassembling piping systems. While working in the field, plumbers normally have to balance one pipe wrench on its spine, holding it either between their knees or under one foot, while using another wrench for assembling / disassembling pipes, valves and fittings. Anyone who's attempted to perform this kind of task has experienced the aggravation, frustration and time loss associated with holding and balancing wrenches in this manner which this device serves to solve.

Owner:HARDY TERRY LYNN

Multipurpose pawl pipe wrench

The invention relates to a multipurpose pawl pipe wrench, which comprises a handle body, an upper jaw clamp, a pin shaft, a torsion spring, an arc tooth surface embedded block and an upper tooth surface embedded block, wherein the upper jaw clamp is hinged to the handle body through the pin shaft; an assembly groove is formed in the handle body; the torsion spring is arranged in the assembly groove; a driving end of the torsion spring is arranged on the upper jaw clamp; the other end is arranged at the bottom of the assembly groove; the arc tooth surface embedded block comprises an arc tooth surface and a lower tenon; a lower mortise is formed in the head part of the handle body; the arc tooth surface embedded block is fixed on the handle body through the matching of the lower tenon and the lower mortise; the upper tooth surface embedded block comprises an upper tooth surface and an upper tenon; an upper mortise is formed in the upper jaw clamp; and the upper tooth surface embedded block is fixed on the upper jaw clamp through the matching of the upper mortise and the upper tenon. Anti-slip teeth on the handle body and the upper jaw clamp can be assembled, dissembled and replaced, a whole jaw clamps a pipe by three tooth surfaces in different directions, the pipe is prevented from sliding, the structure of the upper jaw clamp is reasonable, the weight is light, the strength is good, the performance of the multipurpose pawl pipe wrench is good, the manufacture cost is low, the service life is long, and functions are wide.

Owner:HAIYAN XINGCHEN HANDTOOLS

Pipe wrench with openness capable of being quickly adjusted

The invention relates to hardware manual tools. A pipe wrench with openness capable of being quickly adjusted comprises a fixed jaw, a movable jaw, a wrench body and a wrench body handle. Sawteeth are arranged on the fixed jaw and the movable jaw respectively, the inner side of the front portion of the wrench body handle is provided with inclined teeth, the wrench body handle is provided with scales, one side of the wrench body is provided with a through hole, the direction of the through hole is perpendicular to the movable jaw, the wrench body handle enters the through hole of wrench body, the wrench body can move on the wrench body handle, a groove is formed in the wrench body, the bottom of the groove is axially communicated with the through hole, a worm is installed in the groove, the worm is meshed with the inclined teeth of the inner side of the wrench body handle, a center hole of the worm is sequentially provided with a backing pin, a spring and a ball from top to bottom, the upper end of the backing pin is provided with a radial through hole, the upper portion of the backing pin is arranged in the groove in the wrench body, the backing pin is hinged to the wrench body through a pin, the side, in contact with the groove wall of the wrench body, of the ball is provided with an arc groove, and a rivet is arranged on the position, on the left lower portion of the pin, of the wrench body. The pipe wrench is simple in structure, easy to manufacture, low in cost, low in weight, easy to operate and convenient to use, saves time and labor and is high in work efficiency, and the openness of the jaws can be quickly adjusted.

