Patents

Literature

1750 results about "Polyimide membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

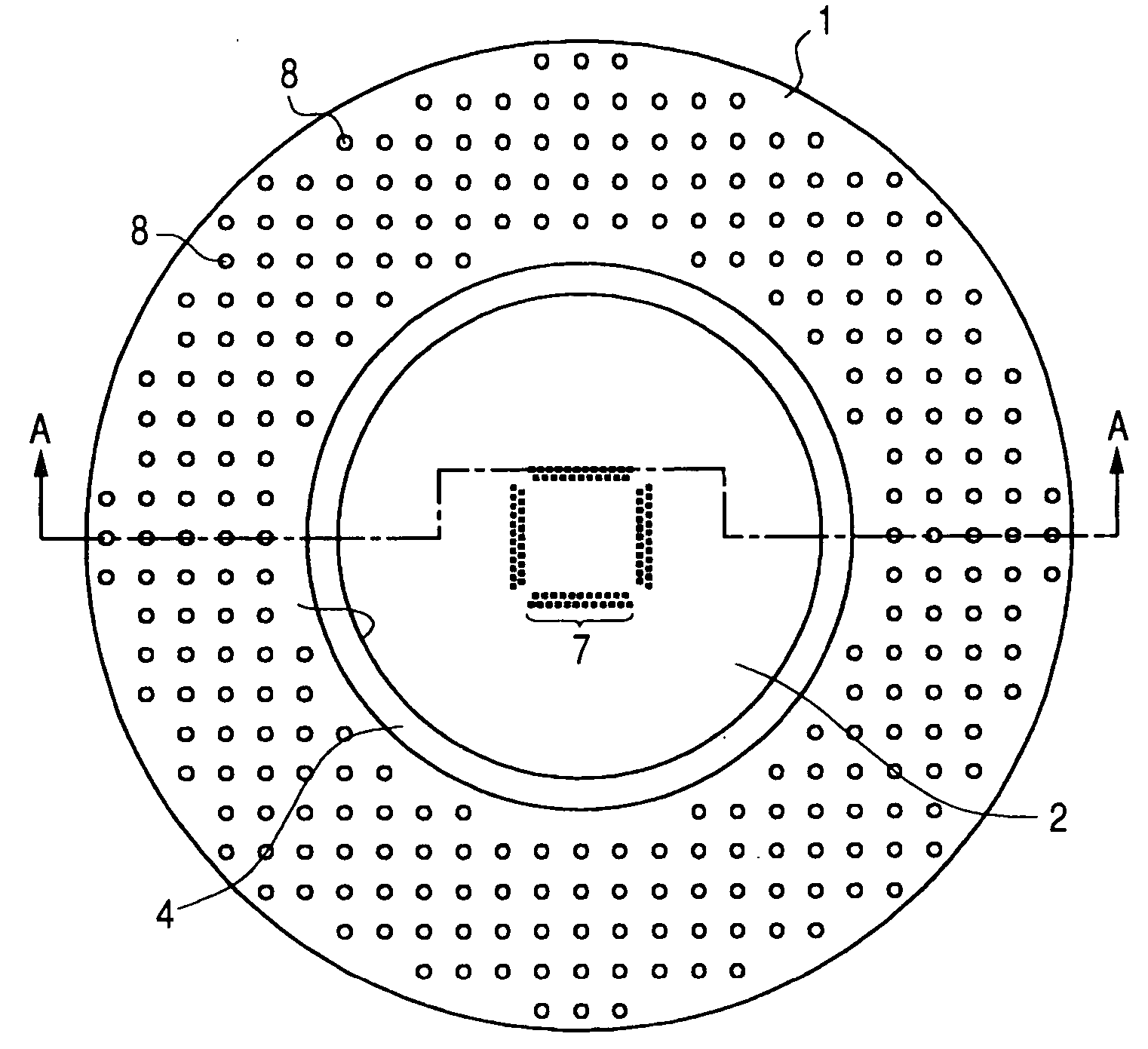

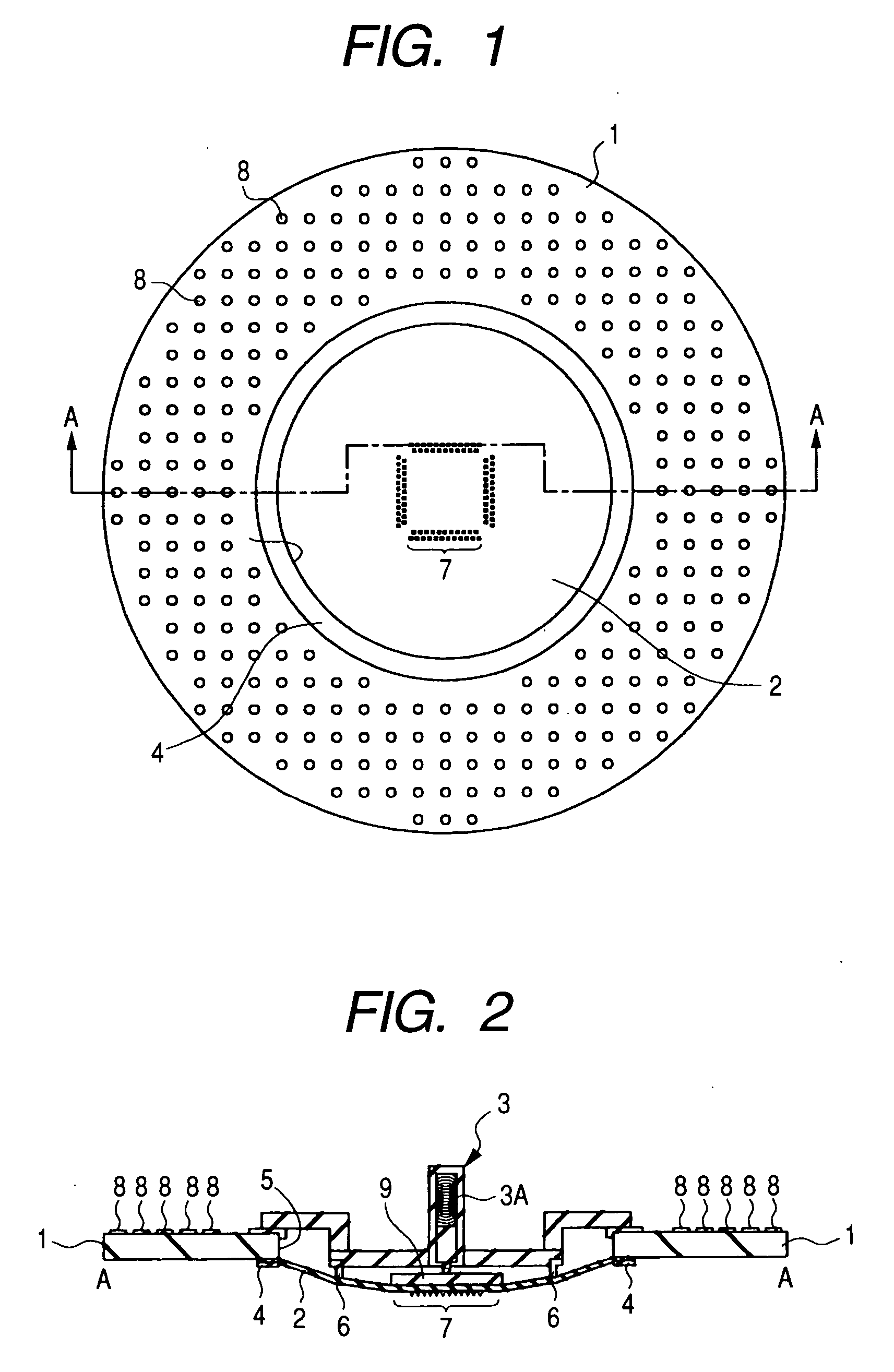

Probing device and manufacturing method thereof, as well as testing apparatus and manufacturing method of semiconductor with use thereof

InactiveUS6900646B2High densityImprove accuracySemiconductor/solid-state device testing/measurementElectronic circuit testingContact formationElectricity

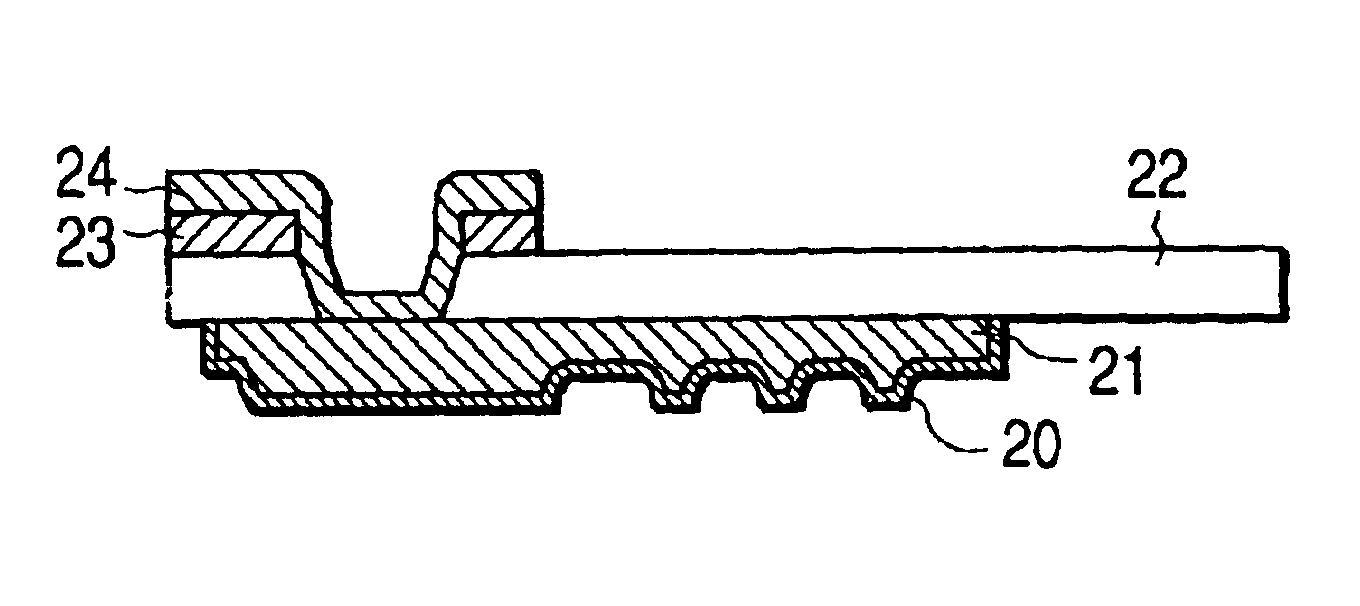

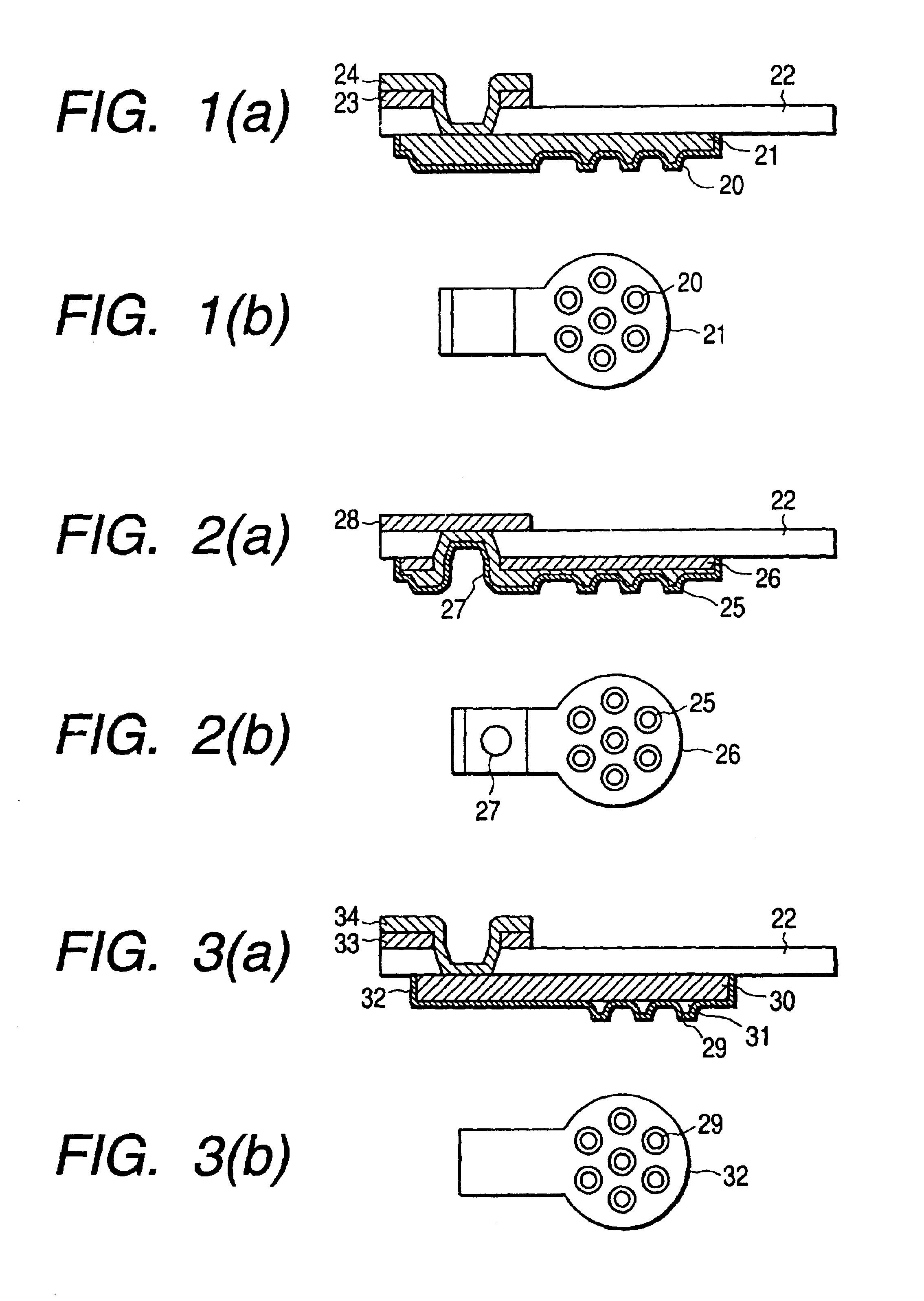

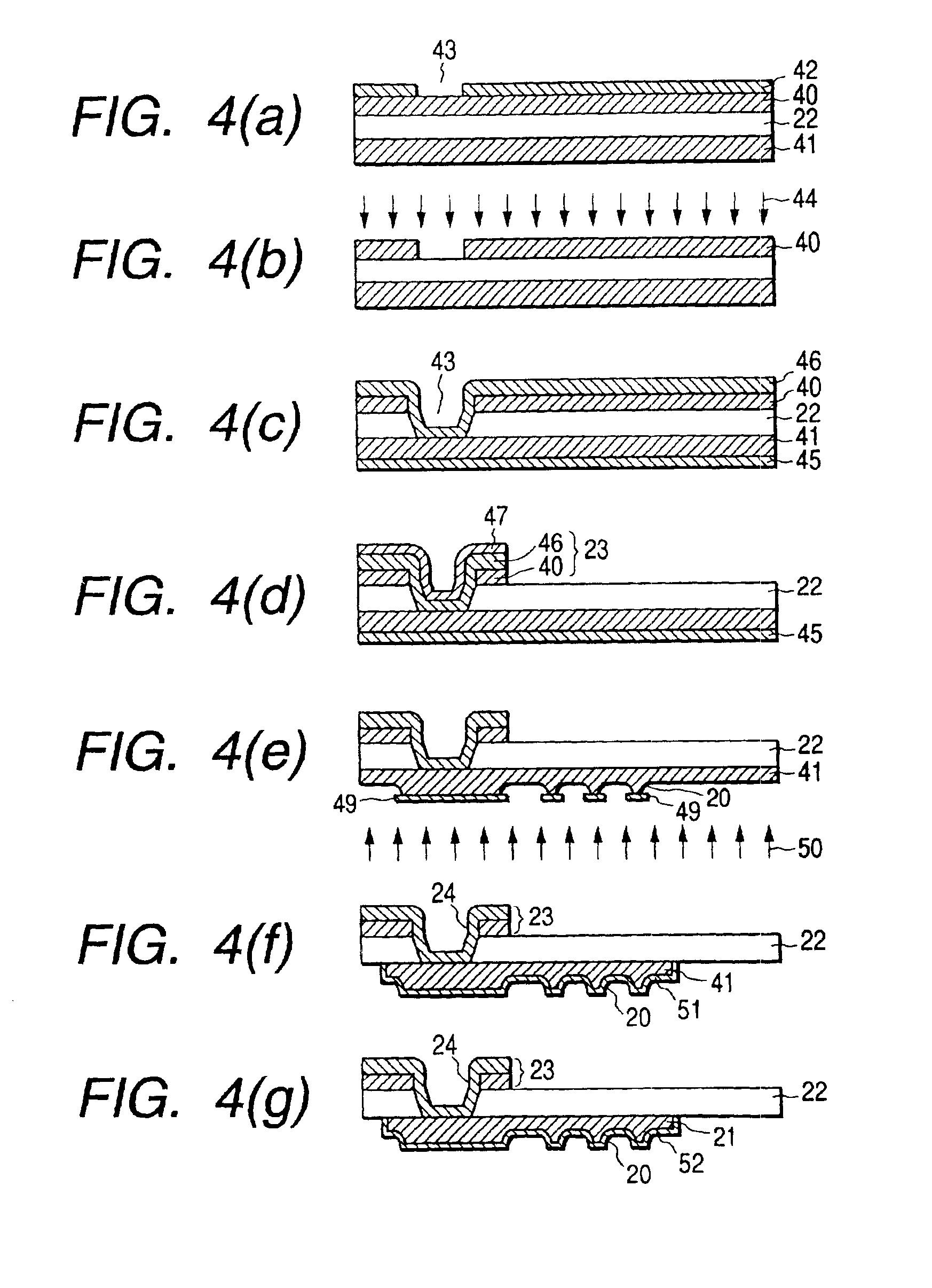

A probing device for electrically contacting with a plurality of electrodes 3, 6 aligned on an object 1 to be tested so as to transfer electrical signal therewith, comprising: a wiring sheet being formed by aligning a plurality of contact electrodes 21, 110b, corresponding to each of said electrodes, each being planted with projecting probes 20, 110a covered with hard metal films on basis of a conductor thin film 41 formed on one surface of an insulator sheet 22 of a polyimide film by etching thereof, while extension wiring 23, 110c for electrically connecting to said each of said contact electrodes being formed on basis of a conductor thin film formed on either said one surface or the other surface opposing thereto of said insulator sheet of the polyimide film; and means for giving contacting pressure for obtaining electrical conduction between said extension wiring and said object to be tested by contacting tips of said projecting contact probe formed onto said each contact electrode through giving pressuring force between said wiring sheet and said object to be tested.

Owner:RENESAS ELECTRONICS CORP

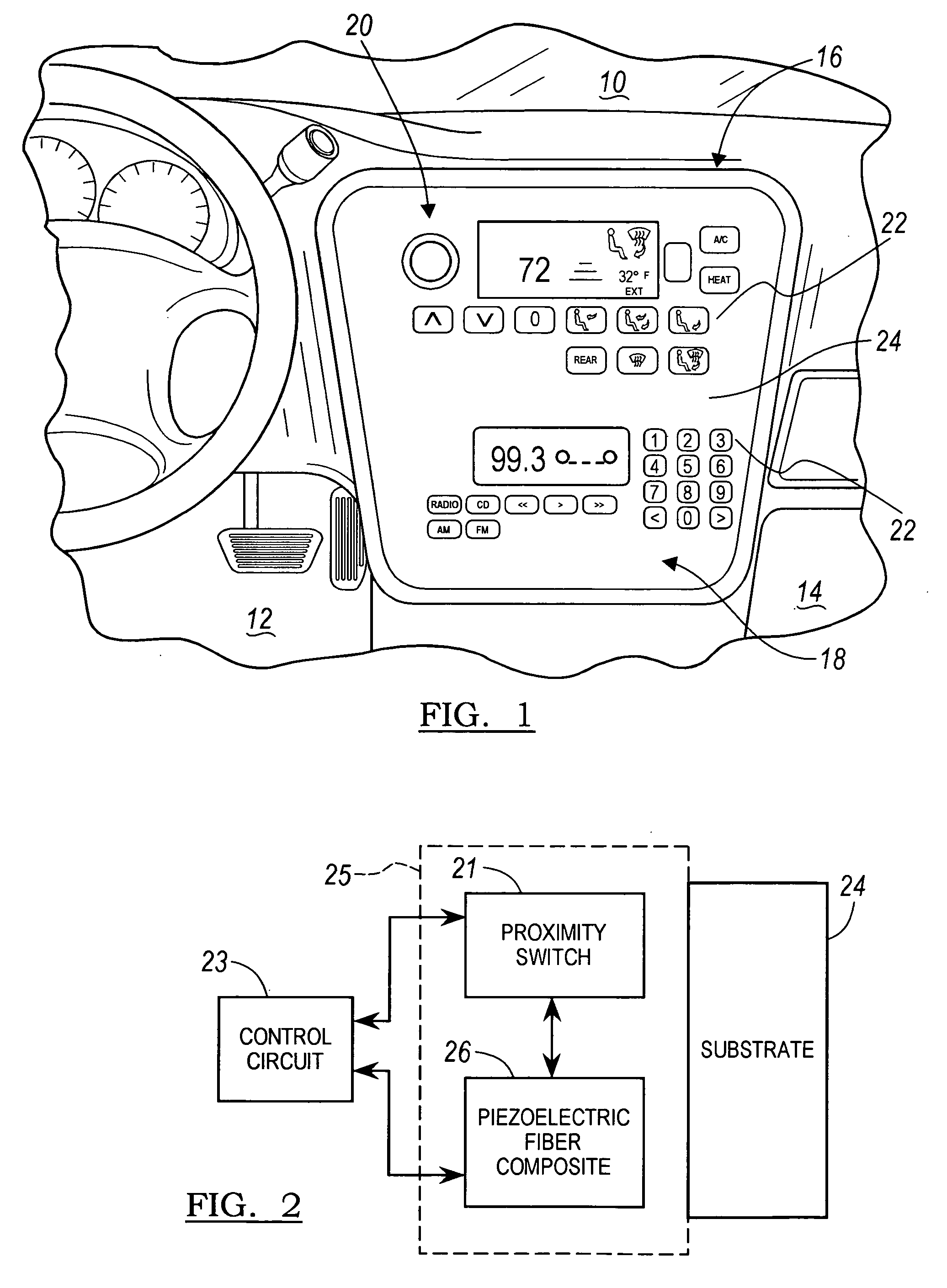

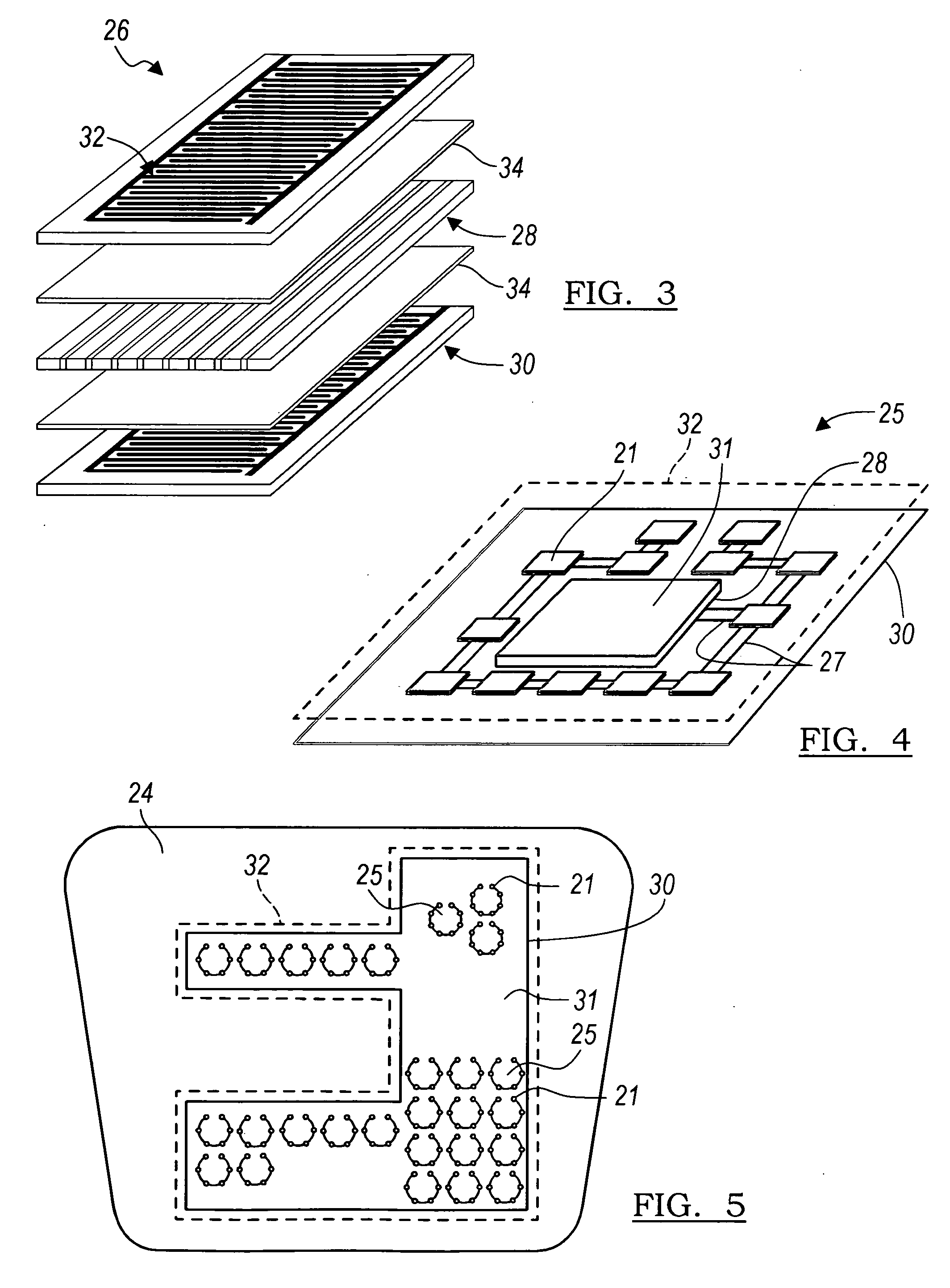

Flexible touch-sense switch

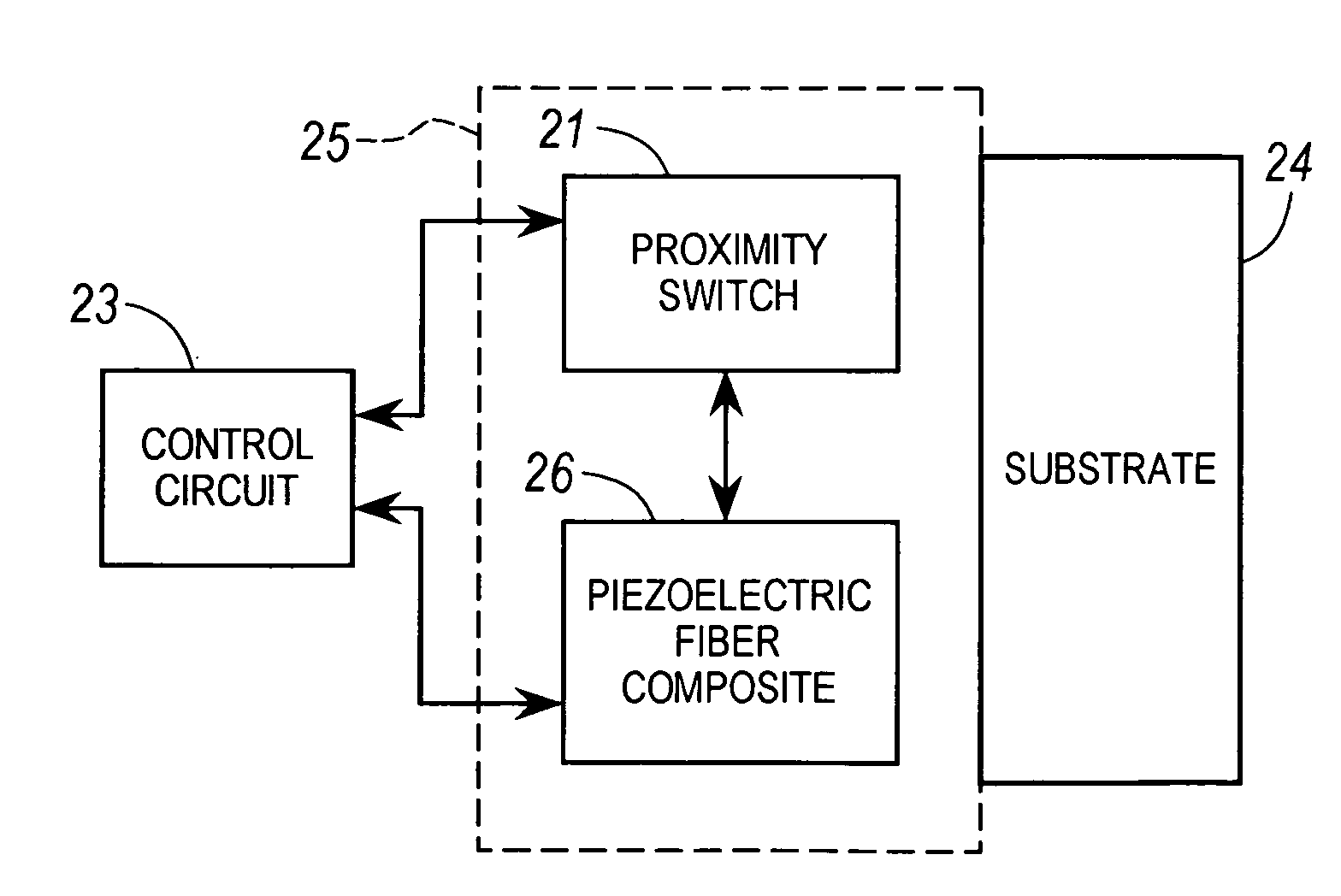

A flexible touch-sense switch includes a force sensitive composite and an at least one proximity sensor. The force sensitive composite includes a plurality of force sensors disposed between a first layer and a second layer of polymide film defining a displacement region. The at least one proximity sensor generates an electromagnetic field that defines a detection region. The force sensitive composite and the at least one proximity sensor are mounted to the first layer of the polymide film for forming a flexible printed circuit board. A control circuit is electrically connected to the force sensitive composite and the at least one proximity sensor for selectively controlling the touch-sense switch activation in response to coincident actuation thereof.

