Patents

Literature

1327 results about "Nanowire array" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light absorption and filtering properties of vertically oriented semiconductor nano wires

InactiveUS9000353B2Optical radiation measurementMaterial nanotechnologyPhotovoltaic detectorsPhotodetector

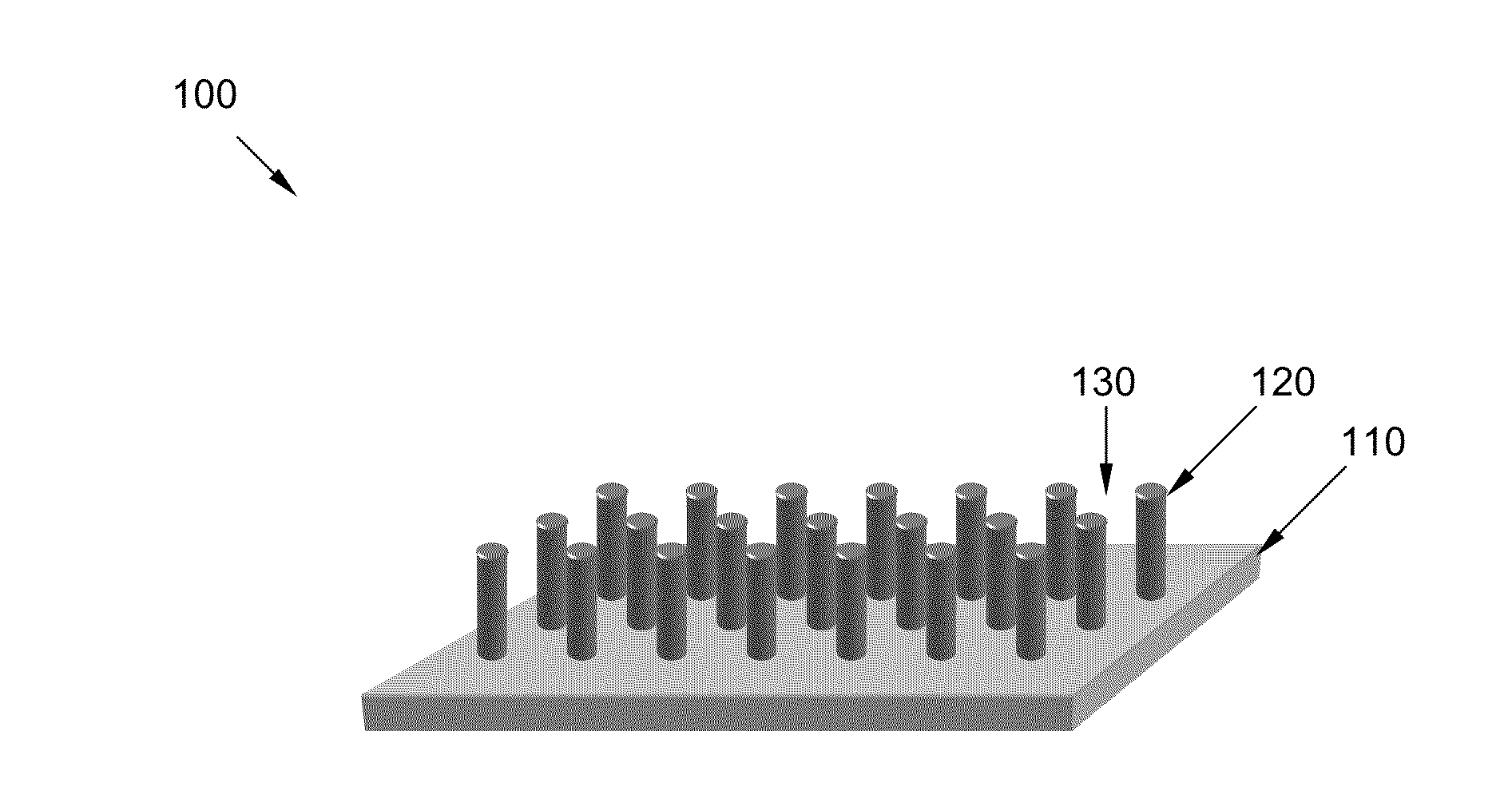

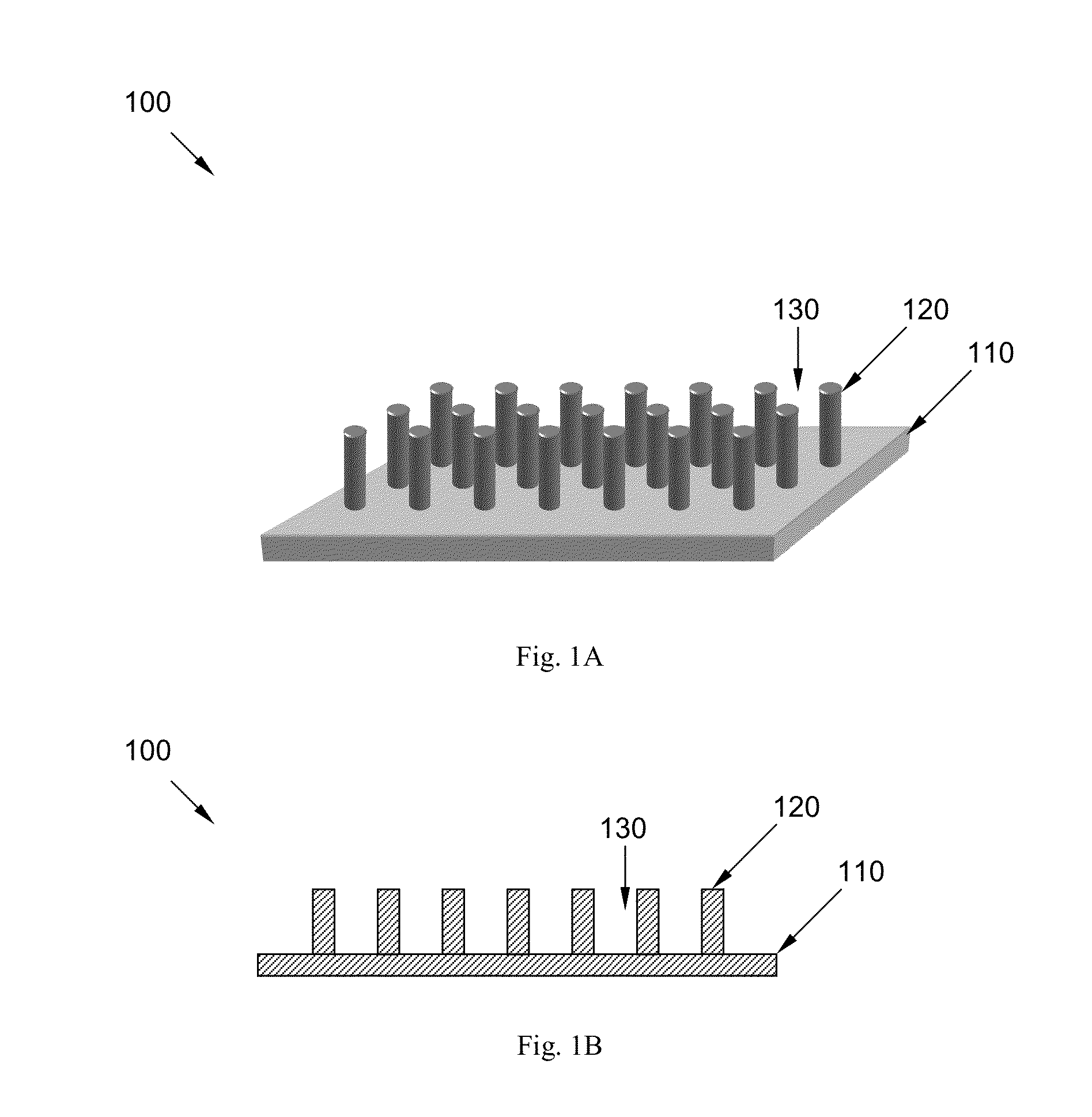

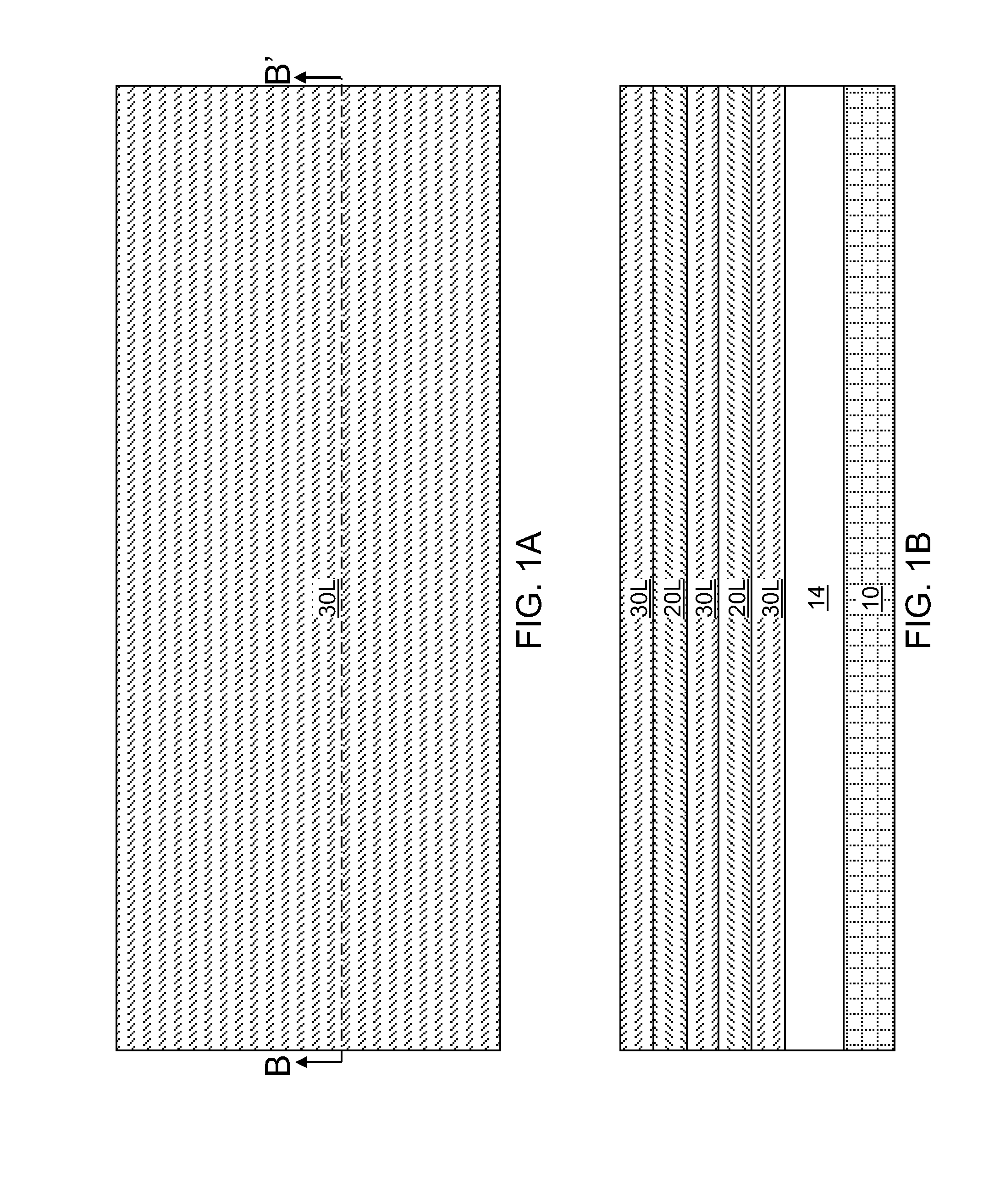

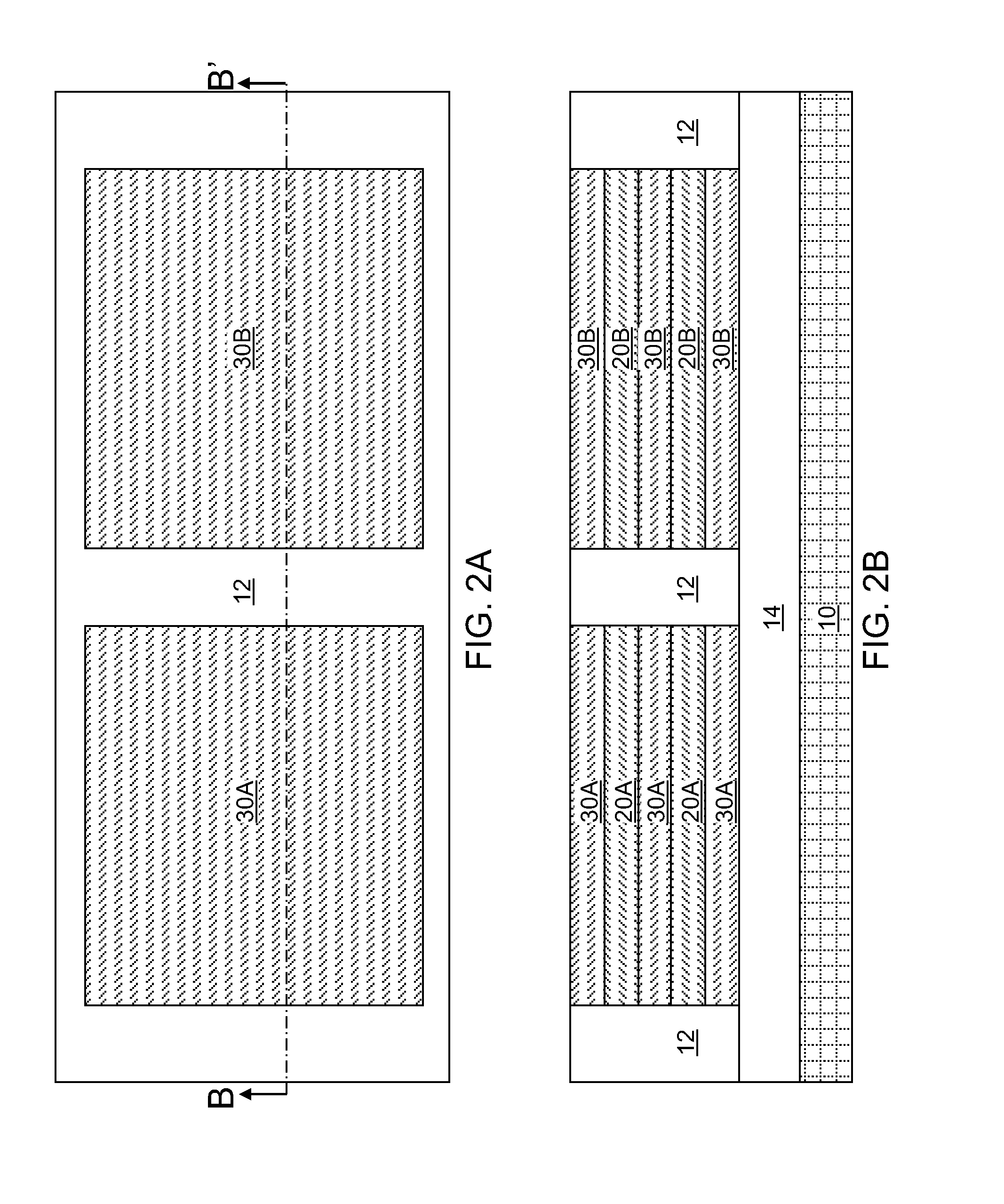

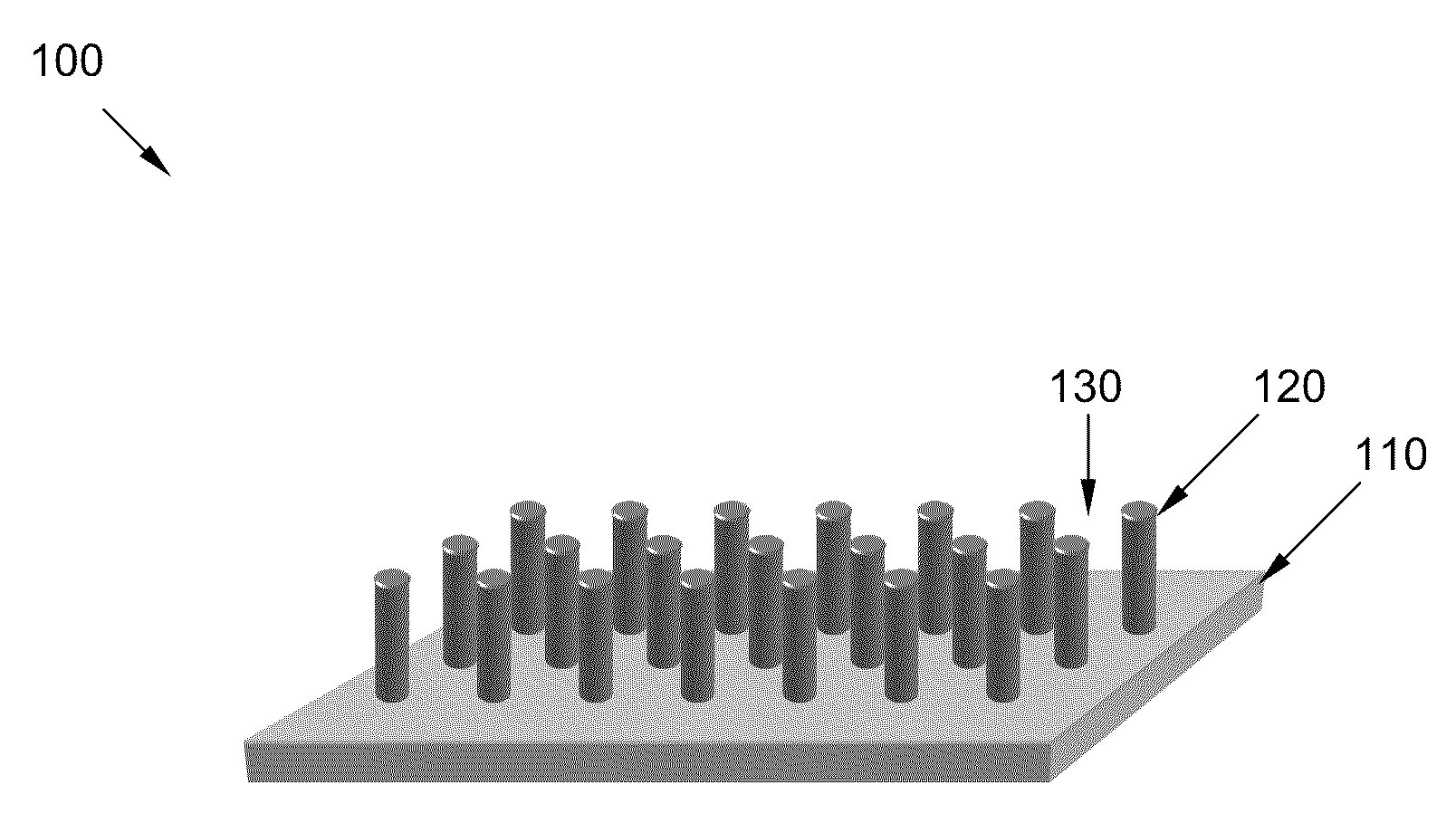

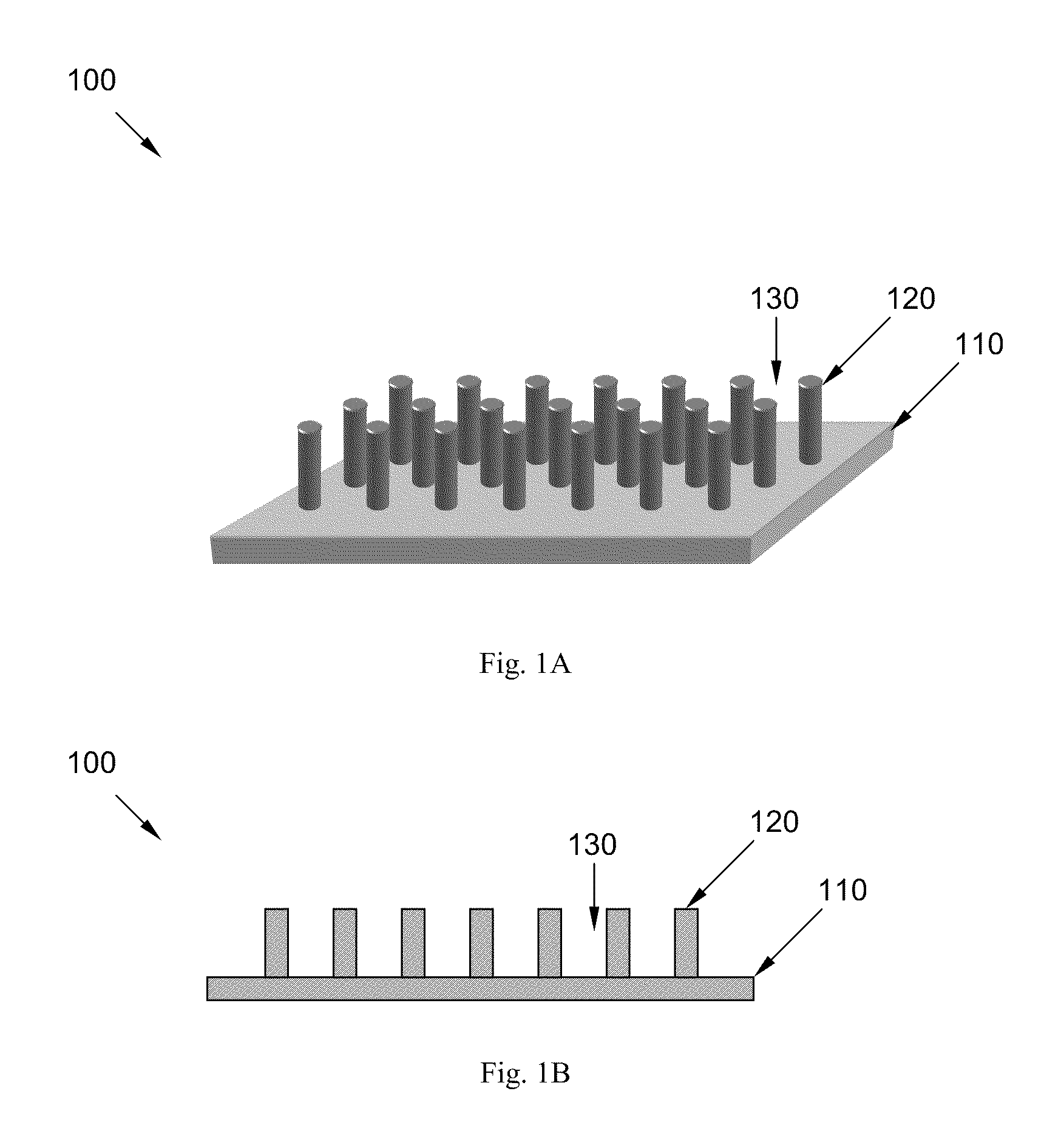

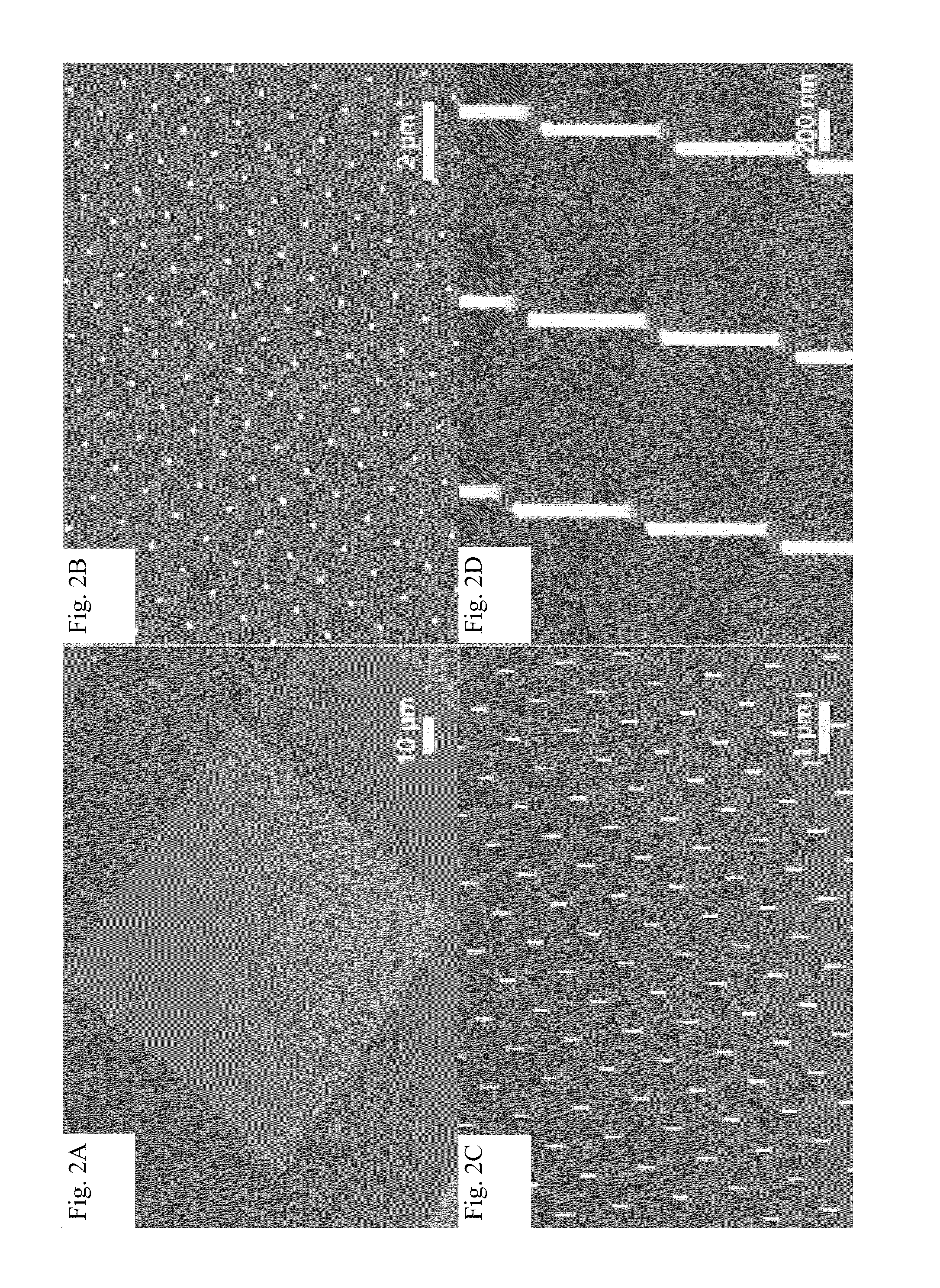

A nanowire array is described herein. The nanowire array comprises a substrate and a plurality of nanowires extending essentially vertically from the substrate; wherein: each of the nanowires has uniform chemical along its entire length; a refractive index of the nanowires is at least two times of a refractive index of a cladding of the nanowires. This nanowire array is useful as a photodetector, a submicron color filter, a static color display or a dynamic color display.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE +1

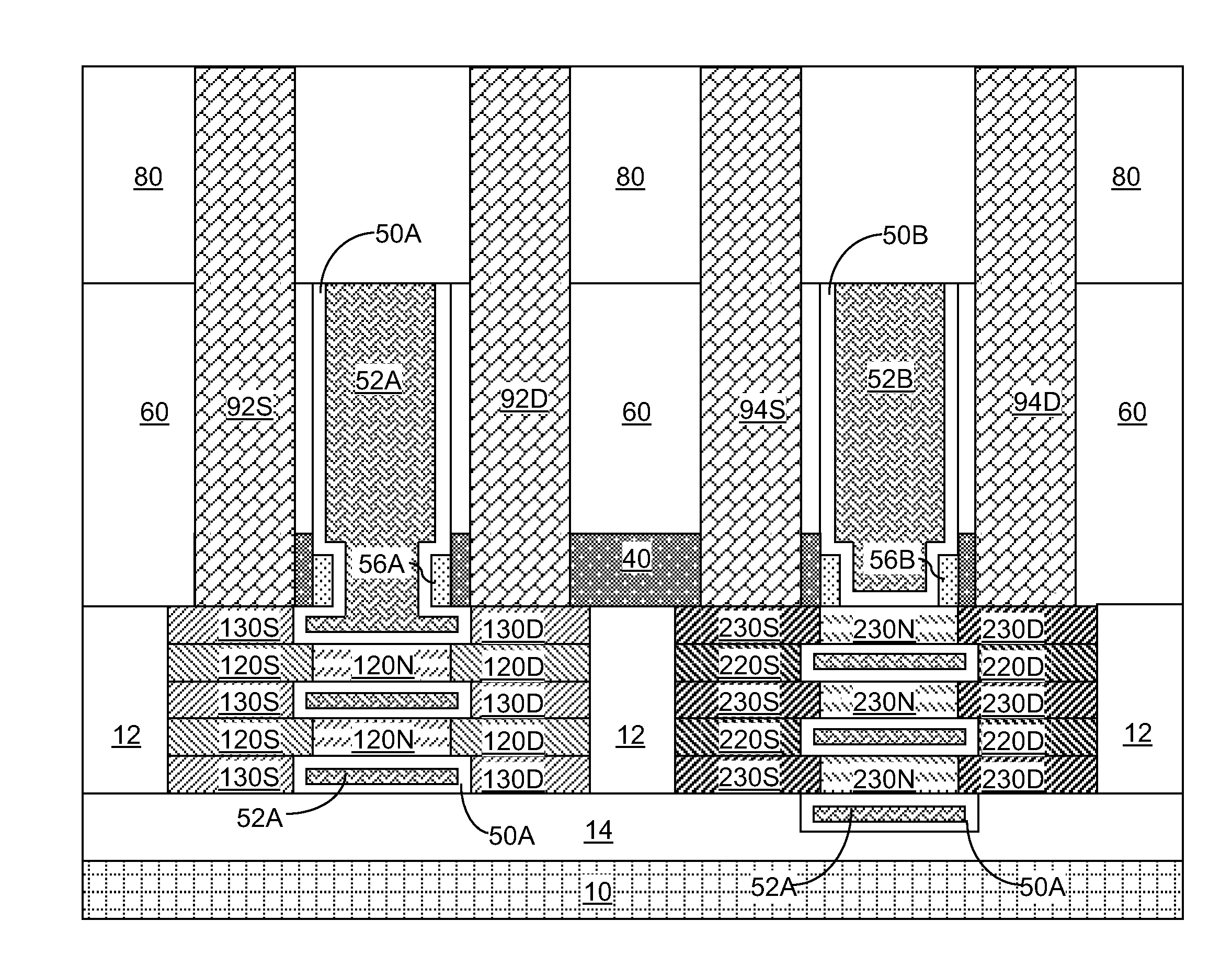

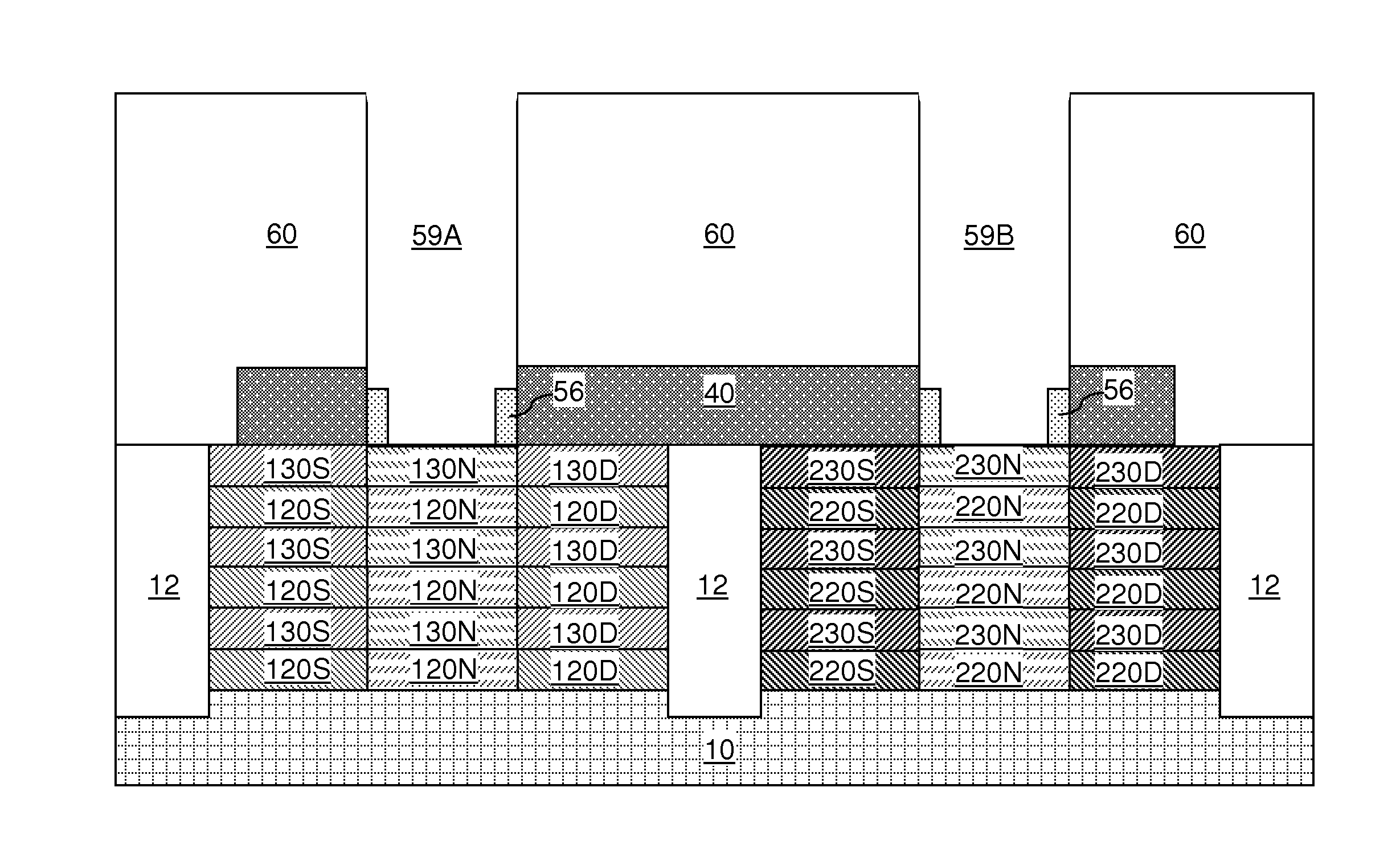

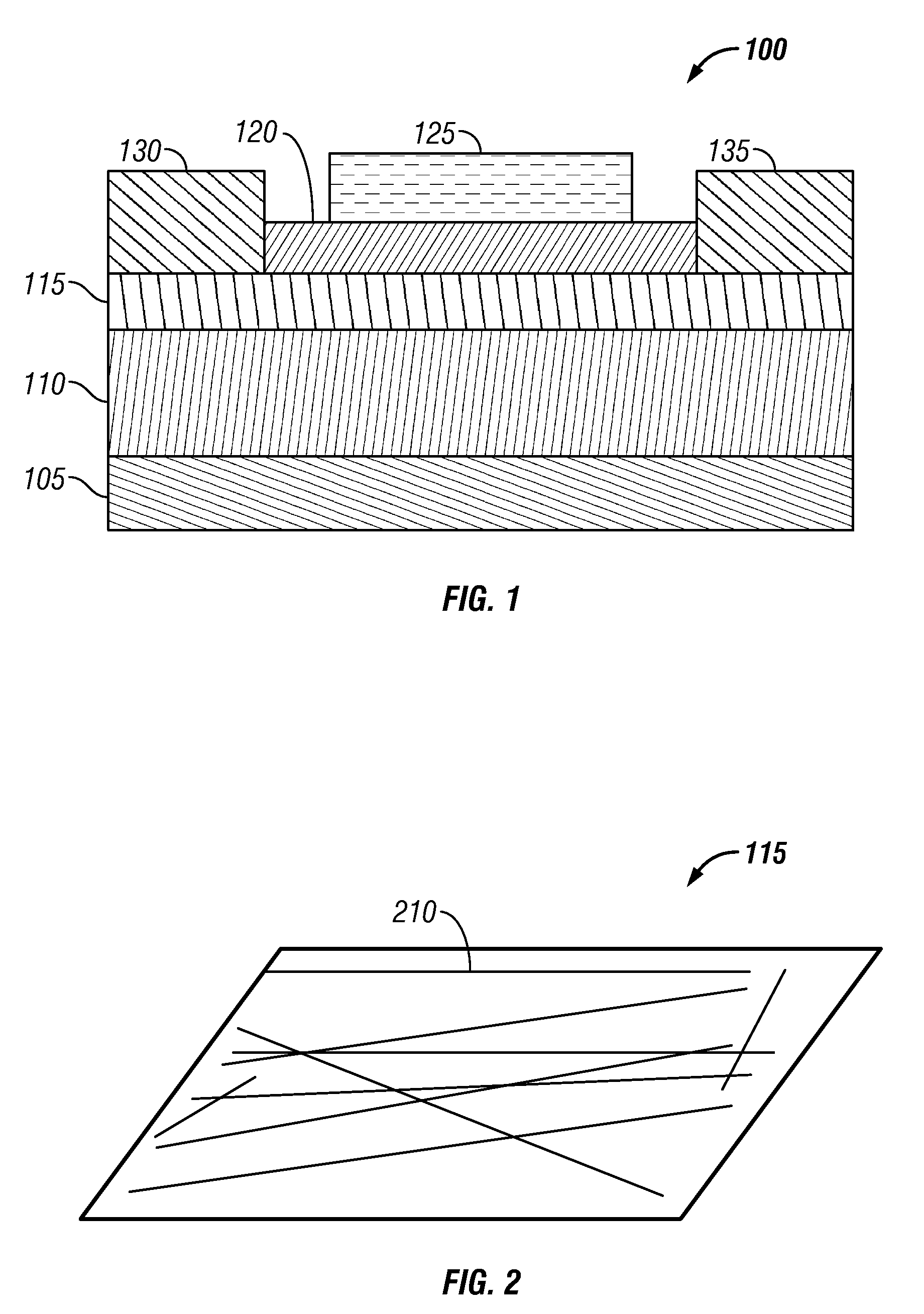

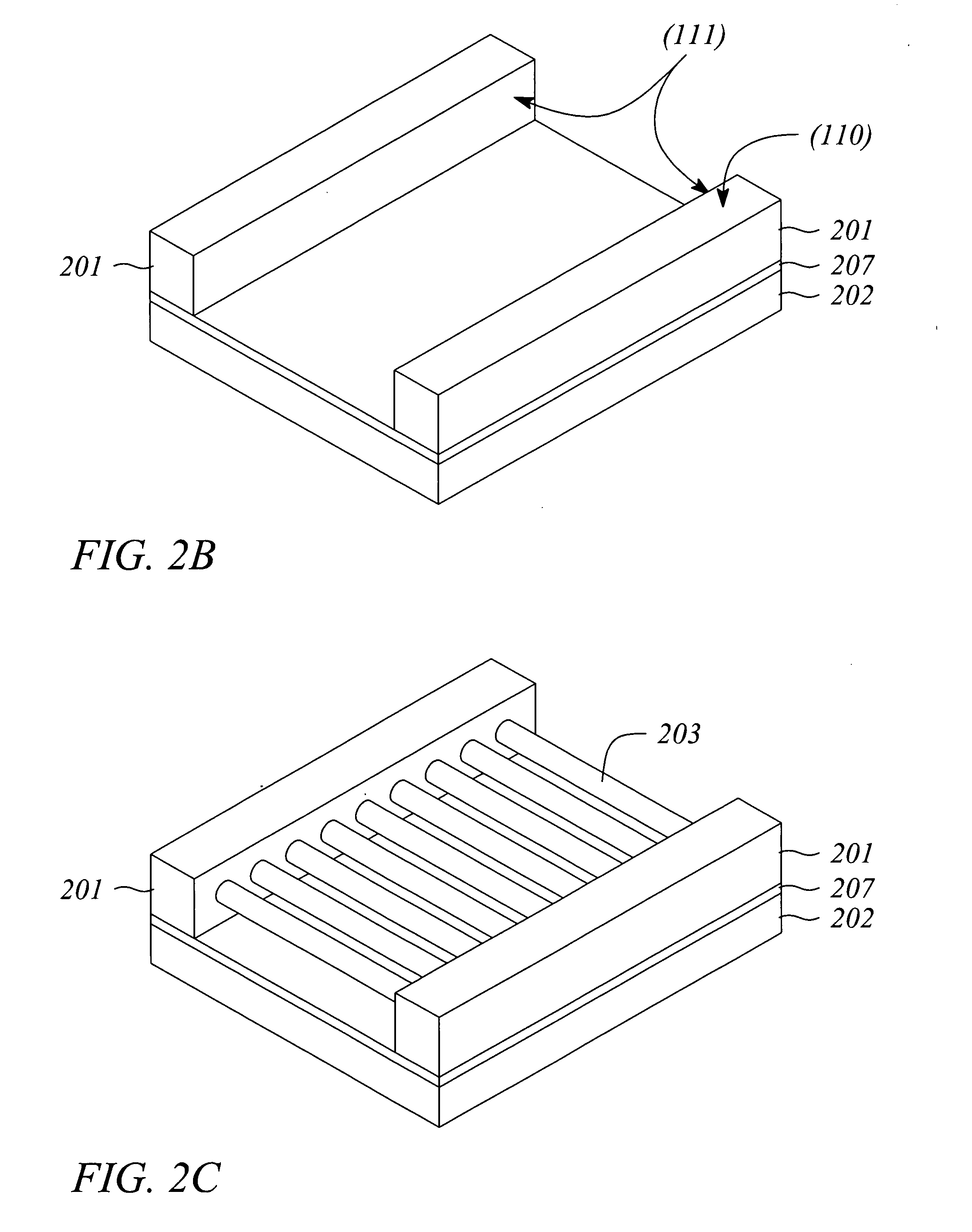

Nanomesh complementary metal-oxide-semiconductor field effect transistors

An alternating stack of first and second semiconductor layers is formed. Fin-defining mask structures are formed over the alternating stack. A planarization dielectric layer and first and second gate cavities therein are subsequently formed. The first and second gate cavities are extended downward by etching the alternating stack employing a combination of the planarization layer and the fin-defining mask structures as an etch mask. The germanium-free silicon material is isotropically etched to laterally expand the first gate cavity and to form a first array of semiconductor nanowires including the silicon-germanium alloy, and the silicon-germanium alloy is isotropically etched to laterally expand the second gate cavity and to form a second array of semiconductor nanowires including the germanium-free silicon material. The first and second gate cavities are filled with replacement gate structures. Each replacement gate structure laterally can surround a two-dimensional array of semiconductor nanowires.