Owner:WEIHAISHIWEILI TOP GRADE TOOL CO

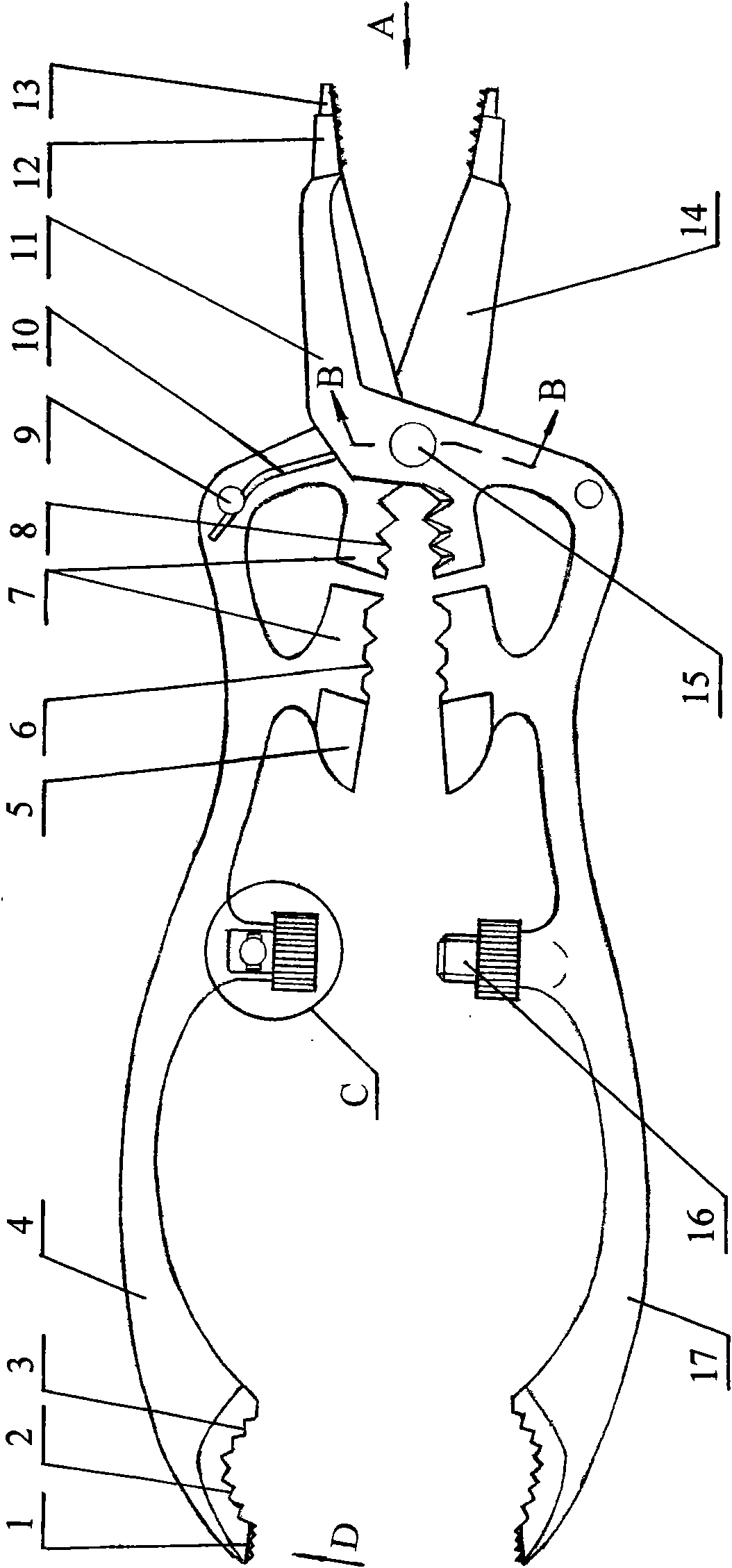

Cutting nippers having nine functions

InactiveCN101870113AReduce operating forcePrevent slippingPliersMetal working apparatusPipe wrenchWire cutter

The invention relates to a pair of cutting nippers having nine functions. An upper scissors body and a lower scissors body are hinged through hinging bolts, wherein the extending ends of the upper and lower scissors are a snap spring nipper and a nipper pliers; a torsion spring which is embedded in the groove of the upper and lower scissors is sleeved on the hinging bolt; two ends of the torsion spring extend outwards and are resisted on a baffle pin of the torsion spring so as to actuate the heads of the upper and lower scissors to open; interiors of the upper part of left and right handles extend into a support stem; a wire stripper, a wire presser and a diagonal pliers are arranged on the support stem; the tail end of the support stem is provided with a wrench, a pipe wrench and a wire cutter; a clamping force regulating mechanism which comprises a double-end bolt, a locking nut, a pressure spring cassette, a pressure spring, a cassette pin, and the like, is arranged on the inside middle part of the left and right handles. The cutting nipper of the invention is provided with nine functions in order to meet the demands of daily work and life. The operation is labor-saving and the clamping force can be regulated and fixed so as to smoothly and safely operate.