Owner:LEAR CORP

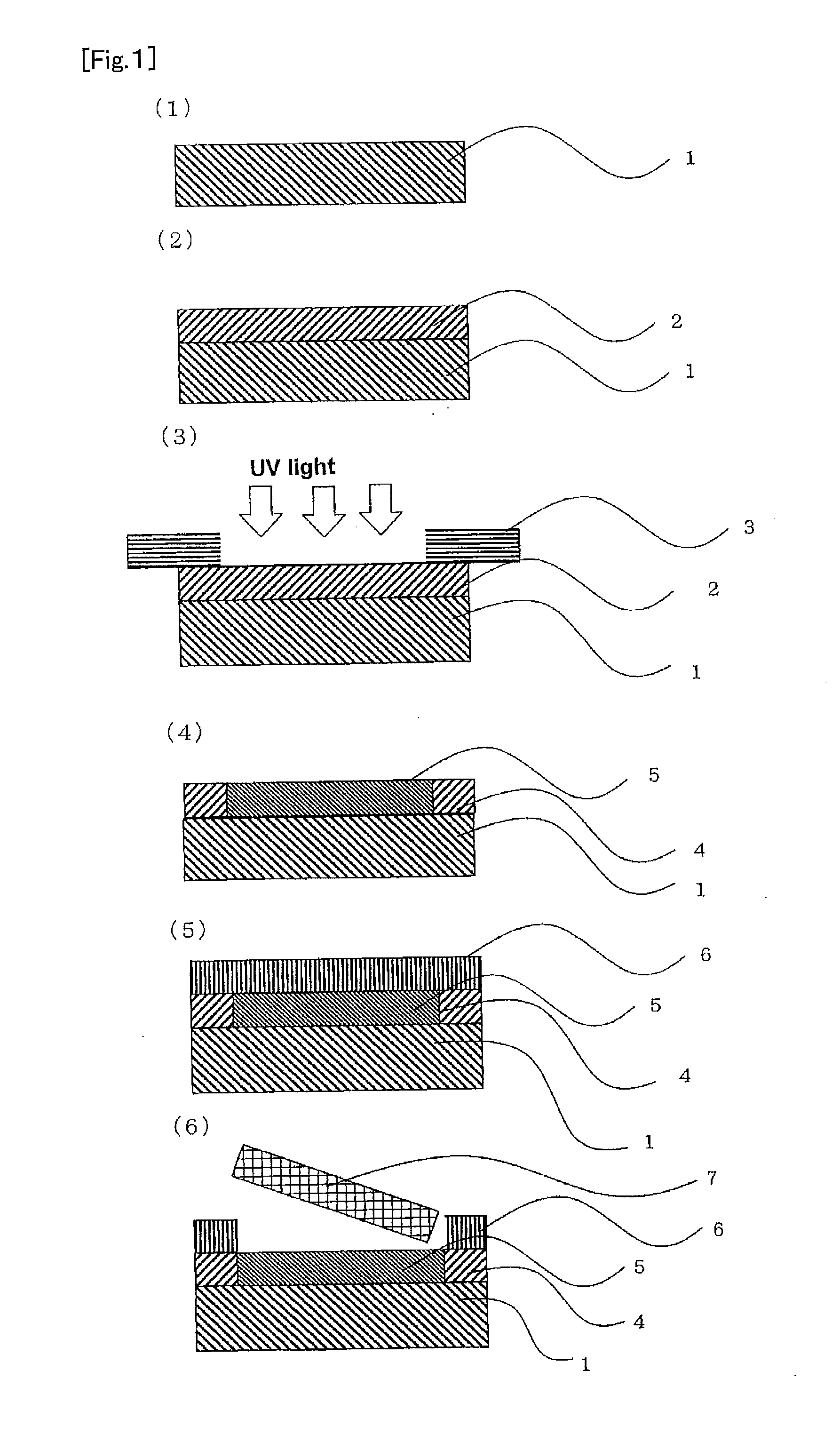

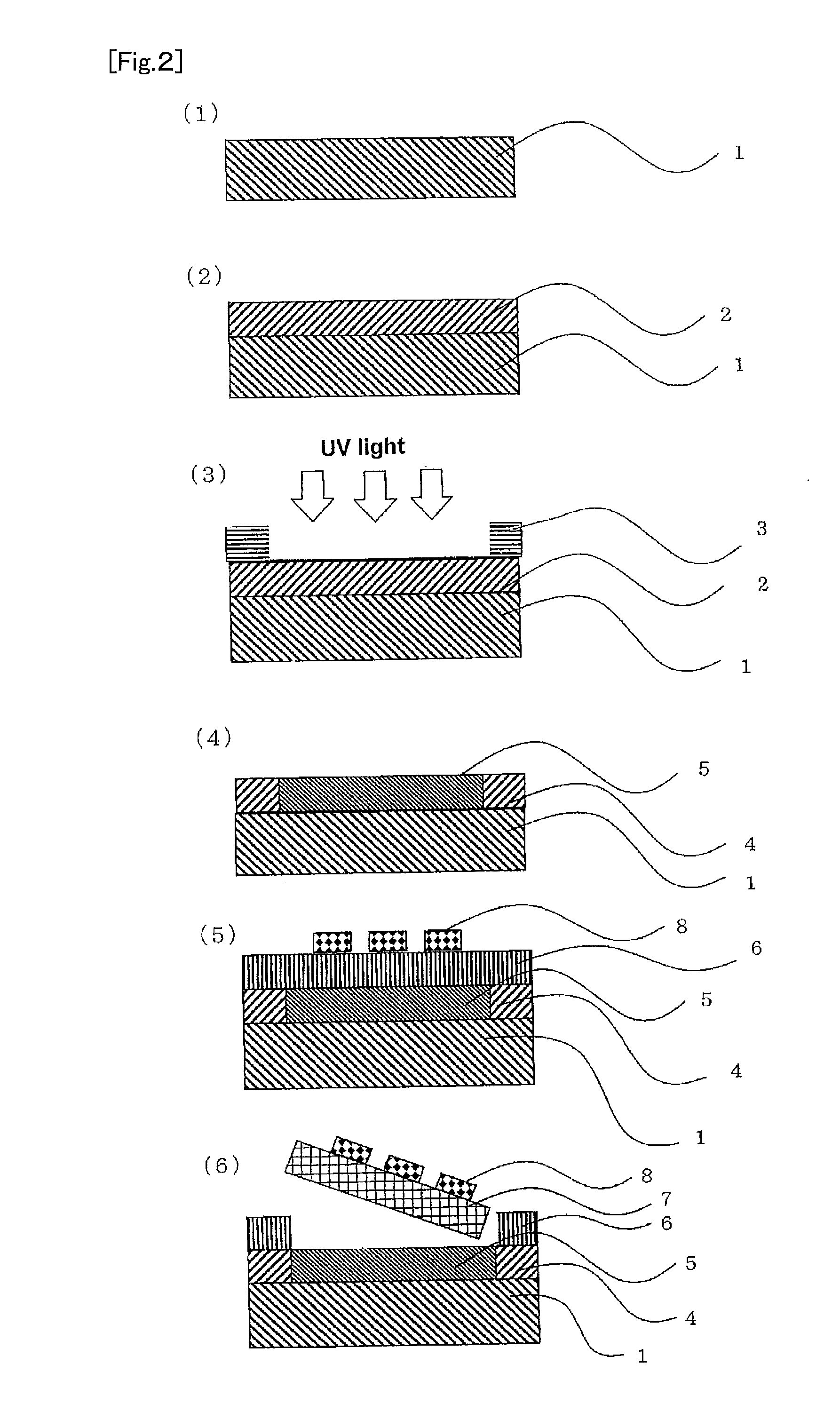

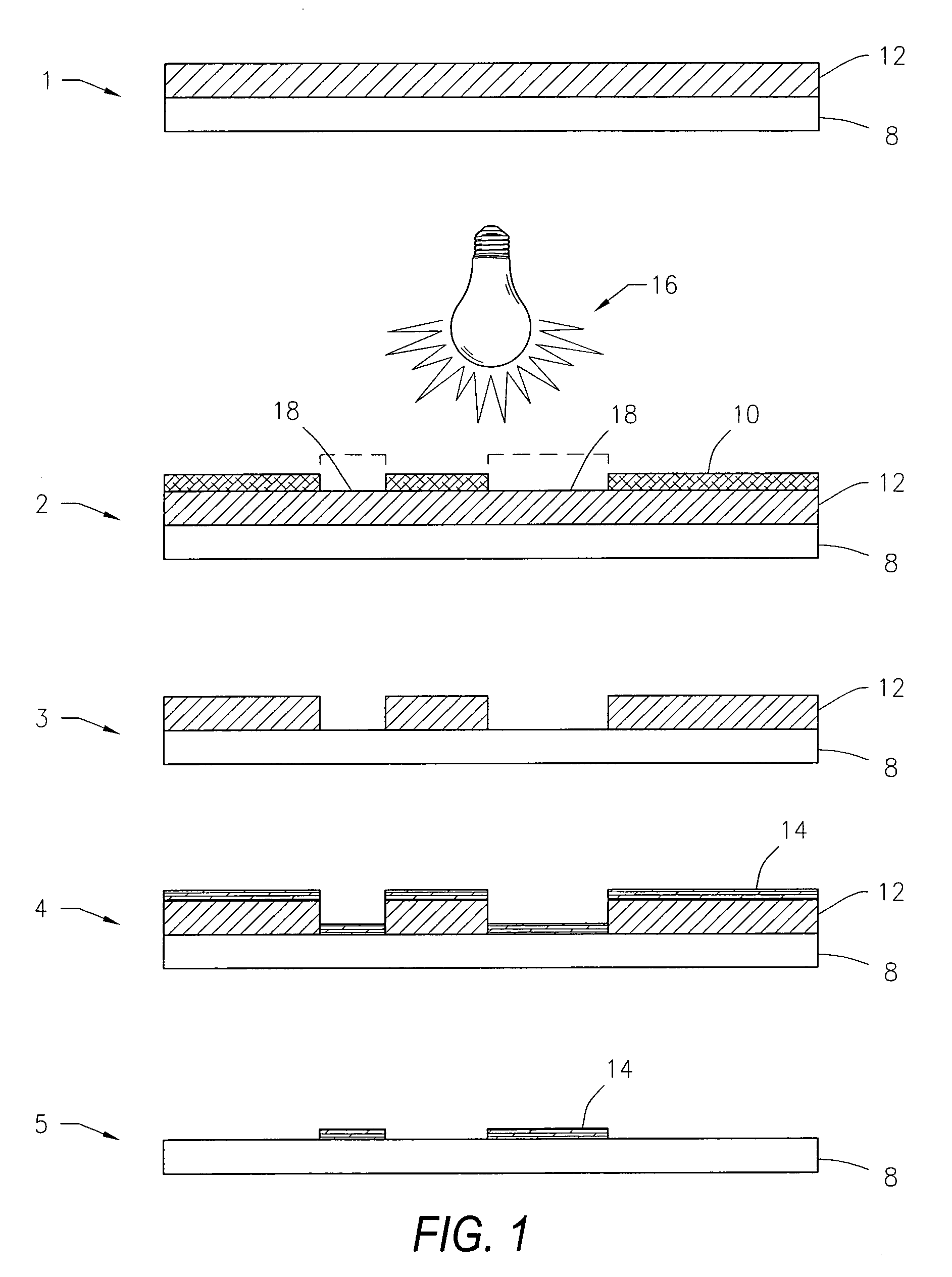

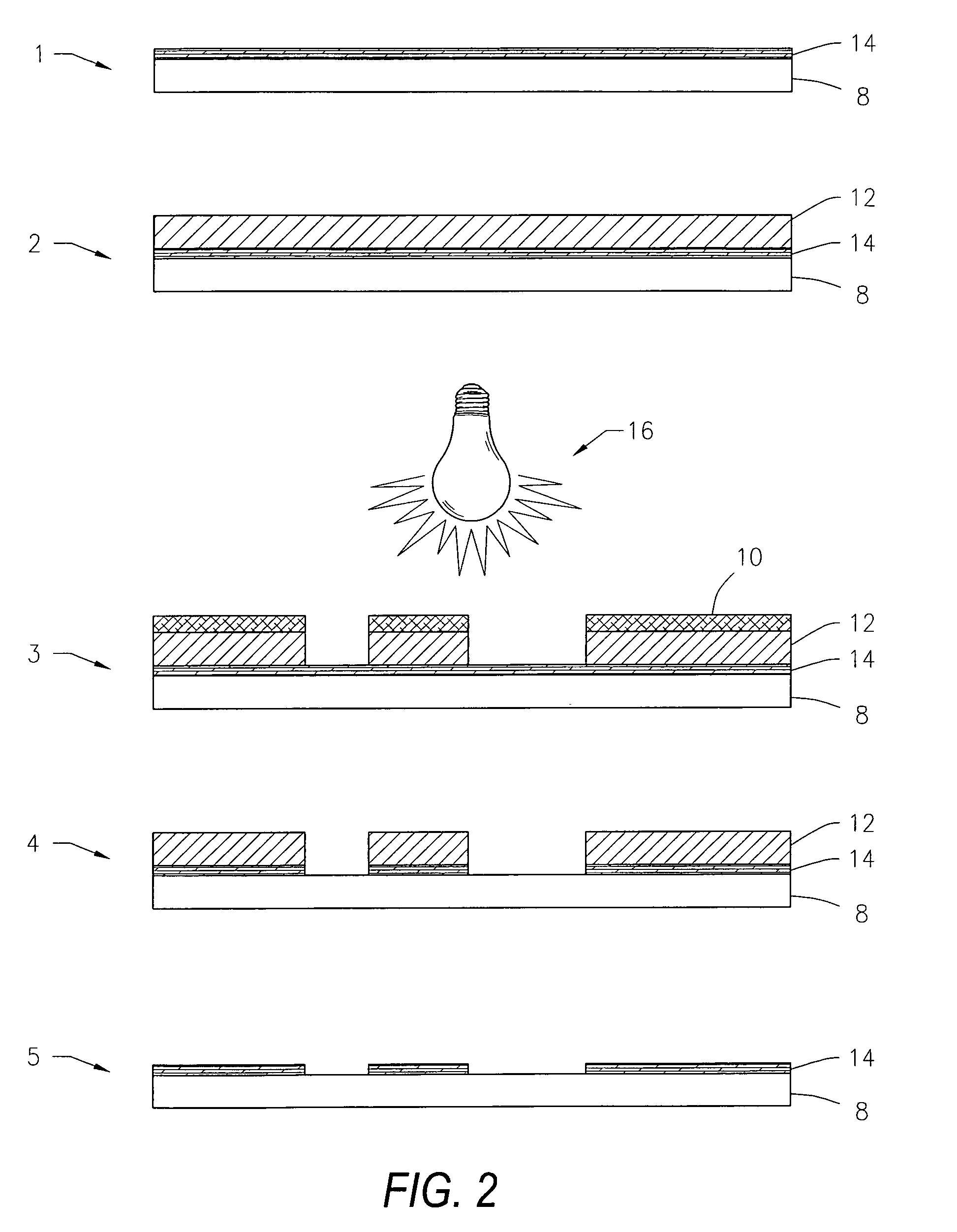

Laminate, method for producing same, and method for producing device structure using same

ActiveUS20140041800A1Easy to getGood partitionLamination ancillary operationsDecorative surface effectsCouplingEngineering

The invention provides a laminate of a substrate, a polyimide film, and a coupling treatment layer interposed therebetween, which provides different delamination strengths between the substrate and the polyimide film to form a prescribed pattern. The invention also provides a method for producing such a laminate formed from at least a substrate and a polyimide film, whereby, using a film obtained by plasma treatment of at least the surface facing the substrate as the polyimide film, coupling agent treatment is performed on at least one of the surfaces facing the substrate and the polyimide film to form a coupling treatment layer, deactivation treatment is performed on a portion of the coupling treatment layer to form a pre-determined pattern, and then pressing and heating are performed with the substrate and polyimide film overlapping.

