Patents

Literature

41results about How to "Small defect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tempered glass substrate and method of producing the same

ActiveUS20090197088A1High ion exchange capacityExcellent devitrification resistanceGlass/slag layered productsThin material handlingToughened glassMaterials science

A tempered glass substrate of the present invention is a tempered glass substrate, which has a compression stress layer on a surface thereof, and has a glass composition comprising, in terms of mass %, 40 to 71% of SiO2, 3 to 21% of Al2O3, 0 to 3.5% of Li2O, to 20% of Na2O, and 0 to 15% of K2O.

Owner:NIPPON ELECTRIC GLASS CO LTD

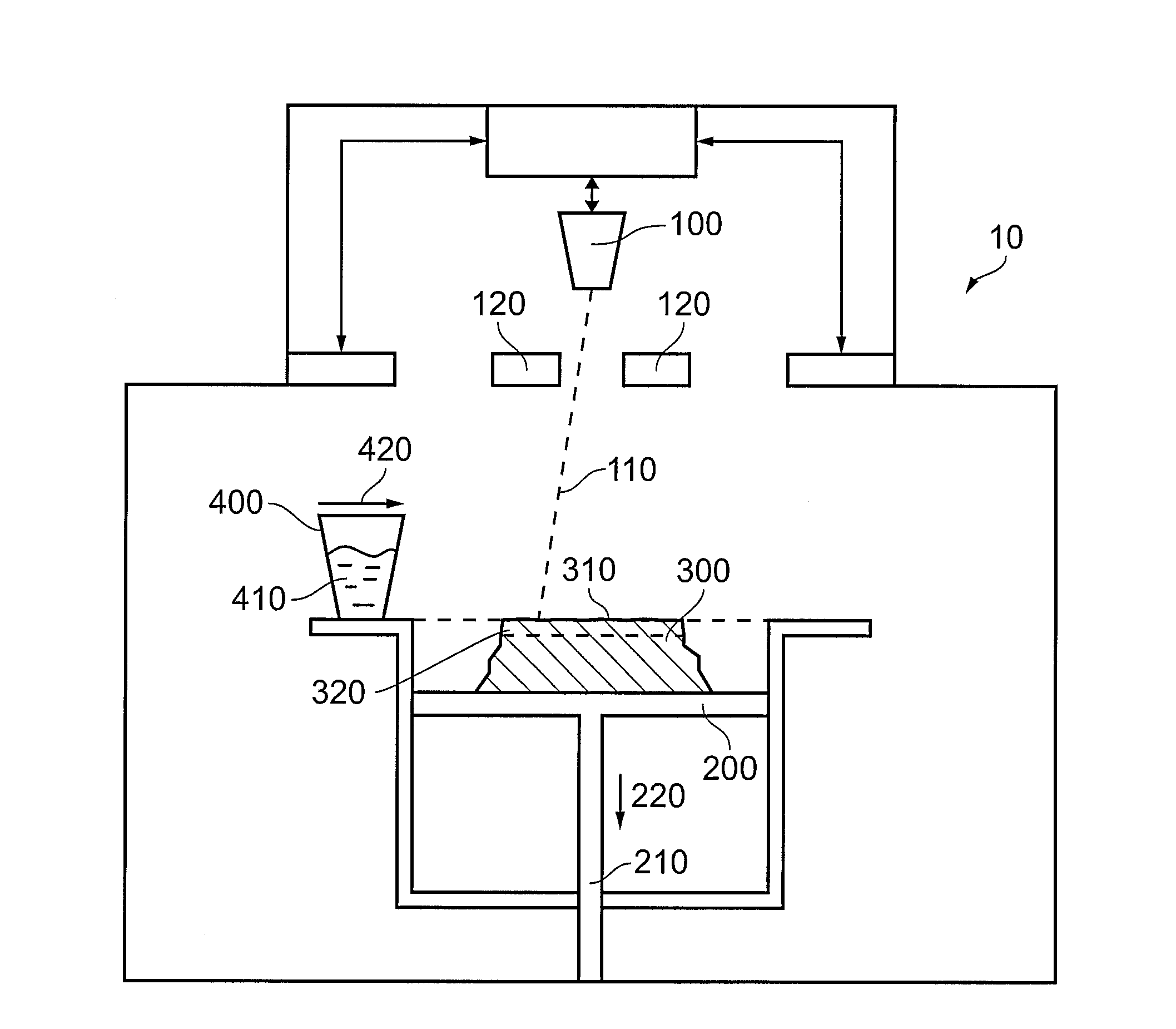

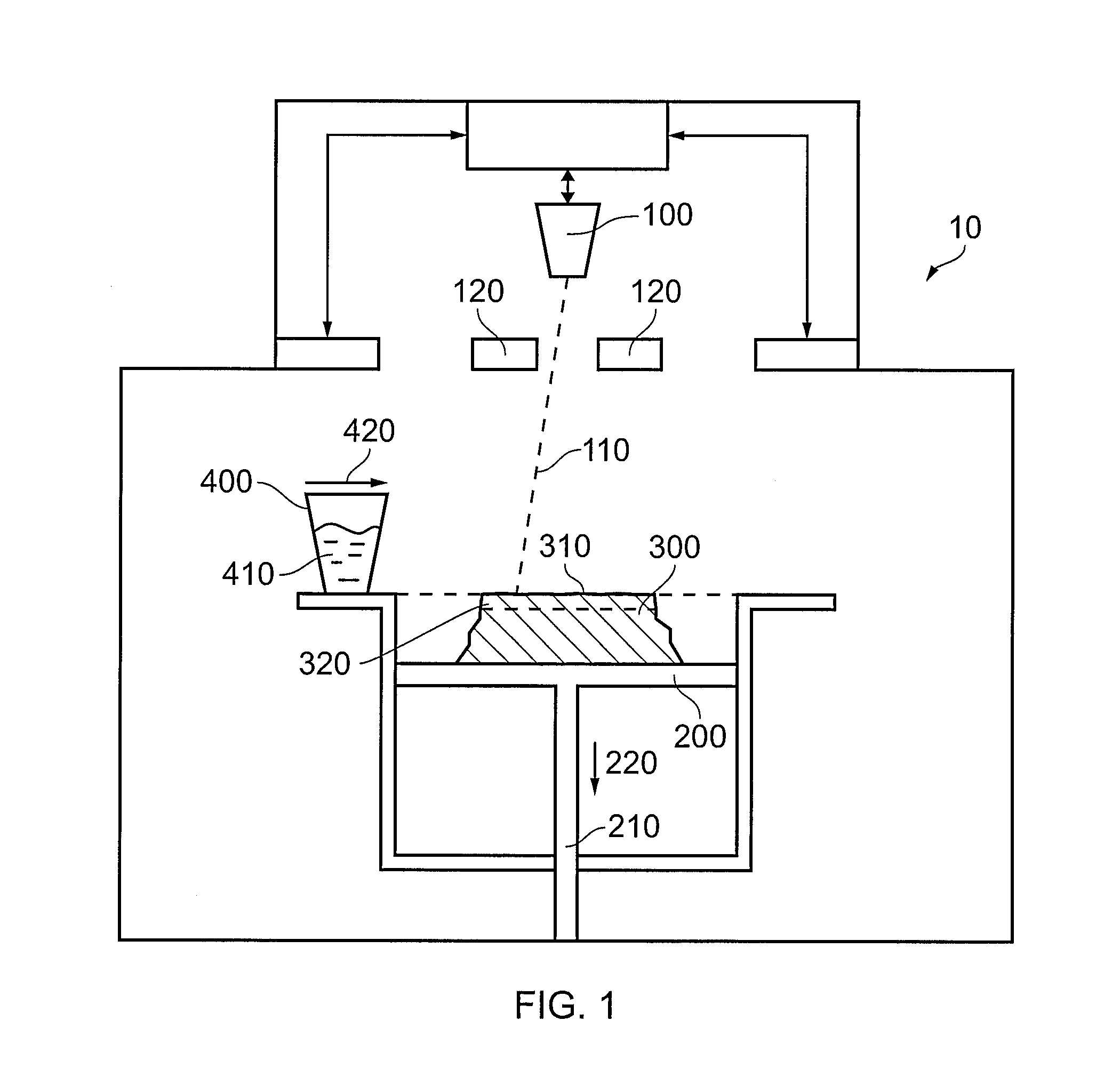

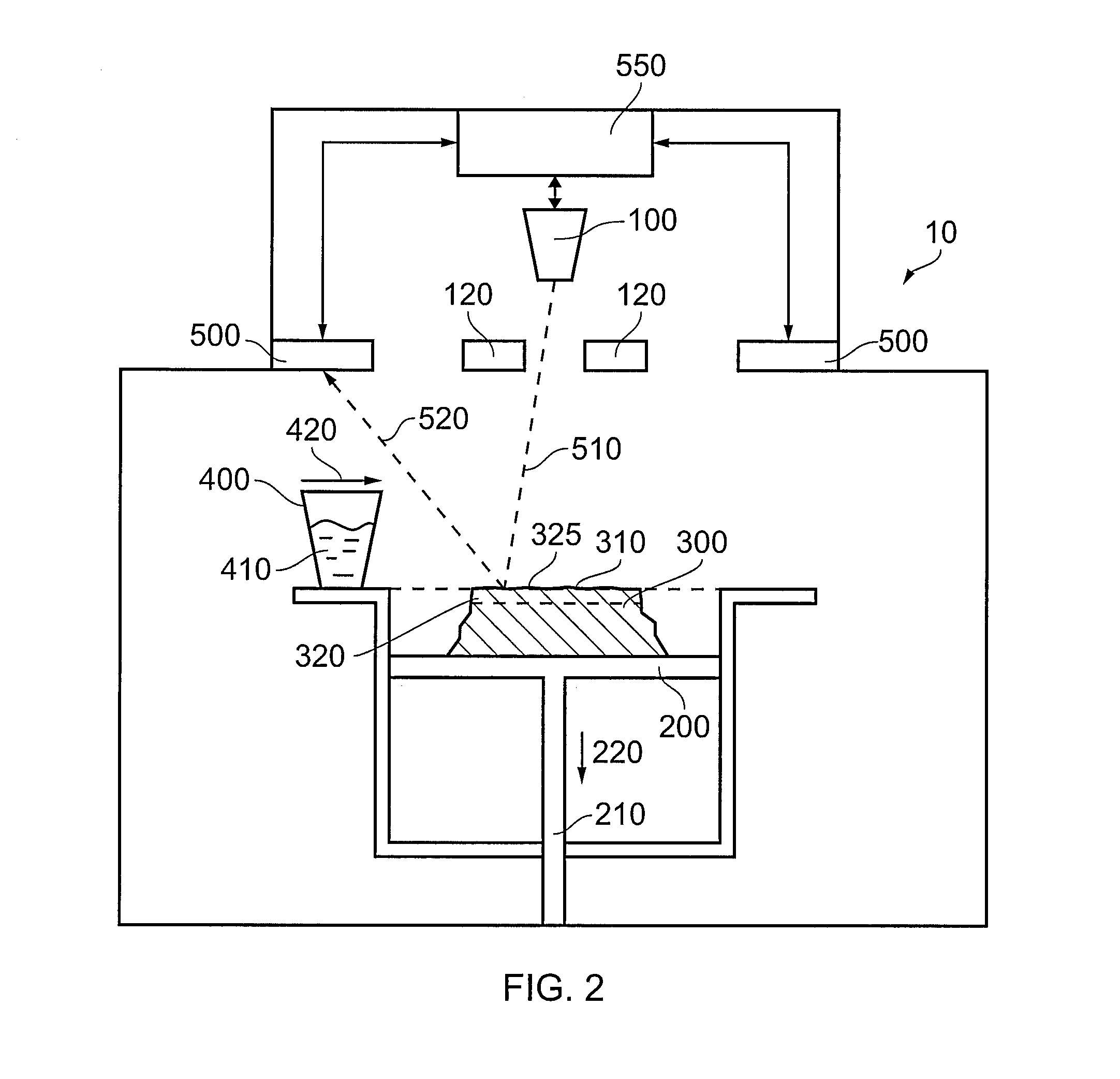

Method of manufacturing a component

ActiveUS20150037599A1High resolutionSmall defectAdditive manufacturing apparatusArc welding apparatusMetal powderMechanical property

An additive layer manufacture (ALM) machine generates a first electron beam for selectively melting a layer of metal powder, and a second electron beam for detecting defects in the selectively melted layer once it has solidified. The second electron beam has a lower power than the first electron beam so as to be used to identify any defects without performing further melting. If any defects are detected, they can be removed, for example by re-melting, before the next layer of powder is supplied. The process may be repeated to generate a finished component with good mechanical properties.

