Patents

Literature

3048 results about "Polymer composite materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer Composite. A polymer composite is a multi-phase material in which reinforcing fillers are integrated with a polymer matrix, resulting in synergistic mechanical properties that cannot be achieved from either component alone [1].

Surface modified particulate and sintered or injection molded products

ActiveUS20150080495A1Simple technologyWeaken energyConductive materialCeramic shaping apparatusParticulatesPolymer science

Disclosed are interfacially modified particulate and polymer composite material for use in injection molding processes, such as metal injection molding and additive process such as 3D printing. The composite material is uniquely adapted for powder metallurgy processes. Improved products are provided under process conditions through surface modified powders that are produced by extrusion, injection molding, additive processes such as 3D printing, Press and Sinter, or rapid prototyping.

Owner:TUNDRA COMPOSITES LLC

Flue gas purification process using a sorbent polymer composite material

ActiveUS20050019240A1Easy to fixImprove removal efficiencyGas treatmentNitrogen compoundsSorbentFluoropolymer

This invention provides a process of removing sulfur oxides, mercury vapor, and fine particulate matters from industrial flue gases that contain such pollutants. The pollutants are removed by modules, which contain microporous adsorbent (i.e., sorbent) material that is held within a polymer matrix. The preferred polymers are fluoropolymers. The composite material that contains the microporous absorbent material held within a polymer matrix removes sulfur oxides by converting them into high concentration sulfuric acids. It also removes mercury vapor by chemically adsorbing the mercury into the matrix. It also removes fine particulate matters by surface filtration. The sulfuric acid that is produced inside the composite material is automatically expelled onto the external surfaces of the composite material and is drained into an acid reservoir together with the fine particulate matters which are washed from the external surfaces of the composite material by the constant dripping of the sulfuric acid along the external surfaces of the composite material.

Owner:WL GORE & ASSOC INC

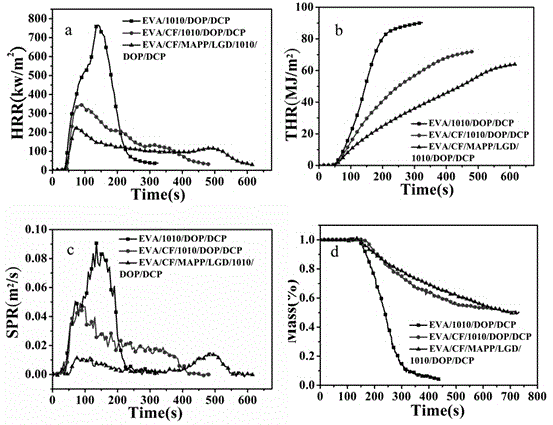

Flame retardant microcapsule and application thereof

ActiveCN101885859AImprove flame retardant performanceHigh mechanical strengthThin material handlingMicroballoon preparationCellulosePolymer science

Owner:INST OF CHEM CHINESE ACAD OF SCI

Thermoplastic composite material, and preparation method and application thereof

The invention belongs to the field of polymer composite materials, and discloses a thermoplastic composite material, and a preparation method and an application thereof. The composite material is composed of the components of, by weight: 1-99 parts of a prepreg and 1-99 parts of a thermoplastic composition or thermoplastic resin. The preparation method comprises the steps that: the 1-99 parts of thermoplastic composition or thermoplastic resin is added into a feeding hopper of an injection molding machine, and is mixed with the 1-99 parts of prepreg already in an injection mold; and injection molding is carried out. The invention also discloses an application of the thermoplastic composite material in car bumpers, car door inner panels, car bumper beams, cars toe-boards, car hood, car rear lift door, building templates, biogas digesters, train sidings, train wall panels, or train roof panels. The composite material provided by the invention has the advantages of smooth outer surface, high gloss, good appearance, excellent mechanical performance, high strength, and good impact resistance.

Owner:HEFEI GENIUS NEW MATERIALS

Drug/polymer composite materials and methods of making the same

InactiveUS20070009564A1Powder deliveryPharmaceutical non-active ingredientsSolventPolymer composites

A method of forming a drug / polymer composite material is carried out by combining a drug material with a polymer material under pressure in the presence of a compressed gas solvent (e.g., carbon dioxide) to form the drug / polymer composite material. Drug / polymer composite materials and shaped articles (e.g., subcutaneous drug depots) which may be produced by a process are also described, along with methods of use thereof.

Owner:MICELL TECH INC

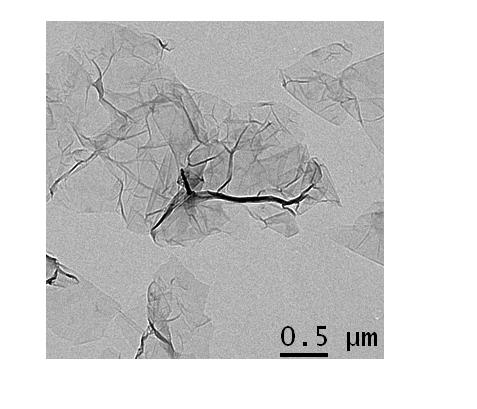

Method for preparing nano cellulose microfibril reinforced polymer composite material

ActiveCN102344685AUniform structureTransparent structureConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsSolubilityFiber

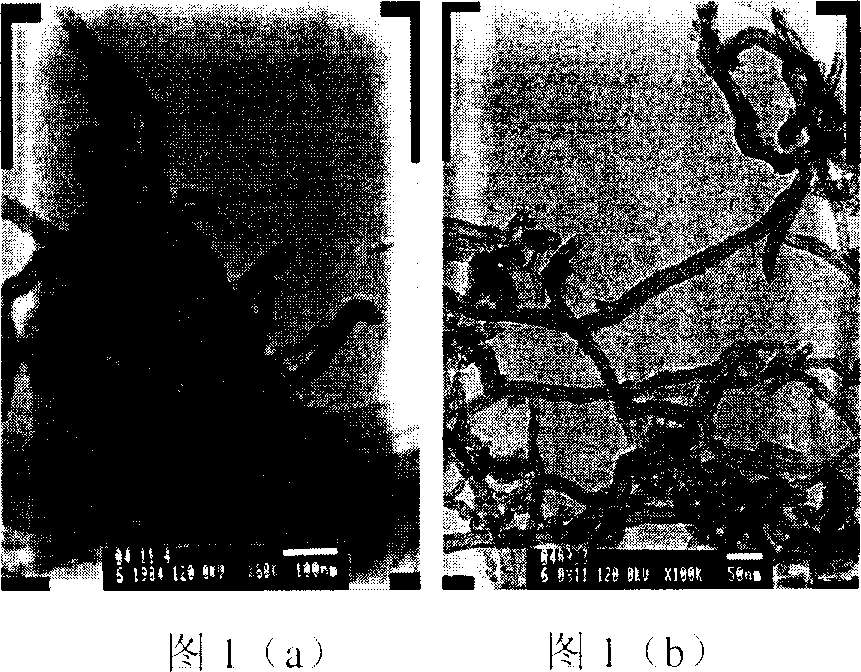

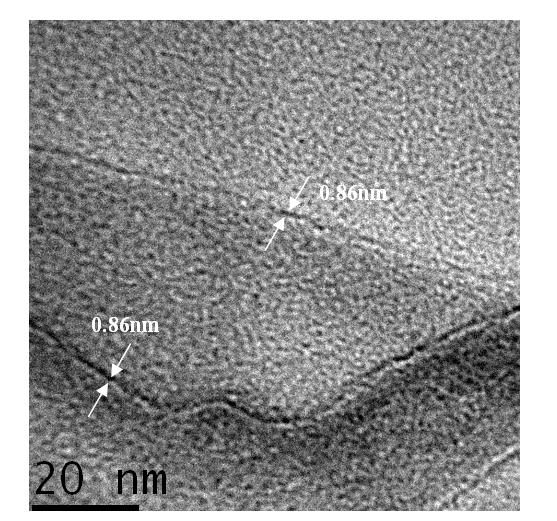

The invention discloses a method for in situ generating a nano cellulose microfibril reinforced polymer composite material, comprising the following steps: using ionic liquid as a primary solvent, dissolving cellulose, or mixing cellulose with other polymers via solution mixing, and controlling the solubility of the cellulosic material in the solvent to maintain naturally occurring nano cellulose microfibril in the cellulosic material, so as to in situ obtain the nano cellulose microfibril reinforced polymer composite material. The nano microfibril can be observed under a transmission microscope obviously, which is different from the completely dissolved cellulose solution. In the preparing process, the dissolving temperature is controlled within 30-150 DEG C, and stirring and vacuum deaeration are used as auxiliary. By controlling the dissolving time, solution concentration and ratio of mixing, a polymer solution containing cellulose microfibril with dimension of 5-300 nanometers can be obtained. The polymer solution can be used for preparing composite material fiber, hollow fibrous membrane, diaphragm, film, gel, porous material and other known applications of enhanced material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

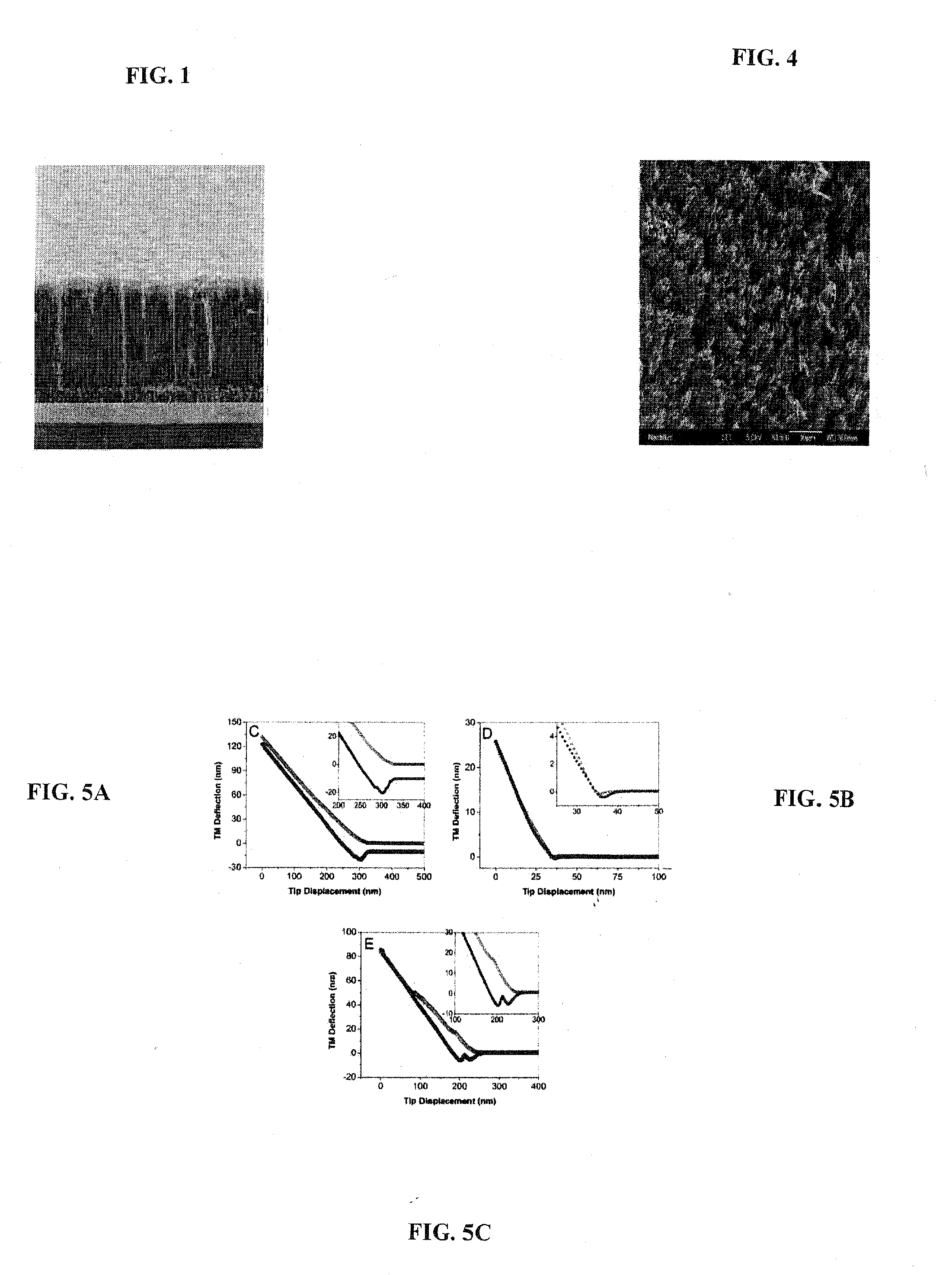

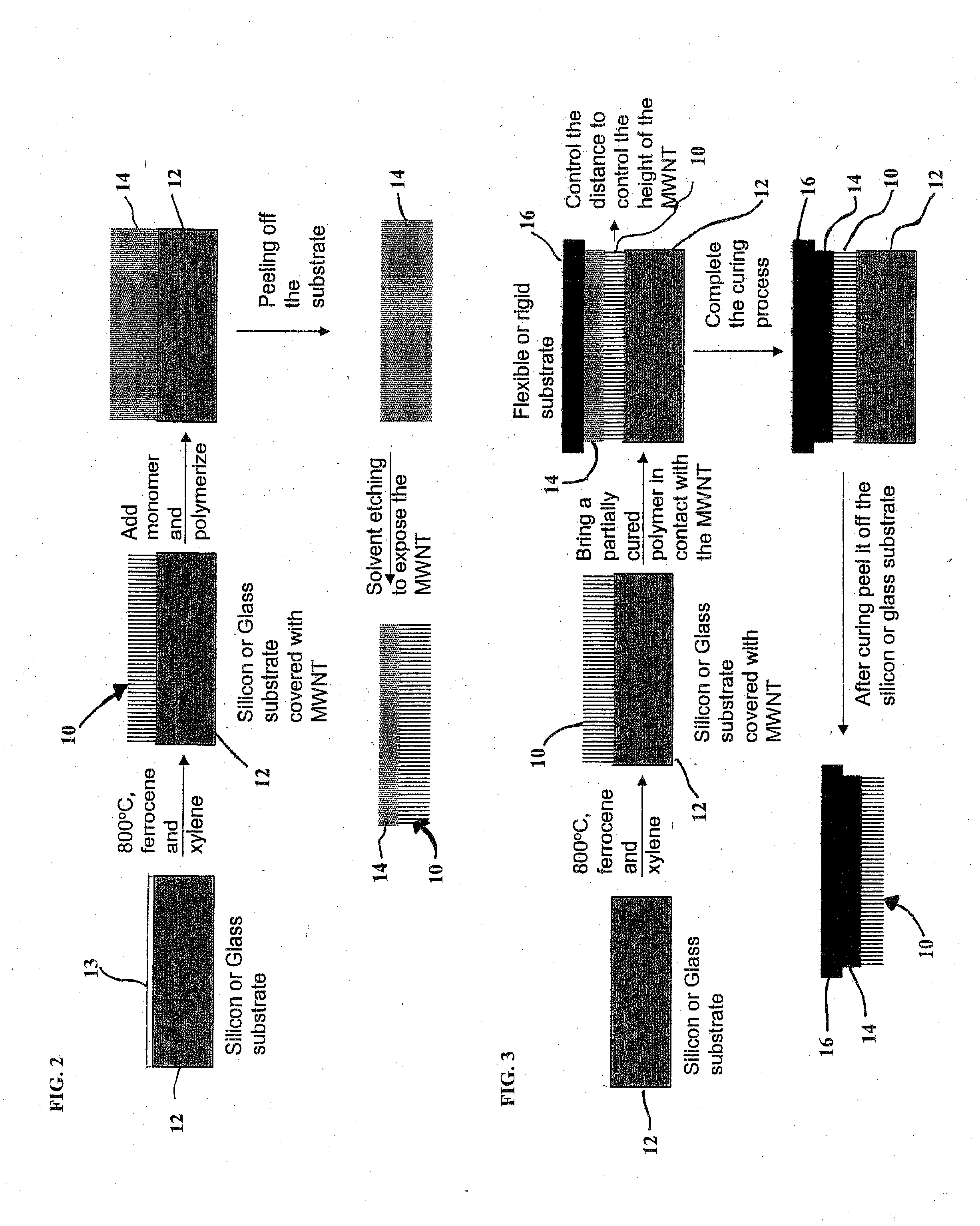

Aligned carbon nanotube-polymer materials, systems and methods

ActiveUS20080280137A1Stable positionMaterial nanotechnologySurgical adhesivesAdhesivePolymer composites

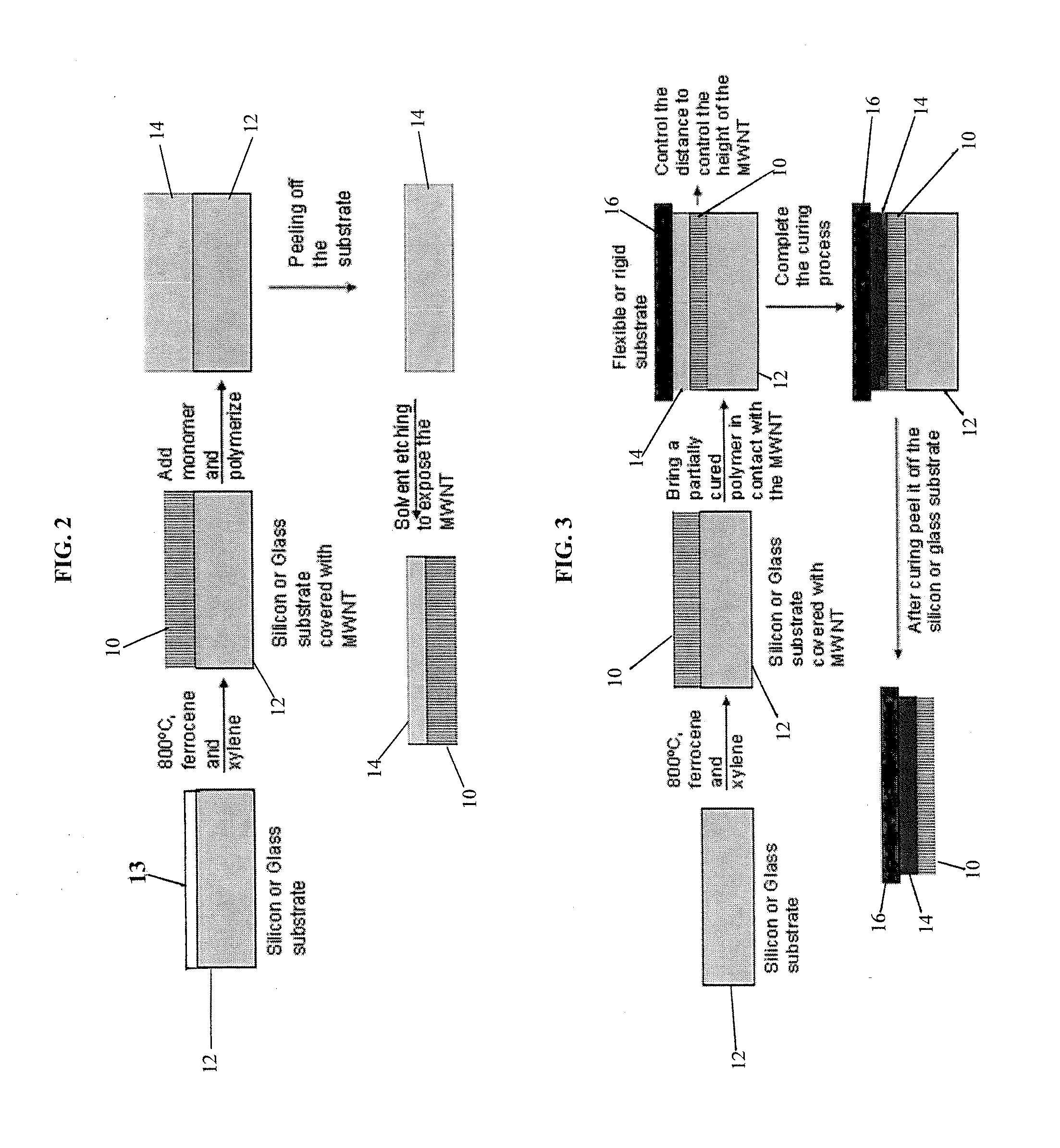

The invention is directed to carbon nanostructure composite systems which may be useful for various applications, including as dry adhesives, electronics and display technologies, or in a wide variety of other areas where organized nanostructures may be formed and integrated into a flexible substrate. The present invention provides systems and methods wherein organized nanotube structures or other nanostructures are embedded within polymers or other flexible materials to provide a flexible skin-like material, with the properties and characteristics of the nanotubes or other nanostructures exploited for use in various applications. In one aspect, the invention is directed to a carbon nanotube / polymer composite material having a plurality of carbon nanotubes formed into a predetermined architecture, with each of the plurality of nanotubes having a desired width and length. The architecture of the plurality of nanotubes defines at least one orientation for a plurality of nanotubes, and also defines the approximate spacing between nanotubes and / or groups of nanotubes. The carbon nanotube architecture is at least partially embedded with a polymer matrix in a manner that the architecture is stabilized in the predetermined architecture. The polymer matrix may also be formed to have a desired predetermined thickness.

