Patents

Literature

96results about How to "Improve alignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

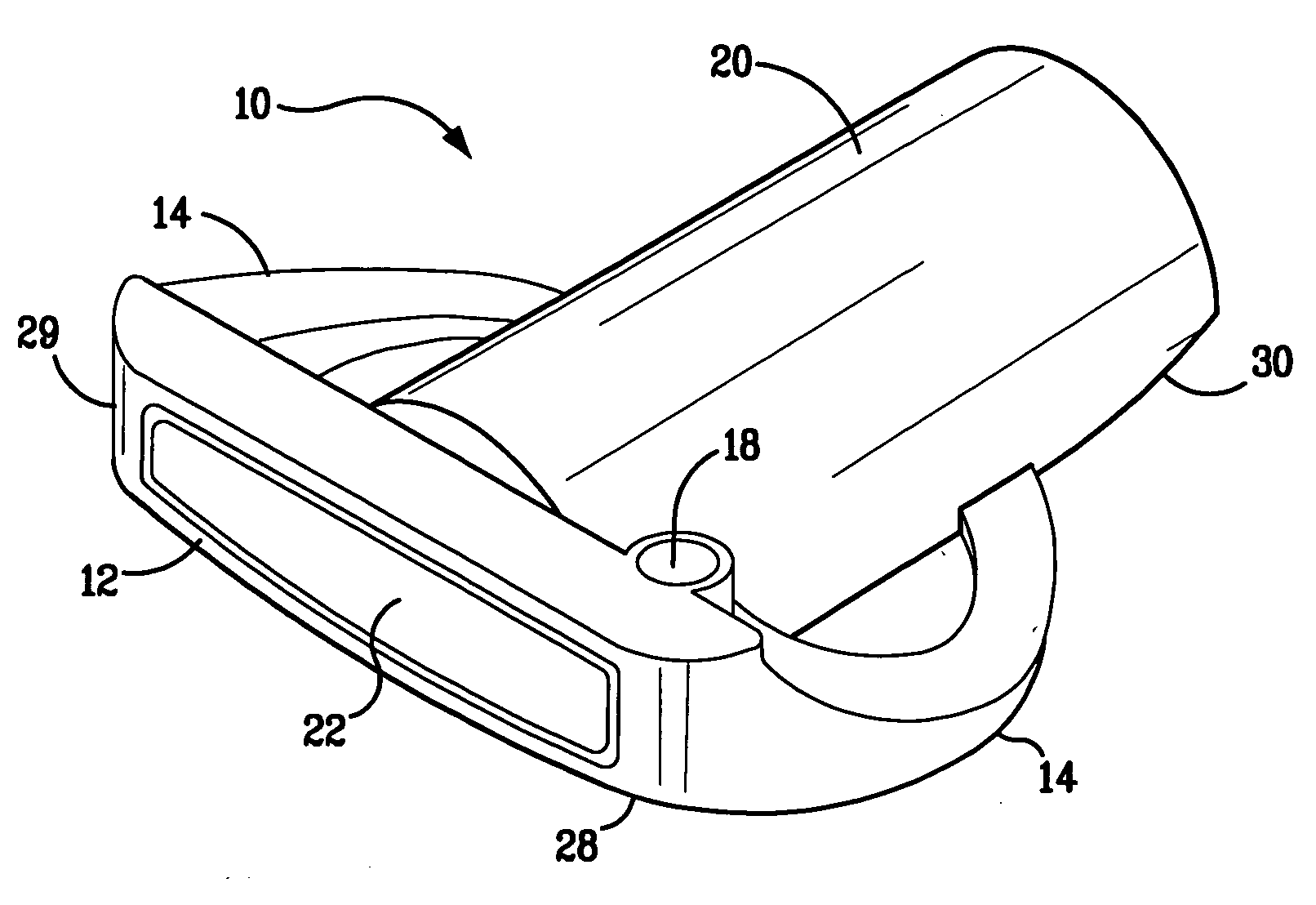

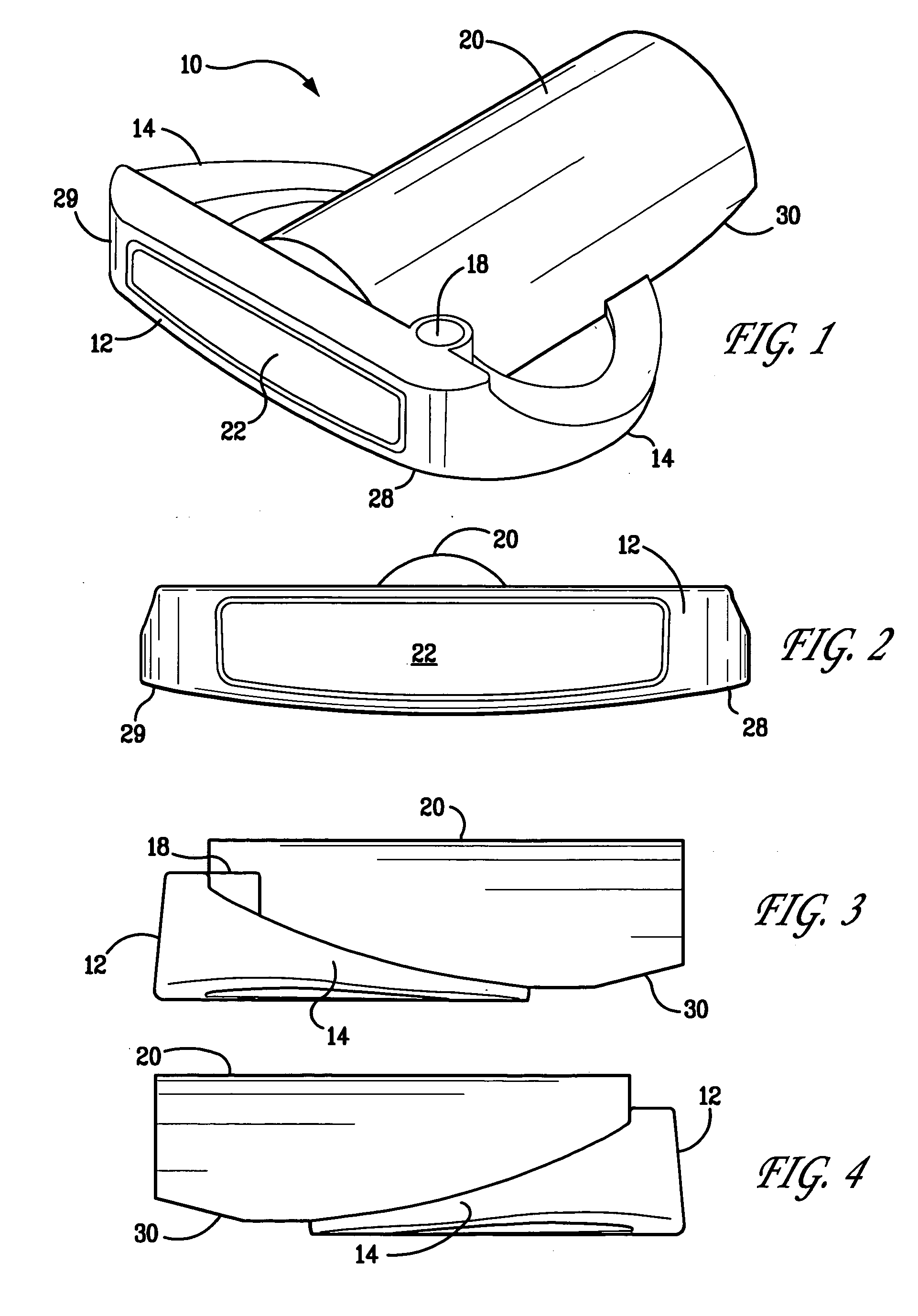

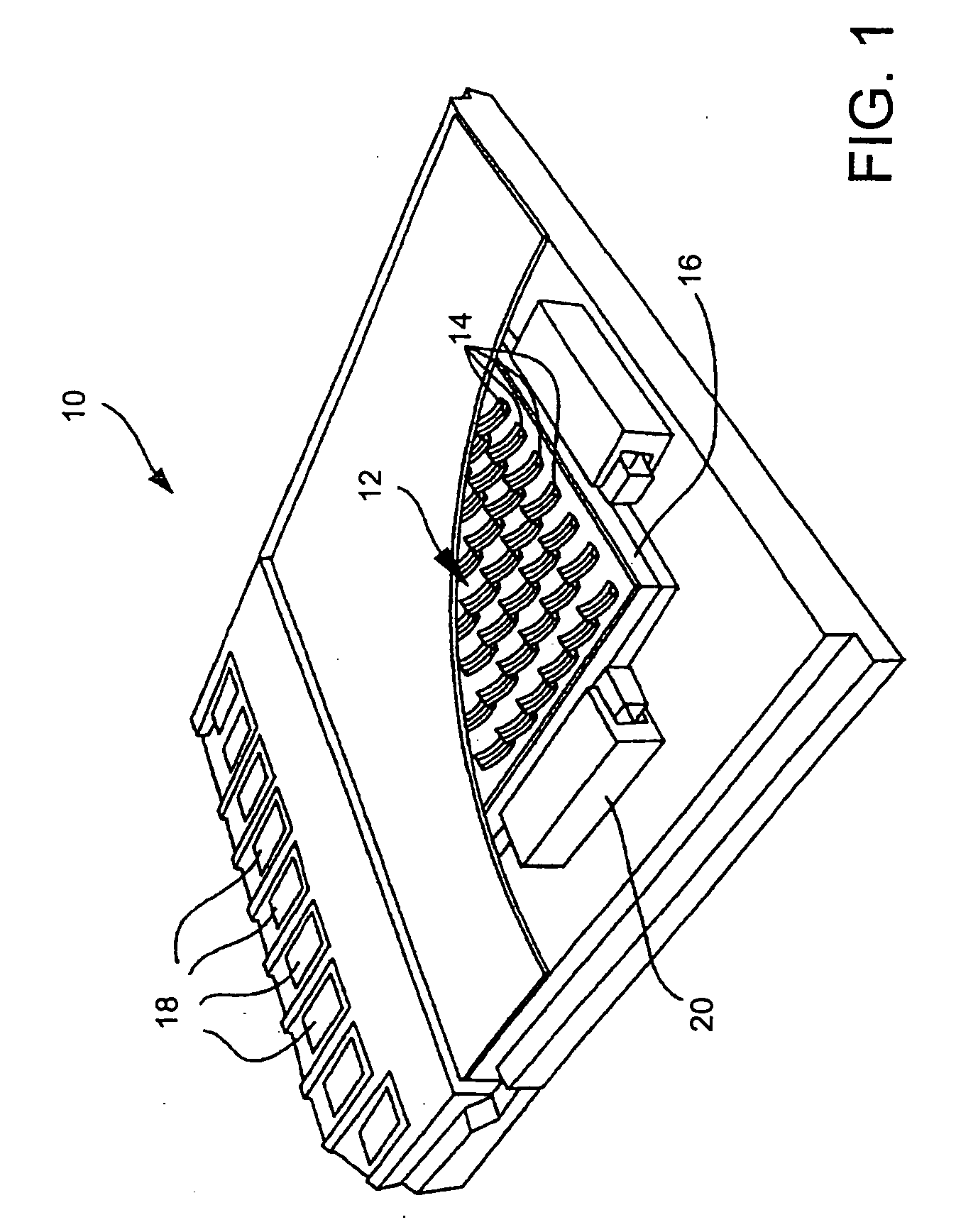

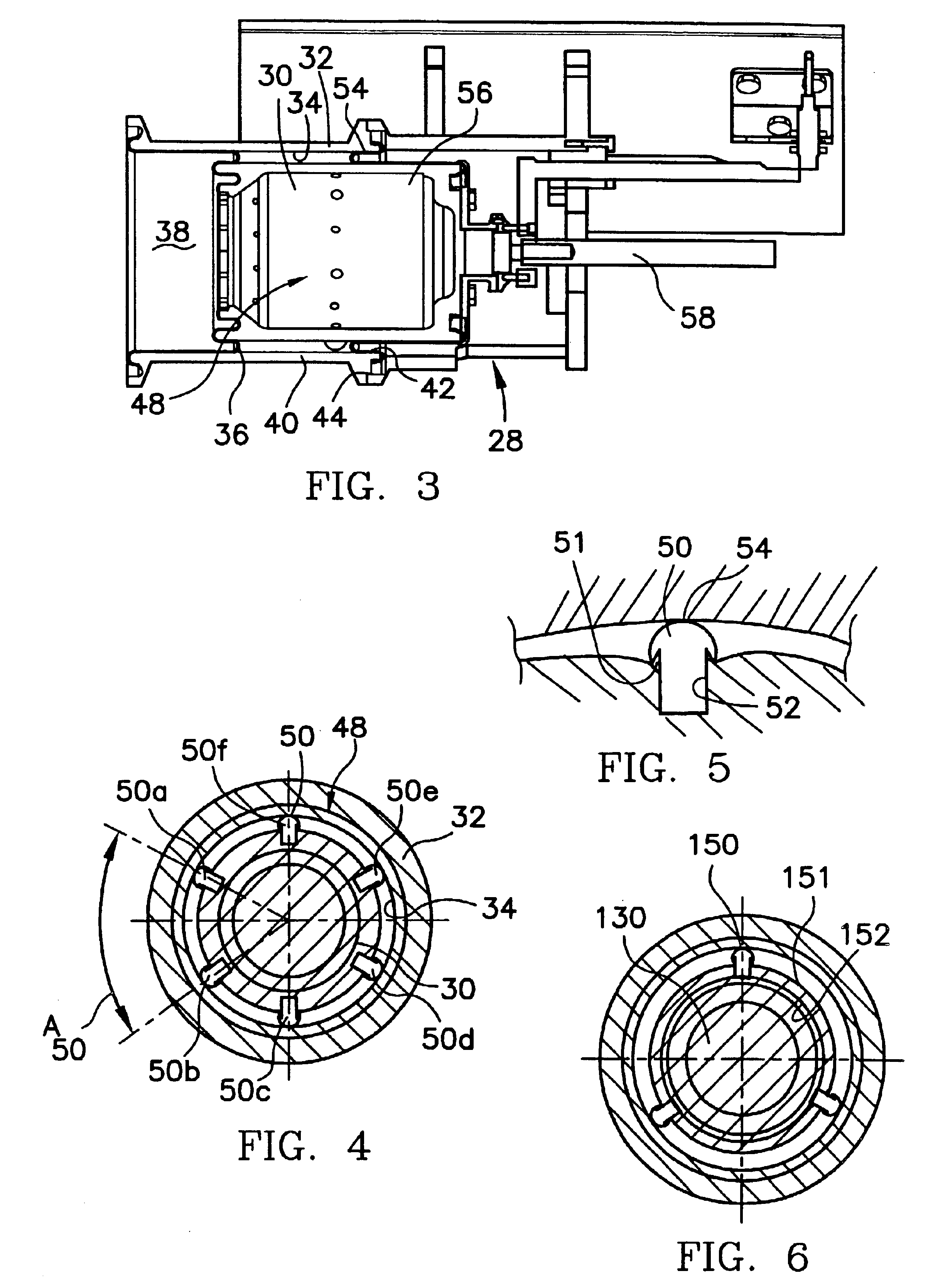

Golf putter head with visual alignment system

InactiveUS20060166755A1Simple alignmentImprove alignmentGolf clubsRacket sportsMoment of inertiaGolf Ball

A mallet-style golf ball putter with a hollow pipe component that has generally the same diameter as a golf ball, is positioned about the sweet spot in the vertical and lateral dimensions on the putter striking face, and extends longitudinally towards the rear of the putter to assist the golfer to align the striking face of the putter with the golf ball when in an address position and with the intended line of putt during takeback and follow-through. Peripheral weighting further enhances the moment of inertia of the golf putter head. The pipe component so designed permits a visual alignment of the striking face with the golf ball in the lateral and vertical dimensions and for a smooth perpendicular stroke along an axis of the pipe.

Owner:SIENNA SPORT

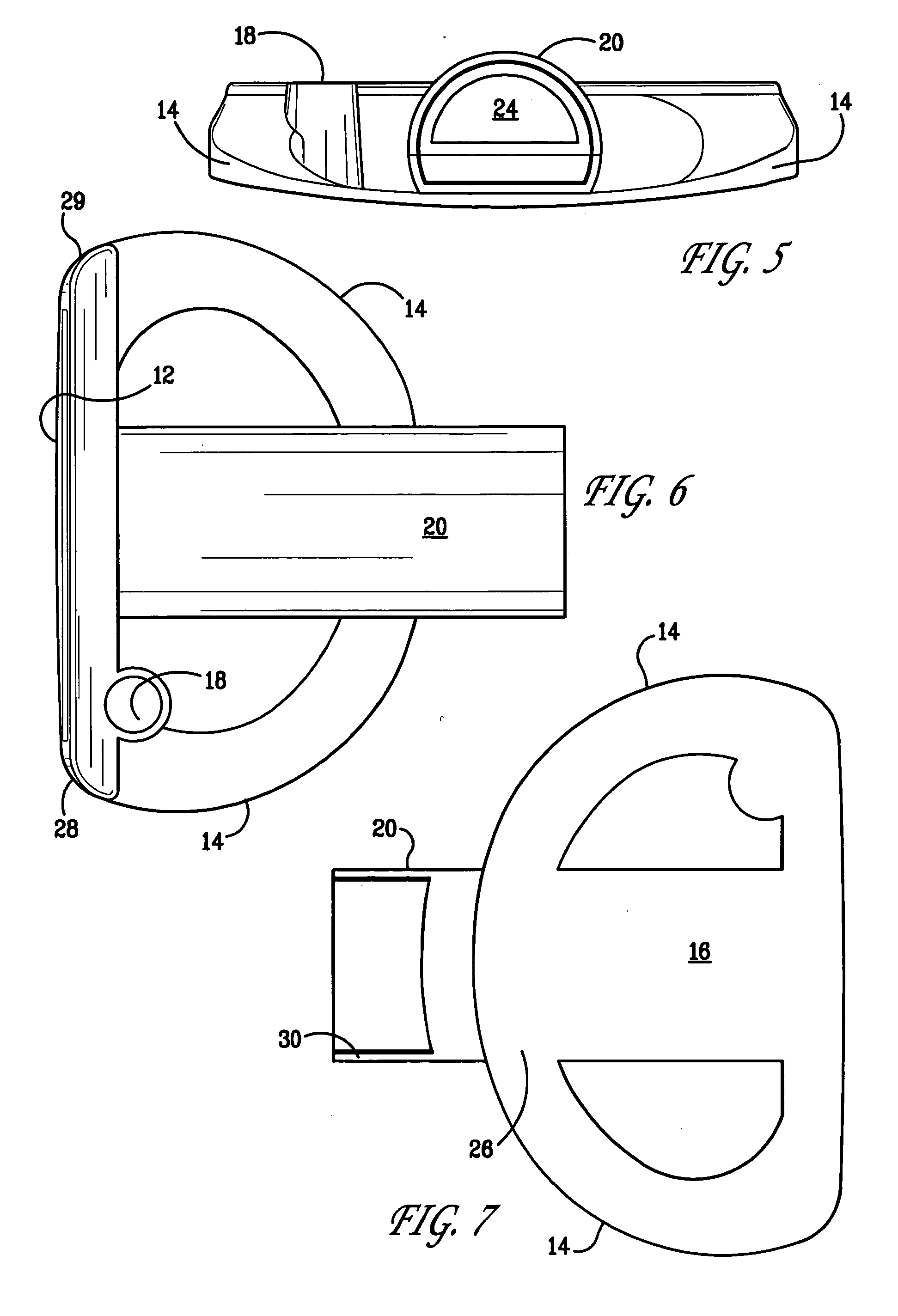

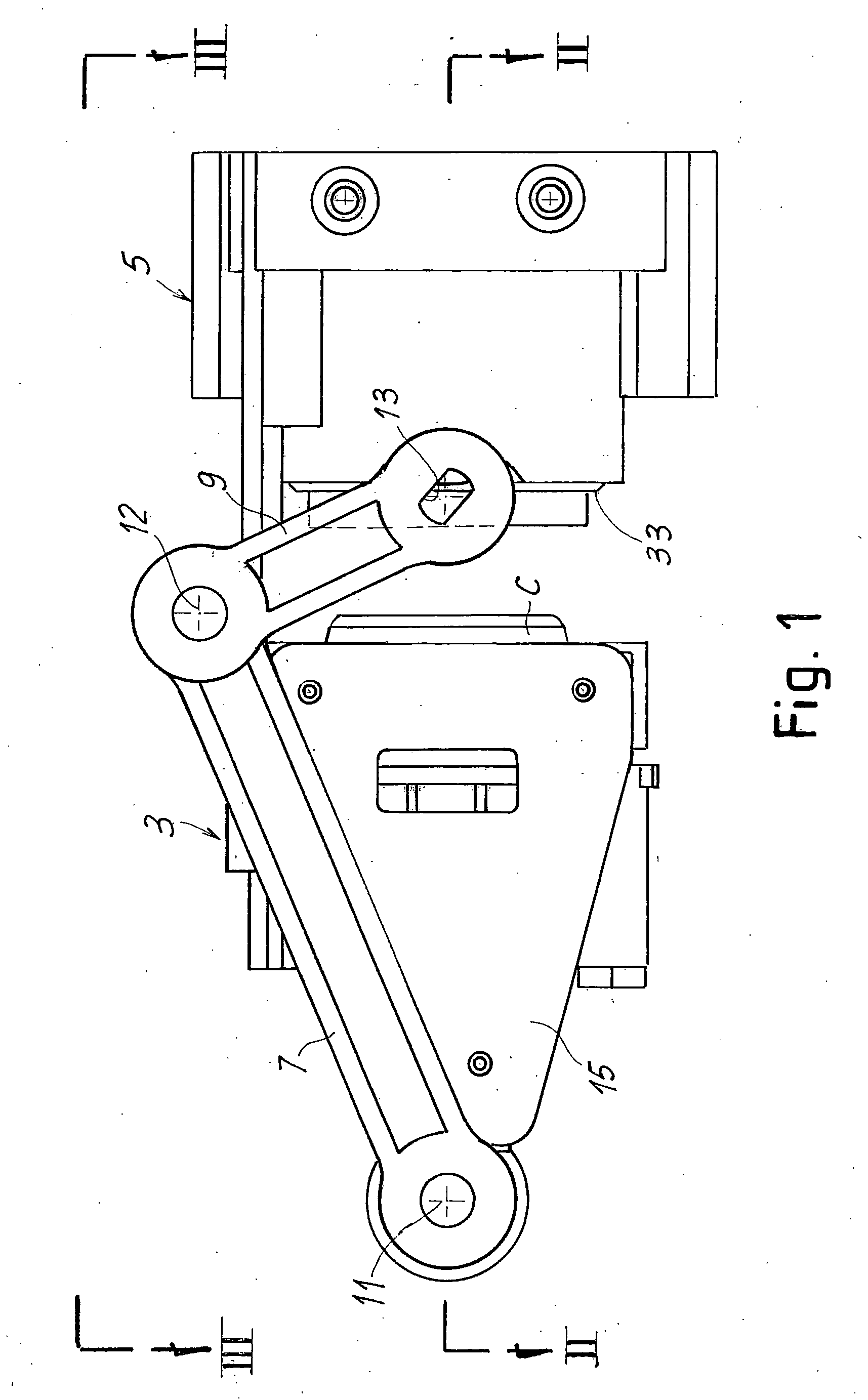

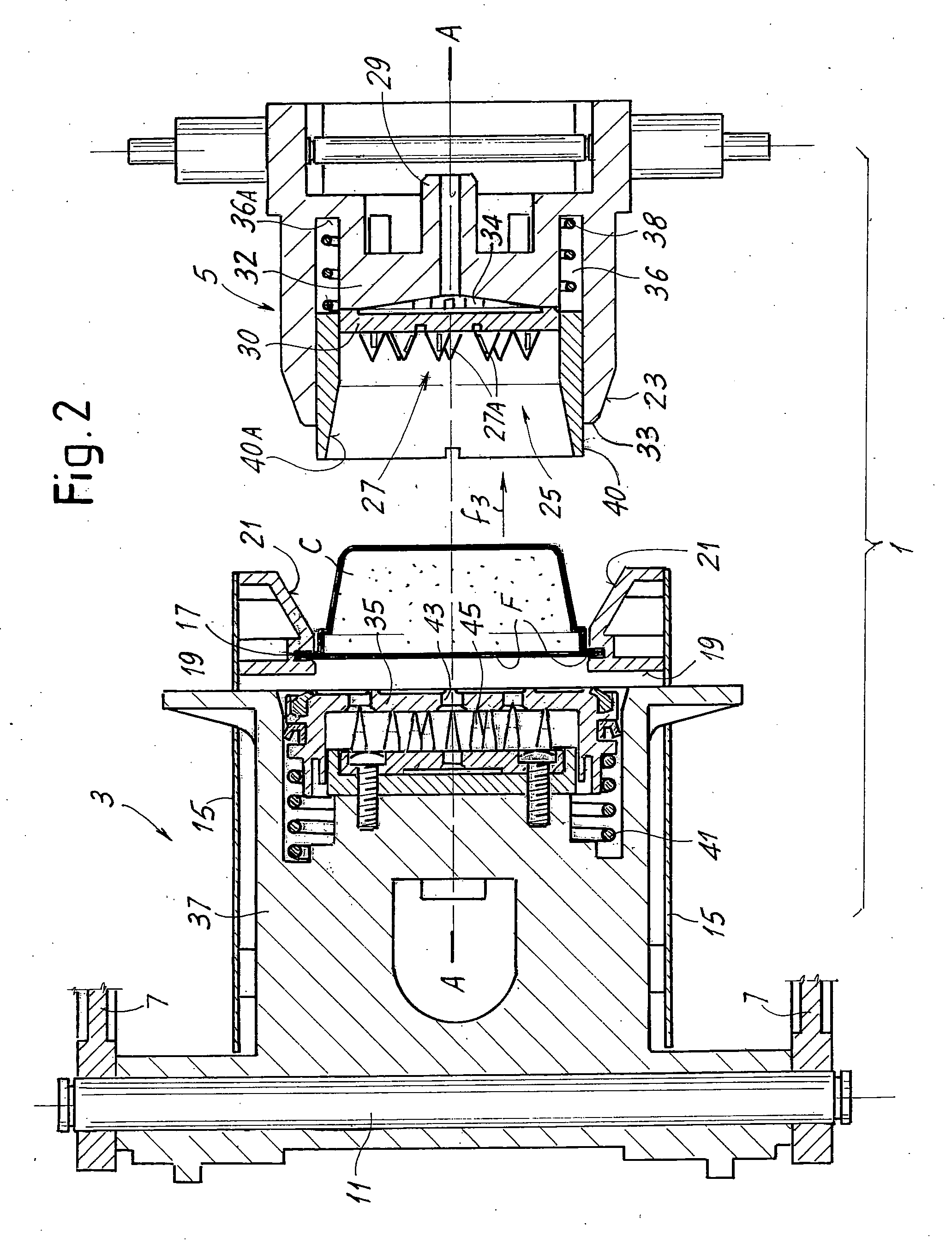

Infusion device to prepare beverages form single-serving capsules with capsule centering device

The infusion device comprises an infusion chamber with a first portion (5) and a second portion (3), movable with respect to each other, and one of which defining a seat (25) for the capsules (C). In the seat there is disposed at least one perforator (27) to perforate the capsule. A first duct (47) feeds an infusion fluid into the chamber and a second duct (29) allows delivery of the food product from the infusion chamber. In said seat (25) there is housed a centering member (40) of the capsules (C), elastically movable in an axial direction and provided with a guide and centering surface (40A) of the capsules, facing towards the second of said portions of the infusion chamber.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

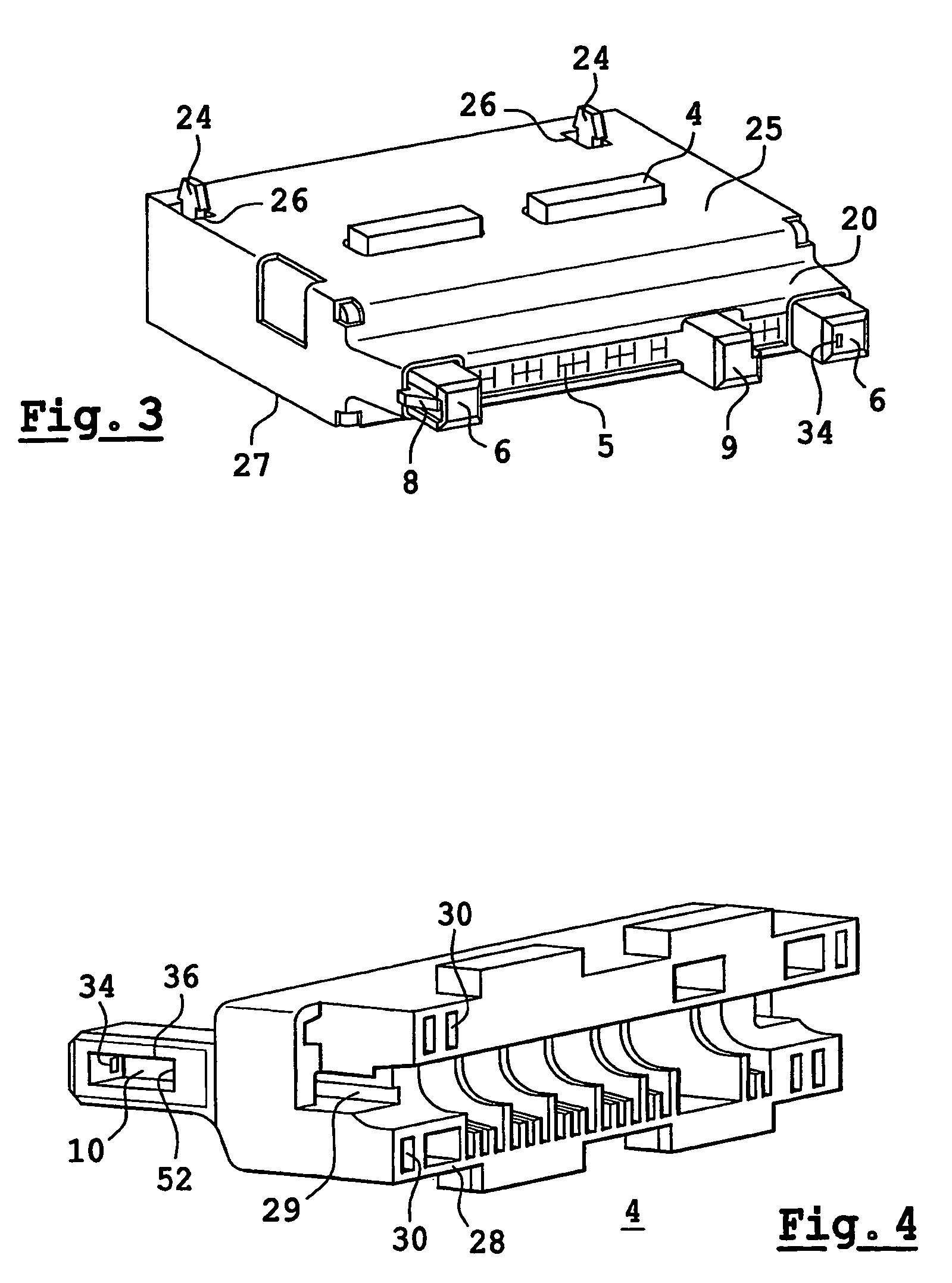

Plug connector provided with means for lateral locking

InactiveUS7207825B2Wear and damage be avoidImprove alignmentCoupling device detailsEngineeringMechanical engineering