Owner:ROLLS ROYCE PLC

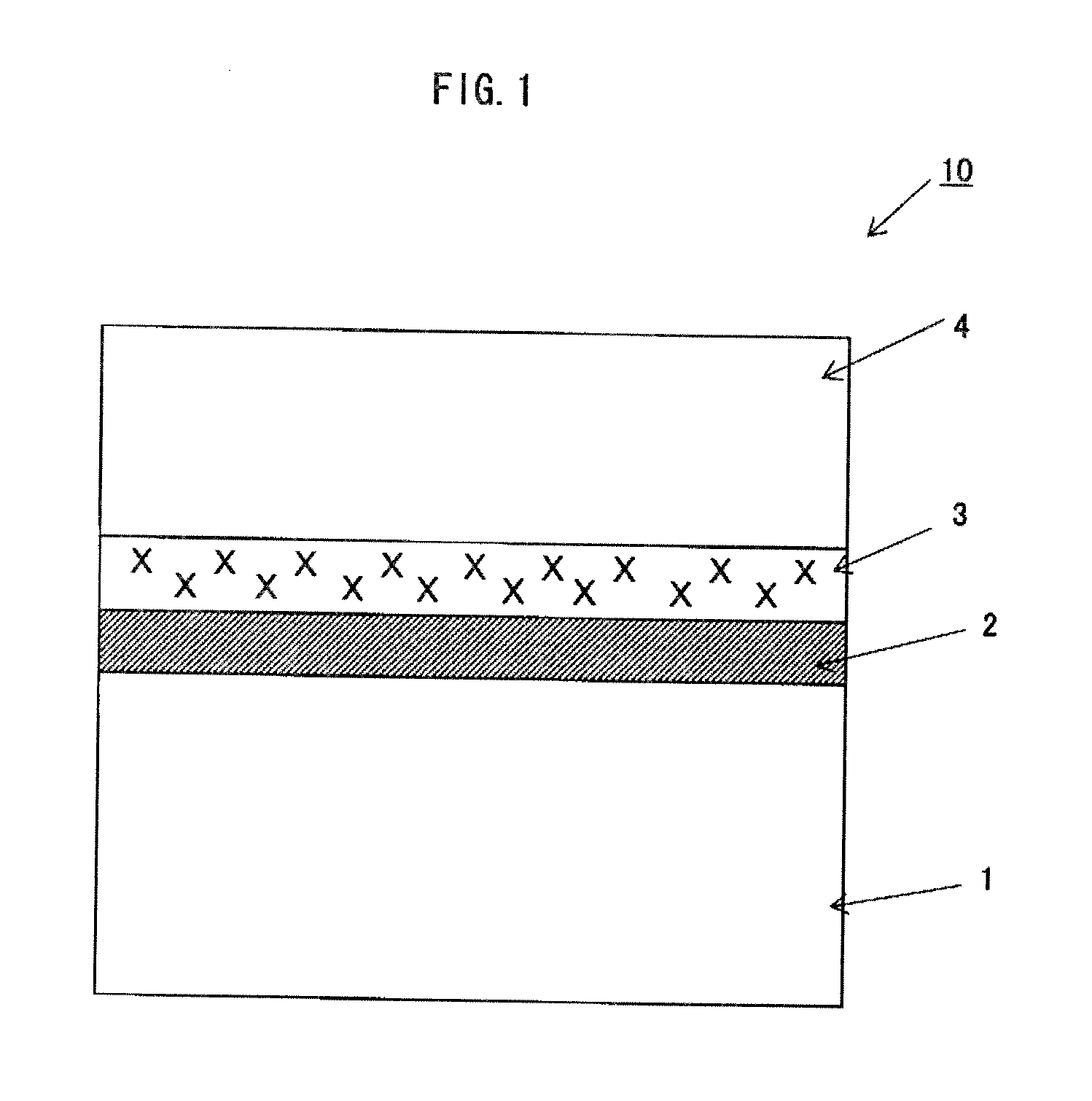

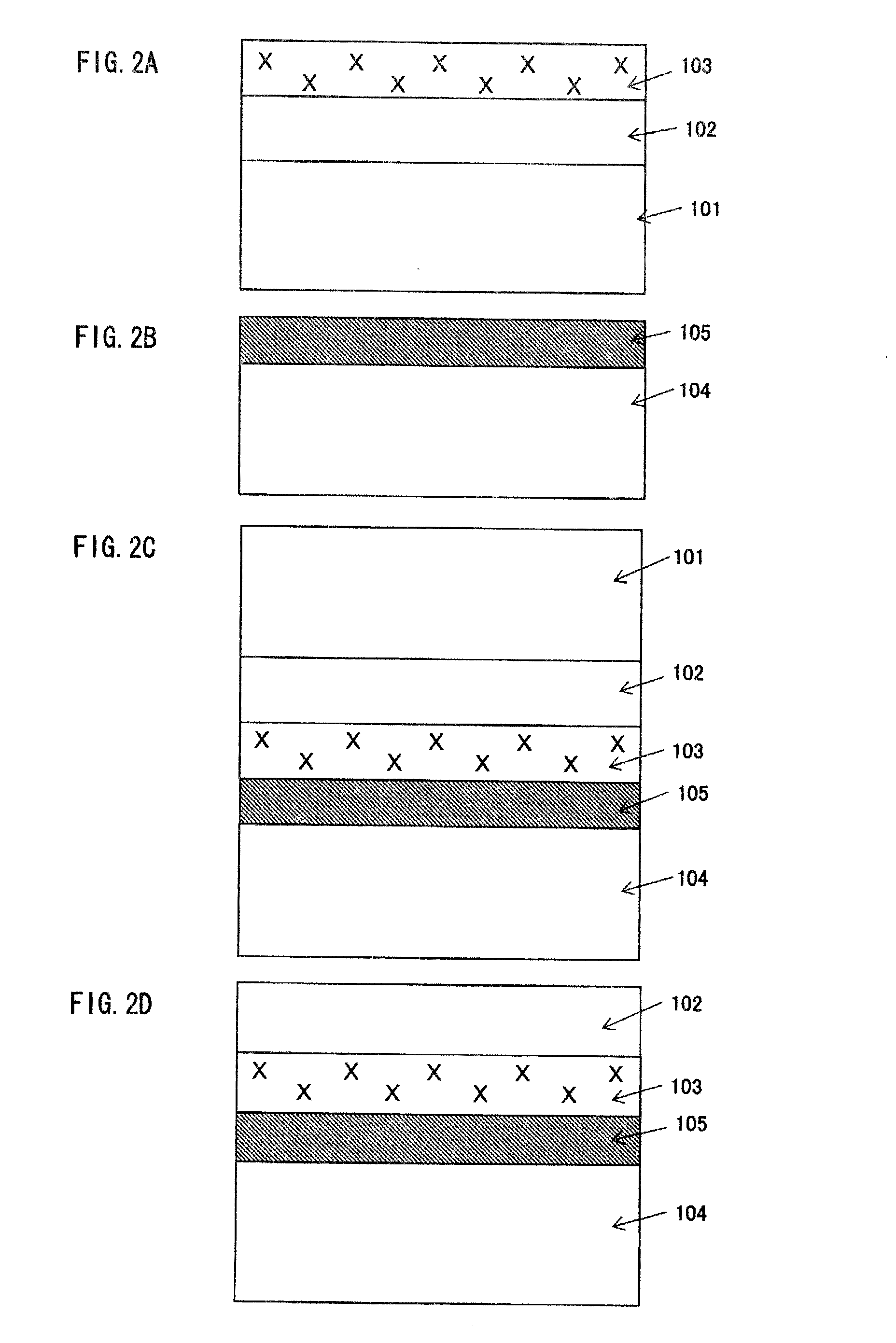

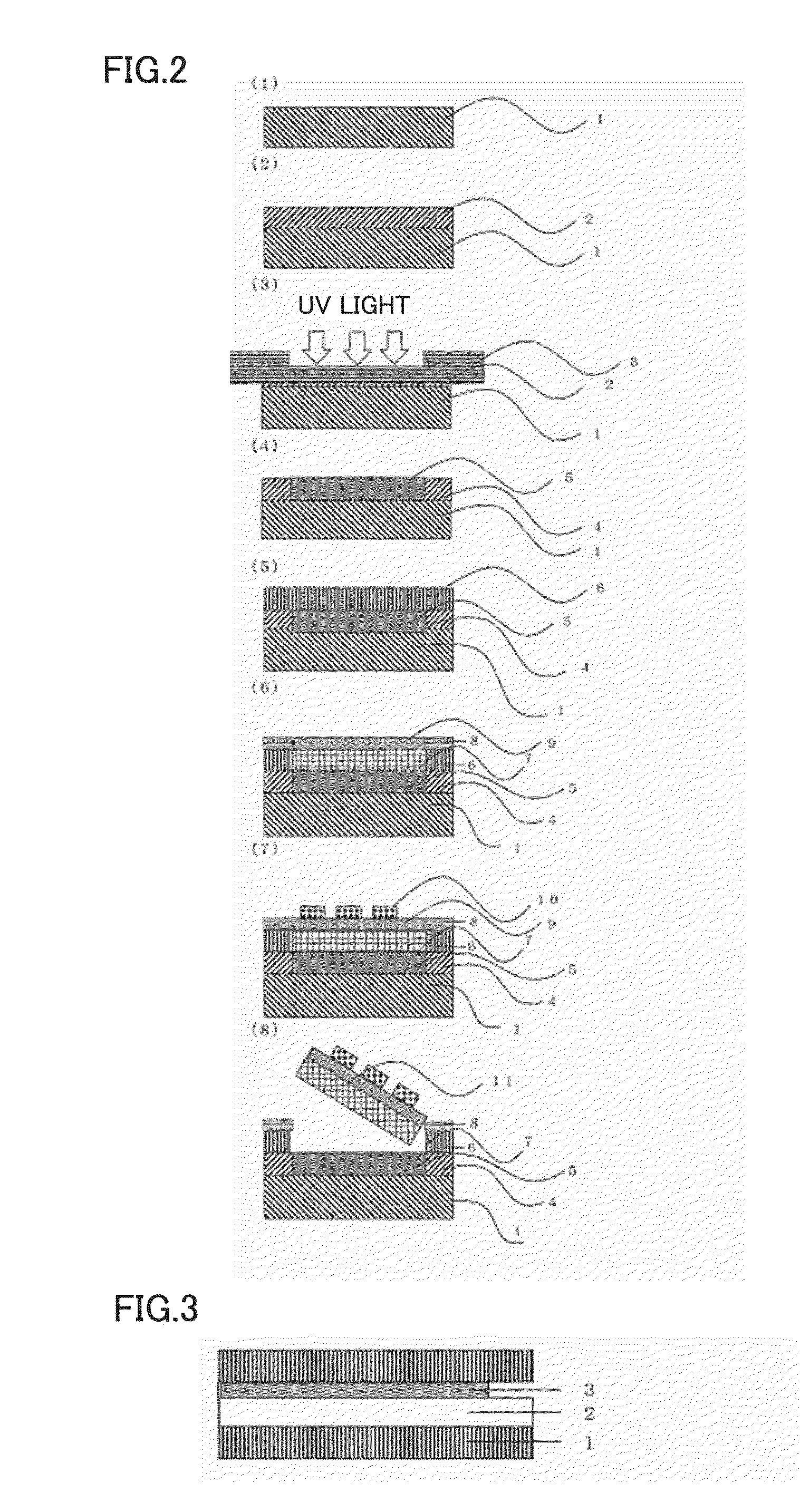

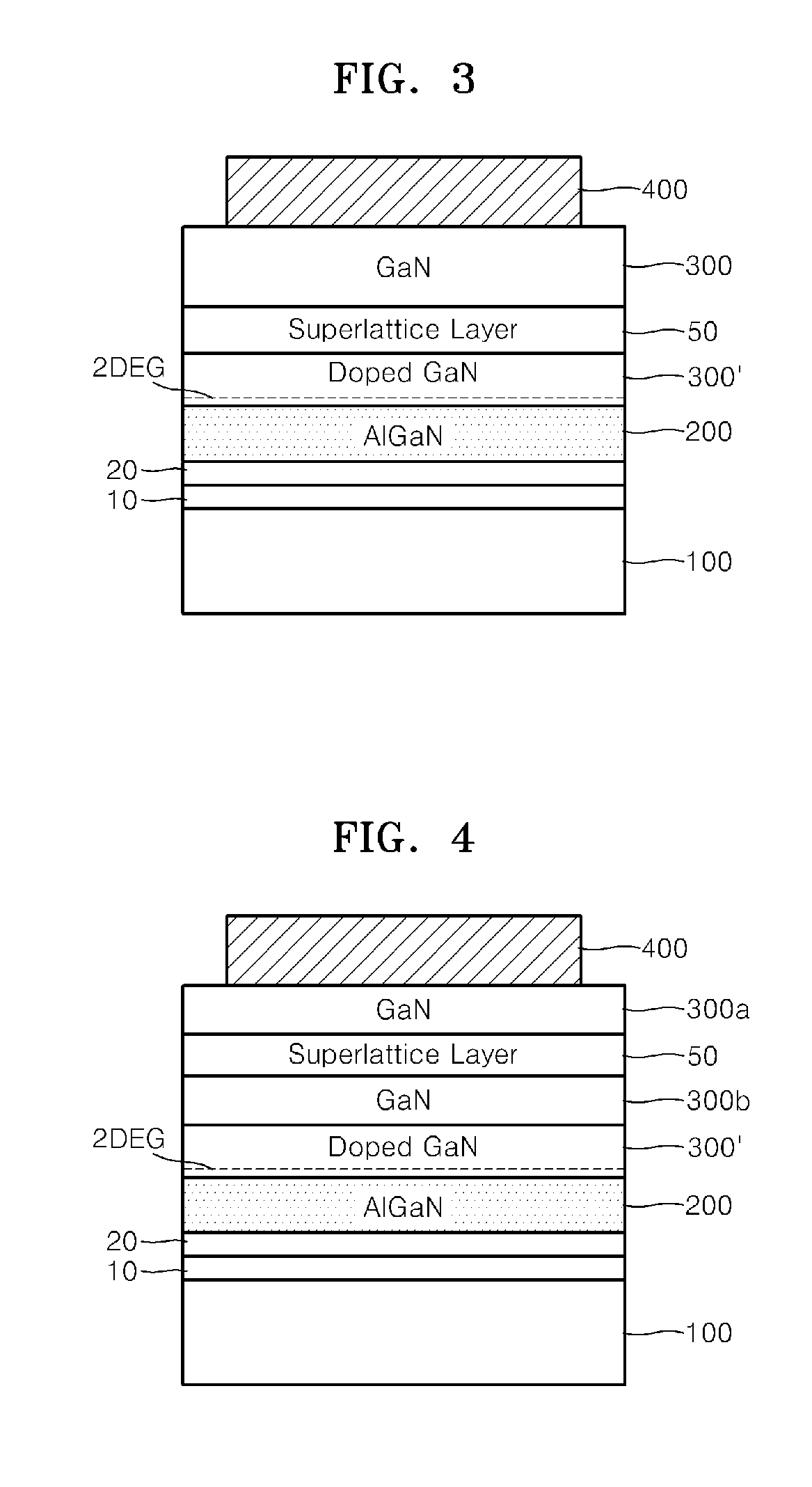

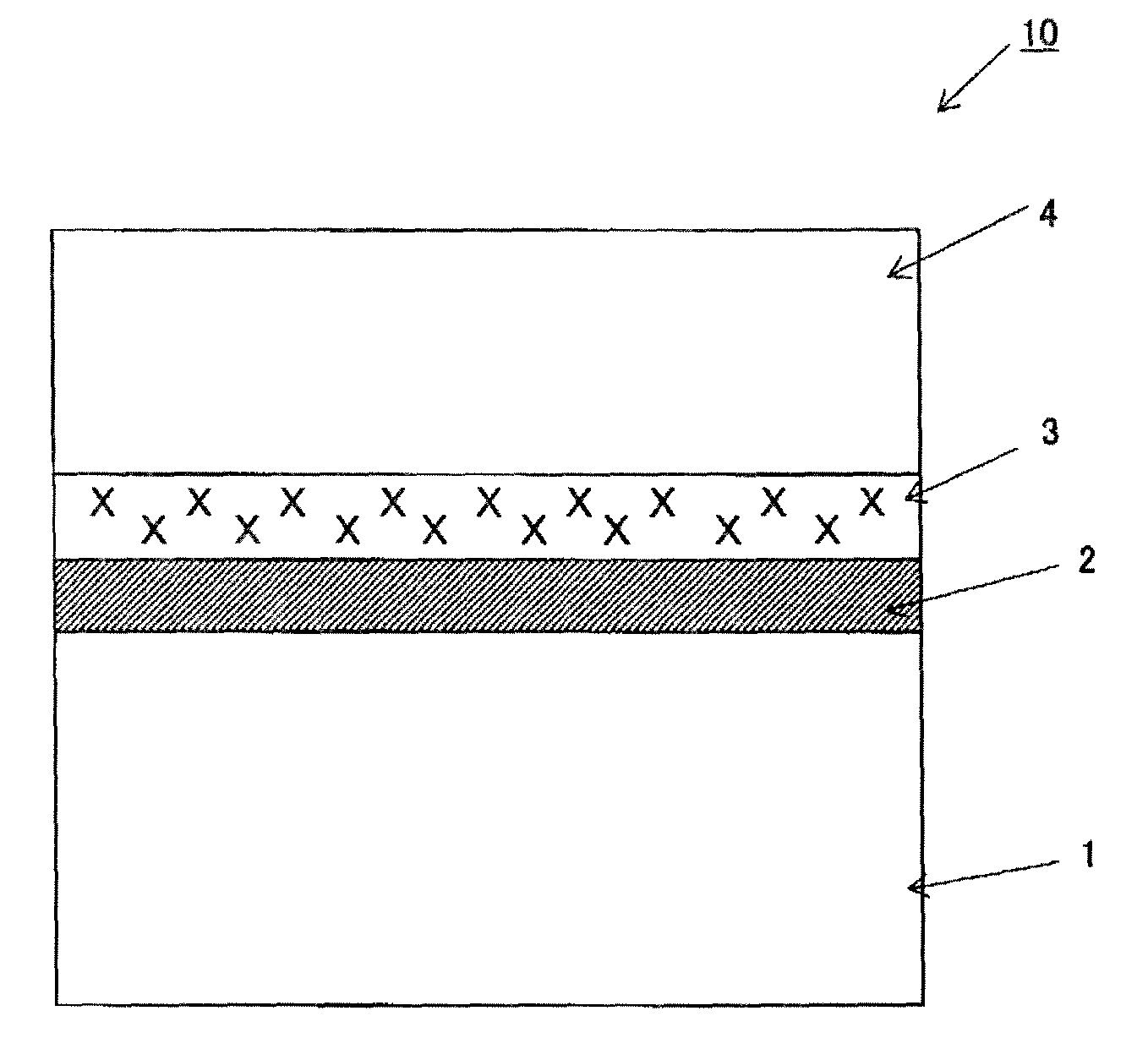

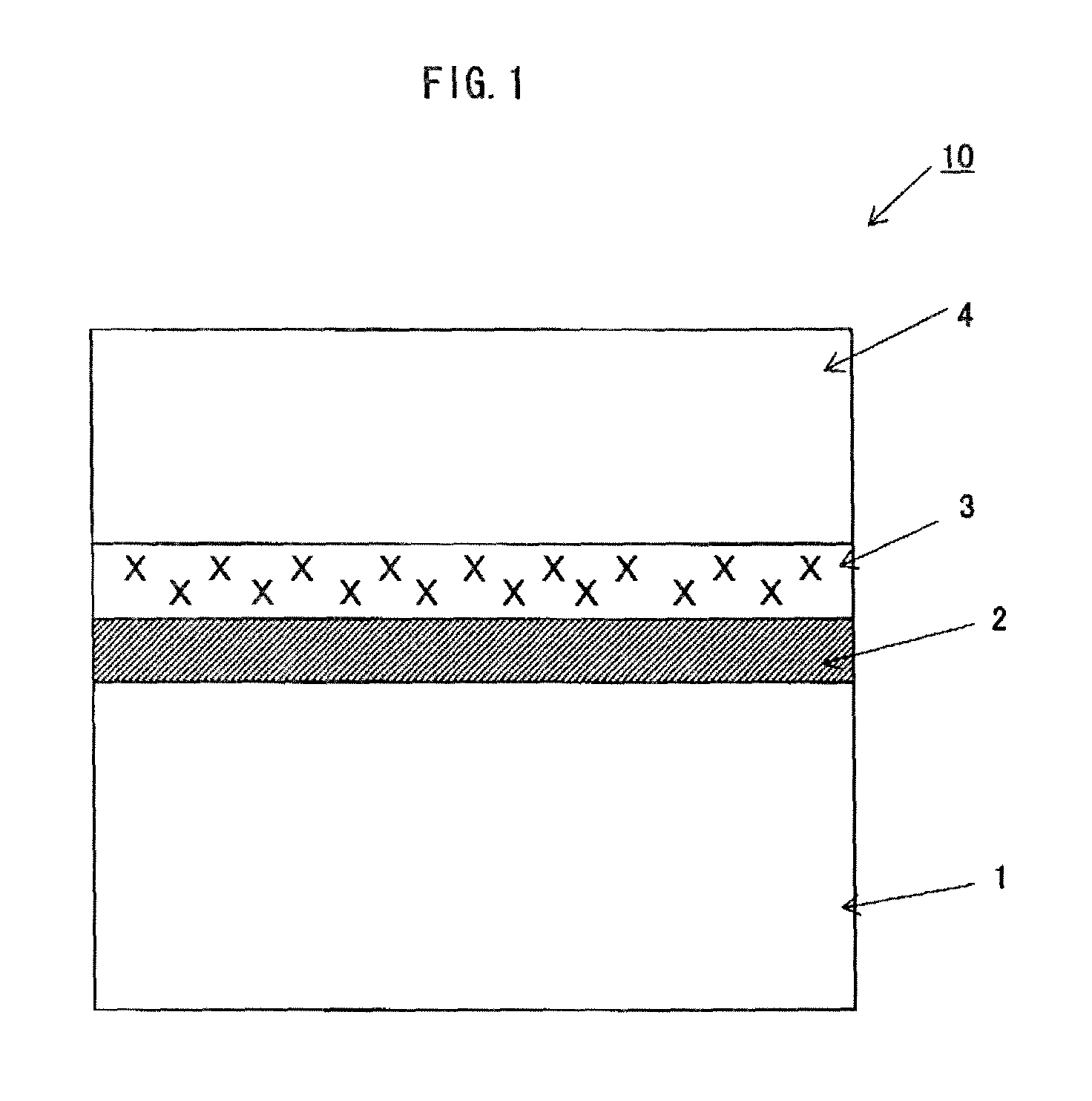

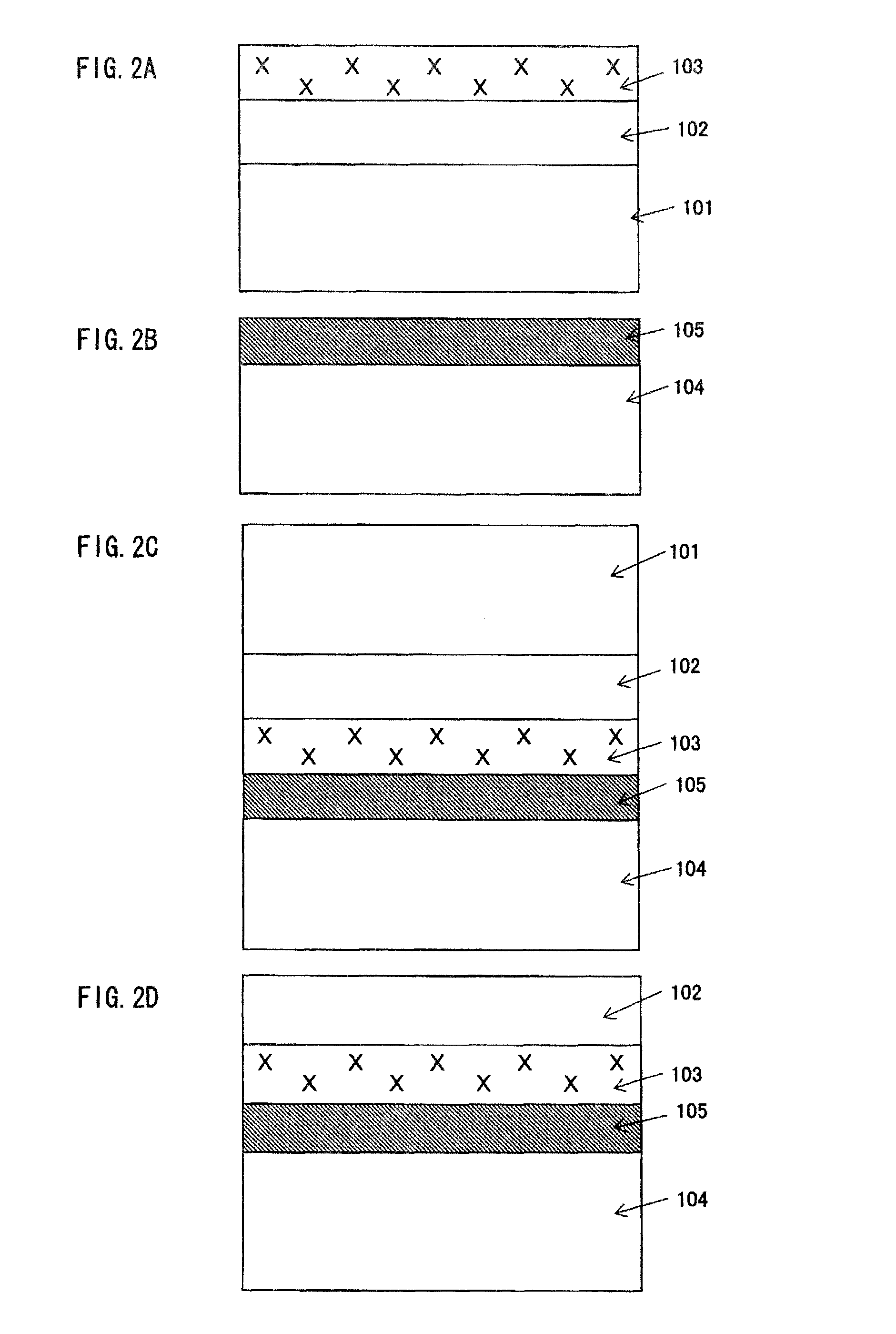

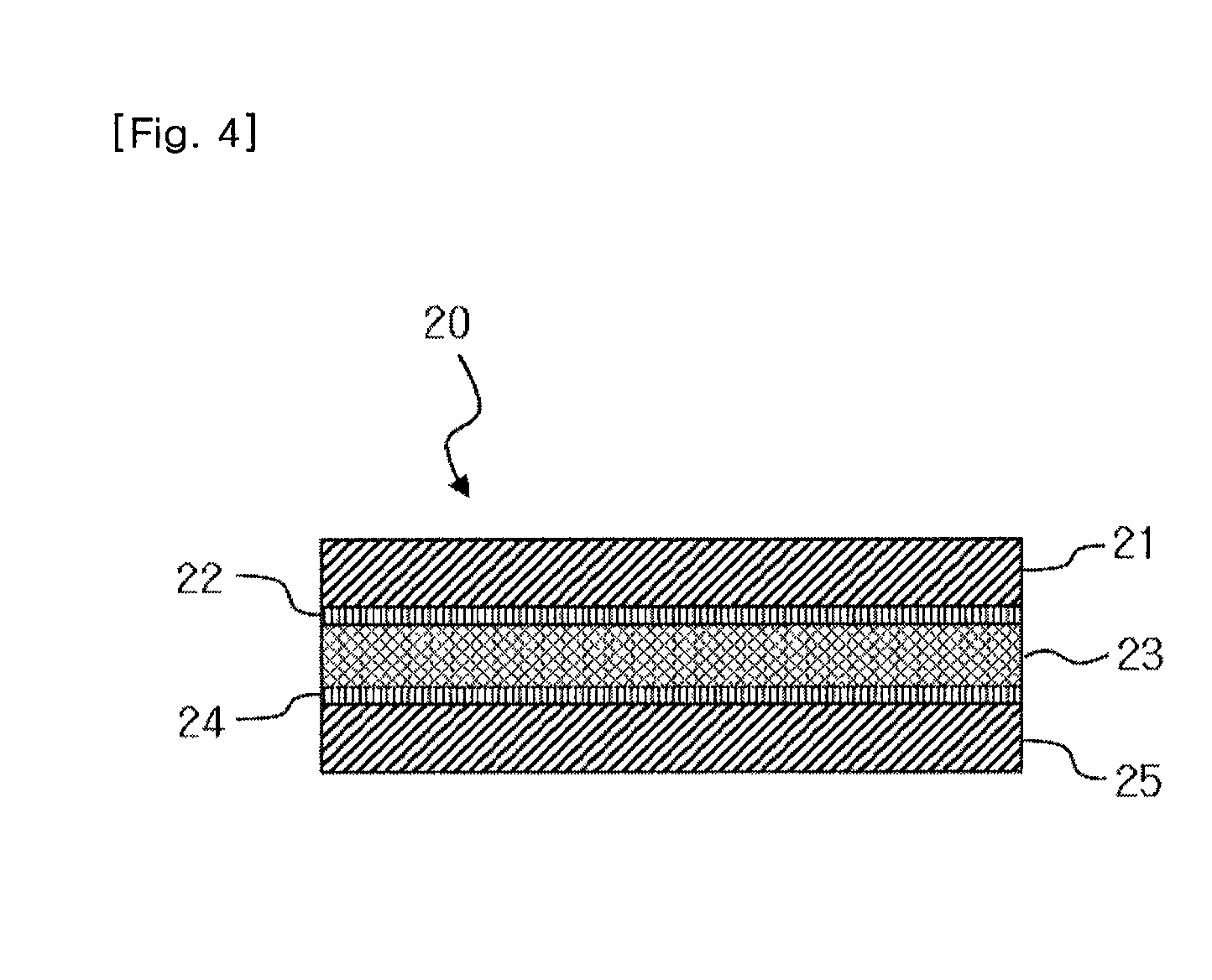

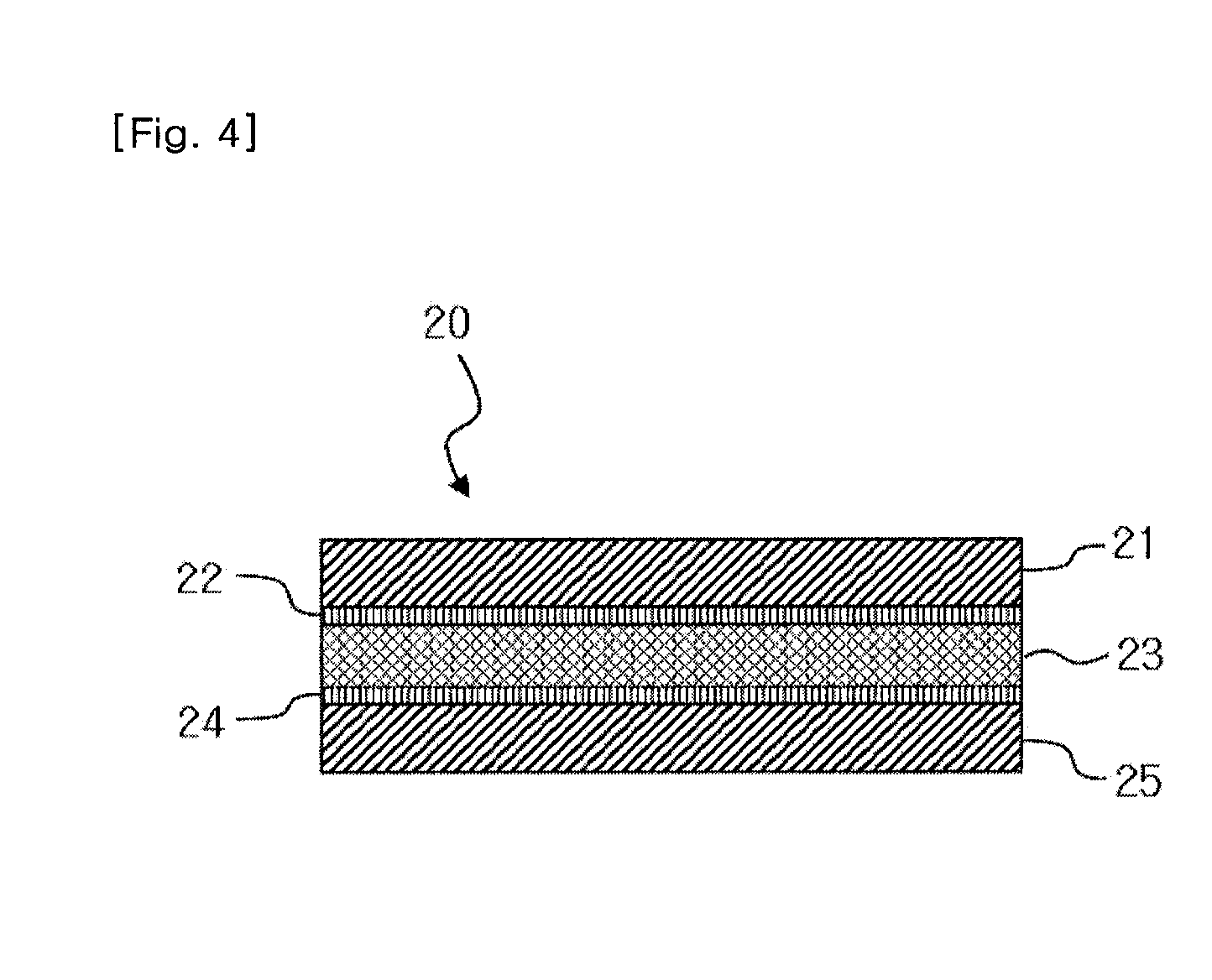

Soi wafer, method for producing same, and method for manufacturing semiconductor device

ActiveUS20110298083A1Promote precipitationImprove inhalation capacitySolid-state devicesSemiconductor/solid-state device manufacturingNitrogenOxygen

An SOI wafer including: a supporting substrate 1; a BOX layer 2 provided above the supporting substrate 1, the BOX layer 2 being formed by a thermal oxidization; a gettering layer 3 provided immediately on the BOX layer 2 and mainly composed of a silicon which contains one or more of oxygen, carbon and nitrogen and contains at least oxygen; and an S layer 4 in which semiconductor devices are to be formed, the S layer 4 being mainly composed of a monocrystalline silicon.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

