Patents

Literature

153results about How to "Small surface roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tempered glass substrate and method of producing the same

ActiveUS20090197088A1High ion exchange capacityExcellent devitrification resistanceGlass/slag layered productsThin material handlingToughened glassMaterials science

A tempered glass substrate of the present invention is a tempered glass substrate, which has a compression stress layer on a surface thereof, and has a glass composition comprising, in terms of mass %, 40 to 71% of SiO2, 3 to 21% of Al2O3, 0 to 3.5% of Li2O, to 20% of Na2O, and 0 to 15% of K2O.

Owner:NIPPON ELECTRIC GLASS CO LTD

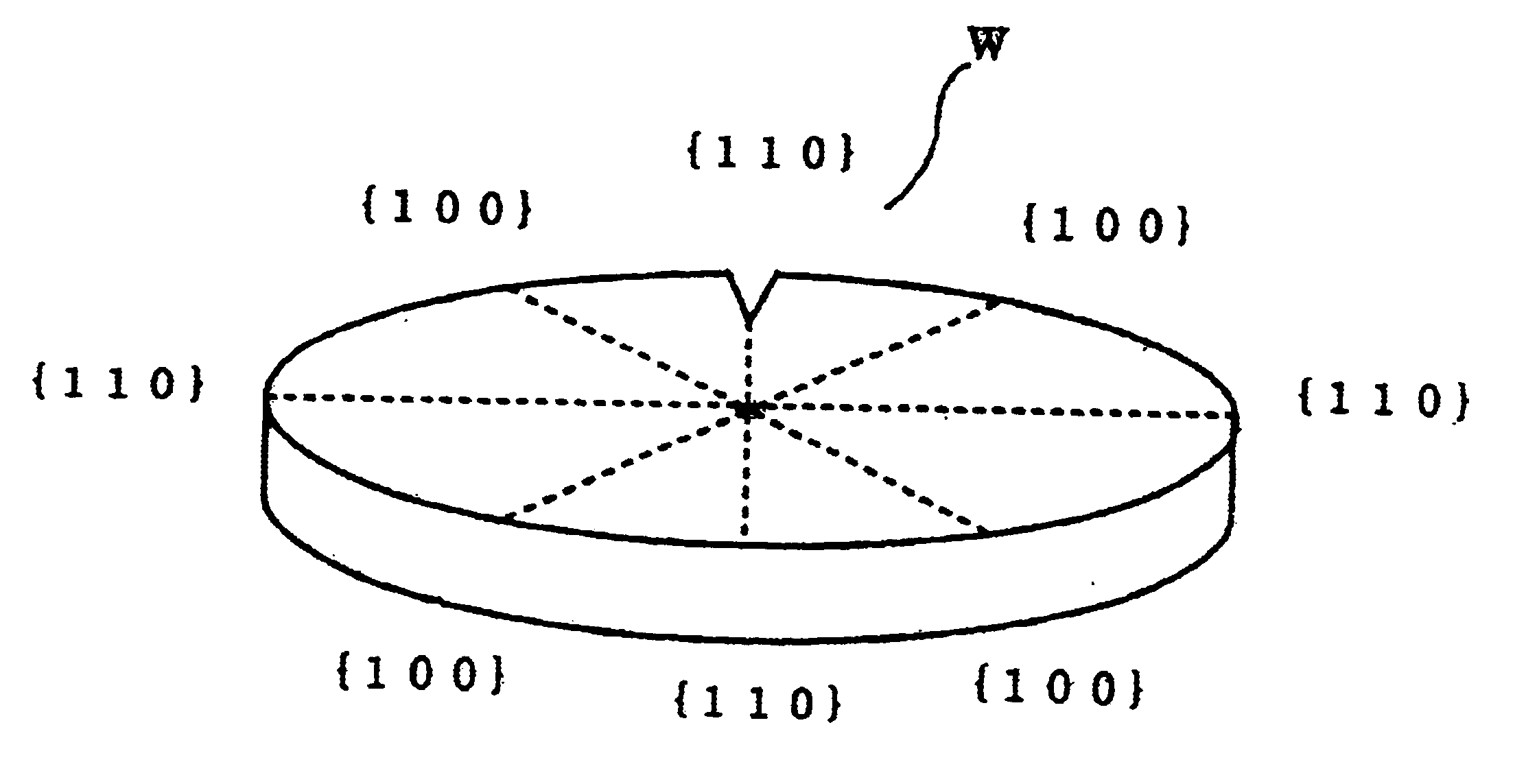

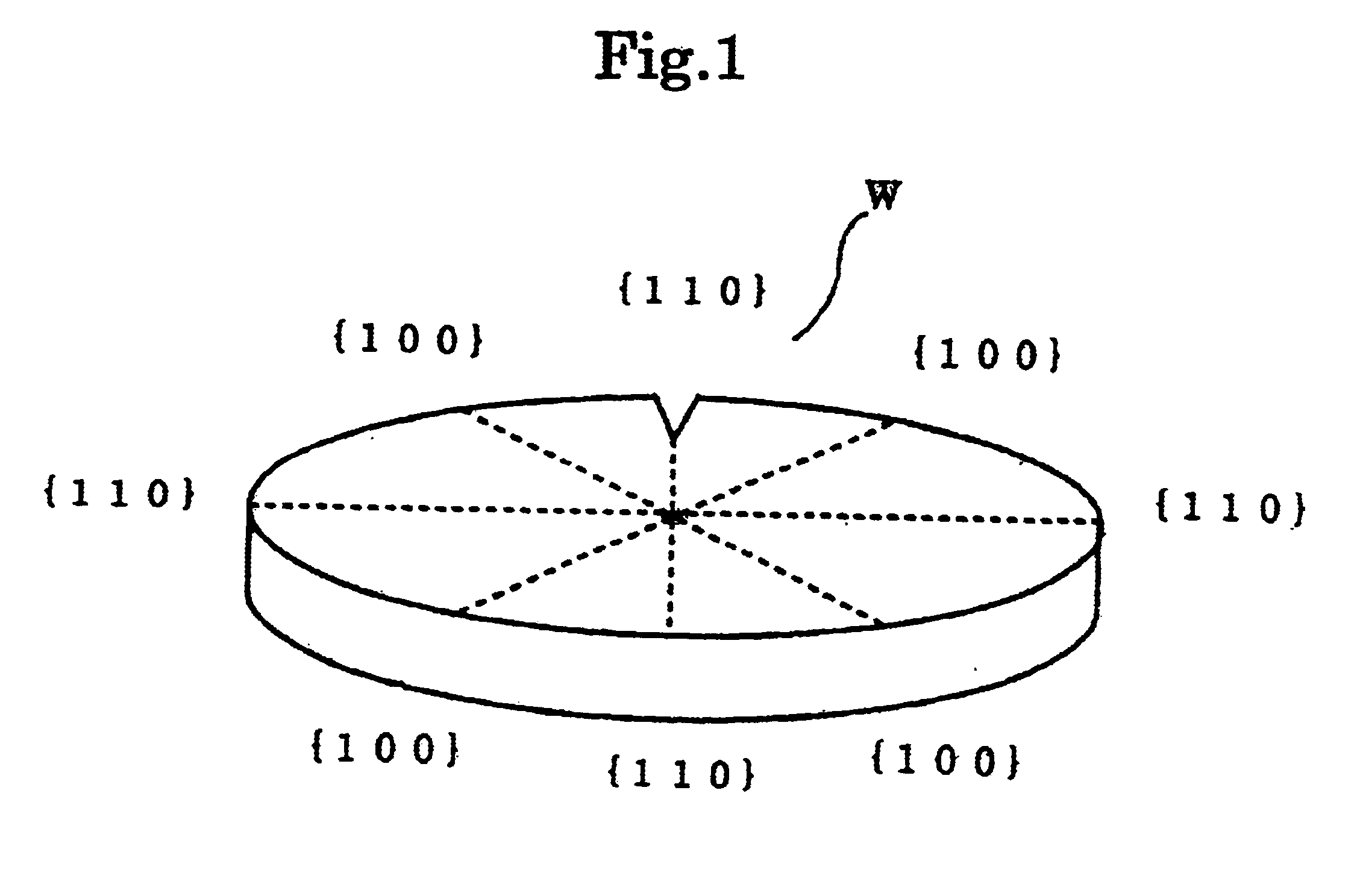

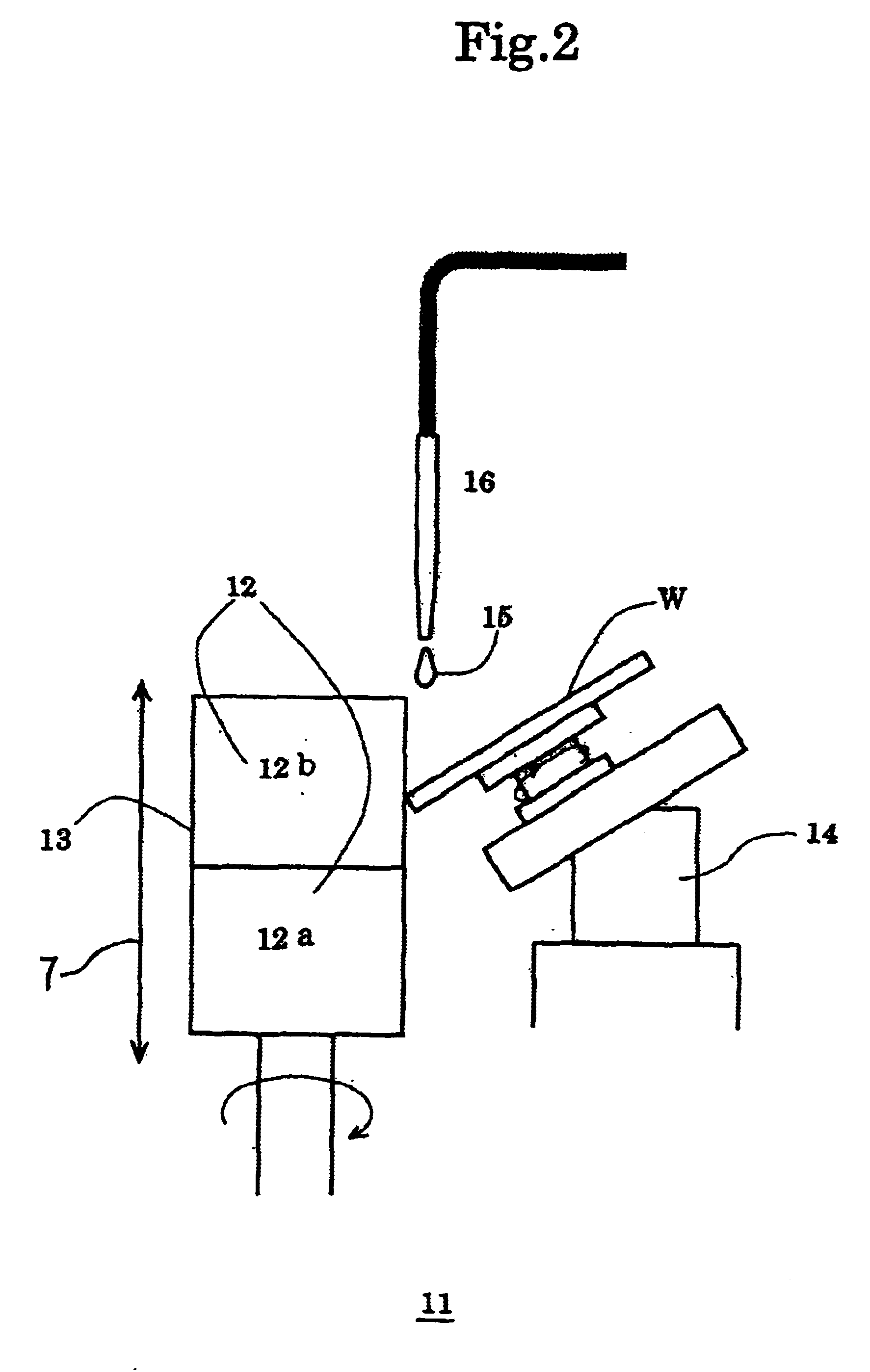

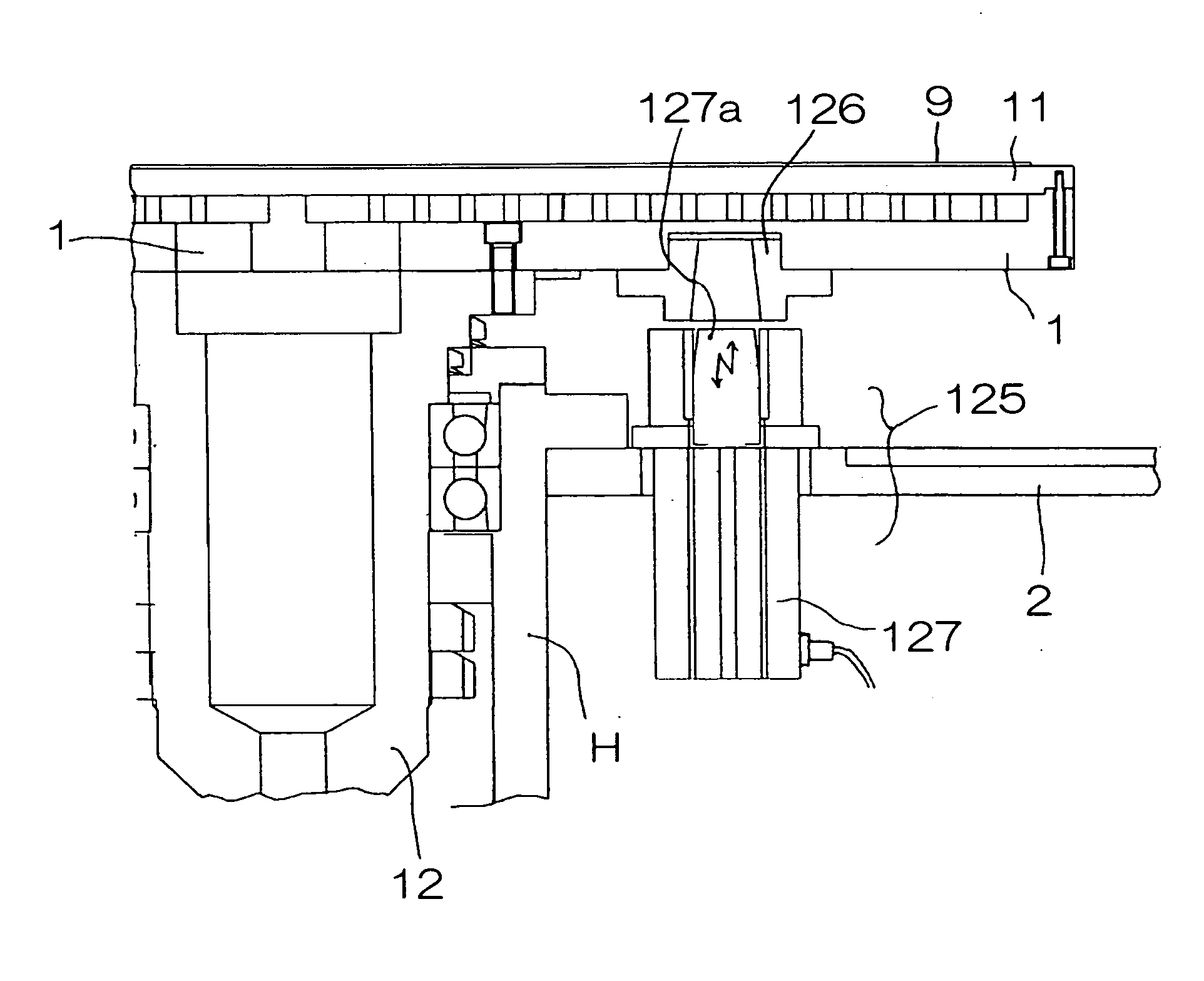

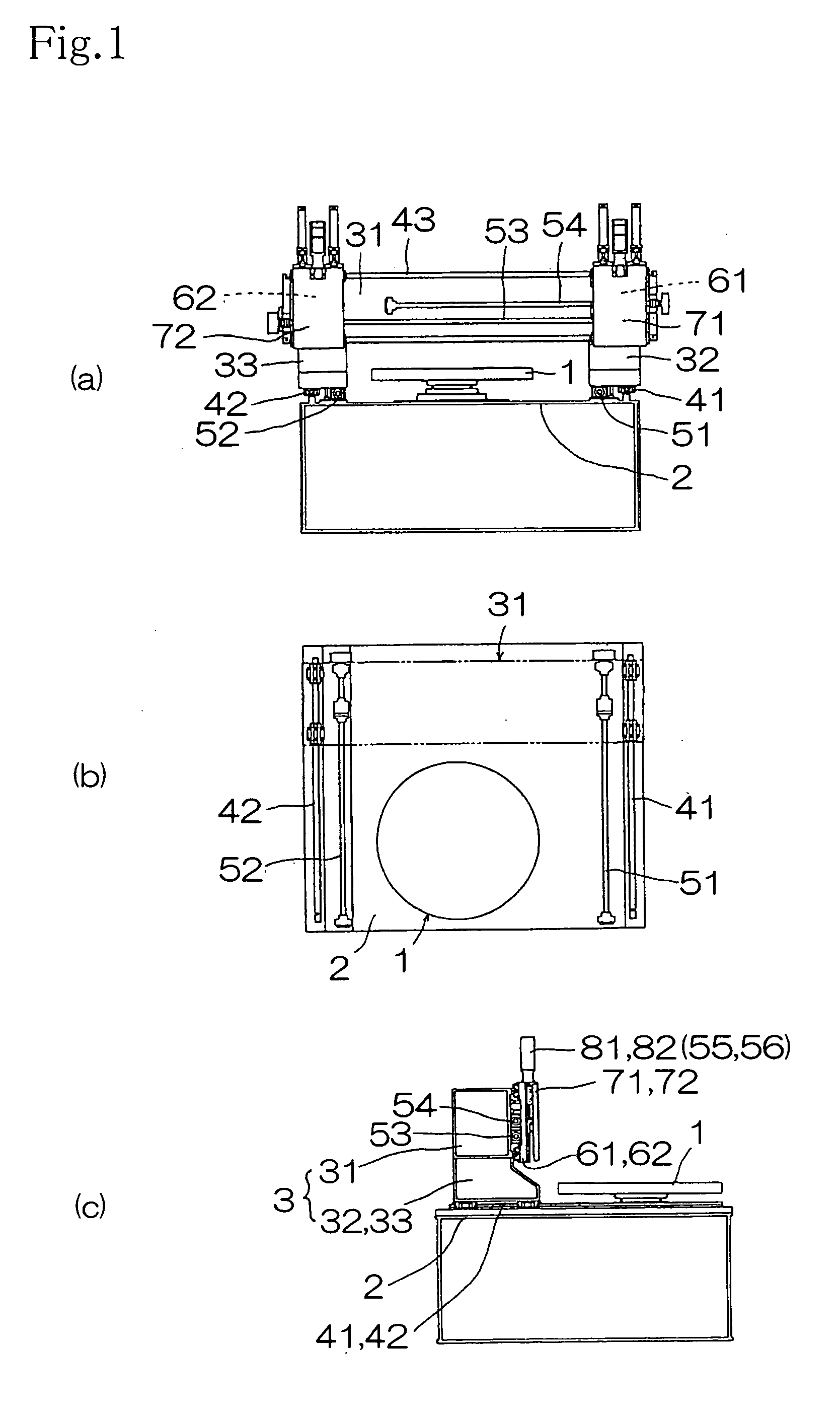

Method for apparatus for polishing outer peripheral chamfered part of wafer

InactiveUS6884154B2Improve productivityShorten polishing timeEdge grinding machinesPolishing machinesProduction rateHardness

In a process for polishing the chamfered peripheral part of a wafer using a polishing cloth while supplying a polishing slurry in order to improve productivity of the process by reducing a polishing time, at least two steps of polishing processes are performed in sequence. The process comprises a first polishing process to polish a particular part, e.g. the part corresponding to the {110} plane of a peripheral part of the wafer and a second polishing process in which the whole part of a peripheral part of the wafer is polished for finishing by means of varying a hardness of the polishing clothes and / or a particle size of abrasives in the slurry such as the hardness of the polishing cloth in the second polishing process being softer than that of in the first polishing process and a particle size of abrasives in the slurry in the second polishing process being finer than that of in the first polishing process.