Owner:FRAMATOME CONNECTORS INT SA

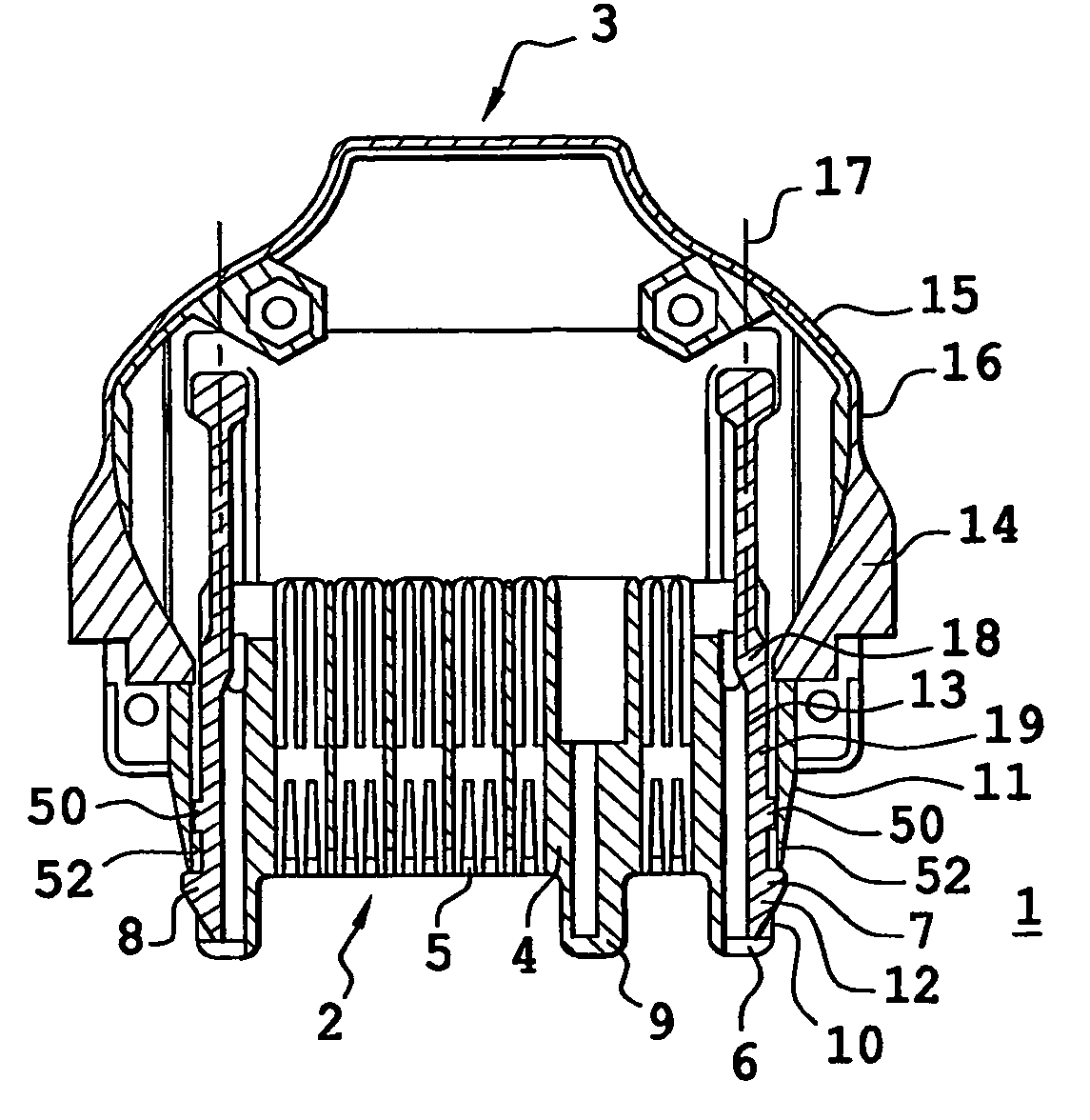

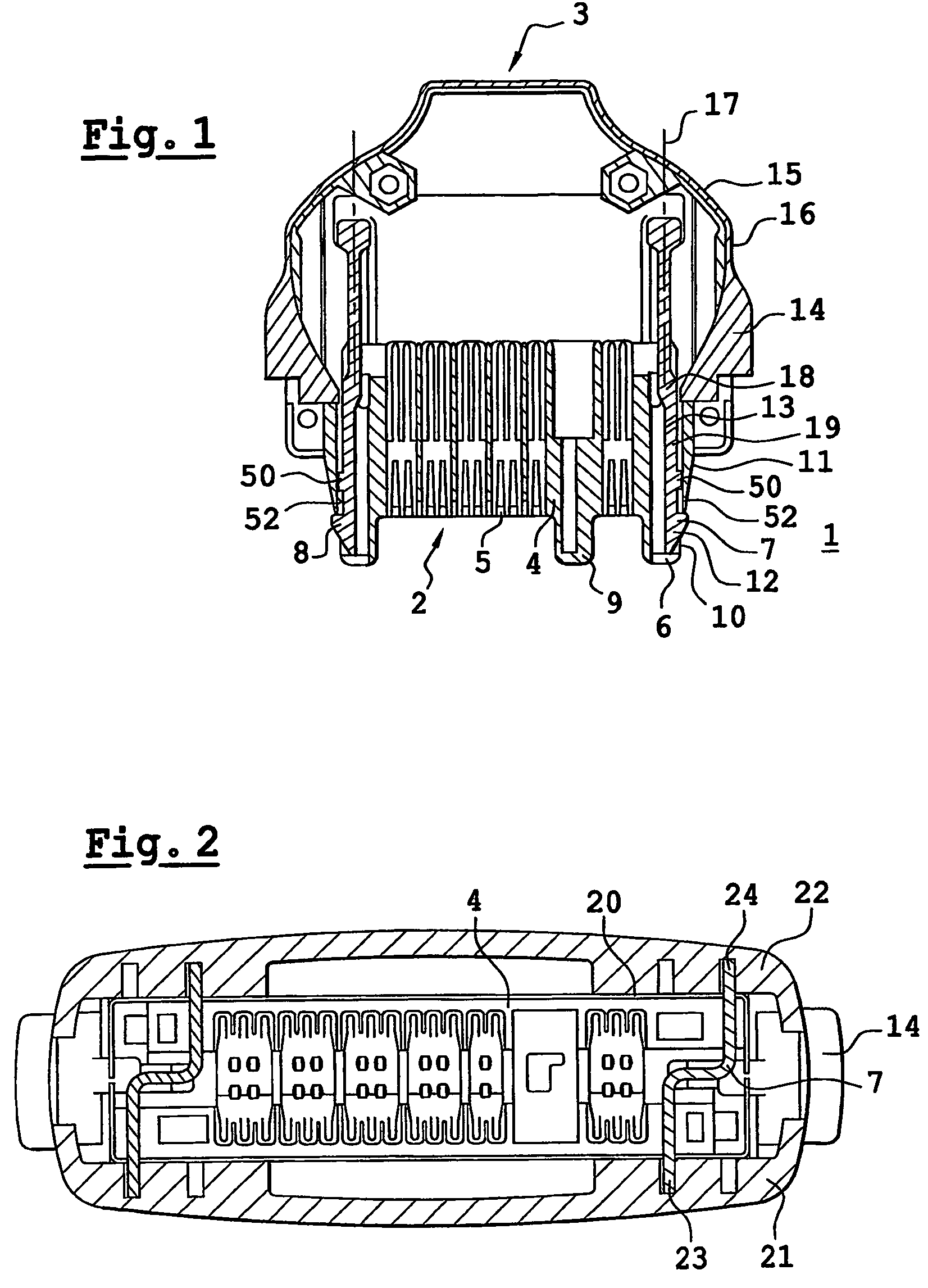

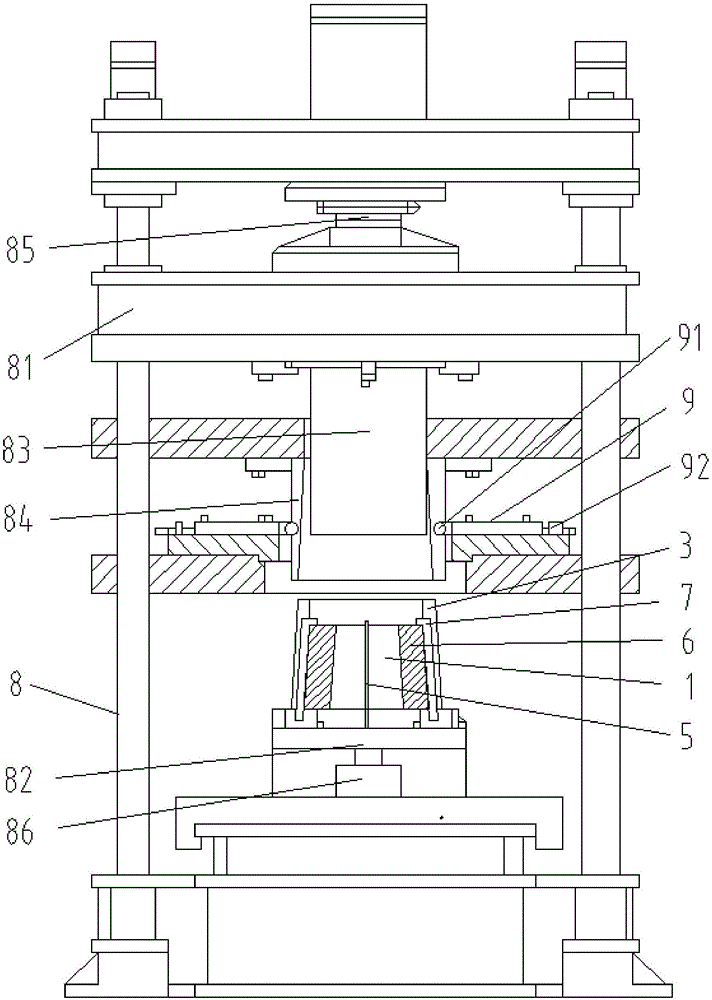

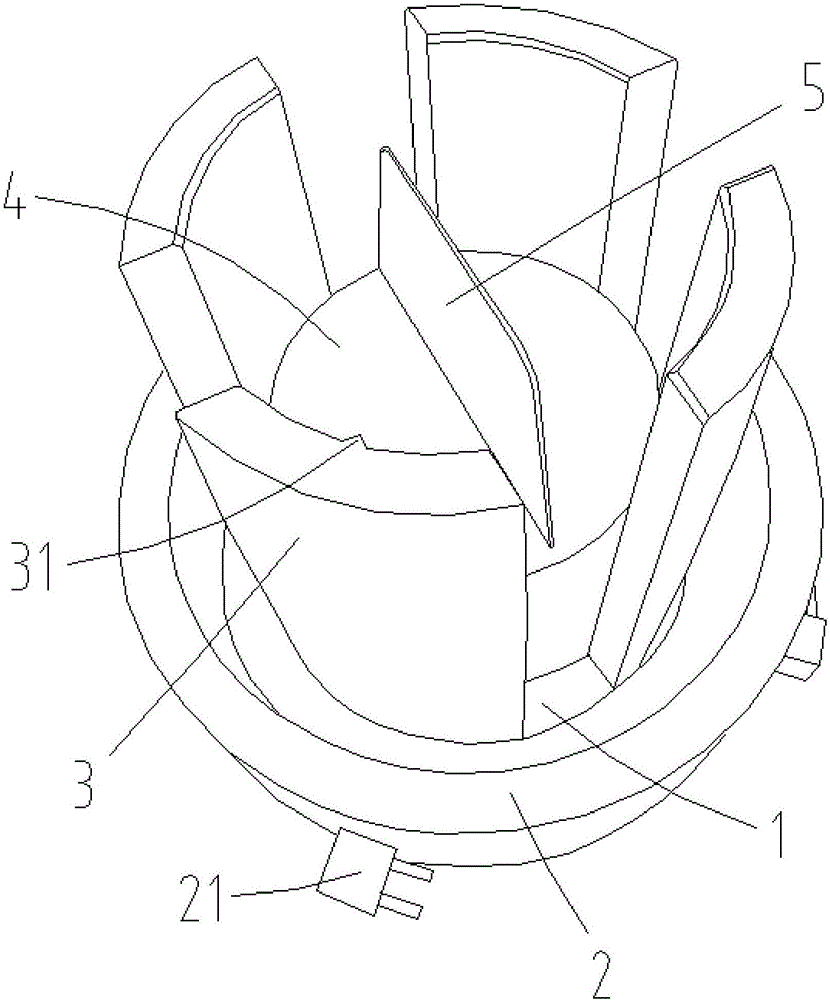

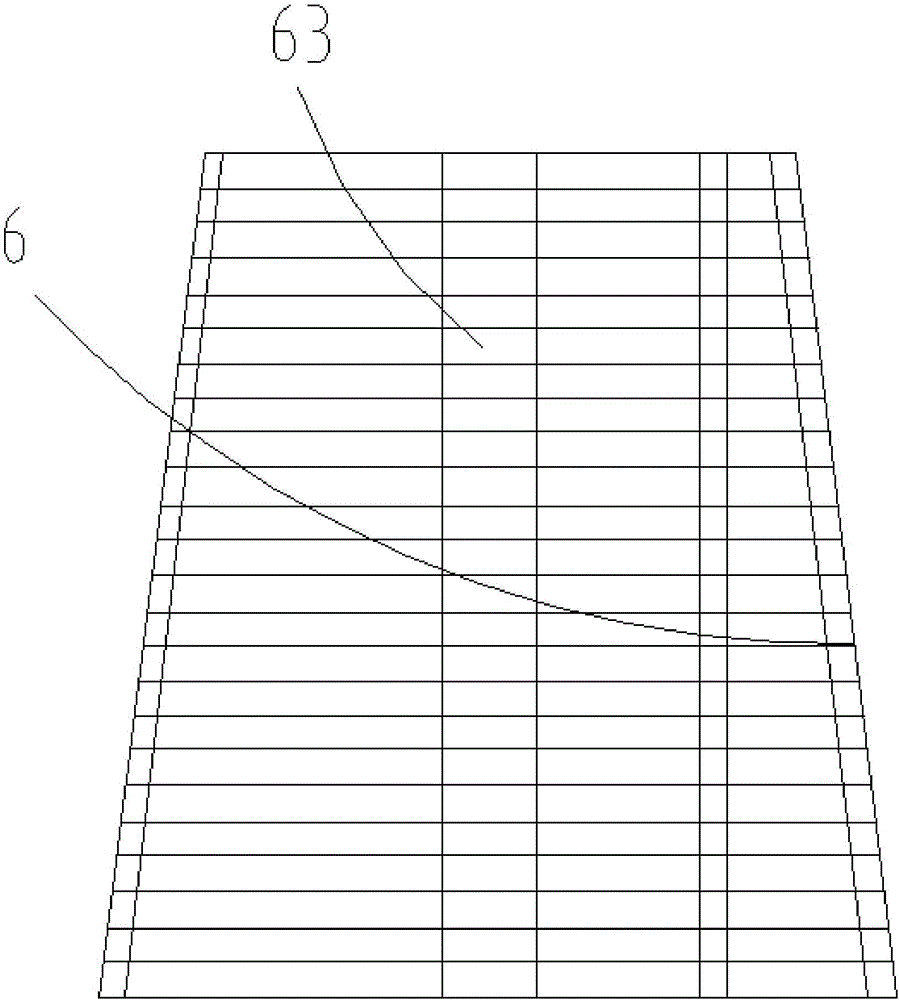

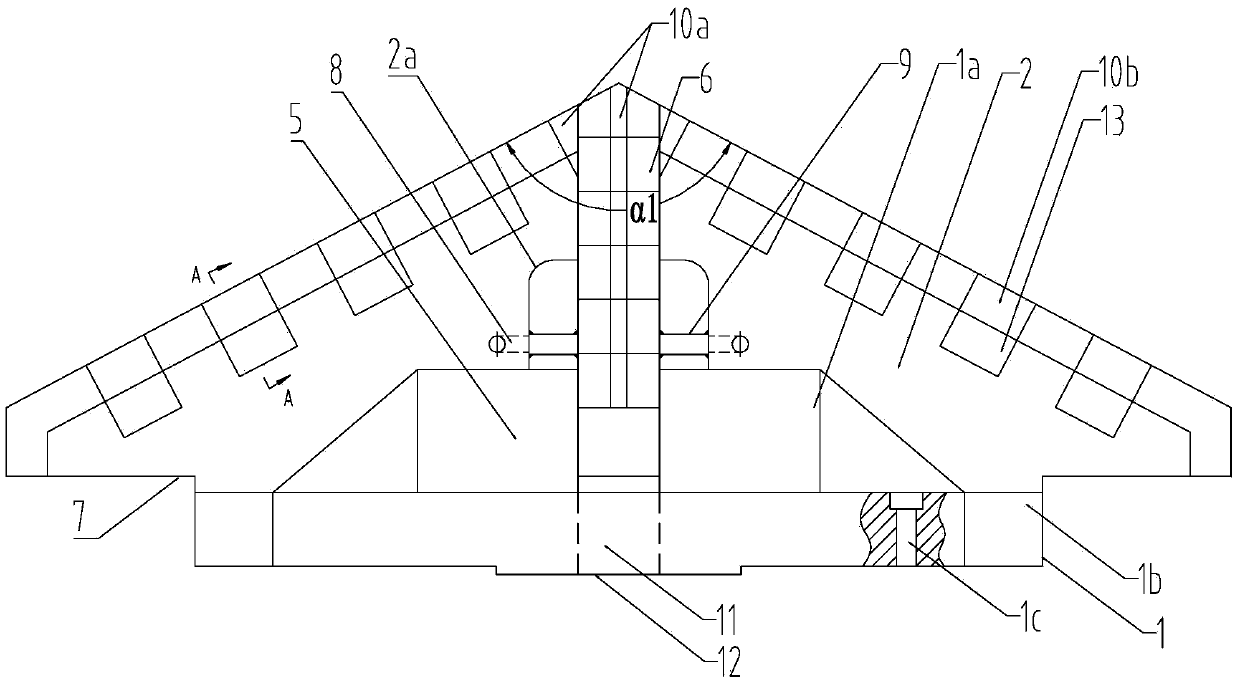

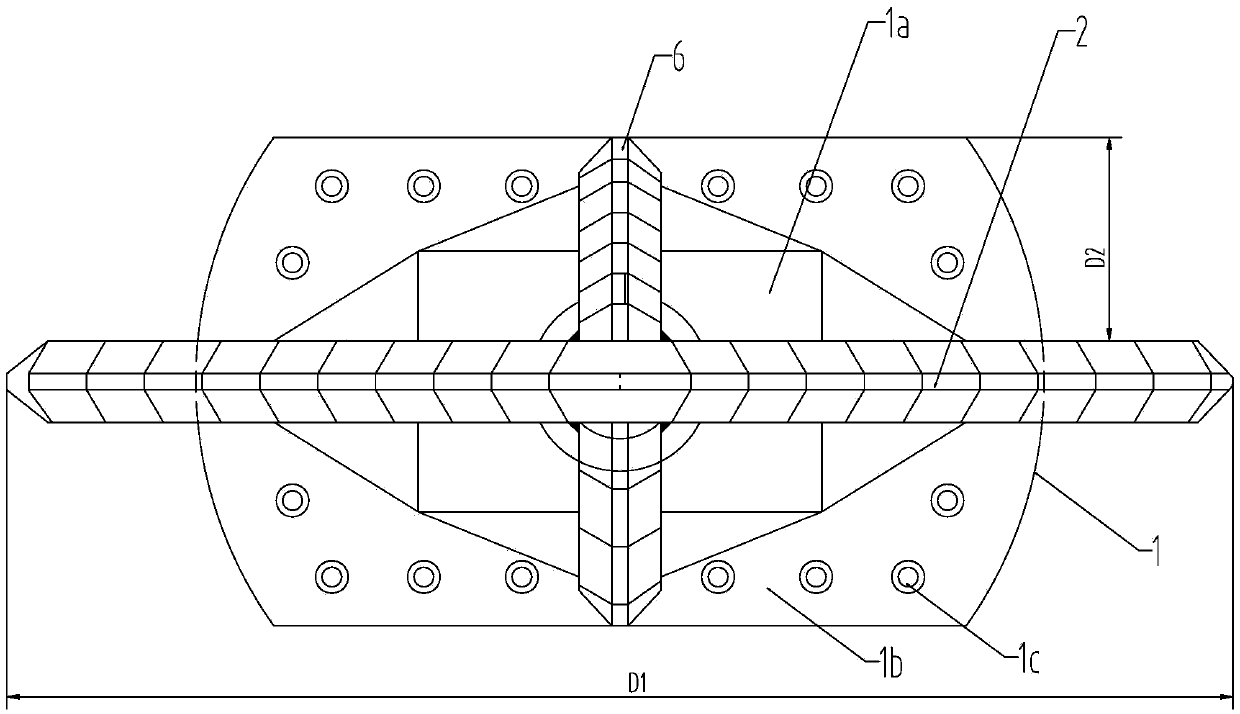

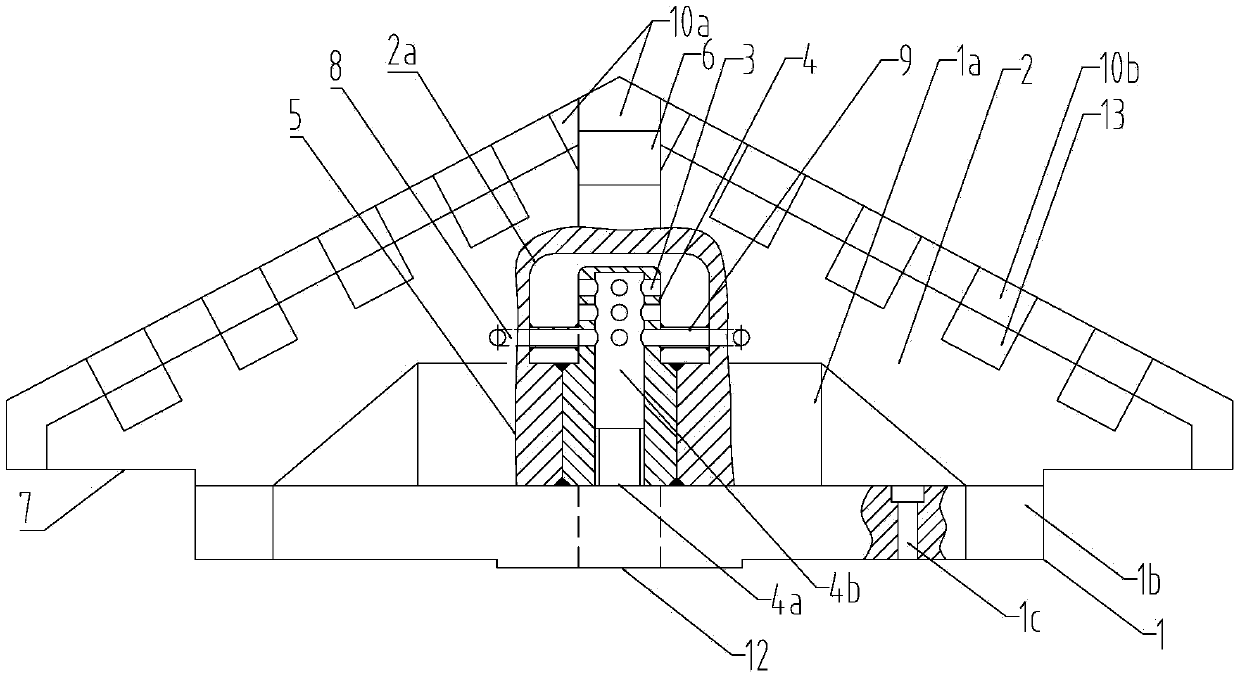

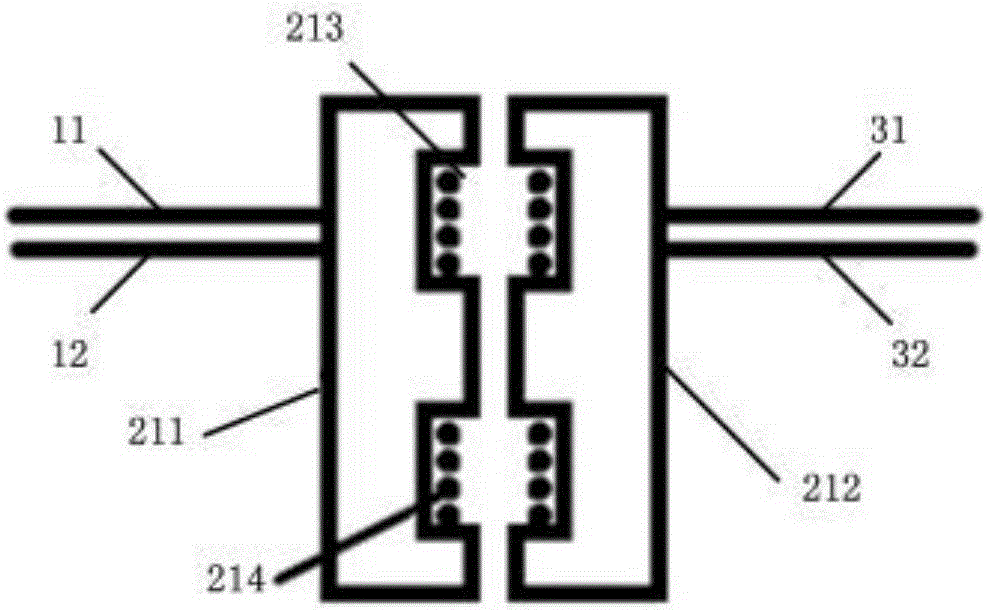

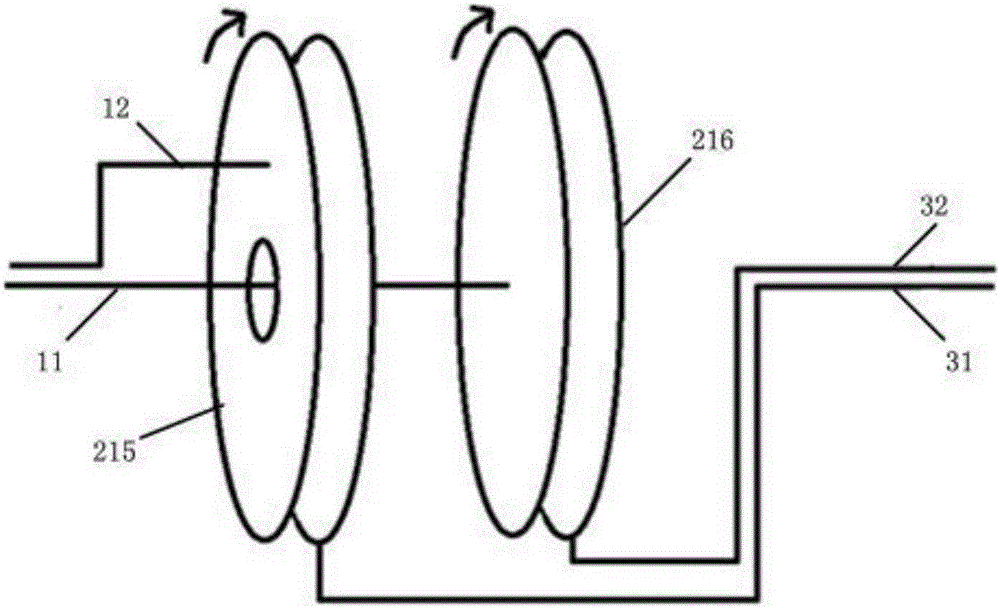

Buckle piece lamination device of conical stator punching sheet

ActiveCN106533079AImprove alignmentEasy alignmentManufacturing stator/rotor bodiesPunchingEngineering

The invention discloses a buckle piece lamination device of a conical stator punching sheet. The buckle piece lamination device comprises a stator punching sheet lamination device, a leveling device and a buckle piece lamination device, wherein an expansion sleeve, lower external cone tools and a stator punching sheet fixing seat are arranged on the stator punching sheet lamination device and are in clearance fit with one another, a trapezoidal plate is fixedly arranged on the stator punching sheet fixing seat and is arranged vertically, inclined surfaces of two sides of the trapezoidal plate can be inserted into two corresponding inner grooves of each stator punching sheet, the leveling device comprises a flattening tool, an upper internal cone tool sleeves the flattening tool, the flattening tool and the upper internal cone tool can downwards press on the stator punching sheet lamination device under the push of a leveling air cylinder, the buckle piece lamination device comprises a roller capable of transversely moving and a roller air cylinder, the roller transversely mover under the driving of the roller air cylinder, and an upper end and a lower end of a buckle piece are respectively bent and are attached onto an upper surface and a lower surface of a conical stator so that the stator punching sheets forming the conical stator can be fixed together. The buckle piece lamination device has the advantages of good perpendicularity in each stator punching sheet, stack compactness, stator inner groove orderliness and high appearance cylindricality.

Owner:安徽金箔机电产业集团股份有限公司

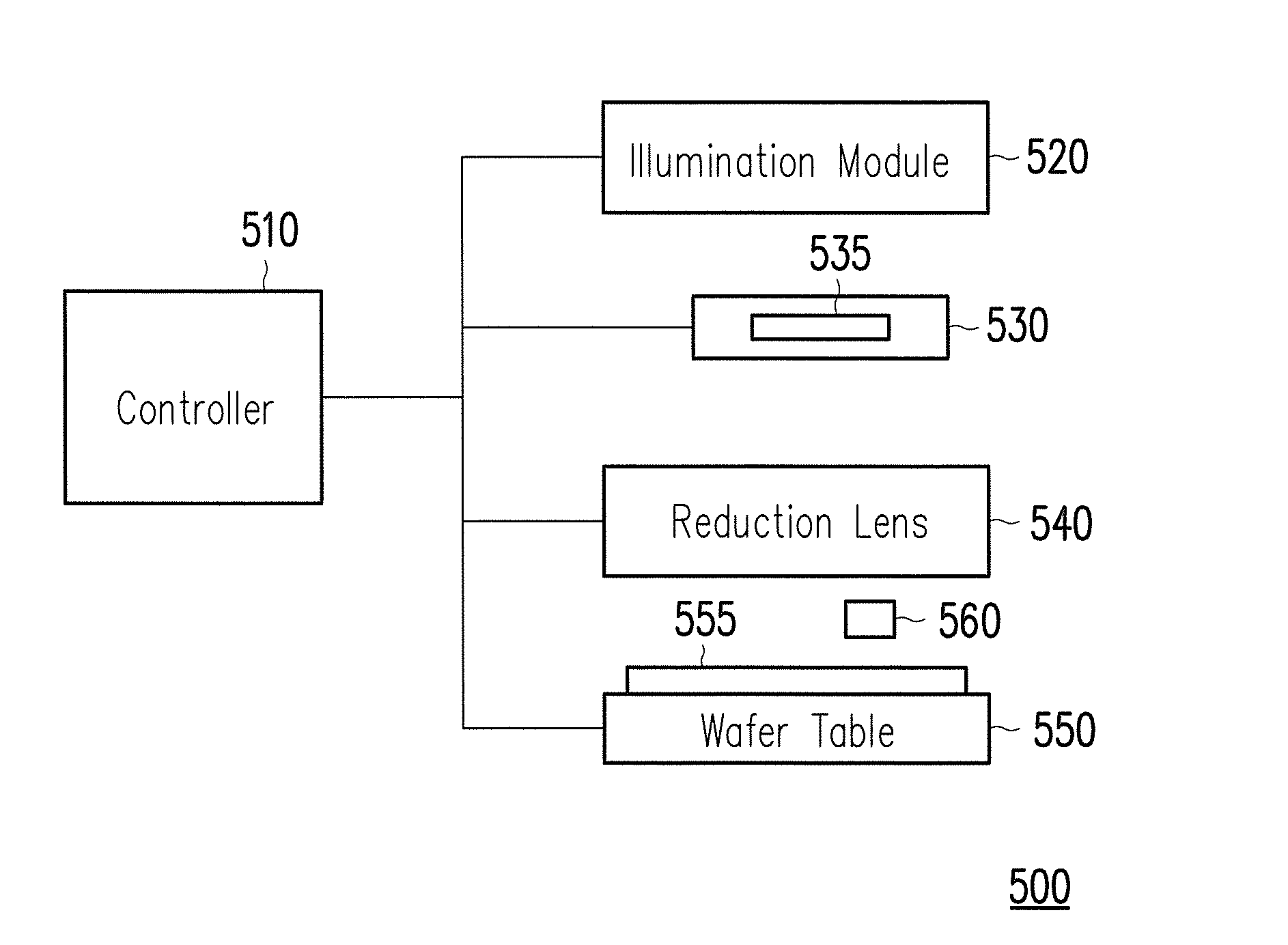

Semiconductor wafer and pattern alignment method

InactiveCN102063015AImprove alignmentImproved Alignment MarksSolid-state devicesPhotomechanical exposure apparatusIntegrated circuitStress relief

A semiconductor wafer and pattern alignment method are disclosed. The semiconductor wafer can include an exposure field; a die within the exposure field, wherein the die comprises an integrated circuit region, a seal ring region, and a corner stress relief region; and a die alignment mark disposed between the seal ring region and the corner stress relief region.