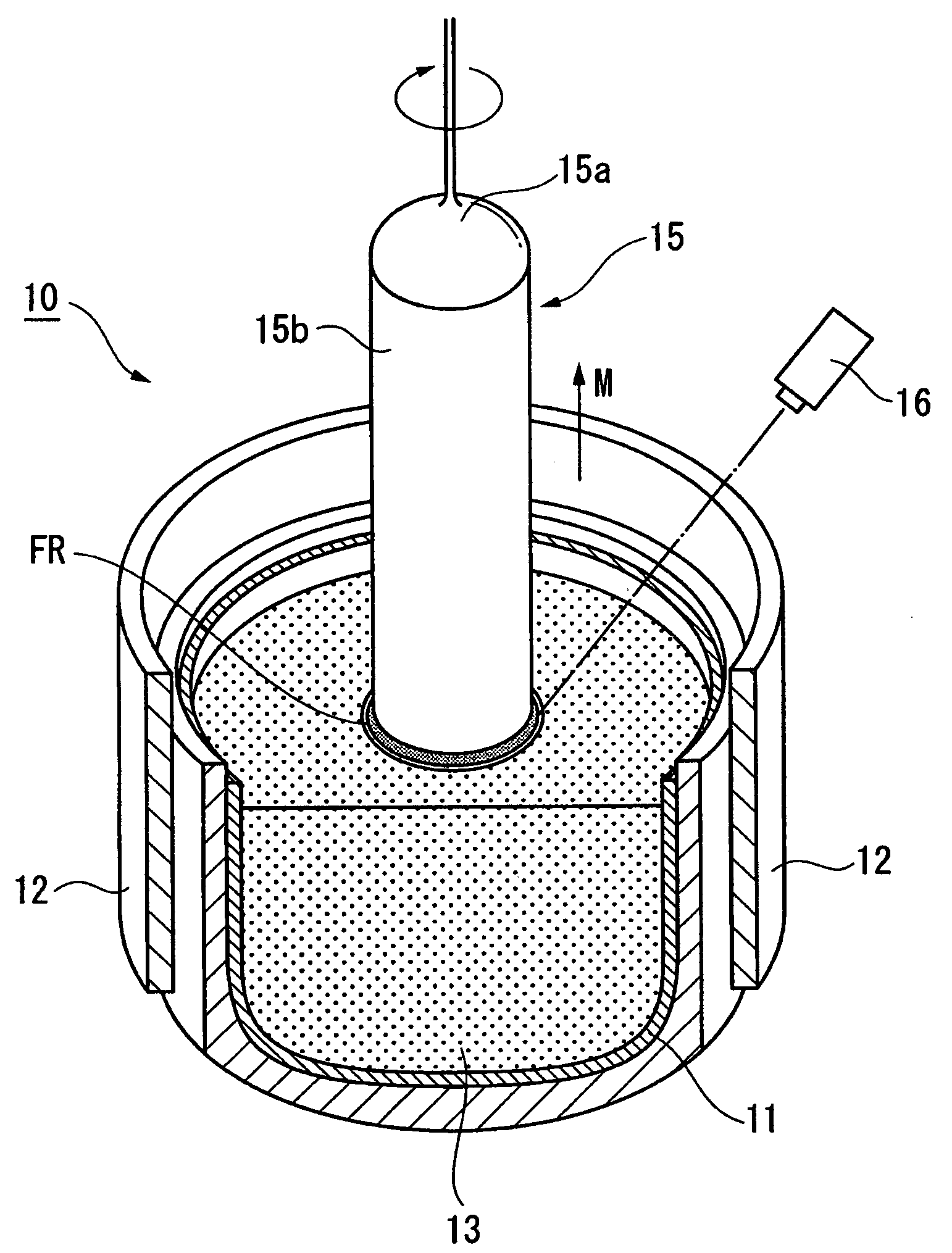

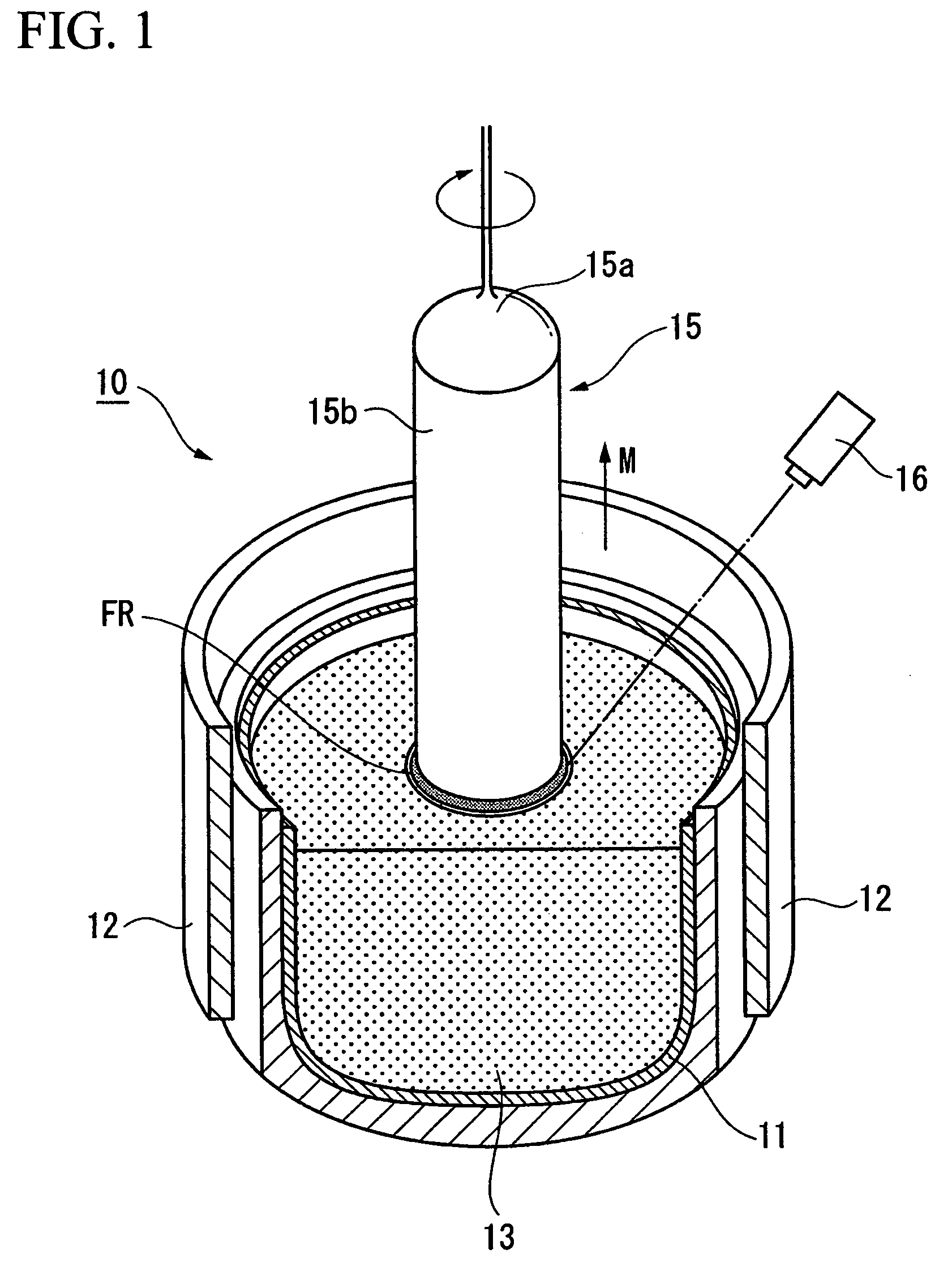

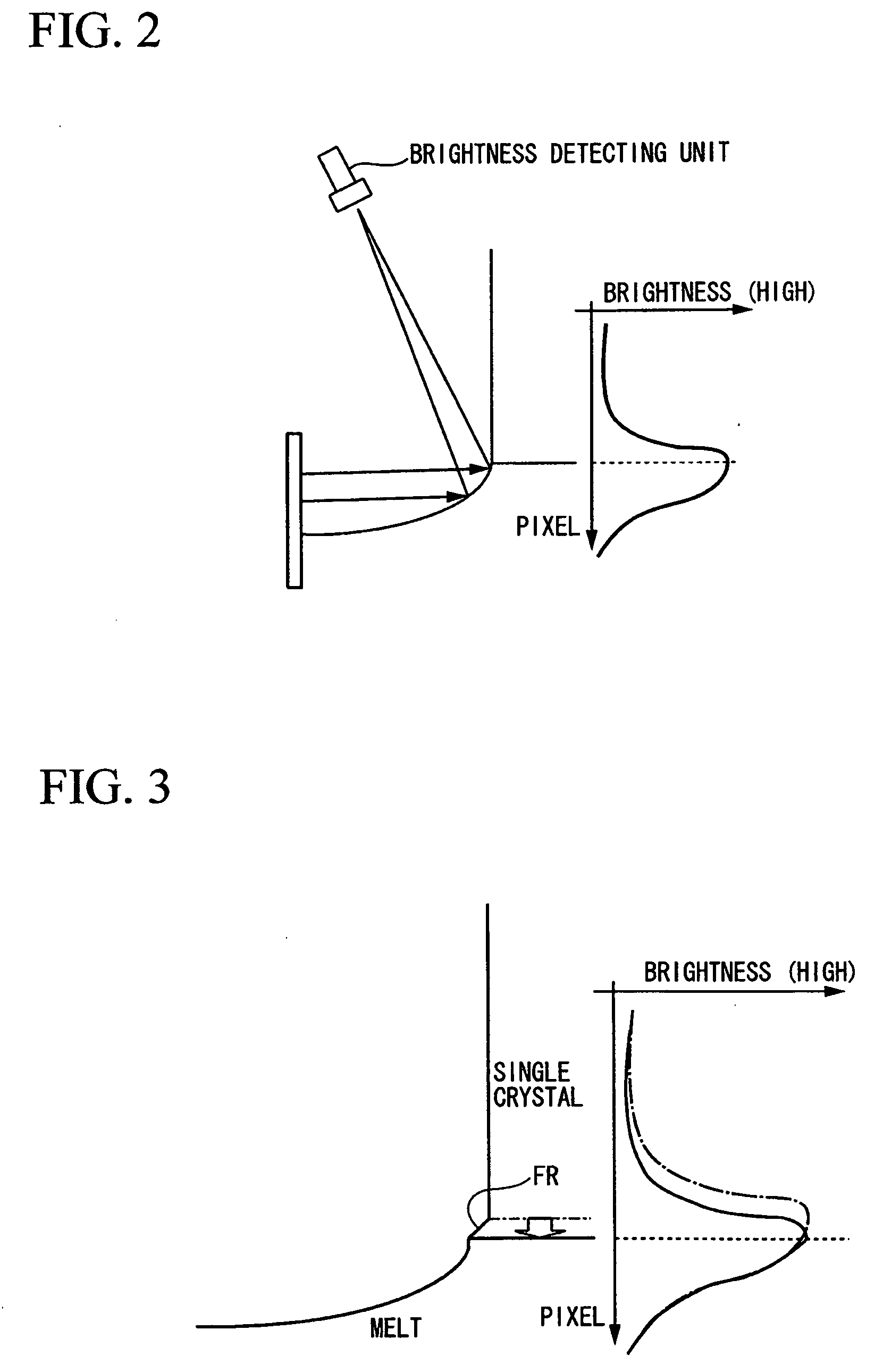

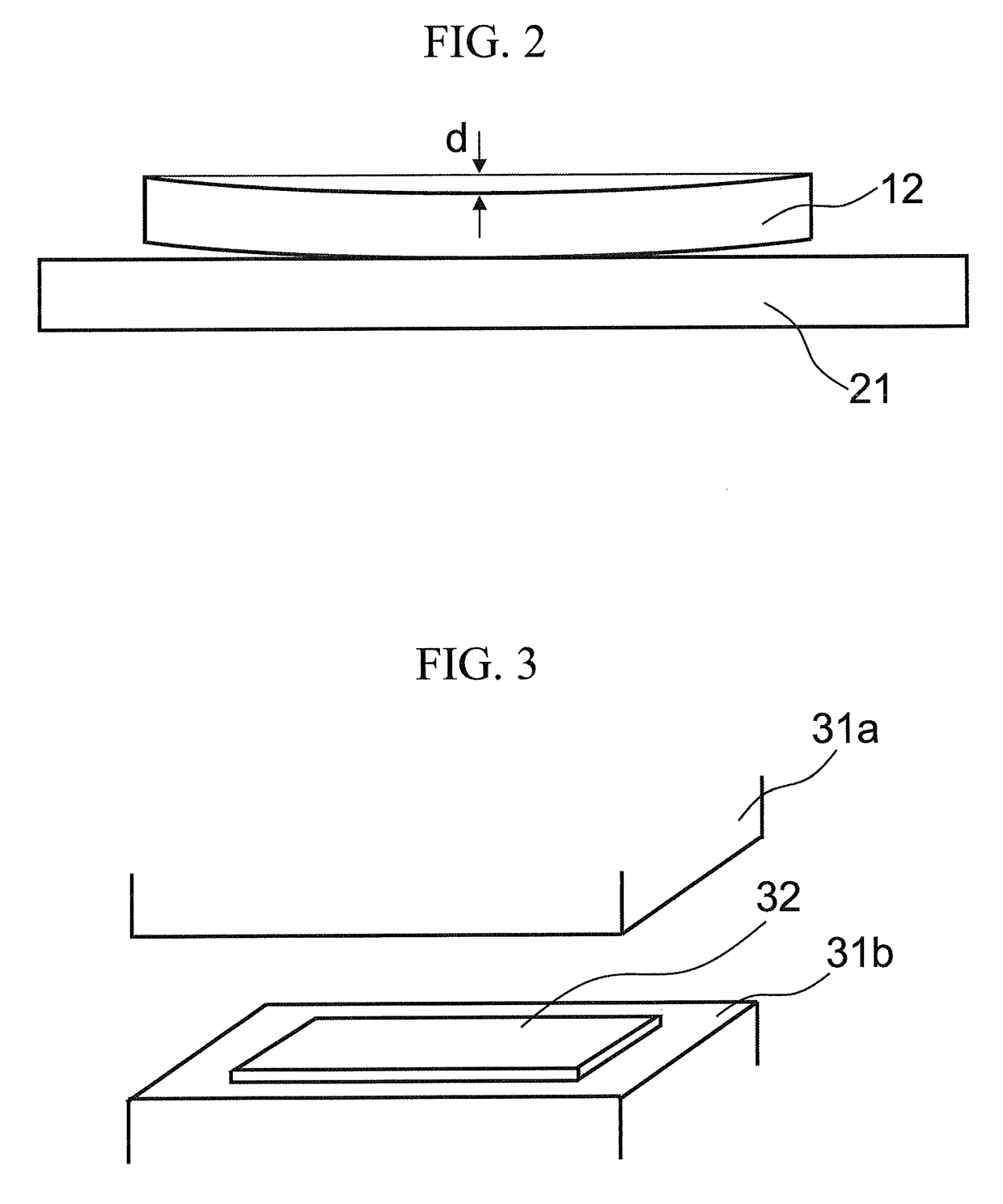

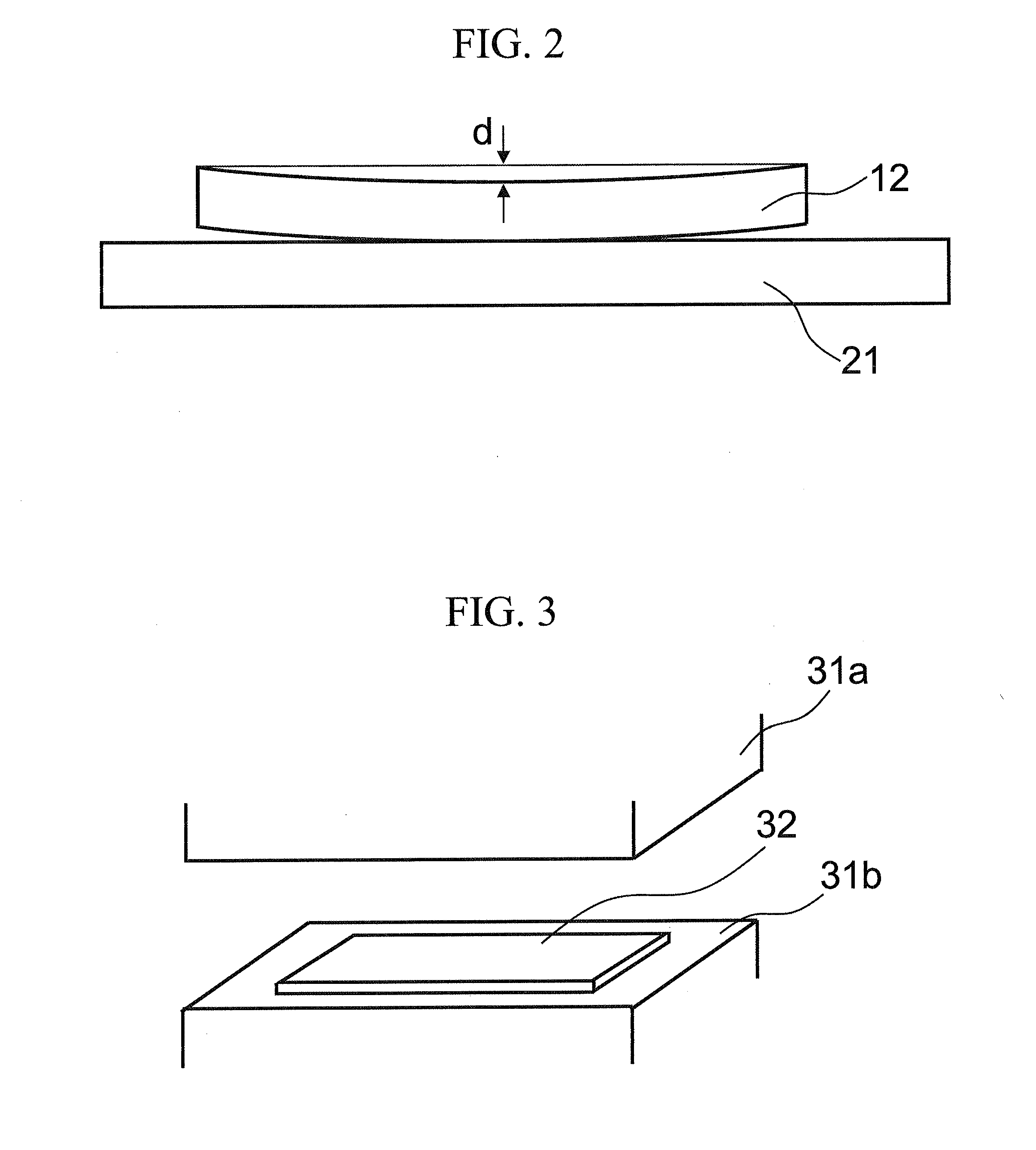

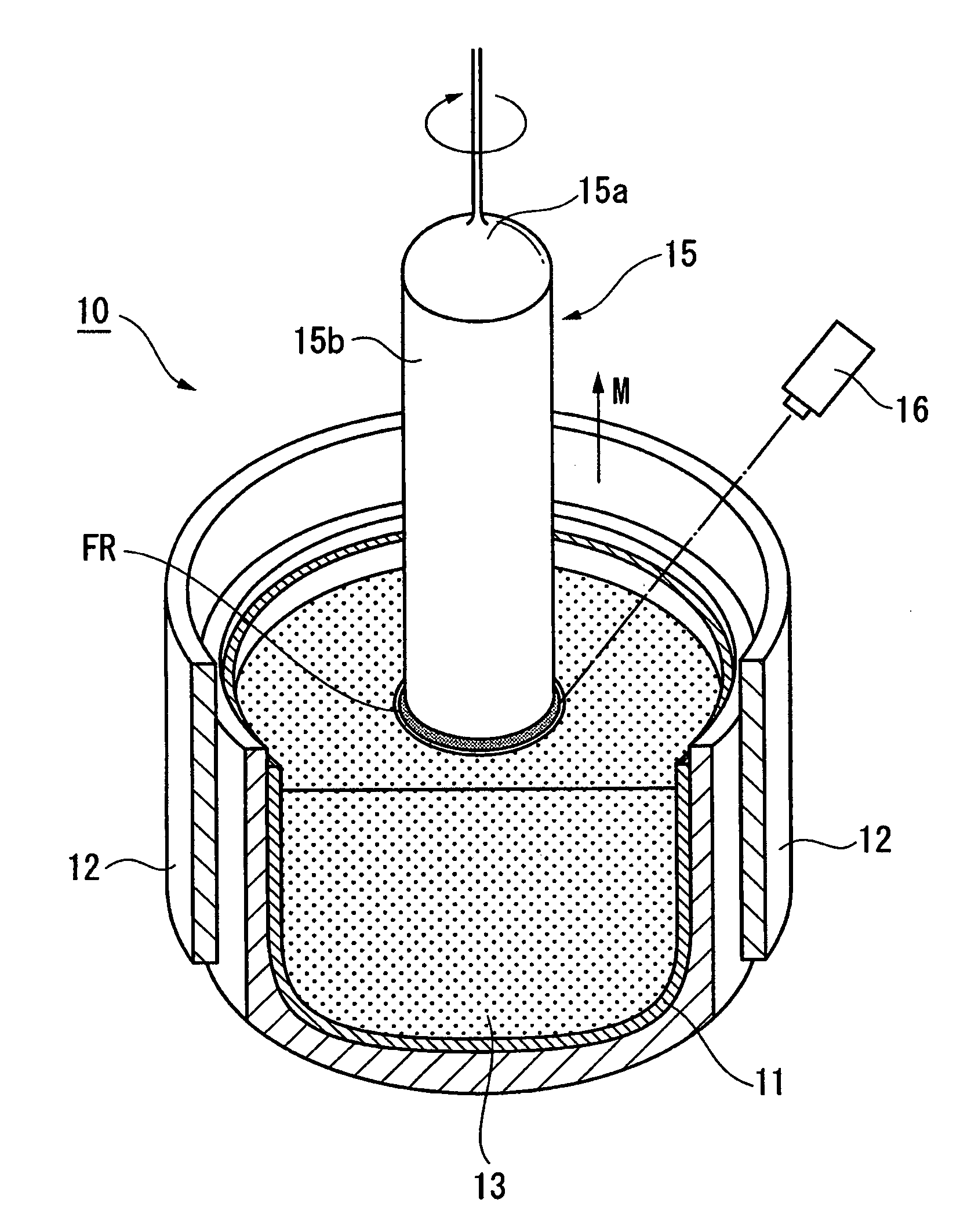

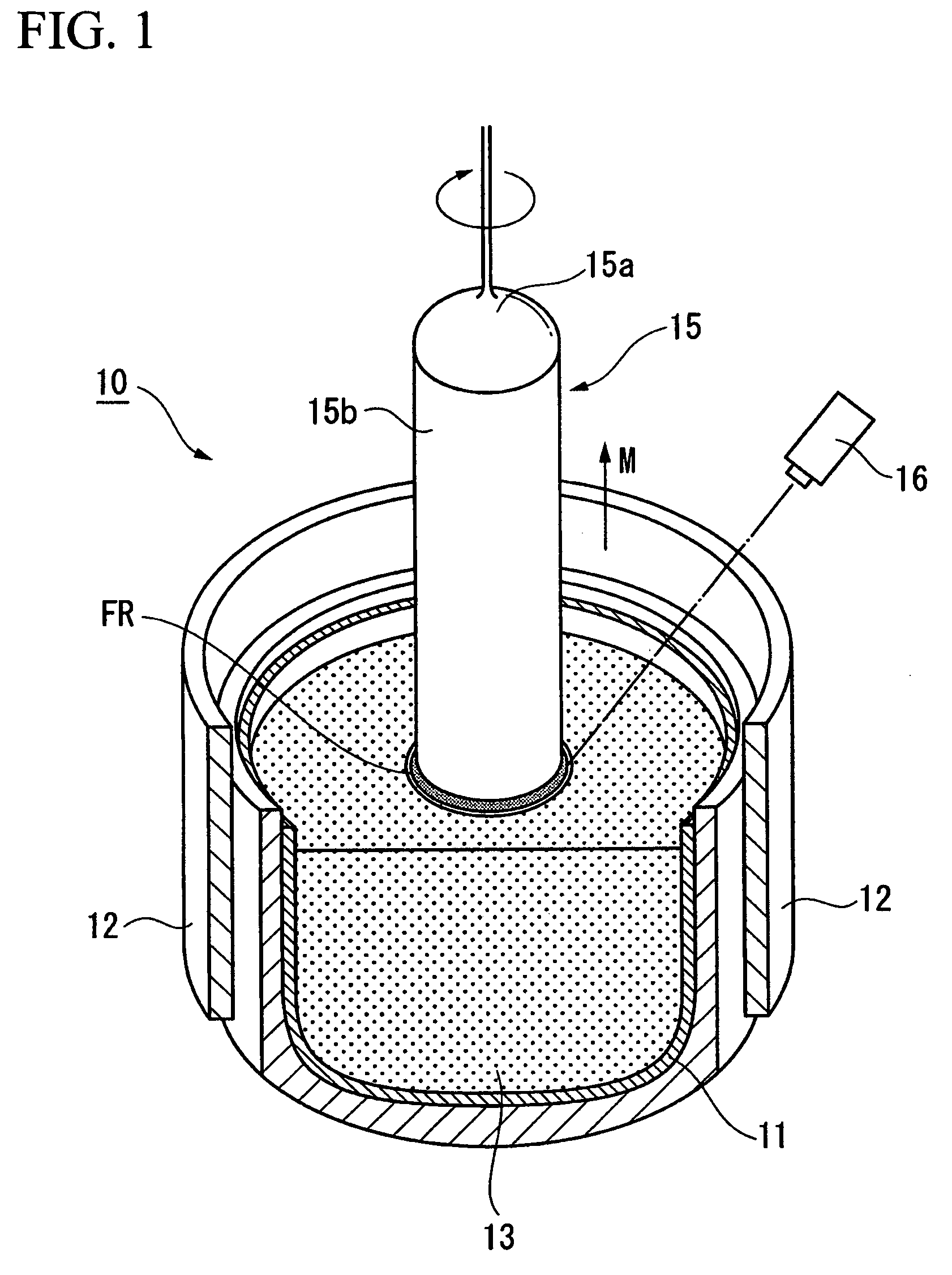

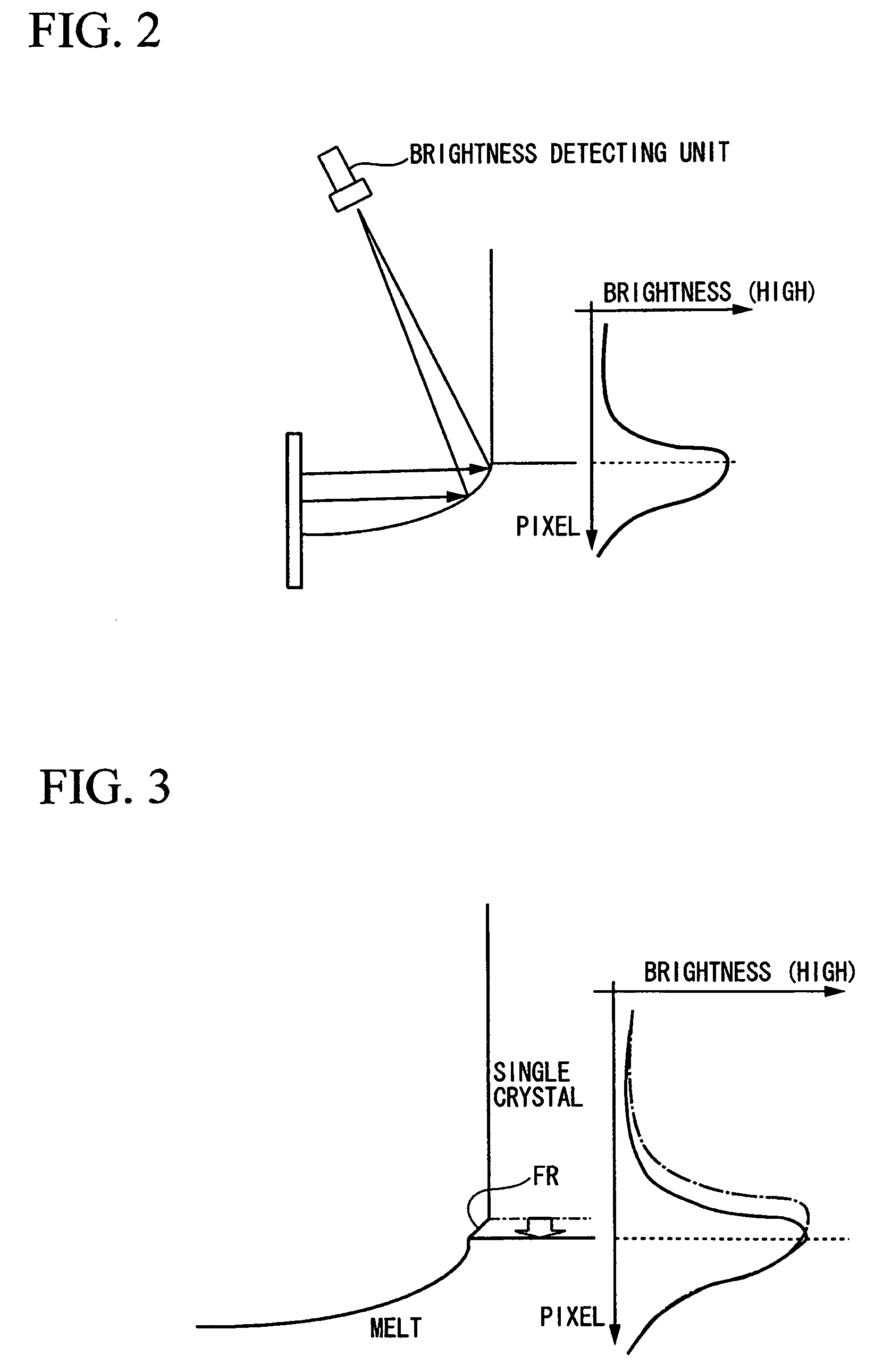

Silicon single crystal pulling method

ActiveUS20090064923A1Small defectPolycrystalline material growthSemiconductor/solid-state device manufacturingImage captureLiquid interface

An object of the present invention is to provide a silicon single crystal pulling method of accurately controlling the diameter of a silicon single crystal, thereby obtaining a high-quality silicon single crystal with little crystal defect.According to an aspect of the present invention, the pulling step includes: capturing an image of the silicon single crystal using an imaging device; measuring the brightness distribution of a fusing ring generated in the vicinity of a solid-liquid interface between the silicon melt and the silicon single crystal for each image scan line in the image captured by the imaging device; detecting the liquid level of the silicon melt and the position of the solid-liquid interface; and controlling the diameter of the silicon single crystal on the basis of a meniscus height, which is a difference between the liquid level and the position of the solid-liquid interface.

Owner:SUMCO CORP

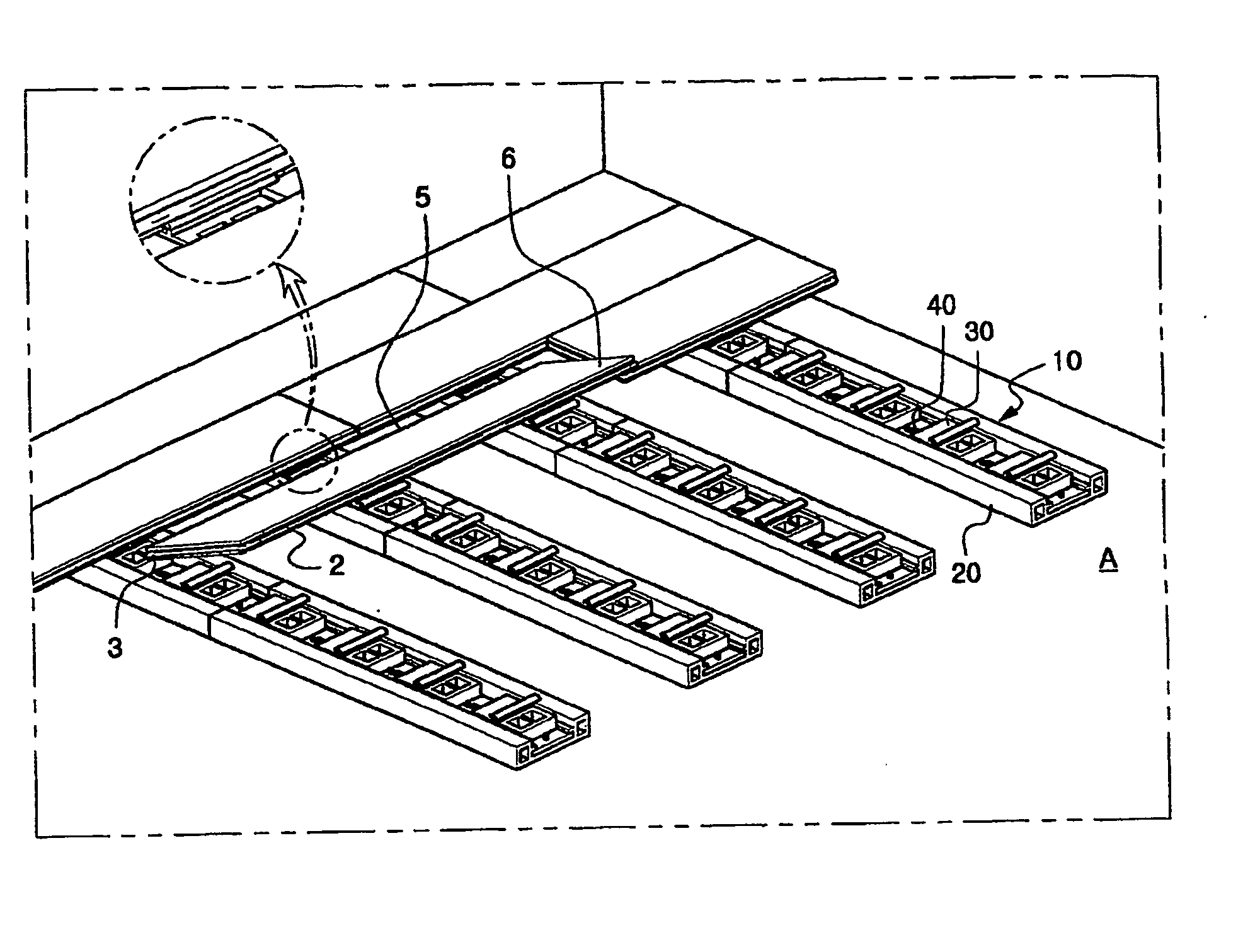

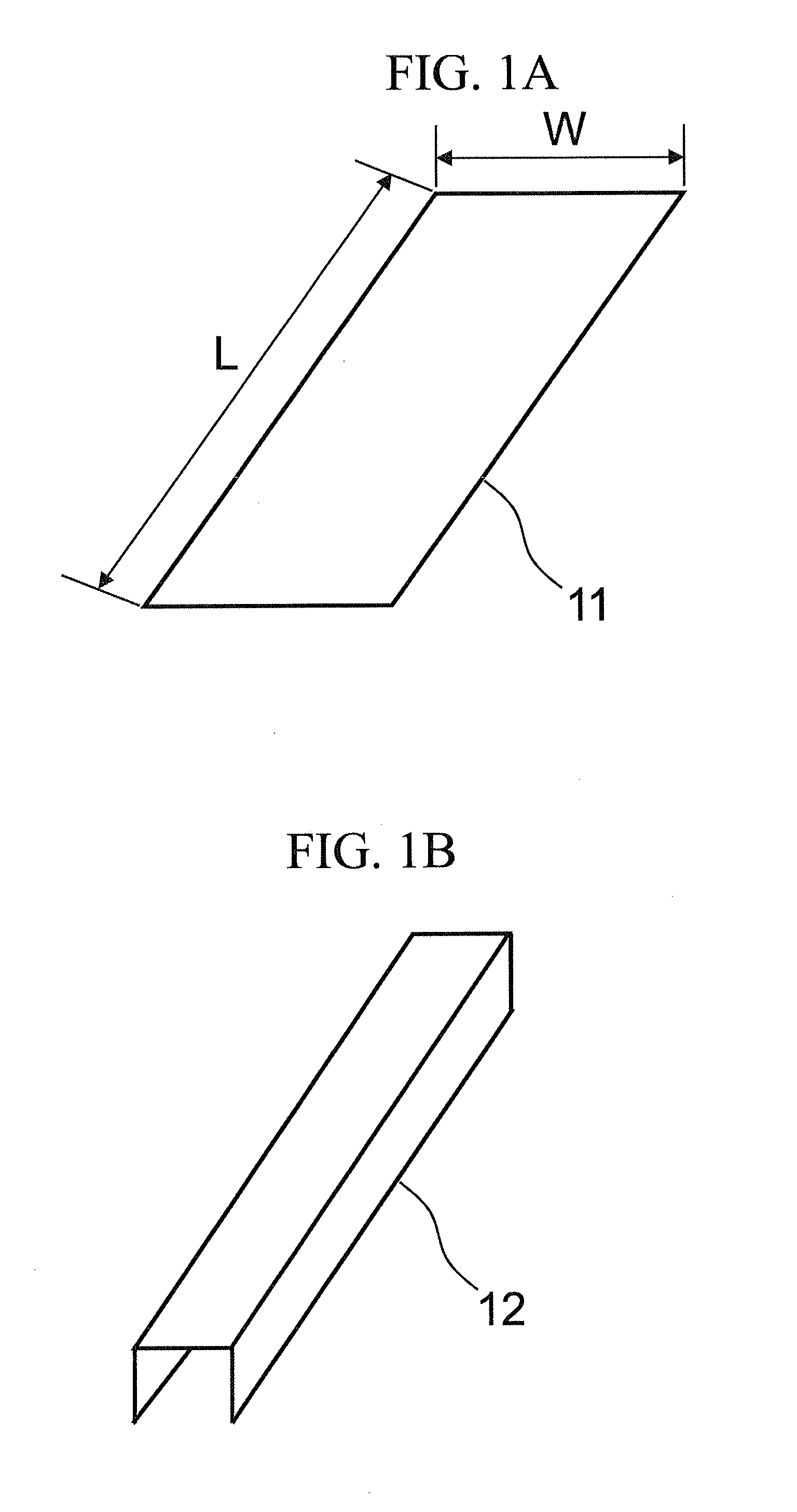

Installation method of panel and rail-type fixing apparatus

InactiveUS20060156664A1Simple and rapid installationSmall defectCeilingsCovering/liningsEngineeringSurface plate

The present invention is related to an installation method of panel comprising a step of assembling panels by fitting projection parts 2, 3 of one panel 1 to insertion grooves 5, 6 of another panel 1, and a step of elastically attaching panels by applying an elastic force between assembled part of panels. Also, the present invention is related to a rail type fixing apparatus for installing panels comprising a rail 20 having a guide groove 21 formed in a longitudinal direction thereof, and a plurality of attaching plates which are guided to the guide groove 21 and are provided movably in the longitudinal direction of the rail 20 and in which a hook projections 32 are provided, and an elastic member which is provided between adjacent attaching plates and applies elasticity between hook projections of the attaching plates.

