Patents

Literature

170results about How to "Sufficient adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

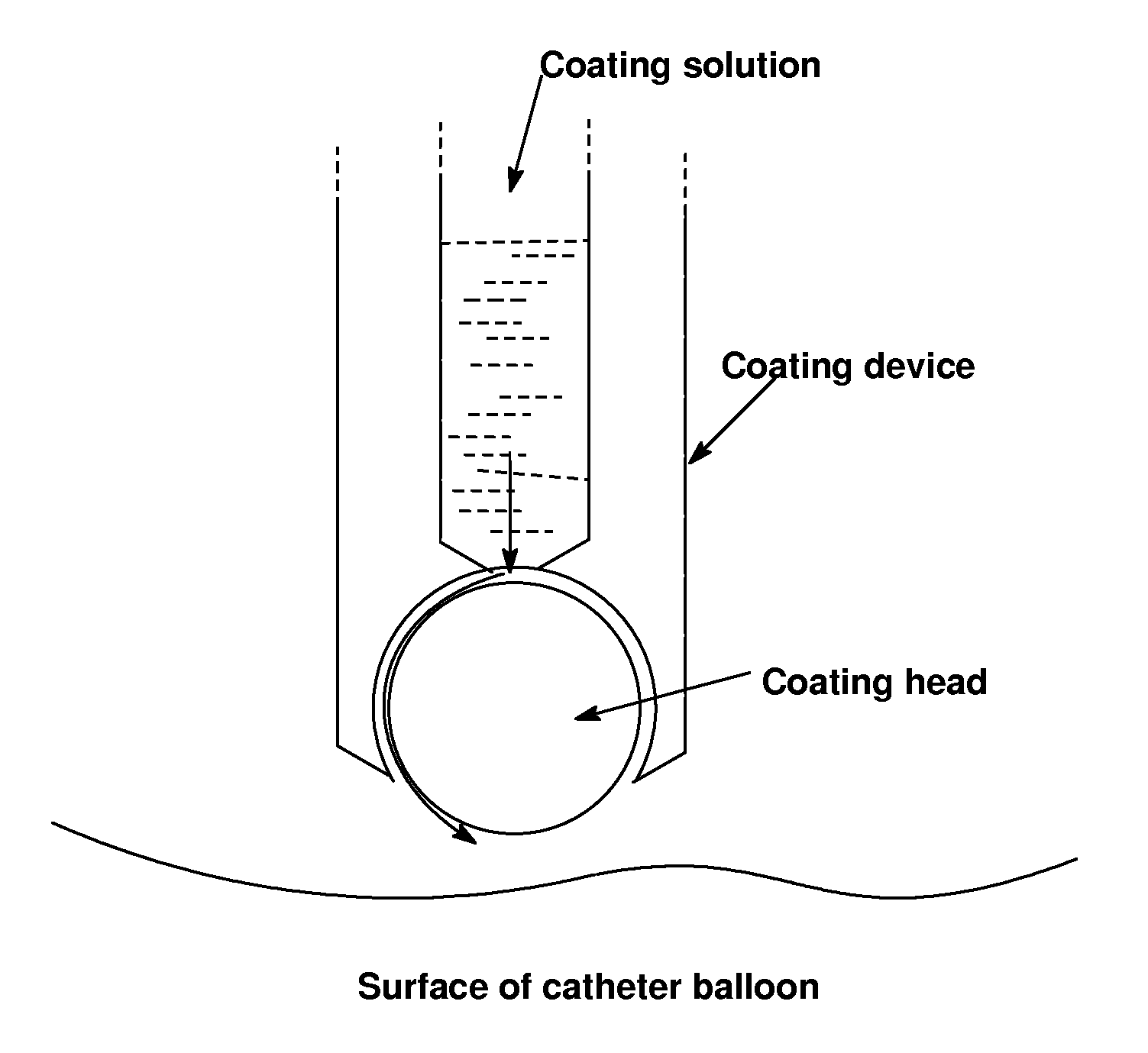

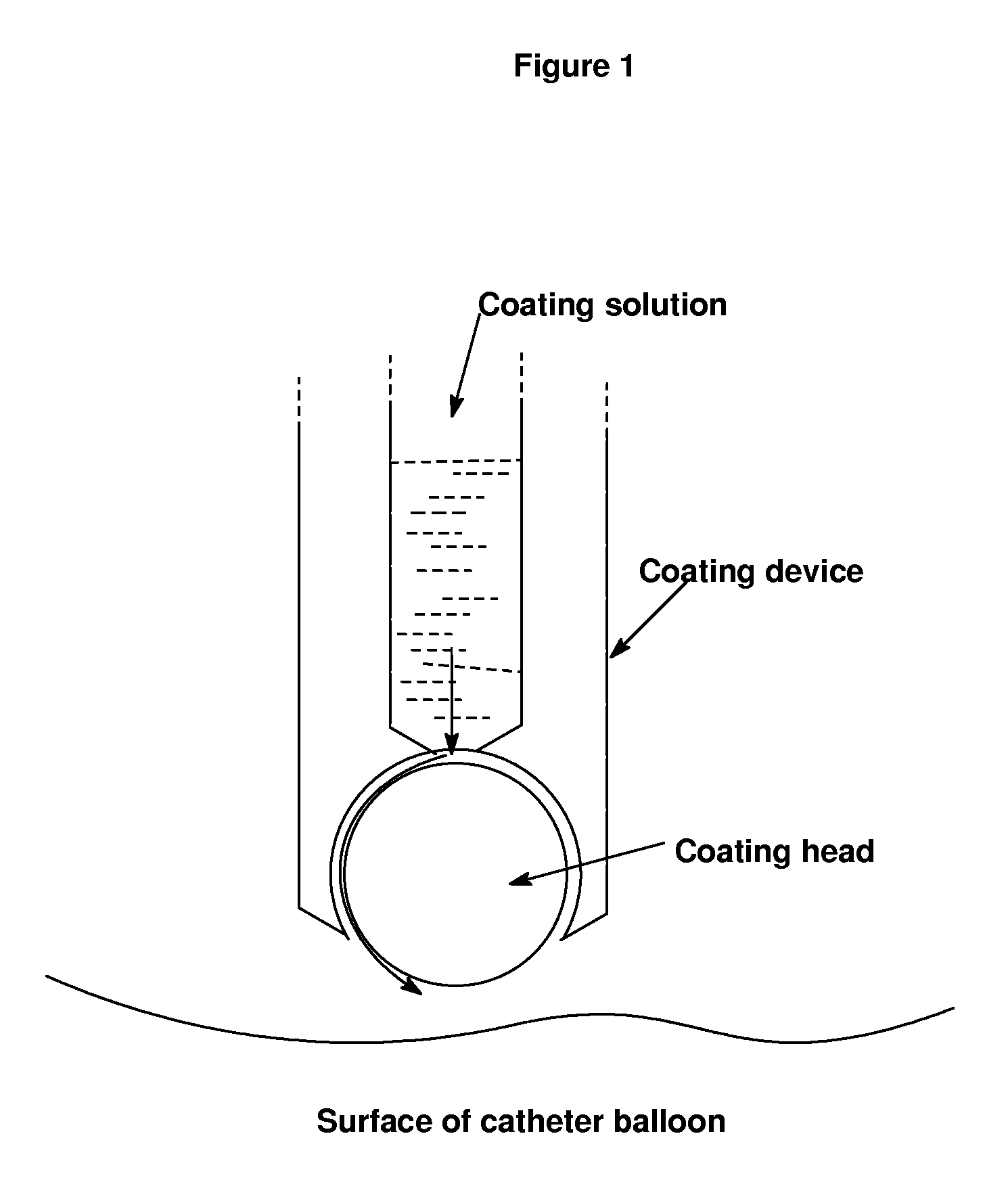

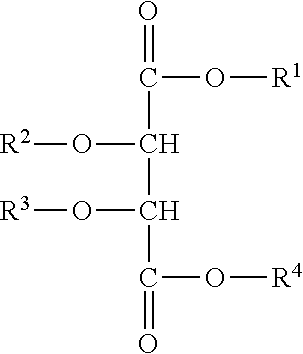

Use of compositions to coat catheter balloons and coated catheter balloons

InactiveUS20120316496A1Solve the lack of adhesionEasy transferStentsBalloon catheterBiological bodyMedical product

The present invention is related to dilatable medical products having short-term contact with the organism, as e.g. balloon catheters coated with at least one layer of at least one antiproliferative, immunosuppressive, anti-angiogenic, anti-inflammatory, fungicidal and / or anti-thrombotic agent and a transport mediator or a mixture of transport mediators, methods for coating of these coated dilatable medical products and the use of compositions for this coating.

Owner:HEMOTEQ AG

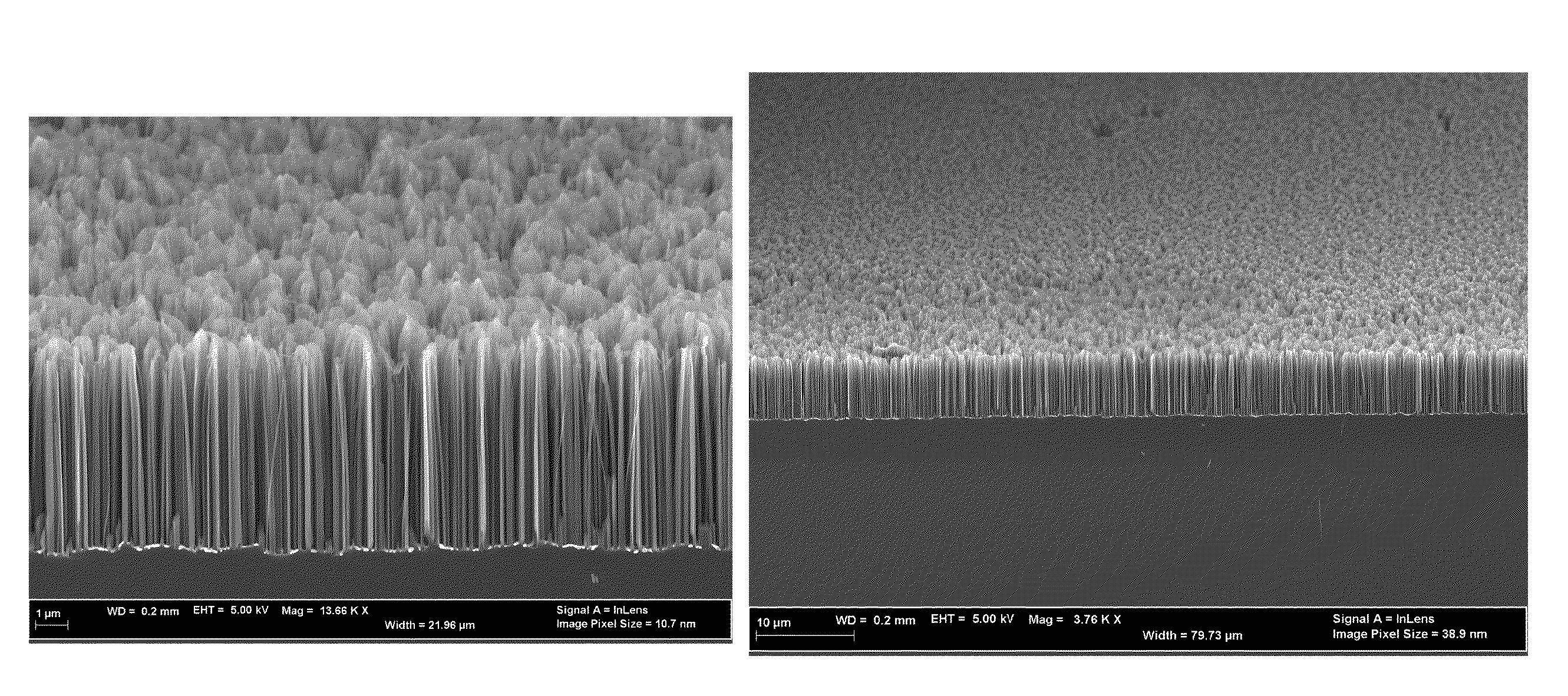

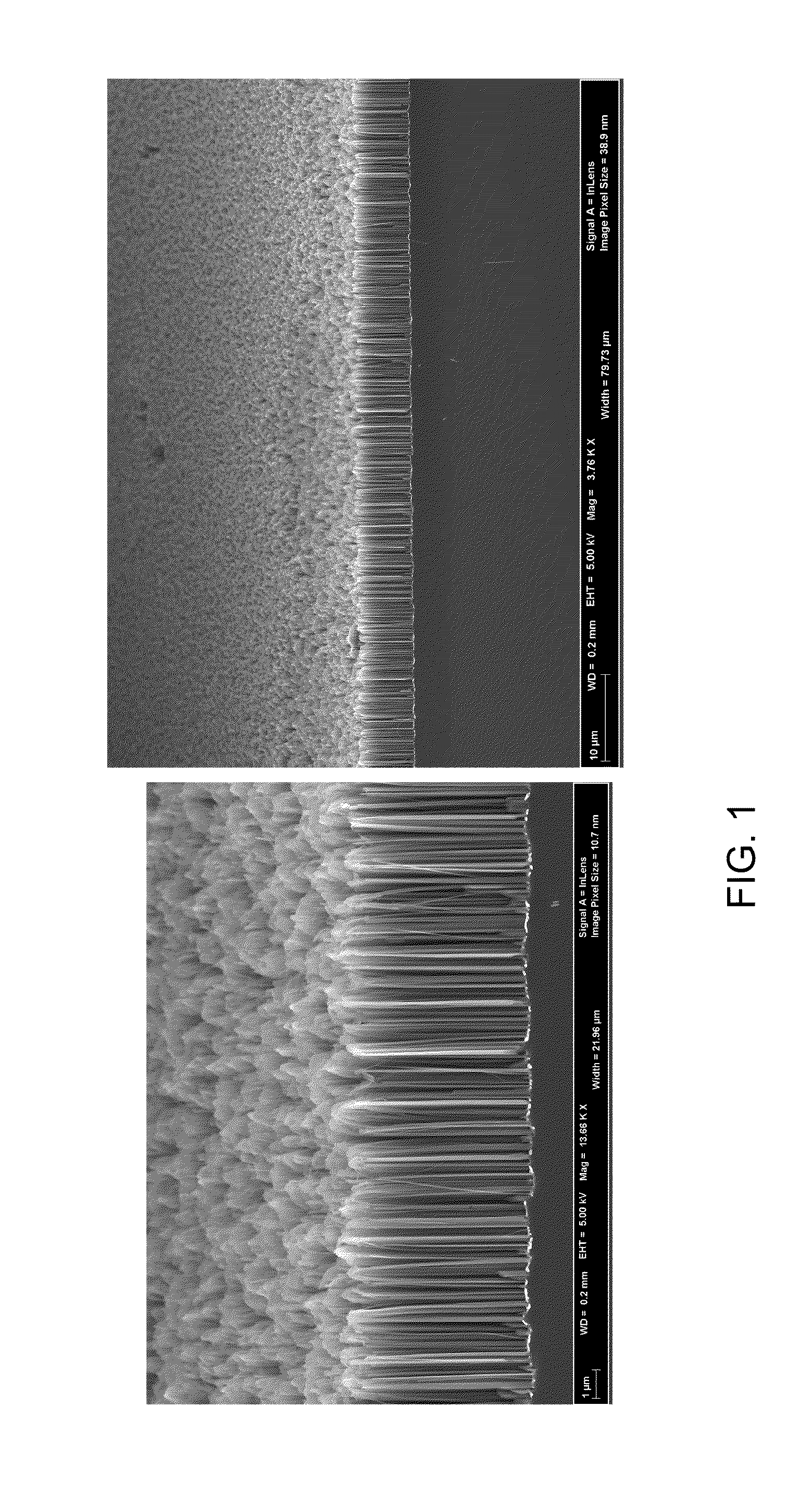

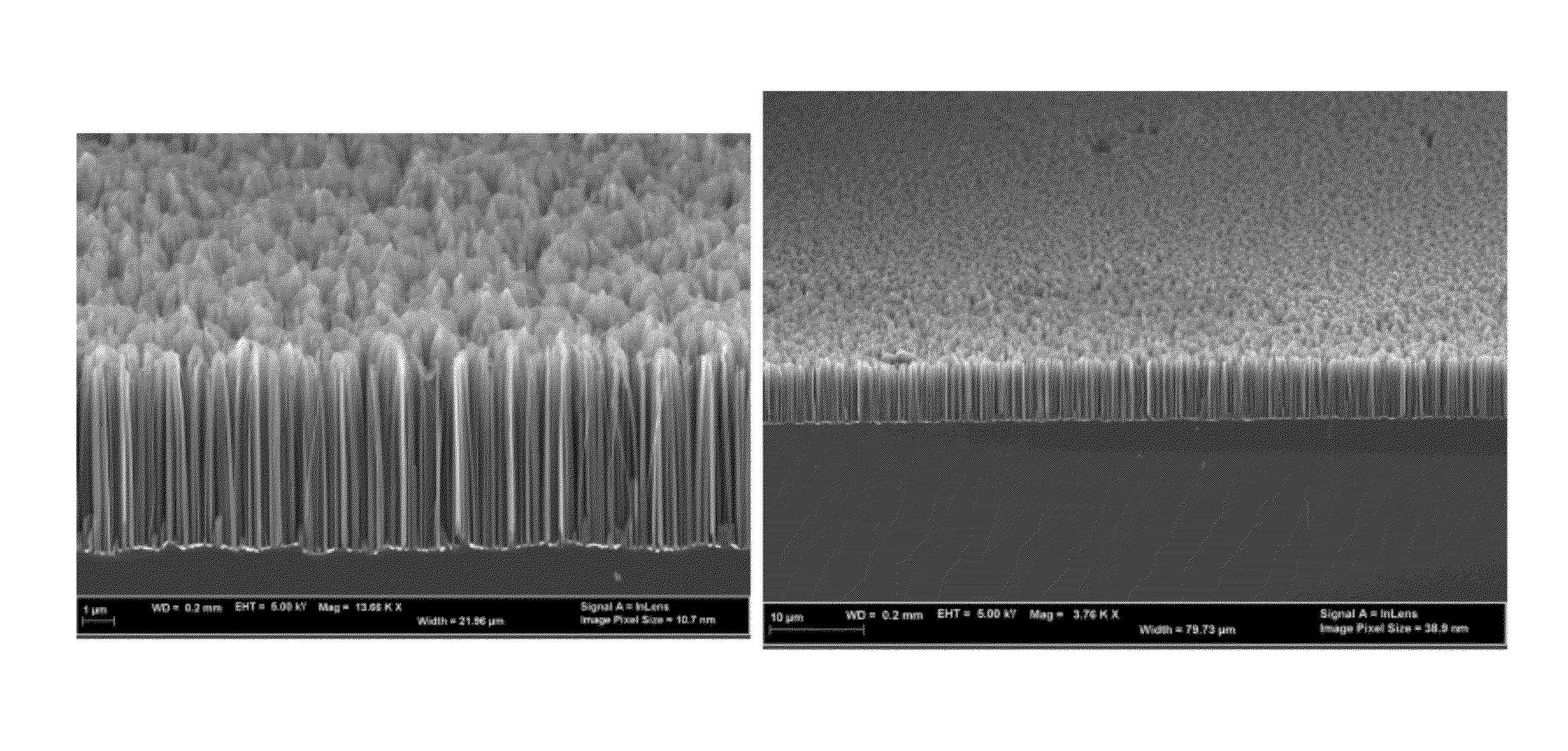

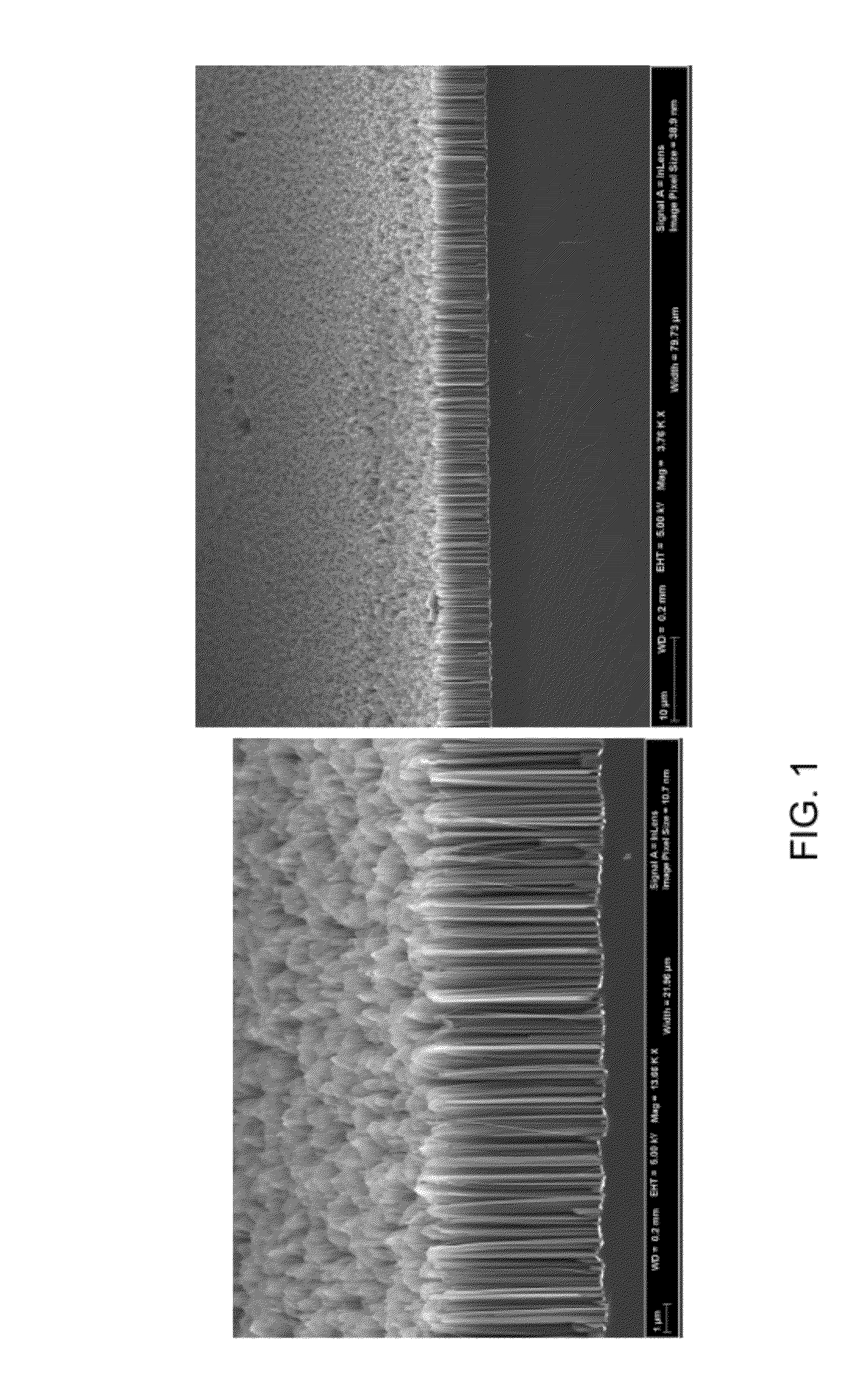

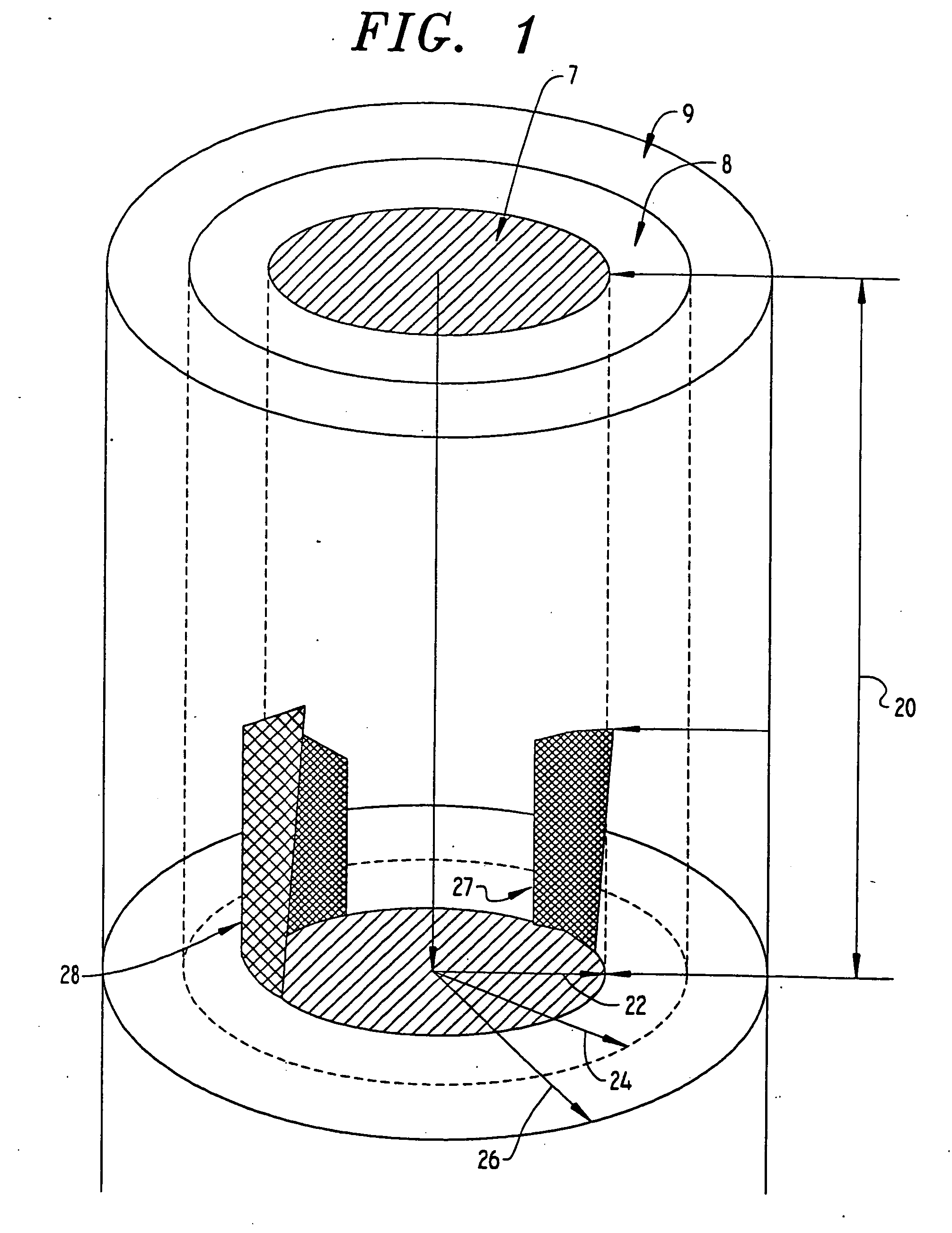

Process for Fabricating Nanowire Arrays

ActiveUS20090256134A1Sufficient adhesionMaterial nanotechnologyOther chemical processesNanoparticleNanowire array

A process is provided for etching a silicon-containing substrate to form nanowire arrays. In this process, one deposits nanoparticles and a metal film onto the substrate in such a way that the metal is present and touches silicon where etching is desired and is blocked from touching silicon or not present elsewhere. One submerges the metallized substrate into an etchant aqueous solution comprising HF and an oxidizing agent. In this way arrays of nanowires with controlled diameter and length are produced.

Owner:ADVANCED SILICON GRP TECH LLC

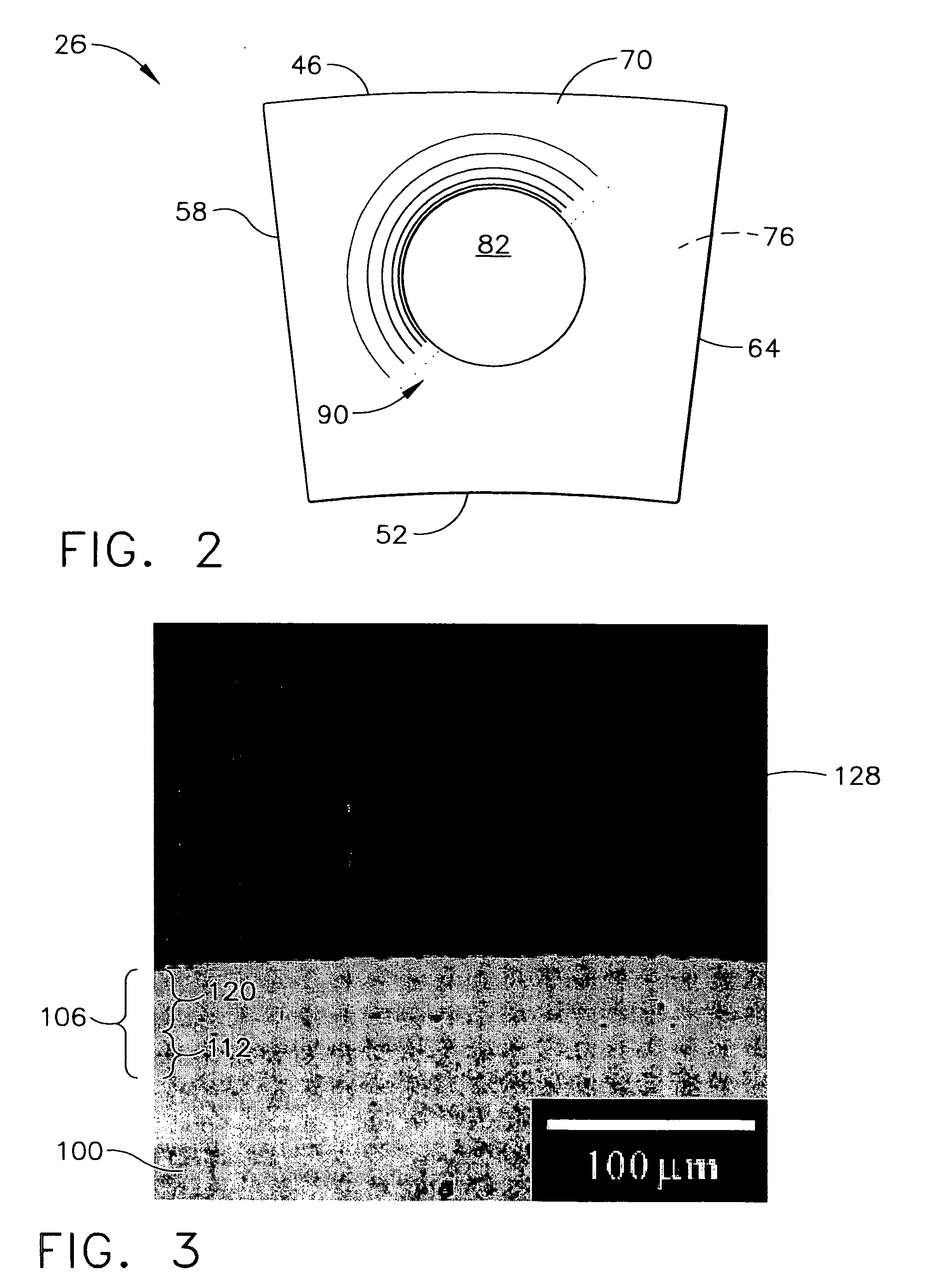

Coatings for Ophthalmic Lens Elements

ActiveUS20090141236A1Sufficient adhesionFacilitate protectionOptical articlesRecord information storageSolventLens plate

The present disclosure provides a method of forming a removable protective coating on a hydrophobic surface of an ophthalmic lens element. The method includes providing an ophthalmic lens element having a hydrophobic surface. A non-aqueous coating composition is applied so as to coat at least part of the hydrophobic surface. The composition includes a film forming coating polymer and a compatible non-aqueous solvent. A substantial portion of the solvent is removed from the composition to form a removable protective coating on the ophthalmic lens element that adheres to the hydrophobic surface. The disclosure also provides a removable protective coating, and an ophthalmic lens element having the coating.