Owner:THE UNIVERSITY OF AKRON +1

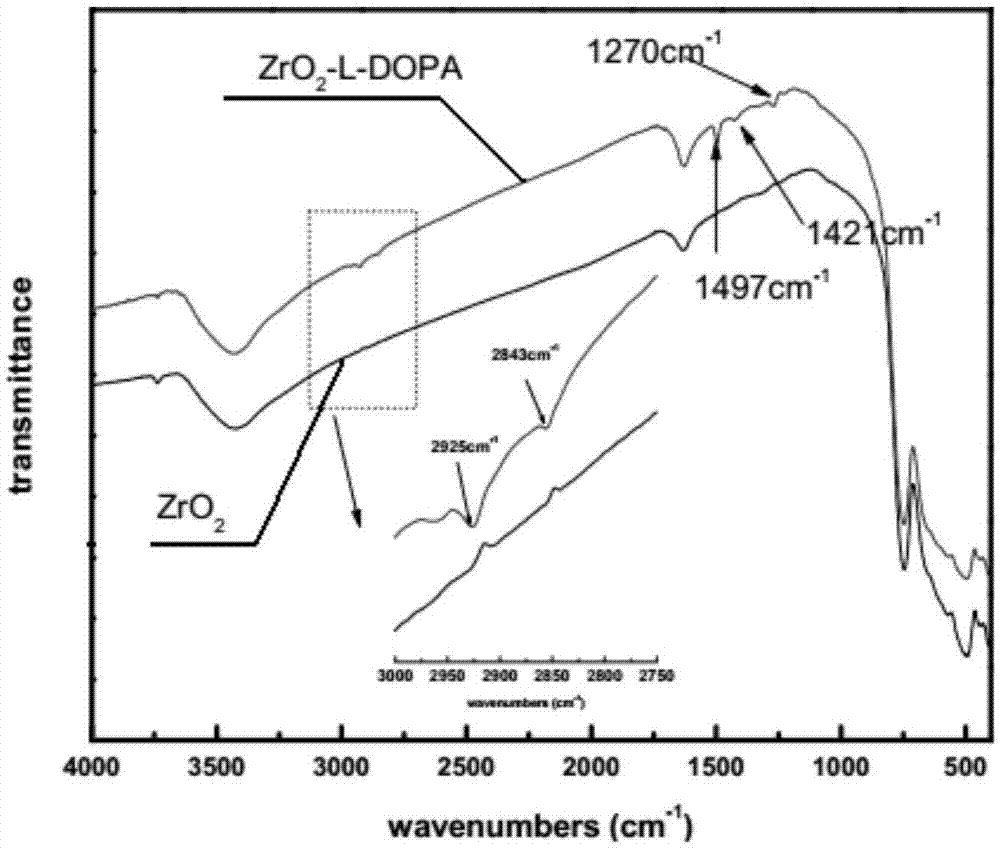

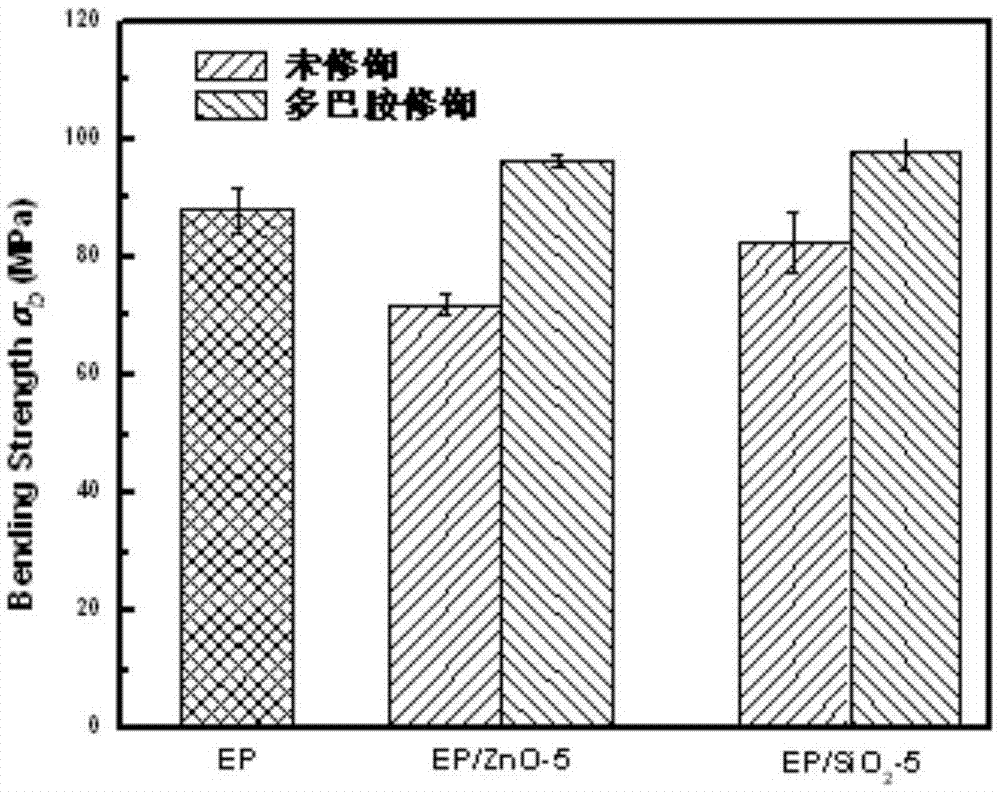

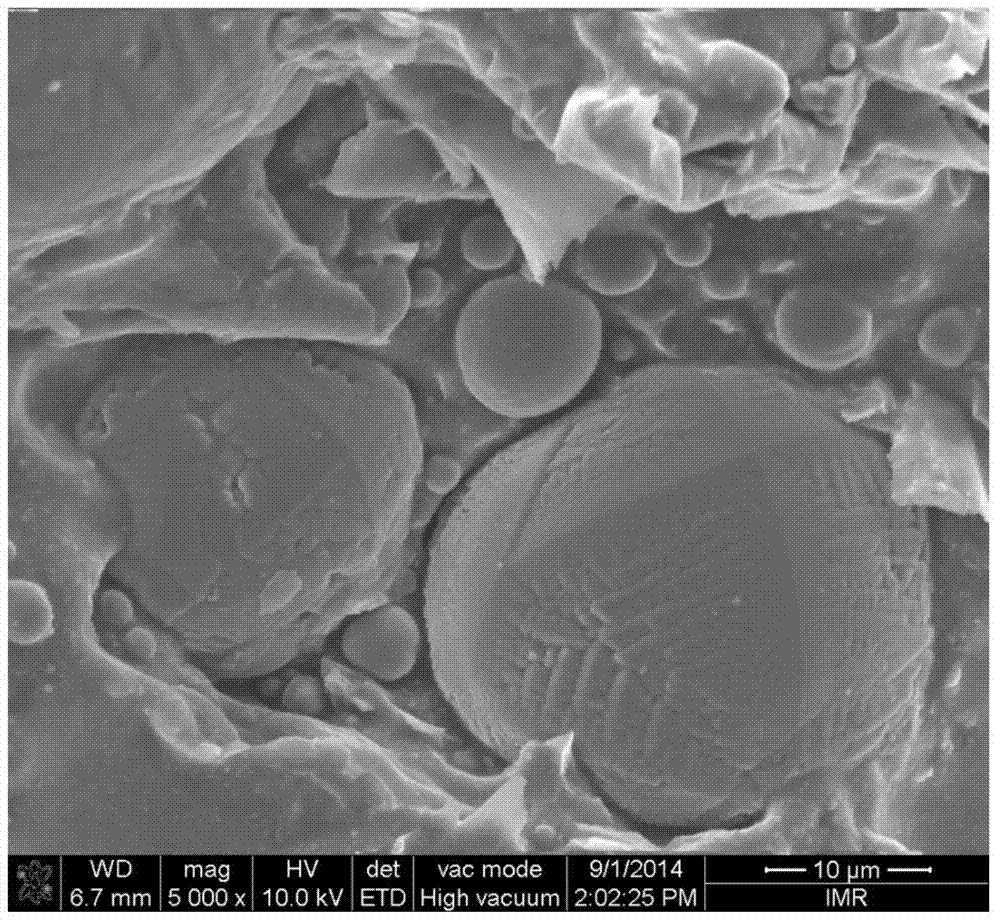

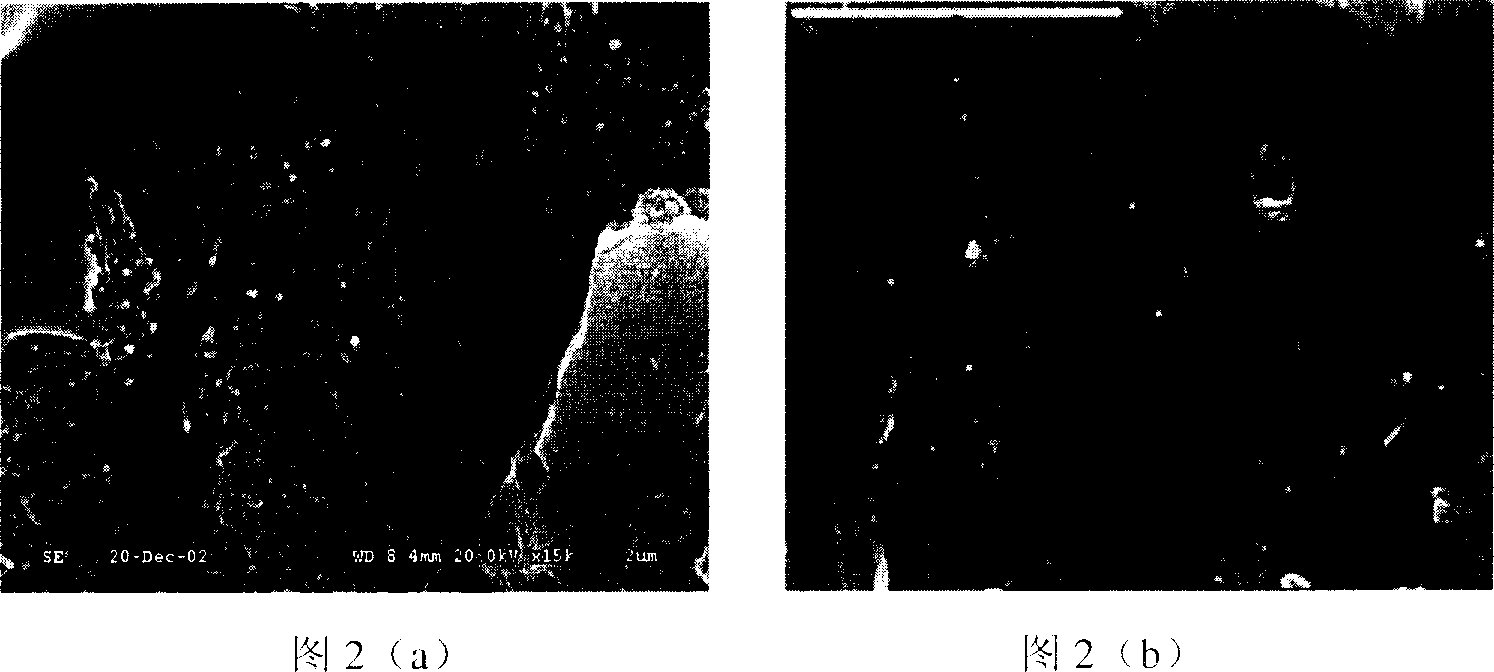

Dopamine compound modified or coated nano particle modified polymer composite material and preparation method thereof

The invention belongs to the field of nano particle or polymer composite material preparation and particularly relates to a dopamine compound modified or coated nano particle modified polymer composite material and a preparation method thereof. The composite material is composed of nano particles with surfaces modified or coated by dopamine compound and a high molecular polymer matrix. The nano particles with the surfaces modified or coated by the dopamine compound are uniformly scattered in the high molecular polymer matrix. According to the dopamine compound modified or coated nano particle modified polymer composite material, the dopamine compound modified or coated nano particles are utilized, the dopamine compound can aggregate spontaneously on the surface of a nano particle material to form a thin film to enable the surfaces of the nano particles to be connected with a function group such as hydroxyl and amidogen with strong activity, the compatibility of the nano particles in the high molecular polymer can be increased, and the dopamine compound is favorable for causing the nano particles and the high molecular polymer matrix to further generate secondary reaction. The dispersibility of the nano particles is good, and the stability is good in the dopamine compound modified or coated nano particle modified polymer composite material, and the comprehensive performance of the composite material can be improved remarkably.

Owner:WUHAN UNIV OF TECH

Aligned Carbon Nanotube-Polymer Materials, Systems and Methods

ActiveUS20100075024A1Stable positionLamination ancillary operationsArtificial flowers and garlandsAdhesivePolymer composites

The invention is directed to carbon nanostructure composite systems which may be useful for various applications, including as dry adhesives, electronics and display technologies, or in a wide variety of other areas where organized nanostructures may be formed and integrated into a flexible substrate. The present invention provides systems and methods wherein organized nanotube structures or other nanostructures are embedded within polymers or other flexible materials to provide a flexible skin-like material, with the properties and characteristics of the nanotubes or other nanostructures exploited for use in various applications. In one aspect, the invention is directed to a carbon nanotube / polymer composite material having a plurality of carbon nanotubes formed into a predetermined architecture, with each of the plurality of nanotubes having a desired width and length. The architecture of the plurality of nanotubes defines at least one orientation for a plurality of nanotubes, and also defines the approximate spacing between nanotubes and / or groups of nanotubes. The carbon nanotube architecture is at least partially embedded with a polymer matrix in a manner that the architecture is stabilized in the predetermined architecture. The polymer matrix may also be formed to have a desired predetermined thickness.

Owner:THE UNIVERSITY OF AKRON +1

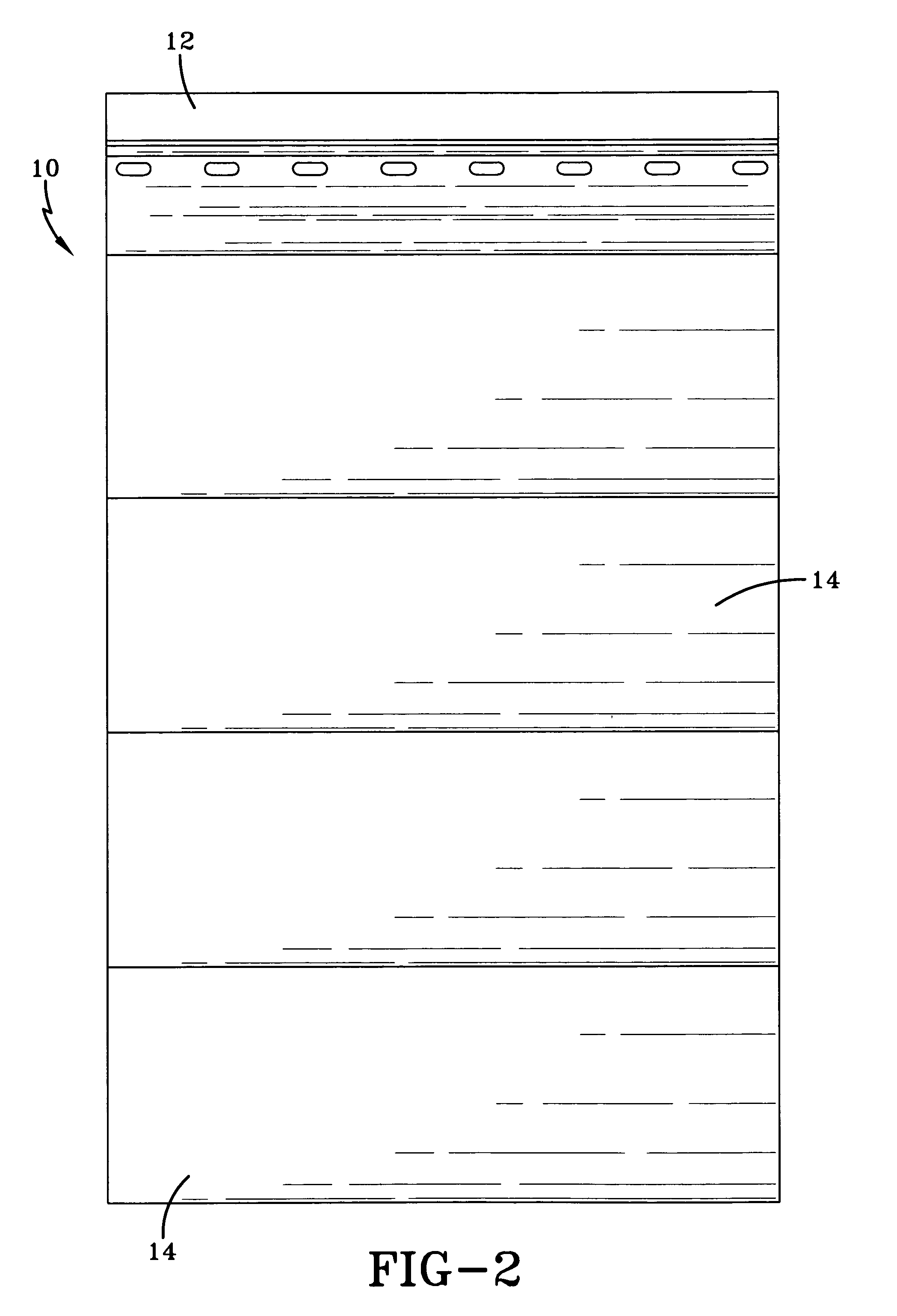

Cellulosic/polymer composite material

InactiveUS6971211B1Superior resistance to wearGood tearConstruction materialRoof covering using tiles/slatesPolypropylene compositesCellulose

The present invention is a component such as a siding panel that may be comprised of various formulations of cellulosic / polymer composite materials. One embodiment of the present invention is a siding panel that is comprised of a cellulosic / PVC composite material. This composite material may include at least one cellulosic filler in the amount of about 30% to about 60% by weight and a PVC material in the amount of about 40% to about 70% by weight. The PVC material may include about 1 to about 10 parts stabilizer(s) per 100 parts of the PVC resin, about 2 to about 12 parts lubricant(s) per 100 parts of the PVC resin, and about 0.5 to about 8 parts process aid(s) per 100 parts of the PVC resin. Another embodiment of the present invention is a siding panel that may be comprised of a cellulosic / polypropylene composite material. This composite material is comprised of at least one cellulosic filler in an amount of about 30% to about 70% by weight and a polypropylene material in an amount of about 30% to about 70% by weight. The polypropylene material includes at least one lubricant in an amount of about 10 to about 20 parts per 100 parts of a polypropylene resin.