Owner:CHAE WAN SHIK

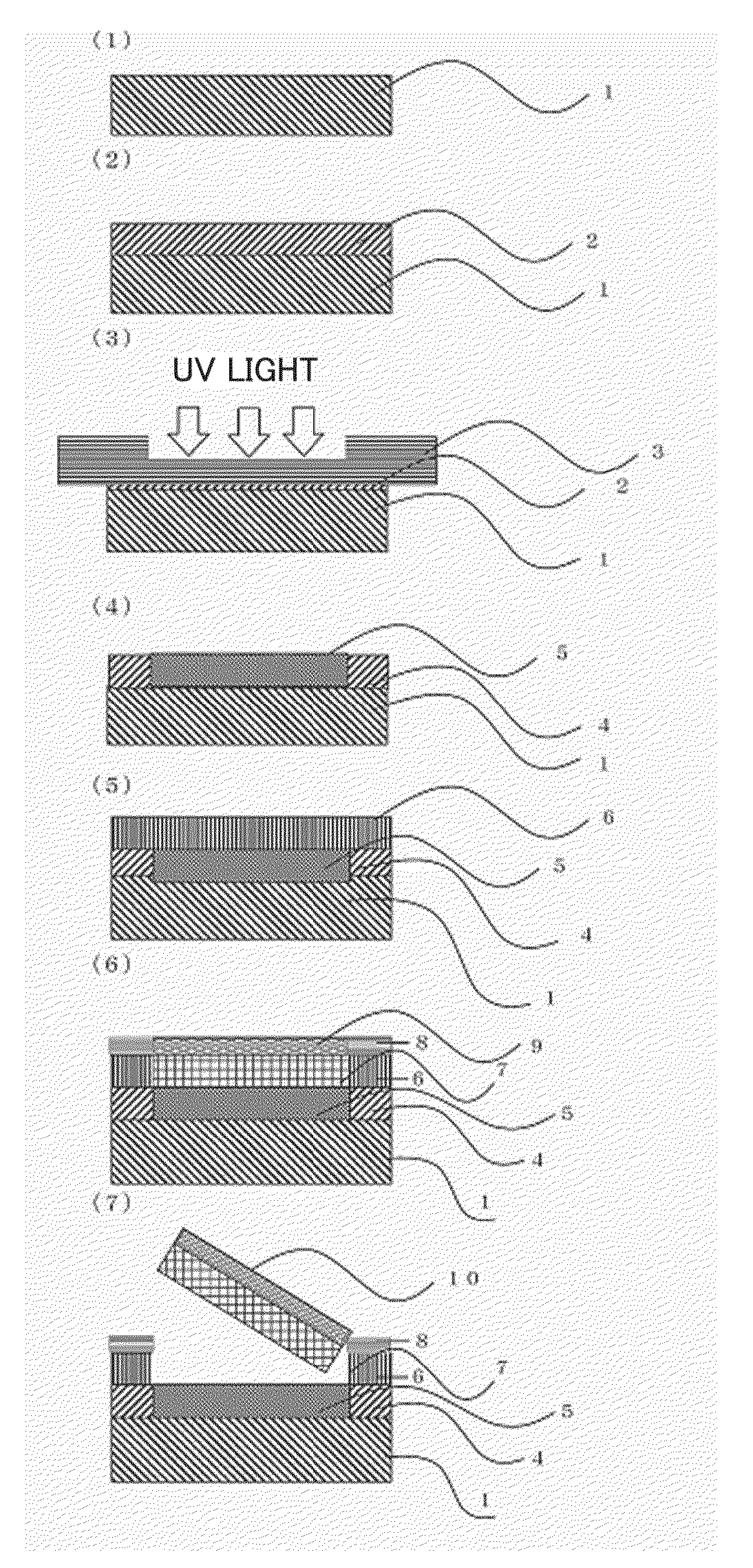

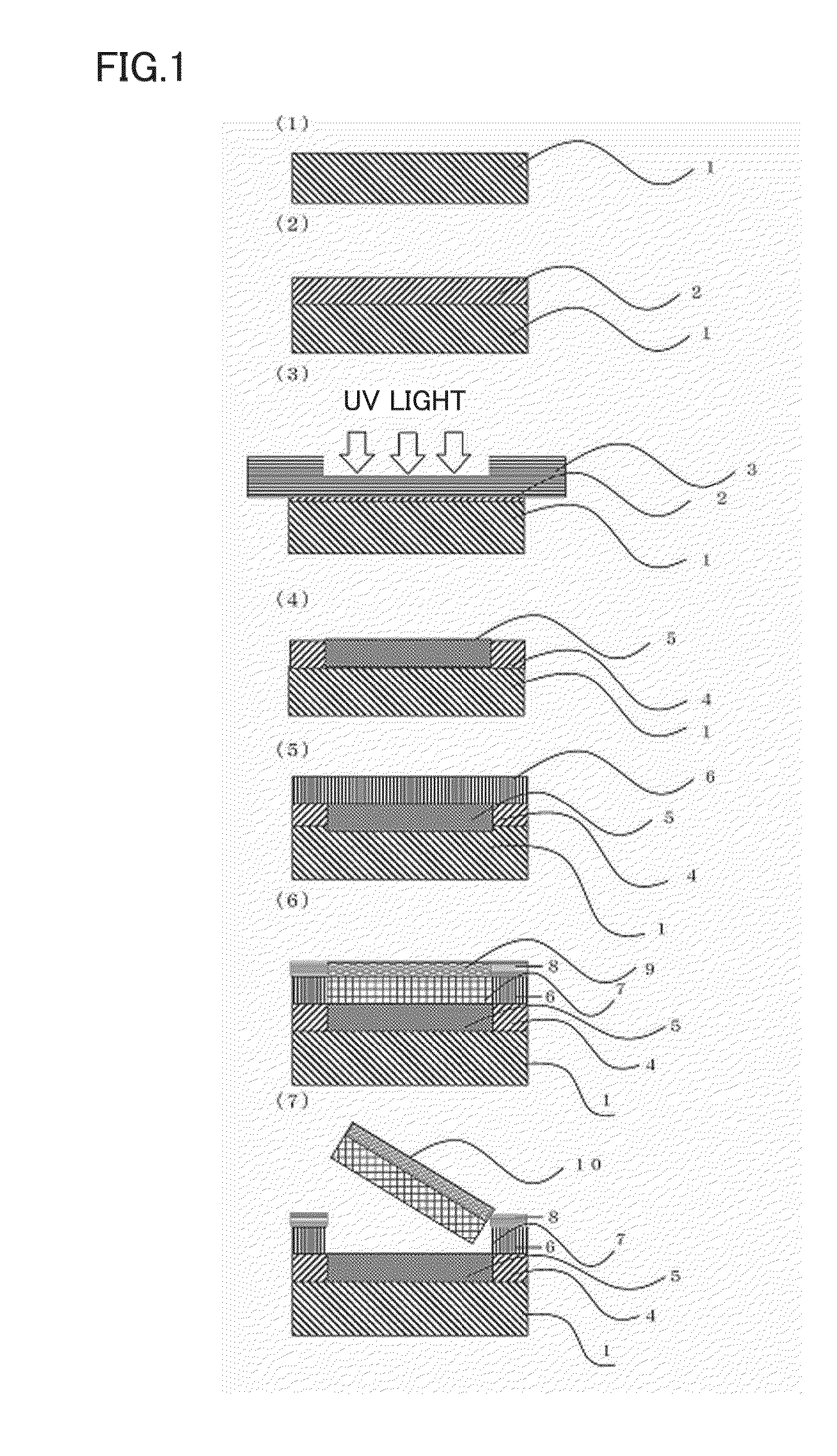

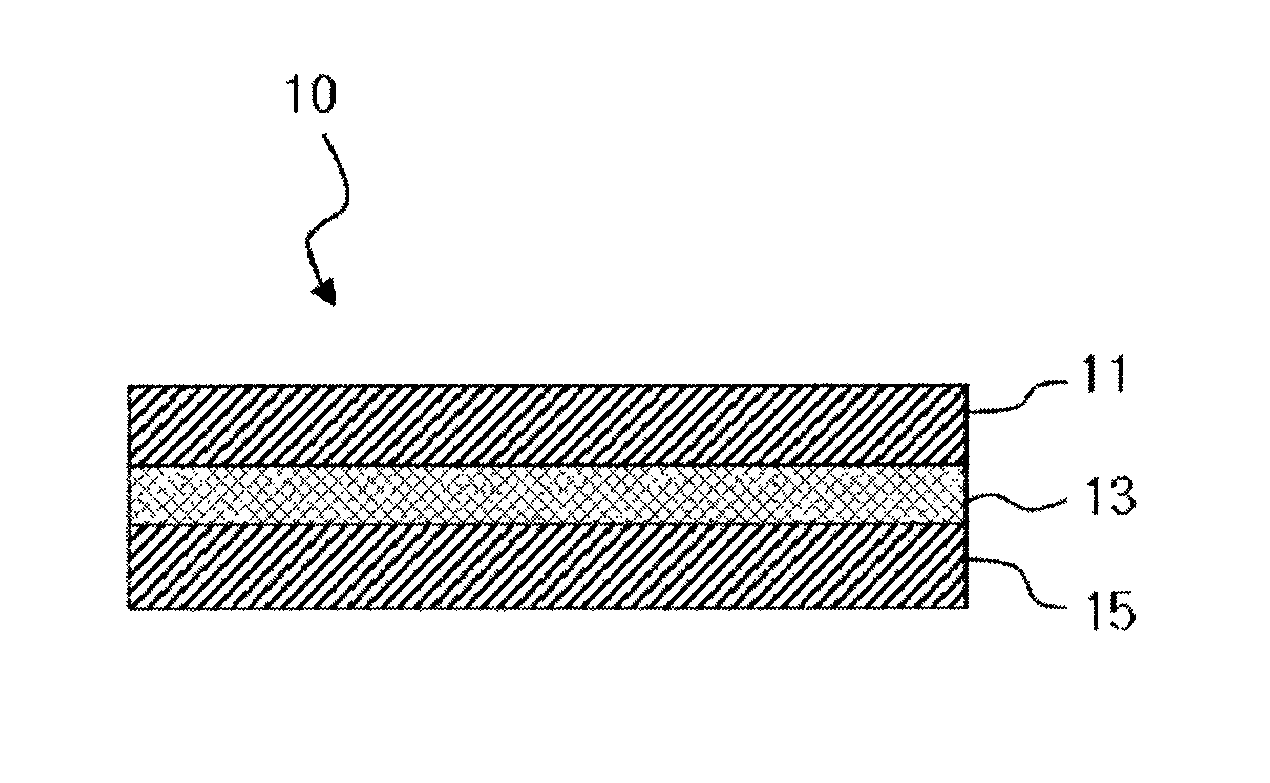

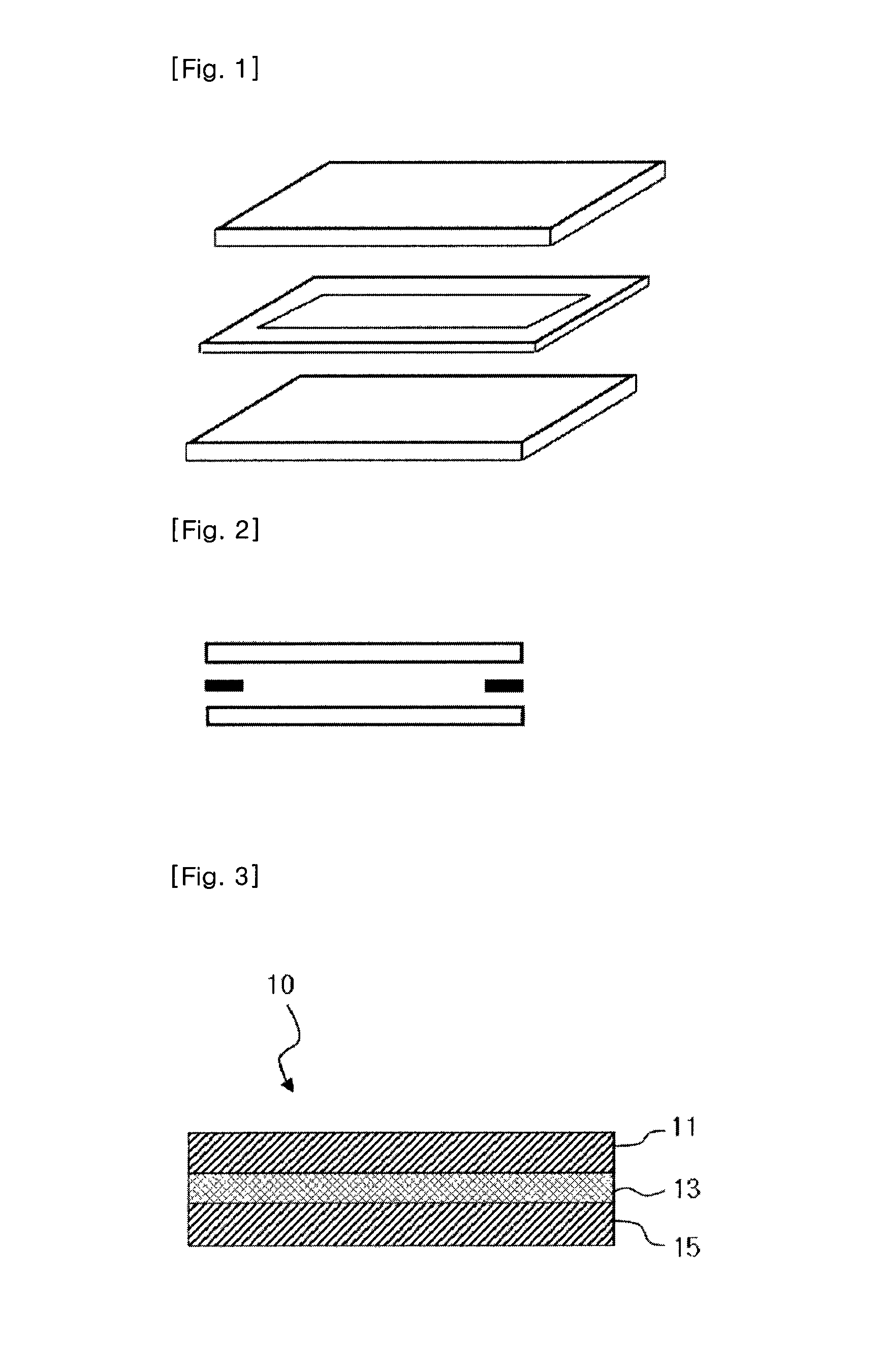

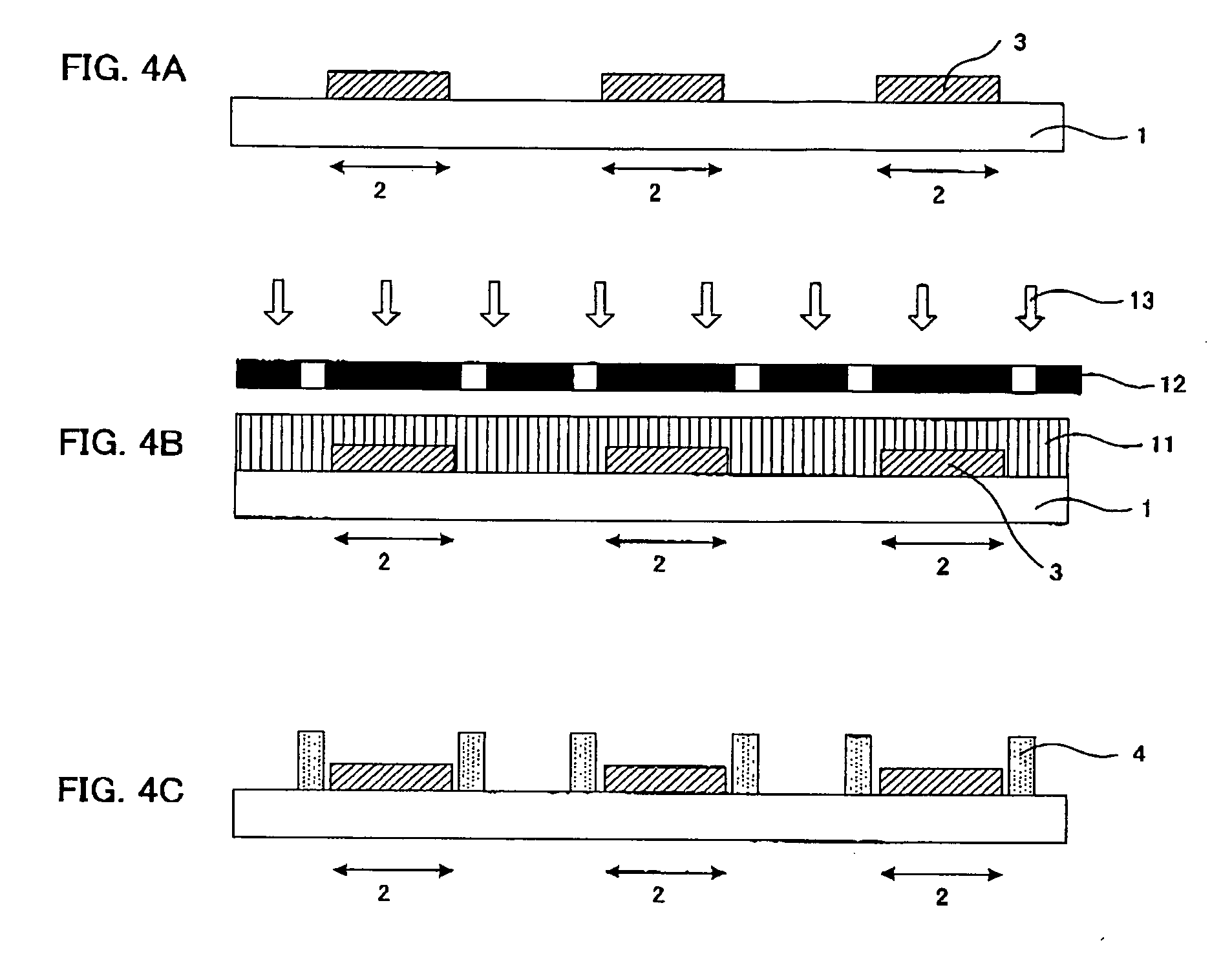

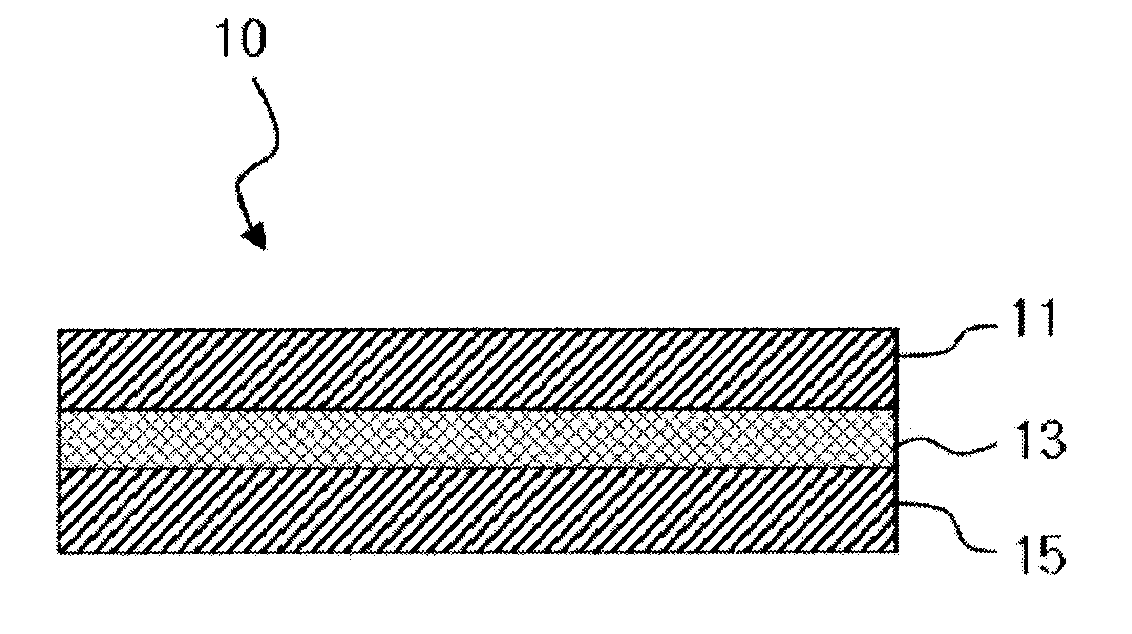

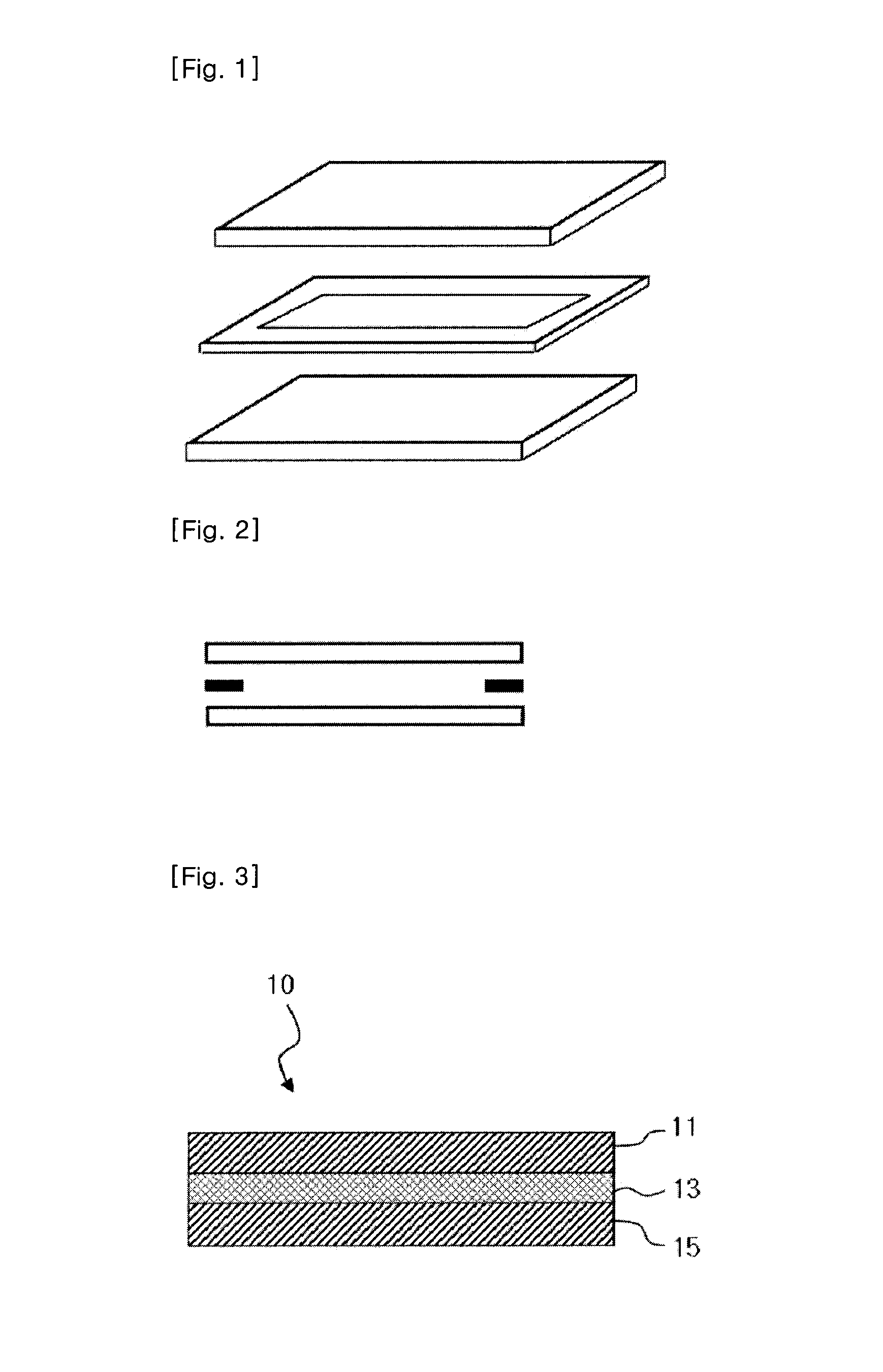

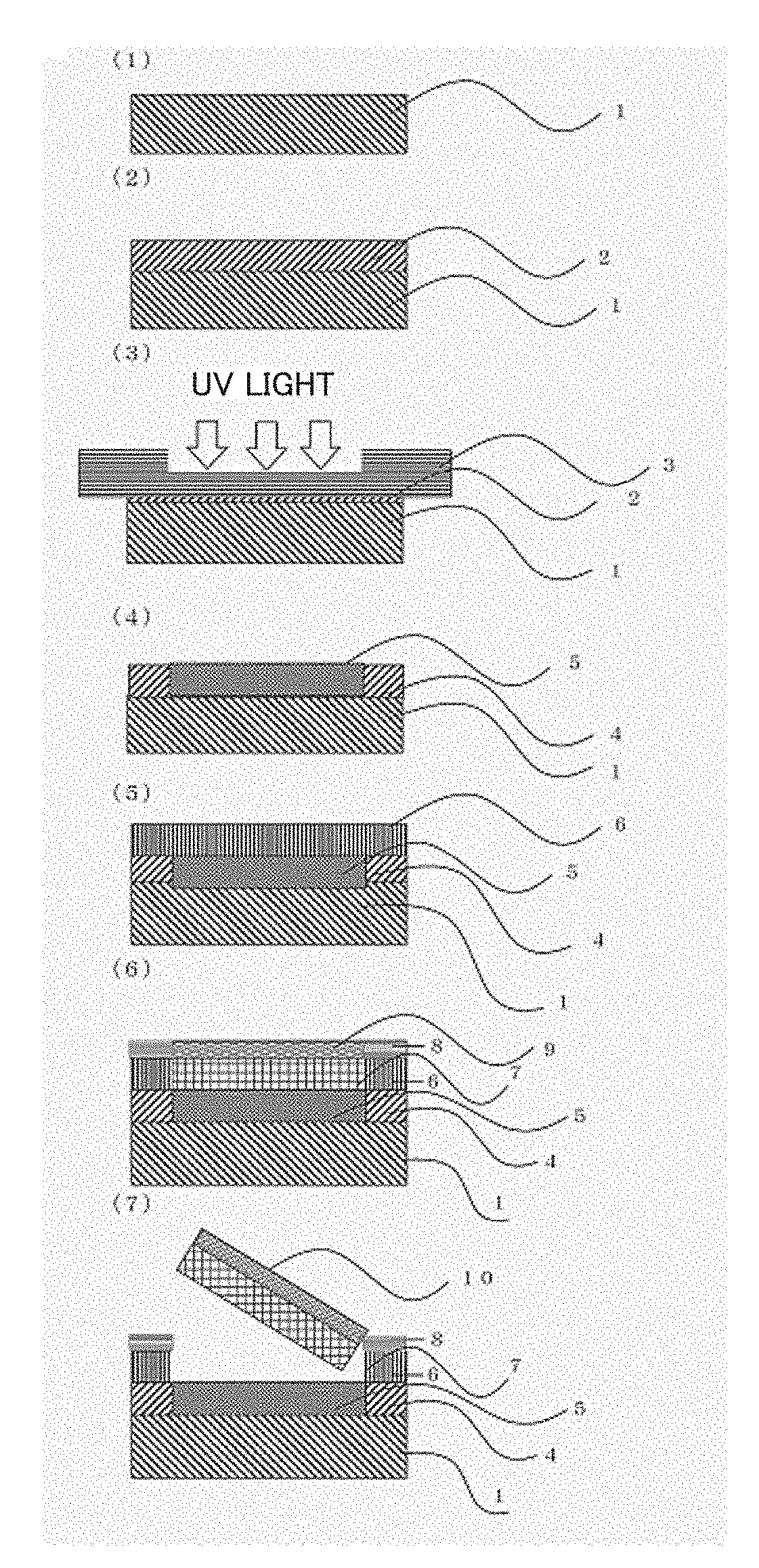

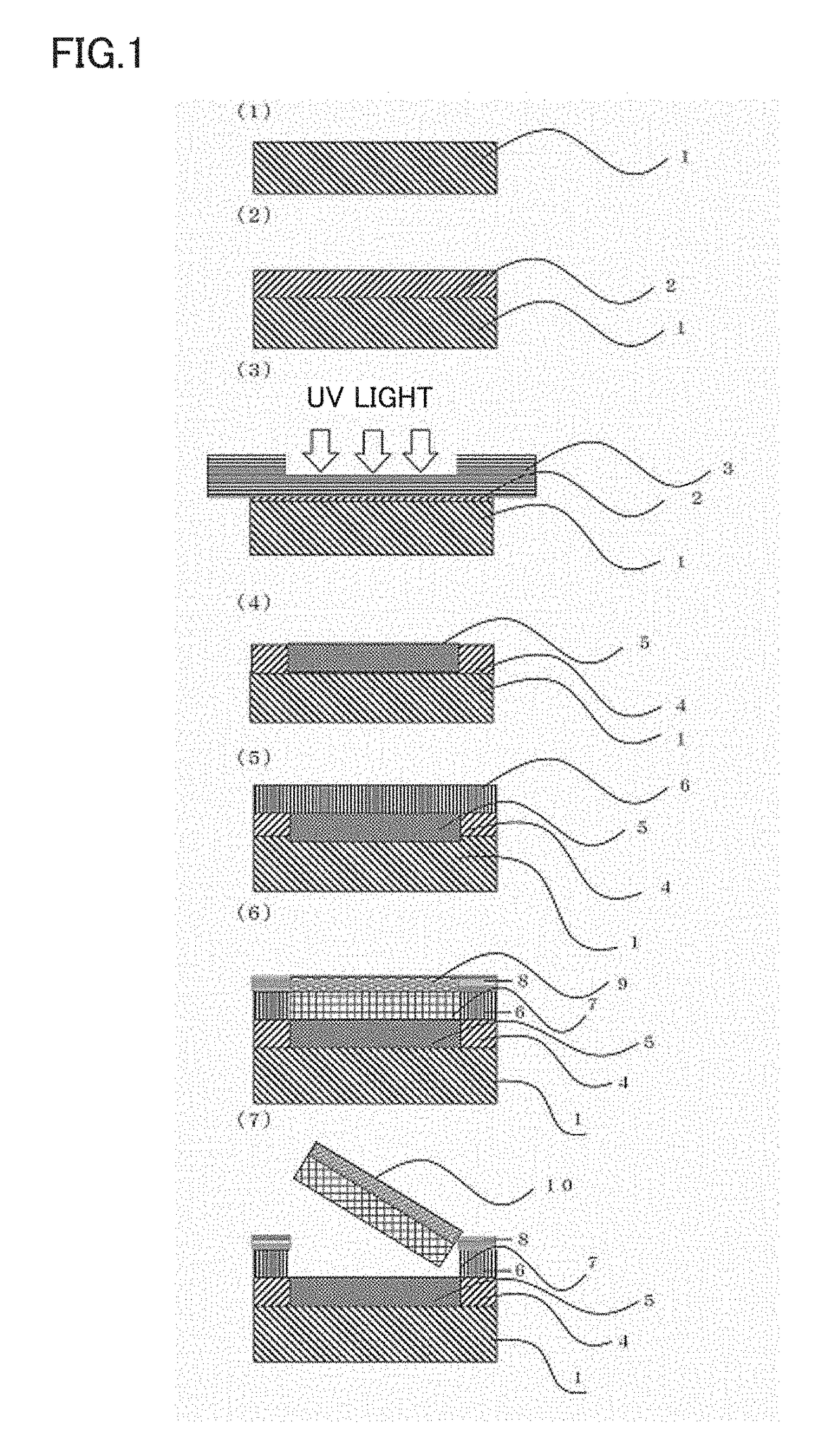

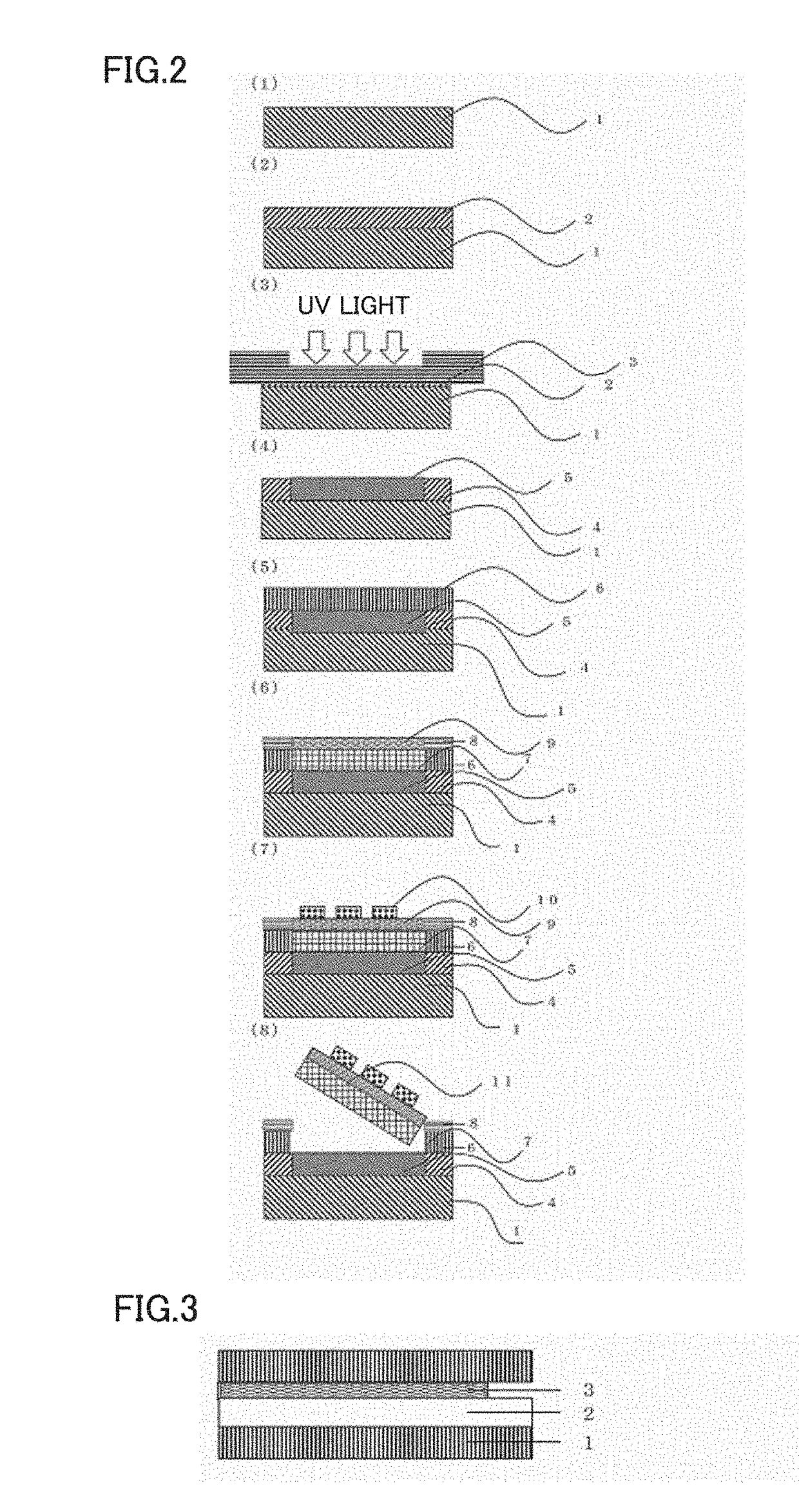

Method for producing layered product, layered product, method for producing layered product with device using said layered product, and layered product with device

ActiveUS20150125665A1Precise positioningSmall defectLamination ancillary operationsPaper/cardboard articlesPolyimide membraneSurface finishing

By preparing a polyimide film with a face at the support side and subjected to a surface treatment; subjecting at least one of a face of the support and the face of the polyimide film which are opposite to each other to a patterning treatment using a coupling agent to form a satisfactorily bondable part and an easily releasable part which differ in adhesion / peel strength; subsequently, superposing the support and the polyimide film to be subjected to a pressurizing / heating treatment and to be bonded to each other, subjecting the surface of the polyimide film to an organic alkali treatment; and then, applying a polyamic acid solution free from a slip agent ingredient, drying the coating film and imidizing the film, a layered product having a structure of at least three layers in which at least one layer contains a slip agent material and both surface layers have no slip agent material is produced.

Owner:TOYO TOYOBO CO LTD

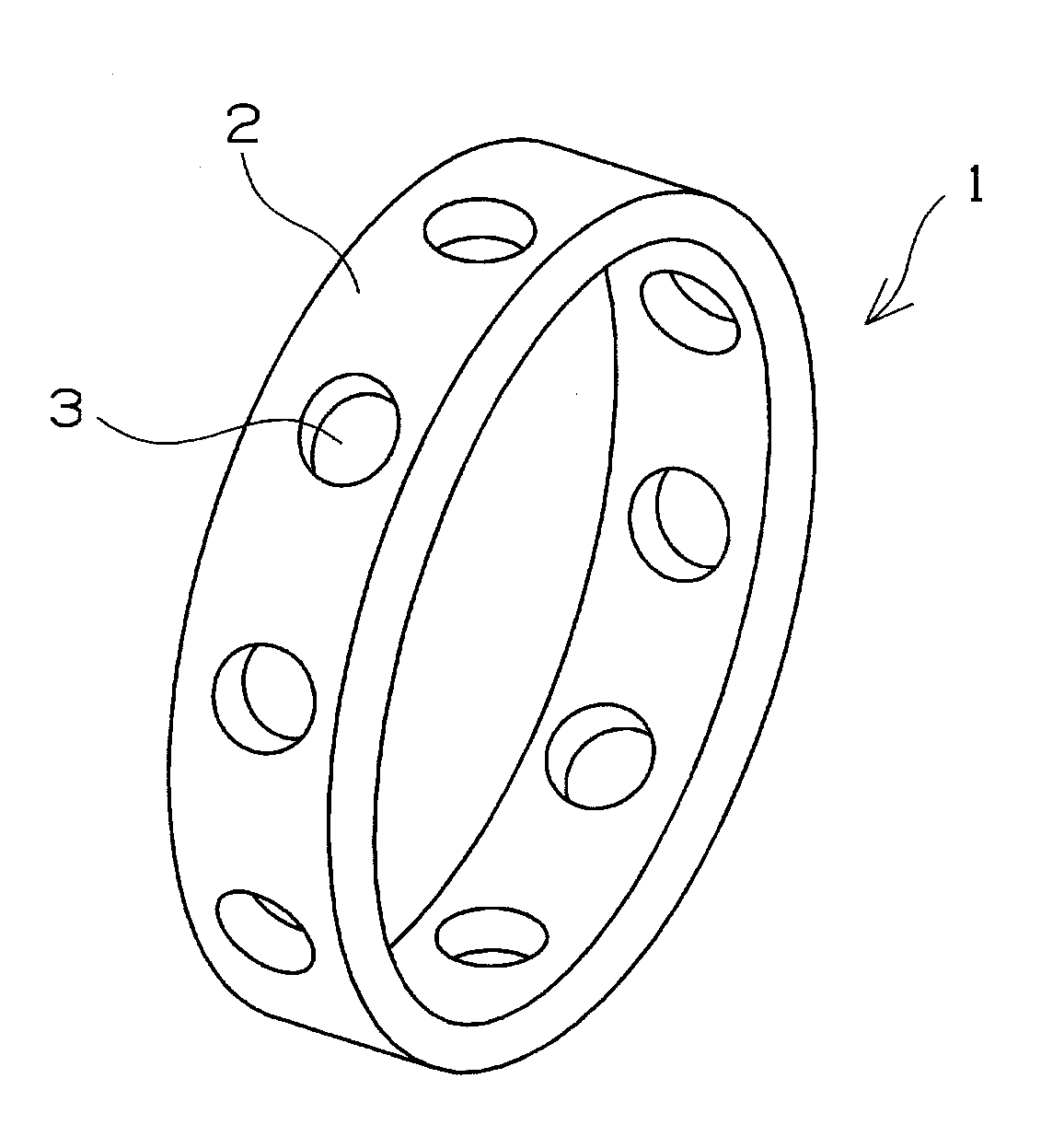

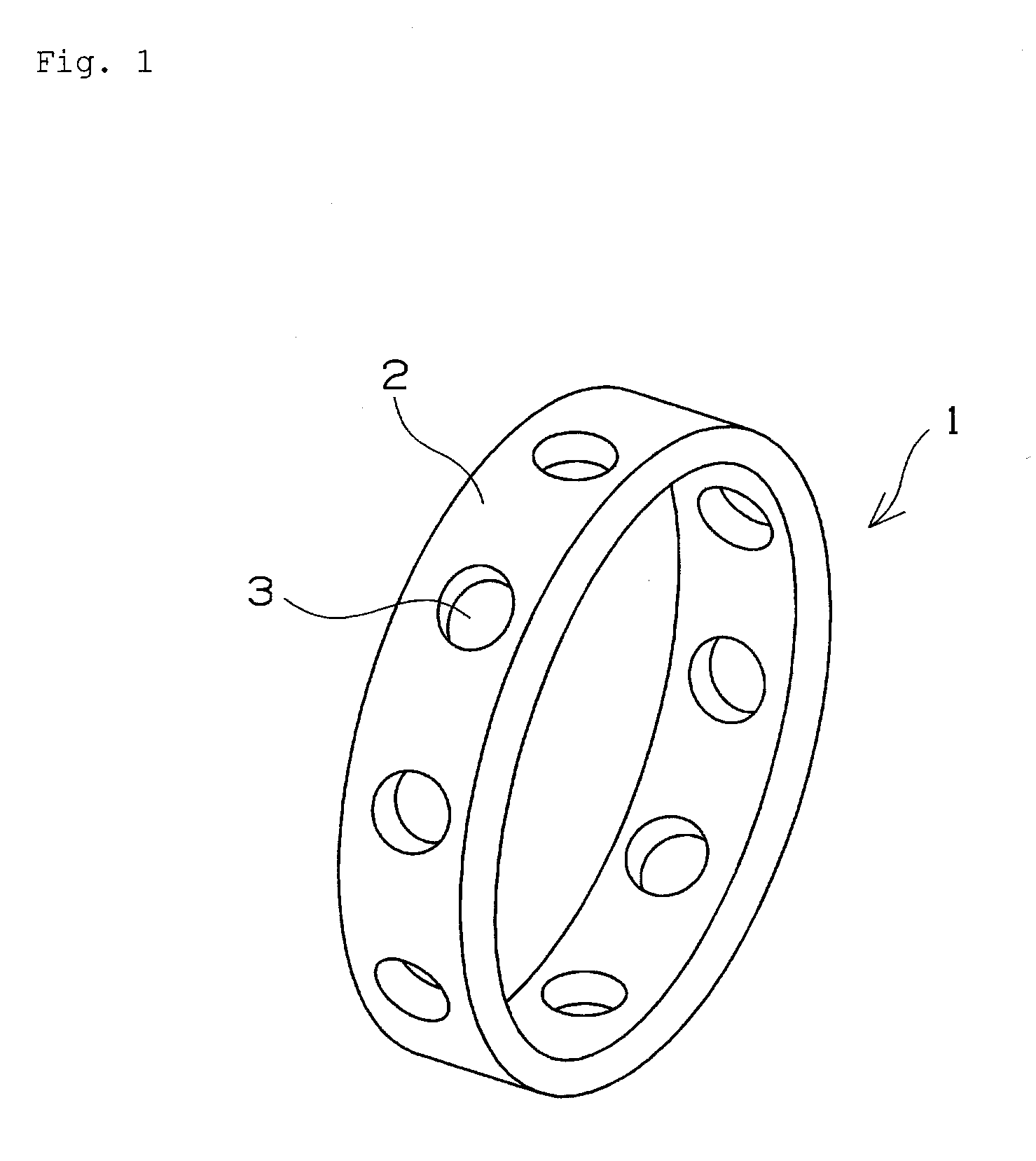

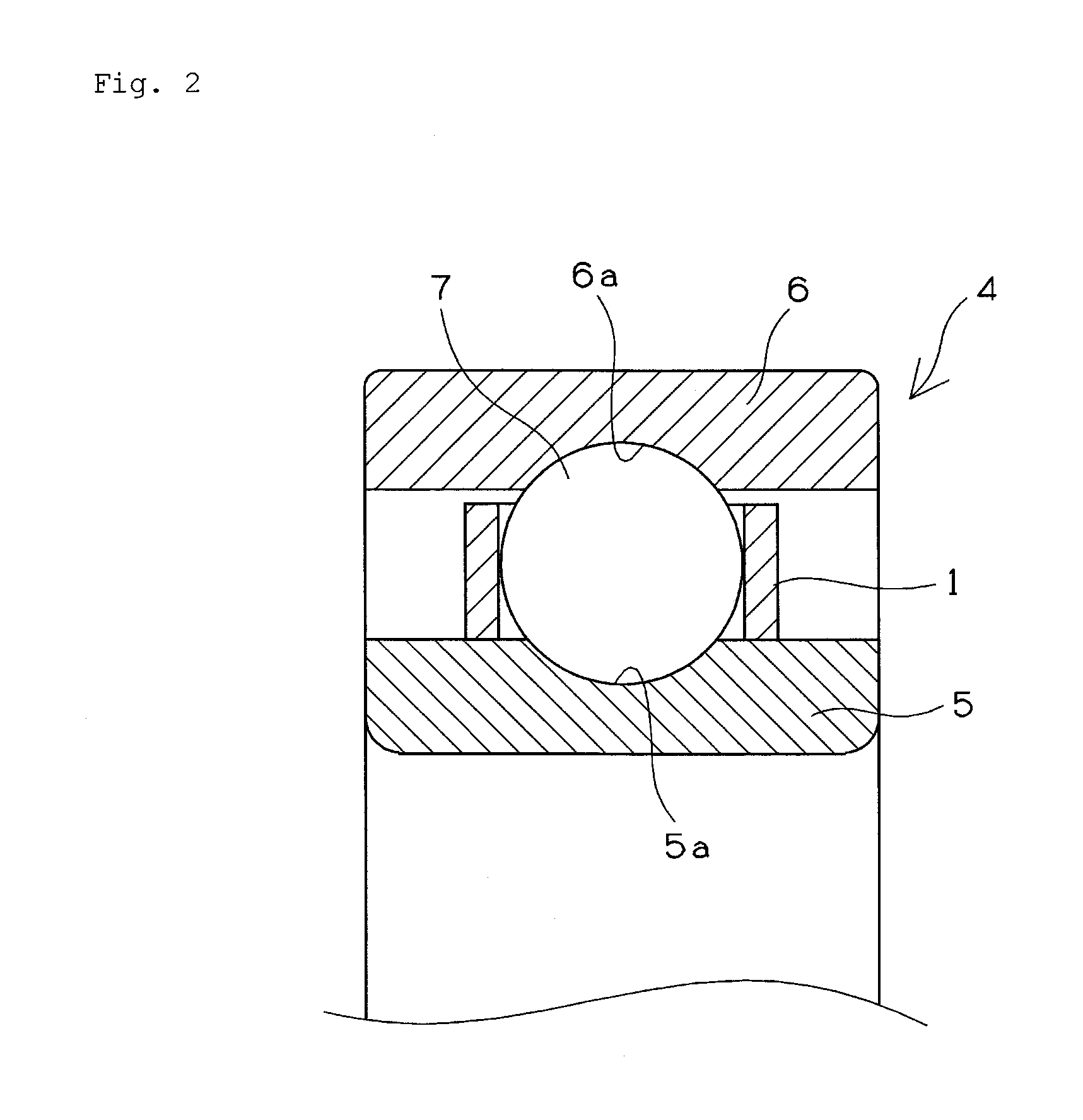

Cage for rolling bearing and rolling bearing

InactiveUS20130182987A1Low degree of adhesionSmall defectRoller bearingsShaftsOperating temperatureCarbon fiber composite

It is an object of the present invention to provide a rolling bearing which can be used in conditions in which a DN value is not less than 1,500,000 and an operating temperature is not less than 200° C. and which can be securely operated for a sufficiently long period of time without seizing, even though the rolling bearing is used in a dry run state and a cage for the rolling bearing. A cage (1) is formed by molding a carbon fiber composite material composed of a matrix consisting of a high-molecular compound reinforced with a carbon fiber material. The carbon fiber material consists of a bundle of 1000 to 5000 monofilaments, a woven cloth or a unidirectional material consisting of the bundle of the monofilaments. The high-molecular compound is polyimide resin or the like whose glass transition temperature is not less than 200° C. after the high-molecular compound thermally hardens.