Owner:TAIWAN SEMICON MFG CO LTD

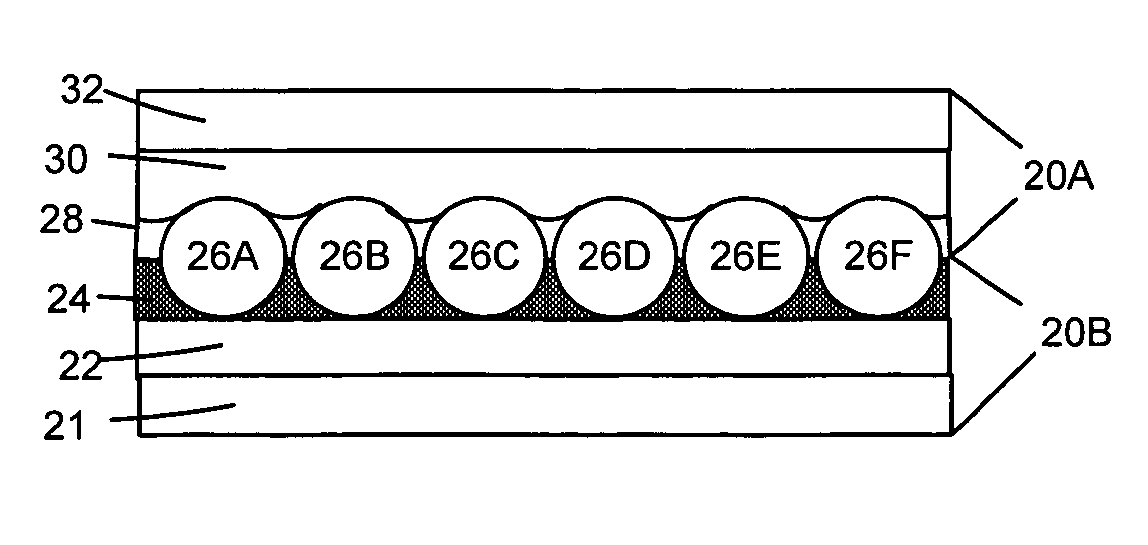

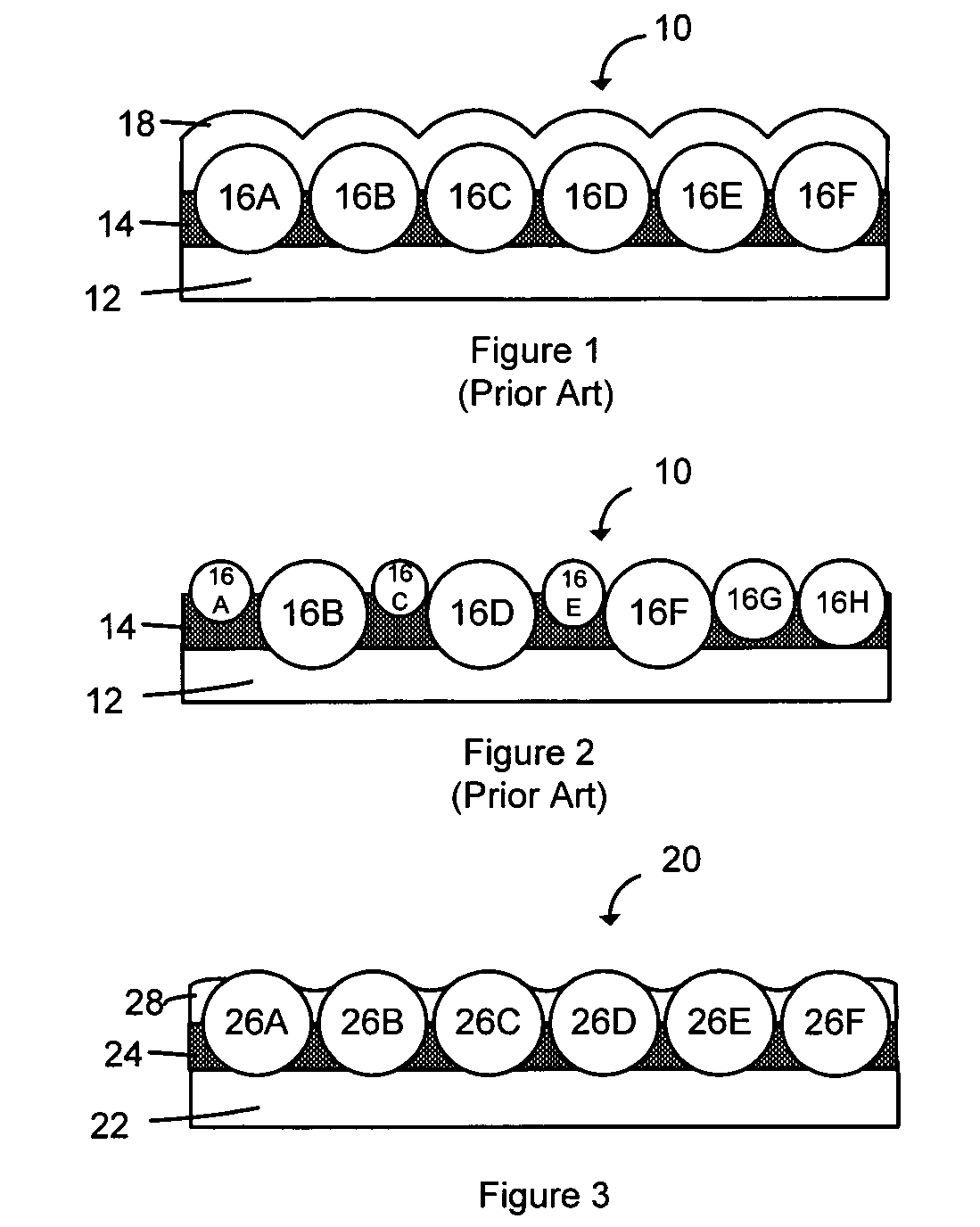

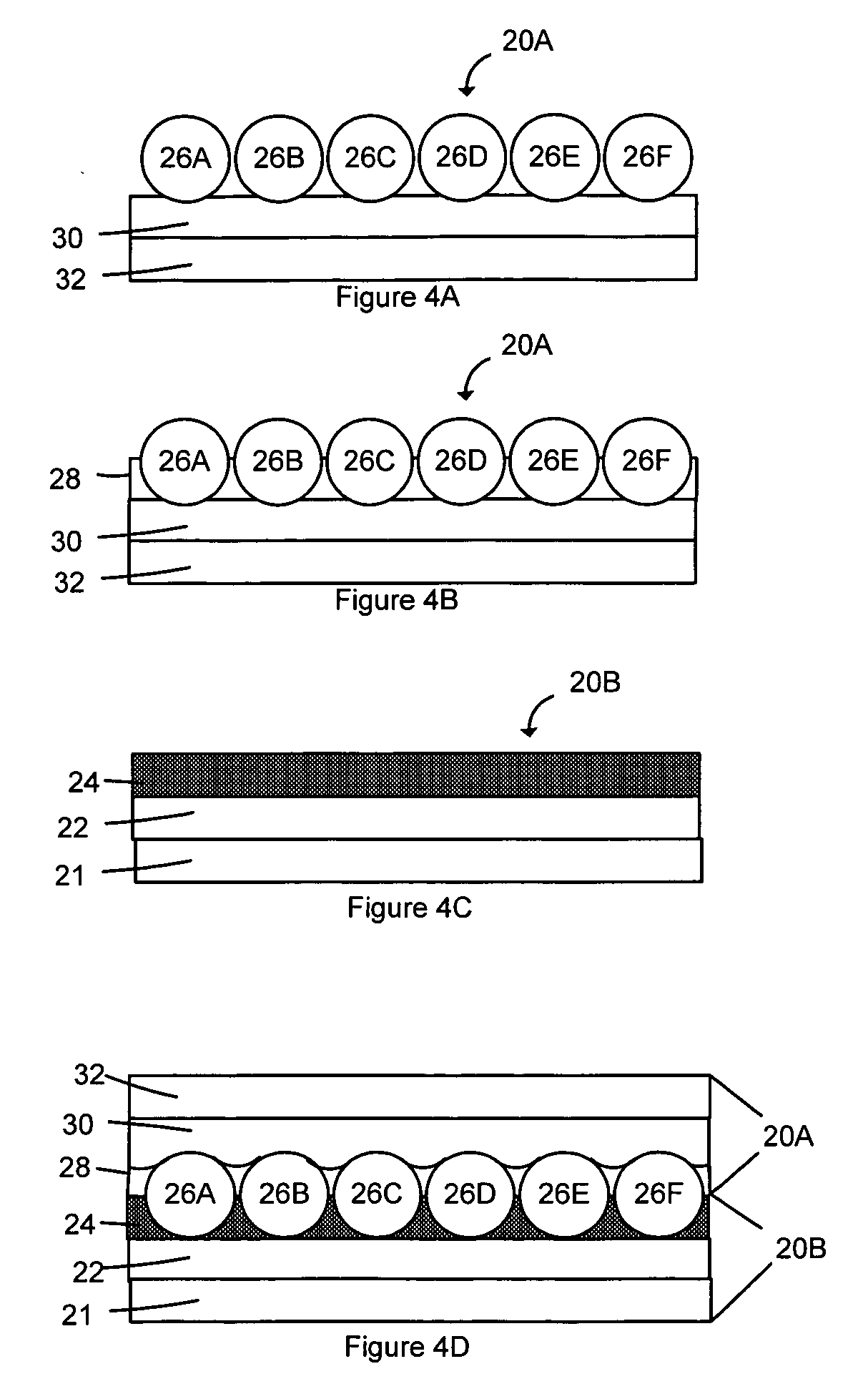

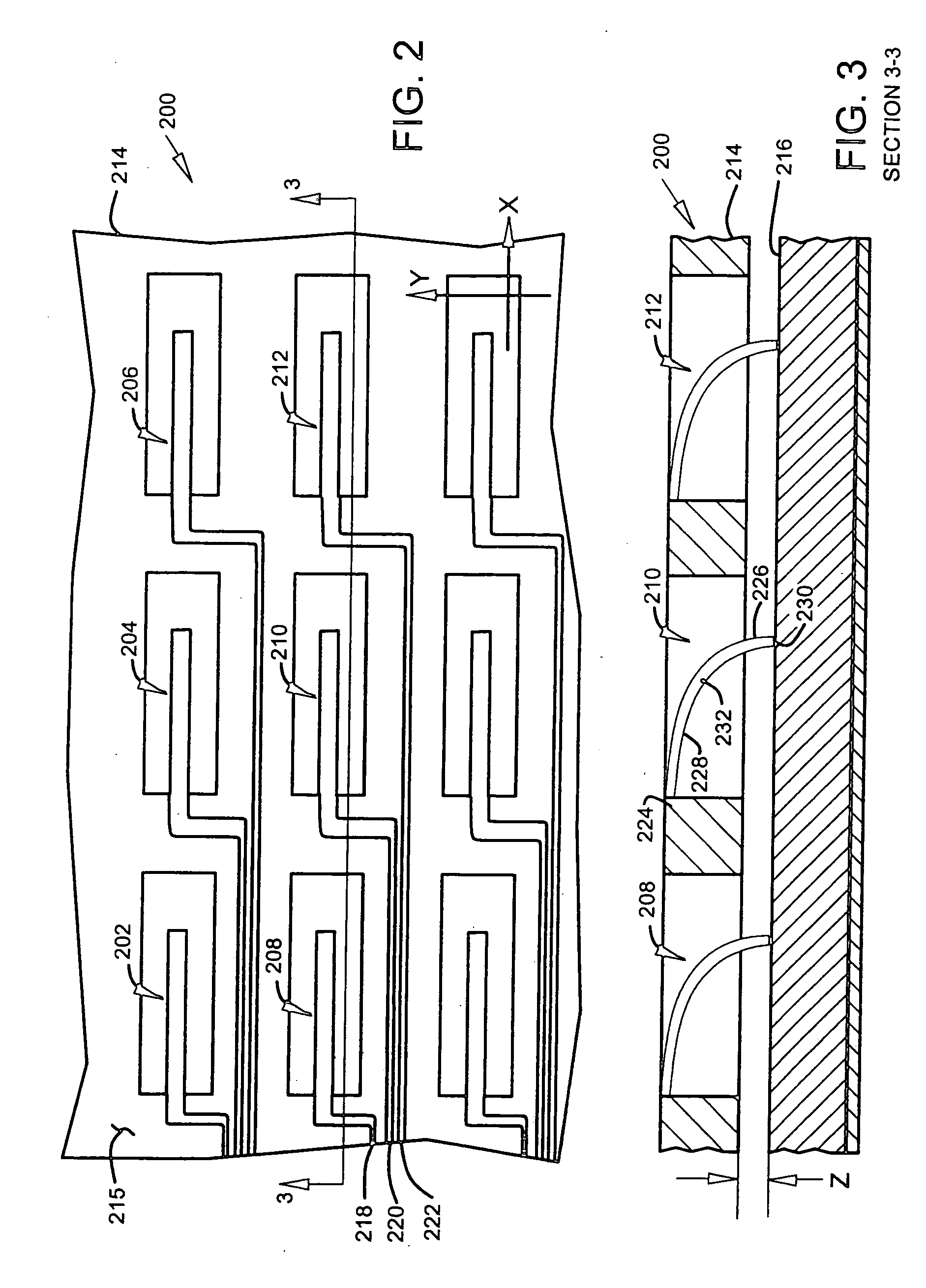

Discontinuous or variable thickness gain modification coating for projection film and method for making same

ActiveUS20060198020A1Improve alignmentProjectorsPlanar/plate-like light guidesExit surfaceMicrosphere

The present invention relates to projection films and methods of making the same. In particular, the present invention relates to a projection film whereby the microspheres exhibit improved alignment on the light exit surface and have alignment on the light entrance surface that varies according to the individual microsphere diameter. In another embodiment, the present invention relates to a projection film that has the attributes of variable gain within the single projection film. In another embodiment, the present invention relates to an exposed microsphere projection film construction that provides modification of the head-on and angular pattern of light transmission (gain).

Owner:AVERY DENNISON CORP

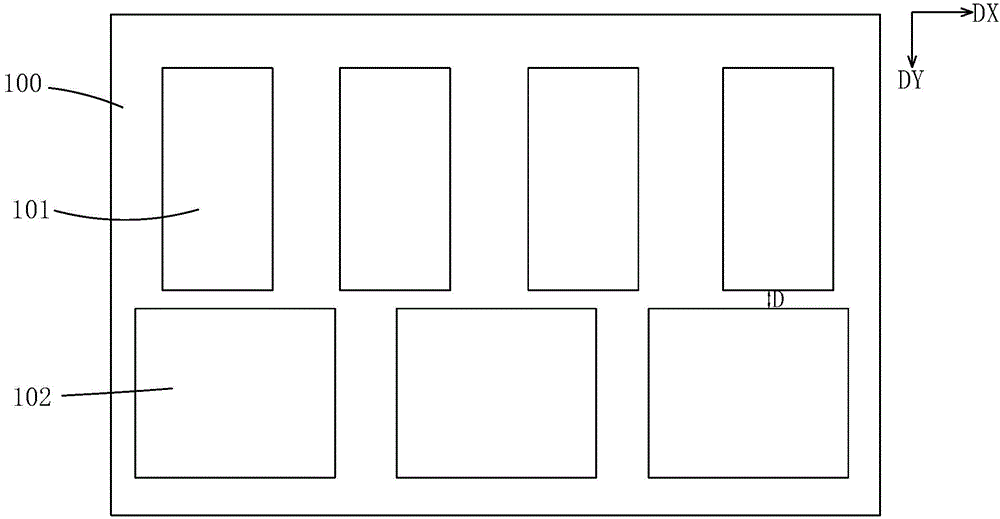

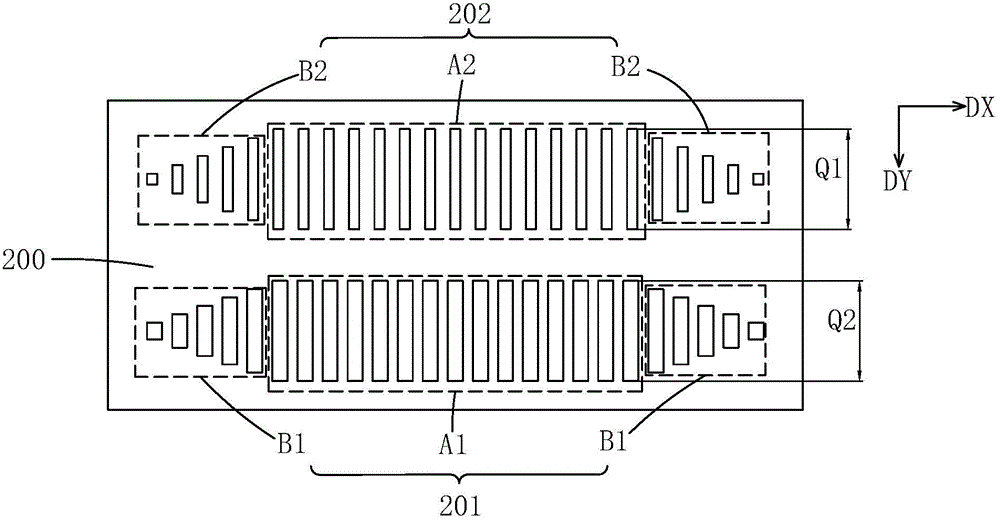

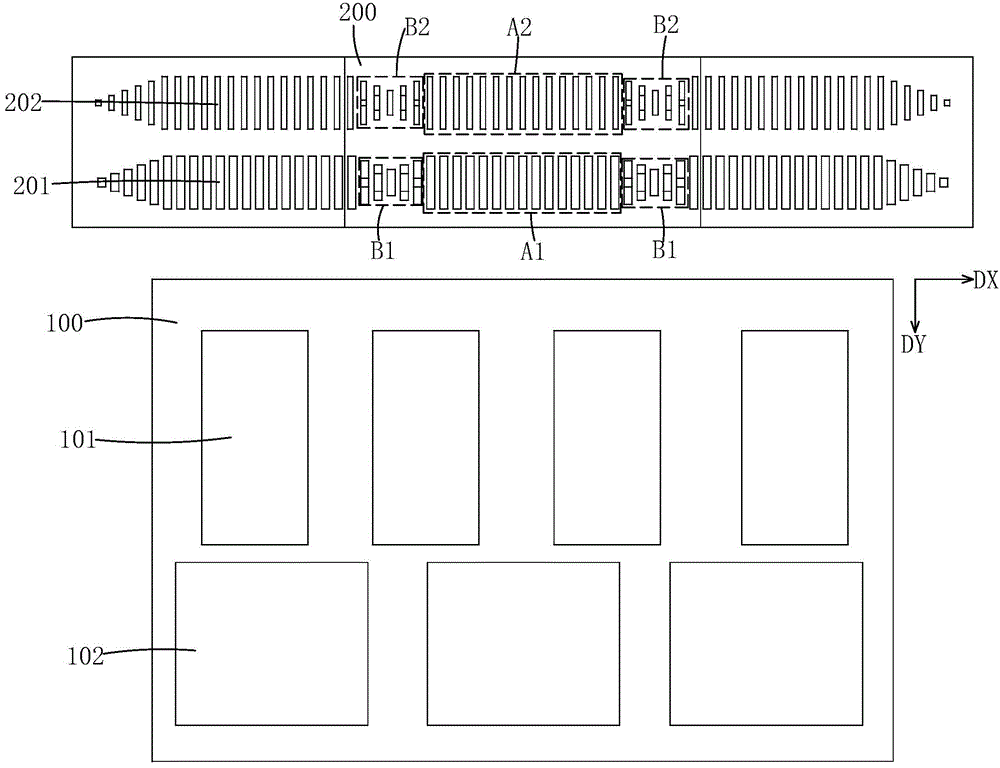

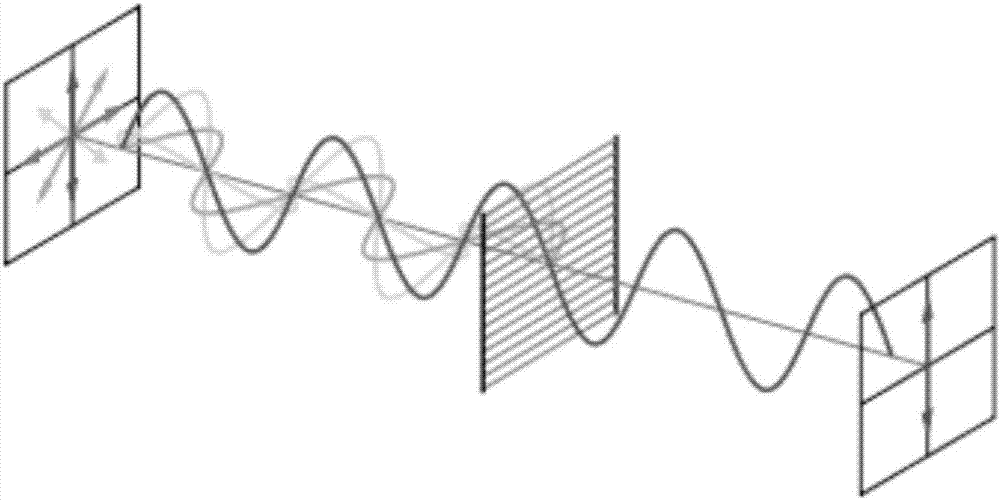

Photomask for photo alignment and photo-alignment method

ActiveCN104965388AImprove alignmentAvoid mura problemsPhotomechanical exposure apparatusMicrolithography exposure apparatusPhysicsPhotomask

The invention provides a photomask for photo alignment and a photo-alignment method. The photomask for photo alignment comprises a photomask body (2) and a plurality of light-transmitting patterns arranged on the photomask body (2), wherein the plurality of light-transmitting patterns are arrayed along the first direction (DY) line by line and are arranged along the second direction (DX) perpendicular to the first direction (DY); each light-transmitting pattern comprises a non-overlapping domain and overlapping domains, and the non-overlapping domain is not overlapped with adjacent photomasks during use; the overlapping domains are respectively positioned on the left side and the right side of the non-overlapping domain and are overlapped with the adjacent photomasks during use; the first direction (DY) is the translation forward direction of the photomask when the phototmask is used for exposure and alignment; one ends, towards the first direction (DY), of the light-transmitting patterns positioned in the overlapping domains are aligned to one ends, towards the first direction (DY), of the light-transmitting patterns positioned in the non-overlapping domain, so that the alignment effect can be improved, and the mura problem due to the fact that the unexposed domains or insufficiently-exposed domains exist when MMG products are aligned is avoided.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

