Patents

Literature

291 results about "High performance polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High performance polymers are characterized by outstanding thermal stability, chemical resistivity, and mechanical properties. Noted examples include Kapton polyimide film and Nomex and Kevlar aramid fibers, developed by Dupont in the 1960s. High performance polymers have a variety of applications in many different areas,...

Process for preparing 4,4'-dichlorodiphenylsulfone employing sulfoxide oxidation method

InactiveCN104557626AMeet the synthesis requirementsFully contactedOrganic chemistryOrganic compound preparationSolventHydrogen peroxide

The invention relates to a process for preparing 4,4'-dichlorodiphenylsulfone, in particular to a process for preparing 4,4'-dichlorodiphenylsulfone employing a sulfoxide oxidation method. The process comprises the following steps: carrying out friedel-crafts reaction with chlorobenzene and thionyl chloride under the action of a catalyst to obtain the 4,4'-dichlorodiphenylsulfone; dissolving the obtained 4,4'-dichlorodiphenylsulfone with a solvent; adding hydrogen peroxide and carrying out oxidation reaction to obtain a 4,4'-dichlorodiphenylsulfone crude product; carrying out secondary oxidation refining on the obtained 4,4'-dichlorodiphenylsulfone crude product; and finally preparing high-purity 4,4'-dichlorodiphenylsulfone. The purity of the 4,4'-dichlorodiphenylsulfone purified by the refining process is greater than 99.5%; the refining yield is greater than 98.5%; and the process completely meets the synthesis requirements of high-performance polymers.

Owner:SHANDONG KAISHENG NEW MATERIALS

Polymer Membranes Derived from Aromatic Polyimide Membranes

ActiveUS20100243567A1Improve breathabilityHigh selectivitySemi-permeable membranesMembranesImidePolymer science

The present invention discloses a new type of high performance polymer membranes derived from aromatic polyimide membranes and methods for making and using these membranes. The polymer membranes described in the present invention were derived from aromatic polyimide membranes by crosslinking followed by thermal treating. The aromatic polyimide membranes were made from aromatic polyimide polymers comprising both pendent hydroxy functional groups ortho to the heterocyclic imide nitrogen and cross-linkable functional groups in the polymer backbone. The high performance polymer membranes showed significantly improved permeability for gas separations compared to the aromatic polyimide membranes without any treatment. The high performance polymer membranes also showed significantly improved selectivity for gas separations compared to the thermal-treated but non-UV-crosslinked aromatic polyimide membranes. The high performance polymer membranes of the present invention are suitable for liquid, gas, and vapor separations, as well as for catalysis and fuel cell applications.

Owner:UOP LLC

Thermoplastic Composites and Methods of Making and Using Same

ActiveUS20110097575A1Crystallize fastReduce manufacturing costLamination ancillary operationsSynthetic resin layered productsPolymer scienceSurface layer

Thermoplastic composites having a core composite layer including a fibrous substrate and one or more high performance polymer, and a surface layer polymer applied to at least one surface of the core composite layer, which forms a polymer blend with the high performance polymer thereby imparting improved toughness and processing times, and methods for making and using same, are provided herein.

Owner:CYTEC TECH CORP

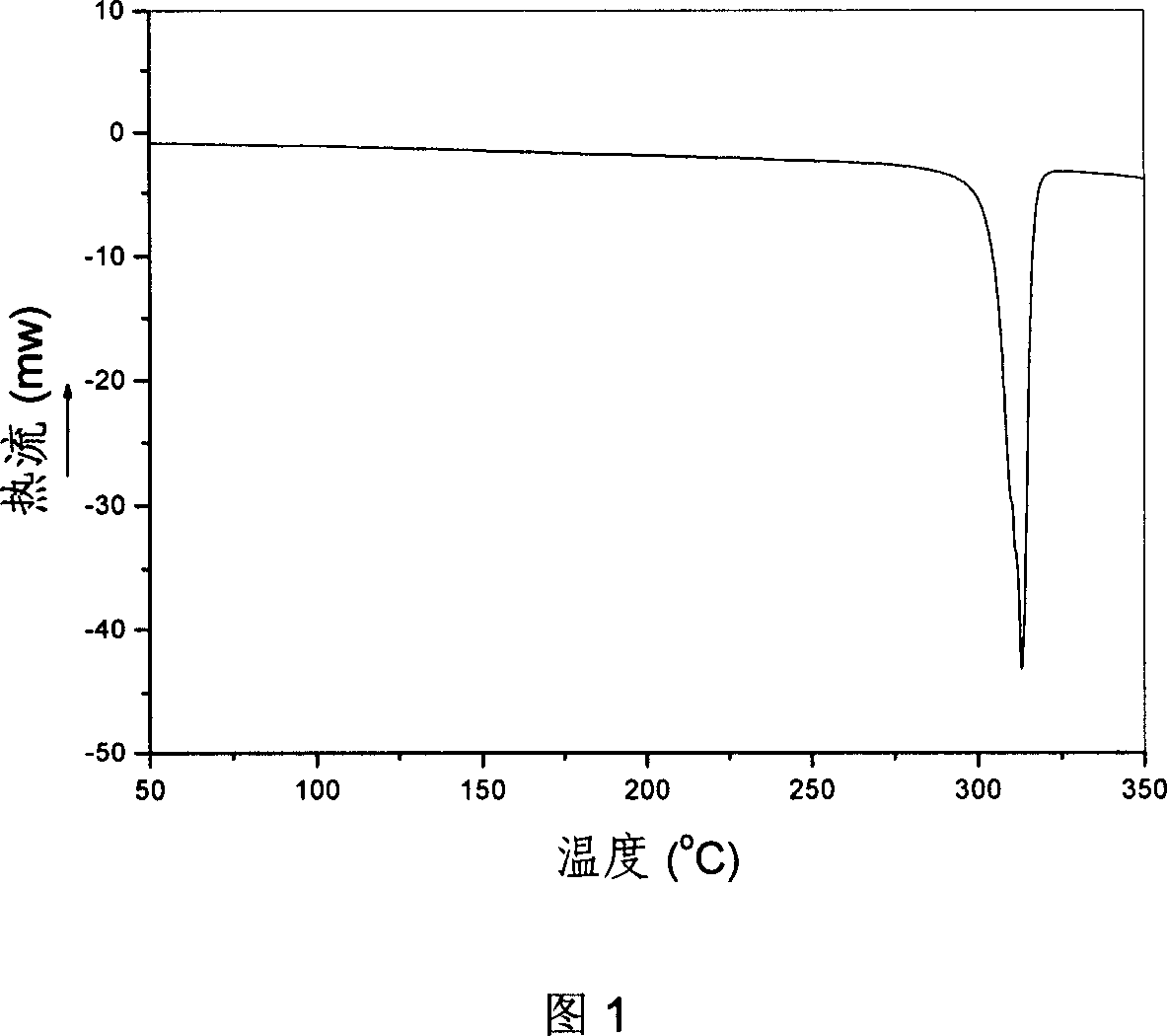

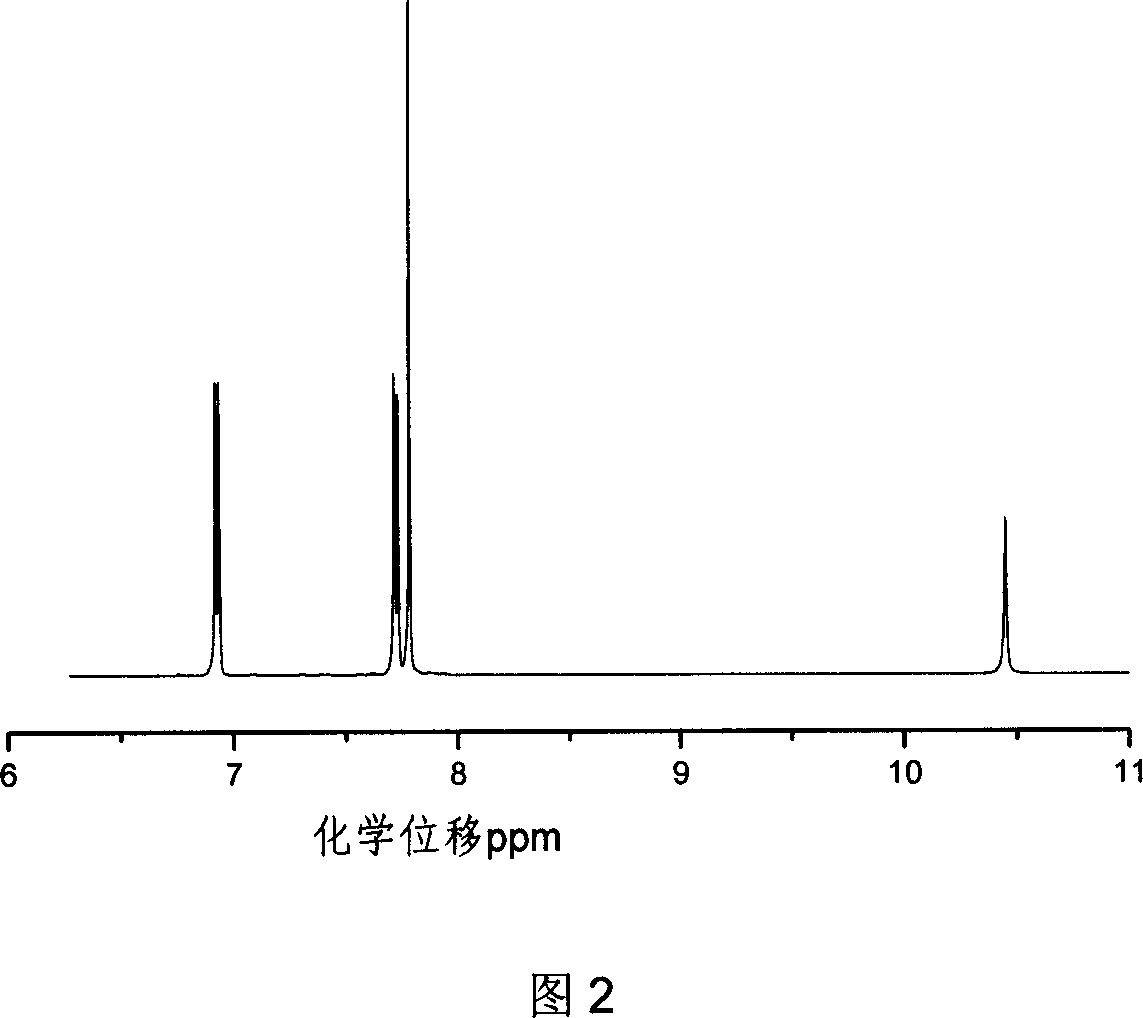

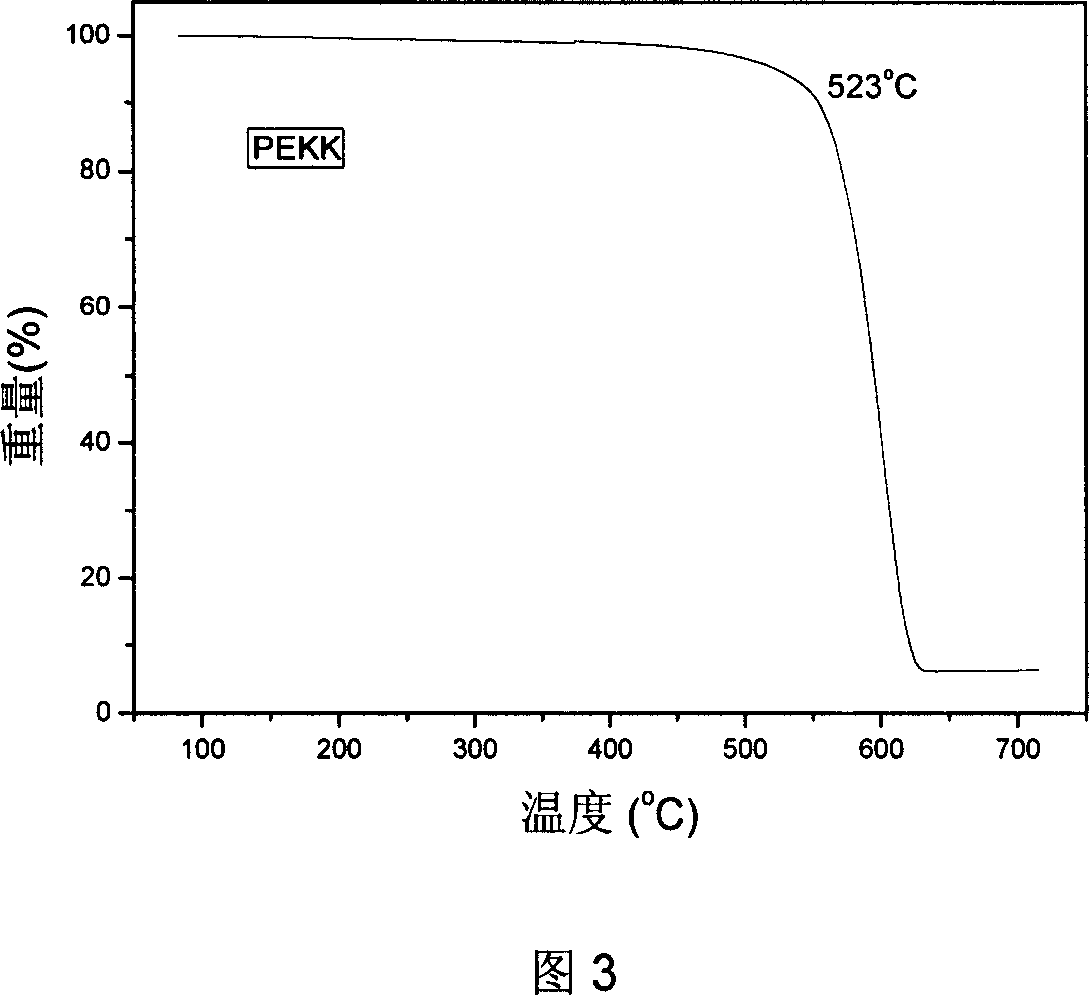

Prepn process of poly (ether-ketone-ketone) as high performance polymer

The present invention belongs to the field of polymer material, and is especially the preparation process of poly(ether-ketone-ketone) prepared through polymerizing bisphenol and bifluoric monomer. The preparation process includes adding bis-(4-hydroxybenzoyl)-benzene, bis-1, 4-(4-fluorobenzoyl)-benzene or bis-1, 3-(4- fluorobenzoyl)-benzene, Na2CO3 as salt-forming agent and diphenyl sulfone as solid solvent into flask with mechanical stirrer, thermometer and nitrogen duct; introducing high purity nitrogen, heating to 100-130 deg.c and stirring to melting solid matter completely; heating slowly to react; pouring the reaction product into water to separating out white solid; crushing, washing with acetone and water for several times, drying at 80-150 deg.c for 10-20 hr to obtain polymer in the yield over 90 %.

Owner:JILIN UNIV

Thermotropic type shape memory composite material

InactiveCN105802188ASmall mechanical propertiesImprove mechanical propertiesWoven fabricsCarbon nanotubeDual function

The invention belongs to the field of shape memory functionalized application technology of high performance polymer matrix composite materials, and provides a thermotropic type shape memory composite material. The material comprises the following components: a shape memory polymer and carbon nanotube, wherein the content of the shape memory polymer is 15-85wt%, and the content of the carbon nanotube is 85-15wt%. The carbon nanotube has excellent mechanical properties, electrical property and thermal conductance performance; the carbon nanotube can be used as an enhancer of the polymer matrix composite material, and can be used as a heating element of the thermotropic type shape memory composite material. The thermotropic type shape memory composite material needs to be heated to a certain temperature in order to realize the function thereof, the carbon nanotube of the carbon nanotube enhanced polymer matrix shape memory composite material can be directly electrified for heating, so that dual functions for enhancing and heating the shape memory composite material are realized.

Owner:AVIC COMPOSITES

Polymer Membranes Prepared from Aromatic Polyimide Membranes by Thermal Treating and UV Crosslinking

ActiveUS20100133192A1Improve performanceImprove permeabilityMembranesMethane captureImidePolymer science

The present invention discloses a new type of high performance polymer membranes prepared from aromatic polyimide membranes by thermal treating and crosslinking and methods for making and using these membranes. The polymer membranes were prepared from aromatic polyimide membranes by thermal treating under inert atmosphere followed by crosslinking preferably by using a UV radiation source. The aromatic polyimide membranes were made from aromatic polyimide polymers comprising both pendent hydroxy functional groups ortho to the heterocyclic imide nitrogen and cross-linkable functional groups in the polymer backbone. The membranes showed significantly improved selectivity and permeability for gas separations compared to the aromatic polyimide membranes without any treatment. The membranes can be fabricated into any convenient geometry and are not only suitable for a variety of liquid, gas, and vapor separations, but also can be used for other applications such as for catalysis and fuel cell applications.

Owner:UOP LLC

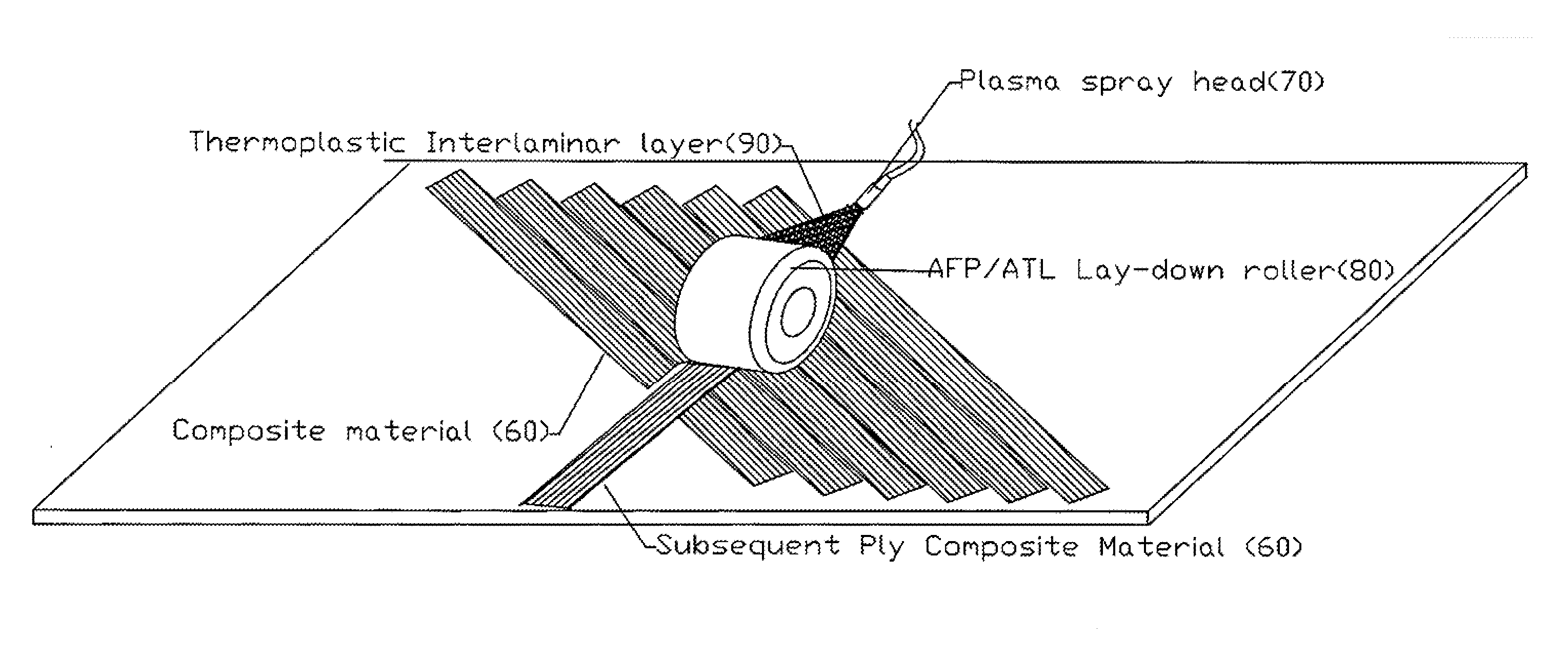

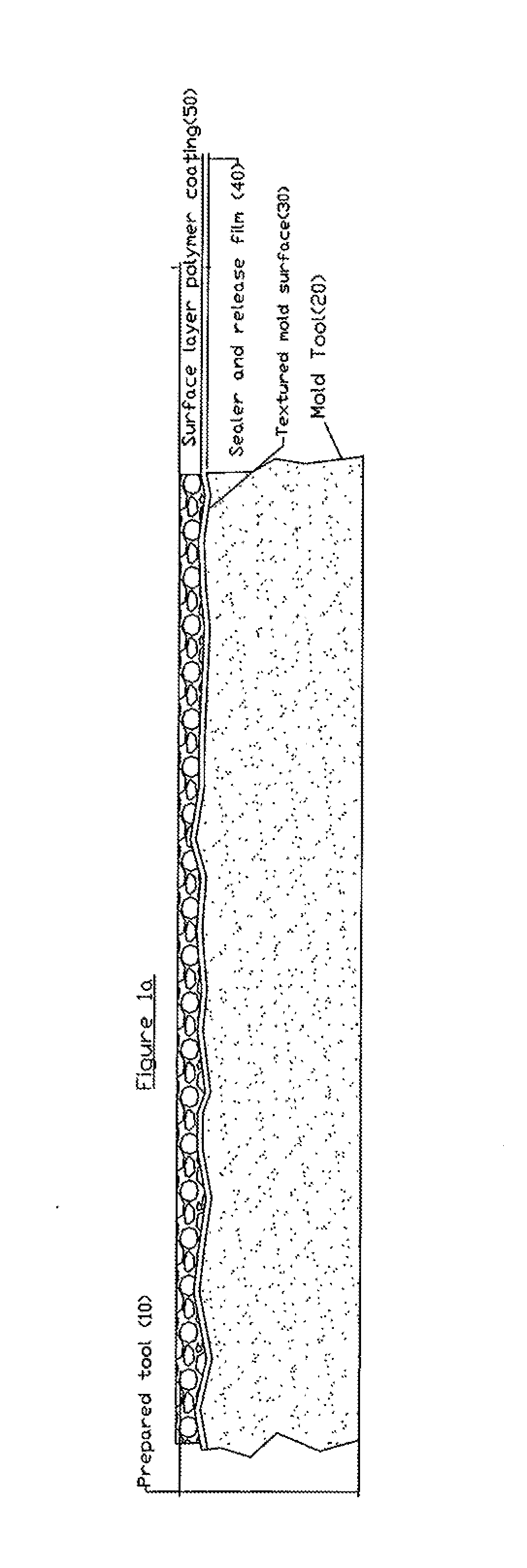

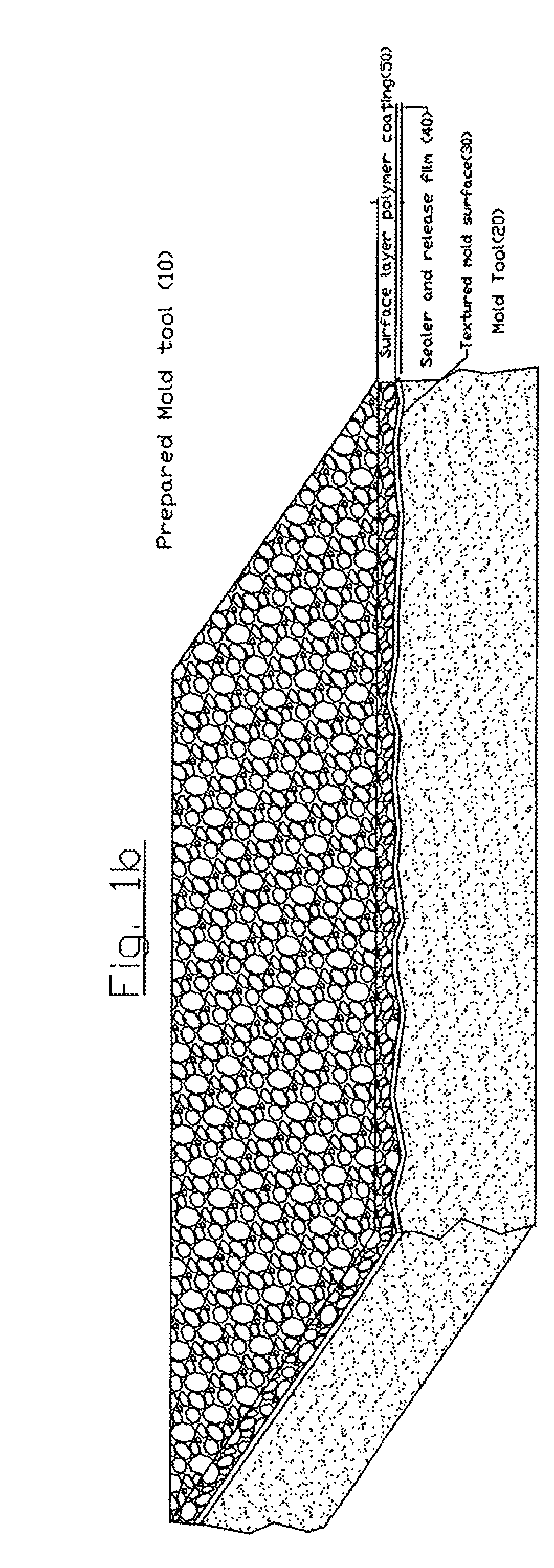

Surface Engineering of Thermoplastic Materials and Tooling

InactiveUS20140110633A1Improve propertiesEasy to separateLiquid surface applicatorsMechanical working/deformationSurface engineeringSurface layer

A prepared mold tool having a thermoplastic surface layer polymer coating on the mold surface of the mold tool or prepared prepreg having a thermoplastic surface layer polymer coating on the surface of the thermoplastic fiber reinforced prepreg are described that enhance first ply laydown of thermoplastic fiber reinforced composite prepregs onto mold tools for prepreg forming or in situ tape placement. Resulting thermoplastic fiber reinforced composite parts from a thermoplastic fiber reinforced thermoplastic composite material having structural reinforcement fibers with one or more high performance polymers, and a thermoplastic surface layer polymer coating which forms a polymer blend with the high performance polymers of the thermoplastic fiber reinforced composite material thereby imparting improved properties, and methods for making and using same, are provided herein.

