Patents

Literature

1037 results about "Green environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Basically, going green means to live life, as an individual as well as a community, in a way that is friendly to the natural environmental and is sustainable for the earth. It means contributing towards maintaining the natural ecological balance in the environment, and preserving the planet and its natural systems and resources.

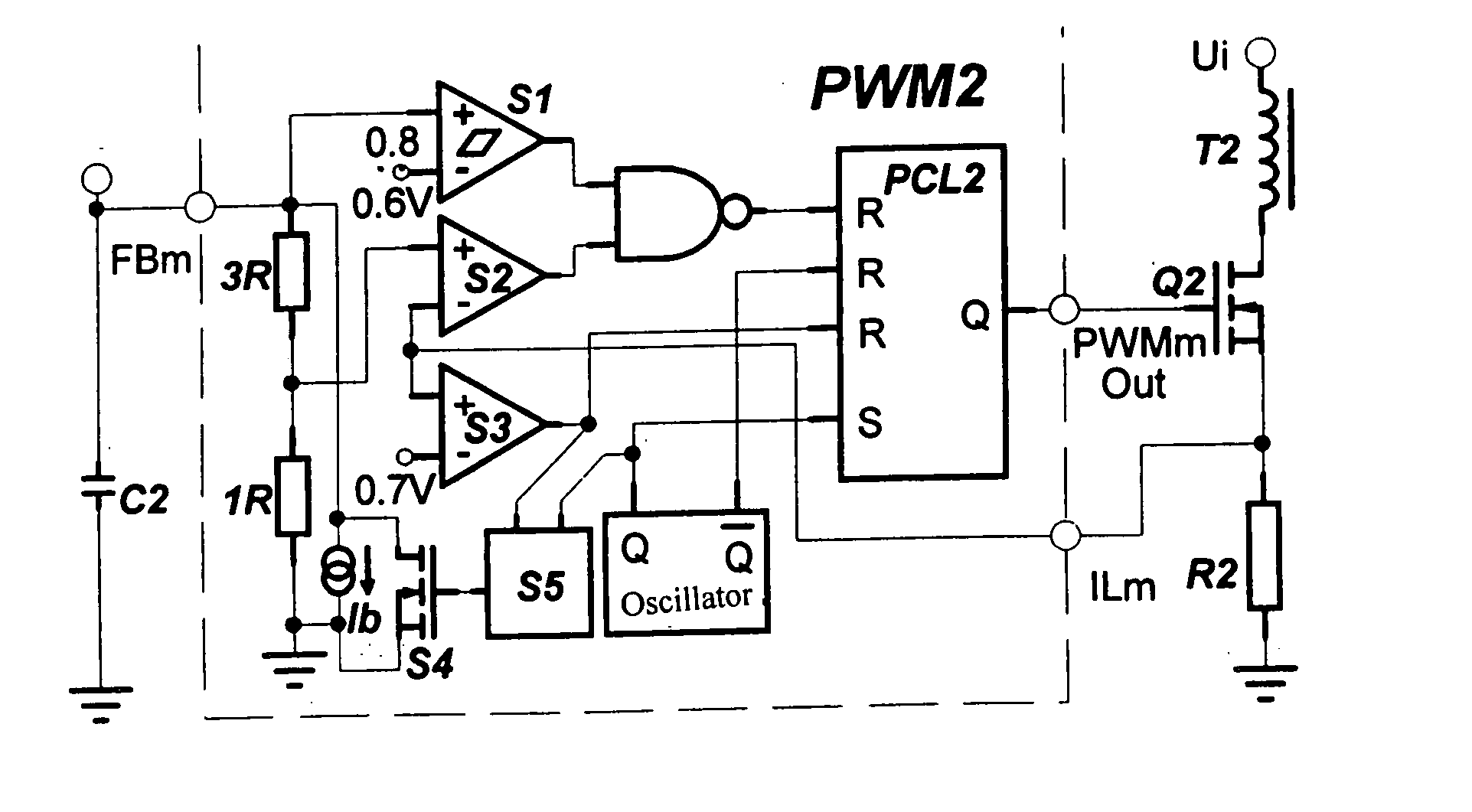

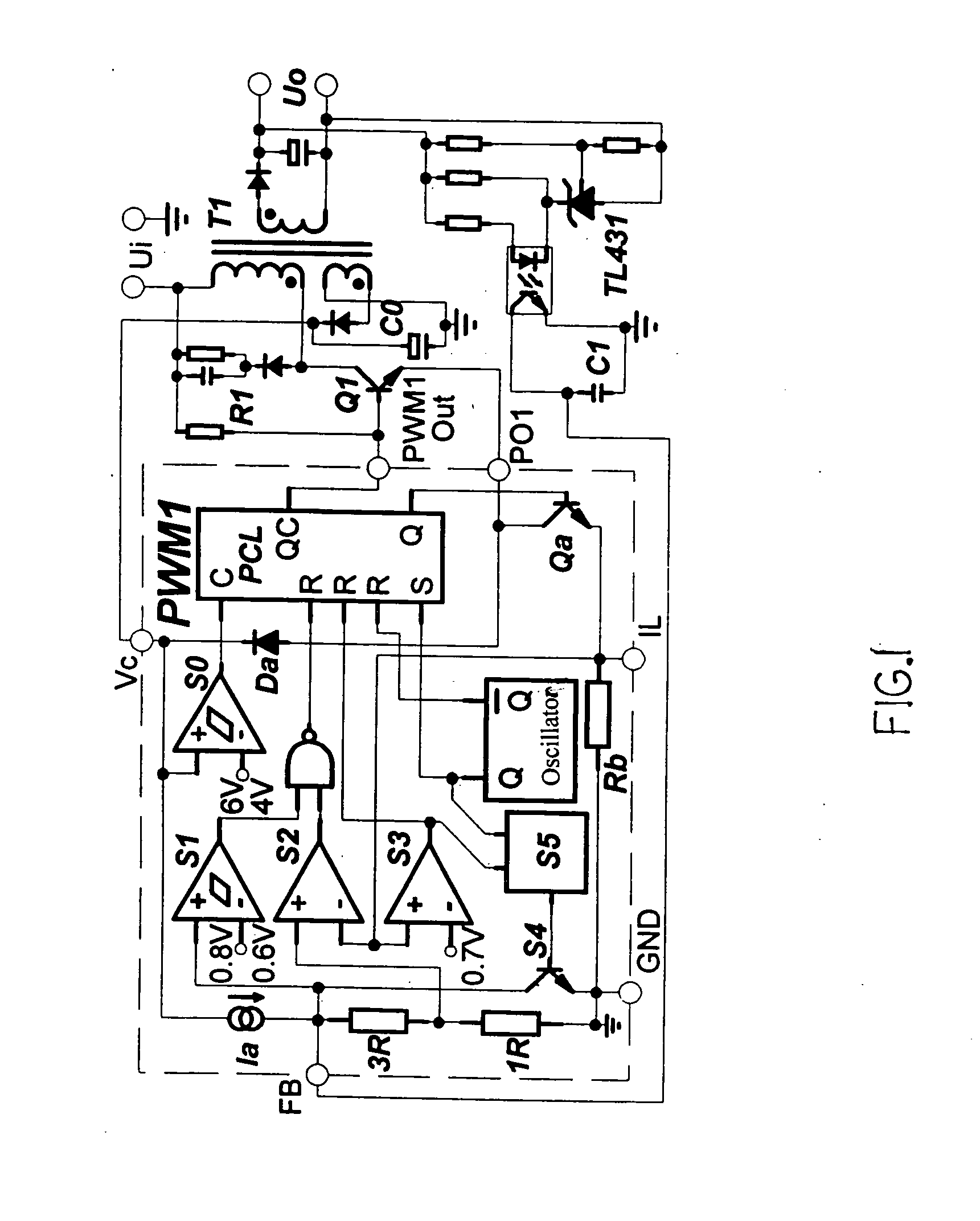

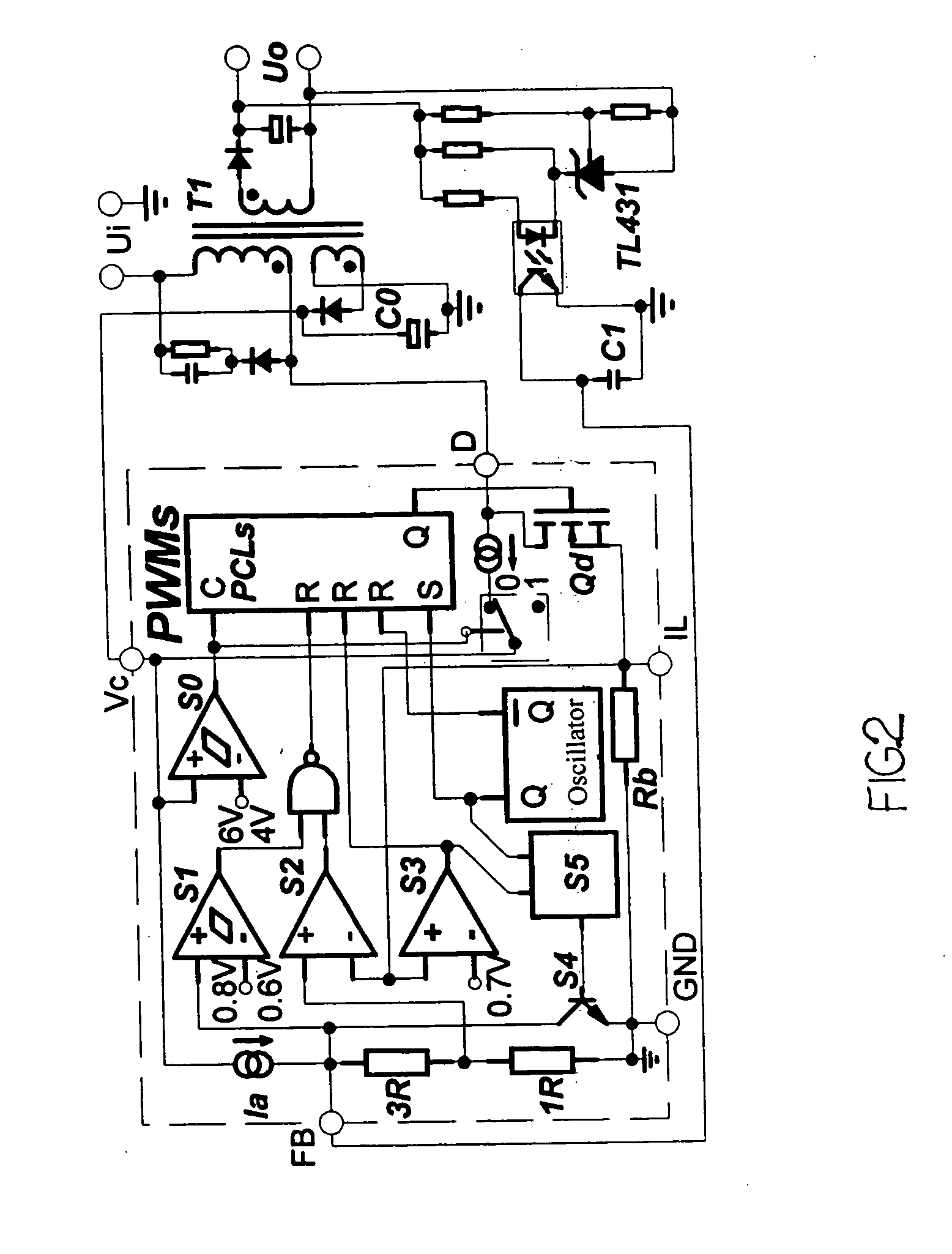

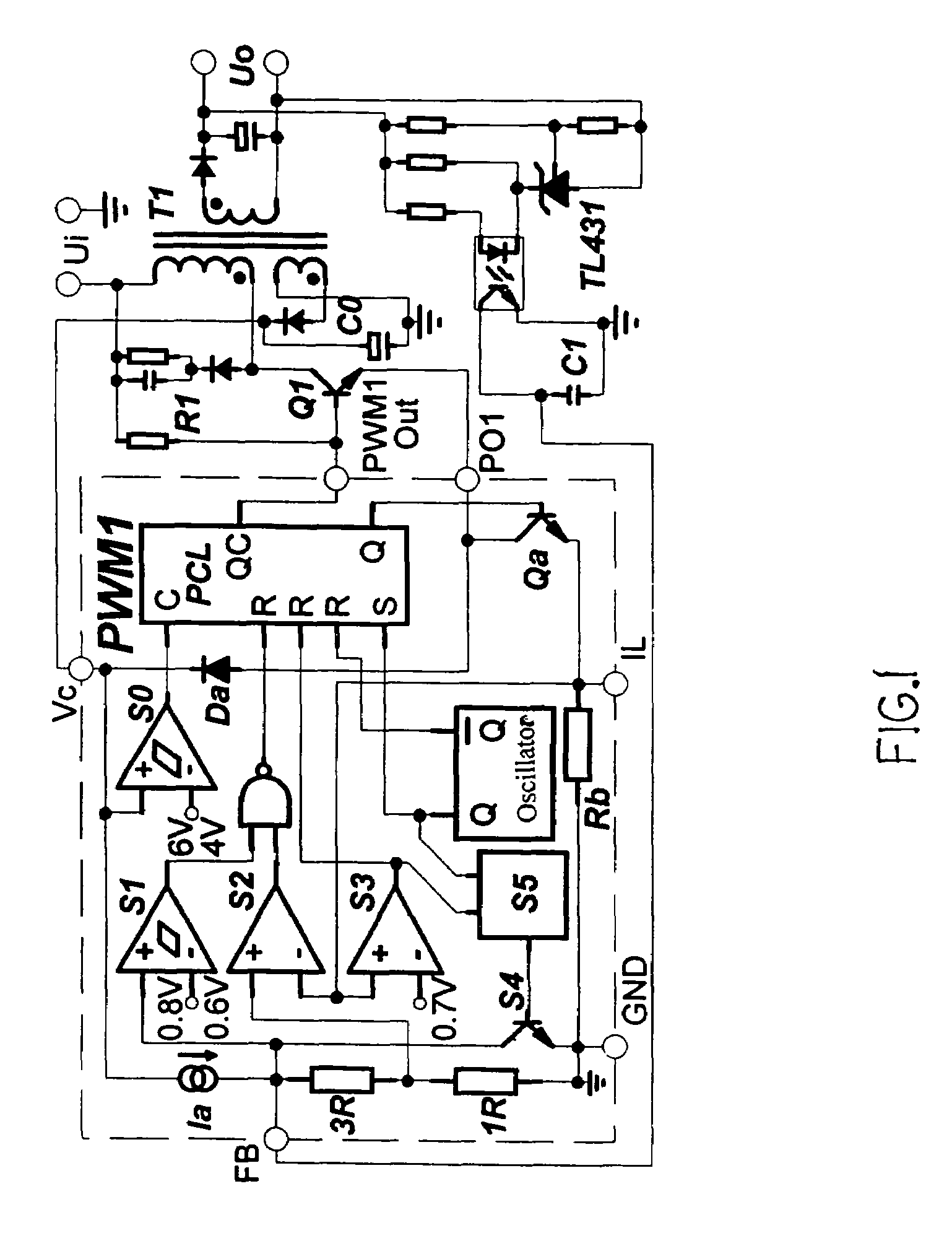

Green switch power supply with standby function and its ic

InactiveUS20050207189A1Cost effectiveEfficient power electronics conversionConversion with intermediate conversion to dcGreen environmentRemote control

A switch power supply with standby function is disclosed. The power supply can satisfy the need of the green environment protection. And a single ended green switch power supply IC or thick film or modular circuit design with standby function is disclosed, too. It comprises a standby power supply, a main power supply, a PFC device, and a supplemental circuit, wherein a remote control signal is transmitted to main control circuit in response to a main error signal to control main power supply. A method for preventing switch power current from overload and saturation is disclosed too. Finally, the present invention also provides a green power supply with standby function as well as its IC associated with digital processing highly qualified PFC, and a PC standard (such as ATX, ATX12, SSI) computer switch power supply.