Owner:CARL ZEISS VISION AUSTRALIA HO

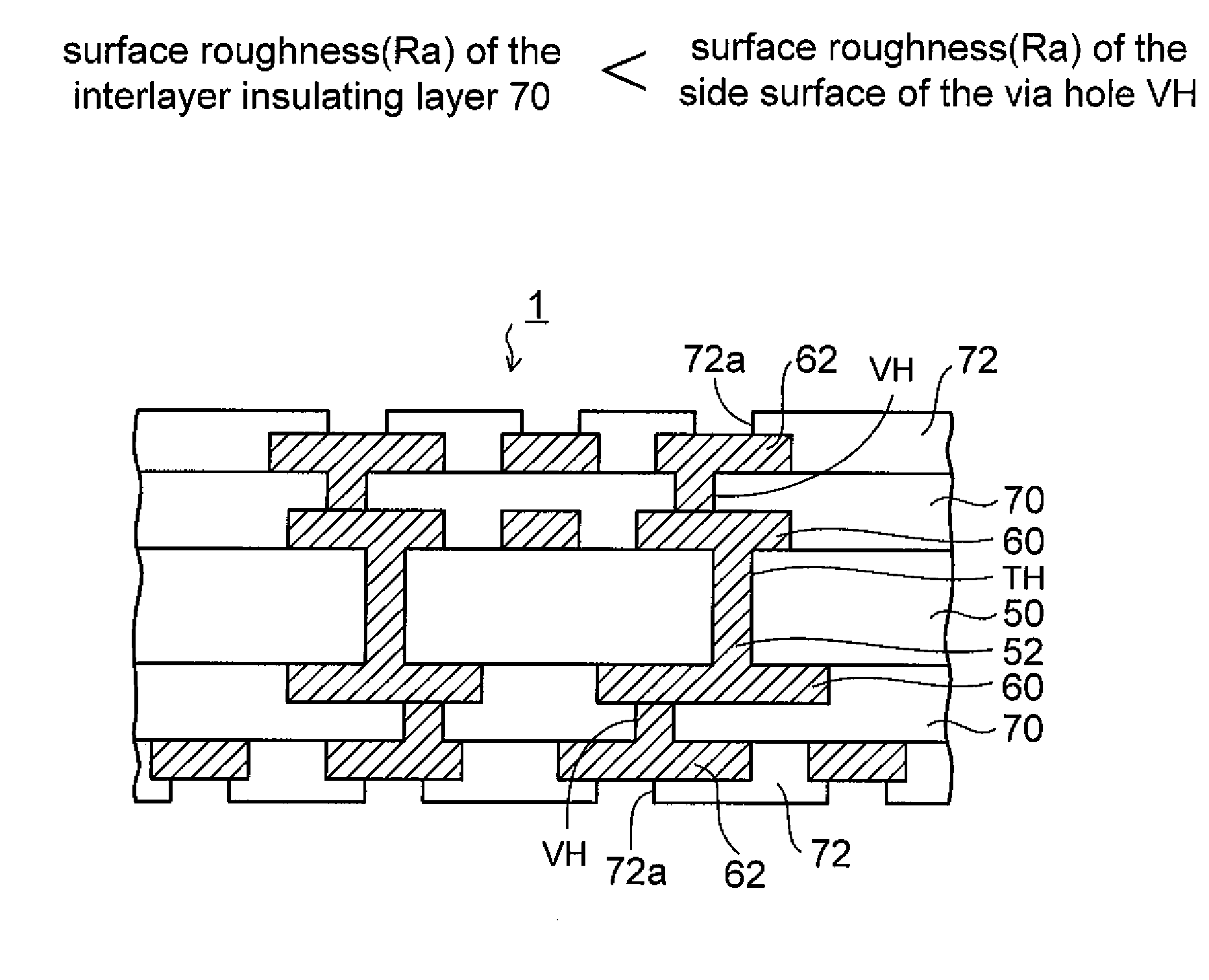

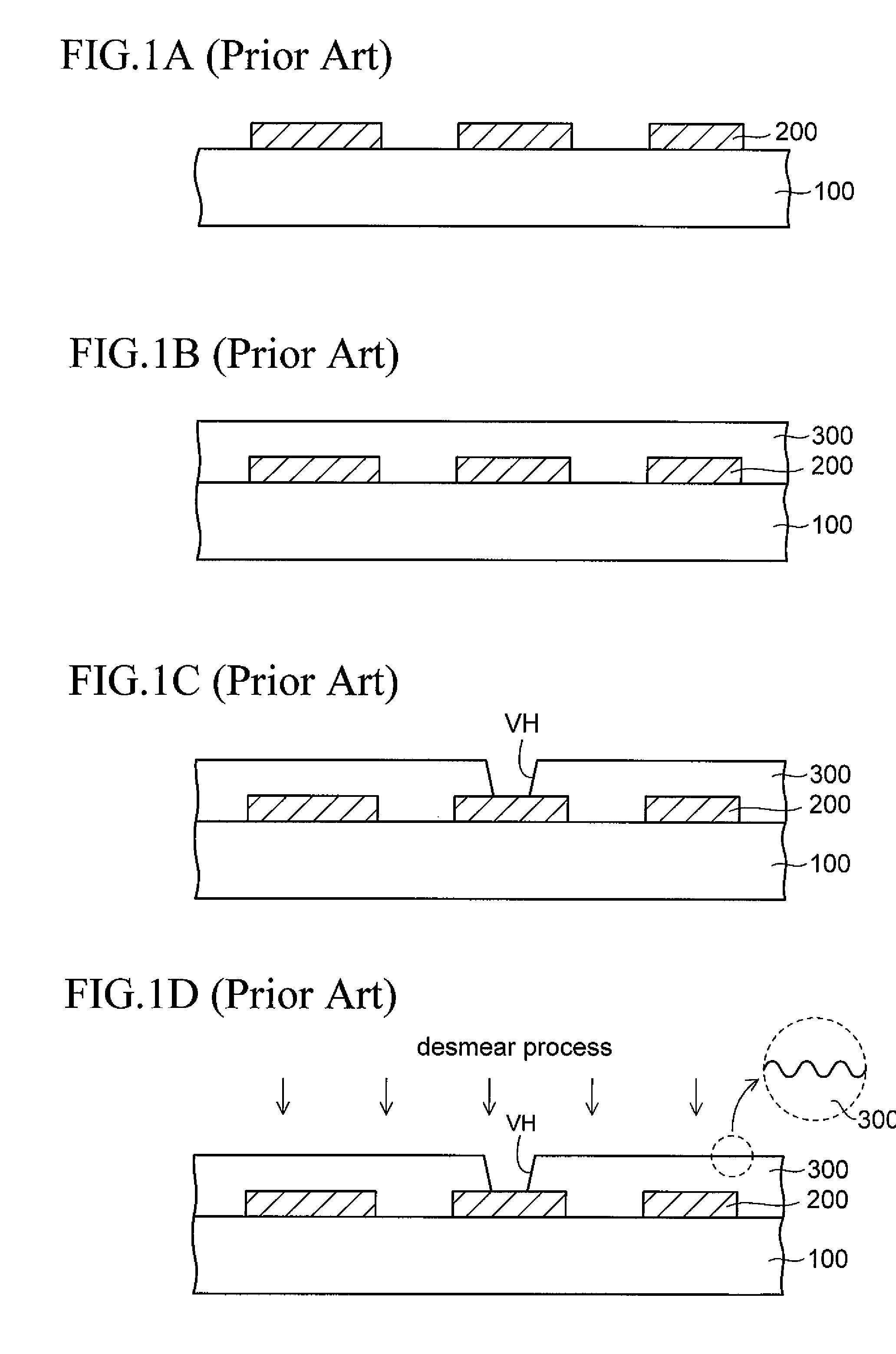

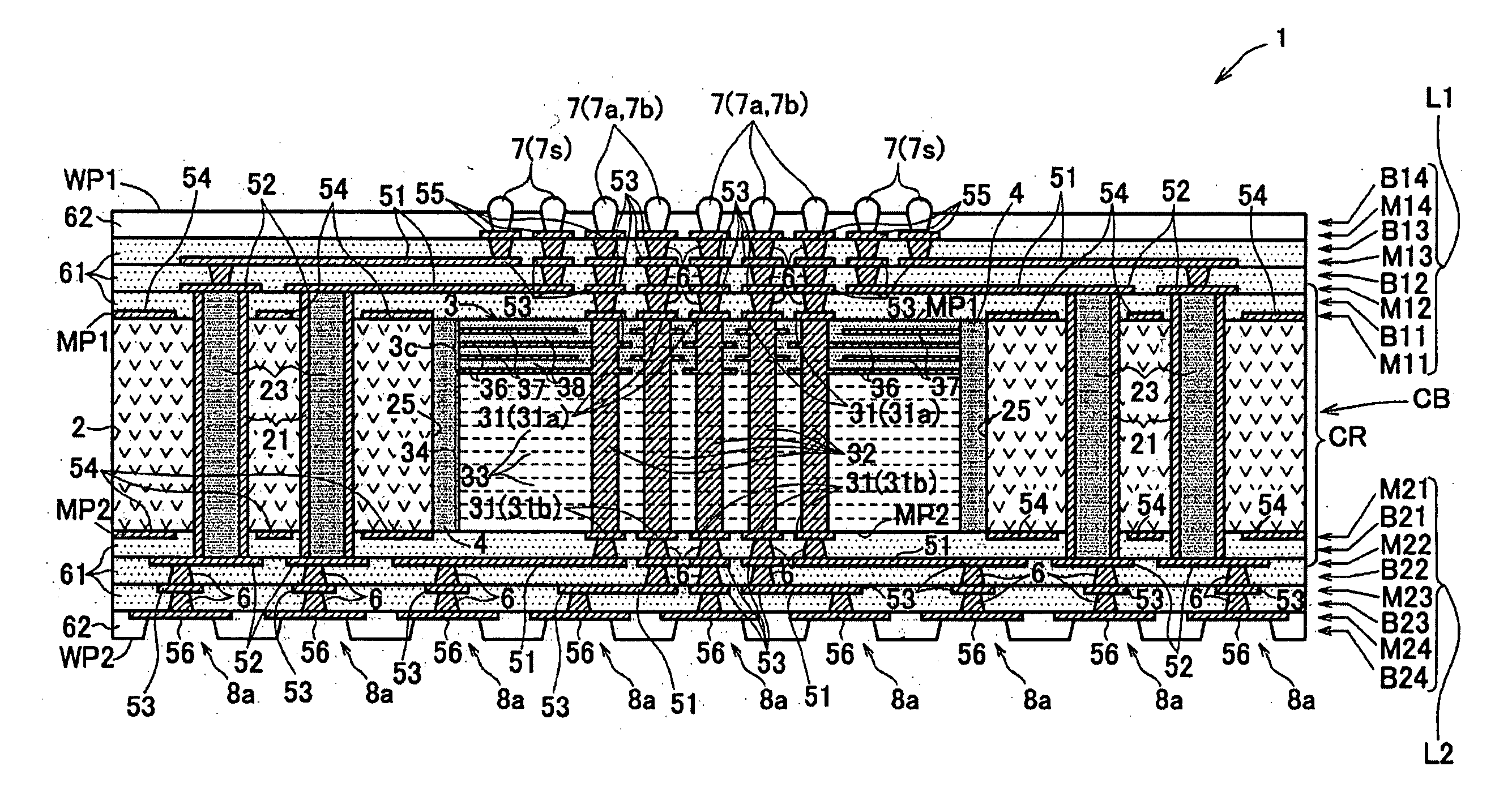

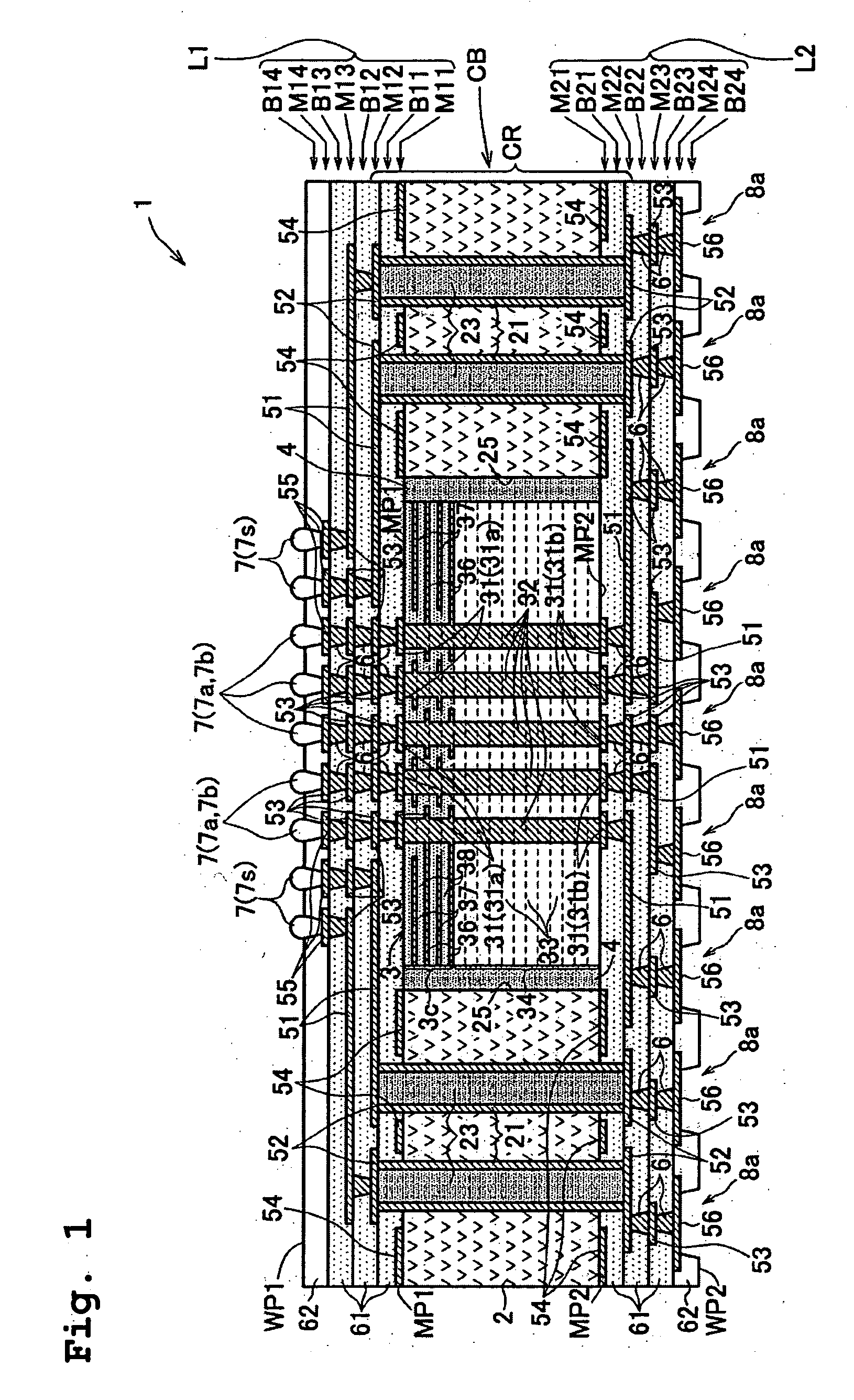

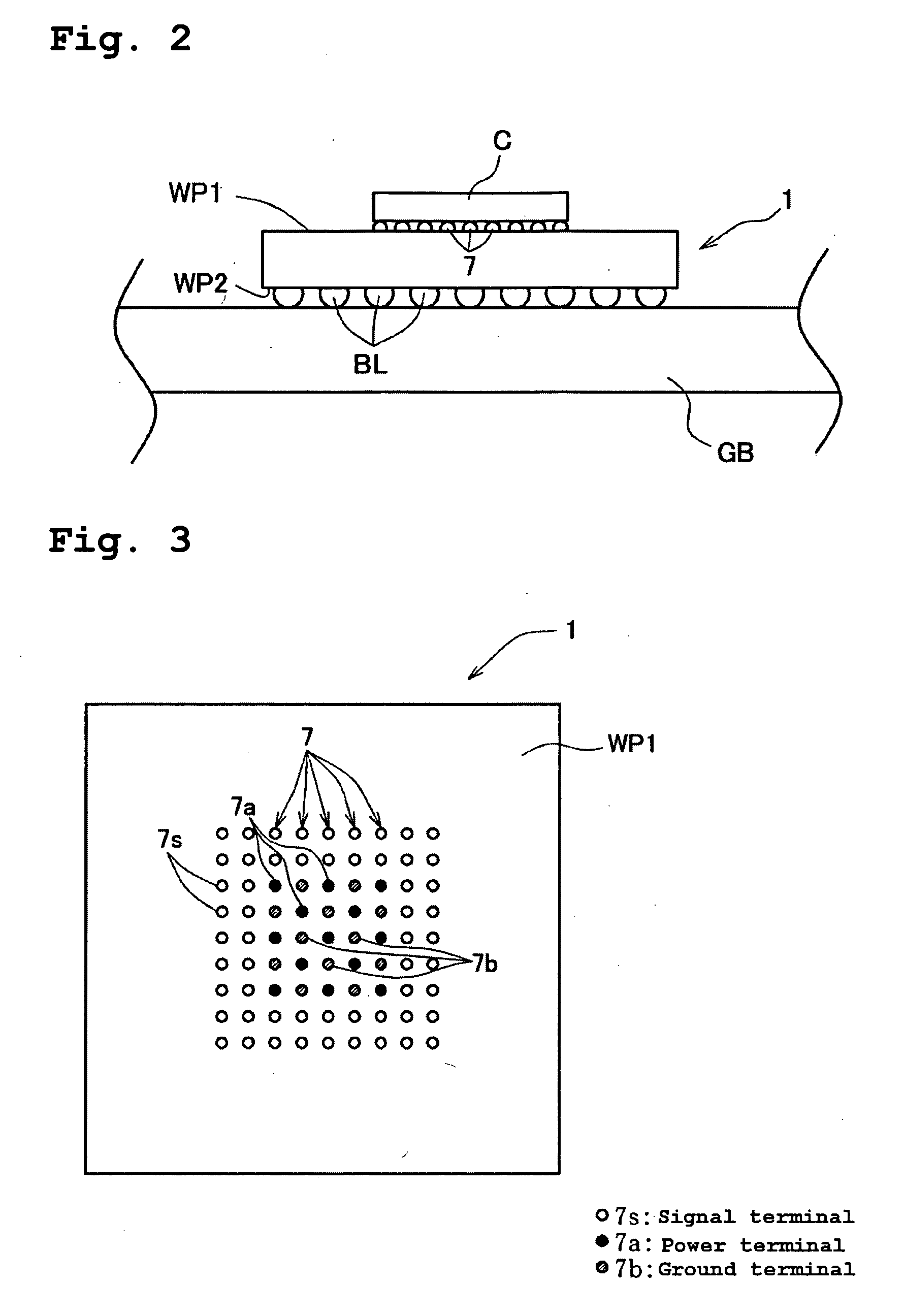

Wiring substrate and method of manufacturing the same

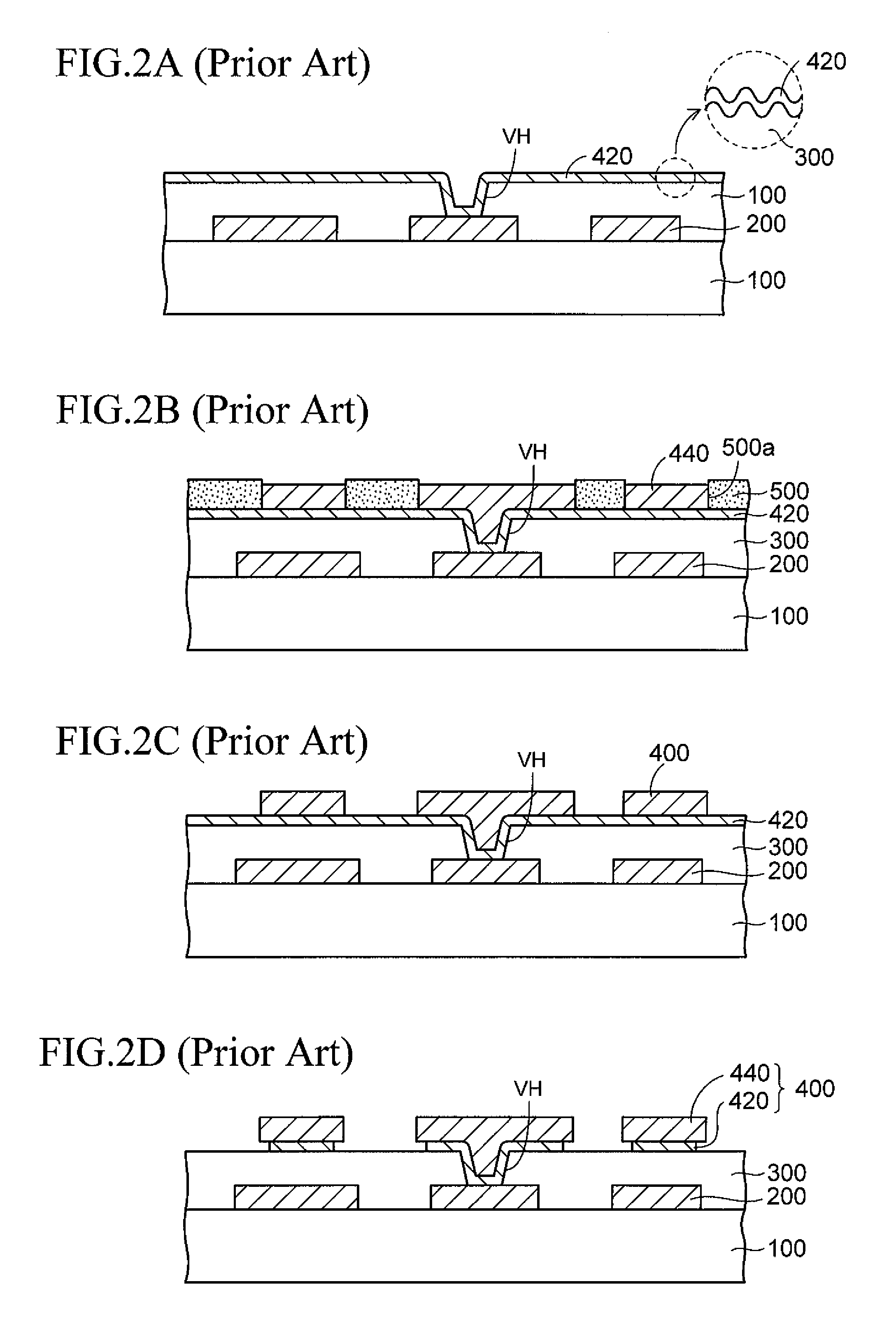

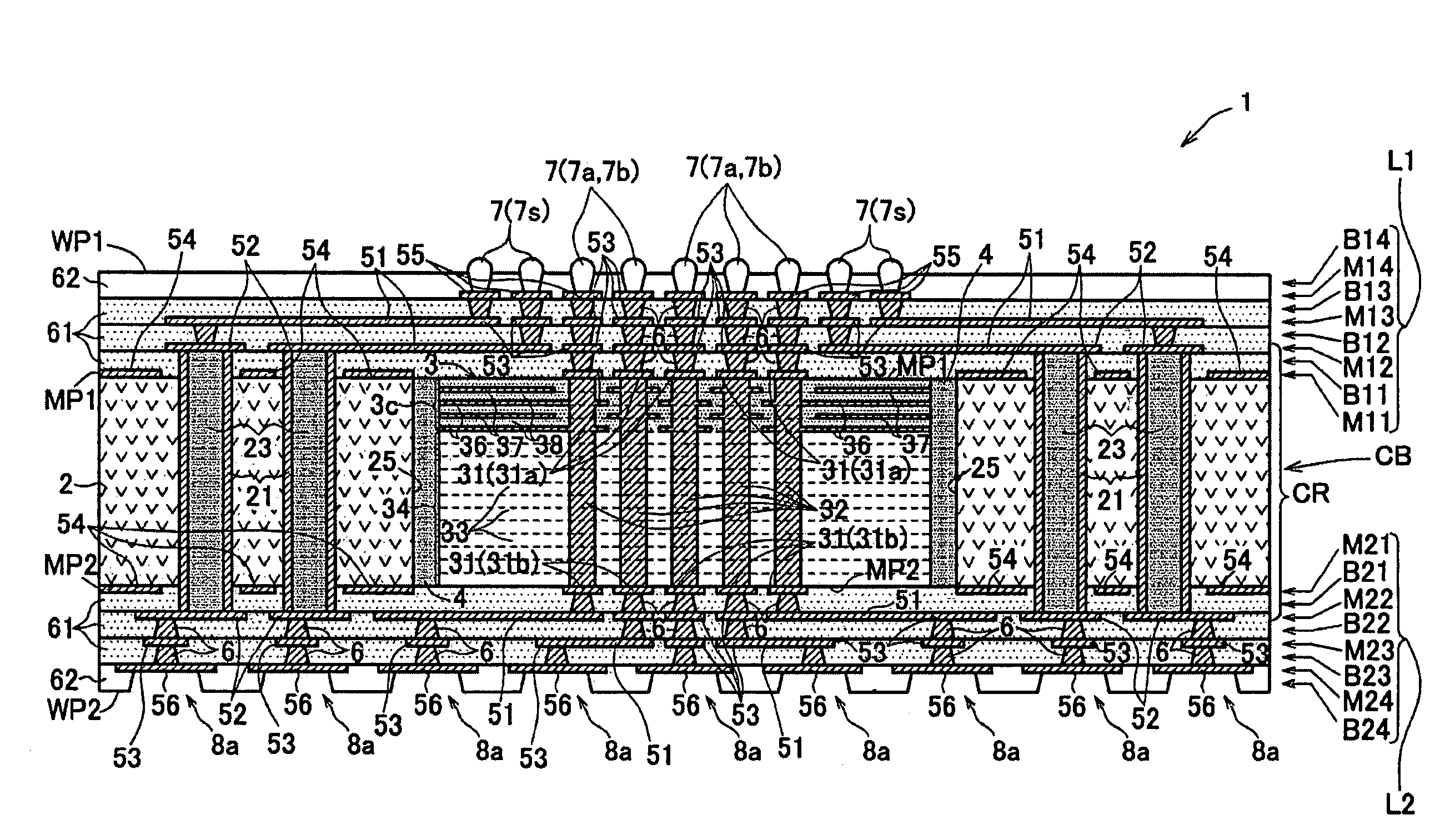

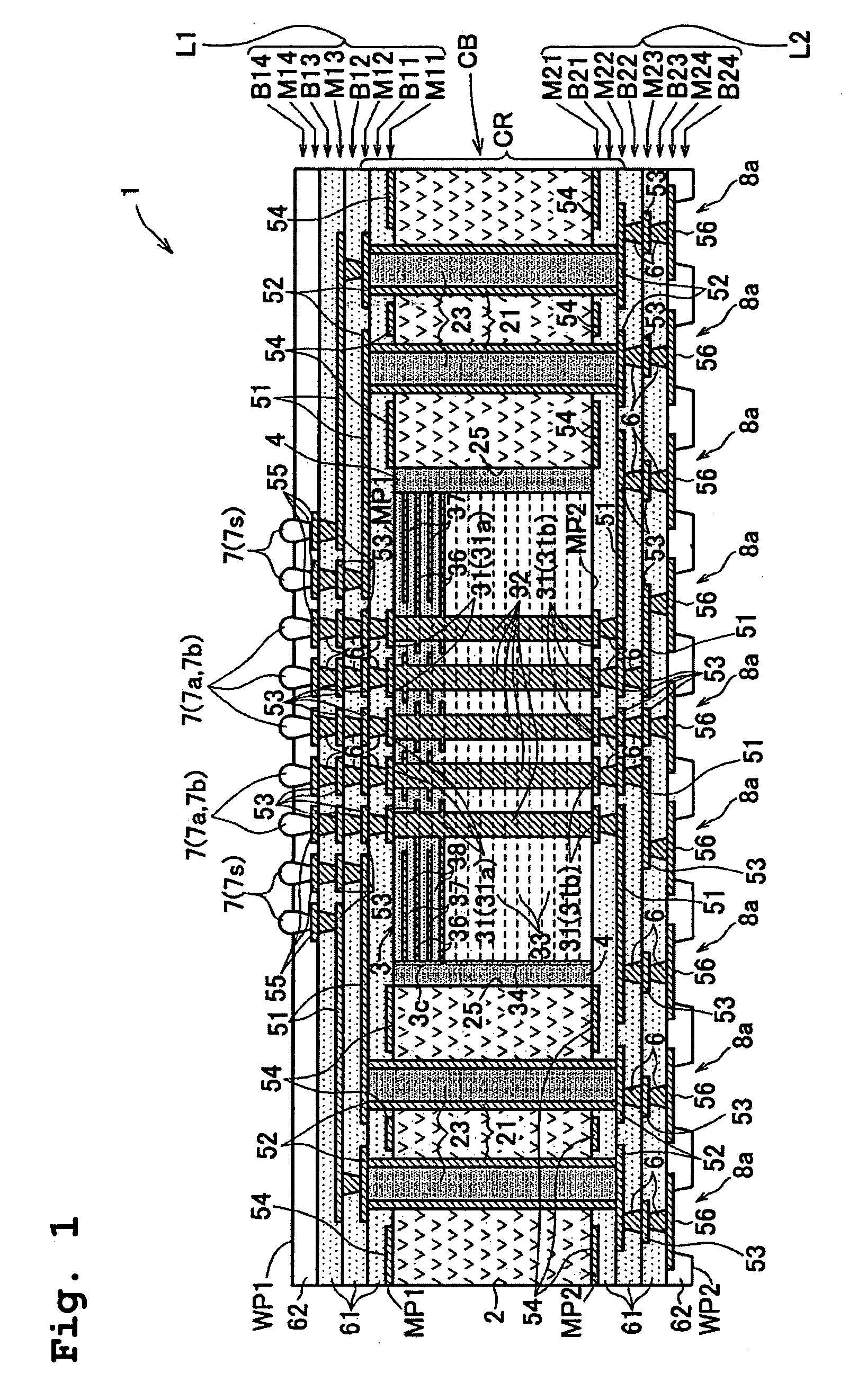

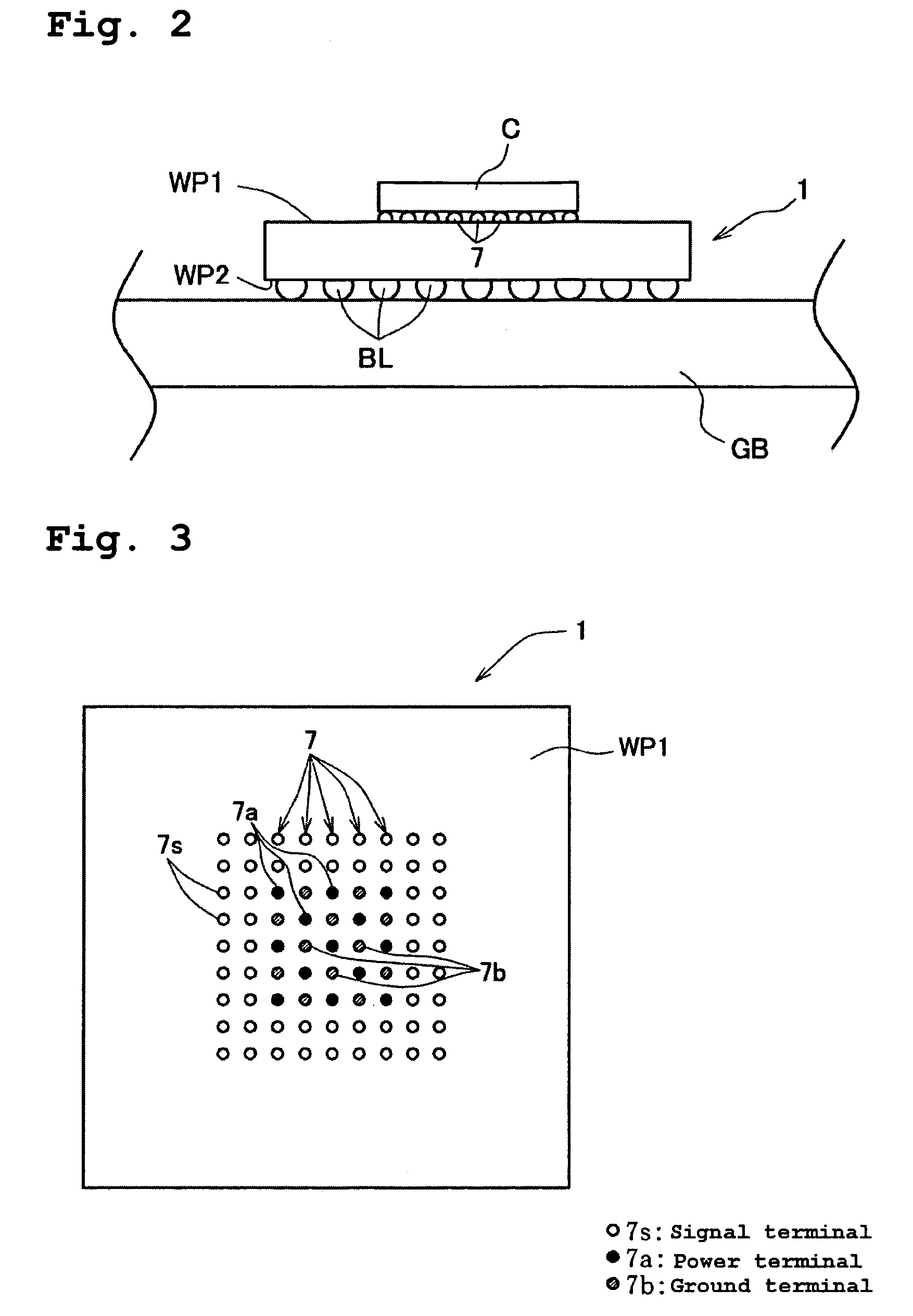

InactiveUS20090288870A1Improve adhesionHigh yieldSemiconductor/solid-state device detailsSolid-state devicesEngineeringProtection layer

A method of manufacturing a wiring substrate of the present invention, includes a step of forming a first wiring layer on an underlying layer, a step of forming a stacked body in which a protection layer is provided on an insulating layer, on the first wiring layer, a step of forming a via hole reaching the first wiring layer by processing the protection layer and the insulating layer, a step of roughening a side surface of the via hole by applying a desmear process to an inside of the via hole while using the protection layer as a mask, a step of removing the protection layer, and a step of forming a second wiring layer, which is connected to the first wiring layer via the via hole, on the insulating layer. The second wiring layer may be formed after the surface of the insulating layer is roughened, or the second wiring layer may be formed without roughening of the surface of the insulating layer.