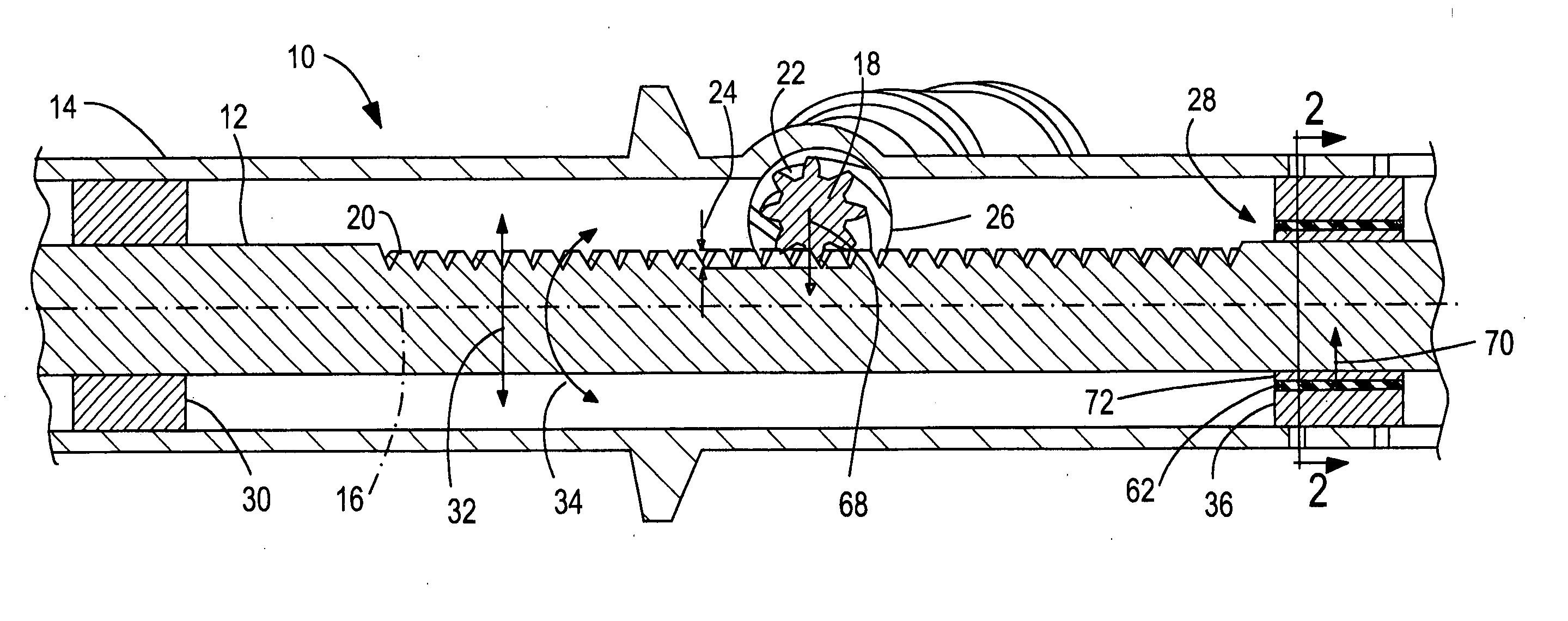

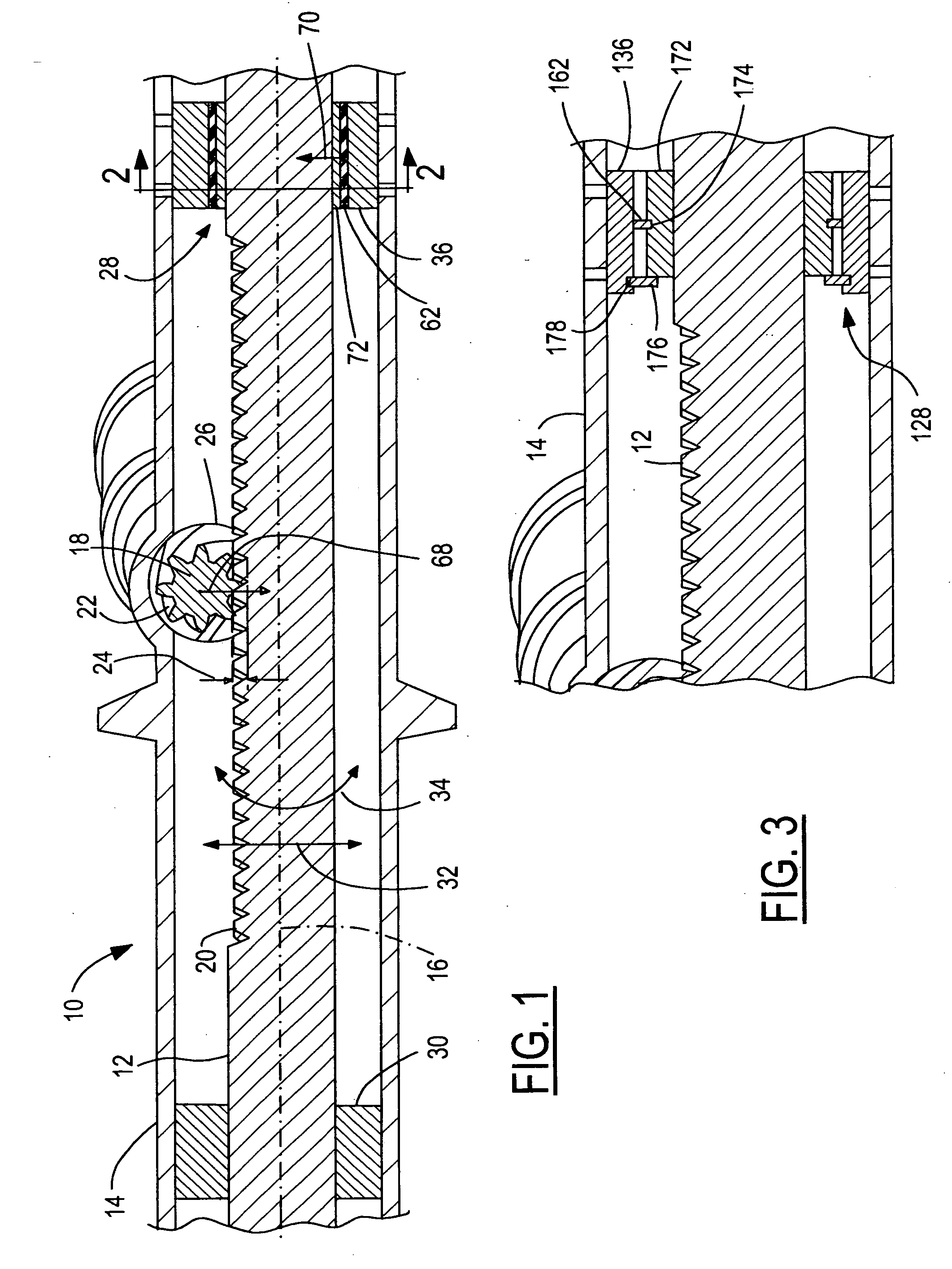

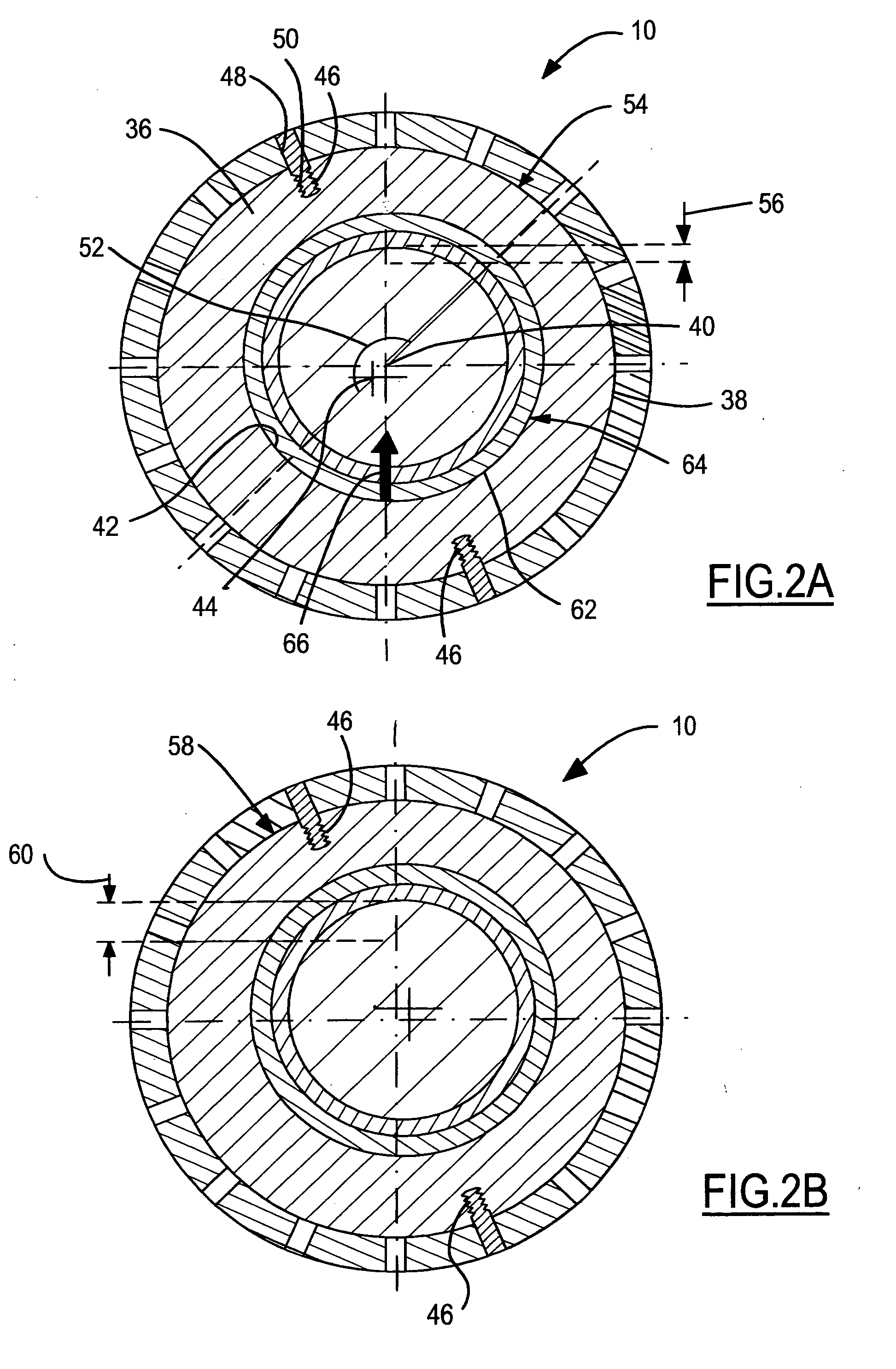

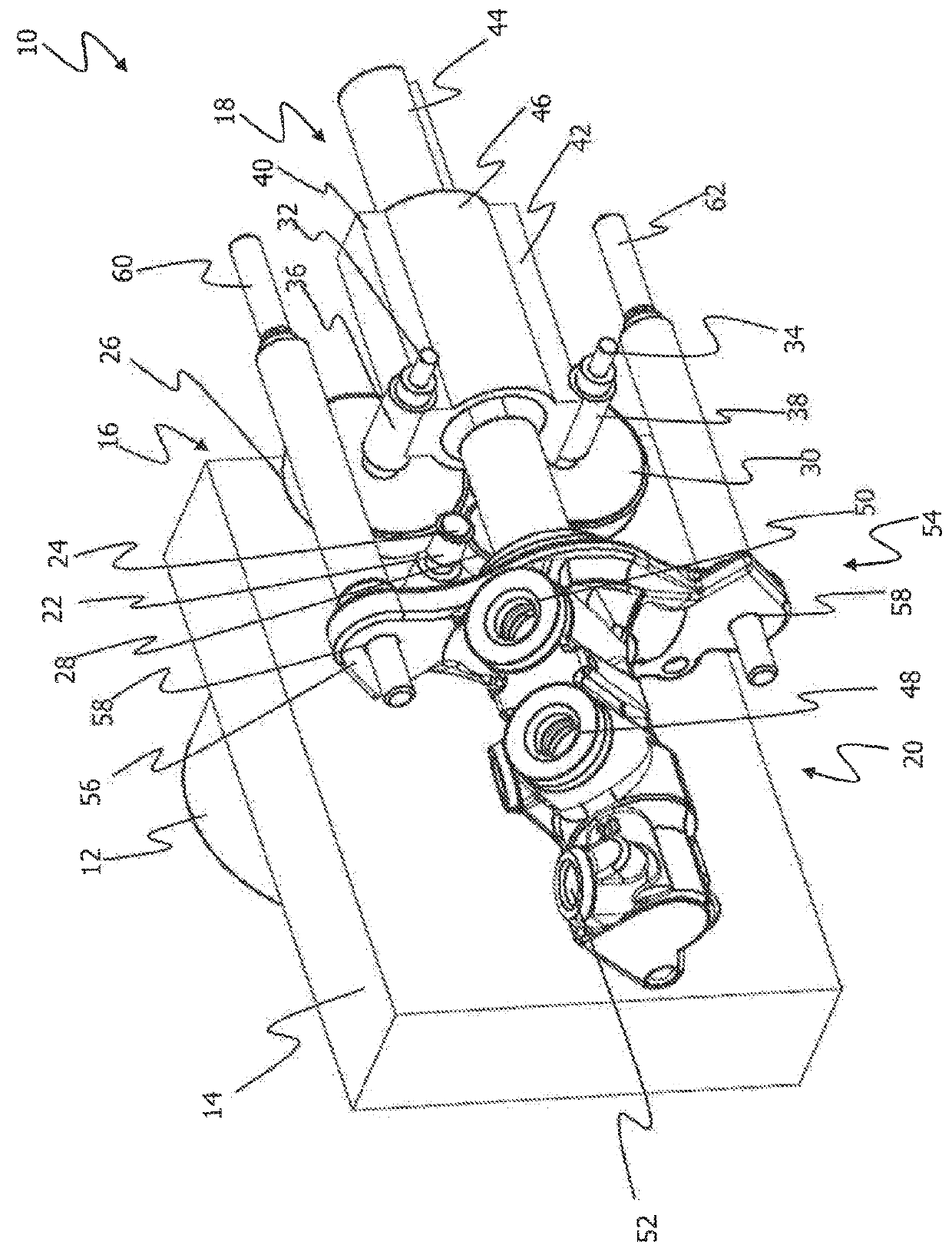

Mesh control for a rack and pinion steering system

ActiveUS20070137375A1Improve alignmentEasy alignmentPortable liftingToothed gearingsAngular rangeMesh grid

A steering mechanism is provided, including a rack, a rotatable support member, and an automatically-adjustable support member. The rack includes a rack gear portion and the pinion includes a pinion gear portion coupled with the rack gear portion. The rotatable support member is positioned with respect to the rack or the pinion such that rotation of the rotatable support member adjusts an overlap distance between the rack gear portion and the pinion gear portion. The automatically-adjustable support member automatically urges together the rack and the pinion along an urging direction. The urging direction remains substantially constant throughout the rotation of the rotatable support member within a desired angular range.

Owner:FORD GLOBAL TECH LLC

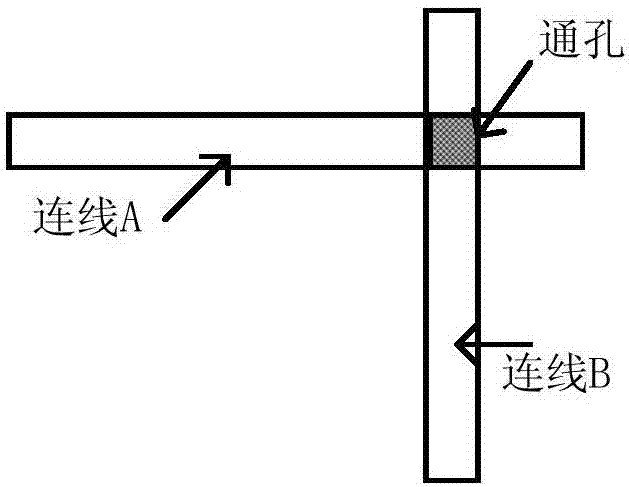

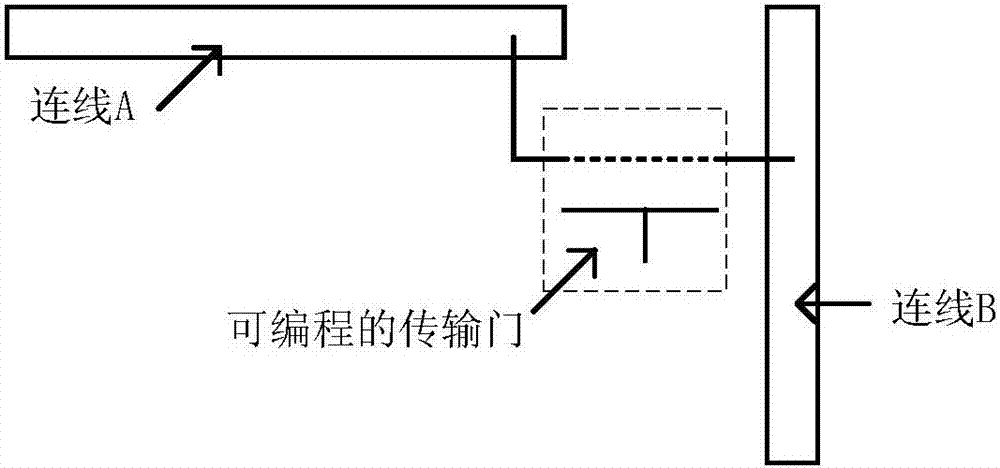

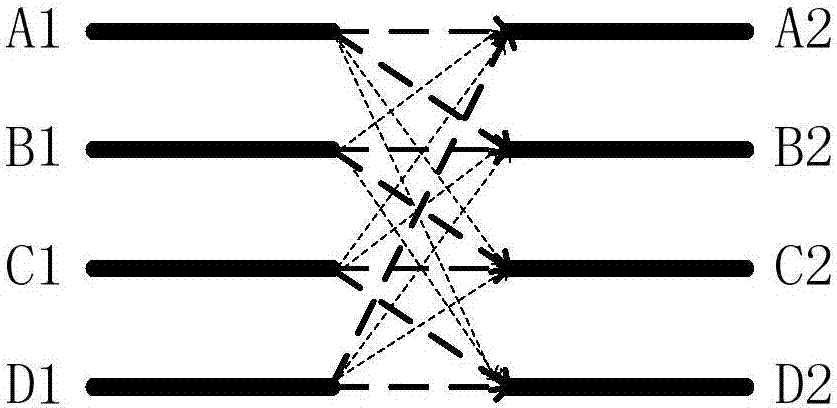

Connection structure of programmable logic device, wiring system and method of programmable logic device and layout system and method of programmable logic device

ActiveCN107194075AConnectivity preservationReduce areaCAD circuit designSpecial data processing applicationsTransmission gateProgrammable logic device

The invention relates to layout design and a software system of a programmable logic device, and discloses a connection structure of the programmable logic device, a wiring system and method of the programmable logic device and a layout system and method of the programmable logic device. In the connection structure of the programmable logic device, only adjacent wire rails in one wire rail group are connected through a programmable transmission gate, so that a cross-wire rail group programmable transmission gate is saved; new multipath selectors are increased to serve as wire rail selectors, so that wire rails of different wire rail groups can be accessed to logic units, the connectivity of all the wire rails is provided, and then the chip area, power consumption and construction cost are decreased while the connectivity of each wire rail group is kept. Moreover, the layout and wiring of the programmable logic device are improved, so that the routing rate of the connection structure is further improved and the using quantity of the multipath selectors is decreased.

Owner:SHANGHAI ANLOGIC INFOTECH CO LTD

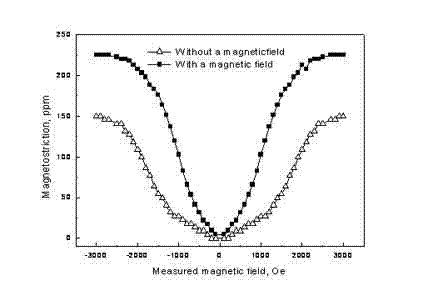

FeGa magnetostriction alloy wire and preparation method thereof

ActiveCN102400034AGrowth-promoting alignmentConvenient ArrangementDirectional solidificationThermal treatment

The invention provides a FeGa magnetostriction alloy wire which comprises the following components by atomic percent: 15-30% of Ga and the balance of Fe. The diameter of the alloy wire is 0.1-1mm, the tensile strength is 400-650MPa, and the magnetostrictive strain without action of external stress is 80-225ppm. The invention also provides a preparation method of the FeGa magnetostriction alloy wire, and the preparation method comprises the following steps: cast master alloy preparation, alloy directional solidification under a magnetic field, alloy thermal treatment under the magnetic field, drawing plastic deformation and the like. According to the invention, the characteristic of an alpha-Fe phase that the preferred direction and the preferred growth direction are (100) crystallographicdirections is fully utilized, and the action of the magnetic field is utilized to control the alloy solidification and thermal treatment processes, thus the obtained FeGa alloy wire through preparation has the advantages that the magnetostrictive strain is improved by 0.9-2.8 times compared with the FeGa alloy wire with same Ga content prepared in the prior art and the magnetostrictive strain is improved by 30-85% compared with the FeGa alloy wire without the action of the magnetic field under same conditions.

Owner:NORTHEASTERN UNIV LIAONING

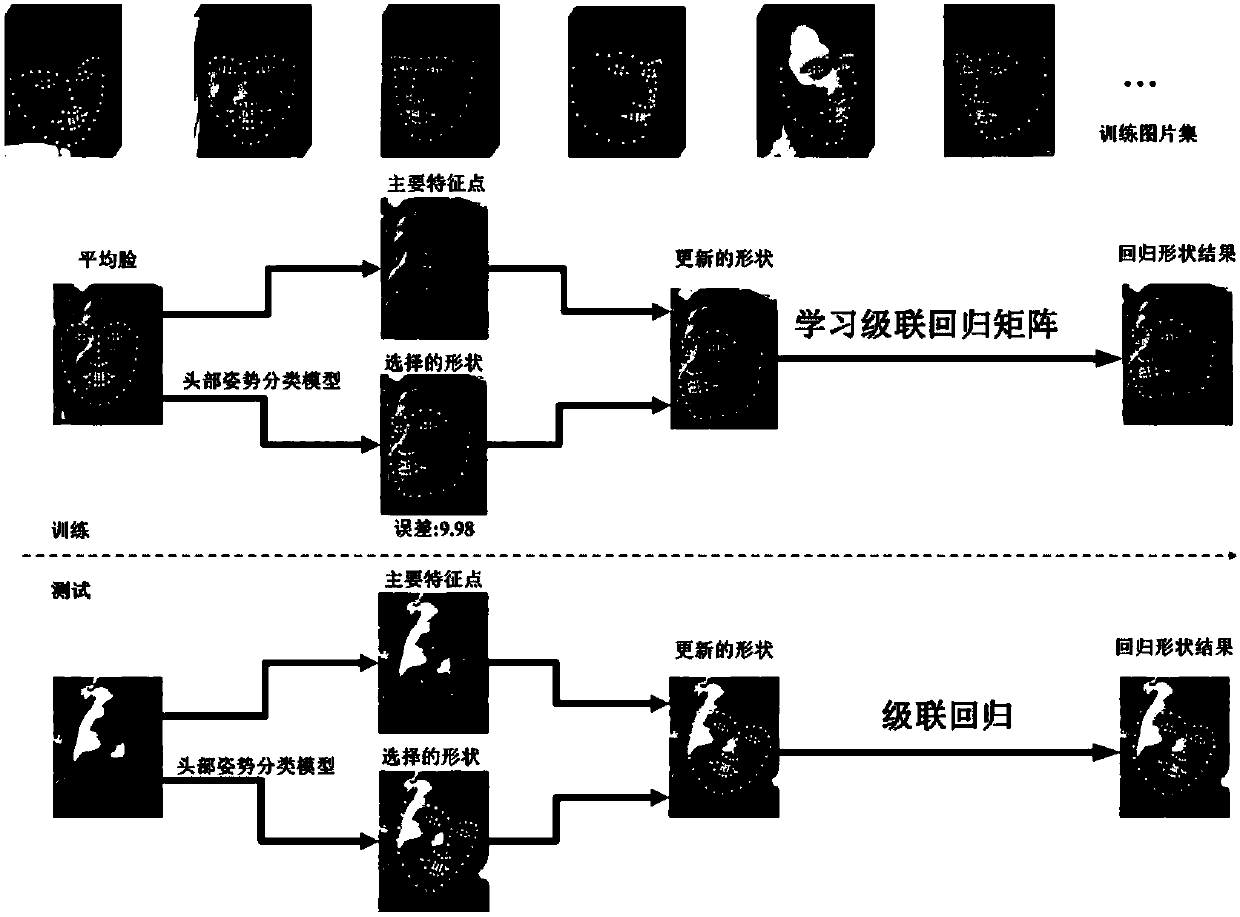

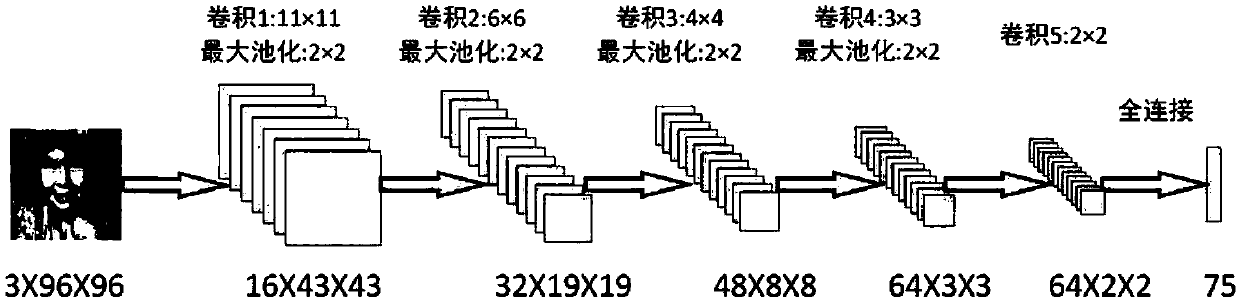

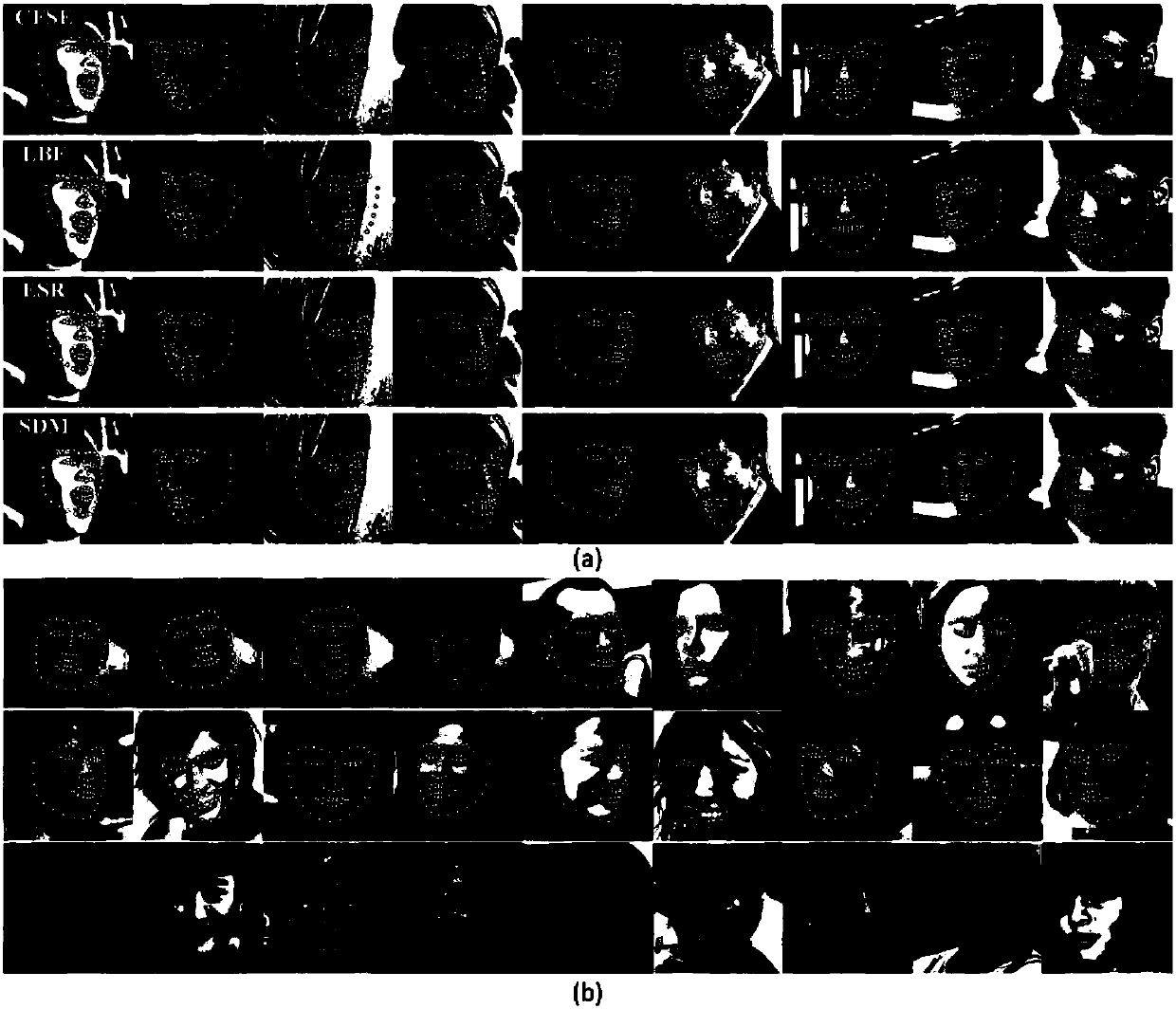

Face alignment method based on thick-to-thin face shape estimation

InactiveCN108446672AGood robustnessImprove alignmentCharacter and pattern recognitionClassification resultPostural orientation

The invention discloses a face alignment method based on thick-to-thin face shape estimation. As for any one input face image, firstly the initialized face shape is estimated and then the real shape of the face is gradually approximated, including estimation of the position of the main feature points of the face and the face expressions through the multitask deep learning framework, a head postureclassification model based on the convolutional neural network is constructed to perform accurate estimation and classification of the heat posture of the face, and the more accurate initialized shape is obtained by using the head posture classification result and the estimation result of the face expressions and the position of the main feature points; and the respective regressor is trained based on the initialized shape according to the classification result of the posture and the expressions and the face shape is updated so as to be approximate to the standard shape. The more accurate face initialized shape is constructed and the more advanced cascade regression framework is used so that the robustness of the face expressions, the head posture and the illumination shade difference canbe enhanced.

Owner:WUHAN UNIV

Sensing contact probe

InactiveUS20070011899A1Improve alignmentEasy alignmentNanoinformaticsFerroelectric carrier recordingPhysicsStress relief

A sensing contact probe includes a beam support and a probe. The probe has a bent beam body that extends from the beam support to a probe tip face that has a position and faces in an angular direction. The bent beam body has first and second beam layers bonded together and have differing residual stresses that bend the beam body. A stress relief region is formed in the bent beam body. The stress relief region has an adjusted stress property that adjusts the bending to control the probe tip face position and angular direction.

Owner:SEAGATE TECH LLC

Central fishtail cutter

The invention discloses a central fishtail cutter and belongs to the field of parts of shield tunneling machines. The central fishtail cutter comprises a cutter holder, a first cutter body, an additive injection block and two second cutter bodies, wherein the two second cutter bodies are respectively and symmetrically arranged on two sides of the first cutter body and are vertically fixed on the first cutter body; the bottoms of the two second cutter bodies are fixed on the cutter holder; a second accommodation groove is formed in a position, corresponding to the additive injection block, of each second cutter body; the additive injection block is located in an accommodation cavity and is mounted in an additive injection block mounting hole; injection channels are formed in the first cutter body and the two second cutter bodies; a plurality of injection holes are formed in the position, corresponding to the accommodation cavity, of the additive injection block; the lower injection holes are connected with the injection channels through connection tubes. Through the central fishtail cutter, the injection channels of the first cutter body and the second cutter bodies are capable of guiding additives in the additive injection block to outlets of the injection channels through the connection tubes, so that the injection range of the additives can be broadened; the problem of formation of mud cakes can be effectively avoided.

Owner:WUHAN MARINE MACHINERY PLANT

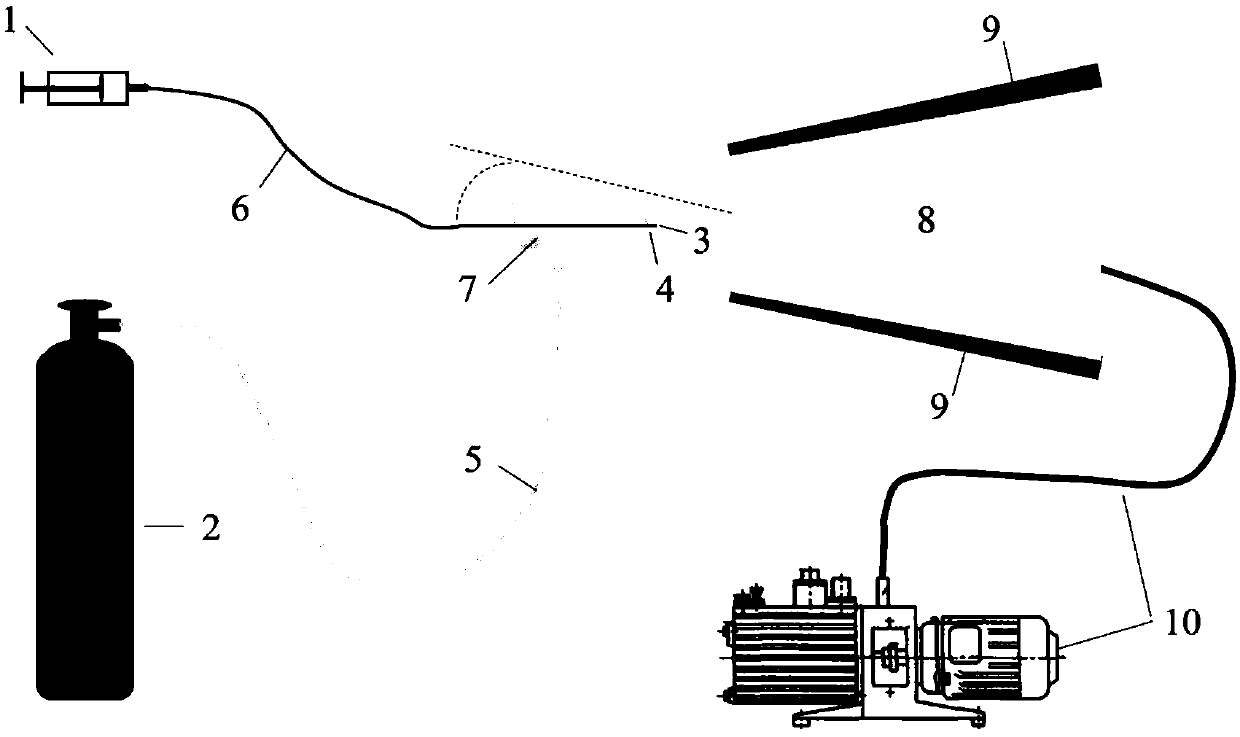

Device and method for preparing directionally arranged fiber by solution blow-spinning technology

ActiveCN109537073AEase of mass productionFacilitate single batch preparationNew-spun product collectionNon-woven fabricsFiberSpin system

The invention discloses a device and a method for preparing directionally arranged fiber by a solution blow-spinning technology. The device comprises a solution blow-spinning system and a system for collecting fiber directionally arranged by airflow; the solution blow-spinning system comprises a spinning solution, an airflow control system and a blow-spinning device; the blow-spinning device, a spinning solution and the airflow control system are connected; a spinning collection system comprises a paving collection net; the paving collection net is connected with a negative pressure device; and the solution blow-spinning system collects directionally arranged nanometer fiber on the paving collection net by adjusting the angle of the spinning air flow and the paving collection net and by taking high-speed airflow as a directional driving force. The device and the method are relatively simple to operate, have many adjustable parameters and are high in precision; and the fiber obtained through preparation is high in arrangement degree, large in preparation quantity and high in uniformity.

Owner:XI AN JIAOTONG UNIV

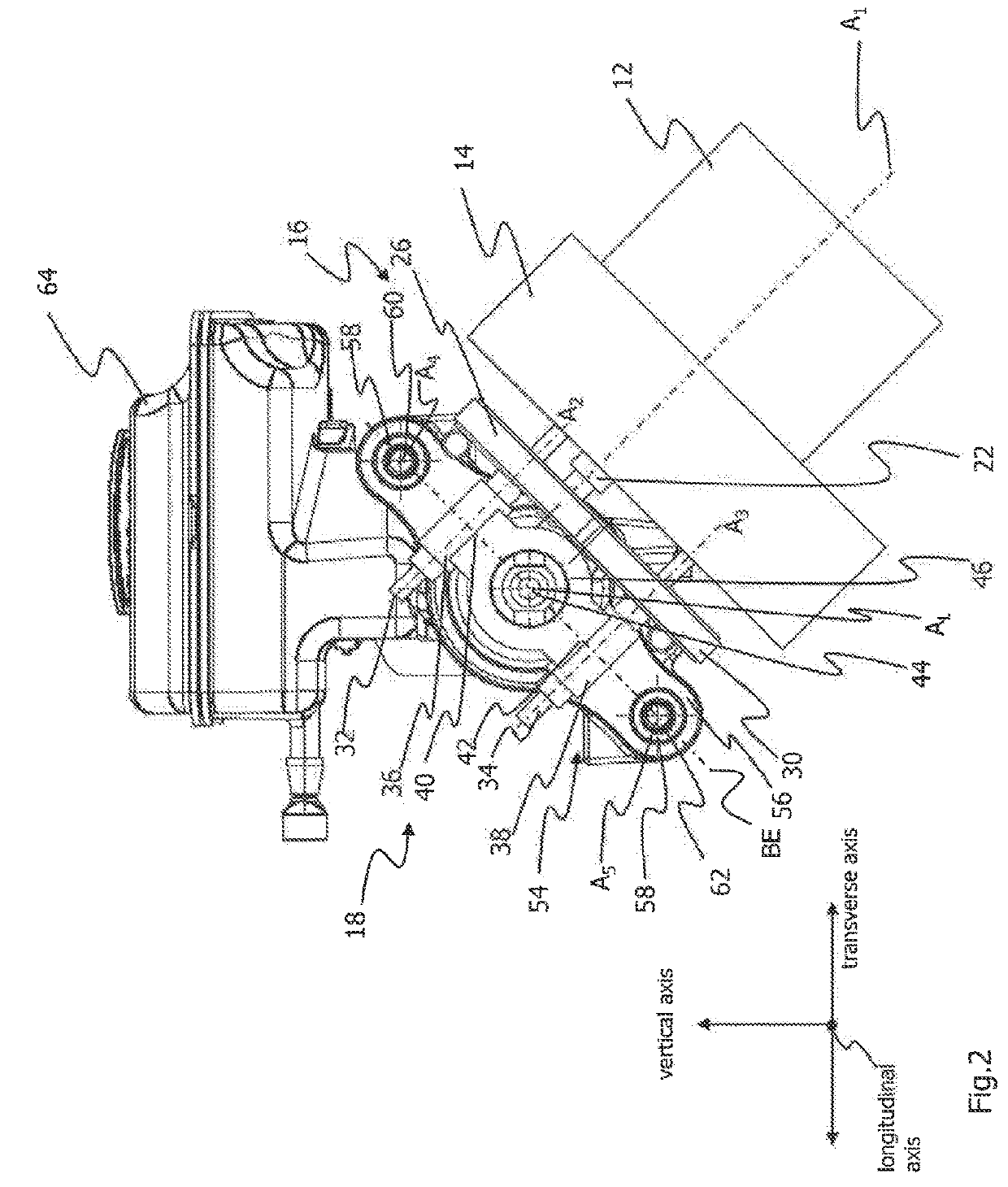

Assembly Having a Brake Cylinder and an Electromechanical Brake Booster

ActiveUS20180273011A1Reduce structural space requirementImprove alignmentBraking action transmissionToothed gearingsEngineeringVehicle brake

The invention relates to an assembly for a vehicle brake system, which comprises at least one brake cylinder and an electromechanical brake booster, having a drive arrangement for driving at least one actuating device designed for actuating a brake cylinder, wherein the drive arrangement has at least one electric motor and a gear mechanism for coupling the electric motor to the at least one actuating device, wherein at least one fastening device is provided for fastening the assembly to a vehicle, said fastening device defining a fastening plane. According to the invention the rotary shaft of the electric motor is arranged perpendicular to the longitudinal axis of the actuating device and at an angle of between 60° and 120° to the fastening plane.