Owner:SHIN-ETSU HANDOTAI CO LTD

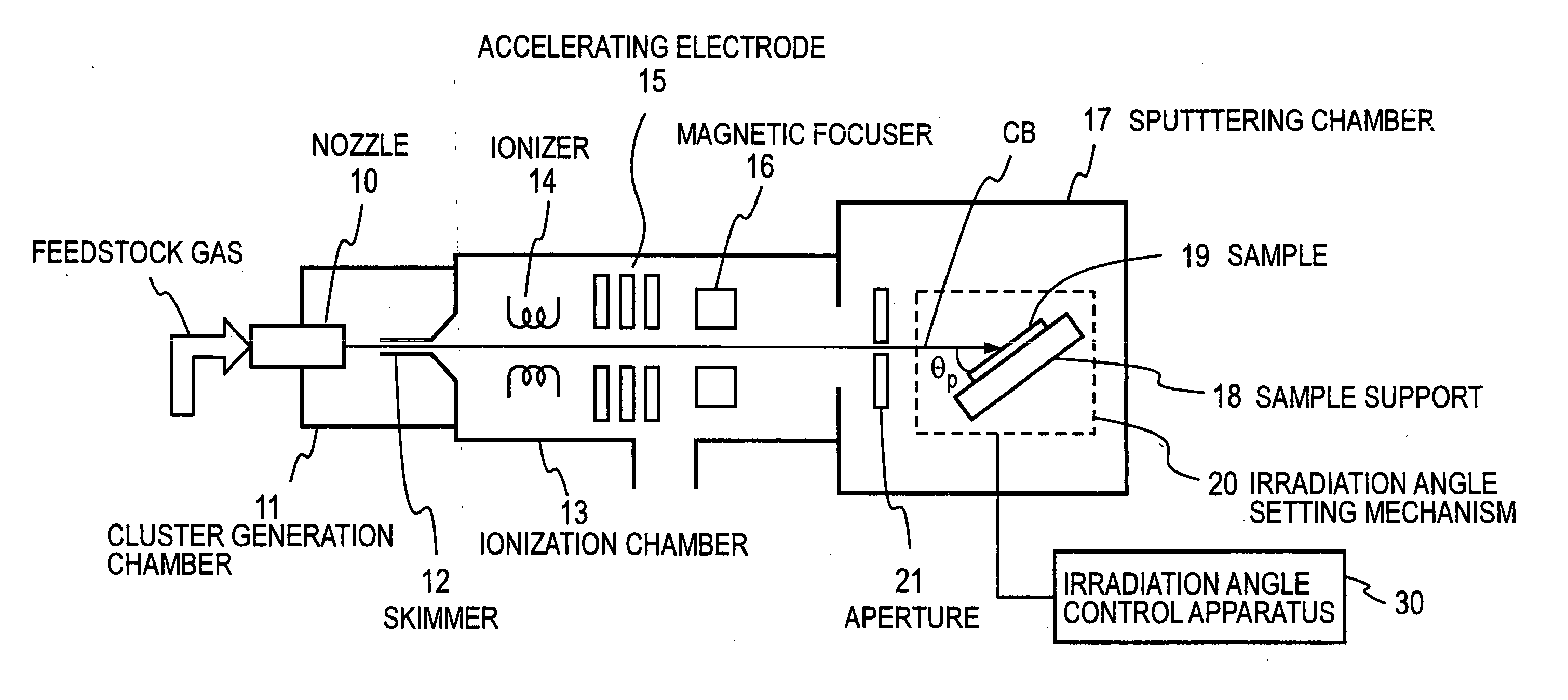

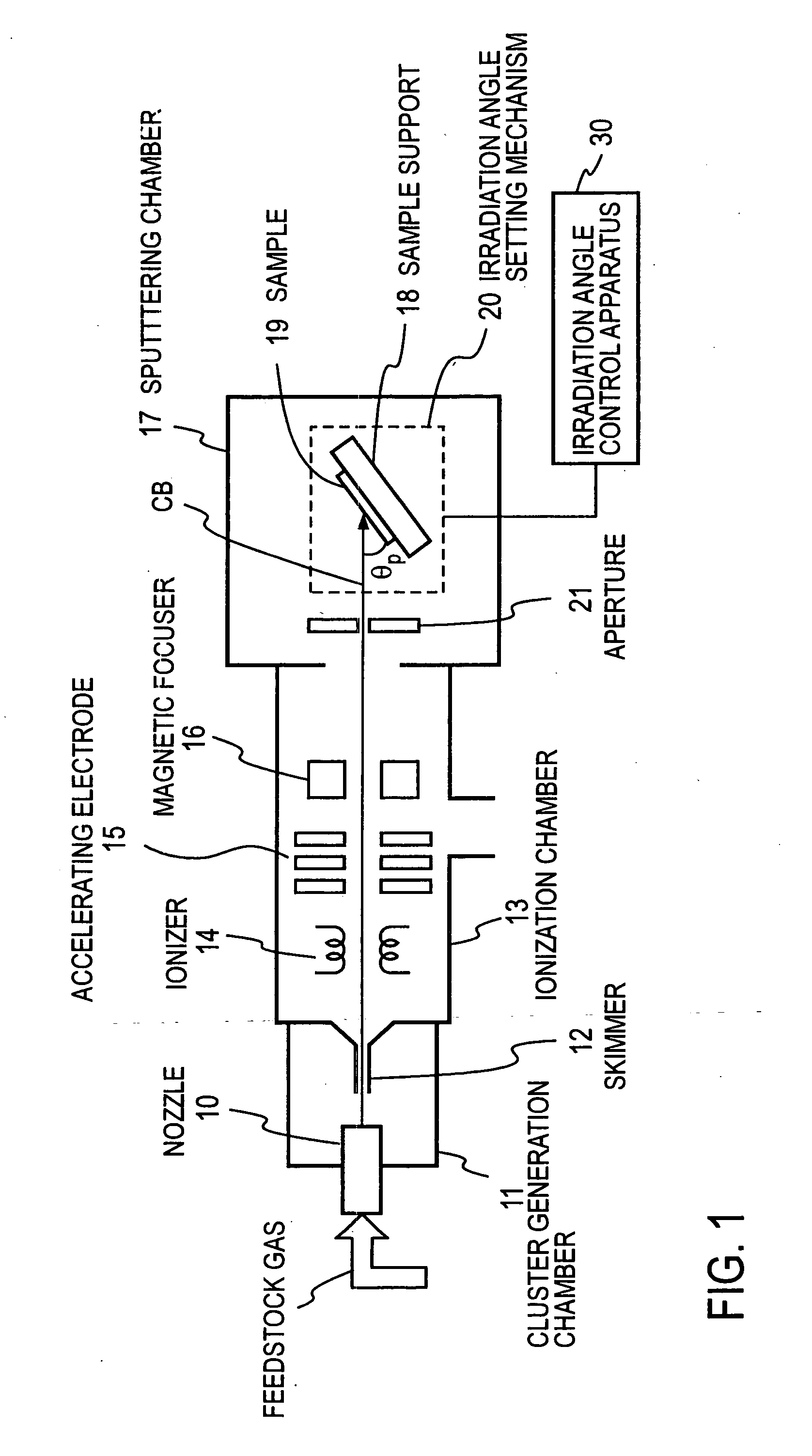

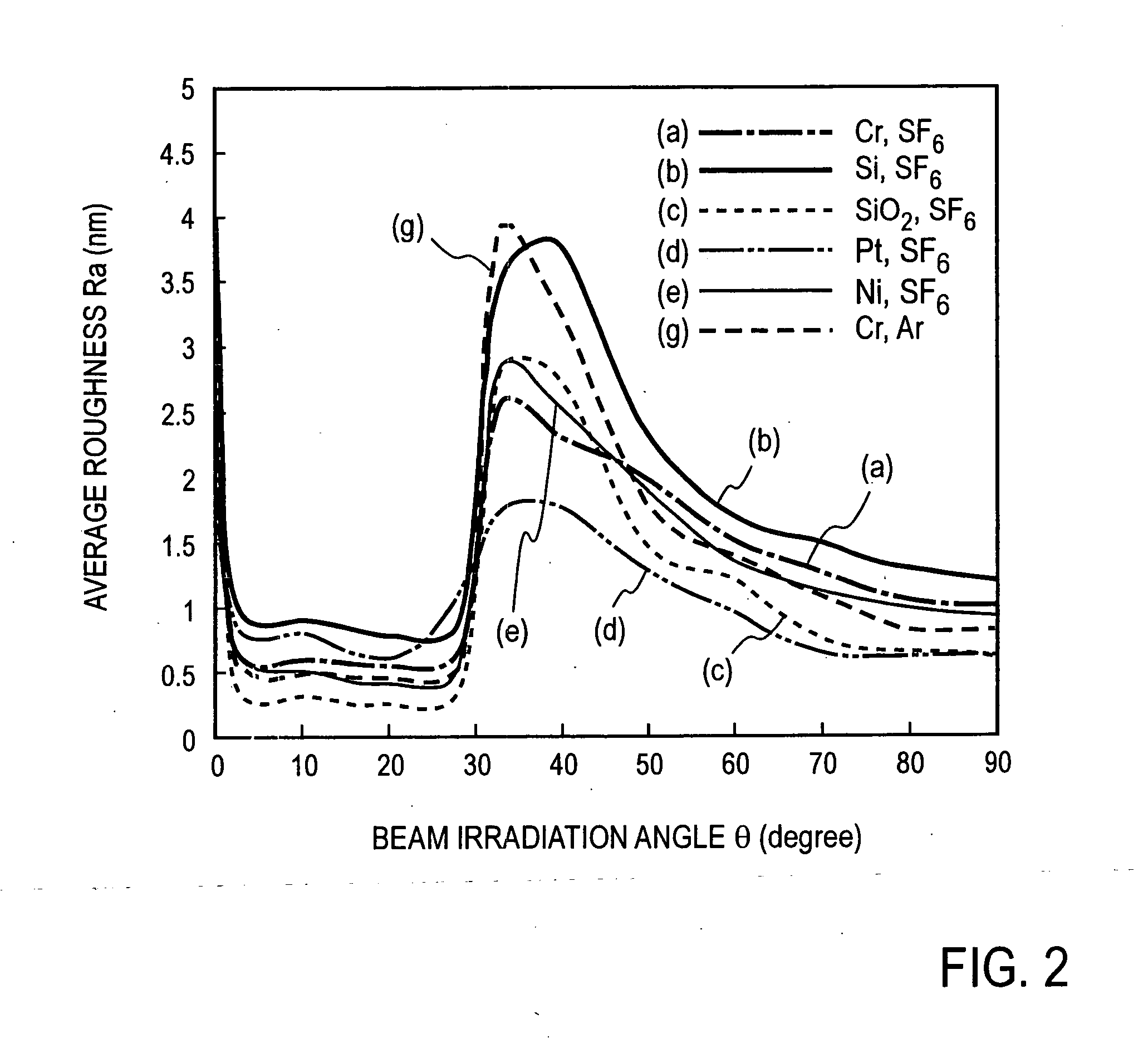

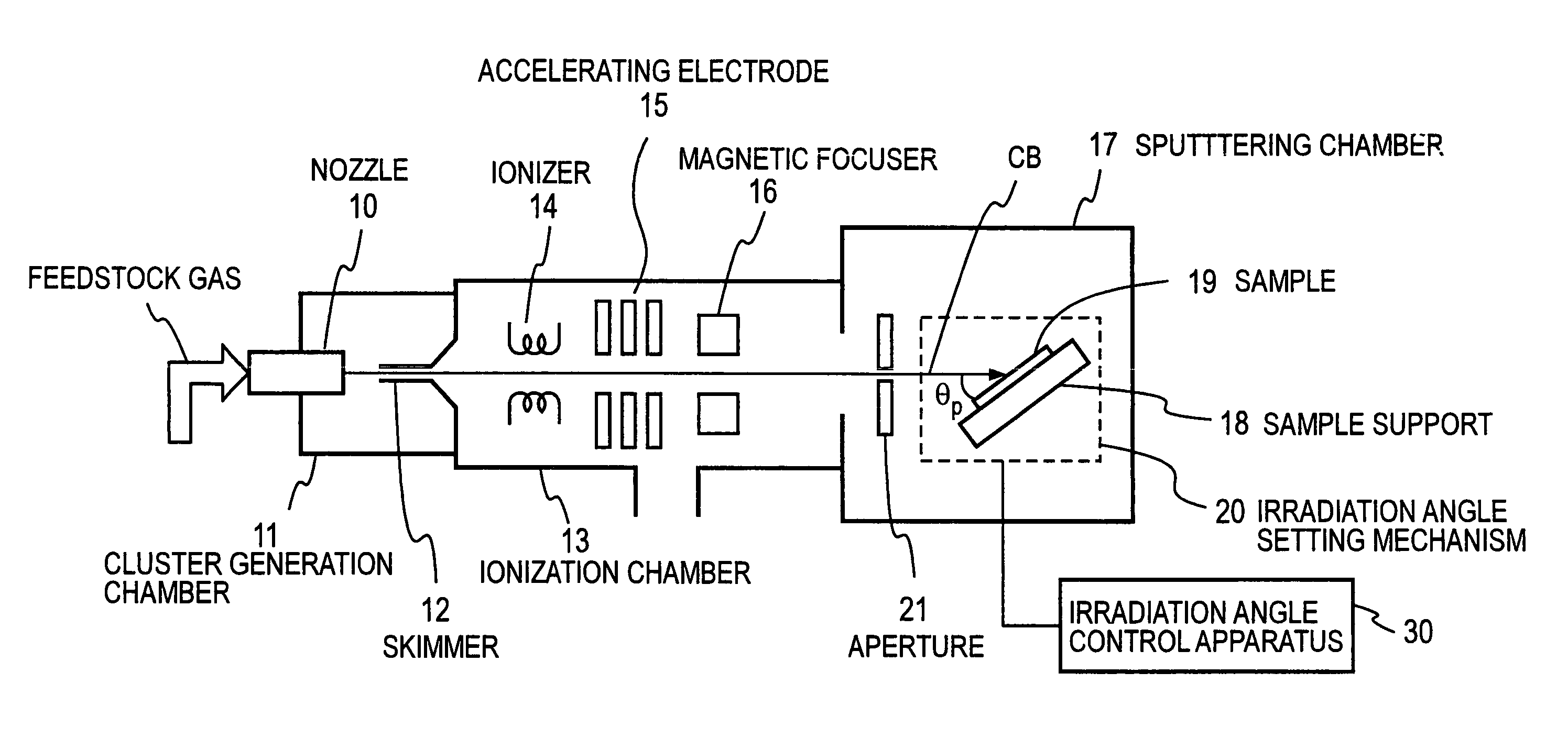

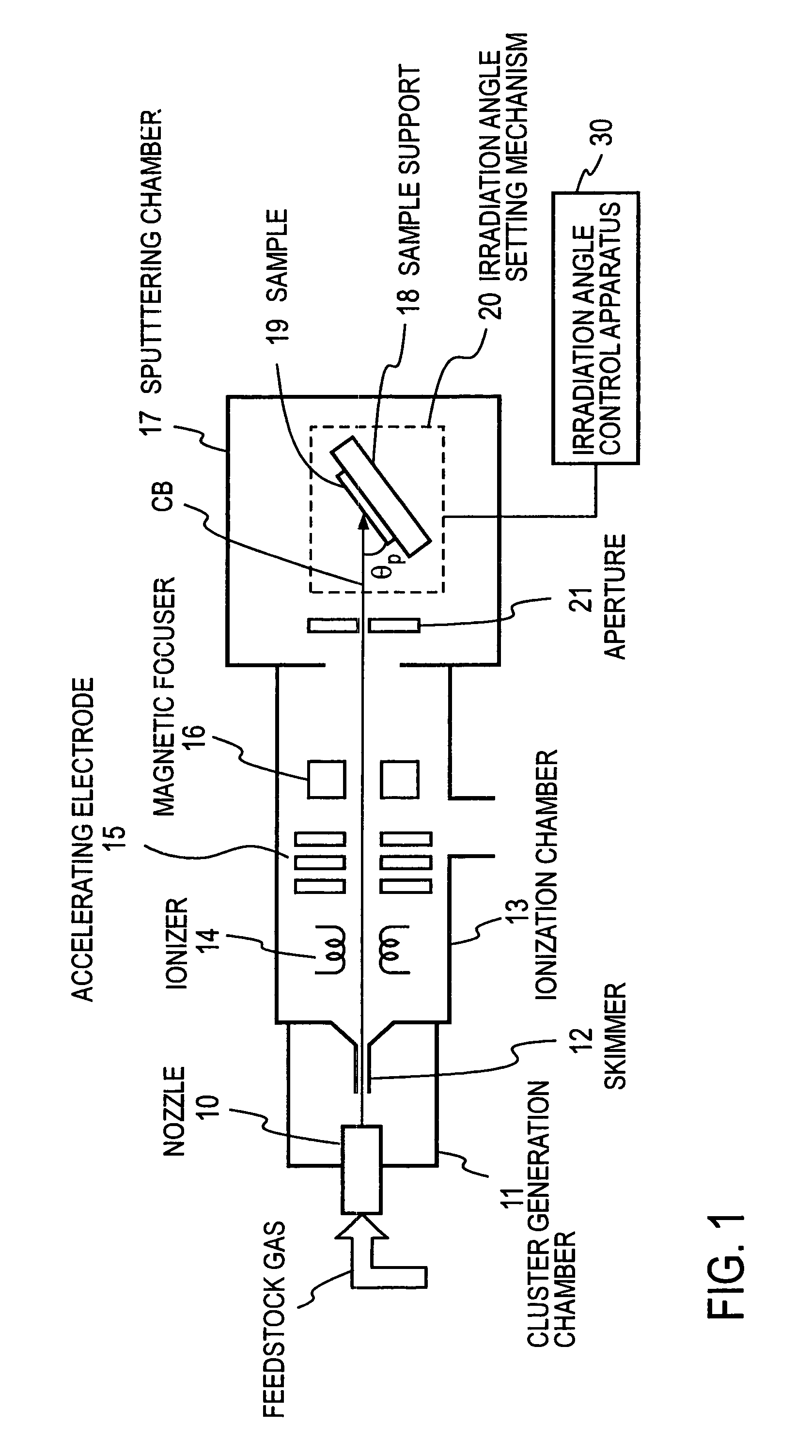

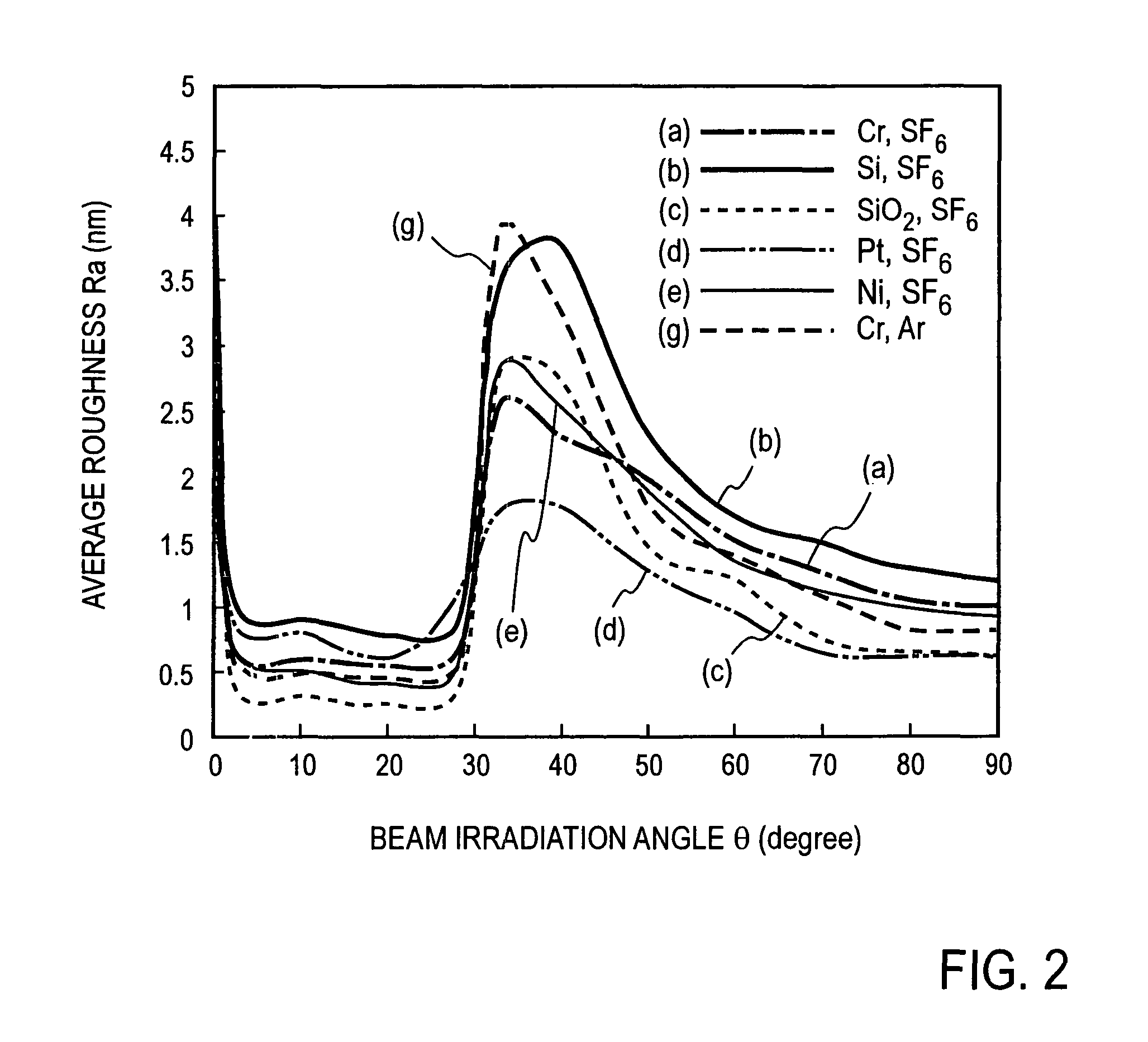

Method and device for flattening surface of solid

ActiveUS20060278611A1Small surface roughnessElectric discharge tubesDecorative surface effectsGas cluster ion beamIrradiation

In a method of irradiating a gas cluster ion beam on a solid surface and smoothing the solid surface, the angle formed between the solid surface and the gas cluster ion beam is chosen to be between 1° and an angle less than 30°. In case the solid surface is relatively rough, the processing efficiency is raised by first irradiating a beam at an irradiation angle θ chosen to be something like 90° as a first step, and subsequently at an irradiation angle θ chosen to be 1° to less than 30° as a second step. Alternatively, the set of the aforementioned first step and second step is repeated several times.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

Silica glass containing TiO2 and optical material for EUV lithography

ActiveUS20050245383A1Small surface roughnessGlass shaping apparatusSensing by electromagnetic radiationTitanium dioxideRefractive index

A silica glass containing TiO2, characterized in that the fluctuation of the refractive index (Δn) is at most 2×10−4 within an area of 30 mm×30 mm in at least one plane. A silica glass containing TiO2, characterized in that the TiO2 concentration is at least 1 mass %, and the striae pitch is at most 10 μm. An optical material for EUV lithography, characterized in that it is made of a silica glass containing TiO2, and the fluctuation of the refractive index (Δn) is at most 2×10−4 in a plane perpendicular to the incident light direction. An optical material for EUV lithography, characterized in that it is made of a silica glass containing TiO2, wherein the TiO2 concentration is at least 1 mass %, and the difference between the maximum value and the minimum value of the TiO2 concentration is at most 0.06 mass % in a plane perpendicular to the incident light direction.

Owner:ASAHI GLASS CO LTD

Method of producing ultra-thin copper foil with carrier, ultra-thin copper foil with carrier produced by the same, printed circuit board, multilayer printed circuit board and chip on film circuit board

InactiveUS20050048306A1Small surface roughnessThermometers using material expansion/contactionSolid-state devicesChip on filmSurface roughness

An object of the present invention is to produce an ultra-thin copper foil with a carrier which has few pinholes and small surface roughness and which has an the thickness of less than 5 μm, and to produce the method of producing the foil, and further to produce a printed circuit board for fine pattern, a multilayer printed circuit board and a chip on film circuit board by using the ultra-thin copper foil with a carrier. The present invention provides an ultra-thin copper foil with a carrier produced by stacking a peeling layer and an ultra thin copper foil in order on the surface of a carrier copper foil which is made smooth so that the mean surface roughness of at least one side is Rz of 0.01 to 2.0 μm by the chemical polishing, the electrochemical dissolution, or the smoothing plating processing method independently, combining two or more, or further combining the mechanical polishing.

Owner:FURUKAWA ELECTRIC CO LTD

Method of machining semiconductor wafer-use polishing pad and semiconductor wafer-use polishing pad

InactiveUS20040266326A1Easily and accurately formedInner surfacePigmenting treatmentOther chemical processesWater insolubleSurface roughness

A processing method of a polishing pad for semiconductor wafer capable of forming a groove, a concave portion, a through hole and the like having a small surface roughness of the inner surface of the groove and the like of 20 mum or less, a high dimensional accuracy and a uniform cross-sectional shape, and a polishing pad for semiconductor wafer. In the processing method, a surface of a polishing pad including a water-insoluble matrix containing a crosslinked polymer and a water-soluble particle dispersed in the water-insoluble matrix is processed by cutting and the like. Additionally, when a groove and the like are formed, it is preferable that a polishing pad is placed on one surface side of a machining table having a sucking hole, the pad is fixed on the one surface side of the machining table by vacuuming sucking it from the other surface of the machining table, and then a groove and the like are formed.

Owner:JSR CORPORATIOON

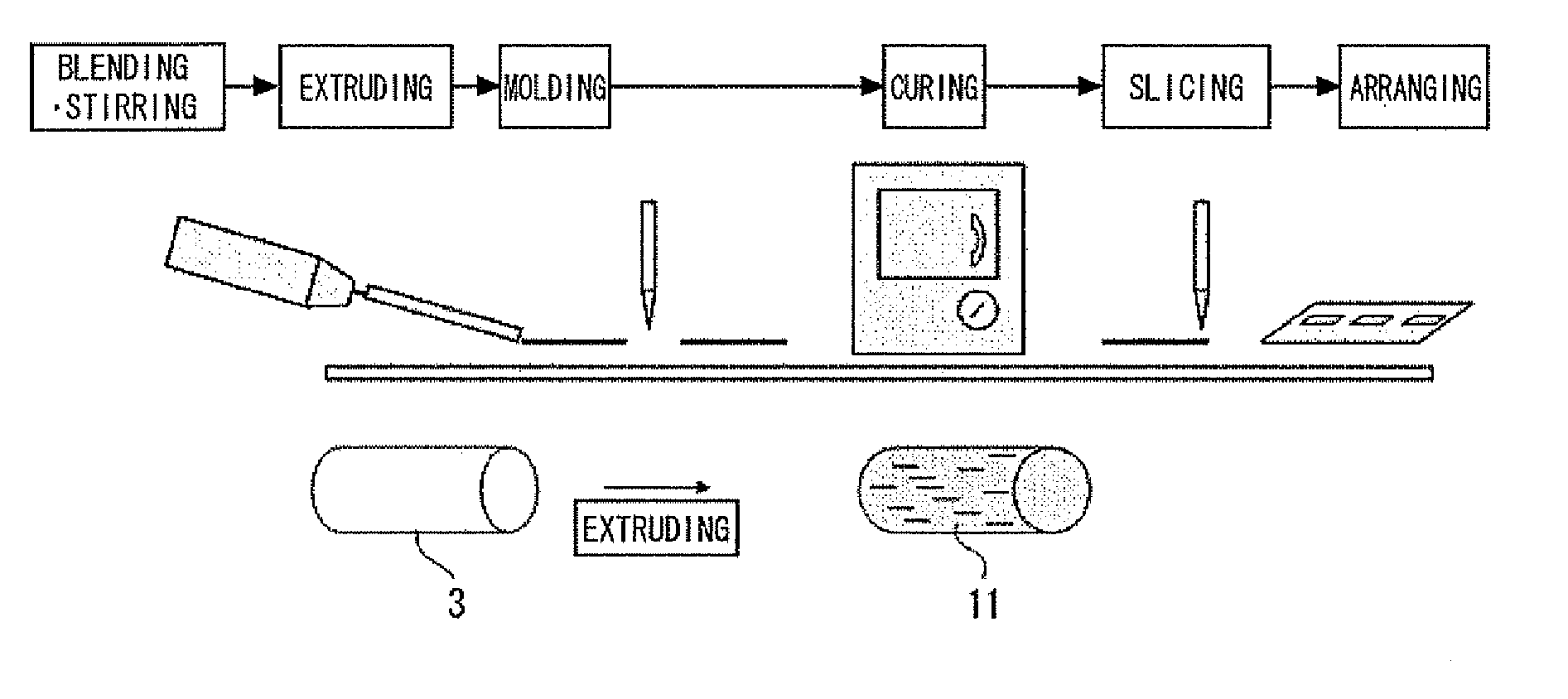

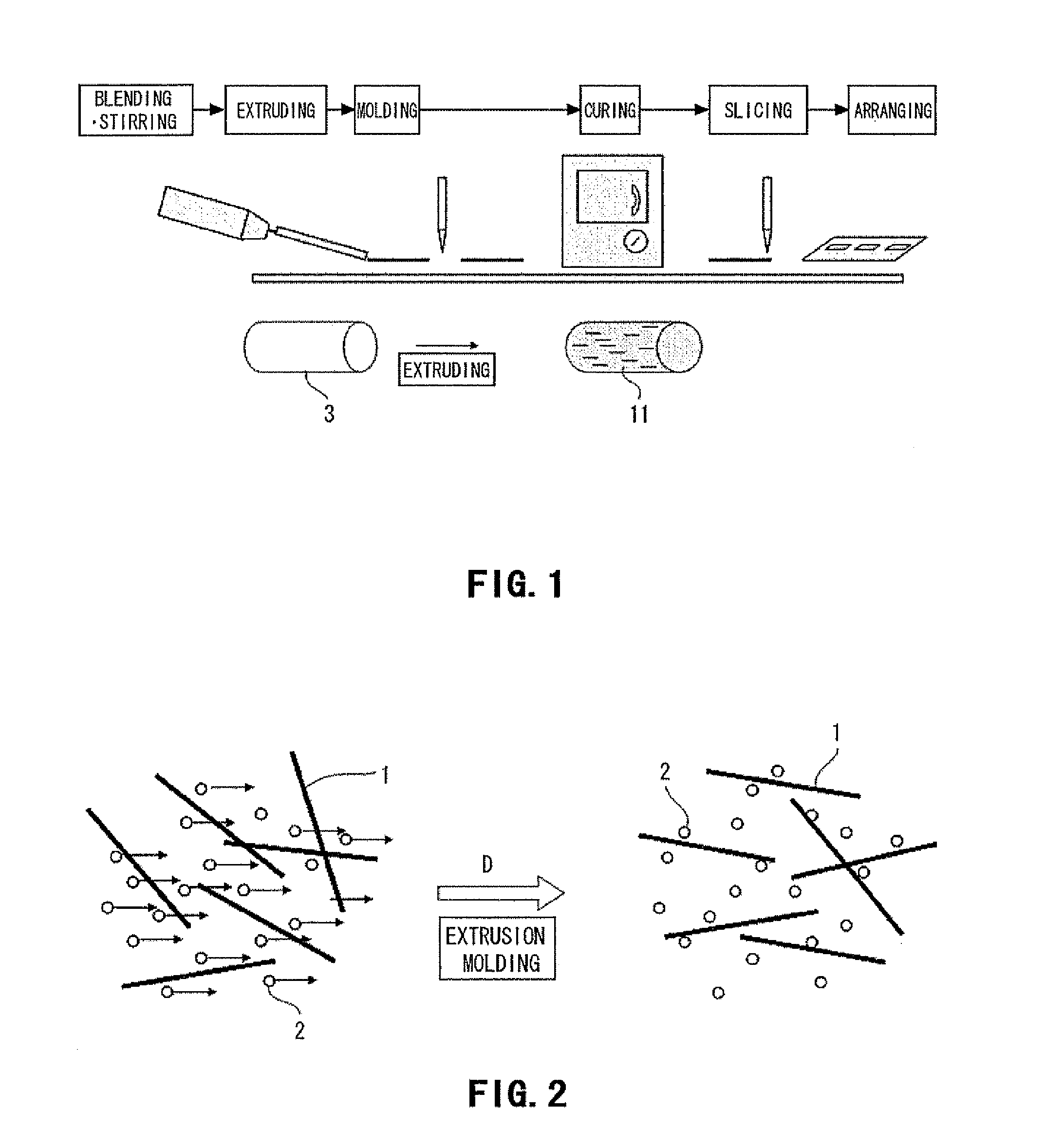

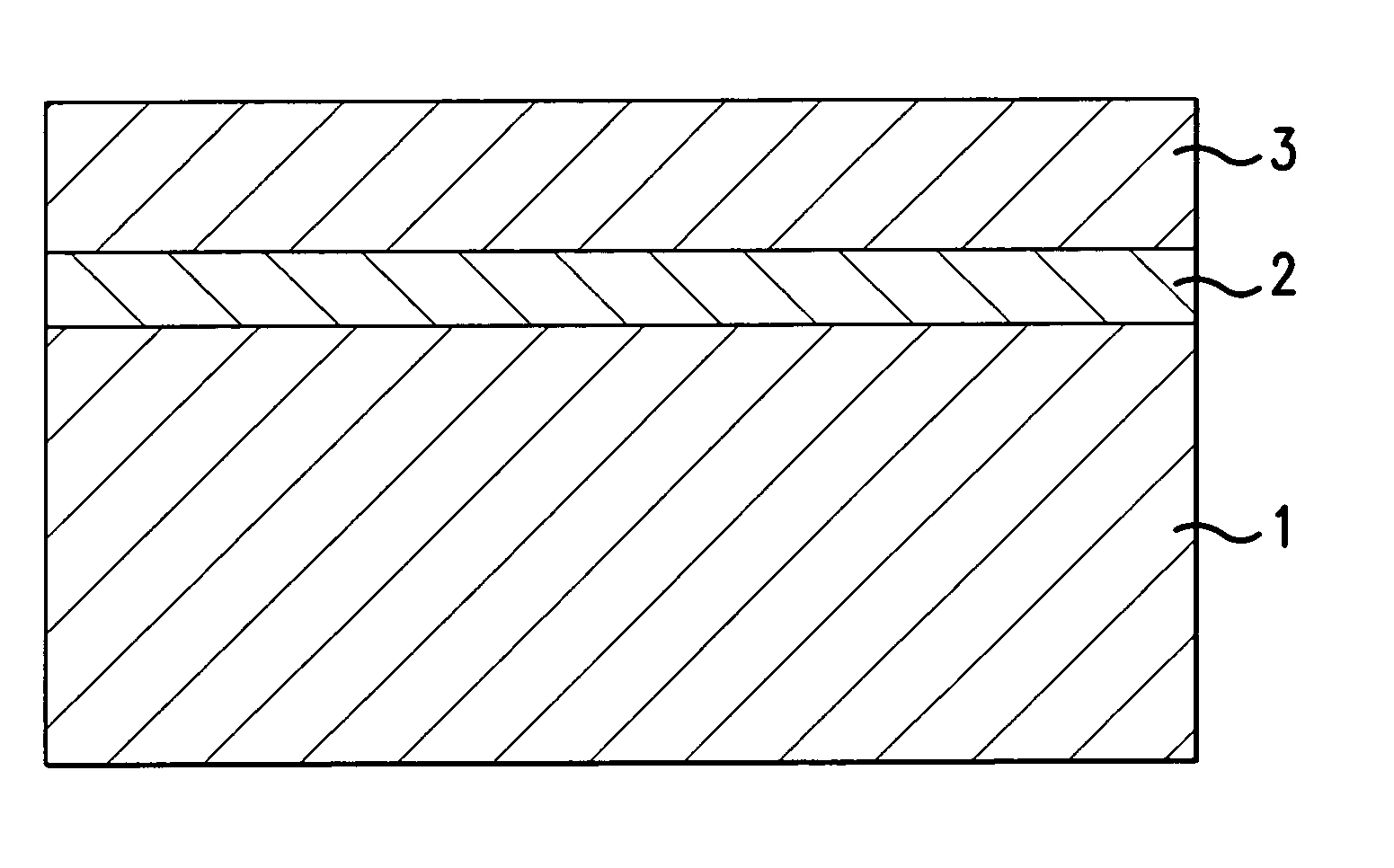

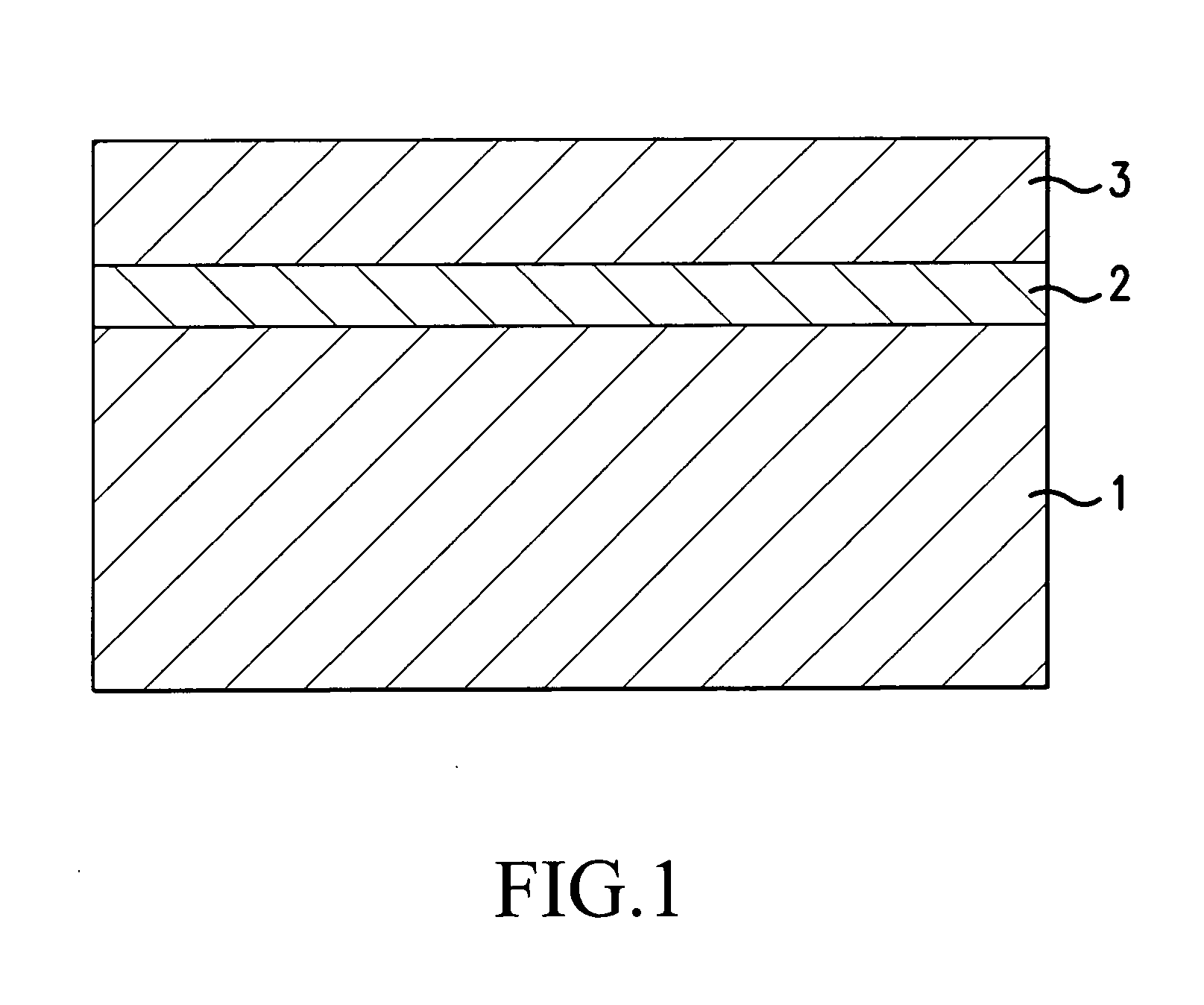

Thermally conductive sheet and process for producing same

ActiveUS20130136895A1Reduce thermal resistanceImprove thermal conductivityLayered productsSemiconductor/solid-state device detailsSurface roughnessPolymer