Owner:TOYO TOYOBO CO LTD

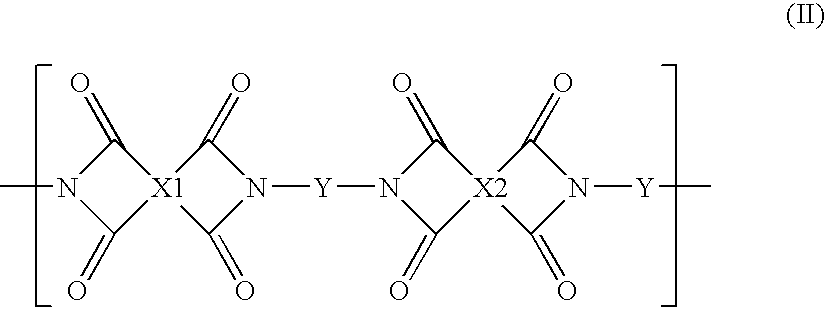

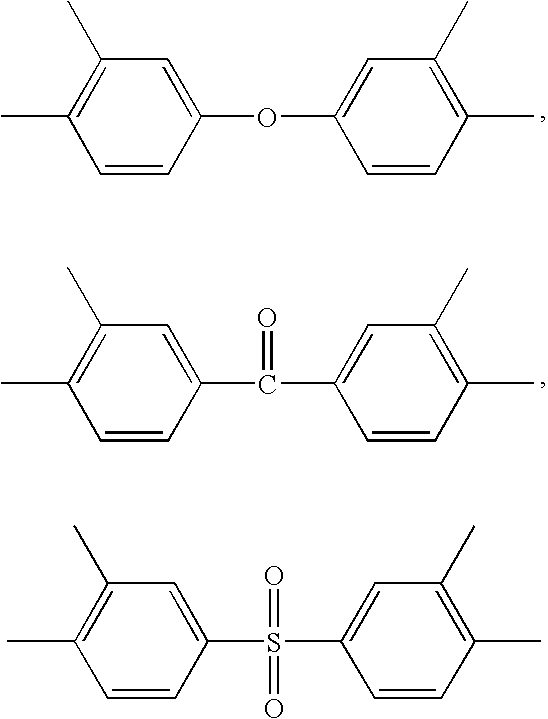

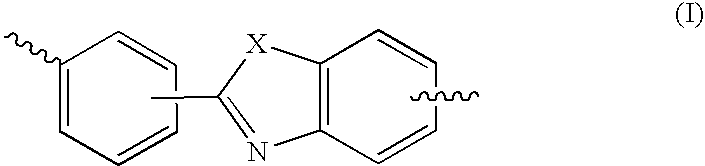

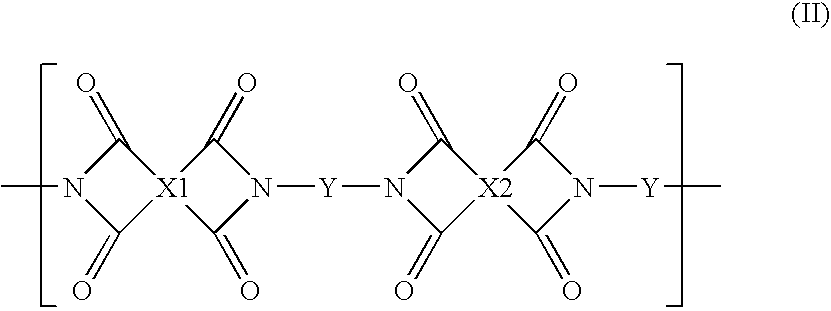

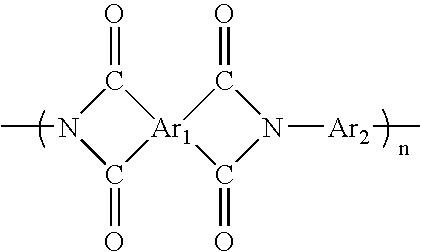

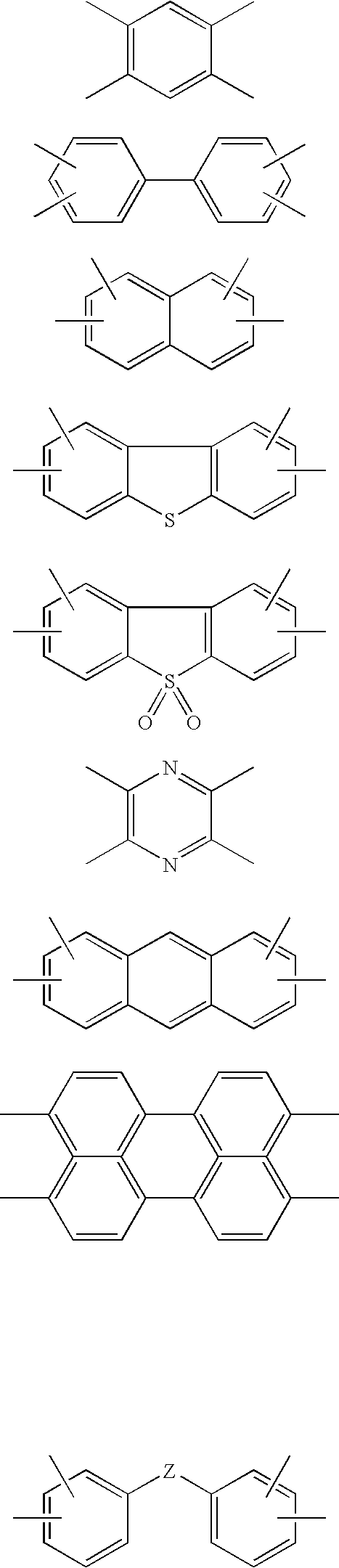

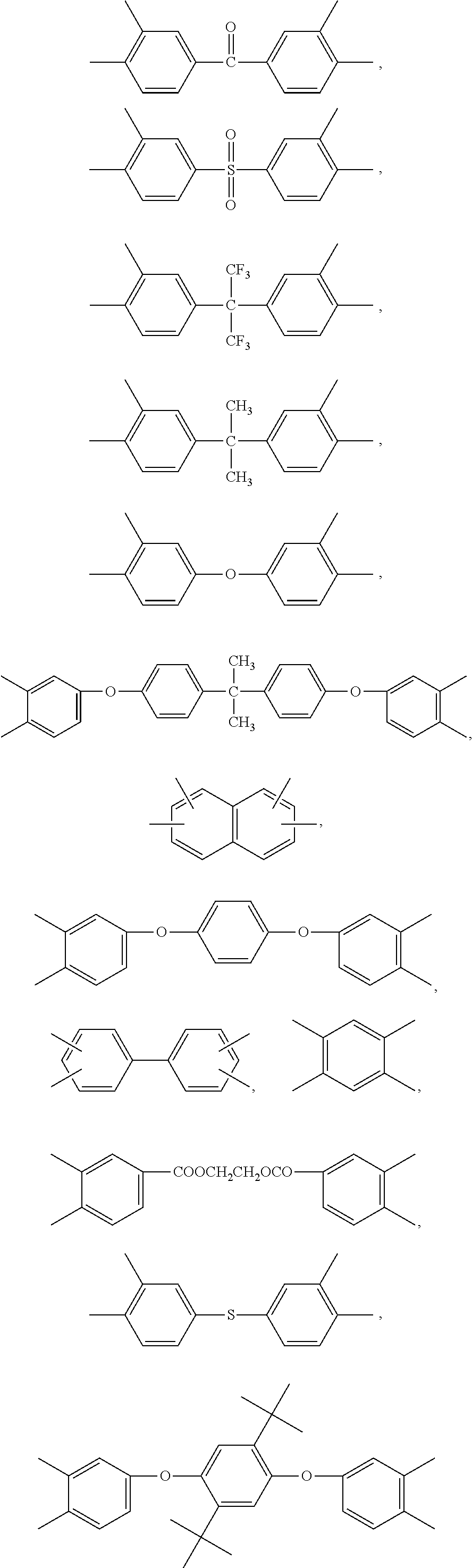

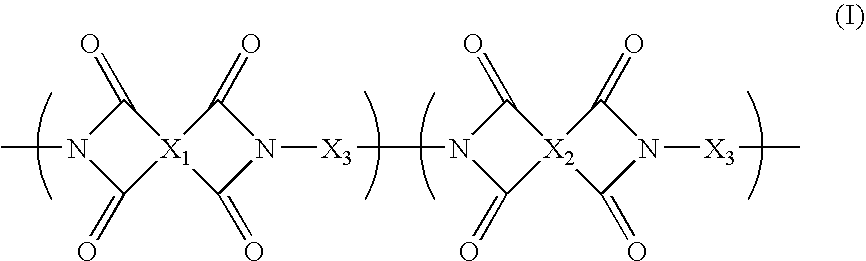

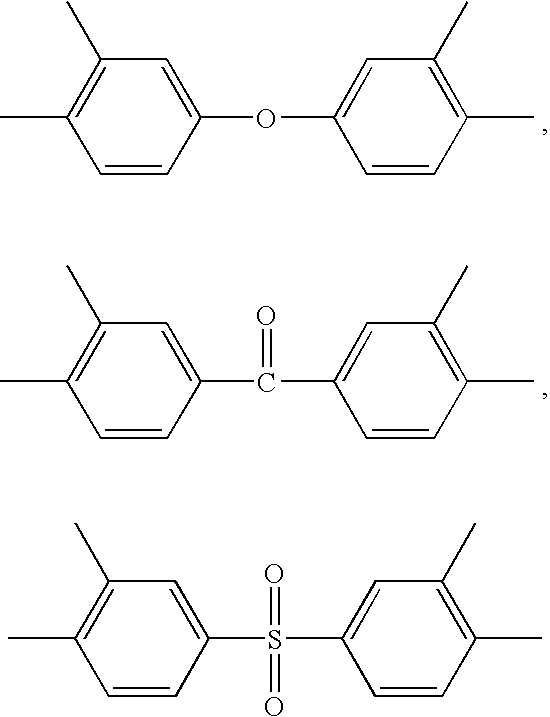

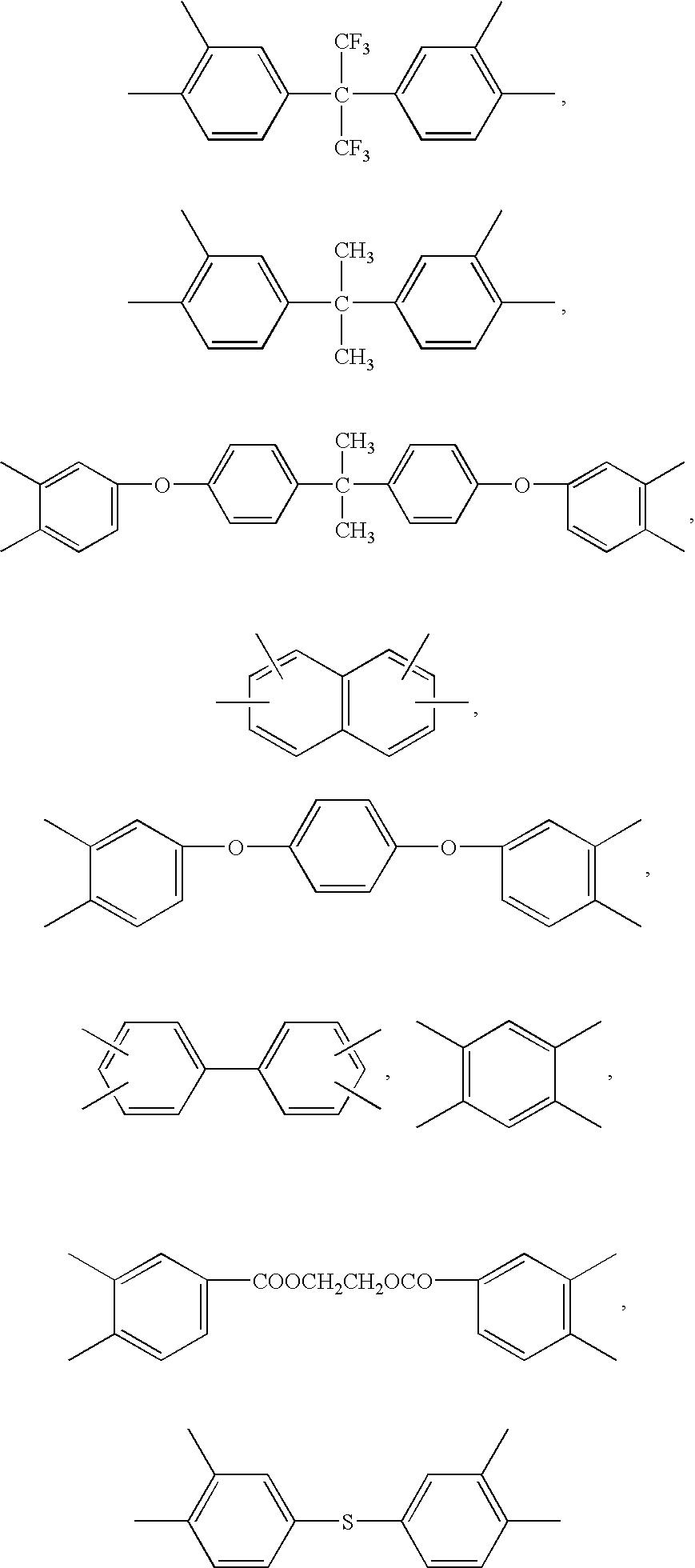

High performance cross-linked polybenzoxazole and polybenzothiazole polymer membranes

In the present invention high performance cross-linked polybenzoxazole and polybenzothiazole polymer membranes and methods for making and using these membranes have been developed. The cross-linked polybenzoxazole and polybenzothiazole polymer membranes are prepared by: 1) first synthesizing polyimide polymers comprising pendent functional groups (e.g., —OH or —SH) ortho to the heterocyclic imide nitrogen and cross-linkable functional groups in the polymer backbone; 2) fabricating polyimide membranes from these polymers; 3) converting the polyimide membranes to polybenzoxazole or polybenzothiazole membranes by heating under inert atmosphere such as nitrogen or vacuum; and 4) finally converting the membranes to high performance cross-linked polybenzoxazole or polybenzothiazole membranes by a crosslinking treatment, preferably UV radiation. The membranes can be fabricated into any convenient geometry. The high performance cross-linked polybenzoxazole and polybenzothiazole polymer membranes of the present invention are suitable for a variety of liquid, gas, and vapor separations.

Owner:UOP LLC

High performance cross-linked polybenzoxazole and polybenzothiazole polymer membranes

InactiveUS8127936B2High selectivityImprove stabilitySemi-permeable membranesMembranesImidePolymer science

In the present invention high performance cross-linked polybenzoxazole and polybenzothiazole polymer membranes and methods for making and using these membranes have been developed. The cross-linked polybenzoxazole and polybenzothiazole polymer membranes are prepared by: 1) first synthesizing polyimide polymers comprising pendent functional groups (e.g., —OH or —SH) ortho to the heterocyclic imide nitrogen and cross-linkable functional groups in the polymer backbone; 2) fabricating polyimide membranes from these polymers; 3) converting the polyimide membranes to polybenzoxazole or polybenzothiazole membranes by heating under inert atmosphere such as nitrogen or vacuum; and 4) finally converting the membranes to high performance cross-linked polybenzoxazole or polybenzothiazole membranes by a crosslinking treatment, preferably UV radiation. The membranes can be fabricated into any convenient geometry. The high performance cross-linked polybenzoxazole and polybenzothiazole polymer membranes of the present invention are suitable for a variety of liquid, gas, and vapor separations.

Owner:UOP LLC

Asymmetric Gas Separation Membranes with Superior Capabilities for Gas Separation

InactiveUS20080143014A1Excellent permeation fluxHigh selectivityMembranesSemi-permeable membranesCellulose diacetatePolymer science

This invention relates to a method of making flat sheet asymmetric membranes, including cellulose diacetate / cellulose triacetate blended membranes, polyimide membranes, and polyimide / polyethersulfone blended membranes by formulating the polymer or the blended polymers dopes in a dual solvent mixture containing 1,3 dioxolane and a second solvent, such as N,N′-methylpyrrolidinone (NMP). The dopes are tailored to be closed to the point of phase separation with or without suitable non-solvent additives such as methanol, acetone, decane or a mixture of these non-solvents. The flat sheet asymmetric membranes are cast by the phase inversion processes using water as the coagulation bath and annealing bath. The dried membranes are coated with UV curable silicone rubber. The resulting asymmetric membranes exhibit excellent permeability and selectivity compared to the intrinsic dense film performances.

Owner:UOP LLC

Multilayer microcavity devices and methods

InactiveUS7144486B1Rapid Detection AnalysisImmobilised enzymesBioreactor/fermenter combinationsConductive materialsPolyimide membrane

Microcavities and micropores that are microscopic (<1 mm) in width and depth and contain any number of individually-addressable electrodes, separated by insulators, along the walls of each cavity. The conducting materials, and the insulator materials can be deposited alternately onto a starting substrate, which is typically an oxidized silicon wafer or polyimide film, but may be any substrate that shows good adhesion to the materials layered on it. The cavities are etched through these layers, perpendicular to the plane of the substrate, exposing the layers at their edges. Pores may be carved entirely through the device.

Owner:SMITHKLINE BECKMAN CORP +1

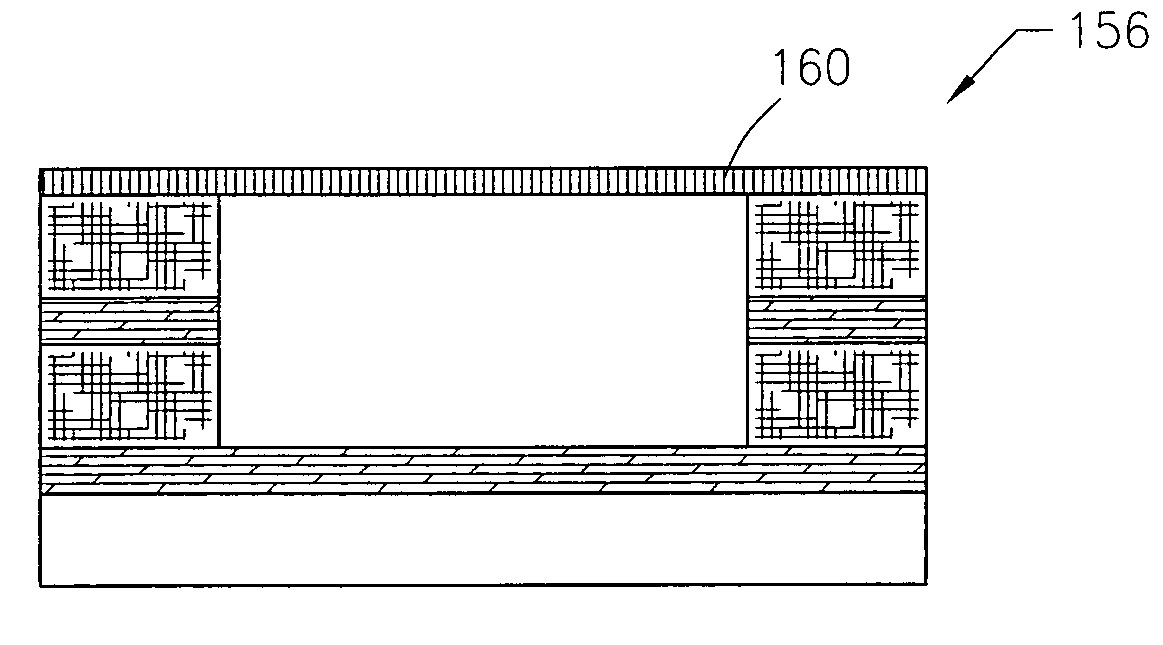

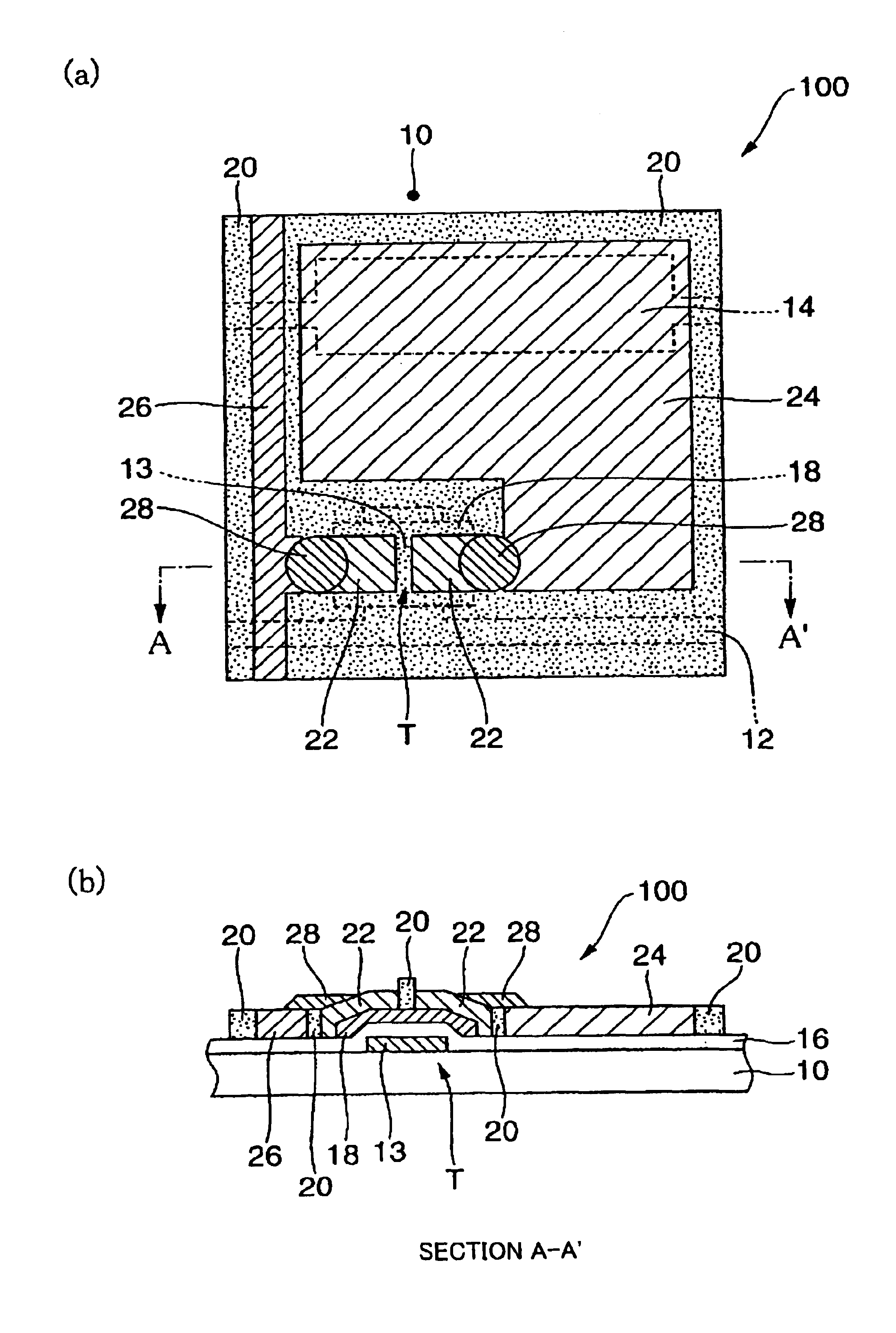

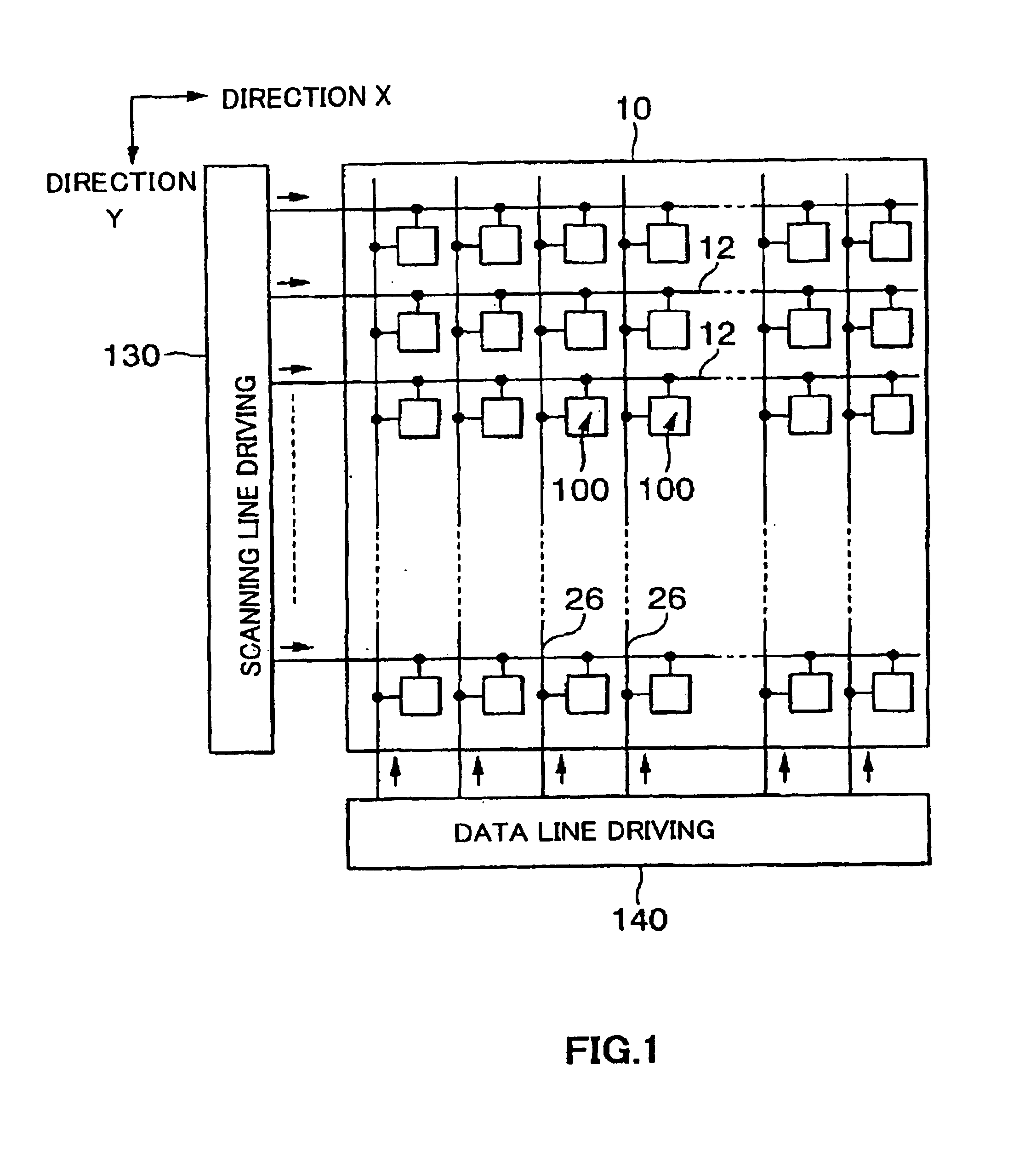

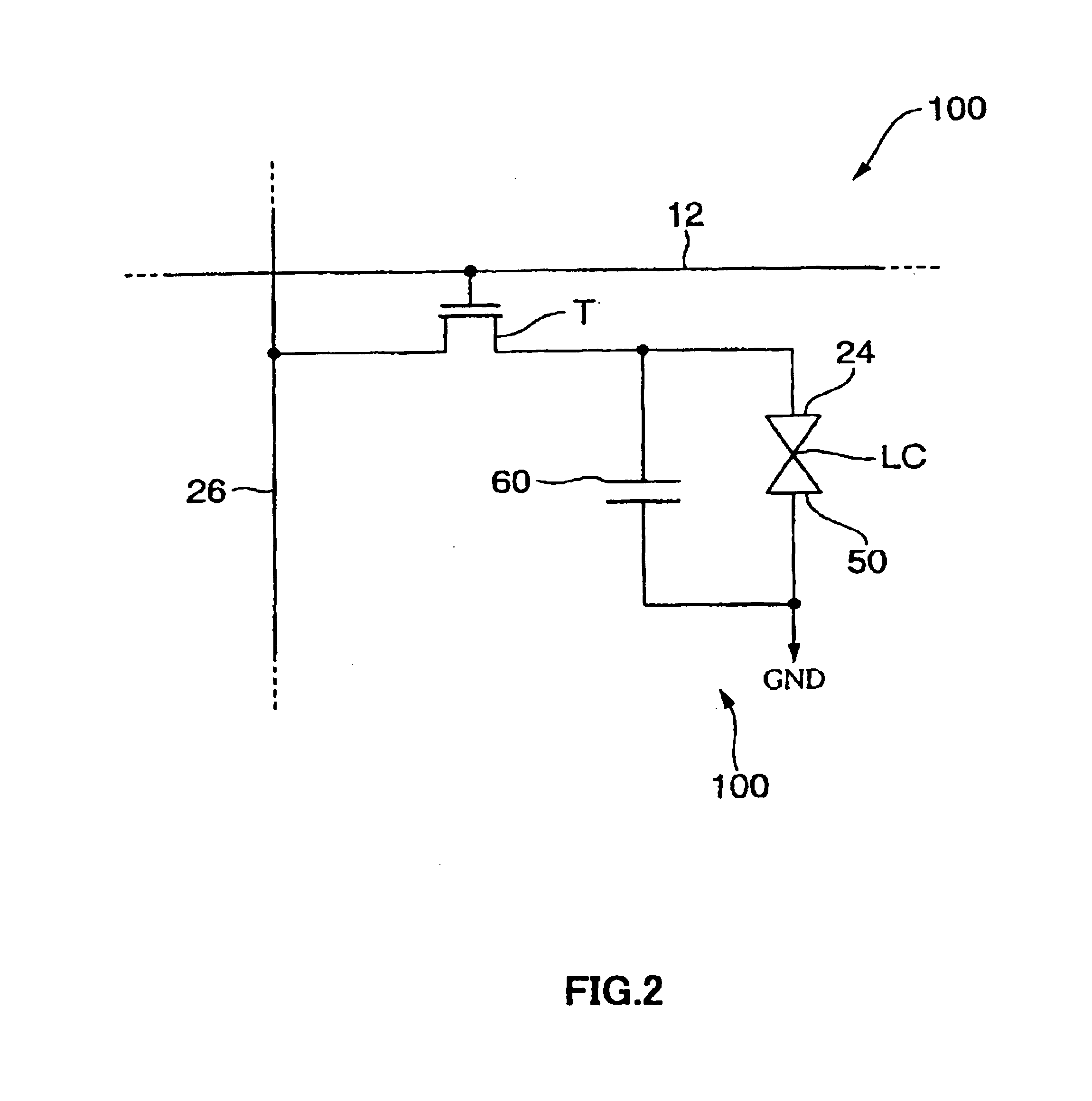

Method of manufacturing an electro-optical device

InactiveUS6908796B2Simple manufacturing processReduce manufacturing costTransistorStatic indicating devicesLiquid-crystal displayEngineering

A pixel portion 100 of a liquid crystal display device includes a thin film transistor T including a gate electrode 13, a gate insulating film 16, a channel region 18, and source / drain regions 22, a source line (data) 26 for supplying current to the thin film transistor T and a pixel electrode 24. In the formation of a pixel circuit 100, a gate electrode 13, a gate insulating film 16, and the channel region 18 are firstly formed on a glass substrate 10. After the formation of the channel region 18 and the like, a polyimide film 20 surrounding the peripheries of the regions to be provide with the source / drain regions 22, the pixel electrode 24 and the source line 26 on a glass substrate 10 is formed. The regions surrounded with the wall of the polyimide film 20 are applied with a liquid material and subjected to a thermal treatment, thereby forming the element of the source / drain regions 22 and the like.

Owner:SEIKO EPSON CORP

Polyimide membranes

InactiveUS20040177753A1Improve performanceStable membranes for gas/vapourMembranesIsotope separationDendrimerHydrocarbon mixtures

The present invention deals with a process for treating a polyimide comprising exposing said polyimide to a compound selected from the group consisting of dendrimers, hyperbranched polymers and mixtures thereof. The polyimide may be in the form of a membrane and the membrane, after treatment according to the process of the invention, may be suitable for use in a membrane-based separation technique, for example gas separation, filtration, microfiltration, ultrafiltration, reverse osmosis or pervaporation. The membrane may for example be suitable for separation of gas and hydrocarbon mixtures including mixtures of H2 / N2, H2 / CO2, He / N2, CO2 / CH4, and C2-C4 hydrocarbon mixtures.

Owner:NAT UNIV OF SINGAPORE

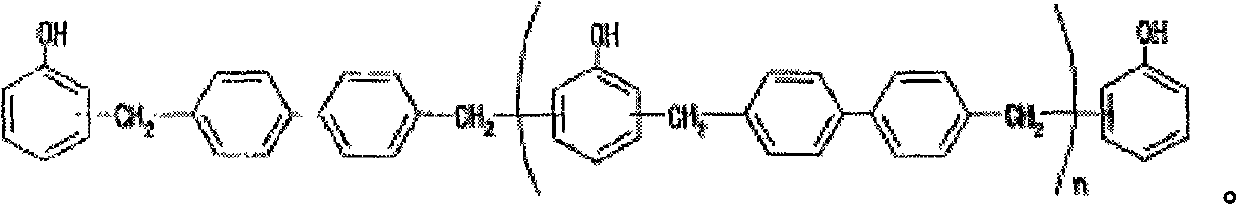

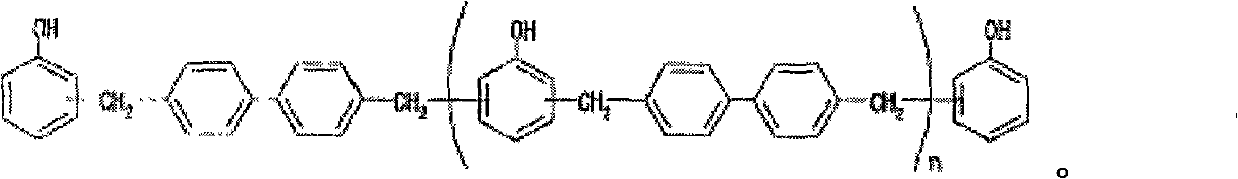

High thermal conductivity resin composition and high thermal conductivity coated metal foil board manufactured by using same

ActiveCN101974208AImprove thermal conductivityImprove heat resistanceMetal layered productsPolyesterEpoxy

The invention relates to a high thermal conductivity resin composition and a high thermal conductivity coated metal foil board manufactured by using the same. The high thermal conductivity resin composition comprises the following components of: epoxy resin, at least one phenoxy resin or carboxy terminal butadiene acrylonitrile, biphenyl phenolic resin and a high thermal conductivity packing material, wherein the biphenyl phenolic resin has the structure shown in the specification. The high thermal conductivity coated metal foil board manufactured by using the high thermal conductivity resin composition comprises a high thermal conductivity adhesive film and metal foils coated on both sides of the high thermal conductivity adhesive film, wherein the high thermal conductivity adhesive film comprises a carrier film and the high thermal conductivity resin composition coated on the carrier film, and the carrier film is a polyester film or a polyimide film. The high thermal conductivity coated metal foil board comprises a resin composite metal foil and a metal foil or another resin composite metal foil coated on the previous resin composite metal foil, and the resin composite metal foil comprises a metal foil and the high thermal conductivity resin composition coated on the metal foil.