Owner:GLOBALFOUNDRIES INC

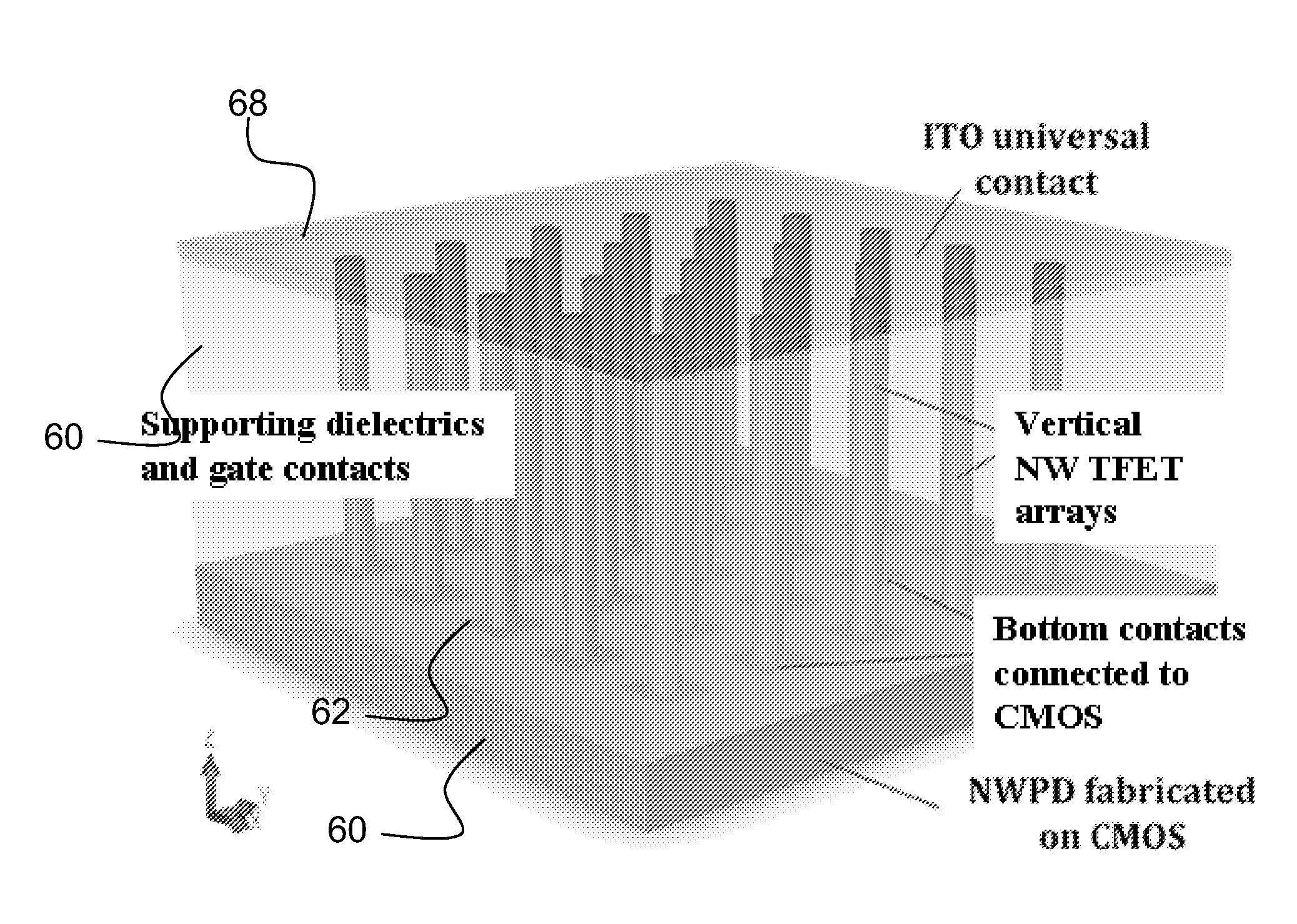

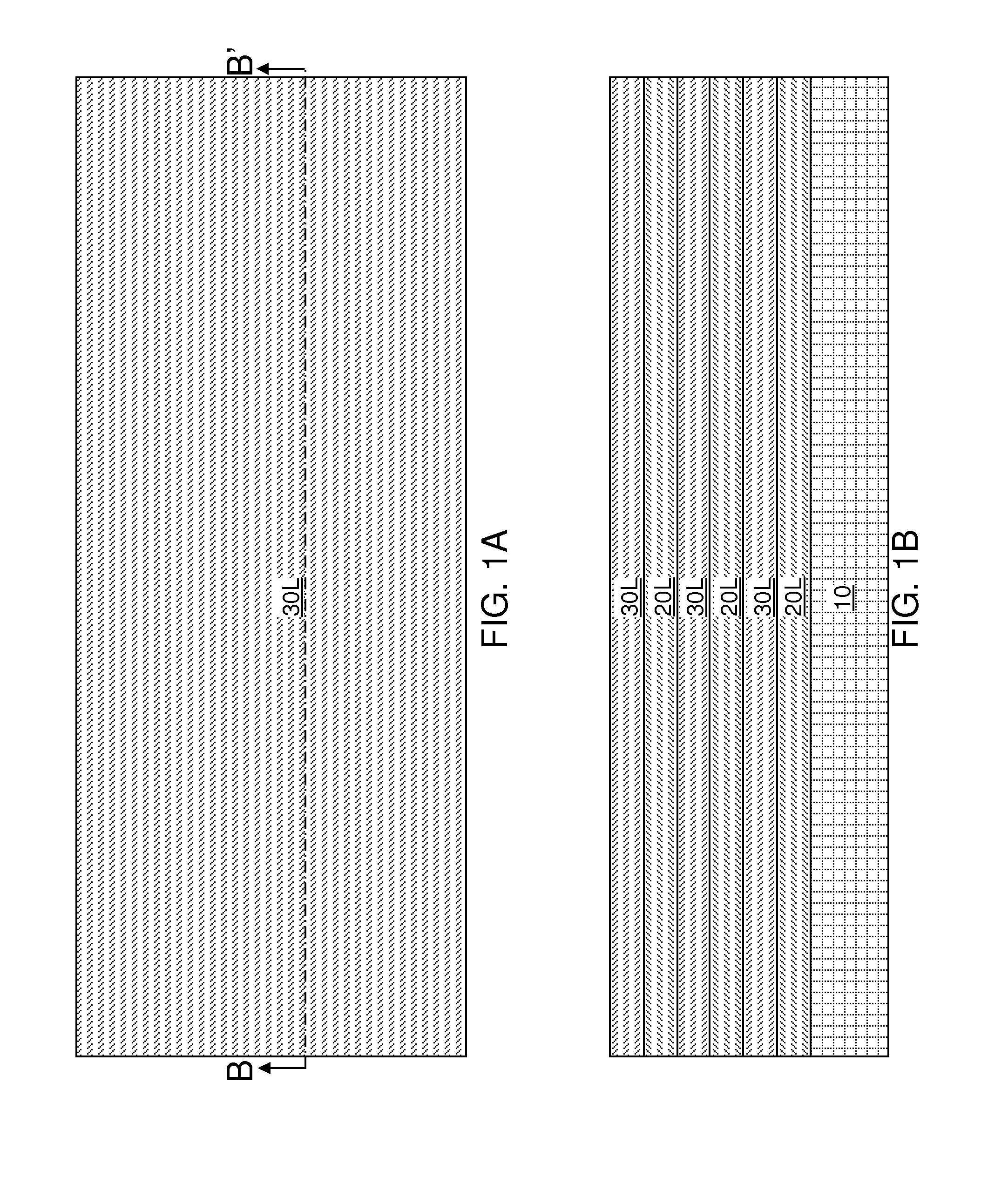

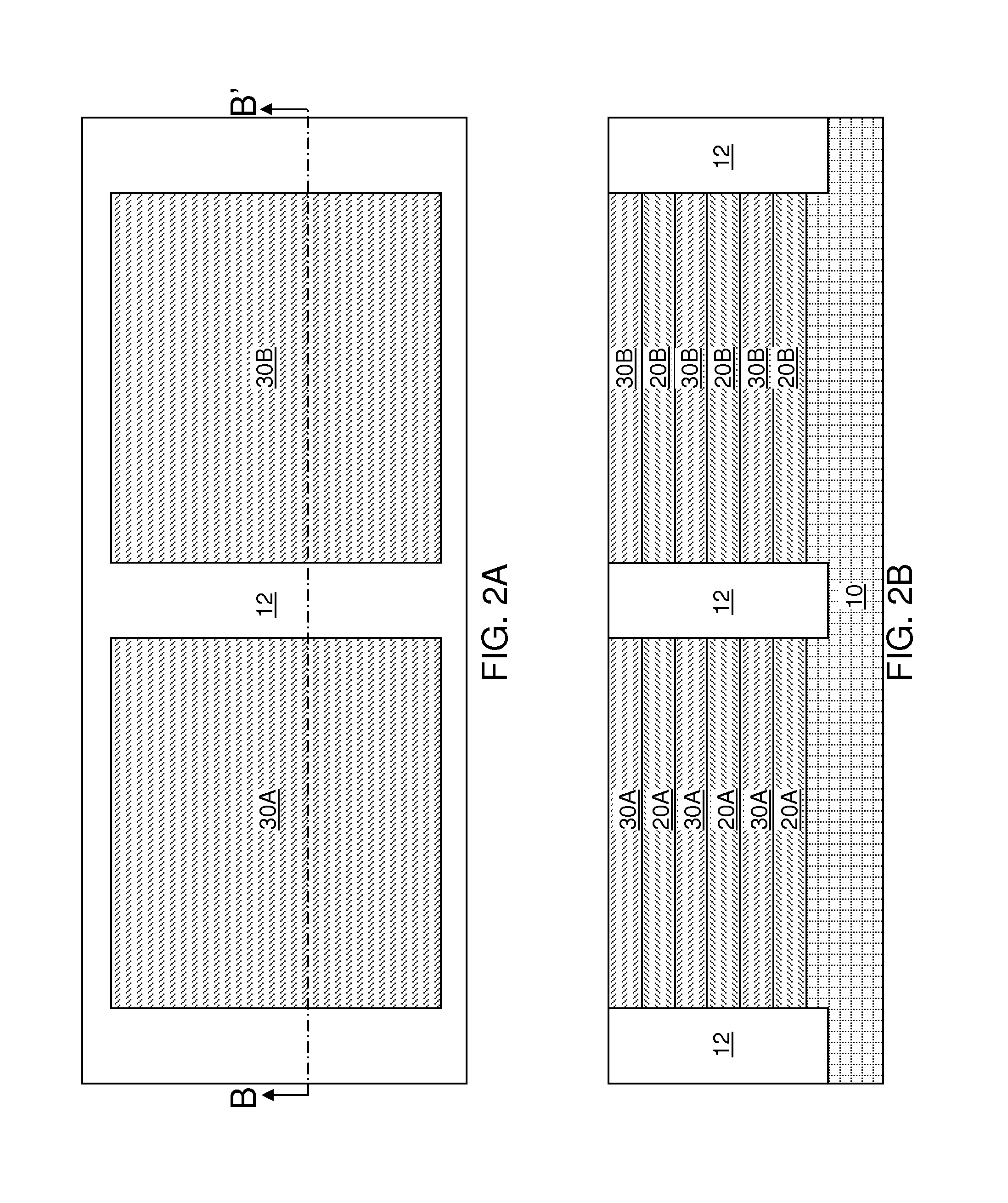

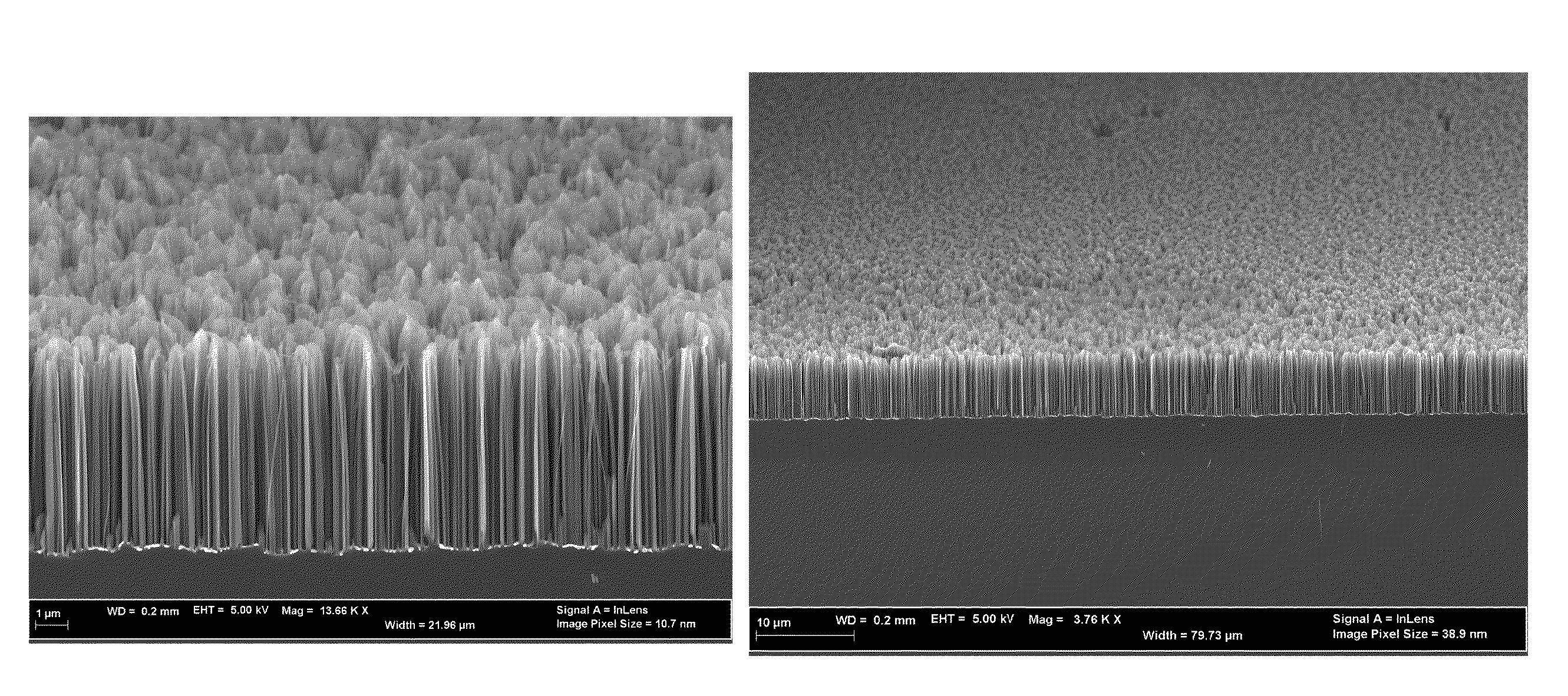

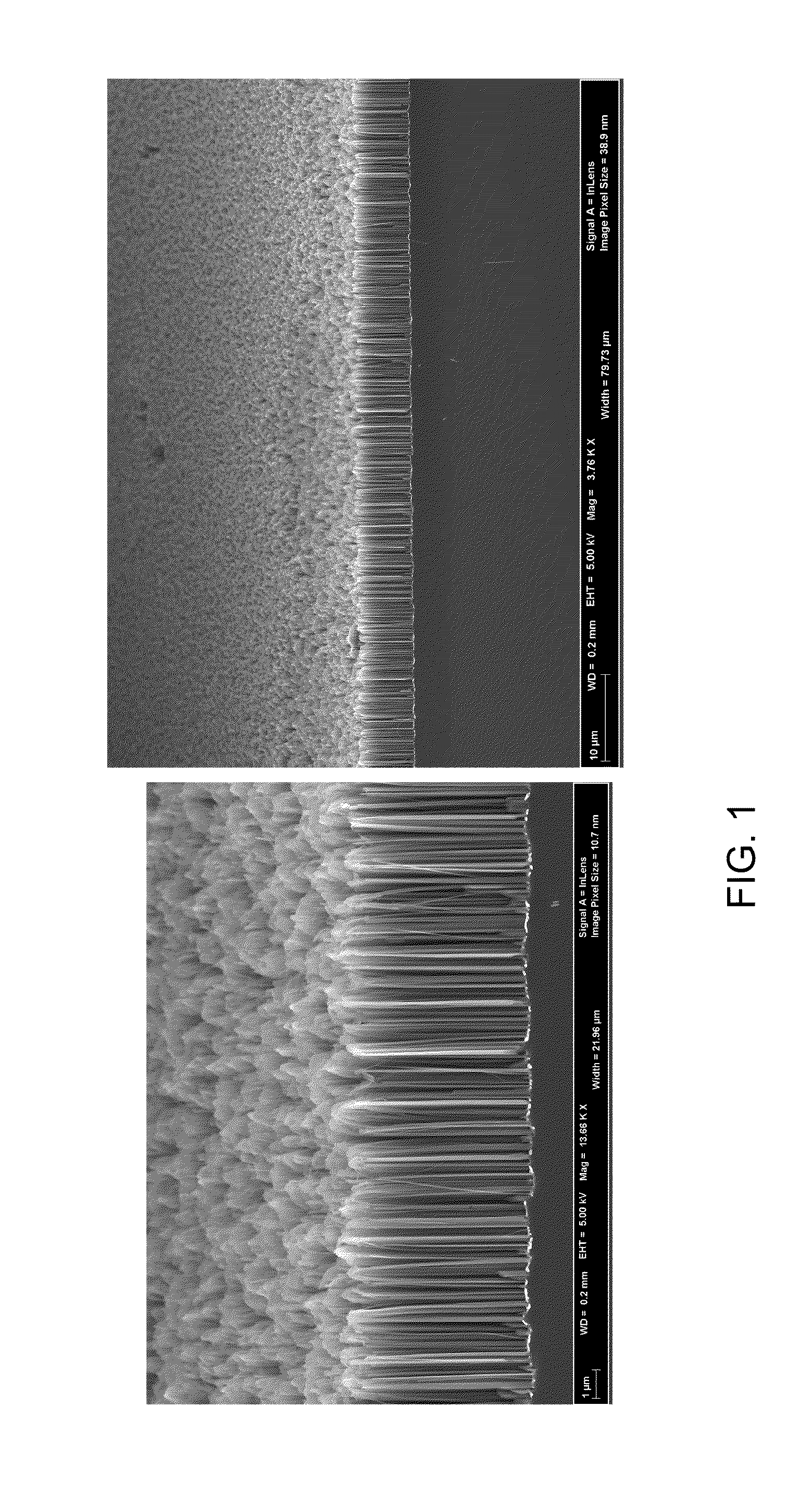

Vertical group iii-v nanowires on si, heterostructures, flexible arrays and fabrication

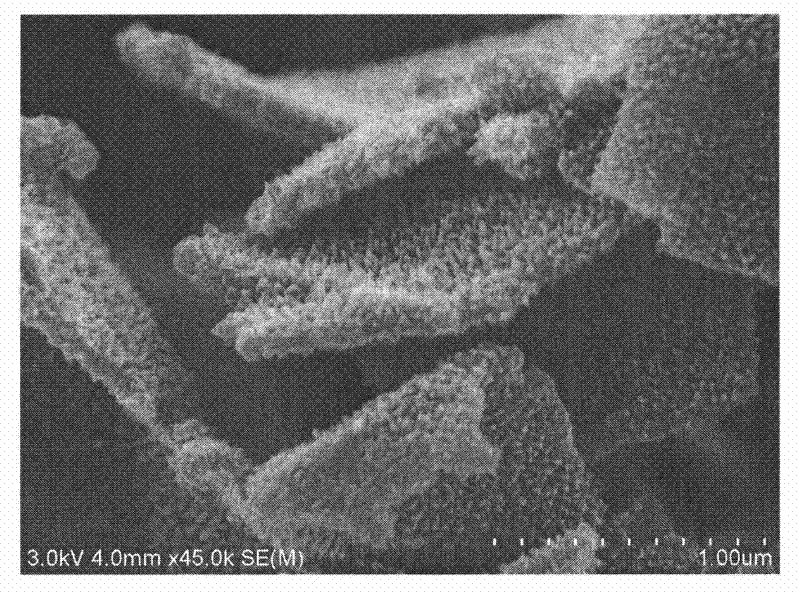

ActiveUS20110253982A1Promote absorptionReduce distanceNanoinformaticsSolid-state devicesNanowire arrayCore shell

Embodiments of the invention provide a method for direct heteroepitaxial growth of vertical III-V semiconductor nanowires on a silicon substrate. The silicon substrate is etched to substantially completely remove native oxide. It is promptly placed in a reaction chamber. The substrate is heated and maintained at a growth temperature. Group III-V precursors are flowed for a growth time. Preferred embodiment vertical Group III-V nanowires on silicon have a core-shell structure, which provides a radial homojunction or heterojunction. A doped nanowire core is surrounded by a shell with complementary doping. Such can provide high optical absorption due to the long optical path in the axial direction of the vertical nanowires, while reducing considerably the distance over which carriers must diffuse before being collected in the radial direction. Alloy composition can also be varied. Radial and axial homojunctions and heterojunctions can be realized. Embodiments provide for flexible Group III-V nanowire structures. An array of Group III-V nanowire structures is embedded in polymer. A fabrication method forms the vertical nanowires on a substrate, e.g., a silicon substrate. Preferably, the nanowires are formed by the preferred methods for fabrication of Group III-V nanowires on silicon. Devices can be formed with core / shell and core / multi-shell nanowires and the devices are released from the substrate upon which the nanowires were formed to create a flexible structure that includes an array of vertical nanowires embedded in polymer.

Owner:RGT UNIV OF CALIFORNIA

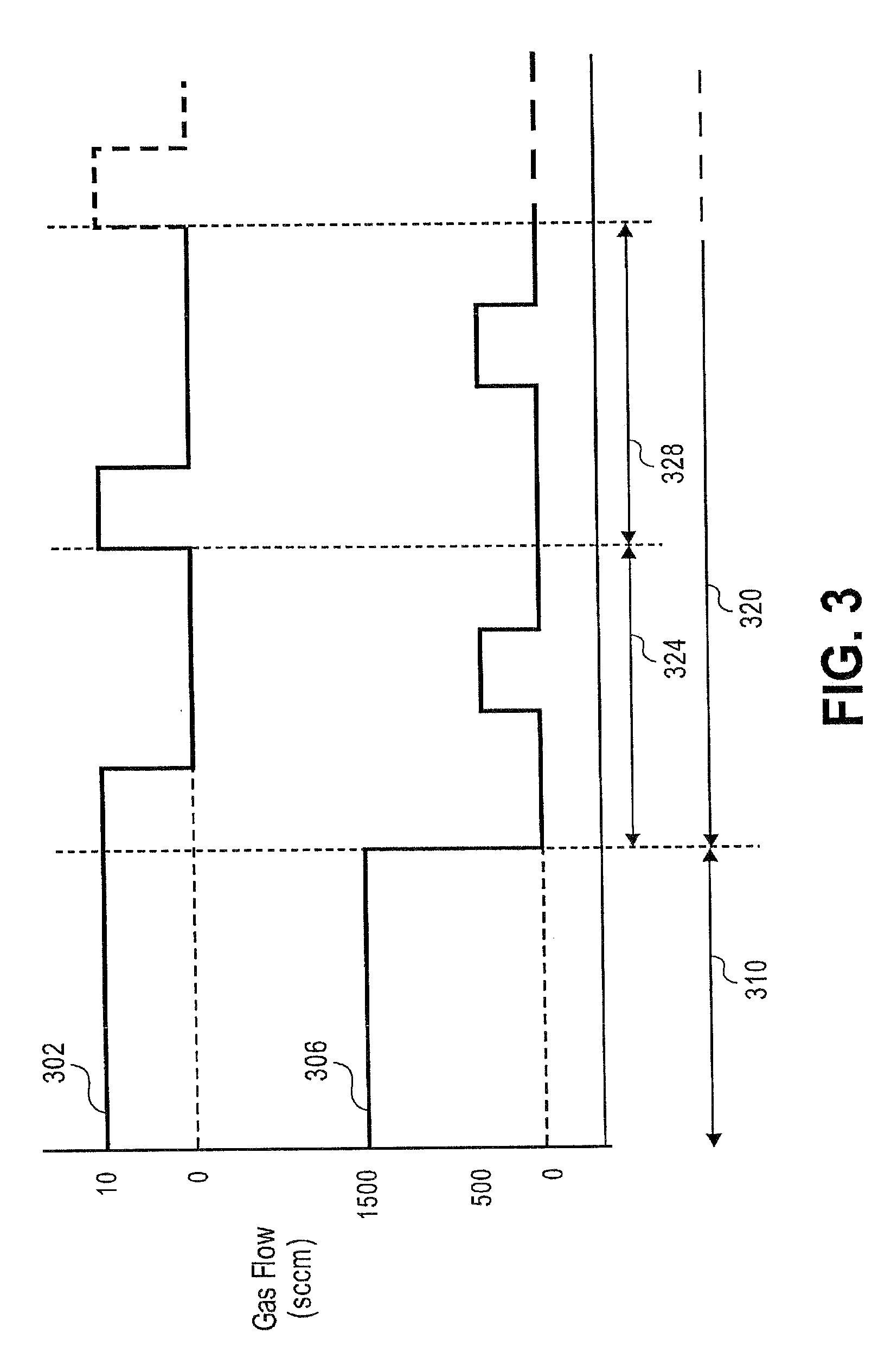

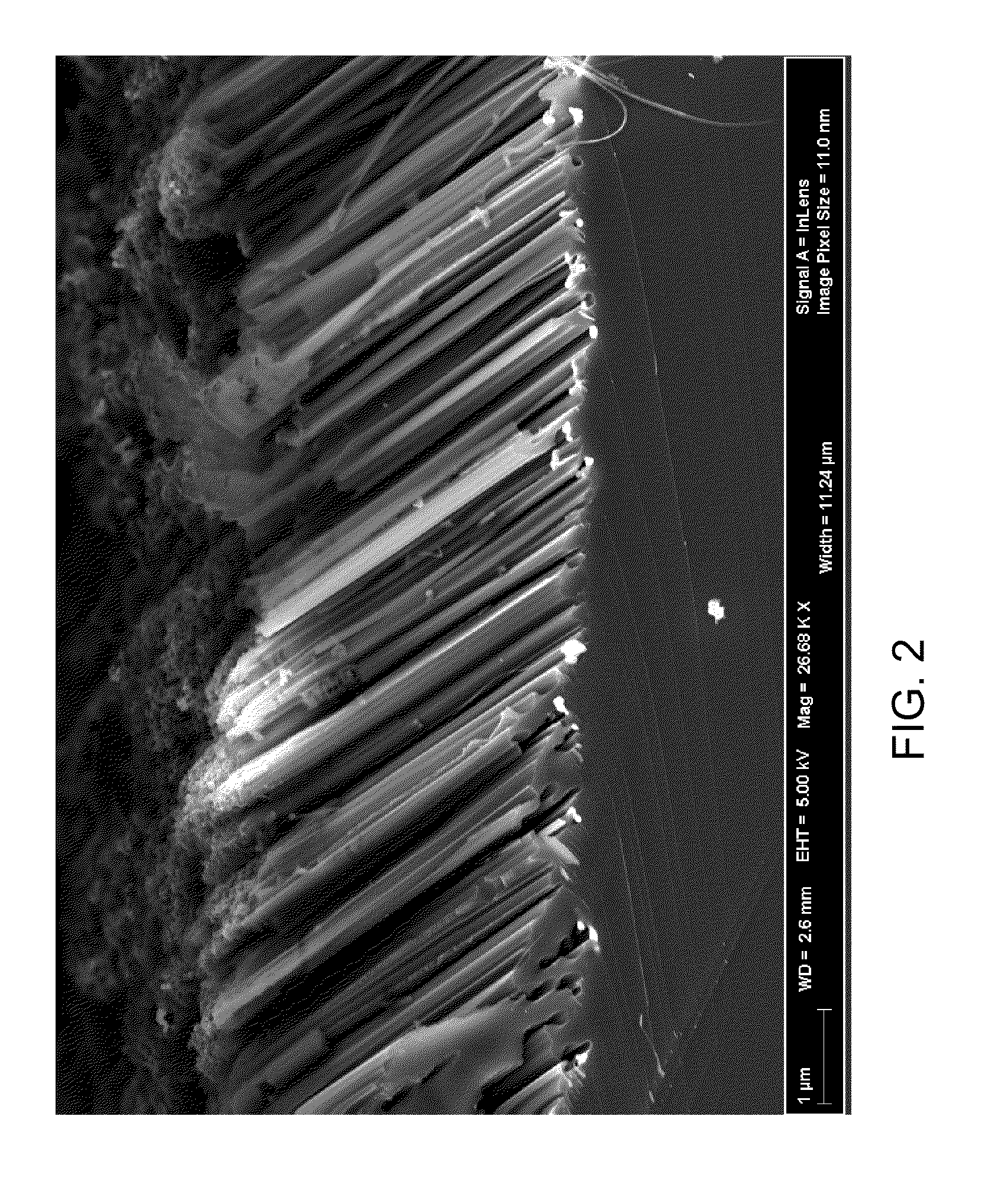

Pulsed growth of catalyst-free growth of GaN nanowires and application in group III nitride semiconductor bulk material

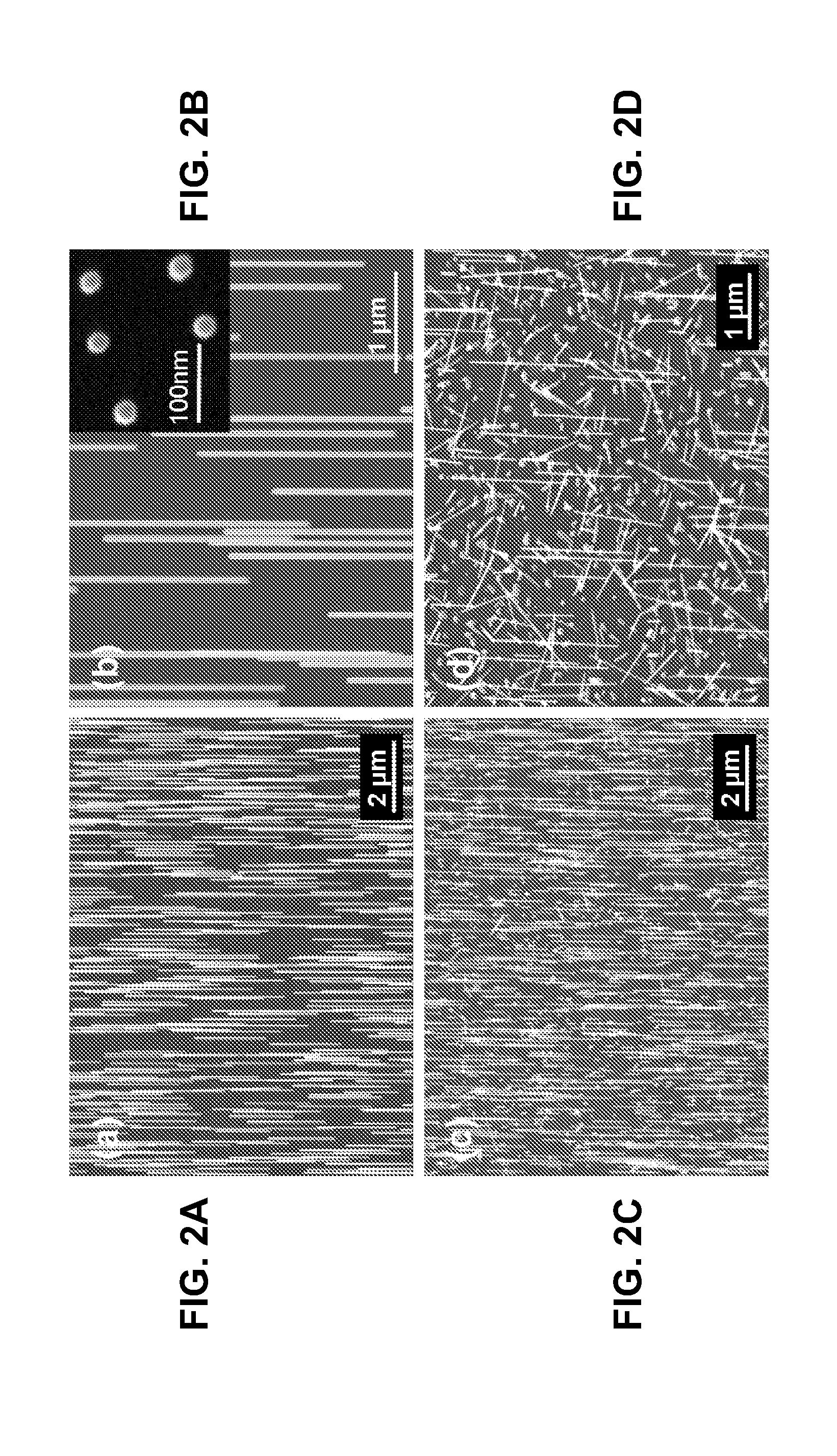

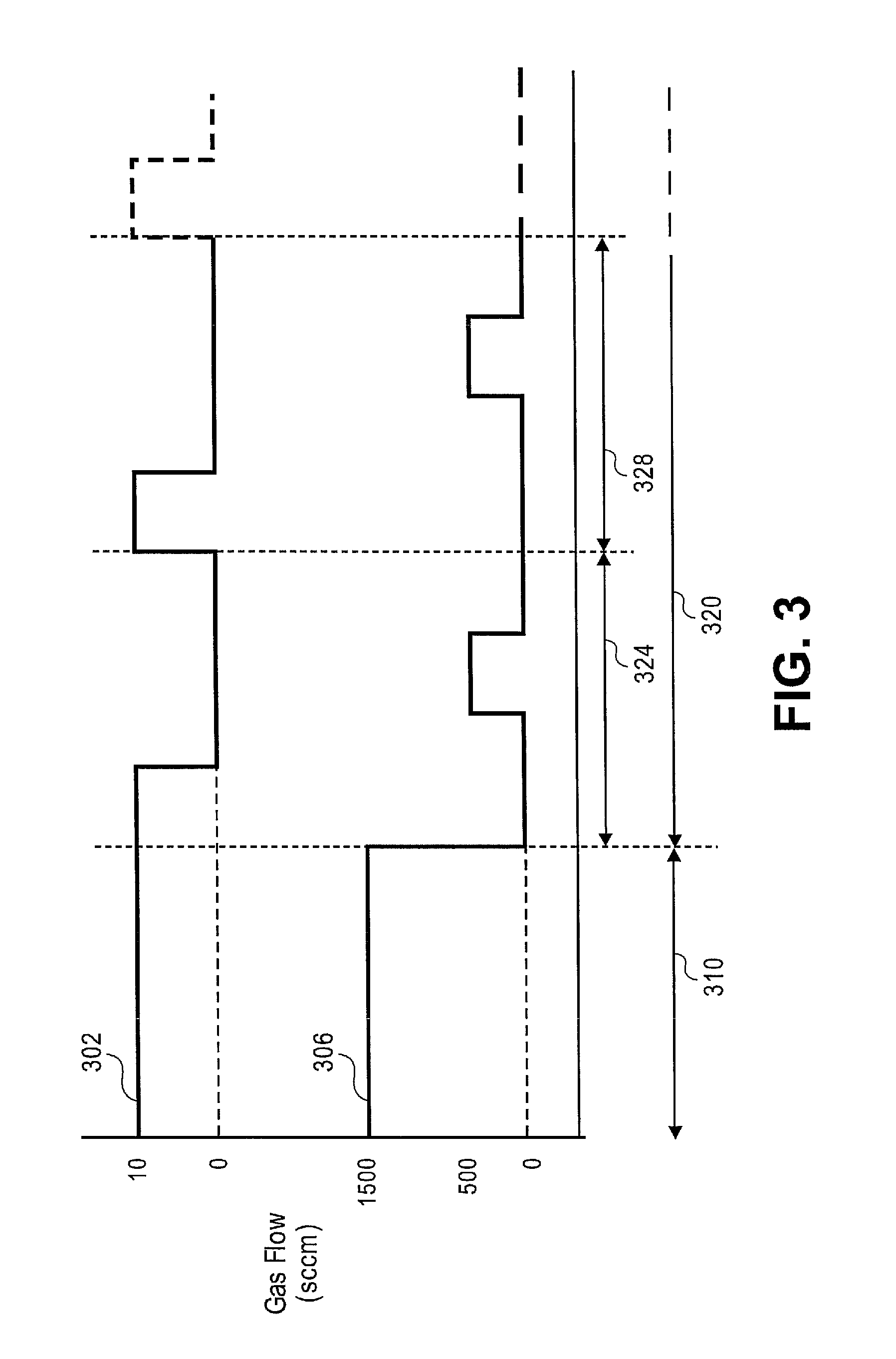

Exemplary embodiments provide semiconductor devices including high-quality (i.e., defect free) group III-N nanowires and uniform group III-N nanowire arrays as well as their scalable processes for manufacturing, where the position, orientation, cross-sectional features, length and the crystallinity of each nanowire can be precisely controlled. A pulsed growth mode can be used to fabricate the disclosed group III-N nanowires and / or nanowire arrays providing a uniform length of about 10 nm to about 1000 microns with constant cross-sectional features including an exemplary diameter of about 10-1000 nm. In addition, high-quality GaN substrate structures can be formed by coalescing the plurality of GaN nanowires and / or nanowire arrays to facilitate the fabrication of visible LEDs and lasers. Furthermore, core-shell nanowire / MQW active structures can be formed by a core-shell growth on the nonpolar sidewalls of each nanowire.

