Thin film material used for terahertz and infrared light polarization modulation and preparation method thereof

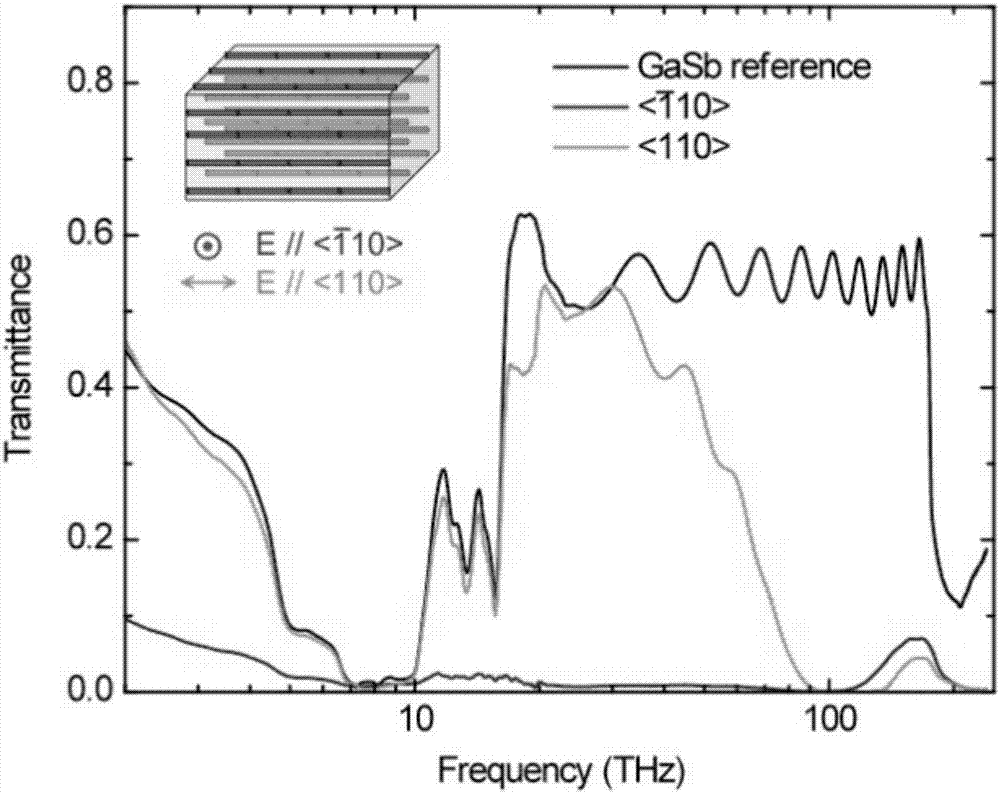

A thin-film material and polarization modulation technology, applied in the direction of polarizing elements, optics, optical elements, etc., can solve the problems that materials are not fully developed, and achieve the improvement of continuity and alignment, light absorption rate, and polarization extinction ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] The invention provides a controllable growth method of molecular beam epitaxy to self-assemble and grow different ErSb nanostructures in a GaSb matrix. The specific preparation method is as follows:

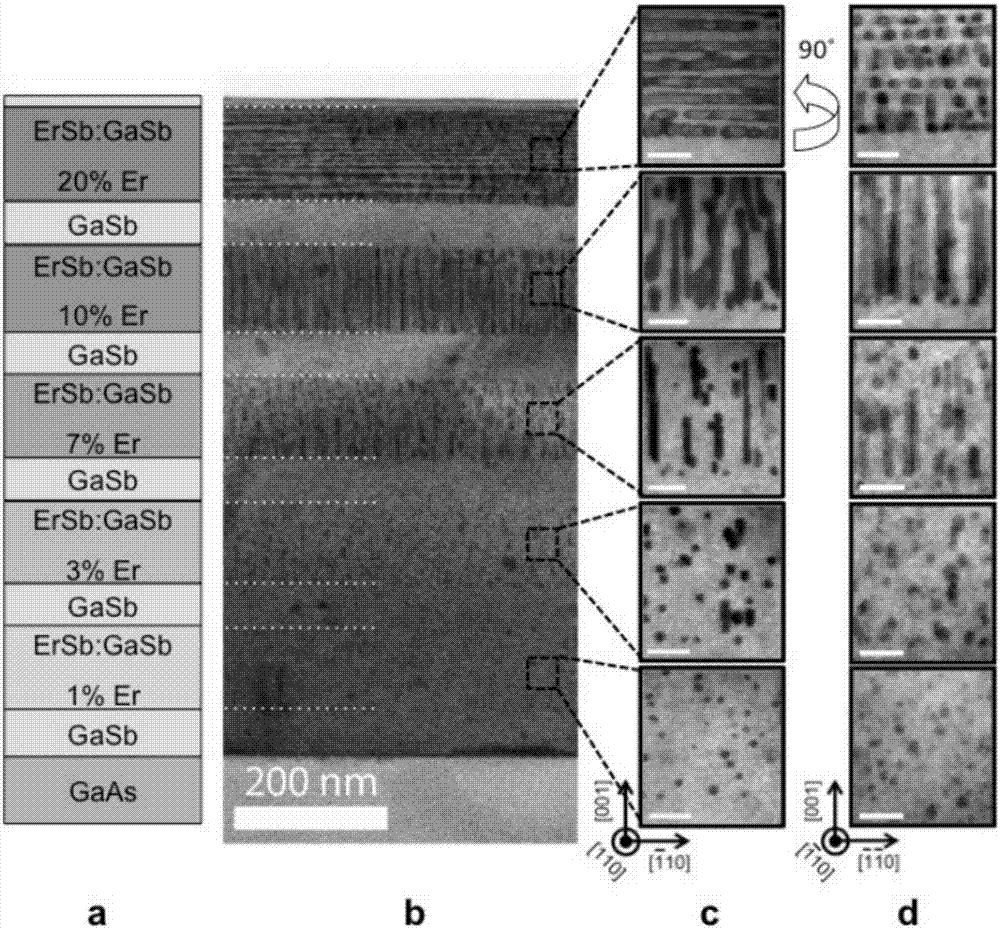

[0023] On the selected (100) crystal plane GaAs substrate by solid-state source molecular beam epitaxy, first remove the surface oxide layer by thermal evaporation, and grow a 200nm-thick GaAs buffer layer at 580°C to facilitate epitaxy. The surface is flat, and then the growth temperature is set to 530° C. to grow a GaSb stress release layer with a thickness of 60 nm. In this example, a multilayer ErSb:GaSb sample is designed, and the ErSb:GaSb layers with different doping concentrations are characterized to understand the growth mechanism of the material, and it is proved that different ErSb can be regulated by adjusting the do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com