Owner:CYTEC IND INC

Toughened polymer compositions

Toughened thermoplastic compositions comprising a thermoplastic polymer toughened by the inclusion of a thermoplastic elastomer derived from a particulate rubber dynamically vulcanized in the presence of a matrix polymer. The toughened thermoplastic composition exhibits properties including toughness, improved impact resistance, and improved hardness. The compositions are utilized wherever toughened, high performance polymers are desired. A method for forming the toughened polymer compositions is also described. Processing methods, such as rotational molding, utilizing the toughened polymer compositions are described.

Owner:TEKNOR APEX

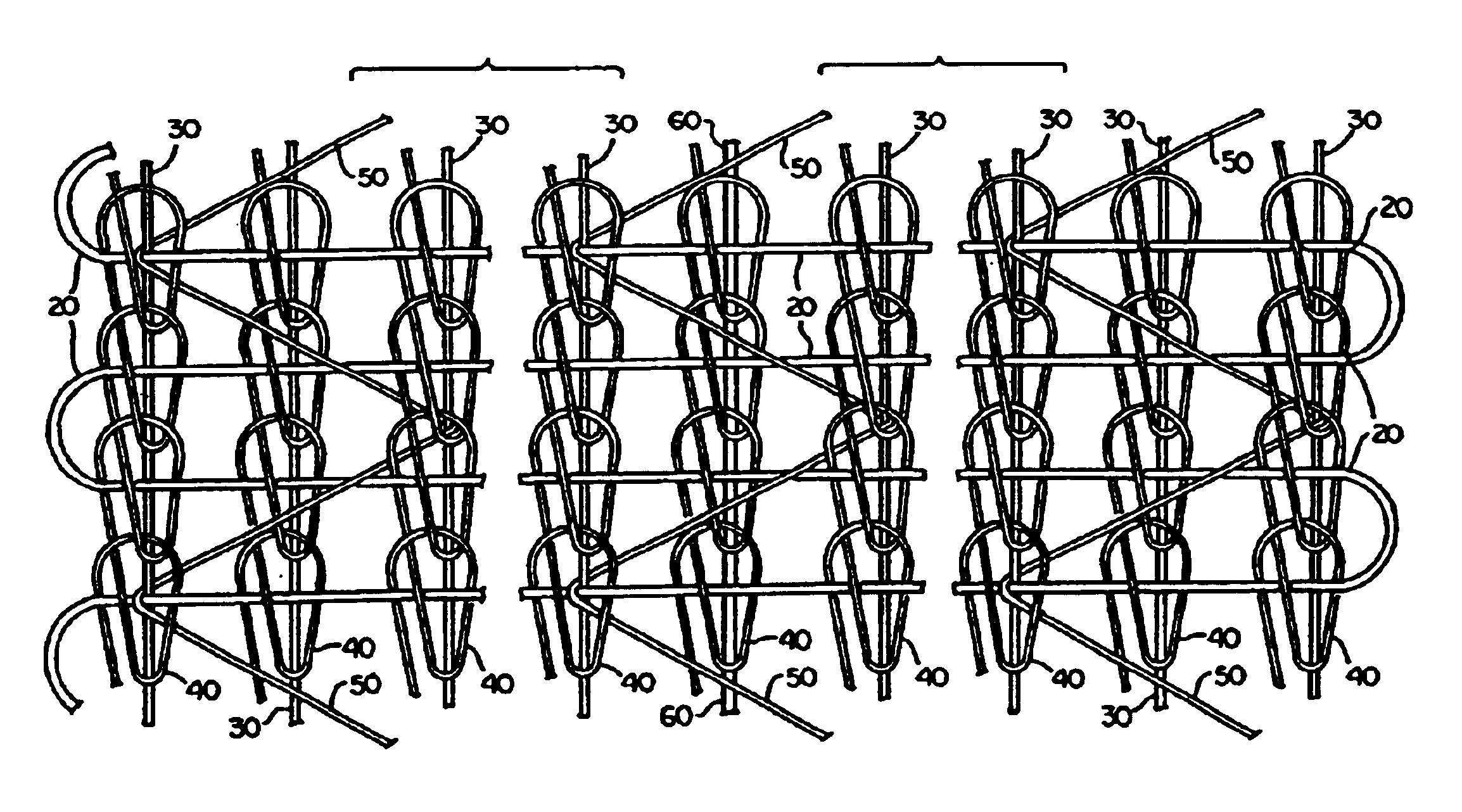

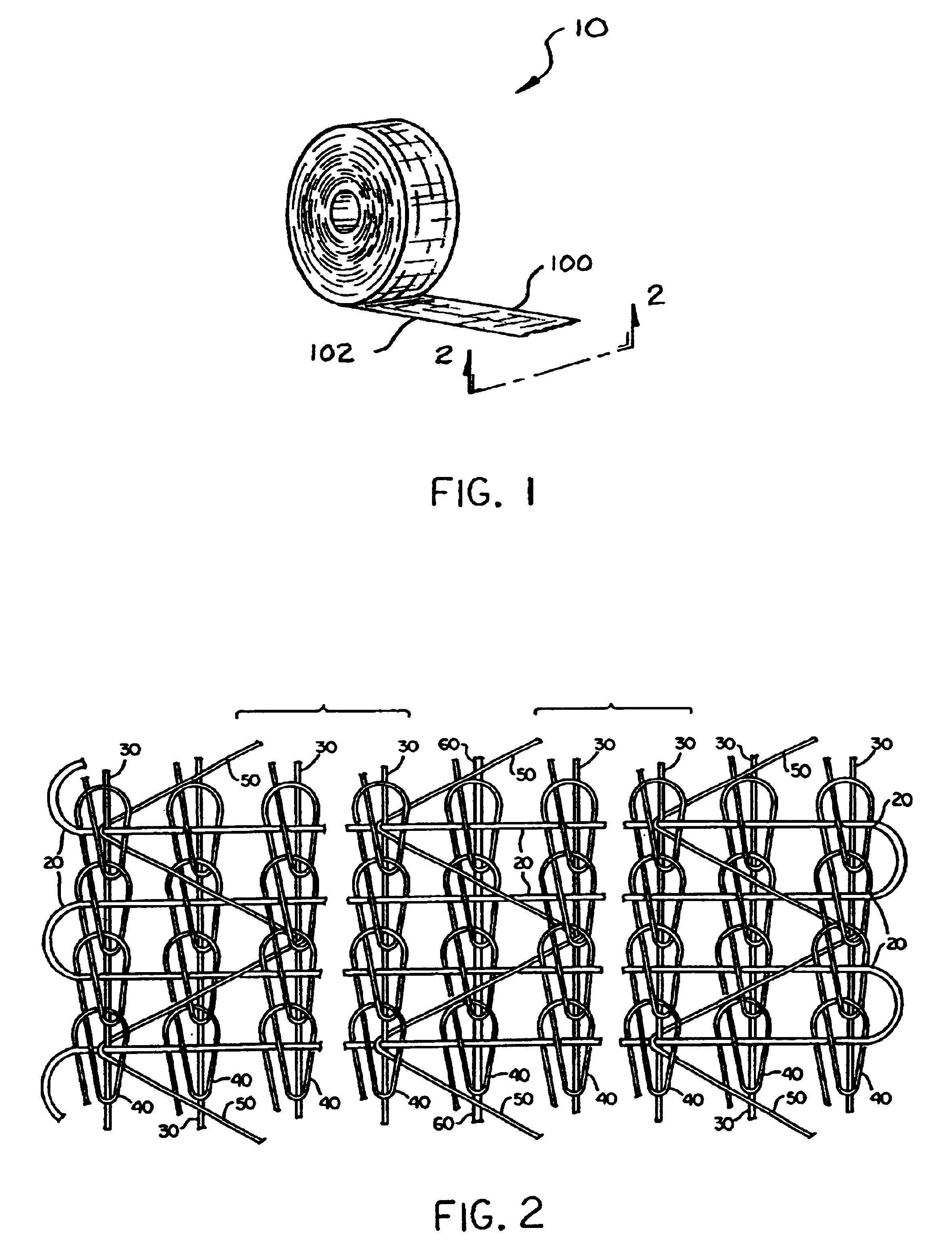

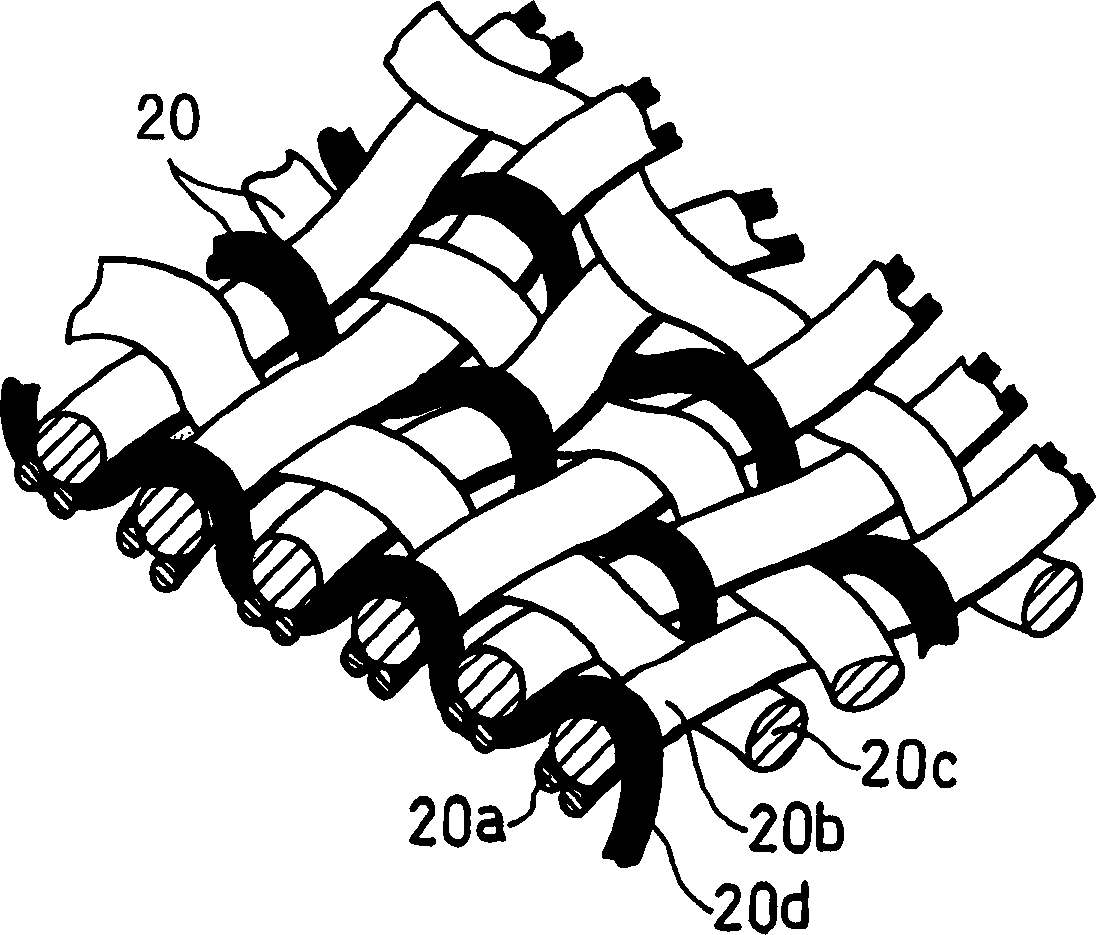

Webbing reinforced with high-performance polymeric yarns

InactiveUS6840066B2High tensile strengthLimited elongationWeft knittingOrnamental textile articlesPolyesterYarn

A reinforced webbing material is disclosed for use in furniture, bedding and the like. The webbing includes a flat knitted fabric comprised of conventional yarns such as polyester. Elastomeric yarns or cords may also be, but are not necessarily, integrally knitted into the fabric structure in a warpwise direction. One or more high-performance polymeric reinforcement yarns are integrally knitted into the fabric structure in a lengthwise direction. The reinforcement yarns may comprise aramid fibers, ultra high molecular weight polyethylene, or other suitable high tensile strength polymeric yarns. The reinforcement yarns and elastomeric cords combine with the knitted fabric to provide a substantially elastic webbing material having a finite amount of stretch that is limited by the high performance yarns.

Owner:HICKORY SPRINGS MFG

High performance polymer base composite material for support roller and preparation method

InactiveCN101423665AMeet the requirements for preparing idlersImprove corrosion resistanceGlass fiberAntistatic agent

The invention discloses a high performance polymer based composite material for carrier rollers and a method for preparing the same. The composite material comprises the following components in proportion: 50 to 80 percent of polycaprolactam, 5 to 30 percent of glass fiber, 0 to 30 percent of ceramic powder, 2 to 10 percent of lubricant, 1 to 15 percent of fire retarding agent, 0.05 to 1 percent of antistatic agent and 0.05 to 0.5 percent of anti-ageing agent; and, the adding amount of surface active is 5 percent of the weight of the ceramic powder. The composite material has the advantages of high strength, wearing resistance, high temperature resistance, electrostatic resistance, fire resistance, anti-ageing, environmental protection and the like.

Owner:CENT SOUTH UNIV +1

Thermoplastic composites and methods of making and using same

ActiveUS8158245B2Crystallize fastReduce manufacturing costSynthetic resin layered productsLaminationPolymer scienceThermoplastic composites