Owner:LUCAS AUTOMOTIVE GMBH +1

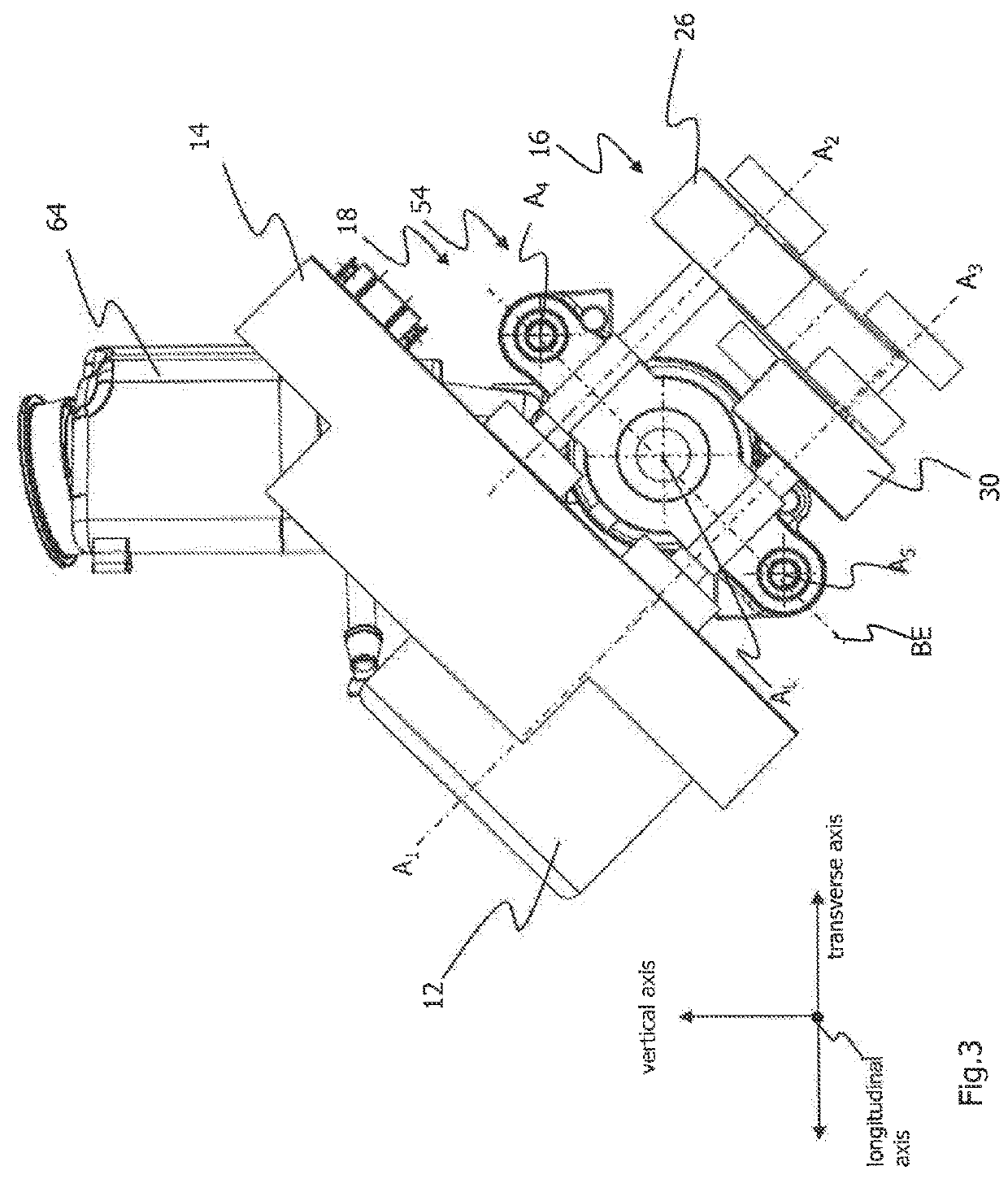

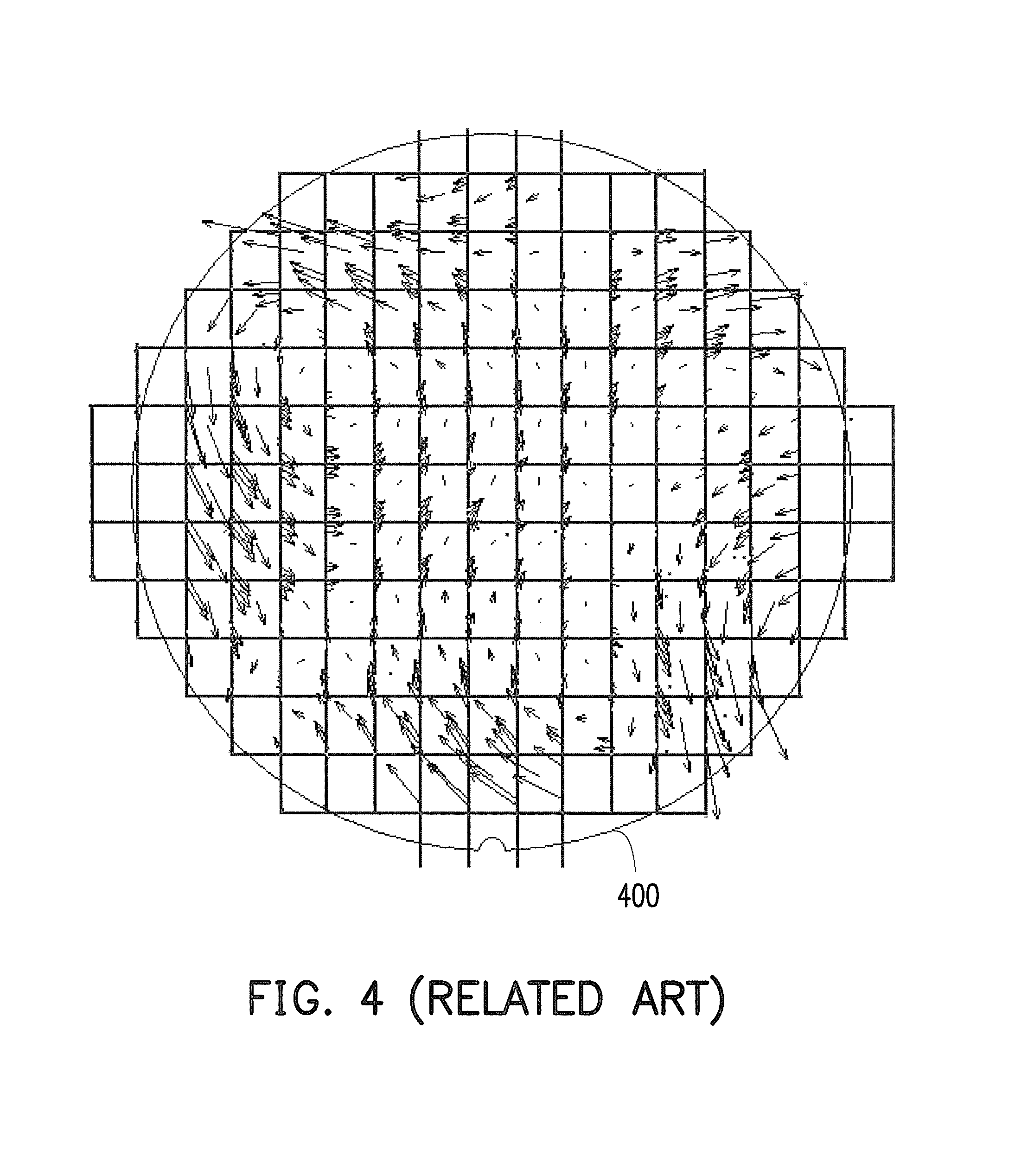

Scanner and method for performing exposure process on wafer

InactiveUS20160048087A1Improve alignmentEasy alignmentSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPhysicsExposure

A scanner and a method for performing an exposure process through a photomask on a wafer are provided. The exposure process includes an alignment step and an exposure step. The method includes the steps of moving a wafer table to align the wafer with an alignment apparatus, wherein the wafer table includes at least one chuck hole to attach the wafer to the wafer table by vacuum chucking, detecting an actual position of each of a plurality of alignment marks on the wafer, calculating an index value based on a difference between a predicted position and the actual position of each alignment mark, adjusting a vacuum pressure of the at least one chuck hole in the alignment step when the index value is larger than a first threshold value, and finishing the exposure process when the index value is smaller than or equal to the first threshold value.

Owner:MACRONIX INT CO LTD

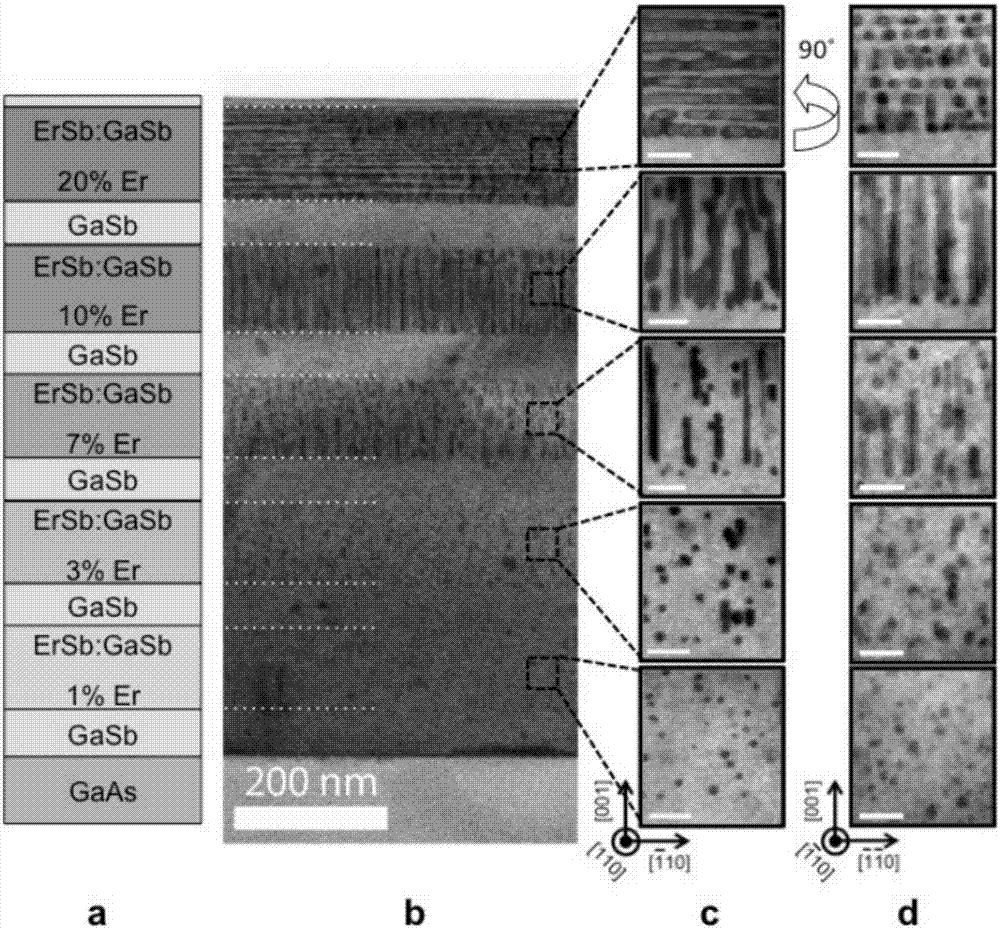

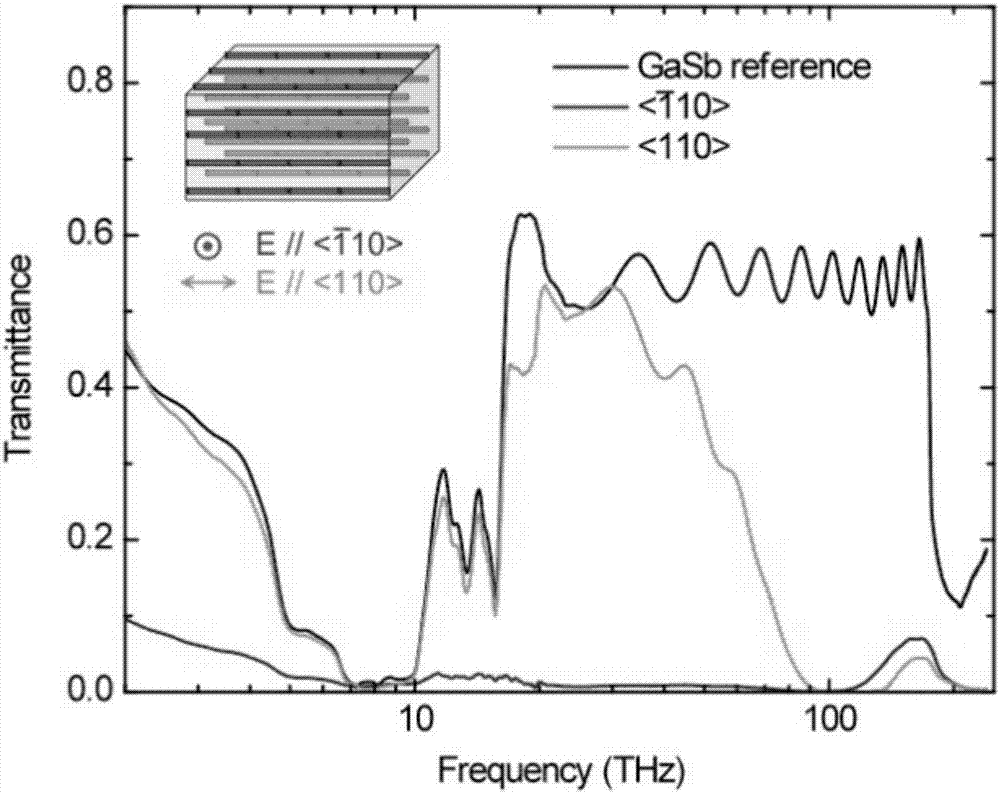

Thin film material used for terahertz and infrared light polarization modulation and preparation method thereof

ActiveCN107065058AEasy to integrateImprove continuityPolarising elementsGallium antimonideSemiconductor materials

The invention discloses a thin film material used for terahertz and infrared light polarization modulation and a preparation method thereof. According to the thin film material, particularly, an ErSb nanowire array is embedded in a GaSb substrate, the direction of the nanowire array is vertical to or parallel with the surface of the substrate, and when the volume by volume concentration of the ErSb is 10%, the direction of the nanowire array is vertical to the surface of the substrate; and when the volume by volume concentration of the GaSb is 15 to 25%, the direction of the nanowire array is parallel with t the surface of the substrate. Through a molecular beam epitaxy method, a composite material of embedding the nanowire structure with a semi metallic property in a semiconductor material is acquired, the material can be used for a broadband terahertz and infrared polarizer and can be integrated with a terahertz and infrared optoelectronic device based on III-V semiconductor materials.

Owner:NANJING UNIV

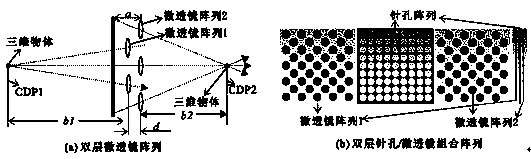

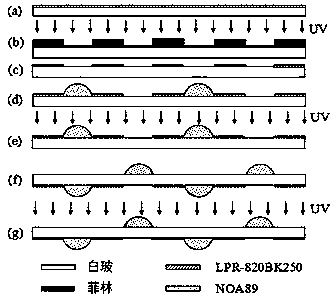

Double-layer pinhole microlens combination array manufacturing method based on inkjet printing

InactiveCN108732661AImprove alignmentQuality improvementDuplicating/marking methodsPrinting after-treatmentPhotolithographyVoltage

The invention discloses a double-layer pinhole microlens combination array manufacturing method based on inkjet printing. The invention provides high-precision and high-aligning-degree precision of the integrated imaging double-layer pinhole / microlens combination array through lithography and inkjet printing. The method comprises the steps of preparing a black circular hole trough array (namely acircular hole array) by means of a lithography method, performing fixation by means of black circular holes; then performing inkjet printing on a cleaned black circular hole array through using UV resin with low viscosity and high transmittance as ink, forming a projected ink liquid drop by means of a hydrophobic effect of a template and an interface tension function of a substrate, regulating a liquid drop parameter through controlling a printing air pressure and a driving voltage, performing multiple times of printing under a precondition that no decorative modification on the substrate surface is not required, regulating a lens height; and obtaining a high-quality microlens array after ultraviolet curing.