Owner:CPG INT

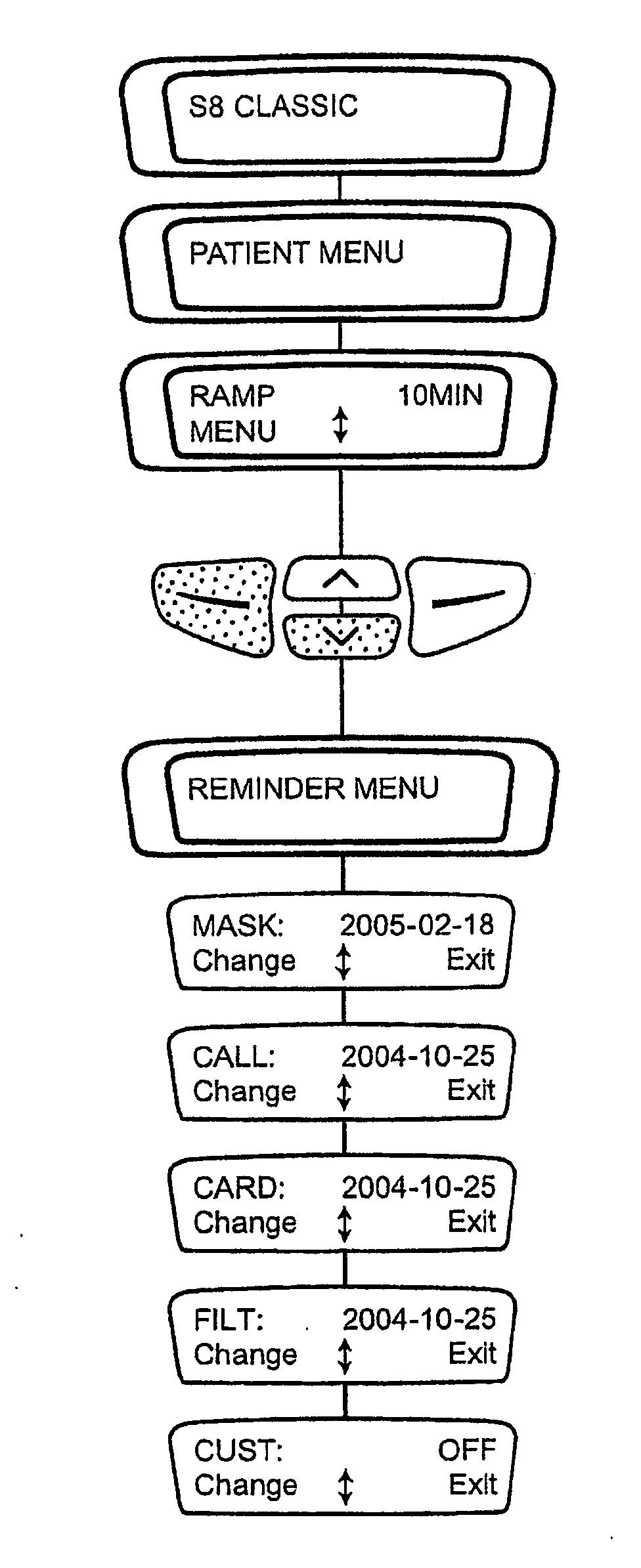

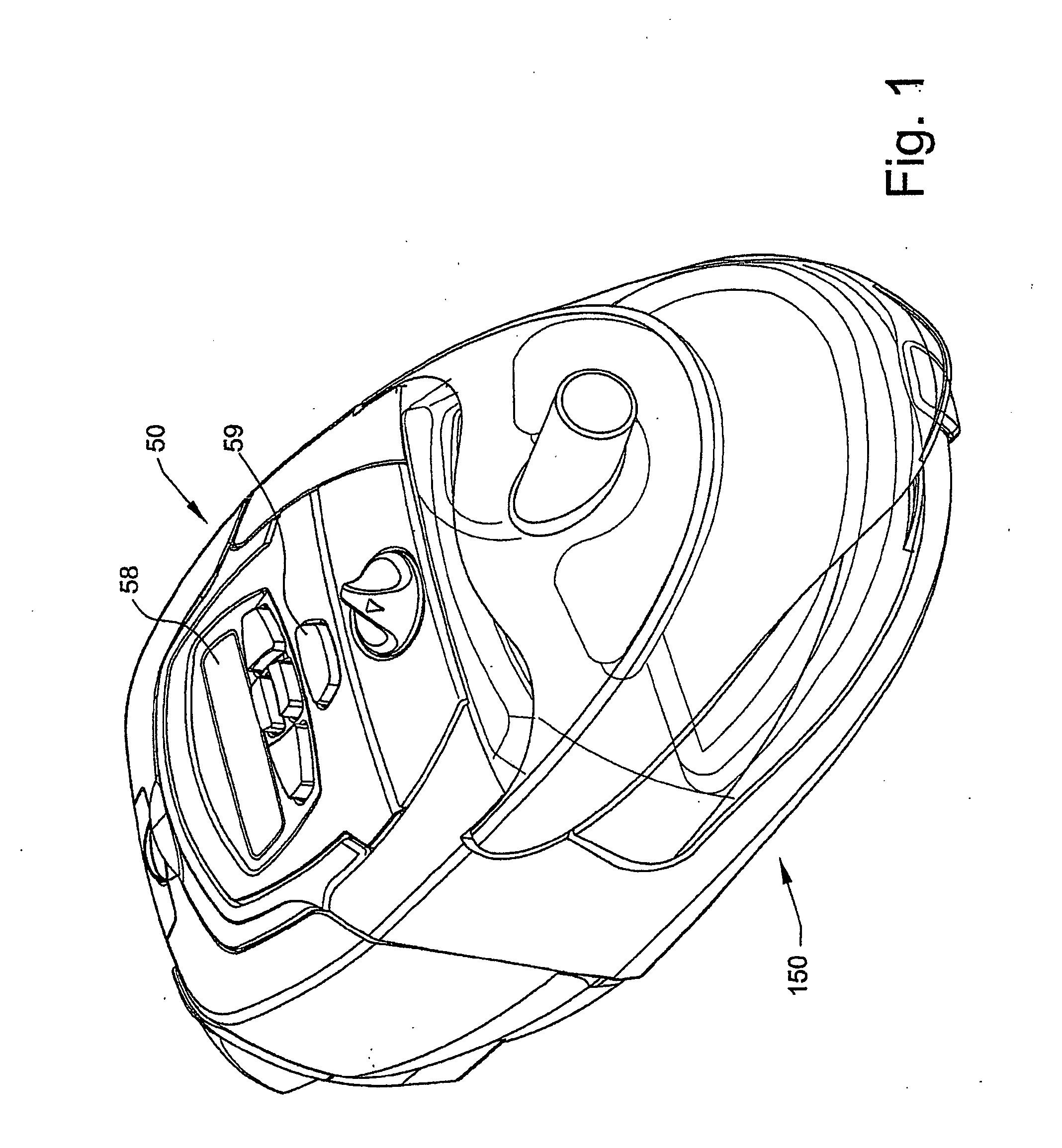

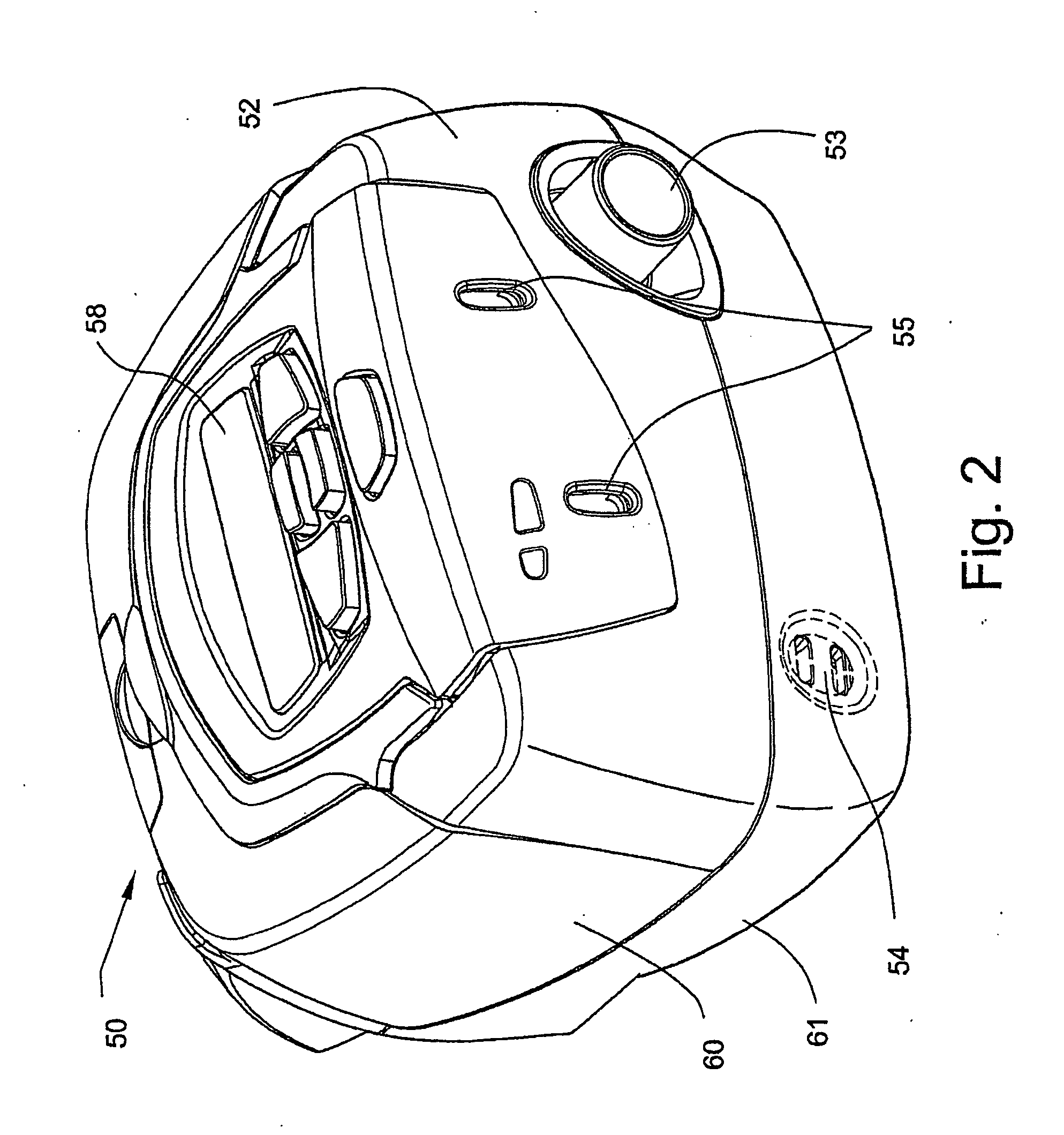

Flow generator with patient reminder

ActiveUS20100192094A1Simple and economical structureEasy to useRespiratorsOperating means/releasing devices for valvesPatient dataEngineering

A flow generator and humidifier construction is described, including a flow generator construction adapted to reduce noise output compared to known flow generators of comparable size. The flow generator includes a chassis forming first and second muffler volumes and a venturi-shaped connection portion, and a metal / polymer composite material blower enclosure which suppresses noise from the blower. The flow generator may be programmed to include a reminder system including a menu from which the user may request a reminder to take specific action, e.g., replace a component, call a physician, and / or enter patient data card, etc.

Owner:JOHN SNOW & COMPANY +1

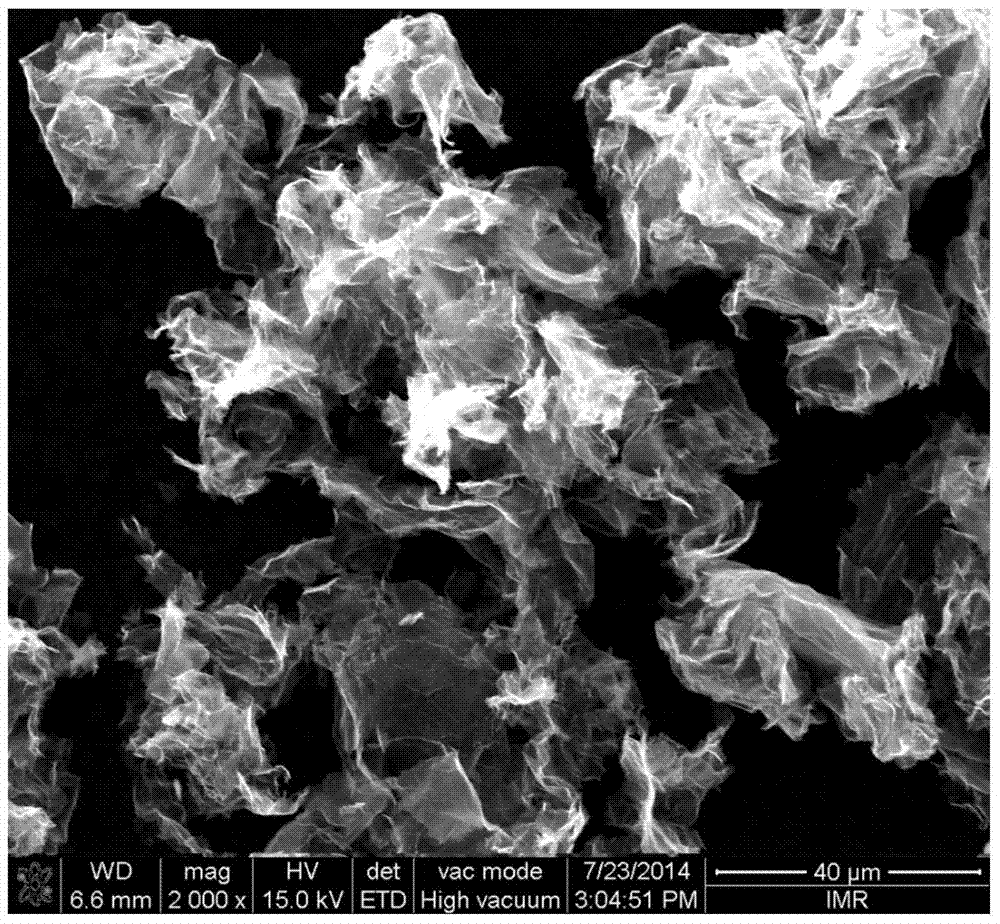

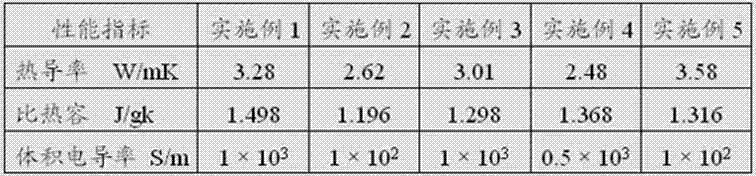

Graphene-containing silicon rubber heat-conducting composite material and preparation method thereof

The invention relates to the field of heat-conducting high-polymer composite materials, particularly a graphene-containing silicon rubber heat-conducting composite material and a preparation method thereof. The heat-conducting composite material is mainly composed of graphene, an inorganic heat-conducting filler and a silicon rubber matrix, wherein the graphene accounts for 0.1-10 wt% of the silicon rubber heat-conducting composite material, and the graphene constitutes a heat-conducting network in the heat-conducting composite material. The method comprises the following steps: uniformly compounding the inorganic heat-conducting filler, graphene, crosslinking agent and other assistants and silicon rubber on a double-roll open mill to obtain a heat-conducting silicon rubber prepolymer; and carrying out primary vulcanization on the prepolymer on a flat vulcanizing machine, and carrying out secondary vulcanization in a drying oven to finally obtain the composite heat-conducting silicon rubber. Since the two-dimensional graphene has large thickness-diameter ratio and can easily constitute an effective heat-conducting network in the silicon rubber, a small amount of two-dimensional graphene can obviously enhance the heat-conducting property of the silicon rubber (the heat conductivity coefficient at 40 DEG C is 4.98 W / m.K). The silicon rubber composite heat-conducting material can be widely used in the field of heat dissipation of electronic products.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

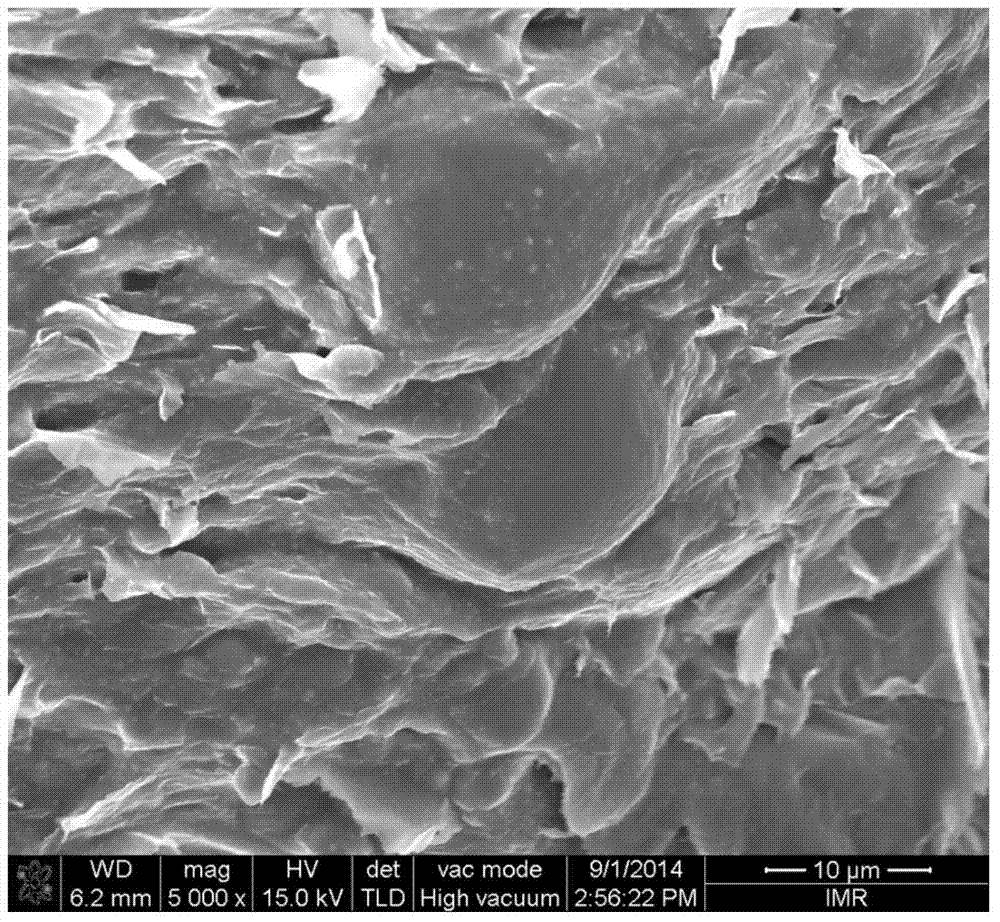

Graphene filled polymer matrix composite material and its preparation method

ActiveCN103087404AImprove conductivityImprove thermal conductivityIn situ polymerizationMechanical property

The invention discloses a graphene filled polymer matrix composite material. The composite material is prepared through using 90-99 parts by weight of a thermoplastic resin, 0.1-10 parts by weight of a graphene microchip, 0.01-1 part of a coupling agent, and 1-10 parts of a lubricant. The invention also discloses a preparation method of the graphene filled polymer matrix composite material. Compared with other carbon system filled composite materials, the graphene filled polymer matrix composite material has the advantages of easy processing, easy forming, less filler filling amount, wide raw material source, environmental protection and the like. The composite material has the characteristics of excellent electric conductivity, excellent thermal conductivity, good mechanical properties, good dimensional stability, good weather resistance and the like; and compared with present technologies for preparing a graphene / polymer composite material through in-situ polymerization or solution polymerization, the melt blending method for preparing the graphene filled polymer matrix composite material in the invention has the advantages of continuous production, suitableness for the large-scale production, and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Polyamide nanocomposites with oxygen scavenging capability

InactiveUS6777479B1Gas barrier improvement increasesIncrease platelet concentrationMaterial nanotechnologyLayered productsPolyesterPolyamide

Polymer composite materials comprising of least one polymer resin and platelet particles from at least one layered silicate material uniformly dispersed in the resin and articles prepared from the polymer composite materials. The polymer composite contains at least one polyamide resin, at least one oxygen scavenging system, and at least one layered silicate material. These polymer composite materials are especially useful for manufacturing clear polyester bottles and polyester film that are recyclable have improved active gas barrier properties to oxygen, and have improved passive barrier properties to carbon dioxide and other gases. The polymer composite materials can be used in relatively minor amounts as either a blend or a coextruded thin layer with virgin or post consumer recycled polyesters and related copolymners.