Owner:CHEN WEIBIN +1

Acetic ester coated controlled-release urea fertilizer and preparation technique

InactiveCN101200400ALow priceReduce manufacturing costAgriculture gas emission reductionUrea compound fertilisersGreen environmentControl release

The invention relates to a coated urea fertilizer, substantially an acetate starch-coated controlled-release urea fertilizer which is prepared by utilizing high-substitute degree acetate starch and a preparation process. The urea is implemented on coating by the coating material which is made by utilizing high-substitute degree acetate starch and other ingredients, so that the acetate starch-coated controlled-release urea fertilizer is generated; the coated urea can be ordinary bulky grain urea or the bulky grain urea with biochemical inhibitor on the surface; the biochemical inhibitor is urease inhibitor or / and nitrification inhibitor, thereby the acetate starch-coated controlled-release urea fertilizer is made. The most notable characteristic of the acetate starch-coated controlled-release urea fertilizer is that: the coating is implemented by utilizing the coating material high-substitute degree acetate starch which can be biodegraded fully, the soil environmental will not be polluted after being fertilized on by the coated urea fertilizer, thereby the coated urea fertilizer is a real green environment-friendly coated fertilizer. And the source of coated material is board and is easy to be obtained, and the price is lower, so the production cost of the coated urea fertilizer can be reduced greatly.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

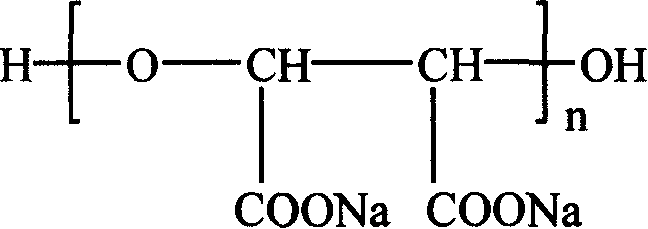

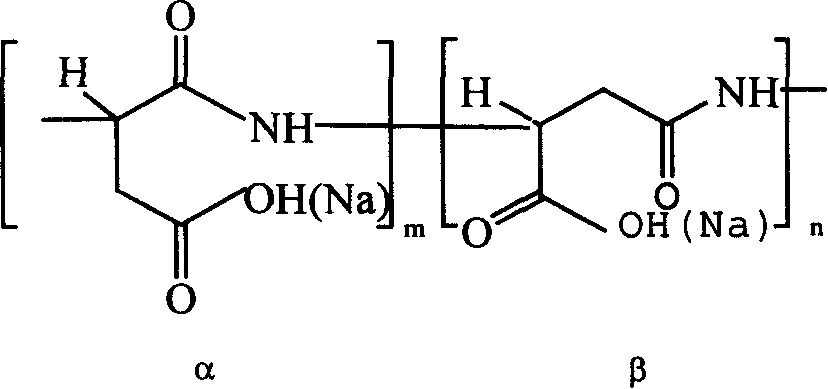

Green environment-protective composite slow-corrosion scale resistor for circulated cooling-water treatment

InactiveCN1850661AGood scale inhibition and dispersibilityObvious synergistic effect of corrosion inhibitionTreatment using complexing/solubilising chemicalsGreen environmentWater quality

The invention belongs to the environmental protection field, concretely relating to a green environmental-protection composite corrosion inhibition antifouling agent for water circulating cooling, compounded of antifouling dispersants and corrosion inhibitors: polyepoxy sodium succinate, polymerized sodium aspartate, hydrolyzed polymaleic anhydride, sodium gluconate, zinc salt, in the mass ratio of 1-6 to 1-4 to 2-6 to 1-2 to 1-2. And it has characters of no phosphorus and biodegradability, an environment-friendly water quality stabilizer, used in a water-circulating cooling system to play the role in corrosion inhibition and antifouling.

Owner:TONGJI UNIV

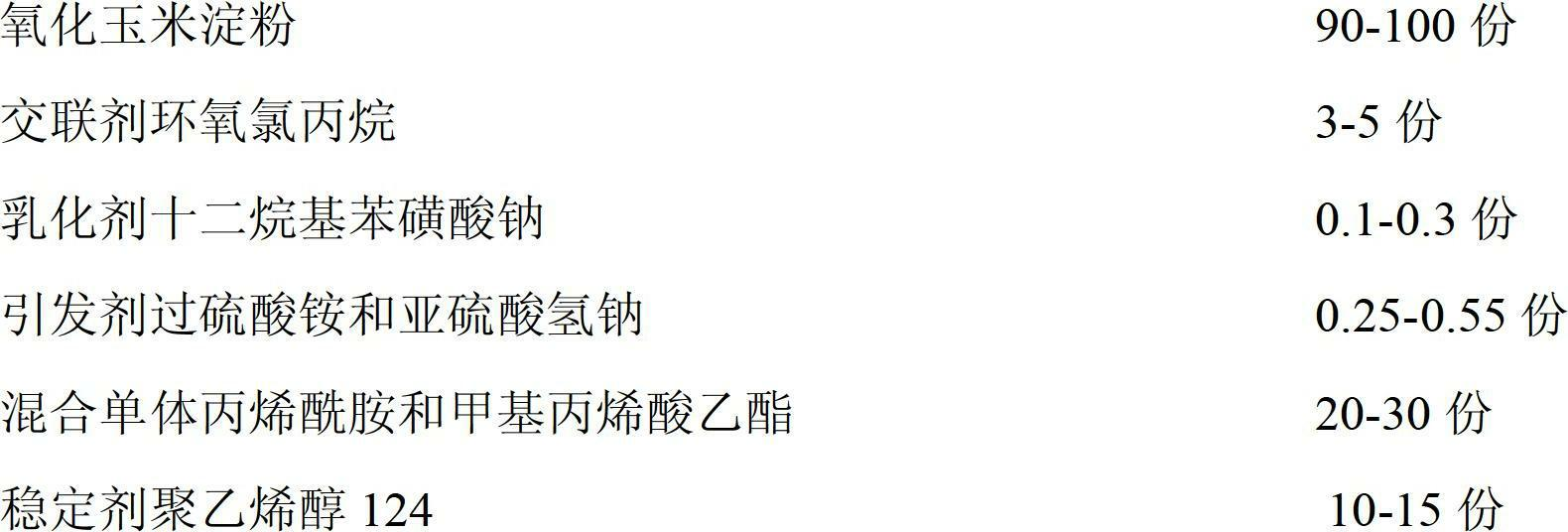

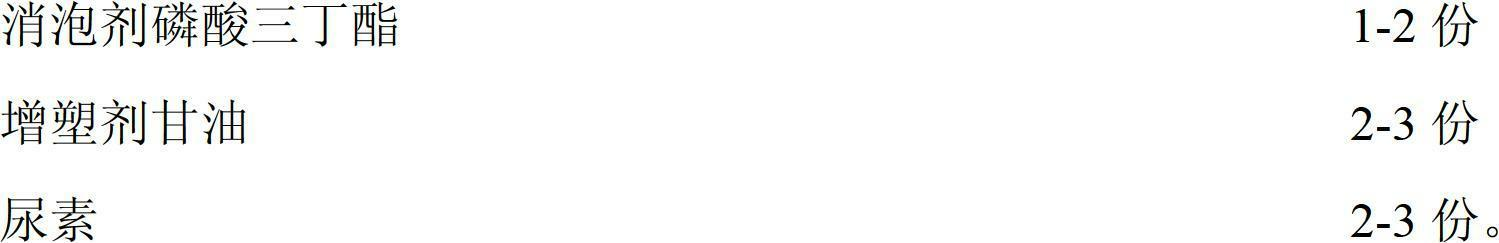

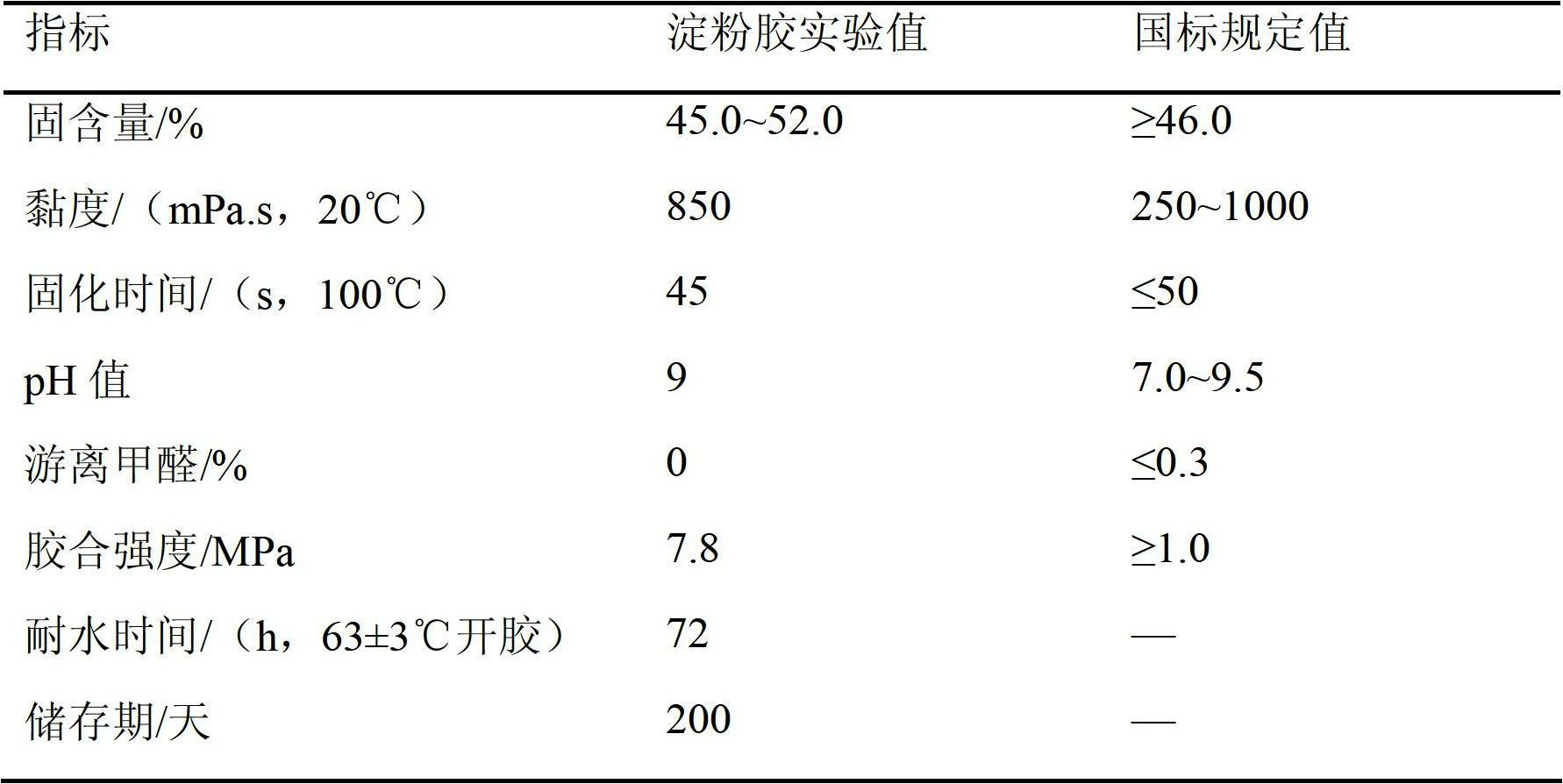

Modified-starch-based wood adhesive and preparation method thereof

InactiveCN102676098AReduce dependenceStrong water resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCelluloseCross-link

The invention discloses a modified-starch-based wood adhesive and a preparation method thereof. The preparation method comprises the steps that oxidized corn starch is used as a main raw material, a cross-linking agent is added into the oxidized corn starch to conduct crosslinking modification, and then an initiating agent and a high molecular monomer are added to the oxidized corn starch to conduct graft modification, so as to obtain a modified starch emulsion in a complex net structure; and after the modified starch emulsion is warmed up and pasted, modifying agents comprising a stabilizing agent, a defoaming agent, a plasticizing agent and the like are added into the modified starch emulsion, and the high-performance green environment-friendly adhesive is manufactured. Each performance of the adhesive disclosed by the invention can reach or exceed requirements of a GB / T9846-2004 standard, the adhesive has the characteristics of high bonding strength, good water resistance, long storage time, high solid content, low cost, greenness, environment friendliness and wide use range, and can be widely applied to the bonding and the use of wood materials such as artificial boards, plywood and cellulose boards.

Owner:HEFEI UNIV OF TECH

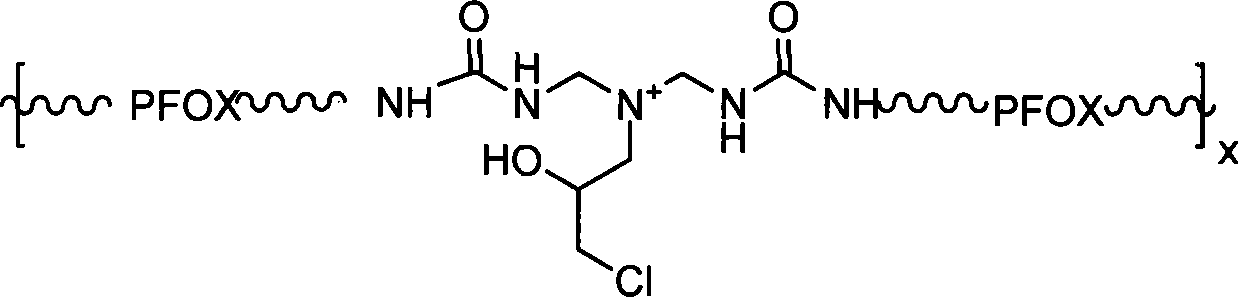

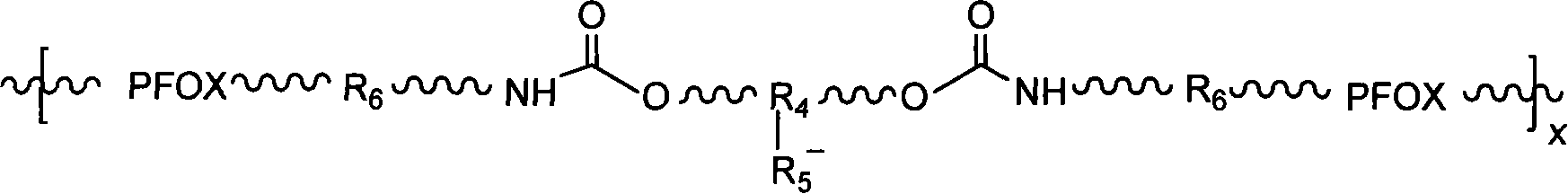

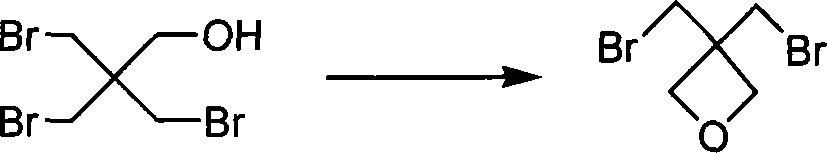

Fluorine-containing aqueous polyurethane and preparation method and application thereof

InactiveCN101041709AIncreased durabilityImprove waterproof performanceAntifouling/underwater paintsOther chemical processesGreen environmentFluorine containing

The invention discloses a making method and application of aqueous fluorine polyurethane, which contains cationic and anionic aqueous fluorine polyurethane with the making procedure comprises the following steps: (1) synthesizing bromoepoxybutane; (2) making fluoepoxybutane; (3) preparing fluorine polyether; (4) synthesizing aqueous polyurethane. The invention can be high-property green environment-protective water repellency, waterproof and stainproof paint, which possesses wide market prospect.