A thermally conductive sheet has cut surfaces with low surface roughness and hence shows reduced thermal resistance at the interfaces, and high thermal conductivity in the thickness direction. Thus, the thermally conductive sheet can be interposed between any of various heat sources and a radiation member. The process for producing the thermally conductive sheet includes at least: an extrusion molding step in which a thermally conductive composition containing a polymer, an anisotropic thermally conductive filler, and a filler is extruded with an extruder to thereby mold an extrusion-molded product in which the anisotropic thermally conductive filler has been oriented along the extrusion direction; a curing step in which the extrusion-molded product is cured to obtain a cured object; and a slicing step in which the cured object is sliced into a given thickness with an ultrasonic cutter in the direction perpendicular to the extrusion direction.

Owner:DEXERIALS CORP

Polishing slurry and polished substrate

InactiveUS20050287931A1Minimizes numberSatisfies high-precision surface polishing performancePigmenting treatmentOther chemical processesAdditive ingredientRare earth

A polishing slurry comprising an abrasive comprising as a basic ingredient rare earth oxides containing cerium oxide, which polishing slurry further comprises an anionic surfactant and a nonionic surfactant and has a pH value of at least 11. The polishing slurry is especially suitable for polishing a glass substrate for magnetic disc, and other substrates used in electronic field.

Owner:SHOWA DENKO KK

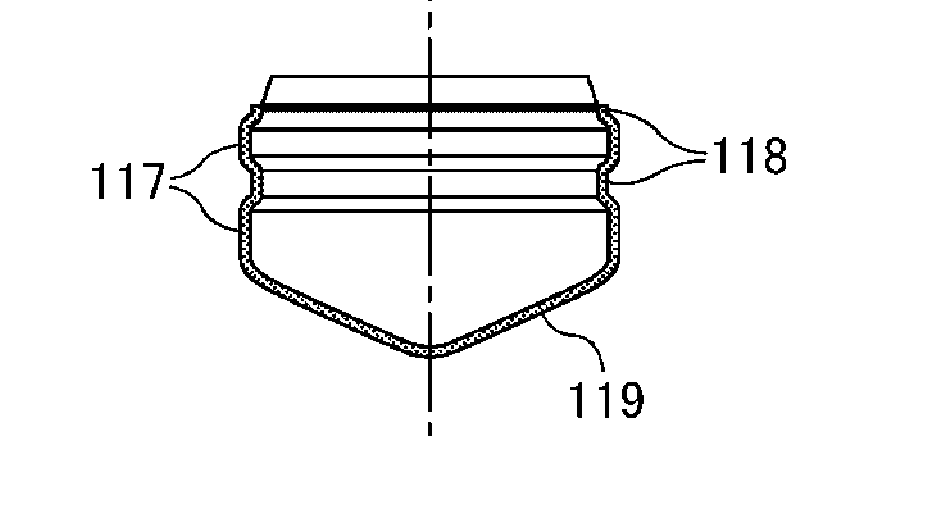

Mold for gasket for prefilled syringe

InactiveUS20130053786A1Excellent air-tightnessSmall surface roughnessAmpoule syringesTailstocks/centresPrefilled SyringeAir tightness

The present invention aims to provide a gasket for a pre-filled syringe which has excellent air-tightness and liquid-tightness and a mold for forming the gasket. The present invention relate to a mold for a gasket laminated with an inactive film for a pre-filled syringe, wherein at least a surface of the mold which forms a seal sliding surface of an annular protrusion of the gasket is mirror finished to have an arithmetic mean roughness Ra of less than 0.03 μm.

Owner:SUMITOMO RUBBER IND LTD

Silica glass containing TiO2 and optical material for EUV lithography

ActiveUS7462574B2Small surface roughnessRadiation pyrometryGlass shaping apparatusRefractive indexMaterials science

A silica glass containing TiO2, characterized in that the fluctuation of the refractive index (Δn) is at most 2×10−4 within an area of 30 mm×30 mm in at least one plane. A silica glass containing TiO2, characterized in that the TiO2 concentration is at least 1 mass %, and the striae pitch is at most 10 μm. An optical material for EUV lithography, characterized in that it is made of a silica glass containing TiO2, and the fluctuation of the refractive index (Δn) is at most 2×10−4 in a plane perpendicular to the incident light direction. An optical material for EUV lithography, characterized in that it is made of a silica glass containing TiO2, wherein the TiO2 concentration is at least 1 mass %, and the difference between the maximum value and the minimum value of the TiO2 concentration is at most 0.06 mass % in a plane perpendicular to the incident light direction.

Owner:ASAHI GLASS CO LTD

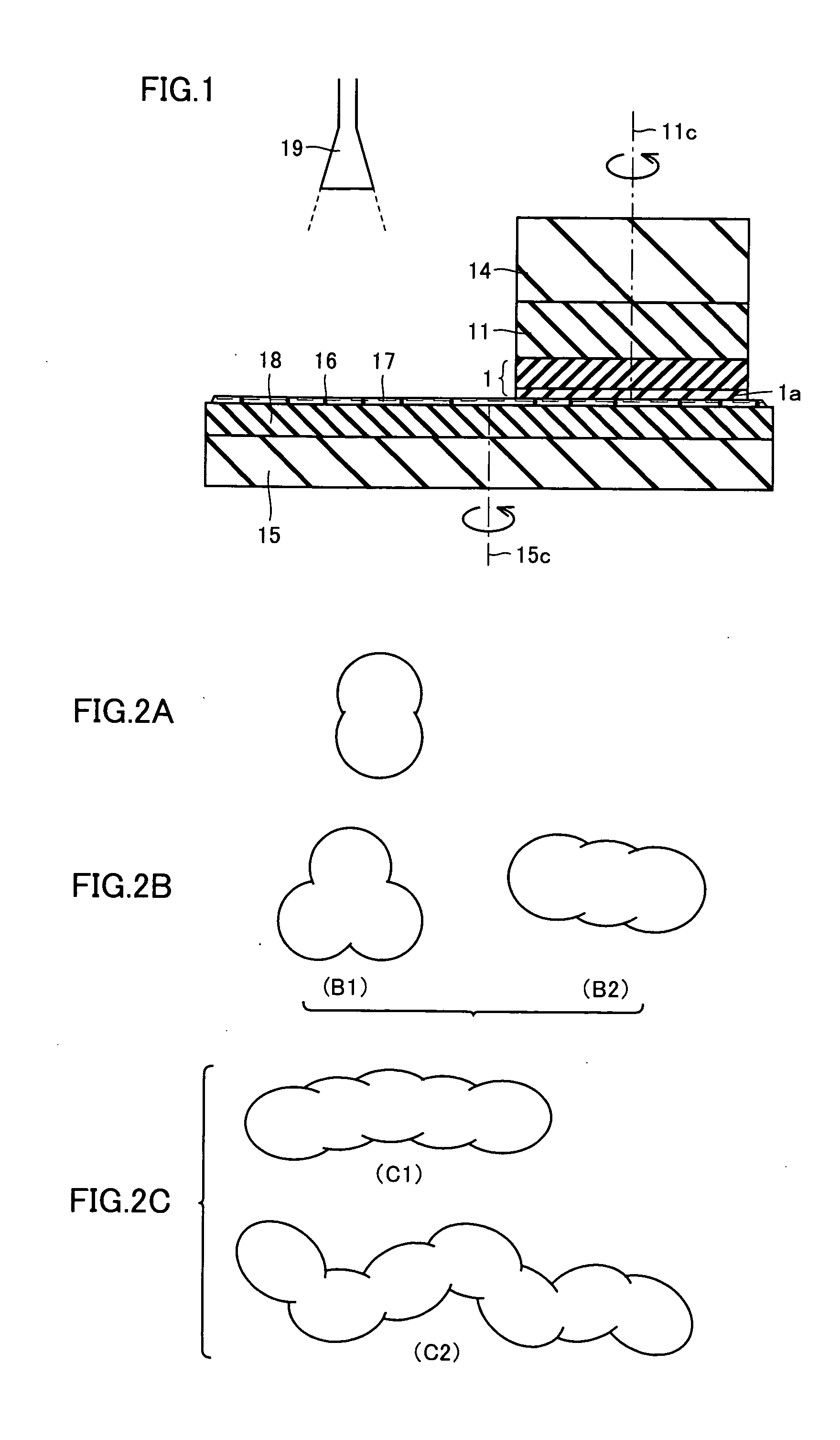

Polishing slurry, method of treating surface of GaxIn1-xASyP1-y crystal and GaxIn1-xASyP1-y crystal substrate

InactiveUS20070075041A1Small surface roughnessHigh ratePigmenting treatmentOther chemical processesMetallurgySurface roughness

The present polishing slurry is a polishing slurry for chemically mechanically polishing a surface of a GaxIn1-xAsyP1-y crystal (0≦x≦1, 0≦y≦1), characterized in that this polishing slurry contains abrasive grains formed of SiO2, this abrasive grain is a secondary particle in which a primary particle is associated, and a ratio d2 / d1 of an average particle diameter d2 of a secondary particle to an average particle diameter d1 of a primary particle is not less than 1.6 and not more than 10. According to such the polishing slurry, a crystal surface having a small surface roughness can be formed on a GaxIn1-xAsyP1-y crystal at a high polishing rate and effectively.

Owner:SUMITOMO ELECTRIC IND LTD

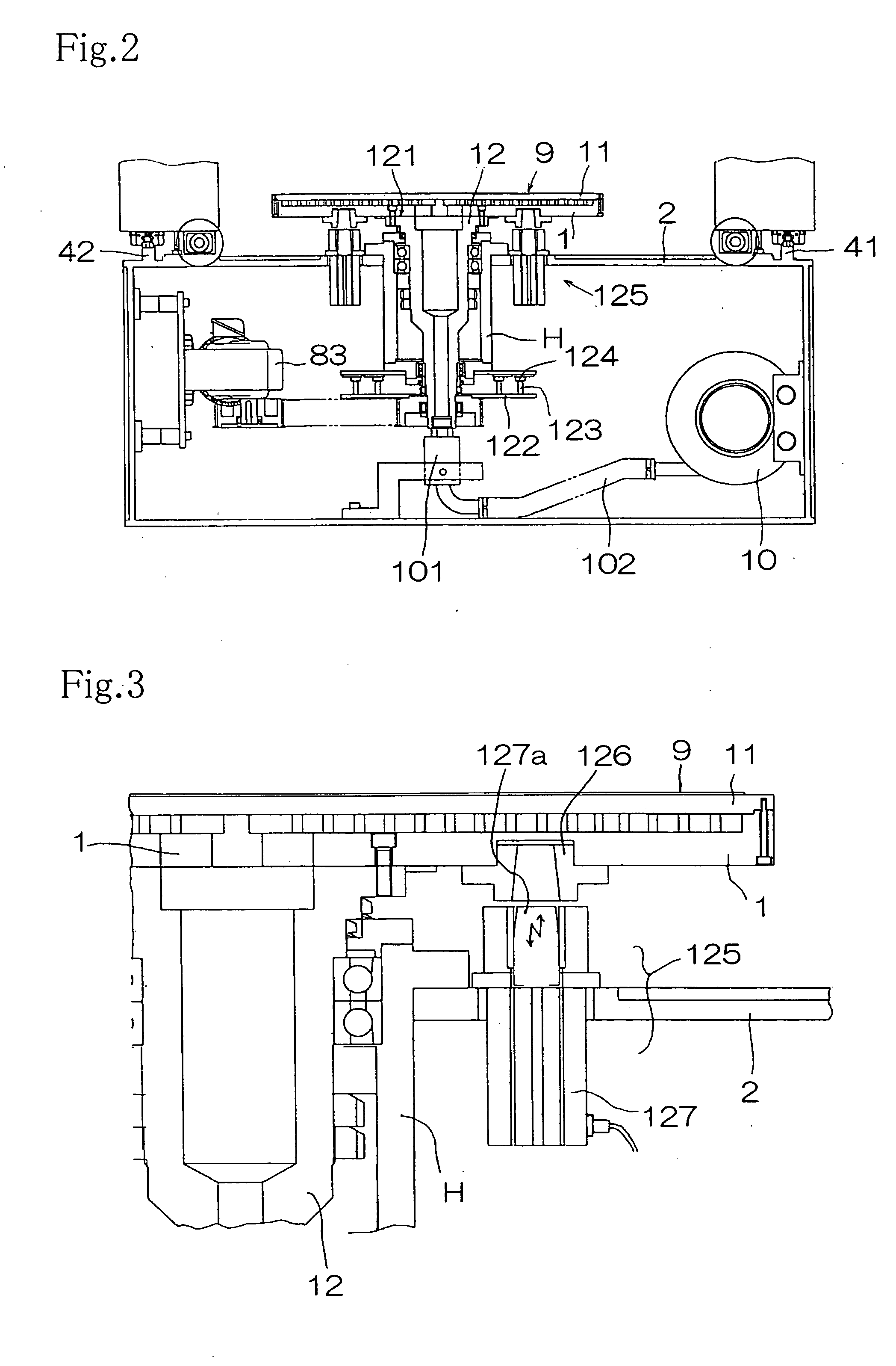

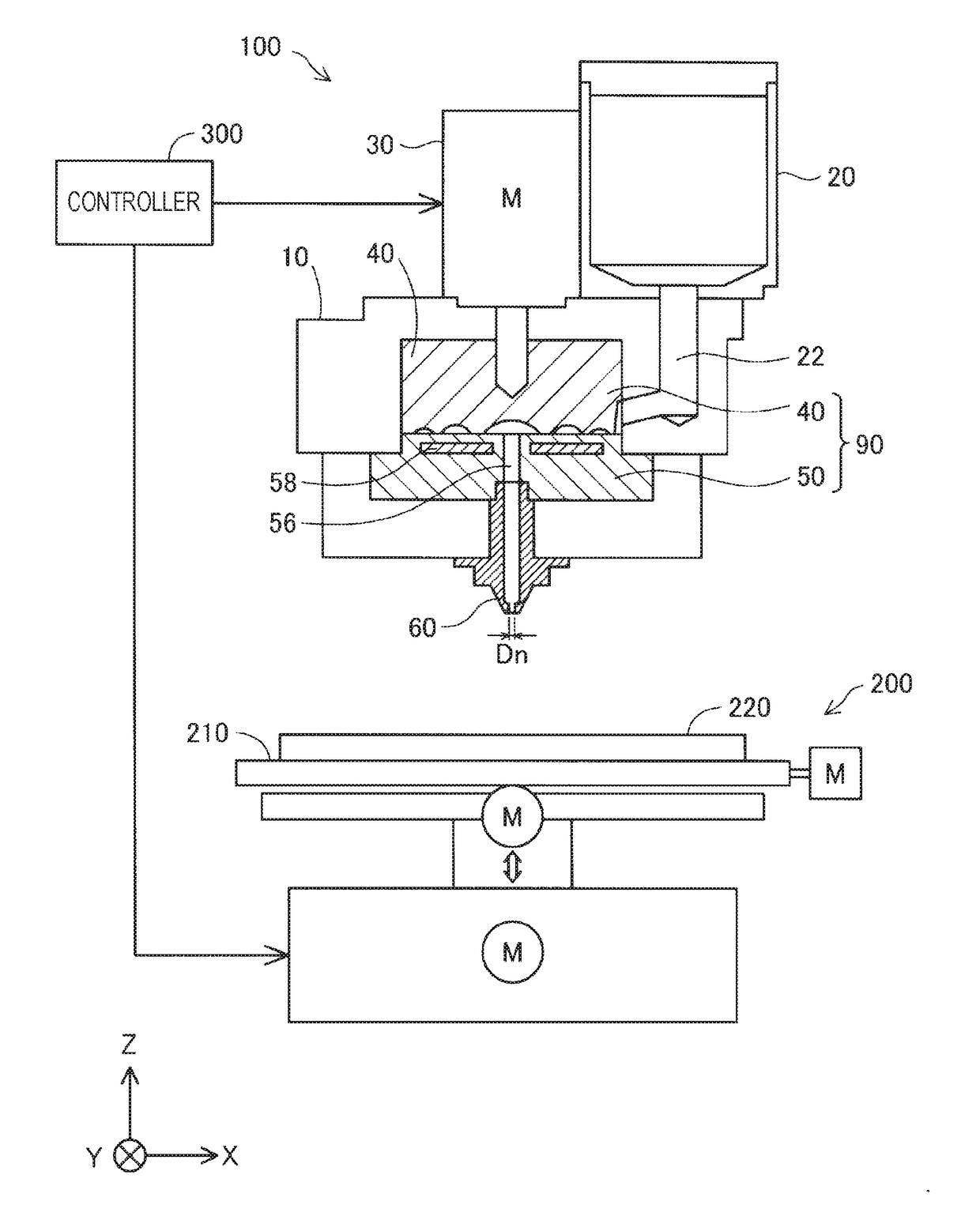

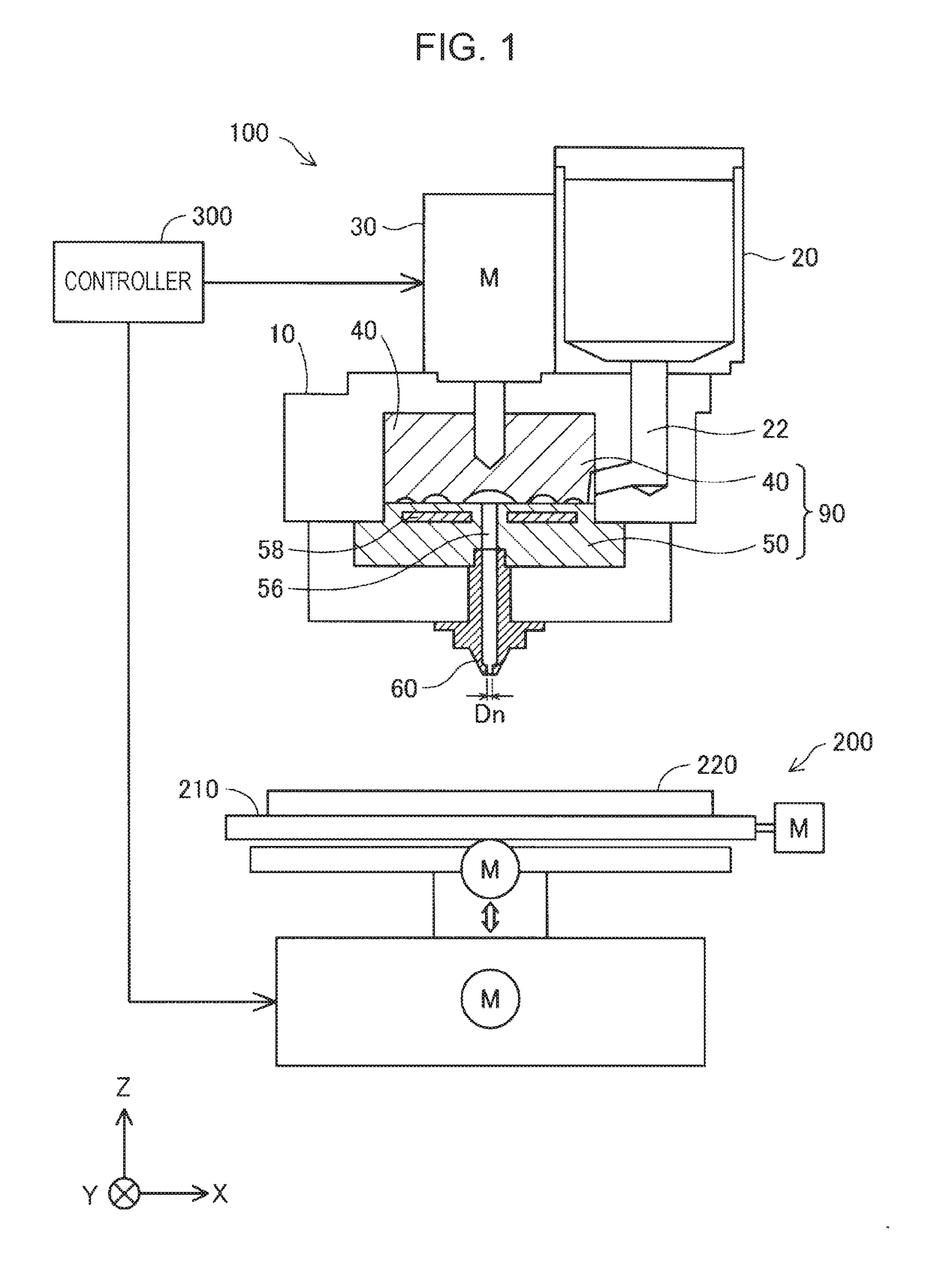

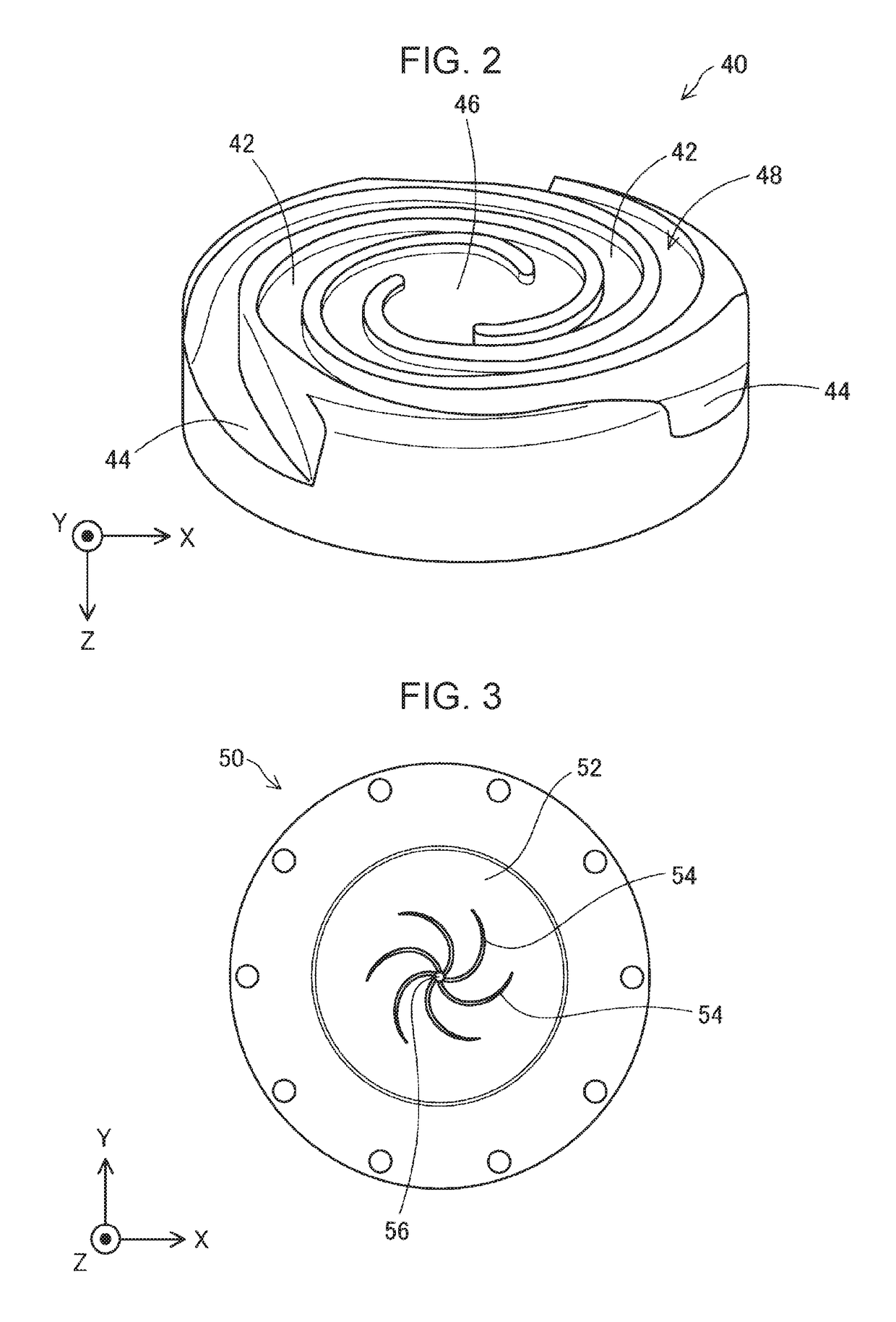

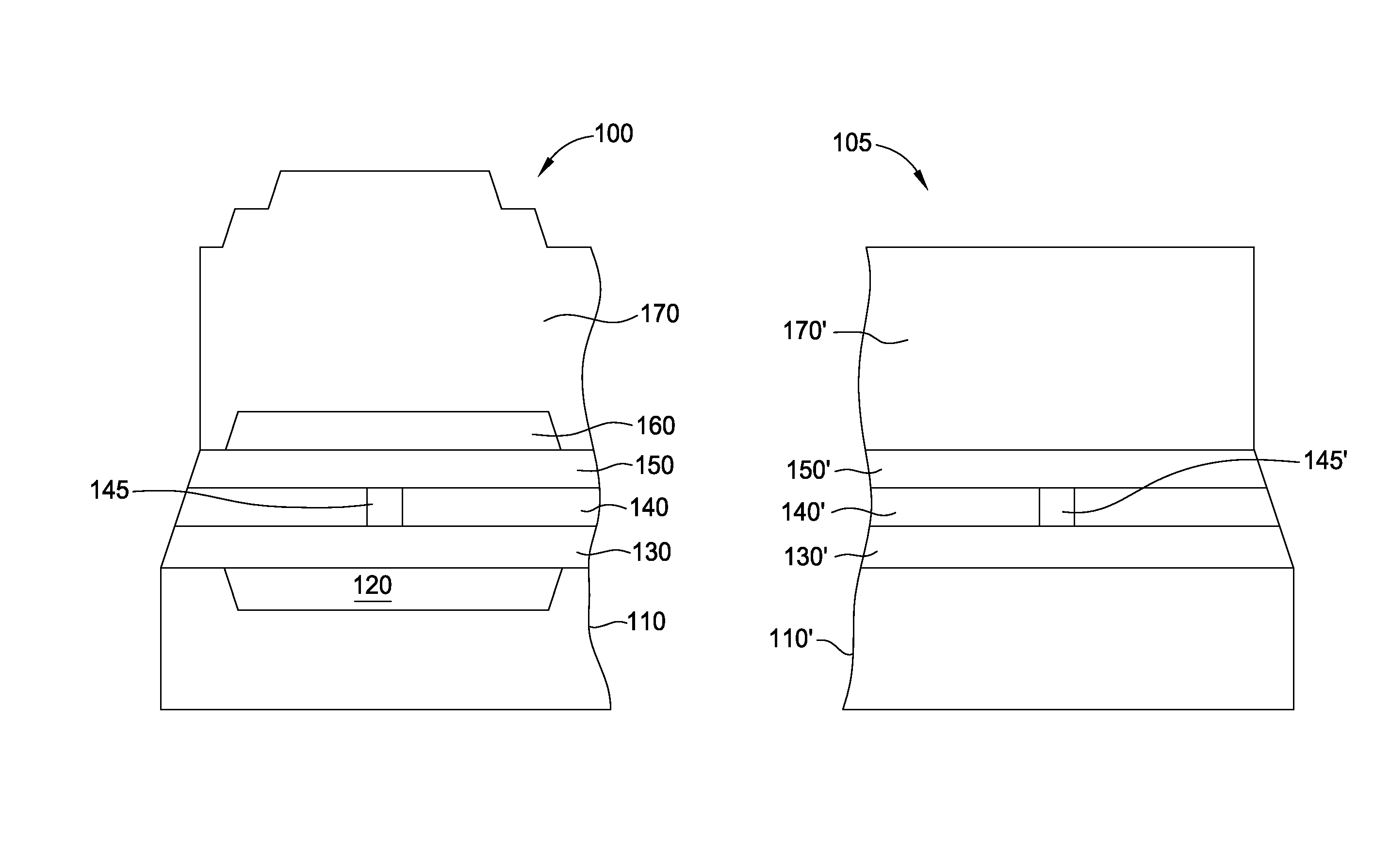

Three-dimensional modeling apparatus and three-dimensional modeling method

ActiveUS20180311894A1Reduce the overall heightSmall sizeManufacturing driving meansManufacturing heating elementsDrive motorDimensional modeling

A three-dimensional modeling apparatus includes a drive motor, a plasticizing section having a flat screw configured to be rotated by the drive motor, the plasticizing section being configured to plasticize and convert the material into a molten material by the rotation of the flat screw, and a nozzle configured to inject the molten material.