Owner:STC UNM

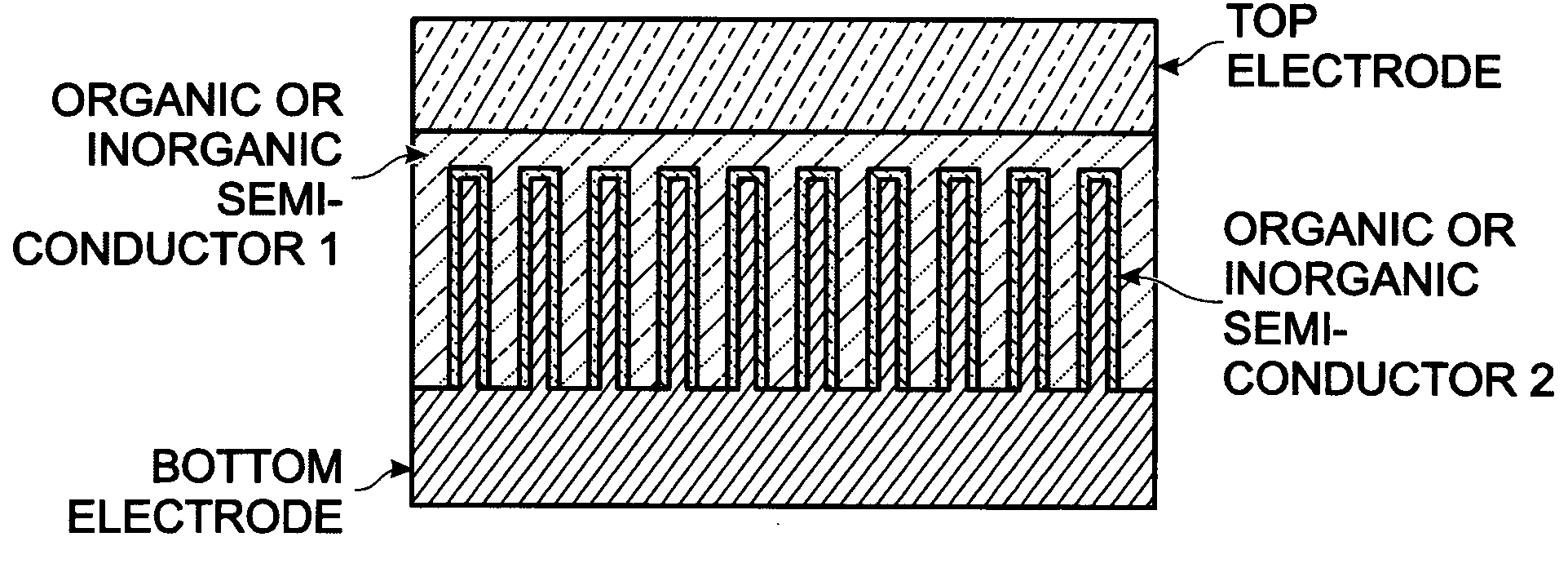

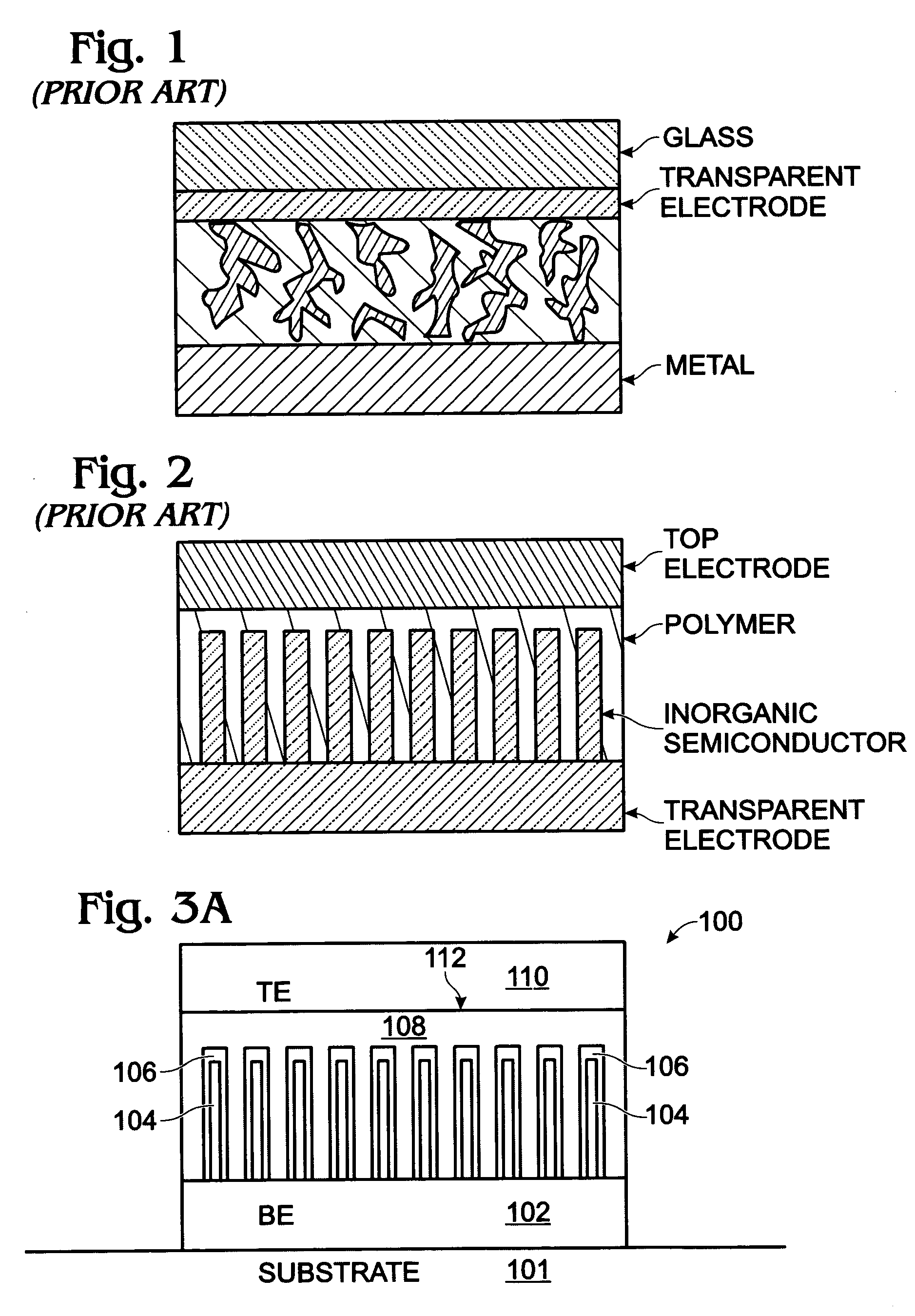

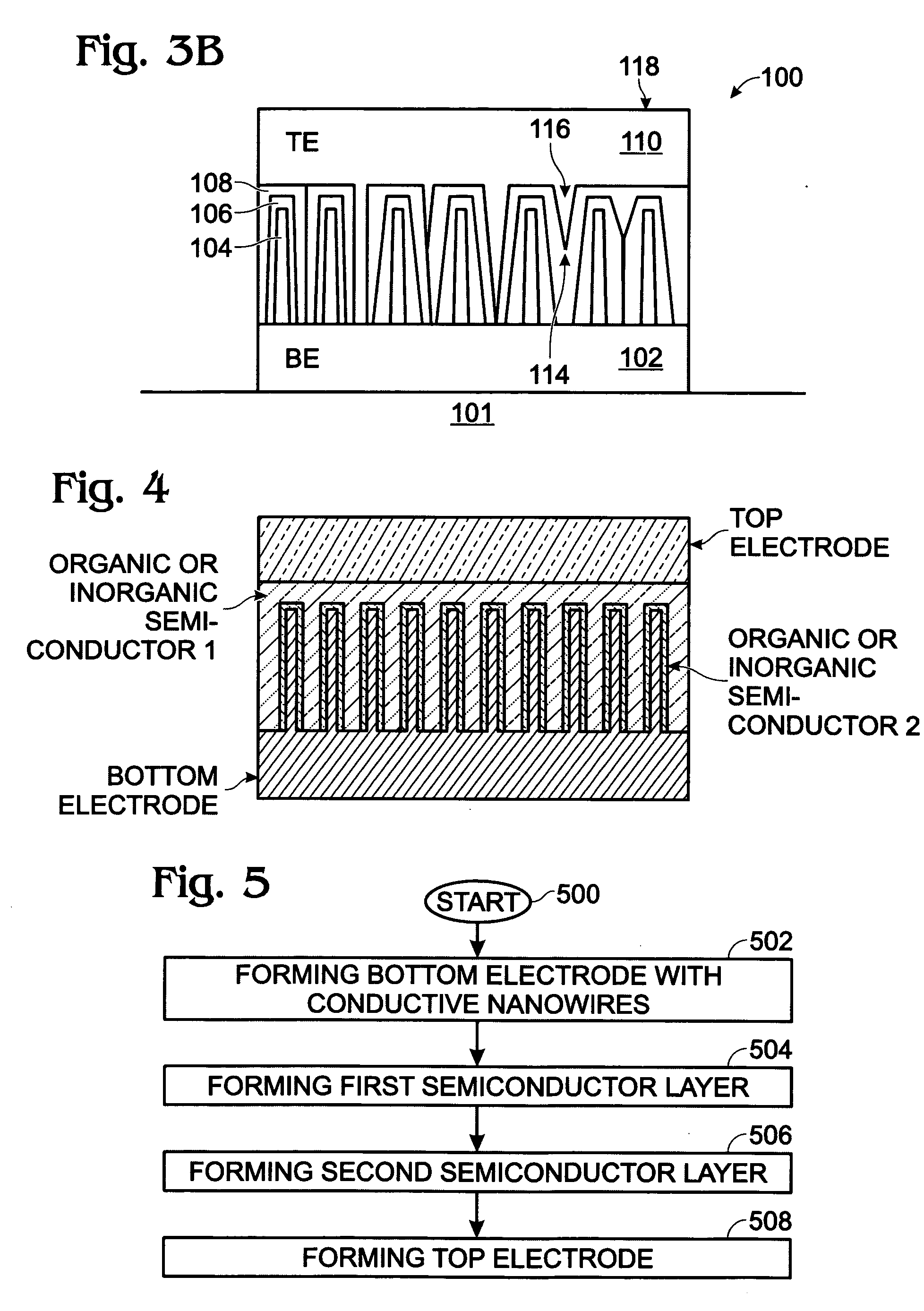

Photovoltaic structure with a conductive nanowire array electrode

A photovoltaic (PV) structure is provided, along with a method for forming a PV structure with a conductive nanowire array electrode. The method comprises: forming a bottom electrode with conductive nanowires; forming a first semiconductor layer of a first dopant type (i.e., n-type) overlying the nanowires; forming a second semiconductor layer of a second dopant type, opposite of the first dopant type (i.e., p-type), overlying the first semiconductor layer; and, forming a top electrode overlying the second semiconductor layer. The first and second semiconductor layers can be a material such as a conductive polymer, a conjugated polymer with a fullerene derivative, and inorganic materials such as CdSe, CdS, Titania, or ZnO. The conductive nanowires can be a material such as IrO2, In2O3, SnO2, or indium tin oxide (ITO).

Owner:SHARP KK

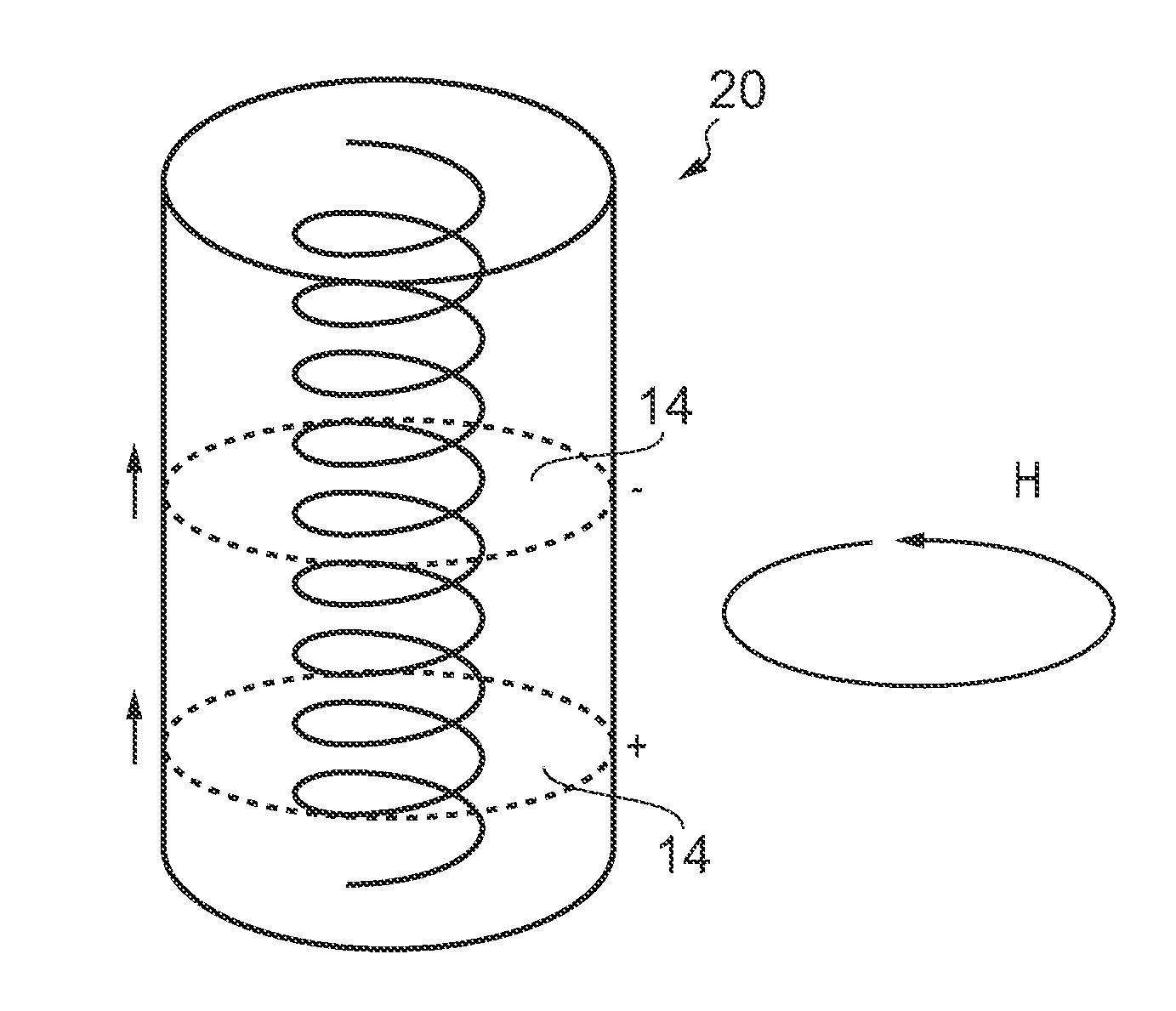

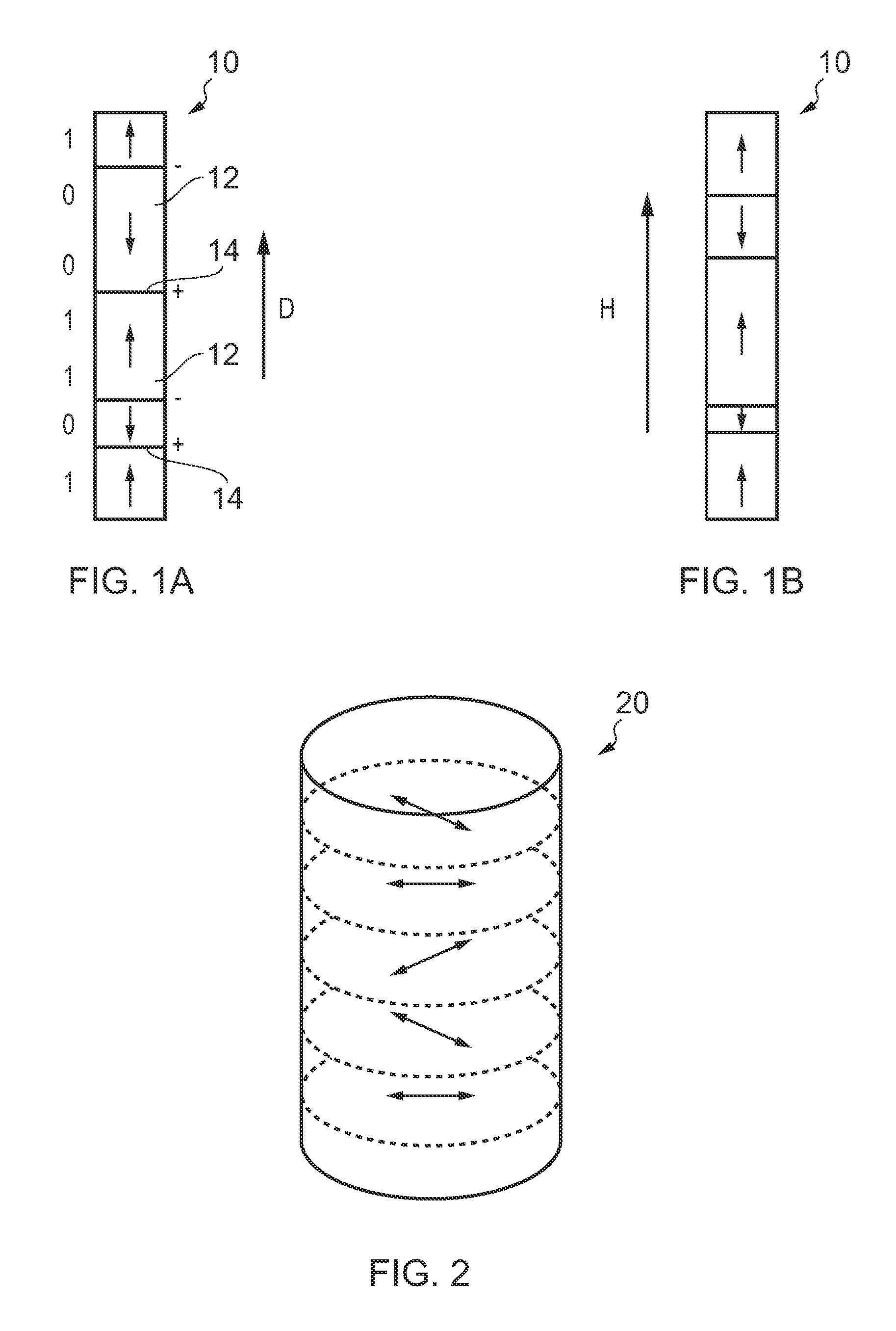

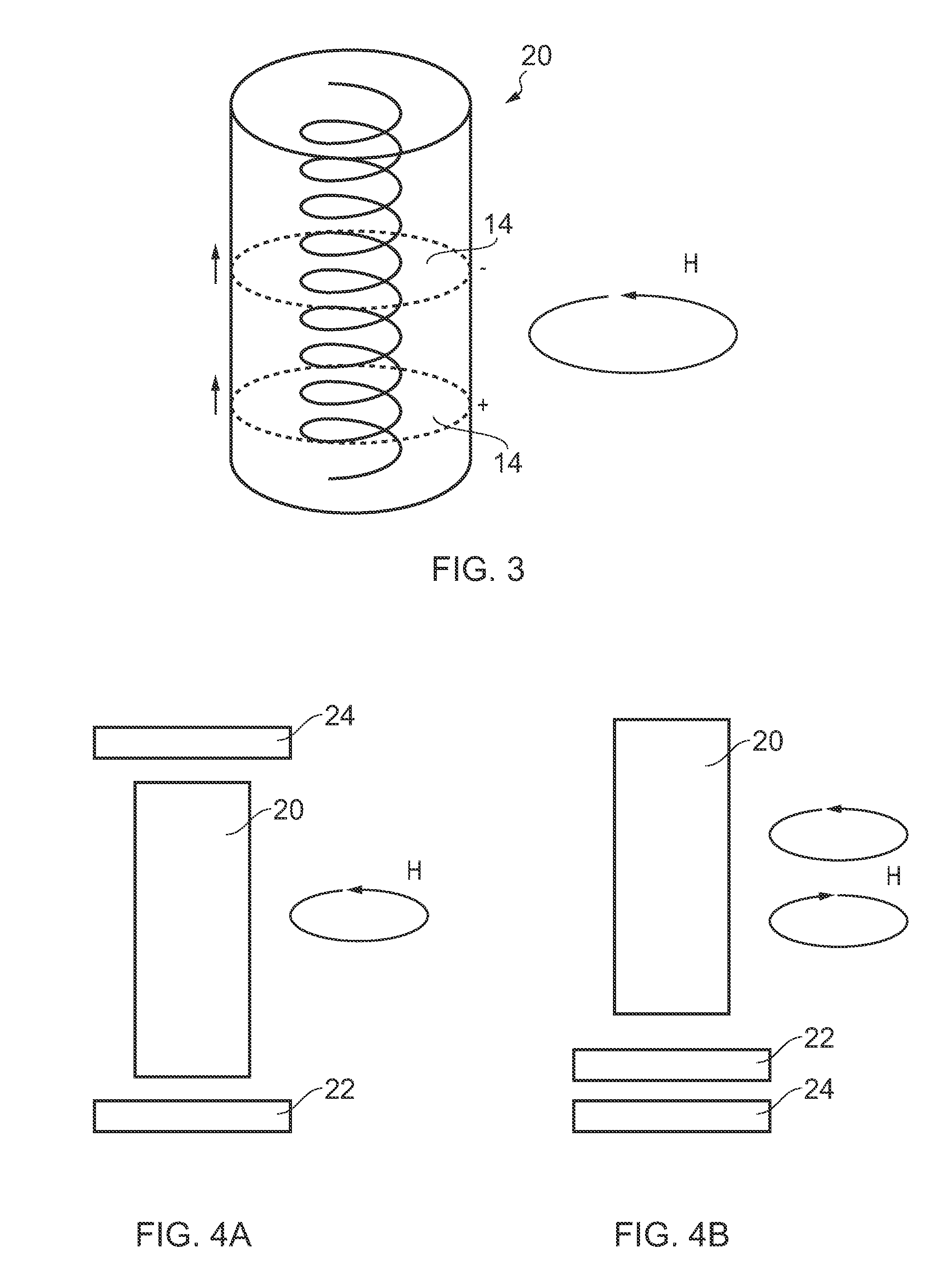

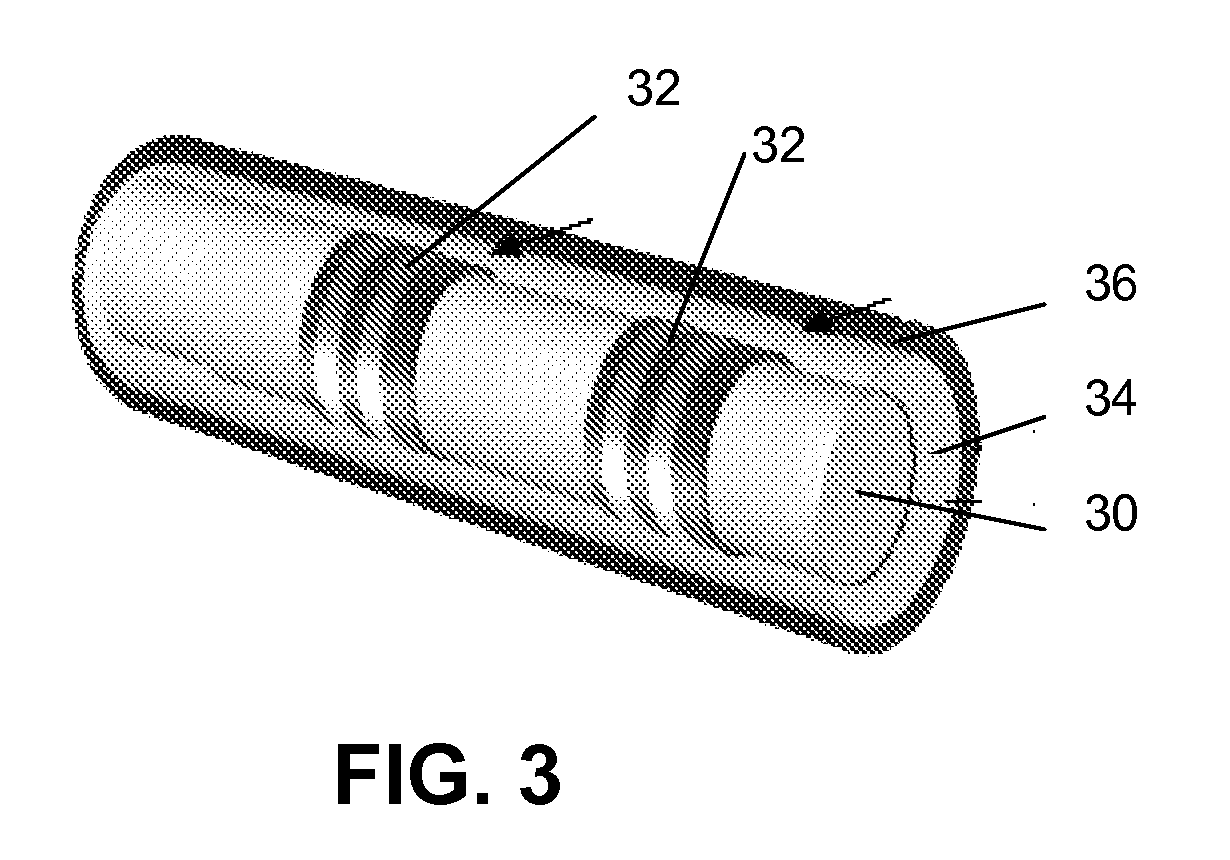

Magnetic Data Storage Device and Method

InactiveUS20100124091A1High densityNanoinformaticsSemiconductor/solid-state device manufacturingNanowire arrayMolecular physics

A data storage device comprises an array of parallel magnetic nanowires each having a uniaxial anisotropy with an easy axis substantially perpendicular to the longitudinal axis of the nanowire and which is rotated about the longitudinal axis along the length of the nanowire, and a magnetisation state that follows the easy axis, where each nanowire has a data input element for nucleating magnetic domains separated by domain walls in an end of the nanowire, the sequence of domains and walls representing binary data, and a data read-out element operable to detect the magnetisation at an end of the nanowire, the device also comprising a magnetic field source operable to generate a magnetic field rotating in a plane substantially perpendicular to the longitudinal axes of the nanowires so as to propagate domain walls along the at least one nanowire. Reversal of the direction of rotation of the magnetic field reverses the propagation direction of the domain walls, so that data can be moved in either direction along the nanowires.