Owner:CYTEC TECH CORP

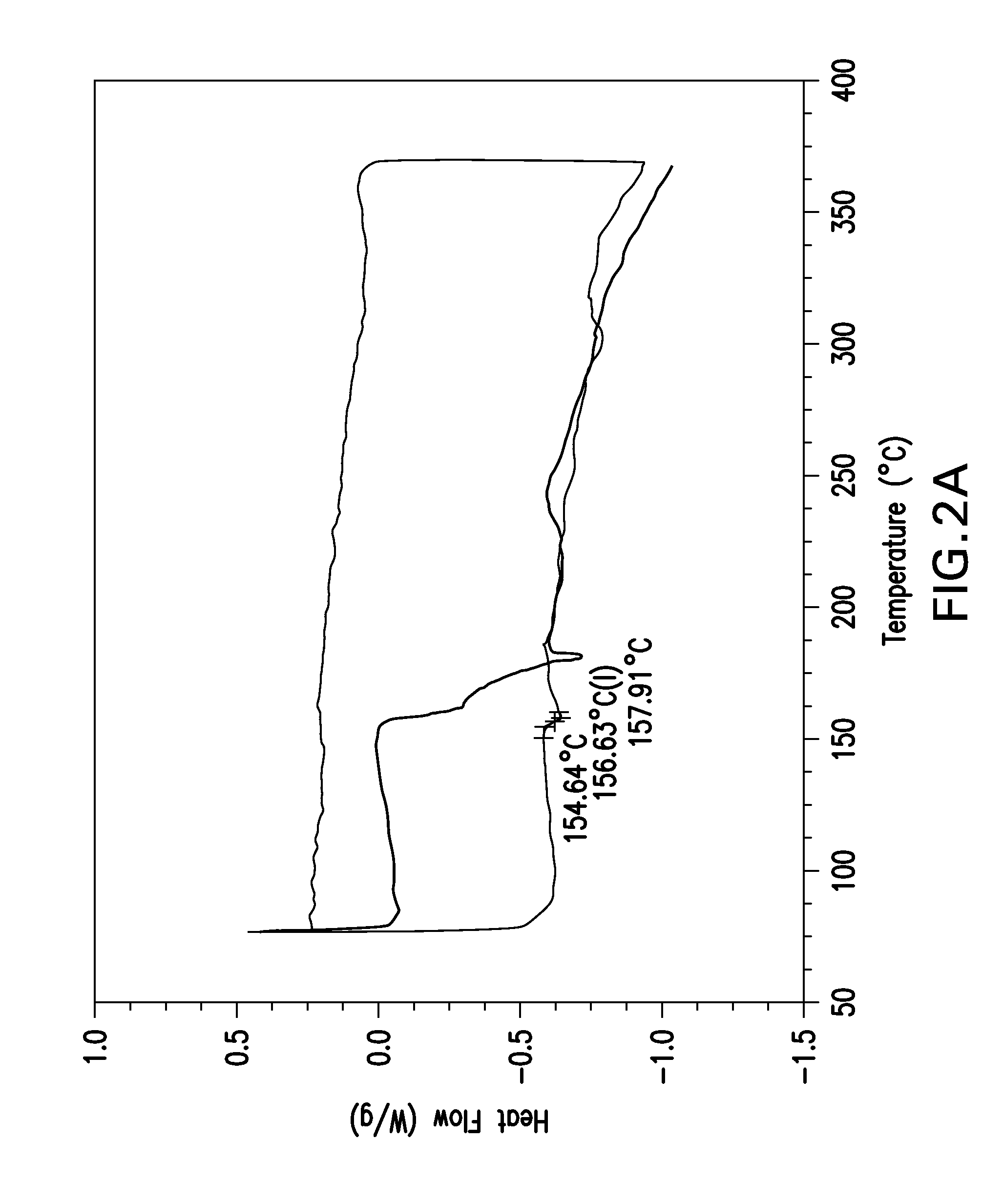

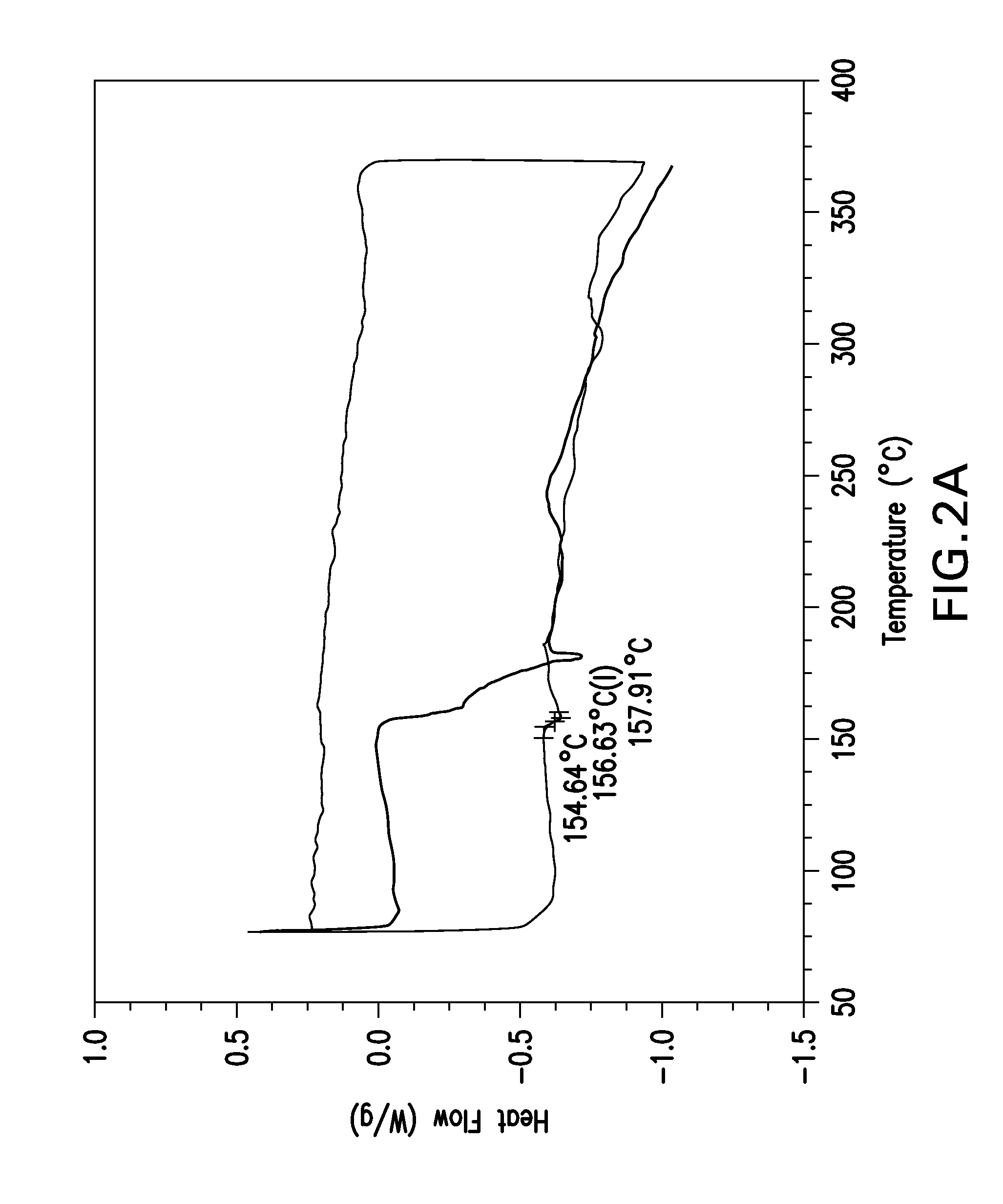

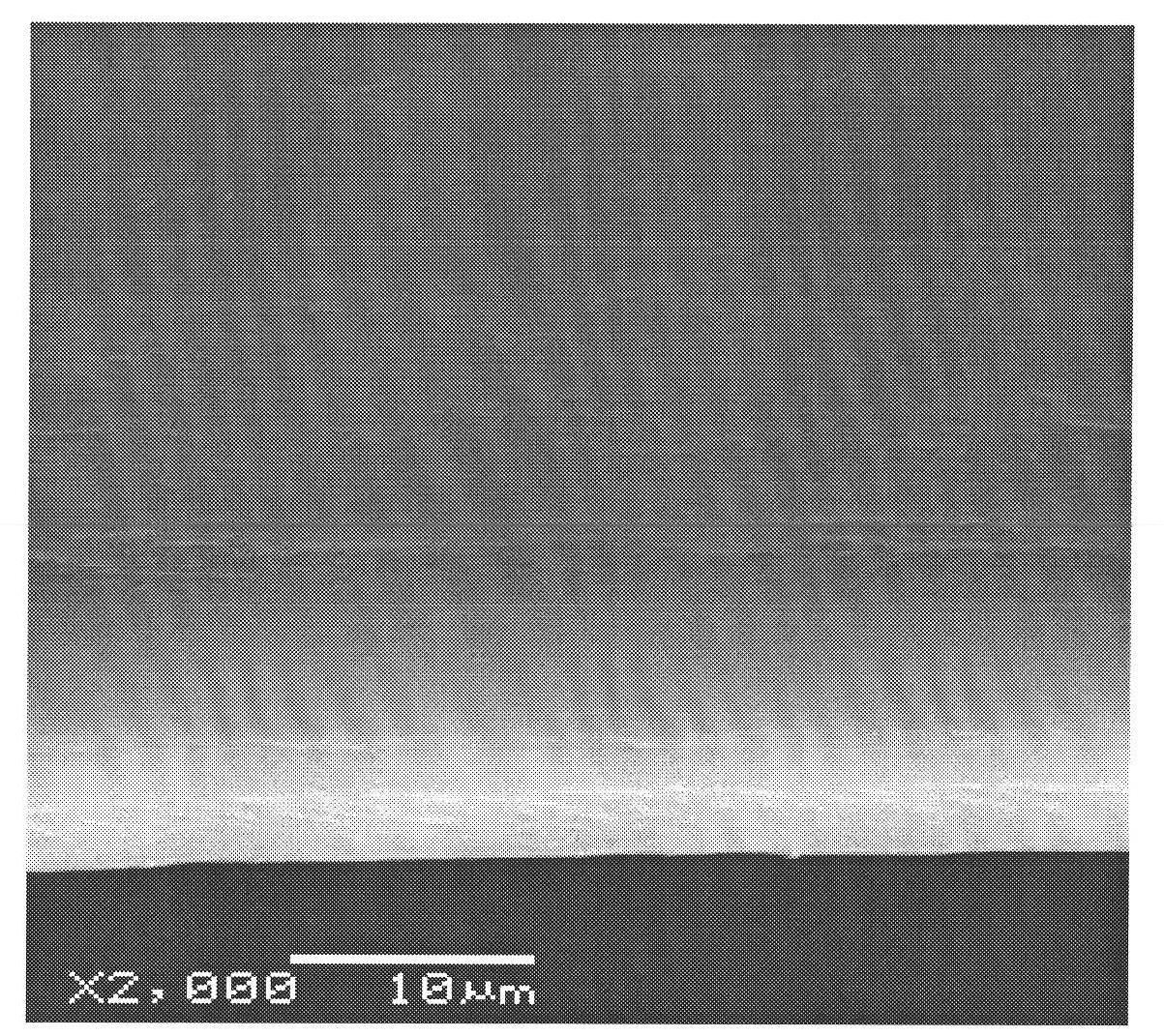

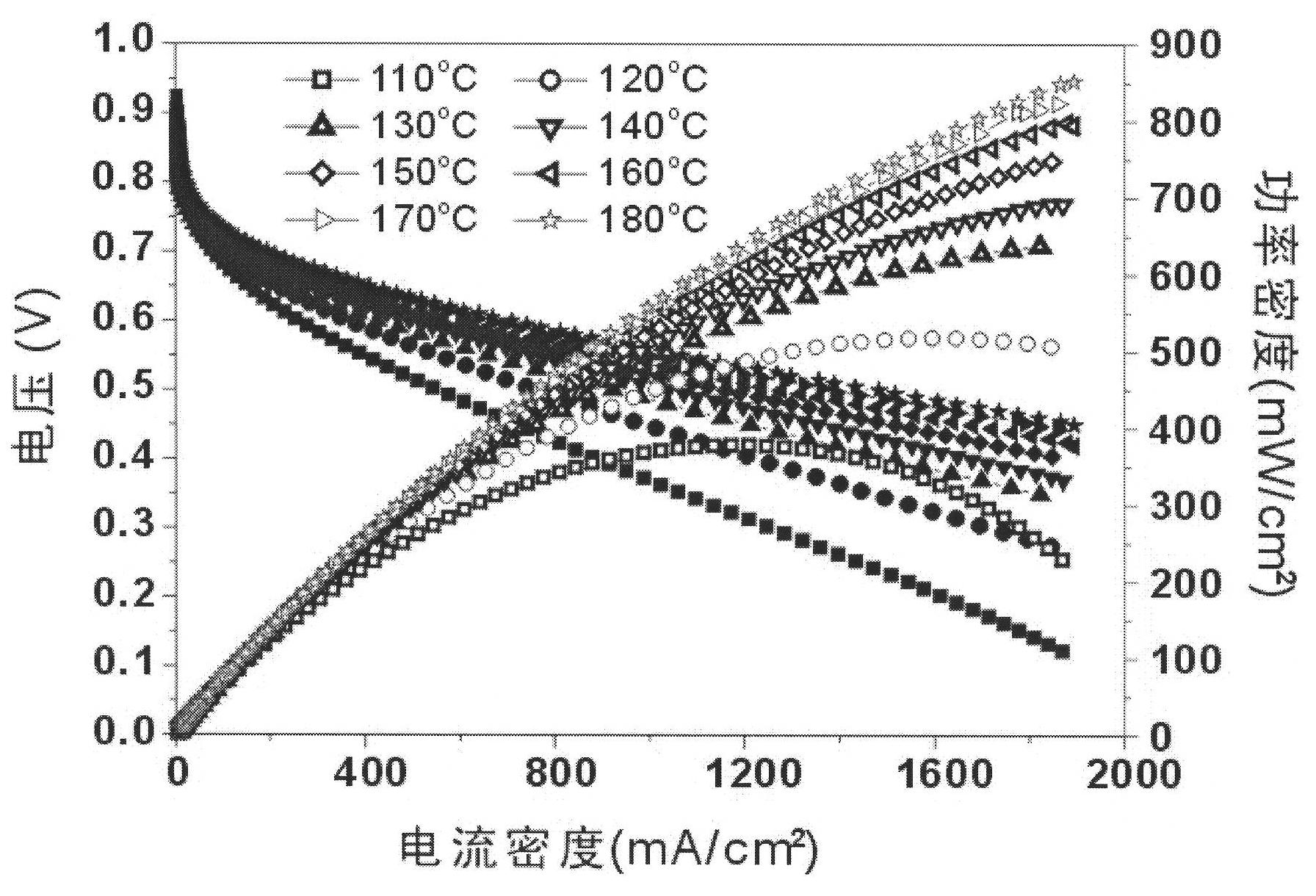

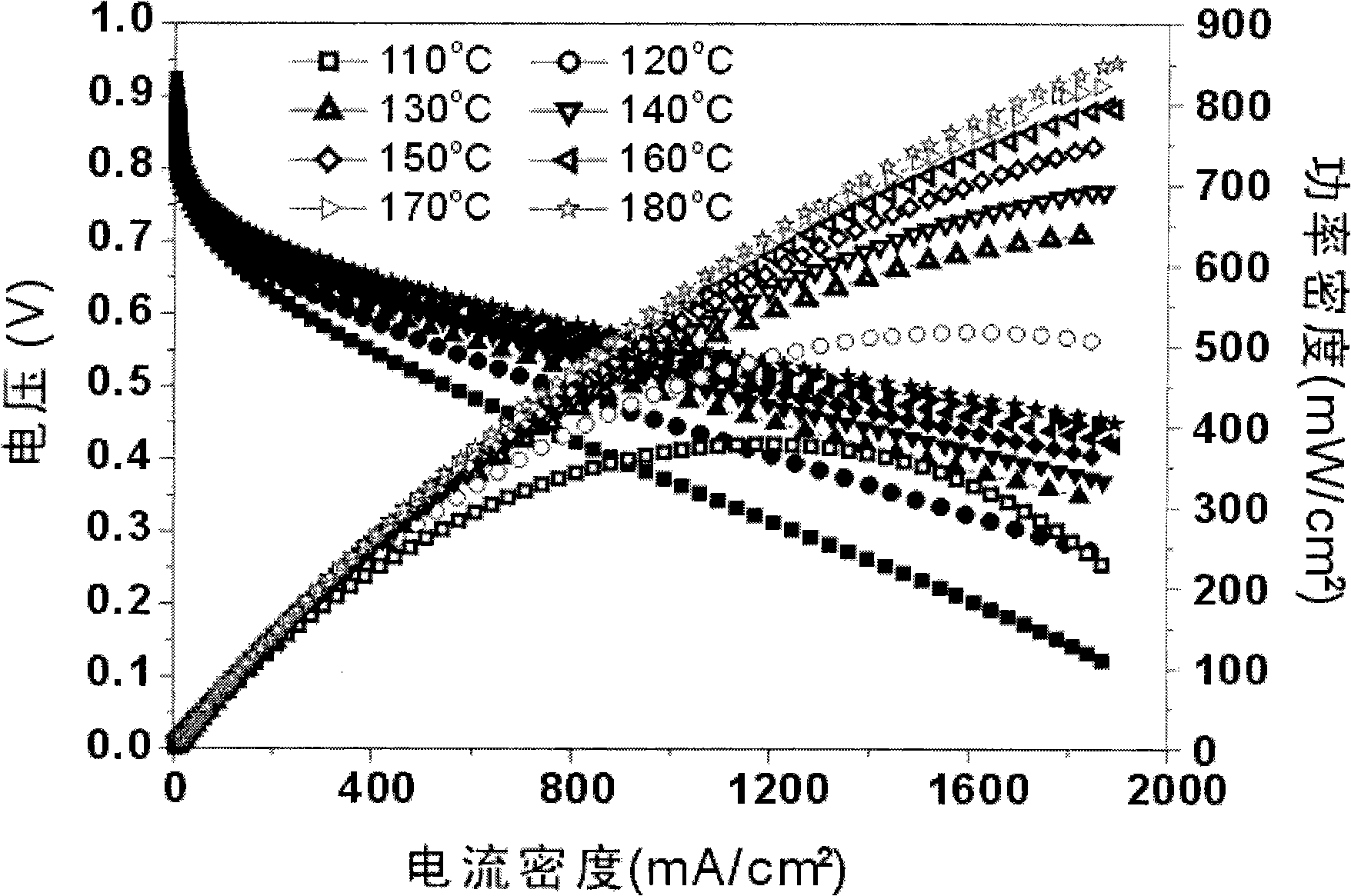

High temperature proton exchange membrane for fuel cell, and preparation method thereof

The present invention discloses a high-performance polymer high temperature proton exchange membrane for a high temperature proton exchange membrane fuel cell, and a preparation method thereof. The method comprises: blending a polymer with excellent thermal stability and chemical stability (such as PES, PSF and other engineering plastics) and a hydrophilic polymer with N-heterocycle on a side chain (such as PVP, P4VP and the like); adopting tape casting membrane forming or solution casting membrane forming; after membrane removing, carrying out an acidification (phosphoric acid or / and heteropoly acid) treatment for the prepared homogeneous blended membrane so as to provide good high temperature proton conductivity for the membrane. The exchange membrane is a homogeneous, transparent, and compact membrane, has characteristics of excellent chemical stability, excellent thermal stability, excellent mechanical property and excellent high temperature proton conductivity, and can meet the application requirements of the high temperature proton exchange membrane fuel cell. The proton exchange membrane can further be used as the membrane material for high temperature water electrolysis apparatuses, high temperature batteries, super capacitors and other devices. The proton exchange membrane material has characteristics of low cost, simple preparation process, wide use temperature range (100-200 DEG C), good high temperature proton conductivity and excellent mechanical property.

Owner:北京海得利兹新技术有限公司

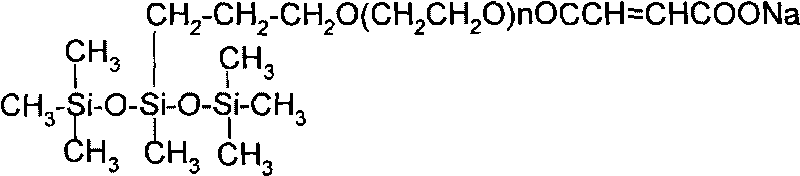

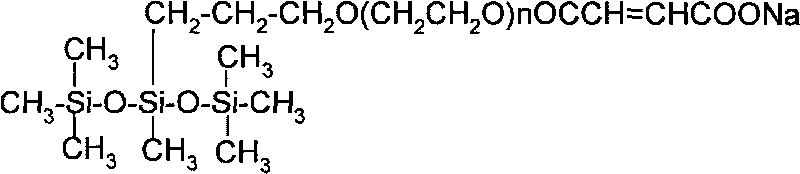

Polymer emulsion and preparation method thereof

The invention discloses polymer emulsion and a preparation method thereof. The polymer emulsion is characterized by using hard monomer, soft monomer and crylic acid as polymer monomers, using crylic acid long-chain alkyl ester as modified monomer, using polymerizable organosilicon emulsifier PMSC as the emulsifier of the system and using thermal decomposition initiator as the initiator to obtain high-performance polymer emulsion by semi-continuous type emulsion copolymerization. The polymer emulsion obtained by the method has favorable waterproofness, water resistance, weather resistance, adhesiveness and film coating effect, and can be widely used as paint, adhesive, fabric waterproof agent, and the like, thereby having bright development potential.

Owner:NANJING UNIV OF TECH

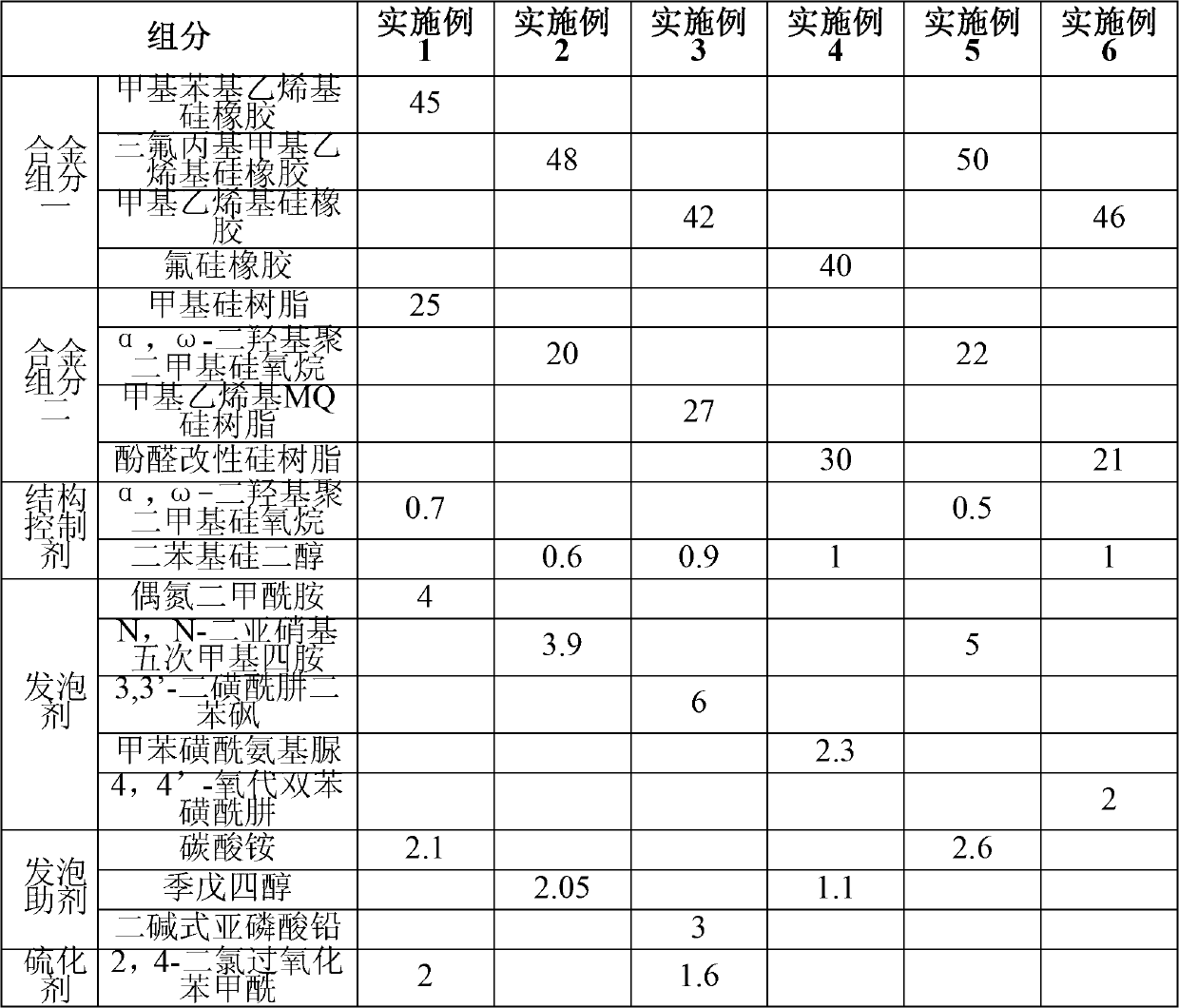

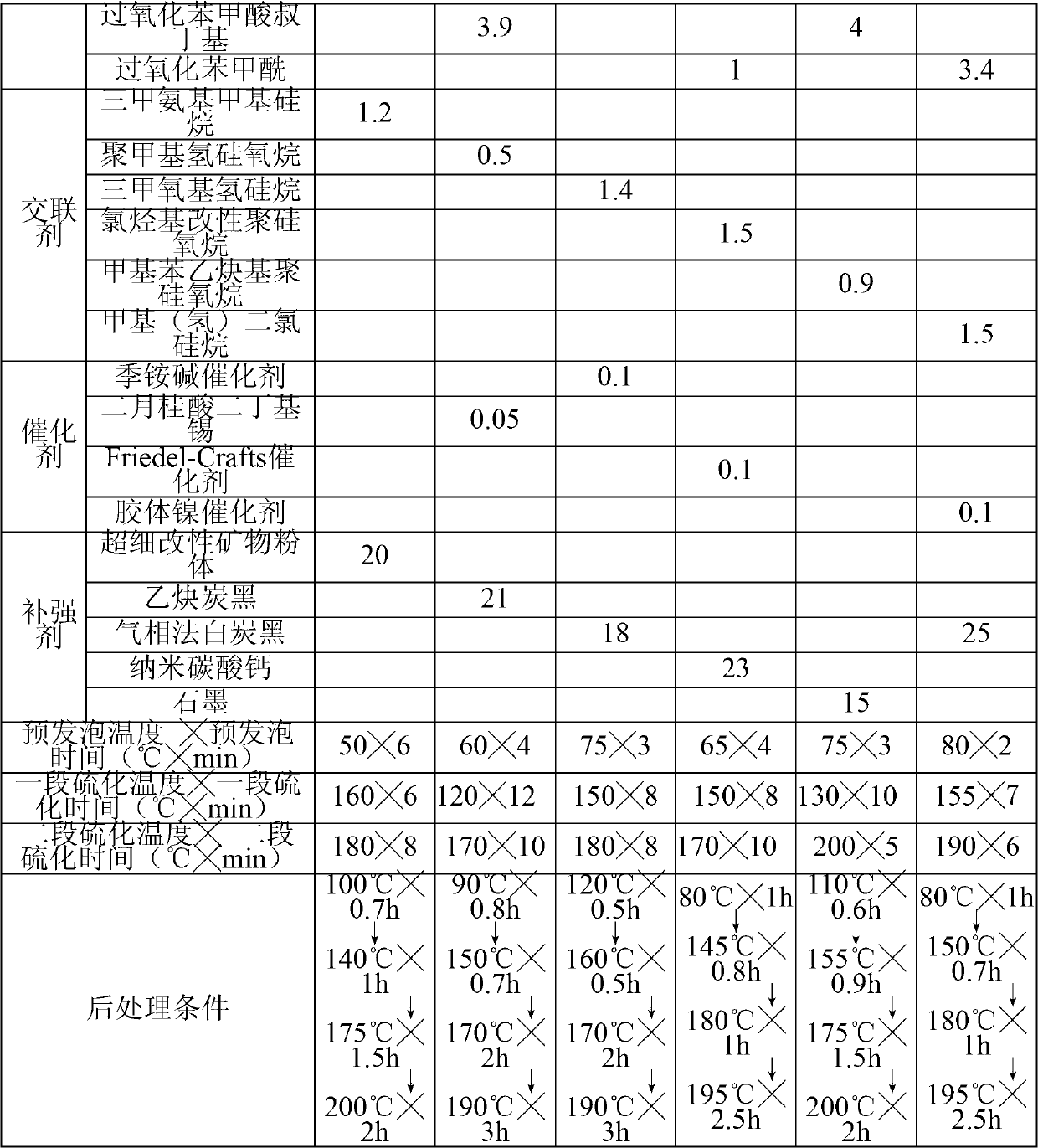

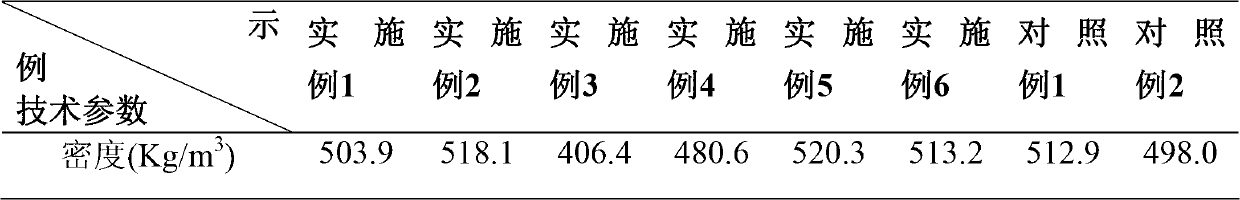

High heat-resistant porous organic silicon alloy elastomer material and method for preparing same

The invention discloses a high heat-resistant porous organic silicon alloy elastomer material and a method for preparing the same. The method comprises master batch preparing: weighing 40% to 50% of alloy component one, 20% to 30% of alloy component two, 0.5% to 1.5% of cross-linking agents, 0.5% to 1.5% of constitution control agents, 15% to 25% of reinforcing agents and 0.05% to 0.15% of catalysts to be fully mixed, and allowing the mixture to stand for 2 to 4 hours; mixing: adding, by weight, 2% to 6 % of foaming agents, 1% to 3% of foaming assistants and 1% to 4% of vulcanizer into the master batch to be mixed for 10 to 30 minutes; vulcanization and foaming: vulcanizing and foaming rubber compound, and cooling and domolding after two phases of reaction; and post-processing: obtaining the high heat-resistant porous organic silicon alloy elastomer material after three phases of stoving. The high heat-resistant porous organic silicon alloy elastomer material has the advantages of low density, high softness, ductility, elasticity and porosity, and good physical properties of mechanical shock or impact absorption and high frequency damping. The material can be used continuously for a long time at a high temperature, is inflaming retardant, and can be widely applied in the fields of industry, agriculture, communication, military, construction, daily articles and the like.