Owner:EASTMAN CHEM CO

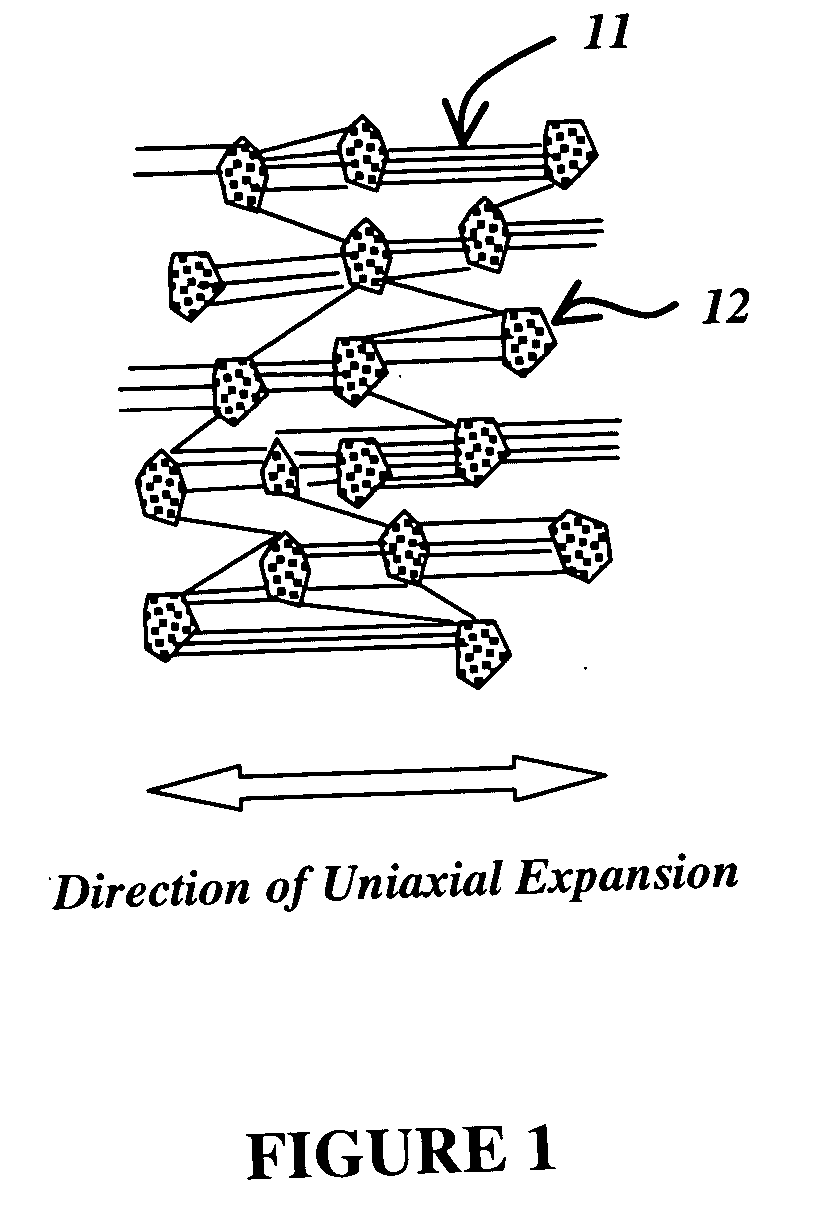

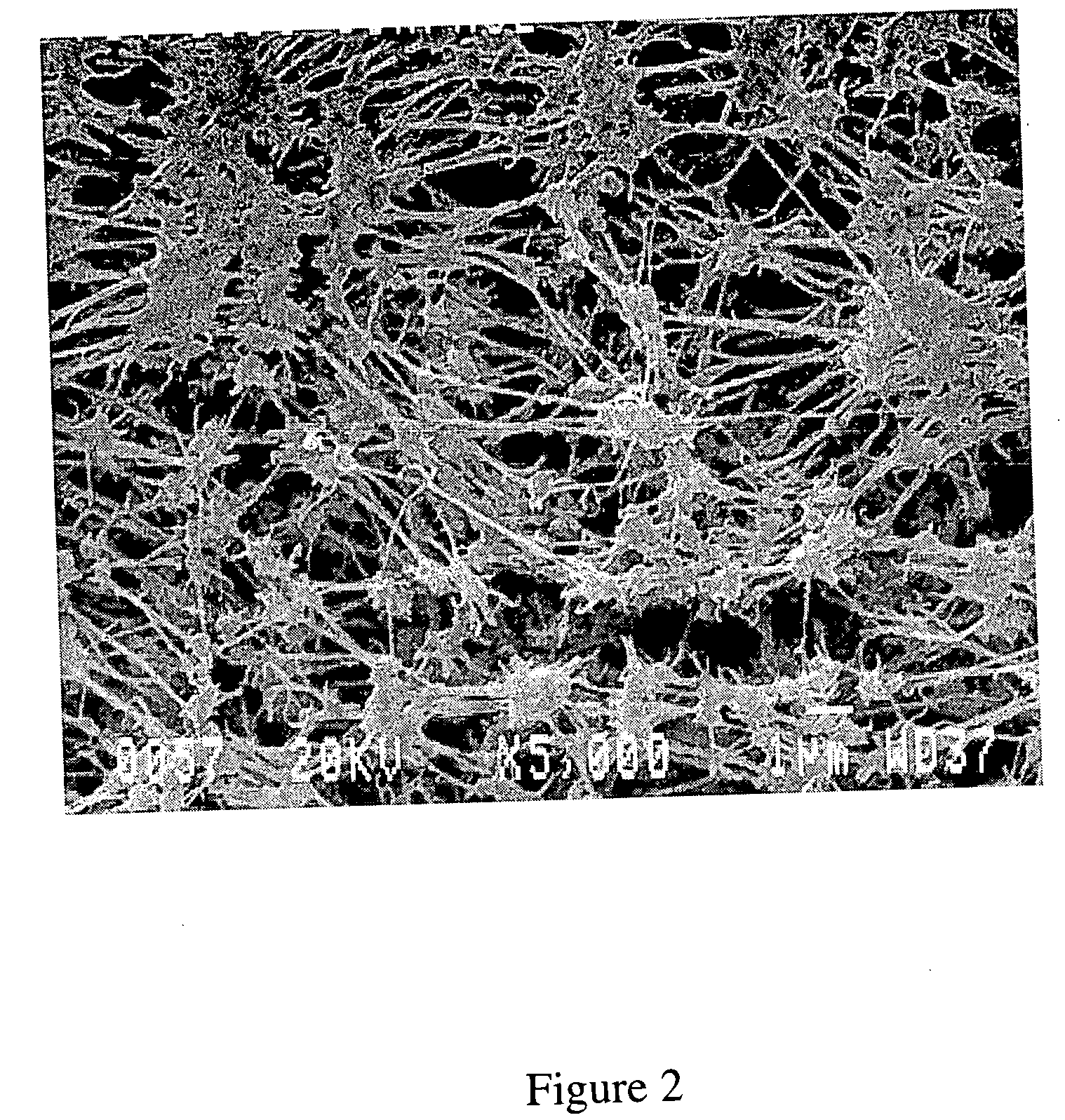

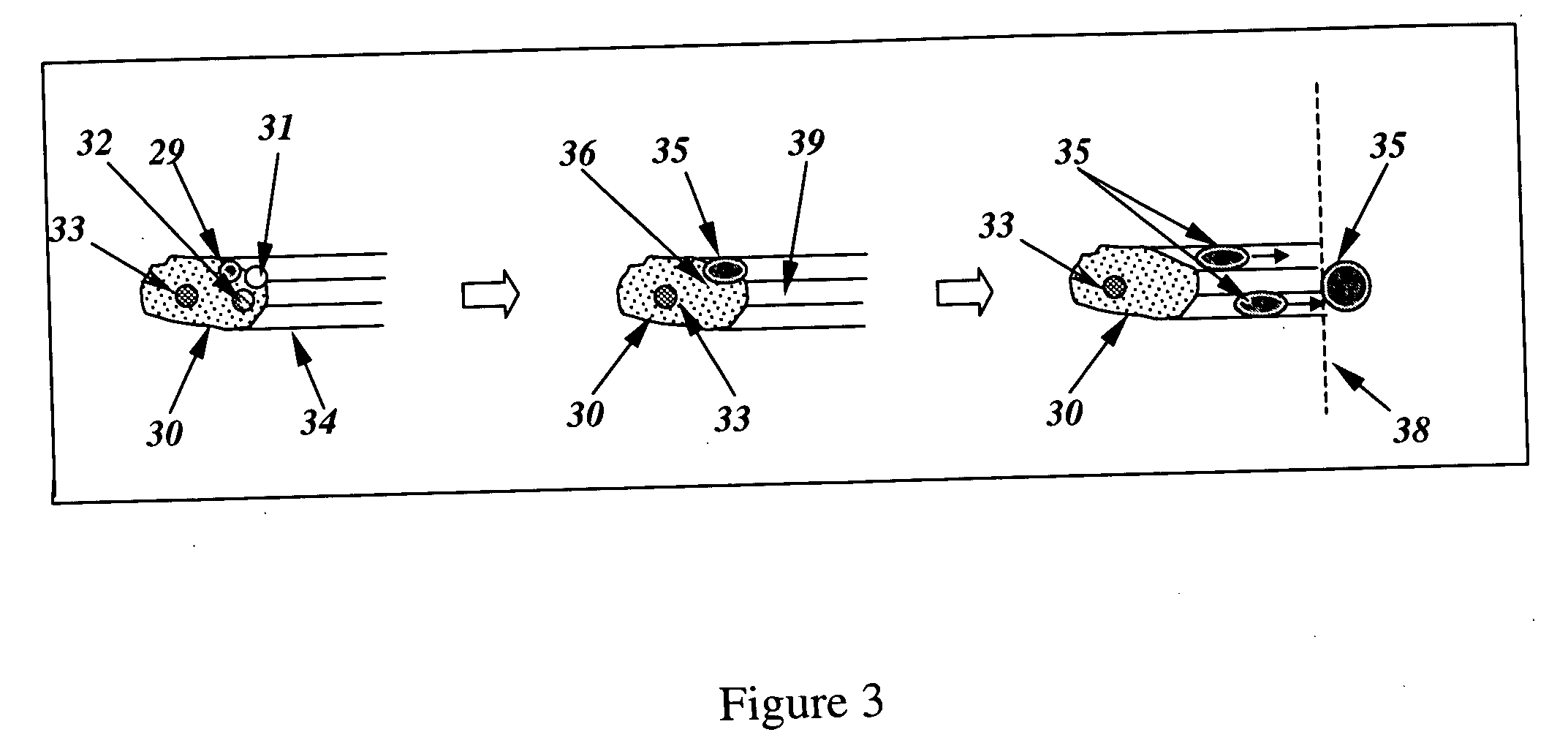

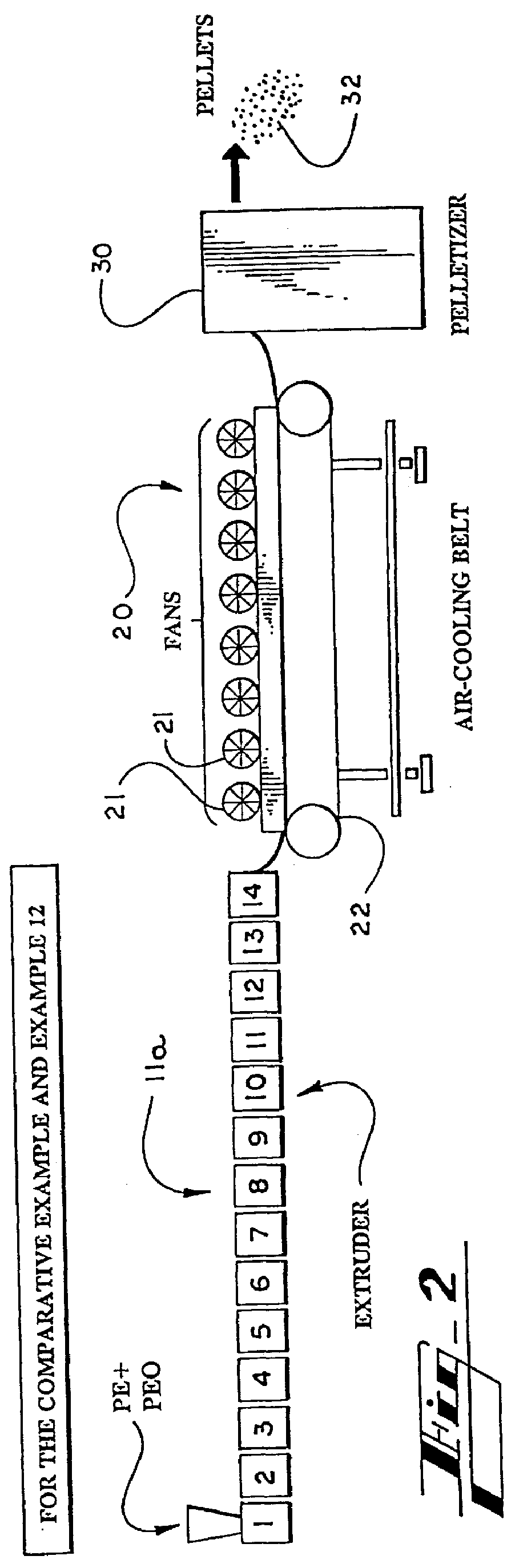

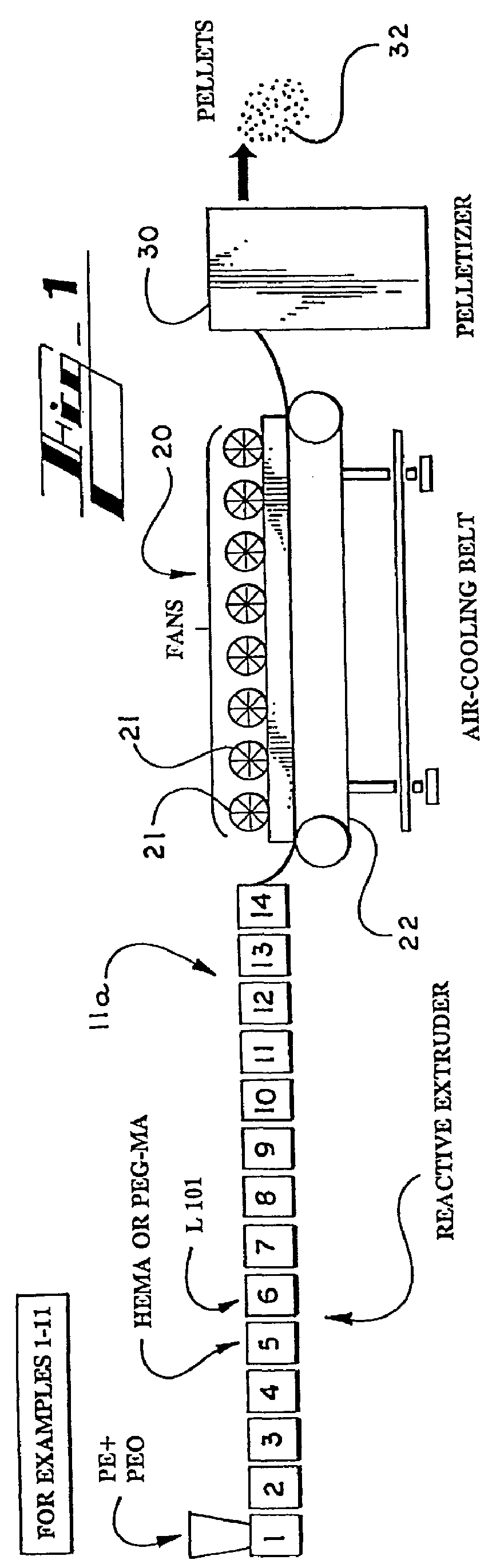

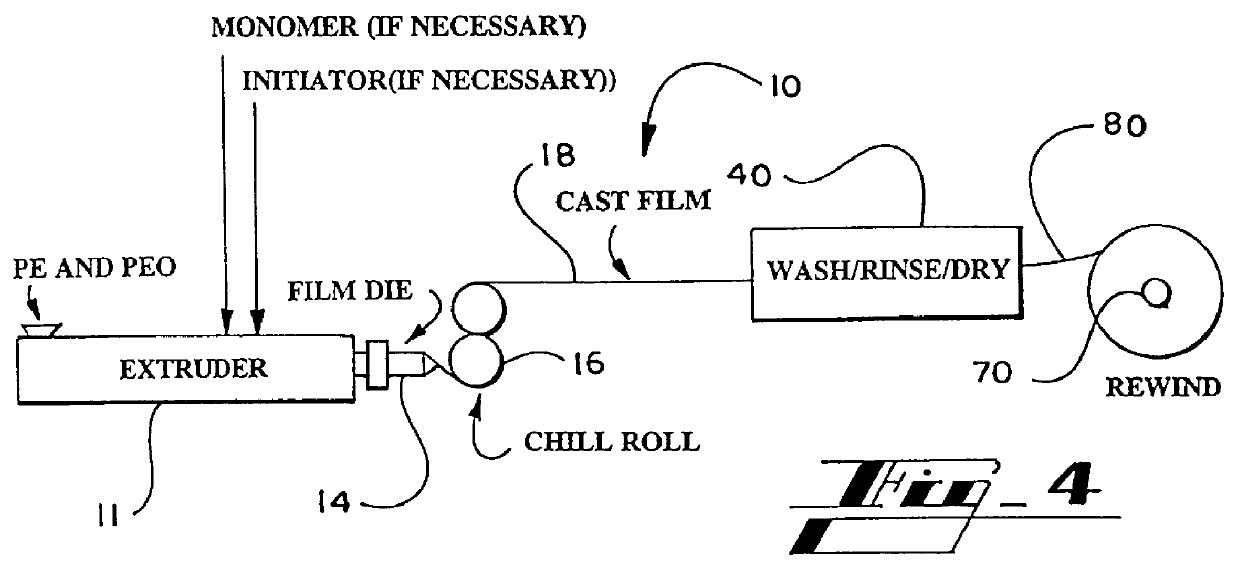

Process for making a nonwoven, porous fabric from polymer composite materials

The present invention is a method for producing a nonwoven fabric from a water modifiable polyolefin-containing film. In order to produce the fabric where polyethylene is the minority constituent, a polymer blend is formed with the polyethylene as the dispersed phase and polyethylene oxide as the continuous phase. In another embodiment wherein the polyethylene is the majority constituent and the polyethylene oxide is the minority constituent of the film, a reactive blend created during processing exhibits an inverse phase morphology so that the polyethylene oxide becomes the continuous phase and the polyethylene becomes the dispersed phase. In either embodiment, the film is then treated with an aqueous solvent to remove the polyethylene oxide to produce the nonwoven, porous fabric. The resulting nonwoven, porous fabric has a silk-like hand and shine ideal for disposable personal hygiene articles, and is flushable through waste water disposal systems.