Owner:DONGHUA UNIV

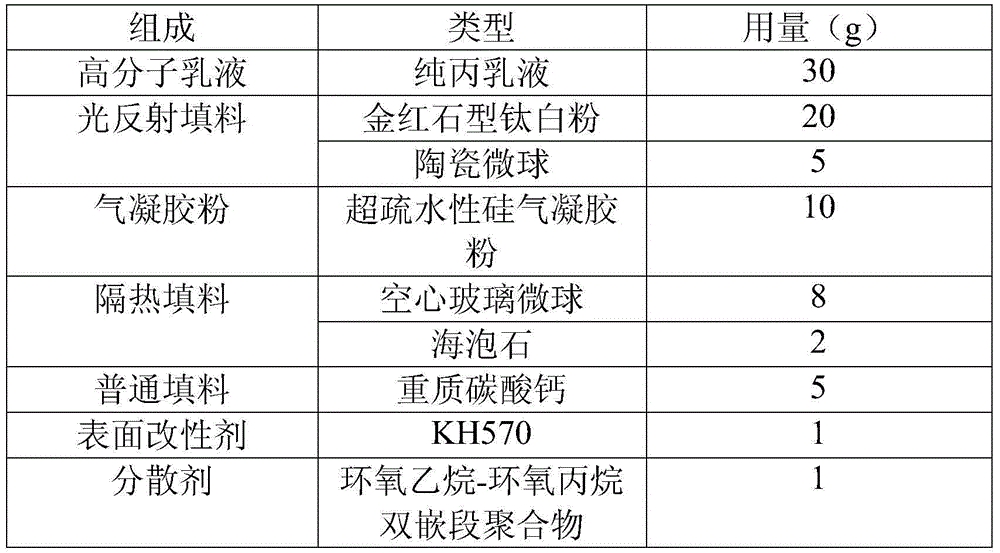

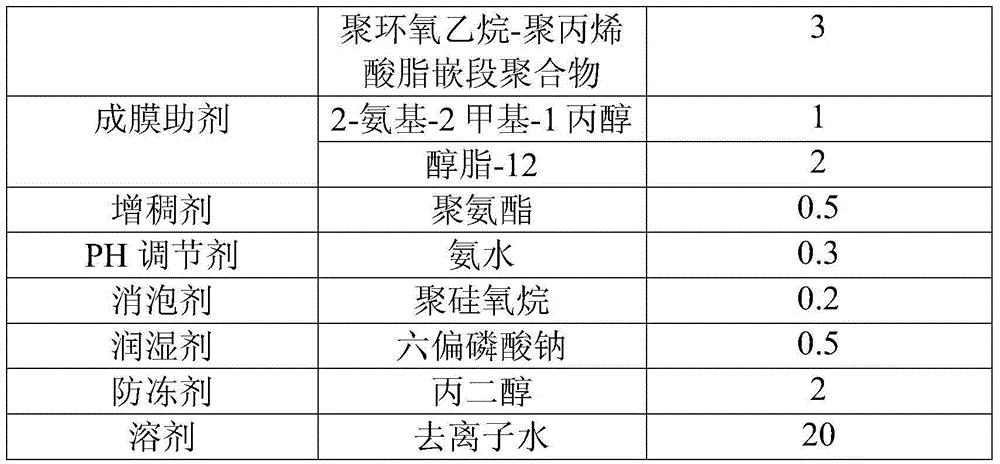

Waterborne energy-saving building coating and preparation method thereof

ActiveCN106700789AGet rid of the shortcomings of severely limited application fieldsIncreased hemispherical emissivityAntifouling/underwater paintsPaints with biocidesGreen environmentEmulsion

The invention specifically relates to a multifunctional green environment-friendly waterborne energy-saving building coating and a preparation method thereof, belonging to the technical field of energy-saving building coatings. The multifunctional high-efficiency energy-saving building coating comprises, by weight, 25 to 50% of a high polymer emulsion, 5 to 30% of a light-reflection filling material, 1 to 5% of aerogel powder, 5 to 10% of a heat-insulation filling material, 5 to 15% of a common filling material, 1 to 2% of a surface modifier, 1 to 5% of a dispersing agent, 0.1 to 4% of a film-forming aid, 0.1 to 2% of a thickening agent, 0 to 1% of an antifoaming agent, 0.01 to 0.5% of a pH regulating agent, 0.1 to 2% of a wetting agent and 0.5 to 2% of an antifreezing agent, with the balance being deionized water. The coating provided by the invention has heat-insulation and cooling effect in summer and heat preservation effect in winter, is applicable to energy-saving reconstruction of buildings in tropical zones and subtropical zones, and has the characteristics of safety, no toxicity, environment friendliness and no pollution; moreover, the coating has good weatherability, contamination resistance, flexibility and scrubbing resistance.

Owner:SHENYANG RES INST OF CHEM IND

Method for preparing carboxylic styrene butadiene latex for carpet back coating

The invention discloses a preparation method of a back lining material used as the back lining of carpets, more particularly relates to a preparation method of the carpets and carboxylic styrene butadiene latex. Butadiene and cinnamene are taken as main monomers, then functional monomers and auxiliary monomers are added, anion emulsifier and non-ionic emulsifier are used complexly, pyrolysis type persulfates of potassium peroxydisulfate water solution or ammonium persulfate water solution, etc. are used as activator, n-dodecylmercaptan is used as molecular weight regulator, a batch feeding or dropwise feeding way is adopted, and vacuum flashing desaeration is used for composing the environment protection carboxylic styrene butadiene latex used as the backing lining of carpets. The carboxylic styrene butadiene latex prepared by the method has good elasticity and enduring performance, high adhesion strength and low volatility harmful substances after being used in woven carpets and tufted carpets, thereby being a green environment protection product upon meeting the requirements of environment protection.

Owner:溧阳巨神科技材料有限公司

Planting method of five-pointed star loquats

InactiveCN105453985AImprove Intrinsic Nutritional QualityRaise the level of competitionCultivating equipmentsGreen environmentPest control

The invention provides a planting method suitable for five-pointed star loquats. The method comprises the steps of orchard construction, fertilizer and water management, deep plowing of soil, drainage and irrigation and intercropping of a young orchard, shaping and pruning, flower and fruit retention and fruit management, pest control and prevention, soil management, shaping and pruning and fruit management. The planting method is beneficial for improving the internal nutrition quality of loquats, green and environmentally friendly, the quality is good, the fruit competition grade is improved, high quality and high yield are achieved, greening environment is achieved, and a traditional industry is revitalized.

Owner:LIUYANG LONGGENG FRUIT PLANTING SPECIALIZED COOP

Method for preparing coating with metal surface corrosion inhibition and self-repair functions

InactiveCN101613543AShape is not limitedUnlimited sizeAnti-corrosive paintsTectorial membraneLayer by layer self assembly

The invention belongs to the field of anticorrosion materials, and relates to a green and environment-friendly method for protecting metal from corroding, which can particularly control metal corrosion for long time effectively, and play a role in self-repairing the metal surface to a certain extent. The method is characterized in that an inhibitor molecule and polyelectrolyte are alternately deposited on the surface of a silicon dioxide nano-particle through green environment-friendly type metal inhibitor micromolecules and polyelectrolyte by adopting layer-by-layer self-assembly technology and utilizing the penetrating controllability of a polyelectrolyte self-assembly membrane so as to prepare a functional nano-particle with the inhibitor and the polyelectrolyte self-assembly composite membrane which are coated on the surface; and the prepared functional nano-particle is mixed with sol-gel to prepare the functional sol-gel membrane coated on the metal surface to be protected. The coating has the function of metal surface self-repairing, and ensures that the inhibitor molecules released by the functional membrane are adsorbed on the metal surface to reform a protecting membrane in a coating damaged microsection to play a certain role in self repairing. The method is applicable to corrosion protection of various metals.

Owner:UNIV OF SCI & TECH BEIJING

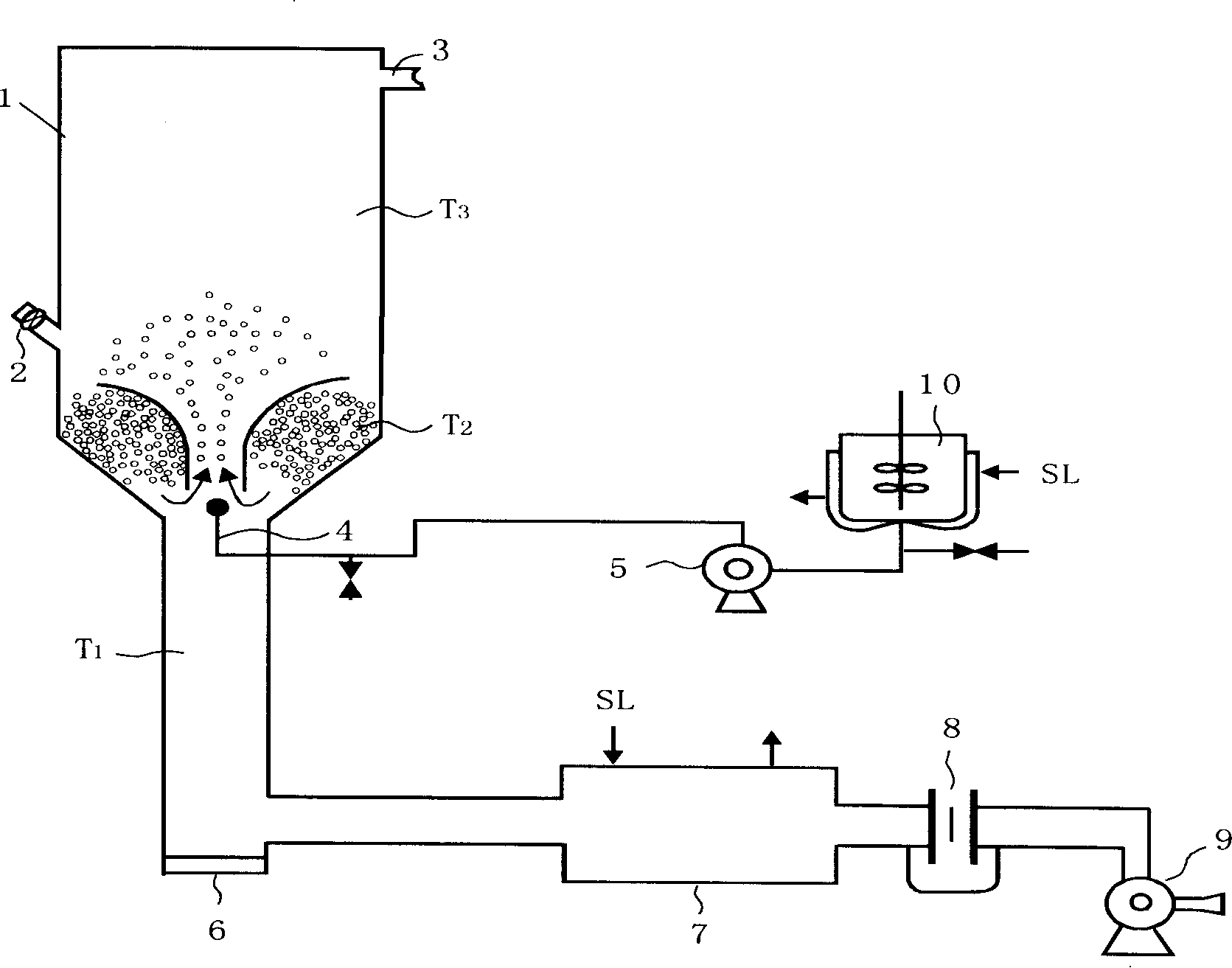

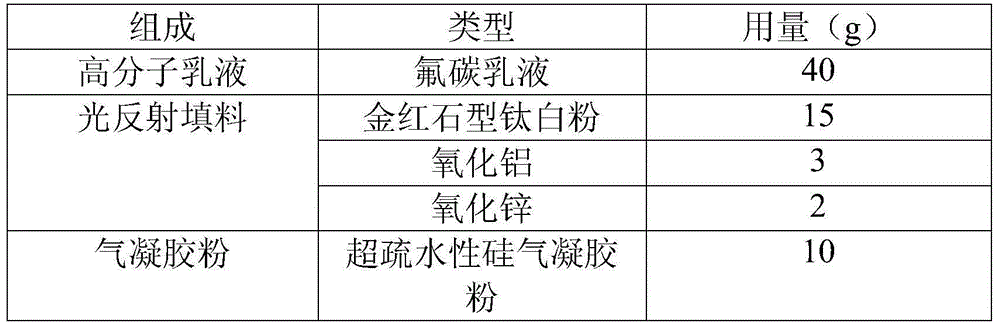

Farm crop straw anaerobic fermentation treatment method

ActiveCN101225003AHarmlessRealize resource processingBio-organic fraction processingWaste based fuelFecesSlurry

The invention relates to a method which adopts anaerobic fermentation technique to make resourceful disposal of the organic compounds such as crop straws and animal droppings. The collected crop straws are cut into small sections no more than 5 cm in length and then sent to a pretreatment system together with the animal droppings to make sizing agent by watering and mixing. The sizing agent is heated to 37positive and negative 2 degrees C, the pH value is adjusted to 6.5 to 7.5 and the solid-containing content of the sizing agent is adjusted to 9.6 to 10.4 percent by water. Then the sizing agent is sent to an anaerobic fermentation tank and then the fermented liquid goes through treatment of solid-liquid separation. The organic fertilizer can be obtained after manuring the solid materials obtained. The liquid separated from the fermented liquid, namely biogas slurry can be used in irrigation of the agriculture and gardening. The marsh gas produced can be used as energy sources after desulfurization treatment. The treatment process has the advantages of no poison, no peculiar smell and no pollution, and achieves the innocent treatment and resourceful disposal of the crop straws and can avoid the bacteria and virus from propagating. The treatment method of resourceful disposal of the organic compounds also has the advantages of good economy and good ecological cycle, so is a green environment-friendly treatment method of organic garbage.