Owner:YANGEN UNIV

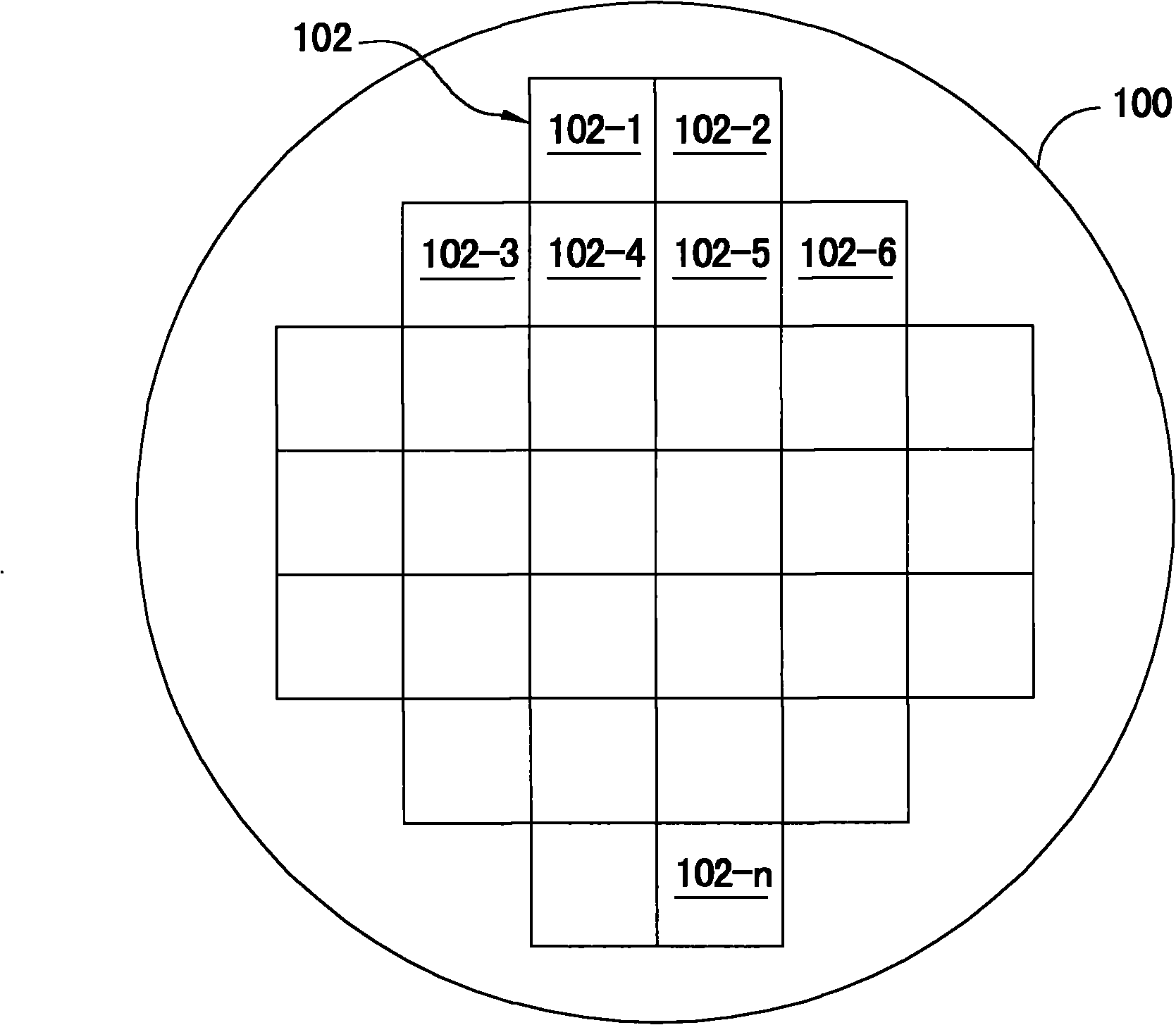

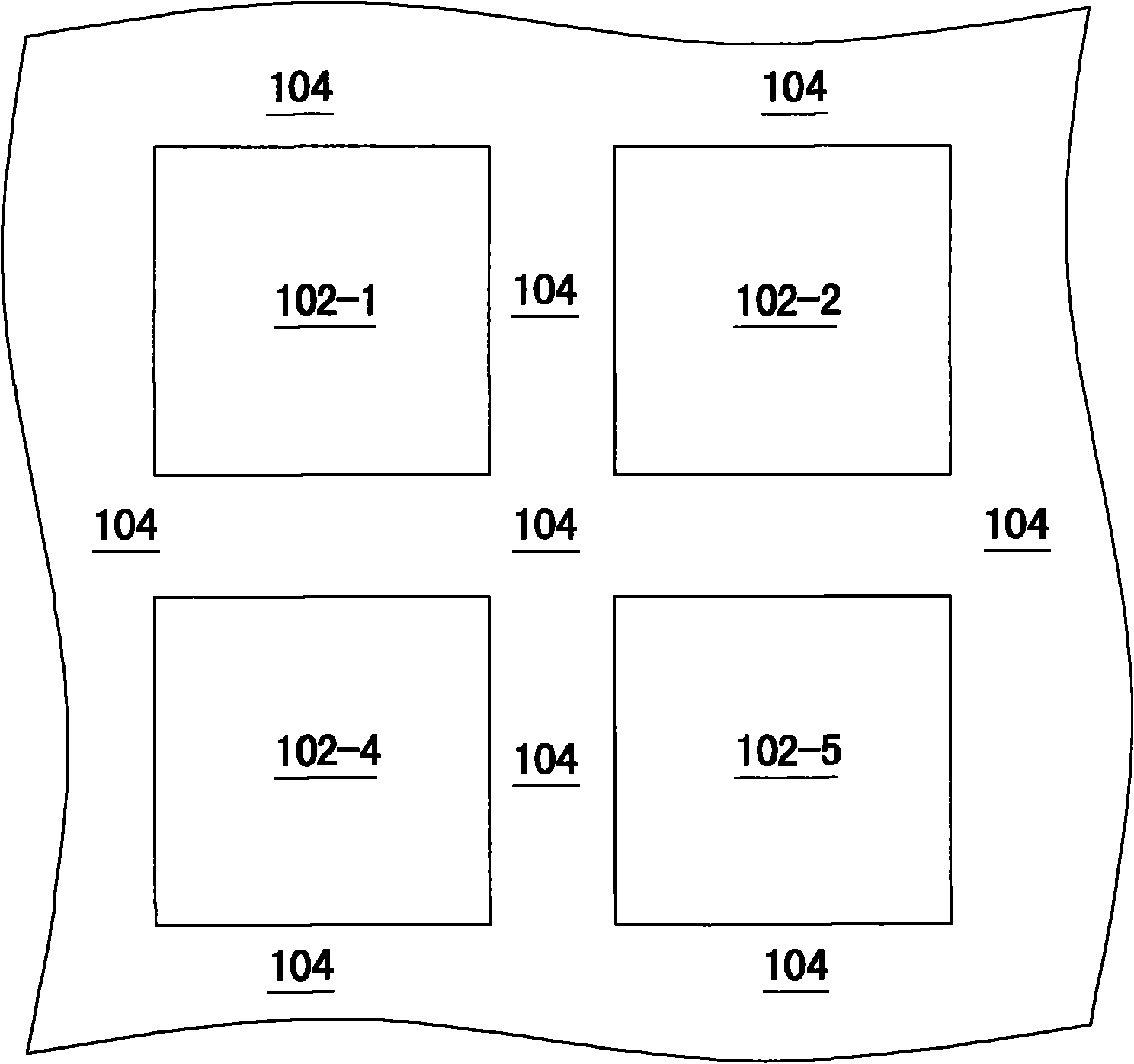

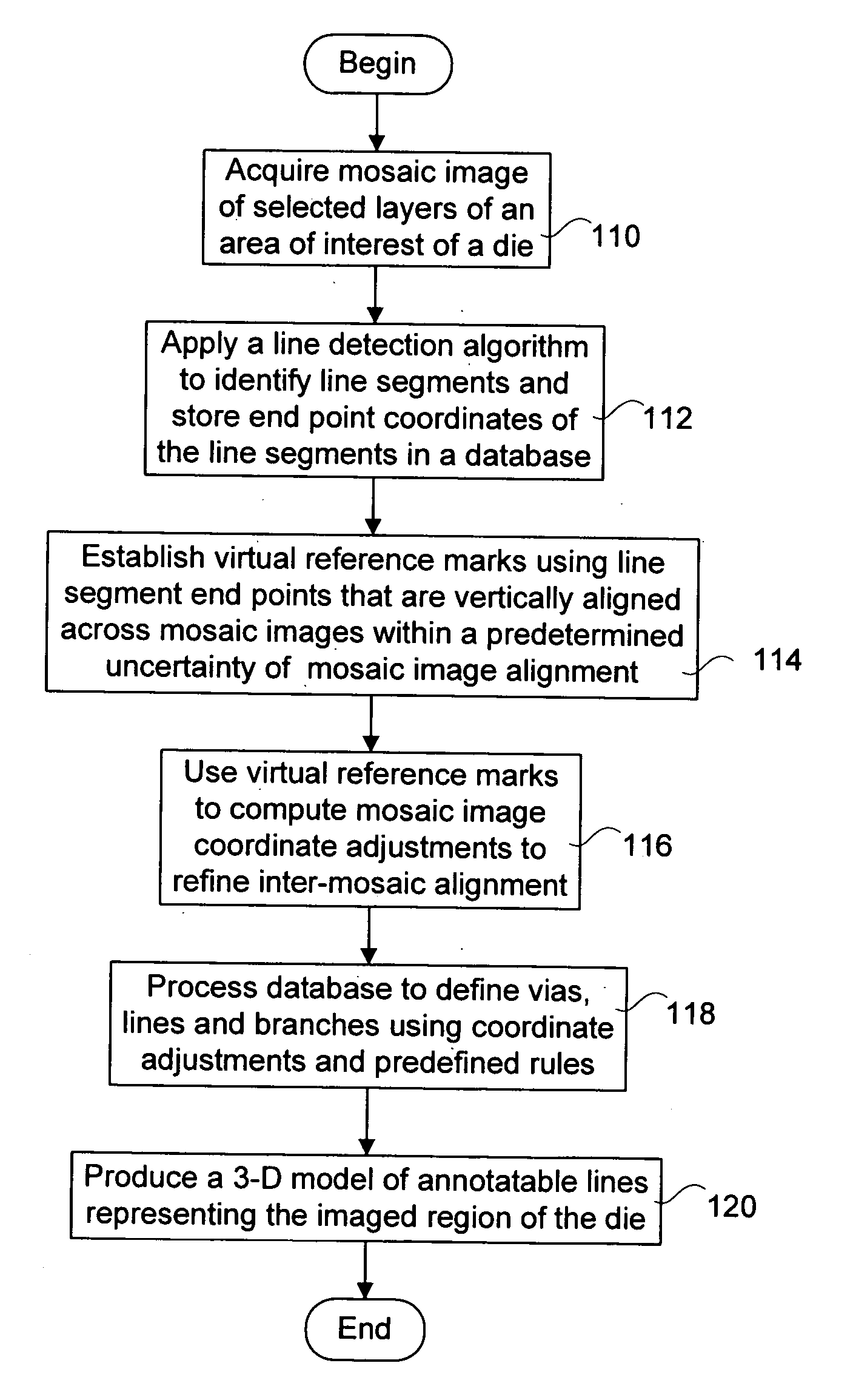

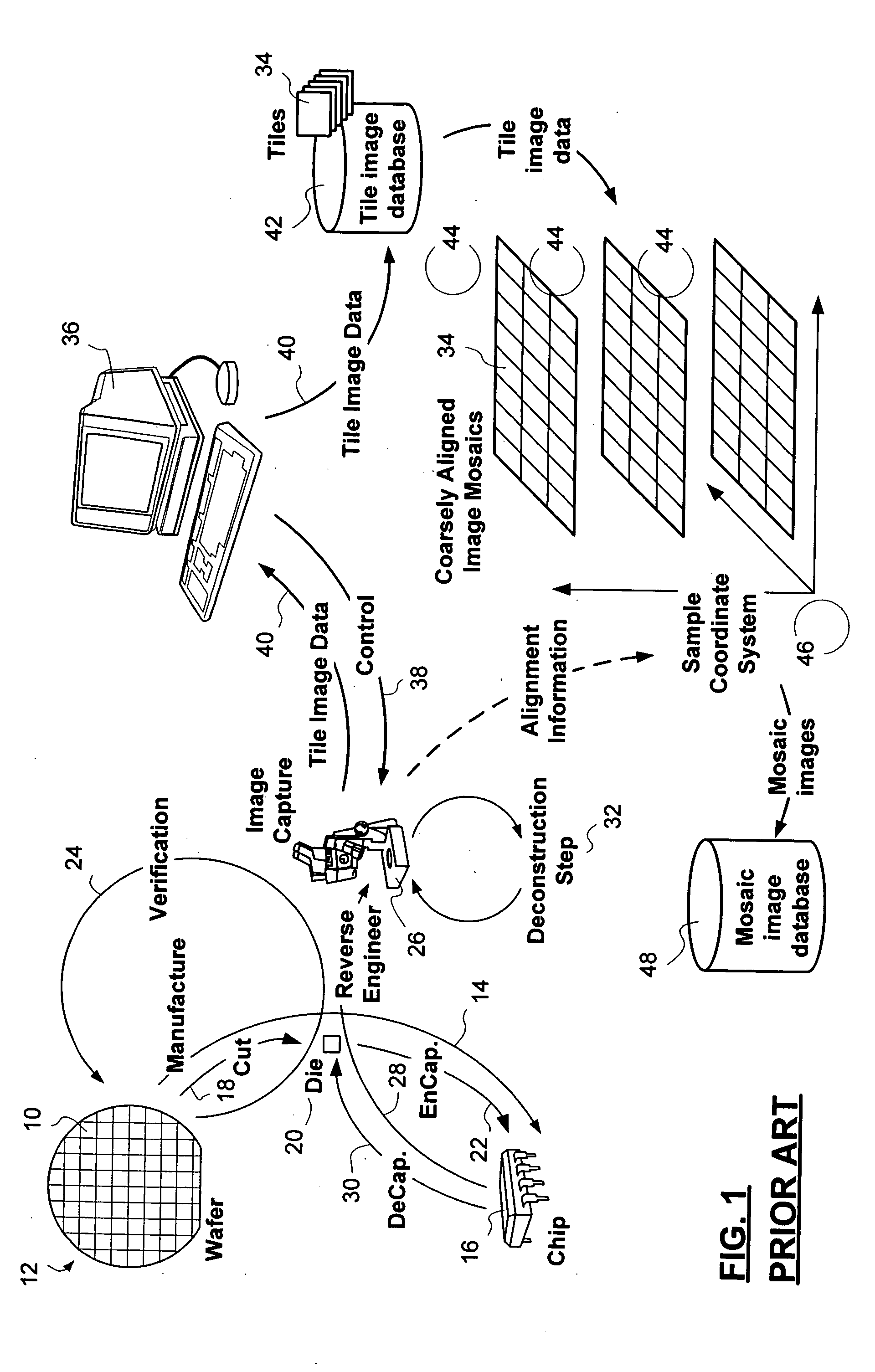

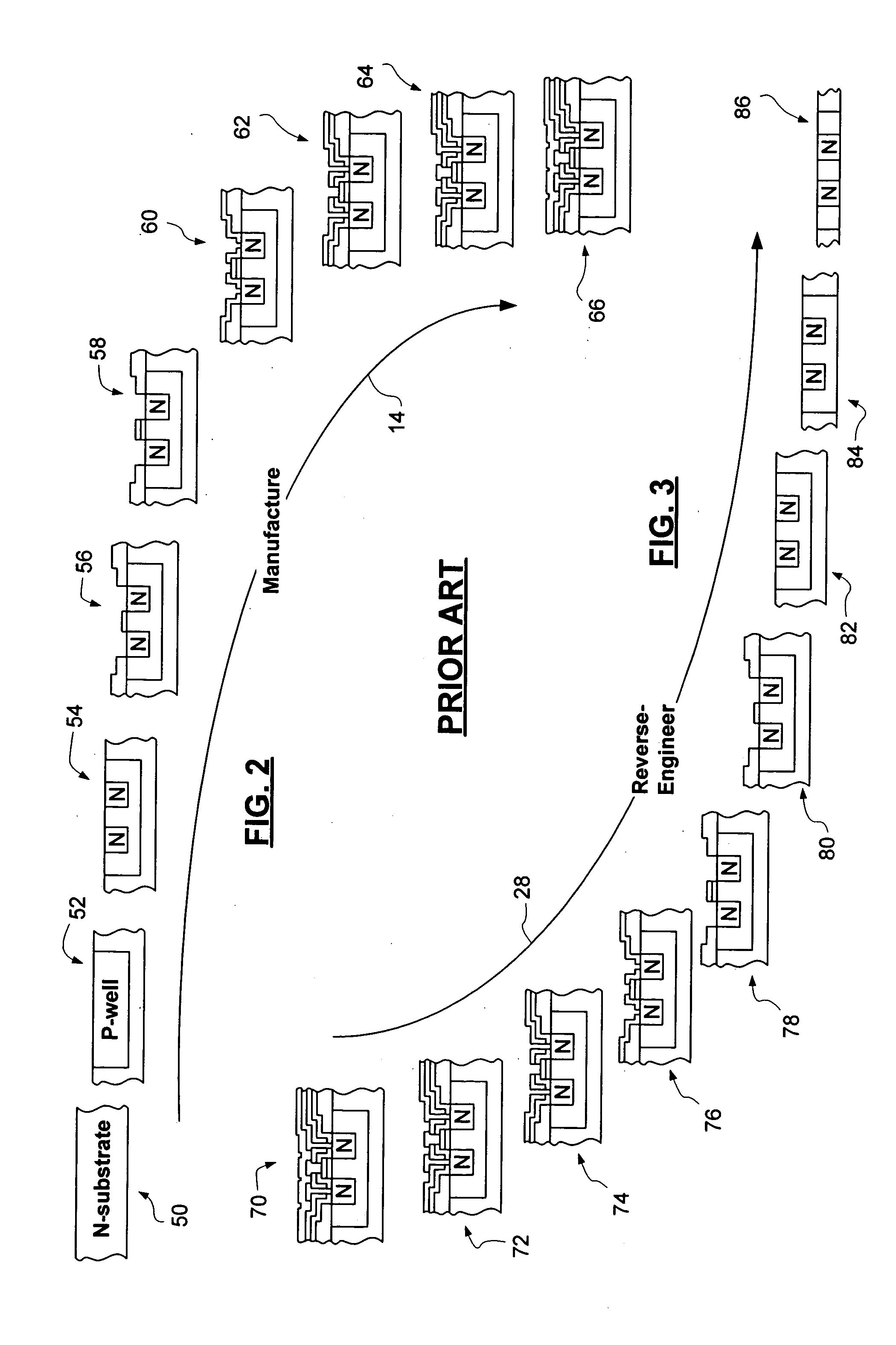

Method and apparatus for producing a 3-D model of a semiconductor chip from mosaic images

InactiveUS20050226521A1Improve alignmentFacilitates automationImage enhancementDetails involving processing stepsThree dimensional modelLine segment

A three-dimensional model of a semiconductor chip is produced from coarsely aligned mosaic images of respective layers of the semiconductor chip using an improved method for aligning the mosaic images, so that minimal operator intervention is required to produce the model. A line detection algorithm is applied to each of the mosaic images to produce a set of line segments identified by x and y coordinates of end points of the line segments with respect to a frame defined by a mosaic image in which each line segment occurs. Virtual reference marks are established using end points of different mosaic images that are vertically aligned to within an uncertainty of the coarse alignment of the mosaic images, and the virtual reference marks are used to compute a mean adjustment of the x and y coordinates of each of the mosaic images to produce a three dimensional coordinate space. The end points are processed within the three dimensional coordinate space to define vias, lines and branch lines of the semiconductor chip, which are used to build the three-dimensional model. Operator intervention is only required to verify putative line segments that are marked as uncertain because of poor agreement with predefined rules. The 3-D model may be annotated and viewed separately from the mosaic images.

Owner:CHIPWORKS INC

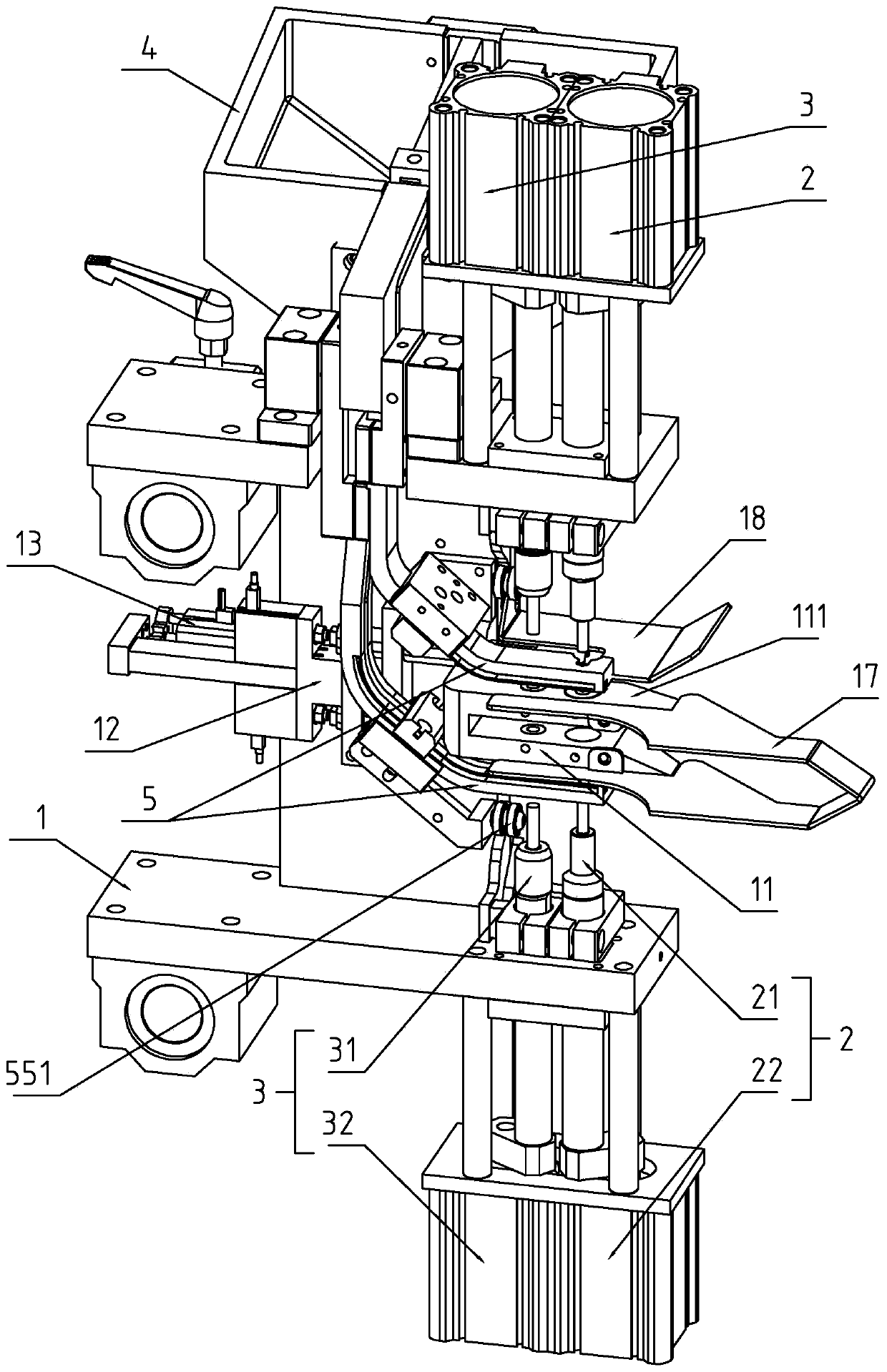

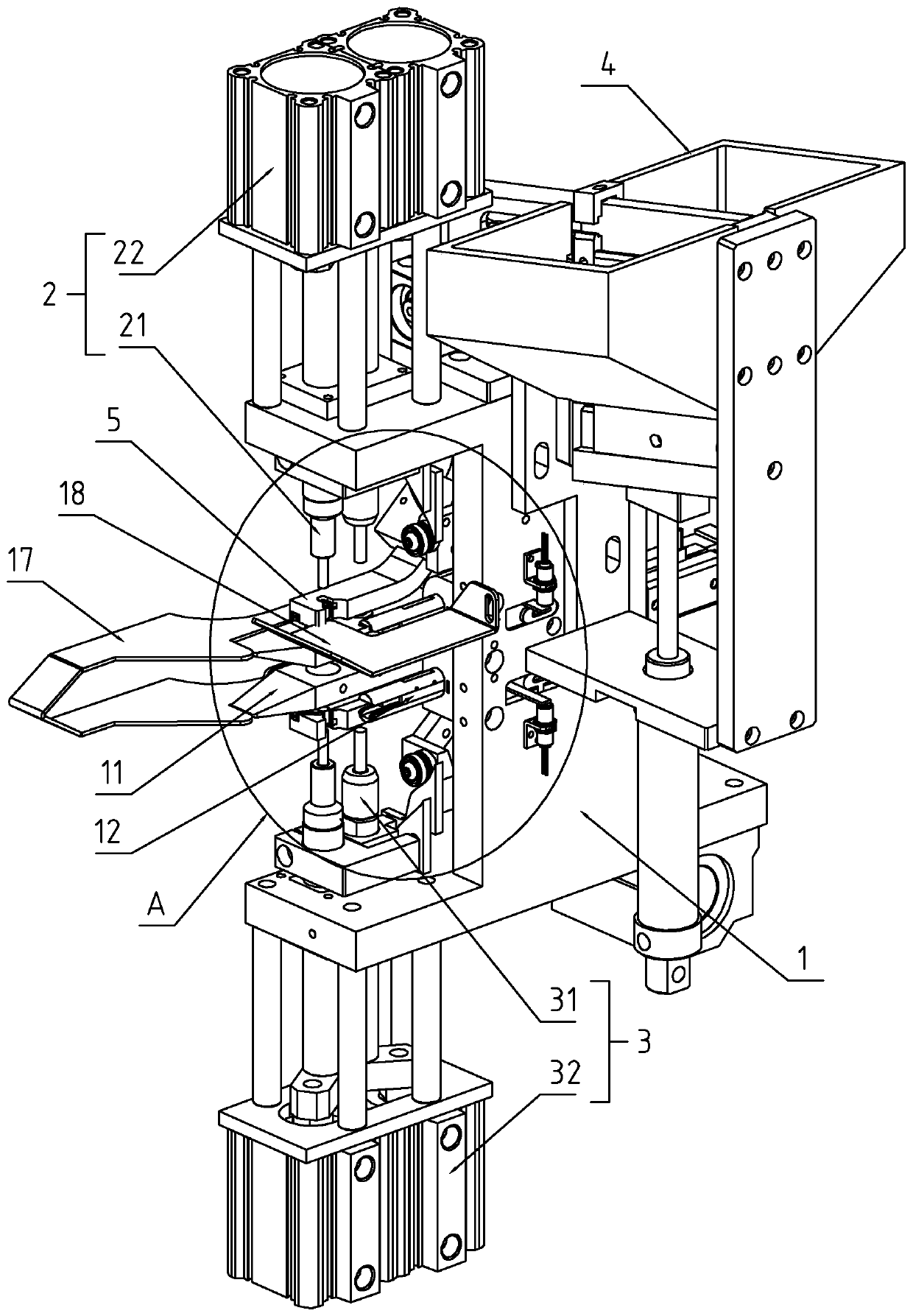

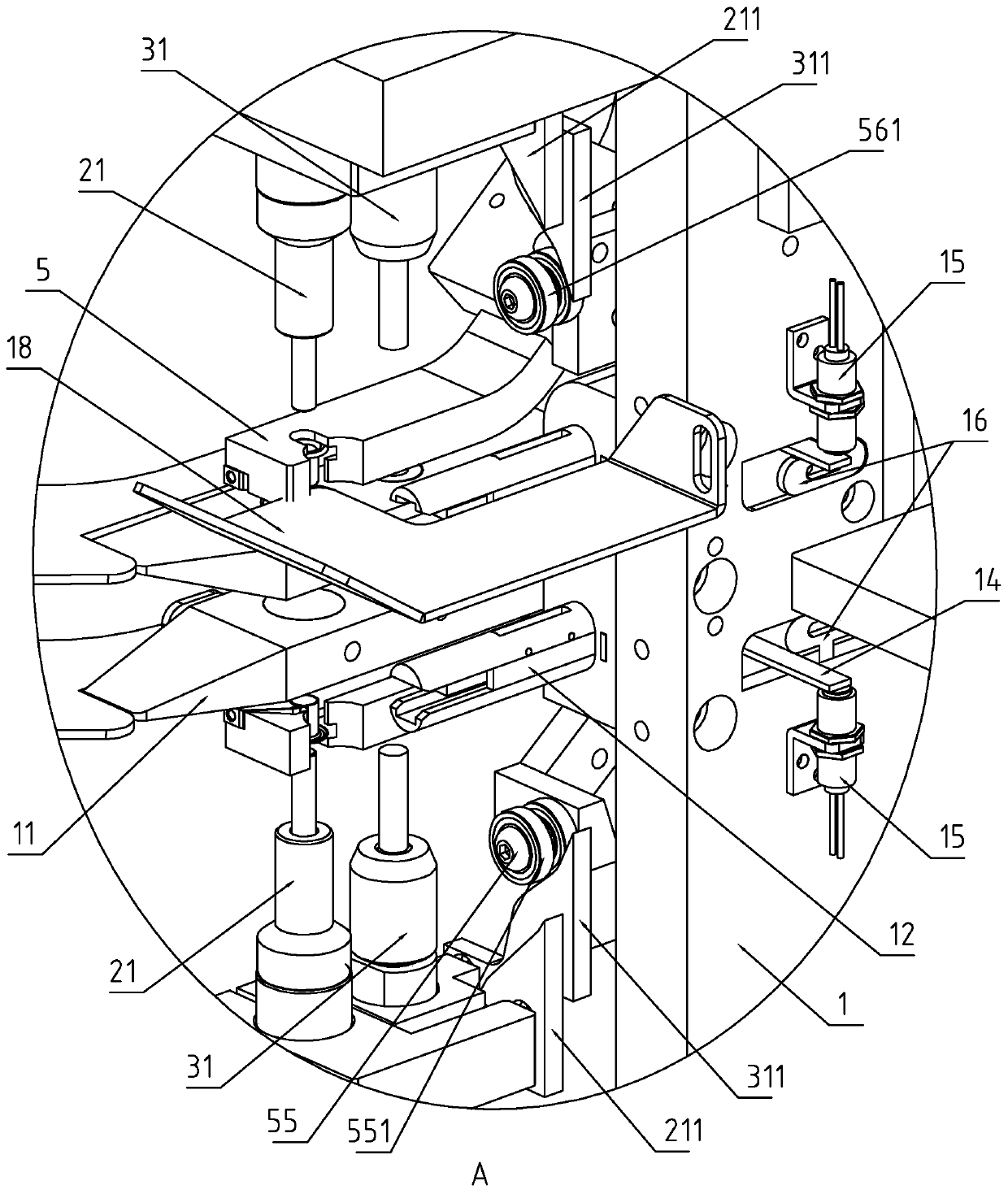

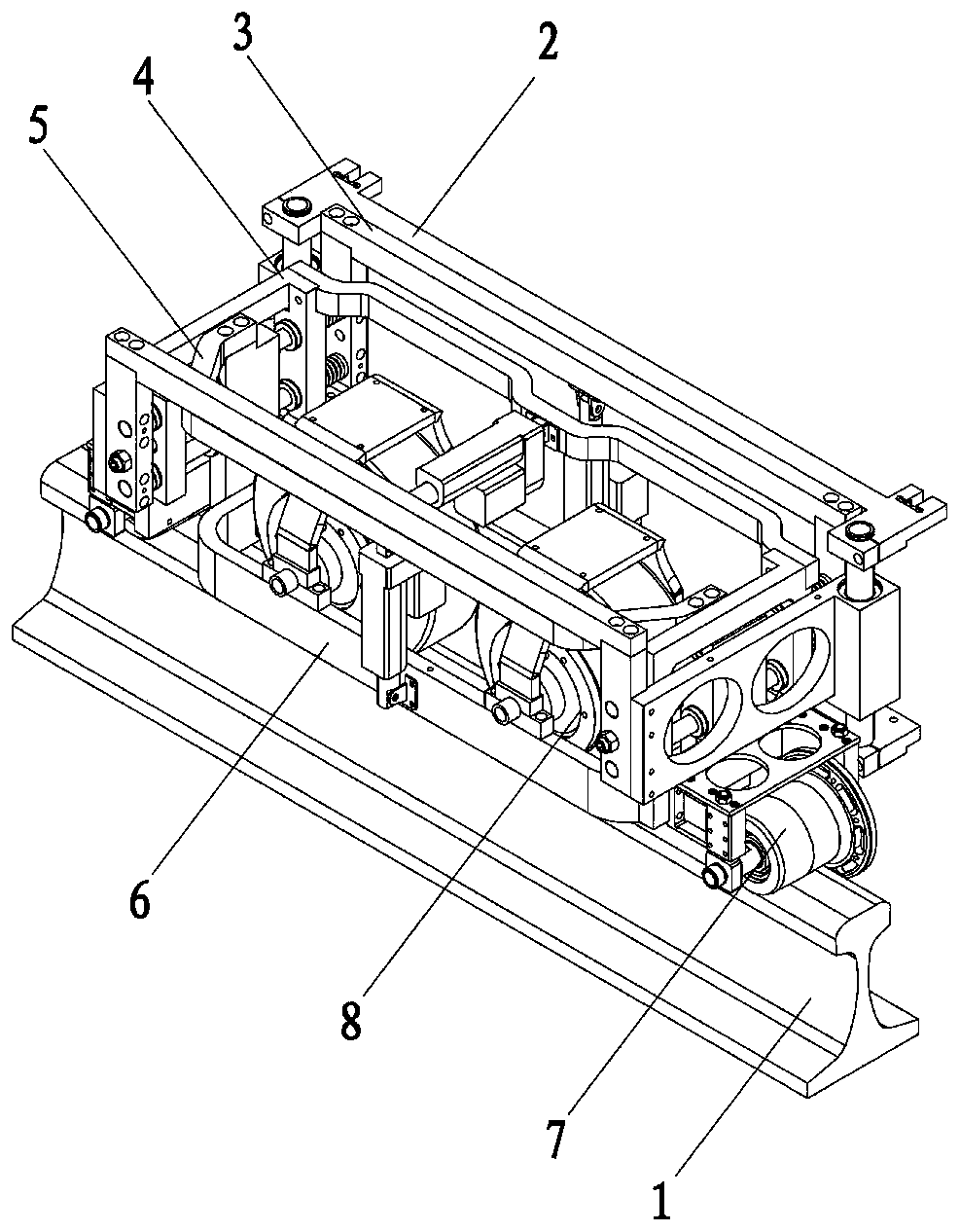

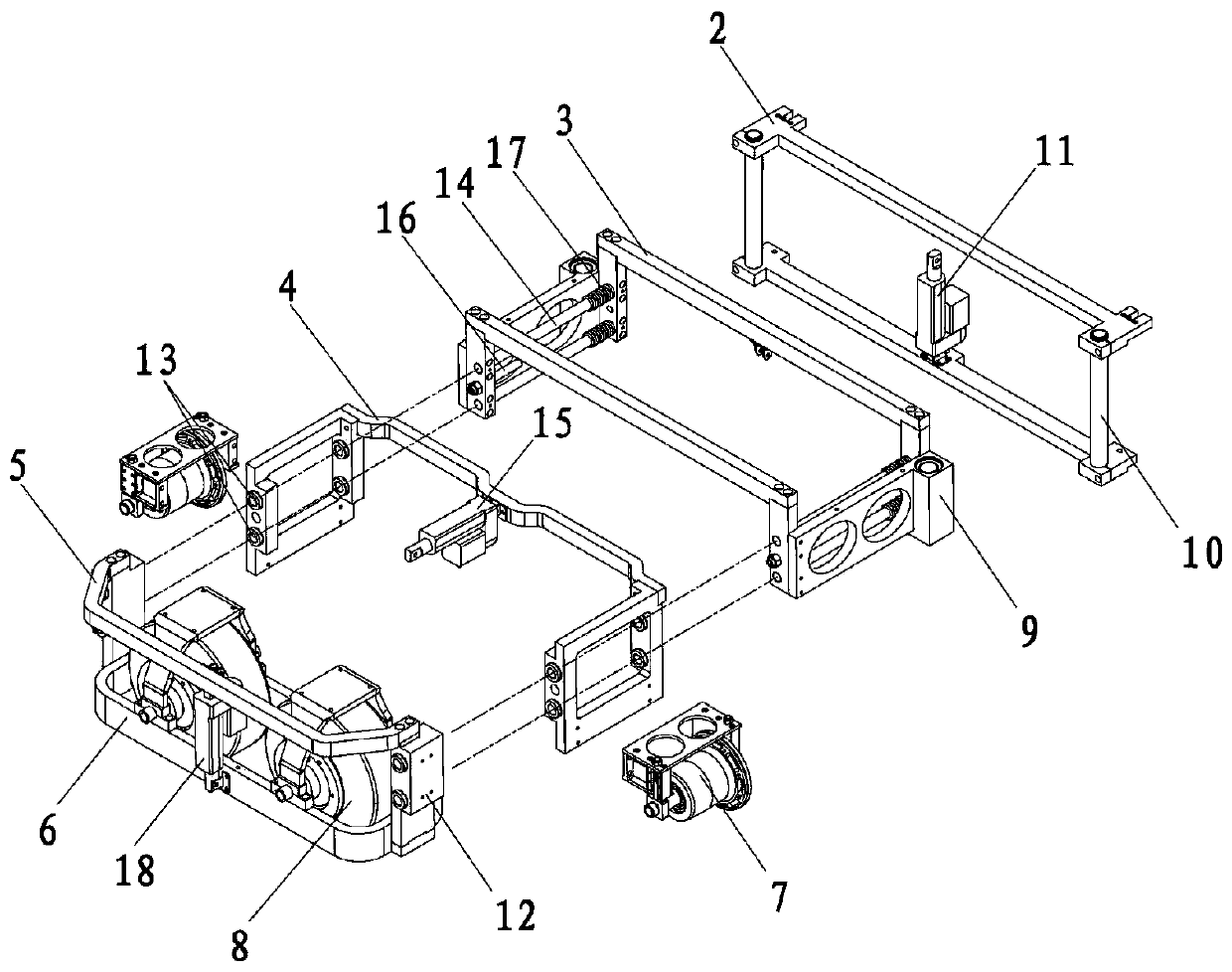

Button attaching machine

PendingCN109968746AImprove work efficiencyReduce the need for repetitive positioningBag making operationsPaper-makingEngineeringManipulator

The invention discloses a button attaching machine. According to the technical scheme, the button attaching machine is characterized by comprising a mounting frame, button attaching devices, a feedingdevice and perforating devices; each button attaching device comprises a button attaching head and a button attaching driver; each perforating device comprises a perforating cutter and a perforatingdriver; the mounting frame is provided with a button attaching table, the button attaching table comprises two button attaching planes, and the two button attaching planes are correspondingly locatedon two opposite sides of the button attaching table; the button attaching devices and the perforating devices are both provided with two groups; the mounting frame is provided with a bag shifting mechanical arm and a bag shifting driver, wherein the sliding direction of the bag shifting mechanical arm driven by the bag shifting driver is the arrangement direction of the perforating cutters and thebutton attaching heads; the feeding device comprises a feeding hopper and two conveying rails, the feeding hopper is provided with two discharging ports, and the two discharging ports are correspondingly in communication with feeding ports of the two conveying rails; and the perforating cutters and the button attaching heads are arranged in the length direction of the conveying rails, a first avoiding component is arranged on the each of the two button attaching heads, and a second avoiding component is arranged on the each of the two perforating cutters. The button attaching machine has theadvantage that the automatic degree is high.