Owner:INGENIA HLDG LTD

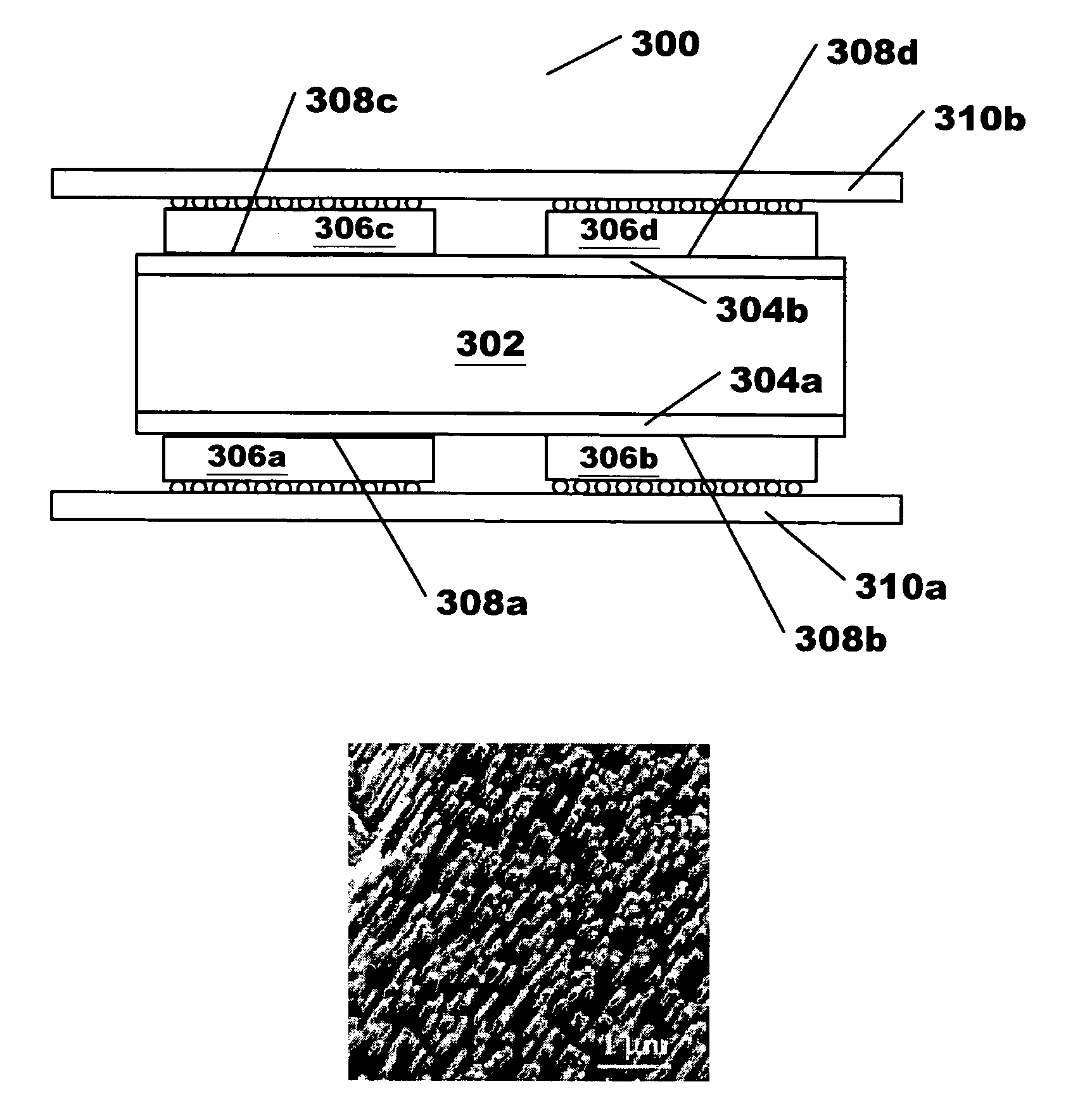

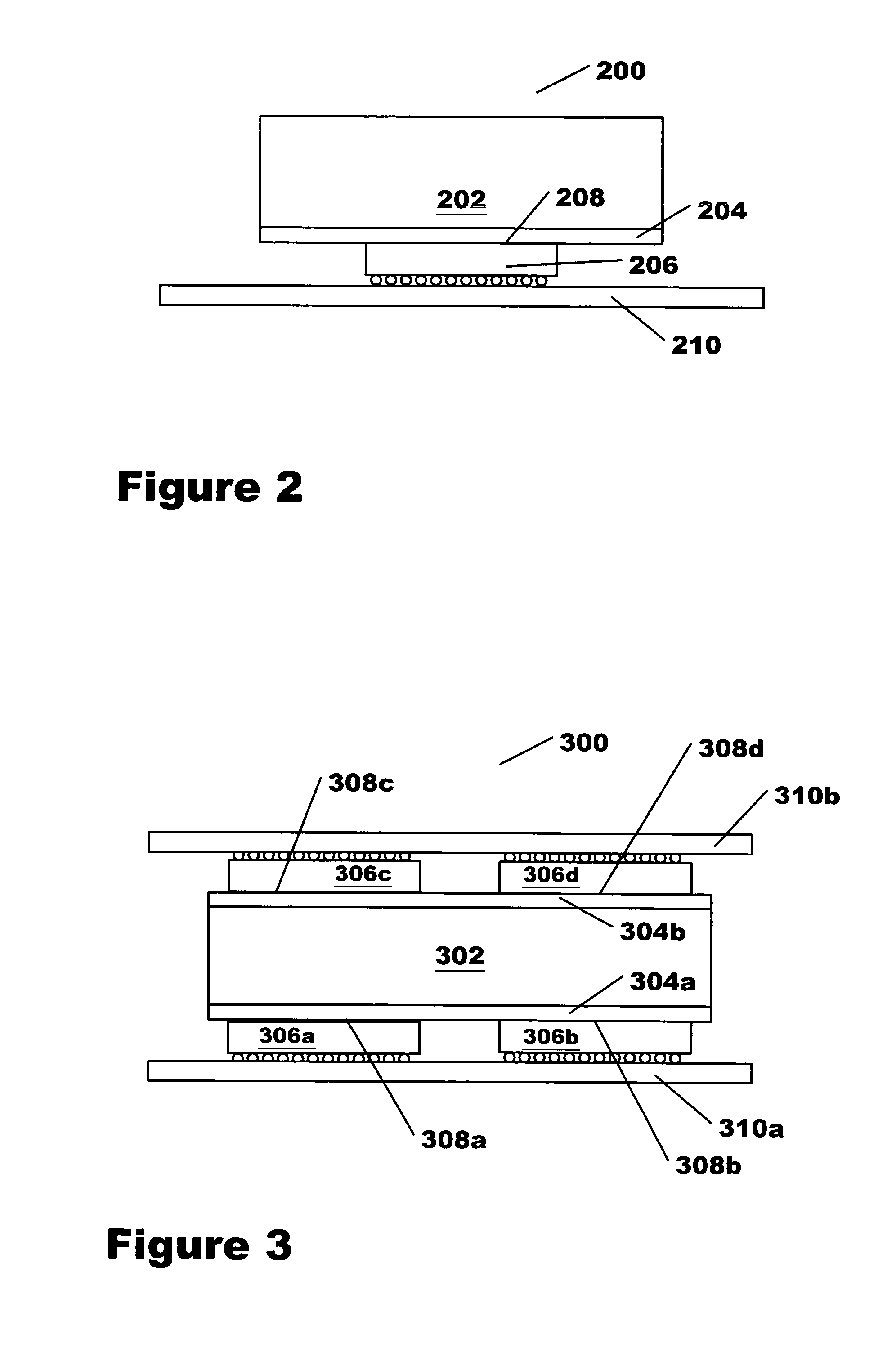

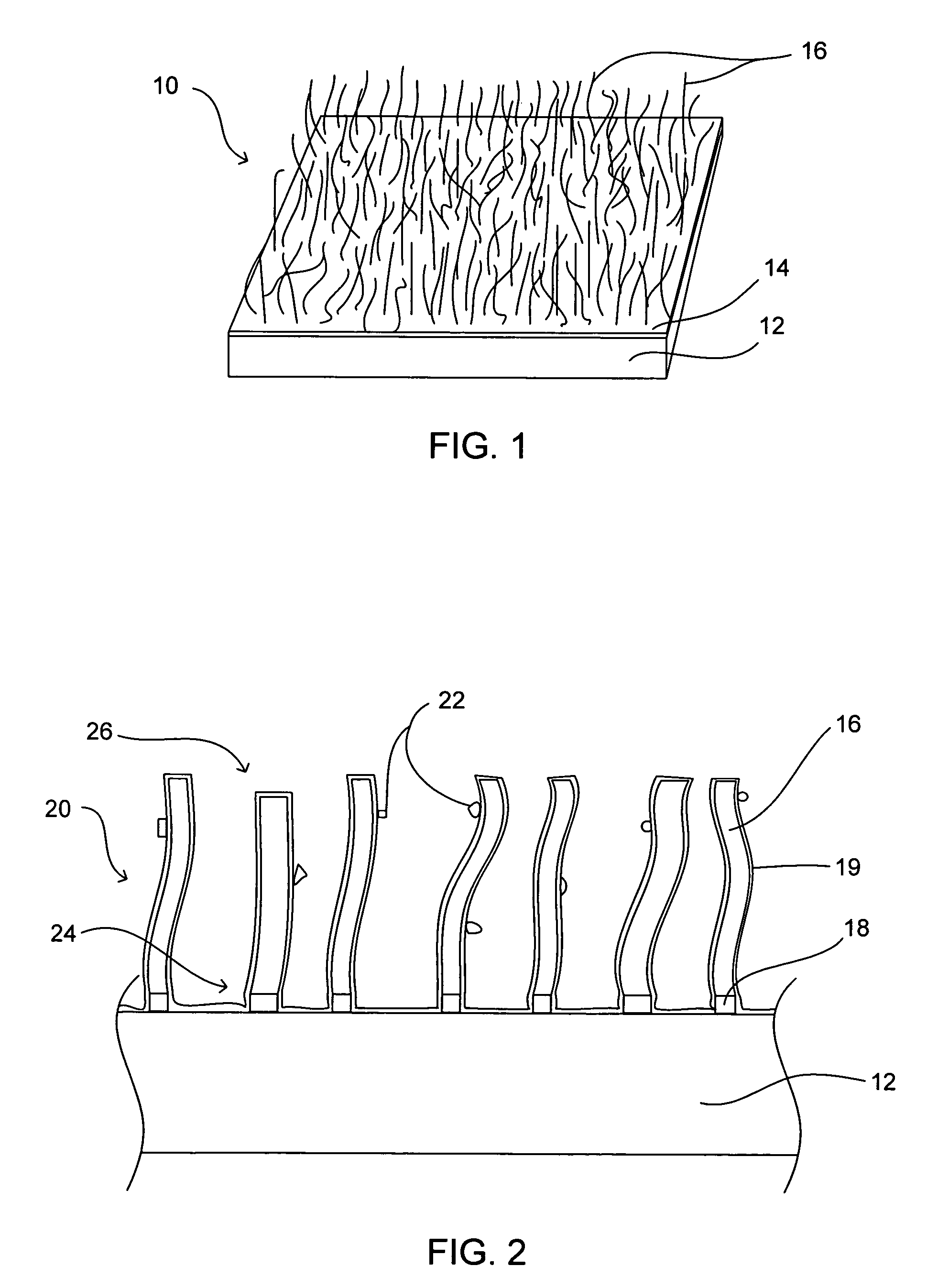

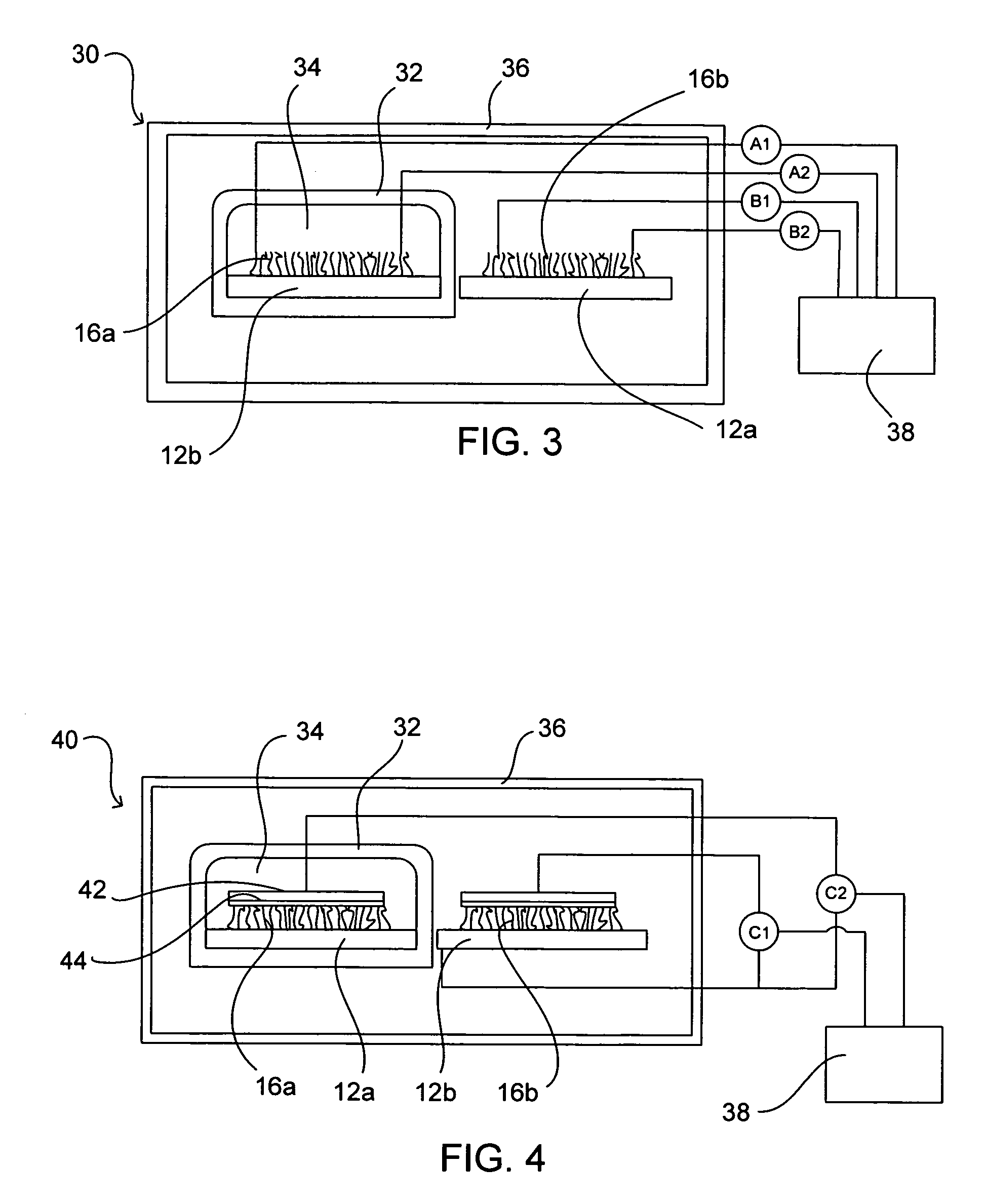

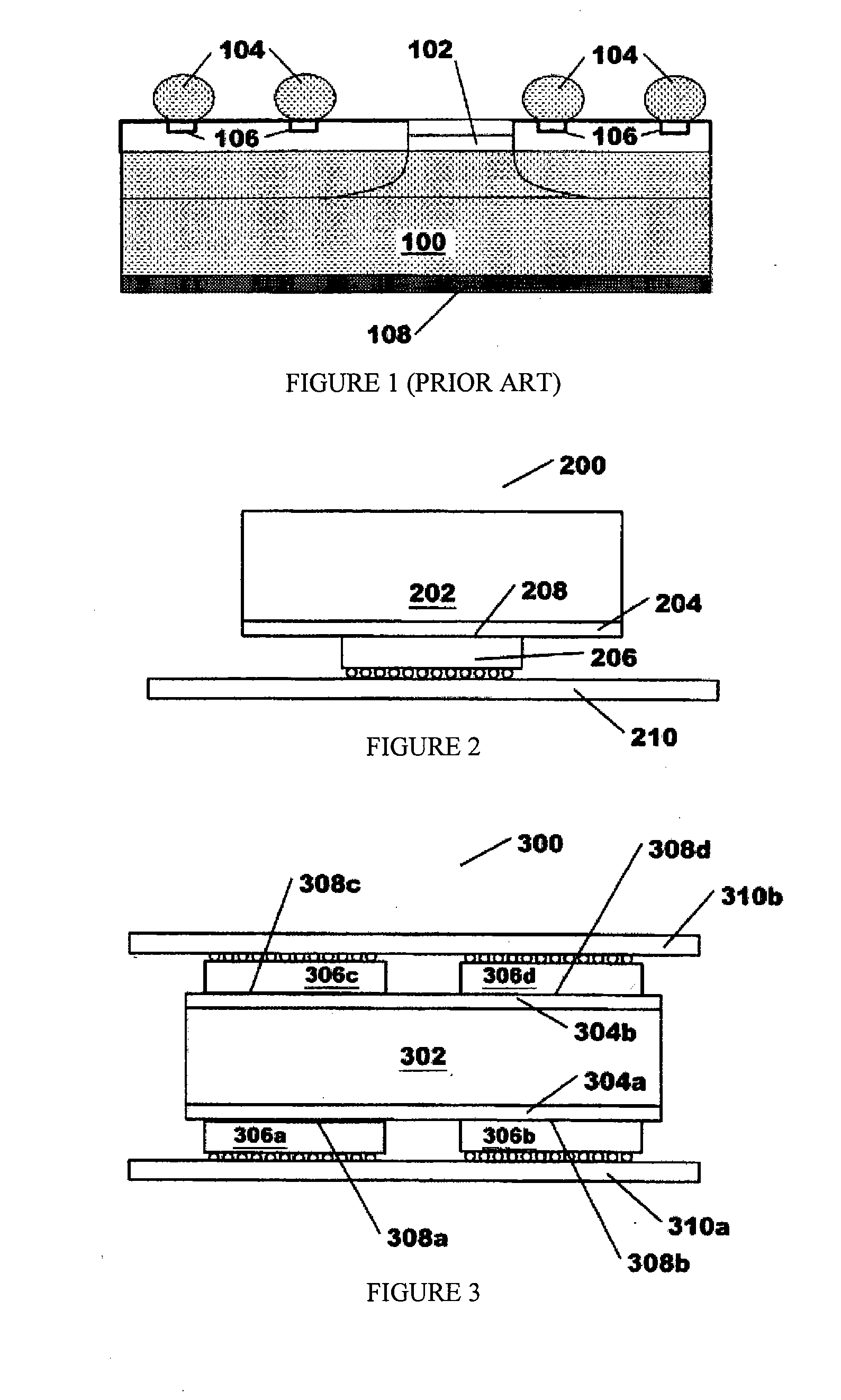

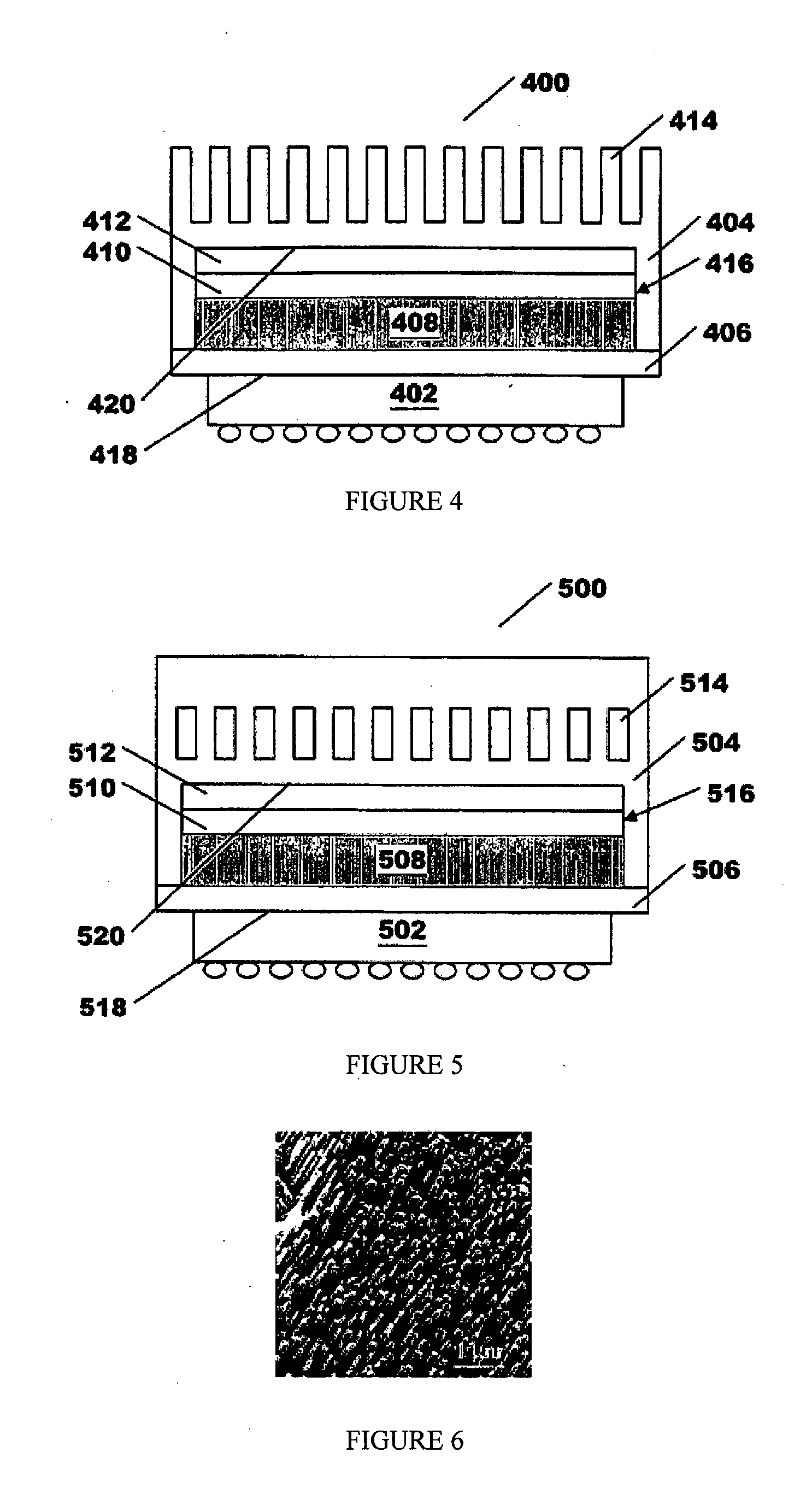

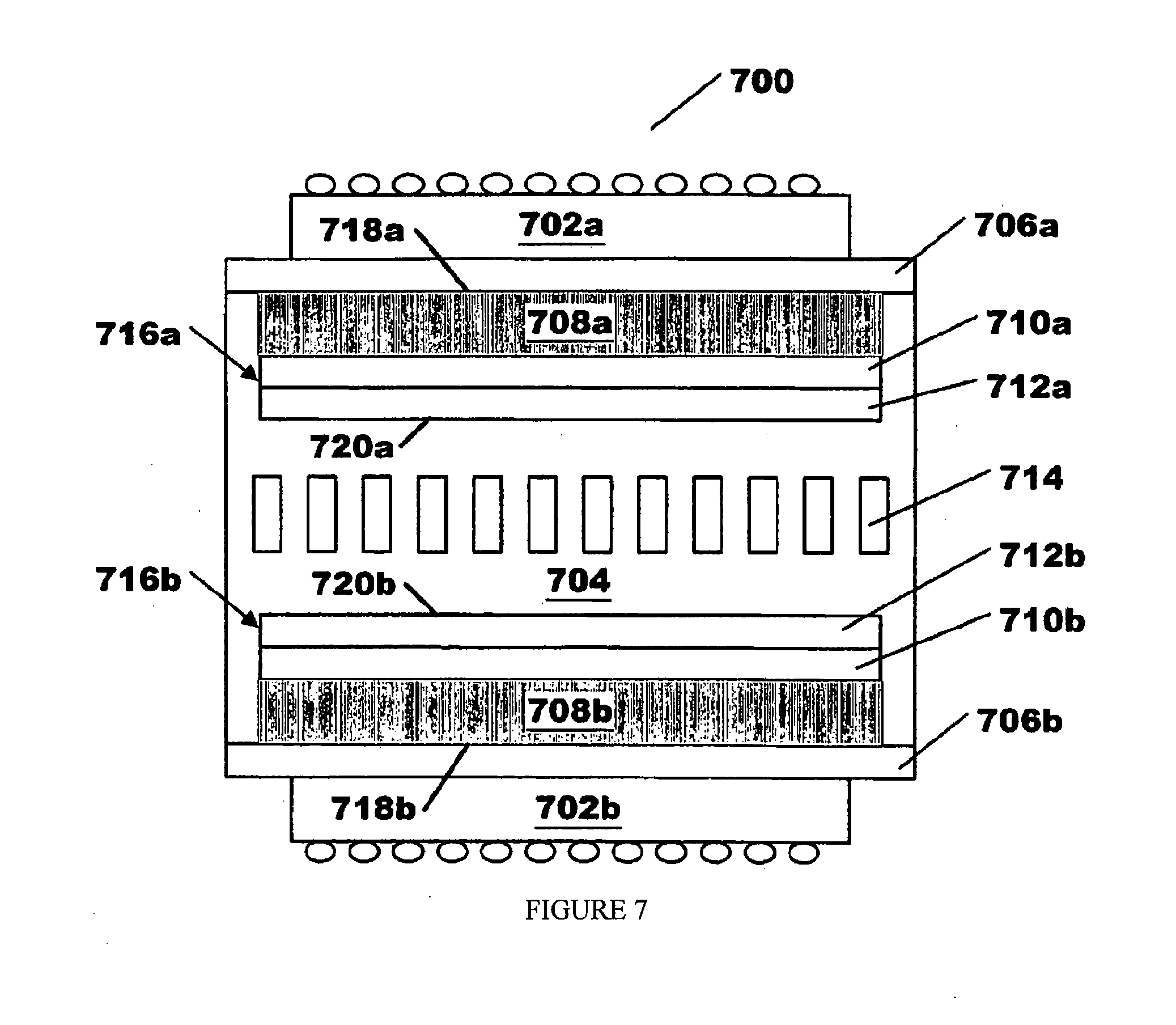

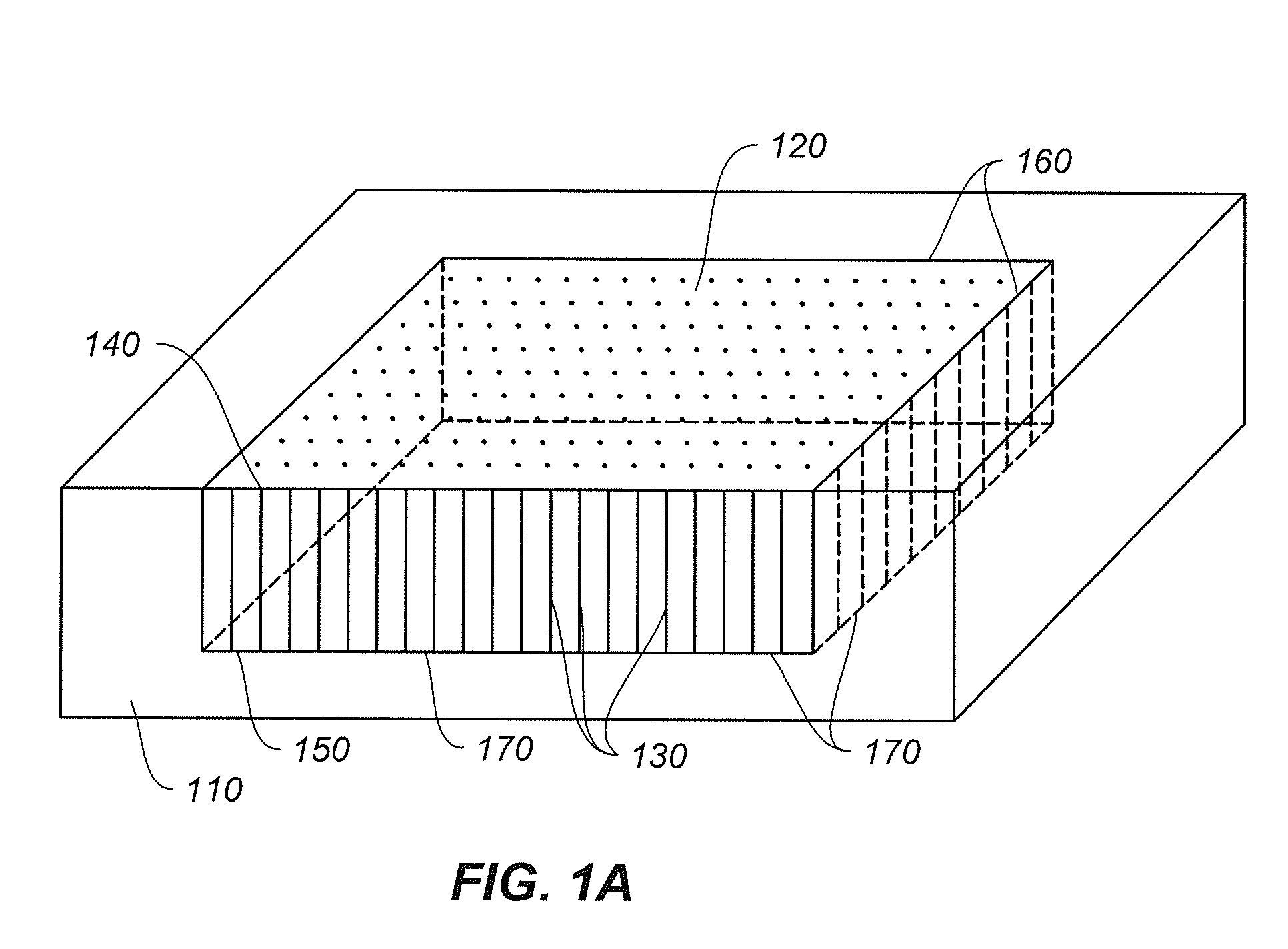

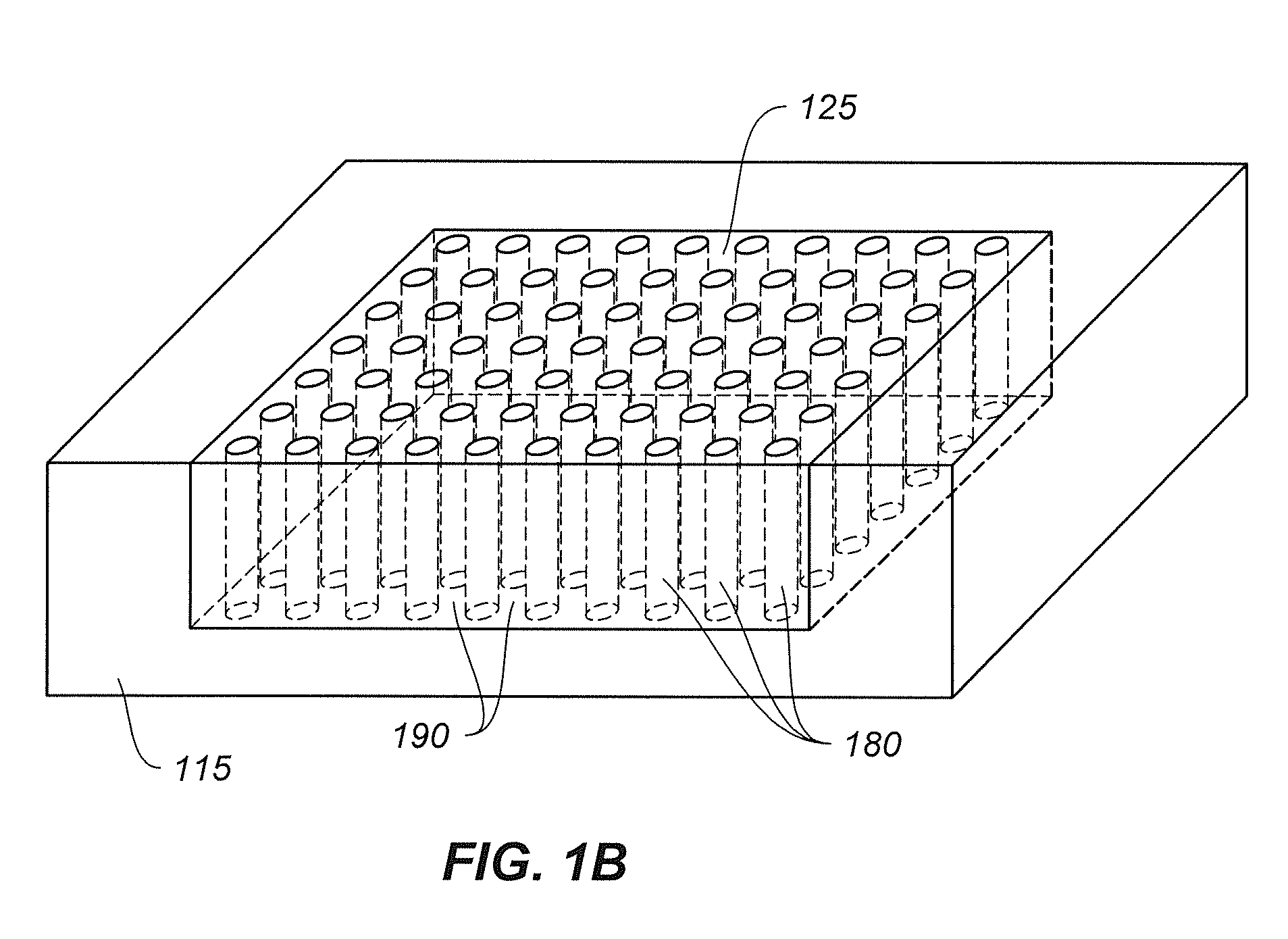

System and method using self-assembled nano structures in the design and fabrication of an integrated circuit micro-cooler

ActiveUS7109581B2Material nanotechnologySemiconductor/solid-state device detailsNano structuringSelf assemble

Heat sink structures employing carbon nanotube or nanowire arrays to reduce the thermal interface resistance between an integrated circuit chip and the heat sink are disclosed. Carbon nanotube arrays are combined with a thermally conductive metal filler disposed between the nanotubes. This structure produces a thermal interface with high axial and lateral thermal conductivities.

Owner:SAMSUNG ELECTRONICS CO LTD +1

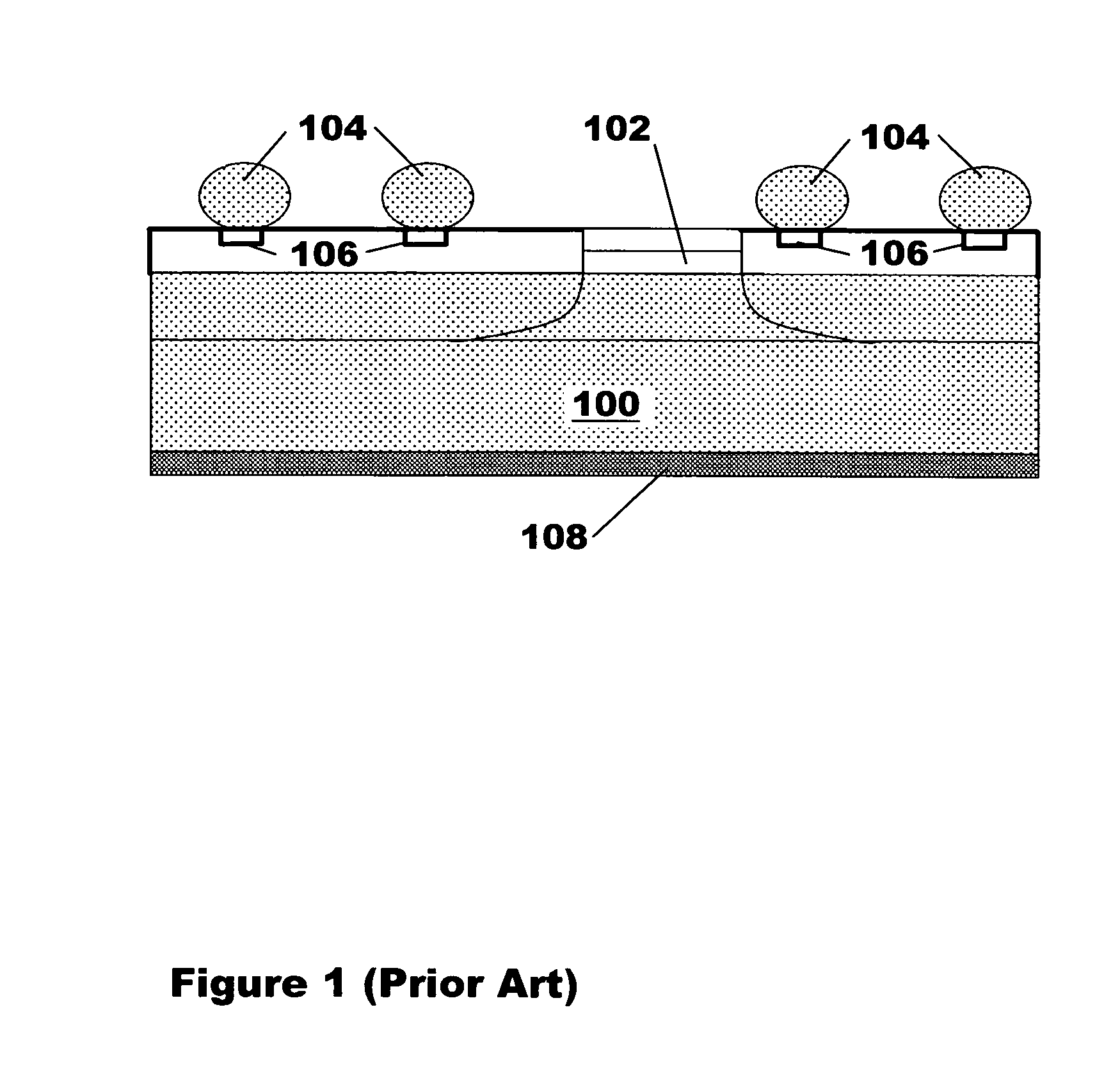

Direct assembly process for fabrication of ionomeric polymer devices

InactiveUS20060266642A1Superior transduction performanceLarge strain generationEngine manufactureMachines/enginesPolymer scienceActuator

Ionomeric polymer sensors, actuators, and transducers and methods for fabricating them are disclosed. One embodiment of the sensors, actuators, and transducers possess a high surface area electrode layer that is applied by hot pressing and a highly conductive surface layer. Another embodiment of these sensors, actuators, and transducers possess a high surface area electrode layer that is penetrated by electronically conductive nanowires. Methods for fabricating these sensors, actuators, and transducers are disclosed. These methods involve the formation of the high surface area layer from a liquid mixture that contains ionomeric polymer, electronically conductive particles, and possibly diluent. This mixture is formed into layers either directly on an ionomeric polymer, on a separate transfer decal, or on an electronically conductive layer. This electronically conductive layer may also include an array of nanowires. These electrode layers are then attached to an ionomeric polymer membrane by hot pressing. The ionomeric polymer membrane may be swollen with a diluent either prior to the hot pressing or after the hot pressing step. Also, the ionomeric polymer membrane may be formed by casting from a liquid mixture containing ionomeric polymer and diluent.

Owner:VIRGINIA TECH INTPROP INC

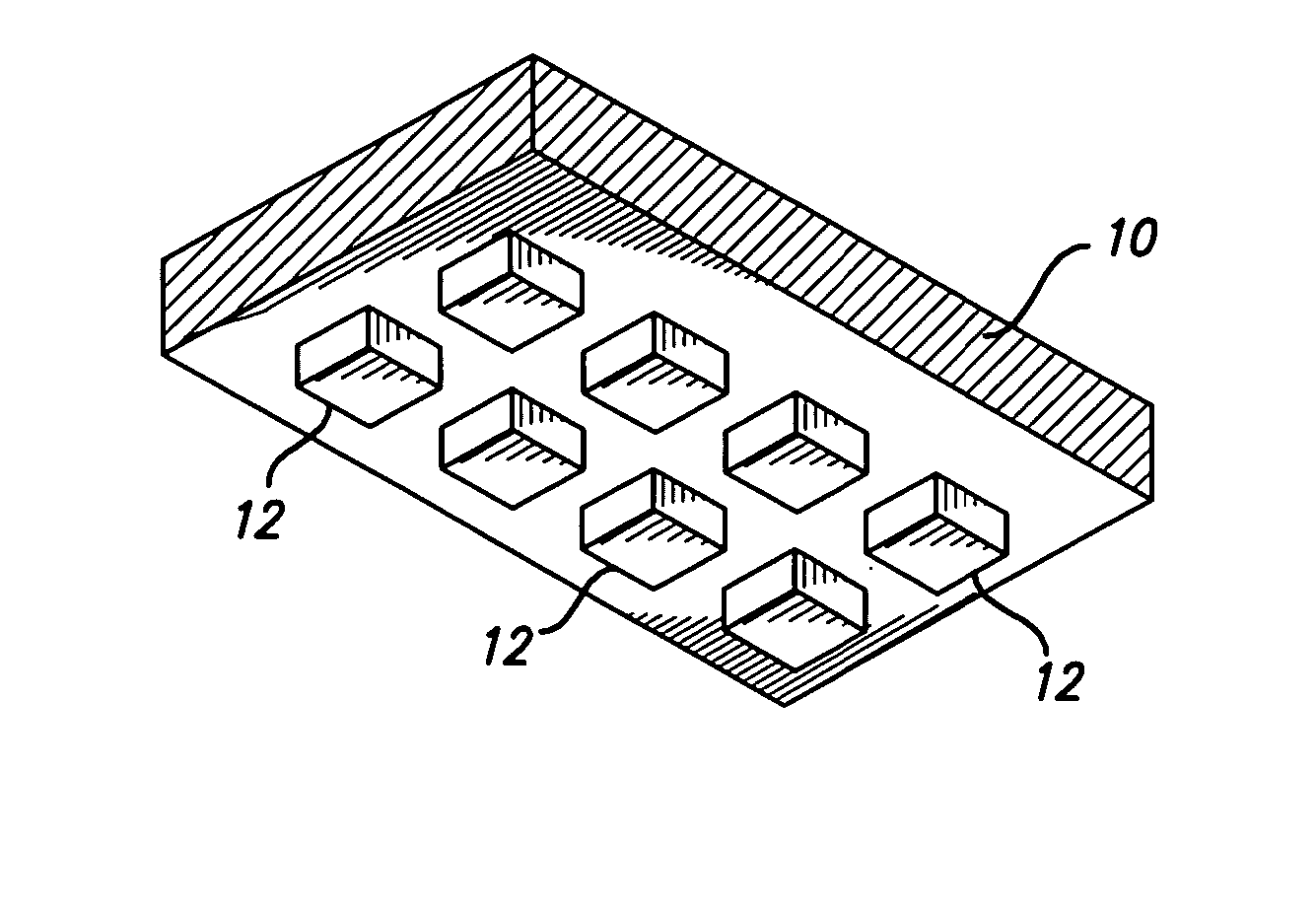

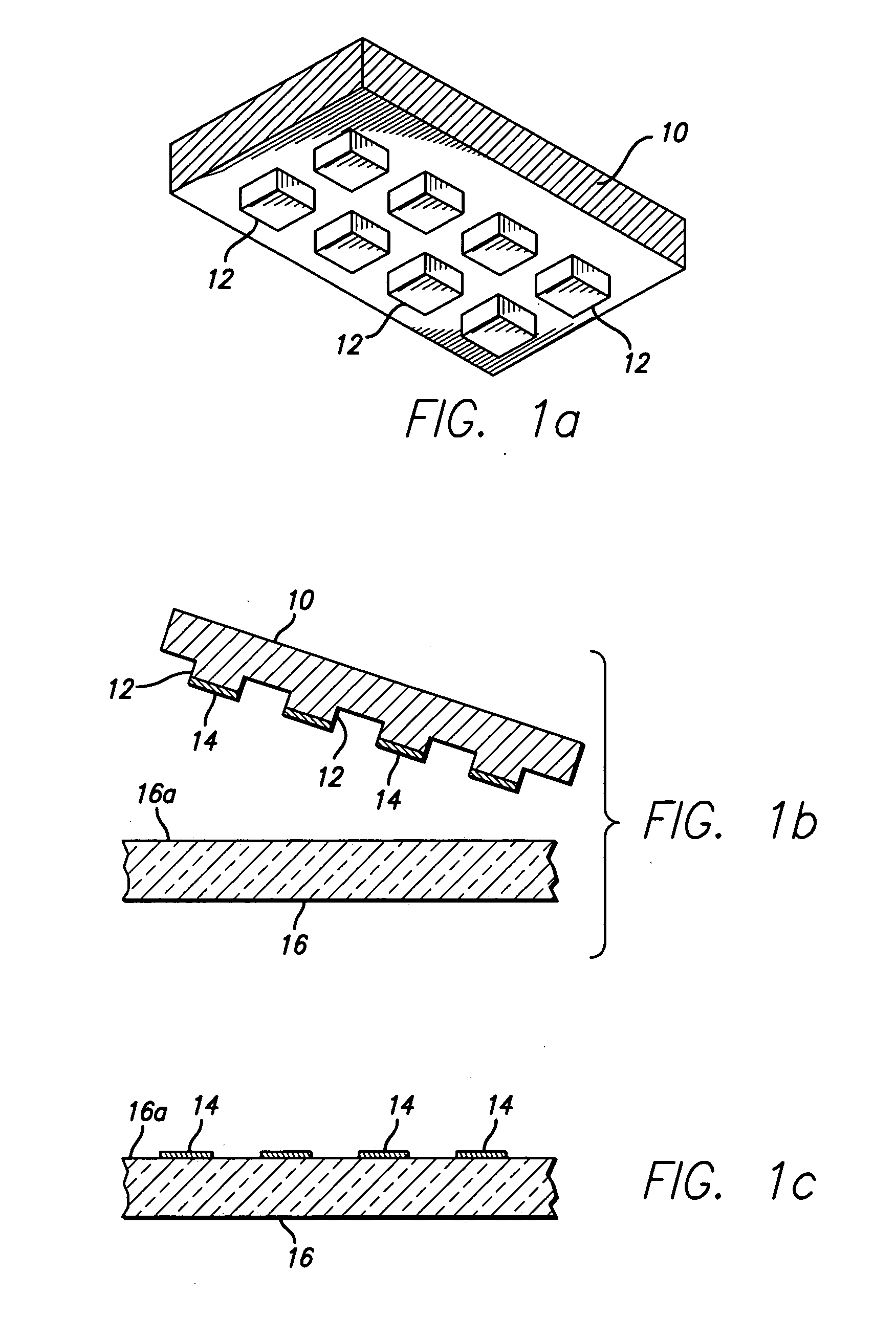

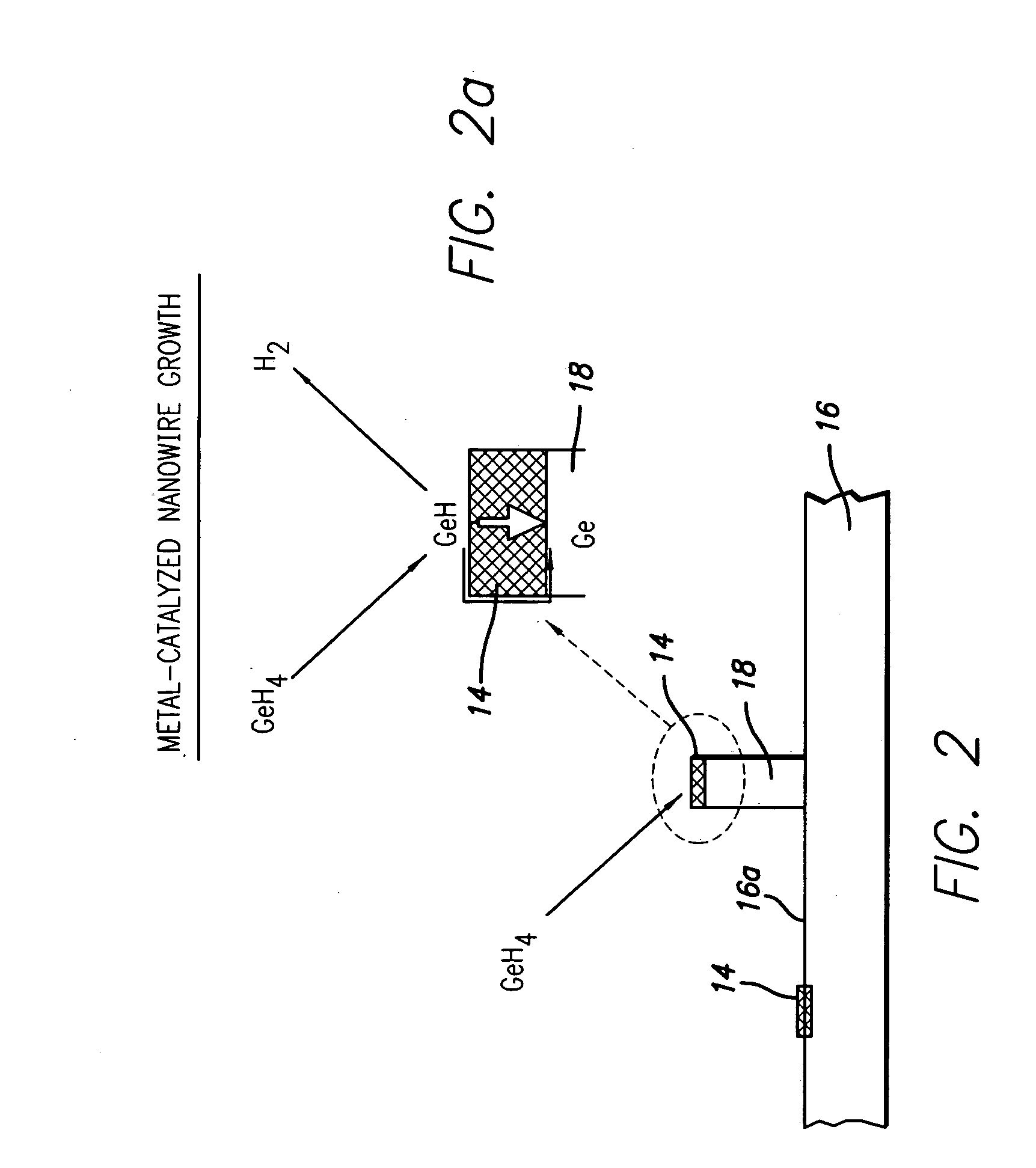

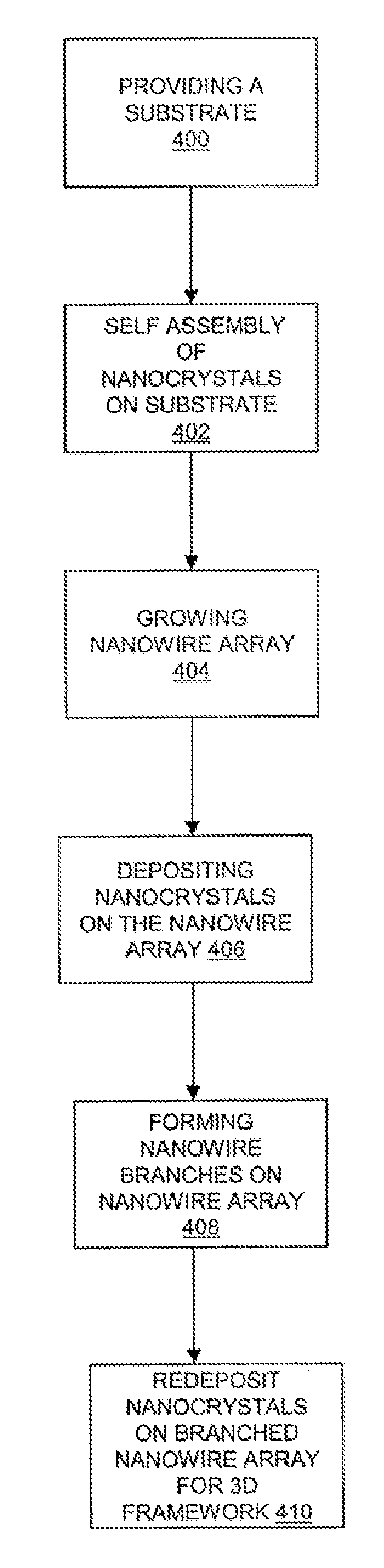

Method of forming three-dimensional nanocrystal array

InactiveUS20040079278A1Material nanotechnologyPolycrystalline material growthPhotonic bandgapQuantum dot

A method of forming an assembly of isolated nanowires of at least one material within a matrix of another material is provided. The method comprises: providing a substrate; forming a catalyst array on a major surface of the substrate; growing an array of the nanowires corresponding with the catalyst array, the nanowires, each comprising at least one material; and forming a matrix of another material that fills in spaces between the nanowires. The method is useful for producing a variety of structures useful in a number of devices, such as photonic bandgap structures and quantum dot structures.

Owner:HEWLETT PACKARD DEV CO LP

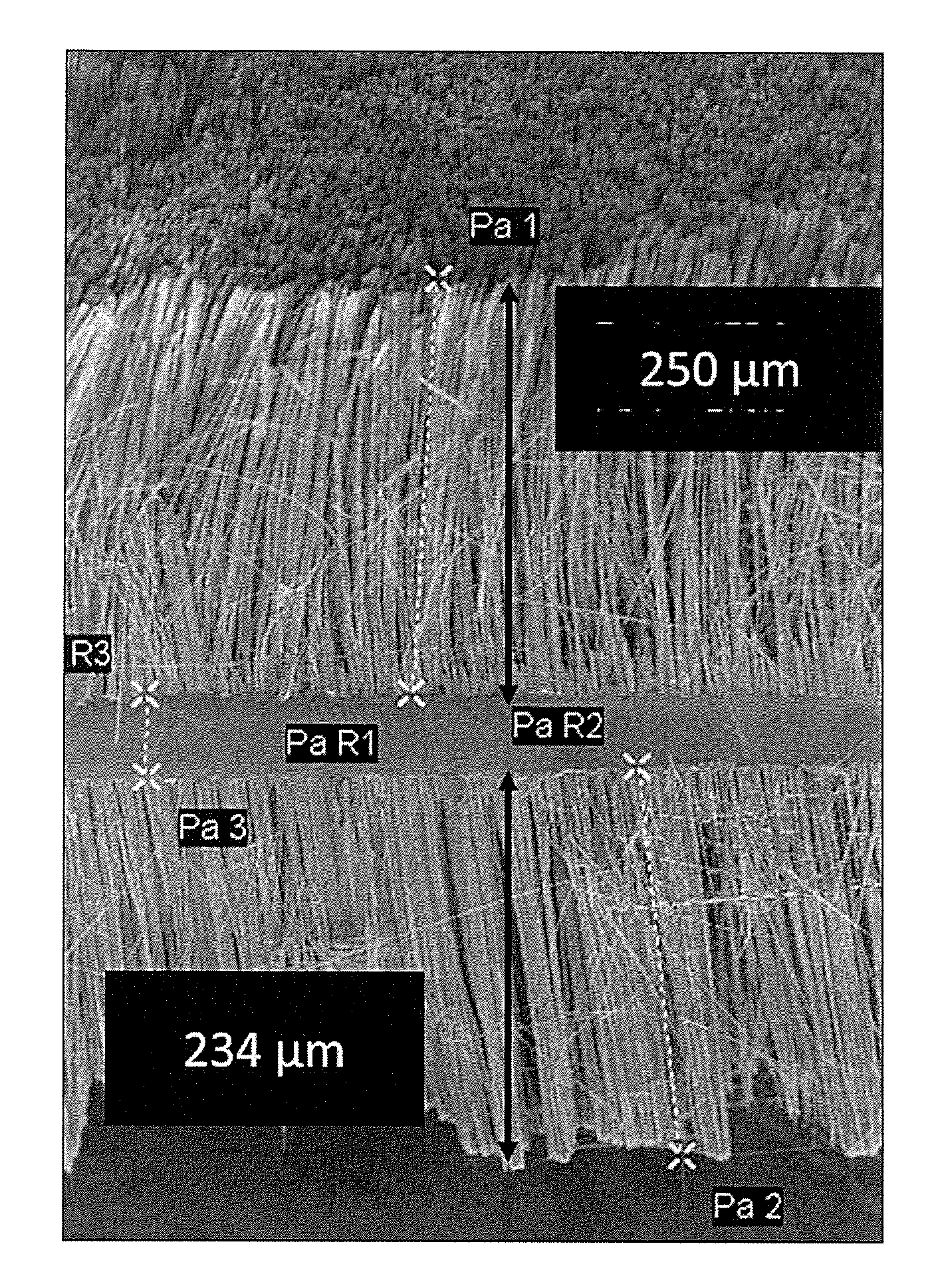

Pulsed growth of gan nanowires and applications in group III nitride semiconductor substrate materials and devices

Exemplary embodiments provide semiconductor devices including high-quality (i.e., defect free) group III-N nanowires and uniform group III-N nanowire arrays as well as their scalable processes for manufacturing, where the position, orientation, cross-sectional features, length and the crystallinity of each nanowire can be precisely controlled. A pulsed growth mode can be used to fabricate the disclosed group III-N nanowires and / or nanowire arrays providing a uniform length of about 10 nm to about 1000 microns with constant cross-sectional features including an exemplary diameter of about 10-1000 nm. In addition, high-quality GaN substrate structures can be formed by coalescing the plurality of GaN nanowires and / or nanowire arrays to facilitate the fabrication of visible LEDs and lasers. Furthermore, core-shell nanowire / MQW active structures can be formed by a core-shell growth on the nonpolar sidewalls of each nanowire.