Owner:XIAN UNIV OF SCI & TECH

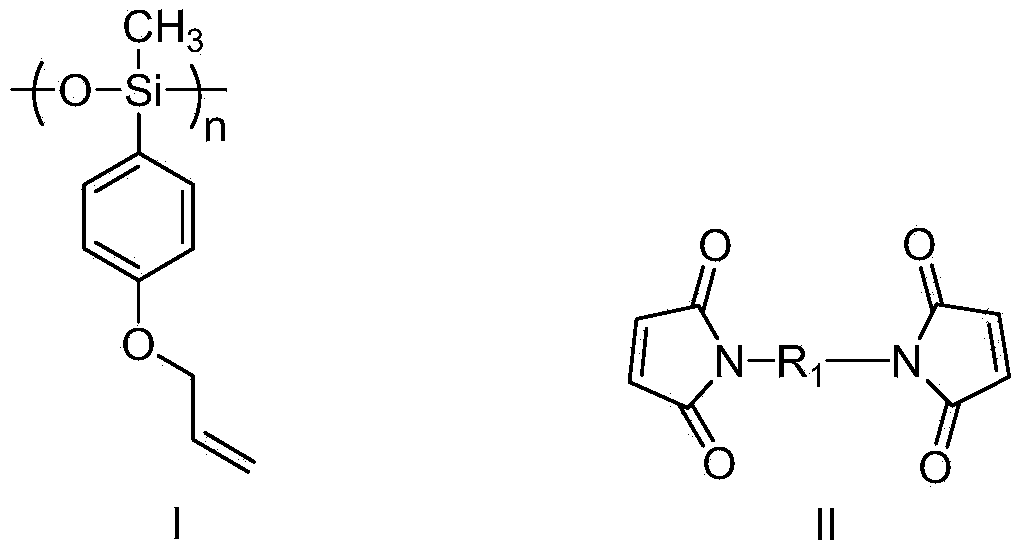

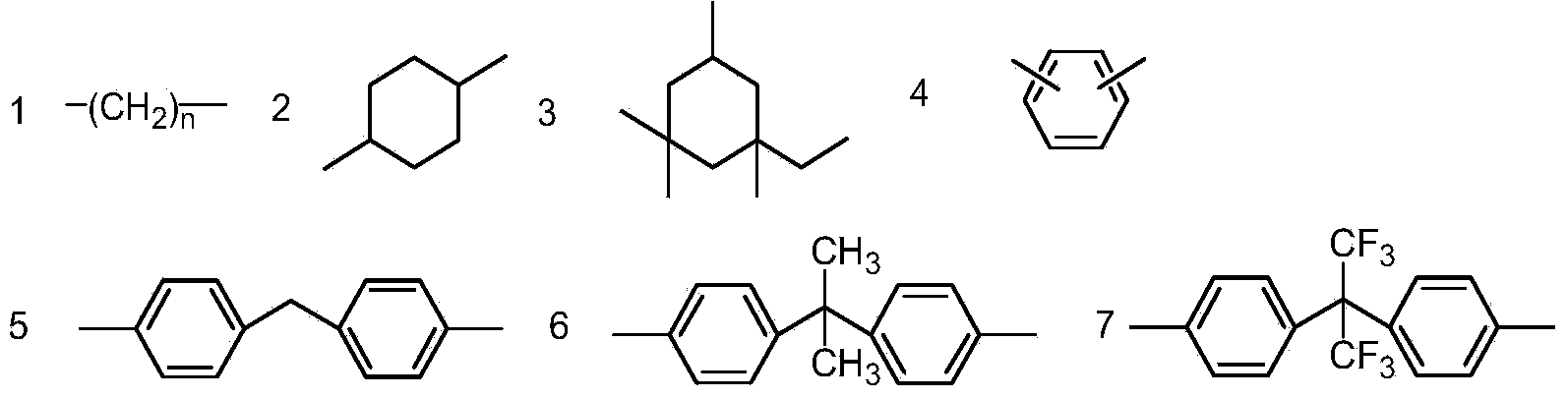

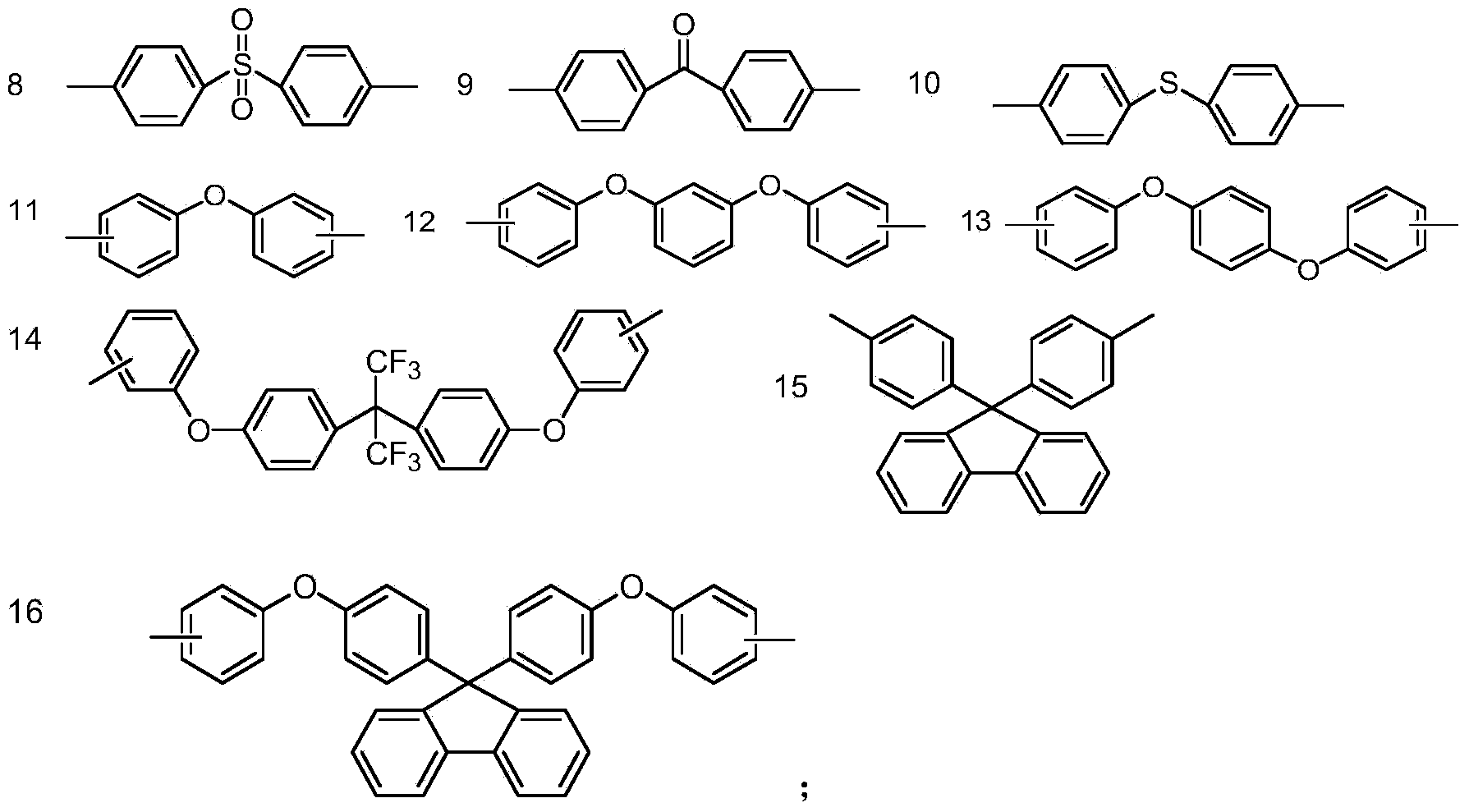

Silicon-containing bismaleimide resin and preparation thereof

The invention belongs to the field of high-performance polymer synthesis and application, and in particular relates to a method for preparing silicon-containing bismaleimide resin. The modified silicon-containing bismaleimide resin is prepared by copolymerizing a bismaleimide monomer with allylic organic silicon resin. Compared with pure bismaleimide resin, the modified silicon-containing bismaleimide resin is high in thermal resistance in addition to relatively low dielectric constant. The modified resin can be used as a high-temperature resisting adhesive as well as a packaging material and laminated substrate resin of electronic devices in the electric industry.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

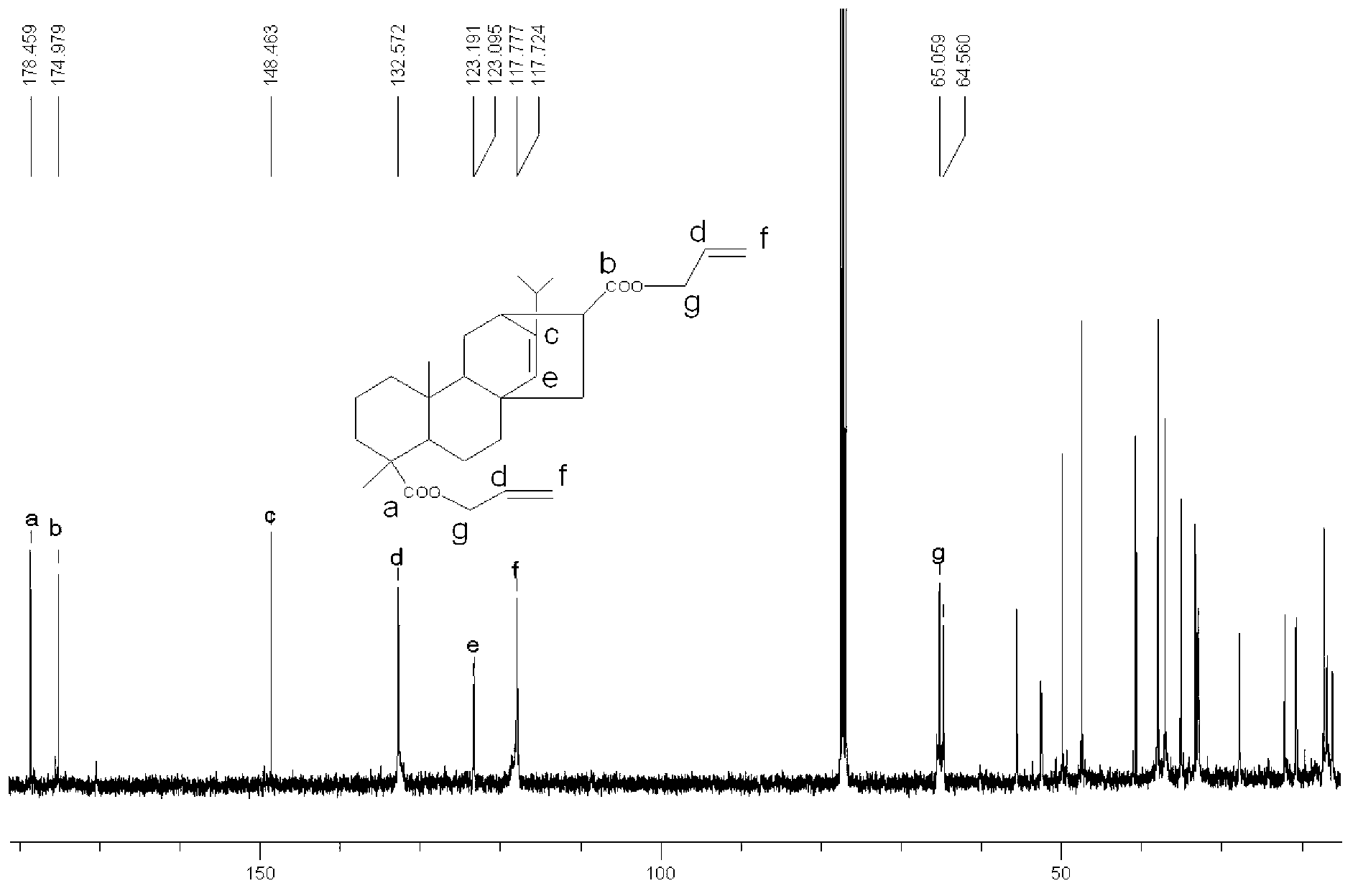

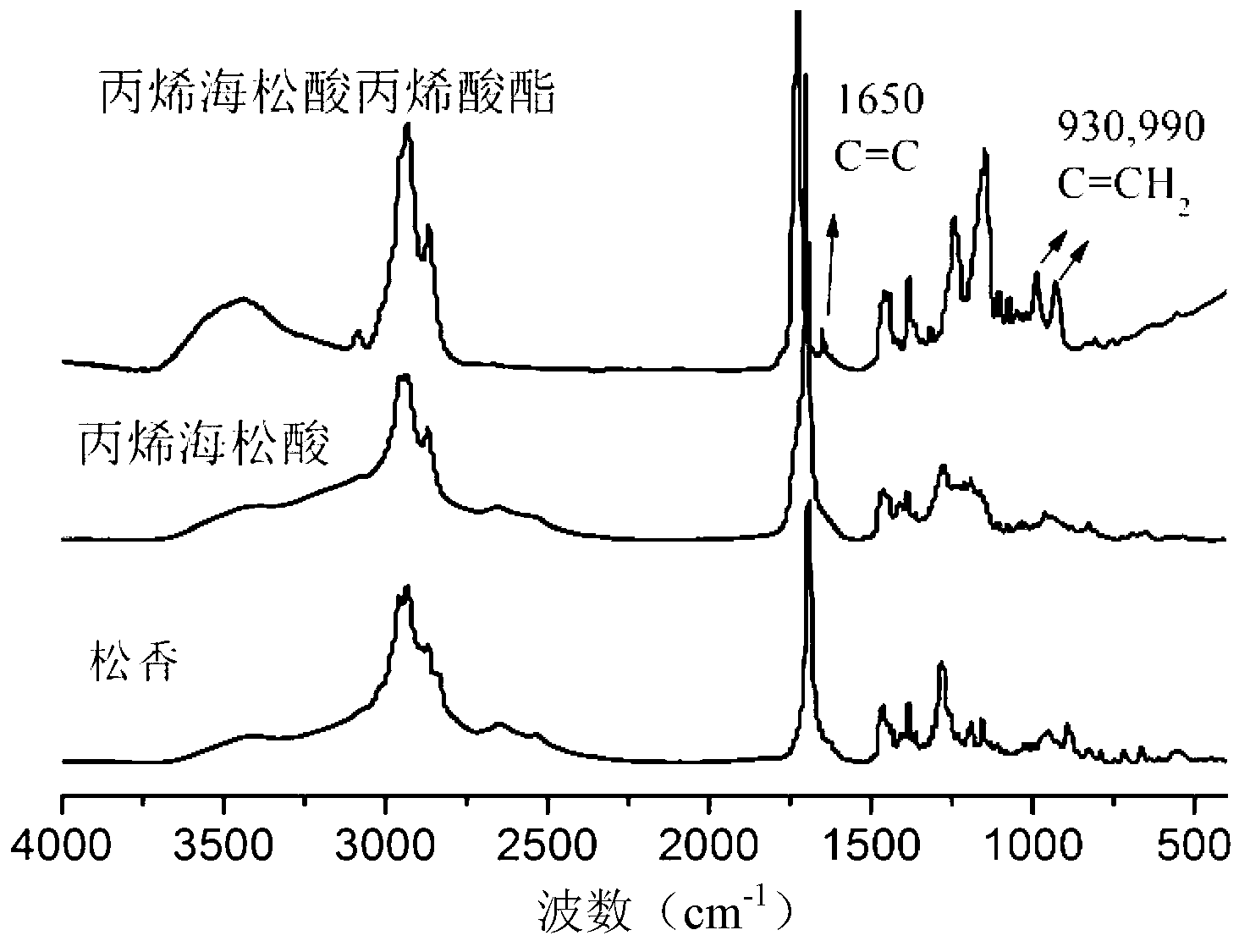

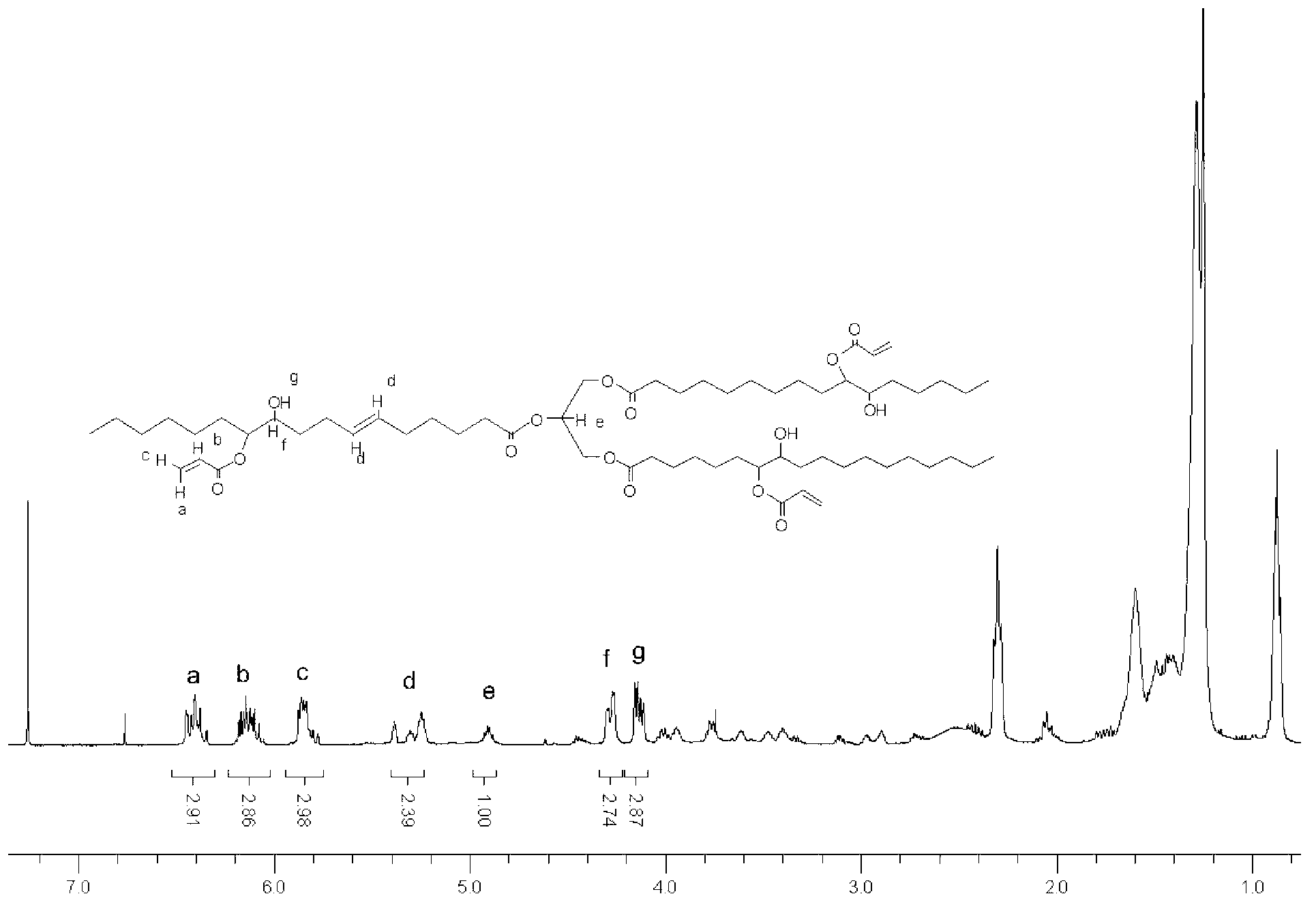

Bio-based unsaturated polyester cured product and preparation method thereof

ActiveCN102977265AImprove performanceHigh Bio-Based ContentOrganic compound preparationCarboxylic acid esters preparationHydrogenUnsaturated polyester

The present invention discloses a bio-based unsaturated polyester cured product, which is prepared from the raw materials including by weight: 40-94% of epoxidized soybean oil acrylate, 4-59.5% of acrylpimaric dipropylene ester, and 0.5-2% of an initiator. The advantage that the hydrogen phenanthrene ring structure in acrylpimaric dipropylene ester has strong mechanical rigidity is fully played. The shortcomings that the epoxidized soybean oil acrylate molecular chain is too flexible and difficult to get high-performance polymer directly are overcome. The bio-based unsaturated polyester cured product with excellent performance and high bio-based components is prepared. The present invention also discloses a preparation method of the bio-based unsaturated polyester cured product. The method includes mixing the epoxidized soybean oil acrylate, the acrylpimaric dipropylene ester and the initiator, and removing into a mold. The bio-based unsaturated polyester cured product is obtained after copolymerization curing at 80-200 DEG C. The preparation conditions are easy to implement and control, and easy for mass industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

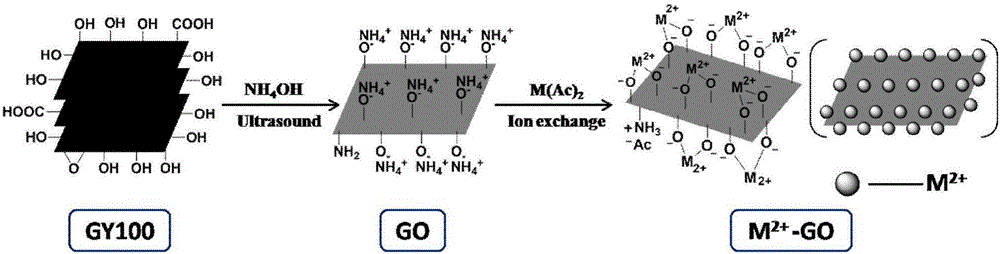

Low-smoke flame-retardant polymer composite material and preparation method thereof

ActiveCN106046683AImprove flame retardant performanceHigh smoke suppression effectEpoxyPolymer science

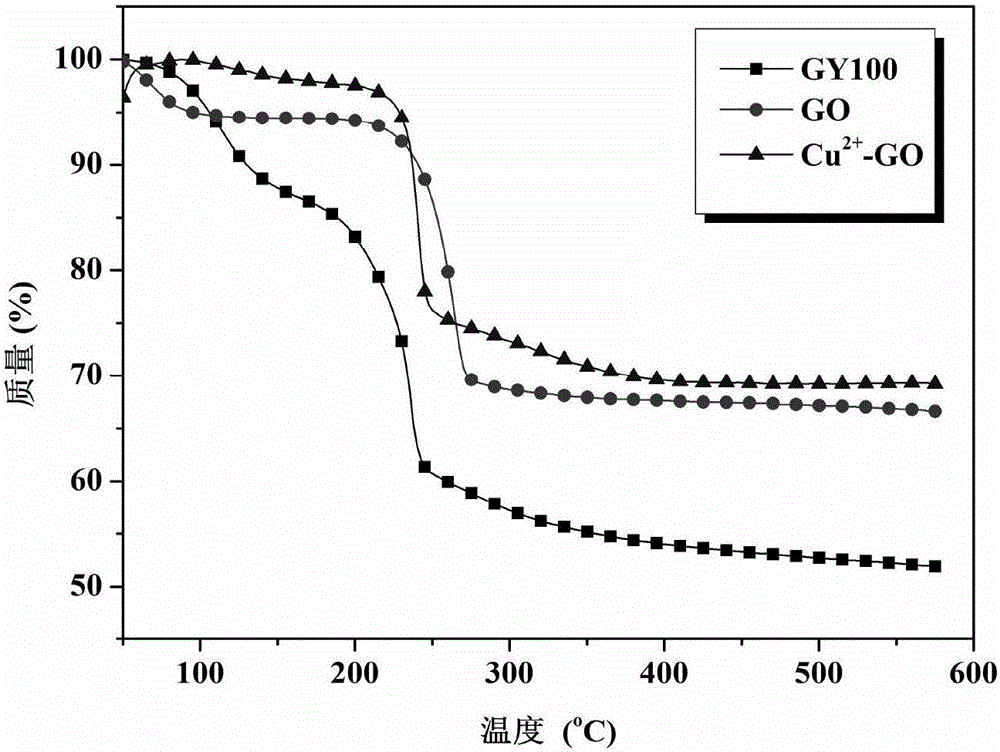

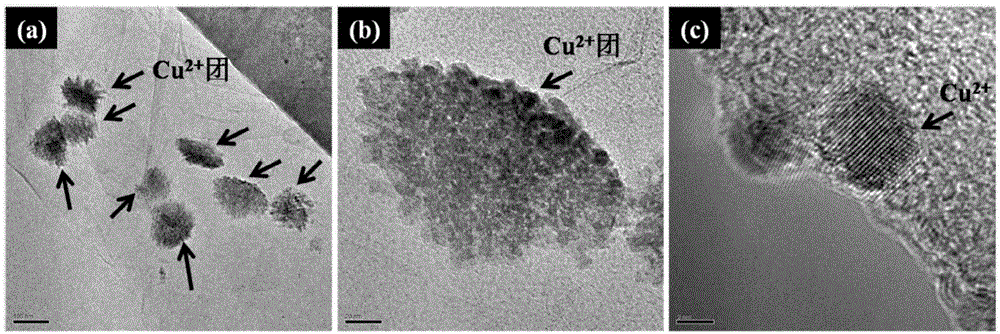

The invention belongs to the field of polymer materials and relates to a low-smoke flame-retardant polymer composite material. The low-smoke flame-retardant polymer composite material is prepared from, by weight, 100 parts of a polymer matrix, 10-60 parts of an intumescent flame retardant, 0-30 parts of a charring agent, 0-20 parts of a foaming agent and 0.5-5 parts of a smoke inhibition synergist, wherein the smoke inhibition synergist is a hybrid formed by loading of metal ions on the surface of graphene oxide. The hybrid formed by loading of the metal ions on the surface of graphene oxide is used as the smoke inhibition synergist which is synergically used with the the intumescent flame retardant to improve flame retardation and smoke inhibition performances of various polymer materials such as epoxy resin and polyurethane. A new approach is provided for preparation of multifunctional high-performance polymer composite materials.