Owner:NTN CORP

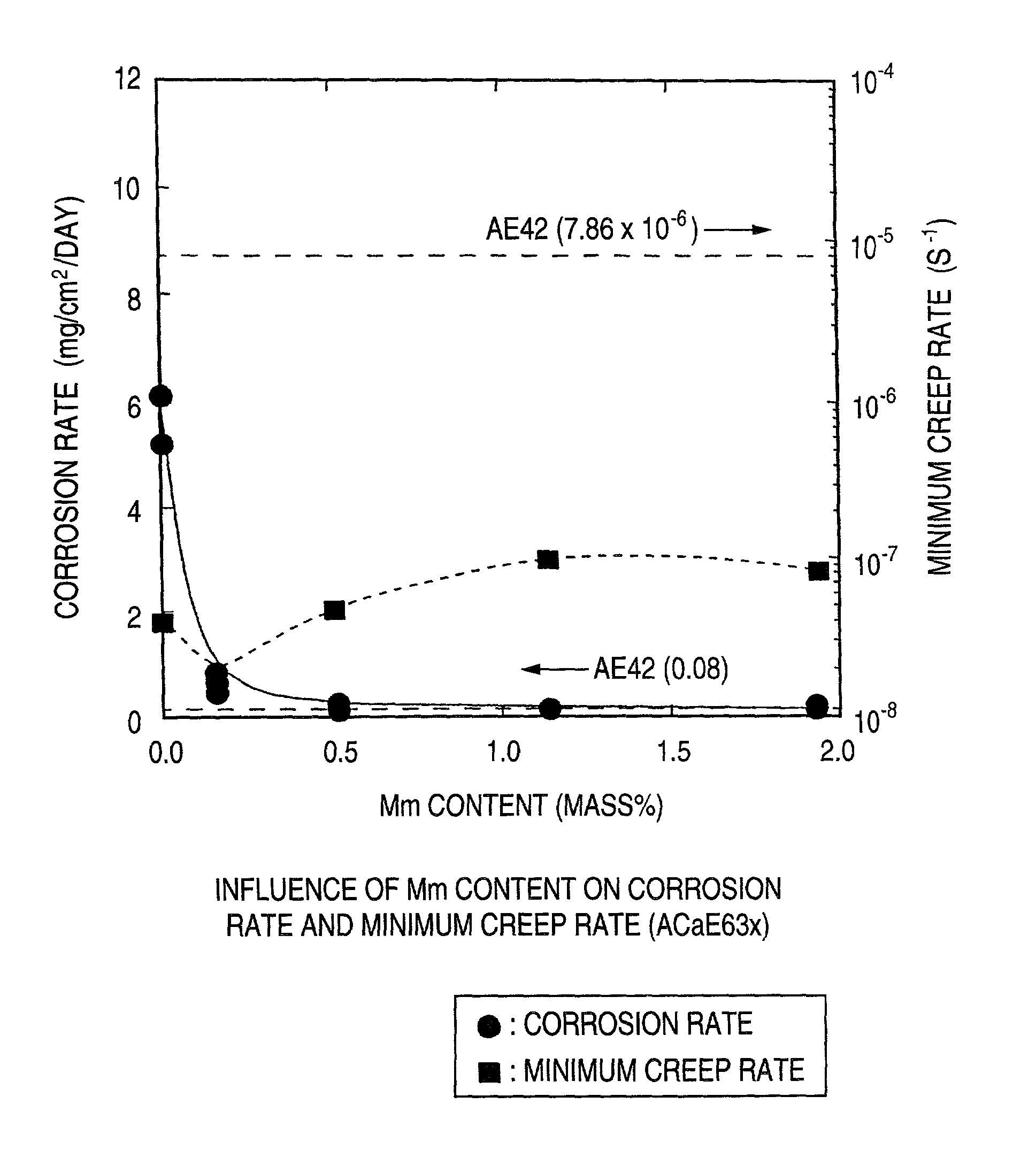

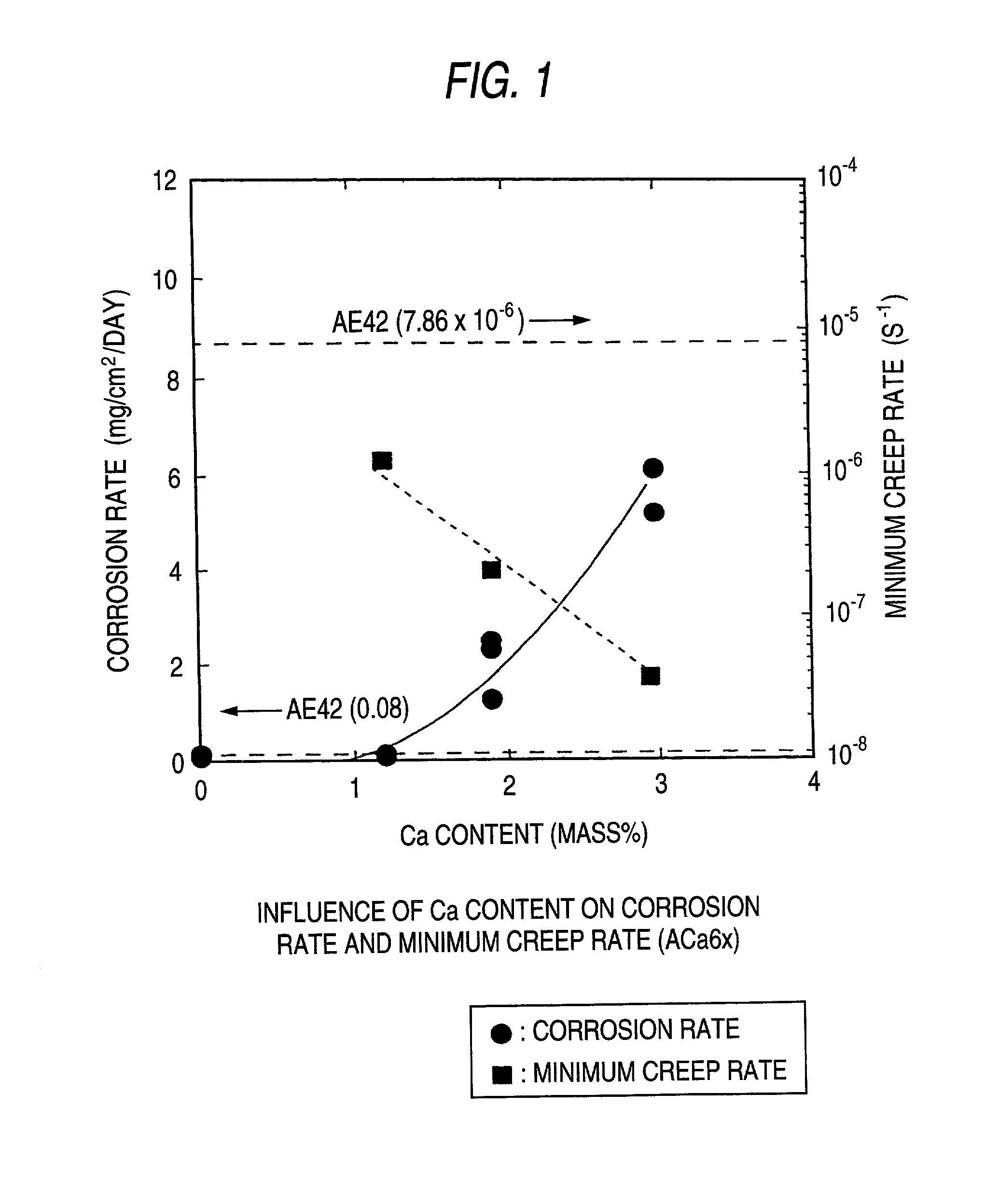

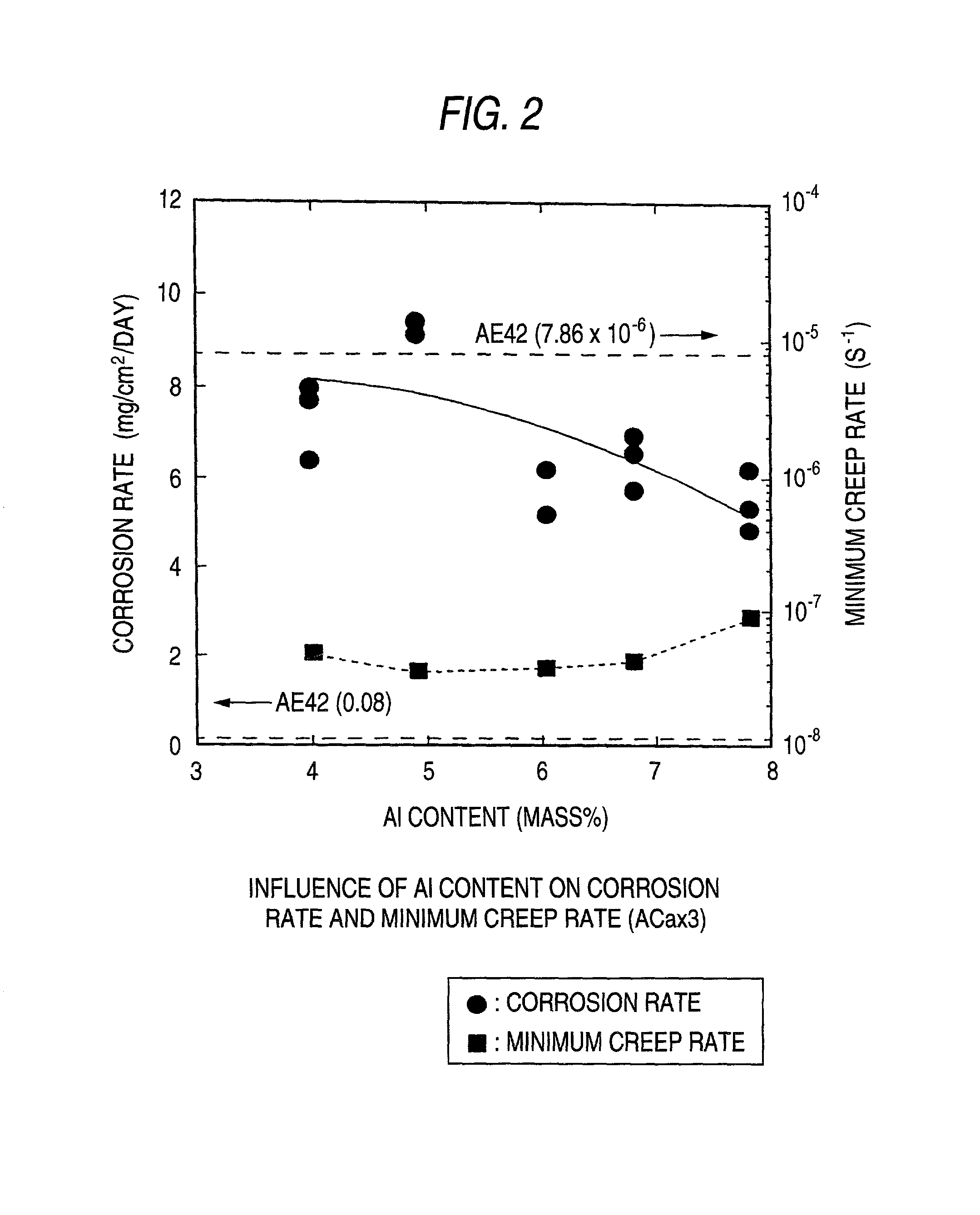

Magnesium alloy and magnesium alloy member superior in corrosion resistance

There is provided a magnesium alloy containing mass percent Al: 5% to 7%, Ca: 2% to 4%, Mn: 0.1% to 0.8%, Sr: 0.001% to 0.05% and rare earth elements: 0.1% to 0.6%. If necessary, an allowable content is set in each of Si, Zn, Cu, Ni, Fe and Cl of the unavoidable impurities, with Si not higher than mass percent 0.01%, Zn not higher than mass percent 0.01%, Cu not higher than mass percent 0.008%, Ni not higher than mass percent 0.001%, Fe not higher than mass percent 0.004%, and Cl not higher than mass percent 0.003%. There is also provided a magnesium alloy member injected in the die by using such an alloy.

Owner:JAPAN STEEL WORKS LTD

Tempered glass substrate and method of producing the same

ActiveUS20110318572A1High ion exchange capacityExcellent devitrification resistanceRecord information storageLight beam reproducingMetallurgyCompression stress

A tempered glass substrate of the present invention is a tempered glass substrate, which has a compression stress layer on a surface thereof, and has a glass composition comprising, in terms of mass %, 40 to 71% of SiO2, 3 to 21% of Al2O3, 0 to 3.5% of Li2O, 7 to 20% of Na2O, and 0 to 15% of K2O.

Owner:NIPPON ELECTRIC GLASS CO LTD

Tempered glass substrate and method of producing the same

ActiveUS20110318571A1High ion exchange capacityExcellent devitrification resistanceRecord information storageLight beam reproducingMetallurgyCompression stress

A tempered glass substrate of the present invention is a tempered glass substrate, which has a compression stress layer on a surface thereof, and has a glass composition comprising, in terms of mass %, 40 to 71% of SiO2, 3 to 21% of Al2O3, 0 to 3.5% of Li2O, 7 to 20% of Na2O, and 0 to 15% of K2O.

Owner:NIPPON ELECTRIC GLASS CO LTD

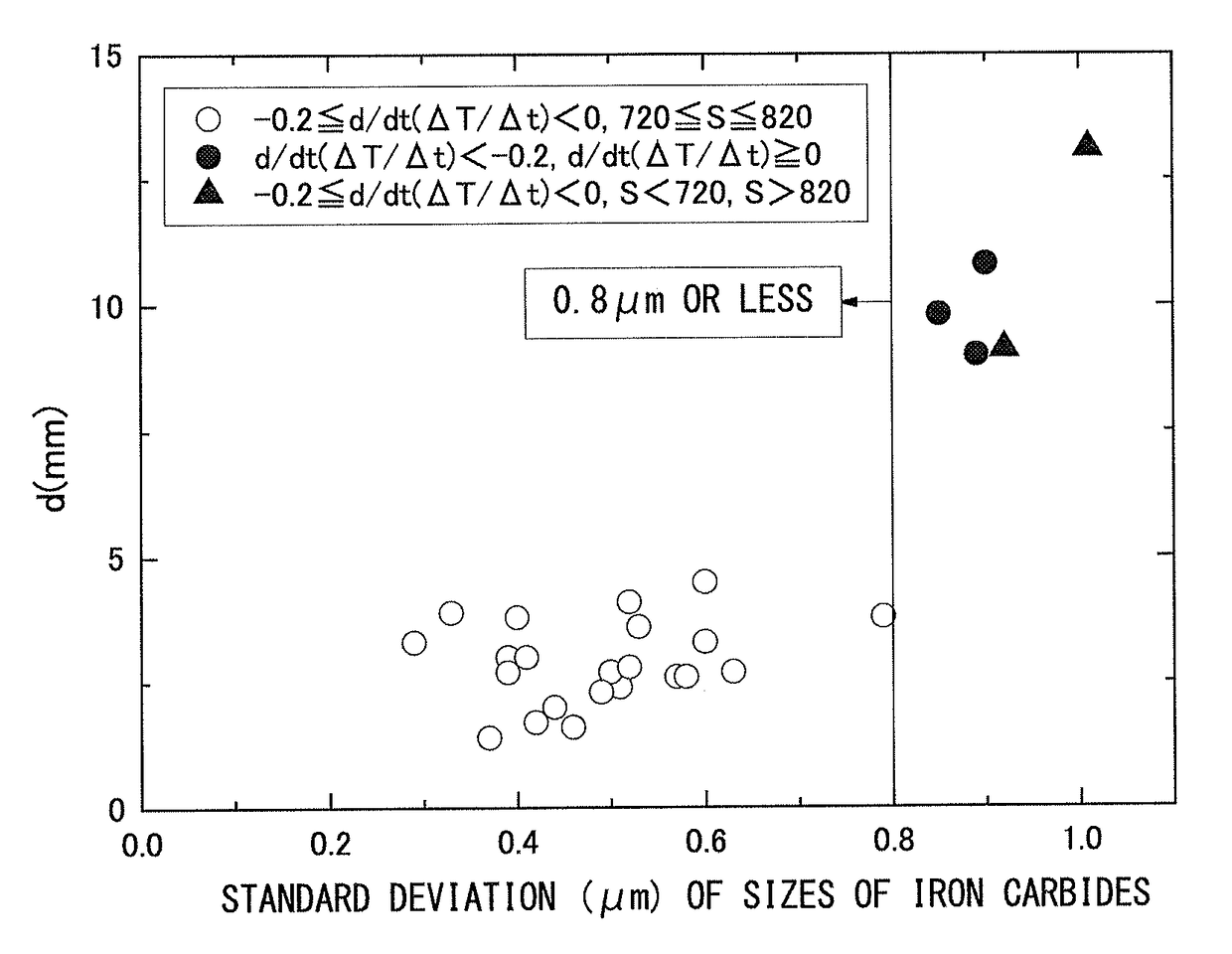

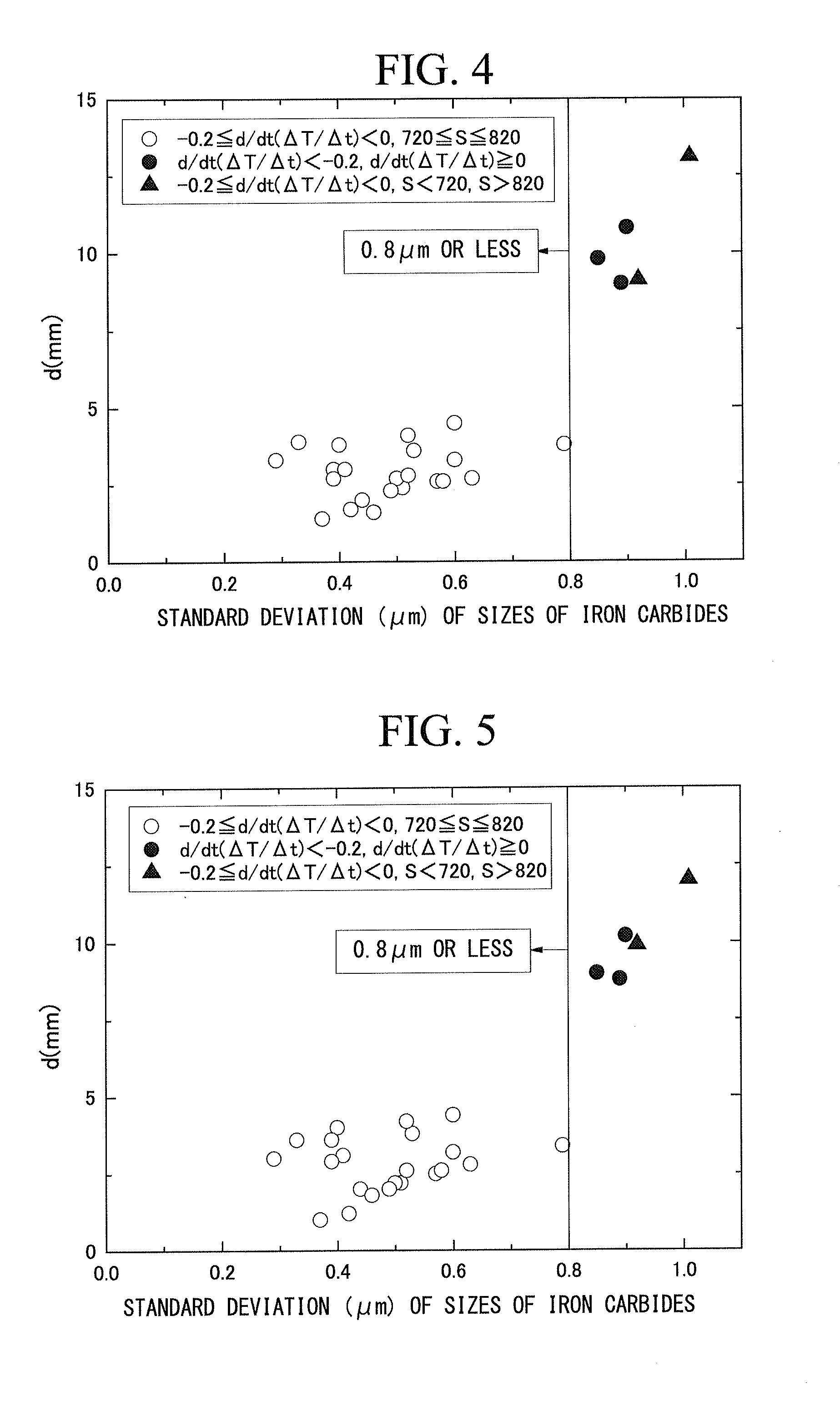

Steel sheet for hot stamping member and method of producing same

ActiveUS9617624B2Reduce the possibilitySmall defectShaping toolsHot-dipping/immersion processesHot stampingChemical composition

A steel sheet for a hot stamping member contains, as a chemical composition, 0.10 mass % to 0.35 mass % of C; 0.01 mass % to 1.0 mass % of Si; 0.3 mass % to 2.3 mass % of Mn; 0.01 mass % to 0.5 mass % of Al; limited to 0.03 mass % or less of P; limited to 0.02 mass % or less of S; limited to 0.1 mass % or less of N; and a balance consisting of Fe and unavoidable impurities, in which a standard deviation of diameters of iron carbides which are contained in a region from a surface to a ¼ thickness position of the steel sheet is less than or equal to 0.8 μm.

Owner:NIPPON STEEL CORP

Steel sheet for hot stamping member and method of producing same

ActiveUS20140044987A1Reduce the possibilitySmall defectHot-dipping/immersion processesShaping toolsHot stampingChemical composition

A steel sheet for a hot stamping member contains, as a chemical composition, 0.10 mass % to 0.35 mass % of C; 0.01 mass % to 1.0 mass % of Si; 0.3 mass % to 2.3 mass % of Mn; 0.01 mass % to 0.5 mass % of Al; limited to 0.03 mass % or less of P; limited to 0.02 mass % or less of S; limited to 0.1 mass % or less of N; and a balance consisting of Fe and unavoidable impurities, in which a standard deviation of diameters of iron carbides which are contained in a region from a surface to a ¼ thickness position of the steel sheet is less than or equal to 0.8 μm.

Owner:NIPPON STEEL CORP

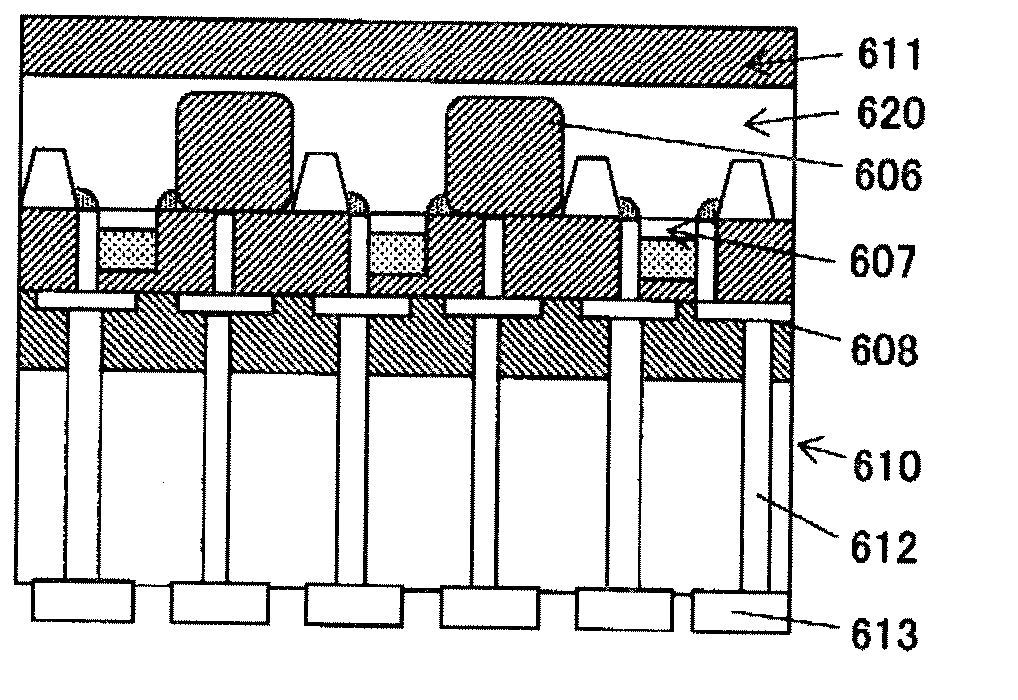

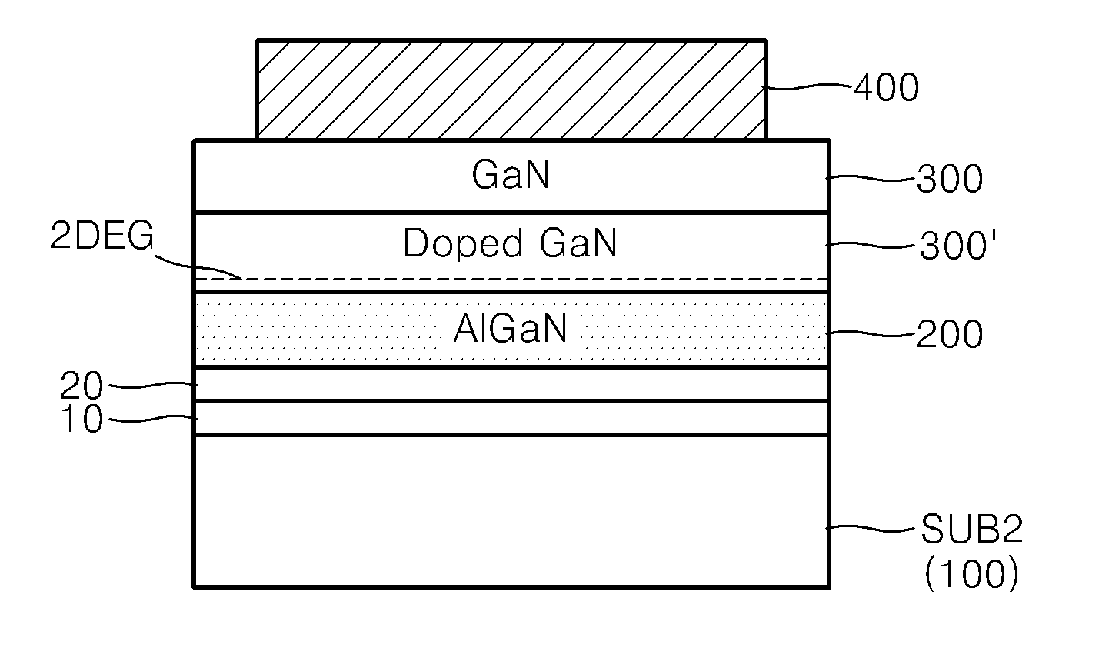

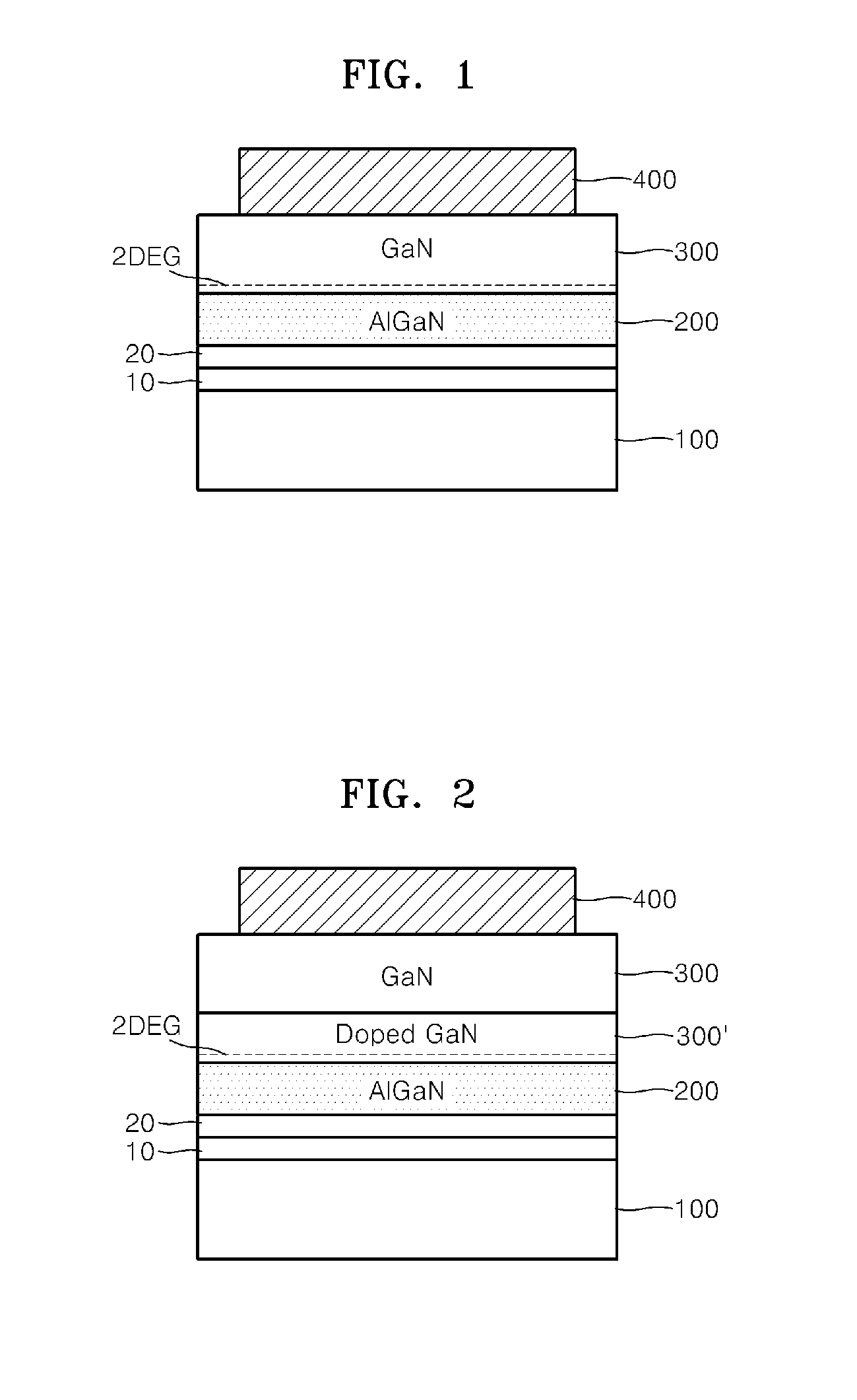

Gallium nitride based semiconductor devices and methods of manufacturing the same

InactiveUS20120074424A1Good heat dissipationSmall defectSemiconductor/solid-state device manufacturingDiodeDevice materialGallium nitride

Gallium nitride (GaN) based semiconductor devices and methods of manufacturing the same. The GaN-based semiconductor device may include a conductive heat dissipation substrate (that is, a thermal conductive substrate); an GaN-based multi-layer arranged on the heat dissipation substrate; and a Schottky electrode arranged on the GaN-based multi-layer. While such a GaN-based semiconductor device is being manufactured, a wafer bonding process and a laser lift-off process may be used.

