Dye compositions for anisotropic dye films, anisotropic dye films and polarizing elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1-1

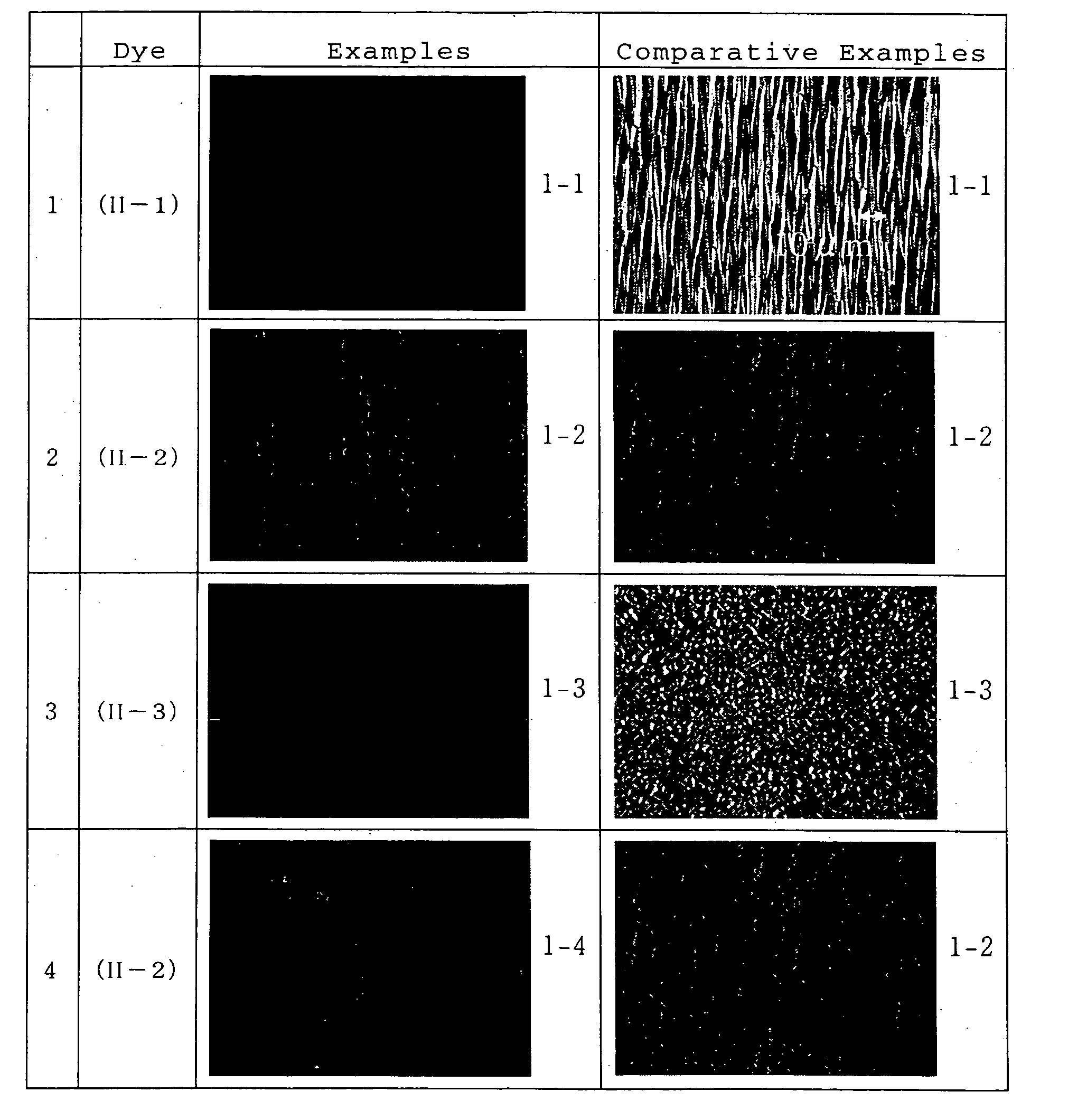

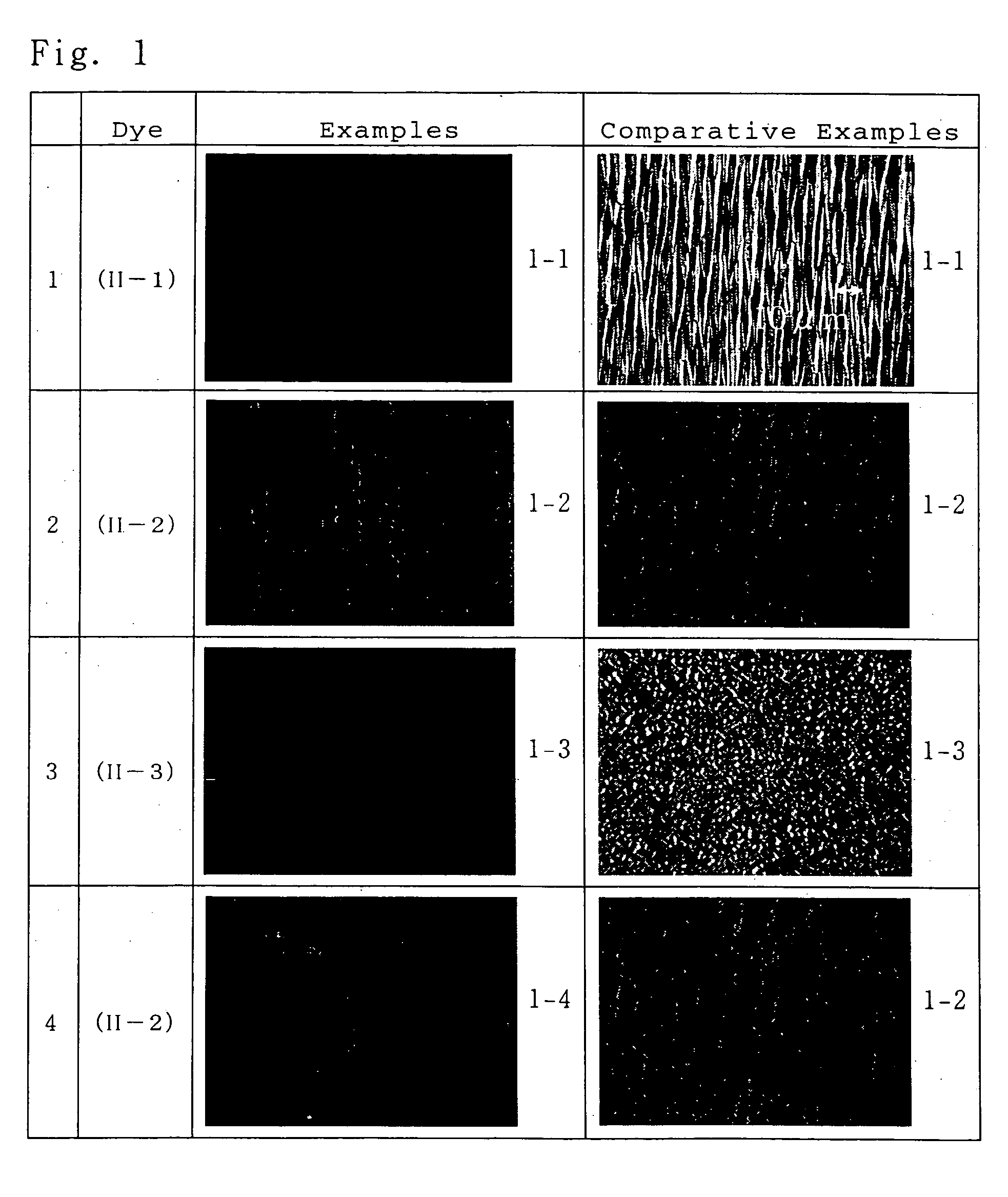

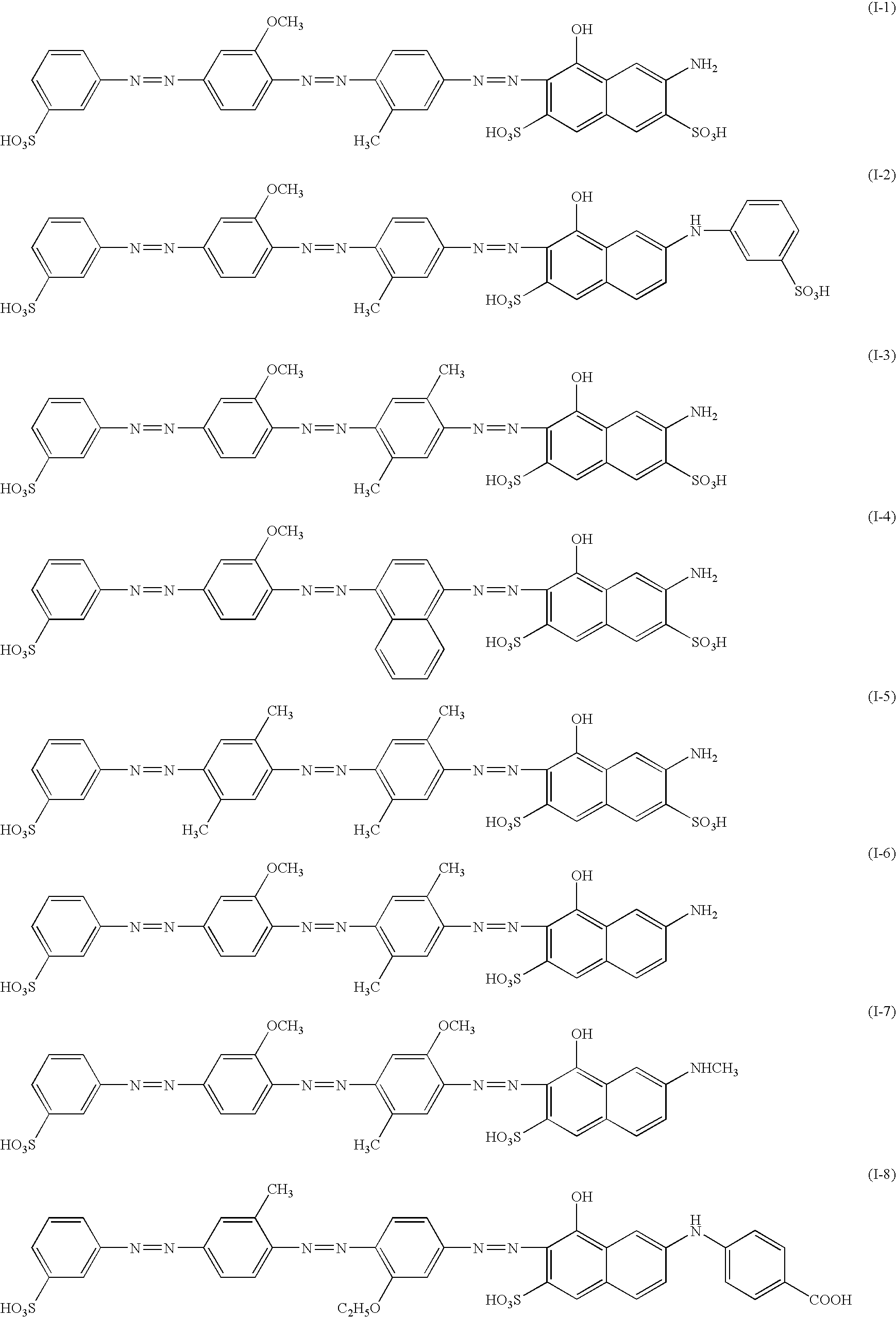

[0132] 5 Parts of Dye No. (II-1) and 2.5 parts of L-(+)lysine monohydrochloride (number of basic groups: 2, number of acidic groups: 1) (manufactured by Tokyo Kasei Kogyo Co., Ltd.) were added to 92.5 parts of water (molar ratio of the dye to L-(+)lysine monohydrochloride=1:1), stirred and dissolved, followed by filtration to obtain a dye composition for an anisotropic dye film of the present invention having a pH of 7. The above dye composition for an anisotropic dye film was applied by an applicator having a gap of 10 μm (manufactured by Imoto Seisakusho) on a glass substrate having a polyimide oriented film formed on its surface by a spin coating method (75 mm×25 mm, thickness: 1.1 mm, a polyimide oriented film having a polyimide film thickness of about 800 Å was preliminarily subjected to rubbing treatment with cloth), followed by drying naturally to obtain an anisotropic dye film having a thickness of about 0.4 μm.