Owner:新墨西哥大学雨林创新公司

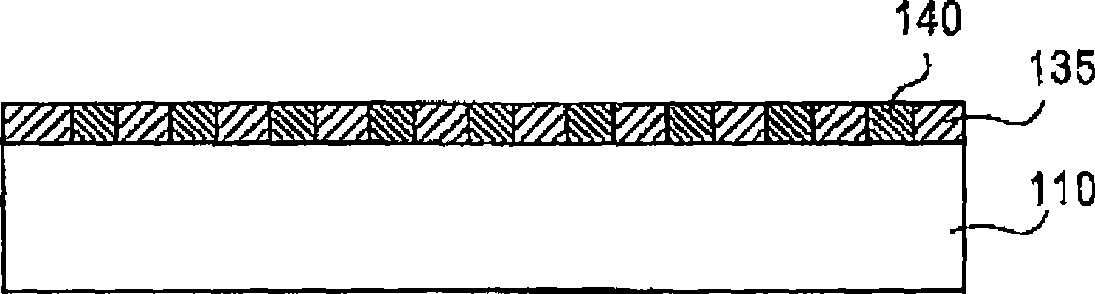

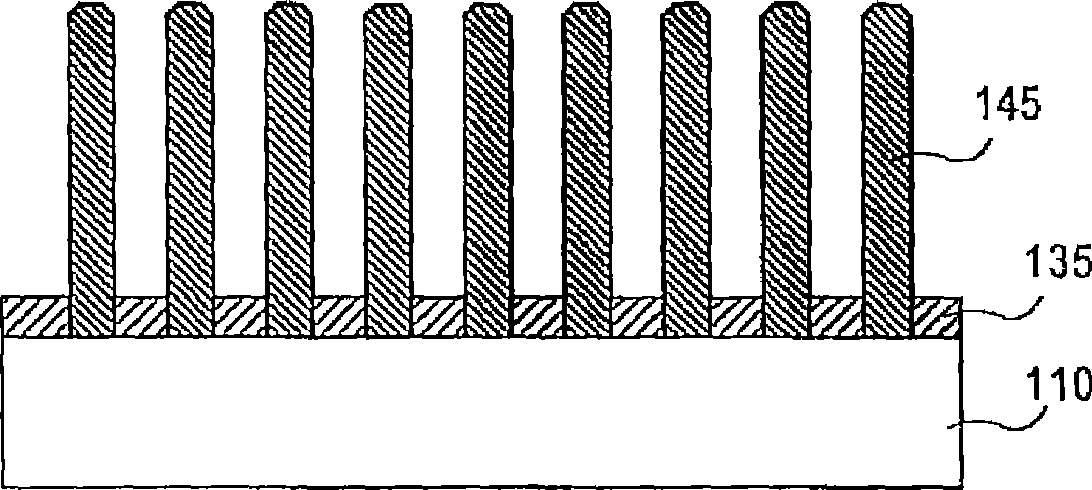

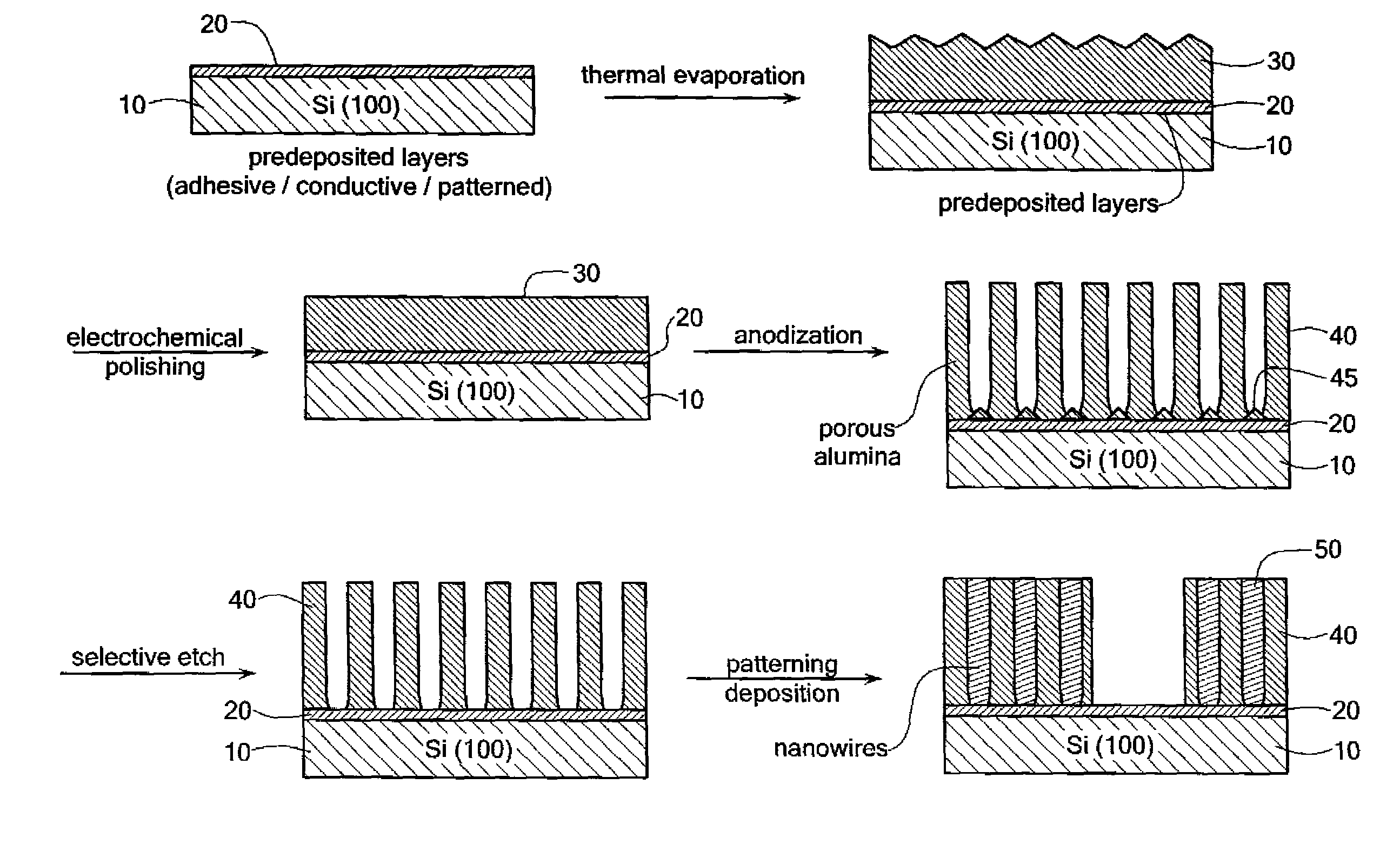

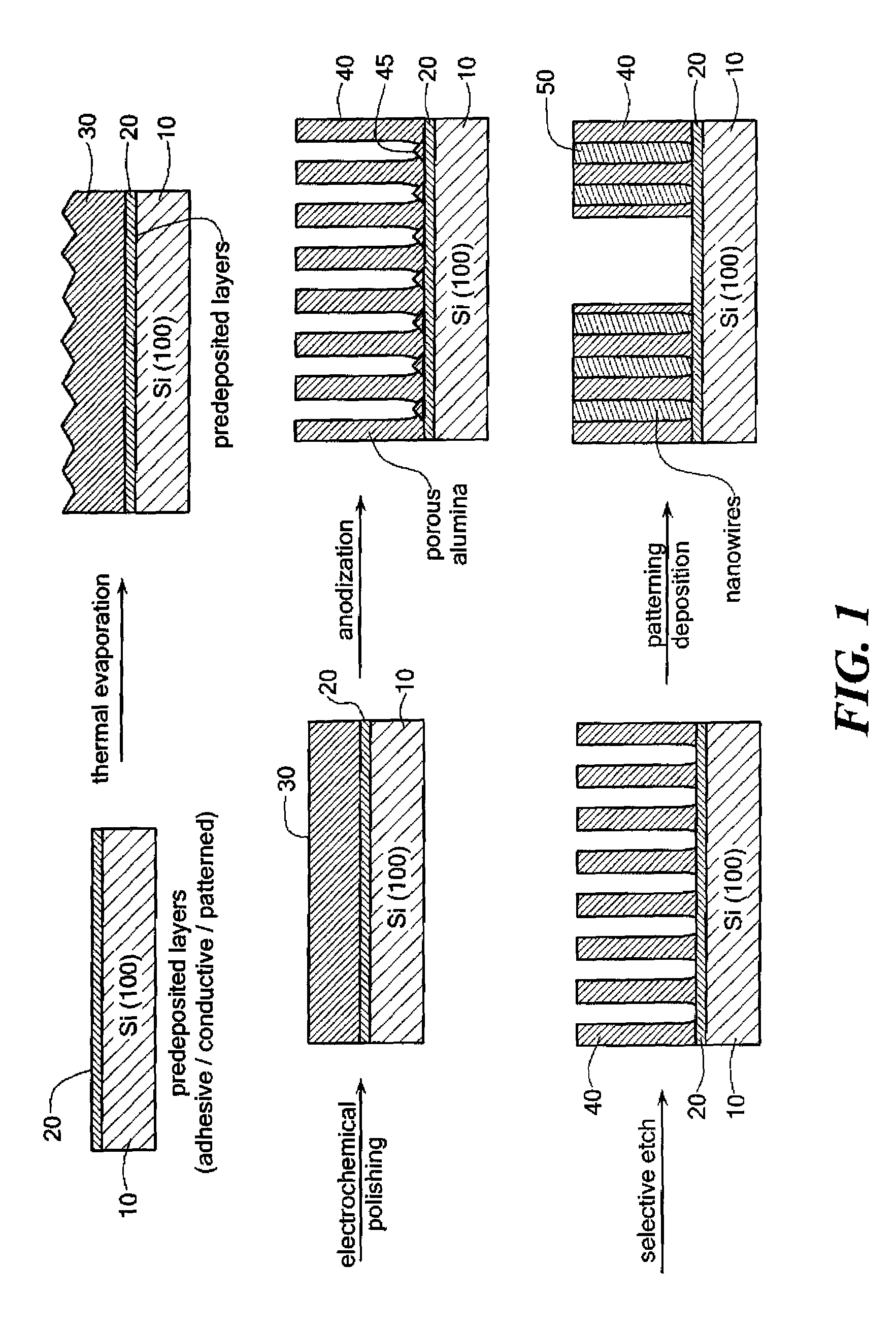

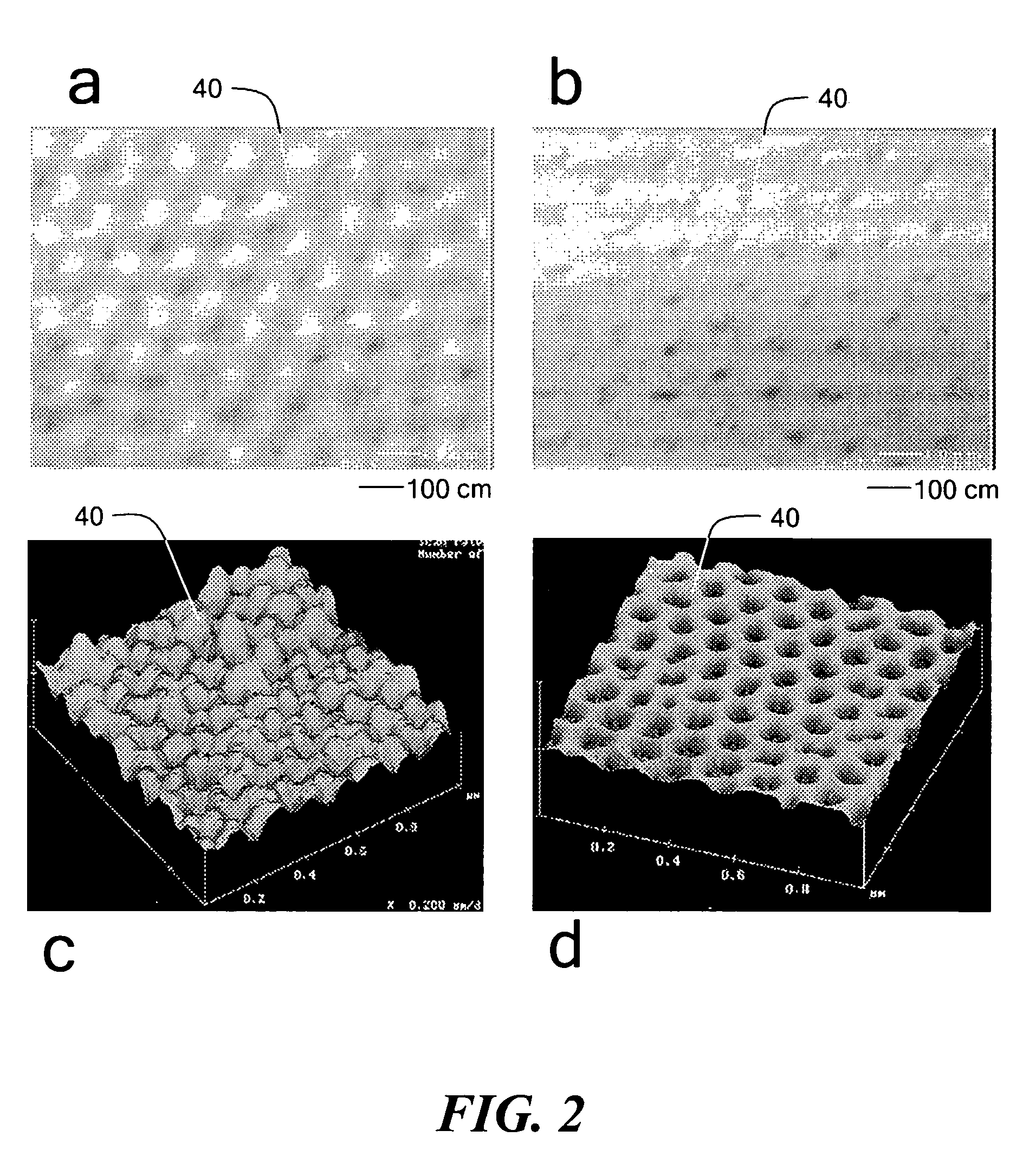

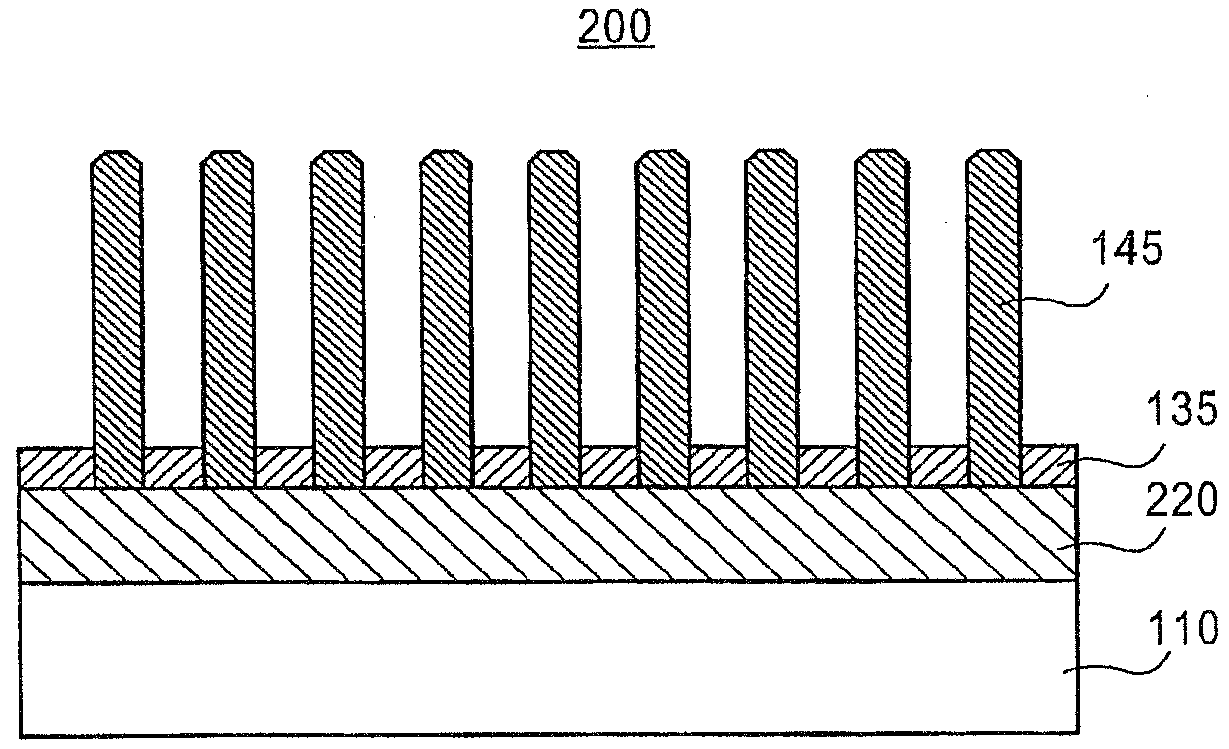

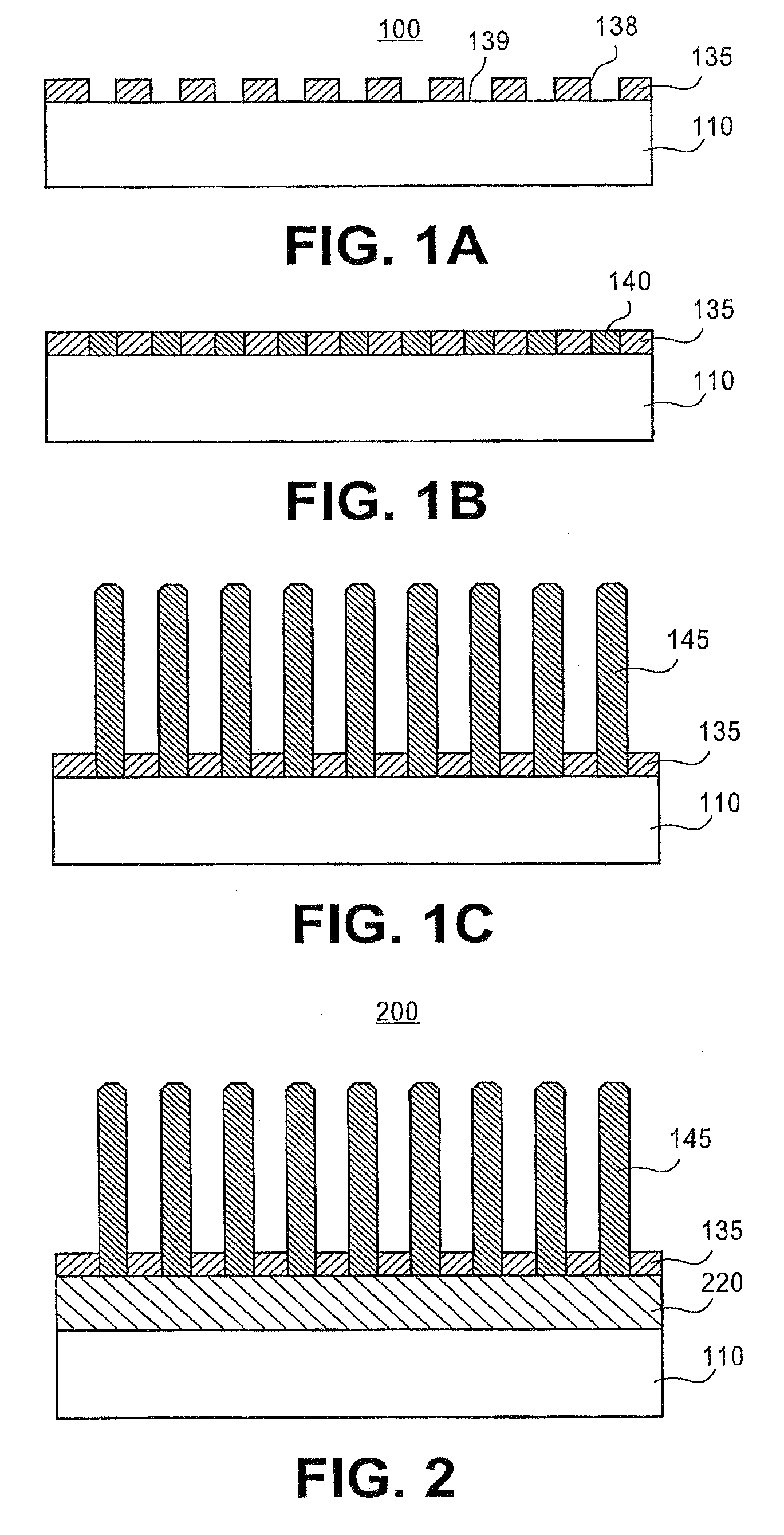

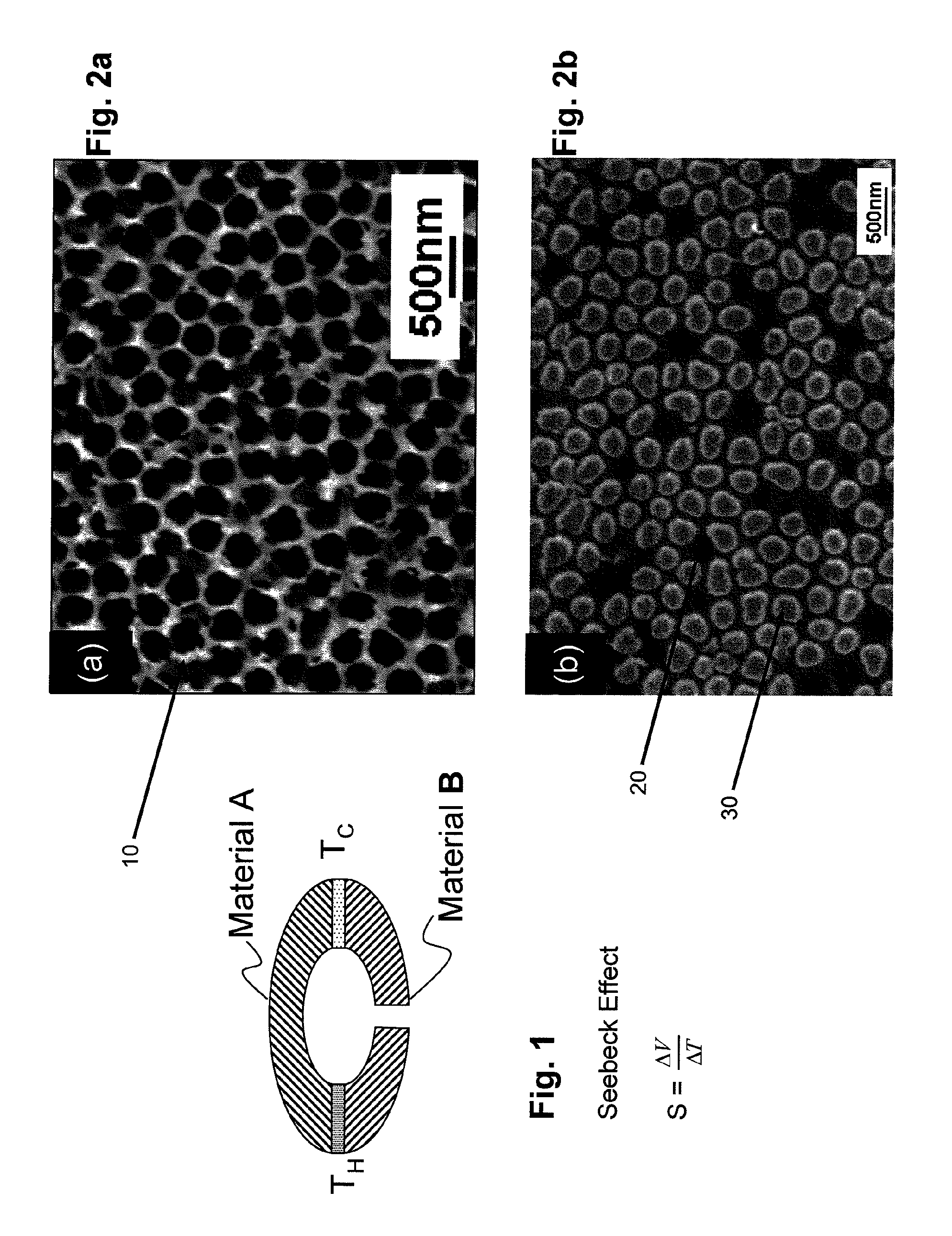

Thick porous anodic alumina films and nanowire arrays grown on a solid substrate

InactiveUS7267859B1Promote growthMore tractableMaterial nanotechnologyAnodisationSingle stageElectrochemistry

The presently disclosed invention provides for the fabrication of porous anodic alumina (PAA) films on a wide variety of substrates. The substrate comprises a wafer layer and may further include an adhesion layer deposited on the wafer layer. An anodic alumina template is formed on the substrate. When a rigid substrate such as Si is used, the resulting anodic alumina film is more tractable, easily grown on extensive areas in a uniform manner, and manipulated without danger of cracking. The substrate can be manipulated to obtain free-standing alumina templates of high optical quality and substantially flat surfaces PAA films can also be grown this way on patterned and non-planar surfaces. Furthermore, under certain conditions the resulting PAA is missing the barrier layer (partially or completely) and the bottom of the pores can be readily accessed electrically. The resultant film can be used as a template for forming an array of nanowires wherein the nanowires are deposited electrochemically into the pores of the template. By patterning the electrically conducting adhesion layer, pores in different areas of the template can be addressed independently, and can be filled electrochemically by different materials. Single-stage and multi-stage nanowire-based thermoelectric devices, consisting of both n-type and p-type nanowires, can be assembled on a silicon substrate by this method.

Owner:MASSACHUSETTS INST OF TECH

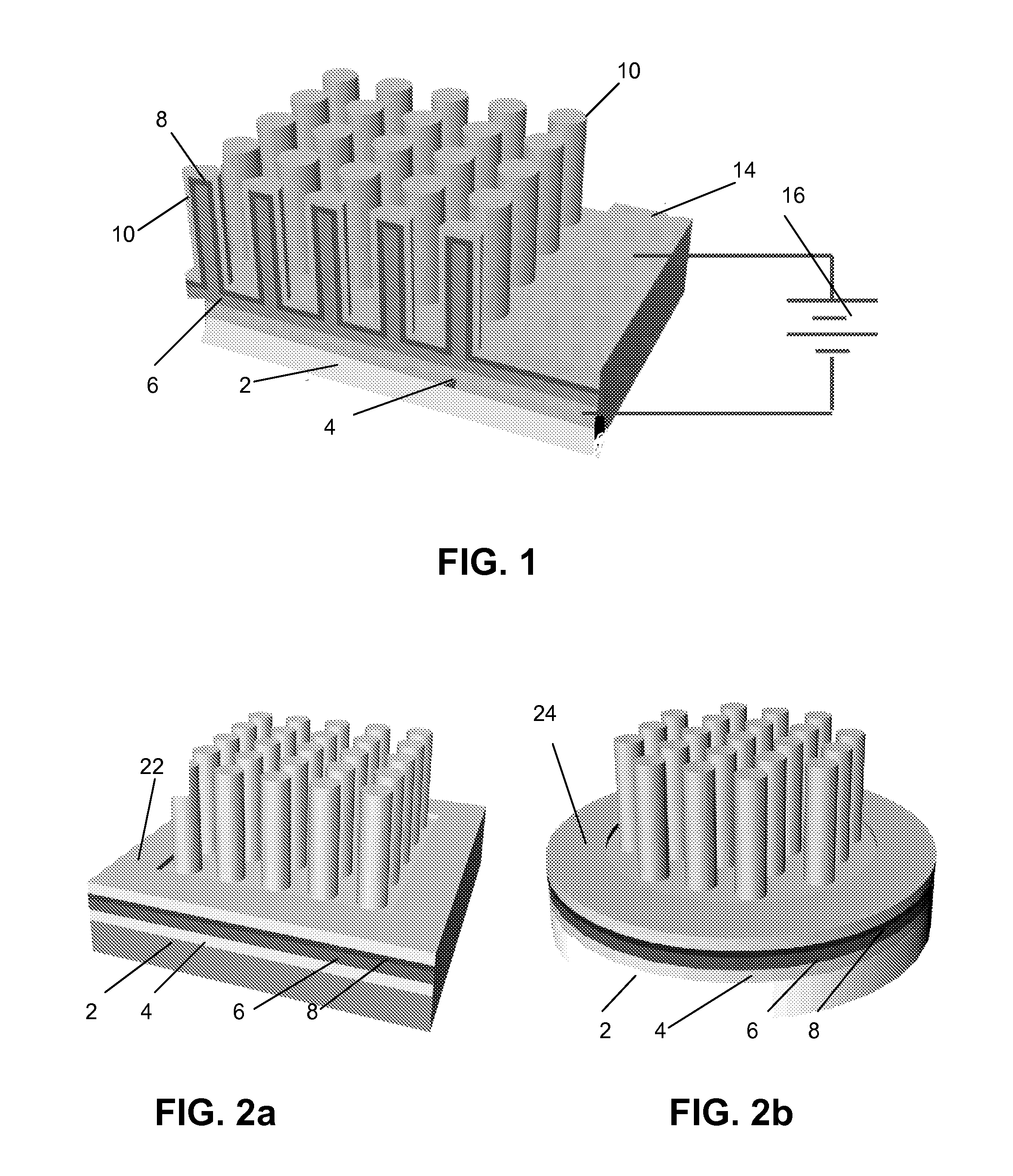

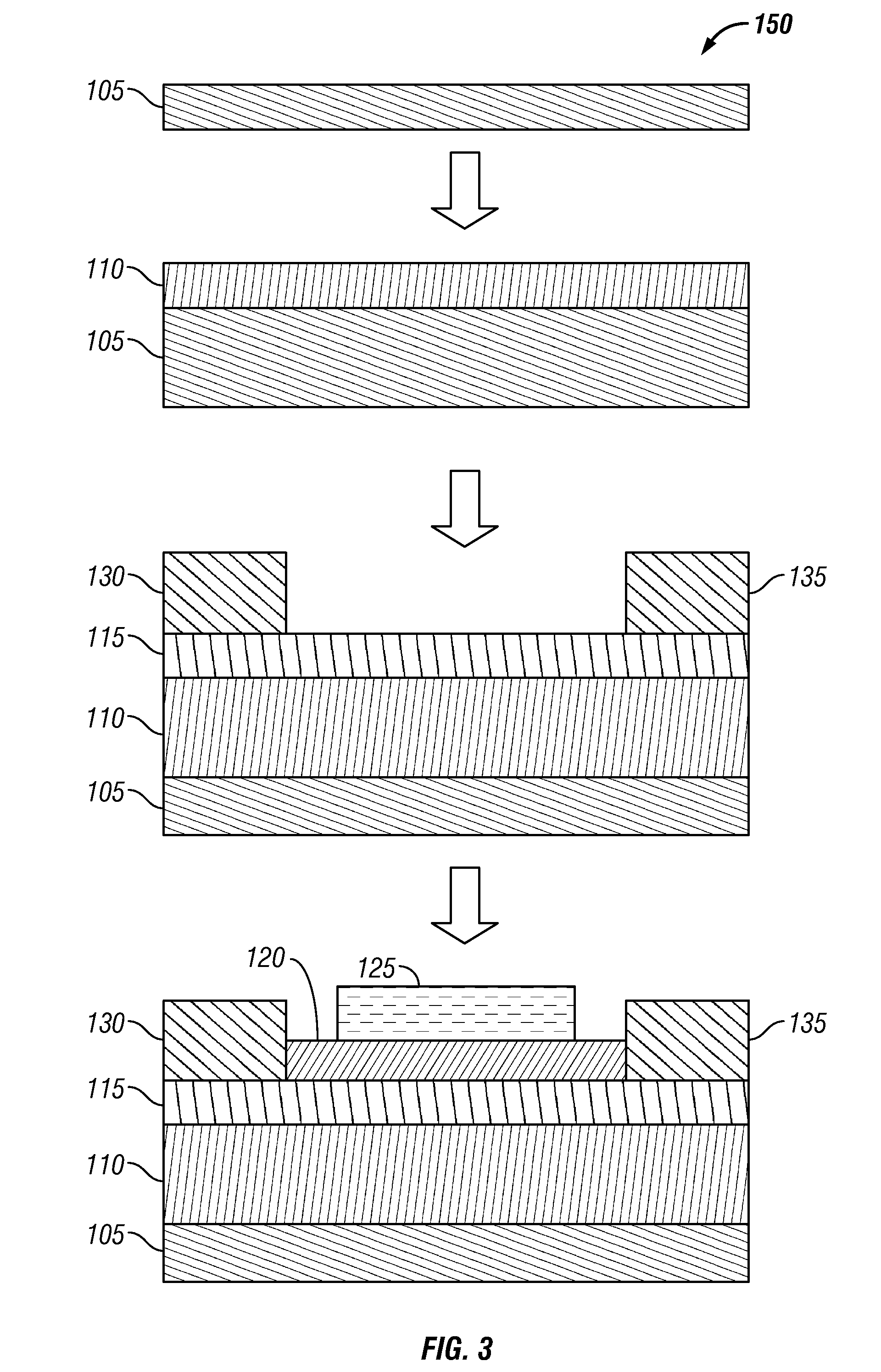

Nanowire Array-Based Light Emitting Diodes and Lasers

InactiveUS20110163292A1Reduce the lasing thresholdImprove efficiencyMaterial nanotechnologySemiconductor/solid-state device manufacturingQuantum wellP–n junction

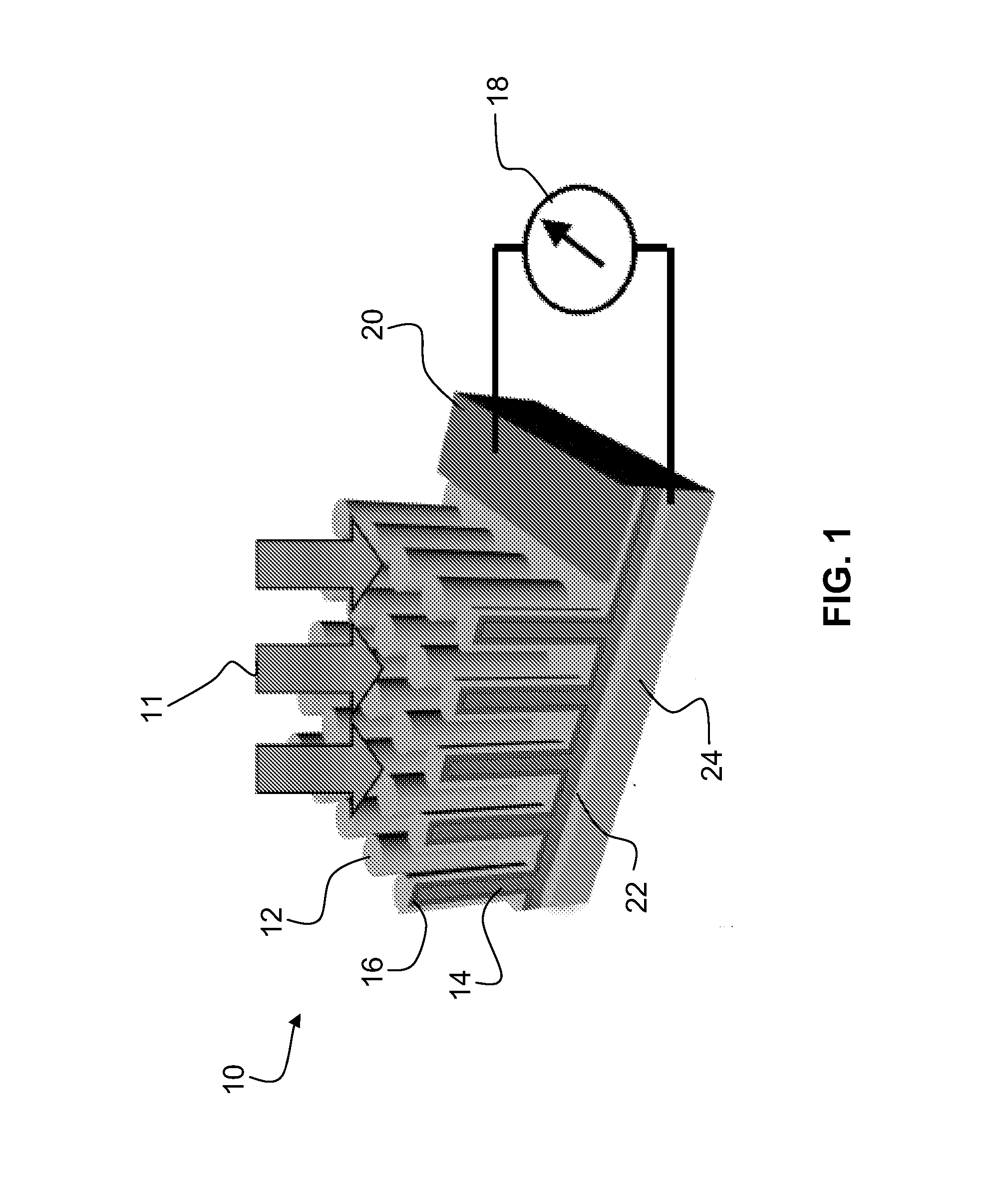

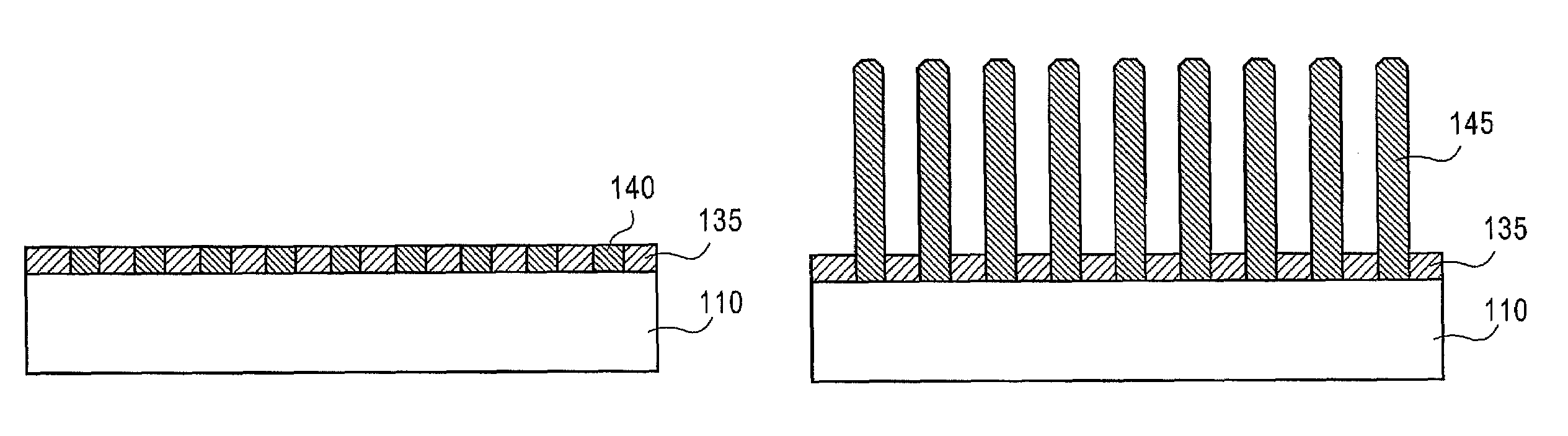

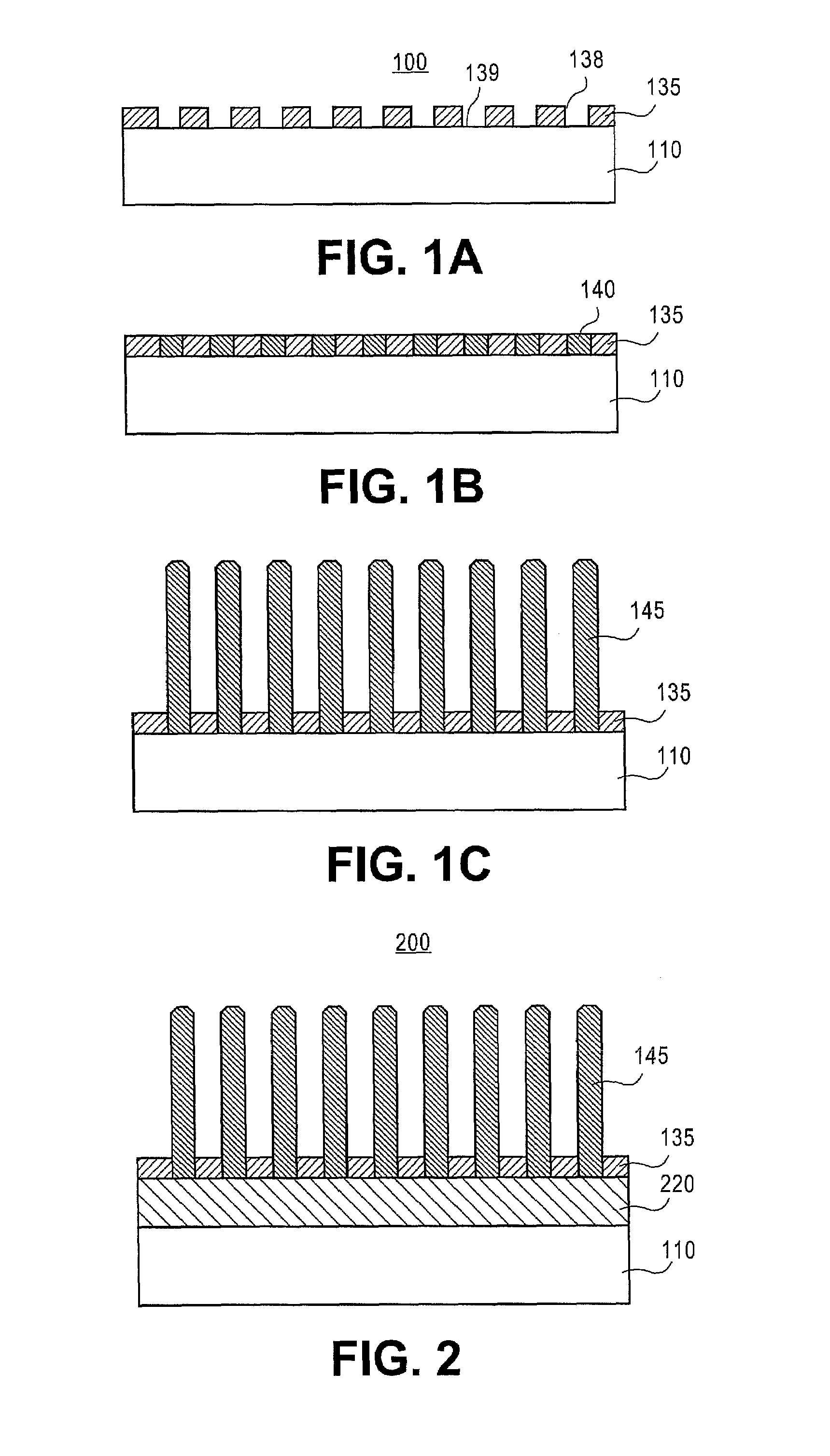

Semiconductor nanowire arrays are used to replace the conventional planar layered construction for fabrication of LEDs and laser diodes. The nanowire arrays are formed from III-V or II-VI compound semiconductors on a conducting substrate. For fabrication of the device, an electrode layer is deposited on the substrate, a core material of one of a p-type and n-type compound semiconductor material is formed on top of the electrode as a planar base with a plurality of nanowires extending substantially vertically therefrom. A shell material of the other of the p-type and n-type compound semiconductor material is formed over an outer surface of the core material so that a p-n junction is formed across the planar base and over each of the plurality of nanowires. An electrode coating is formed an outer surface of the shell material for providing electrical contact to a current source. Heterostructures and superlattices grown along the lengths of the nanowires allow the confinement of photons in the quantum well to enhance the efficiency and as well as color tuning.