Owner:KIMBERLY-CLARK WORLDWIDE INC

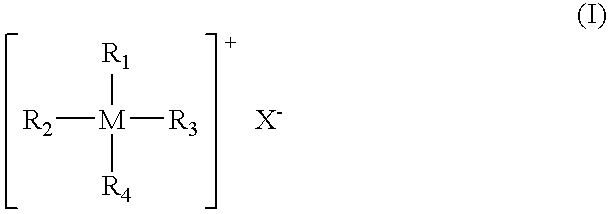

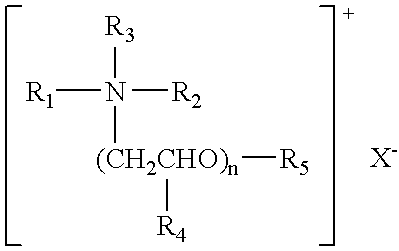

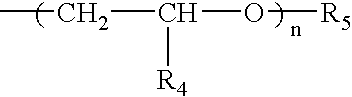

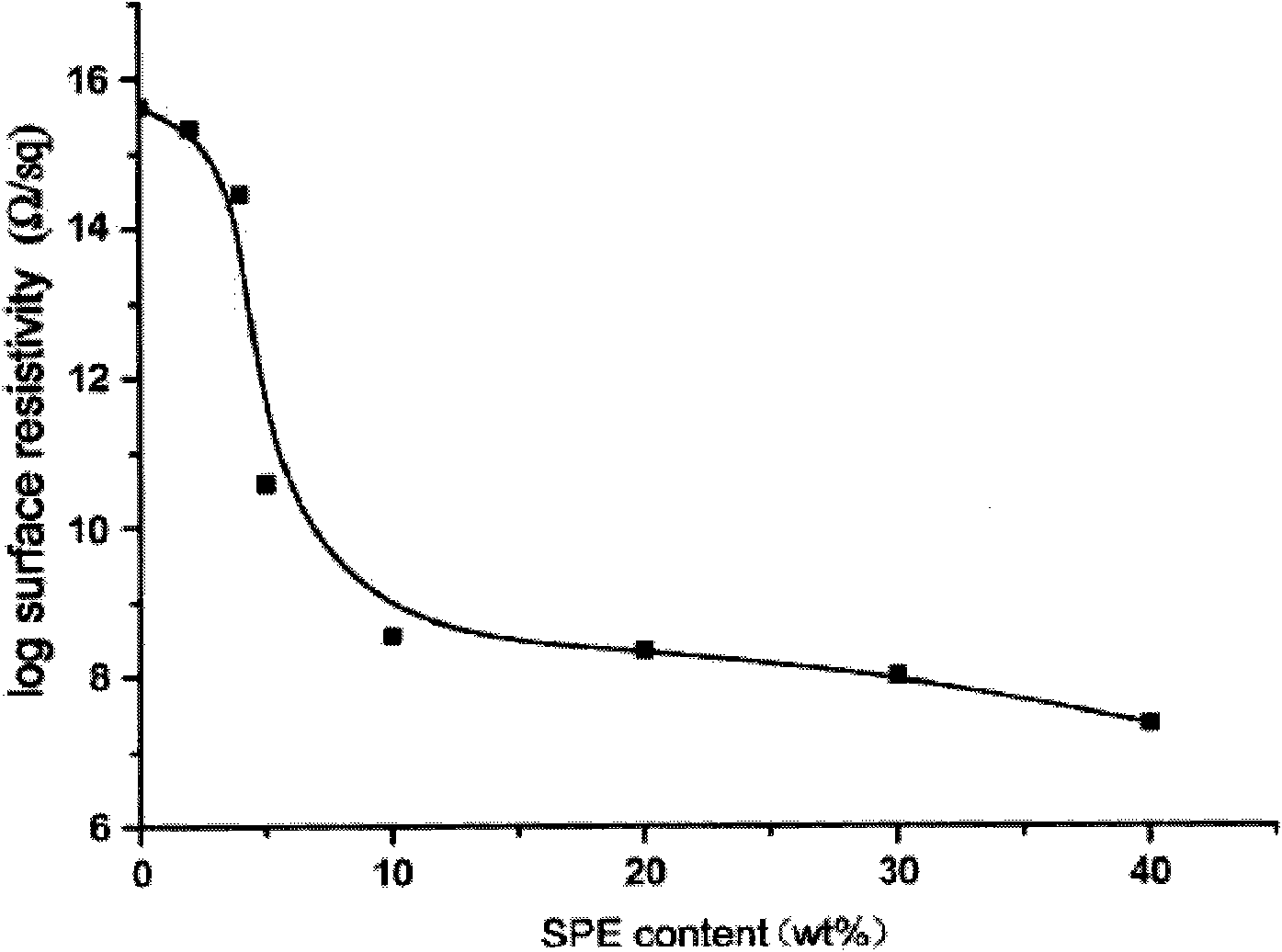

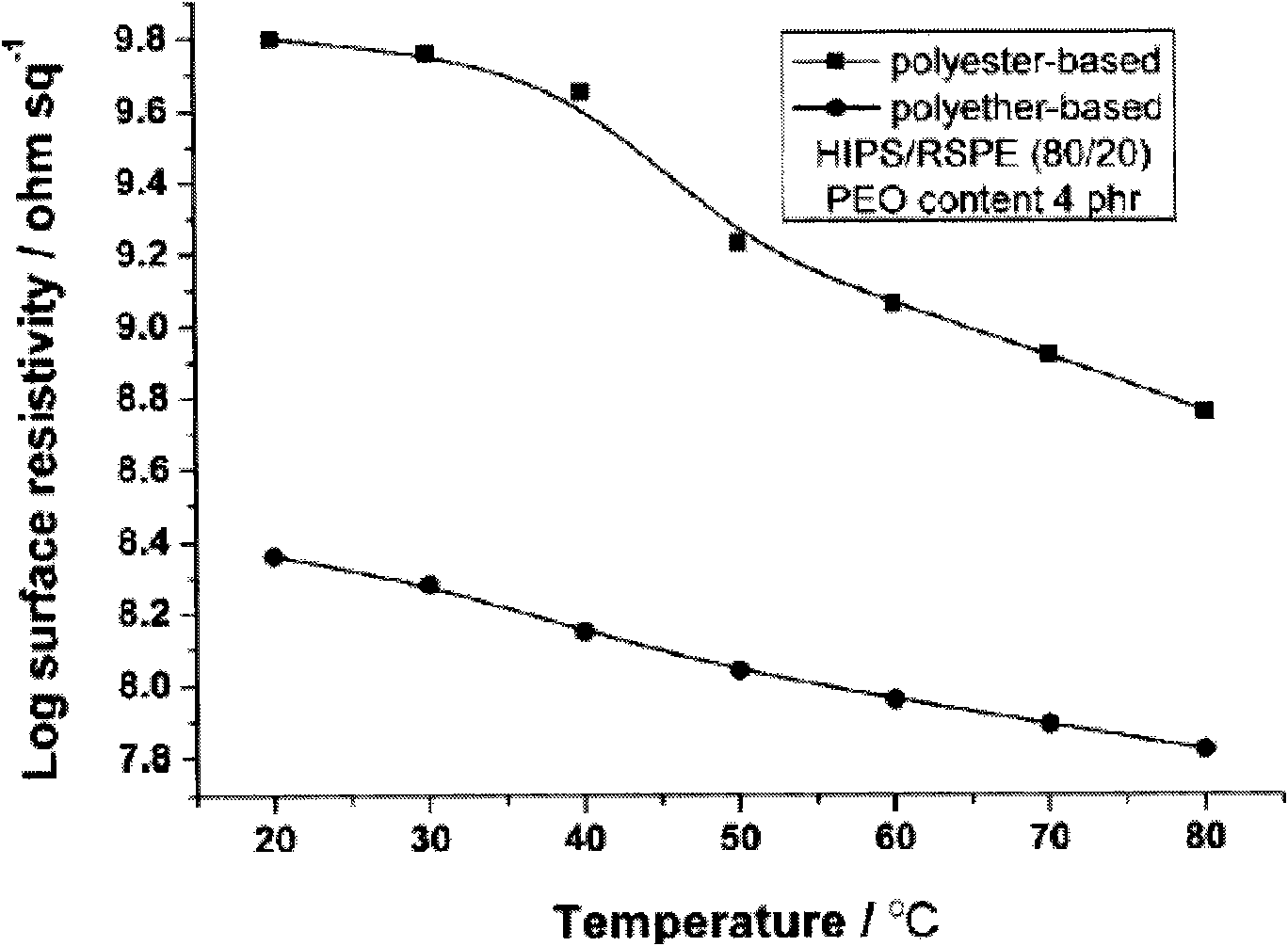

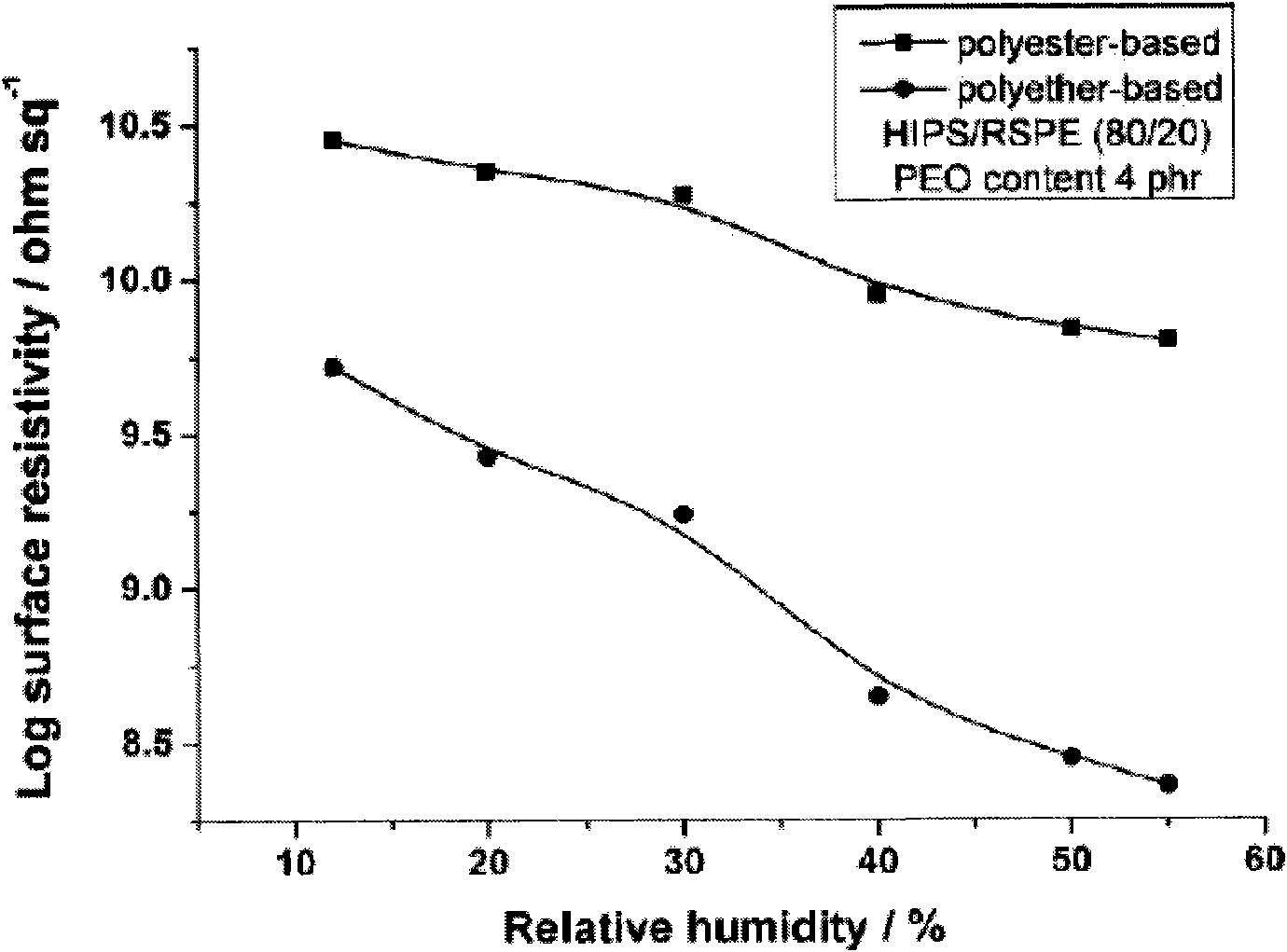

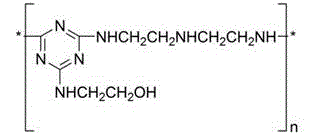

All-weather persistent antistatic master batch capable of being subjected to thermoplastic processing and antistatic composite material

The invention belongs to the field of preparation of macromolecular composite materials and particularly relates to an all-weather persistent antistatic master batch capable of being subjected to thermoplastic processing and an antistatic composite material. The antistatic master batch is prepared by forming of a low-dissociation-energy compounding agent, a processing auxiliary agent and thermoplastic macromolecular resin containing polar groups through macromolecular thermoplastic processing equipment at the temperature of 25-300 DEG C; and the mass ratio of the compounding agent to the thermoplastic macromolecular resin is equal to (1:10)-(1:50). The invention also discloses the antistatic composite material which is obtained after the persistent antistatic master batch and a macromolecular base material are formed through the thermoplastic processing equipment. The antistatic composite material has the characteristics that: 1. the antistatic composite material has light color and dyeability; 2. The master batch of the antistatic composite material and the compounding agent are wider in selection range, low in cost and easy to obtain, and the production process is simple, safe and non-hazardous; and 3. the influence of the ambient environment on the antistatic performance of the antistatic composite material is less, and the antistatic performance is persistent.

Owner:浙江三和塑料有限公司

Ceramic bovine flame retardant polymer composite material and application thereof

InactiveCN104650441AImprove high temperature strengthImprove flame retardant performanceInsulatorsPolyolefinPlasticizer

The invention provides a ceramic bovine flame retardant polymer composite material based on polyolefin or a thermoplastic polyurethane elastomer. The ceramic bovine flame retardant polymer composite material is prepared from the following components in parts by weight: 30-40 parts of polyolefin resin or the thermoplastic polyurethane elastomer, 25-45 parts of a ceramic forming filler, 20-30 parts of a halogen-free flame retardant, 1-5 parts of a flame-retardant synergist, 1-3 parts of a plasticizer, 0.5-2 parts of an antioxidant and 0.02-0.15 part of a crosslinking agent, wherein the ceramic forming filler is prepared from the following components including low softening point glass powder and a silicate mineral filler. The invention also provides application of the ceramic bovine flame retardant polymer composite material in the field of cables. According to the ceramic bovine flame retardant polymer composite material disclosed by the invention, a dense ceramic bovine product can be formed within a range from 600 DEG C to 1000 DEG C, and the formed ceramic bovine product is good in high-temperature strength and flame retardancy and is also good in mechanical properties under room temperature.

Owner:SICHUAN UNIV

Metal-like engineering plastic composite material and preparation method thereof

The invention discloses a metal-like engineering plastic composite material and a preparation method thereof, and relates to a polymer composite material. The invention provides the metal-like engineering plastic composite material which combines plastic with metal and simultaneously keeps the advantages of the two and the preparation method thereof. The composite material comprises thermoplastic engineering plastic, high-density packing, mineral powder, glass fiber, toughener, coupling agent, lubricant and antioxidant. The metal-like engineering plastic composite material has high density, high mechanical properties, excellent thermal deformation temperature and good injection molding property. The preparation method adopts the method of being combined with the coupling agent and the optimized granulation conditions, the process is simple and easy to operate, extrusion and granulation can be carried out by adopting an ordinary twin-screw granulator, and injection molding can be carried out by adopting an ordinary injection machine.

Owner:XIAMEN RUNNER IND CORP

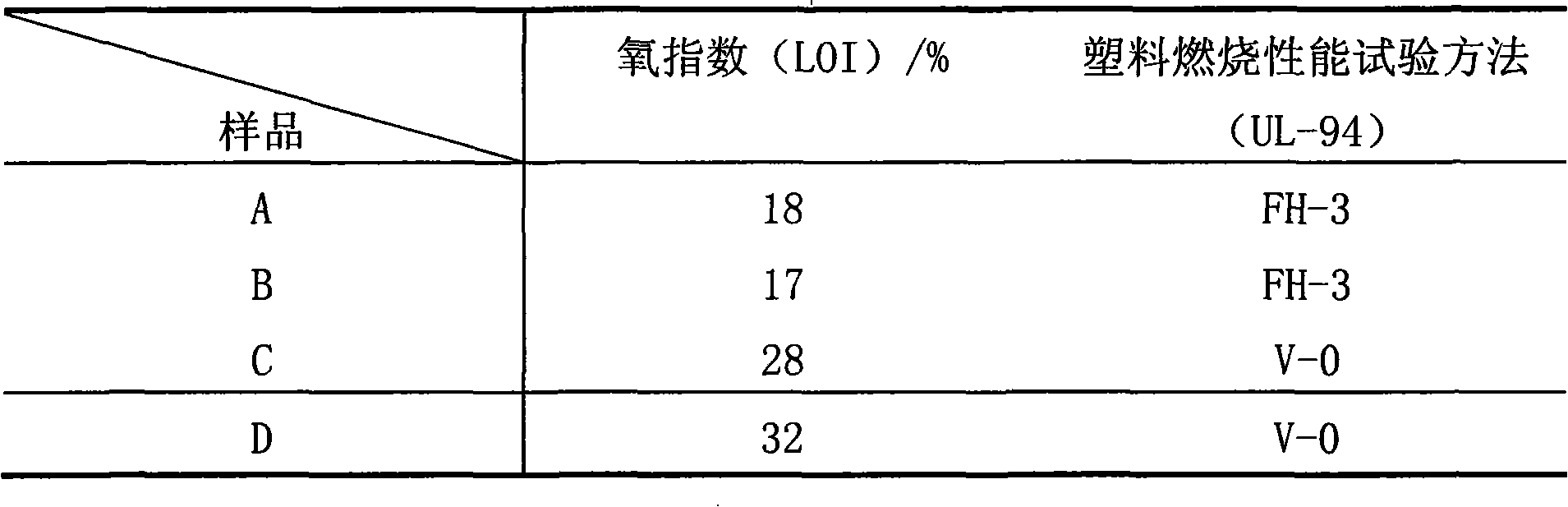

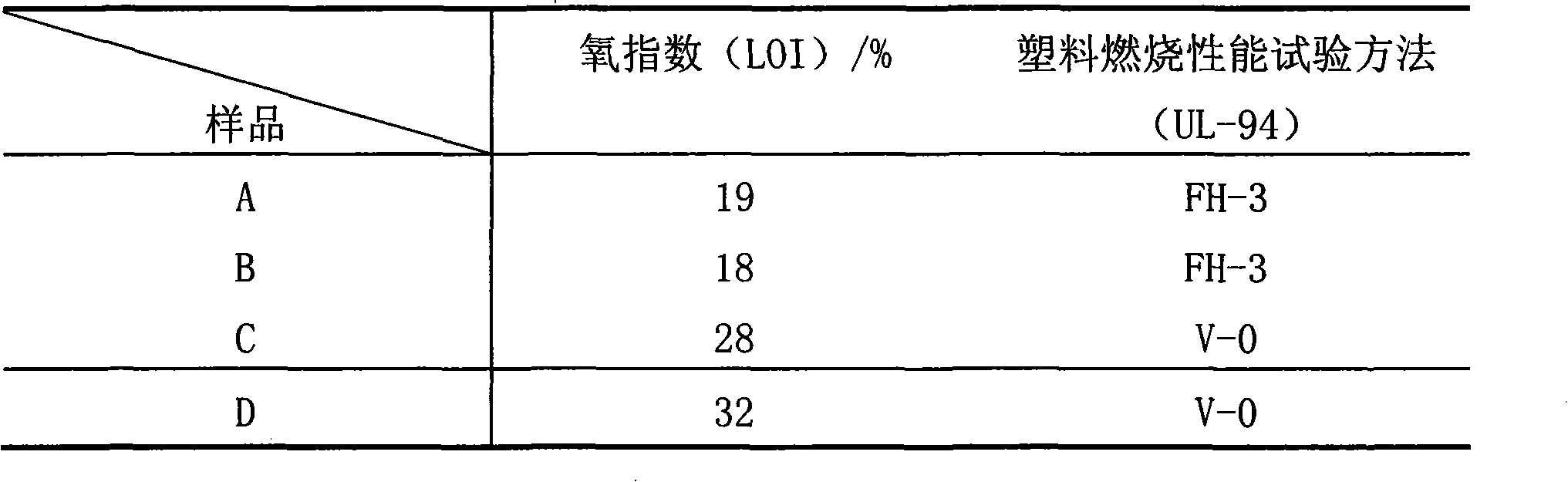

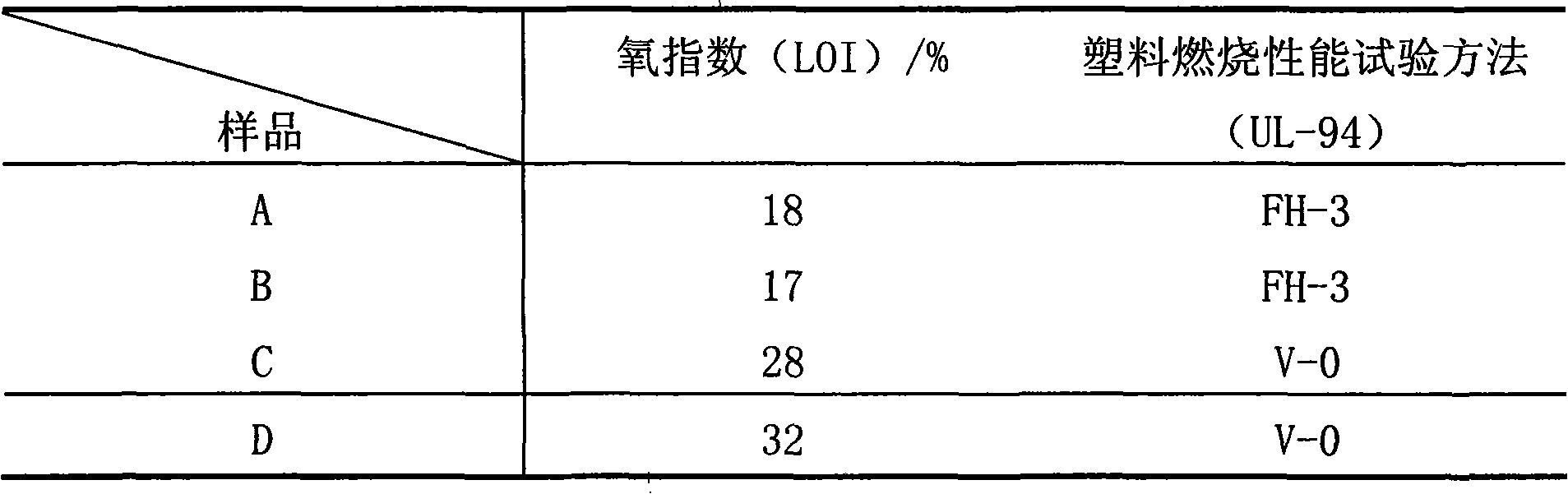

A high flame retardant high thermal conductivity composite material component and its manufacturing method

InactiveCN102260413AImprove thermal conductivityImprove flame retardant performancePolymer sciencePhenol formaldehyde resin

The invention relates to a high-molecular composite material having performances of high heat conduction and high flame retardation, the invention is characterized in that the composite material does not contain any halogen or a non environmentally-friendly heavy metal fire retardant, the flame resistance is capable of reaching a UL94 V0 standard, simultaneously, the composite material has good heat conducting performance, the heat conduction coefficient is more than 0.5 W / m. DEG C. The composite material provided in the invention has good injection moulding performance, extruding performance and hot pressing performance. The composite material comprises the following basic components: 1) one or a plurality of metal hydroxides, such as aluminum hydroxide, magnesium hydroxide, zinc hydroxide and the like, wherein the weight content is 10-70%, 2) about 0.2%-60% of the weight content of expandable graphite flaky powder, the lamina size is more than 10 um, and the expandable coefficient is more than or equal to 20 times; 3) 15%-70% of the weight content of matrix resins, such as epoxy resin, organic silicone resin, phenolic resin, thermosetting polyester resin and thermoplastic resins of nylon 6, nylon 66, PBT, PP, HDP and the like. The composite material component of the invention can be directly used for radiators such as LED, electric appliances and electronic components, the heat can be radiated into colder environment so that the operating temperature of the electronic device can be reduced.