Owner:包长仁

Advanced strap pipe wrench for driving an object having a generally cylindrical shape

Owner:STANLEY BLACK & DECKER MEA FZE

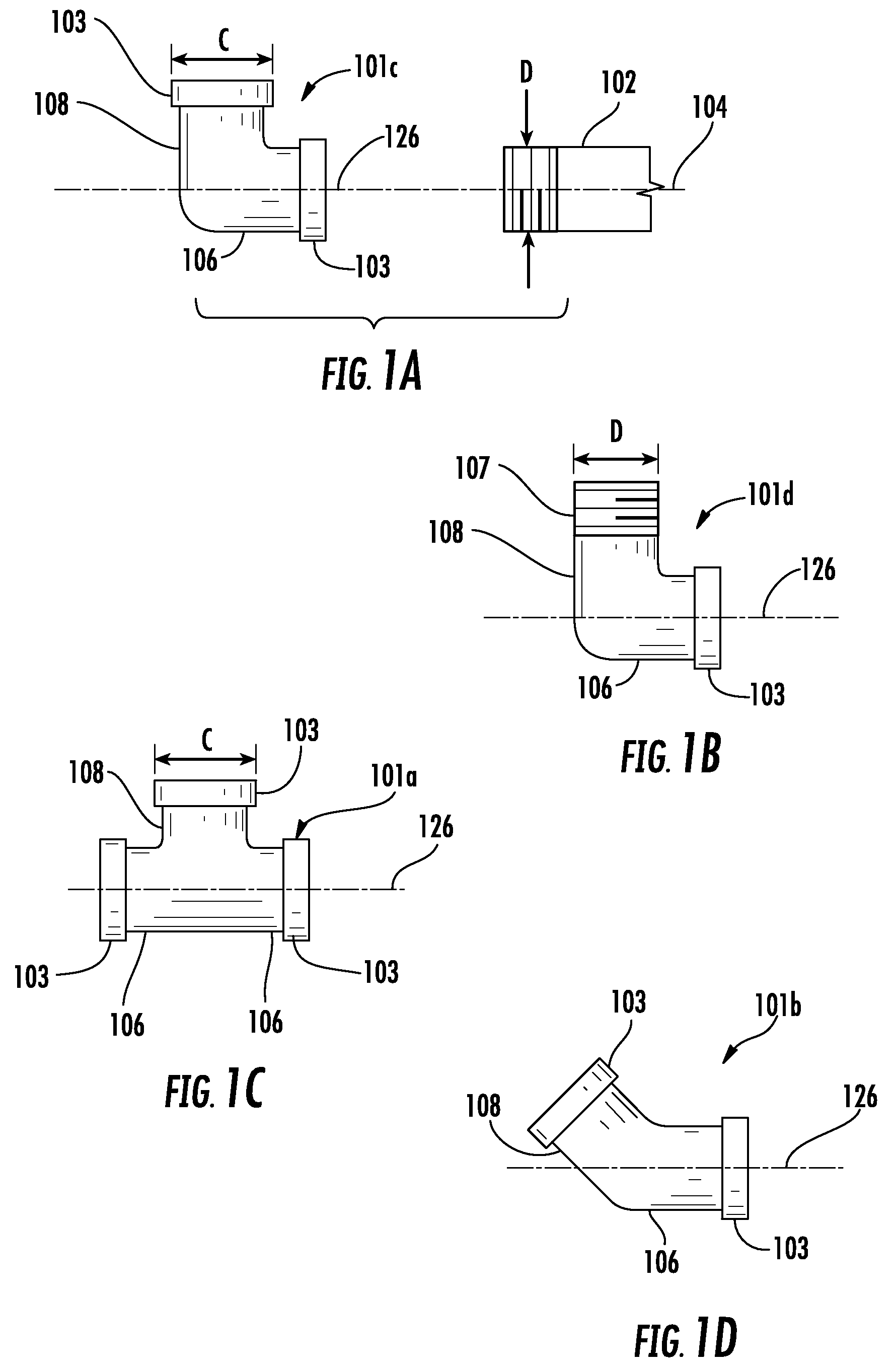

Pipe fitting socket for use with an axial drive mechanism

A pipe fitting socket for use with an axial driving device accepts a variety of angled fittings (e.g. tees, full elbows, slant elbows) snugly within a fitting cavity for torquing onto a fixed threaded end of pipe. Torquing of the fitting is accomplished by inserting a drive stud of the driving device into a drive aperture defining a rotational axis and torquing the driving device, thereby rotating the socket about the rotational axis, or through manually torquing a cylindrical portion of the socket. The socket offers superior efficiency and safety over conventional pipe wrenches by maximizing the effective range of movement available for a wrench used for angled fitting installation and / or removal, while virtually eliminating a wrench's loss of grip on the fitting.