Owner:RGT UNIV OF CALIFORNIA

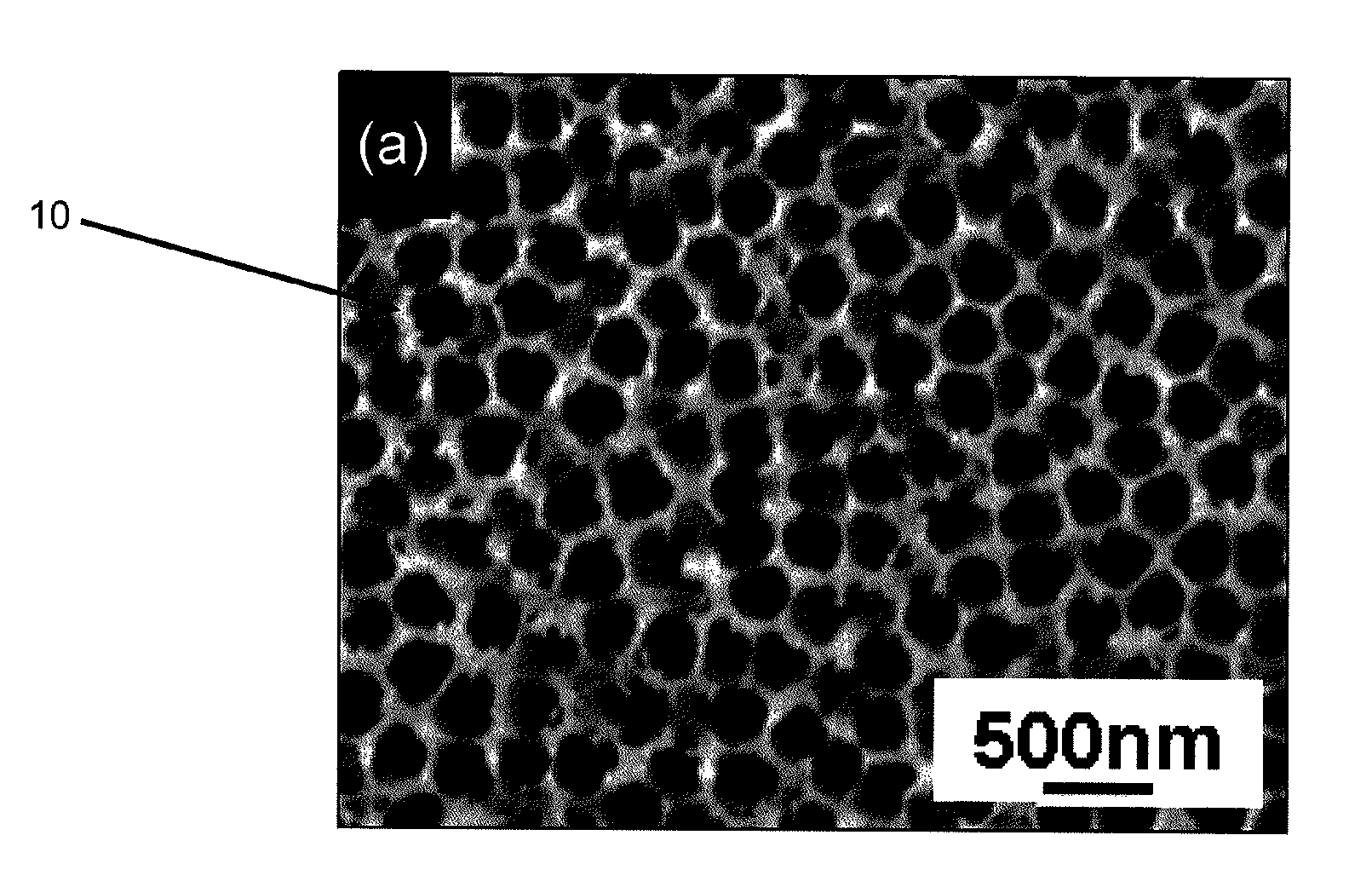

Light absorption and filtering properties of vertically oriented semiconductor NANO wires

InactiveUS20110309237A1Optical radiation measurementMaterial nanotechnologyPhotovoltaic detectorsPhotodetector

A nanowire array is described herein. The nanowire array comprises a substrate and a plurality of nanowires extending essentially vertically from the substrate; wherein: each of the nanowires has uniform chemical along its entire length; a refractive index of the nanowires is at least two times of a refractive index of a cladding of the nanowires. This nanowire array is useful as a photodetector, a submicron color filter, a static color display or a dynamic color display.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE +1

Free-standing nanowire sensor and method for detecting an analyte in a fluid

InactiveUS20080204048A1Analysis using chemical indicatorsMaterial thermal conductivityElectricityAnalyte

A sensor device and method for detecting the presence of an analyte in a fluid solution are disclosed. The sensor device system can comprise a substrate and an array of free-standing nanowires attached to the substrate. The array can include individual free-standing nanowires wherein each of the individual free-standing nanowires have a first end and a second end. The first end can, in some embodiments, be attached to the substrate and the second end unattached to the substrate. Such individual free-standing nanowires are configured for electrical communication with other individual free-standing nanowires through the first end. A chip or computer can be electrically coupled to the array of free-standing nanowires for receiving electrical information from the array of free-standing nanowires. In some embodiments a power source can be used to send current through the nanowire array.

Owner:HEWLETT PACKARD DEV CO LP

PULSED GROWTH OF CATALYST-FREE GROWTH OF GaN NANOWIRES AND APPLICATION IN GROUP III NITRIDE SEMICONDUCTOR BULK MATERIAL

Exemplary embodiments provide semiconductor devices including high-quality (i.e., defect free) group III-N nanowires and uniform group III-N nanowire arrays as well as their scalable processes for manufacturing, where the position, orientation, cross-sectional features, length and the crystallinity of each nanowire can be precisely controlled. A pulsed growth mode can be used to fabricate the disclosed group III-N nanowires and / or nanowire arrays providing a uniform length of about 10 nm to about 1000 microns with constant cross-sectional features including an exemplary diameter of about 10-1000 nm. In addition, high-quality GaN substrate structures can be formed by coalescing the plurality of GaN nanowires and / or nanowire arrays to facilitate the fabrication of visible LEDs and lasers. Furthermore, core-shell nanowire / MQW active structures can be formed by a core-shell growth on the nonpolar sidewalls of each nanowire.

Owner:STC UNM

Hybrid nanomesh structures

An alternating stack of first and second semiconductor layers is formed. Fin-defining mask structures are formed over the alternating stack. A planarization dielectric layer and first and second gate cavities therein are subsequently formed. The first and second gate cavities are extended downward by etching the alternating stack employing a combination of the planarization layer and the fin-defining mask structures as an etch mask. The second semiconductor material is isotropically etched to laterally expand the first gate cavity and to form a first array of semiconductor nanowires including the first semiconductor material, and the first semiconductor material is isotropically etched to laterally expand the second gate cavity and to form a second array of semiconductor nanowires including the second semiconductor material. The first and second gate cavities are filled with replacement gate structures. Each replacement gate structure laterally can surround a two-dimensional array of semiconductor nanowires.

Owner:GLOBALFOUNDRIES INC

Nanowire array and nanowire solar cells and methods for forming the same

Owner:RGT UNIV OF CALIFORNIA

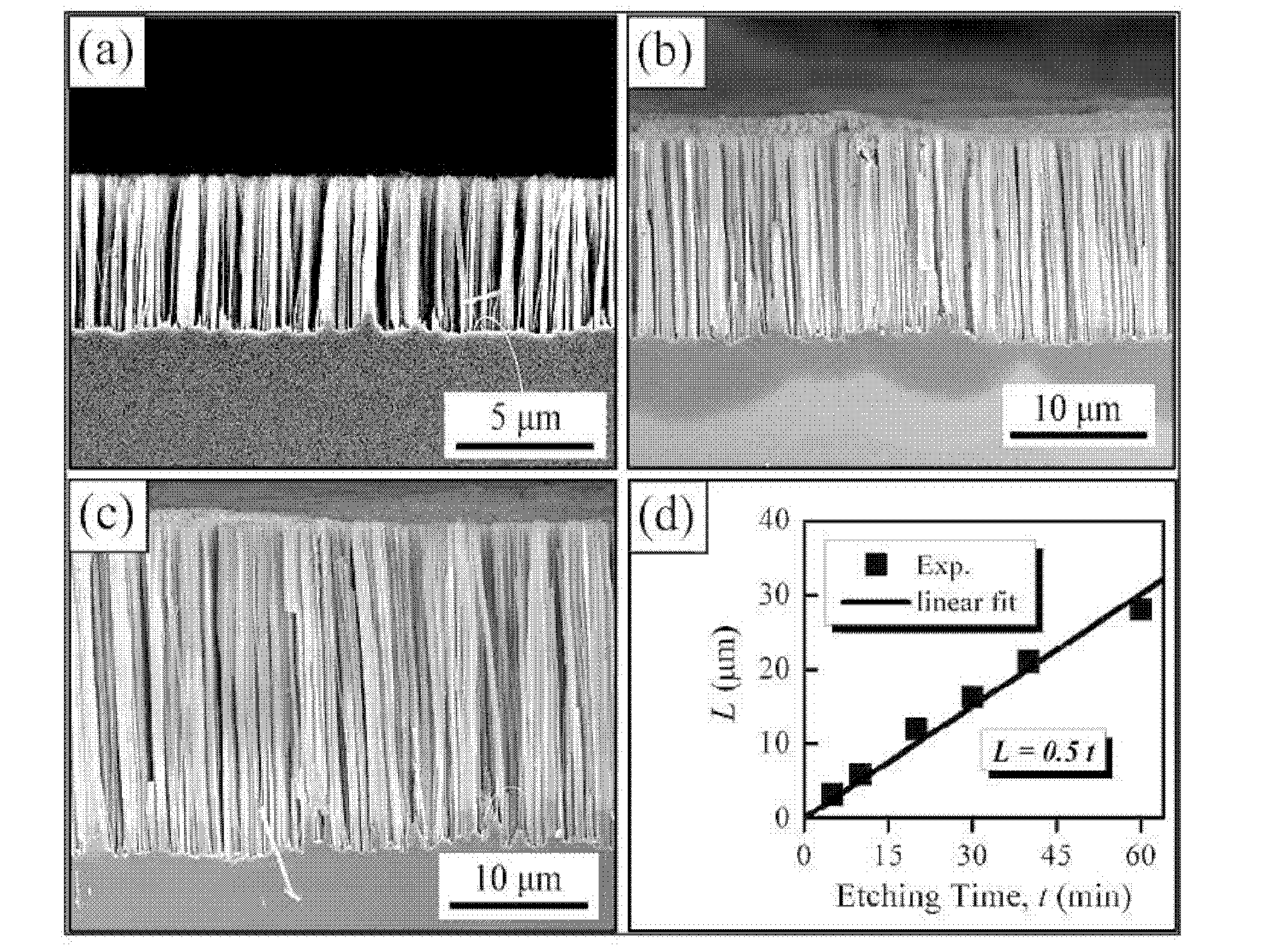

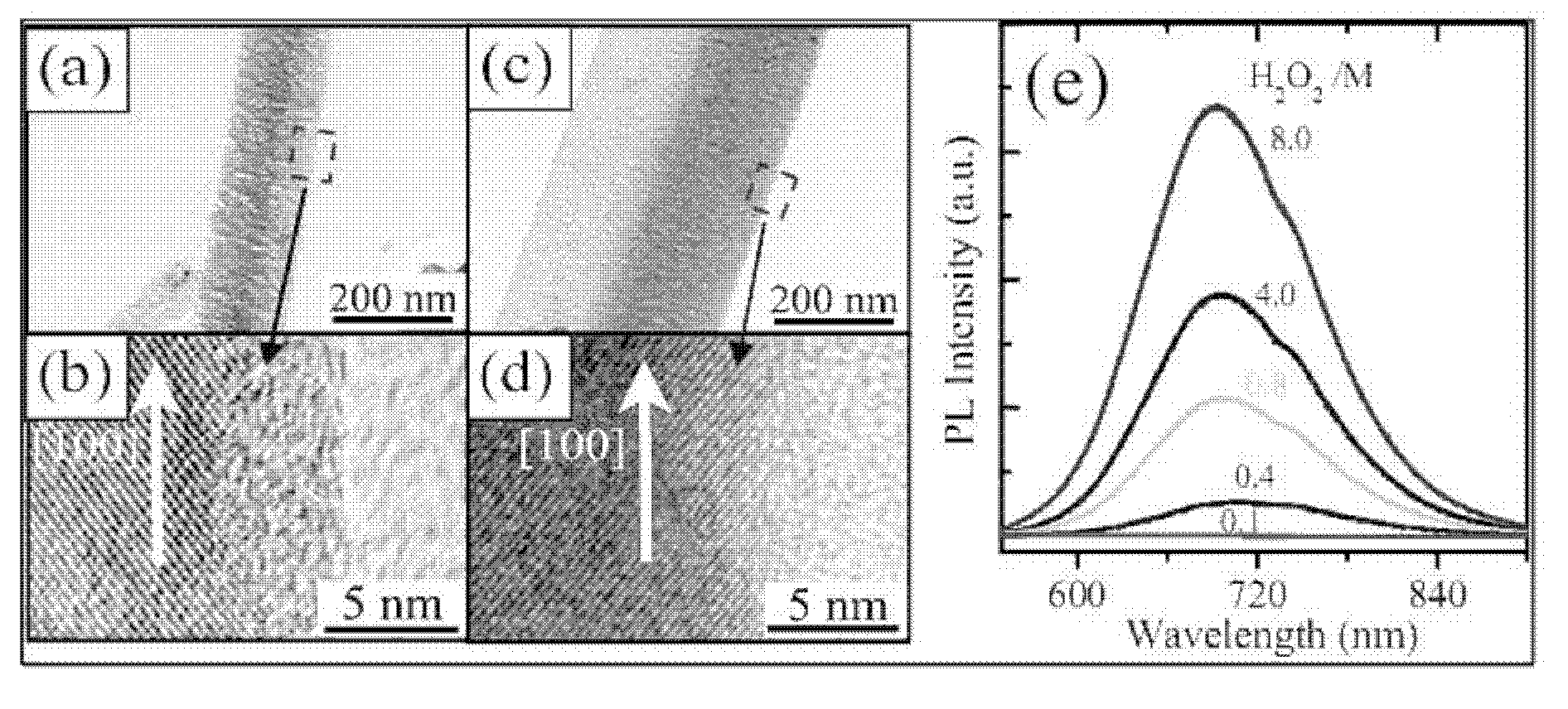

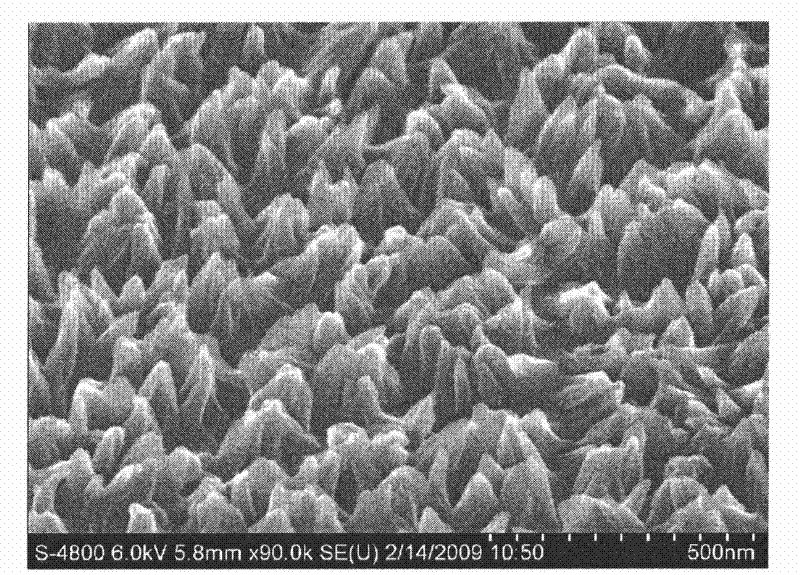

Method for preparing silicon nanowire array with smooth surface

The invention relates to a method for preparing a length-controlled silicon nanowire array with a smooth surface, and belongs to the technology of the preparation of nanometer materials. The method comprises the following steps of: firstly, performing wet chemical cleaning on a silicon wafer; secondly, depositing a silver nanometer granular layer on the surface of the silicon wafer in mixed solution containing hydrofluoric acid and silver nitrate by an electroless chemical deposition method; thirdly, performing chemical etching by mixed solution containing the hydrofluoric acid and hydrogen peroxide; and finally, removing silver nanometer granules by using nitric acid to obtain the silicon nanowire array. In the method, length-controlled silicon nanowires with the smooth surfaces are prepared by regulating the concentration and etching time of the hydrogen peroxide serving as an oxidant simply in a chemical etch system, so the technical problem of preparing the silicon nanowires with fewer surface defects in metal-assisted chemical etching is solved.

Owner:SHANGHAI JIAO TONG UNIV

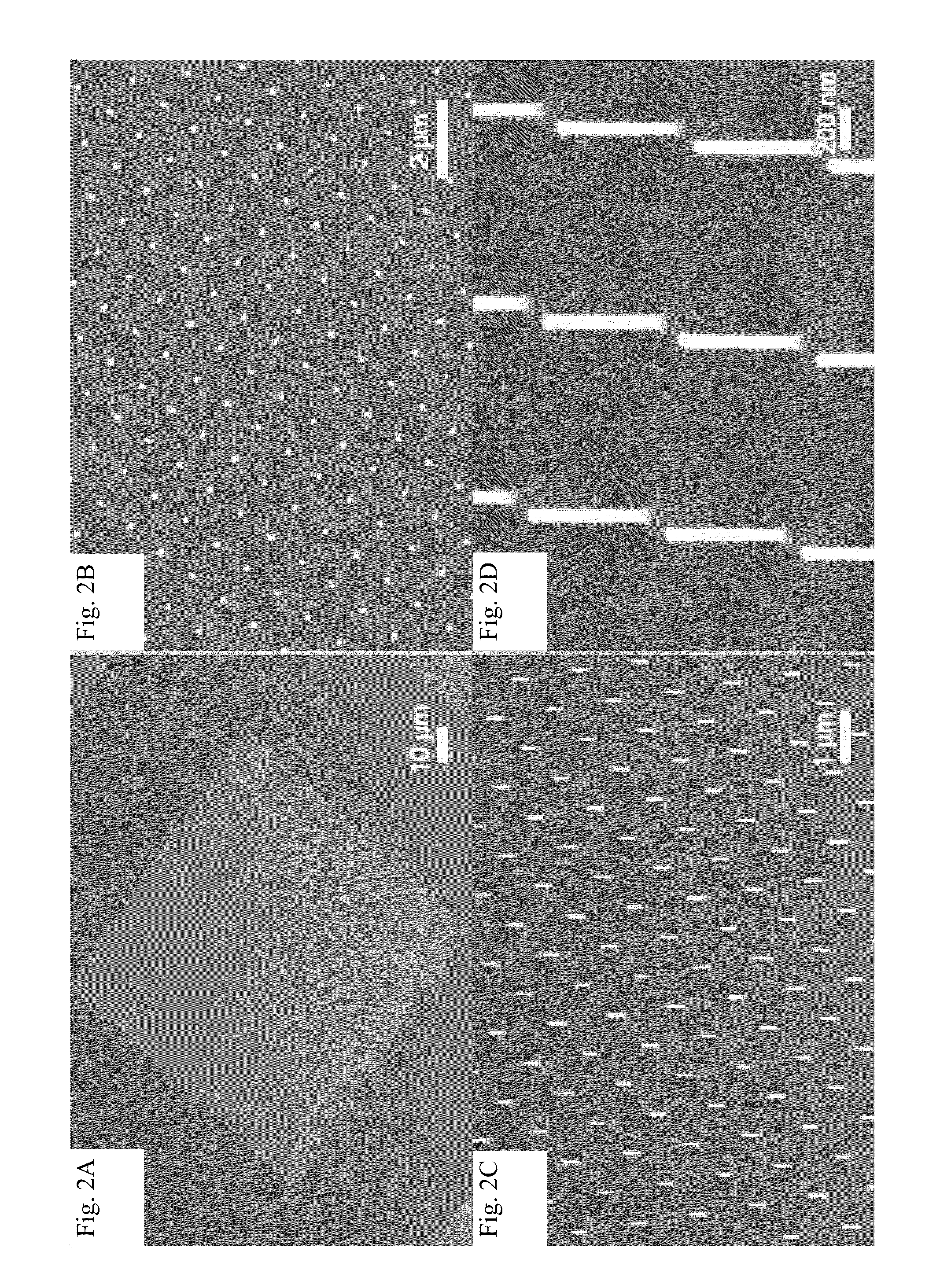

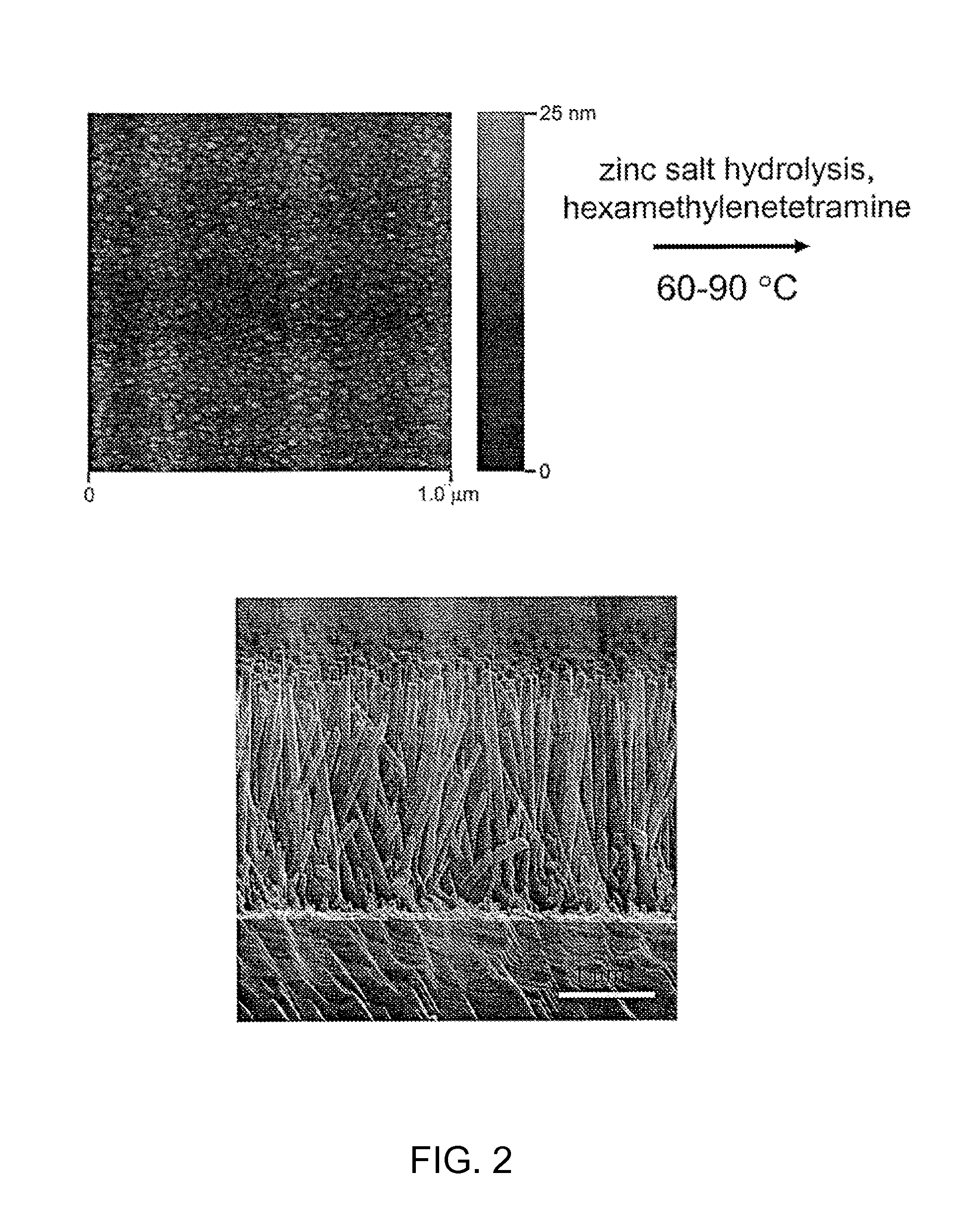

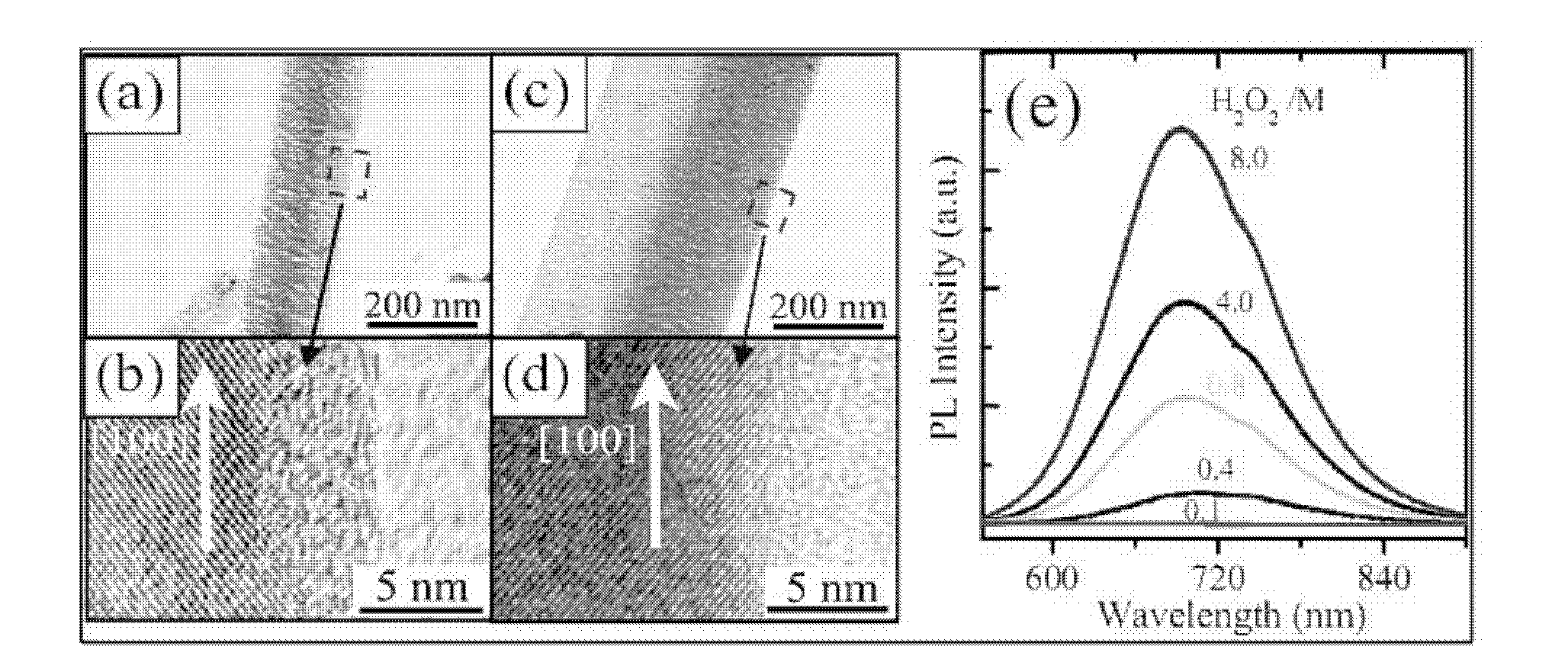

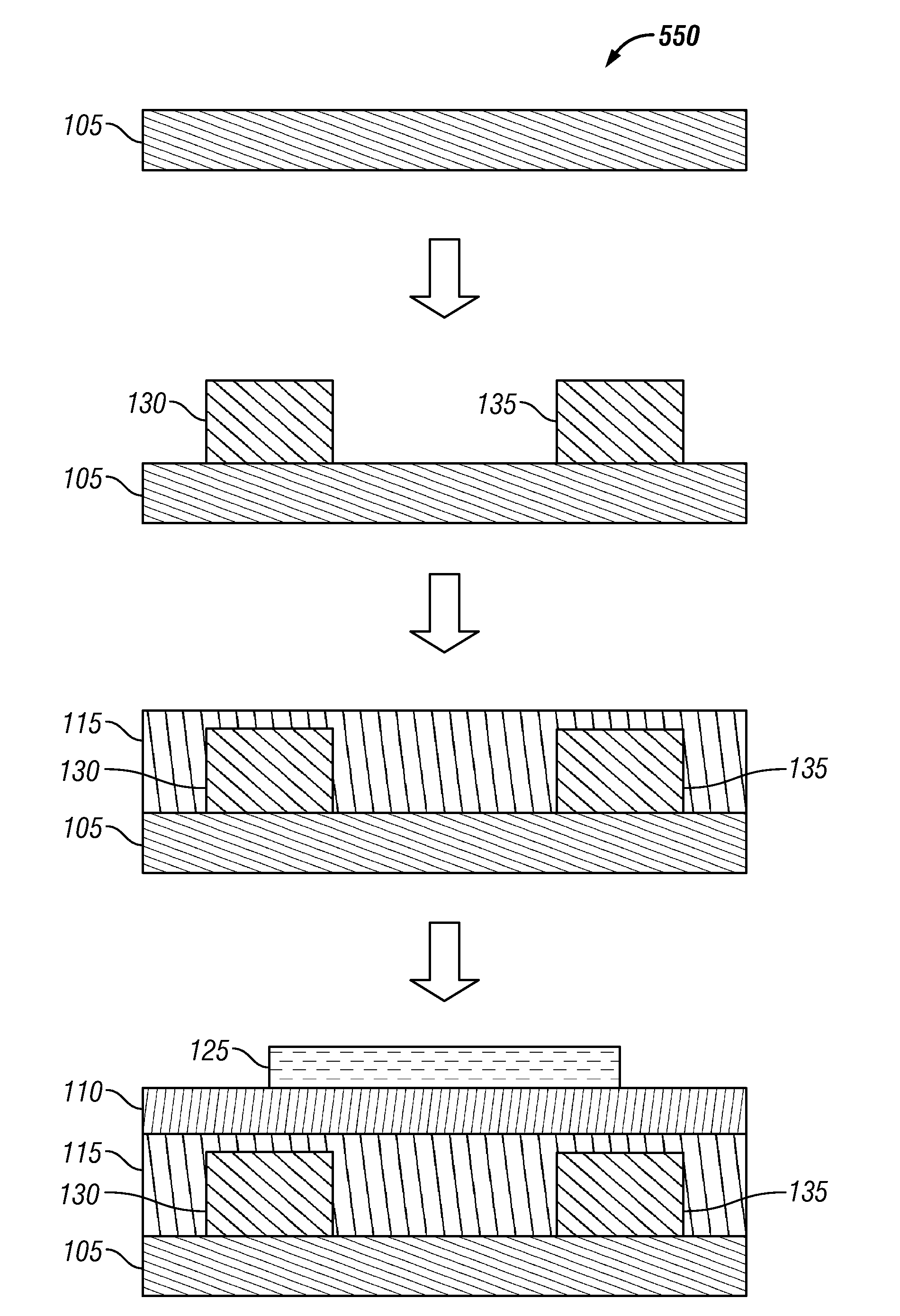

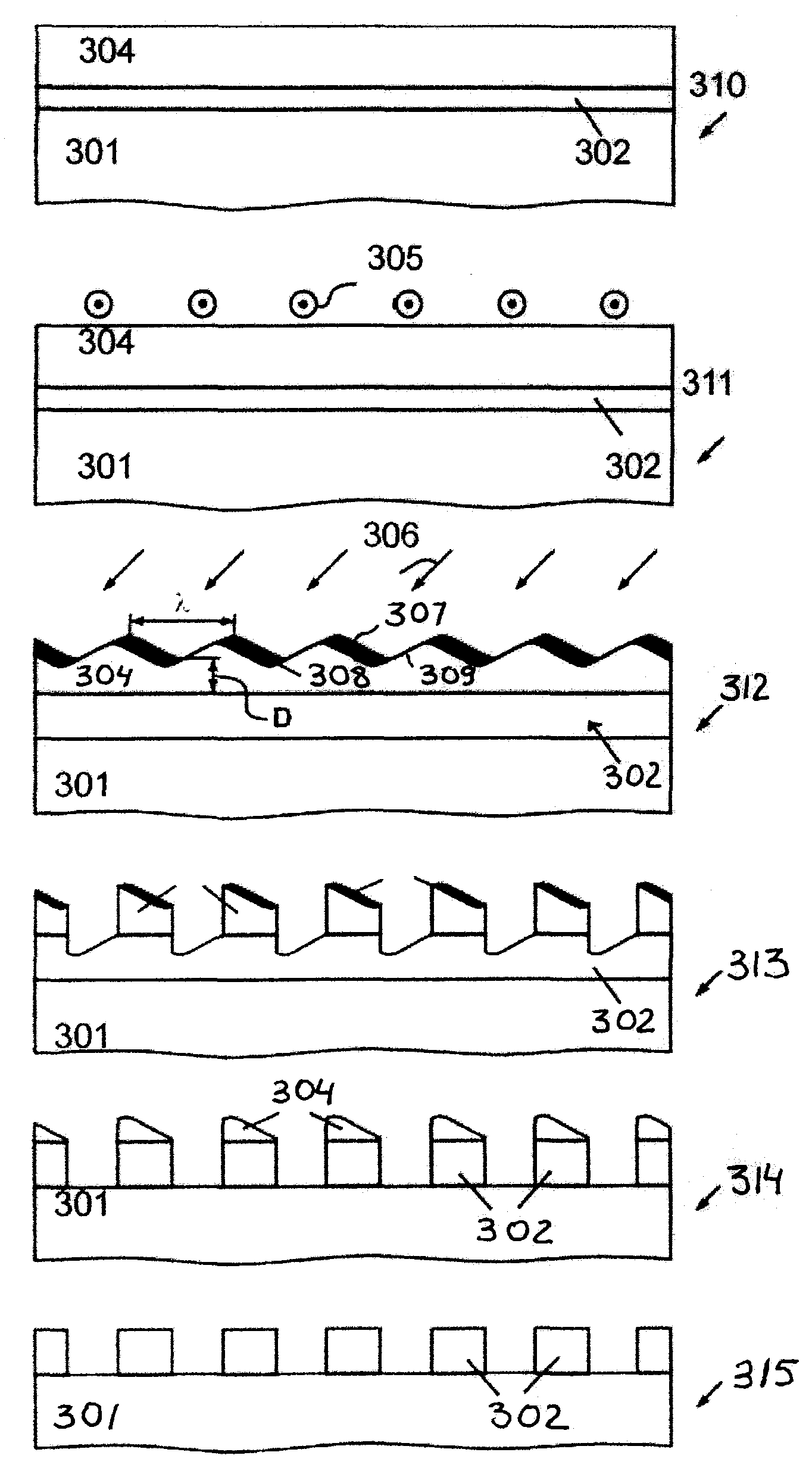

Process for Fabricating Nanowire Arrays

ActiveUS20090256134A1Sufficient adhesionMaterial nanotechnologyOther chemical processesNanoparticleNanowire array

A process is provided for etching a silicon-containing substrate to form nanowire arrays. In this process, one deposits nanoparticles and a metal film onto the substrate in such a way that the metal is present and touches silicon where etching is desired and is blocked from touching silicon or not present elsewhere. One submerges the metallized substrate into an etchant aqueous solution comprising HF and an oxidizing agent. In this way arrays of nanowires with controlled diameter and length are produced.

Owner:ADVANCED SILICON GRP TECH LLC

Integrated Circuit Micro-Cooler Having Tubes of a CNT Array in Essentially the Same Height over a Surface

InactiveUS20070126116A1Semiconductor/solid-state device detailsNanoinformaticsNanowire arrayNanometre

Heat sink structures employing carbon nanotube or nanowire arrays to reduce the thermal interface resistance between an integrated circuit chip and the heat sink, where the nanotubes are cut to essentially the same length over the surface of the structure, are disclosed. Carbon nanotube arrays are combined with a thermally conductive metal filler disposed between the nanotubes. This structure produces a thermal interface having high axial and lateral thermal conductivities.

Owner:NANOCONDUCTION

Thin-film transistor based piezoelectric strain sensor and method

ActiveUS20110049579A1Low costNanoinformaticsSolid-state devicesField-effect transistorNanowire array

A piezoelectric strain sensor and method thereof for detecting strain, vibration, and / or pressure. The sensor incorporates a sequence of piezoelectric and semiconductor layers in a thin-film transistor structure. The thin-film transistor structure can be configured on a flexible substrate via a low-cost fabrication technique. The piezoelectric layer generates an electric charge resulting in a modulation of a transistor current, which is a measure of external strain. The sensor can be formed as a single gate field-effect piezoelectric sensor and a dual gate field-effect piezoelectric sensor. The semiconductor layer can be configured from a nanowire array resulting in a metal-piezoelectric-nanowire field effect transistor. The single and dual gate field-effect piezoelectric sensor offer increased sensitivity and device control due to the presence of the piezoelectric layer in the transistor structure and low cost manufacturability on large area flexible substrates.