Owner:SHINKO ELECTRIC IND CO LTD

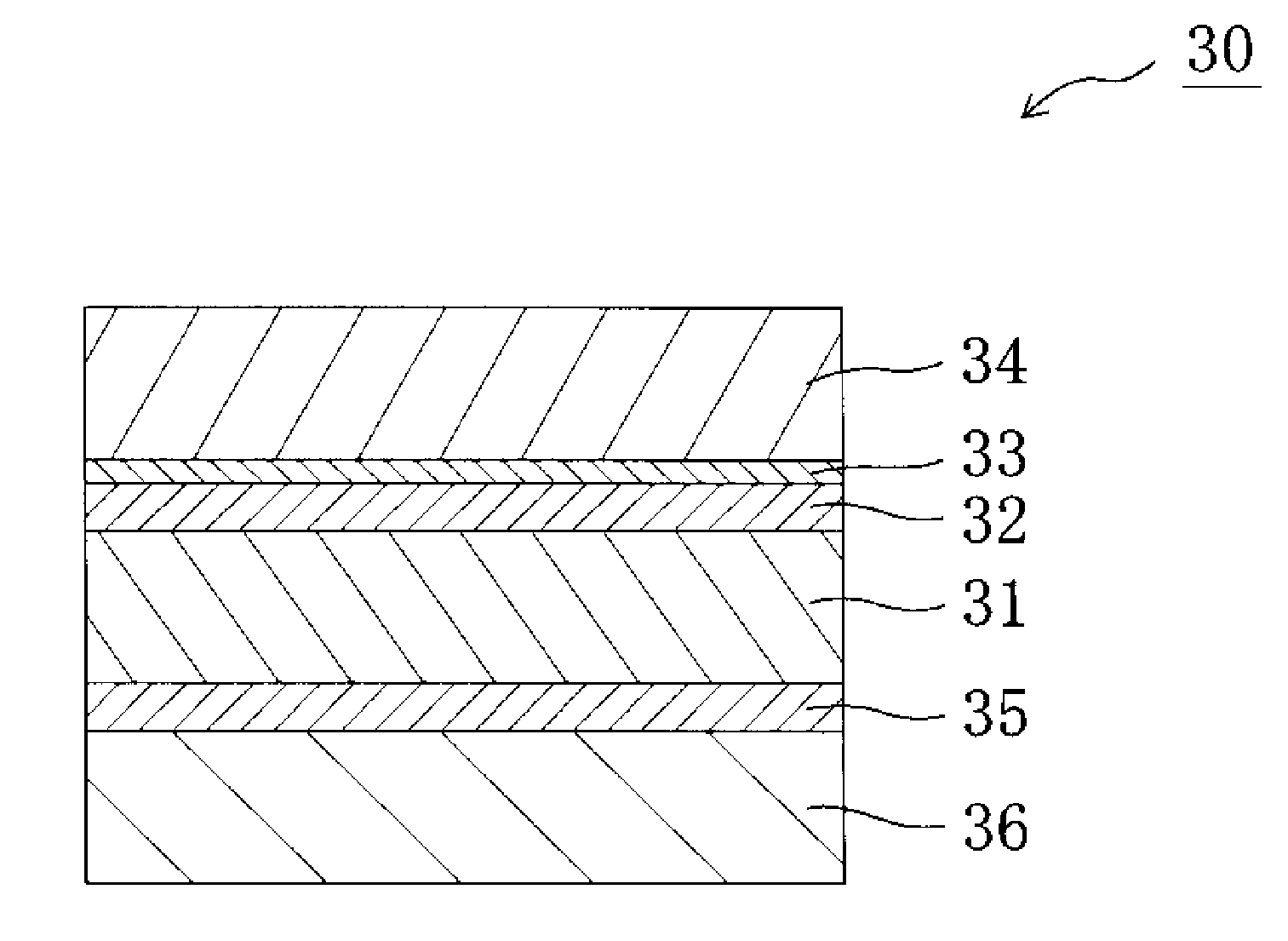

Wiring board and method for manufacturing the same

ActiveUS7525814B2Improve adhesionSufficient adhesionSemiconductor/solid-state device detailsSolid-state devicesChemical treatmentElectrical conductor

A wiring board includes a plurality of via pads disposed on a ceramic sub-core accommodated in a core board. A Cu-plated layer is formed on the surface of a conductor pad and serves as a processed face, i.e., a face to which Cu surface chemical processing is applied in order to improve the adhesion between the surface of the Cu-plated layer and that of an adjacent polymer material. The lowermost dielectric layer of a laminated wiring portion, and a via conductor formed in the dielectric layer, are in electrical contact with the processed face.

Owner:NGK SPARK PLUG CO LTD

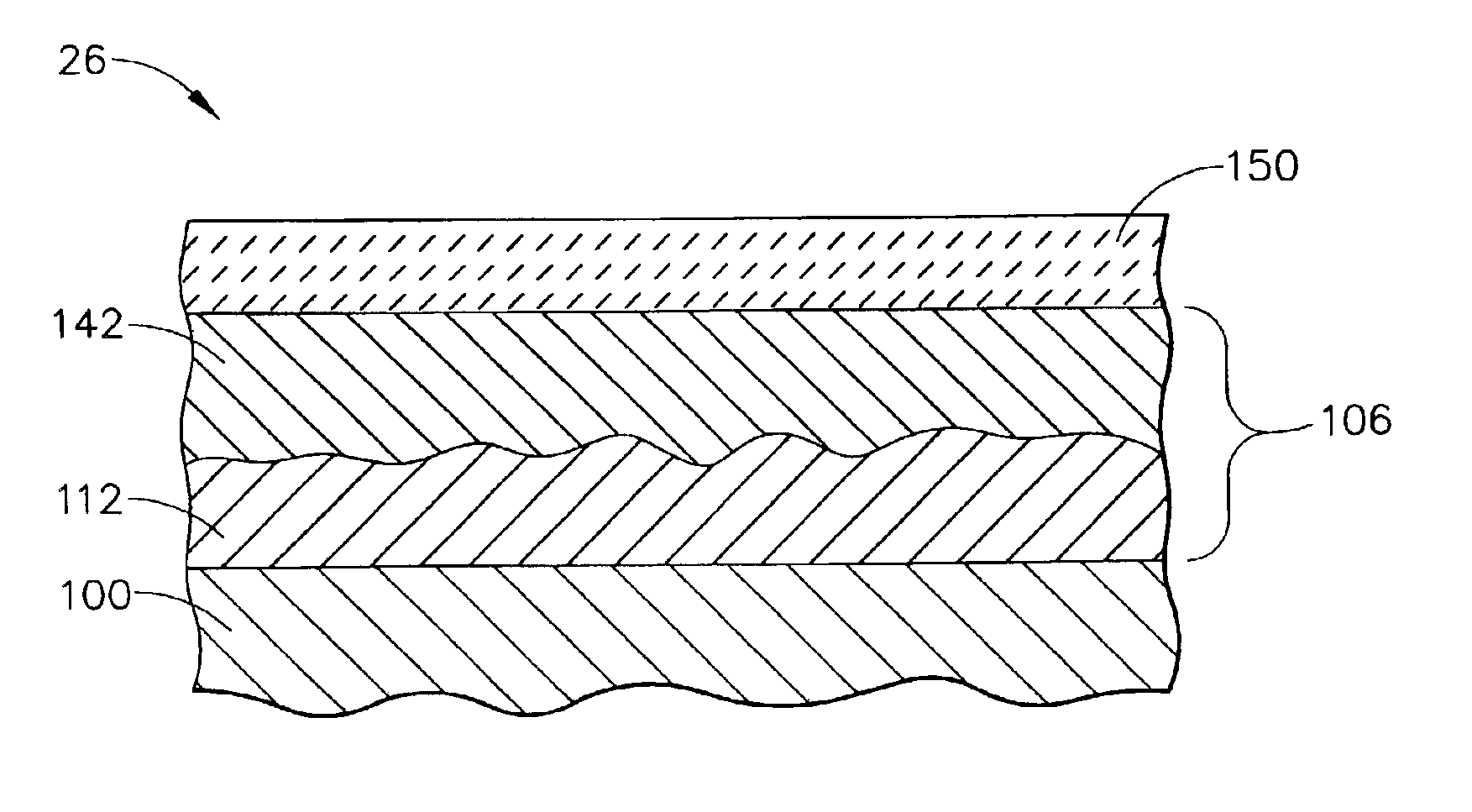

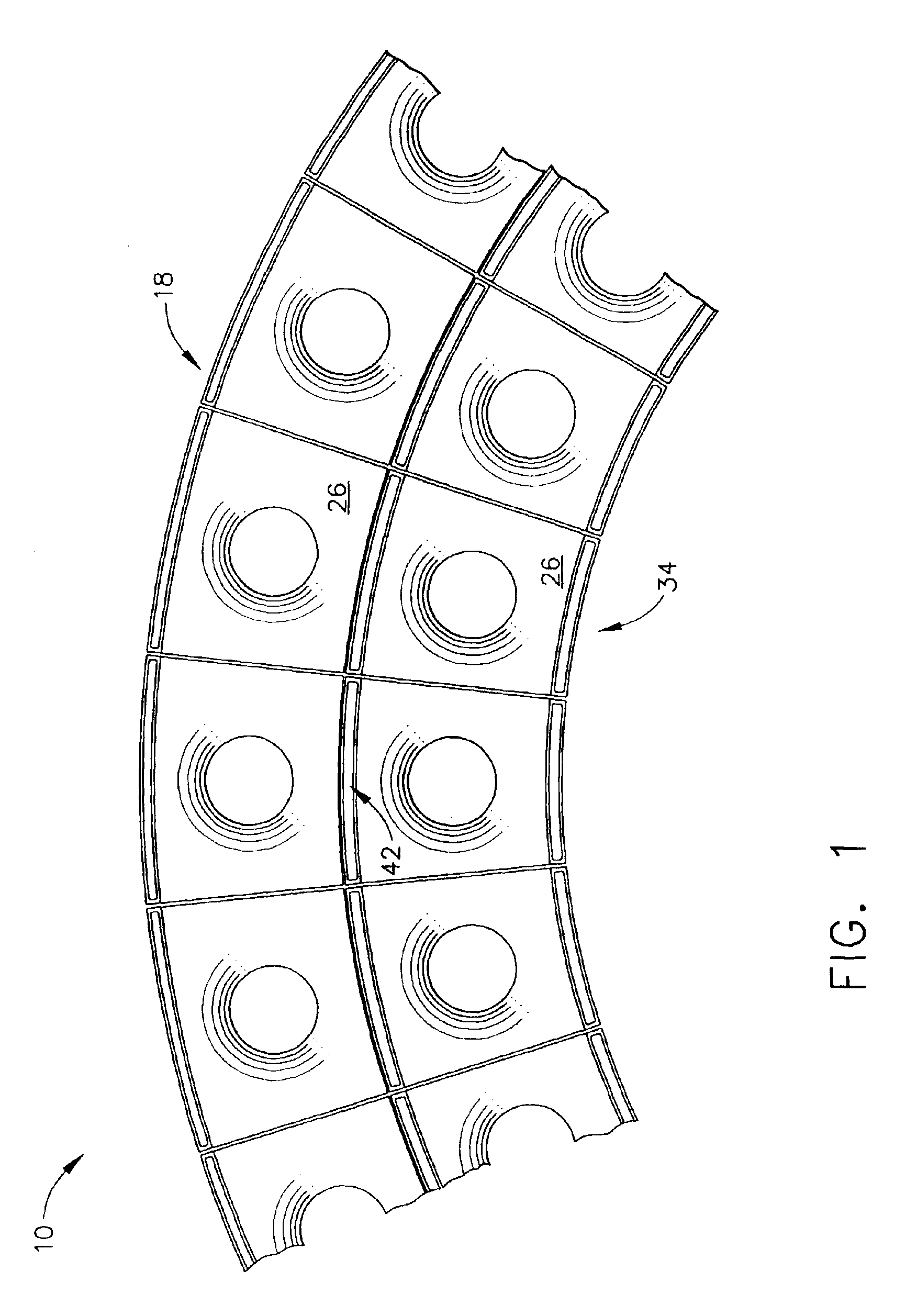

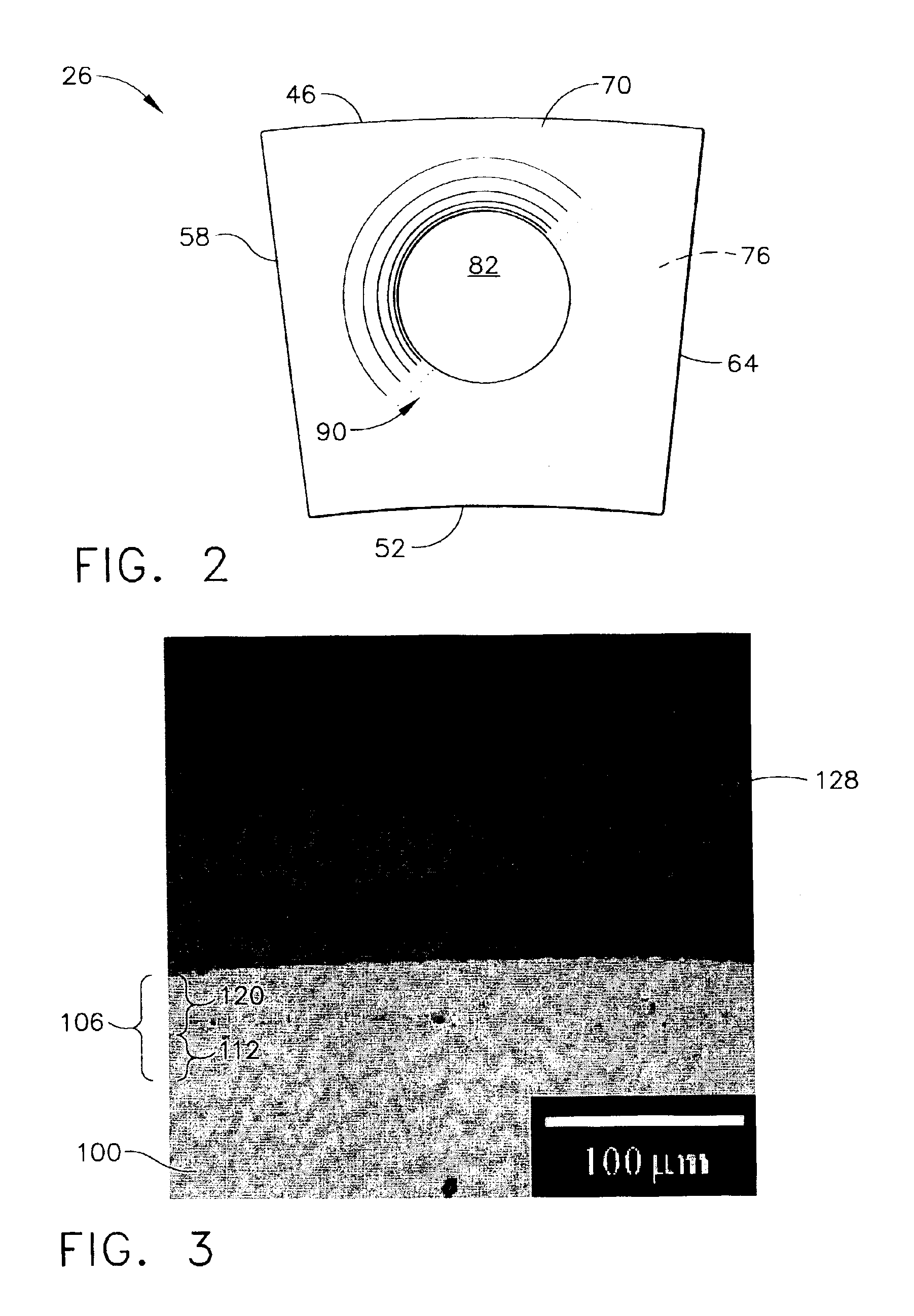

Method for applying or repairing thermal barrier coatings

ActiveUS7094450B2Sufficient adhesionLess time consuming and uncomplicated way to applyMolten spray coatingLayered productsGas phaseBond coating

Owner:GENERAL ELECTRIC CO

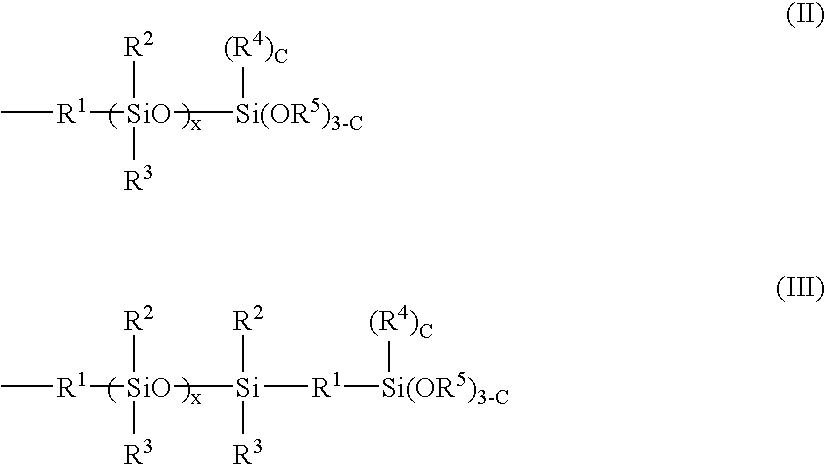

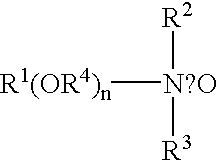

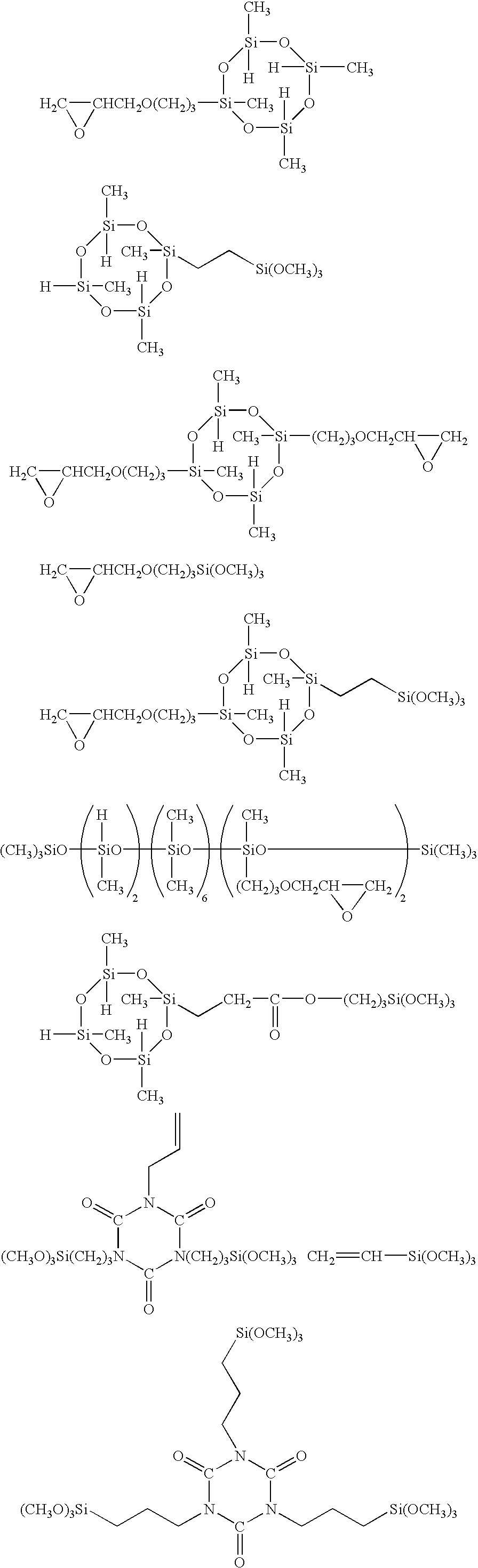

Silicone rubber coating composition and airbag

InactiveUS20050054762A1Sufficient adhesionLiquid surface applicatorsLayered productsCompound (substance)Airbag

A silicone rubber coating composition comprising (A) a diorganopolysiloxane containing an average of at least two alkenyl groups, (B) silica powder having a specific surface area of at least 50 m2 / g, (C) an organosilicon compound containing a ureido group, an isocyanuric acid ester modified with an organosilicon compound or a (partial) hydrolytic condensate thereof, and (D) a curing agent is applied and vulcanized to base fabric to form a coated fabric, from which airbags are prepared. The composition has a sufficient adhesion to withstand high temperature and abrupt elongation upon inflation of the airbag even after long-term storage under hot humid conditions.