Owner:HEFU NEW MATERIAL TECH WUXI

Natural liquid rubber slurry with added carbon nanotube and its prepn process

The present invention relates to composite polymer material performance improving technology. The liquid natural rubber slurry contains natural latex and carbon nanotube (CNT) and has total solid content of natural latex and CNT in 5-30 % and weight ratio between CNT and dry natural latex of 1-50 %. The liquid natural rubber slurry is prepared through surface treatment of CNT for hydrophilicity; mixing with dispersant and deionized water to obtain water suspension of CNT; regulating the pH value of the suspension to 9-12; and finally mixing with natural latex to obtain the liquid natural rubber slurry with added CNT. The liquid natural rubber slurry with homogeneously dispersed CNT is used in preparing CNT modified rubber powder and CNT modified sulfurized rubber products with greatly raised mechanical, electrically conducting, heat conducting, antistatic and other performance.

Owner:TSINGHUA UNIV

Graphene/polymer conductive composite material

The invention belongs to the field of engineering materials, in particular relates to a preparation method of a graphene / polymer composite material with high performance and high conductivity and heat conduction. The composite material contains 80-95 wt% of high-molecular polymer, 0-15 wt% of one or more layers of graphene, 0.1-2 wt% of antioxidant, and 0.1-3 wt% of plasticizer. The prepared composite material has excellent conductivity, higher heat distortion temperature and excellent mechanical performance, and can be widely applied to supercapacitors, automobile antistatic fenders, door handles, mirror boxes and pass boxes.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

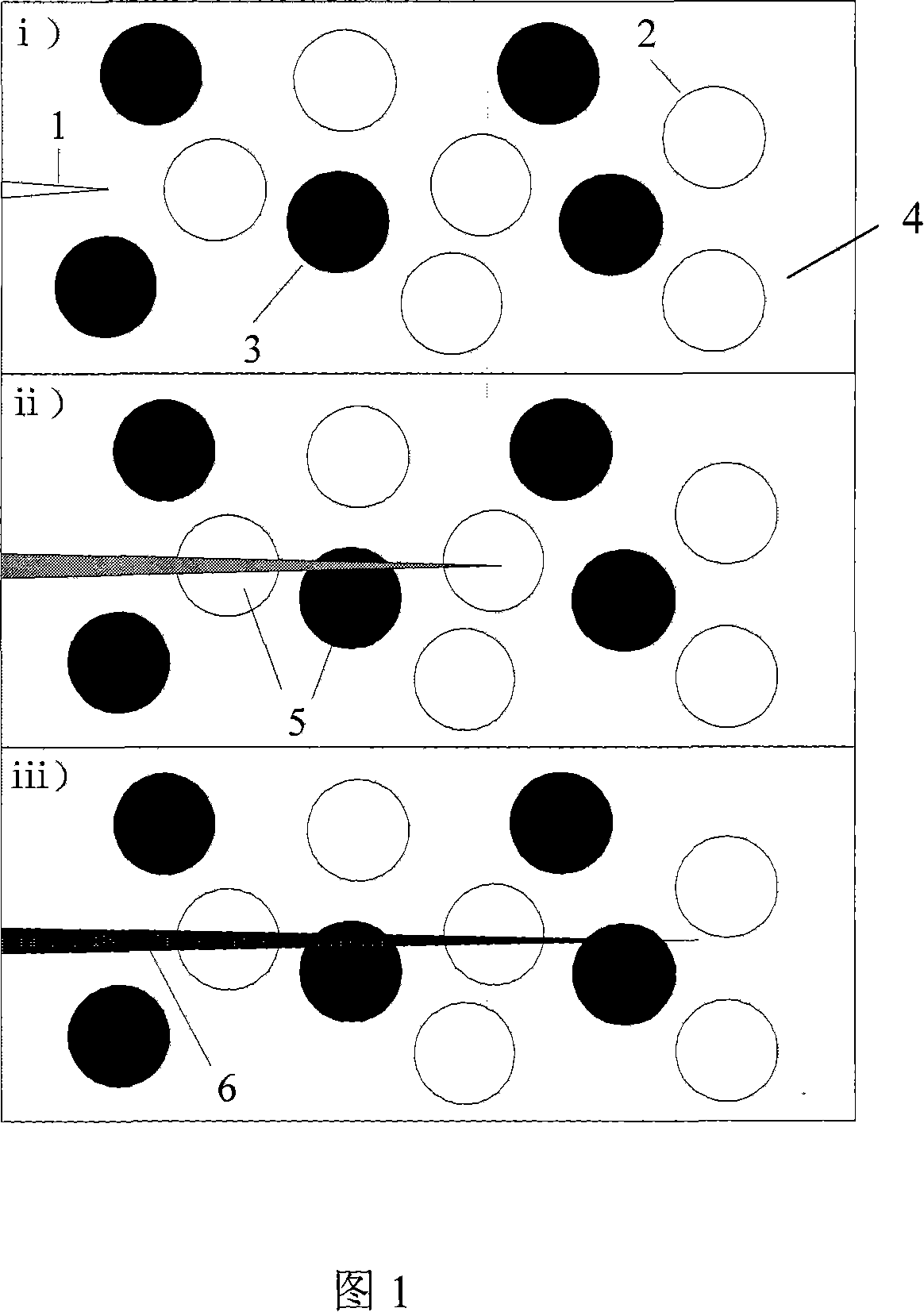

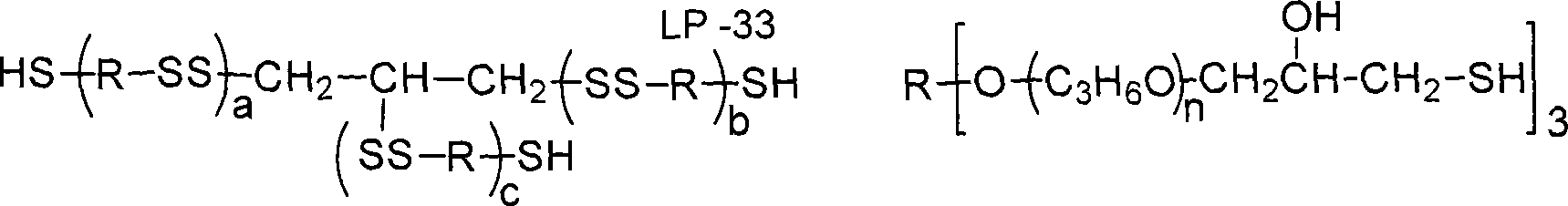

Self-repaired polyalcohol composite material at room temperature

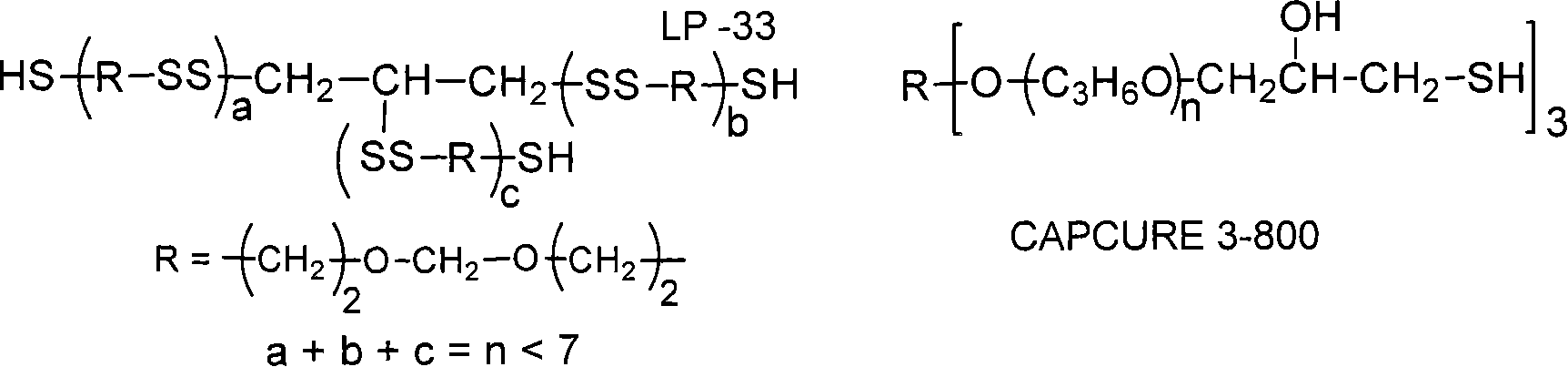

The present invention relates to the technological field of self-repairing polymer material and discloses a self-repairing polymer composite material at the room temperature. The self-repairing polymer composite material is made of the following components of the following weight percentages: 40 percent to 98 percent of polymer matrix, 1 percent to 50 percent of capsule containing liquid epoxy resin, 1 percent to 50 percent of capsule containing liquid poly mercaptan and 0.1 percent to 15 percent of catalyst. The capsules containing the liquid epoxy resin and the poly mercaptan of the present invention can bear the external force of processing when the material is prepared. When the matrix material is damaged and cracked, the crack can be split together with the matrix while passing the capsules to release two reaction substances. The two reaction substances are polymerized rapidly so as to prevent the increase of the crack and to repair the crack. The self-repairing composite material of the present invention needs no heating while repairing; and the crack repair can be automatically finished at the room temperature.

Owner:SUN YAT SEN UNIV

high-filling-content micro-nano powder/polymer composite material for 3D printing and preparation method and product thereof

ActiveCN103980592AEnhanced interactionImprove performance3D object support structuresCross-linkAntioxidant

The invention relates to a high-filling-content micro-nano powder / polymer composite material for 3D printing and a preparation method and a product thereof. The material contains the following raw materials, by weight, 10-30 parts of a polymer, 90-70 parts of a micro-nano powder, 0.05-0.2 part of an irradiation sensitizer and 0.01-0.02 part of an antioxidant. The micro nano powder is used as a main material and polymer resin is used as a binding agent, and moulding is finished by a 3D printing mode. Simultaneously, the irradiation sensitizer is added, and the polymer resin forms a three-dimensional cross-linked network after electron beam irradiation. Then, strength, heat resistance and chemical corrosion resistance are raised after resin bonding. The high-filling-content micro-nano powder endows the moulding material with excellent mechanical properties. In addition, according to changes of product usage environment and demand, types of the micro-nano powder are changed so as to obtain a material with special functionality, such as excellent conductivity, thermal conductivity, flame resistance, impact resistance and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

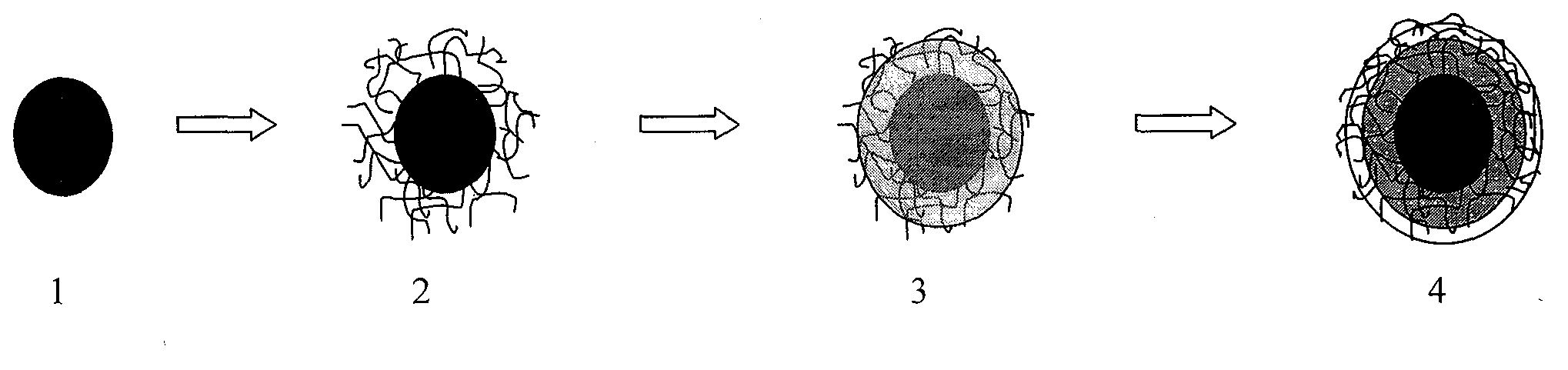

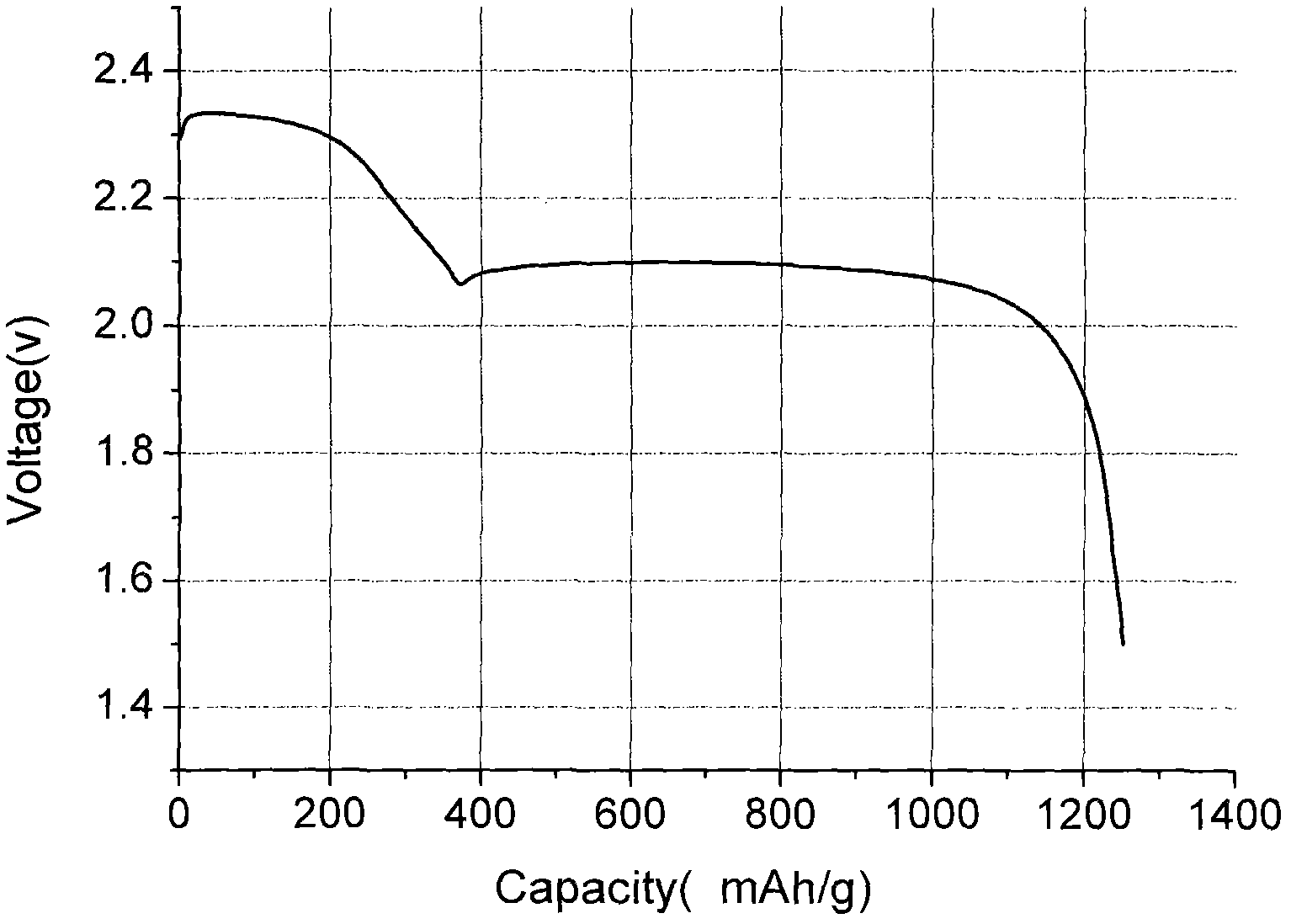

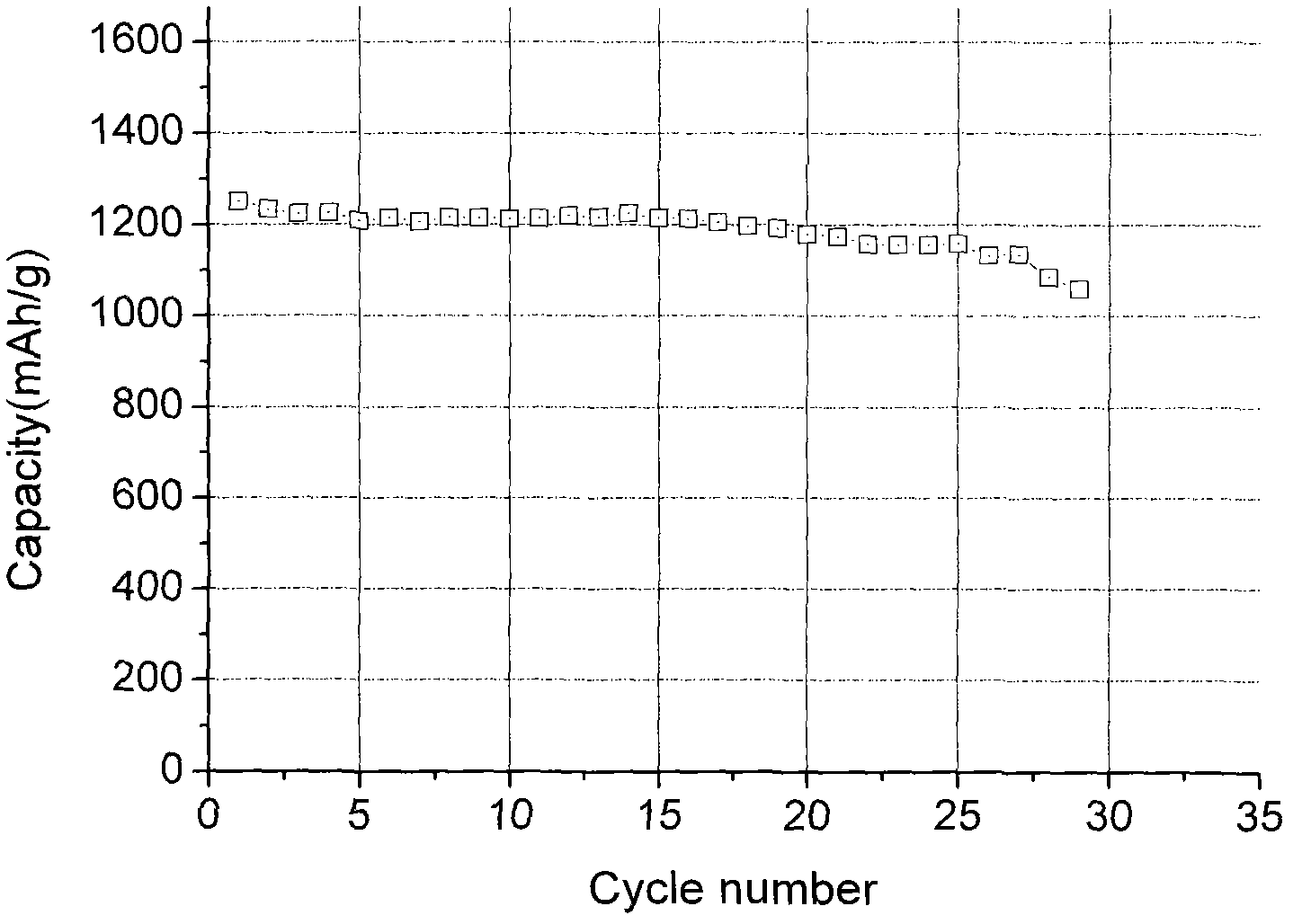

Carbon-sulfur-shell matter composite material having network dual-core shell structure and preparation method thereof