Owner:XIHUA UNIV

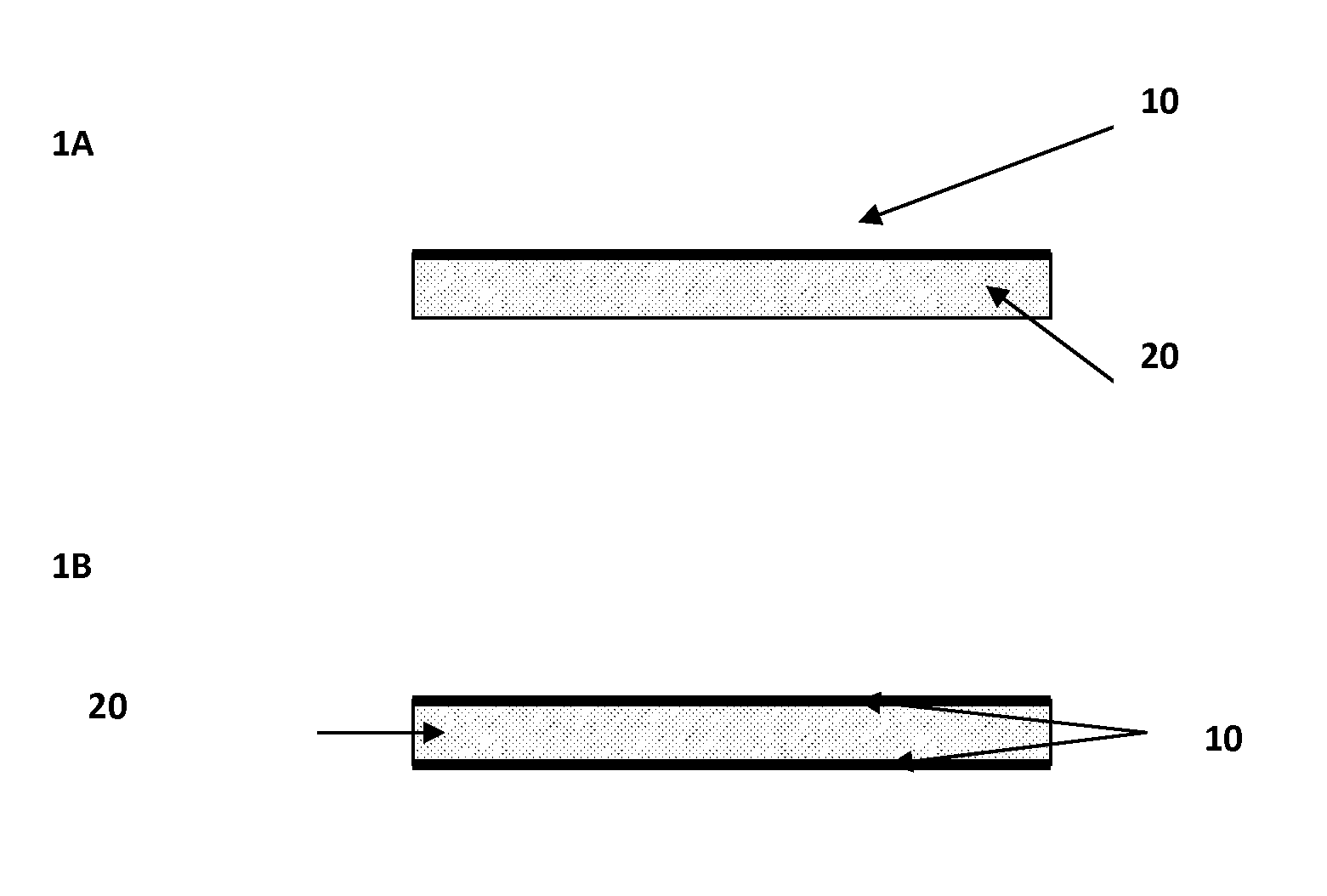

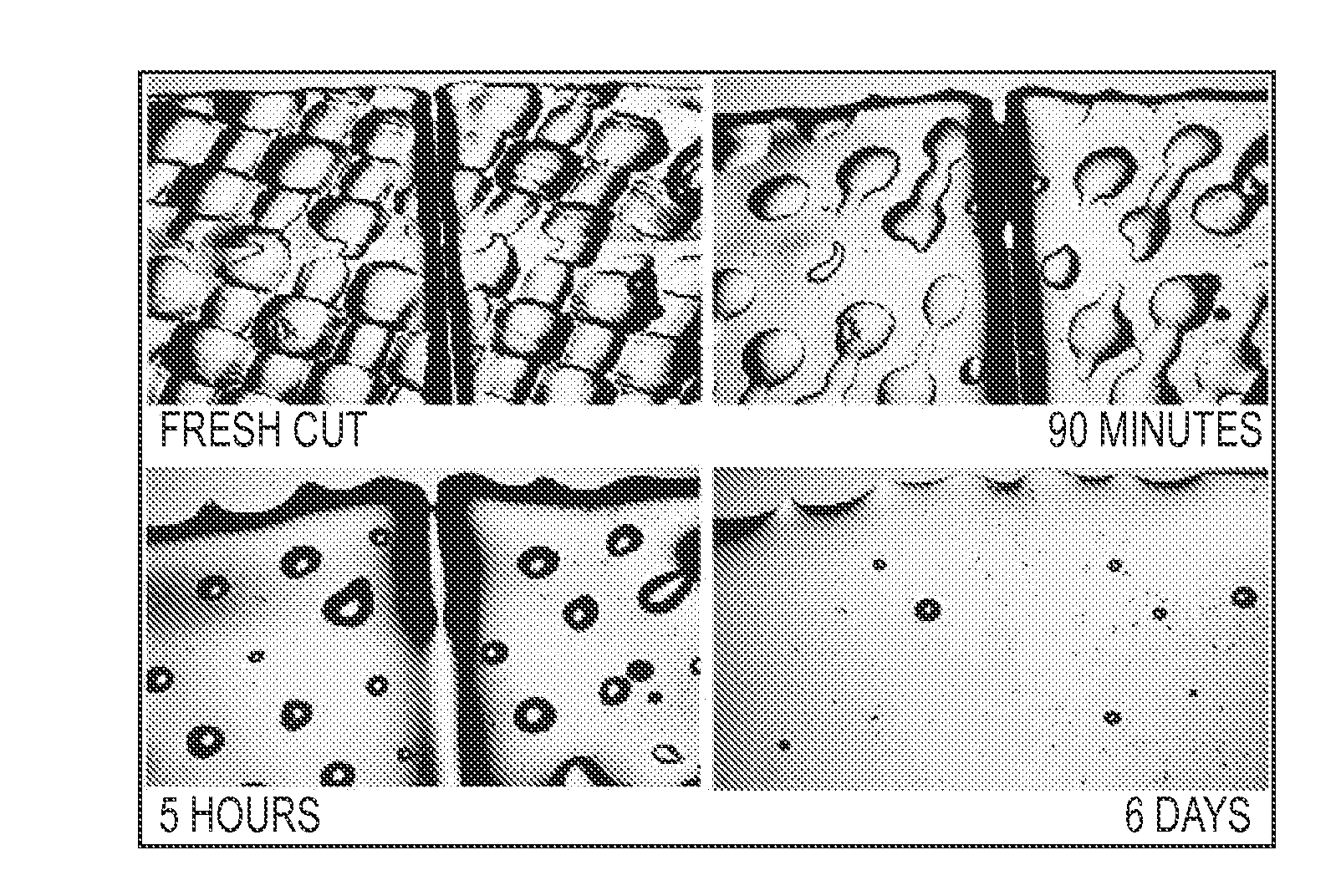

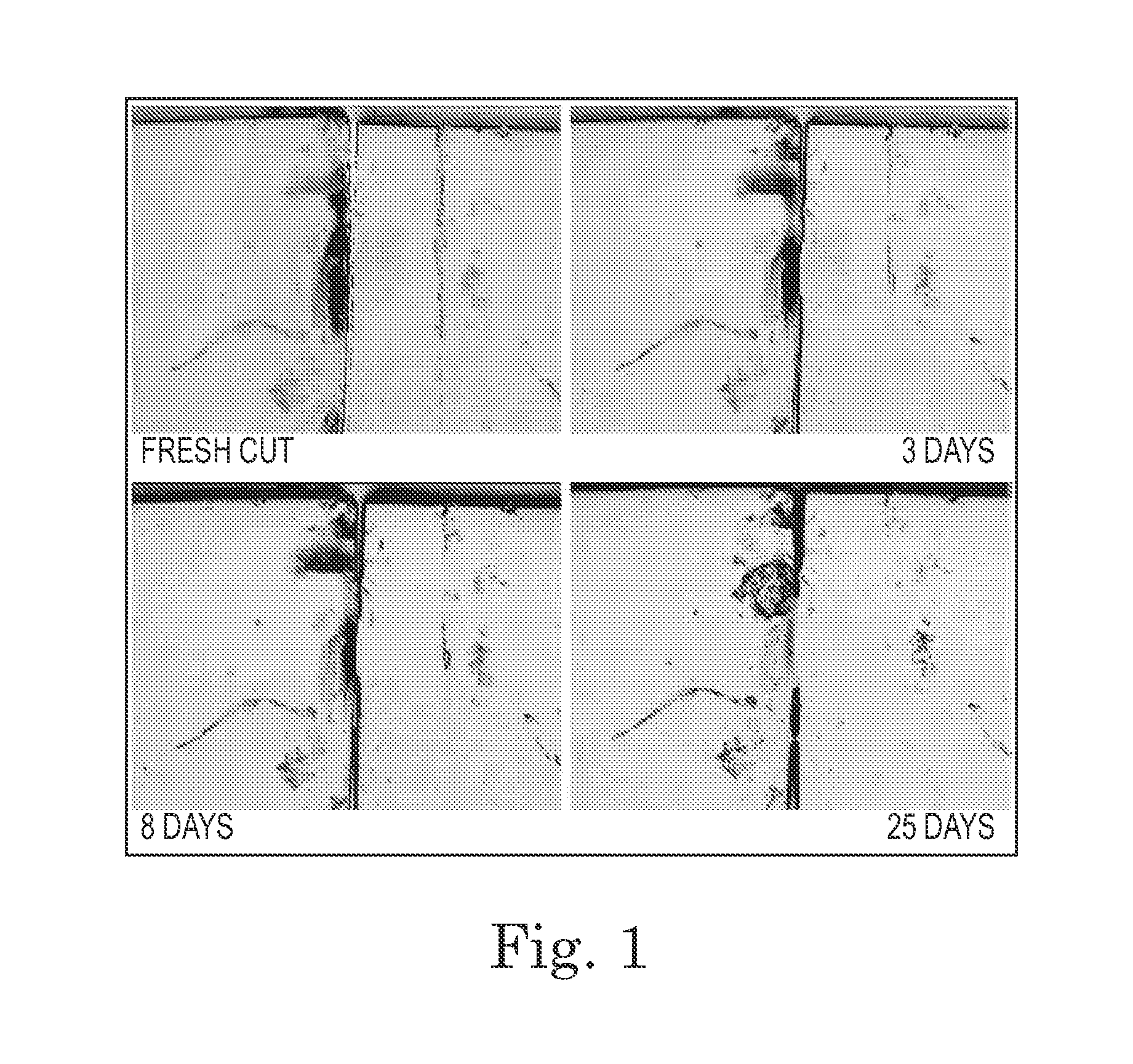

Self-Healing Polymer Materials for Wire Insulation, Polyimides, Flat Surfaces, and Inflatable Structures

ActiveUS20120321828A1Reduce leakagePlastic/resin/waxes insulatorsSynthetic resin layered productsSelf-healingHigh performance polymer

Materials based on low melt polyimide, polyurea, or polyurethane chemistry have been developed which exhibit self-healing properties. These high performance polymers can be utilized either by themselves or in combination with microcapsule technology to deliver self-healing properties to electrical wire insulation or in other high performance, thin wall technologies such as inflatable structures.

Owner:NASA

Toughened polymer compositions

Toughened thermoplastic compositions comprising a thermoplastic polymer toughened by the inclusion of a thermoplastic elastomer derived from a particulate rubber dynamically vulcanized in the presence of a matrix polymer. The toughened thermoplastic composition exhibits properties including toughness, improved impact resistance, and improved hardness. The compositions are utilized wherever toughened, high performance polymers are desired. A method for forming the toughened polymer compositions is also described. Processing methods, such as rotational molding, utilizing the toughened polymer compositions are described.

Owner:TEKNOR APEX

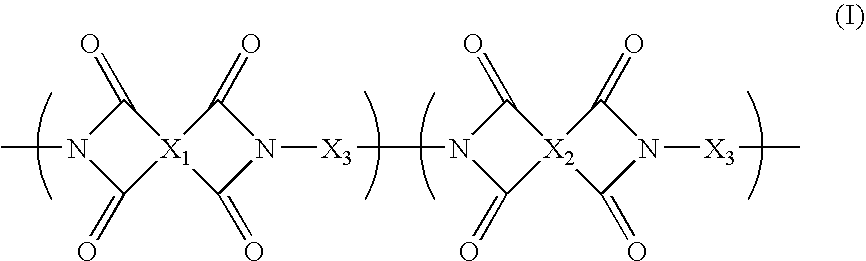

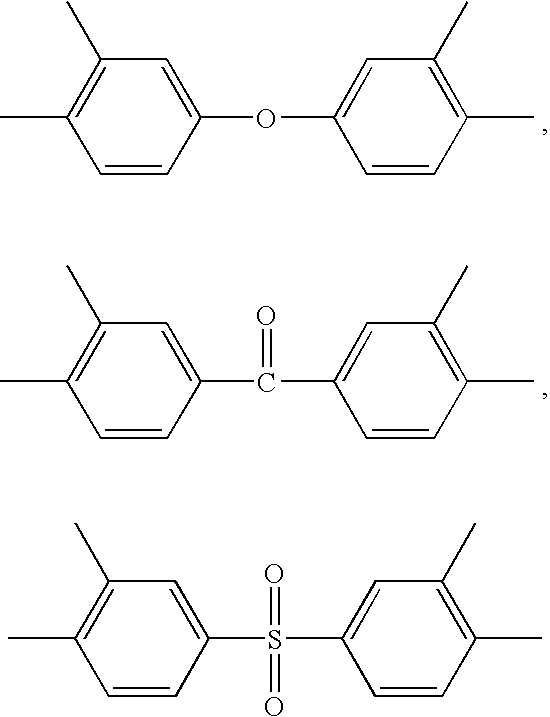

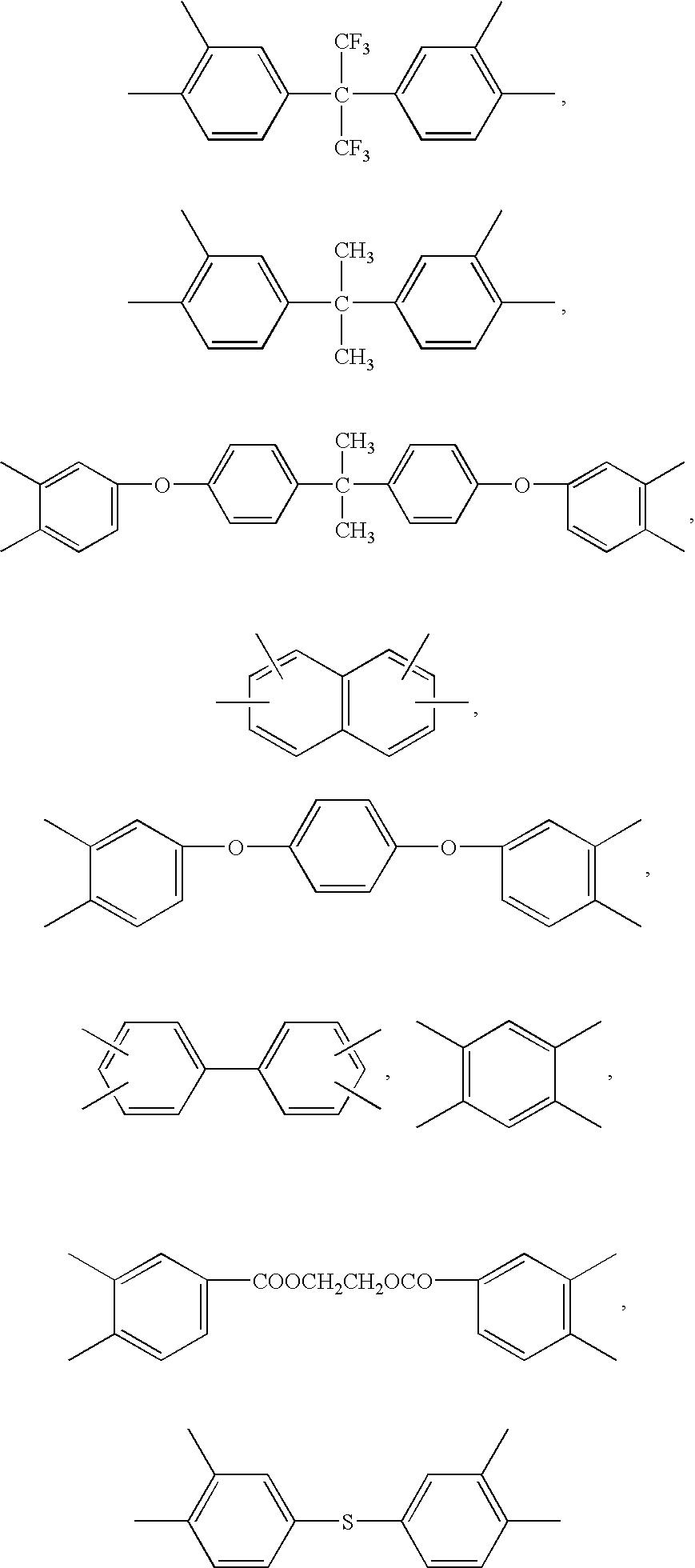

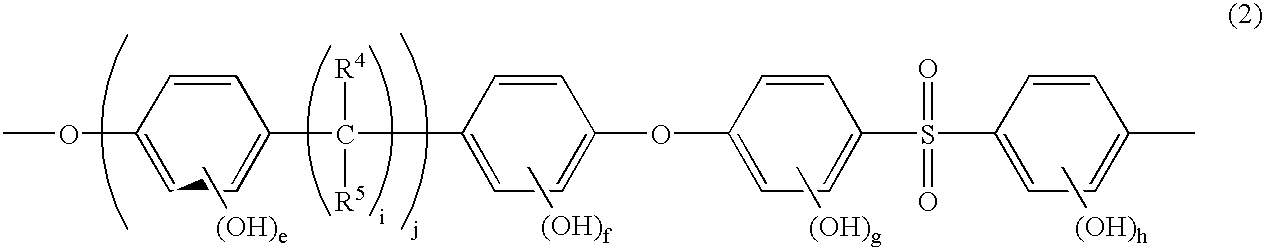

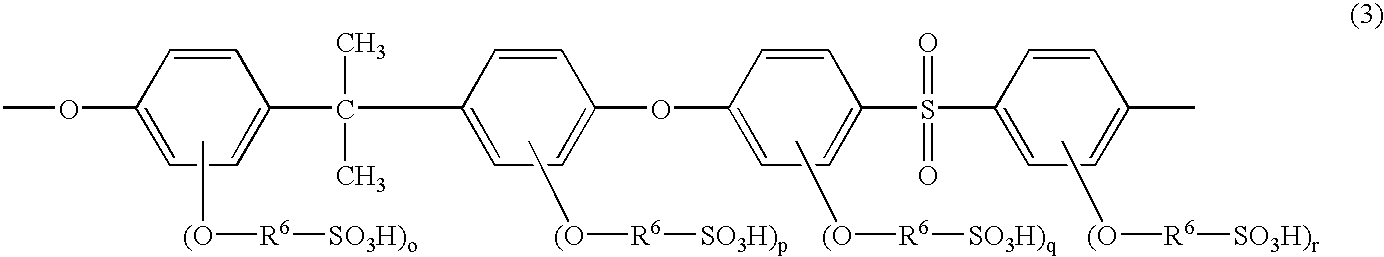

Poly(arylene ether sulfone) having sulfoalkoxy group, process of producing the same, and polymer electrolyte membrane comprising the same

A novel poly(arylene ether sulfone) having a sulfoalkoxy group, which has both of heat resistance and electroconductivity, is suitable as polymer electrolyte membranes used for high performance polymer electrolyte fuel cells, and does not use fluorine so that loads to the environment are small in the synthesis or disposal, a process of producing the same, and a polymer electrolyte membrane comprising the same. The poly(arylene ether sulfone) having a sulfoalkoxy group has a structural unit represented by the formula (1) mentioned hereinabove, and is produced by reacting a poly(arylene ether sulfone) having a hydroxyl group with a specific alkali metal compound and / or an organic base compound, followed by reacting with a specific sulfonating agent and then with a specific acid. A polymer electrolyte membrane is produced by film formation of the polymer.