Owner:甘肃驰奈生物能源系统有限公司

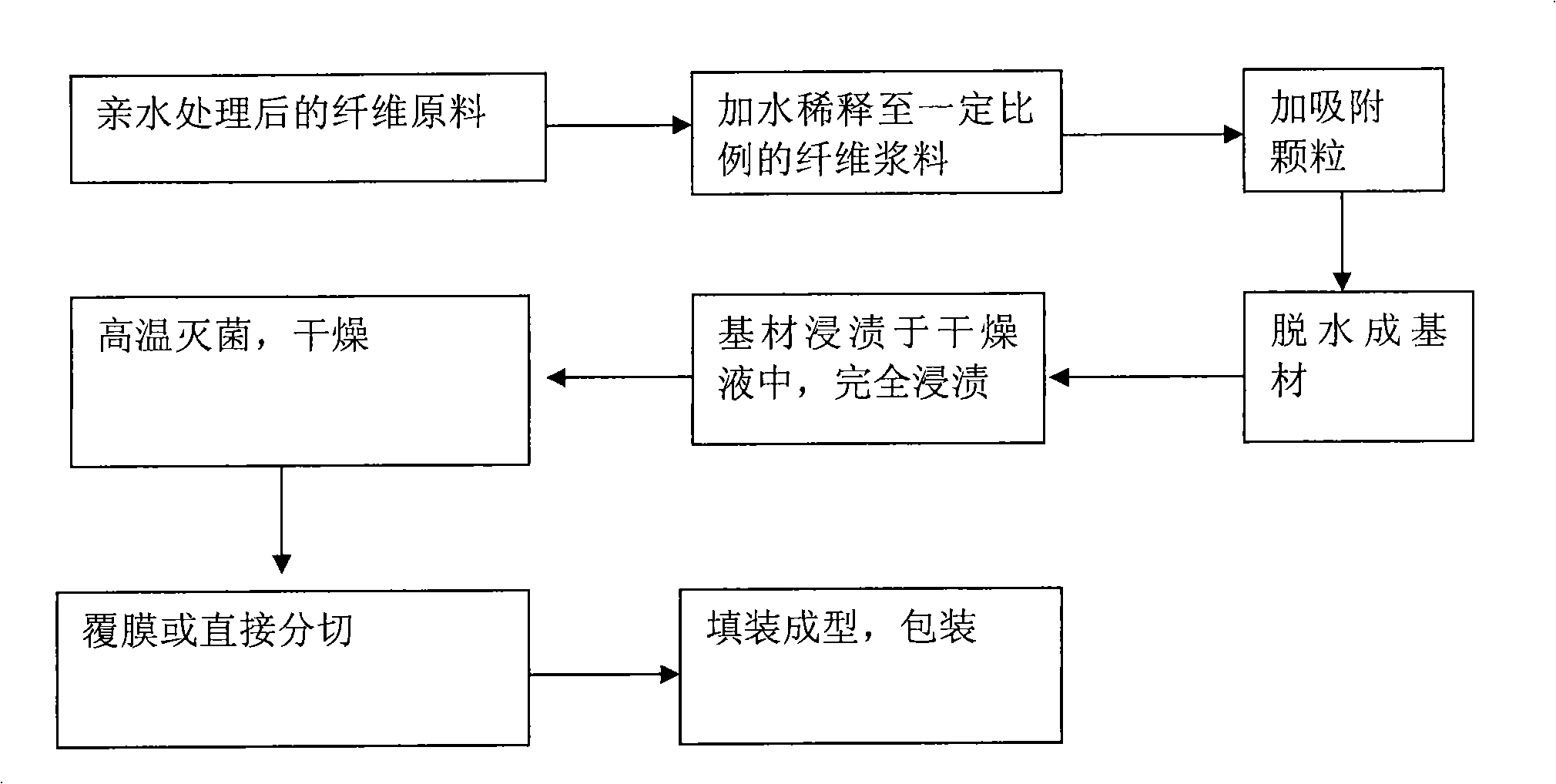

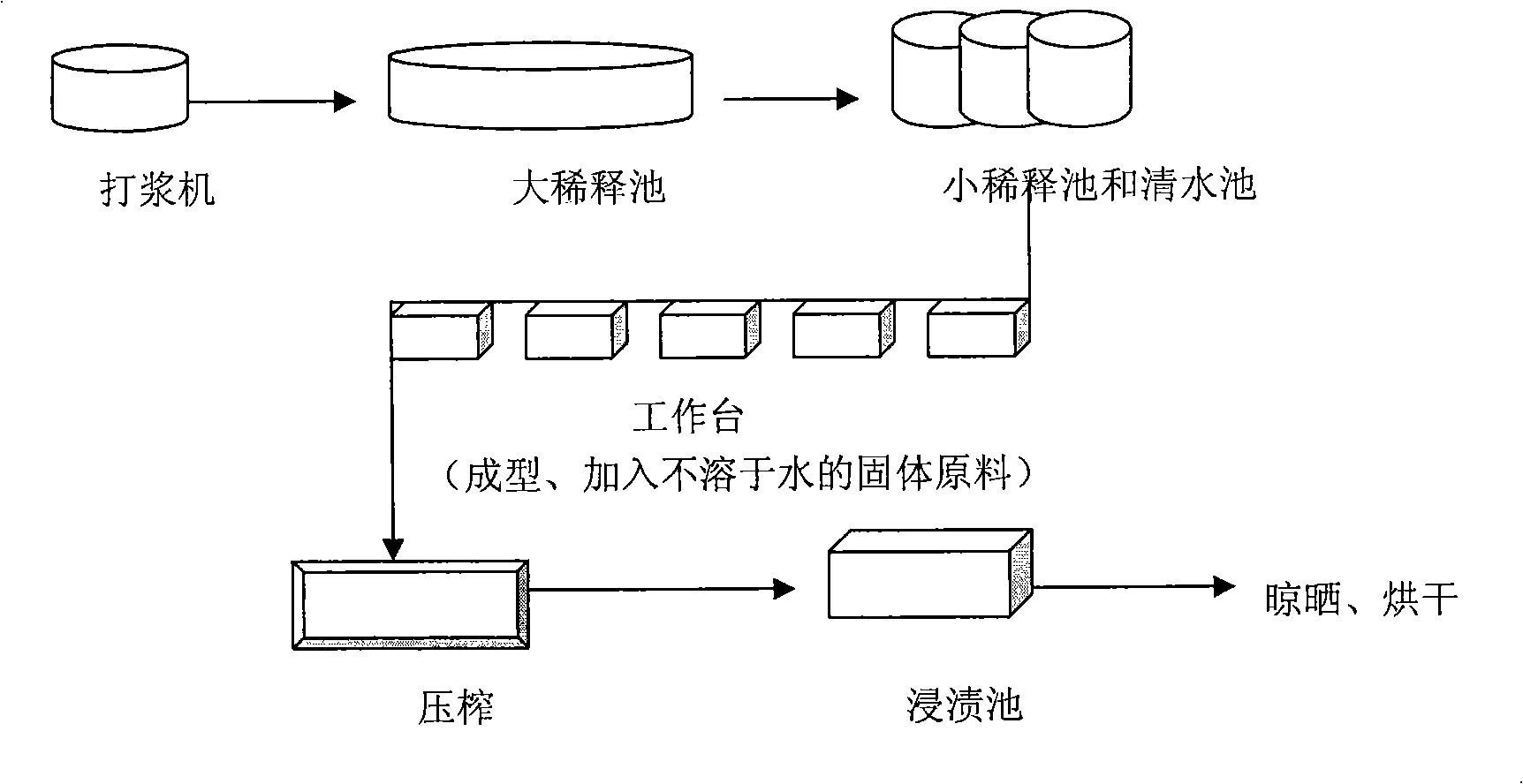

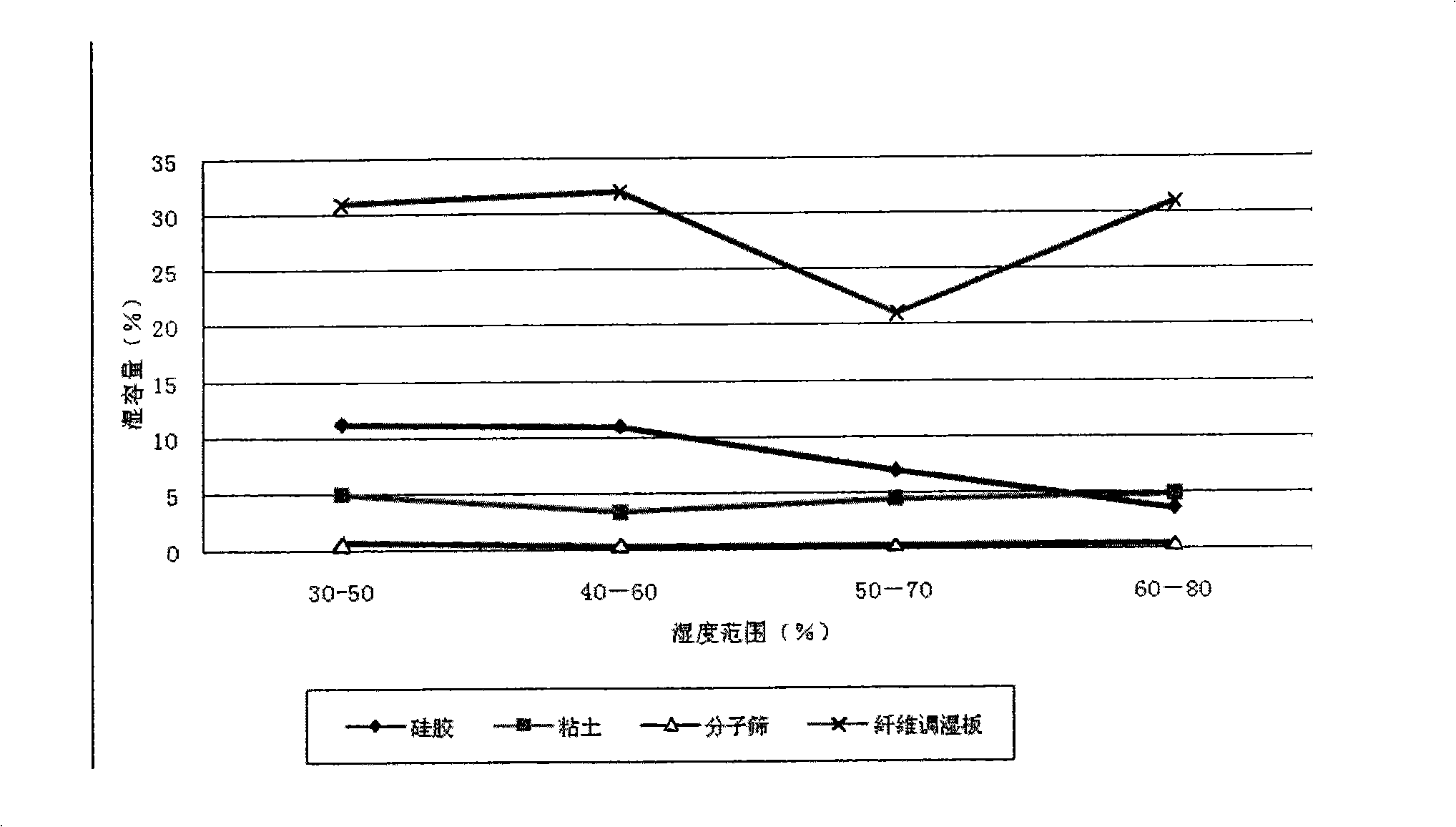

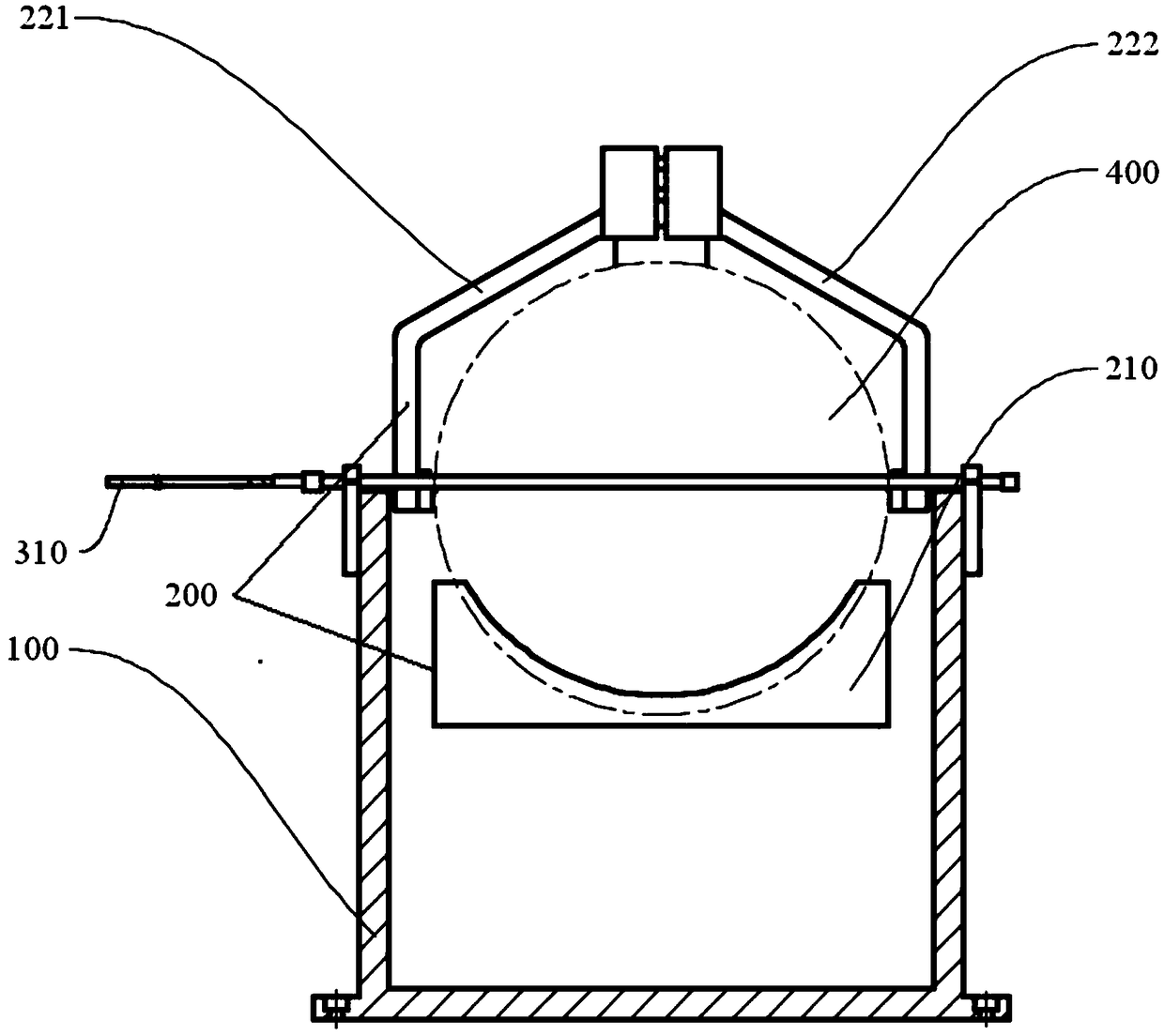

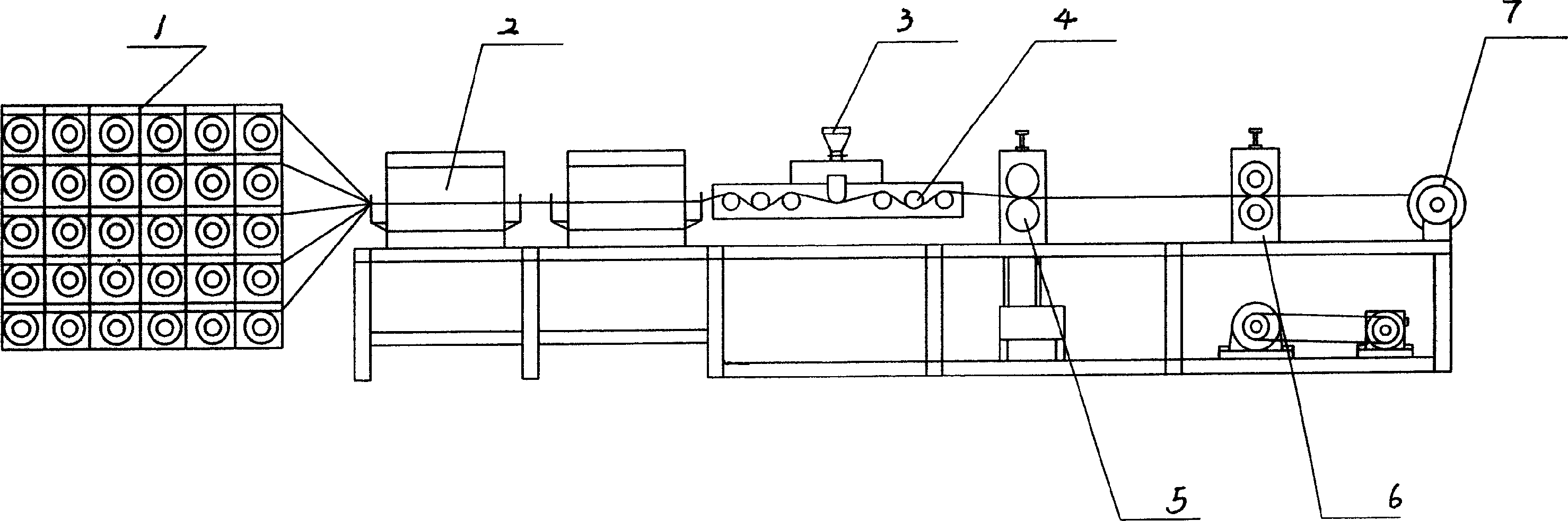

Method for preparing fibre humidity-controlling board and apparatus

The invention provides a method for making a fiber humidity-adjusting board and equipment thereof. The fiber humidity-adjusting board comprise fiber materials, inorganic material or inorganic and organic materials mixing humidity-adjusting agent and adsorption particles, among which fiber materials are taken as the base material component; the method comprise the following steps that: hydrophilic fiber materials are made into water dispersion; the water dispersion is drained on a web plate, and solid adsorption particles are dispersed in the water dispersion, and the water dispersion is dewatered and turned into fiberboard base materials; the fiberboard base materials are soaked in drying fluids; after drying, forming plates or splinter-shaped products are obtained. The humidity-adjusting board has the advantages that because the fiber humidity-adjusting board is splinter-shaped, the fiber humidity-adjusting board can be cut into different shapes; the fiber humidity-adjusting board has the function of adjusting the humidity and reaches and exceeds international seminal humidity-adjusting products in wet volume capacity; nontoxic, harmless and recyclable materials are used; due to the adoption of closed cycle process, no waste gas, waste water and waste slag are generated and discharged, so that the fiber humidity-adjusting board is new-generation green environment friendly product; due to the adoption of the environmental protection process, no waste gas, waste water and waste slag are discharged, and all added solids are not drained, so that the controllability is good.

Owner:SHANGHAI HENGYUAN MACROMOLECULAR MATERIALS CO LTD

Special pigment finishing offset paper and producing method thereof

InactiveCN1584205AReduce particle contentIncrease bulkNon-fibrous pulp additionCoatings with pigmentsGreen environmentXerography

This invention discovers a special pigment groom hectograph paper and its preparation. It utilizes the advantages of high yields machine pulp (PRC-APMP) and deink pulp (DIP) which is well thickness and green environment. That is optimizing pigment spreading formulation, optimizing pulp to materials ratio and its wet end chemical and copy making technique to reach the white value of all bleaching chemical pulp proportioning copy paper. The advantages of the products are: better printing adaptability, better relaxation thickness, better printing effect features compared with all chemical pulp hectograph paper. It's capable of producing top grade office and printing culture special pigment groom hectograph paper which is made according to different clients' requirement and selecting different optimized features' technique for different application such as laser printing, xerography and hectograph etc. So, it's capable of decreasing all chemical pulp quantity, saving wood, protecting forest, protecting environment from pollution.