Owner:SEIKO EPSON CORP

Polishing composition and method for producing a memory hard disk

InactiveUS6280490B1High cutting rateSmall surface roughnessPigmenting treatmentOther chemical processesIron sulfateEthylenediamine

A polishing composition for a memory hard disk, which comprises the following components (a) to (d):(a) from 0.1 to 50 wt %, based on the total amount of the polishing composition, of at least one abrasive selected from the group consisting of silicon dioxide, aluminum oxide, cerium oxide, zirconium oxide, titanium oxide, silicon nitride and manganese dioxide,(b) from 0.001 to 10 wt %, based on the total amount of the polishing composition, of at least one iron salt selected from the group consisting of iron nitrate, iron sulfate, ammonium iron sulfate, iron perchlorate, iron chloride, iron citrate, ammonium iron titrate, iron oxalate, ammonium iron oxalate and an iron chelate complex salt of ethylenediaminetetraacetic acid,(c) from 0.01 to 30 wt %, based on the total amount of the polishing composition, of at least one peroxydisulfate salt selected from the group consisting of ammonium peroxydisulfate, potassium peroxydisulfate and sodium peroxydisulfate, and(d) water.

Owner:FUJIMI INCORPORATED

Method for smoothing a solid surface

In a method of irradiating a gas cluster ion beam on a solid surface and smoothing the solid surface, the angle formed between the solid surface and the gas cluster ion beam is chosen to be between 1° and an angle less than 30°. In case the solid surface is relatively rough, the processing efficiency is raised by first irradiating a beam at an irradiation angle θ chosen to be something like 90° as a first step, and subsequently at an irradiation angle θ chosen to be 1° to less than 30° as a second step. Alternatively, the set of the aforementioned first step and second step is repeated several times.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

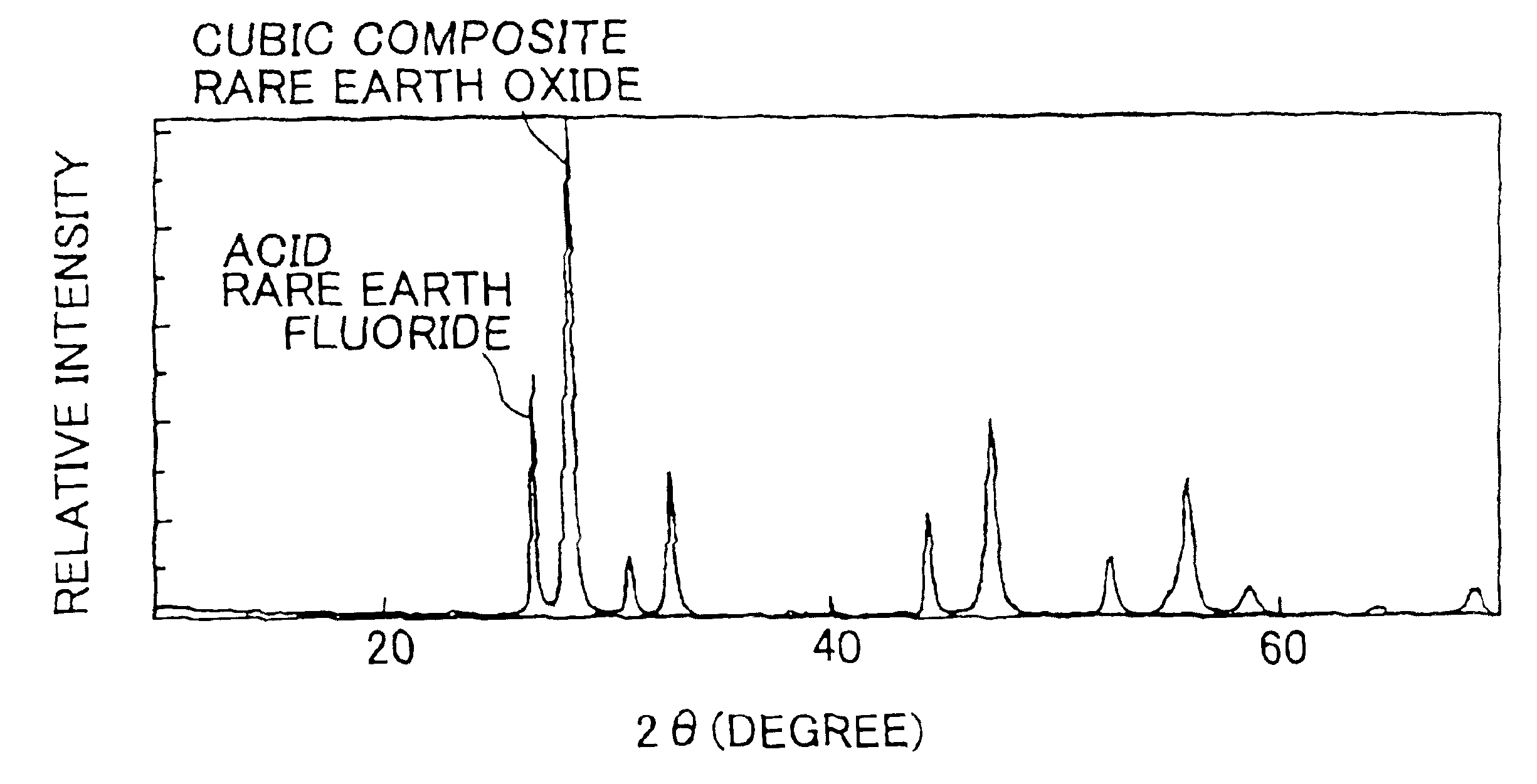

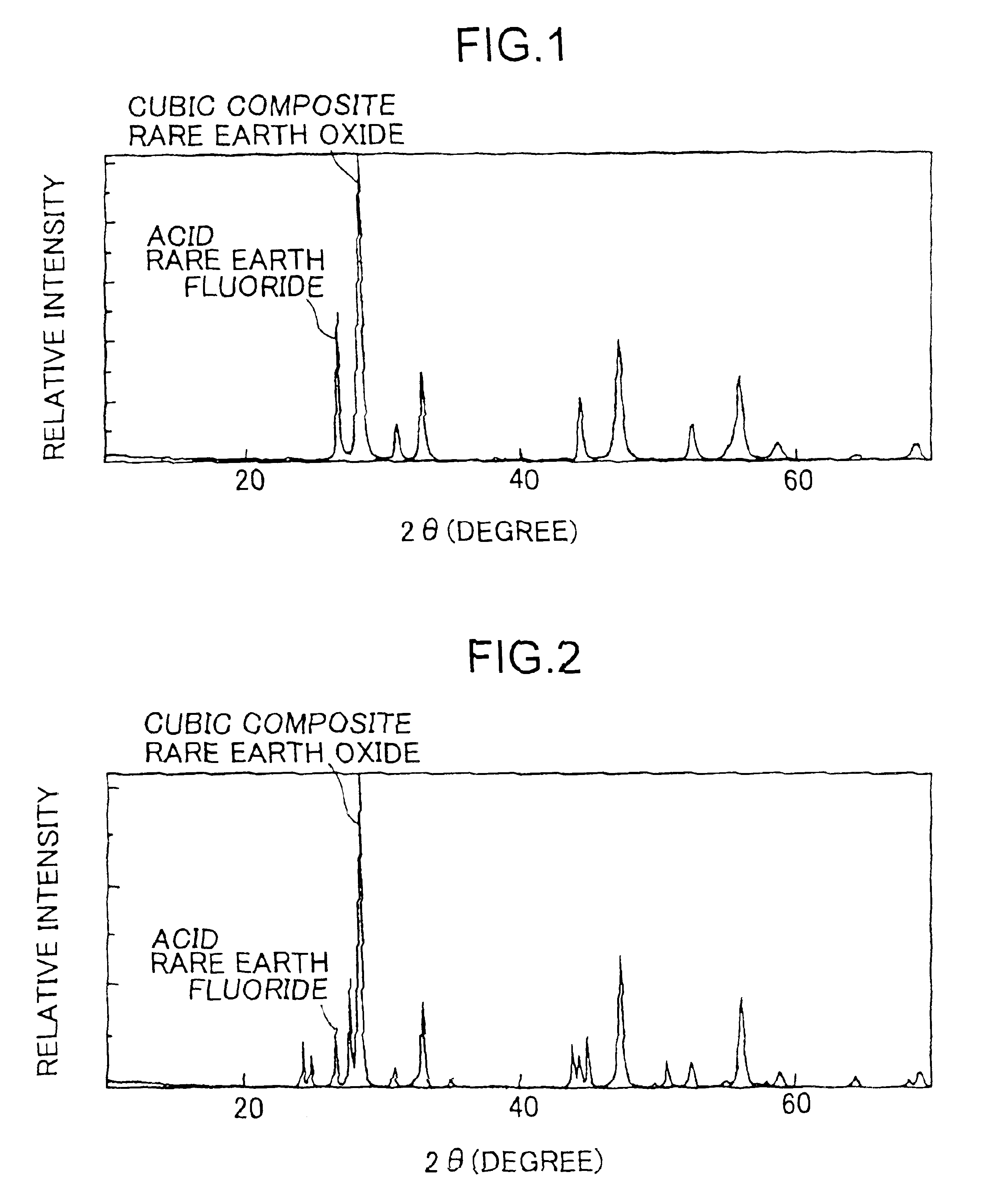

Cerium-based abrasive, production process thereof

InactiveUS6986798B2High quality polishingSmall surface roughnessRare earth metal oxides/hydroxidesPigmenting treatmentRare-earth elementCerium

A mixed light rare earth compound which has been obtained by chemically removing medium-to-heavy rare earth elements, Nd and impurities other than rare earth elements from an ore containing rare earth elements is fired at 500 to 1100° C. to yield a mixed rare earth oxide. A cerium-based rare earth fluoride is added to the mixed rare earth oxide to obtain a mixture. The mixture is subjected to wet-pulverization, drying, firing, disintegration and classification to thereby yield a cerium-containing abrasive.

Owner:SHOWA DENKO KK

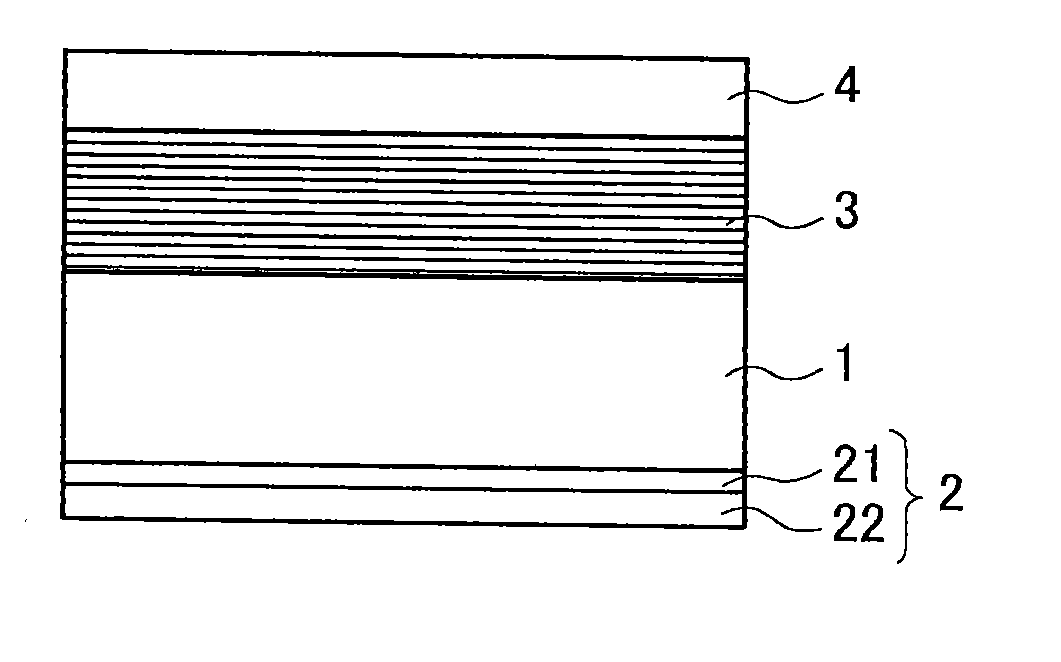

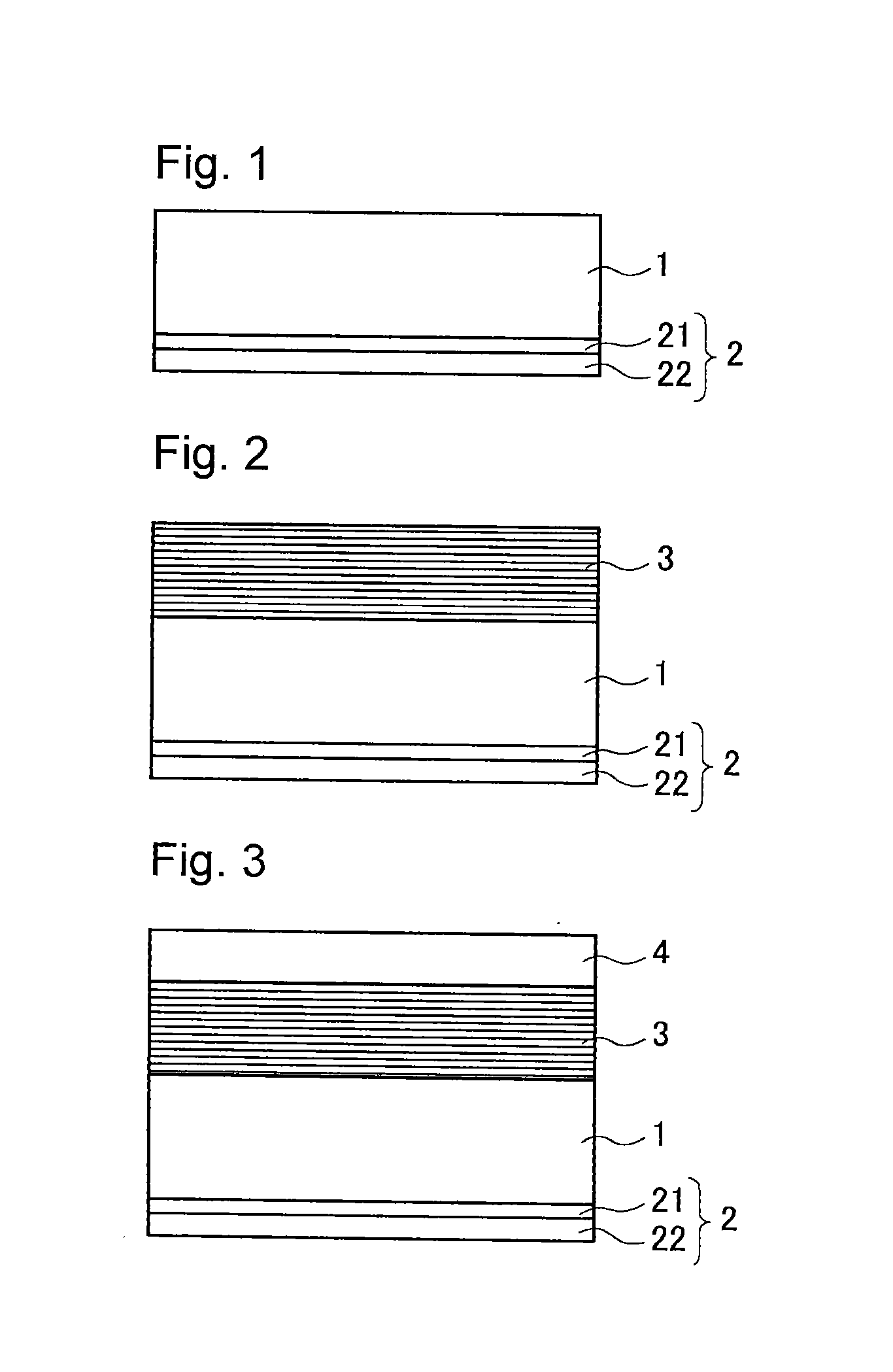

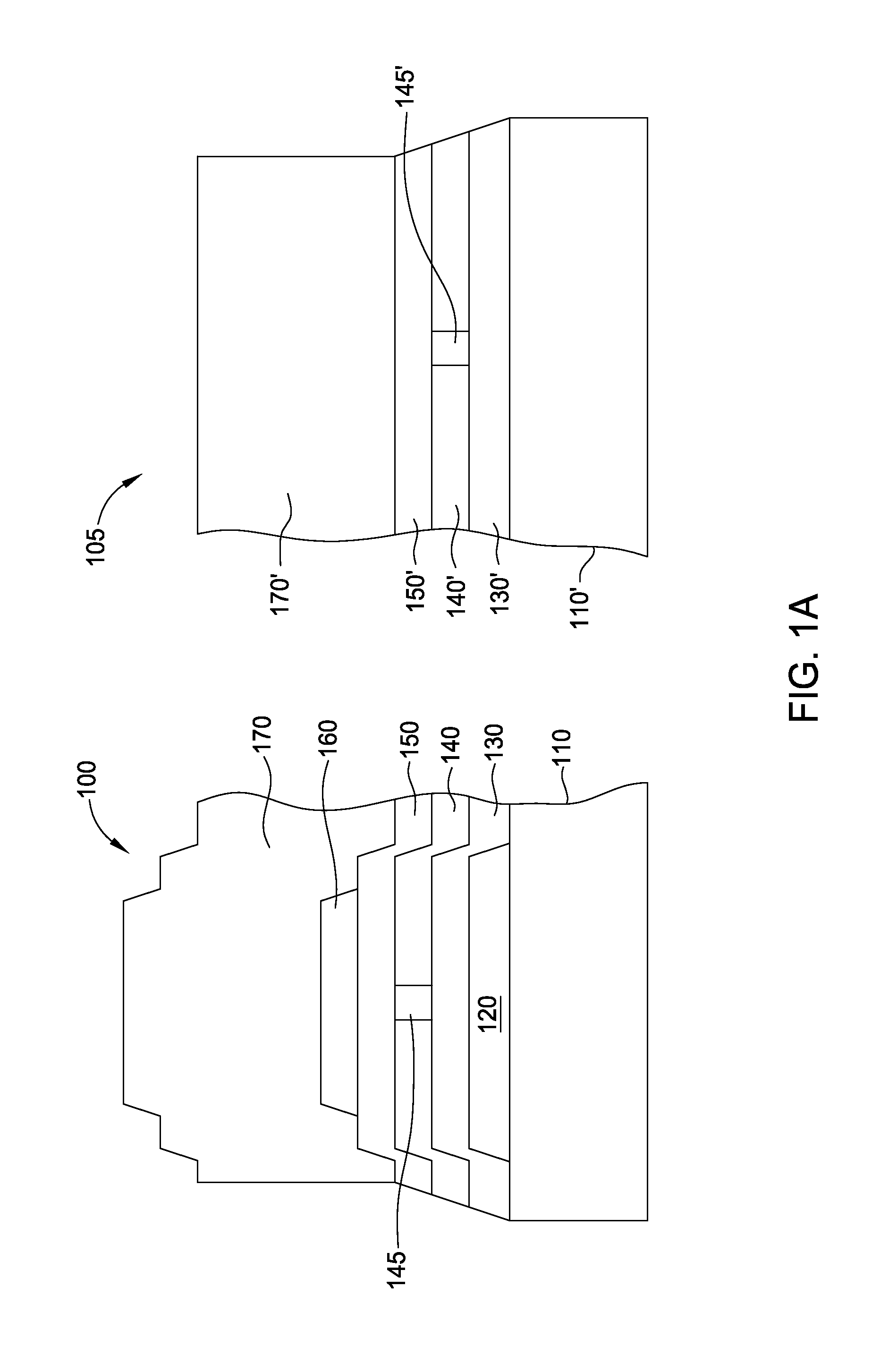

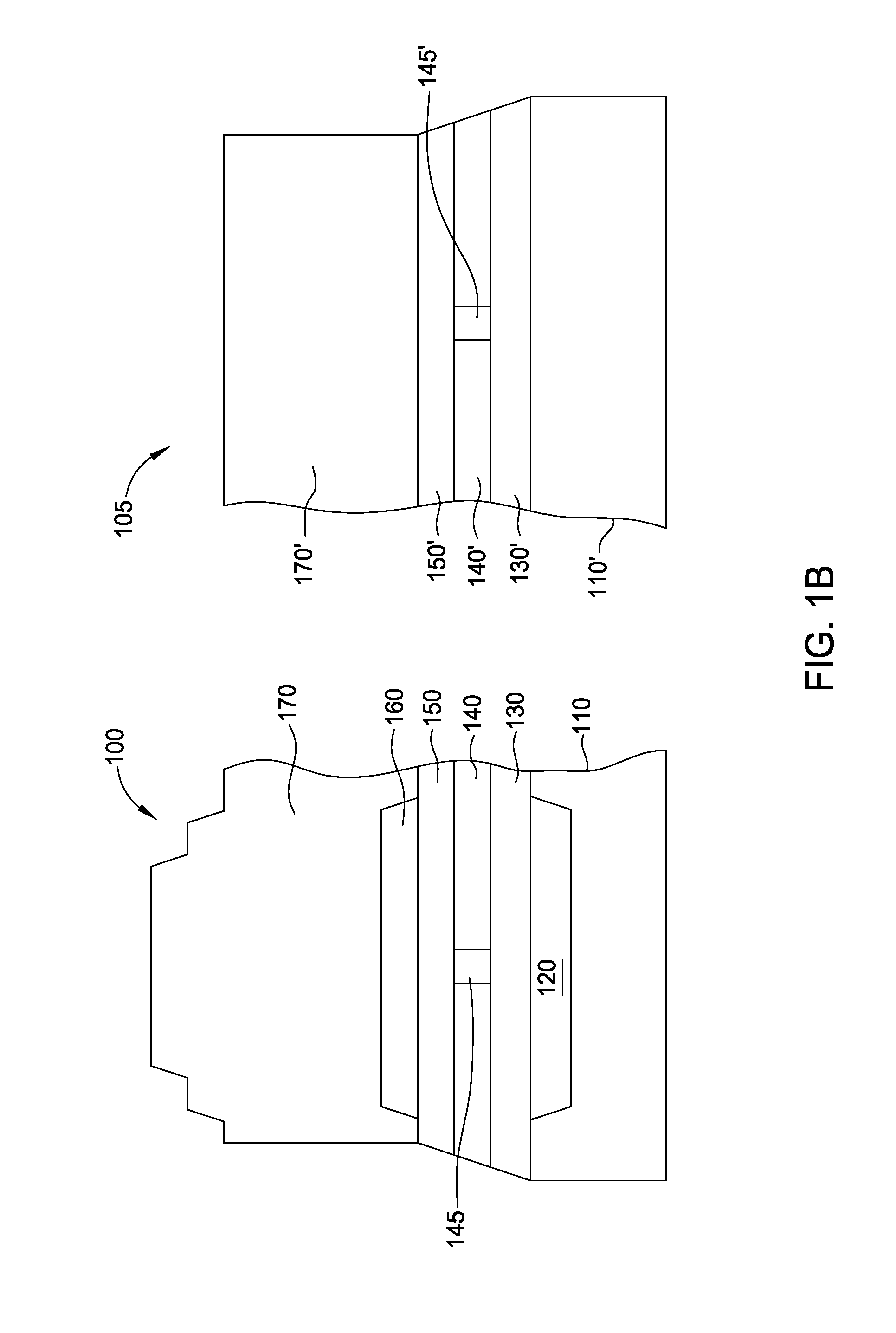

Substrate with conductive film, substrate with multilayer reflective film and reflective mask blank for EUV lithography

ActiveUS20130323630A1Suppress stressReduce resistanceOriginals for photomechanical treatmentElectrical resistance and conductanceLithographic artist

To provide a substrate with a conductive film for an EUV mask blank, which has a conductive film having a low sheet resistance, excellent surface smoothness and excellent contact to an electrostatic chuck, and with which deformation of the substrate by the film stress in an EUV mask blank can be suppressed.A substrate with a conductive film to be used for producing a reflective mask blank for EUV lithography, comprising a conductive film formed on a substrate;wherein the conductive film has at least two layers of a layer (lower layer) formed on the substrate side and a layer (upper layer) formed on the lower layer; andthe lower layer of the conductive film contains chromium (Cr), oxygen (O) and hydrogen (H), and the upper layer of the conductive film contains chromium (Cr), nitrogen (N) and hydrogen (H).