Owner:GUANGDONG SHENGYI SCI TECH

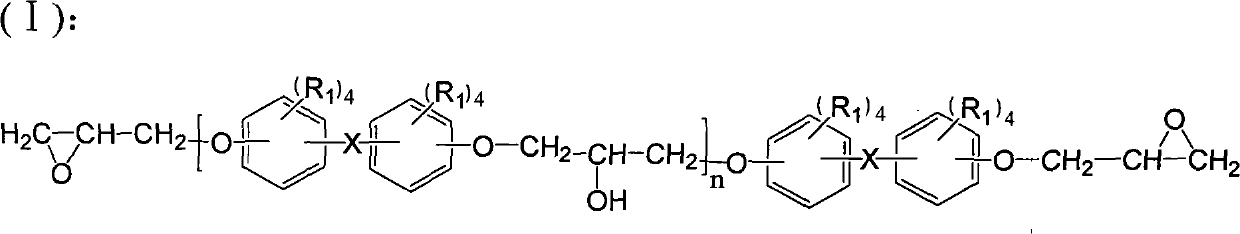

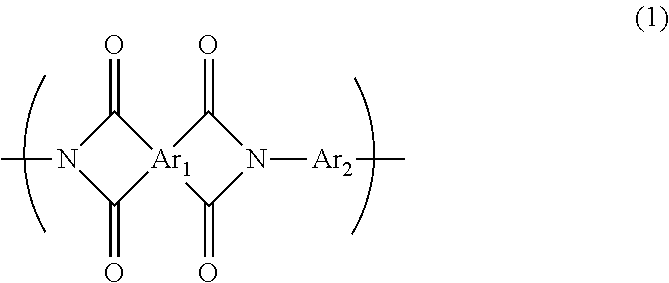

Polyamic acid resin composition and polyimide film prepared therefrom

A polyamic acid resin composition, and a polyimide film and laminate prepared therefrom are provided. The polyamic acid resin composition includes a polyamic acid resin, a solvent, and a polar aprotic solution containing nanoscale silica, with surface hydroxyl groups, modified by a surface modification agent. Particularly, the surface modification agent has a structure represented by formula (I):R1—Si—(OR2)3 formula (I)wherein, R1 is an aliphatic group or an aryl group, and R2 is a C1-8 alkyl group.

Owner:IND TECH RES INST

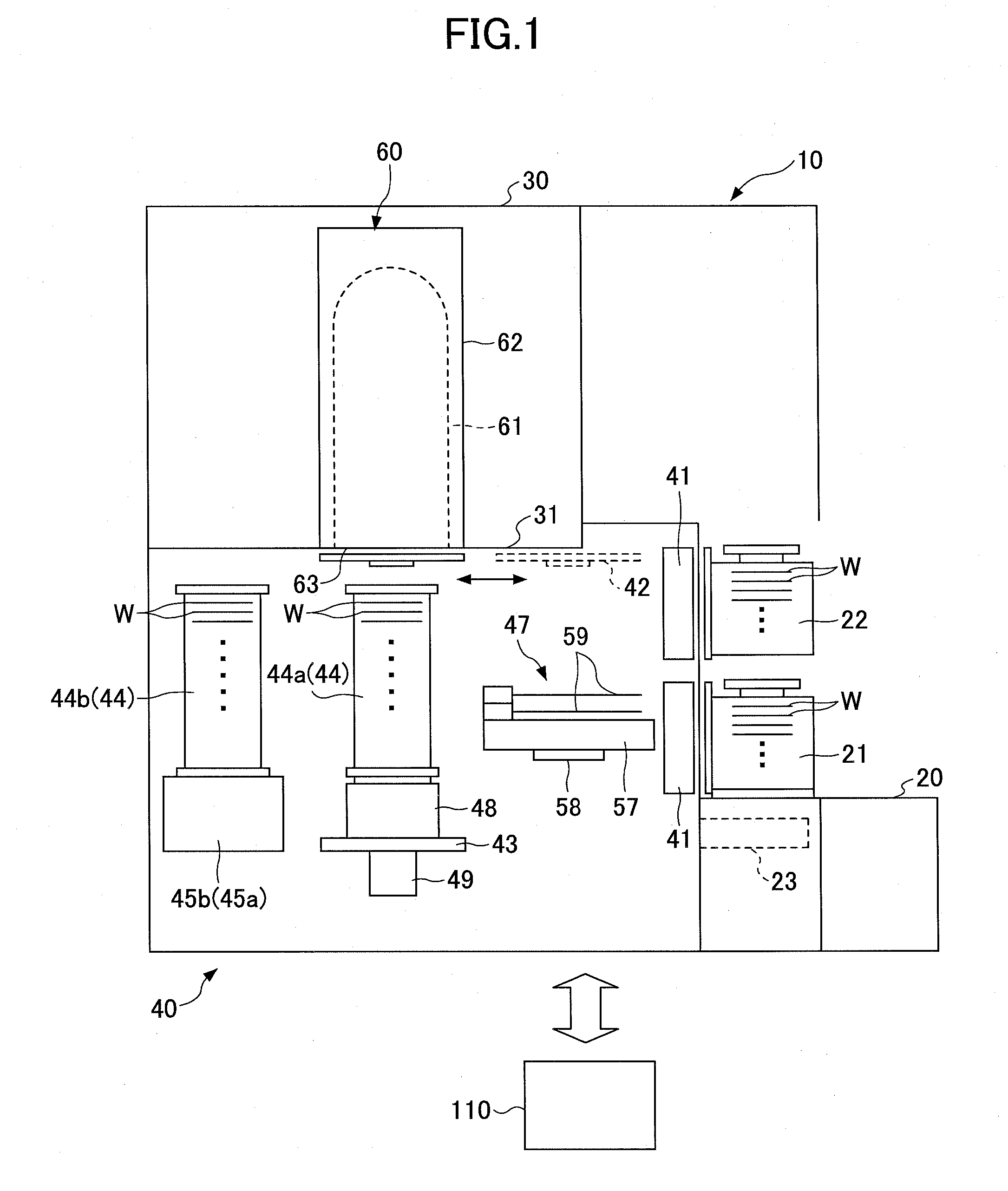

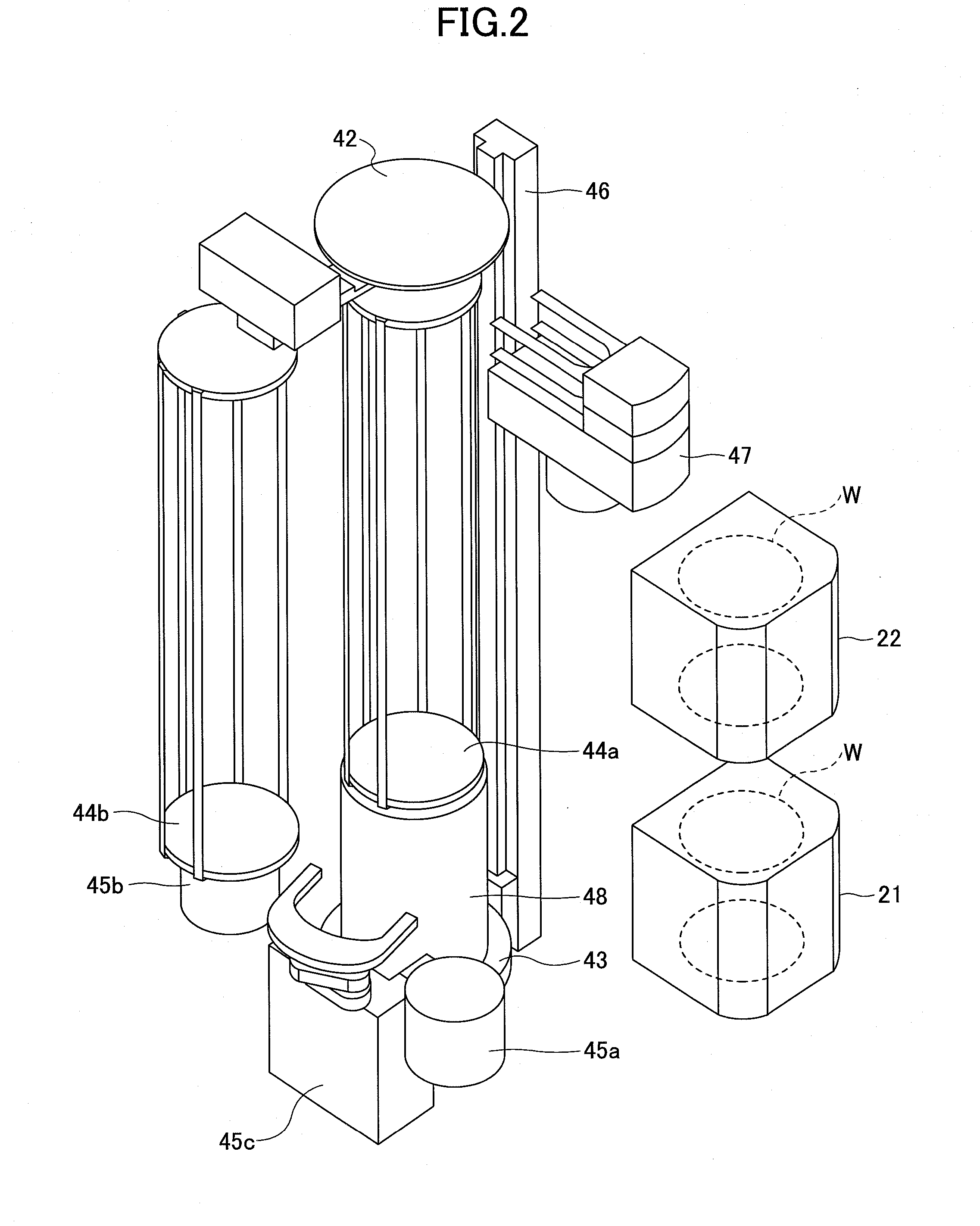

Cleaning method and film depositing method

InactiveUS20120269970A1Avoid problemsLighting and heating apparatusHollow article cleaningDiaminePolyimide membrane

A cleaning method for a film deposition apparatus that deposits a polyimide film conveyed into a film deposition chamber by feeding a first source gas formed of dianhydride and a second source gas formed of diamine into the film deposition chamber, the method including the steps of: generating an oxygen atmosphere in the film deposition chamber, and removing polyimide remaining in the film deposition chamber by heating the film deposition chamber at a temperature of 360° C. to 540° C. in the oxygen atmosphere and oxidizing the polyimide.

Owner:TOKYO ELECTRON LTD

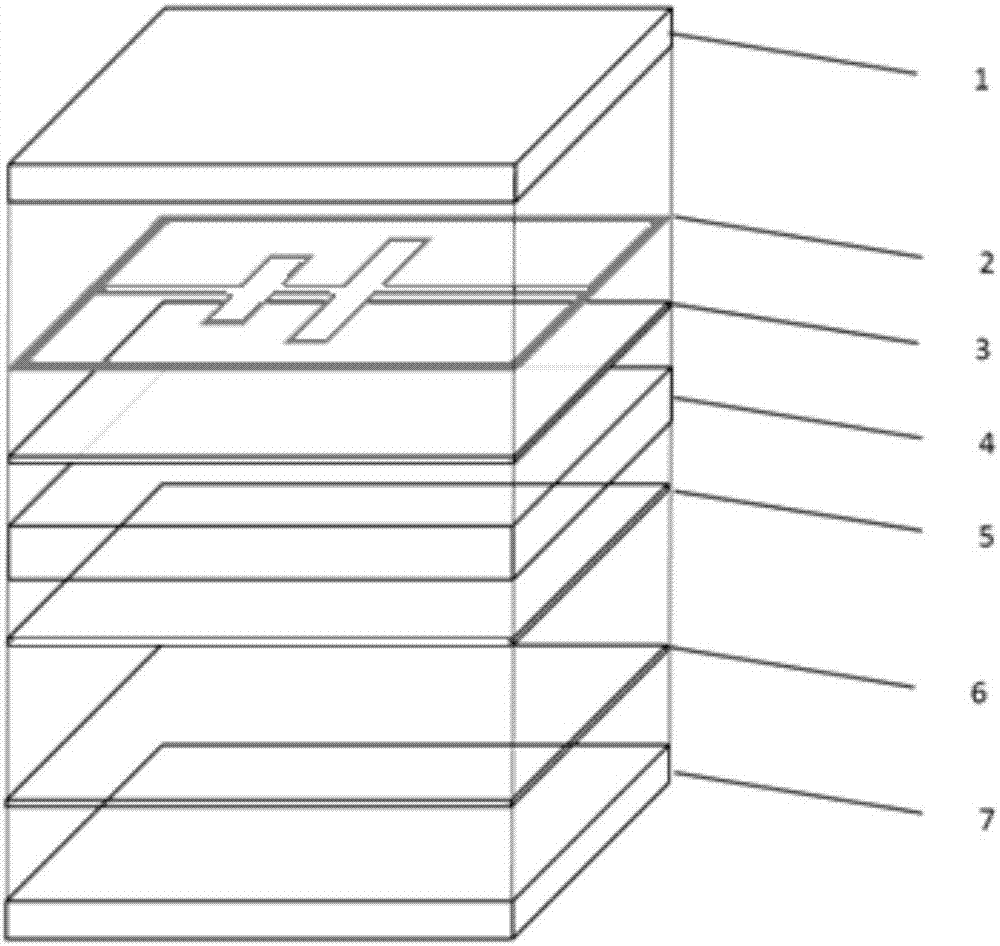

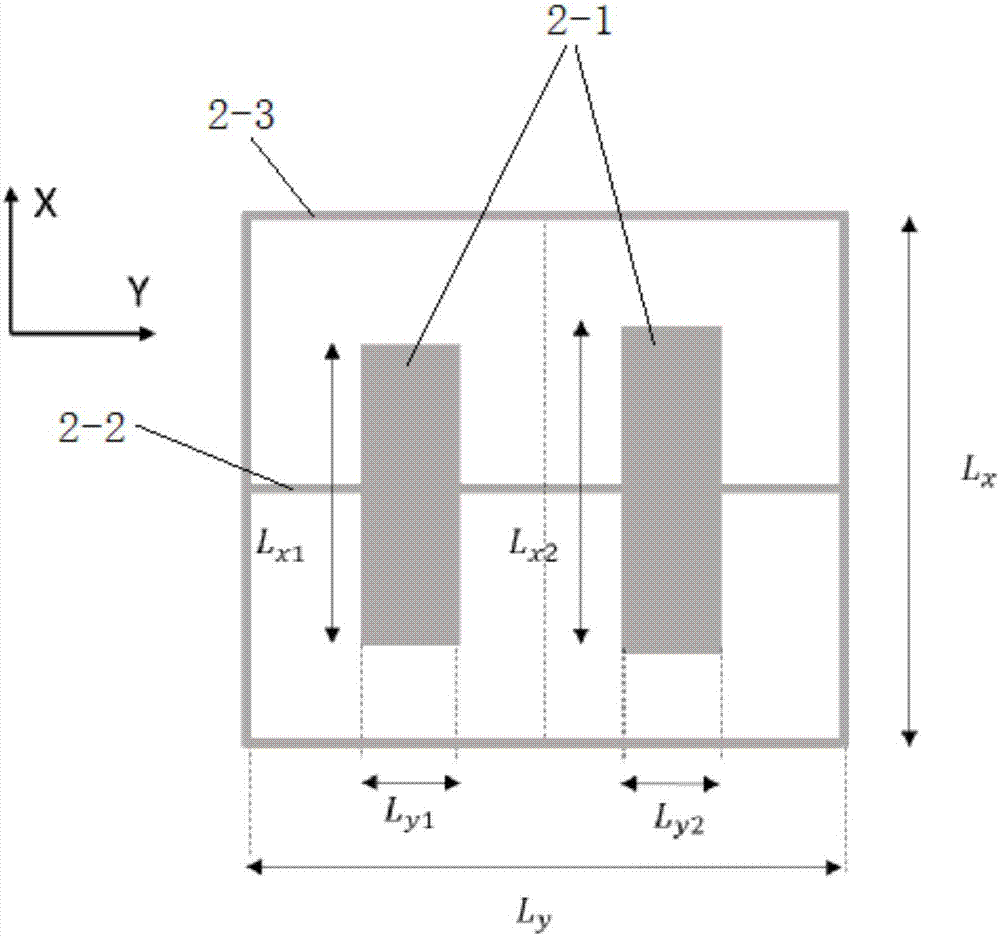

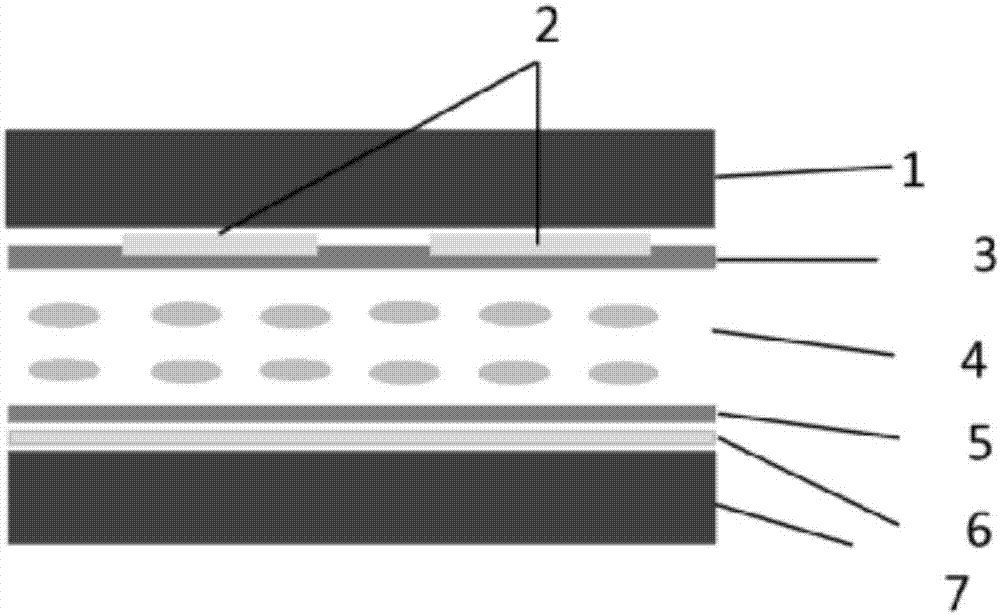

Liquid crystal phase shift unit for reflected adjustable phase shifter

The invention discloses a liquid crystal phase shift unit for a reflected adjustable phase shifter. The liquid crystal phase shift unit comprises two upper and lower layers of medium substrates, a liquid crystal layer is injected in the gap between the two upper and lower layers of medium substrates, a metal microstrip patch electrode is arranged on the lower side of the upper layer medium substrate, a metal total reflection ground electrode is arranged on the upper side of the lower layer medium substrate, and polyimide film coating is respectively arranged on upper and lower surfaces of the liquid crystal layer; the metal microstrip patch electrode comprises two identical dipole patches, an offset voltage loading line and an auxiliary electrode, the two dipole patches are arranged in parallel, the offset voltage loading line is connected with the two dipole patches orthogonally to form a patch unit, the auxiliary electrode is a quadrilateral metal frame, and the quadrilateral metal frame surrounds the whole patch unit and is connected with the offset voltage loading line. The auxiliary electrode has a simple main body structure, educes the saturation bias voltage, and can be used in the field of liquid crystal reflected phase shifters and phase control antennas within microwave, millimeter wave and terahertz frequency bands.

Owner:HEFEI UNIV OF TECH

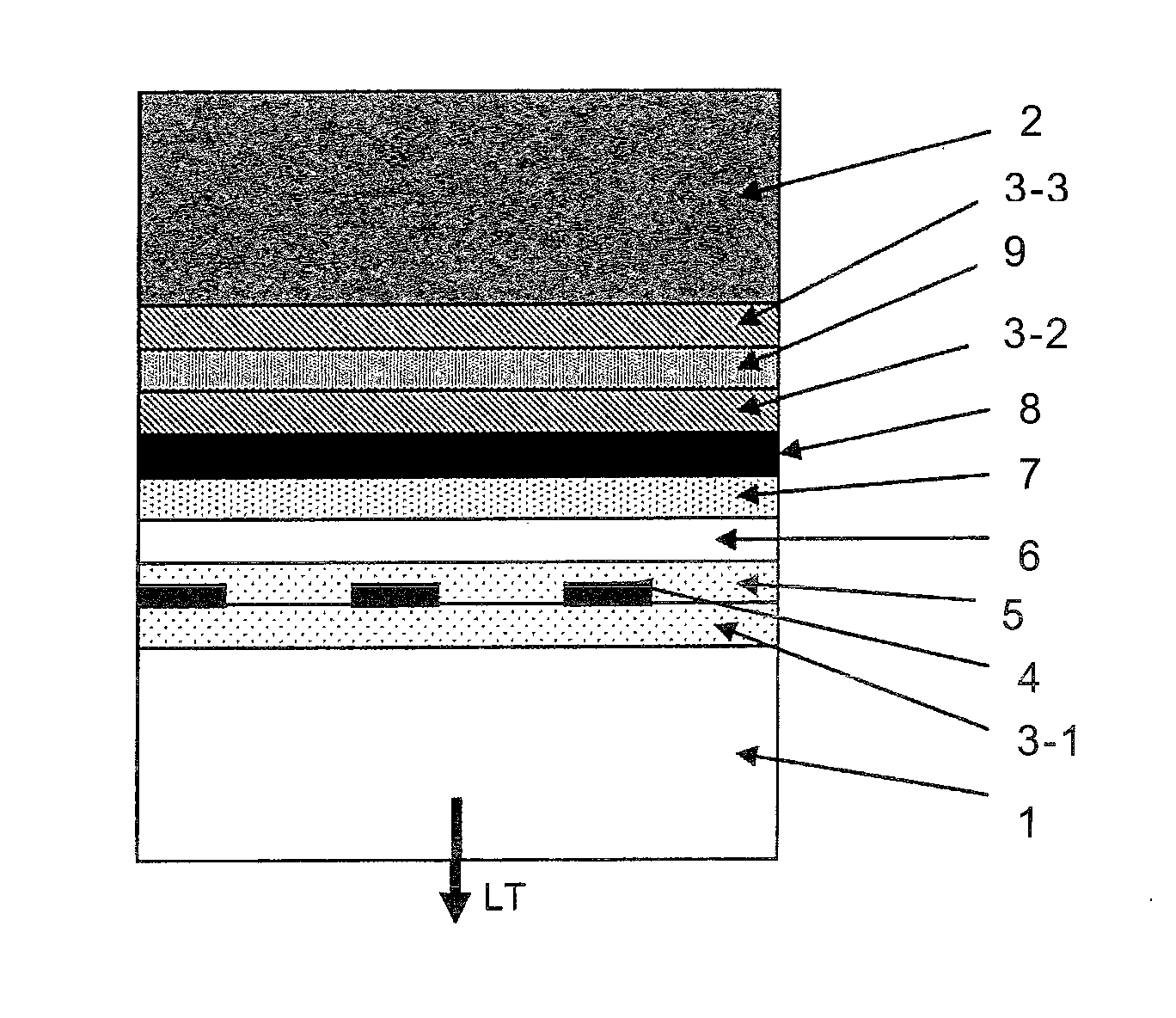

Display device, method for manufacturing same, polyimide film for display device supporting bases, and method for producing polyimide film for display device supporting bases

Provided is a display device that can be made thin, lightweight, and flexible, has no problems of cracks and peeling caused by thermal stress, and is excellent in dimension stability and the like. The display device includes: a supporting base including a polyimide film; and a gas barrier layer formed on the supporting base, in which the polyimide film has a transmittance of 80% or more in a wavelength region of from 440 nm to 780 nm, and a coefficient of thermal expansion of 15 ppm / K or less, and has a difference in coefficient of thermal expansion from the gas barrier layer of 10 ppm / K or less.