Owner:YUEYANG FOREST & PAPER CO LTD

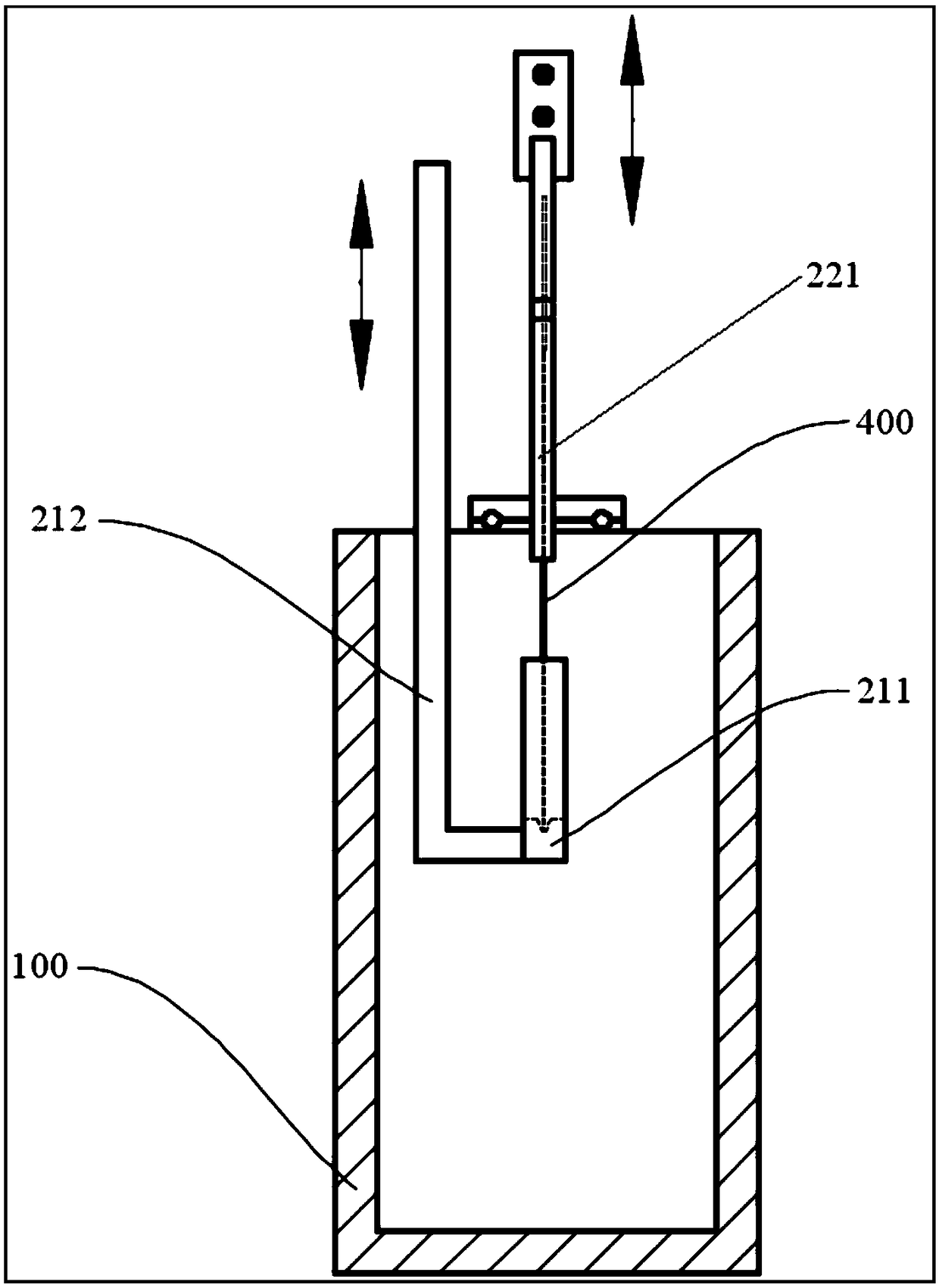

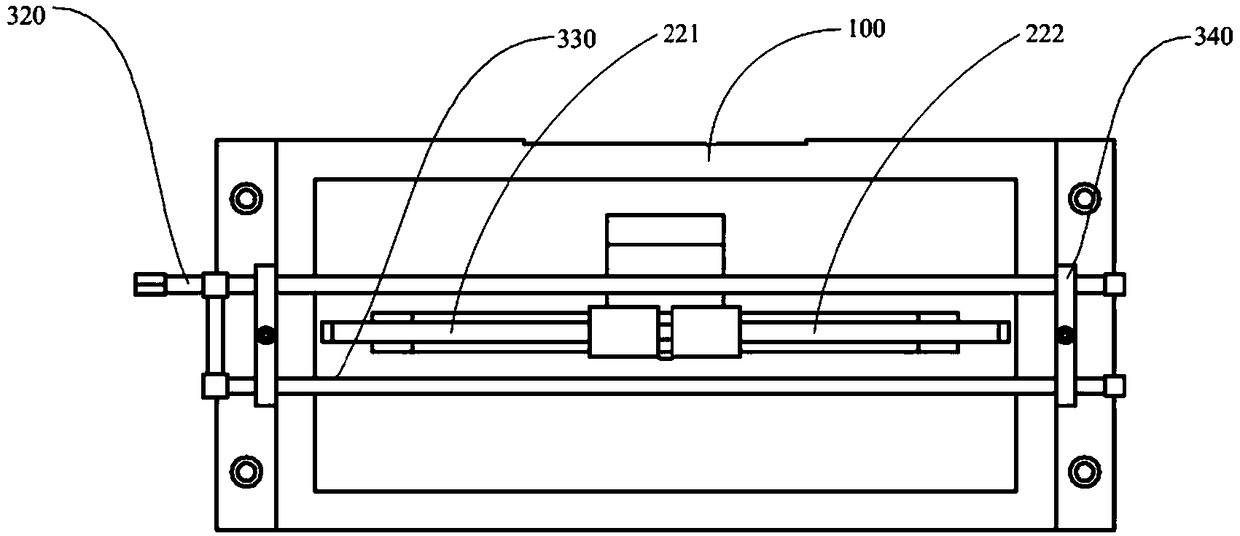

Wafer drying device and method based on Marangoni effect

InactiveCN108831849AKeep dryImprove securitySemiconductor/solid-state device manufacturingGreen environmentWafer

The invention discloses a wafer drying device and method based on a Marangoni effect, wherein the wafer drying device comprises: a water tank for containing deionized water; a wafer lifting device forlifting a wafer from the deionized water; a nitrogen gas source; a nitrogen gas spraying system for spraying a hot nitrogen gas onto the meniscus area of the wafer and deionized water when the waferis lifted in order to induce a temperature gradient in the meniscus area to generate a Marangoni flow downward from the meniscus area, so as to peel off a water absorbing film and achieve ultra-cleandrying of the wafer; and a controller for controlling the wafer lifting device, the nitrogen gas source and the nitrogen gas spraying system. The device and method perform Marangoni drying by using the green environment-friendly hot nitrogen gas instead of a combustible explosive and toxic organic steam, avoids the use of a protection device, simplifies a supply system and improves safety. The wafer lifting device is fixed at two positions and lifts the wafer step by step in order to prevent inability to dry a clamp-wafer contact area and to achieve complete wafer drying.

Owner:TSINGHUA UNIV +1

Prebiotics deodorant finishing liquor for wet tissues

InactiveCN102370598AGood moisturizing effectNo side effectsCosmetic preparationsToilet preparationsGreen environmentPreservative

The invention provides a prebiotics deodorant finishing liquor for wet tissues. The finishing liquor comprises the following components in total 100 parts by mass: 0.5-3 parts of surfactant, 0.01-3 parts of oligosaccharide, 0.001-1 part of preservative, 0.01-0.5 part of auxiliary, 0.01-1 part of stabilizer, 0.01-3 parts of functional additive and the balance of RO water. The invention also provides a preparation method of the finishing liquor and application in one-off hygienic products, in particular wet tissues. The prebiotics deodorant finishing liquor for the wet tissues, provided by the invention, has the following advantages that: by using the surfactant in the wet tissue finishing liquor, the dirt in the pores is dissolved and easily emulsified by water so that the skin is cleaned in deep layer and moisturizing effect is obtained; under the effect of the oligosaccharide, the wet tissue finishing liquor has special effects of natural antibacterial effect and probiotic nutrition; and the functional additive is added to the wet tissue finishing liquor so that better moisture retention, tenderness, no irritation and green environment protection are obtained.

Owner:TIANJIN SINOSH NEW MATERIAL TECH

Multifunctional green environment-friendly interior wall emulsion paint

InactiveCN102391733AAnti-agingSkinnyEmulsion paintsMulticolor effect coatingsPolyvinyl alcoholElectromagnetic radiation

The invention relates to multifunctional green environment-friendly interior wall emulsion paint comprising a styrene-acrylate copolymerized microemulsion, pure water, hydroxyethyl cellulose, an antifoaming agent, propylene glycol, titanium dioxide, heavy calcium carbonate powder, kaolin, saponite, a film-forming auxiliary agent, a plant scent agent, nano-grade titanium dioxide powder, nano-grade silica powder, zinc oxide powder, negative ion powder, ferromanganese powder, pyrethrin, polyvinyl alcohol, an elastic acrylic emulsion, and the like. The multifunctional green environment-friendly interior wall emulsion paint is characterized by aging resistance, peeling resistance, discoloration resistance, good weathering resistance, no toxicity, no odor, good leveling property, and easy construction. The paint can be prepared into a plurality of colors. With the paint, a decorated wall surface can be provided with elegant and splendid effects, and beautiful and dignified appearances as natural marbles. The production cost of the paint is low. With the paint, a produced paint film has a strong antifouling function, and has mould proofing and algae inhibiting functions. Also, the paint has good functions of sterilizing, disinfecting, and electromagnetic radiation resisting.

Owner:袁文君

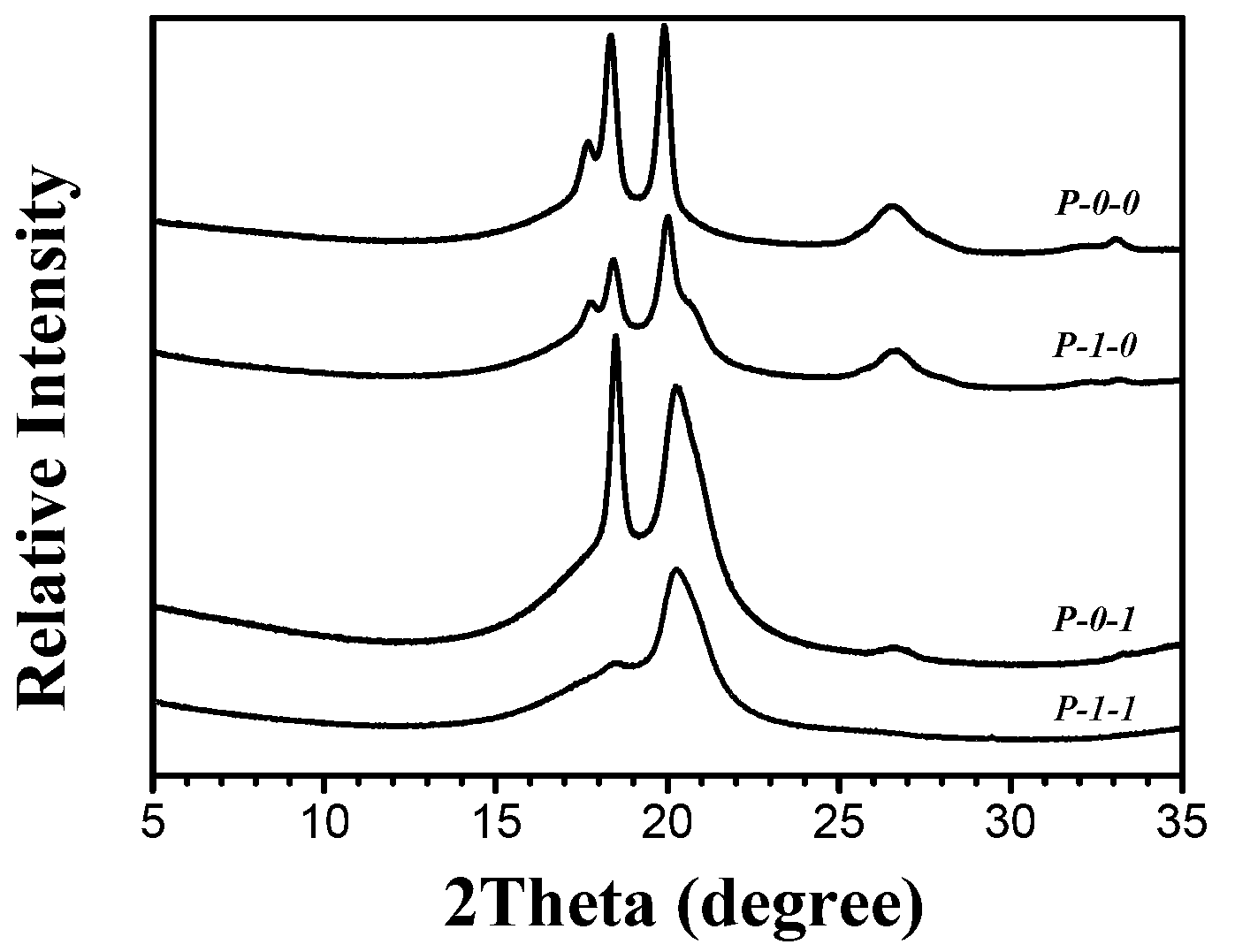

Polyvinylidene fluoride composite material and preparation method thereof

InactiveCN102977524AHigh β crystal contentFast crystallizationThermoelectric materialsGreen environment

The present invention discloses a high beta crystal form content polyvinylidene fluoride composite material and a preparation method thereof. The composite material comprises ionic liquid modified carbon nanotubes and an organic material polyvinylidene fluoride, wherein a mass ratio of the polyvinylidene fluoride substrate to the modified carbon nanotubes is 100:0-12, and a mass ratio of the ionic liquid to the carbon nanotubes is 0-10:1. The preparation method comprises: carrying out coating modification on carbon nanotubes by using an ionic liquid, carrying out melt blending on the modified carbon nanotubes and polyvinylidene fluoride, and carrying out direct melt molding cooling to obtain the finished product. According to the present invention, polar crystal form content of PVDF in the prepared composite material can be 100%, the preparation process has characteristics of simpleness, energy source saving, and green environment protection, and the polyvinylidene fluoride composite material is expected to be provided for preparing various devices in fields such as piezoelectric materials, thermoelectric materials, dielectric materials and the like.

Owner:HANGZHOU NORMAL UNIVERSITY

Green environment friendly flame-proof PA6/PP alloy and method for producing the same

InactiveCN101508840AImprove flame retardant performanceImprove physical and mechanical propertiesGreen environmentAlloy

The invention discloses an environment-friendly flame retardant PA6 / PP alloy and a preparation method thereof. The alloy comprises the components proportioning by weight: 65-76% of PA6, 10-15% of PP, 6-10% of flame retardant, 0.1-0.5% of Anti-dripping agent, 6-10% of toughener, 1-2% of compatilizer, 0.4-0.6% of antioxidizer and 0.3-0.5% of other accessory ingredients. The materials of the invention has excellent combination property, improves the hydroscopicity and processability of the PA6, and enhances the mechanical property, heat resisting property, surface color property and the like of the PP. By being added with the environment-friendly flame retardant, the alloy can reach the requirements of ROSH and WEEE instruction of European Union, thus laying good foundation for the products which are exported into European Union.

Owner:SHENZHEN KEJU NEW MATERIAL

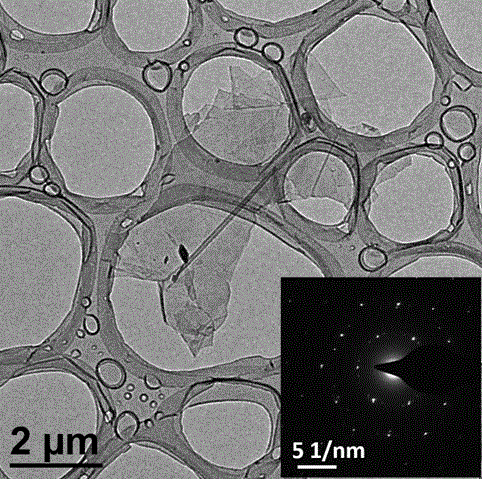

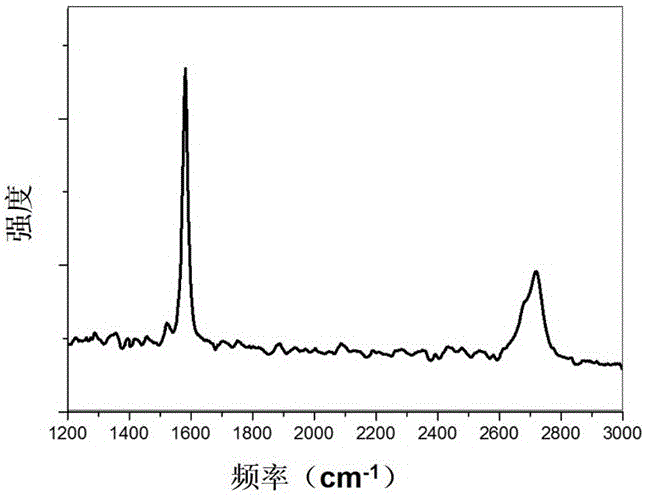

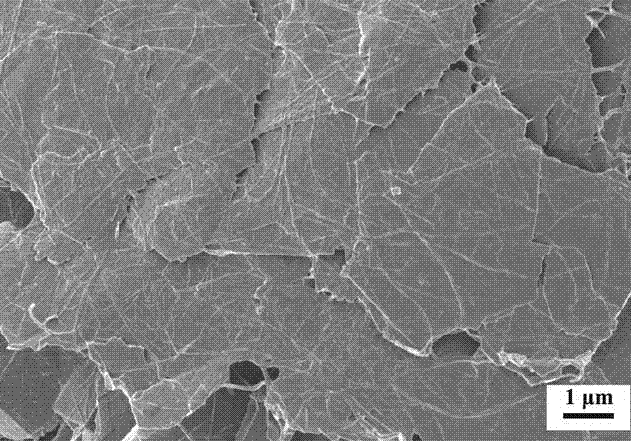

Method for green environmental-protection preparation of high-concentration ultra-clean graphene dispersion liquid

The invention relates to a method for green environmental-protection preparation of a high-concentration ultra-clean graphene dispersion liquid; graphite or a graphite intercalated compound is mainly used as a raw material and is expanded by a certain way to weaken the interaction force between graphite layers, then in an ionic liquid, stripping is achieved under a certain mechanical force by using interaction between pi-anions and pi-cations, and the high-concentration high-electric-conductivity graphene dispersion liquid is obtained. The preparation process is simple and is easy to control, and does not involve any harsh conditions such as high temperature and high pressure, has low energy consumption, and has no need for use of strong oxidizing agents, so as to avoid destruction of acute oxidization on the structure and properties of graphene. In addition, the method has the advantages of green environment protection, does not introduce any impurities, enables the used ionic liquid to be recycled and used, and is quite suitable for large-scale industrialized production.