Owner:ASAHI GLASS CO LTD

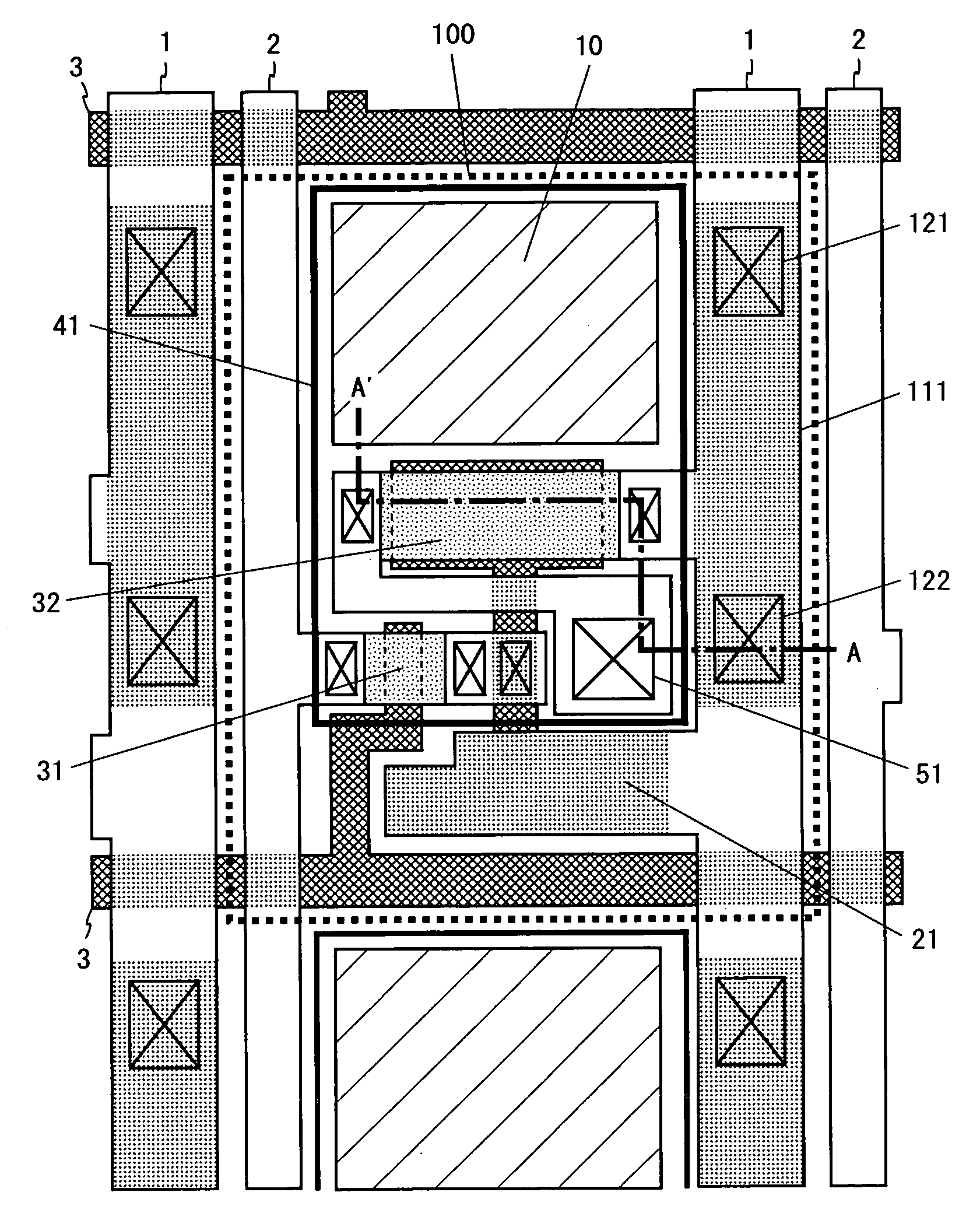

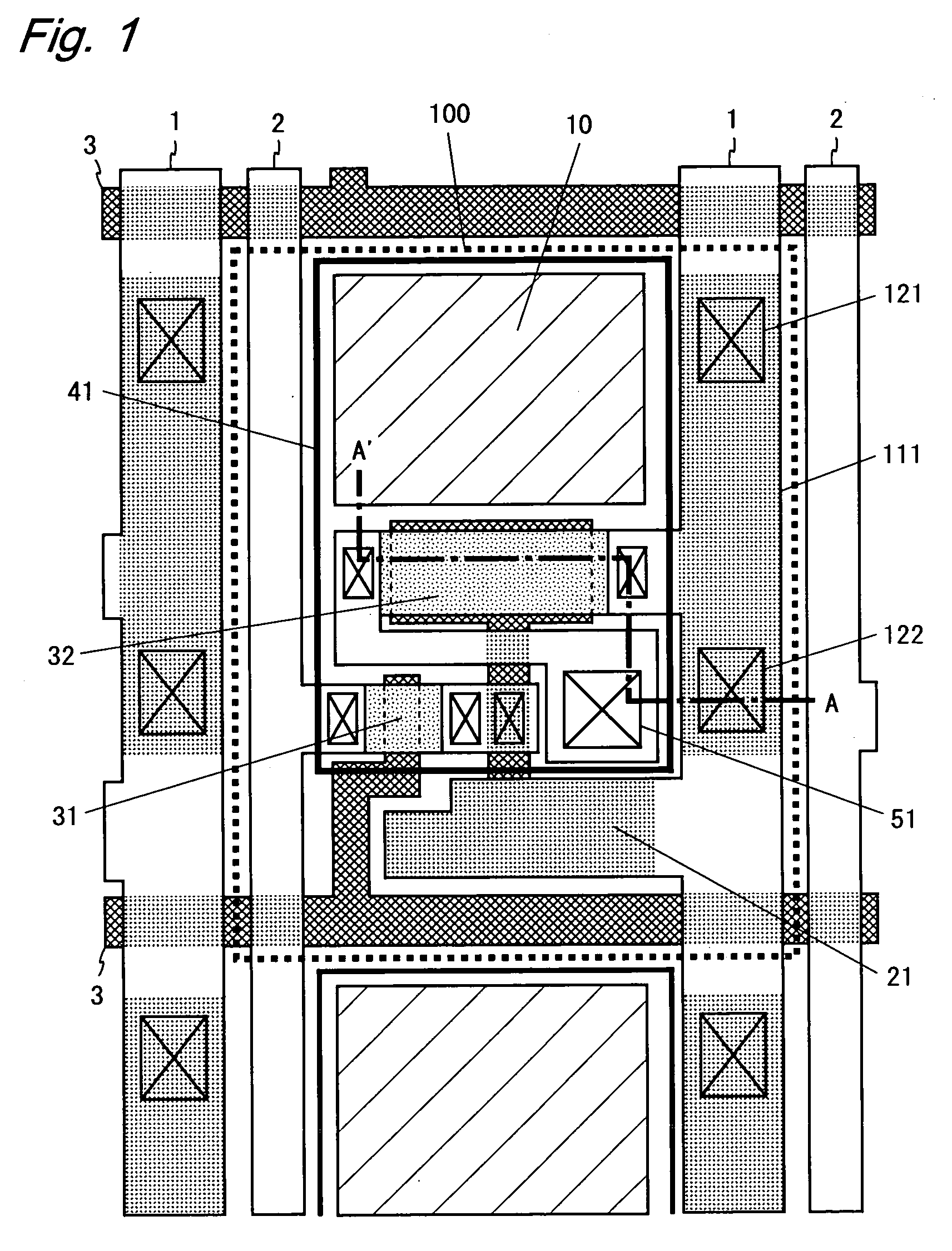

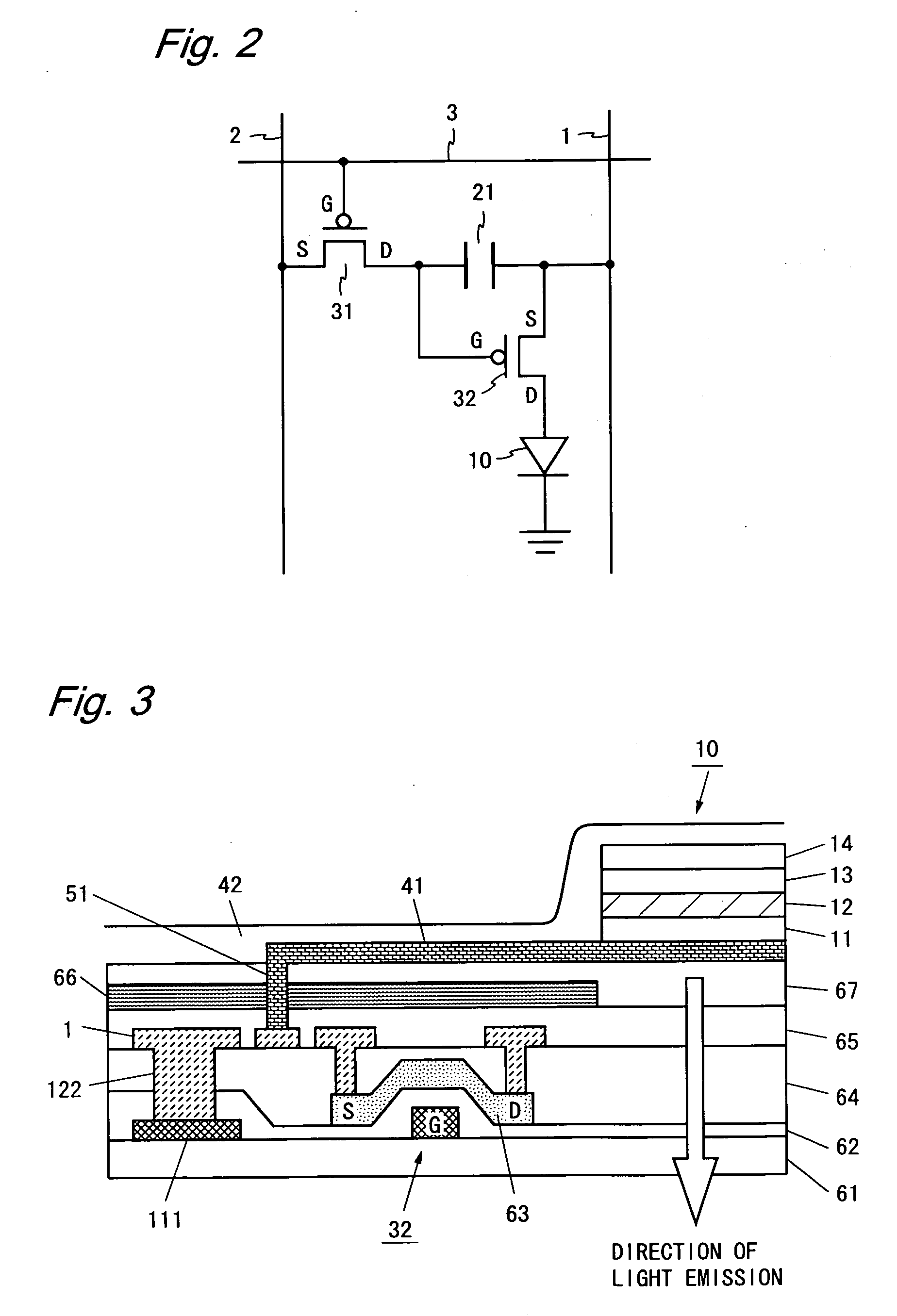

EL Display Device

ActiveUS20090167645A1Decrease power resistanceIncrease costStatic indicating devicesSolid-state devicesElectricityDisplay device

A power source line 1 and a scanning line 3 are arranged on different wiring layers so as to be orthogonal to each other. In the wiring layer on which the scanning line 3 is arranged, a bypass line 111 is arranged on at least a part of a portion obtained by removing a planar position of the scanning line 3 from a planar position of the power source line 1. Contacts 121 and 122 establish electric connection between the power source line 1 and the bypass line 111. As described above, the bypass line 111 is connected to the power source line 1 in parallel, leading to decrease in resistance of the power source line 1 and suppression of unevenness in brightness at a display screen. Moreover, an additional manufacturing step for providing the bypass line 111 is unnecessary. Further, an aperture ratio is not reduced even when the bypass line 111 is provided. When the bypass line 111 is made wider than the power source line 1, a pixel circuit can be prevented from operating erroneously due to external light.

Owner:SHARP KK

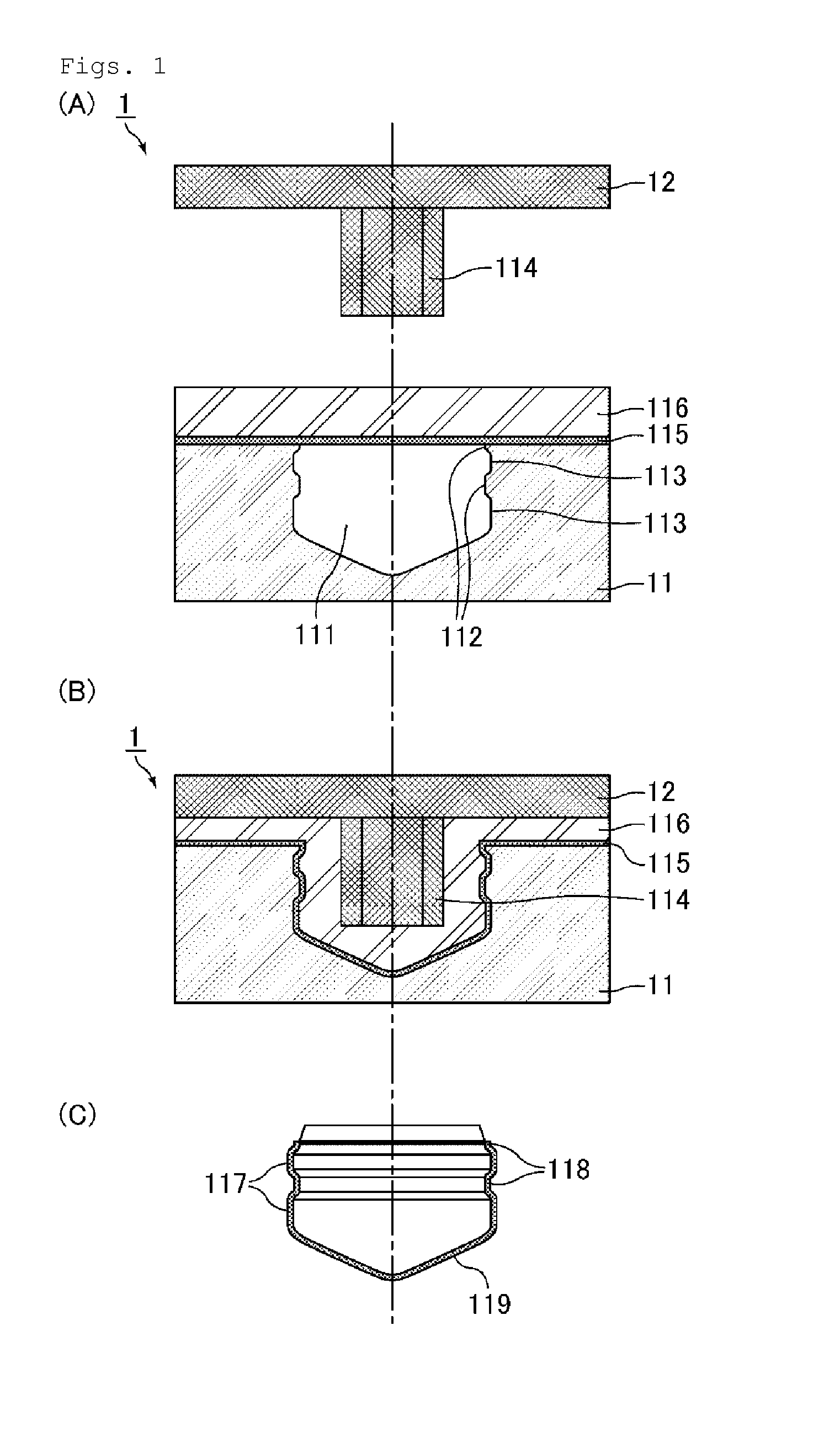

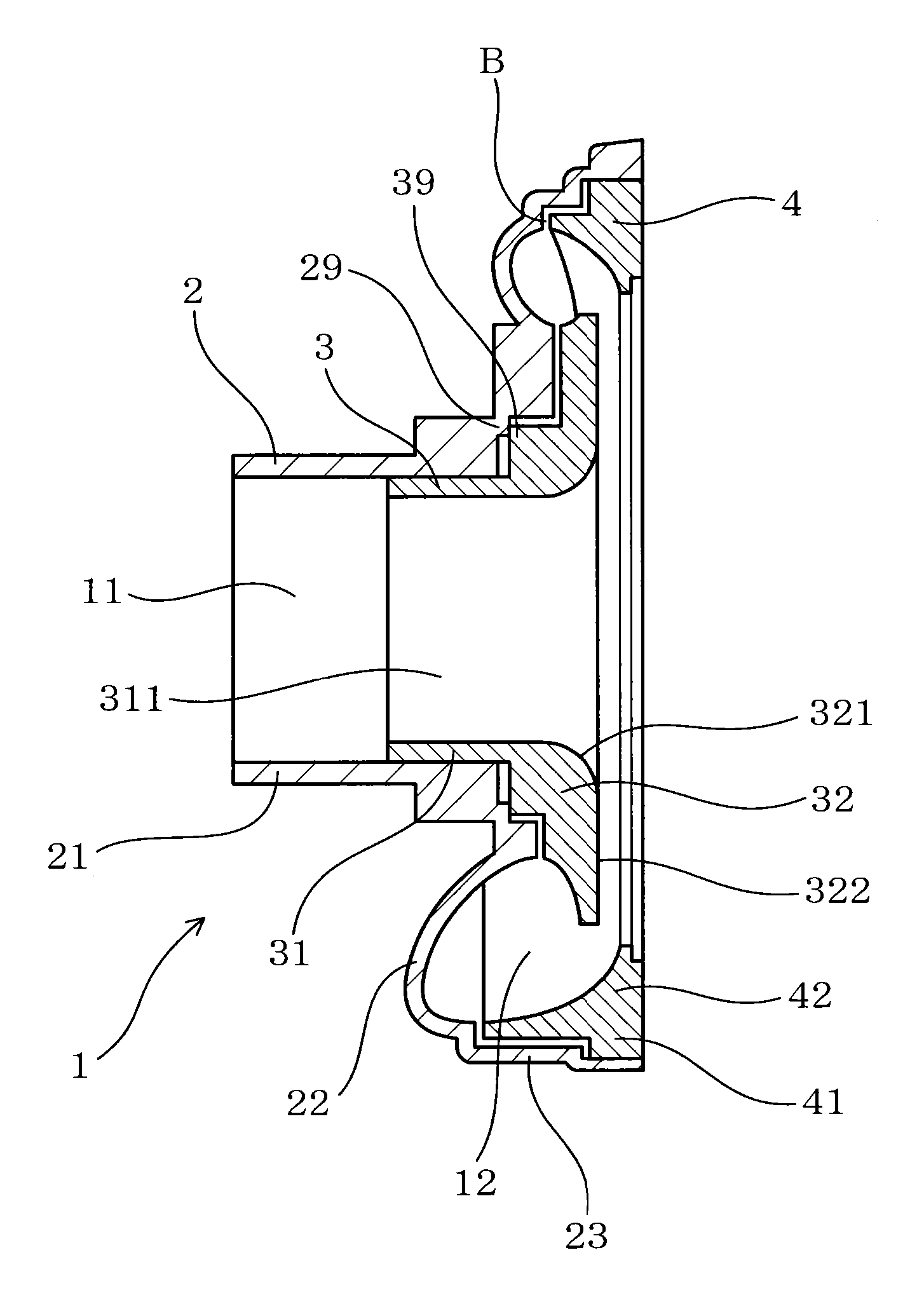

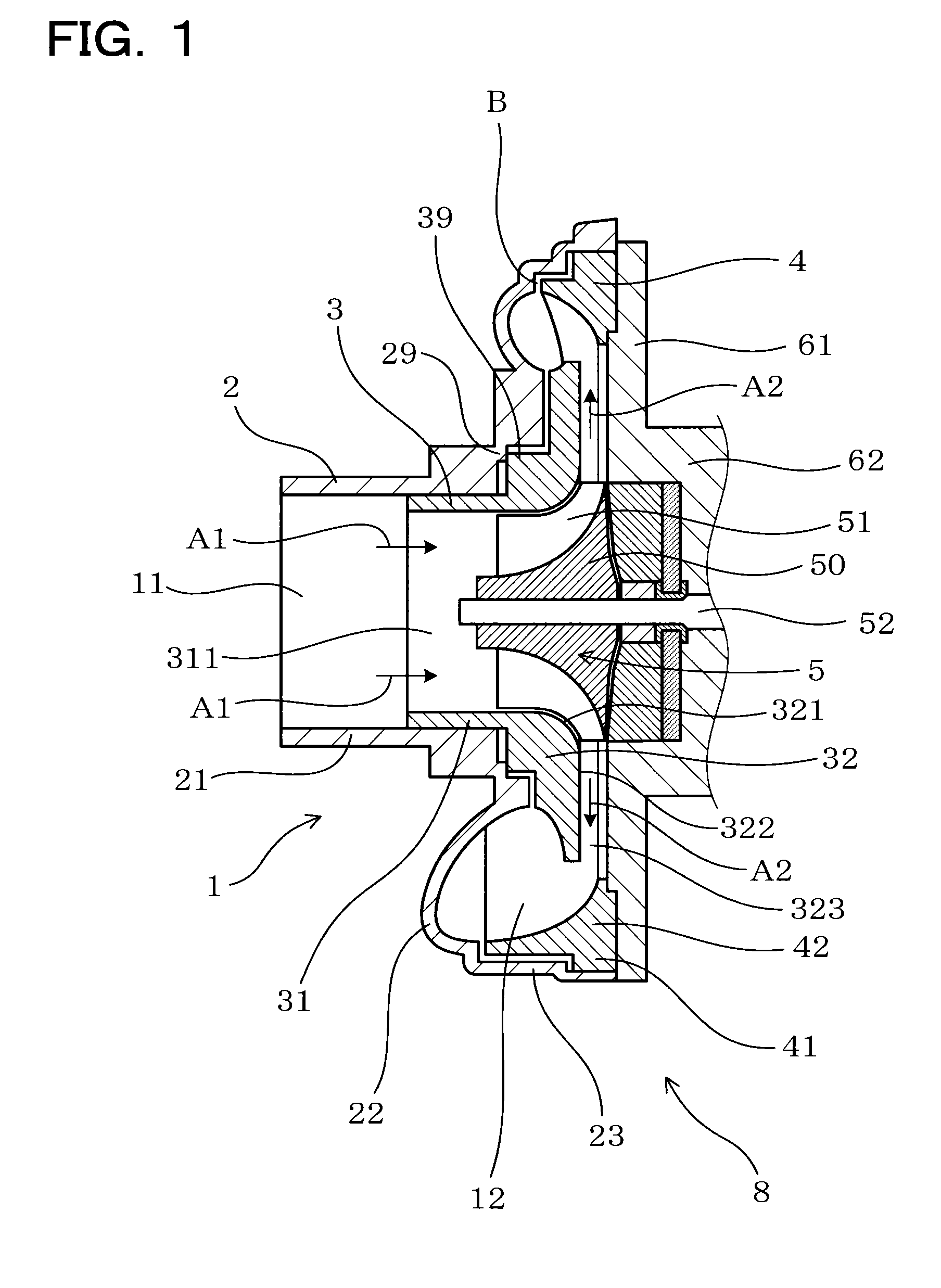

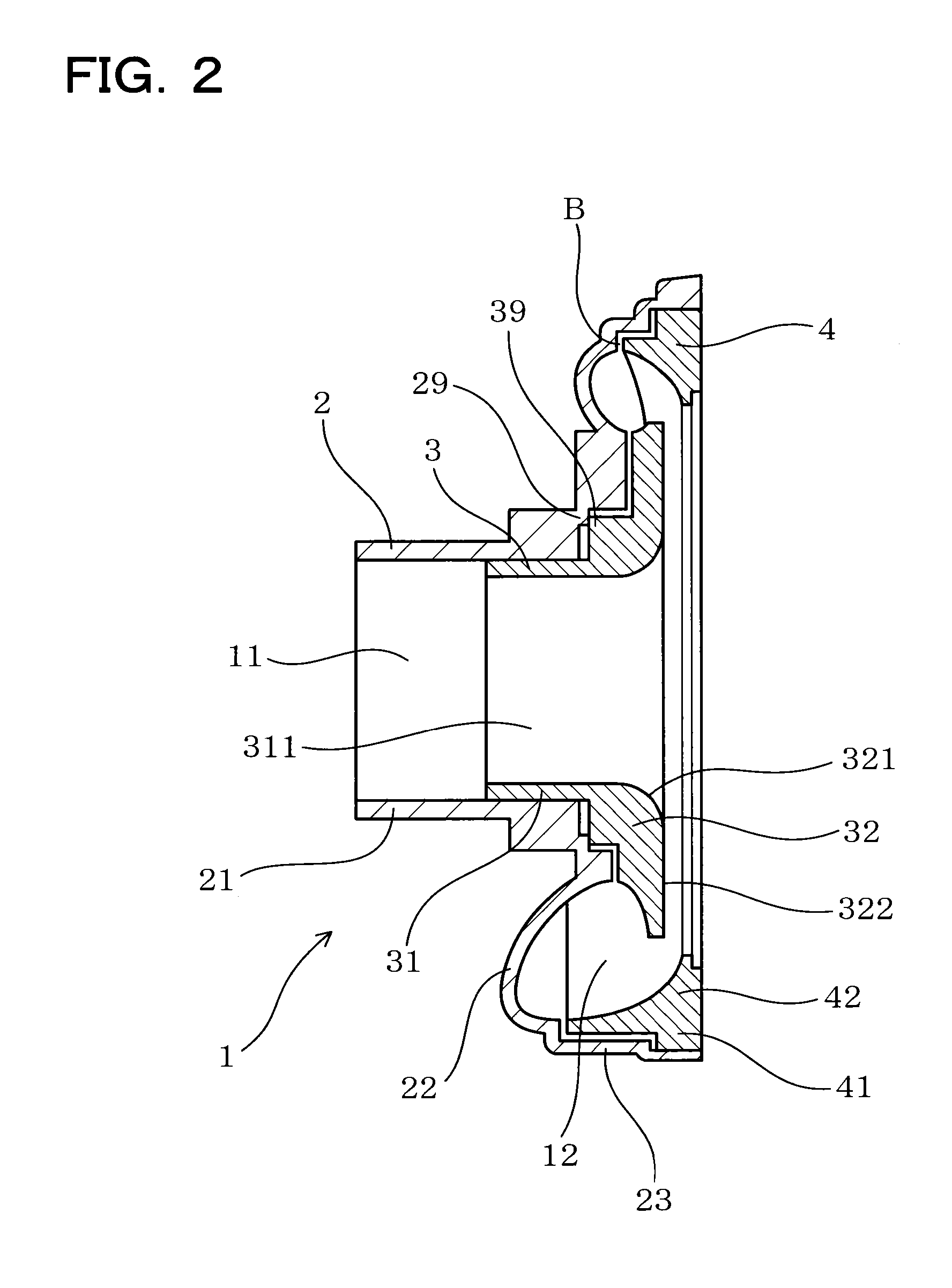

Compressor housing for supercharger and method for manufacturing the same

ActiveUS20130039750A1Improve productivityEasy to shapeEngine manufacturePump componentsImpellerEngineering

A compressor housing is provided with a scroll piece that includes a cylindrical intake port forming section that forms an intake port, a scroll wall surface forming section that forms an air-intake side wall surface of a discharge scroll chamber, and a scroll outer circumferential section that covers an outer circumferential side of the discharge scroll chamber; a shroud piece that includes a cylindrical shroud press fitted section press fitted into the intake port forming section, and a shroud wall surface forming section that forms an inner circumferential side wall surface of the discharge scroll chamber and also forms a shroud surface that opposes an impeller and a diffuser surface; and an outer circumferential annular piece that includes an outer circumferential annular press fitted section that is press fitted inside the scroll outer circumferential section, and an outer circumferential annular wall surface forming section that forms an outer circumferential side wall surface of the discharge scroll chamber.