Owner:温州临界科技有限公司

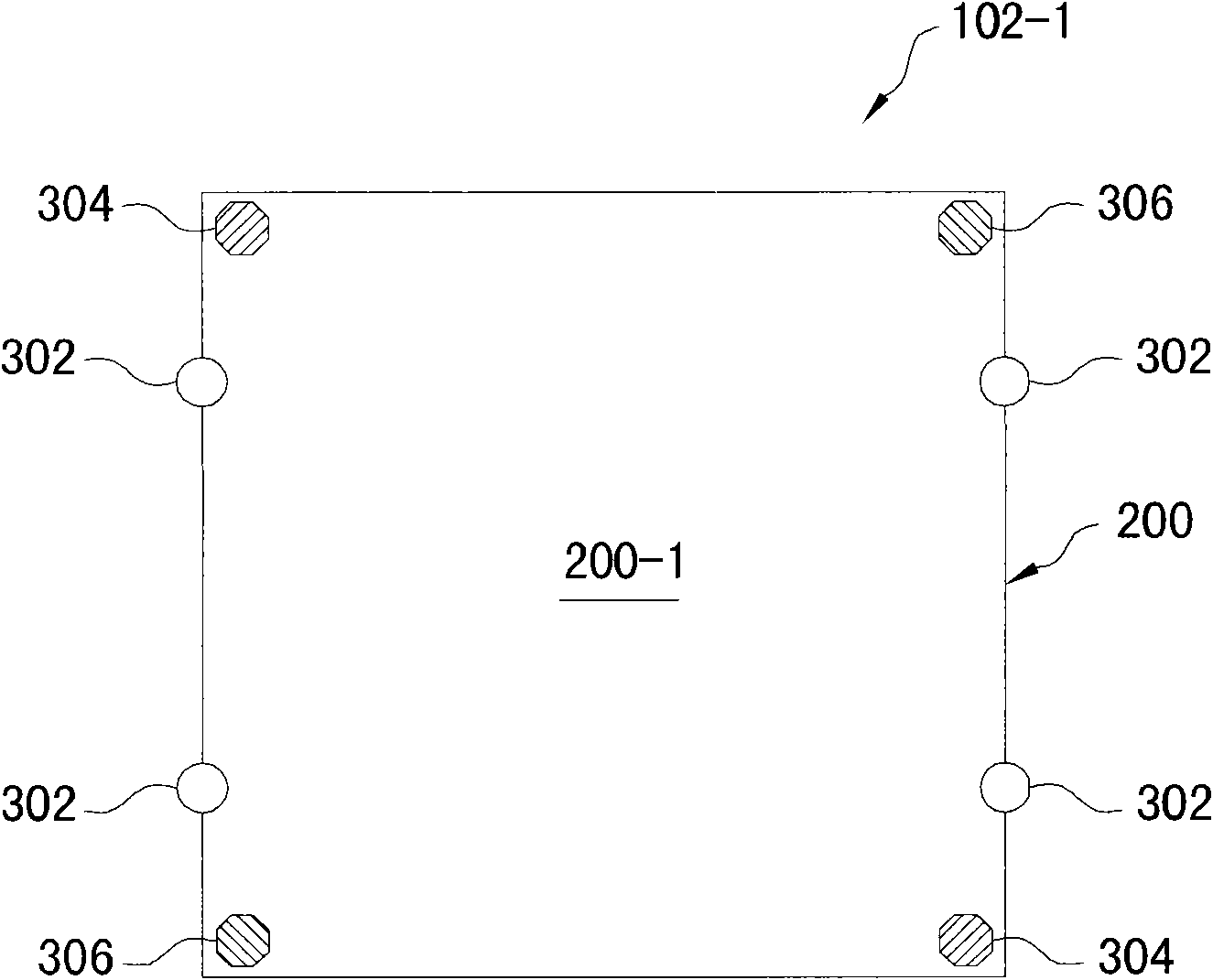

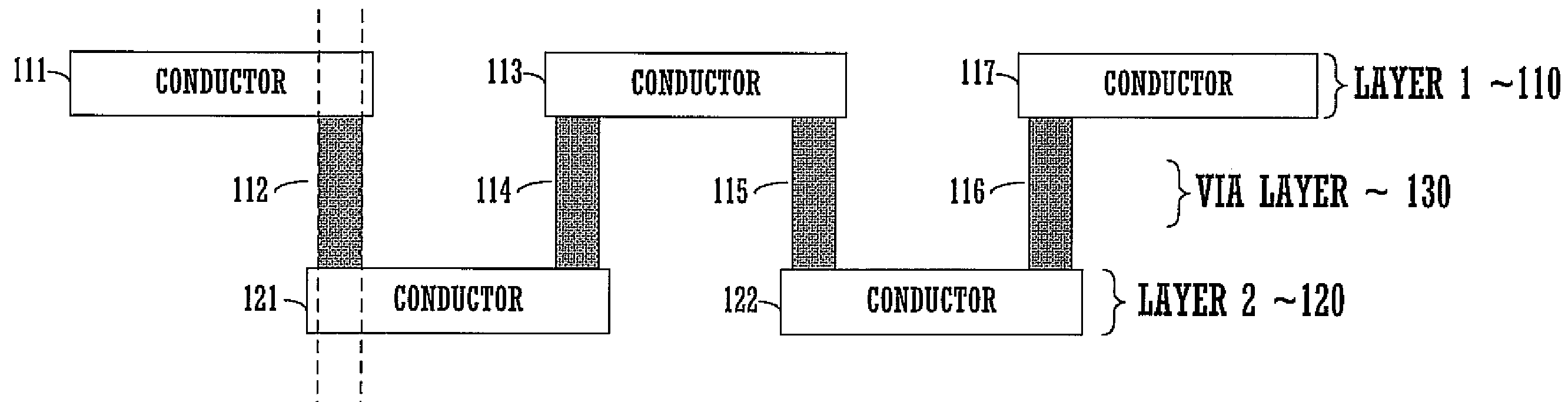

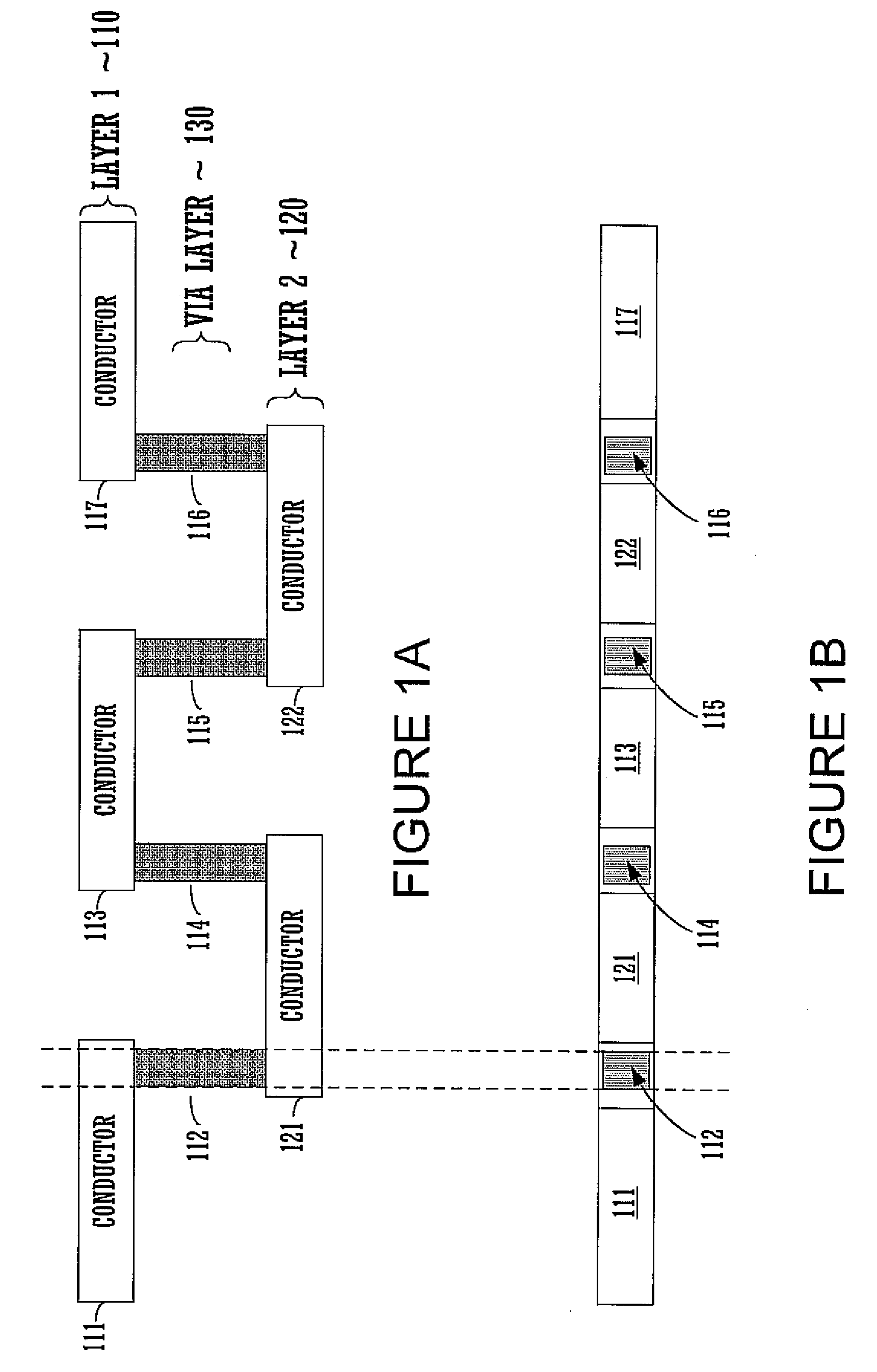

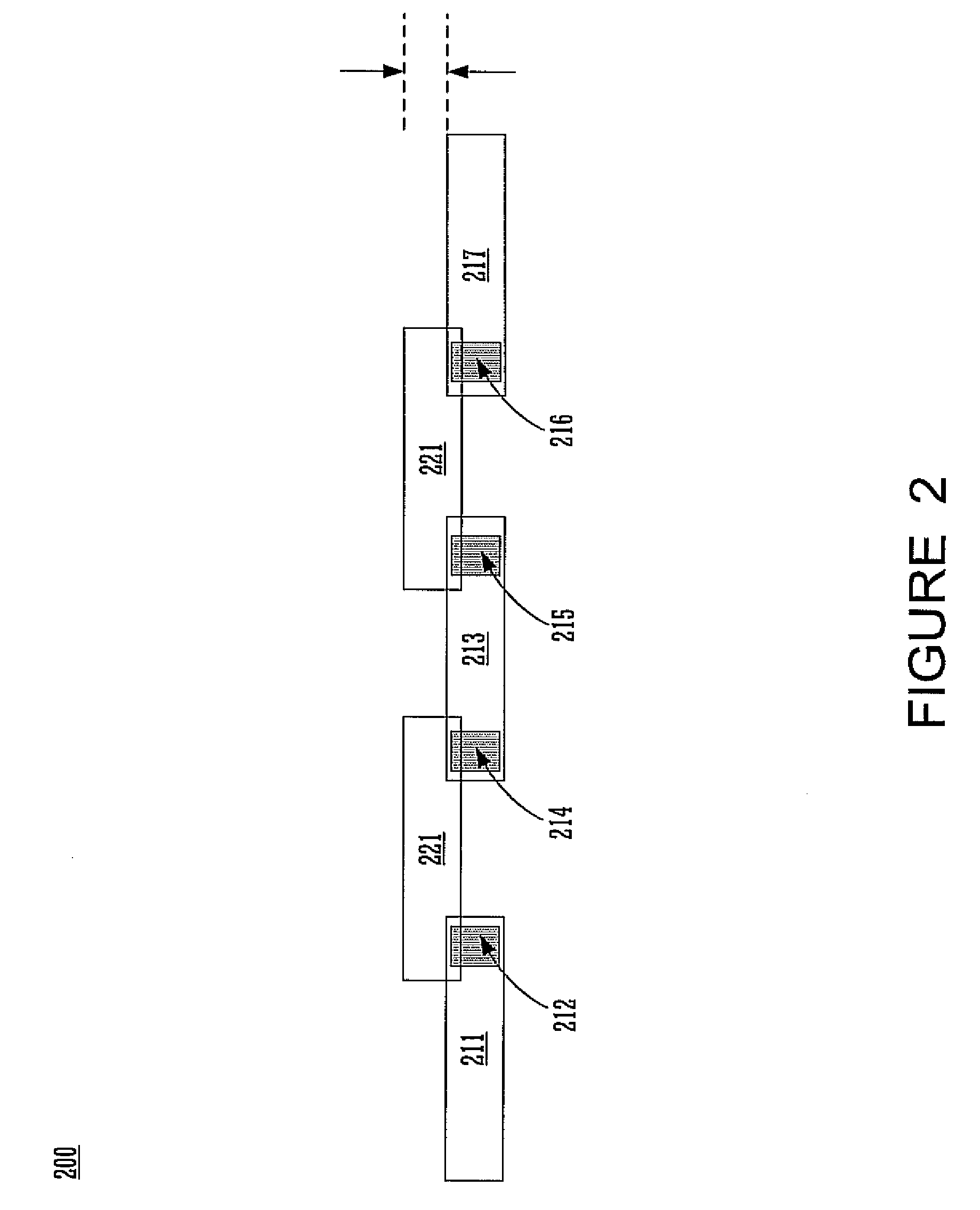

Systems and methods for electrical characterization of inter-layer alignment

InactiveUS20090033353A1Improve alignmentSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsIntegrated circuitTest structure

Systems and methods for electrical characterization of inter-layer alignment. In one embodiment, a wafer including a plurality of test structures are accessed. The plurality of test structures include chains of conductive segments on multiple layers, coupled by vias. The plurality of test structures are designed with varying amounts of intentional misalignment between the multiple layers. The reactance of each of the plurality of test structures is measured. The reactance is analyzed to determine the process-induced inter-layer misalignment of the integrated circuit wafer.

Owner:PDF SOLUTIONS INC

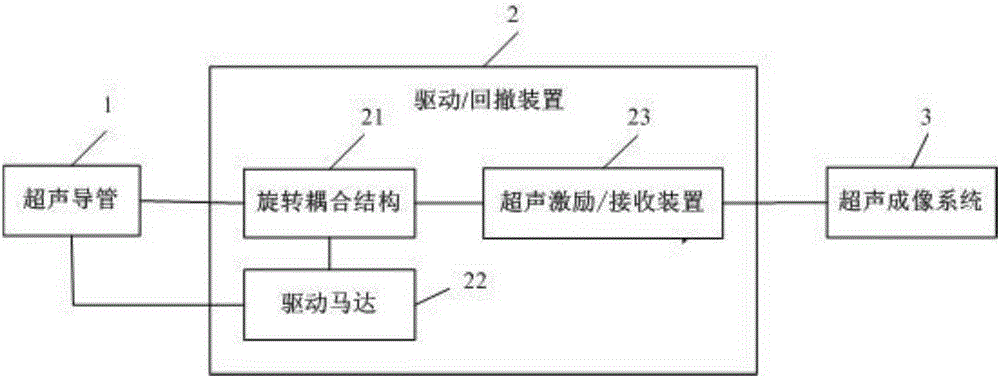

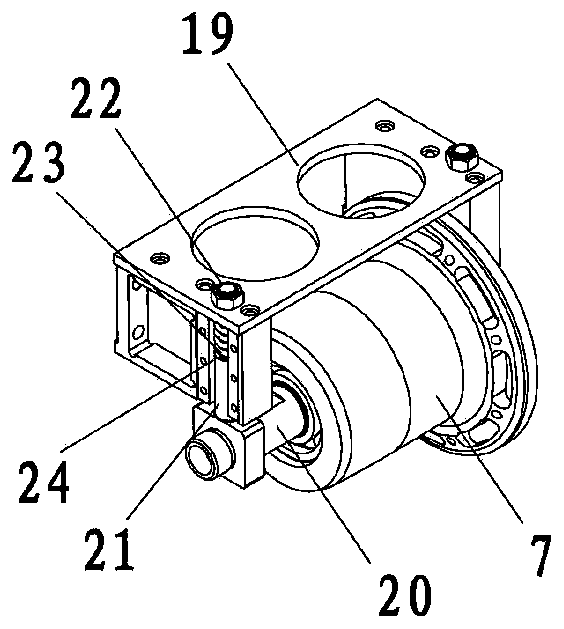

Intravascular ultrasound diagnostic instrument with rotation coupled structure

The invention discloses an intravascular ultrasound diagnostic instrument with a rotation coupled structure. The intravascular ultrasound diagnostic instrument comprises an ultrasound catheter, a driving / withdrawing device and an ultrasound imaging system, wherein one end of the driving / withdrawing device is connected with the ultrasound catheter, and the other end is connected with the ultrasound imaging system; the driving / withdrawing device comprises the rotation coupled structure, a driving motor and an ultrasound excitation / reception device; one end of the rotation coupled structure is connected with the ultrasound catheter, and the other end of the rotation coupled structure is connected with the ultrasound excitation / reception device; the ultrasound excitation / reception device is connected with the ultrasound imaging system; the driving motor is connected with the rotation coupled structure, and is also connected with the ultrasound catheter. According to the intravascular ultrasound diagnostic instrument with the rotation coupled structure, the rotation coupled structure is arranged in the driving / withdrawing device, so that the using cost is reduced, and meanwhile, the possibility is provided for improving the performance of the rotation coupled structure.

Owner:上海爱声生物医疗科技有限公司

Ferrite composite for titanium pumps and preparation method of ferrite composite

The invention discloses a ferrite composite for titanium pumps and a preparation method of the ferrite composite. The ferrite composite is prepared from raw materials including ferric oxide, zinc oxide, manganese oxide, silicon powder, nanometer aluminum oxide, nanometer magnesia, calcium isooctanoate, c zinc dihydrogen phosphate, glass fiber, cobalt oxide, polystyrene, lanthanum oxide, tricresyl phosphate, calcium fluoride, calcium carbonate, lithium oxide, zirconium, zinc borate, manganese carbonate, tin, stibium, ferroboron, gallium, yttrium, strontium carbonate, rubidium, titanium, cerium, vanadium, sodium fluoride, praseodymium, molybdenum, lubricant and clay. The ferrite composite is good in product property and stable in structure; the preparation method is easy to implement; dispersibility and compressibility of ferrite particles are improved, degree of alignment of the ferrite particles along the easily-magnetized direction is greatly increased, and degree of orientation of the ferrite particles is greatly increased.

Owner:南通保来利轴承有限公司

Railway track flaw detection mechanism and flaw detection vehicle

PendingCN110893864AGuaranteed accuracySimple structureRailway inspection trolleysRailway auxillary equipmentTrackwayStructural engineering

The invention relates to the technical field of rail flaw detection, and discloses a railway rail flaw detection mechanism and a flaw detection vehicle, the railway rail flaw detection mechanism comprises a fixing frame, a guide wheel and a flaw detection wheel, and also comprises a longitudinal adjusting frame, a transverse adjusting frame and a flaw detection wheel frame; the longitudinal adjusting frame is installed on the fixing frame in a longitudinal sliding mode. The transverse adjusting frame and the flaw detection wheel frame are mounted on the longitudinal adjusting frame in a transverse sliding manner; a guide wheel is mounted on the transverse adjusting frame; flaw detection wheels are mounted on the flaw detection wheel carriers, are opposite to the wheel edges of the guide wheels and are arranged along a pre-detected track; the railway track flaw detection mechanism is simple in structure and convenient to operate, the wheel edge of the flaw detection wheel makes close contact with the track surface of the track to be detected in the flaw detection process, a good centering state is kept, the flaw detection accuracy is ensured, and the flaw detection efficiency of a flaw detection vehicle is improved.

Owner:BEIJING CENTURY DONGFANG COMMUNICATION EQUIPMENT CO LTD

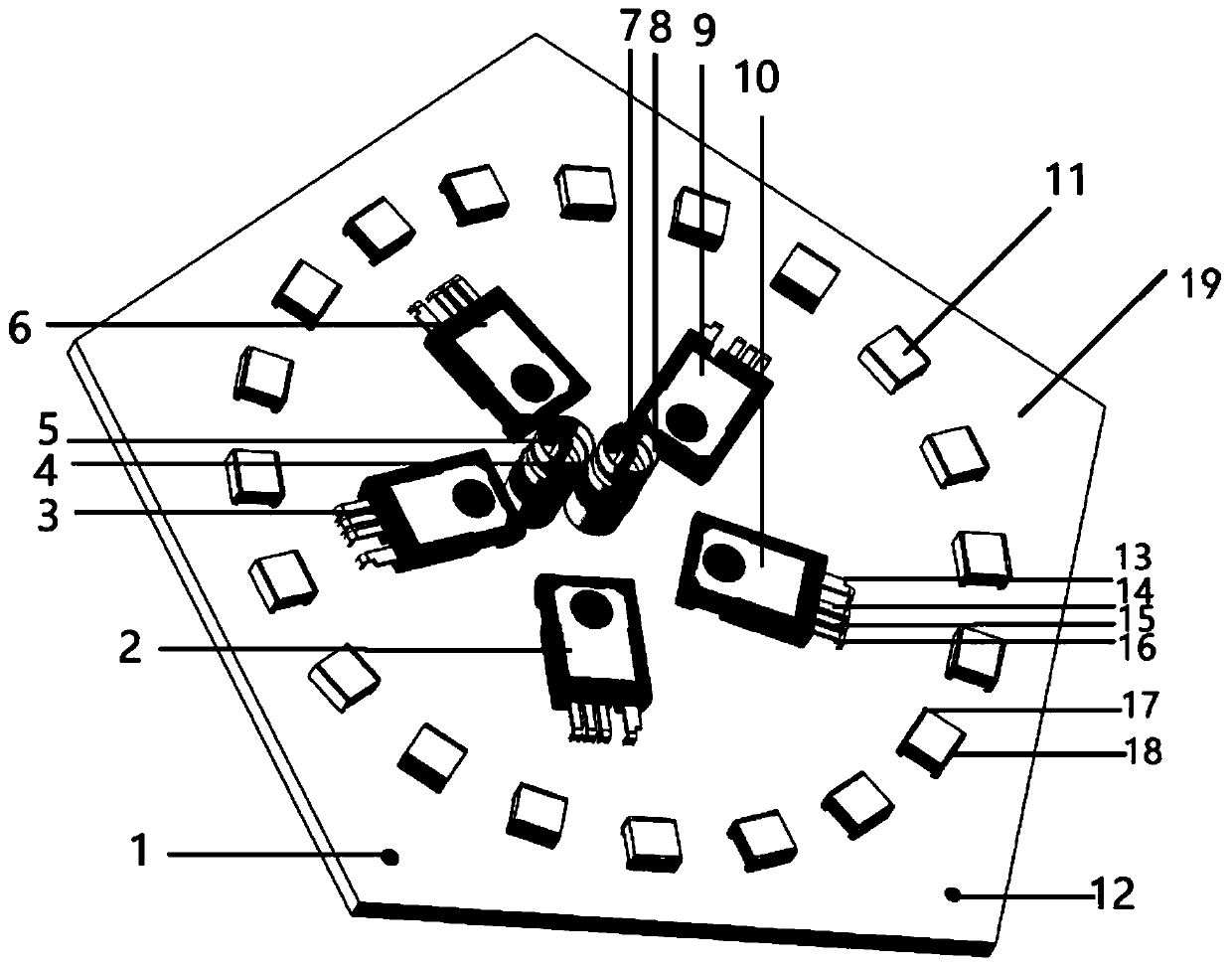

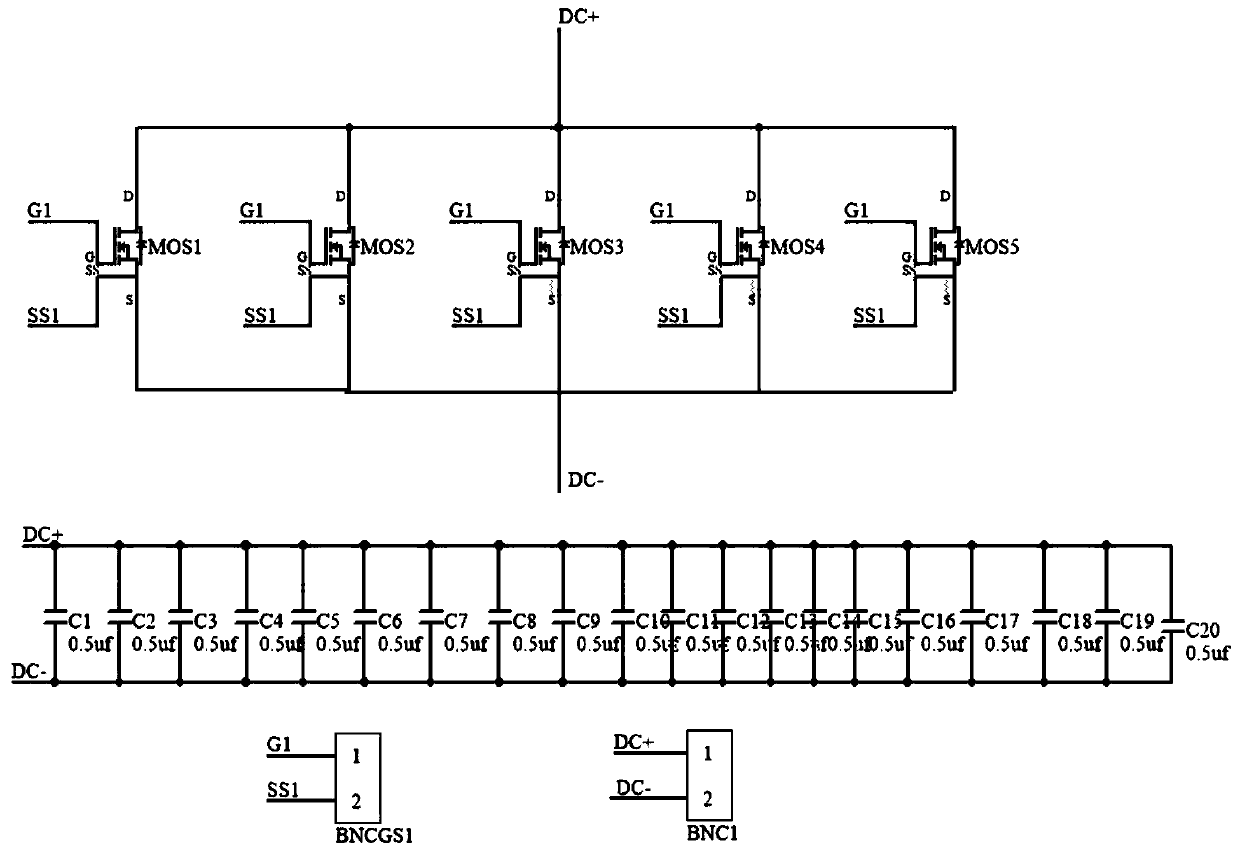

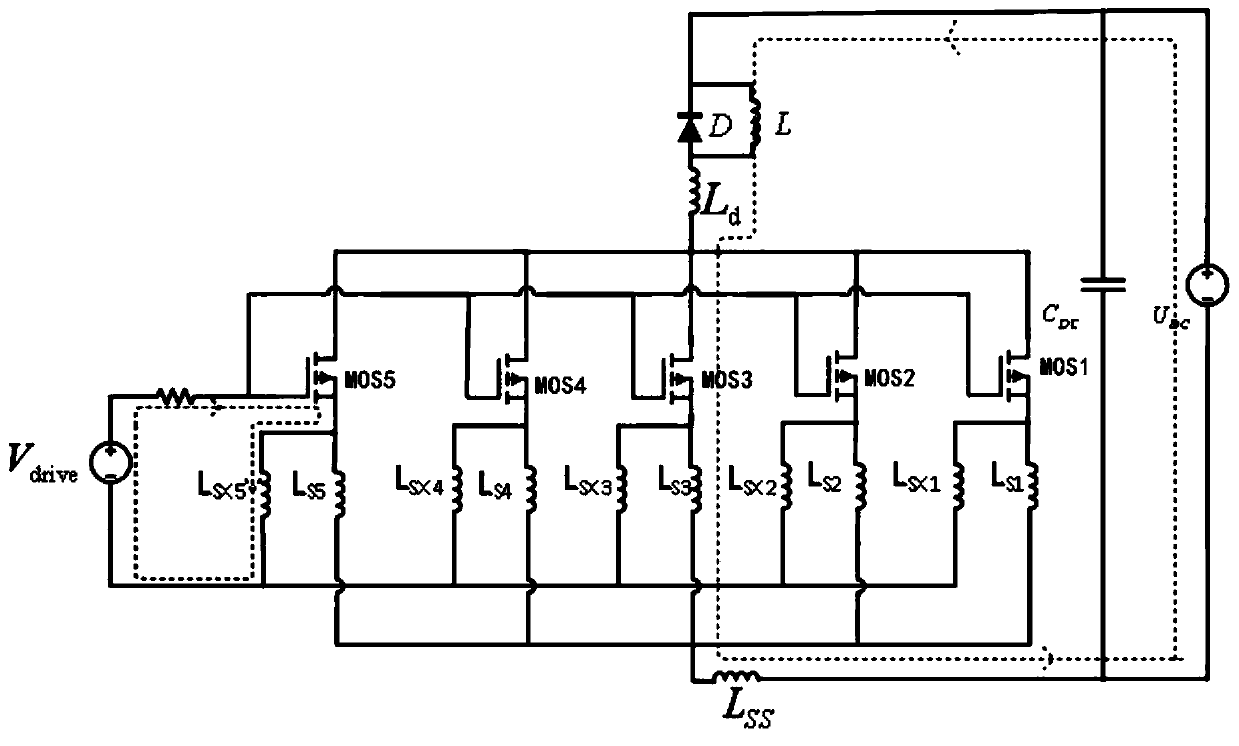

Layout circuit board of multi-device parallel power module

PendingCN111063679AOptimize arrangement positionCircuit Parasitic Parameter MatchingEfficient power electronics conversionSolid-state devicesCarbide siliconCapacitance

The invention discloses a layout circuit board of a multi-device parallel power module. In the layout circuit board of the multi-device parallel power module, a first lotus-shaped BNC interface (comprising a load positive electrode output terminal and a load negative electrode output terminal) is located in the center of a PCB, and a plurality of parallel silicon carbide devices in the silicon carbide device parallel module are arranged in a circumferential mode with the first lotus-shaped BNC interface as the circle center; and a plurality of parallel decoupling capacitors in a decoupling capacitor parallel module are arranged circumferentially by taking the first lotus-shaped BNC interface as a circle center. The arrangement positions of the parallel devices are optimized, so that parasitic parameters of the circuit are matched, the distribution difference of stray inductance of the circuit is reduced, the current coupling effect is eliminated, the transient current imbalance of themulti-device parallel power module can be changed, and the good current sharing characteristic of the parallel silicon carbide devices is realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

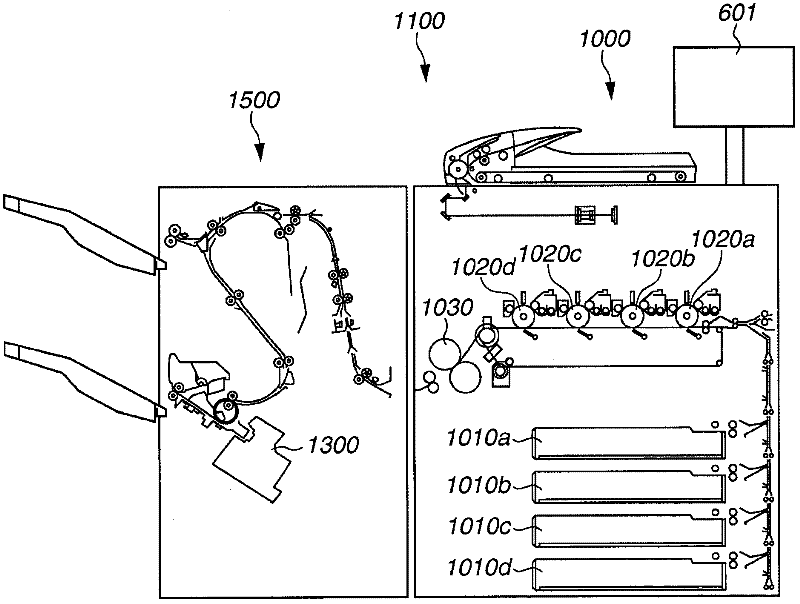

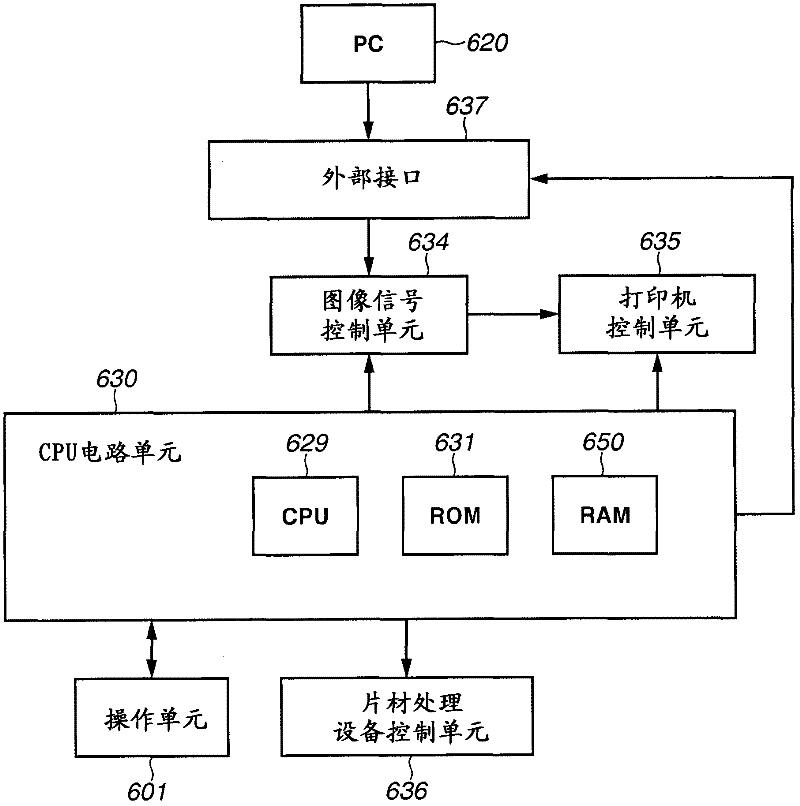

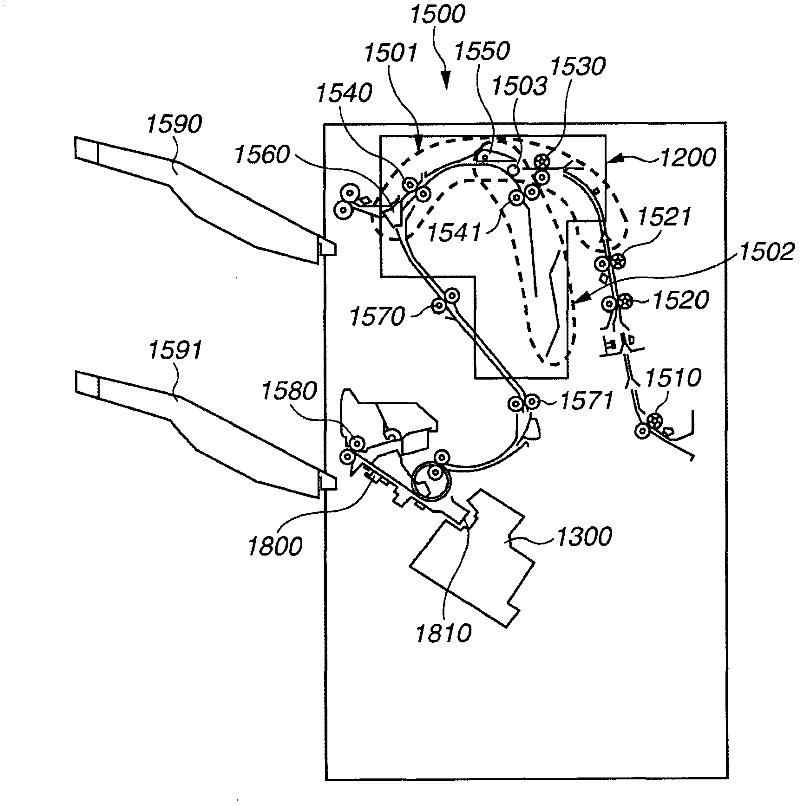

Sheet processing equipment and image forming equipment

ActiveCN102285550AImprove alignmentFunction indicatorsElectrographic process apparatusControl unitSheet material

The invention relates to a sheet processing apparatus and an image forming apparatus. The sheet processing apparatus includes a processing tray configured to stack a sheet to be processed, a sheet overlap unit configured to allow a sheet fed while the sheet to be processed is stacked on the processing tray, to be overlaid and made to wait, first and second bundle conveyance rollers configured to convey the sheet to the processing tray from the sheet overlap unit, and a sheet processing apparatus control unit configured to control an overlap operation in the sheet overlap unit, wherein the sheet processing apparatus control unit determines, based on sheet information relating to the sheet fed to the sheet overlap unit, whether a sheet to be then fed is overlaid on the sheet fed to the sheet overlap unit.