Owner:SAMSUNG ELECTRONICS CO LTD

Ceramic kneaded clay and usage thereof

ActiveUS20090214819A1Maintain strengthPrevent and suppress environmental pollutionLayered productsCeramic shaping apparatusOxide ceramicMaterials science

An oxide-ceramic forming clay comprising an oxide-ceramic forming material, a layered double hydroxide, a pore-forming agent, and water, wherein the amount of the pore-forming agent is between 3 and 50 parts by mass by superaddition to 100 parts by mass of a sum of the oxide-ceramic forming material and the layered double hydroxide and a sum of the pore-forming agent and an organic binder is between 5 and 55 parts by mass also by superaddition which has environment-friendly characteristics in a forming firing step, and usage thereof.

Owner:NGK INSULATORS LTD

SOI wafer, method for producing same, and method for manufacturing semiconductor device

ActiveUS8531000B2Promote precipitationImprove inhalation capacitySolid-state devicesSemiconductor/solid-state device manufacturingNitrogenOxygen

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

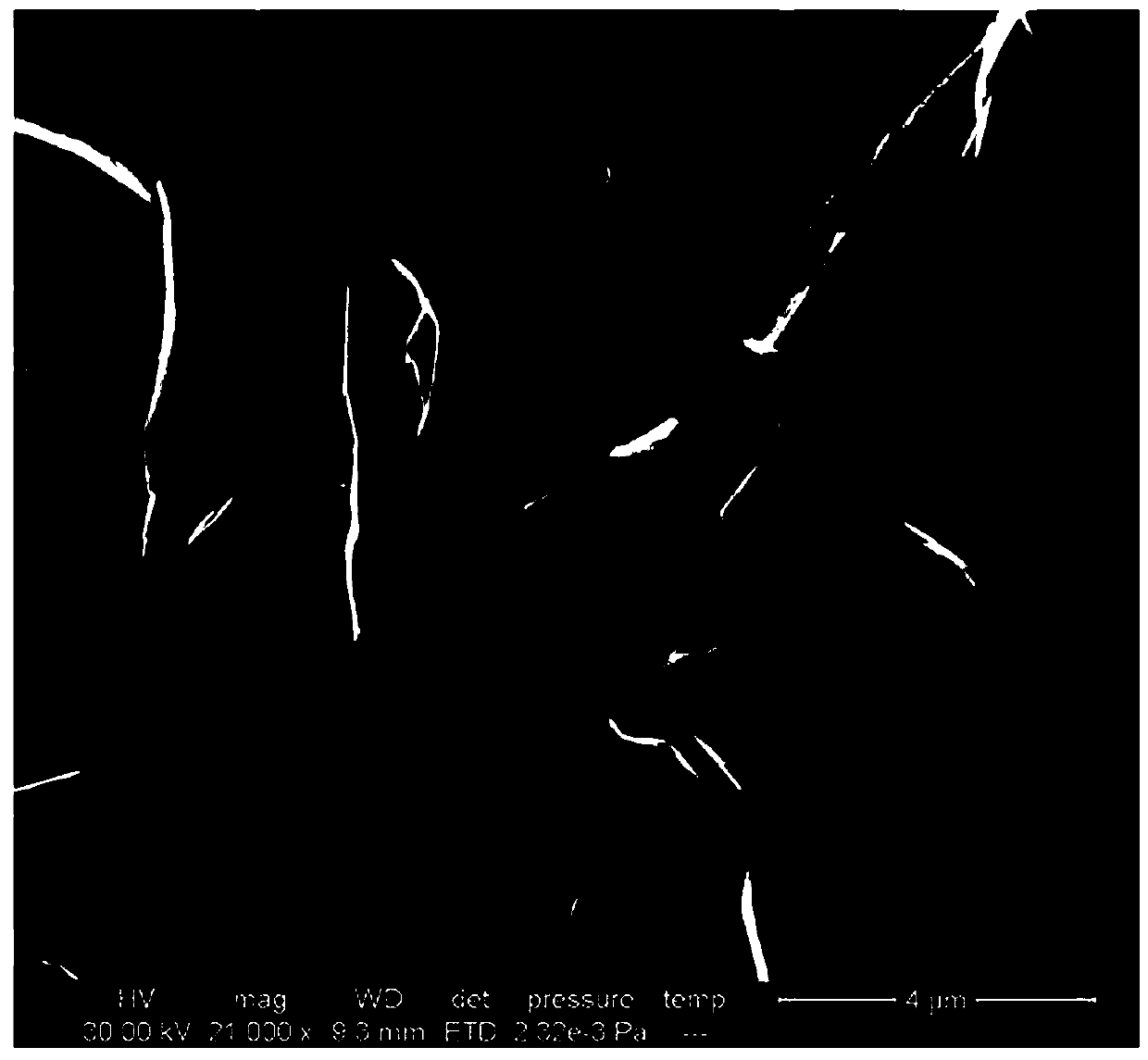

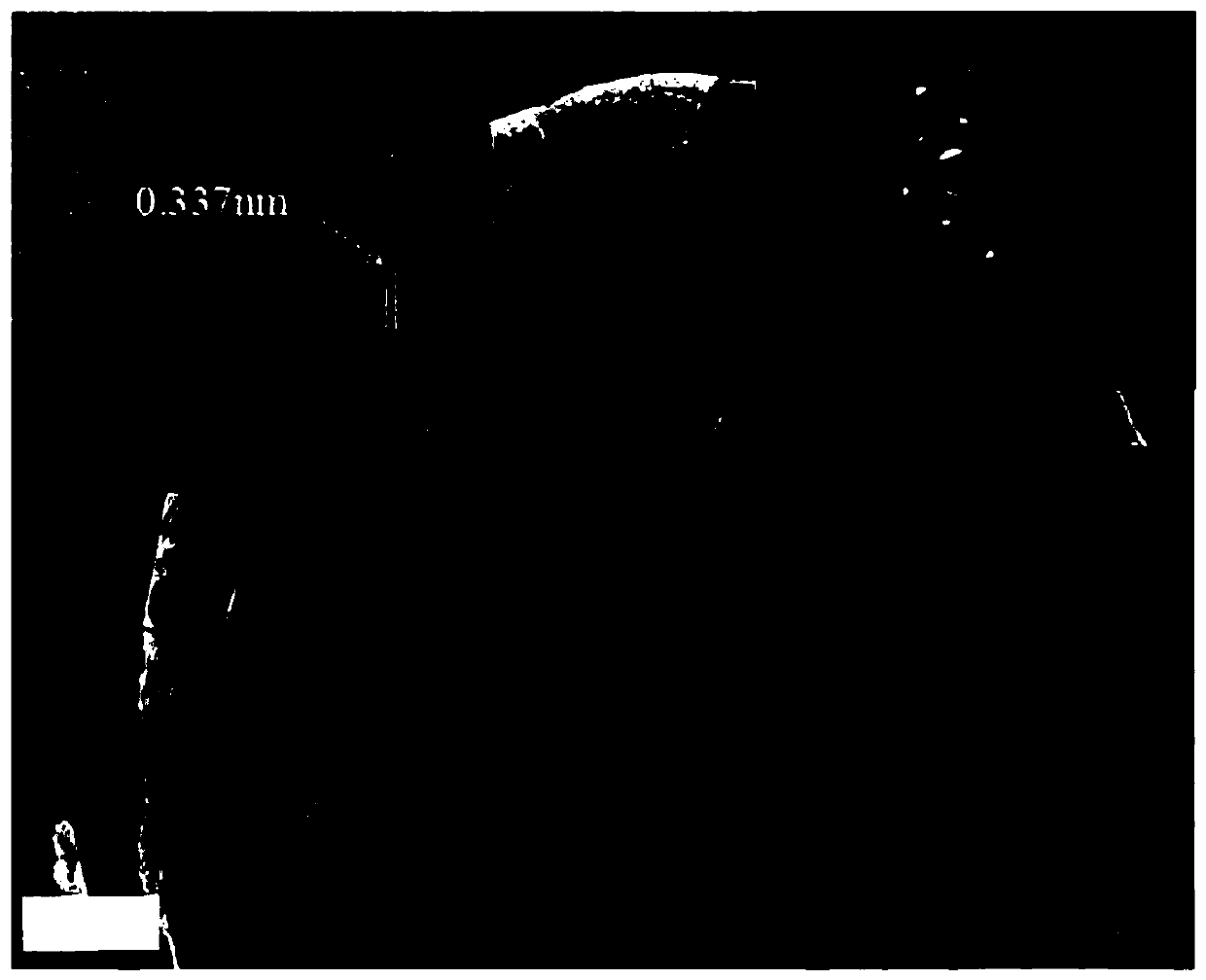

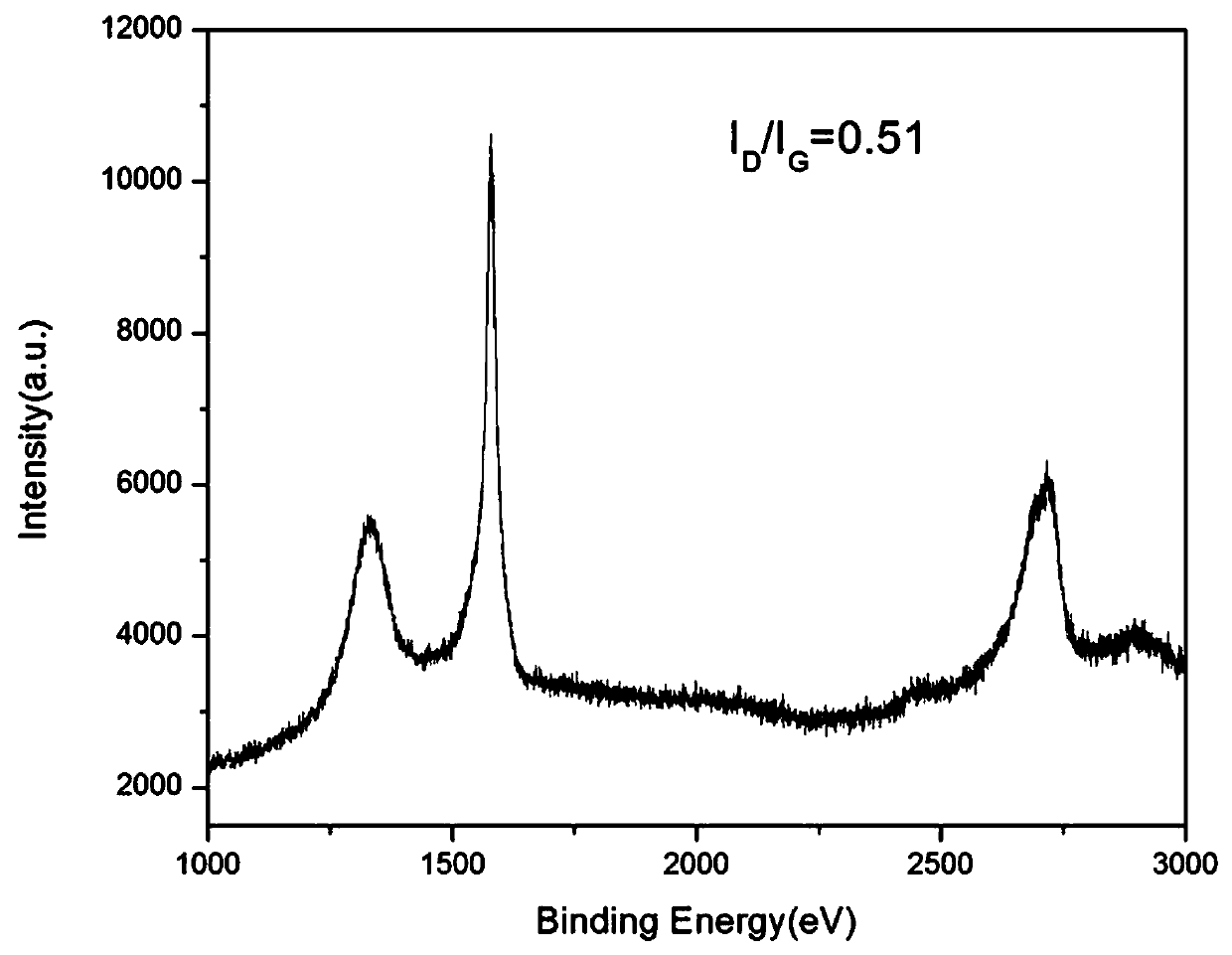

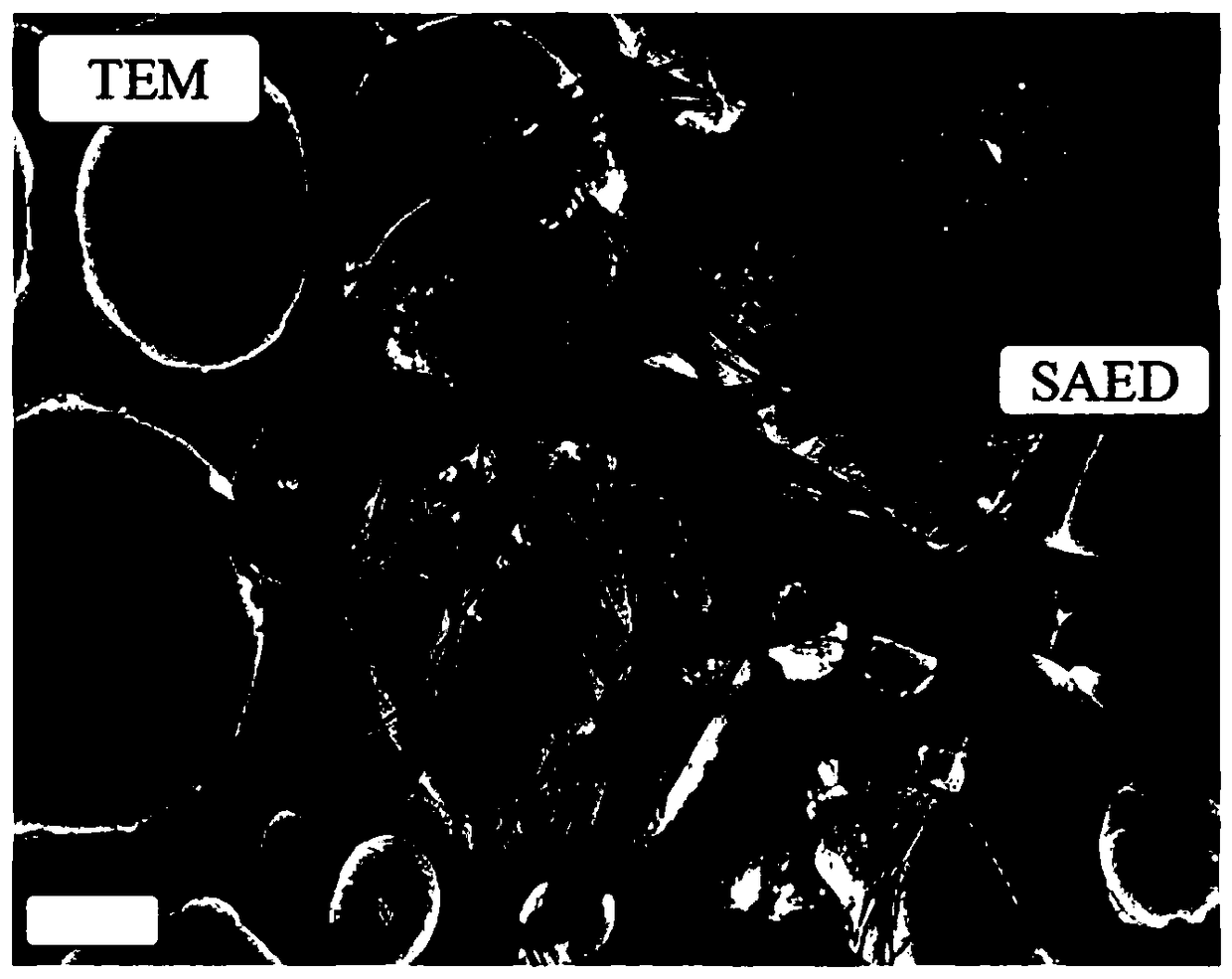

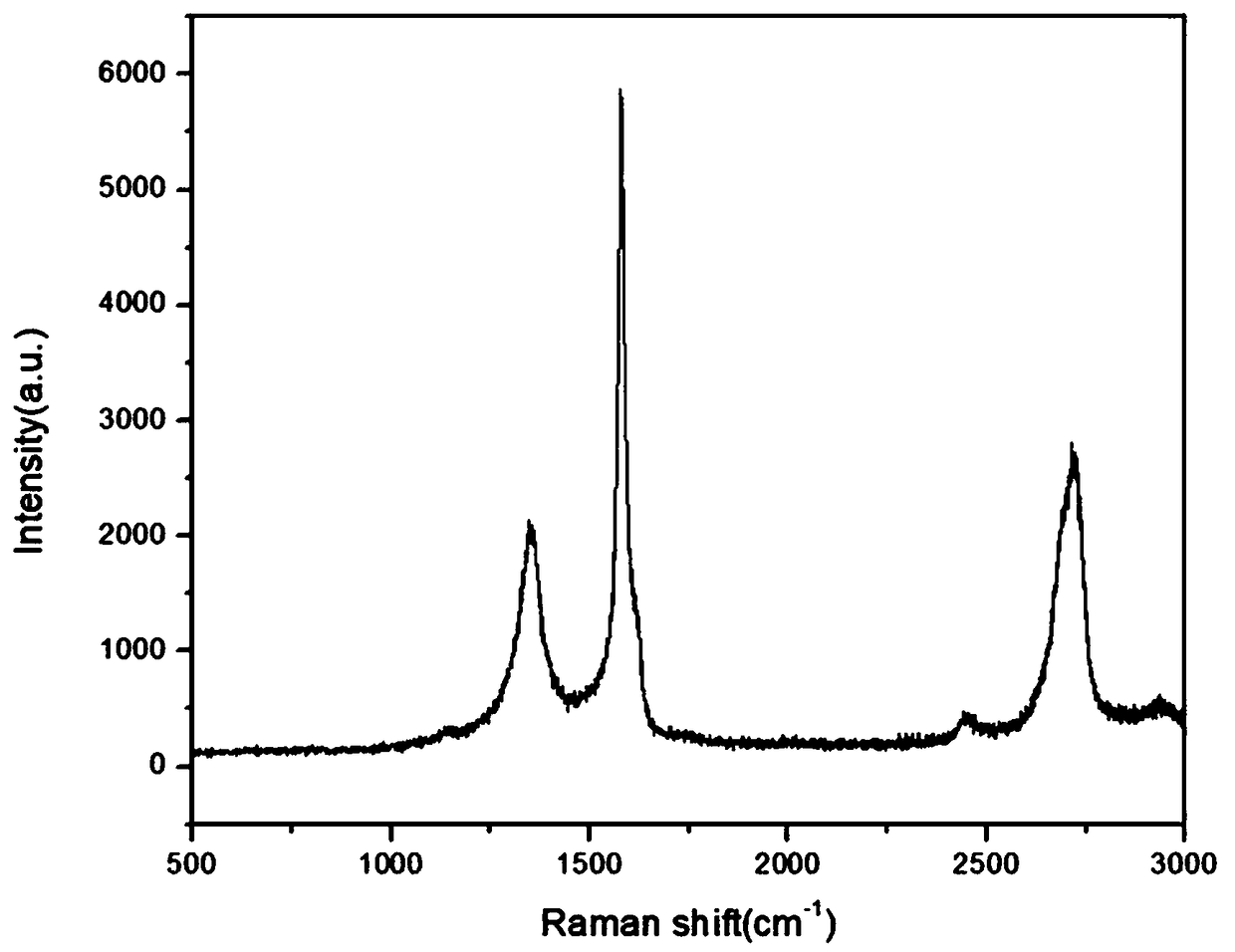

Method for preparing graphene from electrochemical cathode striped graphite foil with TTAB (Tetradecyl Trimethyl Ammonium Bromide) as electrolyte

InactiveCN107902647AEasy to operateRaw materials are easy to obtainGrapheneDefective grapheneFreeze-drying

The invention discloses a method for preparing graphene from electrochemical cathode striped graphite foil with TTAB (Tetradecyl Trimethyl Ammonium Bromide) as electrolyte. The method is characterizedby comprising the following steps: 1) preparing materials; 2) preparing an electric striping solution; 3) assembling an electric stripping device; 4) performing electric stripping; 5) performing filtration and washing; 6) performing ultrasonic dispersion; and 7) performing freeze drying on the obtained graphene solution, thereby obtaining graphene powder. The method has the advantages of being simple and easy in preparation raw material obtaining, easy in operation, low in cost, simple in process, simple in step and short in production period, and the prepared graphene is low in defect degree, small in layer number and very applicable to industrial production.

Owner:GUANGXI NORMAL UNIV

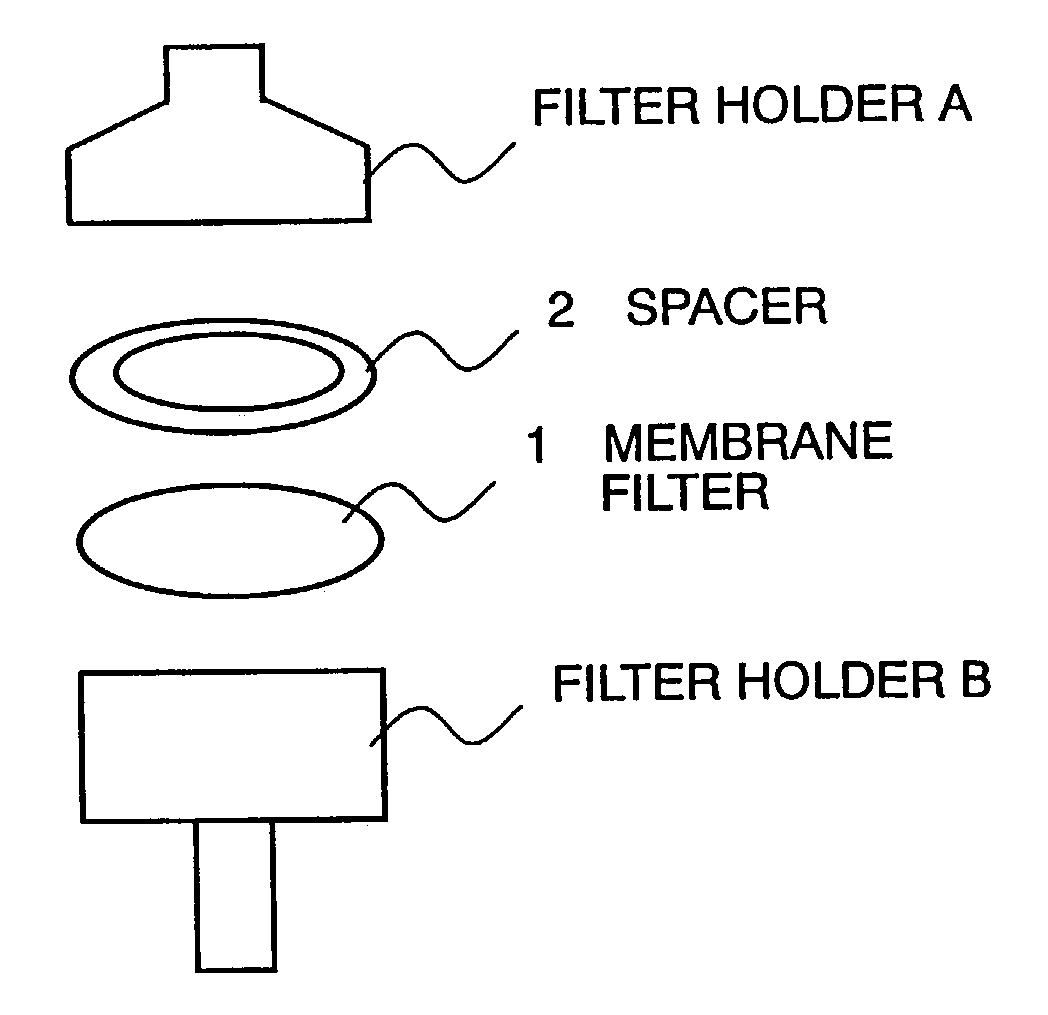

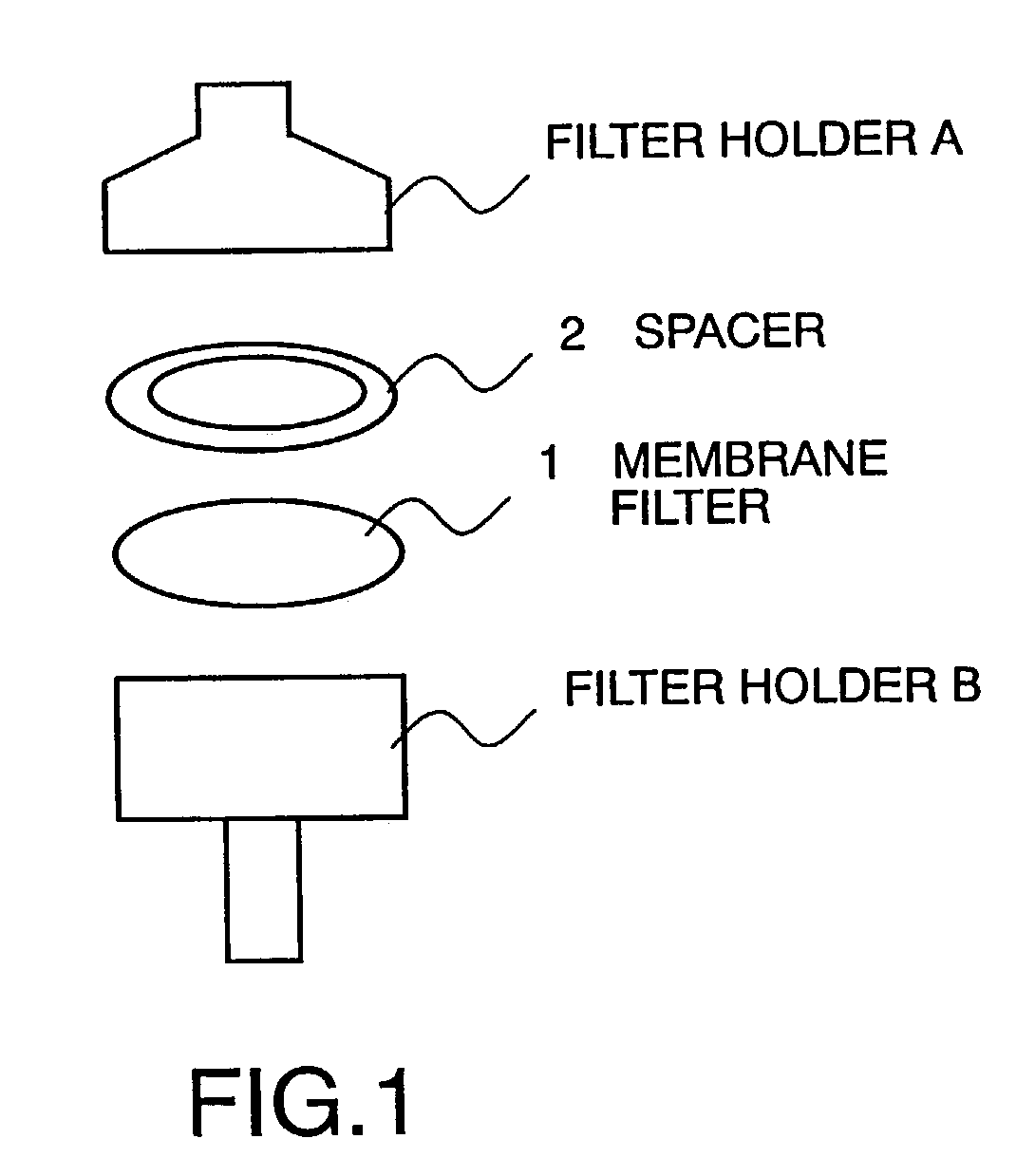

Method of manufacturing glass substrate and method of manufacturing information recording medium

InactiveUS7281394B2Suppressing attachmentInhibition formationDispersed particle filtrationRecord information storageX ray spectraInductively coupled plasma

In a method of manufacturing a glass substrate for an information recording medium including a step for chemically strengthening the glass substrate by contacting the glass substrate with chemical strengthening processing liquid containing chemical strengthening salt, concentration of Fe and Cr is 500 ppb or less in said chemical strengthening salt, respectively. The concentration may be detected by the use of an ICP (Inductively Coupled Plasma) emission spectrometry analyzing method or a fluorescent X-ray spectroscopy analyzing method.

Owner:HOYA CORP

Silicon single crystal pulling method

ActiveUS8187378B2Small defectPolycrystalline material growthSemiconductor/solid-state device manufacturingScan lineSingle crystal

An object of the present invention is to provide a silicon single crystal pulling method of accurately controlling the diameter of a silicon single crystal, thereby obtaining a high-quality silicon single crystal with little crystal defect.According to an aspect of the present invention, the pulling step includes: capturing an image of the silicon single crystal using an imaging device; measuring the brightness distribution of a fusing ring generated in the vicinity of a solid-liquid interface between the silicon melt and the silicon single crystal for each image scan line in the image captured by the imaging device; detecting the liquid level of the silicon melt and the position of the solid-liquid interface; and controlling the diameter of the silicon single crystal on the basis of a meniscus height, which is a difference between the liquid level and the position of the solid-liquid interface.