InactiveCN103474633AInhibition of dissolution and diffusion lossIncrease profitMaterial nanotechnologyElectrode manufacturing processesPolycyclic aromatic hydrocarbonLithium–sulfur battery

The invention relates to a carbon-sulfur-shell matter composite material having a network dual-core shell structure and a preparation method thereof. The carbon-sulfur-shell matter composite material has a carbon-sulfur-shell three layer structure, a central core (inner core) is nano carbon particles, sulfur elemental or a polysulfide containing-Sm-structure (m>2) is directly deposited on the nano carbon particles, or functional groups are introduced onto the nano carbon particles by use of polycyclic aromatic hydrocarbon like reaction capacity of the carbon material and through an irreversible chemical reaction, polymeric chains are introduced in, a crosslinked network structure is formed through stretching, bending and crosslinking of the polymeric chains on the surface of the nano carbon particles, the sulfur elemental or the polysulfide containing the-Sm-structure (m>2) is composited onto the crosslinked network structure to form a nano sulfur layer having a network structure, then a mono-core shell nano composite material having a network structure is obtained and is used as a second layer (outer core) of the carbon-sulfur-polymer composite material having the network dual-core shell structure, an outermost layer is a shell matter layer, electronic and / or ionic conductivity of the material are / is improved, dissolving loss of discharge products can be further inhibited, and structural stability of the material is improved. The material is suitable for positive poles of lithium sulfur batteries, and has a prominent effect on improvement of cycle stability of the lithium sulfur batteries.

Owner:NO 63971 TROOPS PLA

Lignin-epoxy resin composite material and preparation method thereof

The invention discloses a lignin-epoxy resin composite material and a preparation method thereof, relates to a lignin-polymer composite material and a preparation method thereof, and aims to solve the conventional problem of low effective utilization rate of lignin. The lignin-epoxy resin composite material uses the lignin as a substrate; epoxy resin, a curing agent, a toughening agent, and the like are evenly blended with the lignin; and through the processes of pre-pressing, hot-pressing and curing molding, the lignin-based composite material is obtained. The lignin-epoxy resin composite material disclosed by the invention has the advantages of little water absorption, good mechanical performance, degradability, and the like, is suitable for manufacturing floor boards, wall protection boards, construction formworks, door-window profiles, fences, guardrails, louvers, roof boards, and the like in the construction industry, can be used for manufacturing inner decorative boards of automobile doors, seat backing boards, automobile roof lining, and the like in the automobile industry, and can also be used in the fields of the packaging and transportation industry, the furniture industry, office articles, sports facilities, and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

Development method of flexible pressure-sensitive element based on carbon nano-tube filled high polymer composite material

InactiveCN101885463ALarge aspect ratioHigh sensitivityDecorative surface effectsChemical vapor deposition coatingCarbon nanotubeCopper foil

The invention relates to a development method of a flexible pressure-sensitive element based on a carbon nano-tube filled high polymer composite material, which belongs to the technical field of sensors. The method comprises the following steps of: 1. pressure-sensitive material preparation: dispersing carbon nano-tubes into polydimethylsiloxane by utilizing ultrasonic vibration and mechanical stirring methods, and preparing a thin and flexible pressure-sensitive material by using tetraethoxysilane as a crosslinking agent and dibutyltin dilaurate as a catalyst with a spin coating method; 2. pressure-sensitive element packaging, wherein a two-stage sandwich structure is adopted, the first-stage sandwich structure comprises two layers of packaging films and the pressure-sensitive material positioned in the middle; and in the second-stage sandwich structure, each layer of packaging film comprises two layers of polyimide films as well as a copper foil electrode and a lead which are embedded in the two layers of polyimide films. The pressure-sensitive element developed by the invention has good flexibility, high precision, thin thickness, simple process and low cost and is applicable to the fields of pressure monitoring of structures between narrow curved surface layers in the fields of military industry and civil use and artificial electronic skin development and the like.

Owner:NORTHEASTERN UNIV

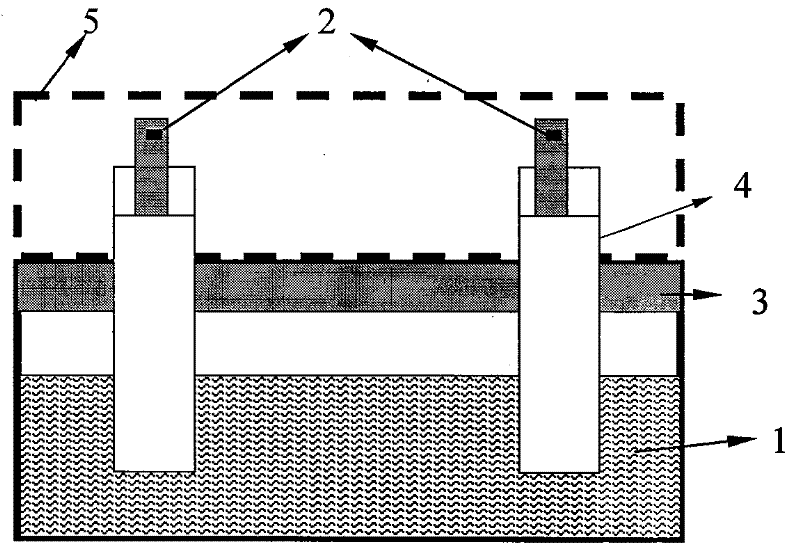

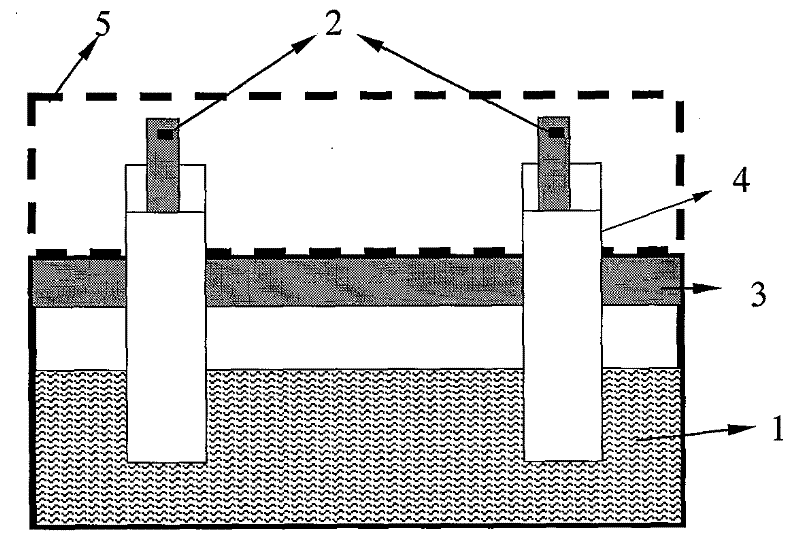

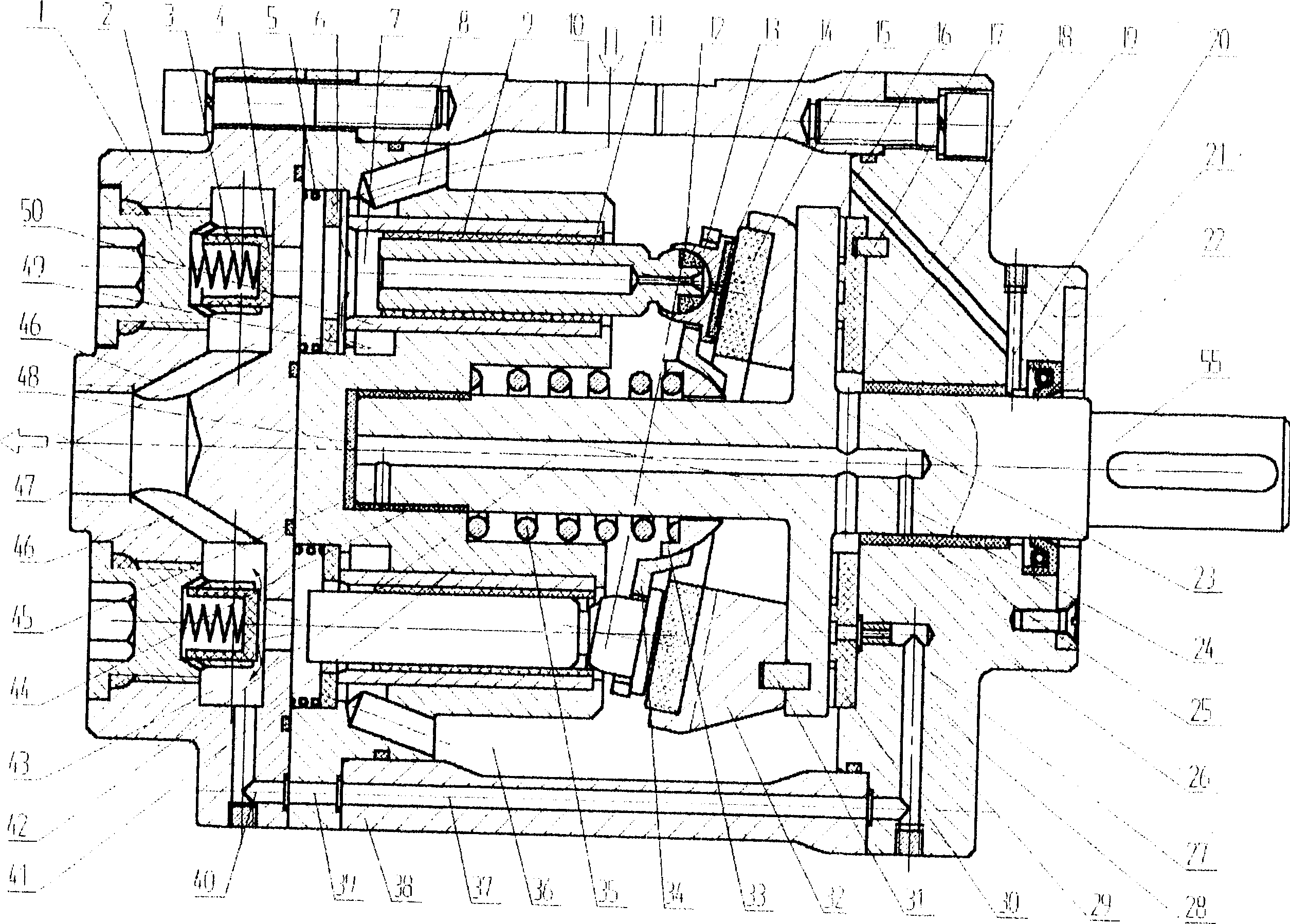

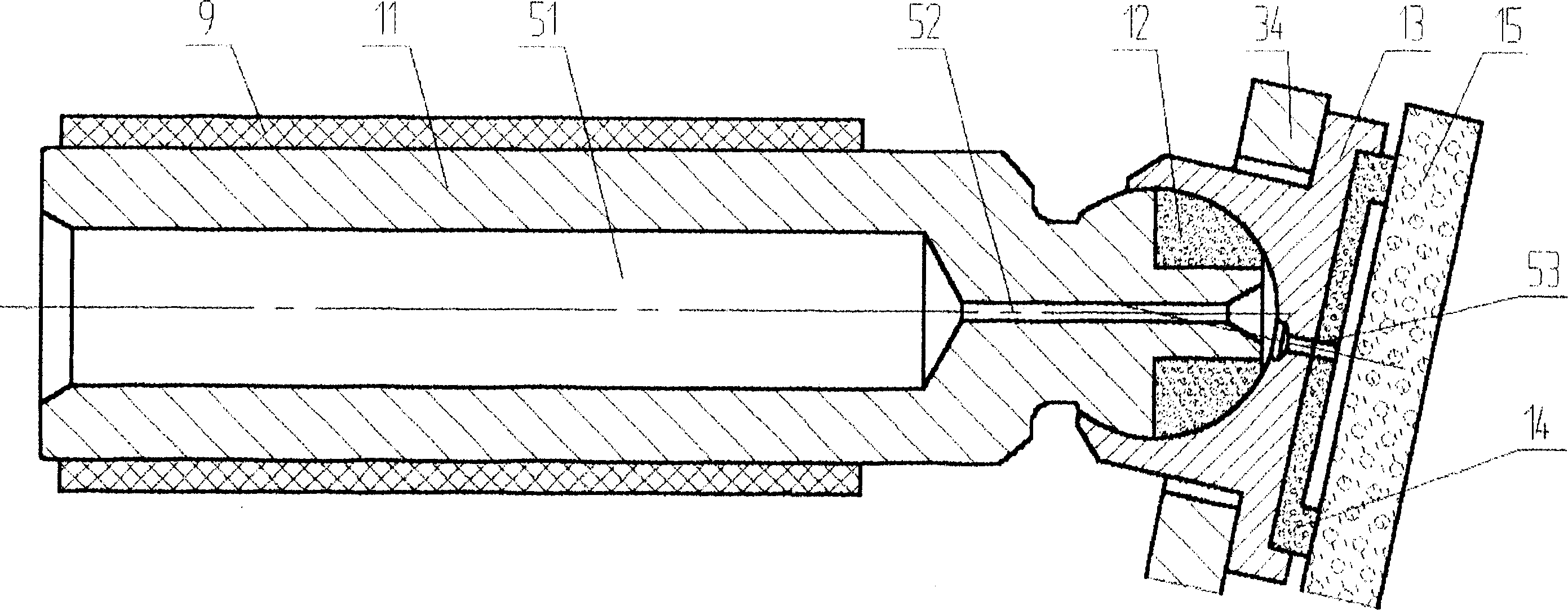

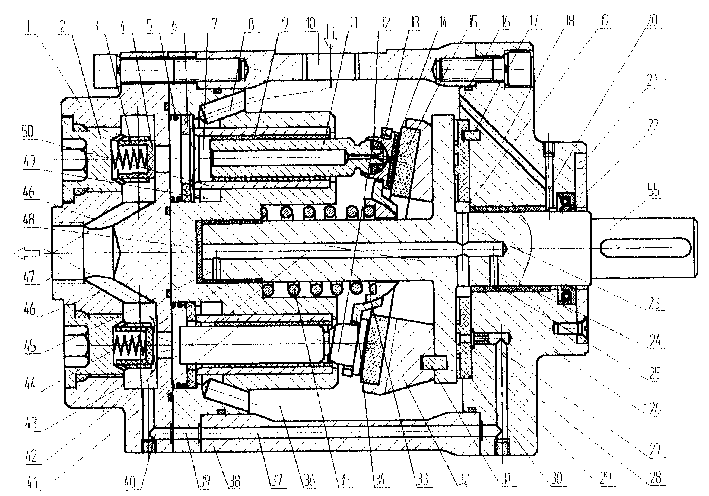

Axial plunger type water hydraulic pump

InactiveCN1434209AImprove responsivenessStable flowPositive-displacement liquid enginesMulti-cylinder pumpsReciprocating motionHydraulic pump

The axial plunger water hydraulic pump is characterized by that it adopts plate value to make flow distribution, the plunger and plunger hole are axial uniformly distributed on the periphery relativeto main shaft, it utilizes an oblique plate and central spring to implement reciprocation of plunger, the plunger, plunger bulb and slipper are equipped with central holes respectively, and on the rear end cover, cylinder body, pump shell and front end cover the flow passages are cut, and the central position of thrust bearing has a ring chavity chamber, interior of the main shaft is equipped with an axial flow passage, and its surface is equipped with a radial flow passage, all the flow passage are communicated to directly water lubricate and cool all the friction pairs.