Owner:FUDAN UNIV

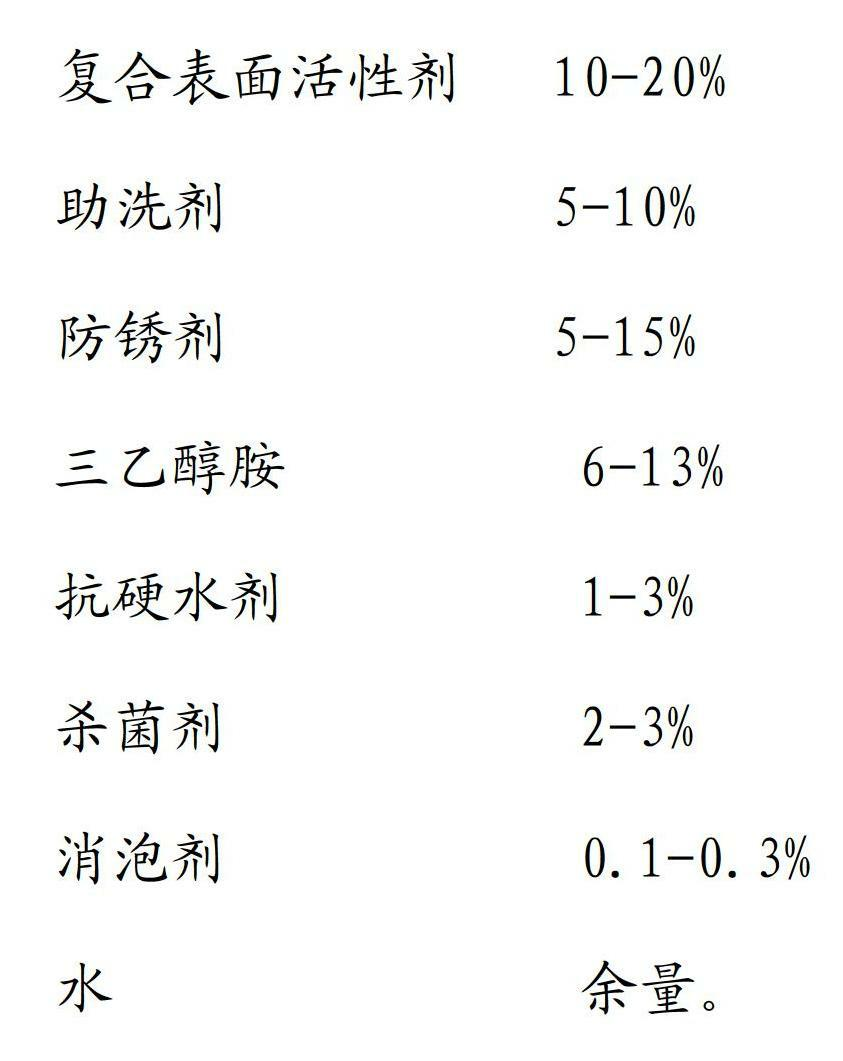

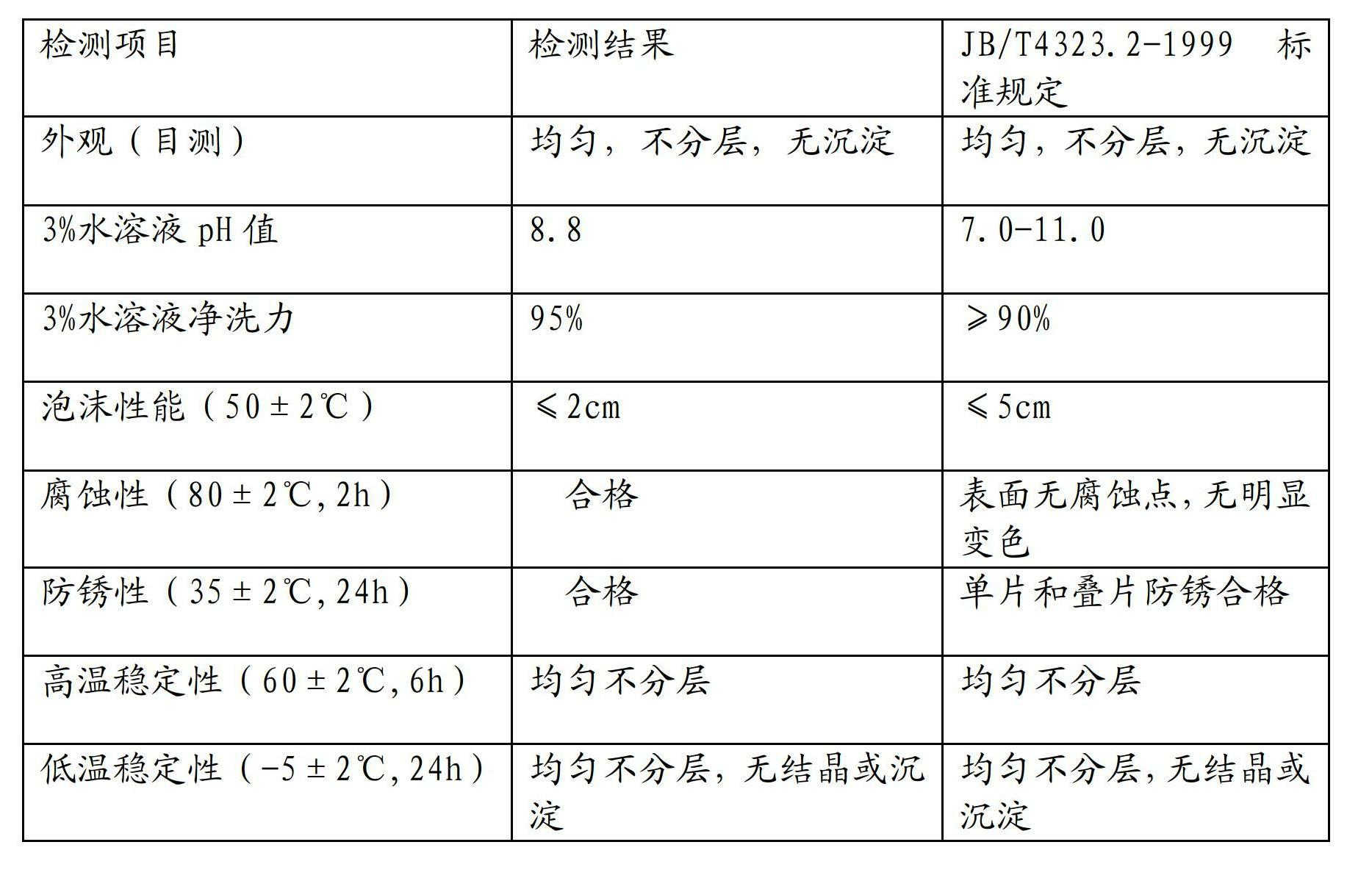

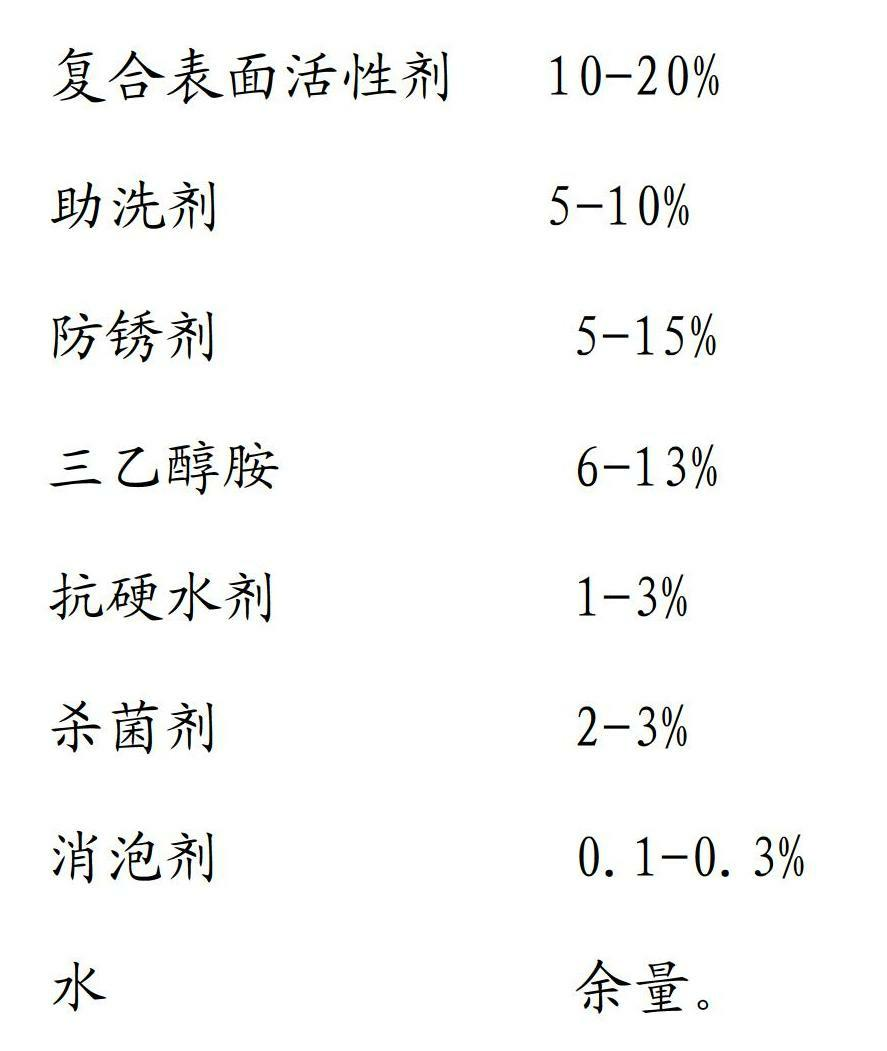

Environment-friendly efficient bubble-free cleaning agent

InactiveCN102660752AEasy to rinseGood anti-rust and anti-corrosion performanceCleansing AgentsHigh pressure

The invention discloses an environment-friendly efficient bubble-free cleaning agent which is prepared from the following components in percentage by weight: 10-20% of a composite surfactant, 5-10% of an auxiliary detergent, 5-15% of an antirust agent, 6-13% of triethanolamine, 1-3% of a hard water resisting agent, 2-3% of a sterilizing agent, 0.1-0.3% of a de-foaming agent and the balance of water. The environment-friendly efficient bubble-free cleaning agent has high cleaning speed and is easy to rinse, can efficiently clean oil stains on the surface of a work piece and improves the machining quality; the environment-friendly efficient bubble-free cleaning agent has fewer bubbles and strong seepage force, and a bubble-free property provides guarantee to the use of a high-pressure spraying field; the environment-friendly efficient bubble-free cleaning agent has excellent anti-rusting and anti-corrosion properties, is suitable for a long-period machining process, effectively avoids corroding and rusting of the work pieces, saves the next section of an anti-rusting and anti-corrosion work procedure, saves the production cost, simplifies the machining process and improves the production efficiency; and the green environment-friendly performance and the low odor of the cleaning agent guarantee the physical health of staff.

Owner:上海福岛新材料科技有限公司

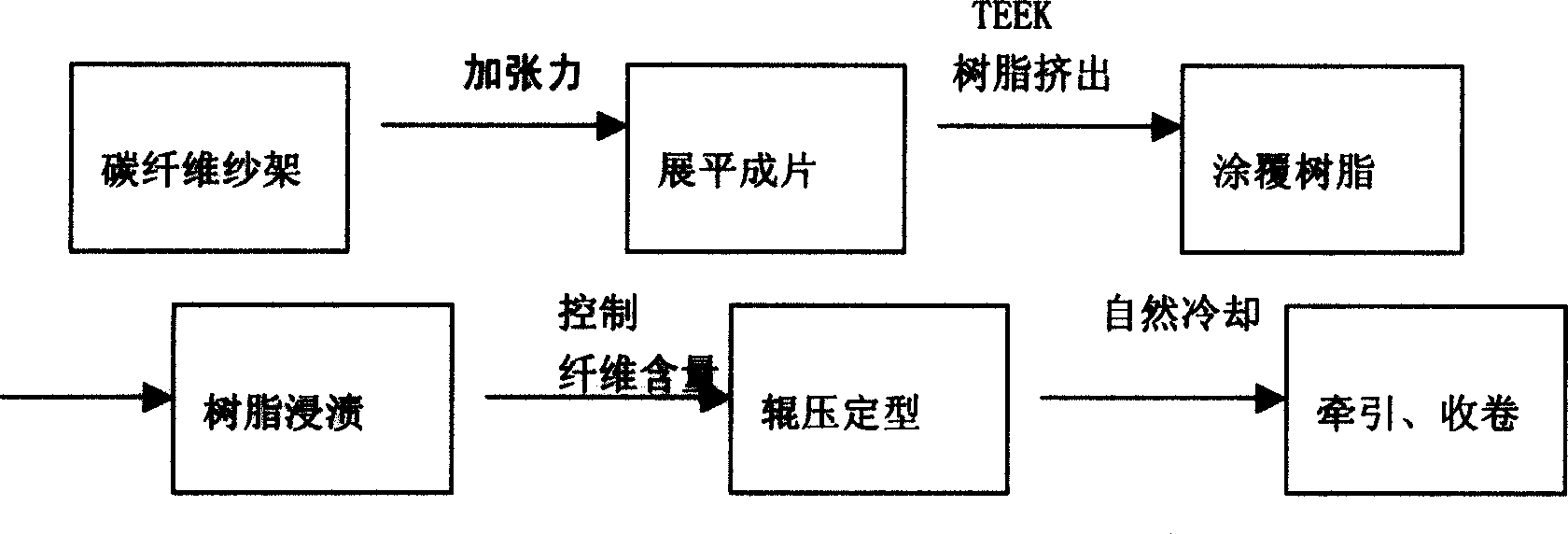

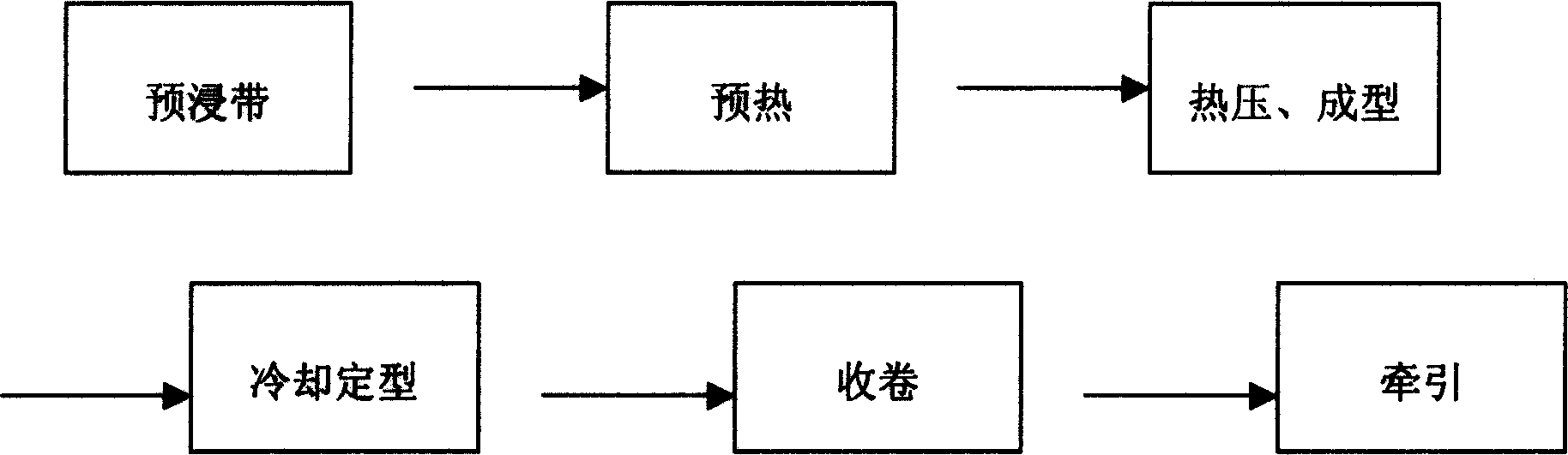

Thermoplastic resin base carbon fiber composite material, and its manufacturing method and apparatus

This invention is about a kind of sheet material of thermoplastic resin continuous carbon fiber composite and its method of making and equipment and refers to the stiffening sheet material of architecture. The resin matrix is thermoplastic resin. The preparation method can be divided into 2 steps: first step is to make the thermoplastic preliminary dip cincture, add tensility to the carbon fiber to make it into pieces, extract thermoplastic resin and spread it on the carbon fiber, then infuse, roll and press it, tow and wrapup after natural cooling. Second step is pultrude thermoplastic molding: get the turnoff after the preliminary dip cincture got from first step passes through the procedures of warm-up, hot pressing, molding, cooling, rolling and draught. This invention improves the dynamic resistance, tenacity and specific elongation of the turnoff and is a kind of green environment-protecting material which can be broken down and disposed.