Owner:SUMCO CORP

Photochromic films and method for manufacturing the same

ActiveUS7961372B2High transparencyIncreased durabilityGlass/slag layered productsNon-linear opticsPhotochromismAcrylate

Owner:LG CHEM LTD

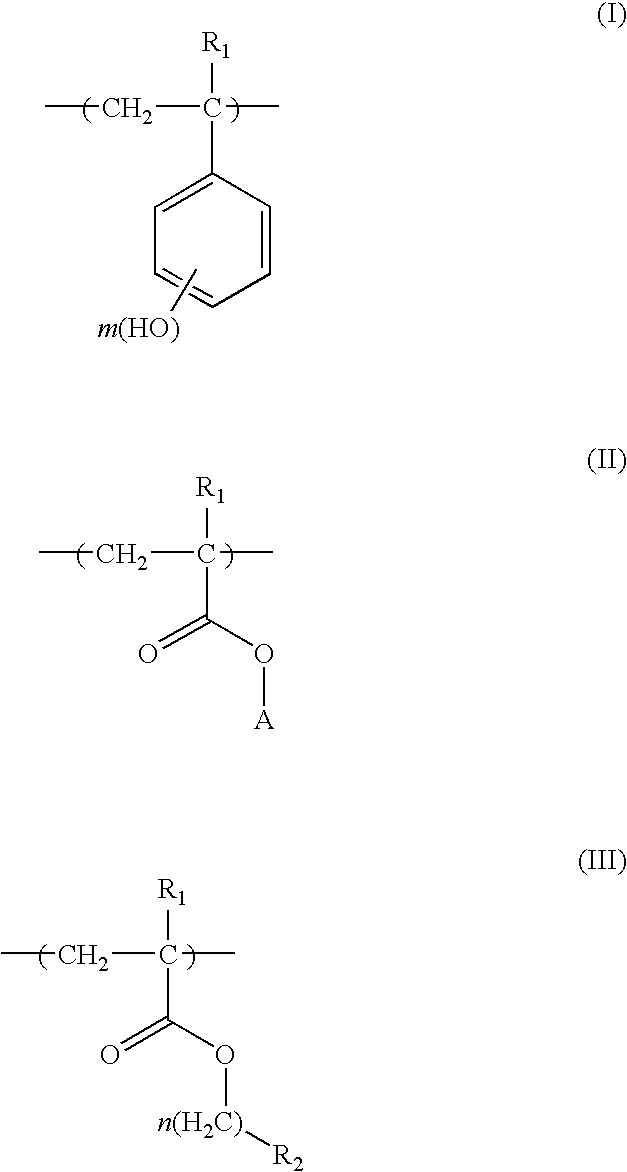

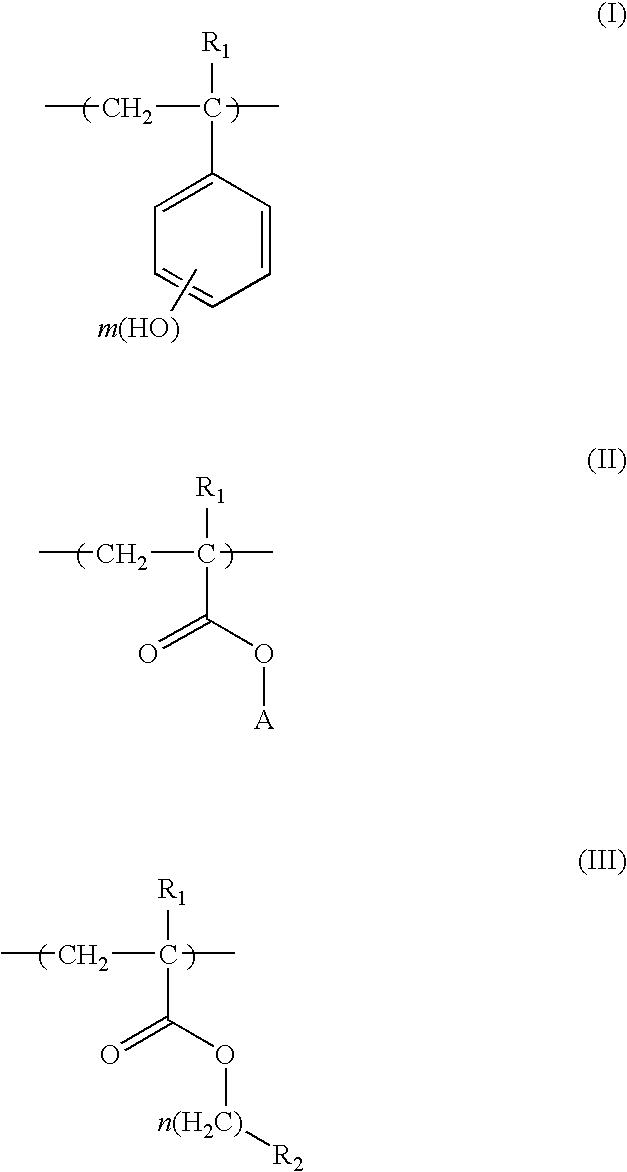

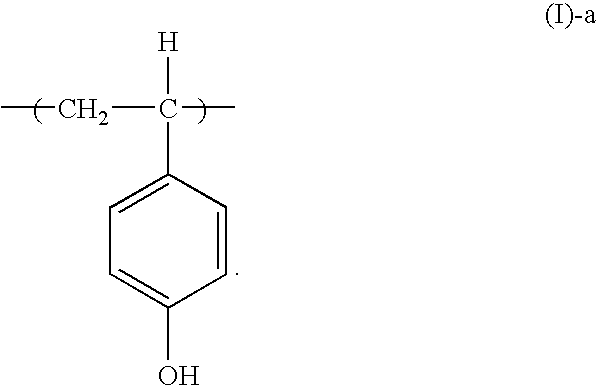

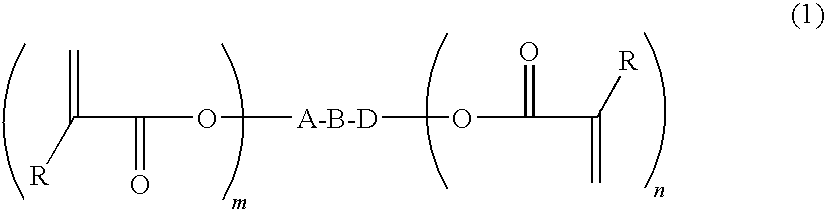

Positive resist composition and pattern forming method using the same

ActiveUS7923196B2High resolutionImproved profilePhotosensitive materialsRadiation applicationsActinic RaysHydrogen

A positive resist composition comprising (A) a resin which contains all of the repeating units represented by formulae (I) to (III), and becomes soluble in an alkali developer by the action of an acid, and (B) a compound capable of generating an acid upon irradiation with an actinic ray or radiation; and a pattern forming method using the composition. A represents a group capable of decomposing and leaving by the action of an acid, each R1 independently represents hydrogen or a methyl group, R2 represents a phenyl group or a cyclohexyl group, m represents 1 or 2, and n represents an integer of 0 to 2. By virtue of this construction, a resist composition ensuring high resolution, good pattern profile, sufficient depth of focus, little defects after development, and sufficiently high plasma etching resistance is provided.

Owner:FUJIFILM CORP

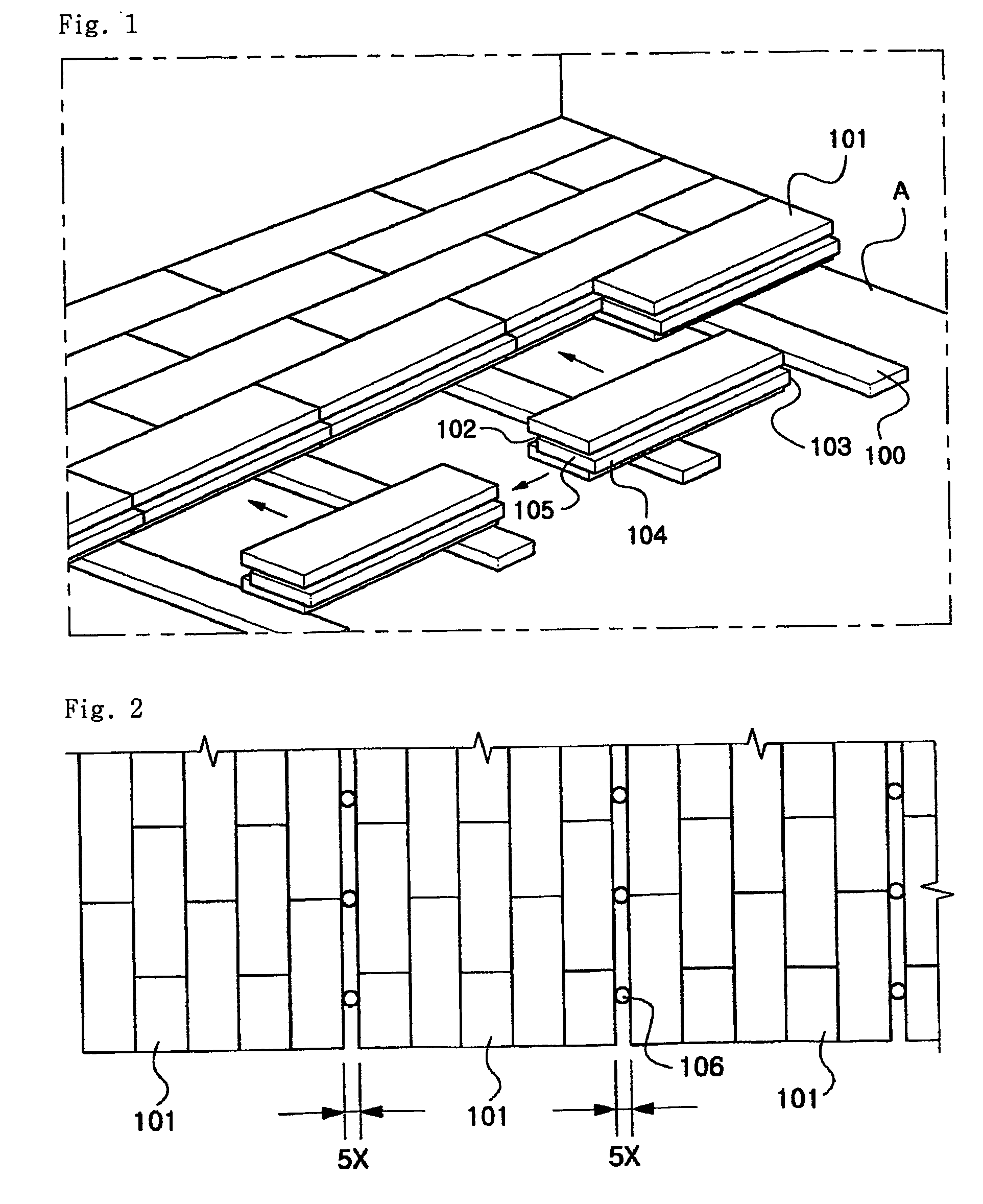

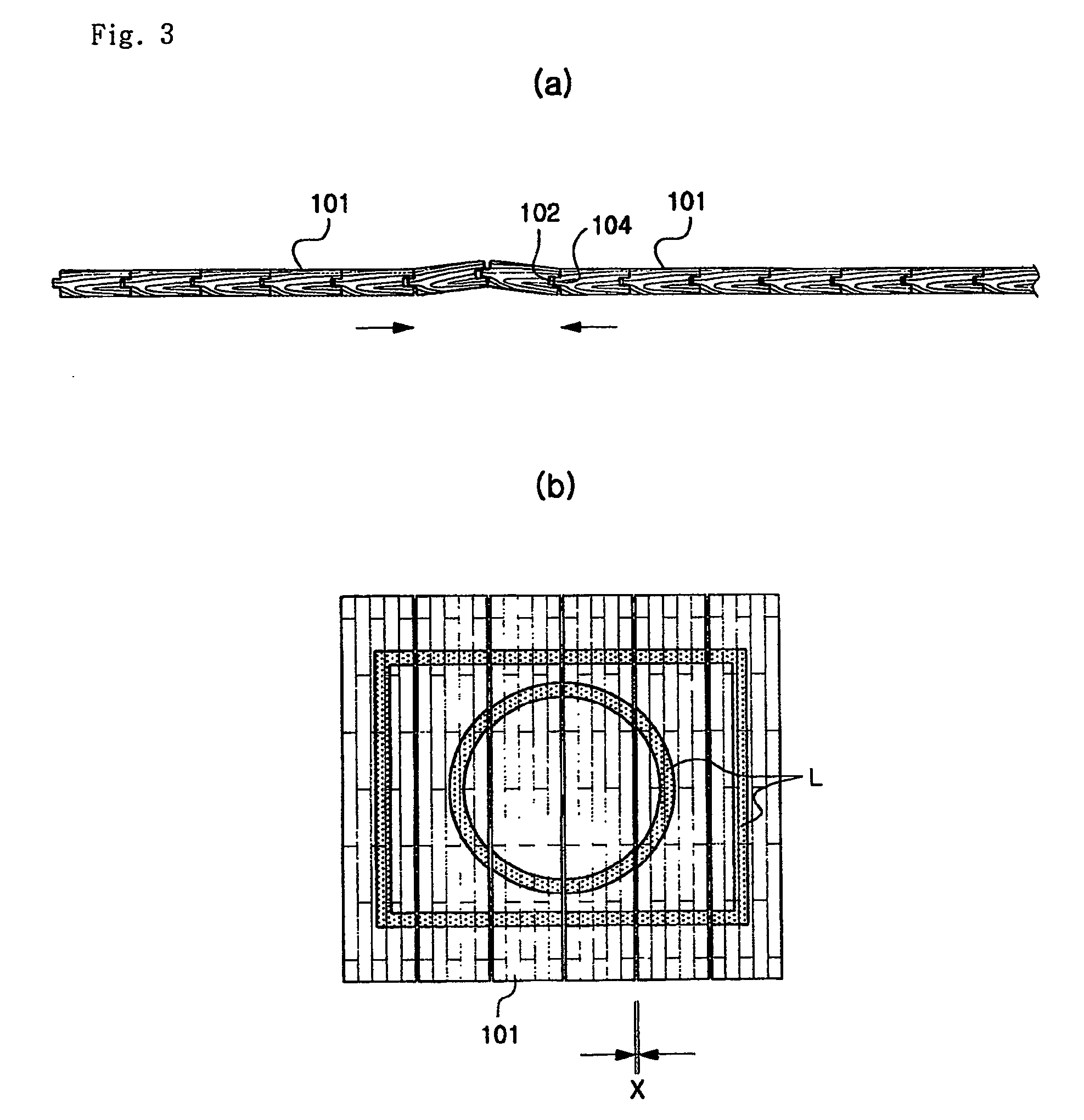

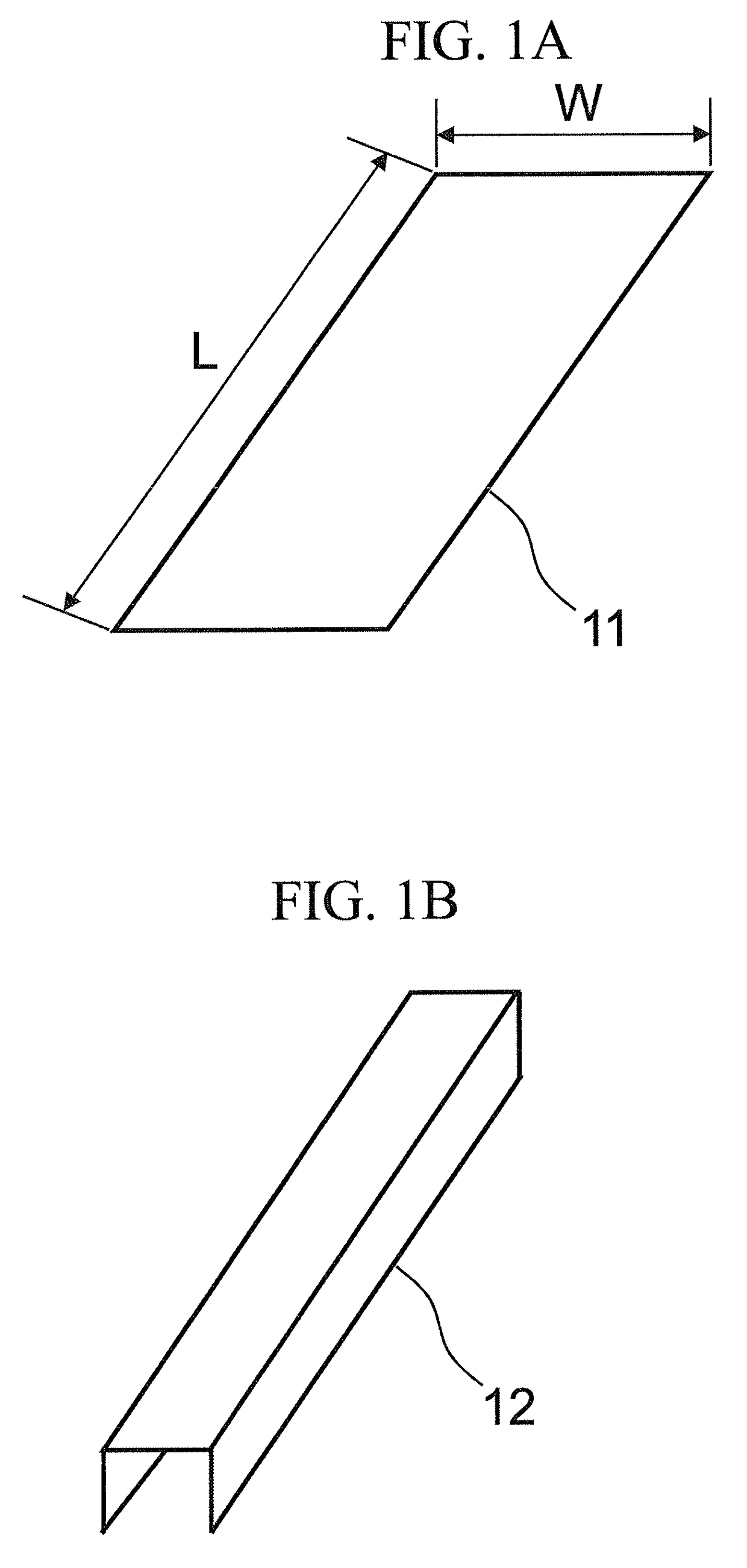

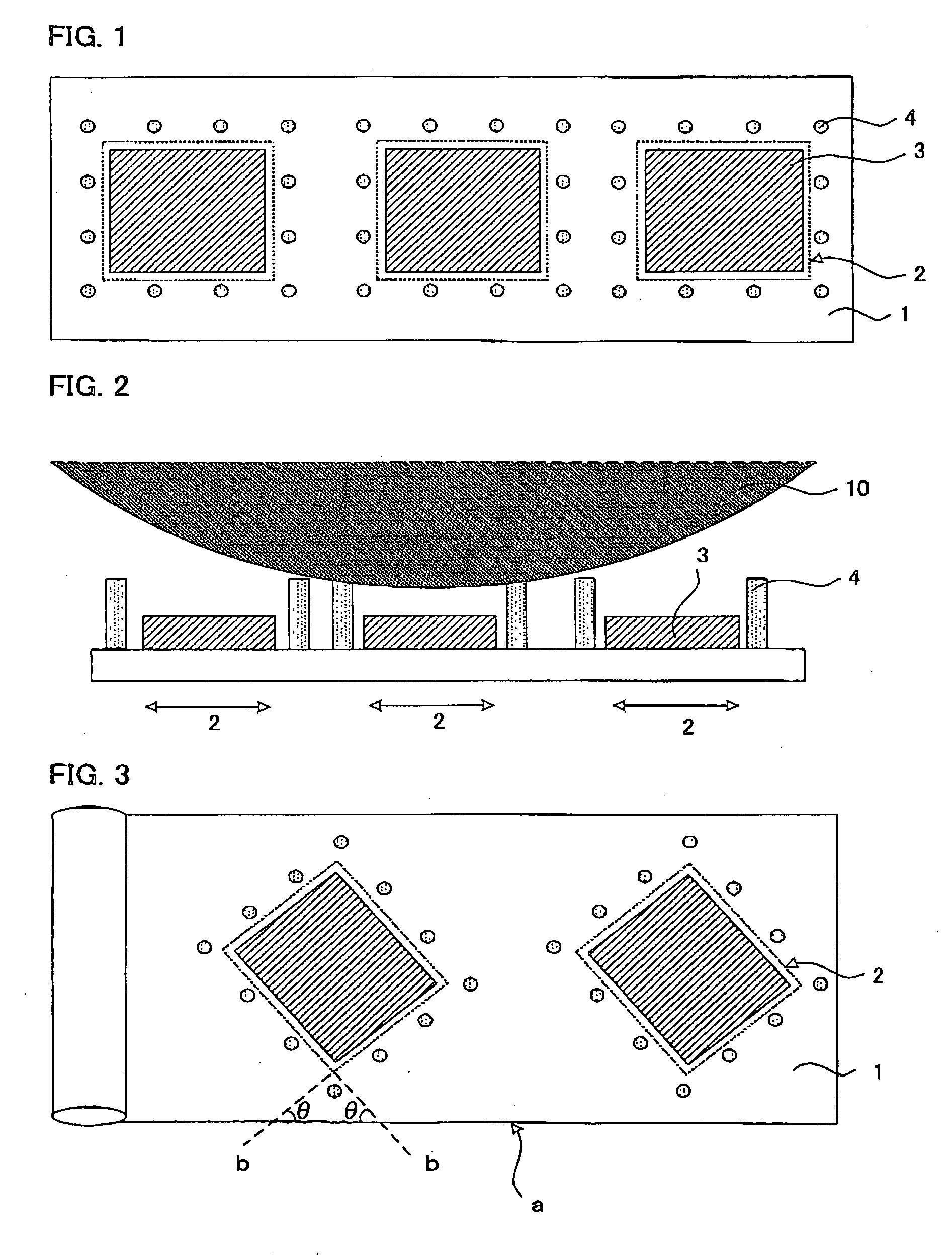

Multi-face substrate for color filter and method for producing the same

InactiveUS20060147682A1Quality improvementSmall defectDecorative surface effectsDuplicating/marking methodsManufactured apparatusEngineering

The main object of the present invention is to provide a high quality multi-face substrate for a color filter without causing defects by contact between members or with a manufacturing apparatus during production, and the method of producing the same. To realize the object, the invention provides a multi-face substrate for a color filter comprising a base material, a colored layer formed on each of a plurality of pixel regions of the base material and a column portion formed in a region outside of each of the pixel regions of the base material.

Owner:DAI NIPPON PRINTING CO LTD

Method for preparing graphene through electrochemical cathodic disbonding graphene sheets by taking DTAB as electrolyte

InactiveCN108101033AEasy to operateRaw materials are easy to obtainGrapheneDefective grapheneElectrochemistry

The invention discloses a method for preparing graphene through electrochemical cathodic disbonding graphene sheets by taking DTAB as electrolyte. The method is characterized by comprising the following steps: firstly, preparing materials; secondly, preparing electrical disbonding liquor; thirdly, assembling an electrical disbonding device; fourthly, performing electrical disbonding; fifthly, filtering and washing; sixthly, performing ultrasonic dispersion; seventhly, performing freeze drying, so as to obtain an aqueous solution of graphene, and performing freeze drying, so as to obtain graphene powder. The method has the advantages that raw materials for preparation are simple and easy to obtain, the method is easy to operation, the cost is low, the technical process is simple, steps areless, the production cycle is short, the defect level of the formed graphene is low, the number of layers is small, and the graphene is very suitable for industrial production.

Owner:GUANGXI NORMAL UNIV

Resin composition for micropattern formation and method of micropattern formation

InactiveUS20100009292A1Low costPromote pattern shrink ratePhotosensitive materialsPhotomechanical exposure apparatusResistAlcohol

A resin composition which can increase the pattern shrink rate while maintaining the advantages of capability of effectually and precisely micronizing the resist pattern gaps irrespective of the surface conditions of the substrate and forming resist patterns exceeding the wavelength limit economically at low cost in a good condition having only small defects, and a method of efficiently forming a micropattern using the resin composition are disclosed. The resin composition for forming a micropattern includes a hydroxyl group-containing resin, a crosslinking component, and an alcohol solvent which contains an alcohol and not more than 10 mass % of water relative to the total solvent. The crosslinking component includes a compound having two or more acryloyloxy groups in the molecule.

Owner:JSR CORPORATIOON

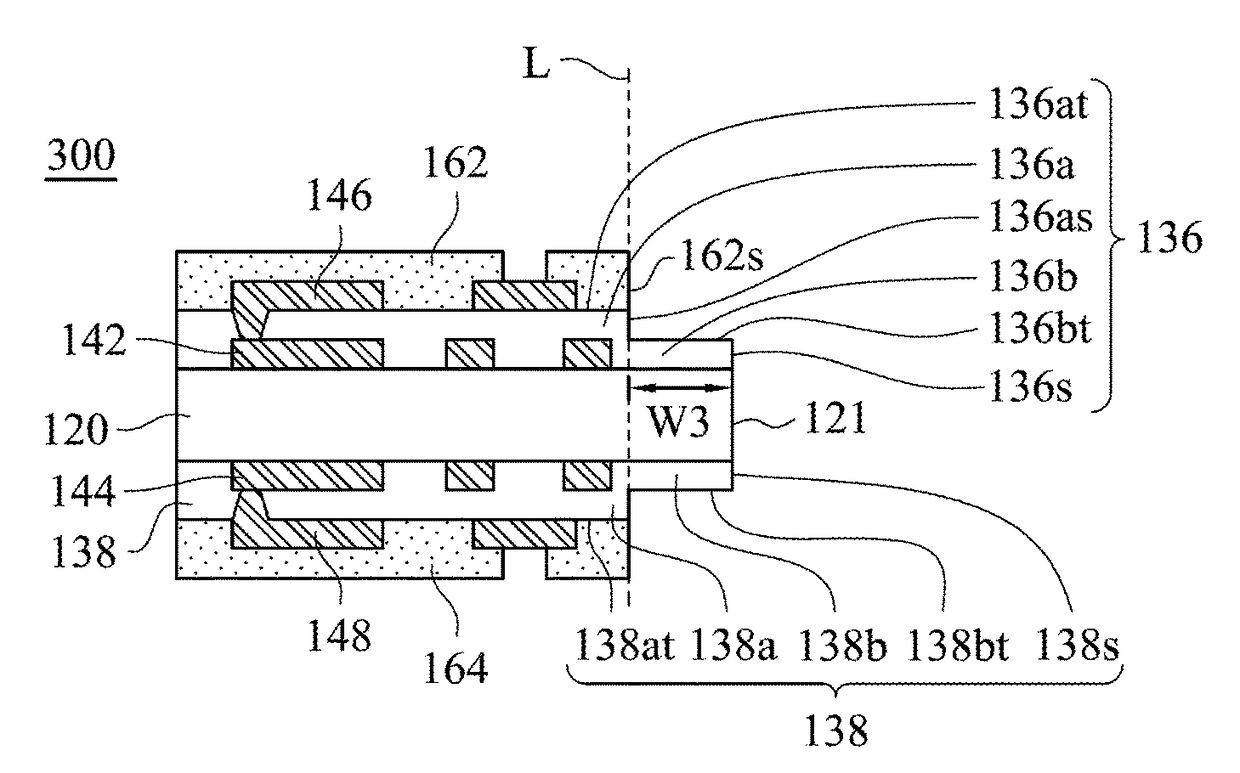

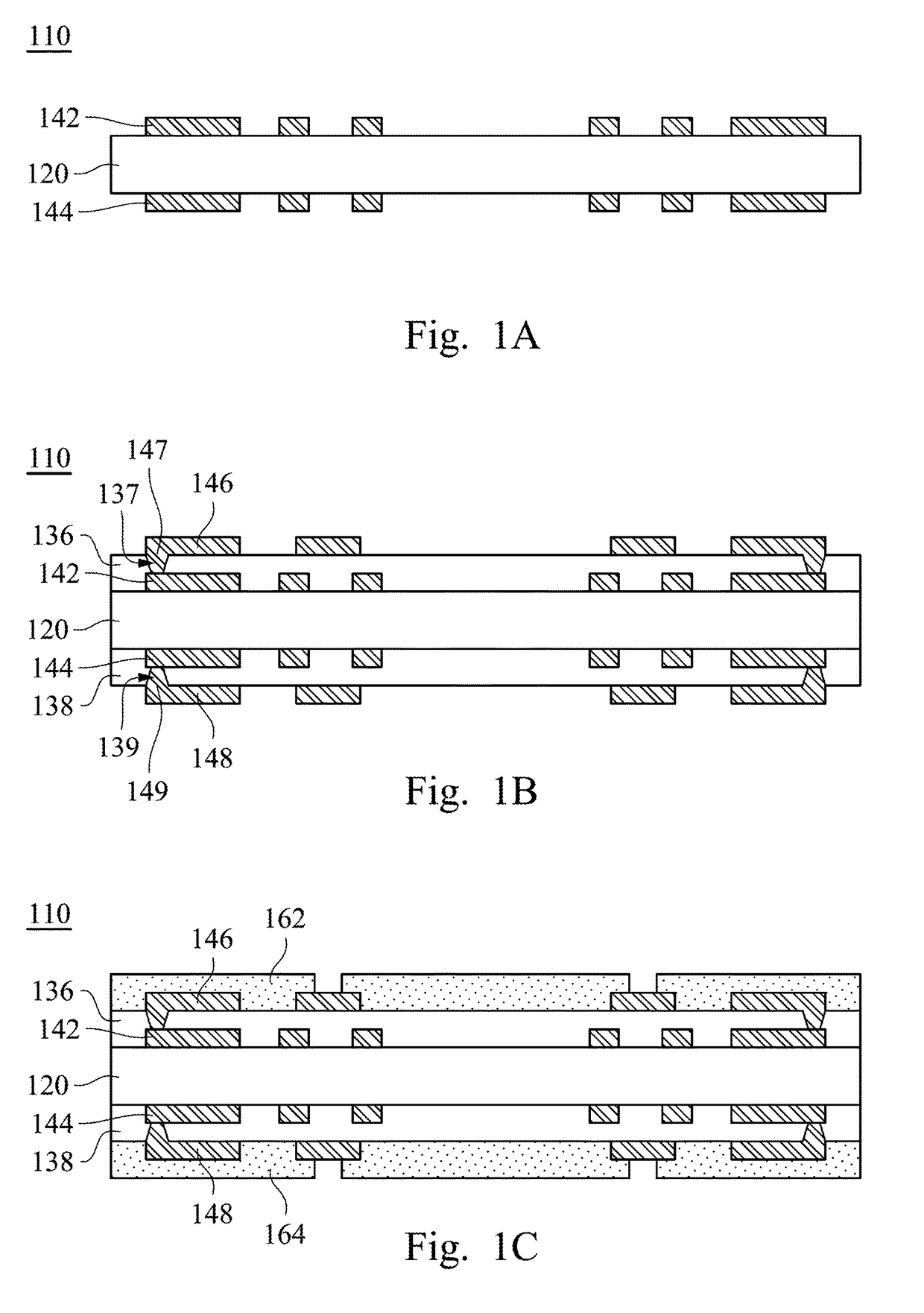

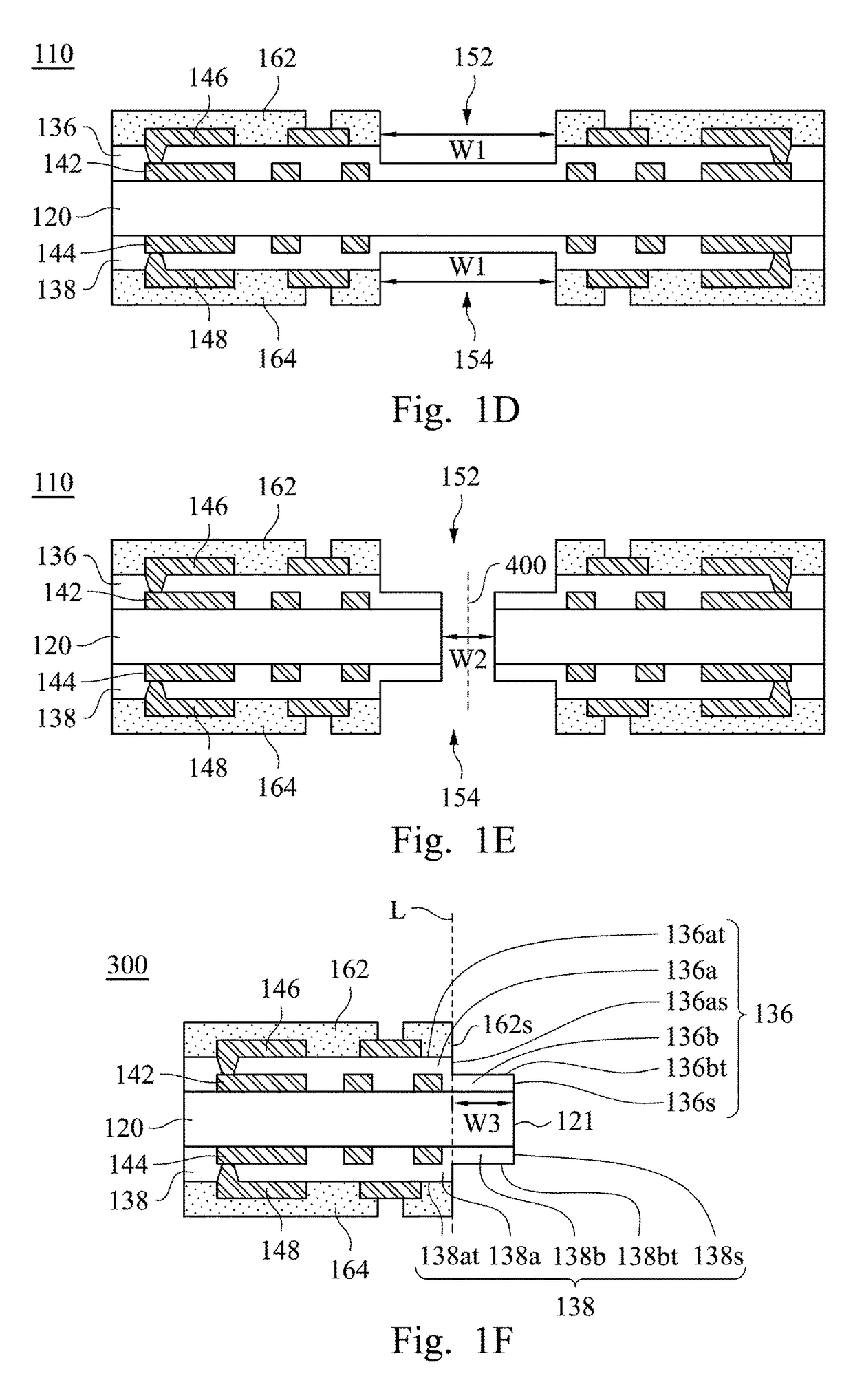

Circuit board element

ActiveUS9860980B1Enhance structure stability and wiring densityLow costPrinted circuit aspectsPrinted circuits stress/warp reductionOptoelectronicsDielectric layer

A circuit board element includes a glass substrate, a first dielectric layer, and a first patterned metal layer. The glass substrate has an edge. The first dielectric layer is disposed on the glass substrate and has a central region and an edge region. The edge region is in contact with the edge of the glass substrate, and the thickness of the central region is greater than the thickness of the edge region. The first patterned metal layer is disposed on the glass substrate and in the central region of the first dielectric layer.