Owner:SHIN ETSU CHEM IND CO LTD

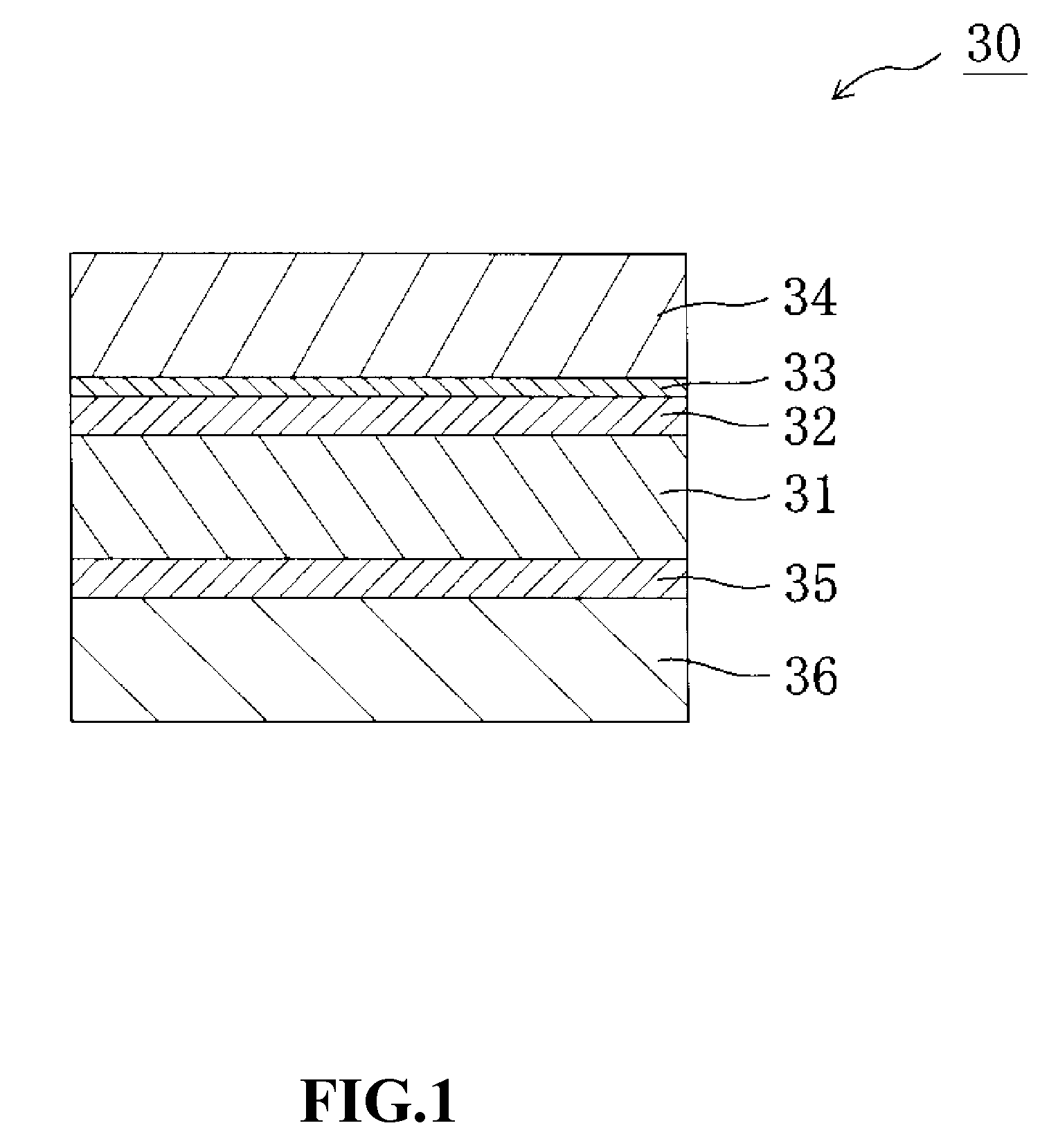

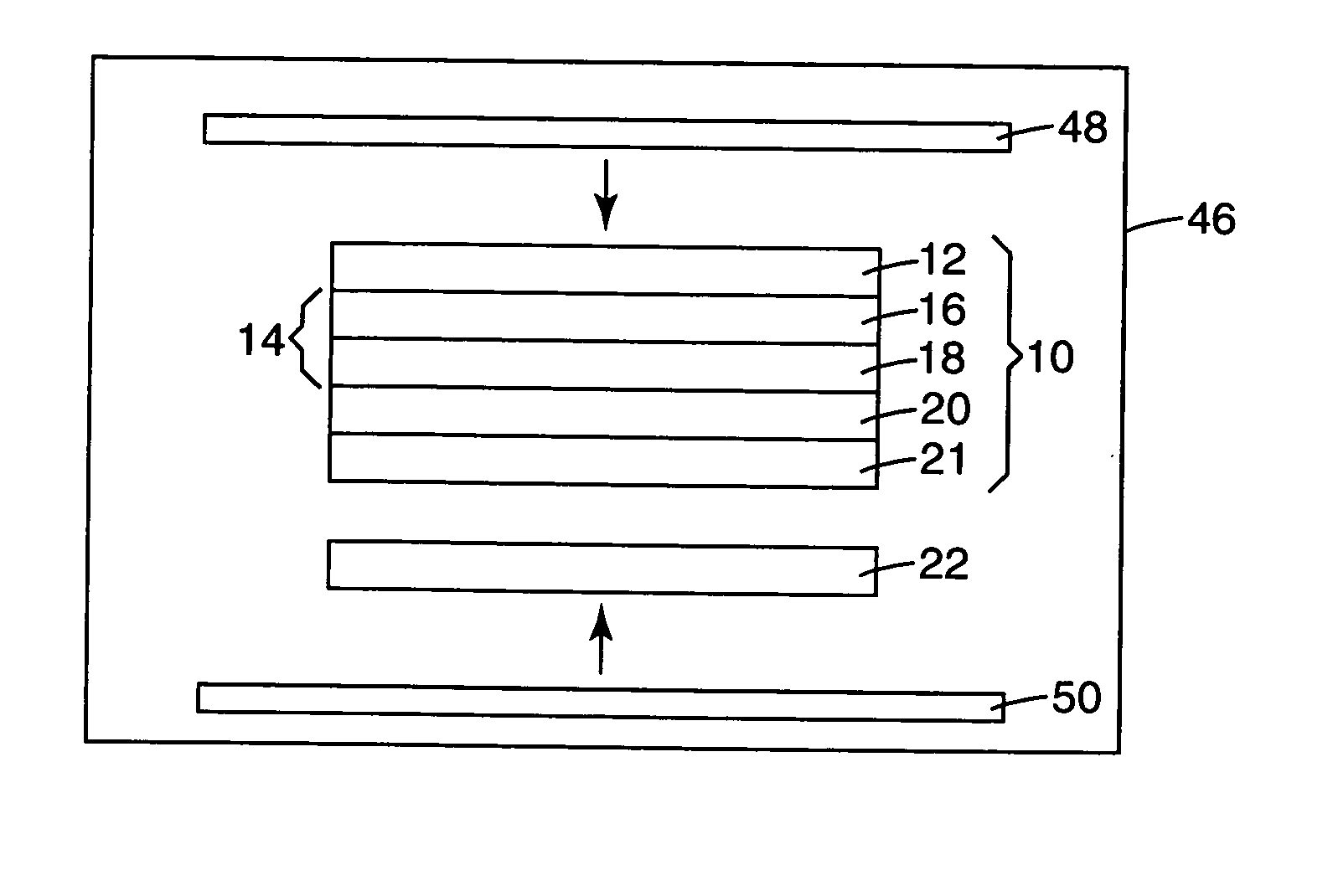

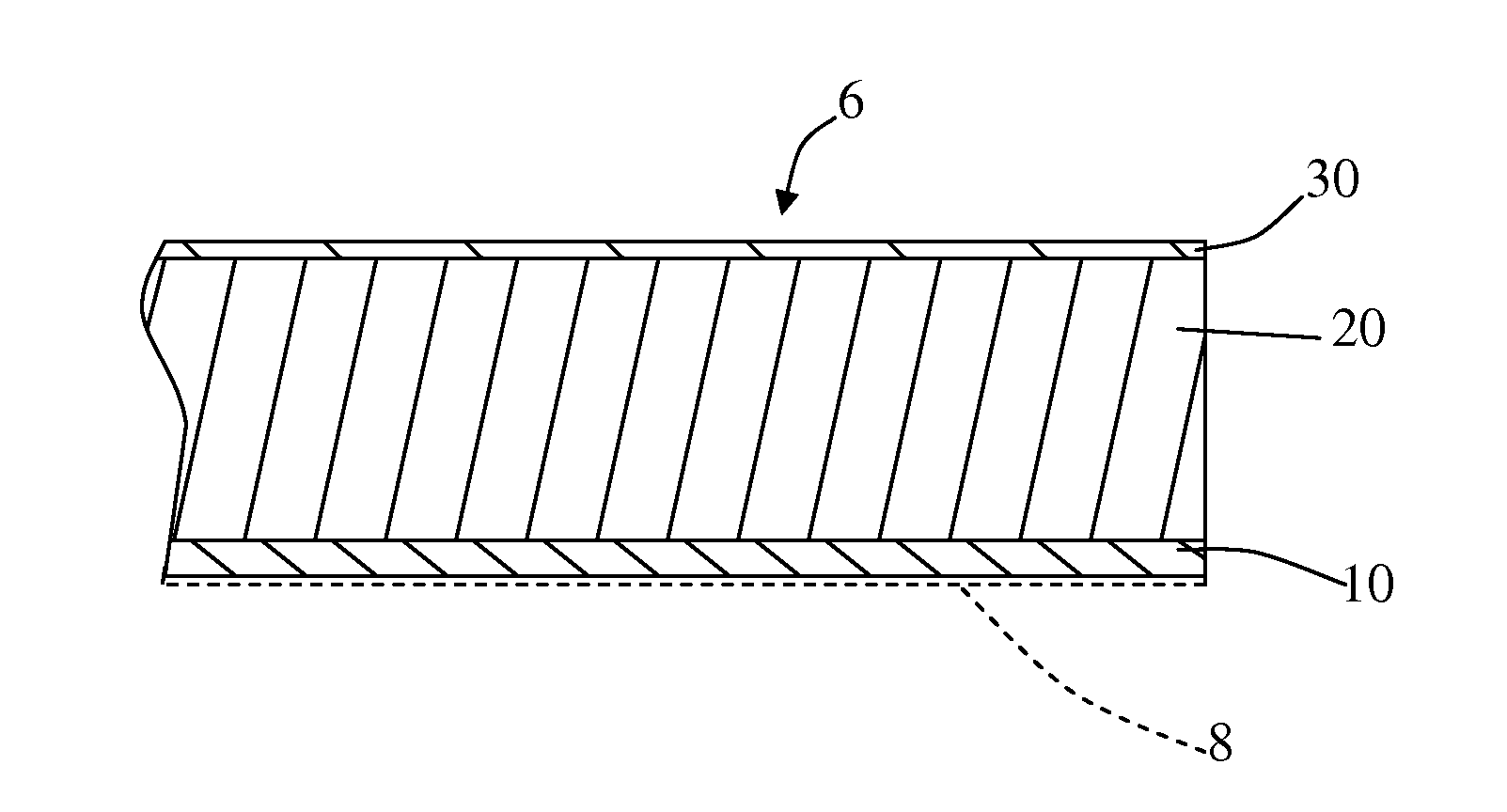

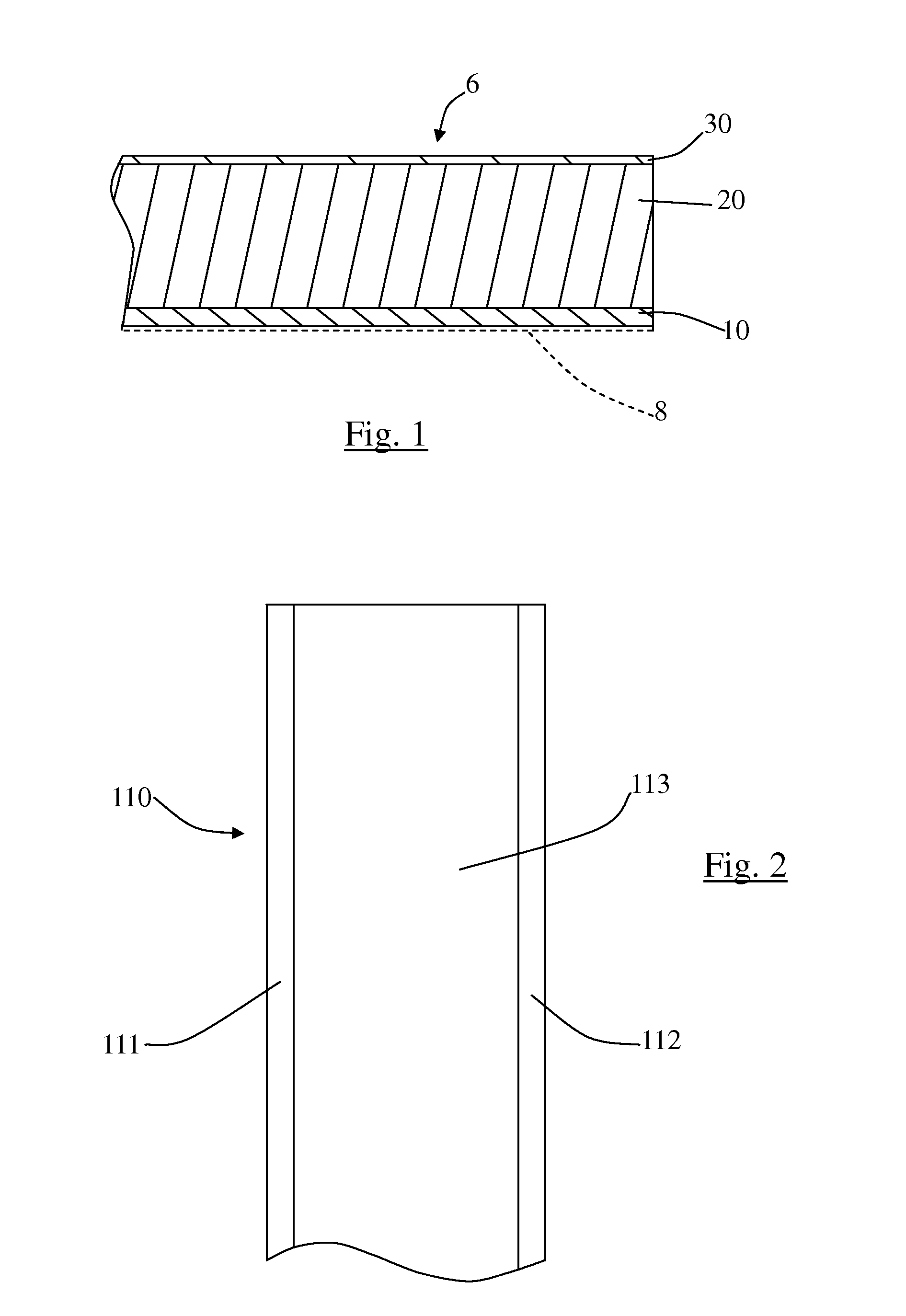

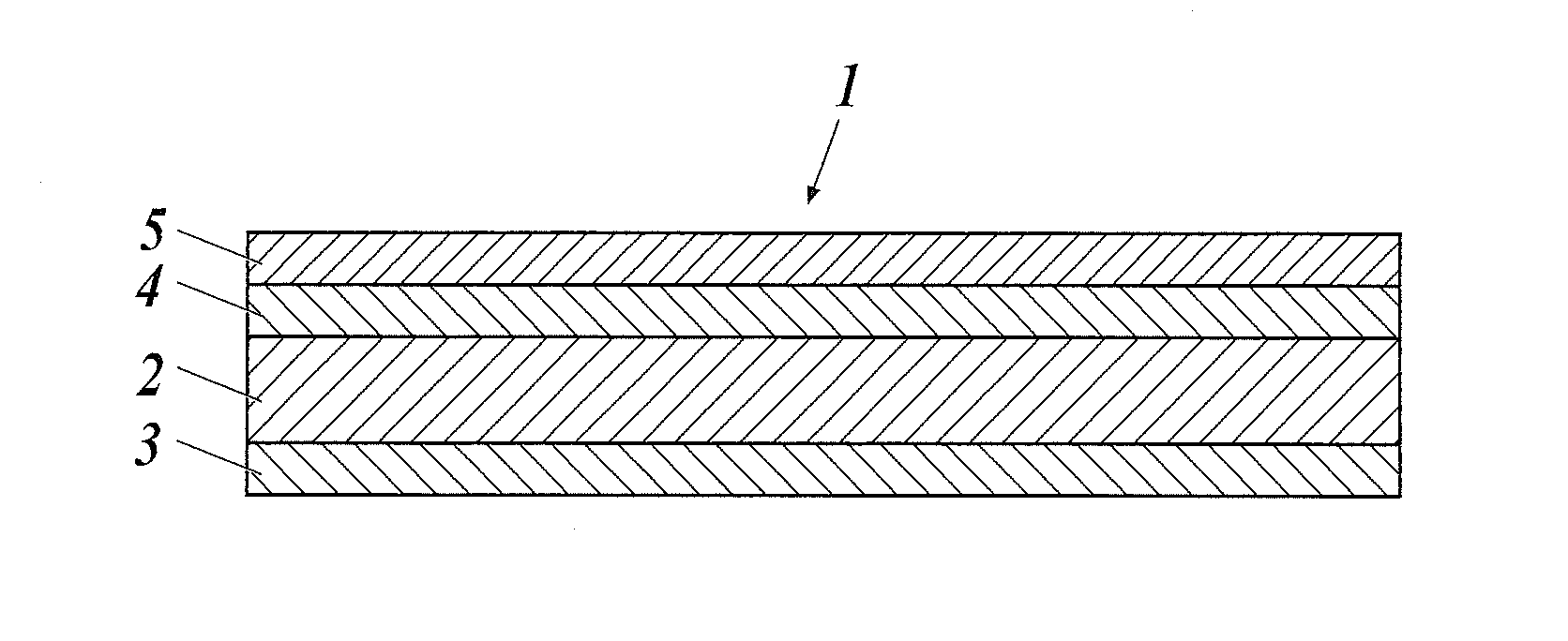

Multi-layer anode comprising natural graphite and artificial graphite, and lithium secondary battery comprising same

ActiveCN108701816AImprove output characteristicsImprove life characteristicsSecondary cellsNegative electrodesChemical physicsElectrical battery

The present disclosure relates to a multilayer negative electrode comprising a negative electrode current collector configured to transfer electrons between an outer lead and a negative electrode active material, a first negative electrode mixture layer formed on one surface or both surfaces of the current collector and containing natural graphite as a negative electrode active material and a second negative electrode mixture layer formed on the first negative electrode mixture layer and containing artificial graphite as a negative electrode active material, and a lithium secondary battery including the same.

Owner:LG ENERGY SOLUTION LTD

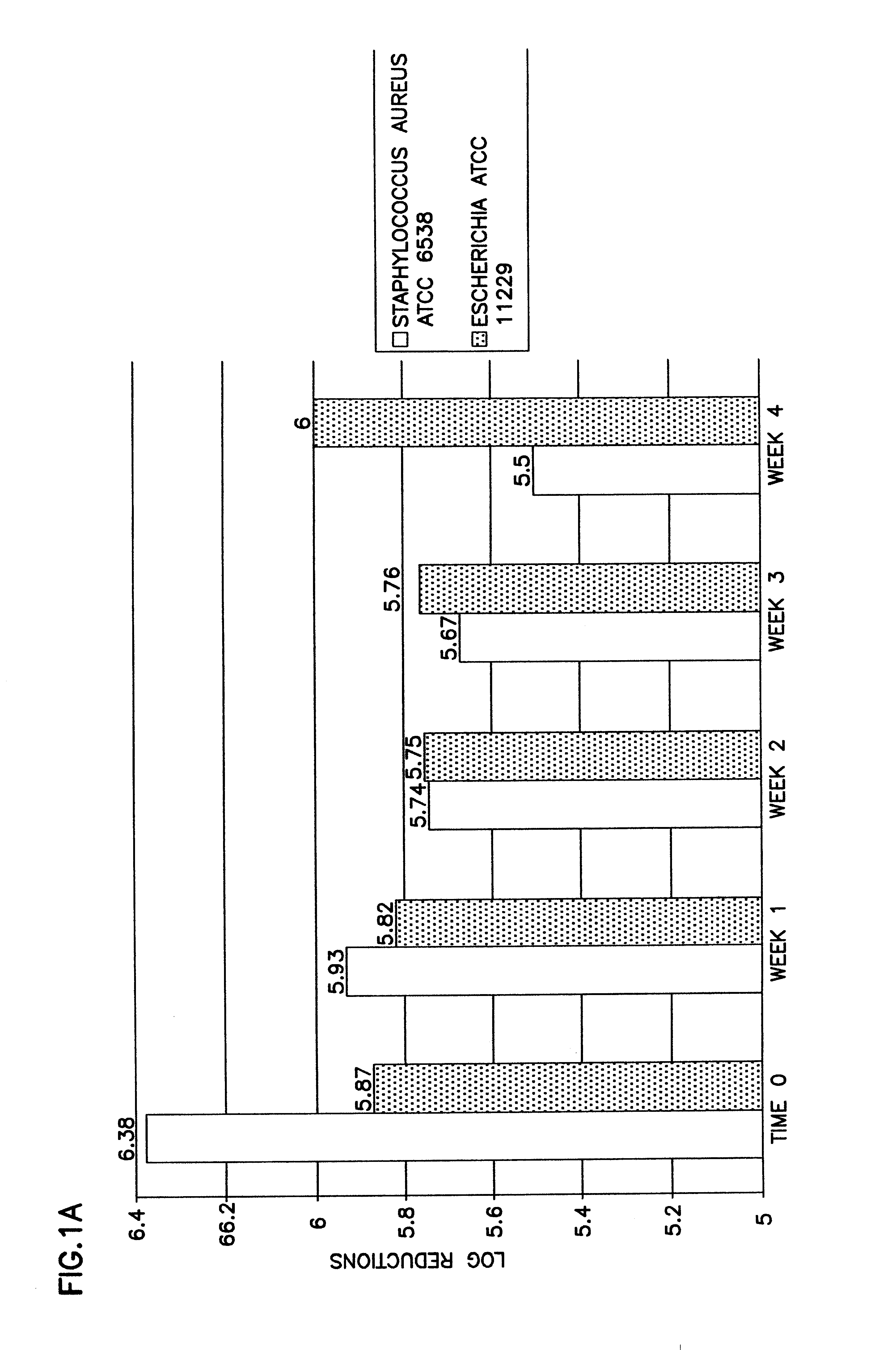

Acidic aqueous chlorite teat dip with improved visual indicator stability, extended shelf life, sanitizing capacity and tissue protection

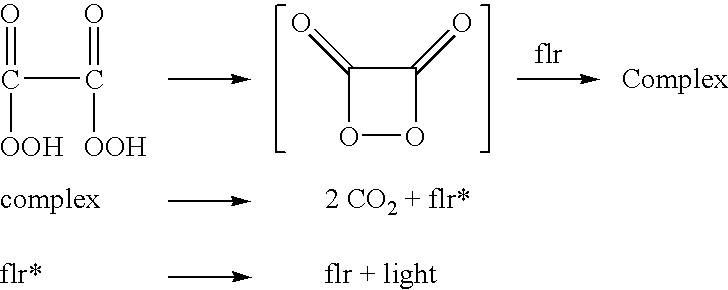

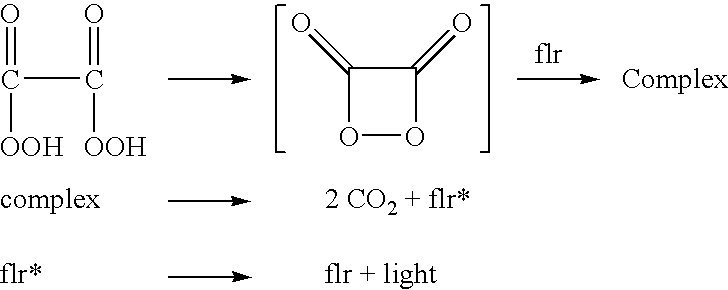

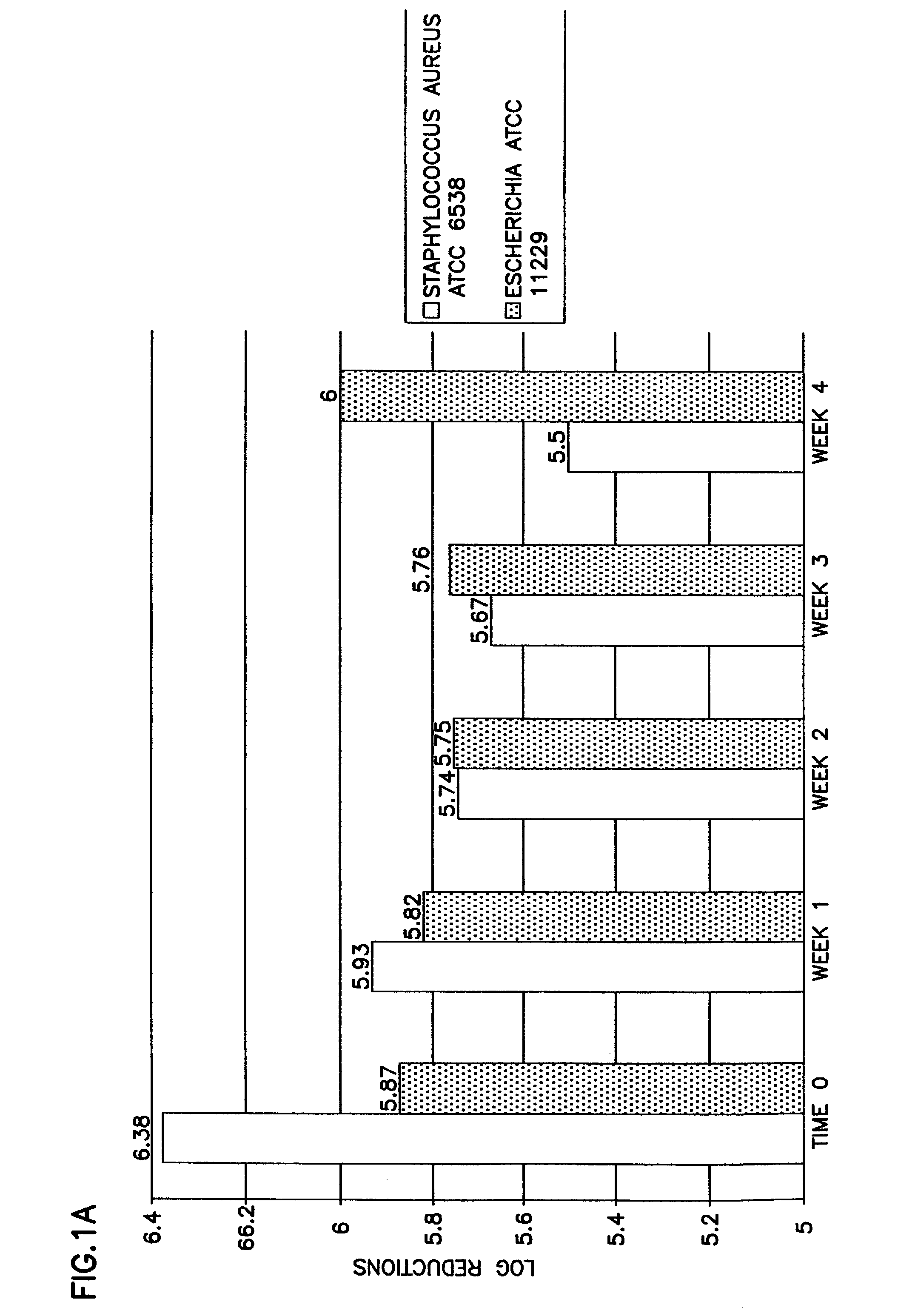

InactiveUS6699510B2Enhanced softening and smoothing and characterImmobilizes mastitis treatmentAntibacterial agentsBiocideChlorine dioxideTissue protection

The mastitis control teat dip composition having a visible indicator aspect of the invention provides a softening, soothing, smoothing, relaxing property, a rapid initial kill, a useful highly pseudoplastic rheology, a barrier / film-forming capacity, a unique antimicrobial composition that is stable over an extended period of time, and unexpected long term microbial control when compared to the prior art materials disclosed in patents and used in the marketplace. The indicator aspect provides ease of visually detecting the material on the animal skin and can indicate efficacy of the material. The compositions of the invention are made by combining an aqueous liquid composition containing the visual indicator combined with the organic components which can be combined with a simple aqueous solution of a salt of chlorous acid, preferably an alkali metal chlorite. The materials after they are combined and blended into a smooth viscous material containing an emollient package generates active antimicrobial chlorine dioxide and can be immediately contacted with the target animals. The compositions of the invention provide stable visual indication, rapid initial kill, consistent long term kill with chemical and rheological stability.

Owner:ECOLAB USA INC

Wiring board and method for manufacturing the same

ActiveUS20060283547A1Improve adhesionAdhesionSemiconductor/solid-state device detailsSolid-state devicesChemical treatmentElectrical conductor

A wiring board includes a plurality of via pads disposed on a ceramic sub-core accommodated in a core board. A Cu-plated layer is formed on the surface of a conductor pad and serves as a processed face, i.e., a face to which Cu surface chemical processing is applied in order to improve the adhesion between the surface of the Cu-plated layer and that of an adjacent polymer material. The lowermost dielectric layer of a laminated wiring portion, and a via conductor formed in the dielectric layer, are in electrical contact with the processed face.

Owner:NGK SPARK PLUG CO LTD

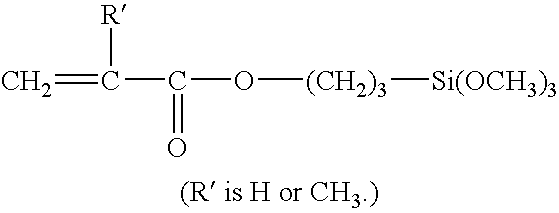

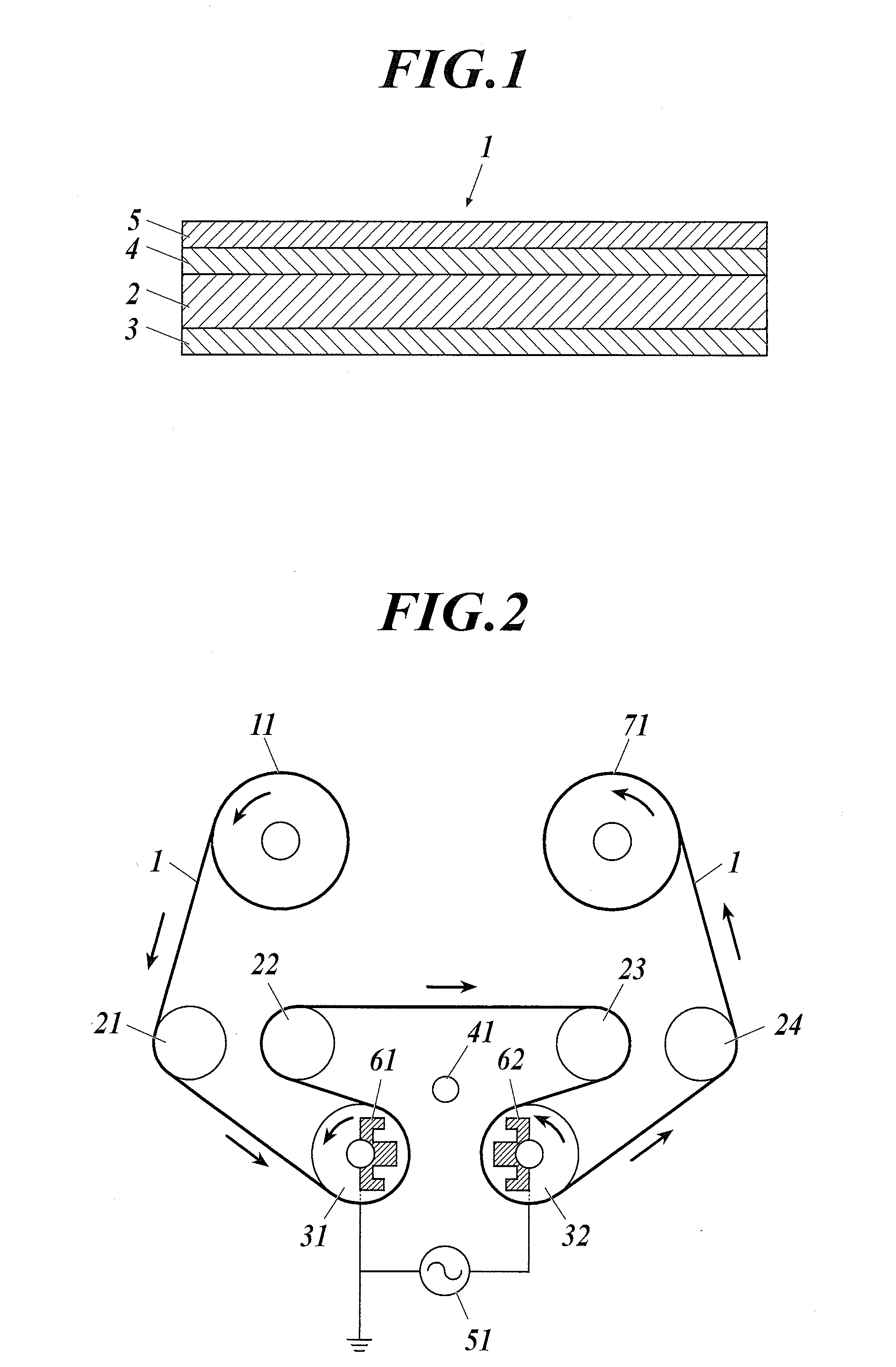

Polarizer protective film, polarizing plate, and image display apparatus

InactiveUS20100002298A1Improve adhesionSufficient adhesionSynthetic resin layered productsCellulosic plastic layered productsTectorial membraneAcrylic resin

Provided are a polarizer protective film containing a (meth)acrylic resin as a main component and being excellent in adhesion with a polarizer, a polarizing plate including the polarizer protective film and a polarizer which are unlikely to peel off from each other, and an image display apparatus of high quality using the polarizing plate. The polarizer protective film of the present invention includes a coating layer containing a (meth) acrylic resin (B) as a main component on at least one surface of a film containing a (meth)acrylic resin (A) as a main component.

Owner:NITTO DENKO CORP +1

Film base material for adhesive skin patch and adhesive skin patch

InactiveUS20050169975A1Change physical propertiesFailure in characteristicAdhesive dressingsAbsorbent padsFilm basePolypropylene glycol

To have acceptable moisture permeability and enable prevention of deformation due to swelling, the film base material for an adhesive skin patch includes an ether-based urethane resin obtained from at least one member selected from the group consisting of polyoxytetramethylene glycol, butanediol, polyethylene glycol, and polypropylene glycol as a diol component, and methylene diphenyl-diisocyanate as an isocyanate component. The film base material for an adhesive skin patch has a moisture permeability of preferably 800 to 4,000 g / m2·24 hrs. The adhesive skin patch can be produced by forming a pressure-sensitive adhesive layer on one side of the film base material for an adhesive skin patch.