Owner:申屠年

Green environment protective biological organic compound fertilizer and production method thereof

InactiveCN101671204AEasy to handleDealing with environmental pollution is goodBacteriaClimate change adaptationGreen environmentLitter

The invention relates to a green environment protective biological organic compound fertilizer produced by adopting biological azotobacter, organic phosphorus bacteria, crop growth factor, organism, inorganic substance and microelement which are processed by a special technology, and a production method thereof. Biological bacterial fertilizer, organic fertilizer and inorganic fertilizer are interdependent and decomposed, and play mutual synergistic action to reach the special efficacy of fully utilizing the biological bacterial fertilizer to decompose the organic fertilizer and the inorganicfertilizer and reach the effect of stimulating the growth of crops, thus leading crops to absorb and utilize fertilizer well so as to achieve the purposes of crop production increasing and fertilizersaving. The invention has simple technical method and process, effectively utilizes urban garbage and subsidiary agricultural product offal as raw materials of the organic fertilizer, saves inorganicfertilizer, reduces cost, can be widely used in crops and fruit bearing forests, is especially suitable for greenhouses, base fertilizer and additional fertilizer of crops at the temperature of more than 20 DEG C, and is suitable for popularization and application across the country.

Owner:北京中国科学院老专家技术中心 +1

Humic acid biological organic composite bacterial manure and production process

InactiveCN101503315AImprove aggregate structureProtect healthBio-organic fraction processingWaste based fuelFecesPotassium

The invention relates to an organic composite bacterial fertilizer of humic acid and a production technology. The organic composite bacterial fertilizer mainly comprises the following materials by weight portions: 80 to 200 portions of plant straws, 20 to 60 portions of excrement, 10 to 30 portions of oil residue, 5 to 10 portions of pure humic acid, 1 to 3 portions of trace element, 5 to 10 portions of bran, 1 to 4 portions of brown sugar, 5 portions of strain and 600 to 1200 portions of water. The straws are crushed and fermented with the excrement according to proportion, the biogas residues after fermented are added into oil residue and pure humic acid, stirred evenly, air-dried naturally and ground by ball milling after air-dried; the auxiliary materials are added and fermentation is carried out continuously; after seven days, the trace elements and the strain are added so as to form juice; then water is added for dilution; the obtained mixture is filtered, the filtered liquid fertilizer is inspected to be qualified and then bottled; the filtered residues are combined with the strain, granulated, dried, screened, inspected to be qualified and bagged. The content of nitrogen, phosphorus and potassium of the organic composite bacterial fertilizer are extracted from the straws of crops, the content of the organic matters are extracted from the humic acid and various excrements; therefore, the microorganism fertilizer is not added with chemical compositions; multiple nutrient elements which are rich in the straws are absorbed by the crops. Therefore, the organic composite bacterial fertilizer is a green environment-friendly product without public nuisance, pollution and residues.

Owner:TIANSHUI YINBAO CHEM PLANT OF HUAFU HUMIC ACID GROUP

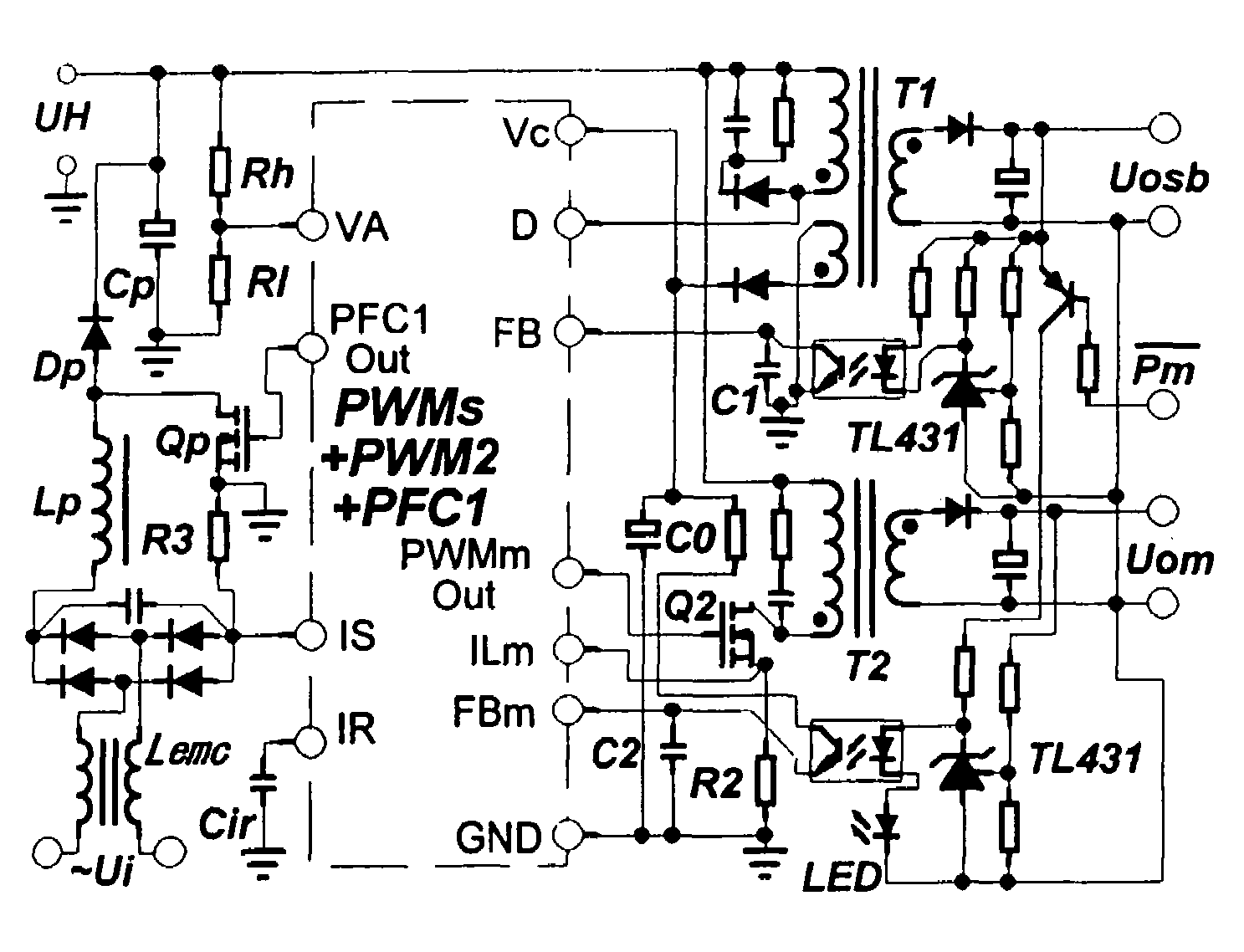

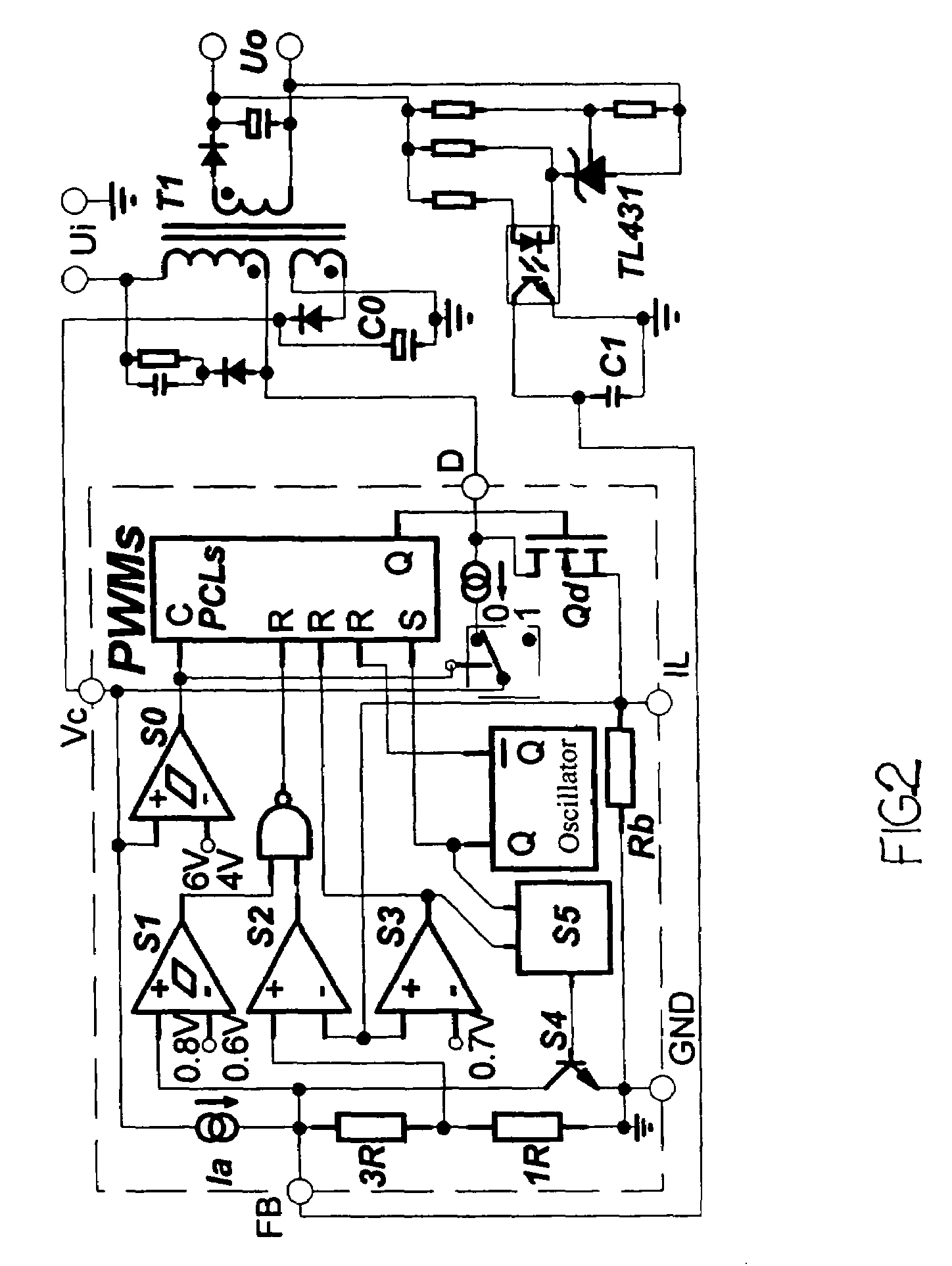

Green switch power supply with standby function and its IC

InactiveUS7471527B2Cost effectiveEfficient power electronics conversionConversion with intermediate conversion to dcGreen environmentRemote control

A switch power supply with standby function is disclosed. The power supply can satisfy the need of the green environment protection. And a single ended green switch power supply IC or thick film or modular circuit design with standby function is disclosed, too. It comprises a standby power supply, a main power supply, a PFC device, and a supplemental circuit, wherein a remote control signal is transmitted to main control circuit in response to a main error signal to control main power supply. A method for preventing switch power current from overload and saturation is disclosed too. Finally, the present invention also provides a green power supply with standby function as well as its IC associated with digital processing highly qualified PFC, and a PC standard (such as ATX, ATX12, SSI) computer switch power supply.

Owner:CHEN WEIBIN +1

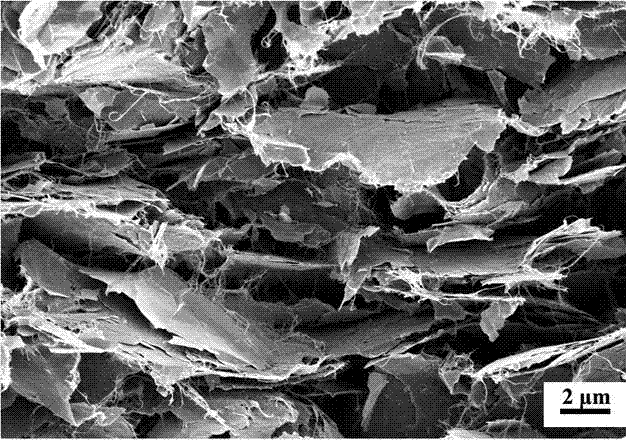

Preparation method of tough graphene/cellulose composite heat-conductive and electro-conductive film

InactiveCN107293377AReduce manufacturing costEasy to operateNon-conductive material with dispersed conductive materialCable/conductor manufactureCelluloseFiber

The invention discloses a preparation method of a tough graphene / cellulose composite heat-conductive and electro-conductive film. The preparation method of the tough graphene / cellulose composite heat-conductive and electro-conductive film comprises the following steps: firstly, dispersing the wood pulp into an aqueous solution to peel the wood pulp into single nano diameter single fibrous bundles under the action of liquid shear force; diluting the single fibrous bundles with deionized water and obtaining the low concentration cellulose aqueous solution through treating by a high-speed shearing machine for a certain period of time; then dispersing the industrial graphene nanosheets evenly into the aqueous solution containing the dispersant through ultrasonic treatment; then dripping the prepared cellulose aqueous solution gradually into the graphene dispersion; and preparing the graphene / cellulose composite film through ultrasonic mixing, suction filtration, drying and other processes. The obtained film has good flexibility, thermal conductivity and electrical conductivity, and the mechanical, thermal and electrical properties of the film can be further improved through hot pressing treatment. The preparation method of the tough graphene / cellulose composite heat-conductive and electro-conductive film has the advantages of simple process, low cost, green environment protection and wide application value in the field of functional composite materials.

Owner:QILU UNIV OF TECH

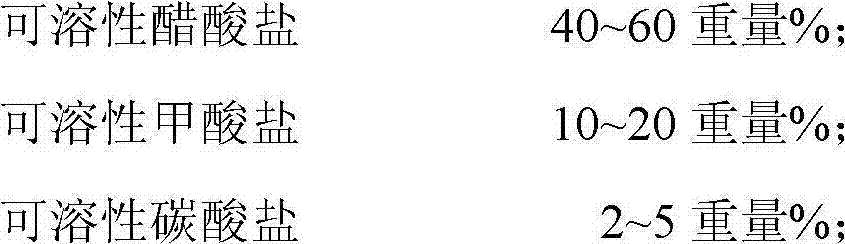

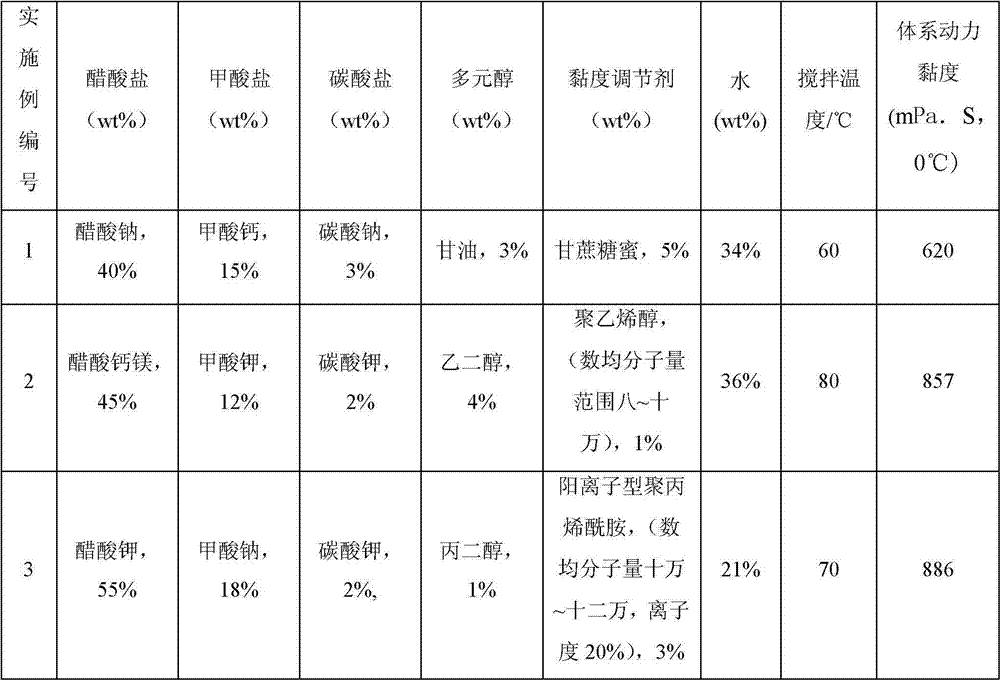

Green environment-friendly snow-melting liquid and preparation method thereof

InactiveCN102899004AFast melting rateNo pollution in the processOther chemical processesFormateMetallic materials

The invention relates to a green environment-friendly snow-melting liquid and a preparation method thereof. The liquid contains the following components: 40-60 wt% of a soluble acetate; 10-20 wt% of a soluble formate; 2-5 wt% of a soluble carbonate; 1-5 wt% of a polyol; 1-5 wt% of a viscosity modifier; and 20-40 wt% of water. The green environment-friendly snow-melting liquid provided in the invention is free of chloride ions, has a fast snow-melting rate, has no corrosion on metal materials such as steel bars, and has no pollution on soil and water bodies, thus being green and environment-friendly. The snow-melting liquid is convenient for storage and transportation, and has wide application. Compared with most of existing solid snow-melting materials, the snow-melting liquid has the characteristics of fully mechanized spreading way, uniform spreading, labor cost reduction, and spreading time reduction, etc.

