Polyvinylidene fluoride composite material and preparation method thereof

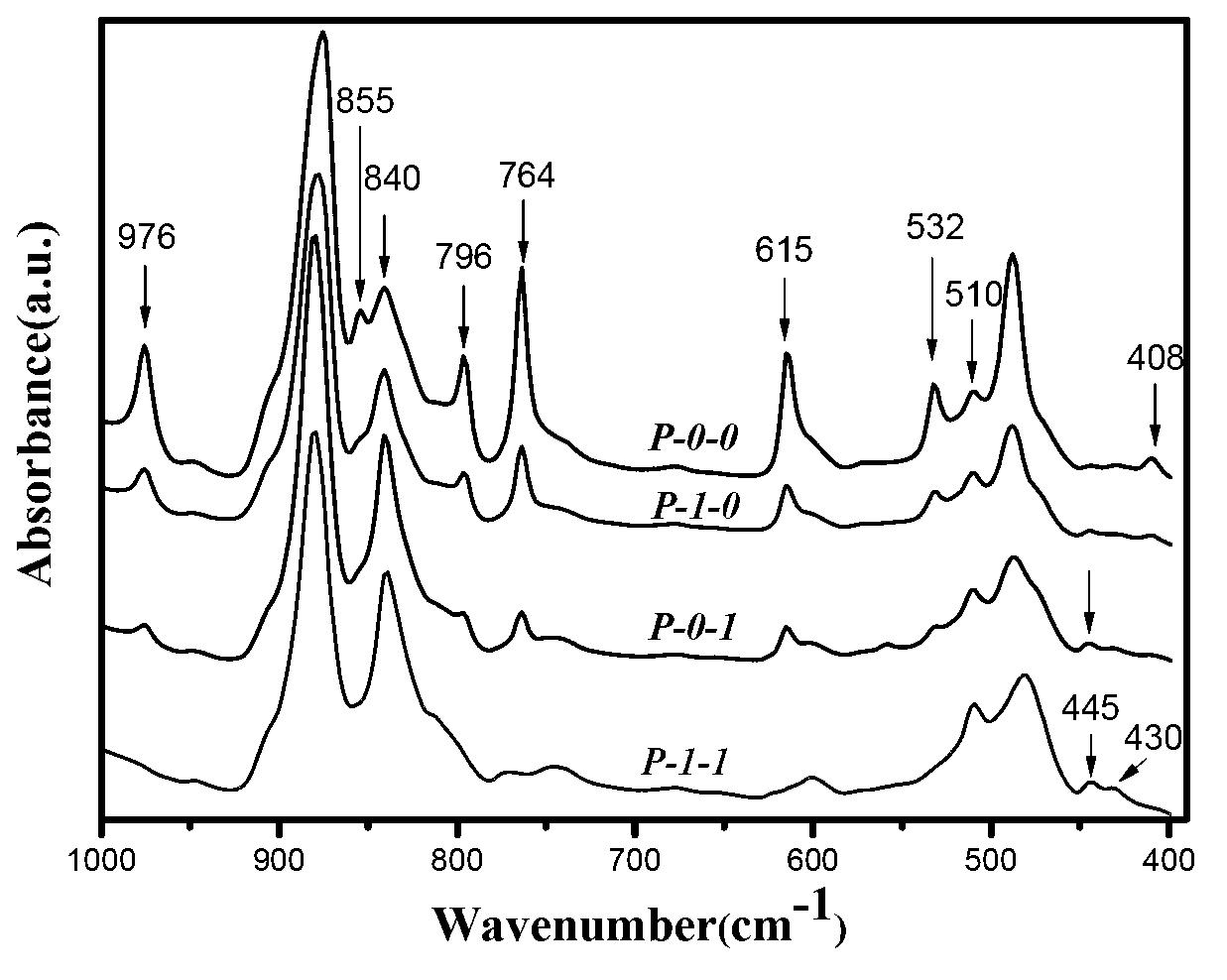

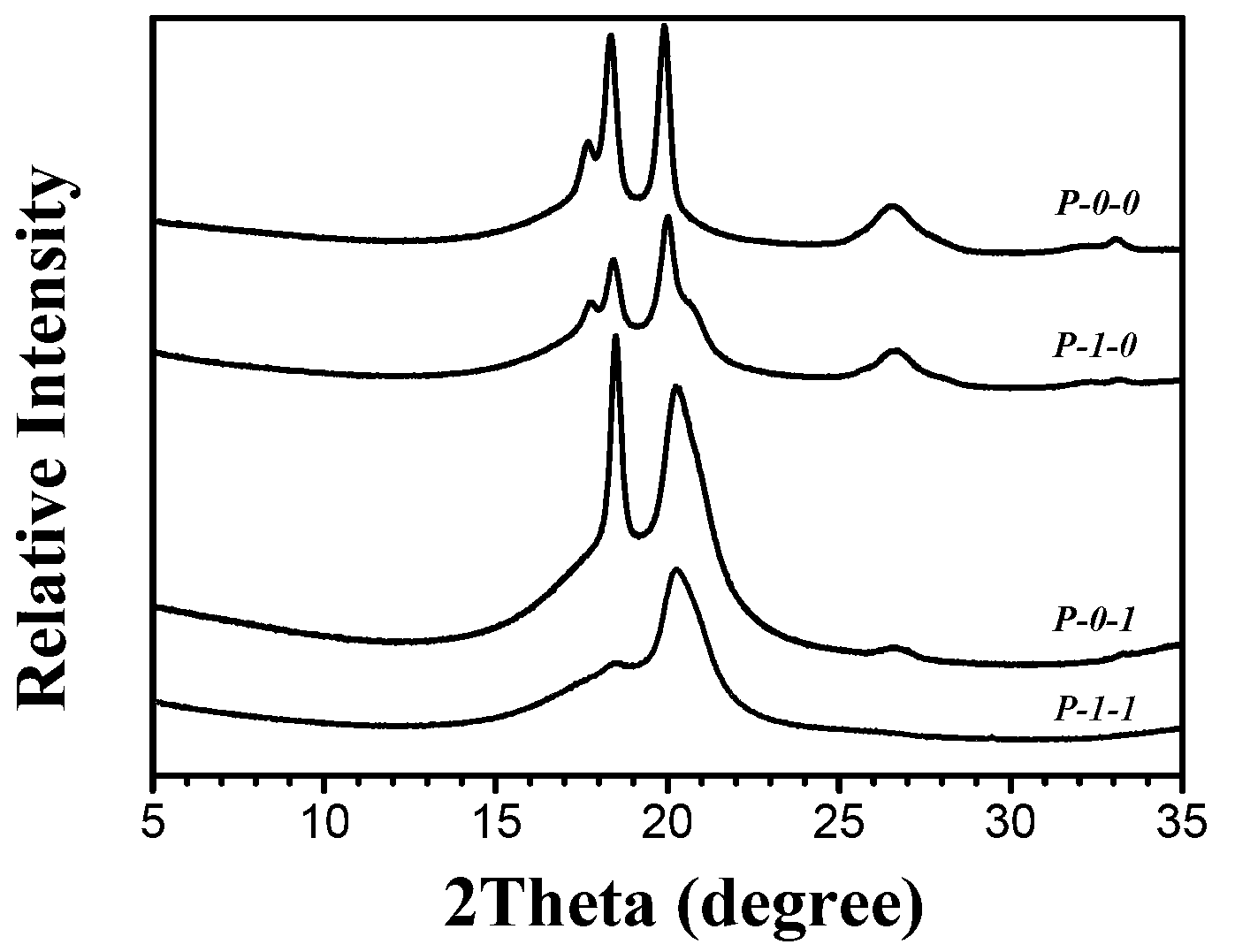

A technology of polyvinylidene fluoride and polyvinylidene fluoride matrix, which is applied in the field of polyvinylidene fluoride composite materials with high β crystal content and its preparation, and can solve the problems of low content, increasing the dispersion of nano fillers, technology promotion and Industrial application constraints and other issues to achieve the effect of increasing the crystallization speed and shortening the molding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