Owner:NICOLAZZO RANDY +1

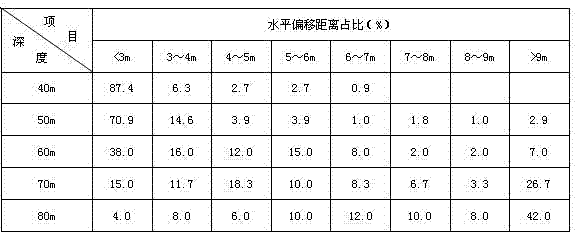

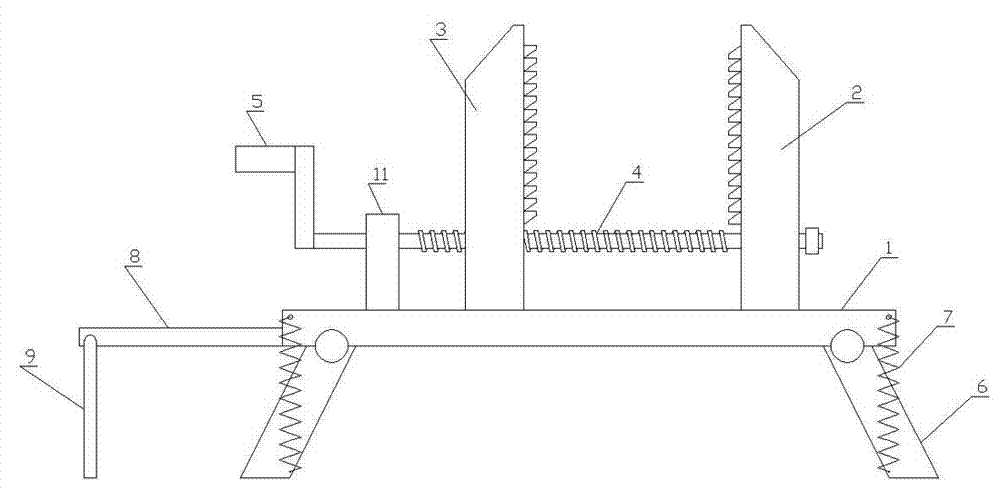

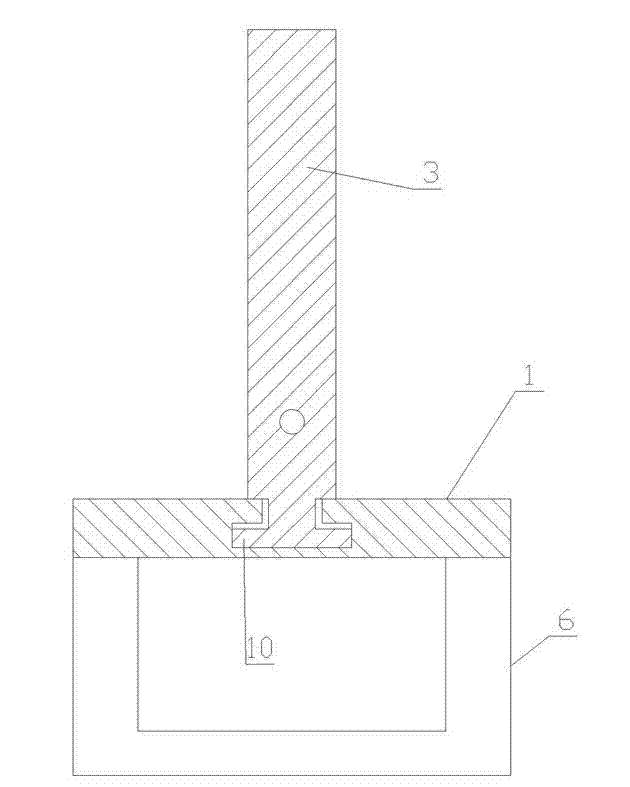

Floor pipe wrench

The invention discloses a floor pipe wrench. The floor pipe wrench comprises a workbench, a propeller shaft, a fixed post, a movable post, a counter-force frame, a stable post and a rocking bar, wherein the counter-force frame is fixedly connected with the two sides of the workbench, respectively; a rail slot is arranged on the workbench; a rail fastener is arranged on the lower part of the movable post; the rail fastener is arranged in the rail slot on the workbench; the propeller shaft penetrates through the counter-force frame, the fixed post and the movable post in sequence; threads are formed on the propeller shaft and matched with the threads of the movable post; and a bracket is hinged below the workbench. Compared with the existing pressure clamp, the size is remarkably reduced, the portable performance is good, the environmental adaptation is stronger and the manufacturing cost is remarkably lowered.