Owner:UNIMICRON TECH CORP

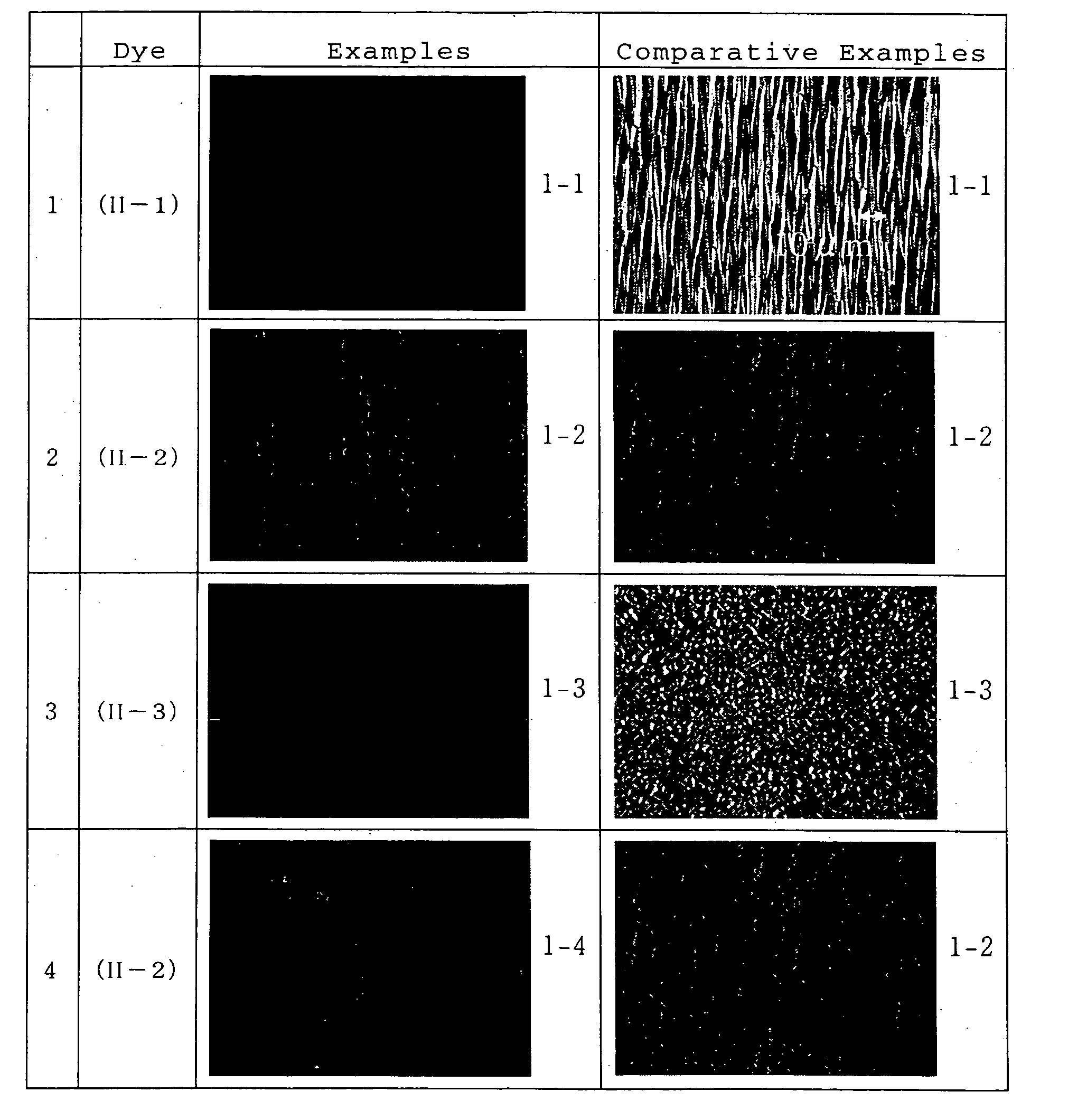

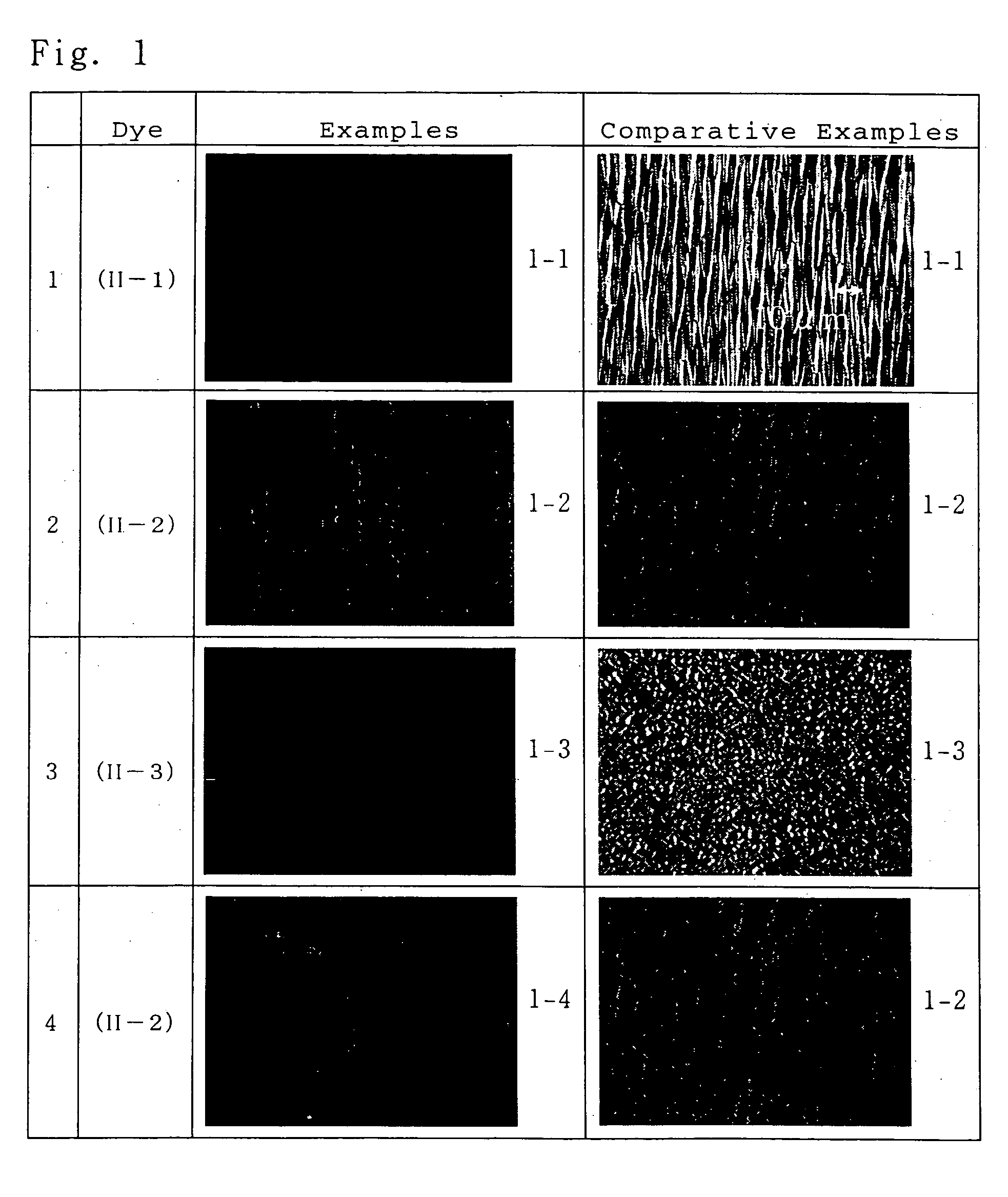

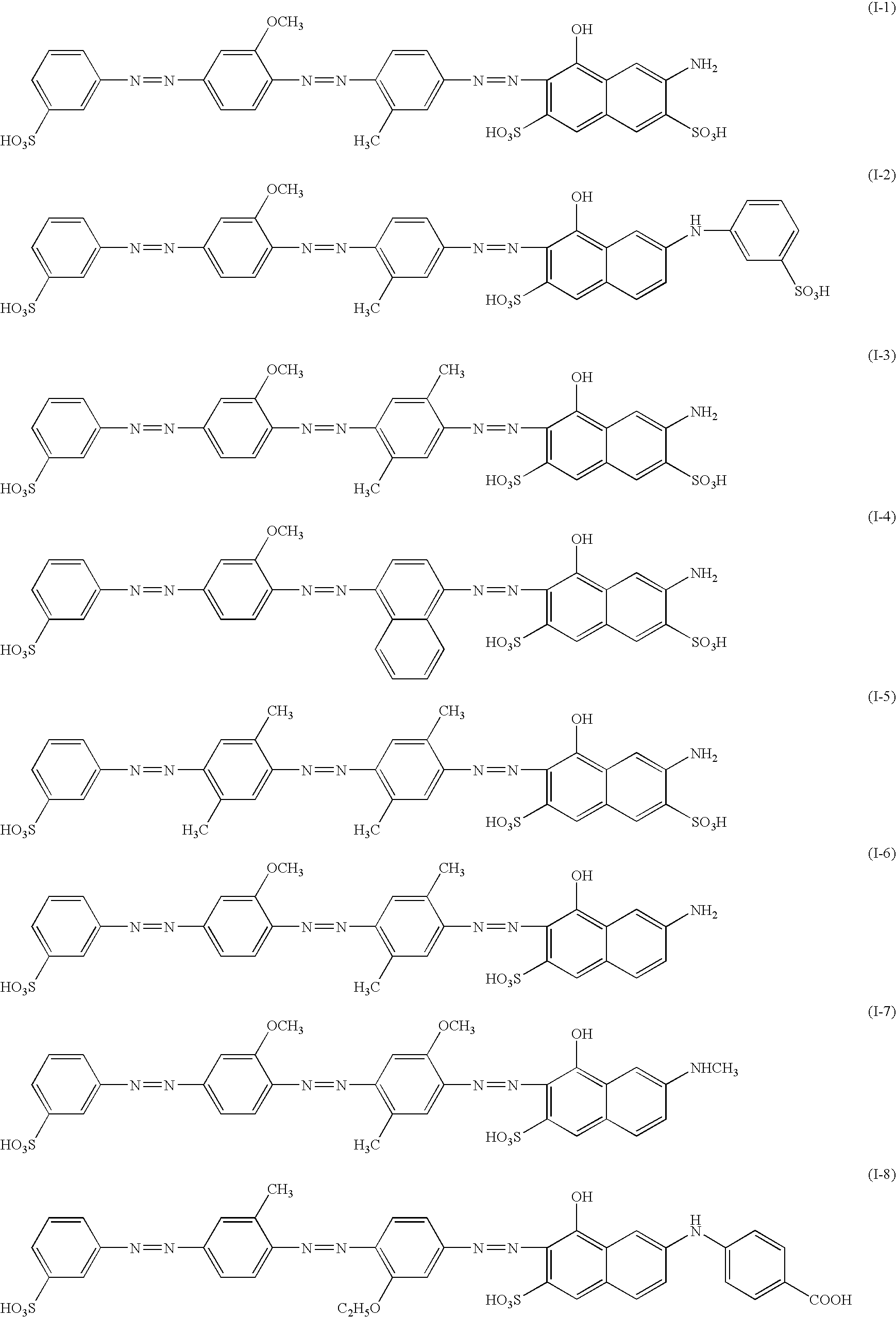

Dye compositions for anisotropic dye films, anisotropic dye films and polarizing elements

InactiveUS20060230551A1Good heat resistanceHigh dichroismAzo dyesPolarising elementsDichroismPhotochemistry

To provide a dye composition for an anisotropic dye film, capable of forming an anisotropic dye film which has good heat resistance, has little defects and shows high dichroism; an anisotropic dye film formed by using such a composition for an anisotropic dye film; and a polarizing element employing such an anisotropic dye film.

Owner:MITSUBISHI CHEM CORP

Photochromic films and method for manufacturing the same

ActiveUS20100157407A1High transparencyIncreased durabilityGlass/slag layered productsNon-linear opticsPhotochromismAcrylate

The present invention provides a photochromic film which is formed by curing a photochromic composition and includes a multifunctional (metha)acrylate-based monomer that has two or more functional groups, and a photochromic dye, a product including the same, and a method for producing the photochromic film.

Owner:LG CHEM LTD

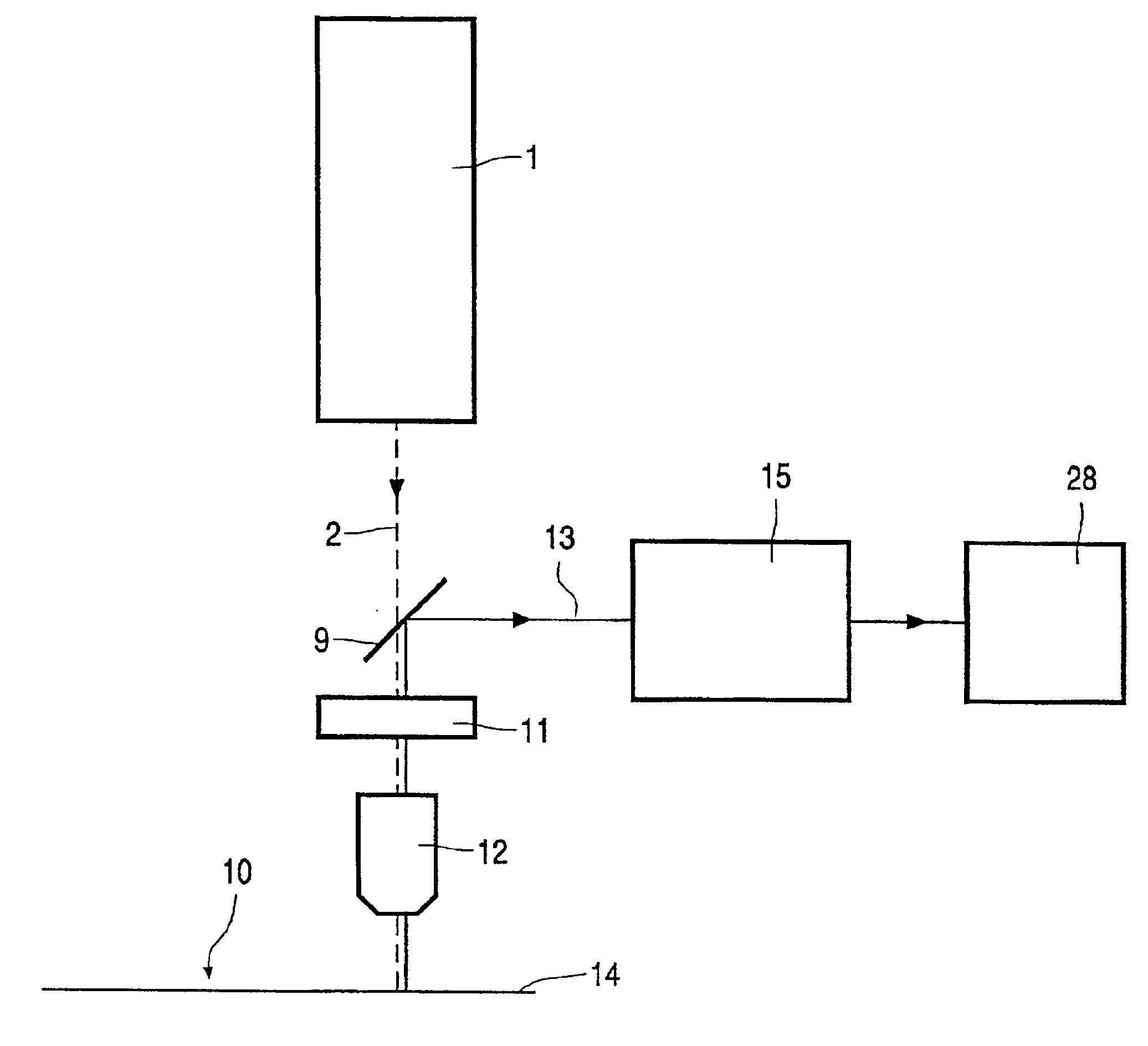

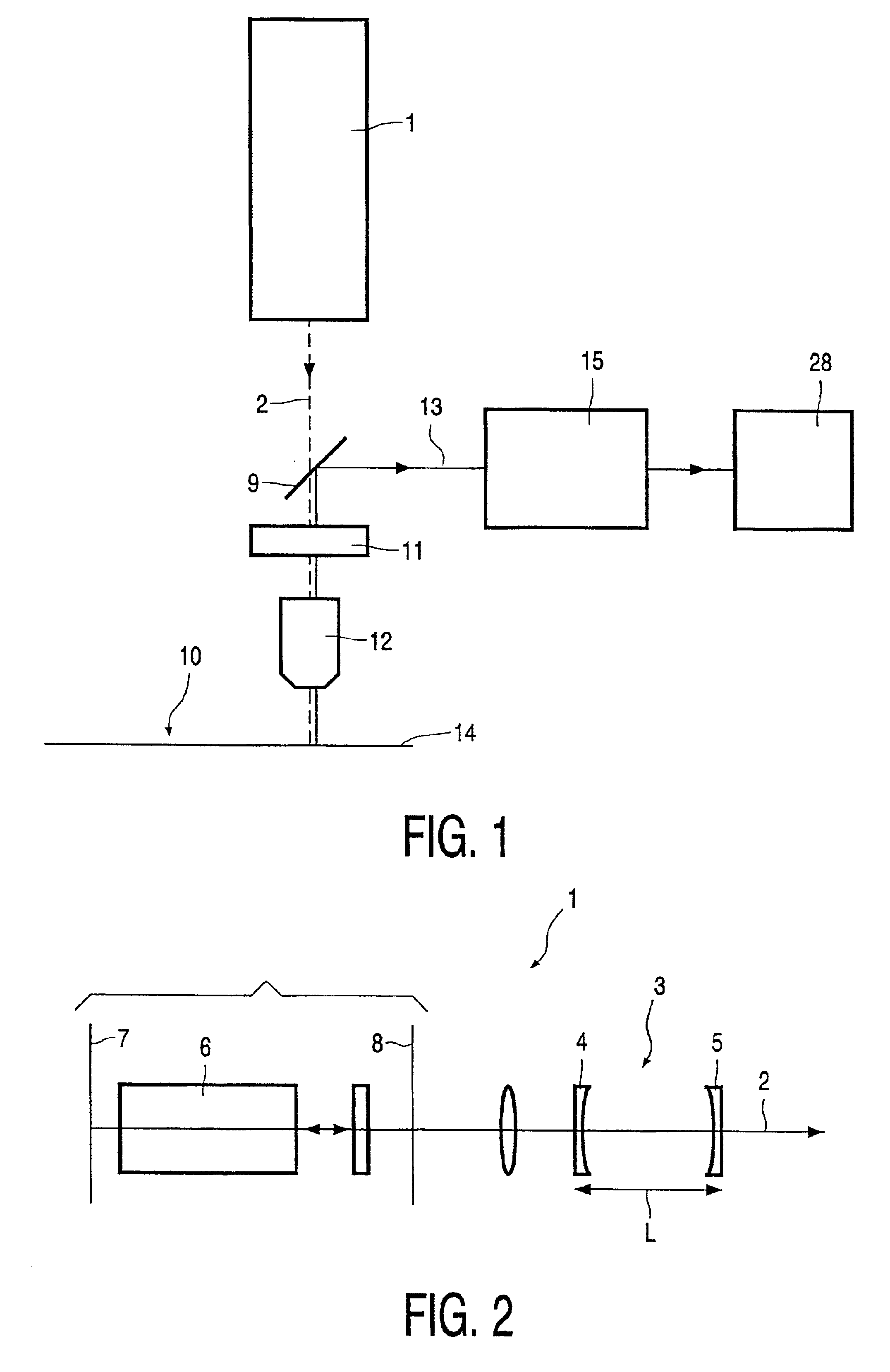

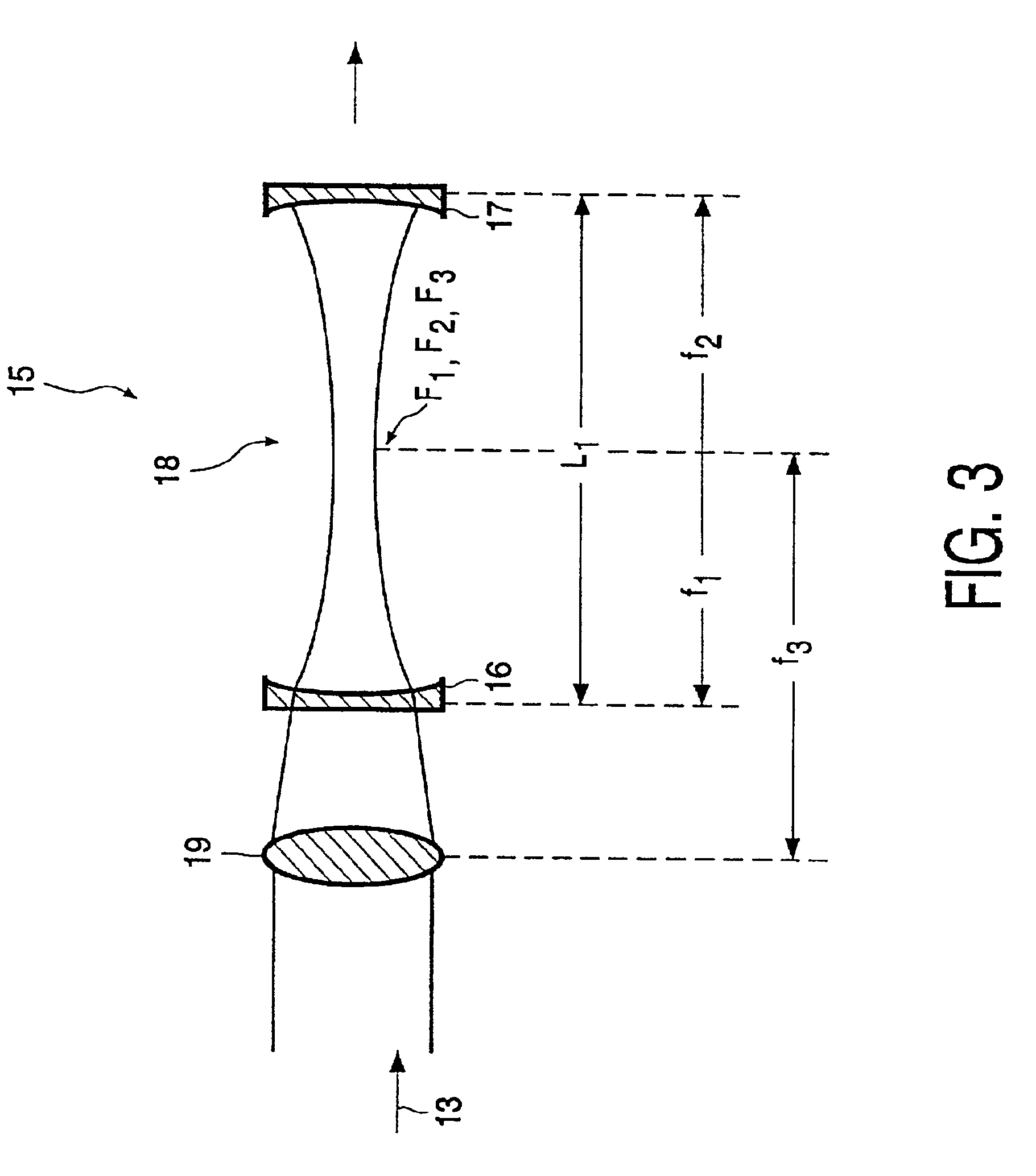

Inspection of surfaces

InactiveUS6906803B2Easy to measureSignificant changeOptically investigating flaws/contaminationMicroscopesLaser lightSemiconductor

A device for the inspection of surfaces, notably for the inspection of a surface of a semiconductor (14), which device comprises at least one laser light source (1) and a detector for detecting the light (13) that is reflected from the surface (10) to be inspected; the device also includes at least one mode filter (15; 15.1) for filtering the reflected light.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Method for producing layered product, layered product, method for producing layered product with device using said layered product, and layered product with device

ActiveUS9895868B2Small defectFlat surfaceLamination ancillary operationsLayered product treatmentSurface layerPolyamic acid

By preparing a polyimide film with a face at the support side and subjected to a surface treatment; subjecting at least one of a face of the support and the face of the polyimide film which are opposite to each other to a patterning treatment using a coupling agent to form a satisfactorily bondable part and an easily releasable part which differ in adhesion / peel strength; subsequently, superposing the support and the polyimide film to be subjected to a pressurizing / heating treatment and to be bonded to each other, subjecting the surface of the polyimide film to an organic alkali treatment; and then, applying a polyamic acid solution free from a slip agent ingredient, drying the coating film and imidizing the film, a layered product having a structure of at least three layers in which at least one layer contains a slip agent material and both surface layers have no slip agent material is produced.

Owner:TOYOBO CO LTD

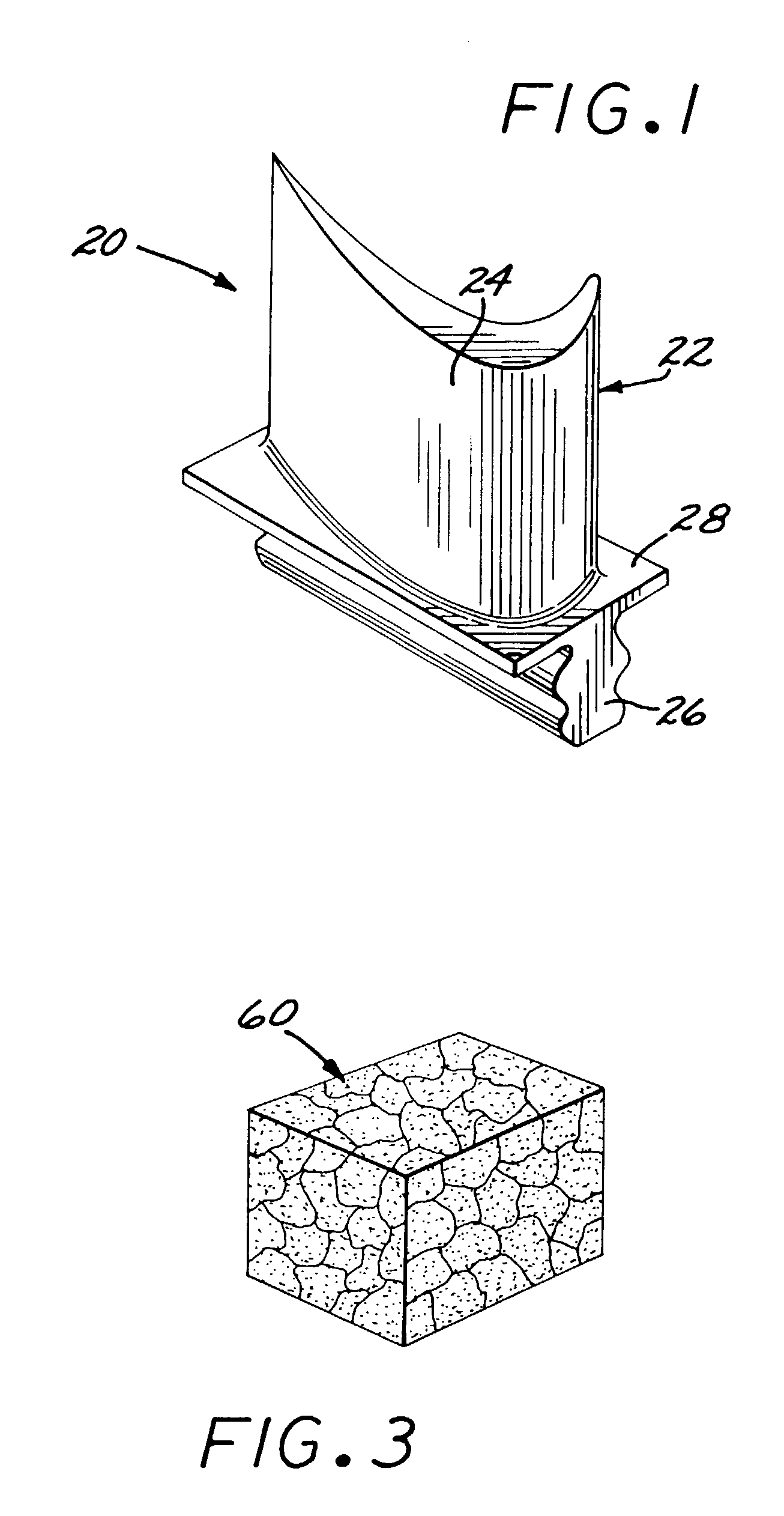

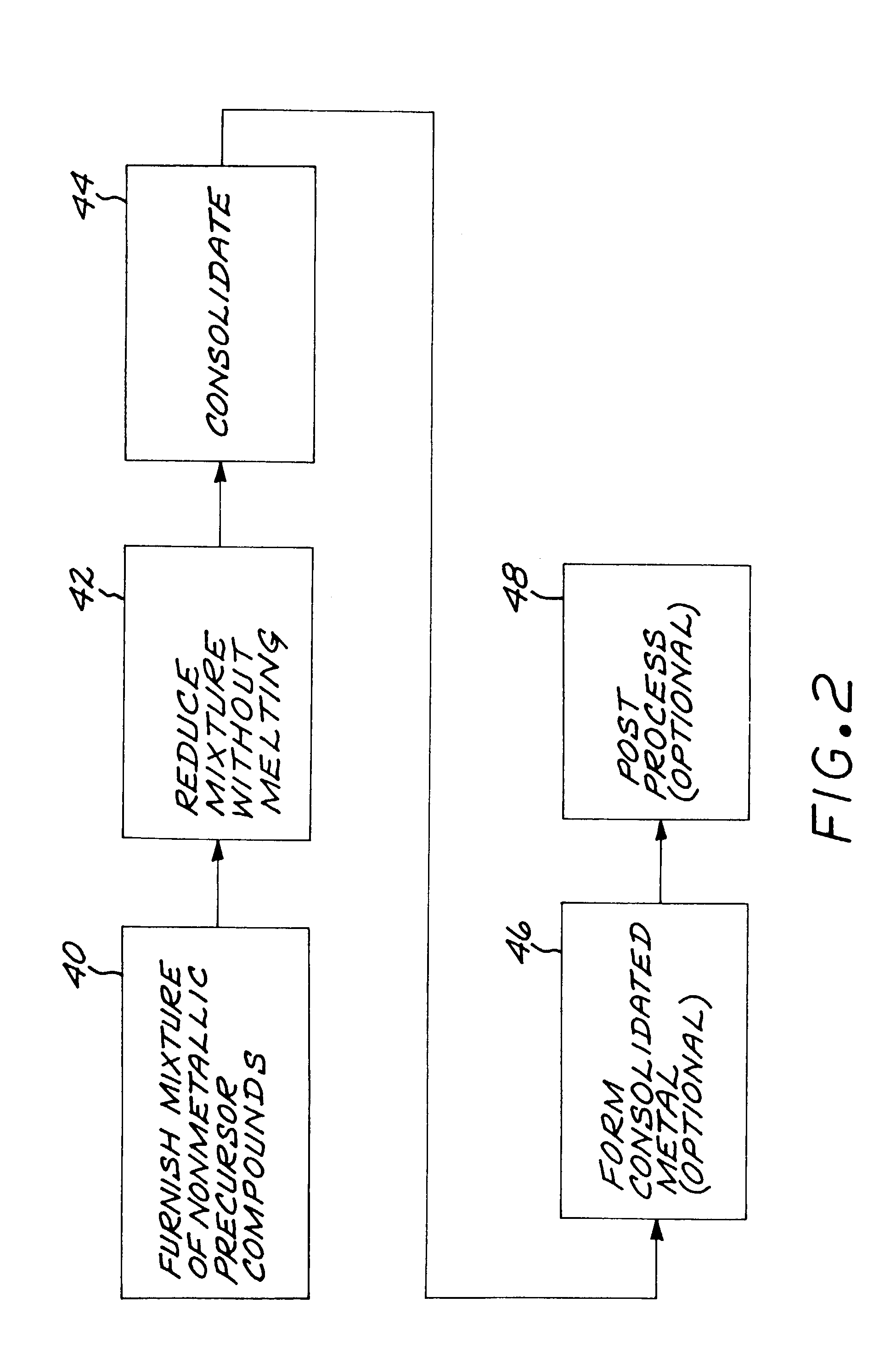

Method for fabricating a superalloy article without any melting

A metallic article made of metallic constituent elements is fabricated from a mixture of nonmetallic precursor compounds of the metallic constituent elements. The mixture of nonmetallic precursor compounds contains more of a base-metal element, such as nickel, cobalt, iron, iron-nickel, and iron-nickel-cobalt than any other metallic element. The mixture of nonmetallic precursor compounds is chemically reduced to produce a metallic superalloy material, without melting the metallic superalloy material. The metallic superalloy material is consolidated to produce a consolidated metallic article, without melting the metallic superalloy material and without melting the consolidated metallic article.

Owner:GENERAL ELECTRIC CO

Composition for forming silica layer, method for manufacturing silica layer and silica layer

ActiveUS10106687B2Small defectUniform thicknessSilicaSemiconductor/solid-state device manufacturingSolventSilicon dioxide

A composition for forming a silica layer includes a silicon-containing polymer and a mixed solvent including at least two solvents, wherein the mixed solvent has a surface tension of about 5 mN / m to about 35 mN / m at a temperature of about 25° C.

Owner:SAMSUNG SDI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com