Owner:NITTO DENKO CORP

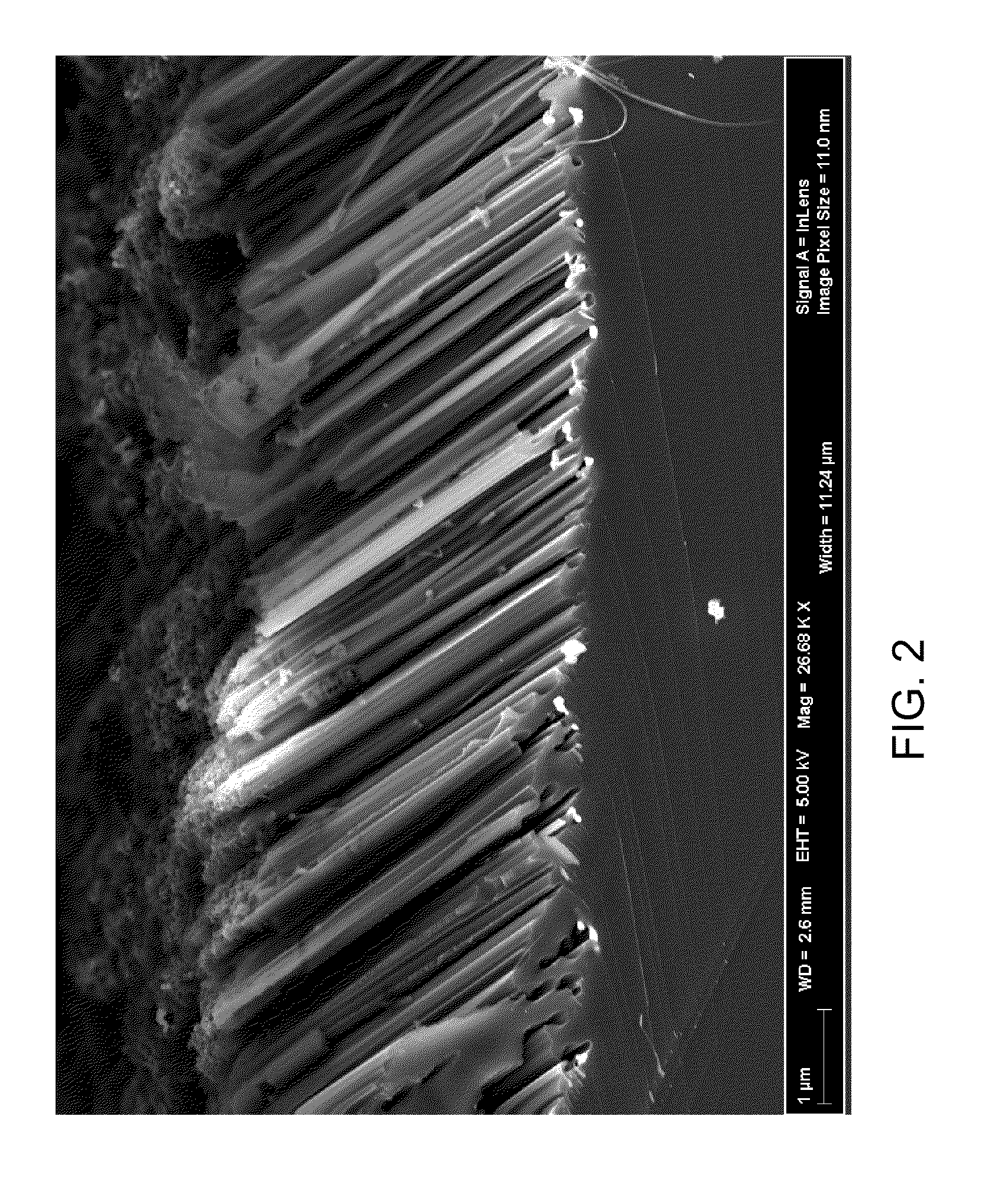

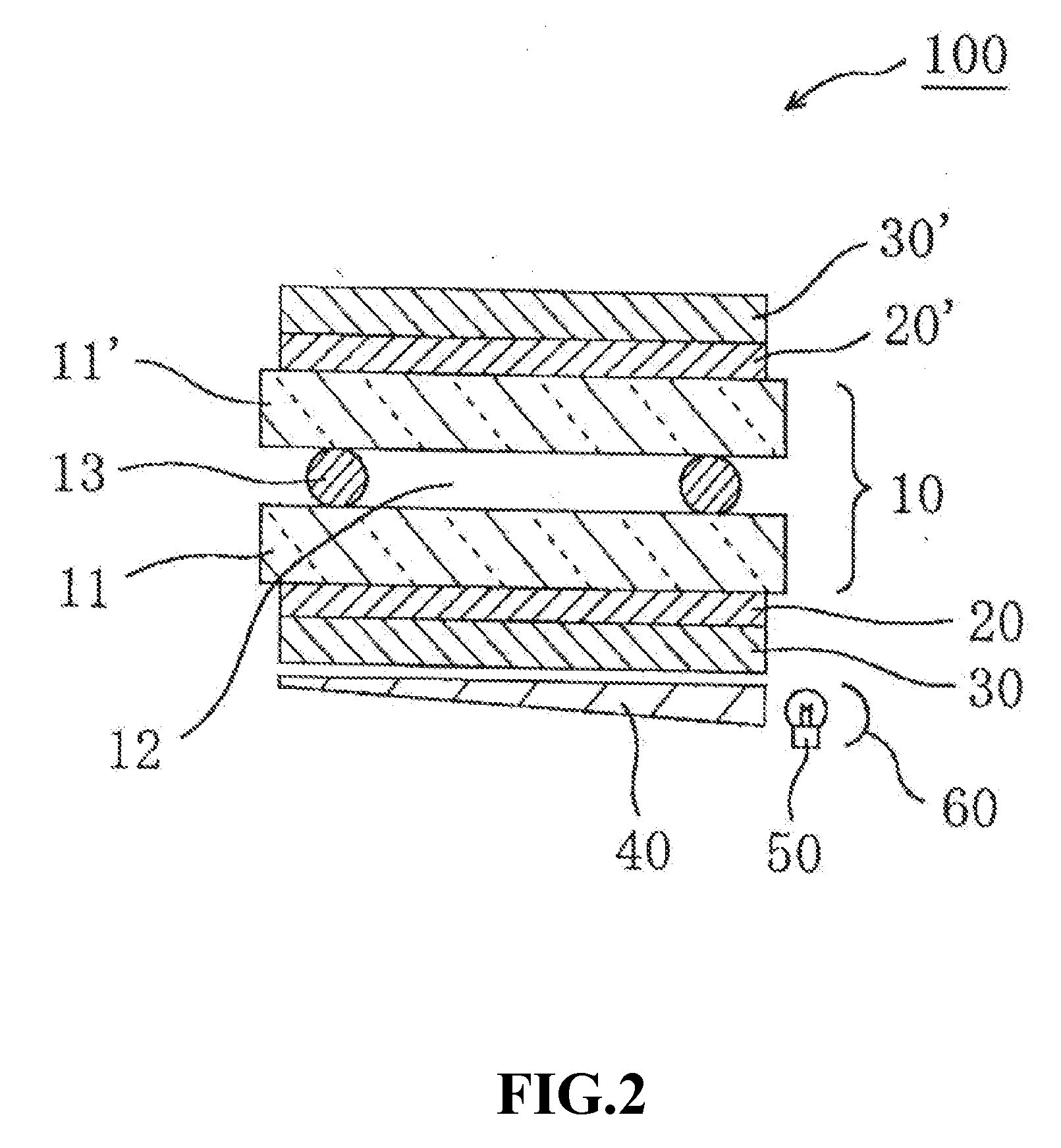

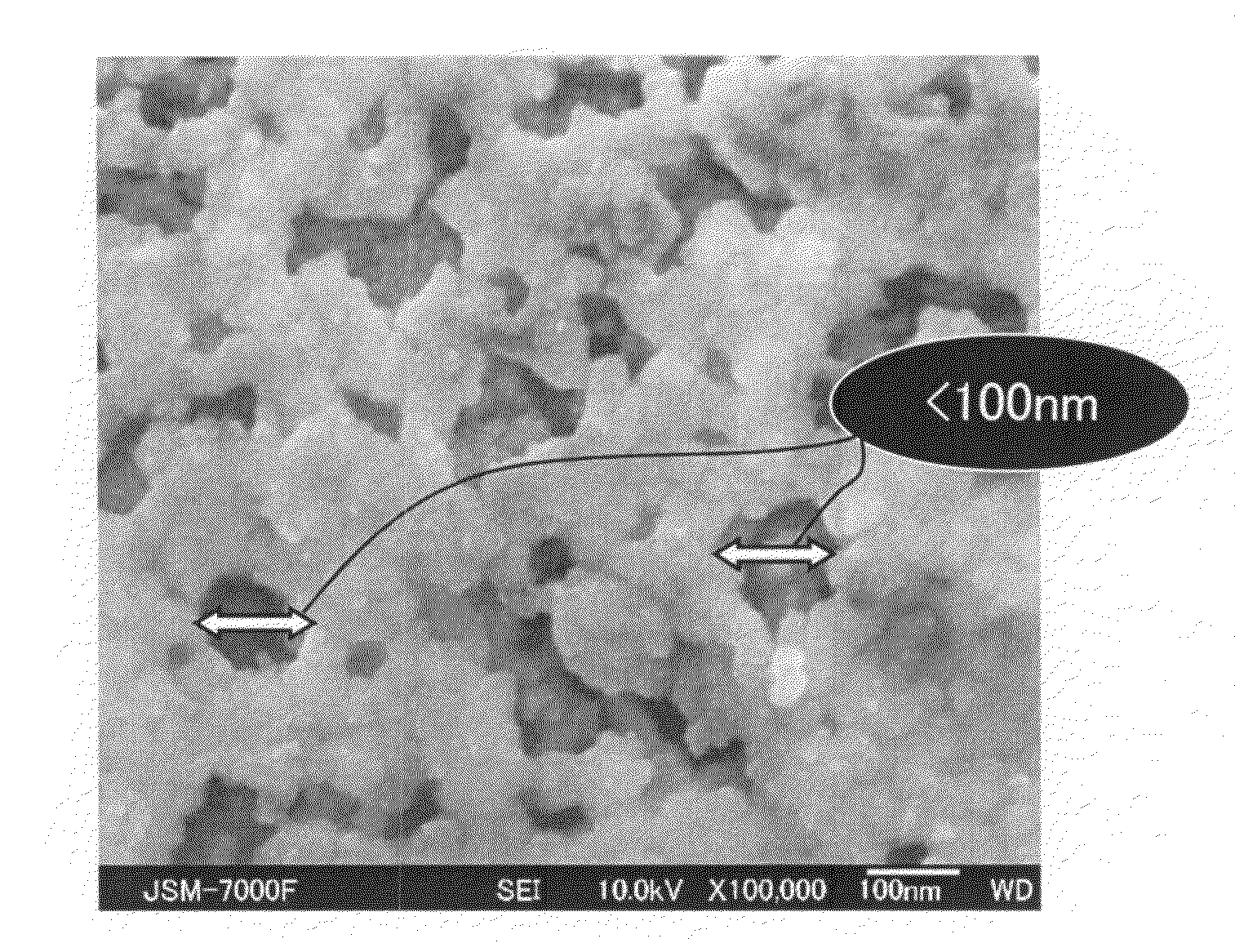

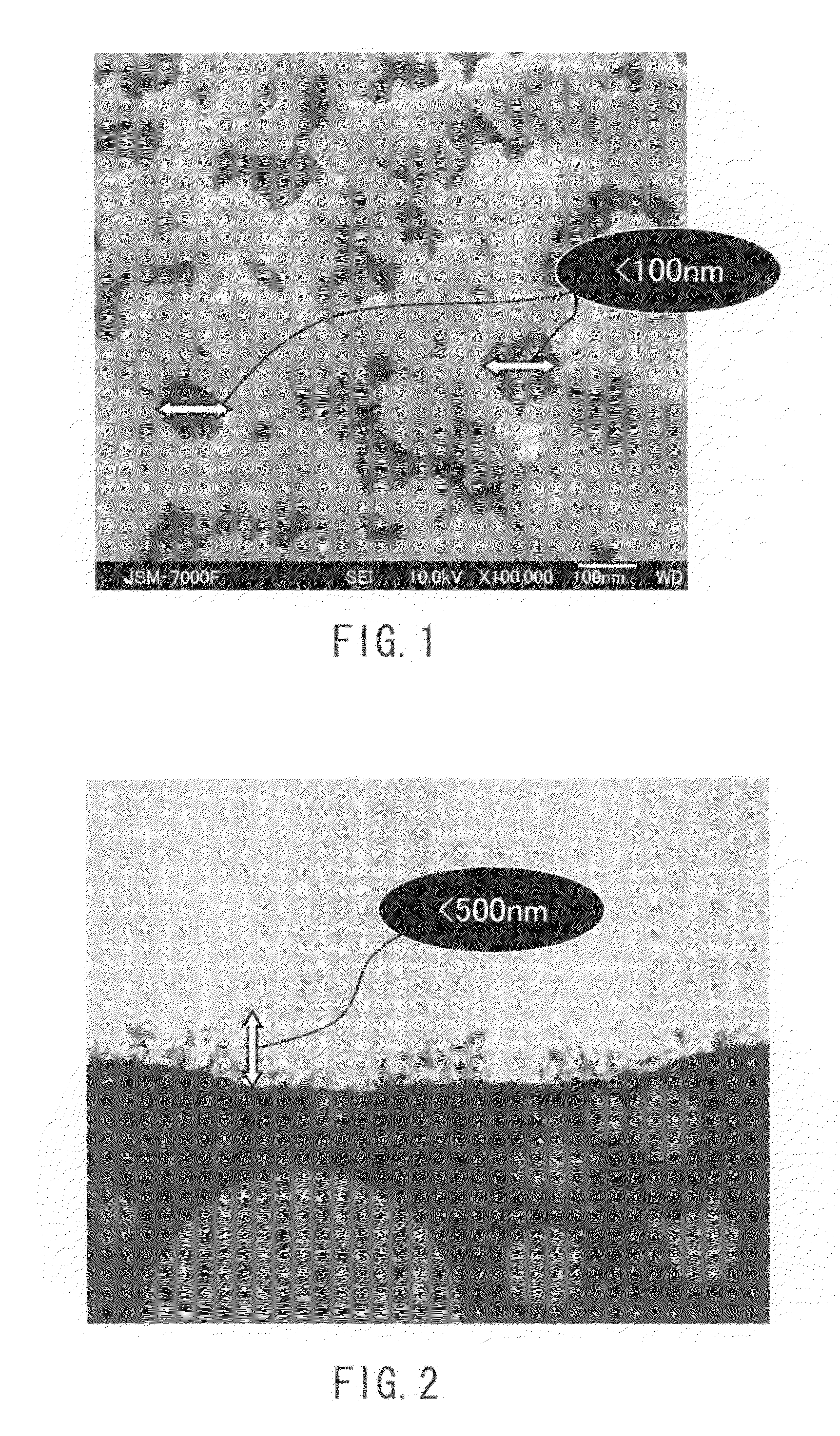

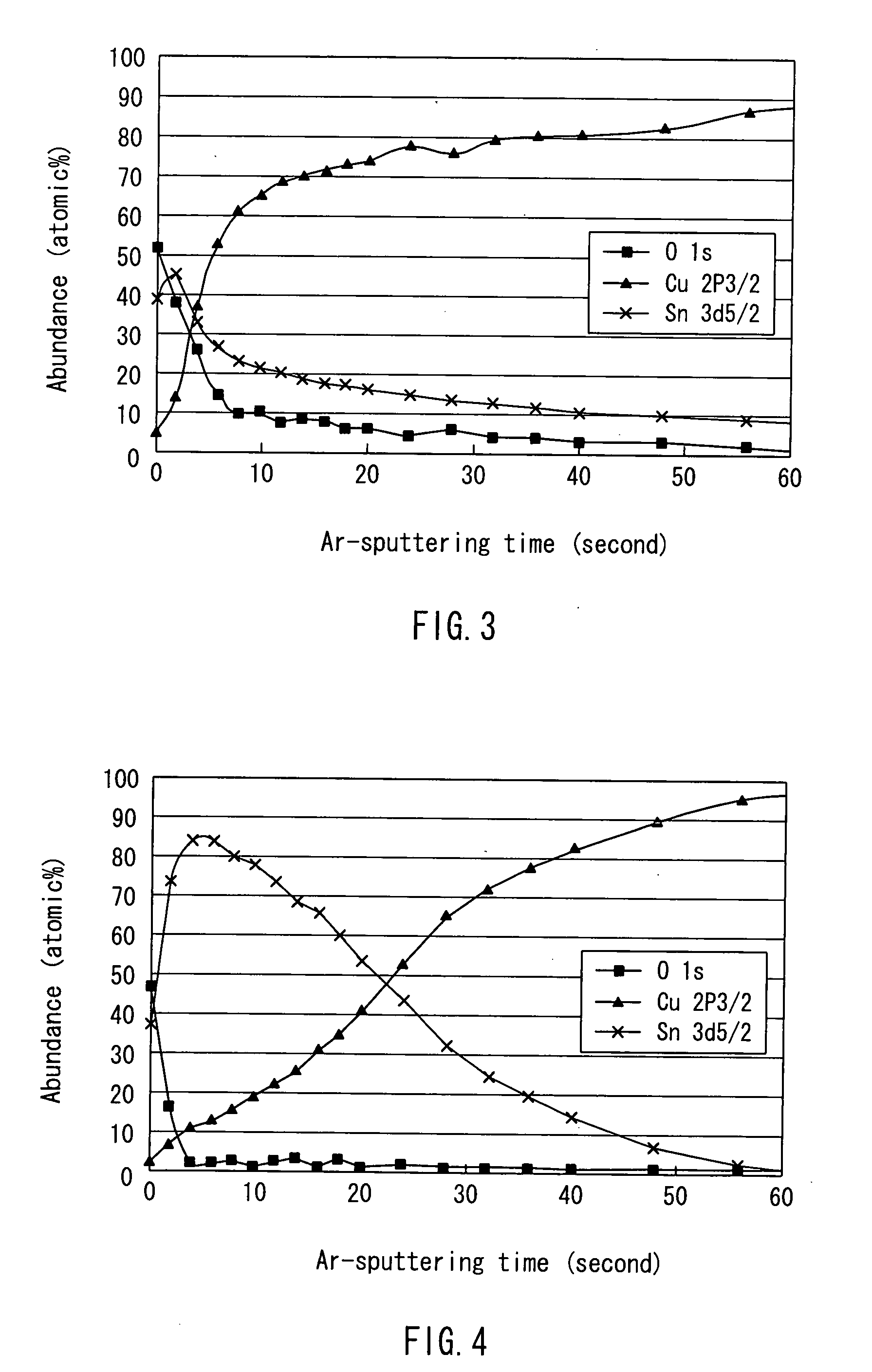

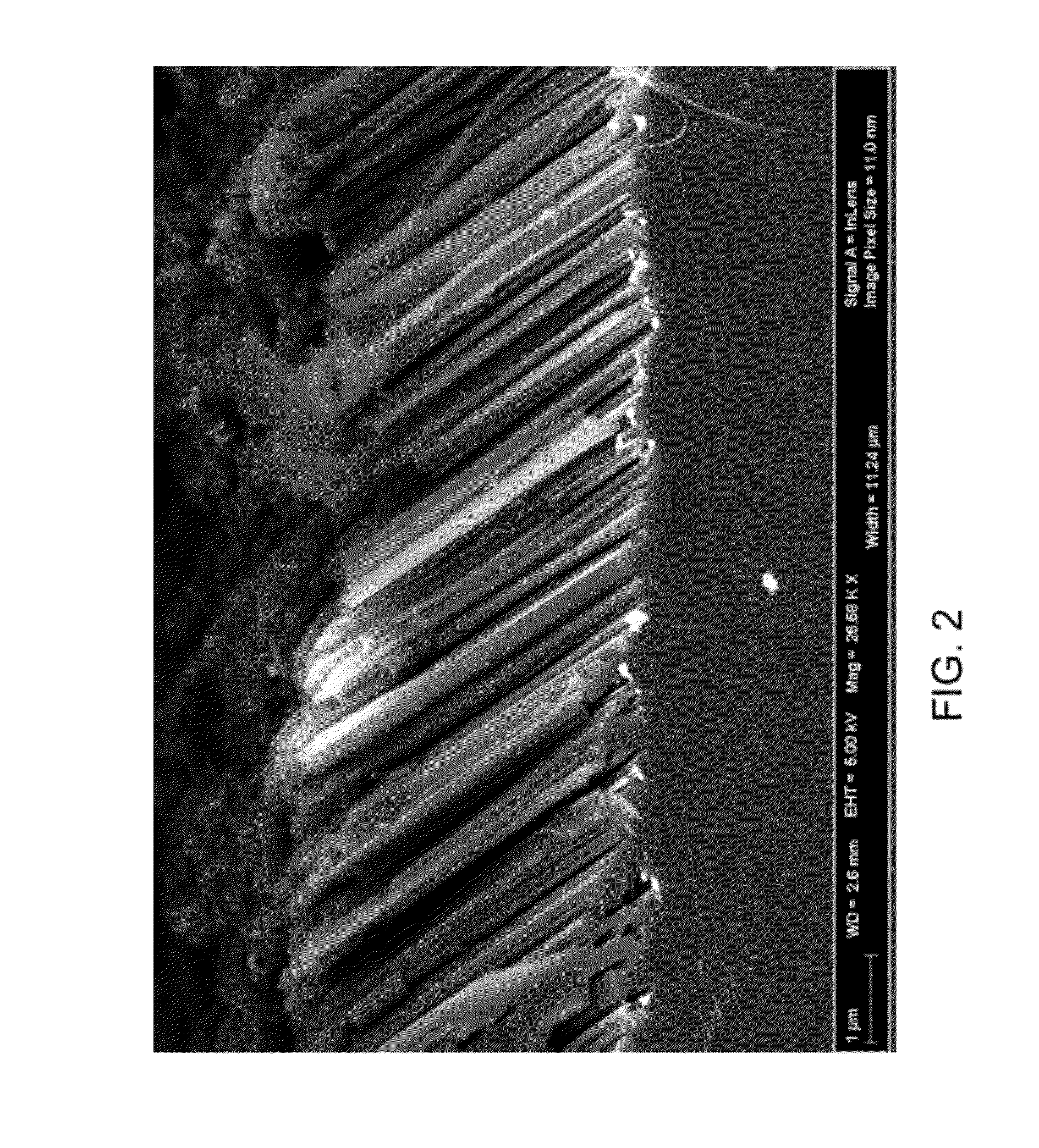

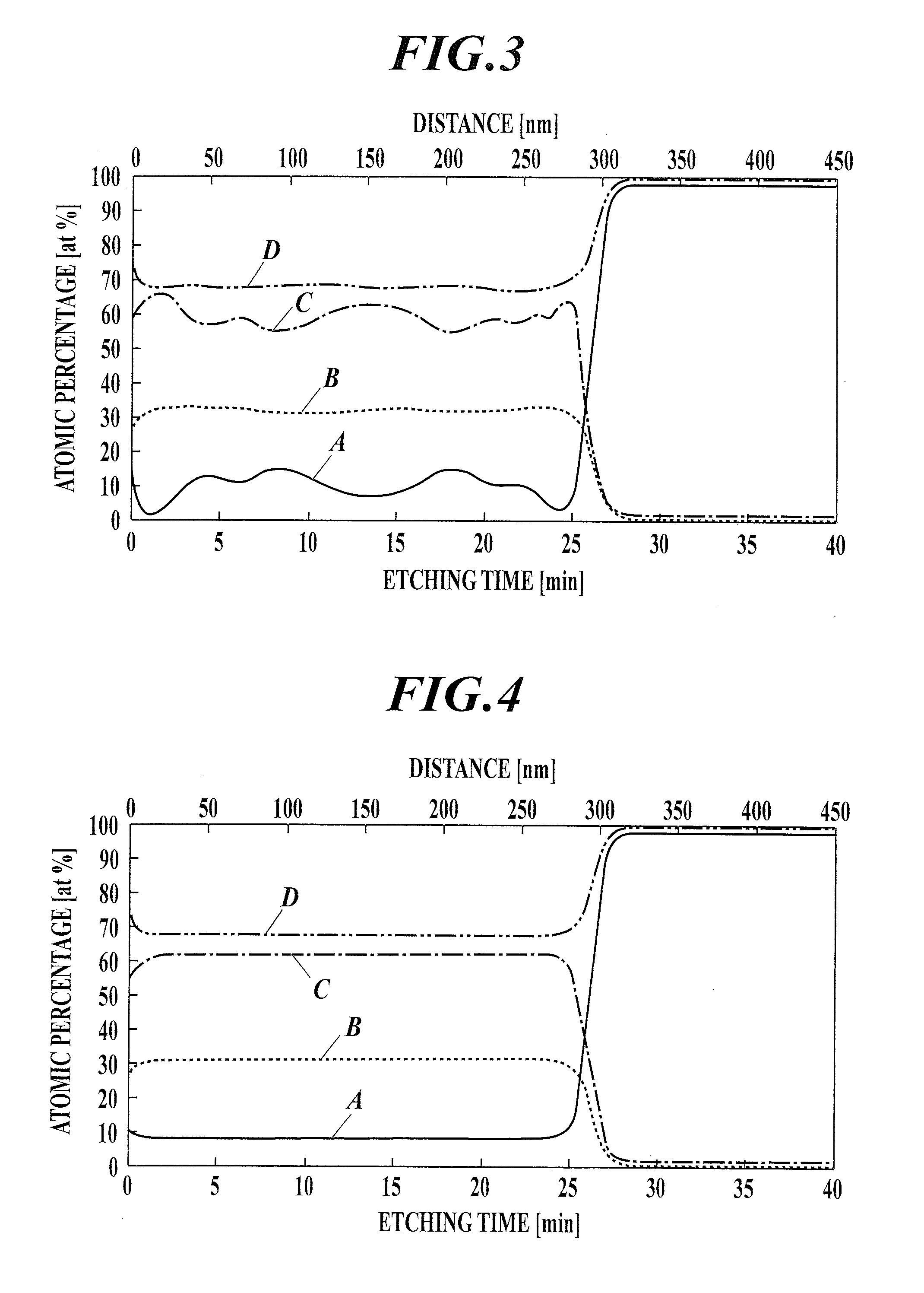

Adhesive layer for resin and a method of producing a laminate including the adhesive layer

InactiveUS20080261020A1Solve the lack of adhesionImprove adhesionPorous dielectricsWood working apparatusDendriteGlass transition

An adhesive layer for resin according to the present invention is formed of copper or a copper alloy for adhering a resin to a layer of copper or a copper alloy. The adhesive layer is formed of a metal layer of a coralloid structure made of an aggregation of a number of particles of copper or a copper alloy with gaps between the particles, and a plurality of micropores are present on the surface. The micropores have an average diameter in a range of 10 nm to 200 nm, and at least two micropores in average are present per 1 μm2 of the metal layer surface. Thereby, sufficient adhesion between the resin and the copper or copper alloy is provided. This serves to prevent ion migration caused by dendrites, which has been a problem in a conventional layer of tin or a tin alloy, and the adhesion to a resin having a high-glass transition temperature (Tg) is improved as well. The present invention also provides a method of producing a laminate including the adhesive layer.