Owner:OTICS CORP +1

Method of producing ultra-thin copper foil with carrier, ultra-thin copper foil with carrier produced by the same, printed circuit board, multilayer printed circuit board and chip on film circuit board

InactiveUS7223481B2Small surface roughnessThermometers using material expansion/contactionSolid-state devicesChip on filmSurface roughness

Owner:FURUKAWA ELECTRIC CO LTD

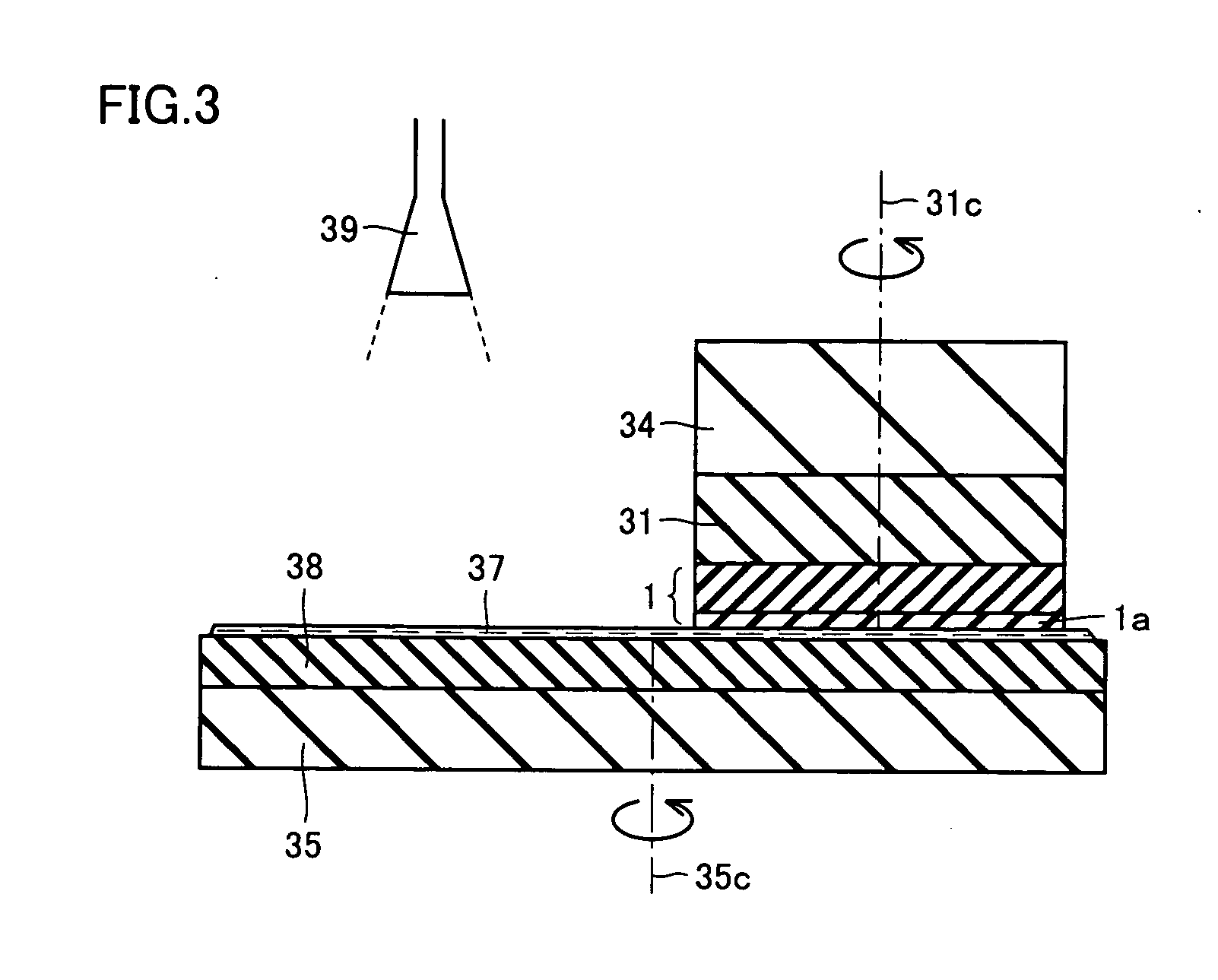

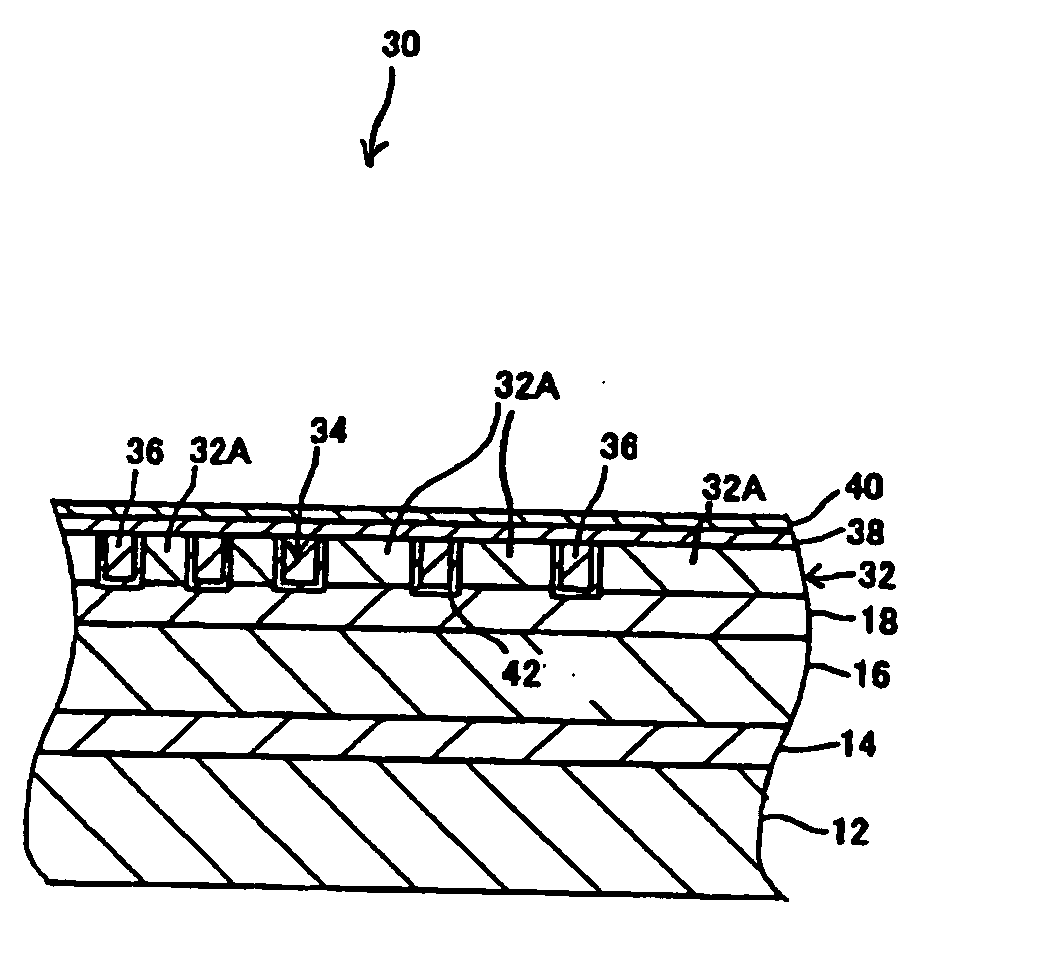

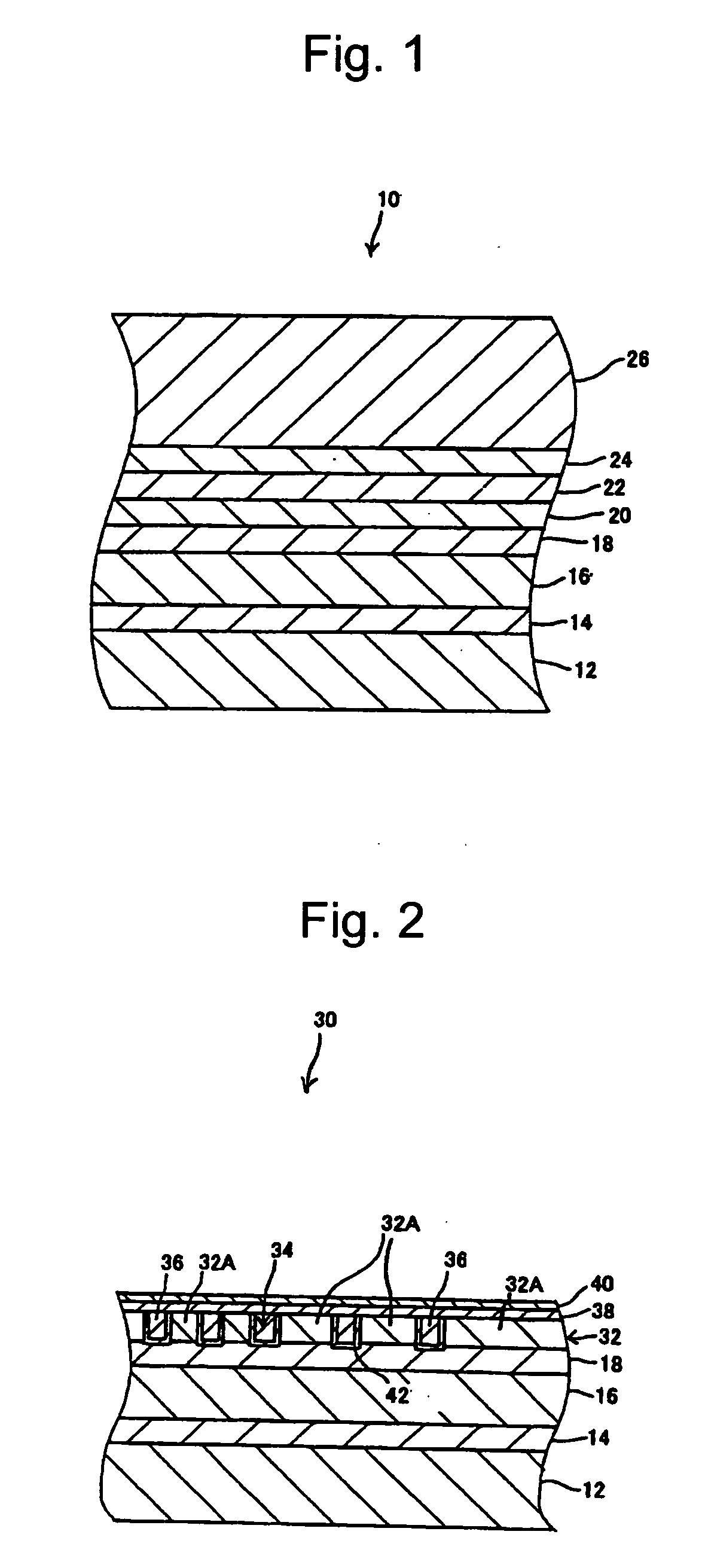

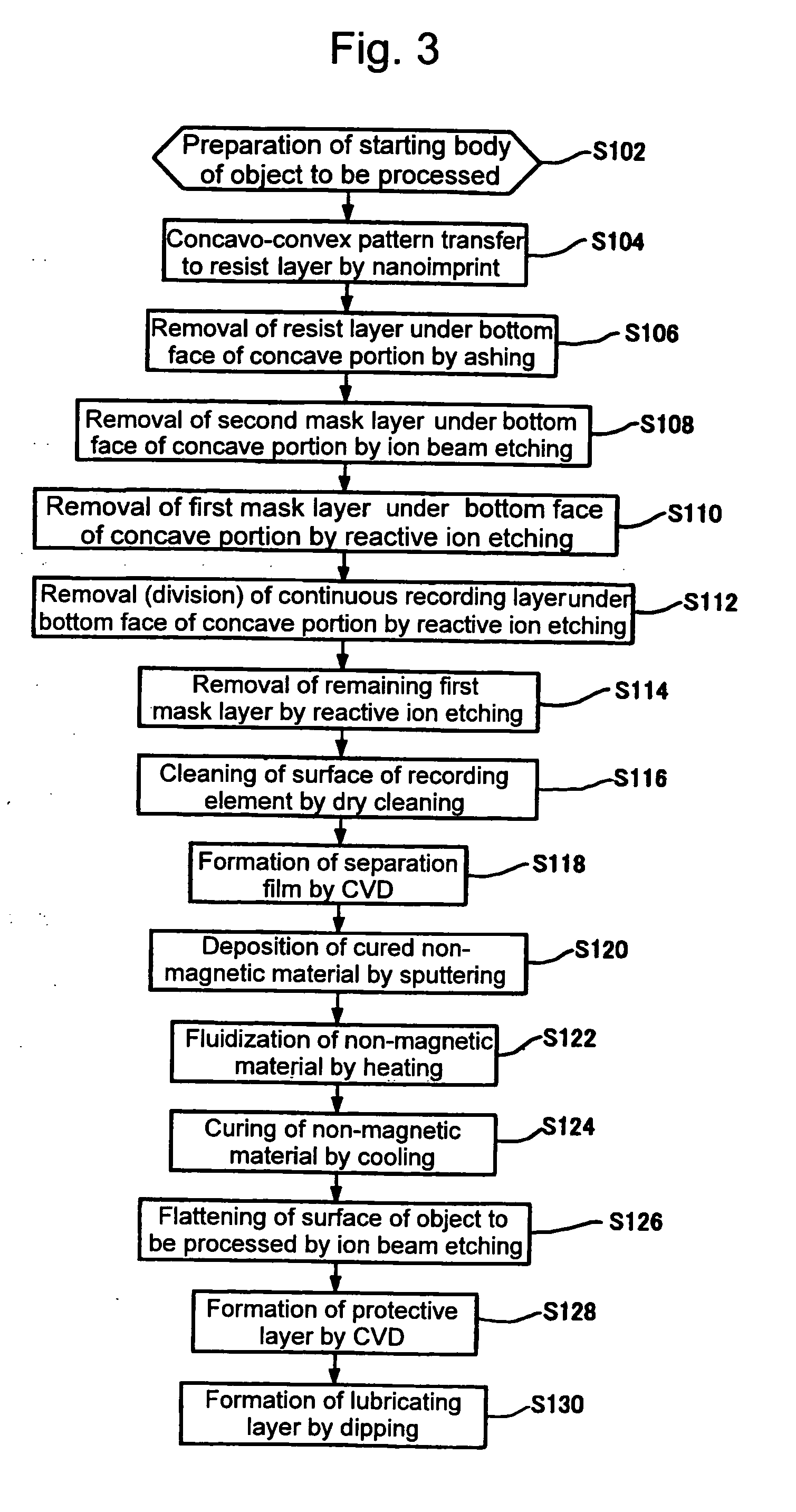

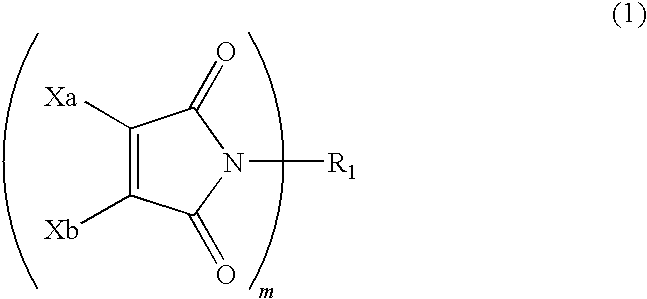

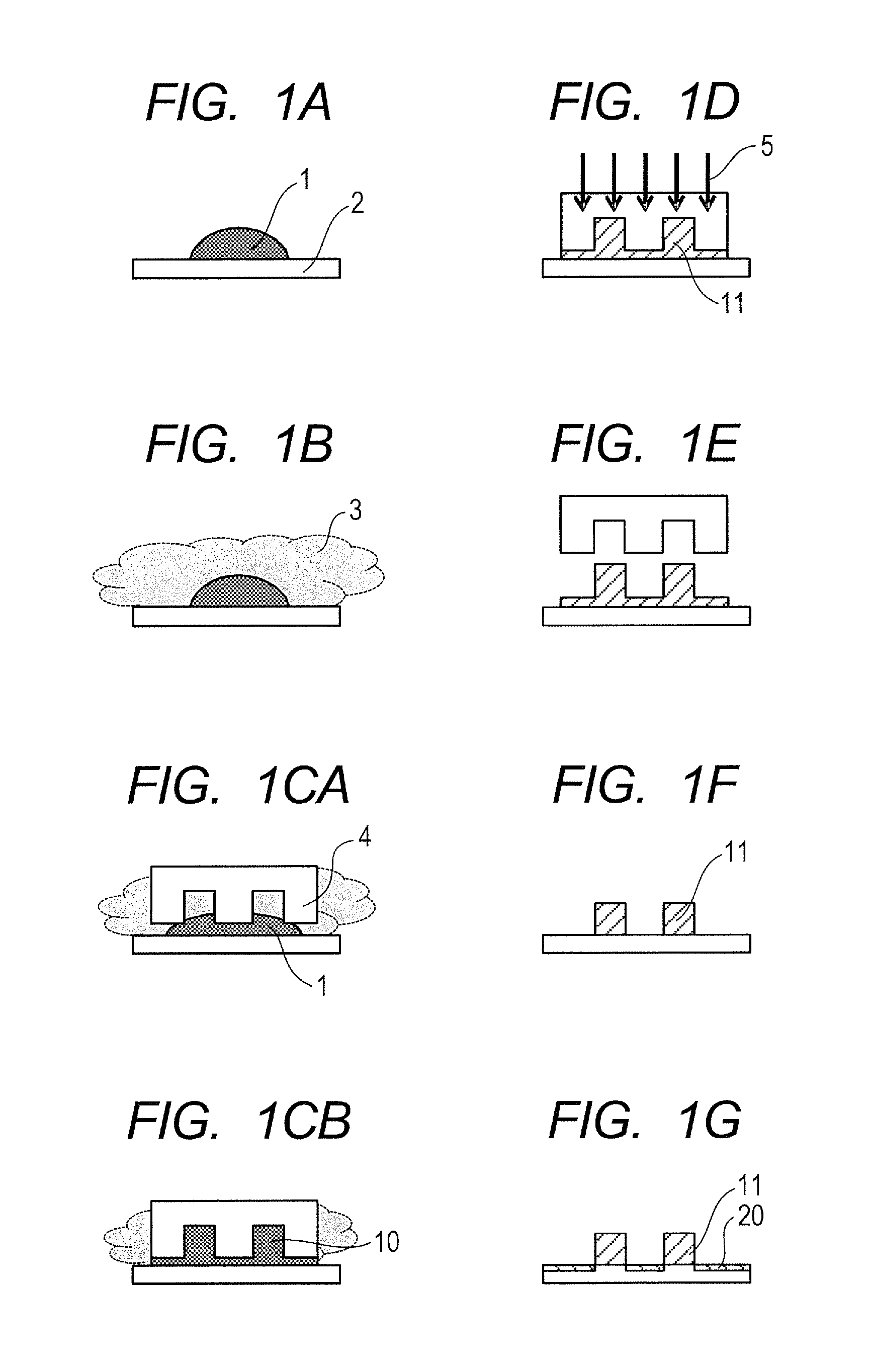

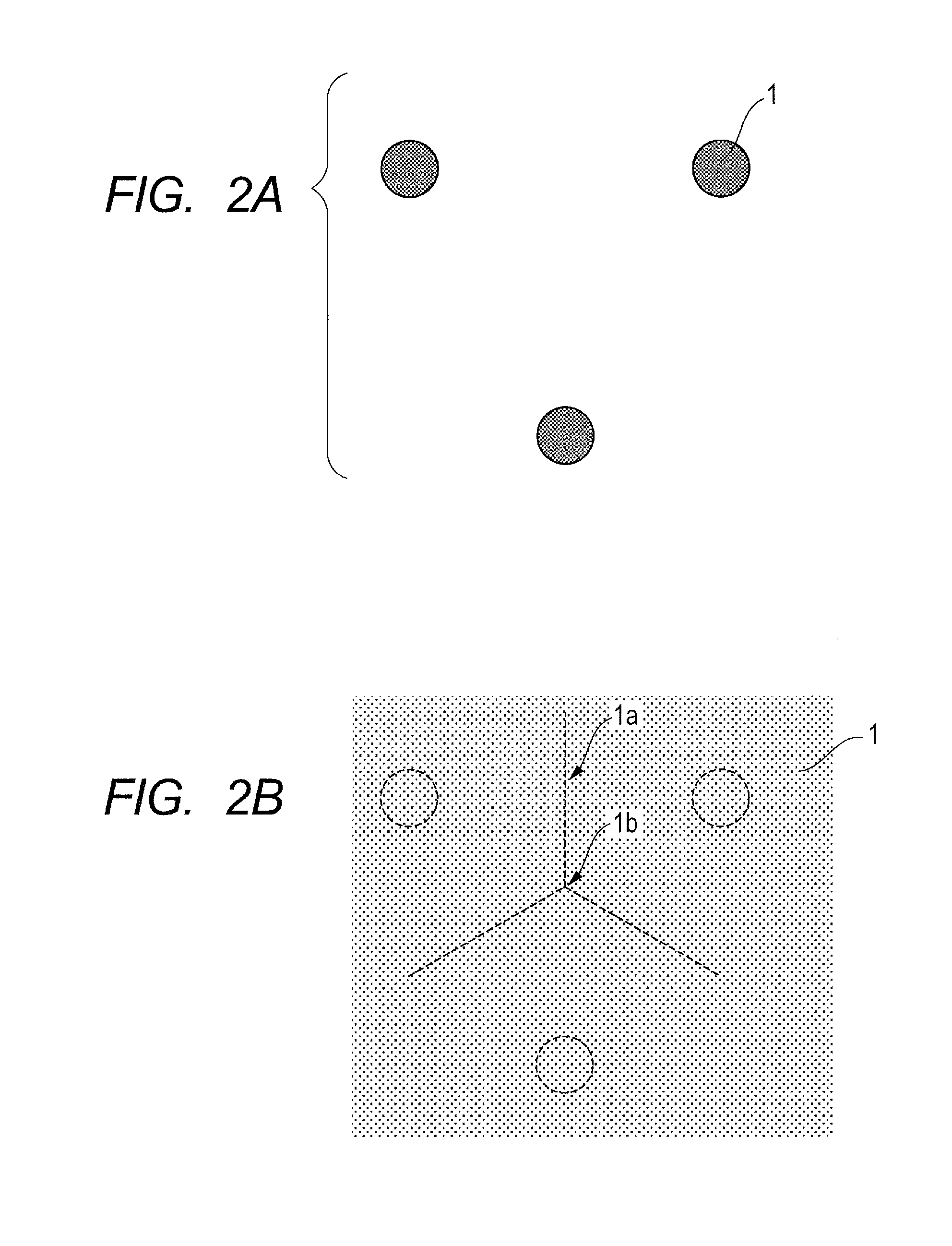

Method for producing magnetic recording medium and magnetic recording medium

InactiveUS20070031706A1Efficiently and surely manufacturedReduce surface roughnessPretreated surfacesRecord information storageNon magneticRecording layer

A method for manufacturing a magnetic recording medium, which enables efficient and ensured manufacture of a magnetic recording medium having a recording layer formed in a concavo-convex pattern and a satisfactorily flat surface, and a magnetic recording medium are provided. According to the method for manufacturing a magnetic recording medium, a material whose state is selectable between a flowing state and a cured state is used as a non-magnetic material 36. After the non-magnetic material 36 is formed in a flowing state on a surface of an object to be processed 10 including a recording layer 32 formed in a concavo-convex pattern over a glass substrate 12, then the non-magnetic material 36 is cured.

Owner:TDK CORPARATION

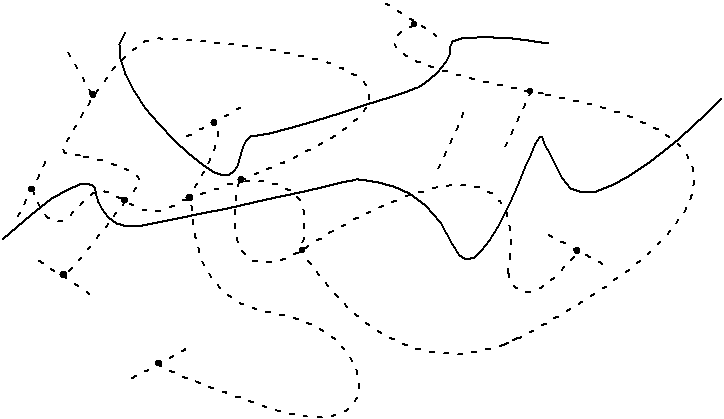

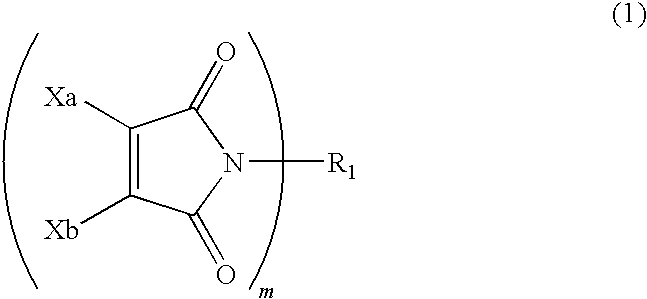

Thermosetting Resin Composition of Semi-IPN Composite, and Varnish, Prepreg and Metal Clad Laminated Board Using the Same

ActiveUS20100233495A1Good high-frequency propertyGood heat resistanceSynthetic resin layered productsPrinted circuit aspectsPrepolymerMetal foil

Provided is a thermosetting resin composition which can be used for the production of printed circuit boards, having good dielectric properties in high frequency bands so that transmission loss can be significantly lowered, having excellent heat resistance after moisture absorption and thermal expansion properties, and satisfying peeling strength between the resin composition and metal foil.The present invention relates to a thermosetting resin composition of a semi-IPN composite, comprising (A) a polyphenylene ether, and a prepolymer formed from (B) a chemically unmodified butadiene polymer containing 40% or more of a 1,2-butadiene unit having a 1 2,-vinyl group in a side chain of a molecule and (C) a crosslinking agent, in a compatibilized and uncured state; and a resin varnish, a prepreg and a metal clad laminated board using the same.