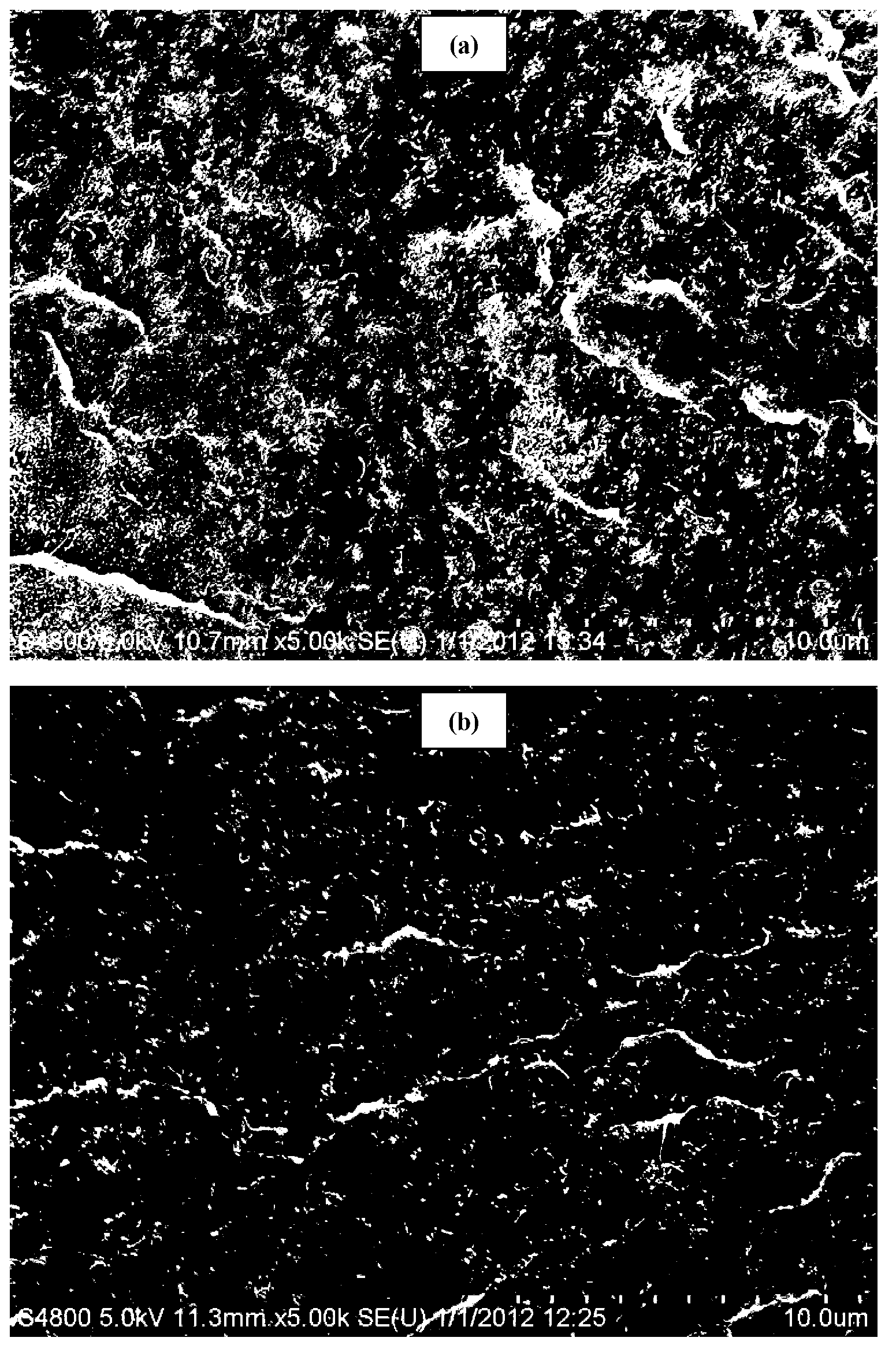

[0045] PVDF was dried overnight in a vacuum drying oven at 80°C, and 50.00 g was weighed for later use; a certain mass of carbon nanotubes and a certain mass of ionic liquid were weighed according to the formula in Table 1, and placed in the mortar of an automatic grinder, at room temperature Grinding for 15 minutes to obtain modified carbon nanotubes. Add the modified carbon nanotubes and PVDF into the internal mixer in batches. The temperature of the internal mixer is 190°C. When the rotor speed of the internal mixer is 20rpm / min, the internal mixer is mixed for 1min; then the speed is increased to 50rpm / min And banburying 5min after discharge. After discharging, the samples are hot-pressed into sheets or films on a press at 200°C. See Table 1 for the sample code and the ratio of the three components in the sample.

Embodiment 8

[0047] PVDF was dried overnight in a vacuum oven at 80°C, and 50.00 g was weighed for later use; carbon nanotubes and ionic liquid were weighed according to the formula in Table 1, and stirred evenly without grinding. Add the modified carbon nanotubes and PVDF into the internal mixer in batches. The temperature of the internal mixer is 190°C. When the rotor speed of the internal mixer is 20rpm / min, the internal mixer is mixed for 1min; then the speed is increased to 50rpm / min And banburying 5min after discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com