Owner:MEC CO LTD

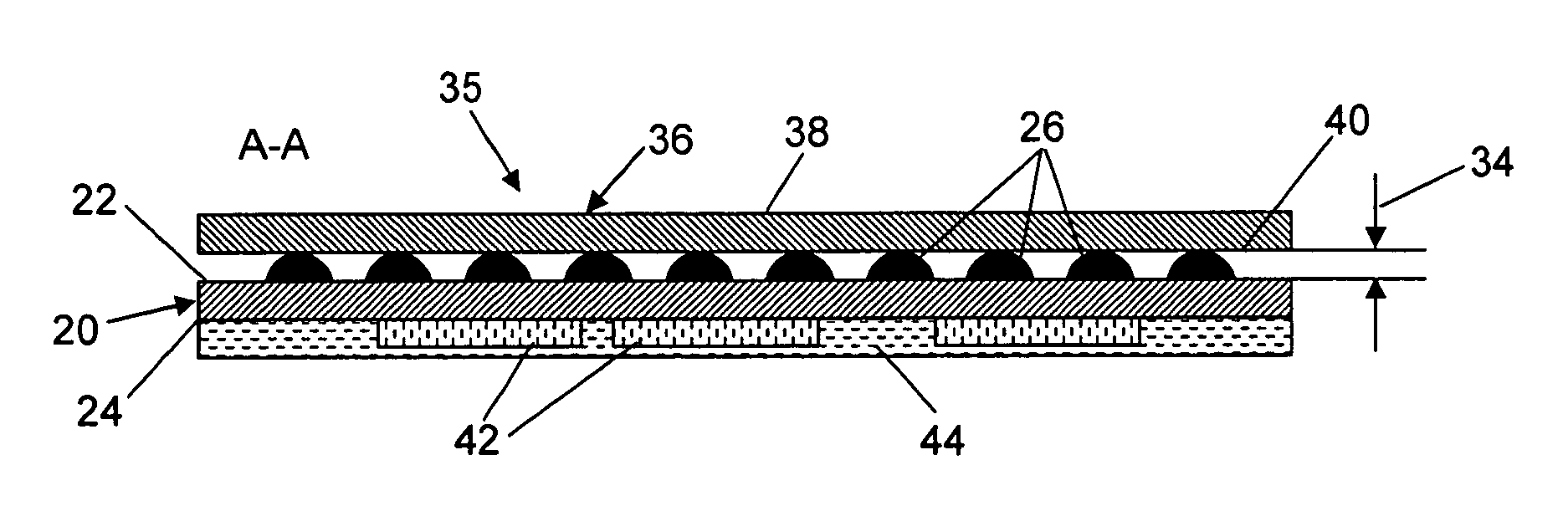

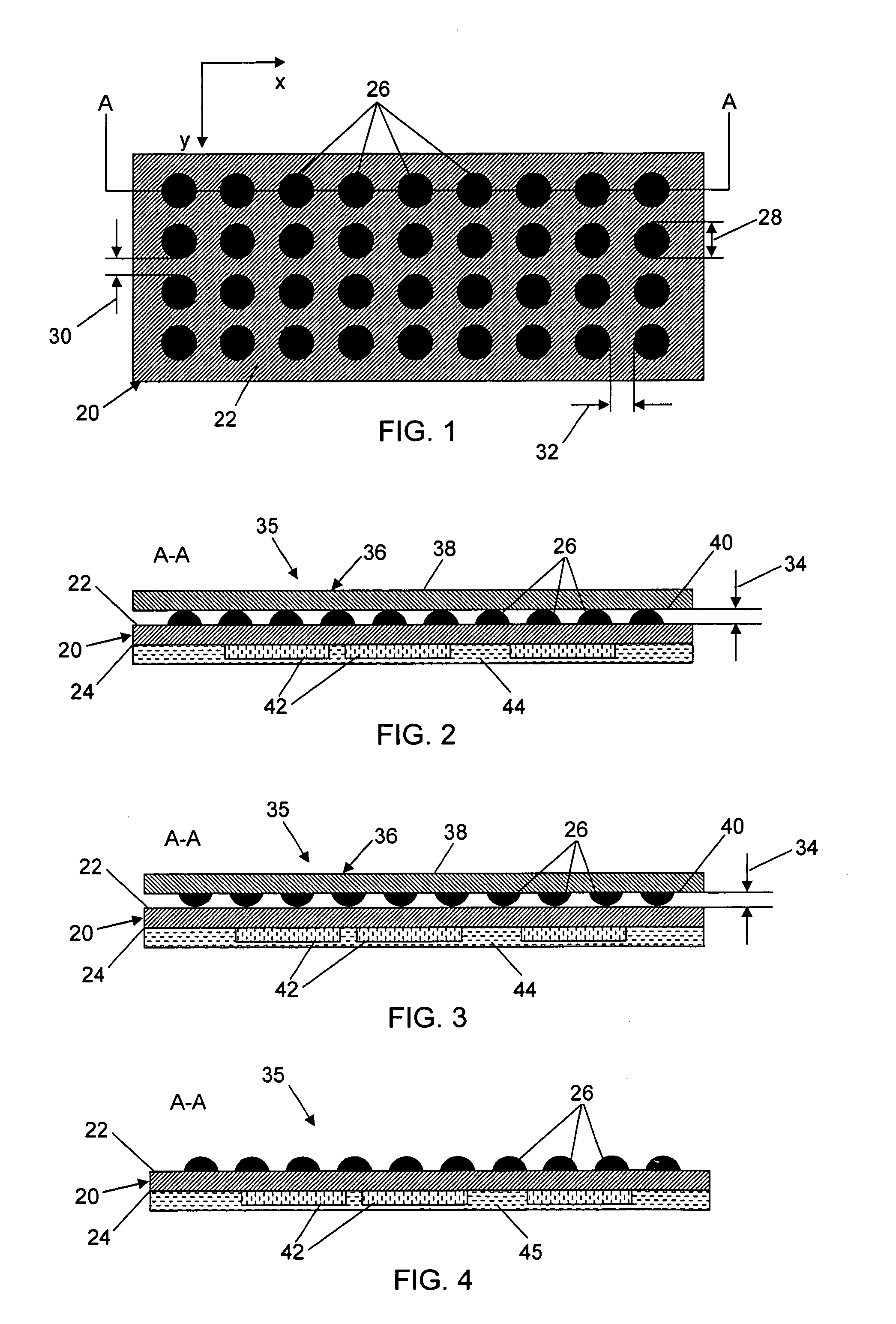

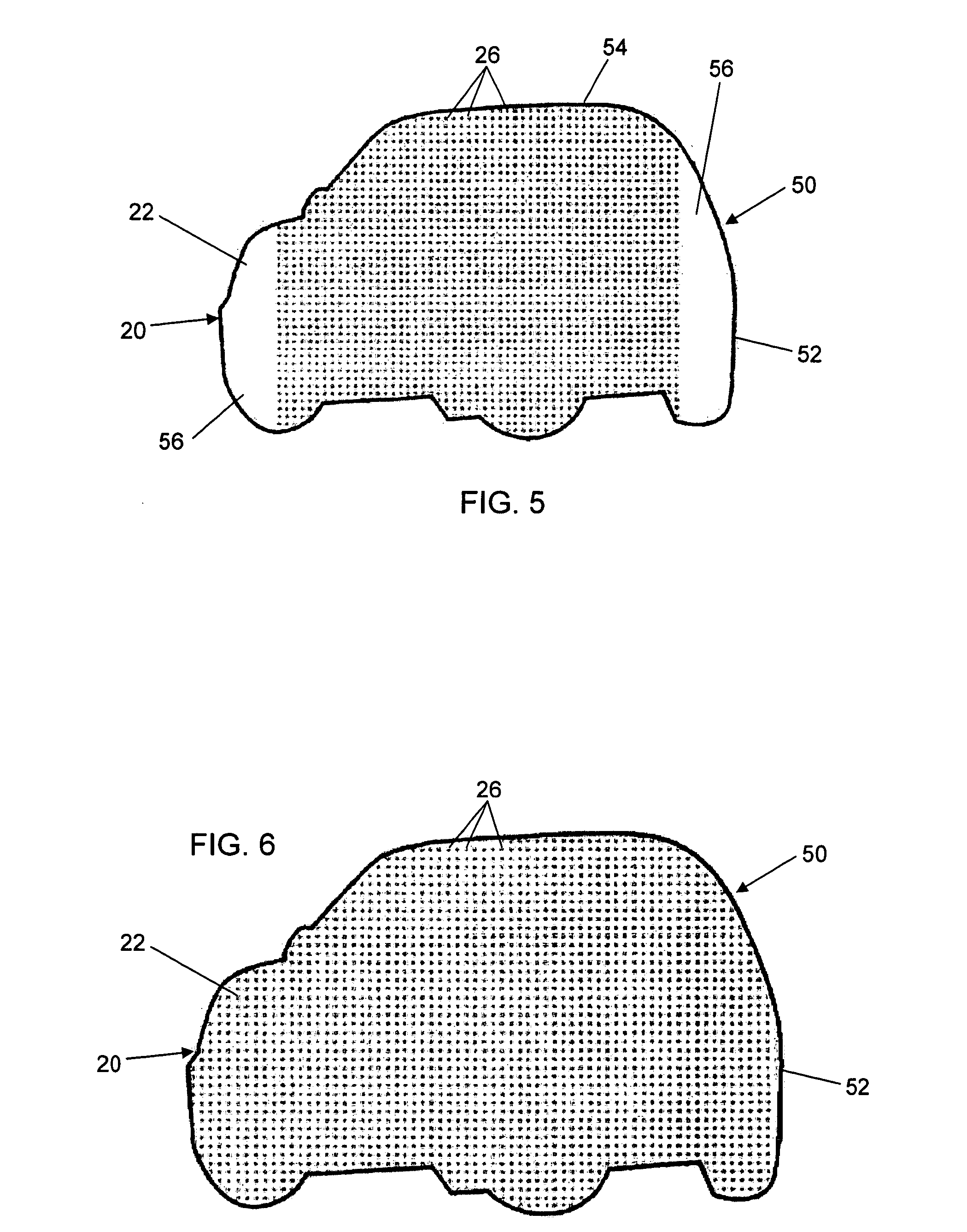

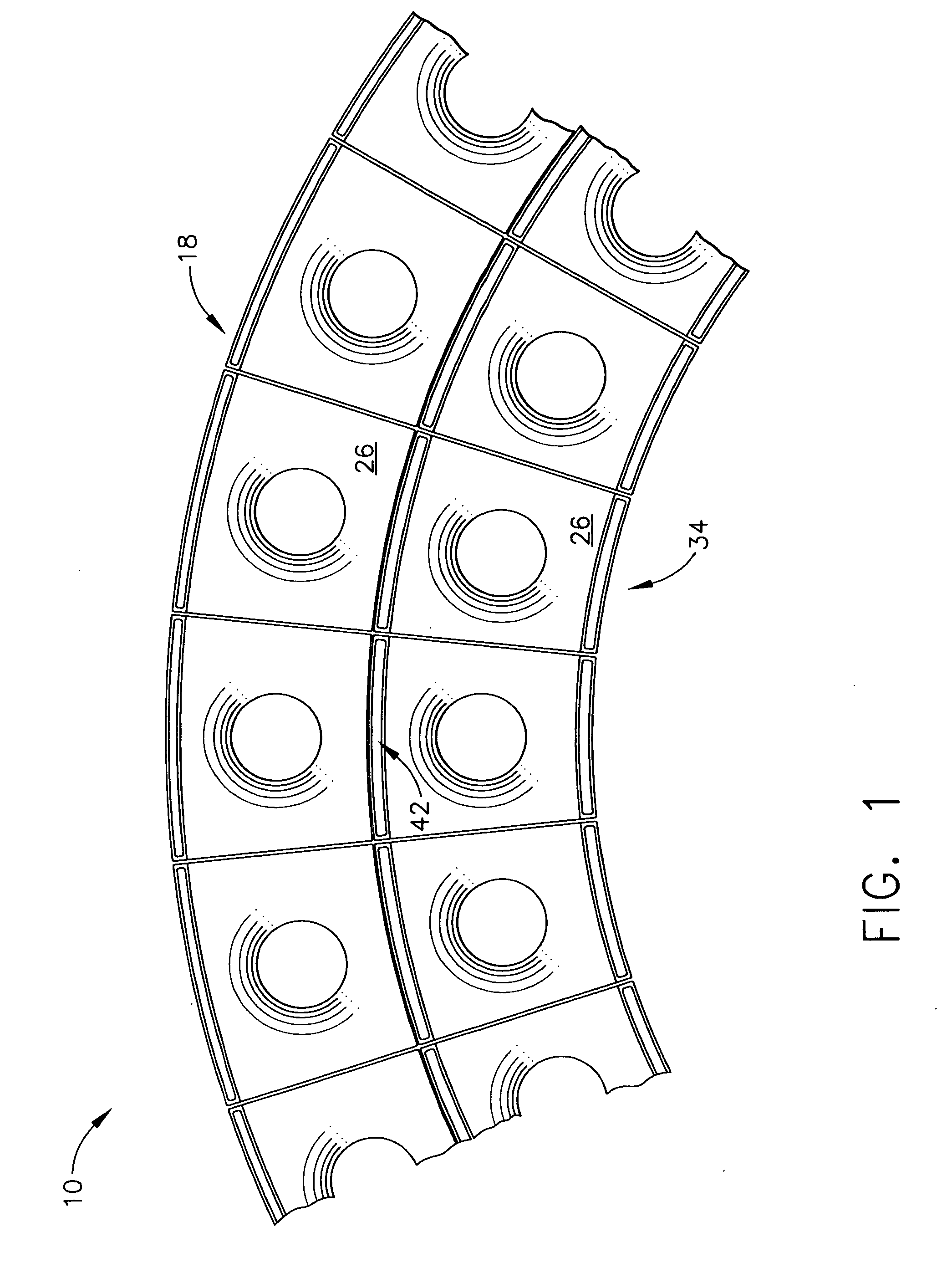

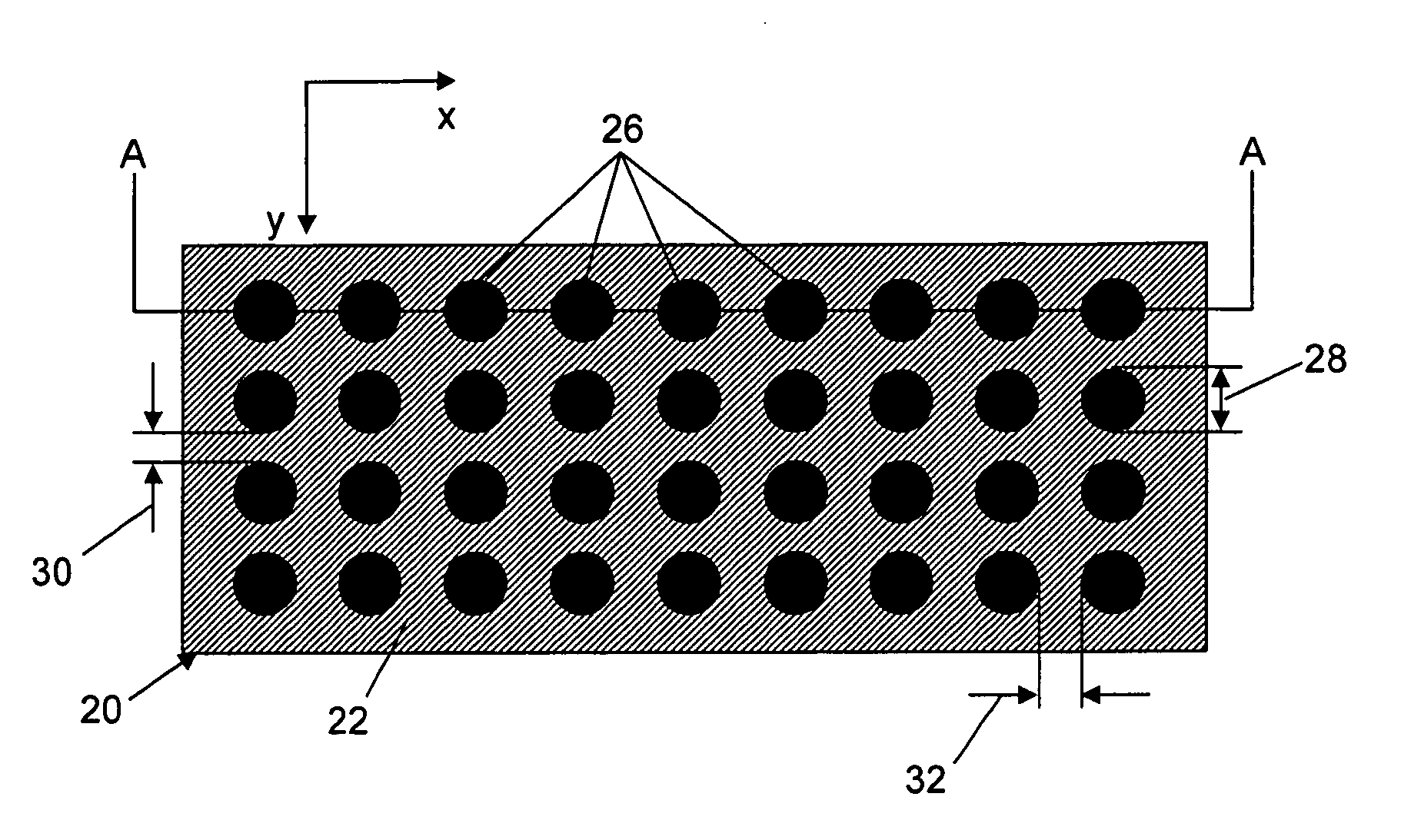

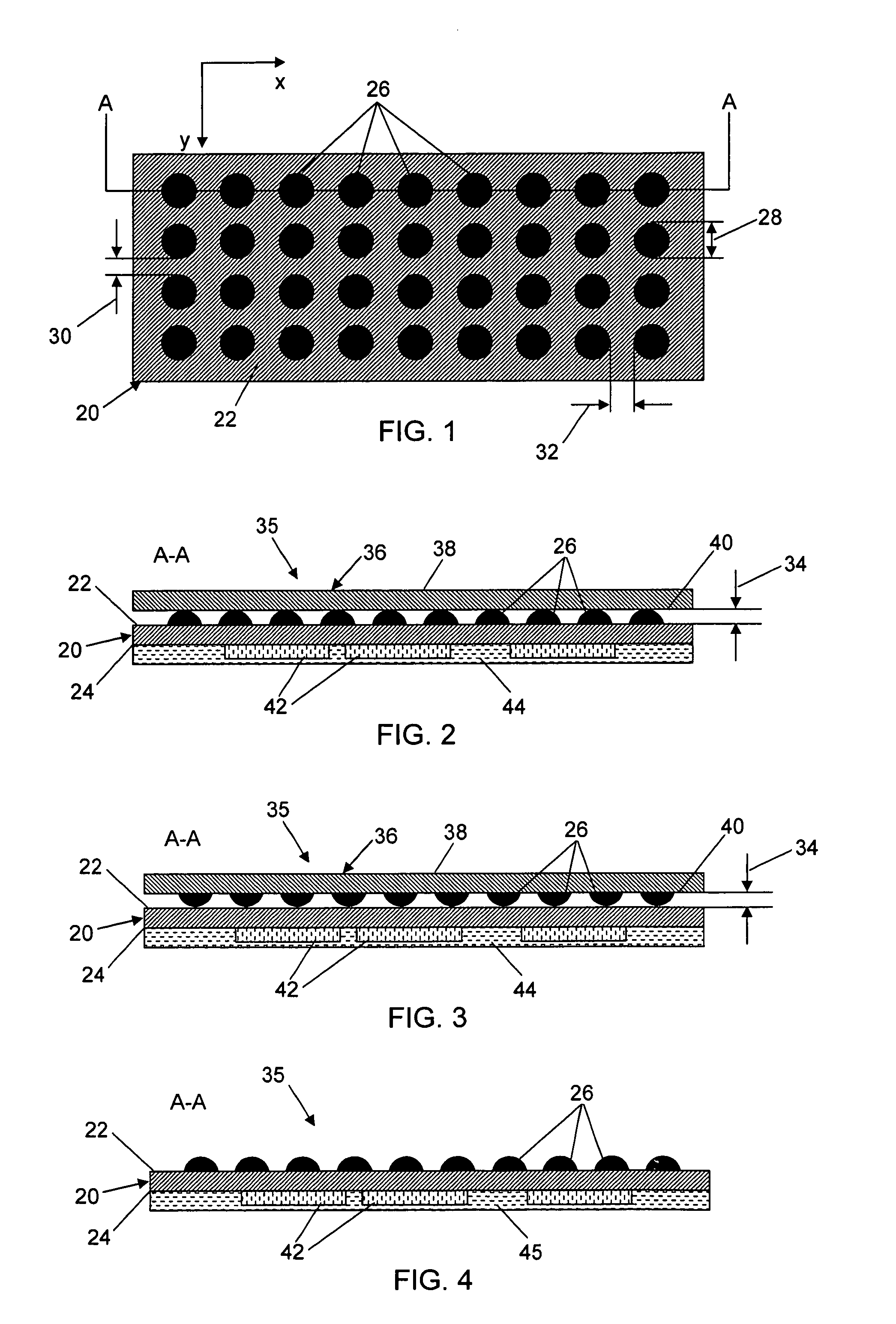

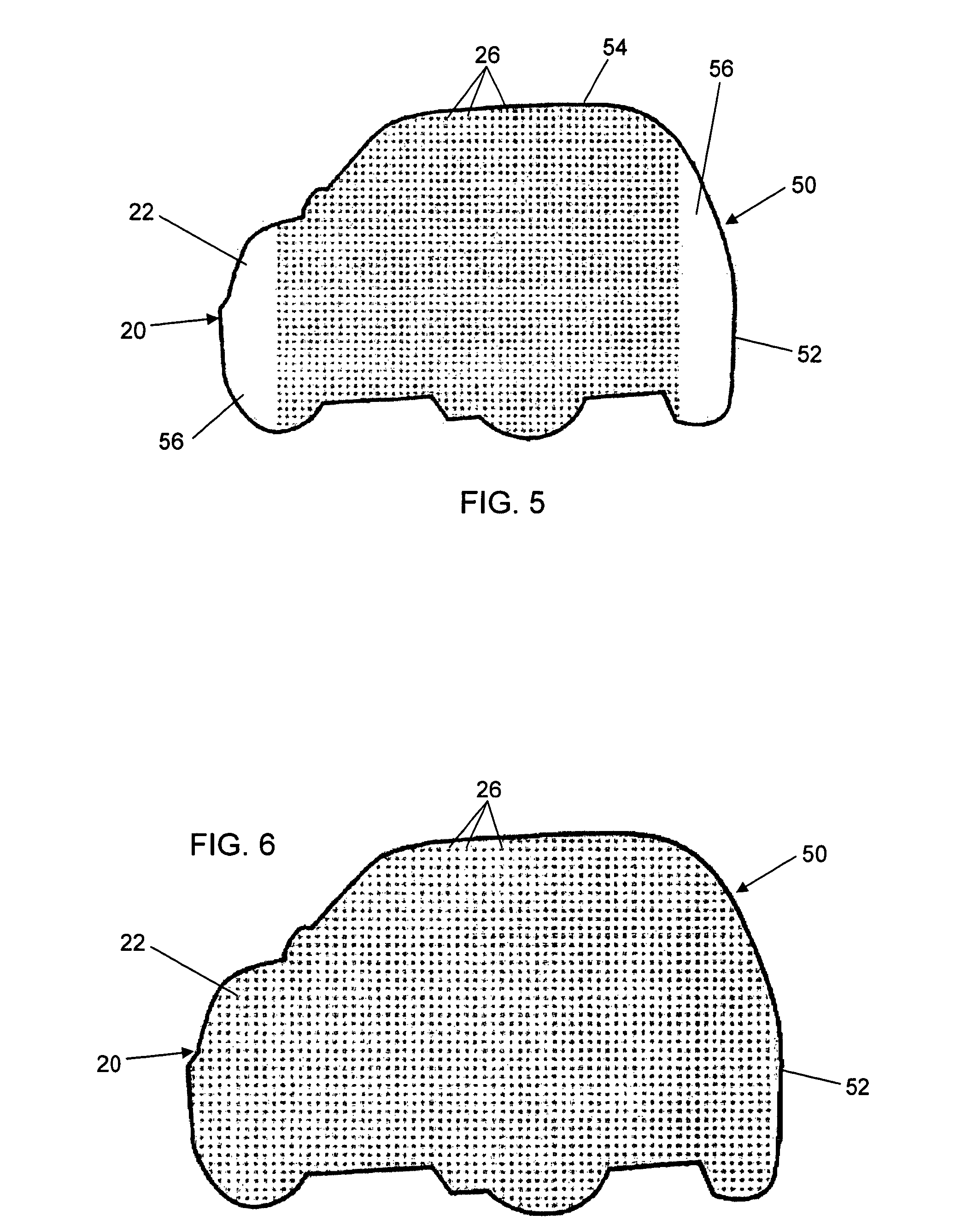

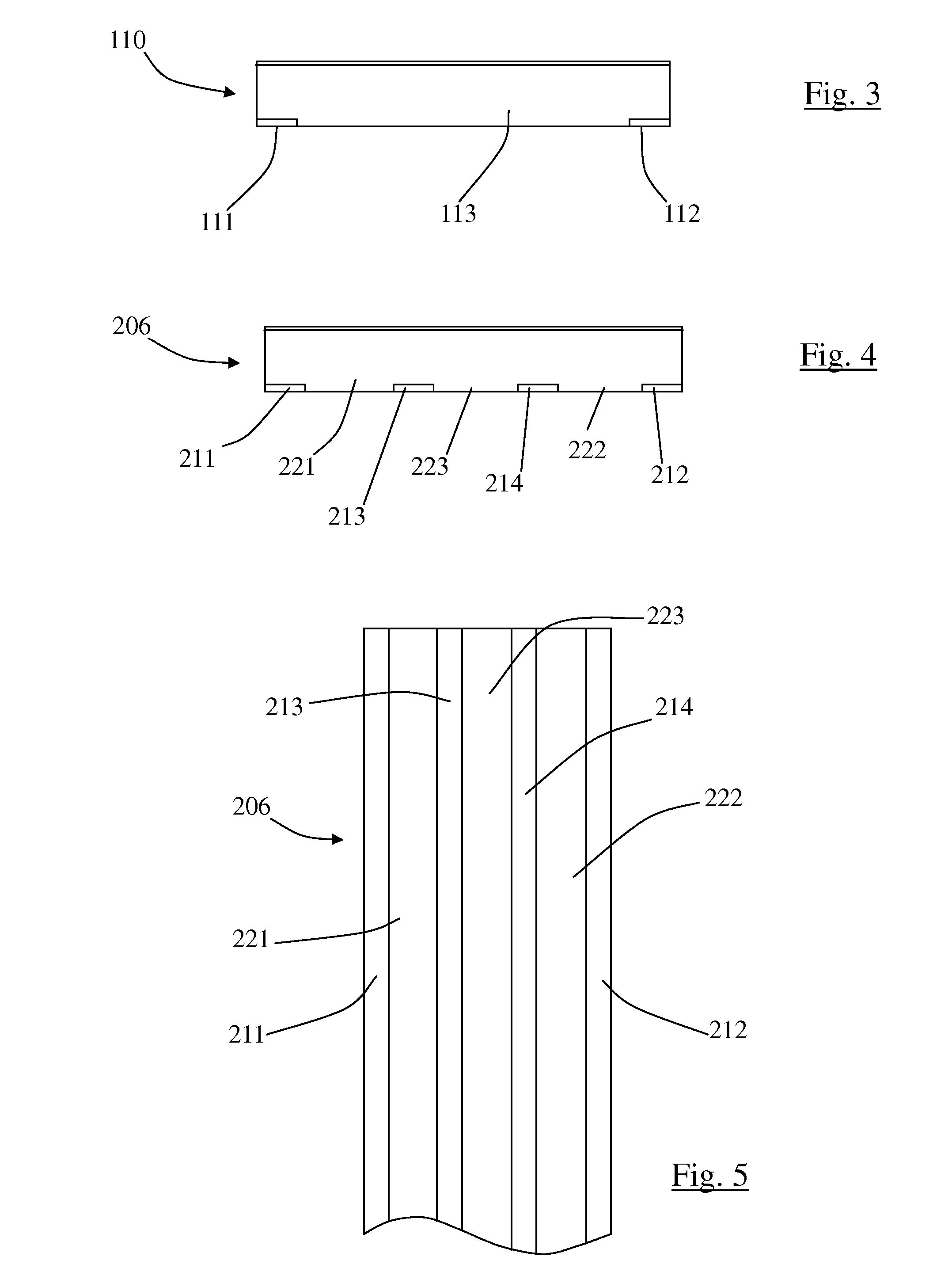

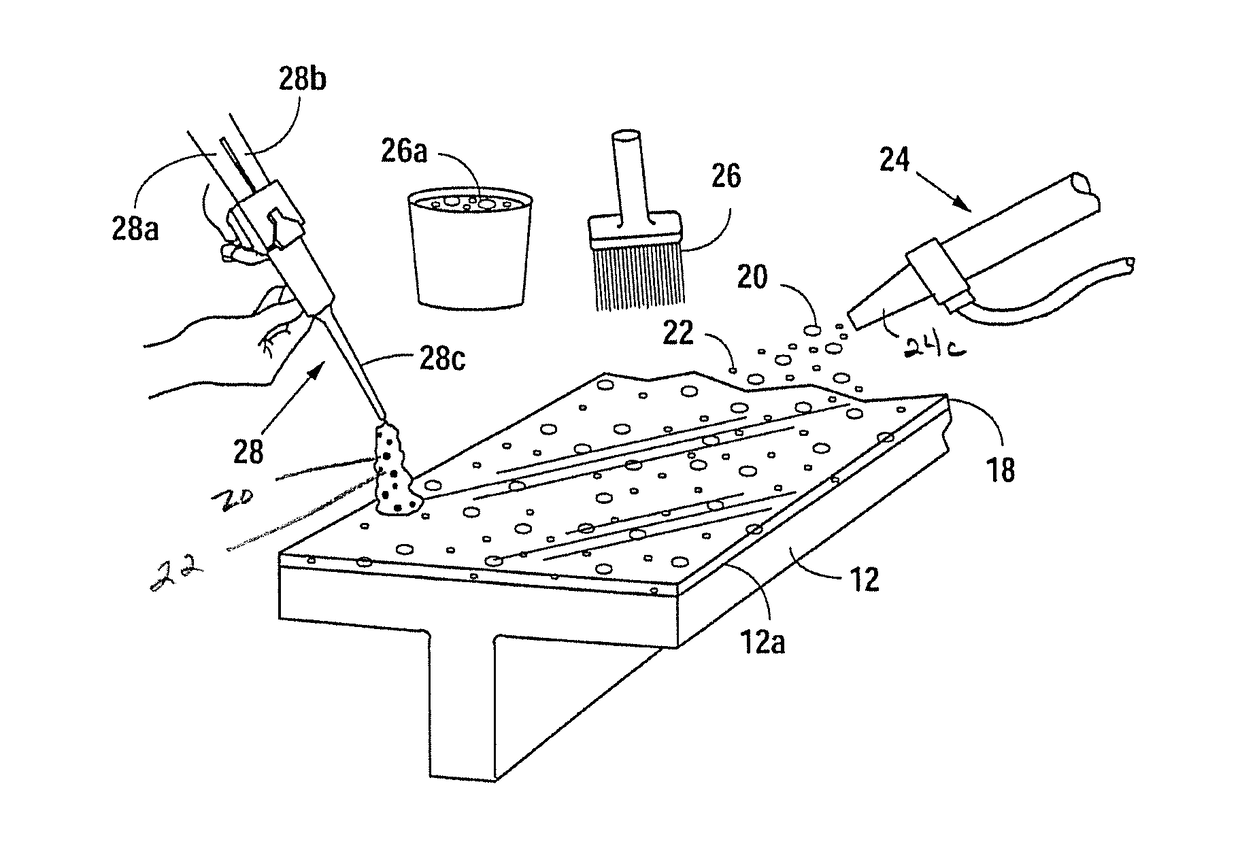

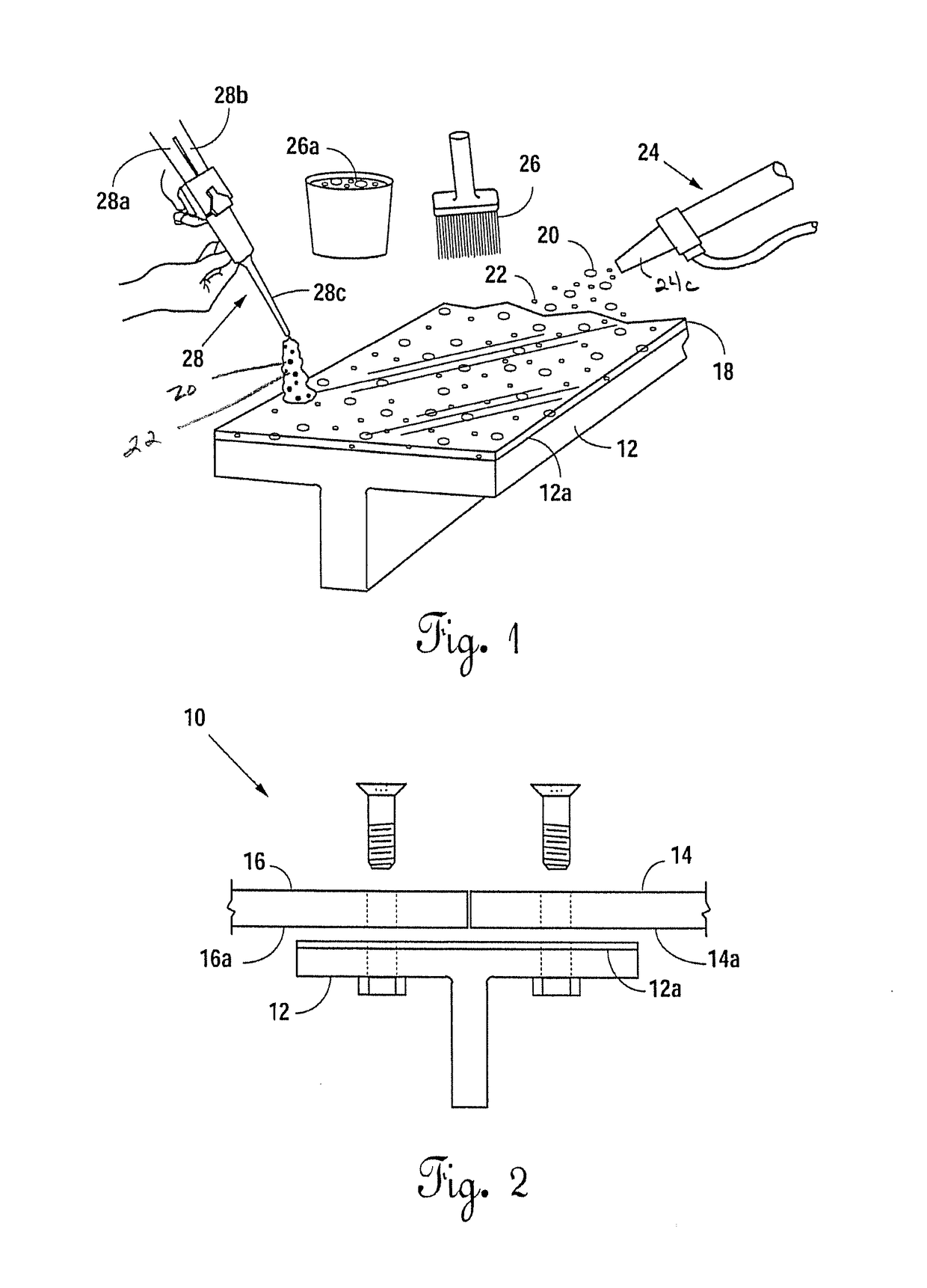

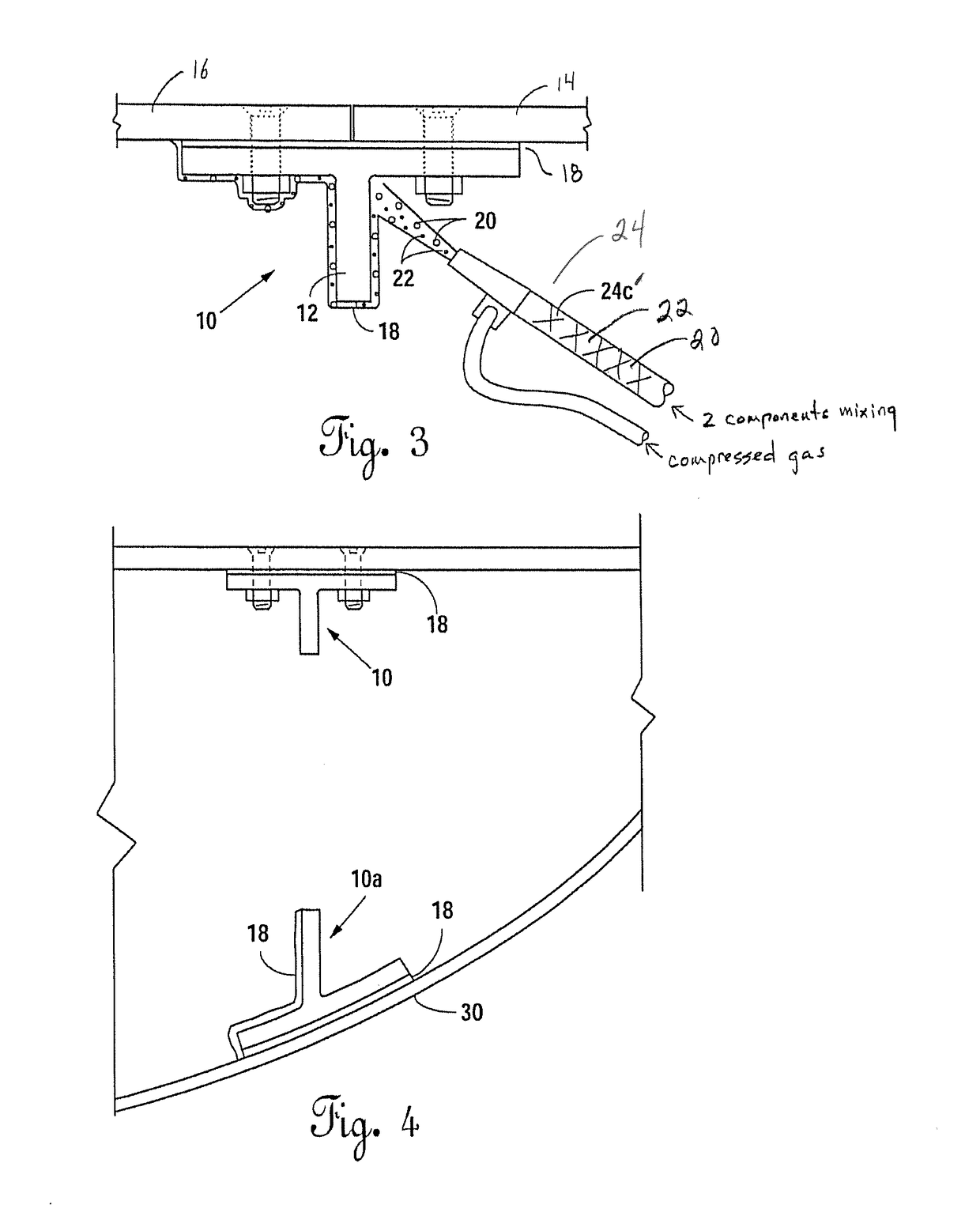

Repositionable labels using dot patterned adhesive

ActiveUS20060216451A1Solve the lack of adhesionSufficient adhesionStampsPaper/cardboard articlesWater basedEngineering

A method for forming a sheet of label material is provided. The label material is used to form a label for placement on an object and for subsequent removal from the object without damaging the object. The method includes providing a paper substrate that has an adhesive receiving face and coating an adhesive on the adhesive receiving face of the paper substrate using a gravure coater to form a repetitive pattern of adhesive areas. For example, repetitive dots of adhesive assure a uniform, discontinuous coating of adhesive that allows repositioning of the label, that prevents tearing of or damage to a substrate when the label is removed, including from a newspaper, and that maintains sufficient adhesion to adhere to difficult substrates such as textured surfaces. The adhesive is a water based adhesive. In alternative embodiments, the adhesive is coated on an adhesive receiving face of a release liner, and the adhesive receiving face of the paper substrate removably adheres to the release liner. The label material may include ink printed on a print receiving face of the paper substrate. The sheet of material may be die cut to form an irregularly shaped label.

Owner:NASTAR

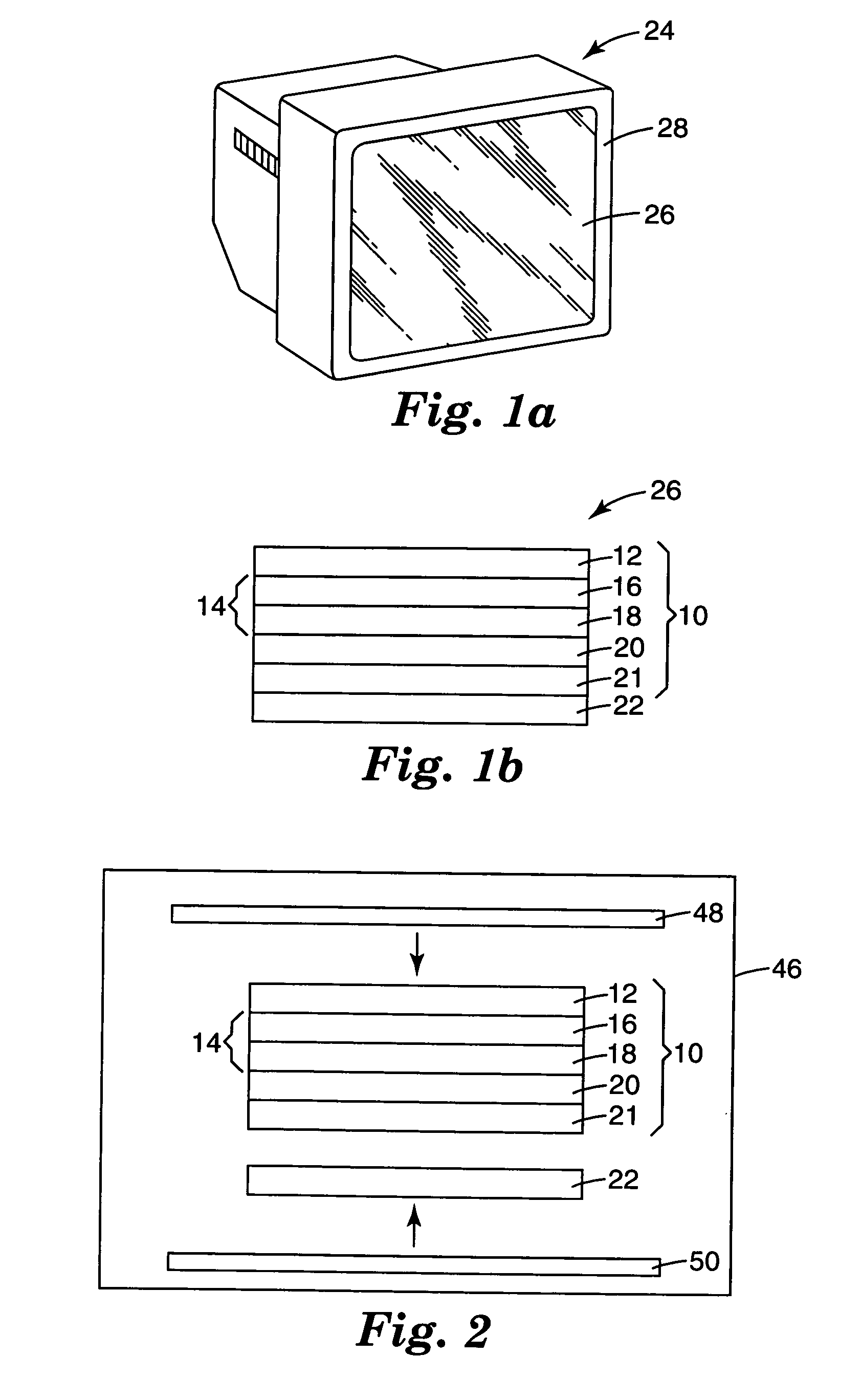

Transferable antireflection material for use on optical display

InactiveUS20060147729A1Sufficient adhesionIncreased durabilityLayered productsThin material handlingUltravioletRefractive index

An optical display, and method for forming an optical display, having improved antireflection properties and durability is formed by applying a transferable antireflection material to an optical substrate through the use of an in-mold or heat press technique or alternatively by an ultraviolet exposure technique. The transferable antireflection material is formed prior to application to the substrate and has at least a low refractive index layer and a high refractive index layer coupled to a release film. The low index reflection layer is preferably a silicon-modified fluoropolymer material having good durability, low refractivity, and appropriate adhesion to the release layer and subsequently applied high index refraction layer. The optical display is then coupled to a housing of an article for use.