Owner:HUAZHONG UNIV OF SCI & TECH

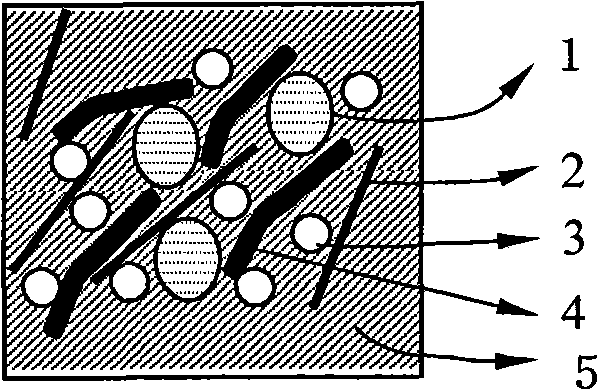

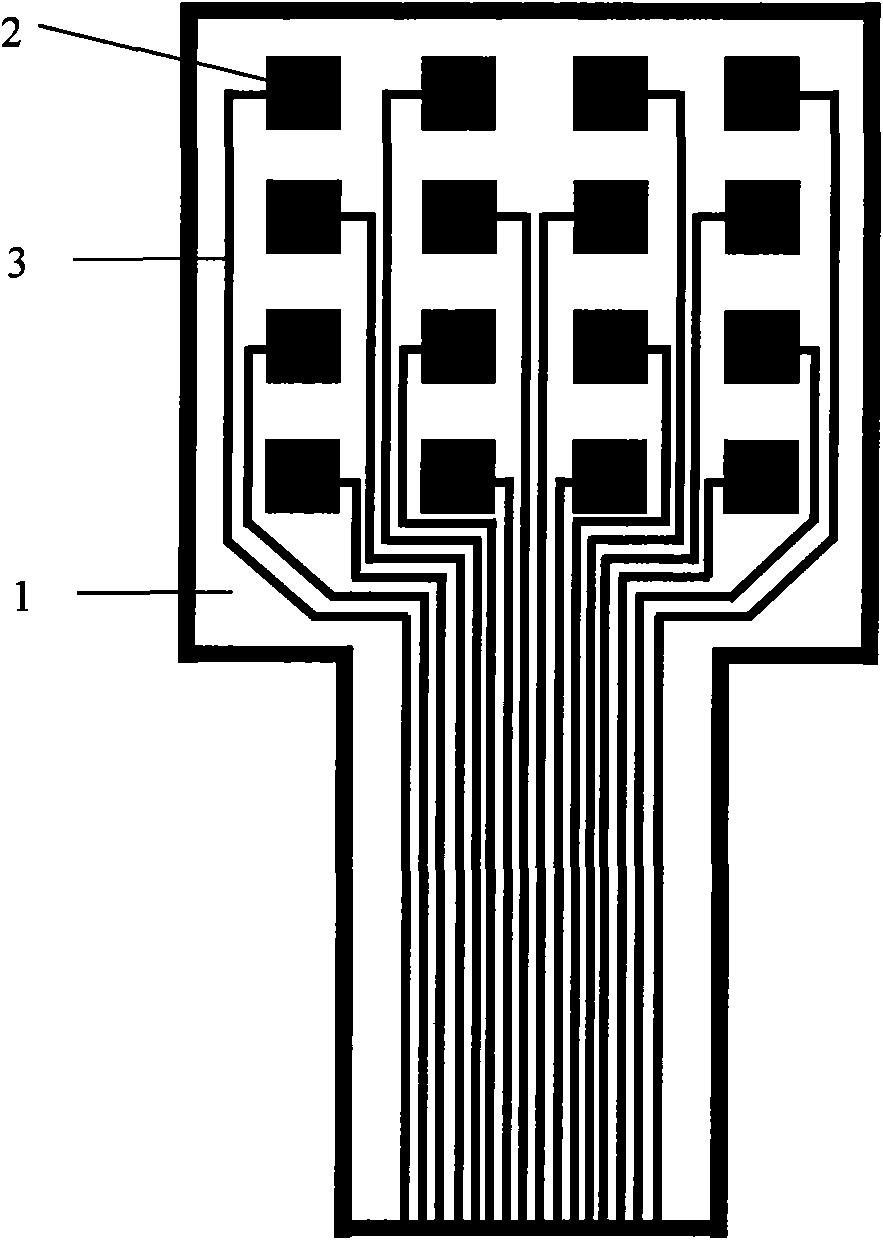

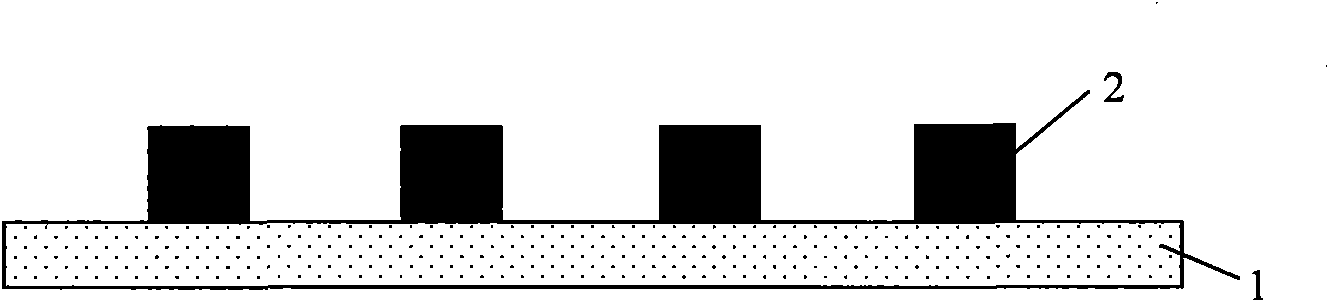

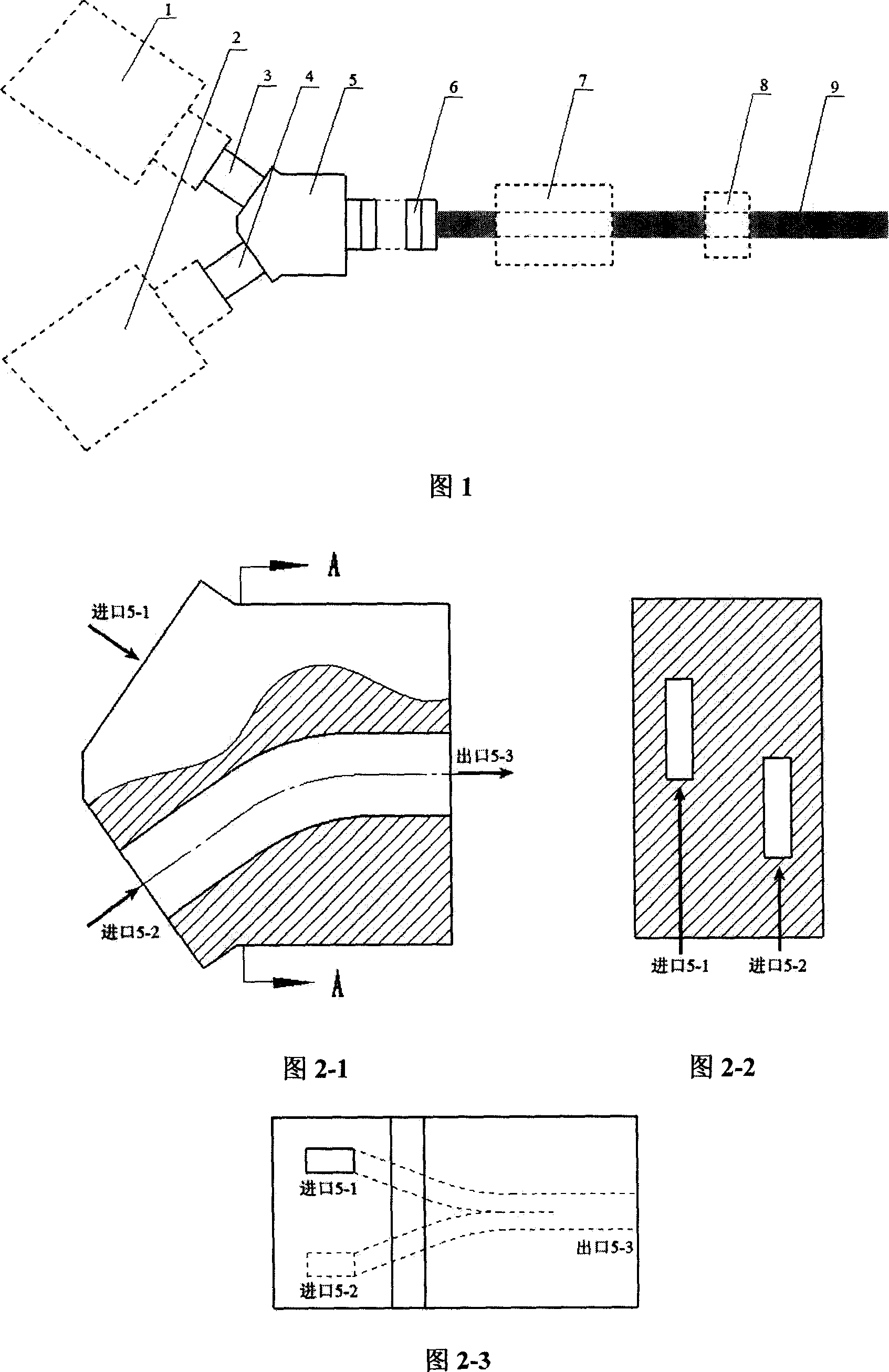

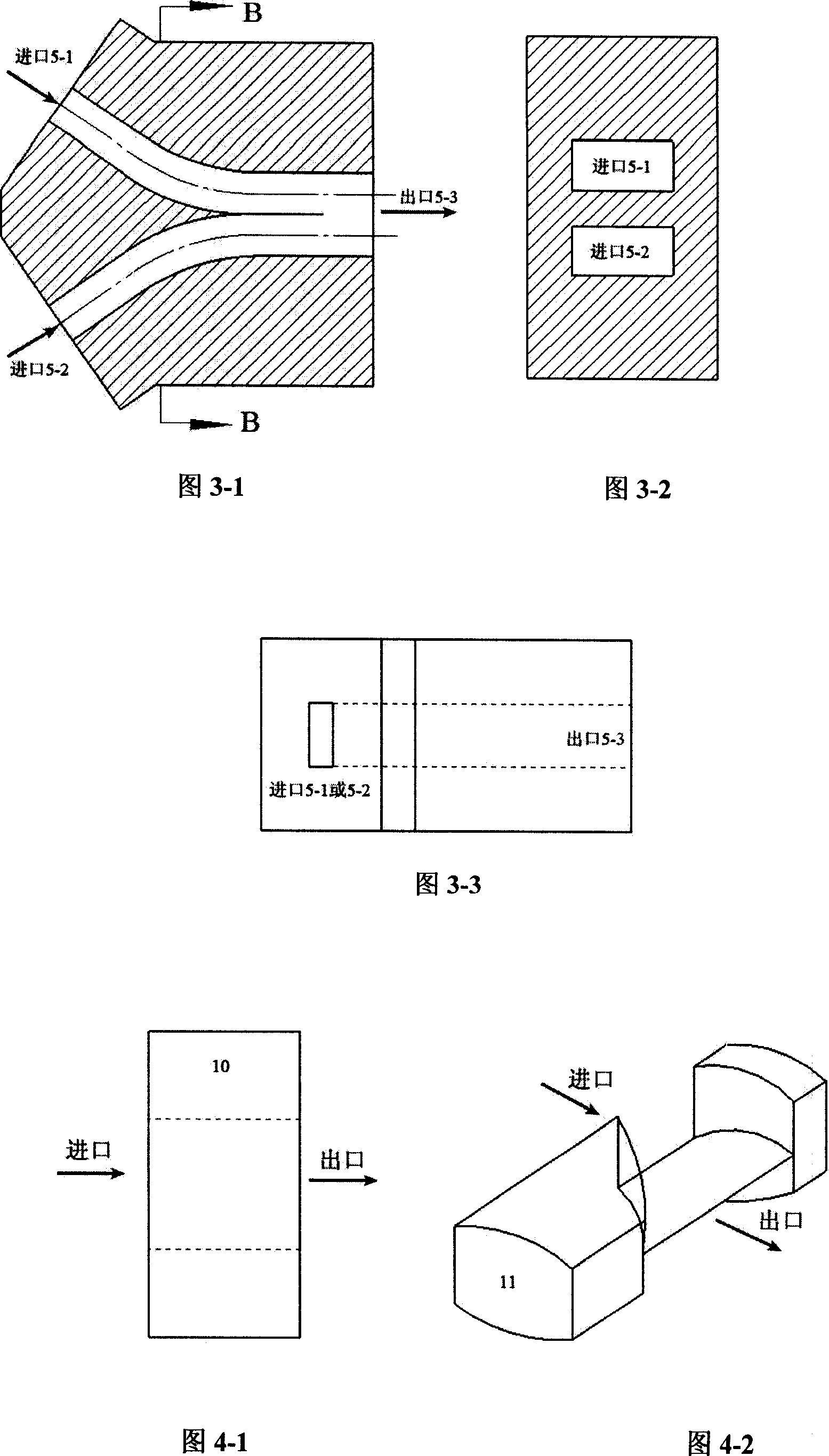

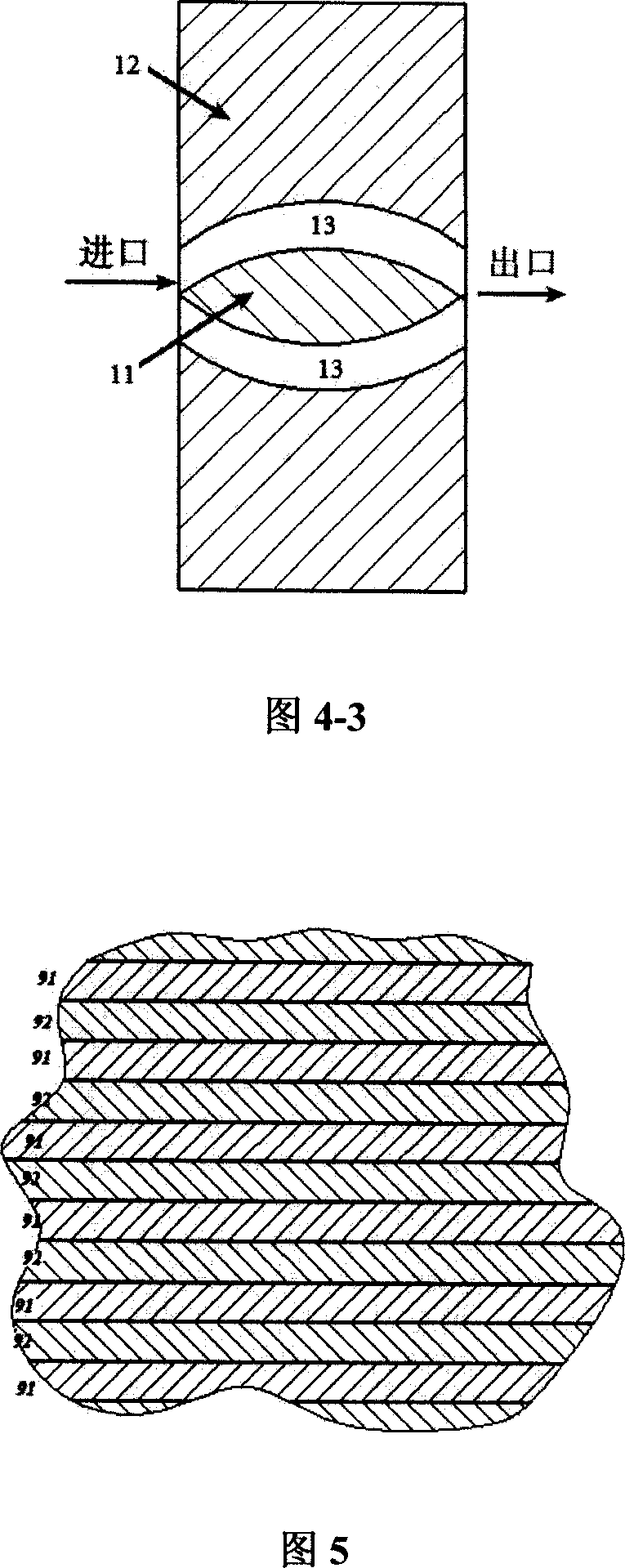

Extrusion port die for preparing alternate multiple high polymer composite material

The invention relates to a extruding mould used to prepare the macromolecule composite in multilayer structure, wherein it comprises two connectors, one collector, and one laminator; the inlets of connectors are connected to the outlet of extruder, while the inlets are connected to the inlet of extruder; the outlet of collector is connected to the inlet of laminator; the laminator has several laminating units formed by unit modules and unit frames to laminate the fusion; the outlet of last unit is connected to the inlet of next unit; the fusion is diverted, changed and laminated in each unit, to be timed in each unit, while the total layer number can reach 2(n+1) when passing n laminate layers. The invention has simple structure and controllable layer number and thickness.

Owner:SICHUAN UNIV

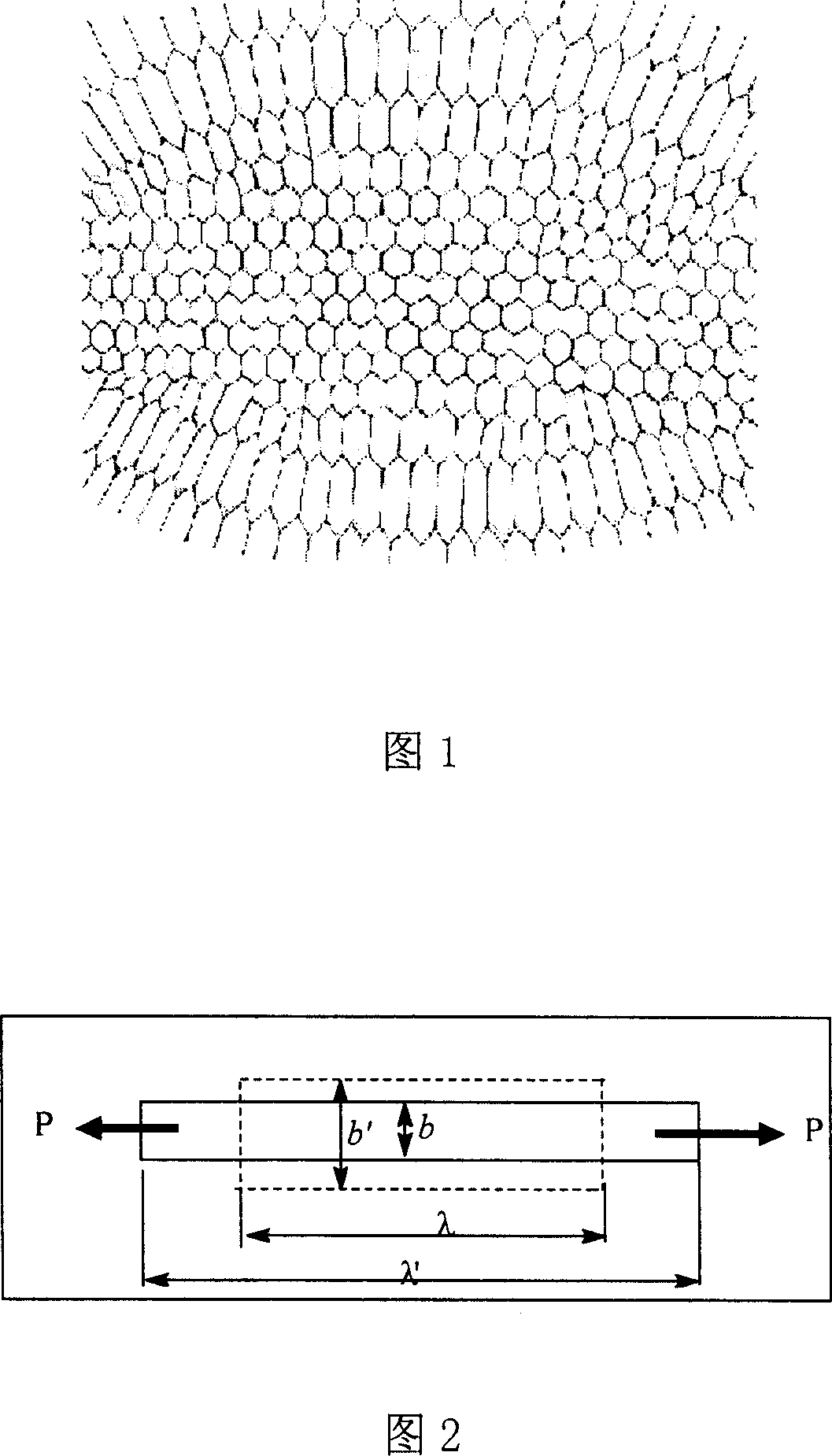

Negative poisson's ratio material and its preparing method and use

InactiveCN1986621AImprove stress resistanceImprove impact absorption performanceSynthetic resin layered productsHoneycomb likeHoneycomb structure

The present invention relates to composite polymer material, and is especially stretching material with negative Poisson's ratio and its preparation process and use. The foamed material obtained through secondary foaming process or screw extrusion foaming process has microscopic double fan-shaped composite structure with middle layer of regular honeycomb structure, outer layer of ordered gradually lengthened arrangement and micropores of 80-150 micron size. The foamed material has the mechanical performance of perpendicularly expanding while being stretched and perpendicularly contracting while being extruded. By means of special preparation process, the foamed material may have raised compression resistance, shock absorption, rebound elasticity and other mechanical performance. The unique mechanical performance makes the material possess application in composite board, waste water treatment, deep water job and other fields.

Owner:INST OF CHEM CHINESE ACAD OF SCI

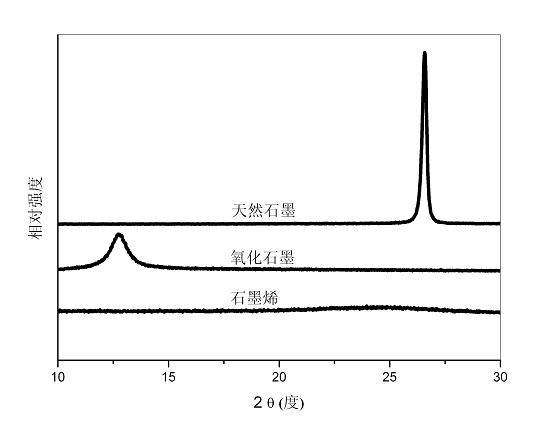

Single-layer graphene capable of dispersing stably and preparation method thereof

ActiveCN102398900AAvoid it happening againMethod environmentally friendlyOrganosolvConductive materials

The invention discloses a single-layer graphene capable of dispersing stably and a preparation method thereof, belonging to the field of nanometer graphite conductive materials. The single-layer graphene capable of dispersing stably in water or in an organic solvent is prepared through reduction of single-layer graphene oxide by phenolic aminated compounds. According to the method, the single-layer grapheme is prepared by employing a phenolic aminated green environment-friendly reducing agent, using graphite as a raw material and carrying out the three steps of oxidation, peeling and reduction. The method enables extreme toxicity of hydrazine reducing agents to be avoided, is green and environment-friendly and is applicable to mass production. The single-layer graphene prepared in the invention has the characteristics of stable dispersion in a water phase and / or an organic phase without addition of any stabilizing agents and good conductivity, and can be used in the fields of battery materials, energy storage materials, electronic devices, current-conducting and heat-conducting polymer composite materials, etc.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com