Owner:HONEYWELL ROMANIA

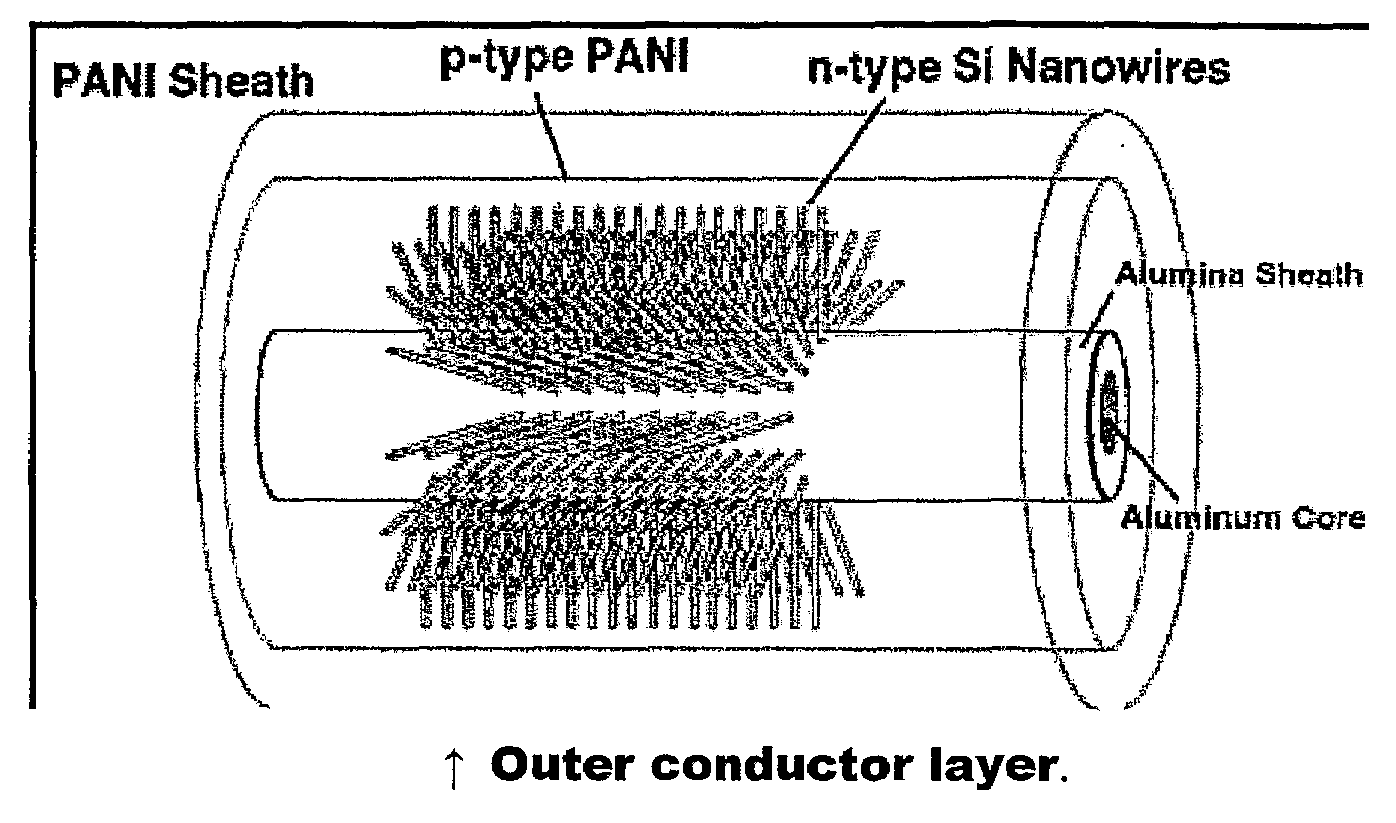

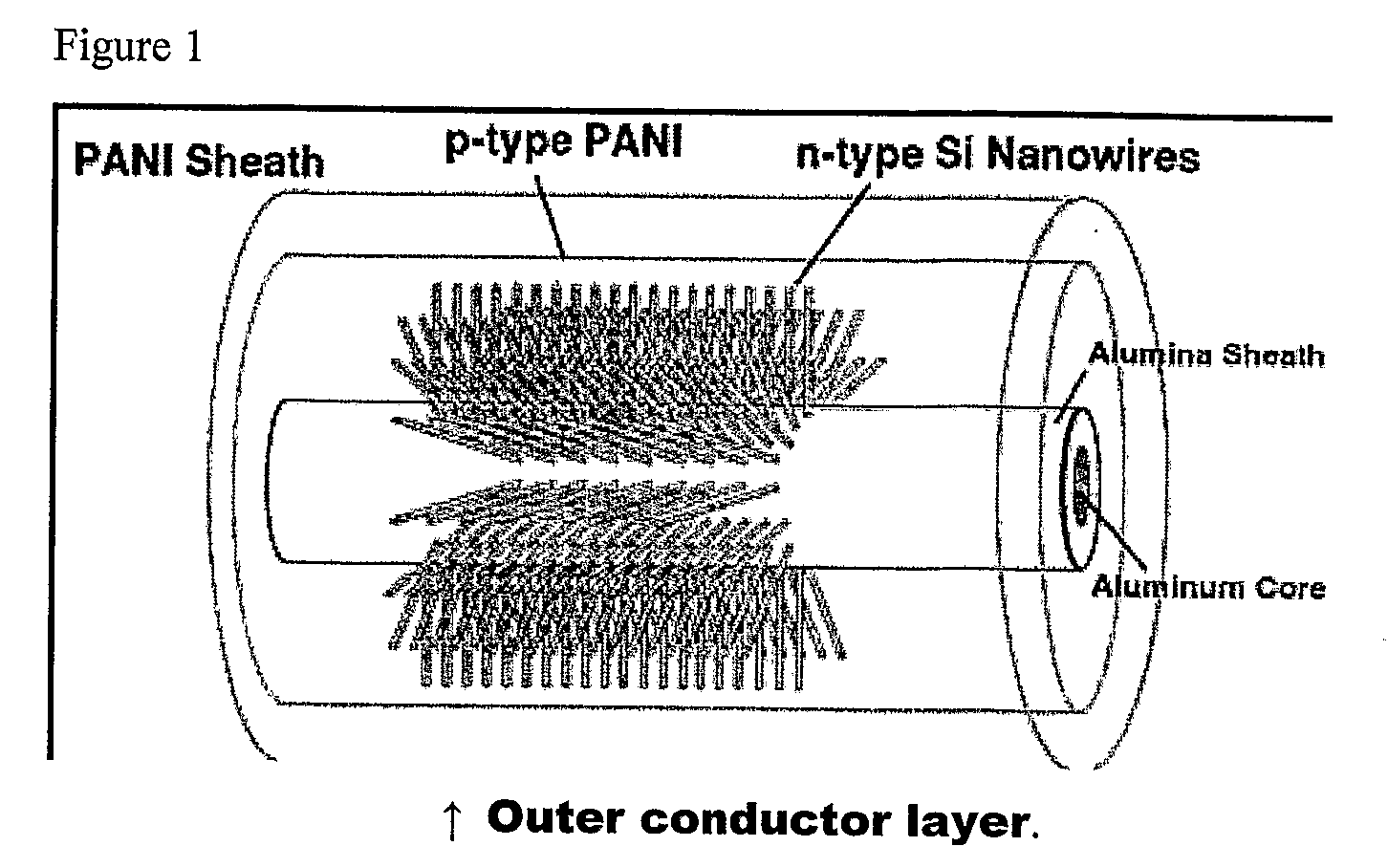

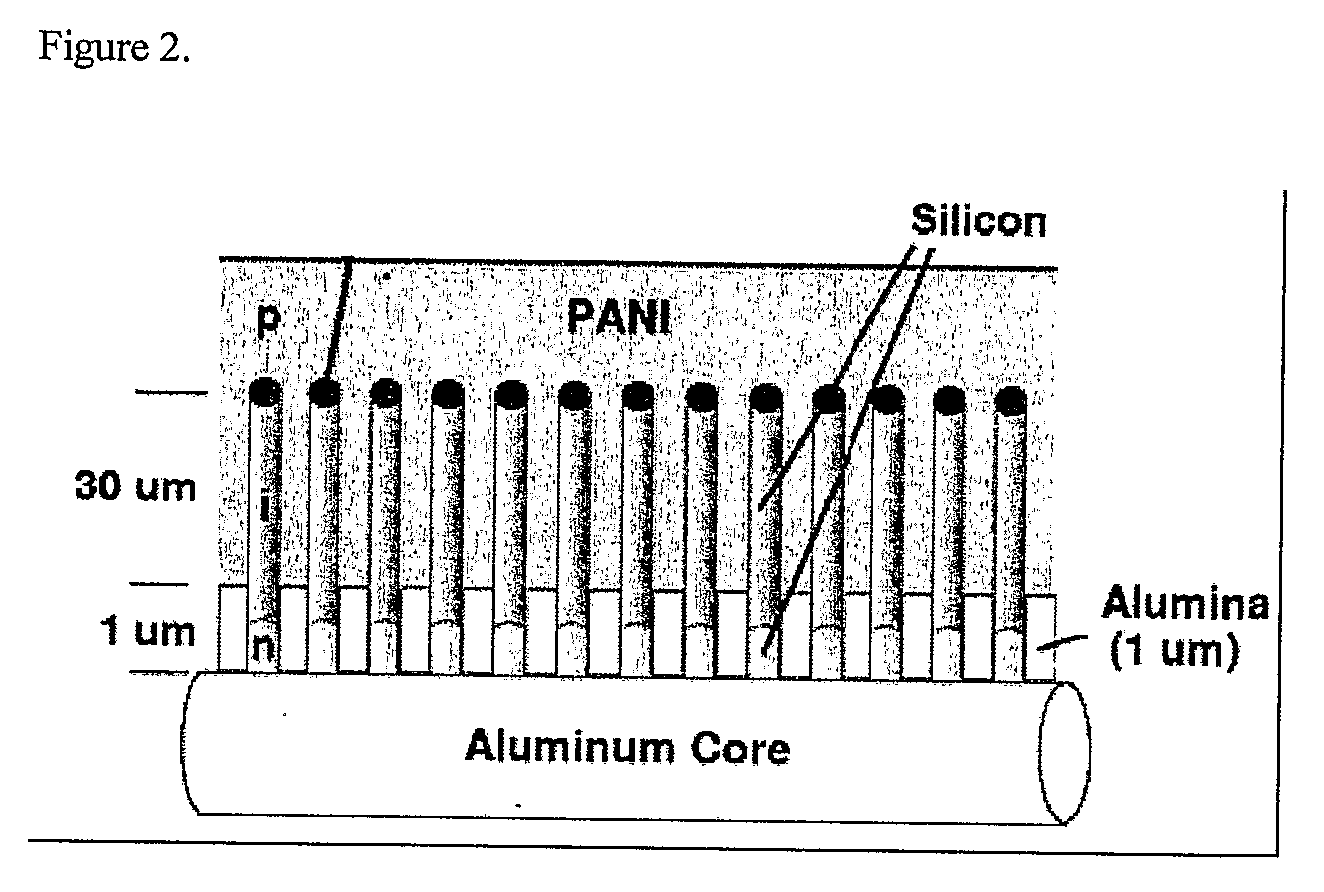

Photovoltaic wire

InactiveUS20090266411A1Efficient and economic use of materialEnhanced light absorptionSolid-state devicesPhotovoltaic energy generationPolymeric surfaceElectrical conductor

A photovoltaic wire is presented where the active layers coat a metallic wire, preferably aluminum. The active layers are an array of doped silicon nanowires electrically attached to the metallic wire that extend from the surface of the wire into a layer of semiconducting polymer, preferably polyaniline. The surface of the polymer is coated with a transparent conductor to complete the photovoltaic circuit.

Owner:ILLUMINEX CORP

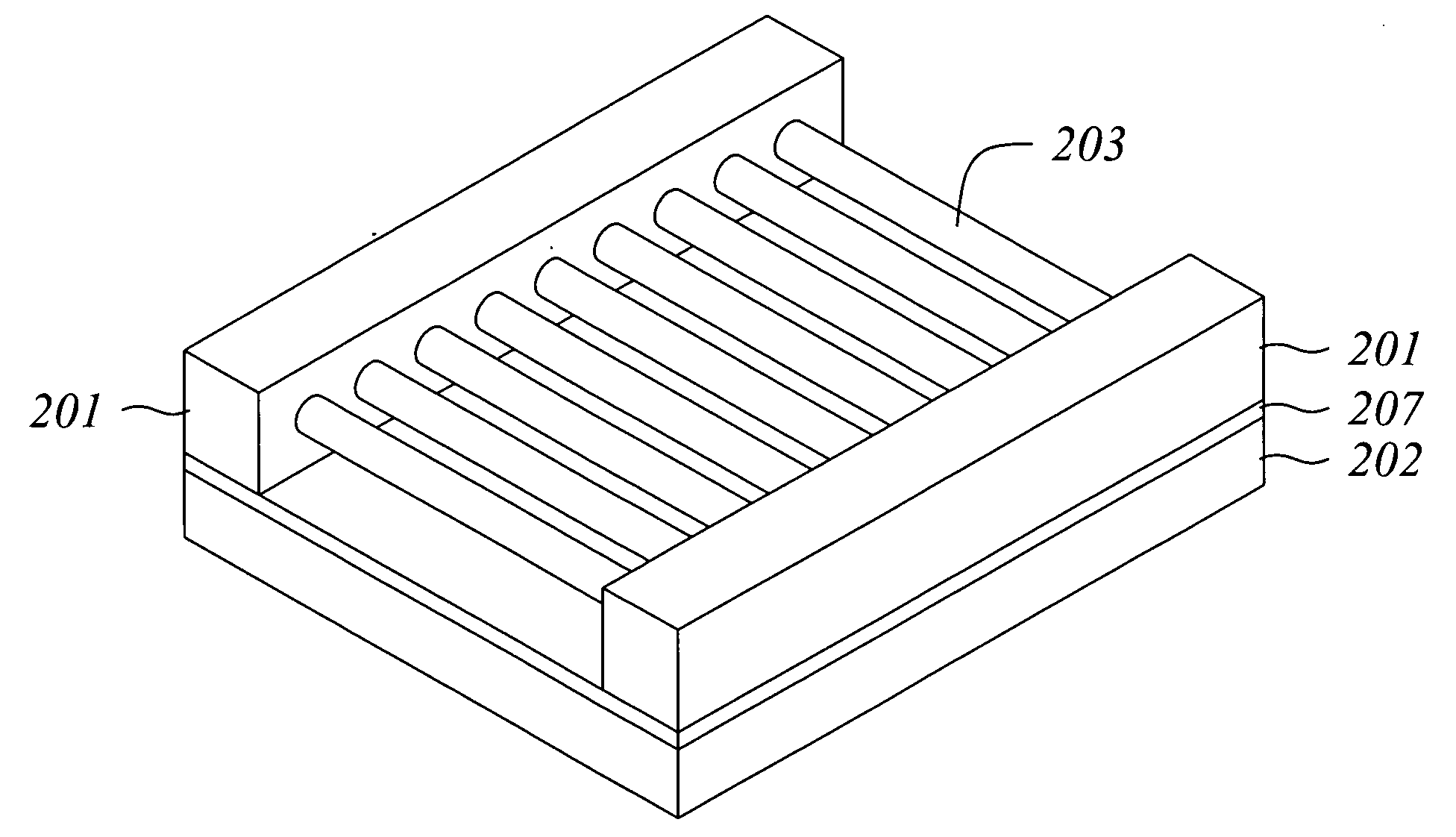

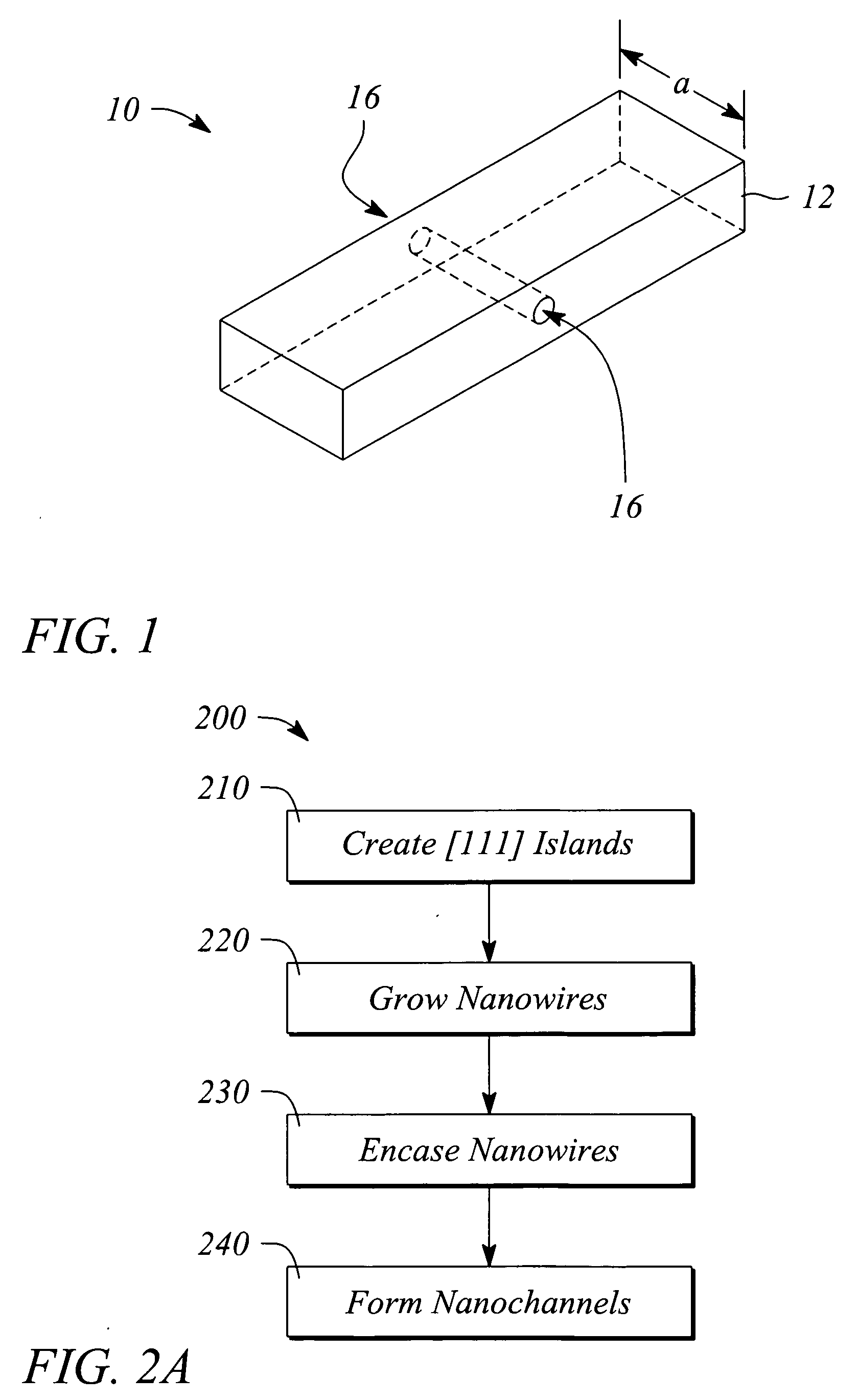

Nanochannel apparatus and method of fabricating

InactiveUS20070122313A1Easy to analyzeEasy to detectMaterial nanotechnologyAnalysis using chemical indicatorsNanowire arrayNanometre

A nanochannel apparatus and method of fabrication provide an array of nanochannels with distal open or exposed ends formed in situ through a permanent support. A nanofluidic system includes the nanochannel apparatus, a fluidic interface, and a component interfaced to the nanochannel apparatus. The method includes encasing an array of nanowires in a support, and forming the array of nanochannels in situ in locations of the nanowires, such that distal ends of the nanochannels are exposed.

Owner:HEWLETT PACKARD DEV CO LP

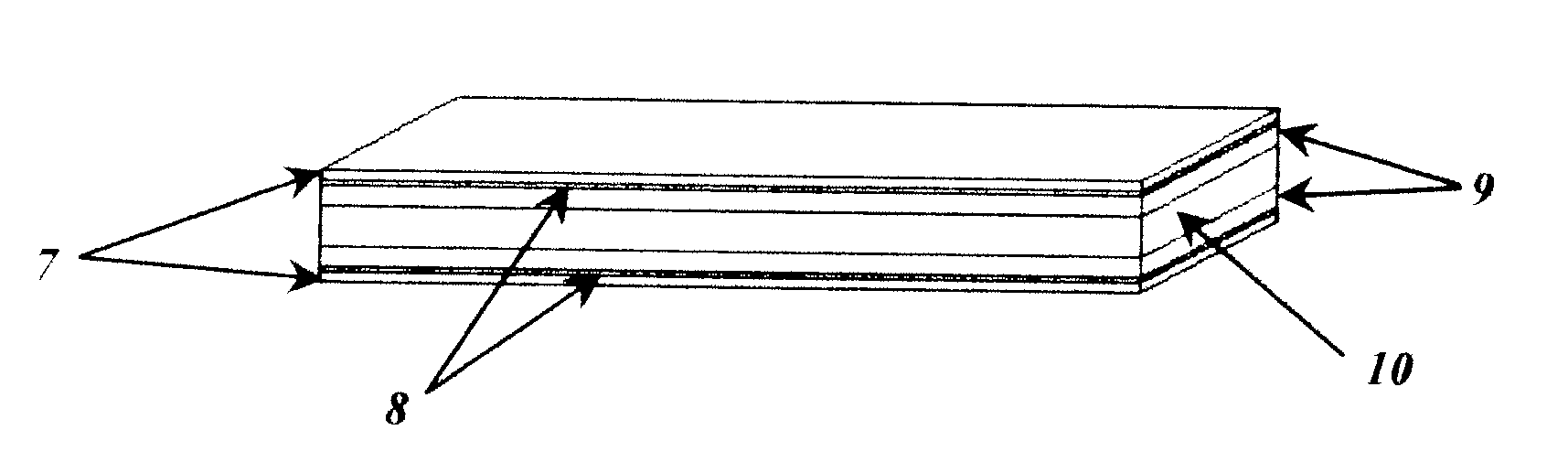

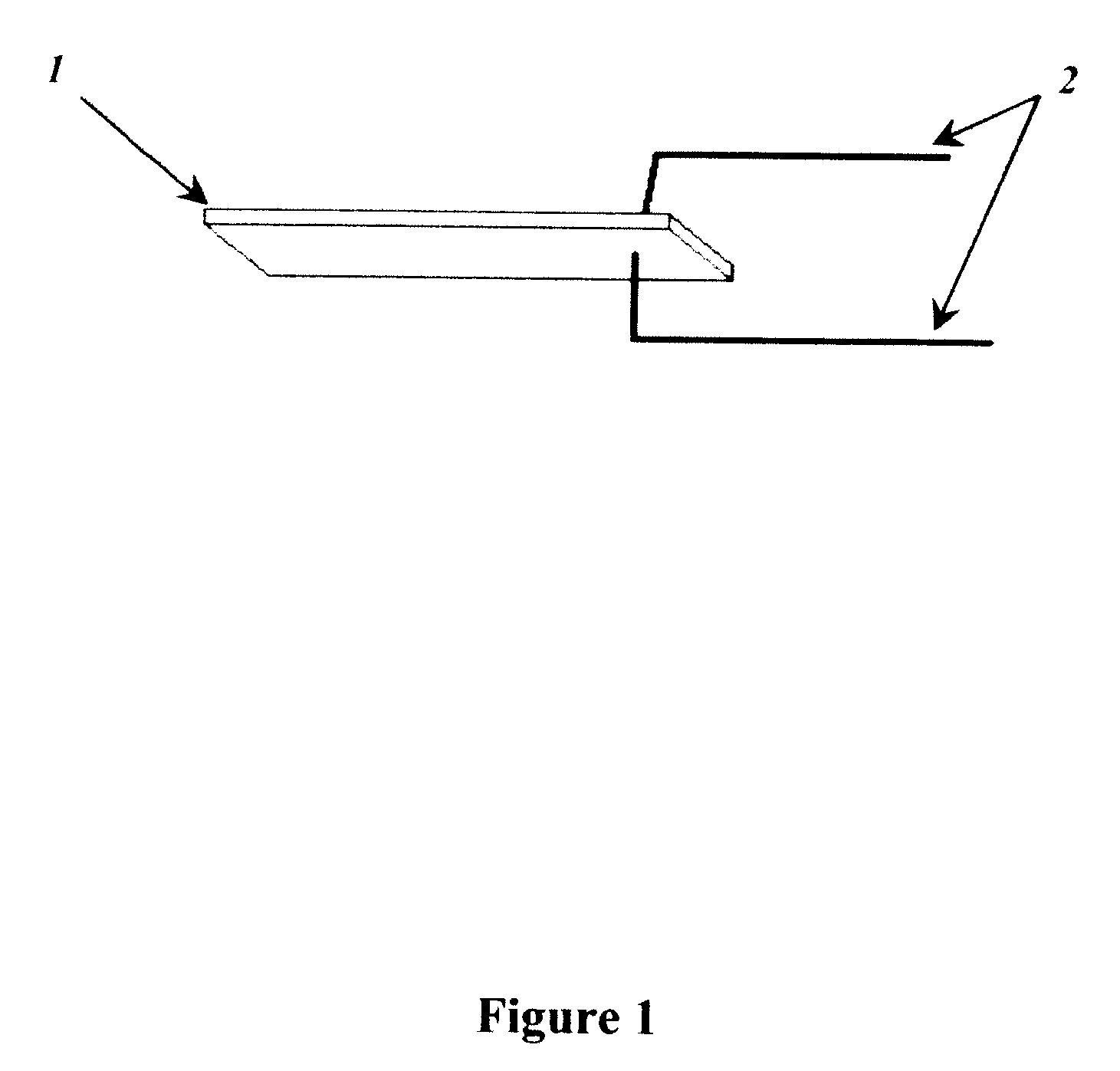

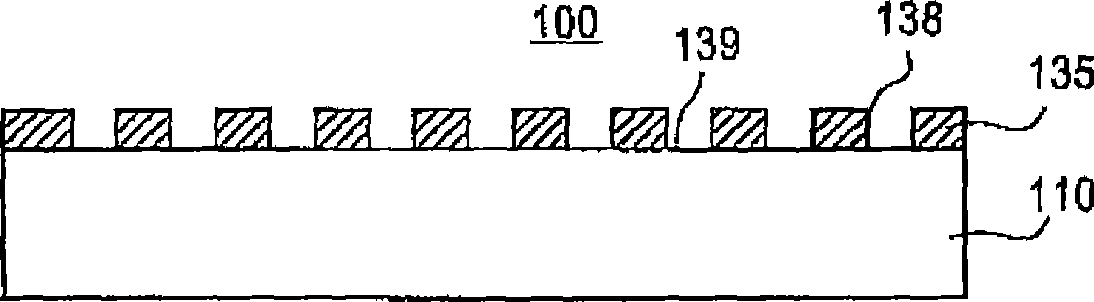

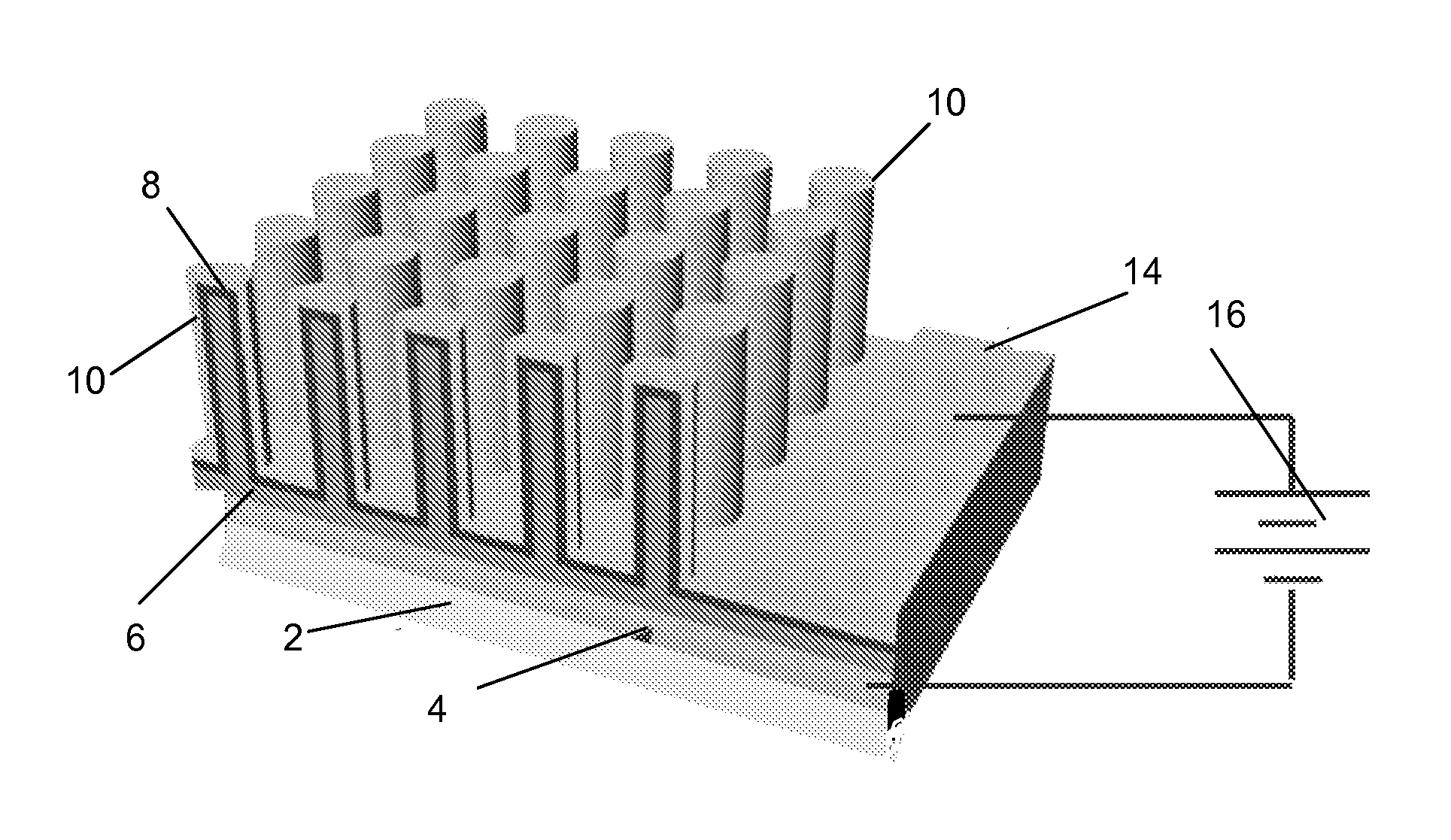

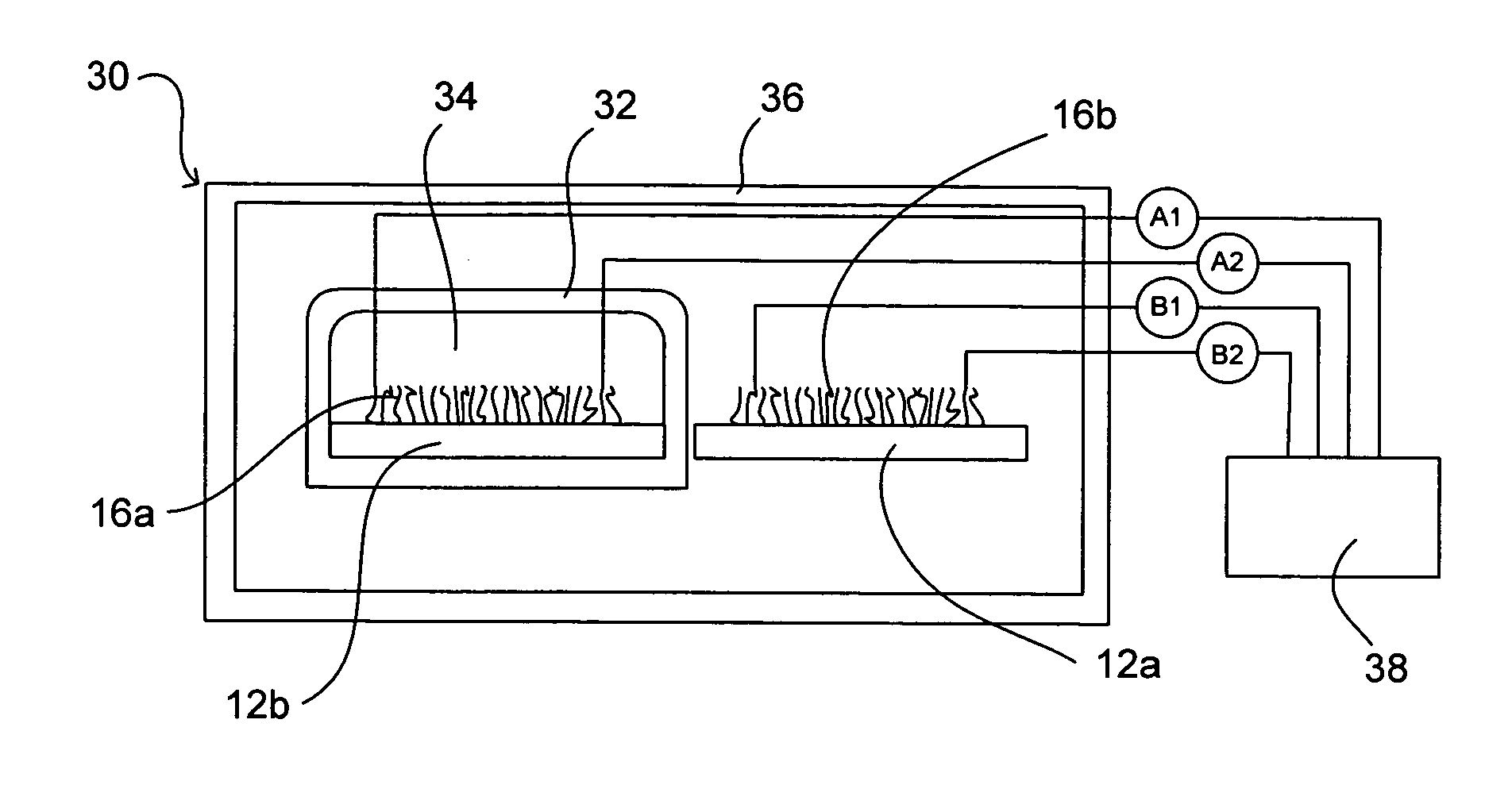

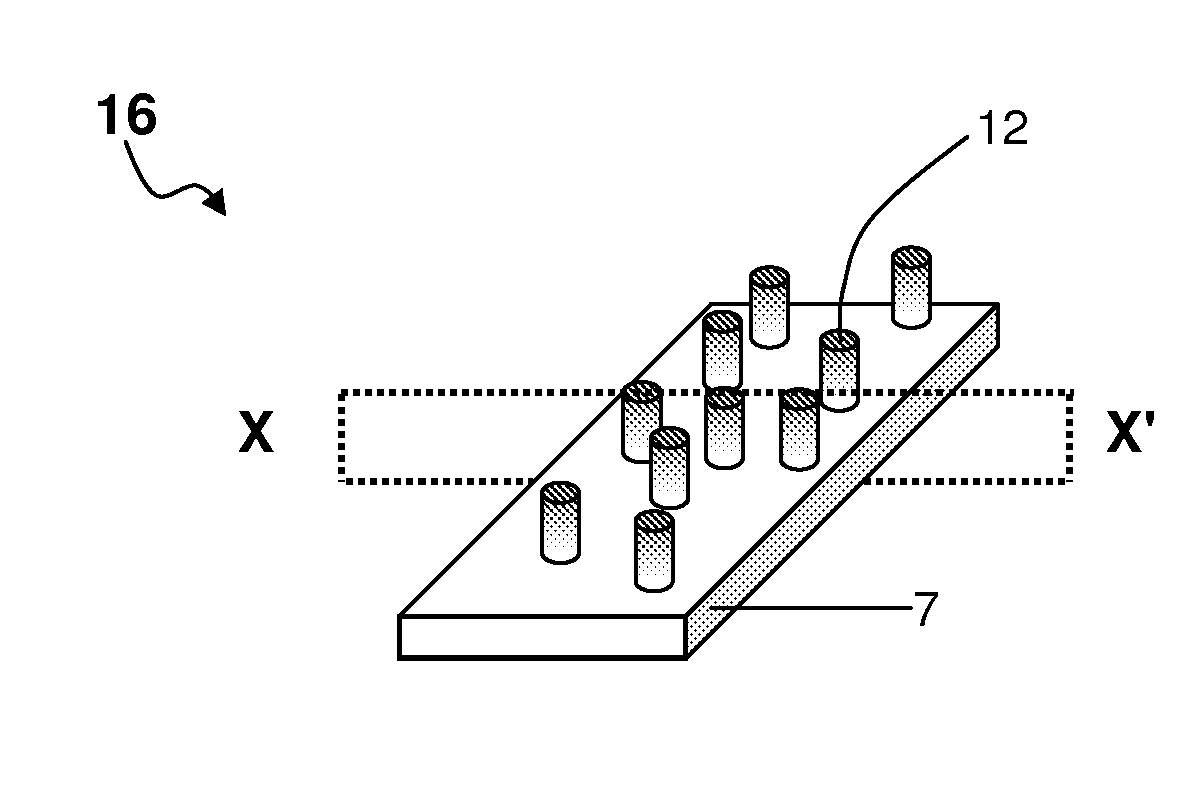

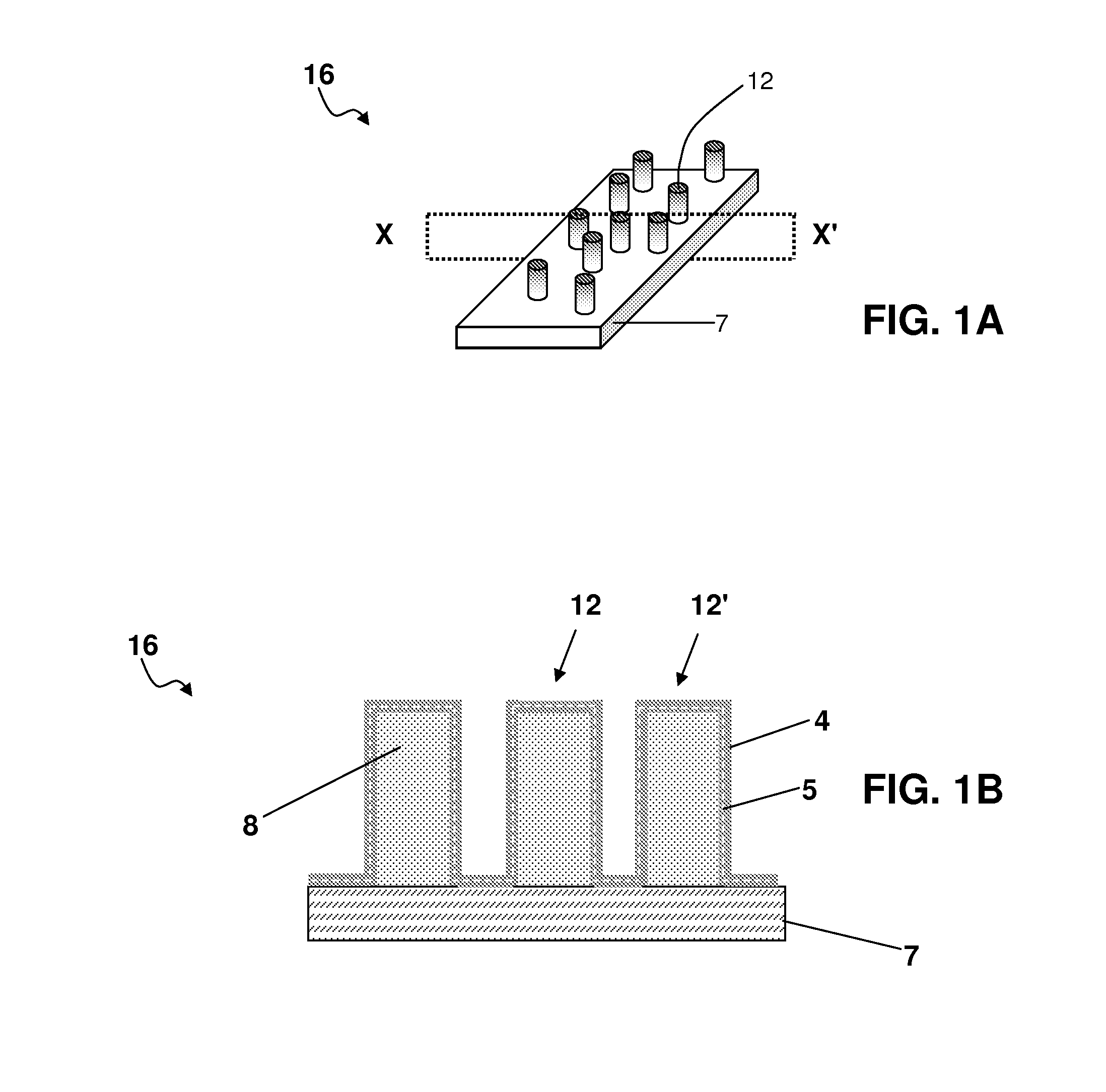

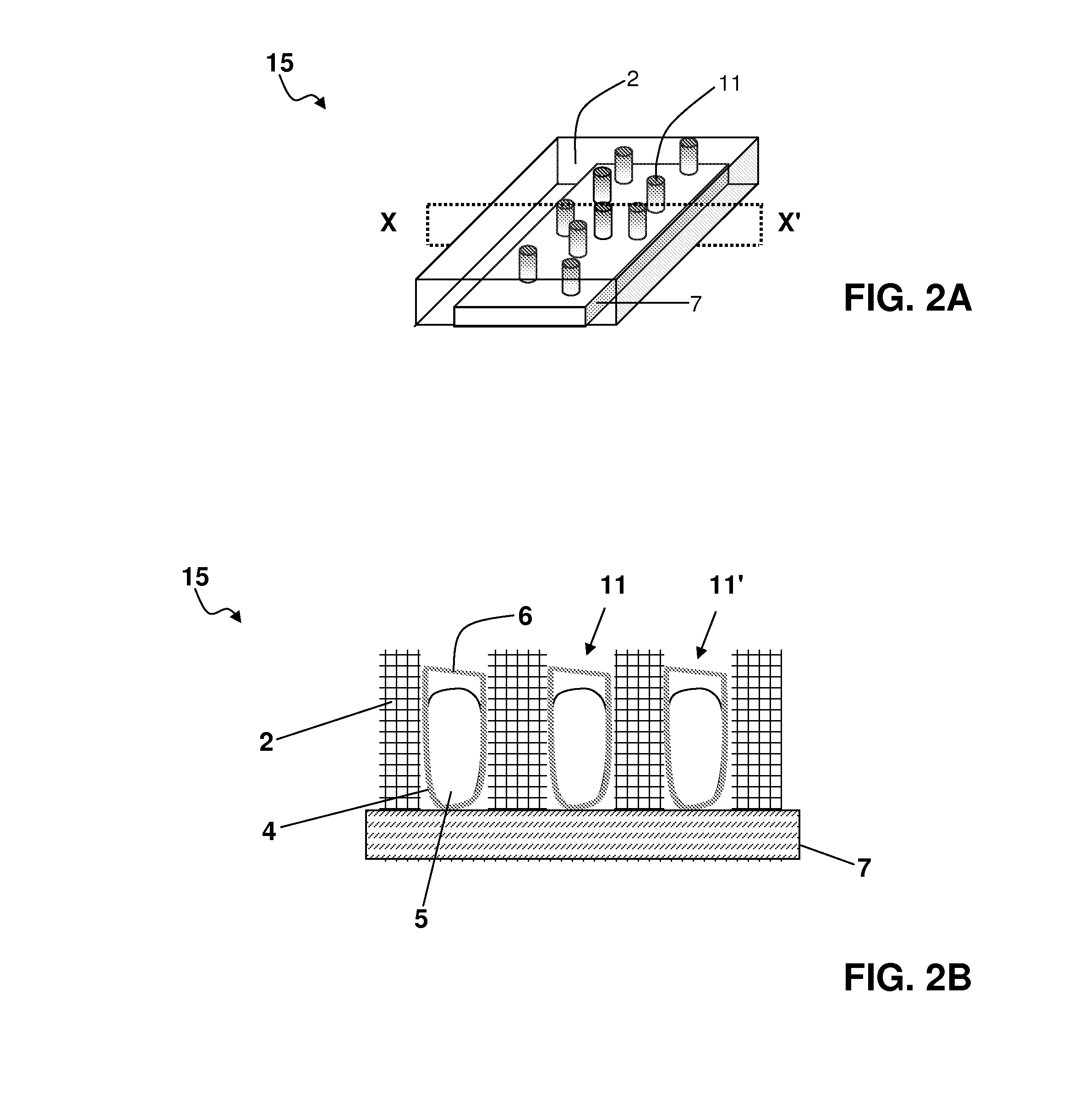

Drug-eluting nanowire array

InactiveUS20100233226A1High activityImprove adhesionOrganic active ingredientsNervous disorderElutionNanowire array