Owner:3M INNOVATIVE PROPERTIES CO

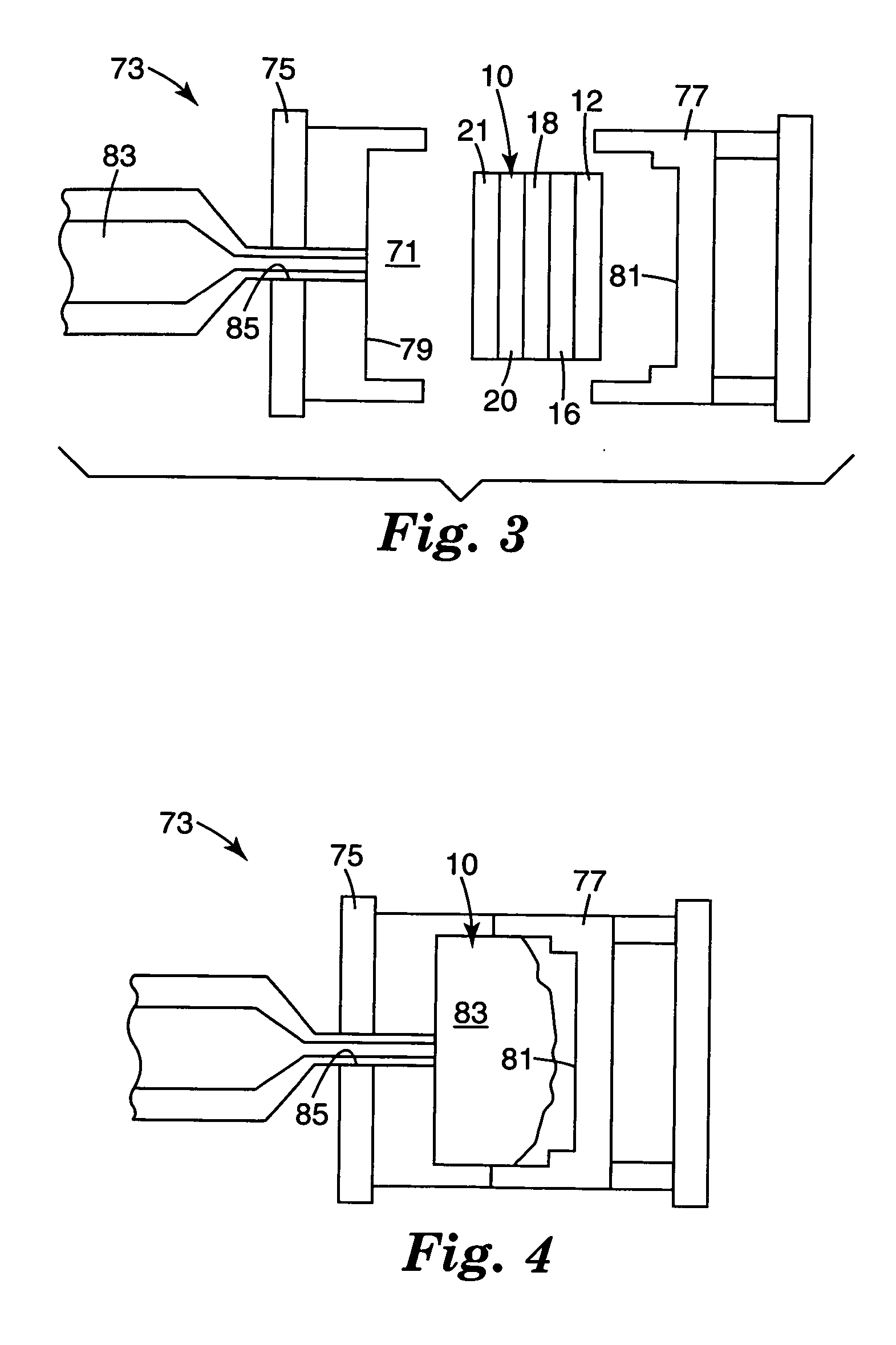

Method for applying or repairing thermal barrier coatings

InactiveUS20050191516A1Sufficient adhesionLess time consuming and uncomplicated way to applyLiquid surface applicatorsMolten spray coatingGas phaseAlloy

A method applying a thermal barrier coating to a metal substrate, or for repairing a thermal barrier coating previously applied by physical vapor deposition to an underlying aluminide diffusion coating that overlays the metal substrate. The aluminide diffusion coating is treated to make it more receptive to adherence of a plasma spray-applied overlay alloy bond coat layer. An overlay alloy bond coat material is then plasma sprayed on the treated aluminide diffusion coating to form an overlay alloy bond coat layer. A ceramic thermal barrier coating material is plasma sprayed on the overlay alloy bond coat layer to form the thermal barrier coating. In the repair embodiment of this method, the physical vapor deposition-applied thermal barrier coating is initially removed from the underlying aluminide diffusion coating.

Owner:NAGARAJ BANGALORE ASWATHA +6

Process for fabricating nanowire arrays

ActiveUS8143143B2Sufficient adhesionMaterial nanotechnologyOther chemical processesNanoparticleNanowire array

A process is provided for etching a silicon-containing substrate to form nanowire arrays. In this process, one deposits nanoparticles and a metal film onto the substrate in such a way that the metal is present and touches silicon where etching is desired and is blocked from touching silicon or not present elsewhere. One submerges the metallized substrate into an etchant aqueous solution comprising HF and an oxidizing agent. In this way arrays of nanowires with controlled diameter and length are produced.

Owner:ADVANCED SILICON GRP TECH LLC

Silicone rubber coating composition and airbag

InactiveUS20060286390A1Solve the lack of adhesionSufficient adhesionLayered productsFibre treatmentCompound (substance)Titanium

A silicone rubber coating composition comprising (A) a diorganopolysiloxane containing at least two alkenyl groups, (B) an organopolysiloxane resin, (C) finely divided silica, (D) an organohydrogenpolysiloxane containing at least two SiH groups, (E) an addition reaction catalyst, (F) an organosilicon compound containing a tackifying functional group, and (G) an organic titanium or zirconium compound is coated onto a base fabric to form a coated fabric, from which airbags are manufactured. The composition has a sufficient adhesion to withstand high temperature and abrupt elongation upon inflation of an airbag even after long-term storage under hot humid conditions, and can form a uniform thin-film.

Owner:SHIN ETSU CHEM IND CO LTD

Electroless metal coatings

InactiveUS20110206532A1Improve corrosion resistanceSufficient adhesionPropellersPump componentsElectroless nickelMetal coating

The present invention provides a method for preparing an electroless nickel coating composition that includes (a) coating a substrate with an electroless nickel coating to provide a coated substrate; and (b) subjecting the coated substrate to a heating protocol comprising heating to a temperature in a range from about 550° C. to about 700° C. for a period of from about 7 to about 30 hours. An article made from the method is also provided.

Owner:GENERAL ELECTRIC CO

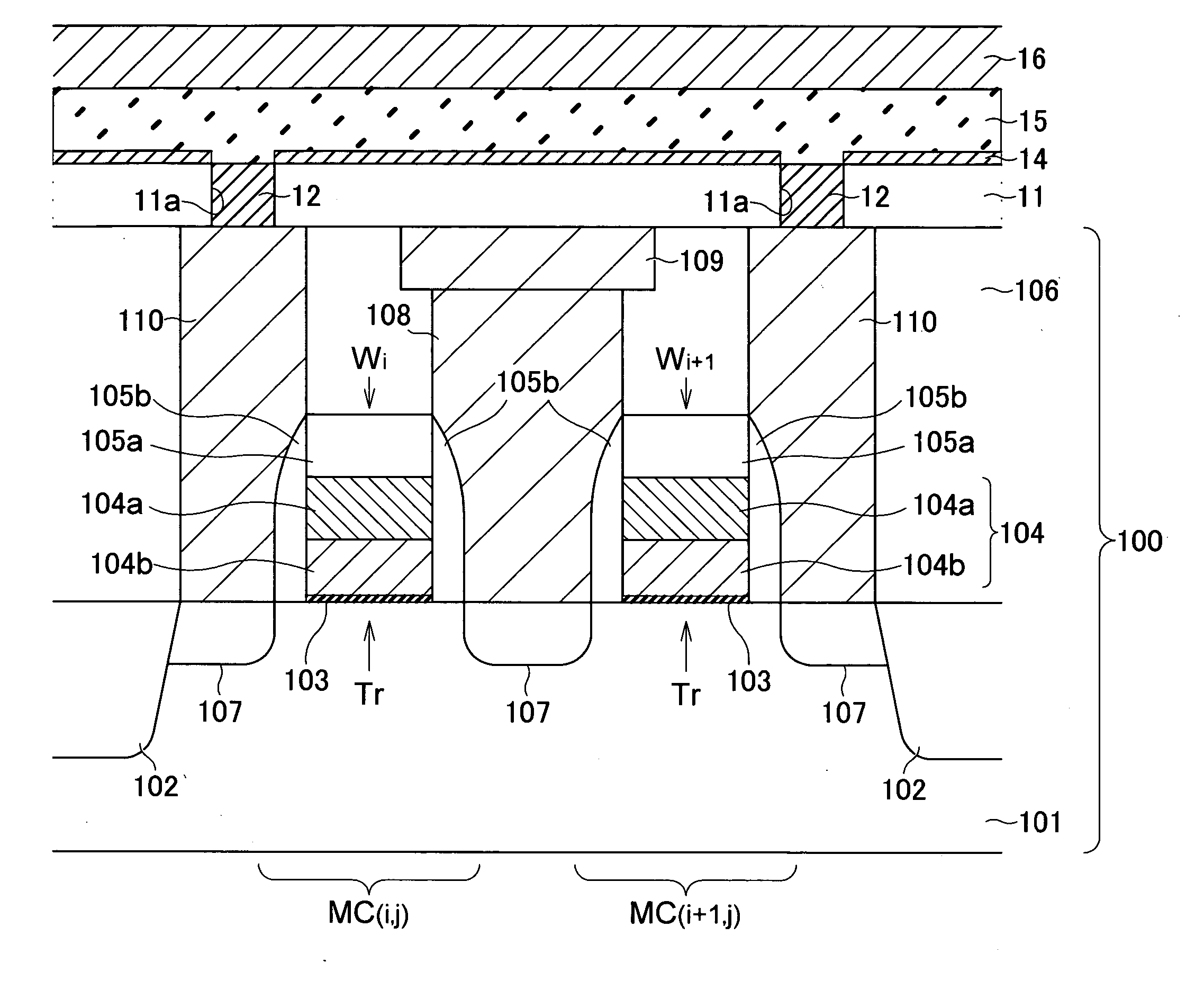

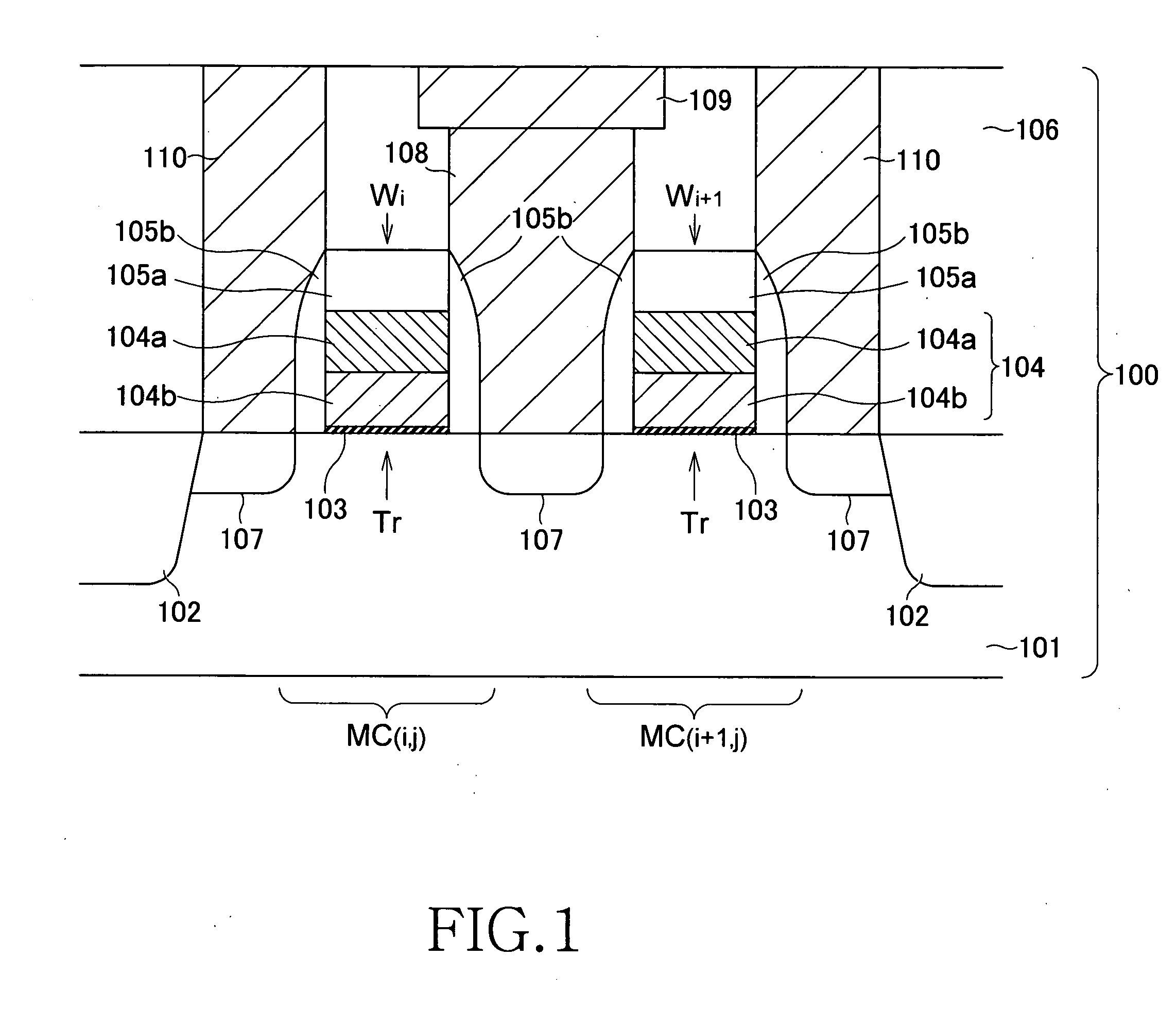

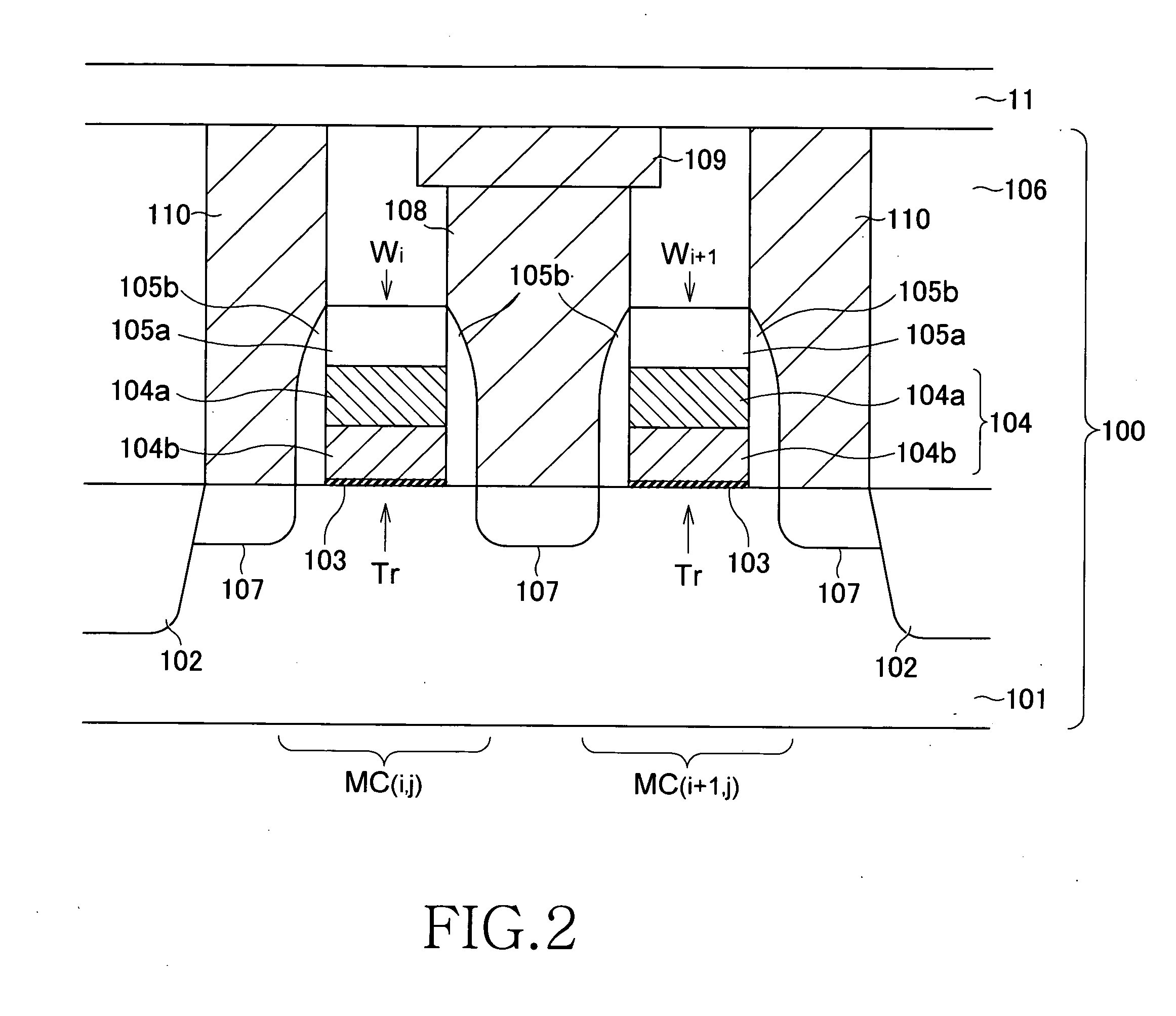

Method of manufacturing non-volatile memory element

InactiveUS20070141786A1Total current dropEffect disappearSolid-state devicesSemiconductor/solid-state device manufacturingElectrical connectionEngineering

A method of manufacturing a non-volatile memory element in the present invention comprises a first step for forming an adhesion layer on an interlayer insulating film so that an electrical connection is established with a lower electrode, a second step for forming a recording layer containing a phase change material on the adhesion layer, a third step for forming an upper electrode that is electrically connected to the recording layer, and a fourth step for diffusing in the recording layer some of the adhesion layer positioned between at least the lower electrode and the recording layer.

Owner:ELPIDA MEMORY INC

Repositionable labels using dot patterned adhesive

A method for forming a sheet of label material is provided. The label material is used to form a label for placement on an object and for subsequent removal from the object without damaging the object. The method includes providing a paper substrate that has an adhesive receiving face and coating an adhesive on the adhesive receiving face of the paper substrate using a gravure coater to form a repetitive pattern of adhesive areas. For example, repetitive dots of adhesive assure a uniform, discontinuous coating of adhesive that allows repositioning of the label, that prevents tearing of or damage to a substrate when the label is removed, including from a newspaper, and that maintains sufficient adhesion to adhere to difficult substrates such as textured surfaces. The adhesive is a water based adhesive. In alternative embodiments, the adhesive is coated on an adhesive receiving face of a release liner, and the adhesive receiving face of the paper substrate removably adheres to the release liner. The label material may include ink printed on a print receiving face of the paper substrate. The sheet of material may be die cut to form an irregularly shaped label.

Owner:NASTAR

Acidic aqueous chlorite teat dip with improved visual indicator stability, extended shelf life, sanitizing capacity and tissue protection

InactiveUS20030206971A1Reduce wasteReducing costly disposalUltrasonic/sonic/infrasonic diagnosticsAntibacterial agentsChlorine dioxideTissue protection

The mastitis control teat dip composition having a visible indicator aspect of the invention provides a softening, soothing, smoothing, relaxing property, a rapid initial kill, a useful highly pseudoplastic rheology, a barrier / film-forming capacity, a unique antimicrobial composition that is stable over an extended period of time, and unexpected long term microbial control when compared to the prior art materials disclosed in patents and used in the marketplace. The indicator aspect provides ease of visually detecting the material on the animal skin and can indicate efficacy of the material. The compositions of the invention are made by combining an aqueous liquid composition containing the visual indicator combined with the organic components which can be combined with a simple aqueous solution of a salt of chlorous acid, preferably an alkali metal chlorite. The materials after they are combined and blended into a smooth viscous material containing an emollient package generates active antimicrobial chlorine dioxide and can be immediately contacted with the target animals. The compositions of the invention provide stable visual indication, rapid initial kill, consistent long term kill with chemical and rheological stability.

Owner:ECOLAB USA INC

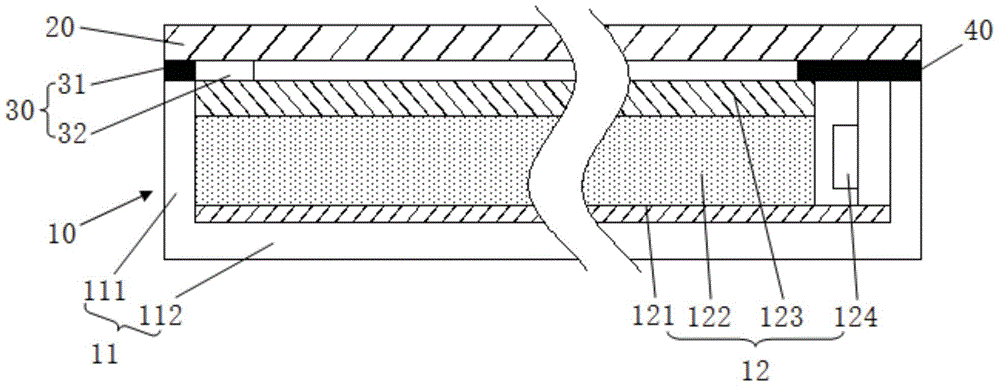

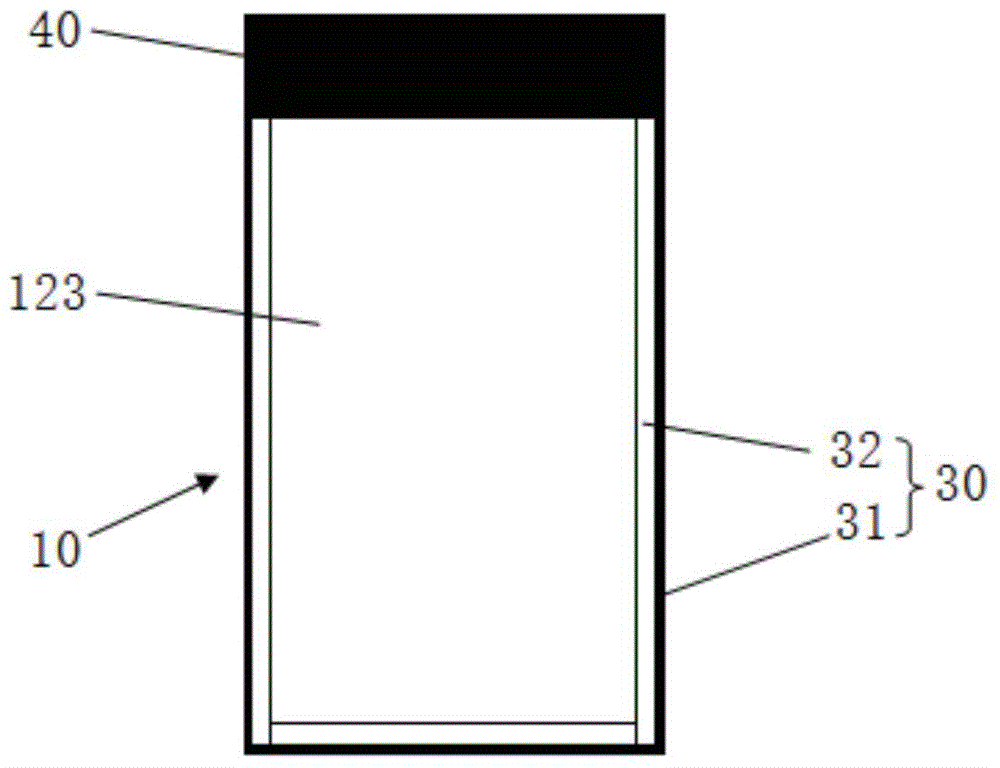

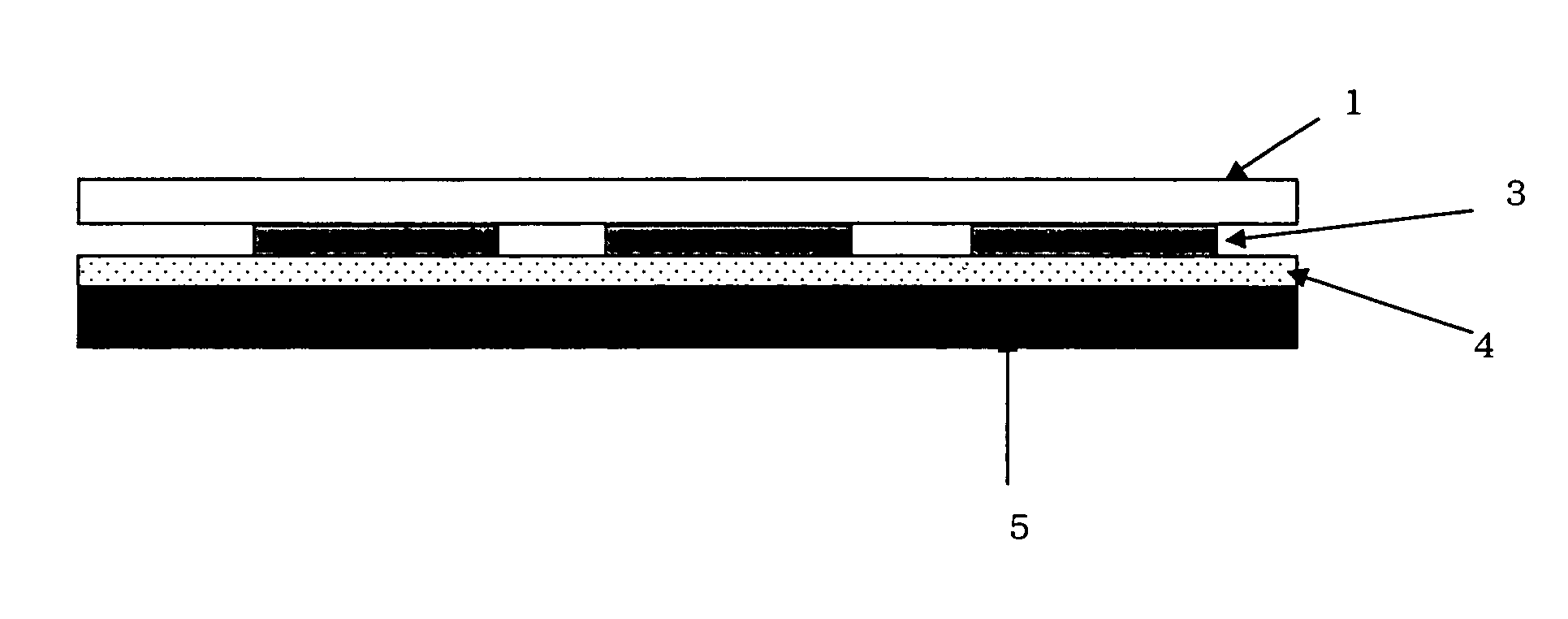

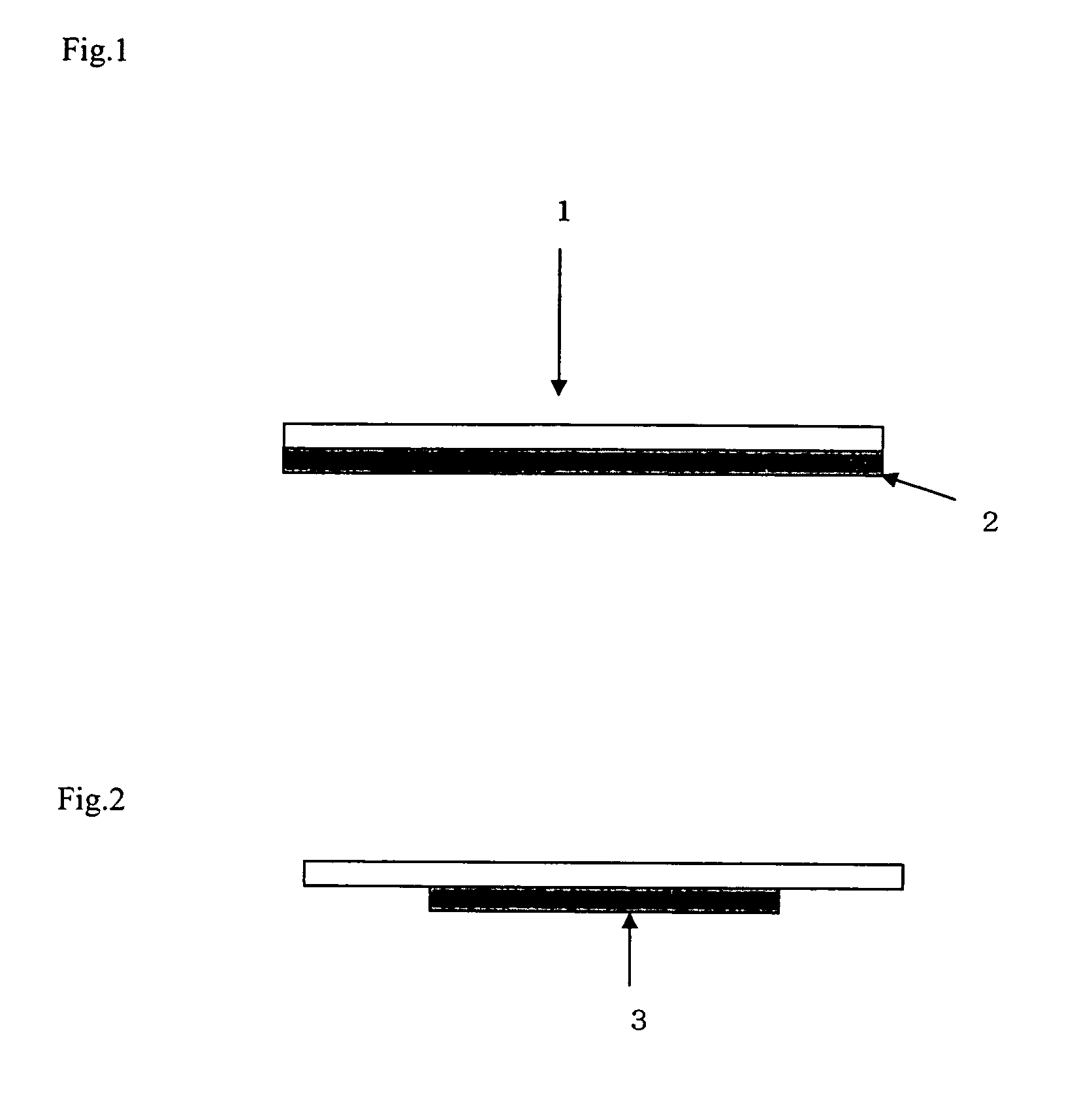

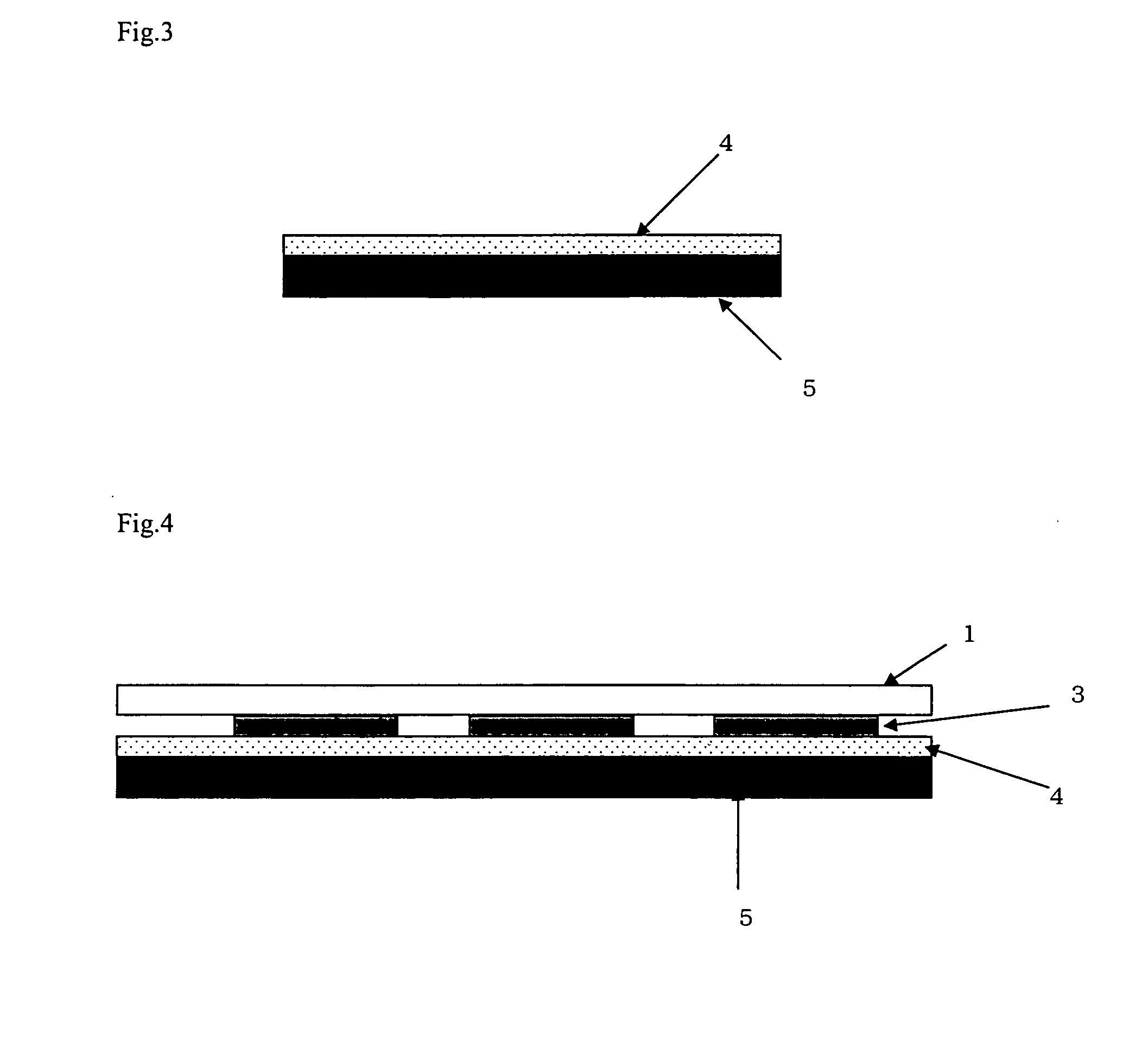

Narrow-frame liquid crystal display module

ActiveCN104834113AIncrease widthEasy to cutOptical light guidesNon-linear opticsAdhesion forceLiquid-crystal display