Owner:NIPPON STEEL CHEMICAL CO LTD

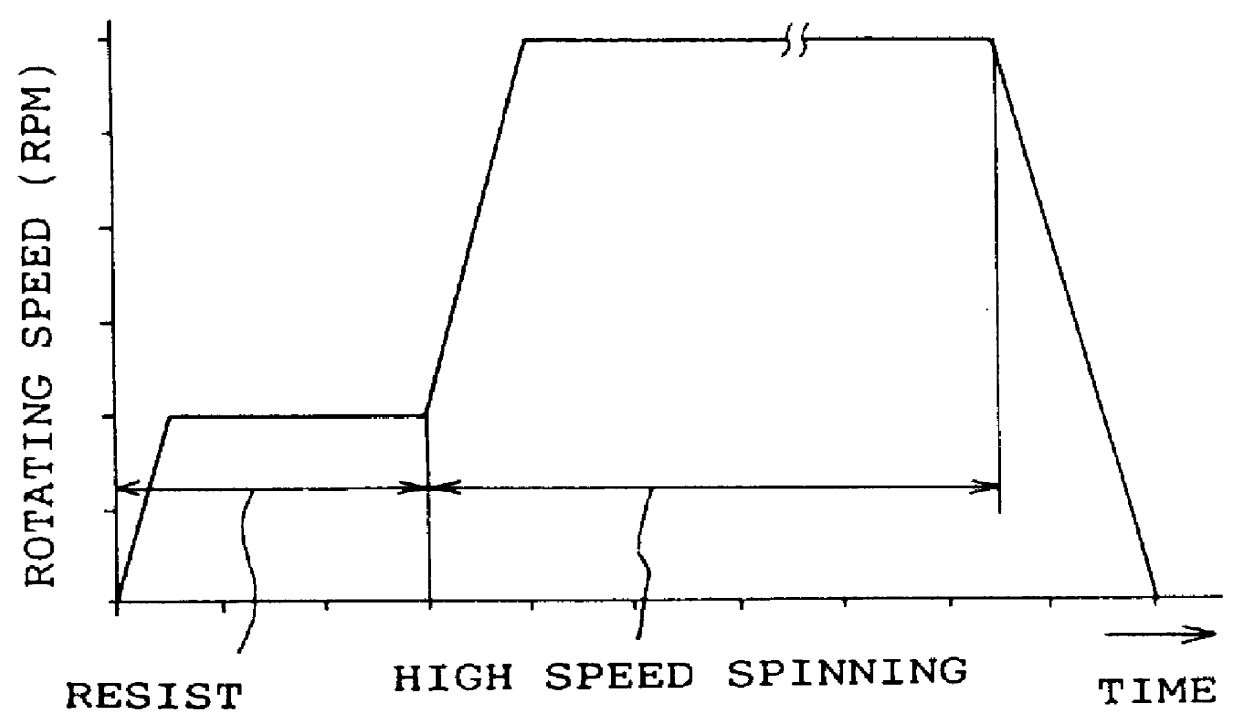

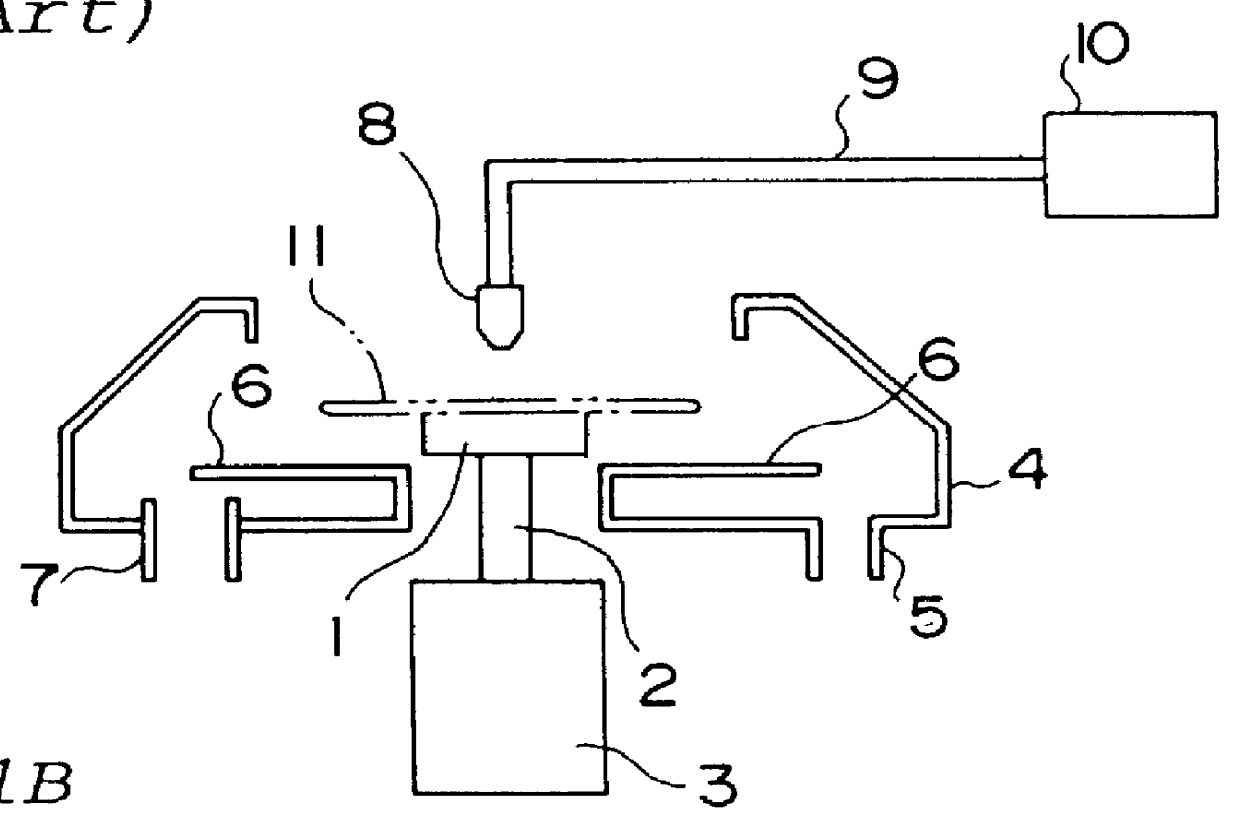

Apparatus for spin coating, a method for spin coating and a method for manufacturing semiconductor device

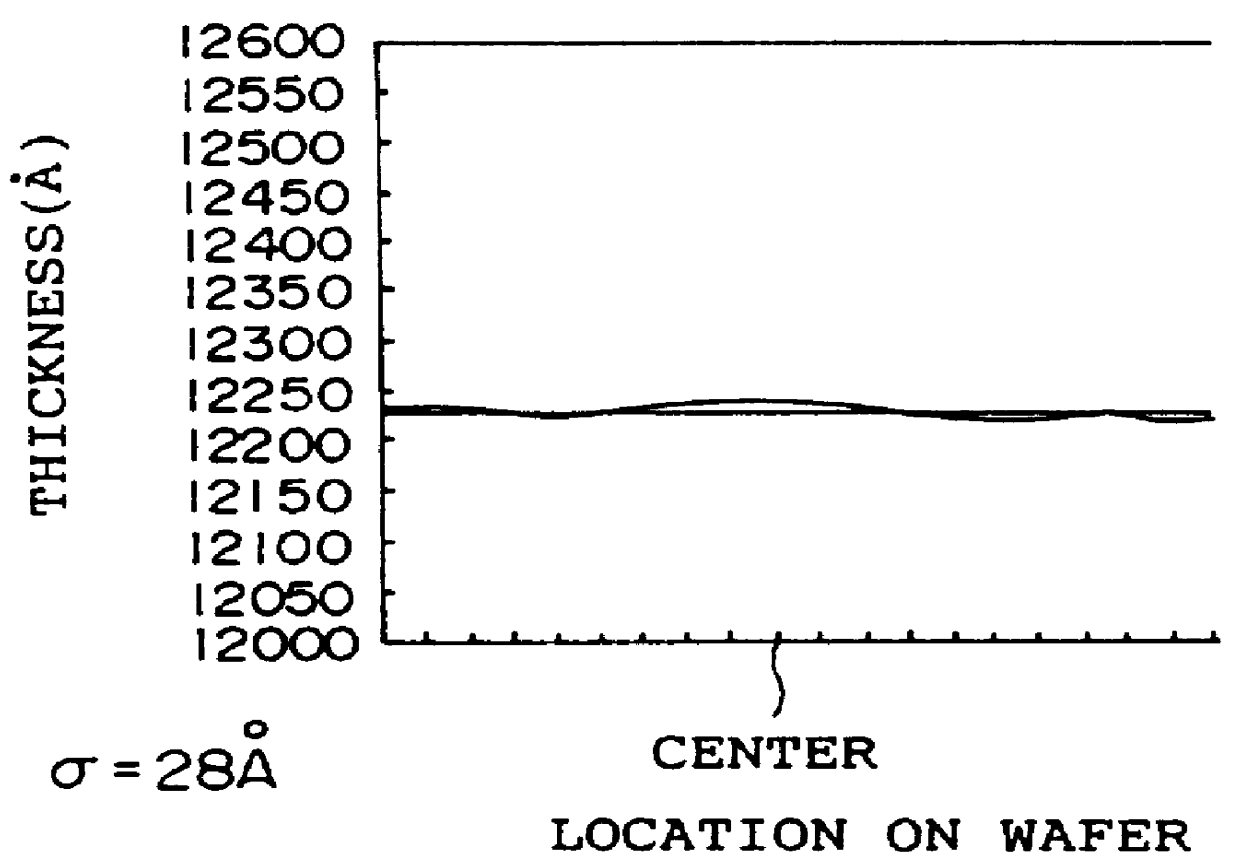

InactiveUS6033728APretreated surfacesSemiconductor/solid-state device manufacturingEngineeringSolvent

The invention relates to an apparatus for spin coating for forming a resist film, an SOG film, a polyimide film, and the like in manufacturing semiconductor devices and has the object of forming a coated film with a specified and uniform thickness even in case that an amount of discharged coating solution is a little. An apparatus for spin coating of the invention comprises a rotatable table for placing a wafer, a coating solution discharging means which is set above the rotatable table and discharges a coating solution on the surface of the wafer, and a solvent discharging means which is above the rotatable table and discharges a solvent capable of dissolving the coating solution.

Owner:FUJITSU SEMICON LTD

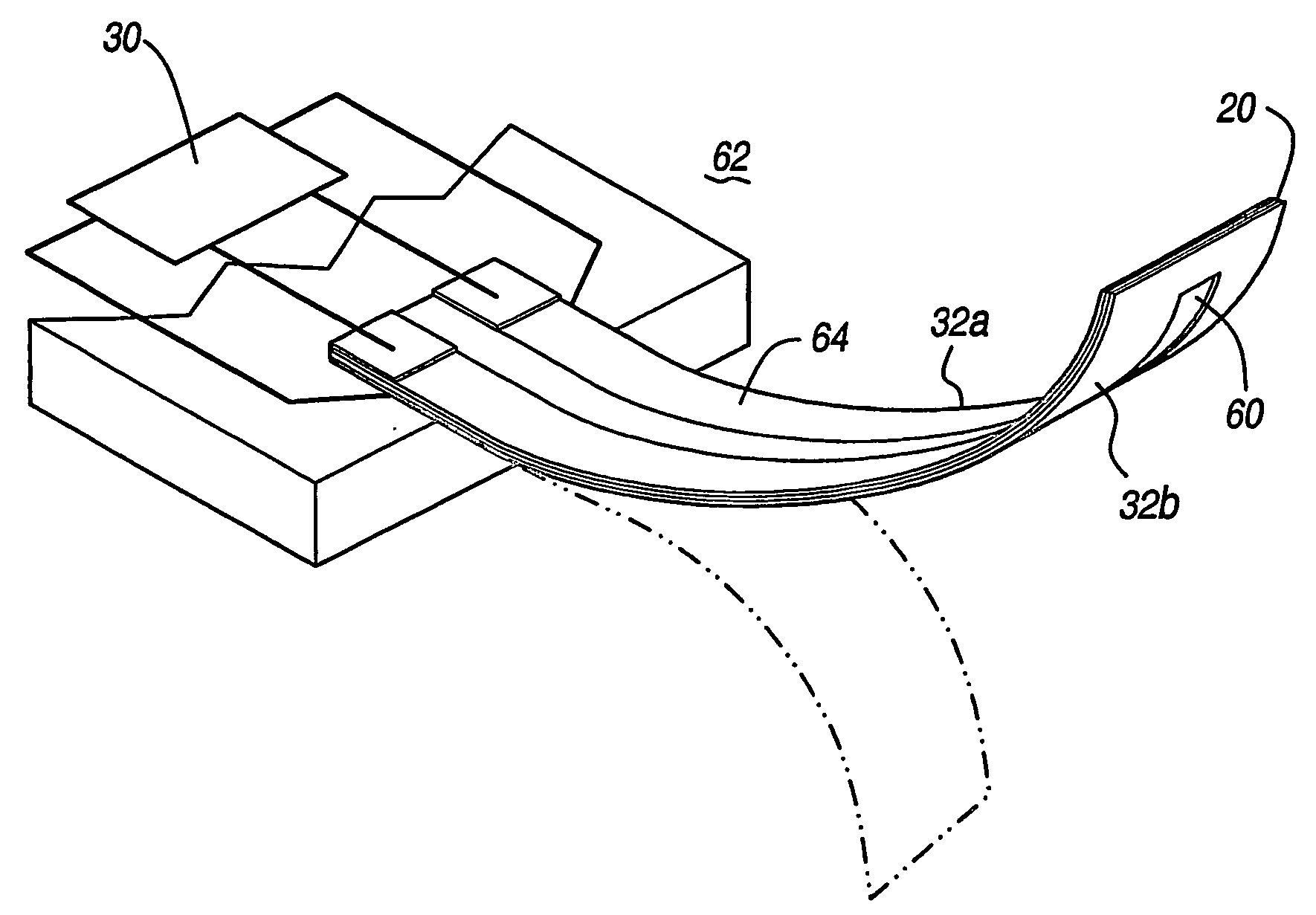

Prestrained thin-film shape memory actuator using polymeric substrates

InactiveUS20070034818A1Maximize heat transfer rateStart fastElectrical transducersOperating means/releasing devices for valvesShape-memory alloyAlloy

A method for producing a plurality of thin film actuators is disclosed. The method includes depositing a film of a shape memory alloy material onto a polyimide film to form a shape memory alloy construction. The shape memory alloy construction is strained from 2 to 8%. Post processing is conducted on the shape memory alloy construction after the step of imparting a 2 to 8% strain. This post processing can be the deposition of additional layers of the slicing of the actuators. Various shape memory metal actuators are disclosed.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

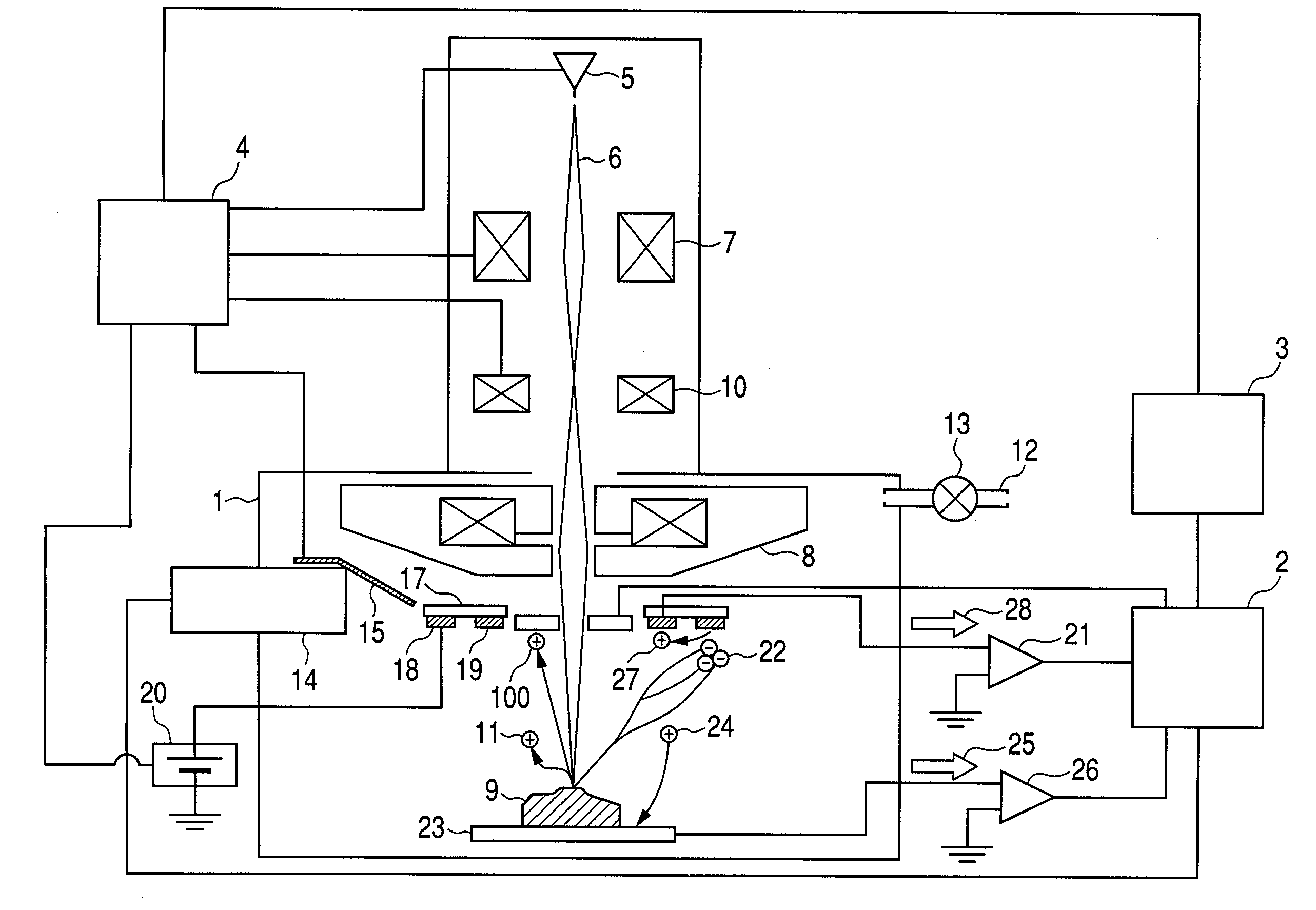

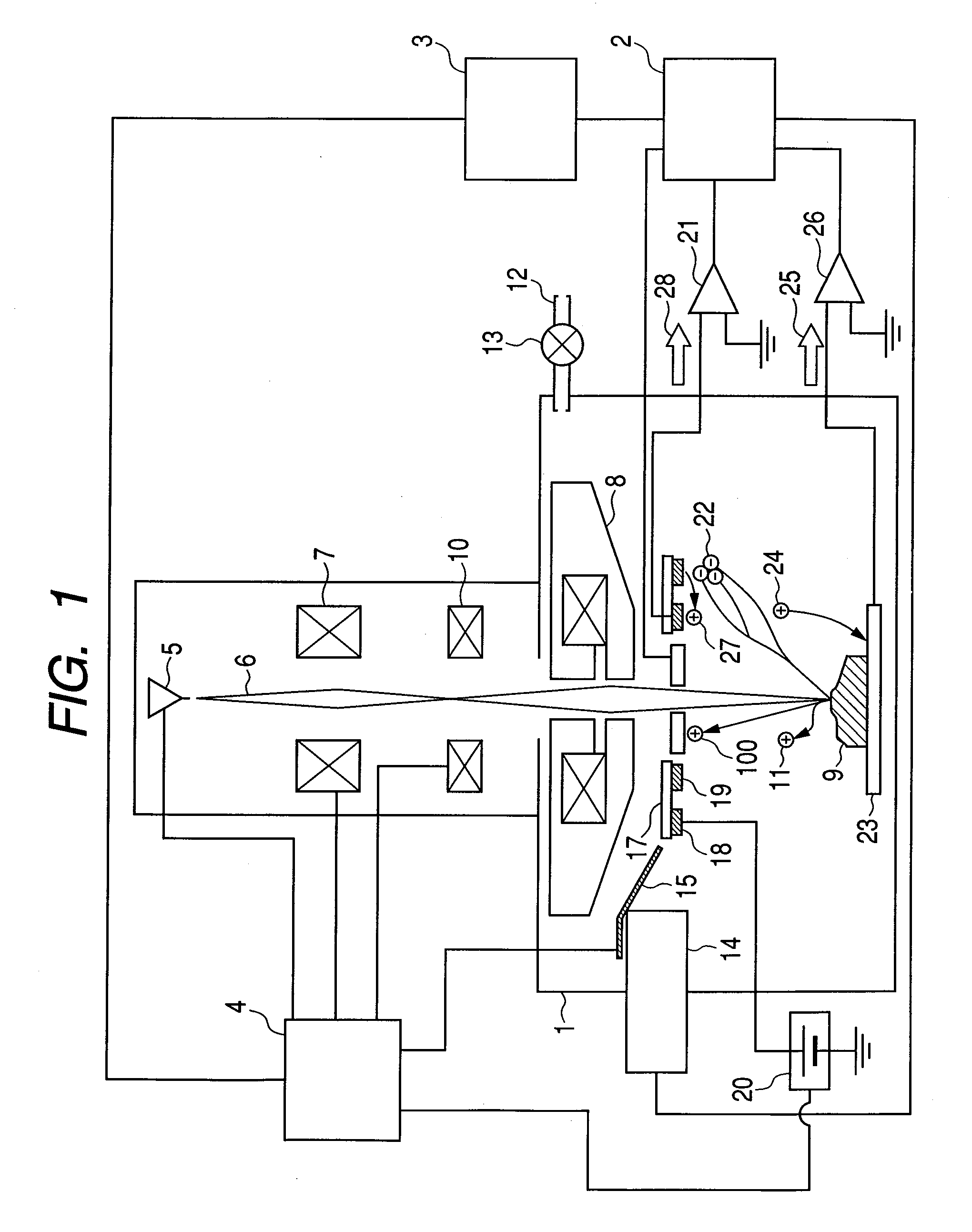

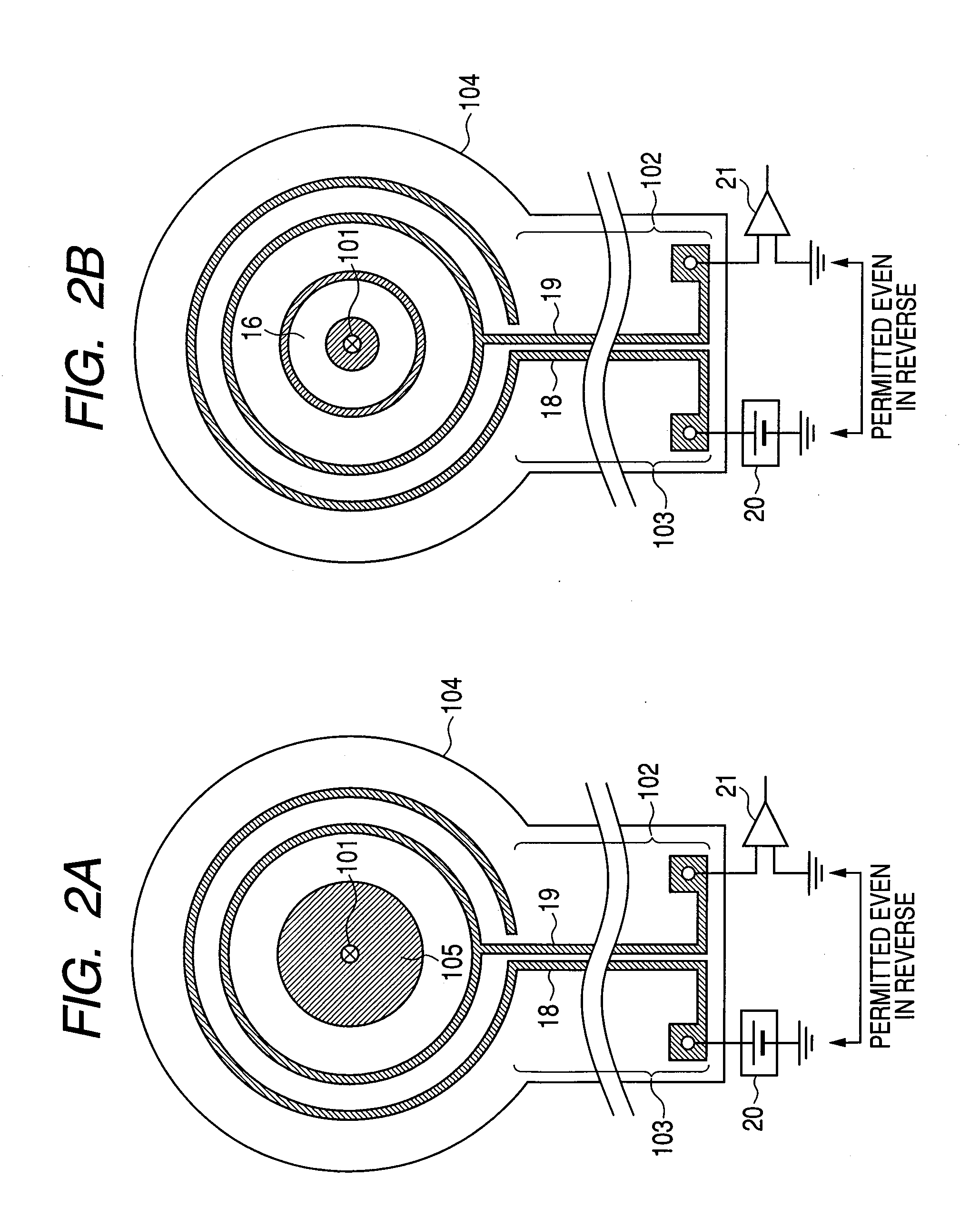

Scanning electron microscope

InactiveUS20090230304A1Low costSave spaceThermometer detailsMaterial analysis using wave/particle radiationScanning tunneling microscopeScanning electron microscope

In a VP-SEM that uses gas multiplication induced within a low-vacuum sample chamber and uses a method of detecting a positive displacement current, a secondary electron detector for the VP-SEM that responds at high speed, which can acquire a TV-Scan rate image at a low cost while saving a space is provided. A secondary electron detector is formed by forming the electron supplying electrode and the detection electrode on the flexible thin film type substrate such as a polyimide film, etc., by an etching method. Thereby, the space can be saved while realizing low cost due to mass production. Further, the ion horizontally moving with respect to the surface of the secondary electron detector is detected and the ion moving in a vertical direction returned to the sample holder is not detected, making it possible to realize a high-speed response.