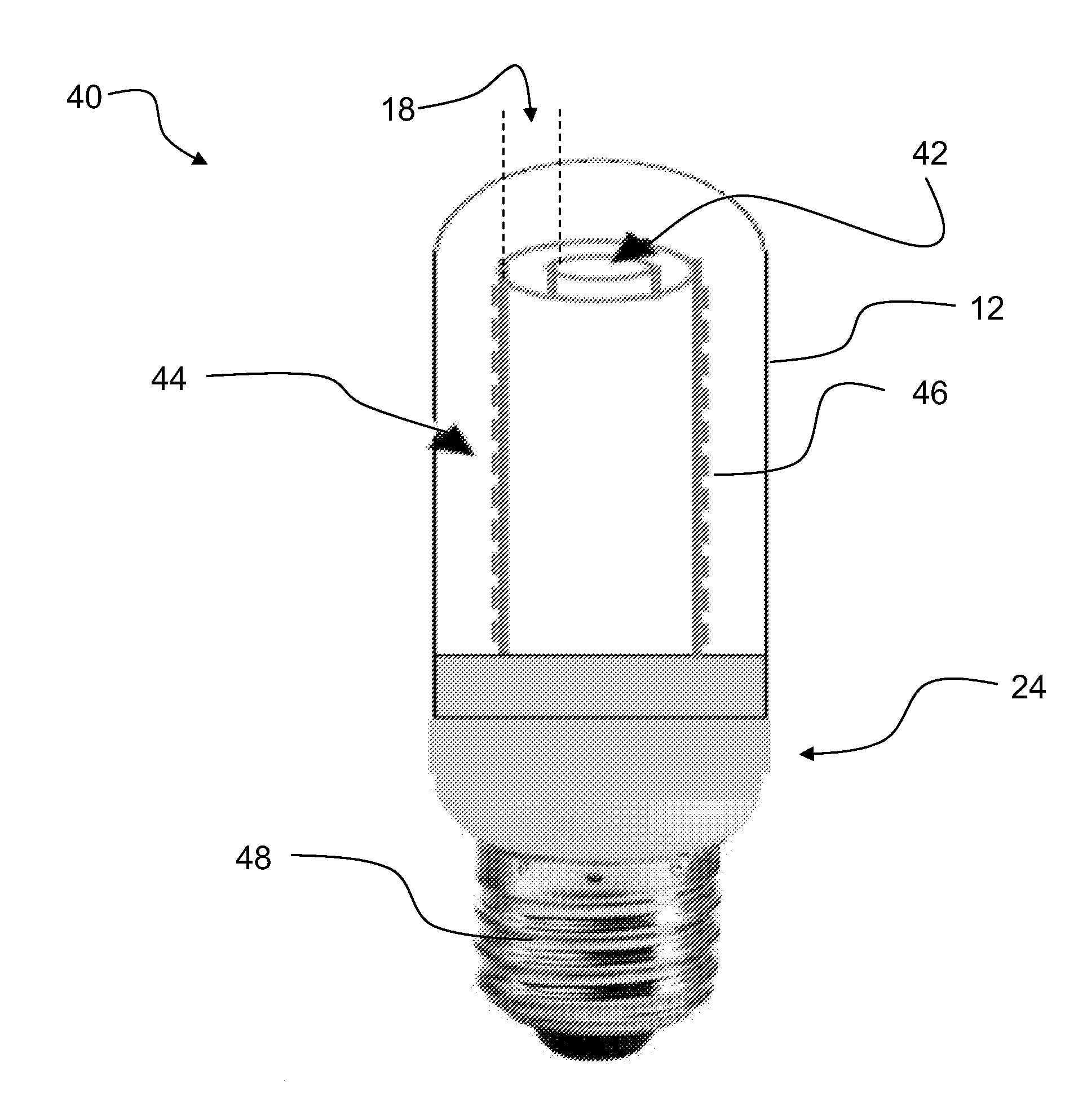

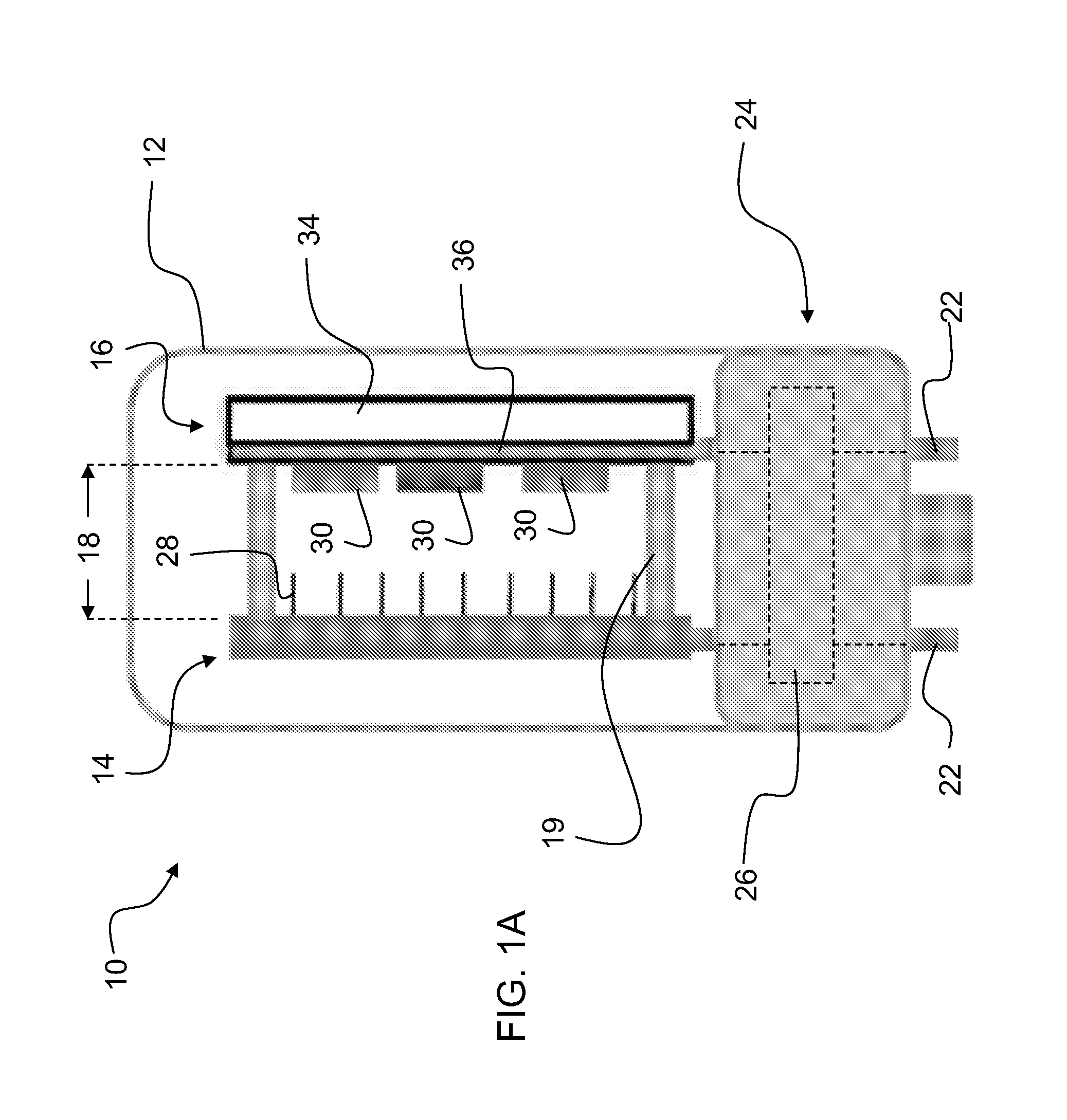

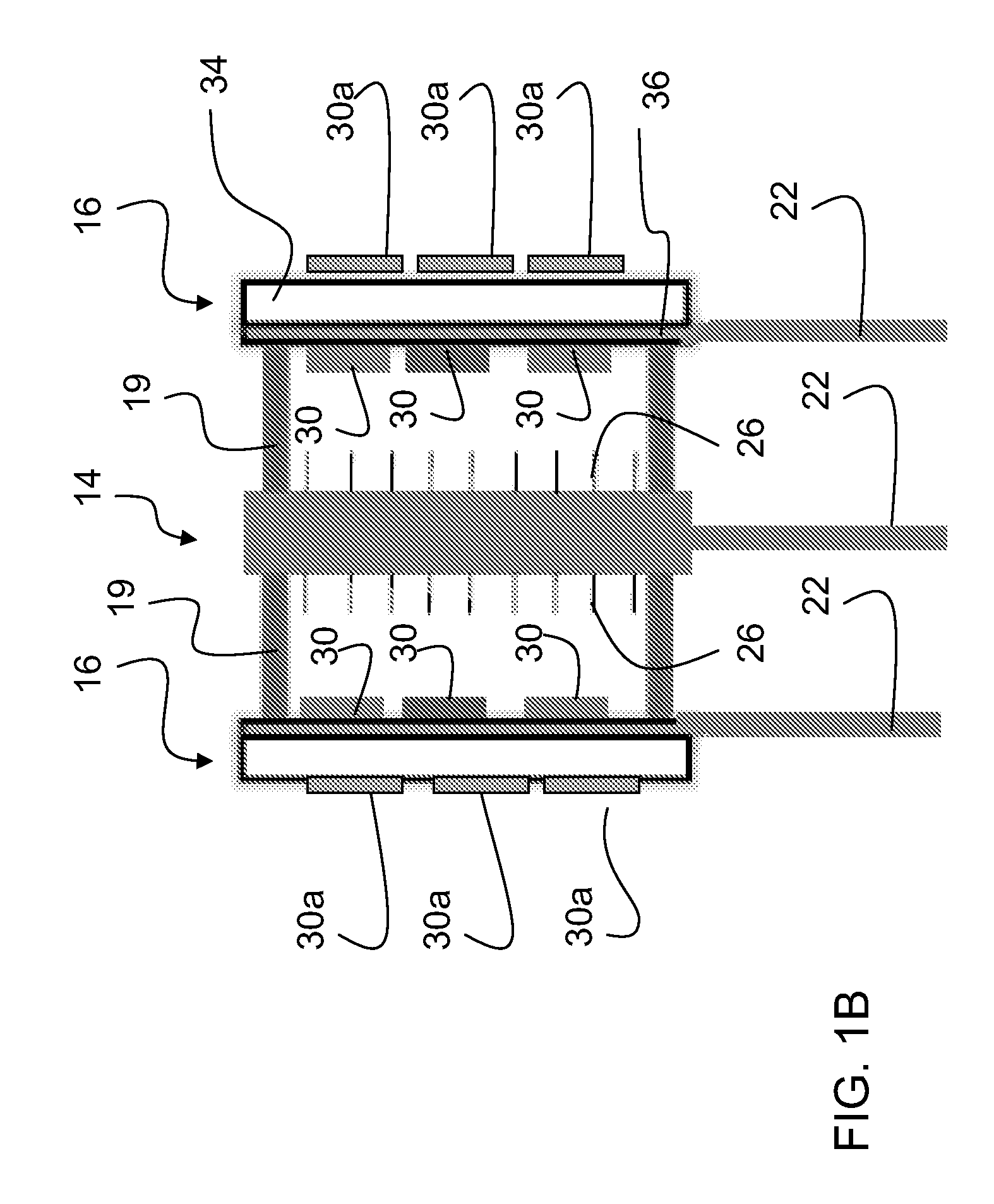

The present invention relates to a nanowire array (15, 16) for electrically-controlled elution of a therapeutic composition (5) comprising a plurality of nanoscopic-sized wires (12, 12), nanowires, attached to an electrically conducting solid support (7), said nanowires formed from electroactive conjugated polymer (4) containing or doped with said therapeutic composition (5) coated over a plurality of nanoscopic sized electrically conducting protrusions (8). It also relates to a method for preparing a nanowire array and an electrode.

Owner:UNIVERSITE CATHOLIQUE DE LOUVAIN

Electron injection nanostructured semiconductor material anode electroluminescence method and device

ActiveUS20110297846A1Lower operating temperatureAccelerate emissionsElectroluminescent light sourcesPhotometryPhoton emissionSemiconductor materials

Embodiments of the invention include methods and devices for producing light by injecting electrons from field emission cathode across a gap into nanostructured semiconductor materials, electrons issue from a separate field emitter cathode and are accelerated by a voltage across a gap towards the surface of the nanostructured material that forms part of the anode. At the nanostructure material, the electrons undergo electron-hole (e-h) recombination resulting in electroluminescent (EL) emission. In a preferred embodiment lighting device, a vacuum enclosure houses a field emitter cathode. The vacuum enclosure also houses an anode that is separated by a gap from said cathode and disposed to receive electrons emitted from the cathode. The anode includes semiconductor light emitting nano structures that accept injection of electrons from the cathode and generate photons in response to the injection of electrons. External electrode contacts permit application of a voltage differential across the anode and cathode to stimulate electron emissions from the cathode and resultant photon emissions from the semiconductor light emitting nanostructures of the anode. Embodiments of the invention also include the usage of nanostructured semiconductor materials as phosphors for conventional planar LED and nanowire array light emitting diodes and CFL. For the use in conventional planar LEDs, the nanostructures may take the form of quantum dots, nanotubes, branched tree-like nanostructure, nanoflower, tetrapods, tripods, axial heterostructures nanowires hetero structures.

Owner:RGT UNIV OF CALIFORNIA

Carbon-based composite electrode material and preparation method thereof, and application of the carbon-based composite electrode material to super capacitor

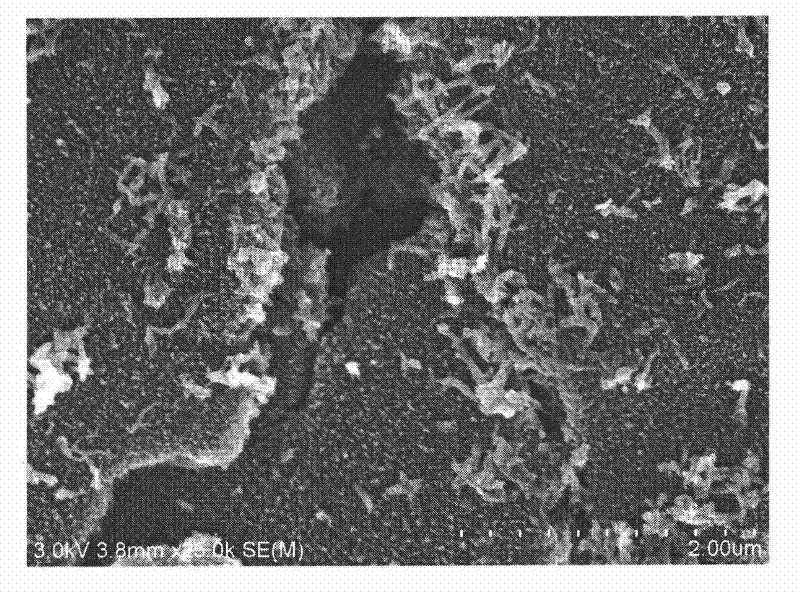

InactiveCN102222565ALarge specific surface areaLower internal resistanceElectrolytic capacitorsCapacitanceNano structuring

The invention relates to a carbon-based composite electrode material and a preparation method thereof, and application of the carbon-based composite electrode material to a super capacitor. The electrode material contains a conductive polymer and a carbon-based material. The conductive polymer is attached to a surface of the carbon-based material in a manner of a nanowire array of a conductive polymer, wherein the arrangement of the nanowire array of the conductive polymer is in a good order; besides, a diameter of the nanowire of the nanowire array of the conductive polymer is 40 to 100 nm and a length of the nanowire is 100 to 1500 nm. The carbon-based composite electrode material provide in the invention has a large specific surface area, so that an active area of a conductive polymer is substantially improved and thus high capacitance can be obtained; besides, the carbon-based composite electrode material provide in the invention has a highly ordered nano structure, so that a transmission path of an electrolyte ion is reduced and an internal resistance of an electrode is also reduced; therefore, the ion in an electrode material can be diffused and transmitted conveniently, and thus high power density can be obtained.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Arrays of long nanostructures in semiconductor materials and methods thereof

InactiveUS20120295074A1Material nanotechnologyThermoelectric device manufacture/treatmentSemiconductor materialsEngineering

Owner:ALPHABET ENERGY +1

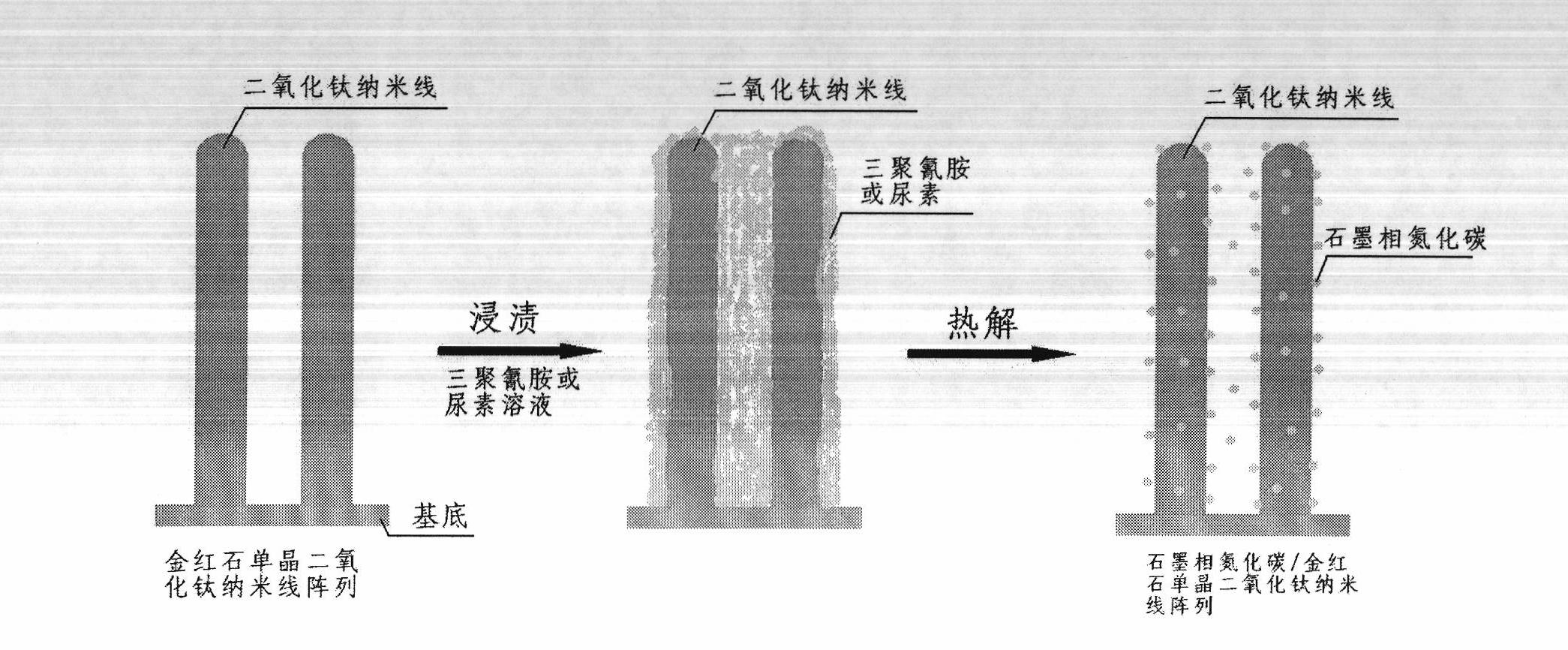

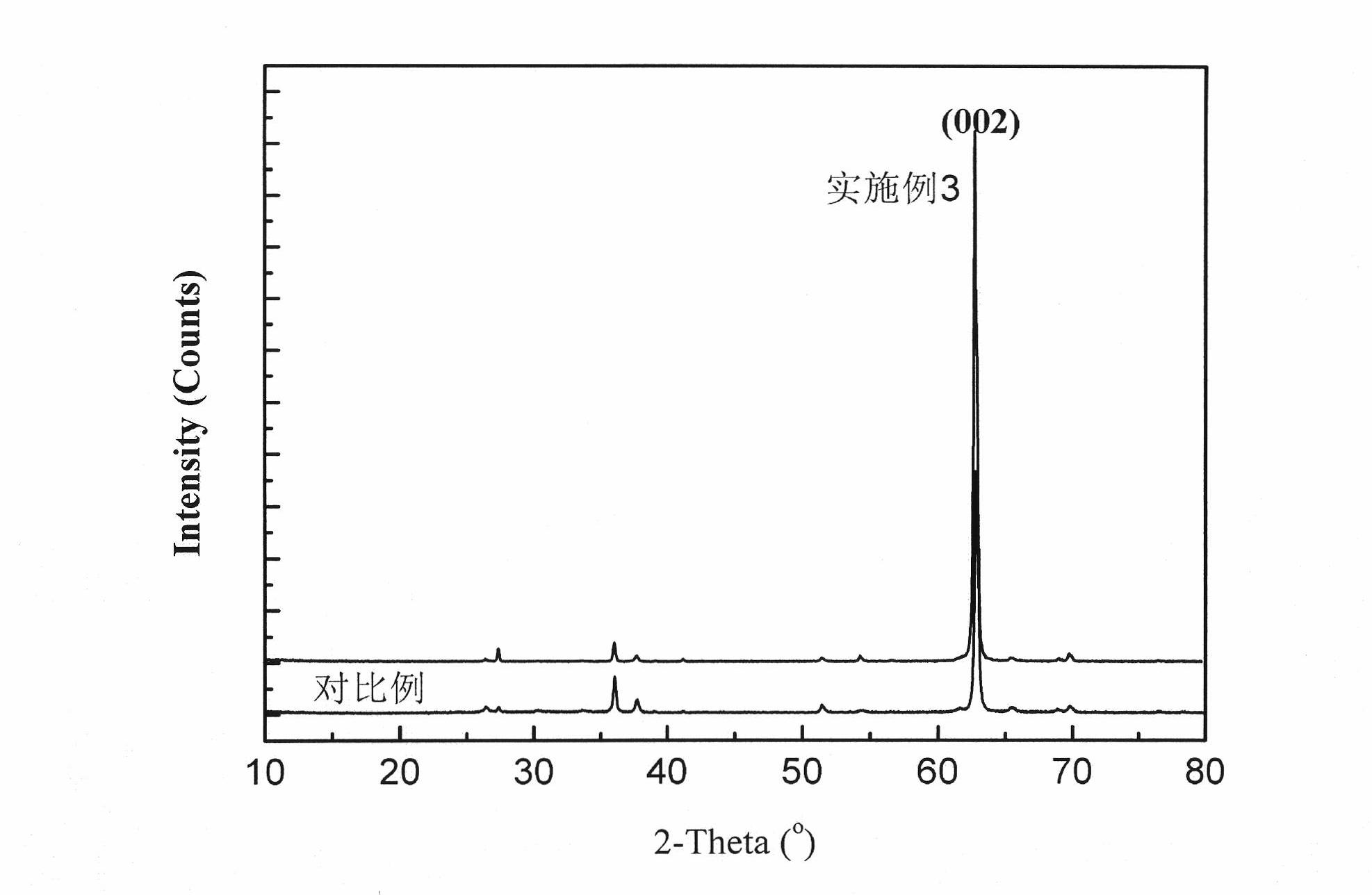

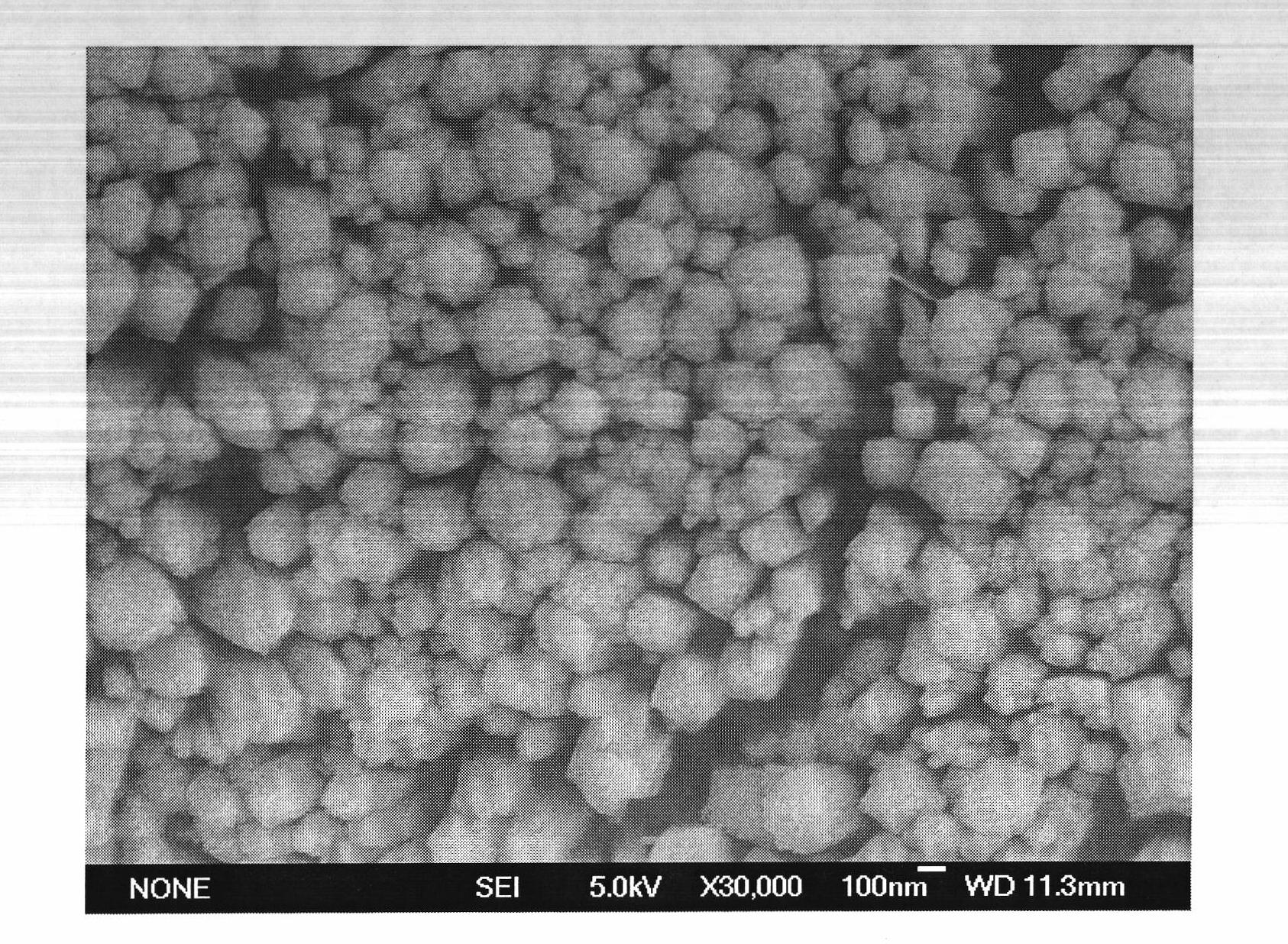

Preparation method of graphite phase carbon nitride/rutile monocrystal titanium dioxide (TiO2) nanowire array

InactiveCN102125863ALow costEasy to useCatalyst activation/preparationSingle crystalCyanamide compound

The invention discloses a preparation method of a graphite phase carbon nitride / rutile monocrystal titanium dioxide (TiO2) nanowire array. The preparation method is characterized by comprising the following steps: (a) dissolving a cyanamide compound or urea in a solution, immersing the prepared rutile monocrystal TiO2 nanowire array into the obtained cyanamide compound or urea solution, and then taking out and drying the nanowire array; and (b) performing heat treatment on the dried nanowire array to finally obtain the graphite phase carbon nitride / rutile monocrystal TiO2 nanowire array. The preparation method has the advantages of simple process and low cost, thus being applicable to large-scale industrial production; and the prepared graphite phase carbon nitride / rutile monocrystal TiO2 nanowire array has good visible light response activity, and can be widely applied to the fields such as photocatalysis, hydrogen production by photocatalytic decomposition of water, photoelectric conversion and the like.

Owner:XIANGTAN UNIV

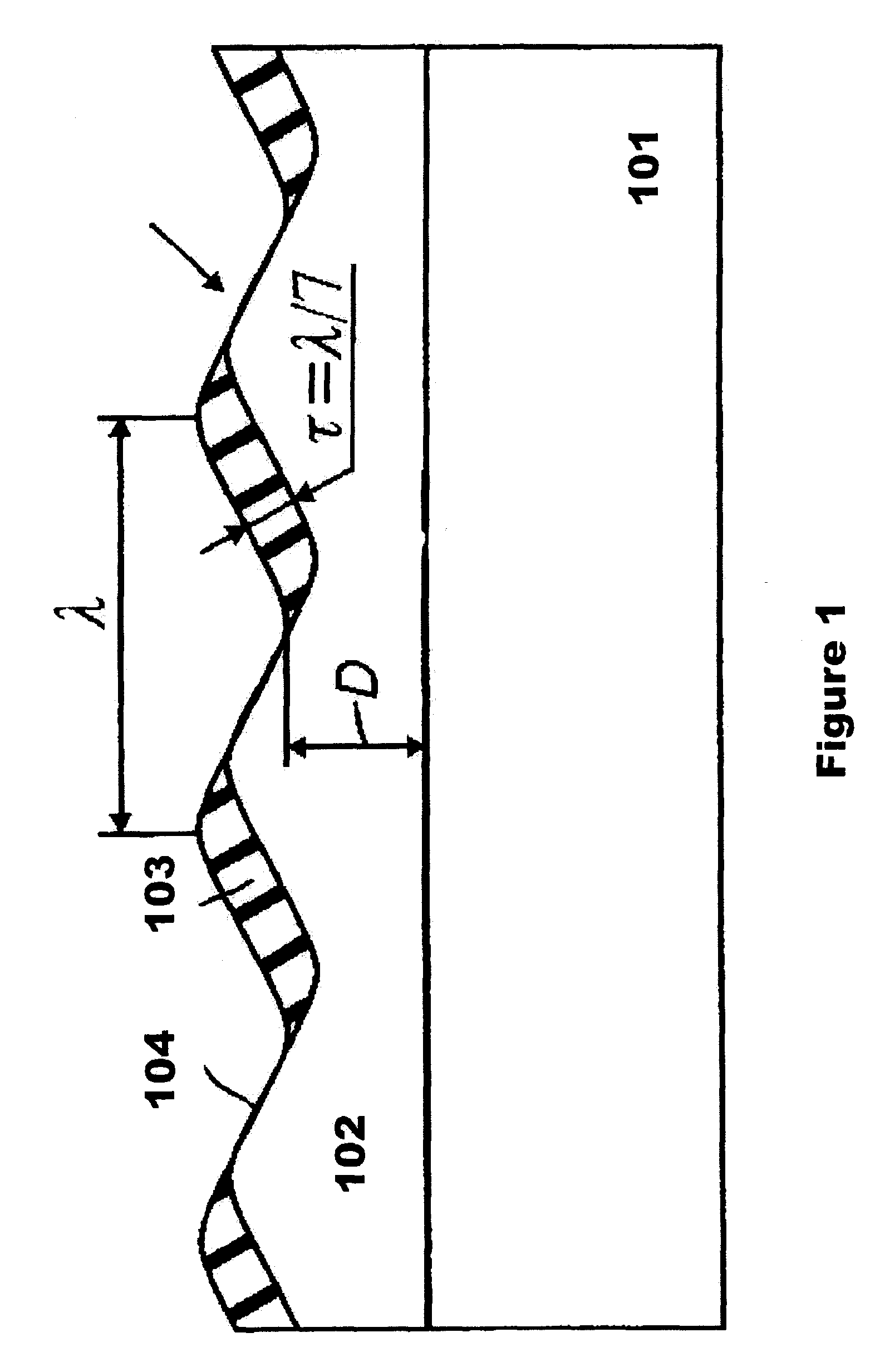

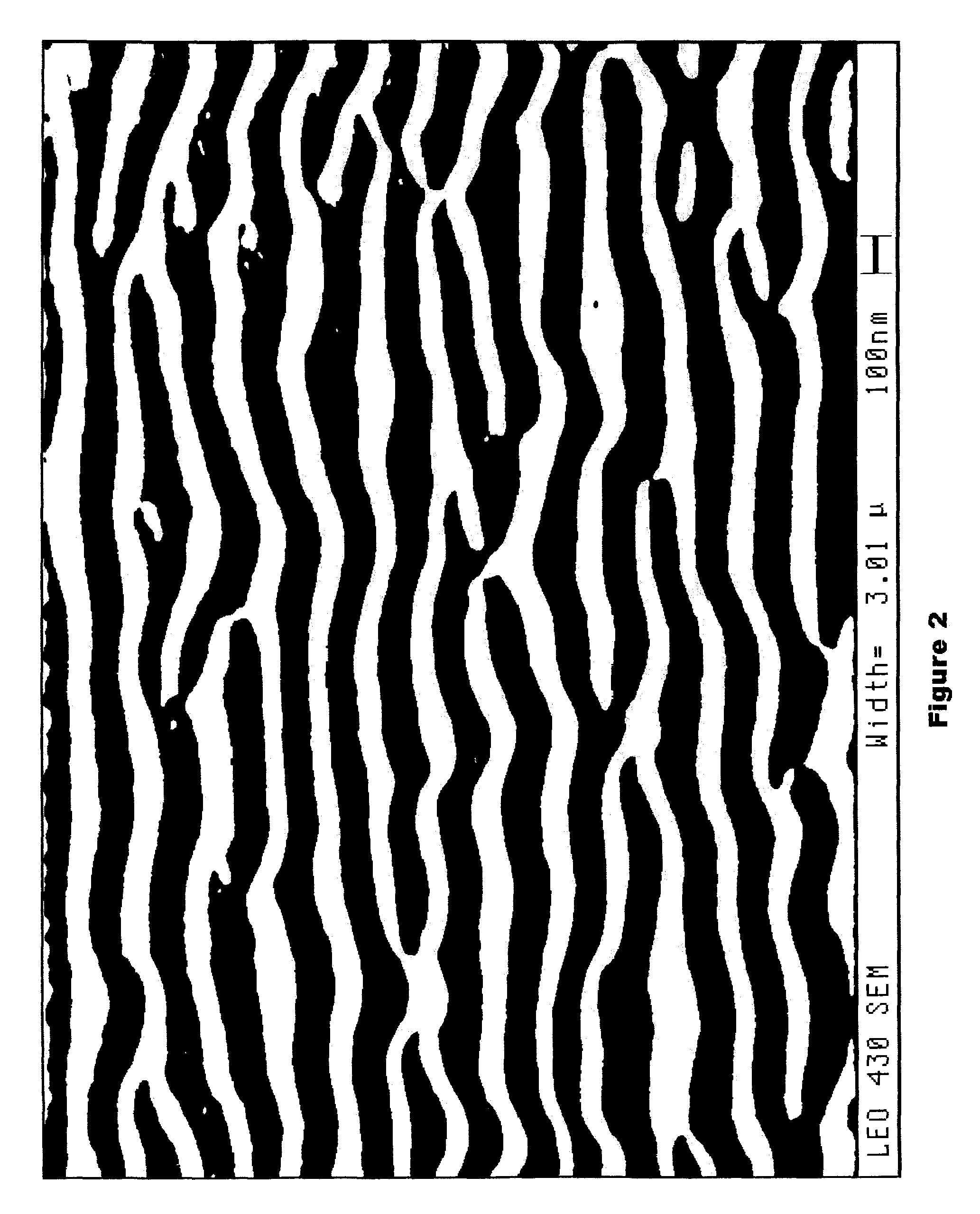

Polarizer based on a nanowire grid

The preferred embodiment provides for development and use of an array of nanowires with a period smaller then 150 nm for applications such as an optical polarizer. To manufacture such structures the preferred embodiment employs a hard nanomask. This nanomask includes a substantially periodic array of substantially parallel elongated elements having a wavelike cross-section.

Owner:WOSTEC

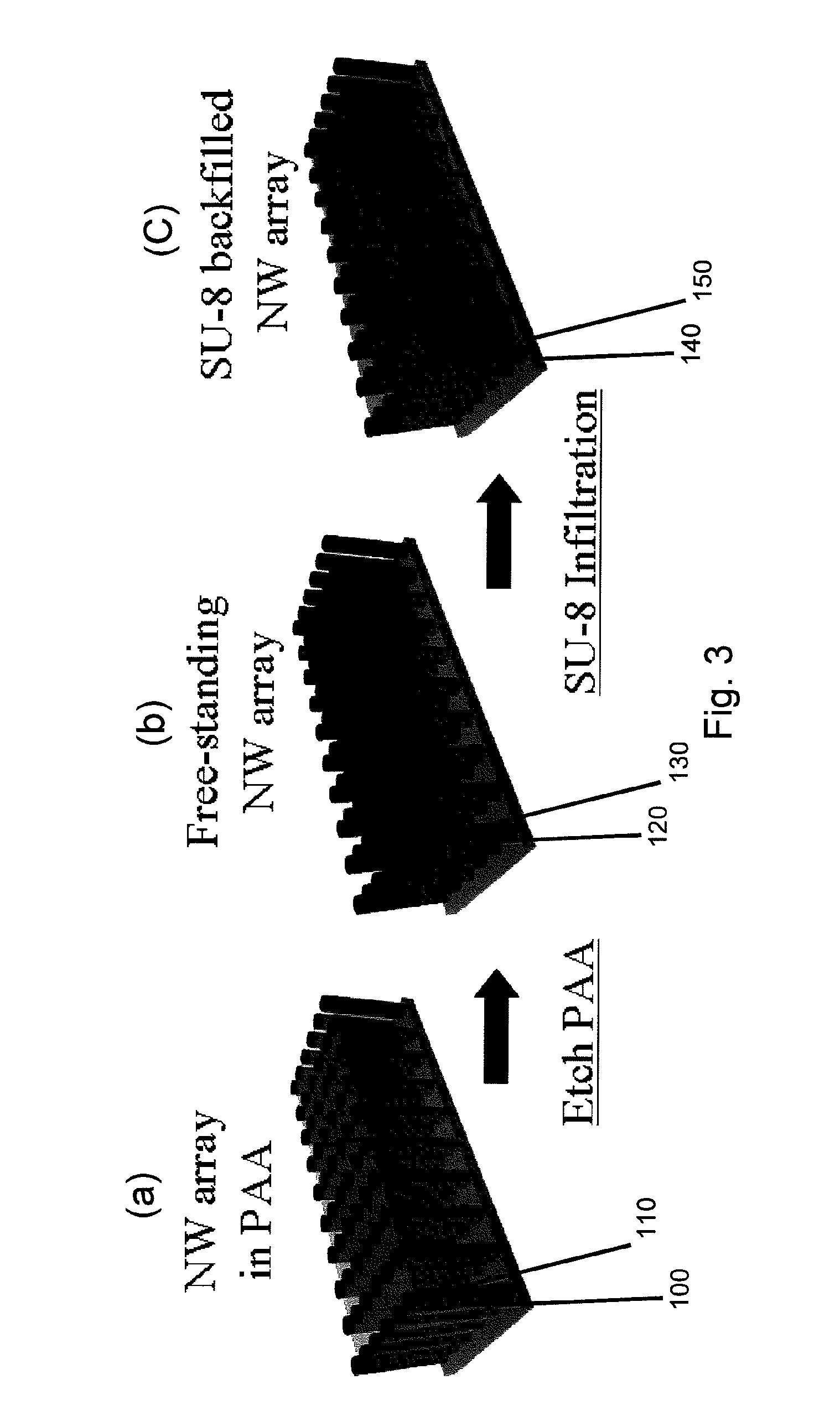

Fabrication of nanowire array composites for thermoelectric power generators and microcoolers

InactiveUS20090214848A1Low thermal conductivityAnodisationThermoelectric device manufacture/treatmentNanowire arrayMaximum temperature

Methods for fabricating a nanowire array epoxy composite with high structural integrity and low effective thermal conductivity to achieve a power conversion efficiency goal of approximately 20% and power density of about 104 W / m2 with a maximum temperature below about 380° C. Further, a method includes fabricating a self-supporting thick 3-D interconnected nanowire array with high structural integrity and low effective thermal conductivity to achieve a power conversion efficiency goal of 20% and power density of about 104 W / m2 with a maximum temperature of about 700° C., the nanowire array having substantially only air between nanowires.

Owner:PURDUE RES FOUND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com