Owner:TOSOH CORP

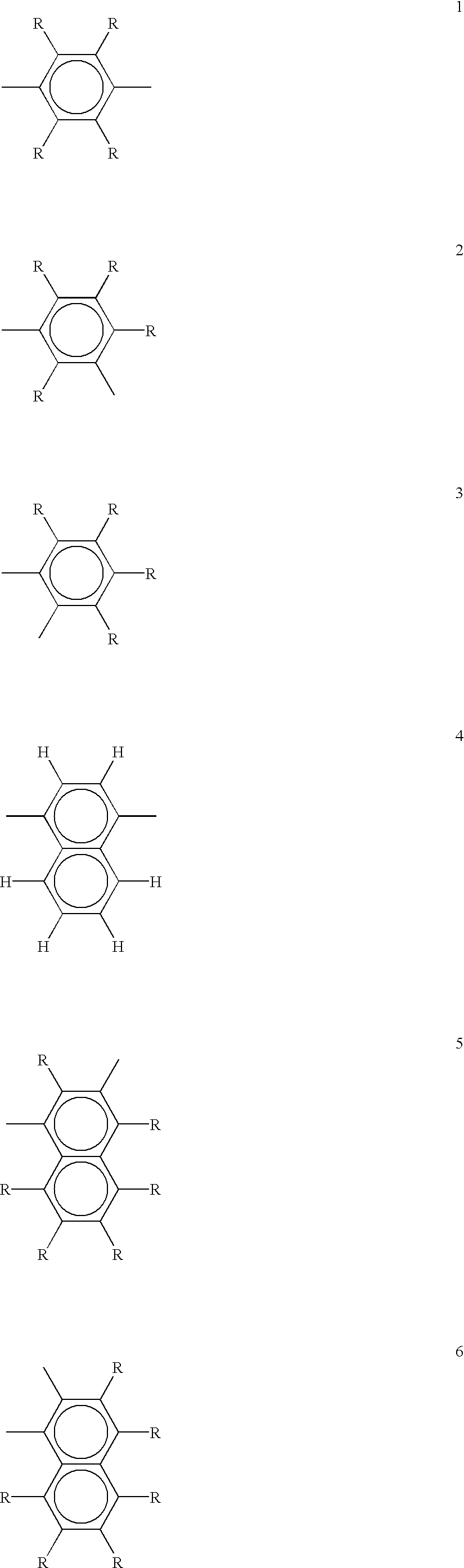

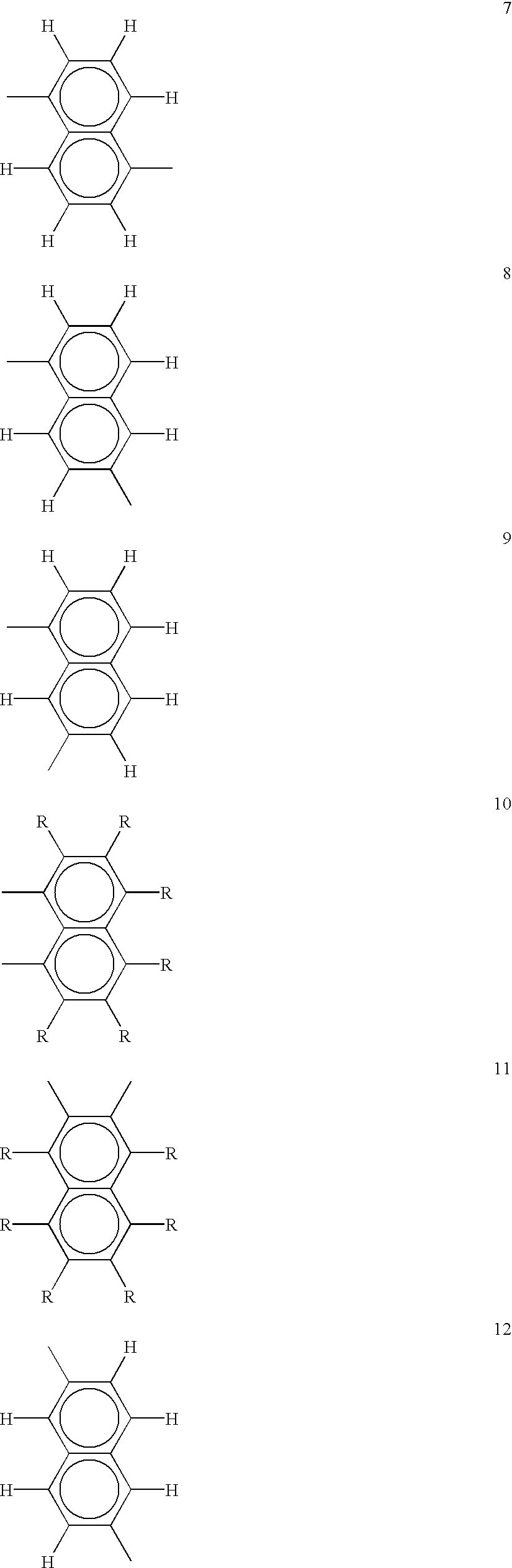

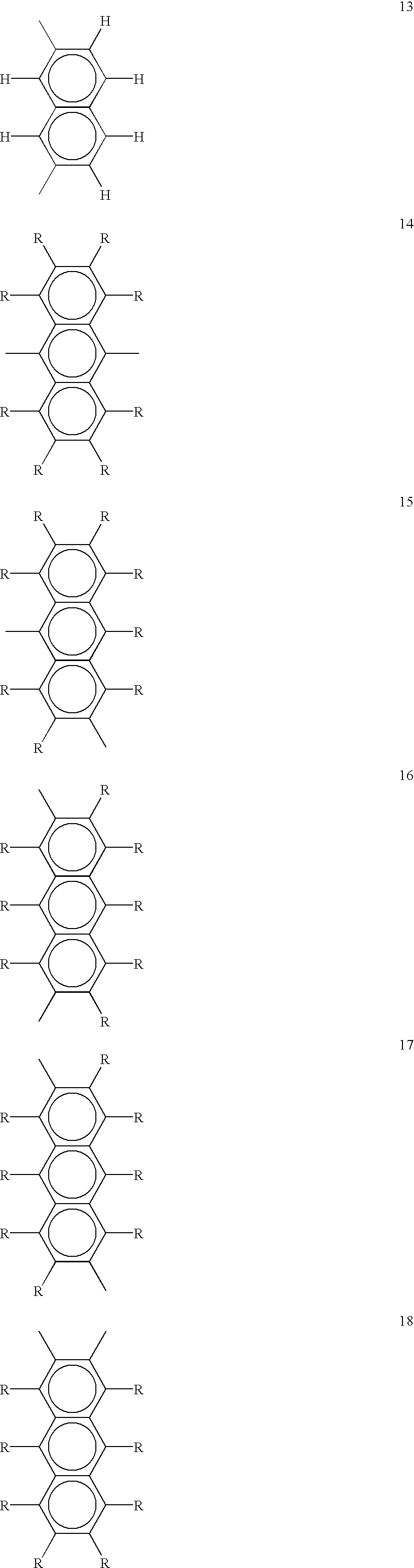

Polymeric fluorescent substance, production thereof and polymer light-emitting device

InactiveUS6905785B2Liquid crystal compositionsDischarge tube luminescnet screensPolymer scienceHeteroatom

Provided is a method of producing a polymeric fluorescent substance wherein one or more monomers represented by the general formula (1) are polymerized in the presence of a zerovalent nickel complex,X1—Ar1—X2 (1)wherein, Ar1 represents a divalent group selected from the group consisting of arylene groups, divalent heterocyclic compound groups, and divalent or trivalent hetero atom-bonded arylene or divalent heterocyclic compound groups, and X1 and X2 represent leaving groups. By using the polymeric fluorescent substance, a high performance polymer LED can easily be obtained.

Owner:SUMITOMO CHEM CO LTD

Polymer compound and components produced using the compound

ActiveCN101864170AExcellent mechanical propertiesOpen up the possibility of usePlastic/resin/waxes insulatorsInsulated cablesImidePolyetherimide

In order to make available polymer compounds that are improved with respect to their properties compared to conventional PTFE, on the one hand, and the further high-performance polymer or polymers, on the other, it is proposed that a polymer compound has a proportion of a fully fluorinated thermoplastic polymer material as well as a proportion of at least one further high-performance polymer different therefrom, selected from the group of polyphenylene sulphide (PPS), polyphenylene sulphone (PPSO2), polyamide (PA), polyimide (PI), polyamide-imide (PAD, and polyether imide (PEI) as well as copolymers and derivatives of these polymers and copolymers, wherein the compound has a homogeneous distribution of the proportions of the polymers and the polymer material.

Owner:ELRINGKLINGER AG

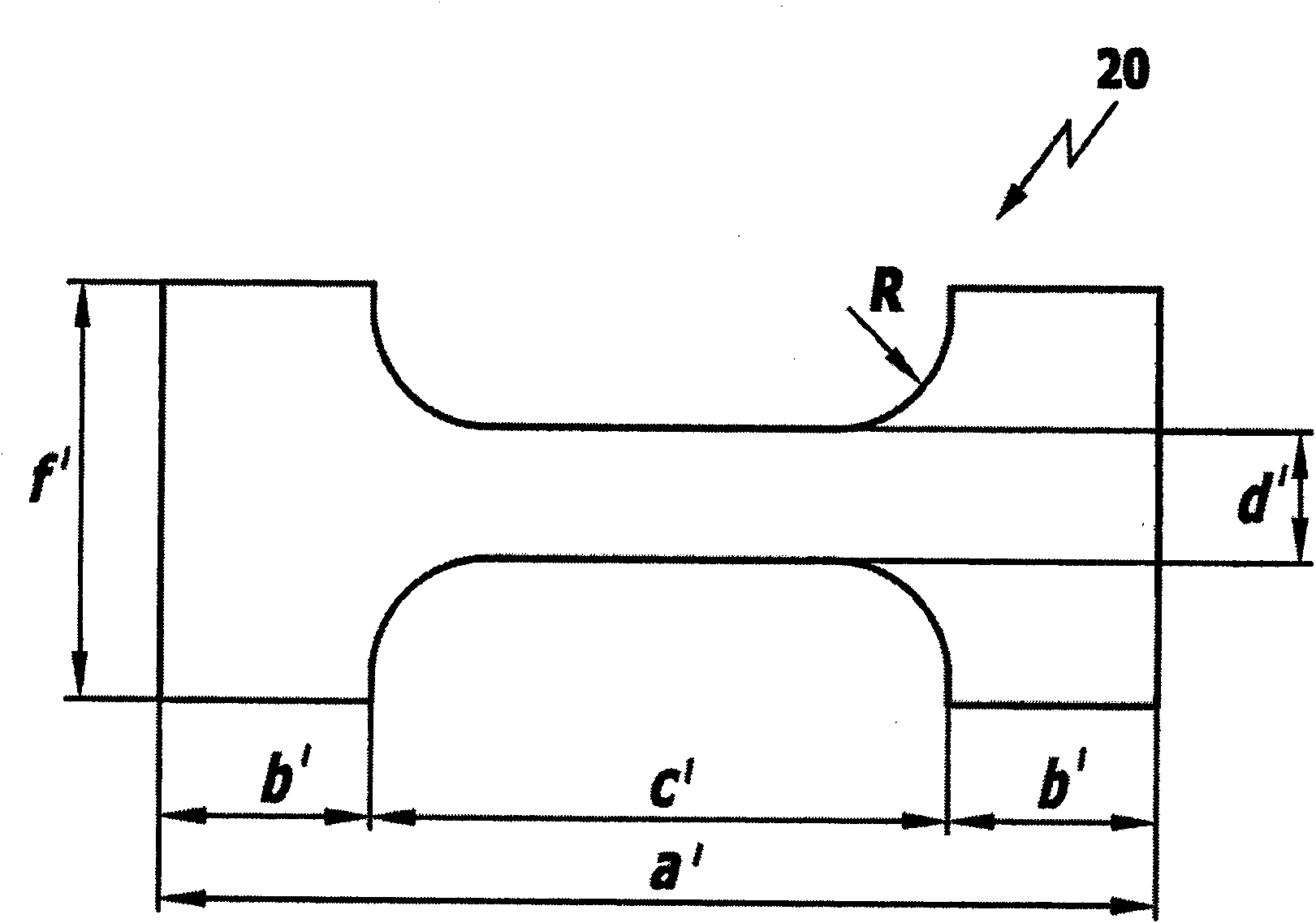

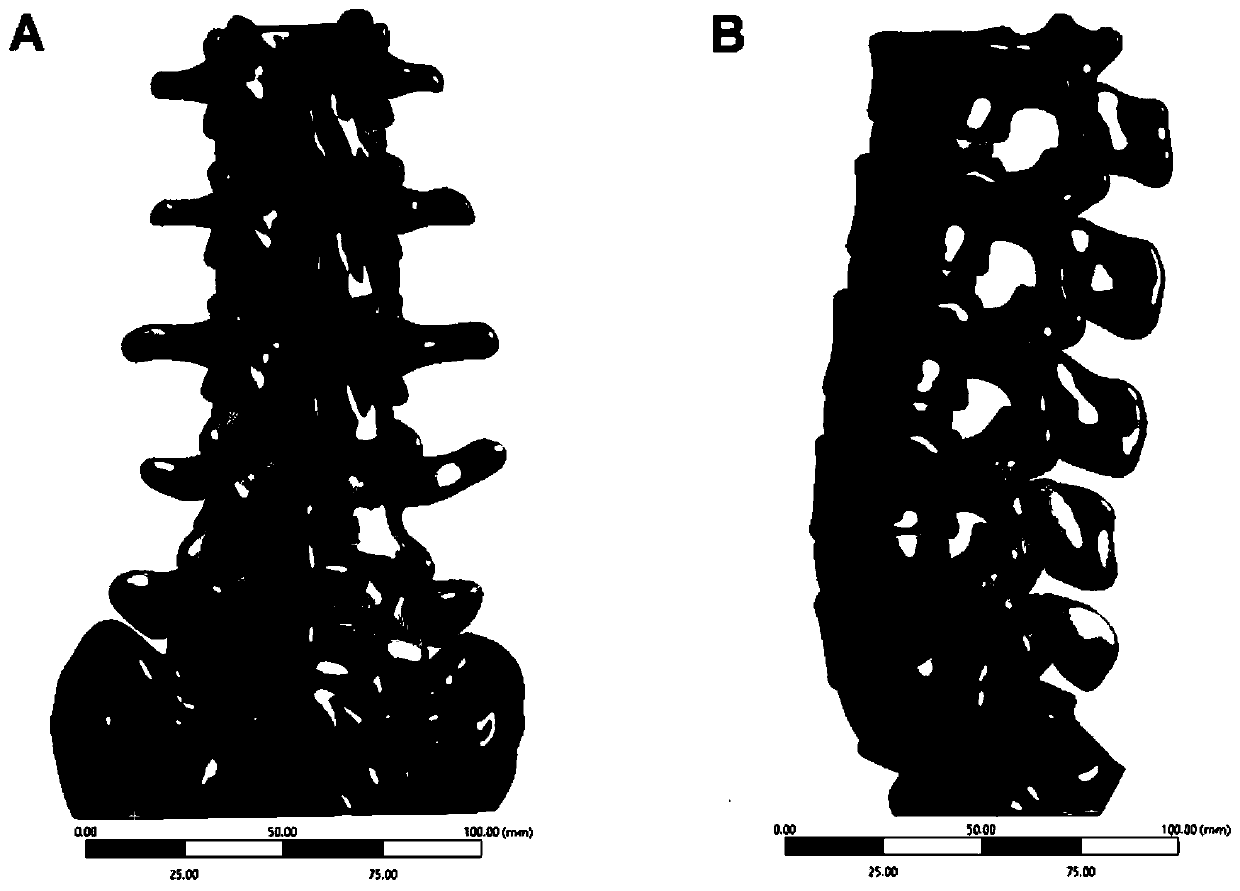

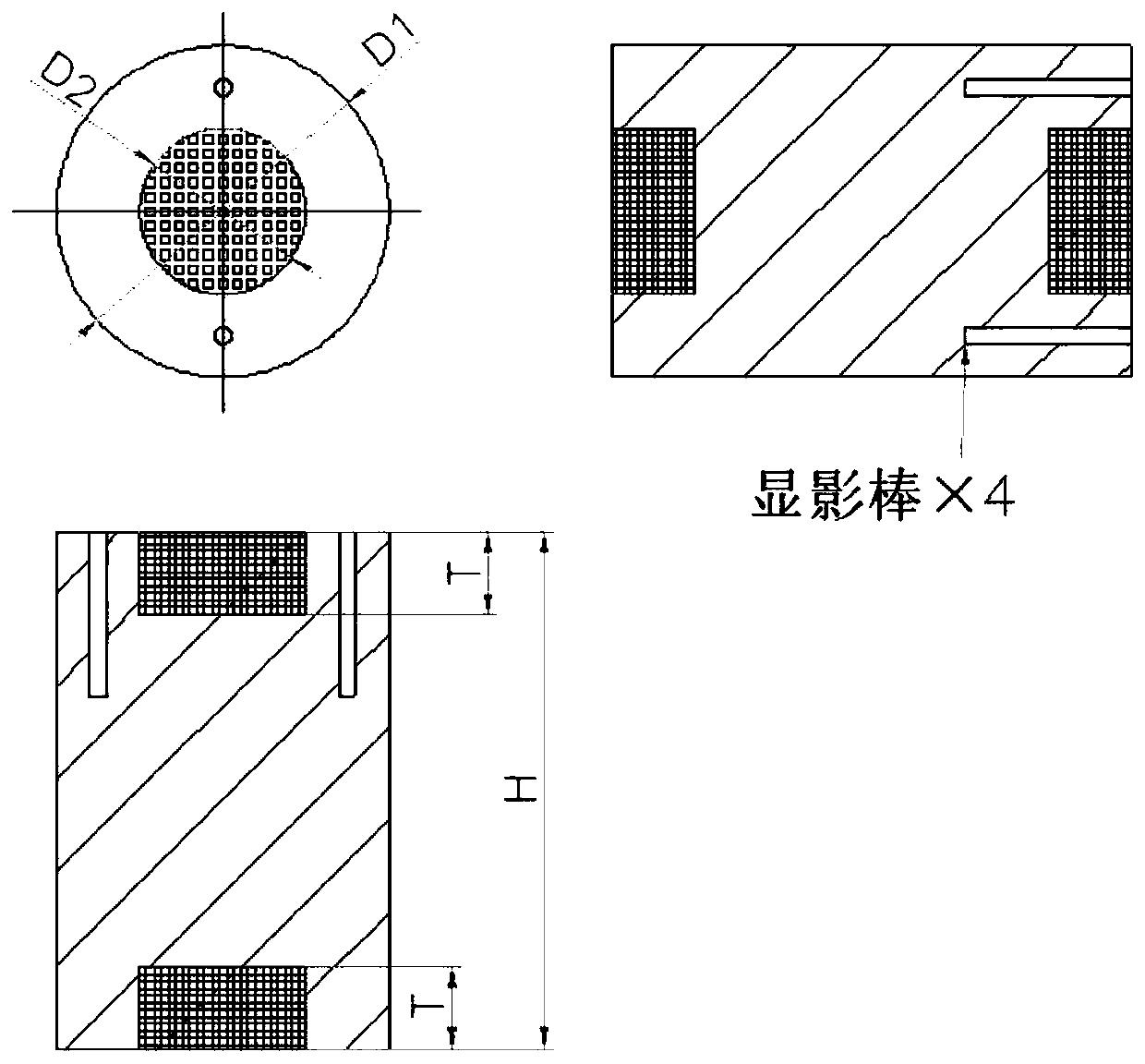

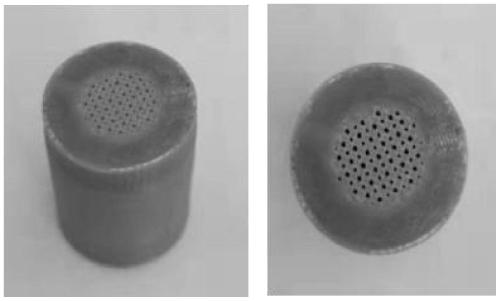

Bionic porous artificial vertebral body preparation method based on 3D printing

ActiveCN111281613AMeet biomechanical requirementsImprove adhesionJoint implantsSpinal implantsSpinal columnPoly ether ether ketone

The invention provides a bionic porous artificial vertebral body preparation method based on 3D printing. The bionic porous artificial vertebral body preparation method comprises the following steps:1, constructing a spine finite element model; 2, performing a simulated biomechanical experiment on the constructed spine finite element model; 3, adjusting the size or position of the artificial vertebral body according to the stress distribution borne by the artificial vertebral body to obtain an artificial vertebral body model most conforming to spine biomechanics; and 4, printing the artificial vertebral body model designed in the step 3 by using a PEEK material by using a 3D printing technology, and printing the contact surfaces of the artificial vertebral body and upper and lower vertebral bodies into a porous structure beneficial to bone ingrowth. The stress distribution borne by the artificial vertebral body is analyzed, so that the artificial vertebral body meets the spine biomechanics requirement, and the fusion, reliability and stability of use are guaranteed; 3D printing is carried out by adopting a high-performance polymer material polyether-ether-ketone (PEEK), so that the biomechanical matching performance is good, no interference is caused to imaging examination, personalized customization is realized, and the biomechanical requirements are met.