Owner:RESONAC CORP

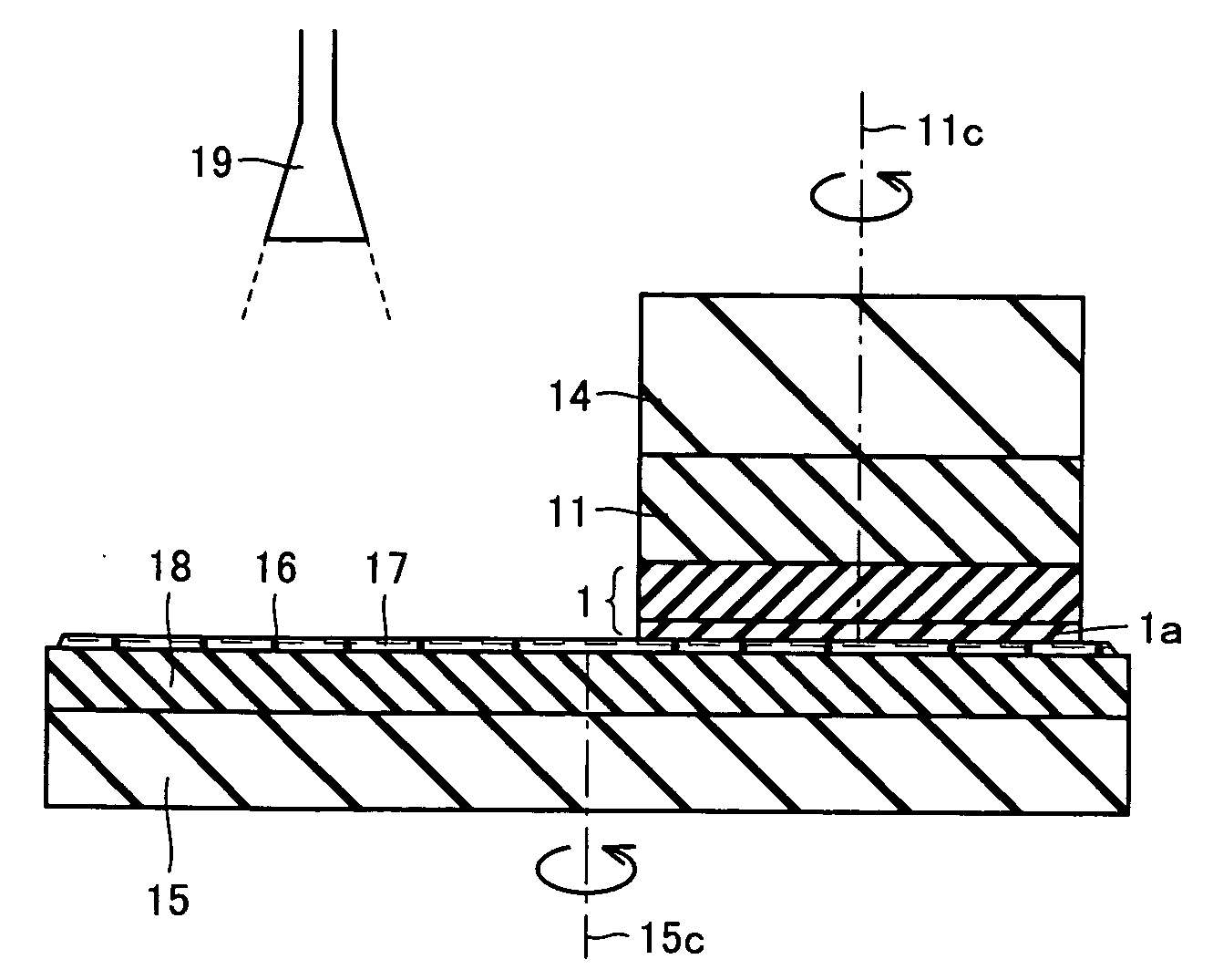

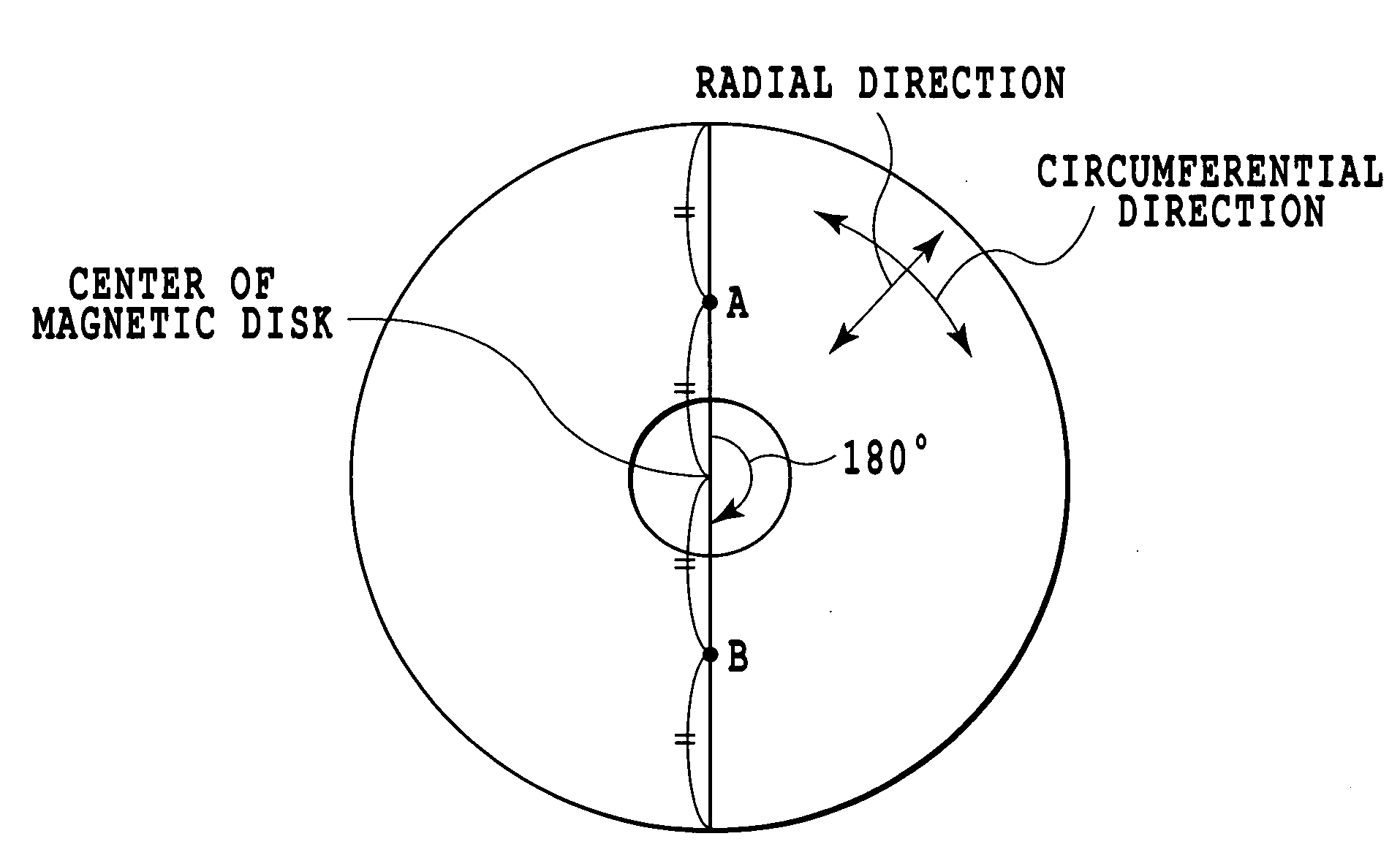

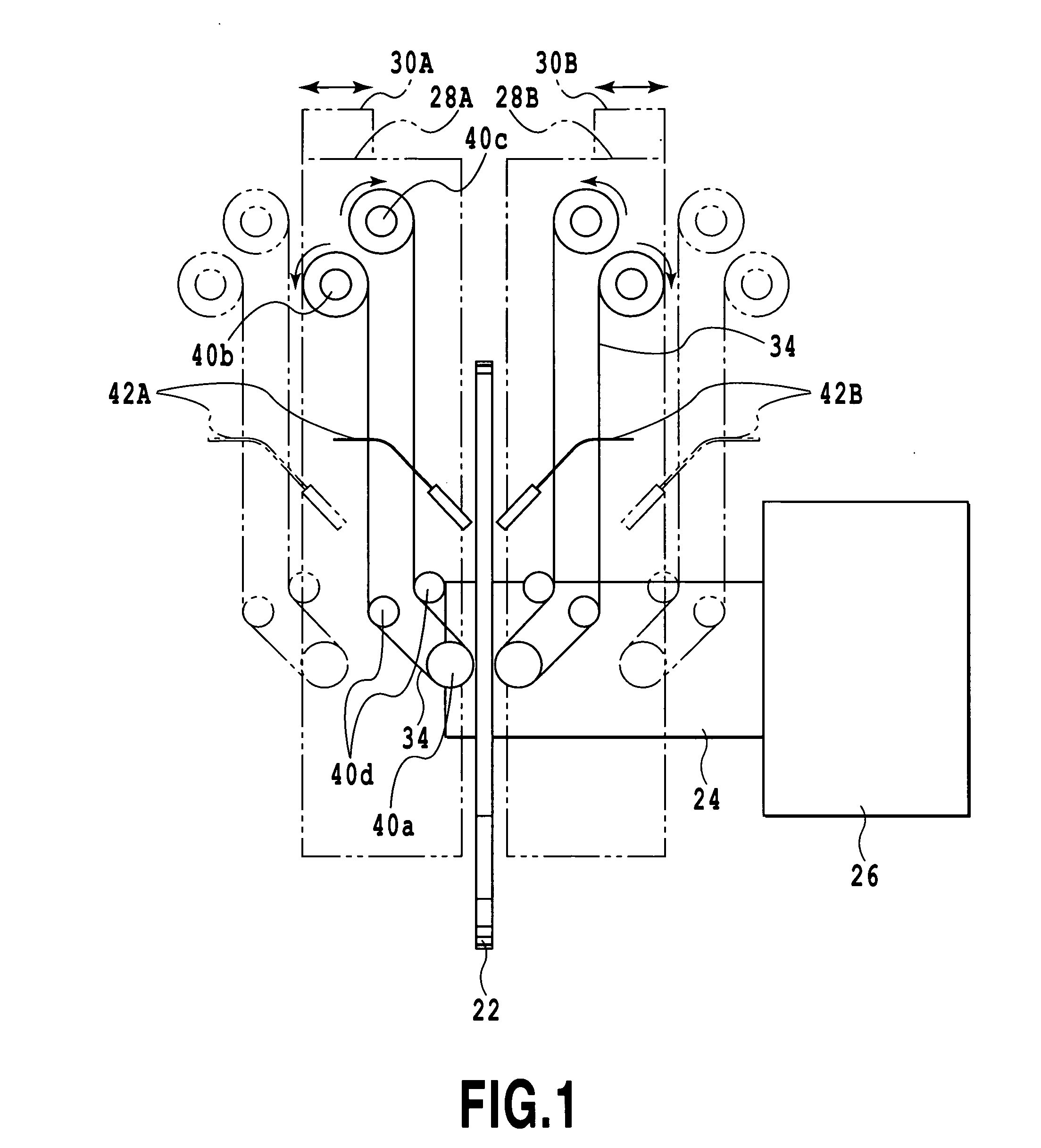

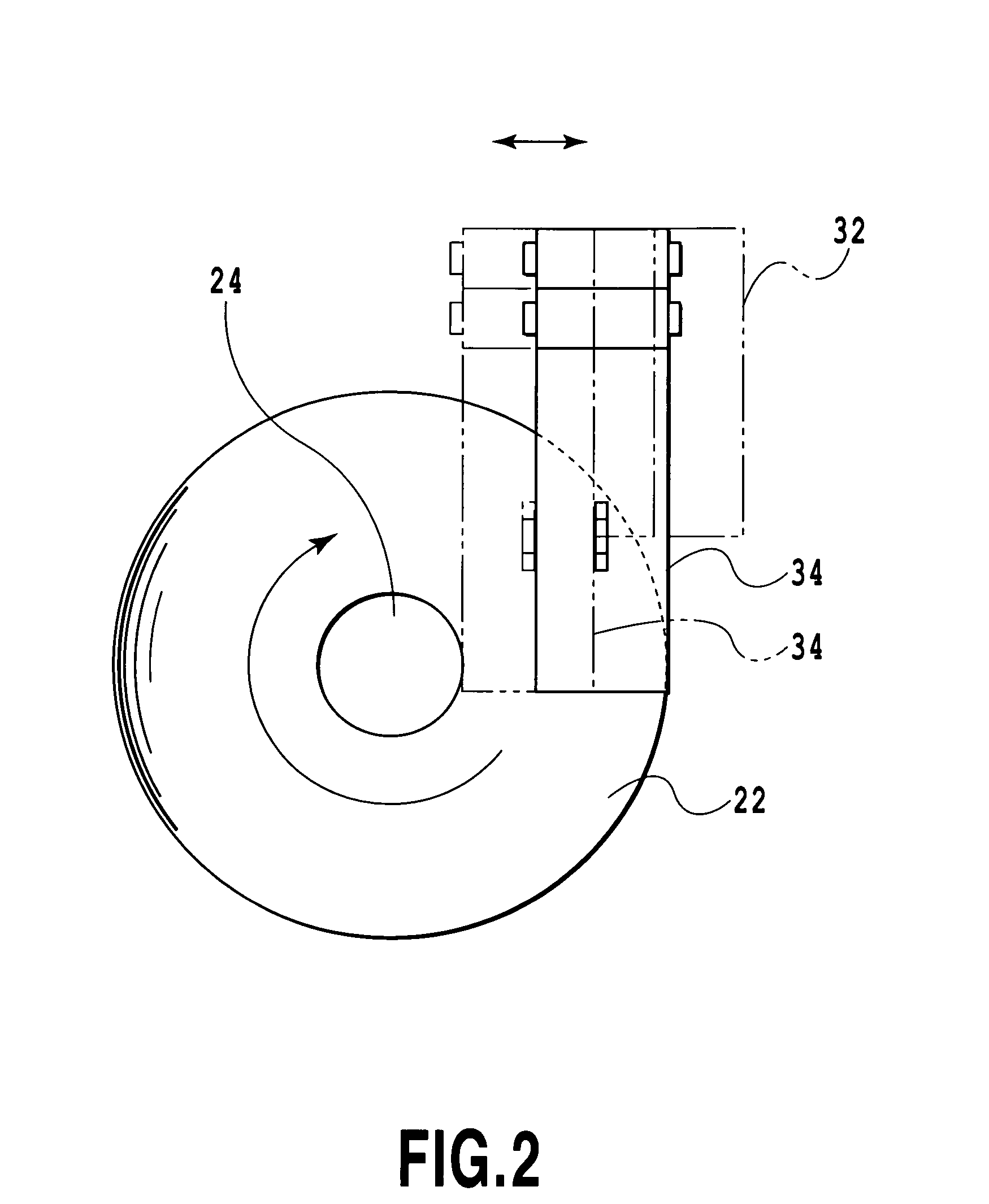

Method for manufacturing disk-substrates for magnetic recording media, disk-substrates for magnetic recording media, method for manufacturing magnetic recording media, magnetic recording media, and magnetic recording device

InactiveUS20080188165A1Appropriate surface roughnessImprove signal-to-noise ratioEdge grinding machinesMagnetic materials for record carriersMagnetic disksPolyester

A method for manufacturing a magnetic recording medium disk substrate is provided for achieving a magnetic disk having a suitable surface roughness, a high in-plane magnetic anisotropy and a high S / N. The manufacturing method has a texturing process wherein the magnetic recording medium disk substrate is rotated in the circumferential direction while a polishing tape is pressed against the rotating substrate. The polishing tape includes polyester fiber having a fiber diameter of 400 nm to 950 nm, on the surface coming into contact with the substrate. All the while, slurry including abrasive grains including a cluster diamond is supplied to the surfaces of the substrate. The present invention relates to a magnetic recording medium disk substrate produced by the manufacturing method; and a magnetic recording medium at least comprising a magnetic layer on the magnetic recording medium disk substrate and manufacturing method of the magnetic recording medium.

Owner:FUJI ELECTRIC CO LTD +1

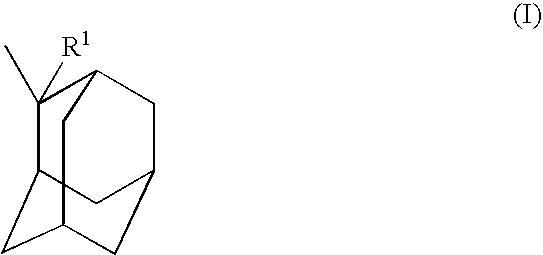

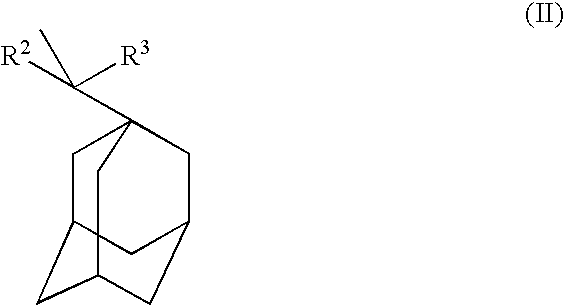

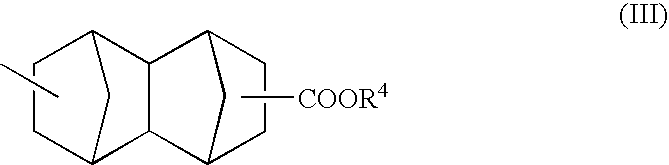

Positive type resist composition and resist pattern formation method using same

InactiveUS20060127808A1Small surface roughnessLittle line edgeRadiation applicationsSemiconductor/solid-state device manufacturingMethacrylateSolubility

There is provided a positive type resin composition comprising (A) a resin component comprising within the principal chain a structural unit derived from a (meth)acrylate ester and incorporating an acid dissociable, dissolution inhibiting group containing a polycyclic group on an ester side chain section, for which the solubility in alkali increases under the action of acid, (B) an acid generator component which generates acid on exposure, and (C) an organic solvent, wherein the component (A) comprises both a structural unit derived from a methacrylate ester and a structural unit derived from an acrylate ester. According to such a resist composition, a resist pattern can be formed which displays little surface roughness and line edge roughness on etching, and also offers excellent resolution and a wide depth of focus range.

Owner:TOKYO OHKA KOGYO CO LTD

Material for use in a TMR read gap without adversely affecting the TMR effect

ActiveUS8804287B2Small surface roughnessAvoid distortionNanomagnetismManufacture head surfaceMagnetic tapeSurface roughness

Structures and methods for fabrication servo and data heads of tape modules are provided. The servo head may have two shield layers spaced apart by a plurality of gap layers and a sensor. Similarly, the data head may have two shield layers spaced apart by a plurality of gap layers and a sensor. The distance between the shield layers of the servo head may be greater than the distance between the shield layers of the data head. The material of the gap layers may include tantalum or an alloy of nickel and chromium. The material for the gap layers permits deposition of gap layers with sufficiently small surface roughness to prevent distortion of the tape module and increase the stability of the tape module operation.