Owner:CANON KK

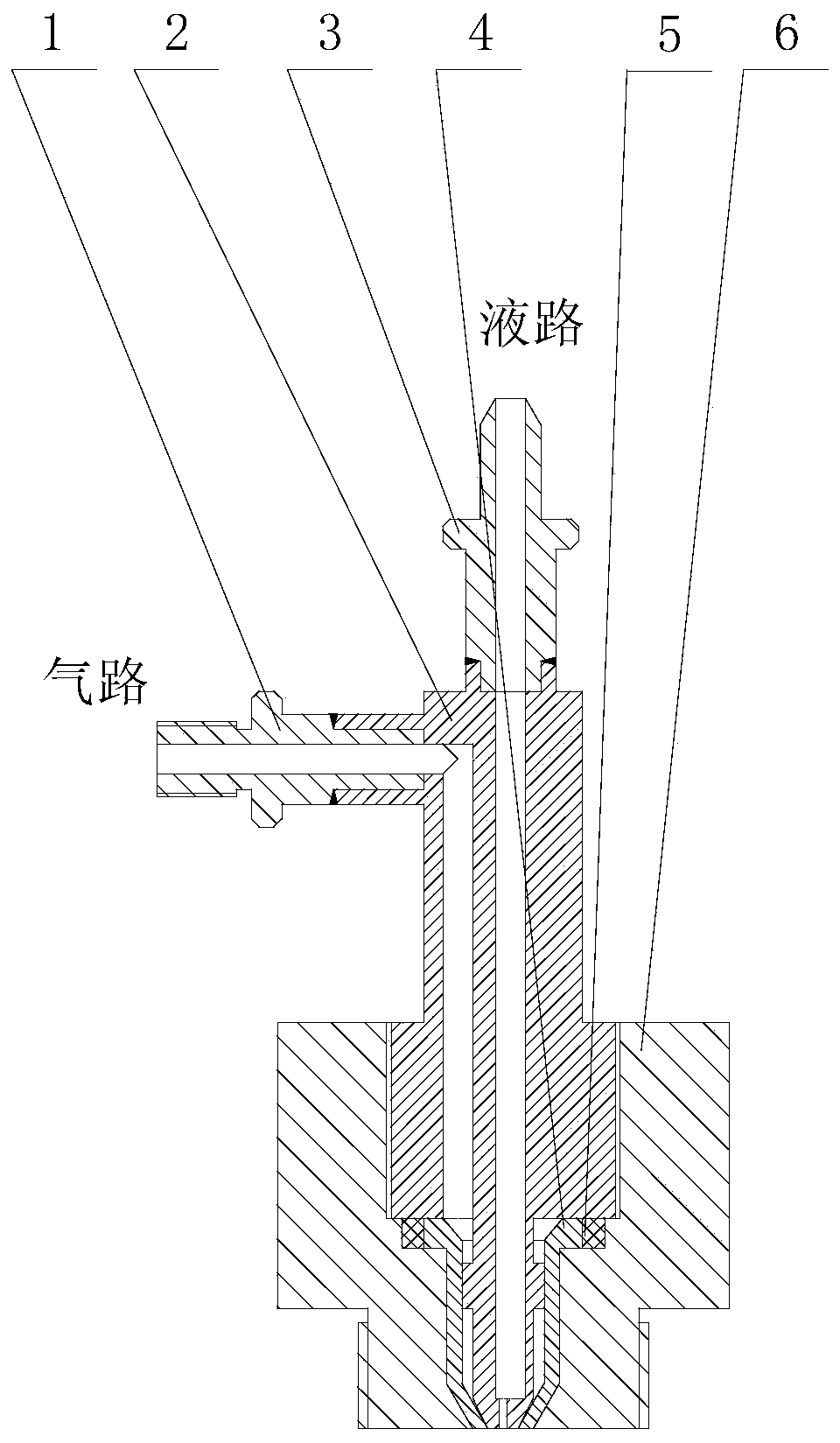

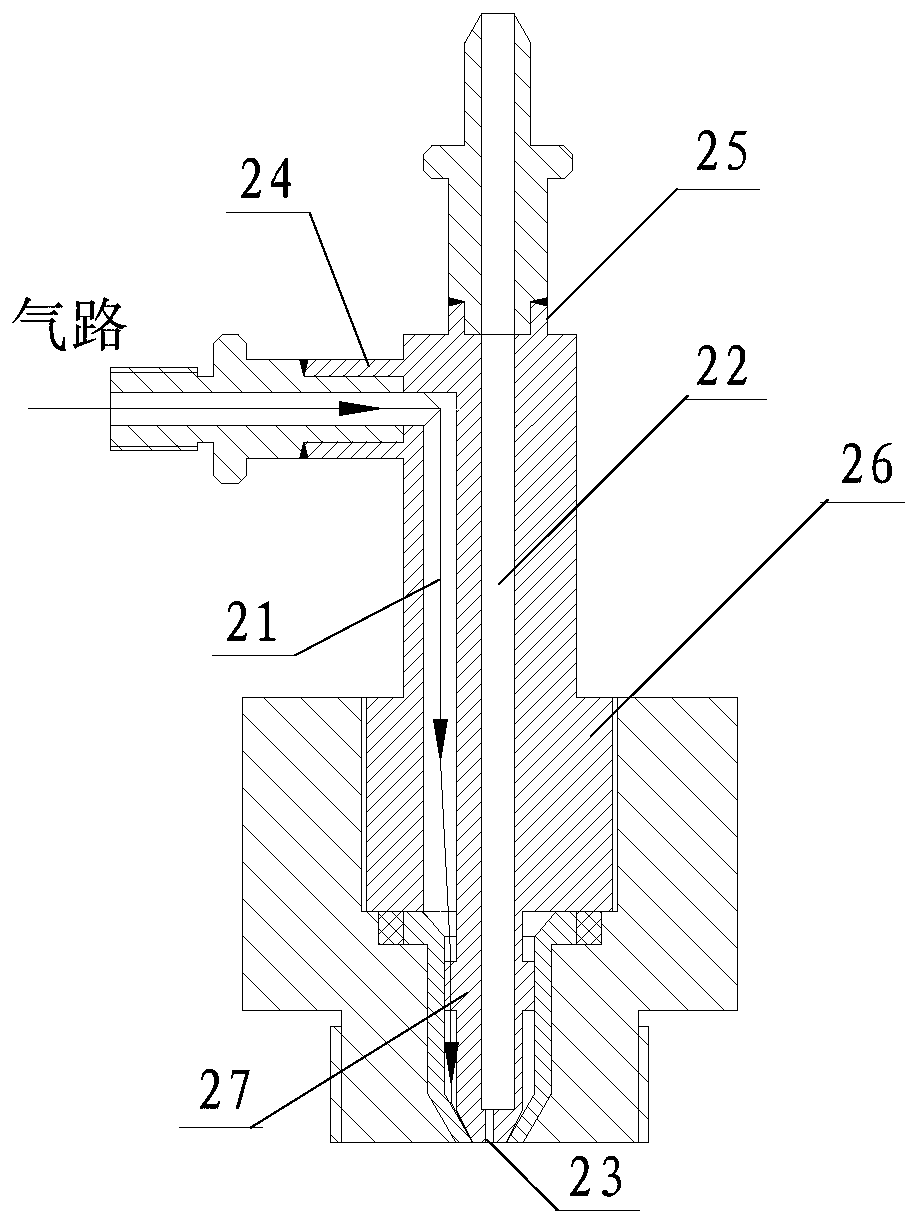

Ultrafine atomization nozzle applied to spray freeze drying device

ActiveCN111299001AImprove uniformityImprove alignmentDrying solid materials without heatLiquid spraying apparatusComposite materialFreeze dry

The invention discloses an ultrafine atomization nozzle applied to a spray freeze drying device; and the nozzle is suitable for providing an uniform ultrafine atomization condition for preparation ofmultiple biological aerosol samples such as bacteria, virus, endospore and toxin. The nozzle comprises a gas path joint, a nozzle body, a liquid path joint, a spray head, a sealing ring and a tightening nut; and under a lower liquid flow and lower gas pressure, a liquid column jet flow is collided through stabilization and impact effects of cyclone gas to intensify instability of the jet flow, sothat droplets are broken and dispersed, and the collision polymerization of the droplets is effectively prevented, high-quality uniform atomization is generated, and a condition is provided for preparation of uniform fine frozen aerosol particles under an ultralow-temperature environment.

Owner:BEIJING INST OF CONTROL ENG

Preparation method of ferrite material

The invention discloses a preparation method of a ferrite material. The preparation method comprises the following steps: 1, preparing a ferrite pre-sintered material, and performing a wet crushing treatment on the ferrite pre-sintered material until the average particle size of the ferrite pre-sintered material reaches 0.2 to 0.5 micrometers; washing with 3mol / L HCl solution, and filtering to remove impurity ions, dissolved in the HCl solution, in the pre-sintered material; 2, adding the ferrite pre-sintered material into alkaline water, standing for 5 minutes and then filtering, washing withdeionized water, and then carrying out drying treatment until ferrite pre-sintered dry powder having a water content of less than 0.4wt% is obtained; carrying out vibration milling treatment on the ferrite pre-sintered dry powder for 30 minutes by using a vibrating mill so as to obtain ferrite pre-sintered powder subjected to vibration milling. The invention provides the preparation method of theferrite material.

Owner:浙江朗基新材料科技有限公司

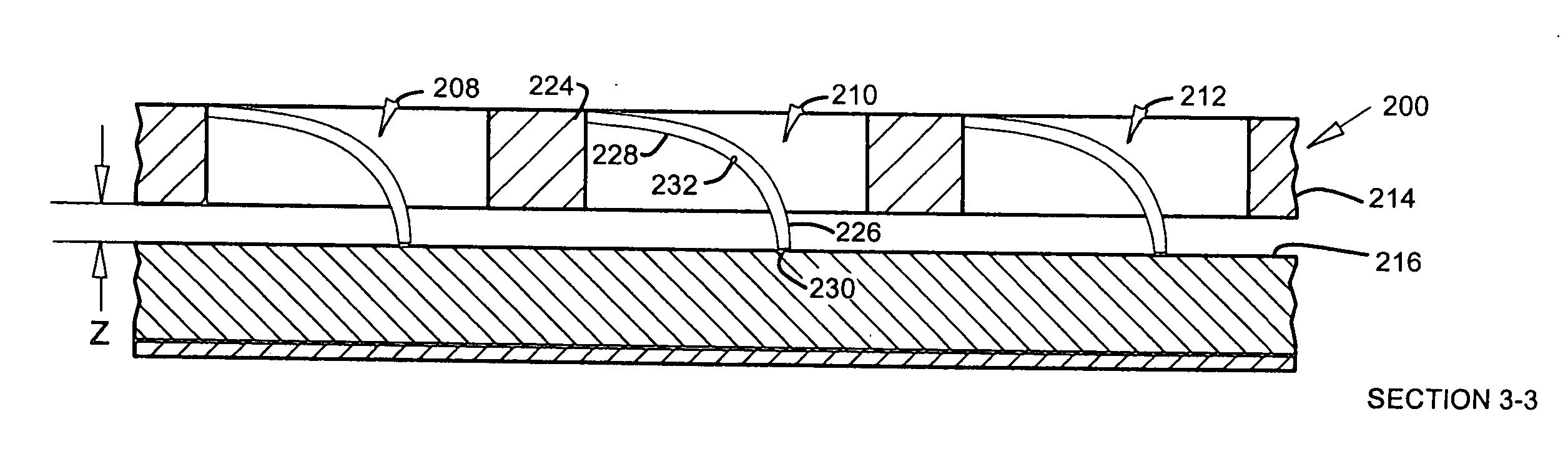

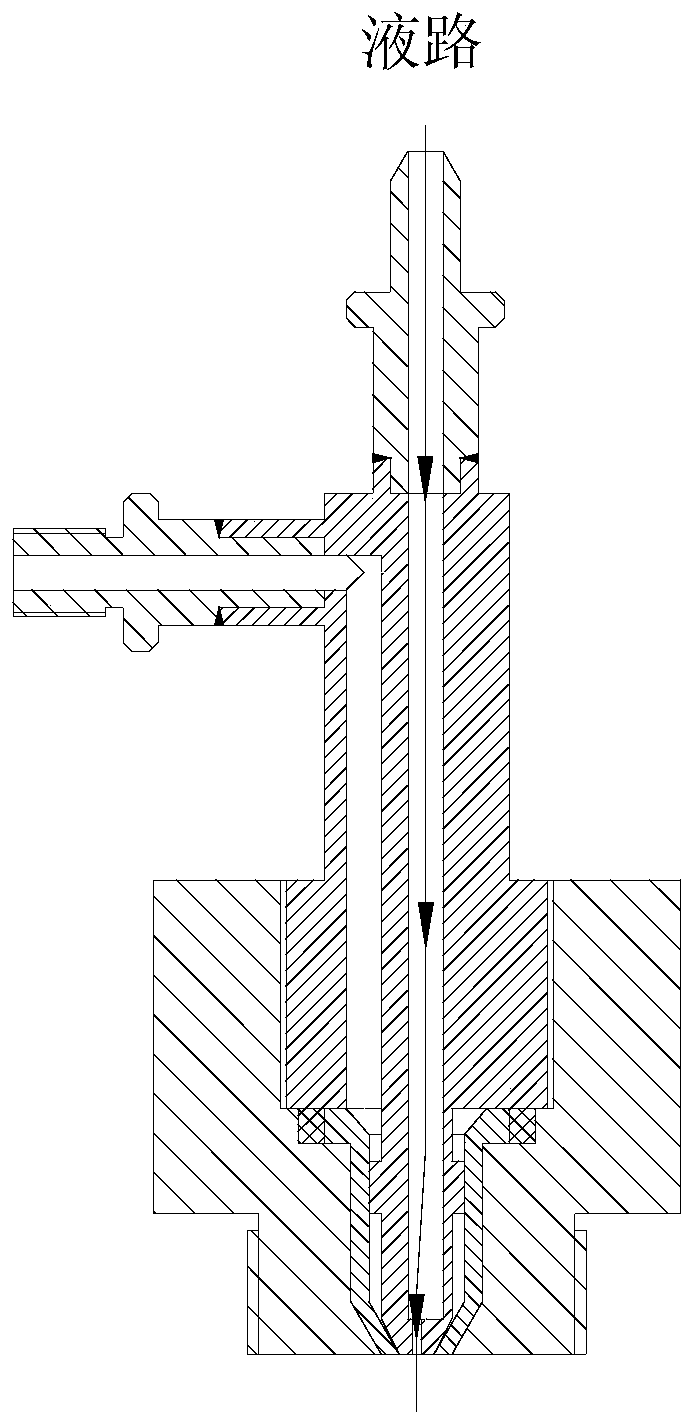

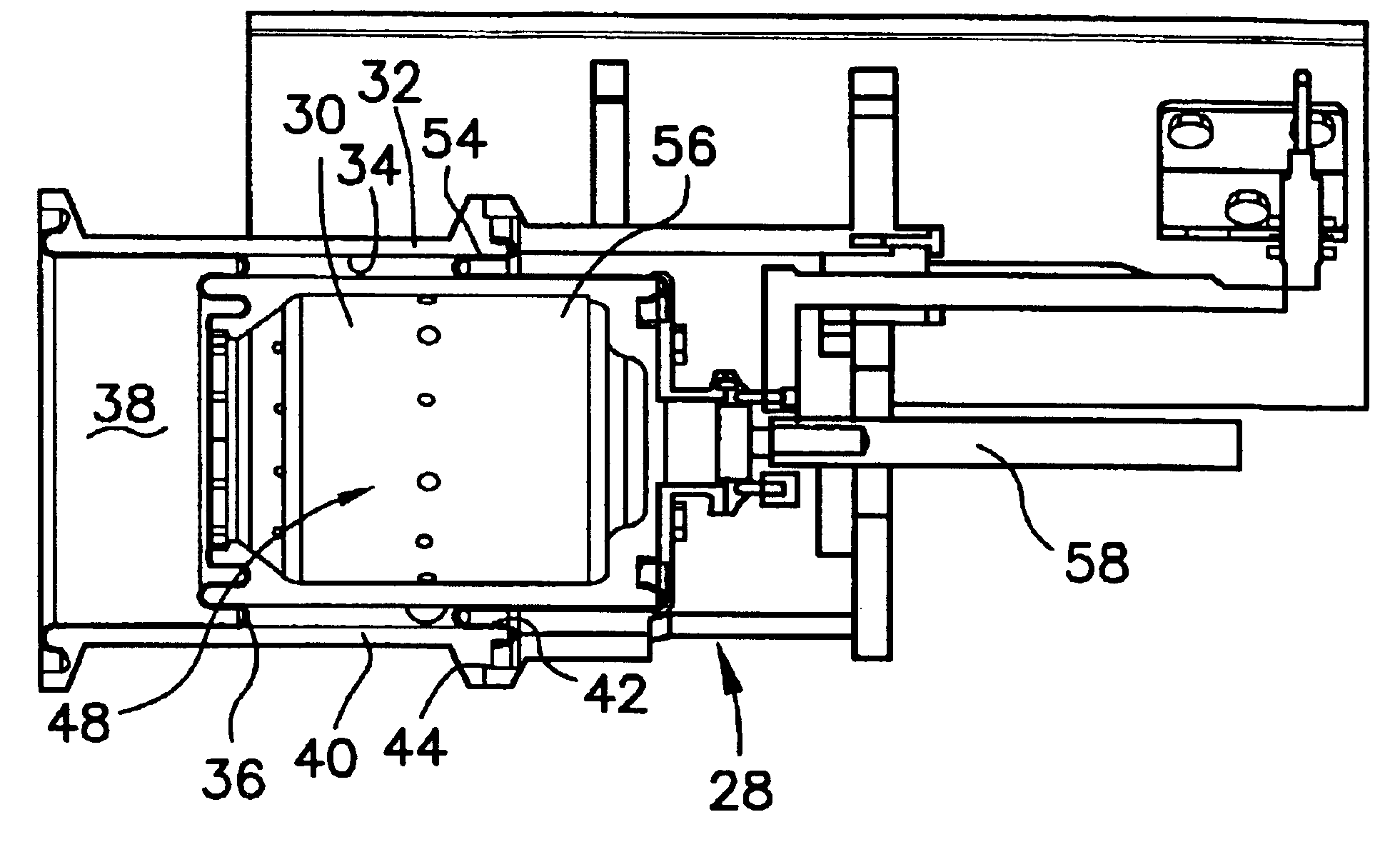

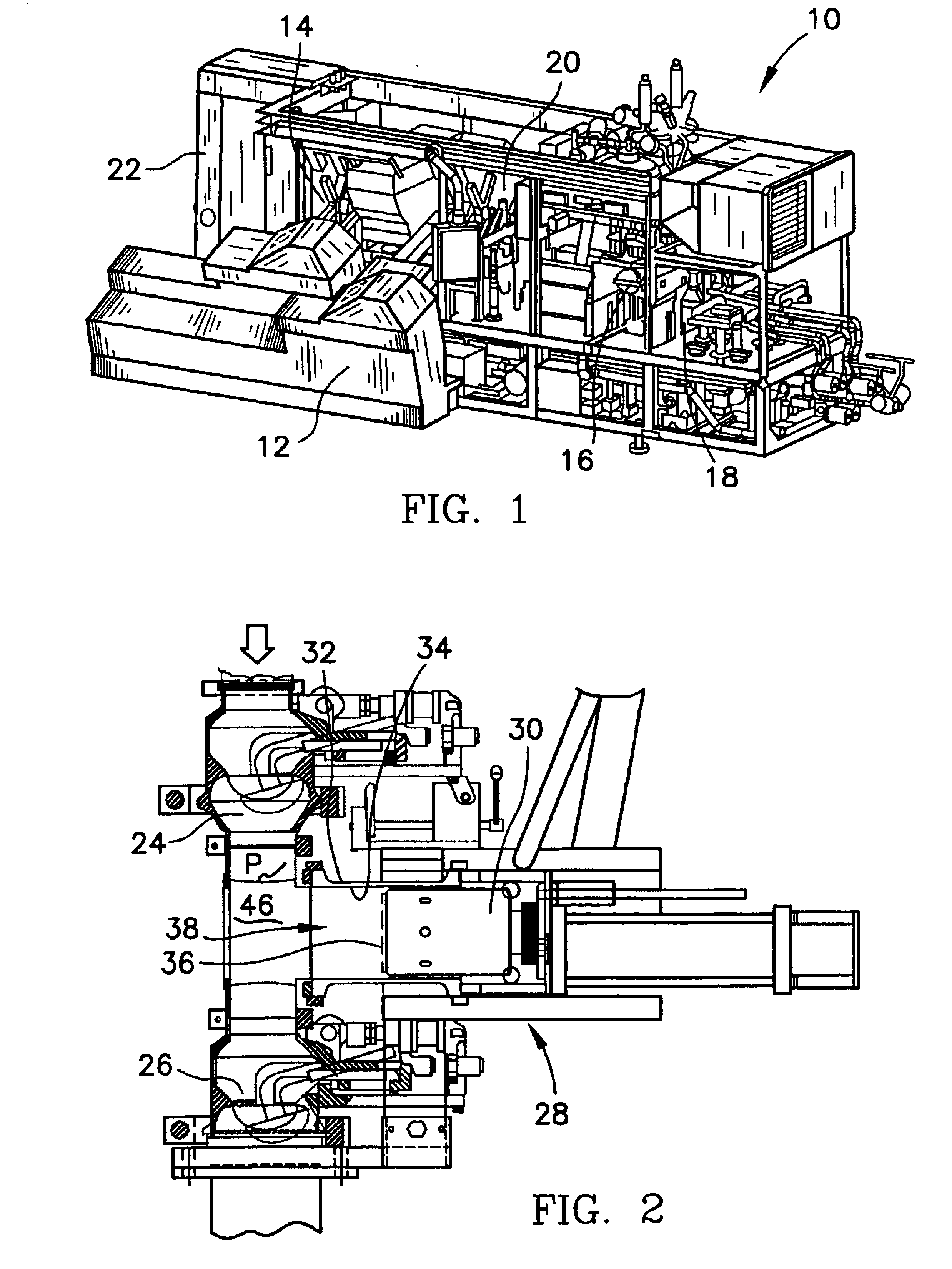

Fill pump piston centering support

InactiveUS6871577B2Reduce wearImprove alignmentFlexible wall reciprocating enginesPlungersCylinder blockMechanical engineering

A centering support for a piston in a piston-type pump having a diaphragm extending between the piston and the cylinder to define a product end of the pump and a driven end of the pump includes at least three equally radially spaced, centering elements extending radially outwardly from the piston for contacting the cylinder wall. The centering elements define a gap between the piston and the cylinder wall. The centering elements are disposed on the piston spaced from the diaphragm at the product end of the pump.

Owner:TETRA LAVAL HLDG & FINANCE SA

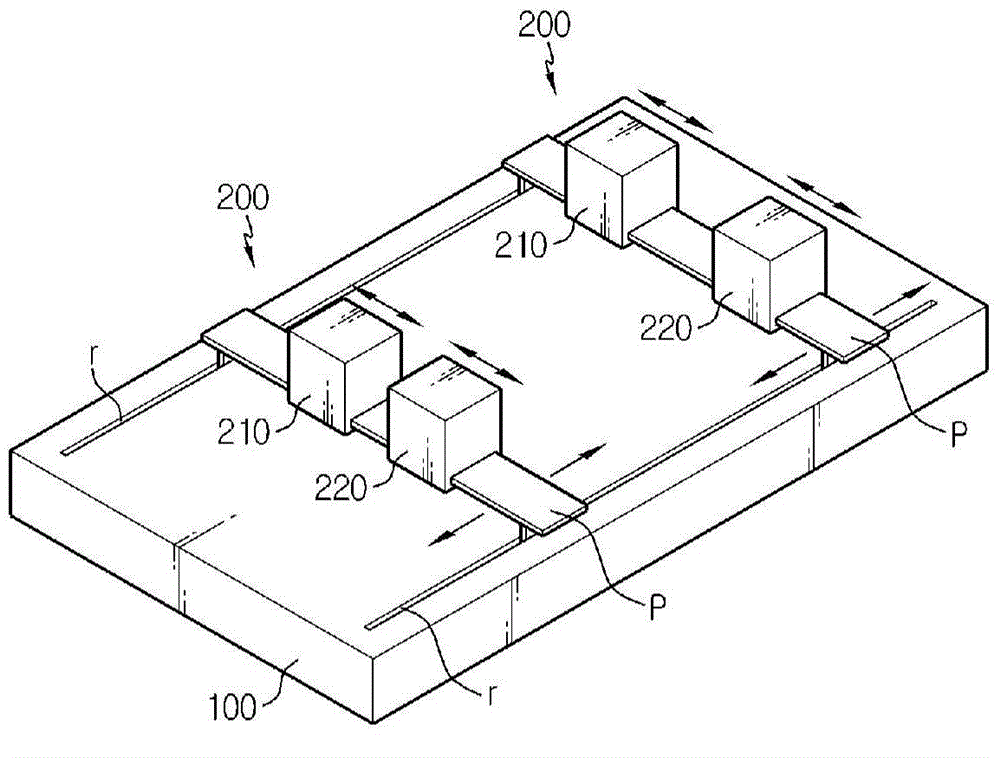

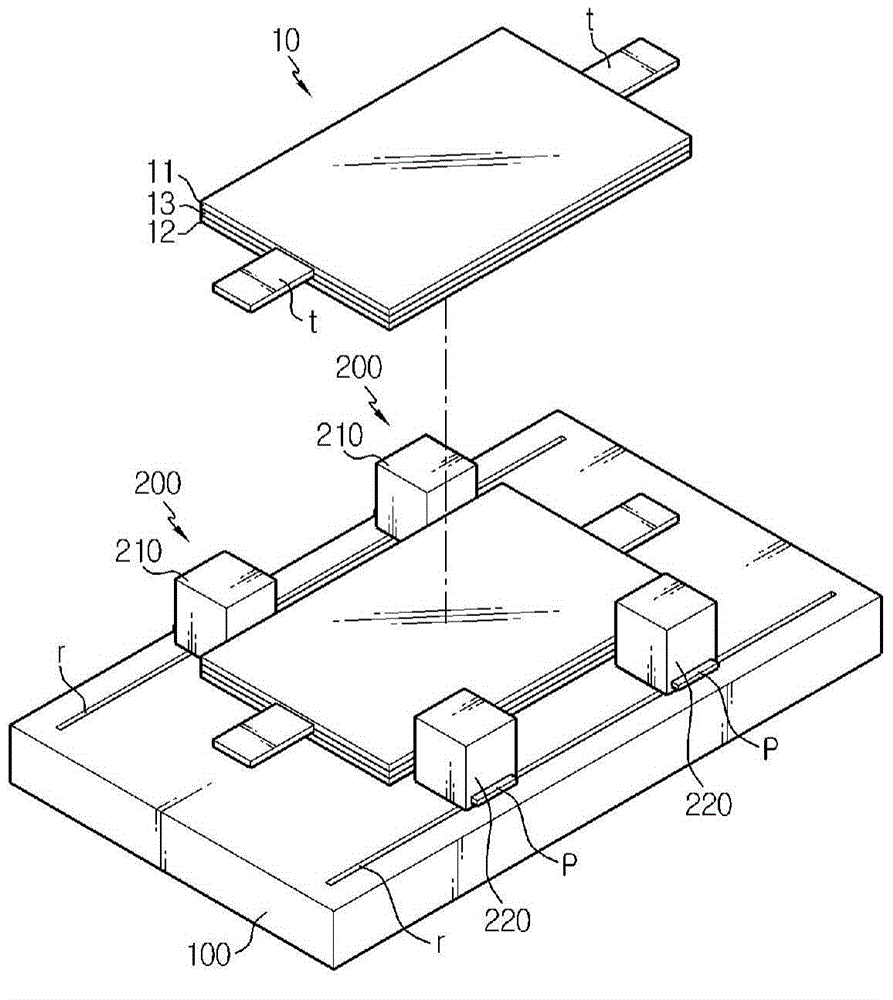

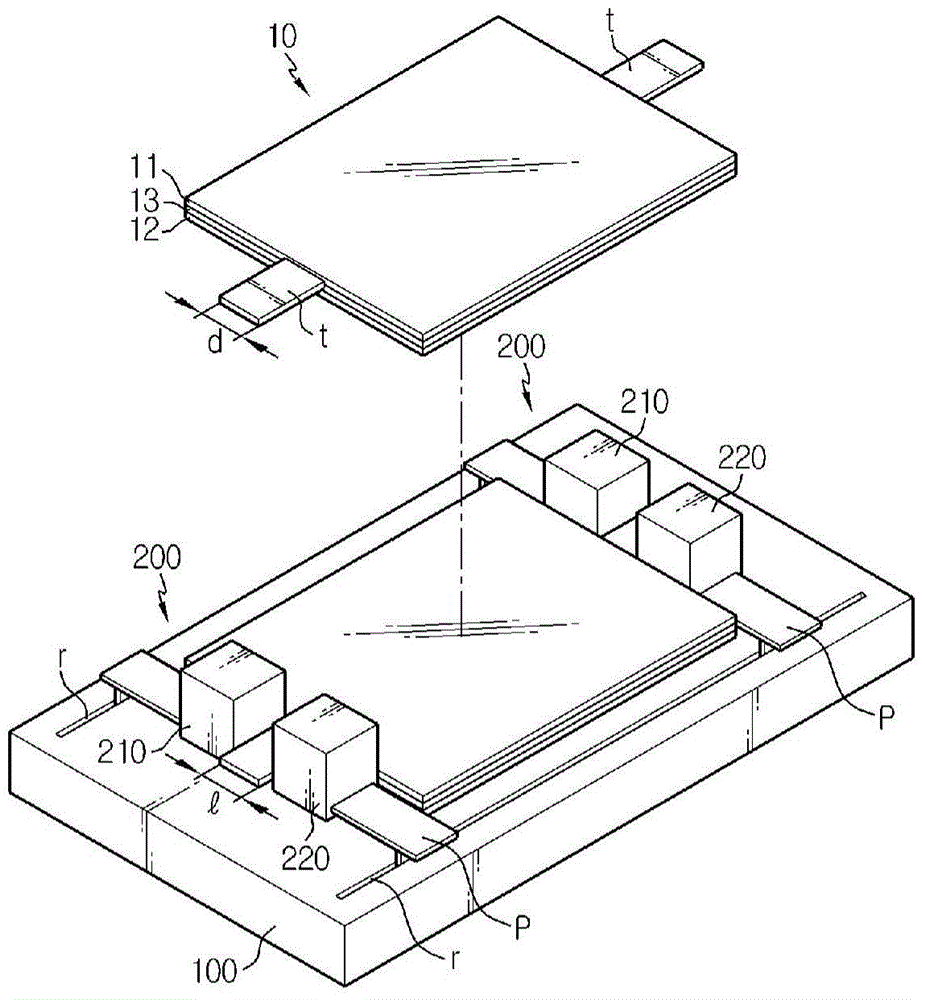

Battery cell stacking jig

ActiveCN104969399AIncrease energy densityImprove alignmentAssembling battery machinesFinal product manufactureBattery cellElectrical and Electronics engineering

The present invention provides a battery cell stacking jig capable of rapidly stacking battery cells and improving the degree of alignment of the stacked battery cells. A battery cell stacking jig according to the present invention is configured to stack at least two battery cells and comprises: a seating portion for providing a space in which the battery cells are seated; and a battery cell alignment portion having a first block, which is mounted on the seating portion, and a second block, which is mounted on the seating portion and is arranged to be spaced apart from the first block by a predetermined distance, at least one of the first block and the second block being mounted on the seating portion to be able to move on the seating portion.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com