Owner:XIEHE HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI & TECH UNIV

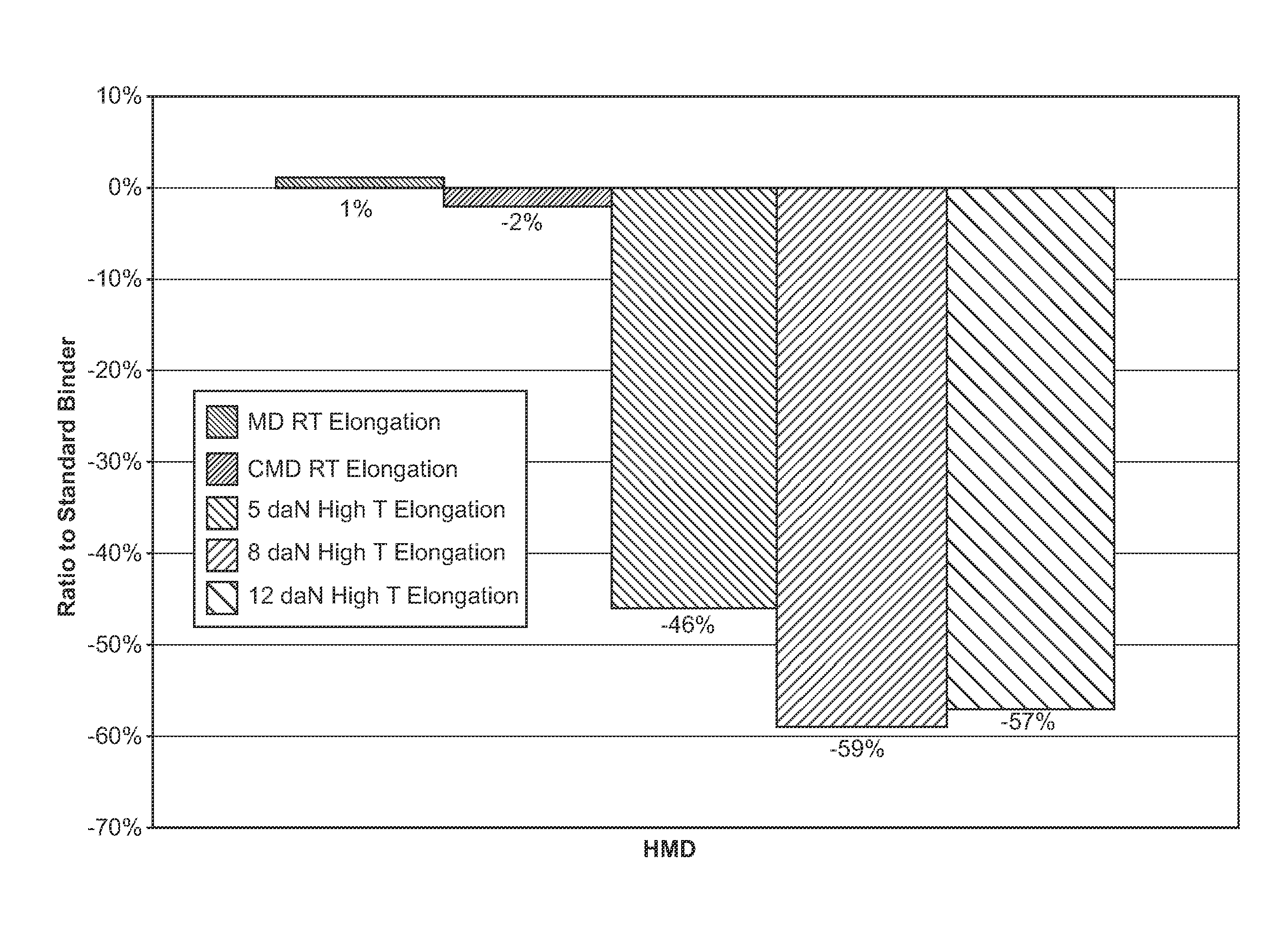

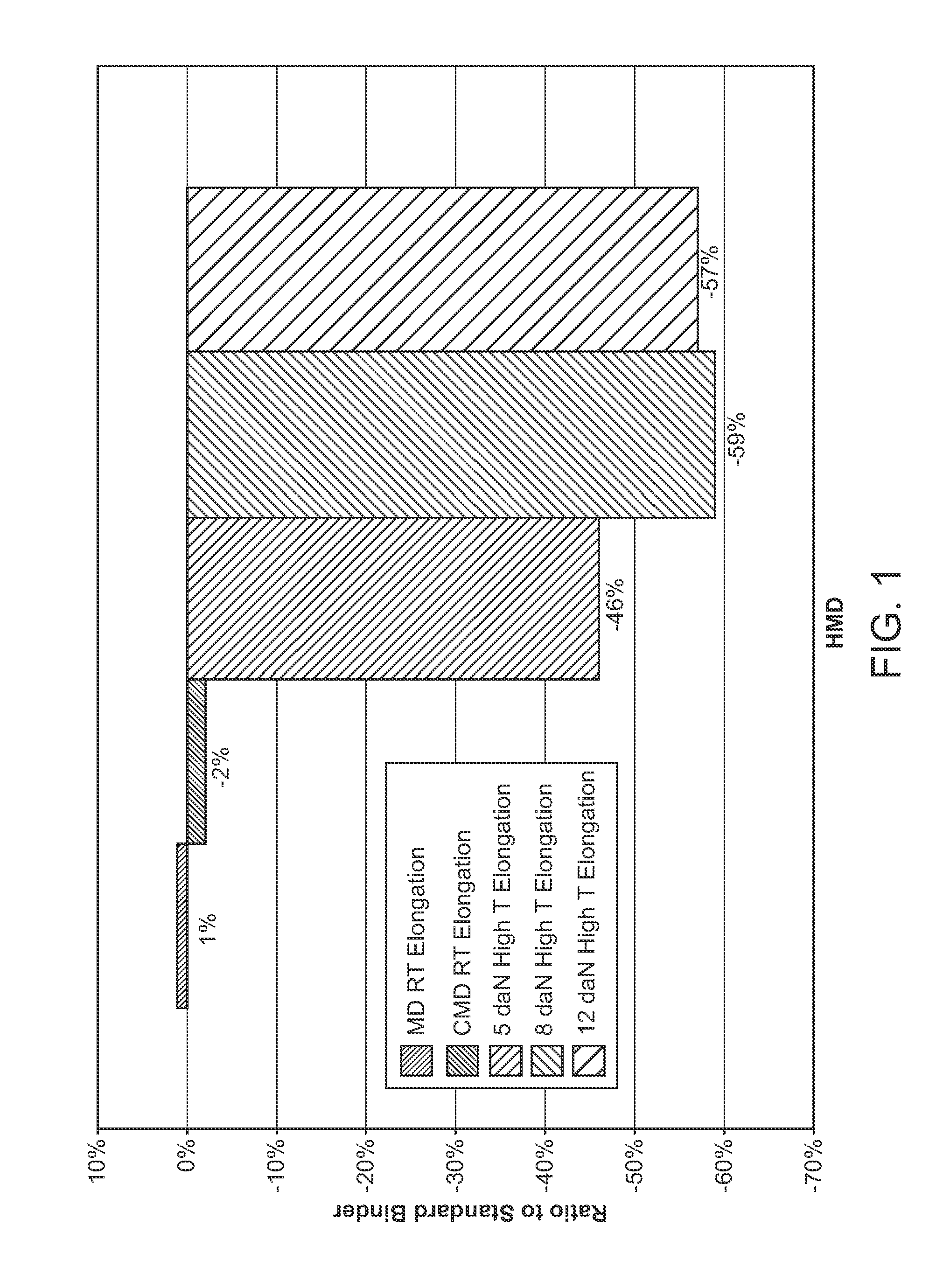

Performance polymeric fiber webs

Provided are nonwoven polymeric fiber webs using an improved curable composition. Such curable composition comprises a reaction product of an amine and a reactant in the form of an amino-amide intermediate. To the amino-amide is added an aldehyde or ketone to form the curable binder composition. The composition when applied to the polymeric fibers is cured to form a water-insoluble polymer binder which exhibits good adhesion and thermo-dimensional stability.

Owner:JOHNS MANVILLE CORP

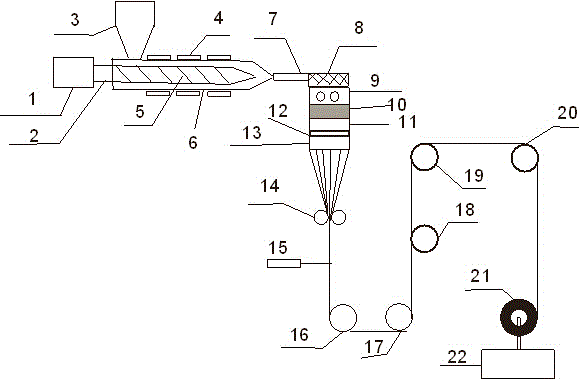

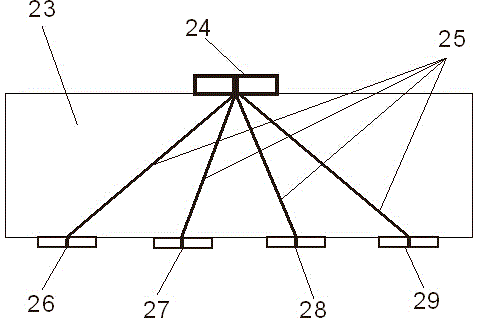

One-step method high-temperature and high-pressure melt spinning equipment and production method of polymer fiber

ActiveCN104313711AHigh crystallinityHigh densitySpinning head liquid feederMonocomponent synthetic polymer artificial filamentImidePolymer science

The invention discloses one-step method high-temperature and high-pressure melt spinning equipment and a production method of a polymer fiber and relates to the one-step method high-temperature and high-pressure melt spinning equipment. The spinning equipment is characterized by comprising a driving device, an extruder system and a spinning device, wherein the driving device comprises a driving motor and a speed reducing device; the extruder system comprises an extruder screw, a charging barrel, a loading hopper, an electric heater and an extruder head; the loading hopper and the electric heater are arranged on the charging barrel of an extruder; one end of the extruder screw is connected with the driving motor through the speed reducing device; the other end of the extruder screw is matched with the extruder head. The spinning equipment also comprises a melt filtering device, a metering pump, a spinning box body and a spinning component. The spinning device sequentially comprises the metering pump, the spinning box body, the spinning component, a spinneret plate, a coldness alleviating deice, a multifilament bundling device, an oiling device, a guide device, a hot roller drafting sizing device and a winding device. The high-temperature and high-pressure melt spinning equipment is special for melt spinning of polymers with high melting point, high melt viscosity and high performance, such as polyether-ether-ketone, polyaryletherketone and polyetherimide.

Owner:CHANGZHOU CHUANGYING NEW MATERIAL TECH

Performance polymeric fiber webs

Provided are nonwoven polymeric fiber webs using an improved curable composition. Such curable composition comprises a reaction product of an amine and a reactant in the form of an amino-amide intermediate. To the amino-amide is added an aldehyde or ketone to form the curable binder composition. The composition when applied to the polymeric fibers is cured to form a water-insoluble polymer binder which exhibits good adhesion and thermo-dimensional stability.

Owner:JOHNS MANVILLE CORP

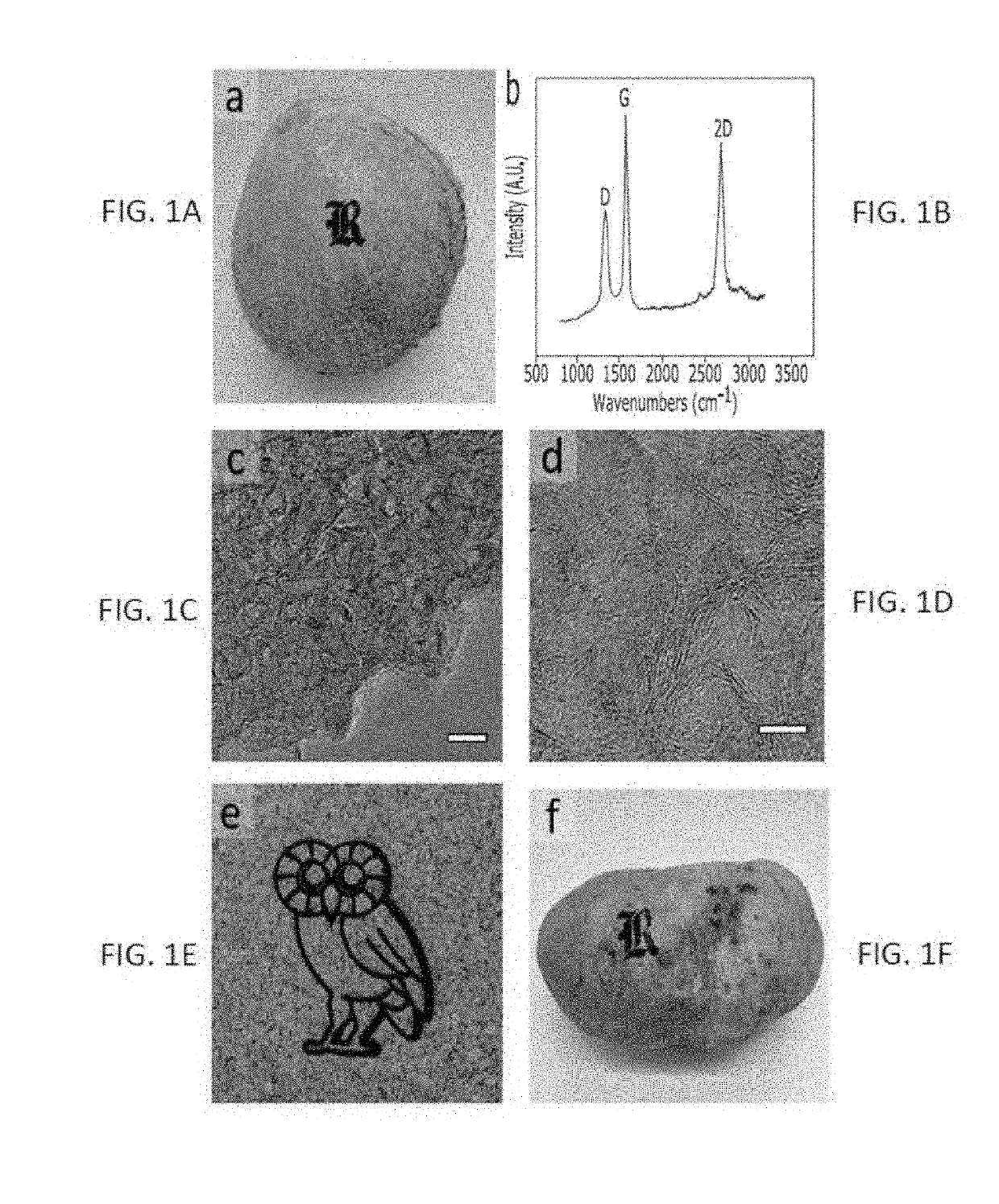

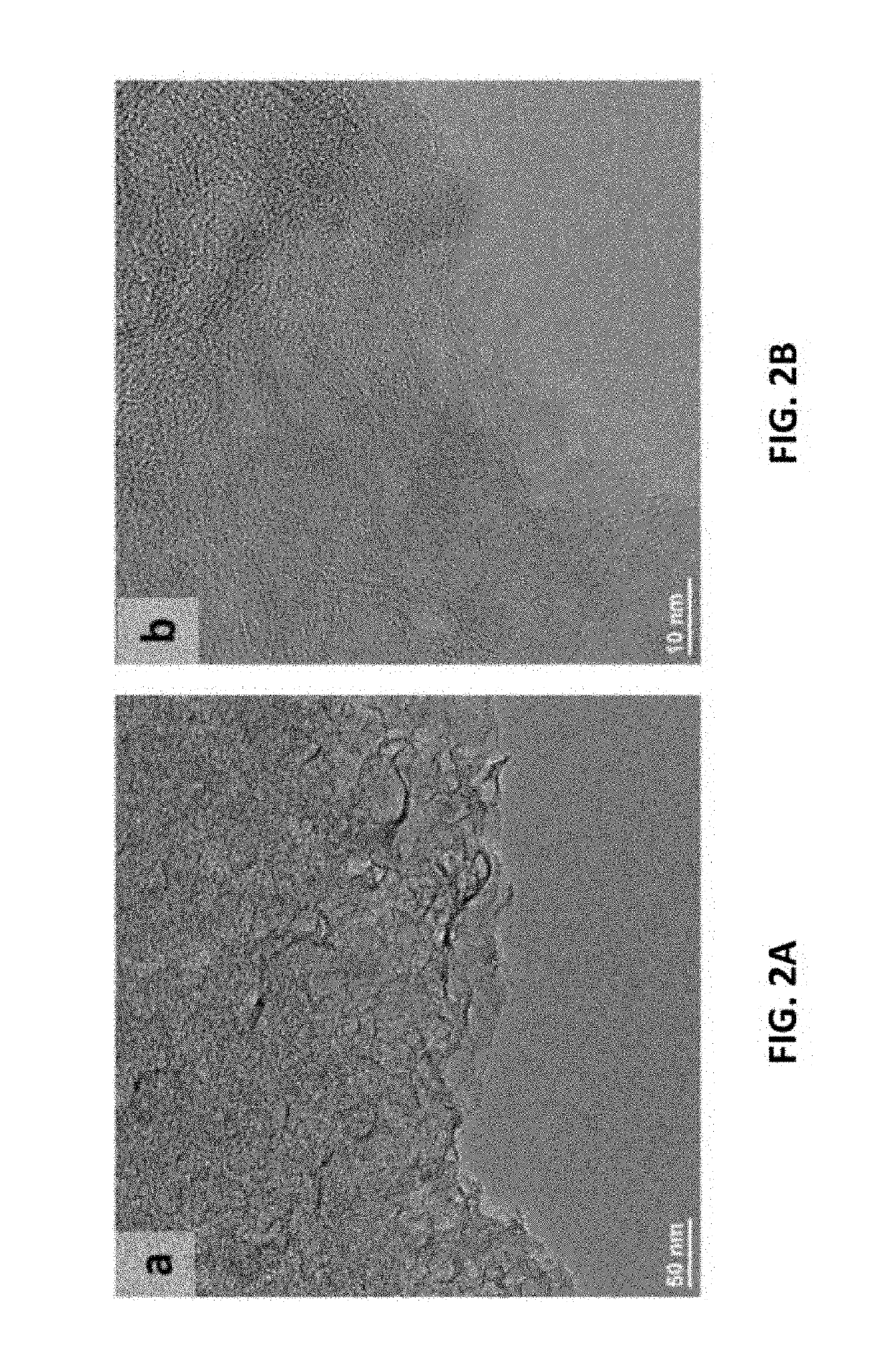

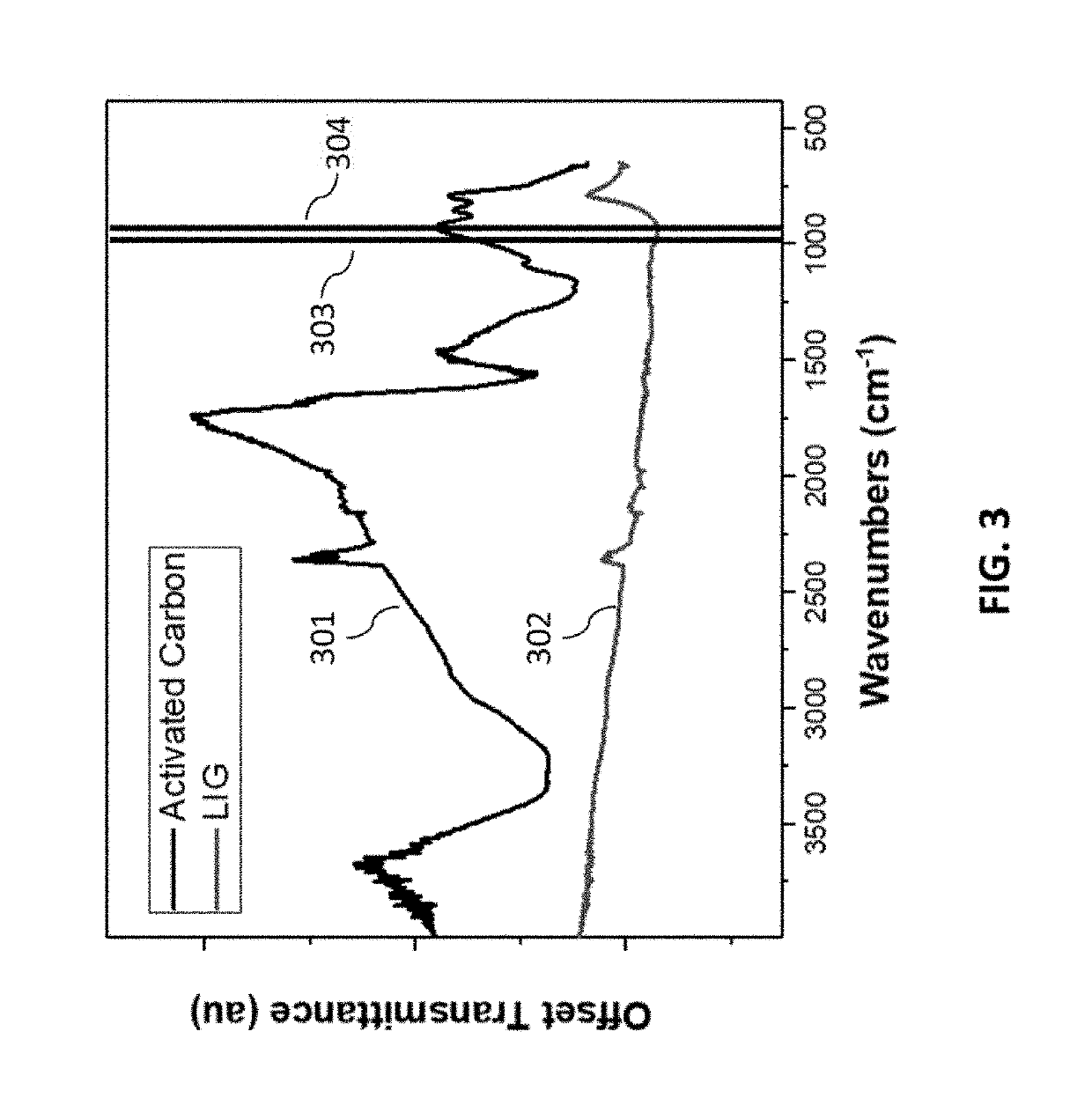

Methods of fabricating laser-induced graphene and compositions thereof

ActiveUS20190330064A1Improve electrical performanceQuality improvementSemi-permeable membranesMembranesFlexible electronicsMultiple pass

Methods that expand the properties of laser-induced graphene (LIG) and the resulting LIG having the expanded properties. Methods of fabricating laser-induced graphene from materials, which range from natural, renewable precursors (such as cloth or paper) to high performance polymers (like Kevlar). With multiple lasing, however, highly conductive PEI-based LIG could be obtained using both multiple pass and defocus methods. The resulting laser-induced graphene can be used, inter alia, in electronic devices, as antifouling surfaces, in water treatment technology, in membranes, and in electronics on paper and food Such methods include fabrication of LIG in controlled atmospheres, such that, for example, superhydrophobic and superhydrophilic LIG surfaces can be obtained. Such methods further include fabricating laser-induced graphene by multiple lasing of carbon precursors. Such methods further include direct 3D printing of graphene materials from carbon precurors. Application of such LIG include oil / water separation, liquid or gas separations using polymer membranes, anti-icing, microsupercapacitors, supercapacitors, water splitting catalysts, sensors, and flexible electronics.