Owner:HITACHI HIGH-TECH CORP

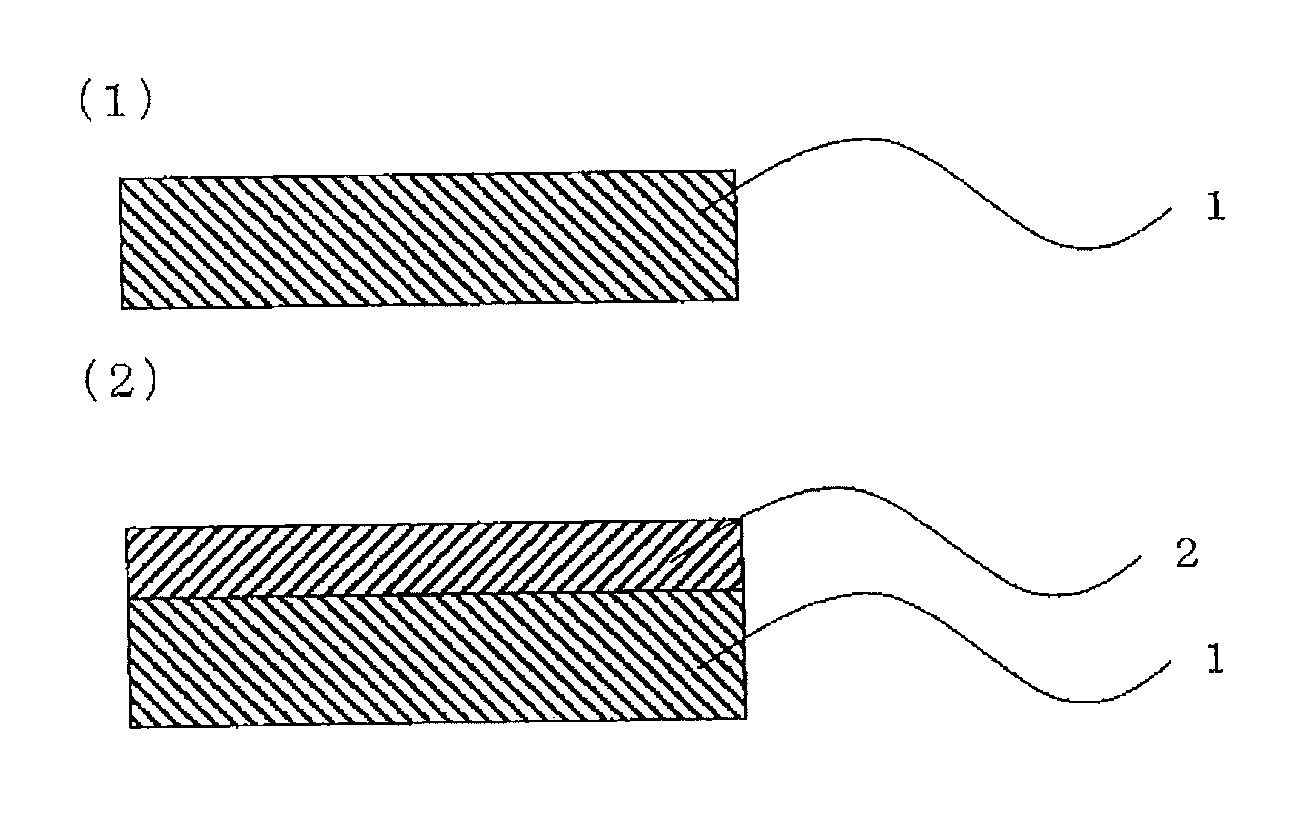

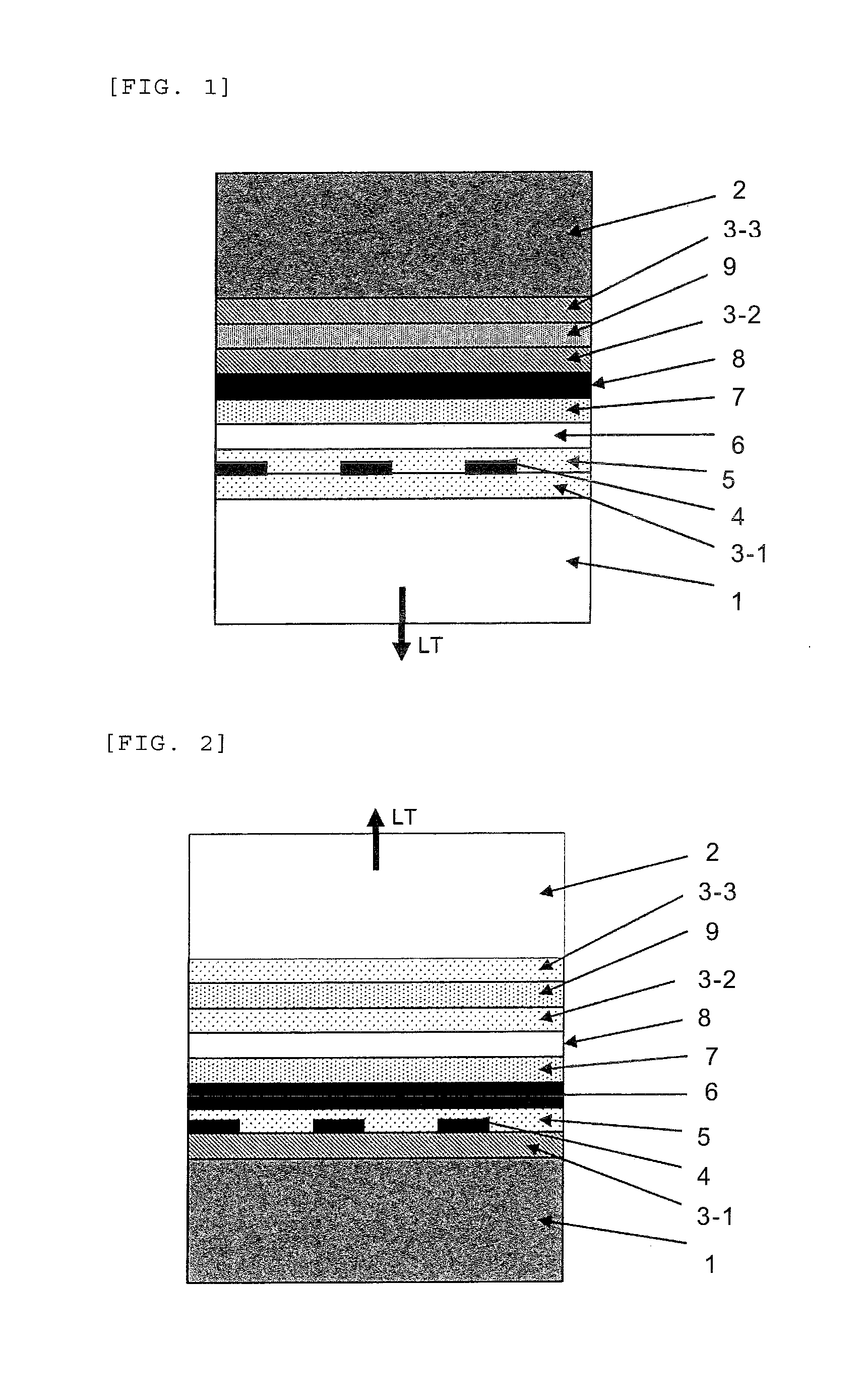

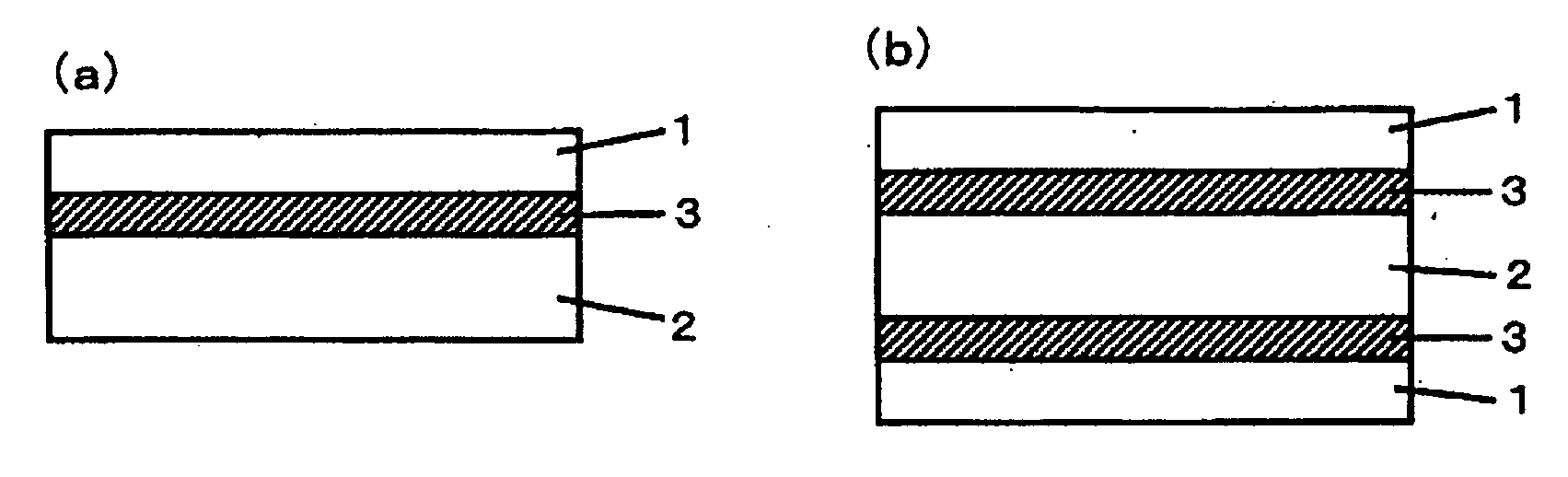

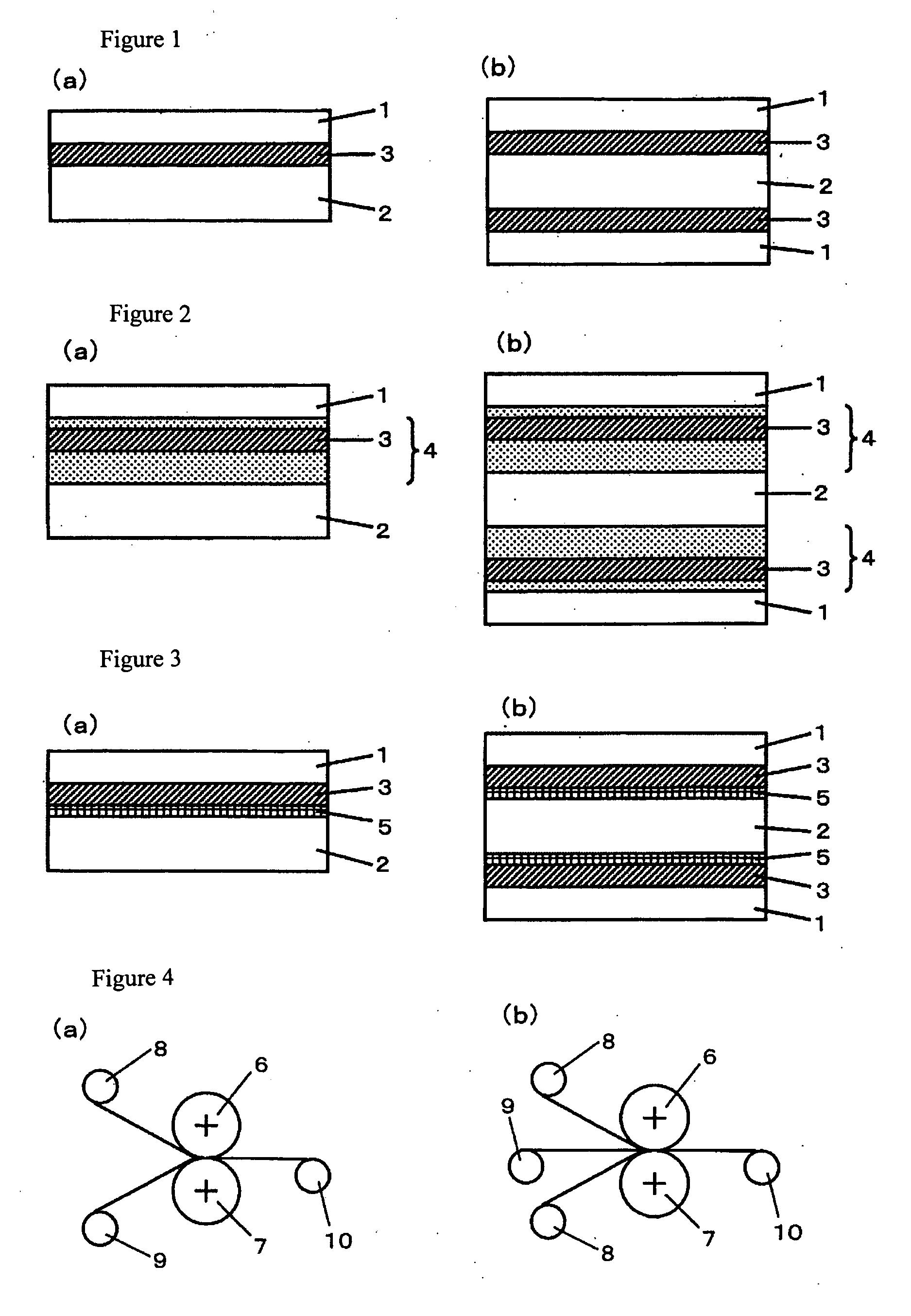

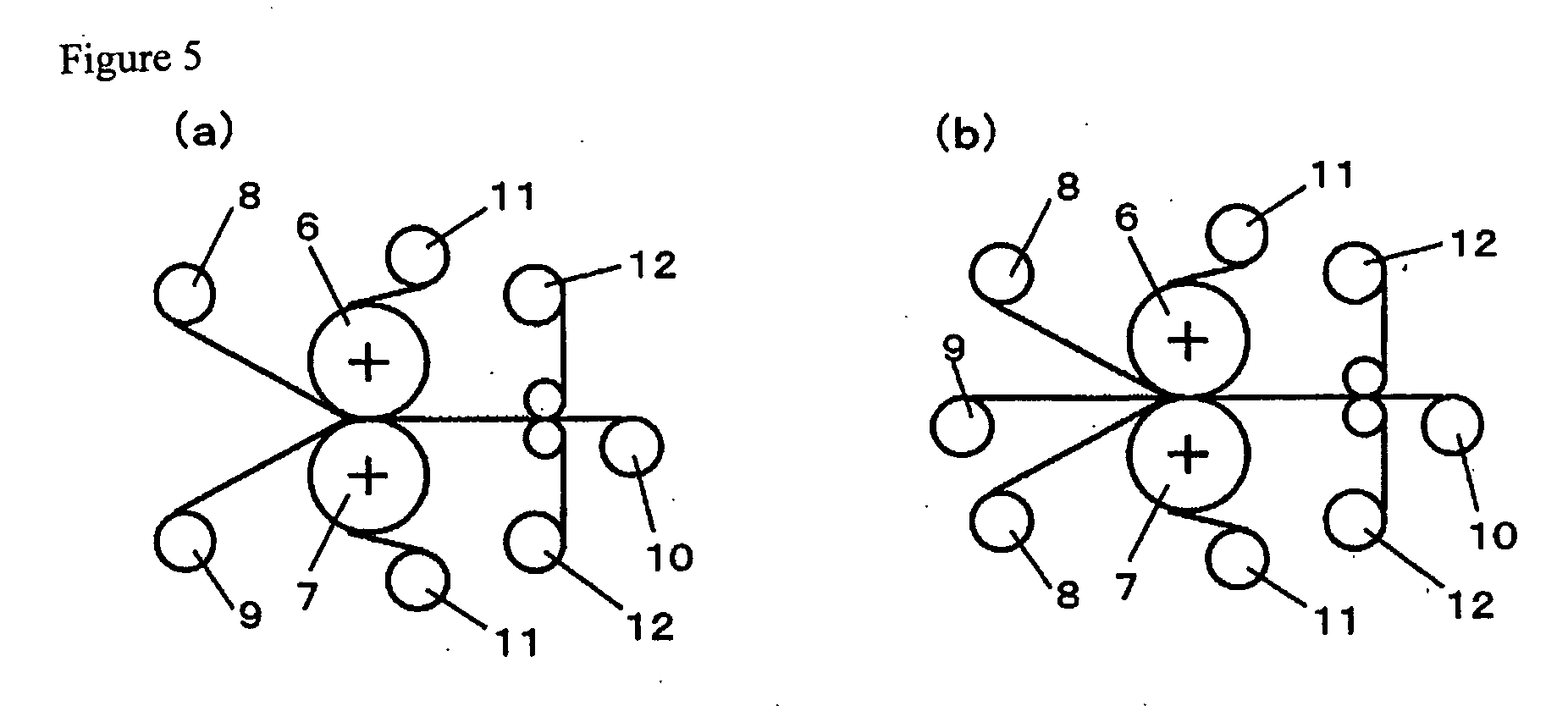

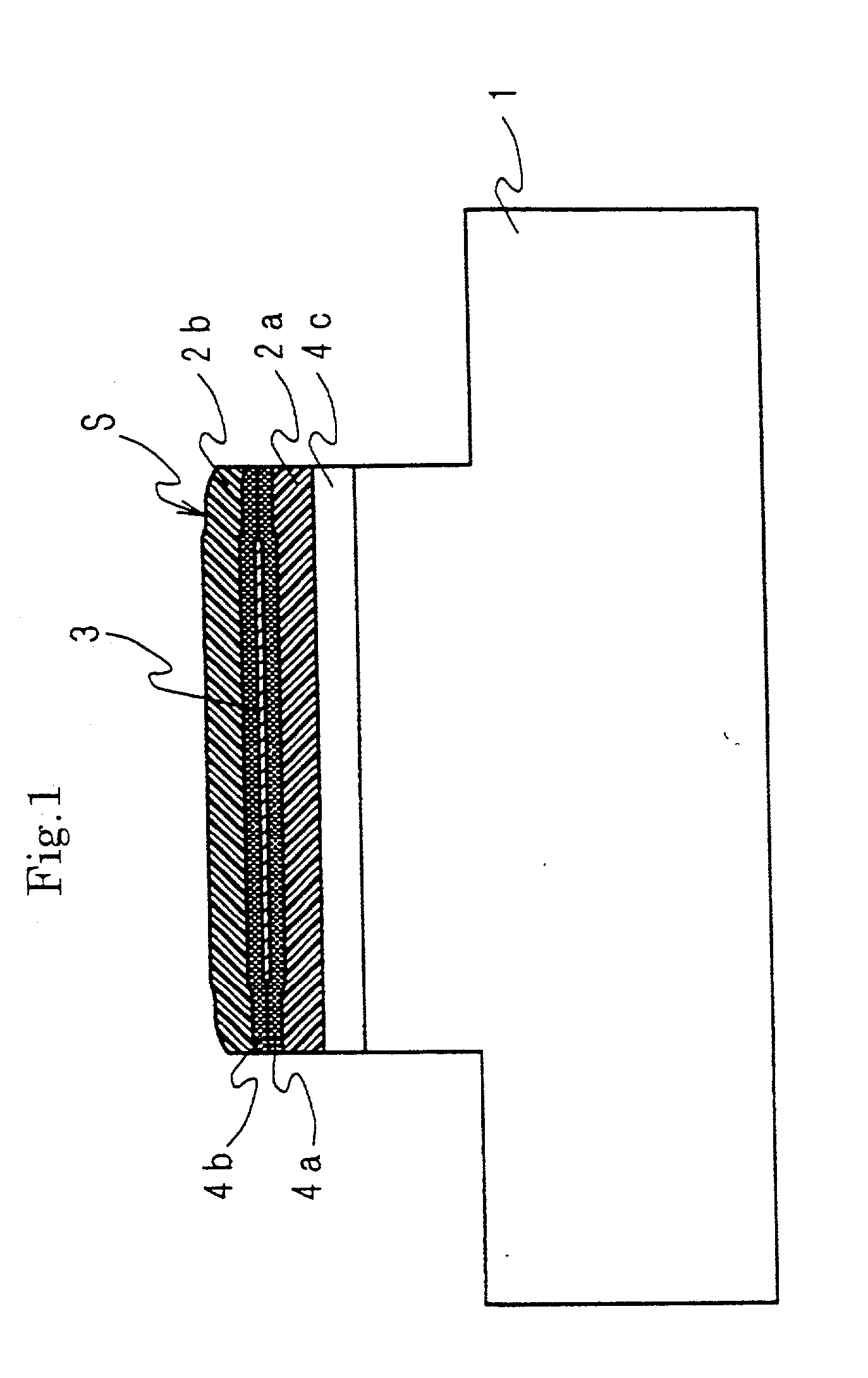

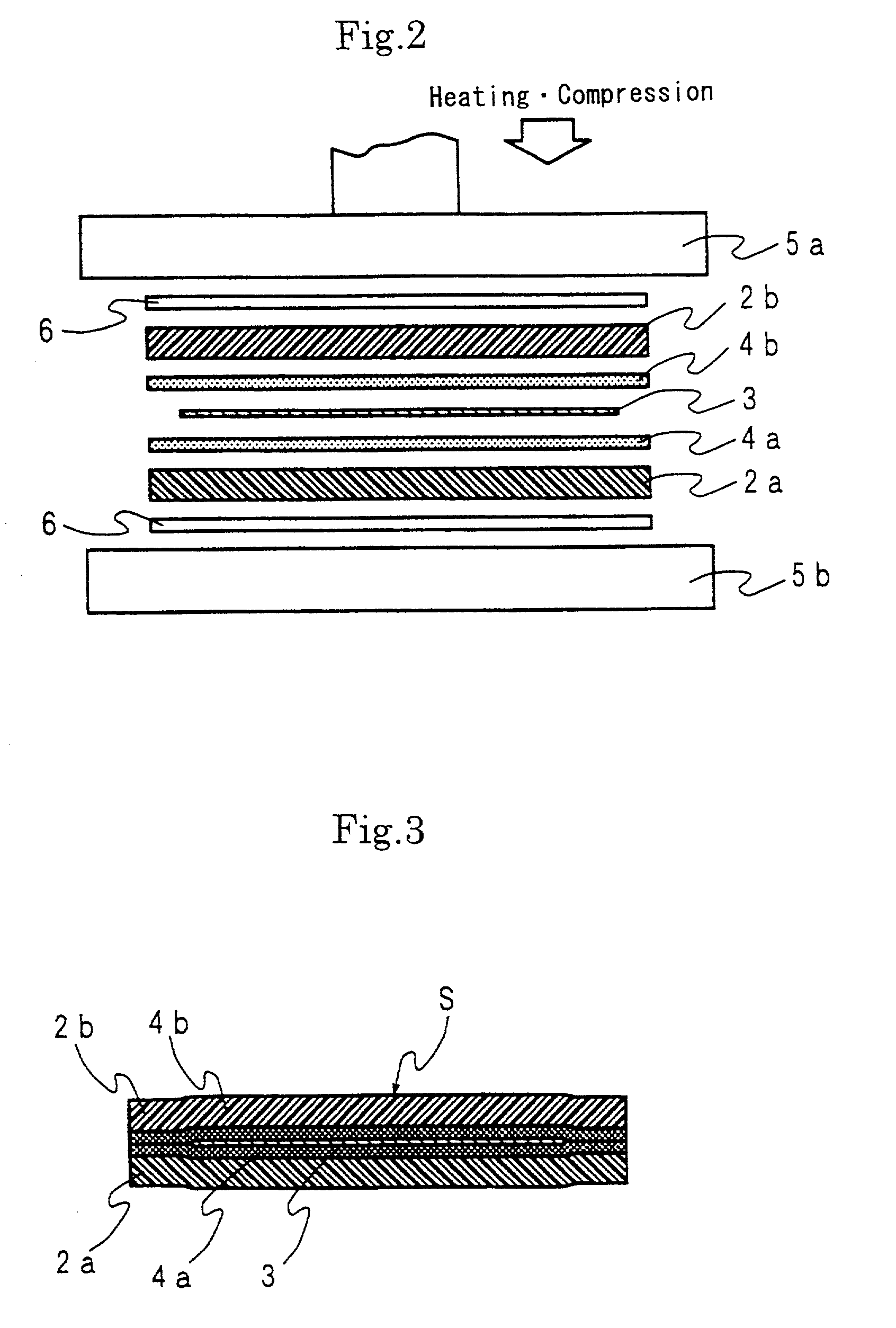

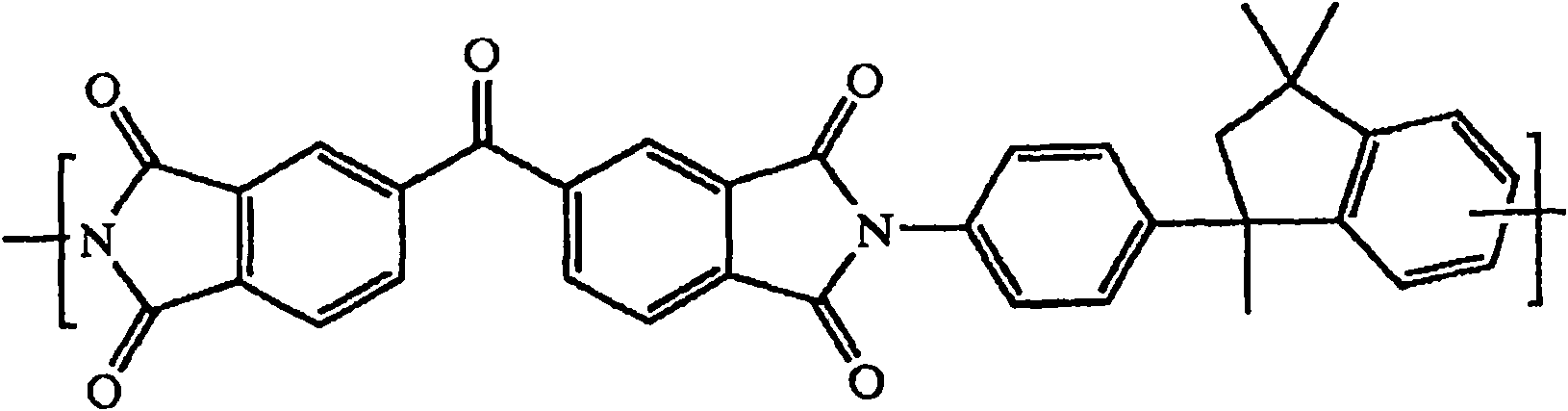

Heat-resistant resin laminated film, multilayer film with metal layer including same and semiconductor device

InactiveUS20070169886A1Improve reliabilityHighly reliable semiconductor deviceSynthetic resin layered productsPrinted circuit aspectsDevice materialPolyimide membrane

Disclosed are a heat-resistant resin laminate film comprising a heat-resistant insulating film such as a polyimide film and a heat-resistant resin layer laminated thereon, which laminate film is free from warp; and a laminate film with a metal layer, comprising a heat-resistant insulating film and a metal layer laminated thereon through a heat-resistant resin layer, which laminate film with a metal layer is free from warp in the state that a circuit pattern is formed. In the heat-resistant resin laminate film, a heat-resistant resin layer is laminated on at least one surface of the heat-resistant insulating film, wherein the heat-resistant resin layer has a coefficient of linear expansion kA (ppm / ° C.) within the range of k−10≦kA≦k+20 (k: coefficient of linear expansion of the heat-resistant insulating film). The laminate film with a metal layer is one obtained by laminating the metal layer on the heat-resistant resin layer of the heat-resistant resin laminate film.