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

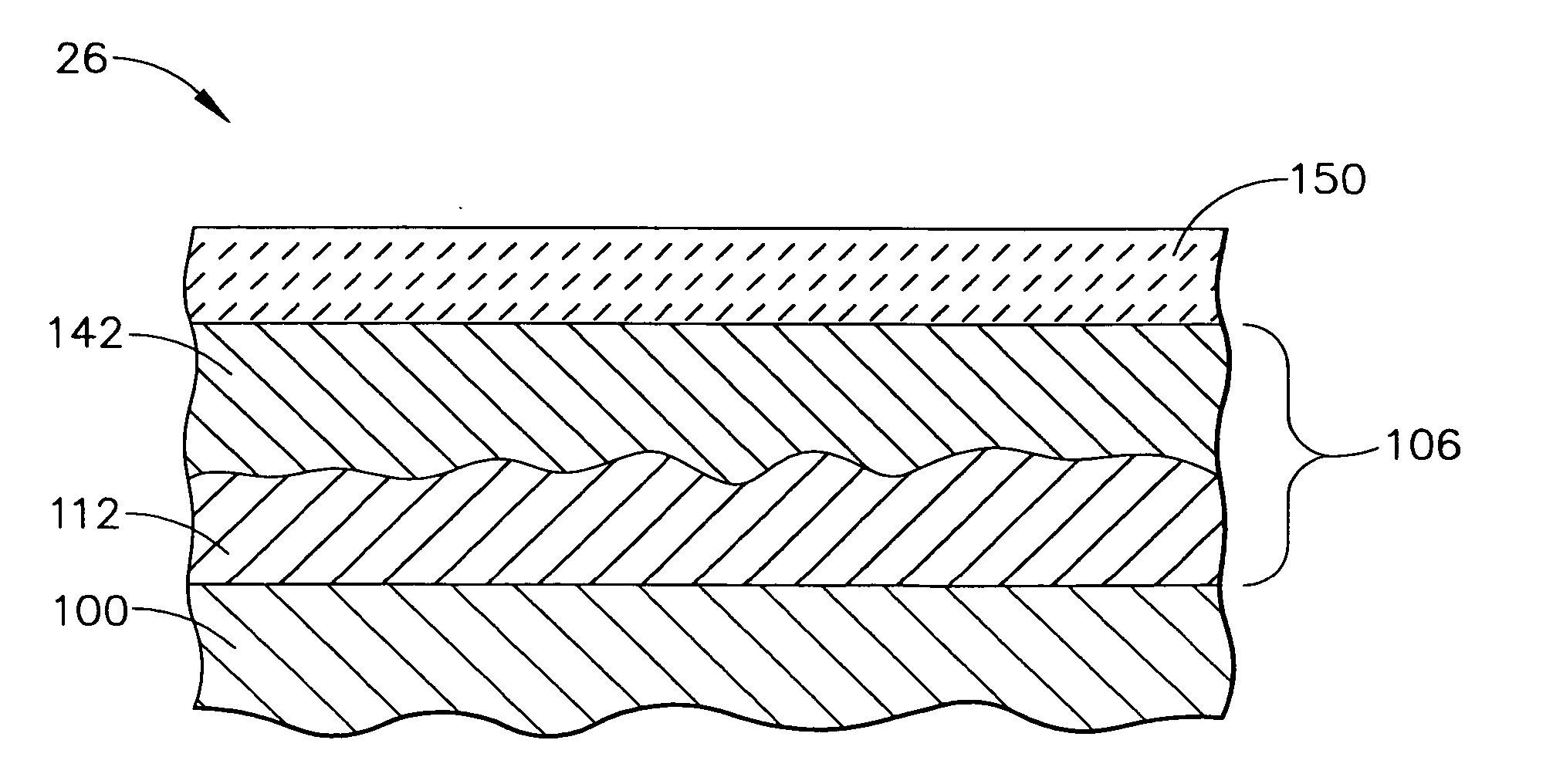

Flashing and waterproofing membrane

ActiveUS20110091675A1Solve the lack of adhesionCost is not prohibitiveLayered product treatmentRoof covering using flexible materialsParticulatesAdhesive

A laminate tape that has a bottom layer of aggressive adhesive formulated to have sufficient adhesion to construction materials to as low as 20 degrees F. The adhesive is applied in a layer of about 2 to 5 mils. A second layer that is about 10 to 60 mils thick is made of rubberized asphalt, which provides self-sealing capabilities. In one embodiment, the first layer has strips of adhesive and sections of rubberized asphalt. The third layer is a film, which can be a thin, contiguous polymer, fabric or particulate. The laminate can be used where a strong adhesive is needed that will adhere to construction materials at or near 20 degrees Fahrenheit, while still retaining self-sealing characteristics.

Owner:GARLAND INDS

Adhesive Film and Method for Manufacturing Semiconductor Device Using Same

InactiveUS20080185700A1Solve the lack of adhesionSuperior in anti-chipping property propertySemiconductor/solid-state device detailsSynthetic resin layered productsDicing tapeUltimate tensile strength

The invention provides an adhesive tape which acts as a dicing tape which is excellent in dicing property and pickup property in a dicing step, and as an adhesive tape which is excellent in connection reliability in a step of bonding a semiconductor device with a supporting member. The adhesive film comprises a layer in which an adhesive layer (A) comprising an olefin polymer and an adhesive layer (B) are directly laminated to each other, wherein the 180° peel strength between the layer (A) and the layer (B) is not more than 0.7 N / 10 mm.

Owner:MITSUI CHEM INC

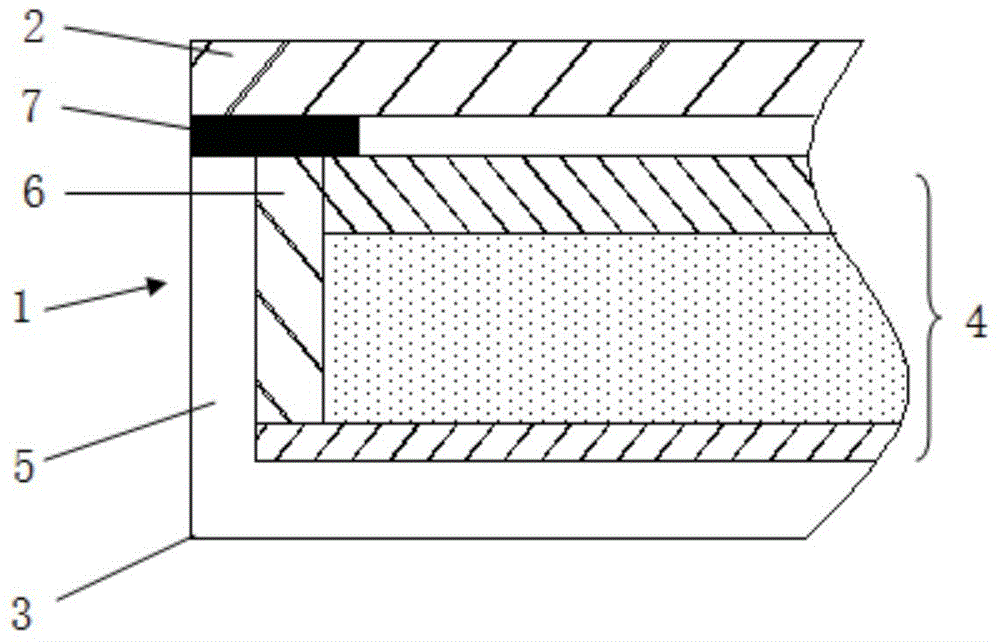

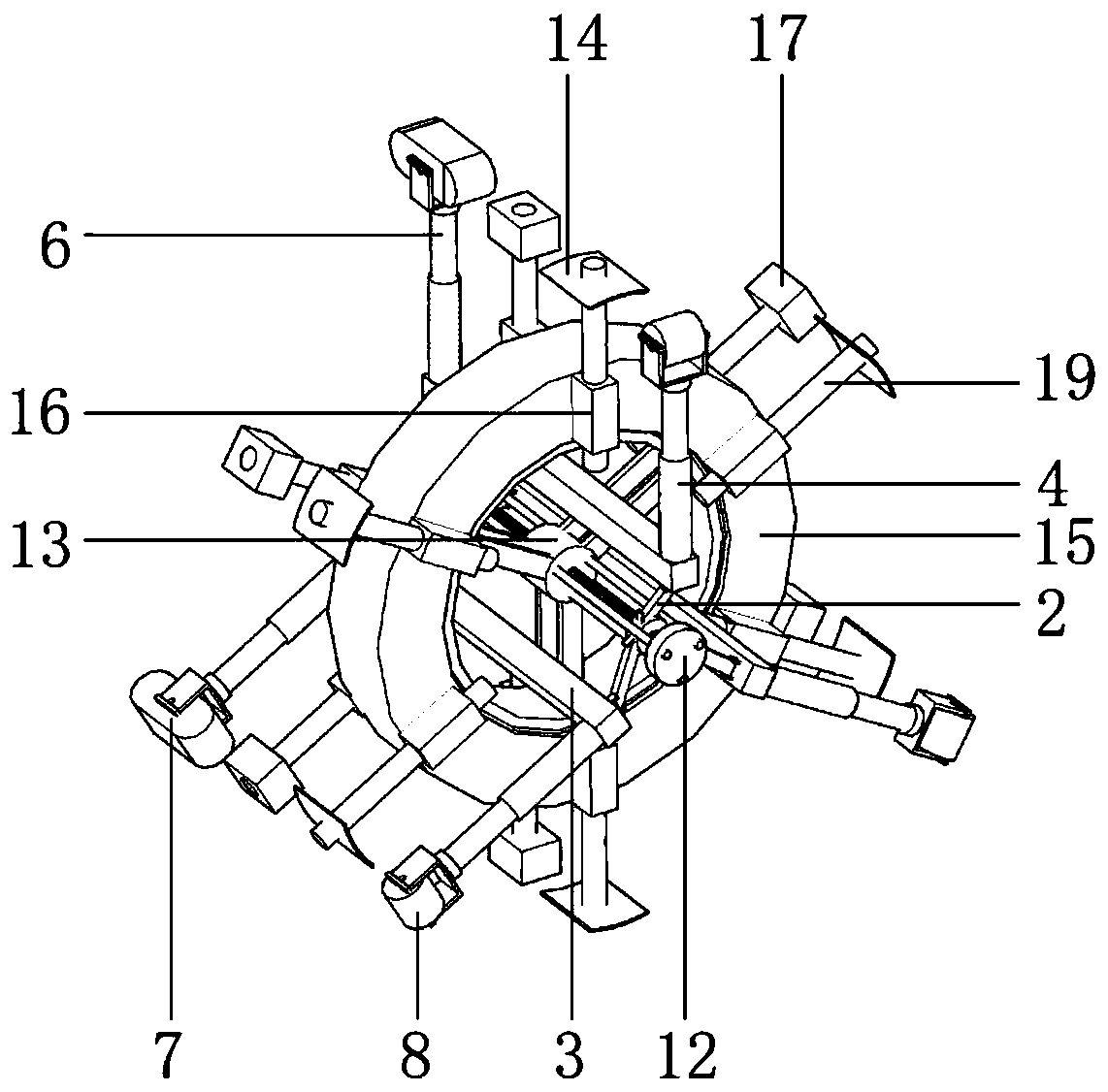

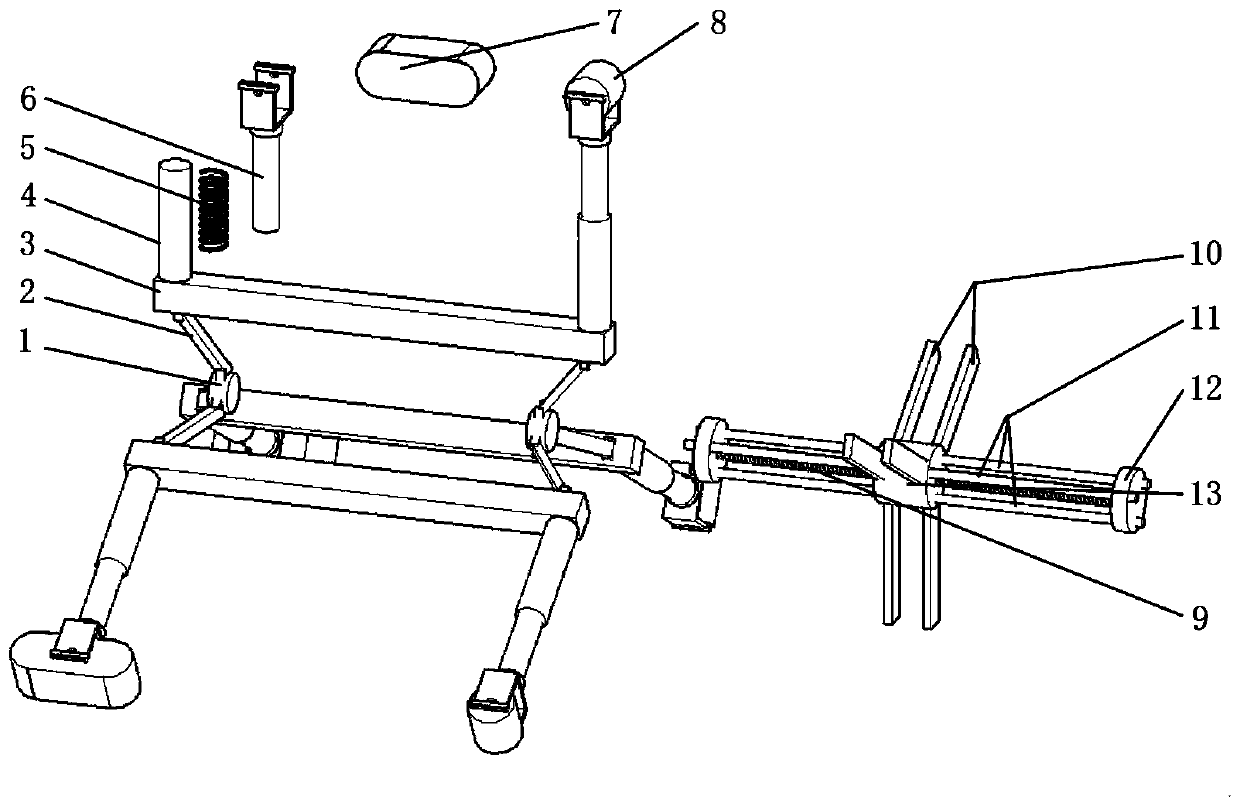

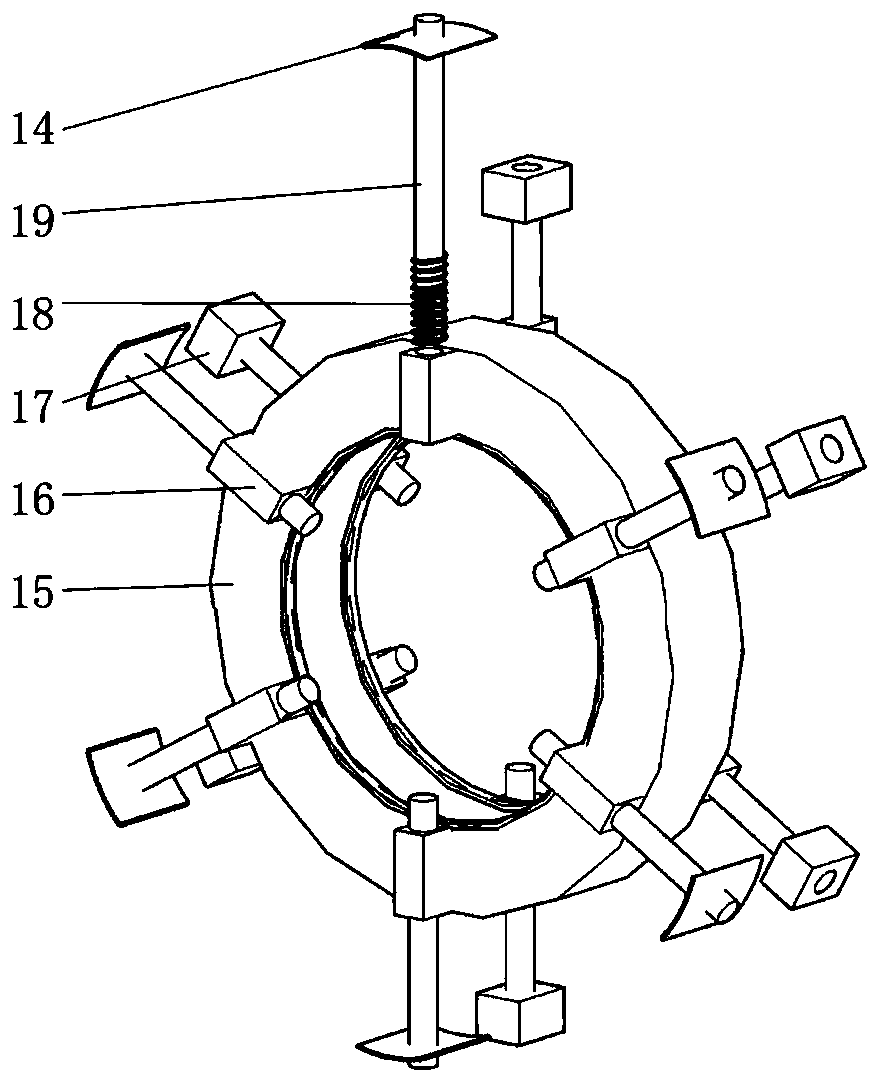

Petroleum pipeline cleaning and detecting robot

ActiveCN110701429AEnsure stabilityWon't wash awayHollow article cleaningPigs/molesGear wheelControl engineering

The invention discloses a petroleum pipeline cleaning and detecting robot. The petroleum pipeline cleaning and detecting robot comprises a walking mechanism, a cleaning and detecting mechanism and a control mechanism; the walking mechanism is provided with an axis motor, through forward and reverse rotation of the motor, lead screws are driven to rotate, then lead screw slide blocks and slide rodsare made to move to the two sides or to the middle, and the height of a transverse beam and the height of wheels are changed to achieve diameter varying, so that different pipe diameters are adaptedto; the control mechanism is provided with a control module and gear sets which are covered with a shell, the control module of the control mechanism comprises a power source, a motor and a single-chip microcomputer, and the control mechanism is furthermore connected to the walking mechanism through a support, and conducts information interaction with the axis motor of the walking mechanism and pressure sensors at the legs; the cleaning and detecting mechanism covers the outer side of the control mechanism, and through the arrangement of a runner, a replaceable tool, a brush and a detection instrument are carried. The overall structure of the petroleum pipeline cleaning and detecting robot is annular, the influence of the robot on the flow of fluid of a pipeline caused when the robot worksin the pipeline can be effectively lowered, the efficiency of cleaning and detecting the pipeline is improved, and the petroleum pipeline cleaning and detecting robot has the advantages of being reasonable in structure, high in working efficiency and strong in practicability.

Owner:XI'AN PETROLEUM UNIVERSITY

Method for producing gas barrier film, gas barrier film, and electronic device

InactiveUS20150247241A1Increase flexibilitySolve the lack of adhesionRadiation applicationsSynthetic resin layered productsHigh humidityHot Temperature

A method for producing a gas barrier film with excellent gas barrier performance is maintained even in a high-temperature. The high-humidity usage environment properties and the flexibility (bendability) and adhesiveness are excellent. A gas barrier film, and an electronic device using the same is also disclosed.

Owner:KONICA MINOLTA INC

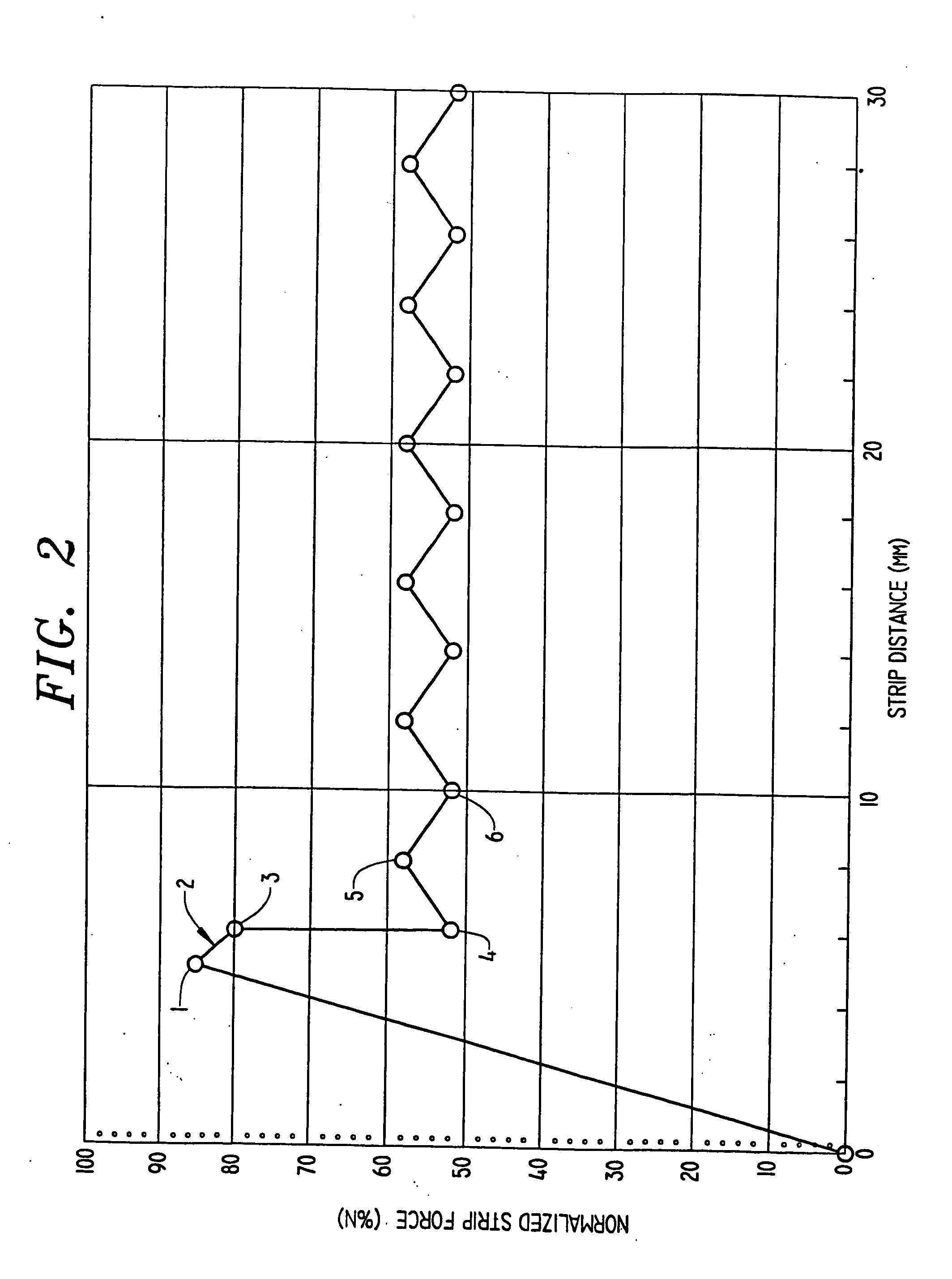

Radiation-curable optical glass fiber coating compositions, coated optical glass fibers, and optical glass fiber assemblies

InactiveUS20050158000A1Improved ribbon stripping capabilitySufficient adhesionOptical fibre with multilayer core/claddingFibre mechanical structuresGlass fiberOligomer

Optical fiber coatings are disclosed having excellent ribbon stripping and adhesion behavior. The coatings are radiation-curable. The excellent stripping and adhesion behavior can be achieved by several means which include by use of additives, by use of radiation-curable oligomers having higher molecular weight, or by use of coatings having certain thermal properties. Combination of means can be employed. Stripping behavior can be measured by crack propagation and fiber friction measurements.

Owner:DSM NV

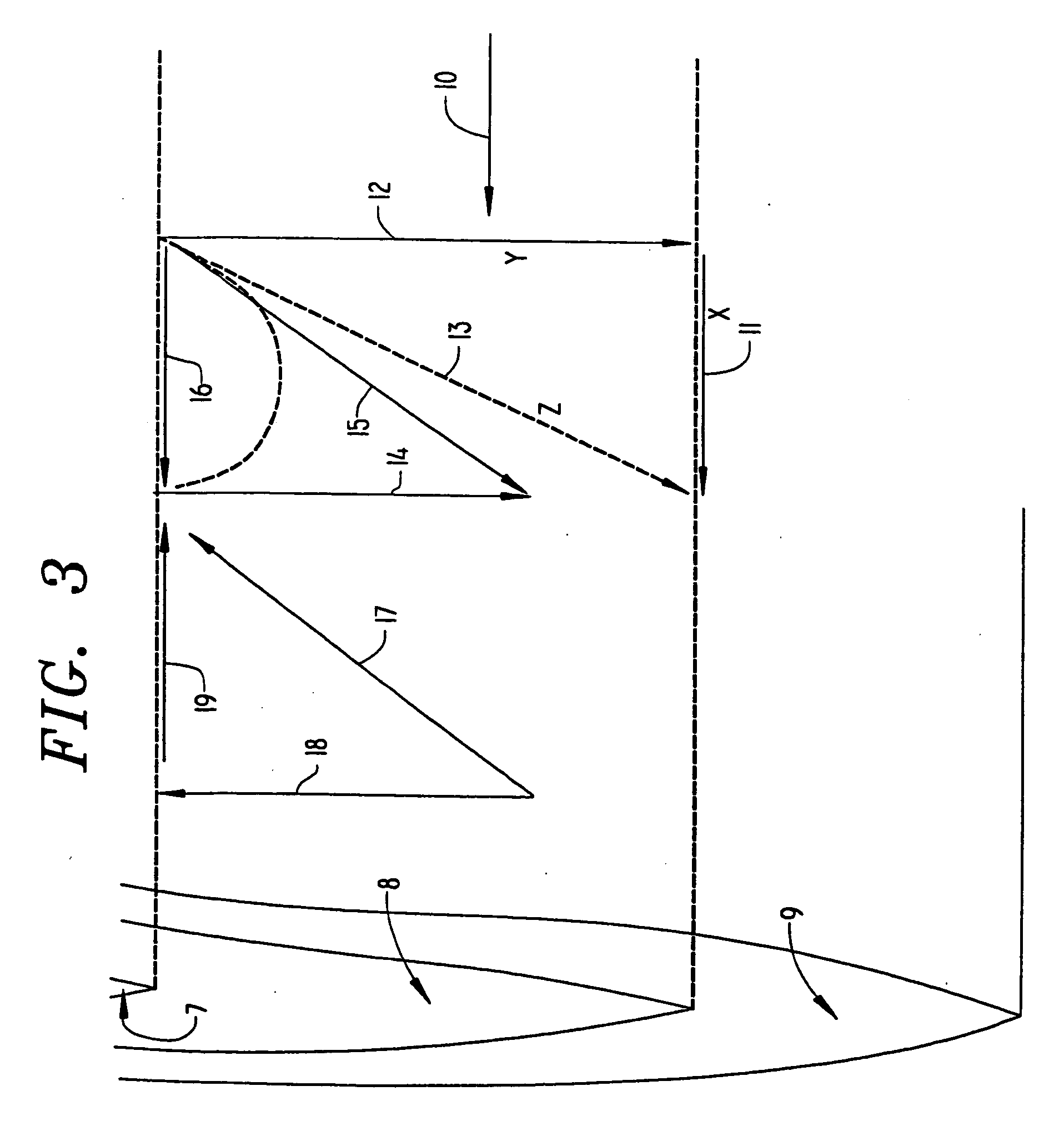

Clear sprayable sealant for aircraft parts and assemblies

ActiveUS20170282196A1Improve adhesionSolve the lack of adhesionPretreated surfacesSheet joiningAssembly lineEngineering

Applicant discloses a two part polymer mix for use in the aircraft industry that is applied with pneumatic mix and spray gun. The two part cartridge is used in the mix and spray gun so the mix is applied immediately upon mixing, but the two components are kept separated unless the gun is applying the mix. The mix cures to form a clear sealant that allows for inspection of cracks and corrosion beneath the sealant. It cures quickly so that the coated part may be further processed, for example in the assembly line during aircraft build.

Owner:THE PATENT WELL LLC

Method for producing a medical device with a cross-linked hydrophilic coating

InactiveUS20100159116A1More hydrophilicIncrease surface wettabilityPharmaceutical containersPretreated surfacesChemistryHydrophilic coating

A time and cost effective production method for medical devices with a hydrophilic coating is provided, which ensures adequate adhesion to the substrate, as well as good water retention and low friction properties. Specifically, the method comprises the steps of: providing a substrate; applying, in one or more steps, a coating solution comprising a hydrophilic polymer to a surface of said substrate to form a non-cross-linked hydrophilic coating on said substrate; and irradiating the coated substrate, wherein said irradiation is adapted both to cross-link said hydrophilic coating and to simultaneously sterilize the medical device.Hereby, a non-cross linked hydrophilic coating is first obtained on the substrate, which coating is loosely connected to the substrate, and which is not fit for use as a catheter coating. However, after the step of irradiating the coated substrate, the hydrophilic coating becomes cross-linked, and fit for use e.g. on a urinary catheter. Further, since one and the same irradiation step is used to effect both cross-linking and sterilization, the production can be made more efficient, using fewer production steps and with a shortened production time.

Owner:ASTRA TECH SE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com