Owner:B G NEGEV TECH & APPL LTD +1

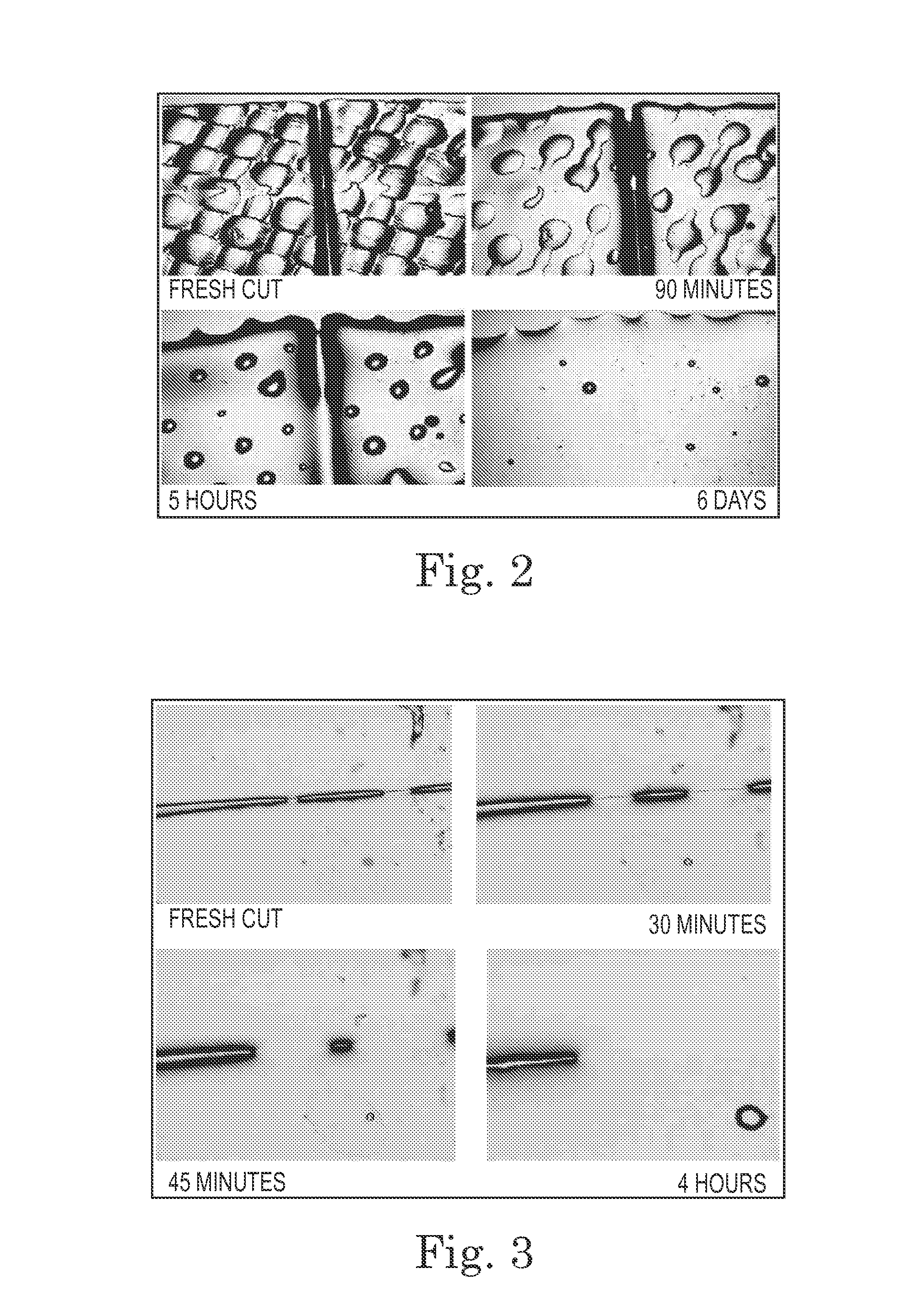

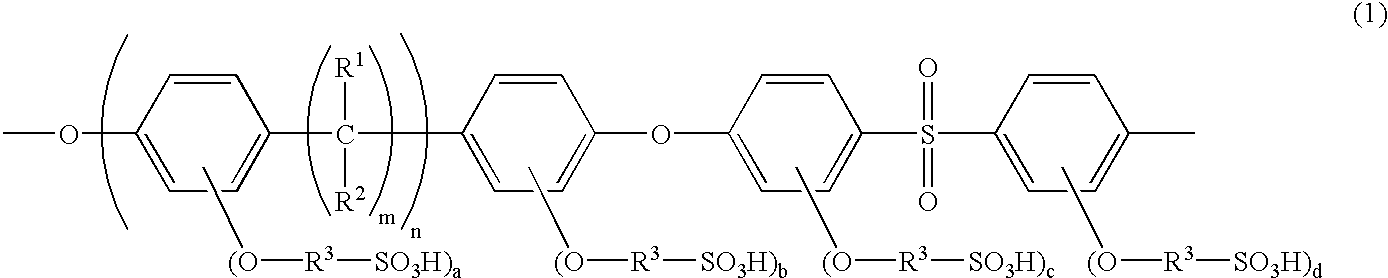

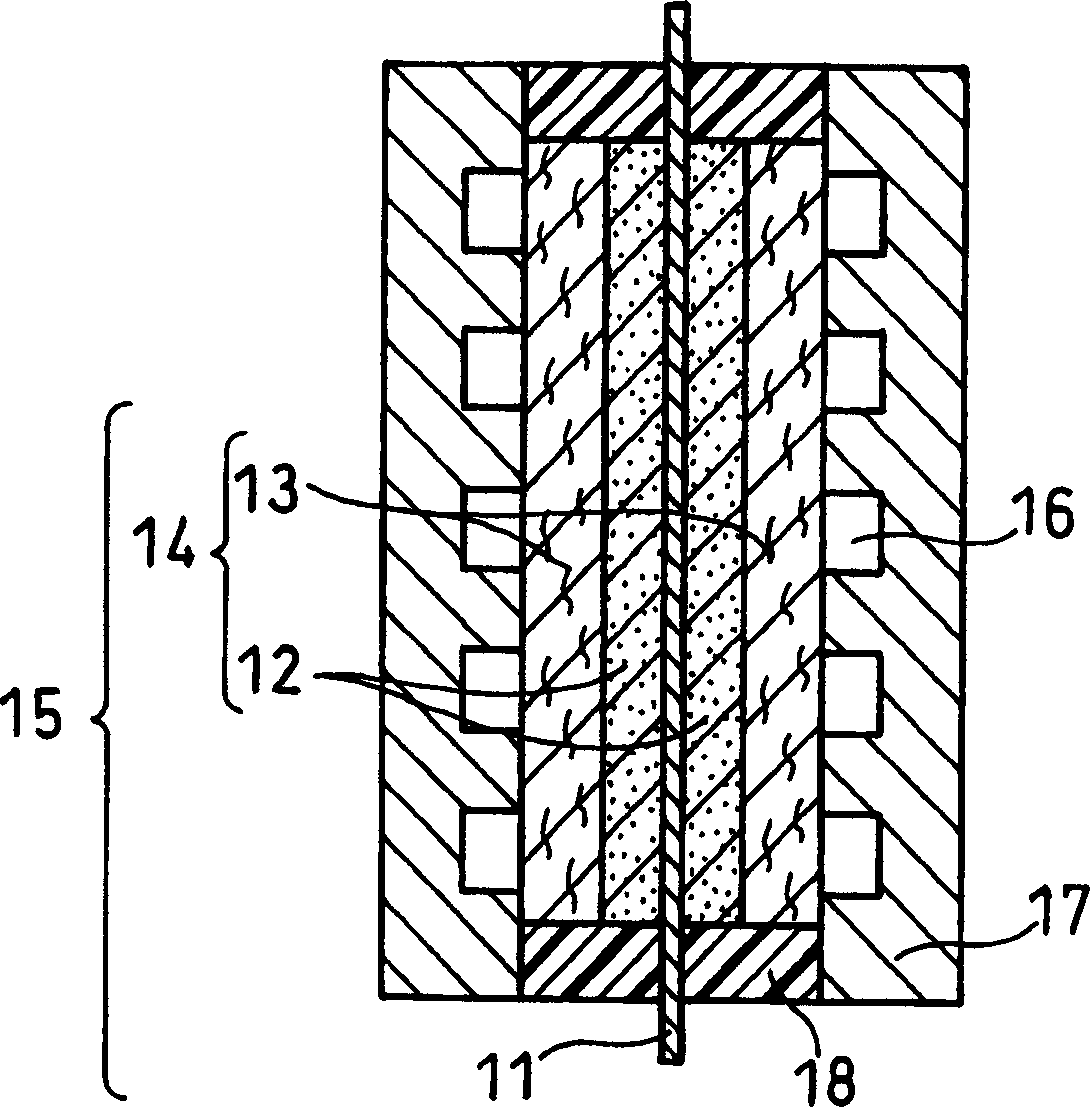

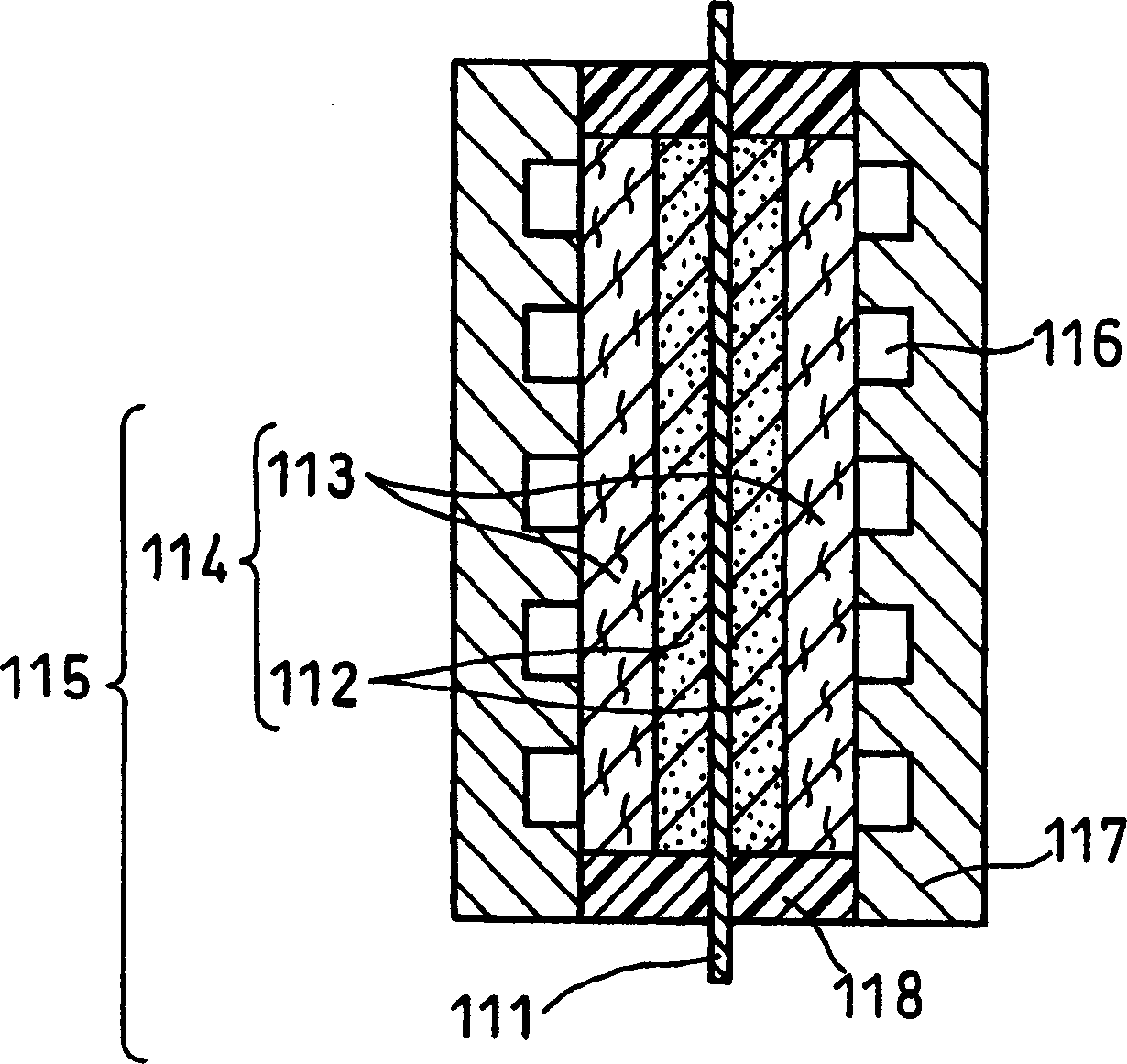

Polymer electrolyte fuel cell

InactiveCN1411089AImprove output performanceSufficient supplyCell electrodesFuel cell auxillariesElectrolysisCrystallinity

The present invention provides a high performance polymer electrolyte fuel cell in which excessive water can be prevented from retaining in the gas diffusion electrode, with the polymer electrolyte membrane being maintained at an appropriately wet condition. The gas diffusion layer is provided with an electrically conductive polymer-containing layer comprising carbon particles and a polymer material. In it, a combination of two kinds of carbon particles having different amounts of acidic function group is used in a manner that the weight ratio of one kind having a larger acidic function group, relative to the other kind, increases from one end of the gas diffusion layer to the other end. Thereby, the water permeating function at the surface of the gas diffusion layer can be so adjusted that the inside of the MEA is maintained at an appropriately wet condition, while excessive water is quickly exhausted to outside of the fuel cell together with e.g. the reactive gas. This can also be achieved by using a combination of two kinds of polymer materials in the electrically conductive polymer-containing layer in a manner that the two kinds have either different degrees of crystallinity or different coefficients of moisture permeability, so that the degrees of crystallinity decreases and the coefficients of moisture permeability increases from the one end to the other end of the gas diffusion layer.

Owner:PANASONIC CORP

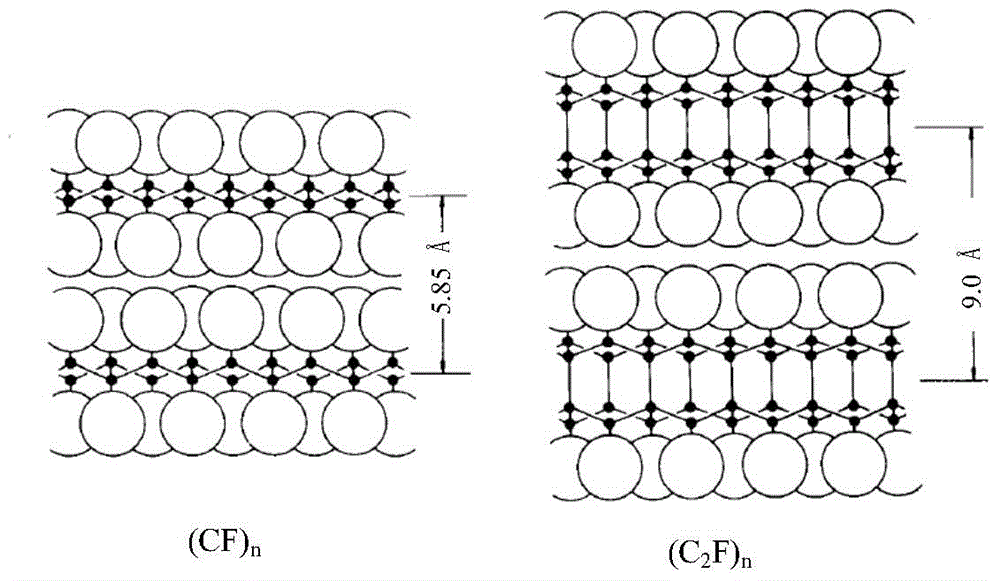

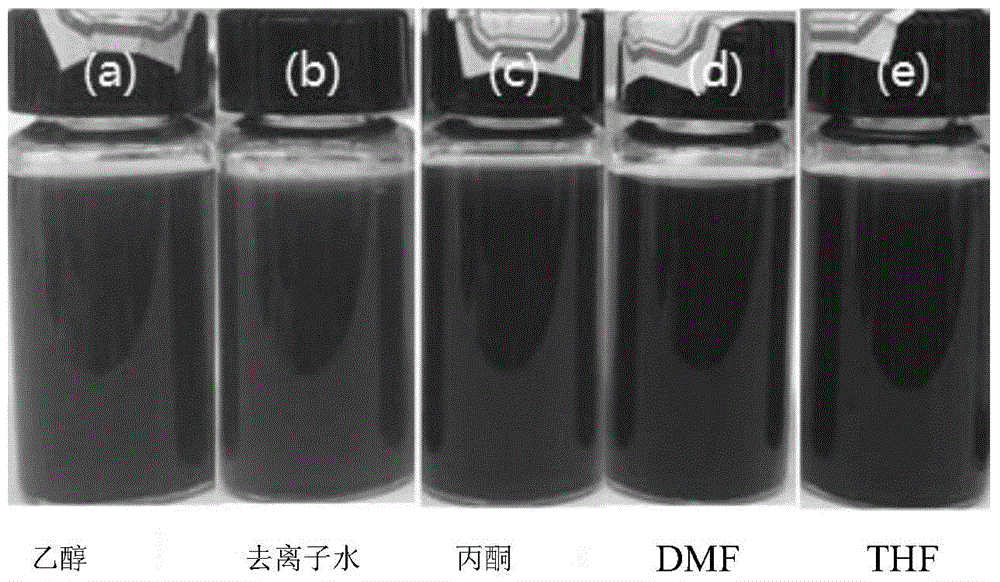

Applications of amine compounds in dispersing of fluorocarbon materials, and method used for dispersing fluorocarbon materials

The invention discloses applications of amine compounds in dispersing of fluorocarbon materials, and a method used for dispersing the fluorocarbon materials. Electrophilic-nucleophilic interaction between the fluorocarbon materials and the amine compounds is similar to chemical bonding, so that the fluorocarbon materials can be dissolved in amine compound mediums, and other organic mediums, or water so as to obtain steadily dispersed fluorocarbon materials which can be used as lubricating oil additives or high-performance polymer composite materials effectively.

Owner:SHENZHEN NANKE NEW MATERIALS TECH CO LTD

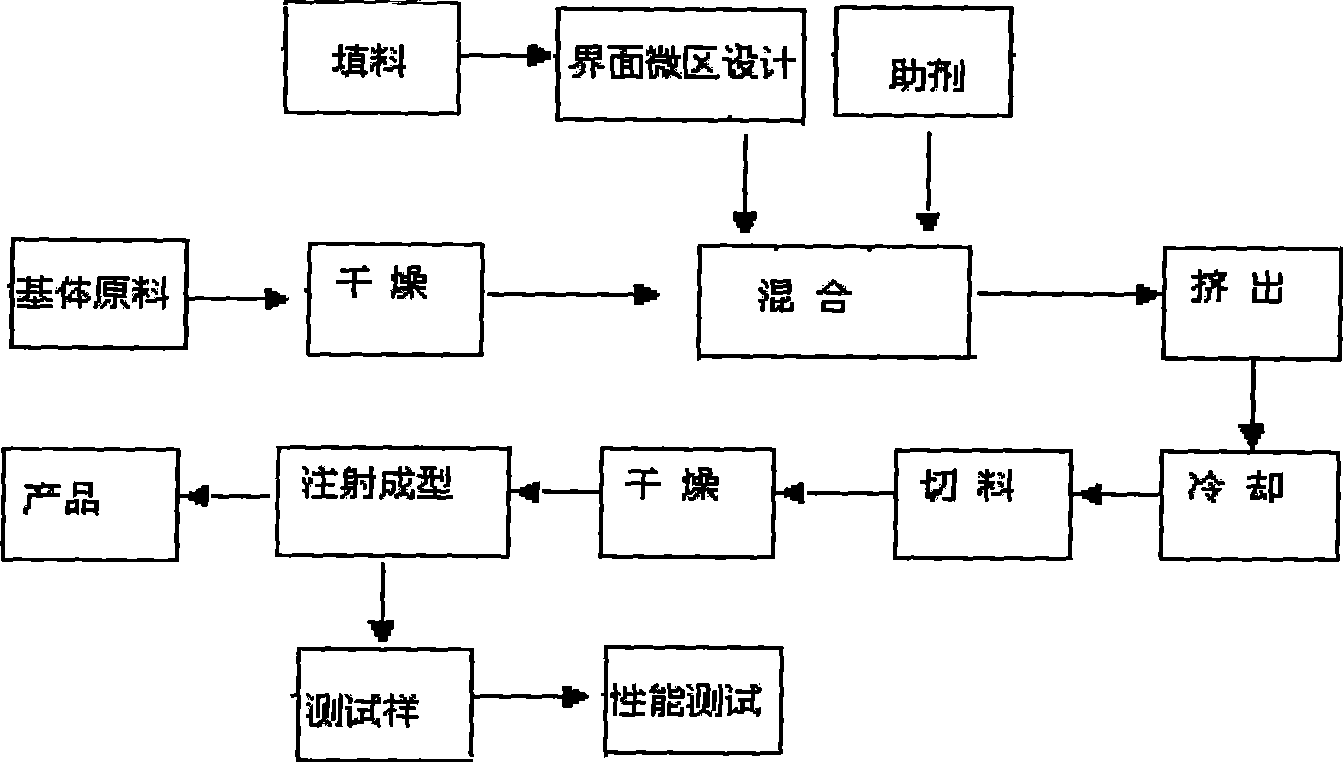

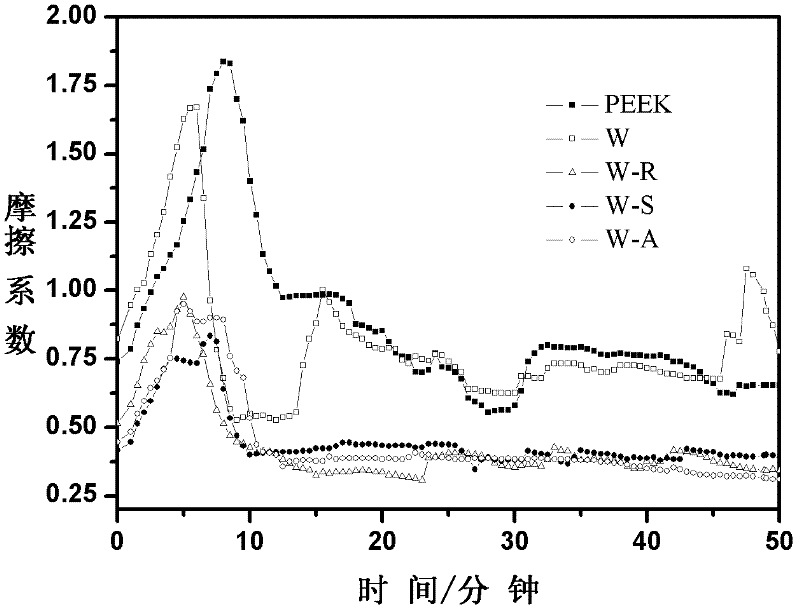

High-dimension-stability and friction-resistant polyether-ether-ketone composite material and preparation method thereof

The invention belongs to the field of high-performance polymer, and relates to a high-dimension-stability and friction-resistant polyether-ether-ketone composite material and a preparation method thereof. The composite material comprises the following components in terms 100 percent by weight: 60-90 percent of polyether-ether-ketone resin, 0.05-0.12 percent of high-temperature-resistant coupling agent, 5-20 percent of wollastonite and 0-30 percent of glass fiber. The preparation method comprises the following steps of: dissolving the high-temperature-resistant coupling agent into an organic solvent under the protection of N2; adding the wollastonite; stirring; heating to a reflow temperature; adding water and continuously heating to reflow for 1-4 hours; performing extraction filtration to obtain modified wollastonite; washing the modified wollastonite, drying and mixing with polyether-ether-ketone powder; extruding through a double-screw extruder; and granulating to obtain the polyether-ether-ketone composite material. The composite material prepared by the invention has extremely low linear expansion coefficient and forming shrinkage rate, also has self-lubrication property and high mechanical performance and is applied to preparation of bearings, gears, valve plates and the like.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com