Owner:TORAY IND INC

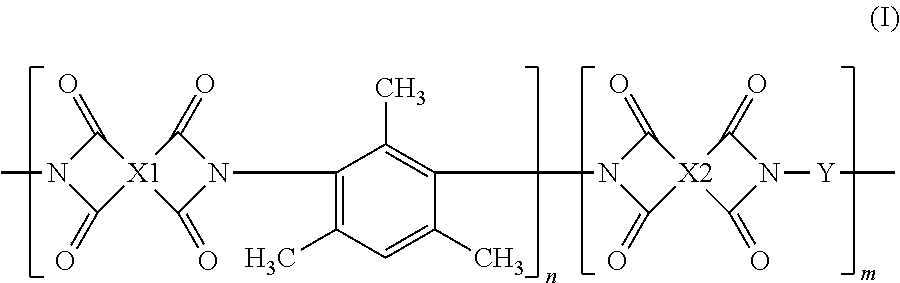

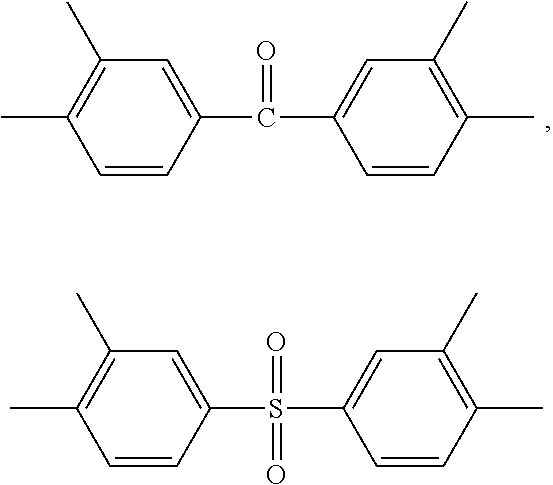

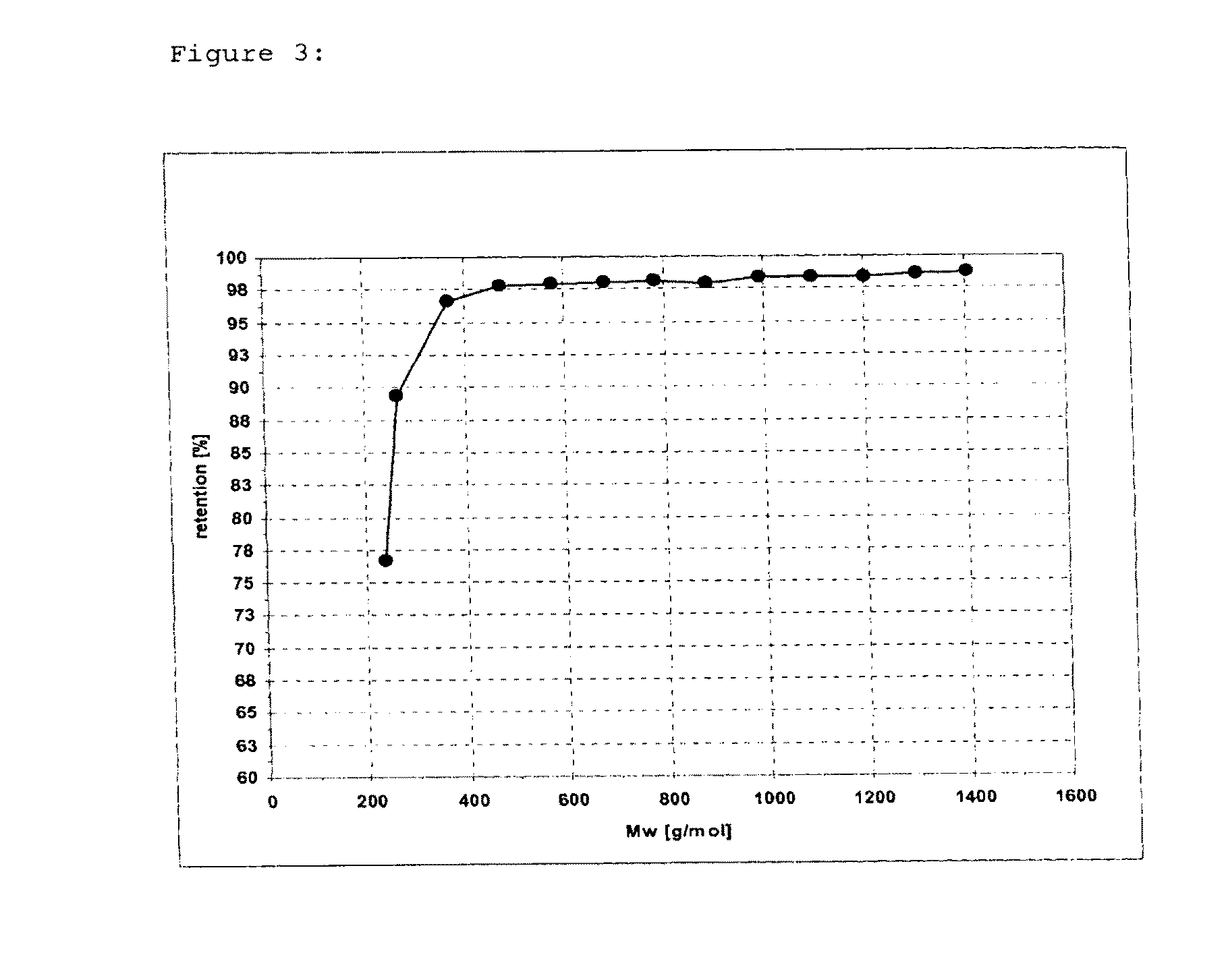

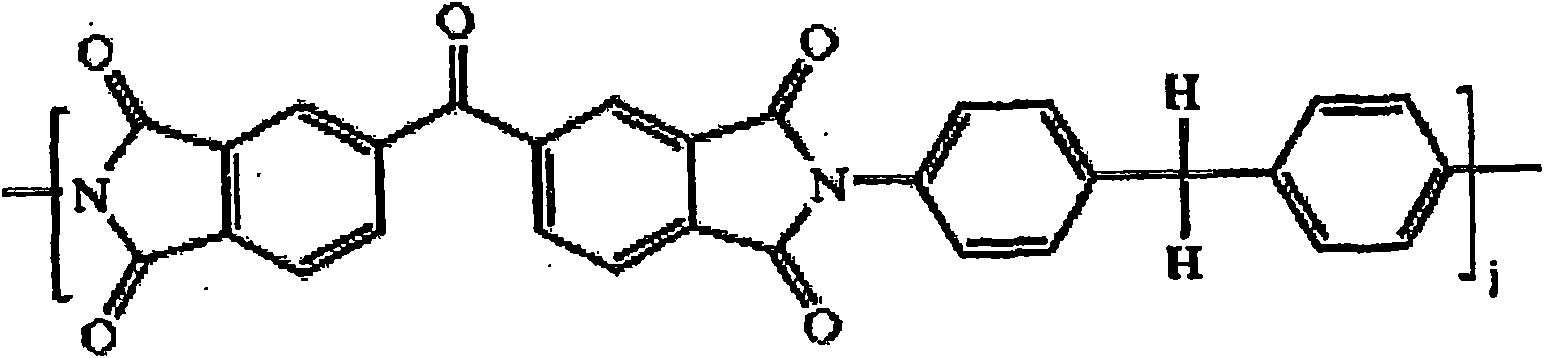

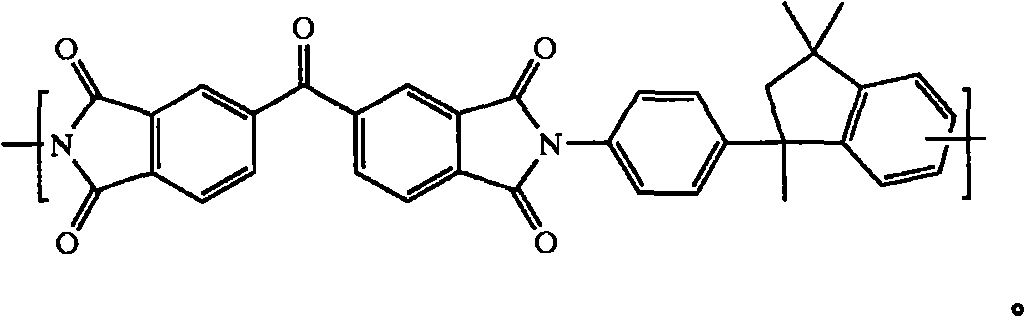

Process of separating gases using polyimide membranes

ActiveUS20120323059A1Improve conductivityHigh selectivityMethane captureIsotope separationCross-linkPolyimide membrane

The present invention discloses a new type of polyimide membrane with high permeances and high selectivities for gas separations and particularly for CO2 / CH4 and H2 / CH4 separations. The polyimide membranes have CO2 permeability of 50 Barrers or higher and single-gas selectivity for CO2 / CH4 of 15 or higher at 50° C. under 791 kPa for CO2 / CH4 separation. The polyimide membranes have UV cross-linkable functional groups and can be used for the preparation of UV cross-linked polyimide membranes having CO2 permeability of 20 Barrers or higher and single-gas selectivity for CO2 / CH4 of 35 or higher at 50° C. under 791 kPa for CO2 / CH4 separation.

Owner:UOP LLC

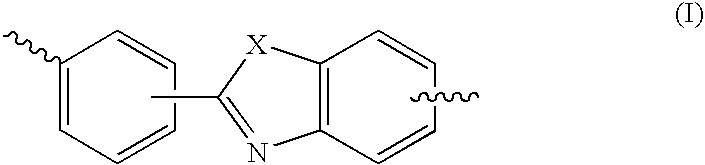

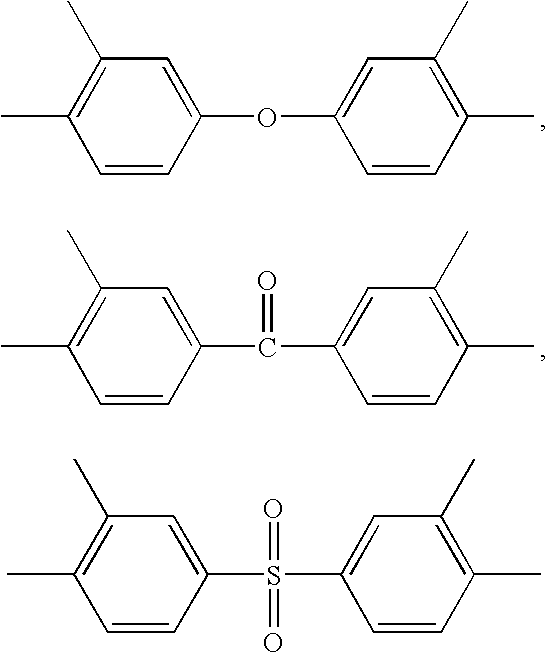

Polymer Membranes Derived from Aromatic Polyimide Membranes

ActiveUS20100243567A1Improve breathabilityHigh selectivitySemi-permeable membranesMembranesImidePolymer science

The present invention discloses a new type of high performance polymer membranes derived from aromatic polyimide membranes and methods for making and using these membranes. The polymer membranes described in the present invention were derived from aromatic polyimide membranes by crosslinking followed by thermal treating. The aromatic polyimide membranes were made from aromatic polyimide polymers comprising both pendent hydroxy functional groups ortho to the heterocyclic imide nitrogen and cross-linkable functional groups in the polymer backbone. The high performance polymer membranes showed significantly improved permeability for gas separations compared to the aromatic polyimide membranes without any treatment. The high performance polymer membranes also showed significantly improved selectivity for gas separations compared to the thermal-treated but non-UV-crosslinked aromatic polyimide membranes. The high performance polymer membranes of the present invention are suitable for liquid, gas, and vapor separations, as well as for catalysis and fuel cell applications.

Owner:UOP LLC

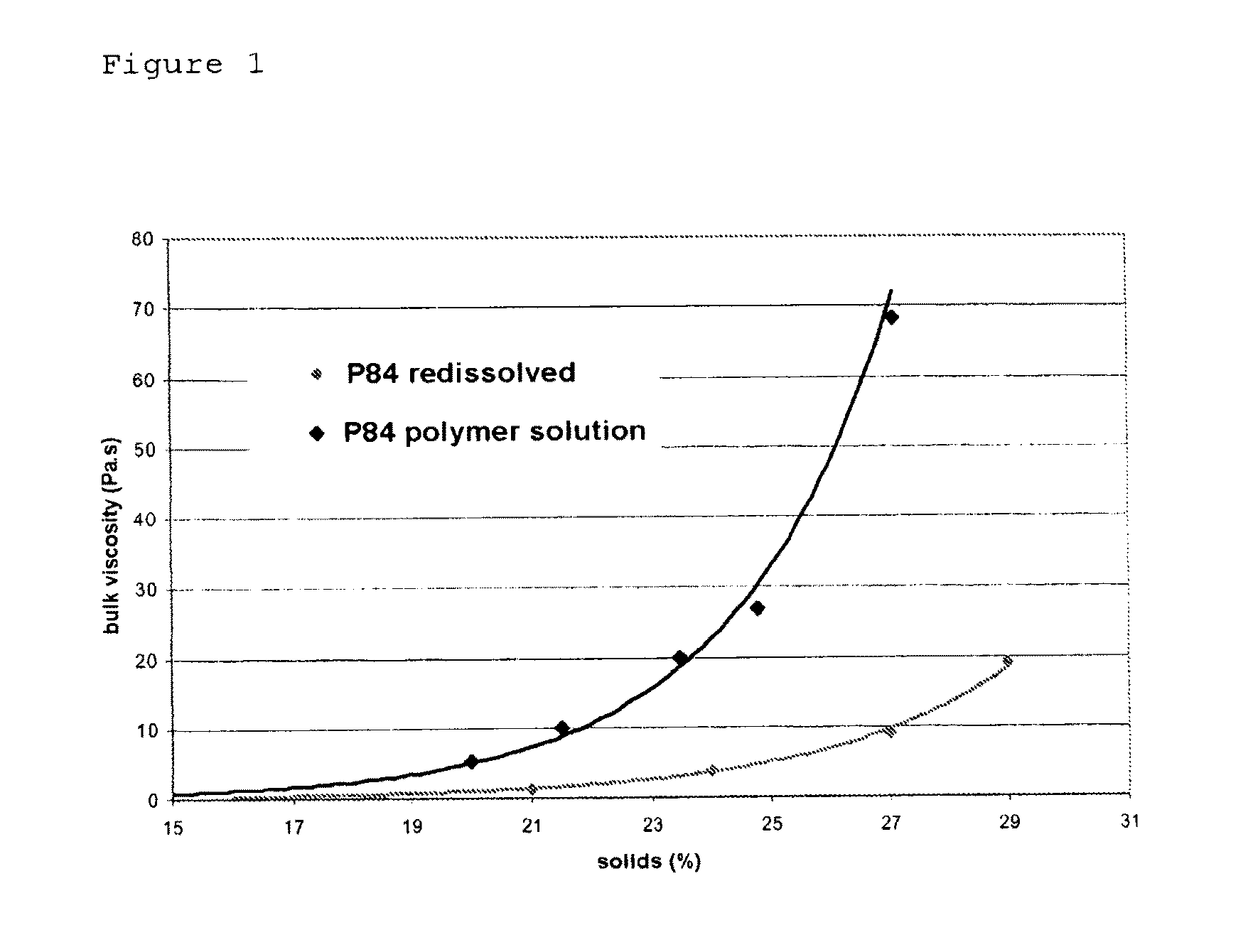

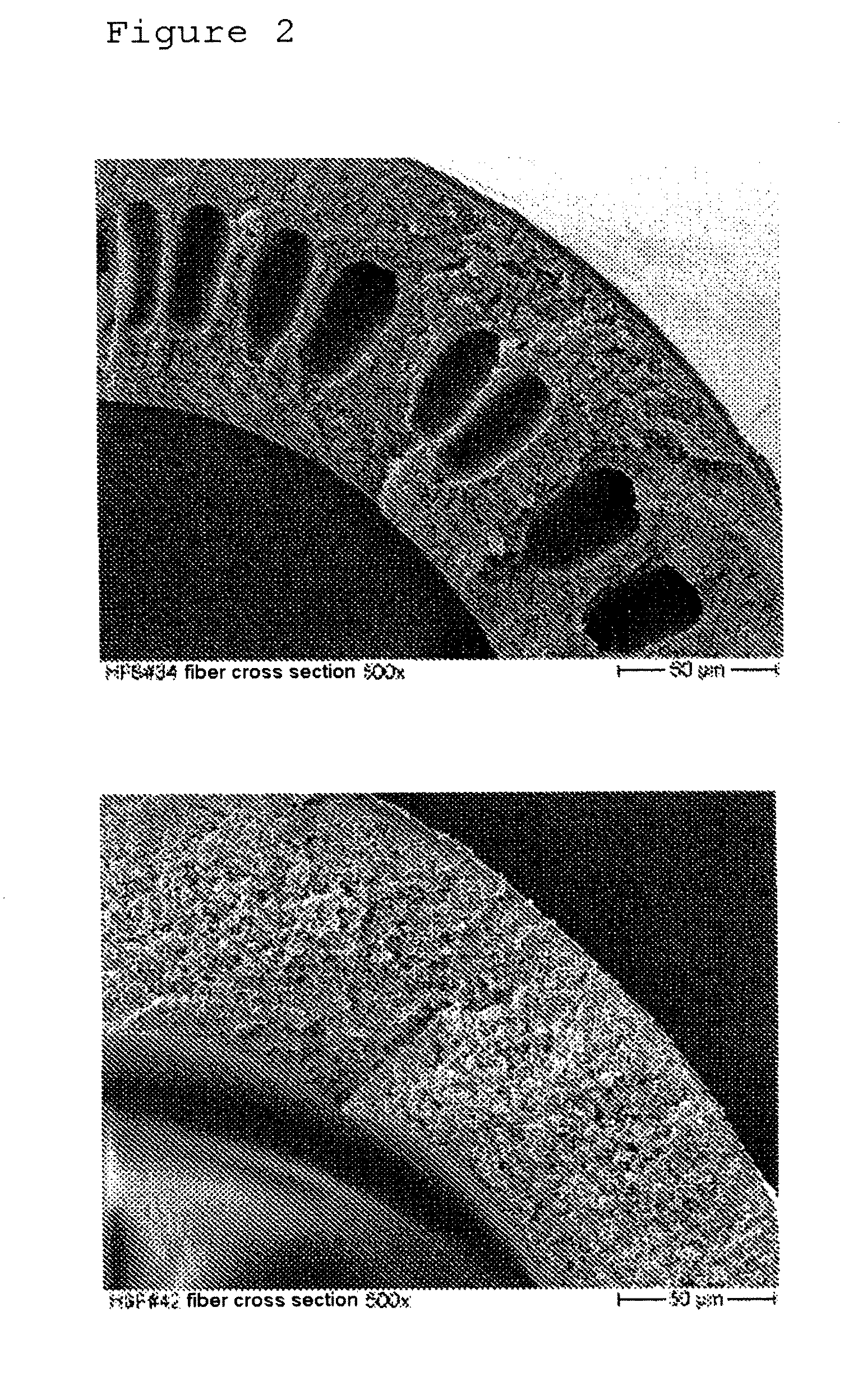

Polyimide membranes made of polymerization solutions

InactiveUS20120123079A1Sufficient mechanical propertySemi-permeable membranesMembranesPolyimide membranePhotochemistry

The invention relates to polyimide membranes and to a phase inversion method for the production thereof. The polyimide membranes can be used to separate different gas mixtures.

Owner:EVONIK FIBERS

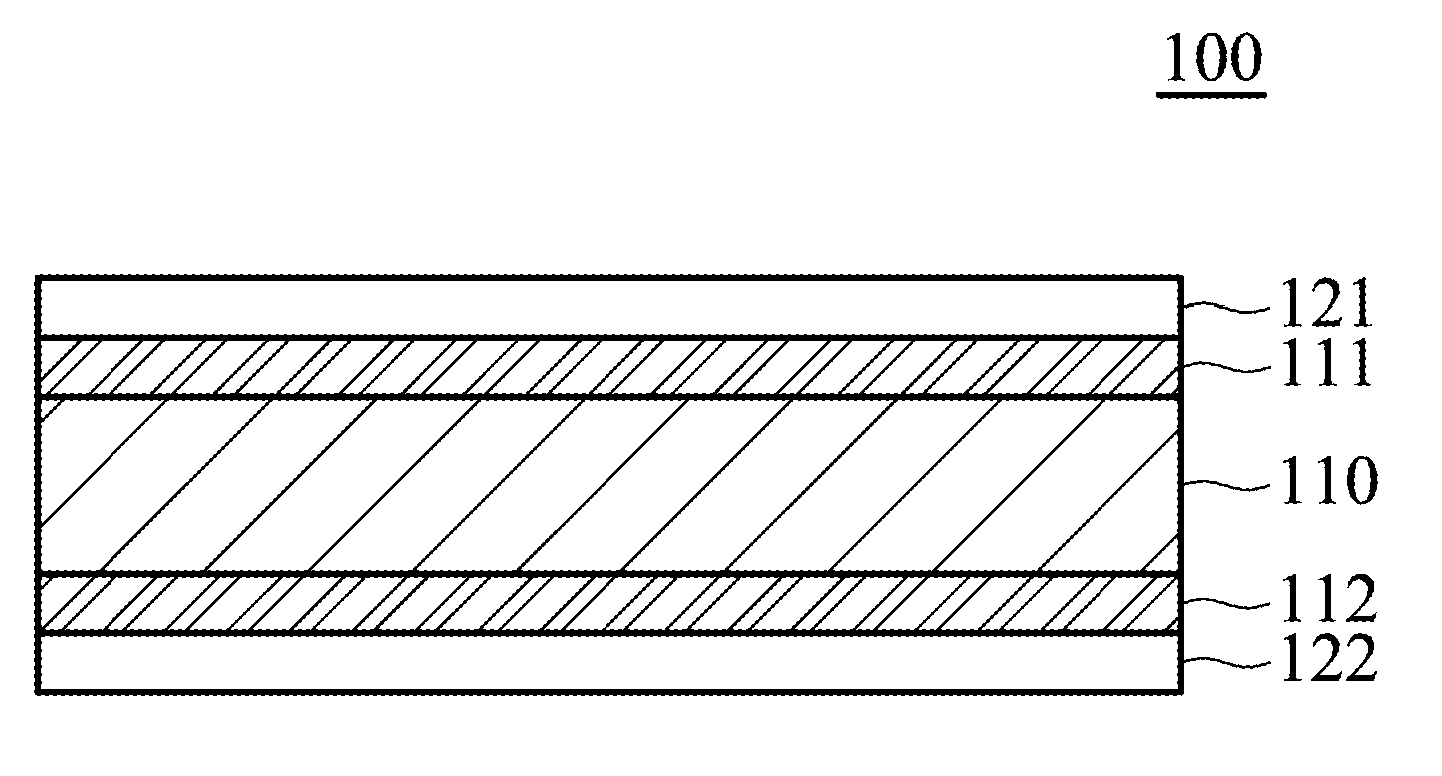

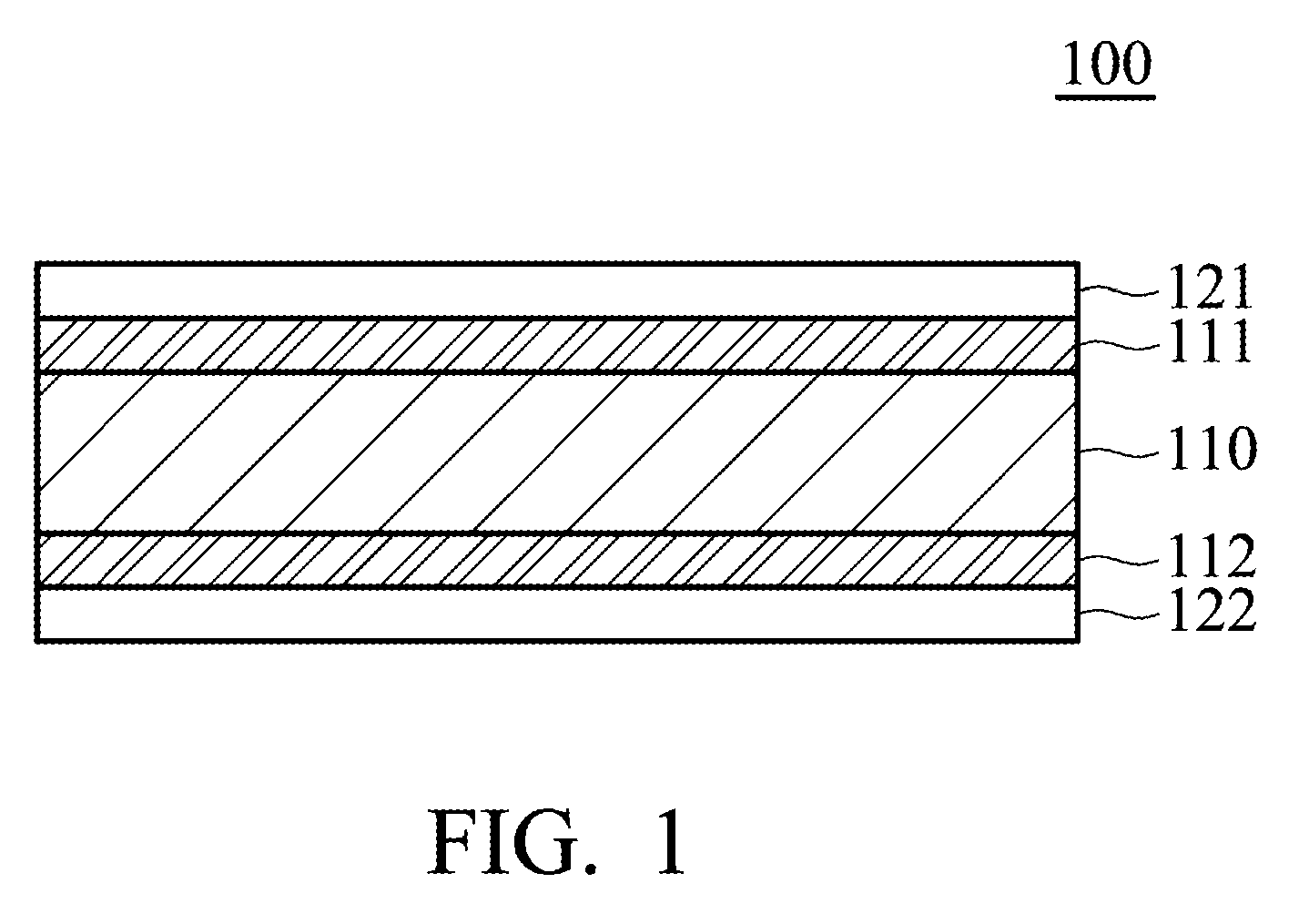

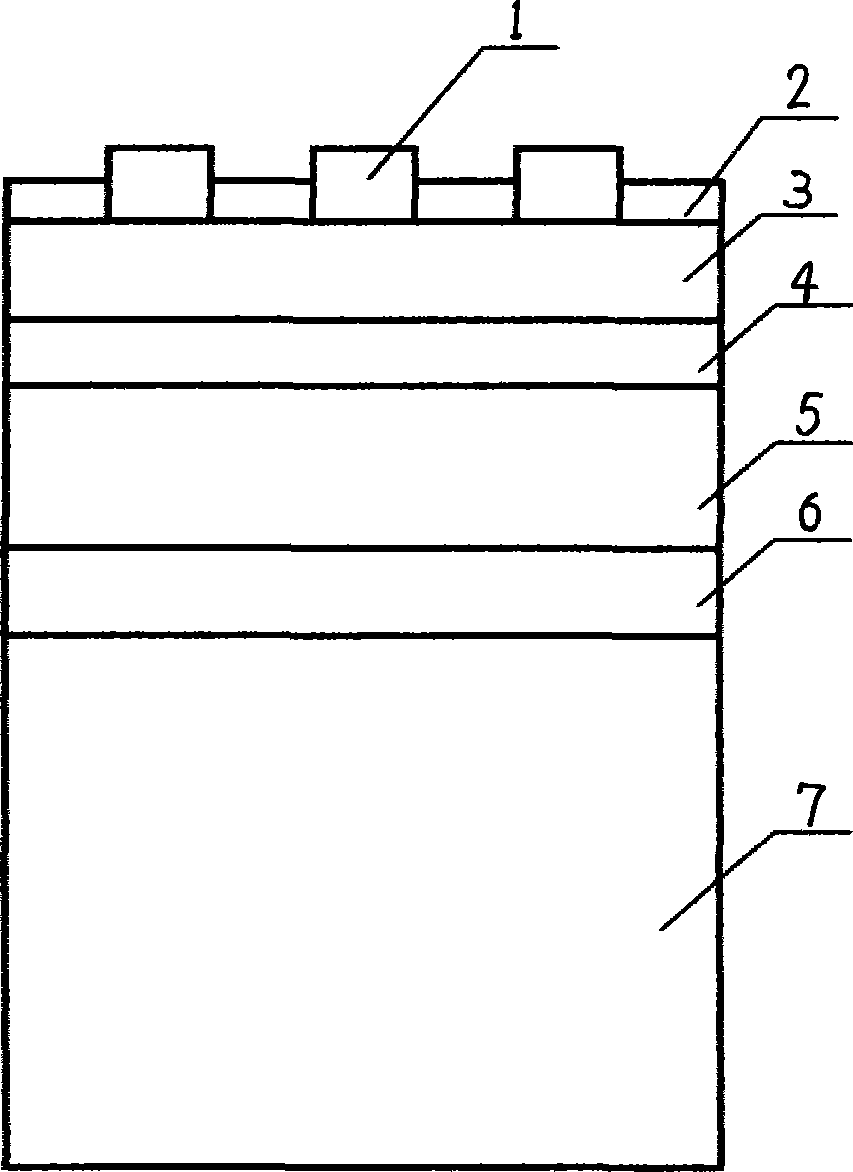

Flexible CIGS thin-film solar cell and absorption layer preparation thereof

ActiveCN101459200AReduce dosageThe process is easy to controlFinal product manufacturePhotovoltaicsIndiumMetallic materials