Owner:WESTERN DIGITAL TECH INC

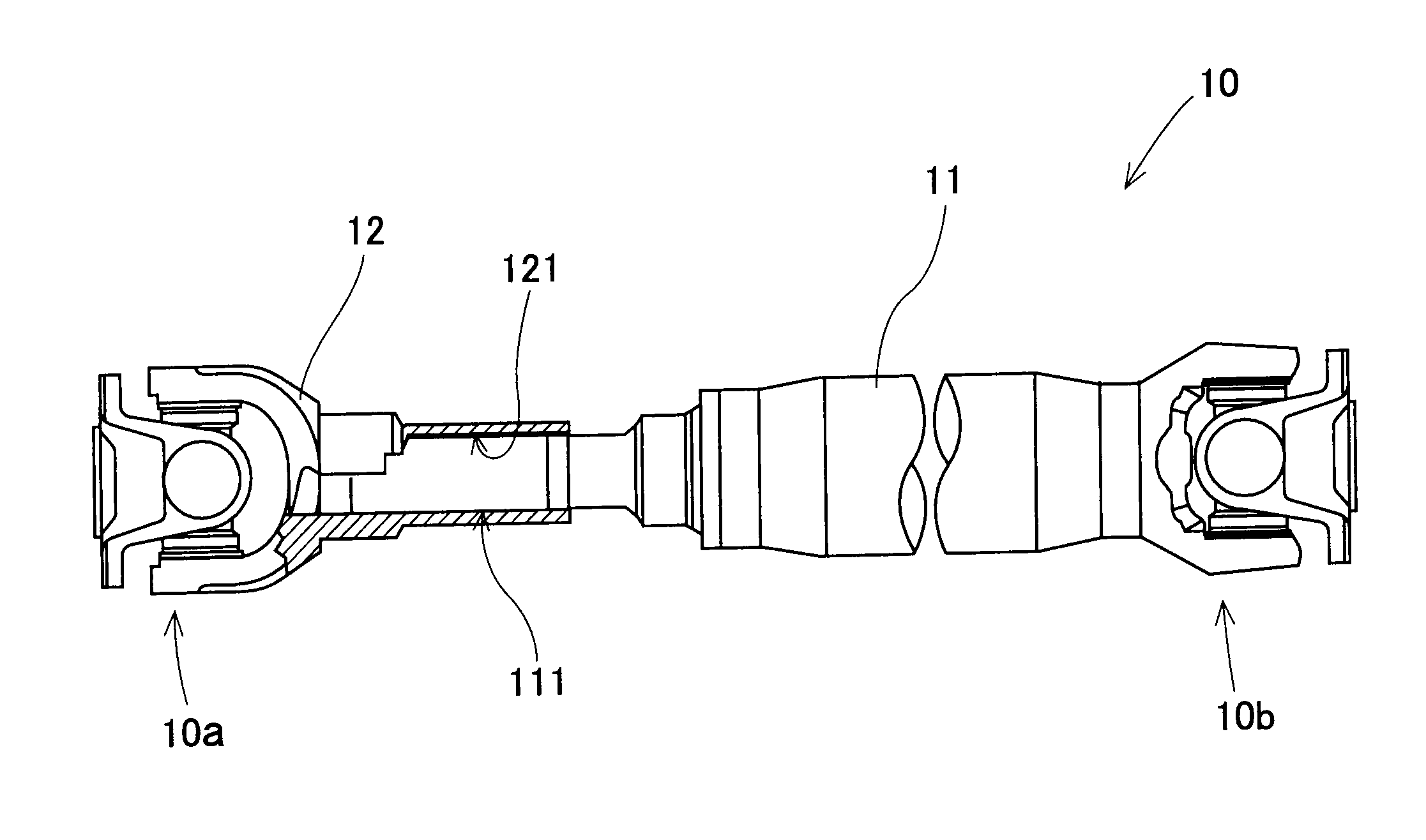

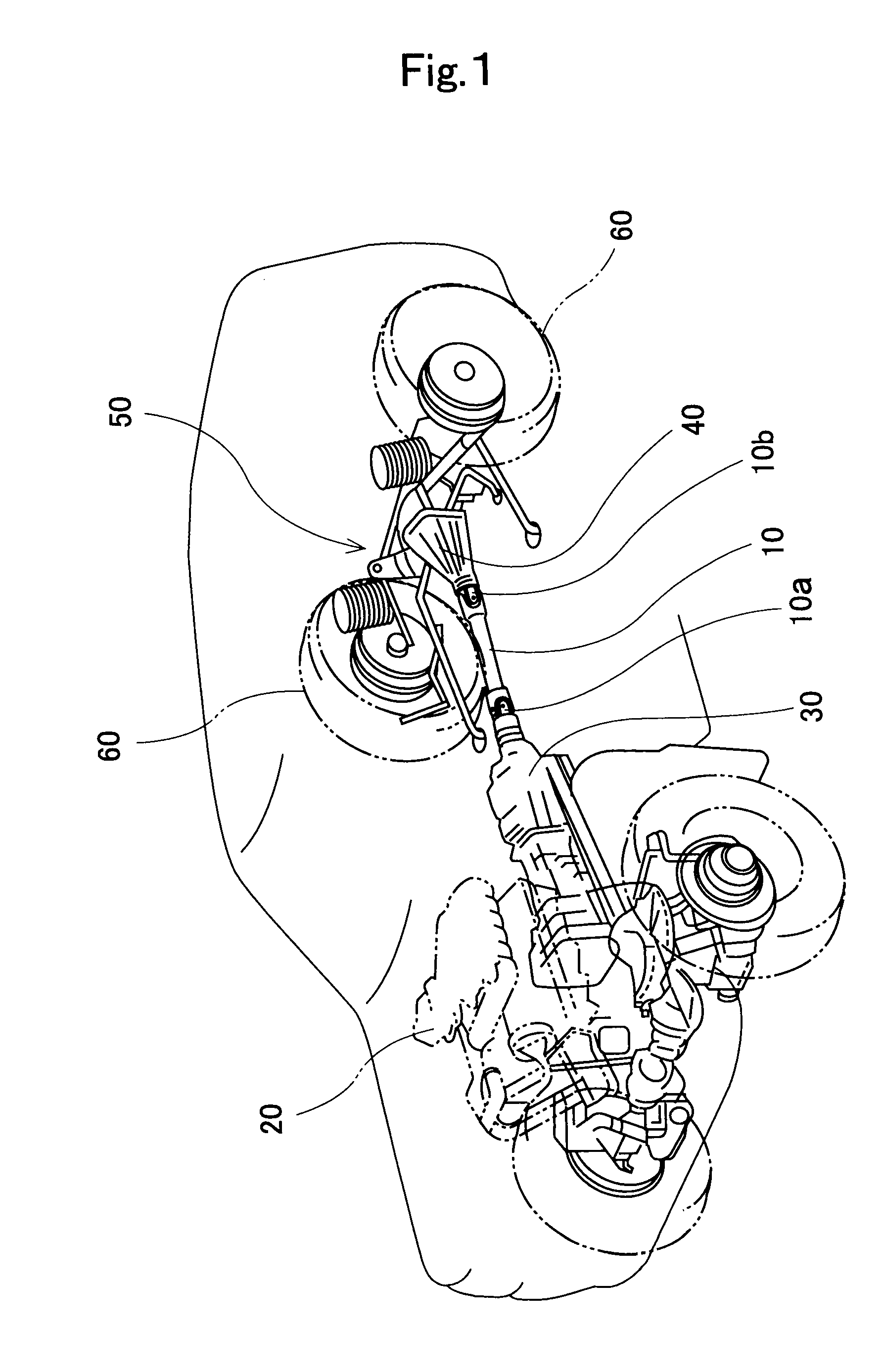

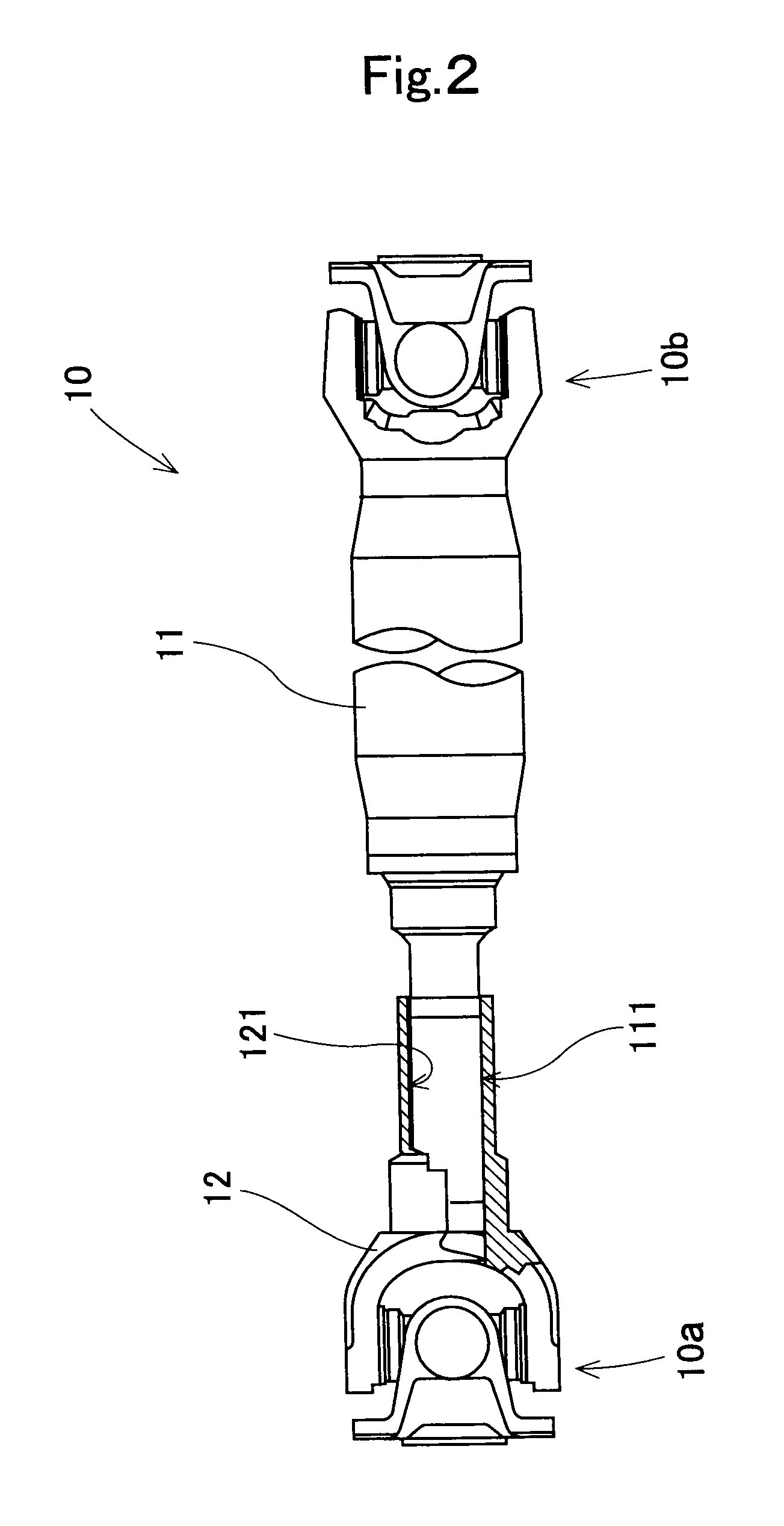

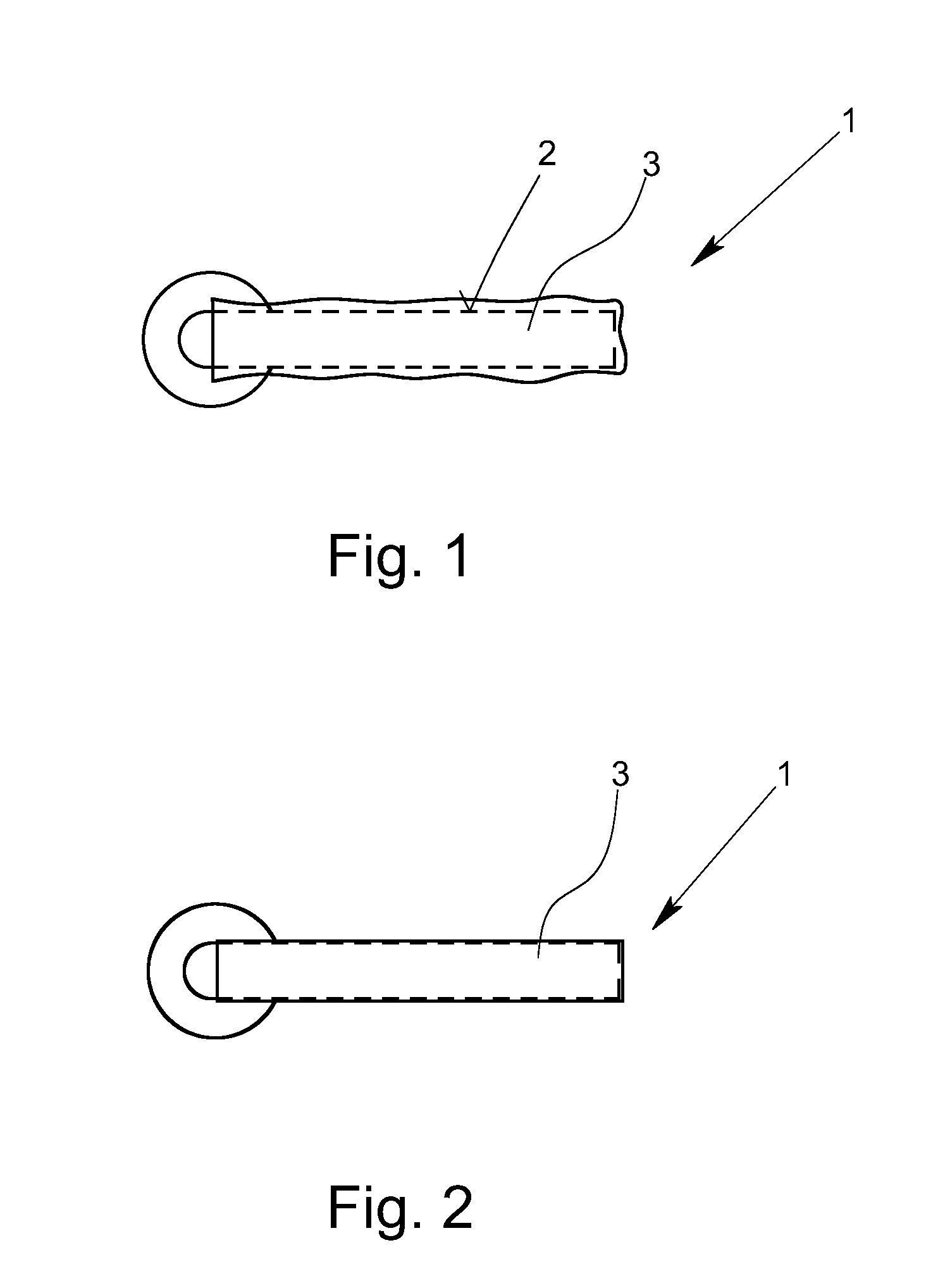

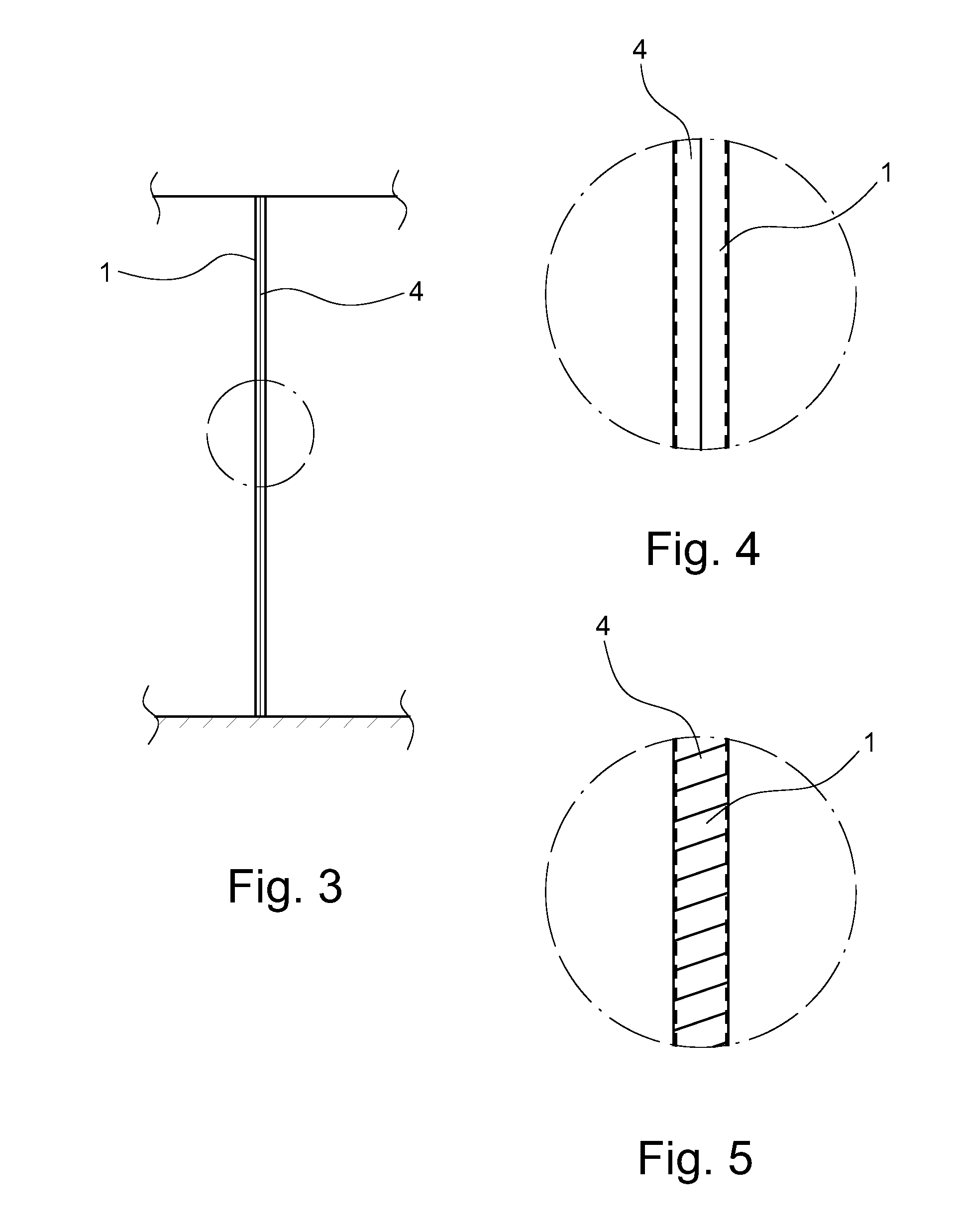

Spline shaft

InactiveUS20100130291A1InhibitionSmall surface roughnessClutchesYielding couplingSurface roughnessEngineering

A spline shaft that can suppress occurrence of stick slip by measures other than just simply making the surface roughness smaller. The spline shaft includes a first shaft with an outer-peripheral spline formed, and a second shaft with an inner-peripheral spline, which engages with the outer-peripheral spline peripherally and that is made slidable axially, formed. And, at least either one of the outer-peripheral spline and the inner-peripheral spline includes a substrate whose surface is formed to a predetermined surface roughness, and an amorphous carbon-system hard thin film, which coats and forms the surface of substrate.

Owner:JTEKT CORP

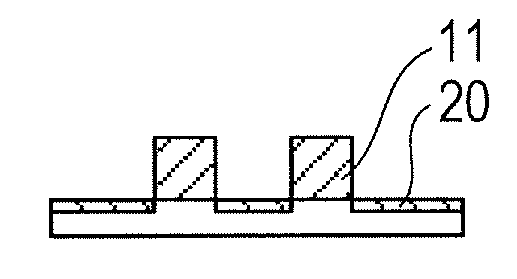

Method for manufacturing photo cured material

ActiveUS20150075855A1Raise transfer toSmall surface roughnessPrinted electric component incorporationPhotomechanical apparatusSurface roughnessDissolution

Provided is a method for manufacturing a photo cured material, by which transferring precision can be improved and a small surface roughness can be obtained. The method includes the steps of: placing a photo-curable composition on a substrate; brining a mold into contact with the photo-curable composition; irradiating the photo-curable composition with light; and releasing the mold from the photo-curable composition. The contact is performed in a condensable gas atmosphere, the condensable gas condensing under a temperature condition at the contact and under a pressure condition that the condensable gas receives when the photo-curable composition intrudes gaps between the substrate and the mold or concavities provided on the mold, and the photo-curable composition includes a gas dissolution inhibitor having a rate of weight change with reference to the condensable gas that is −1.0% to 3.0%.

Owner:CANON KK

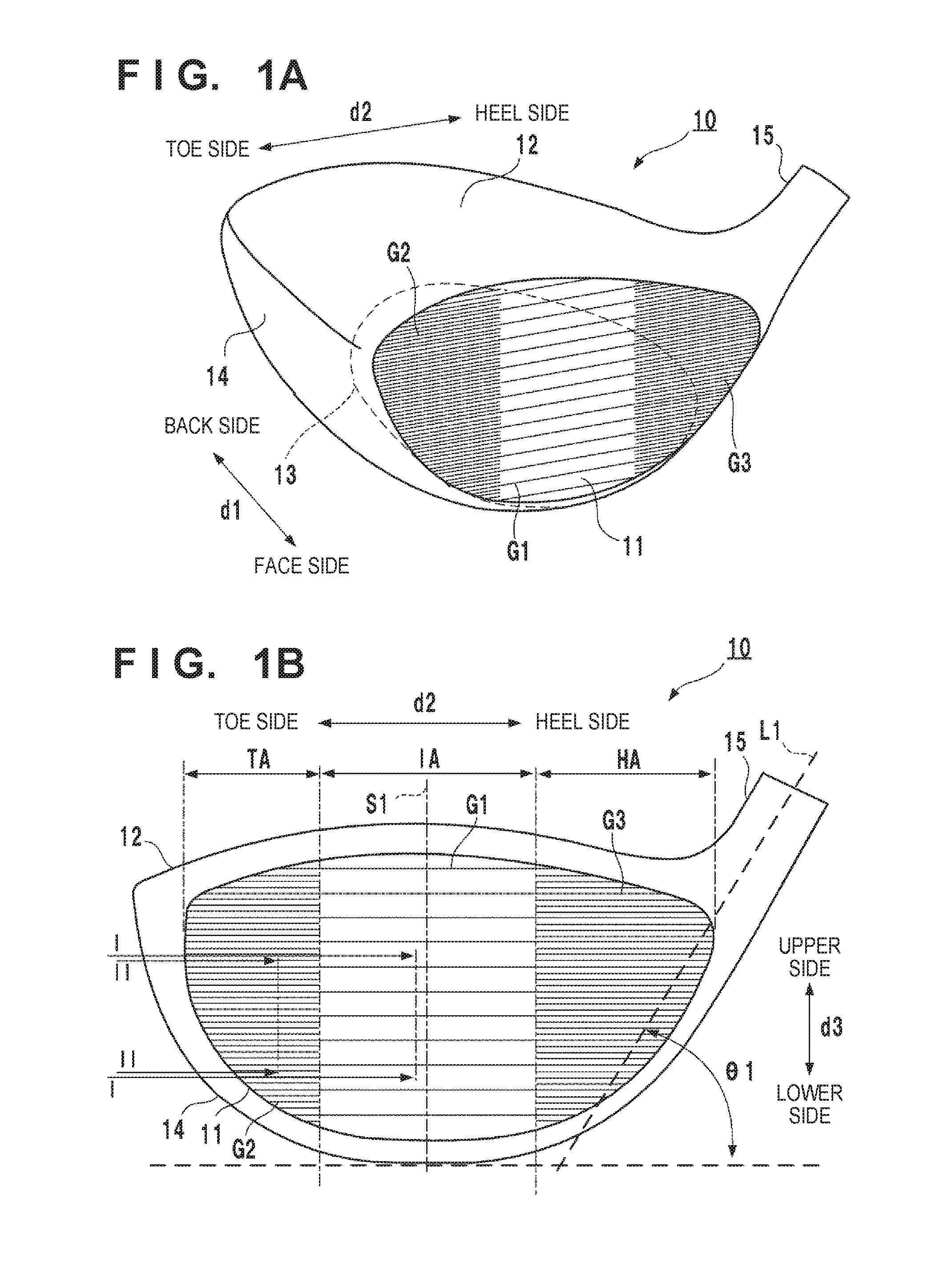

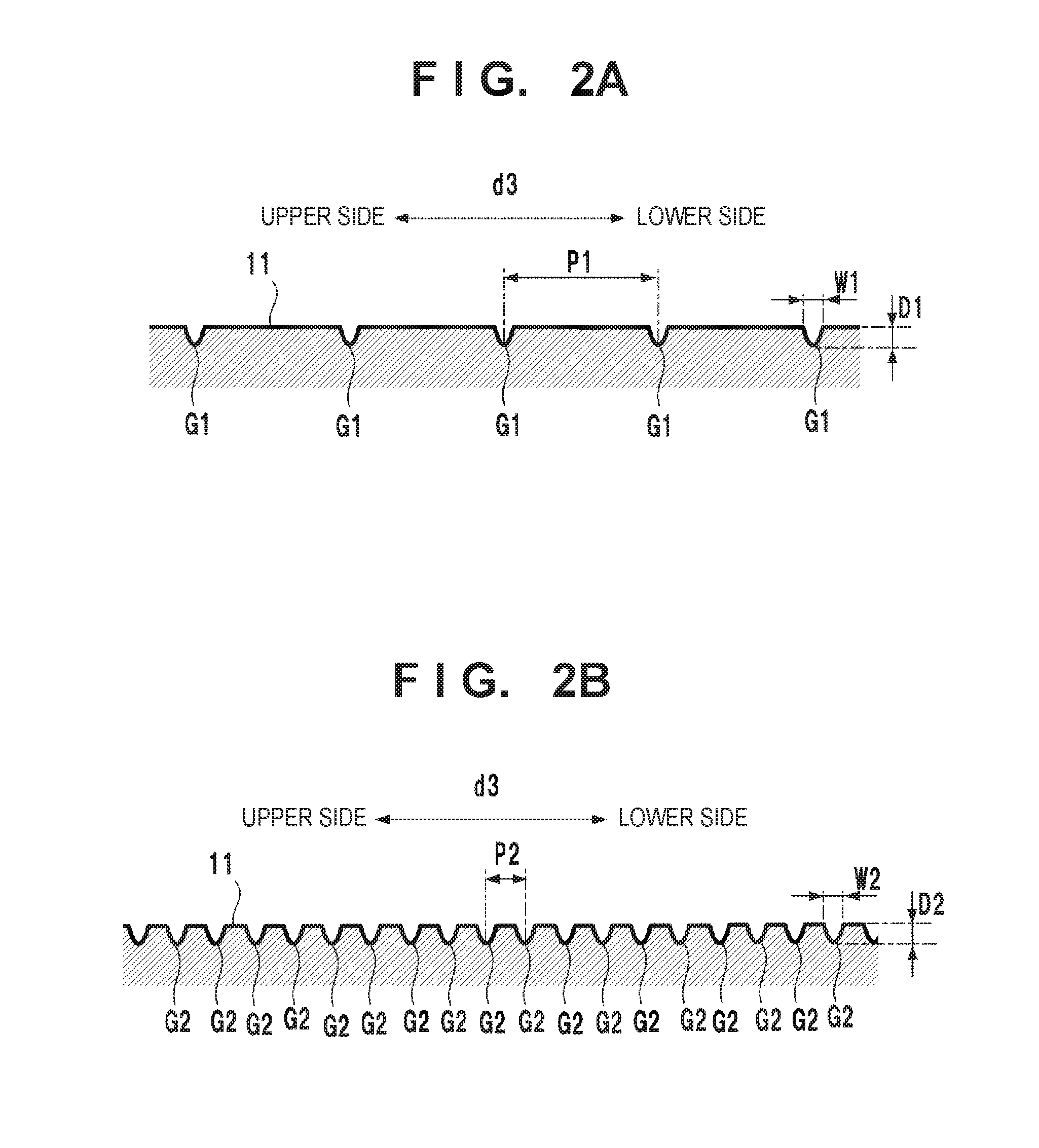

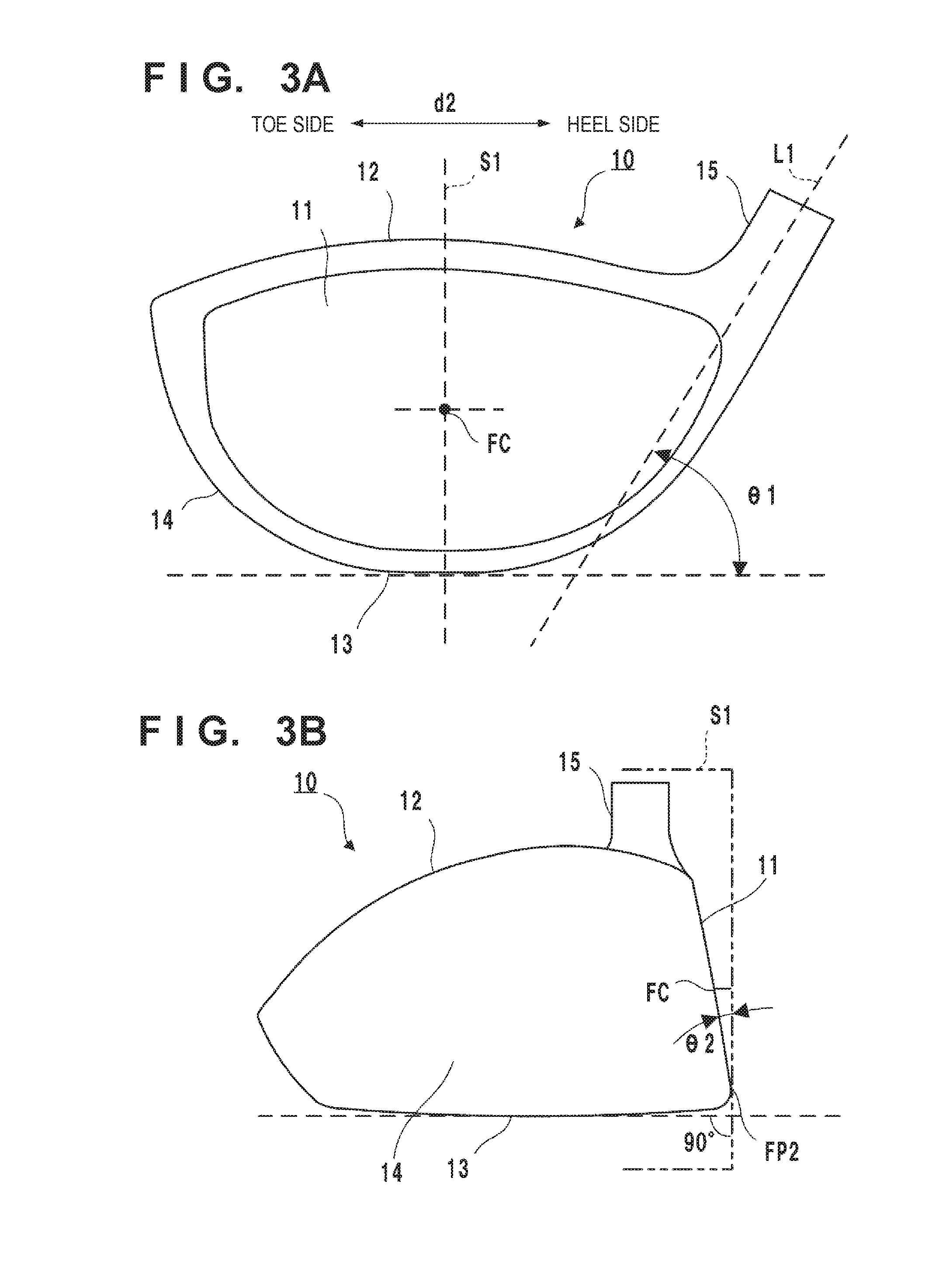

Manufacturing method, golf club head, and design method

InactiveUS20160354652A1Large surface roughnessSmall surface roughnessGolf clubsSurface roughnessEngineering

The present invention relates to a method of manufacturing a wood type golf club head including a face portion, a crown portion, and a sole portion. The method includes a setting step of setting a surface roughness of the face portion and a step of forming the face portion based on the surface roughness set in the setting step. In the setting step, the larger a moment of inertia of the golf club head is, the larger the surface roughness outside an impact area of the face portion is set, and the smaller the moment of inertia is, the smaller the surface roughness outside the impact area of the face portion is set.

Owner:BRIDGESTONE SPORTS

Cerium Oxide-Based Abrasive, and Production Method and Use Thereof

ActiveUS20090035202A1Low costHigh surface-precision glass substratePigmenting treatmentOptical surface grinding machinesCeriumSurface roughness

The present invention provides a cerium oxide-based abrasive ensuring high removal rate, less generation of scratches, high-precision polished surface with small surface roughness, and a safe, simple and low-cost production process. Further, the present invention provides a method for producing such an abrasive. The method of the present invention comprises (a) adding a precipitant to an aqueous cerium-containing light rare-earth salt solution to precipitate a light rare-earth salt, thereby obtaining a first slurry containing a light rare-earth salt particle; (b) adding a fluorinating agent to a slurry containing a light rare-earth salt particle to react the light rare-earth salt with the fluorinating agent, thereby obtaining a second slurry containing a light rare-earth fluoride particle; (c) mixing the first slurry and the second slurry to obtain a mixed slurry; and (d) drying and firing the mixed slurry, and a cerium oxide-based abrasive obtained by this method. The abrasive of the present invention is produced by the method of the present invention.

Owner:RESONAC CORP

Coating for objects, in particular in public facilities and/or means of transportation, for preventing the transmission of infections

Owner:BLUCHER GMBH

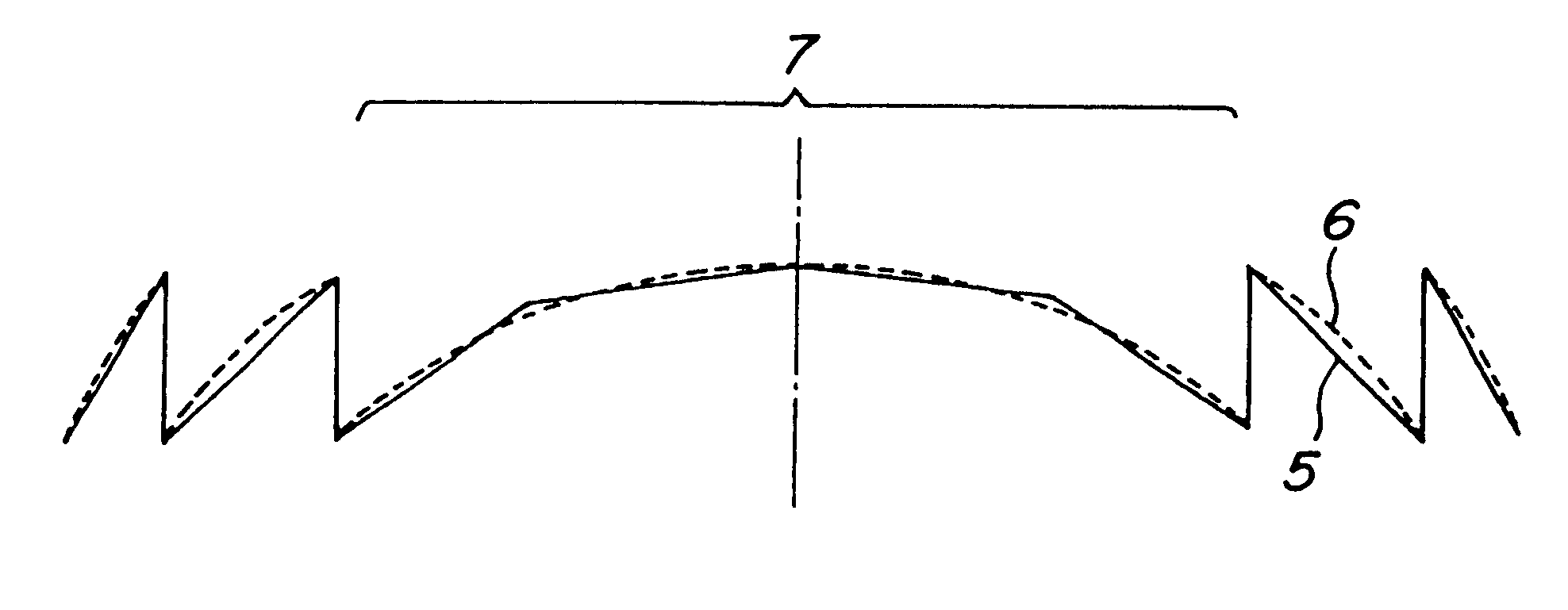

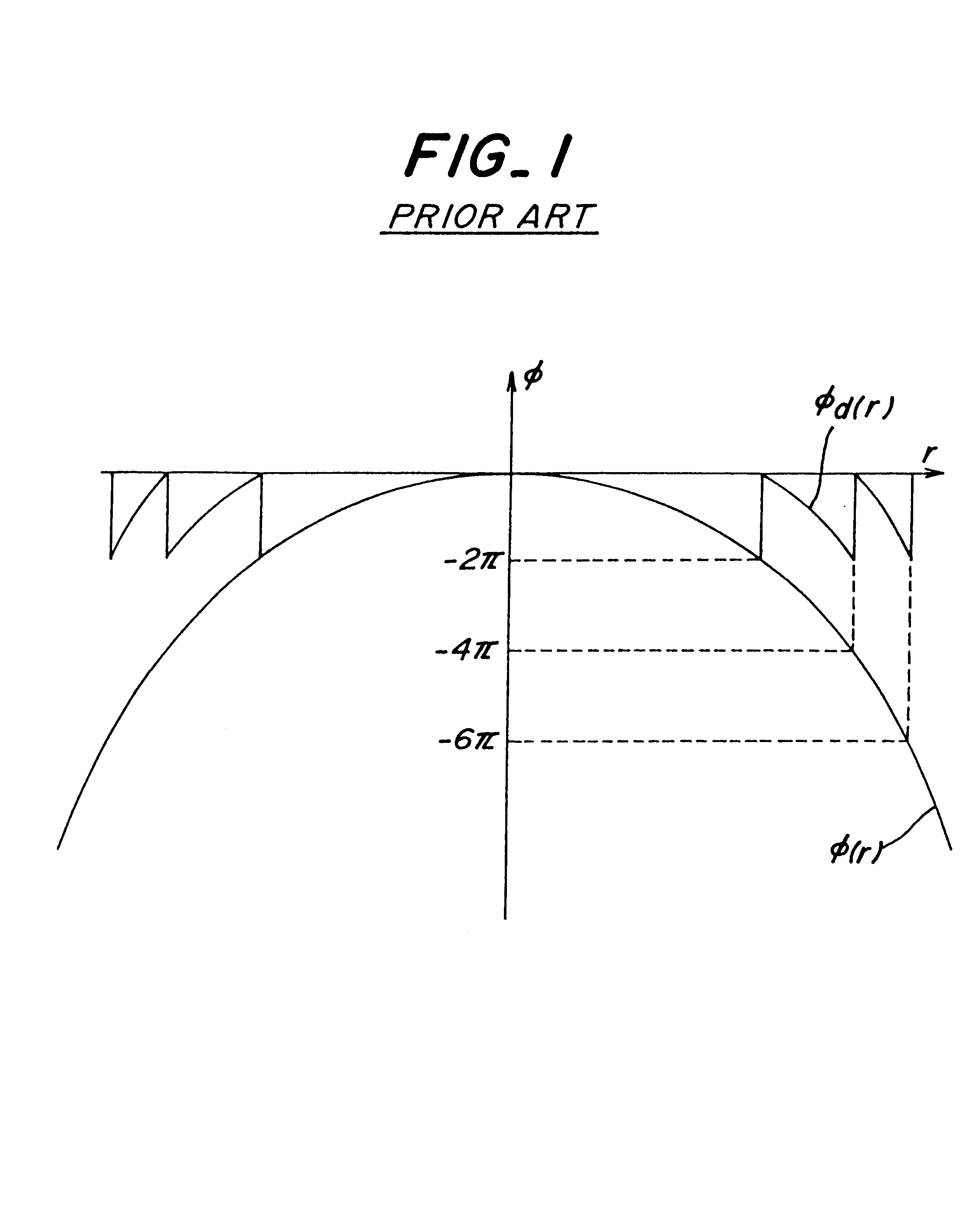

Relief type diffraction optical element, optical system comprising the same and mold for manufacturing the same

InactiveUS6839174B1Easily manufactureSuperior converging performanceDiffraction gratingsLensPhase shiftedElectrical and Electronics engineering

A relief type diffraction optical element including a substrate made of an optical material, said substrate having formed on its surface a non-even width relief pattern which include a first zone group consisting of at least one zone whose cross sectional configuration is formed by a curvilinear portion which follows a phase shift function or at least two rectilinear portions which approximates the phase shift function, and a second zone group consisting of a plurality of zones each having a single rectilinear portion approximating the phase shift function.

Owner:OLYMPUS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com