[0133] A photograph of defects of the obtained anisotropic dye ...

example 1-2

[0135] 14 Parts of the above exemplified Dye No. (II-2) and 3.1 parts of L-(+)lysine monohydrochloride (number of basic groups: 2, number of acidic groups: 1) (manufactured by Tokyo Kasei Kogyo Co., Ltd.) were added to 82.9 parts of water (molar ratio of the dye to L-(+)lysine monohydrochloride=1:1), stirred and dissolved, followed by filtration to obtain a dye composition for an anisotropic dye film of the present invention having a pH of 7. This dye composition for an anisotropic dye film was applied on the same substrate as in Example 1-1 under the same conditions to obtain an anisotropic dye film having a thickness of about 0.9 μm.

[0136] A photograph of defects of the obtained anisotropic dye film is shown in FIG. 1. Further, the maximum absorption wavelength (λmax) and the dichroic ratio (D) of the obtained anisotropic dye film are shown in Table 1.

[0137] Defects of the anisotropic dye film obtained in this Example were sufficiently little, and the film had a high dichroic ra...

example 1-3

[0138] 15 Parts of the above exemplified Dye No. (II-3) and 3.3 parts of L-(+)lysine monohydrochloride (number of basic groups: 2, number of acidic groups: 1) (manufactured by Tokyo Kasei Kogyo Co., Ltd.) were added to 81.7 parts of water (molar ratio of the dye to L-(+)lysine monohydrochloride=1:1), stirred and dissolved, followed by filtration to obtain a dye composition for an anisotropic dye film of the present invention having a pH of 7. This dye composition for an anisotropic dye film was applied to the same substrate as in Example 1-1 under the same conditions to obtain an anisotropic dye film having a thickness of about 0.9 μm.

[0139] A photograph of defects of the obtained anisotropic dye film is shown in FIG. 1. Further, the maximum absorption wavelength (λmax) and the dichroic ratio (D) of the obtained anisotropic dye film are shown in Table 1.

[0140] Defects of the anisotropic dye film obtained in this Example were sufficiently little, and the film had a high dichroic ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com