Owner:李乃生

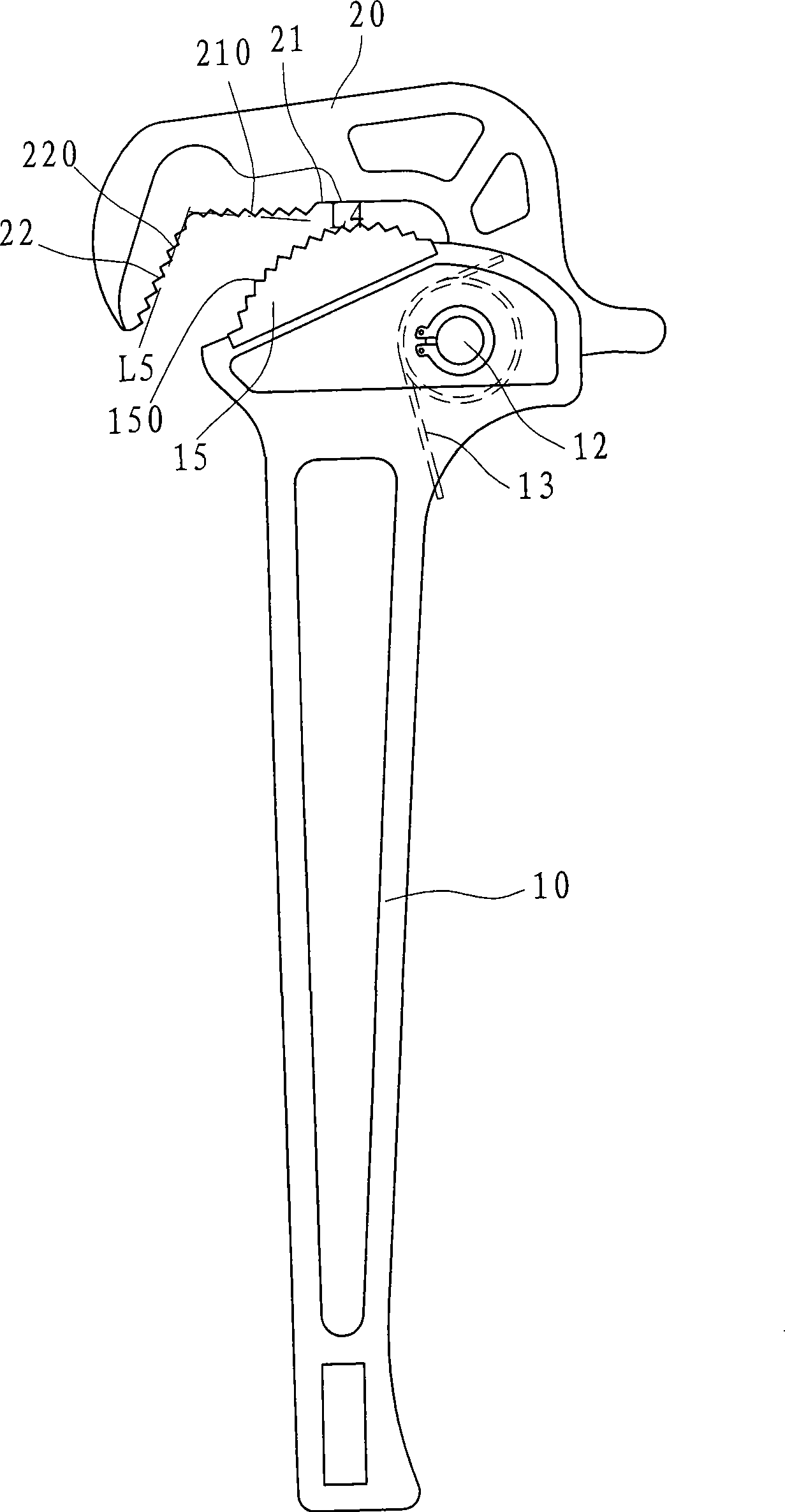

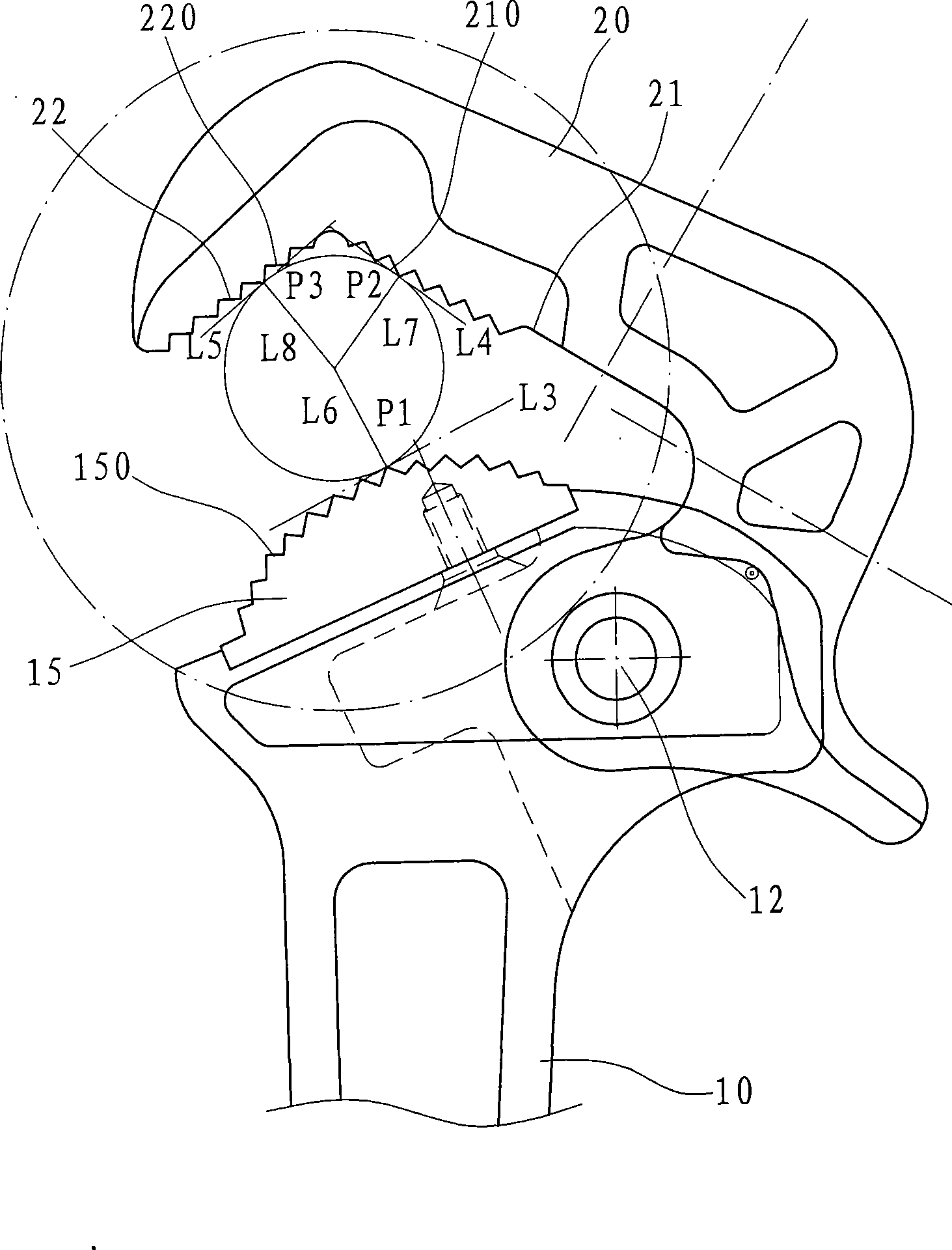

Pipe wrench

The invention relates to a structure of pipe tongs. The pipe tongs comprise a handle and a movable clamping jaw, wherein the top surface of the handle is fixedly provided with an arc-shaped jaw block. The movable clamping jaw is pivoted at the top end of the handle and is made clamp and close relative to the arc-shaped jaw block of the handle through a torsion spring. The inner surface of the movable clamping jaw has a first tooth surface and a second tooth surface which are in opposite horizontal V shapes. The included angle between the first tooth surface and the second tooth surface is 135 degree. The included angles between an occlusion point of the first tooth surface of the movable clamping jaw and an occlusion point of the arc-shaped jaw block and the perpendicular dividing line of the center of a clamped object are between 160 and 170 degrees. The pipe tongs of the invention can prevent an circular object clamped from moving toward the opening between the movable clamping jaw and the arc-shaped jaw block, apply a major part of force on a circular surface perpendicular to the occlusion points, and generate larger friction forces on the occlusion points to prevent a pipe from deforming or sliding when the jaw block and the clamped object occlude.

Owner:MH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com