Injection method for static sounding probe rod

A probe rod and penetration technology, which is applied in the field of foundation soil survey, construction, infrastructure engineering, etc., can solve the problems of time-consuming, labor-intensive, labor-intensive, etc., and achieve the effect of improving the verticality of the probe rod and reducing the work intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment one: if Figure 5 As shown, two kinds of probe rods with different diameters are used for combination. The front part of 20m-25m uses a 36mm diameter probe rod, and the latter part uses a 40mm or 42mm diameter probe rod. This combination method can effectively ensure the rigidity of the probe rod. It will not break easily when penetrating.

[0033] Before the start of construction, the straightness of each probe rod can be inspected, generally by visual method. In the case of high precision requirements, the probe rod is leaned against the inner side of the angle steel with high straightness and passed the visual inspection while rotating. Straightness of the probe rod.

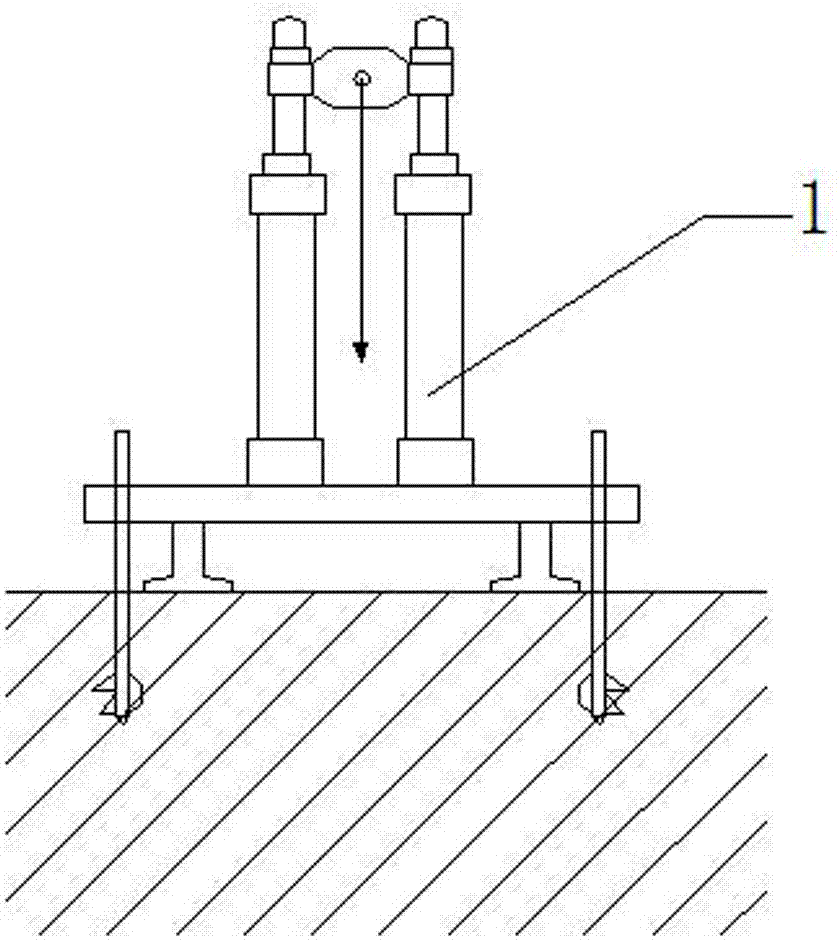

[0034] Such as image 3 As shown, the preparatory work before penetration: Arrange enough ground anchors of drilling rig 1, level the body of the drilling rig so that its outriggers are in full contact with the ground, and use a spirit level to check the levelness. Check the verticality o...

Embodiment 2

[0044] Embodiment 2: The method of this embodiment is basically the same as that of Embodiment 1. The difference is that a 15-20m protective pipe is used to press into the protection probe rod, which is suitable for soft soil layers in the test area and higher penetration depth requirements (for example, greater than 60m).

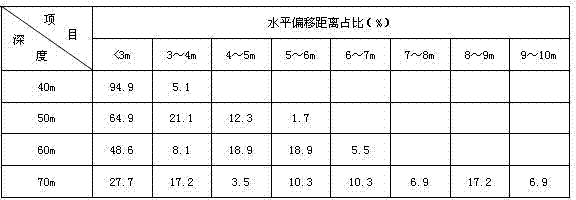

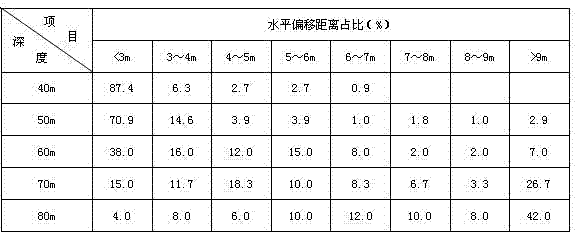

[0045] Such as figure 1 , 2 as shown, figure 1 For adopting the operation method of the present embodiment in the test data of 59 holes in the Chongming country park project in Shanghai; figure 2 In order to adopt the test data of 119 holes operated in the China Expo Convention and Exhibition Complex Project (North Block) in this embodiment, it can be clearly seen from the two figures that the present invention has a significant effect on reducing the inclination when the probe rod penetrates , to increase the test success rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com