The invention belongs to a flexible CIGS thin-film solar cell and a process for preparing an absorption layer thereof, the flexible CIGS thin-film solar cell is a multi-layer film structure, which comprises an substrate, a bottom electrode, an absorption layer, a buffer layer, a window layer, an anti-reflecting film and an upper electrode, and the flexible CIGS thin-film solar cell is characterized in that the substrate is made of flexible metals or polyimide. The process for preparing the adsorption layer of the flexible CIGS thin-film solar cell is characterized in that the substrate is made of flexible metals or polyimide, the bottom electrode Mo of the thickness of 0.5-1.5 mu m is deposited by magnetron sputtering, a metal prefabricating layer is prepared on a Mo thin-film, and is in vacuum seal to be placed in a furnace to heat, the temperature of the area of a solid selenium source is controlled between 180-300 DEG C to perform selenizing treatment, thereby enabling the metal prefabricating layer to be transformed into a semiconductor thin-film. Through performing selenizing or vulcanizing under saturation vapor pressure of selenium or sulfur in a vacuum seal silica tube, controllable repeatability of the technique process is fine, use quantity of selenium or sulfur is reduced, besides, the process is controllable and the equipment is simple.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

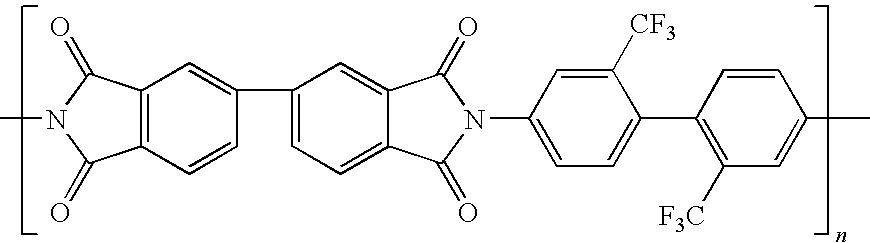

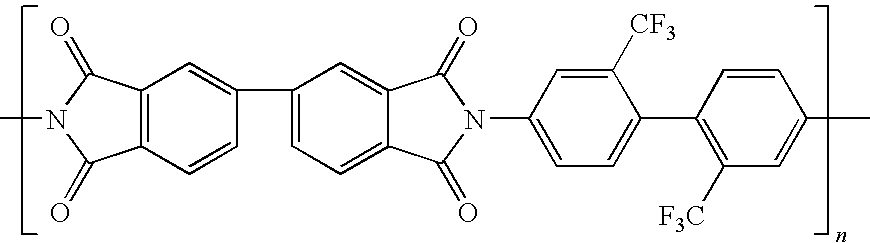

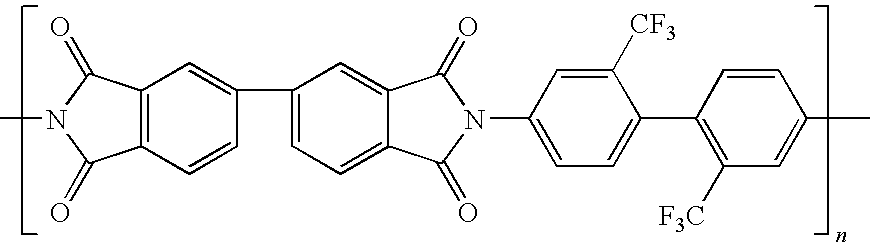

Low color polyimide compositions useful in optical type applications and methods and compositions relating thereto

ActiveUS20080138537A1Low color requirementLiquid crystal compositionsFilm/foil adhesivesIn planeDisplay device

Perfluorinated polyimides (and co-polyimide) compositions, particularly films are disclosed, comprising at least 50 mole percent of a polymeric repeat unit derived from contacting 3,3′,4,4′-biphenyltetracarboxylic dianhydride (BDPA) and 2,2′-bis(trifluoromethyl) benzidine (TFMB) monomers. The perfluorinated polyimide (and co-polyimide) films of the invention have an in-plane coefficient of thermal expansion (CTE) between −5 and +20 ppm / ° C. and a average light transmittance percent of from about 65.0 to about 99.0 (on a 75-micron thick film basis). The films of the present invention were converted to a polyimide using a chemical conversion method instead of typically employed thermal conversion step thus yielding these desirable properties. The films of the present invention can be an excellent substrate in an optical display device and can be used to replace rigid glass substrates. Finally, the polyimide films of the invention can also be used to manufacture flexible display devices (e.g., cellular phones, personal digital assistants, portable video games, laptops, and the like).

Owner:DUPONT ELECTRONICS INC

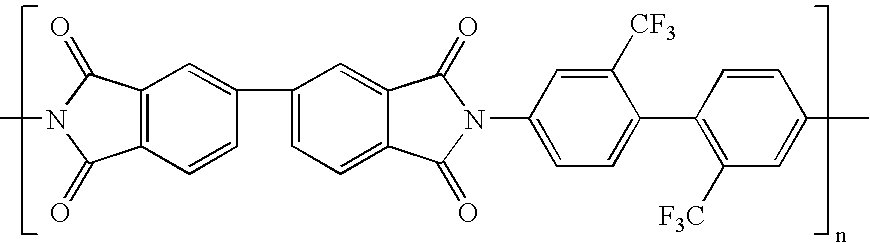

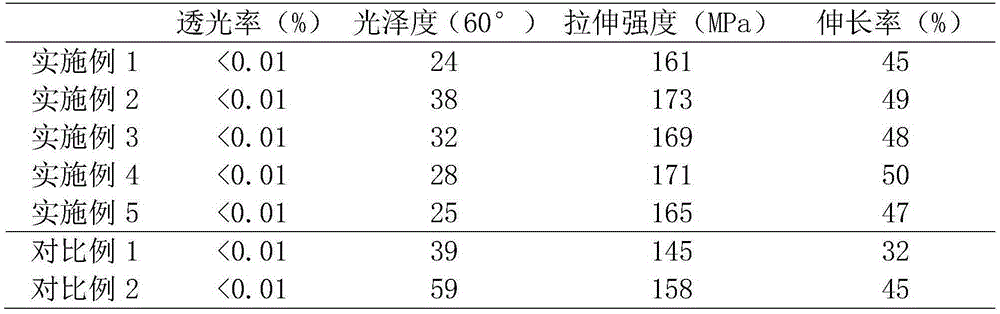

Black matte polyimide thin film and preparation method thereof

The invention discloses a black matte polyimide thin film and a preparation method thereof. The preparation method comprises the following steps that 1, black slurry is prepared, wherein a silane coupling agent is added to dimethylacetamide to be stirred to be uniform, black pigment is added, and the black slurry is obtained after high-pressure homogenization treatment is conducted; 2, inorganic filler dispersion liquid is prepared, wherein a matting agent and talcum powder are added to organic solvent and stirred to be uniform, and shear dispersion and ultrasonic dispersion treatment is conducted; 3, the black matte polyimide thin film is prepared, wherein diamine is dissolved in an organic solution, tetracarboxylic acid dianhydride with isoequivalent weight is added, PAA resin is obtained after a reaction is conducted, the PAA resin, the black slurry prepared in the first step and the inorganic filler dispersion liquid prepared in the second step are taken, mixed, stirred and defoamed, and the black matte polyimide thin film is obtained through two-way stretching and high-temperature imidization. The black matte polyimide thin film is low in light transmittance and lustrousness and excellent in mechanical property.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

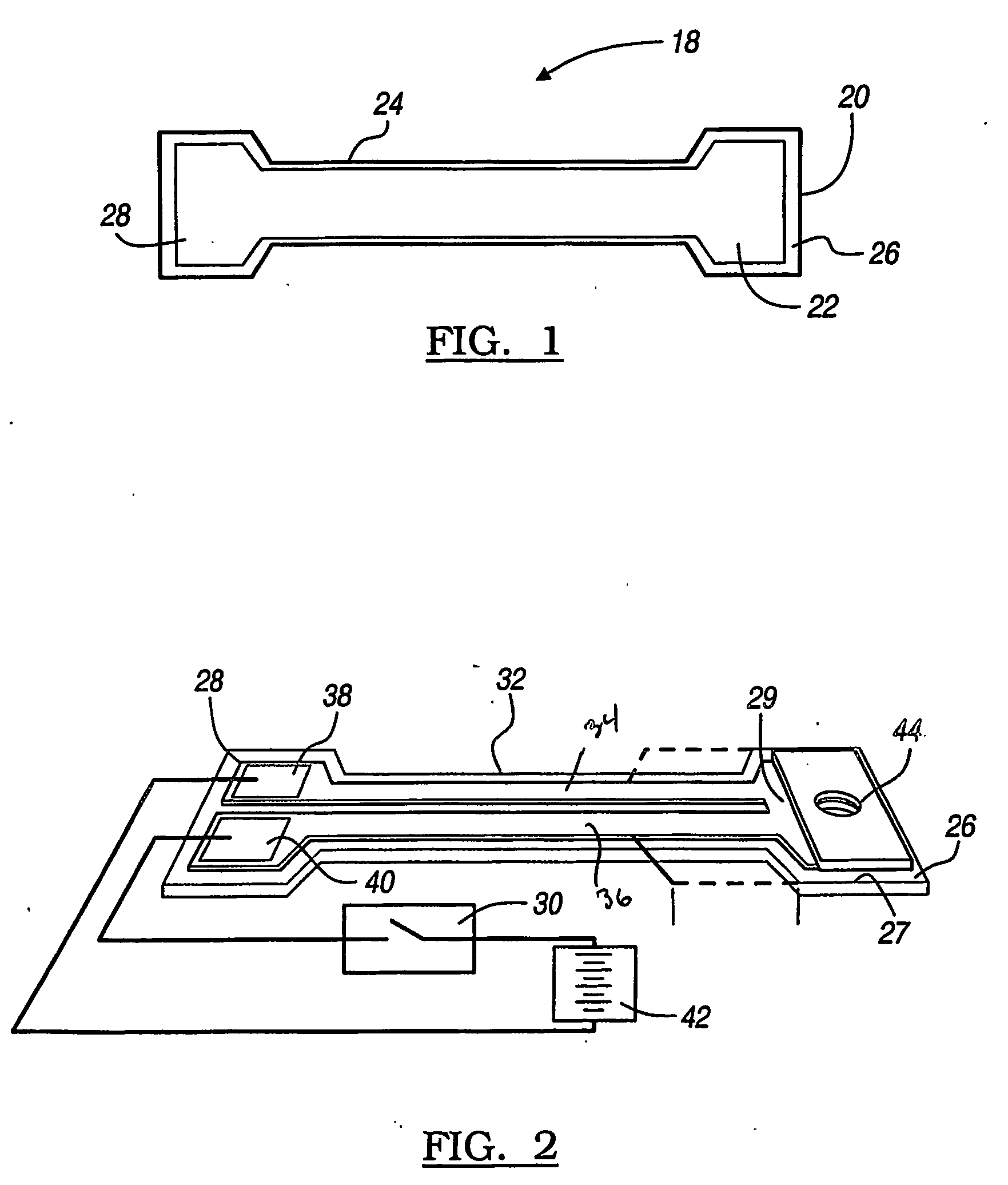

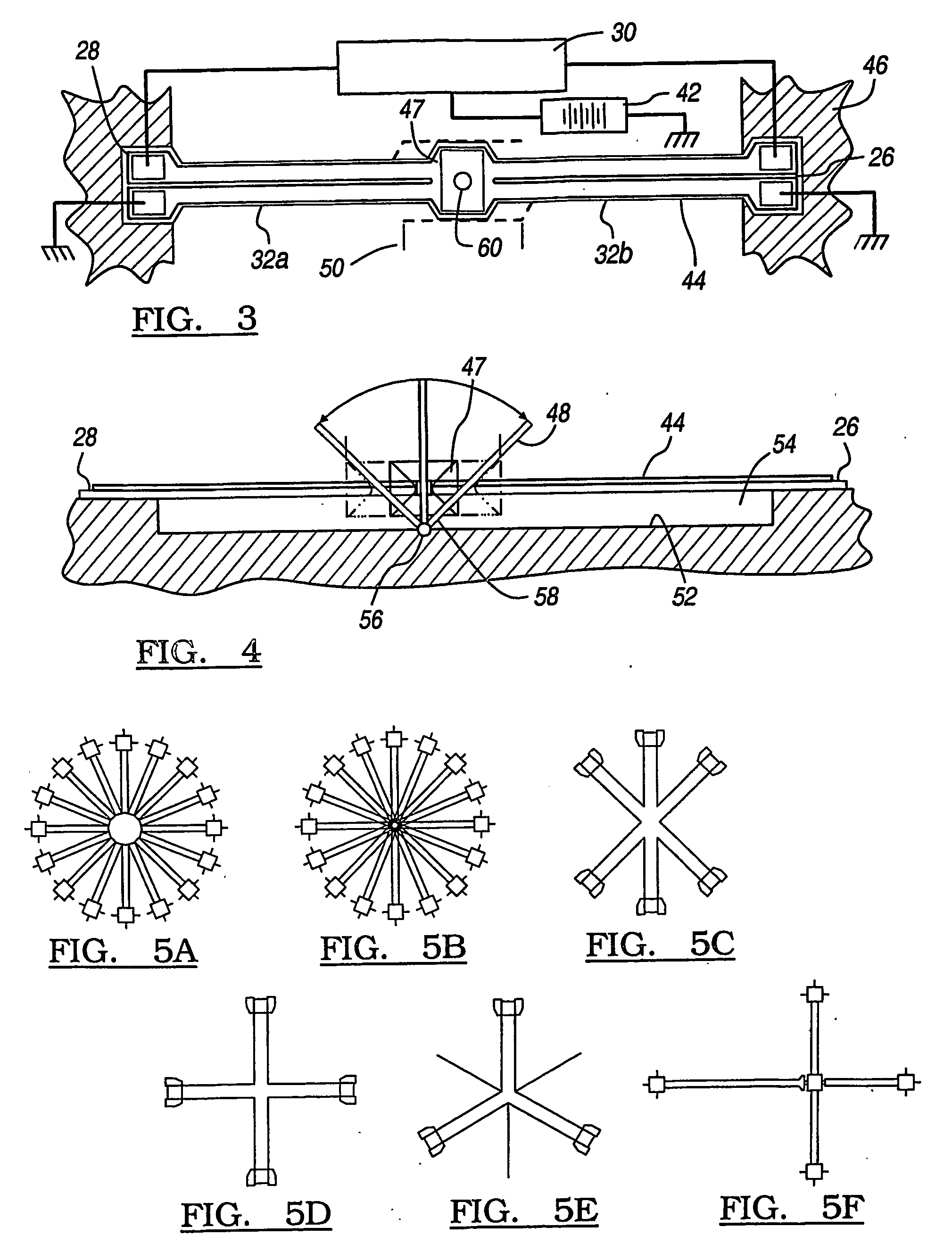

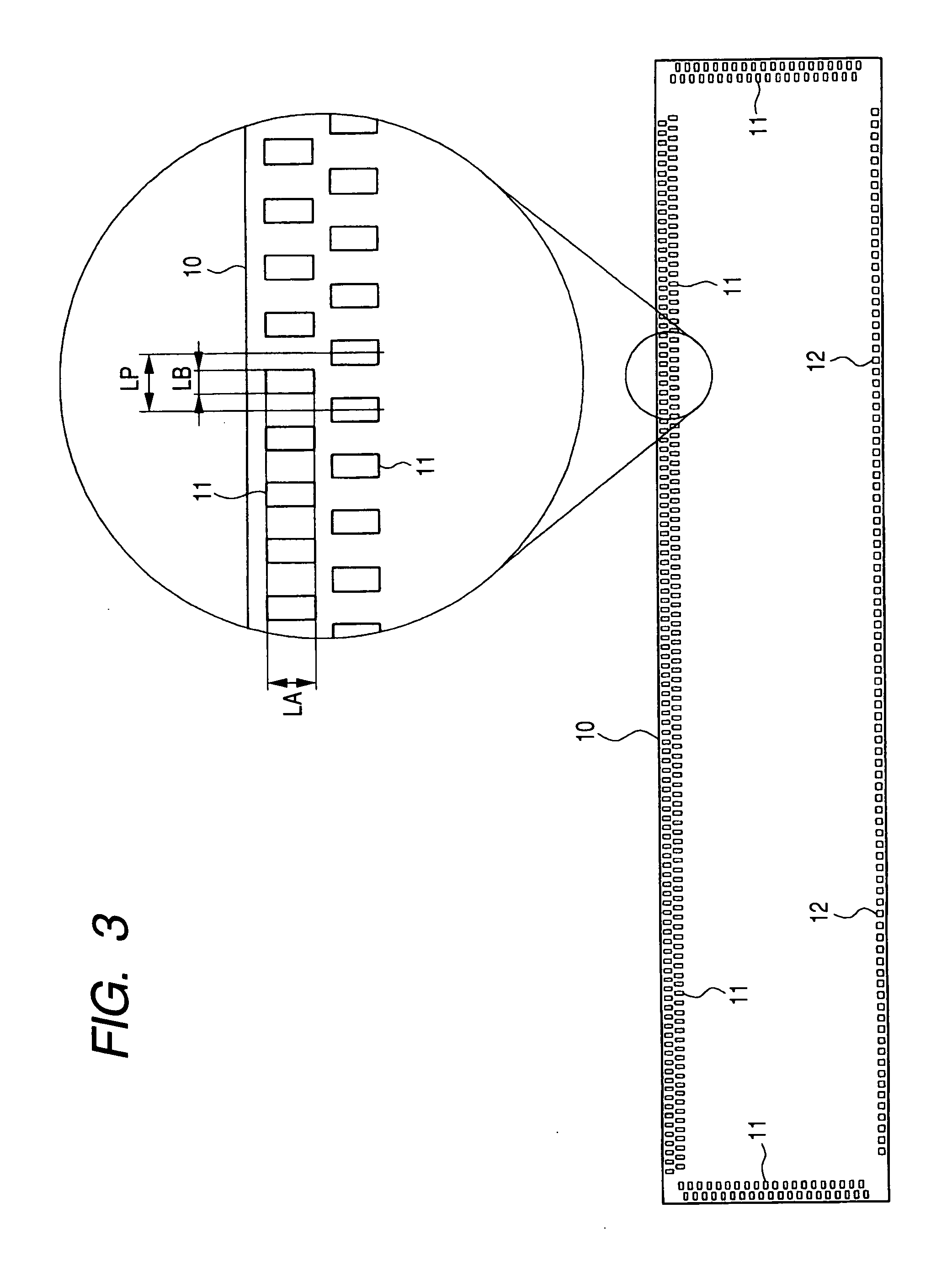

Fabrication method of semiconductor integrated circuit device

InactiveUS20050093565A1Reduce manufacturing costIncrease the number ofSemiconductor/solid-state device testing/measurementElectronic circuit testingElectrical testingEngineering

To permit electrical testing of a semiconductor integrated circuit device having test pads disposed at narrow pitches probes in a pyramid or trapezoidal pyramid form are formed from metal films formed by stacking a rhodium film and a nickel film successively. Via through-holes are formed in a polyimide film between interconnects and the metal films, and the interconnects are electrically connected to the metal films. A plane pattern of one of the metal films equipped with one probe and through-hole is obtained by turning a plane pattern of the other metal film equipped with the other probe and through-hole through a predetermined angle.

Owner:RENESAS TECH CORP

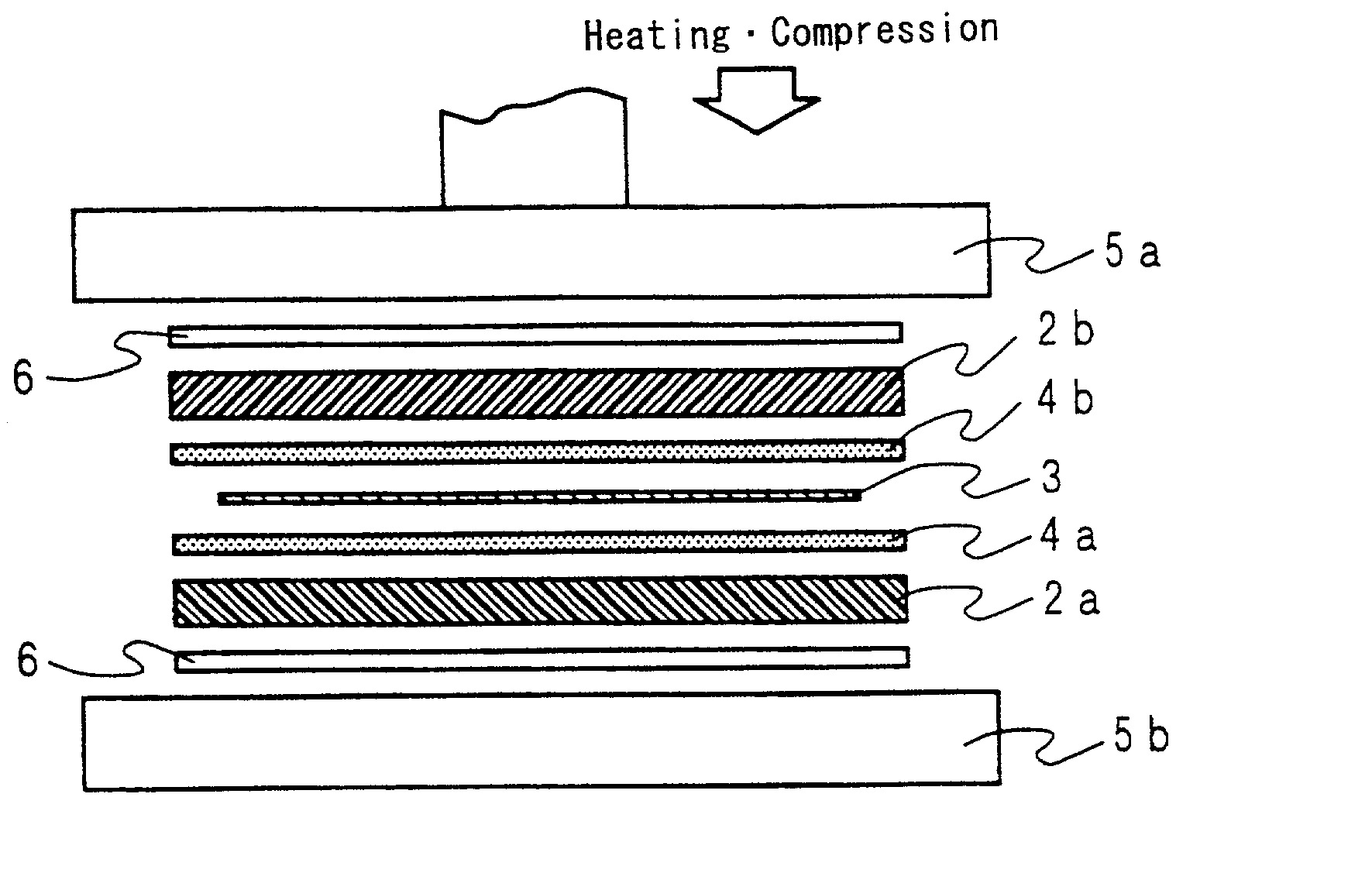

Electrostatic chucking device and manufacturing method thereof

InactiveUS20020021545A1Improve abilitiesIncreased durabilitySleeve/socket jointsSemiconductor/solid-state device manufacturingInsulation layerHeat resistance

The present invention discloses an electrostatic chucking device having a laminated structure which is formed by sequentially laminating a first insulation layer, an electrode layer and a second insulation layer on metal substrate, wherein the first insulation layer and the second insulation layer are constituted of polyimide films, and at least the adhesion between the metal substrate and the first insulation layer, and, preferably, further, the adhesions including the adhesion between the first insulation layer and the electrode layer and the adhesion between the electrode layer and the second insulation layer are performed by using thermoplastic polyimide-based adhesive films having a film thickness of 5 to 50 mum. Further, to manufacture the electrostatic chucking devices having such a constitution, the present invention also discloses an electrostatic chucking device manufacturing method which performs the low-temperature compression bonding processing under pressure at a temperature of 100 to 250° C. between the metal substrate and the first insulation layer, between the first insulation layer and the electrode layer, and between the electrode layer and the second insulation layer using thermoplasticpolyimide-based adhesion films. According to the present invention, the electrostatic chucking device can exhibit the excellent attraction performance over a long period while ensuring the excellent durability and the excellent heat resistance. Further, the method can manufacture the electrostatic chucking devices which do not contaminate a periphery of the device and a wafer.

Owner:CREATIVE TECH CORP

Cross-linked polyimide membranes

InactiveCN101678286AGuaranteed permeabilityGood solvent resistanceMembranesDispersed particle separationCross-linkFiltration

The present invention provides a method for improving the performance of polyimide membranes as used in solvent-resistant nanofiltration. More specifically the method of the present invention allows to imrove the solvent stability of the polyimide membranes to solvents or solvent mixtures that would dissolve polyimide under the conditions applied during the filtration, such as dimethylforrnamide (DMF), N-methylpyrrolidinone (NMP), dimethylacetamide (DMAC), tetrahydrofuran (THF), y-butyrolacton (GBL), dimethylsulphoxide (DMSO) and chlorinated solvents.

Owner:EVONIK FIBERS

Polyimide film, and method for production thereof

InactiveUS20090197068A1Increase production capacityImprove productivitySynthetic resin layered productsPrinted circuit aspectsToluenediamineCarboxylic acid

Disclosed is a polyimide film prepared from an aromatic tetracarboxylic acid component consisting essentially of 3,3′,4,4′-biphenyltetracarboxylic dianhydride and an aromatic diamine component consisting essentially of not less than 65 mol phenylenediamine % but less than 97 mol % of p-phenylenediamine and not less than 3 mol % but less than 35 mol % of 2,4-toluenediamine.

Owner:UBE IND LTD

Polyimide film for flexible printed board and flexible printed board using the same

InactiveUS7018704B2Printed circuit aspectsSynthetic resin layered productsThermal expansionEngineering

The present invention provides a flexible printed circuit which is free from curl, torsion and warpage due to temperature change and excellent flexural endurance. By using polyimide film having an average coefficient of thermal expansion of 1.0×10−5 to 2.5×10−5 cm / cm / ° C. in a temperature range of 100° C. to 200° C. and a stiffness value of 0.4 to 1.2 g / cm as the base film for the flexible printed circuit, a flexible printed circuit having excellent thermal dimensional stability and flexural endurance can be prepared.

Owner:KANEKA CORP

Low color polyimide compositions useful in optical type applications and methods and compositions relating thereto

Perfluorinated polyimides (and co-polyimide) compositions, particularly films are disclosed, comprising at least 50 mole percent of a polymeric repeat unit derived from contacting 3,3′,4,4′-biphenyltetracarboxylic dianhydride (BDPA) and 2,2′-bis(trifluoromethyl) benzidine (TFMB) monomers. The perfluorinated polyimide (and co-polyimide) films of the invention have an in-plane coefficient of thermal expansion (CTE) between −5 and +20 ppm / ° C. and a average light transmittance percent of from about 65.0 to about 99.0 (on a 75-micron thick film basis). The films of the present invention were converted to a polyimide using a chemical conversion method instead of typically employed thermal conversion step thus yielding these desirable properties. The films of the present invention can be an excellent substrate in an optical display device and can be used to replace rigid glass substrates. Finally, the polyimide films of the invention can also be used to manufacture flexible display devices (e.g., cellular phones, personal digital assistants, portable video games, laptops, and the like).

Owner:DUPONT ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com