Owner:HUBEI PROVINCE FREEWAY IND DEV +1

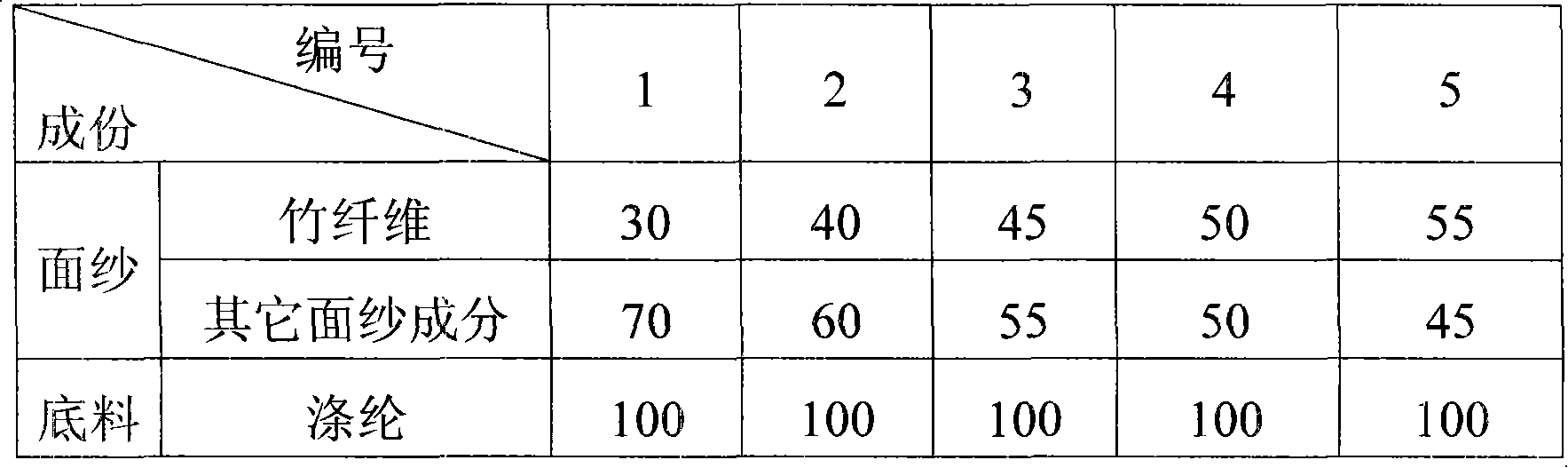

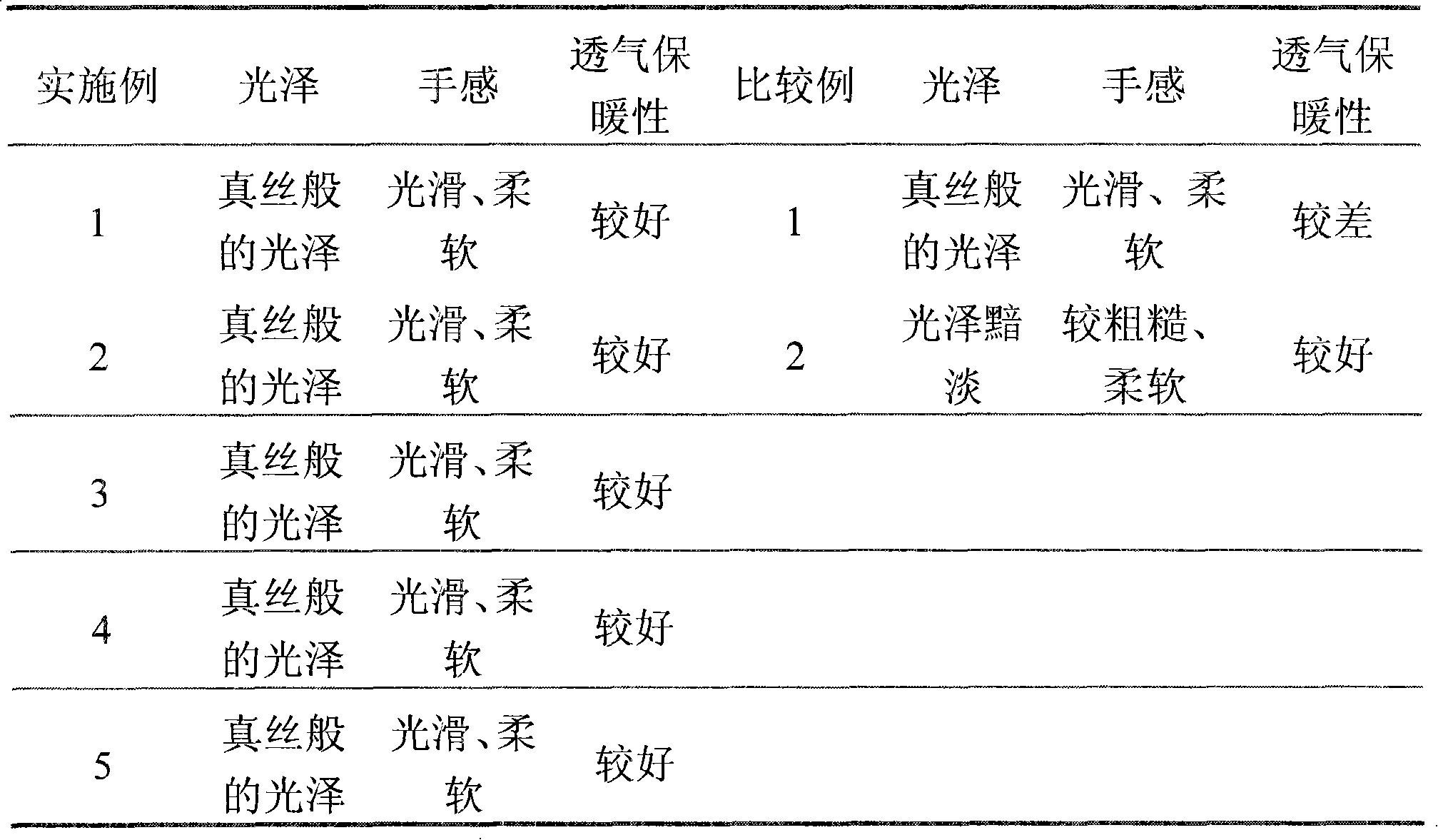

Bamboo fibre raschel blanket material and product thereof

InactiveCN101205659AImprove performanceBreathable and warmWarp knittingGreen environmentMoisture absorption

The invention relates to a bamboo fiber and other composition materials as well as a bamboo fiber Raschel carpet knitted by the bamboo fiber and the other composition materials; the compositions of the material by weight proportion are that: 20 to 80 portions of bamboo fiber, 120 to 200 portions of the other compositions, wherein, the other compositions are one or more types in cotton, nylon, polypropylene fiber, hemp, nitrilon, terylene and silk fiber. The invention also provides the bamboo fiber Raschel carpet knitted by the raw material, the bamboo fiber and other veiling compositions are blended into the pile yarn used by the carpet, the polyester filament can be used as the chain stitch yarn and the inlay yarn of the carpet; the Raschel carpet produced by the material and the weaving process of the invention not only has the performance of smooth surface, softness, good heat insulation and ventilation property, quick moisture absorption and releasing, germproof and bacteriostasis, green environment protection and anti-ultraviolet radiation, but also has the property of natural mite prevention, deodorization, anti-insect, negative ion and so on as well as touch feeling of cashmere, polishing of silk fiber, air permeability and heat insulation of cotton, the healthcare effect is ideal with a favorable compatibility on human skin, which is a natural green environment protection home-furnishing product.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

Preparation method of halogen-free flame-retardant polylactic acid fiber

ActiveCN103122498AReduce dosagePromote pyrolysis into charFlame-proof filament manufactureMonocomponent polyesters artificial filamentMasterbatchGreen environment

The invention relates to a preparation method of halogen-free flame-retardant polylactic acid fiber, which comprises the following steps of: (1) mixing polylactic acid slices with a flame retardant agent, performing melt blending at 180-220 DEG C, and cooling and granulating to obtain flame-retardant polylactic acid masterbatch; (2) mixing the polylactic acid slices with a synergist, performing melt blending at 190-220 DEG C, and cooling and granulating to obtain synergistic polylactic acid masterbatch; and (3) mixing the polylactic acid slices, the flame-retardant polylactic acid masterbatch, the synergistic polylactic acid masterbatch and a dispersing agent, spinning to obtain nascent fiber, and performing drafting post processing of the nascent fiber to obtain halogen-free flame-retardant polylactic acid fiber. The polylactic acid composite fiber material provided by the invention has good spinning formability and excellent fiber quality; the flame retardant agent is a halogen-free flame retardant agent, and the halogen-free flame-retardant polylactic acid fiber is safe and non-toxic in the using and burning process, thereby being green environment-friendly fiber; and the halogen-free flam-retardant polylactic acid fiber can be applied to the fields with high requirement for flame retardance such as clothing, trim, home textile and the like, and has broad market prospect.

Owner:DONGHUA UNIV +1

Regenerated silk fiber with alcohols as coagulating bath and method for preparing same

InactiveCN1664184AControl degradationReduce usageMonocomponent fibroin artificial filamentWet spinning methodsGreen environmentPolymer science

This invention is a rebirth silk fibre and preparation method. Silk is broad use because of excellent mechanics capability. But the produce is work force denseness and high cost. This invention take the raw material used high chroma rebirth silk protein water liquor (10-40%) with filature former liquor from industry scrap silk to process wet way filature. And adopt pure compound or multi-pure polymer water liquor to process concreting. This invention have some trait: abroad raw material source, high capability rebirth silk fibre, low cost, blare of nature silk and simple filature process, green environment protecting. In this method, rebirth silk fibre's rupture intention can get 0.1~1.0Gpa and its rupture elongate rate can be 10%-60%.

Owner:FUDAN UNIV

Regenerated silk fiber with salt solution as coagulating bath and method for preparing same

InactiveCN1664183AControl degradationReduce usageMonocomponent fibroin artificial filamentWet spinning methodsInorganic saltsGreen environment

This invention adopts wet way filature to prepare a high capability rebirth silk fibre method according to raw material used with industry scrap silk. The method take the high chroma rebirth silk protein water liquor (10-40%) with filature former liquor, take the quite high inorganic salt acidity water liquor with curdle liquor. Then get the excellent mechanics capability rebirth silk fibre after wet way filature and extending, heat manage. In this way, rebirth silk fibre have blare of nature silk fibre and excellent synthesis mechanics capability. The rupture intention can get 0.6Gpa and rupture elongate rate can be 30%. This invention has the trait that is abroad raw material source, low cost and simple filature process, green environment protecting.

Owner:FUDAN UNIV

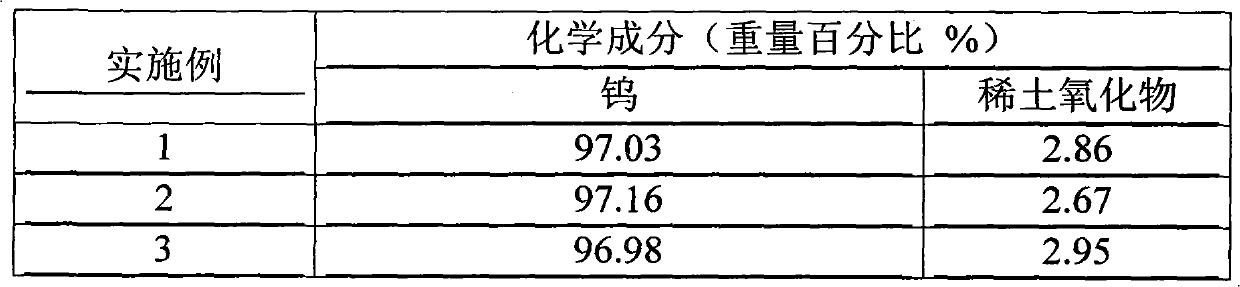

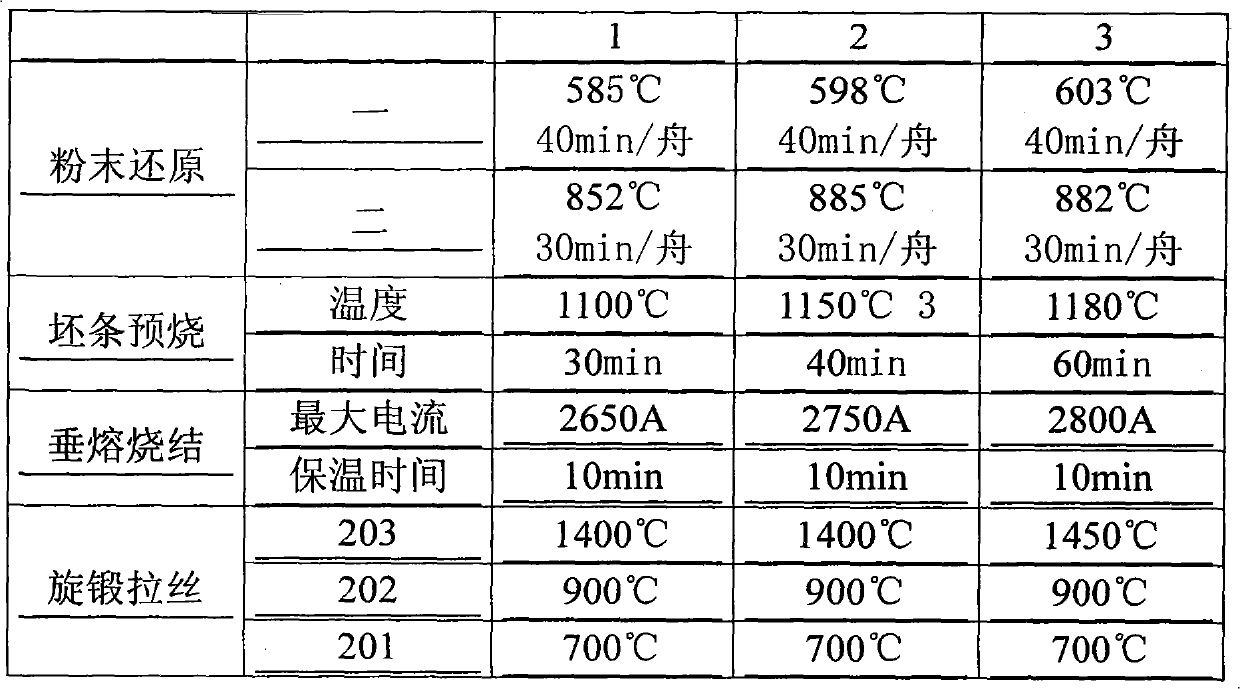

Multi-element composite rare earth tungsten electrode material and preparation method thereof

InactiveCN102000923AGood welding performanceGood thermionic emission performanceWelding/cutting media/materialsSoldering mediaRheniumRare earth

The invention relates to a multi-element composite rare earth tungsten electrode material, which is prepared by adding rare earth oxides in a tungsten metal substrate, wherein the weight percentage of the tungsten metal substrate is 95 to 98%; and the weight percentage of the rare earth oxides is 2.0 to 5.0%. The preparation method comprises: the tungsten substrate powder is weighed according to the proportioning weight and is poured into a mixing pot, and deionized water is added to the mixture to be stirred so as to prepare a uniform suspension; lanthanum nitrate, cerous nitrate, rhenium nitrate and erbium nitrate are weighed according to the required proportioning weight and are prepared into a solution; the solution is added to the suspension to be stirred uniformly, and the mixing solution is heated and dried to prepare the mixing alloy powder; the mixing alloy powder is prepared into the rare earth tungsten composite powder through the twice hydrogen reduction; and the argon arc welding electrodes with various specifications are prepared through tamping, presintering, vertically sintering and rotary swaging. The rare earth tungsten electrode material has the advantages of good welding property, green environment protection type electrode material, good arc strike and retention of electrodes, and rapid heating and cooling properties, and the heat input on welding pieces and the dimension of a melting pool can be accurately controlled.

Owner:天津市春风钨业有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com